Thermosetting resin grinding pad and preparation method thereof

A polishing pad and thermosetting technology, which is applied in the direction of grinding tools, grinding/polishing equipment, grinding devices, etc., can solve the problem of affecting the service life of the mechanical performance of the grinding pad, the uneven distribution of the solid material of the grinding pad, and the porosity of the grinding pad, etc. problems, to achieve the effect of increasing material removal rate, improving grinding efficiency and reducing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

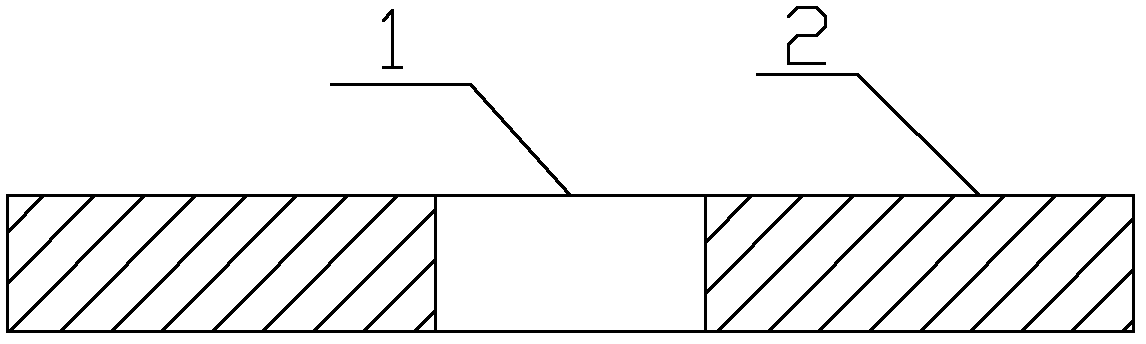

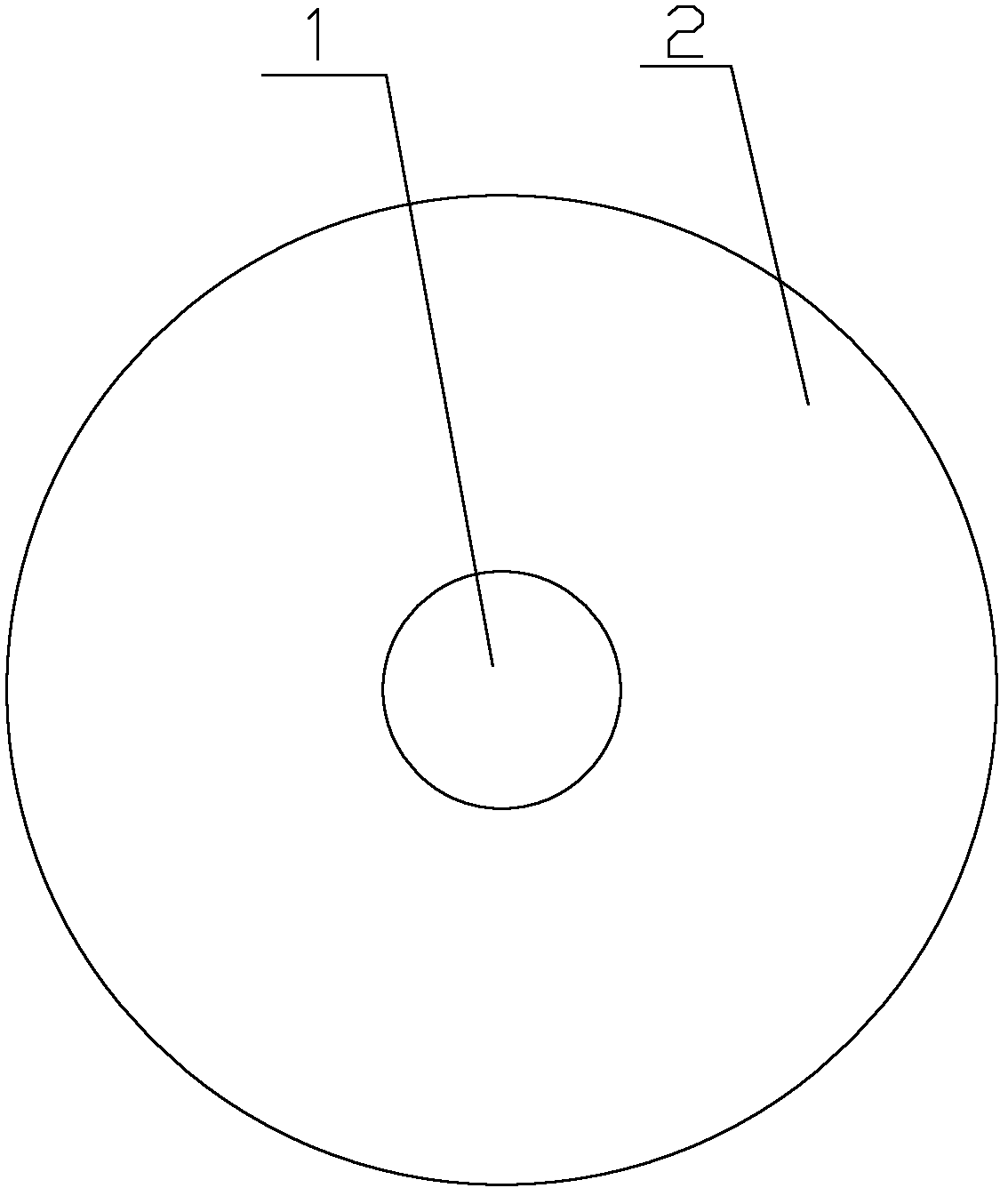

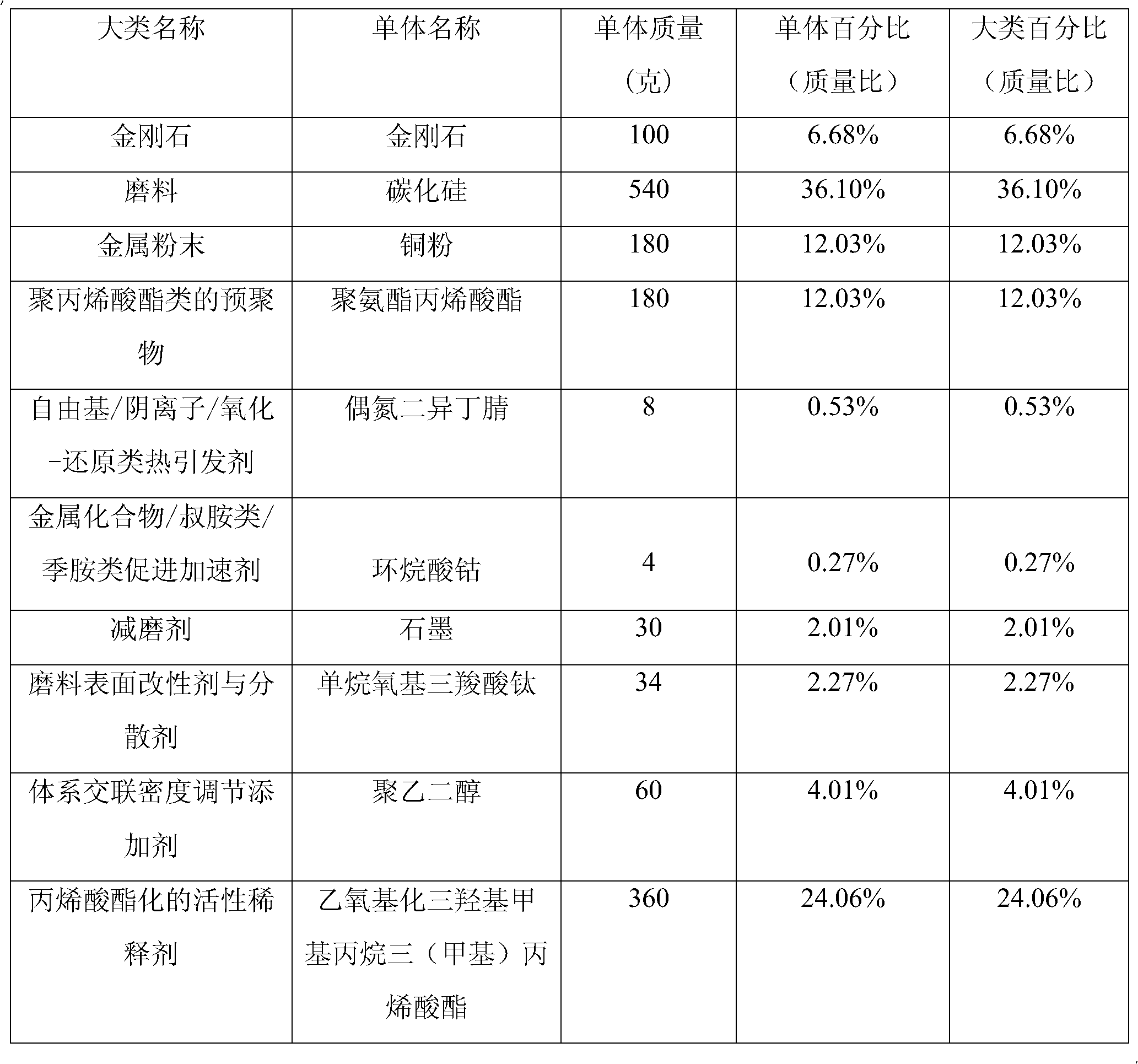

[0049] The thermosetting resin polishing pad has a structure such as figure 1 shown. It is manufactured by the following method: Weigh 100 grams of diamond abrasives with a particle size of 40 to 50 microns and 540 grams of silicon carbide with a particle size of 320 mesh (also can be replaced by silicon dioxide and aluminum oxide abrasives), 180 grams Particle size is 400 mesh copper powder (can also be replaced by iron powder, silver powder, aluminum powder, nickel powder, lead powder, titanium powder, zinc powder, tin powder), 30 grams of particle size is 8000 mesh graphite (also can be replaced by carbon black , molybdenum disulfide, replaced by cryolite), 180 grams of polyurethane acrylate (also can use bisphenol A epoxy acrylate, novolac epoxy acrylate ethylamine modified epoxy acrylic acid, utilize oleic acid, linoleic acid to carry out Chain-modified long aliphatic epoxy acrylate, polyester acrylate, polyether acrylate or acrylated polyacrylate instead), 8 grams of az...

Embodiment 2

[0056] Increase the copper powder content in Example 1 to 300 grams, weigh 500 grams of silicon carbide with a particle size of 320 mesh, and other compositions are the same as the preparation process, see Table 2, which shows the composition and the mass percentage of each component. The grinding pad prepared by the above method has a higher density, and it can be seen from the cross section of the grinding pad that the pores in the grinding pad are less and denser; the produced grinding pad does not have delamination. It can also be found in the experiment of grinding crystal hanging chains with the fully automatic crystal grinding equipment produced by Hangzhou Fuyang Mihong Machinery Co., Ltd. During the grinding process, the grinding pad will have a small amount of decomposed odor of the resin matrix, and there will also be a small amount of smoke. The average wear amount of grinding once is 4.06um.

[0057] Table 2 embodiment 2 component ratio table

[0058]

Embodiment 3

[0060] The copper powder content in Example 1 was increased to 600 grams, and 380 grams of silicon carbide with a particle size of 320 mesh was weighed. The other compositions were the same as the preparation process. See Table 3, which shows the composition and the mass percentage of each component. The grinding pad prepared by the above method has a relatively high density. As can be seen from the cross-section of the grinding pad, the pores in the grinding pad are less and denser; The solid material distribution is relatively uniform. It can also be found in the experiment of grinding crystal hanging chains with the fully automatic crystal grinding equipment produced by Hangzhou Fuyang Mihong Machinery Co., Ltd. During the grinding process, the grinding pad will have a small amount of decomposed odor of the resin matrix, and there will also be a small amount of smoke. The average wear amount of one grinding is 3.00um.

[0061] Table 3 Example 3 component ratio table

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com