Patents

Literature

1020 results about "Polymer adhesive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

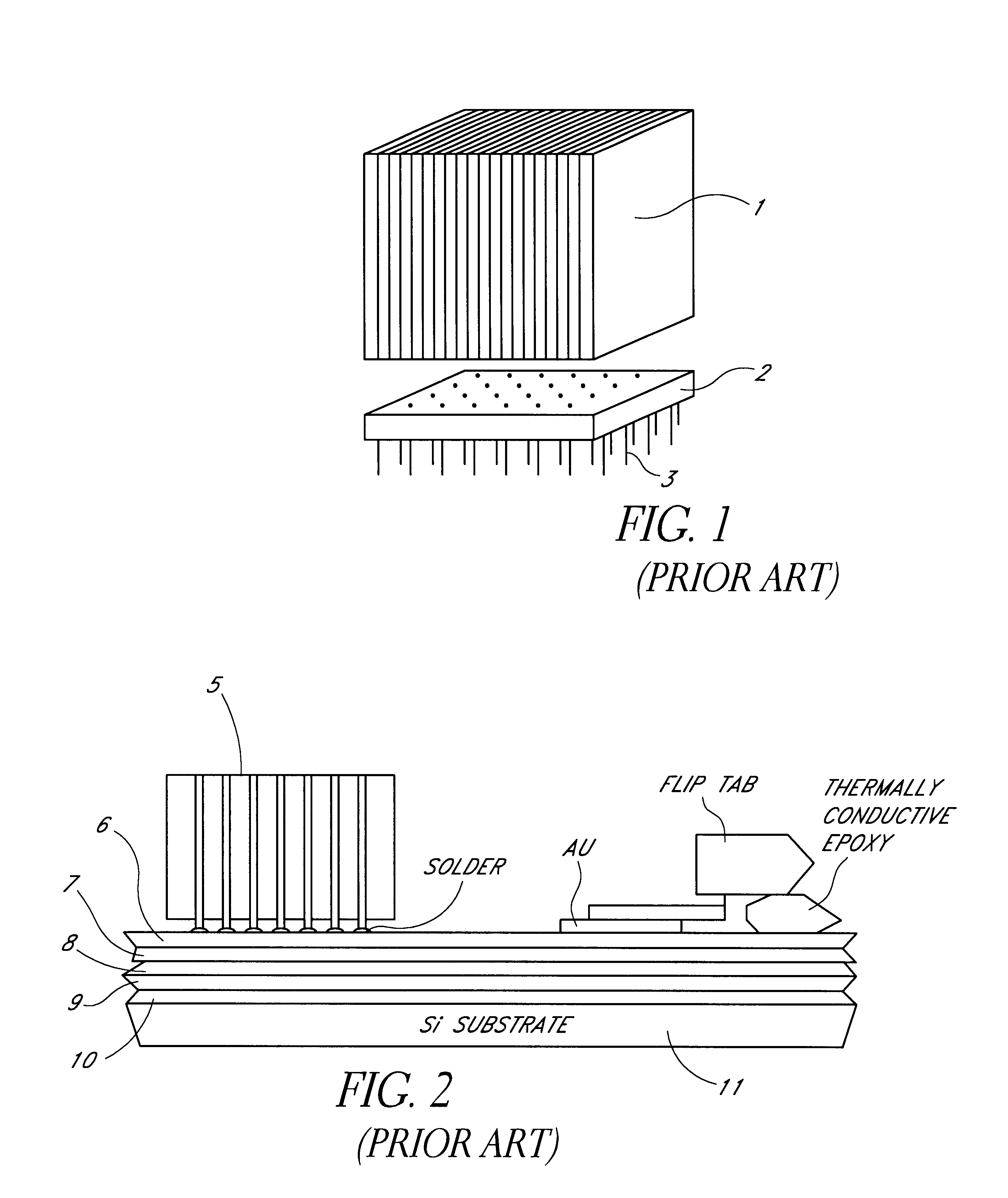

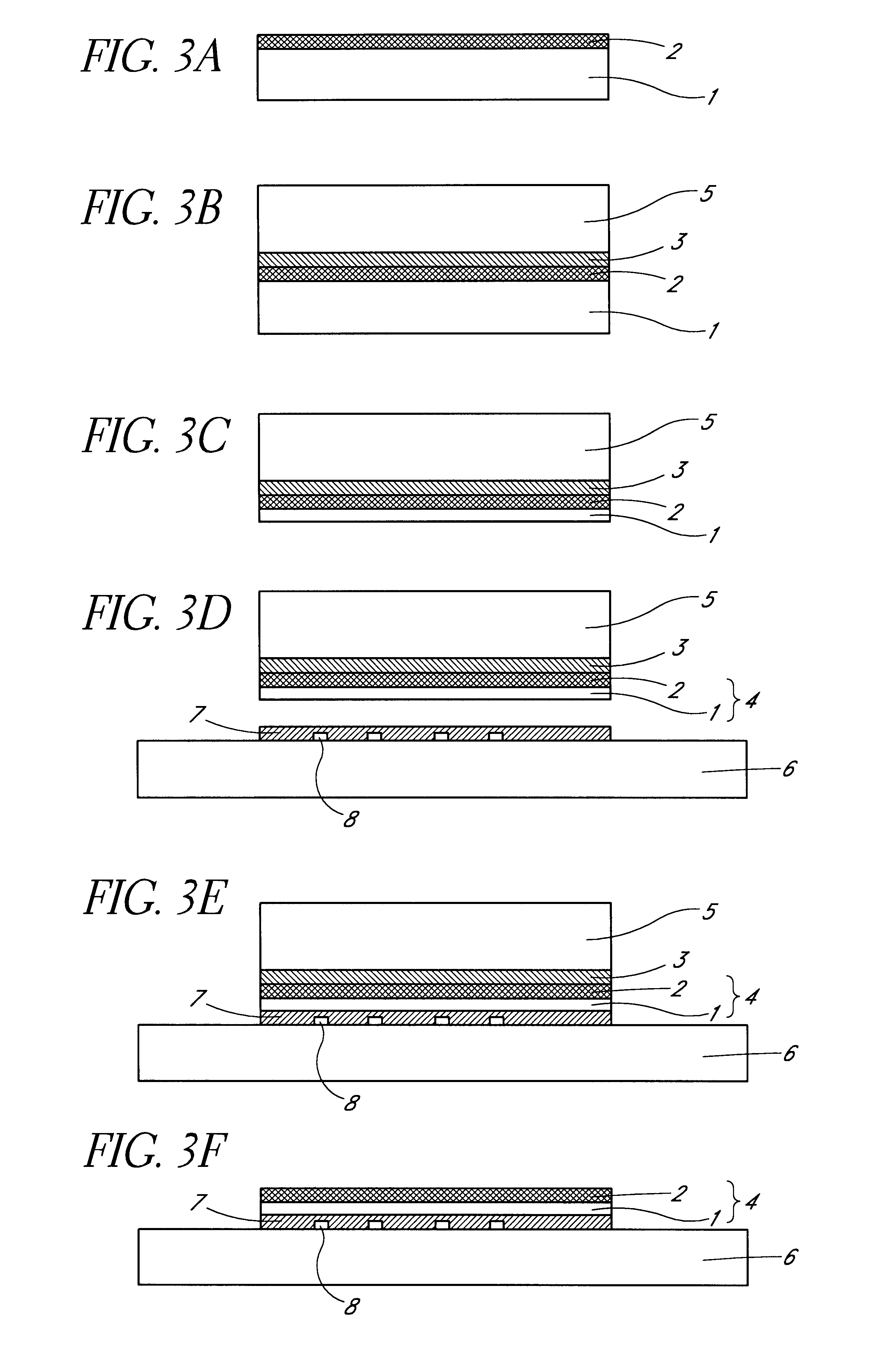

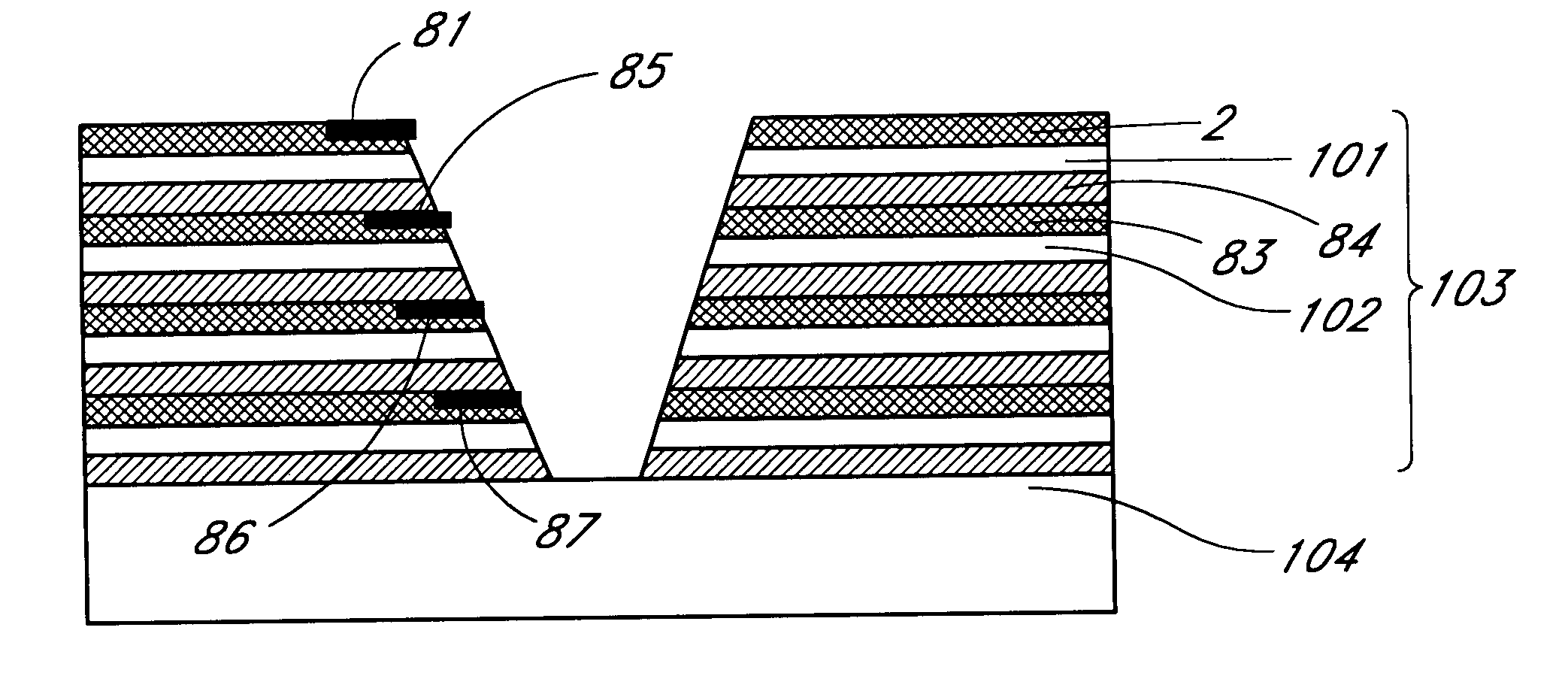

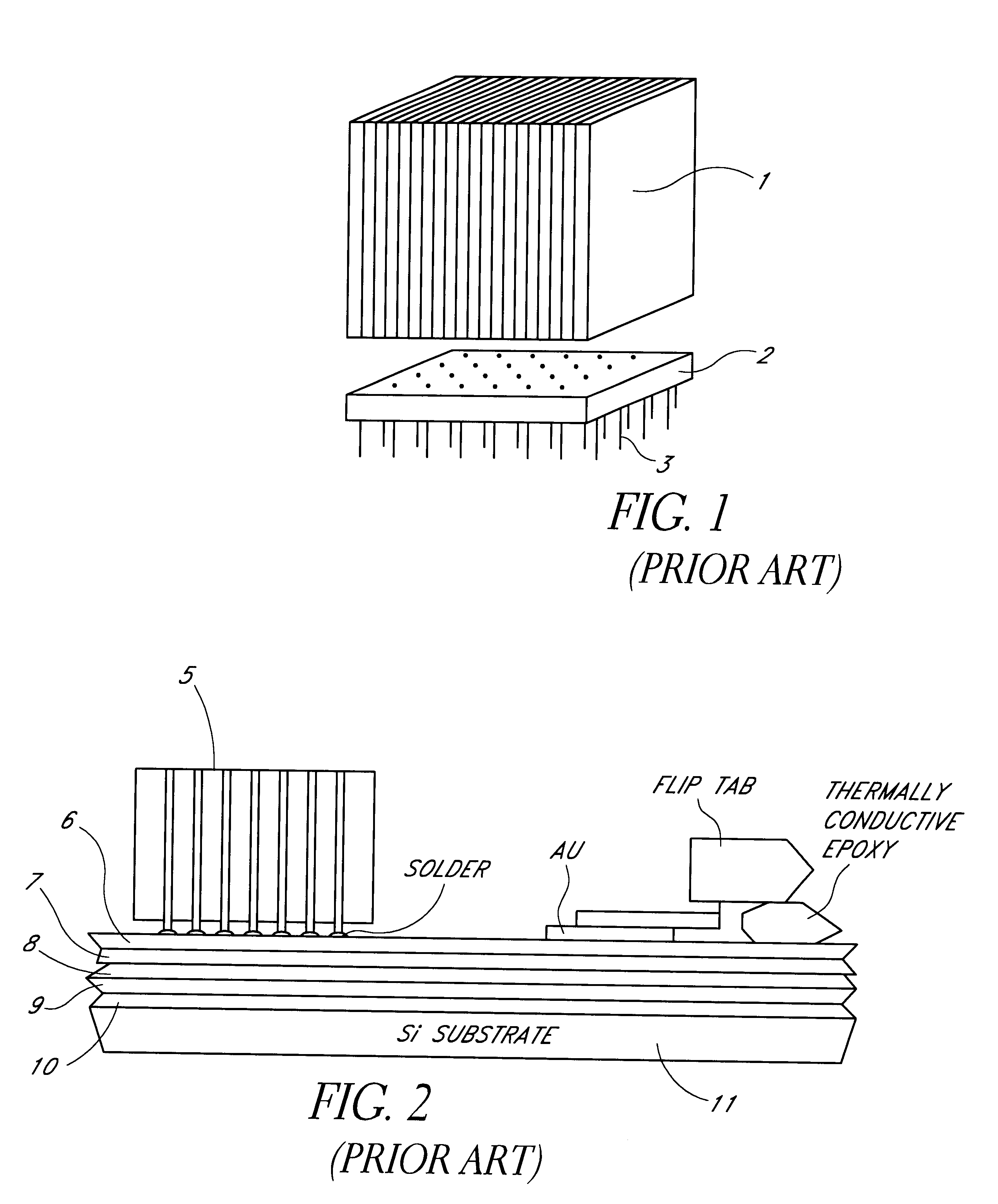

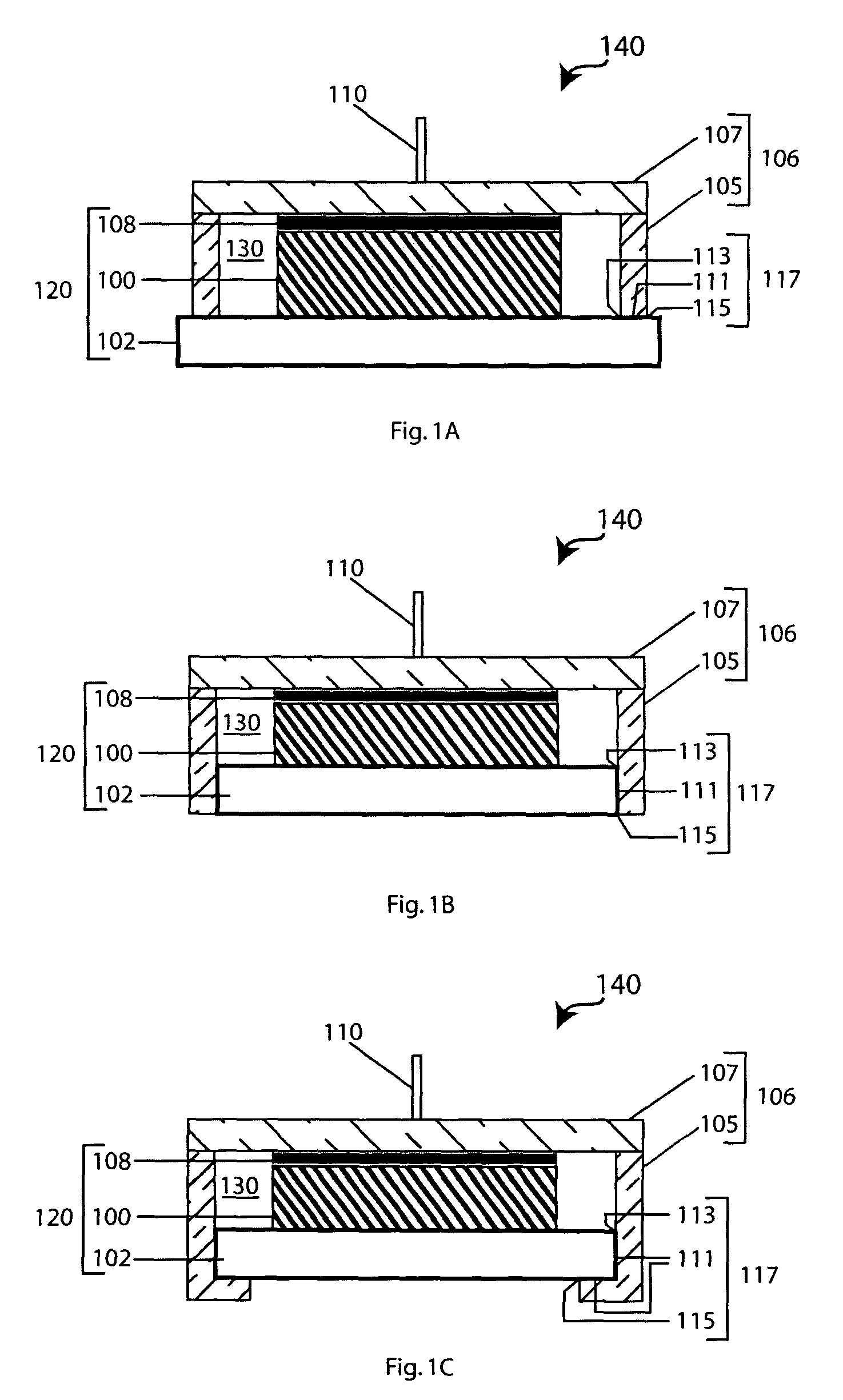

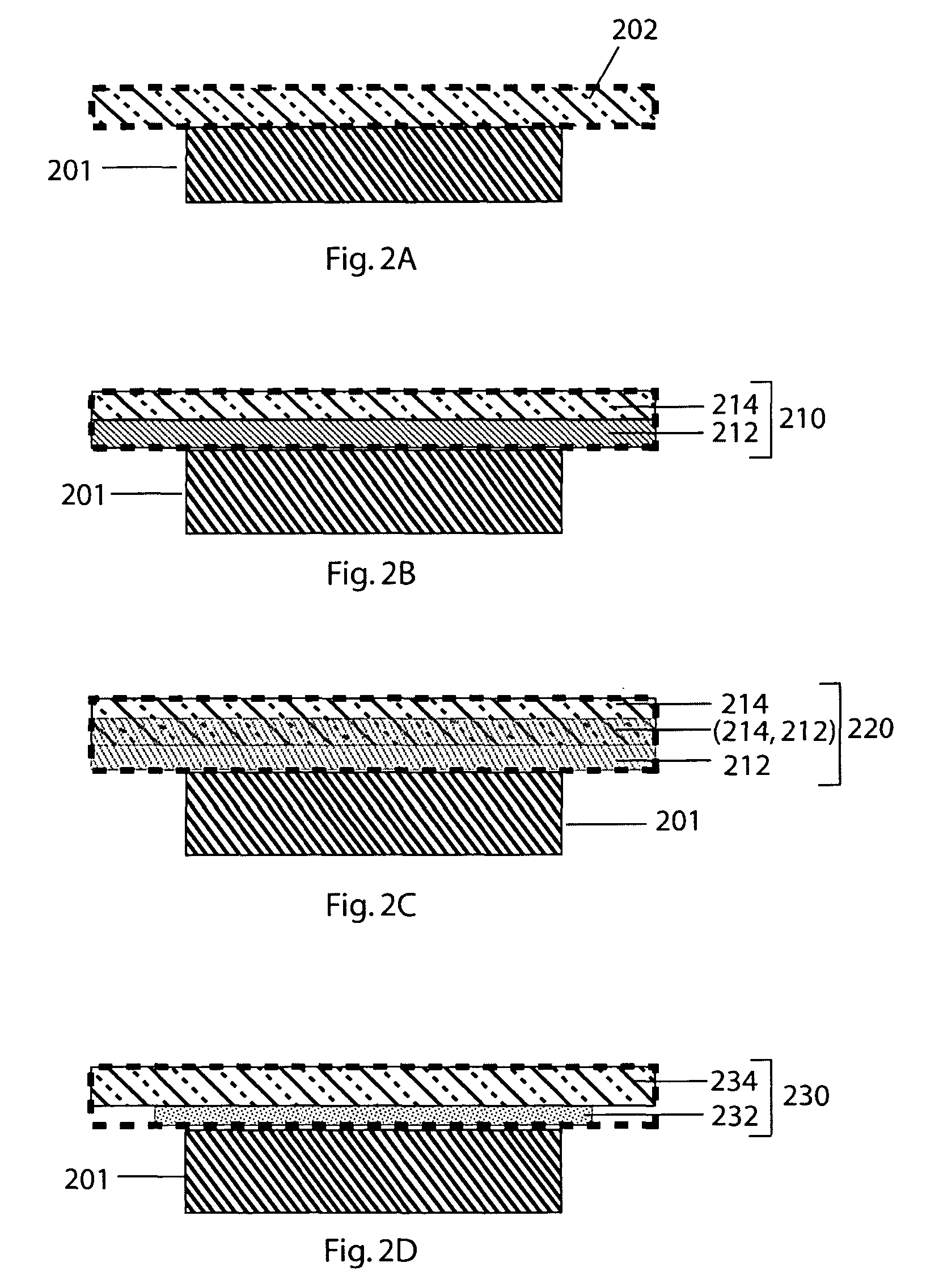

Method of transferring ultra-thin substrates and application of the method to the manufacture of a multi-layer thin film device

InactiveUS20030060034A1High densitySafe transferSemiconductor/solid-state device detailsSolid-state devicesPolymer adhesivePlanar substrate

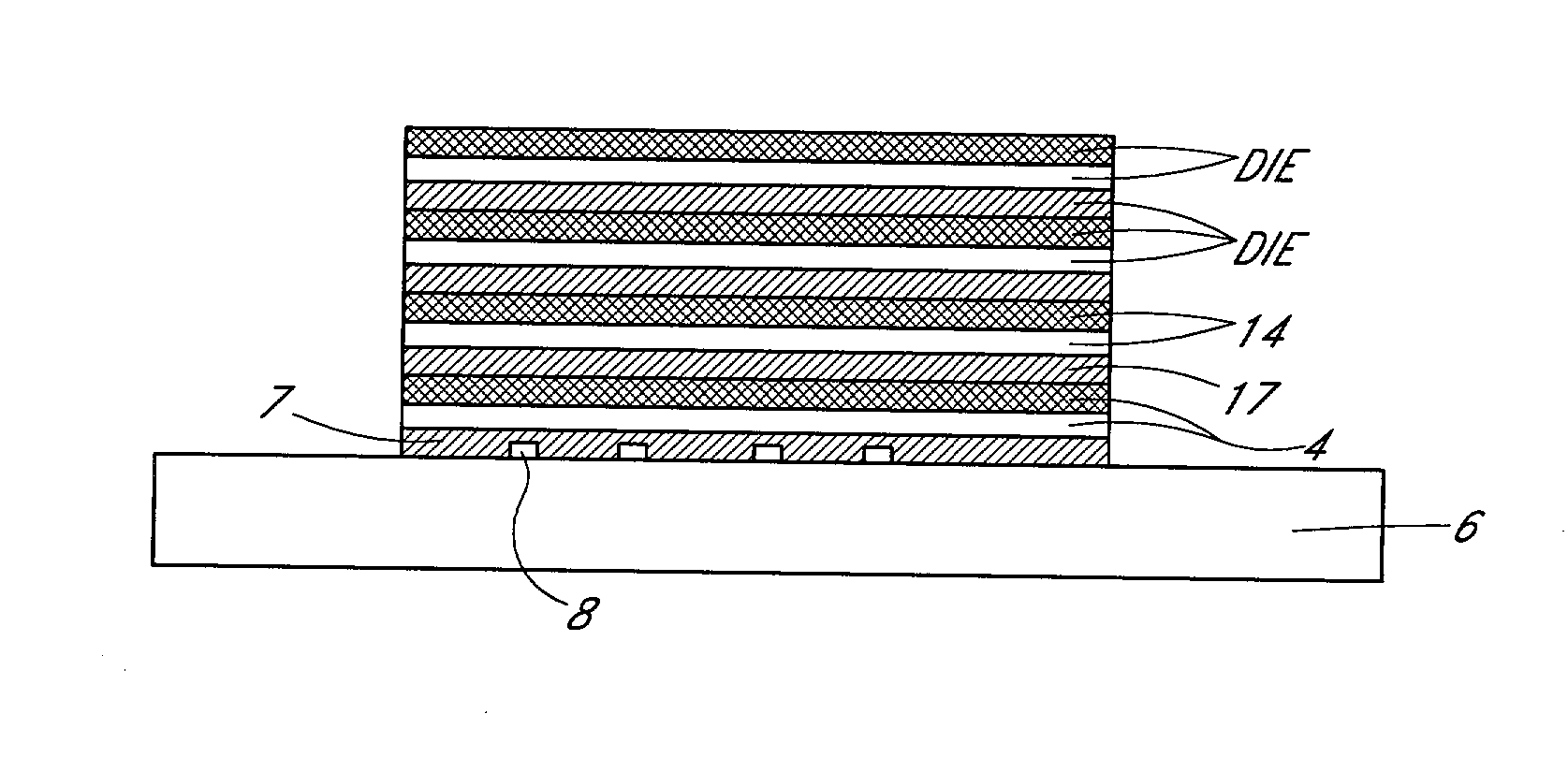

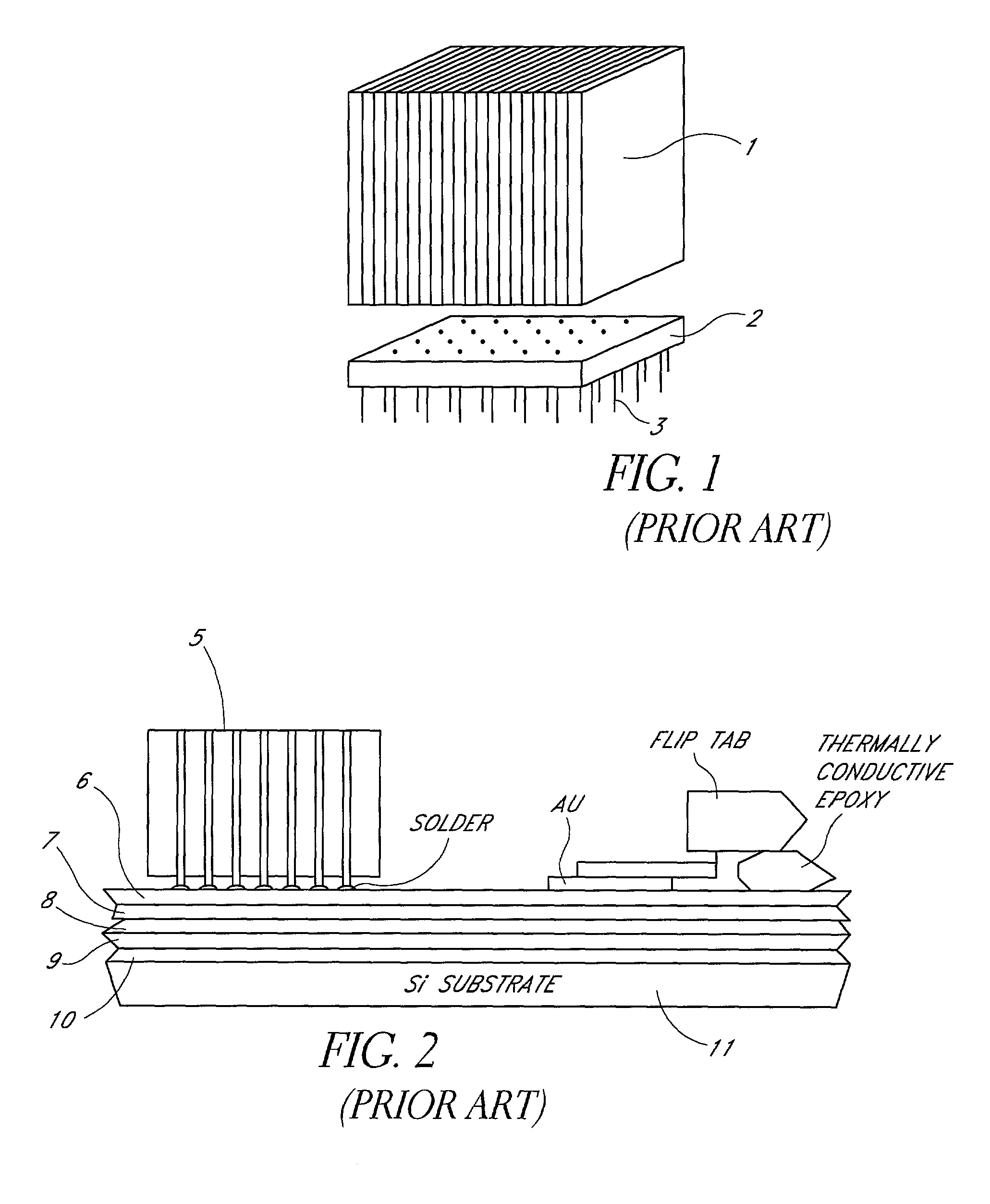

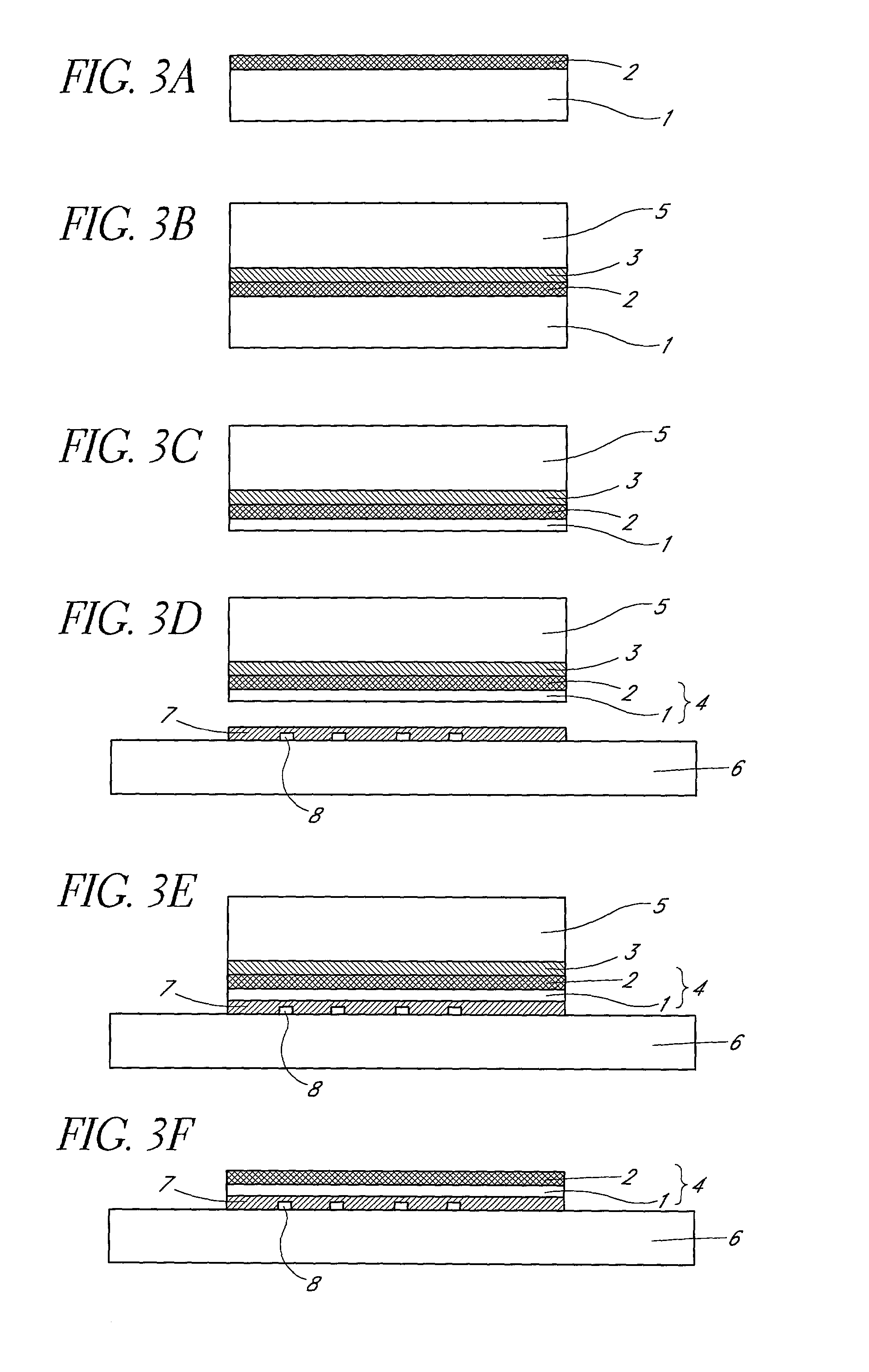

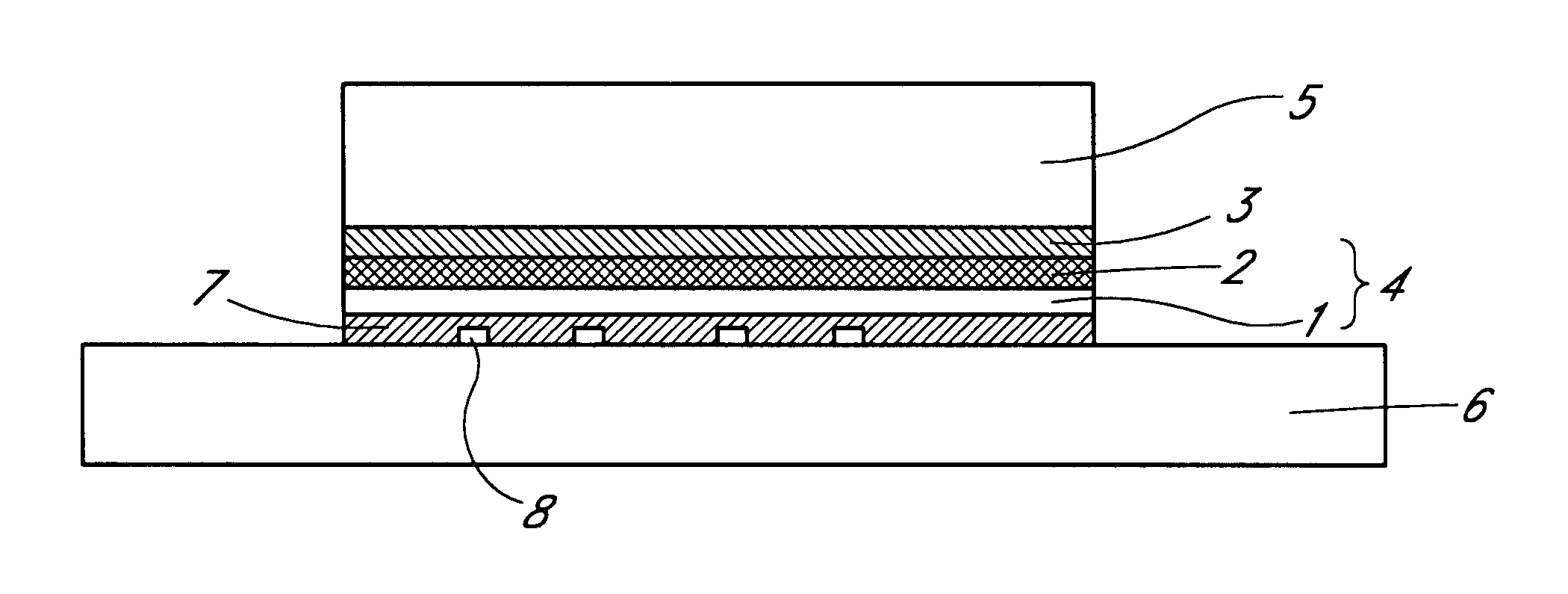

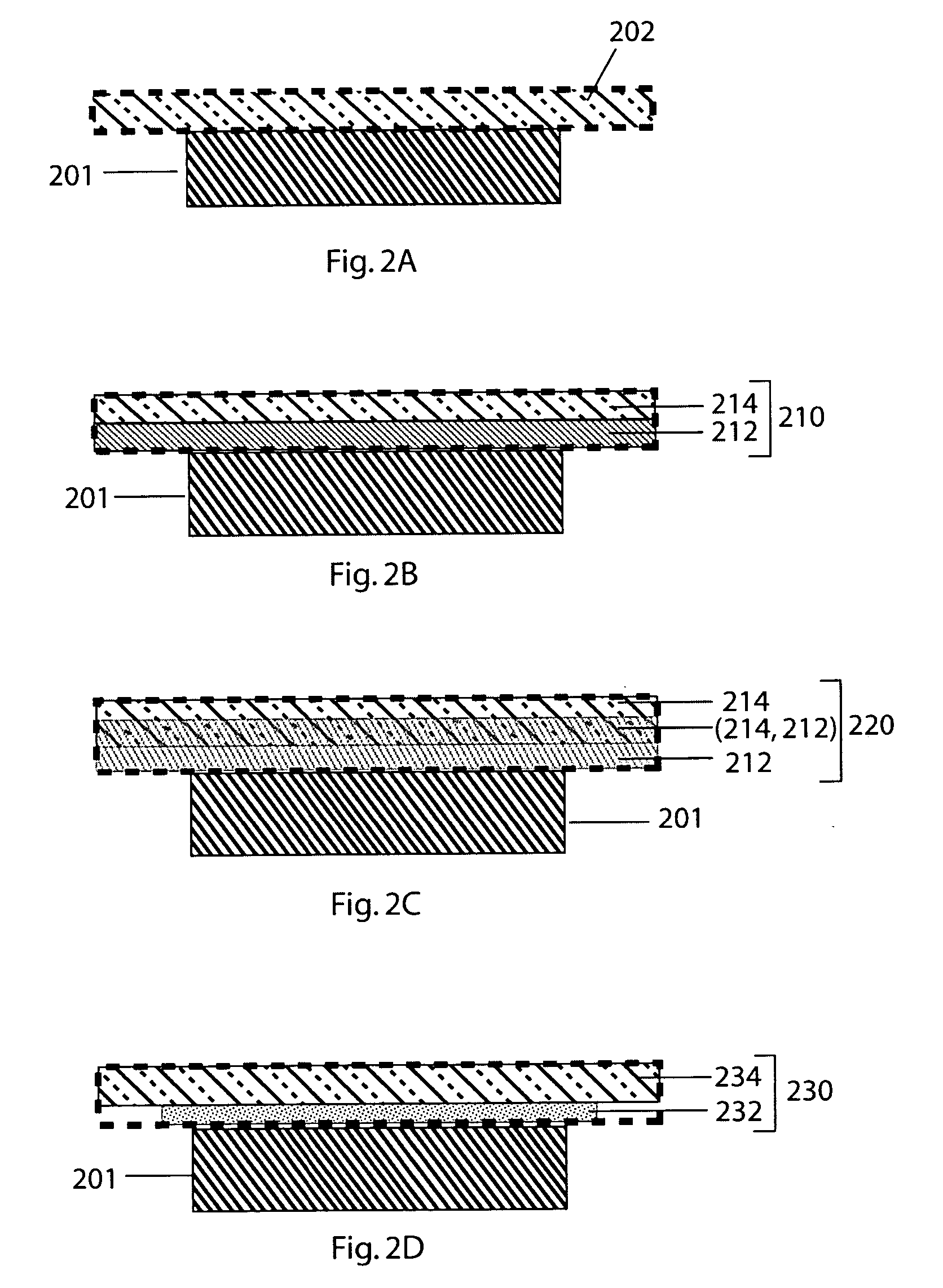

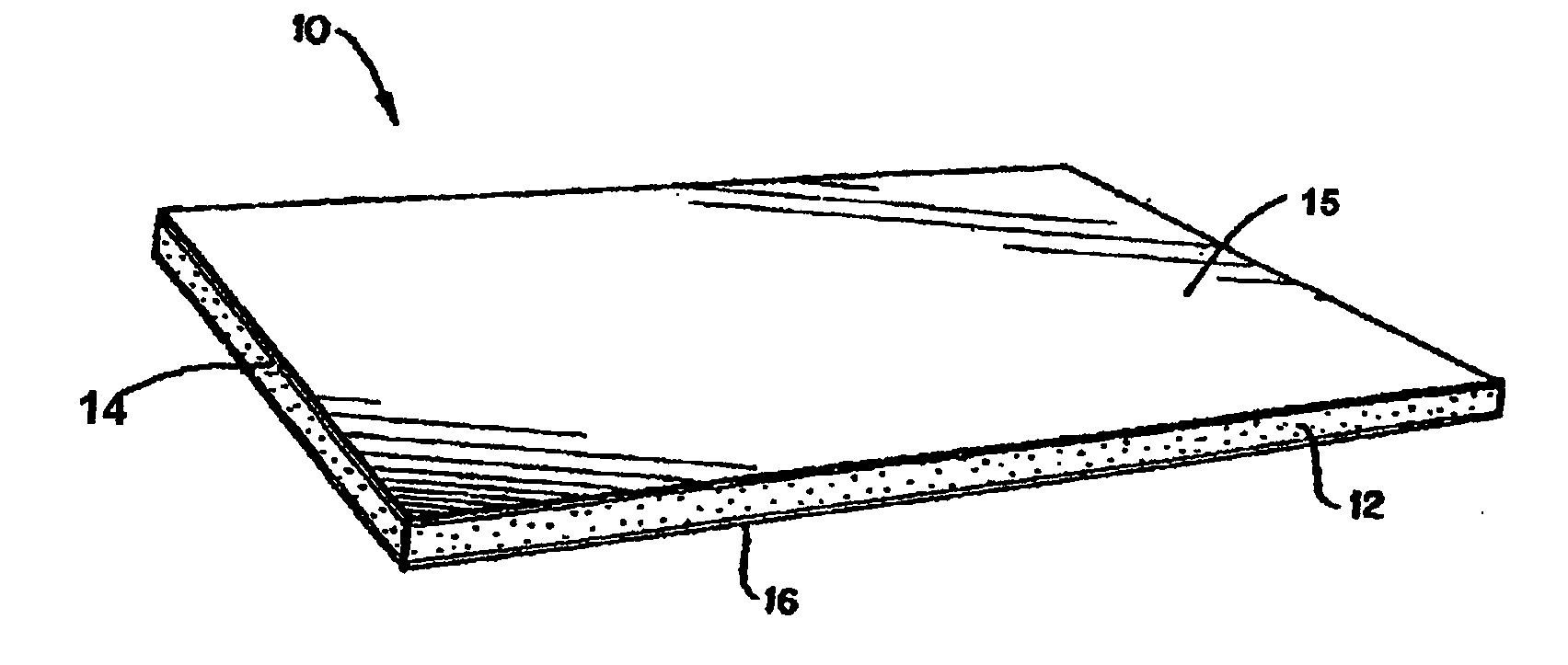

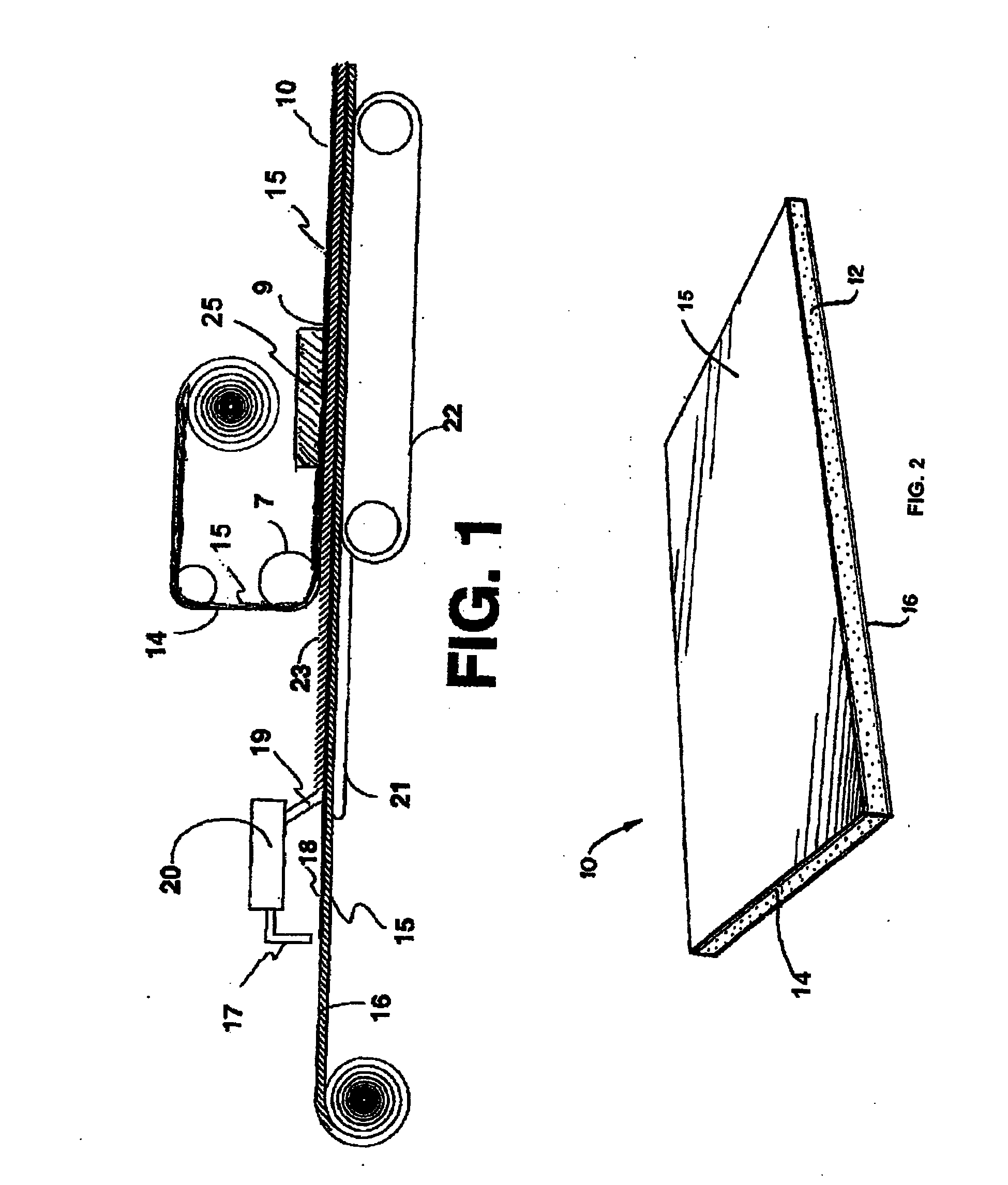

The present invention provides a method of transfer of a first planar substrate with two major surfaces to a second substrate, comprising the steps of forming the first planar substrate, attaching one of the major surfaces of the first planar substrate to a carrier by means of a release layer attaching the other major surface of the first substrate to the second substrate with a curable polymer adhesive layer partly curing the polymer adhesive layer, disconnecting the release layer from the first substrate to separate the first substrate from the carrier, followed by curing the polymer adhesive layer. The method may be used to form a stack of dies (4, 14 . . . ) which are adhered together by cured polymeric layers (7, 17). Each die (4, 14 . . . ) may include a device layer and an ultra-thin substrate manufactured and assembled by the method described above.

Owner:INTERUNIVIR MICRO ELEKTRONICA CENTRYM VZW IMEC

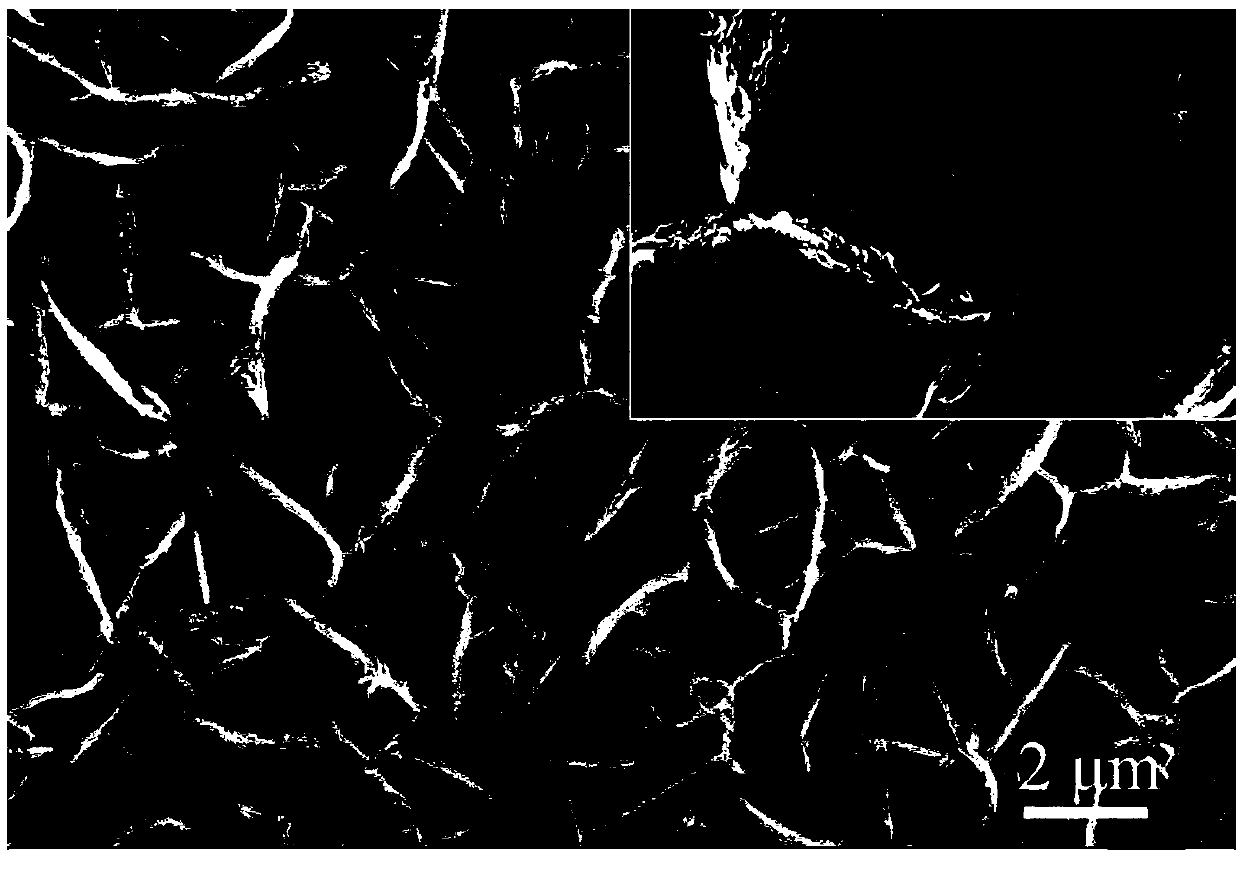

Preparation method of polymer/graphene composite material through in situ reduction

ActiveCN101864098AEvenly dispersedQuality improvementSpecial tyresNon-conductive material with dispersed conductive materialElectrical conductorVulcanization

The invention relates to a preparation method of a polymer / graphene composite material through in situ reduction, which is characterized by comprising the following steps: adopting ultrasonic wave or grinding to evenly disperse the graphite oxide prepared by a Hummers method into polymer dispersion; introducing reducing agent into the polymer dispersion for in situ reduction, enabling the graphite oxide to be reduced into the grapheme so as to obtain stable polymer / graphene composite emulsion; carrying out demulsification, agglomeration and drying to obtain the composite polymer / grapheme composite master batch; adding the dried polymer / grapheme composite master batch and various assistants into the polymeric matrix according to a certain ratio; and carrying out double-roller mixing, vulcanization, melt extrusion or injection molding to obtain the polymer / graphene composite material with excellent physical and mechanical properties.

Owner:成都创威新材料有限公司

Method of transferring ultra-thin substrates and application of the method to the manufacture of a multi-layer thin film device

InactiveUS6506664B1High densityHigh-density productSemiconductor/solid-state device detailsSolid-state devicesPolymer adhesivePlanar substrate

The present invention provides a method of transfer of a first planar substrate with two major surfaces to a second substrate, comprising the steps of: forming the first planar substrate, attaching one of the major surfaces of the first planar substrate to a carrier by means of a release layer; attaching the other major surface of the first substrate to the second substrate with a curable polymer adhesive layer; partly curing the polymer adhesive layer, disconnecting the release layer from the first substrate to separate the first substrate from the camer, followed by coing the polymer adhesive layer.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

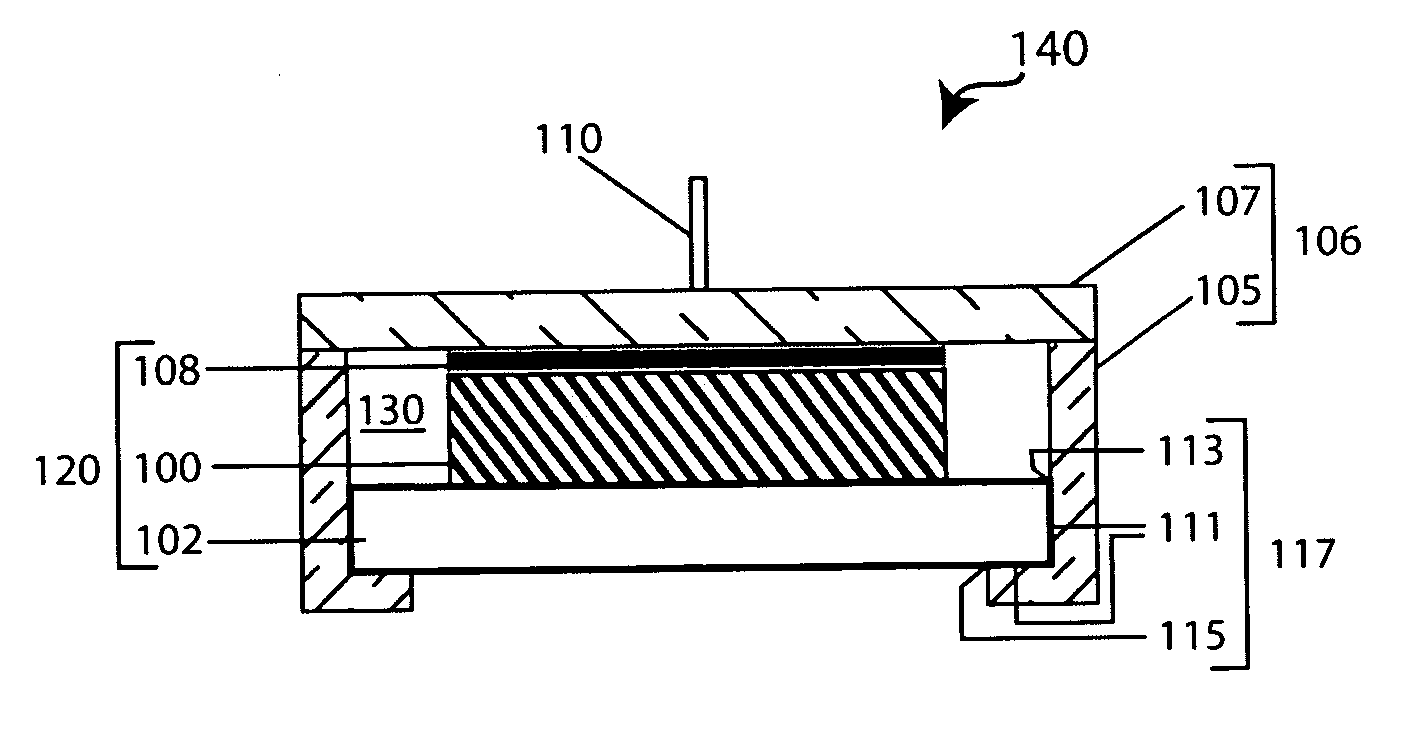

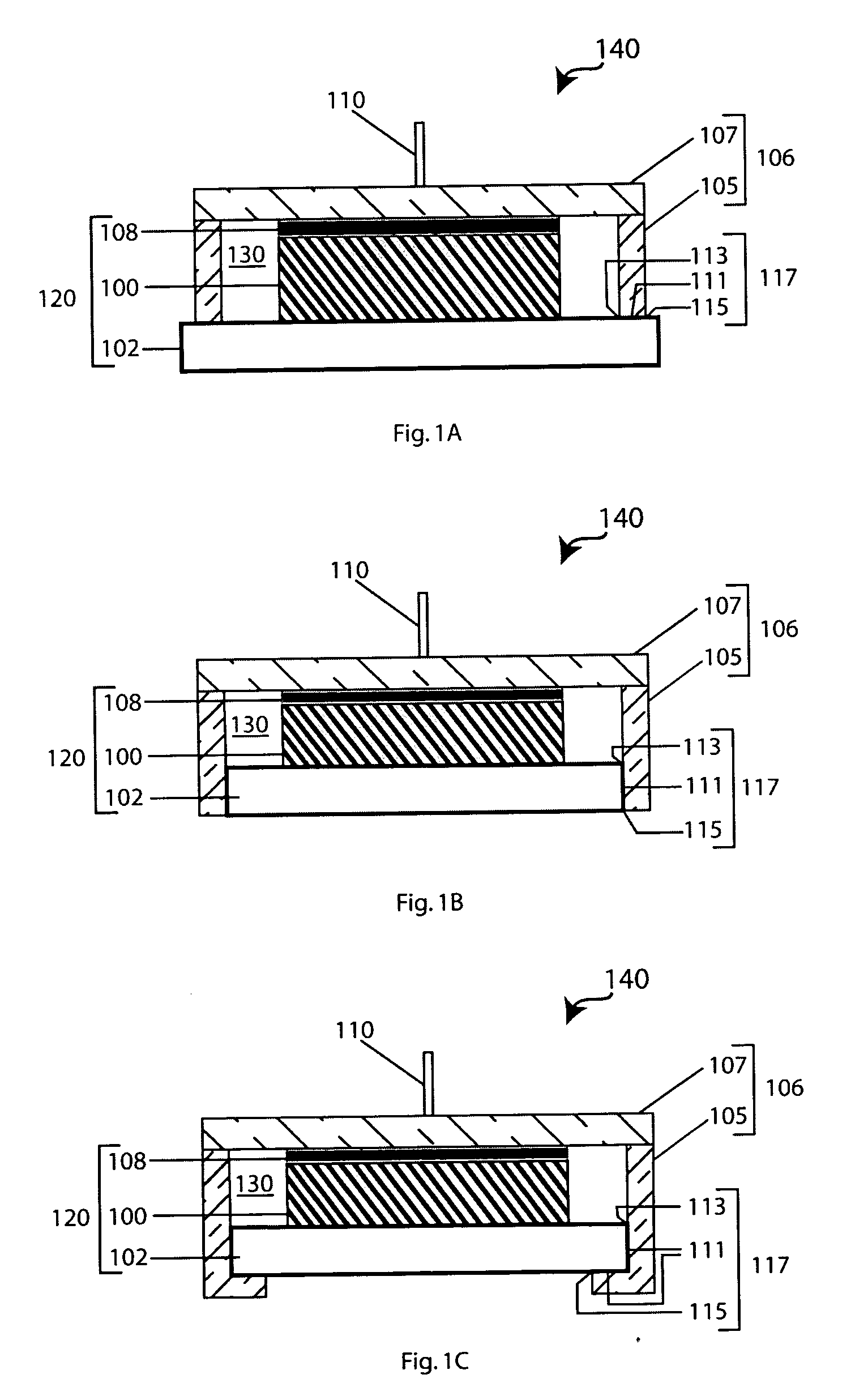

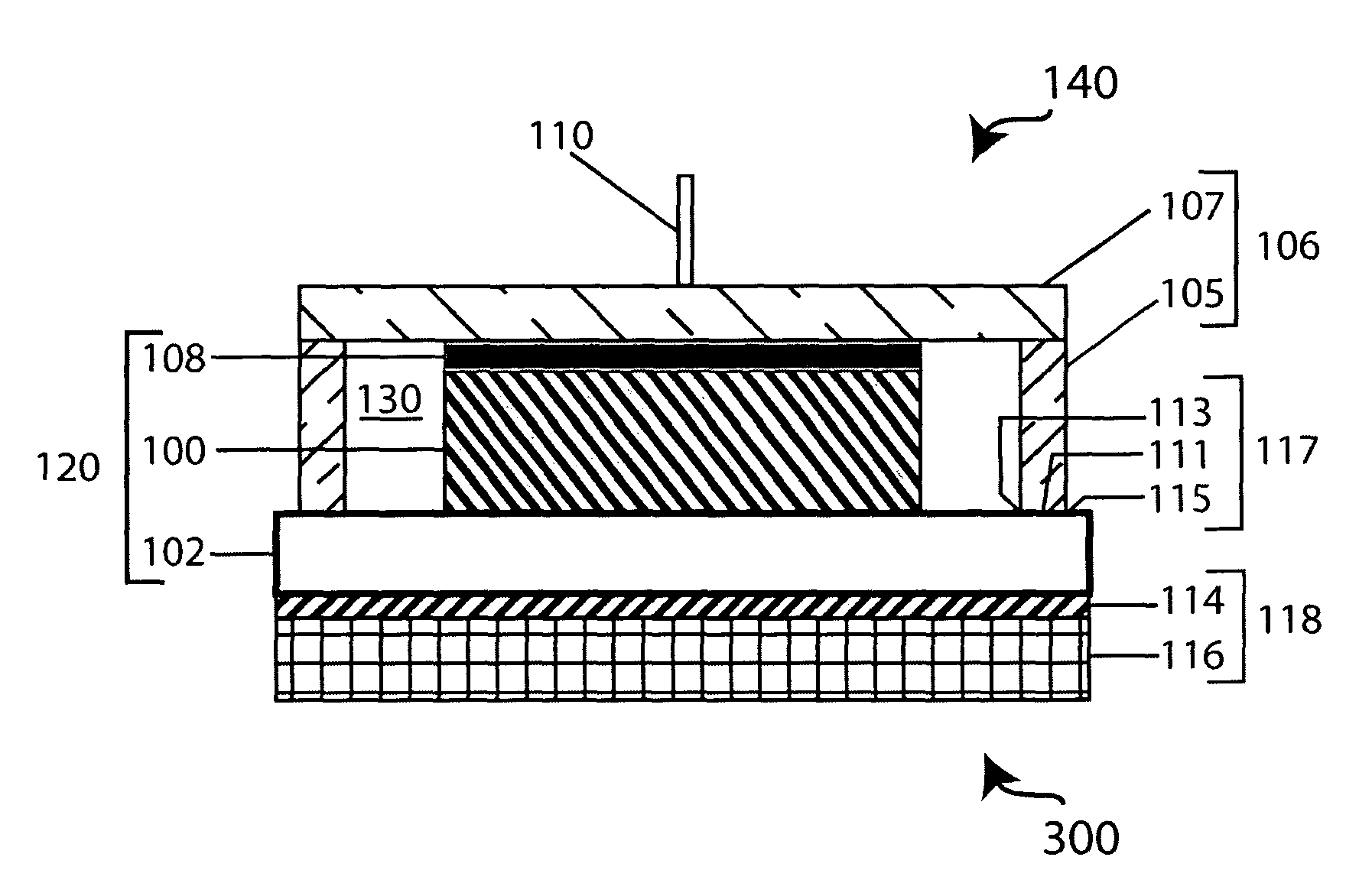

Polymer adhesive seals for protected anode architectures

ActiveUS20070051620A1Avoid componentsEasy to useFuel and primary cellsHybrid cell detailsPolymer adhesiveHermetic seal

Protected anode architectures for active metal anodes have a polymer adhesive seal that provides an hermetic enclosure for the active metal of the protected anode inside an anode compartment. The compartment is substantially impervious to ambient moisture and battery components such as catholyte (electrolyte about the cathode), and prevents volatile components of the protected anode, such as anolyte (electrolyte about the anode), from escaping. The architecture is formed by joining the protected anode to an anode container. The polymer adhesive seals provide an hermetic seal at the joint between a surface of the protected anode and the container.

Owner:POLYPLUS BATTERY CO INC

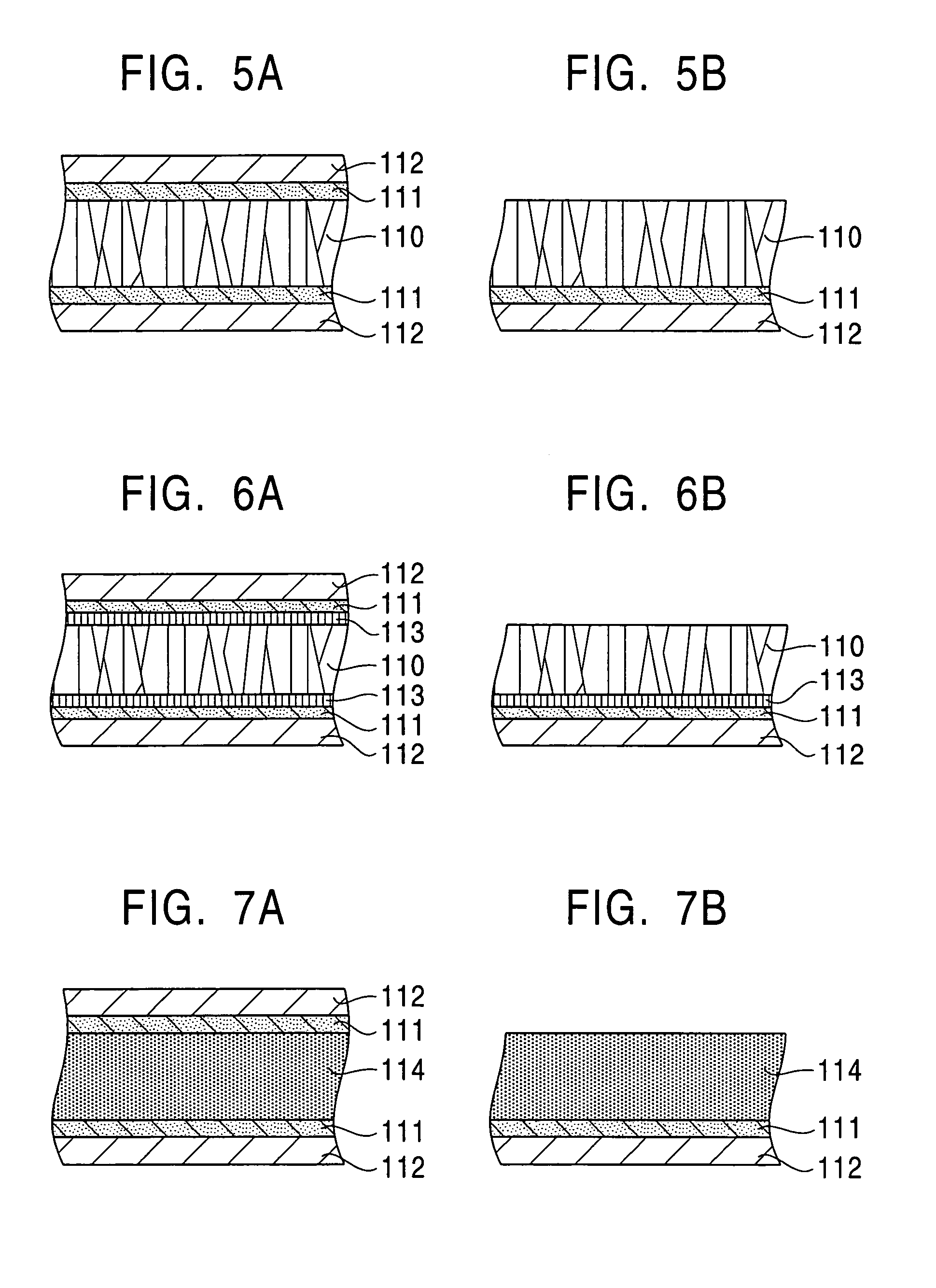

Heat spreader and semiconductor device and package using the same

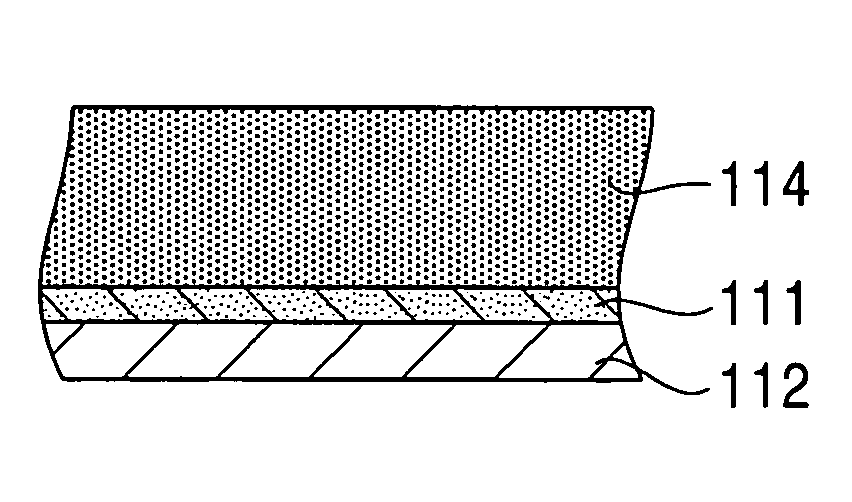

InactiveUS7067903B2Improve thermal conductivityLarge thermal conductivitySemiconductor/solid-state device detailsSolid-state devicesPolymer adhesiveCeramic

A semiconductor device and package has a heat spreader directly disposed on the reverse surface of the semiconductor device. This heat spreader includes a diamond layer or a layer containing diamond and ceramics such as silicon carbide and aluminum nitride. The heat spreader is directly formed on a substrate for the semiconductor device. In particular, the heat spreader is composed of a diamond layer and one or two metal or ceramic members, which are bonded to the diamond layer with one or two polymer adhesive layers. This diamond layer has a fiber structure across the thickness or a microcrystalline structure. Cilia are formed on a surface of the diamond layer facing the one or two metal or ceramic members.

Owner:KOBE STEEL LTD

Polymer colloid-containing ink-jet inks for printing on non-porous substrates

ActiveUS20050176847A1Improve adhesionMeasurement apparatus componentsDuplicating/marking methodsPorous substrateParticulates

The present invention is drawn toward an ink-jet ink, comprising an aqueous liquid vehicle having acid-functionalized polymer colloid particulates and polymer-attached pigment colorants dispersed in the liquid vehicle. The liquid vehicle can include at least one volatile co-solvent, each volatile co-solvent present having a boiling point at or below about 285° C. The total amount of volatile co-solvent present in the ink-jet ink can be from 5 wt % to 50 wt %. These ink-jet inks can be printed on traditional as well as non-porous substrates. Optionally, heat can be applied to an image printed with the ink-jet ink to drive off at least a portion of the volatile co-solvent(s).

Owner:HEWLETT PACKARD DEV CO LP

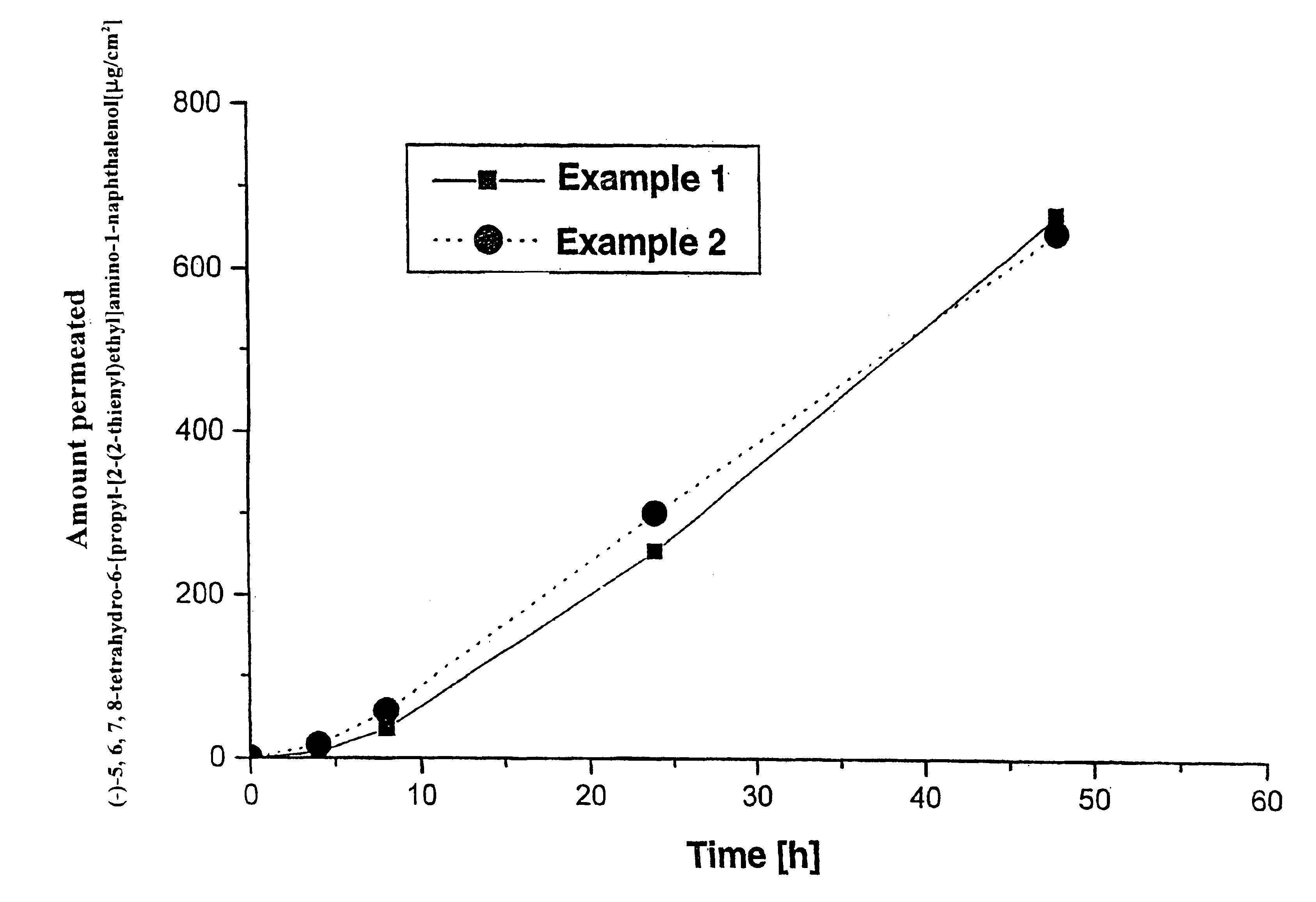

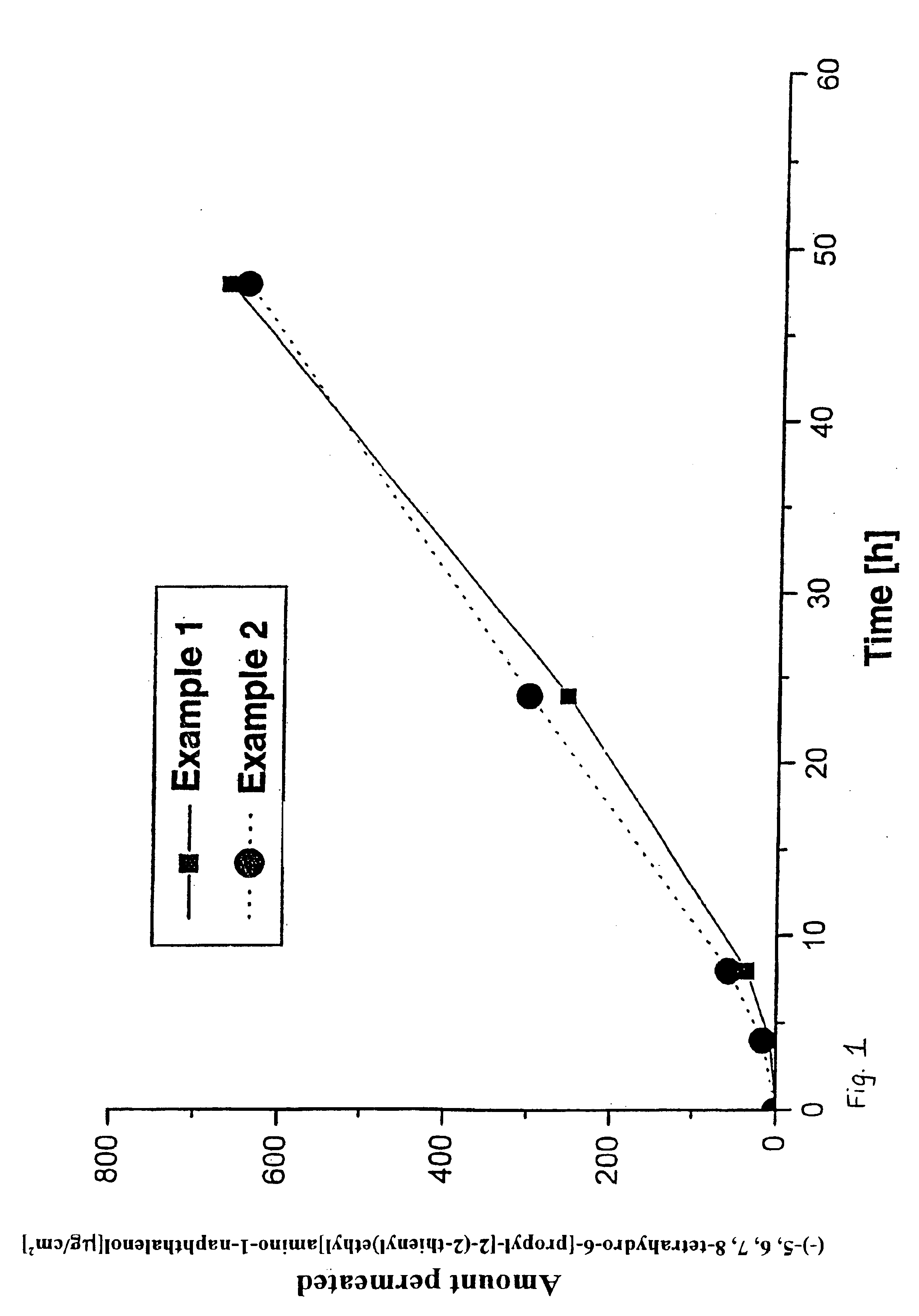

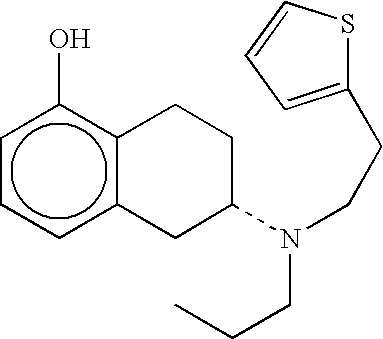

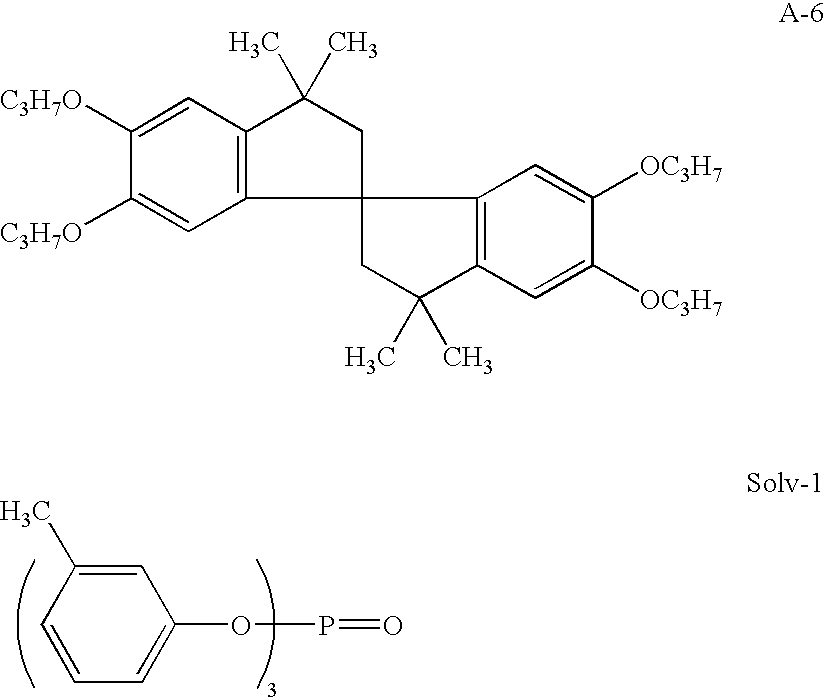

Transdermal therapeutic system which contains a d2 agonist and which is provided for treating parkinsonism, and a method for the production thereof

Owner:LTS LOHMANN THERAPIE-SYST AG

Heat-sensitive transfer image-receiving sheet and method for producing heat-sensitive transfer image-receiving sheet

InactiveUS7485402B2Easy to optimizeHigh transfer densityDiffusion transfer processesRadiation applicationsPolymer adhesiveHeat sensitive

A heat-sensitive transfer image-receiving sheet comprising at least one receiving layer containing a polymer latex and at least one heat insulating layer containing a hollow polymer on a support, wherein the polymer latex contained in the receiving layer comprises two or more dyable polymers having different glass transition temperatures.

Owner:FUJIFILM CORP

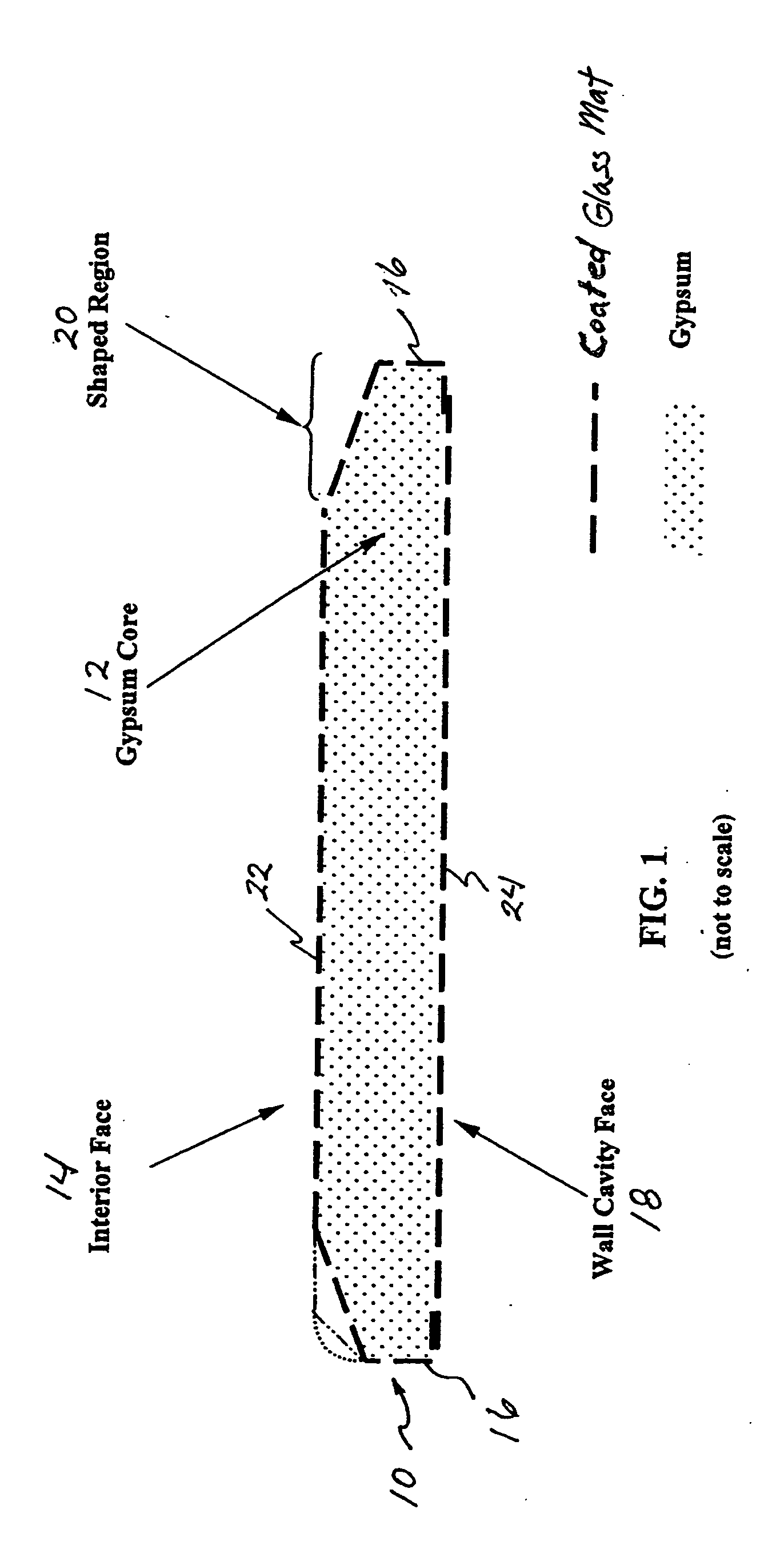

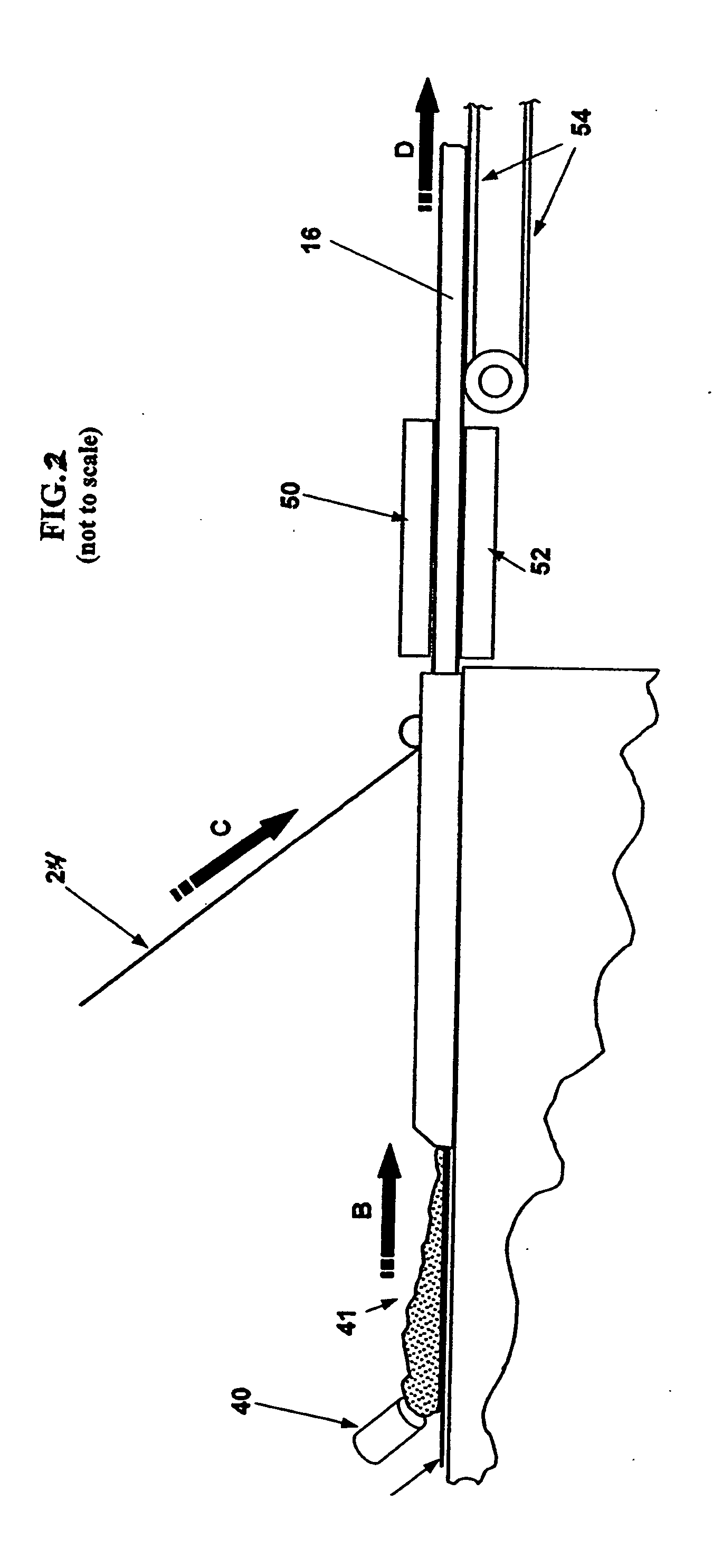

Pre-coated non-woven mat-faced gypsum panel

InactiveUS20090208714A1Covering/liningsLayered product treatmentPolymer scienceVolumetric Mass Density

A gypsum panel suitable for use in constructing a roof deck comprising a set gypsum core having at least about 0.3 pounds of reinforcing fibers per 100 square feet and a density sufficient to provide a board weight of 130 lbs per 100 square feet, where the core sandwiched between and faced with coated non-woven fibrous mats, wherein the free surface of each mat is pre-coated with a combination of a mineral pigment and a polymer latex adhesive binder applied to the mat surfaces as an aqueous coating composition.

Owner:GEORGIA PACIFIC GYPSUM LLC

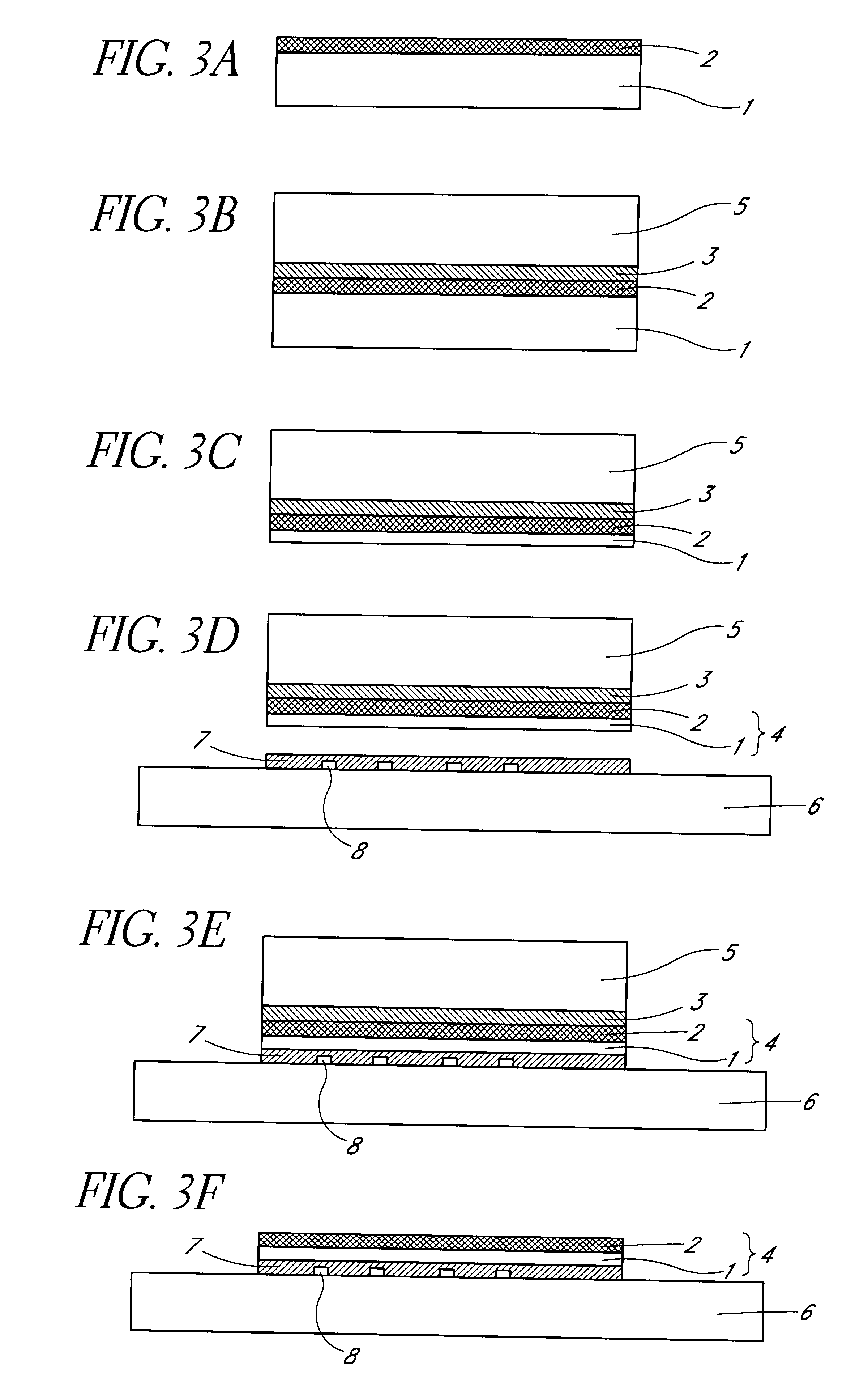

Method of transferring ultra-thin substrates and application of the method to the manufacture of a multi-layered thin film device

InactiveUS6730997B2High densitySafe transferSemiconductor/solid-state device detailsSolid-state devicesPolymer sciencePolymer adhesive

The present invention provides a method of transfer of a first planar substrate with two major surfaces to a second substrate, comprising the steps of forming the first planar substrate, attaching one of the major surfaces of the first planar substrate to a carrier by means of a release layer attaching the other major surface of the first substrate to the second substrate with a curable polymer adhesive layer partly curing the polymer adhesive layer, disconnecting the release layer from the first substrate to separate the first substrate from the carrier, followed by curing the polymer adhesive layer.The method may be used to form a stack of dies (4, 14 . . . ) which are adhered together by cured polymeric layers (7, 17). Each die (4, 14 . . . ) may include a device layer and an ultra-thin substrate manufactured and assembled by the method described above.

Owner:INTERUNIVIR MICRO ELEKTRONICA CENTRYM VZW IMEC

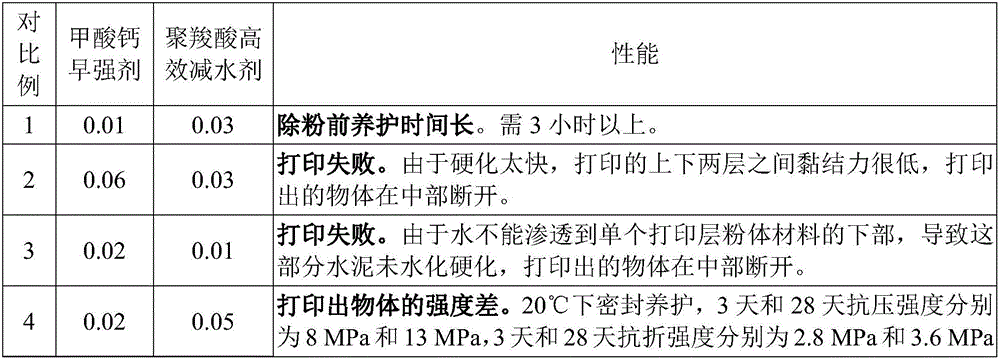

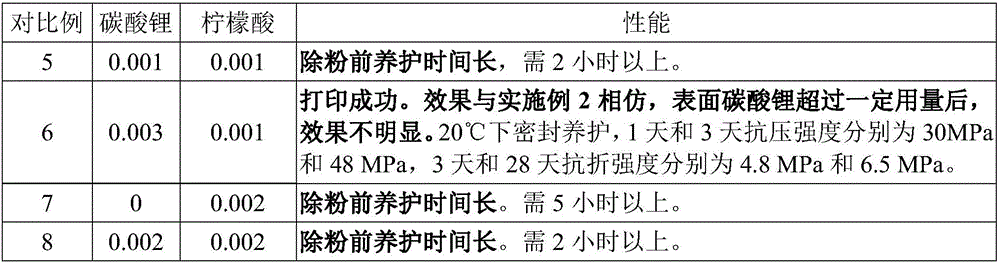

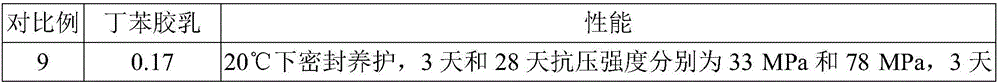

Cement-based composite material for powder-bonding three-dimensional (3D) printing, and powder-bonding 3D printing method applying cement-based composite material

ActiveCN106800391AAppropriate hardening speedAppropriate water distribution effectAdditive manufacturing apparatusPolymer adhesivePhosphate

The invention provides a cement-based composite material for powder-bonding three-dimensional (3D) printing. The material is prepared from the following components in parts by weight: 1 part of cement, 0-5 parts of sand, 0-5 parts of a mineral admixture, 0-0.2 part of an expanding agent, 0-0.2 part of a toughening agent, 0-0.2 part of mineral pigment, 0.1-0.5 part of water, 0-0.25 part of polymer emulsion, 0.001-0.05 part of an additive and 0-0.03 part of fibers, wherein the cement is selected from one or a mixture of more in silicate cements, sulphoaluminate cement, high belite sulphoaluminate cement, aluminate cement, fluoroaluminate cement, aluminosilicate cement, phosphate cement or magnesium oxide cement; the additive is selected from one or a mixture of more in a water reducing agent, an early strength agent or a coagulating regulating agent. After being contacted with water, the cement-based composite material can be hardened, thus not needing a great deal of polymer adhesive; the cement-based composite material is rapid and controllable in hardening speed; the cement-based composite material is small in deformation in the hardening process, thus being suitable for a powder-bonding 3D printing technology. The invention also provides a method for carrying out powder-bonding 3D printing by using the cement-based composite material.

Owner:万玉君

Fragrance compositions

A composition comprising:(a) a fragrance oil wherein the fragrance oil comprises greater than 0.5% of a top note perfume raw material, or mixture of top note perfume raw materials, with a boiling point of less than, or equal to, 250° C. at 1 atmosphere pressure;(b) an entrapment material which is selected from the group consisting of polymers; capsules, microcapsules and nanocapsules; liposomes; film formers; absorbents; cyclic oligosaccharides and mixtures thereof;(c) greater than 50% volatile solvent;wherein the perfume raw material and the entrapment material exist in an associated form on the substrate and wherein the weight ratio of the top note perfume raw material to the entrapment material within the associated form is in the range from about 1:20 to about 20:1.The present invention provides compositions wherein the light, fresh, fruity, citrus, green or delicate floral top note fragrance character remains detectable for greater than about 2 hours, preferably greater than about 4 hours, more preferably greater than about 6 hours, after the composition has been applied to the substrate.

Owner:PROCTER & GAMBLE CO

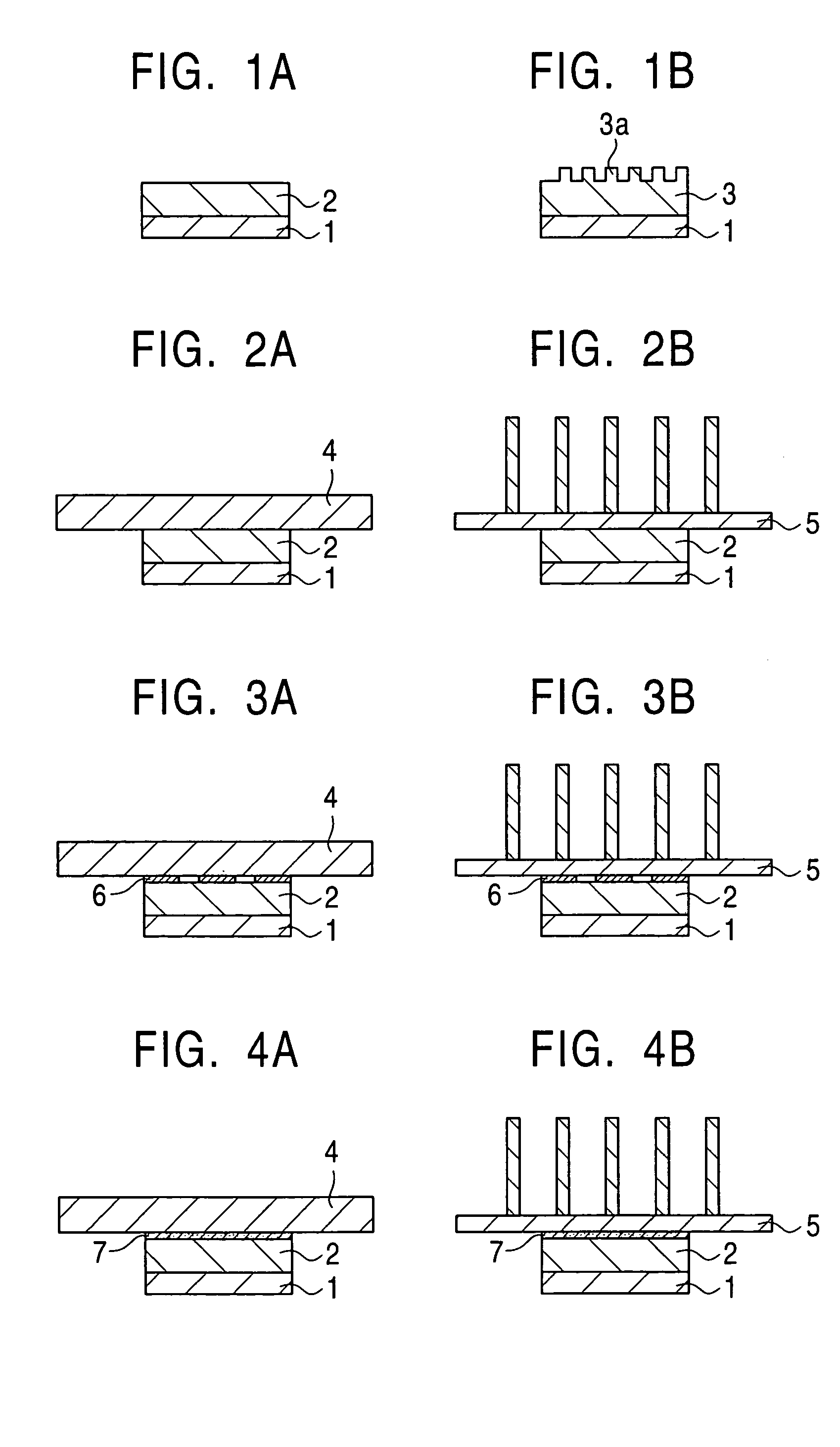

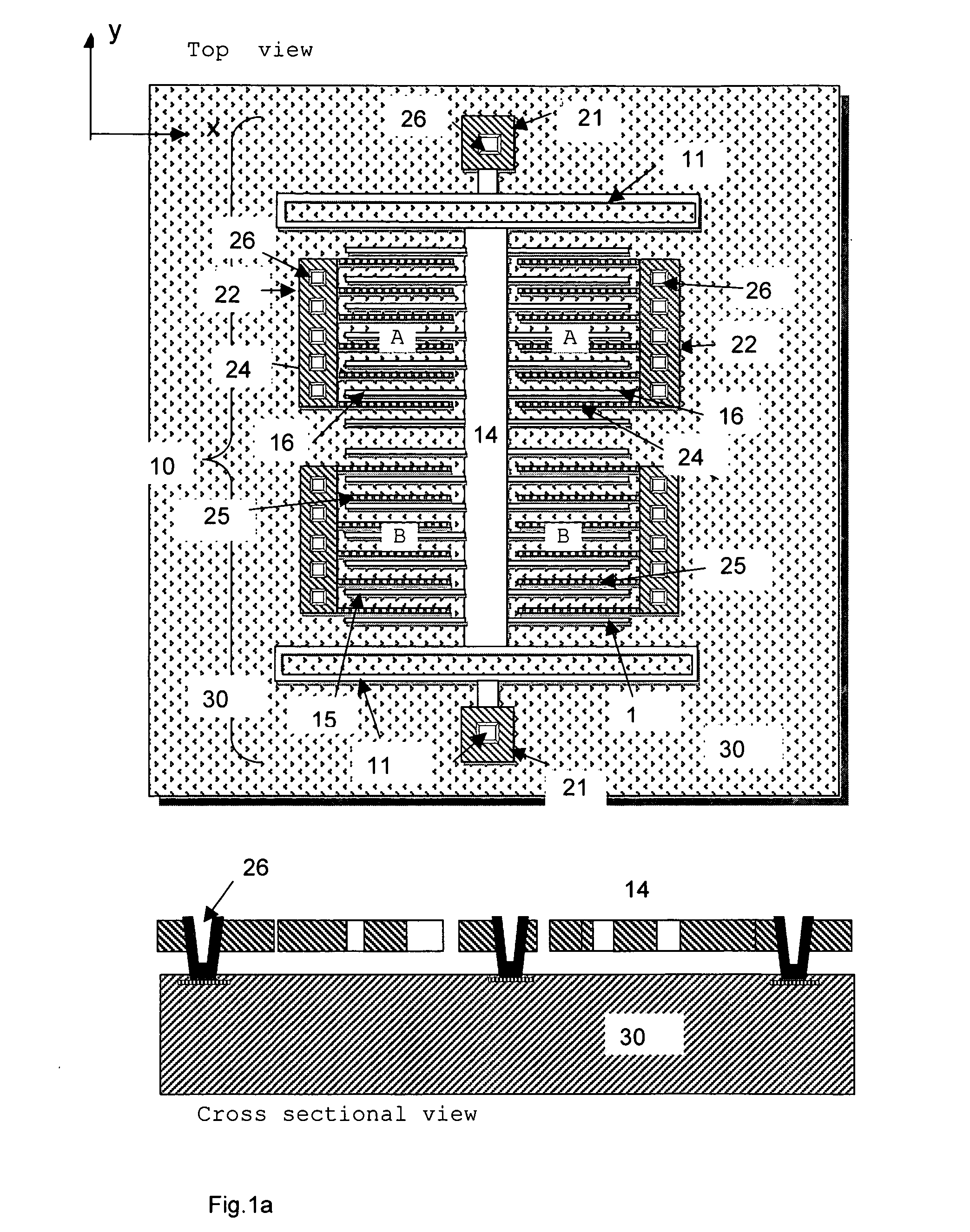

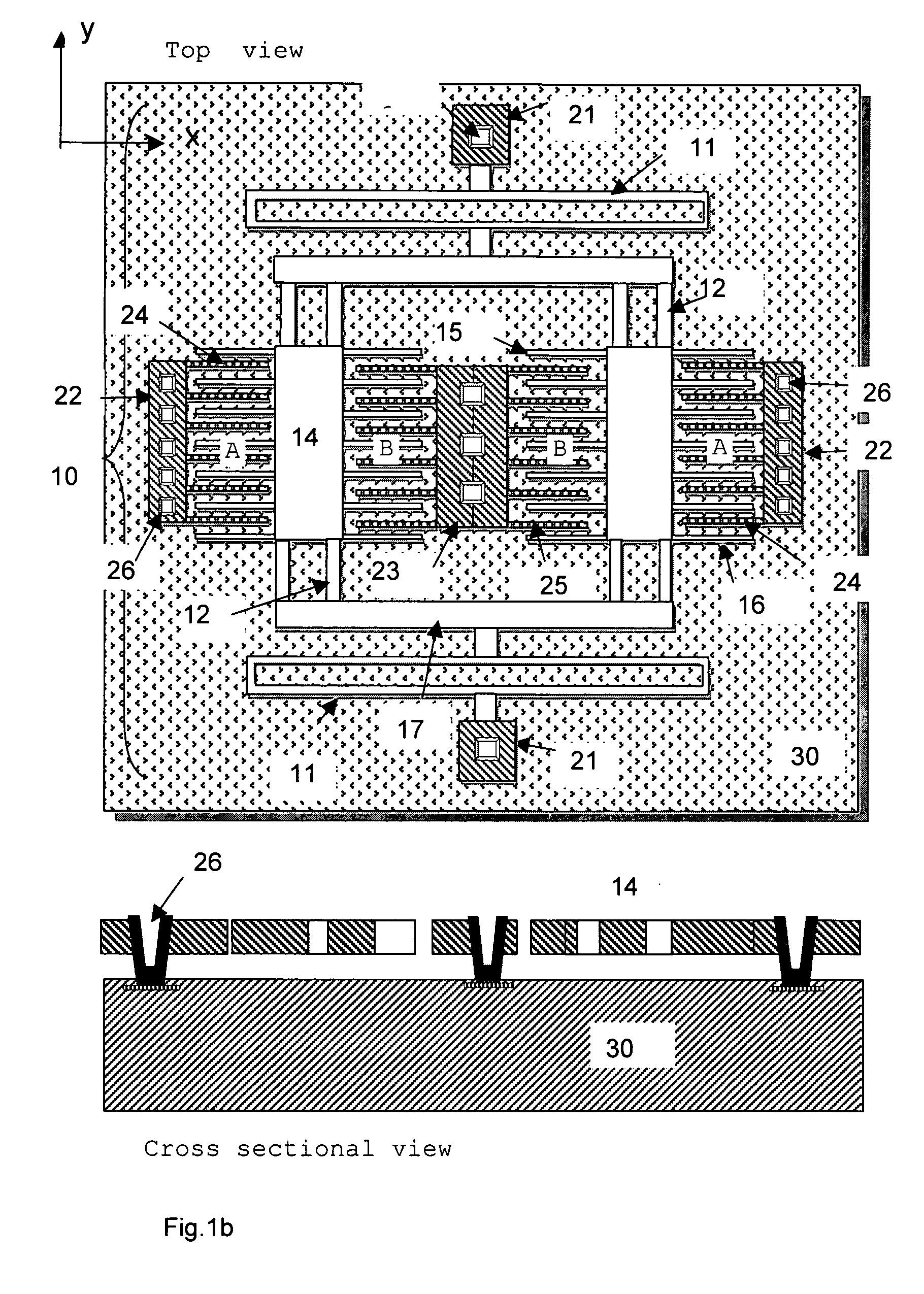

Micro-electro mechanical device made from mono-crystalline silicon and method of manufacture therefore

InactiveUS20080138922A1Improve performanceSimple methodSemiconductor/solid-state device manufacturingMicrostructural device manufacturePolymer adhesiveEngineering

The present invention is related to a method for manufacturing micro-electro-mechanical systems (MEMS) having movable and stationary suspended structures formed from mono-crystalline silicon wafer or chip, bonded to a substrate wafer with an polymer adhesive layer that serves as spacer and as a sacrificial layer which is undercut by dry etch means. The substrate wafer contains electronic circuits for sensing and actuating the suspended structure by electrical means. Electrical interconnections between the suspended structures and the substrate can be made by etching through via holes in the suspended structure and the adhesive, depositing metal layers in the via holes, and removing the metal layers from outside the via holes. The metal layers in the via holes can also be used as pillars for supporting the suspended structures. This method can be used to manufacture inertial sensors.

Owner:WAN CHANG FENG

Non-sticking lining with wearing resistance and anti-corrosive property and coating method thereof

The invention discloses a non-stick coating with wear resistance and corrosion resistance and a coating method thereof. The coating comprises an anti-corrosive bottom layer, a wear-resistant intermediate layer and a non-stick finish coat, wherein the bottom layer contains a fluoropolymer, 1 to 15 weight percent of at least one heat-resistant polymer adhesive, and 1 to 15 weight percent of pigment and filler; the intermediate layer is coated on the bottom layer, and contains the fluoropolymer and inorganic filler particles; and the finish coat is coated on the intermediate layer and contains the fluoropolymer with non-stick effect. A priming coat has good anti-corrosion performance due to small content and small fineness of the pigment and the filler, an intermediate coating has good wear-resistant property due to the fact that partial large particles in an organic filler are embedded into the bottom layer and are convex into the finish coat, and the finish coat has good non-stick performance.

Owner:ZHEJIANG PFLUON TECH CO LTD +1

Janus particle with double properties and preparation method thereof

The invention discloses a Janus particle with double properties and a preparation method thereof. By employing cross-linked polymer colloidal particles as seeds and through a seed emulsion polymerization method, Janus particles with double properties are obtained on the basis of a phase separation mechanism; inorganic, metal and metal oxide compounded Janus particles with electrical, magnetic, optical properties are obtained through functional group modification and composition of function materials and can be used for the material field. The Janus particles have an emulsifying property in organic, inorganic dispersed phases or different organic dispersed phases and meanwhile the Janus particles have a great application prospect in the aspects of self-assembly, superhydrophobicity, nanomotor and the like. The preparation method provided by the invention is easy to operate, has the feasibility of mass production and can adapt to different needs by modification and composition of function materials.

Owner:INST OF CHEM CHINESE ACAD OF SCI

Detergent compositions for cleaning and fabric care

InactiveUS20070293414A1Increase depositionOrganic detergent compounding agentsNon-surface-active detergent compositionsPolyolefinPolymer science

Detergent compositions comprising selected deposition polymers for improved deposition of fabric care benefit agents, such as organosilicones, polyolefin dispersions, polymer latexes, microencapsulated fabric care actives, onto fabrics through the laundering operation.

Owner:THE PROCTER & GAMBLE COMPANY

Preparation method of nano Ni3S2 material with lamellar structure

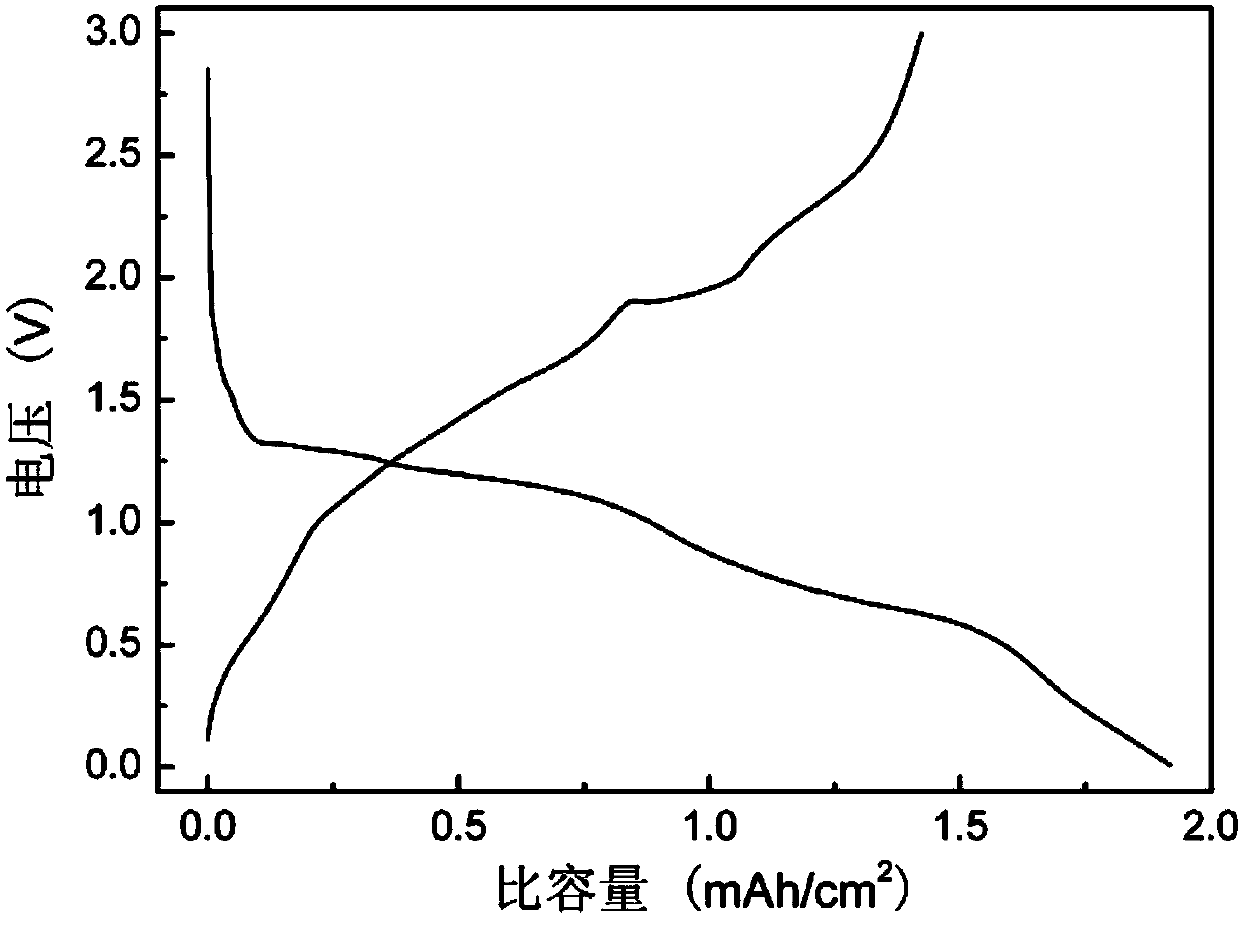

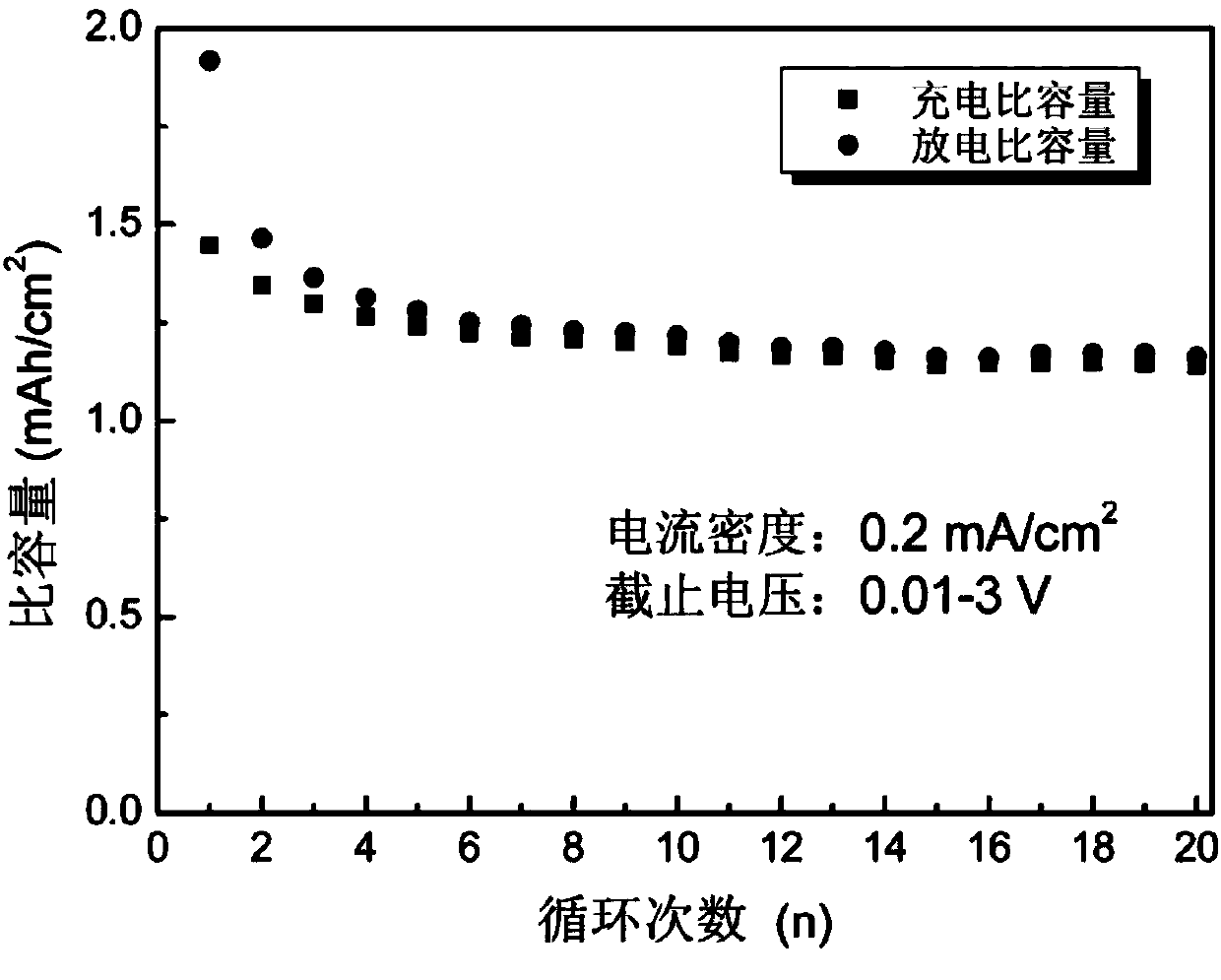

InactiveCN104201380AImprove electrochemical performanceSmall particle sizeMaterial nanotechnologyCell electrodesPolymer adhesiveAstronautics

The invention discloses a preparation method of a nano Ni3S2 material and belongs to the field of novel energy resources and electrochemistry. The preparation method of the nano Ni3S2 material is characterized by synthesizing the nano Ni3S2 material by taking a Ni net with a three-dimensional porous structure by virtue of a solvothermal method. A nano Ni3S2 active substance formed during the solvothermal process is directly loaded on an upper matrix of the Ni net, so that the active substance Ni3S2 is in relatively firm contact with a Ni net of a current collector; gaps of the porous Ni net can effectively buffer the volume change of the Ni3S2 in the processes of removing and embedding lithium, so that the cycle stability of the composite material can be improved; meanwhile, by virtue of a three-dimensional conductive network of the Ni net, the electronic conductivity of the composite material can be improved, so that the rate performance of the material is improved. The preparation method of the nano Ni3S2 material is simple, green, free from pollution, low in cost and suitable for industrial production. The Ni3S2 material prepared by adopting the method is small in particle size and uniform in particle distribution; according to an electrode prepared from the material, a polymer adhesive and a conductive agent do not need to be added in the electrode; the electrode has the high electrochemical performance and can be widely used in the fields of various portable electronic devices, electric automobiles, aeronautics and astronautics, and the like.

Owner:UNIV OF SCI & TECH BEIJING

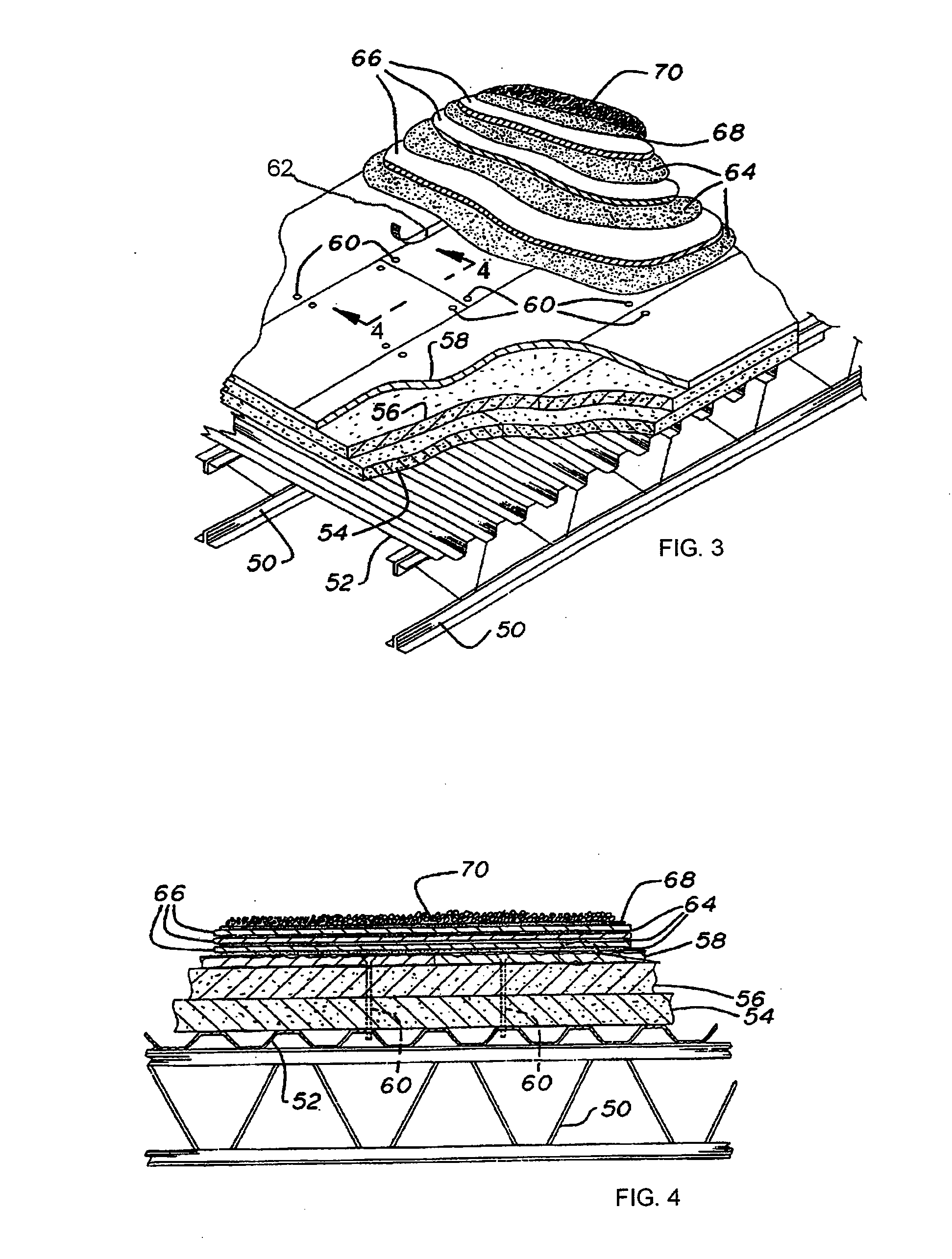

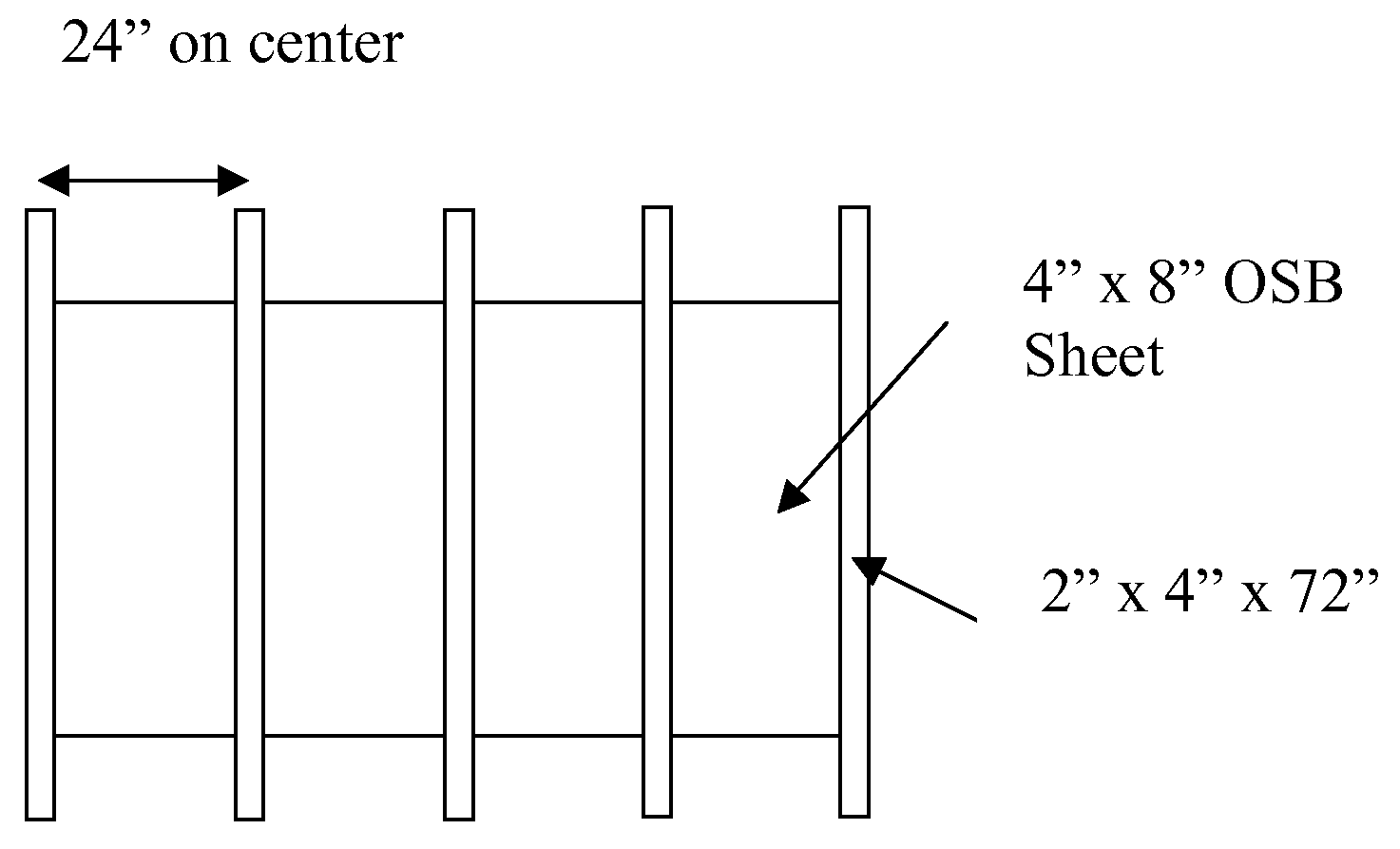

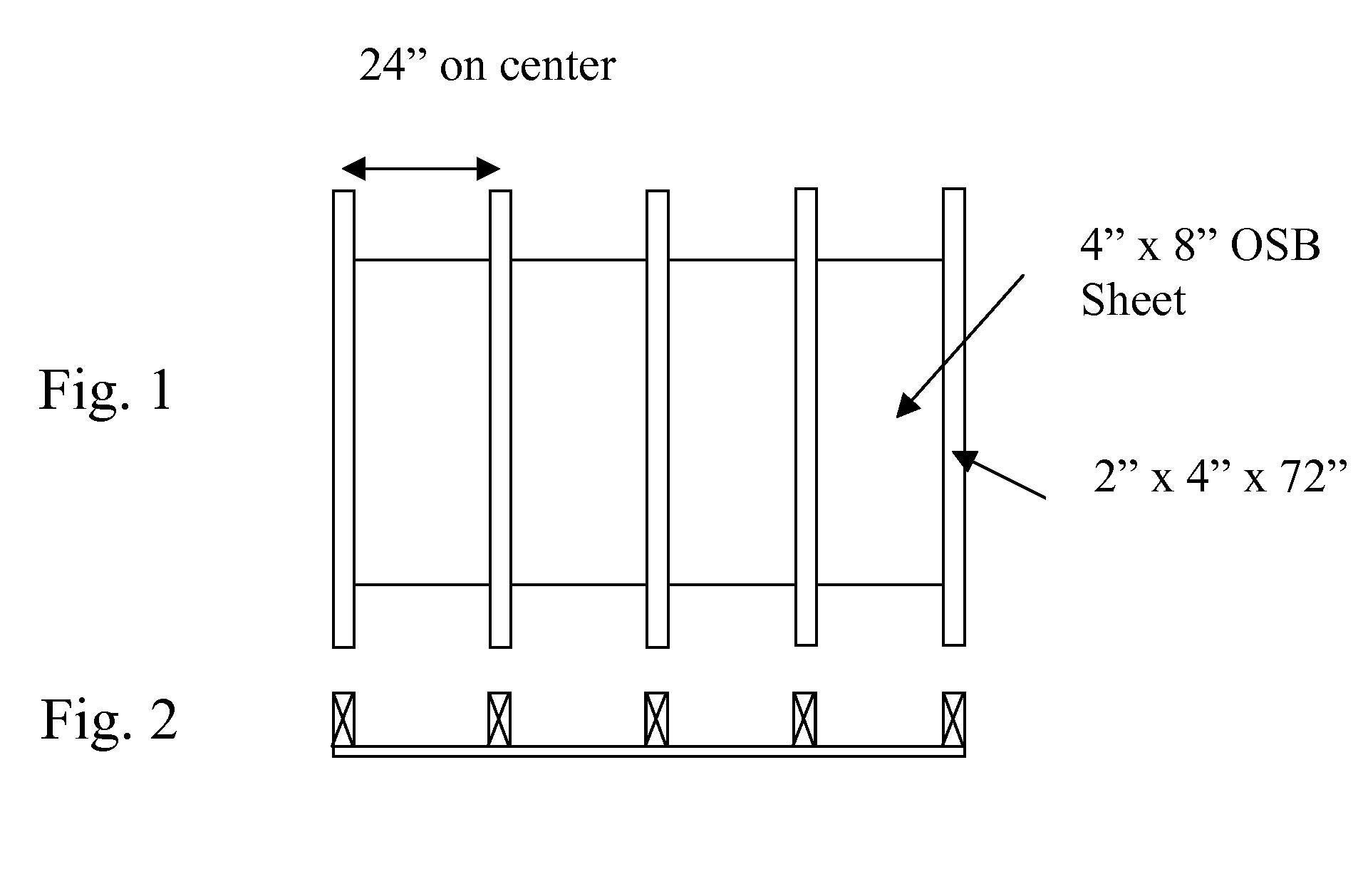

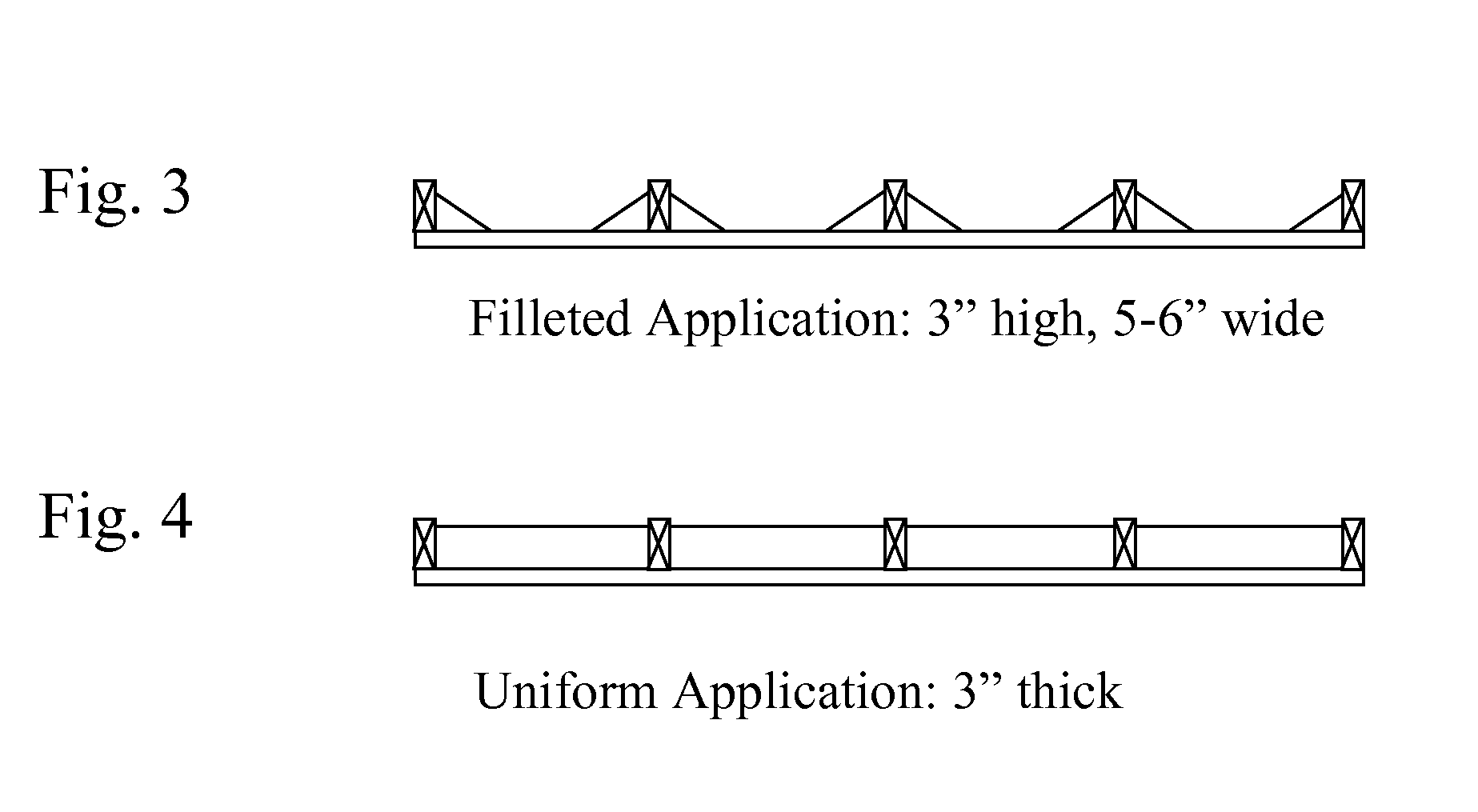

Method for increasing wind uplift resistance of wood-framed roofs using closed-cell spray polyurethane foam

InactiveUS20080313985A1High bonding strengthSignificant energy savingBuilding roofsConstruction materialPolymer adhesiveStructural engineering

The invention provides a method and structural member for securing a roof or an outer wall of a building against wind forces tending to lift the roof or outer wall off the building. A structural member has a panel, said panel comprising a plurality of spaced apart beam members, and a sheathing having an inner side and an outer side, the sheathing spanning a space between adjacent beam members and being attached to the beam members such that the inner side of the sheathing is in juxtaposition with the beam members. A layer of a rigid, closed cell foam comprising a polymer adhesive composition is on substantially the entirety of said beam members and substantially the entirety of the inner side of the sheathing such that the layer on the sheathing and the beam members is substantially continuous, and adheres the sheathing to the beam members.

Owner:HONEYWELL INT INC

Interior wallboard and method of making same

A gypsum wallboard suitable for Level 4 finishing having a coated non-woven glass fiber mat facing material where the glass fiber mat has a majority of fibers of a fiber diameter between 8 and 11 microns and a fiber length between ¼ and ¾ inch and preferably between ¼ and ½ inch and preferably has a basis weight between about 0.8 lb. / 100 ft.2 and about 2.2 lb. / 100, and wherein the fibers in the non-woven glass fiber are bound together with an acrylic adhesive binder and wherein the non-woven glass mat has a coating of a dried aqueous mixture of (i) a mineral pigment, (ii) a polymer latex adhesive binder and optionally (iii) an inorganic adhesive binder such that the coated non-woven glass mat facing material has a porosity which allows water to evaporate through said coated mat from the gypsum core during preparation of the wallboard.

Owner:GEORGIA PACIFIC GYPSUM LLC

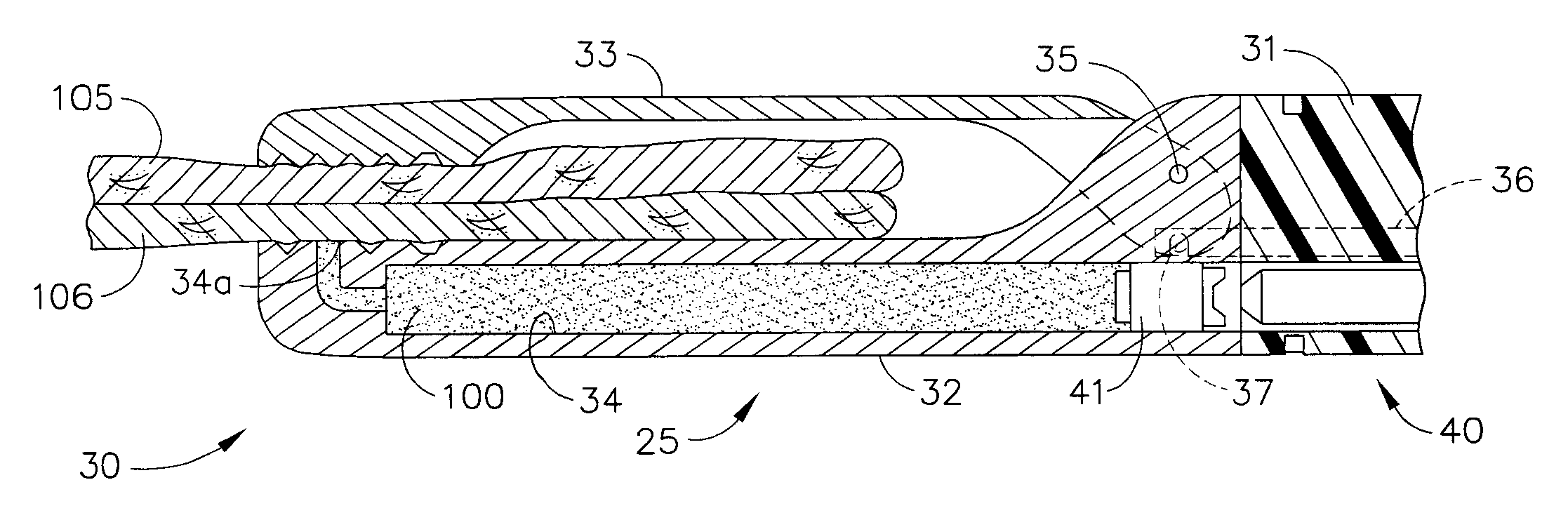

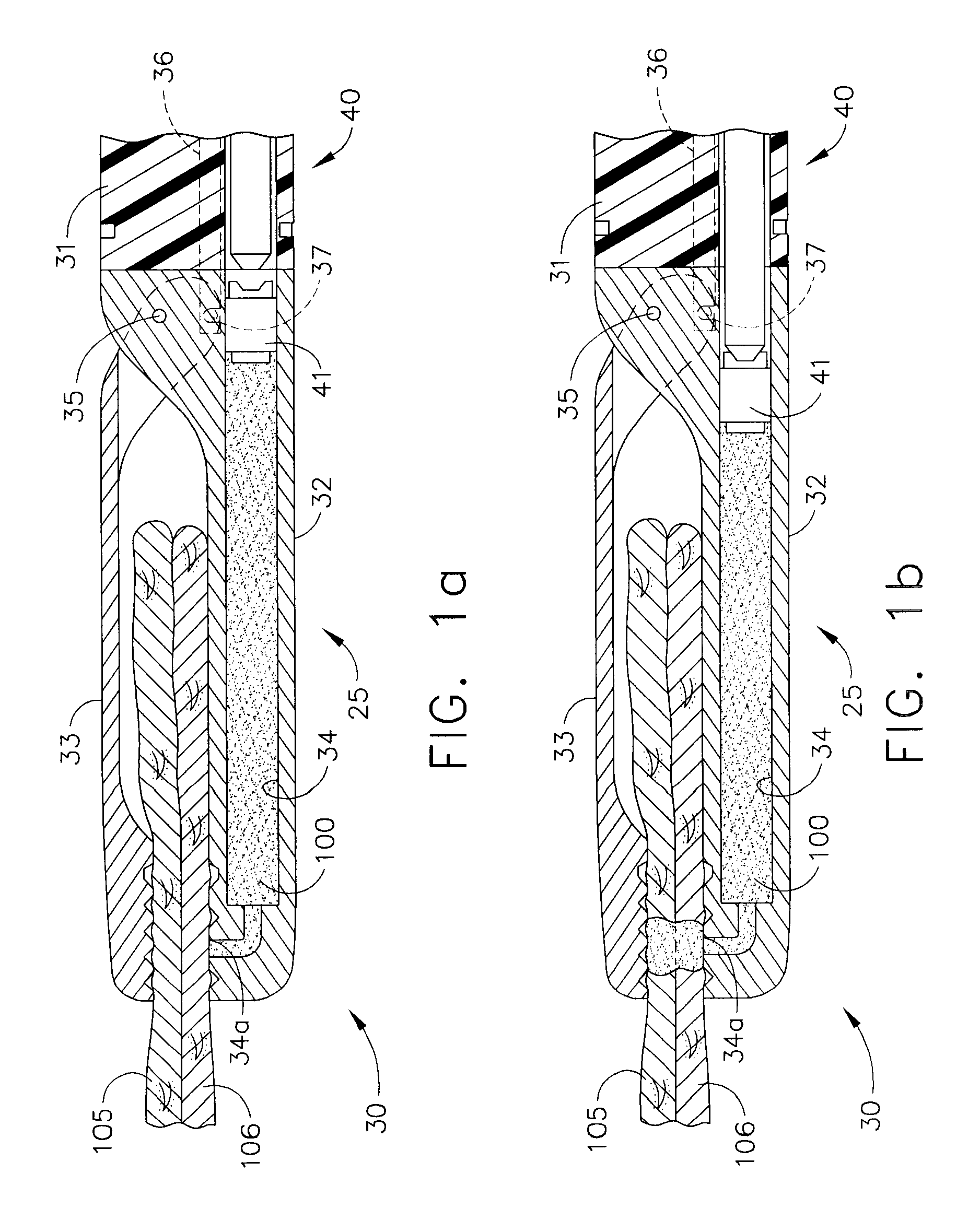

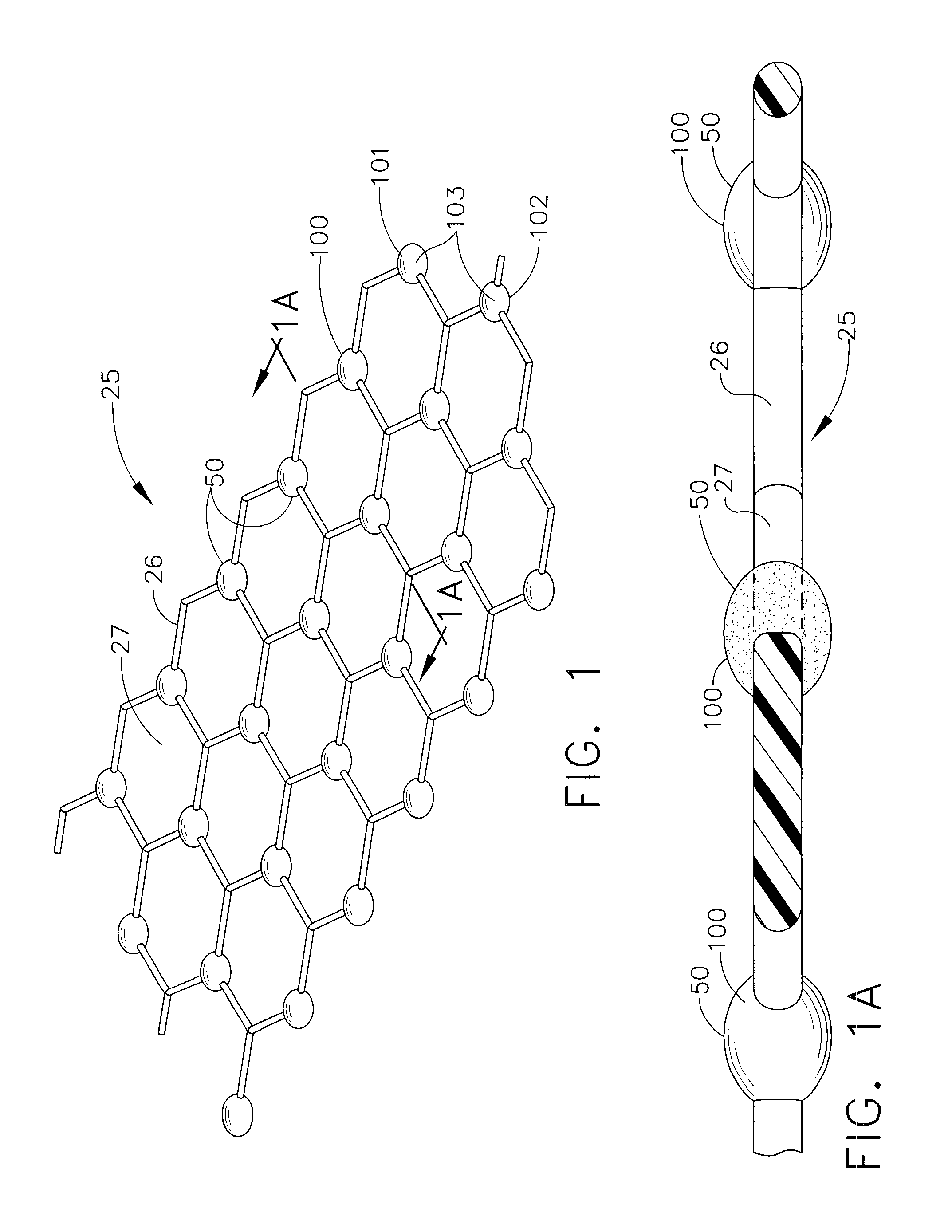

Form in place fasteners

A fastening device for clamping and fastening tissue together with fasteners formed from an adhesive is disclosed. An embodiment of the adhesive fastening device can clamp a first and a second portion of tissue together between a first and a second jaw, and can place a fluid polymer adhesive into tissue and form it into a polymerized surgical fastener within the tissue. The adhesive fastener can be formed as a polymerized shank or shaft extending through the tissue, and can have one or more heads formed on the shank. The shank can be formed solely from the polymerizable adhesive, or can be formed from another material such as nitinol, titanium, stainless steel, suture, or a plastic. Shanks of other material can be combined with the adhesive. Alternately, an adhesive fastener can be formed extending distally from a distal end of the surgical device. And, an adhesive fastener can be formed around a luminal tissue or within luminal tissue.

Owner:ETHICON ENDO SURGERY INC

Fragrance compositions

A composition comprising:(a) from about 0.01% to about 99%, by weight, of a fragrance oil, wherein the fragrance oil comprises about 5% or greater, by weight of fragrance oil, of a top note perfume raw material, or mixture of top note perfume raw materials, and wherein the top note perfume raw materials have a boiling point of less than, or equal to, about 250° C. at 1 atmosphere pressure;(b) an entrapment material which is selected from the group consisting of polymers; capsules, microcapsules and nanocapsules; liposomes; pro-perfumes selected from more than 1 type of pro-chemistry; film formers; absorbents; cyclic oligosaccharides and mixtures thereof;(c) greater than about 50% volatile solvent.The present invention provides compositions wherein the light, fresh, fruity, citrus, green or delicate floral top note fragrance character remains detectable for greater than about 2 hours, preferably greater than about 4 hours, more preferably greater than about 6 hours, after the composition has been applied to the substrate.

Owner:THE PROCTER & GAMBLE COMPANY

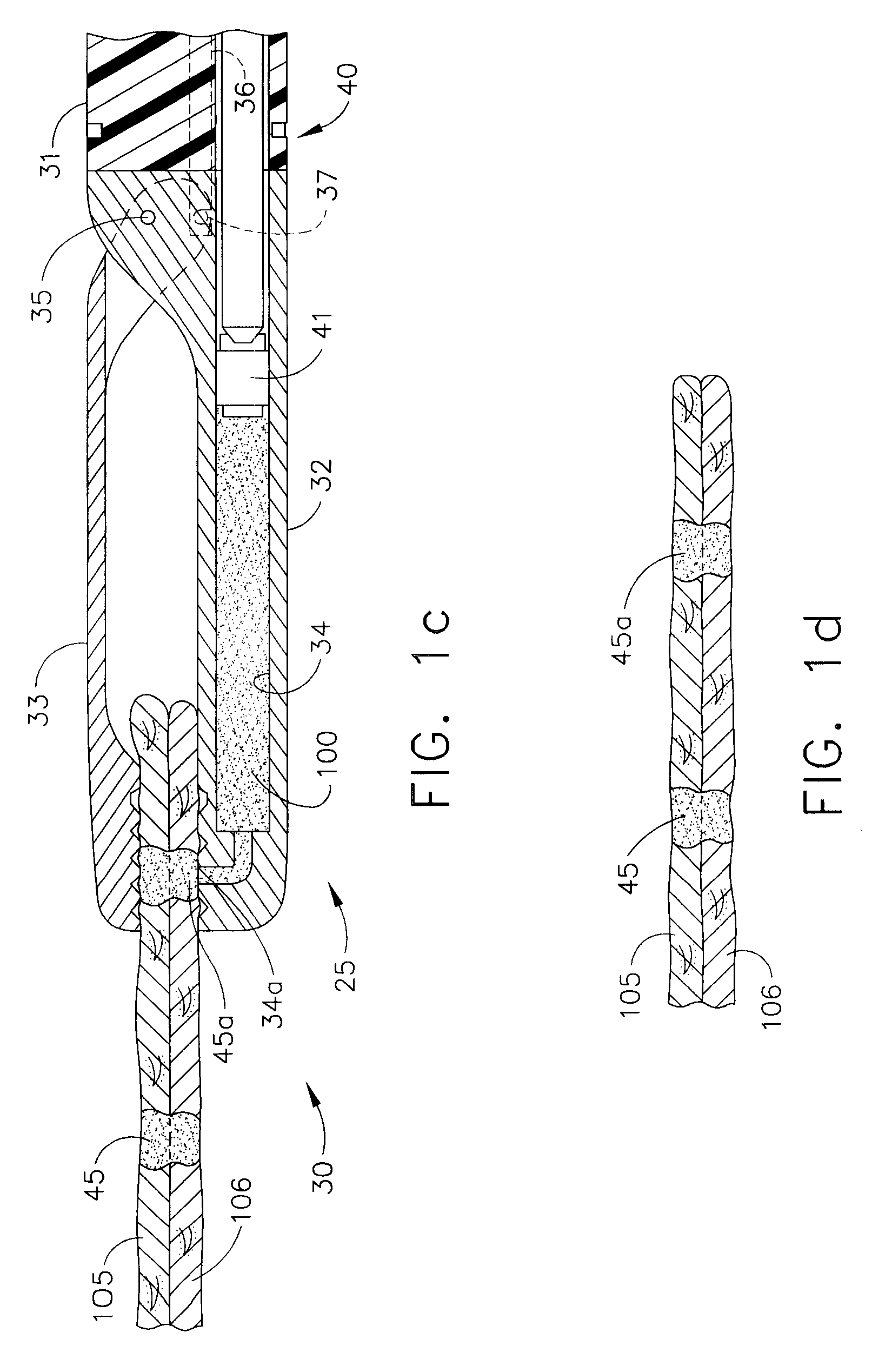

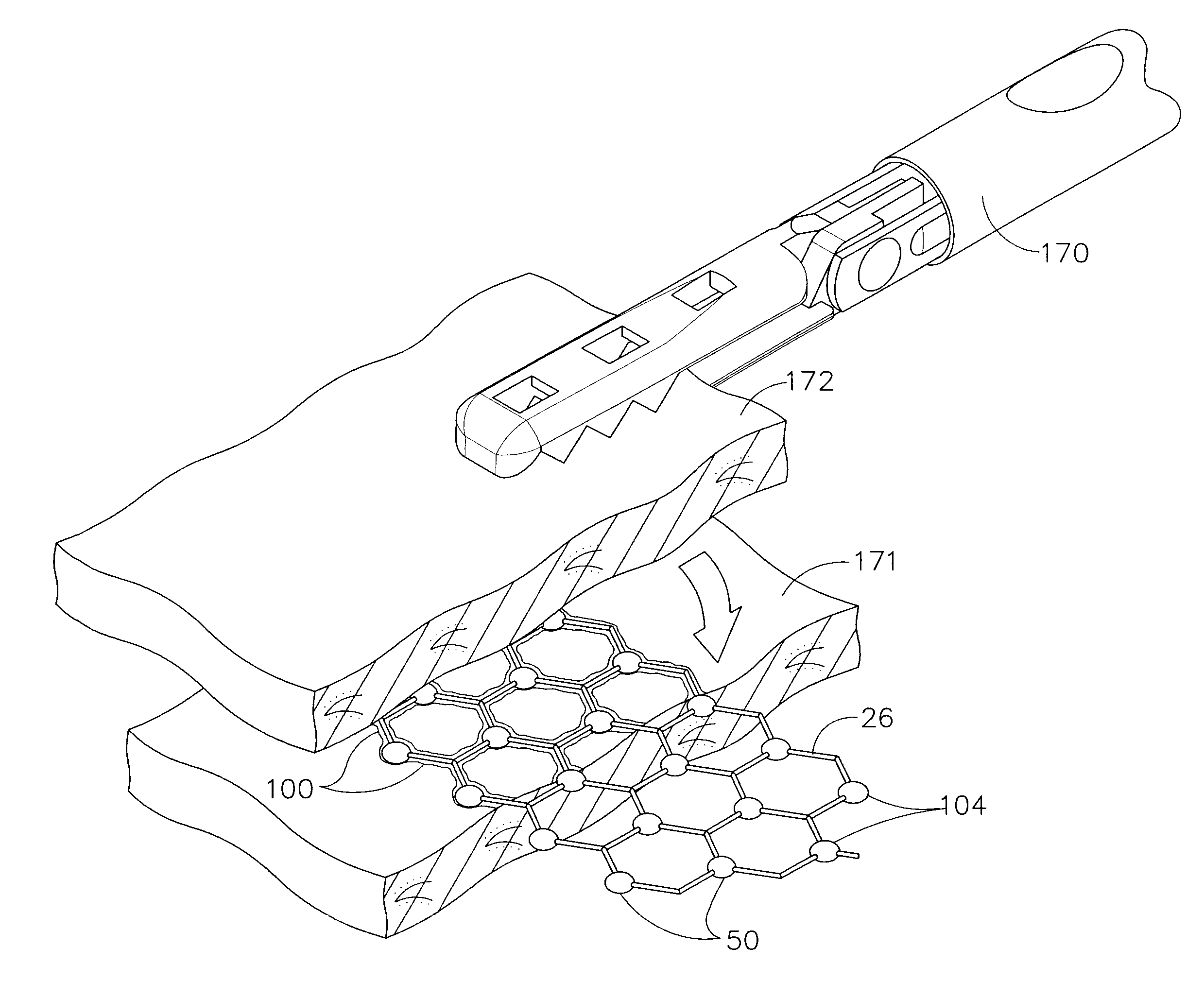

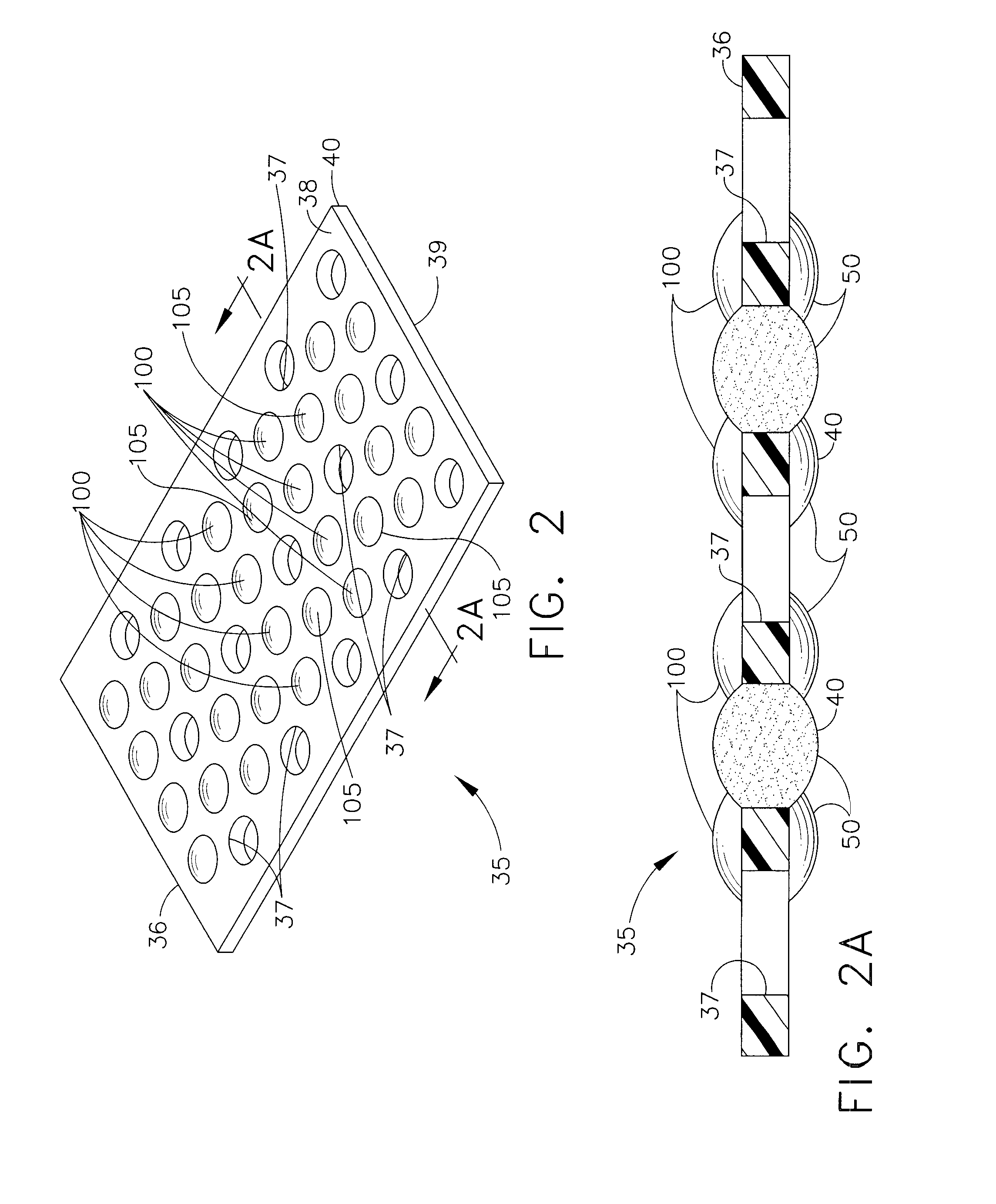

Controlled Adhesive Locations Facilitating Tissue Remodeling

A surgical implant for adhering two portions of tissue together with a polymer adhesive is disclosed. The surgical implant has a matrix structure with one or more layers and a plurality of holes for tissue growth therethrough. The matrix structure controls placement of the adhesive to minimize adhesive area and maximize tissue regrowth areas. In addition, the surgical implant can include drugs and adhesive initiators, and can include multiple layers of structure with any combination of holes, drugs, adhesives and adhesive initiators within. Additionally, the surgical implant can be surrounded by a rapidly dissolving pouch to prevent unwanted polymerization of the adhesive prior to placement in the body.

Owner:ETHICON ENDO SURGERY INC

Polymer adhesive seals for protected anode architectures

ActiveUS8129052B2Avoid componentsEasy to useFuel and primary cellsHybrid cell detailsPolymer adhesiveHermetic seal

Protected anode architectures for active metal anodes have a polymer adhesive seal that provides an hermetic enclosure for the active metal of the protected anode inside an anode compartment. The compartment is substantially impervious to ambient moisture and battery components such as catholyte (electrolyte about the cathode), and prevents volatile components of the protected anode, such as anolyte (electrolyte about the anode), from escaping. The architecture is formed by joining the protected anode to an anode container. The polymer adhesive seals provide an hermetic seal at the joint between a surface of the protected anode and the container.

Owner:POLYPLUS BATTERY CO INC

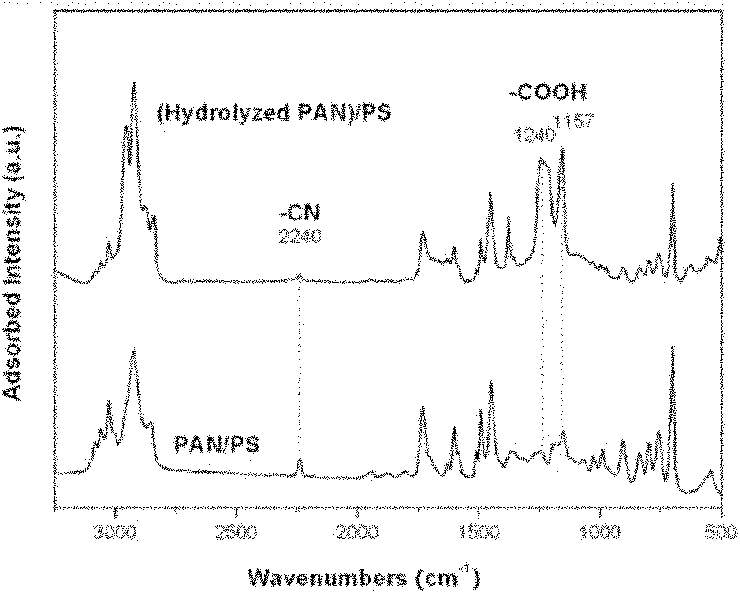

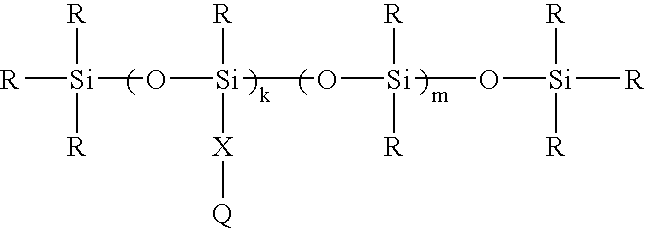

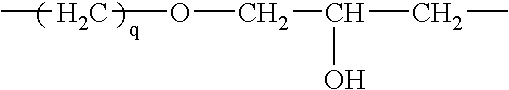

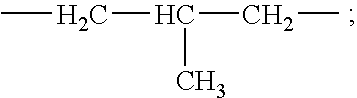

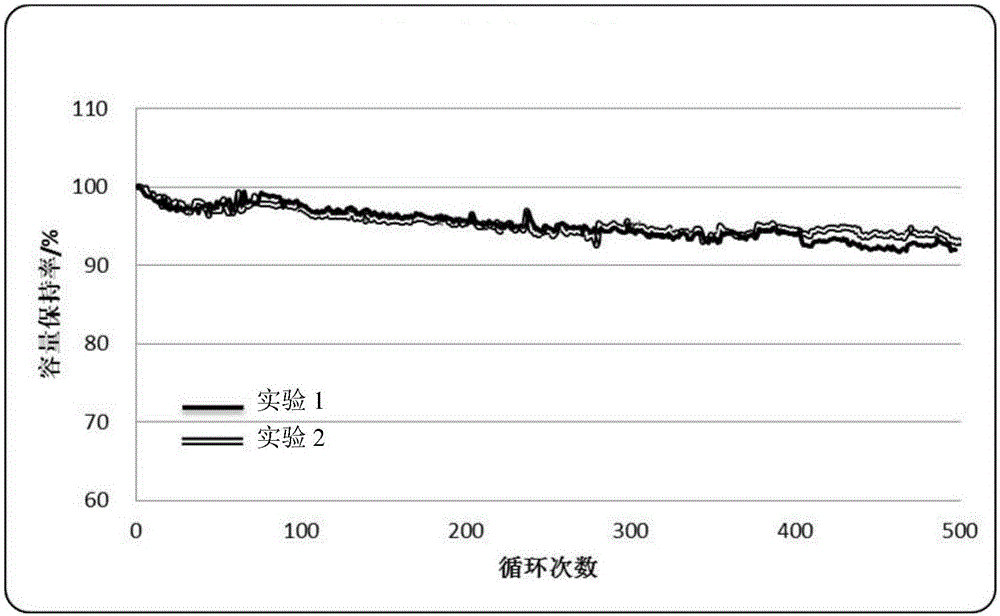

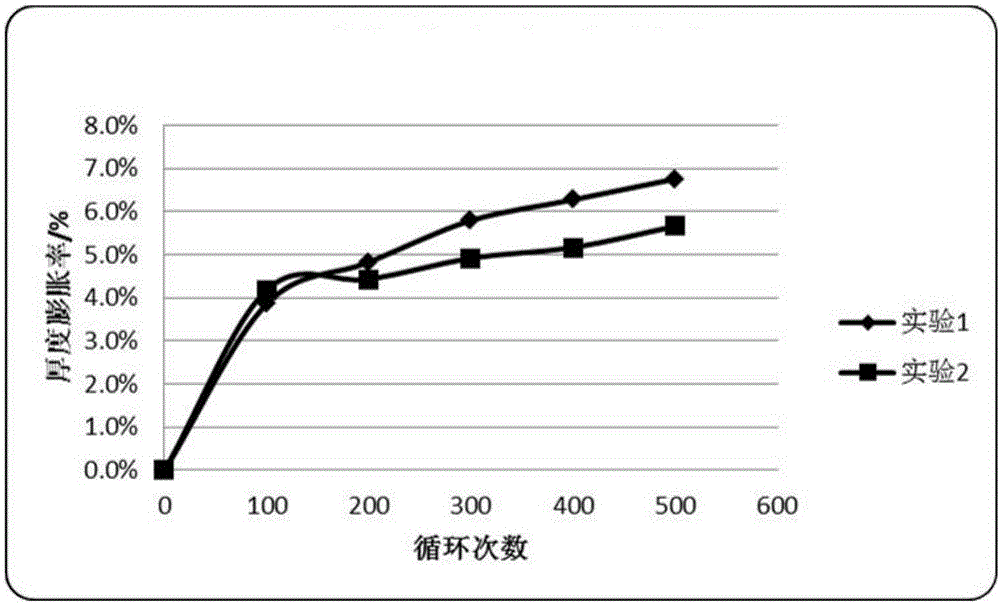

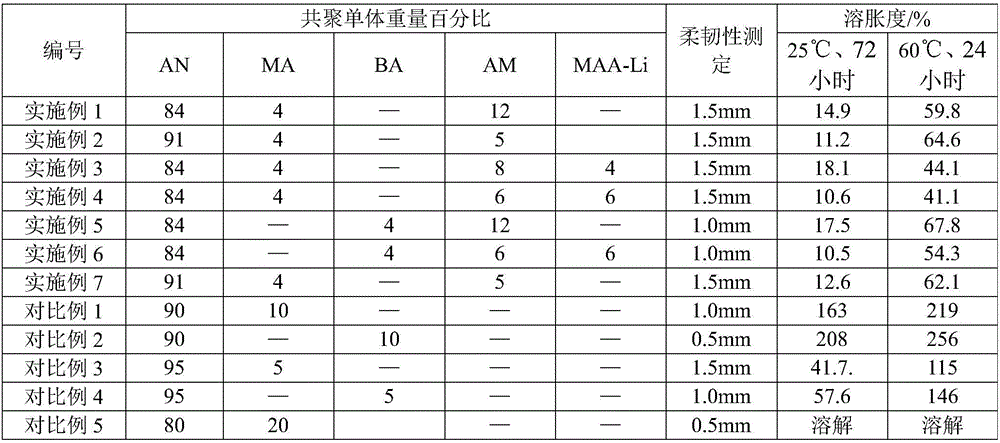

Acrylonitrile copolymer adhesive and application thereof in lithium ion batteries

ActiveCN106220779AImprove flexibilityAppropriate degree of swellingNitrile polymer adhesivesSecondary cellsPolymer adhesivePolymer science

The invention belongs to the field of lithium ion batteries and relates to an acrylonitrile copolymer adhesive and application thereof in lithium ion batteries. The acrylonitrile copolymer adhesive structurally comprises, by weight, 78-95% of an acrylonitrile unit, 1-10% of an acrylate unit and 2-15% of an acrylamide unit. Acrylate monomers, high-polarity acrylamide monomers or acrylate monomers are added into acrylonitrile monomers serving as a main material to implement copolymerization, so that high adhesive power or intermolecular force of acrylonitrile polymer molecules is kept while a polymer adhesive film is given flexibility, electrolyte affinity and appropriate swelling degree in electrolyte to adapt to periodical volumetric changes of electrode active materials along with embedding / escaping of lithium ions in a charging and discharging process, and energy density and cycle performance of the lithium ion batteries are improved.

Owner:SICHUAN INDIGO TECH CO LTD

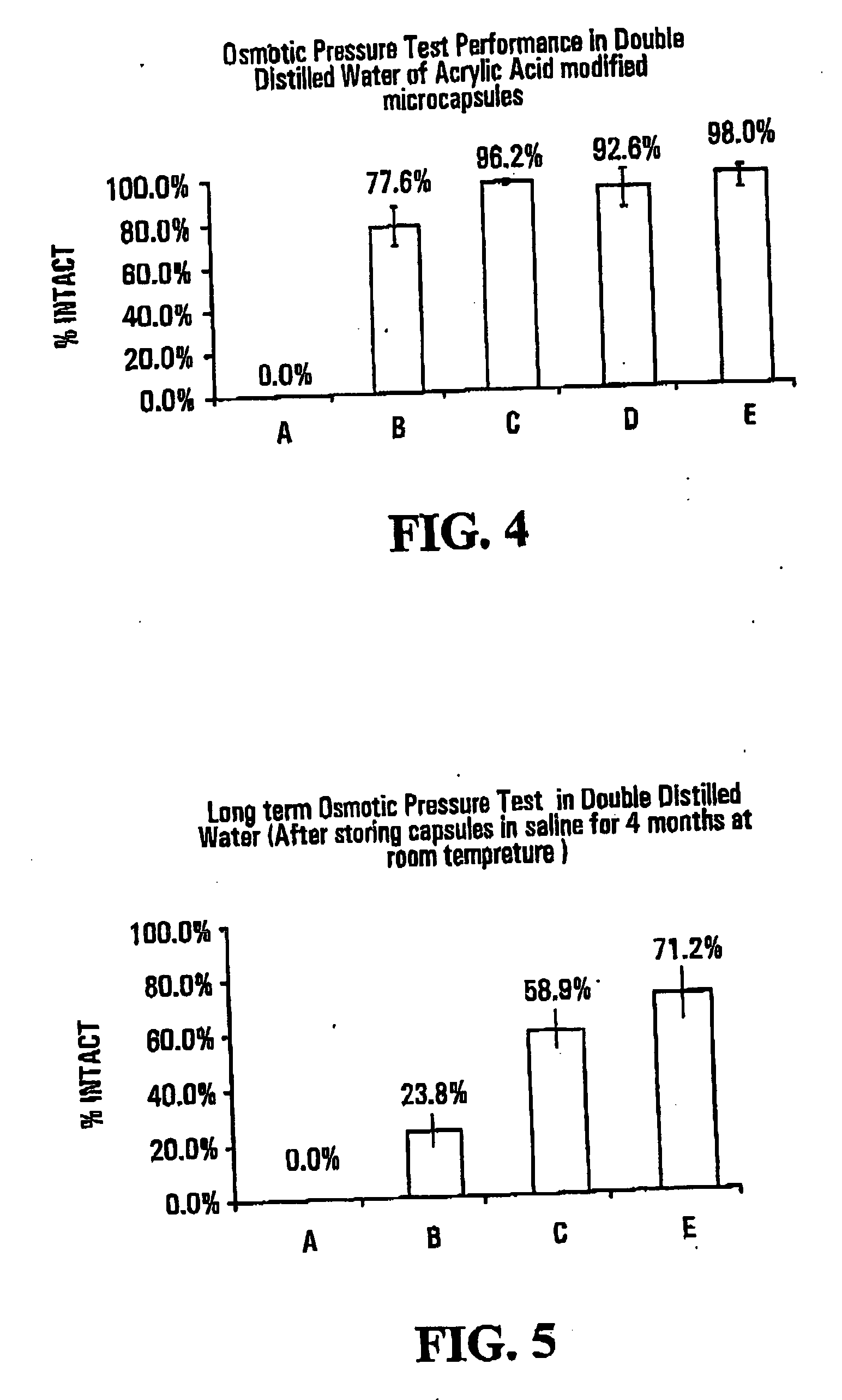

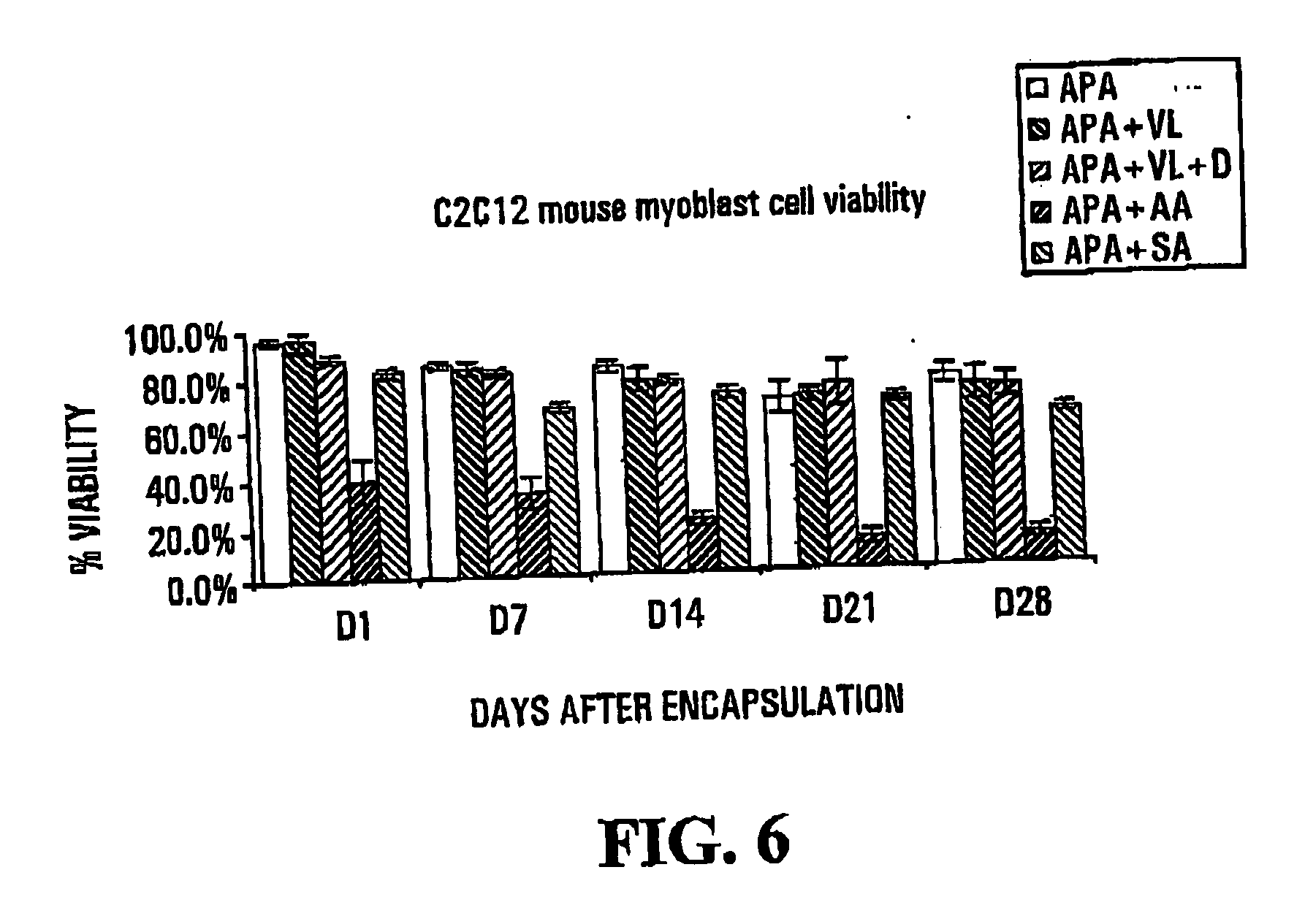

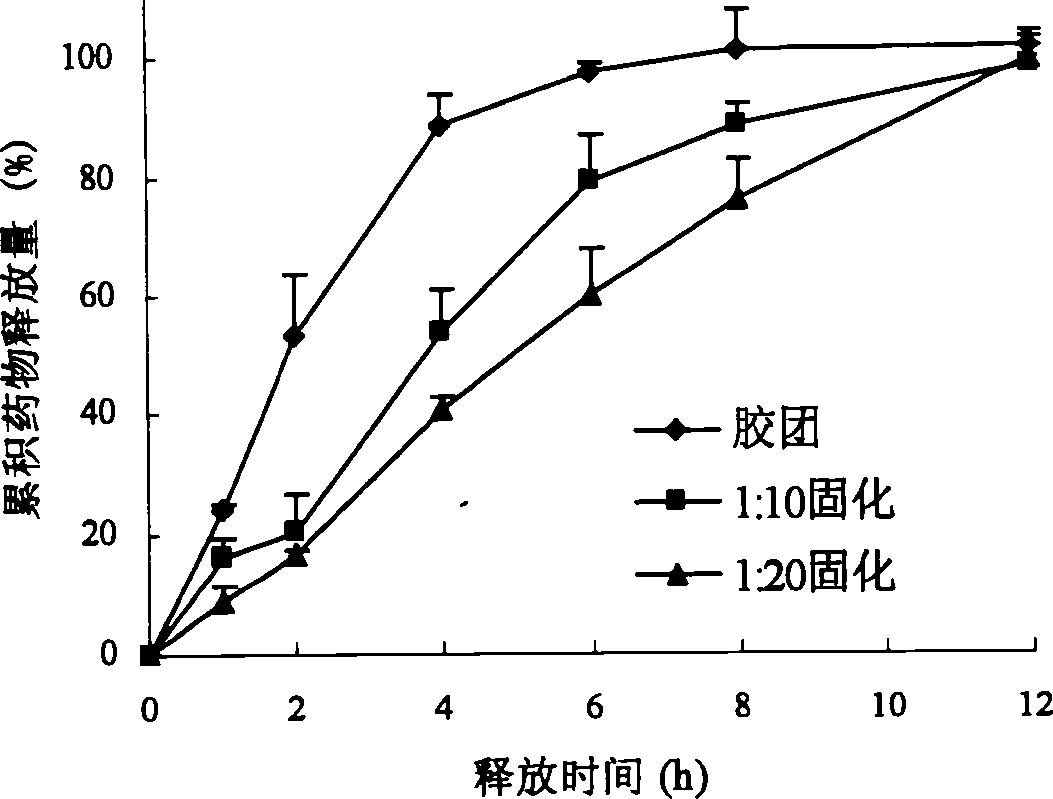

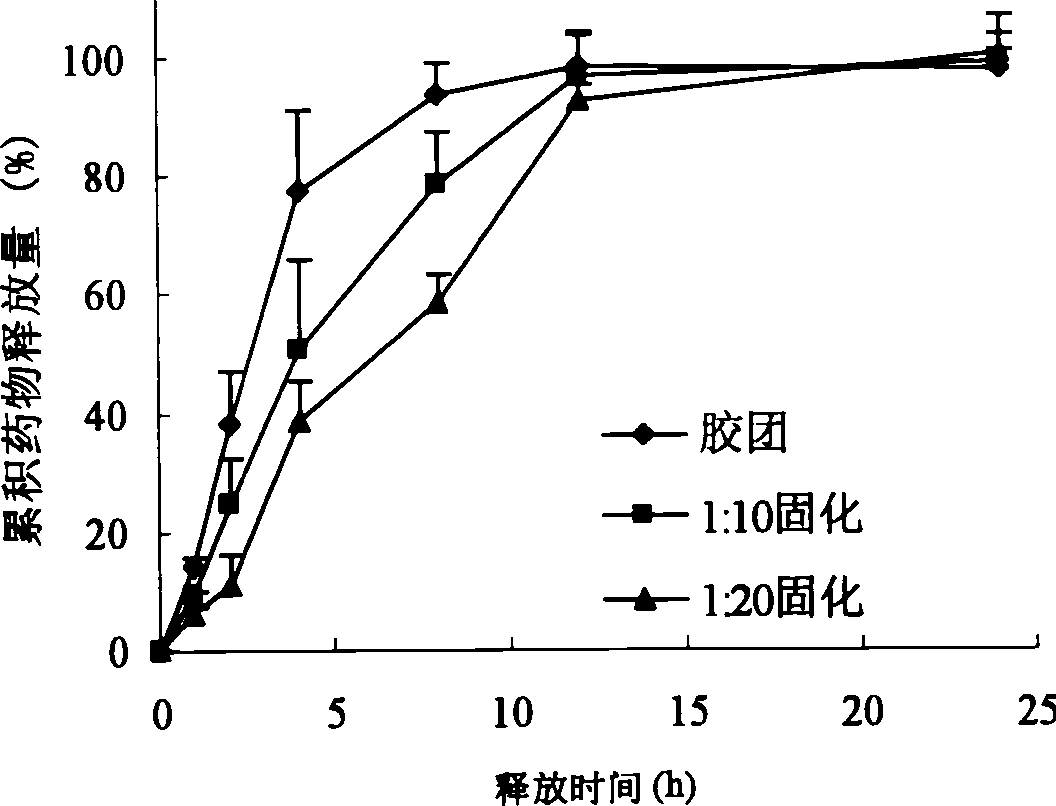

Microcapsules containing biomedical materials

InactiveUS20050118425A1Low costSimple processSolid materialGlass/slag layered productsPolymer adhesiveCrosslinked polymers

Biomedical materials are encapsulated in ionically crosslinked polymer capsules, preferably alginate microcapsules. The alginate capsules are then subjected, in a liquid vehicle, to an ethylenically unsaturated monomer and an initiator, to induce polymerization of the unsaturated monomer and therey enhance the strength of the capsule wall. The microcapsules can be after-treated with, for example, polysine and alginate to reduce their tendency to elicit an immune response if implanted in an animal. The invention extends to the microcapsules and also to a method of treating or preventing medical conditions in an animal particularly a human, by implanting microcapsule containing biomedical material in the animal.

Owner:MCMASTER UNIV

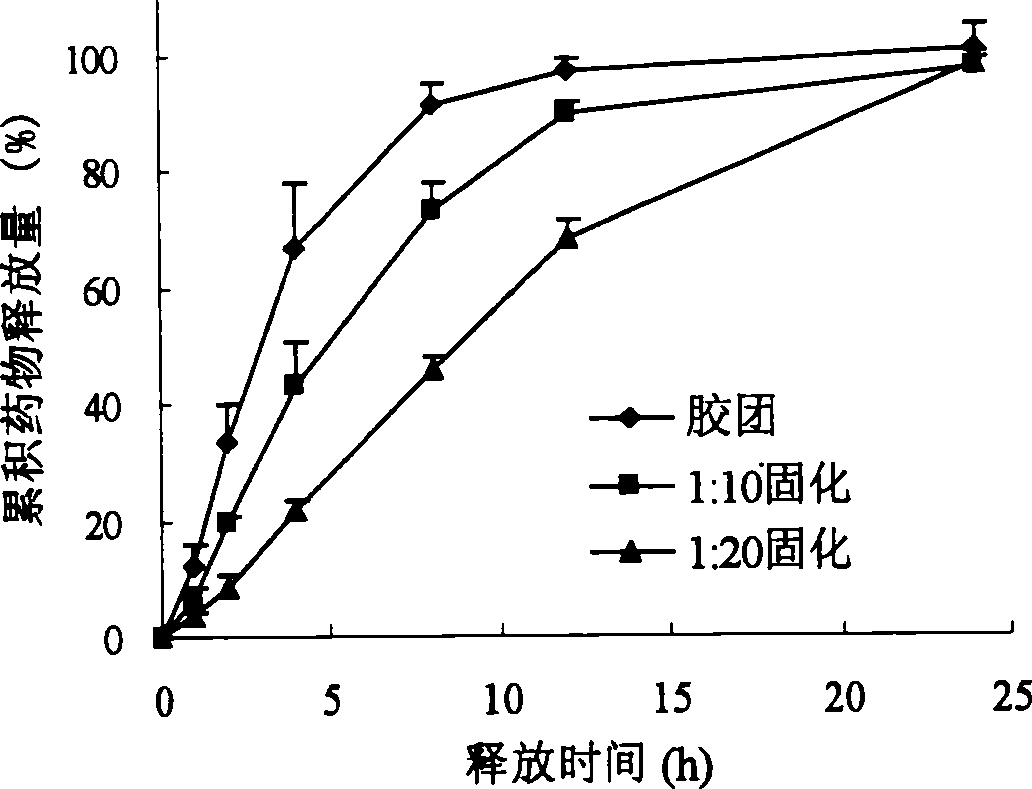

Surface-modified hydrophobically modified drug-carried chitosan polymer micelle and method for preparing same

InactiveCN1883708AGood curative effectImprove instabilityPowder deliveryPharmaceutical non-active ingredientsPolymeric surfaceNanocarriers

Disclosed is a surfacely modified hydrophobic Chitosan oligosaccharide polymer drug-loaded colloidal cluster, obtained by grafting chitosan with a average molecular weight of 1.5kD-51kD and aliphatic acid of C10-C22, comprising based on hydrophobic modified Chitosan oligosaccharide polimer colloidal clusters, modifying amidogens or hydroxy groups of Chitosan oligosaccharide molecules on polimer surface with bi-functional small organic moleculers, forming chemical bond bridges between molecules on the surfaces of polymer colloidal clusters,to improve the instability of polymer colloidal cluster diluted, and to imorove the original loose structure of polimer colloidal cluster surfece to form a fine and close net-shaped structure, to decrease a sudden release of drugs, and to control drugs with slow release. The drug-loaded colloidal cluster provided is a nano-carrier with excellent organelle targeting, is applicated in life science field and pharmacy field.

Owner:ZHEJIANG UNIV

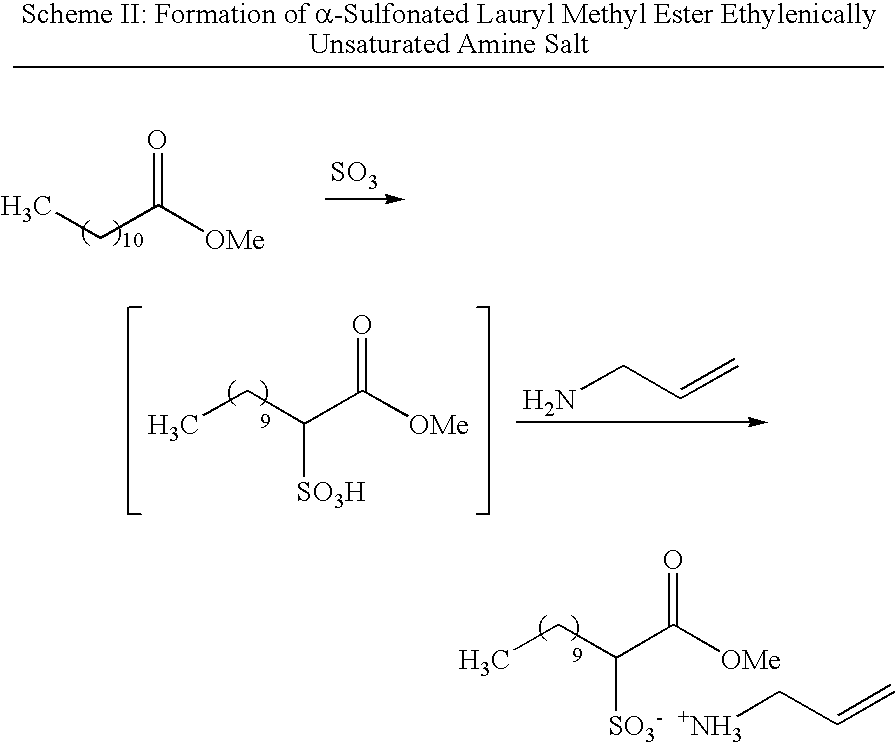

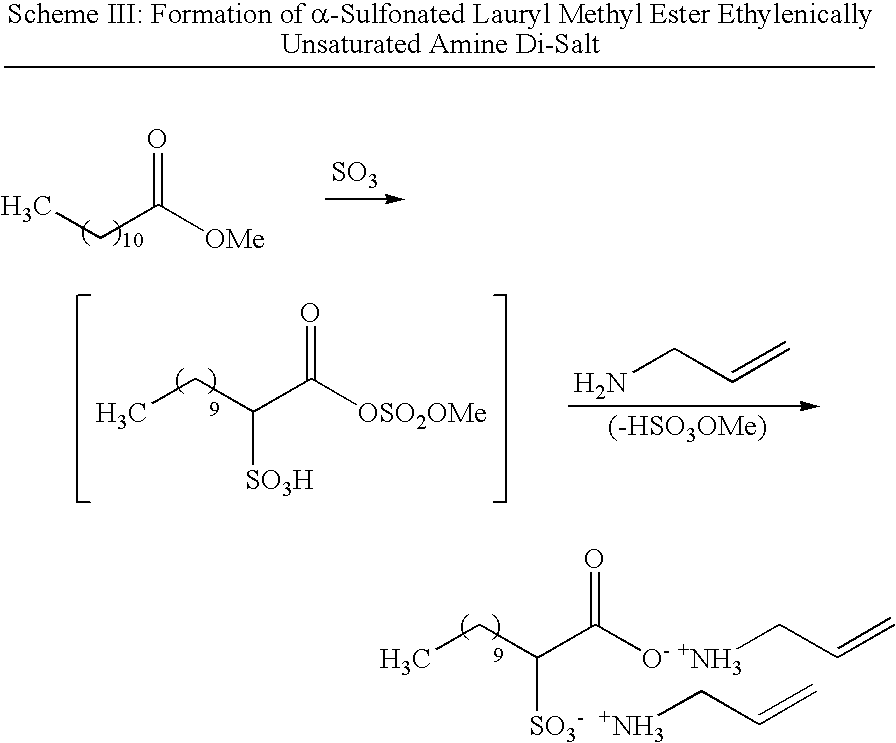

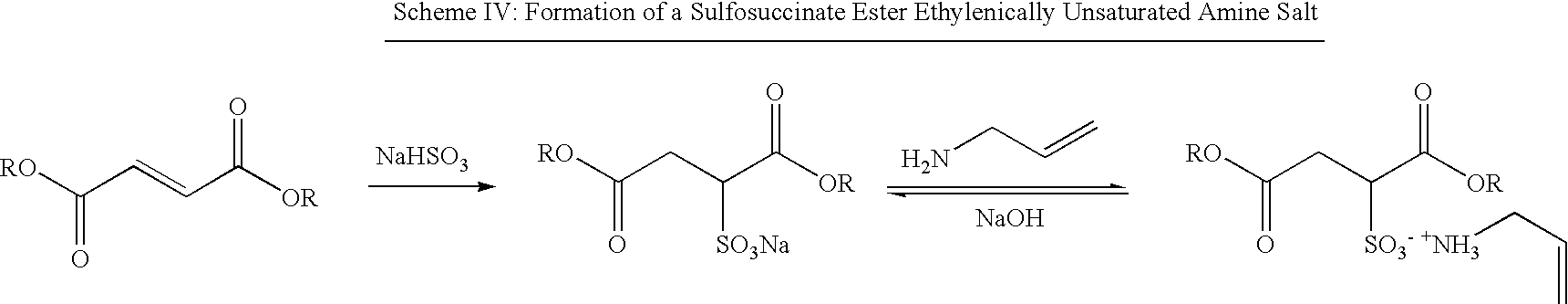

Antimicrobial polymer latexes derived from unsaturated quaternary ammonium compounds and antimicrobial coatings, sealants, adhesives and elastomers produced from such latexes

InactiveUS6900265B2Improve propertiesImprove water sensitivitySpecial tyresCoatingsElastomerPolymer science

An improved method of making CASE materials is provided, wherein the method utilizes a polymer latex derived from at least one ethylenically unsaturated monomer and at least one polymerizable surface active agent. The polymerizable surface active agent is capable of co-polymerization with traditional monomers and is preferably substantially completely consumed during the course of the polymerization. Latex polymers produced by the method of the present invention are well suited for use in coatings, adhesives, sealants, elastomers. Additionally, the present invention relates to improved coating, adhesive, sealant and elastomer (CASE) materials utilizing polymer latexes derived from various monomers and ethylenically unsaturated amine salts of sulfonic, phosphoric and / or carboxylic acids.

Owner:STEPAN COMPANY

Polymer adhesive resin for corrosion-prevention of steel pipe and preparation process thereof

InactiveCN1754932AHigh bonding strengthSimple technical solutionAdhesivesNon-disconnectible pipe-jointsLow-density polyethyleneLinear low-density polyethylene

The invention relates to adhesive resin with antiseptic function for steel pipe, which is prepared by HDPE, LLDPE, LDPE, PP, maleic anhydride, initiator, EVA, tackifier, antioxidant, color filler, and structural modifying agent with double-screws extruder. The product has high joint strength, and friend environment.

Owner:赵璐

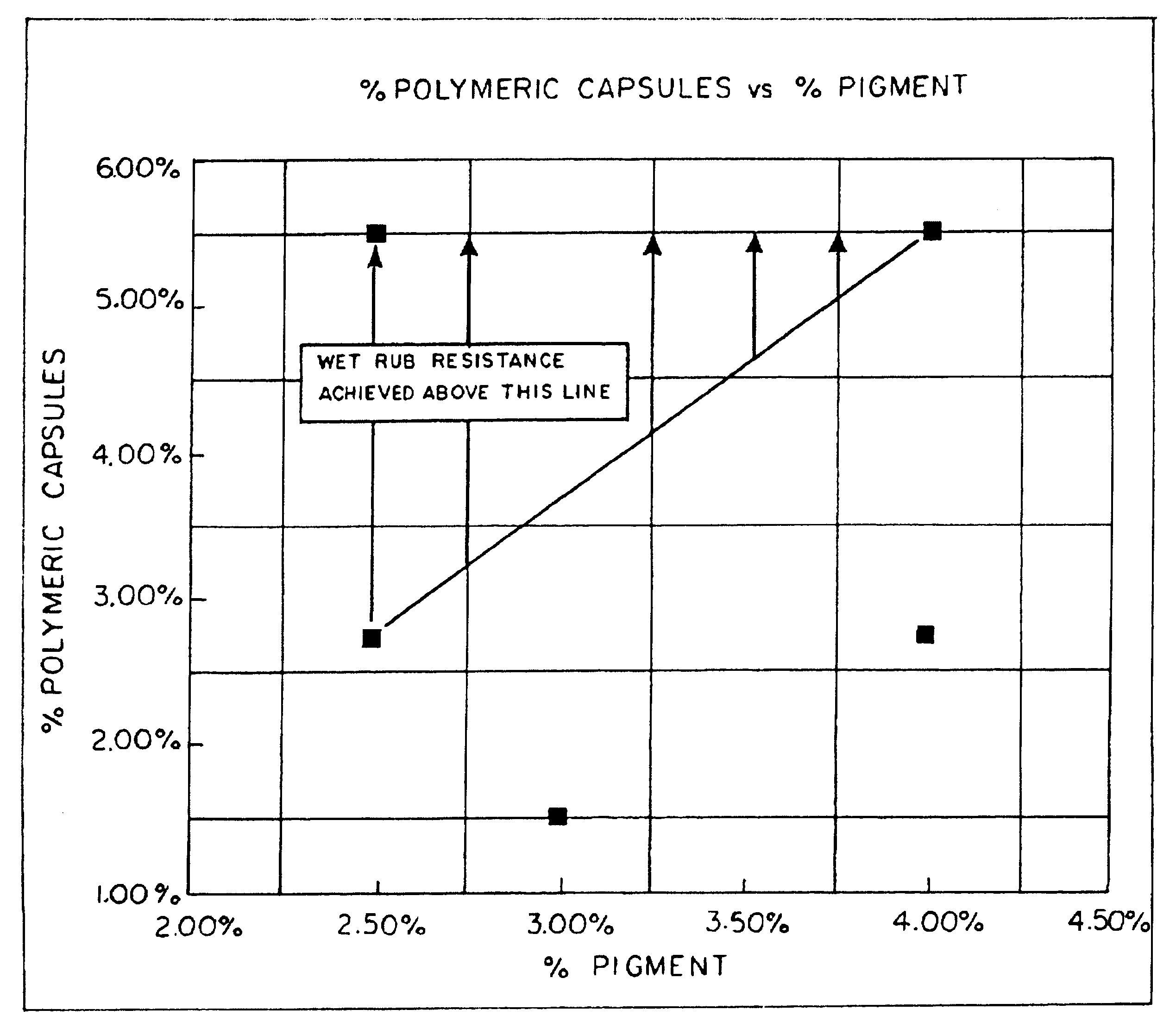

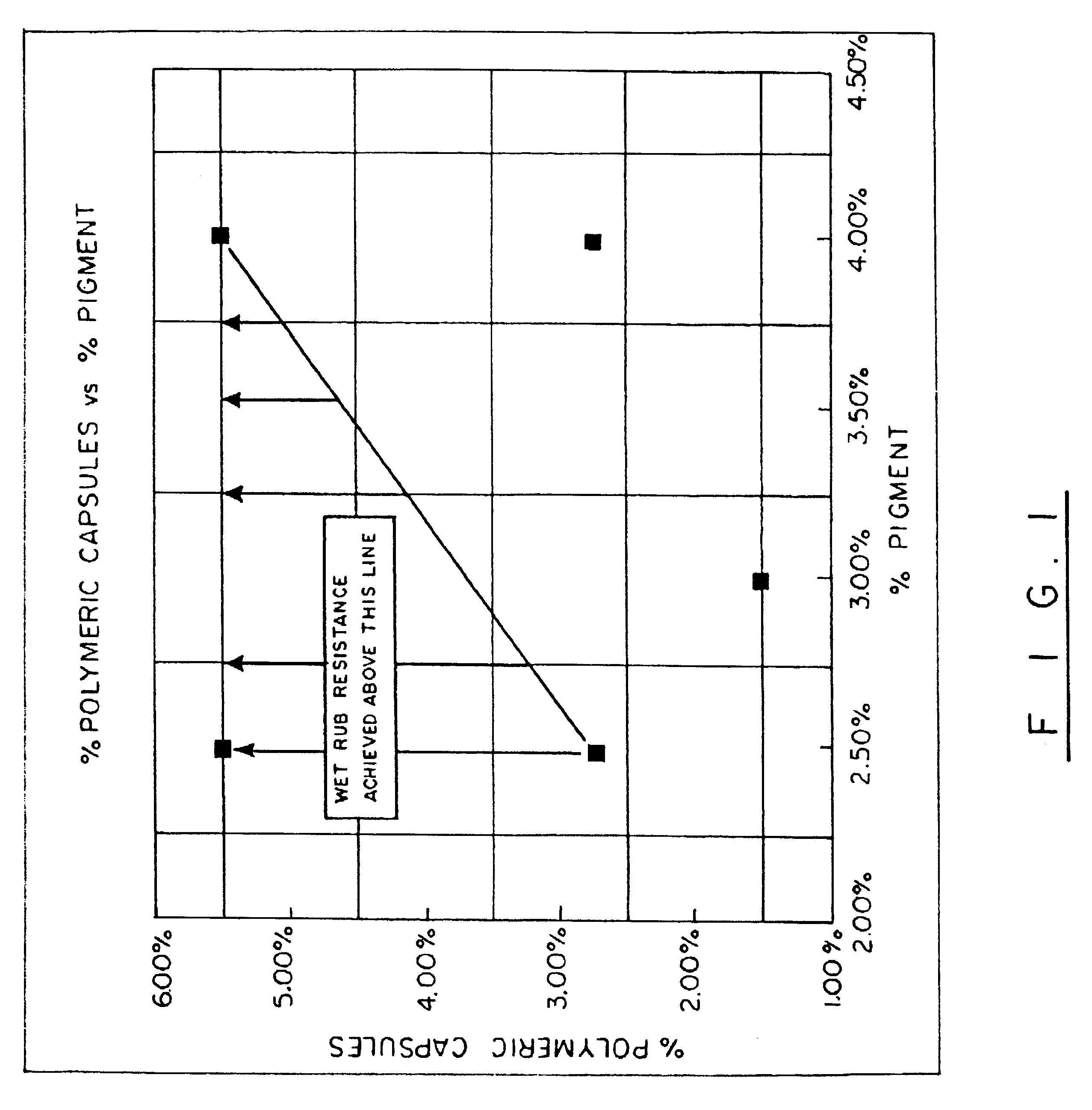

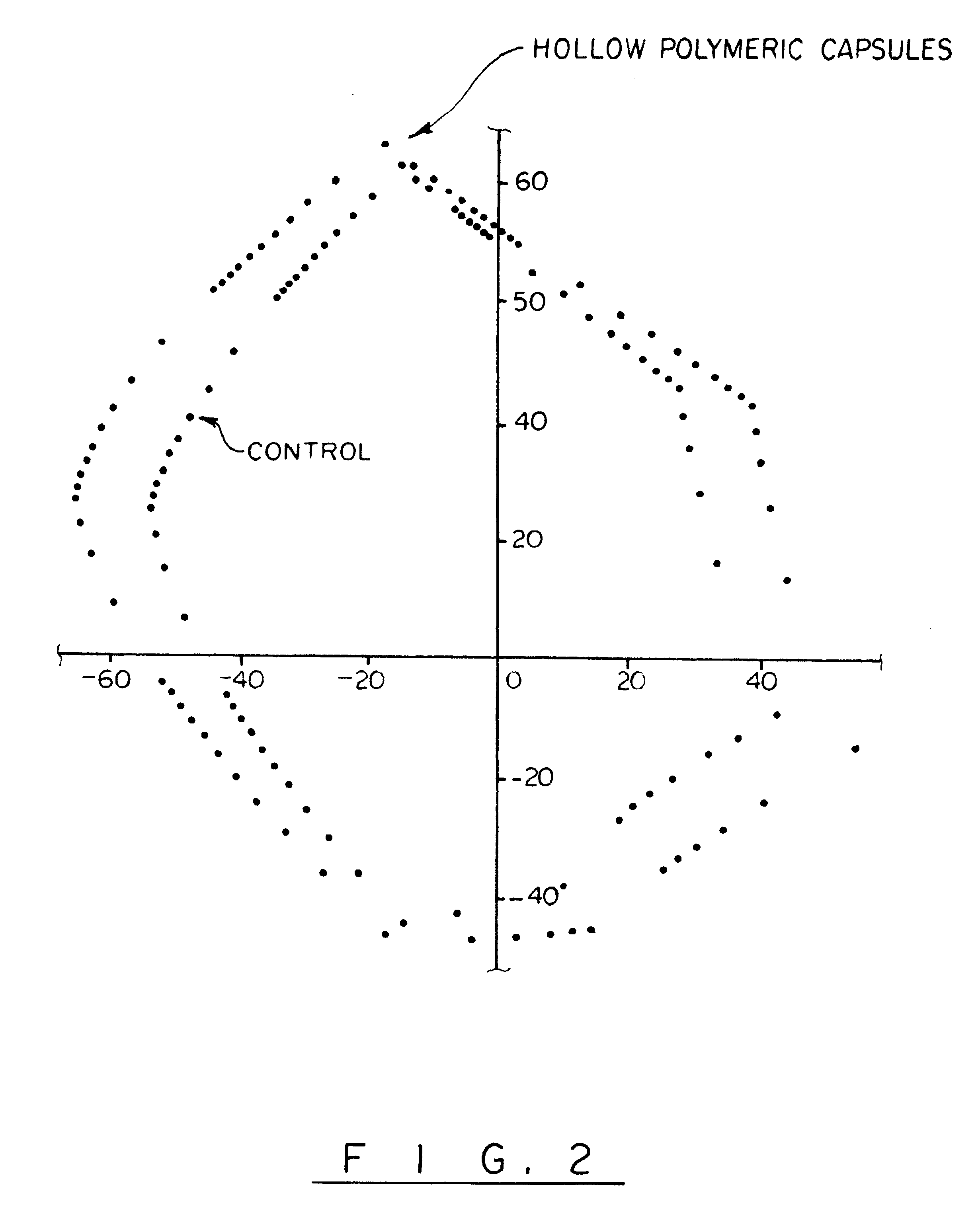

Wet rub resistant ink compositions

InactiveUS6309452B1Increase resistanceImprove color gamutInksAblative recordingPolymerColoring agents

A wet rub resistant ink composition comprises, by weight, at least about 15% carrier medium, colorant in an amount of no more than about 20%, and at least about 2% polymeric capsules having central cavities containing water. The composition is substantially free of film-forming resins. The ink composition may be used in combination with other ink compositions having different colors or shades to increase the color gamut of an ink system.

Owner:FUNAI ELECTRIC CO LTD

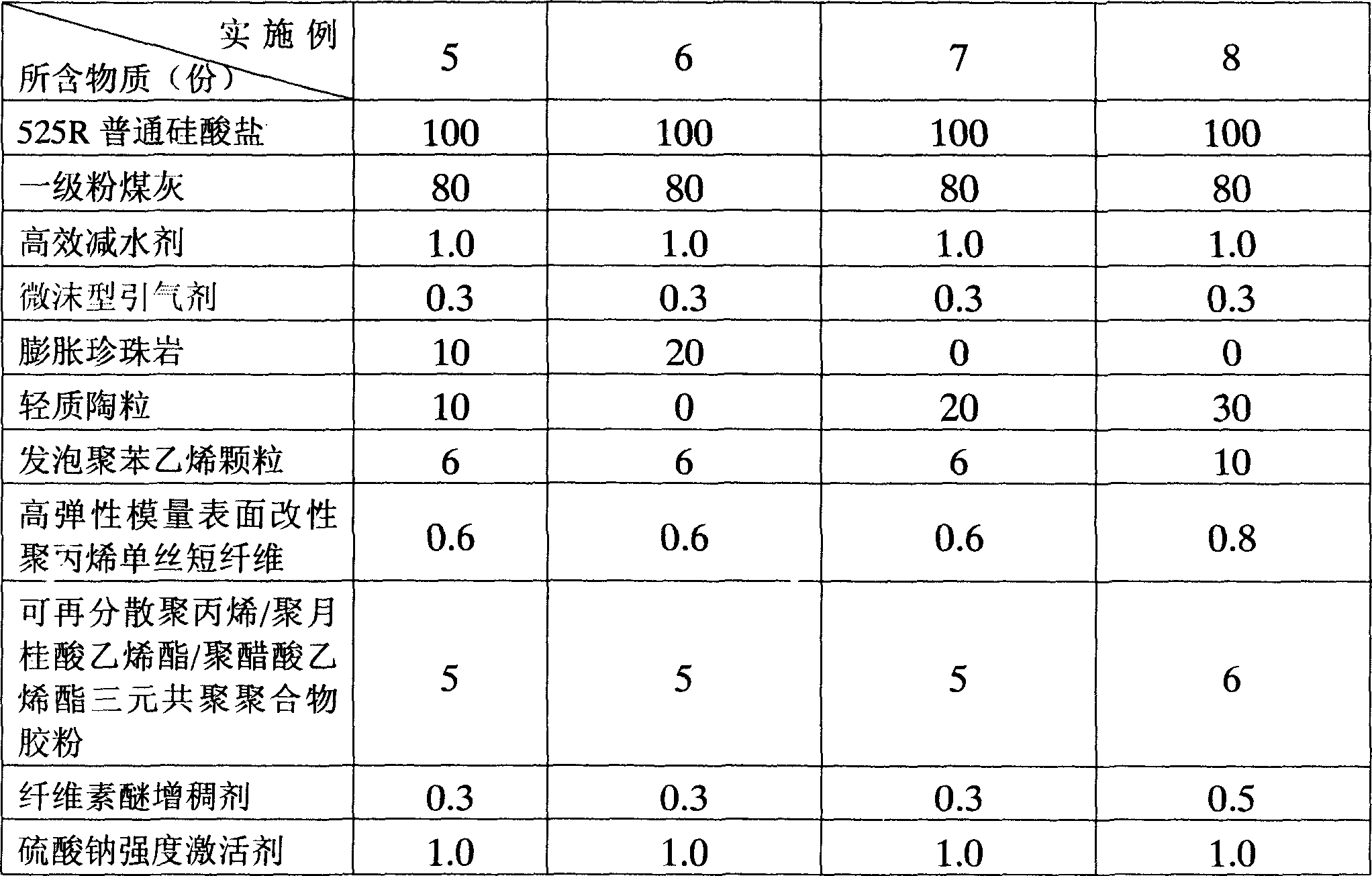

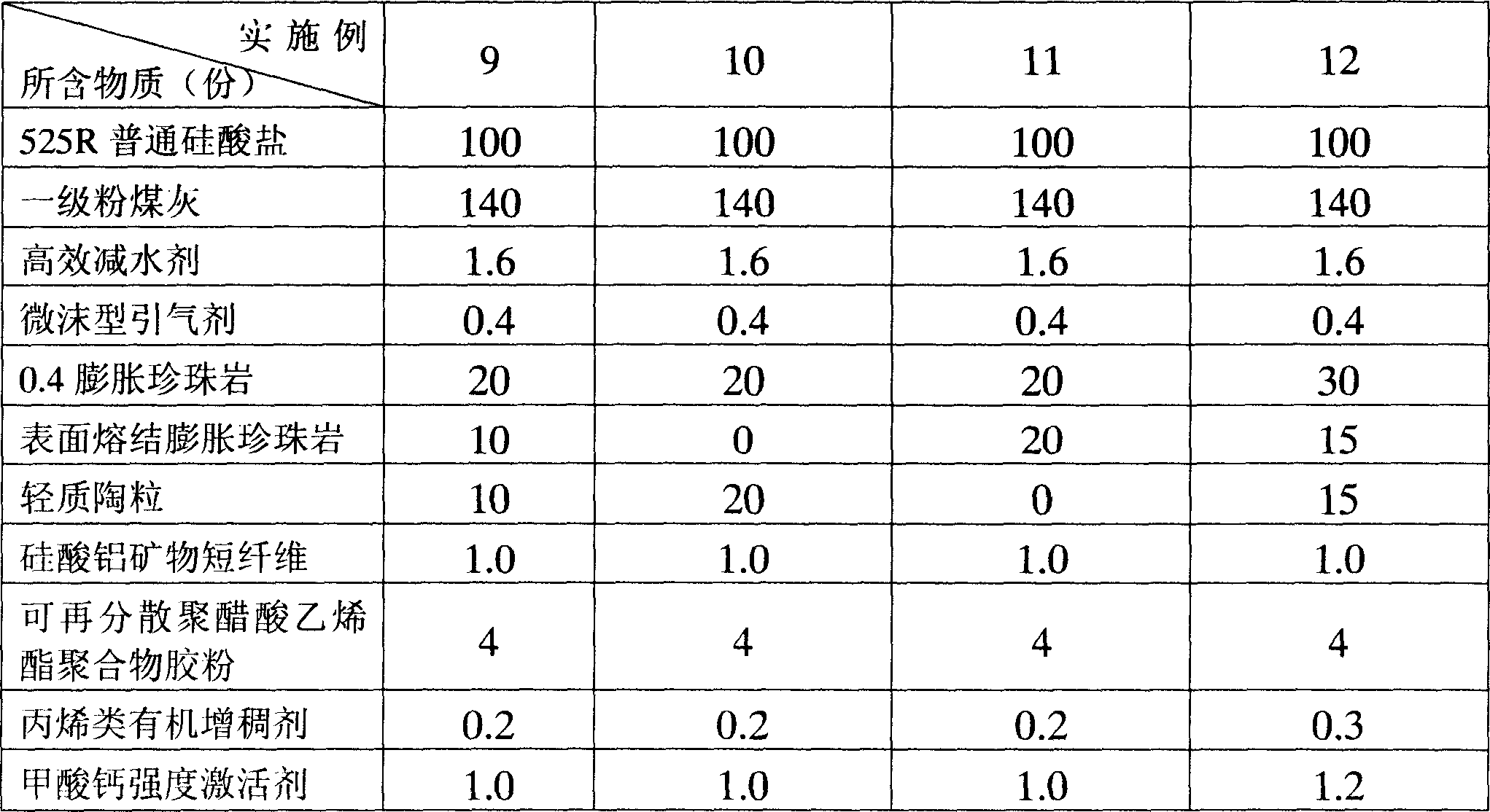

Heat-insulating mortar for external wall of building

InactiveCN1690008APrevent shrinkage crackingPrevent moisture absorptionSolid waste managementPolymer modifiedPolymer science

The heat insulating mortar for outer building wall consists of hydraulic Portland cement, flyash, high efficiency water reducing agent, compound heat isolating aggregate, short fiber, re-dispersible polymer adhesive powder, and strength activator. It is prepared by means of fiber reinforcing technology, polymer modification technology and comprehensive flyash utilizing technology. It forms heat insulating system for outer building wall has the advantages of excellent heat insulating performance, no cracking, being hydrophobic, high wall adhering strength, excellent construction performance, etc.

Owner:宁波荣山新型材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com