Patents

Literature

197results about How to "Prevent shrinkage cracking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

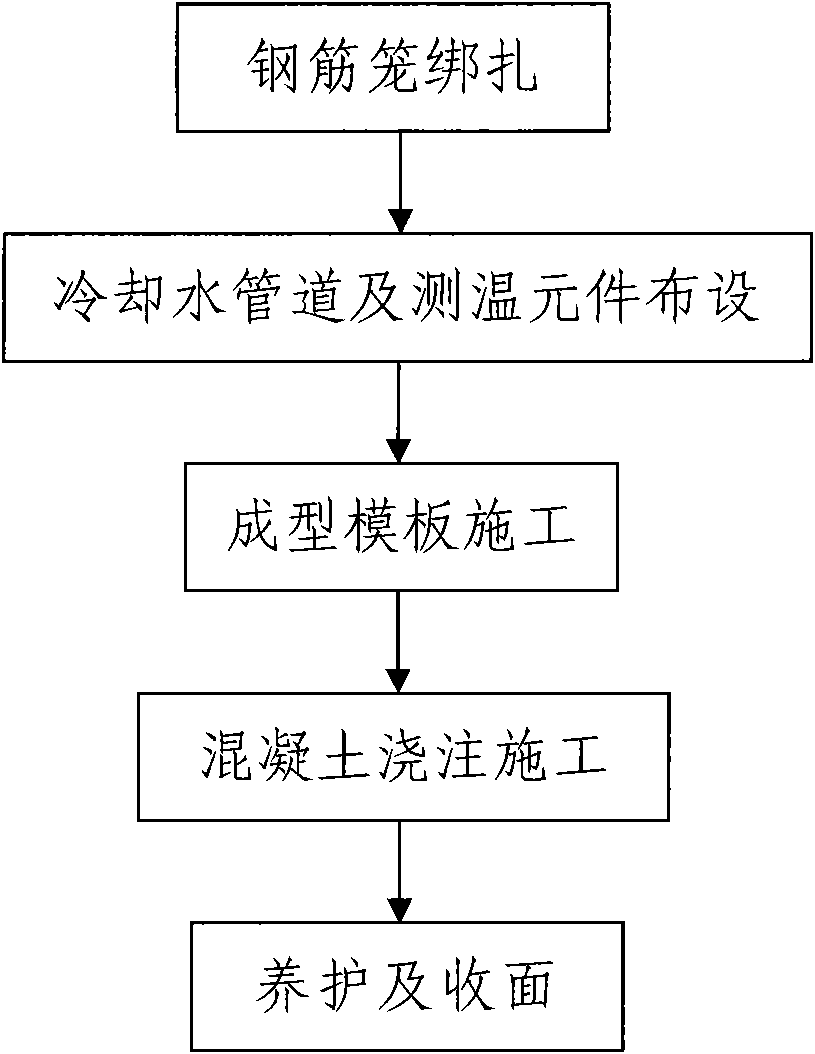

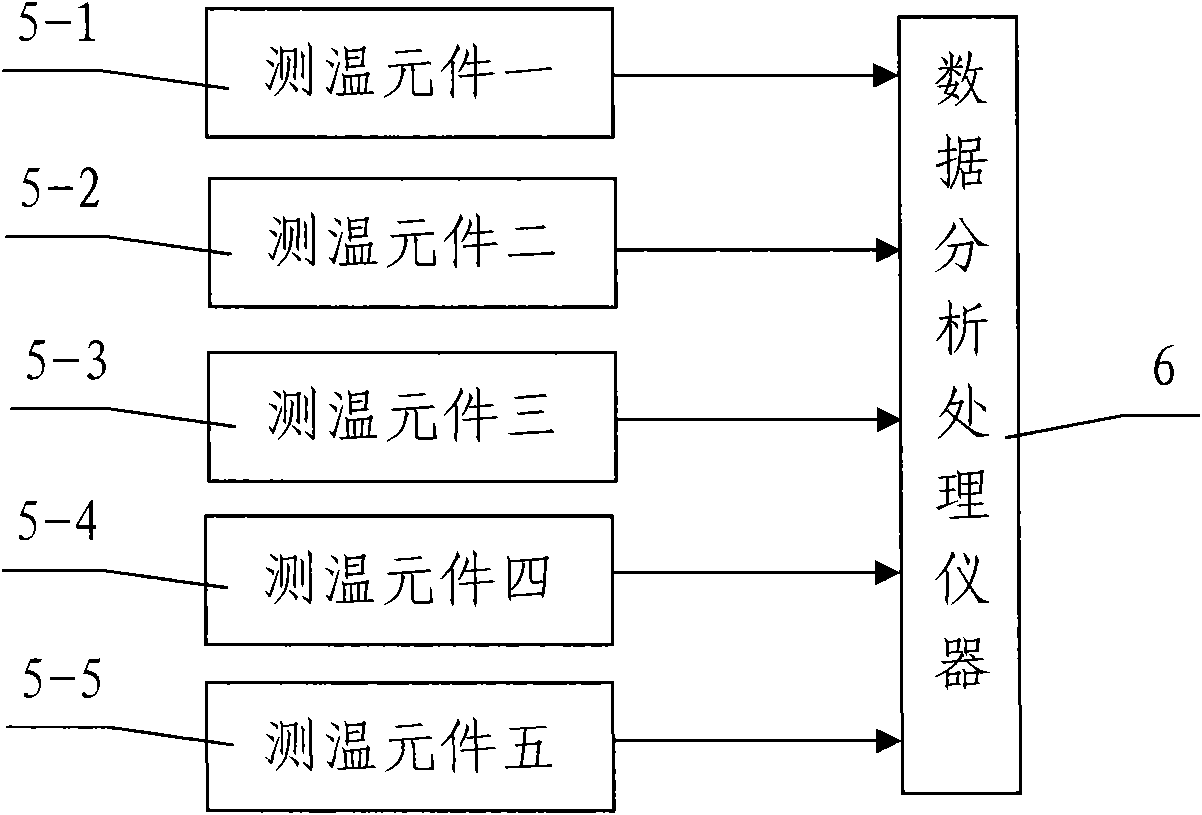

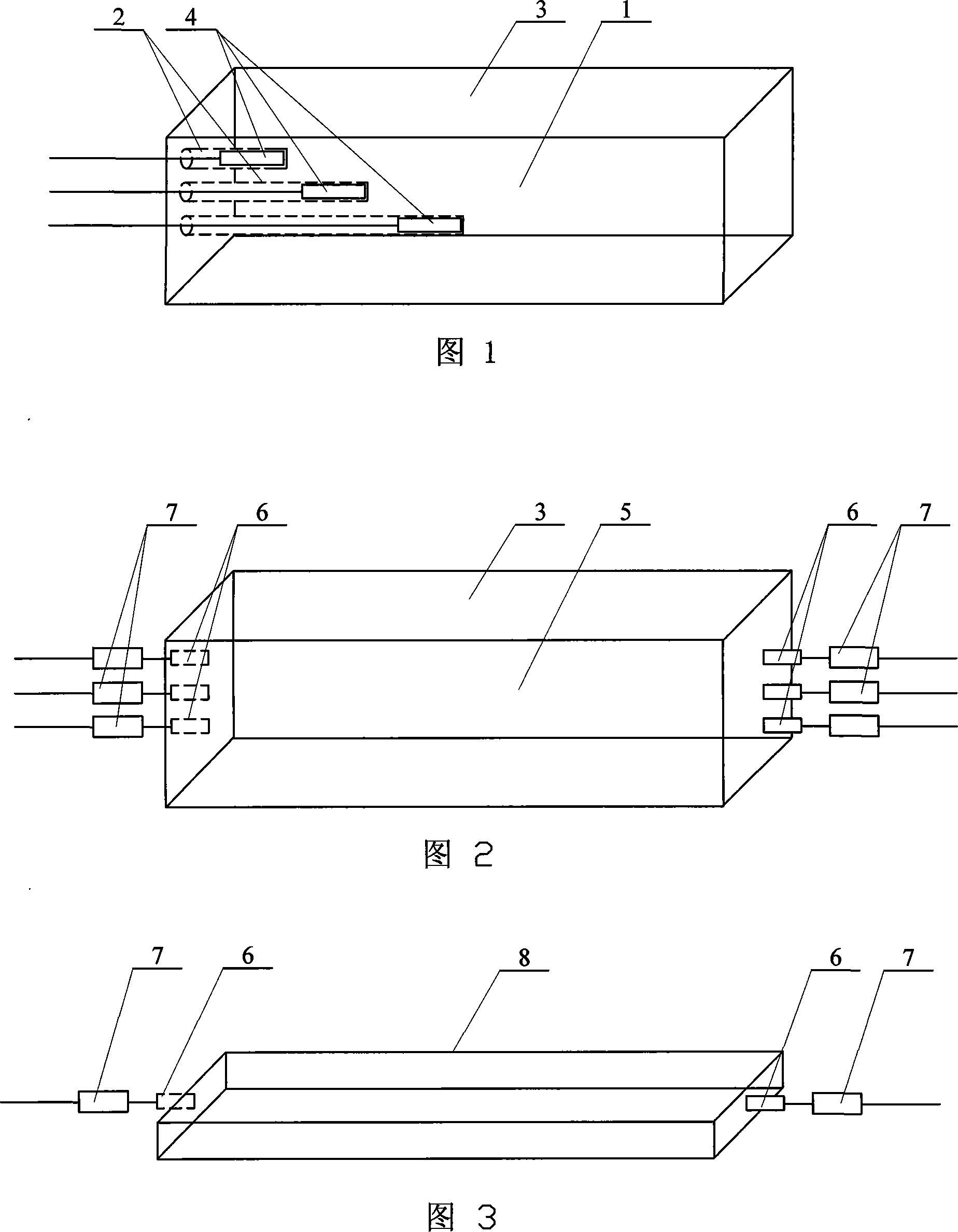

Construction method of large-volume concrete bearing platform with one-time pouring in winter

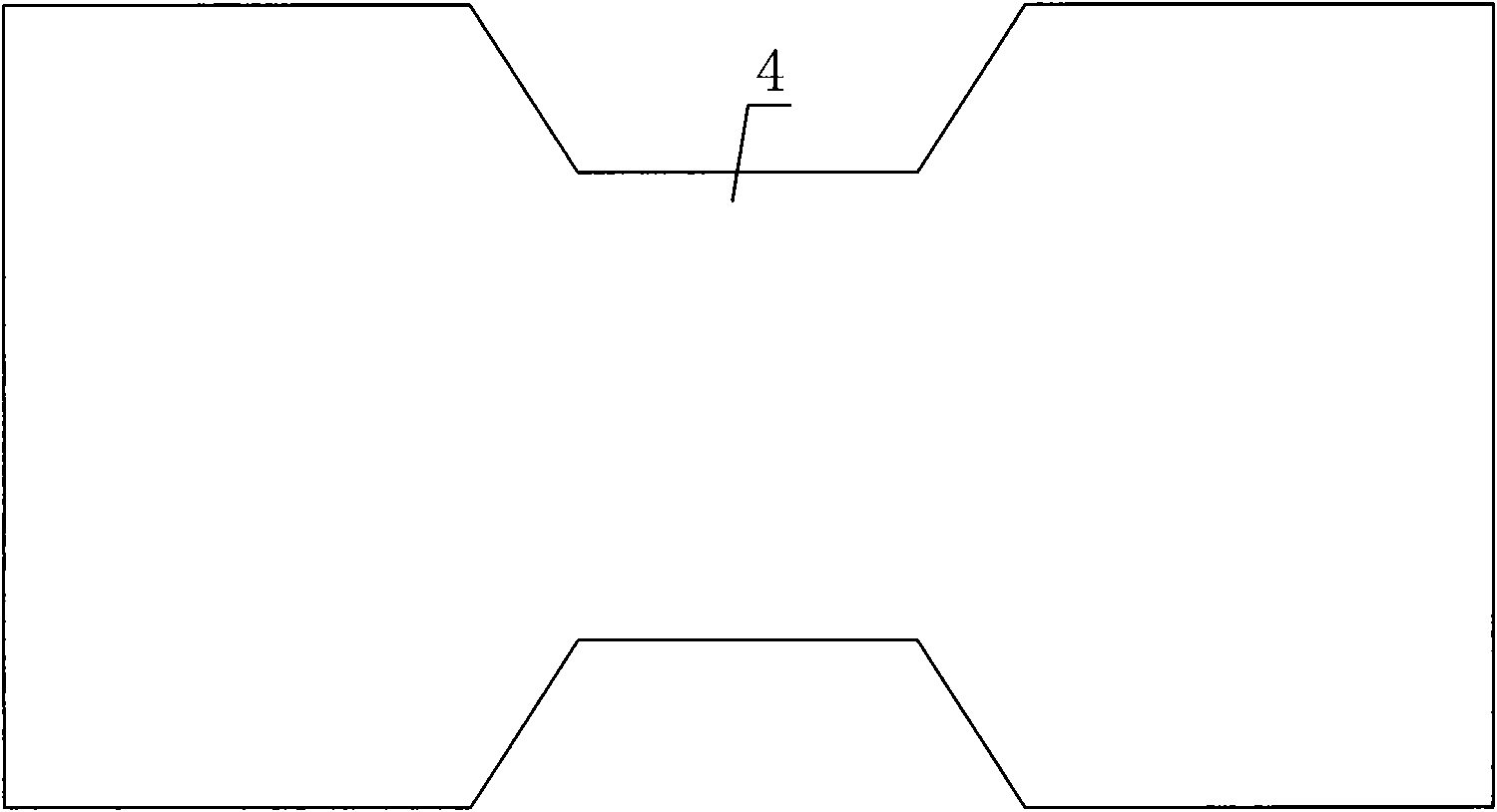

The invention discloses a construction method of a large-volume concrete bearing platform with one-time pouring in winter, comprising the following steps of: step 1, binding steel reinforcement cages; step 2, laying cooling water pipelines and temperature measuring elements; step 3, constructing formed templates, wherein the construction process comprises delimiting template lines and constructing formed brick dies; step 4, pouring concrete; and step 5, conserving and finishing surface: finishing surface in time when completing the pouring of the concrete, carrying out the surface finishing twice, carrying out the first surface finishing when pouring the concrete to the top, carrying out the second surface finishing when the concrete is initially congealed, and adopting a mode that external stores water for conserving when the concrete is initially congealed. The invention has the advantages of reasonable design, simple construction method step, convenient operation, short construction period, one-time pouring molding and strong maneuverability, the large-volume concrete bearing platform constructed for molding in winter has good quality, the poured concrete is not frozen, and the surface of the bearing platform can not have temperature cracks.

Owner:CHINA RAILWAY 20 BUREAU GRP +3

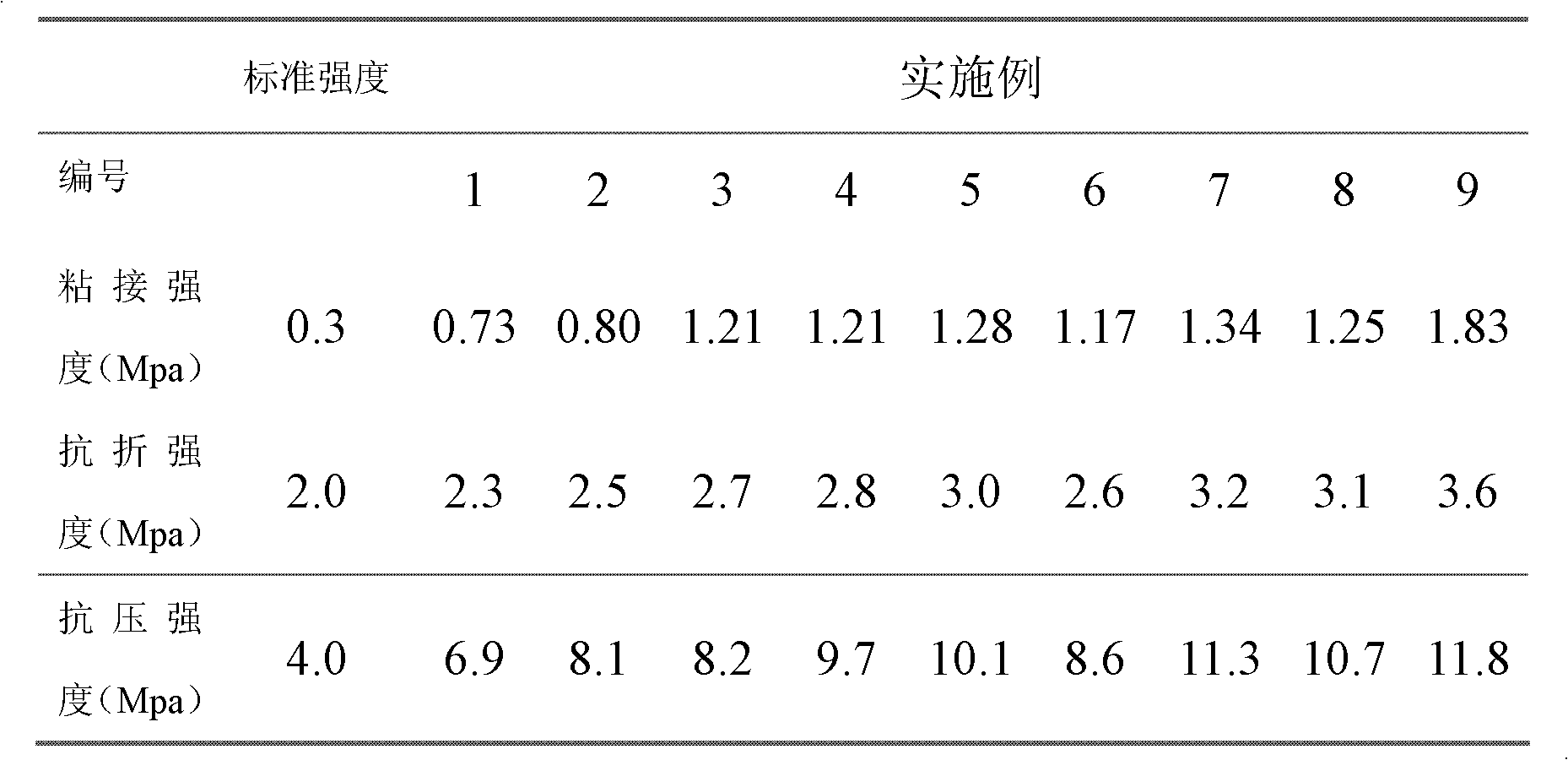

Composite fiber reinforced foam concrete and preparation method thereof

InactiveCN102199044APrevent shrinkage crackingImprove flexural strengthSolid waste managementCeramicwareFoam concreteFoaming agent

The invention relates to composite fiber reinforced foam concrete and a preparation method thereof. The foam concrete comprises the following components in parts by weight: 0-400 parts of fly ash, 100-900 parts of cement, 500-1000 parts of sands, 300-600 parts of water, 0.4-1 part of organic fiber, 1-3 parts of plant fiber, 0.2-15 parts of early strength agent, 3-20 parts of foaming agent, 0.5-4 parts of water reducing agent and 0.5-2 parts of water retention agent. The preparation method of the foam concrete comprises the following steps of: generating foams by using the foaming agent, adding the foams to fully stirred cement mortar containing composite fibers and the like and keeping stirring so that the foams are dispersed in the mortar uniformly, measuring the volume weight and carrying out casting forming or coating forming and carrying out standard curing for 28 days. In the invention, industrial and agricultural wastes, such as fly ash, plant fiber and the like, are used, shrinkage crack of the foam concrete is inhibited obviously, and the composite fiber reinforced foam concrete has low price; and the foam concrete has simple formula, good workability, long foam stabilizing time, light weight and low coefficient of thermal conductivity and is suitable for exterior wall thermal insulation, roof thermal insulation and non-load-bearing wall manufacturing.

Owner:TONGJI UNIV

Cement concrete self-restriction contraction stress test approach

InactiveCN101221164ATest accurateEasy to testUsing mechanical meansMaterial testing goodsLong axisPrism

A concrete self-restriction shrinkage stress detecting method relates to a method for detecting the concrete self-restriction shrinkage stress. The method aims at solving the problem of generating the self-restriction shrinkage stress caused by the shrinkage deformation difference at various positions in a concrete sample that is not considered by the existing concrete shrinkage stress detecting method. The method is provided with a humidity sensor arranged in a preformed hole of a first concrete sample with a prism shape, embedded with a plurality of groups of metal gauge heads at the two ends of an axes of a long axis of a second concrete sample with a prism shape in advance, respectively embedded with a metal gauge head along two ends of an axis of a thin slice shape sample, respectively detects relative humidity value, shrinkage value, and completely free shrinkage and deformation value at the location with a distance of h from the surface of the concrete, thereby calculating the self-shrinkage capacity at the location with the distance of h from the surface of the concrete. The detecting method of the invention can accurately and conveniently detect the self-shrinkage capacity of the concrete generated by the shrinkage and deformation at different positions of the inner and outer layers under different environmental conditions.

Owner:甘肃土木工程科学研究院有限公司

Preparation and application of municipal dewatering sludge based coating material for seal of landfill site

ActiveCN102690085AWide variety of sourcesRealize resource utilizationSludge treatmentSolid waste disposalVegetationLand resources

The present invention relates to preparation of a municipal dewatering sludge based coating material for seal of landfill site, is mainly used for seal covering of the landfill site, and belongs to the field of environmental geotechnical engineering. The municipal dewatering sludge is employed as a basis material and modified to be used in seal covering of the landfill site. An air-out layer of the coating material for seal of landfill site has good gas guide performance; an impervious layer is not easily cracking and has low permeability; and a vegetation nutrient layer has rich nutrients and good hydrophobicity. The covering material of the present invention realizes resource utilization of municipal dewatering sludge and saves land resource; the covering material can be produced by industrialized production, has a simple construction for application to seal covering of the landfill site, and has advantages of simpleness, fastness, strong operability, high survival ratio of plants, so as to guarantee quality of seal covering of the landfill site, meet various technological indexes of seal of the landfill site, and greatly improve the landfill environment.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

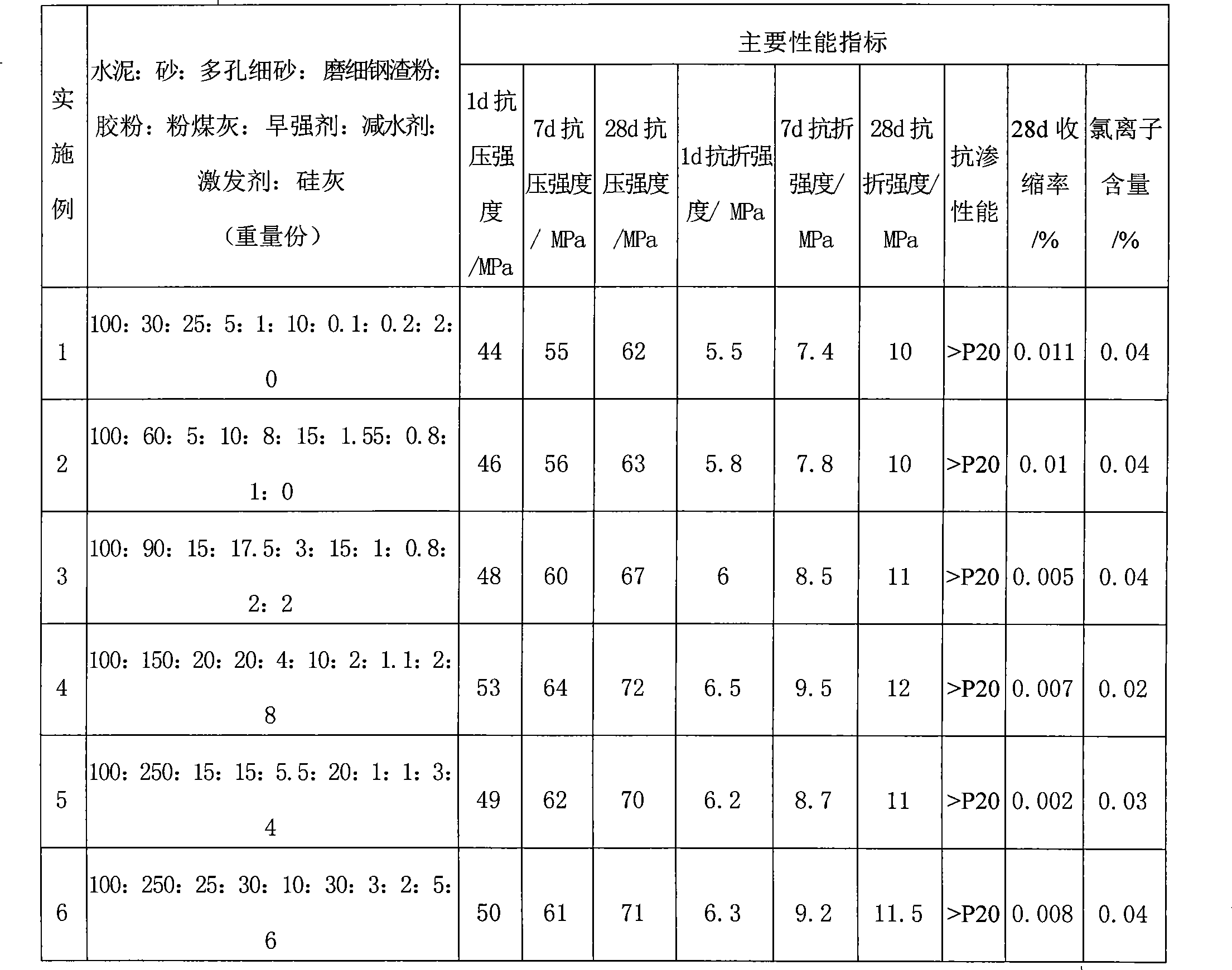

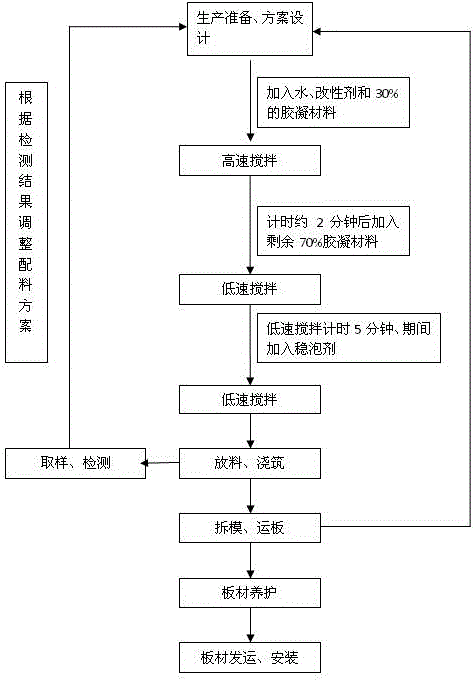

Early-strong-fast-hard end capping anchorage mortar material for fragment-free railway plate

ActiveCN101508547APrevent shrinkage crackingVolume stabilitySolid waste managementBallastwaySlagRebar

The invention relates to an early strength fast hardening terminated anchor mortar material, which is characterized in that the material is formed by mixing and stirring cement, sand, porous fine sand, finely ground steel slag powder, fly ash, an early strength agent, rubber powder, silicon ash, a water reducing agent and an excitant. The parts by weight of the components are as follows: 100 parts of cement, 30-250 parts of sand, 5-25 parts of porous fine sand, 5-30 parts of finely ground steel slag powder, 10-30 parts of fly ash, 0.1-3 parts of early strength agent, 1-10 parts of rubber powder, 0-8 parts of silicon ash, 0.2-2 parts of water reducing agent and 1-5 parts of excitant. Finely ground converter slag which is naturally stored for 3-6 months is adopted for the finely ground steel slag powder and the specific surface area is 400-800m / kg; the content of magnesium oxide is 8-15%; the porous fine sand is shale ceramic sand or fly ash ceramic sand or the mixture of the shale ceramic sand and the fly ash ceramic sand based on random mixture ratio, with grain size of 0.10-2.6mm. The material provided by the invention has good mechanical property and adhesive property, low chloride ion content and shrinkage property, and high impermeability and anti-cracking performance, thereby preventing the prestressed reinforcement of track slabs from rusting.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +1

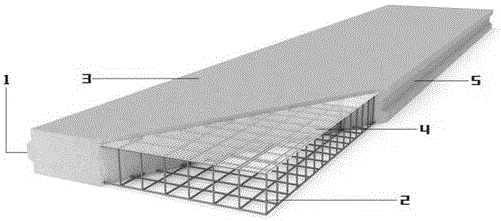

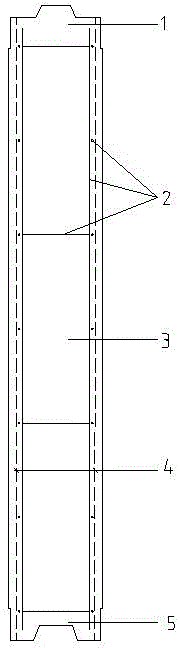

Steel wire mesh and fiber enhanced integrated foam concrete lightweight wall plate and manufacturing method thereof

ActiveCN105804315AIncreased durabilityImprove securityWallsHeat proofingFoam concreteCarvacryl acetate

The invention relates to a steel wire mesh and fiber enhanced integrated foam concrete lightweight wall plate and a manufacturing method thereof. The wall plate comprises foam concrete, wherein the foam concrete covers a 3D steel wire mesh; alkali-resisting glass fiber gridding cloth is arranged on each of the upper and lower surfaces of the 3D steel wire mesh; proper amount of alkali-resisting anti-cracking fibers are added into the foam concrete; the 3D steel wire mesh and the alkali-resisting glass fiber gridding cloth are integrally poured and molded to form an integrated structure sheet material through foam concrete paste; a tenon convenient for mounting and a groove matched with the tenon are pre-formed on the two sides of the sheet material respectively. The manufacturing method of the wall plate comprises the following steps: preparing the foam concrete paste and pouring and molding the integrated structure sheet material; and preparing a compound type high molecular modifier containing an ethylene / vinyl acetate copolymer, calcium stearate, lithium carbonate and silicon resin polyether emulsion. The wall plate has the advantages of light weight, high strength, heat preservation and heat insulation, good waterproof performance, good durability, no layering and cracking, simple manufacturing process and capability of greatly improving industrial production efficiency.

Owner:唐山冀东发展集成房屋有限公司

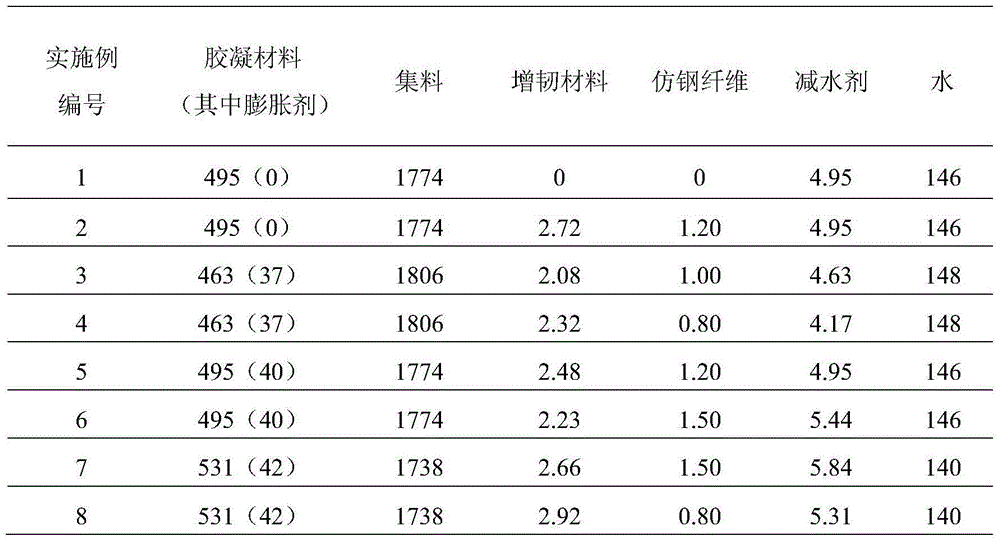

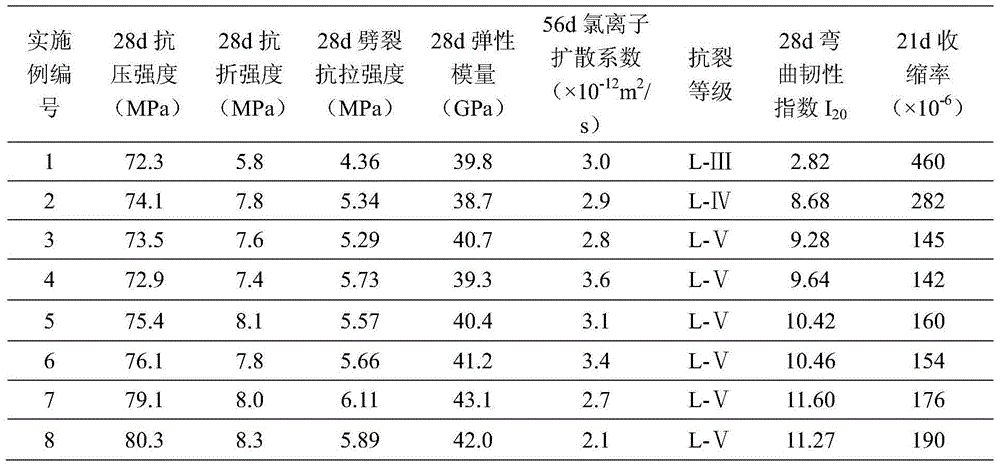

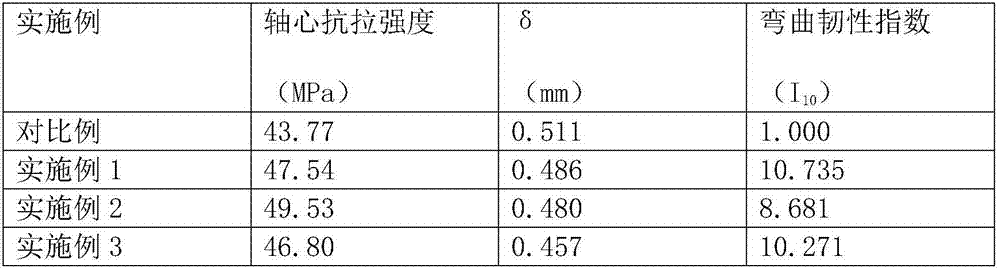

Micro-expansion fiber reinforced concrete and preparation method thereof

The invention discloses micro-expansion fiber reinforced concrete for a steel-concrete combined beam bridge panel wet joint and a preparation method of the micro-expansion fiber reinforced concrete, and relates to the preparation field of the micro-expansion fiber reinforced concrete. The micro-expansion fiber reinforced concrete comprises gel materials (cement, coal ash, slag powder and an expanding agent), aggregate, reinforcing materials, imitated steel fibers, a water reducer and water, wherein the 28 compressive strength of the micro-expansion fiber reinforced concrete is not lower than 69.0MPa, the 28d breaking strength of the micro-expansion fiber reinforced concrete is not lower than 7.0 MPa, the 28d splitting tensile strength of the micro-expansion fiber reinforced concrete is not lower than 5.0 MPa, the 28d elasticity modulus of the micro-expansion fiber reinforced concrete is not lower than 36.0 GPa, the cracking resistance level of the micro-expansion fiber reinforced concrete reaches L-IV level, the 28d bending toughness index I20 of the micro-expansion fiber reinforced concrete is not lower than 8, the 56d chlorine ion diffusion coefficient of the micro-expansion fiber reinforced concrete is lower than 4.0*10<-12>m<2> / s, the 21d shrinkage percentage of the micro-expansion fiber reinforced concrete is lower than 200*10<-6>. By using the preparation method, the shrinkage cracking of the micro-expansion fiber reinforced concrete can be effectively avoided, so that the reinforced concrete is relatively compact. The micro-expansion fiber reinforced concrete disclosed by the invention is relatively high in strength, relatively low in shrinkage percentage, good in bending toughness and durability, relatively low in cost and conveniently to widely use.

Owner:THE 2ND ENG CO LTD MBEC +1

Light masonry mortar with heat insulation and preservation

InactiveCN101643349AImprove insulation effectAvoid "Cold Bridge" PhenomenonSolid waste managementFiberSlag

The invention discloses a light masonry mortar with heat insulation and preservation, comprising the following components by weight percent: 20 percent to 65 percent of portland cement, 5 percent to 50 percent of fly ashes, 0 percent to 50 percent of furnace bottom slag, 0 percent to 55 percent of slag, 10 percent to 23 percent of vitrified microspheres, 0.1 percent to 1.0 percent of water retention and thickening materials, 0.1 percent to 0.5 percent of lignocellulose and 0.1 percent to 1.0 percent of water reducing agent. The mortar has the dry density of 750 to 1000 kg / m<3>, the thermal conductivity of 0.15 to 0.20 w / m k, the lowest compressive strength of 5 Mpa and the liner shrinkage rate of less than 0.1 percent, satisfies the requirements of heat insulation and preservation of an energy-saving building, has the advantages of favorable heat insulation and preservation performance, favorable water retention, favorable workability, high adhesion strength of a wall body, simple construction, energy saving, environmental protection and the like, completely avoids the occurrence of the phenomenon of cold bridge, and efficiently prevents dry-shrinkage cracking and the phenomenon ofmoisture absorption of the wall surface.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

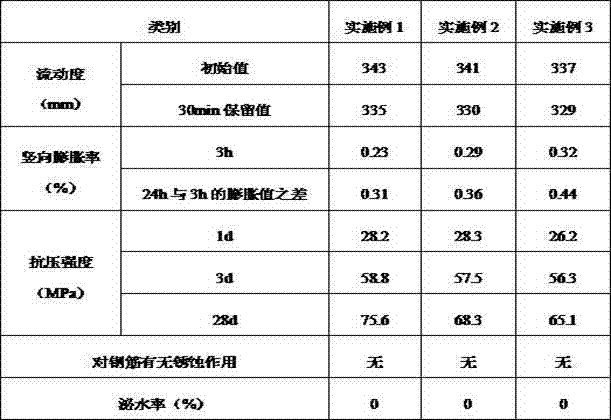

Special plastic expansion agent for cement-based grouting material and preparation method of same

The invention discloses a special plastic expansion agent for cement-based grouting material. The special plastic expansion agent comprises the components by weight percent: 3.0% to 5.0% of plastic expansion source, 0.05% to 0.15% of stearate, 5.0% to 10.0% of catalyst, 25.0% to 50.0% of quick lime and 35.0% to 60.0% of water retaining admixture. The special plastic expansion agent can hydrolyze and give off gas during the initial stage of cement hydration, and the gas which is given off uniformly enables cement slurry to expand slightly in volume, so that settling and cracking of grouting material can be avoided, and the slurry is ensured denseness and fullness. When the special plastic expansion agent is used with efficient water reducer or other admixtures, the purpose of efficiently ensuring that the plastic expansion of cement-based grouting material is greater than 0.1% in 3h under the condition of realizing the fluidness, the strength and the durability of the cement-based grouting material can be achieved, and expansibility that the expansion difference between 3h and 24h is greater than two ten thousandth and smaller than five thousandths can be achieved, so that plastic expansion of the cement-based grouting material can be realized.

Owner:NANJING RUIDI HIGH TECH

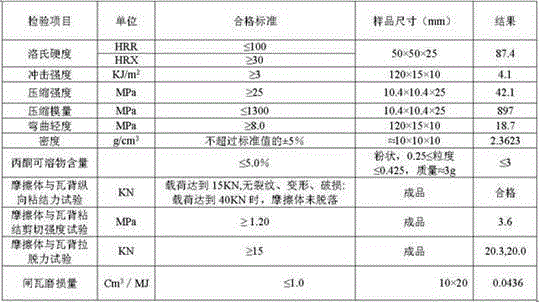

High-friction coefficient composition brake shoe and production method thereof

The invention relates to a high-friction coefficient composition brake shoe. The high-friction coefficient composition brake shoe comprises a steel backing and a friction material, the friction material comprises the following raw materials including, by weight, 1-5 parts of aramid fiber, 8-12 parts of butadiene-acrylonitrile rubber, 0.5-1 part of stearic acid, 0.3-1 part of an accelerant, 0.6-1 part of sulphur, 0.5-1 part of zinc oxide, 4-7 parts of phenolic resin, 10-20 parts of inorganic composite fiber, 8-15 parts of iron powder, 10-20 parts of barium sulfate, 7-15 parts of kibdelophane powder, 5-10 parts of steel wool fiber, 1-3 parts of bauxite, 8-15 parts of potassium feldspar powder, 2-5 parts of mica, 2-5 parts of flake graphite, 5-10 parts of sepiolite fiber and 2-5 parts of molybdenum disulfide. By means of the high-friction coefficient composition brake shoe, the change of the speed of the wear rate of the high-friction coefficient composition brake shoe can be basically identical to the change of the adhesion coefficient of a wheel track, the abrasion loss when a vehicle is braked is less, failure can not occur in braking, and the traffic safety is guaranteed. The invention provides a production method of the high-friction coefficient composition brake shoe at the same time.

Owner:HEBEI XINJI TENGYUE INDAL

Cement polymer based high-temperature concrete permeable pavement bricks and manufacturing method thereof

The invention provides cement polymer based high-temperature concrete permeable pavement bricks and a manufacturing method thereof and belongs to the field of road surface pavement materials. Each cement polymer based high-temperature concrete permeable pavement brick is prepared from a permeable base layer and a permeable surface layer, wherein the permeable base layer is prepared from 290 to 345 parts of cement A, 0 to 6 parts of ultra-light aggregate A, 1630 to 1765 parts of coarse aggregate, 255 to 290 parts of sand, 0.50 to 0.85 part of polymer emulsion A, 0.35 to 0.50 part of an interface reinforcing agent A and 0 to 0.65 part of a loose soil constriction resisting agent; the permeable surface layer is prepared from 390 to 425 parts of cement B, 0 to 2 parts of ultra-light aggregate B, 0 to 7.5 parts of micro-pore fine aggregate, 1350 to 1400 parts of wear-resisting fine aggregate, 0.65 to 0.85 part of polymer emulsion B, 0.65 to 0.95 part of an interface reinforcing agent B, 8 to 13 parts of a deicer salt scaling resisting and alkali adsorption agent and 15 to 17 parts of pigment. According to the cement polymer based high-temperature concrete permeable pavement bricks, all technological performances of the permeable bricks are comprehensively improved.

Owner:葛兆明 +3

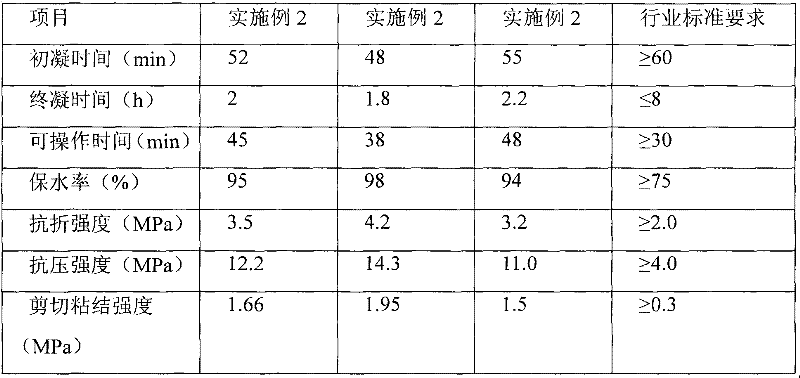

Bottom layer brushing gypsum and application thereof

The invention discloses a bottom layer brushing gypsum, which is prepared by mixing the following components in parts by weight: 200-500 parts of building gypsum, 485-785 parts of quartz sand, 3 parts of regulator, 5 parts of inorganic gel, 0.2-0.5 part of retarder and 2 parts of anti-cracking agent, wherein the quartz sand is one or the mixture of more than two of the quartz sands of 30 meshes, 40 meshes and 60 meshes in any proportion, the regulator is hydroxypropyl methyl cellulose, the inorganic gel is sodium bentonite, the retarder is a special retarder for polyphosphate gypsum, and the anti-cracking agent is lignocellulose; and the building gypsum is prepared by desulfurized gypsum according to the following method that the desulfurized gypsum enters a boiling calcinator after being pre-dried at the temperature of 80-90 DEG C, is calcined at the temperature of 120-130 DEG C, then is added into an impact type flour mill to be ground, and is prepared into the building gypsum after being cooled and aged. The invention has strong adhesive force, effectively inhibits the phenomenon of shrinkage cracking in plastering, and has good water resistance.

Owner:上海每天节能环保科技股份有限公司

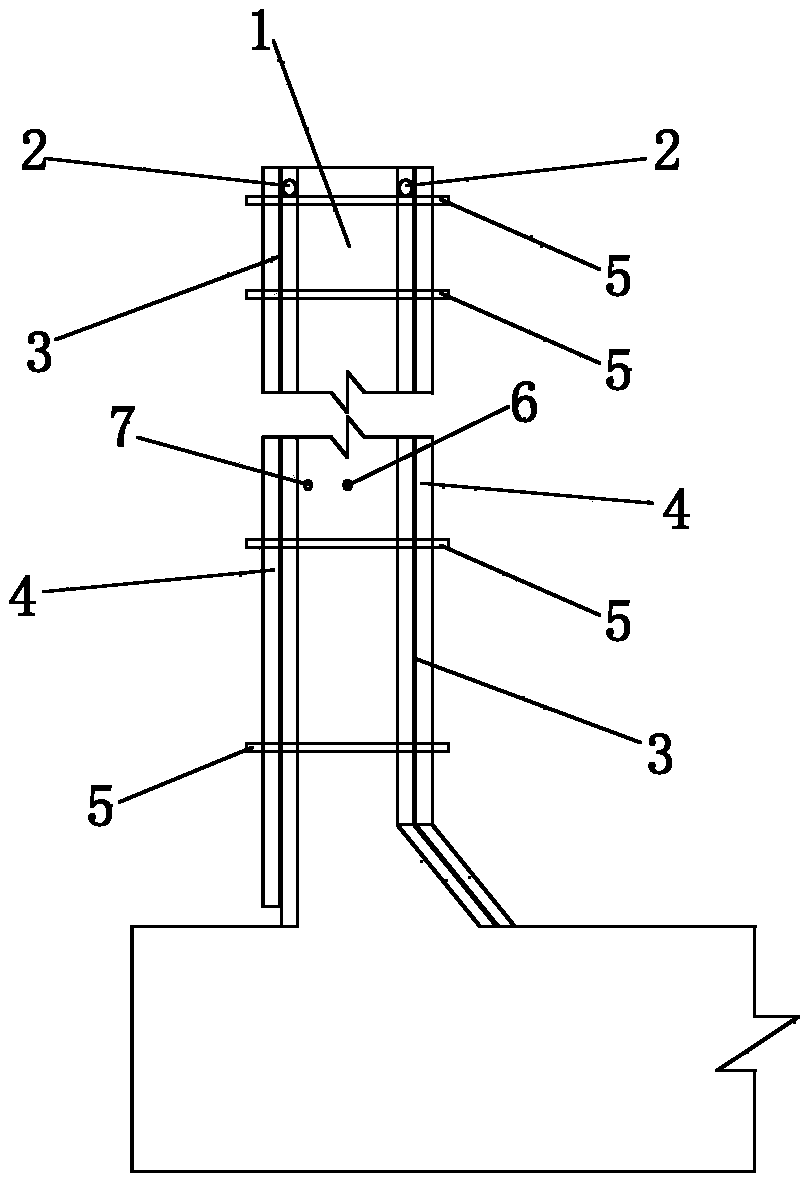

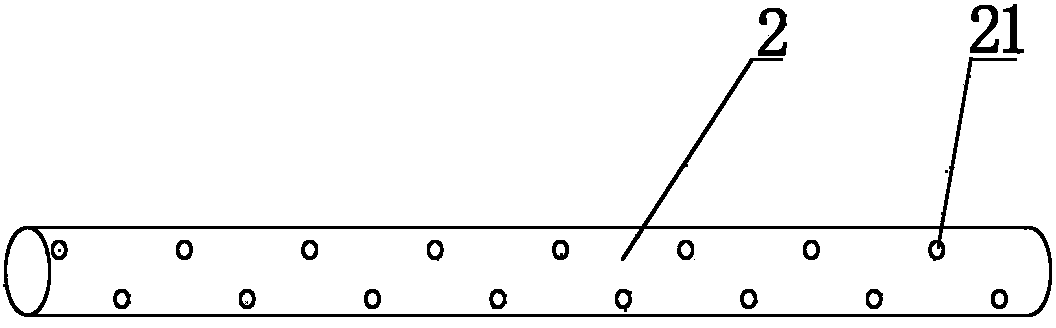

Long-wall structure concrete curing device and curing method thereof

ActiveCN103978547AExpand the scope of influenceReduce temperature stressCeramic shaping apparatusTemperature stressNumerical control

The invention relates to a long-wall structure concrete curing device and a curing method thereof. The curing device comprises a moisturizing device, a heat-preservation device and a temperature measurement device, wherein the moisturizing device comprises a spraying pipe, and the spraying pipe is fixed through a split bolt of a formwork at the top of a wall; the heat-preservation device comprises a plastic film and a heat-preservation material, the spraying pipe and the wall are wrapped with the plastic film, and the plastic film is wrapped with the heat-preservation material; the temperature measurement device comprises a center temperature measurement point and a surface temperature measurement point, the center temperature measurement point and the surface temperature measurement point are buried at the same elevation of the wall, and the center temperature measurement point and the surface temperature measurement point are connected with a numerical control temperature measurement instrument through a temperature measurement line. According to the curing device and the curing method, the outside of the surface of a long-wall concrete structure is provided with the moisturizing device capable of spraying fine water mist slowly and wrapped with the heat-preservatoin device composing of the plastic film and the heat-preservation material, the difference of temperatures inside and outside concrete is controlled, temperature stress in the concrete is reduced, temperature cracks of the concrete are reduced, and the problem of how to control the cracks in long-wall structure construction in the environment with a dry climate and a large temperature difference is solved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

Ground floor plastering gypsum

The invention discloses a preparation method of a ground floor plastering gypsum, which is improvement of the ground floor plastering gypsum. The ground floor plastering gypsum is prepared mainly by the following ingredients according to weight percentage: 30-50% of desulfurization building gypsum, 50-70% of fine sand, 0.01-0.04% of binder, 0.015-0.05% of water retaining agent and 0.01-0.05% of retarder. The ground floor plastering gypsum is strong in cohesive force, good in water resistance and low in cost, and does not crack, thus being an ideal choice for replacing traditional plastering materials.

Owner:INNER MONGOLIA UNIV OF SCI & TECH

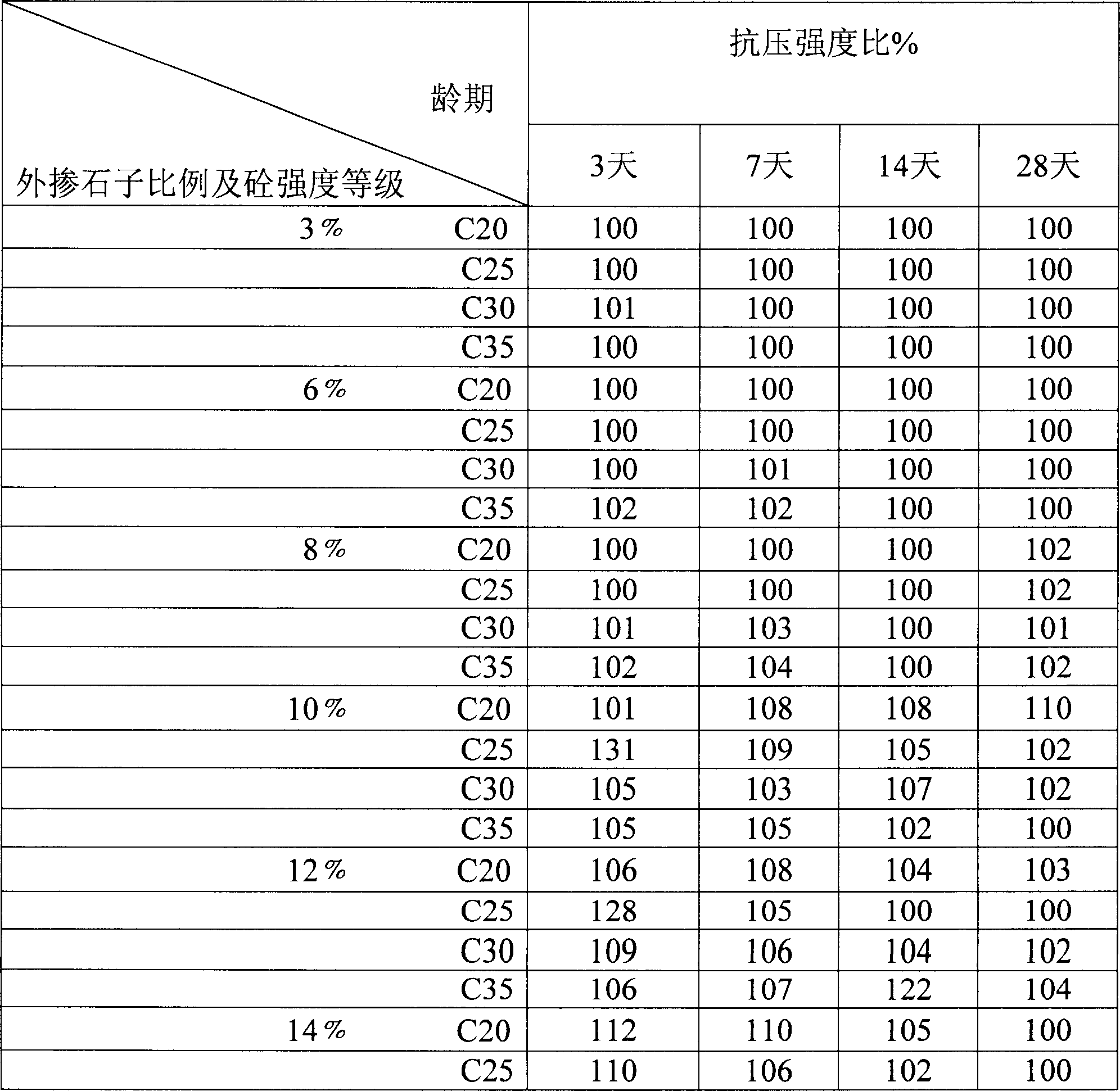

Construction method for delivering concrete through pump

InactiveCN1916332AImprove early strengthShorten the construction periodBuilding material handlingMaterials scienceDry stone

Owner:CHENGJIAN BUILDING ENG QINHUANGDAO CITY

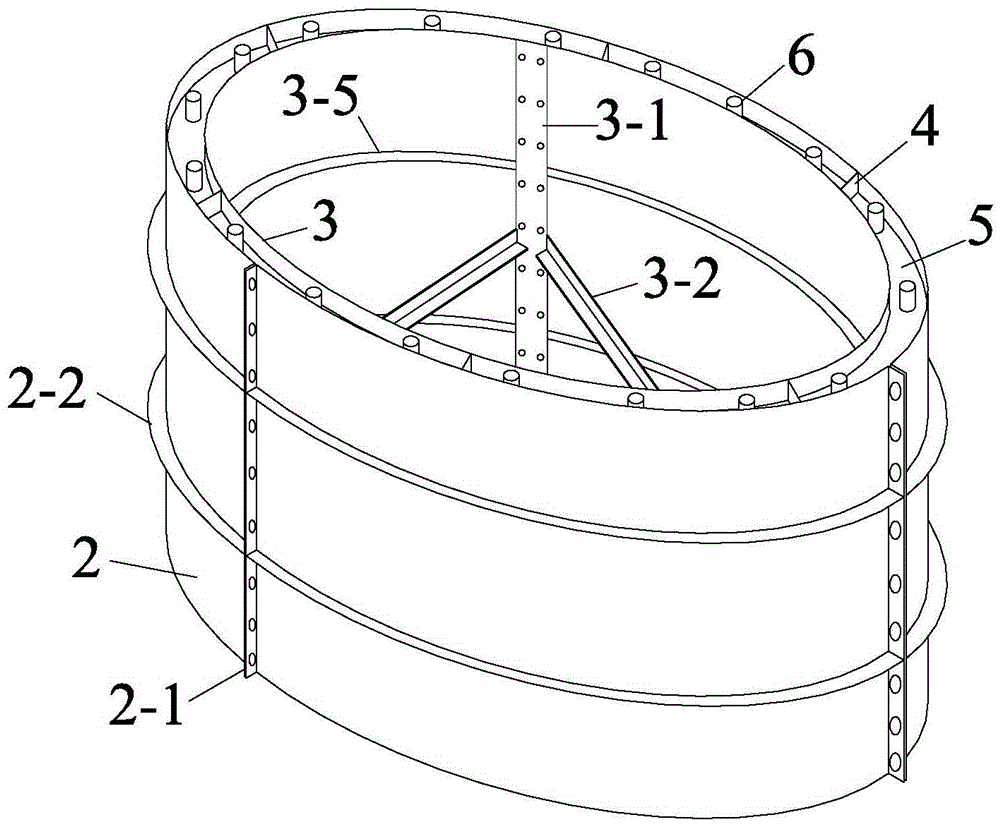

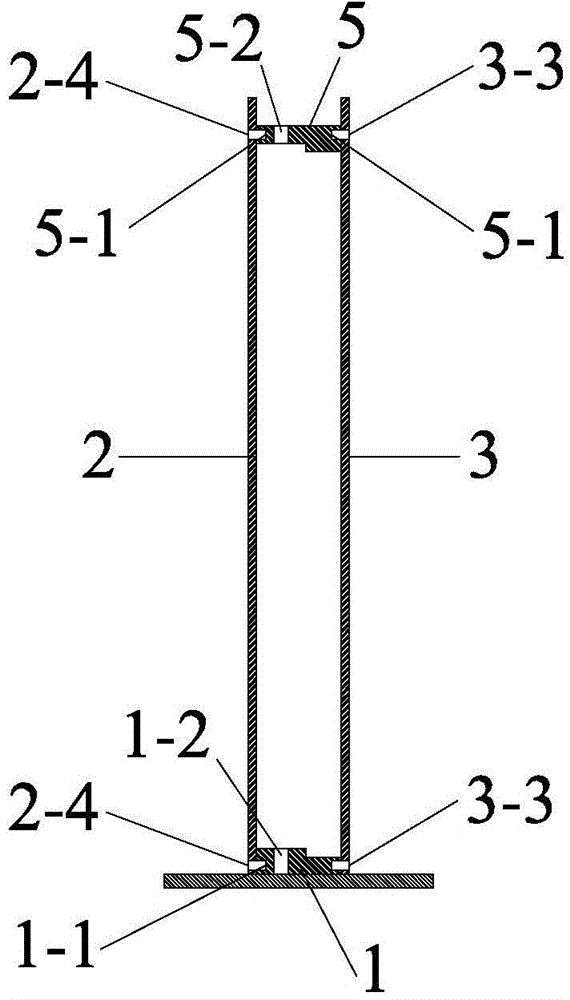

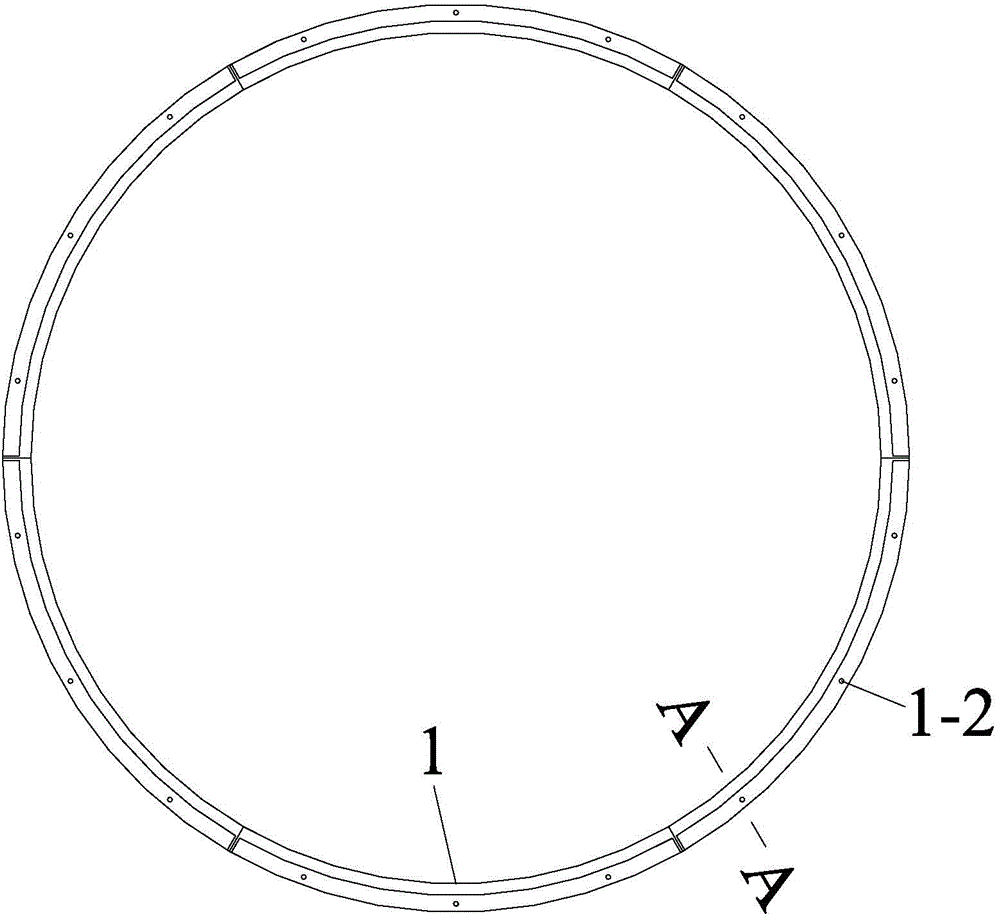

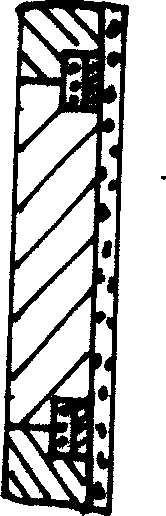

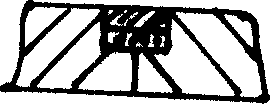

Vertical integral forming mould of novel prefabricated concrete segment and forming method thereof

The invention discloses a vertical integral forming mould of a novel prefabricated concrete segment and a forming method thereof, and the forming mould is assembled by an inside template, an outside template, a partitioning board, a bottom die, a cover plate and a positioning spigot. The forming method comprises the following steps: firstly assembling the mould, positioning and fixing reinforcing bars in the segment to the mould, reserving pre-stressed ducts, casting high-intensity and self-compaction concrete, and finally installing the cover plate on the mould to form the prefabricated concrete segment with the special shape. In the forming mould and the forming method, prefabricated concrete segments with different shapes and sizes can be manufactured as needed and are accurate in size and simple in manufacturing method, thus the forming mould and the forming method are applied to industrialization quantity production.

Owner:SOUTHEAST UNIV +2

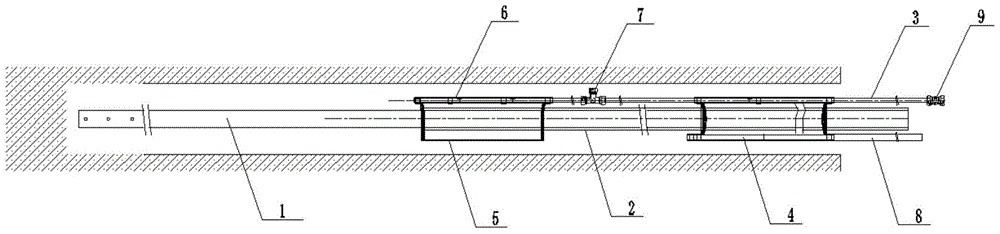

Mining hole packer and hole packing method

InactiveCN105696967ASolve the problem of sealing holes in gushing water drillingQuality improvementSealing/packingGeomorphologyMaterial resources

The invention discloses a mining hole packer and a hole packing method, and solves the hole packing problem of downward drilling holes and drilling holes filled with water. The mining hole packer comprises a drainage sleeve and a grouting pipe. The drainage sleeve is arranged at the hole pre-packing section of a gas drainage pipe. Pockets sleeve the two ends parts of the drainage sleeve respectively. The grouting pipe passes through the two pockets to be fixed on the drainage sleeve. The tail end of the grouting pipe is sealed. One-way valves are arranged at the position sections, in the pockets, of the grouting pipe. An explosion valve is arranged at the position section between the exteriors of the two pockets of the grouting pipe. The mining hole packer and the hole packing method can realize automatic hole packing, are convenient to operate, improve the drilling hole packing quality and the extraction effect, and besides, save manpower and material resources.

Owner:淮南久辉工贸有限责任公司

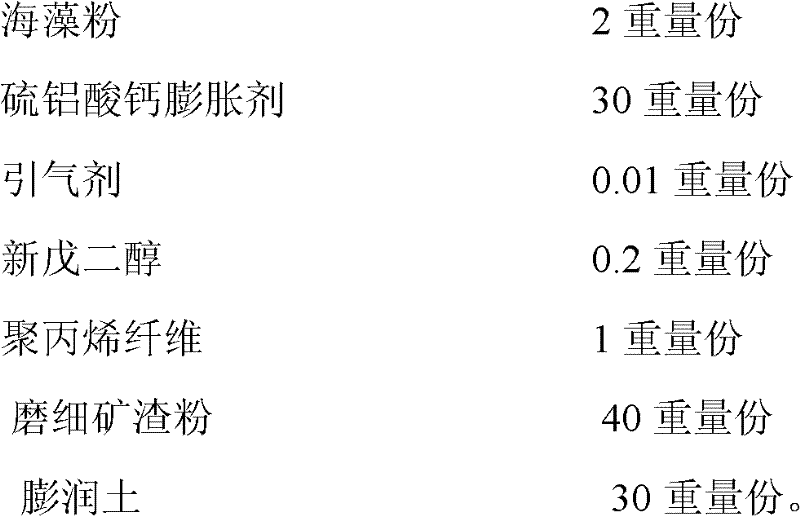

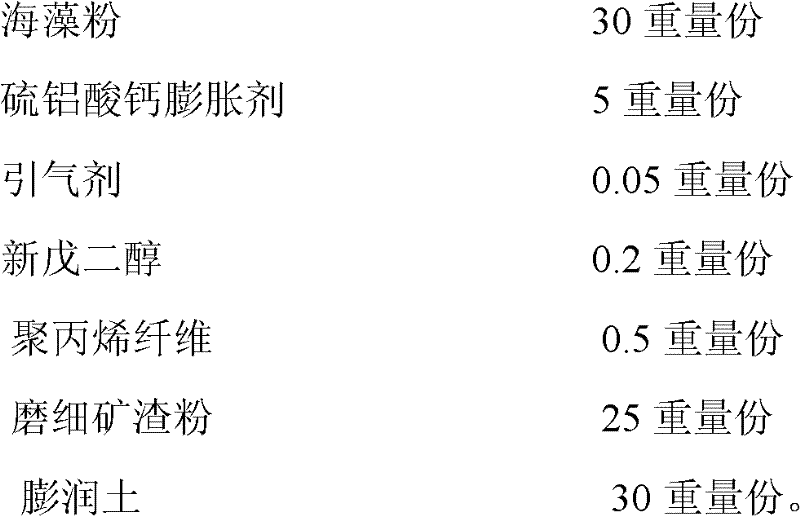

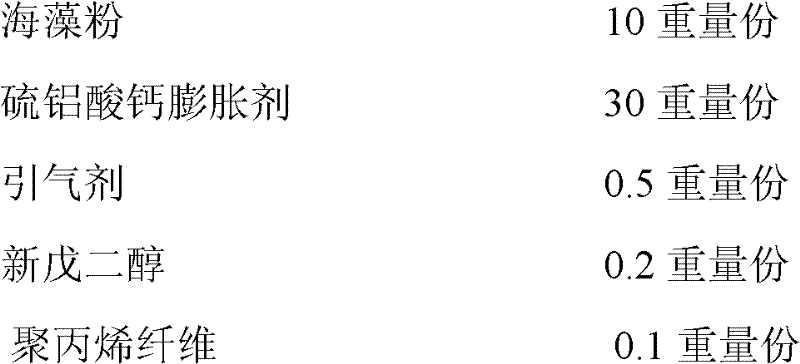

Plastic expanding agent used for cement base material shrinkage and compensation, its preparation method and its application

The invention relates to a novel plastic expanding agent used for cement base material shrinkage and compensation, concretely relates to the concrete expanding agent which is capable of generating expansion in a plastic phase to compensate cement base material shrinkage in the plastic phase, and continuously generating certain expansion in a hardening phase to compensate the anaphase shrinkage and cracking of the cement base material. The plastic expanding agent comprises the following ingredients by weight part: 2-30 parts of kelp powder or seaweed powder, 5-35 parts of calcium sulphoaluminate expanding agent, 0.005-0.5 parts of air-entrainer, 0.2-1 part of neopentylene glycol, 0-1.2 parts of micro synthesized fiber, 10-40 parts of levigated slag powder and 5-30 parts of bentonite. The plastic expanding agent can be widely used in the cement base materials of cement mortar, concrete, grouting materials, repairing mortar and the like, and can be used in concrete engineering of water conservancy, electric power, building, transportation and the like.

Owner:TONGJI UNIV

Using method for soil curing agent

InactiveCN101100856AImprove compactnessImprove the modulus of resilienceSoil preservationWater solubleFly ash

Owner:张京杰

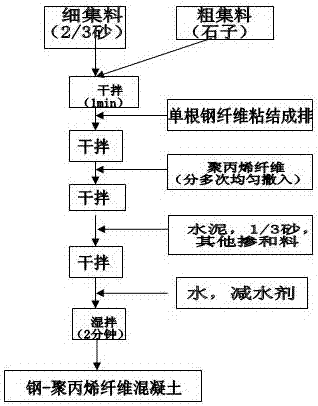

High-performance expanded hybrid fiber concrete material for wet joints, and preparation method thereof

The invention provides a high-performance expanded hybrid fiber concrete material for wet joints, and a preparation method thereof. According to the present invention, based on the practical problems of the wet joint in the whole simply supported-continuous structure system, high-strength hybrid fiber reinforced concrete is used as a joint material to provide the hybrid effect at different levels and different load applying stages so as to well inhibit and restrict the development of cracks, wherein the development of the concrete micro-crack is limited by releasing the concentrated force of the micro-crack in the concrete with Durafibers, the development of the macro-crack is limited by steel fibers, and by mixing the Durafibers and the steel fibers, a variety of mechanical properties of the whole concrete can be improved in the case of the low doping volume, such that the concrete can have characteristics of high bending resistance, high toughness, high impermeability, high fatigue resistance and the like so as to prevent the occurrence of diseases.

Owner:WUHAN UNIV OF TECH

Calcium enriched high strength concrete admixture and its preparation method and use method

InactiveCN1903773AHigh strengthIncreased durabilitySolid waste managementHigh strength concreteCalcium hydroxide

The present invention relates to a calcium-increased type high-strength concrete blending material, its preparation method and application method. Said concrete blending material includes 70-90% of fly ash, 5-20% of tap cinder, 1-5% of calcium hydroxide, 0.5-3% of sodium sulfate, 0.1-0.5% of silane coupling agent, 0.01-1% of triethanolamine and 0.1-1% of water reducer. Said invention also provides the concrete steps of its preparation method and application method.

Owner:姜博

Concrete cracking resisting waterproofing agent

The invention relates to a novel concrete cracking resisting waterproofing agent and particularly relates to an aluminum-slag-powder concrete cracking resisting waterproofing agent which is prepared from aluminum slag powder, steel slag powder, mineral slag, fly ash and a small amount of admixture, wherein the aluminum slag powder, the steel slag powder, the mineral slag and the fly ash serve as the raw materials. The aluminum slag powder accounts for 0.3-0.7%, the steel slag powder accounts for 10-30%, the mineral slag accounts for 20-70%, the fly ash accounts for 5-20% and the admixture accounts for 1-3%, wherein the total percent by weight of the components is 100%. The concrete cracking resisting waterproofing agent is low in construction cost and can be used to maintain easily, and the mixing amount of components of the concrete cracking resisting waterproofing agent is easy to control.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Profundity sterilization borehole face high-strength high-performance concrete

InactiveCN101152977AImprove carrying capacityStrong water sealingSolid waste managementChemical admixtureSlag

The present invention discloses a concrete with high strength and high performance for deeply and thickly frozen well wall. The double-doping technology of milled slag as the main mineral doping and different chemical doping is used; the invention is prepared after optimized combination and blending of mixture. The concrete is made by mixing P.0.42.5cement, machine-made sand, limestone rubble, milled rubble, I-level powder coal ash, TK-M intensifier, J851-D early strengthening high-early-strength water reducing agent, JQ-D anti-crack intensifying agent, high-efficiency water reducing agent of liquid polycarboxylic salt, and water. The present invention has the characteristics of the low preparation cost, the simple operation process, the applicability to engineering of the inside of a deeply and thickly frozen and a well wall on the outer layer, and so on.

Owner:盛天宝 +2

Gypsum substrate render material

The gypsum-based whitewash material consists of beta-gypsum with beta-CaSO4.1 / 2H2O as main component 99-99.9 wt% and anhydrous citric acid or its salt as coagulation regulator 0.1-1 wt%. The presentinvention has strong adhering capacity, and can inhibit the shrinkage and cracking in whitewashing. It has excellent surface decoration performance, fireproof performance and heat insulating performance. It has simple production process, low production cost and light weight.

Owner:NANJING EFFUL

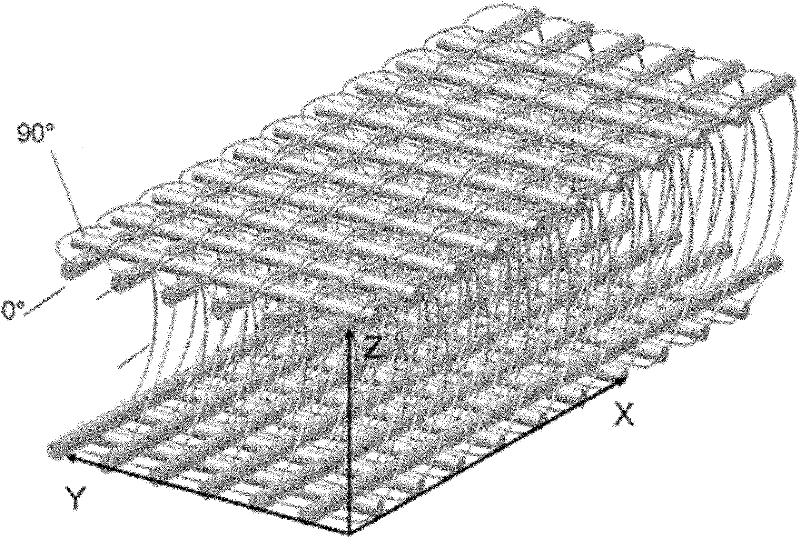

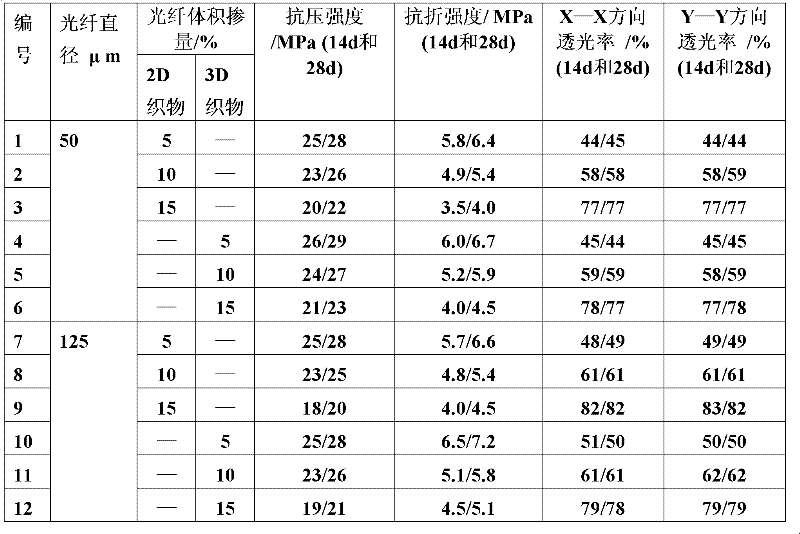

Method for preparing light-transmitting concrete by spinning optical fiber technology

The invention relates to a method for preparing light-transmitting concrete by a spinning optical fiber technology, and belongs to the field of novel building materials. Organic multi-mode optical fibers with the diameter of 2 to 200mu m are adopted and spun into fiber cloth or a fiber integrated body according to a certain rule, the fiber cloth or the fiber integrated body is taken as a conductor for transmitting light rays to achieve special effects of transmitting light and images and the like of a cement concrete material, and the content of the optical fibers in a building block can be greatly reduced to 5-15 volume percent. The material has the advantages of high light-transmitting property and stability, convenient preparation process, designable decorative effect and the like, andis a novel second-generation light-transmitting cement concrete material.

Owner:BEIJING UNIV OF TECH

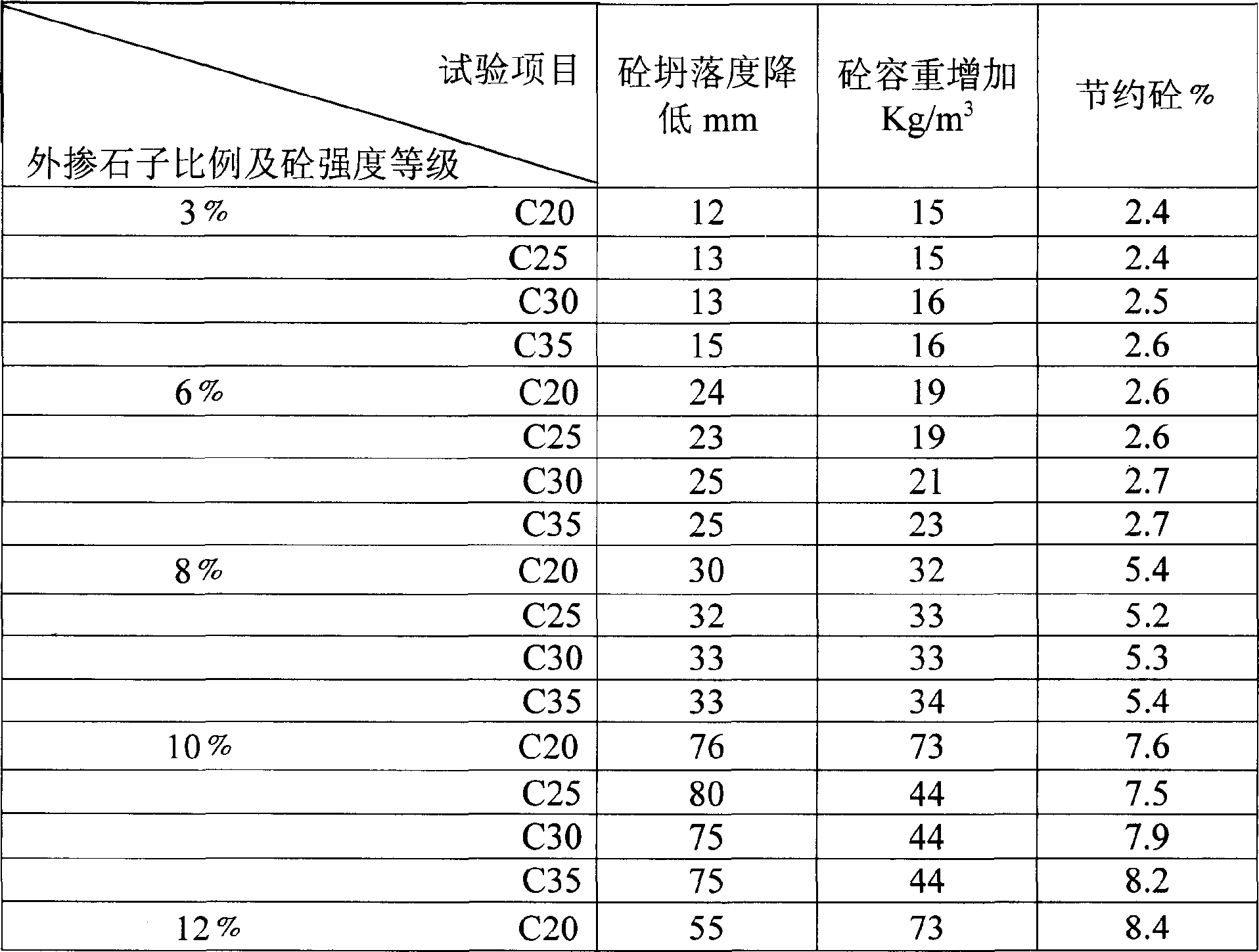

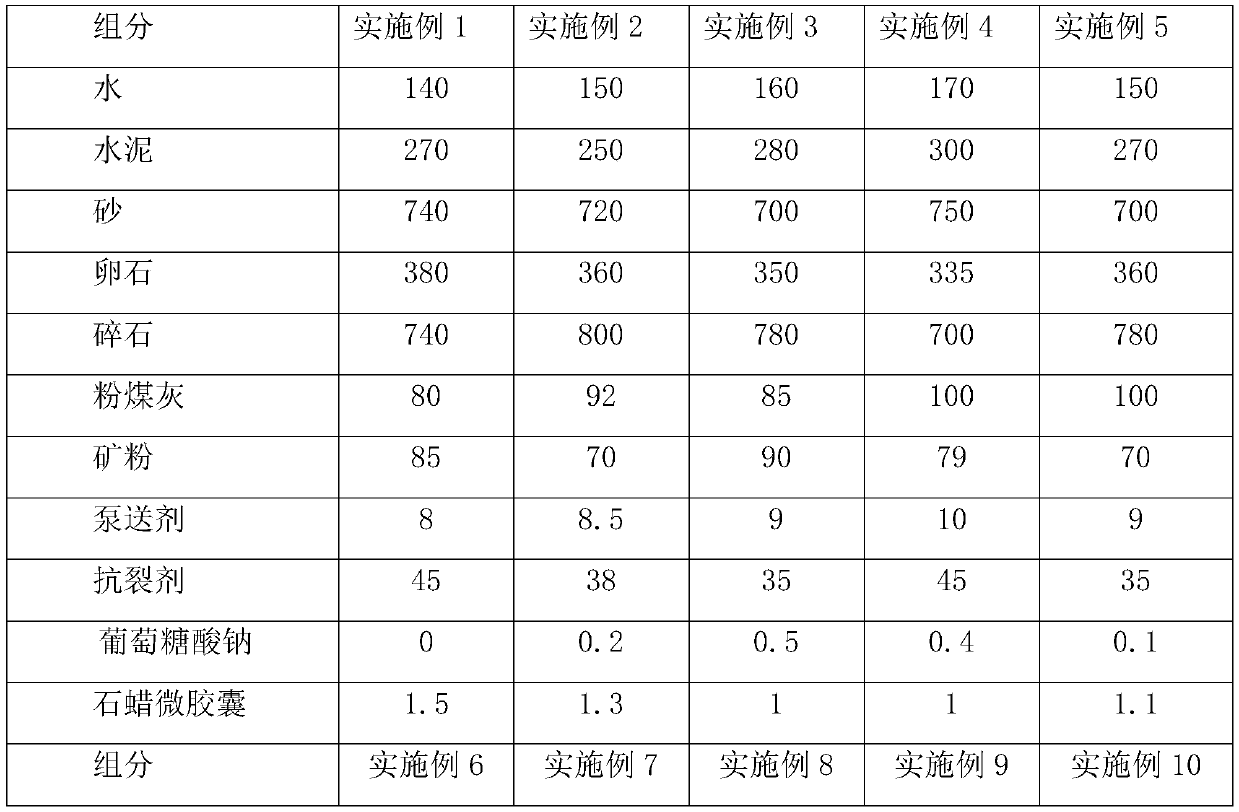

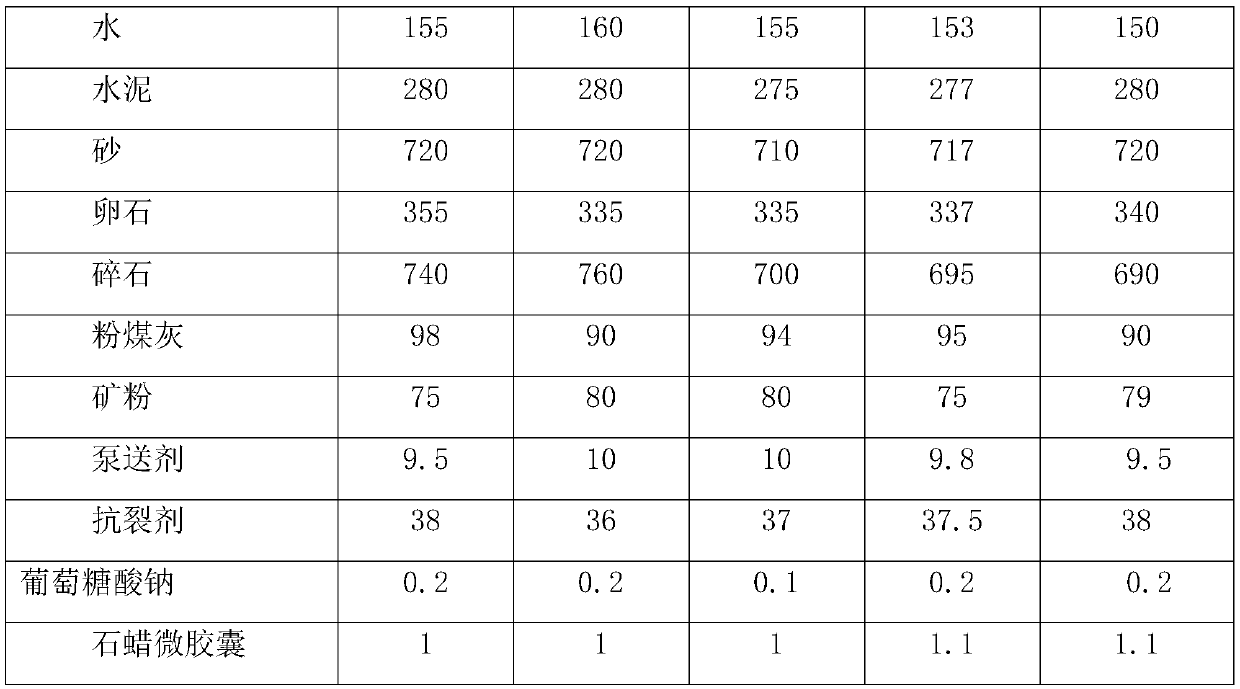

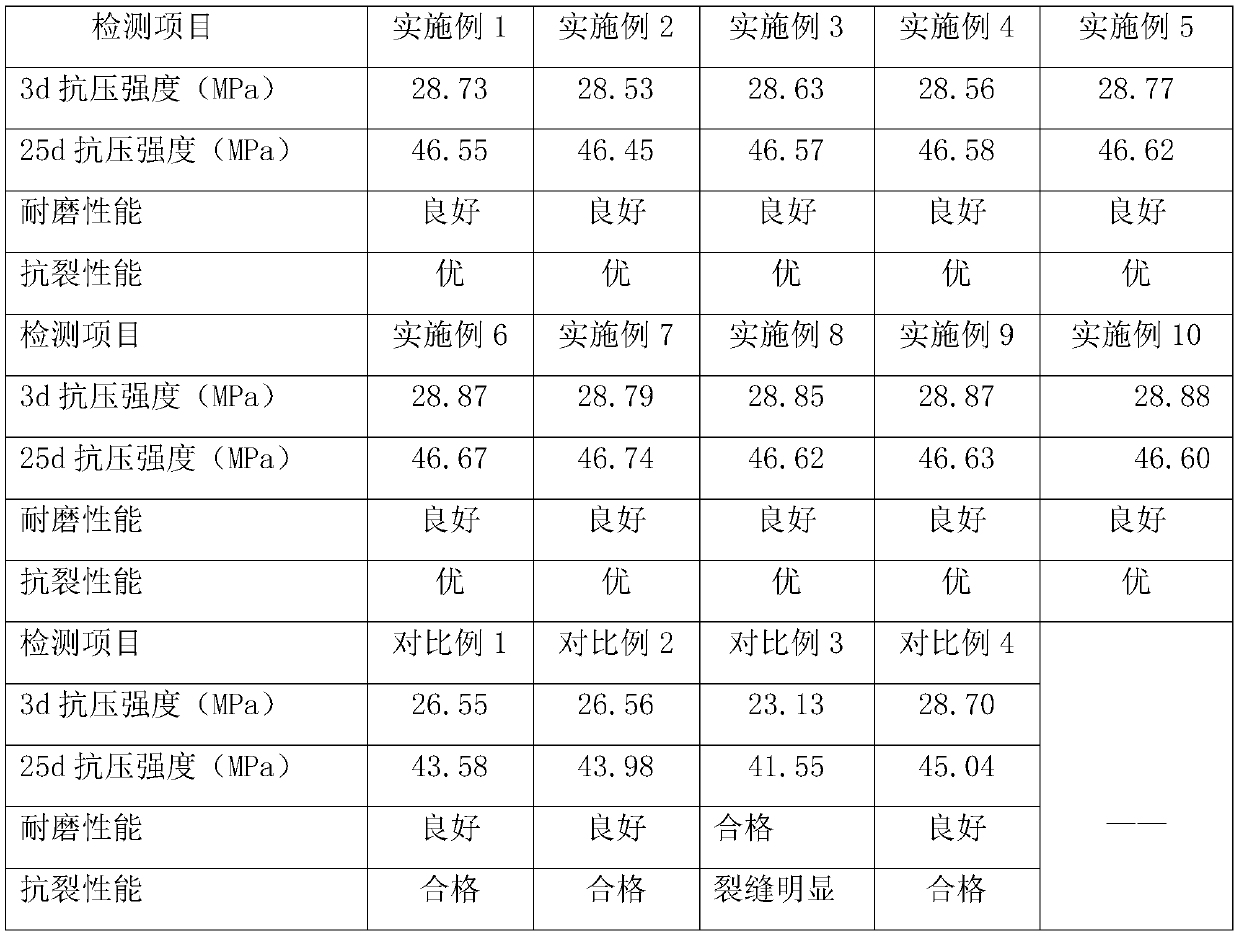

C45 mass concrete and preparation process thereof

The invention relates to C45 mass concrete and a preparation process thereof, wherein the C45 mass concrete comprises: 140-170 parts of water, 250-300 parts of cement, 700-750 parts of sand, 335-380 parts of pebble, 700-800 parts of crushed stones, 80-100 parts of fly ash, 70-90 parts of mineral powder, 8-10 parts of a pumping agent, 35-45 parts of an anti-cracking agent, and 1-1.5 parts of a modifier. The preparation method comprises: 1, uniformly stirring sand, pebble, crushed stone and water to obtain an intermediate product; and 2, adding cement, fly ash, mineral powder, a pumping agent, an anti-cracking agent and a modifier, and uniformly stirring to obtain concrete. According to the technical scheme of the present invention, by simultaneously adding fly ash and mineral powder, the consumption of cement is reduced, such that the release rate of hydration heat is delayed, and the occurrence of shrinkage is reduced; and by adding the paraffin microcapsules, the temperature regulation effect can be achieved, such that the influence of the paraffin phase change volatilization on the environment can be avoided.

Owner:陕西恒盛混凝土有限公司

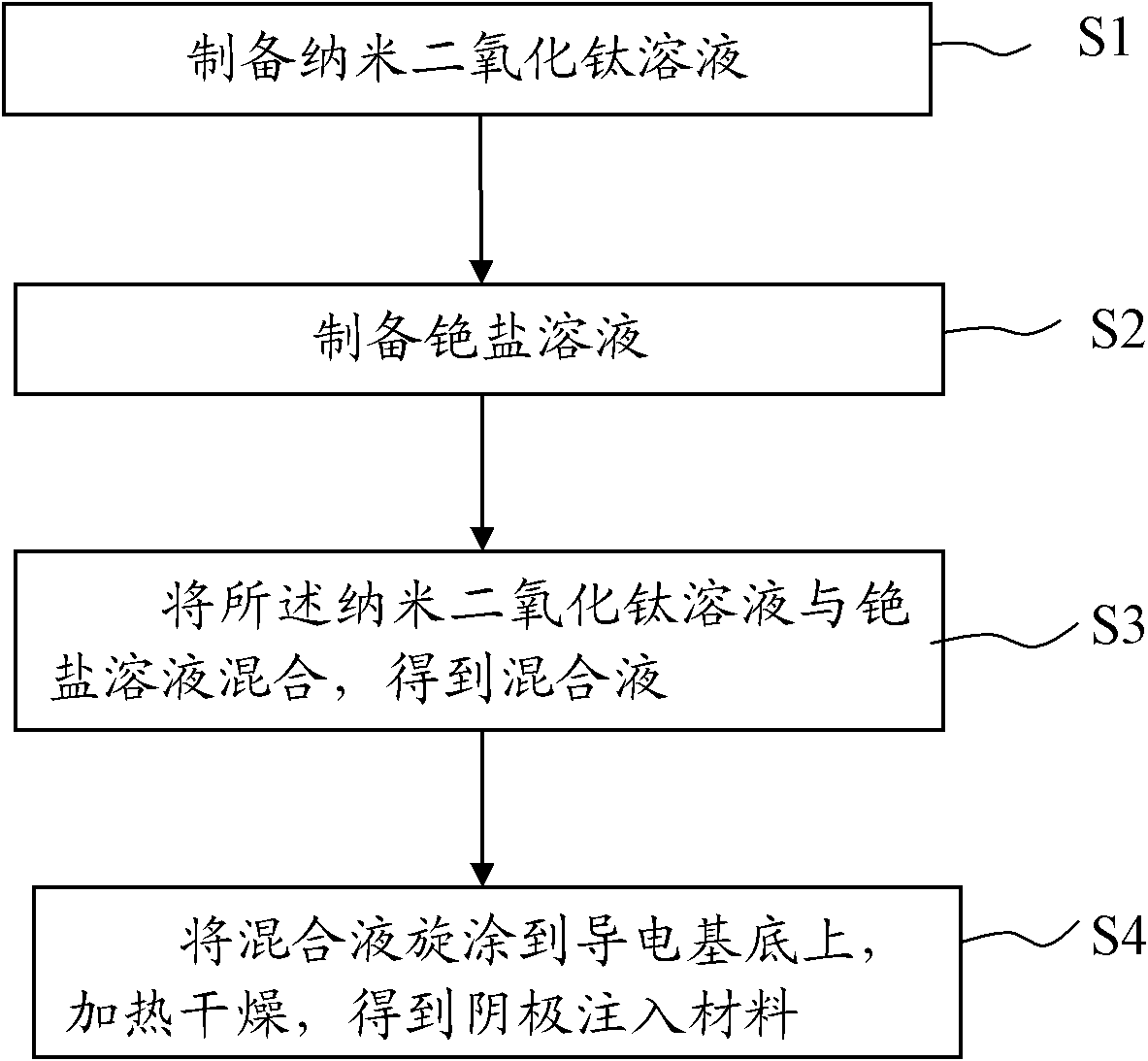

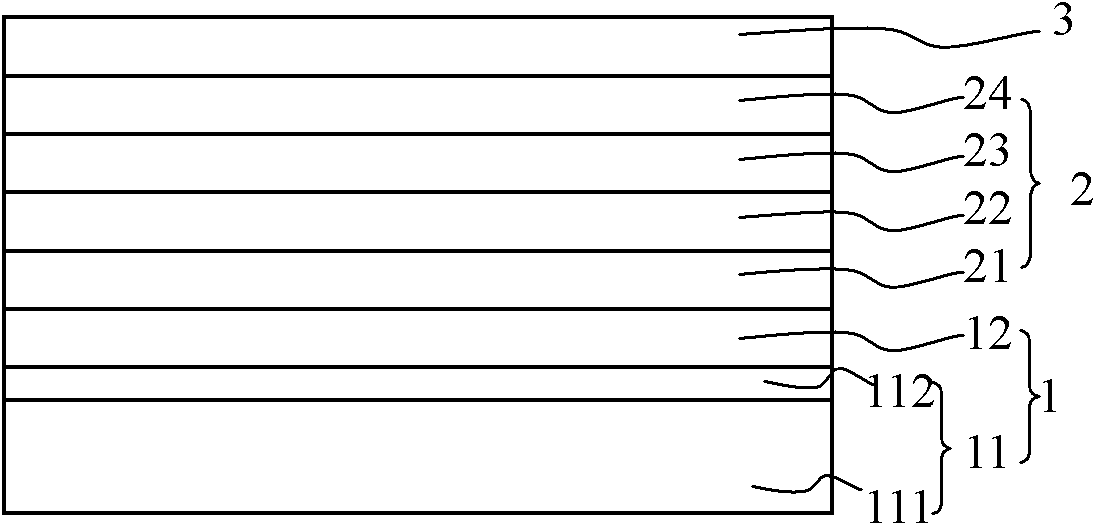

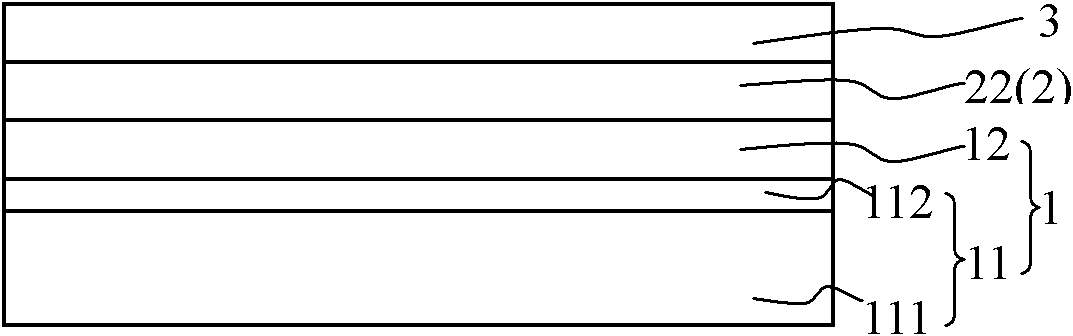

Cathode injection material, and manufacturing method and application thereof

ActiveCN102468446AAvoid leakage currentReduce lossSolid-state devicesSemiconductor/solid-state device manufacturingOrganic electroluminescenceChemistry

The invention discloses a cathode injection material, and a manufacturing method and an application thereof. The cathode injection material comprises nano-titanium dioxide and a cesium salt doped mutually. The manufacturing method comprises the following steps of: preparing a nano-titanium dioxide solution and a cesium salt solution respectively; mixing a nano-titanium dioxide solution dispersion system with the cesium salt solution to obtain a mixed solution; and coating the mixed solution onto a conductive substrate in a spinning way, and heating and drying to obtain the cathode injection material. The cathode injection material disclosed by the invention has the advantages of low cost, capability of effectively enhancing the input and the transmission of charges, increase in the LUMO energy level of a cathode when applied to an organic electroluminescent device, matching with the energy level of an organic electroluminescent structure, reduction in a potential barrier between the cathode injection material and the organic electroluminescent structure, more suitability for electron injection, increase in the electron injection efficiency, preferable increase in the light extraction capability of the organic electroluminescent device, high luminance and long service life. The manufacturing method of the cathode injection material has a simple procedure and high production efficiency.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

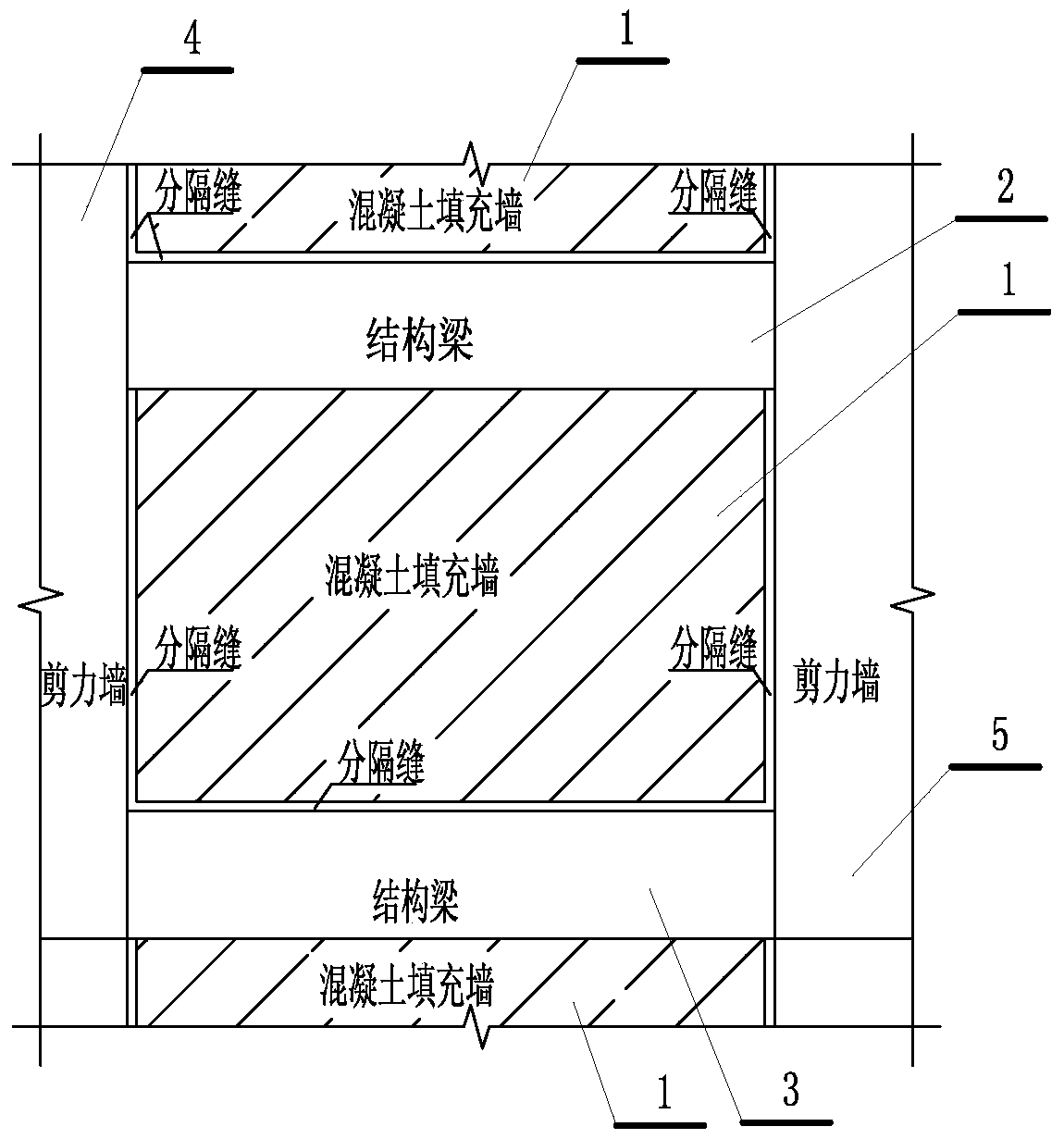

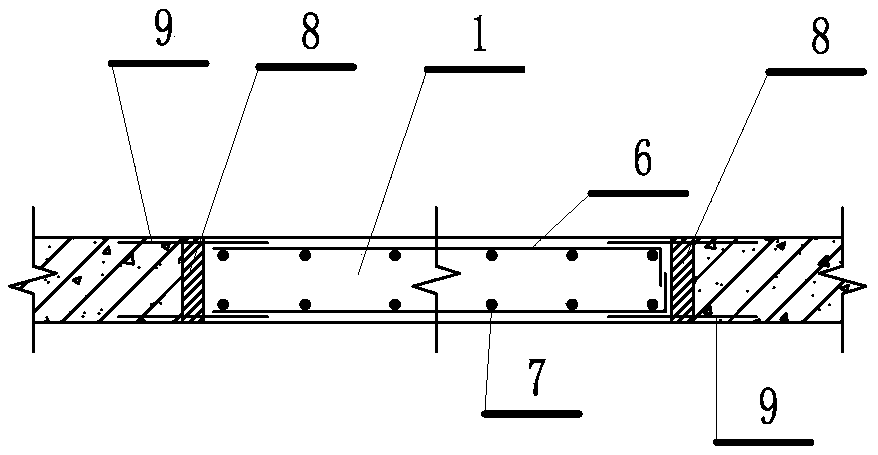

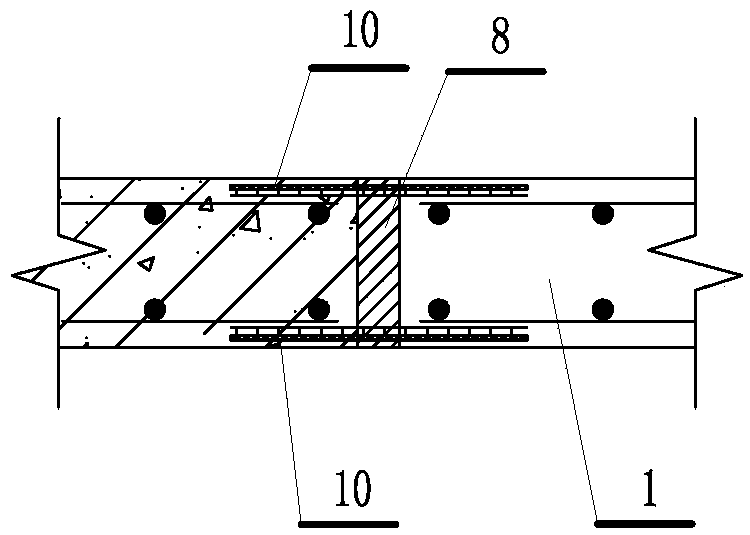

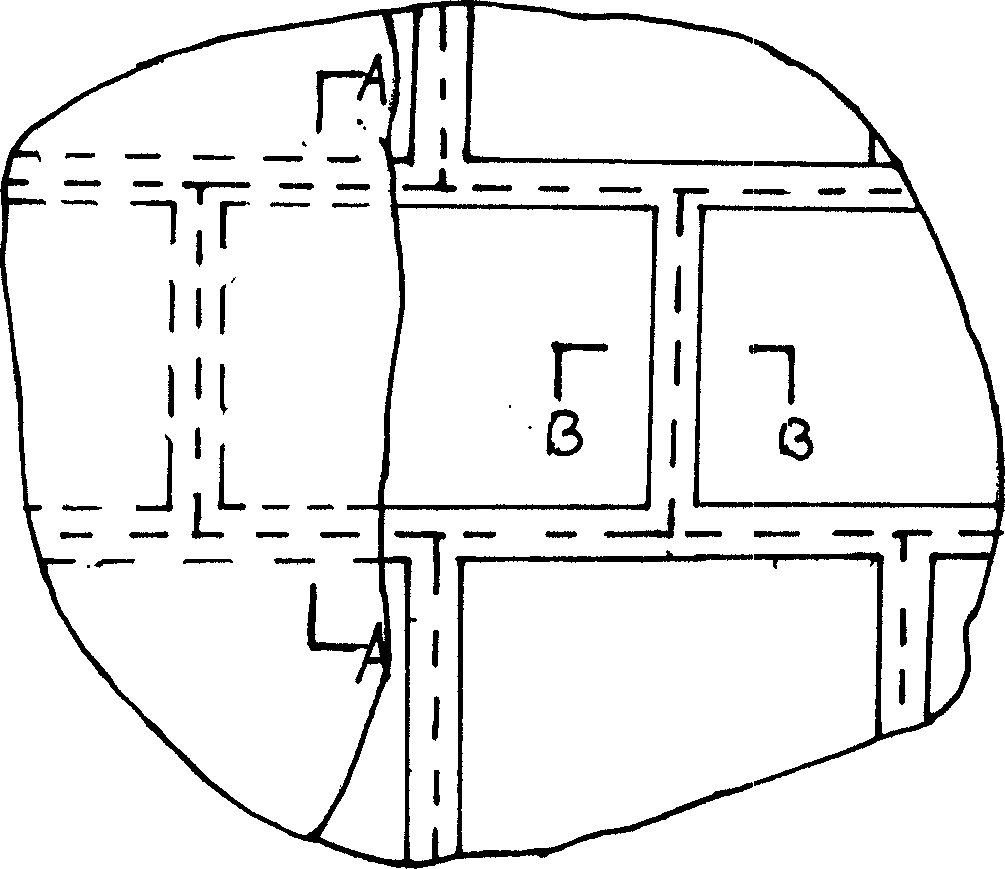

Concrete filled wall and cast-in-place structure synchronous construction structure and method

PendingCN110777983AAvoid slottingPrevent shrinkage crackingWallsBuilding material handlingStructural rigidityRebar

The invention discloses a concrete filled wall and cast-in-place structure synchronous construction structure and method. The synchronous construction structure comprises structure beams surrounding the upper and lower portion of a filled wall, and shear walls on the two sides. Rebars are distributed in the filled wall horizontally and vertically. Plastic cushion plates are arranged between the vertical two sides of the filled wall and the shear walls, as well as between the lower side of the filled wall and the structure beams on the lower side correspondingly so as to form separation seams.No separation seam is formed between the upper end and the filled wall and the structure beams on the upper side, and the upper end and the filled wall and the structure beams on the upper side are connected into a whole after concrete pouring. The filled wall and an original structure are separated through structure separation seam materials so as to achieve flexible connection, and structural rigidity is restored. Anchor bars of which the tops are connected with a concrete structure and the separation seam materials serve as damping devices, an anti-seismic effect is achieved, the anti-seismic mode is similar to that of a swing wall system, and certain advantages are more achieved in the aspect of anti-seismic ability compared with a masonry filled wall.

Owner:CHINA XINXING BAOXIN CONSTR CORP

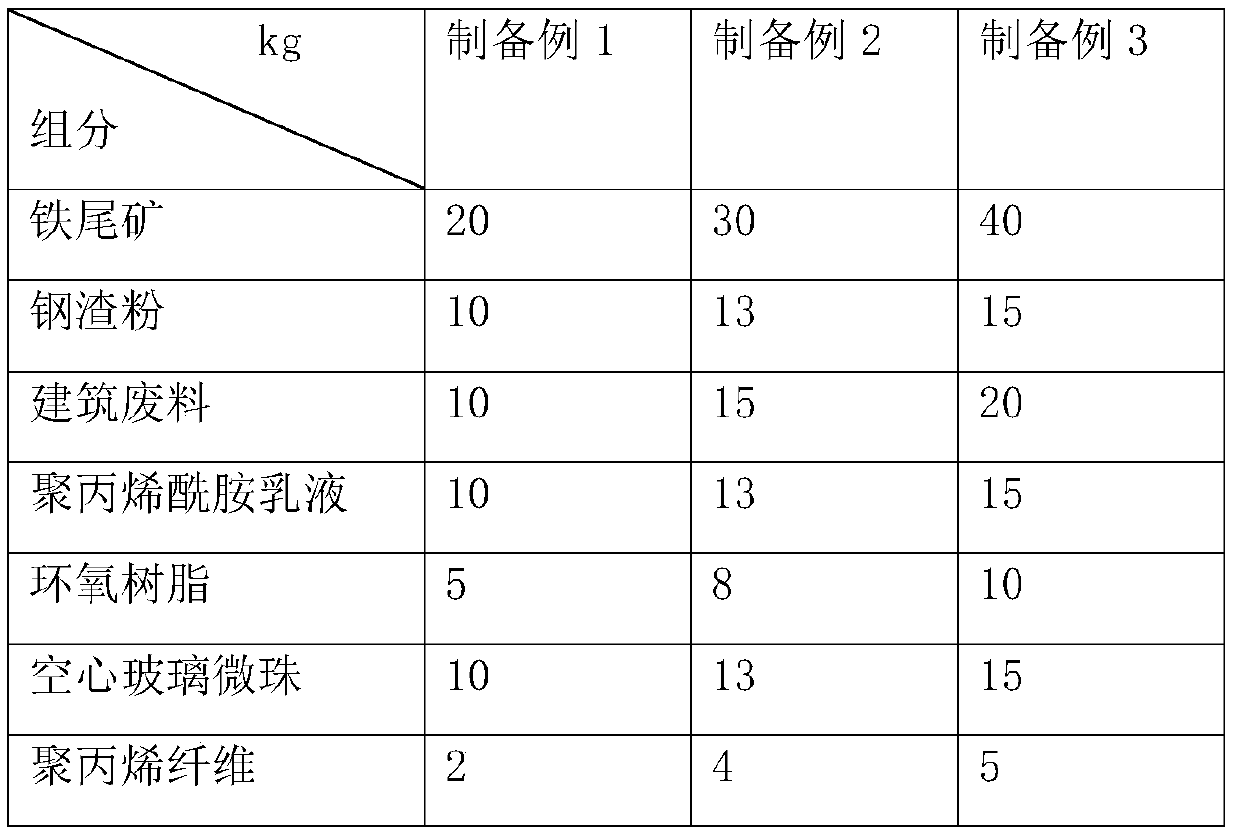

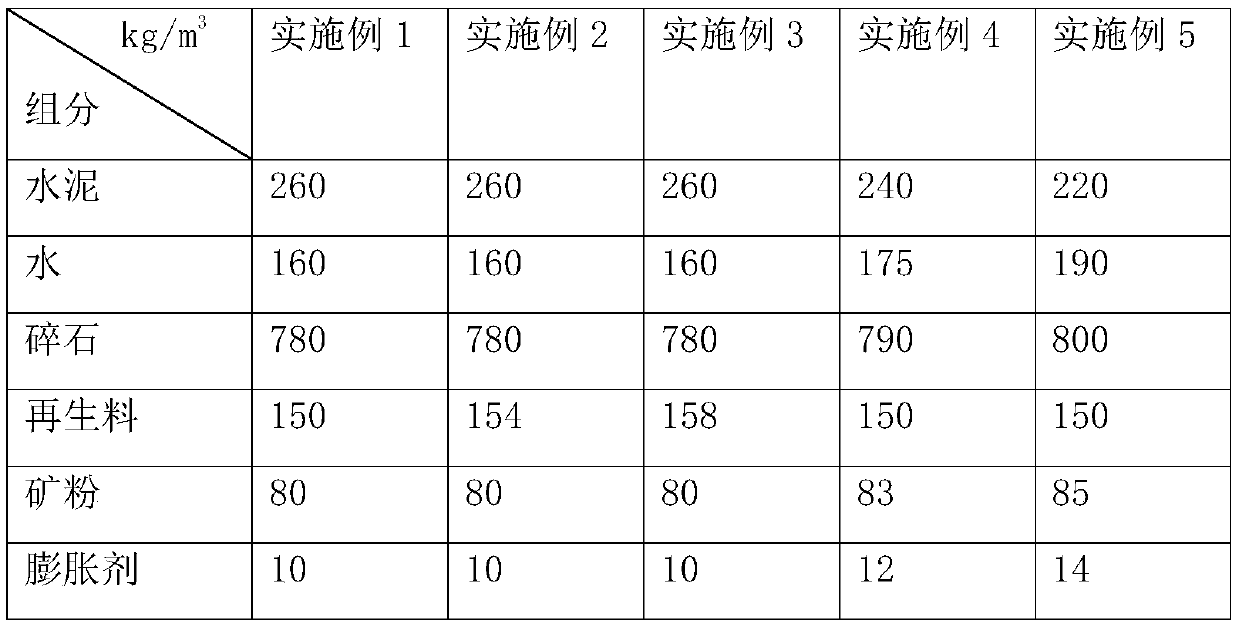

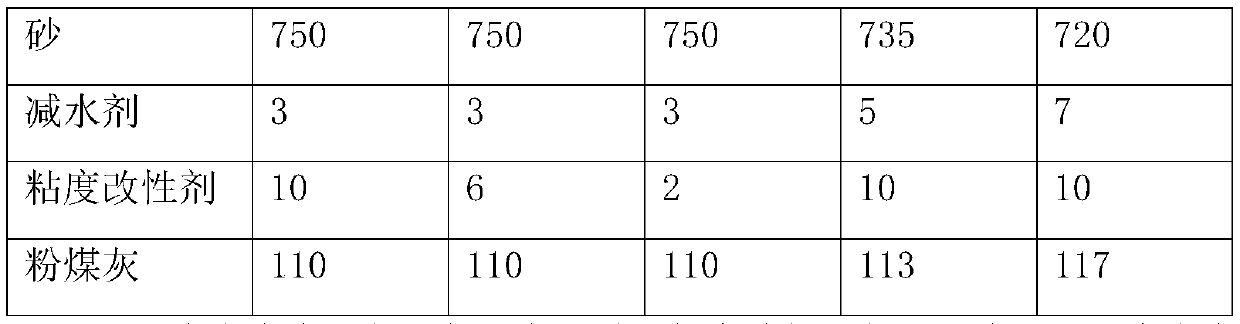

Recycled self-compacting concrete and preparation method thereof

The invention discloses recycled self-compacting concrete and a preparation method thereof. The recycled self-compacting concrete comprises the following components in parts by weight: 220 to 260 parts of cement, 160 to 190 parts of water, 780 to 800 parts of broken stone, 150 to 158 parts of a recycled material, 80 to 85 parts of mineral powder, 10 to 14 parts of an expanding agent, 720 to 750 parts of sand, 3 to 7 parts of a water reducer, 2 to 10 parts of a viscosity modifier and 110 to 117 parts of coal ash; and the recycled material comprises the following components in parts by weight: 20 to 40 parts of iron tailings, 10 to 20 parts of building waste and 20 to 30 parts of steel slag powder. The recycled self-compacting concrete disclosed by the invention has the advantages of high flowing property, filling property and segregation resistance, and the wastes of steel slag and iron tailings are utilized sufficiently.

Owner:西安新意达建筑制品有限公司

External insulation construction method for fiber polymer cement mortar composite polyphenylene plate

InactiveCN1594771AHigh degree of mechanizationReduce the impact of construction qualityHeat proofingFiberFiberglass mesh

The invention relates to an external insulation construction method for fiber polymer cement mortar composite polyphenylene plate, which pertains to an external insulation construction method for outer wall. The method comprises steps of: connecting the polystyrene plate with processed wall surface, then arranging a plane separation gap separately in terms of cutting groove on upper and lower portion of each layer of window; having downwards concave table at connection portion of the polystyrene plate, and coating fiber polymer concrete mortar on each two blocks of connection polystyrene plate, and clinging alkali-proof fiberglass mesh cloth strip on the fiber polymer concrete mortar; then spraying fiber polymer concrete mortar as protection layer. The advantages are that the mechanical degree is high, effect of artificial factor is greatly reduced, which not only resolve the problem of water-proof, but also avoids the constriction flaw. And the construction is simple, the quality is easy to handle. The invention is useful for energy saving complex wall system.

Owner:CHINA RAILWAY CONSTR BRIDGE ENG BUREAU GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com