Micro-expansion fiber reinforced concrete and preparation method thereof

A technology of fiber toughening and concrete, which is applied in the field of micro-expansion fiber toughening concrete and its preparation for the wet joints of steel-concrete composite beam bridge decks, and can solve the problems of reducing the durability of concrete structures, increasing the shrinkage of concrete itself, and shrinking High rate and other problems, to achieve low cost, low shrinkage, good bending toughness and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The preparation method for the above-mentioned micro-expansion fiber toughened concrete in the embodiment of the present invention comprises the following steps:

[0035] S1: Add the cementitious material and aggregates to the mixer, stir evenly for 30 seconds, and go to step S2;

[0036] S2: Sprinkle the imitation steel fiber into the mixer, mix the cementitious material, the aggregate and the imitation steel fiber together for 30 seconds, and go to step S3;

[0037]S3: Combine the water reducer and water to form a mixed liquid; add the mixed liquid and liquid toughening material to the mixer in turn, and stir the cementitious material, aggregate, imitation steel fiber, mixed liquid and toughening material together for 3 minutes to obtain a slump Concrete mixture with a thickness of 180-220mm.

Embodiment 1

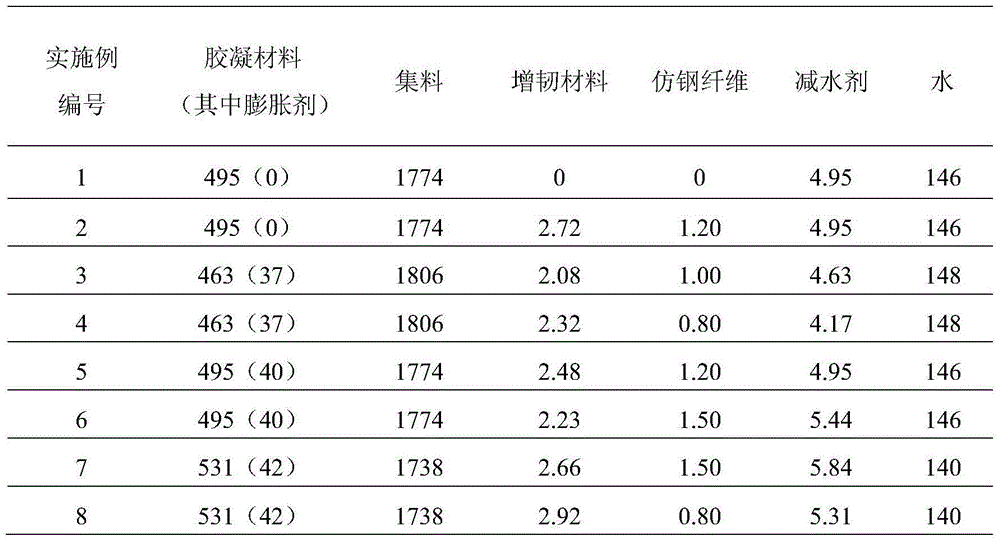

[0039] The mass ratio of each component in Examples 1 to 8 is shown in Table 1, wherein Example 1 is a comparative example without adding imitation steel fibers, toughening materials, and expansion agents; Example 2 is a comparison without adding expansion agents. Comparative examples, Examples 3-8 are micro-expansion fiber-toughened concrete used in wet joints of steel-concrete composite girder bridge decks in the present invention. In Examples 3 to 8, Example 5 is the theoretical mixing ratio of micro-expansion fiber toughened concrete applied to the wet joints and shear nail grooves of solid steel-concrete composite girder decks in cross-sea bridge engineering, and it is predicted that it can meet the requirements of 120 years. Design service life, Examples 1-4, 6-8 are test examples for research.

[0040] Table 1 Component mass ratio table of Examples 1-8

[0041]

[0042] The mass ratio of cement, fly ash, slag powder and expansion agent in the cementitious material i...

Embodiment 2

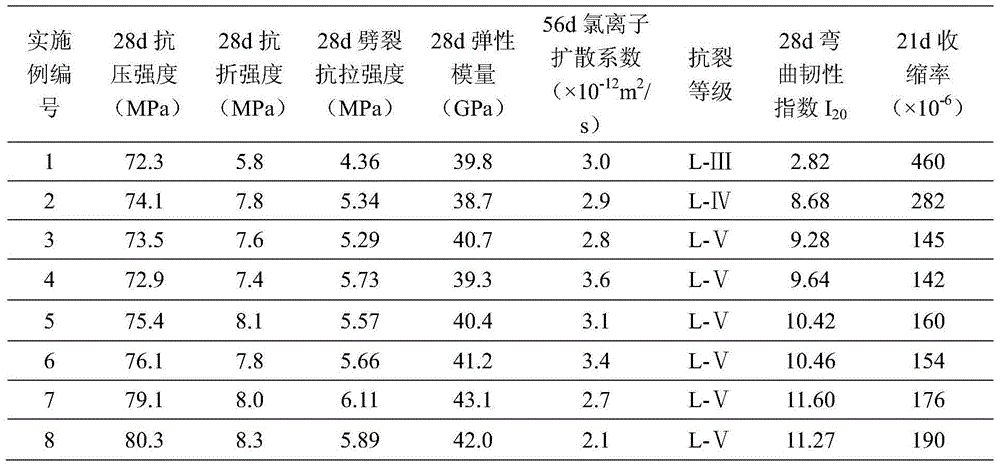

[0059] Example 2 Compared with Examples 3-8, the test data of 28d compressive strength, 28d flexural strength, 28d splitting tensile strength, 28d elastic modulus, and 56d chloride ion diffusion coefficient are almost the same, but the crack resistance grade, 28d The flexural toughness index and 21d shrinkage rate are lower than those of Examples 3-8, and the 21d shrinkage rate of Example 2 does not meet the 21d shrinkage rate of wet joint concrete of bridge engineering entity bridge deck -6 Require. Therefore, the micro-expansion fiber toughened concrete in Examples 3-8 has good fatigue resistance, high flexural tensile strength, good crack resistance and flexural toughness, and very small shrinkage.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com