Patents

Literature

42 results about "Flexural toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Crack-resisting mortar for insulation of modified rubber powder and preparation method thereof

ActiveCN102225856AHigh compressive strengthImprove flexural strengthSolid waste managementCellulosePolymer science

The invention provides crack-resisting mortar for insulation of a modified rubber powder and a preparation method thereof. The crack-resisting mortar for insulation comprises the following raw materials in parts by weight: 5-60 parts of modified rubber powder, 50-110 parts of cement, 10-50 parts of sand, 0.5-2 parts of polypropylene fiber, 0.5-3 parts of dispersible latex powder, 2-3 parts of quick lime, 0.1-1 part of cellulose ether and 0.01-0.03 part of air entraining agent. The preparation method comprises the following steps: preparing a modifier; preparing the modified rubber powder; carrying out air-drying for later use; and carrying out mix preparation so as to obtain the crack-resisting mortar for the insulation of the modified rubber powder. Compared with the crack-resisting mortar for the insulation of the unmodified rubber powder, the compression strength, rupture strength and flexural toughness of the crack-resisting mortar in the invention are improved under the same flowability condition, wherein the rupture strength is larger than 450kpa, the compression strength is larger than 700KPa, the bonding strength is more than 180KPa, linear shrinkage is less than 1%, and the softening coefficient is more than 0.9. The crack-resisting mortar in the invention has a huge effect in the building field and a wide market prospect.

Owner:CHINA XINXING BAOXIN CONSTR CORP

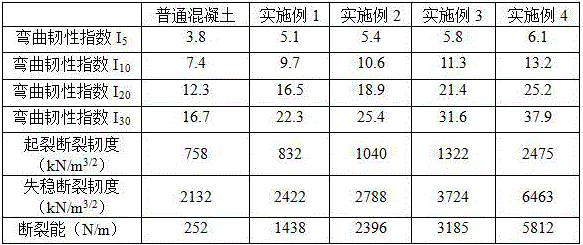

High-toughness hybrid fiber reinforced concrete and a preparing method thereof

The objective of the invention is to provide high-toughness hybrid fiber reinforced concrete and a preparing method thereof. Nanometer silica and hybrid fiber are added into the concrete. Flexural toughness and fracture toughness are significantly improved. The hybrid fiber reinforced concrete can be used for long-span and high-layer building structure projects having high toughness requirements.

Owner:ZHENGZHOU UNIV

Polypropylene fiber for cement reinforcement, molded cement made with the fiber, method of constructing concrete structure, and method of spray concreting

InactiveUS20060078729A1High indexImprove hydrophilicityFibre typesBuilding reinforcementsShotcretePolymer science

Polyolefin resin fibers for cement reinforcement which have hydrophilicity imparted thereto and show excellent adhesion to cement matrices. The fibers are ones which have been formed from a polypropylene resin by spinning and have undergone a surface modification treatment selected from oxidation treatment and fluorination treatment so that the fiber surface has an index of wetting of 38 dyn / cm or higher. The polypropylene resin fibers for cement reinforcement, when used in the application or placing of various mortars or concretes, give cement moldings improved in flexural toughness, such as flexural strength and impact strength.

Owner:HAGIHARA IND INC

Fiber-reinforced sludge curing agent

InactiveCN103880378ARetain toughnessGive full play to the role of micro-reinforcementSludge treatment by de-watering/drying/thickeningSlagShock resistance

The invention discloses a fiber-reinforced sludge curing agent, which mainly comprises 99%-99.9% by weight of curing material and 0.1%-1% by weight of fiber material, wherein the curing material comprises the following components in percentage by weight: 10-30% of mineral slag, 15%-45% of pulverized ash, 10%-25% of cement, 20%-30% of lime and 0.5%-5% of exciter. Aiming at the problems of the existing sludge curing material, such as high addition quantity, poor mechanical performance, poor tensile toughness and poor bending toughness, the sludge curing agent is reinforced by the fiber material, and therefore the comprehensive mechanical performances of the sludge curing soil, such as compressive strength, splitting tensile strength and toughness, as well as shock resistance property, can be effectively enhanced; moreover, the addition of fibers is small, the fiber-reinforced sludge curing agent is convenient to produce and wide in application range.

Owner:JIANGSU NATURE WAY TECH

Chitosan modified geopolymer cementing material

ActiveCN106746788AReduce fold ratioImprove flexural toughnessCement productionPolymer scienceGeopolymer

Owner:太原理工恒基岩土工程科技有限公司

PVA fiber reinforced cement-based composite material

InactiveCN105906261ALow costReduce cement consumptionSolid waste managementClimate change adaptationStress concentrationNatural resource

The invention discloses a PVA fiber reinforced cement-based composite material, which is composed of the following ingredients (by weight): 11.8-26.8 parts of cement, 32.2-47.2 parts of flyash, 20.8-21.5 parts of river sand, 0.53-0.54 part of a water reducing agent, 0.03 part of an antifoaming agent, 0.03 part of a thickening agent, 1.24-1.25 parts of fiber and 17.7-17.9 parts of water. By replacing cement in the PVA fiber reinforced cement-based composite material with high volume of flyash, wastes are changed into valuable things, cost is reduced, CO2 emission is minimized, and lots of natural resources and energy are saved. In addition, crack width and natural air shrinkage of the PVA fiber reinforced cement-based composite material are reduced, long-term durability of the structure is enhanced, stress concentration degree of crack tip is weakened, fiber crack-retarding mechanism is fully performed, and flexural toughness of the fiber reinforced cement-based composite material is enhanced.

Owner:BEIJING UNIV OF CIVIL ENG & ARCHITECTURE

Novel flexible composite shotcrete layer support material

The present invention relates to a novel flexible composite shotcrete layer support material which comprises the following components in parts by weight: 80-100 parts of cement, 80-120 parts of sands, 100-120 parts of stones, 60-100 parts of rubber particles, 40-60 parts of coal ash, 20-30 parts of hooked end steel fibers, 50-80 parts of water, 6-7 parts of a crosslinking agent, 5-8 parts of an additive, 2-10 parts of polyamic acid resin with a solid content of 10%-25% and 3-5 parts of a 1% silane coupler solution. The prepared shotcrete layer material is greatly improved in compression strength, rupture strength and flexural toughness. The novel flexible composite shotcrete layer support material can be applied to the field of support to surrounding rocks of complex rock layers with characteristics of high stress, soft rock, expansion, flowing deformation, fault structure fracture zones, mining influence and the like or other dynamic pressure tunnel as well as the field of underground engineering of tunnels, subways and the like.

Owner:SHANDONG UNIV

Bone cement compositions having fiber-reinforcement and/or increased flowability

The present invention relates in general to implantable compositions, and method for preparing same, containing a calcium salt-containing component, optionally demineralized bone, a plurality of discrete fibers, optionally a flow additive, and optionally continuous reinforcing fibers or an array of organized fibers in the form of mesh. Advantageously, the discrete fibers have a specific aspect ratio (length / diameter) from about 50:1 to about 1000:1. The addition of a small amount of discrete fibers and / or the continuous reinforcing fibers or fiber mesh can cause drastic increases in certain mechanical properties including flexural strength, flexural strength, flexural toughness, and / or screw pullout strength.

Owner:辛西斯有限责任公司

High-performance rubber concrete

InactiveCN102557539AAchieve regenerationImprove stress resistanceSolid waste managementPolymer sciencePolyvinyl alcohol

The invention relates to high-performance rubber concrete which is prepared by mixing 150-400 parts of concrete, 150-400 parts of rubber particles, 50-60 parts of calcium carbonate, 5-6 parts of crosslinking agent and 2-4 parts of polyvinyl alcohol, and stirring and polymerizing the mixture and polyamic acid resin and a nano-scale modified material at normal temperature, wherein the polyamic acid resin has solid content of 10-25%. The regeneration of waste rubber can be realized, the production process causes no pollution, and the production efficiency is high. The compression resisting strength, the rupture resisting strength and the flexural toughness of the produced concrete are greatly improved.

Owner:天津市宝坻区兴海盛橡胶加工厂

Road cement concrete rubber particle surface modifier

The invention discloses a rubber particle surface modifier for road cement concrete, which relates to a wasted rubber particle surface modifier used in road-use cement concrete. The mixture ratio of the modifier is as above: the modifier has wild material source, low price and convenient manufacture, which can carry out the modification treatment to the rubber particles in a wasted rubber particle processing plant or a concrete mixing location, the modified rubber particles can be directly packaged in a damp state or be properly dried and packaged to leave the factory. Compared with the unmodified rubber particle one, the cement concrete prepared by modified wasted rubber particles can increase the compressive strength by 20%, the breaking strength by 10%-30% and the flexural toughness by 30%-50% under the condition of the same fluidness, thereby having valuable economic and social benefit.

Owner:TONGJI UNIV

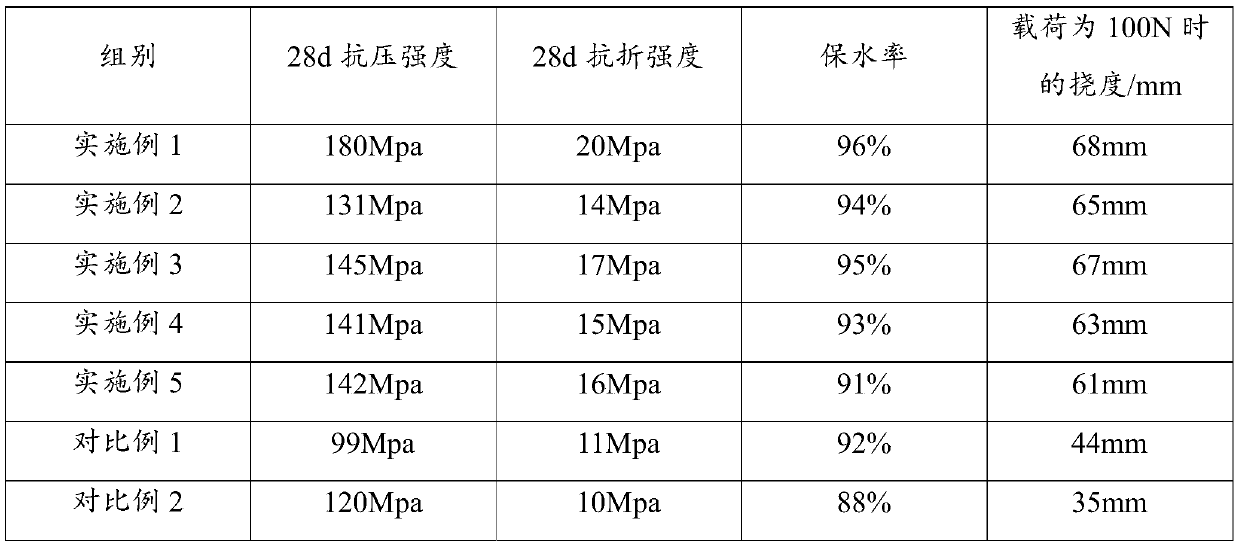

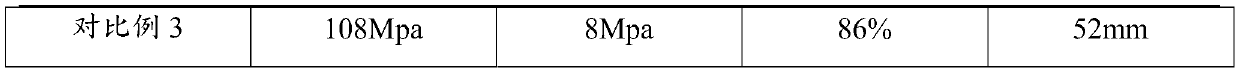

High-toughness and high-strength gypsum product and preparation method thereof

The invention discloses a high-toughness and high-strength gypsum product and a preparation method thereof. The high-toughness and high-strength gypsum product is prepared from the following components in parts by weight: 70-80 parts of gypsum powder, 15-20 parts of filler, 0.2-0.5 part of dispersing agent, 0.1-0.2 part of defoaming agent, 2-5 parts of dispersible latex powder, 5-10 parts of gypsum whisker and 1-5 parts of glass short fiber (or 0.1-0.5 part of chemical fiber short fiber). The high-toughness and high-strength gypsum product is high in strength: the 28d flexural strength is up to 20Mpa at most, and the 28d compressive strength is up to 180Mpa at most; and the surface hardness is up to 6H. The toughness is good: the maximum bending toughness is tested to be 68mm by adopting an MEW-40 wood universal testing machine. The technical problems that the traditional gypsum product is low in strength and poor in toughness are solved.

Owner:JINGMEN QIAN NIAN JIAN HEALTH CARE TECH

Crack-resisting mortar for insulation of modified rubber powder and preparation method thereof

ActiveCN102225856BHigh compressive strengthImprove flexural strengthSolid waste managementCelluloseLatex rubber

The invention provides crack-resisting mortar for insulation of a modified rubber powder and a preparation method thereof. The crack-resisting mortar for insulation comprises the following raw materials in parts by weight: 5-60 parts of modified rubber powder, 50-110 parts of cement, 10-50 parts of sand, 0.5-2 parts of polypropylene fiber, 0.5-3 parts of dispersible latex powder, 2-3 parts of quick lime, 0.1-1 part of cellulose ether and 0.01-0.03 part of air entraining agent. The preparation method comprises the following steps: preparing a modifier; preparing the modified rubber powder; carrying out air-drying for later use; and carrying out mix preparation so as to obtain the crack-resisting mortar for the insulation of the modified rubber powder. Compared with the crack-resisting mortar for the insulation of the unmodified rubber powder, the compression strength, rupture strength and flexural toughness of the crack-resisting mortar in the invention are improved under the same flowability condition, wherein the rupture strength is larger than 450kpa, the compression strength is larger than 700KPa, the bonding strength is more than 180KPa, linear shrinkage is less than 1%, and the softening coefficient is more than 0.9. The crack-resisting mortar in the invention has a huge effect in the building field and a wide market prospect.

Owner:CHINA XINXING BAOXIN CONSTR CORP

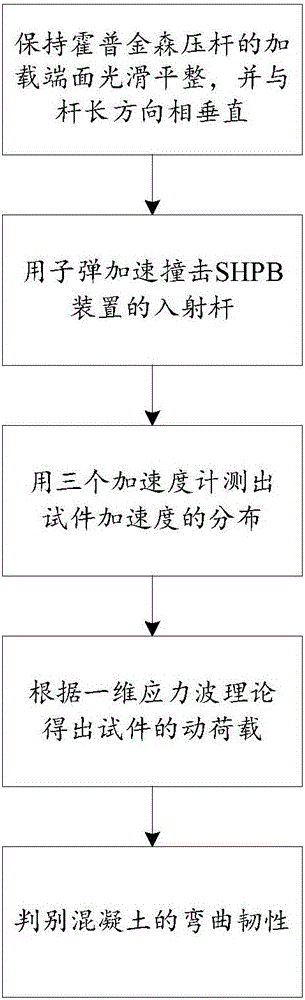

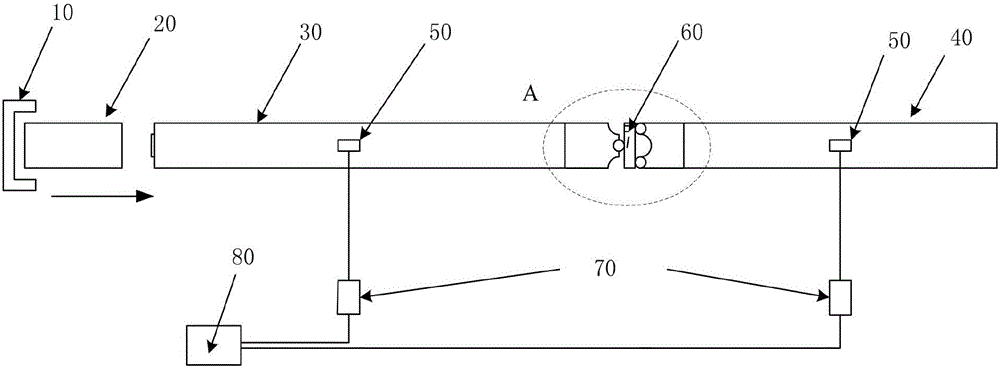

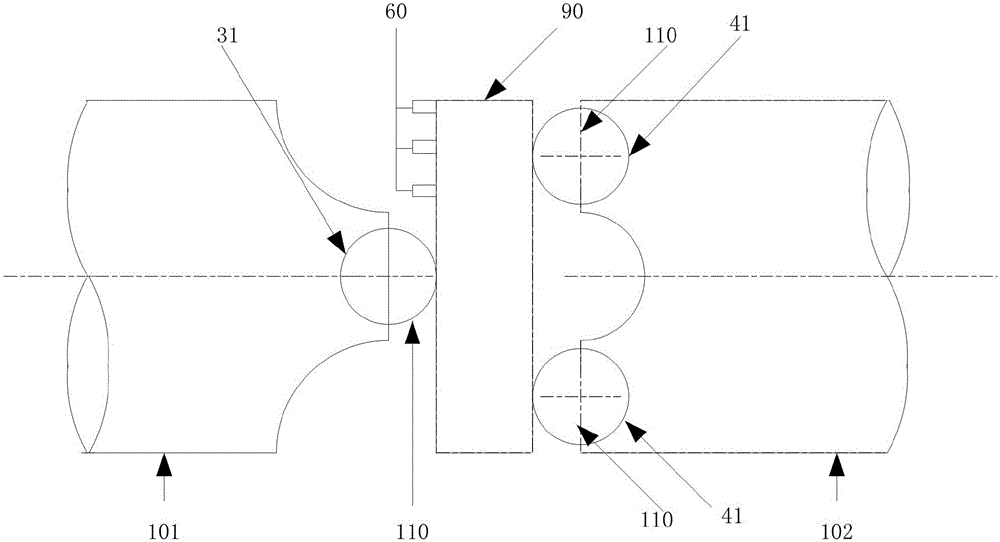

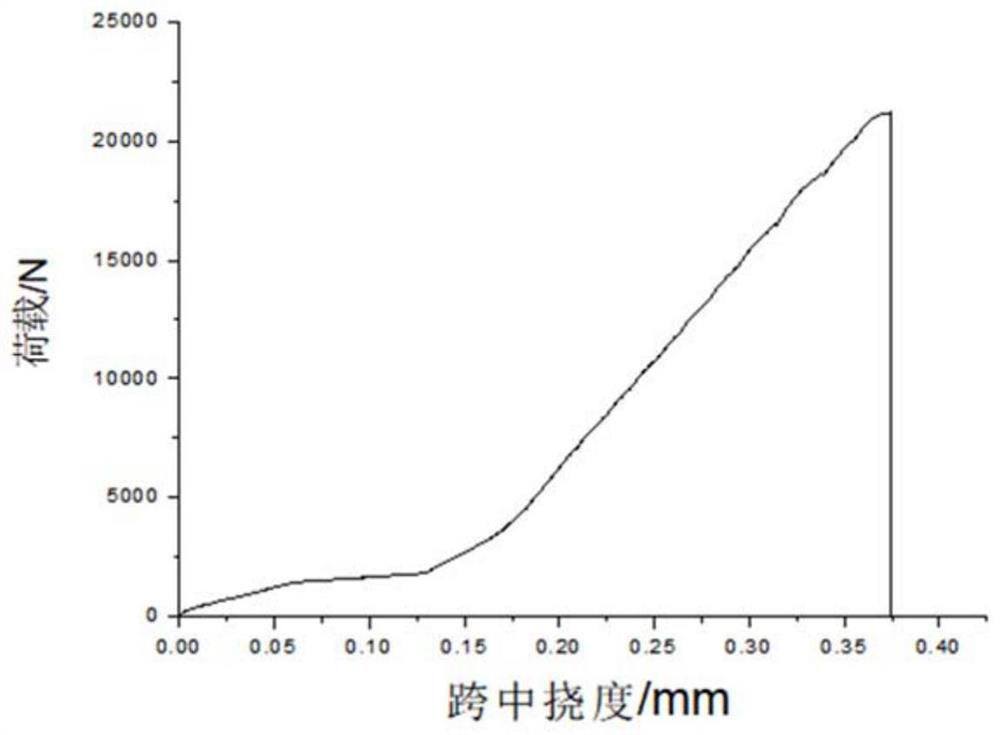

Testing method and device for flexural toughness of fiber reinforced concrete components

InactiveCN105043895AAddress resilienceSolve computing problemsMaterial strength using steady bending forcesAccelerometerFlexural toughness

The invention discloses a testing method and device for flexural toughness of fiber reinforced concrete components. The testing device for flexural toughness of fiber reinforced concrete components is formed based on a split Hopkinson pressure bar device for testing the flexural toughness of concrete samples. Firstly, a sample is dynamically loaded; a graph of an accelerometer is recorded. The testing method is characterized by also comprising the following steps: (1) replacing an inertial force distributed on the sample with a generalized inertia load acting in the middle of the sample; (2) according to a dynamic equilibrium equation, evaluating a real flexural load; (3) based on the one-dimensional stress wave theory, calculating a dynamic load of the concrete sample; and (4) according to the magnitude of energy absorbed by a fiber reinforced concrete component, determining the flexural toughness of the fiber reinforced concrete component. The testing method and the testing device disclosed by the invention are easy to operate and high in loading speed, and can effectively test the toughness of the fiber reinforced concrete component at high strain rate.

Owner:POWERCHINA XIBEI ENG +1

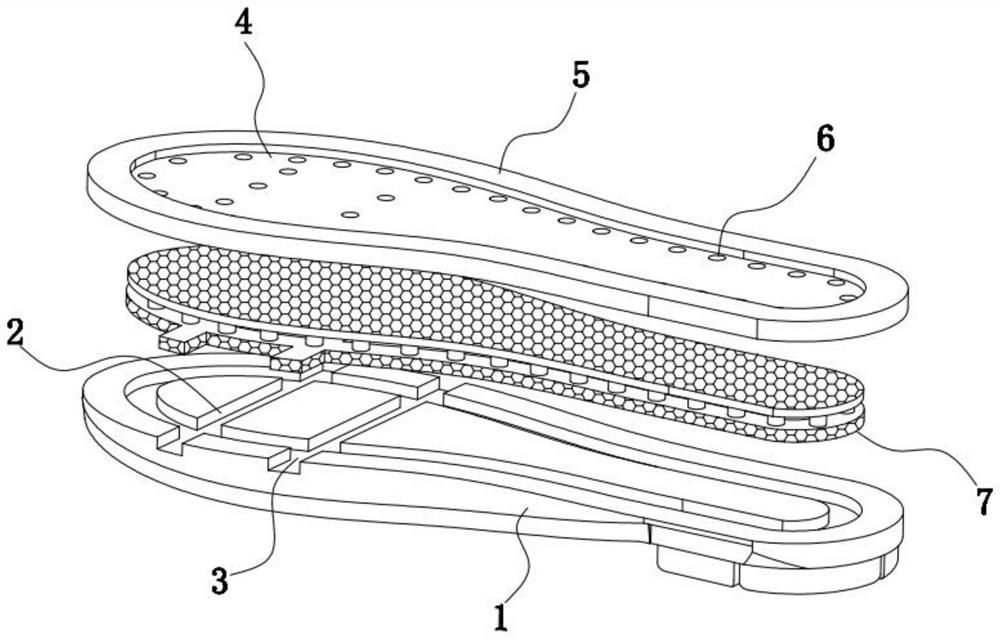

Preparation method of anti-puncture breathable sole and safety shoe with sole

InactiveCN112568551APlay the role of secondary protectionStrong puncture resistanceSolesDomestic footwearFiberAcrylic resin

The invention discloses a preparation method of an anti-puncture breathable sole, and belongs to the technical field of labor protection articles. The preparation method is characterized in that: composite fibers are firstly formed, carbon nanotubes are contained in the composite fibers, the carbon nanotubes are evenly distributed in a net-shaped structure formed by acrylic resin under the actionof ultrasonic dispersion, and therefore the prepared composite fibers are high in tensile strength and good in bending toughness; and after molding, the sole has an extremely strong anti-puncture effect, a honeycomb foaming body integrally molded by foaming is arranged between the outsole and the midsole, and the honeycomb foaming body is exposed on the surface of the midsole and the side surfaceof the outsole, so that after the safety shoe is manufactured, air in the shoe can be ventilated and dissipated through the honeycomb foaming body, and when the midsole is subjected to the action force of stepping, the honeycomb foaming body can improve the wearing flexibility of the sole, and meanwhile, the puncture resistance is not influenced.

Owner:泉州朗盟鞋业有限公司

High-toughness bridge deck pavement fibre concrete and preparation method thereof

The invention discloses high-toughness bridge deck pavement fibre concrete and a preparation method thereof. The high-toughness bridge deck pavement fibre concrete is prepared from the following components in parts by weight: 470 to 490 parts of cement, 800 to 820 parts of sand, 535 to 555 parts of rough stones, 350 to 370 parts of fine stones, 4.7 to 6.7 parts of imitation steel fibres, 1.5 to 3.5 parts of a polycarboxylate superplasticizer and 155 to 175 parts of water. The high-toughness bridge deck pavement fibre concrete has the advantages that the performance is excellent; the flexural toughness index I5 of the high-toughness bridge deck pavement fibre concrete is 2.7 times that of plain concrete; the fatigue strength is improved by 7.2 percent compared with that of the plain concrete; the splitting tensile strength is improved by 16.6 percent; the compressive strength of the concrete is not affected. The durability is improved; the high-toughness bridge deck pavement fibre concrete is particularly suitable for a concrete structure, which is exposed in natural environment for a long time and is greatly influenced by the environment, such as a bridge deck.

Owner:北京新桥技术发展有限公司 +2

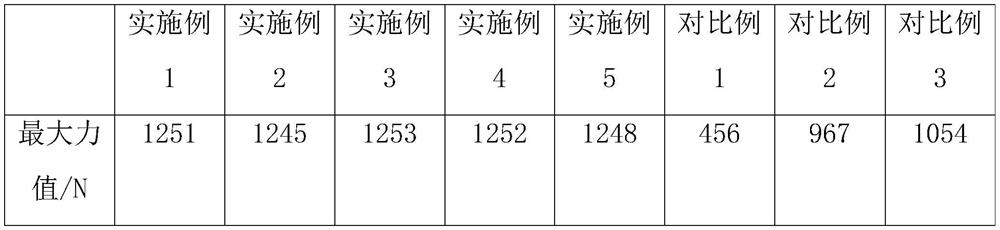

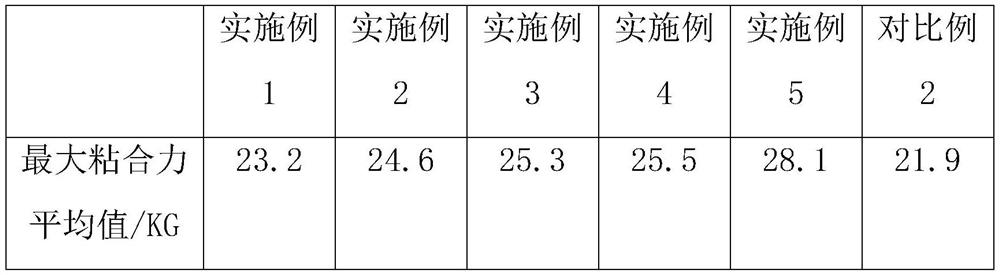

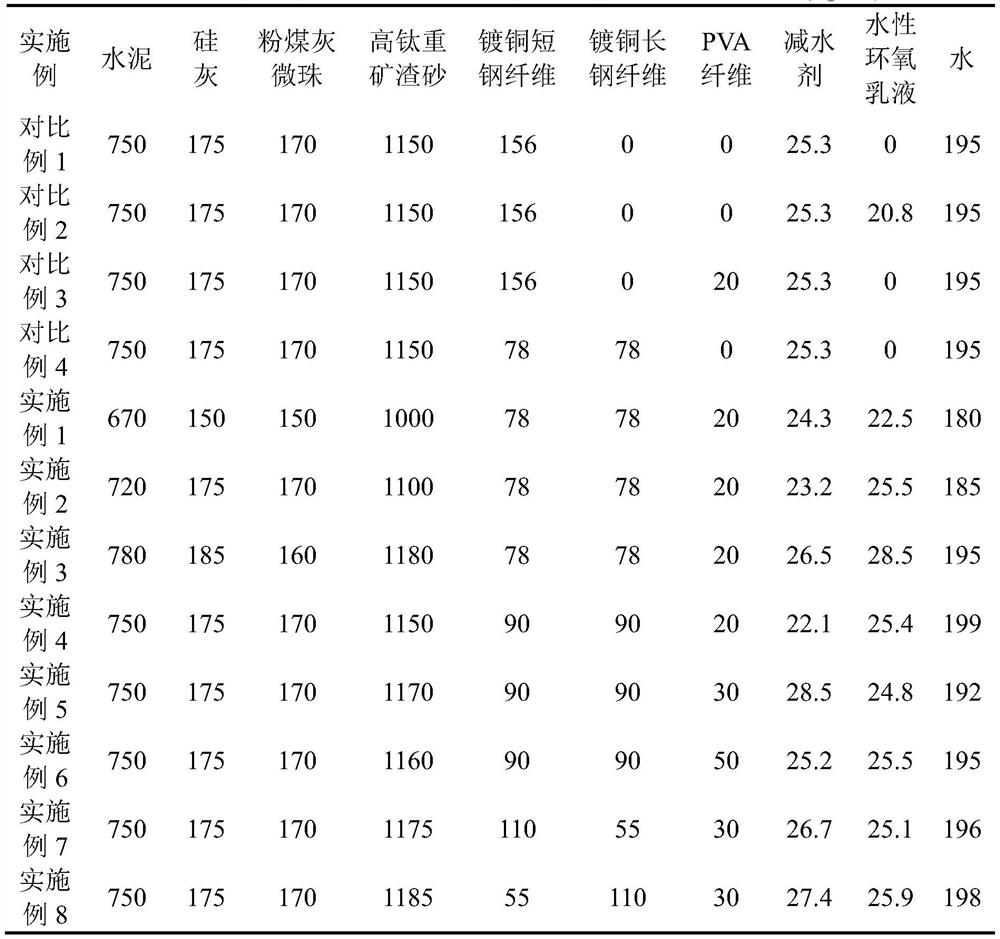

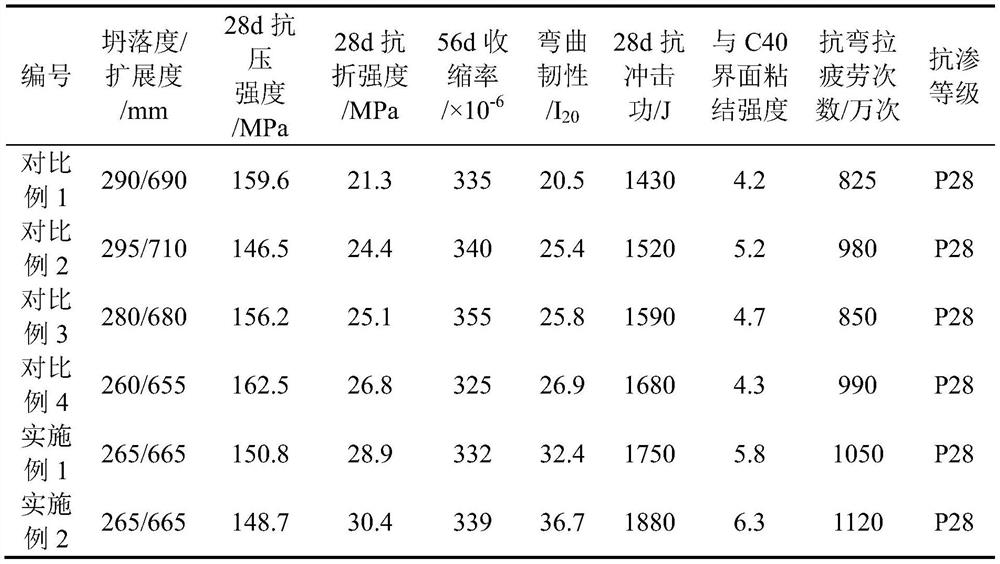

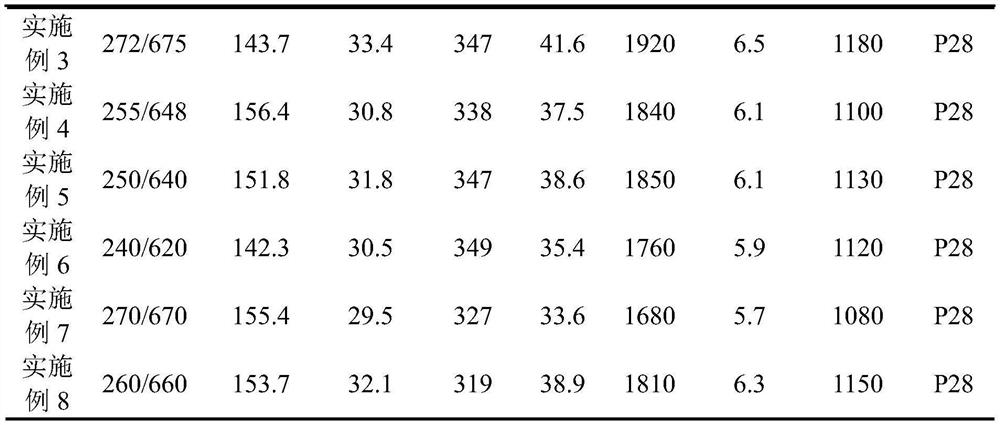

A kind of ultra-high performance concrete in the transition zone of expansion joints and its preparation method

The invention discloses an ultra-high performance concrete for an expansion joint transition area. The ultra-high performance concrete is prepared from the following main raw materials: cement, fly ash microbeads, silica fume, high-titanium heavy slag sand, organic-inorganic hybrid fiber, a waterborne epoxy emulsion, a water reducing agent and water. According to the invention, the high-titanium heavy slag sand is used as aggregate, the internal curing and pin effects of the aggregate are utilized to improve the volume stability, anti-permeability and cracking resistance, and mechanical properties of the concrete; an organic-inorganic fiber composite toughening technology is adopted to enhance the bending toughness and impact resistance; the water reducing agent and fly ash microbeads areadded to improve the working performance and compactness; and the obtained ultra-high performance concrete has the advantages of high flow state, low shrinkage, high toughness, high adhesion, high impact performance, fatigue resistance and the like, can fundamentally solve the problems of repeated repairing, repeated damage and the like of concrete in expansion joint transition areas, and has important practical application value.

Owner:WUHAN UNIV OF TECH

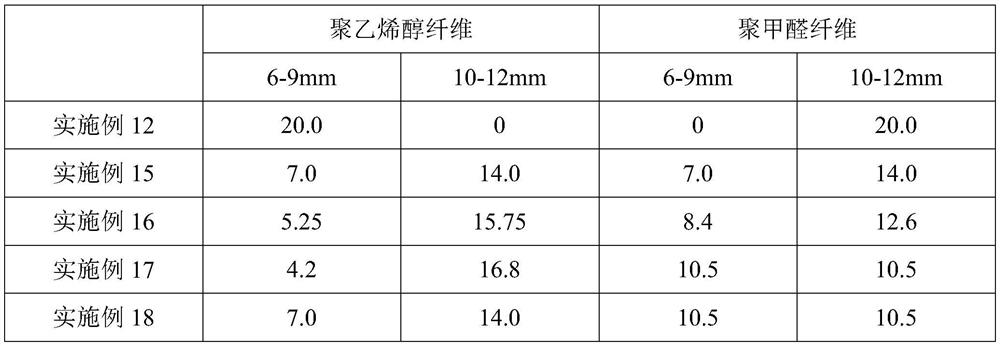

High-ductility cement-based composite material and preparation method thereof

ActiveCN113754382AHigh strengthImprove toughnessFibre typesUltrasonic/sonic fibre treatmentCelluloseAggregate (composite)

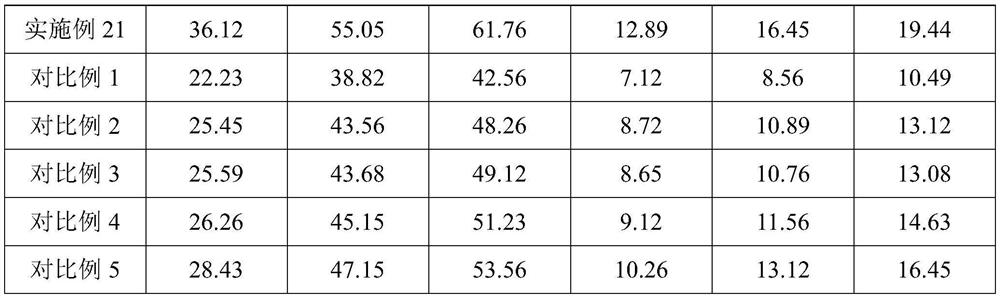

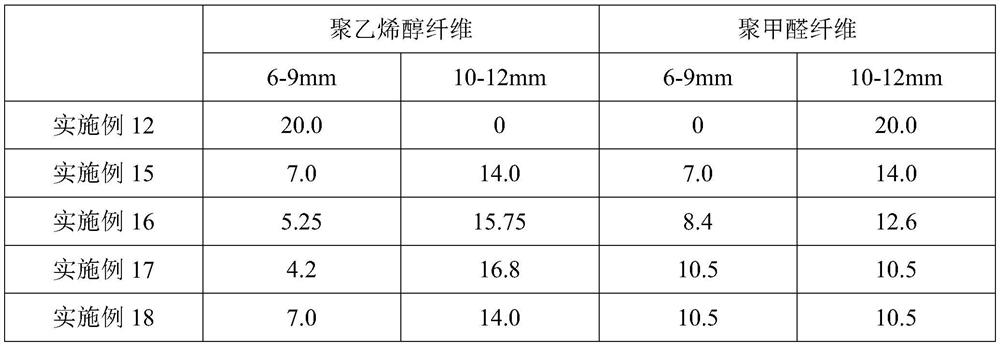

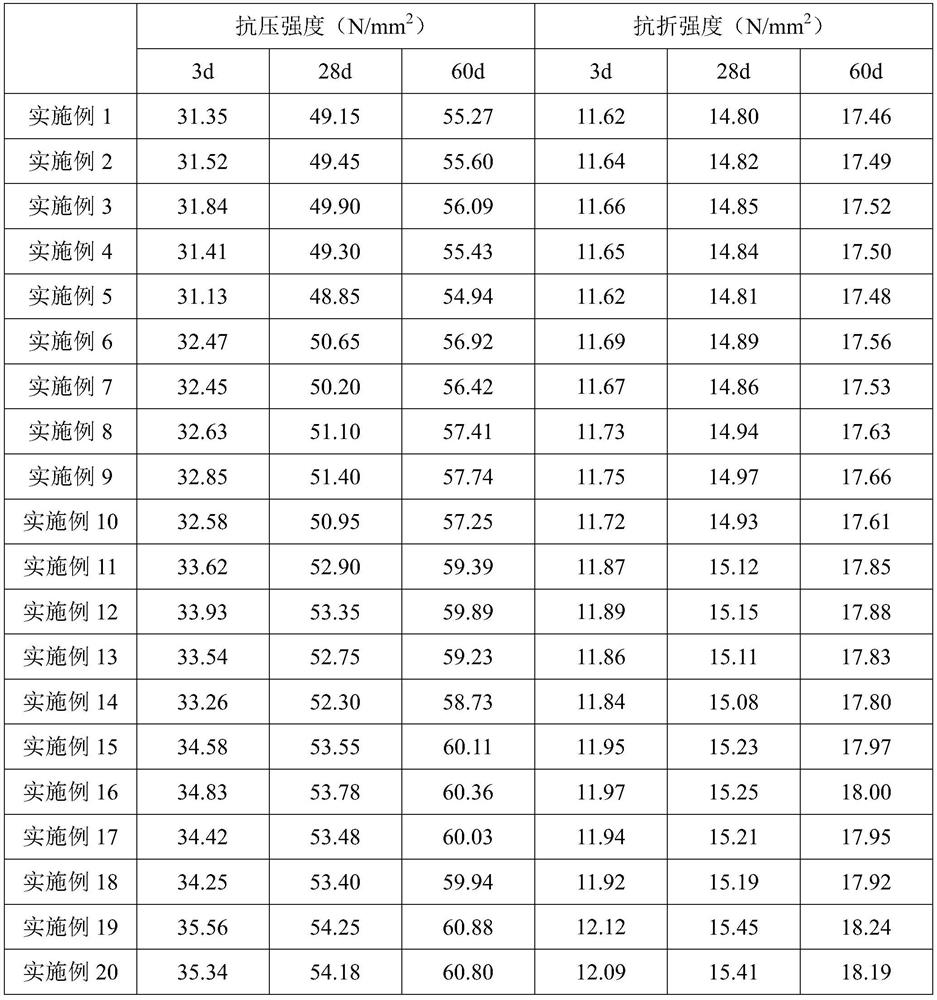

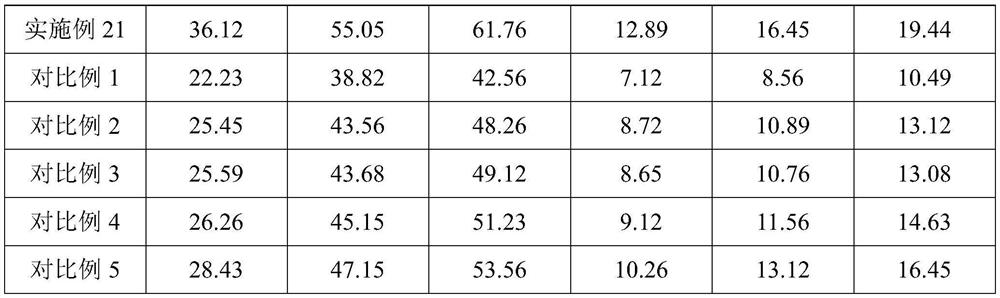

The invention relates to the technical field of building materials, and particularly discloses a high-ductility cement-based composite material and a preparation method thereof. The high-ductility cement-based composite material is prepared from the following raw materials in parts by weight: 200 to 450 parts of cement, 100 to 350 parts of fly ash, 100 to 350 parts of mineral powder, 100 to 450 parts of aggregate, 20 to 45 parts of silica fume, 5 to 25 parts of a water reducing agent, 1 to 6 parts of a de-foaming agent, 0.1 to 0.8 part of cellulose ether, 0.5 to 6 parts of a spraying regulator, 5 to 40 parts of polyvinyl alcohol fiber and 1000 to 3000 parts of water, wherein the spraying regulator comprises magnesium aluminum silicate and starch ether in a weight ratio of (2-6):1. The 60d compressive strength of the composite material reaches 61.76 N / mm<2>, the breaking strength reaches 19.44 N / mm<2>, the bending strength reaches 15.10 N / mm<2>, the bending toughness reaches 138.15 KJ / m<3>, and the strength and toughness of the composite material are good.

Owner:河北拓创远威科技有限公司

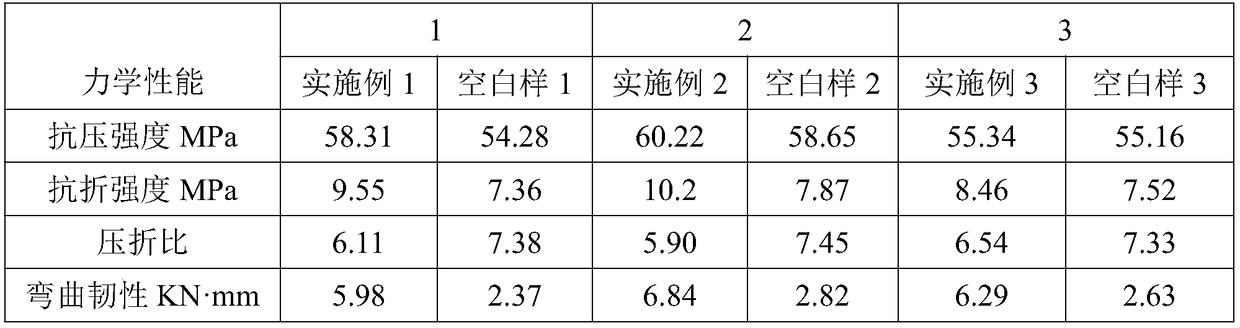

Grouting material for energy-consuming node of prefabricated part

The invention discloses a grouting material for an energy-consuming node of a prefabricated part. The material has the expansion degree of 180-300mm, the compressive strength of 30-80MPa, the breaking strength of 12-17MPa, the flexural toughness of 9-24KN.mm and the ductility of 0.5-0.7%. The grouting material is composed of the following components in parts by weight: 100 parts of a cementing material A, 67-400 parts of a cementing material B, 50-150 parts of a fine aggregate A, 0-36 parts of a fine aggregate B, 33-150 parts of water, 0.4-1.9 parts of a plasticity regulator and 3.3-10.4 parts of synthetic fibers. The material disclosed by the invention makes up the defect that an existing grouting material is a fragile material; the material has good ductility, thereby having a good energy-consuming effect; and meanwhile, the material is stable in all the performances and excellent in concrete interface bonding property, and interface shear strength is not lower than 8MPa.

Owner:SOUTHEAST UNIV

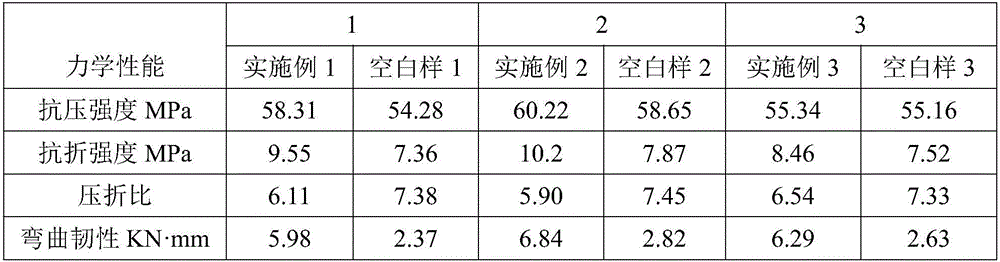

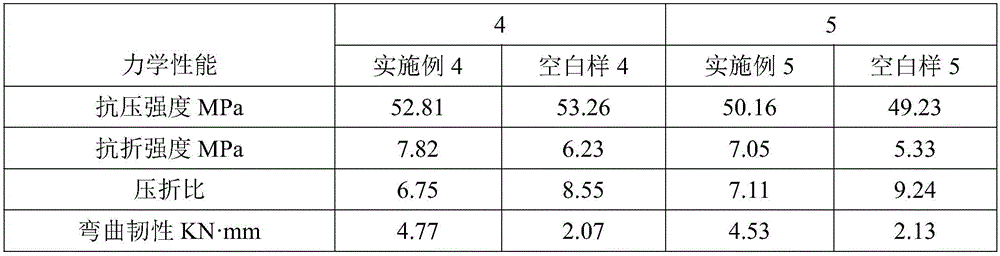

A kind of chitosan-modified polymer gelling material

The invention discloses a chitosan modified geopolymer cementing material. Chitosan is added into an alkali excitant to be sufficiently stirred and dissolved to obtain mixed solution; then the mixed solution is gradually added into a salic solid material to be stirred and uniformly mixed; the obtained product is injected into a die to perform a reaction, and after demoulding, maintenance is carried out to obtain the chitosan modified geopolymer cementing material. According to the chitosan modified geopolymer cementing material disclosed by the invention, the salic solid material is used as a main raw material; excitation is carried out by the alkali excitant; chitosan is used as a main toughening agent; a type, a mixing amount and a mixing mode of each raw material and a modulus and an alkali equivalent weight of the alkali excitant when the chitosan is used for carrying out toughening modification are determined; the system has excellent mechanical performance in a normal-temperature maintenance environment; a ratio of compressive strength of the material is obviously reduced and flexural toughness of the material can be obviously improved; as one type of cementing material, geopolymer can be applied to a concrete component with a high requirement for flexural toughness.

Owner:太原理工恒基岩土工程科技有限公司

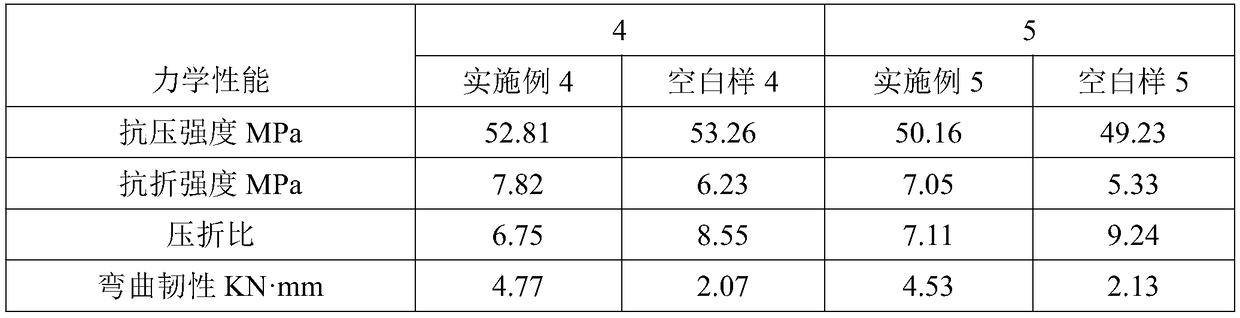

Internal reinforced type composite pipe

The invention discloses an internal reinforced type composite pipe which comprises a tubular outer layer and a tubular inner layer, wherein a middle layer is arranged between the outer layer and the inner layer, and is of a meshed structure formed by weaving chemical fibers; and a reinforcing layer consisting of a nylon wire spiral structure is embedded into the middle layer. The internal reinforced type composite pipe disclosed by the invention has the advantages that the reinforcing layer consisting of the nylon wire spiral structure is embedded into the middle layer, so that on the one hand, the composite pipe can be bent at a smaller arc radius and is higher in toughness, and laying of the pipe is greatly facilitated; and on the other hand, the pressure resistance and the durability of the composite pipe are further improved, and the composite pipe is longer in service life and high in practicability.

Owner:JIANGSU ASOE NEW MATERIAL TECH

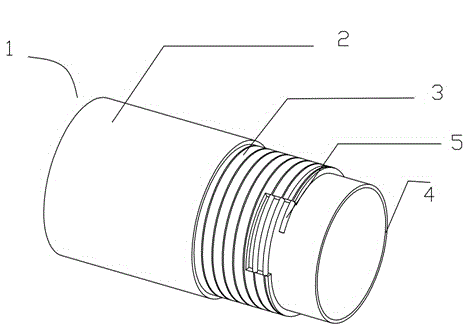

Preparation method of composite rare earth oxide reinforced molybdenum alloy piercing mandrel

ActiveCN104511591AHigh hardnessImprove toughnessTurbinesOther manufacturing equipments/toolsZirconium hydrideTitanium zirconium

The invention discloses a preparation method of a composite rare earth oxide reinforced molybdenum alloy piercing mandrel. The method includes the steps: firstly, uniformly mixing carbon powder, titanium hydride powder, zirconium hydride powder and rare earth oxide powder in a three-dimensional mixer to obtain doped powder, and then uniformly mixing the doped powder and molybdenum powder to obtain mixed powder raw materials; secondly, pressing the mixed powder raw materials to form piercing mandrel blanks; thirdly, finishing the piercing mandrel blanks to remove redundant piercing mandrel blanks; fourthly, sintering the finished piercing mandrel blanks, and cooling the sintered the piercing mandrel blanks to reach indoor temperature to obtain the composite rare earth oxide reinforced molybdenum alloy piercing mandrel. Composite rare earth oxide is added based on a TZM (titanium zirconium molybdenum) alloy, and the molybdenum alloy piercing mandrel with fine high-temperature hardness and flexural toughness is prepared by the aid of technological processes such as mixing, pressing, finishing and sintering and can stably adapt to high-temperature, high-pressure, splat cooling and quick heating working environments.

Owner:JINDUICHENG MOLYBDENUM CO LTD

A kind of gypsum base material imitation wood board and wood square, its preparation method and composite gypsum board

The invention discloses a gypsum base material imitation wood board and a wood square, a preparation method thereof and a composite gypsum board. The gypsum base material imitates wood planks and wooden squares, and the raw materials, in parts by weight, include: 80-120 parts of gypsum powder, 5-10 parts of silica sol, 2-10 parts of latex powder, 1-3 parts of chopped glass fiber, wood 0.5-1 part of fiber, 0.1-0.4 part of dispersant and / or water reducing agent, 0.1-0.3 part of crystallizing agent, 0.2-0.5 part of foaming agent and 45-70 parts of water. The gypsum products provided by the invention all have the advantages of low density and high strength, and have obvious effect of imitating wood. At the same time, according to different application occasions, products with different densities, flexural and compressive strengths, hardness and bending toughness can be produced.

Owner:JINGMEN QIAN NIAN JIAN HEALTH CARE TECH

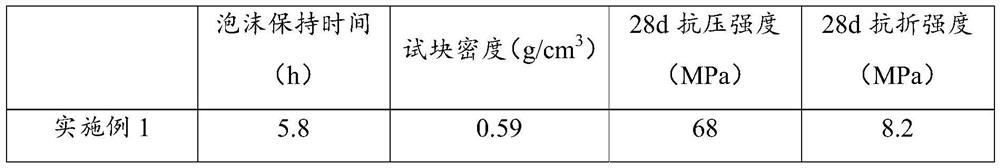

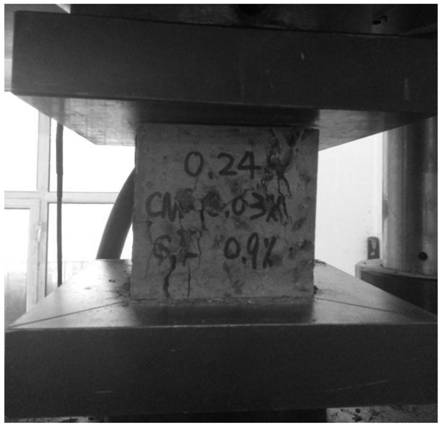

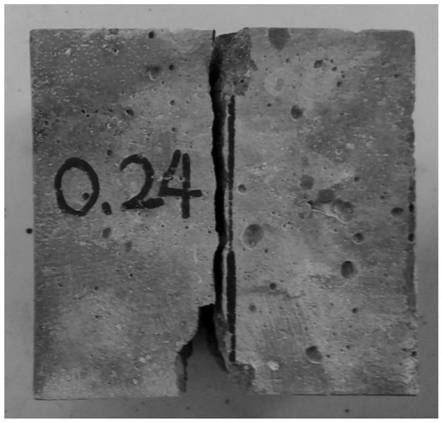

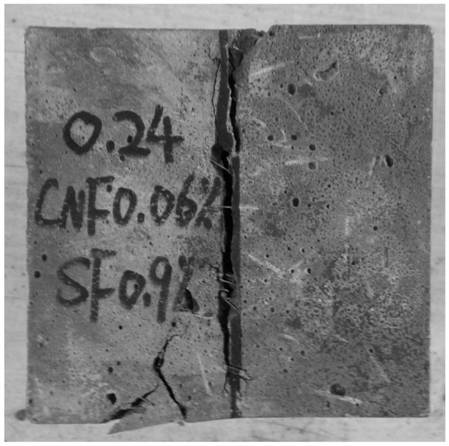

A hybrid fiber reinforced toughened high-strength self-compacting concrete and its preparation method

The invention relates to a hybrid fiber-reinforced toughened high-strength self-compacting concrete and a preparation method thereof. The invention belongs to the technical field of concrete, and solves the disadvantage that the conventionally prepared self-compacting concrete cannot improve the basic mechanical properties of the concrete while improving its bending toughness. The concrete is mixed with nano-carbon fiber and copper-plated micro-wire steel fiber, and the compression resistance, splitting, flexural strength and bending toughness are all significantly improved, and can be applied to over-dense reinforcement, thin-walled, Complex shapes and other structures. The preparation method is to weigh cement, fly ash, silica fume and copper-plated microwire steel fiber by weight and put them into the mixed aggregate, mix evenly, and mix nano-carbon fiber and polycarboxylate superplasticizer with a ratio of 1:2 The mass ratio is added to an appropriate amount of water, and the nano-carbon fiber mixture is obtained by ultrasonic dispersion; finally, the remaining water, polycarboxylate high-efficiency water reducer and nano-carbon fiber mixture are put into the dry material, and stirred evenly, that is, nano-carbon fiber and copper-plated microfiber Wire-steel fiber hybrid fiber-reinforced concrete.

Owner:NORTHEAST FORESTRY UNIVERSITY

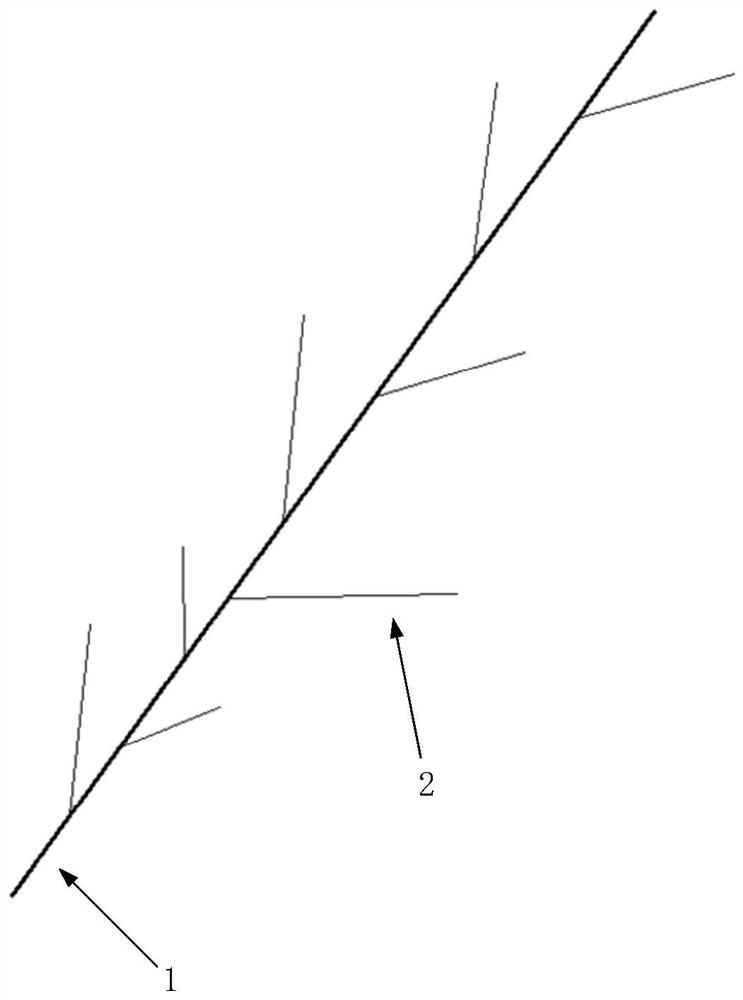

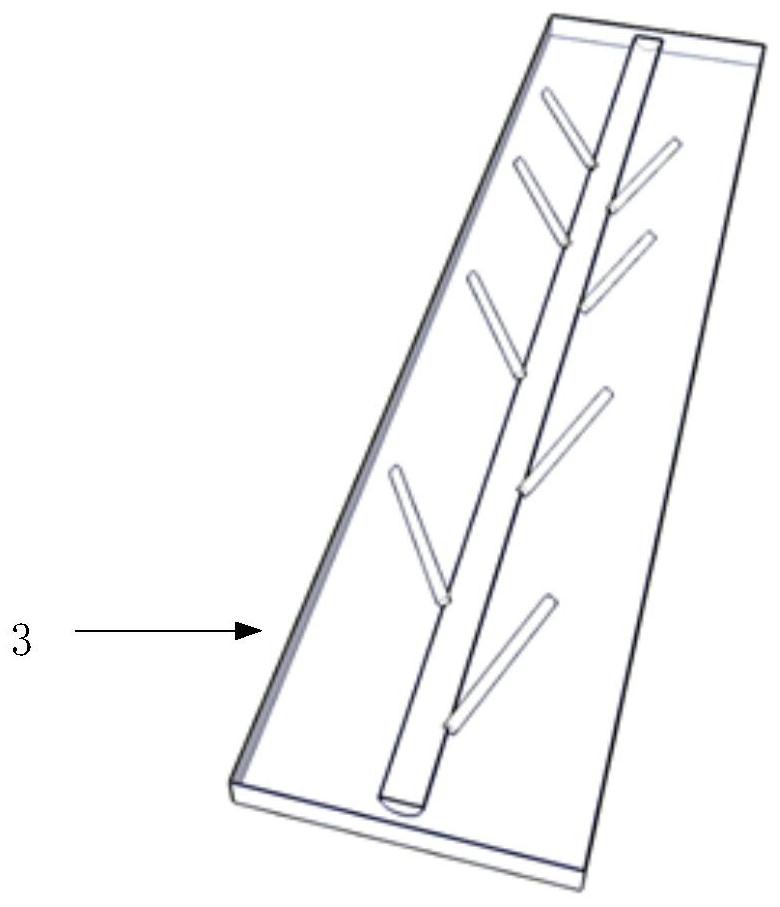

Synthetic fiber concrete and preparation method thereof

The invention discloses synthetic fiber concrete and a preparation method thereof.The synthetic fiber concrete is doped with 0.9-2.0 kg / m3 of synthetic fiber, and the synthetic fiber comprises a fiber trunk and fiber branches arranged at intervals in the length direction of the fiber trunk. The diameter of the fiber trunk is 2-10 times that of the fiber branches, and the length of the fiber trunk is 3.1-3.4 times that of the fiber branches. The bending toughness of the concrete can meet certain requirements under the condition that 0.9 kg / m3 of synthetic fibers are doped only by changing the shape and structure of the fibers doped into the concrete without adding other dispersing agents with a dispersing effect.

Owner:CHINA TEST & CERTIFICATION INT GRP CO LTD

Road cement concrete rubber particle surface modifier

The invention discloses a rubber particle surface modifier for road cement concrete, which relates to a wasted rubber particle surface modifier used in road-use cement concrete. The mixture ratio of the modifier is as above: the modifier has wild material source, low price and convenient manufacture, which can carry out the modification treatment to the rubber particles in a wasted rubber particleprocessing plant or a concrete mixing location, the modified rubber particles can be directly packaged in a damp state or be properly dried and packaged to leave the factory. Compared with the unmodified rubber particle one, the cement concrete prepared by modified wasted rubber particles can increase the compressive strength by 20%, the breaking strength by 10%-30% and the flexural toughness by30%-50% under the condition of the same fluidness, thereby having valuable economic and social benefit.

Owner:TONGJI UNIV

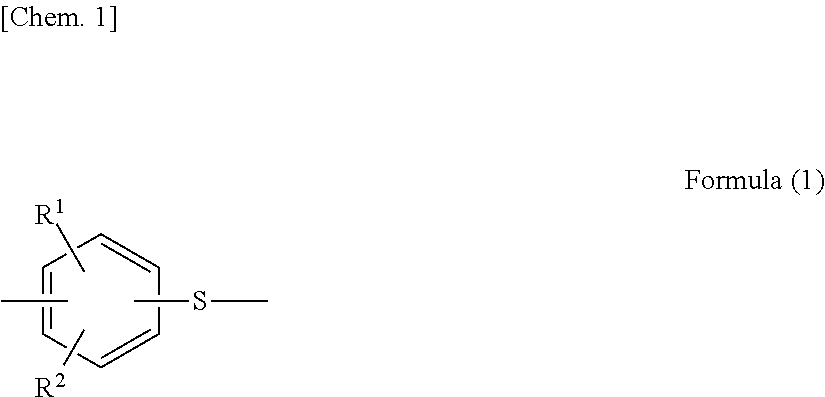

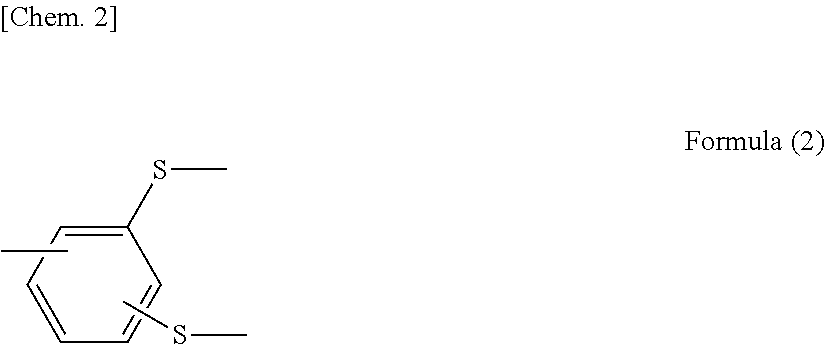

Polyarylene sulfide resin composition, molded body of same, method for producing polyarylene sulfide resin composition, and method for producing molded body

Provided are a polyarylene sulfide resin composition which is a raw material for a molded body having excellent thermal shock properties and for a molded body having excellent mechanical strength at a weld portion and excellent flexural toughness in the TD direction, a molded body of the polyarylene sulfide resin composition, a method for producing the polyarylene sulfide resin composition, and a method for producing the molded body. More specifically, provided are a polyarylene sulfide resin composition containing a polyarylene sulfide resin (A), an olefin polymer (B), zeolite (C), glass fibers (D1), and glass flakes (D2), wherein the glass flakes (D2) have a weight average particle diameter in the range of 100 μm or less, a molded body, and a method for producing the same.

Owner:DAINIPPON INK & CHEM INC

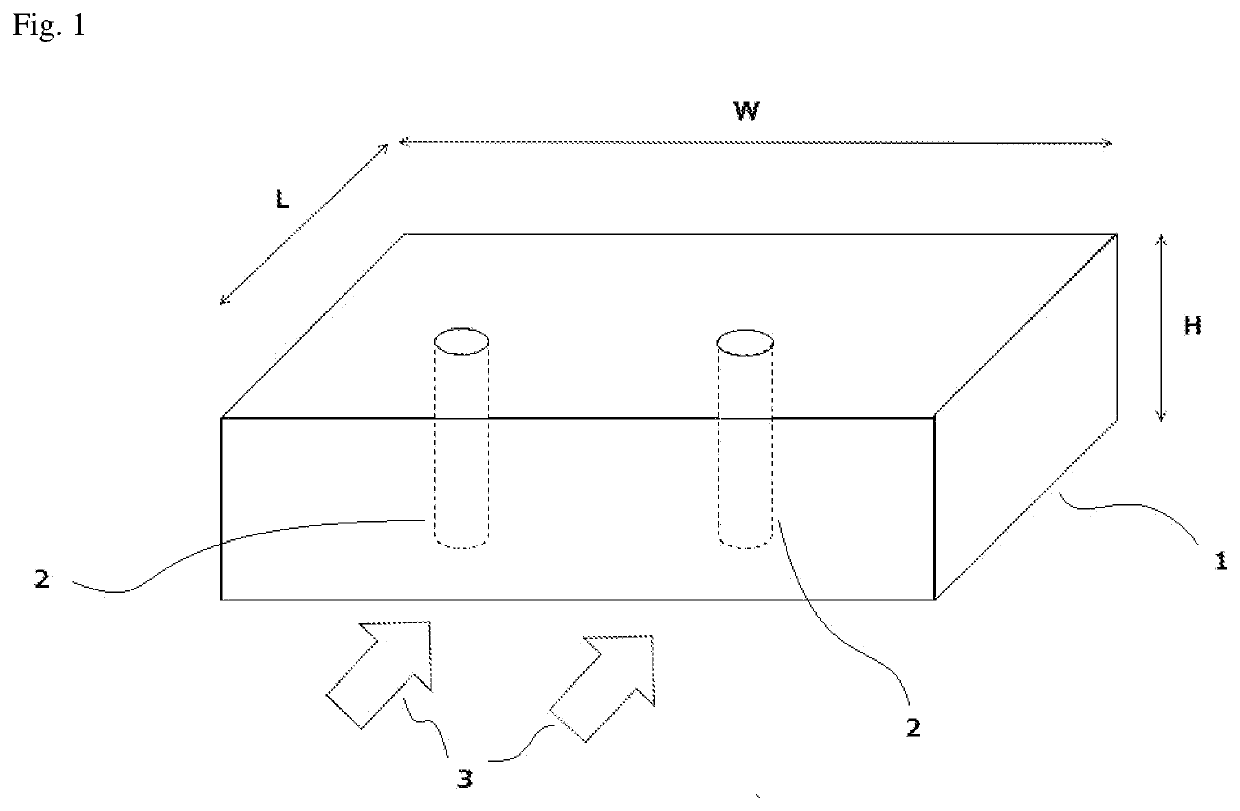

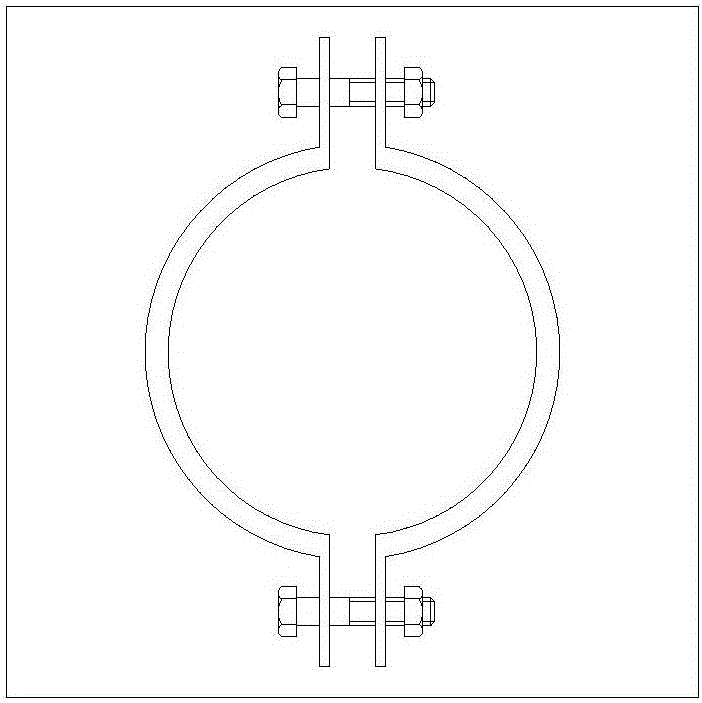

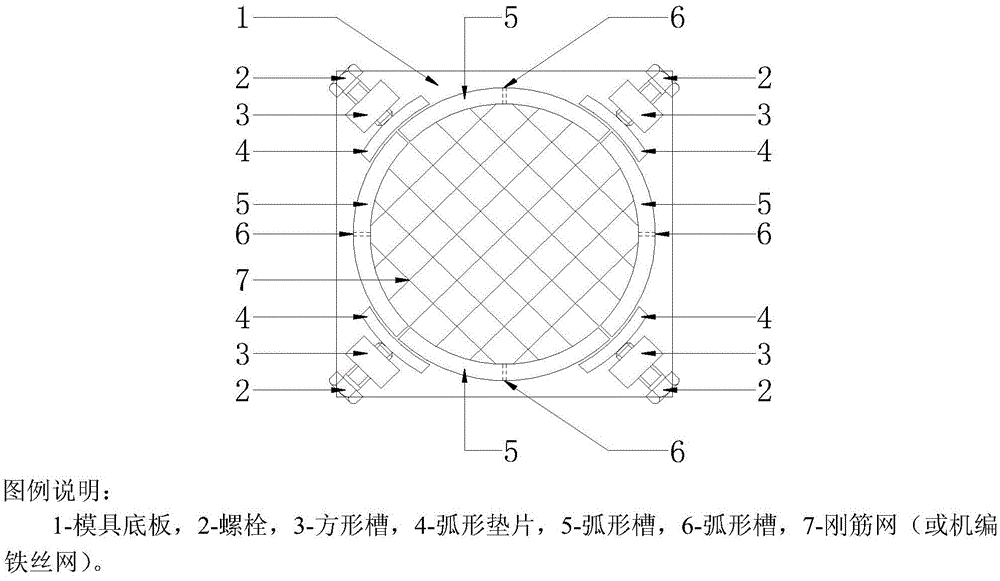

Sampling method for disc-process shotcrete flexural toughness testing

InactiveCN105973658AEasy to disassembleEasy to transportDischarging arrangementPreparing sample for investigationShotcreteStructure of the Earth

When a reinforcing mesh (or wire mesh) concrete support structure is adopted in projects of tunnels, side slopes, coal mine tunnels and the like by an injection process, concrete needs to be sampled and tested in order to test flexural toughness of concrete. The method for sampling a round specimen plate (sample) during flexural toughness testing of concrete is based on a new mold (see an attached drawing in an abstract of the description): the round reinforcing mesh (or wire mesh) concrete sample which meets requirements of the disc-process concrete flexural toughness testing can be prepared; the concrete specimen plate dismounting process is simplified, and the damage of dismounting mold to the sample is reduced; and mechanical property of the sample remains consistent with mechanical property of the reinforcing mesh (or wire mesh) concrete support structure in practical engineering to the maximum extent. The application aims to provide a new method for preparing the round reinforcing mesh (or wire mesh) concrete sample for concrete flexural toughness tests at the construction sites of tunnels, side slopes, coal mine tunnels and the like.

Owner:ANHUI UNIV OF SCI & TECH

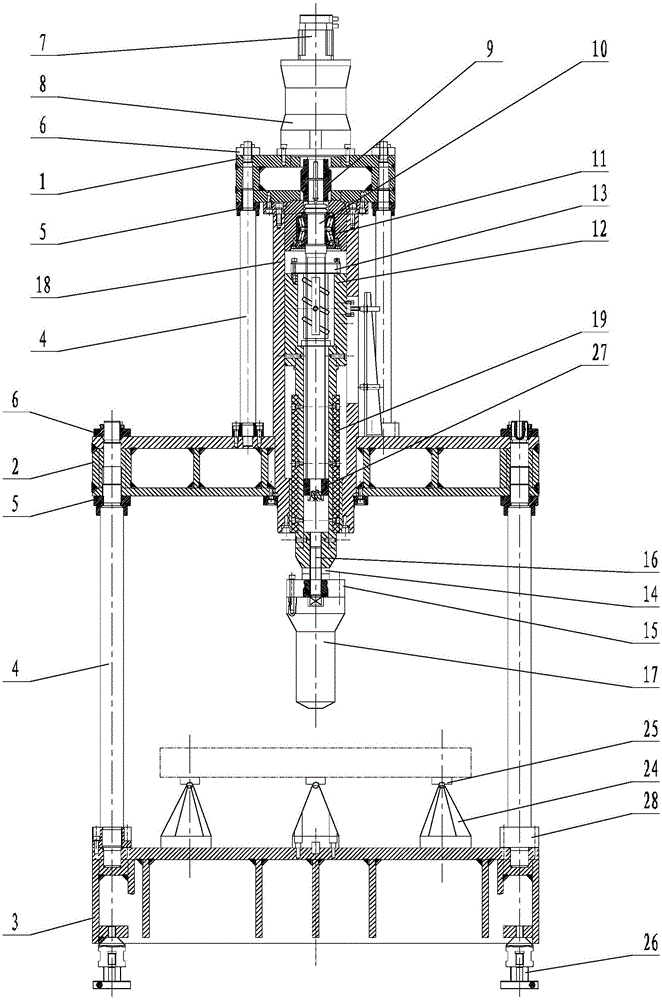

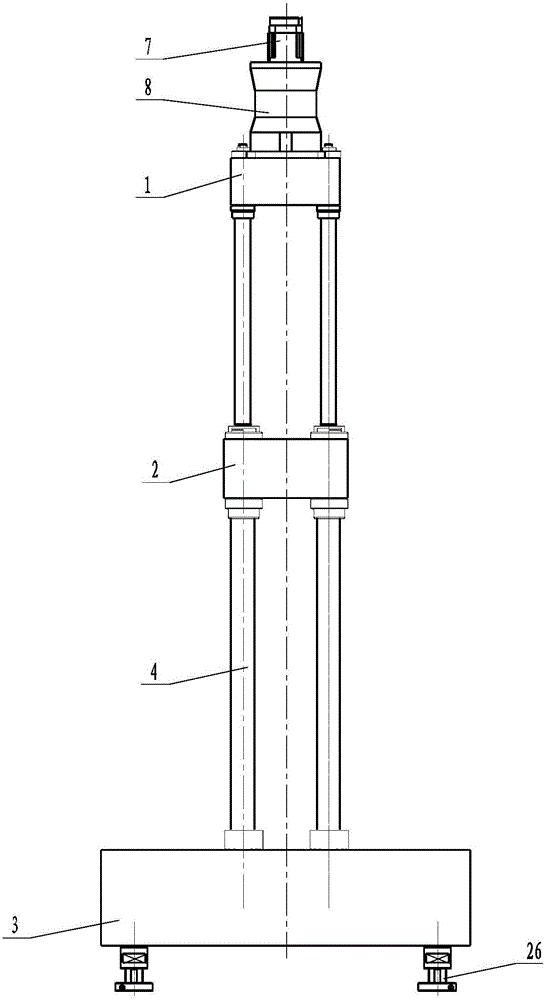

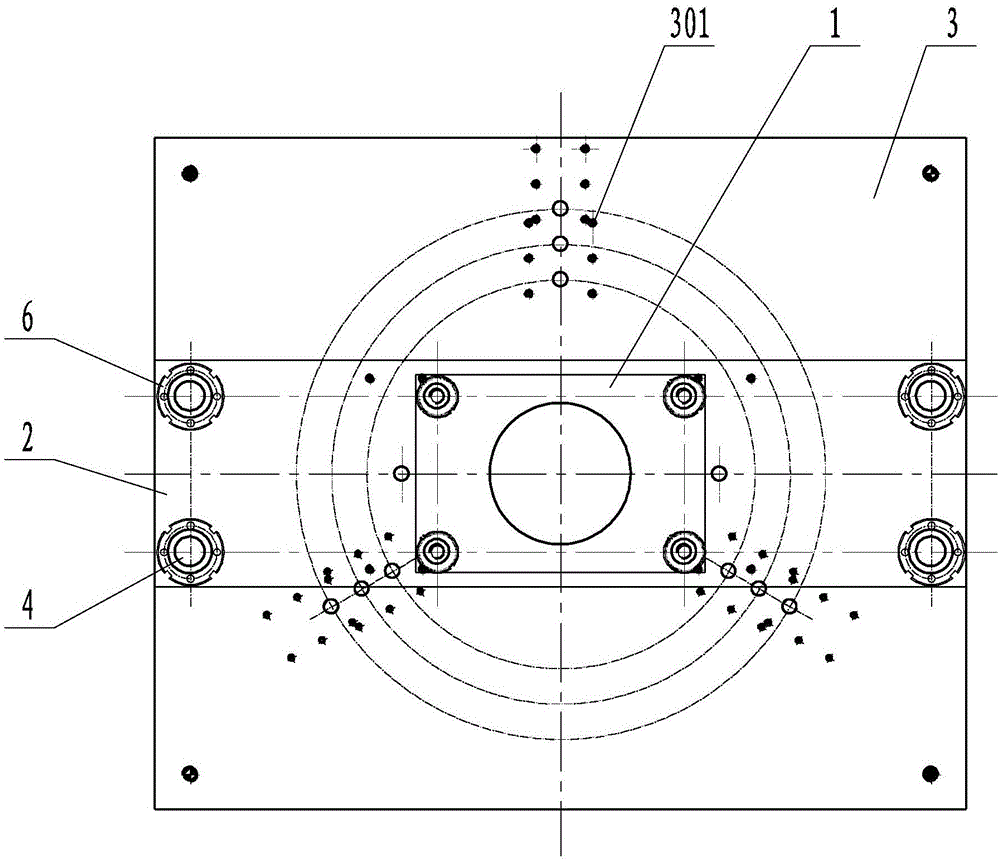

A flexural toughness testing machine for fiber-reinforced reinforced concrete

ActiveCN103698221BEasy to measureImprove flexural toughnessMaterial strength using tensile/compressive forcesCouplingBall screw

The invention discloses a bending toughness tester for fiber reinforced concrete. The bending toughness tester is characterized in that a servo motor is fixed on the top of a vertical three-layer support framework; an output shaft of the servo motor is vertically stretched downwards into the framework and connected with the upper end of a screw rod of a ball screw rod nut pair through a speed reducer and a coupler, and the ball screw rod nut pair is vertically arranged in the center of the support framework; the lower end of the screw rod is movably stretched into a hollow inner cavity of a pushing rod; the upper end of the pushing rod is fixed on a nut of the ball screw rod nut pair; the lower end of the pushing rod is locked with an inclined-plane gasket and a spoke type sensor integrally through a stressed stud which penetrates through central thread holes of the pushing rod, the inclined-plane gasket and the spoke type sensor; a jacking head is coaxially mounted at the bottom of the spoke type sensor; three sample supports are symmetrically mounted on a stressed base; four support adjusting gaskets are symmetrically arranged under the stressed base along the center of the support framework. The bending toughness tester for the fiber reinforced concrete takes the servo motor as power, so that the problems of large noise and serious pollution of current hydraulic power are solved; the bending toughness tester for the fiber reinforced concrete is simple and convenient to operate and capable of easily testing the bending toughness tester of the fiber reinforced concrete.

Owner:SHANGHAI HUALONG TEST INSTR

A kind of high ductility cement-based composite material and preparation method thereof

ActiveCN113754382BHigh strengthImprove toughnessFibre typesUltrasonic/sonic fibre treatmentCelluloseAggregate (composite)

The application relates to the technical field of building materials, and specifically discloses a high-ductility cement-based composite material and a preparation method thereof. A high-ductility cement-based composite material, comprising the following raw materials in parts by weight: 200-450 parts of cement, 100-350 parts of fly ash, 100-350 parts of mineral powder, 100-450 parts of aggregate, 20-45 parts of silica fume 5-25 parts of water reducing agent, 1-6 parts of defoamer, 0.1-0.8 parts of cellulose ether, 0.5-6 parts of spray regulator, 5-40 parts of polyvinyl alcohol fiber, 1000-3000 parts of water; The regulator includes magnesium aluminum silicate and starch ether in a weight ratio of (2-6):1. The compressive strength of the composite material 60d of the present application reaches 61.76N / mm 2 , The flexural strength reaches 19.44N / mm 2 , Bending strength reaches 15.10N / mm 2 , Bending toughness reaches 138.15KJ / m 3 , the strength and toughness of composite materials are better.

Owner:河北拓创远威科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com