Patents

Literature

16990 results about "Air drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

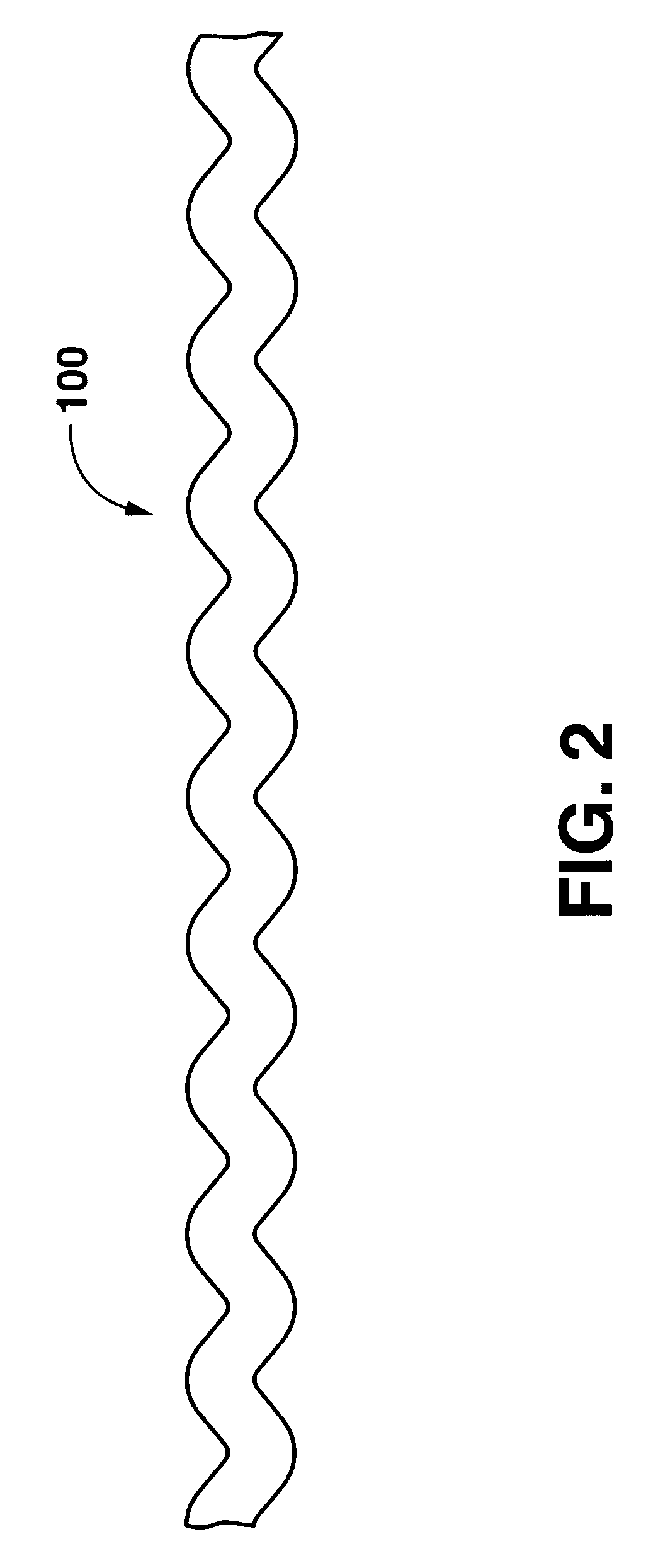

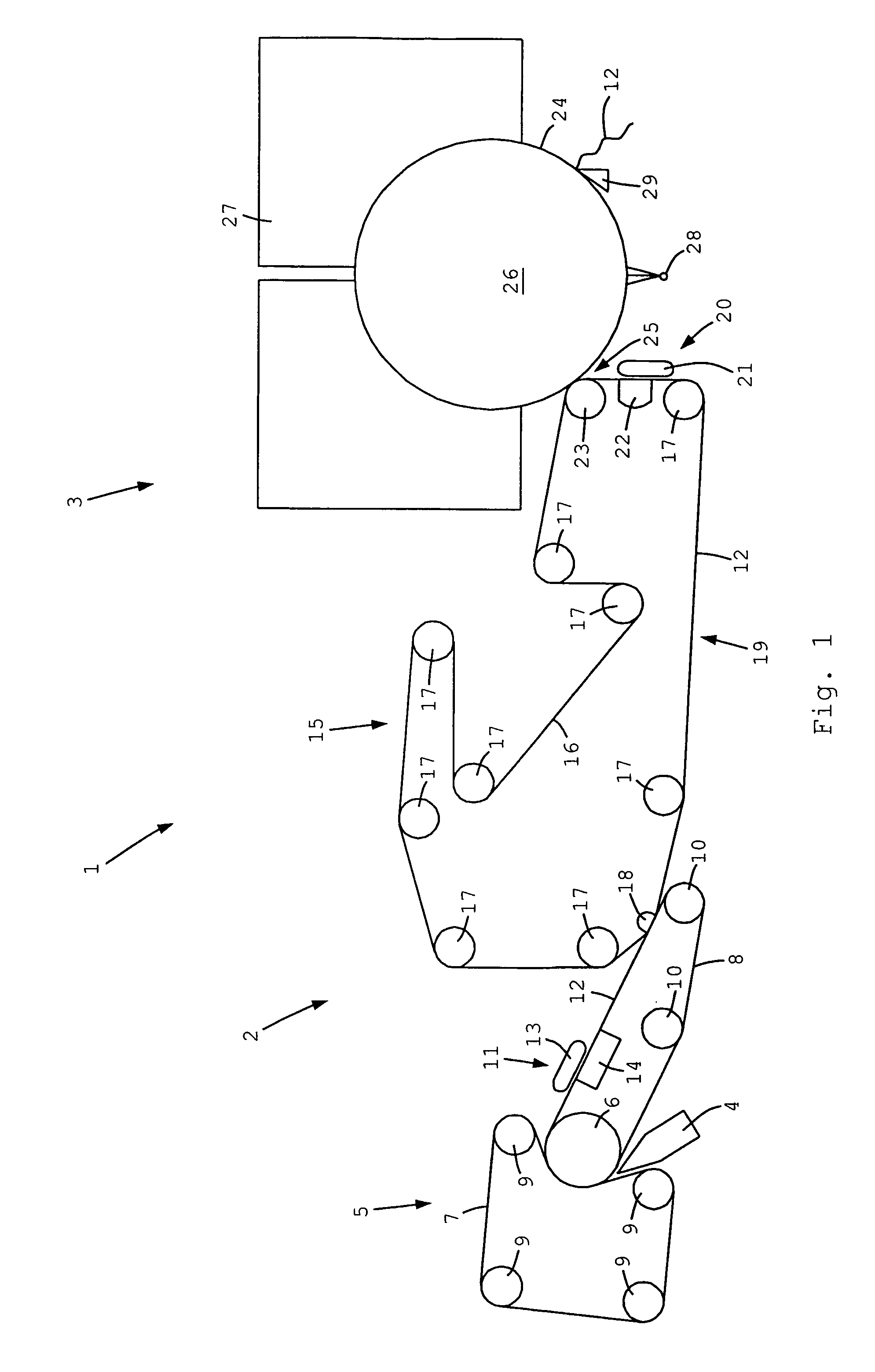

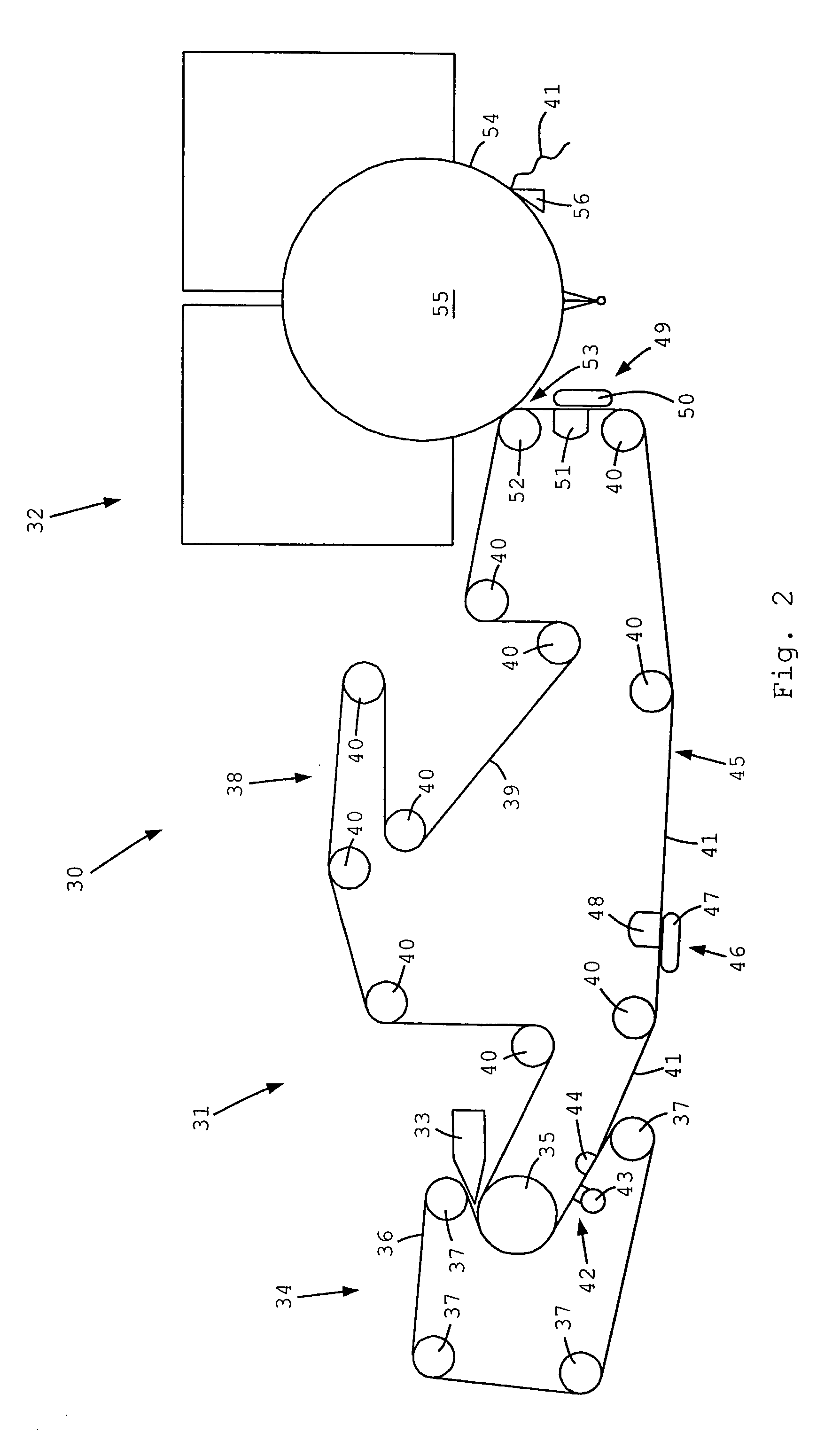

Tissue products having enhanced cross-machine directional properties

ActiveUS20070131366A1Enhanced cross-machine directional propertyHigh peak stretchNon-fibrous pulp additionNatural cellulose pulp/paperMedicineUltimate tensile strength

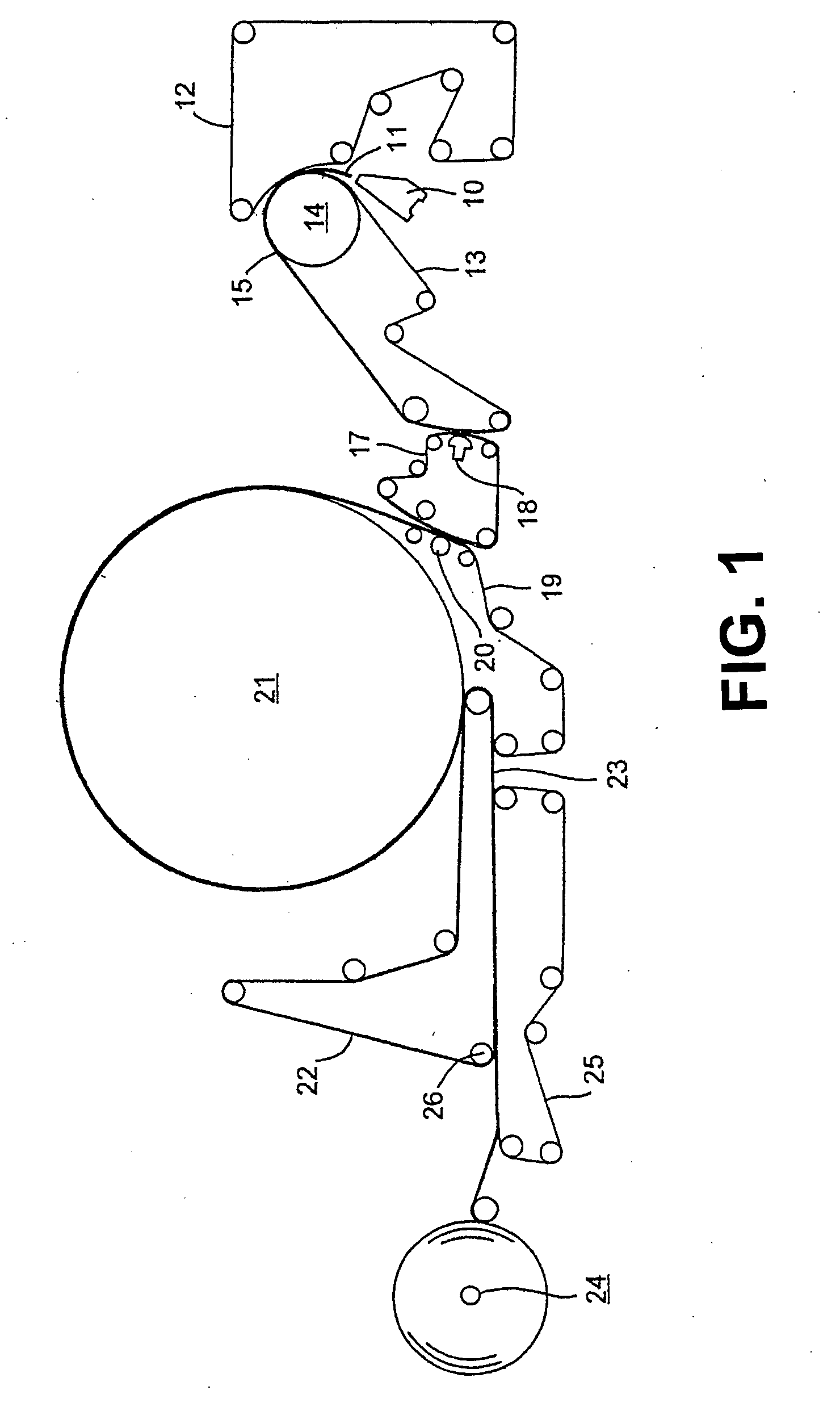

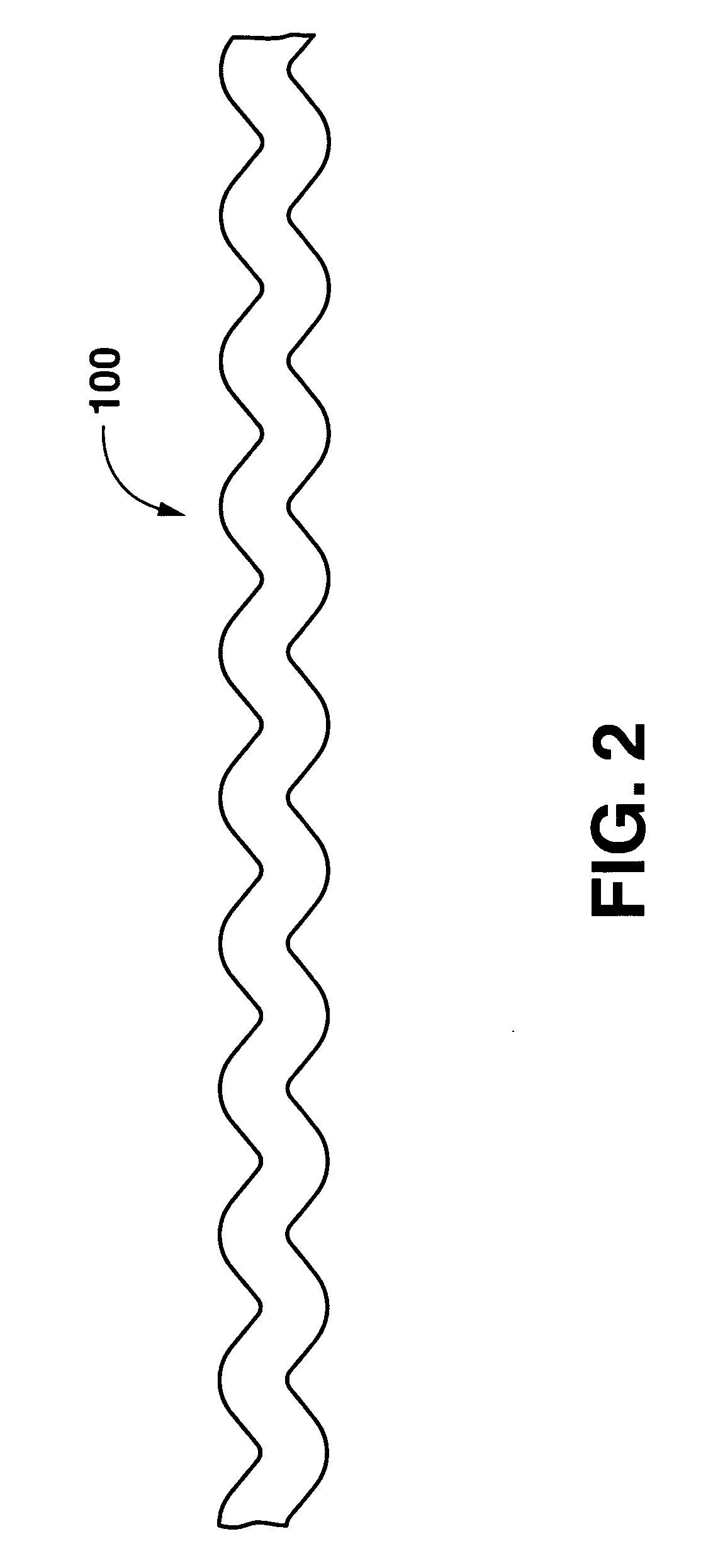

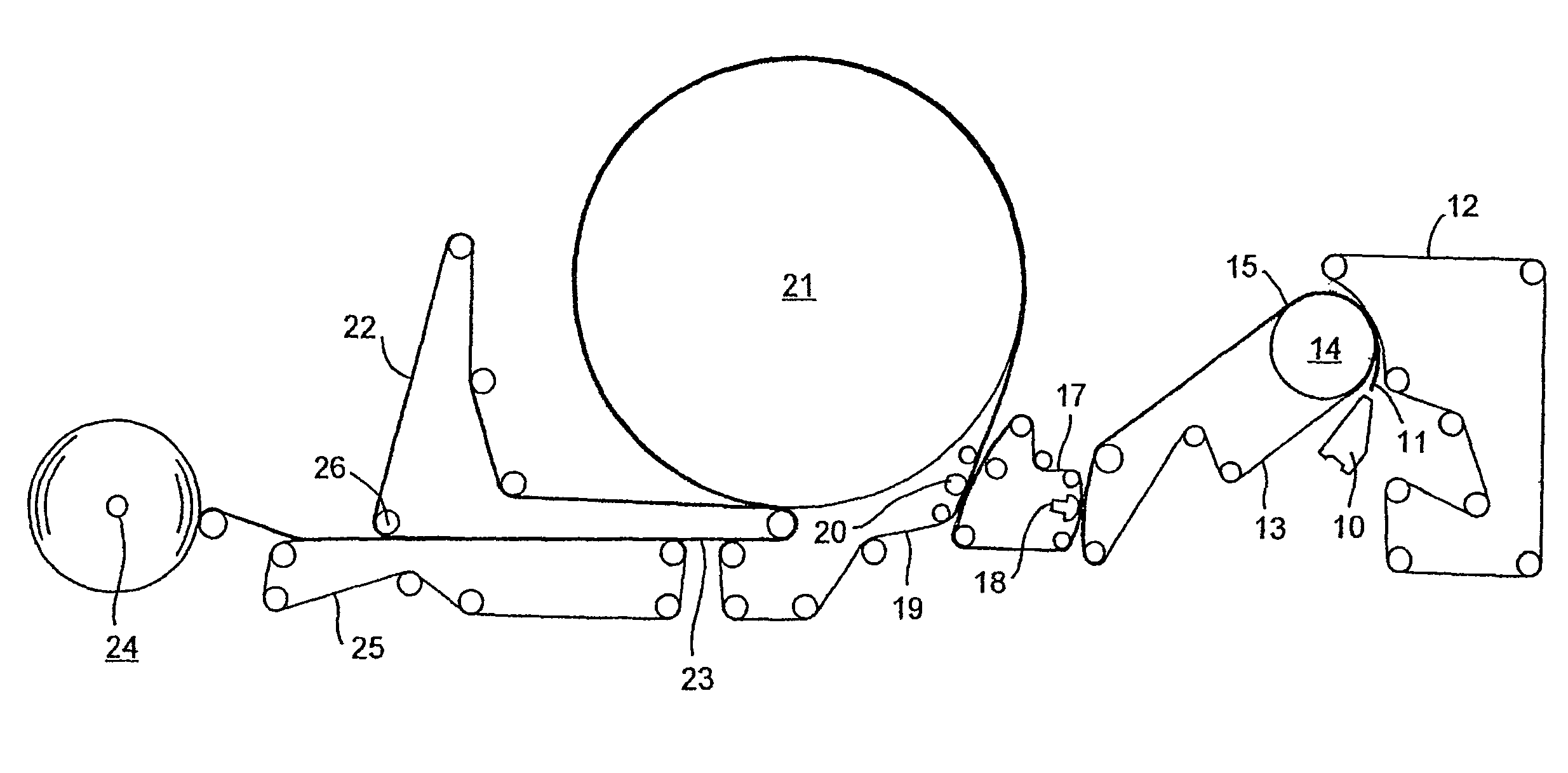

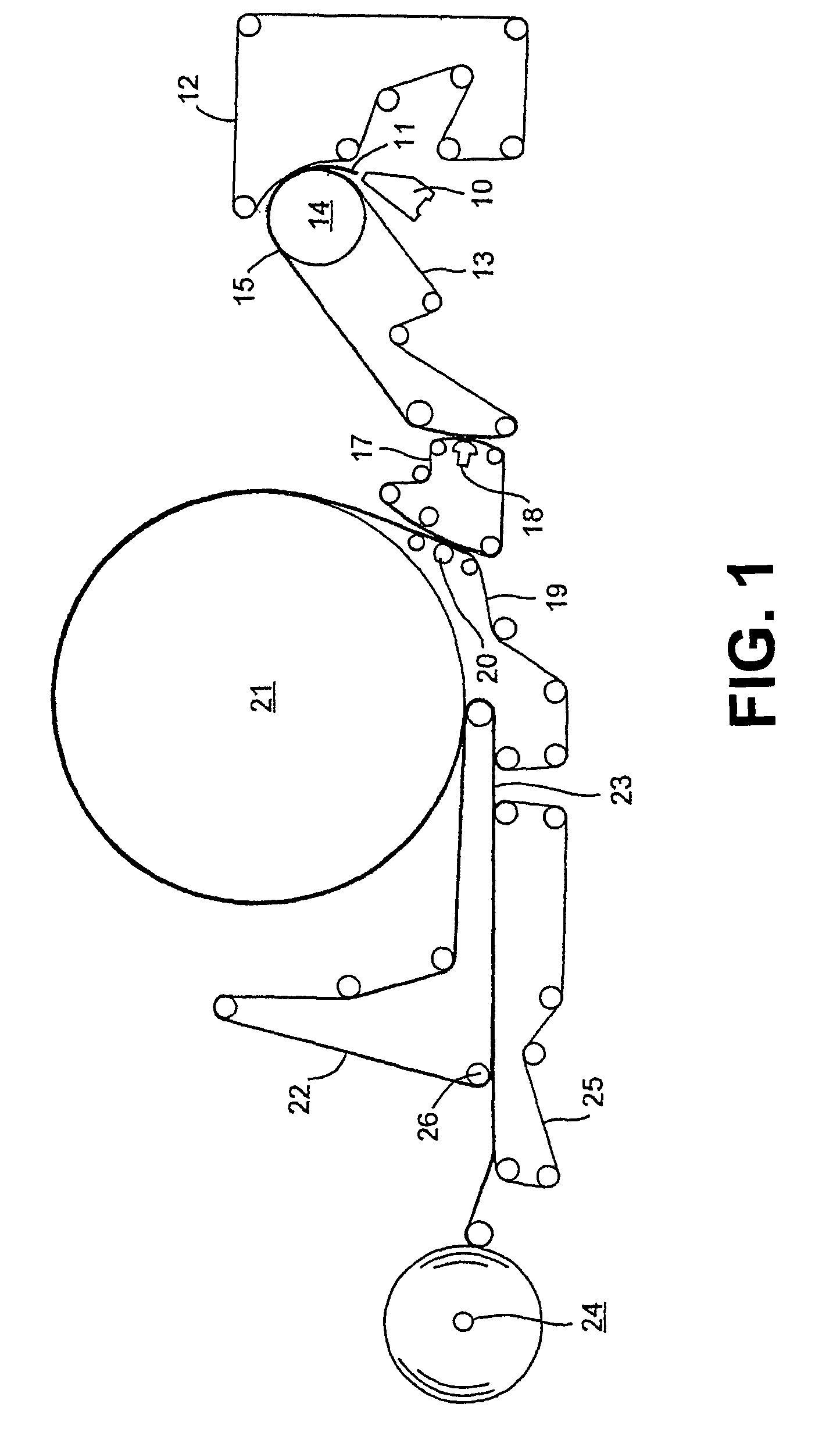

Tissue products are disclosed having desirable strength, stretch and softness properties. In particular, the tissue products exhibit relatively high strength while still having a relatively low stiffness and a significant amount of stretch. The tissue webs generally comprise uncreped through-air dried webs. In accordance with the present disclosure, the webs are formed in a through-air drying process in which the transfer fabric and the through-air drying fabric are both textured fabrics having a substantially uniform high strain distribution in the cross-machine direction. Various improvements in properties in the cross-machine direction are exhibited by deforming or molding a tissue web against one or more of the fabrics during the tissue making process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Valve body surface protection treatment process

InactiveCN108103483AReduce rustReduce corrosionLiquid/solution decomposition chemical coatingImpurityHeat treated

The invention provides a surface protection process used for long-time corrosion prevention and rust prevention. The process comprises the following process flow: sandblasting: performing surface blasting of brown steel shot on a valve body after heat treatment; pretreatment: cleaning to remove impurities such as oil stains, oxides, or water scales on the surface of the valve body by utilizing analkaline cleaning liquid; cleaning: rinsing chemical substances remaining on the surface of the valve body with clean water; plating solution preparation: preparing a plating solution according to a ratio of 5% to 14% of phosphorus content; preheating: putting the valve body in hot water to be preheated so that the temperature of a workpiece is close to the temperature of the plating solution; plating: putting the preheated workpiece into the plating solution for plating; treatment after plating: after the plating is completed, cleaning, air drying and storing the workpiece sequentially withinone hour. The surface protection process provided by the invention can delay the premature rust and corrosion of the valve body in the use process, and prolong the service life of the valve body to 20 to 30 hours.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

Tissue products having enhanced cross-machine directional properties

ActiveUS7972474B2Enhanced cross-machine directional propertyHigh peak stretchNon-fibrous pulp additionNatural cellulose pulp/paperMedicineHardness

Tissue products are disclosed having desirable strength, stretch and softness properties. In particular, the tissue products exhibit relatively high strength while still having a relatively low stiffness and a significant amount of stretch. The tissue webs generally comprise uncreped through-air dried webs. In accordance with the present disclosure, the webs are formed in a through-air drying process in which the transfer fabric and the through-air drying fabric are both textured fabrics having a substantially uniform high strain distribution in the cross-machine direction. Various improvements in properties in the cross-machine direction are exhibited by deforming or molding a tissue web against one or more of the fabrics during the tissue making process.

Owner:KIMBERLY-CLARK WORLDWIDE INC

High-dietary-fiber nutritional meal replacement powder and processing method thereof

InactiveCN104757545ARich in vitaminsComprehensive Mineral NutrientsFood preparationFiberMeal replacement

The invention discloses high-dietary-fiber nutritional meal replacement powder and a processing method thereof, relates to a meal replacement powder food, and particularly relates to the high-dietary-fiber nutritional meal replacement powder which contains polyunsaturated fatty acids, is rich in nutrition, diversified in mouthfeel, and easy to process, store and eat as well as a processing method thereof. The high-dietary-fiber nutritional meal replacement powder comprises the following raw materials in parts by weight: 3-30 parts of flaxseed powder, 20-60 parts of cereal powder, 10-35 parts of soybean powder, 3-16 parts of dietary fiber powder and 1-15 parts of fruit and vegetable powder. The processing method of the high-dietary-fiber nutritional meal replacement powder comprises the following steps: carrying out hot air drying curing or expansion curing on cereals and soybeans respectively, and crushing at a low temperature to 80-100 meshes for later use; drying flaxseed powder, dietary fiber powder, cereal powder, soybean powder and fruit and vegetable powder, blending in proportion, and mixing evenly; and packaging quantitatively so as to obtain the nutritional meal replacement powder.

Owner:XIAMEN BAIQUAN LIKANG BIOLOGICAL SCI & TECH CO LTD

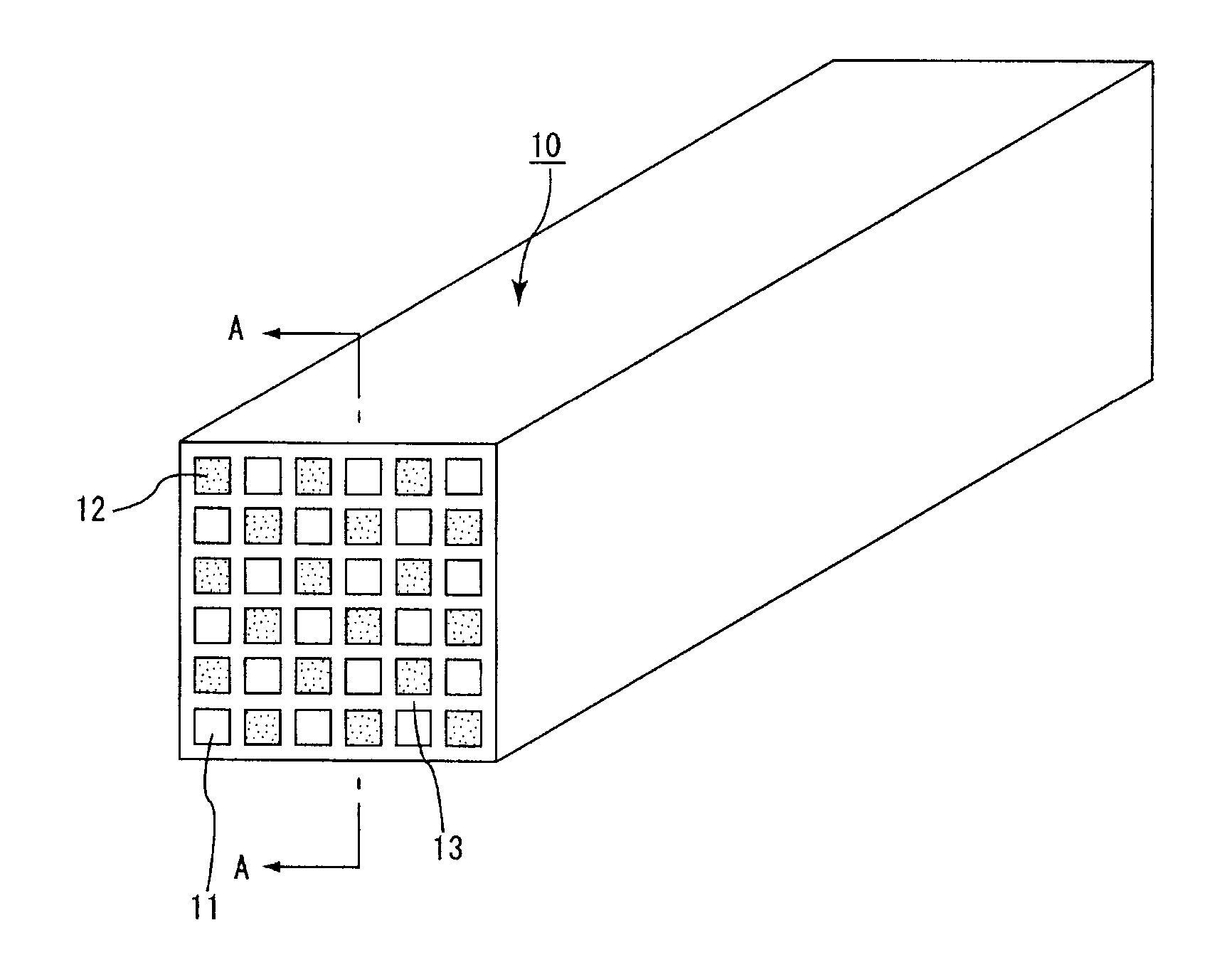

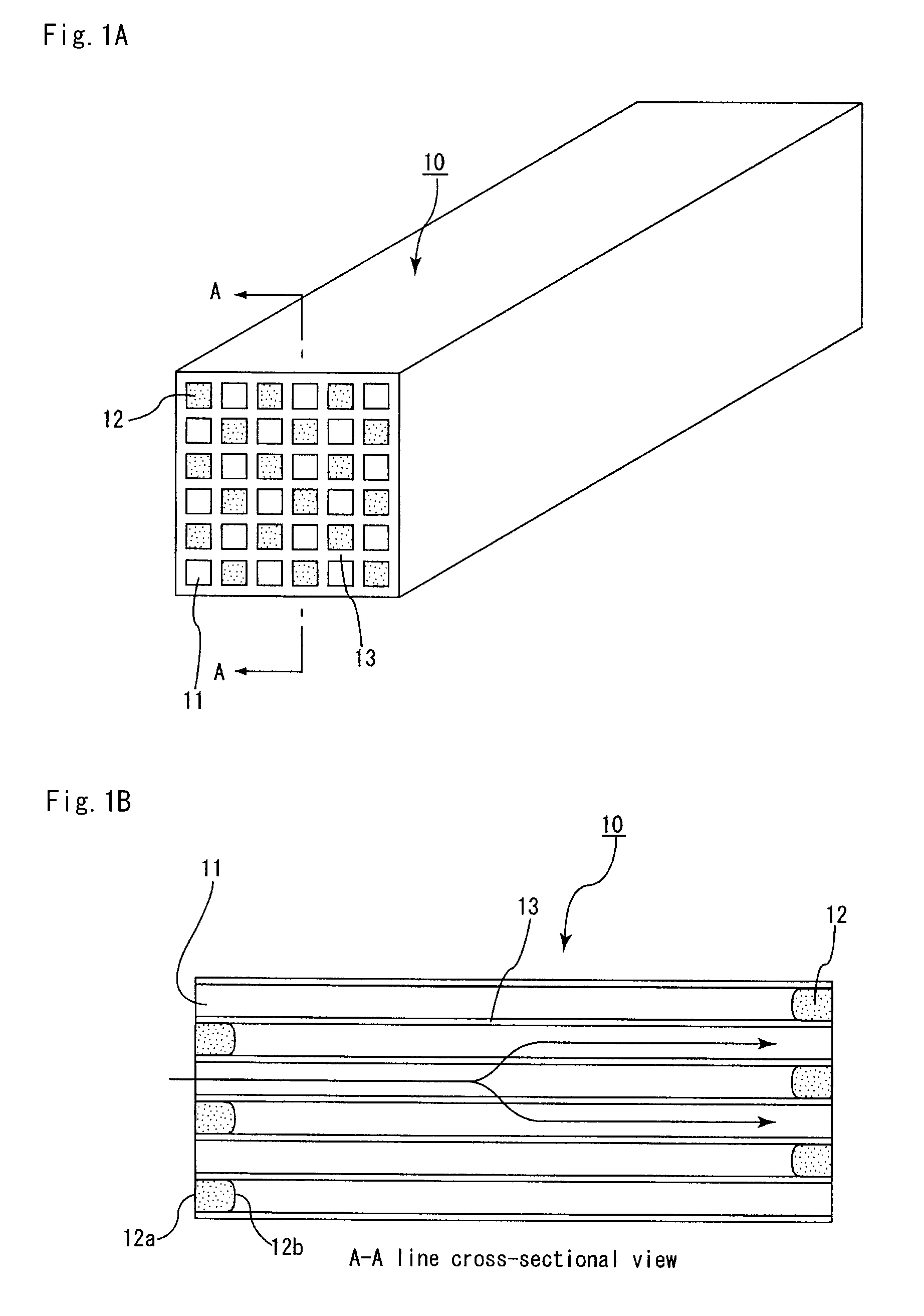

Method for manufacturing a honeycomb structured body

A method for manufacturing a honeycomb structured body including molding ceramic raw material to form a pillar-shaped honeycomb molded body having a multiplicity of cells disposed in parallel with one another in the longitudinal direction with a cell wall therebetween, and filling in either one of the end portions of each of the cells with a plug material paste, and firing the honeycomb molded body to manufacture a honeycomb structured body comprising a honeycomb fired body, wherein after having filled in either one of the end portions of each of the cells of the honeycomb molded body with the plug material paste, a plug material paste drying process to dry the plug material paste is conducted by blowing hot air to an end face of the honeycomb molded body using a hot air drying apparatus.

Owner:IBIDEN CO LTD

Intelligent environment monitoring system

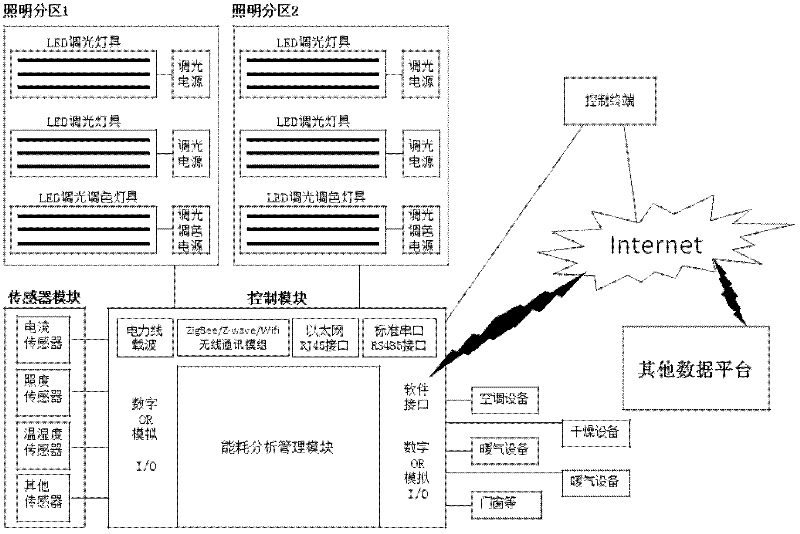

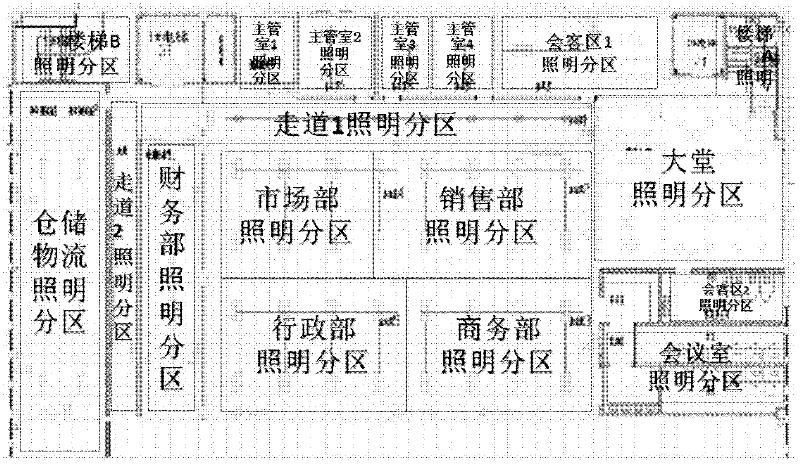

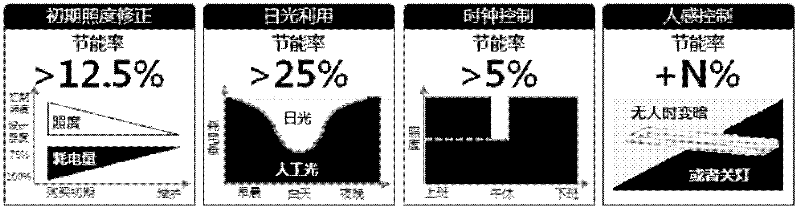

InactiveCN102591277AReduce wasteLow costEnergy industryElectric light circuit arrangementIntelligent environmentIntelligent lighting

The invention discloses an intelligent environment monitoring system. The system comprises an LED lamp provided with a light-dimming or light-dimming and color-matching power supply, electric equipment, a sensor module, a control module and a control terminal. The system can automatically control the lightness of the lamp by sensing and measuring luminance / human body / objects so as to realize intelligent lighting control and reduce unnecessary energy waste; by measuring the environmental temperature / humidity, an air conditioner / heating equipment / air drying equipment / humidifying equipment can be automatically controlled; when the temperature / humidity is abnormal, the system automatically alarms to remind a manager by a short message / email so as to avoid safety accidents in the production and management. Meanwhile, the system can further monitor the use condition of energy sources in real time, provide an accurate energy consumption data report for a manager, and reduce the energy cost for the production and management.

Owner:得实半导体照明(江门)有限公司

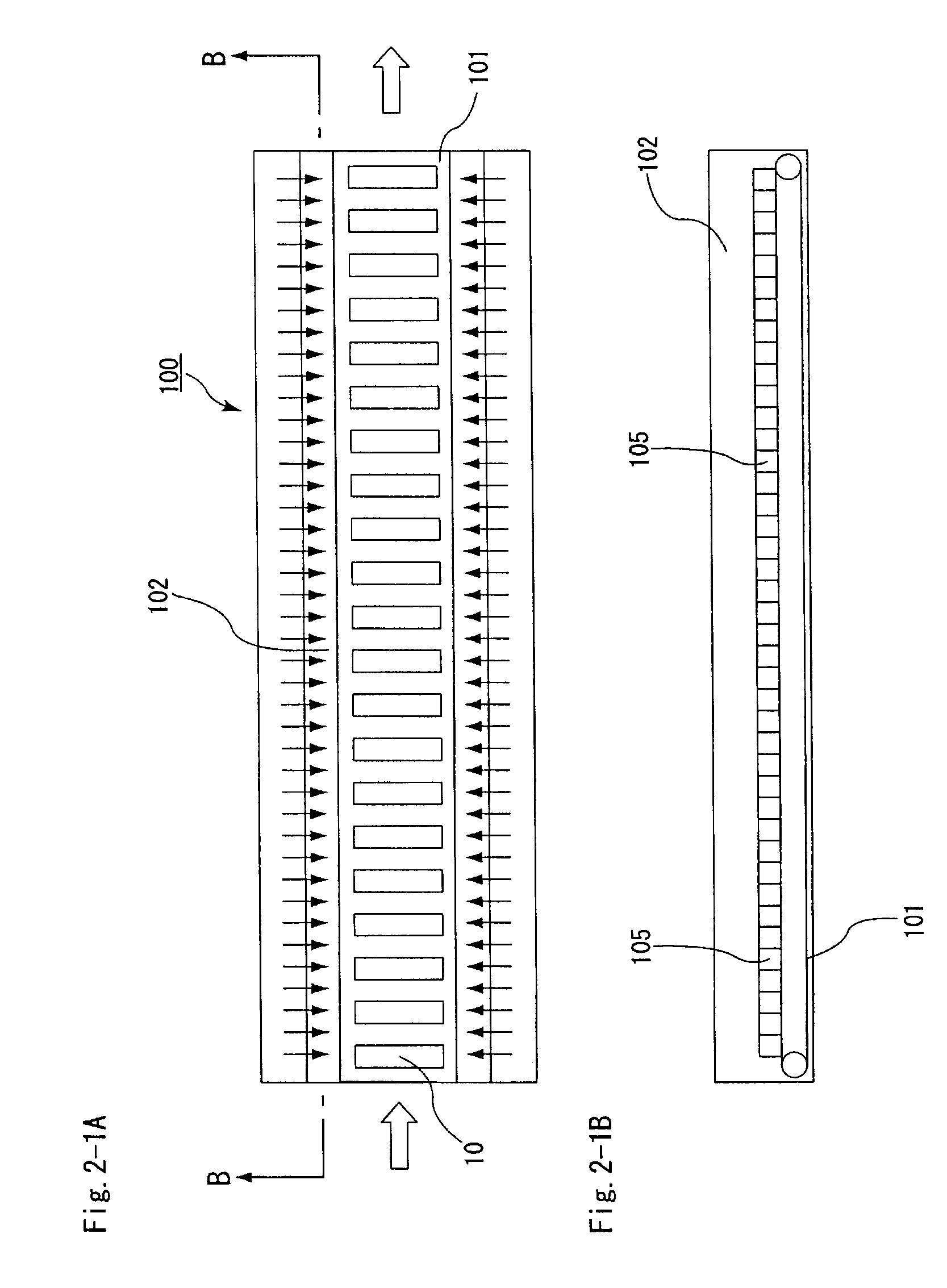

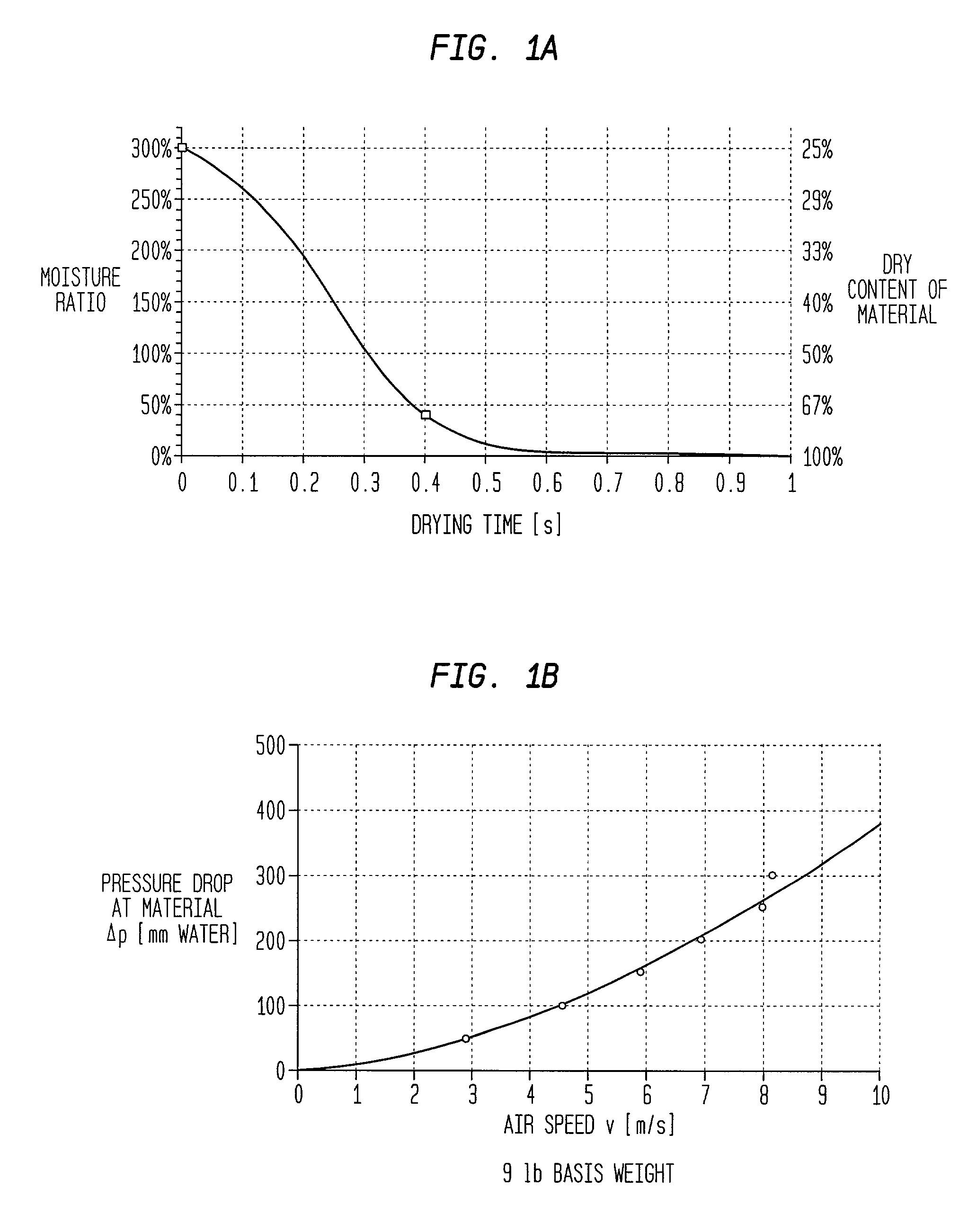

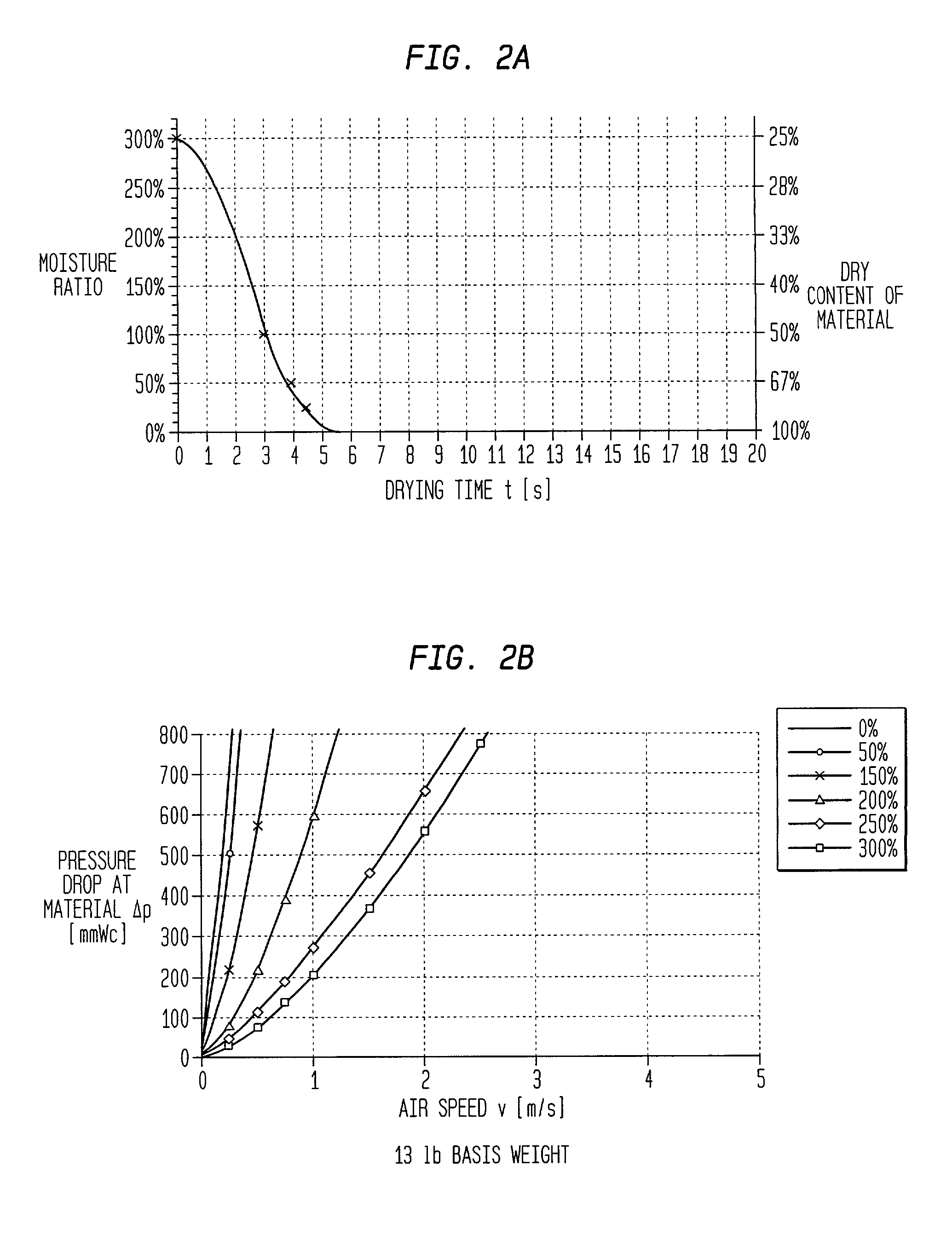

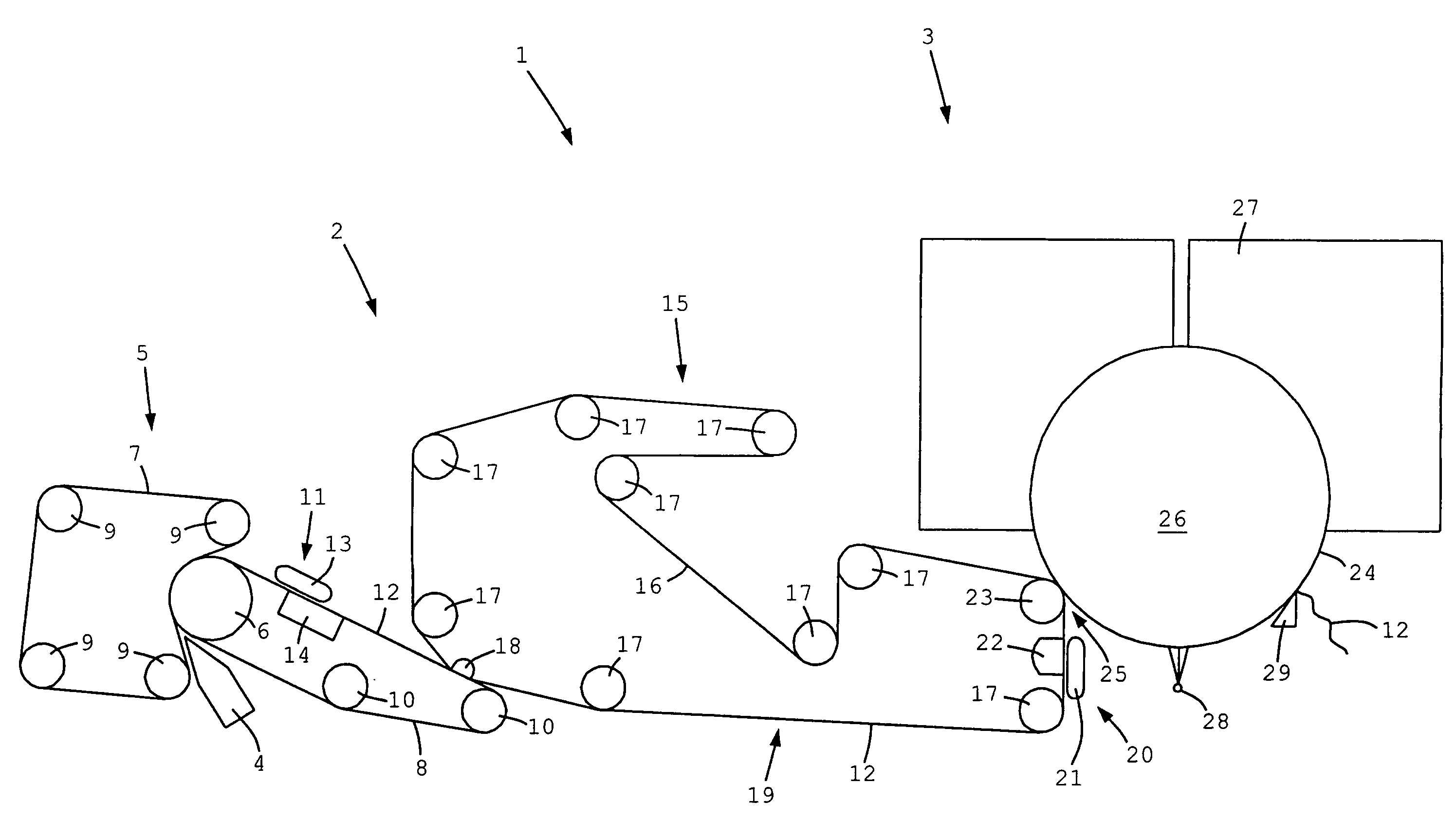

Impingement air dry process for making absorbent sheet

InactiveUS20020088577A1Easy to appreciateNon-fibrous pulp additionNatural cellulose pulp/paperPolymer sciencePapermaking

A process for making absorbent sheet includes: (a) depositing an aqueous furnish of cellulosic fiber on a forming fabric; (b) dewatering the wet web to a consistency of from about 15 to about 40 percent; (c) transferring the dewatered web from the forming fabric to another fabric traveling at a speed of from about 10 to about 80 percent slower than the forming fabric; (d) wet-shaping the web on an impression fabric whereby the web is macroscopically rearranged to conform to the surface of the impression fabric; and (e) impingement air drying the web. The process is particularly suitable for making high bulk products form difficult to process furnishes such as recycle furnishes and for making high basis weight products without compressive dewatering with a papermaking felt.

Owner:GPCP IP HLDG LLC

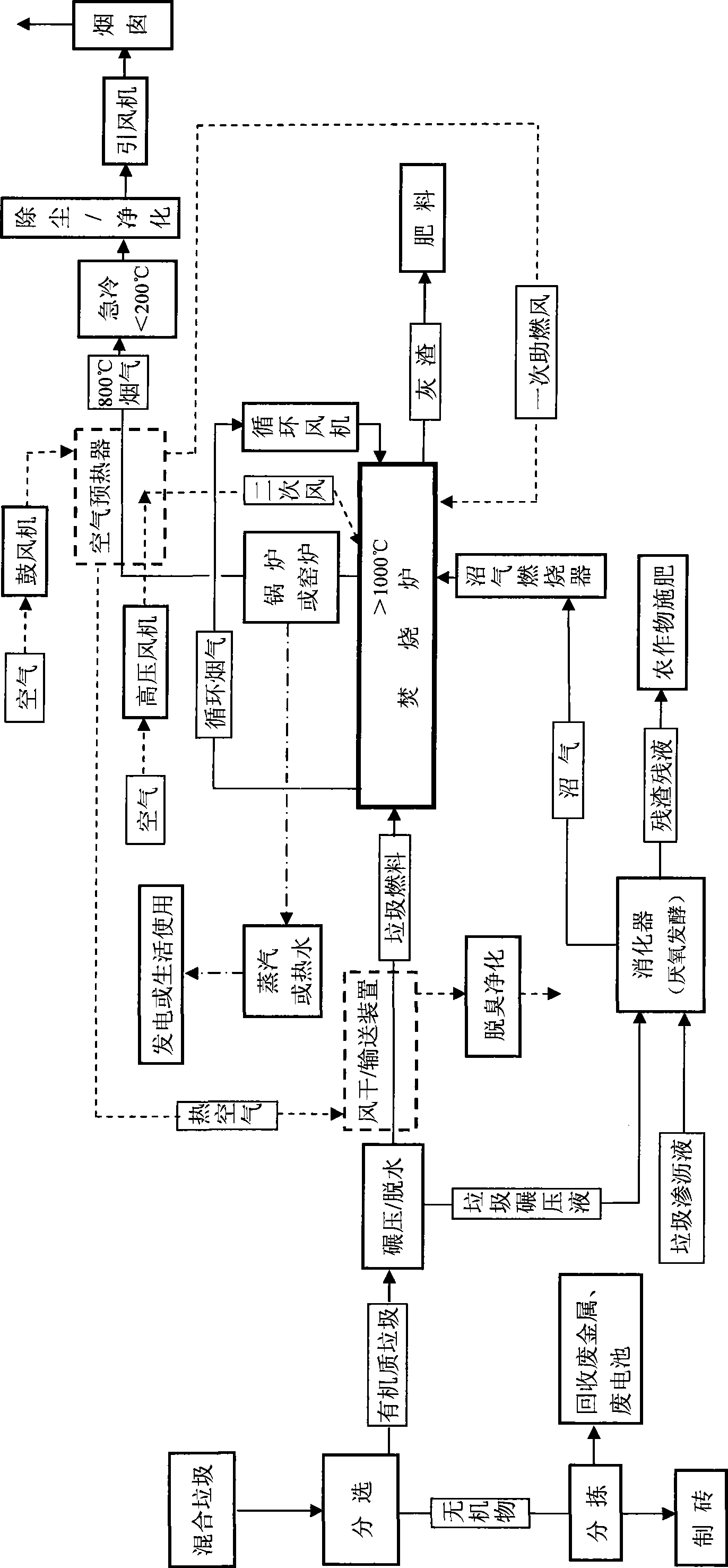

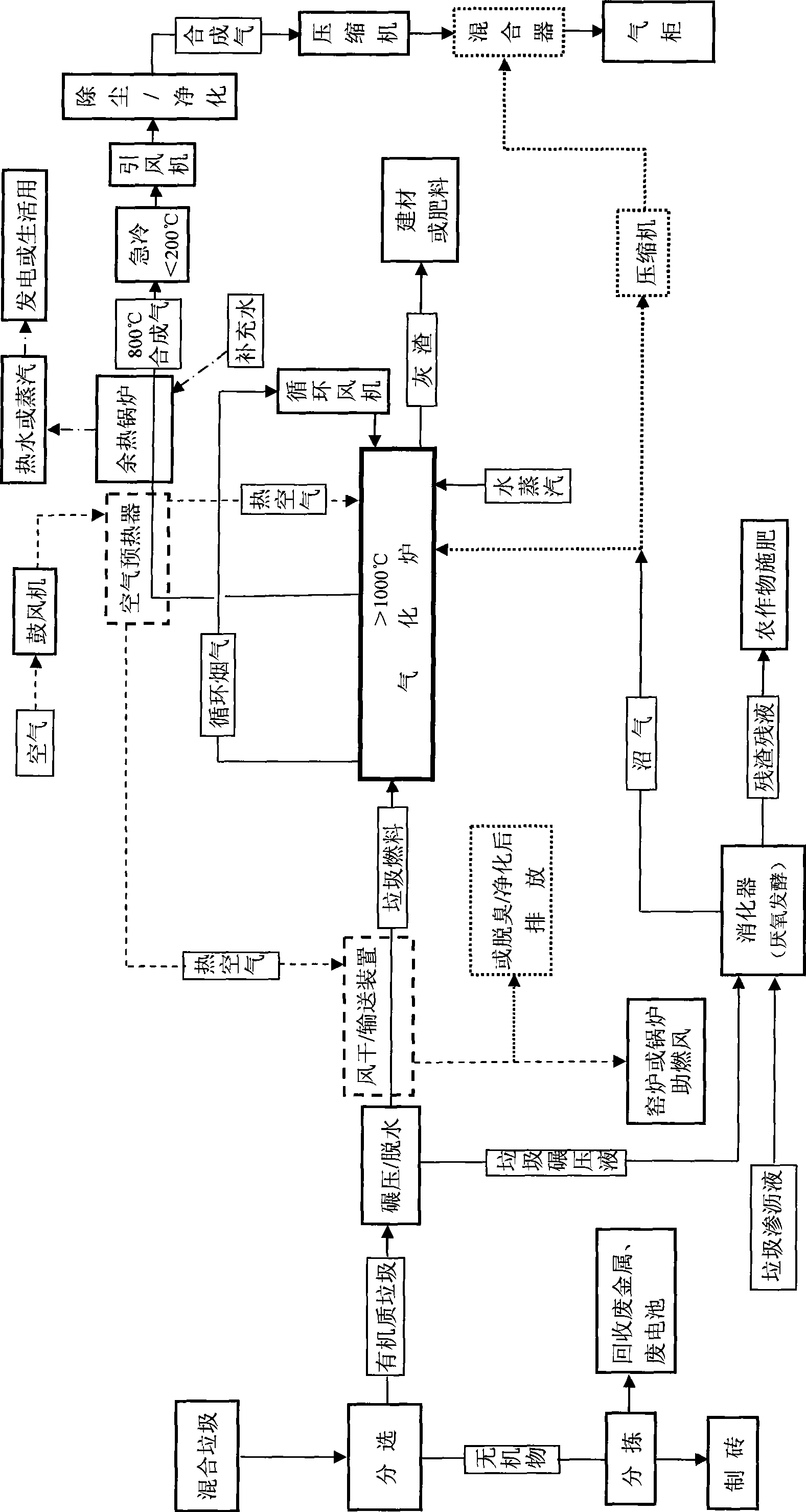

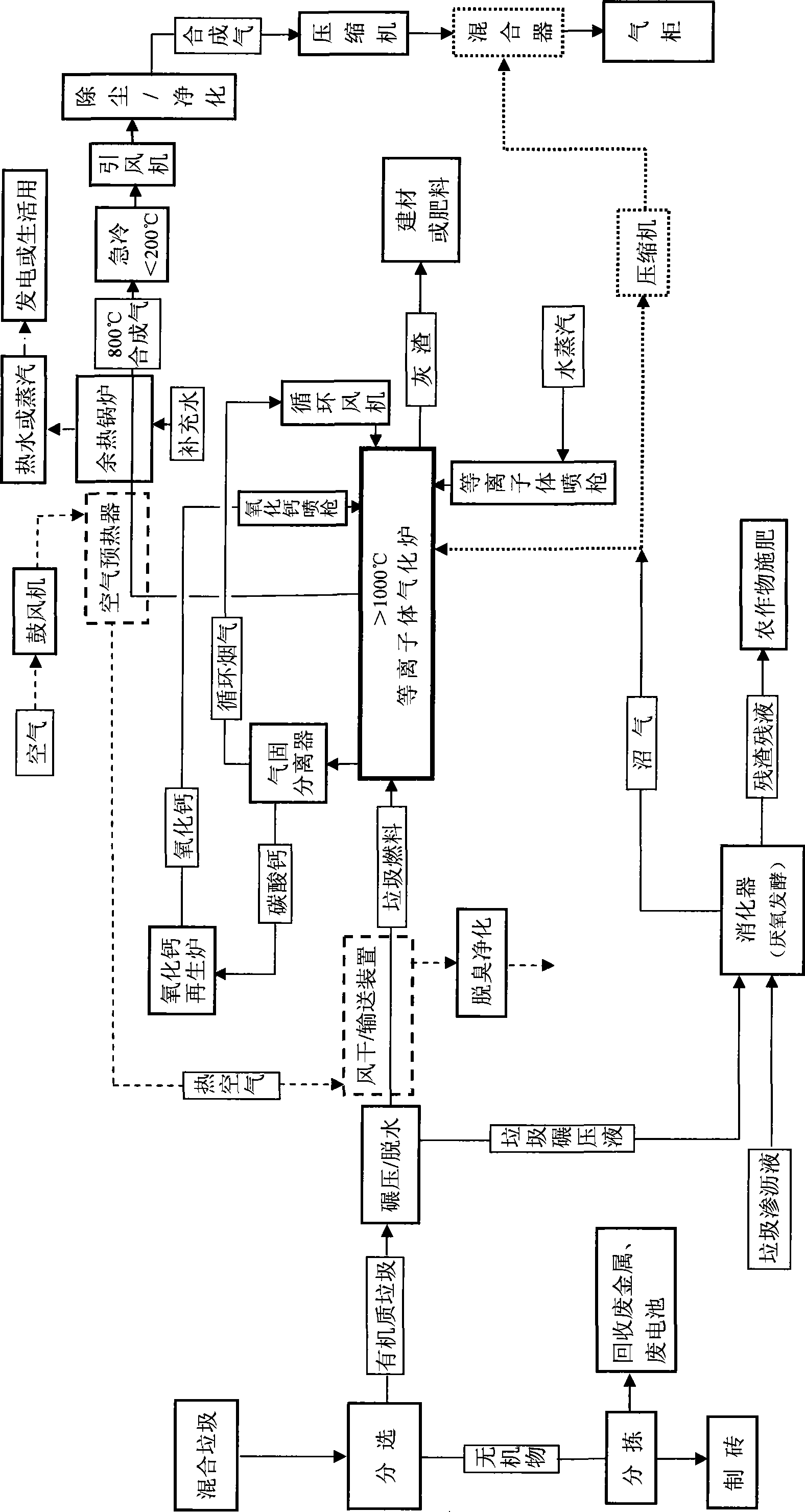

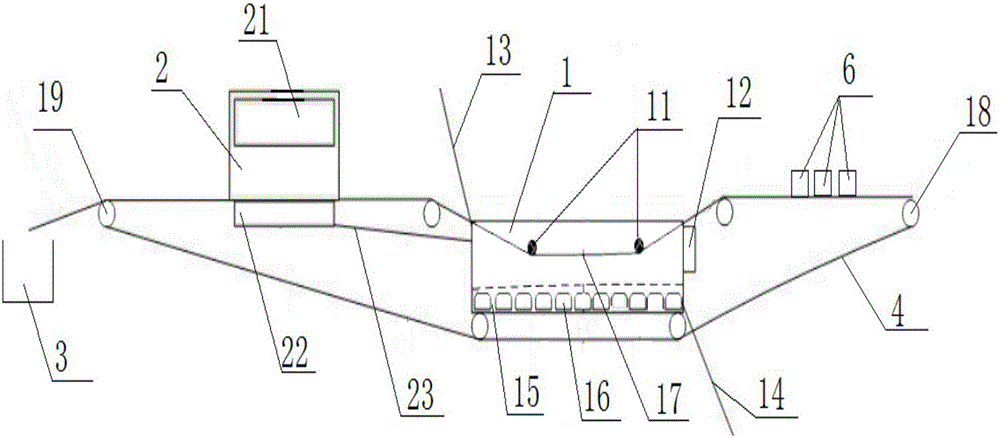

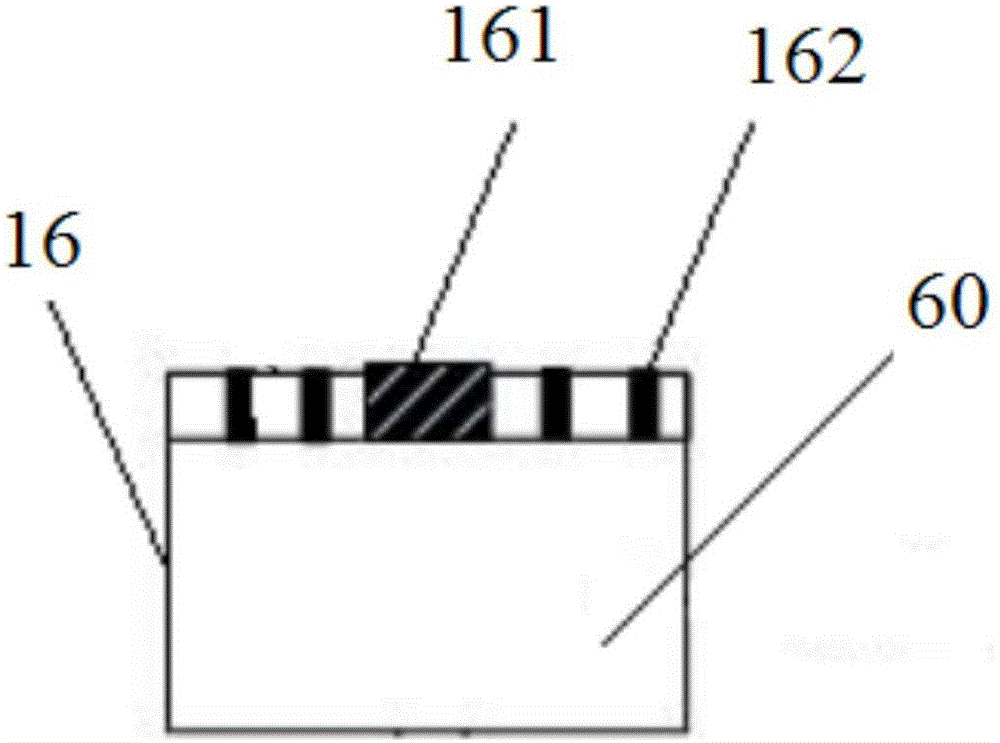

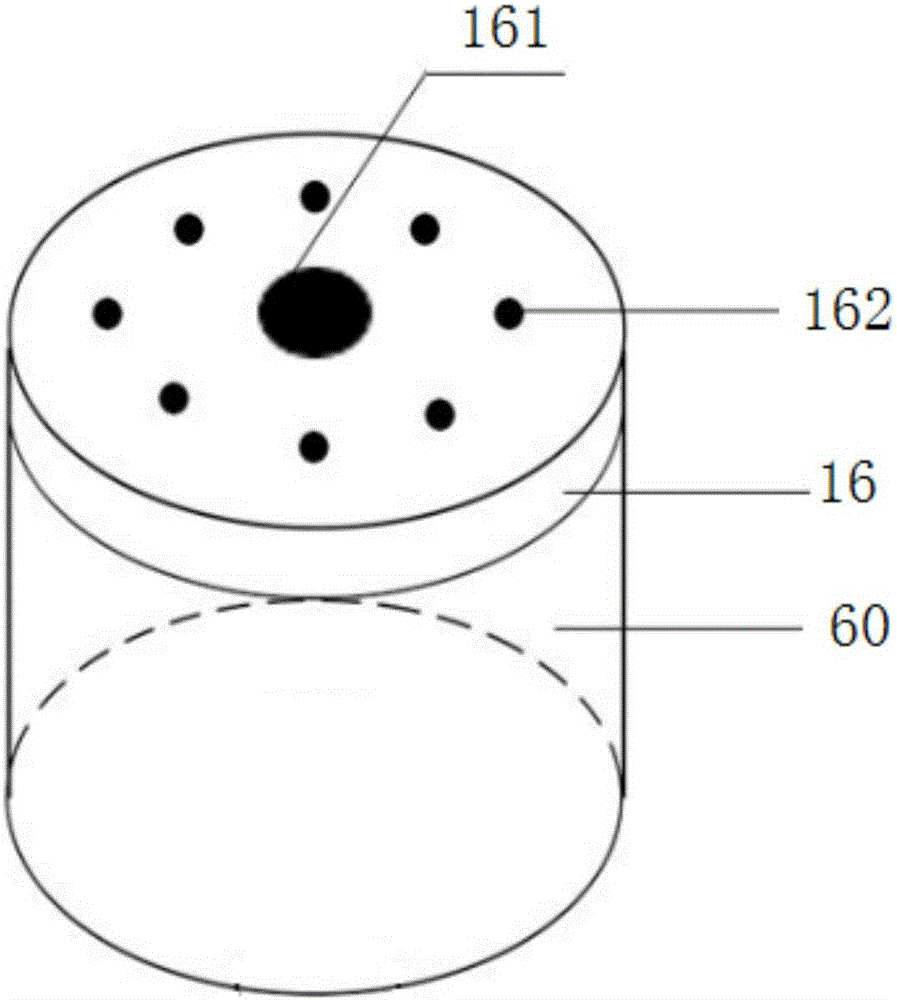

Domestic garbage transformation technique, system and apparatus without conventional fuel for combustion supporting

InactiveCN101468789AReduce pollutant contentLow investment costBio-organic fraction processingSolid waste disposalBrickClean energy

The invention provides a process, a system and equipment for converting household garbage without support combustion of the prior fuels, which relates to a process and equipment for processing garbage. The process is characterized in that the household garbage is sent into a gasification furnace or an incinerator after separating, dehydrating by rolling compaction and air-drying treatment; garbage fuel is converted in the furnace by a mode of gasification or incineration, and is subjected to baking, pyrogenation, gasification and carbon residue burn-out in the furnace; the converted synthesis gas is used for cleaning energy; waste heat of incineration is absorbed by heat-exchange equipment for reclamation; garbage rolling liquid is sent into a digesting machine for anaerobic fermentation so as to produce biogas, the biogas is used as auxiliary fuel of the incinerator, and the digested residue and residual liquid are used for fertilizing crops; and inorganic substances separated from the garbage are used as raw materials to manufacture bricks, and clinker discharged from the incinerator or the gasification furnace is used for producing cement or fertilizer. The process, the system and the equipment comprehensively utilize the garbage so as to achieve complete dissolving treatment, and the equipment has a simple structure and low investment cost, and is easy to popularize..

Owner:周开根

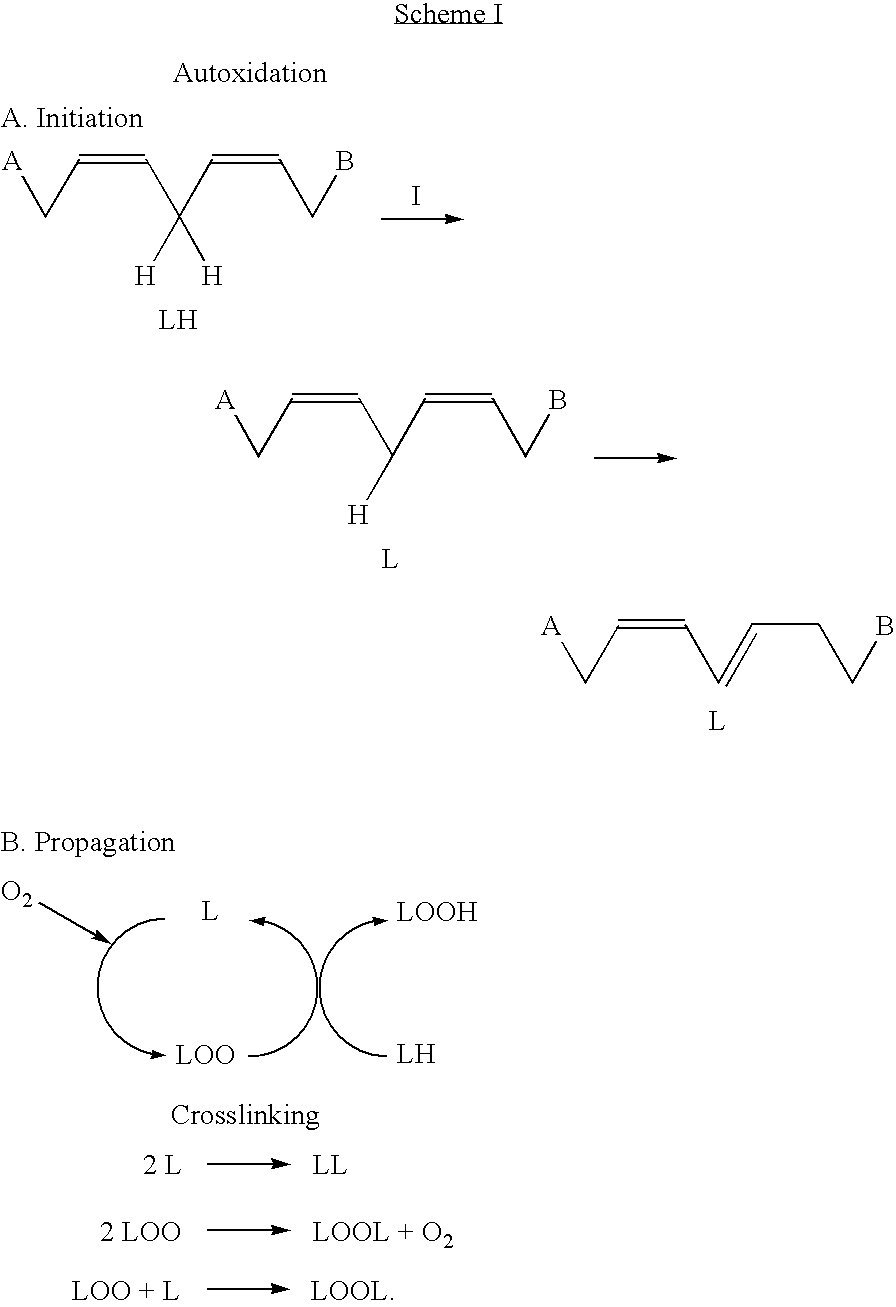

Drier for air-drying coatings

The invention pertains to a drier composition for air-drying alkyd-based coatings, inks, or floor coverings, comprising a combination of the following components: a) a transition metal salt with the formula: (Men+)(Xk−)m in which Me is the transition metal; X− represents a coordinating ligand; and k− is the valence state of the transition metal and m is the number of ligands X. b) a reducing biomolecule. The reducing biomolecule is in particular ascorbic acid or a derivative thereof, including ascorbyl palmitate.

Owner:ATO

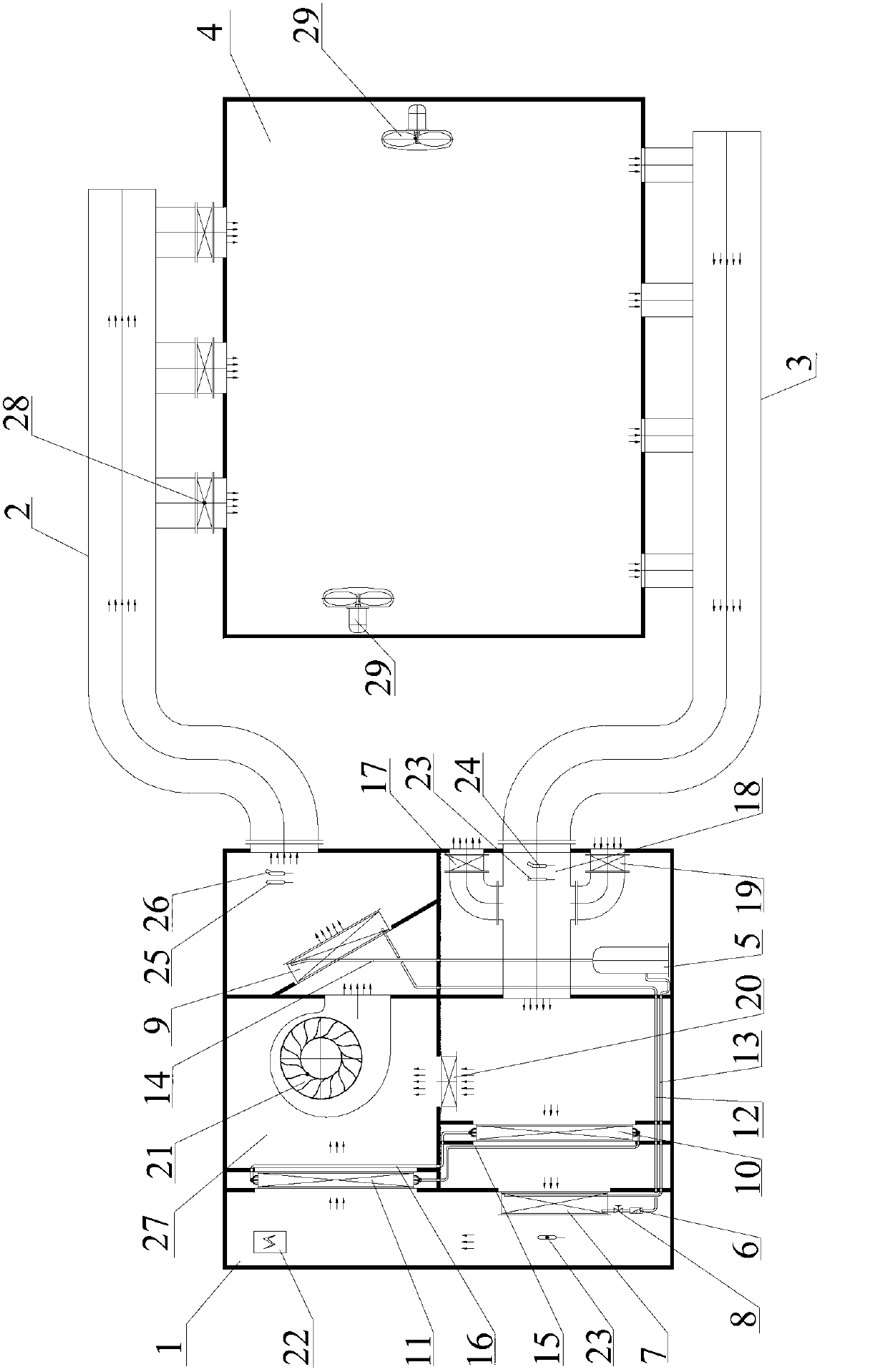

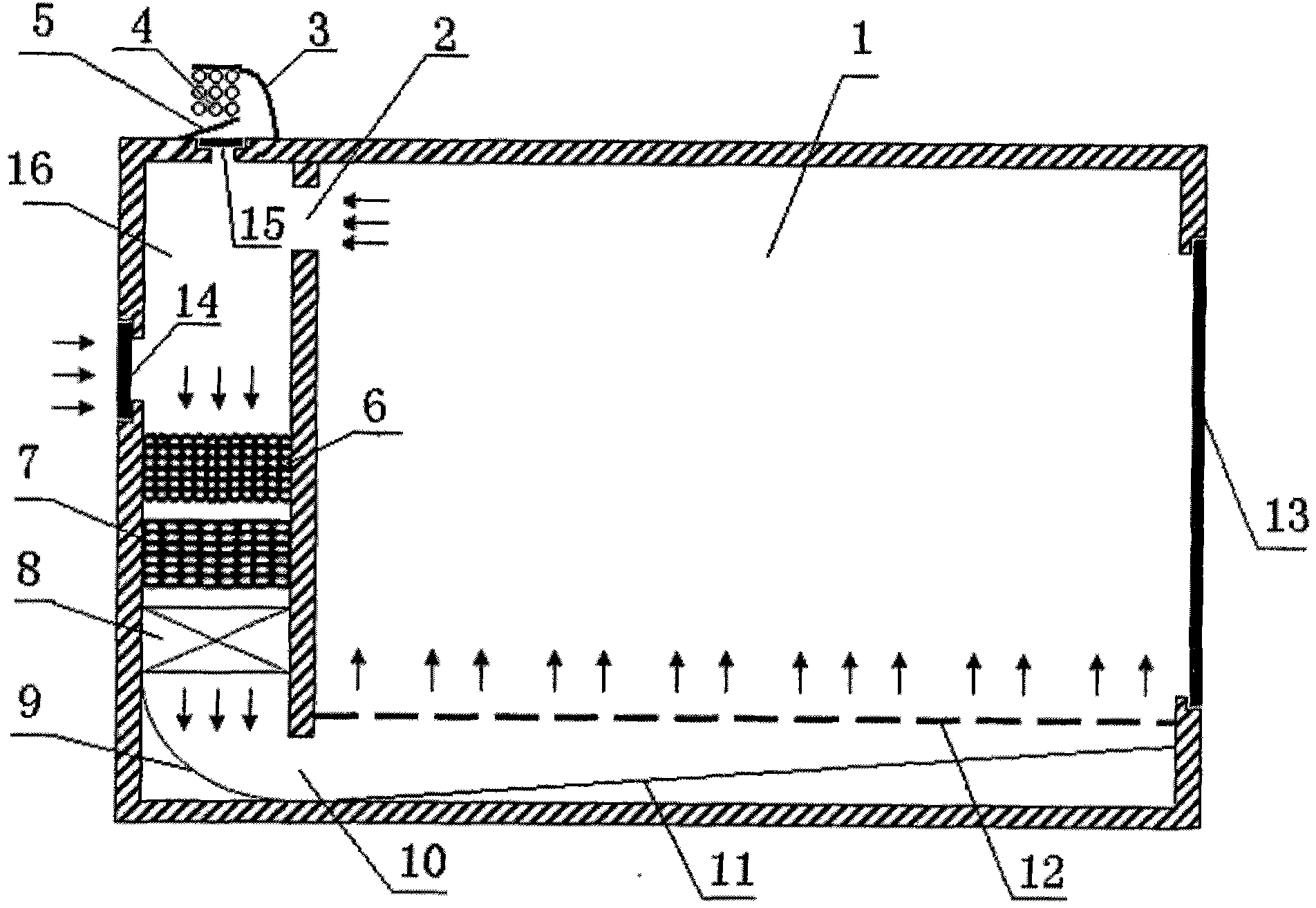

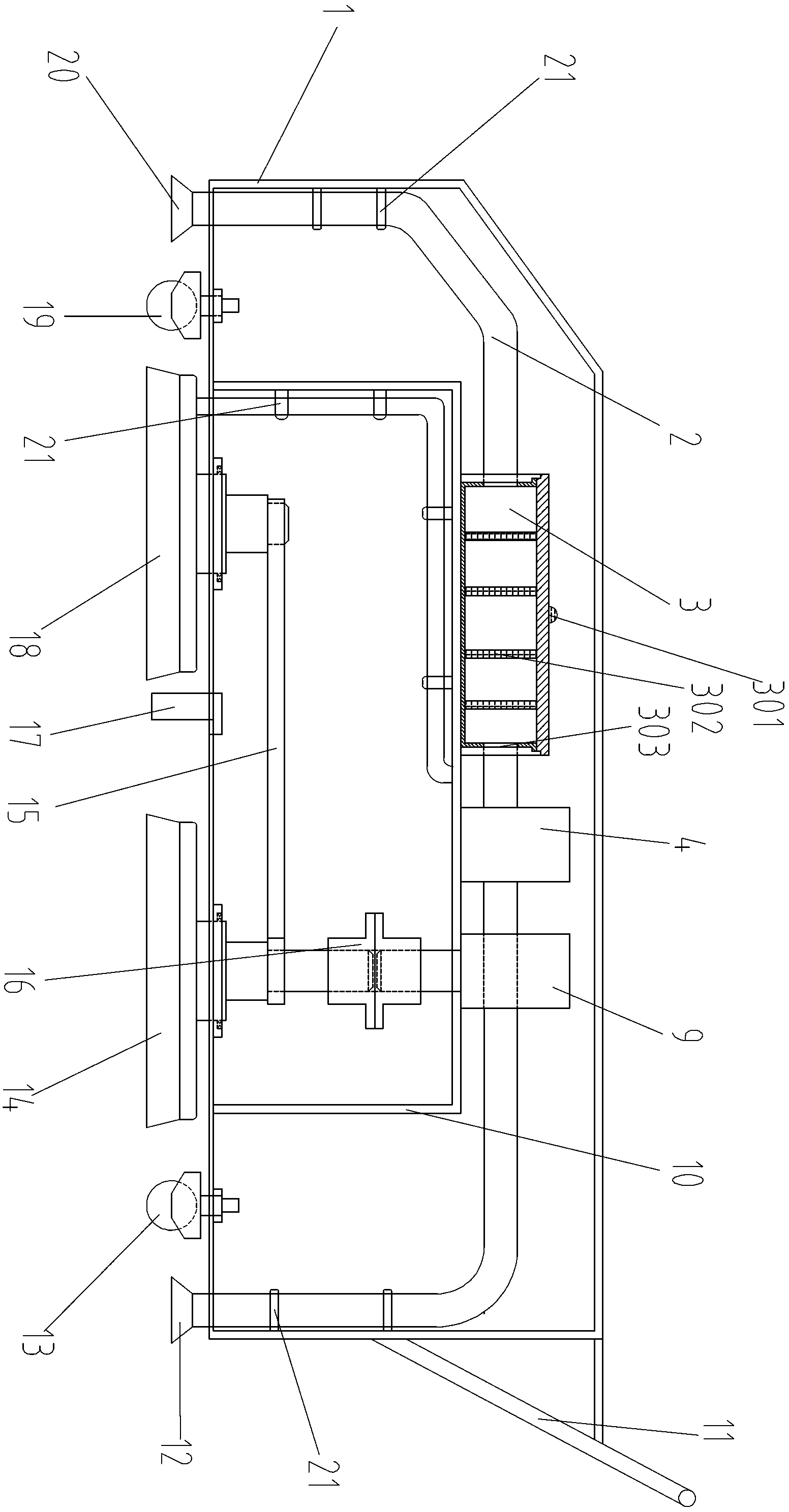

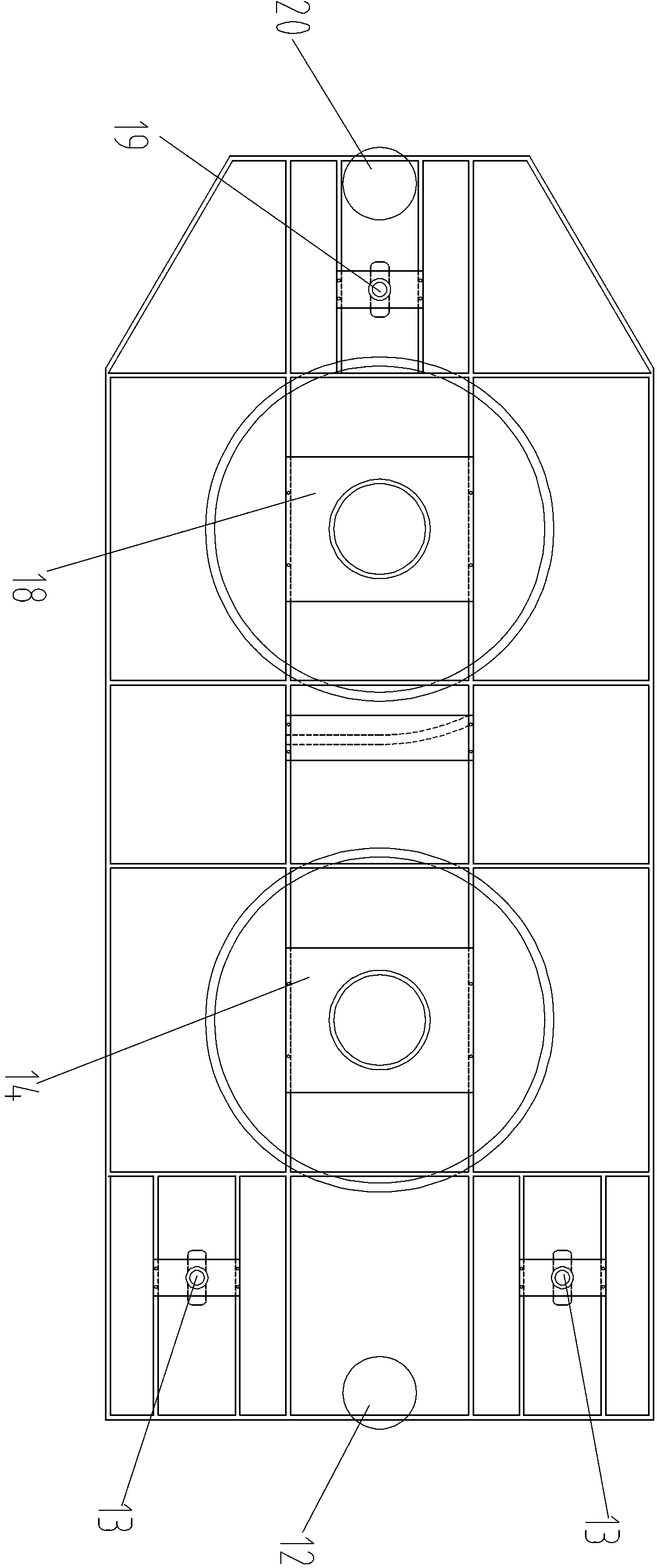

Intelligent hot-air drying control device

InactiveCN103123215AReduce energy consumptionReduced dehumidification loadDrying gas arrangementsEngineeringAir blower

The invention discloses an intelligent hot-air drying control device which comprises a heat exchange box and a drying chamber, wherein he heat exchange box is separated into multiple spaces, and the drying chamber is connected with the heat exchange box through an air supplying main pipe and a general air return pipe. A heat pump dehumidifying and heating system, a heat pipe return heat exchange system, a hot air circulating system and an intelligent control system are arranged in the heat exchange box. The heat pump dehumidifying and heating system which is composed of a compressor, a drying filter, a dehumidifying evaporator, a throttle valve and a heating condenser. The heat pipe return heat exchange system is composed of a heat pipe evaporator and a heat pipe condenser. The hot air circulating system is composed of a high-pressure refrigerant liquid connecting pipe, a low-pressure refrigerant return gas connecting pipe, a high-pressure refrigerant gas connecting pipe, a liquid refrigerant connecting pipe, a gas refrigerant connecting pipe, an air exhaust regulating valve, a mixed air box, a fresh air regulating valve, a secondary air flow regulating valve and an air blower assembly. The intelligent control system is composed of the a temperature sensor, a humidity sensor, a hot air temperature sensor and a hot air humidity sensor, wherein the temperature sensor, the humidity sensor, the hot air temperature sensor and the hot air humidity sensor are connected in the various systems. The intelligent hot-air drying control device can regulate the temperature and the humidity of drying air automatically and improve the material drying efficiency.

Owner:孙应真

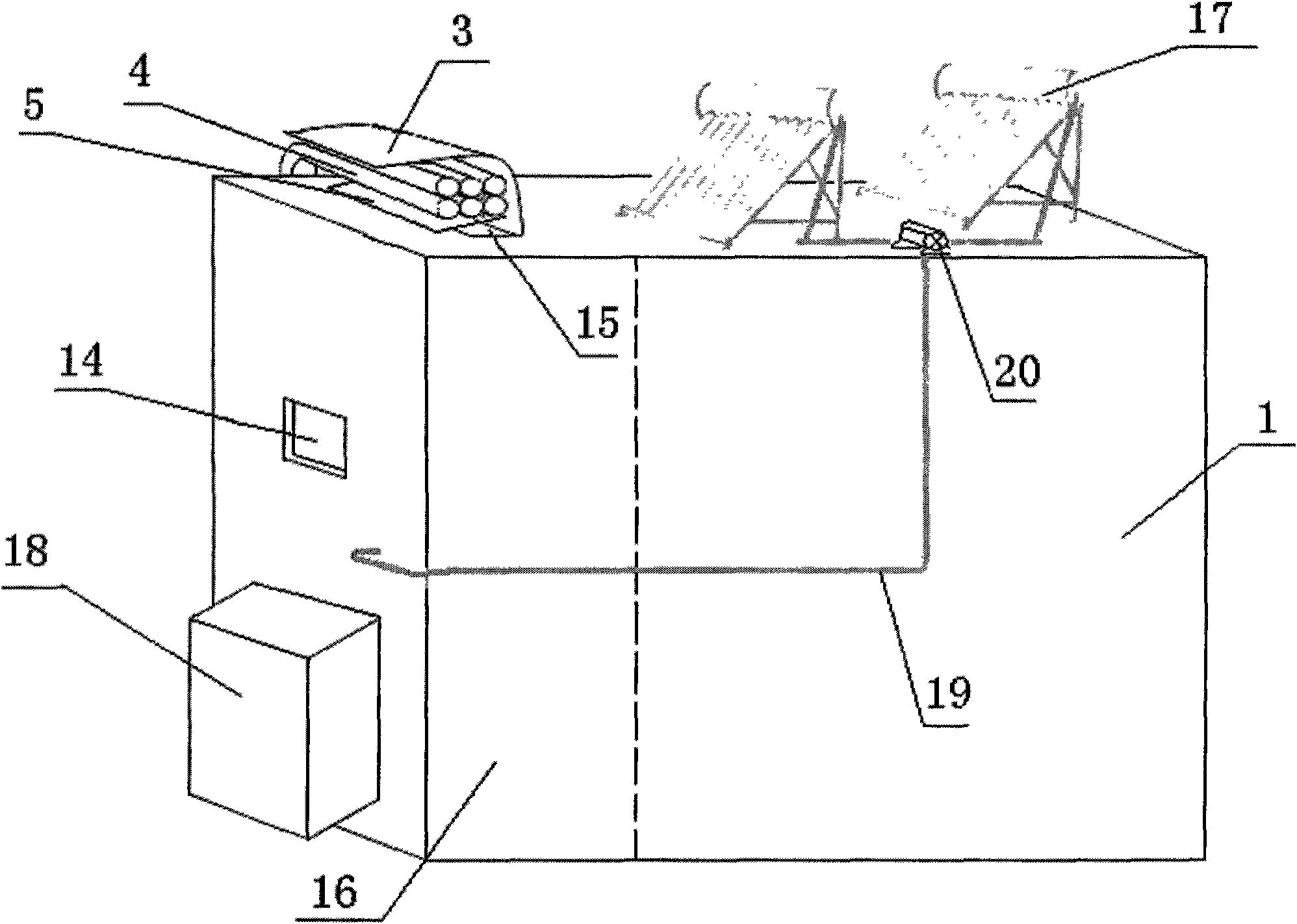

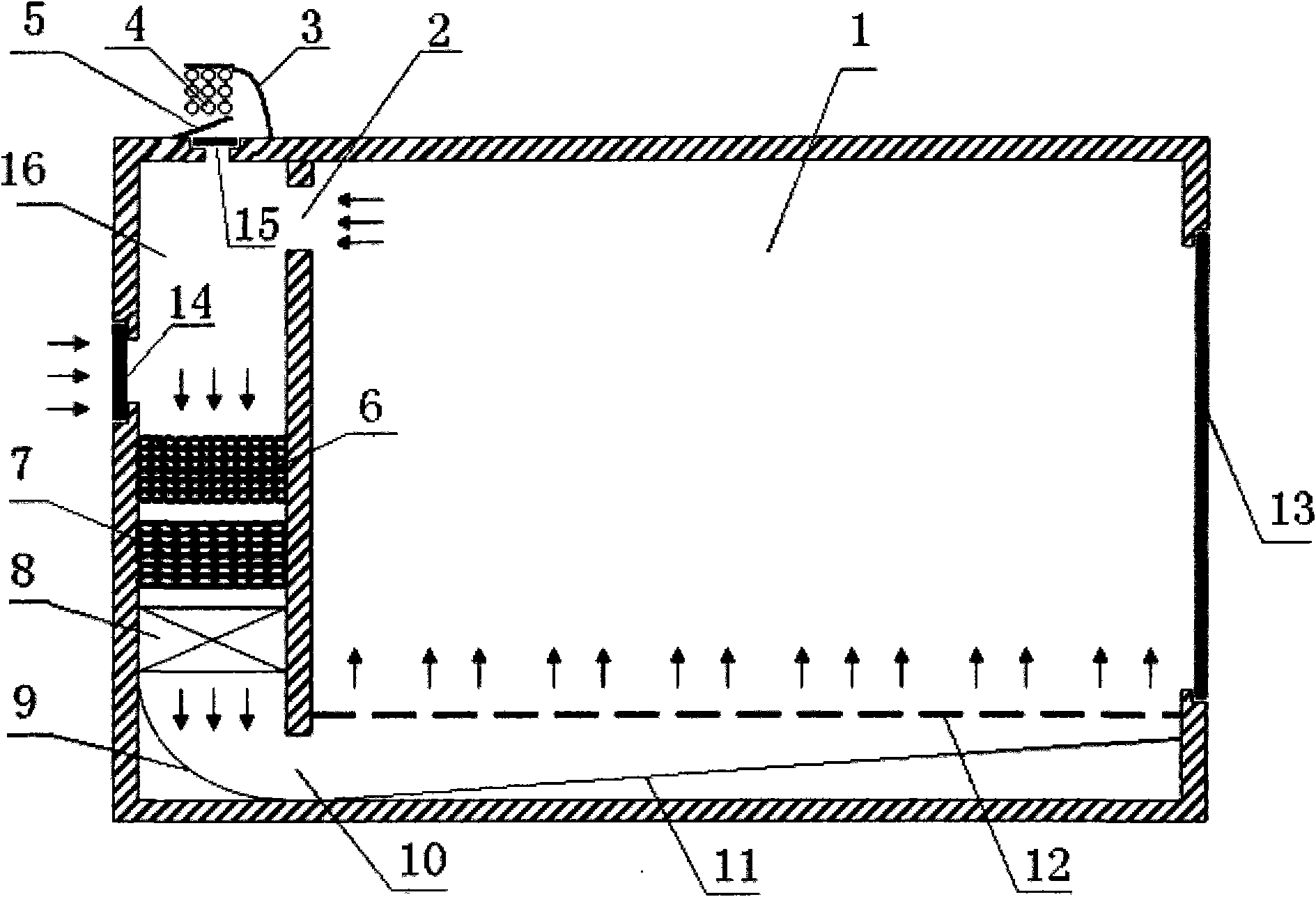

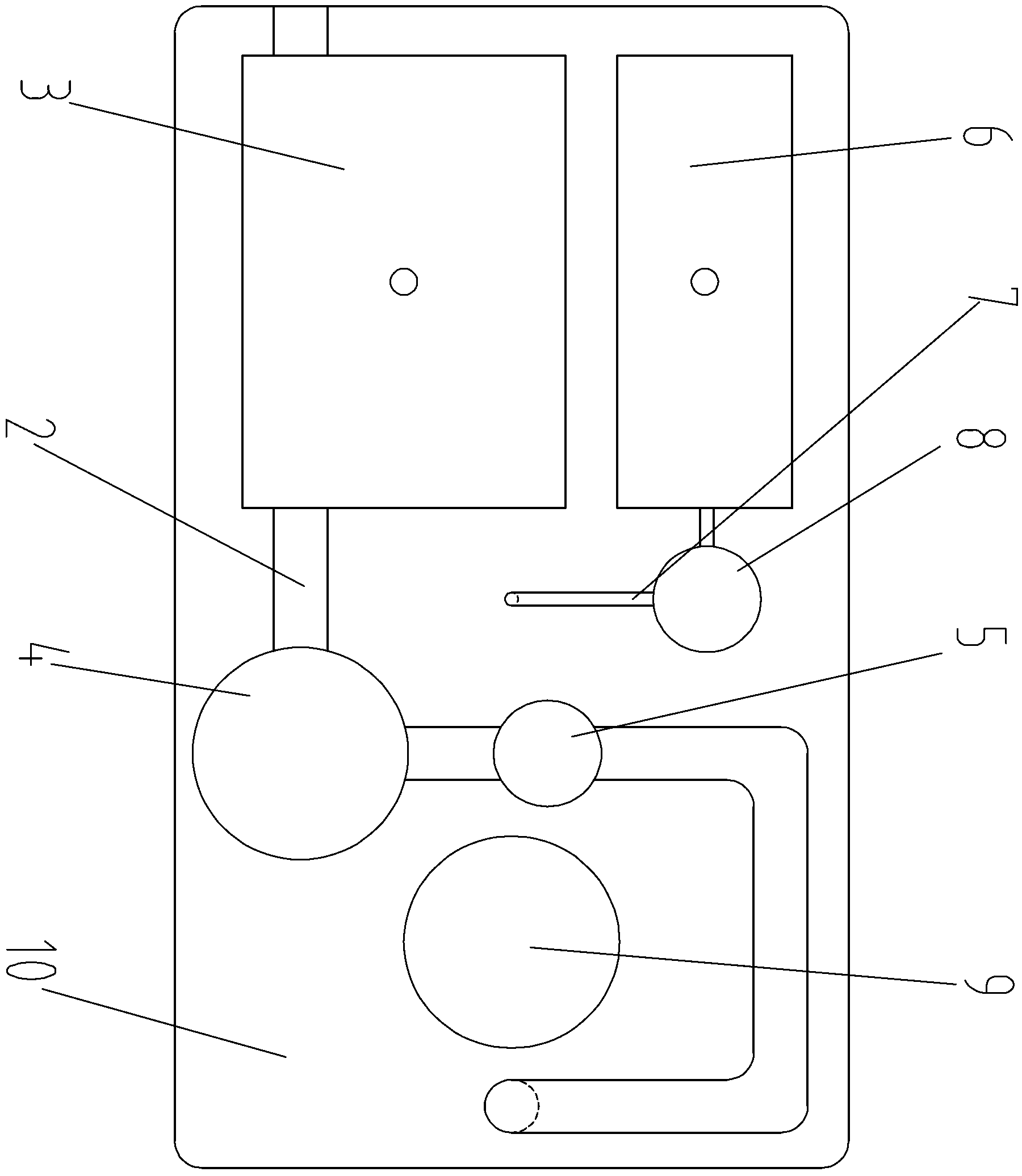

Hot air drying system heated by double energy sources

InactiveCN101936644AIncrease the heat exchange areaReduce deliveryTobacco preparationDrying solid materials with heatPlate heat exchangerBusiness efficiency

The invention discloses a hot air drying system heated by double energy sources, which comprises a heating chamber with a fresh air opening, a drying chamber, a solar heating device, an air source heat pump and a condenser fan of the air source heat pump, wherein the upper part of the heating chamber or the drying chamber is provided with a dehumidifying opening; a condenser and the condenser fan of the air source heat pump are arranged in the heating chamber; a hot water heat exchanger of the solar heating device is arranged at the front end of an air inlet of the condenser in the heating chamber; the condenser fan supplies air in an induced draft way; the ratio of the heat exchange area of the condenser to the input power of a compressor is 5.3 to 11 m<2> / kw; the ratio of the heat exchange area of the hot water heat exchanger to the input power of the compressor is not less than 1.5 m<2> / kw; and the total pressure of the condenser fan is 100 to 400 Pa. The hot air drying system heated by the double energy sources makes full use of solar energy as a hot air heat source for drying, solves the problems of the independent use of the solar energy, achieves high energy efficiency ratio by adopting the air heat pump as the hot air heat source, is energy-saving, environmentally-friendly and low in running cost, and manifests the advantages of the combined use of the air source and the solar energy in oven-drying.

Owner:湖南省浏阳市择明热工器材有限公司

Dried product and a drying process

InactiveUS6268012B1Minimize impactNot to damageFruits/vegetable preservation by dehydrationMeat/fish preservation by dryingWater activityFresh air

A dried fruit or vegetable has a water content in the range 4% to 7%, and has a water activity of 0.4. Substantially all of the cells of the dried product are undamaged. An air drying process is gentle and contains four phases, during which the temperature of the drying air is maintained at 60° C. In a first phase the relative humidity of the drying air is allowed to rise to between 50% and 55%, and is maintained substantially constant at this value during a second phase by maintaining exchange of the drying air with fresh air substantially constant. In a third phase of the process, the relative humidity of the drying medium is permitted to decrease relatively rapidly until the fourth phase commences, at which stage the relative humidity is permitted to asymptotically approach a predetermined relative humidity value. During the drying process, excessive temperature differences and relative humidity differences between the temperature and relative humidity, respectively of the drying medium and the product are avoided in order to minimize damage to the cellular structure of the product.

Owner:DTL

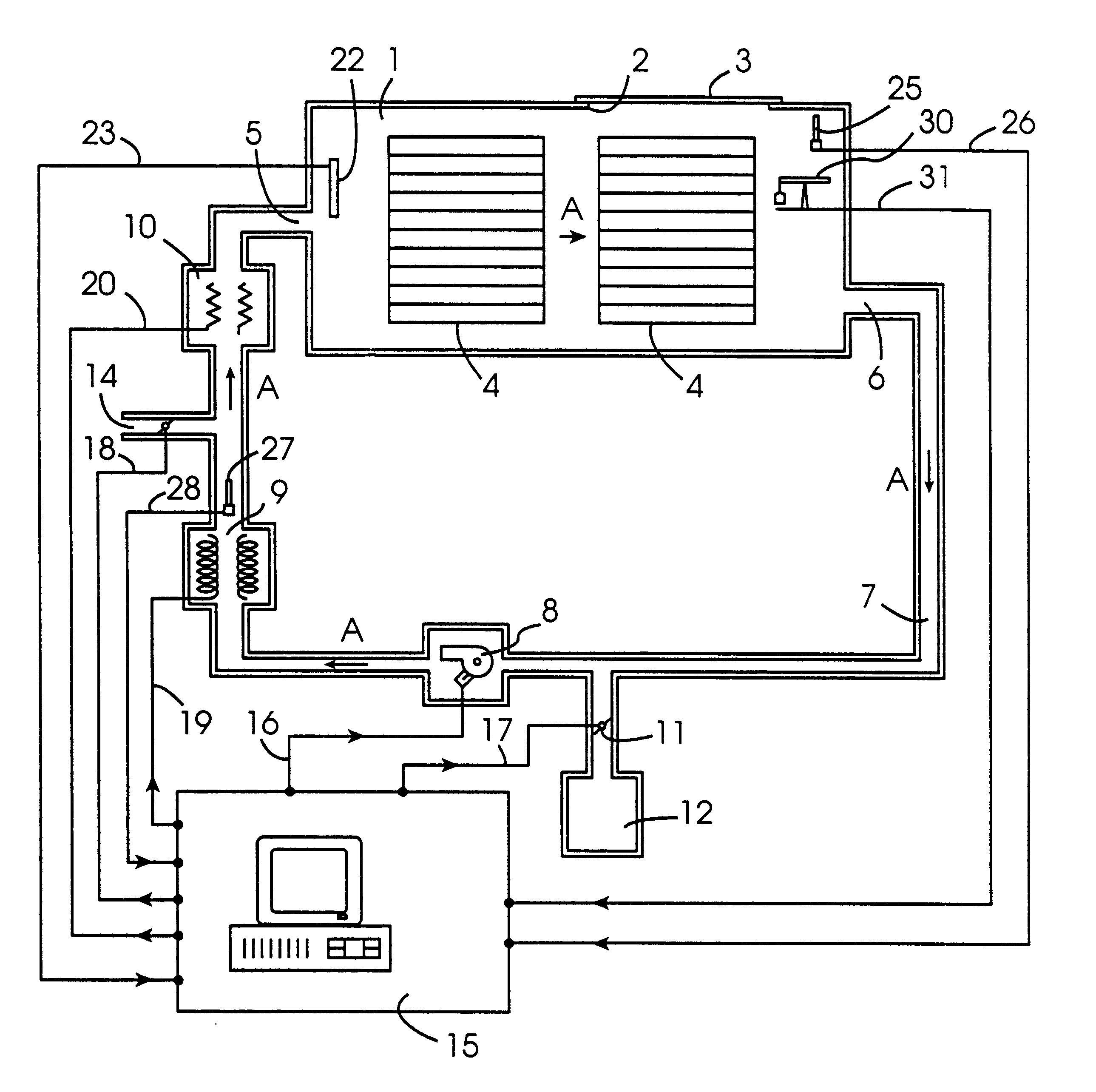

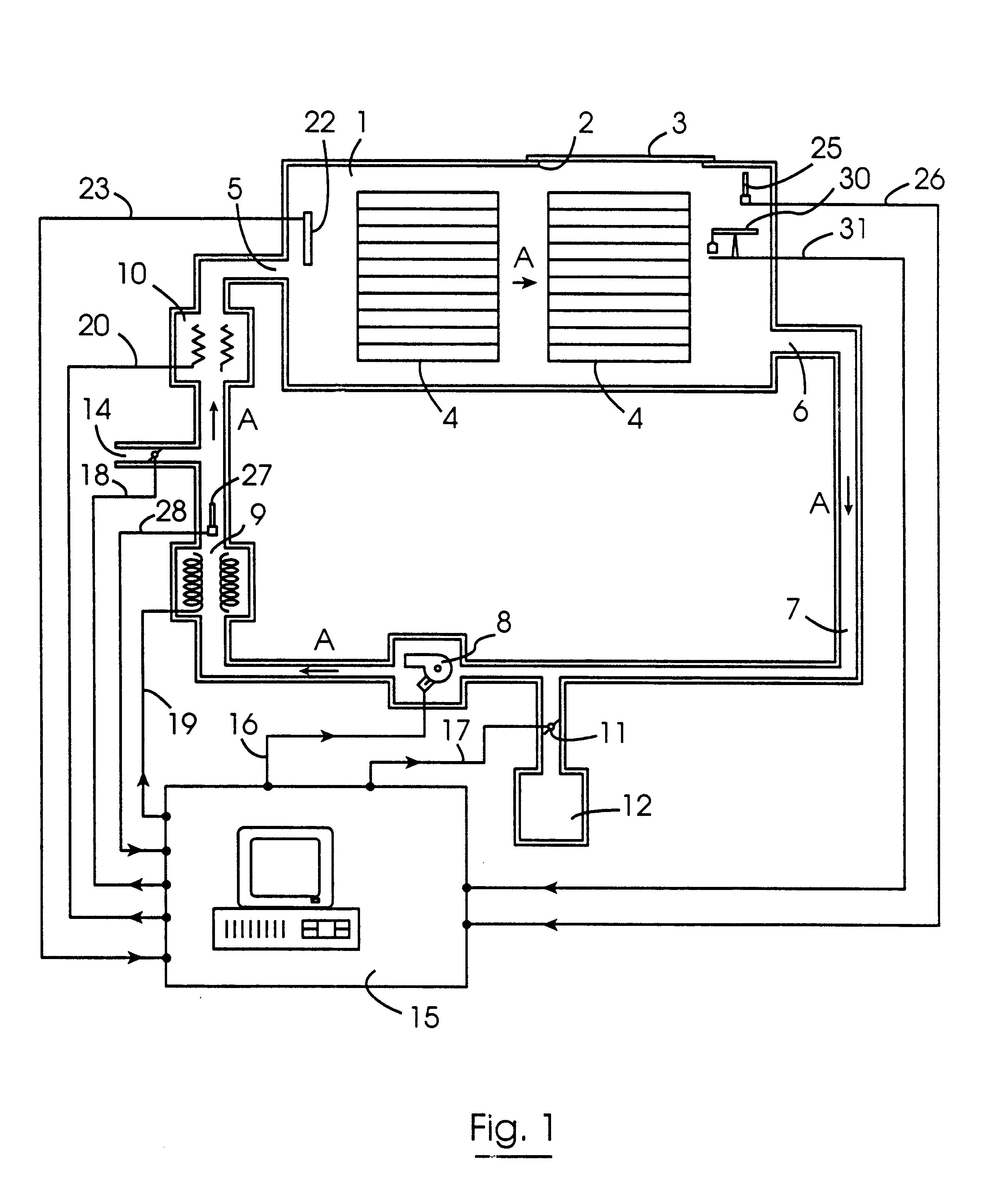

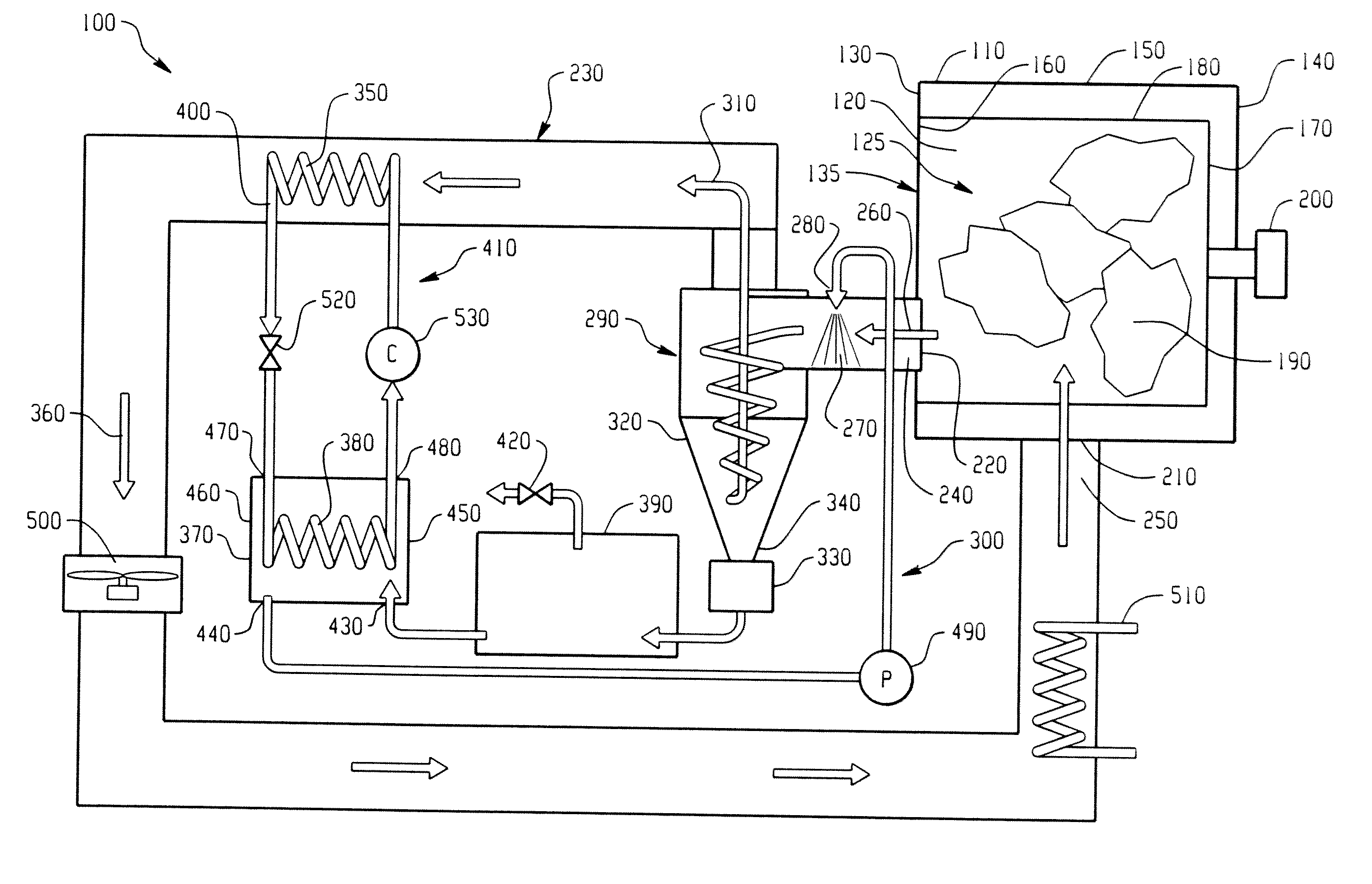

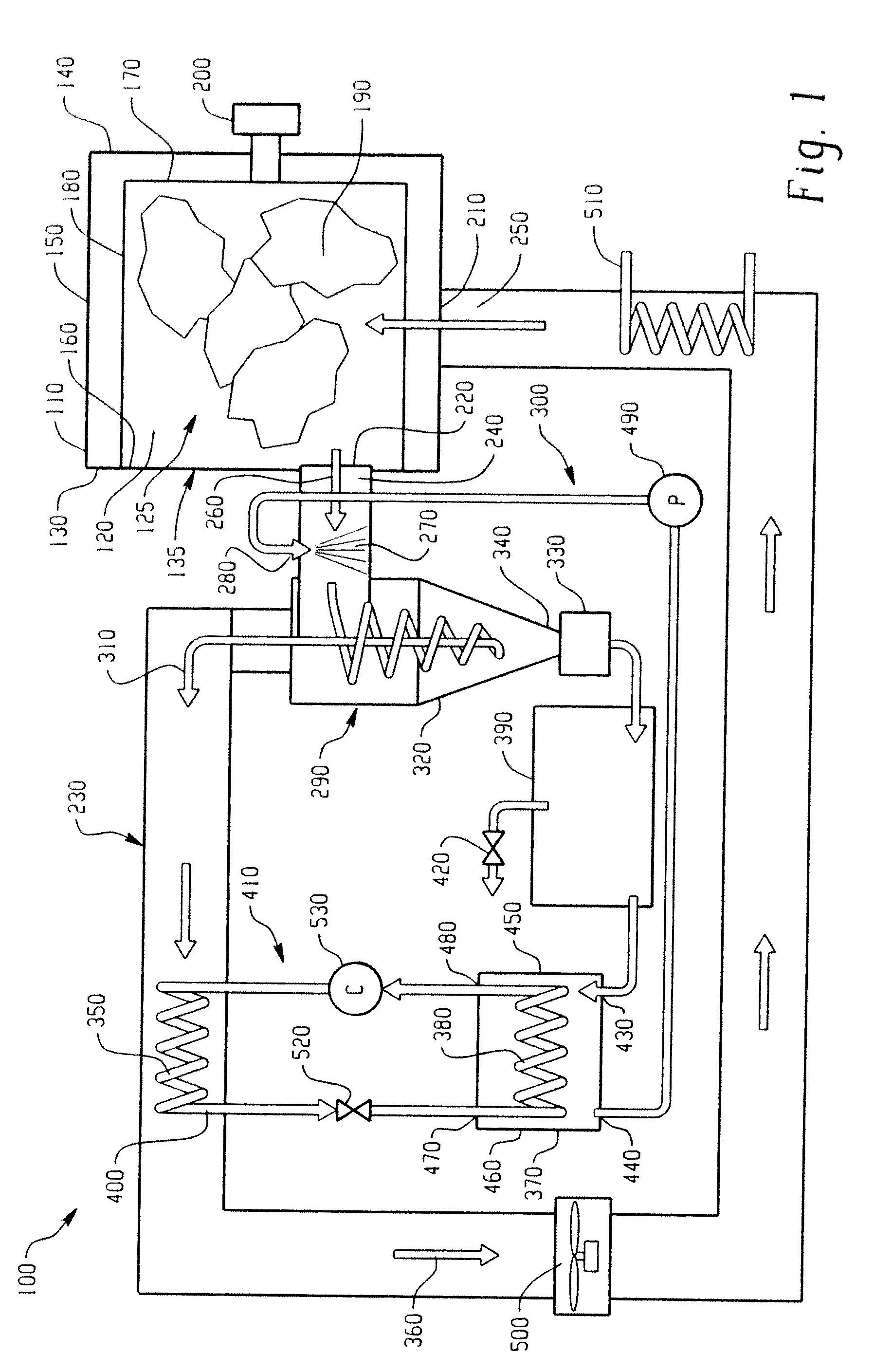

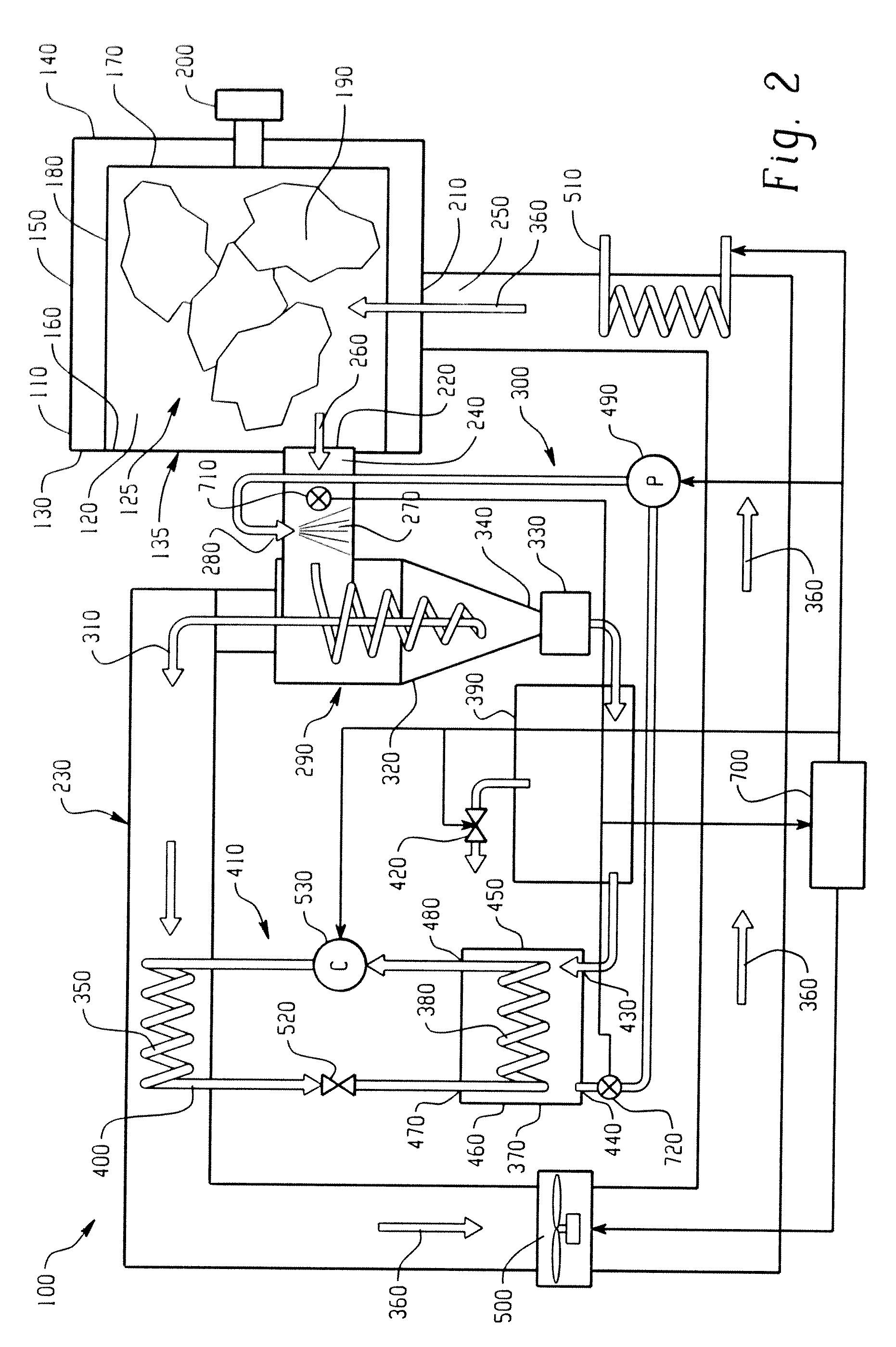

Device and method for heat pump based clothes dryer

ActiveUS20130008049A1Easy to useDrying solid materials with heatDrying gas arrangementsEngineeringRefrigerant

The present disclosure relates to a heat pump based dryer or a combination washer and dryer device comprising a housing receiving a drum for containing associated articles to be dried by air that flows along a pathway between an outlet and an inlet of the housing. A fluid is provided in the pathway to at least partially remove moisture from the air. A heat pump includes a heat source located at least partially within the pathway and a heat sink being operatively adapted to the heat source to circulate a refrigerant therein. An enclosure at least partially containing the heat sink is arranged to accept the fluid from the pathway to exchange heat with the heat sink and return the fluid to the pathway. Fluid may be provided to the pathway by a spray nozzle adjacent the outlet or by an evaporative media downstream of a lint separator.

Owner:HAIER US APPLIANCE SOLUTIONS INC

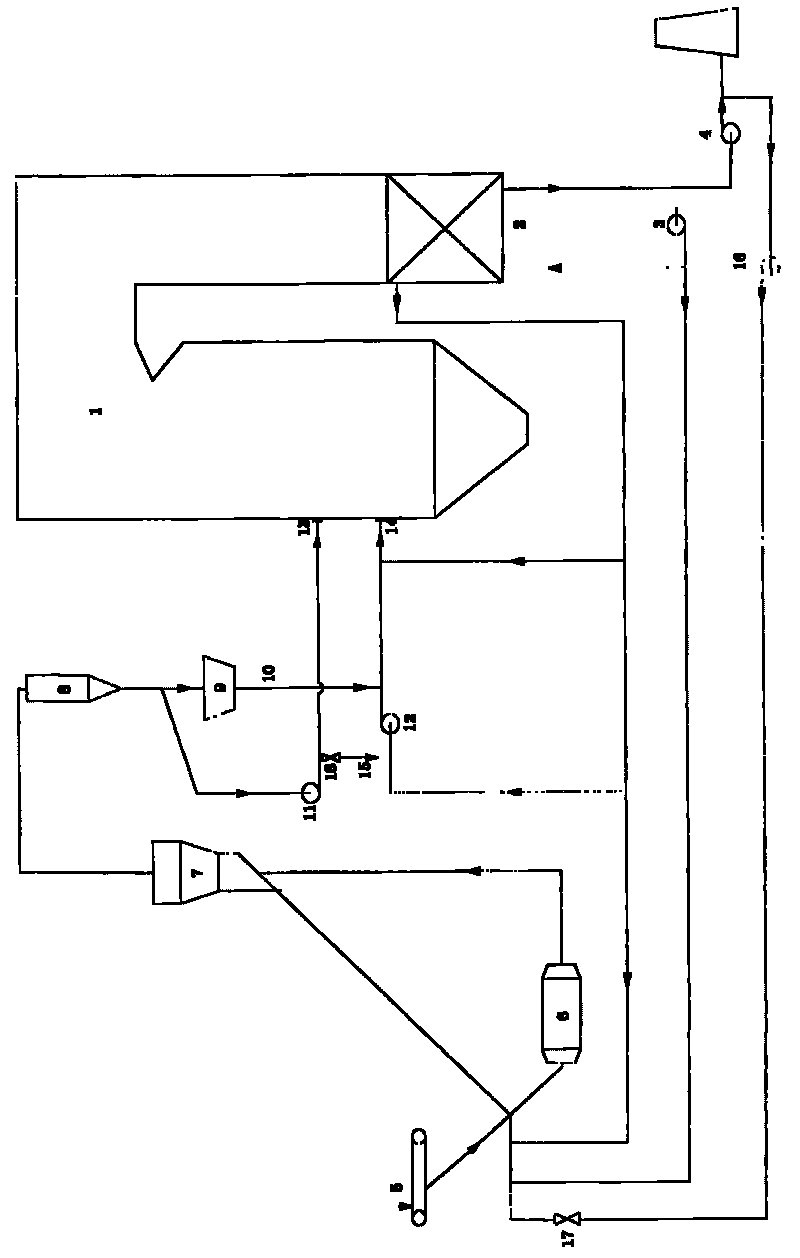

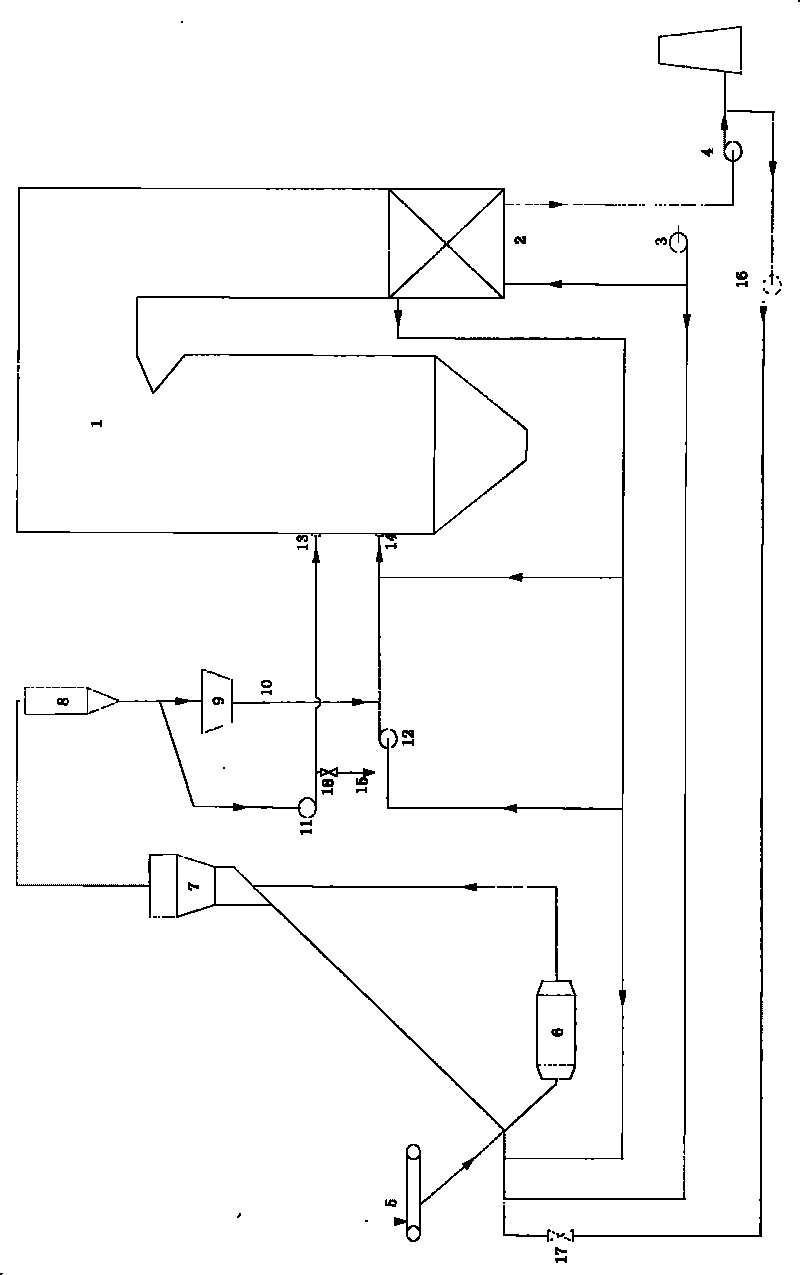

Low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system

ActiveCN101761933ALow oxygenReduce the temperatureGrain treatmentsLump/pulverulent fuel feeder/distributionAir preheaterPowder mixture

The invention relates to a low-temperature furnace smoke sucking exhaust gas and hot air drying composite powder feeding bituminous coal and meagre coal universal type powder preparing system. A middle bin storage type steel ball coal mill hot air power feeding and meagre coal power preparation system is adopted as a prototype, and part of low-temperature furnace smoke is sucked from an outlet of a suction fan by a furnace smoke fan as an inert medium and part of drying mediums to be mixed with hot air taken from an outlet of an air preheater to enter a coal mill for drying and delivering coal powder; the oxygen content of the powder preparation system is reduced, and the explosion preventing requirement on grinding bituminous coal can be met. In addition, part of exhaust gas at an outlet of a power exhauster is led to an inlet of a heat primary fan by an exhaust gas transfer pipeline to be mixed with hot air to enter a primary bellows for delivering the coal powder; the temperature of a primary air and powder mixture and the oxygen concentration of the system are effectively reduced, and the combustion and explosion preventing requirement of bituminous coal delivery is met. Isolating doors are both installed on a furnace smoke system and an exhaust gas transfer system; by the switch control of the isolating doors, the switching of a typical hot air power feeding meagre coal system and a low-temperature furnace smoke exhaust gas and hot air drying composite powder feeding bituminous coal system is realized, and the invention is not only suitable for the meagre coal, but also suitable for the bituminous coal.

Owner:XIAN THERMAL POWER RES INST CO LTD

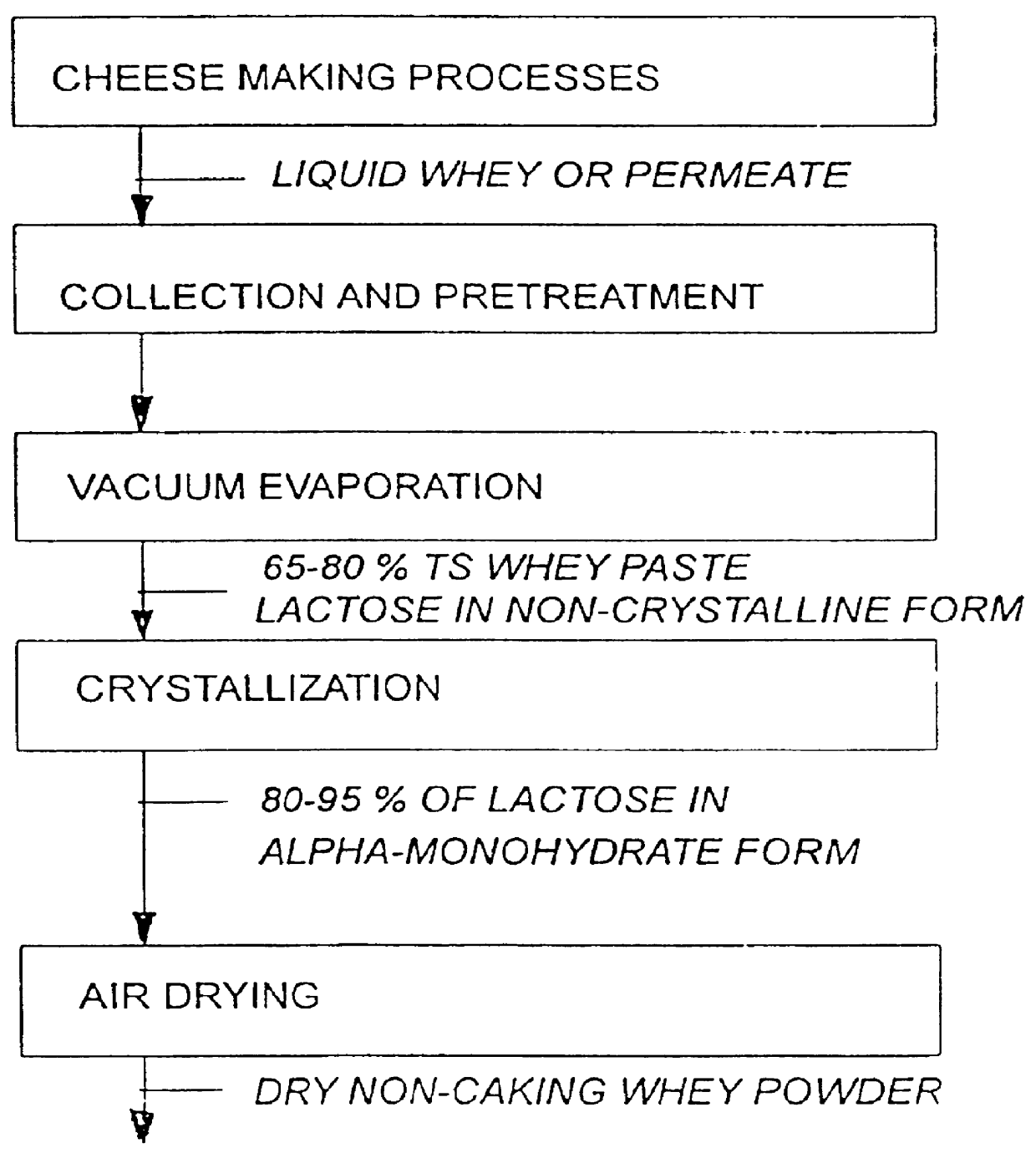

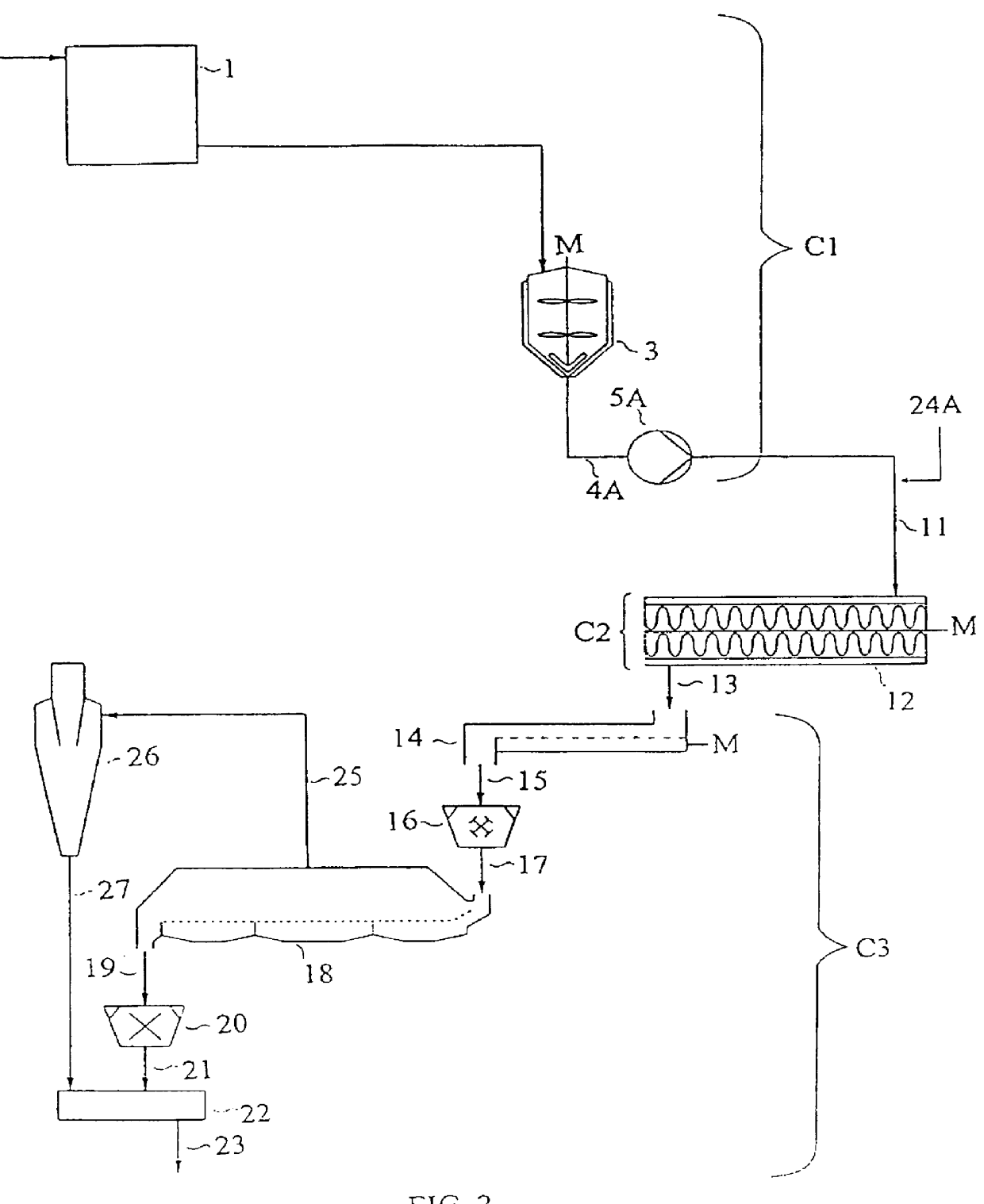

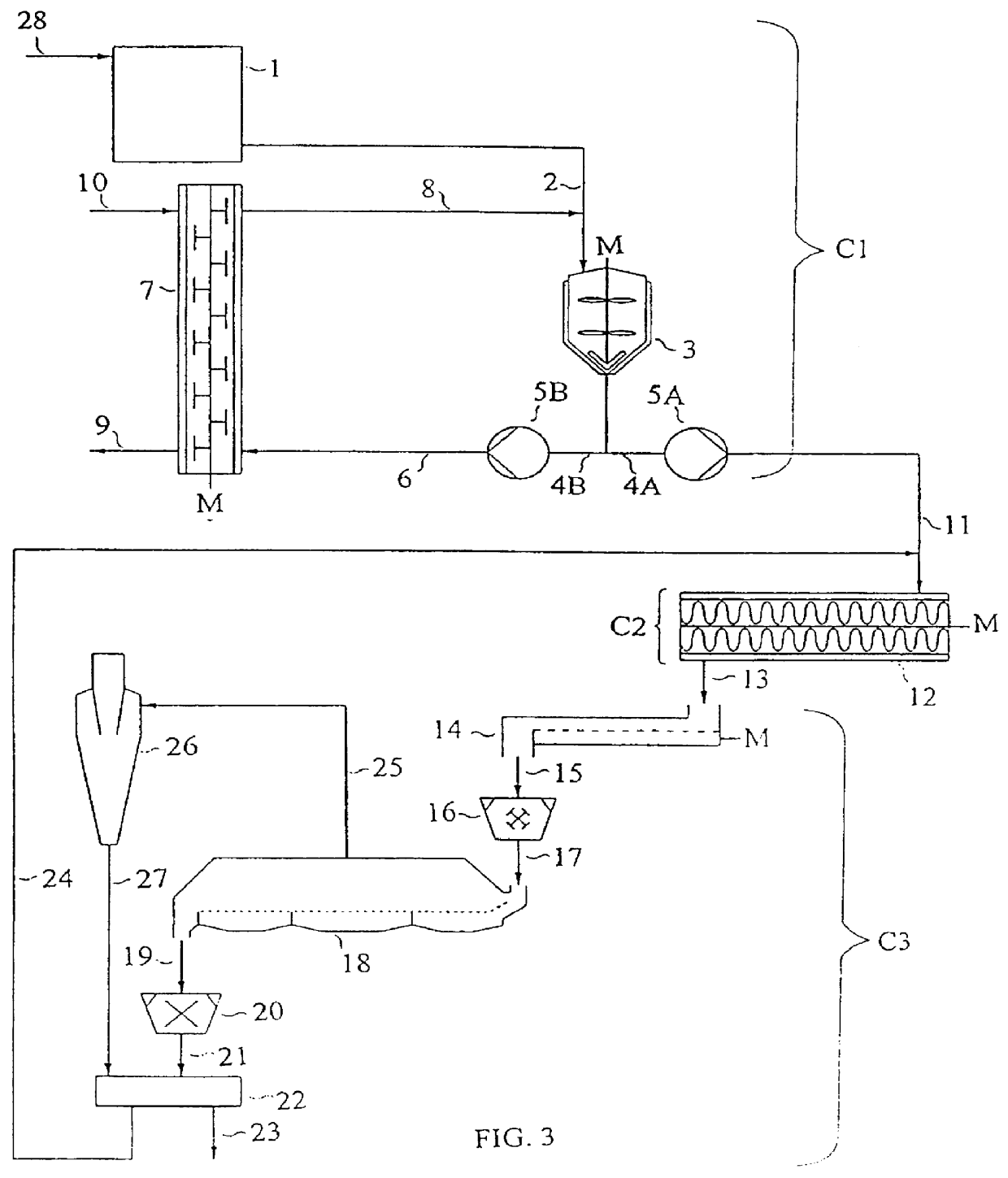

Process and apparatus for converting liquid whey into powder

InactiveUS6048565AIncrease contentHigh nutritional valueMilk preparationMilk preservationSolid contentVacuum evaporation

Owner:SPX FLOW TECH DANMARK

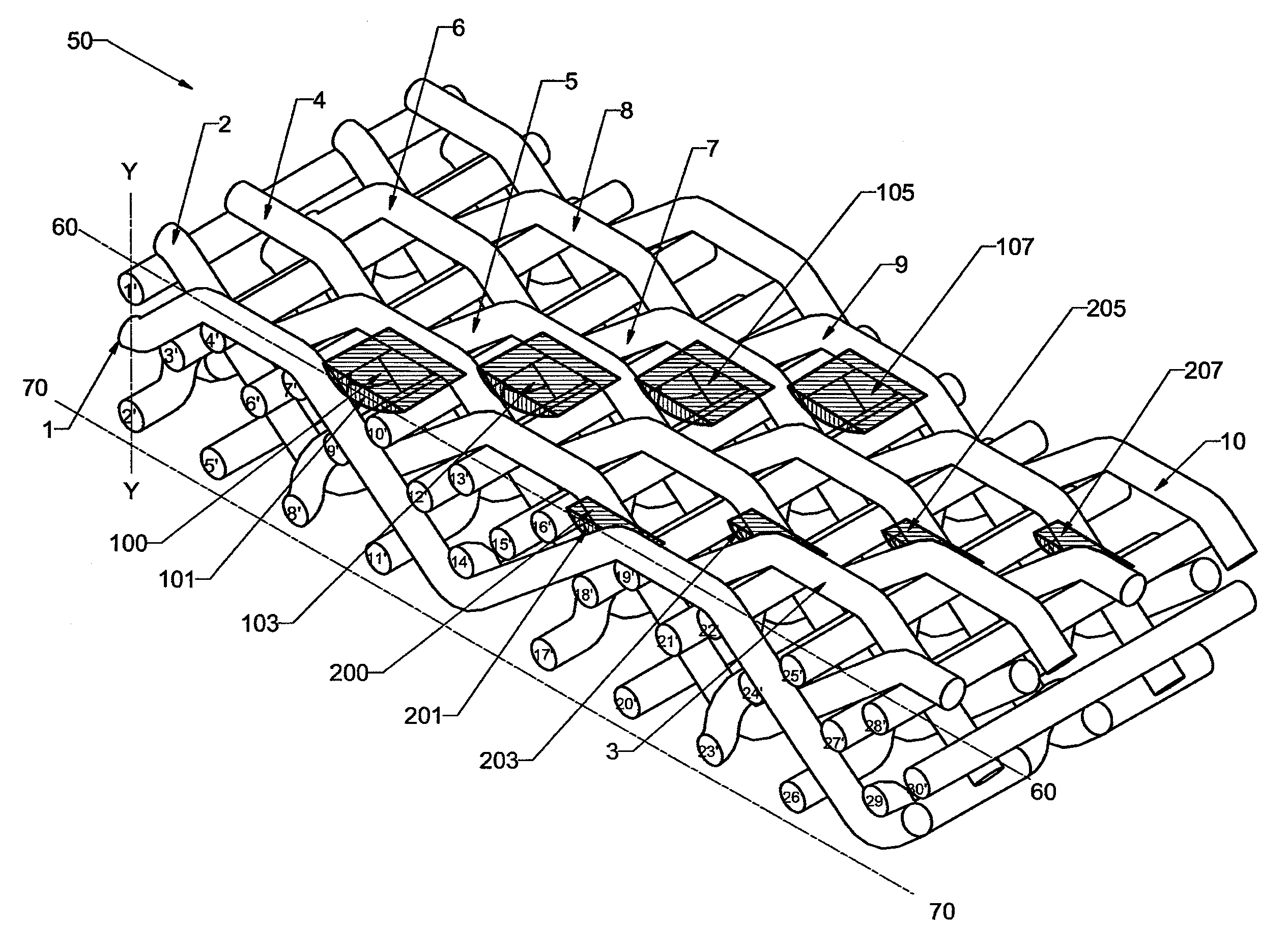

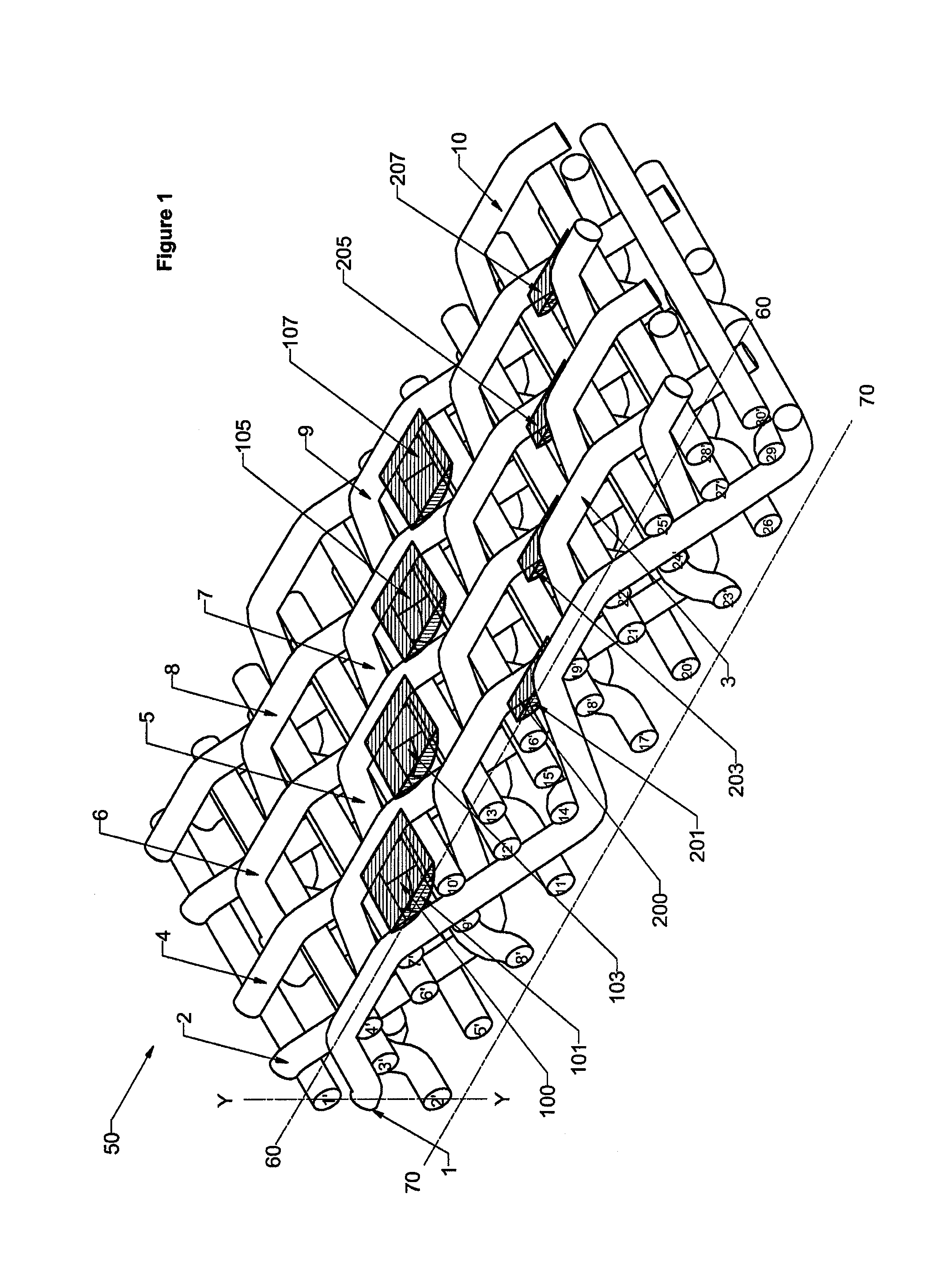

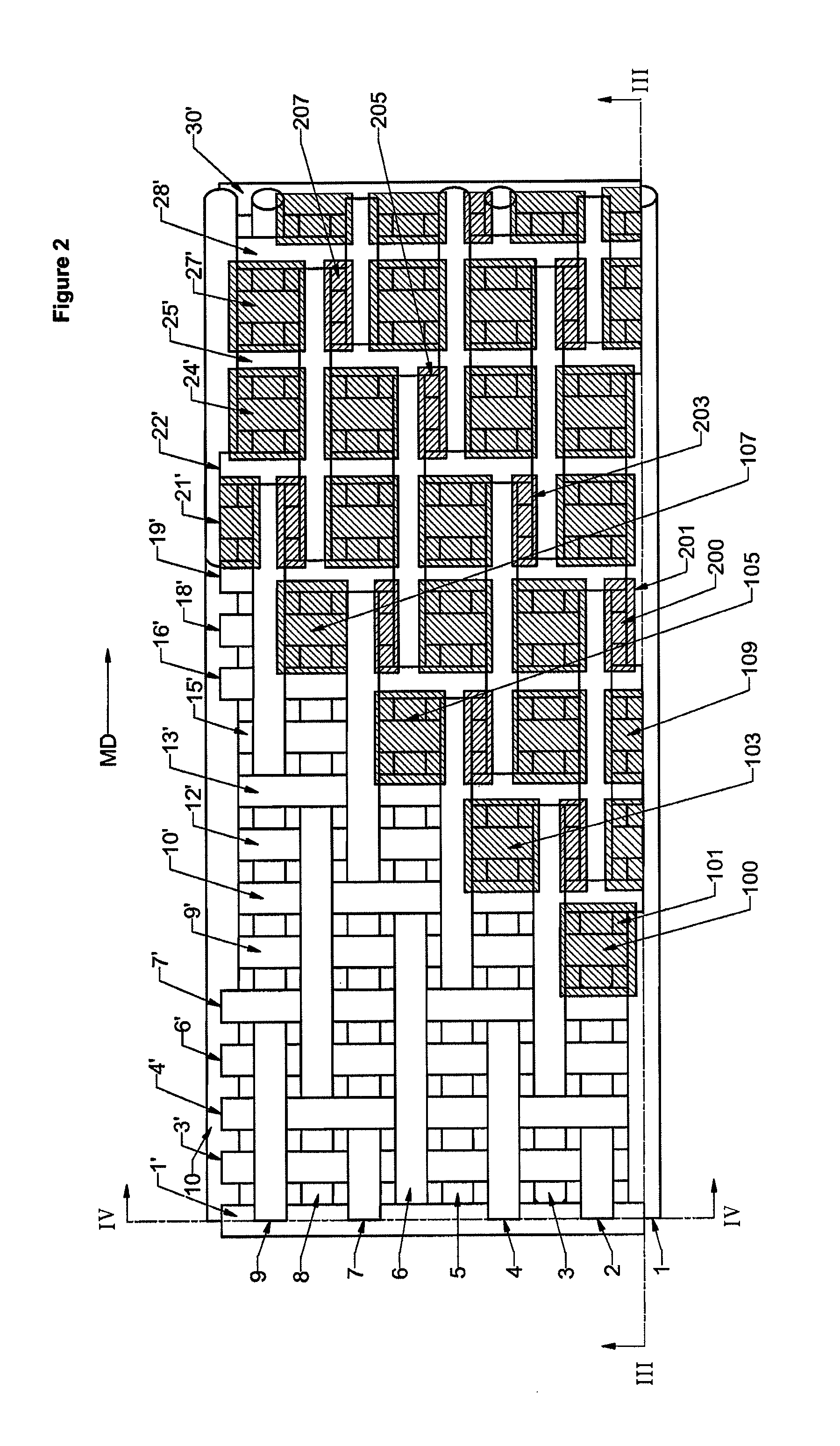

Double layer papermakers fabric with pockets for bulk enhancement

InactiveUS7493923B2Impart surface roughnessSignificant formMachine wet endPress sectionEngineeringWeft yarn

A double layer papermakers' fabric that is particularly suitable for forming or through-air drying (TAD) of high bulk tissue and towel product is provided. The fabric includes a single warp yarn system interwoven with three weft yarn systems such that: a first of the weft yarn systems is located on the paper side (PS) surface of the fabric; a second of the weft yarn systems is located on the machine side (MS) surface of the fabric; and the third weft yarn system is located intermediate between the first and second weft yarn systems. The yarns of the first and second weft yarn systems are interwoven with the warp yarn system such that they are vertically stacked with respect to one another in the fabric. The yarns of the third weft yarn system are interwoven so as to be located in a central plane of the fabric that is intermediate of the first and second weft yarn systems, and each yarn of the third yarn system is located in between the vertically stacked pairs of weft yarns of the first and second weft yarn systems. The warp and weft yarn systems are interwoven according to an asymmetric design which provides generally rectangular pockets on each of the PS and MS of the fabric with the yarns of the third weft yarn system forming the “bottom” of each pocket. There may be from about 50 to 750 pockets per sq. in. of fabric, each ranging in depth from about 0.1 mm to about 1.0 mm in depth; these pockets impart unevenness to the fabric surface which assists in creating bulk in the sheet formed or conveyed thereon. The fabrics of the invention also offer low sheet contact area, typically less than 30% of the total fabric surface, and generally in the range of from 15% to about 20%. The fabrics are also highly air permeable to ensure good air flow and drainage of the sheet.

Owner:ASTENJOHNSON

Nutritional porridge mixture and preparation method thereof

InactiveCN104351659AEasy to changeBalanced NutrientsClimate change adaptationFood preparationFood additiveAdditive ingredient

The invention relates to a nutritional porridge mixture and a preparation method thereof, belonging to the technical field of production and processing of nutritional foods. The food mixture consists of coarse cereals, vegetables, fruits, dried fruits, nuts, seeds, beans, funguses, alga and special foods. According to various characters and different qualities of the foods, the foods are treated by a method and a process of washing, soaking, washing, airing, steaming, boil-drying, air drying and sun drying, then the dried food products are mixed together, milled in a flour mill and sent to a molding machine to be prepared into oatmeal, and finally the products are subjected to vacuum packaging under the illumination of an ultraviolet sterilizing lamp. The nutritional porridge disclosed by the invention is free of any food additives, anti-corrosive agents, sugar, salt and the like, so the original taste and flavor as well as the natural nutritional ingredients and effects of the foods are retained.

Owner:杨征宇

Process for producing stephanoporate composite inorganic phase-changing material

InactiveCN101294064APrevent crystallizationGuaranteed thermal stabilityHeat-exchange elementsPhase-change materialInorganic materials

The invention relates to the preparation method of a composite porous inorganic phase-change material. The preparation method of the composite porous inorganic phase-change material is characterized in that the method comprises the following steps: (1) selecting a hydrate phase-change material, a porous material and a hole sealing agent in a weight ratio of (10 to 15):(5 to 10):1 for later use, wherein the hydrate phase-change material is an inorganic material with hydrate crystals, and the porous material has micropores within the range of 1 to 1,000 nm; and (2) adding the hydrate phase-change material into water to obtain saturated solution, adding into the porous material, stirring, aging for 12 to 48 h, adding the hole sealing agent, stirring completely for 4 to 8 h, air-drying, and crushing to obtain the porous inorganic phase-change material. The method solves the stability problem of the phase-change material as well as the problem in compatibility of the phase-change material with other construction materials, and has the advantages of simple process and low cost.

Owner:WUHAN UNIV OF TECH

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

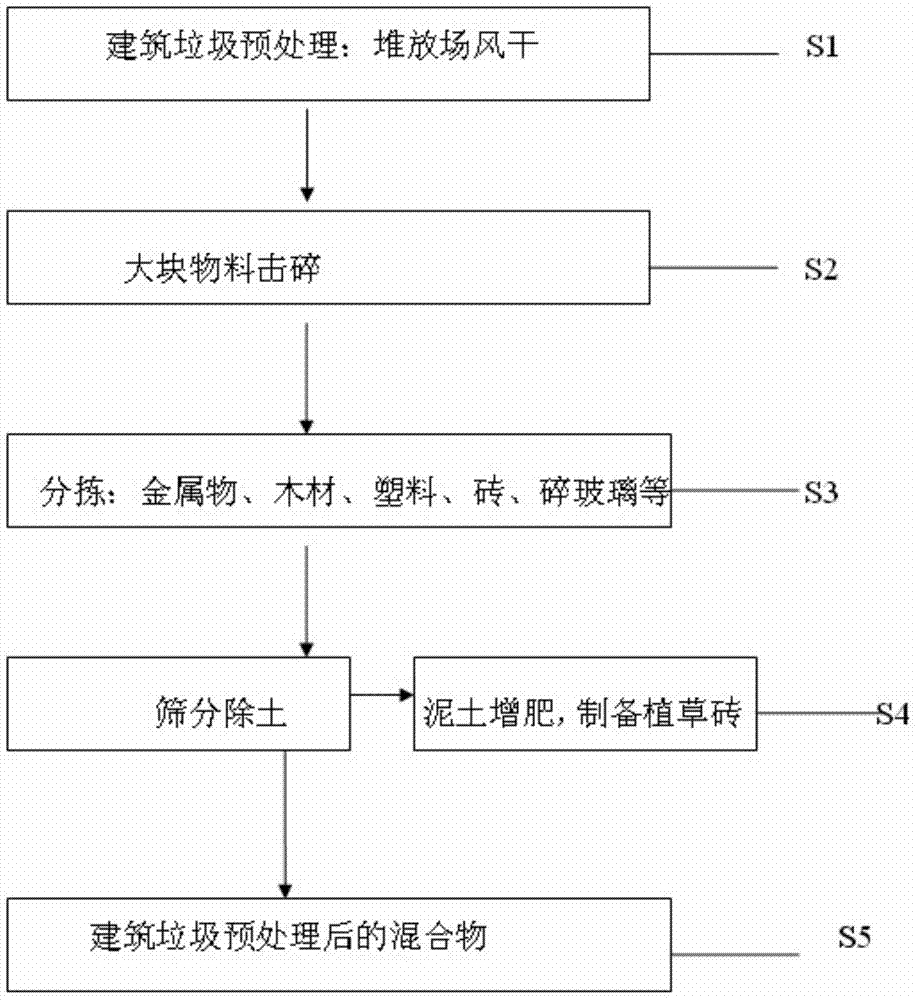

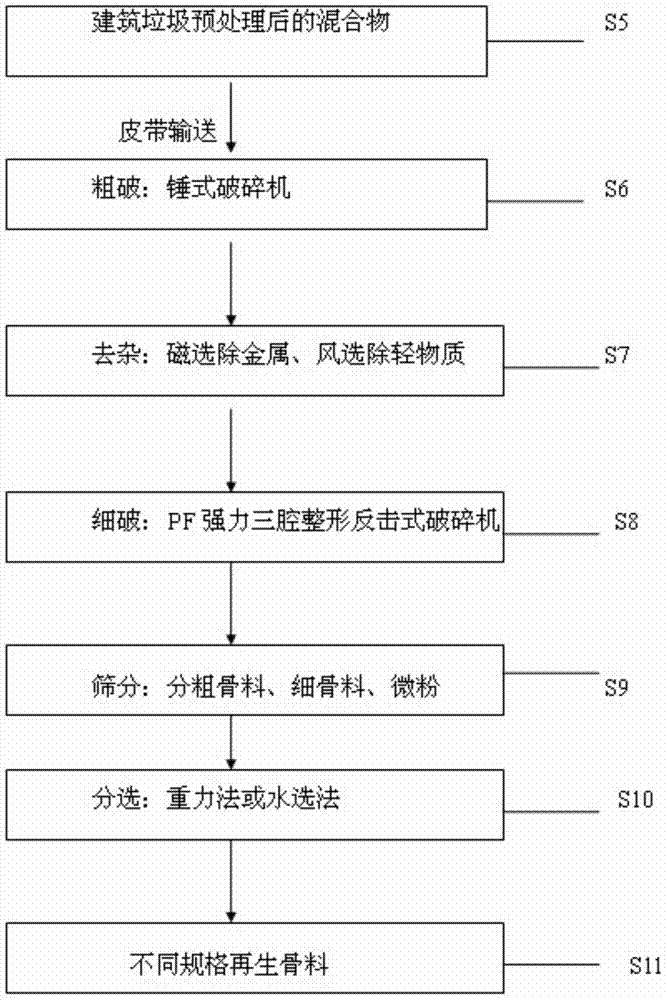

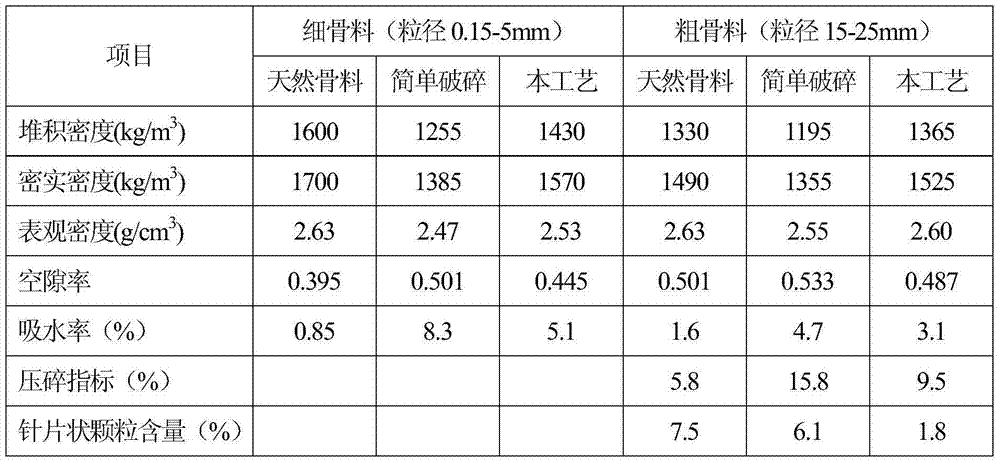

Ecological treatment technology for construction waste

The invention belongs to the field of recycling of construction waste, energy conservation and environment protection, and construction materials, and relates to an ecological treatment technology for construction waste, and particularly relates to the ecological treatment technology for construction waste and a preparation method for regenerated novel construction materials, which can efficiently use the construction waste and does not generate secondary pollution. The ecological treatment technology comprises the following steps of pretreating in a construction waste dump, namely, air drying the construction waste, crushing big blocks, sorting and removing soil through vibrating, adding a fertilizer in the soil to be used for filling grass planting bricks; preparing recycled aggregate, namely, crushing roughly, removing impurities, precisely crushing and simultaneously reinforcing and shaping the recycled aggregate, screening out the recycled aggregate with particle size less than 0.15mm as well as 0.15-5mm, 5-15mm and 15-25mm and micro powder for the secondary time, finally, separating the brick from concrete by a gravitational method or a hydraulic mineral beneficiation method according to different densities of the brick and concrete in the mixed recycled aggregate. Recycling and high value-added utilization of the construction waste are realized, and the ecological treatment technology gets major breakthrough in recycling industry of construction waste.

Owner:DALIAN HONG YUAN GREEN BUILDING MATERIALS

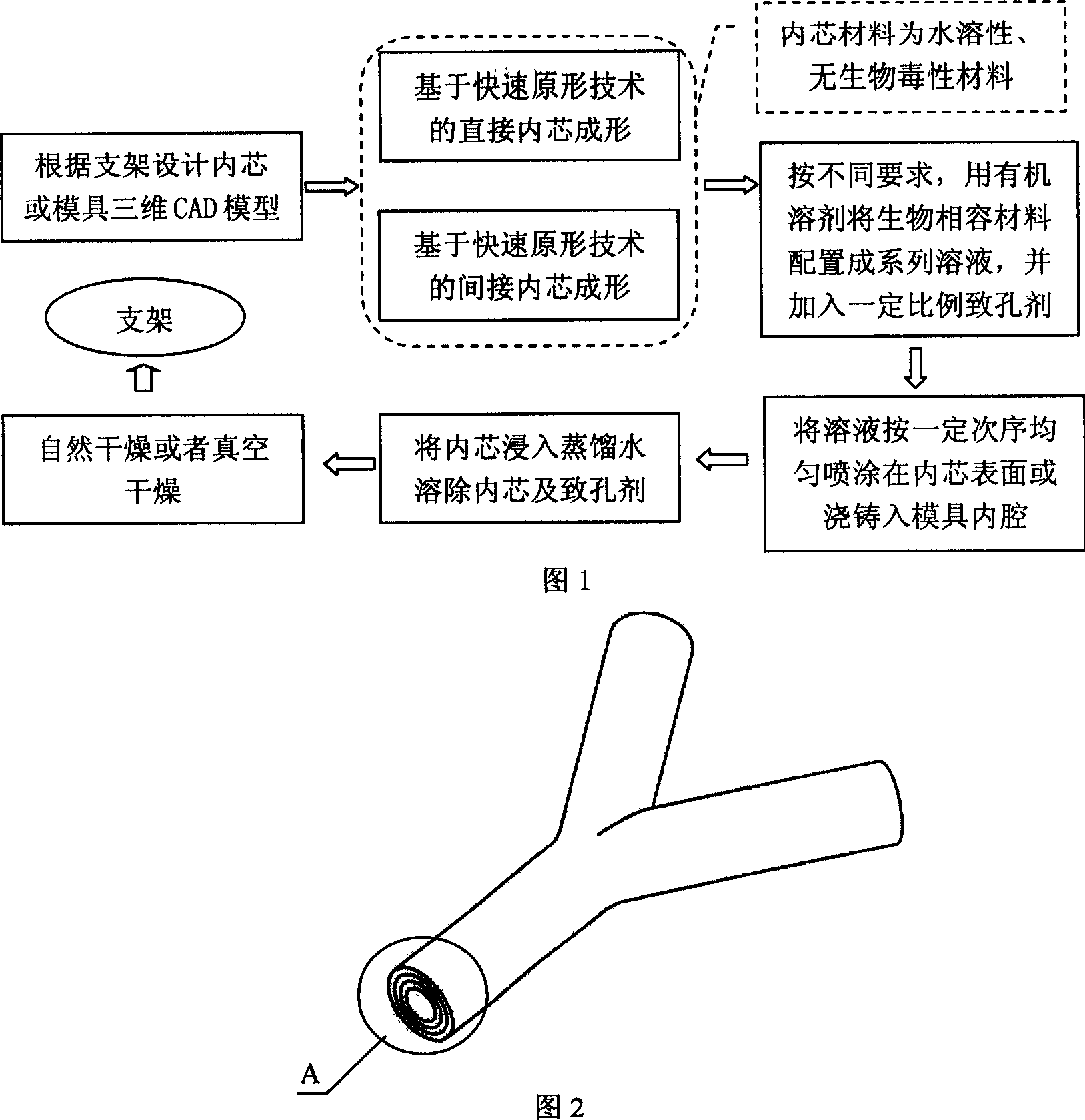

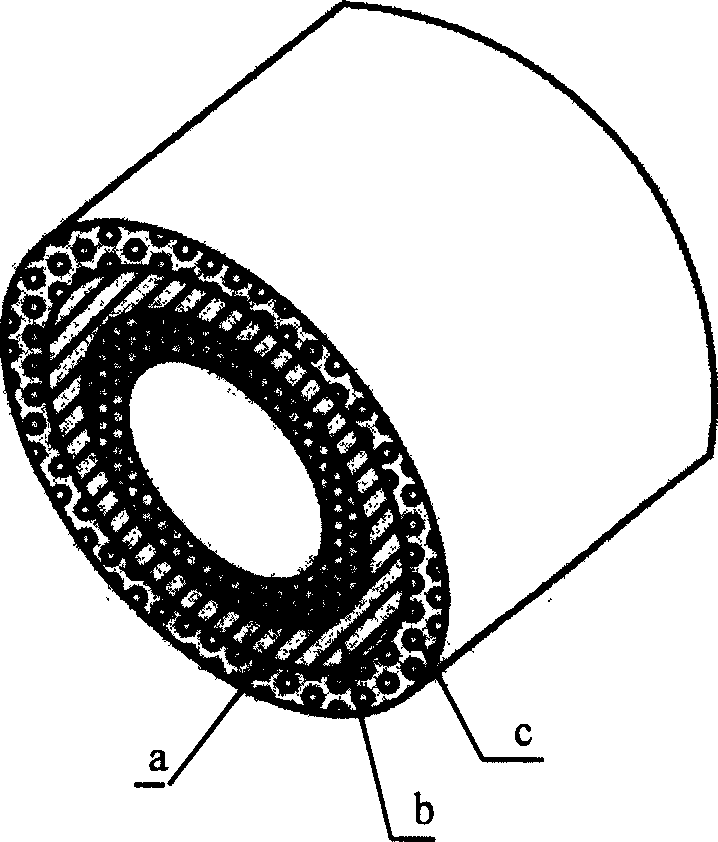

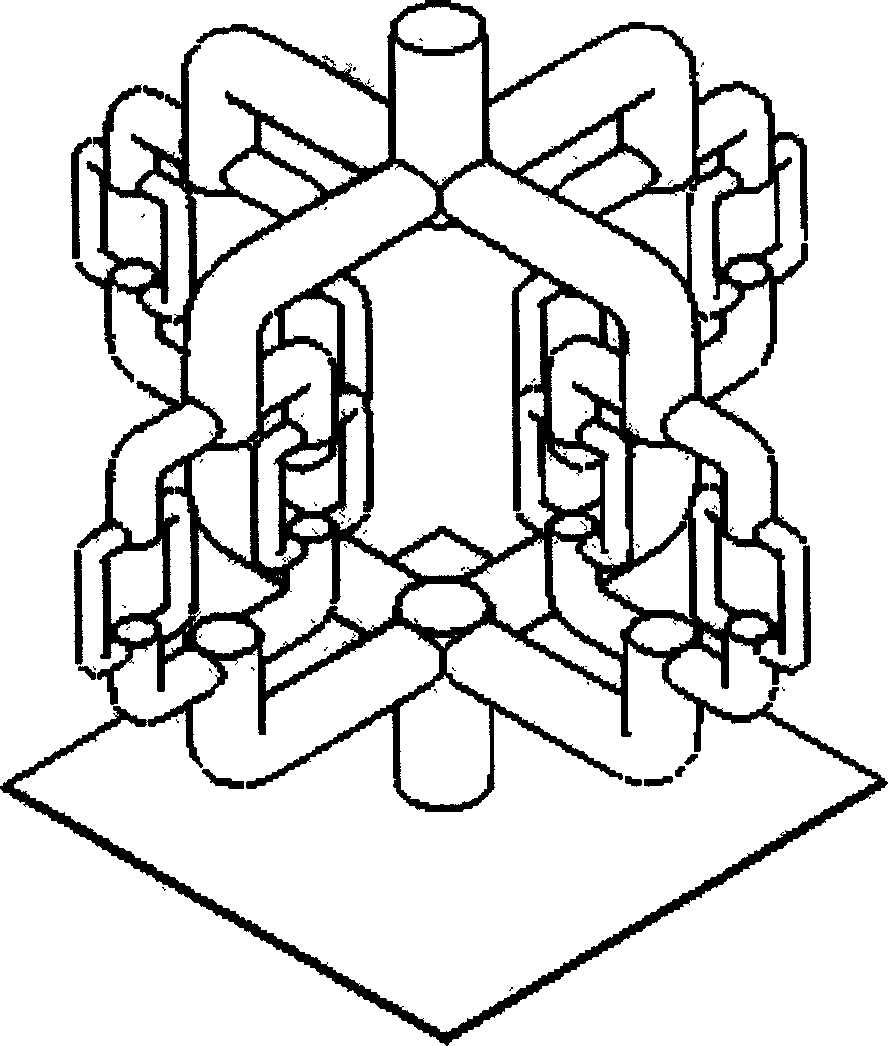

Tissue engineering complex grid shape stent forming method base on core dissolving technology

InactiveCN1654028AAddressing Biocompatibility EffectsShort processBlood vesselsManufacturing technologySpatial structure

The method of complicated tubular netted tissue engineering rack forming technology based on core dissolving technique belongs to the field of tissue engineering rack manufacturing technology. The technological process includes first designing 3D model of rack and rack core; making rack core with water soluble material without biotoxicity through fast laminated formation; compounding solution of biocompatible material with proper amount of pore creating agent and coating the solution onto the rack core; air drying, soaking in distilled water to dissolve out rack core and pore creating agent, taking out and volatilizing water and coating different forming material with or without pore creating agent successively to form the tubular netted rack with complicated spatial structure, different material gradient and different pore gradient.

Owner:TSINGHUA UNIV

Paper machine and method for manufacturing paper

InactiveUS7887673B2Fast productionNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaper sheet

Paper machine for manufacturing a fiber web of paper without through air drying (TAD) or pressing, comprising: a wet end, having a wire section with at least one forming wire, a clothing, being air and water permeable, and a dewatering unit for dewatering the fiber web; and a drying section, comprising a drying surface for the fiber web; and also a transfer roll for transferring the fiber web to the drying section, wherein the fiber web is supported by said clothing from the wire section all the way to and over the transfer roll. The clothing has a three dimensional structure for structuring the fiber web.

Owner:VALMET AB

Dust collecting, mopping and drying integrated cleaning cart

InactiveCN103054523AEasy to cleanImprove cleaning efficiencyCarpet cleanersFloor cleanersEngineeringAir heater

The invention provides a dust collecting, mopping and drying integrated cleaning cart and solves the problem that an existing dust collector is single in function of dust collecting and cleaning and is time and labor wasting when cannot realize multiple cleaning tasks simultaneously. The dust collecting, mopping and drying integrated cleaning cart comprises a closed cart housing, a pushing handle is fixedly arranged at the tail end of the cart housing, wheels are arranged on a chassis of the cart housing, a dust collecting and drying pipeline is arranged in the cart housing and provided with a front dust collecting port and a rear air outlet and is sequentially serially connected with a dust collecting barrel, a fan and an air heater from front to back, a wet rotating mop and a dry rotating mop extent out of the chassis of the cart housing, the wet rotating mop is connected with a water supply device, the dry rotating mop is connected with a driving device, and the dry rotating mop and the wet rotating mp are in transmission connection. The dust collecting, mopping and drying integrated cleaning cart is capable of orderly completing serial cleaning steps of dust collecting, wet wiping, dry wiping and air drying, can guarantee good cleaning effect and doubly improve cleaning efficiency, and is timesaving and laborsaving.

Owner:SHANDONG UNIV OF SCI & TECH

Long glass fiber reinforced recycled polypropylene material and preparation method thereof

The invention discloses long glass fiber reinforced recycled polypropylene material and a preparation method thereof. The long glass fiber reinforced recycled polypropylene material comprises components according to mass percent: 25-55% of polypropylene, 30-60% of long glass fiber, 0.4-0.8% of coupling agent, 3-8% of graft of thermoplastic elastomer, 0.1-0.3% of fused finger modifier, 0.2-0.4% ofantioxygens, 1-4% of lubricant and 1-3% of selective assistant. The preparation method is as follows: mixing and stirring components except for long glass fiber, and then adding the components exceptfor long glass fiber to a screw extruder; adding long glass fiber, mixing, extruding, cooling, air drying and pelleting; as the fused finger modifier is added, the requirements on polypropylene are reduced; various recycled polypropylene materials can be used as backing material. The preparation method is simple and has low cost; the prepared long glass fiber einforced recycled polypropylene material has good comprehensive performances and can replace a plurality of metal parts to be applied to various fields.

Owner:惠东美化塑胶实业有限公司

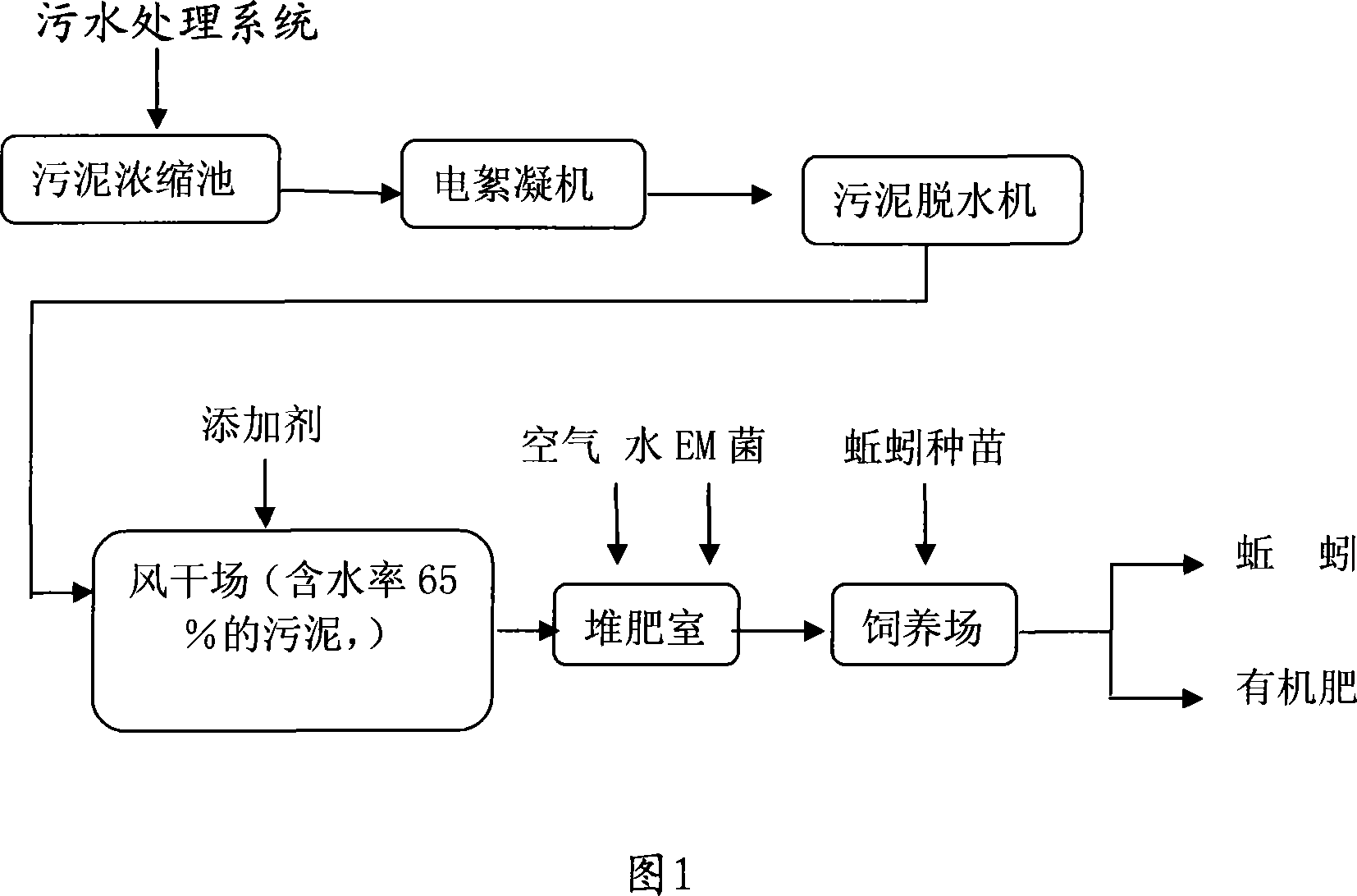

Method for circulating and reutilizing sludge during process of sewage

InactiveCN101074142ASolve processing problemsFungiSludge treatment by de-watering/drying/thickeningHuman wasteCompost

Treatment of refused pollutant is carried out by EC treating for sludge in sewage treatment plant, removing heavy metal, pesticides and antibiotics residues, entering into sludge dewatering apparatus to dewater, delivering dewatered sludge to air-drying farm to air dry, adding into additives to adjust N, P and K proportion in sludge, entering dried sludge into composting chamber to compost, transferring air to composing chamber, spraying water while timing agitating, adding into EM, fermenting, delivering manure mixture to livestock farm and feeding by earthworm. Earthworm's excrement can be used as biological organic fertilizer. It's cheap and economical.

Owner:上海荣禄投资管理有限公司 +1

Large automatic ultrasonic dish washing machine

InactiveCN106235981AUltrasonic intensity is highBig impactTableware washing/rinsing machine detailsCleaning equipmentUltrasonic sensorEngineering

The invention discloses a large automatic ultrasonic dish washing machine. The large automatic ultrasonic dish washing machine comprises an ultrasonic washing tank, an air-drying tank and a collecting tank in sequence from front to back. The ultrasonic washing tank is internally provided with ultrasonic emitting head devices and a driving device, and the driving device is connected with the ultrasonic emitting head devices and used for driving the ultrasonic emitting head devices to work. Each ultrasonic emitting head device comprises an ultrasonic transducer and a high pressure air nozzle which enables input high pressure air to form bubbles in a cleaning fluid, each ultrasonic transducer is used for providing energy for the cleaning fluid, the bubbles in the cleaning fluid are broken to produce an impact force, and the impact force is utilized for washing dishes to be washed. The large automatic ultrasonic dish washing machine is simple and exquisite in structure and is used for washing dishes and the like; the high pressure gas is introduced, the strength of ultrasonic waves produced by the emitting head devices is high, the impact force and friction force of the ultrasonic waves produced by breaking of the bubbles are large, no surfactant or detergent is needed, the effect is good, and environmental protection and sanitation are achieved.

Owner:曾仲林 +1

Artificial domesticating and cultivating fodder for wild boar

The present invention provides a kind of wild boar fodder, which is suitable for domesticating wild boar and raising wild boar quality. The wild boar fodder is produced with green juicy fodder material, coarse fodder material, fine feed material, protein feed, feed additive, etc. as well as water, and through mixing, palletizing and air drying. It is fed to wild boar directly or after being mixed with some water.

Owner:刘军政

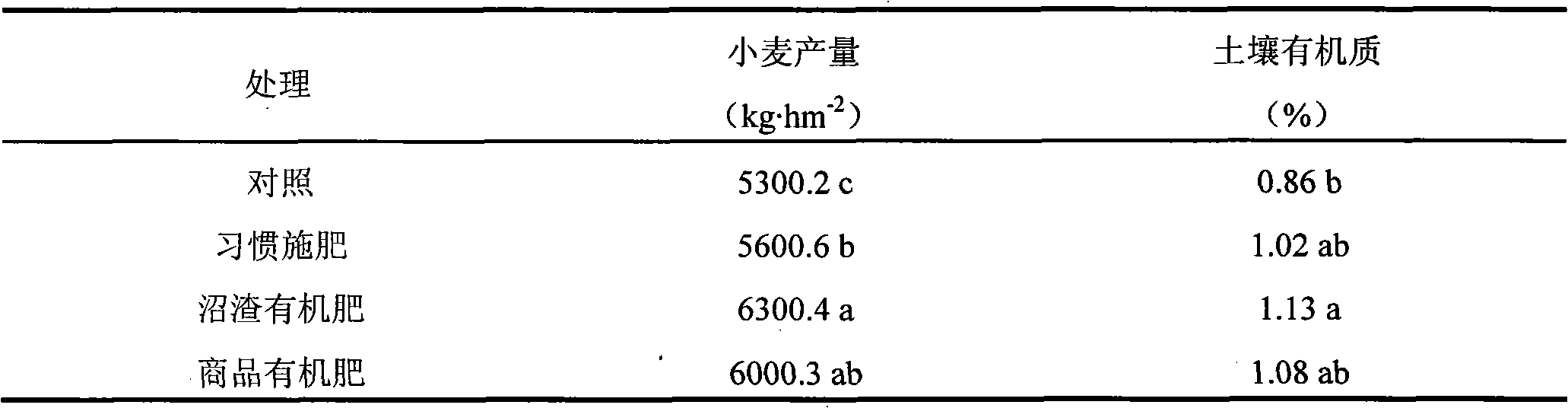

Biogas residue organic fertilizer and preparation method thereof

ActiveCN101774848AIncrease profitEasy accessBio-organic fraction processingClimate change adaptationHigh energyFermentation

The invention relates to a biogas residue organic fertilizer and a preparation method thereof. The biogas residue organic fertilizer uses biogas residue as major raw materials (the consumption is higher than 80 percent) to be mixed with humic acid, nitrogenous fertilizers, phosphate fertilizers, potash fertilizers and trace elements. By aiming at two problems that the biogas residue can not be dewatered and solidified easily and the mechanical dewatering has high energy consumption, the invention utilizes a shallow tank natural solidifying and air drying process, and the biogas residue carries out aerobic secondary fermentation, air drying and solidification in a shallow tank to meet the pelletization moisture and physical property requirements. The biogas residue organic fertilizer of the invention can meet the requirement of nutrient required by crop growth, and can also fertilize the soil and improve the yield.

Owner:INST OF SOIL & FERTILIZER SHANDONG ACAD OF AGRI SCI

Stage method for improving uniform expansion effect of granular fruits and vegetables during microwave spouted drying

The invention discloses a stage method for improving the uniform expansion effect of granular fruits and vegetables during microwave spouted drying, which belongs to the technical field of the processing of fruit and vegetable foods. The method mainly comprises the steps of: performing selection, washing, dicing, enzyme killing by blanching, and color protection treatment on fruit and vegetable raw materials; placing the pretreated fruit and vegetable cubes into a microwave spouted drying bed; setting the microwave power and the air inlet heating temperature; then performing the combined drying of stage hot air drying and microwave drying; and controlling different spouted air intakes at different drying stages, wherein the uniform expansion effect of products is improved during the quick microwave drying. The method has the advantages that the method ensures that the granular fruits and vegetables are evenly heated in a microwave field through a hot air and microwave spouted drying stage method, has quick moisture evaporation, ensures that the fruits and vegetables have porous structures after the drying, effectively improves the expansion degree of the products, also improves the expansion effect of the products and ensures the uniform expansion of the products while the granular fruits and vegetables are quickly dried, and has the characteristics of good preservation of nutrient content and good qualities of color luster, sense and the like.

Owner:JIANGNAN UNIV +1

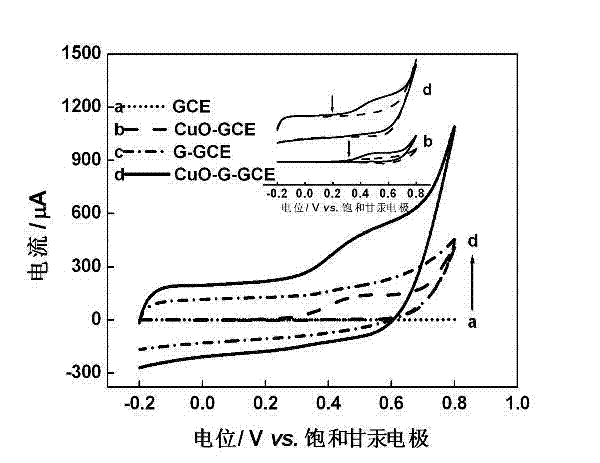

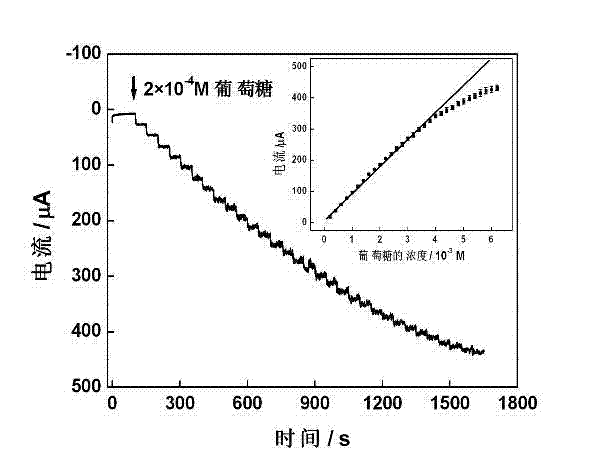

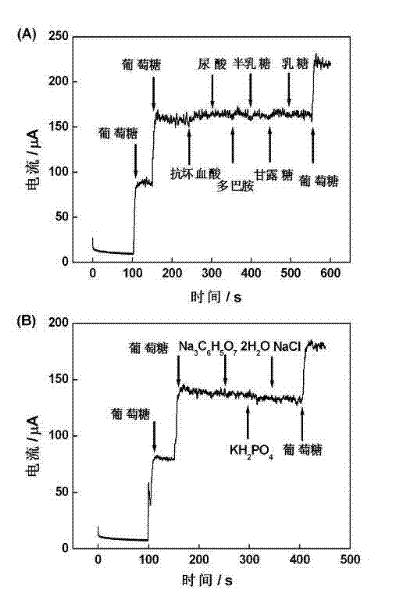

Preparation method for copper oxide-graphene nano-complex modification electrode, and application of modification electrode in glucose detection

InactiveCN102520035AAvoid the disadvantages of easy deactivation and instabilityAchieve electrocatalysisMaterial electrochemical variablesGlucose sensorsCatalytic oxidation

The present invention relates to a preparation method for a copper oxide-graphene nano-complex modification glassy carbon electrode, and an application of the electrode as a glucose electrochemical sensor in rapid glucose detection, and belongs to the technical field of electrochemical analysis detection. According to the present invention, an electrochemical catalytic oxidation effect is adopted, and a current-time curve method is adopted to carry out sensitive quantitative analysis determination on the glucose, wherein the electrochemical catalytic oxidation effect is provided by the glucose sensor, and the copper oxide-graphene nano-composite material is adopted to modify the glassy carbon electrode to prepare the glucose sensor. The key point of the invention is: coating a naphthol suspension of the graphene on the surface of the treated glassy carbon electrode in a dropwise manner; carrying out open-air drying to form a layer of uniform modification layer; and adopting an electrodeposition method with a characteristic of simple operation to prepare a sensitive layer of the copper oxide-graphene nano-complex to achieve the stable catalysis of the glucose oxidation. The prepared glucose sensor of the present invention can be used clinically in detection analysis of blood glucose content in serum, and the determination process has characteristics of rapidness, sensitivity, accuracy, stability, low interference and the like.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com