Patents

Literature

223results about "Siccatives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drier for air-drying coatings

The invention pertains to a drier composition for air-drying alkyd-based coatings, inks, or floor coverings, comprising a combination of the following components: a) a transition metal salt with the formula: (Men+)(Xk−)m in which Me is the transition metal; X− represents a coordinating ligand; and k− is the valence state of the transition metal and m is the number of ligands X. b) a reducing biomolecule. The reducing biomolecule is in particular ascorbic acid or a derivative thereof, including ascorbyl palmitate.

Owner:ATO

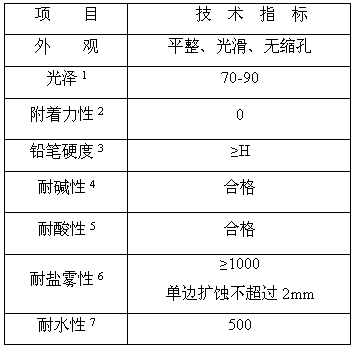

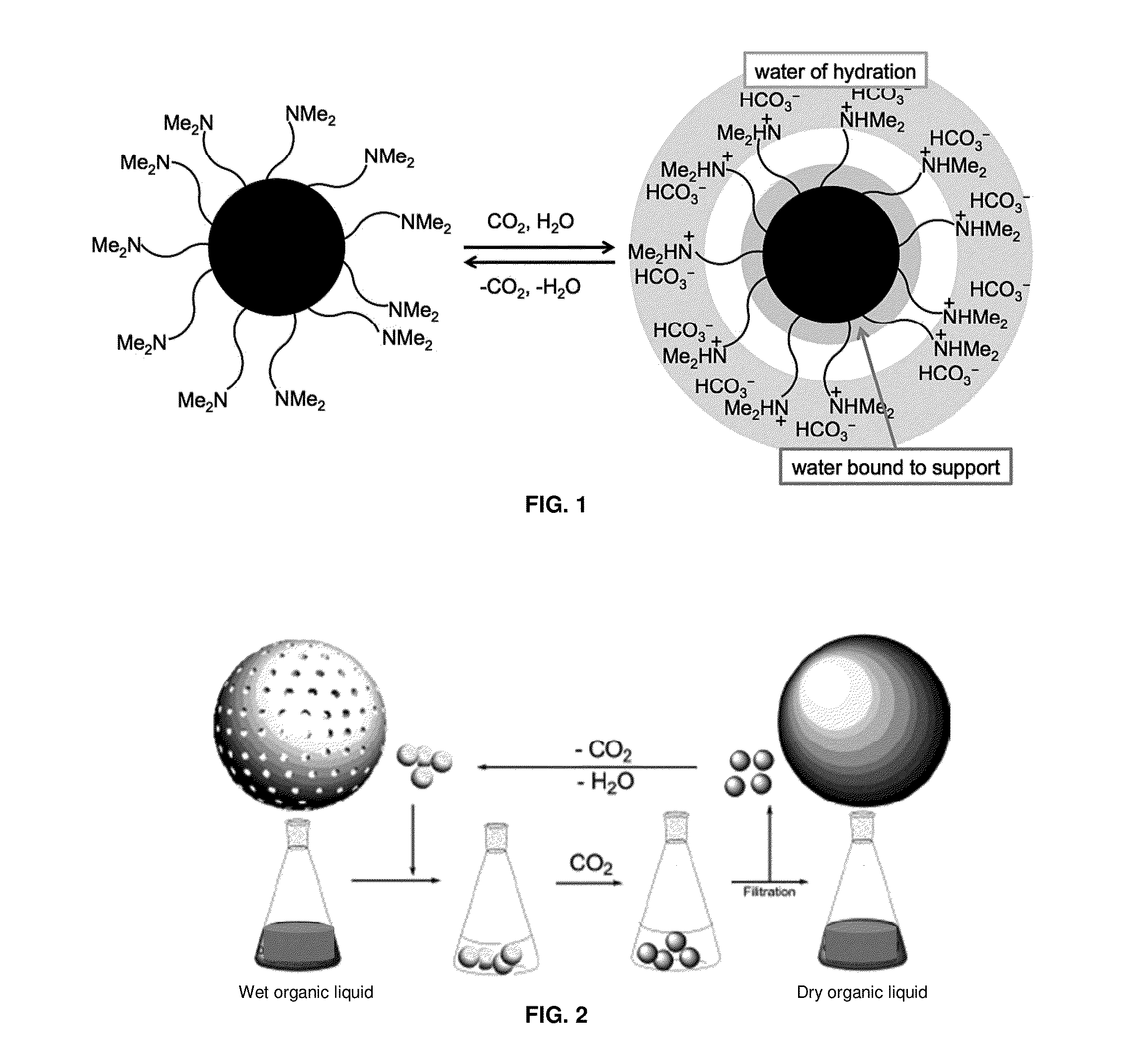

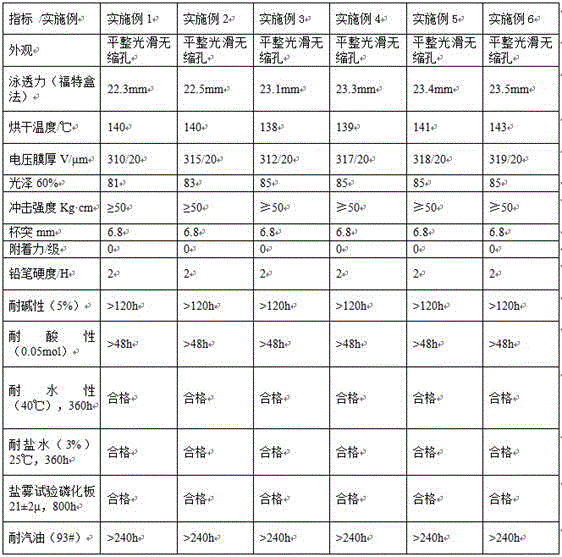

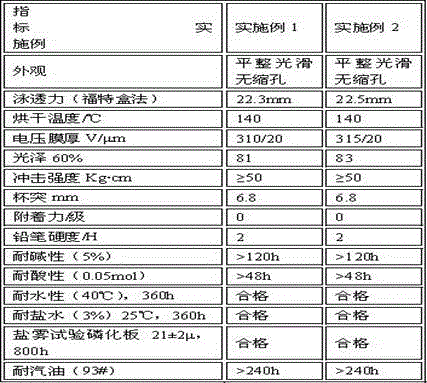

Cathode electrophoretic paint containing environmental-friendly type drier and preparation and use method thereof

The invention discloses cathode electrophoretic paint containing an environmental-friendly type drier and a preparation method of the pain. The preparation method comprises the following steps: preparing a curing agent, preparing a composite drier, preparing a main body resin, preparing cathode electrophoretic paint emulsion, preparing color paste, subsequently mixing the color paste, the cathode electrophoretic paint emulsion and the deionzed water according to a ratio of 1:(3-5):4, adjusting the content of the paint working liquid solid to be 15-30%, and circulating for 48 hours so as to obtain the cathode electrophoretic paint containing the environmental-friendly type drier. A painted article, which is applicable to the electrophoretic coating method, only needs to be conductive and has no other limit. The electrophoretic paint disclosed by the invention is simple to prepare and good in storage stability and does not need to be dispersed in a sanding manner. The prepared cathode electrophoretic paint is good in flowability and good in surface effect.

Owner:GUANGDONG KODEST EP SC CO LTD

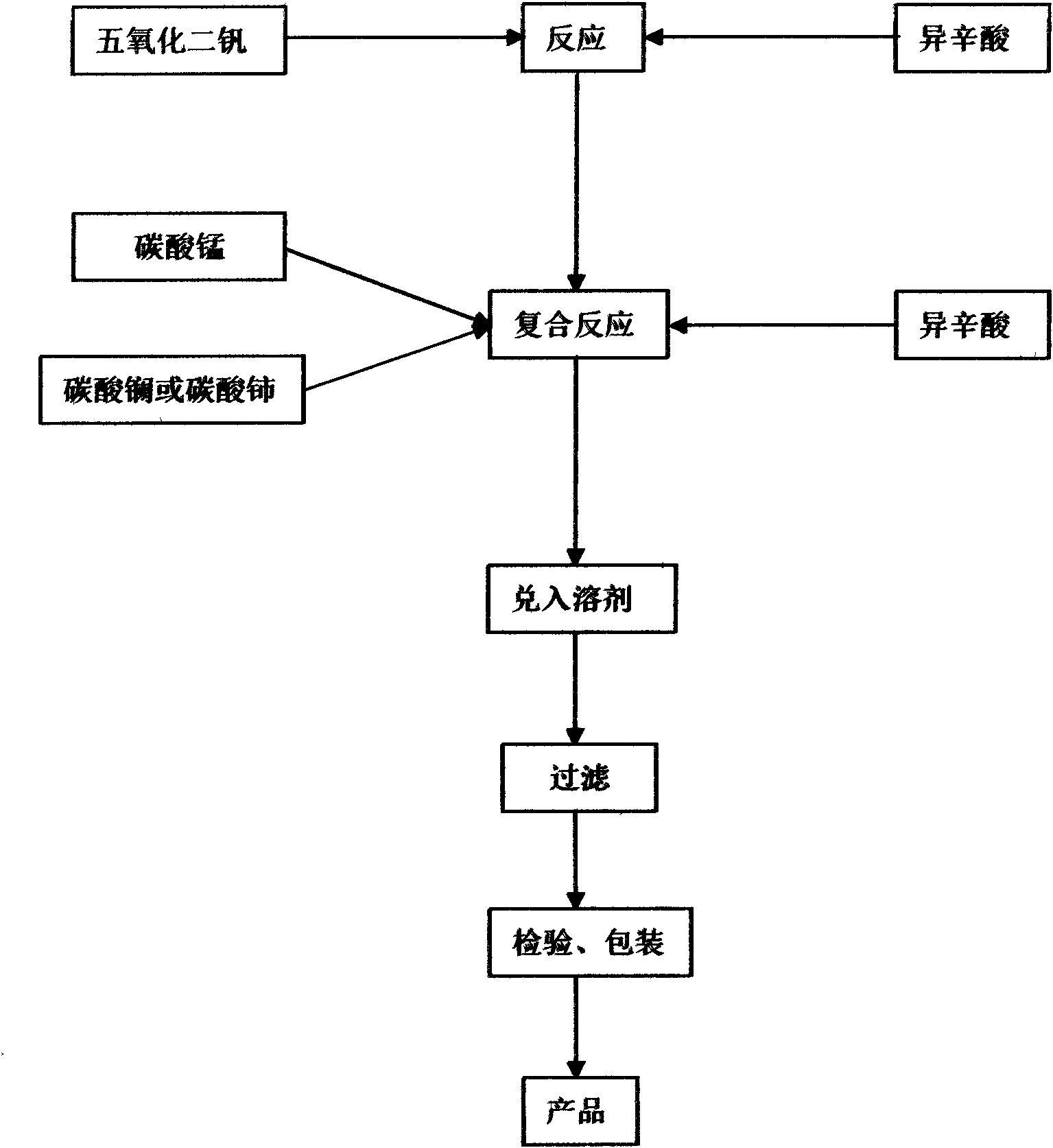

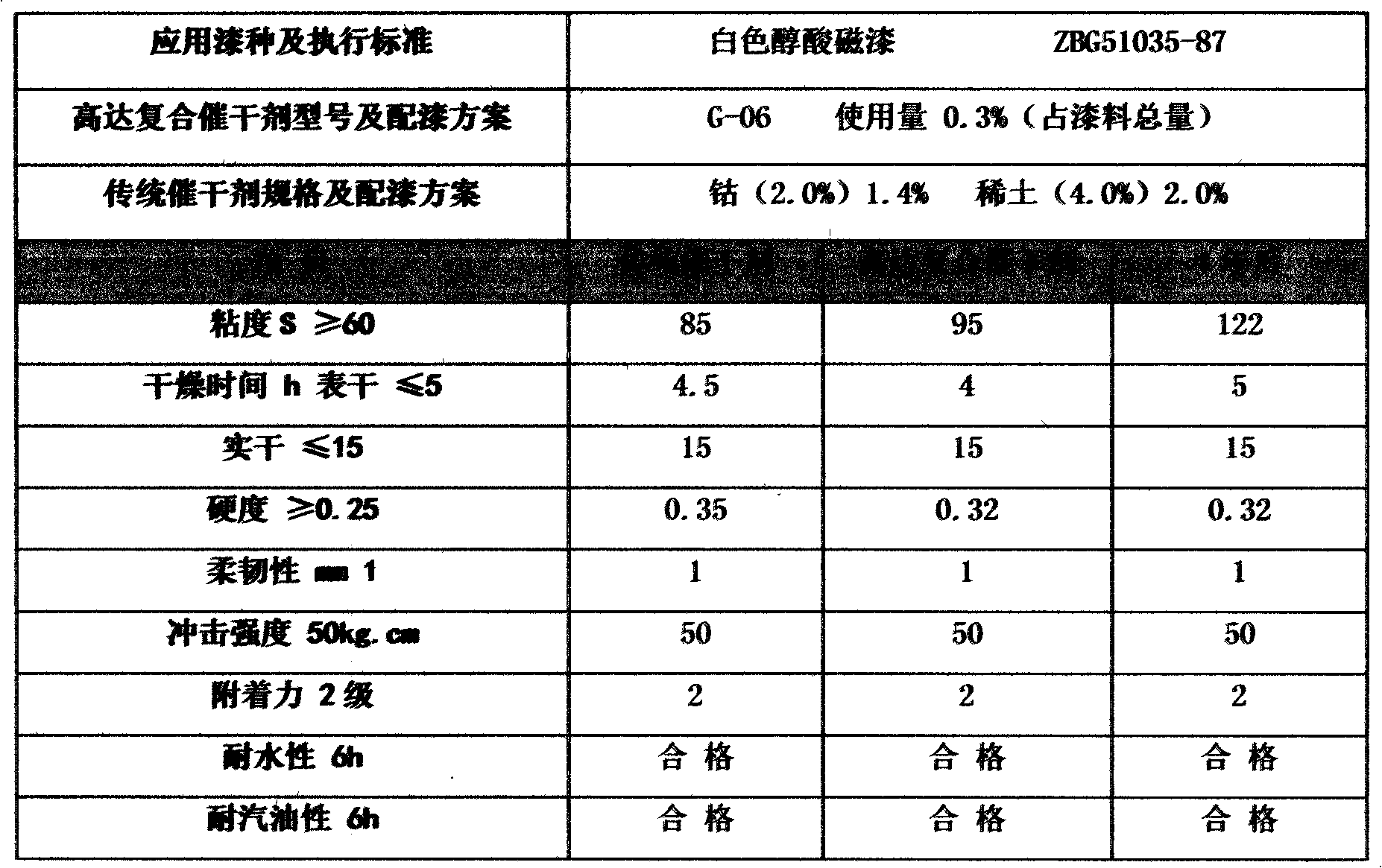

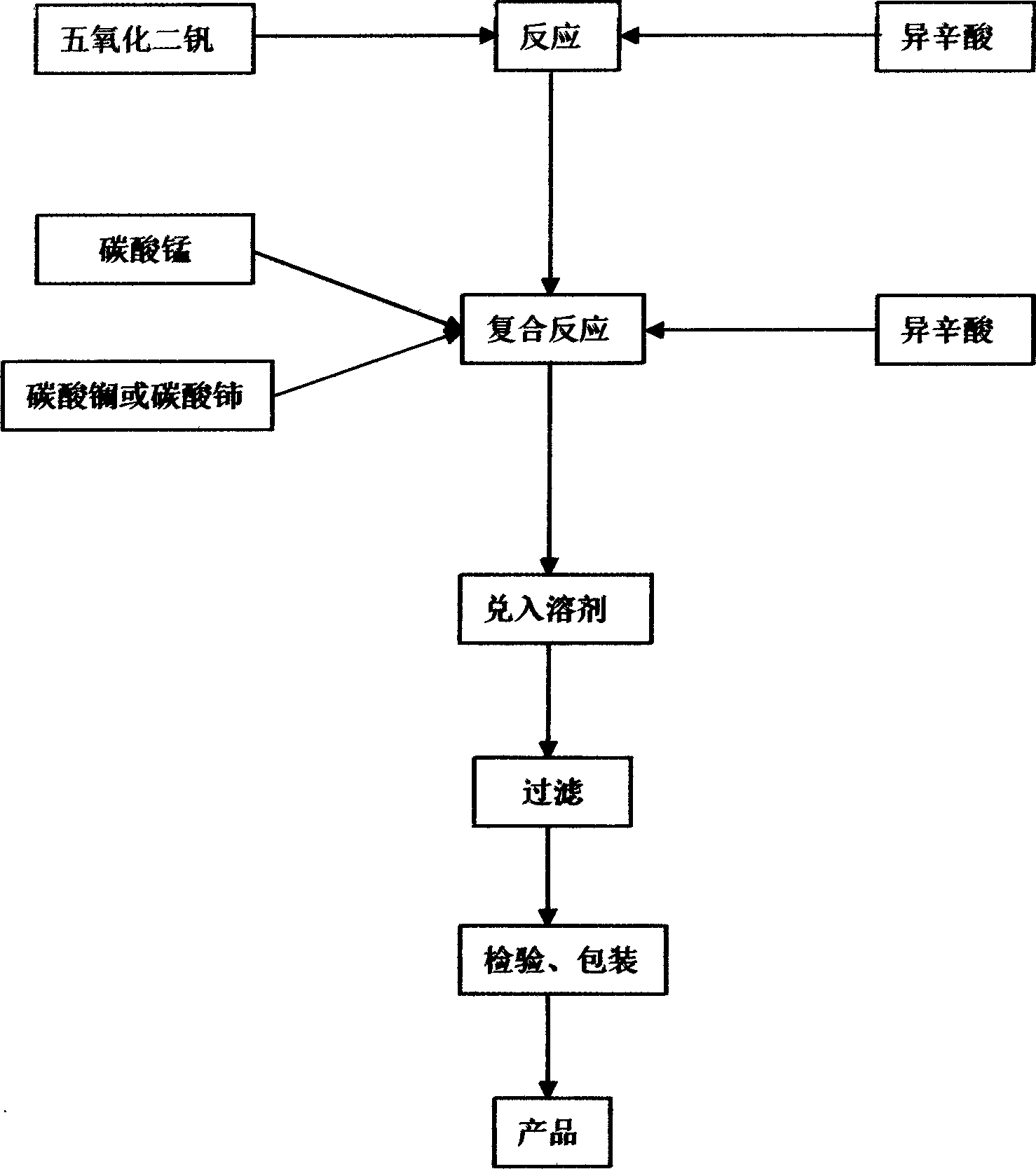

Composite dryer for paint and production method thereof

The invention discloses a production method of a composite dryer for paint. The production method comprises that a mixture of a light rare earth carbonate, manganese carbonate, vanadium pentoxide and isocaprylic acid undergo a composite reaction to produce the composite dryer for paint. The invention also provides the composite dryer for paint. The composite dryer for paint comprises active components of 1.5 to 2wt% of vanadium ions, 1.5 to 2.5wt% of manganese ions and 4 to 4.5wt% of cerium or lanthanum ions, wherein the total valence-alterable metal ion content is in a range of 7 to 9wt%. The composite dryer for paint can fully replace cobalt as a dryer, can eliminate the pollutants of cobalt and lead, and is nontoxic and environmentally friendly. The composite dryer for paint has integrated effects of a plurality of the existing driers. The production method saves a cost, simplifies a paint blending test, and is convenient for production. The composite dryer for paint has a low use amount and a low cost.

Owner:FUZHOU GAODA RARE EARTH MATERIALS

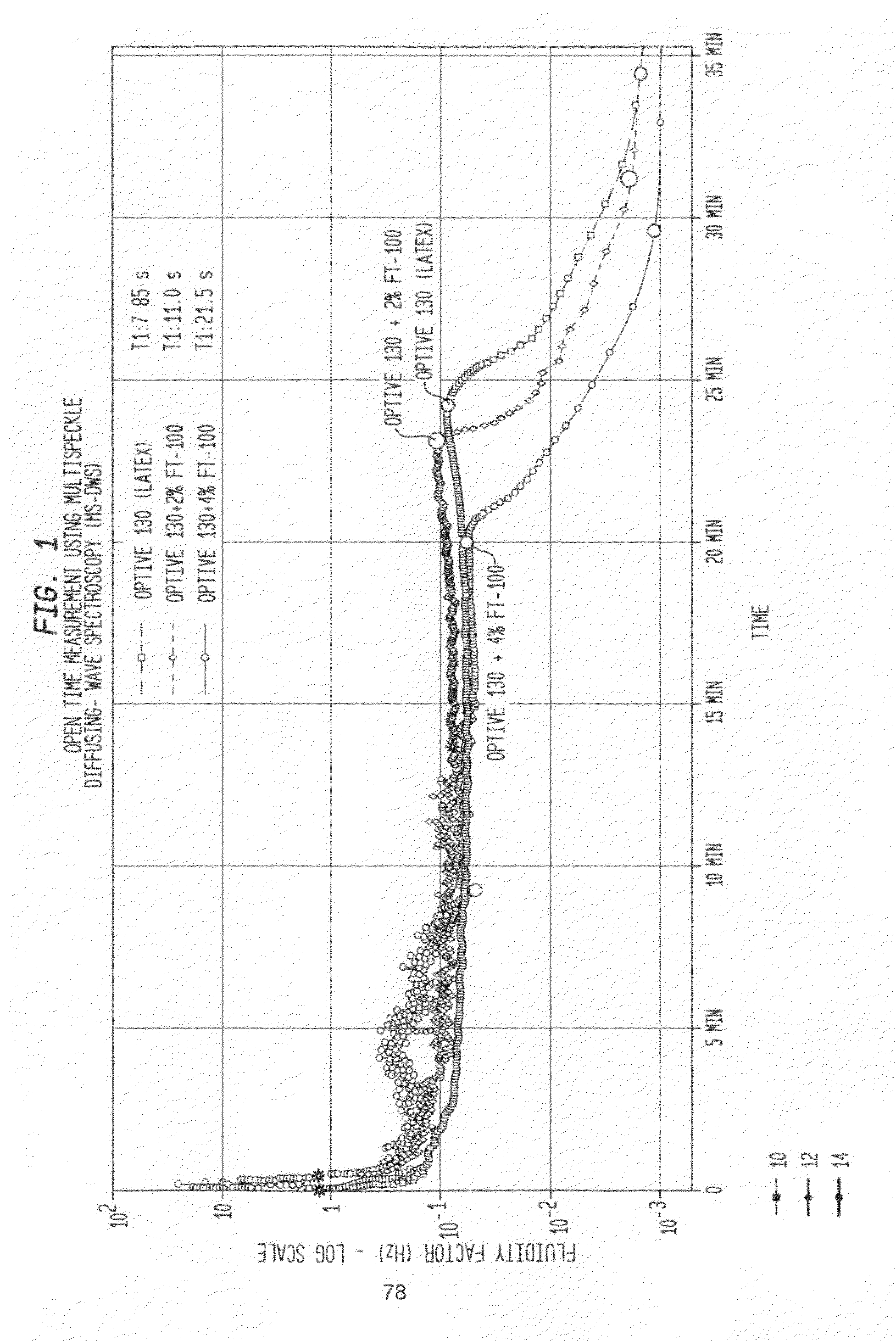

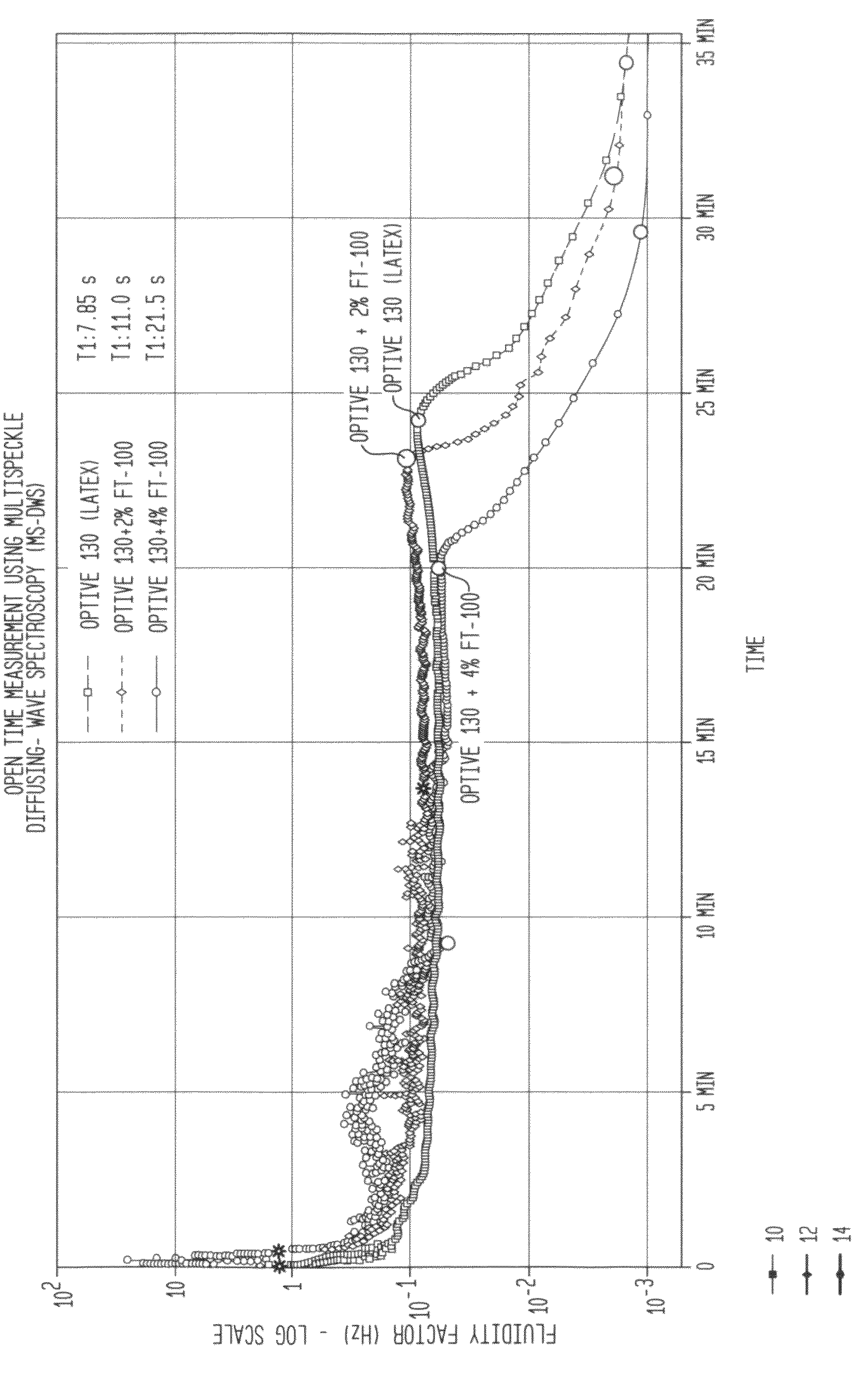

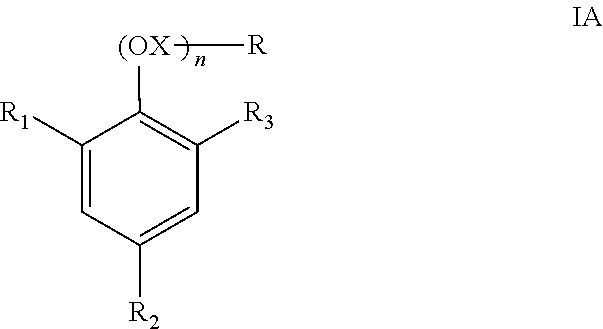

Methods and systems for improving open time and drying time of latex binders and aqueous coatings

ActiveUS20110144248A1Improving open time characteristicExtended opening timeOrganic chemistryOther rubber coatingsTime profileDrying time

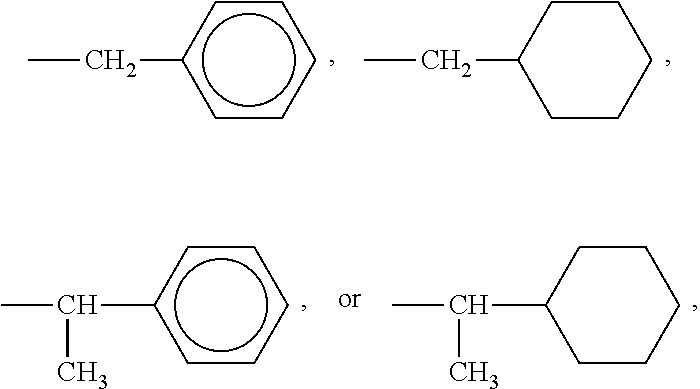

Disclosed are low Tg latex polymers and low VOC aqueous coating compositions having an improved open time profile, as well as drying time, stain resistance, wet edge time, low temperature film formation, block resistance, adhesion, water sensitivity and low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or alkoxylated compounds or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating or adhesive composition including at least one latex polymer, water and one or a blend of two or more open time additives or drying time additives. The blend can comprise nonionic and anionic open time additives. Typically, the open time and / or drying time additive is present in an amount greater than about 1.3% by weight of the polymer or composition, typically in an amount greater than about 2% by weight of the polymer or composition, in an amount greater than about 4% by weight of the polymer or composition, in an amount greater than about 7.5% by weight of the polymer or composition, in an amount greater than about 10% by weight of the polymer or composition or in an amount greater than about 20% by weight of the polymer or composition.

Owner:RHODIA OPERATIONS SAS

Drier composition and use thereof

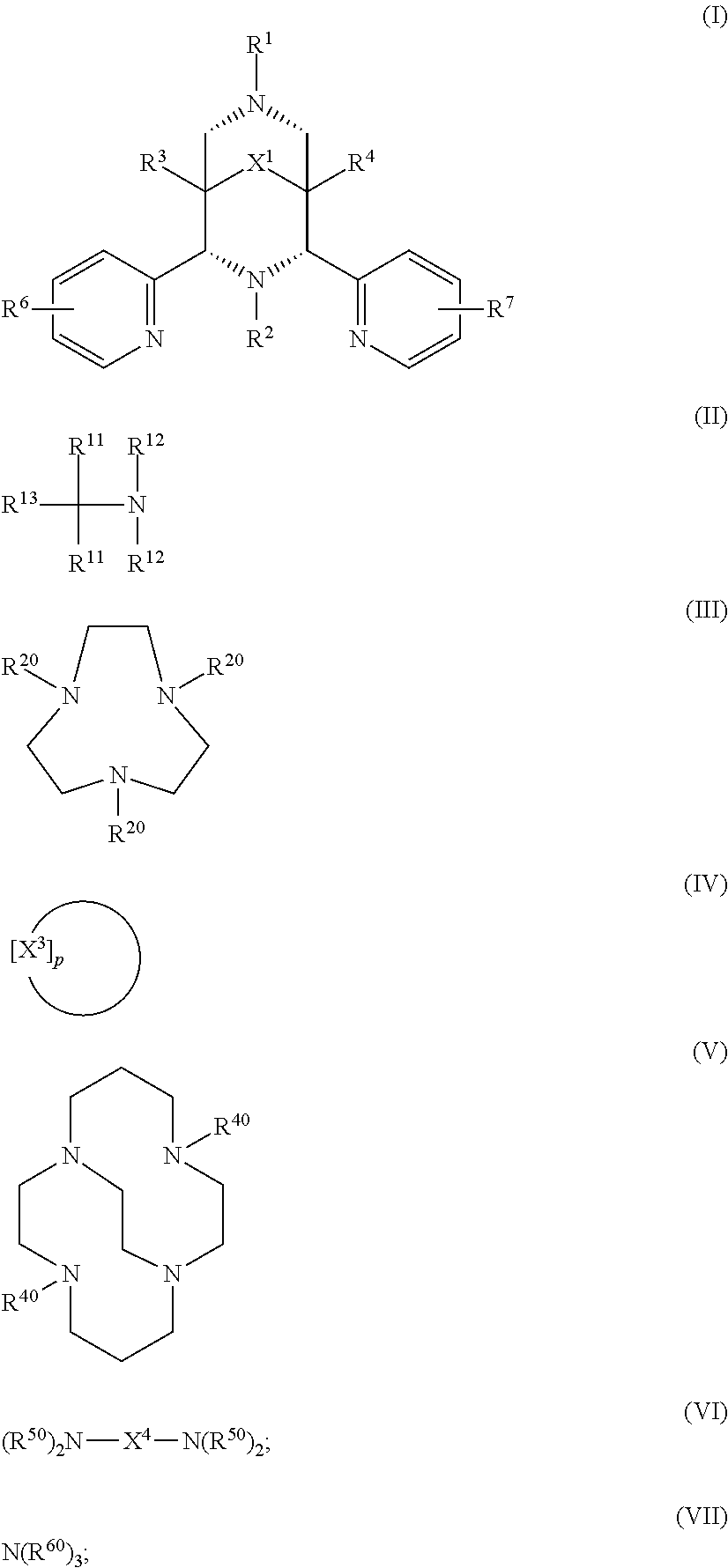

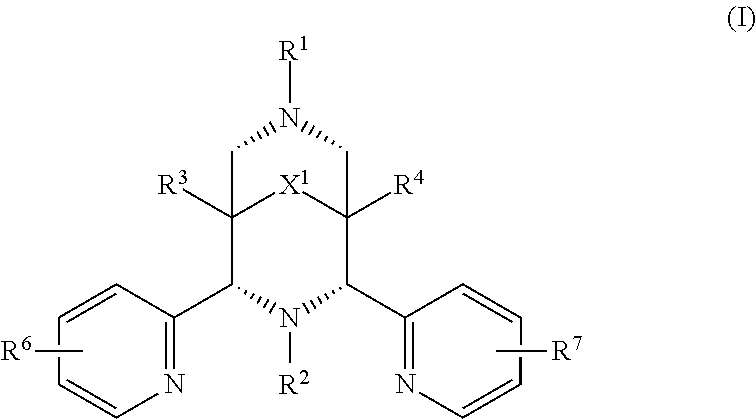

The invention relates to a drier composition for an oxidatively air-drying alkyd based coating composition, comprising: a) at least one metal complex comprising a metal and at least one nitrogen donor ligand, wherein the metal is selected from the group consisting of Fe and Mn, and wherein said at least nitrogen donor ligand is selected from the group comprising monodentate, bidentate, tridentate, tetradentate, pentadentate and hexadentate nitrogen donor ligands; and b) at least one K salt of an organic acid. The present invention also relates to a coating composition comprising said drier composition and the use thereof.

Owner:PPG EURO BV

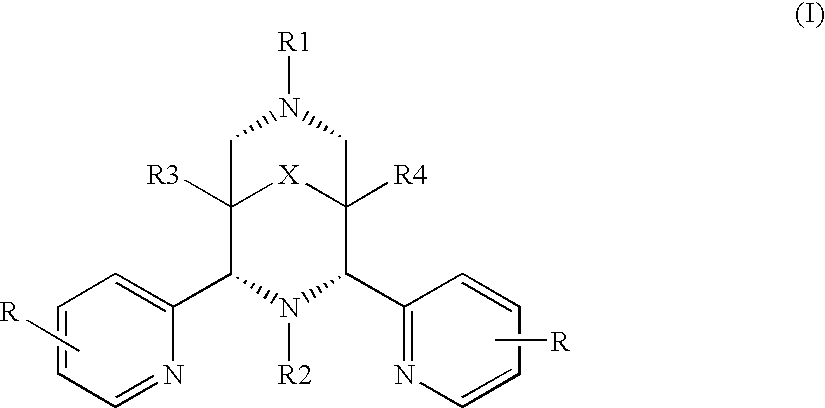

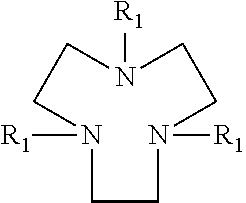

Environmental-friendly drier and printing ink composition thereof

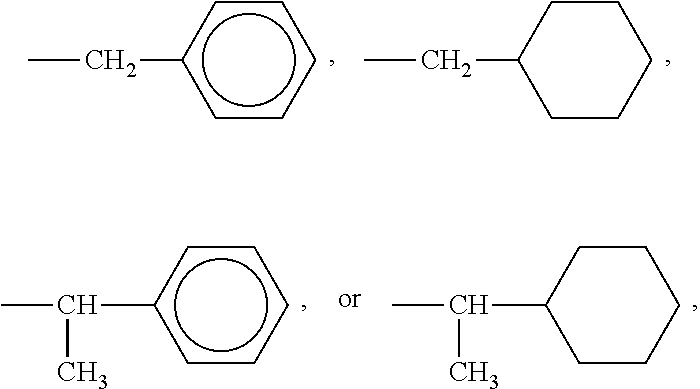

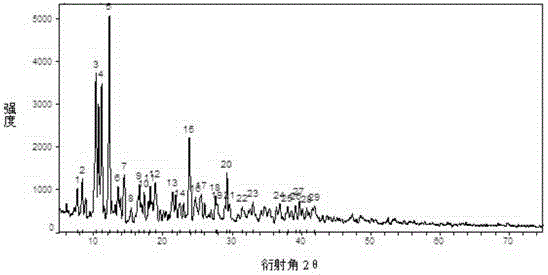

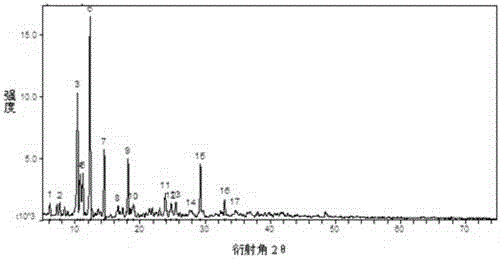

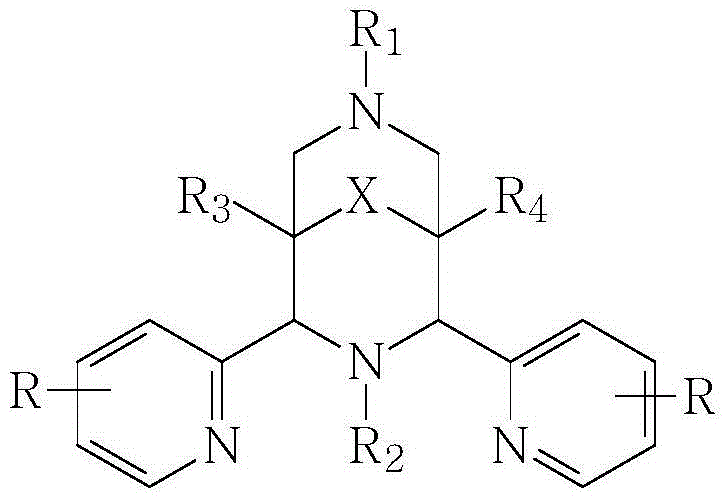

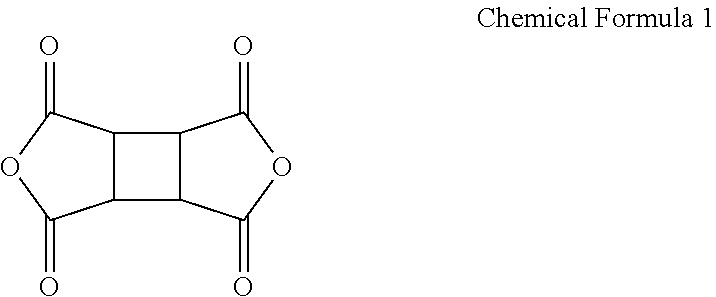

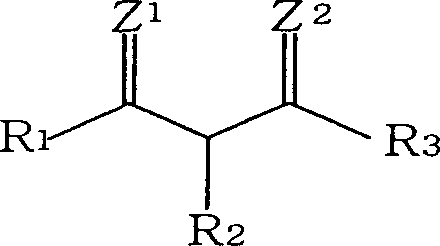

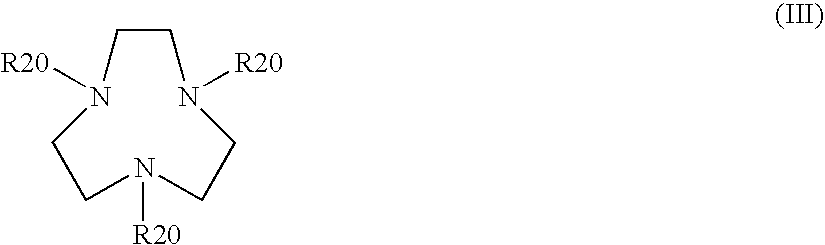

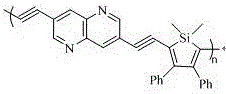

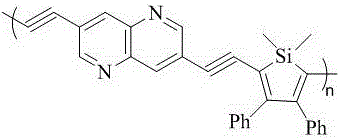

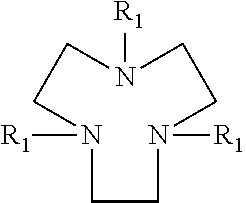

The invention discloses an environmental-friendly drier, a preparation method thereof and applications thereof. The drier is characterized in that: a reaction product of a ligand 3,7-diazabicyclo[3.3.1] nonane and a metal chloride is in a mixed crystal type or a solid-state solution type; and beneficial effects of the drier are that: the drier is free from metal cobalt having risks of "three cause", and has little bad influence on the environment and health; the drier is used for oxidation polymerization drying-type printing ink; and the ink film surface is free from skinning and wrinkling even when the printing ink layer is thick. According to the drier and the preparation method, the ratio of iron to manganese in a complex and the constitution of the ligand can be adjusted according to the drying condition of the printing ink so as to achieve an effect of adjusting the drying time of the printing ink. The ligand 3,7-diazabicyclo[3.3.1] nonane has a general chemical formula shown as follows.

Owner:CHINA BANKNOTE INK

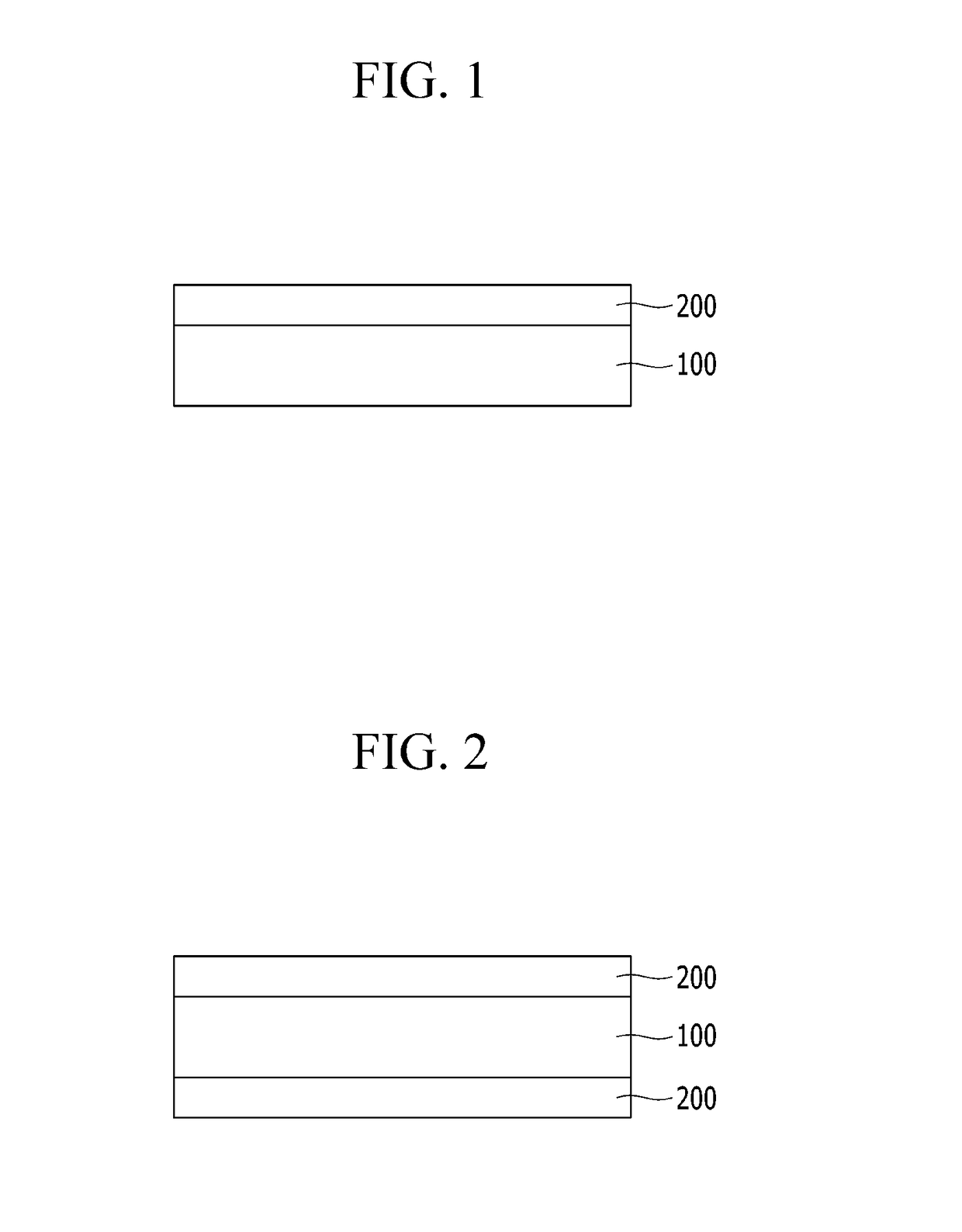

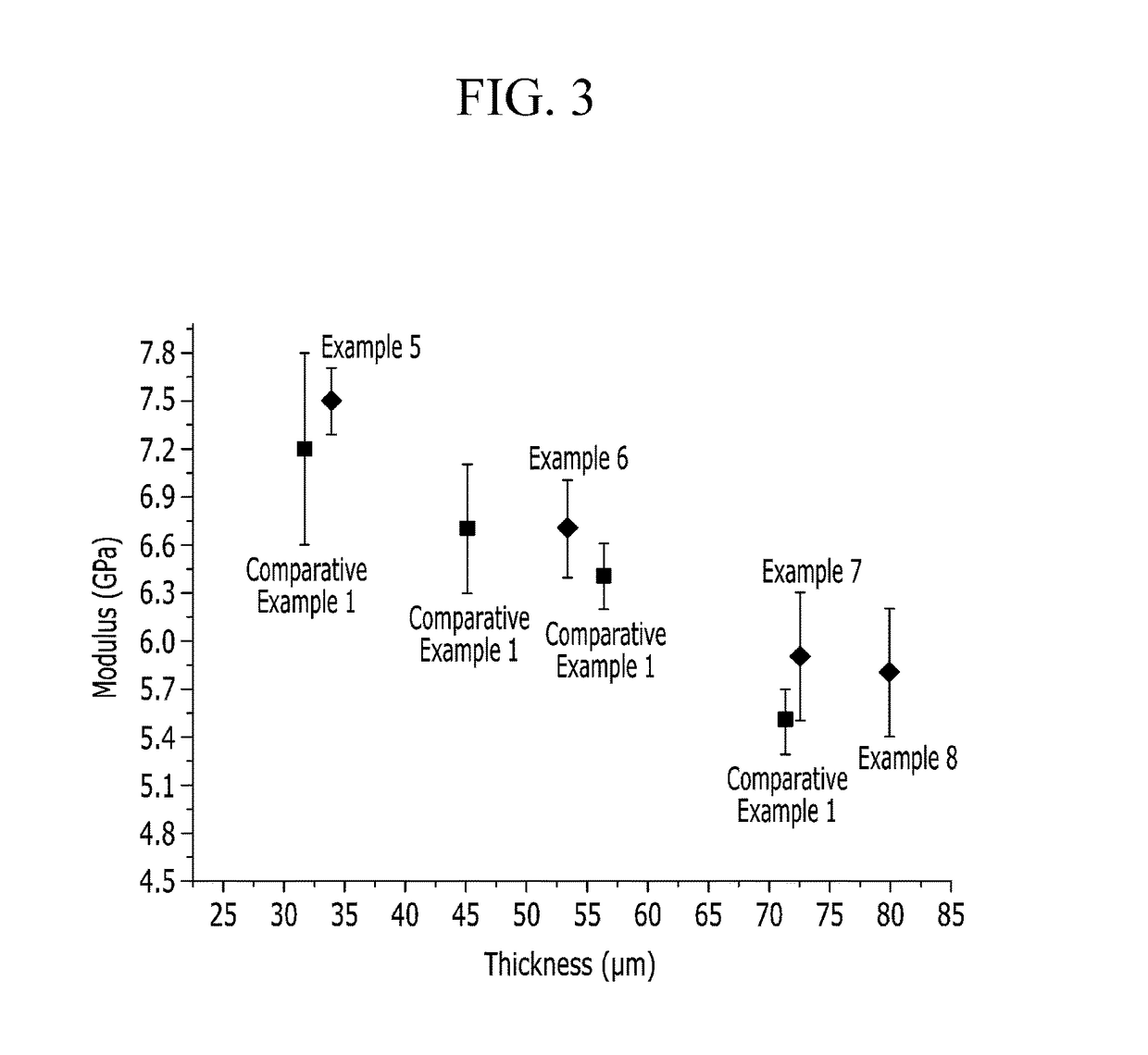

Poly(amide-imide) copolymer film, window for display device, and display device

ActiveUS20170342224A1Improve mechanical propertiesExcellent optical propertiesSiccativesDigital data processing detailsImidePolyamide-imide

A poly(amide-imide) copolymer film having a tensile modulus of greater than or equal to 5.4 GPa, and a yellowness index of less than or equal to 3.6, wherein the poly(amide-imide) copolymer film is a reaction product of an aromatic dianhydride including biphenyl tetracarboxylic dianhydride and 4,4′-hexafluoroisopropylidene diphthalic dianhydride, an aliphatic dianhydride including 1,2,3,4-cyclobutane tetracarboxylic dianhydride, an aromatic diamine including 2,2-bis(trifluoromethyl) benzidine, and an aromatic dicarbonyl compound including terephthaloyl dichloride.

Owner:SAMSUNG ELECTRONICS CO LTD +1

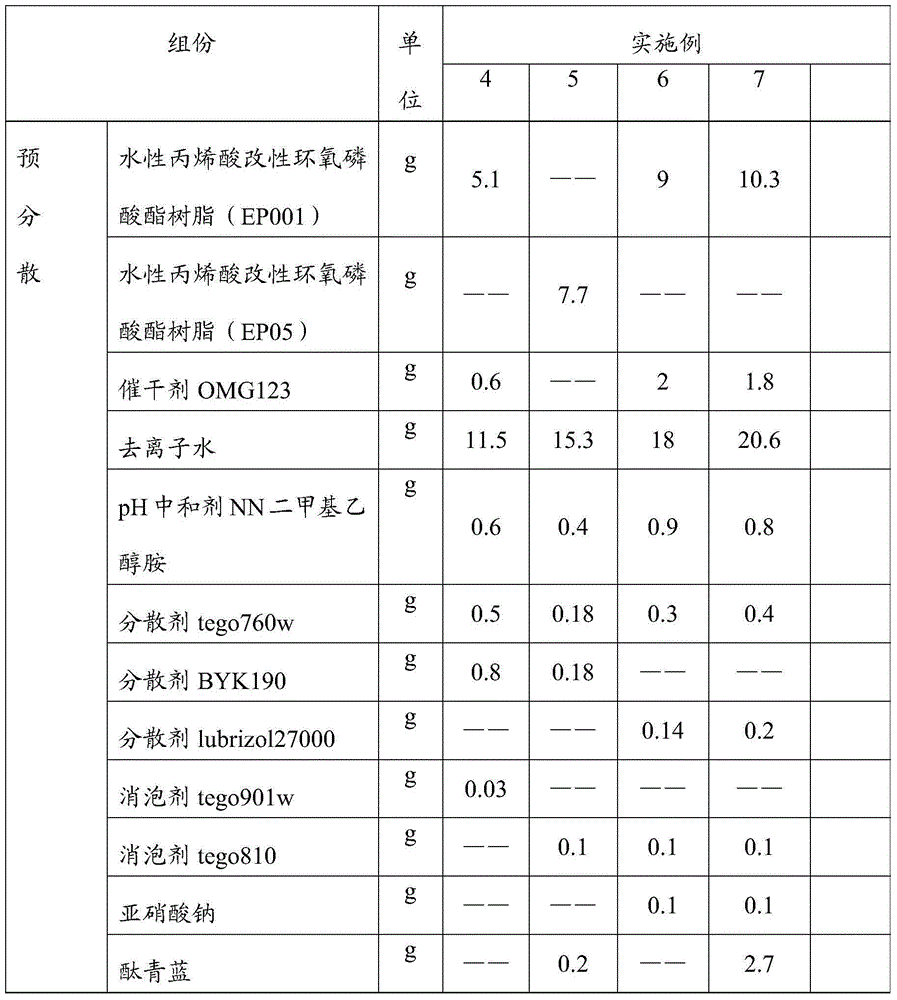

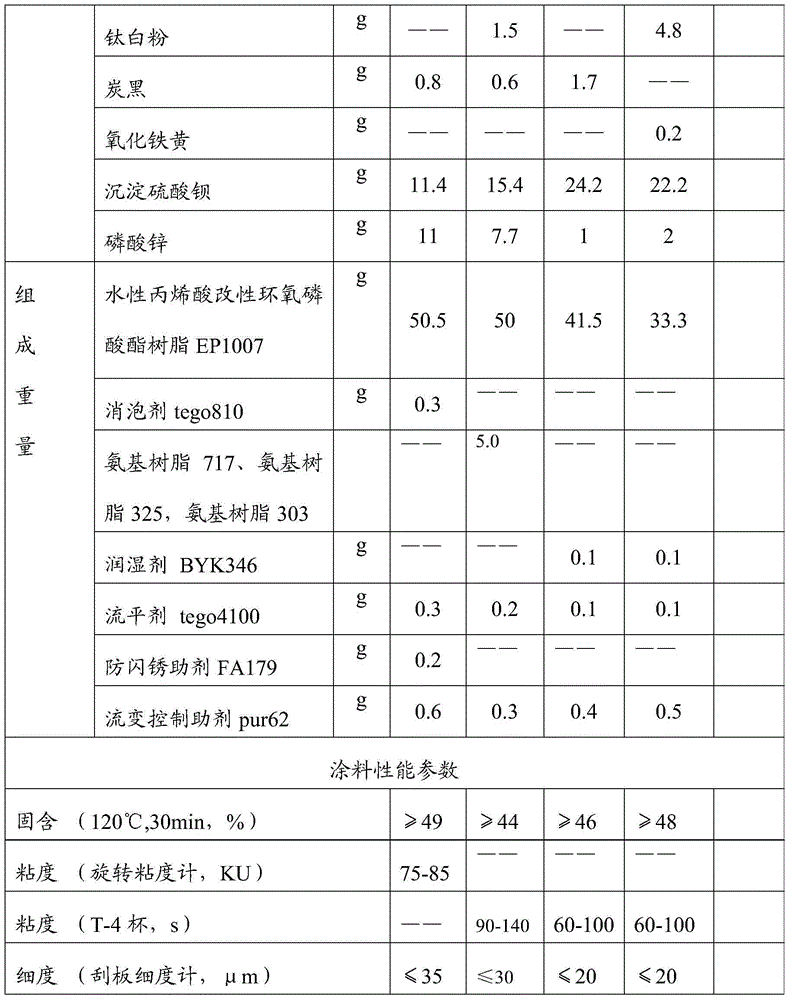

Paint containing water-based acrylic modified epoxy phosphate resin and preparation method thereof

InactiveCN104877526AImprove stabilityHigh solidsSiccativesAnti-corrosive paintsEpoxyPhosphoric Acid Esters

The invention belongs to the field of painting, and particularly relates to acrylic acid modified epoxy phosphate resin and an aqueous dispersion thereof. In the formula, the acrylic acid modified epoxy phosphate resin is prepared from 40-45 parts of epoxy resin, 20-30 parts of a solvent, 0.4-0.5 part of phosphoric acid, 8-12 parts of acrylic acid (ester) monomer of which acrylic acid accounts for 1.4-2 parts, 0.5-0.8 part of an initiator, 3.2-5.2 parts of neutralizer and 80-100 parts of water. The resin is prepared by the following steps: modifying epoxy resin with phosphoric acid, and reacting with acrylic acid and ester monomers thereof; adding the neutralizer and deionized water, stirring and emulsifying to obtain the acrylic acid modified epoxy phosphate aqueous dispersion, wherein the acid value of the emulsion is 10-12mgKOH / g, and the solid content is 28-38 percent. The prepared main resin dispersion body is epoxy resin, has a phosphate structure, and has a good adhesive force for metal base materials, thus having good corrosion resistance; acrylic resin is modified, introduced with carboxyl and neutralized by the neutralizer to give aqueous dispersion to resin, so that the resin can be produced into water-borne painting, and the content of VOC is greatly reduced; and multiple hydroxyl radicals are arranged on the main chain of the epoxy resin, and can be crosslinked with amino resin, urea resin and phenolic resin to produce stoving varnish.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Composite drier for aqueous air drying type coating

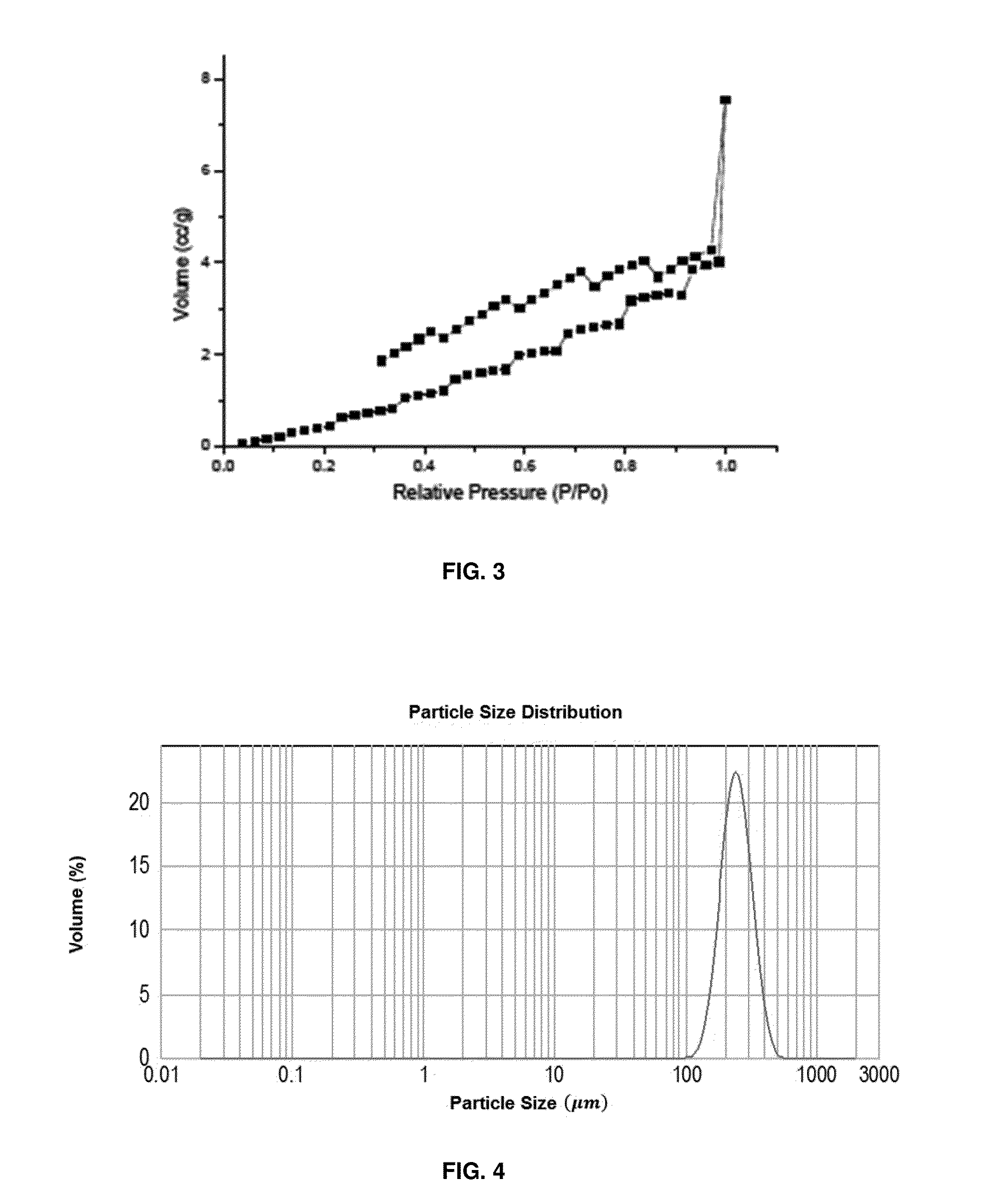

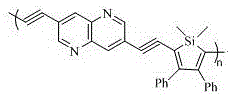

ActiveCN101407698AGood dispersionThere will be no "graining" phenomenonSiccativesEmulsionSolid content

The invention relates to a compound drier emulsion which has a 'nuclear-shell' structure and is used for a waterborne air-drying coating, which is characterized in that the compound drier emulsion is the purple emulsion containing various metal ingredients, which takes an organic metal soap as a 'nuclear', takes a reactive non-migrant surfactant as a 'shell' and is compounded by being matched with a special emulsifier, and the solid content is 45 to 72 percent by weight. The compound drier emulsion can ensure the stability of the coating and the effectiveness of the drier, reduce the defects of a paint film and improve the gloss of the paint film by being used for the waterborne air-drying coating.

Owner:上海华谊涂料有限公司

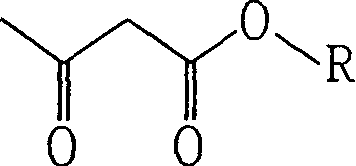

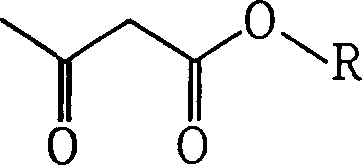

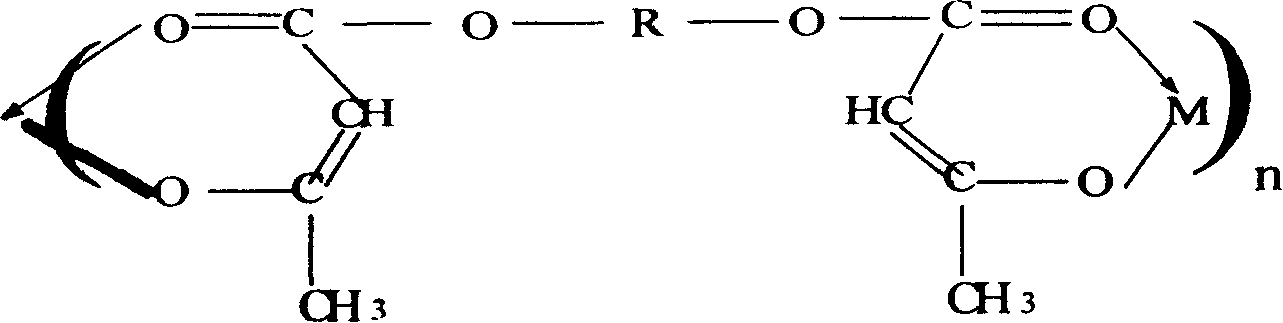

Acetacetic acid alkyl ester metal chelate coating drier and production thereof

A drier of acetacetic acid alkyl ester metal chelate paint and its production are disclosed. The procedure is carried out by reacting alkyl alcohol with diketene to obtain acetacetic acid alkyl ester chelant, and synthesizing the chelant with inorganic metal salt to obtain drier of acetacetic acid alkyl ester metal chelate. Its advantages include solid storage, light color, non-toxic, various raw material resources, simple process and more output.

Owner:上海市涂料研究所有限公司

Liquid hardening

ActiveUS8013044B2Facilitates drying and curing and setting and hardeningOrganic chemistrySiccativesNitrogenManganese

Owner:OMG UK TECH

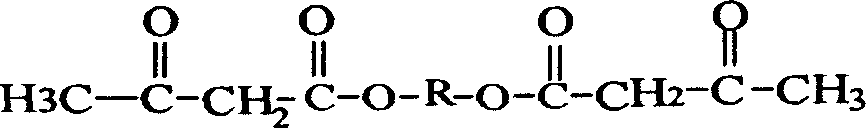

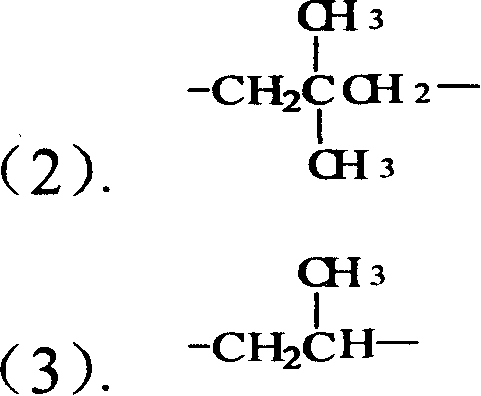

Oligomer diacetyl acetate alkylene diester metal chelate coating drier and preparation and application

InactiveCN1955238ASimilar drying performanceWide variety of sourcesSiccativesVegetable oilMetal chelate

This invention is an oligomerization diacetic acid alkylene diester metal chelate compound, and it is a neotype oxidoreduction polymerizing siccative which can be used in coating industry. It not only can be used in solvent coating containing dry vegetable oil, but also can be used in waterborne coating after making into aqueous dispersions. The diacetic acid alkylene diester metal chelate agent is made by the reaction of dihydric alcohol and diethenone under accelerant, and then this metal chelate agent reacts with inorganic metallic salt to obtain oligomerization diacetic acid alkylene diester metal chelate compound siccative. The drying properties of this siccative are similar to traditional metallic soap siccative in solvent coating and waterborne coating. But it is different from traditional metallic soap siccative, beacuase this invention is oligomerization metal chelate polymer, which can be preserved in solid. It is of light color and luster, low toxicity, extensive synthesis material, simple preparation and higher yield, and so it is suitable for industrial production.

Owner:上海市涂料研究所有限公司

Drier

The invention relates to a drier which comprises 5 to 50 percent of nonionic surfactant which is poly-oxypropylene polyoxyethylene block type polyether; 0.1 to 5 percent of one or a plurality of organic polyprotic acid inhibition antisludging agents; 5 to 25 percent of solubilizer; 2 to 10 percent of anion surface surfactant and dispersant, and the rest of deionized water. The drier can cause the drier to be dispersed fully in the final rinsing water of a dishwasher with no lumping precipitation and not to be precipitated easily in high temperature environment, can reduce effective component loss, make full use of effective component and reduce device pollution.

Owner:HUNAN LICHEN INDAL

Coating containing quick drying agent and preparation method thereof

ActiveCN104194566AImprove use valueCoating environmental protectionSiccativesEpoxy resin coatingsEpoxyAcrylic resin

The invention belongs to the field of coatings and particularly relates to a coating containing a quick drying agent and a preparation method thereof. The coating comprises a paint component and a curing agent component in a mass ratio of (2-3) to 1, wherein the paint component comprises the following components by mass percent: 40-50% of polysulfide modified epoxy resin, 5-10% of acrylic resin, 15-20% of polydimethylsiloxane, 1-5% of additive, 10-15% of pigment and filler, 10-20% of a solvent, 5-10% of tea stem powder and 2-5% of coupling agent; the curing agent component comprises the following components by mass percent: 60-70% of a curing agent, 20-30% of n-butyl acetate and 10-15% of quick drying agent; and the quick drying agent comprises the following components by weight percent: 10-15% of a dehydrating agent, 15-25% of drier and 60-70% of n-butyl acetate. According to the coating, the tea stem powder is added to be reacted with volatile organic gas and thus the VOCs (Volatile Organic Chemicals) released by the coating is reduced and meanwhile the quick drying agent is added so as to quickly dry the coating and coating is a solvent-type relatively environment-friendly, quick drying material.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

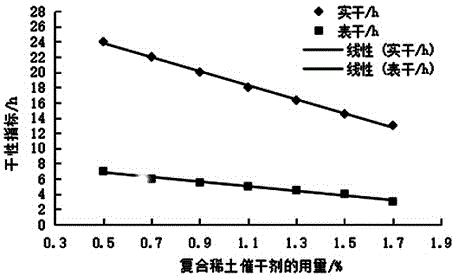

Preparation method of high efficient rare-earth paint drier

The invention discloses a preparation method of efficient rare-earth paint drier, taking isooctanoic acid, sodium hydroxide, lanthanum cerium solution, 200# solvent oil, water and corresponding auxiliary agent as main raw materials to prepare the efficient rare-earth paint drier, controlling the concentration of organic acid, the concentration and saponification rate and saponification time of the saponification agent, the extraction time and the addition quantity of auxiliary agent to ensure that the drier can reach set metal content and optimized drying performance. The results show that all technical indexes of the rare-earth drier prepared by the method can reach the national standard, satisfy application requirements of various paints, and overcome the shortage that the sample plate of the rare-earth drier in white alkyd ready mixed paint gets dark. The content of metal of the rare-earth paint drier prepared by the method is 4% to 10%, and the appearance is clean and transparent, no precipitate is generated.

Owner:甘肃稀土新材料股份有限公司

Corrosion-resistant low-temperature-curing cathode electrophoretic paint

InactiveCN105885640AImprove thermal stabilityImprove uniformitySiccativesAnti-corrosive paintsCross-linkEpoxy

The invention relates to the field of paint, in particular to corrosion-resistant low-temperature-curing cathode electrophoretic paint which comprises 1-2 parts of color paste, 4-6 parts of an emulsion and 5-7 parts of deionized water. The color paste comprises 20-30 parts of main resin, 5-10 parts of an alcohol-ether cosolvent, 3-8 parts of organic acid, 0.3-0.7 part of an emulsifier, 1-5 parts of a compound drier, 30-40 parts of deionized water, 3-7 parts of a first solid additive, 1.5-6 parts of a second solid additive, 6-9 parts of a first compound regulator, 7-11 parts of a second compound regulator, 8-14 parts of a third compound regulator, 3-7 parts of a fourth compound regulator composed of polyacrylate-2-cross-linked polymer and corrosion-resistant liquid, and 15-20 parts of a filler, and the emulsion comprises 40-50 parts of modified epoxy resin A, 10-20 parts of modified epoxy resin B, 10-30 parts of a cross-linking agent, 5-9 parts of a curing agent, 3-8 parts of monomolecular amine, 0.1-2 parts of an emulsifier, 0.1-2 parts of a neutralizing agent and 30-50 parts of deionized water. Different compound formulations are used in the emulsion and the color paste in an improved, so that the cathode electrophoretic paint is corrosion-resistant, supportive of low-temperature curing and resistant to yellowing.

Owner:GUANGDE RUIBANG PAINT

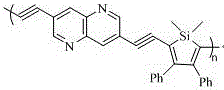

Switchable materials, methods and uses thereof

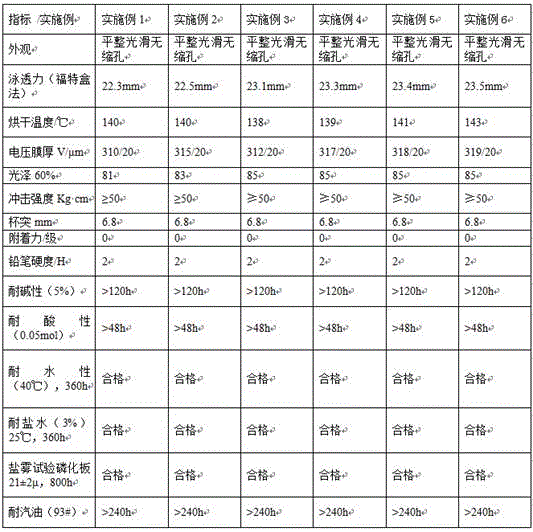

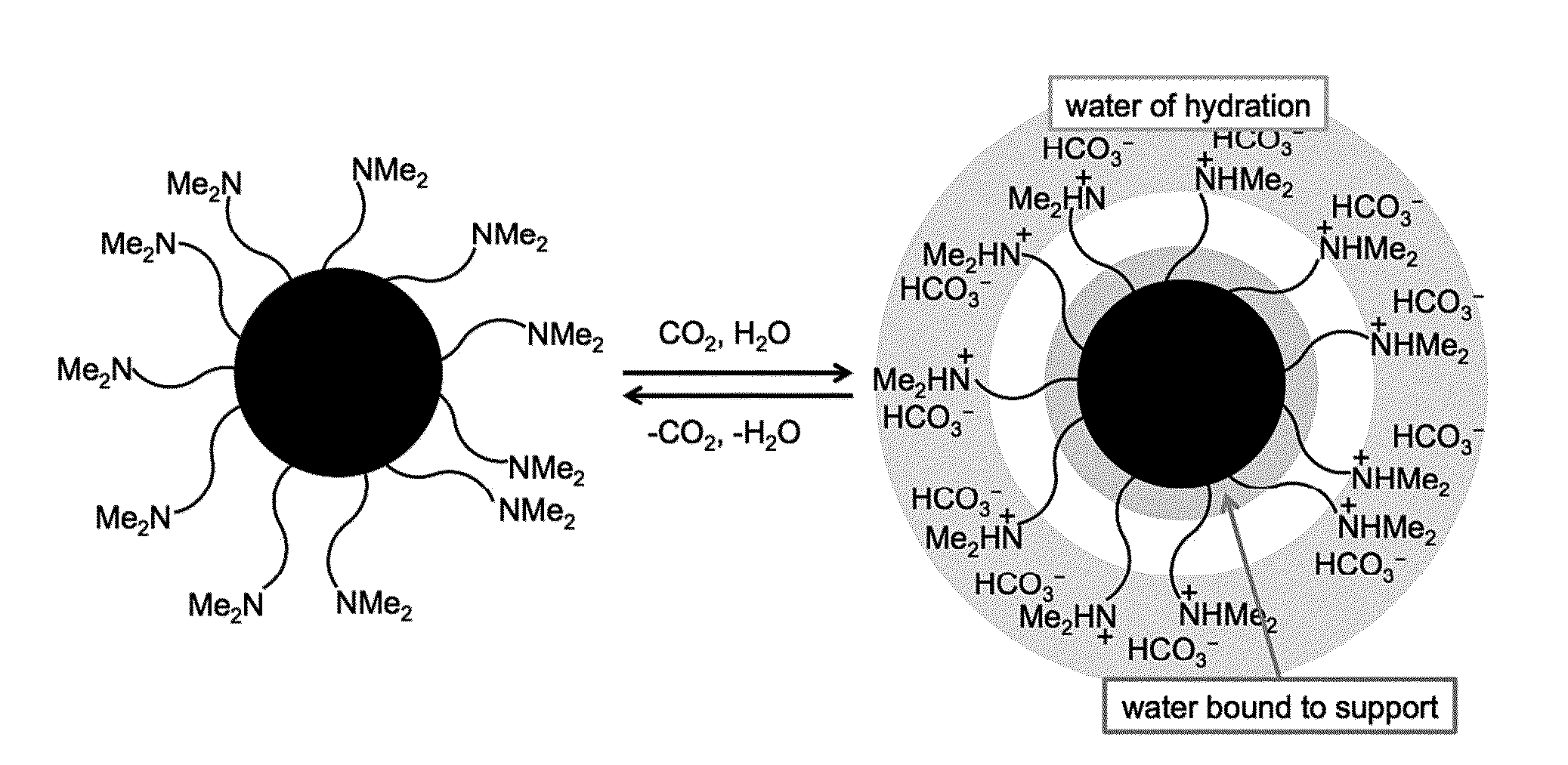

The present application provides a composite material that comprises a solid and solid-supported non-polymeric switchable moiety, wherein the switchable moiety comprises a functional group that is switchable between a first form and a second form, said first form being neutral and hydrophobic, and said second form being ionized and hydrophilic. The composite material converts to, or is maintained in, said second form when the switchable moiety is exposed to CO2 at amounts sufficient to maintain the ionized form. The composite material converts to, or is maintained in, said first form when CO2 is removed or reduced to an amount insufficient to maintain the ionized form. CO2 is removed or reduced by exposing the composite material to heat and / or a flushing inert gas such as N2, Ar, or air. Envisioned uses of these composite materials includes removing water from non-aqueous solvents, removing water vapour from gaseous mixtures, and cleaning industrial reaction vessels and / or pipelines.

Owner:BONIFACE KYLE J

Method for producing environment-friendly efficient electrophoretic paint

InactiveCN105885639APromote oxidationAccelerated aggregationSiccativesPolyurea/polyurethane coatingsOrganic acidEmulsion

The invention relates to the field of coating, in particular to a method for producing environment-friendly efficient electrophoretic paint. The environment-friendly efficient electrophoretic paint comprises 1-2 parts of color paste, 4-6 parts of emulsion and 5-7 parts of deionized water. The color paste in a formula comprises 20-30 parts of matrix resin, 5-10 parts of alcohol ether complex solubilizers, 3-8 parts of organic acid, 0.3-0.7 part of emulsifiers, 1-5 parts of compound driers, 30-40 parts of deionized water and 15-20 parts of fillers. The method for producing the environment-friendly efficient electrophoretic paint includes steps of A, preparing the color paste; B, preparing the emulsion; C, preparing electrophoretic paint. The method has the advantages that the emulsion and the color paste are in different compound formulas when modified, and accordingly the environment-friendly efficient electrophoretic paint which is cathode electrophoretic paint is safe and is environmentally friendly.

Owner:GUANGDE RUIBANG PAINT

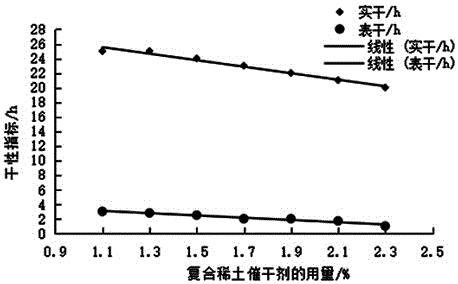

Preparation method of composite rare earth drier for oil paint

The invention discloses a preparation method of a composite rare earth drier for oil paint and relates to a drier for chemical industry. The composite rare earth drier is prepared by mixing cerium isooctanoate, manganese isoocatanoate, zinc isoocatanoate and cobalt isoocatanoate. The four substances realize a synergistic effect to promote the drying of a paint film by using an oxidation and polymerization reaction mechanism. The composite rare earth drier disclosed by the invention is used for coatings such as alkyd color lacquer, phenolic color lacquer and antirust paint; technical indicators such as drying time of the oil paint, the hardness of the paint film, impact resistance and crust property are remarkably improved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

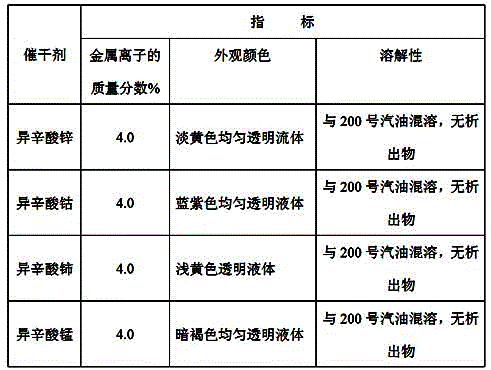

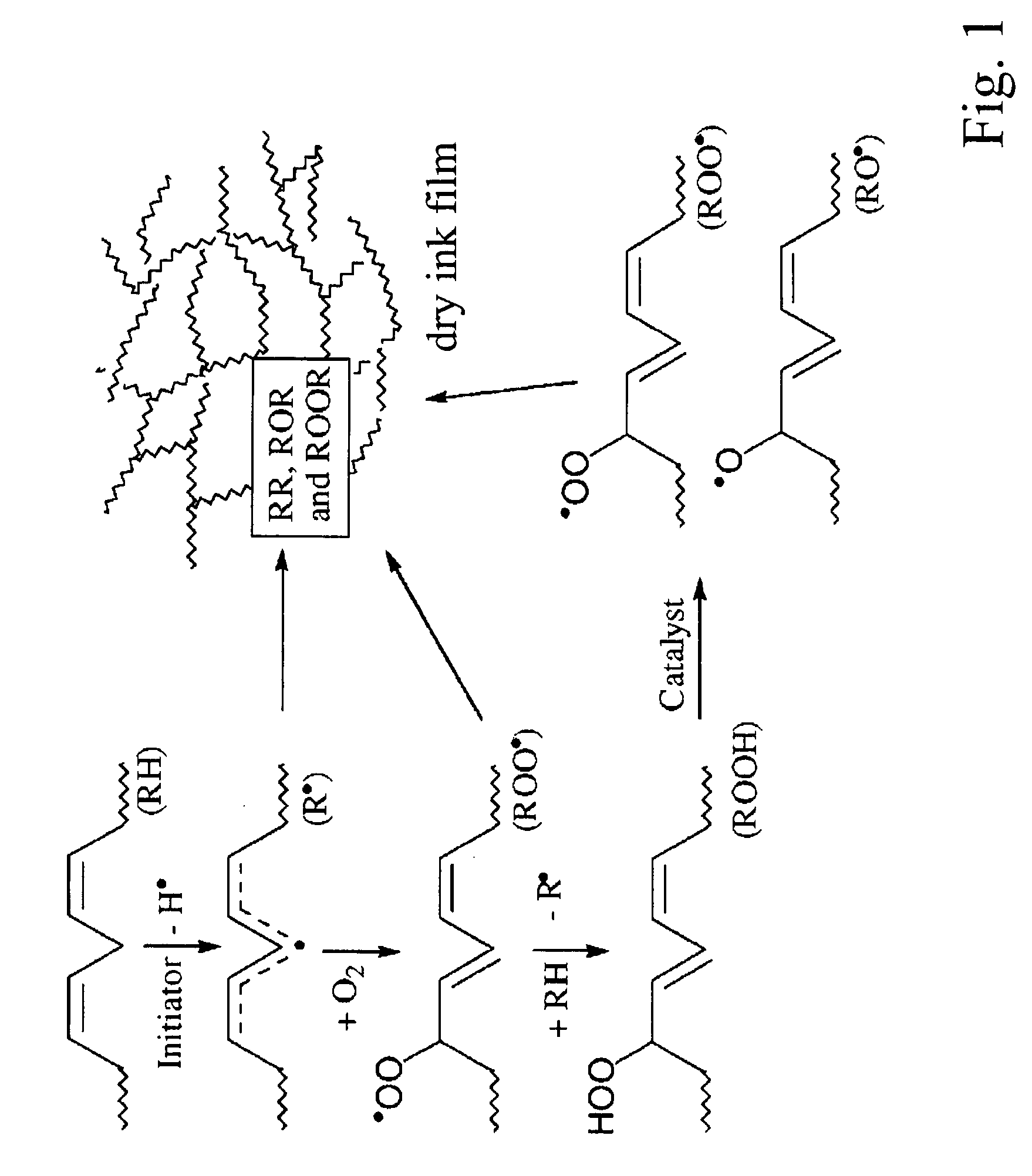

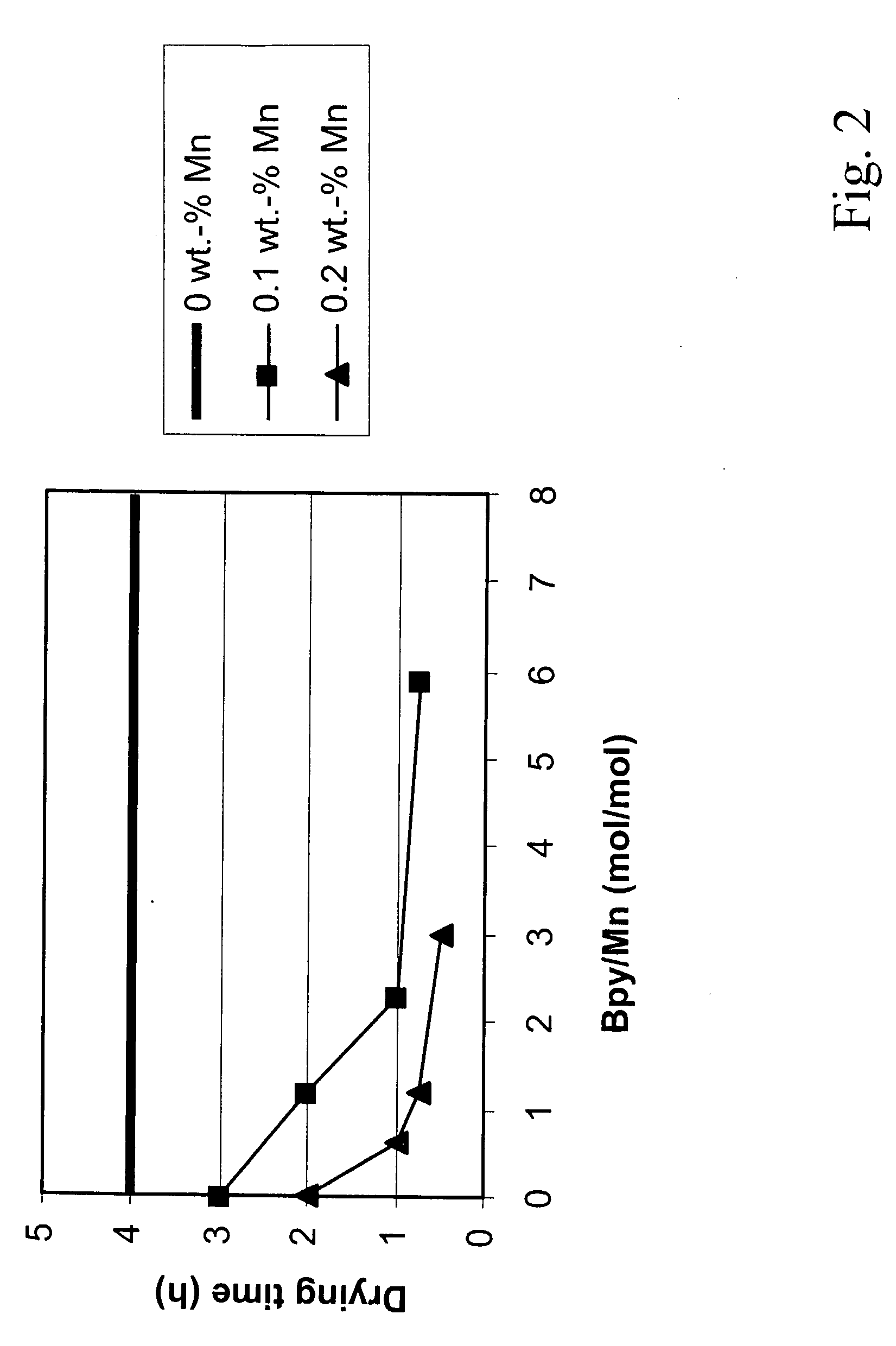

Coating Composition for Offset Paper

Coating for an offset paper comprising a catalyst for fixing polymerisable or crosslinkable constituents of the offset ink. The chemical drying time can be substantially reduced if such a catalyst system is added to the coating, wherein preferentially such a catalyst is a transition metal complex / salt, like Mn (2-ethylhexanoate, bpy).

Owner:SAPPI NETHERLANDS SERVICES

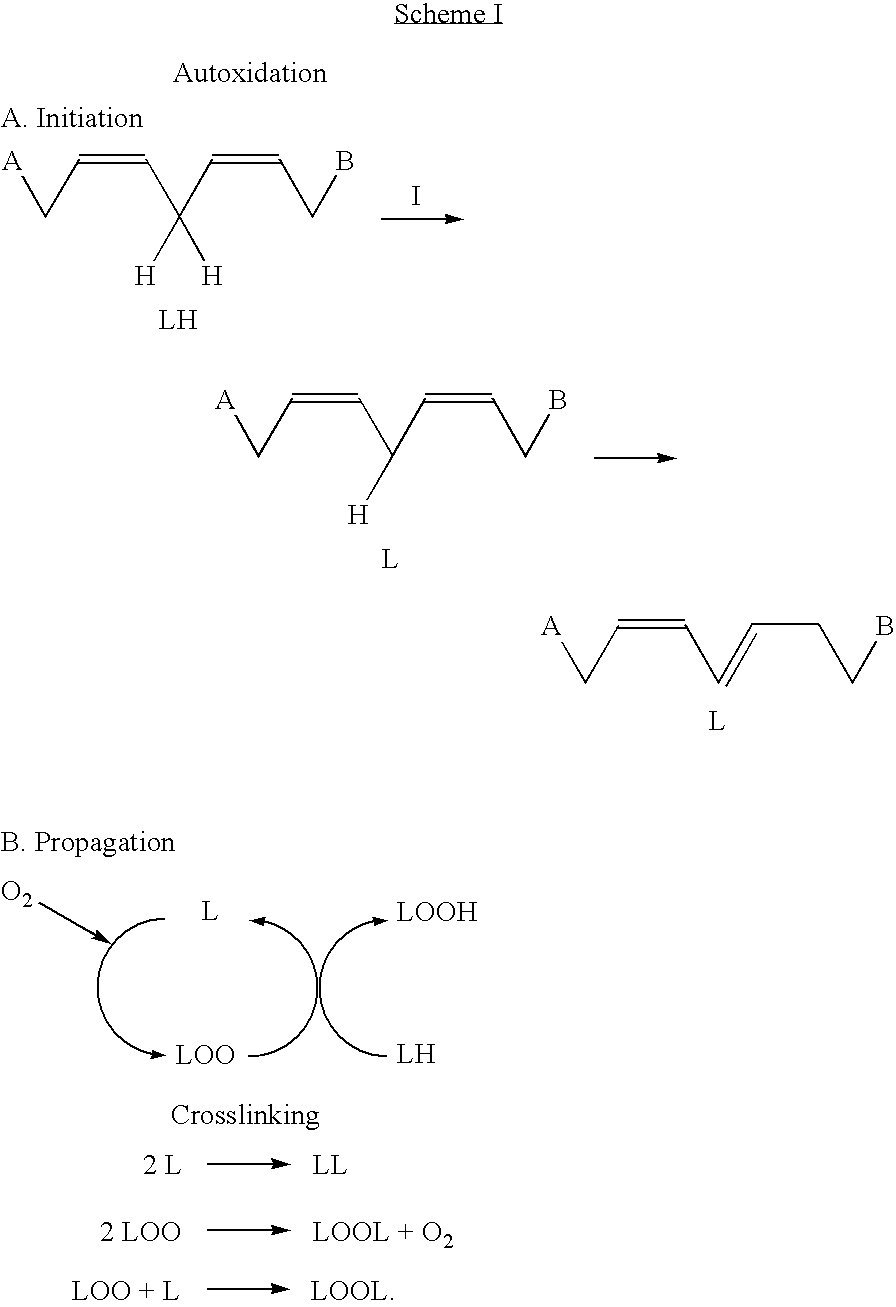

Solvent borne coating composition

InactiveUS20120010344A1Loss of drying rate on aging of solvent borne alkyd based-coating compositions can be minimized or preventedSiccativesConductive materialOrganic acidAutoxidation

The present invention relates to a solvent borne coating composition that comprises an autoxidizable film-forming alkyd binder and a drier system for the autoxidation of the binder, wherein the drier system comprises: (a) at least 0.001 wt % metal, based on binder solids, of at least one metal salt of an organic acid wherein the metal is selected from the group consisting of V, Ce, or Fe; (b) at least 0.01 wt % metal, based on binder solids, of at least one Co salt of an organic acid; and (c) at least 0.01 wt % metal, based on binder solids, of at least one metal salt of an organic acid wherein the metal is selected from the group consisting of Ca, Zn, Ba, K or Li.

Owner:PPG EURO BV

Drier for printing ink and printing ink containing the drier

A drier for oxidative polymerization-drying printing ink is provided, which does not contain cobalt capable of exerting an adverse influence on the environment and health and which is environmentally friendly. A printing ink containing the drier is also provided. The drier for oxidative polymerization-drying printing ink contains an iron salt of a fatty acid and a manganese salt of a fatty acid.

Owner:DAINIPPON INK & CHEM INC

Preparation method of water-based polyurethane drier

The invention relates to a method for preparing a water polyurethane drier, which comprises the following steps: weighing material, oil main drier, oil auxiliary drier, emulsifier, emulsion reaction drier, chelant and deionized water according to 1:1.5-1.5:0.005-0.1:0.0001-0.005:0.001-0.02:1-5; adding deionized water in the emulsifier with high shearing force( the rotary speed is 13000-15000 rotation / minute, the linear speed isn't less than 25m / s); adding oil main drier, oil auxiliary drier, chelant, dilaurate ortho-butyl tin and emulsifier sequentially; starting the recalculated water in the emulsifier when the material temperature in the reactor is 40Deg. C; keeping the temperature of liquid less than 40Deg. C; acquiring the water polyurethane drier by mixing 25-30minutes. The water polyurethane drier can dissolve with water, which can dissolve with water polyurethane according to any proportion, and has the long saving time and the low cost.

Owner:闫里选

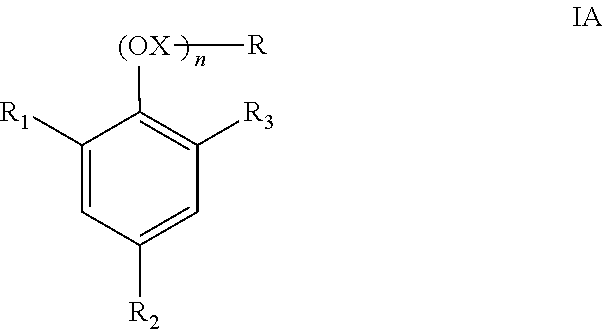

Methods and systems for improving open time and drying time of latex binders and aqueous coatings

ActiveUS8304479B2Extended opening timeIncrease the separation distanceOrganic chemistryOther rubber coatingsTime profileDrying time

Disclosed are low Tg latex polymers and low VOC aqueous coating compositions having an improved open time profile, as well as drying time, stain resistance, wet edge time, low temperature film formation, block resistance, adhesion, water sensitivity and low-VOC content. The latex polymers and aqueous coating compositions include at least one latex polymer derived from at least one monomer copolymerized or alkoxylated compounds or blended with an alkoxylated compound, for example an alkoxylated tristyrylphenol or an alkoxylated tributylphenol. Also provided is an aqueous coating or adhesive composition including at least one latex polymer, water and one or a blend of two or more open time additives or drying time additives. The blend can comprise nonionic and anionic open time additives. Typically, the open time and / or drying time additive is present in an amount greater than about 1.3% by weight of the polymer or composition, typically in an amount greater than about 2% by weight of the polymer or composition, in an amount greater than about 4% by weight of the polymer or composition, in an amount greater than about 7.5% by weight of the polymer or composition, in an amount greater than about 10% by weight of the polymer or composition or in an amount greater than about 20% by weight of the polymer or composition.

Owner:SPECIALTY OPERATIONS FRANCE

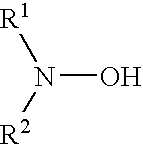

Antiskinning compound and compositions containing them

InactiveUS7201796B2SiccativesSemiconductor/solid-state device manufacturingSkin agentOxygen scavenger

Owner:ARKEMA FRANCE SA

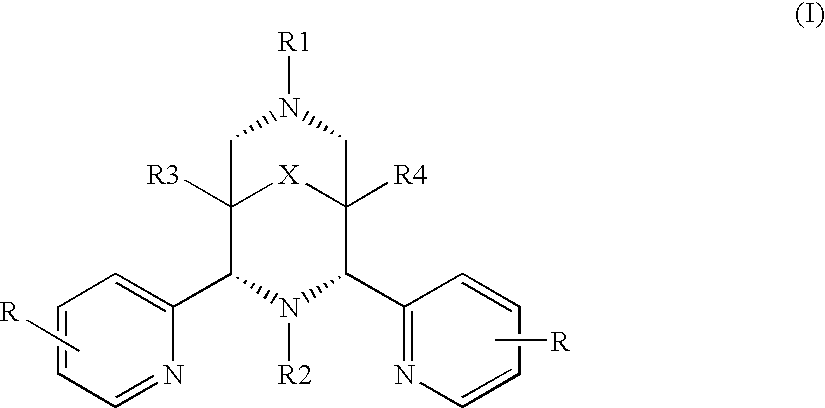

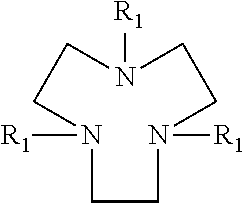

Drier for auto-oxidisable coating compositions

ActiveUS20140342163A1Expedited drying processLow costOrganic chemistryDrying solid materials with heatDesiccantHeteroatom

A mixture for use as a drier for air-drying an auto-oxidizable resin composition, said mixture comprising : 1,4,7-trialkyl-1,4,7-triazacyclononane (L); and, a manganese salt having the general formula Mn2+[X]n, wherein anion X is selected from PF6−, SbF6−, AsF6−, BF4−, B(C6F5)4−, Cl−, Br−, I−, NO3−, or R2COO− in which case n=2, or the anion X is SO42− in which case n=1, and wherein R2 is C1-C20 alkyl optionally substituted with heteroatoms, C6-C20 aryl optionally substituted with heteroatoms, or a polymeric residue; wherein the 1,4,7-trialkyl-1,4,7-triazacyclononane (L) is present in the mixture in an amount such that the molar ratio of L:Mn is at least 1.25:1 and more preferably at least 1.5:1.

Owner:AKZO NOBEL COATINGS INT BV

Drier for bleaching of dish washing machine

ActiveCN101508872AGive full play to the moisturizing effectImprove wettabilitySiccativesWater qualityVaporization

The invention relates to a drier for rinsing dishwashers. The drier takes complex low-foam nonionic surfactant, particularly polyoxyethylene-polyoxypropylene multipolymer, as main component which is high to 50 percents of total weight and uses special cosolvent so as to full play humidification, soften hardwater, purify water quality, enhance humidification of the surfactant and further remove the spots on vessels; meanwhile, molecular mass of the polyoxyethylene-polyoxypropylene is higher than that of common nonionic surfactant so that the hydrophobicity on vessels is changed into hydrophilicity. Rinsing liquid spreads on the surfaces of plastics and stainless dishwares so as to form a film which is easily evaporated, thereby solving problem of hard vaporization on the surfaces of dishwares and being favorable to popularizaion and application.

Owner:深圳市耀星实业有限公司

Preparing technology for environment-friendly cathode electrophoresis paint

InactiveCN105949865AImprove thermal stabilityImprove uniformitySiccativesPaints for electrolytic applicationsEpoxySolvent

The invention relates to the field of paint, in particular to a preparing technology for environment-friendly cathode electrophoresis paint. The electrophoresis paint is prepared from, by mass, 1-2 parts of color paste, 4-6 parts of emulsion and 5-7 parts of deionized water. According to a formula, the color paste is prepared from 20-30 parts of matrix resin, 5-10 parts of an alcohol ether cosolvent, 3-8 parts of organic acid, 0.3-0.7 part of an emulsifying agent, 1-5 parts of a composite drier, 30-40 parts of deionized water and 15-20 parts of filler. A preparing method of the composite drier includes the steps that one of oxalic acid, citric acid, glycolic acid and the like is selected and mixed with deionized water at the proportion of (1-10):10, the mixed solution is pre-mixed for 1 h at 60-80 DEG C, then 1-10 parts of a catalyst is added into the mixed solution in batches under stirring, a reaction is carried out for 4-10 h at 70-90 DEG C, and finally the composite drier soluble in water can be obtained by filtering out precipitate; according to a formula, the emulsion is prepared from 40-50 parts of modified epoxy resin A, 10-20 parts of modified epoxy resin B, 10-30 parts of a curing agent, 3-8 parts of unimolecular amine, 0.1-2 parts of an emulsifying agent, 0.1-2 parts of a neutralizing agent and 30-50 parts of deionized water.

Owner:GUANGDE ZHONGYIN CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com