Paint containing water-based acrylic modified epoxy phosphate resin and preparation method thereof

A technology of epoxy phosphate ester and water-based acrylic acid, which is applied in the direction of epoxy resin coatings, anti-corrosion coatings, chemical instruments and methods, and can solve problems such as damage, high solid content, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

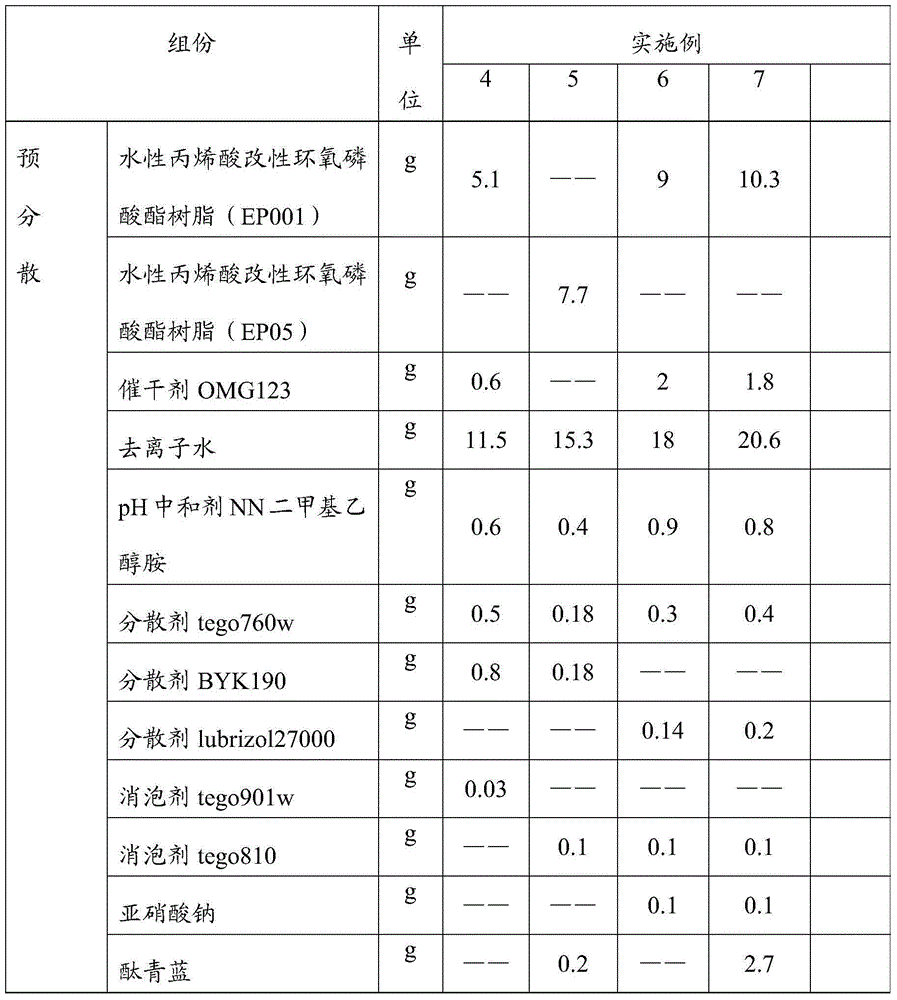

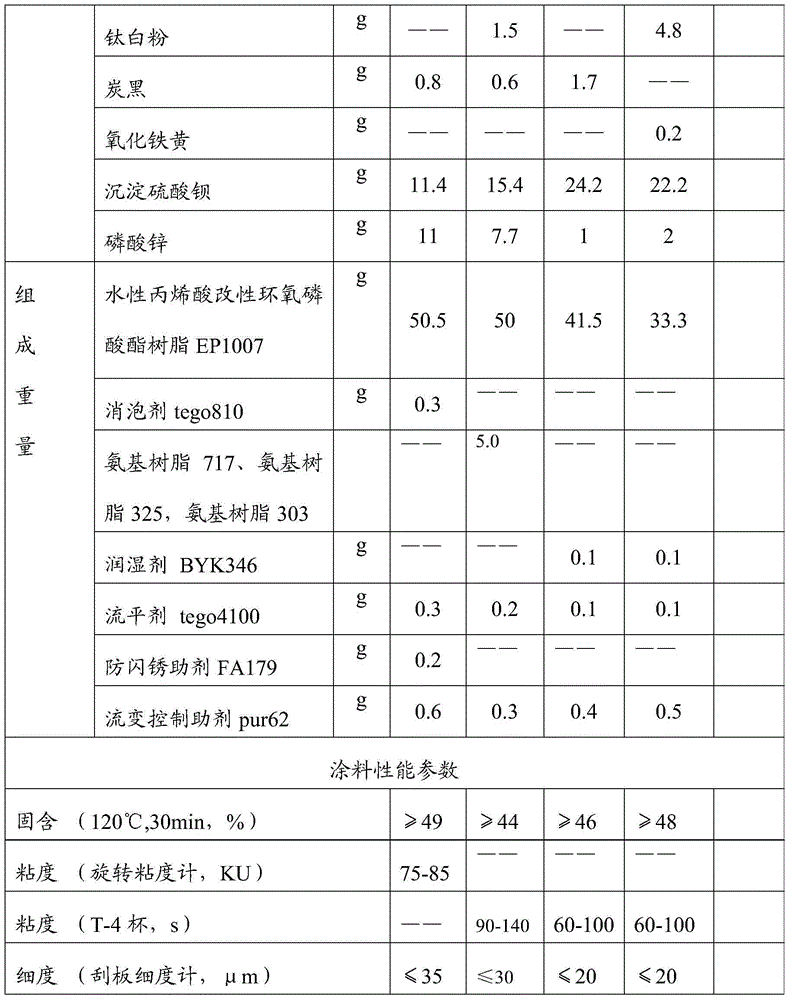

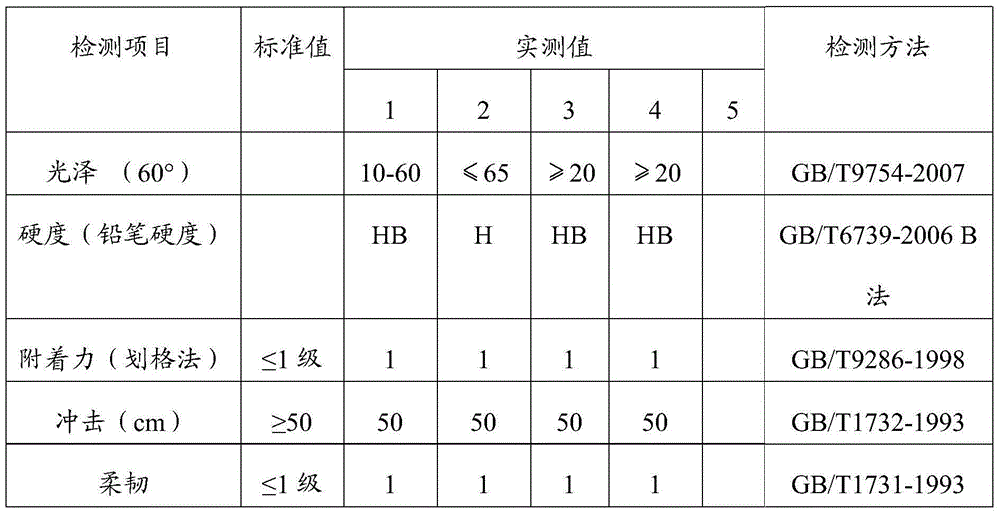

Examples

Embodiment 1

[0028] (1) Add 40g of epoxy resin 609 and 16g of butyl glycol ether into the reaction flask, heat to 155°C and stir to dissolve;

[0029] (2) Add 0.4g of phosphoric acid to 2g of diethylene glycol butyl ether to dissolve, drop into the material in (1) at 150-155°C, add dropwise at a constant speed for 20-30min, finish dropping, and keep warm for 2hr;

[0030] (3) Mix 1.4g of acrylic acid, 0.9g of methyl methacrylate, 4.5g of butyl acrylate, 1.2g of hydroxyethyl acrylate, and 2g of diethylene glycol butyl ether, add 0.5g of cumene hydroperoxide, and mix well Finally, drop it into the above material at 150-155°C for 2-3 hours, and finally keep it warm for 3 hours to obtain acrylic modified epoxy phosphate resin;

[0031] (4) Cool down the modified resin to 100°C, add 3.2g of N,N-dimethylethanolamine, stir evenly, drop 80g of distilled water at 70°C into the resin under strong stirring, emulsify, and make a water dispersion . Its solid content is 32.1%, VOC 15.2%, and the emuls...

Embodiment 2

[0033] (1) Add 42g of epoxy resin 609 and 22g of butyl glycol ether into the reaction flask, heat to 155°C and stir to dissolve;

[0034] (2) Add 0.45 g of phosphoric acid to 2 g of diethylene glycol butyl ether to dissolve, drop into the material in (1) at 150-155 ° C, add dropwise at a constant speed for 20-30 minutes, and keep warm for 2 hours;

[0035] (3) Mix 1.5g of acrylic acid, 0.9g of methyl methacrylate, 4.5g of butyl acrylate, 1.6g of hydroxyethyl acrylate, and 2g of diethylene glycol butyl ether, add 0.7g of cumene hydroperoxide, and mix well Finally, drop it into the above material at 150-155°C for 2-3 hours, and finally keep it warm for 3 hours to obtain acrylic acid-modified epoxy phosphate;

[0036] (4) Cool down the modified resin to 100°C, add 4g of N,N-dimethylethanolamine, stir evenly, drop 85g of distilled water at 70°C into the resin under strong stirring, emulsify, and make a water dispersion . It contains 31% solids and 18% VOC. , the lotion can be p...

Embodiment 3

[0038] (1) Add 607.45g of epoxy resin and 28g of ethylene glycol butyl ether into the reaction flask, heat to 155°C and stir to dissolve;

[0039] (2) Add 0.5 g of phosphoric acid to 2 g of diethylene glycol butyl ether to dissolve, drop it into the material in (1) at 150-155 ° C, drop it at a constant speed for 20-30 minutes, and keep it warm for 2 hours;

[0040] (3) Mix 2g of acrylic acid, 0.9g of methyl methacrylate, 6.5g of butyl acrylate, 1.8g of hydroxyethyl acrylate, and 2g of diethylene glycol butyl ether, add 0.8g of cumene hydroperoxide, and mix well Drop into the above material at 150-155°C for 2-3 hours, and finally keep warm for 3 hours to obtain acrylic modified epoxy phosphate resin;

[0041] (4) Cool down the modified resin to 100°C, add 5.2g of N,N-dimethylethanolamine, stir evenly, drop 100g of distilled water at 70°C into the resin under strong stirring, emulsify, and make water dispersion body. Its solid content is 30.8%, VOC 18.3%, and the emulsion does n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com