Patents

Literature

246results about How to "Excellent medium resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

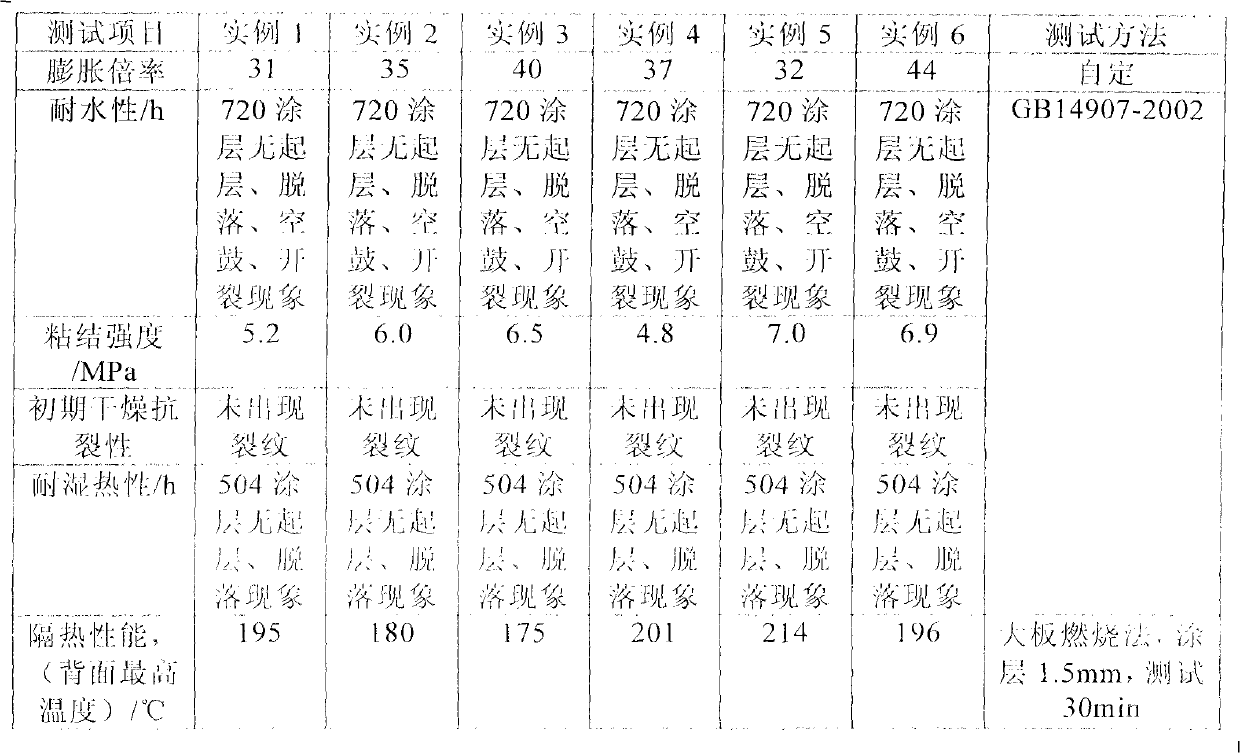

Polyurea expanding type fireproof paint as well as preparation method and application thereof

ActiveCN102559022AImprove insulation performanceImprove fire and heat insulation performanceFireproof paintsPolyurea/polyurethane coatingsFoaming agentPetrochemical

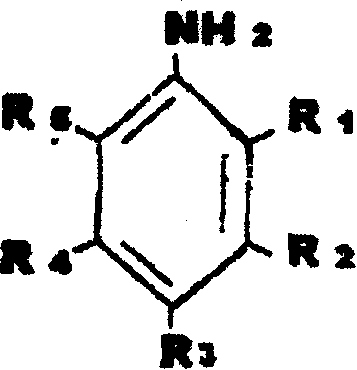

The invention relates to expanding type fireproof paint taking polyurea resin as a film forming substance and application of the expanding type fireproof paint. The expanding type fireproof paint contains a component A and a component B, wherein the component A contains an isocyanate prepolymer, the component B contains an amino-terminated polyether, a polyamine chain expanding agent, a diluting agent, a carbonizing catalyst, a carbonizing agent, a foaming agent, a flame retardant, a smoke suppressing agent, a pigment filler, an adjuvant and a mixed solvent, and the weight ratio of the component A to the component B is 1:5 to 1:7. The fireproof paint is suitable for the fireproof protection of indoor and outdoor steel structures and nonmetal structures and can be used for prohibiting the propagation of flame and the transmission of heat to a substrate. The expanding type fireproof paint is suitable for the fireproof protection in the fields of airport facilities, municipal engineering, vehicles, ships, petrochemical facilities and the like.

Owner:MARINE CHEM RES INST

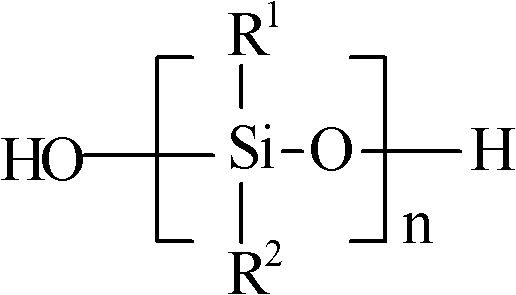

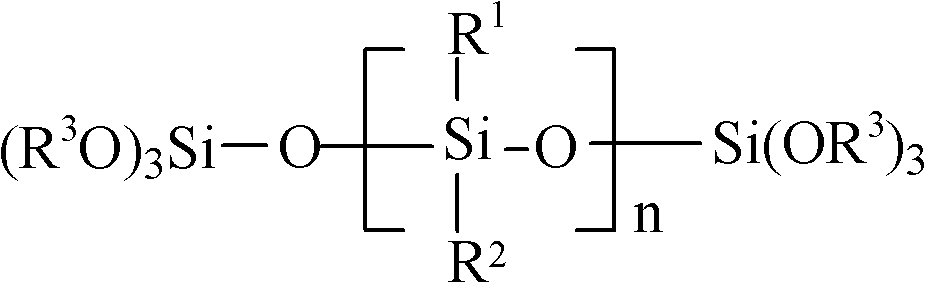

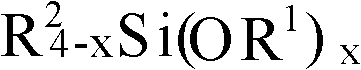

Room-temperature cured phenyl silicon resin conformal coating

The invention discloses a room-temperature cured phenyl silicon resin conformal coating which comprises components A) a segmented copolymer of phenyl silicon resin and linear polyorganosiloxane or methyl phenyl silicon resin and linear polyorganosiloxane, B) alkoxy silane, C) a silane coupling agent containing amino or epoxy group, D) an organic titanium compound, E) organic phosphate flame retardant synergist, and (F) an organic hydrocarbon solvent or low molecular weight siloxane, wherein the organic hydrocarbon solvent is one or multiple of methylbenzene, dimethylbenzene, petroleum ether, cyclohexane and normal heptane; and the low molecular weight siloxane is a mixture of octamethyl-trisiloxan, octamethyl cyclotetrasiloxane or methyl cyclosiloxane. A product produced by the cured resin conformal coating of the invention has the advantages of very high transparency, good elasticity, tough and wearable surfaces as well as excellent high / low temperature performance, waterproofing, heat resistance, cold resistance, weathering resistance, ultraviolet ray resistance, medium resistance, irradiation resistance, flame retarding and the like.

Owner:MIANYANG WELLS ELECTRONICS MATERIAIS

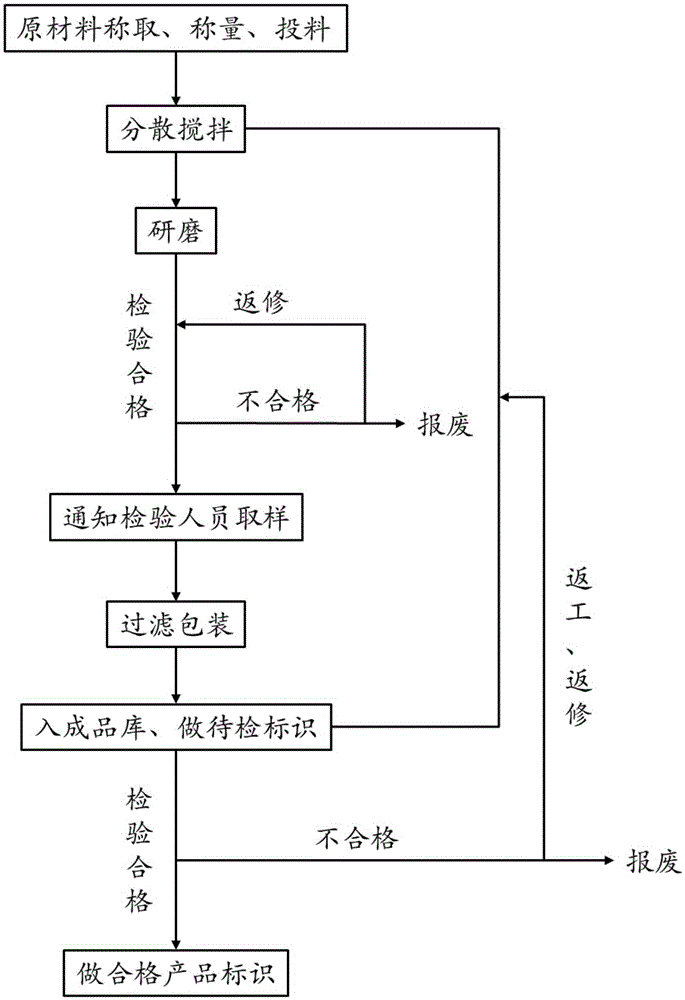

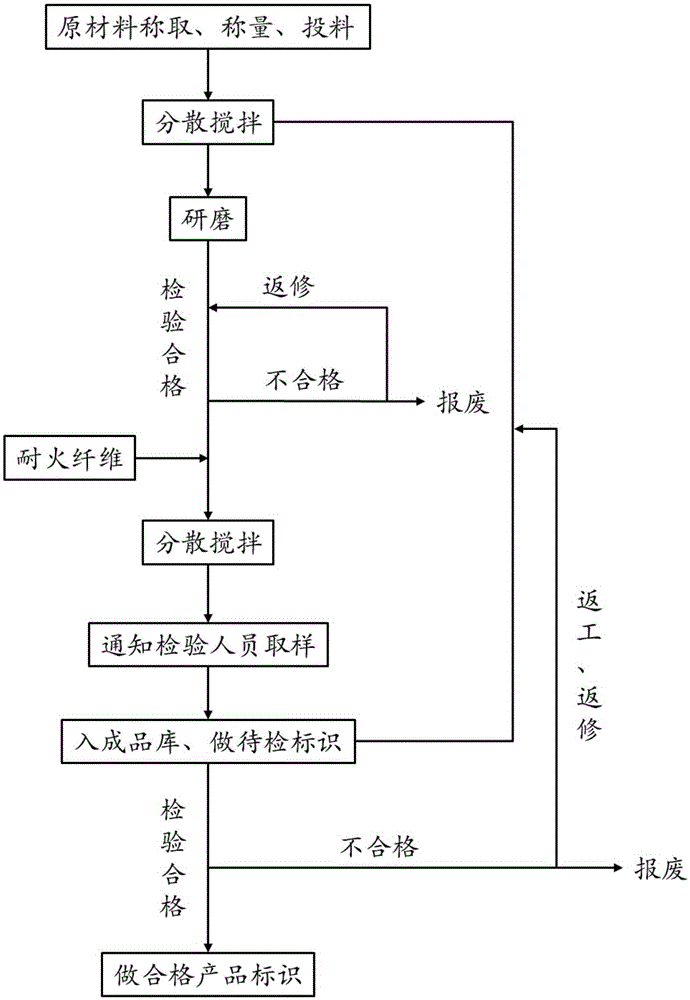

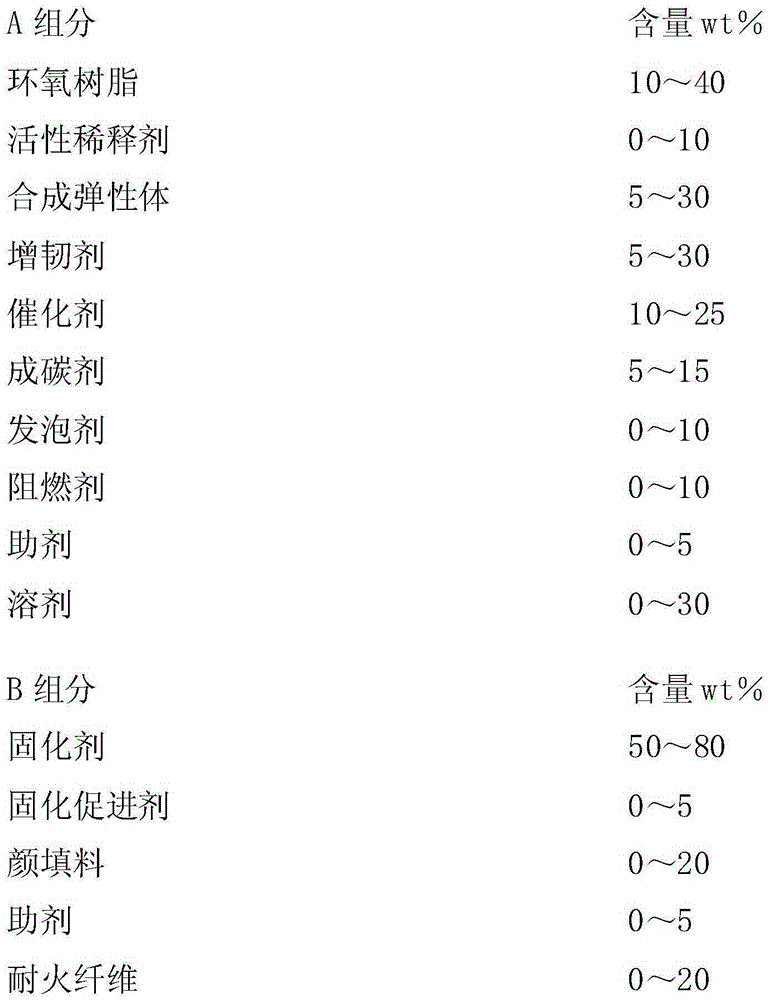

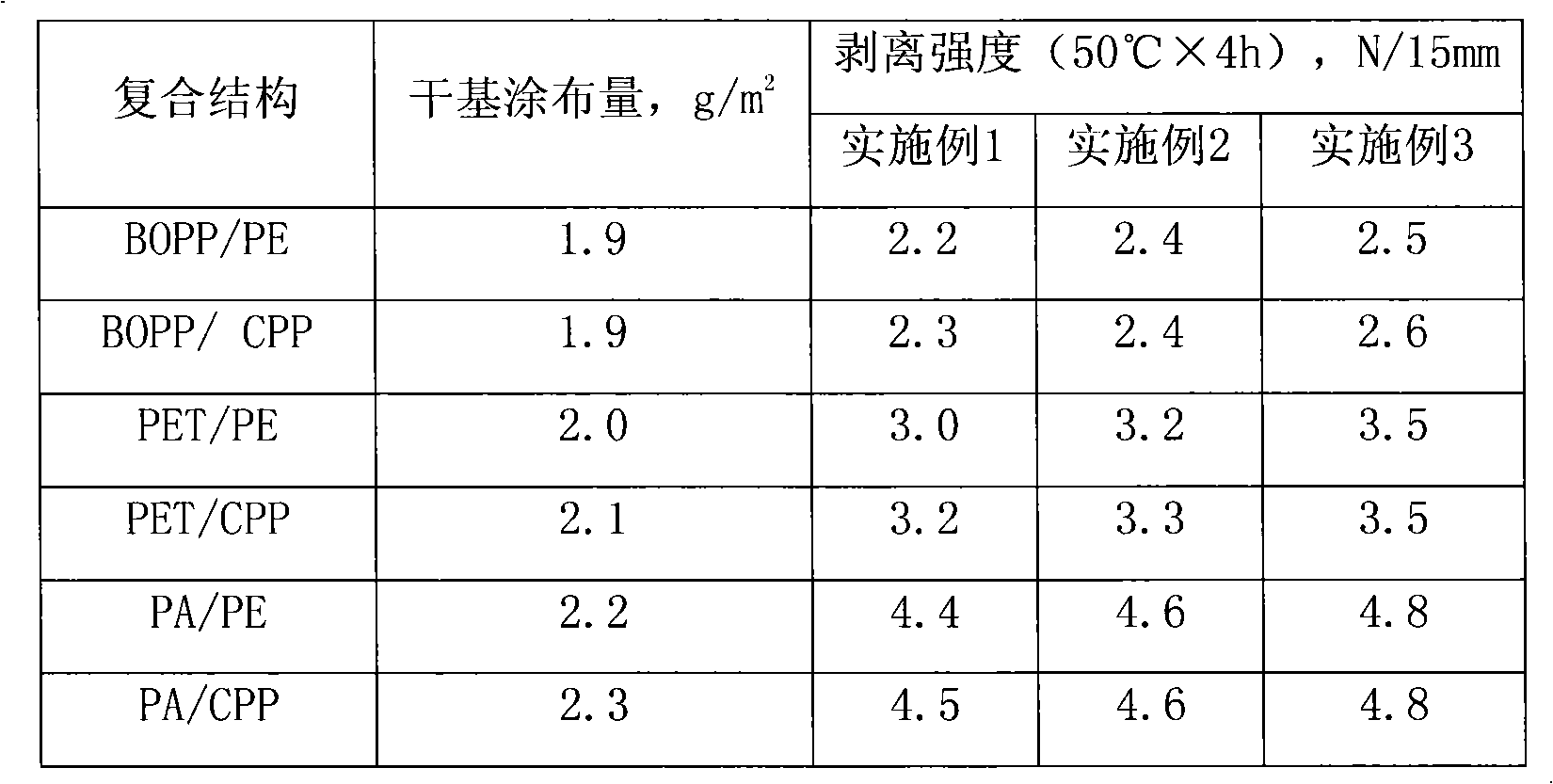

Flexible epoxy intumescence fire-retardant coating and preparation method thereof

InactiveCN105238221AImprove water resistanceExcellent medium resistanceFireproof paintsEpoxy resin coatingsElastomerFiber

The invention relates to a flexible intumescence fire-retardant coating and a preparation method thereof, and belongs to the field of functional coatings. The flexible intumescence fire-retardant coating is composed of a component A and a component B. The component A is prepared from epoxy resin, reactive diluent, synthetic elastomer, flexibilizer, a catalyst, a carbon-forming agent, a foaming agent, fire retardant, auxiliaries and solvent. The component B is prepared from a curing agent, a curing accelerator, pigment filler, auxiliaries, refractory fibers and solvent. The flexible epoxy intumescence fire-retardant coating prepared through the method has certain flexibility, and is particularly suitable for fire-retardant protection of the surface of a flexibility or deformation base material and the surface of a shapeless base material or the surface of light metal. In addition, the flexible epoxy intumescence fire-retardant coating prepared through the method has excellent water resistance, medium resistance, ageing resistance and salt-fog resistance and is suitable for fire-retardant protection of hydrocarbon fire potential risk areas in the ship, airplane and ocean environment and the petrochemical industry.

Owner:MARINE CHEM RES INST CO LTD

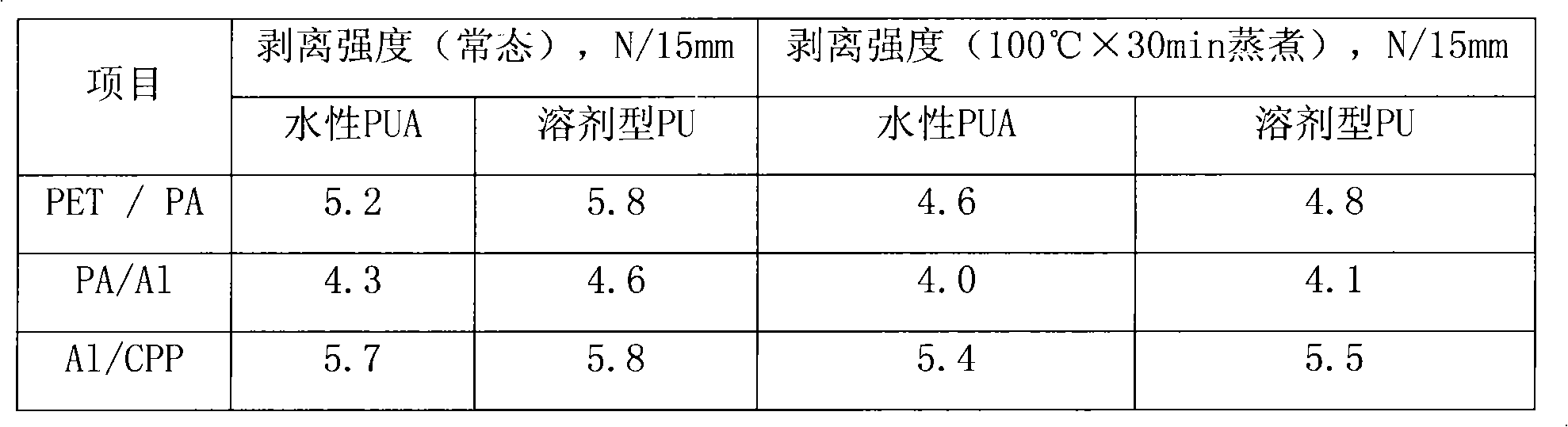

Aqueous composite adhesive and preparation method and use thereof

InactiveCN101768416AImprove water resistanceHigh composite strengthGraft polymer adhesivesIonChemistry

The invention discloses an aqueous composite adhesive and a preparation method thereof, and belongs to the field of high molecular materials. The adhesive is polyurethane / acrylate PUA composite emulsion, wherein based on the total weight of the PUA composite emulsion, the content of the polyurethane is 5 to 20 percent; the content of the polyacrylate is 25 to 45 percent; the content of water is 50 to 70 percent; and the solid content of the PUA composite emulsion is 30 to 50 percent. The preparation method comprises the following steps: preparing the aqueous polyurethane emulsion; preparing the aqueous polyurethane / acrylate PUA composite emulsion from the aqueous polyurethane emulsion; and finally, regulating the solid content of the aqueous polyurethane / acrylate PUA composite emulsion by using de-ionized water, and adding an antifoaming agent, a wetting agent and an antiseptic to prepare the aqueous composite adhesive. In the prepared aqueous PUA composite emulsion, emulsion particles have complex phase structures, a carbamic acid ester chain is knitted tightly with an acrylicacid chain at the molecular level, and the synergic effect between the two makes the performance of a coating better than that of a physically blended coating, so that the aqueous PUA composite emulsion has high performance and environmental protection property.

Owner:BEIJING COMENS NEW MATERIALS

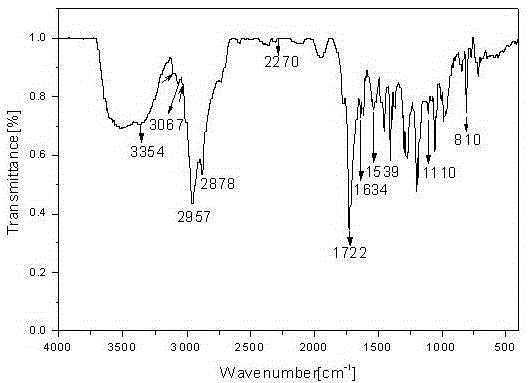

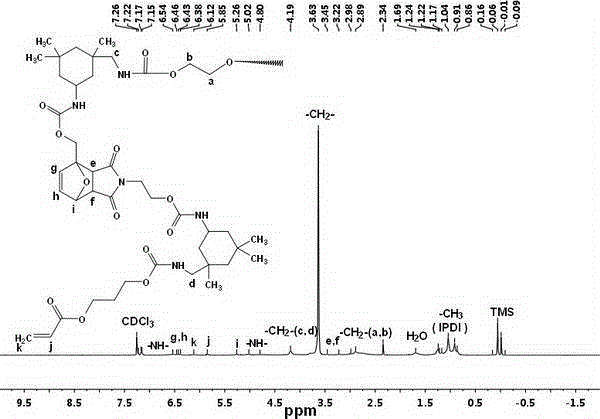

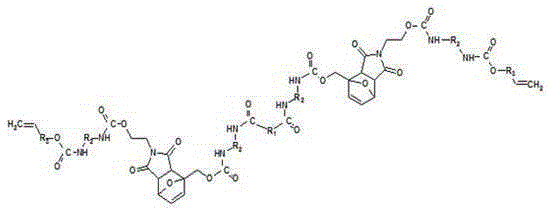

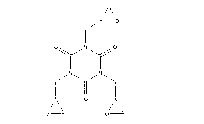

Preparation method for UV-curing self-healing polyurethane based on furan-maleimide structure

ActiveCN105348474AGood physical propertiesImprove mechanical propertiesPolyurea/polyurethane coatingsFuranPolymer science

A preparation method for UV-curing self-healing polyurethane based on a furan-maleimide structure adopts furan, maleic anhydride, ethanolamine, furfuryl alcohol, diisocyanate, divalent alcohol, a mono-hydroxy unsaturated monomer and the like as raw materials to synthesize bifunctional UV-curing polyurethane comprising a furan-maleimide addition product. The polyurethane provided by the invention is synthesized through a conventional way, is practical, low in cost and suitable for industrial production, and can be applied to a UV curing system; energy conservation and emission reduction are realized; moreover, a cured film of the polyurethane is excellent in physical property, mechanical property, medium resistance and thermal performance; through the furan-maleimide addition product in resin, the UV curing system is endowed with the self-healing performance, so that the material safety is improved, the service life is prolonged, and the material life cycle cost is reduced.

Owner:江西国计纳米科技有限公司

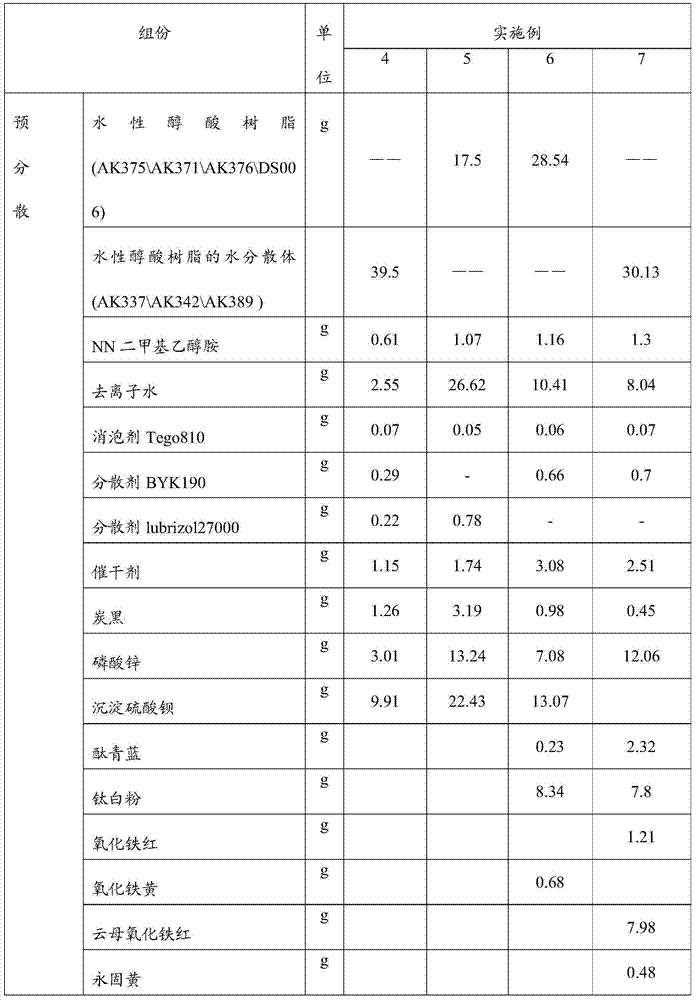

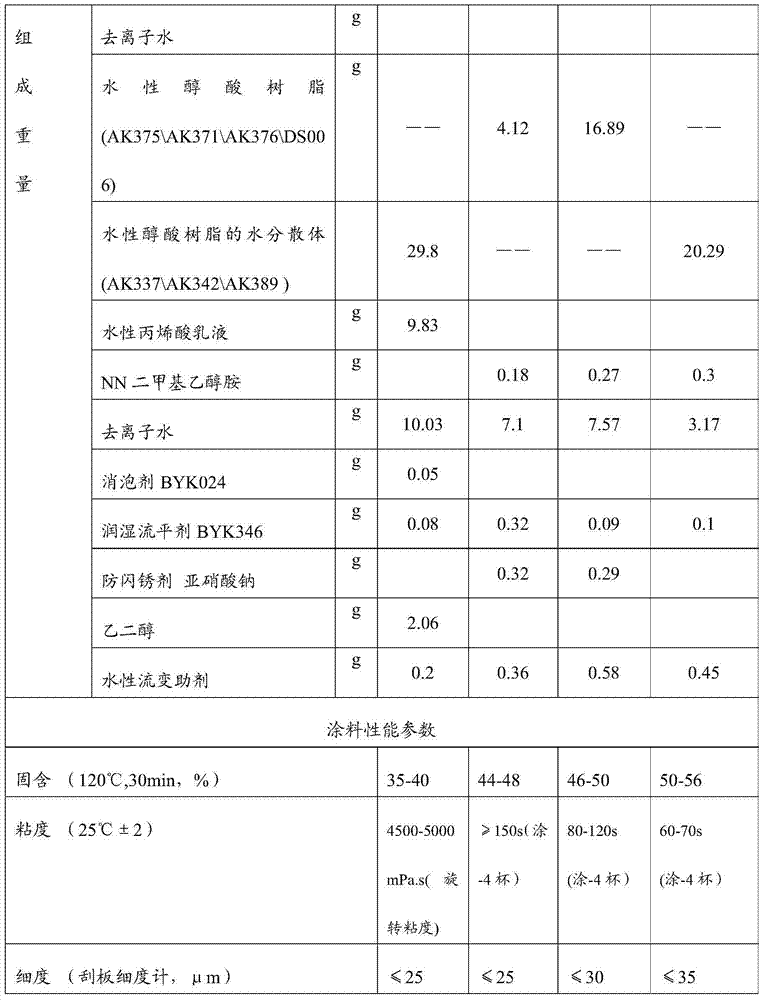

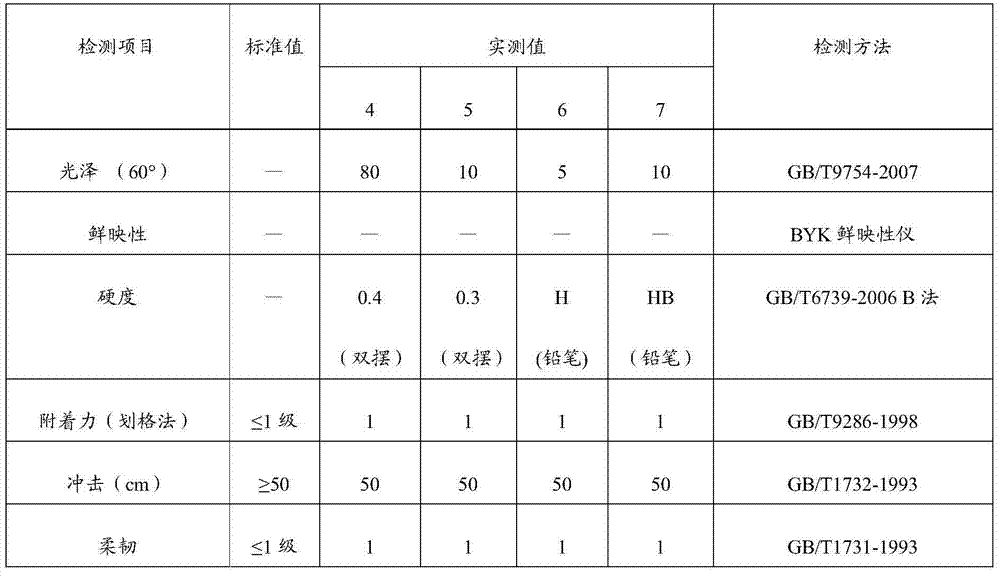

Paint containing waterborne alkyd resin and preparation method of paint

InactiveCN104845510ALow toxicityReduce pollutionAnti-corrosive paintsEpoxy resin coatingsFire hazardWater soluble

The invention belongs to the field of waterborne coatings, and relates to a waterborne alkyd resin and an aqueous dispersion thereof. The formula of the waterborne alkyd resin comprises 18-33 parts of unsaturated fatty acid, 17-26 parts of trimethylolpropane, 1-8.8 parts of benzoic acid, 0-0.055 parts of a catalyst, 14-20 parts of phthalic anhydride or m-phthalic acid, 5-7.7 parts of trimellitic anhydride and 20-25 parts of a cosolvent. 4-6 Parts of a neutralizer is added to 100 parts of the synthesized waterborne alkyd resin, and the obtained mixture is stirred and dispersed in 100-150 parts of water in order to obtain the aqueous dispersion of the waterborne alkyd resin. 2-8 Parts of a drier, a pigment filler and an assistant are added to the dispersion to prepare a waterborne primer or finish. Benzoic acid substitutes parts of fatty acids, so the hardness and the dryness of the alkyd resin are improved; and the resin is water soluble resin and adopts water as a diluent when the resin is used, so the emission of VOC is greatly reduced, VOC decreases to below 15% from about 70% of solvent based paints, the environment is improved, damages to the human body are reduced, and hidden fire hazards are also reduced.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

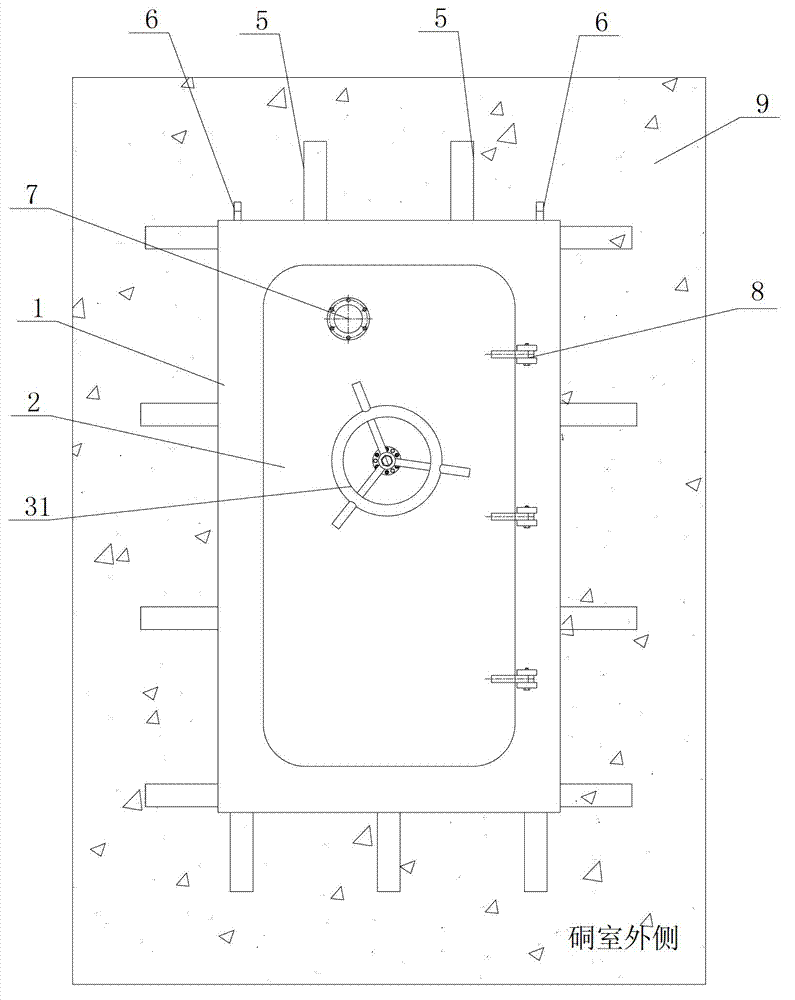

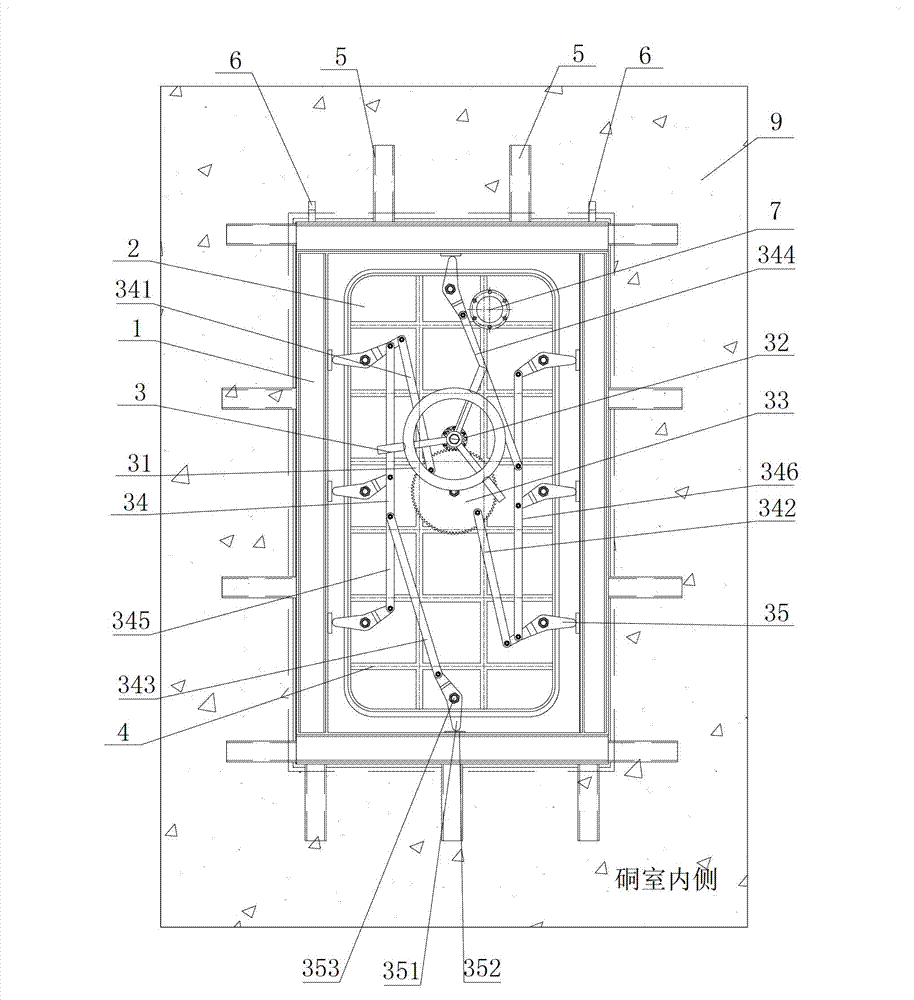

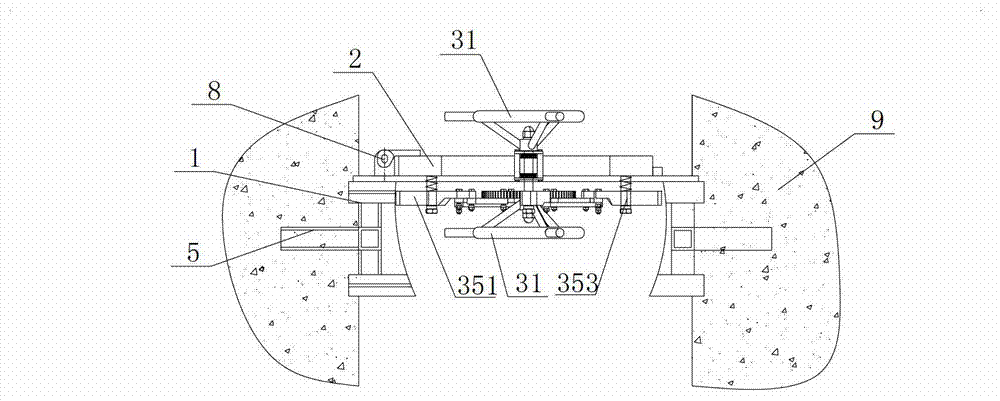

Protective sealing door for underground refuge chamber

ActiveCN102900335AImprove toughnessImprove bindingFireproof doorsConstruction fastening devicesLocking mechanismEngineering

The invention discloses a protective sealing door for an underground refuge chamber. The protective sealing door comprises a door frame and a door plate, wherein the door plate is arranged on the door frame through a rotation shaft; a locking mechanism for locking the door plate on the door frame is arranged on the door plate, a plurality of first reinforcing ribs for reinforcing the strength of the door plate are arranged in the door plate; heat-insulating materials, namely aerogel heat-insulating felts are filled among the reinforcing ribs; at least two annular sealing rings, namely flame-resisting sealing rings are arranged at the joint of the door plate and the door frame; and the periphery of the door plate is locked by the locking mechanism. According to the protective sealing door, the aerogel heat-insulating felts which can bear the temperature of 1,400 DEG C to the maximum are filled in the door plate, so that the door plate can resist high temperature generated during explosion, and the high temperature is insulated out of the refuge chamber; at least two sealing rings which are made of flame-resisting, anti-static, high temperature-resisting and oil-resisting materials are arranged on the contact surface of the door plate and the door frame, so that the protective sealing door has a good sealing effect.

Owner:CCTEG CHINA COAL RES INST

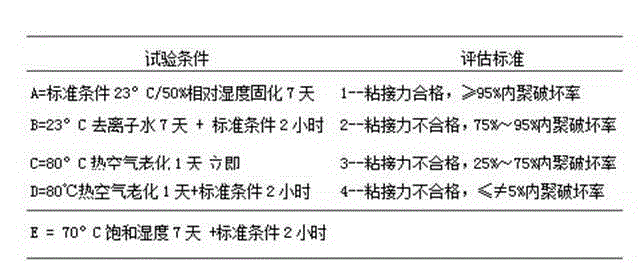

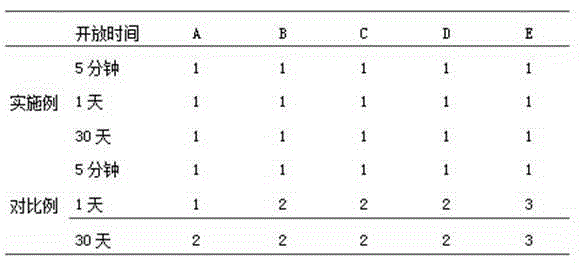

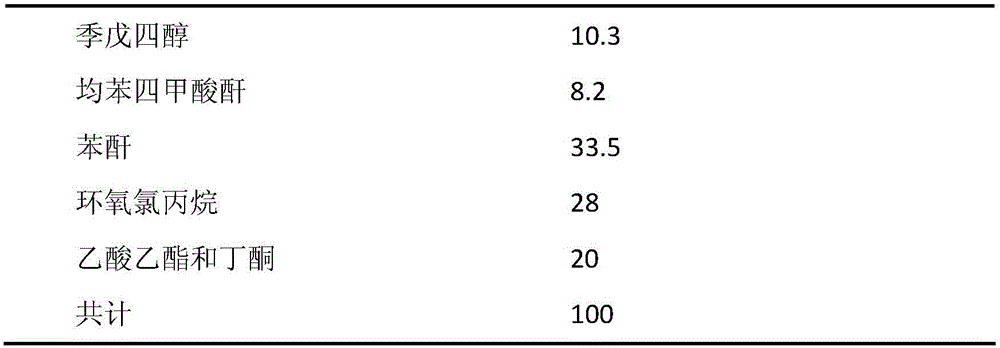

Long-opening-time primer and preparation method thereof

InactiveCN104673170ASlow reaction speedExtended opening hoursNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesIsocyanatePolyurethane adhesive

The invention relates to a long-opening-time primer and a preparation method thereof. The primer is matched with a single-component moisture-curing polyurethane sealant. The primer comprises the following components in percentage by mass: 15-35% of silane terminated polymer, 2-10% of bonding accelerator, 0.1-2% of stabilizing agent, 1-10% of plasticizer, 3-15% of colorant, 0.3-1.5% of dispersing agent, 0.1-2.5% of antioxidant, 0.1-2.5% of ultraviolet absorbent, 0.1-2.5% of light stabilizer and 30-70% of solvent. The primer can be used for enhancing the bonding stability of the single-component polyurethane adhesive when being used for glass assembly and elastic bonding. The system is free of isocyanate, lowers the reaction speed, prolongs the opening time of the primer, has favorable adhesion with ink glass, common primers and finish coats, and enhances the medium resistance and bonding performance of the silane terminated polymer.

Owner:TONSAN ADHESIVES INC

Anti-aging high-flame-retardance natural rubber composite

InactiveCN105754155AGood heat resistanceExcellent weather and oil resistanceMaleic anhydrideDicumyl peroxide

The invention discloses an anti-aging high-flame-retardance natural rubber composite.The composite is prepared from natural rubber, ethylene-propylene-diene monomer rubber, polychloroprene, polyvinyl chloride, natural rubber grafting maleic anhydride, carboxyl liquid nitrile rubber, polypropylene carbonate, zinc oxide, stearic acid, sulphur, dicumyl peroxide, nanosilicon dioxide, kieselguhr, nano-microcrystalline cellulose, medium super abrasion furnace black, cerium oxide, silane coupling agent, accelerant, anti-aging agent, silicon phosphorus flame retardant, HAPCP, aluminum diethylhypophosphite and zinc borate.The composite is high in strength, good in aging resistance, excellent in flame retardance, capable of meeting use requirements of various fields of cables, electric appliances and the like and long in service life.

Owner:宿州学院

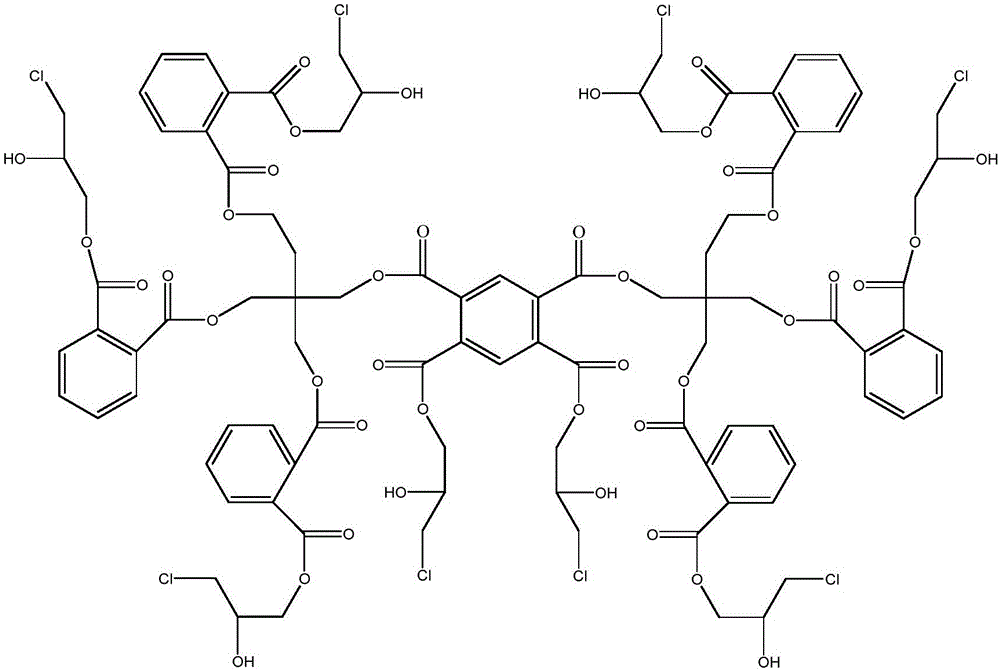

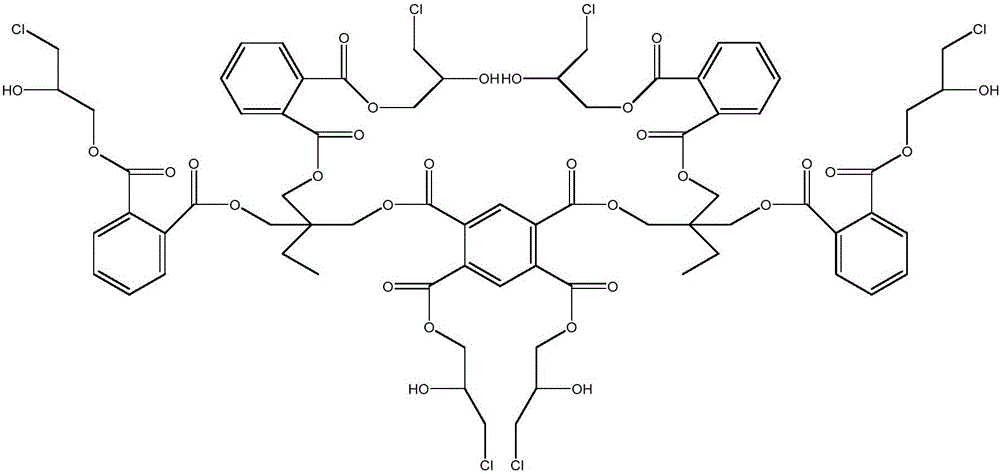

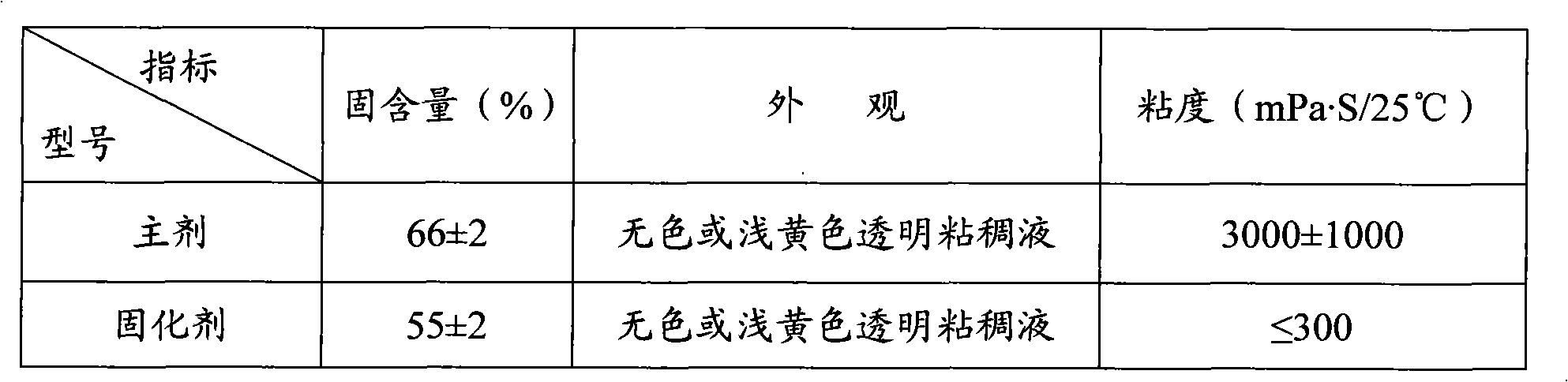

Hyperbranched hydroxyl polyester resin, and preparation method and application of hyperbranched hydroxyl polyester resin

ActiveCN106565965AAnhydrousNo refluxAnti-corrosive paintsPolyurea/polyurethane coatingsNitrogen gasDolichol

The invention discloses hyperbranched hydroxyl polyester resin, and a preparation method and an application of the hyperbranched hydroxyl polyester resin.The preparation method of the hyperbranched hydroxyl polyester resin comprises the following steps: 1) according to molar fraction, 1 part of dicarboxylic anhydride and 2-4 parts of polyhydric alcohol are mixed in a reaction kettle, paratoluenesulfonic acid and an organic solvent are added for reaction at 105-125 degrees under nitrogen protection, then 4-10 parts of phthalic anhydride are added, and reaction for 2-3h is carried out; and 2) according to molar fraction, 6-10 parts of epoxy compounds are added to a matrix prepared in the step 1), a catalyst and an organic solvent are added for reaction for 4-6h at 105-1130 degrees under the nitrogen protection till an acid value is less than 10mgKOH / g, and cooling and discharging are carried out. The solid content of the hyperbranched hydroxyl polyester resin reaches above 70%, and the viscosity is 3000-12000mPa.s. High solid-content bi-component polyurethane dope prepared with the adoption of the hyperbranched hydroxyl polyester resin has high construction solid content, low VOC content, high film hardness, good heat resistance and outstanding anti-corrosion property.

Owner:SOUTH CHINA UNIV OF TECH

High-temperature-resistant anticorrosive coating capable of being solidified at room temperature

InactiveCN109468065AGood three-proof performanceImprove moisture resistanceFireproof paintsAnti-corrosive paintsPetroleum productHeat resistance

The invention belongs to the technical field of coatings, and relates to a high-temperature-resistant anticorrosive coating capable of being solidified at a room temperature. The high-temperature-resistant anticorrosive coating capable of being solidified at the room temperature is characterized by comprising the following components in parts by weight: 20-60 parts of organic silicon resin, 0-30 parts of temperature-resistant powder, 5-40 parts of inorganic coloring pigment, 5-35 parts of temperature-resistant anticorrosive filler, 0.2-10 parts of a promoter and 20-50 parts of a solvent. The high-temperature-resistant anticorrosive coating capable of being solidified at the room temperature has the beneficial effects that (1) the coating both has temperature resistance and corrosion resistance, the tolerable temperature of the coating can reach 500 DEG C, and three-proofing performance (salt mist resistance, damp and heat resistance and mycete resistance) is excellent; (2) the coatingcan be solidified at the normal temperature, the problem that a common organic silicon resin coating needs to be heated for solidification is solved, and the processing property is good; and (3) medium resistance is excellent, and the coating material can resist petroleum products such as jet fuel RP-3.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

Preparation method of epoxy/polyaniline composite base-material for anticorrosion paint

InactiveCN1733836AImprove anti-corrosion performanceStrong adhesionAnti-corrosive paintsEpoxyRoom temperature

The preparation method for epoxide / polyaniline composite basic material in anti corrosive paint comprises, using epoxy resin as dispersant to disperse aniline or its derivative monomer; taking polymerization and doping technique at room temperature to prepare the material. This method is simple and low cost fit to industrial production. The product also has well film-forming and leveling properties and fit to anti electromagnetism or EL material.

Owner:CHONGQING UNIV

Epoxy resin structural adhesive and preparation method thereof

InactiveCN101906282AHigh strengthImprove toughnessNon-macromolecular adhesive additivesCarboxyl rubber adhesivesEpoxyAdhesive

The invention discloses an epoxy resin structural adhesive and a preparation method thereof, belonging to the technical filed of chemical adhesive preparation. The used raw material consists of a resin system, an adhesive component A and a curing agent system component B, and the component A and component B are completely mixed and then cured at room temperature. The structural adhesive in the invention has the advantages of high strength and toughness, good creep resistance, little creep strain, good fatigue resistance and shock resistance, good heat resistance, medium resistance and corrosion resistance, particularly good muggy and aging resistance, excellent creep rupture strength, enough safety and reliability, good flame retardant property, low stress, high strength, high adhesive force, high reliability and the like, and complies with environmental requirements. The epoxy resin structural adhesive is mainly used for adhering composite materials, such as manufacturing yachts, building houses with composite boards, adhering and manufacturing containers made of large-scale composite materials, and the like.

Owner:强军锋

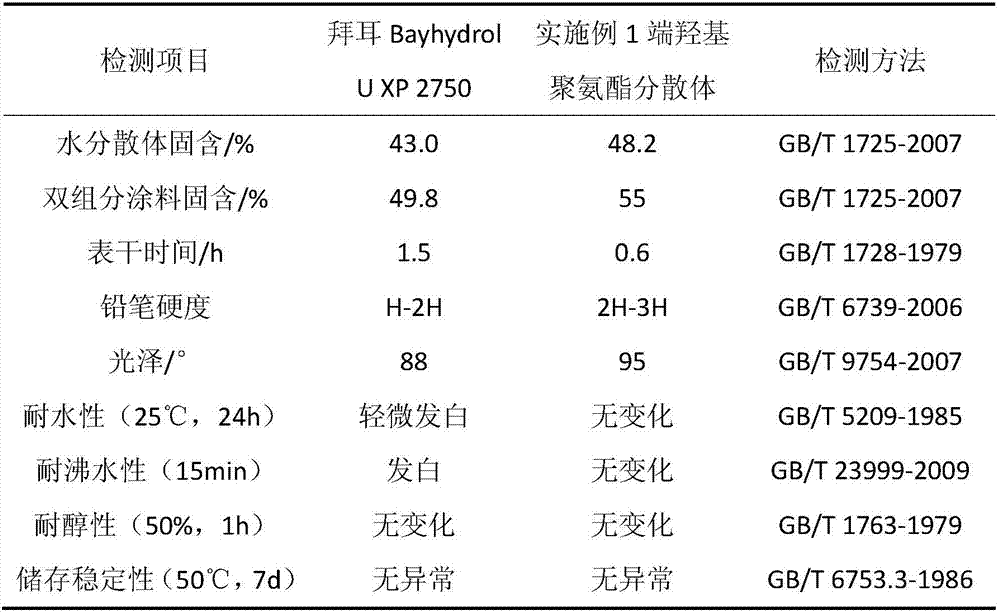

High-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as preparation method and application thereof

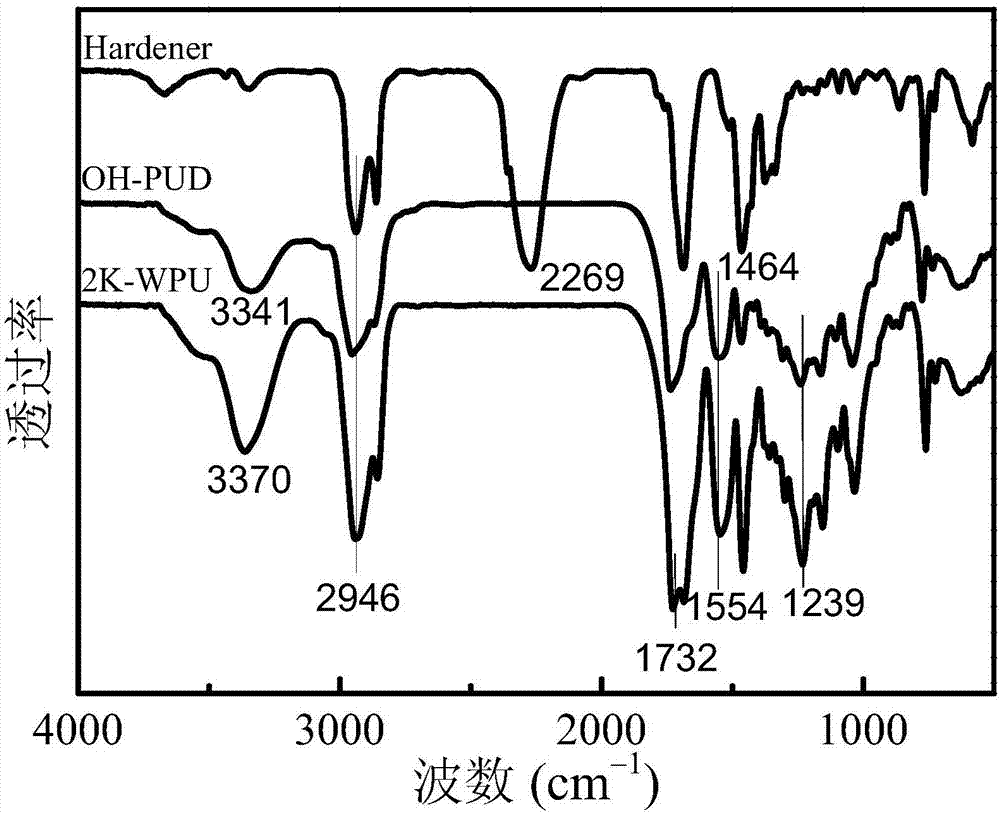

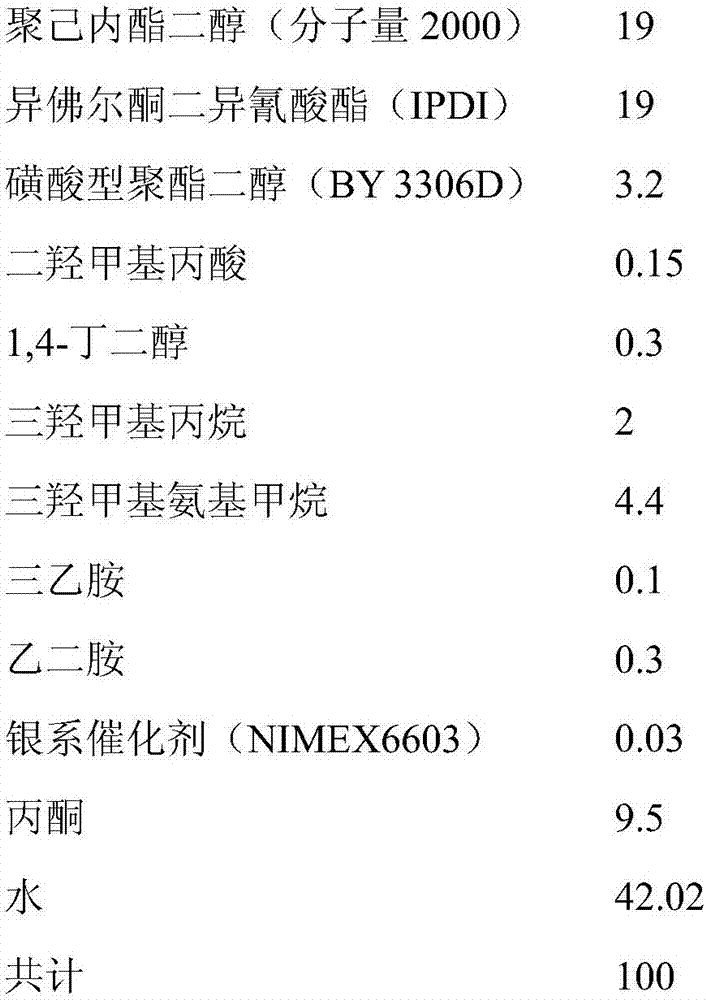

InactiveCN106866923AIncreased average hydroxyl functionalityIncrease crosslink densityPolyurea/polyurethane coatingsEthylenediamineNitrogen gas

The invention discloses a high-functionality hydroxyl-terminated polyurethane aqueous dispersion as well as a preparation method and application thereof. The preparation method comprises the following steps: adding aliphatic diisocyanate, polyvalent alcohol, a hydrophilic chain-extending agent and a catalyst into a reaction kettle; carrying out temperature rise reaction under the protection of nitrogen gas and cooling when the NCO percent of a system reaches a theoretical value; dropwise adding an acetone solution of a dihydric alcohol chain-extending agent and a crosslinking agent, continuously reacting and diluting with acetone when the NCO percent of the system reaches the theoretical value; cooling, and adding triethylamine for neutralizing; adding water for dispersing, and adding alcamines compounds for terminating; finally, carrying out post chain extending by using ethidene diamine to obtain the hydroxyl-terminated polyurethane aqueous dispersion. According to the high-functionality hydroxyl-terminated polyurethane aqueous dispersion disclosed by the invention, an alcamines terminating agent with polyhydroxy functionality is adopted, and a polyhydroxy functional group is introduced on a polyurethane chain segment by a terminating reaction of an amine group and an NCO group; the obtained aqueous dispersion has the advantages of high solid content, small particle size and stable storage; a two-component waterborne polyurethane coating prepared by the high-functionality hydroxyl-terminated polyurethane terminating dispersion has the characteristics of high drying speed of the coating, excellent medium resistance and environment friendliness of a product.

Owner:SOUTH CHINA UNIV OF TECH

Low-temperature-resistant heat-conducting fluororubber material

InactiveCN105086294AImprove high temperature resistanceExcellent high temperature resistance, modified graphene has excellent thermal conductivityPhosphateHeat conducting

The invention discloses a low-temperature-resistant heat-conducting fluororubber material. The fluororubber material comprises, by weight, 90-110 parts of fluororubber, 30-50 parts of ethylene propylene rubber, 30-50 parts of fumed silica, 10-20 parts of nanometer kaolin, 4-7 parts of modified graphene, 10-30 parts of microencapsulated red phosphorus, 5-10 parts of ethyl butyl phosphinate, 5-10 parts of bis(4-hydroxyphenyl) phenyl phosphine oxide, 10-20 parts of acetyl tributyl citrate, 10-15 parts of dioctyl nylon-acdate, 10-20 parts of epoxidized soybean oil, 0.8-1.2 parts of dual-solvent 25, 1-3 parts of triallyl isocyanurate, 0.5-0.9 part of 3# vulcanizing agent, 3-4 parts of Ca / Zn compound stabilizers, 2-4 parts of stearic acid, 1-3 parts of zinc oxide, 1-2 parts of isooctyl phosphate, 1-2 parts of antiager A, 0.5-1.5 parts of antiager 4010 and 3-5 parts of paraffin. The fluororubber material is high in heat conducting performance, low temperature and high temperature resistance and low-temperature elasticity.

Owner:ANHUI JINYANG FLUORINE CHEM

High insulating anticorrosive paint

The invention discloses a high insulating anticorrosive paint, which is designed for solving the technical problem that the comprehensive indexes of temperature resistance, flame resistance, heat insulation, adhesive force, density and the like of the conventional insulating patient are difficult to meet the harsh requirements of the high-speed train field. The paint comprises the following components in percentage by mass: 50 to 70 percent of epoxy modified organic silicon resin, 10 to 20 percent of hollow microspheres, 10 to 15 percent of composite flame retardant, 5 to 15 percent of hydrotalcite, 3 to 8 percent of titanium dioxide and 1 to 3 percent of auxiliary agent. The paint is prepared according to the proportion and requirements. The paint has the advantages that: the preparation process is simple, reasonable and easy to implement; the paint has good heat resistance, heat insulation, anticorrosive performance and heat preservation performance; and the paint is particularly suitable to be applied on high-speed trains and various aviation aircrafts with high comprehensive performance requirements.

Owner:法库县矿产资源研究发展中心

Tetrafluoroethylene-propylene fluorine-containing elastic body and preparing method thereof

An tetrafluoroethylene-propylene fluorine-containing elastomer and its preparation method includes: (1) providing an aqueous dispersions of comonomer, which includes: (a) tetrafluoroethylene, propylene and one or more kind of other comonomers, (b) oxidation-reduction system, which includes: water-soluble inorganic peroxide initiator, water-soluble iron salt reductant, coordination agent, water-soluble inorganic aid reducer, (c) water-soluble metal hydroxide pH modifier, and (d) emulsifier. Its characteristic is (2) under the polymerization temperature of 10~50deg.C and polymerization pressure of 3.1~8MPa, the monomers take polymerization.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD

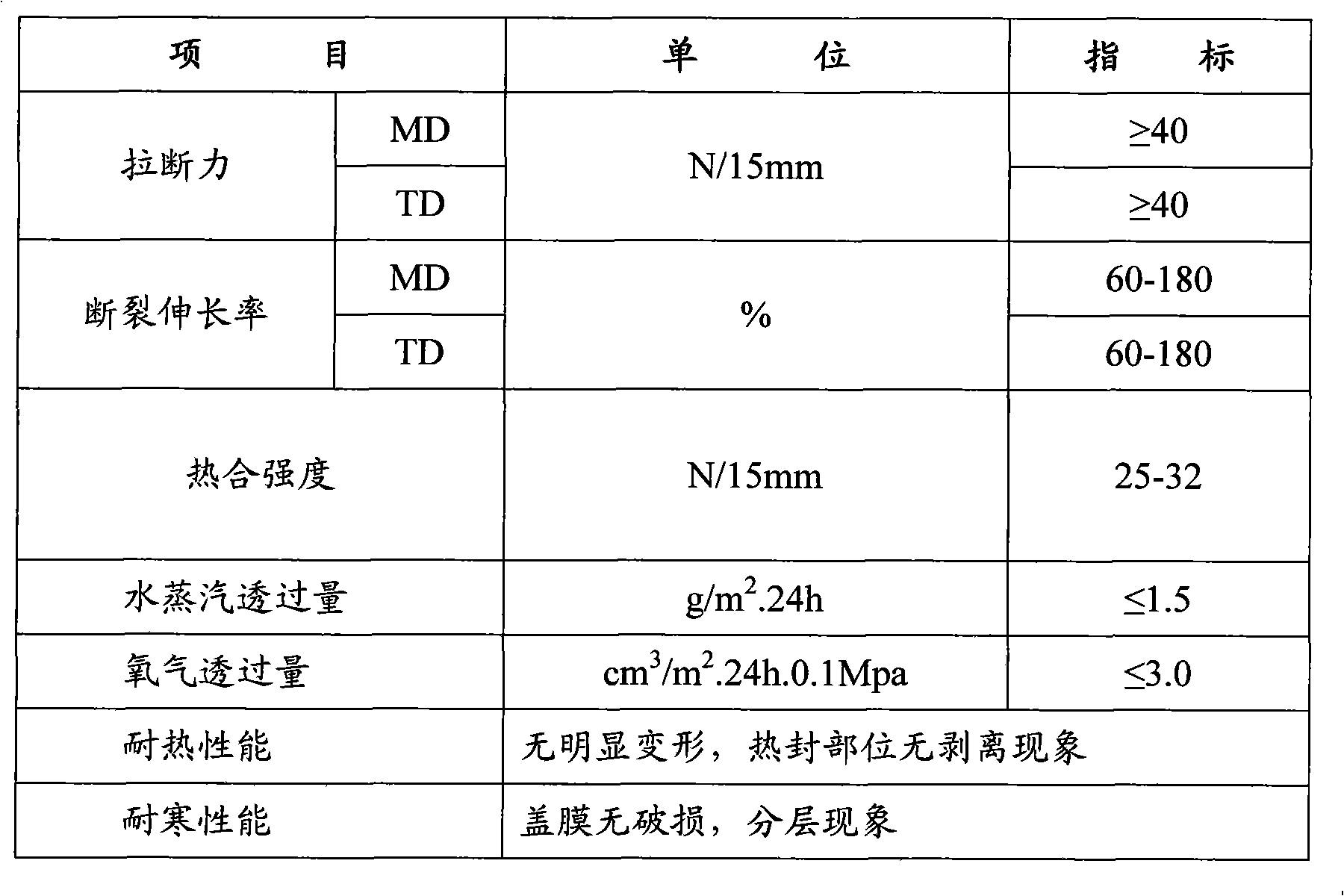

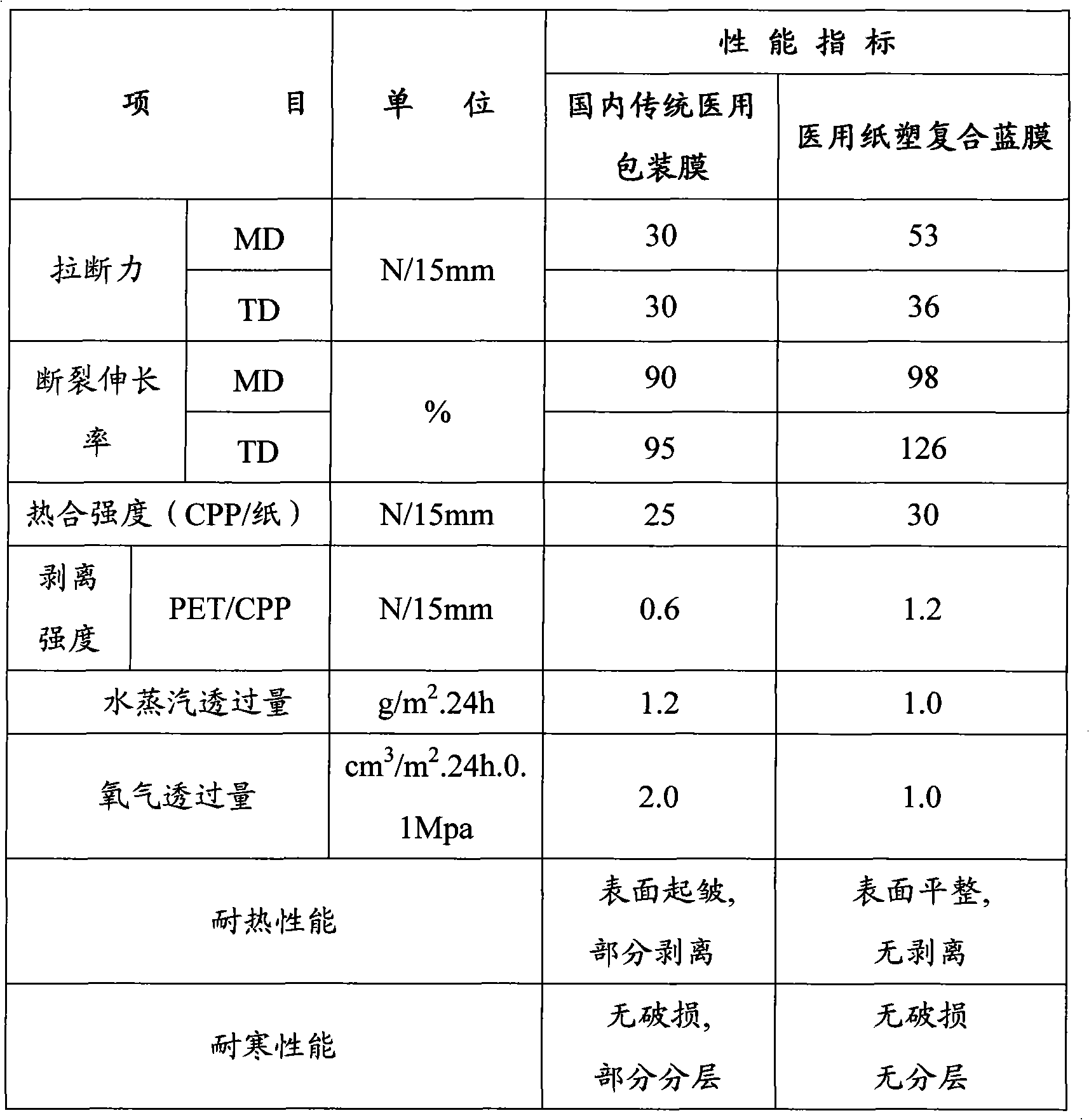

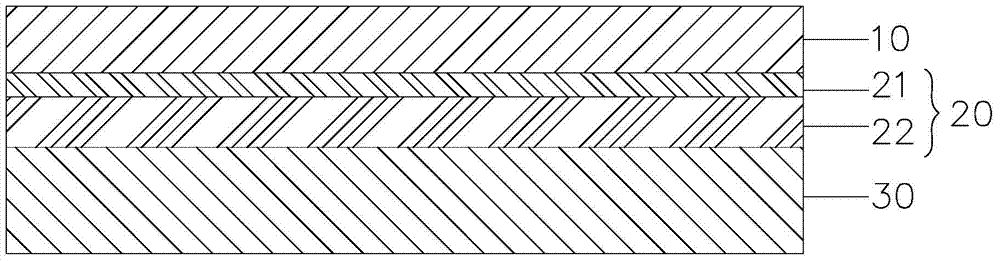

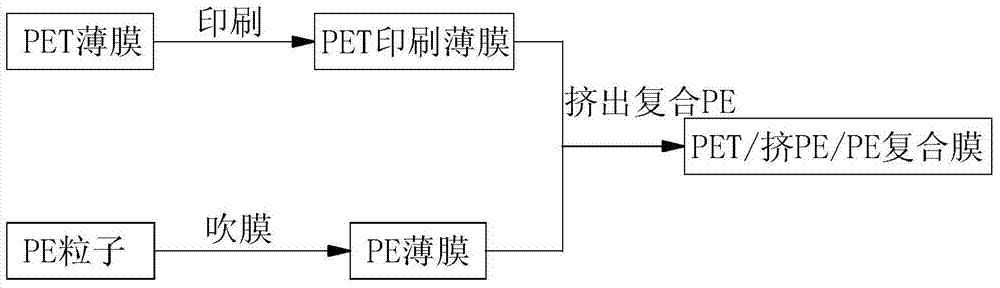

Medical paper-plastic composite blue film and preparation method thereof

ActiveCN101607458AImprove mechanical propertiesImprove folding resistanceNon-macromolecular adhesive additivesLamination ancillary operationsButenePolyester

The invention discloses a medical paper-plastic composite blue film and a preparation method thereof, the medical paper-plastic composite blue film is formed by combining a biaxially orientated polyester film which is printed and coated and a cast polypropylene film, the cast polypropylene film is divided into three layers of a corona layer, an intermediate layer and a heat seal layer, the raw material component of the corona layer is additive-free binary copolymer propylene resin RF401, the raw material components of the intermediate layer are 85-95% of binary random copolymer polypropylene resin F800E and 5-15% of ethylene-butene elastomer A-4085S, and the raw material components of the heat seal layer are 85-90% of binary copolymer propylene resin RF402 containing anti-sticky slipping agent, 5-15% of ethylene-butene elastomer A-4085S, 1-2% of inorganic anti-sticky agent ABPP10S and 0.5-1.5% of slip modified masterbatch SE07PP. The preparation method comprises the steps of printing, preparation of the cast polypropylene film, combination of the biaxially orientated polyester film and the cast polypropylene film and cutting. The medical paper-plastic composite blue film is matched with medical packing paper which can carry out heat sealing, steam sterilization and air infiltration blocking for carrying out packing of medical items, thereby reducing the packing cost and realizing safety performance of packing applications and environment-friendly treatment of packing wastes.

Owner:HUANGSHAN NOVEL

Environment-friendly high-elasticity rubber material

The invention discloses an environment-friendly high-elasticity rubber material which is prepared from the following raw materials in parts by weight: 30-40 parts of powder nitrile-butadiene rubber, 10-18 parts of polyvinyl chloride thermoplastic elastomer, 10-20 parts of ABS (acrylonitrile-butadiene-styrene) resin, 3-5 parts of p-tert-butyl phenol-formaldehyde resin, 1.5-2 parts of sulfur, 1.2-1.8 parts of accelerator TMTD (tetramethyl thiuram disulfide), 2-4 parts of magnesium oxide, 1-3 parts of zinc oxide, 5-8 parts of epoxy soybean oil, 0.5-1 part of paraffin, 1-3 parts of zinc-barium stabilizer, 2-3 parts of organophosphate, 20-30 parts of modified kaolin, 15-20 parts of silica white, 1.5-3 parts of carbon master batch and 0.5-1.5 parts of novel rubber reinforcing agent XRE. The rubber material has the advantages of excellent elasticity, wear resistance, favorable tear resistance and low cost, and reduces the hazard to the environment.

Owner:宁国日格美橡塑股份有限公司

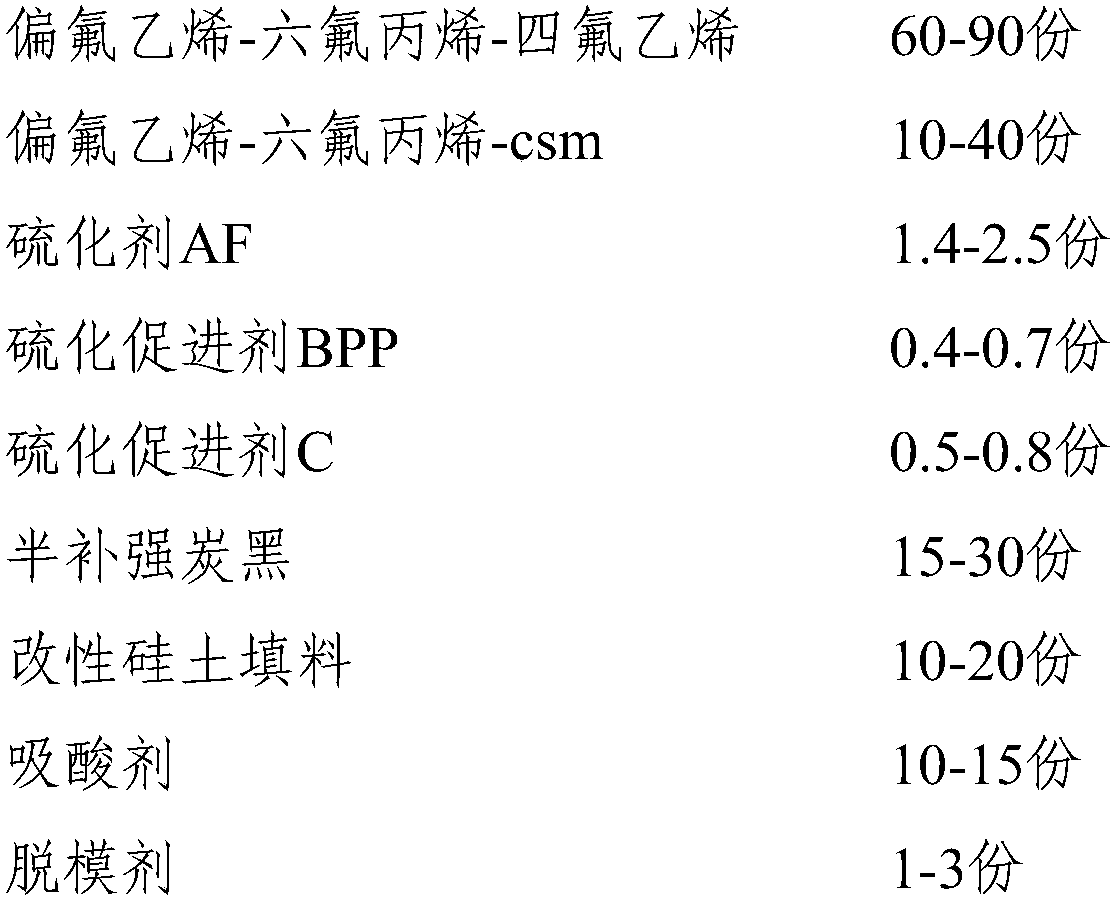

Fluororubber compound and preparation method thereof

ActiveCN107778734AImprove low temperature performanceBoth high and low temperatureHexafluoropropyleneFluoride

The invention relates to the field of rubber, in particular to a fluororubber compound. The fluororubber compound is prepared from the following raw material components in parts by weight: 100 parts of raw fluororubber, 15 to 30 parts of carbon black filler, 10 to 20 parts of modified silica filler and 2.3 to 4 parts of vulcanizing agent, wherein the fluororubber is a mixture of ternary raw rubberand binary raw rubber; the ternary raw rubber is vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene or vinylidene fluoride-hexafluoropropylene-tetrafluoroethylene-csm; the binary raw rubberis vinylidene fluoride-hexafluoropropylene or vinylidene fluoride-hexafluoropropylene-csm. The compound has wider temperature tolerant range and good tolerance to novel fuel or additive, and can be widely applied to sealing products for automobiles, spaceflight, chemical machines and the like.

Owner:ZHONGHAO CHENGUANG RES INST OF CHEMICALINDUSTRY CO LTD

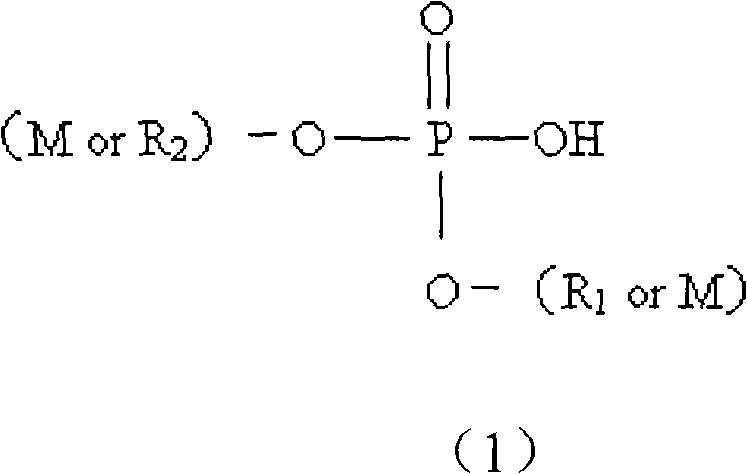

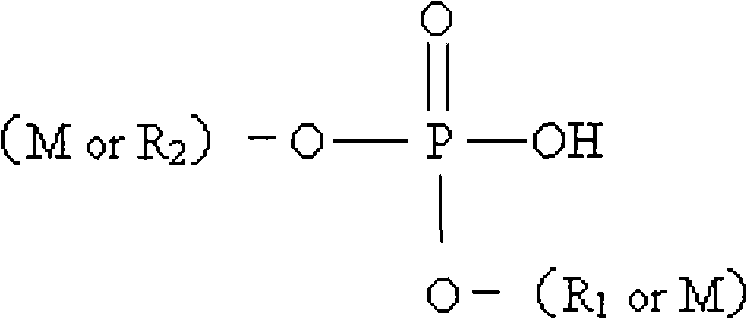

Fast epoxy resin curing agent and preparation method thereof

The invention discloses a fast epoxy resin curing agent and a preparation method thereof. The preparation method comprises the following steps: (1) hydroxyl compound and phosphoric acid esterifying reagent polyphosphoric acid react under the protection of an inert gas, the hydroxyl transformation rate is controlled to be higher than 95 percent, and then water accounting for 1-5 percent of the weight of the phosphoric acid esterifying reagent is added for hydrolysis, therefore, the content of phosphate mono-ester is caused to be over 60 percent, the content of phosphate di-ester is caused to be no higher than 30 percent, and the content of free phosphoric acid is caused to be no higher than 10 percent; and (2) a metal ion compound is added for reaction and then the product can be obtained. The curing agent obtained according to the preparation method, has the excellent properties of light color, high gloss, difficult oxidization, no yellowing, good weather resistance, and the like after being subjected to curing reaction with epoxy resin. Meanwhile, the curing agent of such type has the advantages of low toxicity, low volatility, low odor and low acrimony, and the color is light and conforms to the requirement of present environmental-friendly development.

Owner:ZHANGJIAGANG KABANG NEW MATERIALS

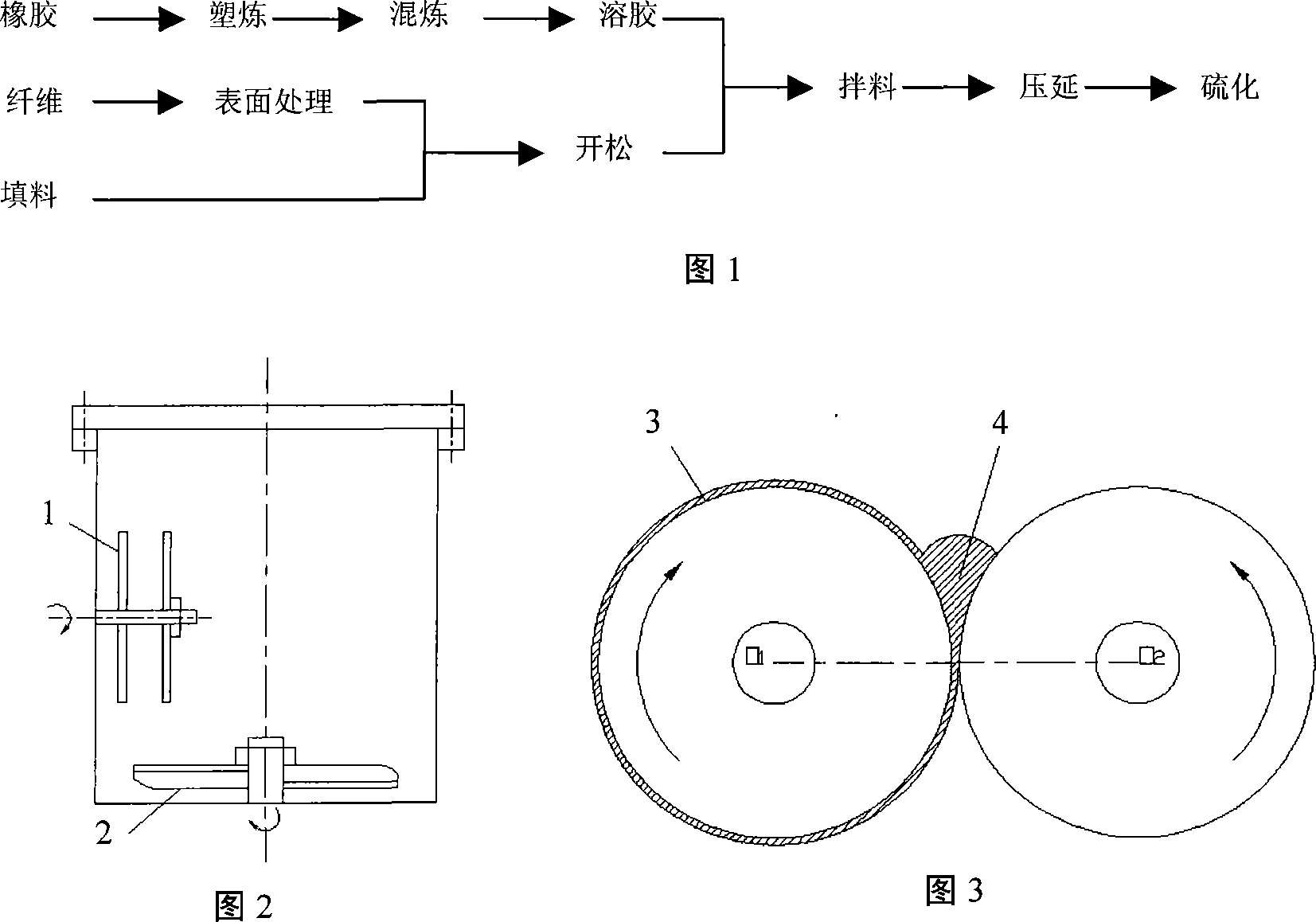

Short carbon fiber-staple glass fiber hybrid reinforced rubber-based sealing composite material and preparation technique thereof

The invention relates to a reinforced rubber based sealing composite materials and the preparation technology, in particular to a short carbon fiber-glass short fiber carbon fiber assorted reinforced rubber based sealing composite materials and the preparation technology. The invention adopts the assorted fiber of short carbon fiber-glass short fiber carbon fiber as the reinforcing fiber to optimize the formula of high temperature resistant NAFC materials on the basis of research of carbon fiber surface processing technology, and optimize the technological parameters of material rolling and sheet-shaping and forming to develop a new type NAFC material; the long term usage temperature can reach 350 DEG C within a year and the long term usage temperature reaches above 250 DEG C within three years which is expected to be used to replace asbestos rubber plate under severe working conditions.

Owner:NANJING UNIV OF TECH

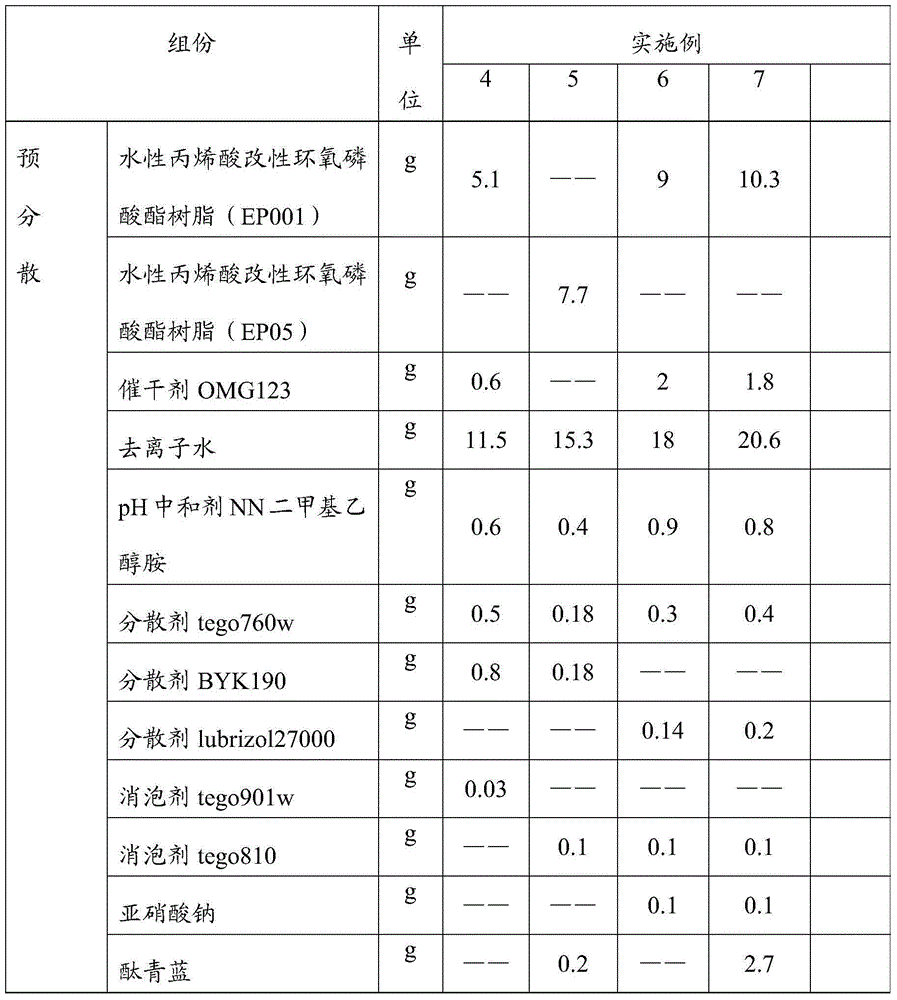

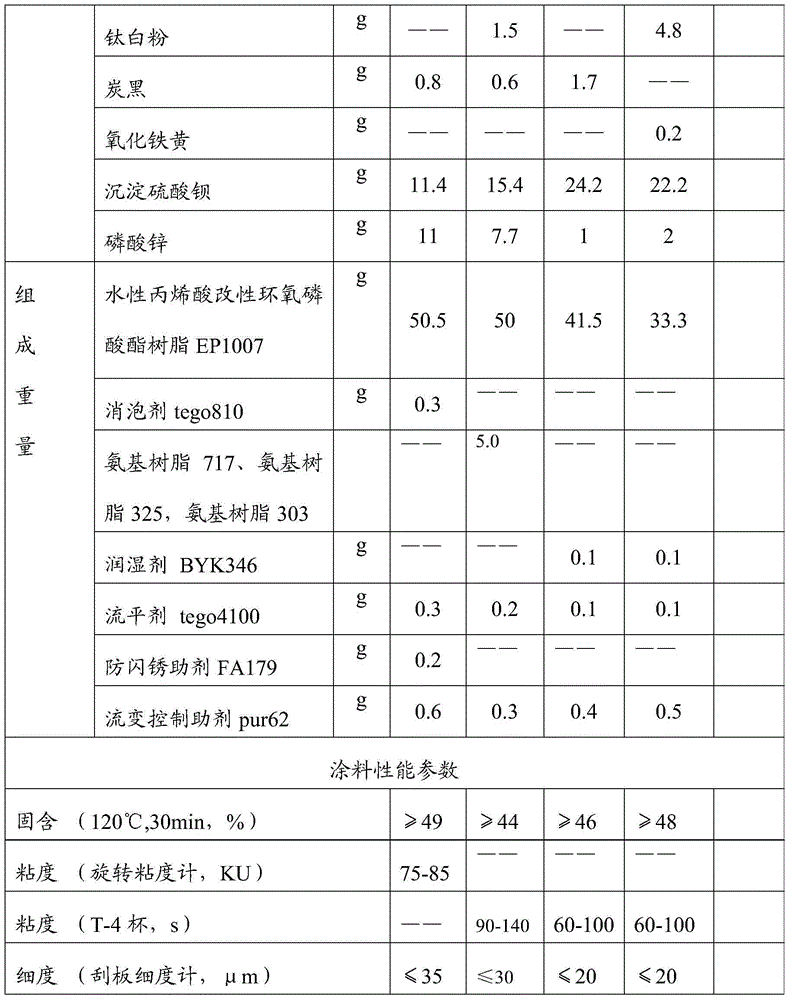

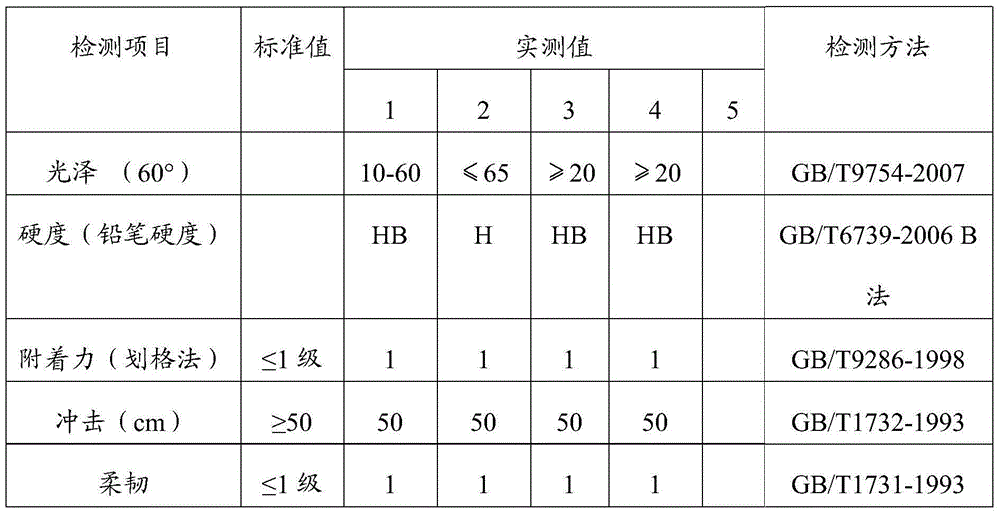

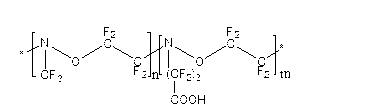

Paint containing water-based acrylic modified epoxy phosphate resin and preparation method thereof

InactiveCN104877526AImprove stabilityHigh solidsSiccativesAnti-corrosive paintsEpoxyPhosphoric Acid Esters

The invention belongs to the field of painting, and particularly relates to acrylic acid modified epoxy phosphate resin and an aqueous dispersion thereof. In the formula, the acrylic acid modified epoxy phosphate resin is prepared from 40-45 parts of epoxy resin, 20-30 parts of a solvent, 0.4-0.5 part of phosphoric acid, 8-12 parts of acrylic acid (ester) monomer of which acrylic acid accounts for 1.4-2 parts, 0.5-0.8 part of an initiator, 3.2-5.2 parts of neutralizer and 80-100 parts of water. The resin is prepared by the following steps: modifying epoxy resin with phosphoric acid, and reacting with acrylic acid and ester monomers thereof; adding the neutralizer and deionized water, stirring and emulsifying to obtain the acrylic acid modified epoxy phosphate aqueous dispersion, wherein the acid value of the emulsion is 10-12mgKOH / g, and the solid content is 28-38 percent. The prepared main resin dispersion body is epoxy resin, has a phosphate structure, and has a good adhesive force for metal base materials, thus having good corrosion resistance; acrylic resin is modified, introduced with carboxyl and neutralized by the neutralizer to give aqueous dispersion to resin, so that the resin can be produced into water-borne painting, and the content of VOC is greatly reduced; and multiple hydroxyl radicals are arranged on the main chain of the epoxy resin, and can be crosslinked with amino resin, urea resin and phenolic resin to produce stoving varnish.

Owner:BEIJING JINHWEILI APPLIED CHEM PROD

Radar wave absorption absorbing coating and preparation method thereof

InactiveCN102358806AImprove absorption efficiencyBroadened absorbing frequency rangePolyurea/polyurethane coatingsRadiation-absorbing paintsFiberAdhesive

The invention discloses the ratio of raw materials for preparing a radar wave absorption absorbing coating and a preparation method for the same. The radar wave absorption absorbing coating is prepared by 25 to 55 parts of nanometer gadolinium-ferrite, 0.03 part to 2.5 parts of metallic cobalt or manganese, 10 to 35 parts of carbonyl iron and 25 to 75 parts of an adhesive. The nanometer gadolinium-ferrite is prepared by using the methods of citrate sol-gel and high temperature cauterization and mainly comprises ferromagnetic nanometer wafer-like particles, hexaplanar ferrite, amorphous magnetic fibers and a particle film. In utilization, the radar wave absorption absorbing coating provided in the invention has the advantages of a small thickness, a light weight, a wide absorption frequency band and high absorptivity.

Owner:朱恩灿

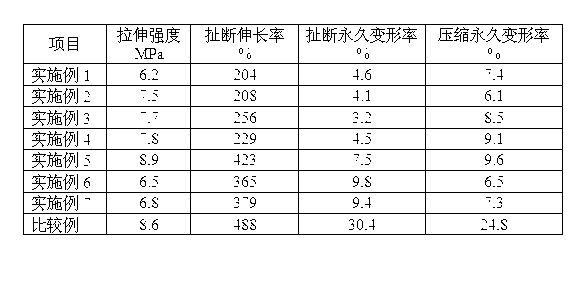

Carboxynitrosofluoroelastomer composition with low permanent deformation rate

The invention relates to a carboxynitrosofluoroelastomer composition with low permanent deformation rate and a part preparation method thereof, and belongs to the field of rubber seal parts. The fluorelastomer composition is prepared from the following raw materials in parts by weight: 100 parts of carboxynitrosofluoroelastomer (CNR raw rubber), 20 to 40 parts of white black carbon, 1 to 3 parts of methylsilicone oil, 1 to 3 parts of triglycidyl isocyanurate (TGIC), and 1 to 3 parts of graphite fluoride. The preparation method comprises the following steps: uniformly blending on a two-roll mill, and performing; and performing two stages of vulcanizing and crosslinking on a press vulcanizer to obtain the fluoroelastomer seal part. According to the preparation method, TGIC is utilized as valcanizer of a vulcanization system, and the carboxynitrosofluoroelastomer composition has the advantages of small toxicity, excellent processing performance, high strength of vulcanized rubber, outstanding compression permanent deformation and tensile permanent deformation, and good seal property.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

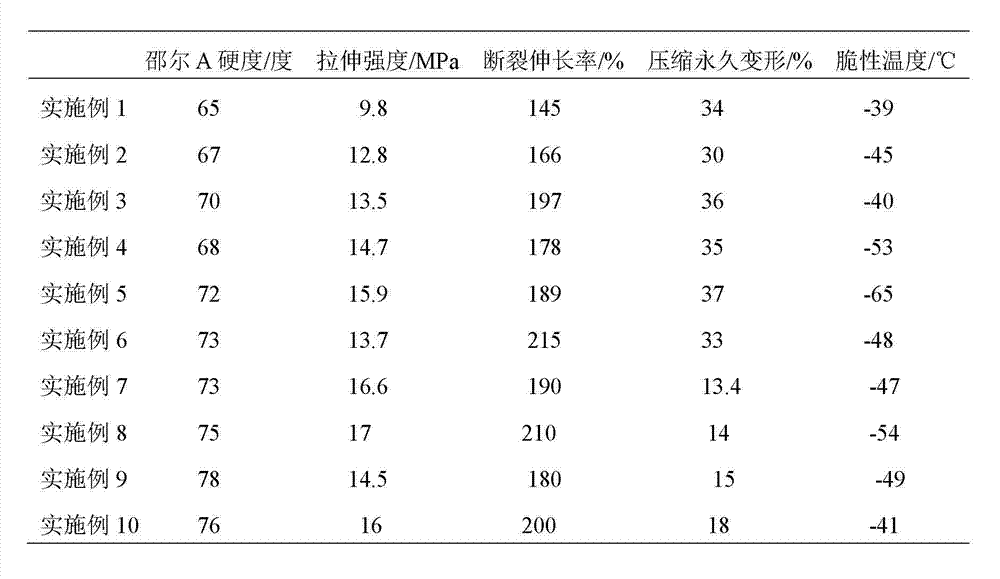

Rare earth complex modified cold-resistant fluororubber gross rubber and preparation method thereof

The invention relates to rare earth complex modified cold-resistant fluororubber gross rubber and a preparation method thereof. The gross rubber is prepared by blending fluororubber crude rubber, a rare earth complex, an acid-acceptor, a reinforcing filling agent, a vulcanizing agent and an accelerating agent. The preparation method of the gross rubber comprises the following steps of: (1) performing plastication covered rolling on the fluororubber crude rubber, and adjusting the roller spacing to ensure that spacer gel exists between two rollers; (2) adding the rare earth complex, the acid-acceptor, the reinforcing filling agent, the vulcanizing agent and the accelerating agent in sequence, controlling the roller temperature to be between 40 and 50 DEG C, taking down thin sheets when the rubber materials are uniformly mixed, and placing the gross rubber for 24 hours; and (3) controlling the roller temperature to be 40 DEG C, adjusting the roller spacing to be 0.2mm, performing re-milling to beat triangular covered thin sheets for more than 10 times, adjusting the roller spacing to be 2mm, and discharging the sheets to obtain the gross rubber. The rare earth complex modified cold-resistant fluororubber gross rubber has the advantages of good cold resistance and medium resistance, and the preparation method is simple and convenient, low in cost, and easy to realize industrial production.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

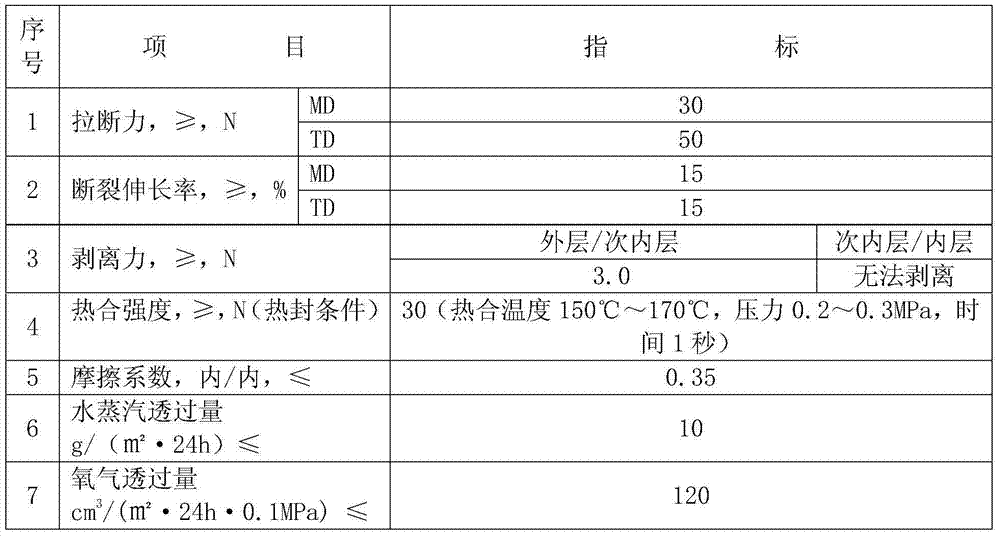

Chilli sauce packaging composite film and preparation method thereof

ActiveCN104260520AHigh sealing strengthLow costFlexible coversWrappersComposite structureLow-density polyethylene

The invention specifically relates to a chilli sauce packaging composite film and a preparation method thereof. The packaging composite film is formed by tightly attaching a PET printing thin film layer which is 12 microns thick, a functional polyethylene thin film layer which is 15-20 microns thick and a PE thin film layer which is 60-80 microns thick, wherein the PET printing thin film layer, the functional polyethylene thin film layer and the PE thin film layer are connected in sequence; the functional polyethylene thin film layer is of a double-layer co-extrusion composite structure, and one side, which is adhered to the PET printing thin film layer, of the functional polyethylene thin film layer is provided with an ethylene acrylic acid copolymer layer; one side, which is adhered to the PE thin film layer, of the functional polyethylene thin film layer is provided with a low-density polyethylene and white master batch blending layer; the weight ratio of low-density polyethylene to white master batches is 20 to 3; the thickness ratio of the ethylene acrylic acid copolymer layer to the low-density polyethylene and white master batch blending layer is 2 to 3. The composite film has high performance such as high sealing intensity, low cost, good sealing effect, high sealing flatness and high pollution resistance and also has the advantages of good anti-medium effect, low cost, difficulty in layering and the like.

Owner:HUANGSHAN NOVEL

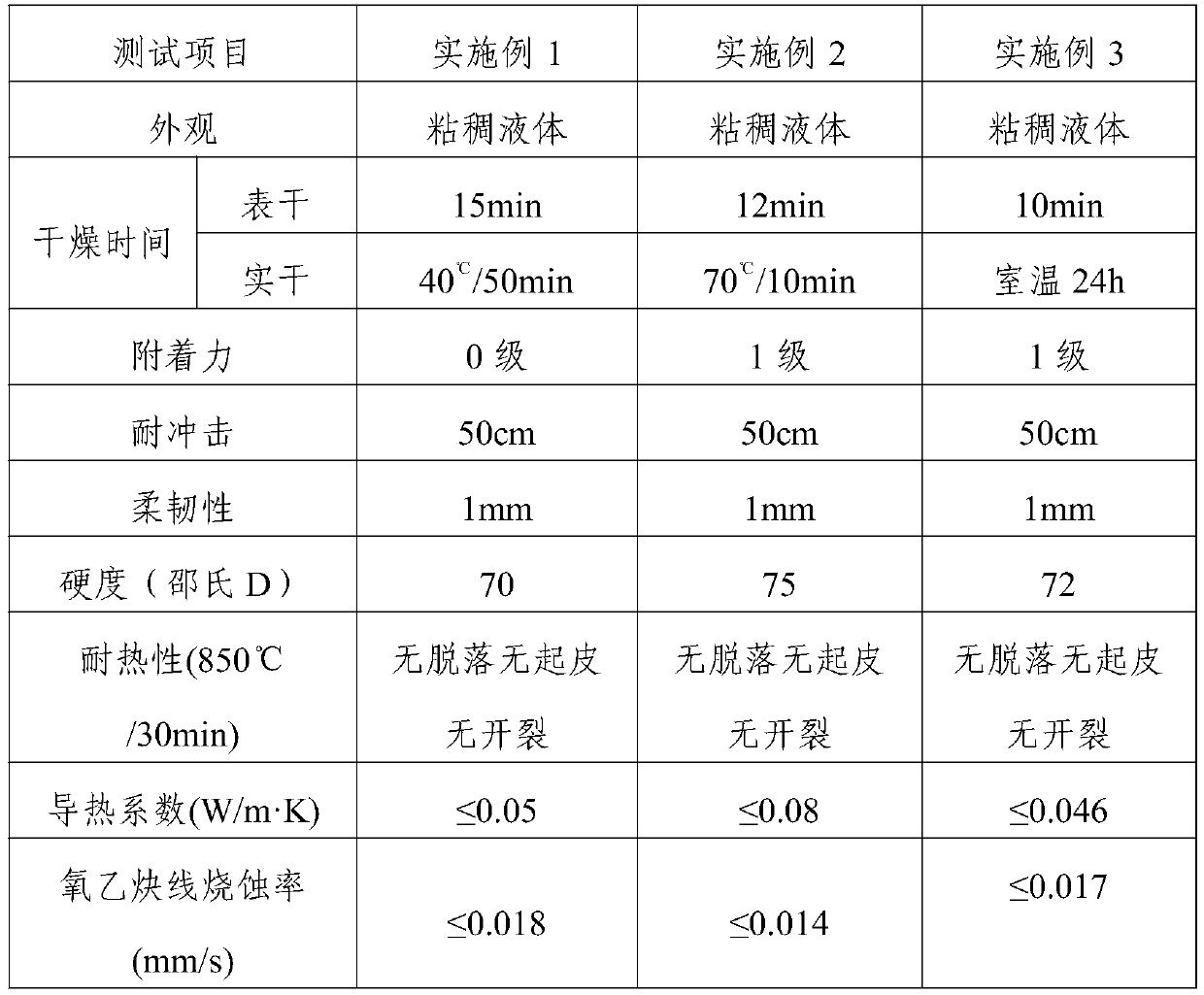

Porcelainizing ablation-resistant coating and preparation method thereof

ActiveCN111171721ALow thermal conductivityReduce wire ablation rateFireproof paintsFlight vehicleUltimate tensile strength

According to the porcelainizing ablation-resistant coating and the preparation method thereof provided by the invention, the porcelainizing ablation-resistant coating is obtained by optimizing the composition and proportion of the coating, and the coating formed by the prepared coating is high in bonding strength, can bear instantaneous high temperature of 1500 DEG C or above, and has a more excellent flame-retardant effect and mechanical strength. A ablation-resistant coating prepared by the method has the advantages of low heat conductivity coefficient, low linear ablation rate, high mechanical property, excellent manufacturability and the like. The preparation method disclosed by the invention is simple, and an effective way is provided for industrially preparing the ablation-resistantcoating on a large scale. The ablation-resistant coating can be cured at room temperature, the heat conductivity coefficient is lower than 0.1 W / (m.k), the linear ablation rate is lower than 0.02 mm / s, and the ablation-resistant coating has a very wide application prospect in an aircraft surface thermal protection system.

Owner:XIAN MODERN CHEM RES INST

Wear resistant raw lacquer coating for mineral dressing equipment concentrating table and preparation thereof

InactiveCN101302398AImprove wear resistanceImprove corrosion resistanceNatural resin coatingsWet separationLacquerWear resistant

The invention discloses abrasion resistant coating used for mineral preparation equipment-a shaking table. The abrasion resistant coating is made by refining of main compositions of raw lacquer, auxiliary film-forming matter, auxiliary agent, diluting agent and abrasion resistant auxiliary agent. The abrasion resistant coating is characterized by maintaining the excellent properties of the raw lacquer and simultaneously improving the construction performance and the abrasion resistance of the raw lacquer and prolonging the service life. The abrasion resistant coating is suitable for application of abrasion and corrosion resistant coatings on the mineral preparation equipment-the shaking table and oilfield equipment.

Owner:中华全国供销合作总社西安生漆涂料研究所

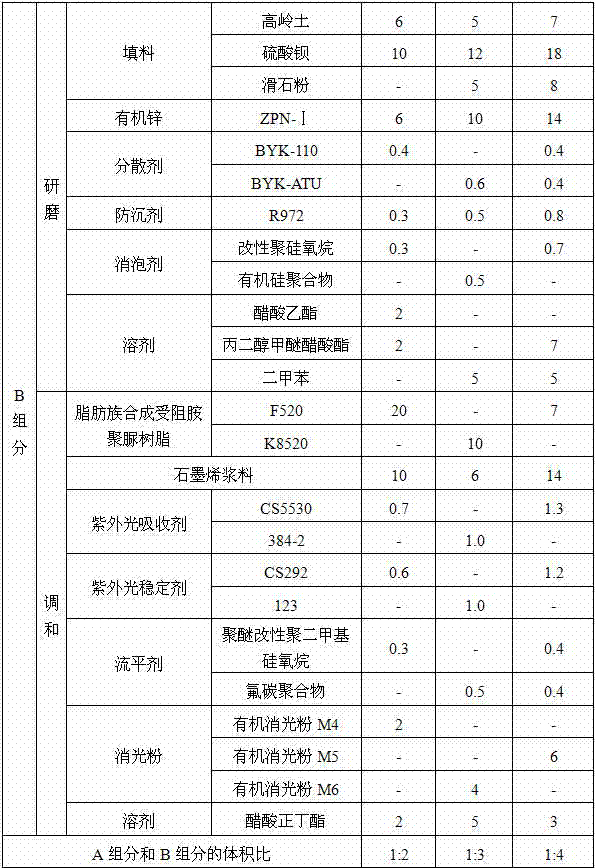

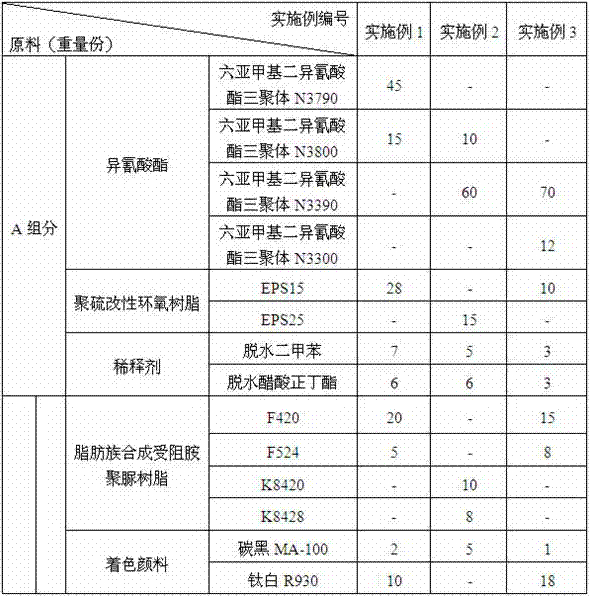

Special primer-topcoat polyurea protection coating for automobile chassis system and preparation method

ActiveCN107446476ASolve easy pulverizationSolve discolorationPolyurea/polyurethane coatingsEpoxy resin coatingsEpoxyUltraviolet lights

The invention discloses a special primer-topcoat polyurea protection coating for an automobile chassis system and a preparation method. The coating is prepared from a component A and a component B in a volume ratio of 1:(2-4), wherein the component A comprises isocyanate, a poly-sulfide modified epoxy resin and a diluent; the component B comprises an aliphatic synthetic hindered amine polyurea resin, a coloring pigment, a filler, graphene pulp, organic zinc, a dispersing agent, an ultraviolet absorbent, an ultraviolet light stabilizer, an anti-settling agent, a leveling agent, a defoaming agent, extinction powder and a dissolvent. The invention further discloses a preparation method of the special primer-topcoat polyurea protection coating for the automobile chassis system. The thickness of a disposable coating membrane is greater than or equal to 80mu m, a coating membrane is rapid in drying speed and high in construction efficiency, a coated layer is good in adhesion to a substrate, good in impact resistance, free of color change in long-term outdoor exposure, very good in aging resistance, salt mist resistance and medium resistance, high in product solid content and good in environmental friendliness, and the method provided by the invention is simple in process, low in cost and applicable to industrial production.

Owner:湘江涂料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com