Special primer-topcoat polyurea protection coating for automobile chassis system and preparation method

A technology for automotive chassis and protective coatings, applied in the direction of polyurea/polyurethane coatings, epoxy resin coatings, coatings, etc., can solve the problems that cannot meet the needs of industrial production line operations, the thickness of the coating film cannot exceed 50 μm, and the frame cannot be used for a long time. Effective protection and other issues to achieve the effect of enhancing market competitiveness, improving the overall coating level, and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

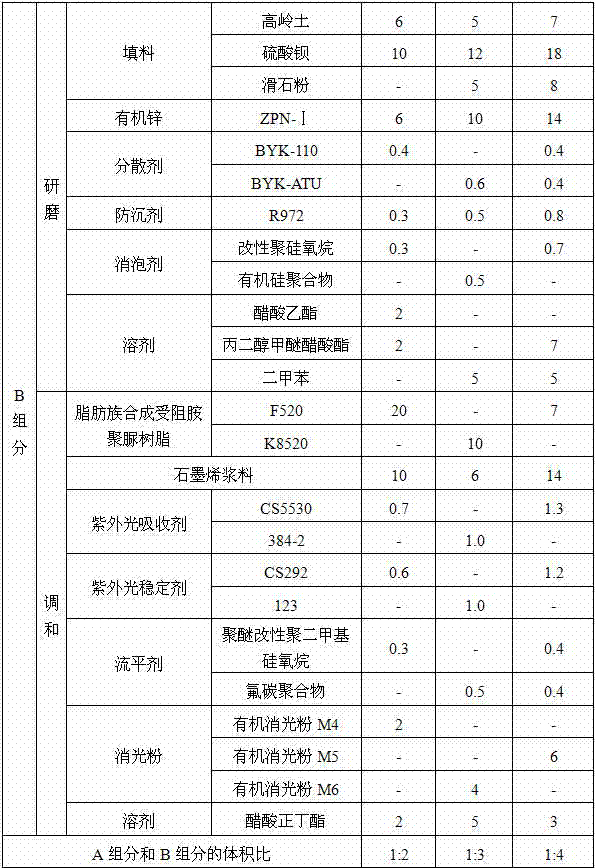

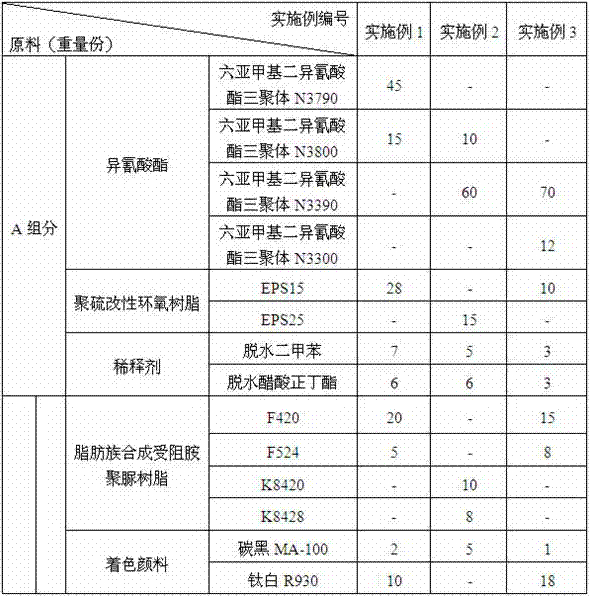

[0049] Examples 1-3 of a kind of bottom-surface-integrated polyurea protective coating for automobile chassis system

[0050] The parts by weight of each raw material are as shown in Table 1:

[0051] Table 1 The parts by weight of the raw materials in Examples 1-3 of a special bottom-surface-integrated polyurea protective coating for automobile chassis systems

[0052]

[0053]

[0054] Note: "-" in the table means not added.

Embodiment 1

[0056] (1) The preparation method of component A: According to the weight parts of the raw materials described in Example 1 in Table 1, first add isocyanate and polysulfide modified epoxy resin into the reaction kettle, stir and heat at a constant speed to 83 at 180r / min ℃, heat preservation reaction for 4 hours, until the mass percentage of isocyanate reached 14.5%, cooled to 48 ℃, then added diluent, and stirred at 120r / min for 35min to obtain component A;

[0057] (2) The preparation method of component B: according to the parts by weight of the raw materials described in Example 1 in Table 1, first mix part of the aliphatic synthetic hindered amine polyurea resin with coloring pigments, fillers, organic zinc, dispersants, anti-settling agents, After mixing the defoamer and part of the solvent, disperse at 800r / min for 40min, and then use a basket sand mill to grind to a fineness of ≤15μm to obtain a slurry, and then add the remaining aliphatic synthetic hindered amine to th...

Embodiment 2

[0060] (1) The preparation method of component A: according to the weight parts of the raw materials described in Table 1, Example 2, first add isocyanate and polysulfide modified epoxy resin into the reaction kettle, stir and heat at a constant speed to 80 at 140r / min ℃, heat preservation reaction for 3 hours, until the mass percentage of isocyanate reached 16%, cooled to 50 ℃, then added diluent, and stirred at 100r / min for 50min to obtain component A;

[0061] (2) The preparation method of component B: according to the parts by weight of the raw materials described in Example 2 of Table 1, first mix part of the aliphatic synthetic hindered amine polyurea resin with coloring pigments, fillers, organic zinc, dispersants, anti-settling agents, After mixing the defoamer and part of the solvent, disperse for 45 minutes at 1000r / min, and then use a basket sand mill to grind to a fineness of ≤17μm to obtain a slurry, and then add the remaining aliphatic synthetic hindered amine to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com