Patents

Literature

115 results about "Polyaspartic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

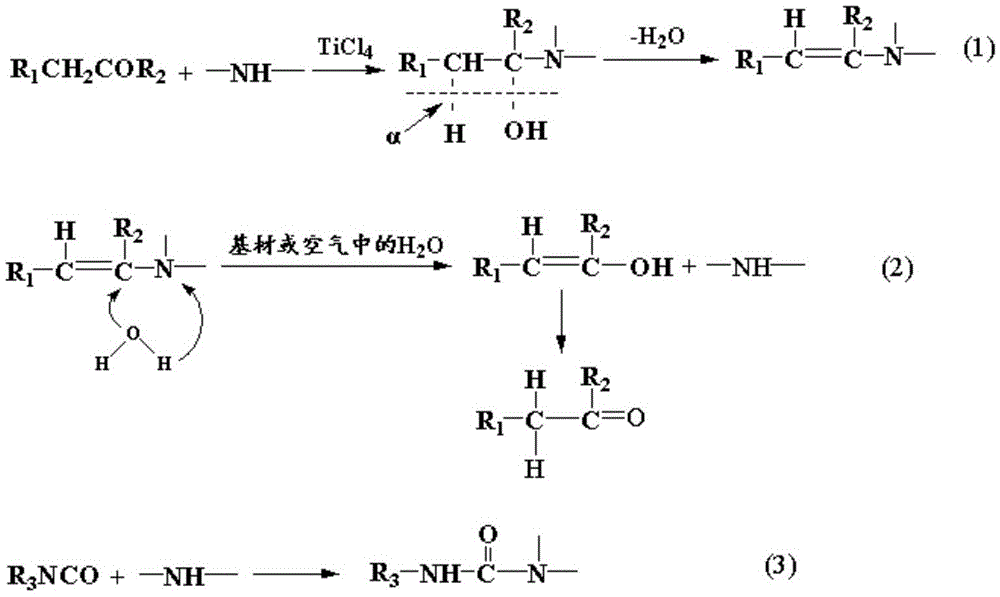

Polyaspartic chemistry was first introduced in the early 1990s making it a relatively new class of coating. Polyaspartic is actually an aliphatic polyurea because it is derived from the reaction product of an aliphatic polyisocyanate component and a polyaspartic ester component, which is a new type of amine/diamine functional coreactant for aliphatic polyisocyanate. Polyaspartic esters perform well as a reactive diluting agent for high solids polyurethane coatings. For this reason, polyaspartic esters initially found use in conventional solvent-borne two-component polyurethane coatings.

Method for preparing novel polyaspartic ester and application thereof

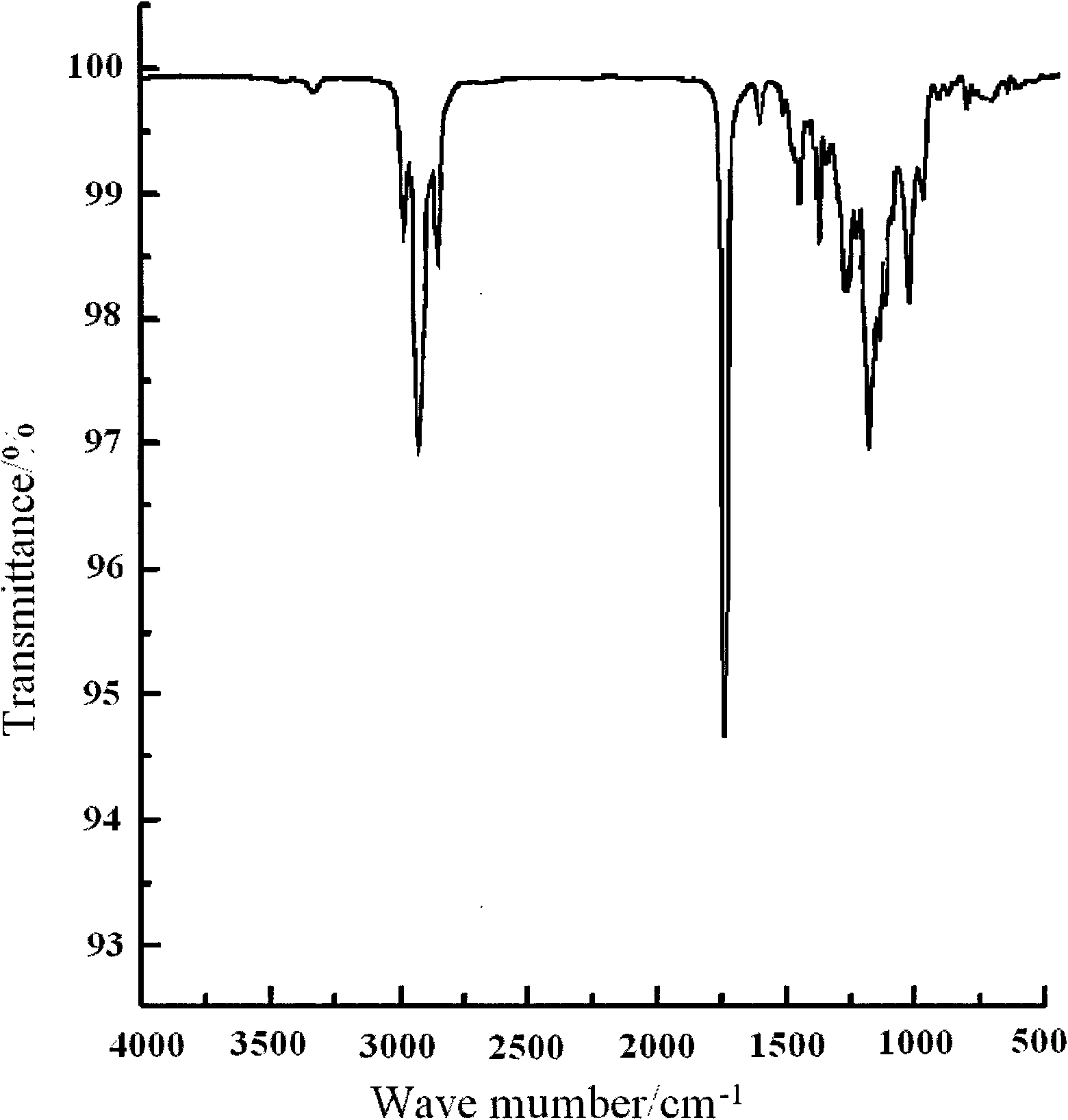

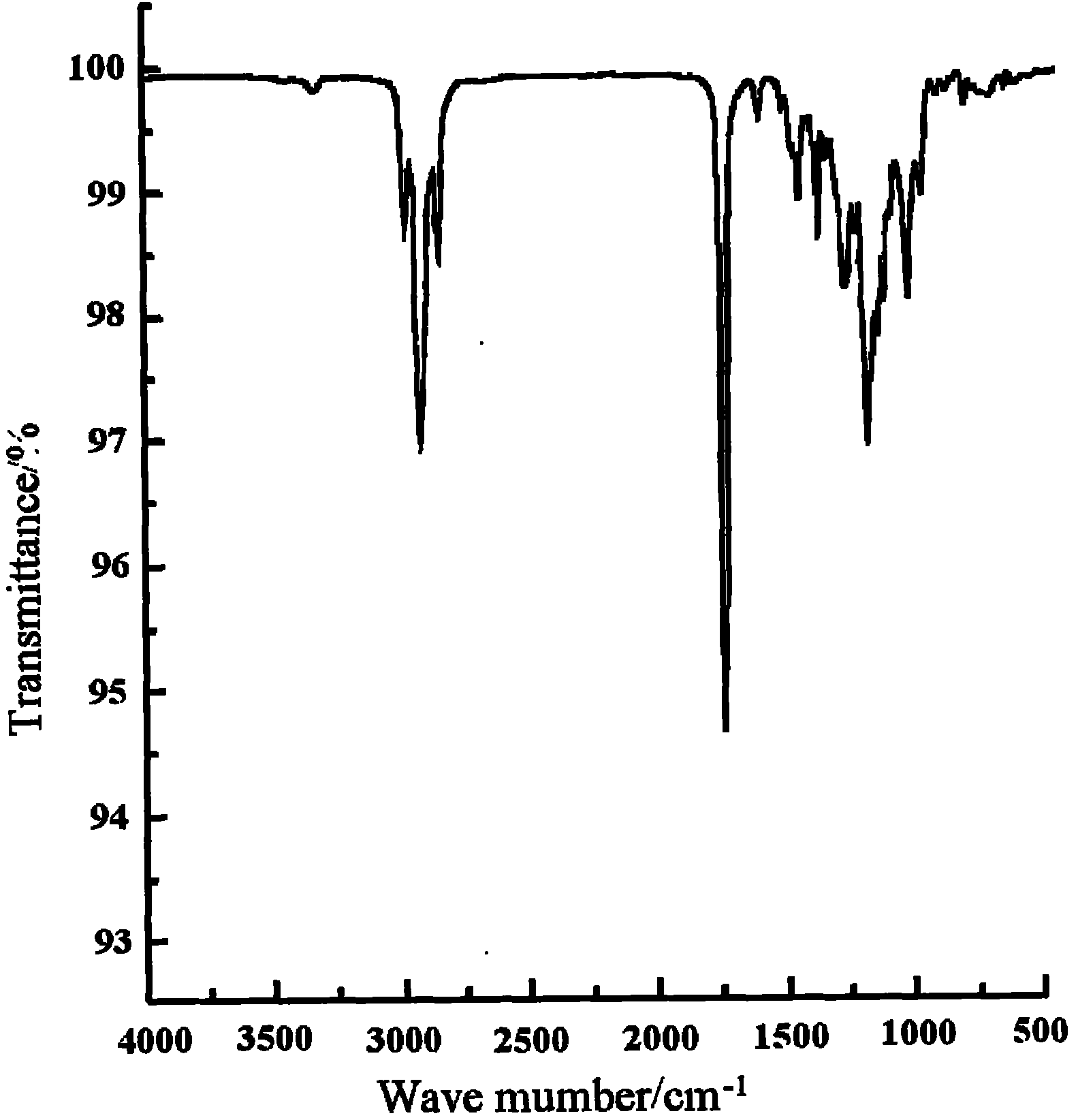

InactiveCN101817924AHigh reaction conversion rateShort reaction timePolyurea/polyurethane coatingsPolyasparticDicarboxylic acid

The invention discloses a method for preparing novel polyaspartic ester, in particular a method for preparing a component for slow reaction type polyurea paints. The method comprises the following concrete steps of: 1) performing a catalytic reaction of dicarboxylic ester and primary amine to obtain a Michael additive product; and 2) adding epoxy resin into the product obtained in the step 1) to obtain the novel polyaspartic ester after reaction. The method for preparing the novel polyaspartic ester shortens the reaction time, improves the reaction conversion ratio, and conveniently realizes industrial preparation. Due to the adoption of the method, the problems of low conversion ratio in short time, long synthesis time, failure of timely delivery, difficult industrial production or low product performance after solidification in the prior art are solved. The novel polyaspartic ester has high tensile strength and high elongation rate.

Owner:SHANGHAI RES INST OF BUILDING SCI CO LTD

Water-dispersible polyaspartic ester resin, preparation method of waterborne polyurea coating and application

ActiveCN109761834ASmall particle sizeLow viscosityOrganic compound preparationAmino-carboxyl compound preparationWater dispersibleAging resistance

The invention relates to polyaspartic ester resin and in particular relates to water-dispersible polyaspartic ester resin, a preparation method of waterborne polyurea coating and application. Water-dispersible polyaspartic ester is obtained by carrying out Michael addition reaction on unsaturated binary carboxylate, unsaturated monocarboxylic acid and a primary amino compound under the action of acatalyst and a neutralizing agent; a coating film of the double-component waterborne polyurea coating is obtained by utilizing a water dispersion body of the water-dispersible polyaspartic ester; theperformance keeps main properties of solvent type polyurea coating, such as rapid curing at room temperature, high glossiness, high transparency, good water resistance, corrosion resistance, ultraviolet resistance and ageing resistance.

Owner:郁维铭 +1

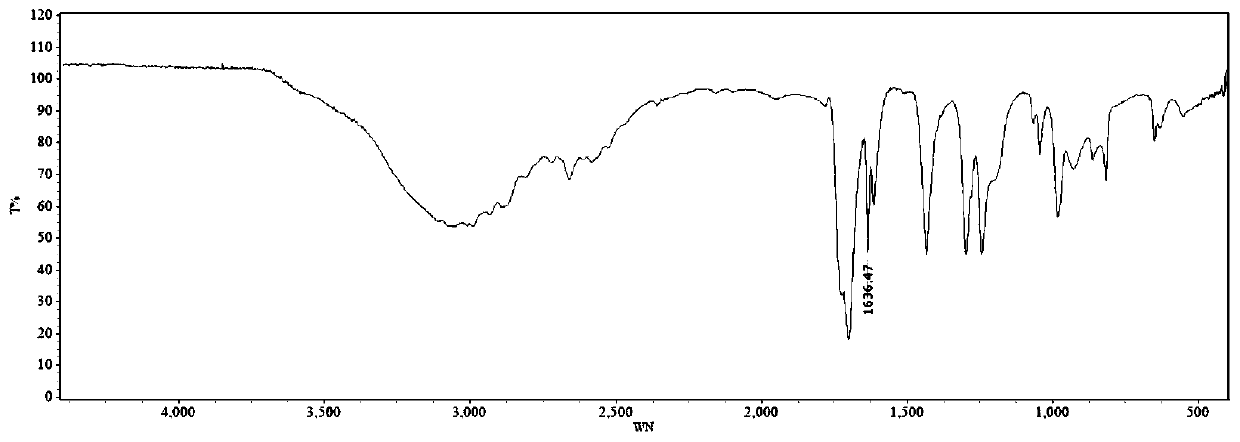

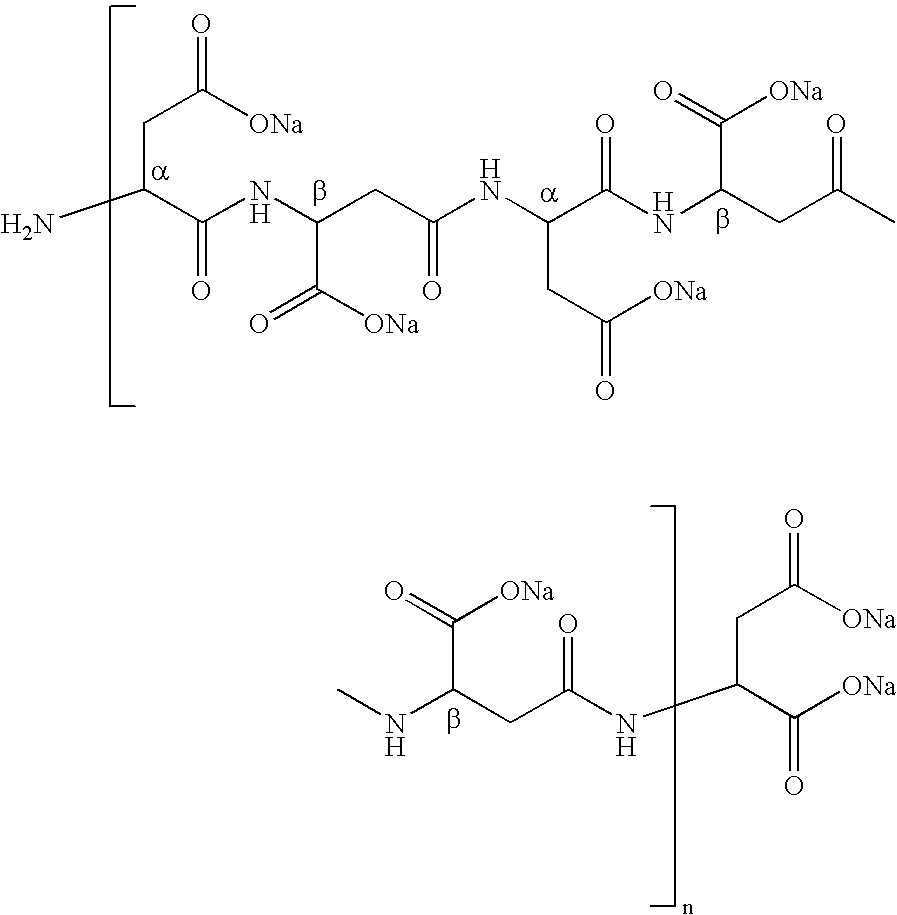

Compositions and process for recovering subterranean oil using green non-toxic biodegradable strong alkali metal salts of polymerized weak acids

InactiveUS20080312108A1Good oil recoveryEliminate needFlushingDrilling compositionPolyasparticSURFACTANT BLEND

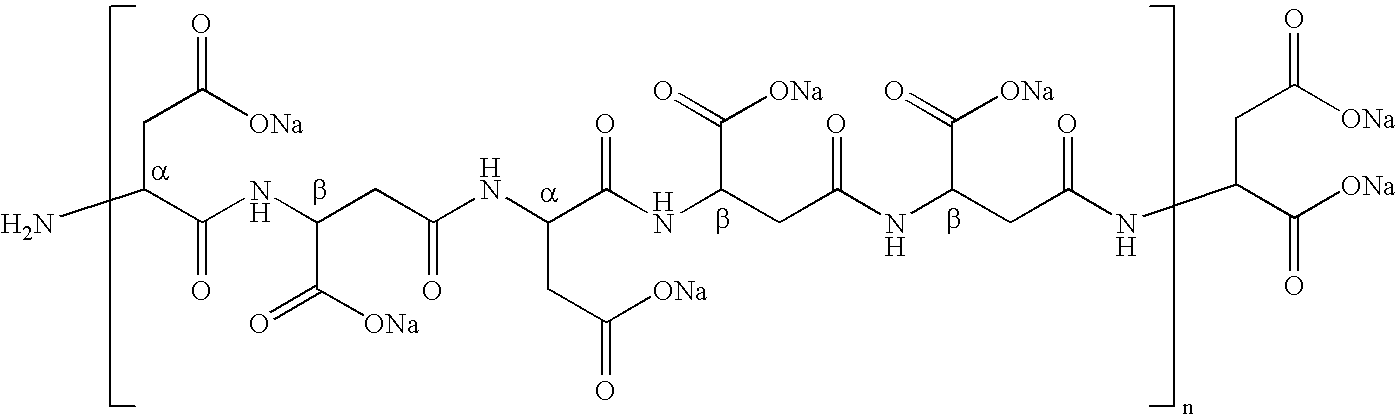

Compositions and process for recovering of oil from subterranean oil-bearing reservoirs consisting of green non-toxic biodegradable strong alkali metal salt of polymerized weak acids, one or more surfactants, an aqueous fluid, a optionally one or more mobility control agents and optionally one or more co-solvents are disclosed. Such compositions are injected into the reservoir through one or more injection wells and assist in recovering trapped oil through one or more producing wells.A preferred green non-toxic biodegradable strong alkali metal salt of polymerized weak acids is the sodium salt of polyaspartic acid shown below where n is 10 to 50.The compositions and the process of the present invention offer the advantage of improved compatibility with unsoftened waters, surfactants, and various mobility control agents. The green non-toxic, biodegradable properties of the alkali makes it particularly suitable for environmentally sensitive applications such as offshore and inland lakes.

Owner:BERGER PAUL DANIEL +1

Novel corrosion inhibition scale inhibitor

InactiveCN101746899AReduce maintenance rateReduce desulfurization costsTreatment using complexing/solubilising chemicalsAlloySodium succinate

The invention discloses a novel corrosion inhibition scale inhibitor, which comprises the following constitutions by weight: 1 to 16 polyepoxy sodium succinate, 1 to 18 polyaspartic sodium, 1 to 13 hydrolytic maleic anhydride, 1 to 25 gluconic acid sodium salt, 1 to 18 acrylic acid - acrylate - sulfonate copolymer, 1 to 8 zinc sulfate, 1 to 12 benzotriazol, and 0.5 to 2 NaOH. The novel corrosion inhibition scale inhibitor has the advantages that: the technology for removing SO2 by Ca(OH)2 can be normally run in a middle-sized and small-sized boiler houses, the repairing rate of the equipment is low, and the desulphurization cost can be reduced by 50 percent; the equipment of the copper or the cooper alloy structure can be protected; and a good corrosion inhibition scale inhibition effect can be realized in the environment that the temperature is less than 150 DEG C, and the PH is less than 12.

Owner:赵 立民

Polyaspartate derivatives for use in detergent compositions

InactiveUS6933269B2Improved formulatabilityImprove combination effectOrganic detergent compounding agentsCarbamic acid derivatives preparationPolyasparticOrganic chemistry

Polyaspartate derivatives, especially hydrophobically modified and / or hydrophilically modified polyaspartate derivatives, most especially polyaspartate derivatives that are both hydrophilically and hydrophobically modified, for use in detergent compositions, specifically laundry detergent compositions for providing cleaning, dispersancy, especially soil dispersion, builder properties and / or improved whitening of fabrics contacted by such detergent compositions; and methods for making such polyaspartate derivatives, and methods and articles employing such detergent compositions, are provided.

Owner:THE PROCTER & GAMBLE COMPANY

Method of preparing mercaptopoly asparagic acid and chitin copolymer and use

A mercapto polyaspartic acid-chitosan copolymer used for adsorbing heavy metal, chlorohydrocarbon, organic pigment, dyeing, etc is prepared from cross-linking reaction between polyaspartic acid with amino side chain and chitosan in acidic aqueous solution, and reacting on mercapto carboxylic acid.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Prepn process of copolymer of polyaspartic acid and chitosan

The present invention discloses process of preparing copolymer of polyaspartic acid and chitosan. Polyaspartic acid with amino group side chain and chitosan are first made to take cross-linking reaction inside acid aqua, and through subsequent alkali adding precipitation to separate out, water washing and vacuum drying, relates to copolymer is prepared. The copolymer has the function of adsorbing heavy metal and some organic matter, and may be applied widely for eliminating heavy metal, halogenated hydrocarbon, organic pigment, dyeing, etc. in medicine industry, food industry, printing and dyeing industry, sewage treatment and other fields.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Polyurea adhesive composition and preparation method thereof

InactiveCN106905911ASolve the shortcomings of fast reaction time and short gel timeReduce shrinkage stressNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesNano siliconPolyaspartic

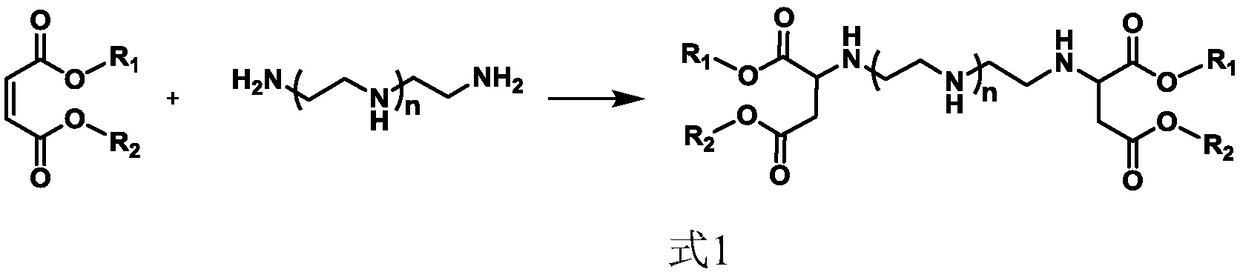

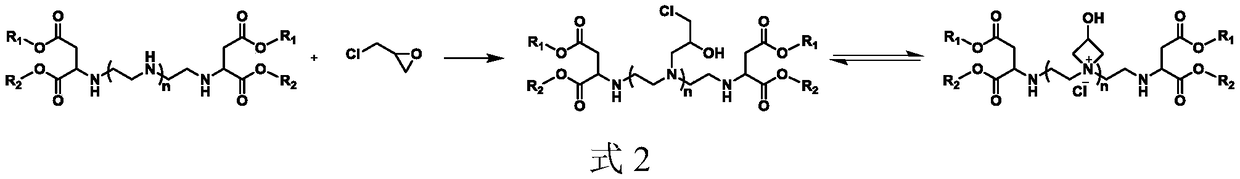

The invention discloses a polyurea adhesive composition and a preparation method thereof. The polyurea adhesive composition is mainly prepared from polyaspartic ester, nanofiller and a curing agent. The polyaspartic ester is prepared by enabling an organic diamine compound and maleate to make a Michael addition reaction; the curing agent is prepared from an organic diisocyanate or polyisocyanate component, and can be a monomer, a polymer, a derivative of isocyanate, a prepolymer or a semi-prepolymer; the nanofiller is selected from nano-silicon dioxide, nano-titanium dioxide and nano-silicon carbide. By utilizing the Michael addition reaction of the organic diamine compound and the maleate, primary amine is transformed into secondary amine on the one hand, and a group having higher steric hindrance is introduced on the other hand, so that the defects that a polyurea material is rapid in reaction time and short in gelation time are overcome; the nanofiller is added into the polyurea adhesive composition, so that the stress shrinkage caused during the curing of an adhesive film is effectively reduced, and the polyurea adhesive composition is high in bonding strength.

Owner:北京奥润联创微电子科技开发有限公司

Two-component systems for producing flexible coatings

ActiveUS20070078255A1Synthetic resin layered productsPolyurea/polyurethane coatingsAllophanePolyaspartic acid

The present invention relates to two-component coating systems for producing flexible coatings. The coating systems comprise polyurethane prepolymers with allophanate structures and also amino-functional polyaspartic esters as curing agents.

Owner:COVESTRO DEUTSCHLAND AG

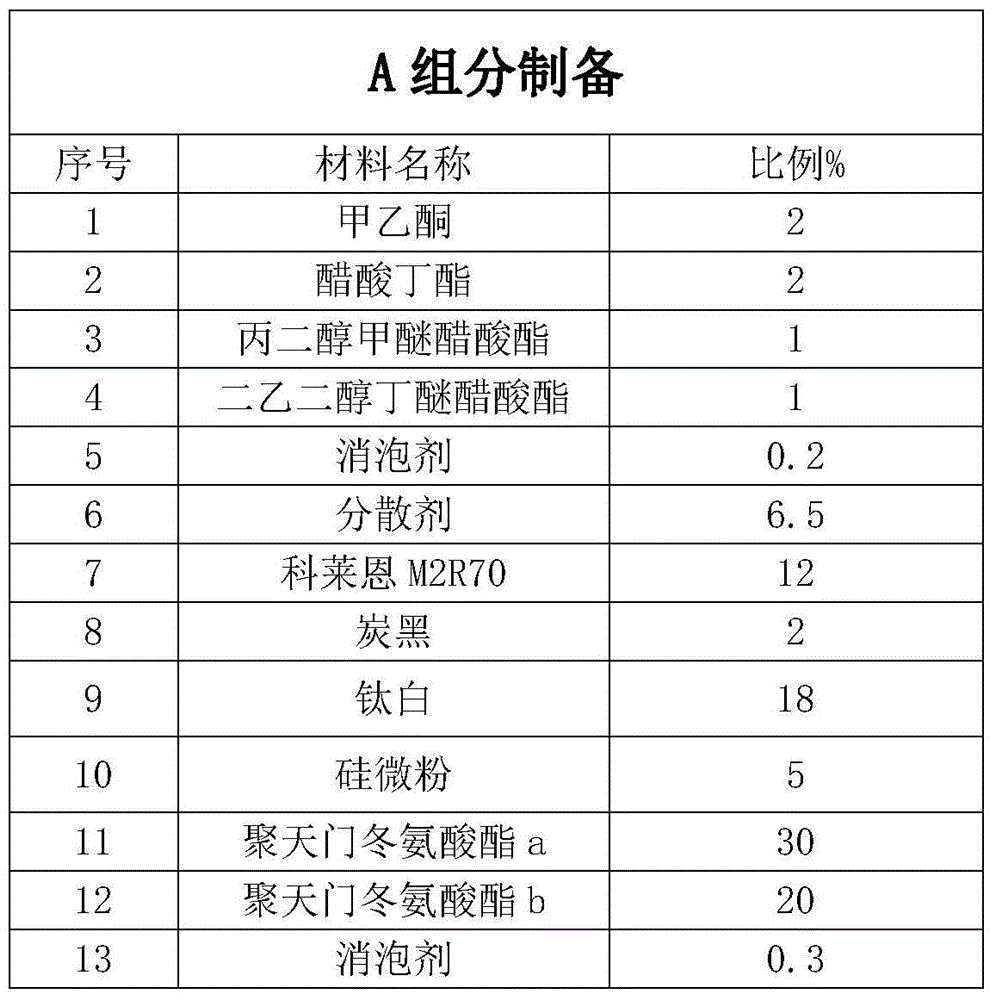

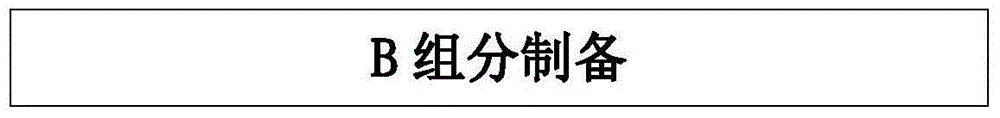

Ultra-low VOC air-drying poly-aspartic paint for engineering machinery

InactiveCN104893523AImprove mechanical propertiesImprove corrosion resistancePolyurea/polyurethane coatingsEquivalence ratioPolyaspartic

The invention relates to an ultra-low VOC air-drying poly-aspartic paint for engineering machinery. The poly-aspartic paint comprises a component A and a component B, wherein the component A comprises the following raw materials: 25 to 37 parts of polyaspartic ester a, 15 to 23 parts of polyaspartic ester b, 30 to 40 parts of pigments and fillers, 3 to 10 parts of one or more additives, and 0 to 15 parts of one or more solvents; the polyaspartic ester a and the polyaspartic ester b are Bayer NH1420 / NH1520, or Zhuhaifeiyang F420 / F520; the mass ratio of the polyaspartic ester a to the polyaspartic ester b is (1 to 2):1; the component B comprises the following raw materials: 50 to 70 parts of HDI uretdione isocyanate, 30 to 40 parts of HDI tripolymer isocyanate, 0 to 3 parts of one or more additives, and 0 to 5 parts of one or more solvents; the mass ratio of HDI uretdione isocyanate and HDI tripolymer isocyanate is (1.5 to 2):1; the equivalence ratio of the component B to the component A, that is, -NCO of the component B to -OH of the component A, is 1.05:1. The poly-aspartic paint provided by the invention is ultra-low in VOC, fast in air drying and film formation, and excellent in coating appearance and performance, and suitable for being applied to environment-friendly one coat paint or finishing coat paint.

Owner:HAOLISEN COATING SHANGHAI

Polyaspartate/polyacrylic acid copolymer IPN (Interpenetrating Polymer Networks) hydrogel and preparation method thereof

The invention relates to polyaspartate / polyacrylic acid copolymer IPN (Interpenetrating Polymer Network) hydrogels and a preparation method thereof. The IPN hydrogel is a heterogeneous continuous hydrogel formed by the interpenetration of the networks of the copolymer of biodegradable cross-linked polyaspartate and polyacrylic acid. The preparation method includes the following steps of: partially neutralizing crylic acid; then swelling the cross-linked polyaspartate in a mixed solution composed of crylic acid, initiator, cross-linking agent, phase catalyst and other unsaturated monomers; andfinally conducting polymerization reaction and drying to obtain the polyaspartate / polyacrylic acid copolymer IPN hydrogel. The distilled water adsorption ratio of the hydrogel disclosed by the invention is 430-1500g / g, and the saline adsorption ratio of the hydrogel is 80-230g / g. The hydrogel is sensitive to both temperature and pH value and is biodegradable.

Owner:TAIYUAN UNIV OF TECH

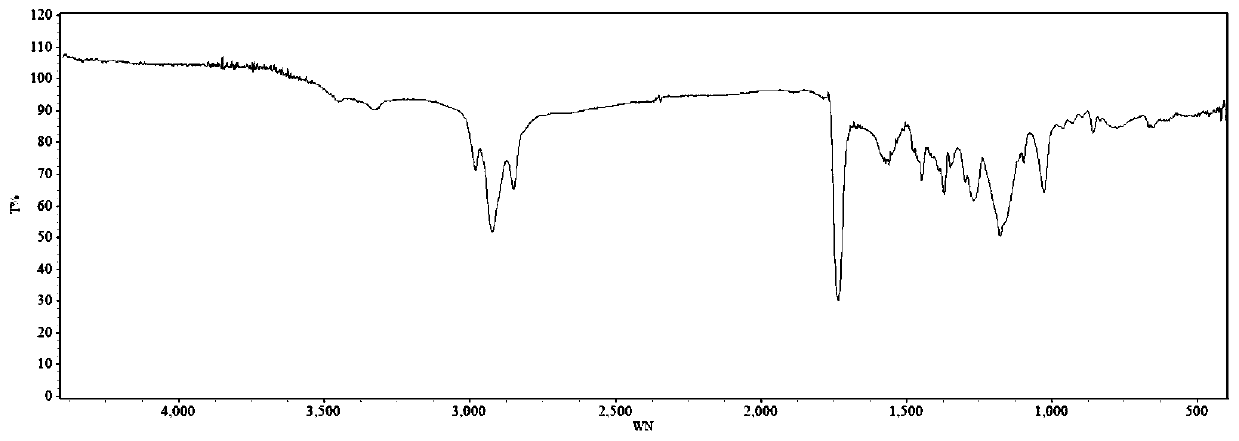

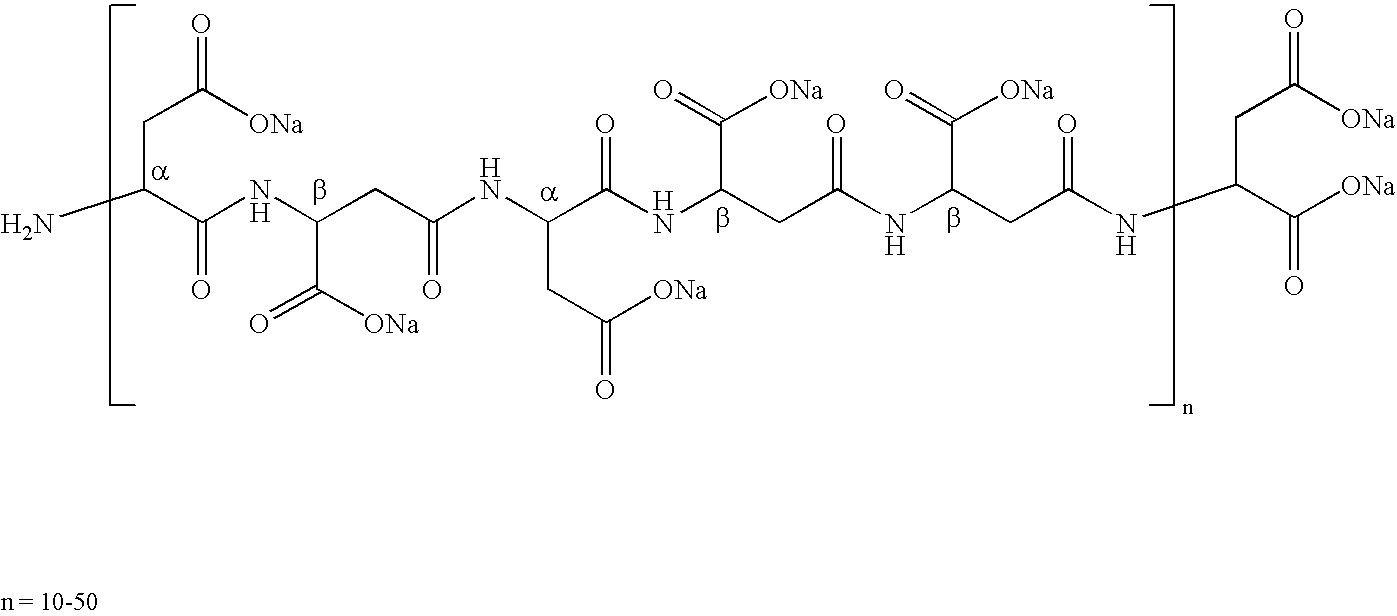

Cementing subterranean zones using cement compositions containing biodegradable dispersants

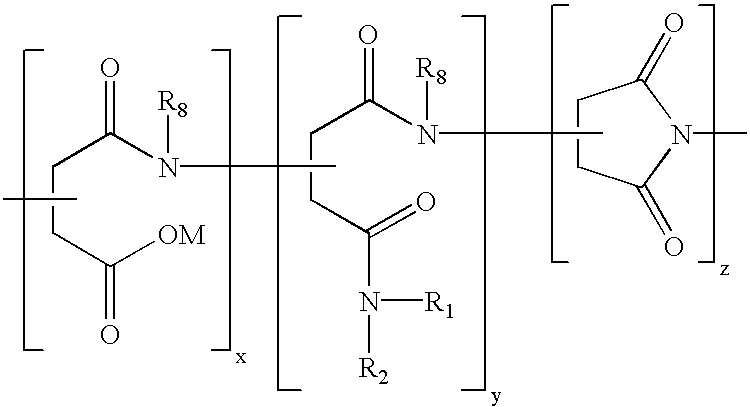

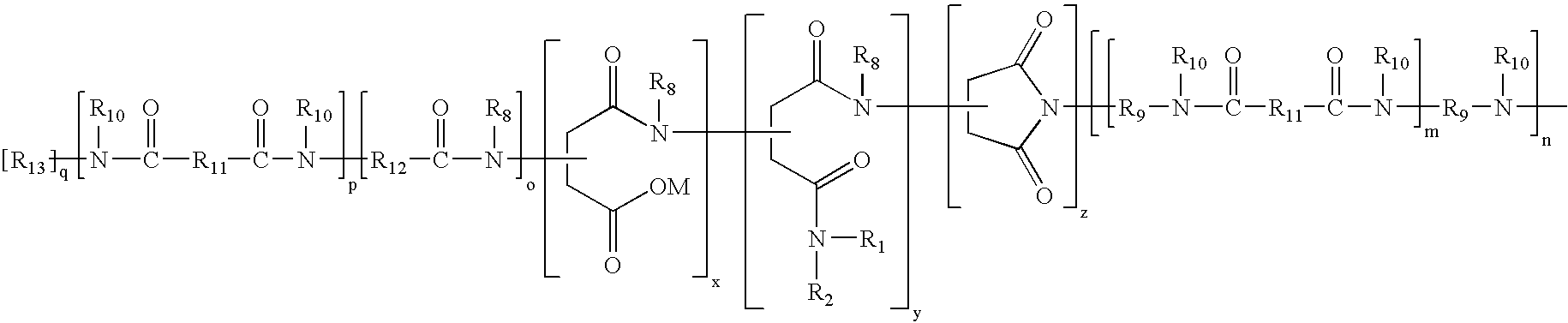

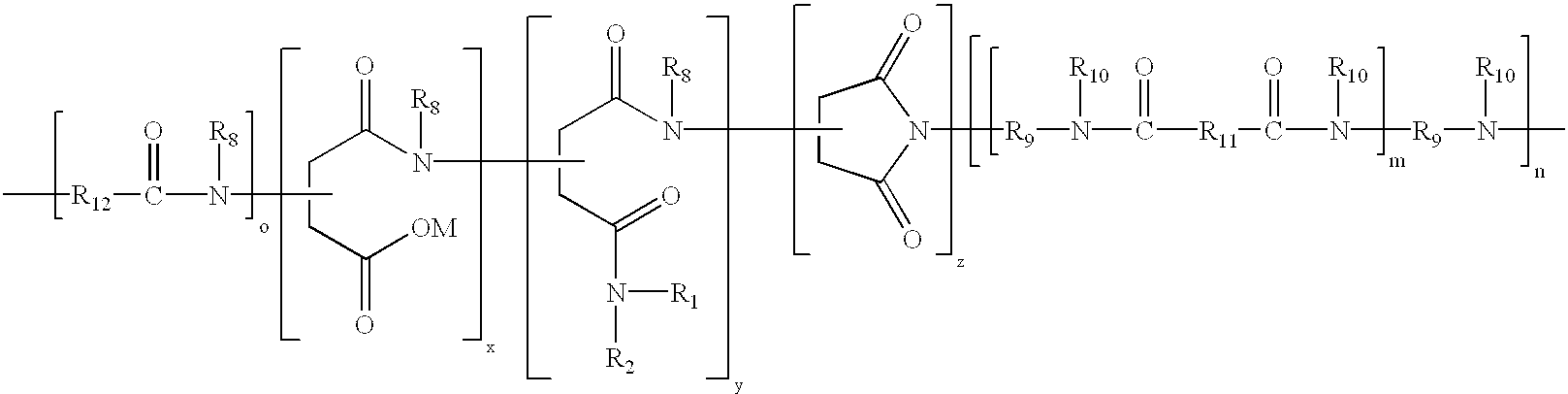

InactiveUS6953090B2Improve efficiencyReduce fluid lossDrilling compositionSealing/packingSolid massSide chain

Methods of cementing subterranean zones using cement compositions containing biogradable dispersants are provided. The methods are basically comprised of the steps of preparing a hydraulic cement, a biodegradable dispersant comprised of polyaspartic acid containing side chains formed by reacting one or more side chain chemicals with said polyaspartic acid and sufficient water to form a pumpable slurry, placing the cement composition into a zone to be cemented and allowing the cement composition to set into an impermeable solid mass therein.

Owner:HALLIBURTON ENERGY SERVICES INC +1

Polyaspartic acid ester polyurea protective coating with enhanced mechanical properties as well as preparation method, use method and application thereof

InactiveCN109439160AImprove adhesionImprove mechanical propertiesPolyurea/polyurethane coatingsPolyolFoaming agent

The invention belongs to the technical field of spray polyurea elastic materials and discloses a polyaspartic acid ester polyurea protective coating with enhanced mechanical properties. The polyaspartic acid ester polyurea protective coating is mainly prepared by the following raw materials: a material A and a material B, wherein the molar ratio of NCO in the material A to NH in the material B is1.05 to 1.1; the material A is mainly prepared by the following raw materials in percentage by weight: 25-49 percent of polyether polyol, 40-60 percent of TDI, 10-25 percent of urethano-modified HDI trimer and 1-5 percent of nanometer graphene oxide; the material B is mainly prepared by the following raw materials in percentage by weight: 70-80 percent of polyaspartic acid ester, 10-15 percent ofnano metal oxide fillers, 5-10 percent of pigments and fillers, 1-3 percent of a de-foaming agent, 1-3 percent of a leveling agent and 2-5 percent of an adhesive force promoter. The polyaspartic acidester polyurea protective coating disclosed by the invention has enhanced mechanical properties such as better tensile strength and elongation at break, and simultaneously has higher adhesive force. In addition, a preparation method of the polyaspartic acid ester polyurea protective coating, disclosed by the invention, is simple and easy to operate and convenient to popularize.

Owner:四川嘉宝莉涂料有限公司

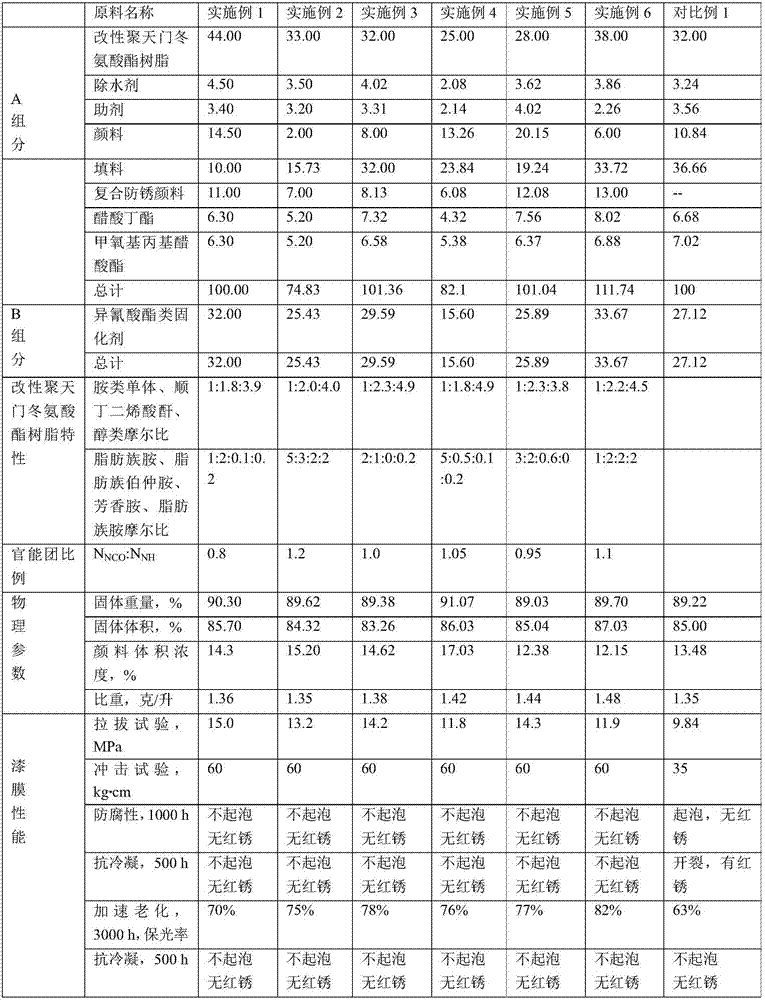

Quick-drying high-solid polyurea coating material, and preparation method and application thereof

ActiveCN107513341AImprove anti-corrosion performanceHigh resistance to salt sprayAnti-corrosive paintsPolyurea/polyurethane coatingsSolventMechanical property

The invention discloses a quick-drying high-solid polyurea coating material, and a preparation method and application thereof. The quick-drying high-solid polyurea coating material comprises the following materials, in parts by weight: 20-45 parts of modified polyaspartic ester resin, 15-35 parts of isocyanate curing agents, 5-15 parts of composite anti-rust pigment, 10-45 parts of a pigment filler, 1-5 parts of an auxiliary agent and 5-15 parts of a solvent, wherein the modified polyaspartic ester resin is prepared from amino monomers, maleic anhydride and alcohol monomers according to a molar ratio of 1:(1.8-2.3):(3.8-4.9). According to the invention, the above specific components and the component contents of the quick-drying high-solid polyurea coating material match perfectly, thus the quick-drying high-solid polyurea coating material provided by the invention has excellent mechanical properties, corrosion resistant performance and decorative performance, and can obviously improve construction production efficiency, and reduce construction time, energy consumption, VOC emissions and labor costs.

Owner:BEIJING BSS CORROSION PROTECTION IND +1

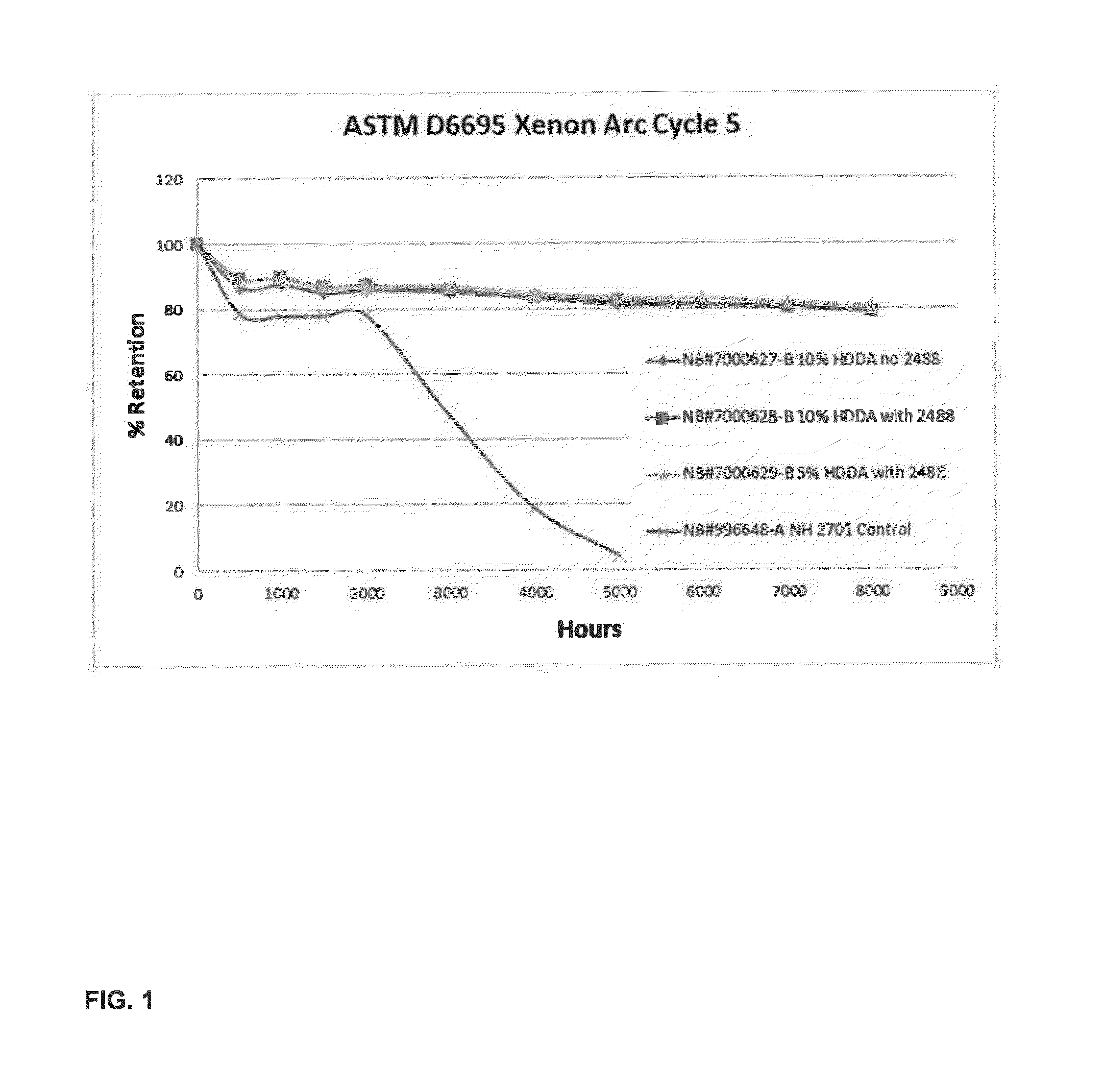

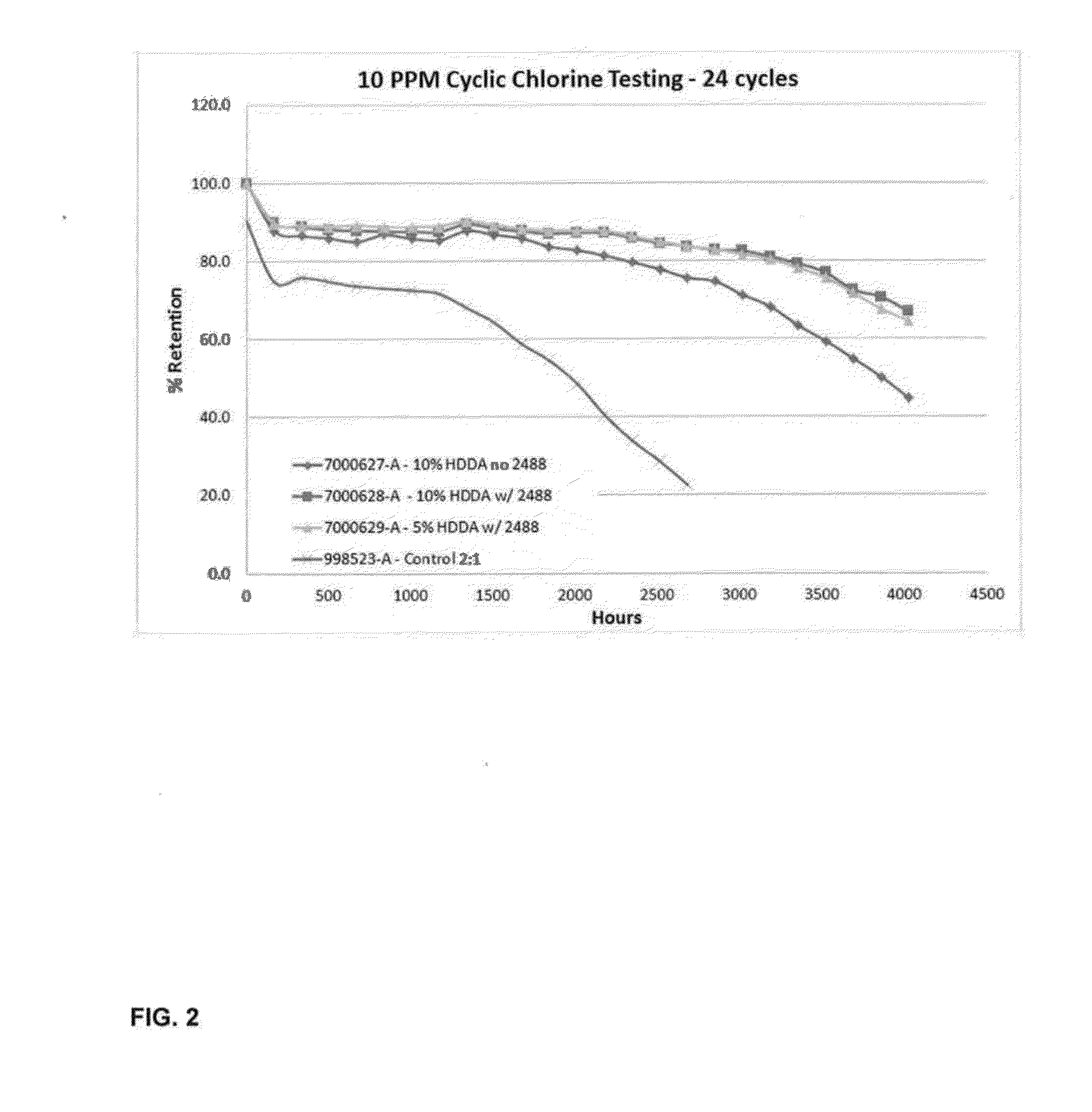

Polyaspartic gel coats with improved weather and chlorine resistance

InactiveUS20140272162A1Organic chemistryLiquid/solution decomposition chemical coatingScavengerPlasticizer

Owner:COVESTRO LLC

Method for preparing interpolymer bionic membrane material of poly-asparagine and chitosan

This invention discloses a method for preparing biomimic membrane material of polyasparagine and chitosan copolymer. The method comprises: preparing polyasparagine or its derivative with different side chains, copolymerizing and crosslinking with chitosan in an acidic medium to obtain environmentally friendly biomimic membrane material of polyasparagine and chitosan copolymer. The biomimic membrane material can be used for membrane separation, or as an environment-sensitive membrane material. The biomimic membrane material can be widely applied in such fields as pharmacy, food industry, printing and wastewater treatment.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Polyaspartic acid bacterial fertilizer and production method and application thereof

The invention relates to a polyaspartic acid bacterial fertilizer and a production method and application thereof. The polyaspartic acid bacterial fertilizer comprises polyaspartic acid or salts thereof, bacillus megatherium, colloid bacillus, bacillus licheniformis, bacillus subtilis, humic acid, and amino acid. The polyaspartic acid bacterial fertilizer can be used for improving the soil, helping crops to absorb nutrient elements including nitrogen, phosphorus, potassium and trace elements, promoting the growth of roots, reducing contamination to environment, activating the soil and reducing the use amount of the fertilizer.

Owner:石家庄中农兴泰生物科技有限公司

Process for preparing composite material of poly-aspartic acid, derivates thereof, chitosan and calcium phosphorous compound

The invention discloses a method for preparing composite material of poly-aspartic acid or a derivative thereof, chitosan and a calcium-phosphate compound. The method is as follows: firstly, the poly-aspartic acid with different side chains or the derivative thereof is synthesized, then the poly-aspartic acid with different side chains or the derivative thereof, the chitosan and calcium-containing solution are mixed, reacted and precipitated under certain temperature and pH value. The obtained product has the characteristic of imitating a cell envelope and is environment-friendly biomimetic material. The material has the function of absorbing heavy metals and certain organic substances, can be used to remove the heavy metals, chlorohydrocarbon, organic pigment, dyes and so on, and is widely used for fields such as medicine industry, food engineering, printing and dyeing industry, sewage treatment and so on.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

Phosphorus-free degreaser

The invention discloses a phosphorus-free degreaser. The phosphorus-free degreaser is prepared from the following raw materials in percentage by weight: 10-36 percent of sodium hydroxide, 0-25 percent of potassium hydroxide, 2-4 percent of sodium carbonate, 2-3 percent of sodium citrate, 2-4 percent of sodium gluconate, 0.5-2 percent of poly-aspartic acid, 0.8-3 percent of polyacrylic acid sodium salt, 0.8-4 percent of a nonionic surfactant and the balance of water. According to the phosphorus-free degreaser disclosed by the invention, saponification is carried out on the sodium hydroxide, the potassium hydroxide and oil; the sodium carbonate and the sodium citrate provide an alkaline condition; reaction is carried out on the sodium gluconate, the poly-aspartic acid and metal ions in the oil; and the polyacrylic acid sodium salt and the surfactants are capable of weakening the surface tension of water. A method provided by the invention is used for solving the technical problems of poor stability and environmental pollution of a degreaser in the prior art. The invention provides the phosphorus-free degreaser which is high storage stability and does not contain harmful elements including heavy metals, phosphorus and the like.

Owner:武汉钢铁有限公司

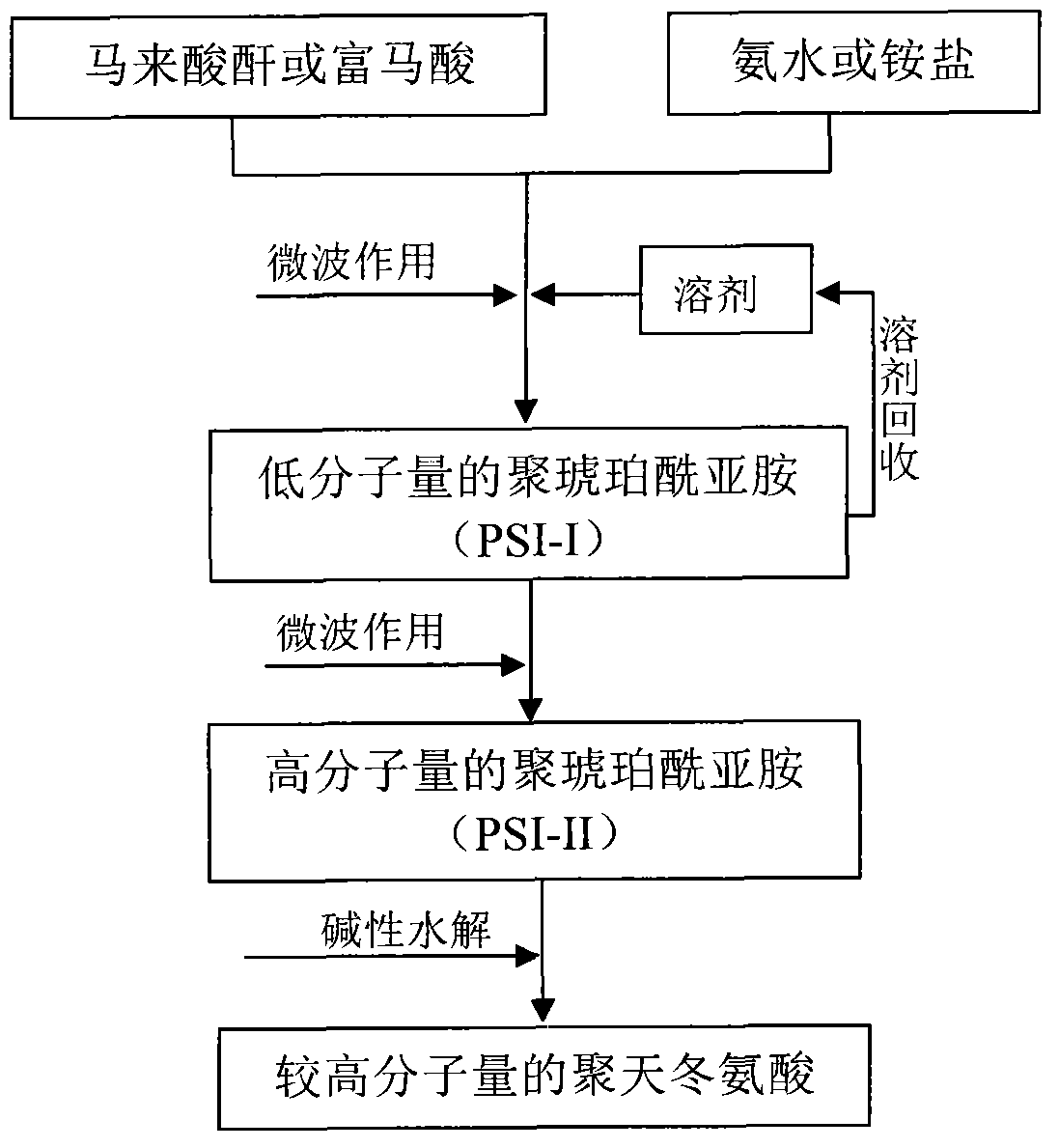

Method for synthesizing green scale inhibitor poly-asparagic acid through microwaves

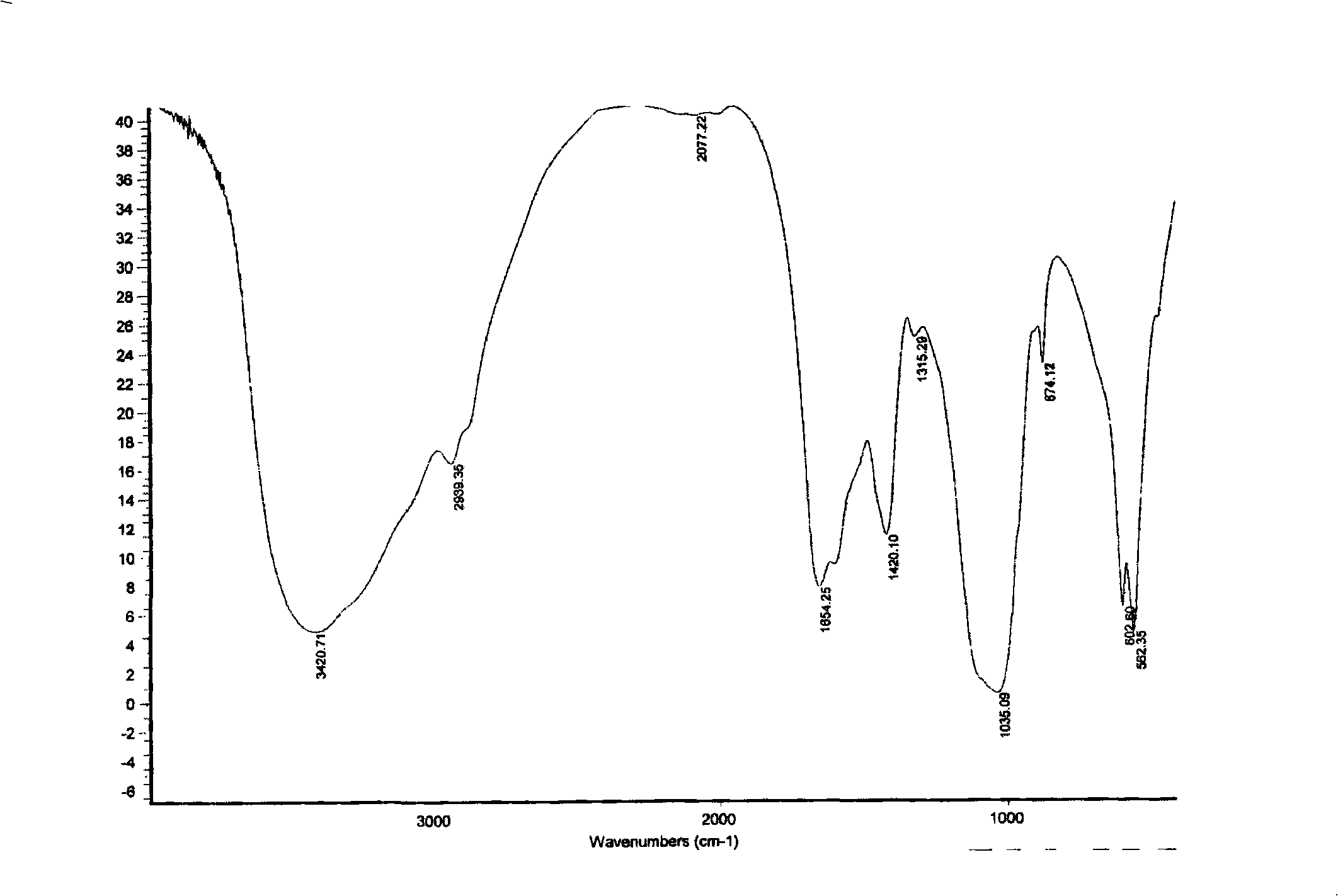

InactiveCN101575413AHigh scale inhibition rateHigh yieldScale removal and water softeningPolyasparticAmmonia

The invention discloses a method for synthesizing a green scale inhibitor asparagic acid through microwaves, which comprises the following steps: using maleic anhydride and ammonia water as raw materials; synthesizing an intermediate poly-succinimide through the microwaves; and then adding an inorganic base to perform hydrolyzation under a condition of microwave radiation so as to generate the poly-asparagic acid. The molecular weight distribution of the poly-asparagic acid prepared by the method is between 2,500 and 5,000, and the poly-asparagic acid has the performances of scale inhibition, corrosion inhibition and biodegradability, belongs to environment-friendly chemical products and has wide applications. The method has the advantages of simple process, high synthesis rate, low energy consumption, less pollution, high yield and stable product nature.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Environment-friendly synergistic anti-caking agent for compound fertilizer and preparation method of anti-caking agent

InactiveCN104446896AIncrease productionImprove qualityLayered/coated fertilisersFertilizer mixturesAnticaking agentPotassium

The invention discloses an environment-friendly synergistic anti-caking agent for a compound fertilizer. The anti-caking agent is prepared from the following components in percentage by mass: 5-15% of polyaspartic acid, 5-10% of polyacrylamide, 10-20% of an anionic surfactant, 5-10% of a non-ionic surfactant and the balance of deionized water, wherein the sum of contents of the above components is100%. The invention also discloses a preparation method of the anti-caking agent. The preparation method comprises the steps of blending raw materials, mixing, heating and stirring. Since the environment-friendly synergistic anti-caking agent for the compound fertilizer is prepared from biodegradable materials, the anti-caking agent can be completely degraded in a natural environment, and degraded products can also be used as a fertilizer for crops; polyaspartic acid has a chelating effect on metal ions, polyaspartic acid having a certain molecular weight can enrich nitrogen, phosphorus, potassium and trace elements and supply the elements to plants so that the fertilizer is efficiently utilized by plants and the yield and quality of plants are increased.

Owner:SHAANXI UNIV OF TECH

Polyaspartic ester urea adhesive and construction technology thereof

ActiveCN107522845AGood physical propertiesGood weather resistancePolyurea/polyurethane coatingsPolyurethane adhesiveEquivalence ratio

The invention discloses a polyaspartic ester urea adhesive and a construction technology thereof. The adhesive comprises a main agent and a curing agent in an equivalence ratio being 1:(0.9-1.1), and the main agent is prepared from 80-90 parts by weight of polyaspartic ester resin, 2-5 parts by weight of an oxazolidine absorbent, 8-12 parts by weight of a molecular sieve, 0.1-0.5 parts by weight of a defoaming agent and 0.1-0.5 parts by weight of a base material wetting agent. The adhesive contains no toxic substances such as free TDI (toluene diisocyanate) and the like, contains no organic solvents, phthalate plasticizers and heavy metal, belongs to a solvent-free system, is environmentally friendly, non-toxic and harmless, further has good physical performance and is good in weather fastness, high in tensile strength and elongation at break, good in rebound resilience and not prone to discoloration, construction is easy, operability and physical performance of the adhesive are equivalent to those of a conventional polyurethane adhesive, and excellent environment-friendly safety and physical characteristics are integrated. The technological process of preparation is simple, conditions are mild, construction performance is good, coating is easy, and therefore, the adhesive is suitable for industrial batch production.

Owner:SHENZHEN FEIYANG JUNYAN TECH DEV

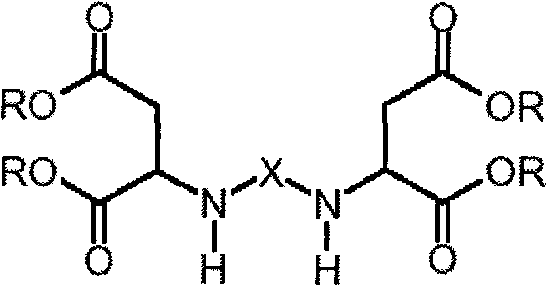

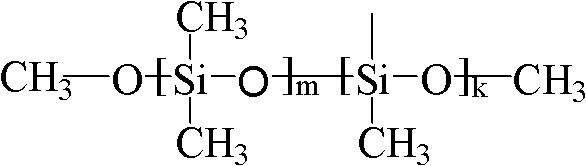

Wax deposition preventing organic paint and preparation method of organic coating containing it

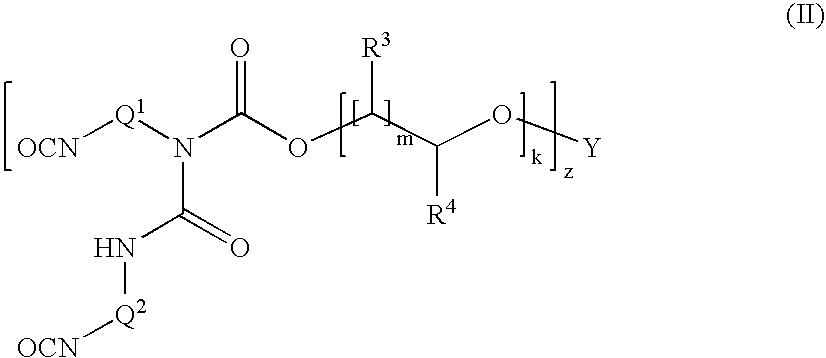

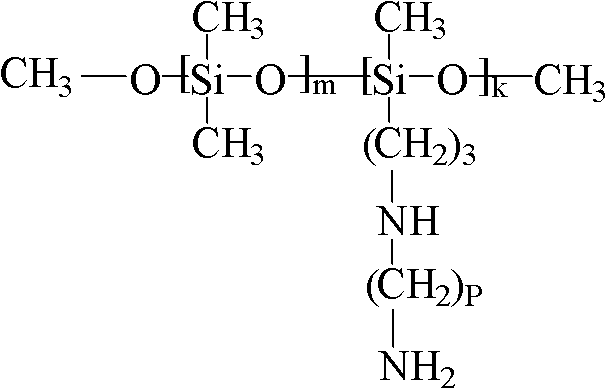

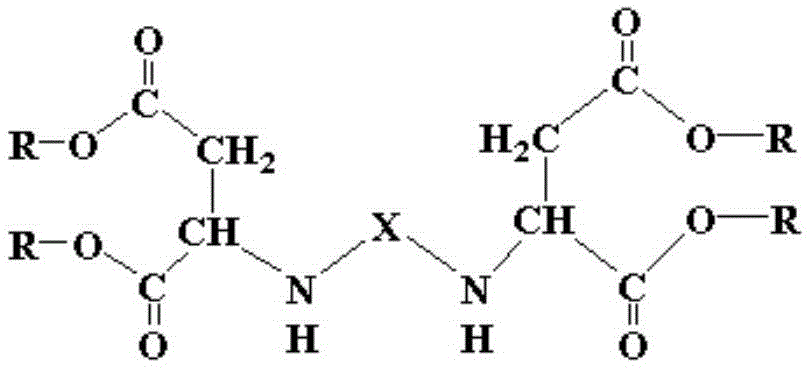

The invention discloses wax deposition preventing organic paint and a preparation method of an organic coating containing it. The wax deposition preventing organic paint comprises an organosilicon polyaspartic ester with a structure shown in formula (1) and isocyanate. In formula (1), R is an alkane group, and when X represents -R'-[SiR"20] nSiR"2-R'-, Y represents H; or, when X is -(CH2)P-, Y represents the wax deposition preventing organic paint provided in the invention. With reduced raw material cost and shortened curing time during the forming of an organic coating from organic paint, the wax deposition preventing organic paint of the invention can form an organic coating with good stability and low surface energy. And the surface of a sucker rod and the inner walls of an oil pipeline and an oil container in crude oil extraction can be coated with the wax deposition preventing organic coating, so that the oil delivery capacity of an oil well can be improved during crude oil extraction and the service life of an oil pumping unit is prolonged. Structural formula (1) is shown below.

Owner:北京碧海云智新材料技术有限公司

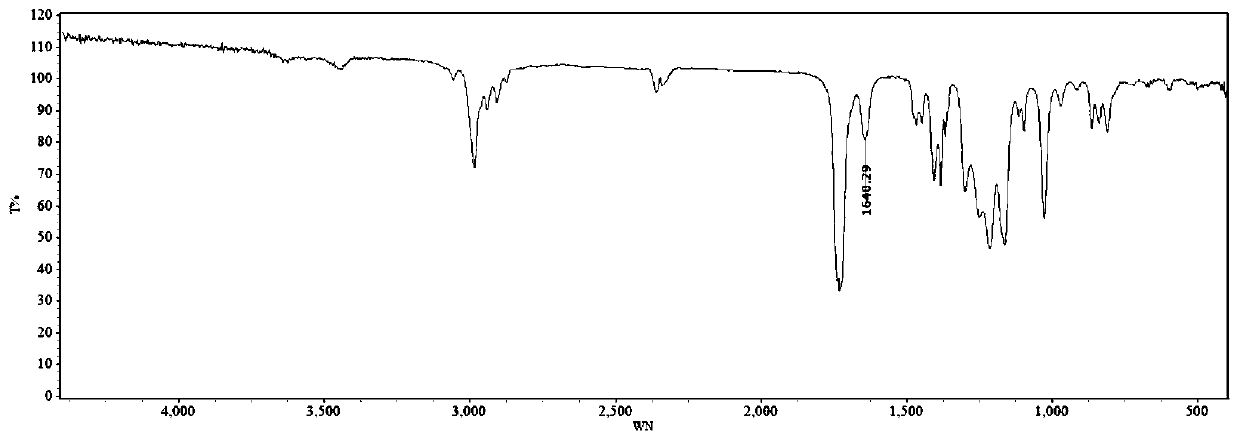

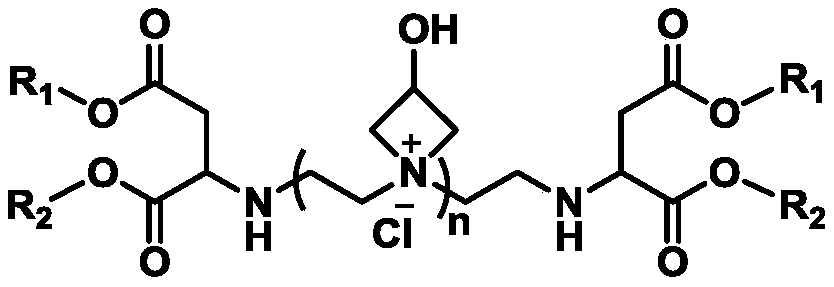

Water-soluble cationic polyaspartic ester, preparation method and application thereof

ActiveCN109020859AImprove stabilityHigh mechanical strengthOrganic chemistryPolyurea/polyurethane coatingsSynthesis methodsPolyaspartic

The invention provides a water-soluble cationic polyaspartic ester and a synthesis method thereof. The substance has a 3-hydroxyazetidine structure. During synthesis, firstly butene diacid diester reacts with polyethylene polyamine to obtain polyaspartic ester polyamine with unreacted secondary amine group, and then adding epoxy chloropropane for reaction with the secondary amine group so as to obtain water-soluble polyaspartic ester with azetidine cationic group. The cationic polyaspartic ester monomer can be compounded with isocyanate to develop water-soluble polyurea or polyurea / polyurethane coating resin.

Owner:WANHUA CHEM GRP CO LTD

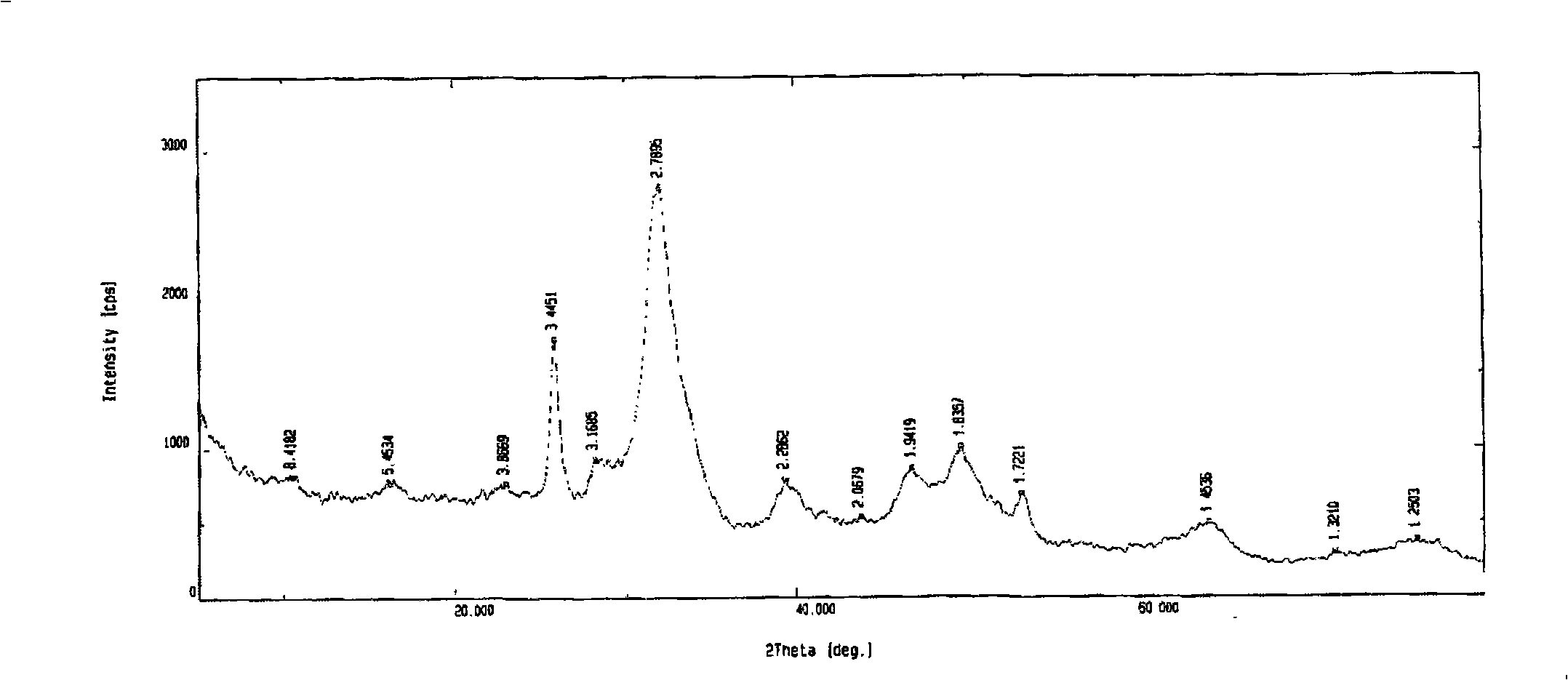

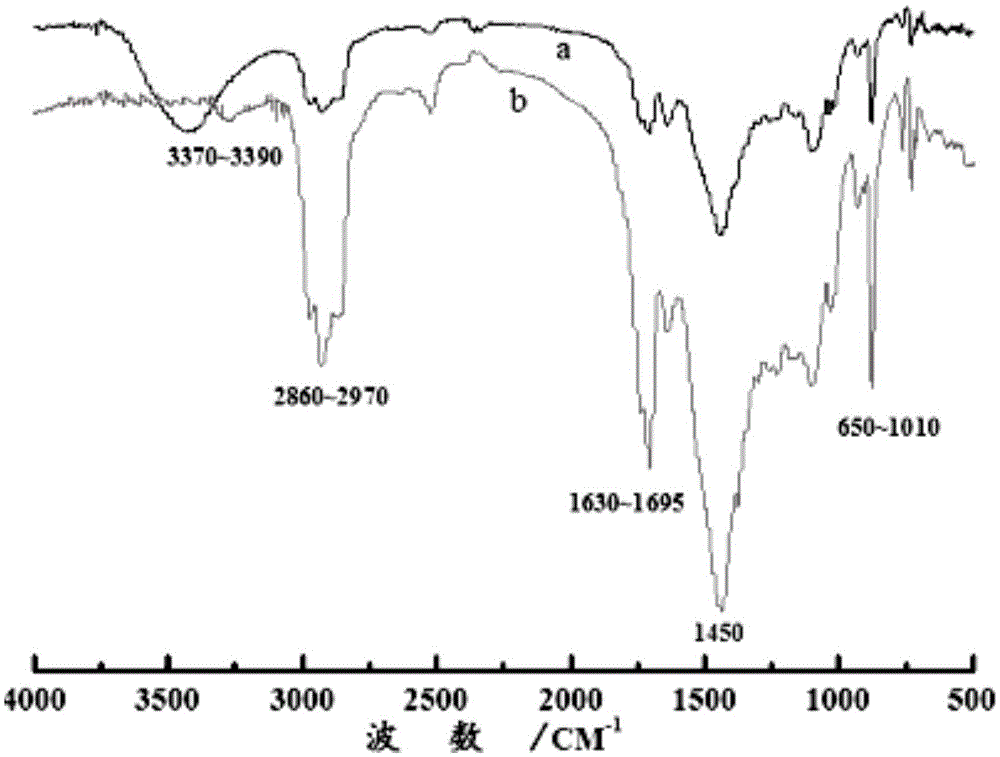

Polyaspartic acid synthesized by microwave half-solvent method

ActiveCN102796263AImprove performanceHigh molecular weightScale removal and water softeningFumaropimaric acidSynthesis methods

The invention relates to a synthesis method of a high-molecular-weight polyaspartic acid, particularly a polyaspartic acid synthesized by a microwave half-solvent method. The invention aims to overcome the defects of low molecular weight of the product, unstable antiprecipitation property, difficulty in solvent separation and the like in the existing microwave synthesis method. The synthetic process comprises the following two steps: 1. by using maleic anhydride or fumaric acid and ammonia water or ammonium salt as raw materials, adding a small amount of solvent, and radiating with microwaves, of which the frequency is 915+ / -50 MHz or 2450+ / -50 MHz and the power is 200-20000W, for 1-40 minutes to synthesize the low-molecular-weight polysuccinimide (PSI-I), wherein the solvent is recycled completely; and 2. by using the PSI-I as the raw material, radiating with microwaves, of which the frequency is 915+ / -50 MHz or 2450+ / -50 MHz and the power is 400-50000W, under the condition of no solvent for 1-30 minutes to synthesize the high-molecular-weight polysuccinimide (PSI-II), and hydrolyzing the PSI-II to obtain the high-molecular-weight polyaspartic acid. The invention has the advantages of simple technique, no need of solvent separation, obviously higher product molecular weight, obviously higher antiprecipitation property, high reaction speed, high yield, energy saving, low pollution and the like.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Ecological slow-release fertilizer of polymerization amino acid

ActiveCN103183573AAgriculture gas emission reductionFertilizer mixturesPolyasparticNitrification inhibitors

The invention provides an ecologic slow release fertilizer of polymerization amino acid, which is characterized by comprising 99 to 99.3 percent of nitrogen-phosphorus-potassium composite fertilizer, and 0.7 to 1 percent of additive, the additive comprise 20 to 30 percent of polyaspartic acid, 20 to 30 percent of polyglutamic acid, 40 to 60 percent of nitrification inhibitor, and the nutrient release period of the ecologic slow release fertilizer of polymerization amino acid can reach more than 100 days.

Owner:石家庄市中嘉化肥有限公司

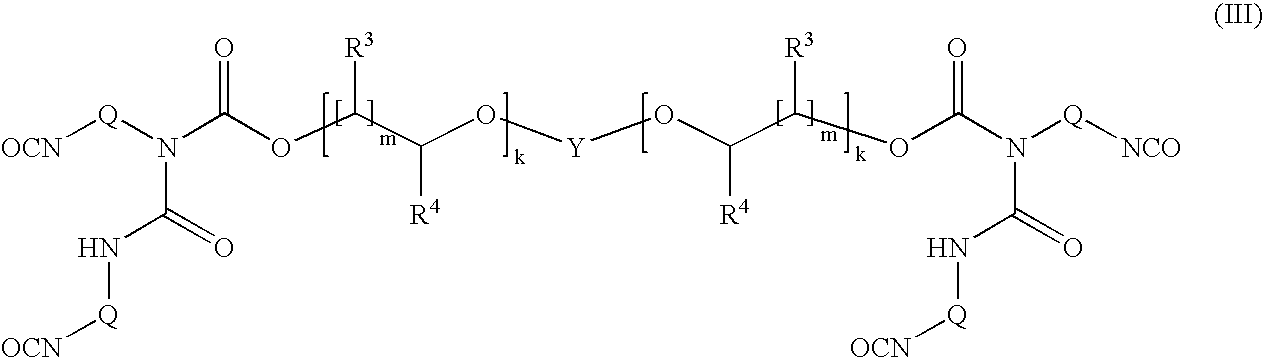

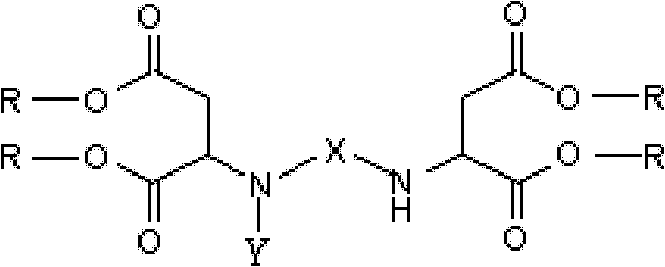

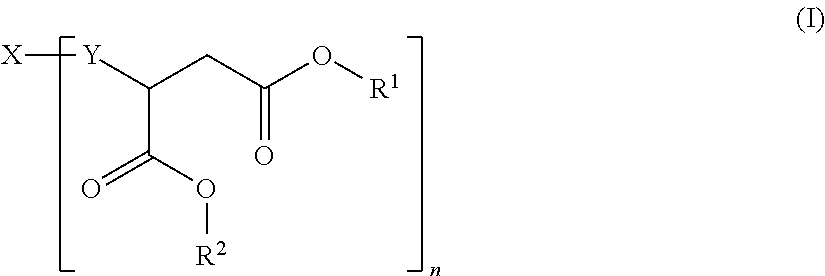

Hydrophilic polyaspartic esters

InactiveUS20160060380A1Organic chemistryPolyurea/polyurethane coatingsPolymer sciencePolyaspartic acid

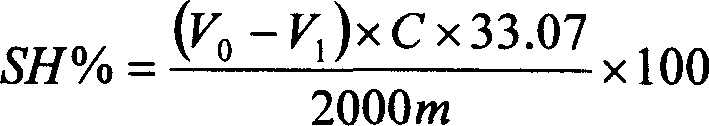

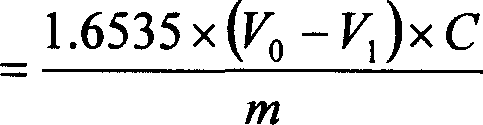

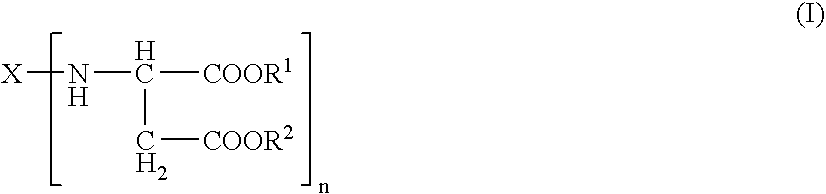

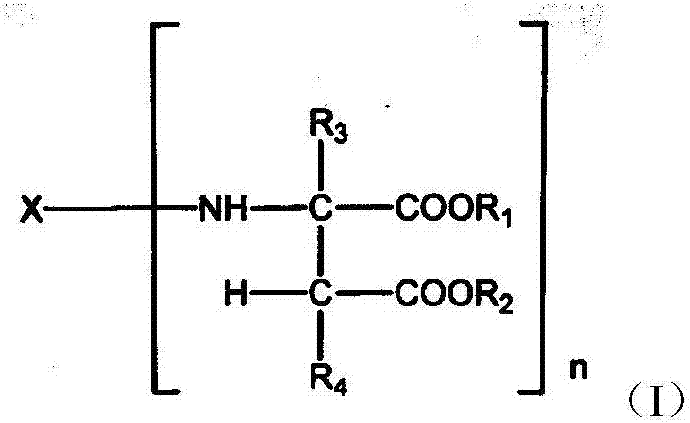

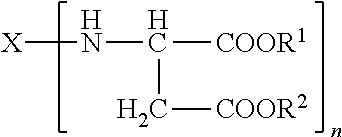

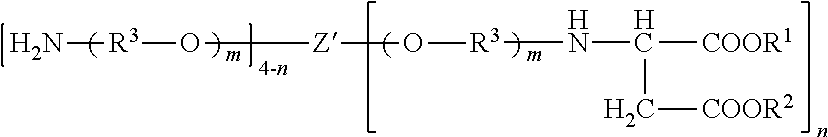

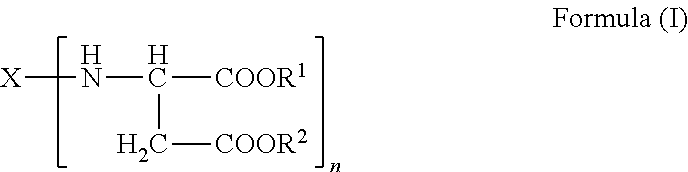

Disclosed are polyaspartic esters obtainable by reaction of at least one polyamine component A), comprising an amine compound of the formula (I),whereX is a saturated or unsaturated, linear or branched, aliphatic or cycloaliphatic or aromatic organic radical which is substituted or unsubstituted and / or has heteroatoms in the chain,Y is a secondary amino group bonded to two carbon atoms,R1 and R2 independently of one another are saturated or unsaturated, linear or branched, aliphatic or cycloaliphatic or aromatic organic radicals having 1 to 18 carbon atoms, and are substituted or unsubstituted and / or have heteroatoms in the chain, andn is a natural number from 1 to 4,with at least one polyisocyanate component B), comprising a polyisocyanate which contains at least one chemically bonded, non-ionic, hydrophilic group, characterized in that the ratio of the number of secondary amino groups Y to the number of isocyanate groups in the polyisocyanate is from 250:1 to 3:1. Further disclosed is a method for producing a coating composition, a 2-component system, the use thereof for producing a coating on a substrate, and the substrates coated accordingly.

Owner:COVESTRO DEUTSCHLAND AG +1

Process for preparation of biodegradable corrosion-scale inhibitor poly-aspartic acid

InactiveCN1557857ASimple processShorten the timeScale removal and water softeningCarboxyl radicalPolyaspartic

The present invention belongs to the field of chemical technology, and is especially the preparation process of polyaspartic acid as one kind of biodegradable corrosion and scale inhibitor. Maleic anhydride is first converted into maleic amine and the maleic amine is spray dried with one spray drier to obtain dry maleic amine; maleic amine is then condensated into succinimide; and succinimide is finally hydrolyzed in the presence of alkali into polyaspartic acid. The present invention is one kind of homopolymer containing amido and carboxyl radical, has excellent scale inhibiting and distributing capacity and excellent corrosion inhibiting performance, and may be used widely in circular cooling water system, boiler, oil field, sea water desalting, etc.

Owner:TONGJI UNIV

Preparation method of one-component polyaspartic ester finishing paint

ActiveCN105542640AImprove outdoor weather resistanceEasy to usePolyurea/polyurethane coatingsOrganic solventPolyol

The invention provides a preparation method of one-component polyaspartic ester finishing paint. The obtained finishing paint is convenient to use. The preparation method includes the following steps that firstly, a ketone end-capping agent, polyaspartic ester and a first catalyst are subjected to a reflux reaction for 4-6 hours in a first organic solvent at the temperature of 120-140 DEG C, secondary amino groups of polyaspartic ester totally react with the ketone end-capping agent, and end-capped polyaspartic ester is obtained after the ketone end-capping agent which does not participate in the reaction and the first organic solvent are removed; secondly, polyurethane pre-polymer is prepared, wherein after polymer polyol and aliphatic isocyanate react, reactant is mixed with a selectable second organic solvent, and the polyurethane pre-polymer is obtained; thirdly, the end-capped polyaspartic ester, the polyurethane pre-polymer and auxiliaries are evenly mixed, and the one-component polyaspartic ester finishing paint is obtained.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Polyaspartic coating compositions

Two-component coating systems and compositions are disclosed. The coating compositions form crosslinked polyurea coatings and have relatively long pot life and relatively short dry time. The coating compositions include a polyisocyanate, a polyaspartic ester, and a polyetheraspartic ester.

Owner:COVESTRO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com