Process for preparing composite material of poly-aspartic acid, derivates thereof, chitosan and calcium phosphorous compound

A technology of polyaspartic acid and composite materials, which is applied in the field of composite materials of chitosan and calcium phosphorus compounds to prepare polyaspartic acid or its derivatives, which can solve the problems of poor mechanical strength and achieve improved mechanical strength , Good environmental compatibility, easy chemical modification effect

Inactive Publication Date: 2008-10-22

TIANJIN UNIVERSITY OF TECHNOLOGY

View PDF2 Cites 12 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the developed material has the disadvantage of poor mechanical strength

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

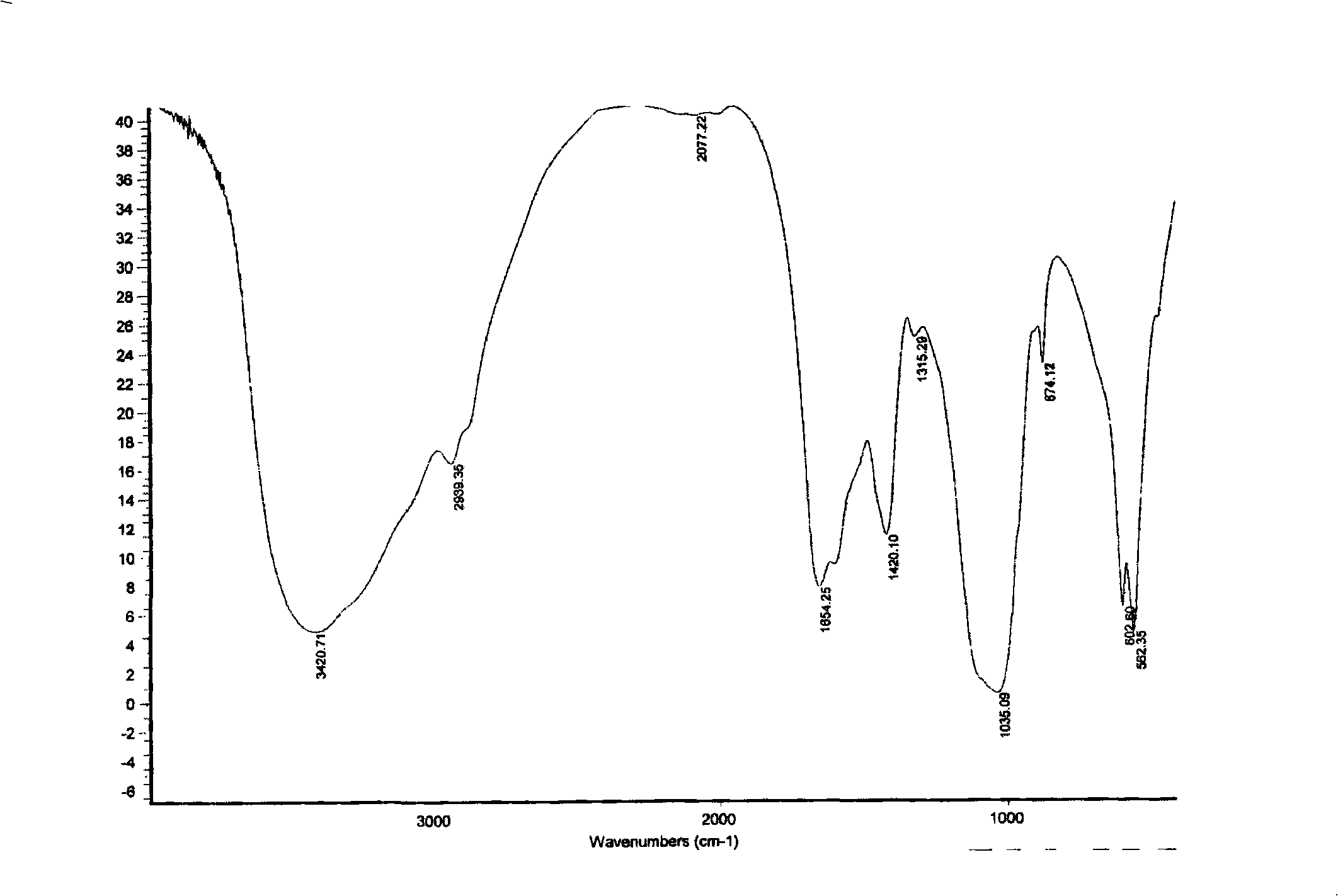

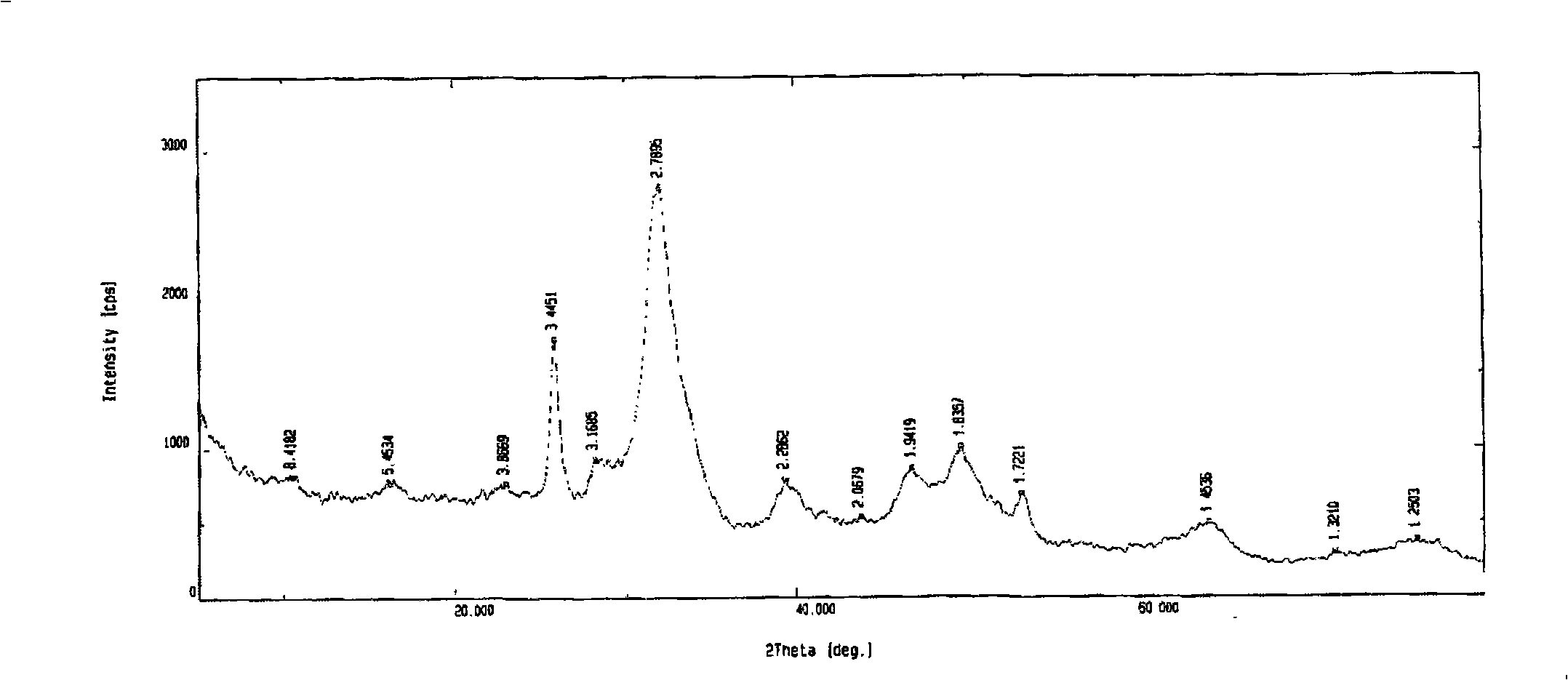

The invention discloses a method for preparing composite material of poly-aspartic acid or a derivative thereof, chitosan and a calcium-phosphate compound. The method is as follows: firstly, the poly-aspartic acid with different side chains or the derivative thereof is synthesized, then the poly-aspartic acid with different side chains or the derivative thereof, the chitosan and calcium-containing solution are mixed, reacted and precipitated under certain temperature and pH value. The obtained product has the characteristic of imitating a cell envelope and is environment-friendly biomimetic material. The material has the function of absorbing heavy metals and certain organic substances, can be used to remove the heavy metals, chlorohydrocarbon, organic pigment, dyes and so on, and is widely used for fields such as medicine industry, food engineering, printing and dyeing industry, sewage treatment and so on.

Description

Method for preparing composite material of polyaspartic acid or its derivative, chitosan and calcium phosphorus compound 【Technical field】 The invention relates to the field of fine chemicals in chemical engineering, in particular to a method for preparing composite materials of polyaspartic acid or its derivatives, chitosan and calcium phosphorus compounds. 【Background technique】 In previous work, we have developed composite materials of polyaspartic acid or its derivatives and chitosan (see ZL200510015063.5 and CN1916052A). However, the developed material has the disadvantage of poor mechanical strength. For this reason, the present invention intends to incorporate inorganic materials therein to prepare composite materials of polyaspartic acid or its derivatives, chitosan and inorganic materials, so as to improve the mechanical strength of the materials. The entire preparation process adopts a clean chemical process without using toxic and harmful solvents, and the obta...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L79/08C08L5/08C08K5/07C08K3/22C08K3/24C08K3/28

Inventor 孙波方叶明王博威孙永跃吴新世安钢

Owner TIANJIN UNIVERSITY OF TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com