Patents

Literature

823results about How to "Good environmental compatibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smoke-free substitute cigarette product

ActiveUS20100126505A1Straightforwardly be carriedReduce weightTobacco treatmentTobacco devicesFlammable gasCigarillo

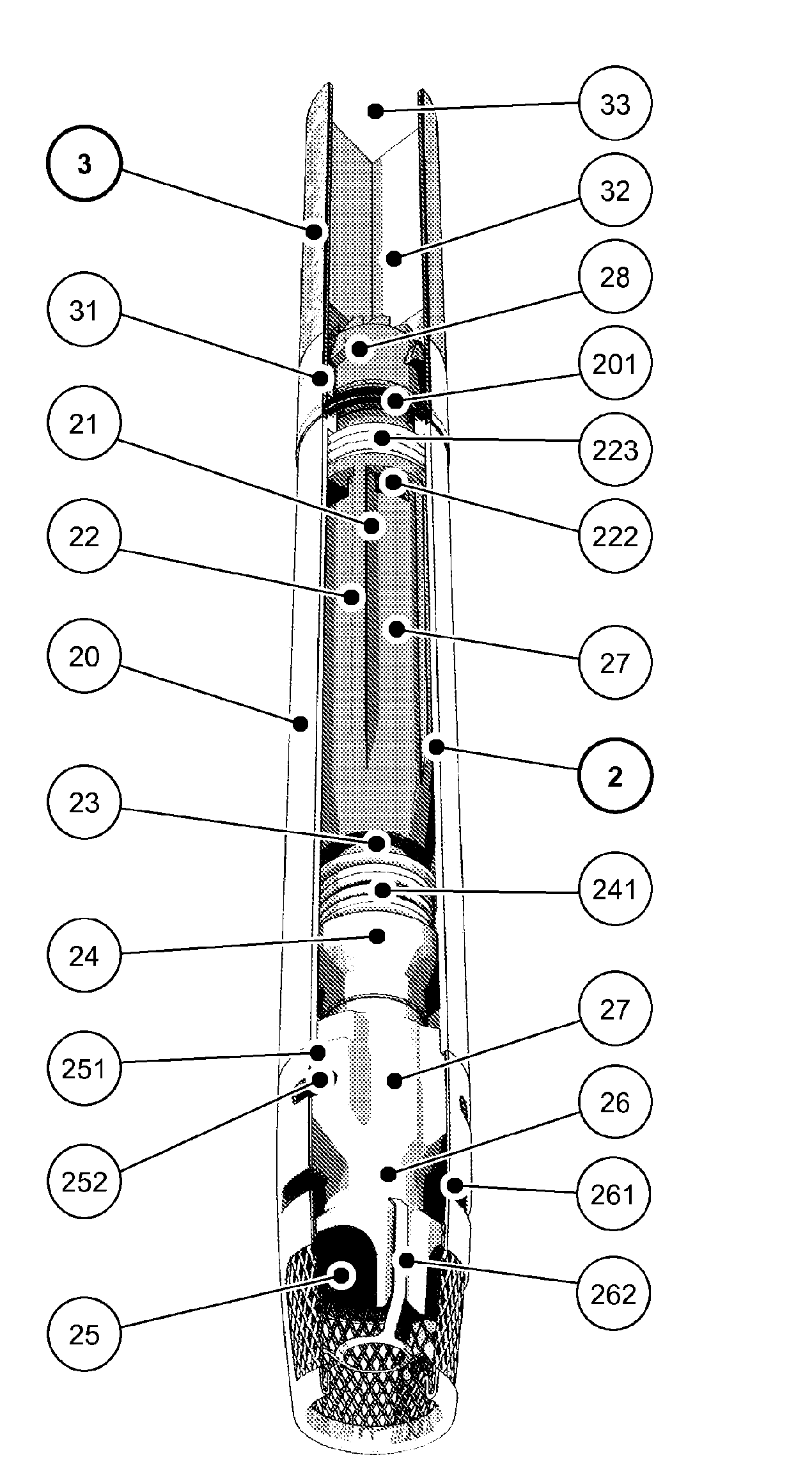

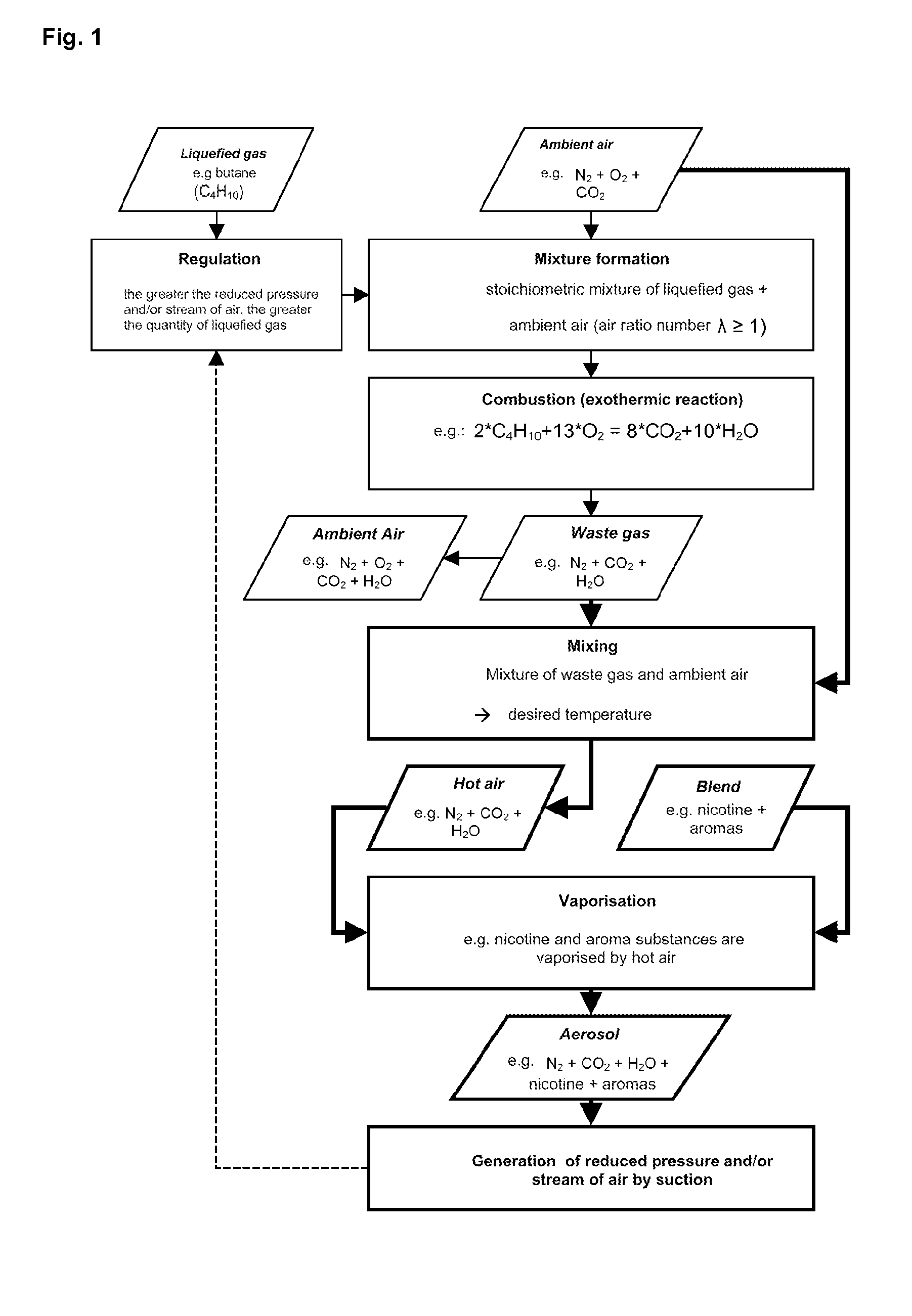

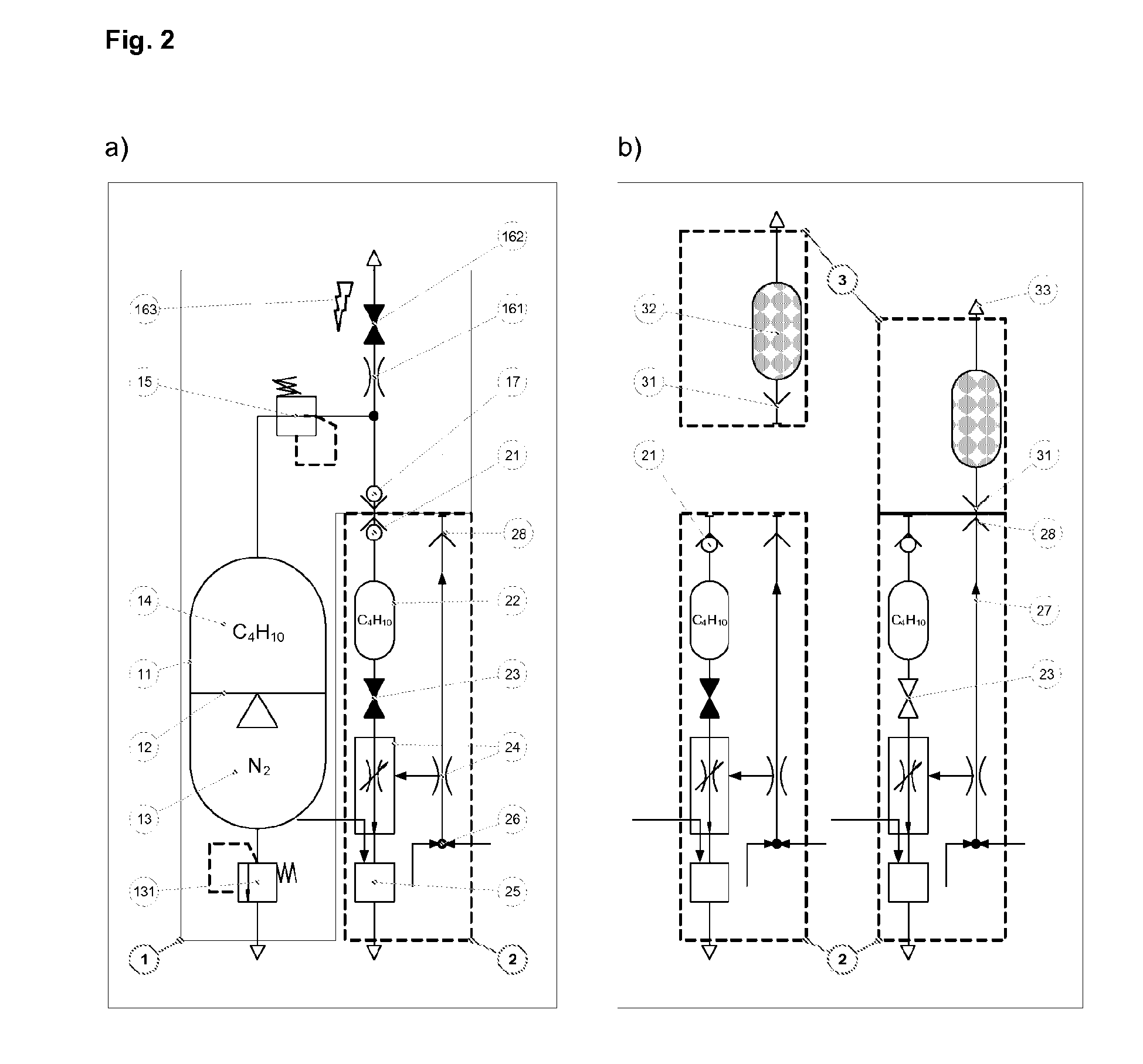

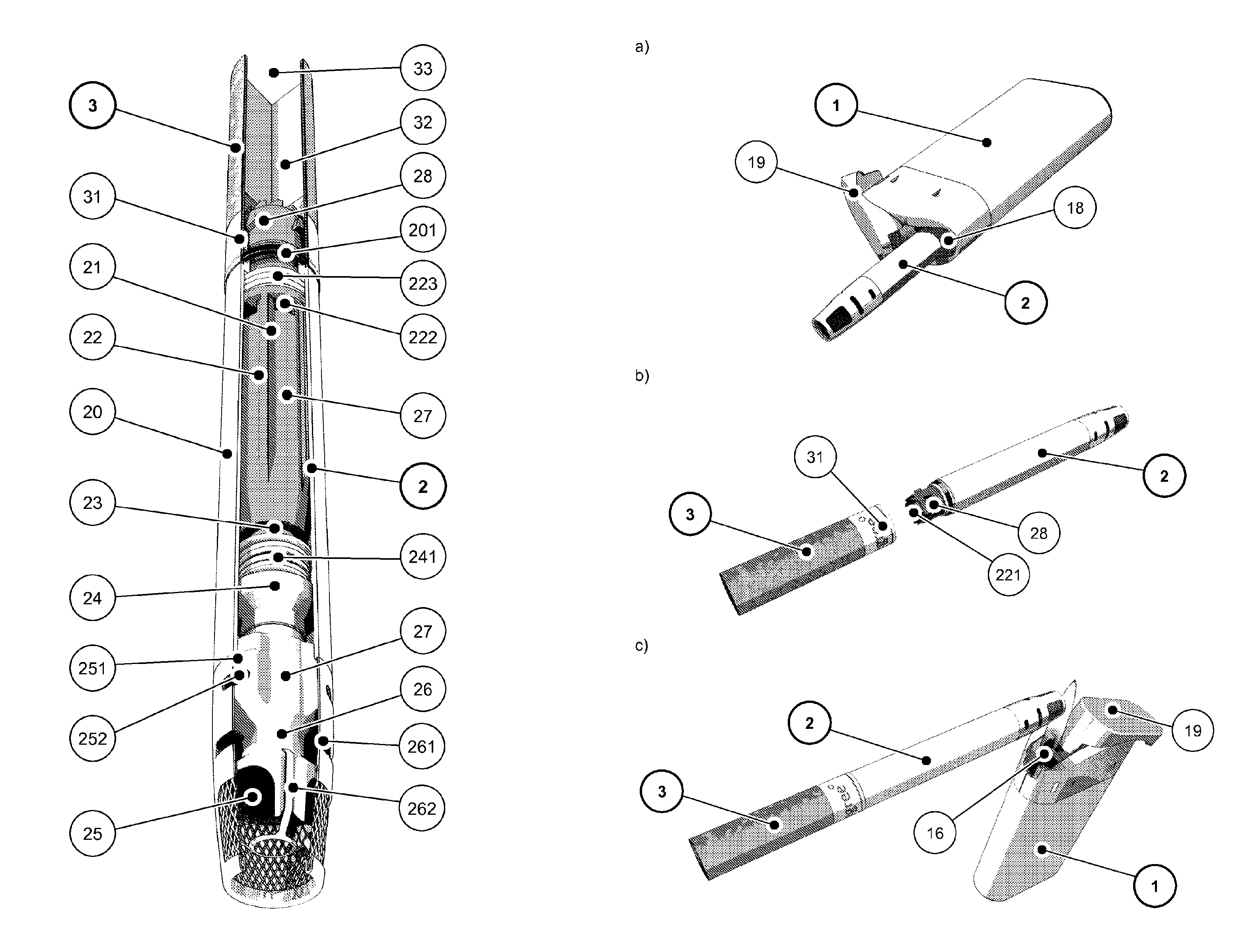

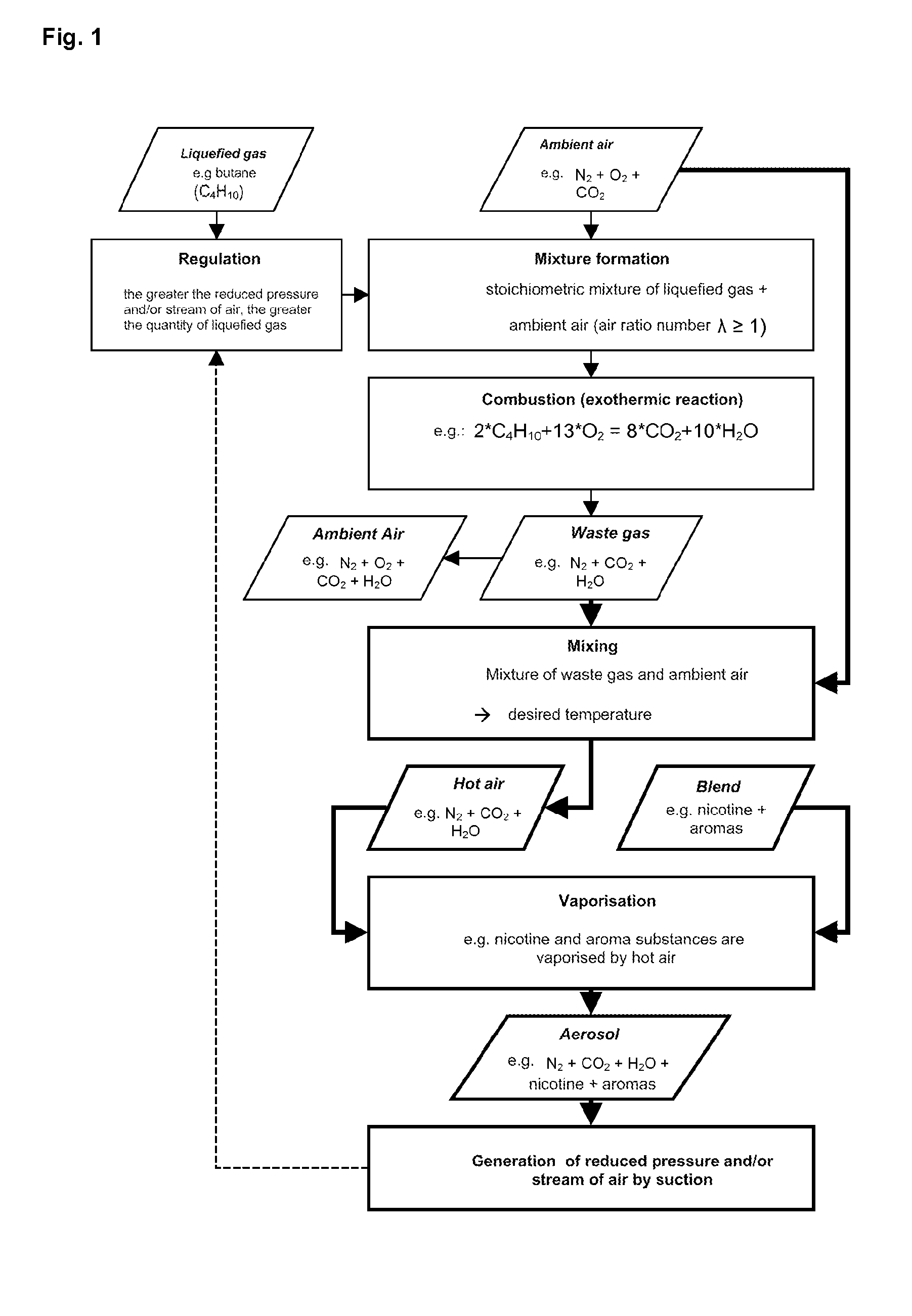

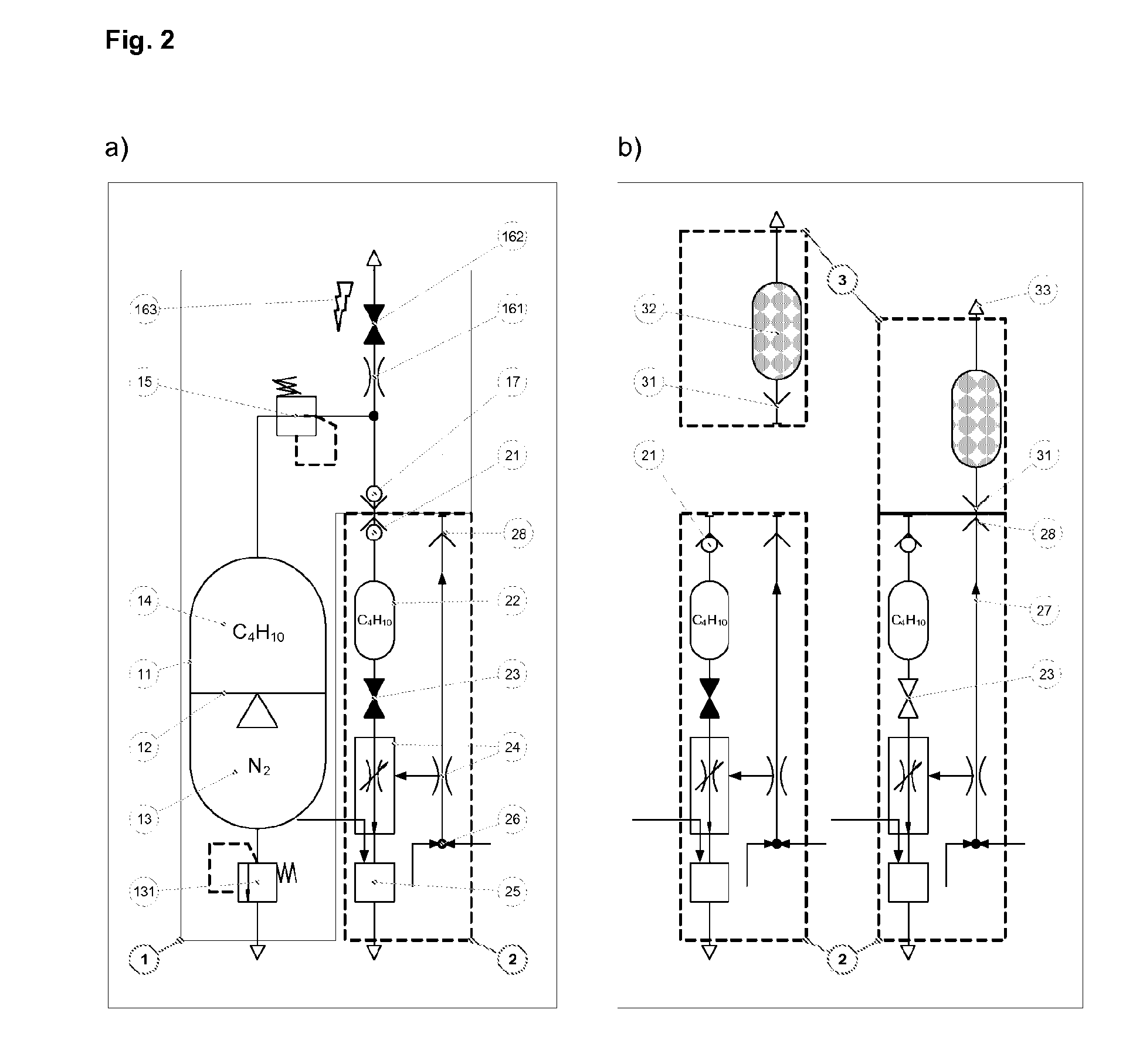

A method for volatilising active and / or aroma substances for the purpose of releasing an inhalable aerosol, wherein combustion gases of a flammable gas, which is preferably combusted with an excess of air, are passed partially or entirely, optionally mixed with ambient air, through an active and / or aroma substance depot and wherein a desired temperature is selectable by the proportion of combustion gases and optionally by the mixing ratio of said combustion gases with ambient air and the device implementing the method in the shape and dimensions of a cigarette or cigar for releasing an inhalable aerosol, comprising a mouthpiece (3) containing an active and / or aroma substance depot (32), a heating member (2) with a housing sleeve with one or more air inlets and one or more hot air outlets at the mouthpiece end, a filling valve (21) for filling a gas tank (22) with a flammable gas, preferably propane or butane gas, a regulating valve (24) for the controlled release of the gas from the gas tank (22) to a burner (25) and a mass transfer exchanger (26) for heating the air by the hot combustion gases produced by means of the burner (24), wherein the mouthpiece (3) is detachably connected to the heating member (2) and control of the regulating valve (24) is effected by means of the reduced pressure and / or stream of air generated by a user's suction on the mouthpiece (3). Fuelling station for such a device.

Owner:PHILIP MORRIS PROD SA

Smoke-free substitute cigarette product

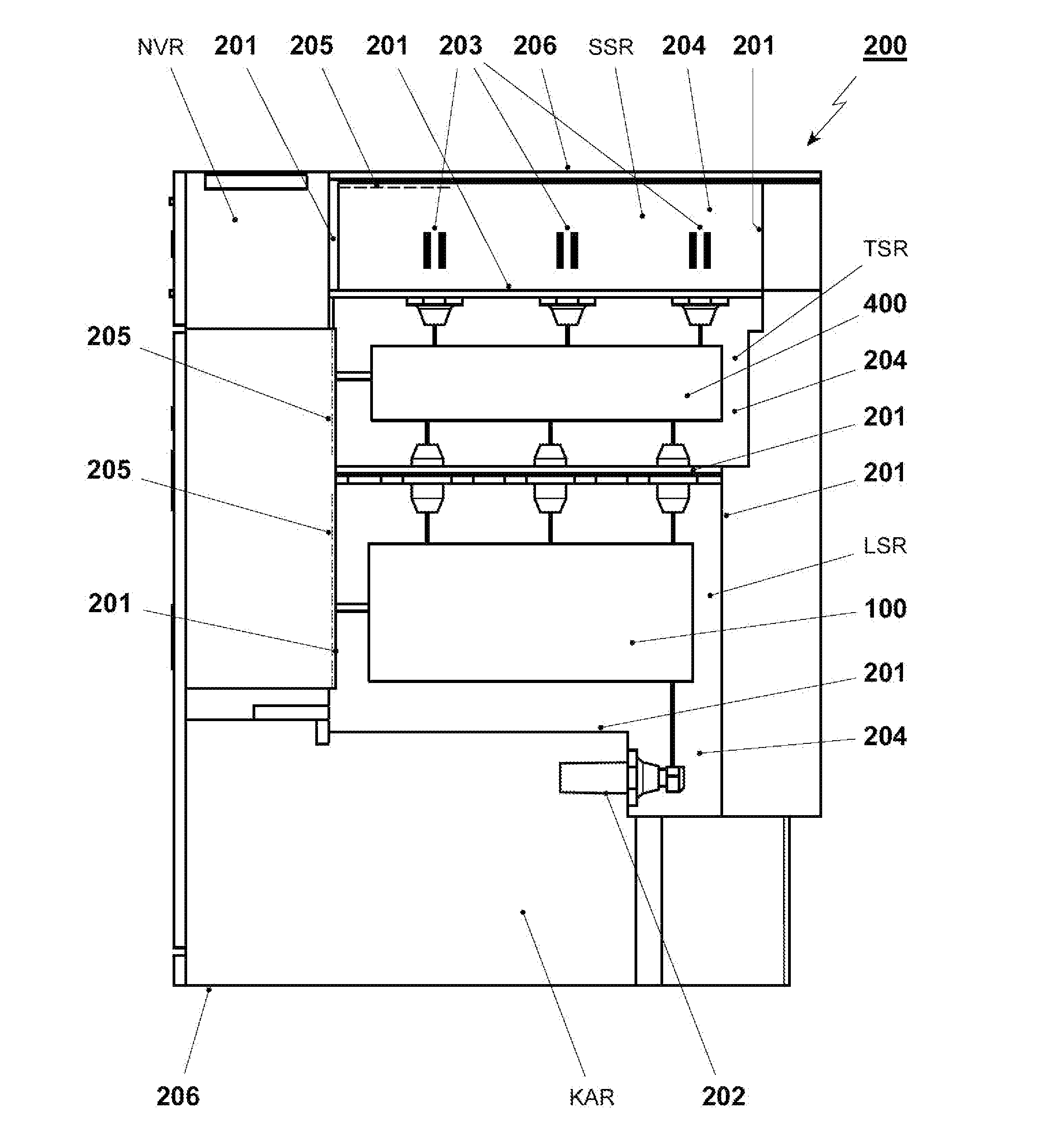

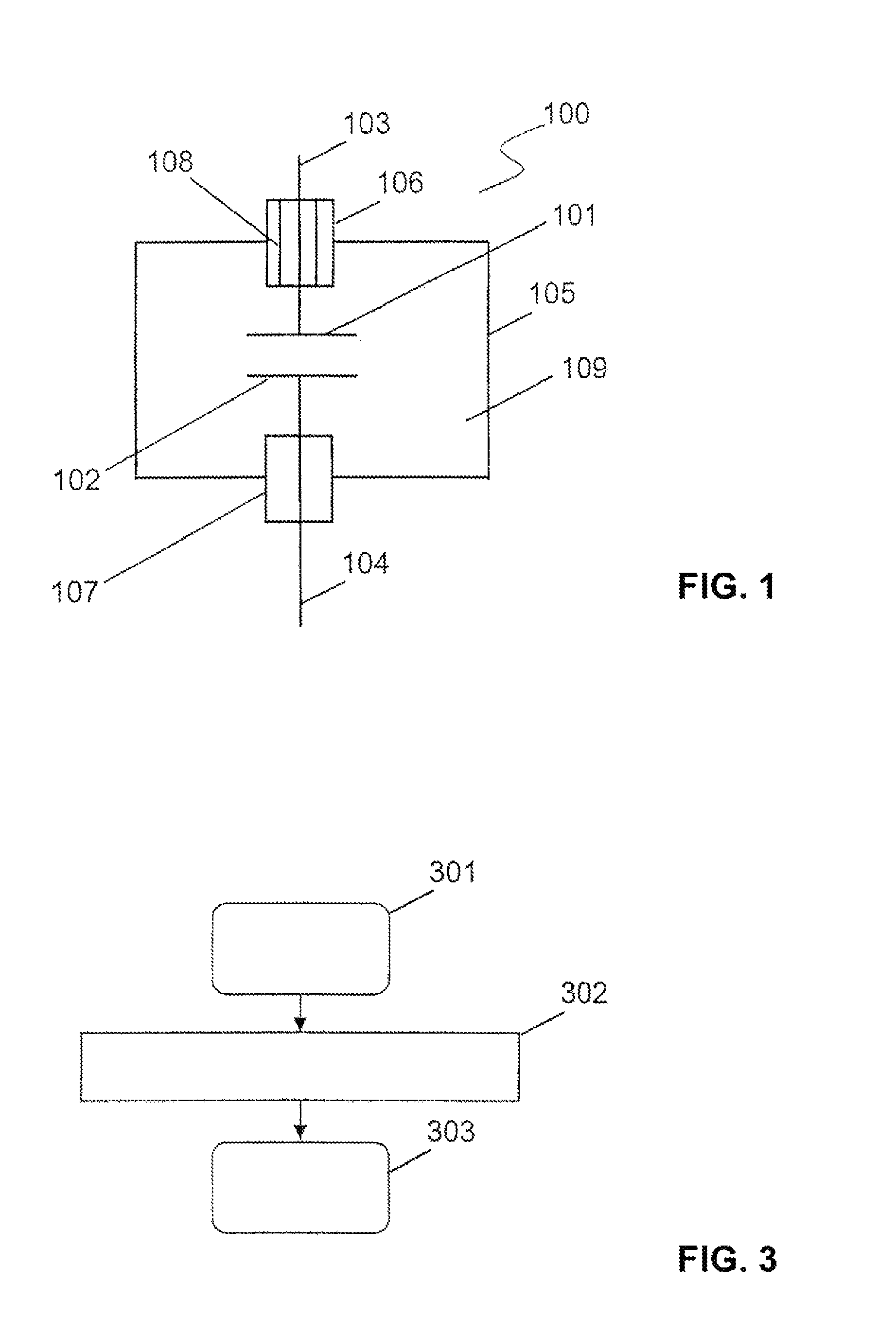

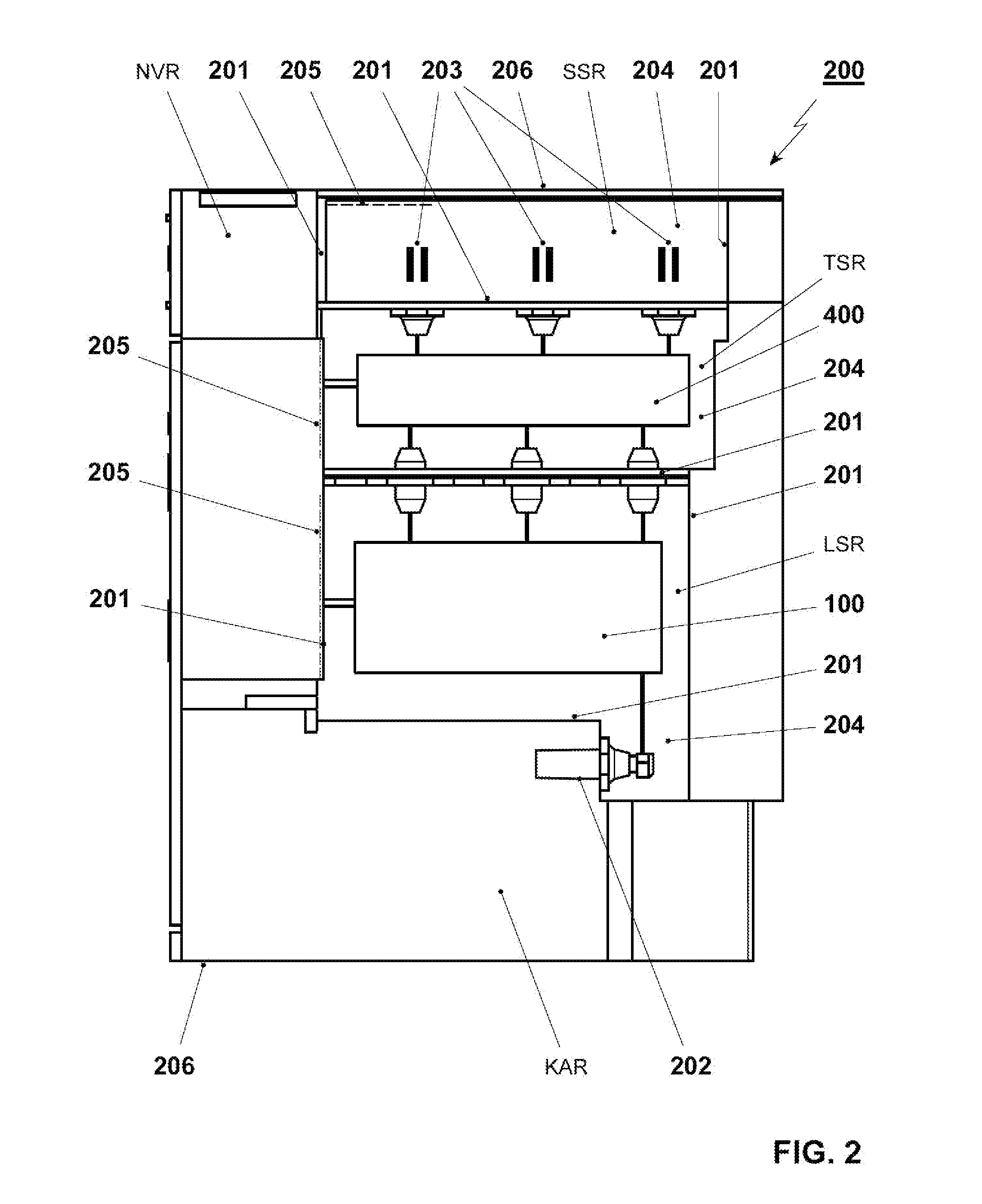

ActiveUS8733346B2High calorific valueGood environmental compatibilityTobacco treatmentTobacco pipesCombustorControl release

An aerosol-releasing inhalation device, fuelling station, and apparatus are provided. The device includes a mouthpiece having a substance depot, and a heating member detachably connected to the mouthpiece for volatilising a substance to release an inhalable aerosol. The heating member includes a housing sleeve having at least one air inlet, and at least one hot air outlet at a mouthpiece end separated from the air inlet; a filling valve at the mouthpiece end to fill a tank with a flammable gas; a premix burner; a regulating valve to control release of the gas to the premix burner by suction on the mouthpiece; and a mass transfer exchanger to heat air by heat generated from the premix burner. The substance depot at least partially passes combustion gases, and a desired inhalation air temperature is selectable by at least a proportion of the combustion gases exiting the mass transfer exchanger.

Owner:PHILIP MORRIS PROD SA

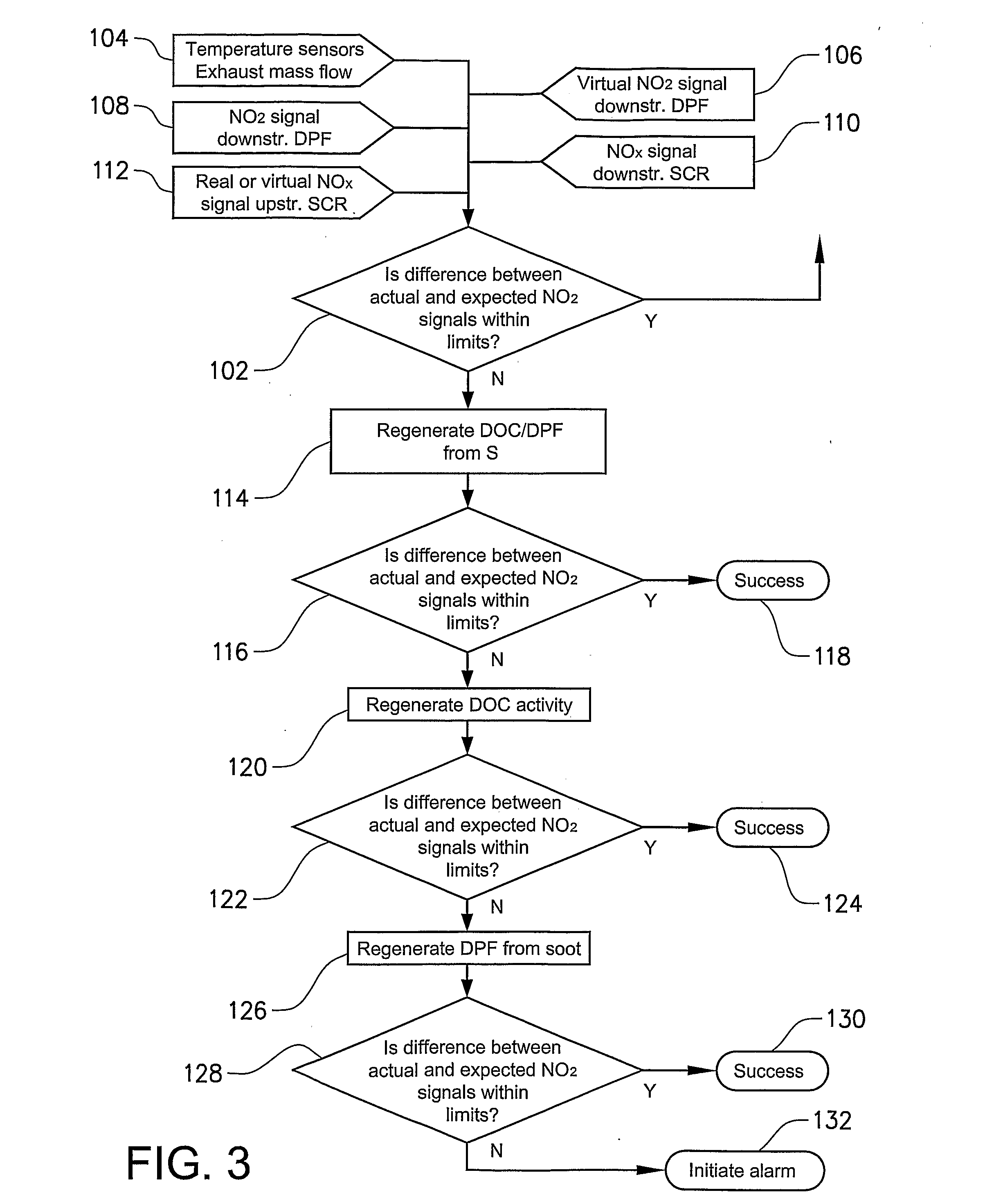

On-board-diagnosis method for an exhaust aftertreatment system and on-board-diagnosis system for an exhaust aftertreatment system

ActiveUS20100101213A1Promote regenerationGood NO /NO ratioElectrical controlInternal combustion piston enginesOn boardDiagnosis methods

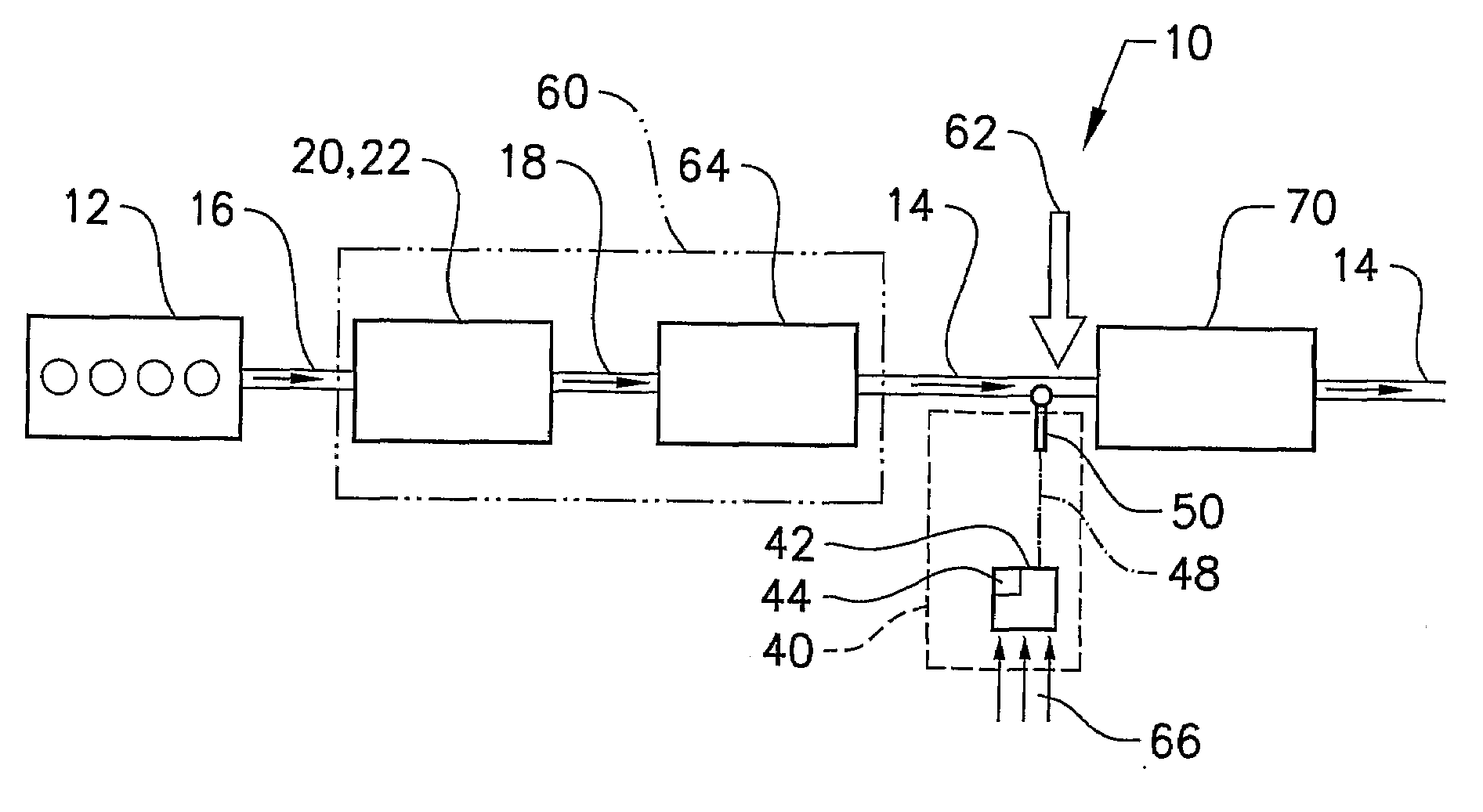

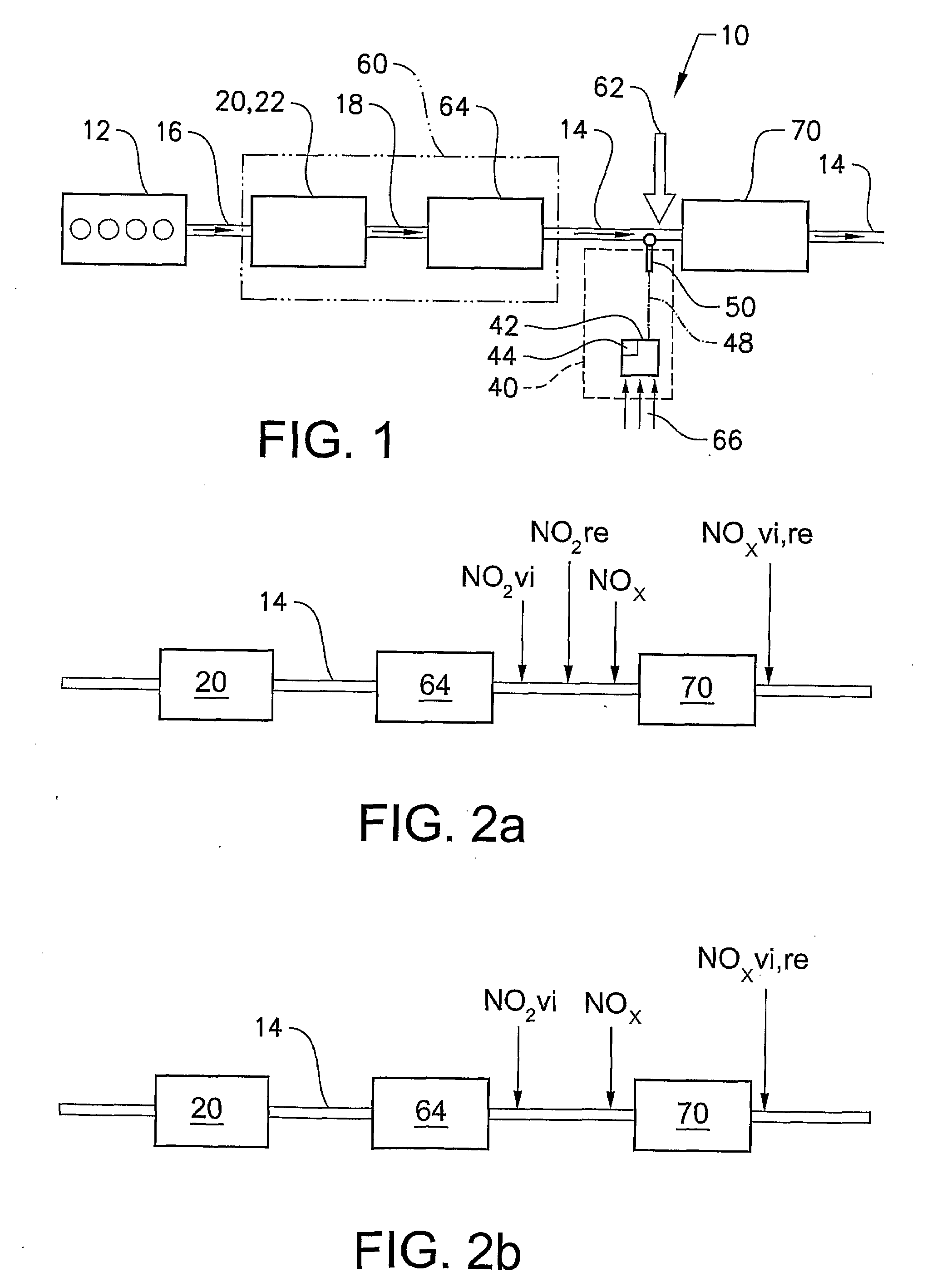

A system and an on-board-diagnosis method is provided for an exhaust aftertreatment system of an engine including a diesel particulate filter unit which encompasses a particulate filter in which soot can be oxidized by NO2 and constituents of the exhaust gas are deoxidized in a nitrogen-oxides reduction unit arranged downstream of the diesel particulate filter unit, wherein the exhaust gas flows from the diesel particulate filter unit to the nitrogen-oxides reduction unit. The on-board-diagnosis method includes estimating an NO2 content upstream of the nitrogen-oxides reduction unit, measuring at least one of an NOx or NO2 content upstream of the nitrogen-oxides reduction unit, performing a comparison between the estimated and the measured contents, and, based on the result of the comparison deciding on at least one conditioning step of the diesel particulate filter unit.

Owner:VOLVO LASTVAGNAR AB

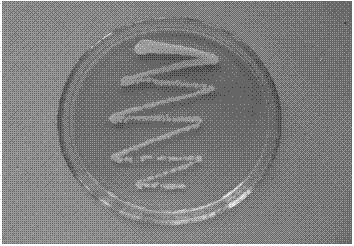

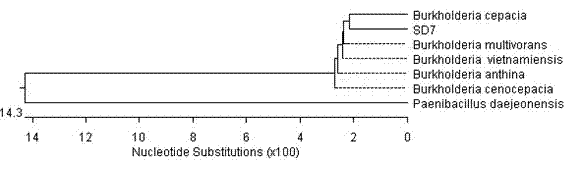

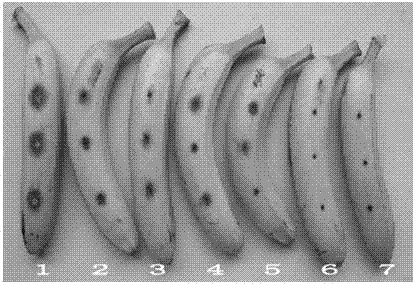

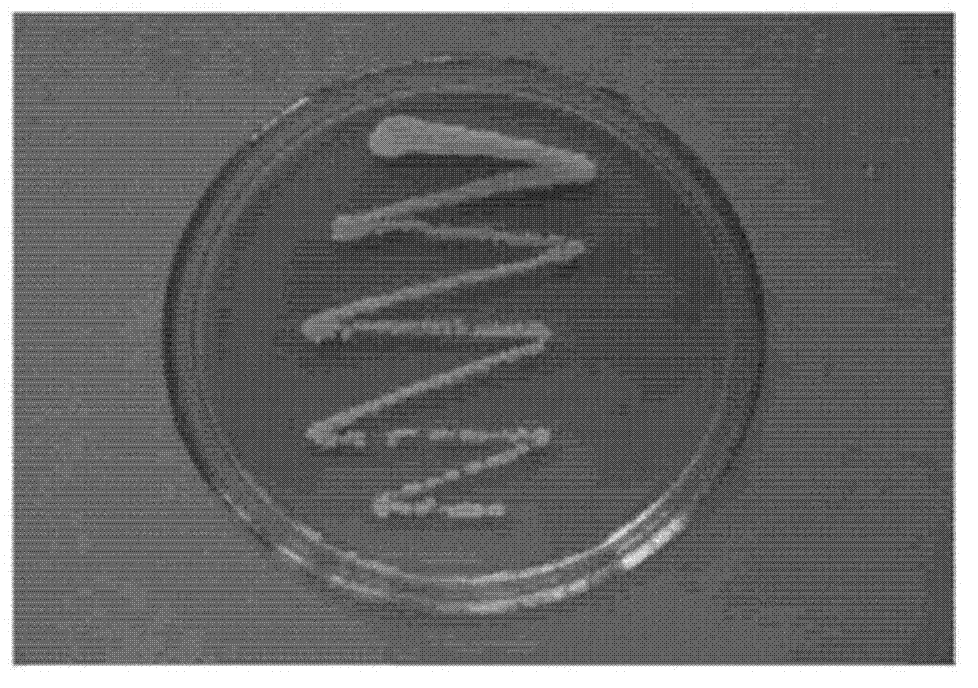

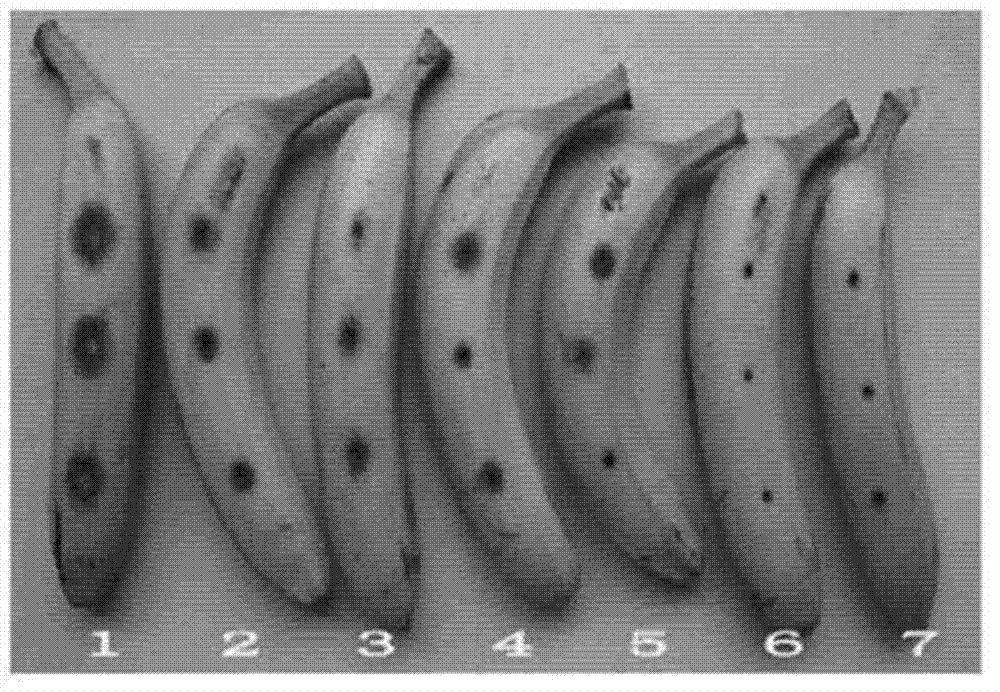

Burkholderia cepacia SD7 and culturing method and application thereof

InactiveCN102533593AGood environmental compatibilityNot easy to develop resistanceBiocideBacteriaBiotechnologyPyricularia grisea

The invention discloses burkholderia cepacia SD7 and a culturing method and application thereof. The bacterial strain is preserved in China General Microbiological Culture Collection Center on October 24th, 2001, and the preservation number is CGMCC No.5384. Through research, the bacterial strain has strong inhibiting effect on rhizoctonia solani, collectotrichum musae, pyricularia grisea, gibberella zeae, fusarium oxysporum f. sp. cubense, peronophythora litchi, ustiago scitamimea syd, fulvia fulva, xanthomonas oryzaepv.oryzae, xanthomonas oryzae pv. Oryzicola, and the like, is broad-spectrum antagonistic bacteria, can be used for preventing and treating a plurality of plant diseases, particularly has better preventing and treating effect for banana fruit anthracnose and rice sheath blight, has the advantages of harmlessness to person and animals, environmental protection and safety, good environmental compatibility, and difficulty in becoming resistant, is good for business development, and has broad application prospect.

Owner:SOUTH CHINA AGRI UNIV

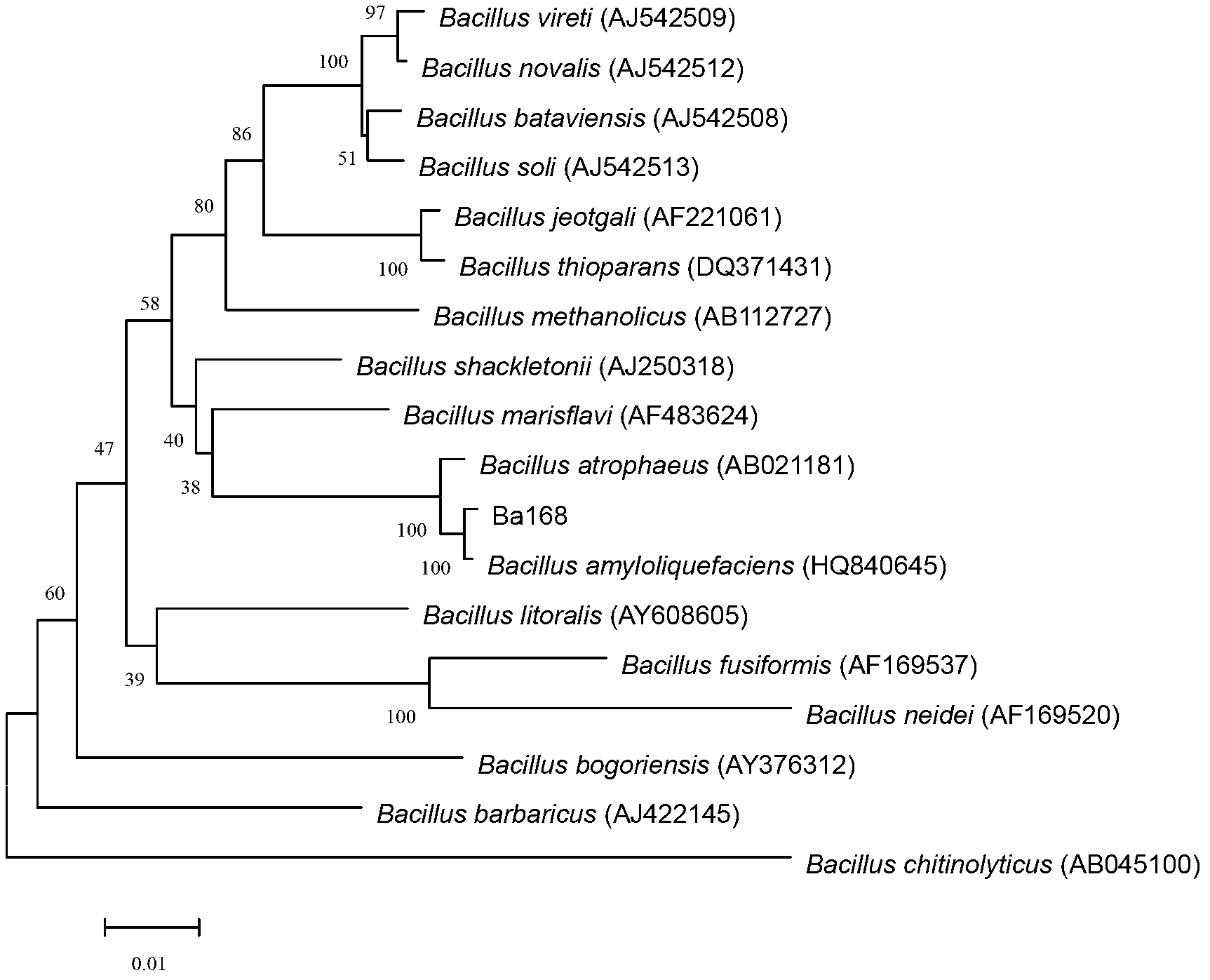

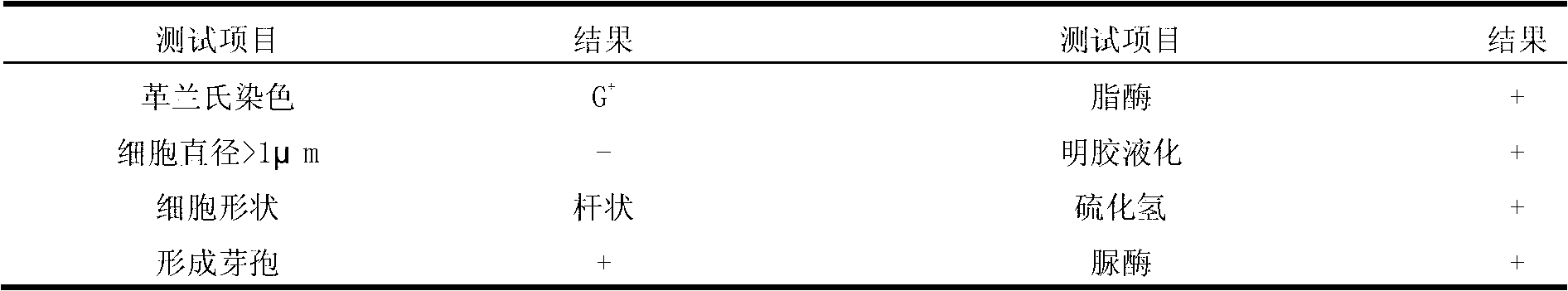

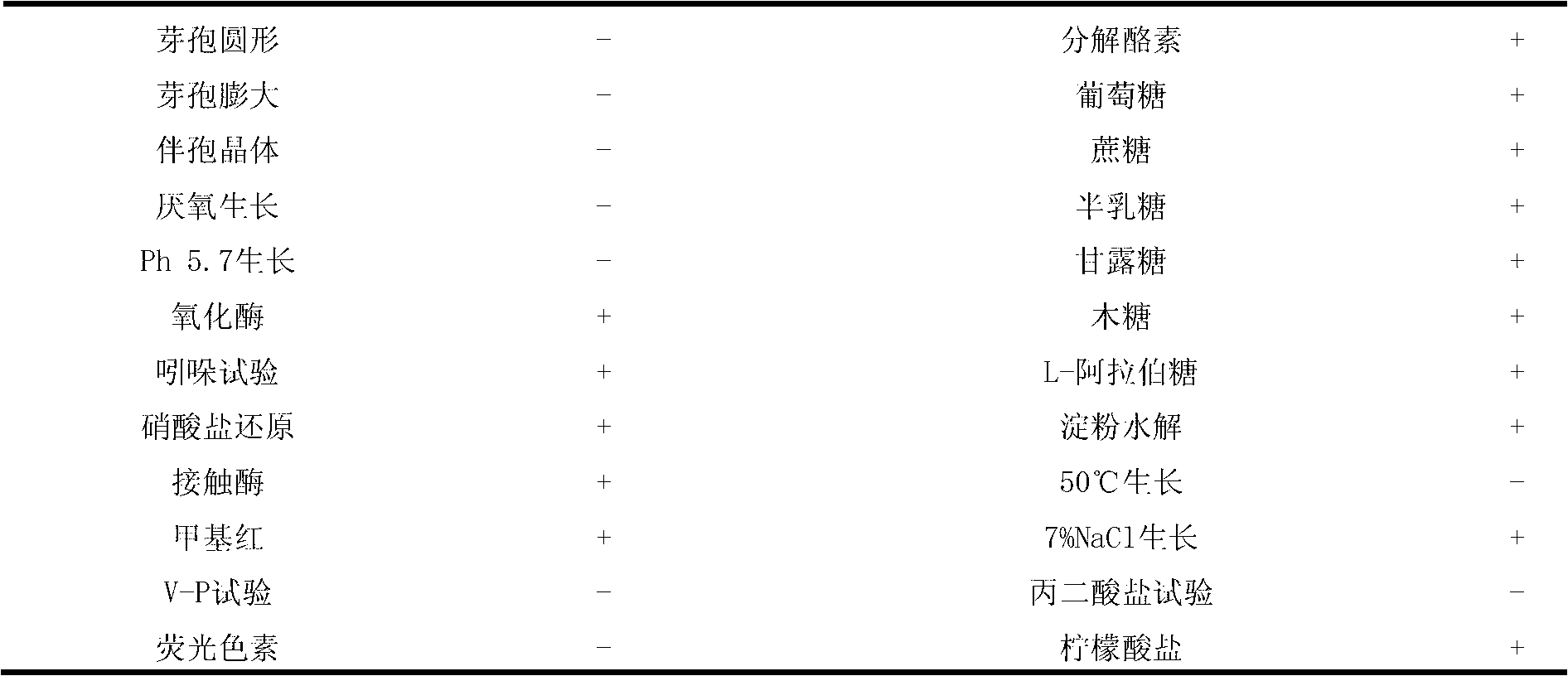

Bacillus amyloliquefaciens (Ba 168) and fermenting culture method and application of bacillus amyloliquefaciens

ActiveCN102839142AGood prevention effectGood environmental compatibilityBiocideBacteriaFiltrationBiological activation

The invention discloses bacillus amyloliquefaciens (Ba 168) and a preparation method and an application of the bacillus amyloliquefaciens, and aims at providing a biological control method of phytopathogens. The bacterial strain is preserved in the China General Microbiological Culture Collection Center (CGMCC), and the preservation number is CGMCC No.6462 on August 21, 2012. The bacterial strain is separated and obtained from soil in the Qinling Mountain virgin forest, and subjected to bacteria activation, shake-flask fermentation, seed liquid fermentation and large tank fermentation to obtain fermentation liquid; and the fermentation liquid is subjected to filtration and concentration, ultrafiltration membrane separation, and spray drying and packaging to be prepared into bactericide. The bacillus amyloliquefaciens has the advantages that the bacillus amyloliquefaciens can well prevent and cure bighead atractylodes rhizome root rot, American ginseng root rot, pseudo-ginseng root rot and other root rot caused by fusarium oxysporum.

Owner:杨凌绿都生物科技有限公司

Agricultural thickening synergistic agent and glufosinate solution prepared from same

ActiveCN103210916AGood wetting and synergistic effectImprove performanceBiocideAnimal repellantsActive agentSurface-active agents

The invention discloses an agricultural thickening synergistic agent which comprises the following components by weight percent: 10-30% of fatty alcohol polyoxyethylene ether sulfate, 10-20% of alkyl glycoside, 5-25% of sodium lauroyl sarcosinate, 5-10% of fatty alcohol polyoxyethylene ether, 5-15% of ammonium sulfate and the balance of water. The invention also discloses a glufosinate solution containing the agricultural thickening synergistic agent. The agricultural thickening synergistic agent has the characteristics of being good in wetting synergistic action and stable in performances, and is good in thickening synergistic effect; the glufosinate solution prepared from the agricultural thickening synergistic agent has higher viscosity, is beneficial to improving the adhesive force and the moisturizing performance of a liquid medicine, is beneficial to the internal absorption and the conductivity of glufosinate, and can promote the pesticide effect to be fully exerted; and furthermore, the agricultural thickening synergistic agent also has excellent biodegradability, and is high in safety to the environment and organisms, thus well fitting the development requirements of future agricultural surface active agents.

Owner:范强

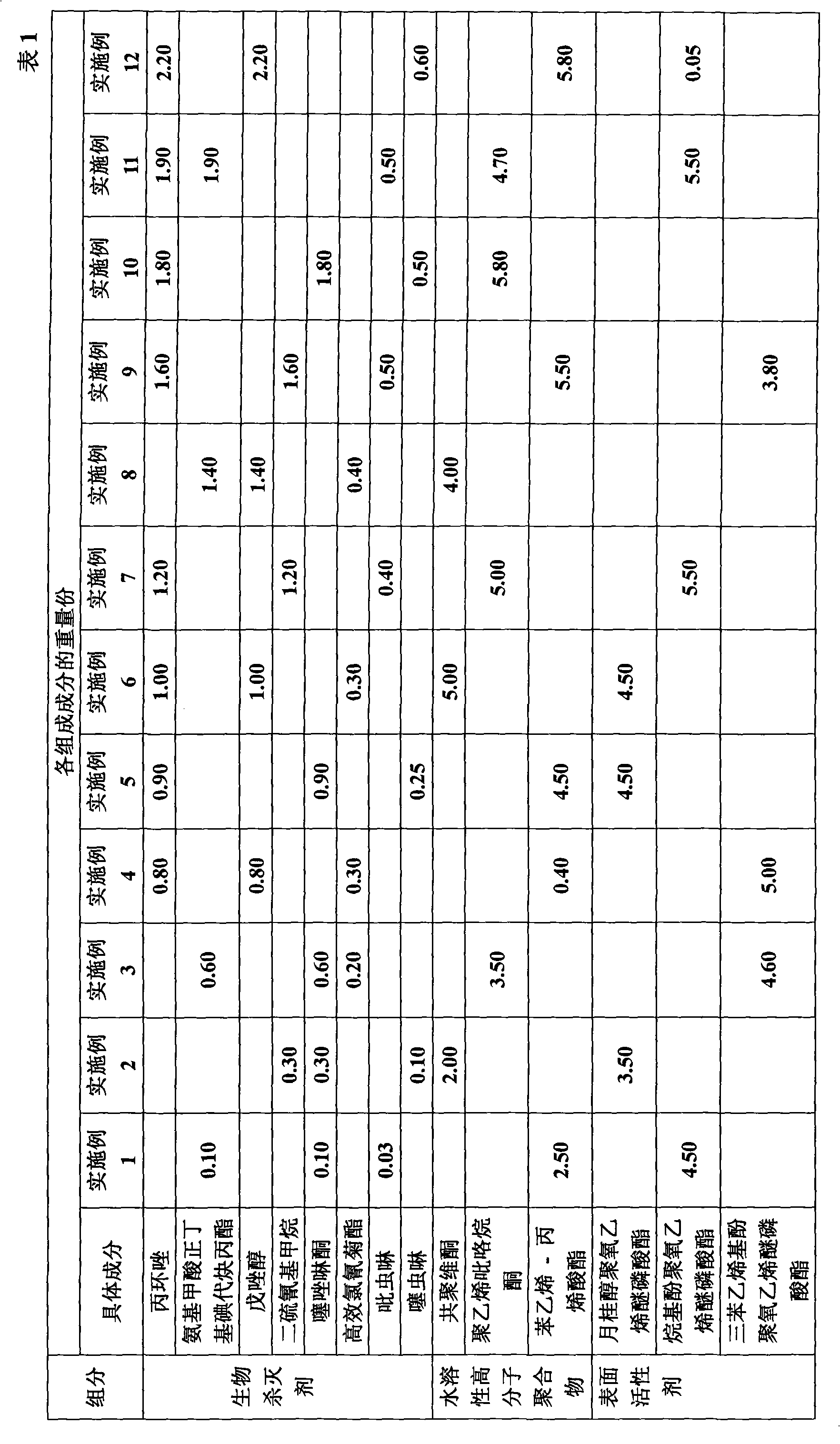

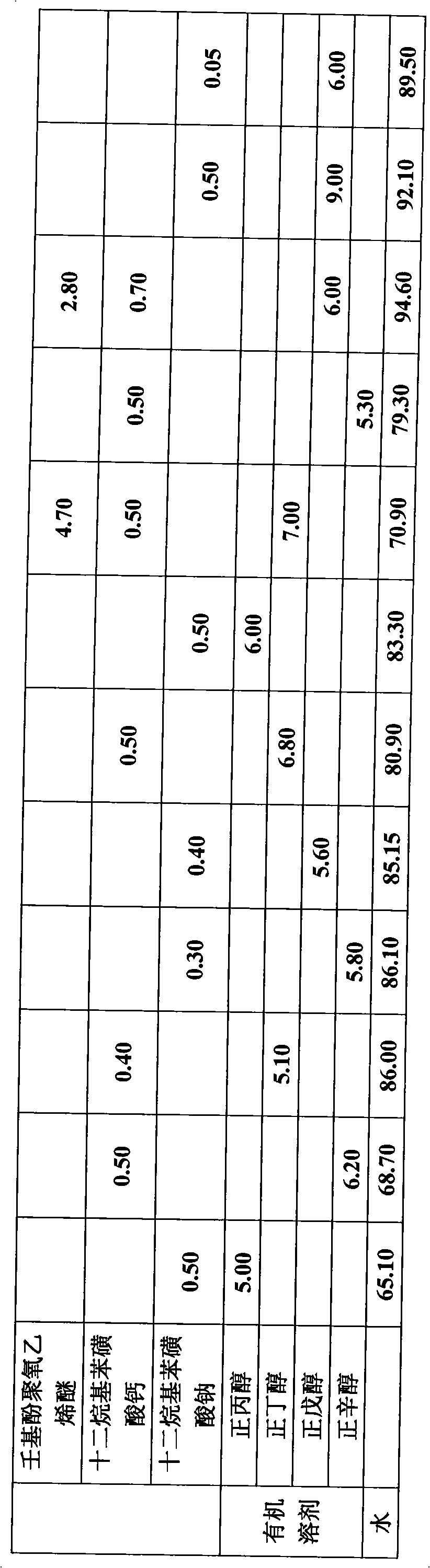

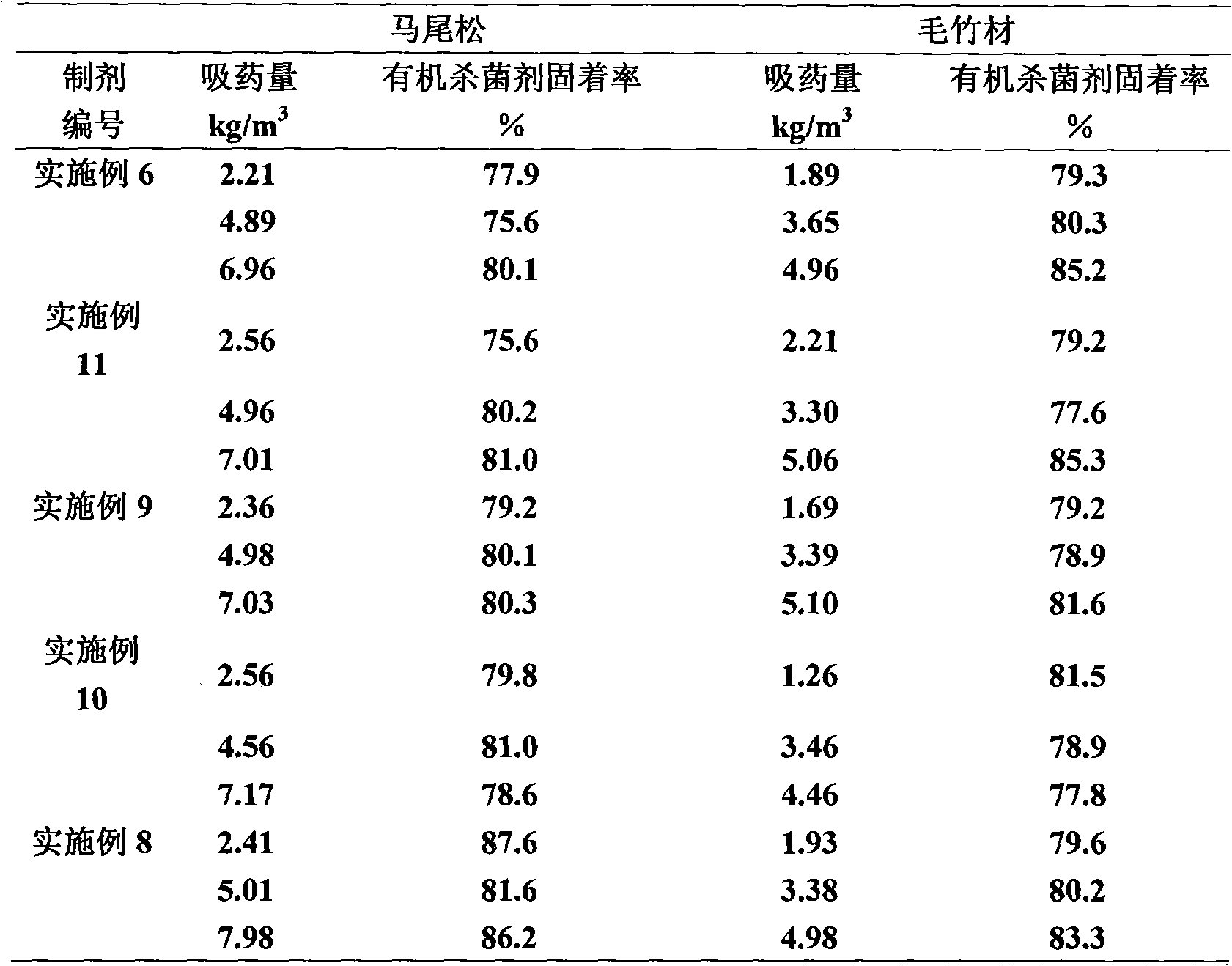

Nano wood antiseptics and manufacturing method thereof

InactiveCN101284386AGood environmental compatibilityImprove anti-corrosion performanceWood impregnation detailsWater solubleCorrosion

A nano-wood preservative and a preparation method thereof are provided. The preservative contains biocide of 0.2-5.0 parts by weight (the same below), water-soluble high polymer of 0.4-6.0 parts, surfactant of 0.1-6.0 parts, organic solvent of 5.0-10.0 parts, and water of 65-95 parts. The preparation method of the preservative includes: dissolving the water-soluble high polymer in the organic solvent, and adding the biocide; further adding the surfactant, holding the temperature at 40-50 DEG C and intensively stirring to obtain the concentrated solution; and adding the water at a proper speed in intensively stirring at a certain stirring speed. The preservative is applicable to the preservative treatment of the plant fiber materials like wood, bamboo, straw, raw hemp, etc., and has the advantages that the preservative contains no heavy metal elements, maintains the inherent qualities of the plant fiber and has high corrosion resistance and no environment pollution; and various methods of treatment like soaking, brushing, spraying and pressure impregnation can be adopted for processing.

Owner:ZHEJIANG FORESTRY UNIVERSITY

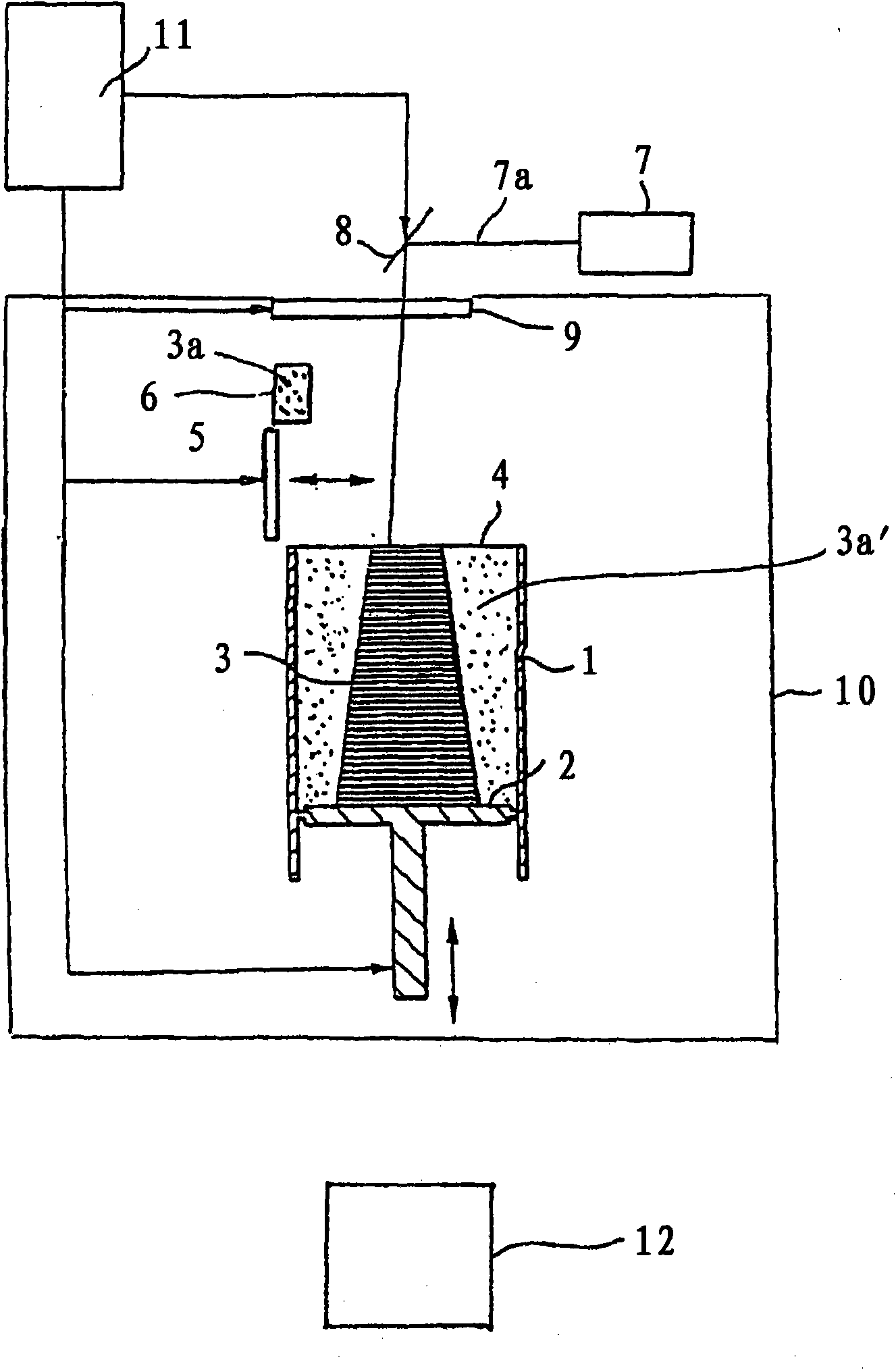

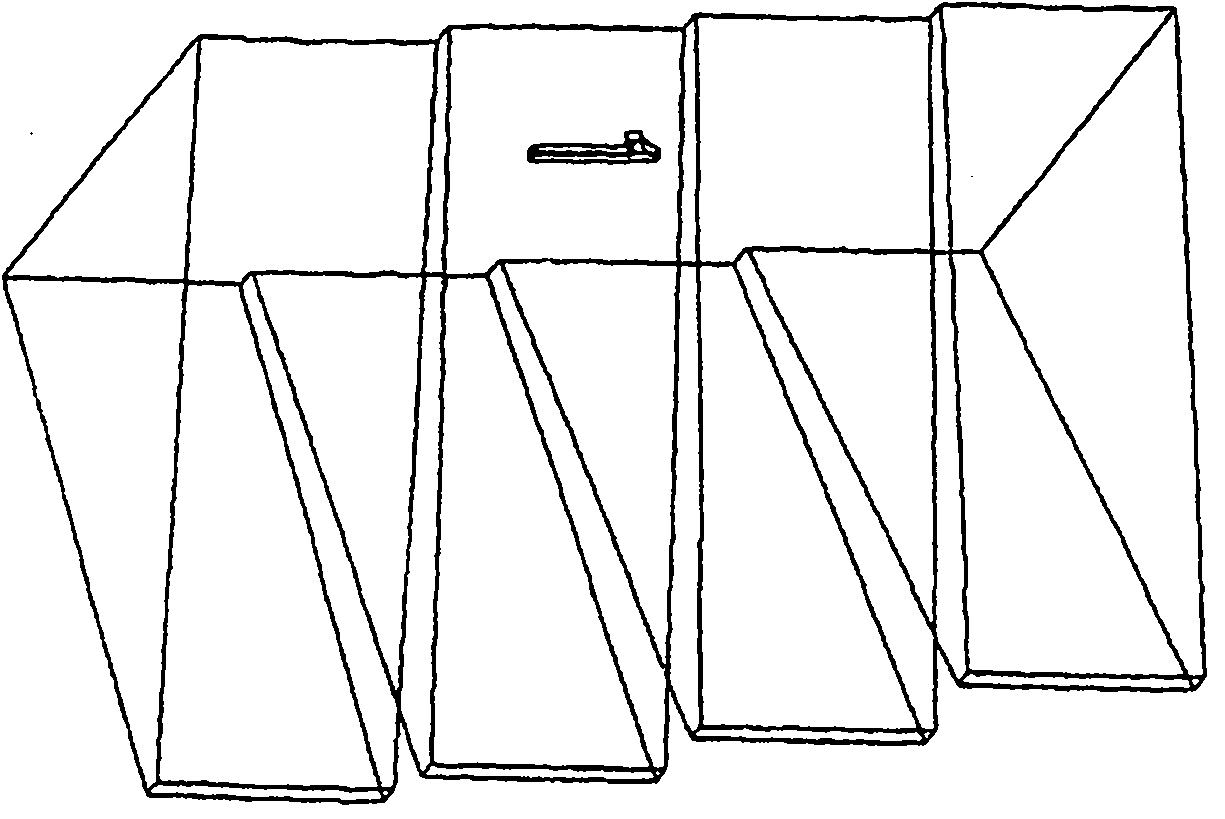

Method and device for the layered production of a three-dimensional object from a powdery material

ActiveCN101842222AGood environmental compatibilityEconomic treatmentAdditive manufacturing apparatusPlastic recyclingElectromagnetic radiationMaterials science

The invention relates to a method for producing a three-dimensional object by selectively compacting layers of a powdery material (3a) in the areas corresponding to the cross-section of the object (3) in the respective layer, by applying electromagnetic radiation (7a). The powder used is a plastic powder, preferably polyamide. After the production of the object, the non-compacted powder (3a') is subjected to a water or vapour treatment at a higher temperature, is subsequently dried and then is used again to produce a new object.

Owner:EOS ELECTRO OPTICAL SYST

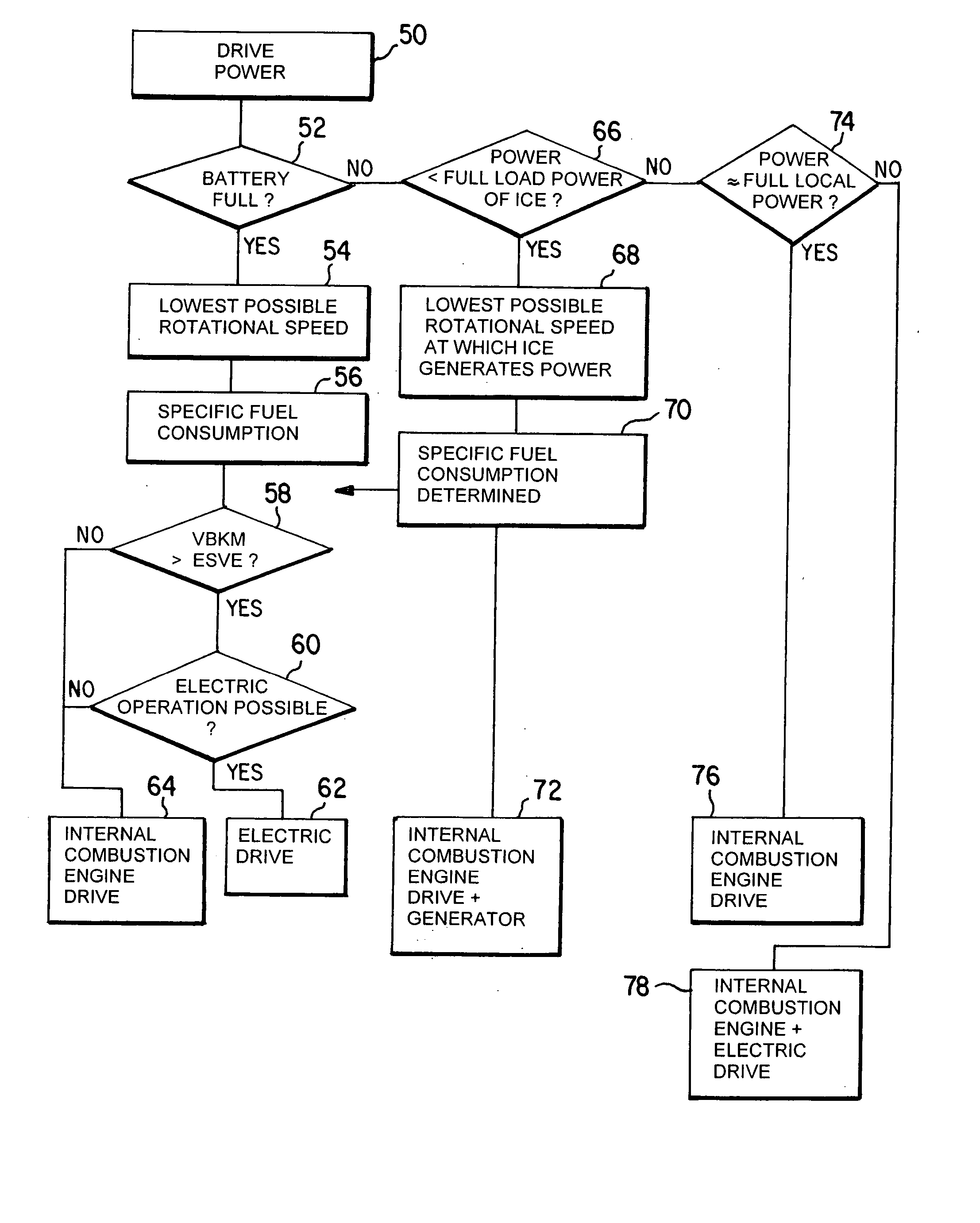

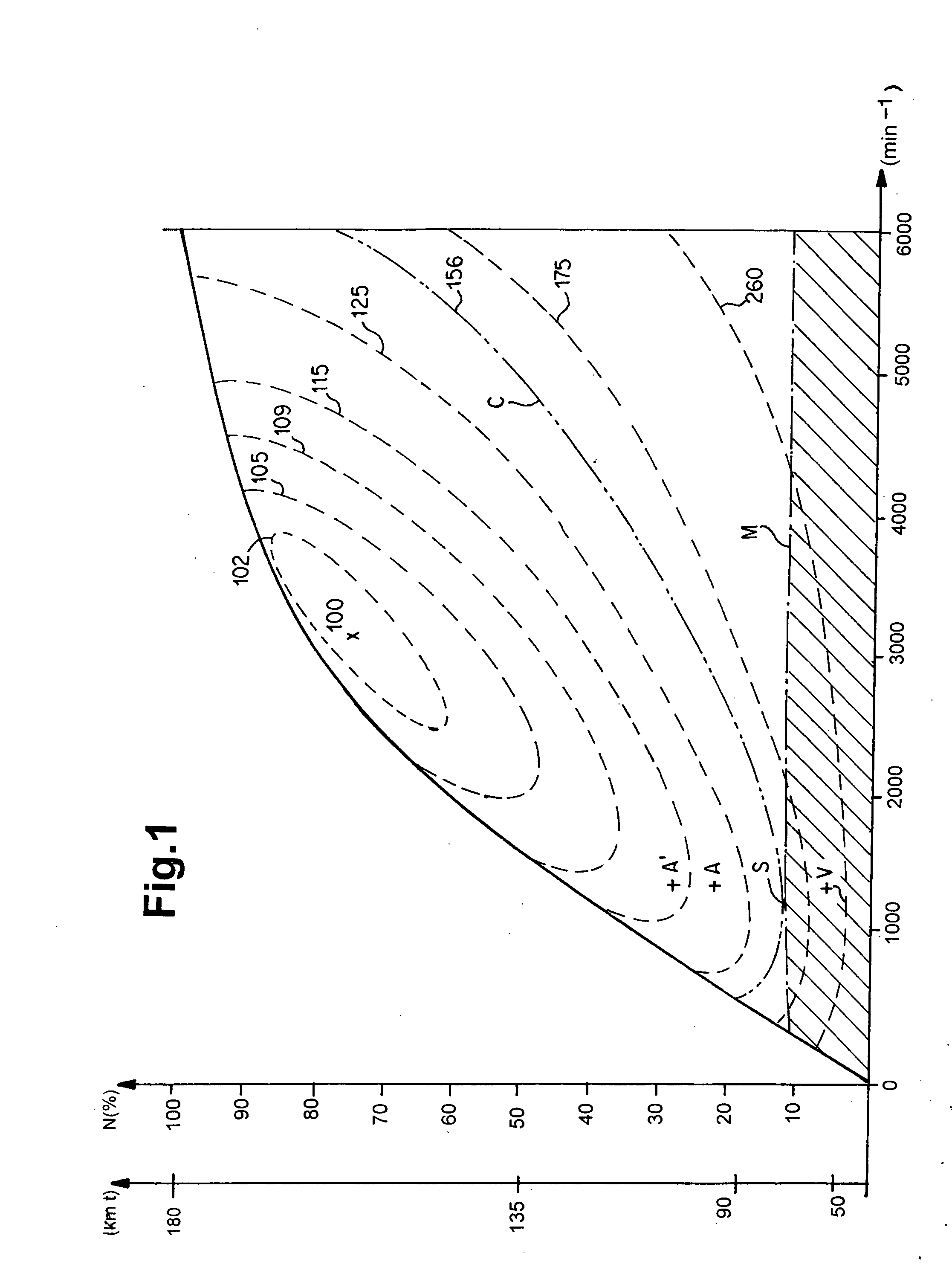

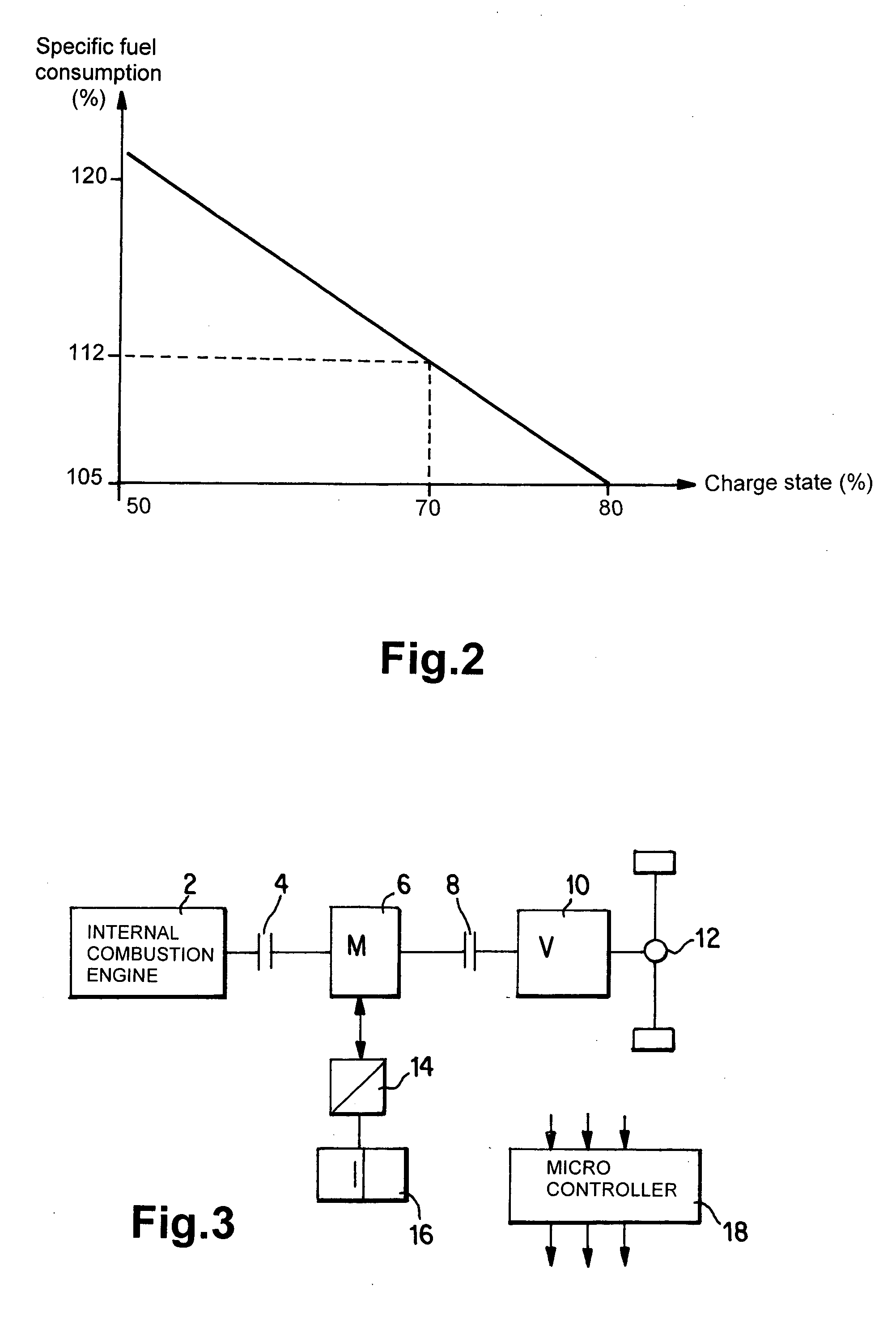

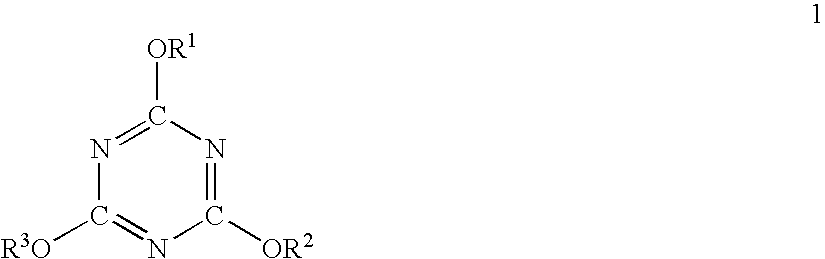

Hybrid drive system for a motor vehicle

InactiveUS20060266568A1Minimal fuel consumptionAvoid operationOperating modesElectric propulsion mountingMotor vehicle partElectric generator

Owner:BAYERISCHE MOTOREN WERKE AG

Extruded styrene resin foam and process for producing the same

InactiveUS6841581B2Improve insulation effectGood environmental compatibilityFireproof paintsPhosphoric Acid EstersTetrazole

An extruded styrene resin foam which is produced by using a blowing agent imposing a reduced load on the environment and has outstandingly excellent thermal insulating property and flame retardant property adapted for construction use. The foam is obtained by extrusion-foaming of a styrene resin and characterized by containing at least, one or more of saturated hydrocarbons having 3 to 5 carbon atoms as a blowing agent, and containing (A) a halogenated flame retardant, and (B) at least one compound selected from the group consisting of phosphorus type flame retardants containing nitrogen atom in a molecule; tetrazole compounds; specific nitrogen-containing compounds; metal borates; boron oxides; phosphoric acid ester compounds, and having a cell structure constituting the foam wherein a cell anisotropic ratio k, which is defined by the formula: k=a / (a×b×c)1 / 3 wherein, in sections of the foam, a (mm) is an average cell size in the thickness direction, b (mm) is an average cell size in the transverse direction and c (mm) is an average cell size in the longitudinal direction, satisfies the relationship: k≦1.1, and a satisfies the relationship: 0.05≦a≦0.30, and the method for producing the same.

Owner:KANEKA CORP

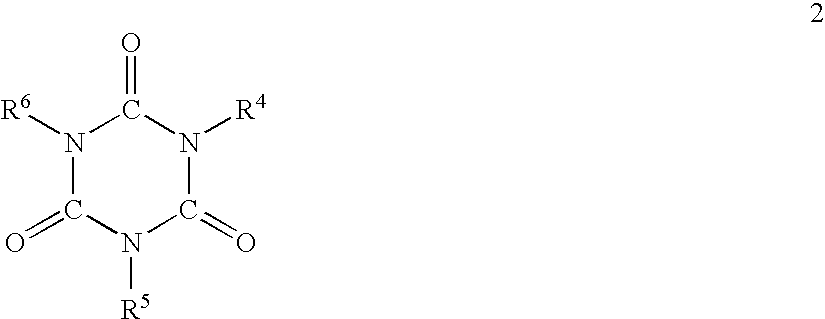

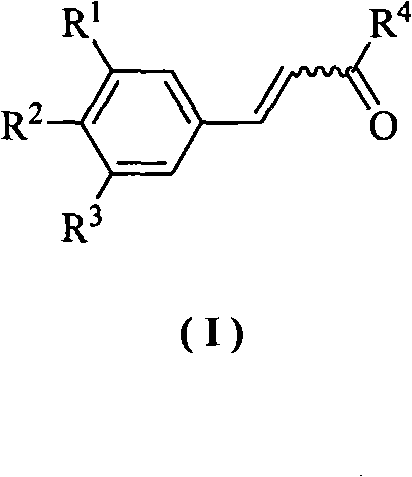

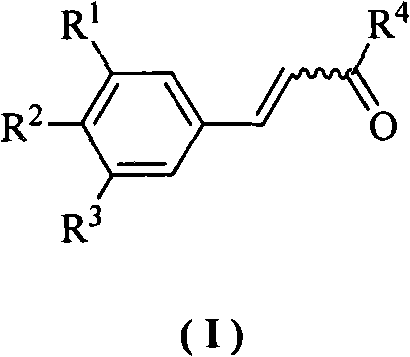

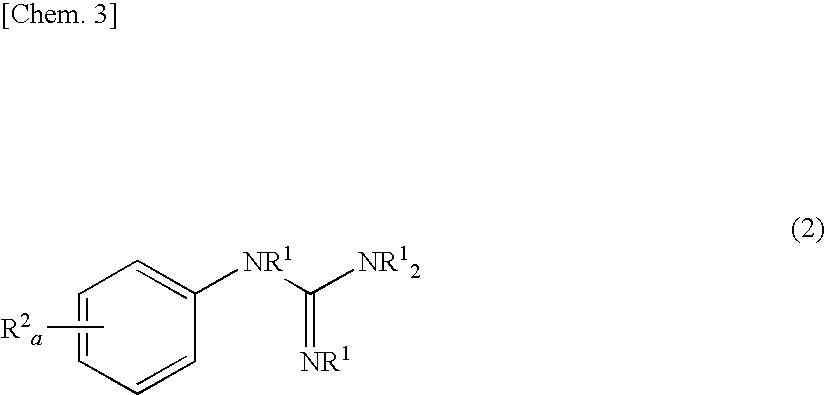

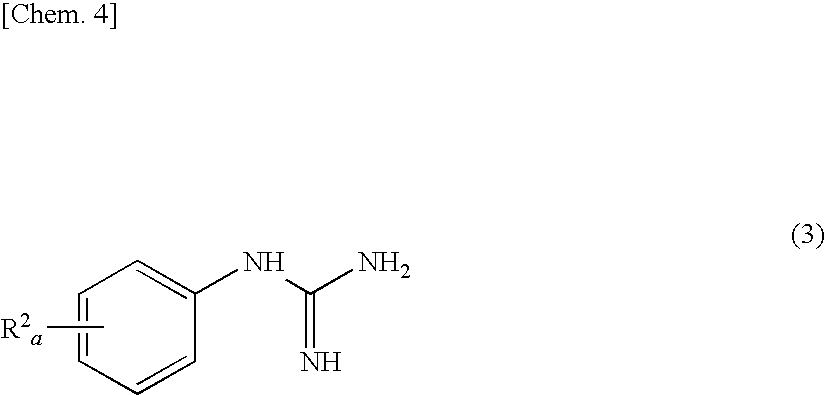

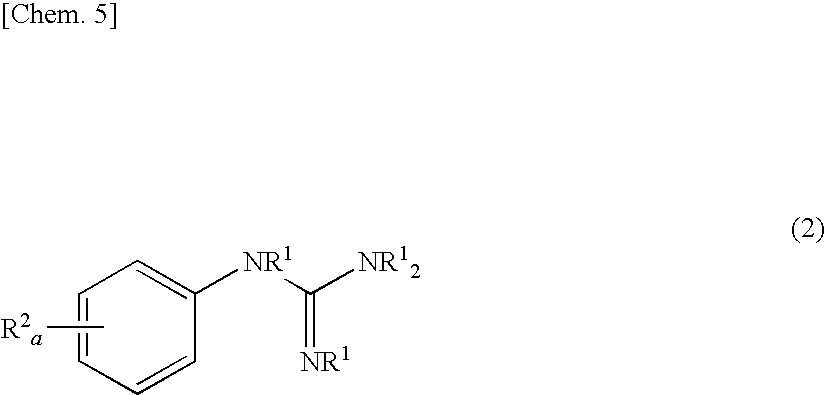

Ferulic acid and ferulic acid derivative anti-phytoviral agents

ActiveCN102090412AExcellent anti-plant virus activityEffectively prevent and treat viral diseasesBiocideOrganic chemistryNicotiana tabacumTobacco mosaic virus

The invention relates to a ferulic acid shown in a general formula (I) and the application of derivatives thereof to pesticides. When used as novel anti-phytoviral agents, the derivatives can well inhibit tobacco mosaic viruses, pepper viruses, tomato viruses, sweet potato viruses, potato viruses, melon viruses, maize dwarf mosaic viruses and the like, and effectively prevent and control the virus diseases of various crops such as tobacco, peppers, tomatoes, melons, grains, vegetables, beans and the like, and are particularly suitable for preventing and controlling tobacco mosaic. Meanings of each group are shown in specifications.

Owner:NANKAI UNIV

Fluorinated ketones as high-voltage insulating medium

ActiveUS20120145521A1Good componentReliable arc extinctionSwitchgear arrangementsOrganic chemistryKetoneHigh pressure

A switching device for medium, high, or extremely high voltage, wherein at least one voltaged component of the switching device is enclosed in an enclosure and the enclosure is filled with a filling medium. The filling medium includes at least one compound from the group of fluorinated ketones, or consists of the same.

Owner:HITACHI ENERGY SWITZERLAND AG +1

Curable composition

ActiveUS20090186993A1Excellent curabilityAdd depthOther chemical processesEster polymer adhesivesArylSilylene

Owner:KANEKA CORP

Agricultural thickening synergist and application thereof

ActiveCN103210915AGood wetting and synergistic effectImprove performanceBiocideAnimal repellantsAgricultural scienceActive agent

The invention discloses an agricultural thickening synergist. The agricultural thickening synergist comprises the following components by mass percent: 1-40% of fatty alcohol polyoxyethylene ether sulfate, 0-30% of alkyl glycoside, 5-15% of sodium lauroyl sarcosinate, 5-10% of sodium alkyl benzene sulfonate, 5-15% of ammonium sulfate and the balance of water. The invention also discloses an application of the agricultural thickening synergist in a glyphosate isopropamide salt water agent and a glyphosate salt water agent. The agricultural thickening synergist has the characteristics of better wetting synergy effect, more stable performance and better thickening synergy effect; by using the glyphosate salt water agent, the agricultural thickening synergist has high viscosity, the adhesive force and moisture property of the liquid medicine are improved, the internal absorption and conductivity of the glyphosate are realized, and the pharmacological function can be fully realized. Besides, the agricultural thickening synergist has excellent biological degradability, has high safety to the environment and organisms, and meets the development requirement of the agricultural surface active agent in the future.

Owner:范强

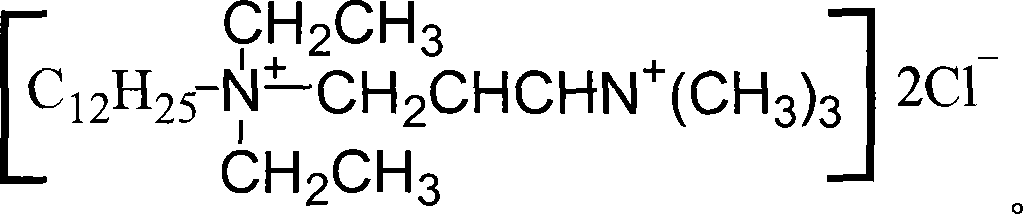

Chemical control method for corrosion microorganism in pipeline conveyance system and product

InactiveCN101244856AEffective eradicationLow costScale removal and water softeningWater/sewage treatment using germicide/oligodynamic-processSulfate-reducing bacteriaChemical control

The invention relates to three compound stabilizer reagents which can effectively protect various water pipelines, water containers and the relevant equipment of the water conveyance system from biodeterioration or scaling and the treatment method and the utilization of the biodeterioration. Particularly, by utilizing the three compound stabilizer reagents acting on the water conveyance system in different period respectively, the addition dosage and the time can change according to different water quality, different microorganism pollution degree and different water treatment demand, wherein each compound stabilizer reagent main component has different sterilization mechanisms and the emphases of the reagent is also different, so that serious corrosion caused by the drug resistance of the bacteria can be solved and the sulfate reducing bacteria, the saprophyte, the iron bacteria, the nitrite bacteria, the ammonium bacteria and algae in the water conveyance system can be completely killed. The compound stabilizer reagents is suitable for the control of pipeline scaling and the pipe wall biodeterioration of the oil field water injection system, the circulating water system and the central air-conditioning cooling water system.

Owner:WUHAN TEXTILE UNIV

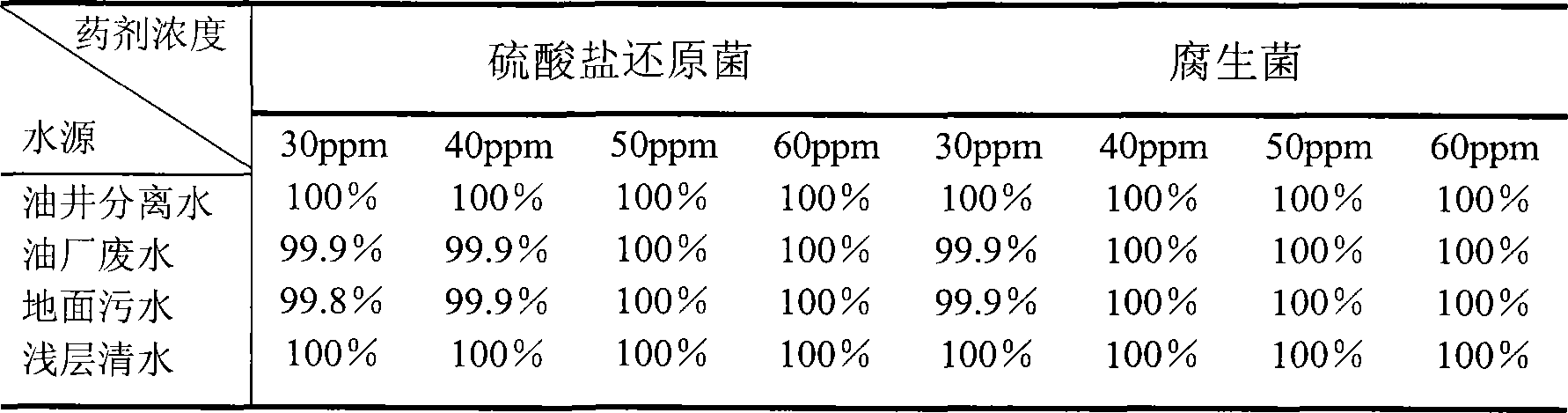

Direct-current electrolytic treatment process and equipment for circulating cooling water

InactiveCN103058336AGood environmental compatibilityGood effectWater/sewage treatmentEnvironmental chemistryCorrosion

The invention relates to a water direct-current electrolytic treatment process for circulating cooling and direct-current electrolytic treatment equipment for the circulating cooling, and shows the core concept that a bypass circulating system is arranged on a circulating cooling water system, and the direct-current electrolytic treatment equipment is arranged to treat the circulating cooling water. The direct-current electrolytic treatment equipment is used for scaling and separating out calcium and magnesium in the circulating water by utilizing cathodic hydrogen evolution reaction, and descaling and discharging the scale to continuously reduce the hardness of the system so as to preventing scale from generating; active materials separated from a specially dimensionally stable anode are utilized for exterminating bacteria and inhibiting the growth of bacteria, so that the problems due to blocking and corrosion are prevented; and simultaneously, the pH is increased by hydrogen evolution reaction, so that electrochemical corrosion can be effectively prevented. The direct-current electrolytic process realizes a plurality of functions in the same process, such as descaling, sterilizing and exterminating the bacteria. Compared with the conventional physical method and chemical method, the direct-current electrolytic treatment process has the advantages of being remarkable in effect, high in cleanability, capable of saving water source, low in energy consumption and low in cost, and can realize unattended operation.

Owner:沈阳瀚威科技有限公司

High density clear brine fluids

Compounds are identified that act as crystallization suppressants when added to clear brine fluids, significantly lowering the true crystallization temperatures of the brines, and allowing for higher salt content in clear brine fluids. The crystallization suppressants of the invention also allow for the preparation of higher density zinc free brines.

Owner:LANXESS SOLUTIONS US INC

Pesticide Composition

InactiveUS20080181968A1Good environmental compatibilityOvercome health and disadvantageBiocideHydroxy compound active ingredientsDisinfectantPesticide

Stable non-toxic pesticide composition having fungicidal and insecticidal properties including a pesticide that is nontoxic to mammals; one or more disinfectants; a vegetable oil; and one or more stabilizing agents. In one example, one or more stabilizing agents are selected and are present in an amount in combination with the selection and amount of a pesticide, one or more disinfectants, and a vegetable oil to provide the composition with stability upon application to a substrate effective to allow lethality against one or more target pests.

Owner:BEDO HLDG

Polyether-Modified Organopolysiloxane, Diorganopolysiloxane-Polyether Block Copolymer, Their Production Methods, and Cosmetic Preparation

ActiveUS20100036062A1Good environmental compatibilityImprove production stabilityCosmetic preparationsHair cosmeticsPolymer scienceHydrosilylation

(Problem) To provide a novel polyether-modified organopolysiloxane and a novel diorganopolysiloxane-polyether block copolymer that are more resistant to oxidation than the heretofore existing polyoxyalkylene-modified organopolysiloxanes and that are thus more resistant to producing allergenically antigenic oxidation products during elapsed time in storage. Also, to provide methods of producing this novel polyether-modified organopolysiloxane and novel diorganopolysiloxane-polyether block copolymer.(Solution) Organopolysiloxane that is modified by silicon-bonded polyglycidyl ether or glycidyl ether / alkylene oxide copolymer; diorganopolysiloxane-polyglycidyl ether block copolymer; a method of producing the preceding by a hydrosilylation reaction between organohydrogenpolysiloxane and polyglycidyl ether having a terminal double bond or a glycidyl ether / alkylene oxide copolymer having a terminal double bond; and a cosmetic that contains this modified organopolysiloxane or diorganopolysiloxane-polyglycidyl ether block copolymer.

Owner:DOW TORAY CO LTD

Method for extracting purple potato pigment by using ultrasonic wave and compound enzyme

InactiveCN101530191AIncreased diffusion rateImprove extraction efficiencyFood preparationSolventMacroporous resin

The invention relates to a method for extracting purple potato pigment by using ultrasonic wave and compound enzyme, which includes steps of (1) preprocessing raw material; (2) extracting the purple potato pigment by using ultrasonic wave and compound enzyme; and (3) refining extract by using macroporous resin. By using ultrasonic wave extraction technology, the present invention accelerates diffusion speed of educt from the raw material to solution, and has characteristics high extraction efficiency, no need of high temperature low energy consumption, and greatly shortened extraction time, the enzyme has characteristics of high catalytic efficiency, strong effect specificity and mild catalytic condition, and can increase productivity, lower energy consumption, reduce pollution, simplify process when being used in industry. By combining the ultrasonic wave extraction technology and the biological enzyme technology, the invention has advantages of short extraction time, high production yield, simple process, easy control of operation, convenience for large scale industrialization production and obvious economic benefit.

Owner:HEFEI UNIV OF TECH

Lead-free and preferably arsenic-free lanthanum heavy flint glass

ActiveUS7091145B2Good chemical resistanceSufficient crystallization resistanceOptical elementsAlkali metal oxideRefractive index

The lead-free and arsenic-free optical glass has a refractive index nd of 1.84≦nd≦1.96 and an Abbé number νd of 27≦νd≦36, with good chemical resistance, excellent crystallization resistance and the following composition (in % by weight based on oxide): SiO2, 1 to 8, B2O3, 13 to 19.5, La2O3, 34 to 50; MgO, 0 to 6, CaO, 0 to 6, BaO, 0 to 6, ZnO, 0 to 9 with ΣMO, 1 to 10; and TiO2, 4 to 15, ZrO2, 0 to 11, Nb2O5, 6 to 14.5. In addition, the glass according to the invention, as well as having a maximum alkali metal oxide content of 10% by weight, may also contain standard refining agents other than arsenic. The glass according to the invention is used in imaging, projection, telecommunications, optical communication and / or laser technology.

Owner:SCHOTT AG

Microemulsion

InactiveCN101036457AGood synergistic effectGood environmental compatibilityBiocideAnimal repellantsMicroemulsionBULK ACTIVE INGREDIENT

The invention relates to a pesticidal microemulsion, comprising agricultural active ingredients and synergy and / or toxicity antagonistic effective amount of natural (macromolecular) materials. The invention also relates to the preparation method of the pesticidal microemulsion and the application of the natural (macromolecular) material in the pesticidal microemulsion used as synergist and / or toxicity antagon. The pesticidal microemulsion in the invention is provided with remarkable synergistic effect and improved safety property in utilization.

Owner:北京华京五方实用纳米科技开发有限公司

Method for treating heavy-metal-containing wastewater by external electric field reinforced micro-electrolysis technology

InactiveCN102432087APromote migrationLower activation energyWater contaminantsWater/sewage treatmentElectrolysisEmission standard

The invention discloses a method for treating heavy-metal-containing wastewater by an external electric field reinforced micro-electrolysis technology, and belongs to the fields of water treatment technologies and recycling. In the method, the heavy-metal-containing wastewater is pretreated or not pretreated and then introduced into an external electric field reinforced micro-electrolysis reactor to be treated, a micro-electrolysis filler is filled in the reactor and is put in an external electric field with certain intensity, and micro-electrolysis reaction is promoted and reinforced through the reinforcing effect of the external electric field, so that metal ions in the wastewater are reduced into metal simple substances on the surface of the filler, and effluent can meet the requirement of the wastewater emission standard or can be directly recycled in the production process. The method has the advantages of high reaction speed, removal rate, recycling efficiency and environment compatibility and the like.

Owner:KUNMING UNIV OF SCI & TECH

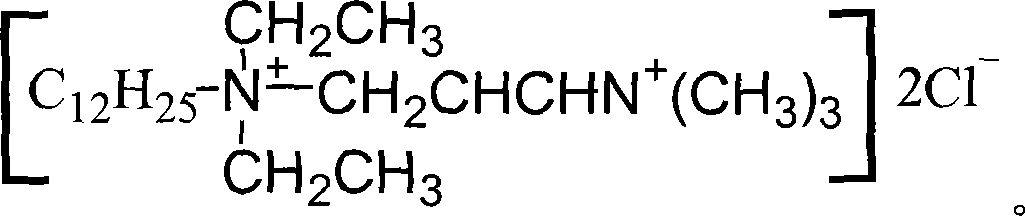

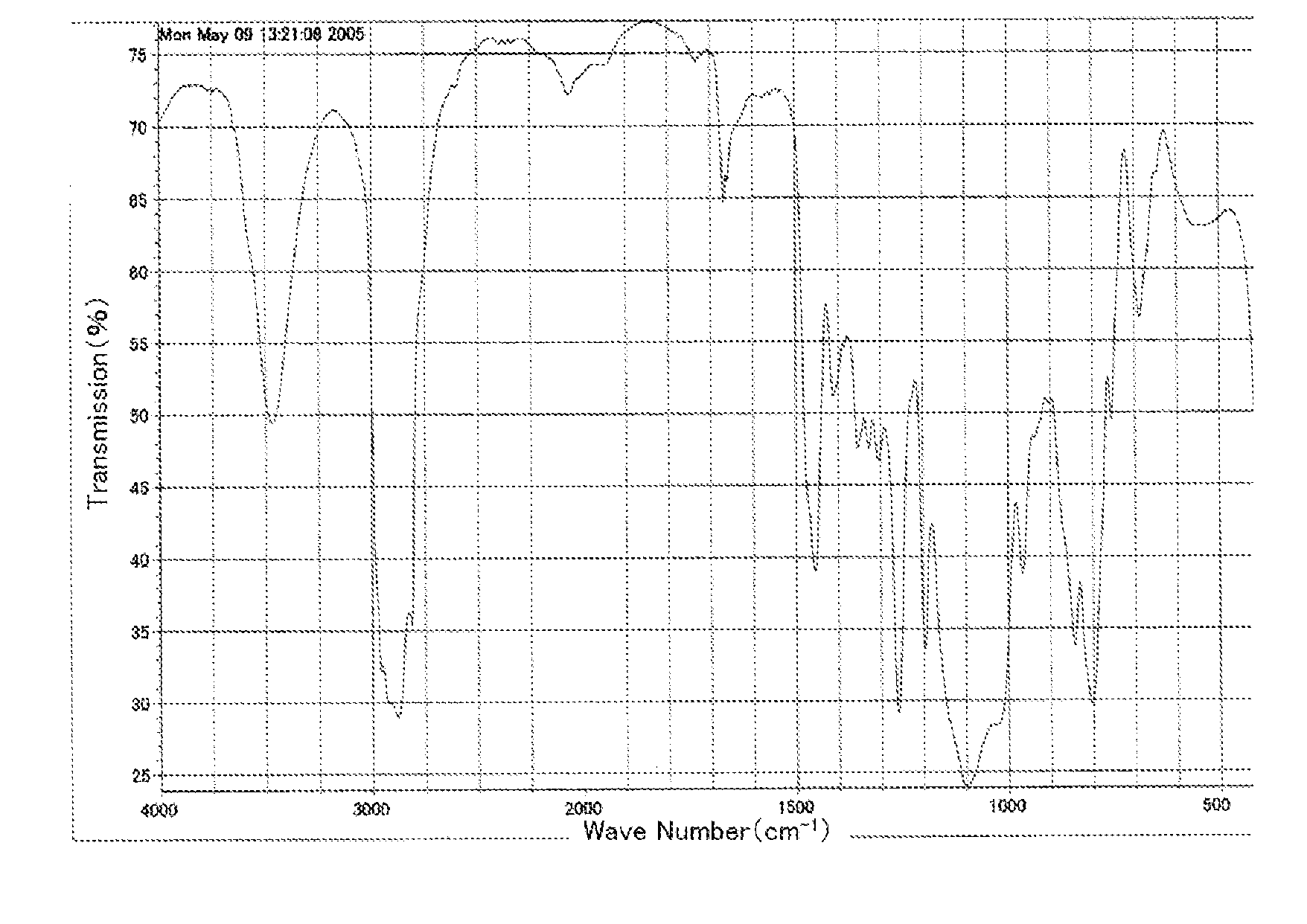

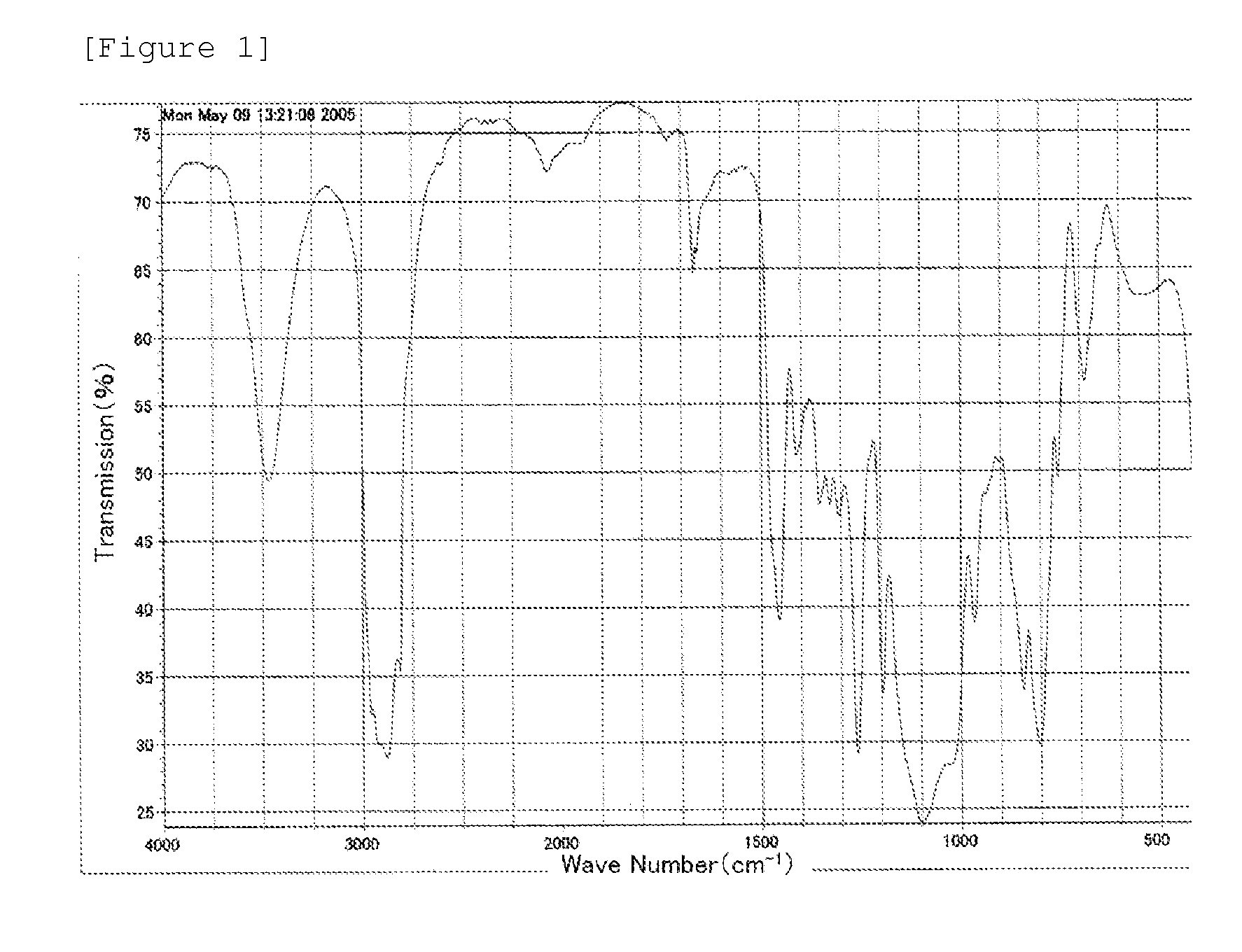

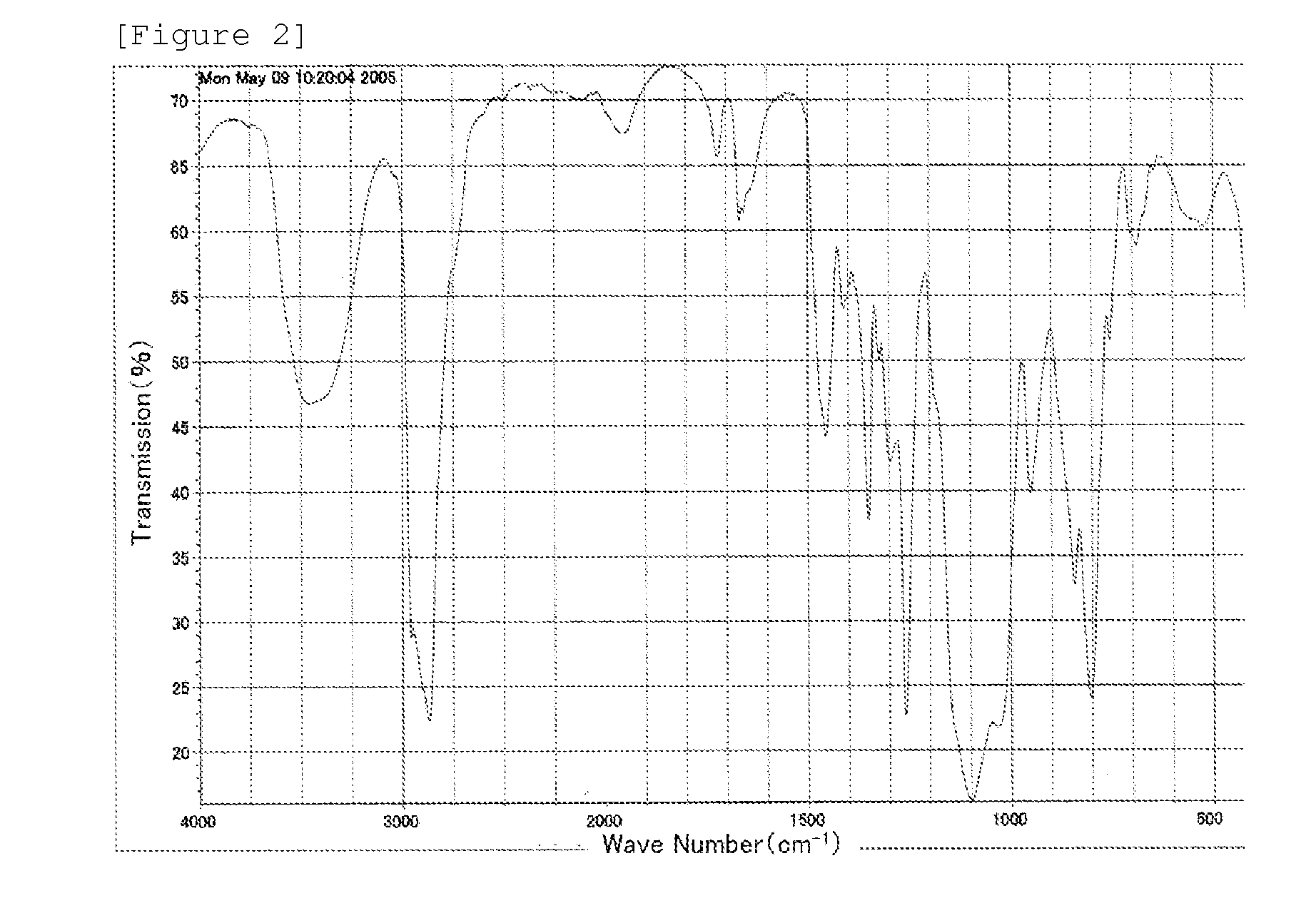

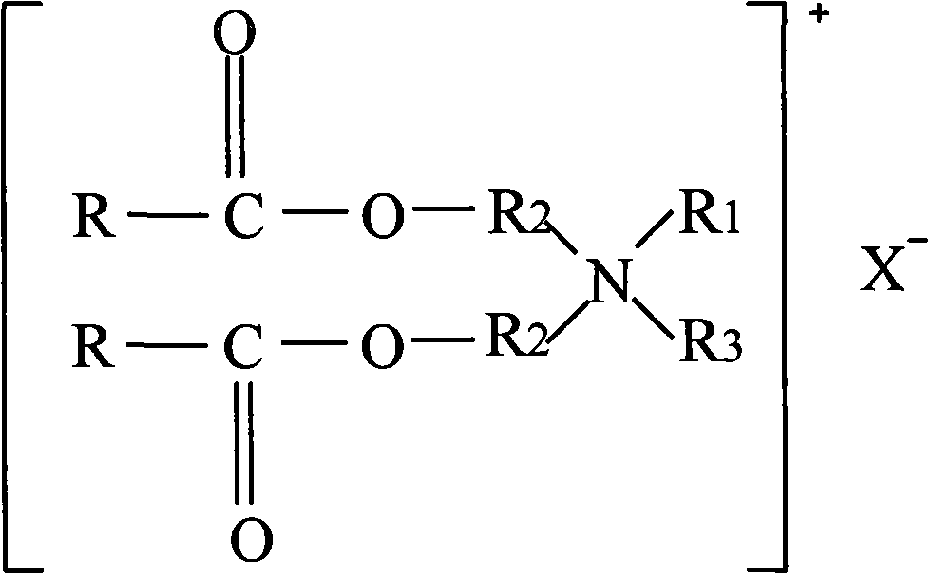

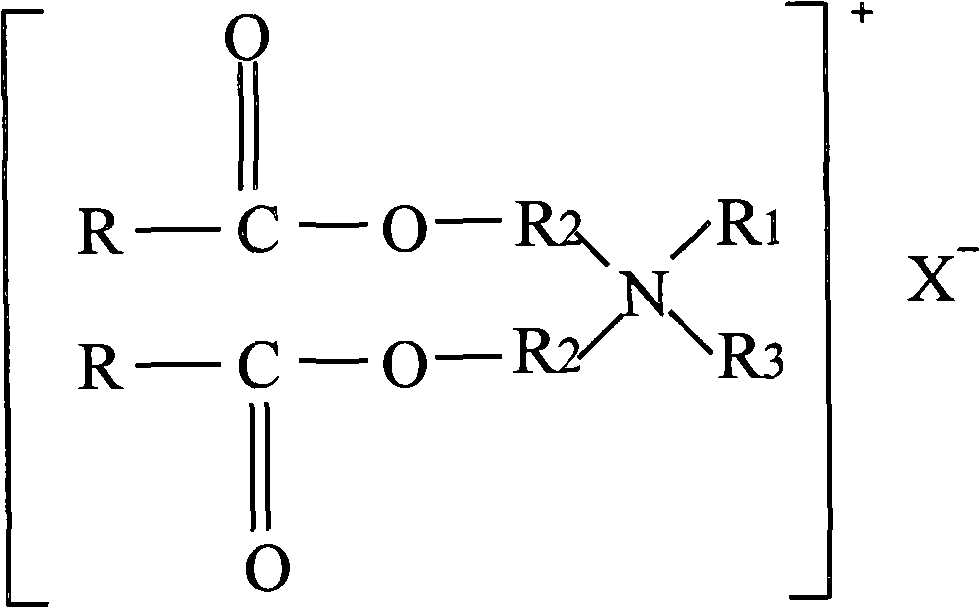

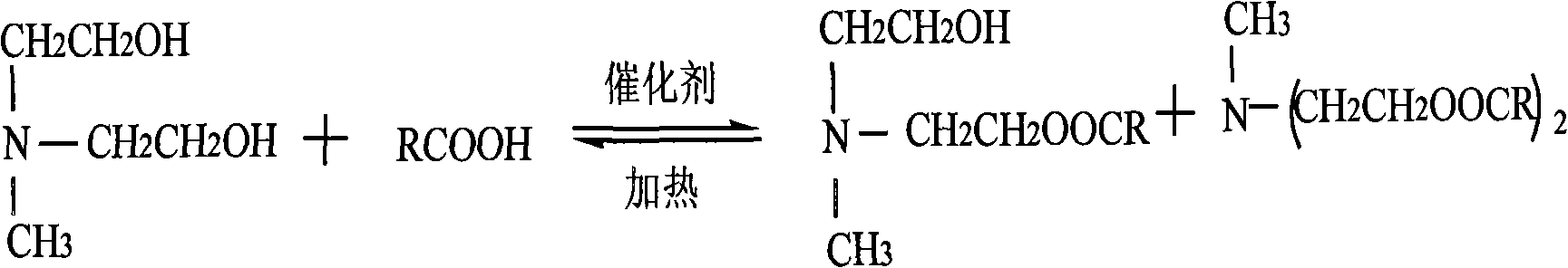

Method for synthesizing dual-long-chain ester based quaternary ammonium salt

InactiveCN101575299AImprove conversion rateGood choiceBiocideOrganic compound preparationHigh concentrationCarboxylic acid

The invention relates to a method for synthesizing a dual-long-chain ester based quaternary ammonium salt, which belongs to the technical field of surfactants. The method comprises the following steps: using long-chain alkyl fatty acid to react with N-methyl diethanolamine and triethanolamine to prepare long-chain carboxylic acid based tertiary amine; and performing alkylation on the long-chain carboxylic acid based tertiary amine to prepare the dual-long-chain ester based quaternary ammonium salt. The method uses two steps of esterification reaction and continuous production, thus the raw material conversion rate is high, the selectivity is good, and the obtained product has high active matter content, light color, excellent biodegradability, low ecological toxicity and excellent environmental compatibility; and the product can improve the grade of compounding a product, is easy to be prepared into a high-concentration product, reduces the production and packing cost, and is convenient to use. The dual-long-chain ester based quaternary ammonium salt is a cationic surfactant, and the using method thereof in various aspects of fabric softeners, leather softeners, bactericides and the like is same as the using method of other cationic surfactants.

Owner:JIANGNAN UNIV

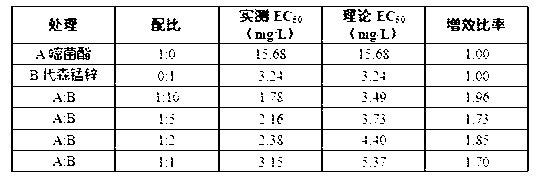

Bactericidal composition of azoxystrobin and mancozeb

The invention discloses a bactericidal composition of azoxystrobin and mancozeb. The bactericidal composition contains azoxystrobin, mancozeb and other auxiliary agents, wherein the weight ratio of azoxystrobin to mancozeb is (1-10): (60-1). The bactericidal composition of azoxystrobin and mancozeb can be applied to prevention and control of potato late blight. The composition is wide in application range, low in cost and good in effect. The indoor test proves that the composition has obvious synergized action.

Owner:常华

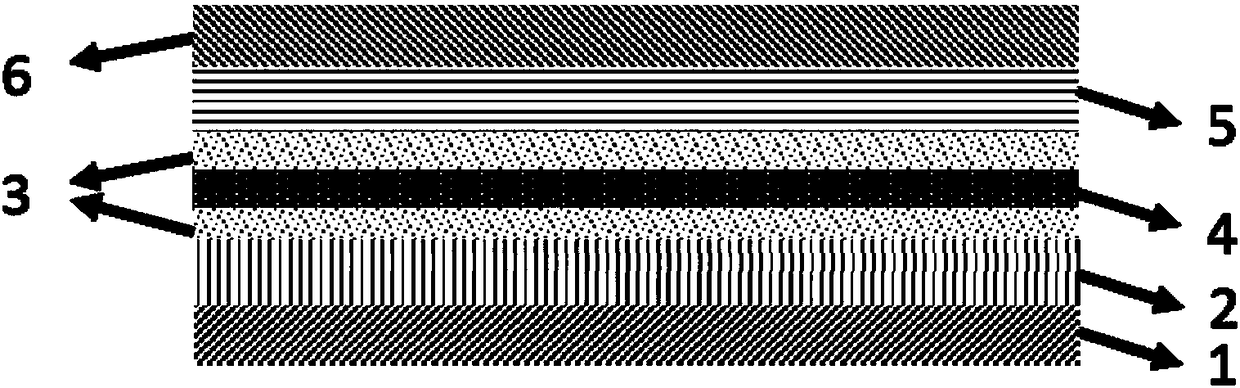

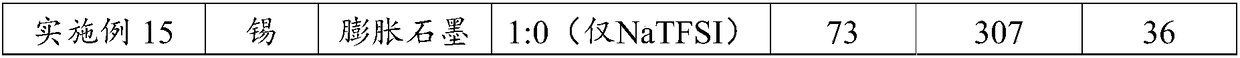

Electrolyte solution, sodion secondary battery and preparation method thereof

ActiveCN108172903AIncrease energy densityGood environmental compatibilityFinal product manufactureElectrolyte accumulators manufactureElectrochemical responseChemical reaction

The invention provides an electrolyte solution, a sodion secondary battery and a preparation method thereof, which belong to the technical field of a battery. The electrolyte solution comprises an electrolyte and a solvent, and the electrolyte comprises at least two different anion sodium salts; and the sodion secondary battery comprises an anode, a cathode, a diaphragm and the electrolyte solution provided in the invention; so that the technical problems of low capacity of the current sodion dual-ion batteries and poor multiplying power can be improved. The sodion secondary battery can increase the energy density of the sodion dual-ion battery and improve the multiplying power performance, easily available sodion with low cost can be taken as a main body for an electrochemical reaction, environment compatibility of the battery is obviously increased, and the cost of the battery is reduced.

Owner:SHENZHEN INST OF ADVANCED TECH

Bidirectional burkholderia as well as culture method and application thereof

InactiveCN103540542AHas inhibitory effectGood environmental compatibilityBiocideBacteriaDiseaseAlternaria

The invention relates to bidirectional burkholderia as well as a culture method and an application thereof and belongs to the field of plant protection (microbial pesticide). The preservation number of the bidirectional burkholderia is CCTCC NO: M2013145. The culture method of the bidirectional burkholderia comprises the following steps: adding 1ml of 2-day-aged seed bacterial strain to an LB (Lysogeny broth) culture medium with the liquid loading of 50ml under a fermentation condition, and culturing for 20-24 hours at the temperature of 25-30 DEG C at the rate of 200r / min. The bidirectional burkholderia has a remarkable inhibition effect on rice sheath blight disease, rice blast, colletotrichum musae, oxysporum, fusarium asiaticum, peronophythora litchi, sugarcane alternaria tenuis, cladosporium fulvum, xanthomonas oryzae, bacterial leaf steak and the like, can be used for the biological prevention and control of plant pathogenic bacteria, has the advantages of low toxicity, easy degradation, environmental friendliness and the like and has a bright application prospect.

Owner:西安西诺农化有限责任公司

Fine particulate flux

InactiveUS20130037172A1High viscosityGood partitionWelding/cutting media/materialsThin material handlingParticulate fluxFine particulate

A fine particulate flux, an aqueous flux preparation comprising this flux, a method for the manufacture of a coated part of aluminum, aluminum alloys, steel, copper or titanium using such flux, and a method for brazing parts of aluminum or aluminum alloys to parts of aluminum, aluminum alloys, steel, copper or titanium using such flux. The flux can be obtained by sieving, or it can be obtained by removing solids, e.g., in a cyclone, from the drying gases obtained when wet fluxes are dried, especially after their manufacture. Fine particulate flux increases the viscosity of flux preparations comprising the flux dispersed in water or an aqueous or liquid organic carrier.

Owner:SOLVAY FLUOR GMBH DE

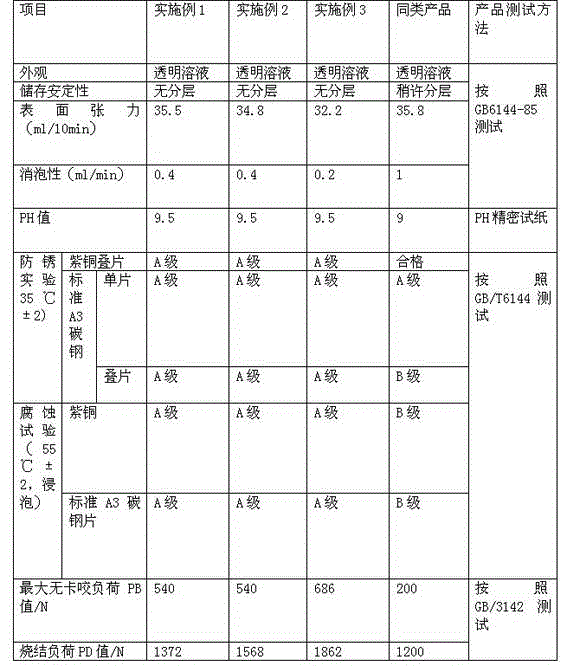

Total synthesis metal cutting solution and preparation method thereof

The invention discloses a total synthesis metal cutting solution comprising the following components by weight percent: 0.5-1% of pH regulator, 10-20% of antirust agent, 10-15% of mixed hydramine, 5-8% of lubricating agent, 0.1-0.3% of copper alloy corrosion inhibitor, 1-2% of sterilizing agent, 0.1-0.2% of defoaming agent, 0-0.5% of EDTA-4 sodium and the balance of water. The invention provides a preparation method of the total synthesis metal cutting solution. The total synthesis metal cutting solution is good in lubricating performance, and the use effect is superior to that of emulsification solution. By utilizing the total synthesis metal cutting solution, surface smoothness of a workpiece can be improved, a grinding wheel can not be sticked, and abrasion of the grinding wheel is reduced. The total synthesis metal cutting solution has a good sedimentation effect and is less in bubbles, long in service life and excellent in anti-rust property, cooling property, permeability and cleanability. By utilizing the total synthesis metal cutting solution, the service life of the grinding wheel can be effectively prolonged. The total synthesis metal cutting solution is suitable for materials, such as bearing steel, carbon steel and the like, the solution is colorless and transparent, and surface processing conditions are easy to observe. Meanwhile, the total synthesis metal cutting solution does not contain toxic and harmful substances, such as sodium nitrite, phenols and the like and is harmless to environment and operator health.

Owner:JIANGSU XINLU NEW MATERIALS CO LTD

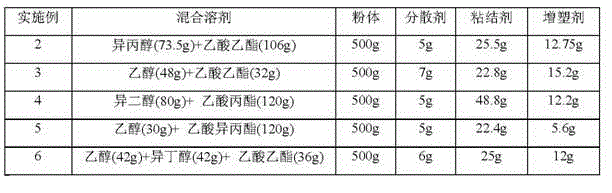

Ceramic casting slurry and preparation method thereof

The invention relates to a ceramic casting slurry and a preparation method thereof. The ceramic casting slurry is characterized by comprising a ceramic powder, a mixed solvent of alcohol and ester, a binder, a plasticizer and a dispersing agent; and the ceramic powder accounts for 65-75wt%, and a weight ratio of the ceramic powder to the mixed solvent is 5:2-4:1. The ceramic casting slurry provided by the invention has high solid content; and the mixed solvent of alcohol and ester has low cost, good environment compatibility, and low poison to the human body.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com