Total synthesis metal cutting solution and preparation method thereof

A metal cutting fluid, fully synthetic technology, used in the preparation of fully synthetic metal cutting fluid, the field of fully synthetic metal cutting fluid, can solve extreme pressure lubrication performance, cooling performance, anti-rust performance, environmental protection performance, comprehensive performance is not ideal, production workers Skin allergy and inflammation, corrosion of mechanical equipment and workpieces, etc., to save time, manpower and material resources, excellent chip removal and sedimentation, and prolong the life of the grinding wheel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

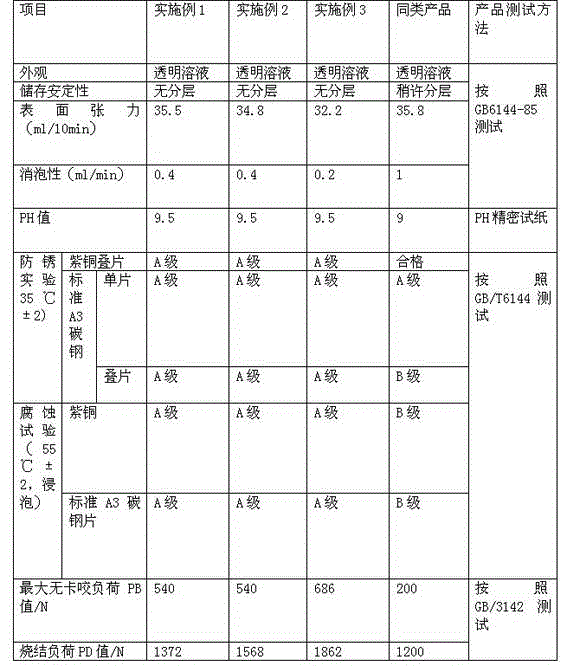

Examples

Embodiment 1

[0028] A fully synthetic metal cutting fluid, which is composed of the following mixture by weight and mass percentage:

[0029] pH regulator 1%

[0030] Rust inhibitor 15%

[0031] Mixed olamines 10%

[0032] Lubricant 5%

[0033] Copper alloy corrosion inhibitor 0.1%

[0034] Fungicide 1.5%

[0035] Defoamer 0.2%

[0036] Sodium EDTA-4 0.5%

[0037] water balance

[0038] Among them, the pH regulator is sodium carbonate; the rust inhibitor is boric acid, undecanedibasic acid, and synthetic ester; the mixed alcohol amine is diethanolamine or triethanolamine; the lubricant is a mixture of polyether 1740 and 1720;

[0039] The copper alloy corrosion inhibitor is benzotriazole and its derivatives; the fungicide is hexahydrotriazine, and the defoamer is modified silicone oil.

[0040] The preparation method of the above-mentioned fully synthetic cutting fluid comprises the following steps:

...

Embodiment 2

[0045] On the basis of Example 1, the proportioning amount of the fully synthetic metal cutting fluid was changed, specifically as follows:

[0046] pH regulator 0.8%

[0047] Rust inhibitor 10%

[0048] Mixed olamines 12%

[0049] Lubricant 5%

[0050] Copper alloy corrosion inhibitor 0.2%

[0051] Fungicide 1%

[0052] Defoamer 0.1%

[0053] Sodium EDTA-4 0.5%

[0054] water balance

[0055] Among them, the pH regulator is sodium carbonate; the rust inhibitor is boric acid, sebacic acid, and synthetic ester; the mixed alcohol amine is monoethanolamine or isopropanolamine; the lubricant is a mixture of polyether 1740 and 1720;

[0056] The copper alloy corrosion inhibitor is benzotriazole and its derivatives; the fungicide is 3-iodo-2-propynyl butyl carbamate (IPBC), and the defoamer is polyether.

[0057] Prepare according to the preparation method of Example 1, and finally take samples ...

Embodiment 3

[0059] On the basis of embodiment 1 or 2, change the proportioning amount of fully synthetic metal cutting fluid, specifically as follows:

[0060] pH regulator 0.5%

[0061] Rust inhibitor 20%

[0062] Mixed alcohol amines 15%

[0063] Lubricant 8%

[0064] Copper alloy corrosion inhibitor 0.3%

[0065] Fungicide 2%

[0066] Defoamer 0.15%

[0067] water balance

[0068] Among them, the pH regulator is potassium hydroxide; the rust inhibitor is sebacic acid, tribasic acid, and synthetic ester; the mixed alcohol amine is a mixture of triethanolamine and special alcohol amine; the lubricant is a mixture of polyether 1740 and 1720;

[0069] The copper alloy corrosion inhibitor is benzotriazole and its derivatives; the fungicide is 3-iodo-2-propynyl butyl carbamate (IPBC), and the defoamer is polyether.

[0070] The preparation method of the above-mentioned fully synthetic cutting fluid comprises the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com