Near-net forming method and device for composite manufacturing fine workpiece based on laser additive manufacturing and subtractive manufacturing

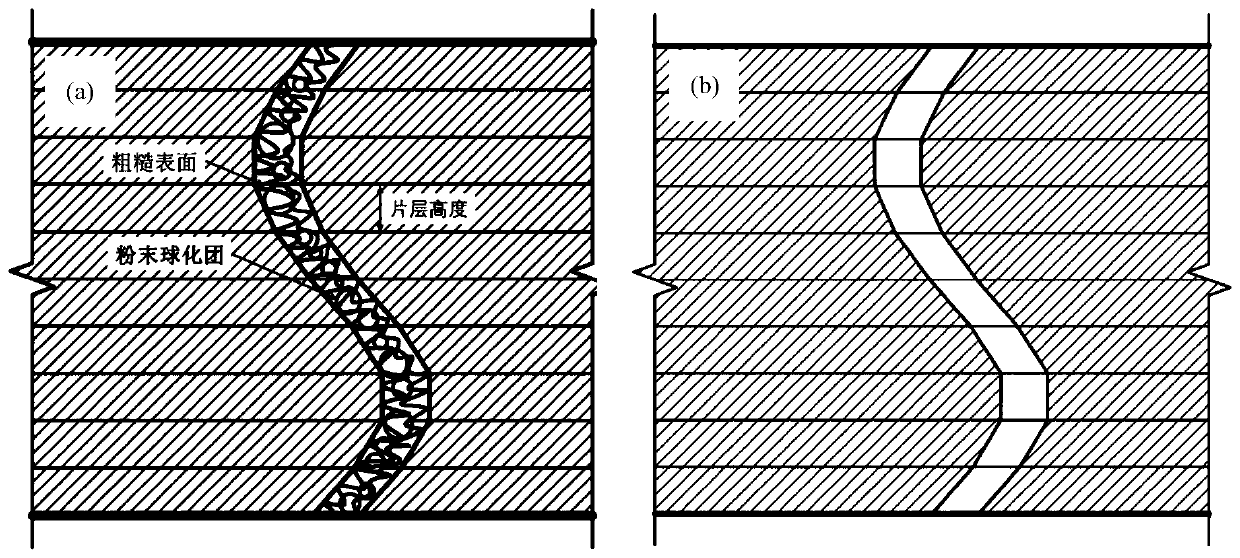

A laser additive and near-net forming technology, which is applied in the direction of additive processing, additive manufacturing, and process efficiency improvement, can solve the problems of low molding precision, high roughness, and insufficient fineness, so as to improve the smoothness and dimensional accuracy, Effect of improving forming accuracy and surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

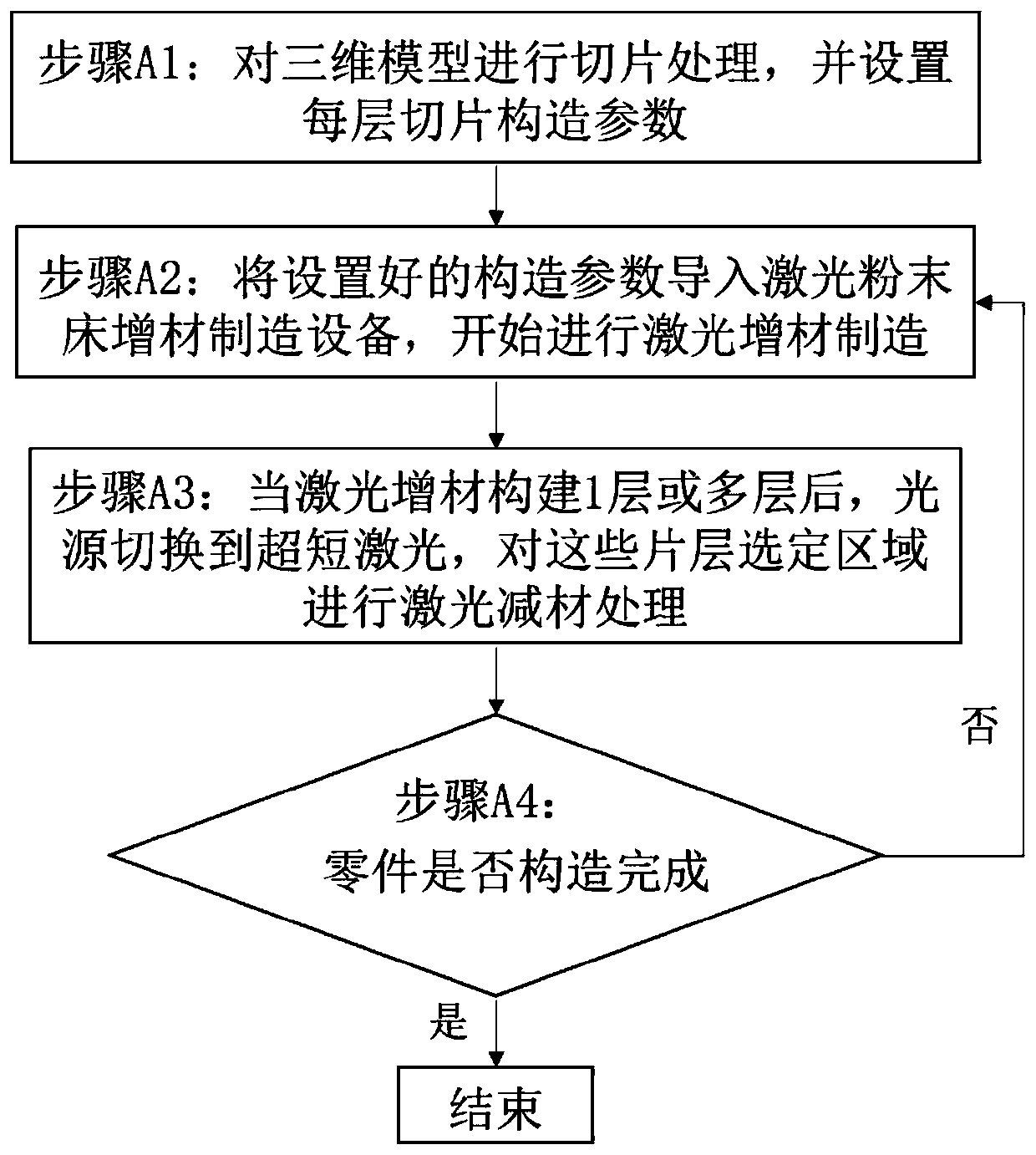

[0044] The following combination figure 2 with image 3 The present invention will be described in detail by taking the near-net forming of 316 stainless steel capillary tube based on laser selective melting additive manufacturing as an example. The selected 316 stainless steel powder is nearly spherical powder with a particle size of 15-53μm.

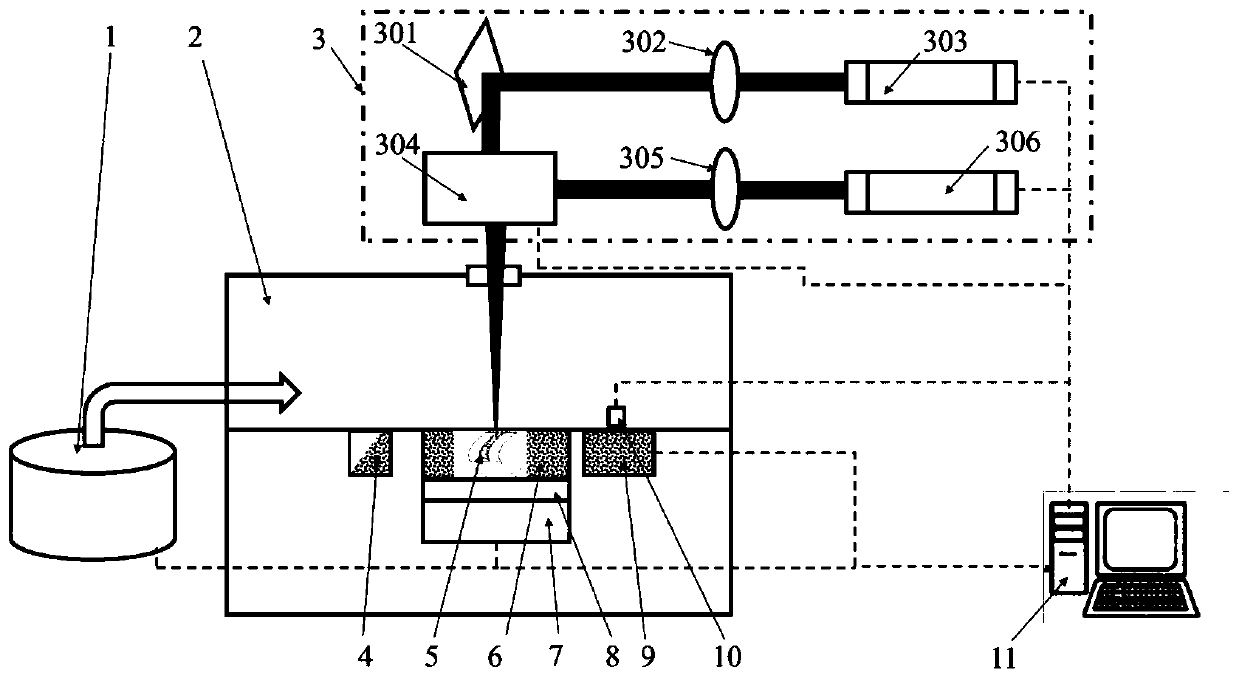

[0045] image 3 The device that implements the near-net shaping method of complex and fine workpieces based on laser adding and reducing materials, mainly includes a computer control device 11, a sealed molding chamber 2, an optical path selection system 3, and an inert protective gas source 1. Among them, the optical path selection system 3 includes an increase Material laser mirror 301, additive laser beam expander 302, additive laser 303, scanning galvanometer 304, subtractive laser beam expander 305, and subtractive laser 306; the additive laser 303 and scanning oscillator in the optical path selection system 3 The mirror 304 and the...

Embodiment 2

[0056] The following combination figure 2 with Figure 4 Take the 316 stainless steel capillary tube based on laser selective melting additive manufacturing as an example to illustrate the present invention in detail. The selected 316 stainless steel powder is a nearly spherical powder with a particle size of 15-53μm.

[0057] Figure 4 The device that implements the near-net shaping method of complex and fine workpieces based on laser adding and reducing materials, mainly includes a computer control device 11, a sealed molding chamber 2, an optical path selection system 3, and an inert protective gas source 1. Among them, the optical path selection system 3 includes an increase The material laser 303 and the additive laser emitting end 307 connected thereto, the subtractive laser 306 and the subtractive laser emitting end 308 connected thereto, the additive laser emitting end 307 and the subtractive laser emitting end 308 are fixed in the sealed molding chamber 2 On the guide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com