Static blasting and energy-gathering device and blasting method thereof

A static blasting and energy-gathering technology, applied in the field of blasting, can solve the problems of crushing amount of medicine and long crushing time, and achieve the effects of reducing the amount of medicine, improving crushing efficiency, and speeding up the blasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

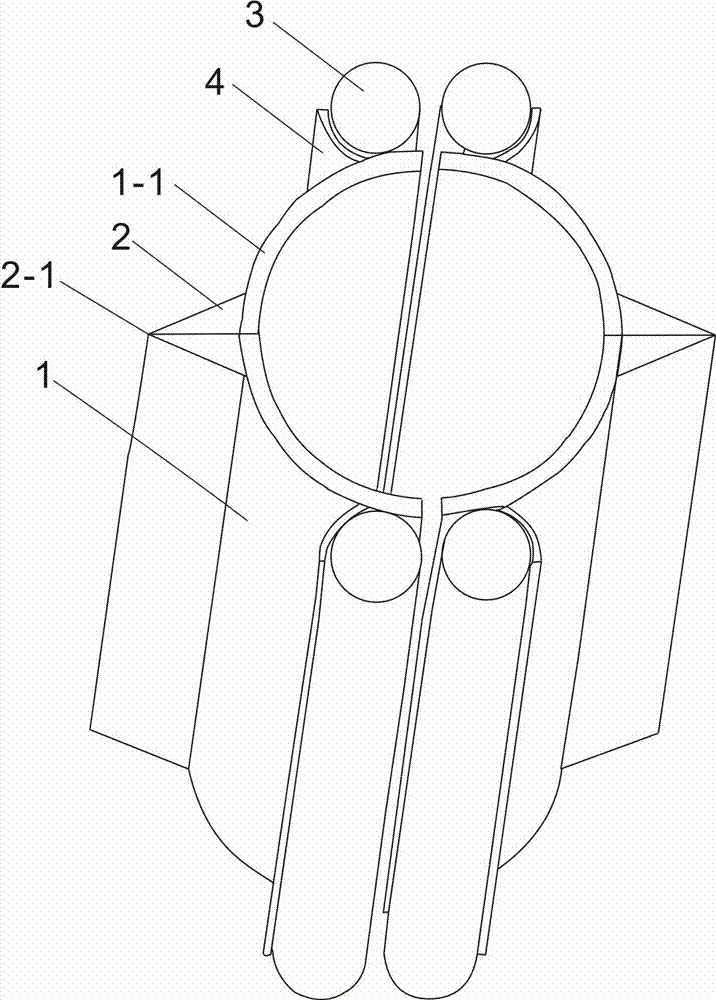

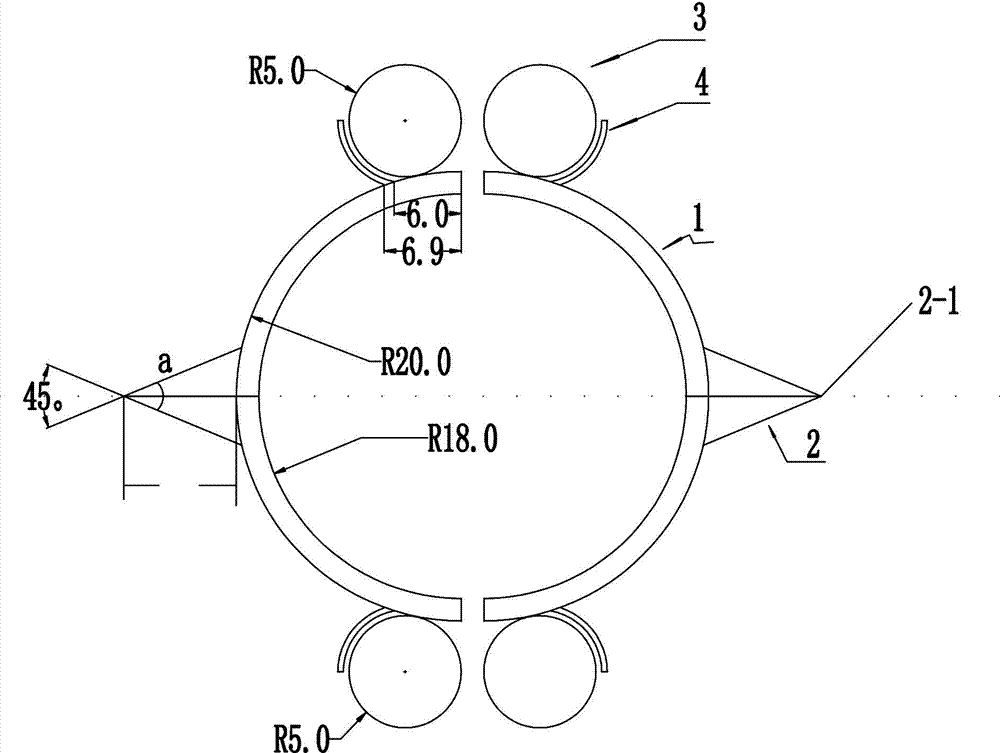

[0042] Such as Figure 1-Figure 4 As shown, a static blasting energy gathering device,

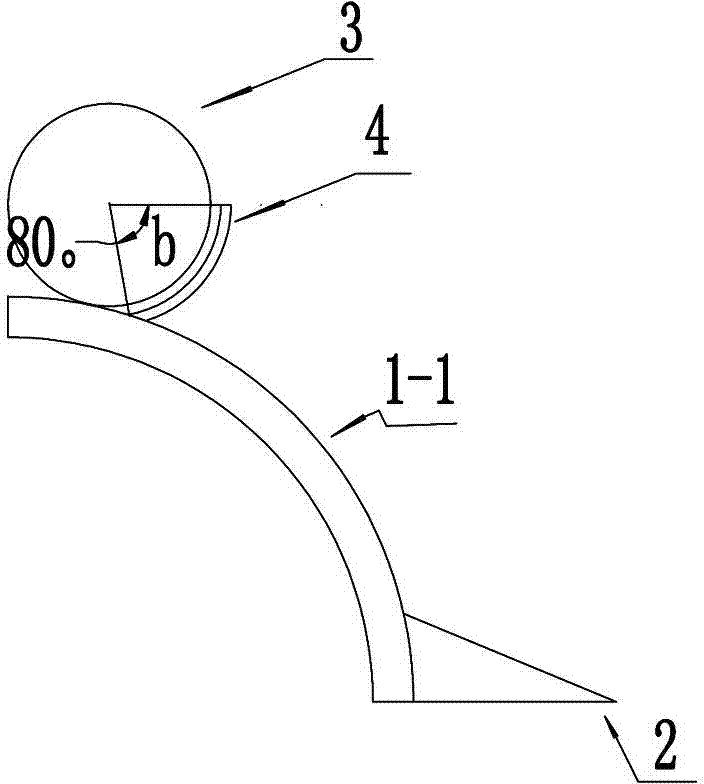

[0043] The device includes a main casing 1 composed of two arc-shaped steel formworks 1-1, the two arc-shaped steel formworks 1-1 are not connected, and the midpoint of the two-valve arc-shaped steel formwork 1-1 The connecting line is perpendicular to the pre-splitting line 5; a splitting angle 2 is provided on the outside of each arc-shaped steel formwork 1-1, and the tip 2-1 of the splitting angle 2 is located on the same straight line as the pre-splitting line 5;

[0044] Both sides of the arc-shaped steel template 1-1 are respectively provided with a stabilizing shaft guide ring 4, and a stabilizing shaft 3 is placed on the stabilizing shaft guiding ring 4;

[0045] The stable shaft 3 has a diameter of 10mm and is made of steel or a stronger alloy material.

[0046] The main body casing 1 is a cylinder with an inner diameter of 36mm, an outer diameter of 40mm, and an axial length of...

Embodiment 2

[0051] A method of blasting using a static blasting energy-gathering device, the method comprising the following steps:

[0052] 1) Drilling: Drilling 6 holes on rocks that require static blasting;

[0053] 2) Place the static rock-cracking energy-gathering device: apply a certain amount of lubricating oil on the guide ring 4 of the stable shaft in advance, and place the main body casing 1 of the static rock-cracking energy-gathering device in the drill hole 6, so that each splitting angle 2 The tip 2-1 and the pre-cracking line 5 are located on the same straight line, and then the four stabilizing shafts 3 are inserted into the stabilizing shaft guide ring 4 to complete the placement of the static rock-cracking energy-gathering device;

[0054] 3) Filling the rock-cracking agent slurry (the static blasting agent referred to in the background technology): fill the rock-cracking agent slurry in the main casing 1 of the placed energy-gathering device, and wait for the rock-crack...

Embodiment 3

[0059] The angle a at the tip of the splitting angle is 45 degrees for the test selection, and the test process is as follows:

[0060] The included angle a is designed to be different degrees, when they are 0 degrees, 30 degrees, 45 degrees, 60 degrees and 90 degrees respectively, the large-scale finite element software adina is used to simulate the different force characteristics of the tip of the splitting angle, so as to select the optimal clamping angle horn.

[0061] When there is no splitting angle, the stress on the tip of the splitting angle is as follows Figure 5 shown;

[0062] When the included angle a of the tip of the splitting angle is 30 degrees, the stress on the tip of the splitting angle is as follows Image 6 shown;

[0063] When the included angle a of the tip of the splitting angle is 45 degrees, the stress on the tip of the splitting angle is as follows Figure 7 shown;

[0064] When the included angle a of the tip of the splitting angle is 60 degr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Axial length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com