Patents

Literature

1178results about How to "Low tensile strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

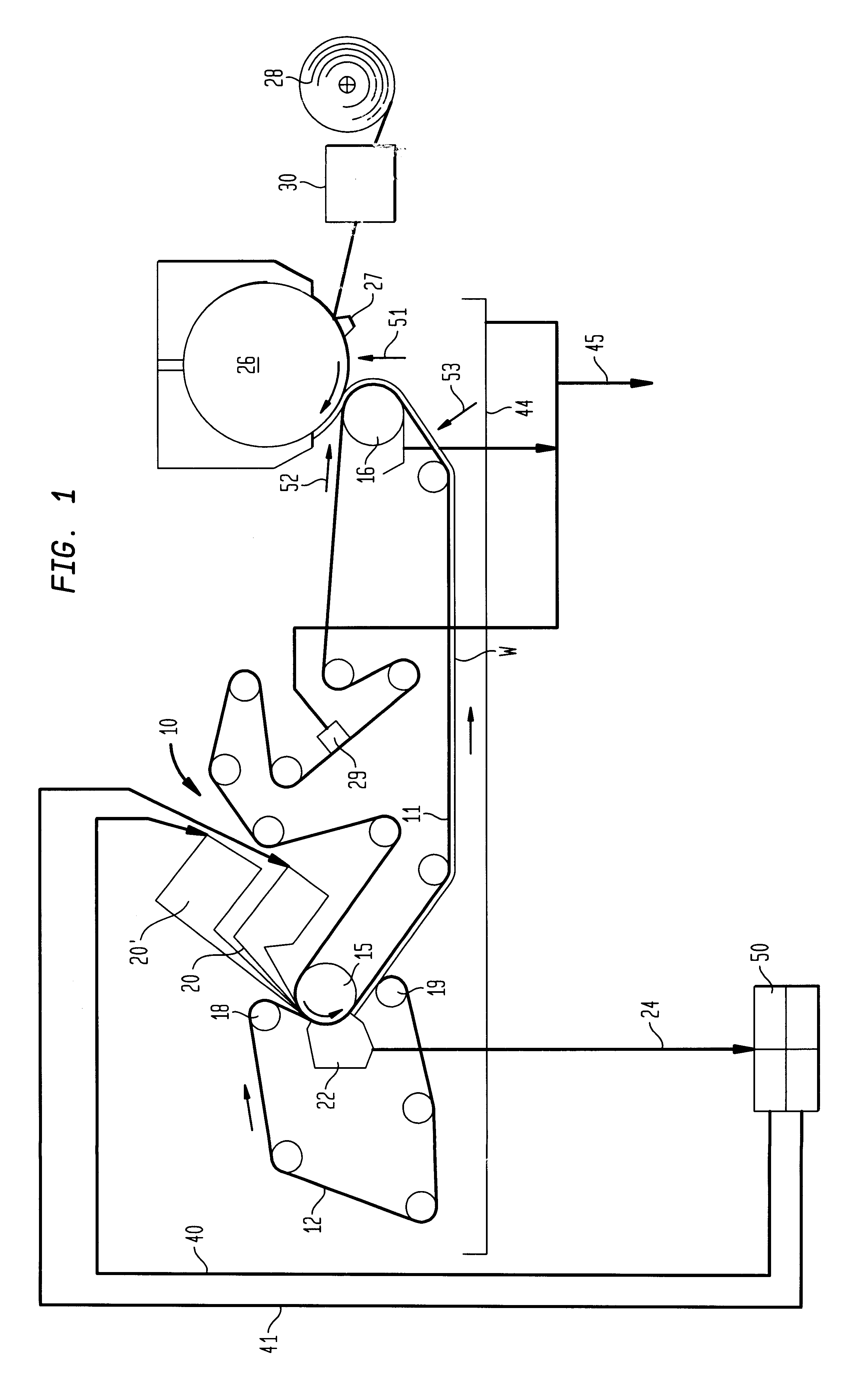

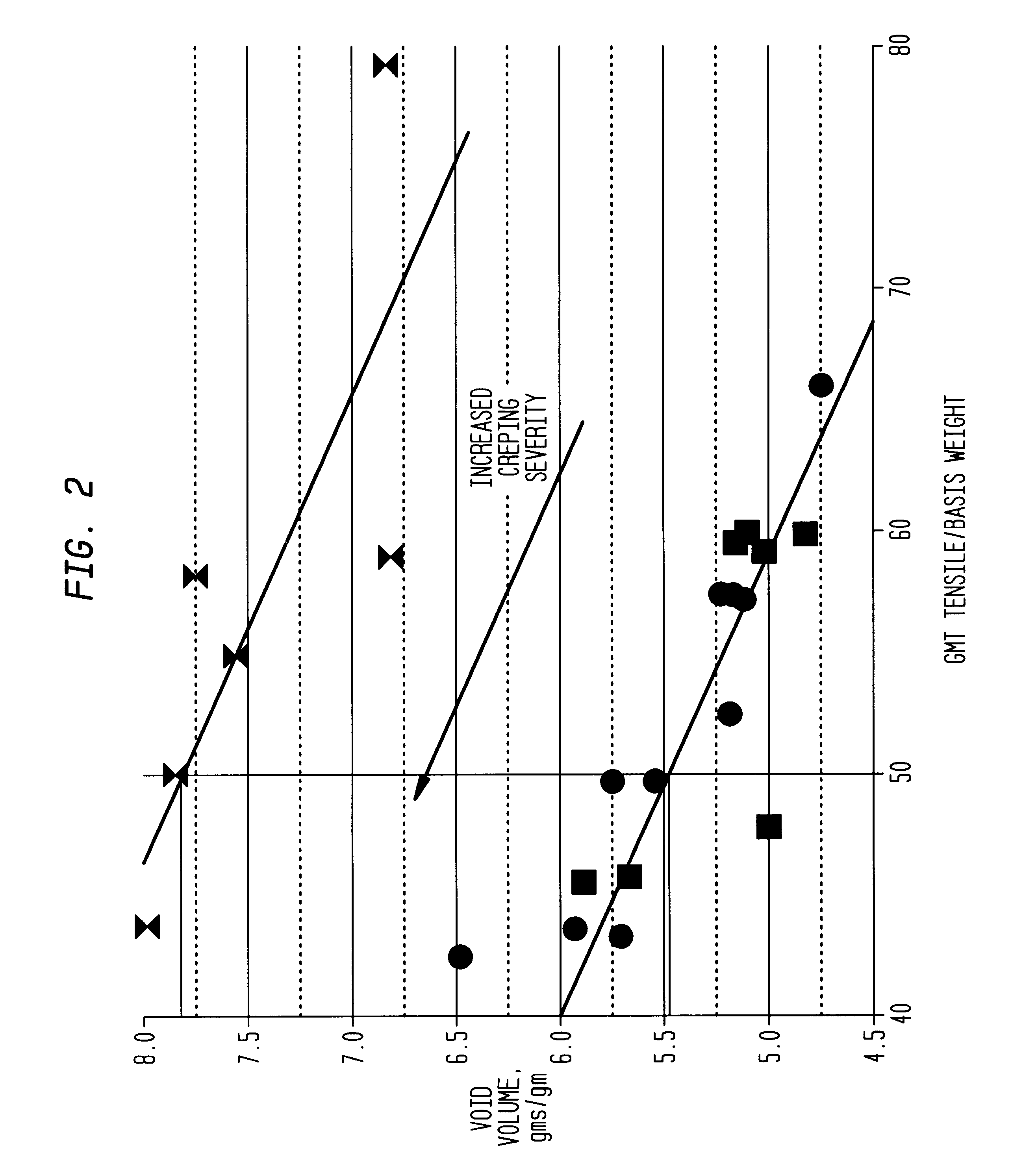

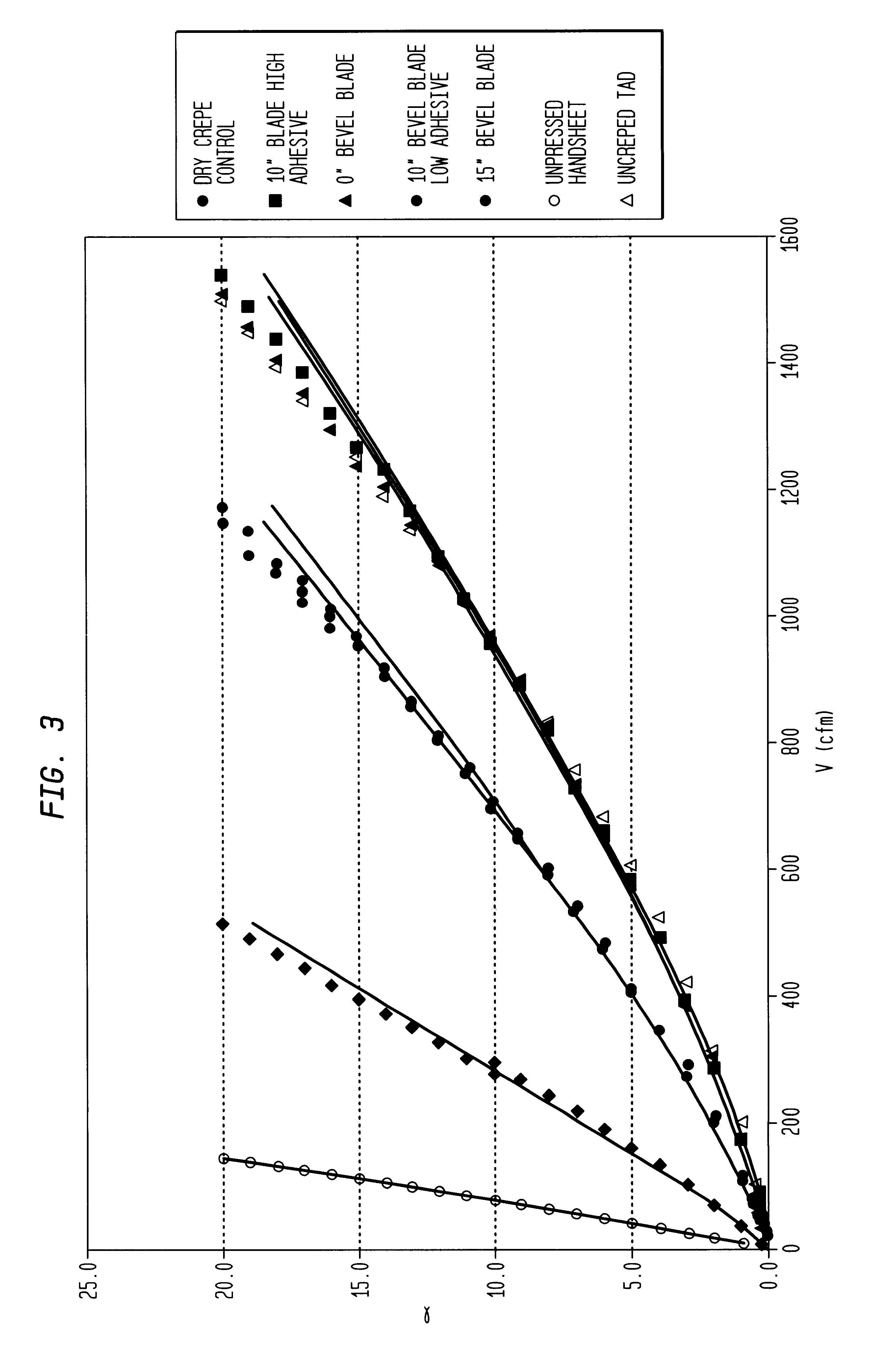

Wet crepe, impingement-air dry process for making absorbent sheet

InactiveUS6432267B1Reduce penetrationIncrease flexibilityDrying using combination processesNon-fibrous pulp additionPulp and paper industryPaper sheet

A wet crepe, impingement-air dried process for producing absorbent paper sheet is disclosed. In preferred embodiments, the process utilizes recycle furnish and the web is delaminated as it is wet-creped from a Yankee dryer. Particular embodiments include high consistency (after-crepe) wet-shaping prior to impingement air drying on a drilled vacuum roll.

Owner:GPCP IP HLDG LLC

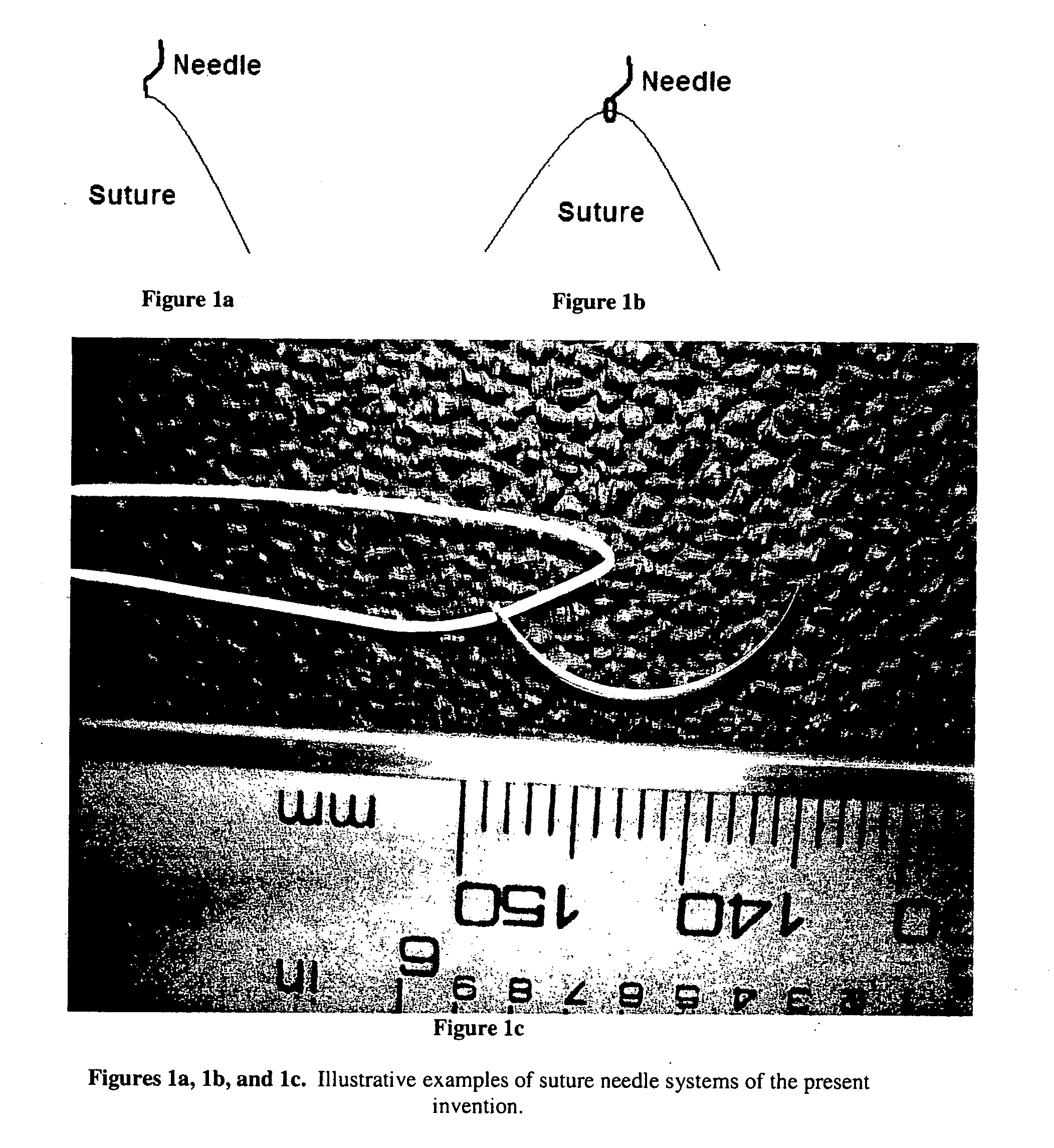

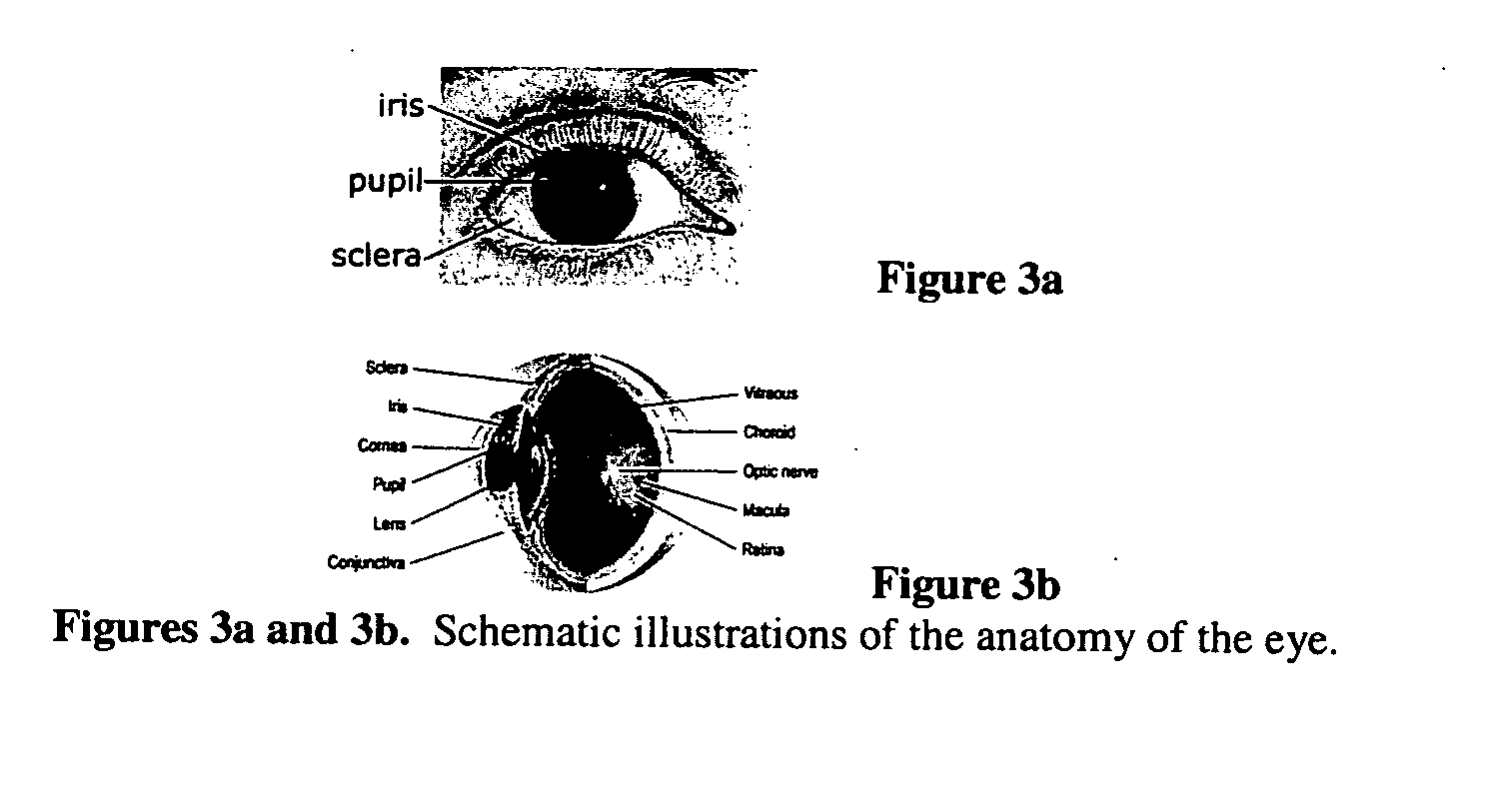

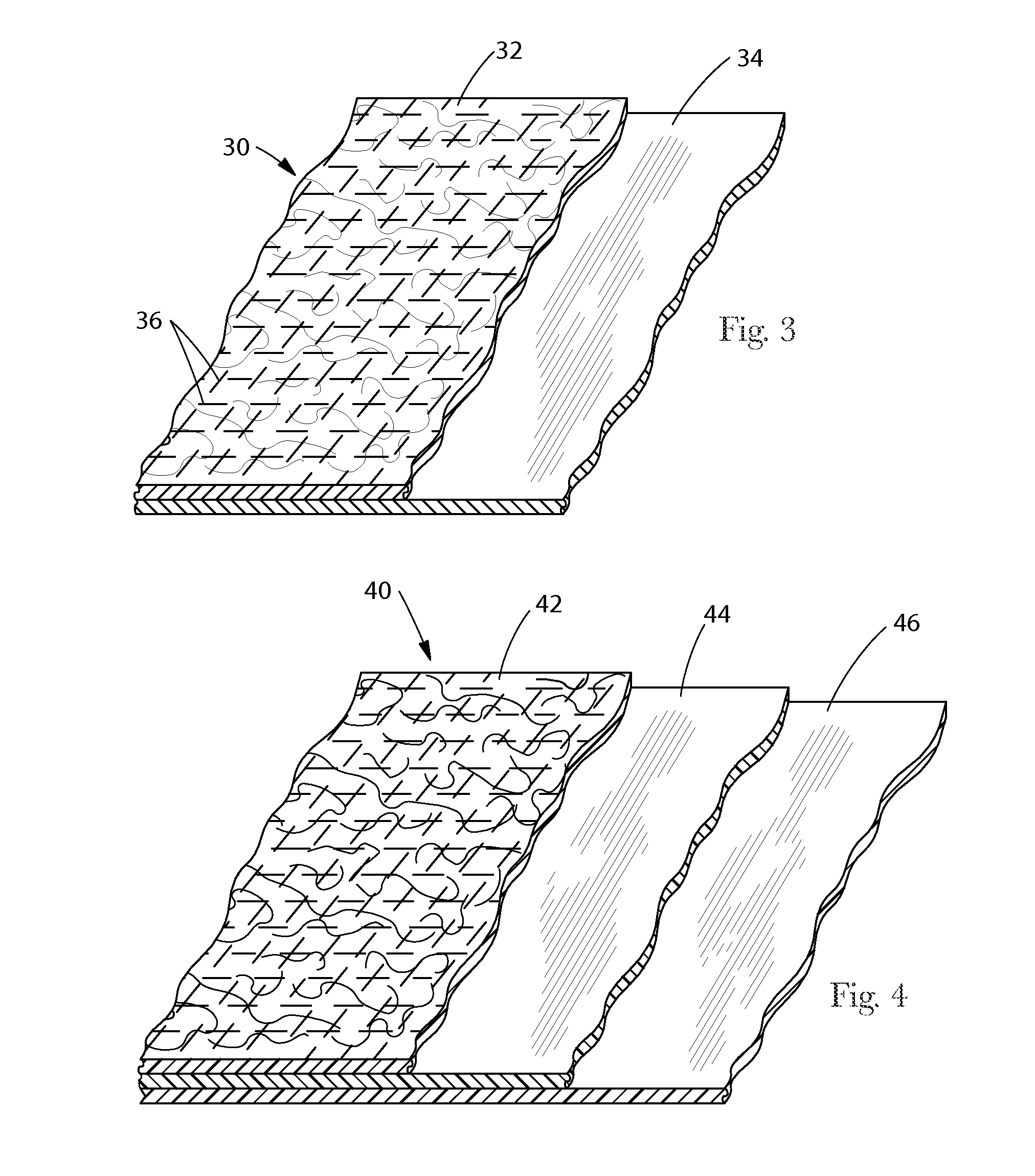

Biodegradable drug-polymer delivery system

ActiveUS20050276841A1Low tensile strengthTensile strengthOrganic active ingredientsBiocideTherapy medicationDisease

A sustained-release biodegradable polymeric drug-eluting fiber is disclosed. In some embodiments, the therapeutic drug is complexed with cyclodextrin. In certain embodiments, the polymeric component of the fiber comprises cyclodextrin. The fiber may be fabricated to provide a thread and / or suture. The fiber may be used for treatment of ocular diseases or disorders.

Owner:CALIFORNIA INST OF TECH

Composition for filling bone defects

InactiveUS7019192B2Low tensile strengthIncrease delayBiocideSurgical adhesivesSodium phosphatesDemineralized bone

The invention is directed toward a formable bone composition for application to a bone defect site to promote new bone growth at the site which comprises a new bone growth inducing compound of demineralized lyophilized allograft bone particles. The particle size ranges from about 0.1 mm to about 1.0 cm and is mixed in a hydrogel carrier containing a sodium phosphate saline buffer, the hydrogel component of the carrier ranging from about 1.0 to 5.0% of the composition and a pH between 6.8–7.4 with one or more additives of a cellular material, growth factor, demineralized bone chips or mineralized bone chips.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

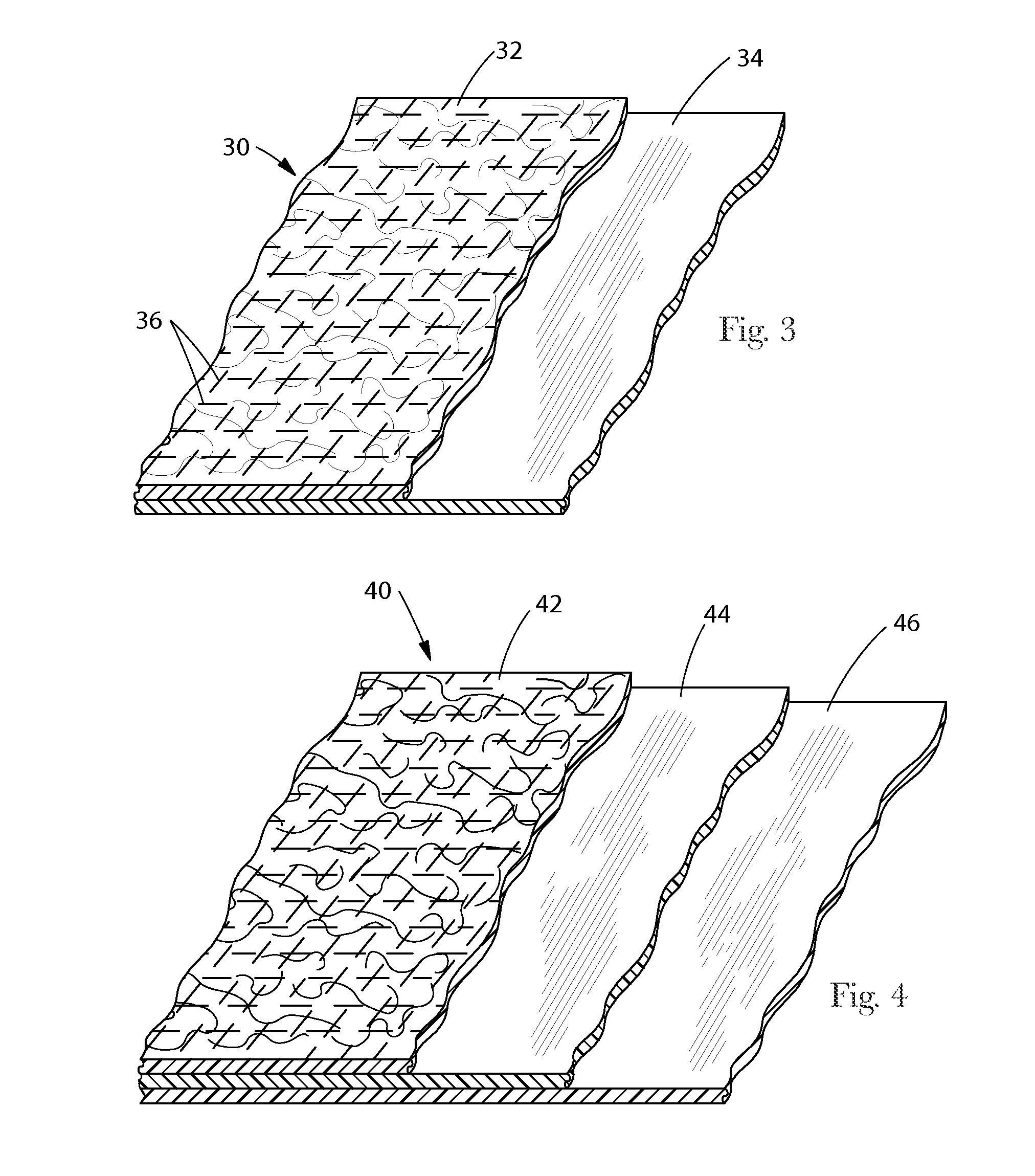

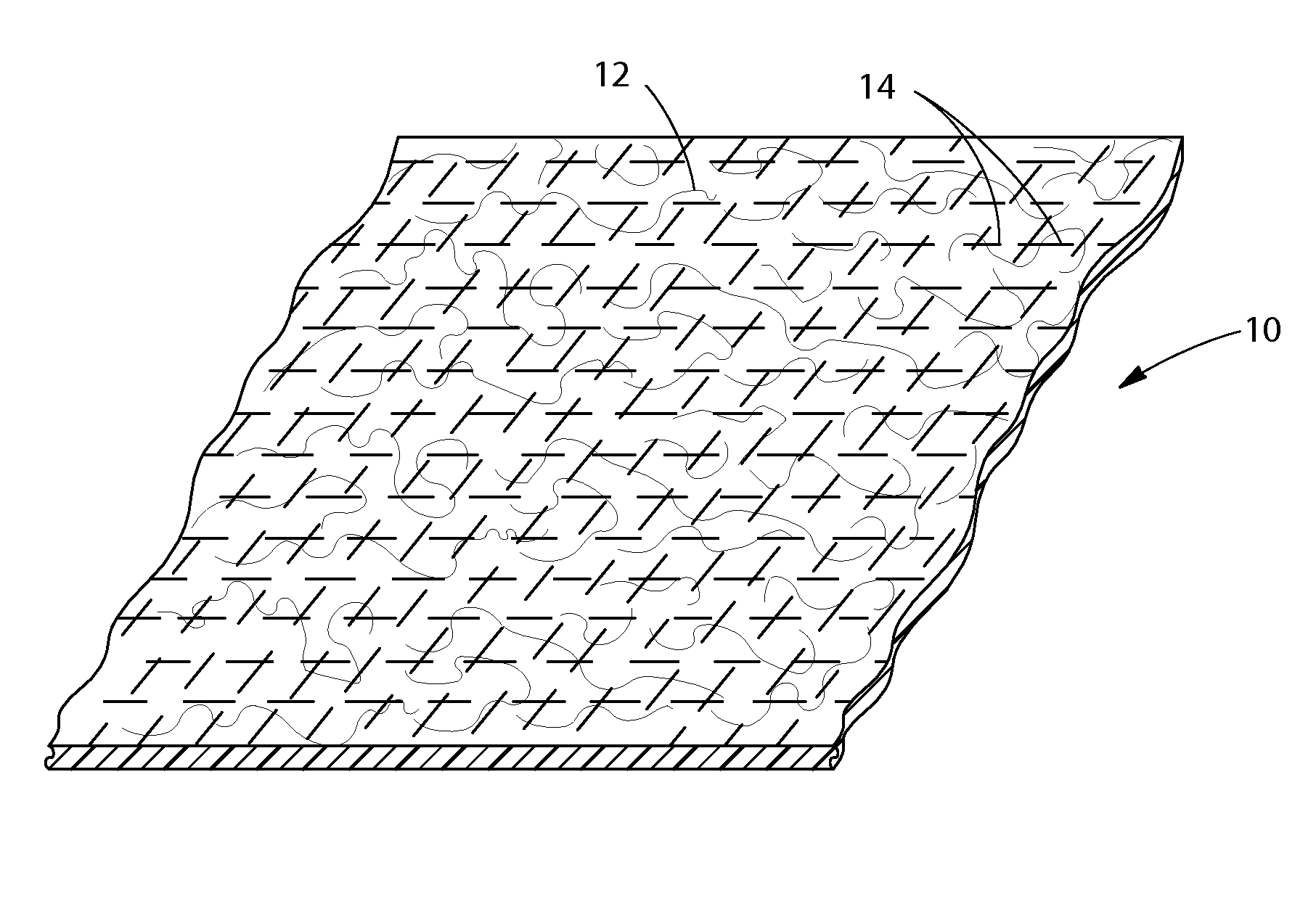

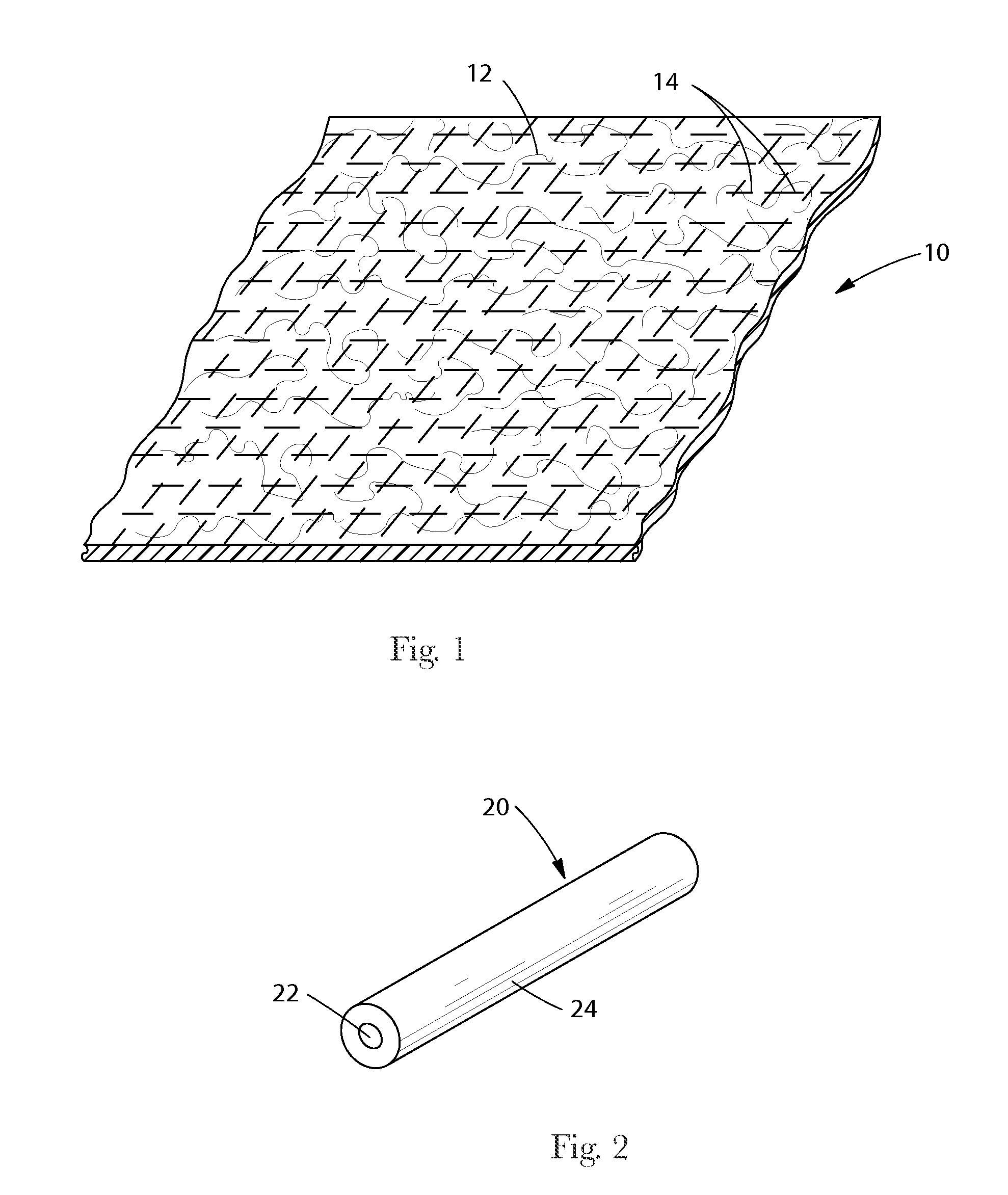

Laminates with Bonded Webs

ActiveUS20110282313A1Excellent abrasion resistanceIncrease resistancePersonal careSynthetic resin layered productsComposite materialMaterials science

Owner:THE PROCTER & GAMBLE COMPANY

Tissue products having low stiffness and antimicrobial activity

InactiveUS20070020315A1Reduce stiffnessLow tensile strengthBiocideSpecial paperChemistryAnti-Microbial Agents

The inner plies of a multi-ply antimicrobial tissue product are selectively weakened by chemical or mechanical means to improve the overall softness of the tissue product. The addition of a deliquescent salt to the inner ply or plies containing the antimicrobial agent is particularly advantageous.

Owner:KIMBERLY-CLARK WORLDWIDE INC

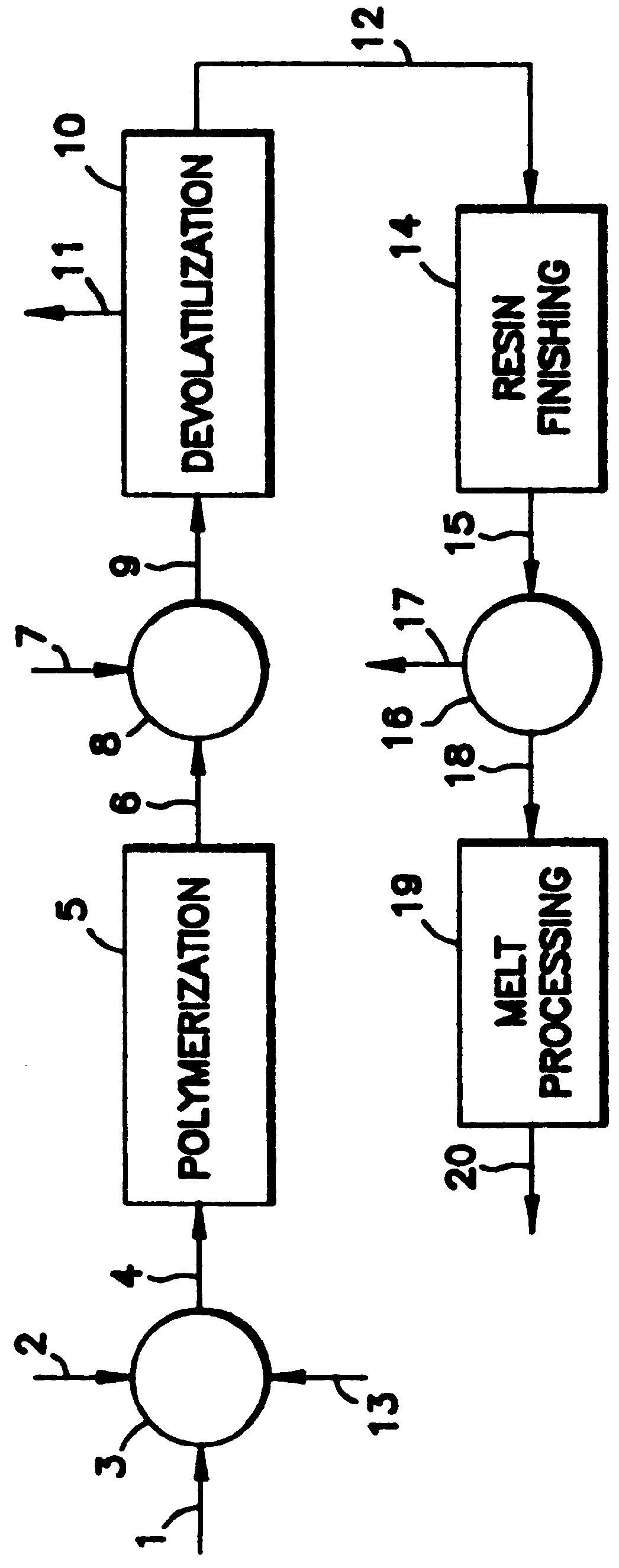

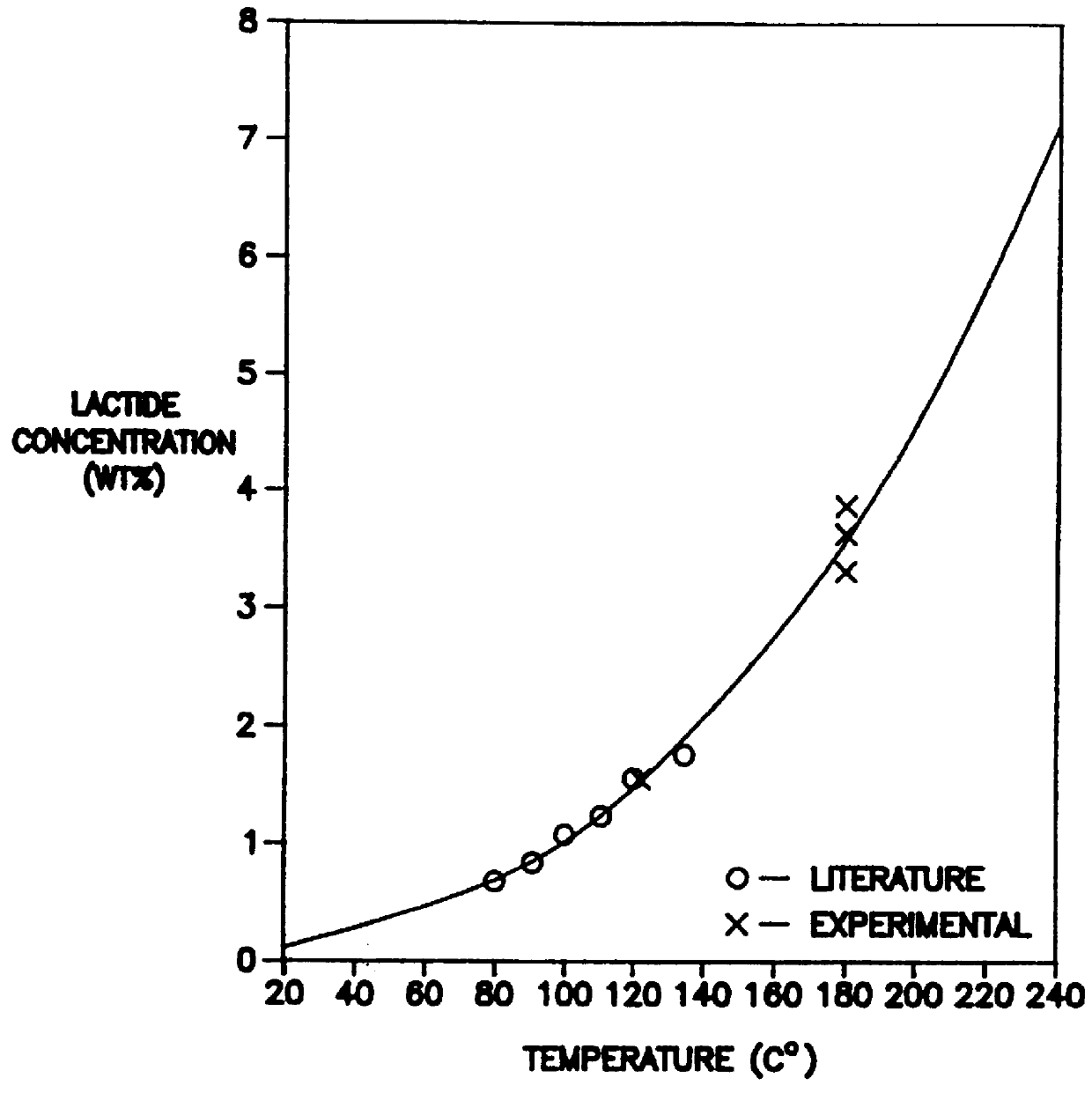

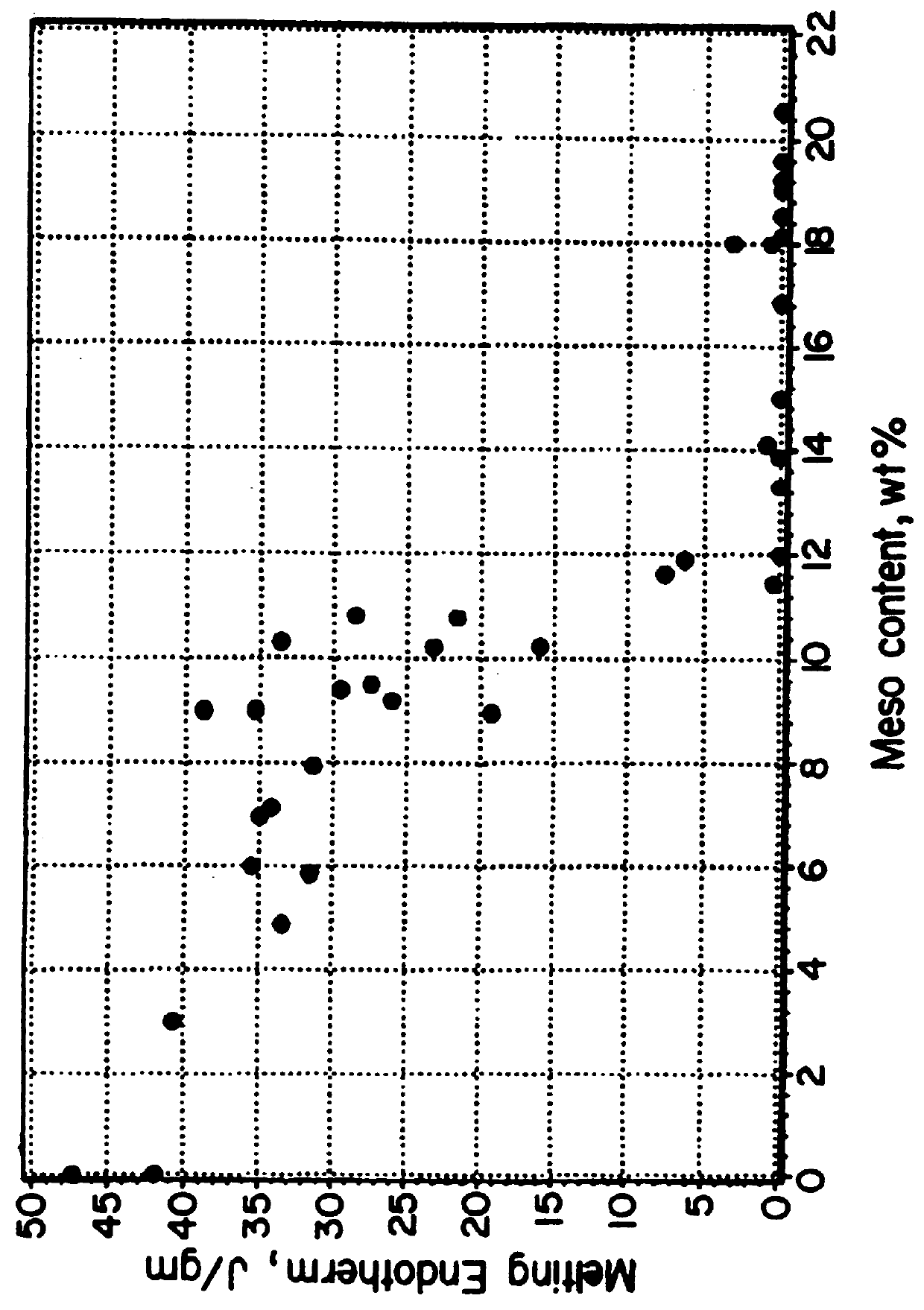

Melt-stable semi-crystalline lactide polymer film and process for manufacture thereof

InactiveUS6121410AHigh surface energyEasy to printCoatings with pigmentsSurgeryLactidePolymer chemistry

A semi-crystalline film comprised of a lactide polymer. The lactide polymer comprises a plurality of poly(lactide) polymer chains, residual lactide in concentration of less than about 5 percent and water in concentration of less than about 2000 parts-per-million. A process for manufacturing a semi-crystalline film with the lactide polymer composition is also disclosed.

Owner:CARGILL INC

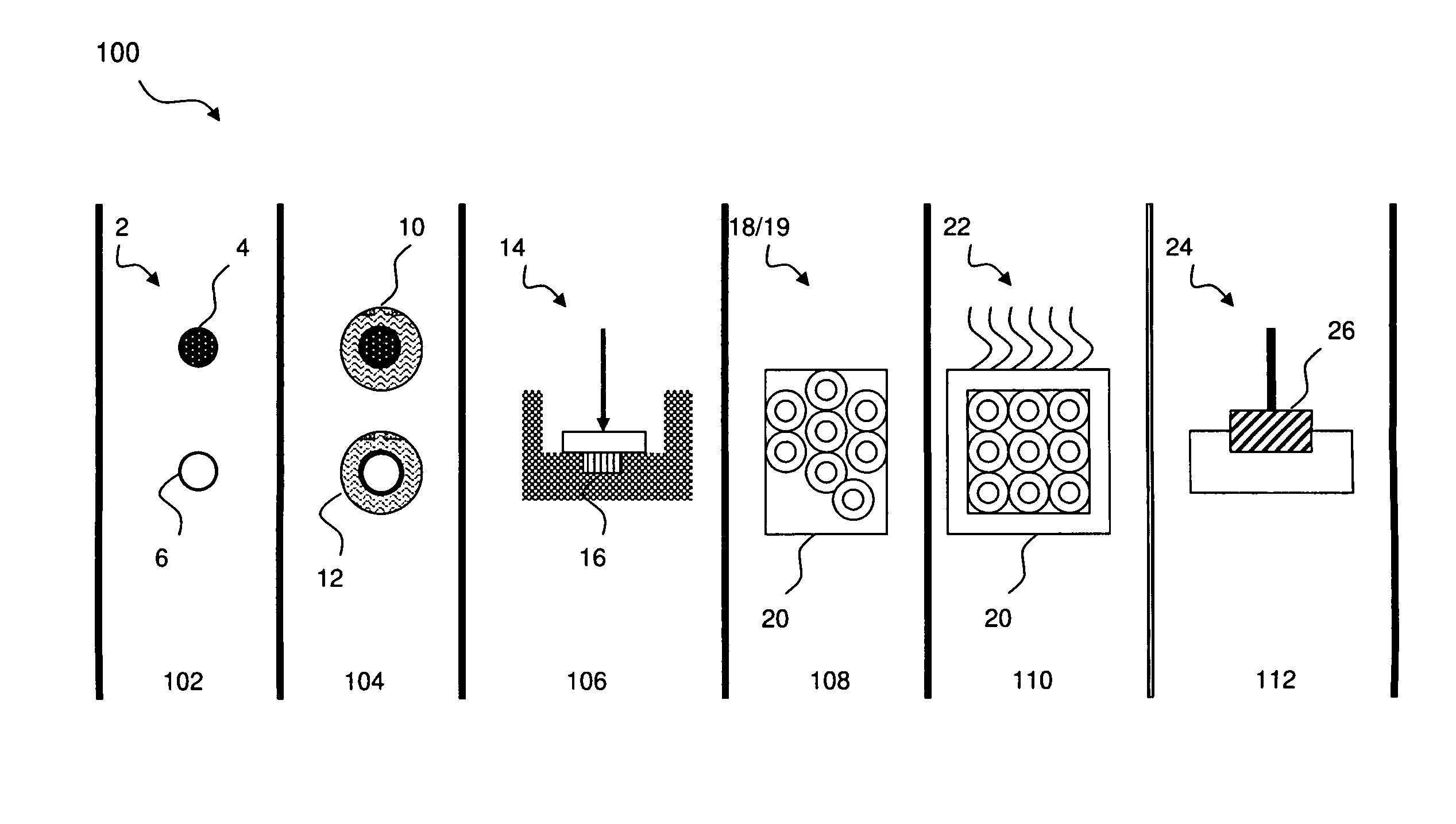

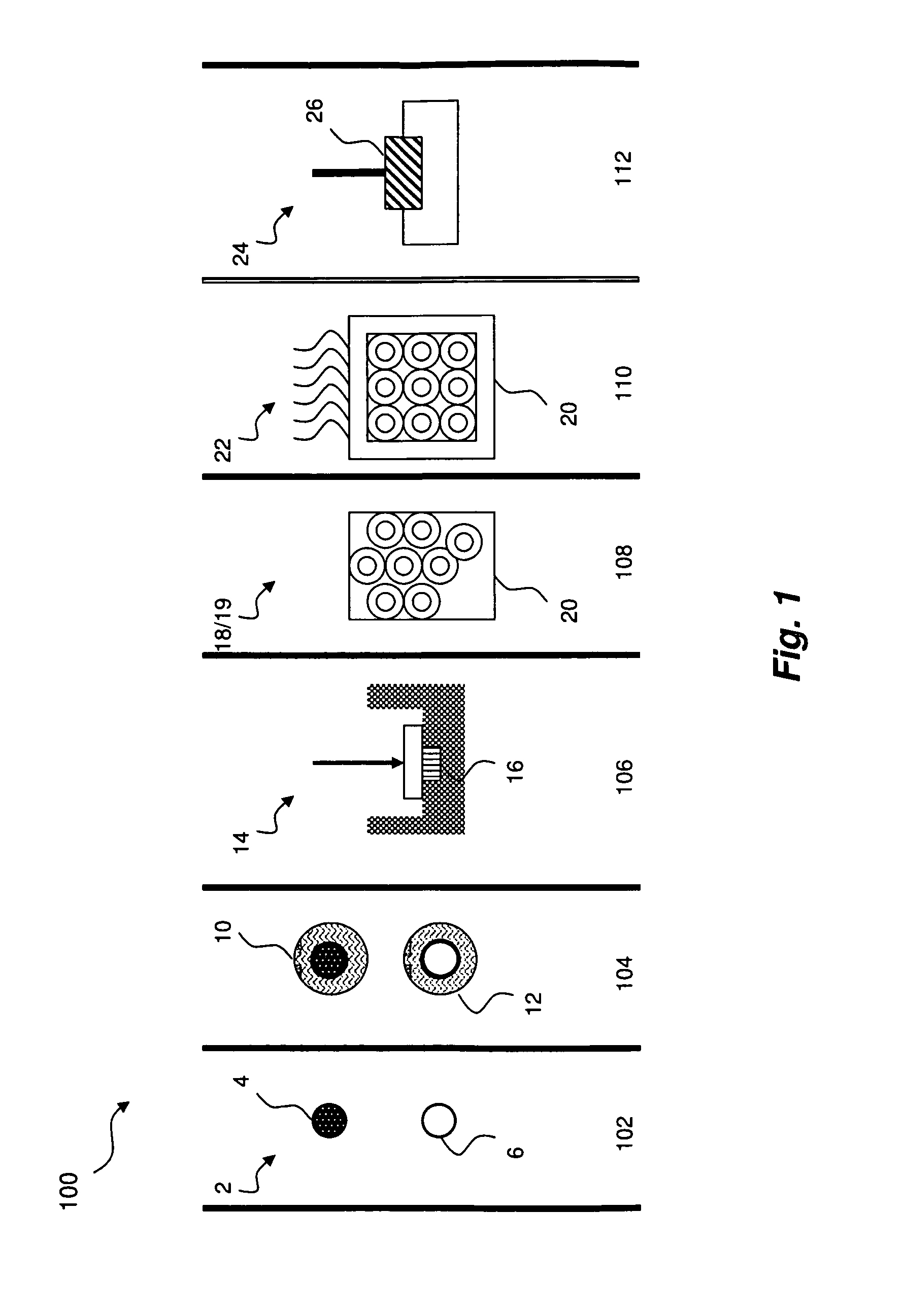

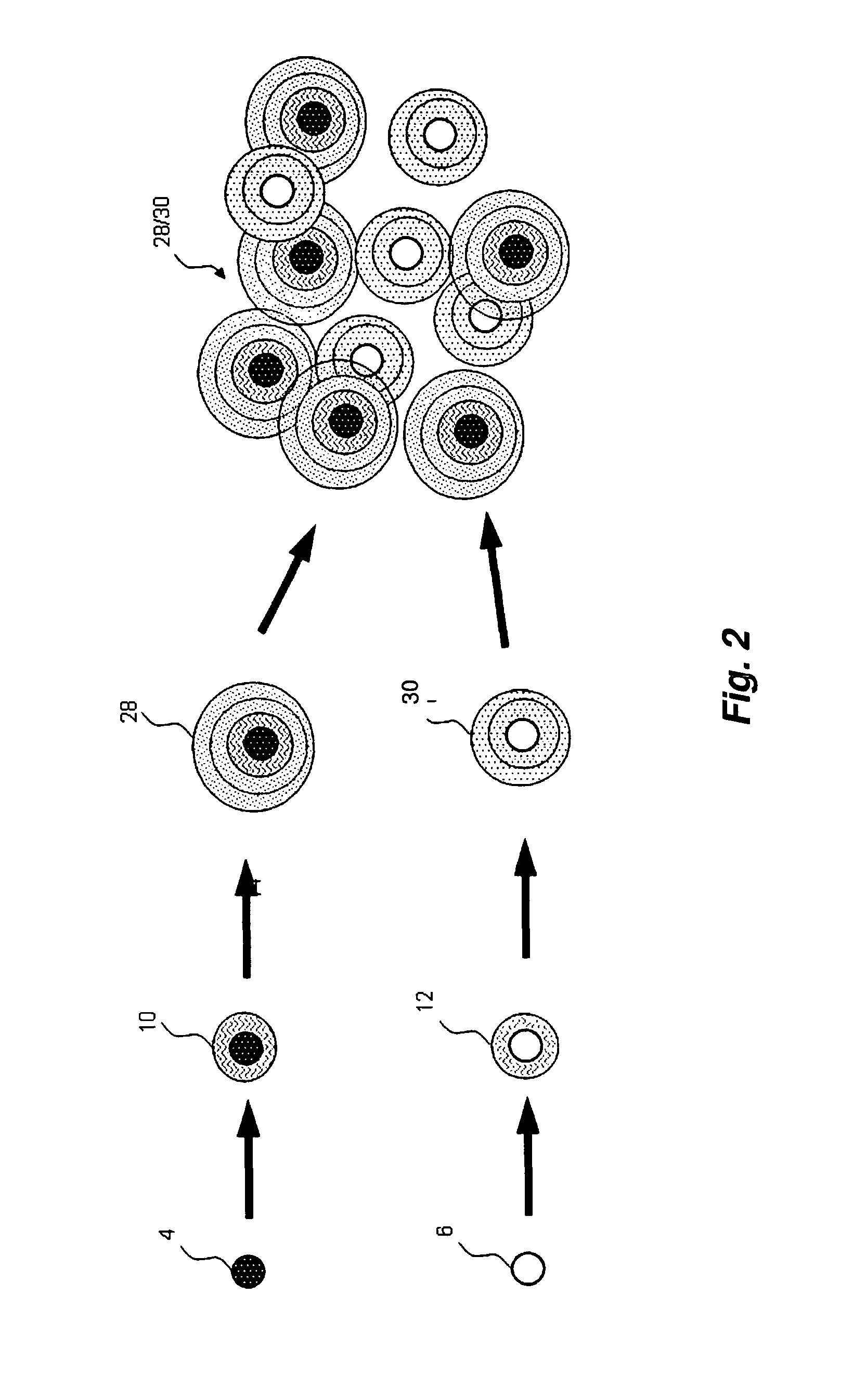

Multifunctional high strength metal composite materials

ActiveUS8535604B1Reduce densityVariable specific strengthMetal-working apparatusCoatingsMicrostructureMagnesium

A method of producing composites of micro-engineered, coated particulates embedded in a matrix of metal, ceramic powders, or combinations thereof, capable of being tailored to exhibit application-specific desired thermal, physical and mechanical properties to form substitute materials for nickel, titanium, rhenium, magnesium, aluminum, graphite epoxy, and beryllium. The particulates are solid and / or hollow and may be coated with one or more layers of deposited materials before being combined within a substrate of powder metal, ceramic or some combination thereof which also may be coated. The combined micro-engineered nano design powder is consolidated using novel solid-state processes that prevent melting of the matrix and which involve the application of varying pressures to control the formation of the microstructure and resultant mechanical properties.

Owner:AMARANTHINE RESOURCES LLC

Nanostructured chemicals as alloying agents in fluorinated polymers

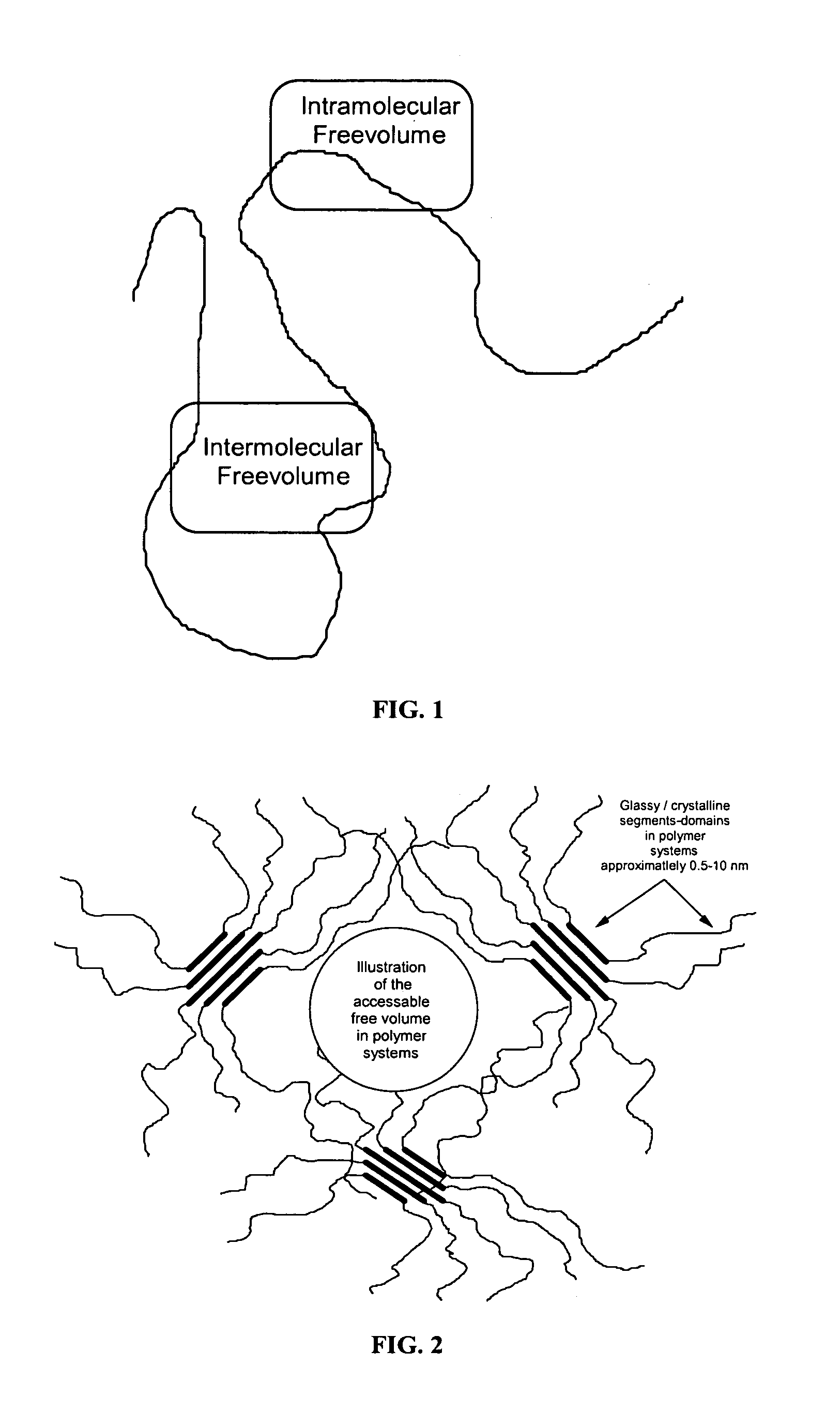

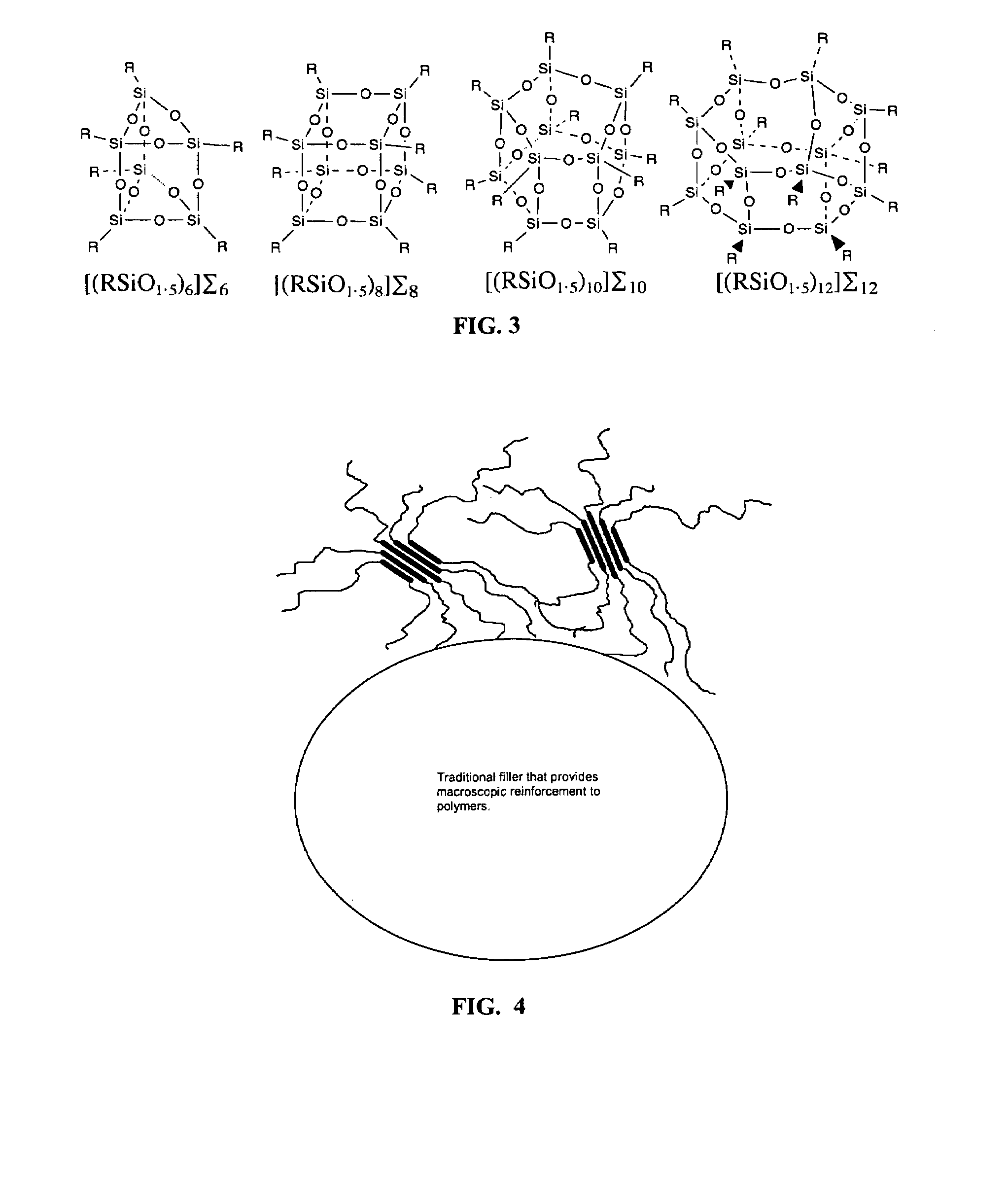

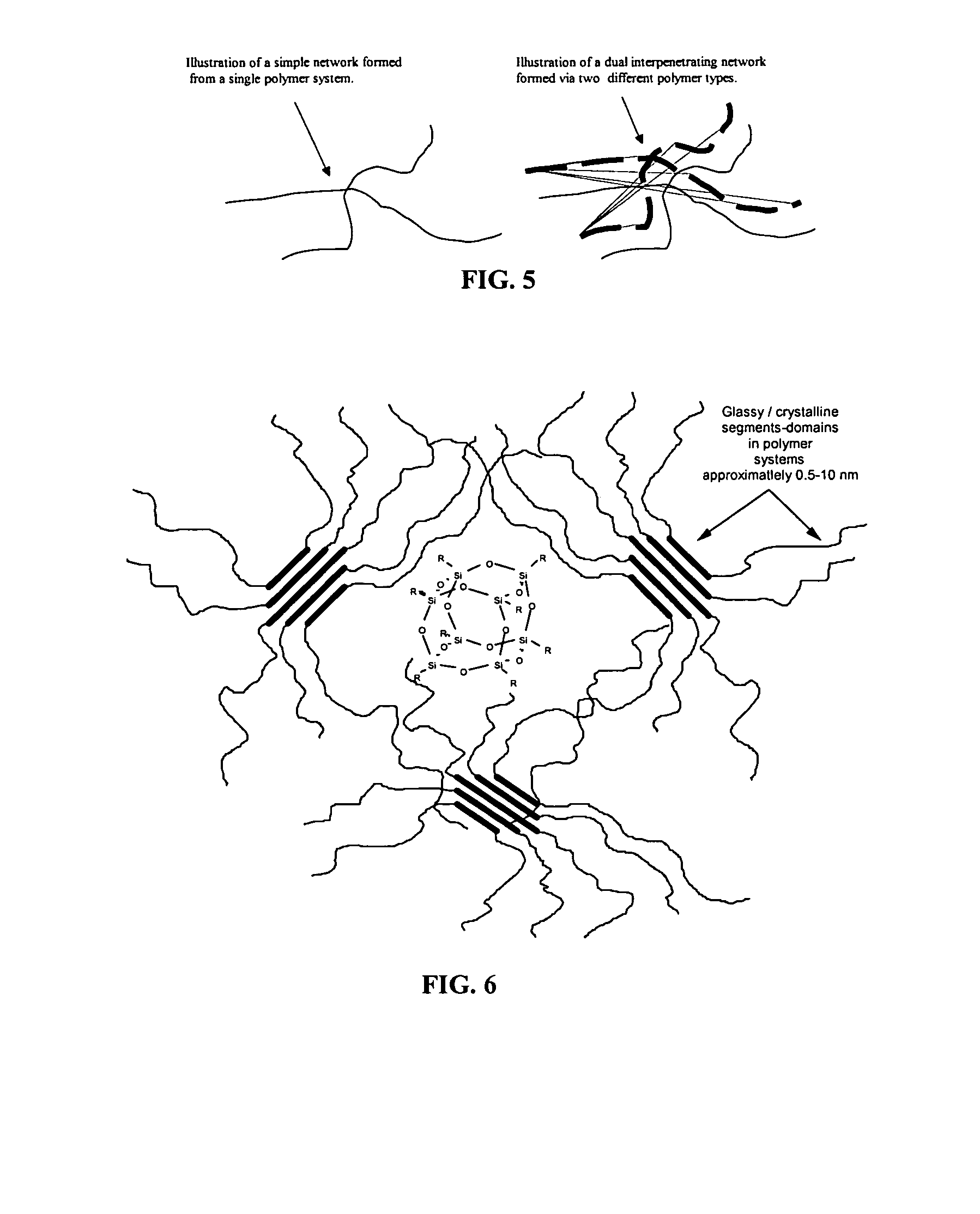

InactiveUS7193015B1Reduce melt viscosityLow dielectric constantMaterial nanotechnologyMolecular levelCompression set

A method of using nanostructured chemicals as alloying agents for the reinforcement of flouropolymer microstructures, including polymer coils, domains, chains, and segments, at the molecular level. Because of their tailorable compatibility with fluorinated polymers, nanostructured chemicals can be readily and selectively incorporated into polymers by direct blending processes. Properties most favorably improved are time dependent mechanical and thermal properties such as heat distortion, creep, compression set, shrinkage, modulus, hardness and abrasion resistance. In addition to mechanical properties, other physical properties are favorably improved, including lower thermal conductivity, fire resistance, and improved oxygen permeability. These improved properties may be useful in a number of applications, including space-survivable materials and creep resistant seals and gaskets. Improved surface properties may be useful for applications such as anti-icing or non-wetting surfaces or as low friction surfaces.

Owner:THE UNITED STATES OF AMERICA AS REPRESETNED BY THE SEC OF THE AIR FORCE

Methods and compositions for coating pipe

InactiveUS20040191439A1Improve stabilityHigh strengthSolid waste managementPretreated surfacesUltimate tensile strengthMechanical property

The present invention includes cement compositions and methods for using such cement compositions to coat pipe surfaces, particularly usefull for providing protection from hostile conditions that may otherwise lead to corrosion of the pipe surface. These cement compositions have improved mechanical properties including tensile strength, elasticity, and ductility.

Owner:HALLIBURTON ENERGY SERVICES INC

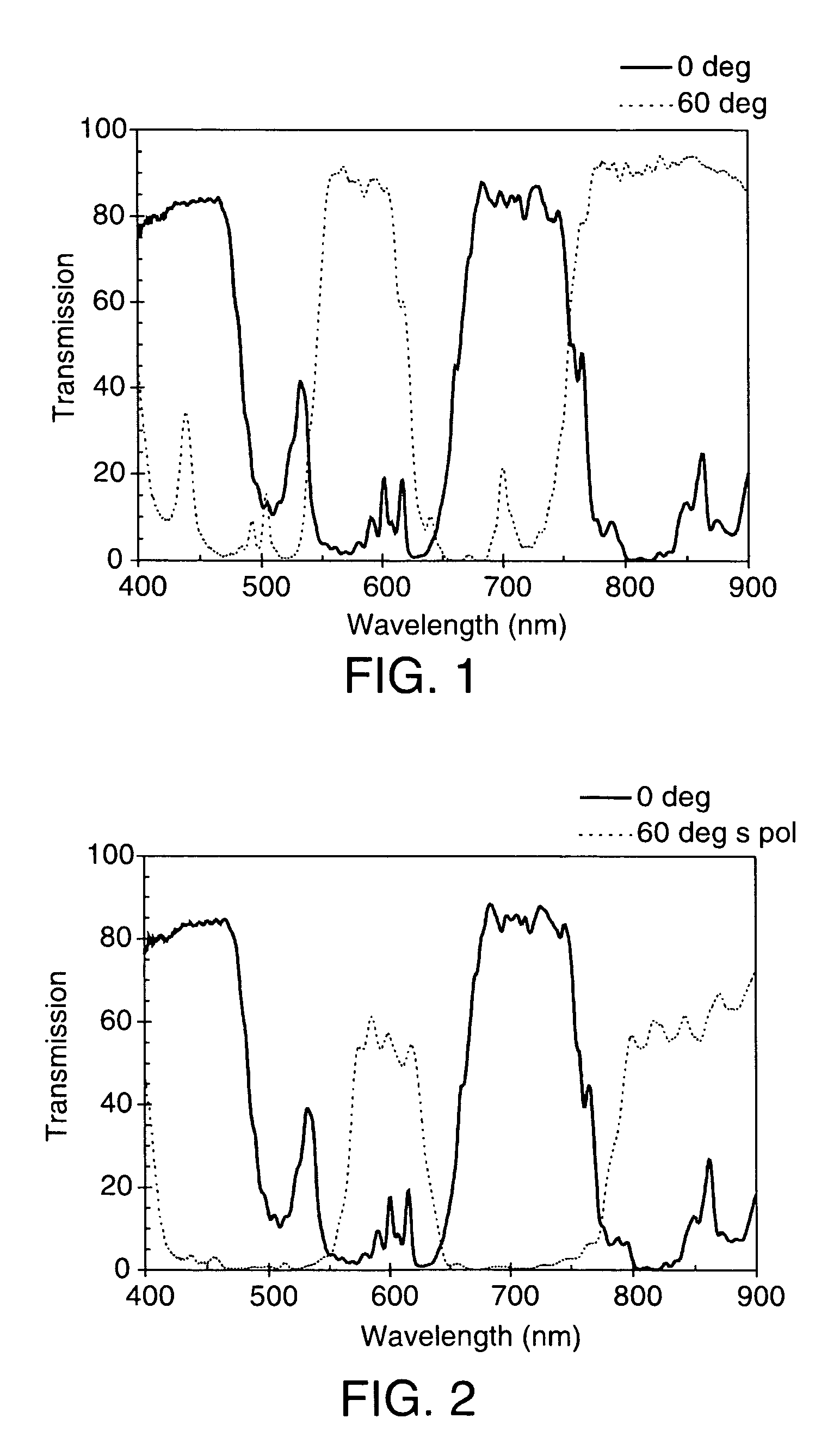

Red-green-blue polymeric interference film

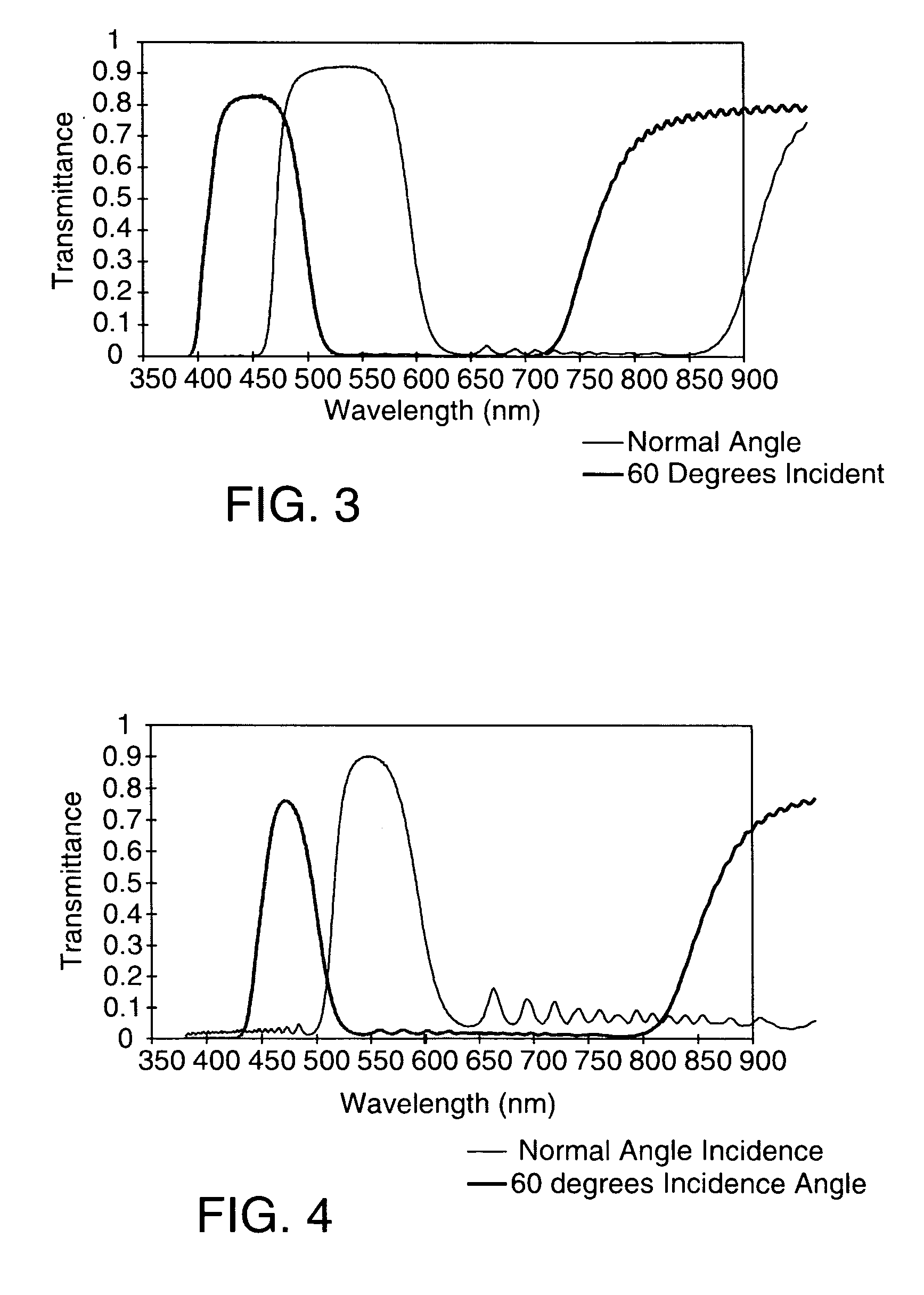

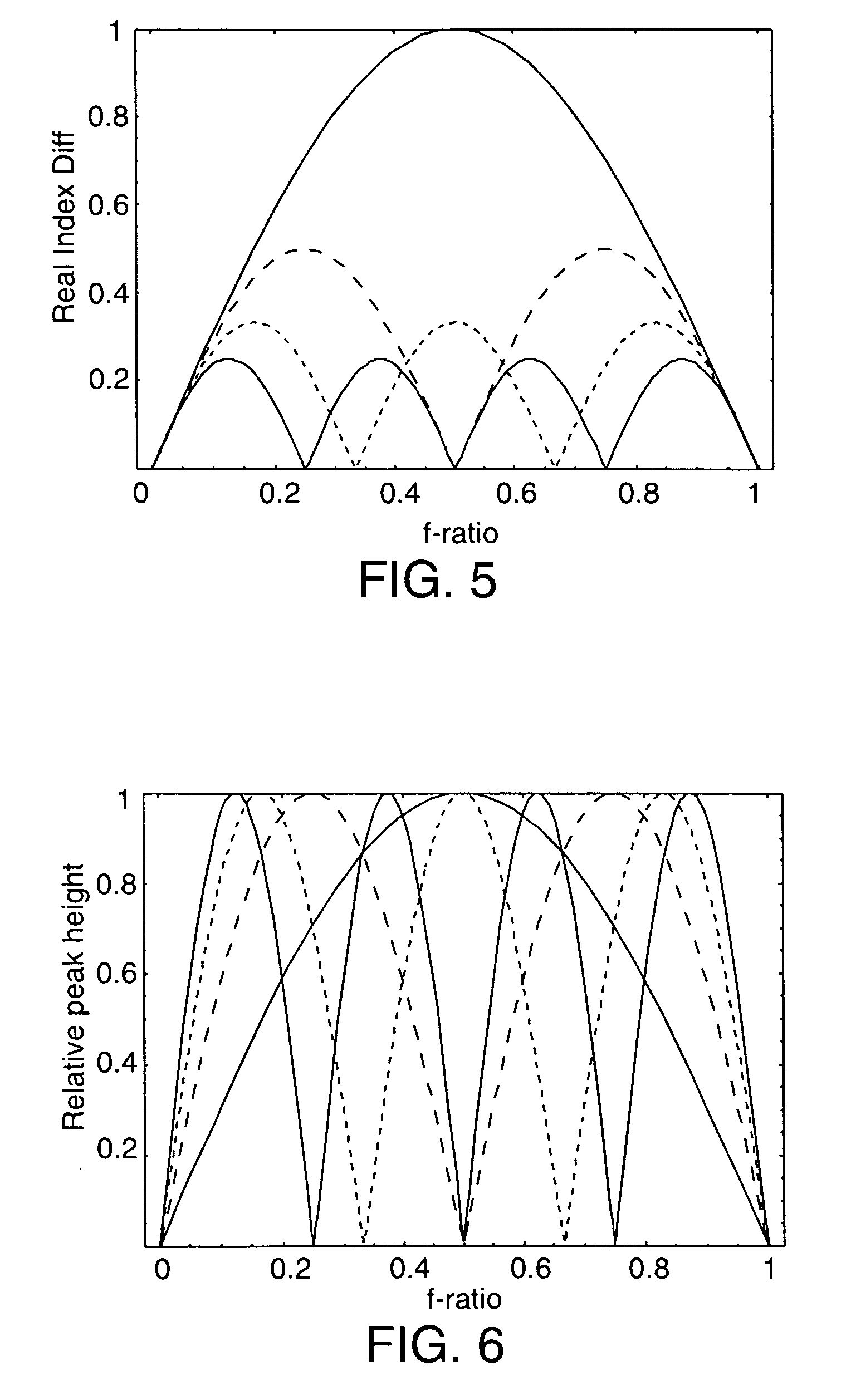

InactiveUS7138173B2Maximum color puritySharp color transitionMirrorsSynthetic resin layered productsPolarizerPolymer

Multilayer polymeric films and other optical bodies are provided which is useful in making colored mirrors and polarizers. The films are characterized by a change in color as a function of viewing angle.

Owner:3M INNOVATIVE PROPERTIES CO

Super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and manufacturing method

The invention relates to a super-thick steel plate for low yield ratio buildings with 460 MPa grade yield strength and a manufacturing method, which belongs to the technical field of high strength low alloy construction steel. The steel pipe comprises the following components by weight percent: 0.14 to 0.18 percent of C, 0.35 to 0.45 percent of Si, 1.40 to 1.50 percent of Mn, 0.025 to 0.035 percent of Nb, 0.040 to 0.050 percent of V, 0.010 to 0.020 percent of Ti, smaller than 0.020 percent of P, and the balance Fe. The rolling technology is as follows: the heating temperature is 1220 to 1250 DEG C, the tapping temperature is 1200 to 1230 DEG C, and two stages (ausrenitic recrystallization region and ausrenitic non-recrystailization region) are used for controlling rolling. The heat treatment technology is as follows: steel plates, the thickness of which is larger than or equal to 80 mm, are obtained after controlled rolling and cooling are carried out on continuously cast bloom, a two-phase region is heated up to 800 to 850 DEG C and insulated for 10 to 20 minutes, and then water quenching is adopted and the final cooling temperature is controlled to be less than or equal to 100 DEG C; 450 to 600 DEG C tempering treatment is carried out on the quenched steel plates, and finally the high strength low alloy construction steel plates are obtained. The steel plate not only has excellent comprehensive mechanical properties, but also lowers the cost and reduces the waste of resources.

Owner:SHOUGANG CORPORATION

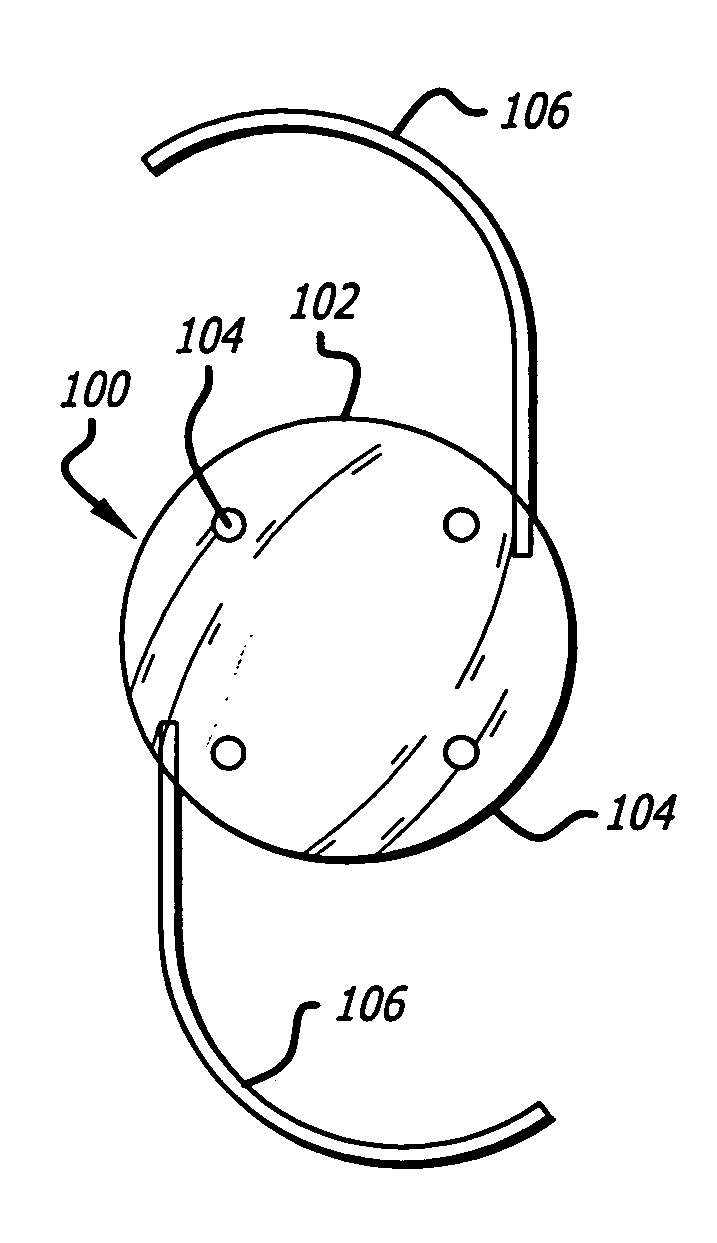

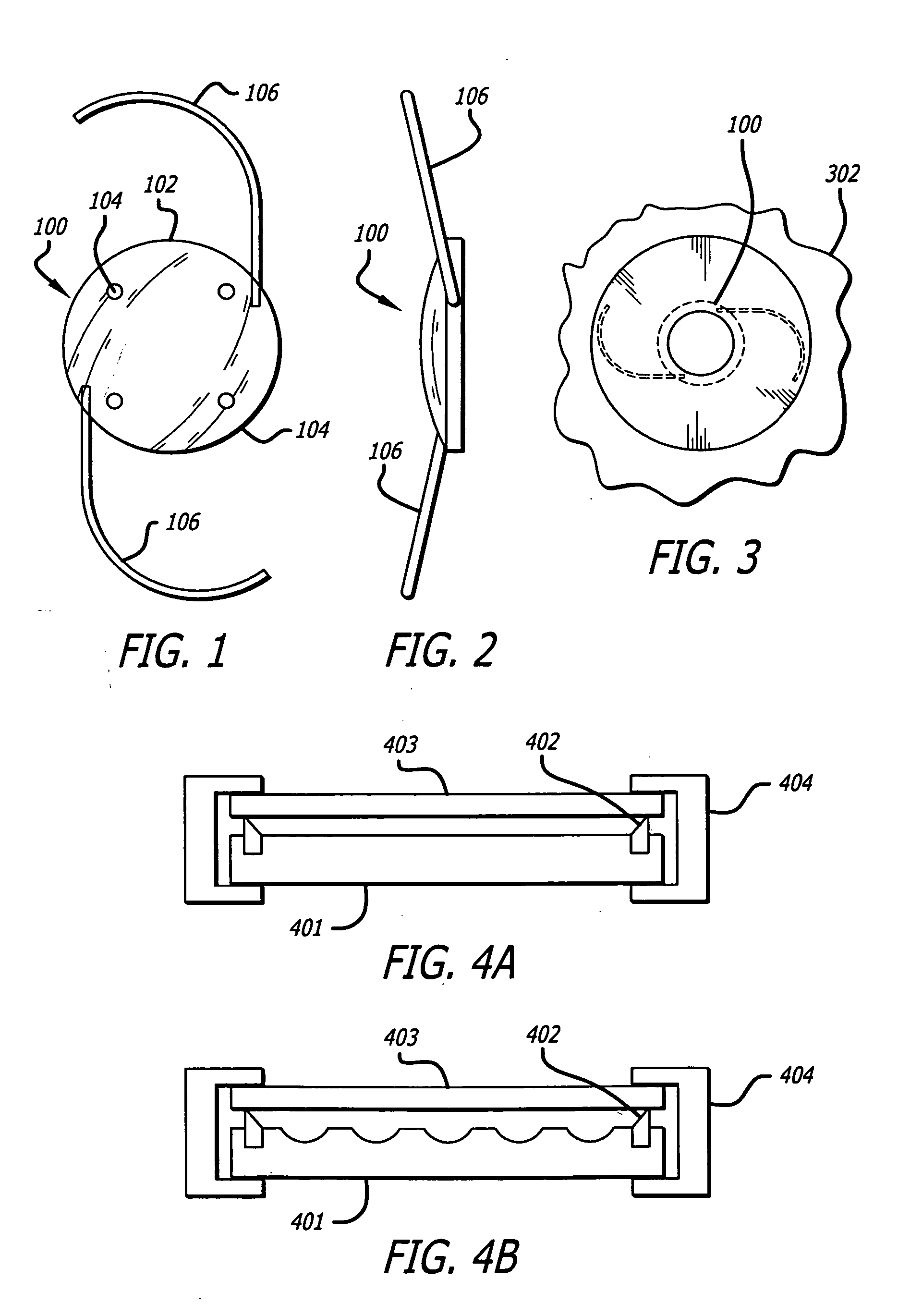

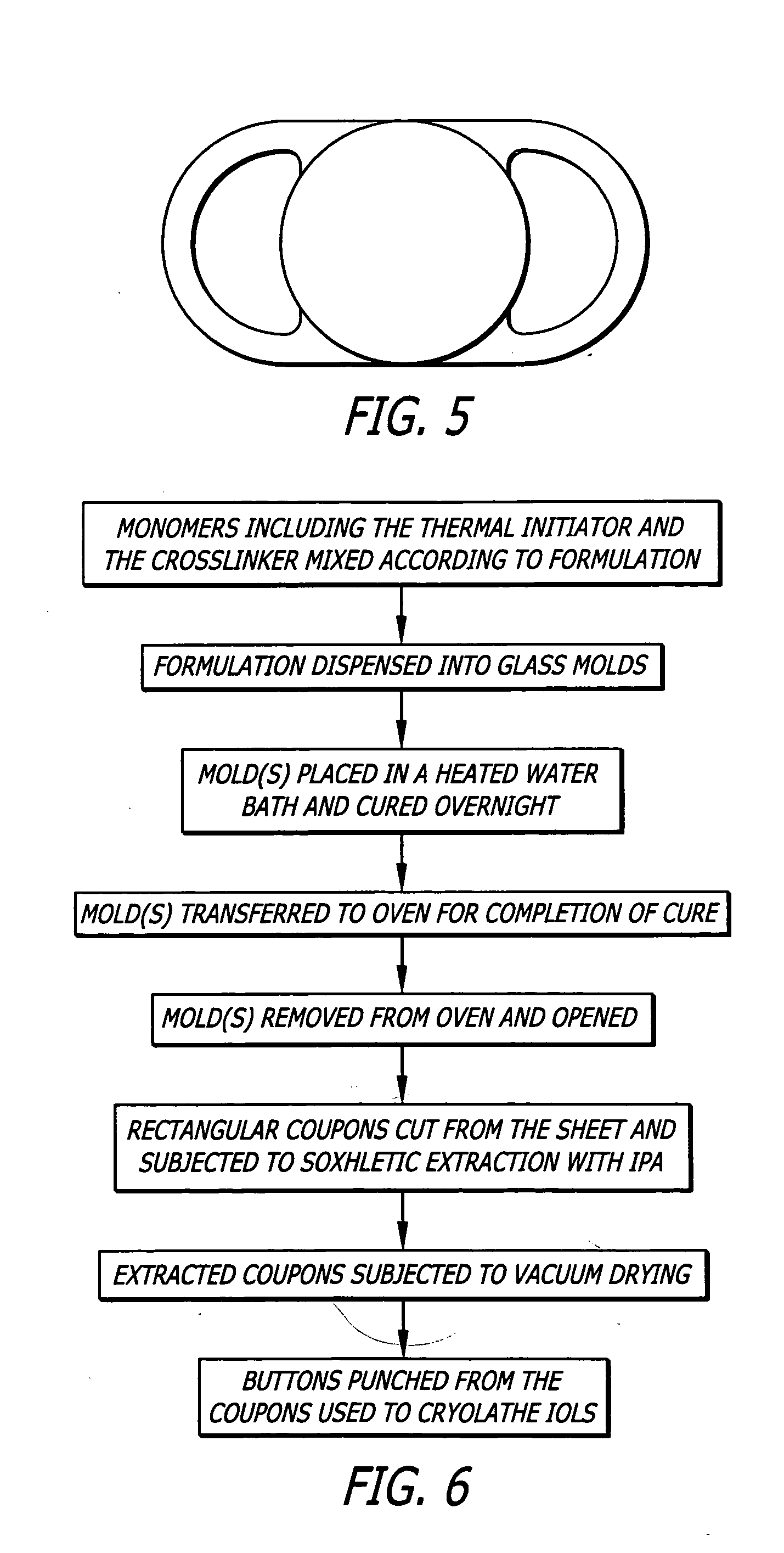

Intraocular lens materials suitable for insertion through a small bore cartridge

InactiveUS20050143751A1Low tensile strengthMinimal cartridge crazingEye treatmentIntraocular lensIntraocular lensMedicine

A polymer material useful for manufacturing an intraocular lens (IOL) suitable for insertion through an IOL inserter barrel having an inner diameter of less than 3 mm is provided. Specifically, acrylic-silicone hybrids having a tensile strength of approximately 100 psi to 400 psi and a percent elongation at break of between 50% and 400% are disclosed.

Owner:JOHNSON & JOHNSON SURGICAL VISION INC

Laminate with Aroma Burst

InactiveUS20100323134A1Low tensile strengthContainer decorationsLevel indicationsPolyolefinActive core

The present invention is a laminate and resultant package expressing an aroma burst. The laminate or package is comprised of a polyolefin sealing layer; a pressure sensitive adhesive layer and microcapsules containing an active core material, the microcapsules dispersed in a resealably tacky pressure sensitive adhesive layer; the pressure sensitive adhesive sandwiched between at least two layers by being disposed along substantially an entire surface of the polyolefin sealing layer and in continuous and direct contact with a second polyolefin layer opposing and coextensive with the polyolefin sealing layer; and the microcapsules in the pressure sensitive adhesive layer having less tensile strength than the adhesive such that a fraction of the microcapsules rupture releasing core material such as an aroma or fragrance when the pressure sensitive adhesive layer is separated when the polyethylene and first polyolefin layers sandwiching the pressure sensitive adhesive are pulled apart. The laminate polyolefin sealing layer can have a portion such as one or more edge areas that are sealed to itself or a second laminate forming a lumen or chamber area. The lumen area is physically isolated from the pressure sensitive adhesive and microcapsule layer by a polyolefin layer until the polyolefin layer is ruptured.

Owner:CHARTER NEX FILMS

Rubber compositions

InactiveUS20010053813A1Reduced wear resistance requirementsReduced processabilityRoof covering using tiles/slatesEmulsion paintsButadiene DioxideEngineering

The present invention provides a rubber composition which has satisfactory processability and dimension stability, exhibits excellent tensile strength and wearing resistance, and the like when vulcanized and is useful as a material for an industrial product such as a rubber roll, a grinding roll, a belt, a hose and a rubber-coated fabric, a shoe part for example of a transparent shoe, a tire of a large-sized or small sized car such as a tread and a side wall and a sanitary material such as a contraceptive rubber or the like. A rubber composition of the invention comprises (1) a crosslinked rubber particle containing as repeating units (a) 39.89 to 79.89% by weight of a conjugated diene unit such as 1,3-butadiene or the like, (b) 20 to 60% by weight of an aromatic vinyl unit such as styrene, (c) 0.01 to 10% by weight of a monomer unit having at least two polymerizable unsaturated group such as divinylbenzene, and the like, and (d) 0.1 to 30% by weight of a monomer unit having one polymerizable unsaturated group and an amino group such as vinylbenzylmethylamine, and the like and (2) a conjugated diene / aromatic vinyl copolymeric rubber such as styrene-butadiene copolymeric rubber and the like.

Owner:JSR CORPORATIOON

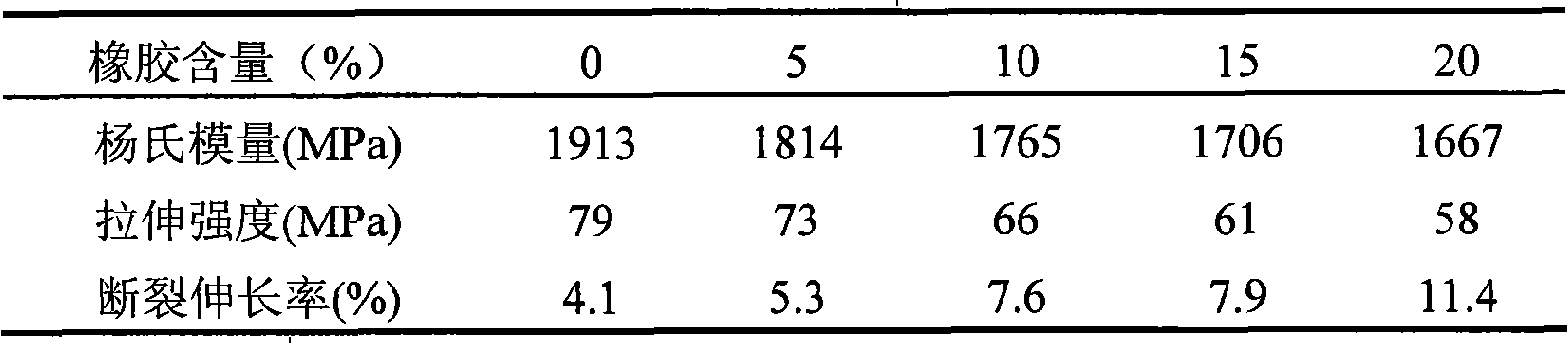

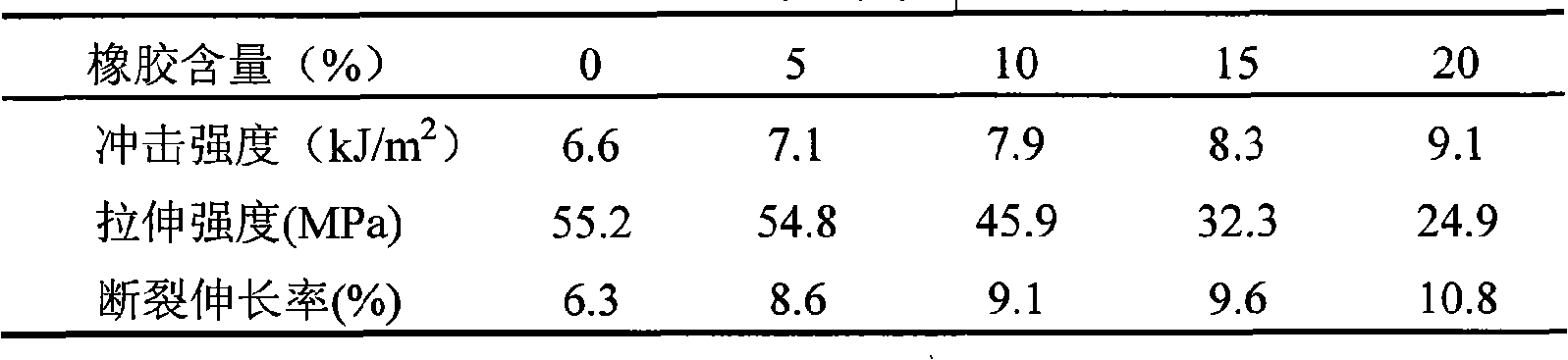

Method for preparing reactive fluid rubber-epoxide resin polymer

The invention provides a method for preparing reactive fluid rubber-epoxide resin polymer, and belongs to the technical field of modified epoxide resin. The method comprises the following steps: 5 to 50 portions of reactive fluid rubber containing carboxyl or hydroxyl as a modifier, and 0.1 to 2.0 portions of catalyst are added into 100 to 200 portions of epoxide resin by weight; when the reactive fluid rubber containing the hydroxyl is used as the modifier, isocyanate or estolide with the same weight portion as the epoxide resin is required to be added; and an active group in the reactive fluid rubber reacts with an epoxide group in the epoxide resin for 2 to 6 hours at a temperature of between 100 and 180 DEG C to prepare the reactive fluid rubber-epoxide resin polymer with excellent toughness. The modified epoxide resin has improved toughness, non organic solvent is used in the whole synthesizing process, non environmental pollution is caused, the synthesizing process is simple and easily controlled, and the problem is not found in amplification experiments carried out for small amount, medium amount and large amount respectively, so that the method is applicable to industrial production.

Owner:JIANGNAN UNIV

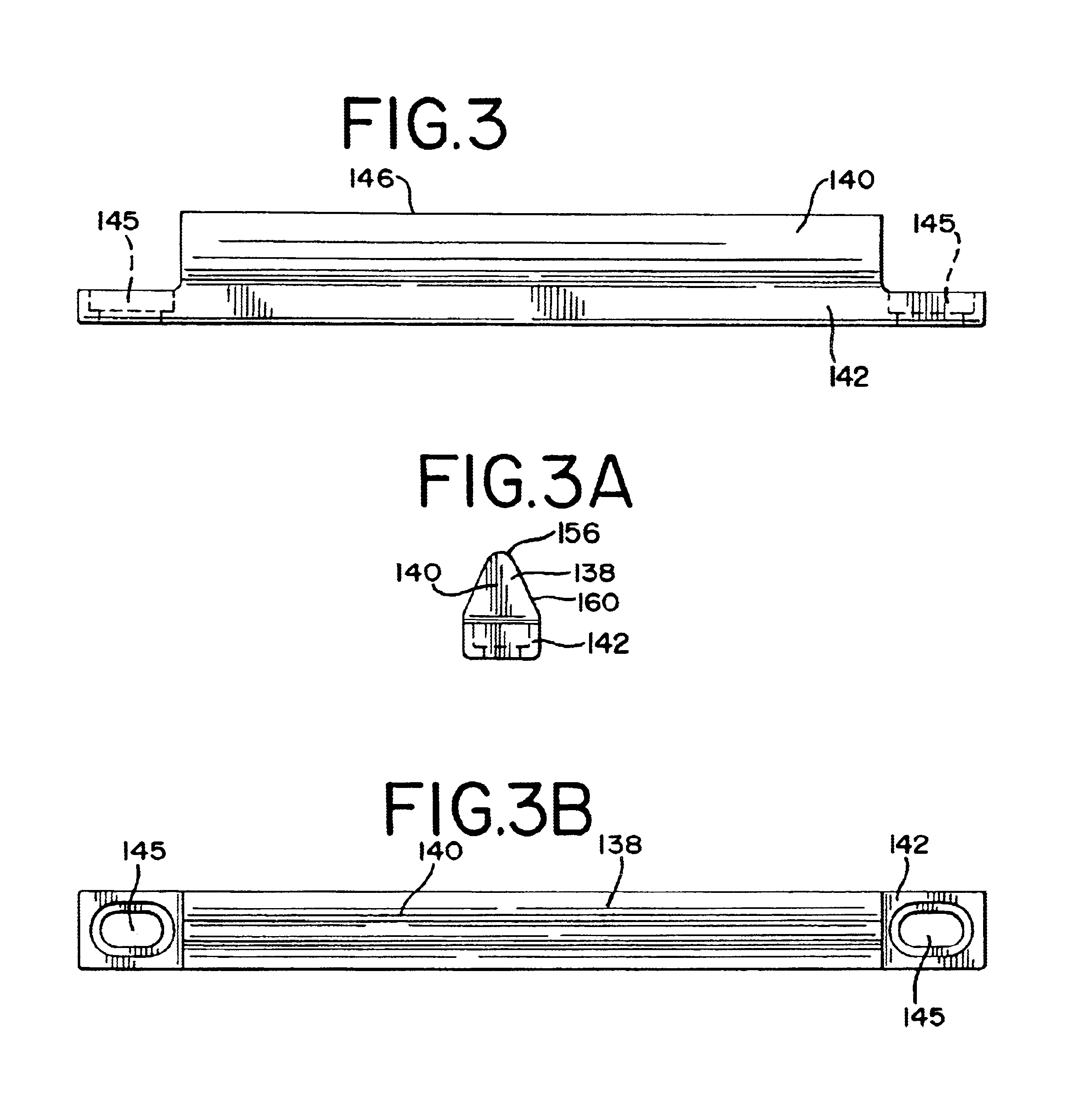

Method for weakening a portion of a web

InactiveUS6838040B2Easily brokenLow tear strengthButtonsMechanical working/deformationEngineeringUltimate tensile strength

A method for weakening a portion of a web includes moving a web in a machine direction between at least a first location and a second location, wherein the second location is positioned downstream of the first location, forming a line of weakness in the web at the first location, wherein the web has a first tensile strength across the line of weakness, and weakening the line of weakness at a second location, wherein the web has a second tensile strength across the line of weakness after the line of weakness is weakened at the second location and wherein the first tensile strength is greater than the second tensile strength.

Owner:KIMBERLY-CLARK WORLDWIDE INC

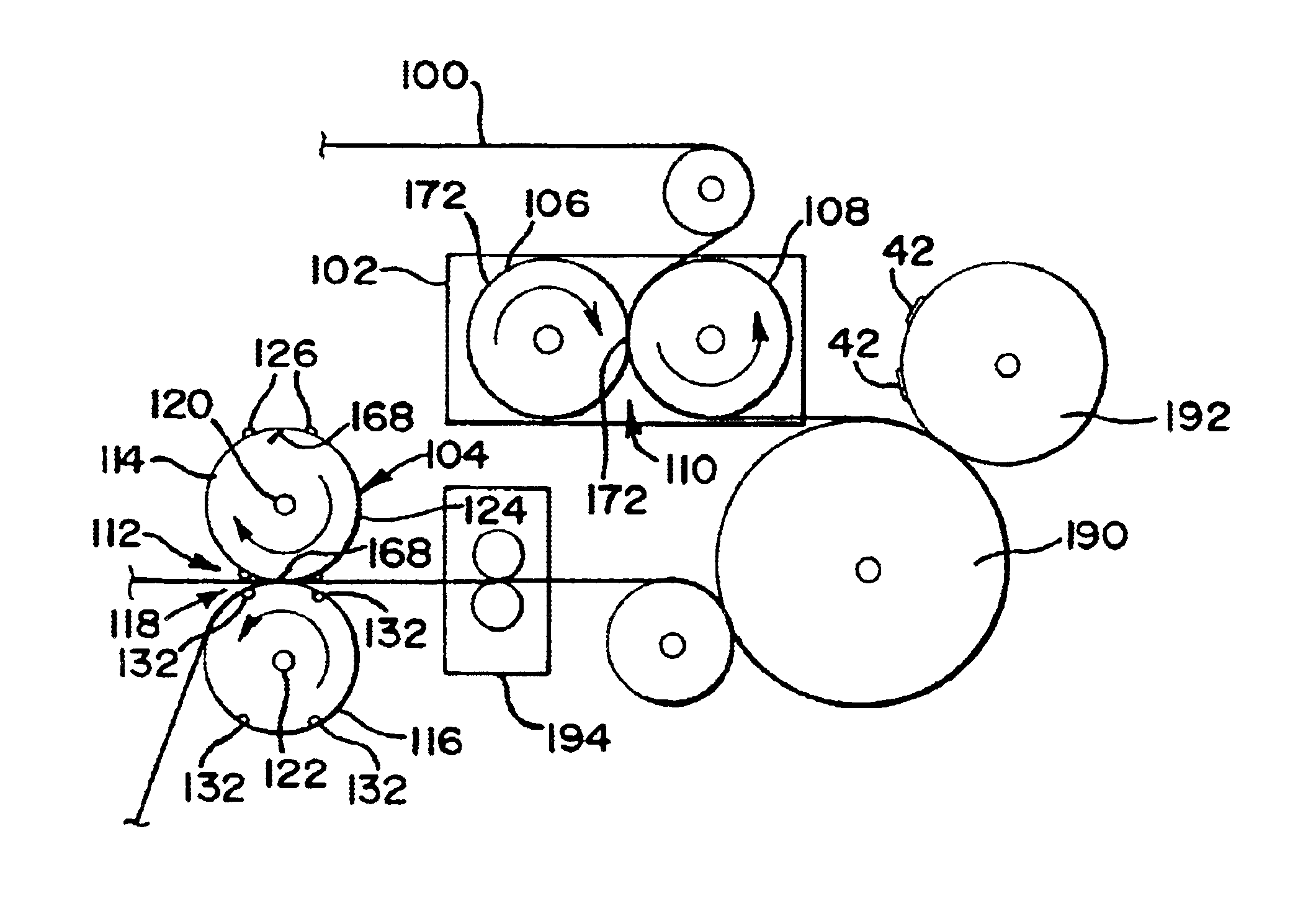

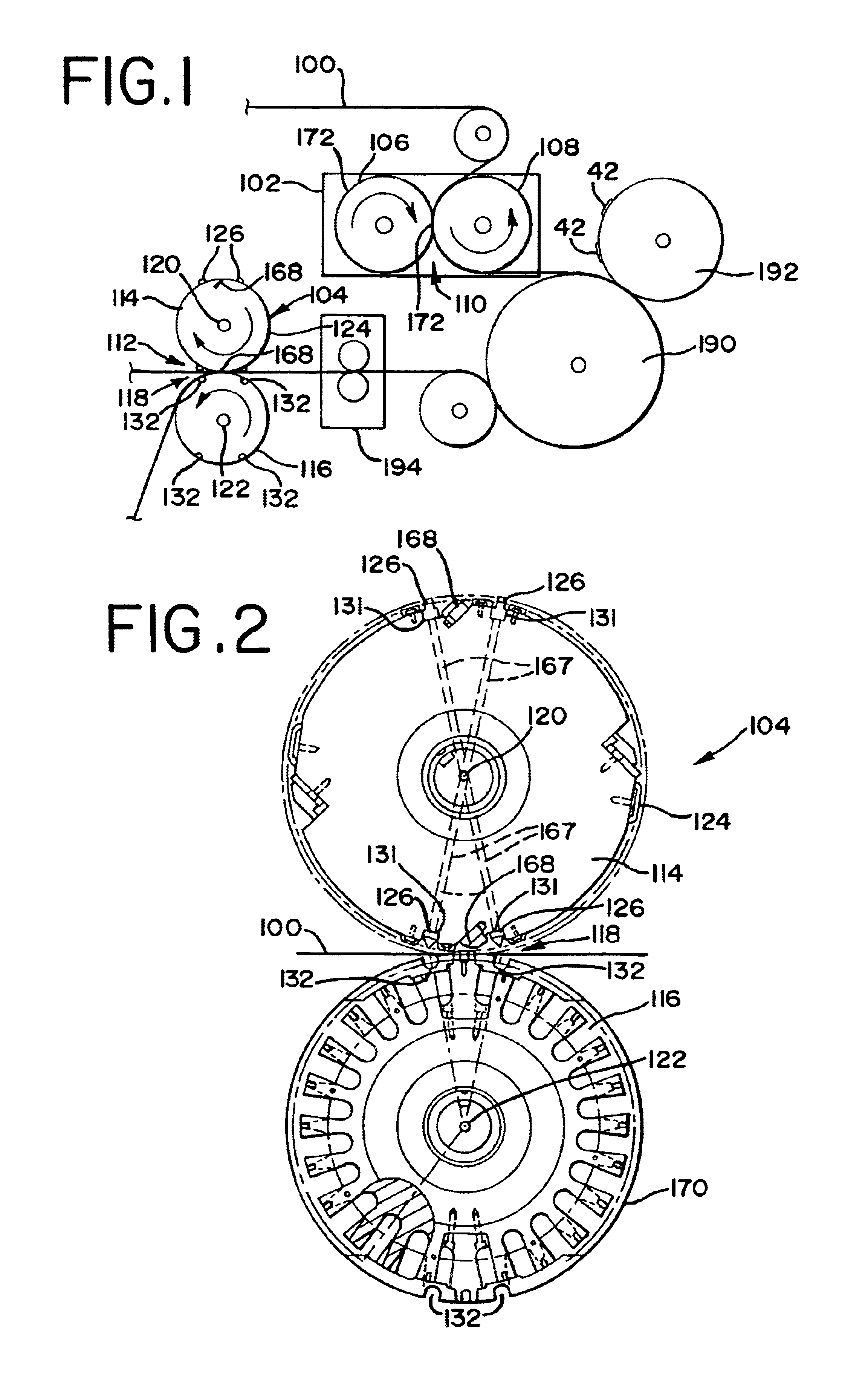

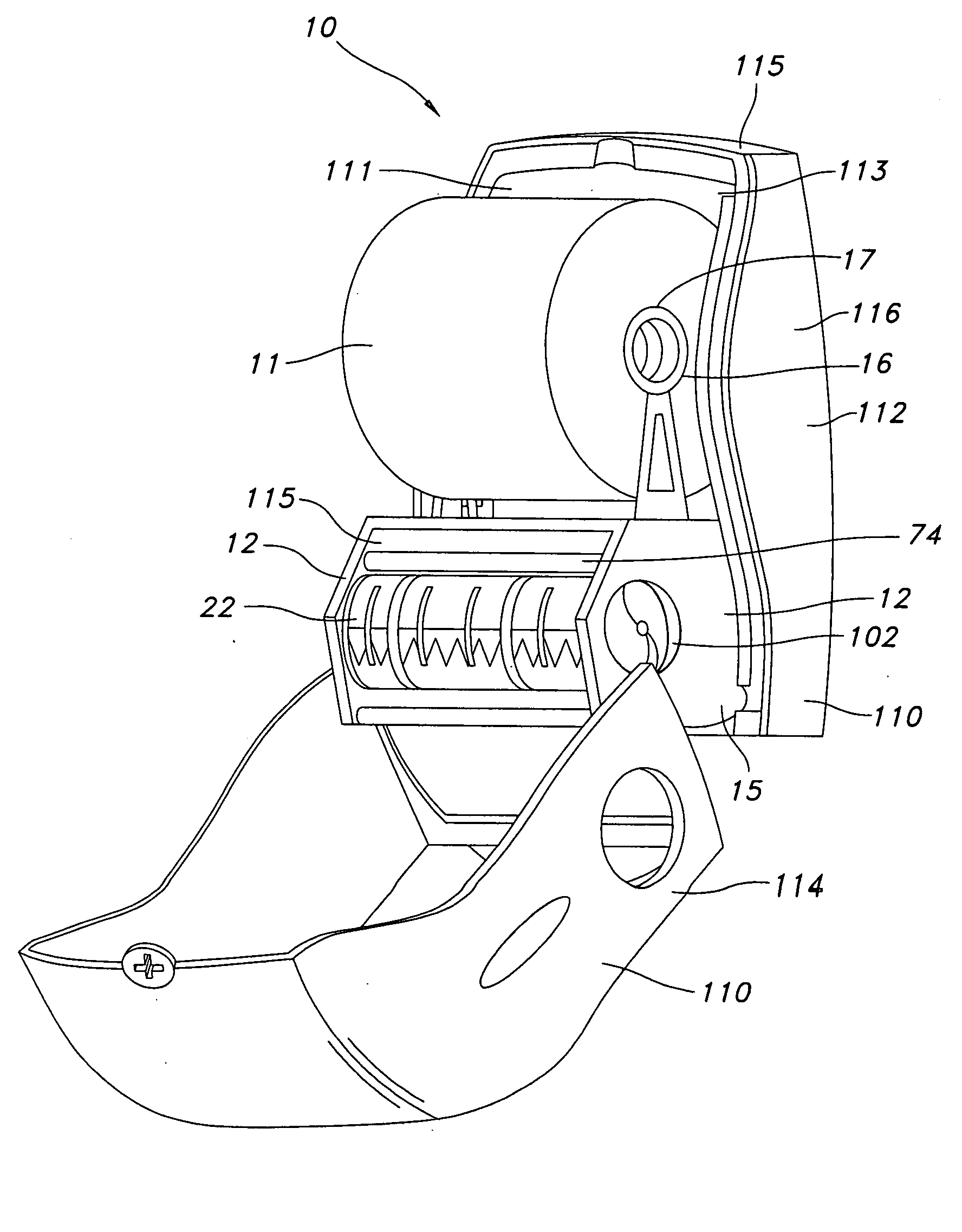

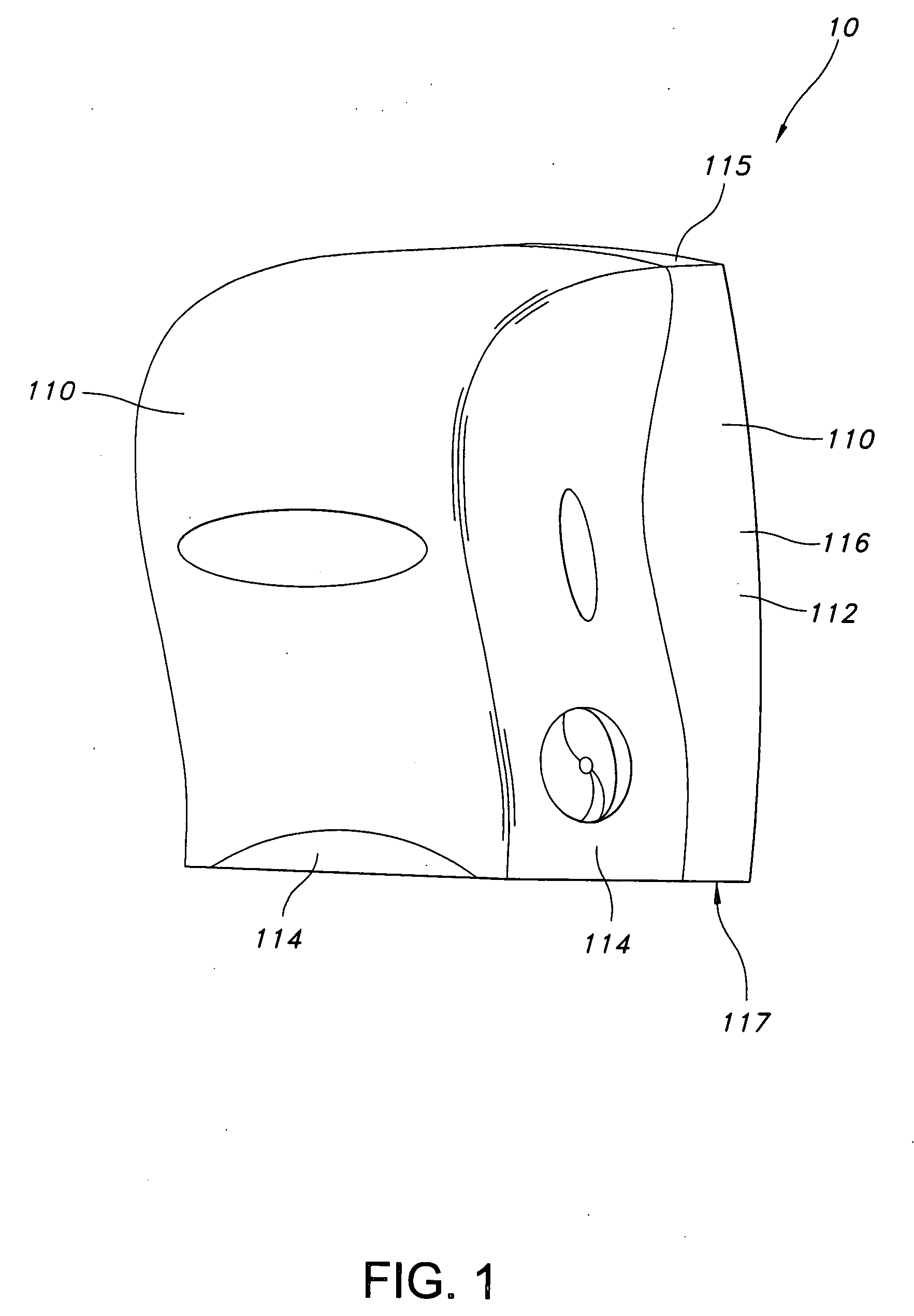

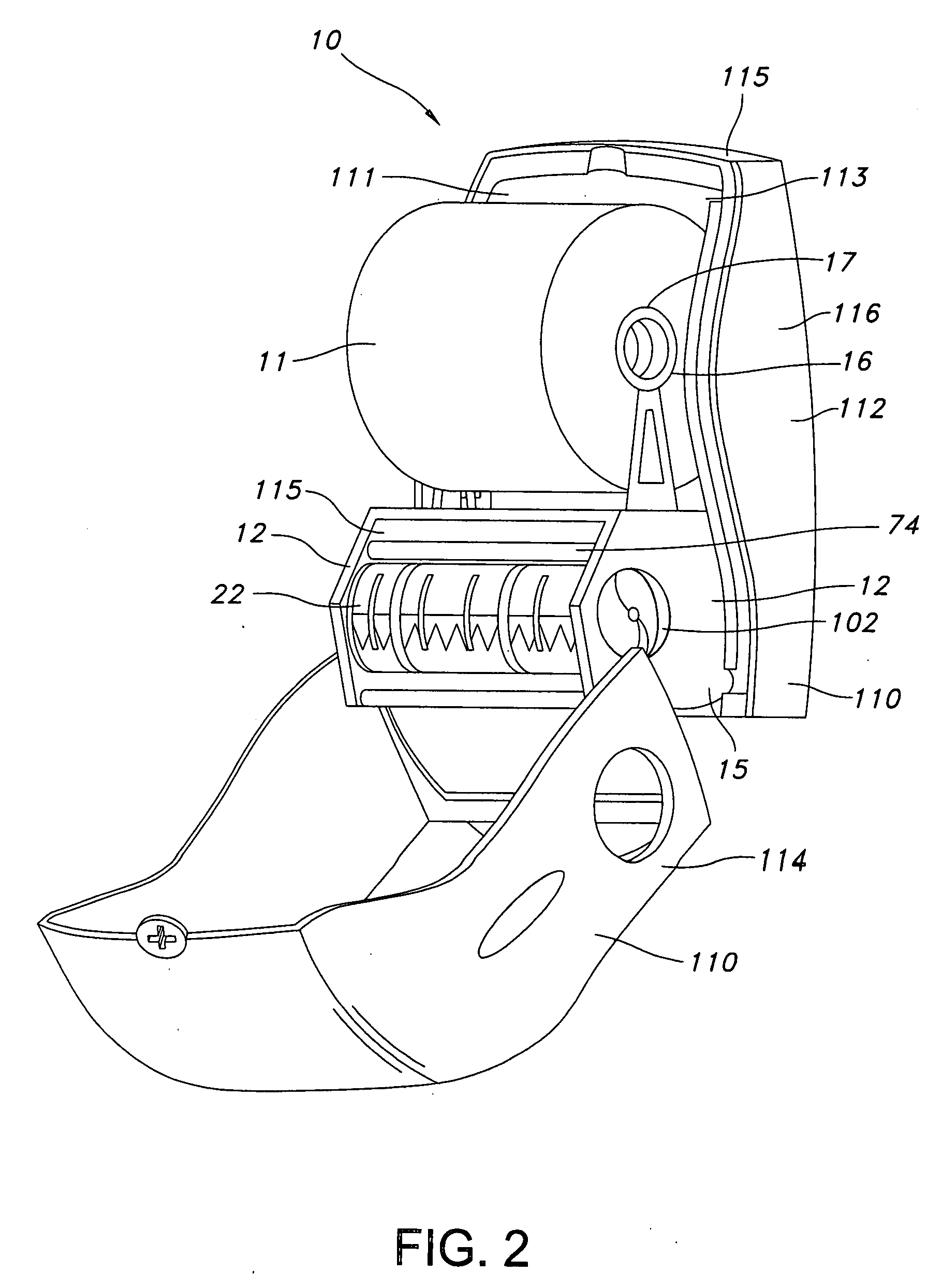

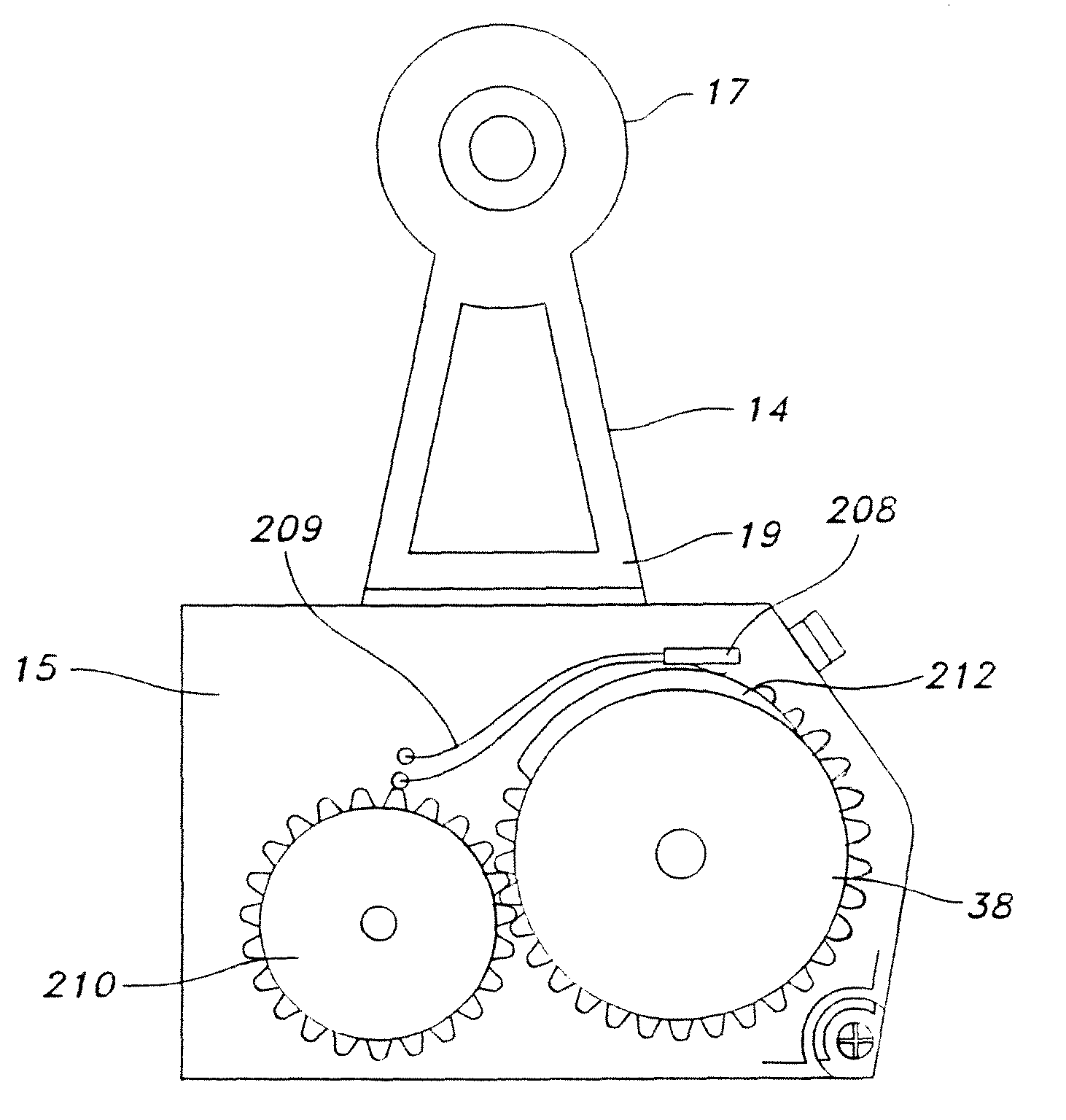

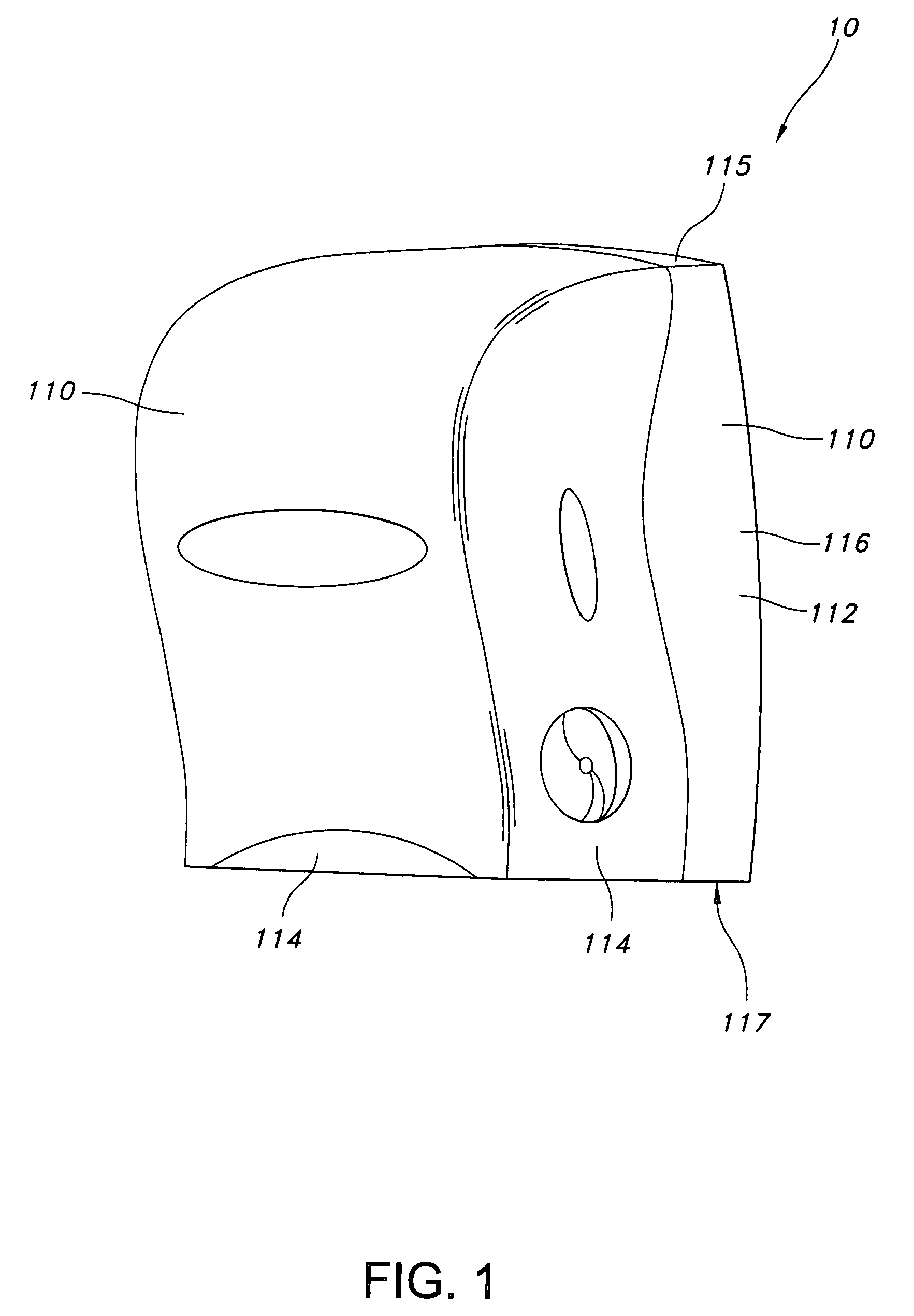

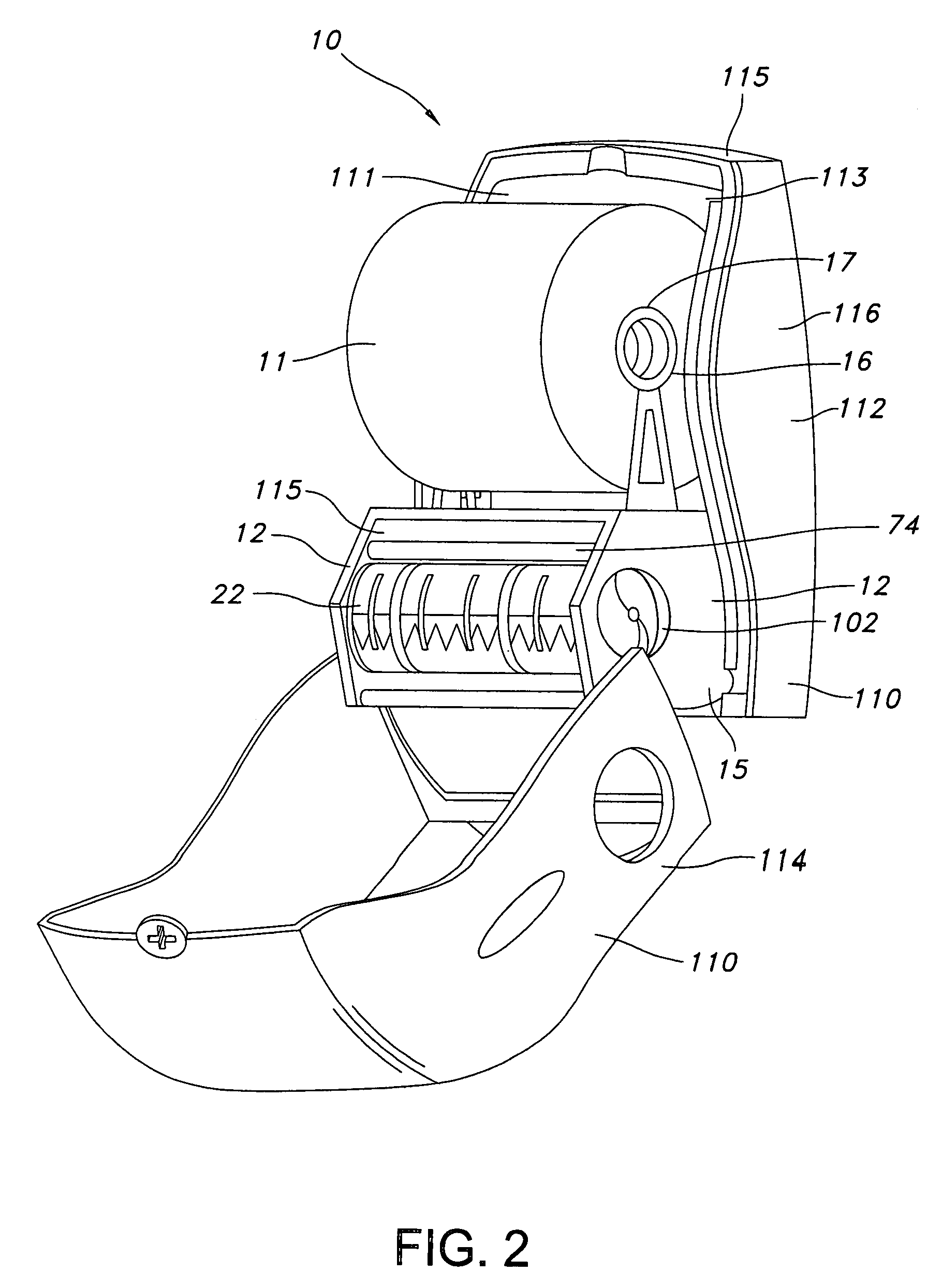

Electro-manual dispenser

ActiveUS20090140001A1Low tensile strengthLess pulling forceCoin-freed apparatus detailsStock shearing machinesPaper towelEngineering

Disclosed is a sanitary or no-touch dispenser which dispenses sheets of a web material, such as a paper towel. The disclosed dispenser provides the web material to a user by using both manual and electronic means to dispense the sheet. This is accomplished by having a motor engagably connected to an actuator roller. The motor is activated by a motor activation means, such as a switch. The motion of the actuator roller, which is started by the user grabbing and pulling a tail of the web material extending from the dispenser, causes the motor activation means to activate the motor which in turn drives the actuator roller to continue it its rotation motion to dispense the sheet from the dispenser.

Owner:KIMBERLY-CLARK WORLDWIDE INC

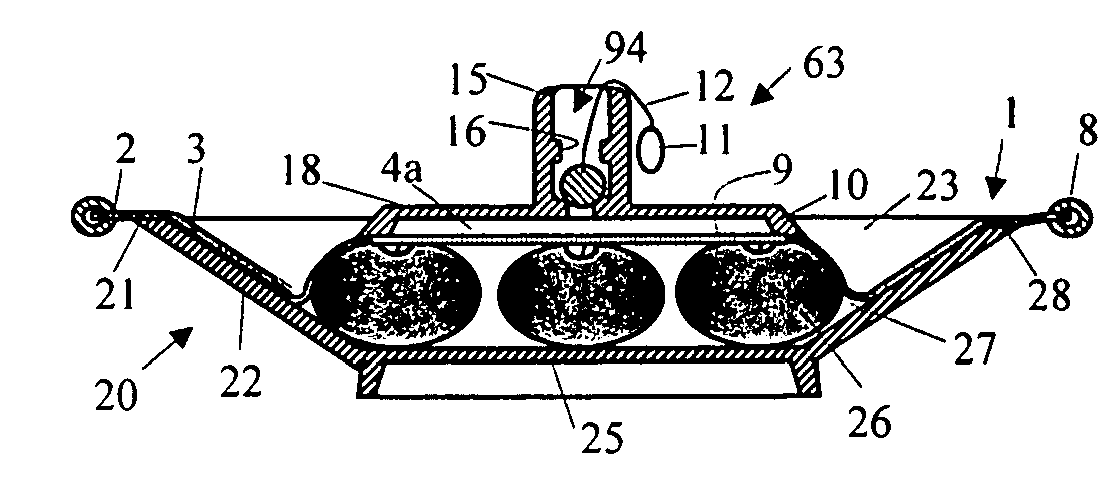

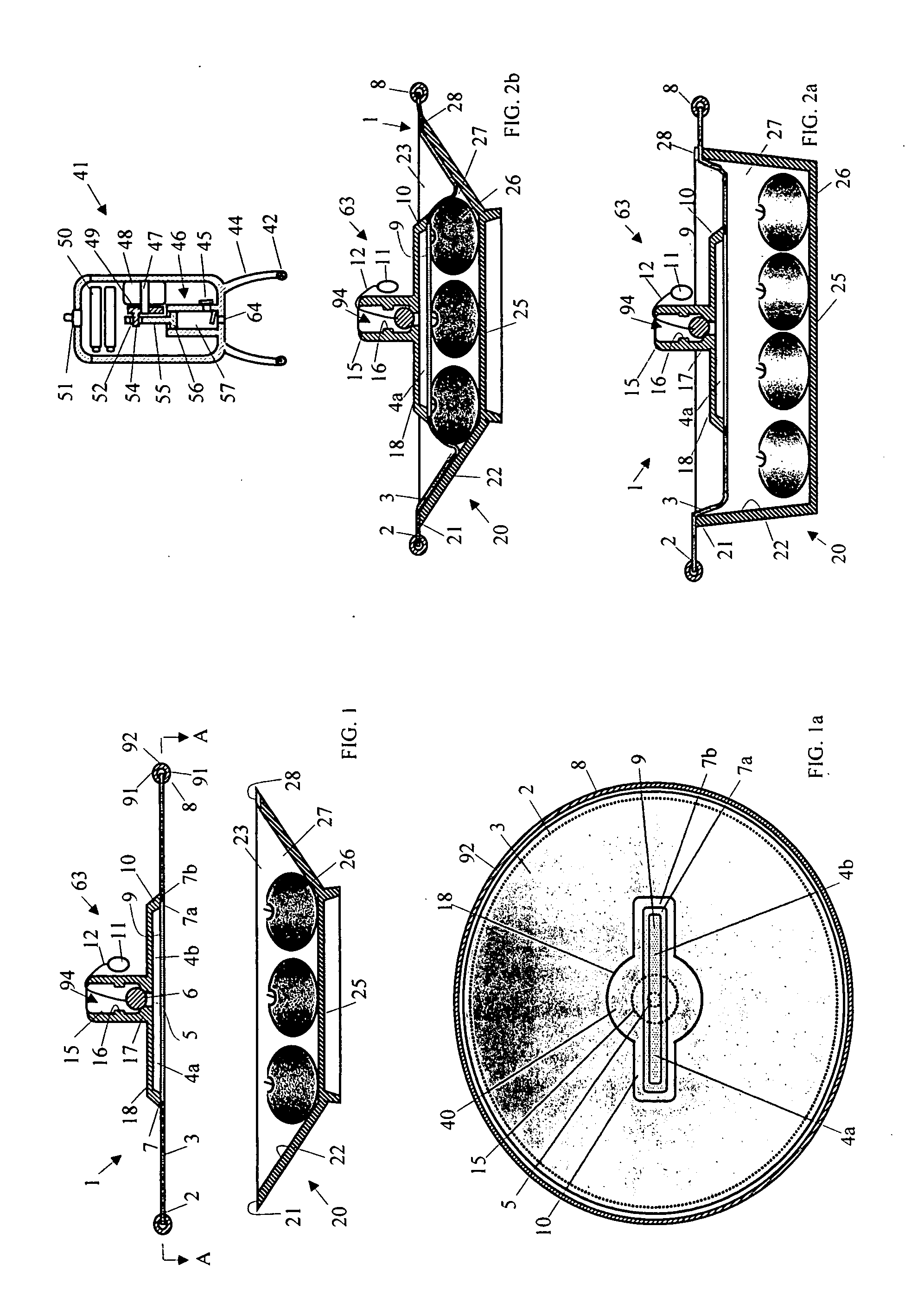

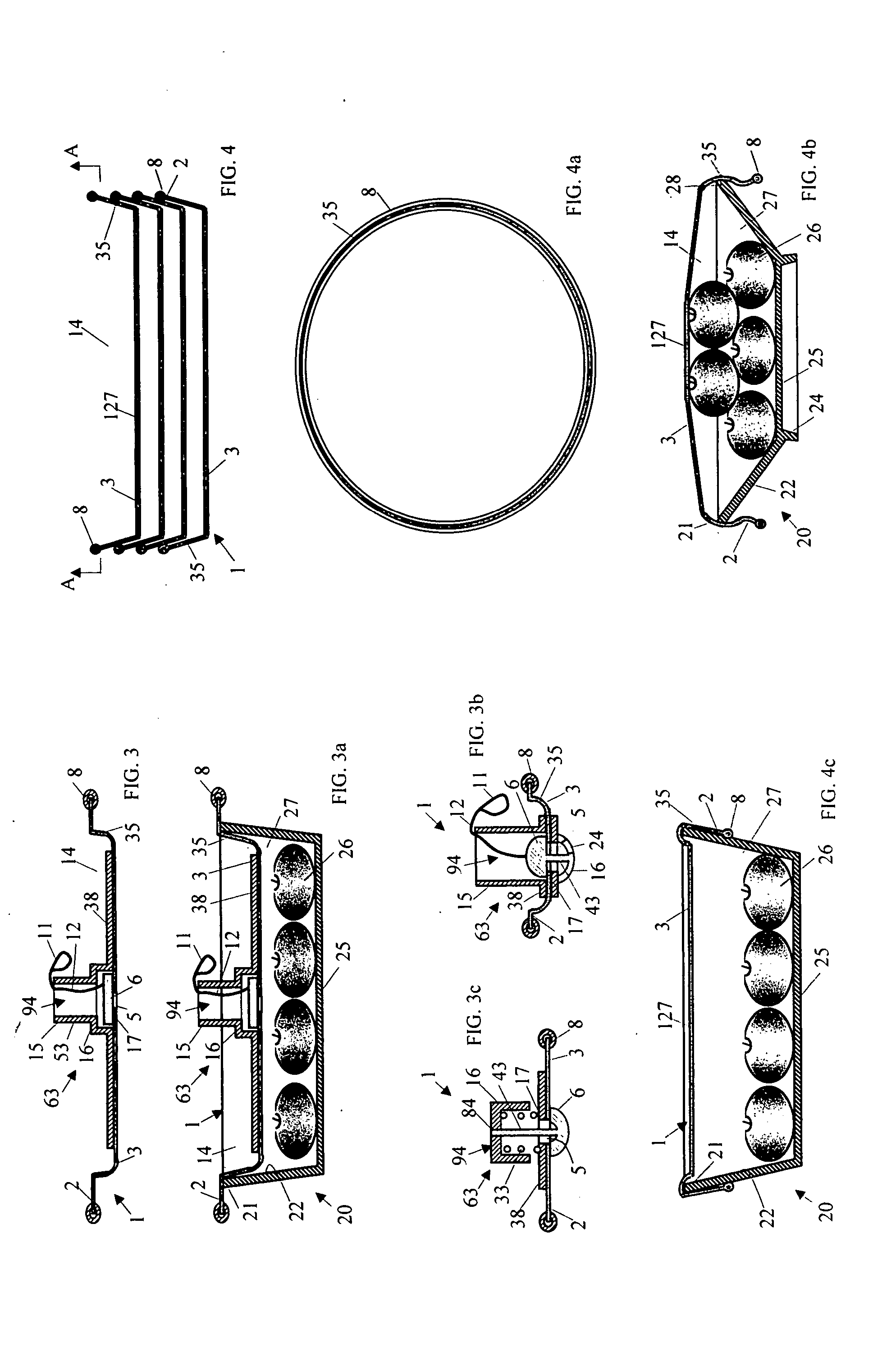

Airtight lid for container and method of use

InactiveUS20060032852A1Facilitated releaseElongate length of timeLidsHermetic sealMembrane deformation

A lid for forming an airtight seal to a bowl or dish plate to elongate the life of product therein comprises an impermeable membrane having an outer perimeter larger than the rim of the container and an enforcement ring for enabling the formation of an airtight seal between the membrane and rim of the container under vacuum. The membrane is sufficiently soft to cause it to fill the lower sections or imperfections on the rim, thus enabling the lid to form an airtight seal to almost all household containers. The membrane may be adapted to have sufficient low tensile stress, thereby preventing the vacuum in the container from imploding or collapsing the container even if it has a thin or weak wall. The enforcement ring has vertical and horizontal rings connected to the membrane perimeter to prevent the membrane deformation at both vertical and horizontal directions. The lid may further comprise an air evacuation passageway having an air collection chamber for extracting air from the container and a valve for allowing air to flow out of the container but preventing air from entering. In use, the lid may be sealed to a container by simply pushing the membrane into the container and releasing the membrane to generate a vacuum to affix the membrane to the container, or may be sealed to a container by connecting a vacuum generator to the evacuation passageway to evacuate the container.

Owner:CAI EDWARD Z

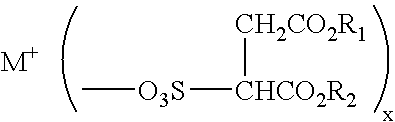

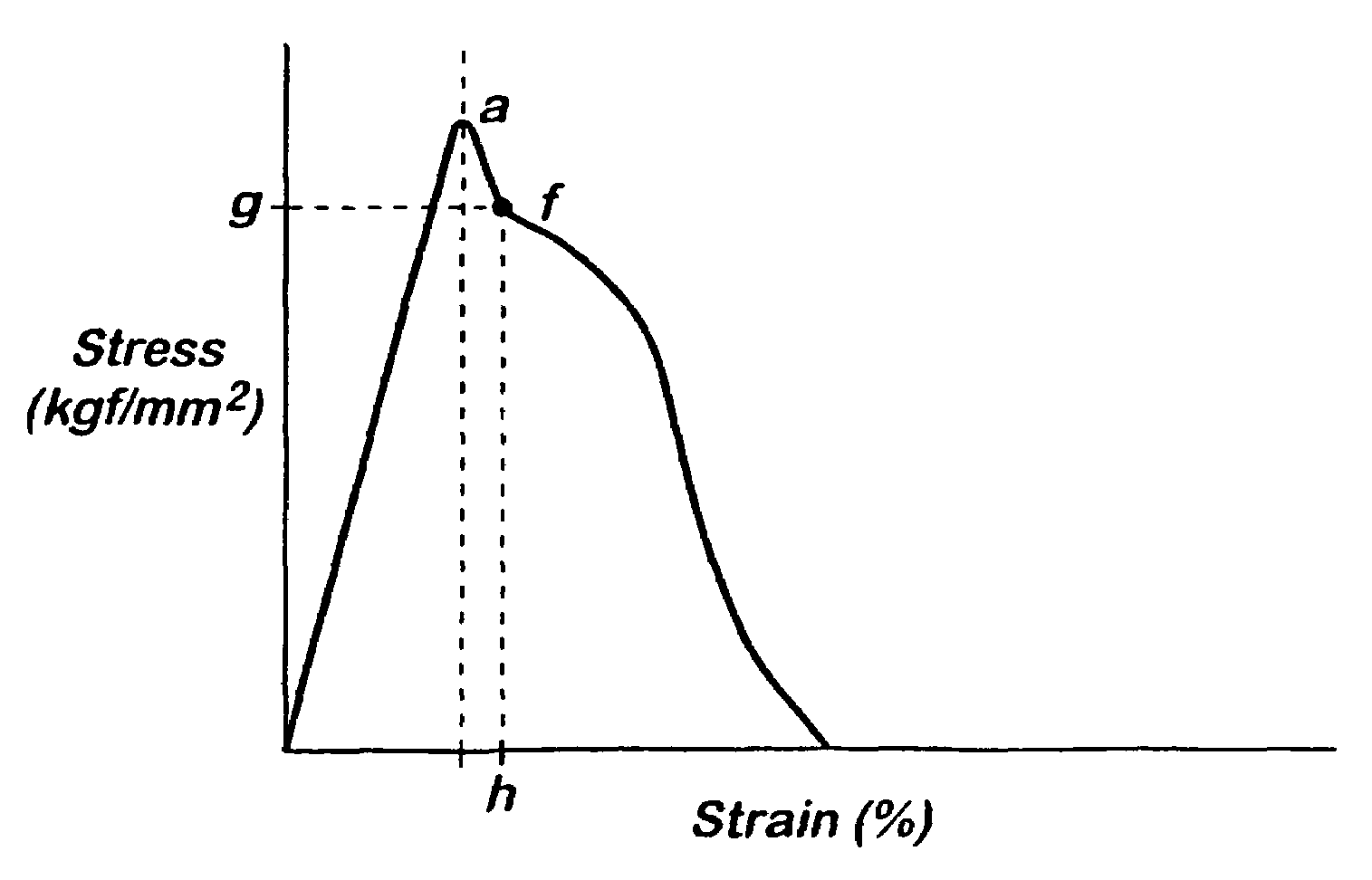

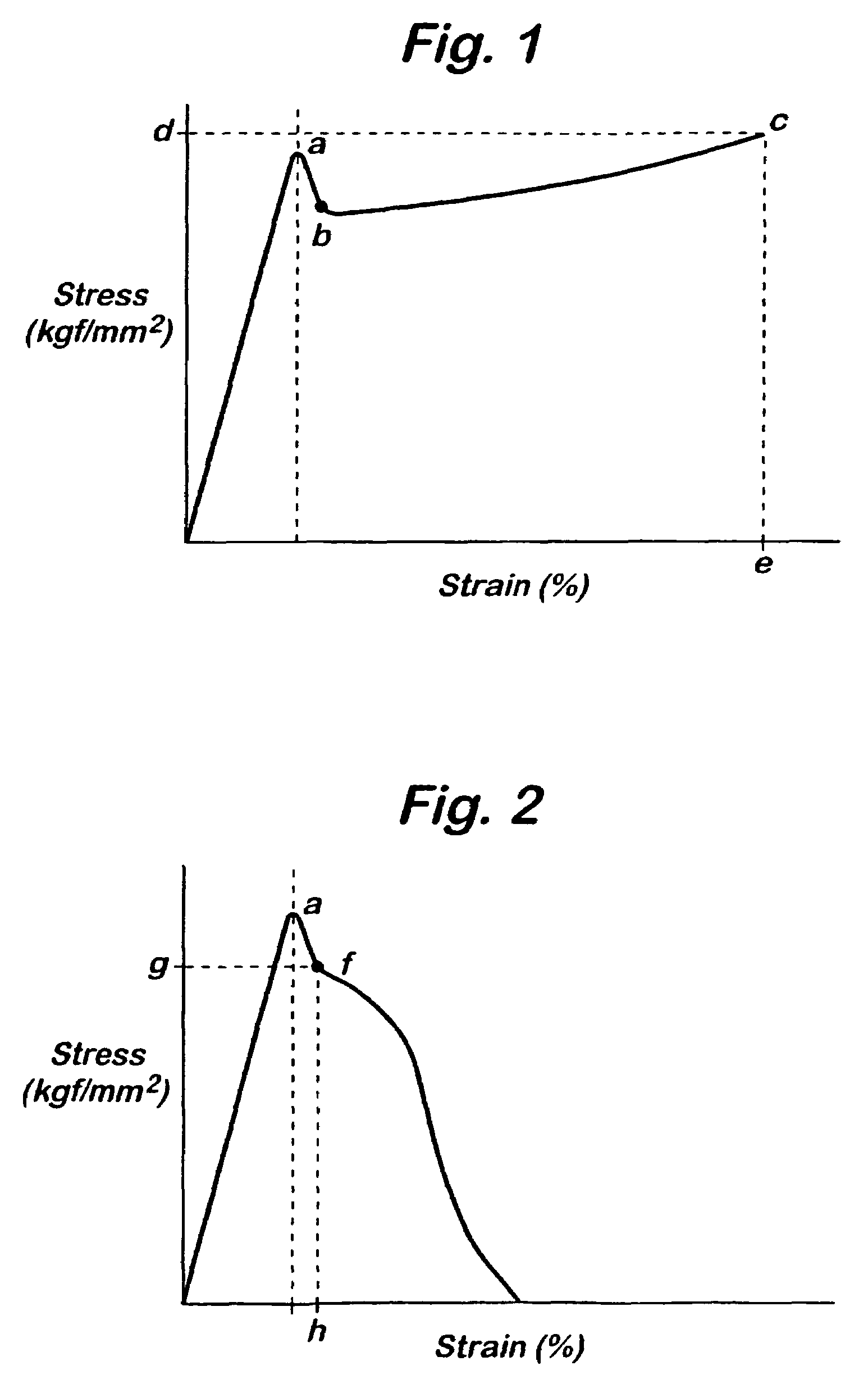

Process for the production of brittle polymeric film

InactiveUS7718104B2Enhance the imageLow tensile strengthStampsCeramic shaping apparatusCarboxylic acidPolymer thin films

A process for the production of a polymeric film comprising a copolyester having an acid component and a diol component, said acid component comprising a dicarboxylic acid and a sulfomonomer containing a sulfonate group attached to the aromatic nucleus of an aromatic dicarboxylic acid, said process comprising the steps of: (i) melt-extruding a layer of said copolyester; (ii) stretching the extrudate in at least one direction; (iii) heat-setting the film by raising the temperature of the stretched film to a temperature T1 in a first heating zone such that (TM-T1) is in the range of from 5 to 30° C., and then raising the temperature of the film to a temperature T2 in a second heating zone such that (TM-T2 is in the range of from 0 to 10° C., wherein TM is the peak melting temperature of the polymeric film; wherein T2 is greater than T1; and wherein the times which a transverse section of the film spends in the first and second heating zones are defined by t1 and t2, respectively, such that the ratio of t1 to t2 is at least 2:1; and a polymeric film obtainable thereby having an ultimate tensile strength at destruction in the range of 2 to 15 kgf / mm2 in the machine direction and 2.5 to 17 kgf / mm2 in the transverse direction.

Owner:DUPONT TEIJIN FILMS US LTD

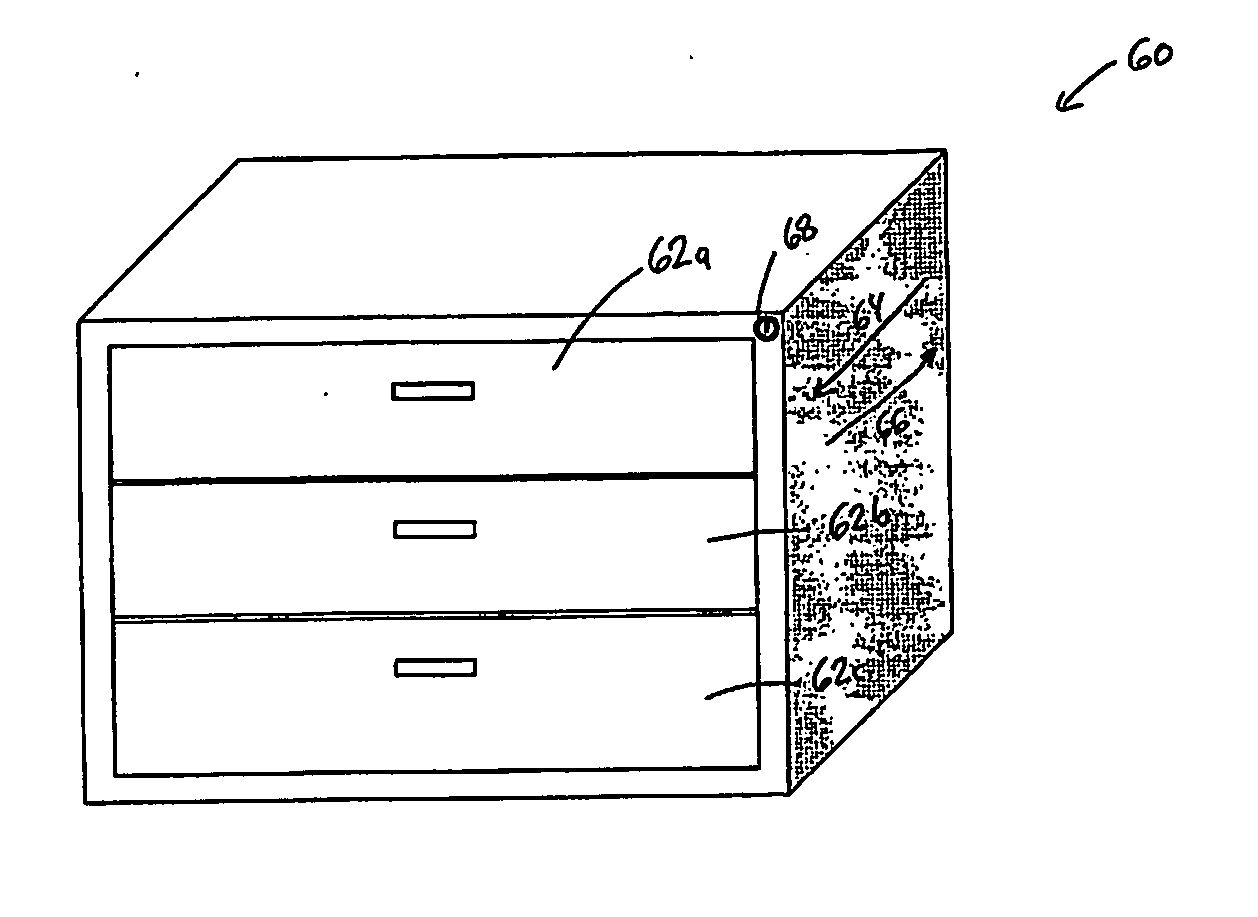

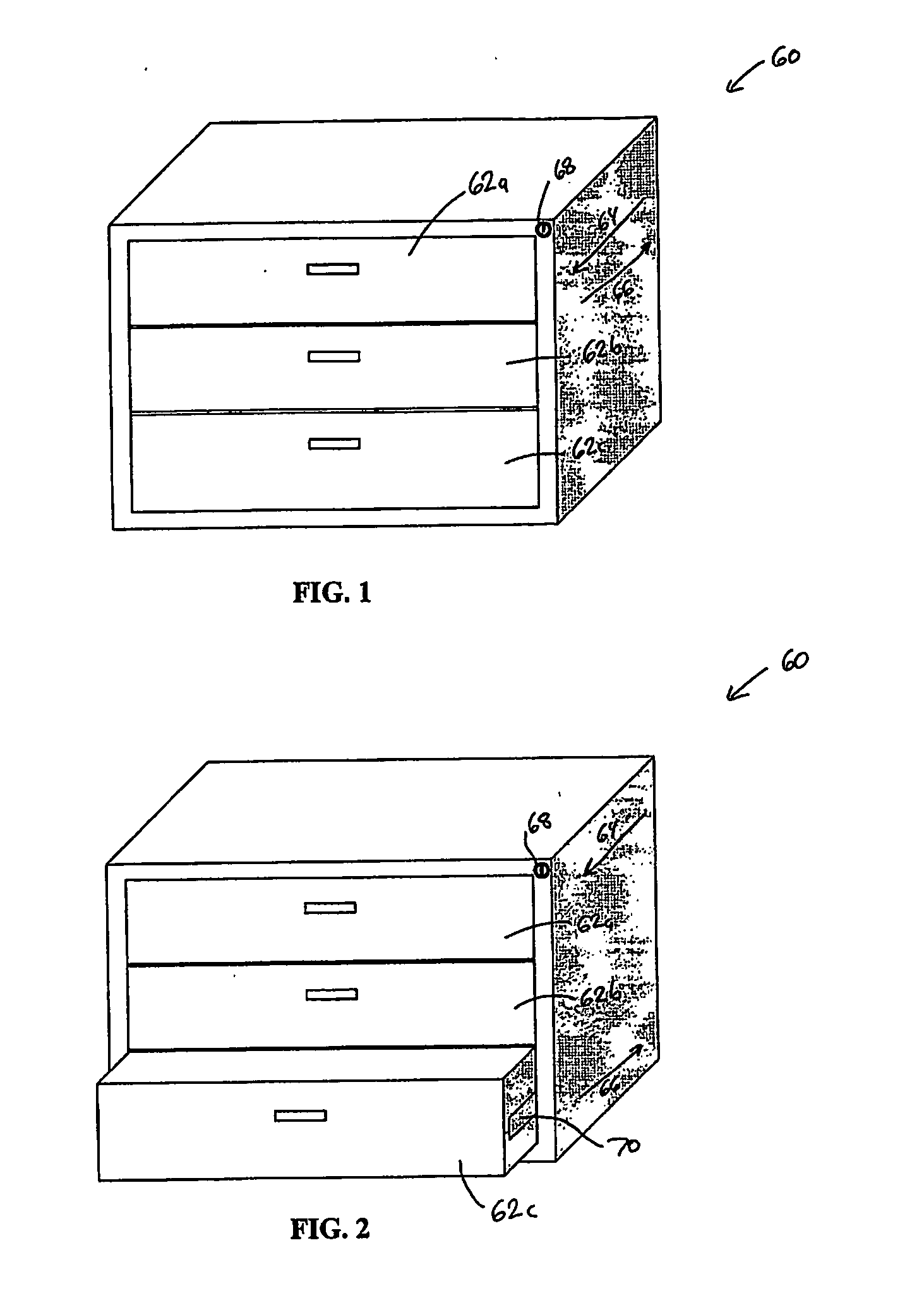

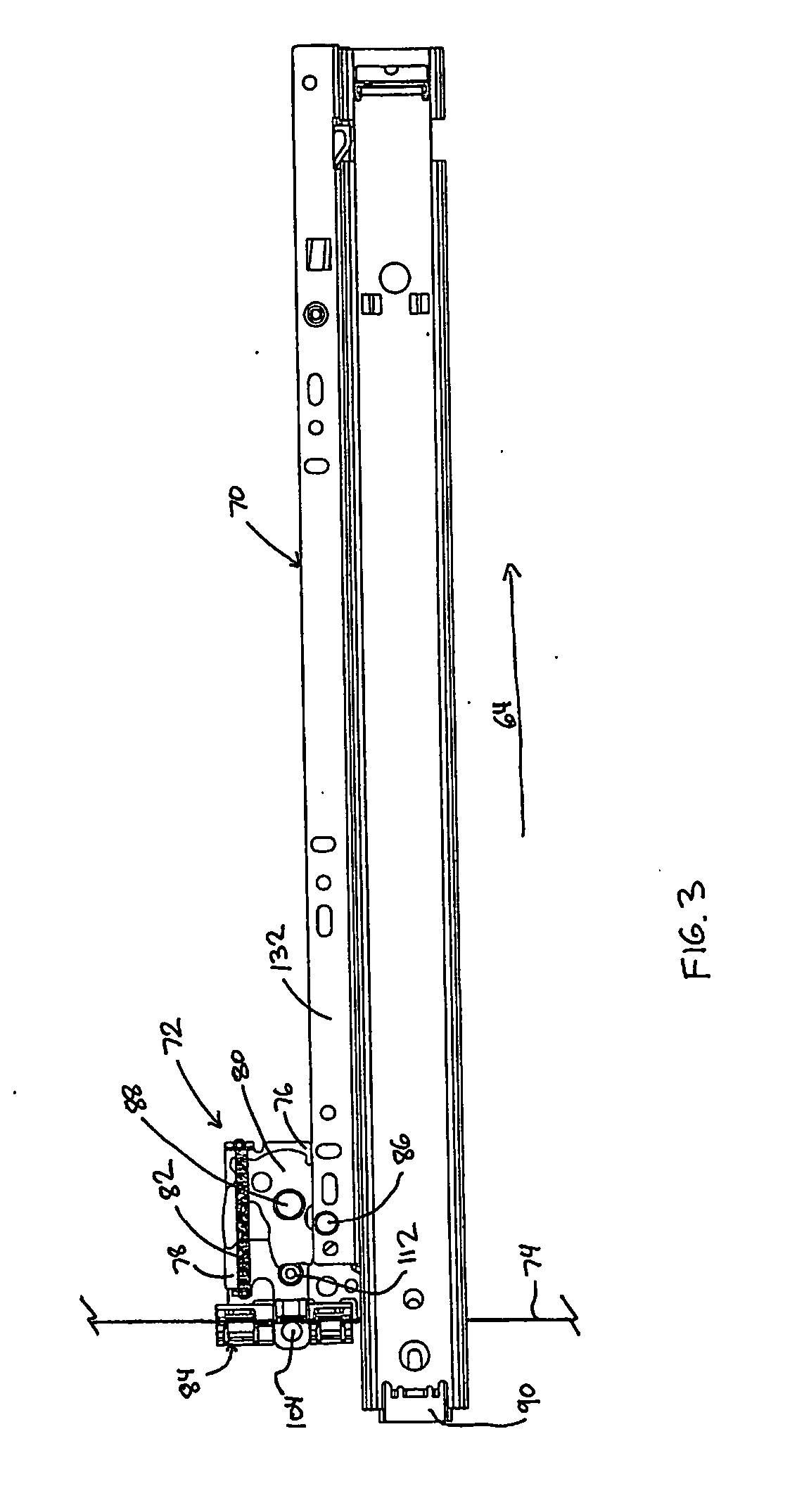

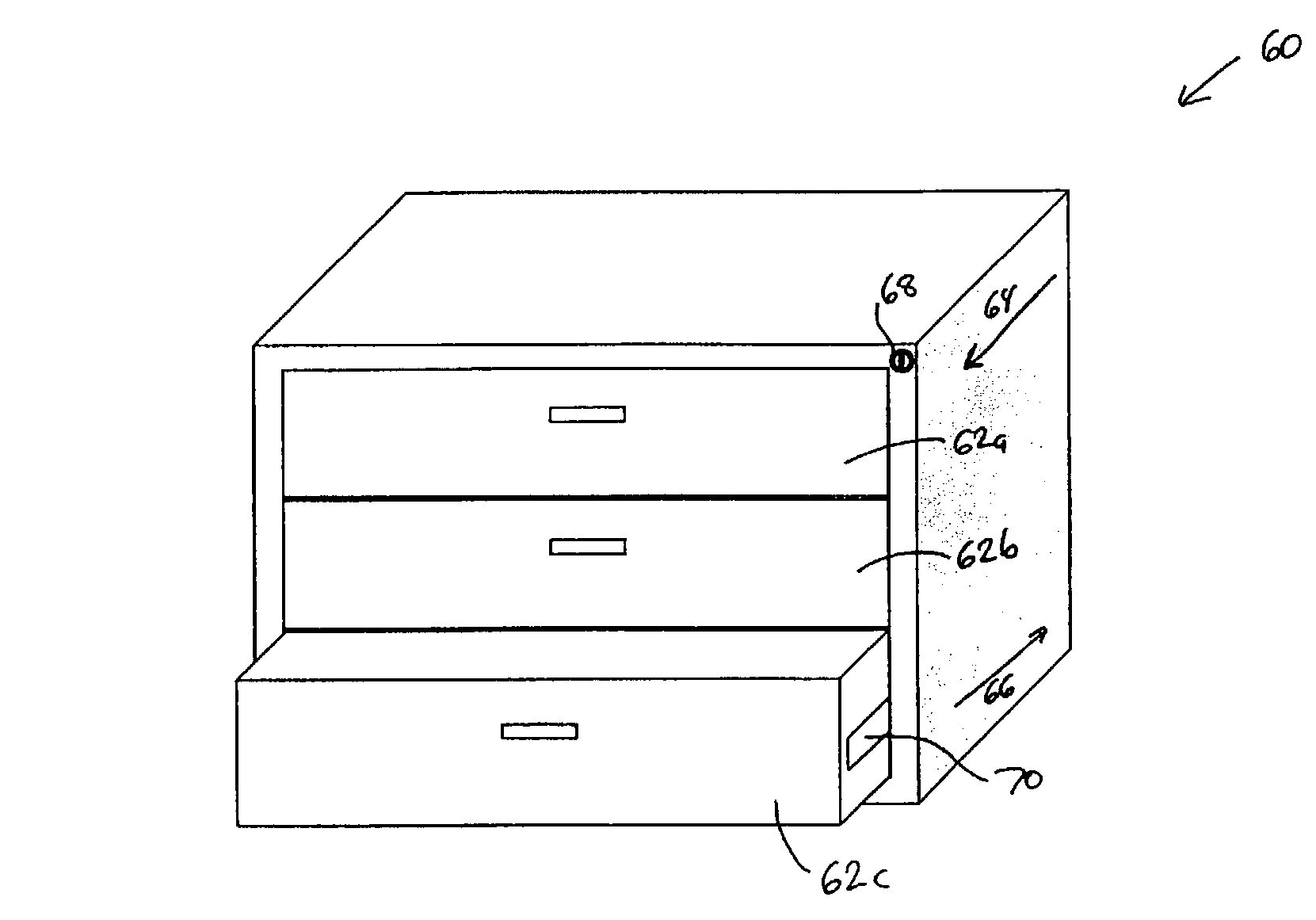

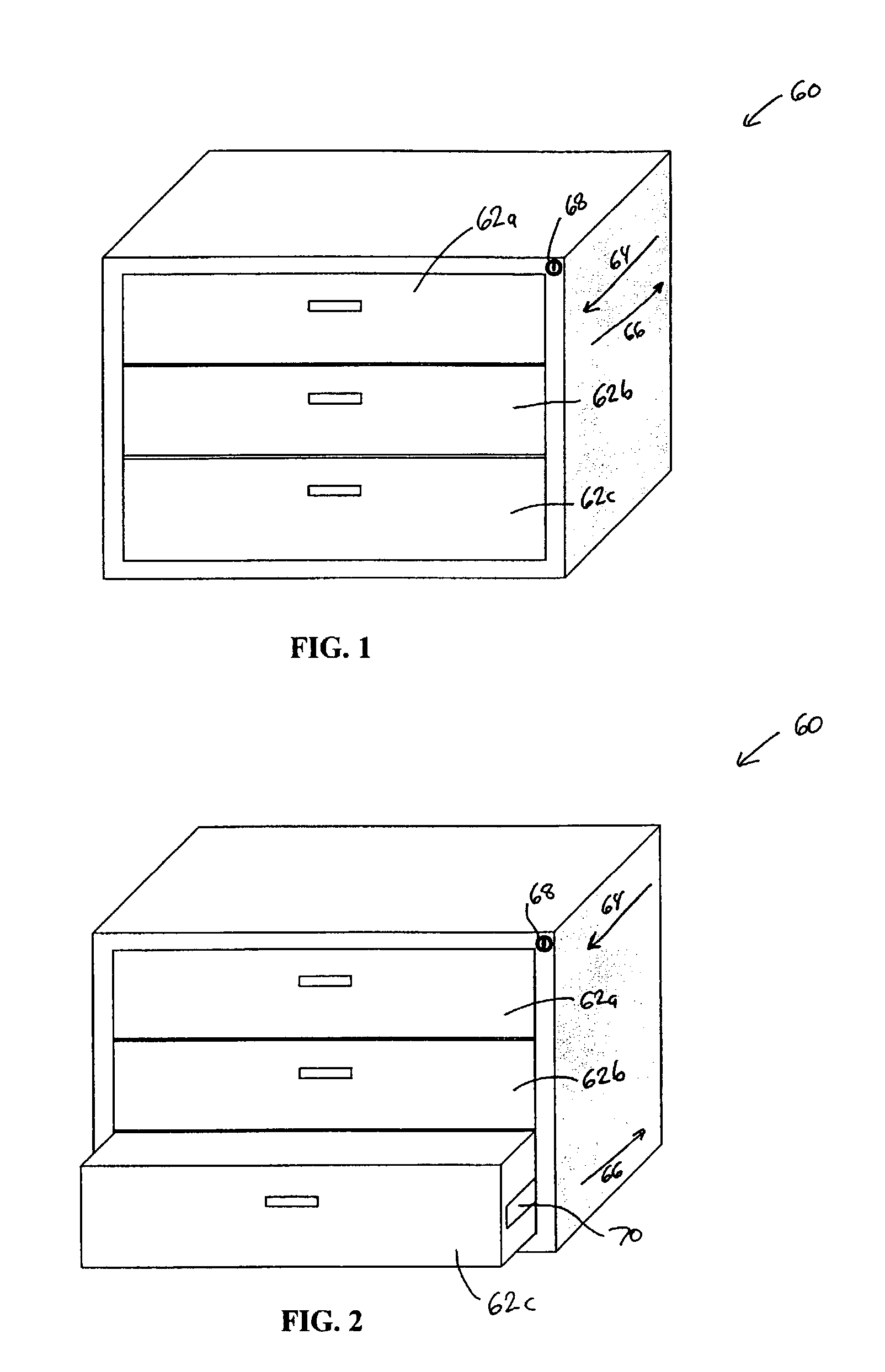

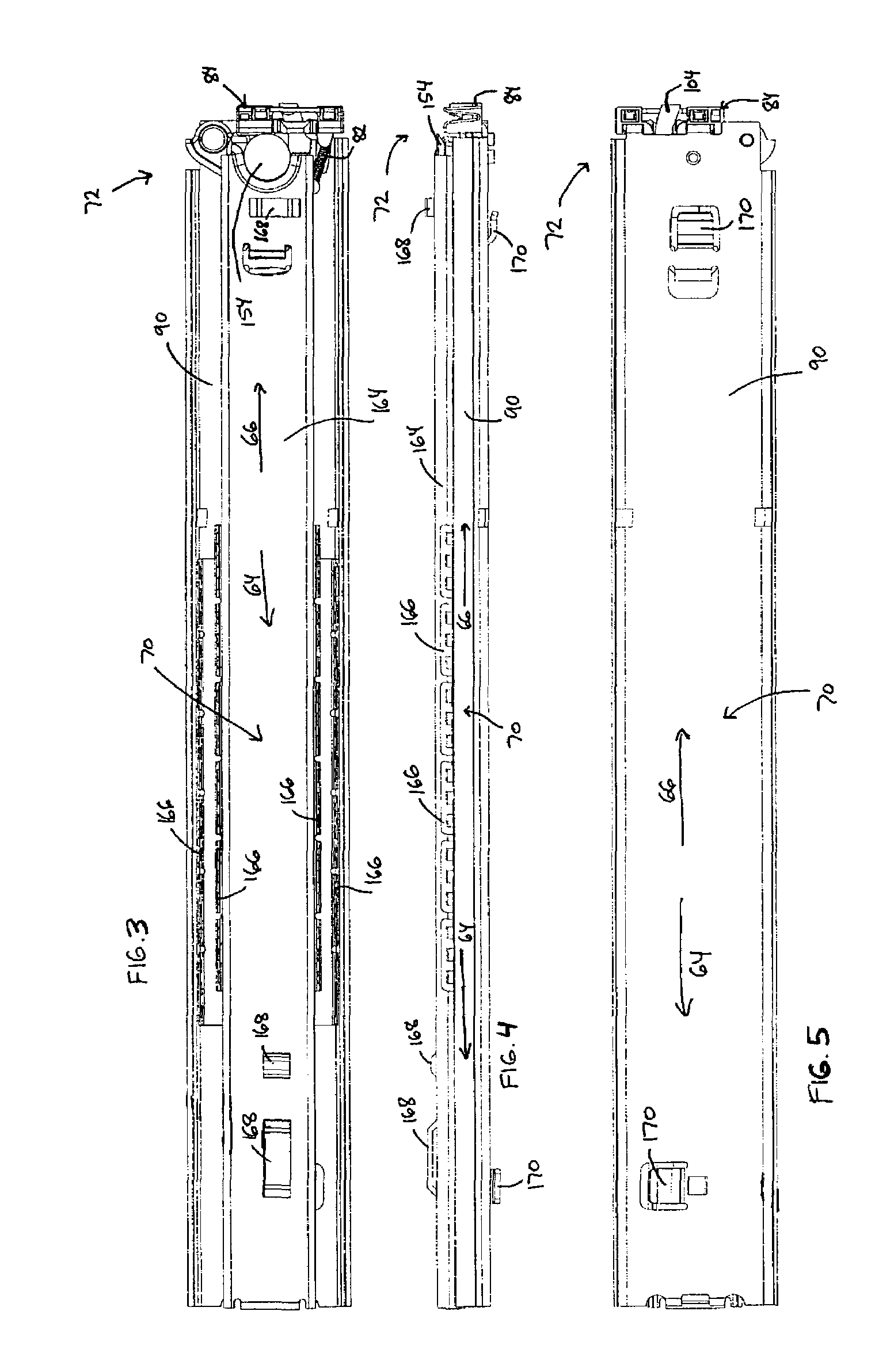

Interlock mechanism for lateral file cabinets

The invention relates to interlocks for file cabinets and the like which generally prevent more than one drawer from being opened at a given time. The interlocks include a cable which is changeable from a slack condition to a taut condition. In the taut condition, the interlocks prevent the associated drawer from being opened. In the slack condition, the interlock allows the associated drawer to be opened. The interlocks may be used in conjunction with a lock that selectively changes the tension in the cable from a slack condition to a taut condition and vise versa. The interlocks may be constructed to exert a tension on a cable that is independent of the pulling force exerted on a locked drawer. Alternatively, the interlocks may be constructed to exert a force on the cable that is a small fraction of the pulling force exerted on a locked drawer.

Owner:KNAPE & VOGT MFG

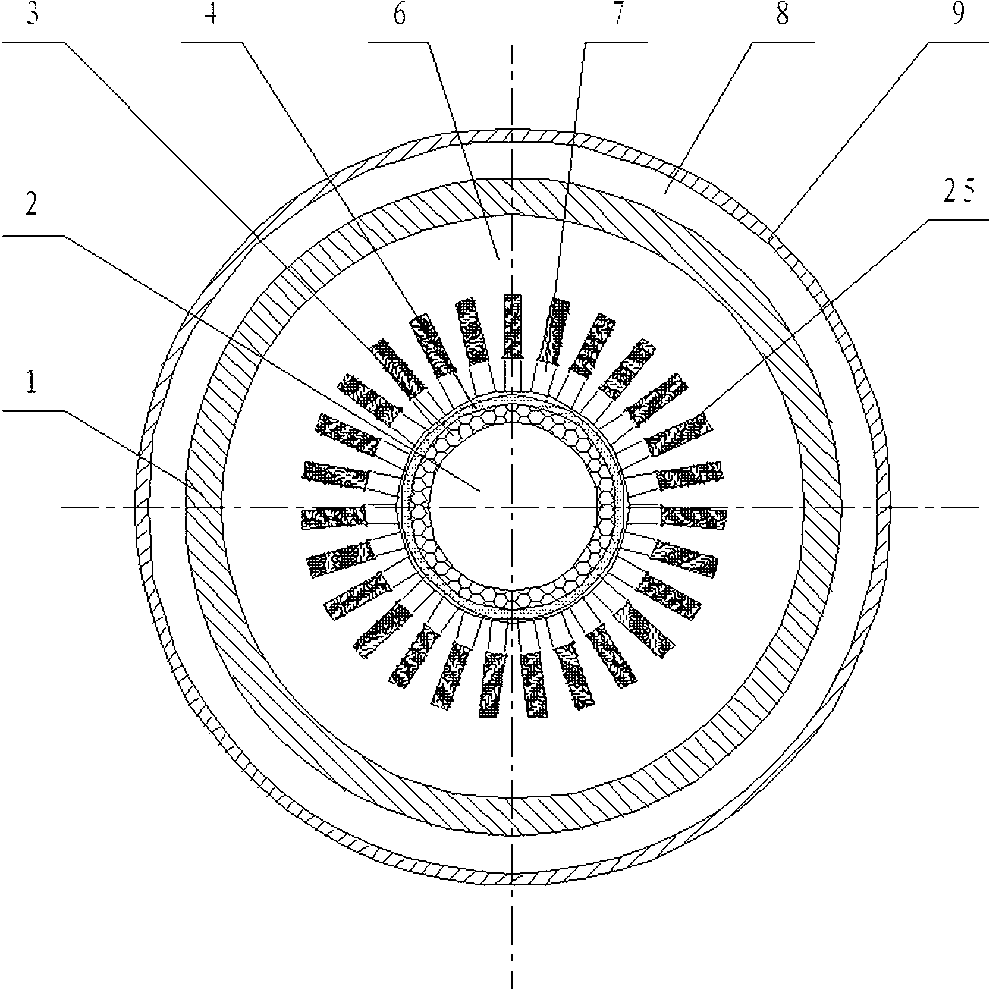

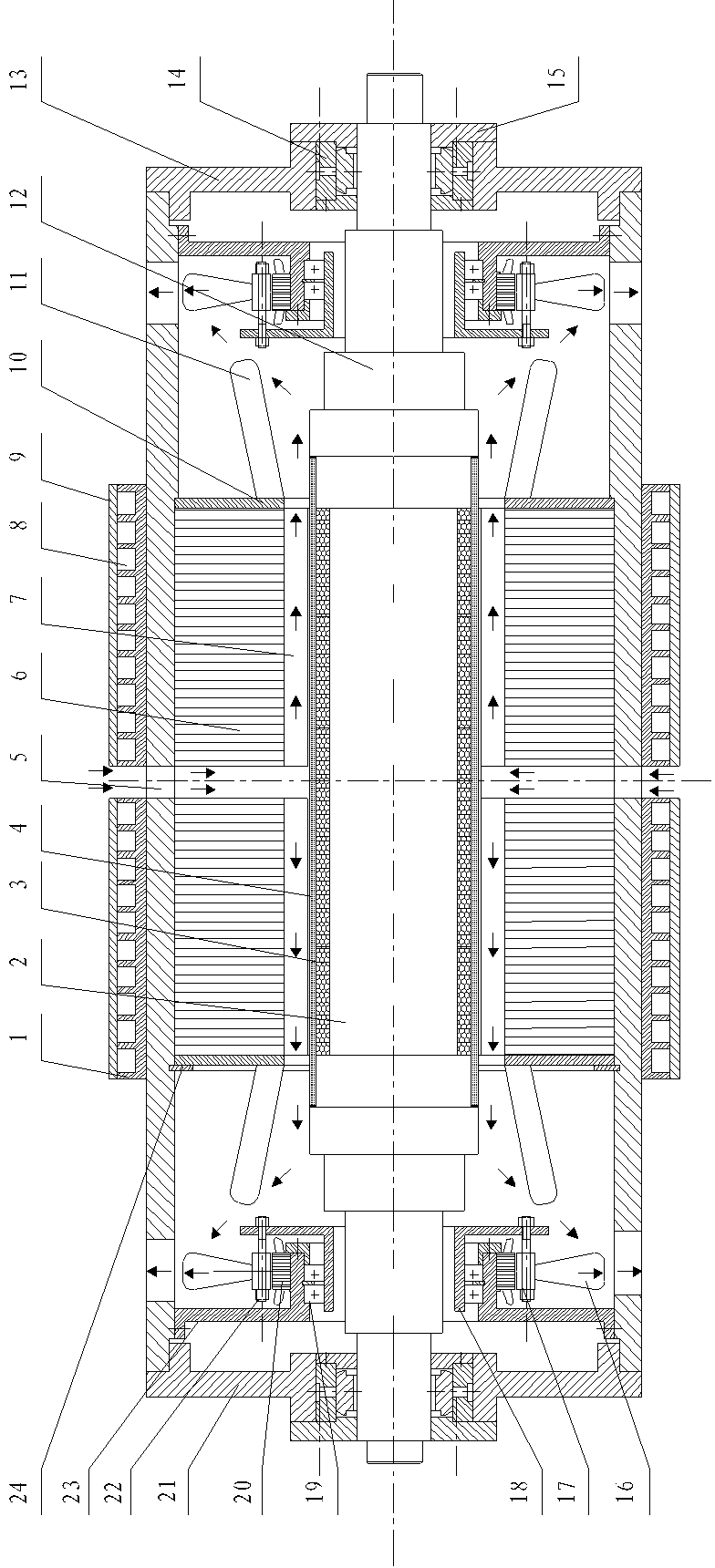

Air and water hybrid cooling high-speed permanent-magnet motor

InactiveCN102983680AReduce eddy current lossLow heat generationMagnetic circuit rotating partsMagnetic circuit stationary partsWater flowPermanent magnet motor

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Owner:SHENYANG POLYTECHNIC UNIV

High strength ultrafine fiber simulation composite lether and its manufacturing method

The present ivnention relates to a high-strength ultrafine fibre imitation leather. It is made up by using sea-island ultrafine fibre base cloth through processes of impregnating with polyurethane, extracting treatment and after-finishing. The described base cloth is a double-layer or more than double-layer composite base cloth formed from sea-island composite fibre woven fabric and non-woven fabric which are combined together by means of needling process or cohesive process, then said invention makes the composite base cloth undergo the processes of impregnating with polyurethane, hardening, extracting 'sea' component in the solvent capable of removing 'sea' component from sea-island fibre to obtain semifinished product, widening forming, mellowing, dyeing, grinding or sticking film so as to obtain the invented product.

Owner:SHANDONG TONGDA ISLAND NEW MATERIALS

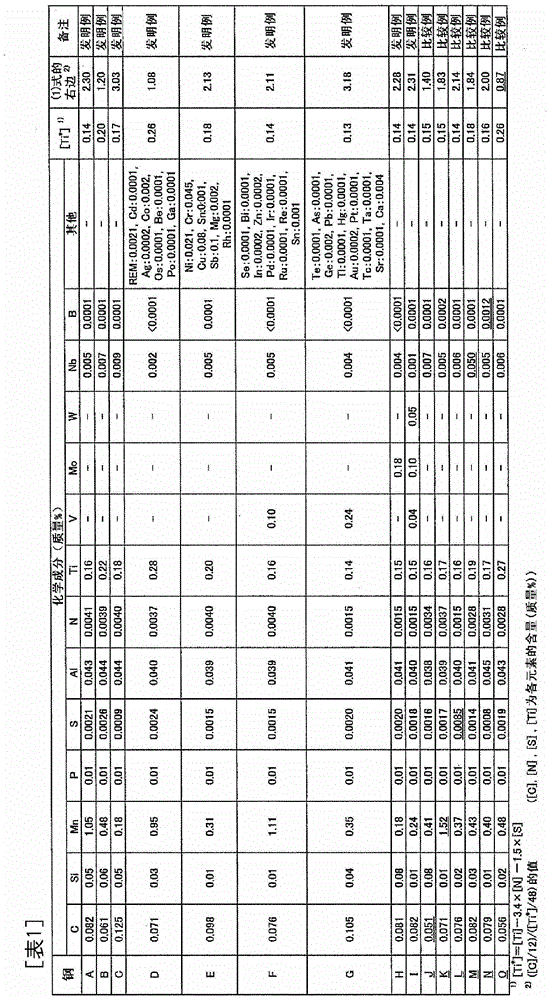

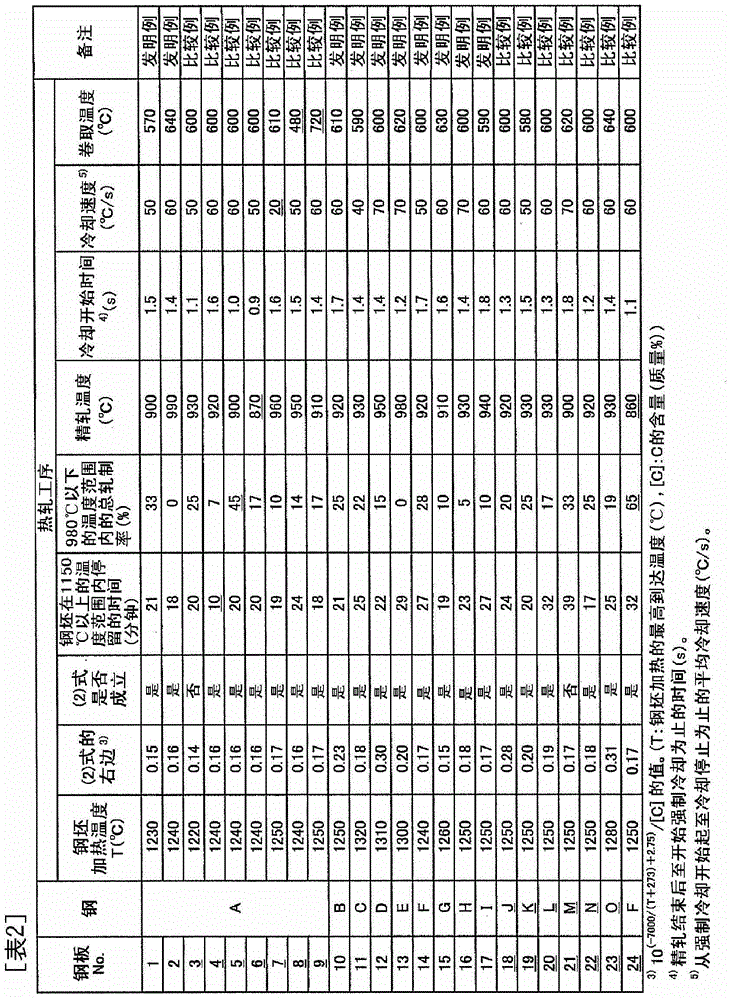

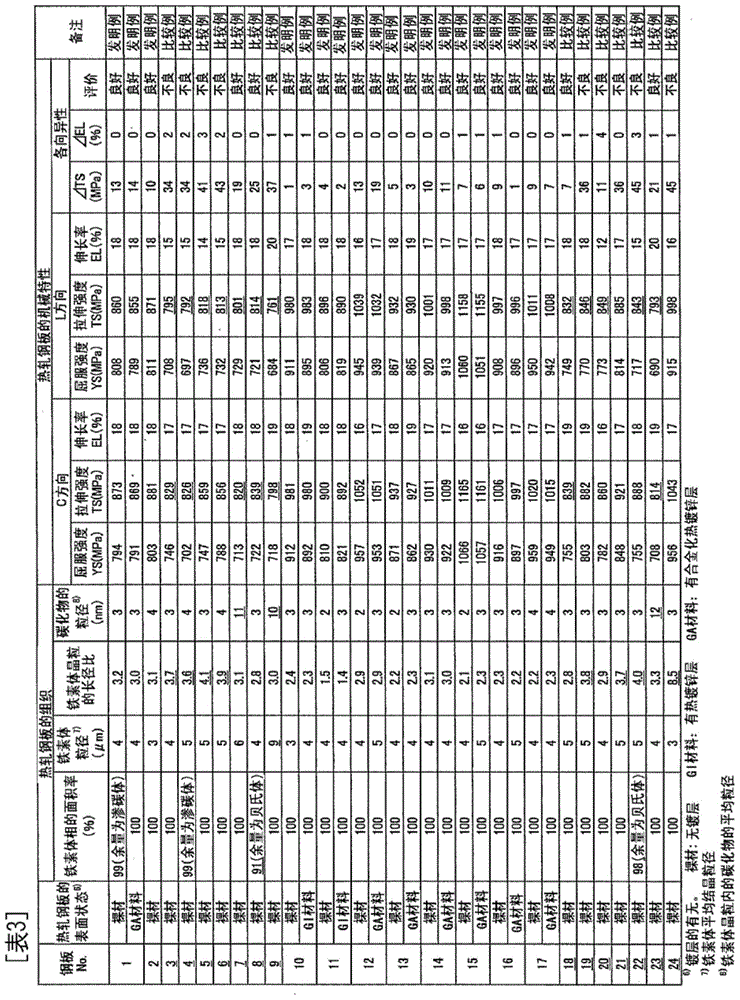

Hot-rolled steel sheet and process for manufacturing same

ActiveCN104011234ALow tensile strengthSmall mechanical propertiesHot-dipping/immersion processesFurnace typesSheet steelHot rolled

The present invention pertains to a process for manufacturing a hot-rolled steel sheet which comprises: heating a steel raw material that contains, in mass%, 0.055 to 0.15% of C, at most 0.2% of Si, at most 1.3% of Mn, at most 0.03% of P, at most 0.007% of S, at most 0.1% of Al, at most 0.01% of N and 0.14 to 0.30% of Ti so as to satisfy the relationship 1.0 <= ([C] / 12) / ([Ti*] / 48) (wherein [Ti*] = [Ti]-3.4[N]-1.5[S]) to a temperature (T) ( DEG C) which is equal to or higher than 1150 DEG C and which satisfies the relationship [Ti*] < 10{-7000 / (T+273)+2.75 / [C]; keeping the steel raw material in a temperature range down to 1150 DEG C for at least 15 minutes; subjecting the resulting steel raw material to hot rolling wherein the total rolling reduction in a temperature range up to 980 DEG C is 40% or less and the finish rolling temperature is 880 DEG C or higher; cooling the hot-rolled steel sheet at a cooling rate of 40 to 200 DEG C / s within three seconds after the completion of the finish rolling; and winding up the cooled steel sheet in a temperature range of 500 to 680 DEG C.

Owner:JFE STEEL CORP

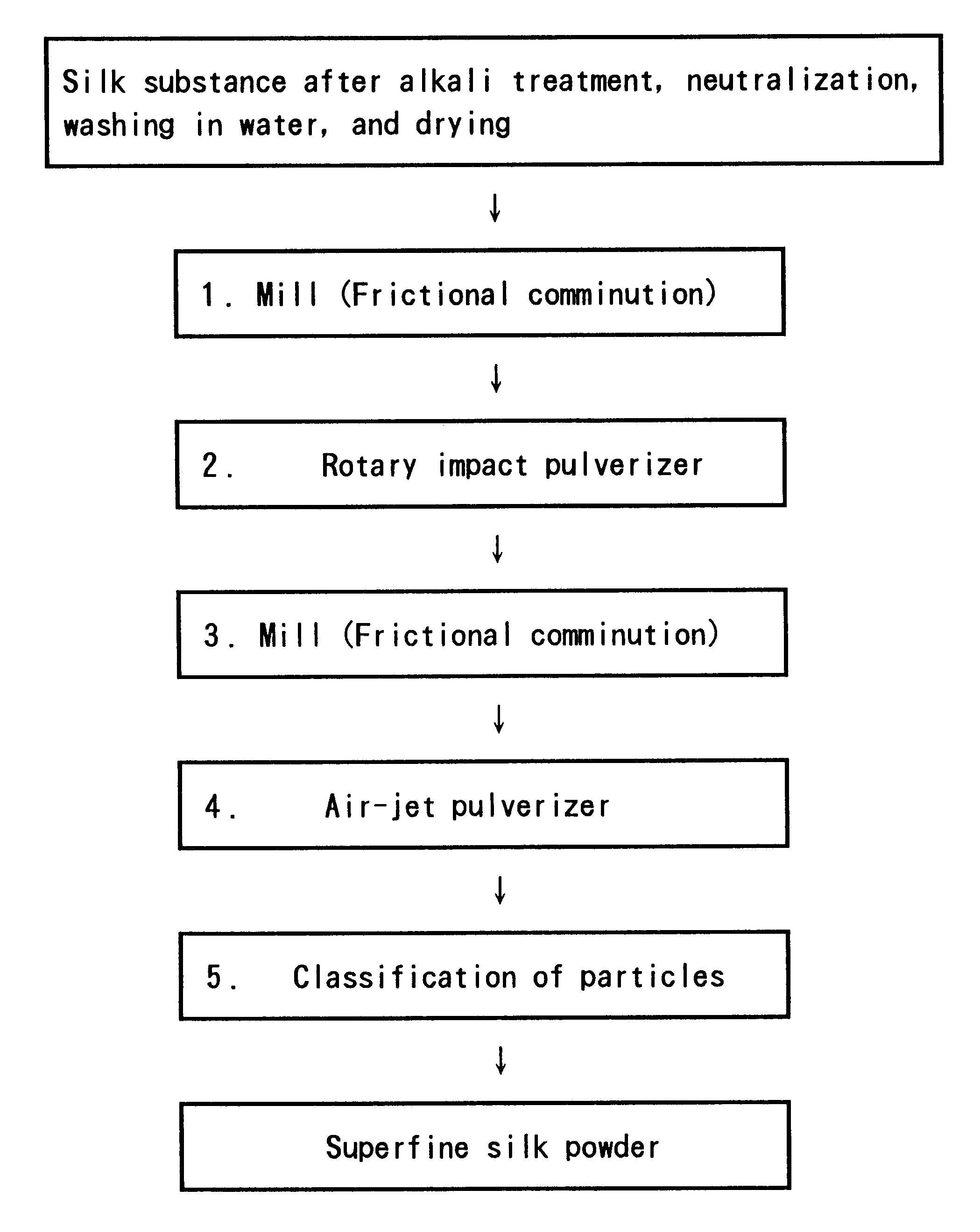

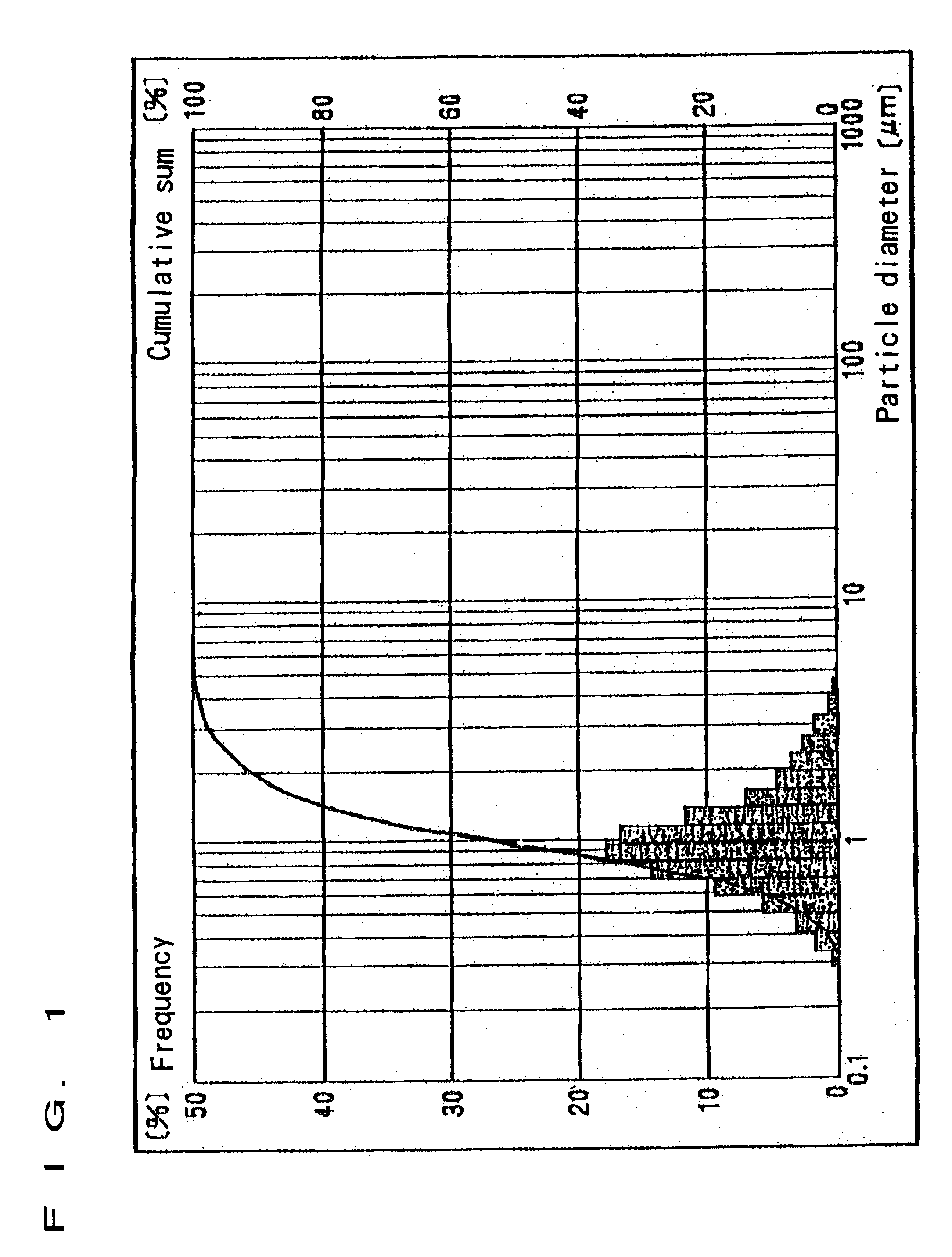

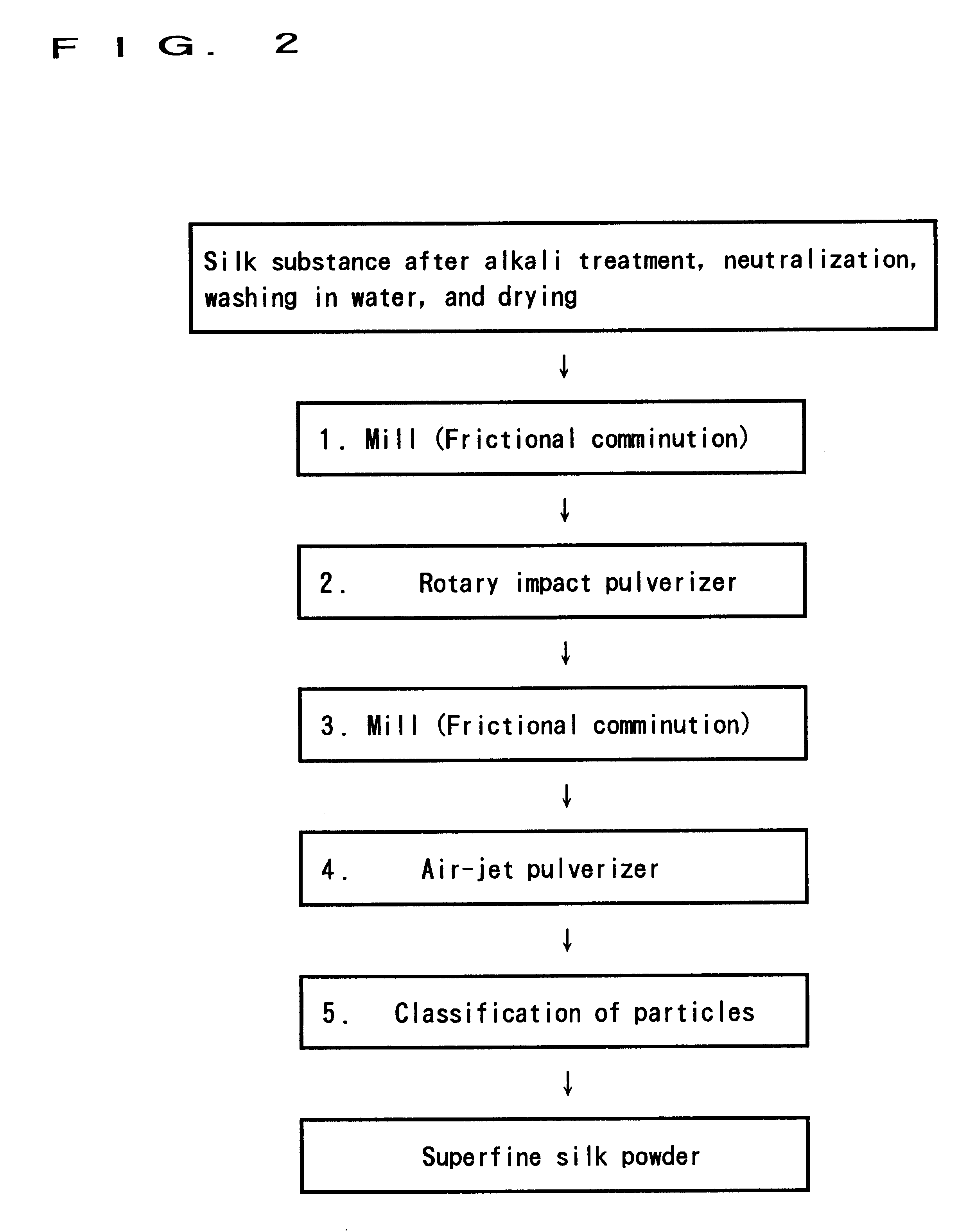

Method for manufacturing crystalline superfine silk powder

The main theme of the invention is to provide a method for manufacturing industrially, by mechanically comminuting silk yarn, crystalline silk fibroin powder below 3 mum in an average particle diameter, which can be used for various applications. A silk substance such as cocoon filament, silk yarn, or raw silk is brought into an alkali aqueous solution under a pressure of 1 through 5 atmospheric pressure at temperatures from 100° C. through 150° C. to reduce the tensile strength of the silk substance to around 0.02 g / d or less. Thereafter, the resultant silk substance is subjected to dealkalization and drying. Subsequently, the resultant dried silk substance is comminuted into powder below 3 mum in an average particle diameter. Thus, the crystalline silk fibroin powder below 3 mum in an average particle diameter is manufactured.

Owner:JAPAN AS REPRESENTED BY DIRECTOR GENERAL OF NAT INST OF SERICULTURAL & ENTOMOLIGICAL SCI MINIST OF AGRI FORESTRY & FISHERIES +1

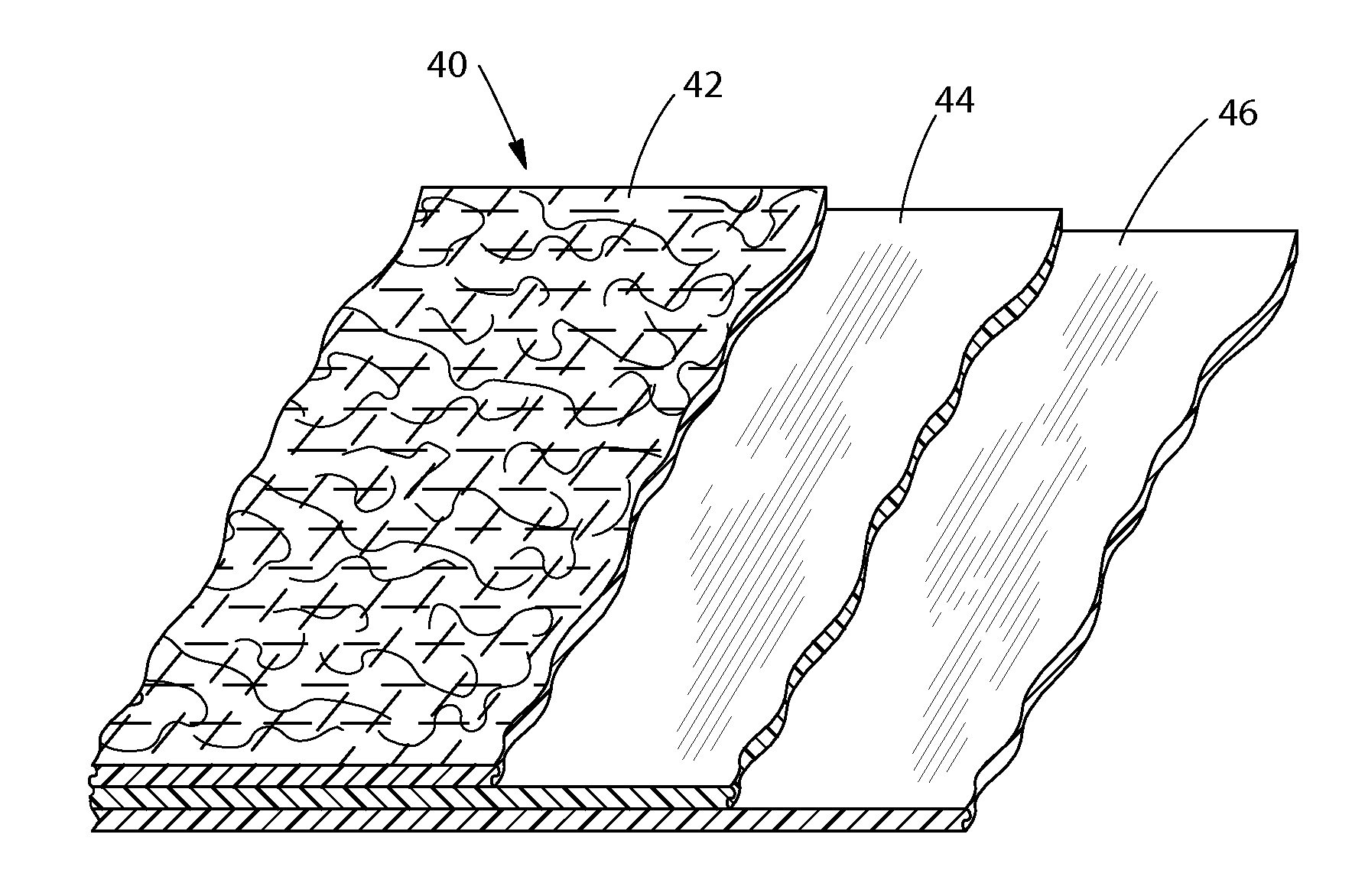

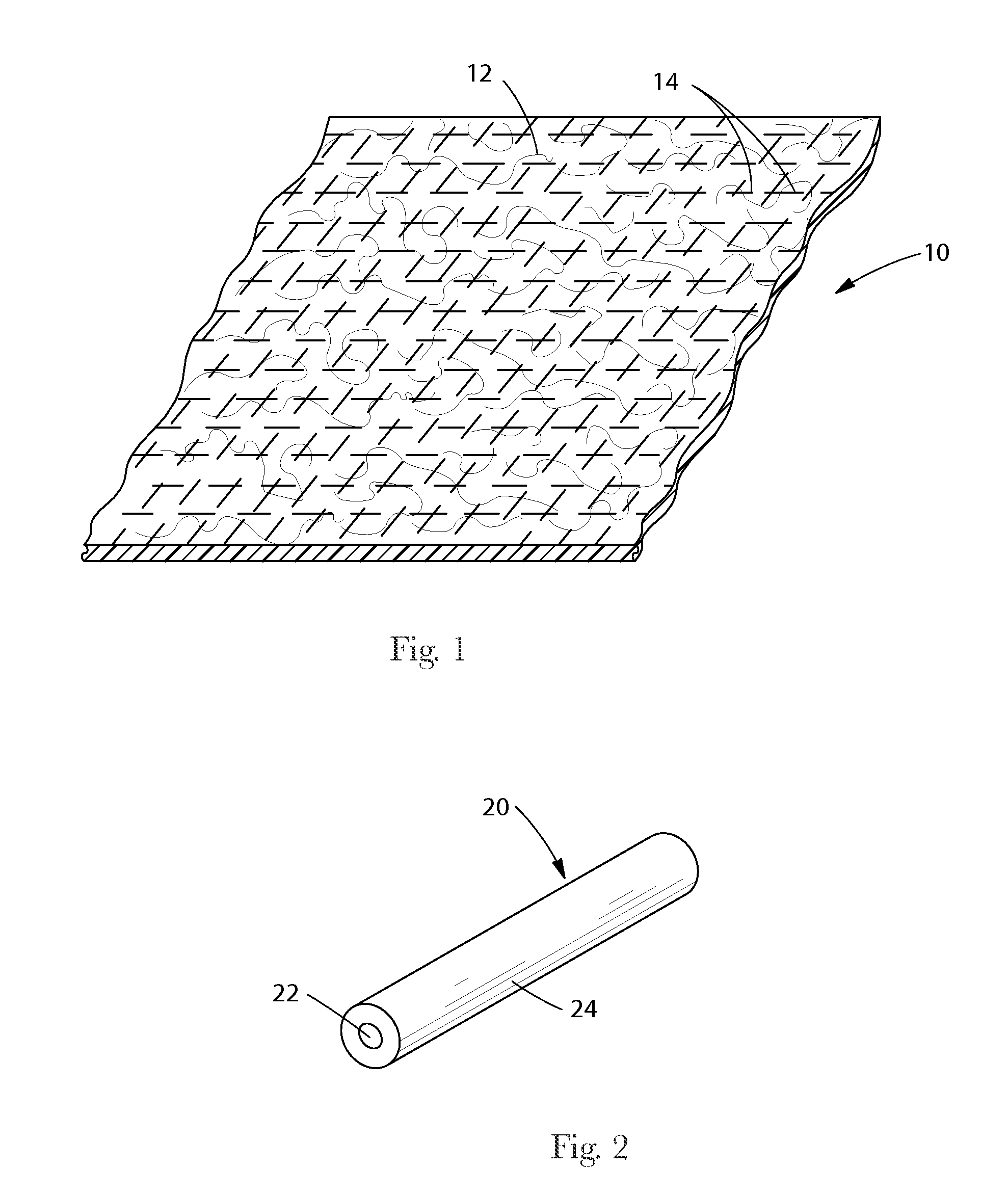

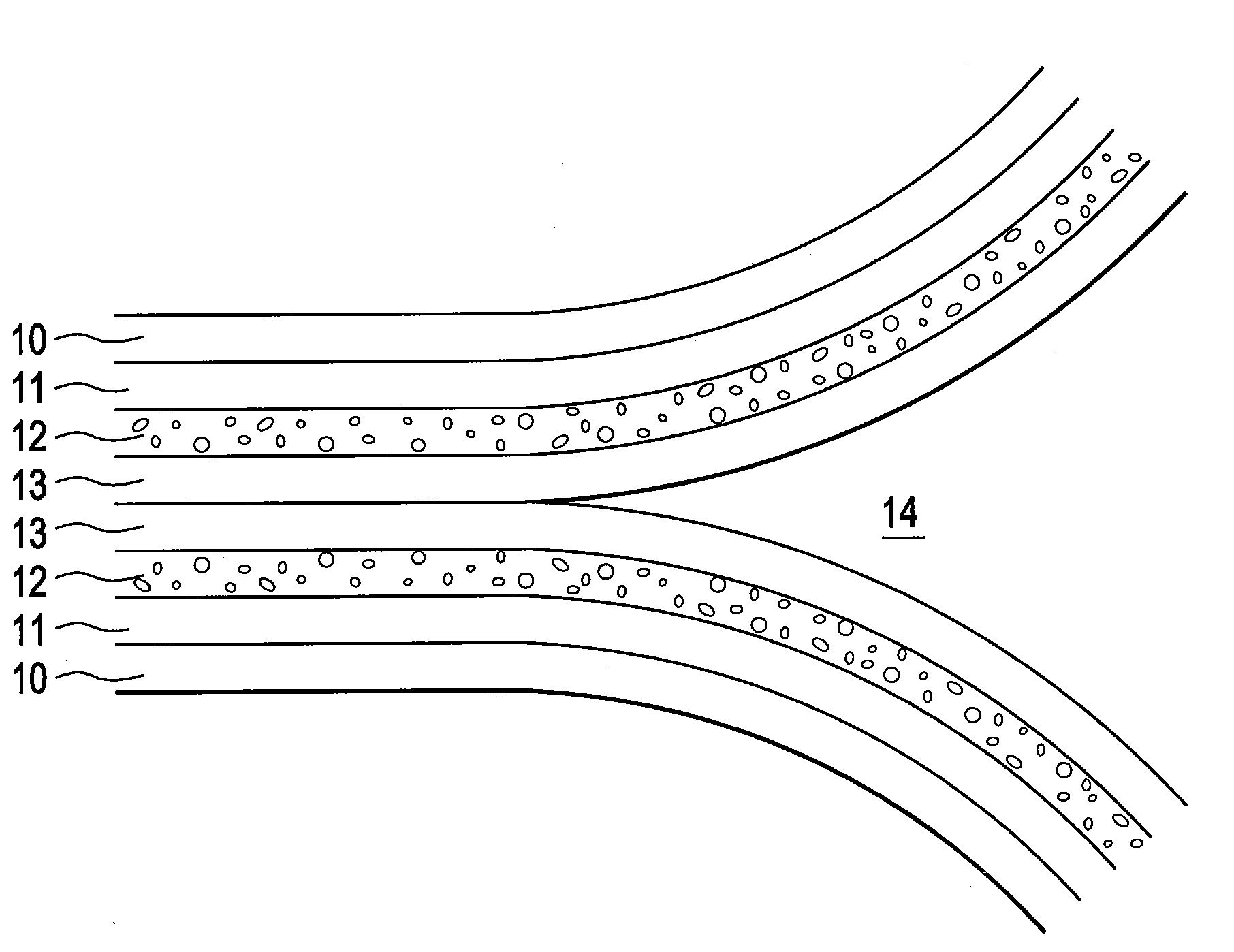

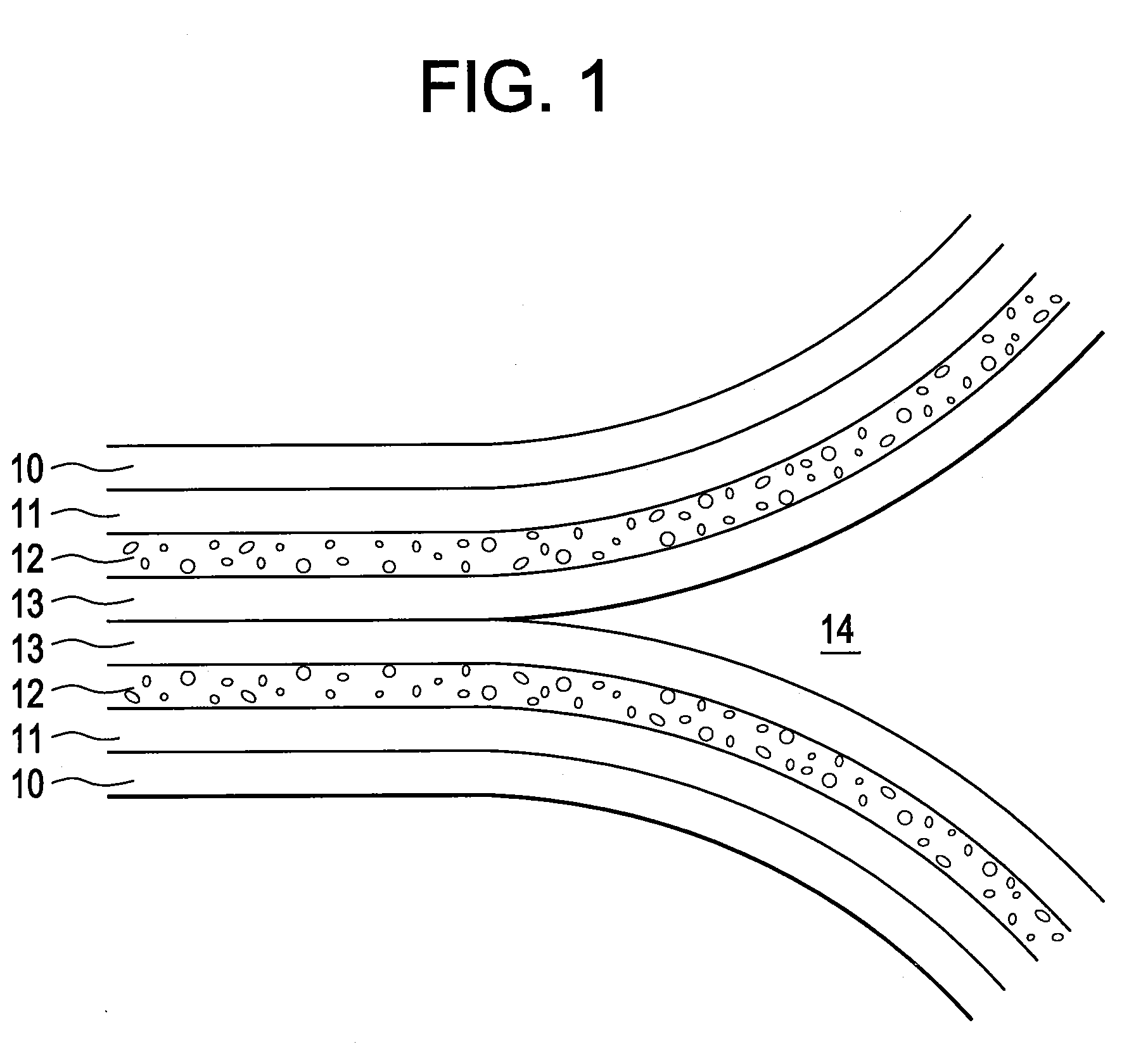

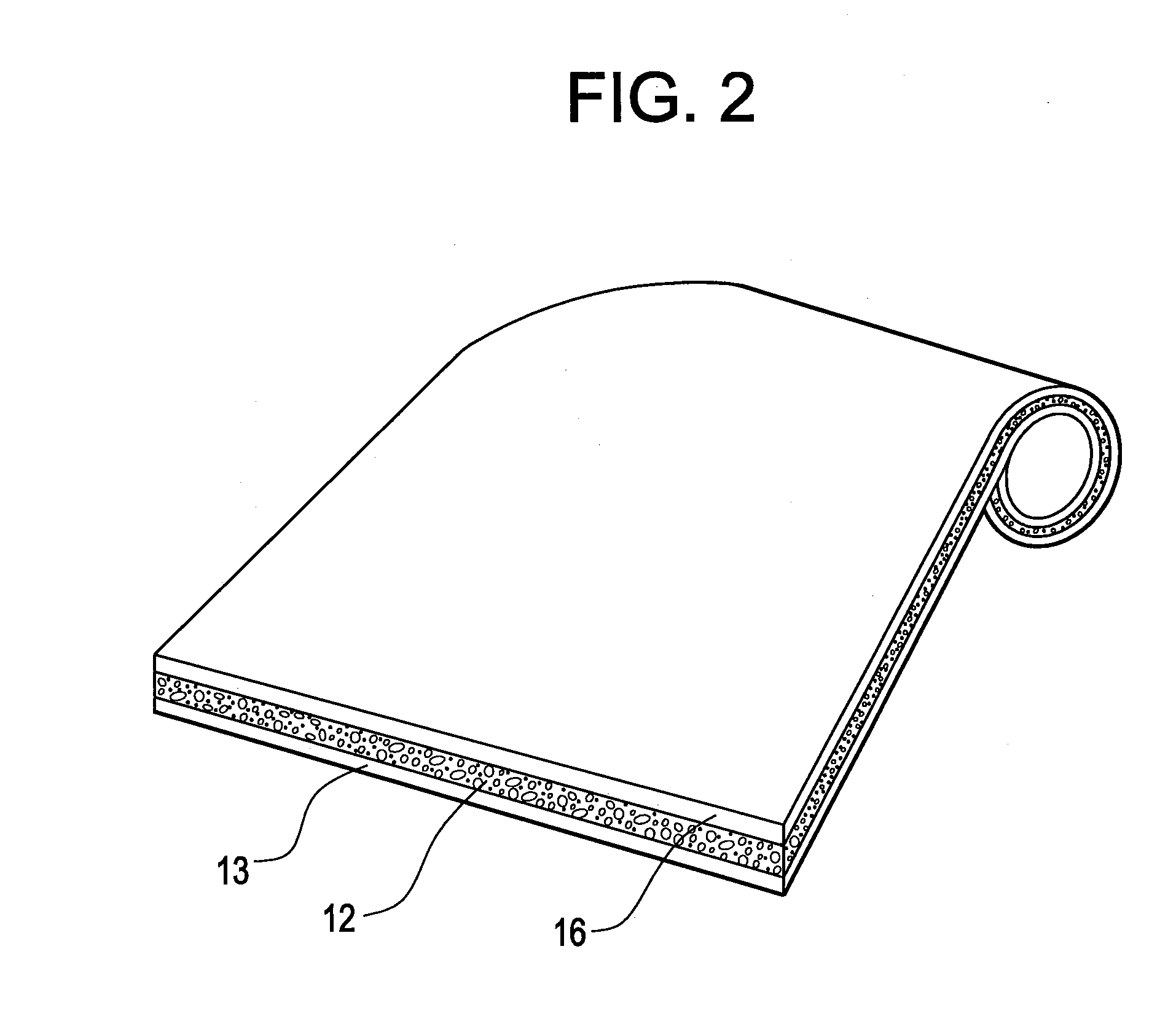

Laminates with bonded webs

ActiveUS8728051B2Increase resistanceGood dimensional stabilityPersonal careSynthetic resin layered productsComposite material

Owner:THE PROCTER & GAMBLE COMPANY

Wire rod used for ultrahigh-strength steel cord and manufacture method of wire rod

ActiveCN110629132AHigh wire breakage rateReduce wire breakage rateTemperature control deviceFurnace typesWire rodTemperature control

The invention discloses a wire rod used for an ultrahigh-strength steel cord and a manufacture method of the wire rod. The manufacture method includes the steel smelting stage, the blank casting stage, the cogging stage, the rolling stage and the controlled cooling stage which are sequentially conducted. In the steel smelting stage, molten steel is smelted, wherein the number density of inclusionswith the size being larger than or equal to 5 micrometers is smaller than or equal to 0.5 / mm<2>, and the inclusion size is smaller than or equal to 30 micrometers. In the blank casting stage, tappingmolten steel of the steel smelting stage is cast into an ingot blank with the central carbon segregation being 0.92 to 1.08. In the cogging stage, the ingot blank is made into an intermediate billetwith the central carbon segregation being 0.95 to 1.05 through cogging. In the rolling stage, the intermediate billet is rolled into the wire rod. In the controlled cooling stage, temperature-controlled cooling is conducted on the wire rod, and the wire rod which is high in cleanliness and high in homogeneity and has the tensile strength being smaller than or equal to 1150 MPa is obtained. The wire rod can be used for the ultrahigh-strength steel cord with the monofilament tensile strength being larger than or equal to 3600 MPa, the low drawing wire breaking rate, the low stranding wire breaking rate and the low mold consumption can be ensured, and the high yield is ensured.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

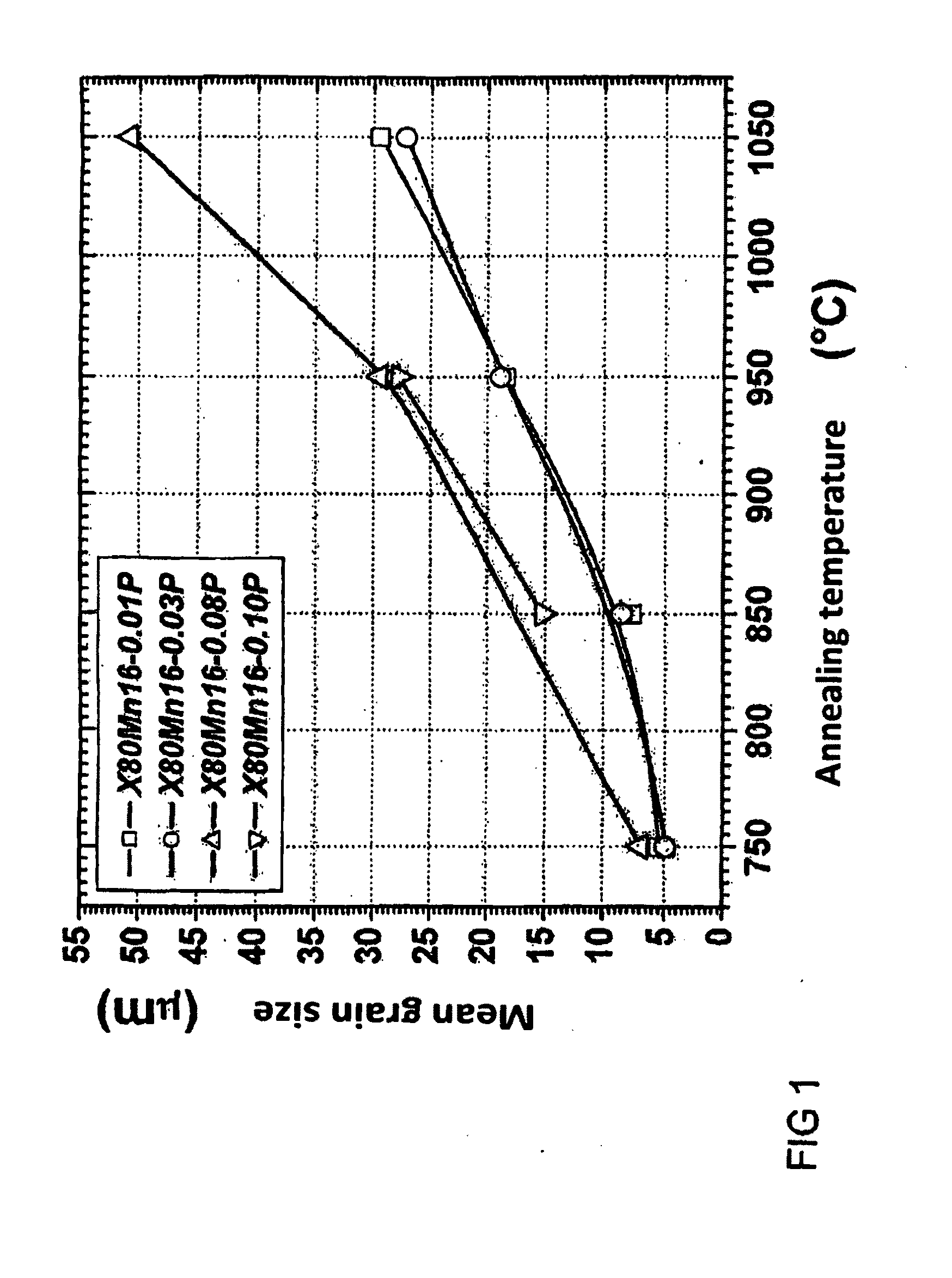

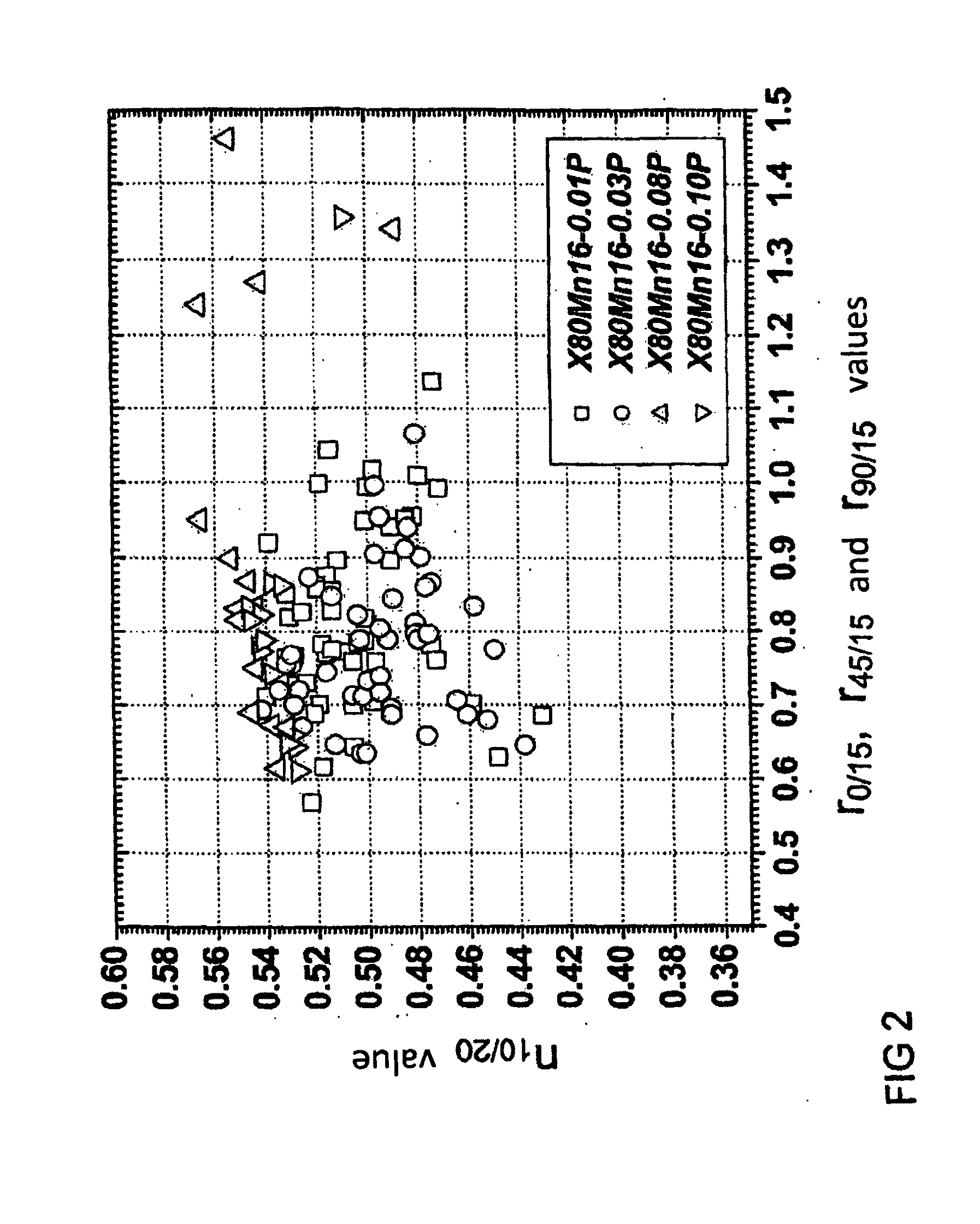

Manganese steel strip having an increased phosphorous content and process for producing the same

InactiveUS20110308673A1Improve solid solubilityImprove solubilityFurnace typesHeat treatment furnacesChemical compositionManganese

A hot-rolled austenitic manganese steel strip having a chemical composition in percent by weight of 0.4%≦C≦1.2%, 12.0%≦Mn≦25.0%, P≧0.01% and Al≦0.05% has a product of elongation at break in % and tensile strength in MPa of above 65,000 MPa %, in particular above 70,000 MPa %. A cold-rolled austenitic manganese steel strip having the same chemical composition achieves a product of elongation at break in % and tensile strength in MPa of above 75,000 MPa %, in particular above 80,000 MPa %.

Owner:VOESTALPINE STAHL GMBH

Electro-manual dispenser

ActiveUS7987756B2Low tensile strengthLess pulling forceStock shearing machinesDomestic applicationsPaper towelEngineering

Disclosed is a sanitary or no-touch dispenser which dispenses sheets of a web material, such as a paper towel. The disclosed dispenser provides the web material to a user by using both manual and electronic means to dispense the sheet. This is accomplished by having a motor engagably connected to an actuator roller. The motor is activated by a motor activation means, such as a switch. The motion of the actuator roller, which is started by the user grabbing and pulling a tail of the web material extending from the dispenser, causes the motor activation means to activate the motor which in turn drives the actuator roller to continue it its rotation motion to dispense the sheet from the dispenser.

Owner:KIMBERLY-CLARK WORLDWIDE INC

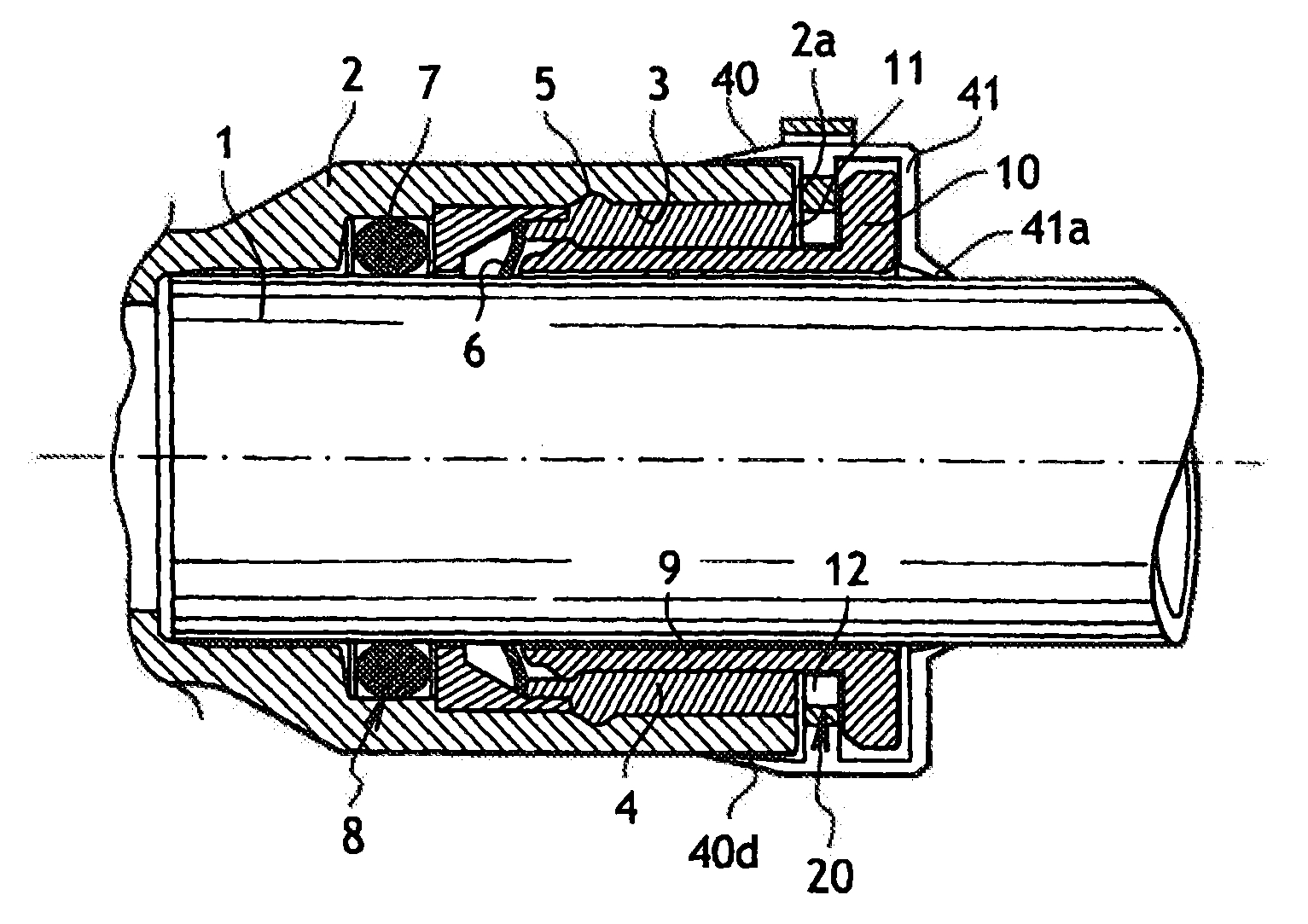

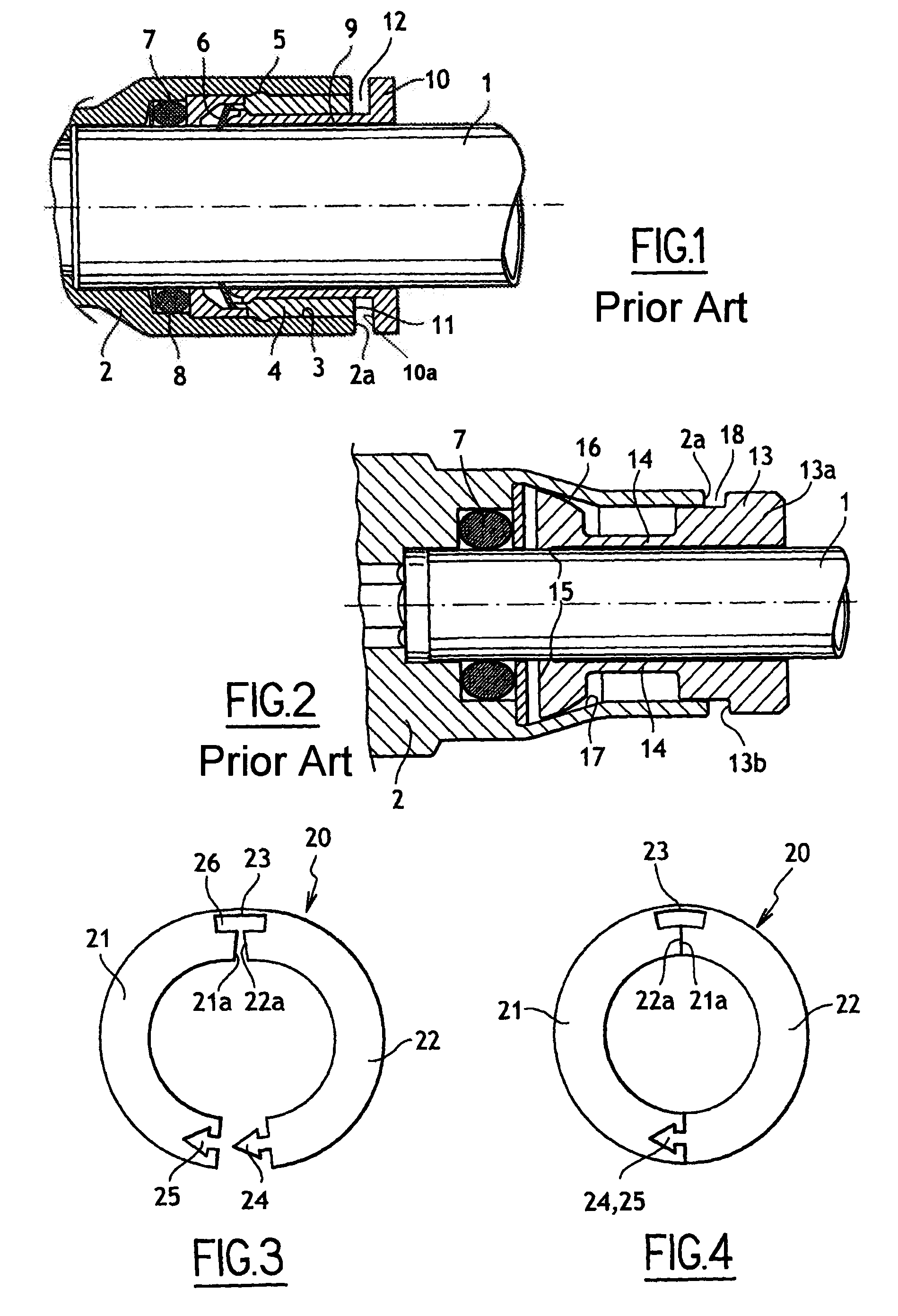

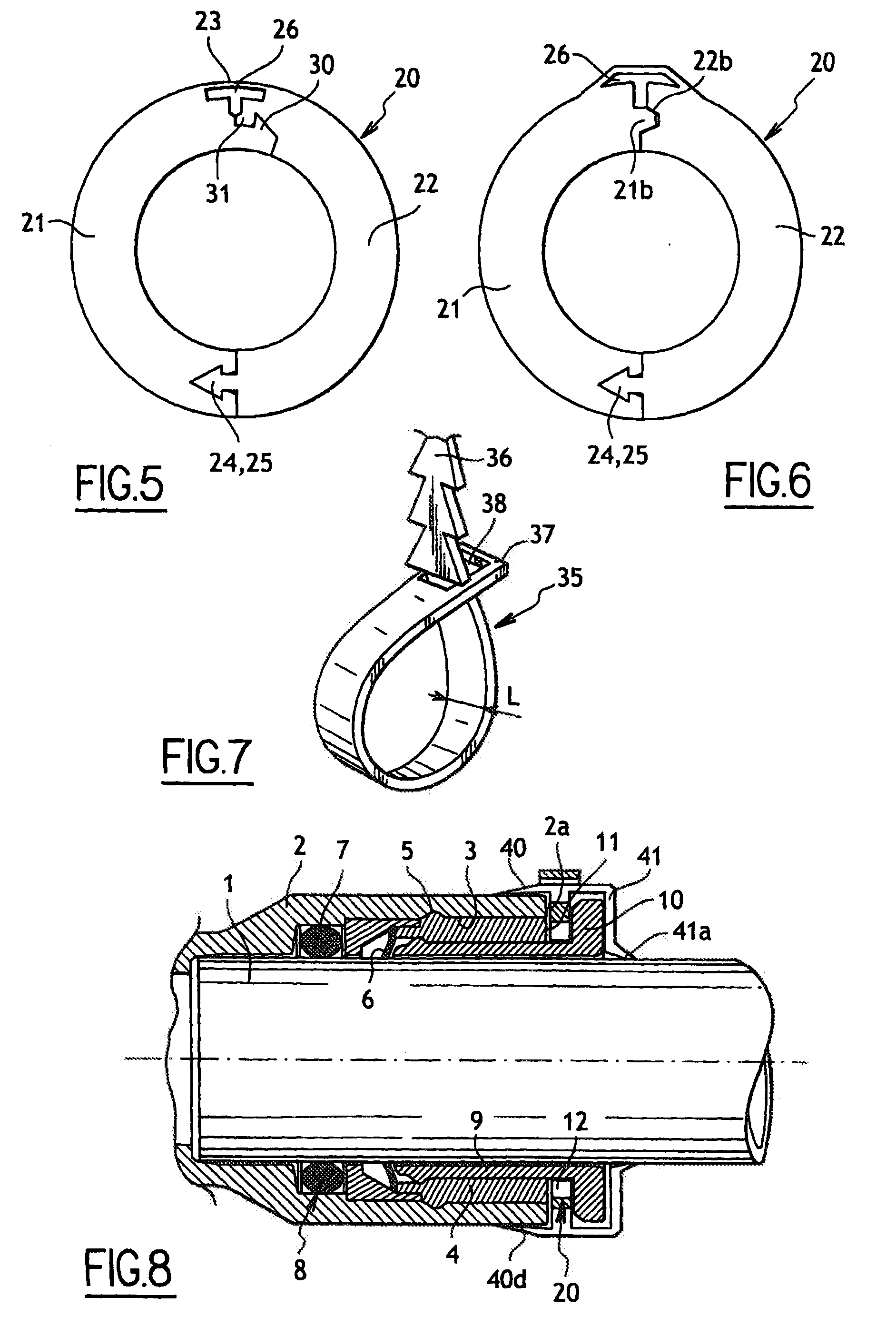

Quick-connect tube fitting connection including a safety ring

A quick-coupling tube fitting for coupling a tube to a body having a bore. The fitting includes a retaining member received within the bore for retaining the tube, and a release member received within the bore to be slidably moveable to release the retaining member when pushed. The release member has a rear portion that projects outwardly from the body. The rear portion has a shoulder surface which faces a stationary surface of the body to define a groove therebetween in which a safety member is disposed to delimit the sliding of the release member. The safety member is provided in the form of an elongate member which is closable to form a ring in the groove.

Owner:LEGRIS

Interlock mechanism for lateral file cabinets

InactiveUS7063398B2Resistant to high forceEasy to installBuilding locksWing fastenersPull forceEngineering

Owner:KNAPE & VOGT MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com