Air and water hybrid cooling high-speed permanent-magnet motor

A hybrid cooling and permanent magnet motor technology, applied in the direction of cooling/ventilation devices, electrical components, electromechanical devices, etc., can solve the problems of damaged high-power high-density motor loss density, unreliable operation of the motor, and insufficient permanent magnet strength, etc., to achieve Effects of reduced rotor heat generation, low density, and large slot size

Inactive Publication Date: 2013-03-20

SHENYANG POLYTECHNIC UNIV

View PDF5 Cites 41 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Purpose of the invention: The present invention provides a wind-water mixed cooling high-speed permanent magnet motor. It is difficult to dissipate heat and the temperature rise is too high, which seriously affects the reliability and operating life of the motor. At the same time, it prevents high-order harmonics from entering the permanent magnet to cause additional loss, and avoids serious loss of magnetism or even irreversible demagnetization of the permanent magnet at high temperature. Phenomena that prevent the motor from operating reliably

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

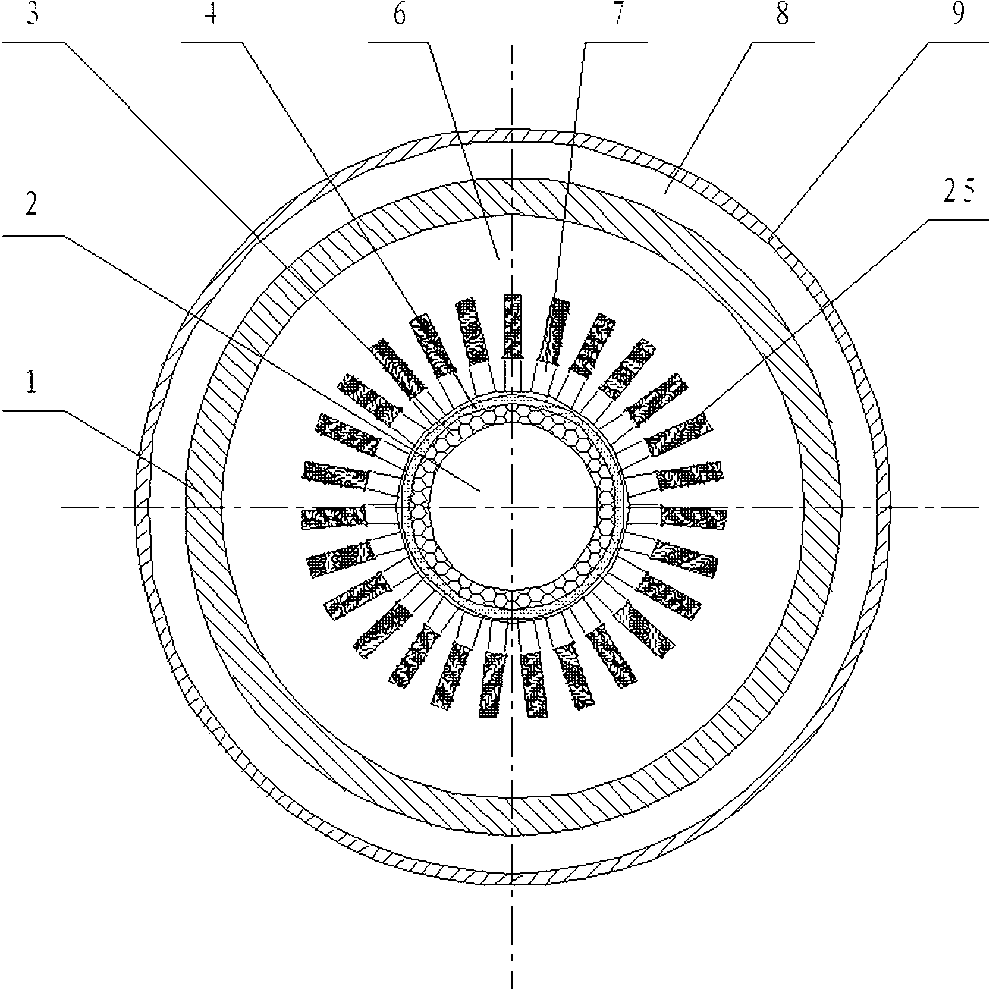

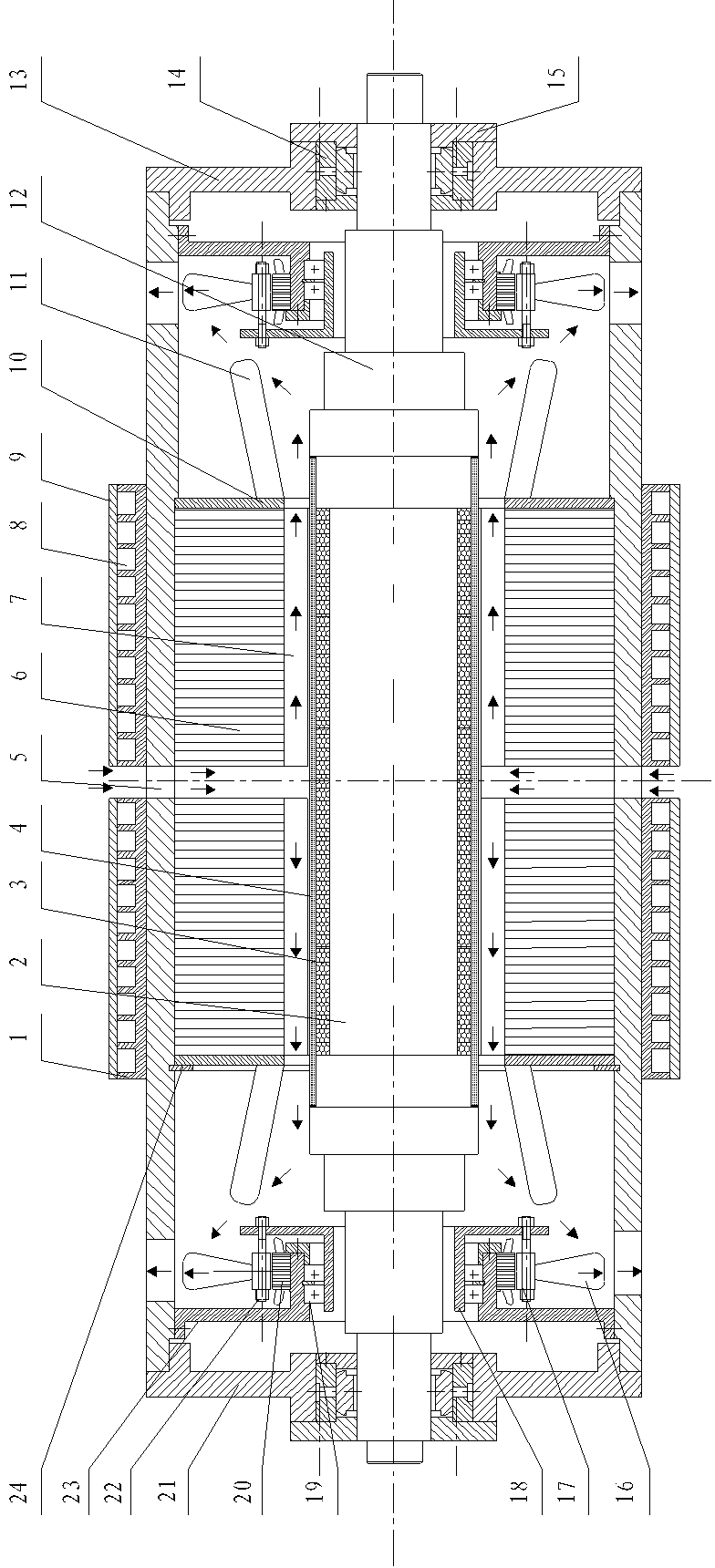

The invention discloses an air and water hybrid cooling high-speed permanent-magnet motor and belongs to the technical field of motors. The large-power high-speed permanent-magnet motor comprises a casing, a cooling water jacket, a stator core, a stator radial air duct, a stator inner air duct, a motor rotor, an outer rotor axial fan, an outer rotor fan fixing frame and two sliding bearings. The stator core is divided into two sections, the radial air duct is reserved in the middle, and the inner air duct is reserved in a stator slot close to the air gap position. The cooling water jacket is arranged outside the stator casing, a spiral water way is arranged in the water jacket, and water flows into the water way from the middle of the water way and flows out from a left spiral water outlet and a right spiral water outlet which are arranged at two ends of the water way. The air and water hybrid cooling high-speed permanent-magnet motor can mechanically solve the problem that a permanent magnet is broken when bearing large pulling stress during high-speed rotating, further solves the problems that the large-power high-speed motor is large in loss density, difficult in heat dissipation and over high in temperature rising, and prevents the permanent magnet from having irreversible demagnetization easily at high temperature.

Description

technical field The invention belongs to the technical field of electric motors, and relates to a high-speed permanent magnet motor with mixed air and water cooling. The motor has the characteristics of high reliability, good heat dissipation system, simple structure and high rotor strength, and is especially suitable for high-power high-speed power generation. machine and electric motor. Background technique The high-speed motor can effectively save materials due to its high speed, high power density and small size; due to its small moment of inertia, the dynamic response is fast; the high-speed motor can be directly connected to the working machine or load, eliminating the need for traditional mechanical speed change devices , thereby reducing noise and improving the efficiency of the transmission system. The research and application of high-speed motors are in line with the economic development needs of energy conservation and emission reduction. At present, it has bec...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): H02K9/19H02K9/06H02K1/27H02K1/16

Inventor 张凤阁王天煜王凤翔杜光辉黄娜

Owner SHENYANG POLYTECHNIC UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com