Low watt consumption permanent magnet offset external rotor hybrid radial magnetic bearing

A permanent magnet bias and hybrid radial technology, applied in the direction of bearings, shafts and bearings, shafts, etc., can solve the problems of weakening the suction force of permanent magnets on the rotor shaft, increasing bearing power consumption, and long axial length, etc., to achieve power consumption Low, reduce copper consumption, the effect of volume reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

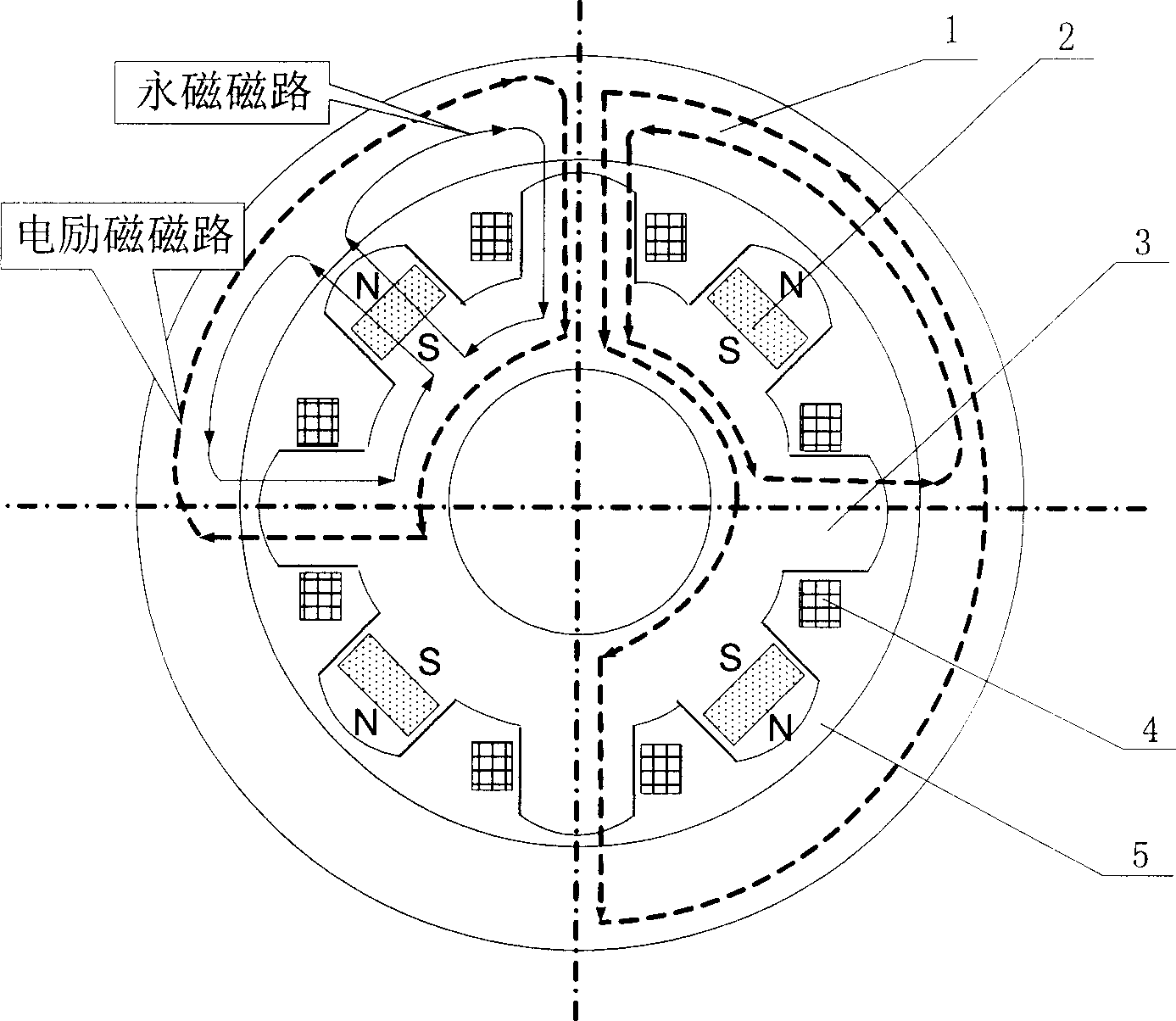

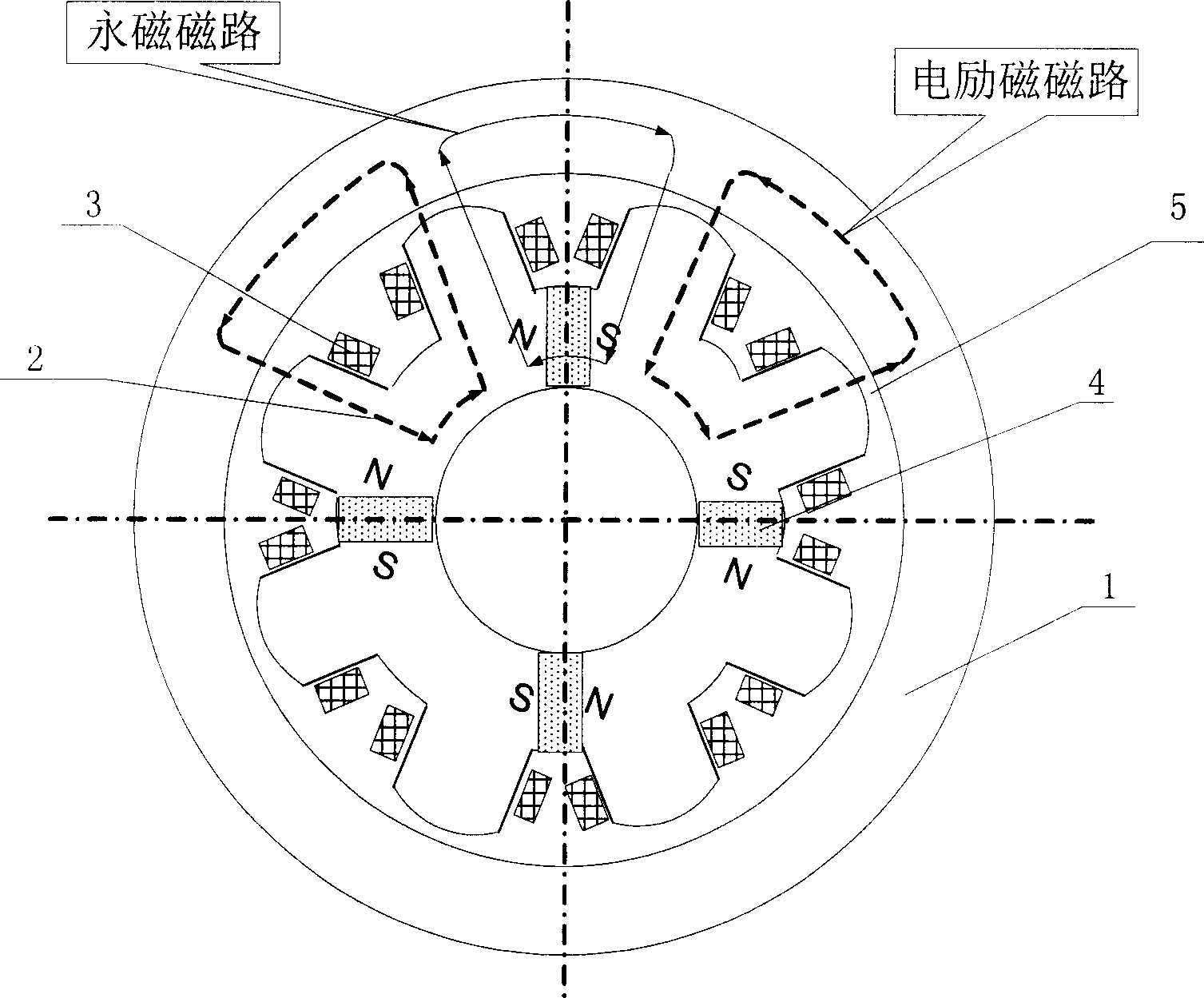

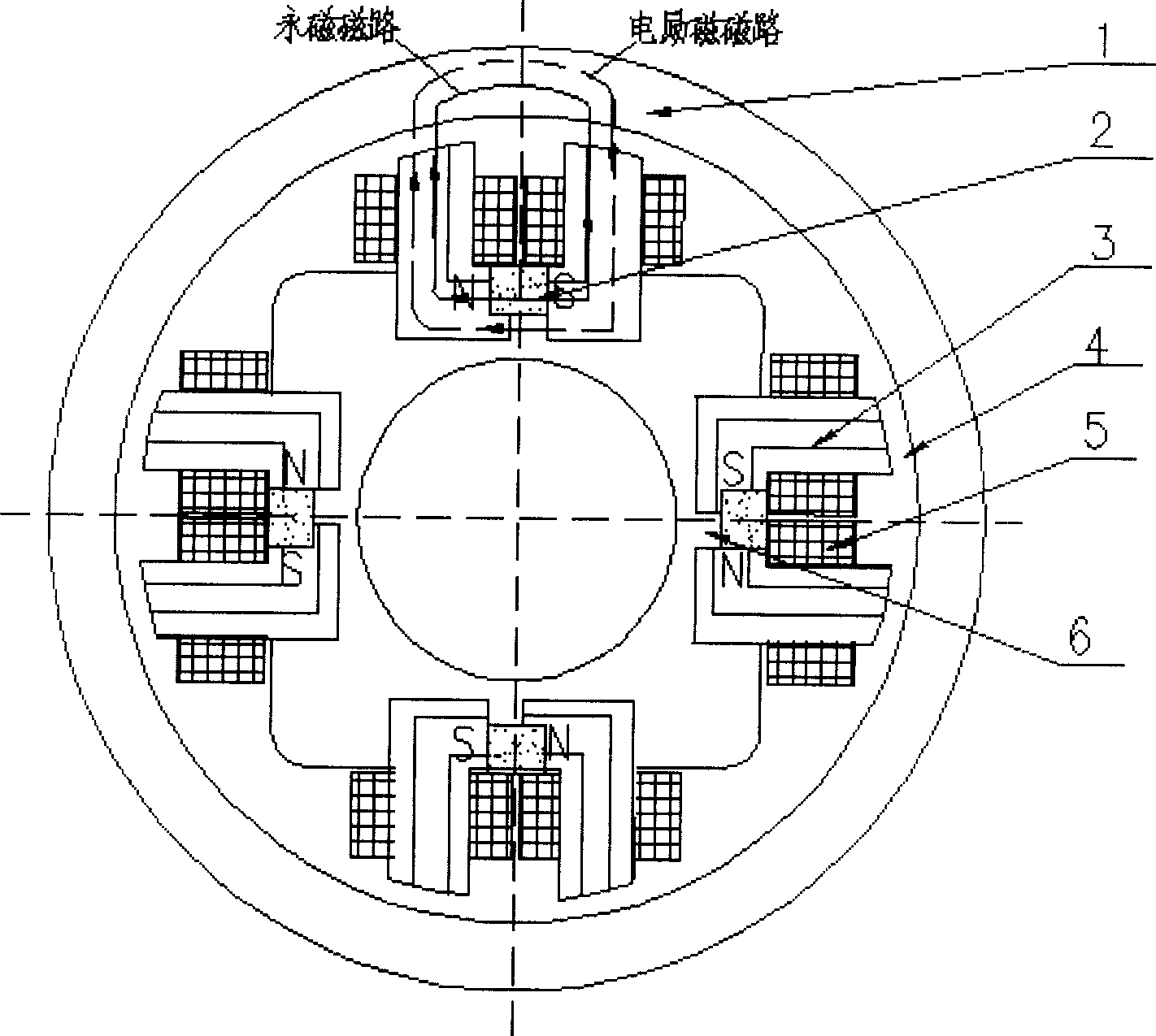

[0010] Such as image 3 As shown, the present invention is composed of a rotor core 1, a permanent magnet 2, a stator core 3, and an excitation coil 5. Eight stator cores 3 magnetic poles form stator core poles in the X and Y directions, and an excitation coil is formed around them. The four permanent magnets 2 are placed between the two stator cores 3 and distributed at 90 degrees. There is a certain gap (generally 0.2-0.4mm) between the outer surface of the stator core 3 and the inner surface of the rotor core 1 to form an air gap 4, and the second air gap between the permanent magnet 2 and the stator core should also be slightly larger than twice the air gap The length of 4 is to reduce the loss of the magnetomotive force of the permanent magnet. The permanent magnet 2 forms a bias magnetic field in the X and Y directions through the stator core 3 poles. In specific applications, the permanent magnet bias outer rotor radial magnetic bearings of the present invention should...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com