Patents

Literature

197 results about "Anodic protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anodic protection (AP) is a technique to control the corrosion of a metal surface by making it the anode of an electrochemical cell and controlling the electrode potential in an zone where the metal is passive.

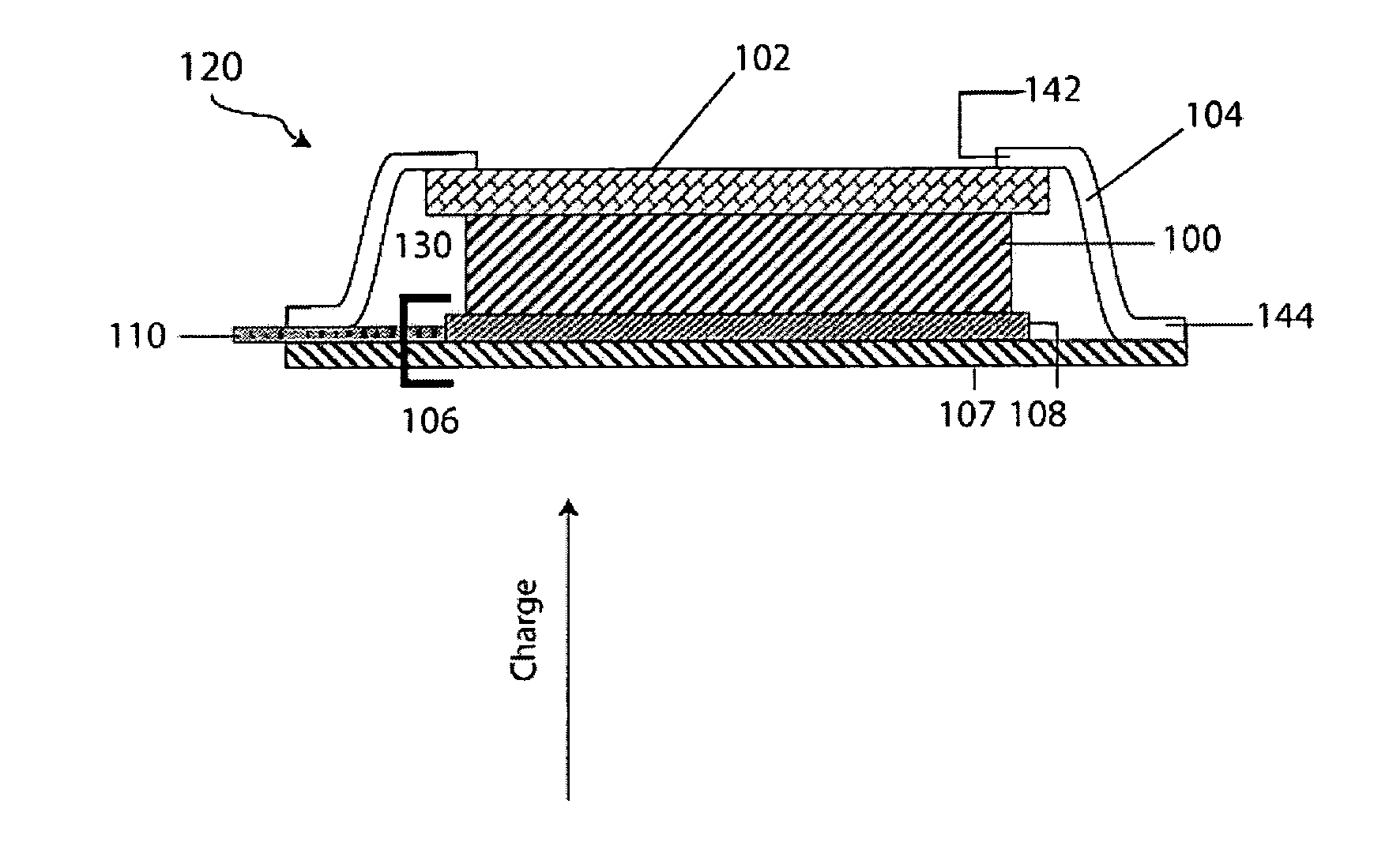

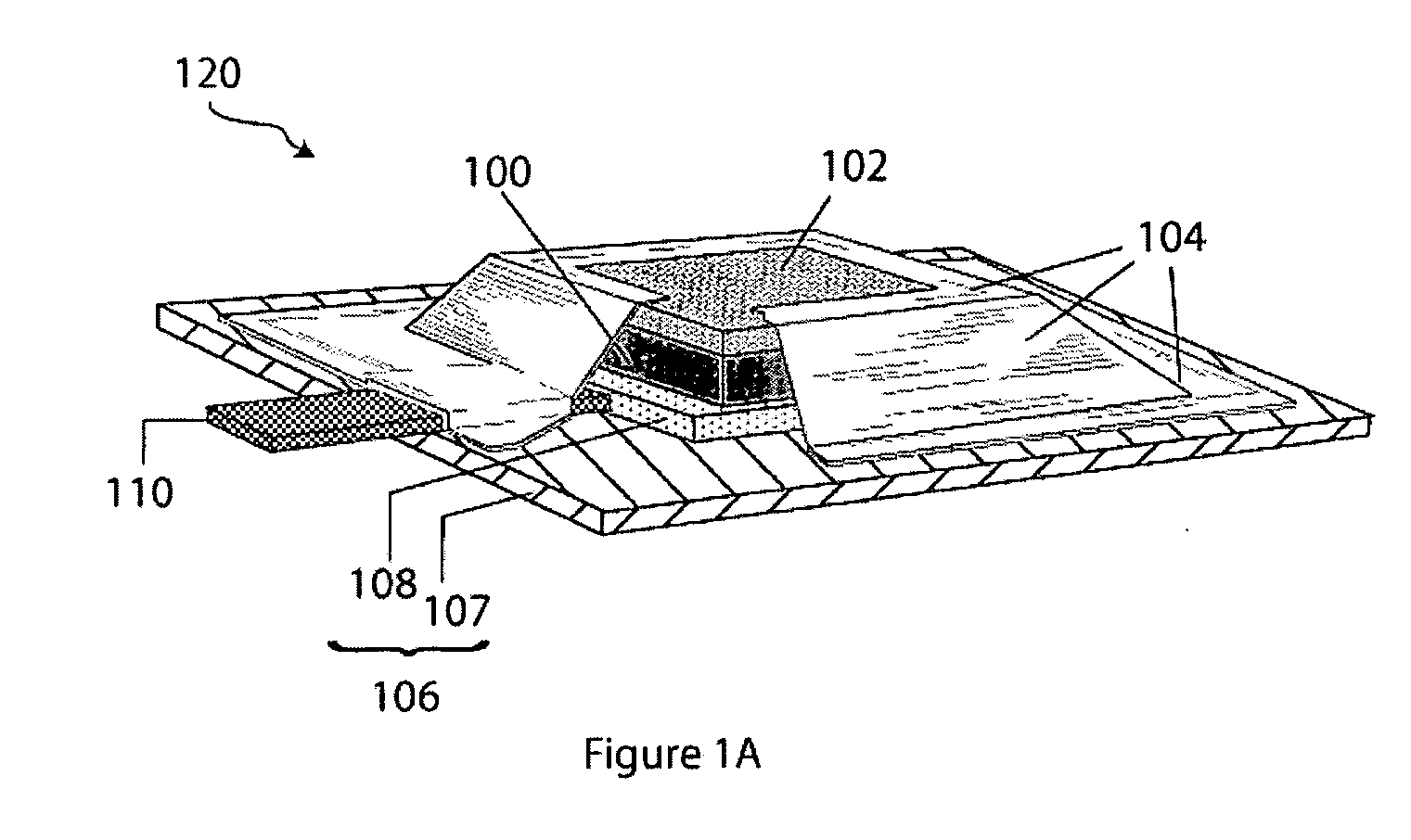

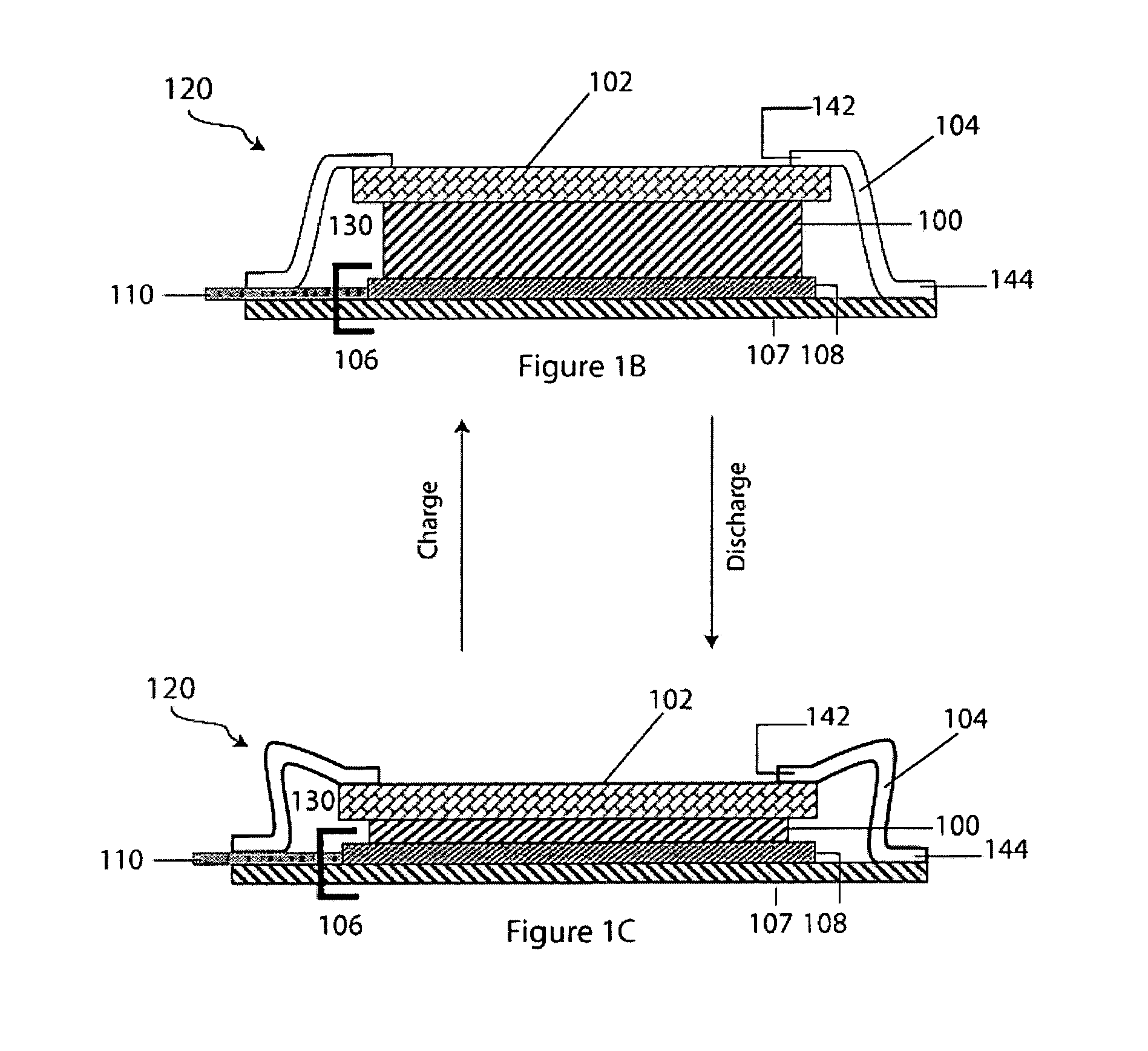

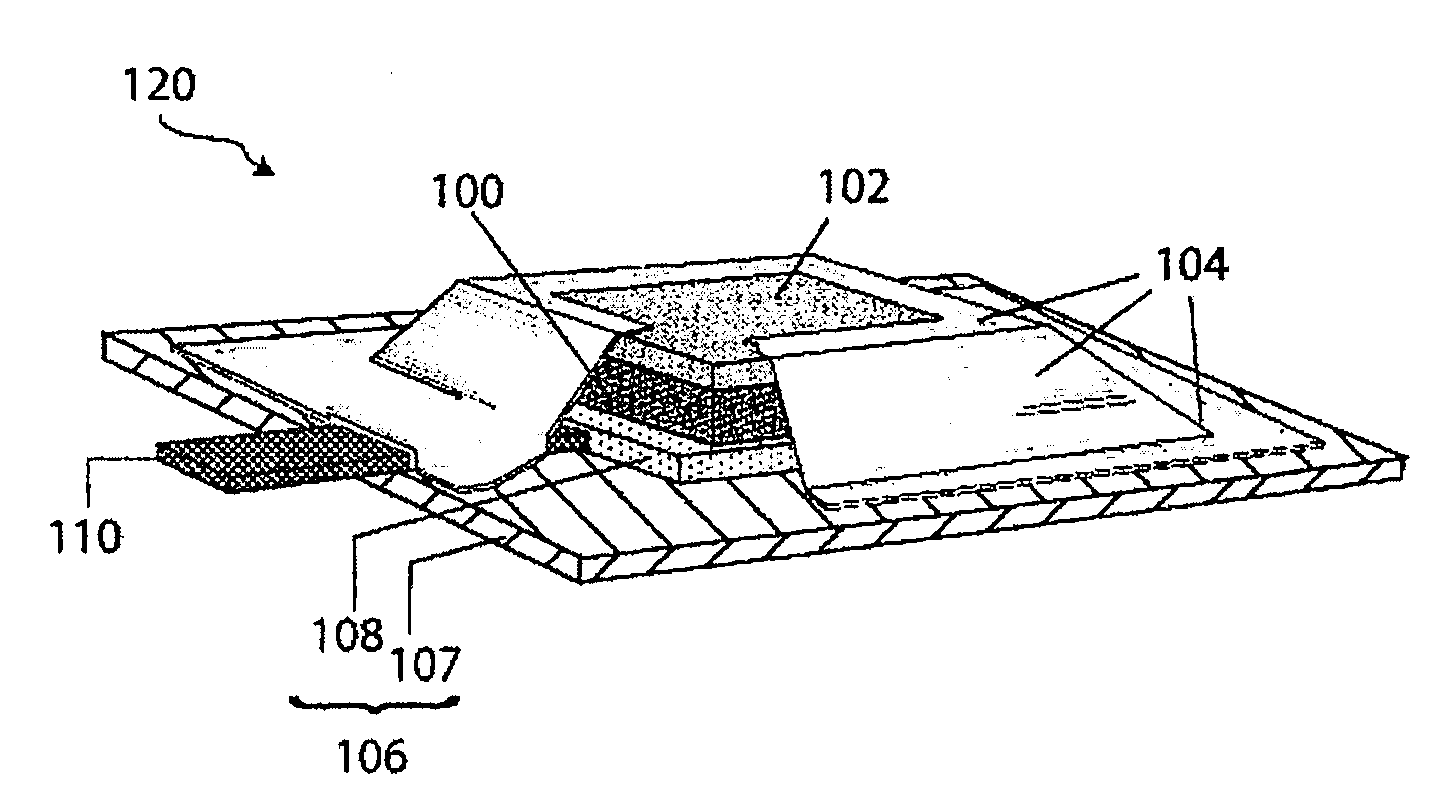

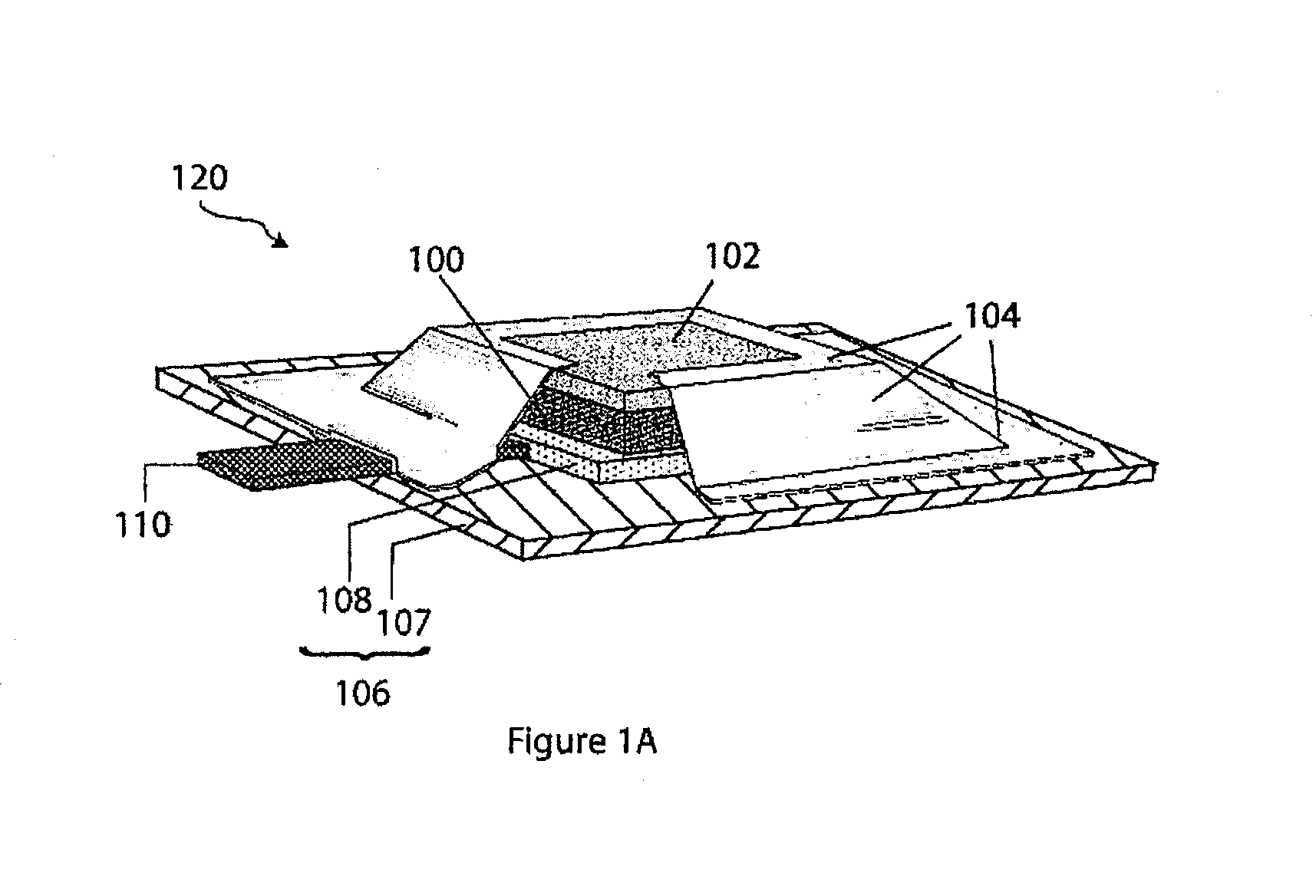

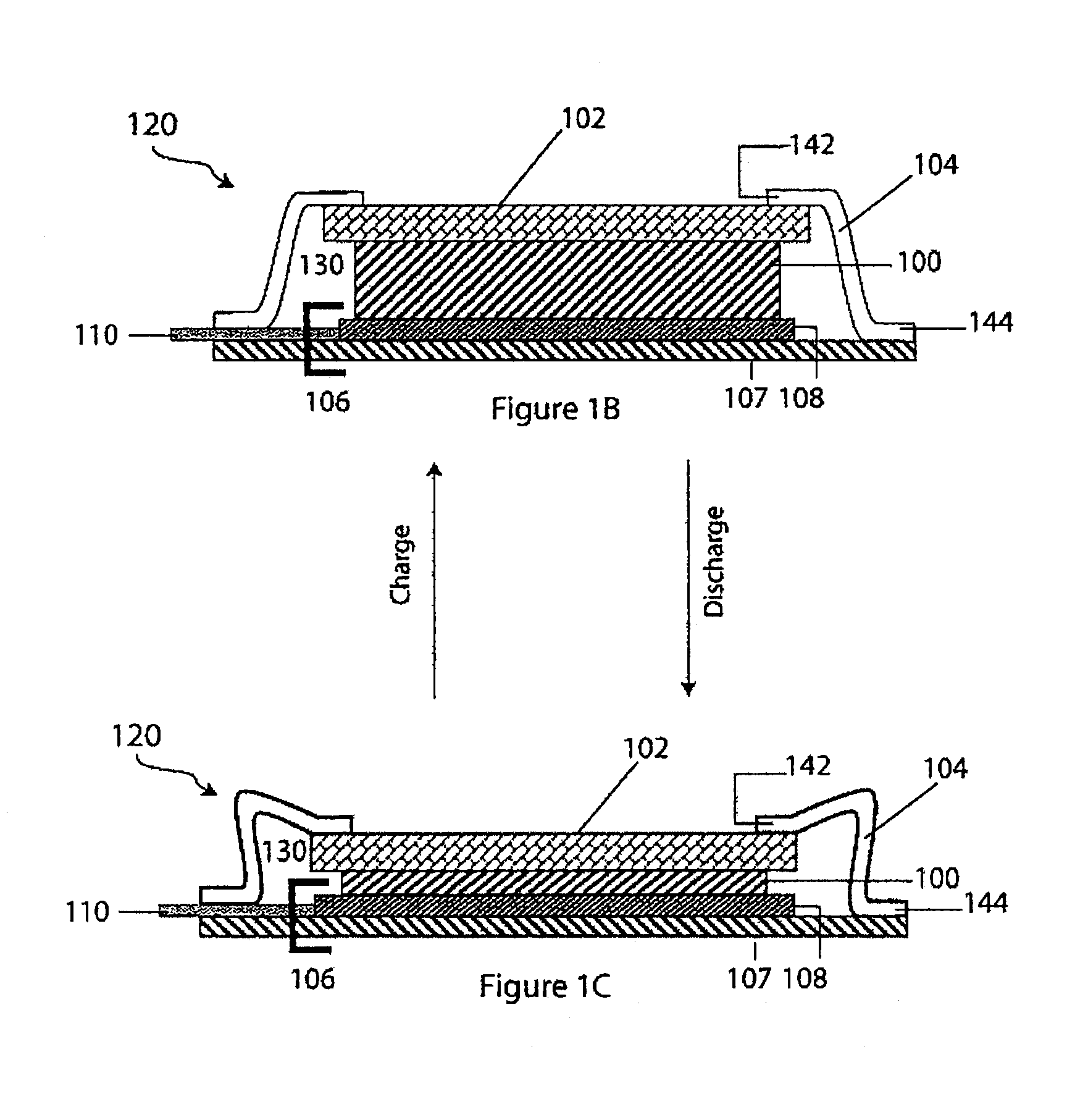

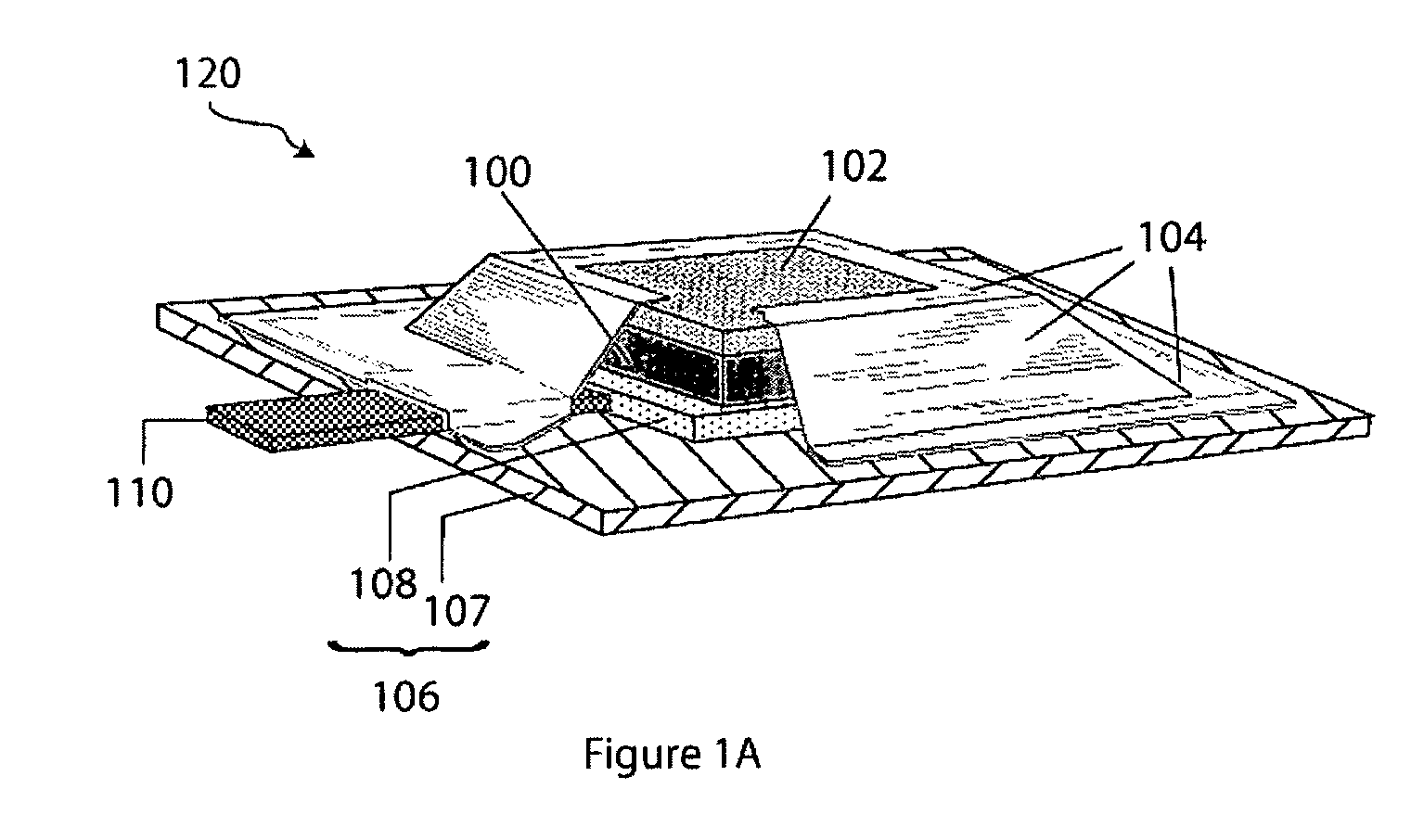

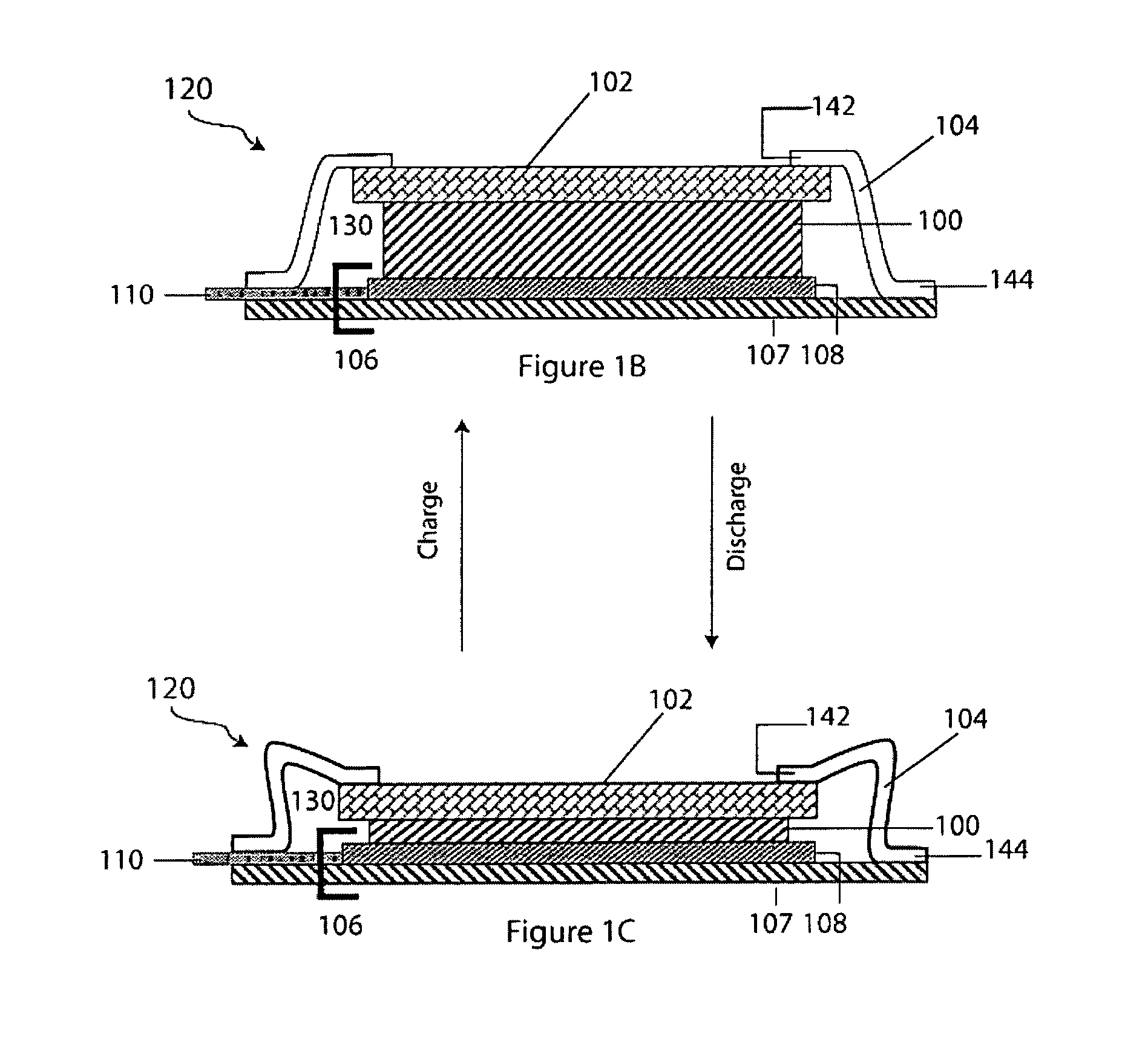

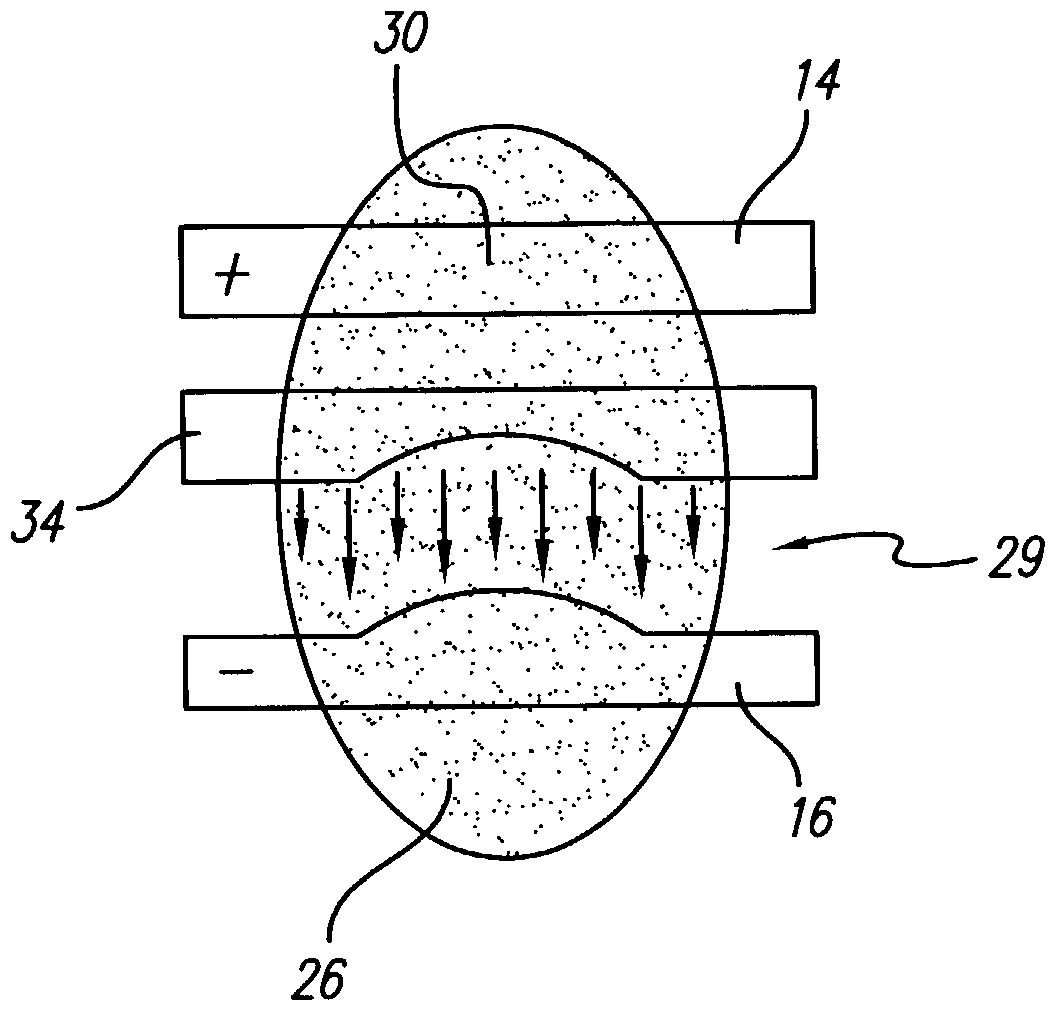

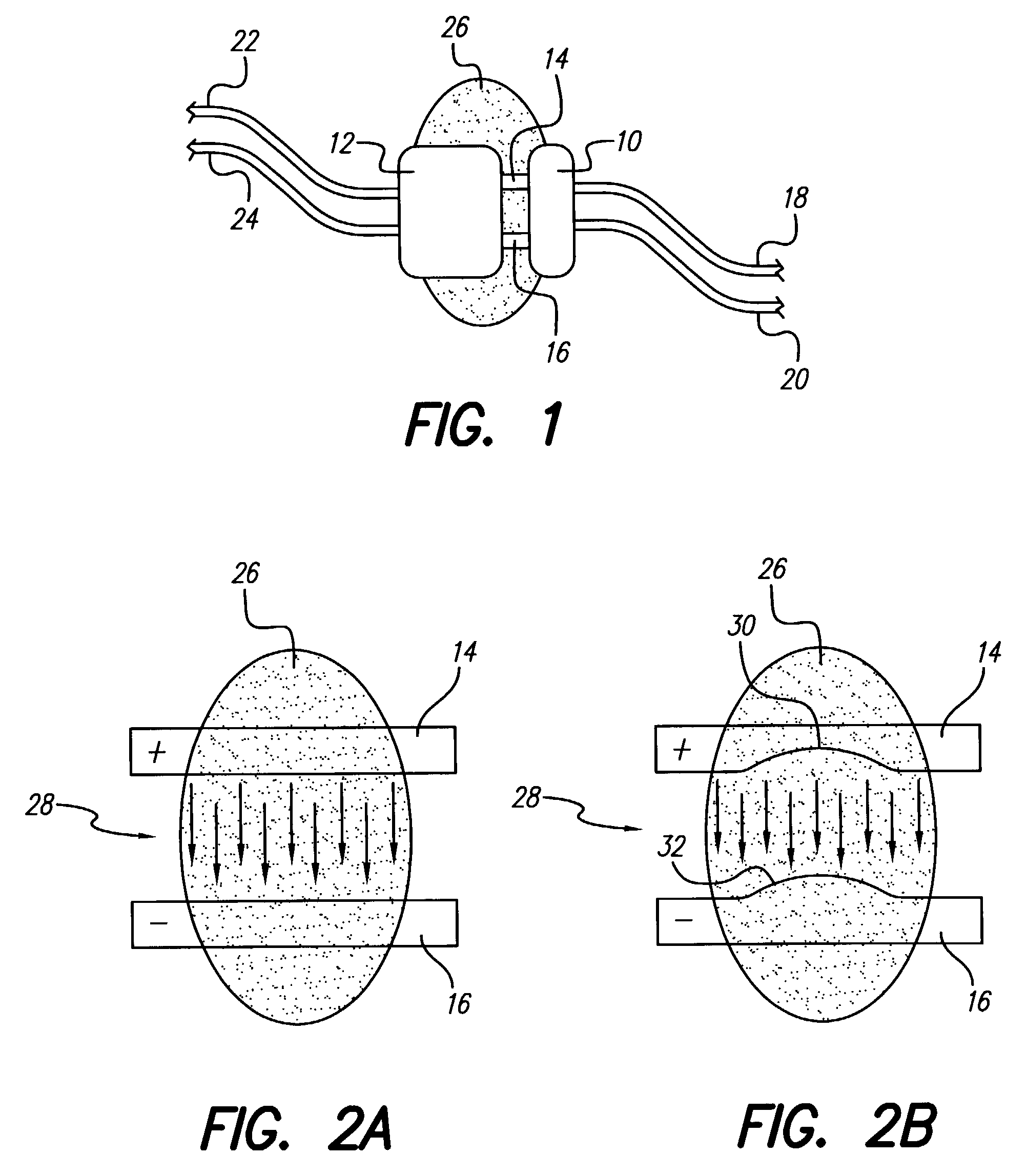

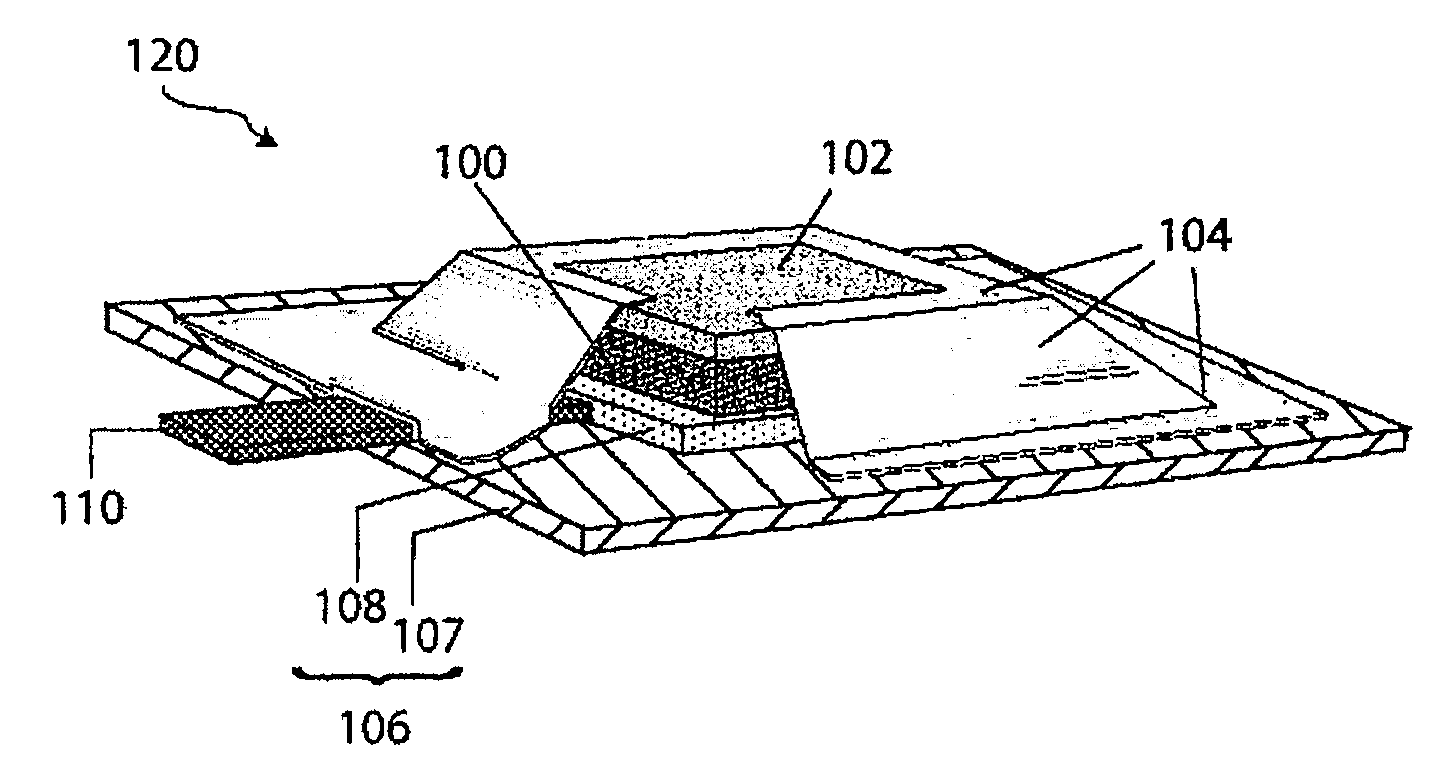

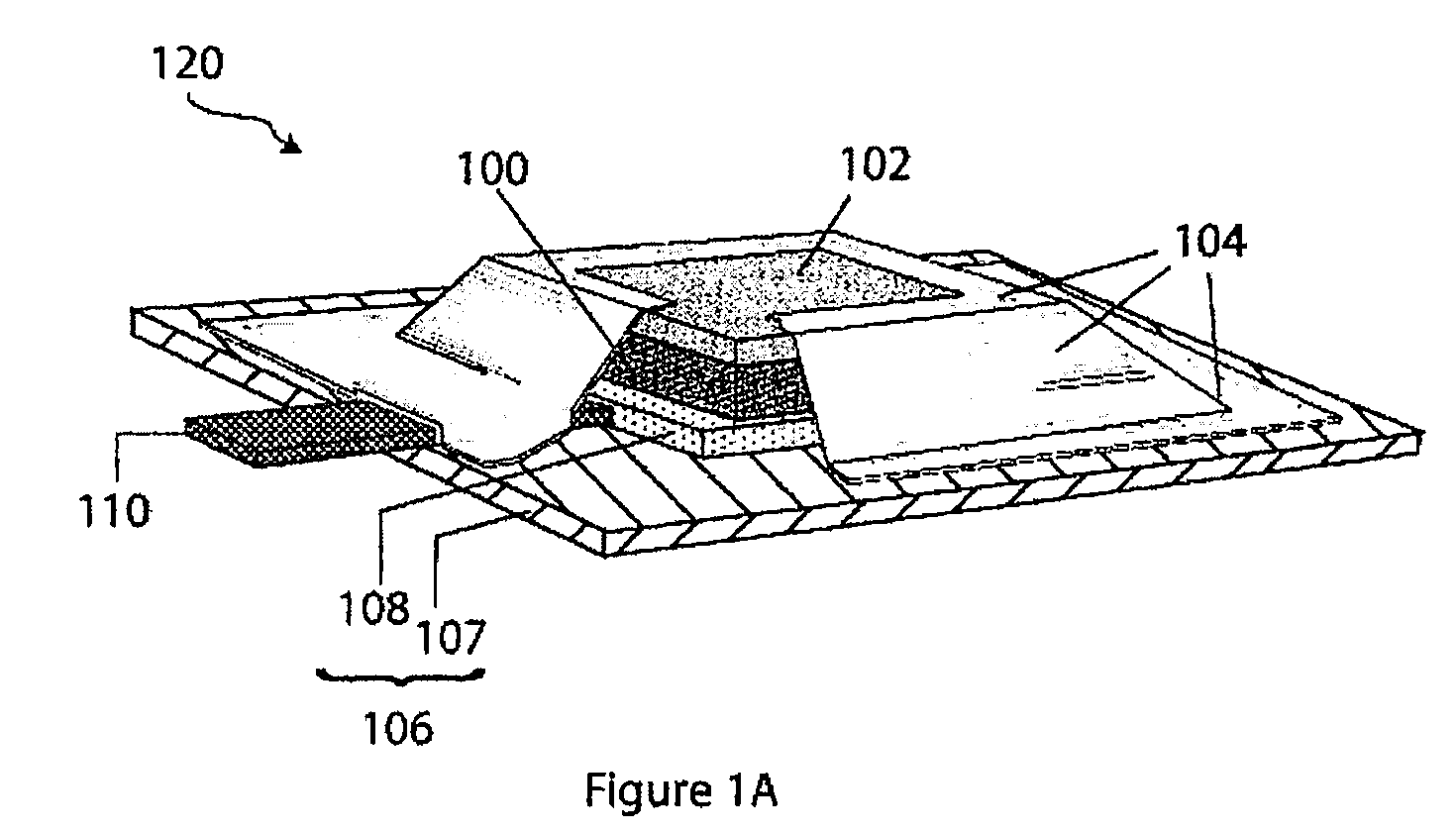

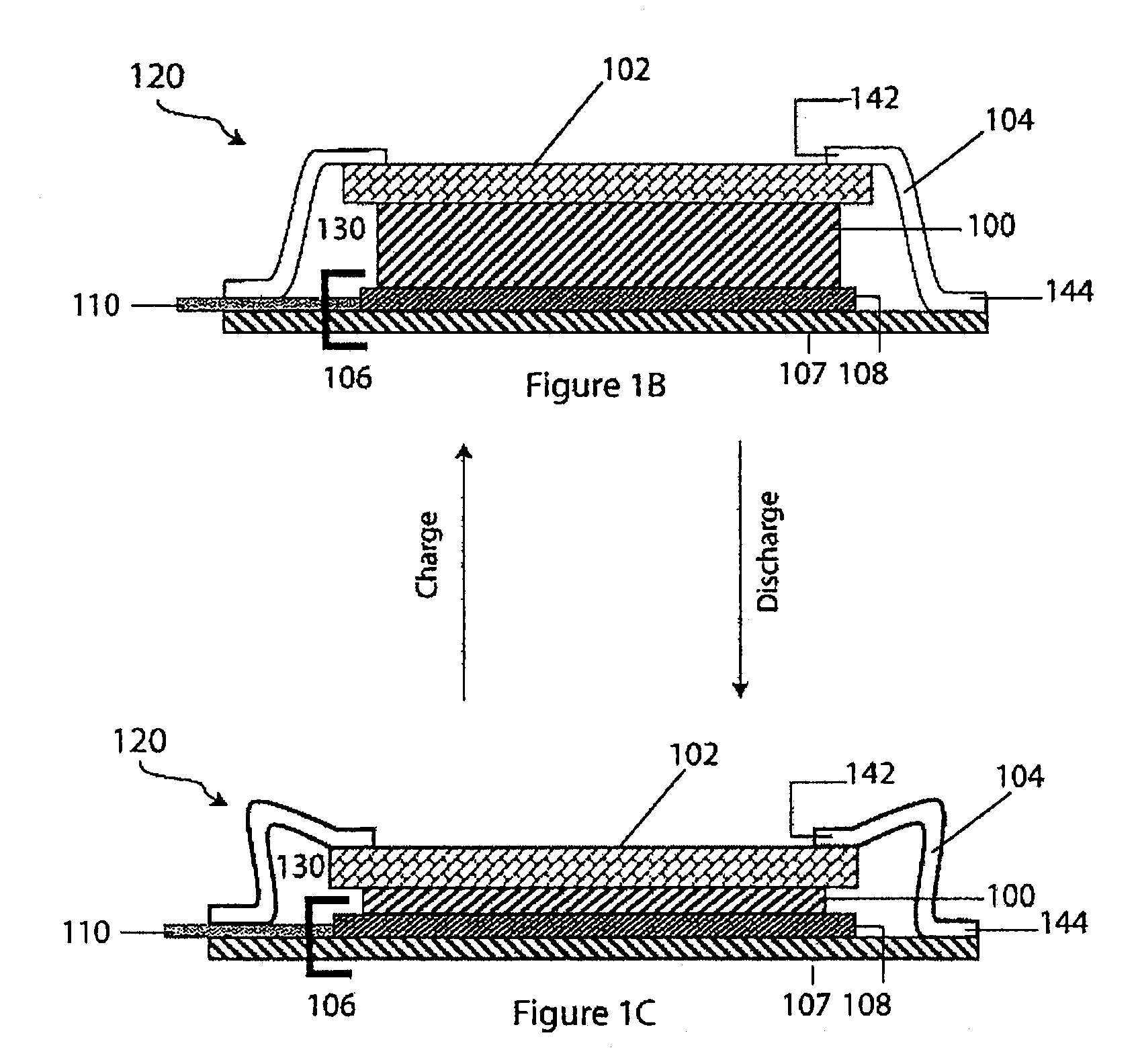

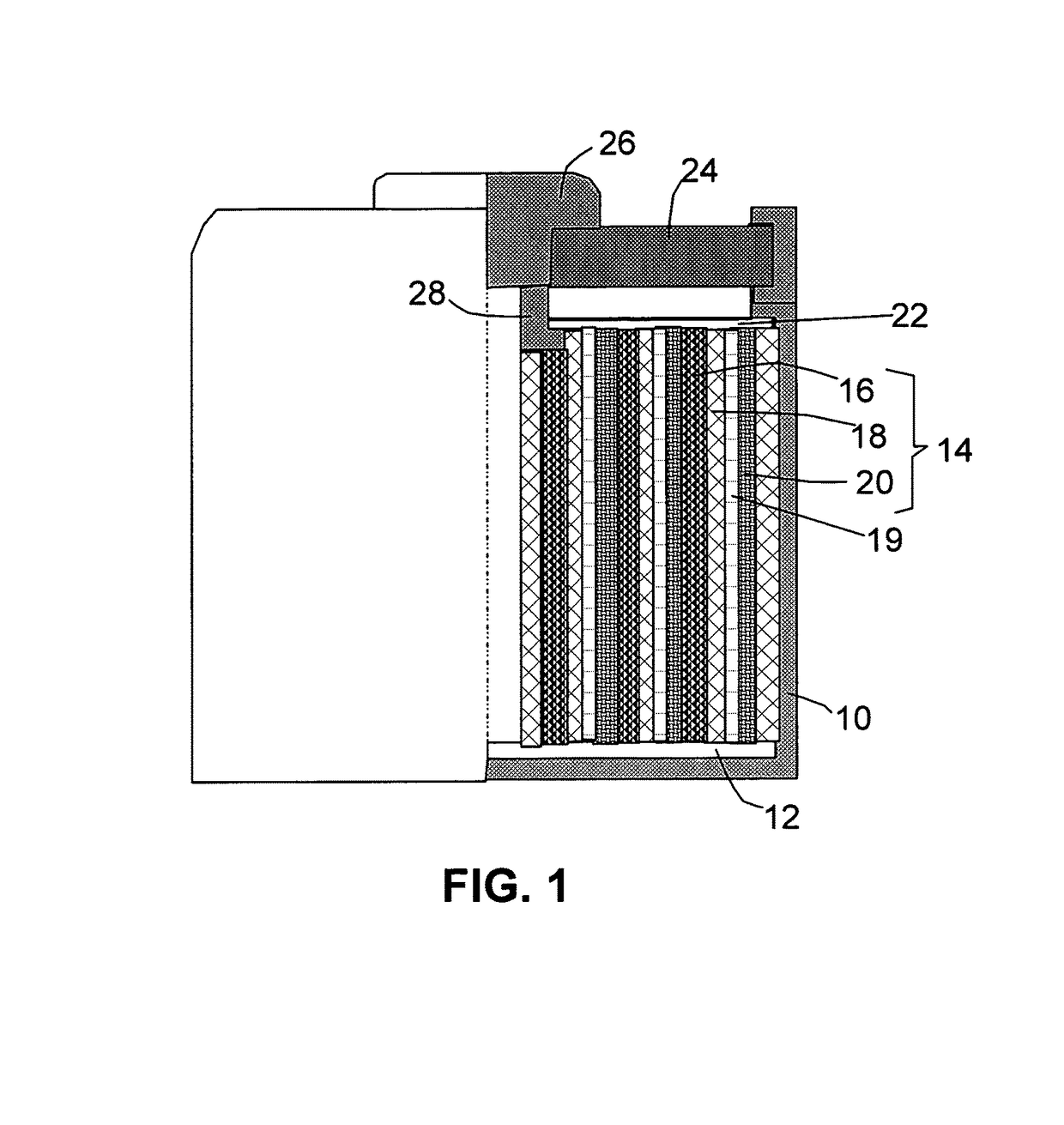

Compliant seal structures for protected active metal anodes

ActiveUS20070037058A1Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

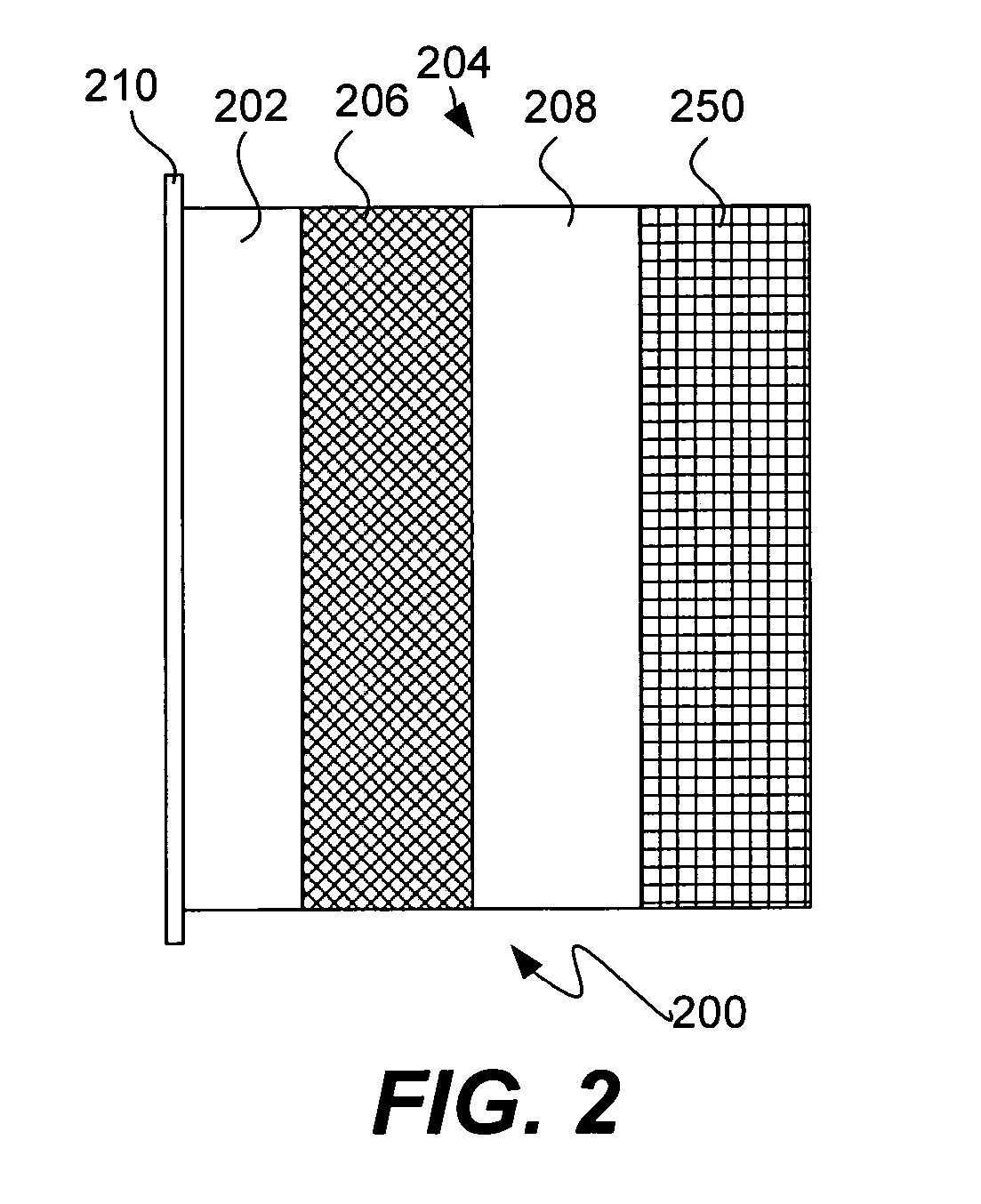

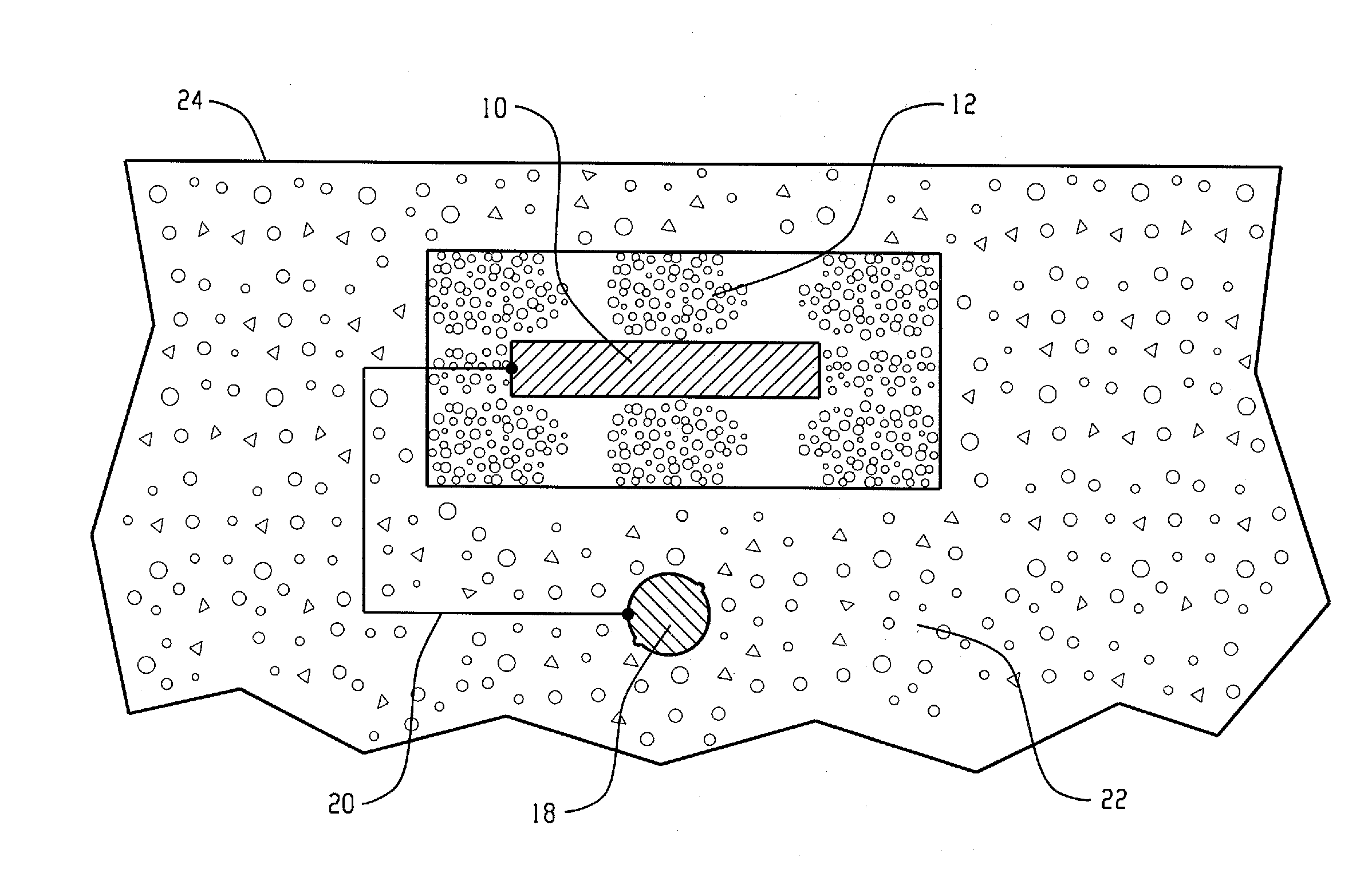

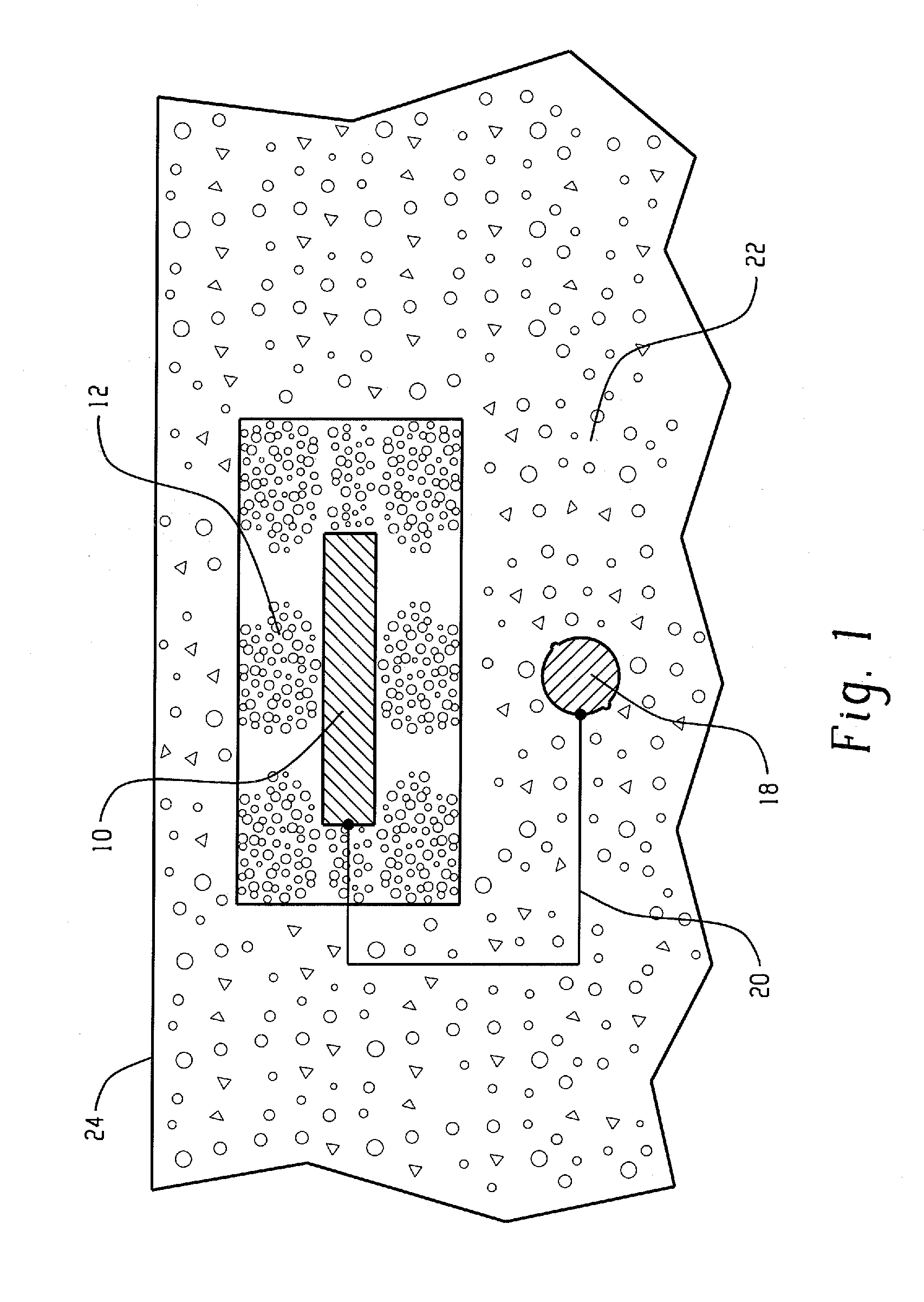

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveUS20100112454A1Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

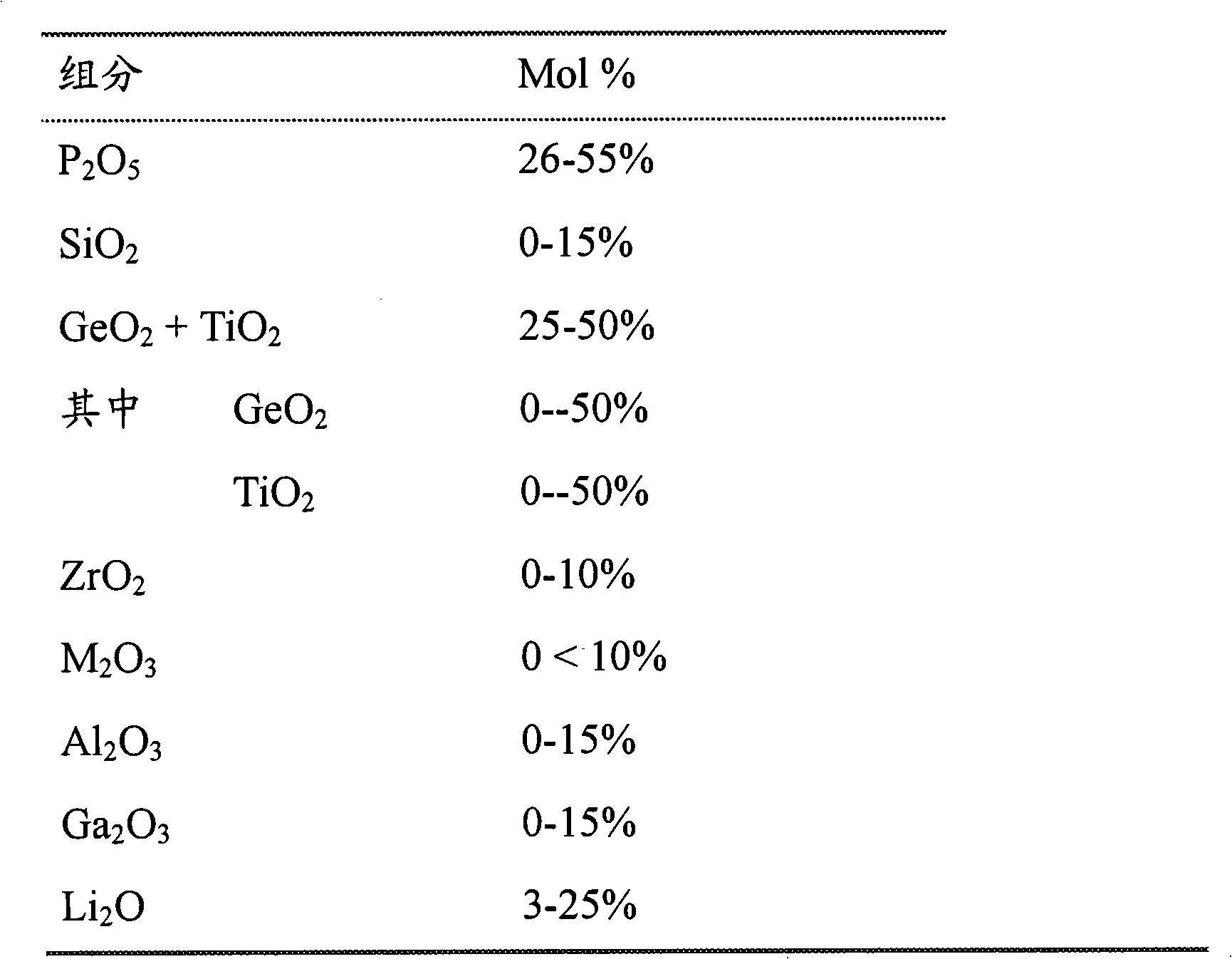

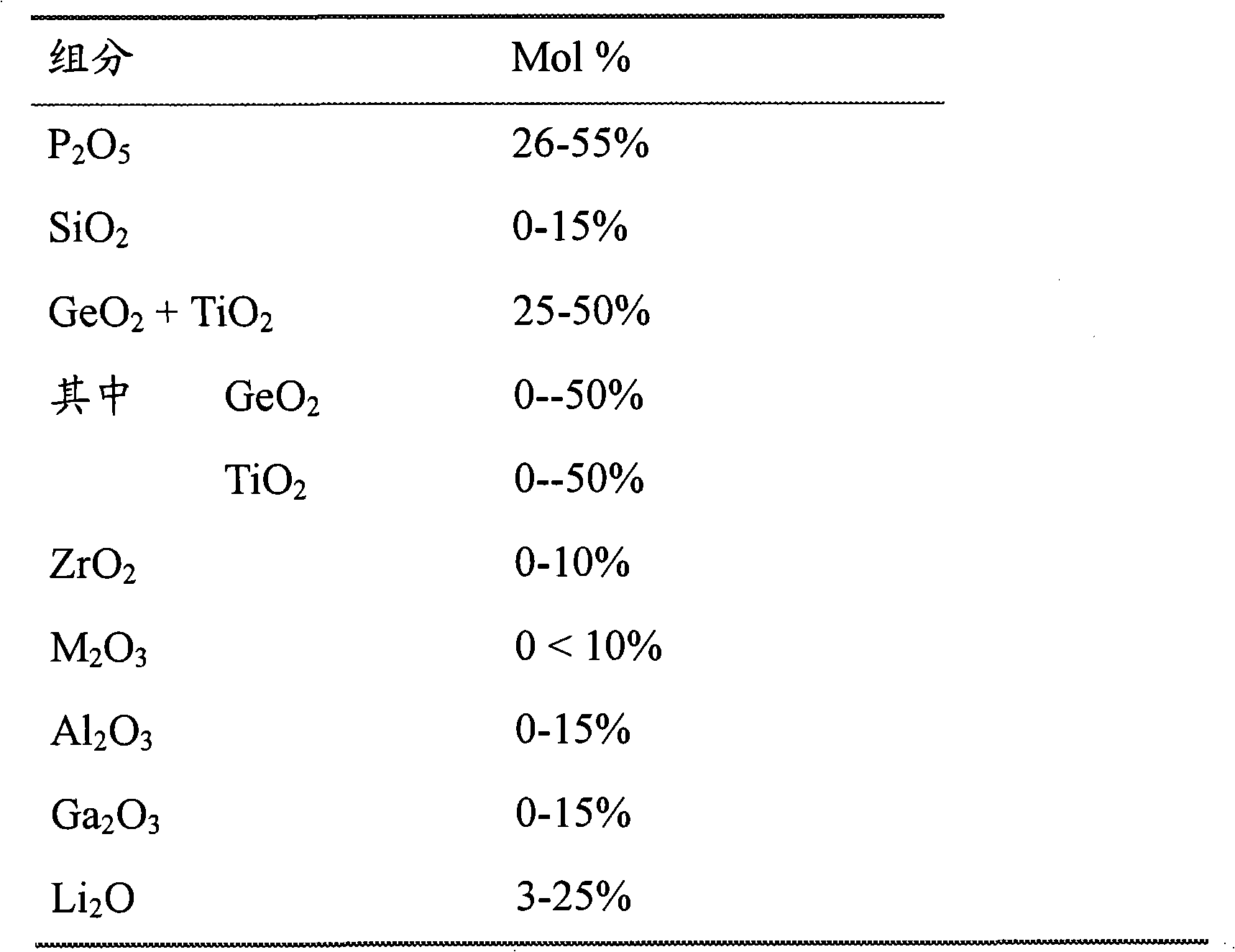

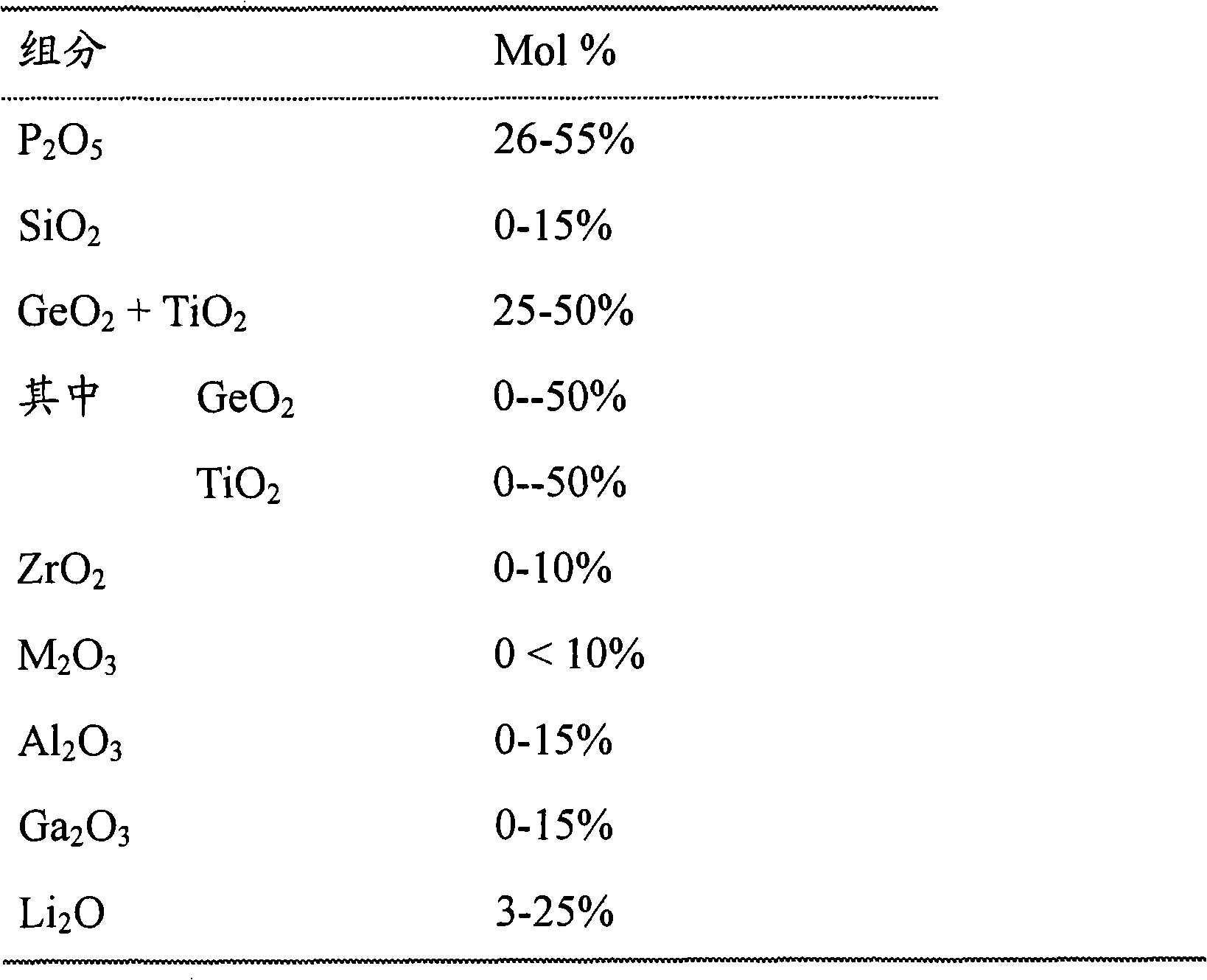

Solid electrolytes based on lithium hafnium phosphate for active metal anode protection

InactiveUS20060078790A1Avoid harmful reactionsCell electrodesNon-aqueous electrolyte cellsPhosphateOrganic liquids

Active metal electrochemical structure, in particular an active metal negative electrode (anode) protected with an ionically conductive protective architecture incorporating a glassy, ceramic or glass-ceramic solid electrolyte material based on lithium hafnium phosphate, and associated electrochemical devices and methods, provides advantages over conventional structures. The protective architecture prevents the active metal from deleterious reaction with the environment on the other (cathode) side of the architecture, which may include aqueous, air or organic liquid electrolytes and / or electrochemically active materials.

Owner:POLYPLUS BATTERY CO INC

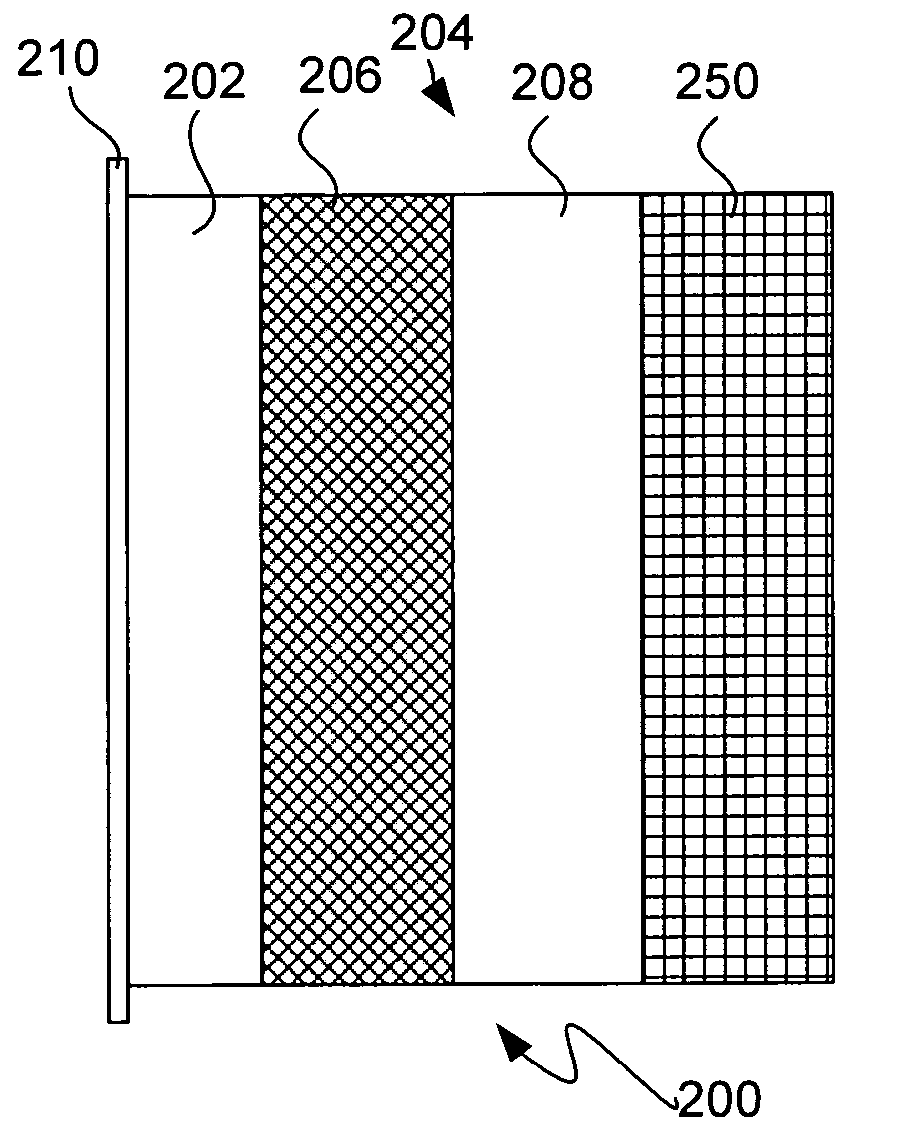

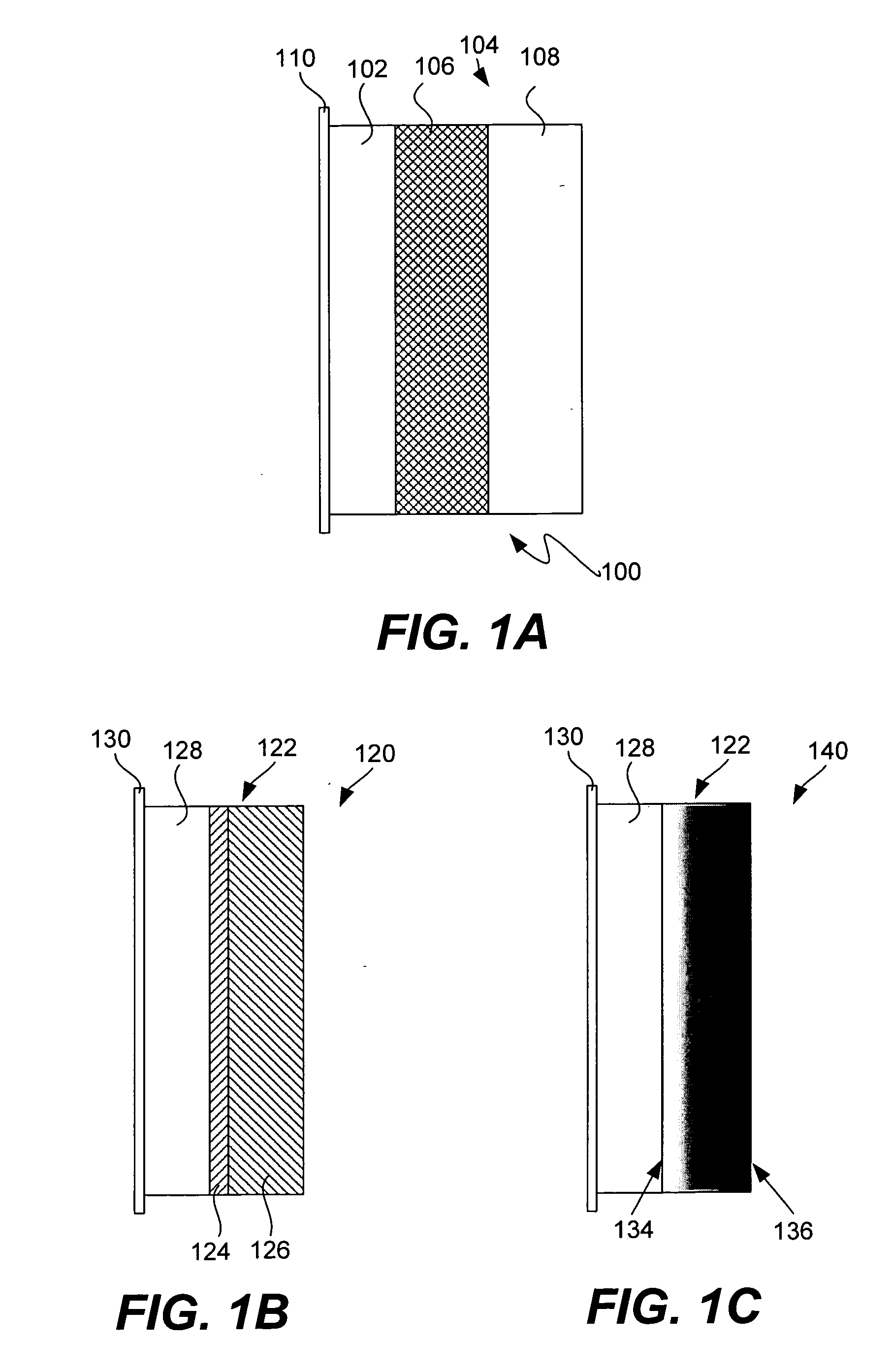

Methods of preparing electrochemical cells

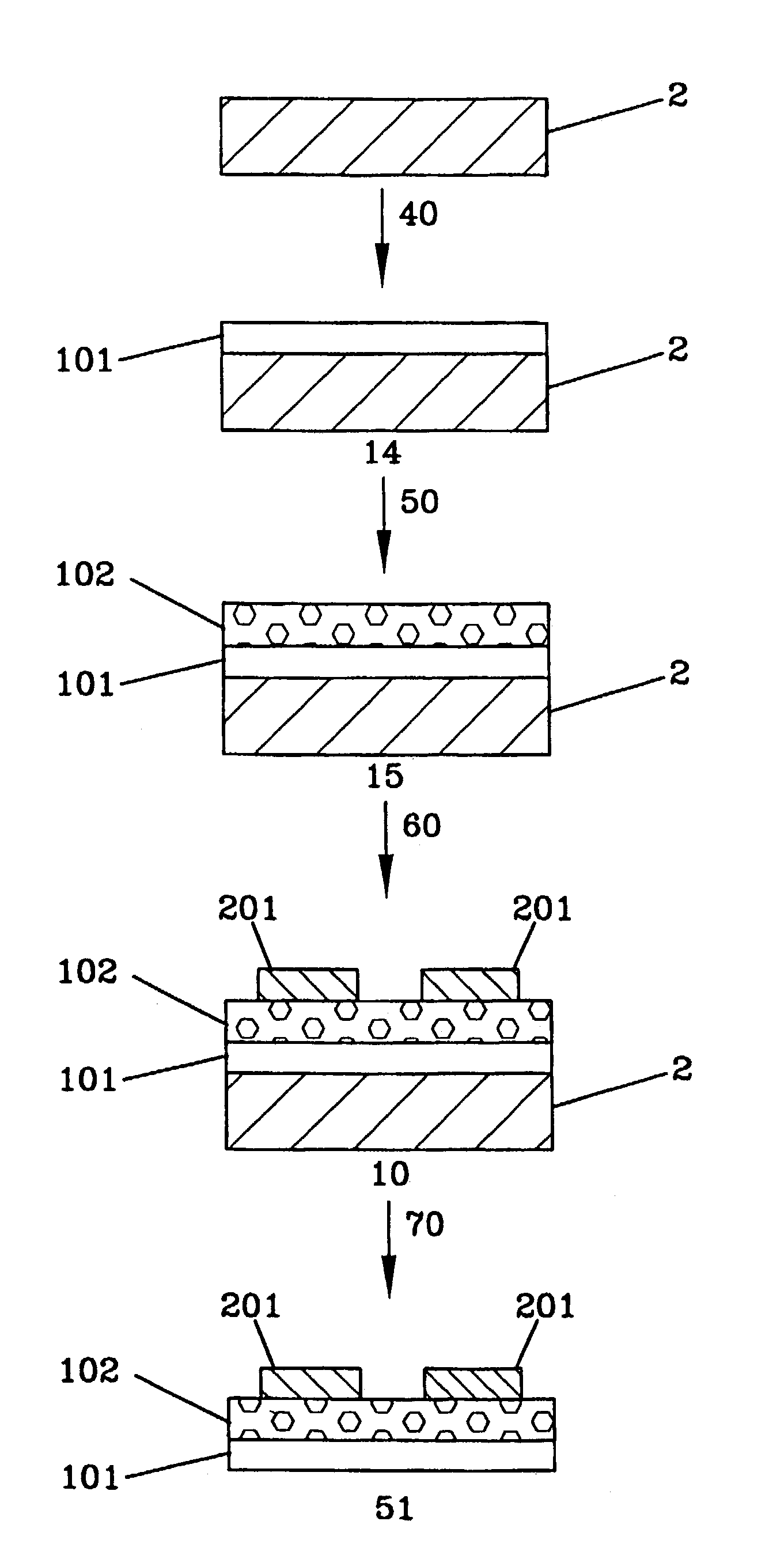

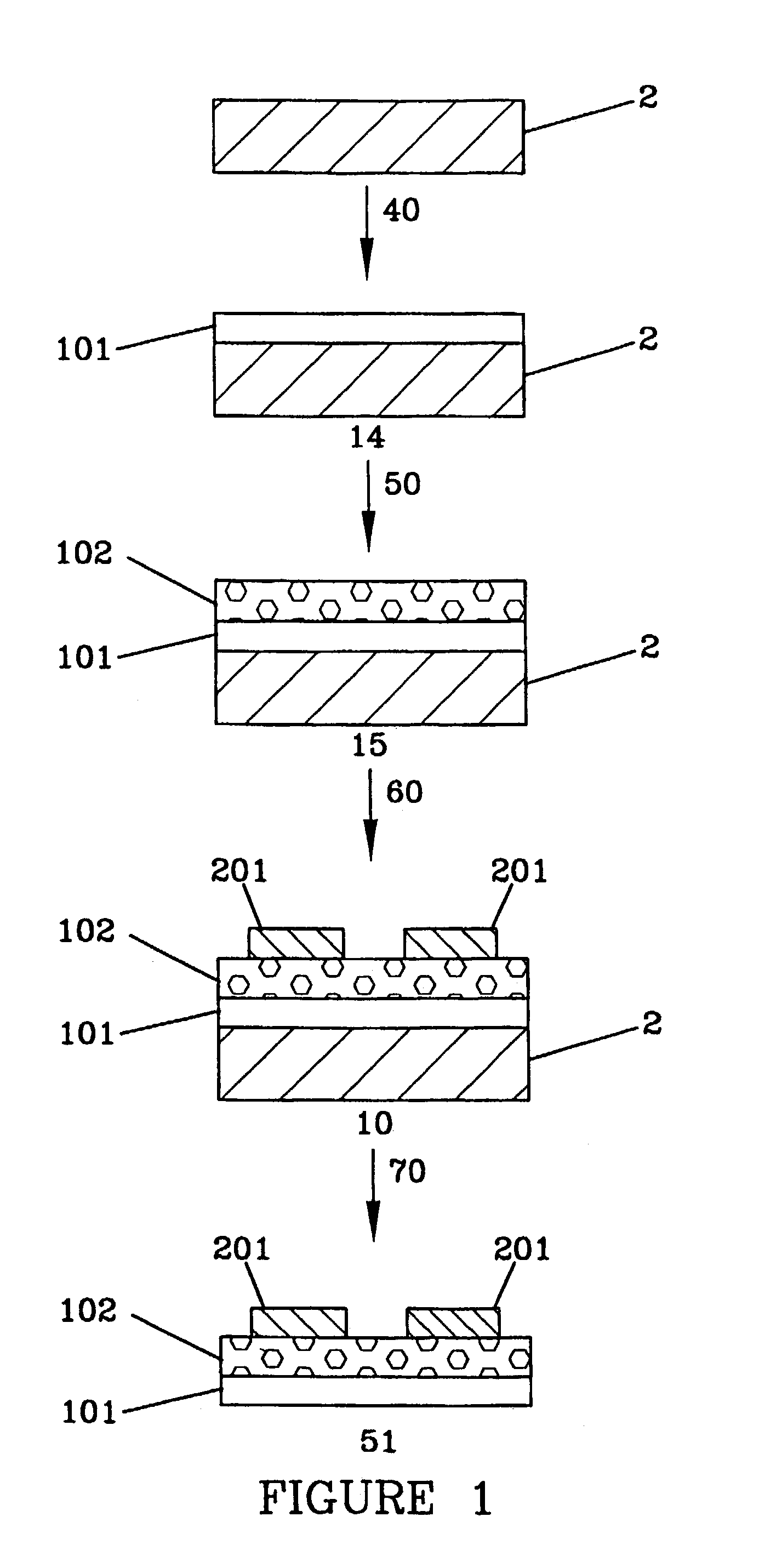

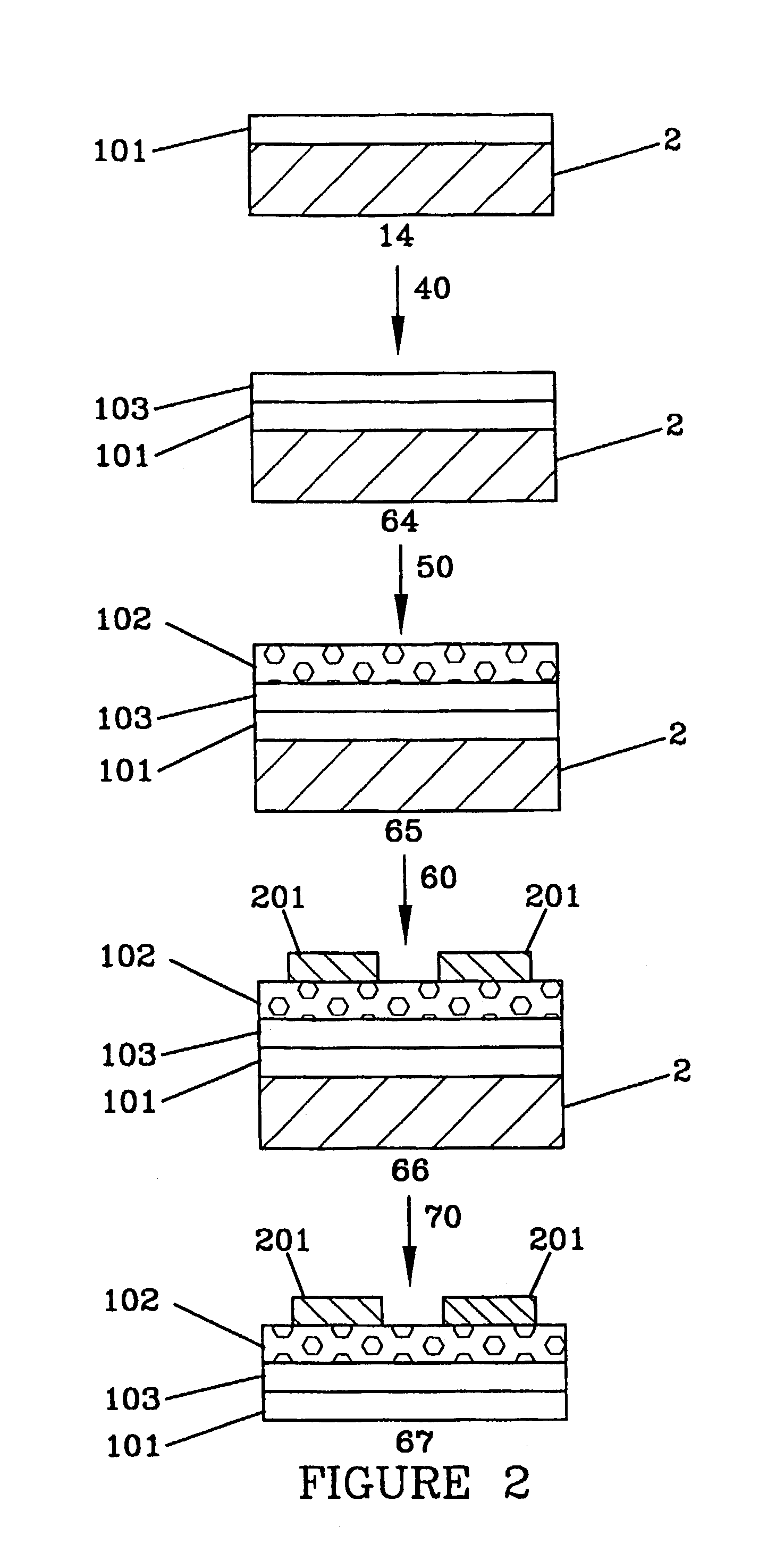

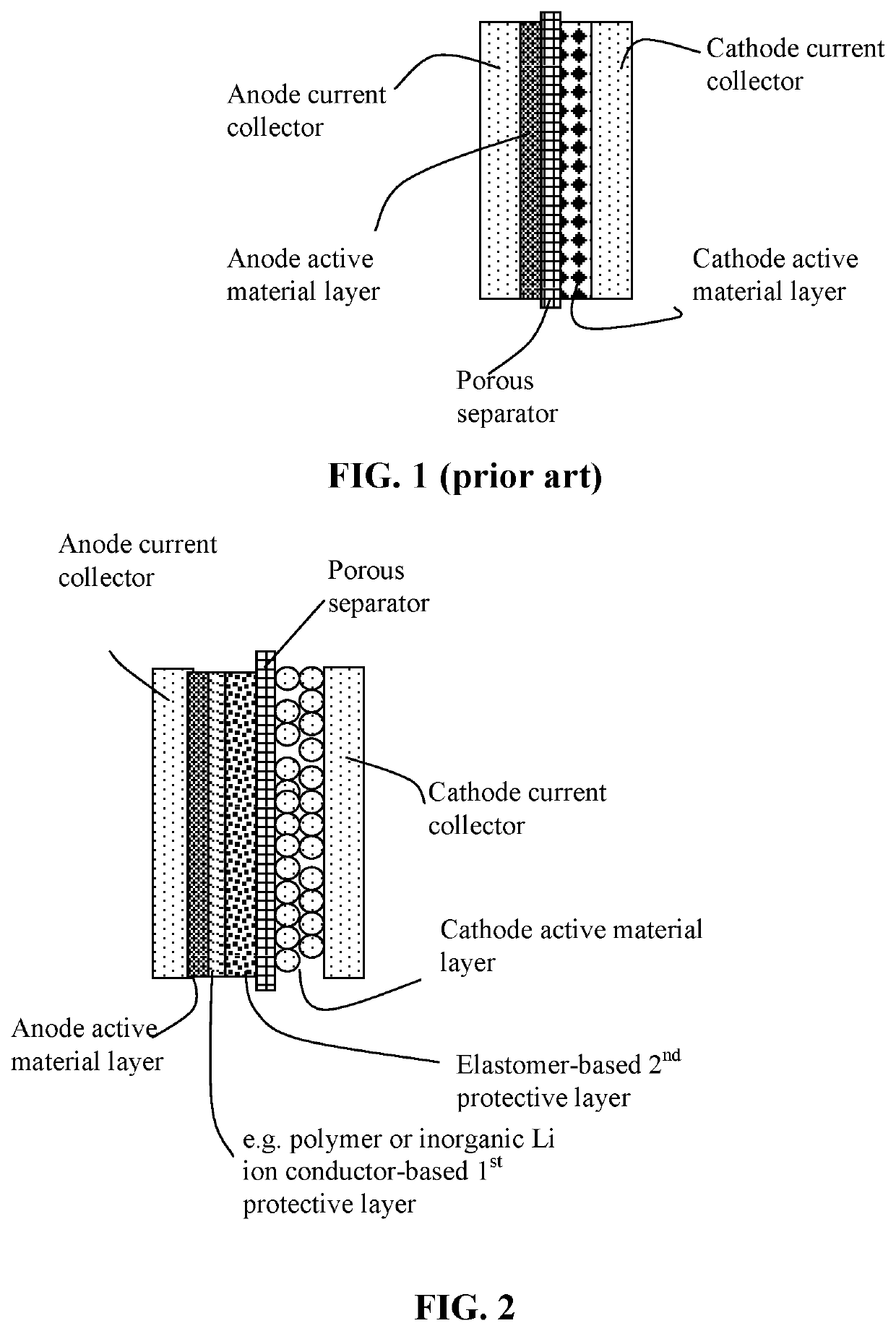

InactiveUS7066971B1Electrode carriers/collectorsActive material electrodesLithium metalAnodic protection

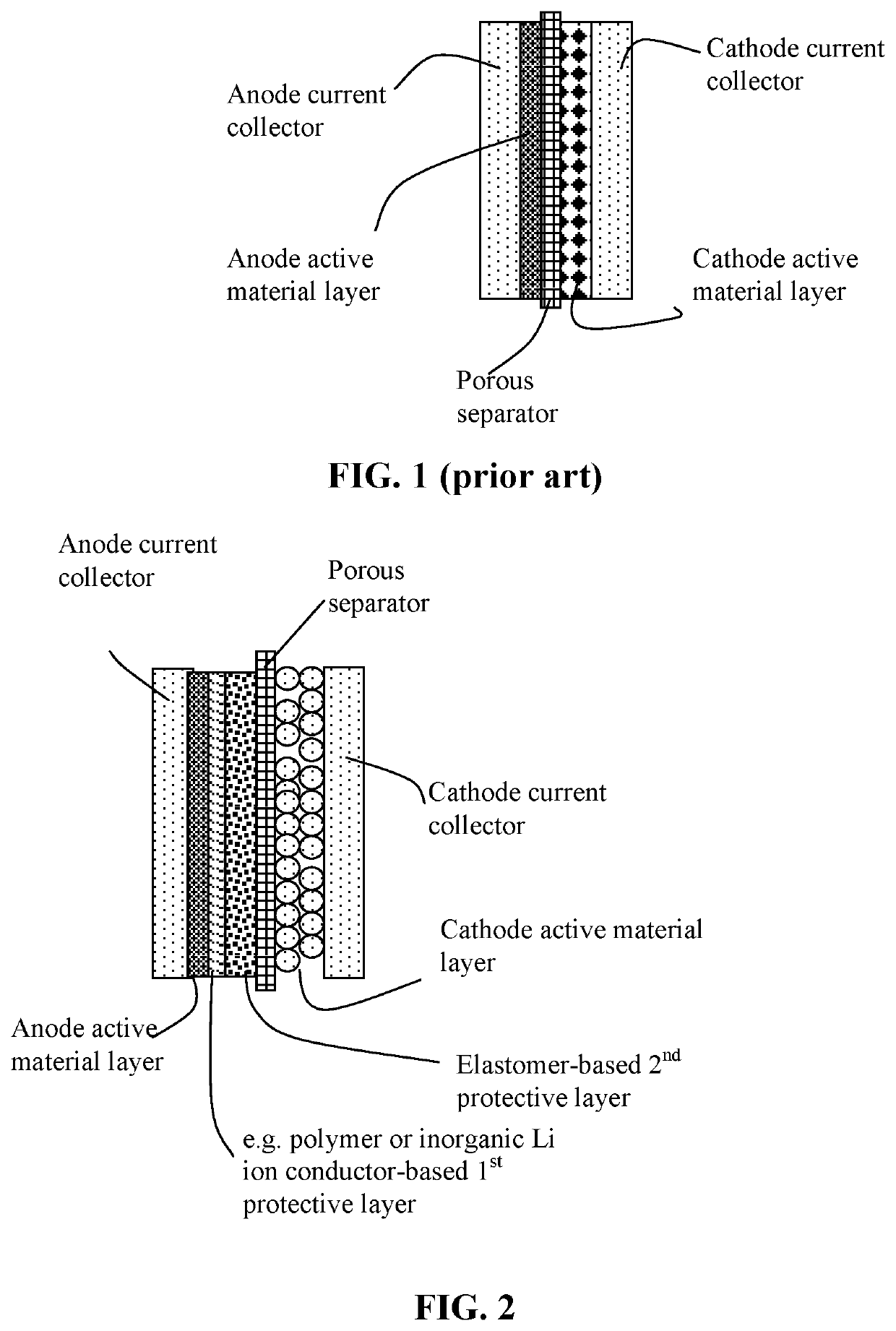

Methods of preparing a cathode / separator assembly for use in electrochemical cells in which a protective coating layer, such as a single ion conducting layer, is coated on a temporary carrier substrate, a microporous separator layer is then coated on the protective coating layer, and a cathode active layer is then coated on the separator layer, prior to removing the temporary carrier substrate from the protective coating layer. Additional layers, including an edge insulating layer, a cathode current collector layer, an electrode insulating layer, an anode current collector layer, an anode layer such as a lithium metal layer, and an anode protective layer, such as a single ion conducting layer, may be applied subsequent to the coating step of the microporous separator layer. Also, methods of preparing electrochemical cells utilizing cathode / separator assemblies prepared by such methods, and cathode / separator assemblies and electrochemical cells prepared by such methods.

Owner:OPTODOT CORP +1

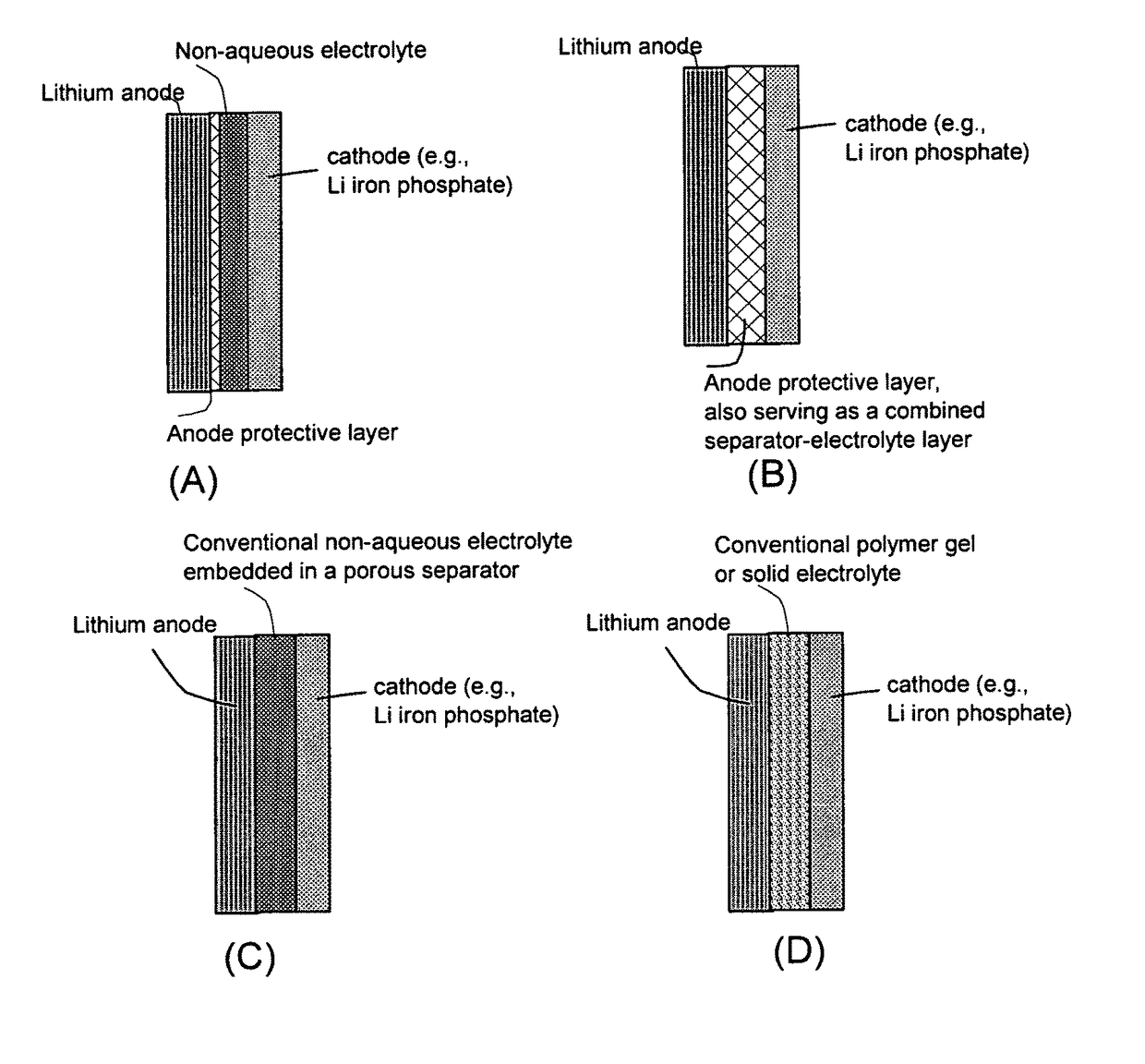

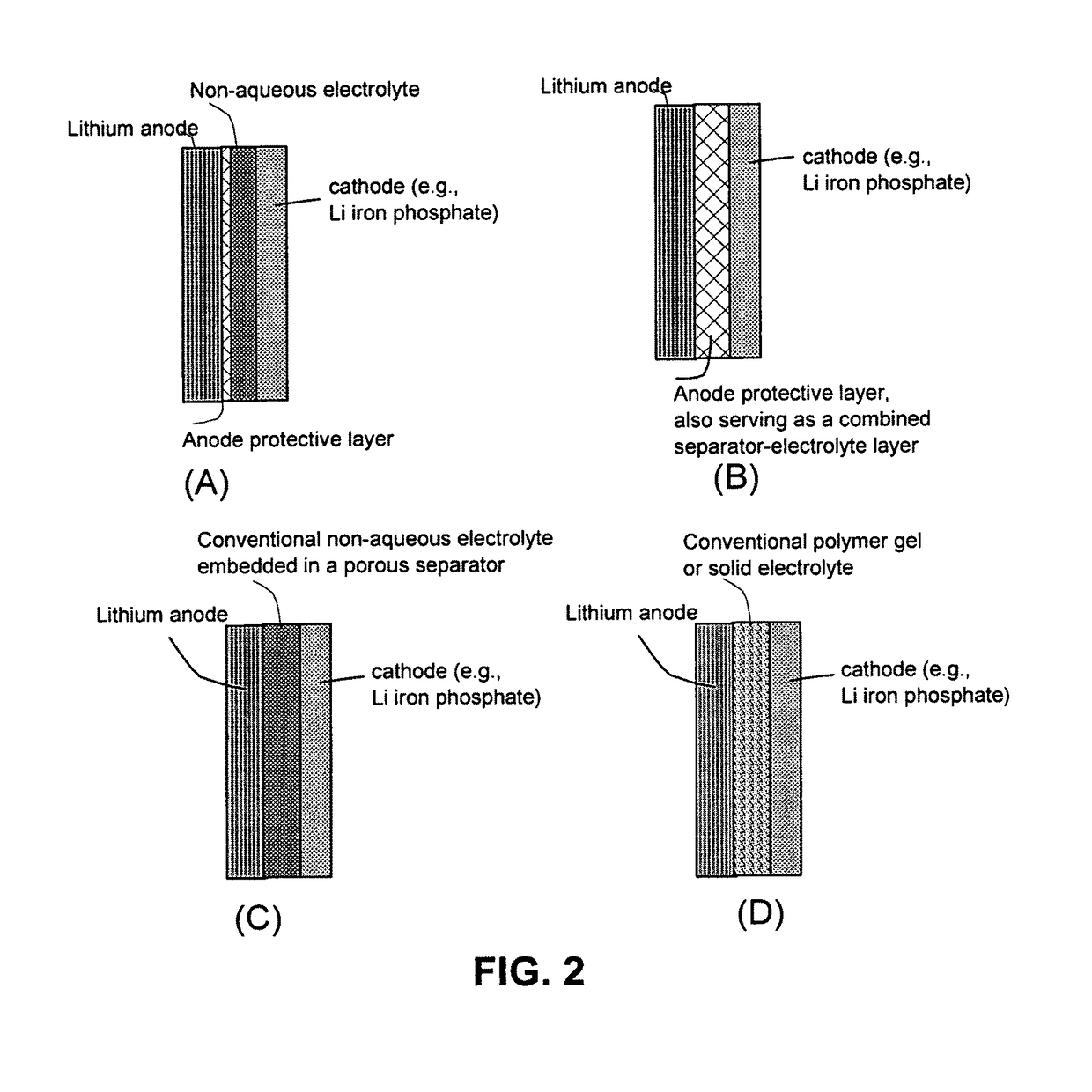

Anode protective layer compositions for lithium metal batteries

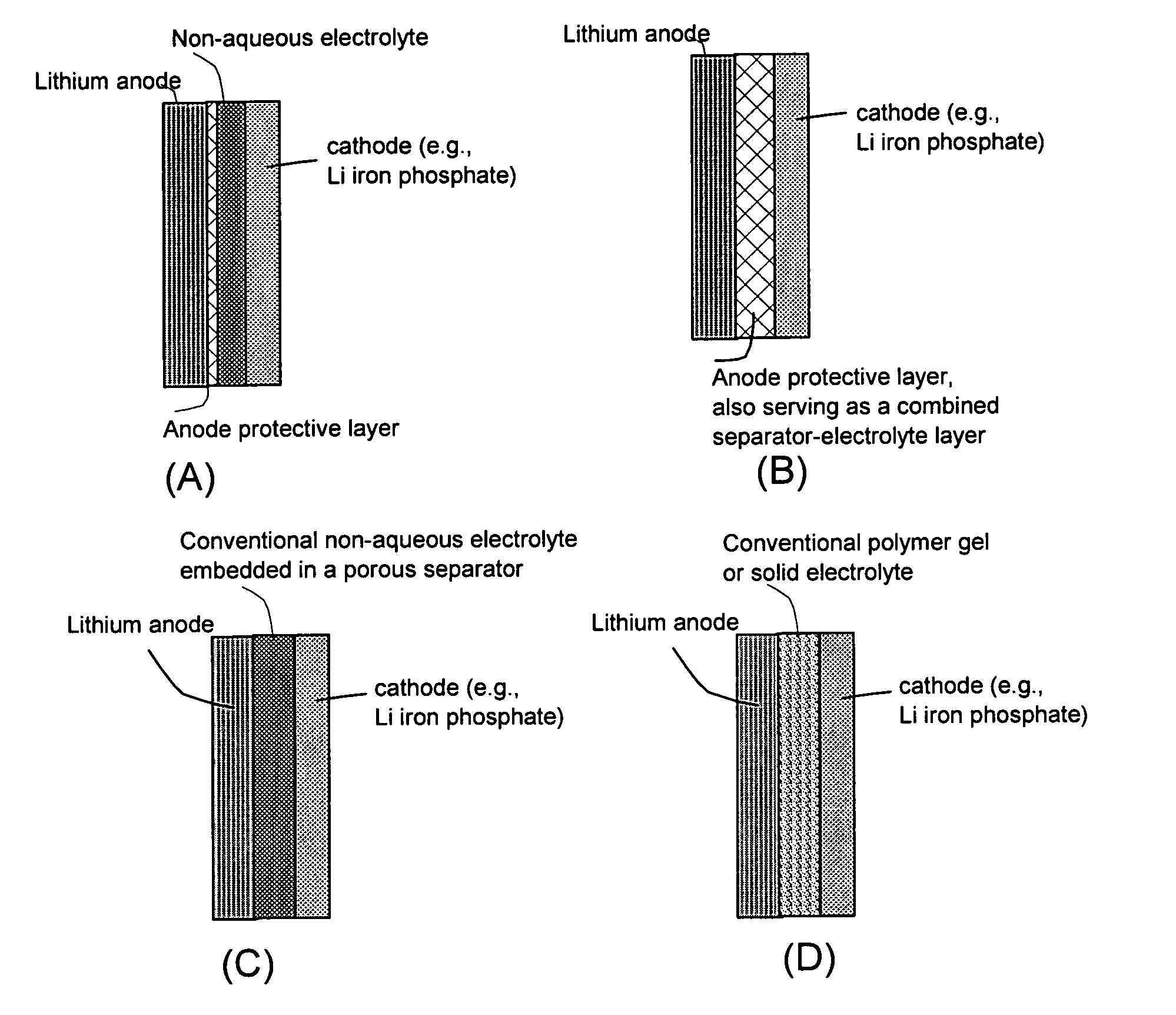

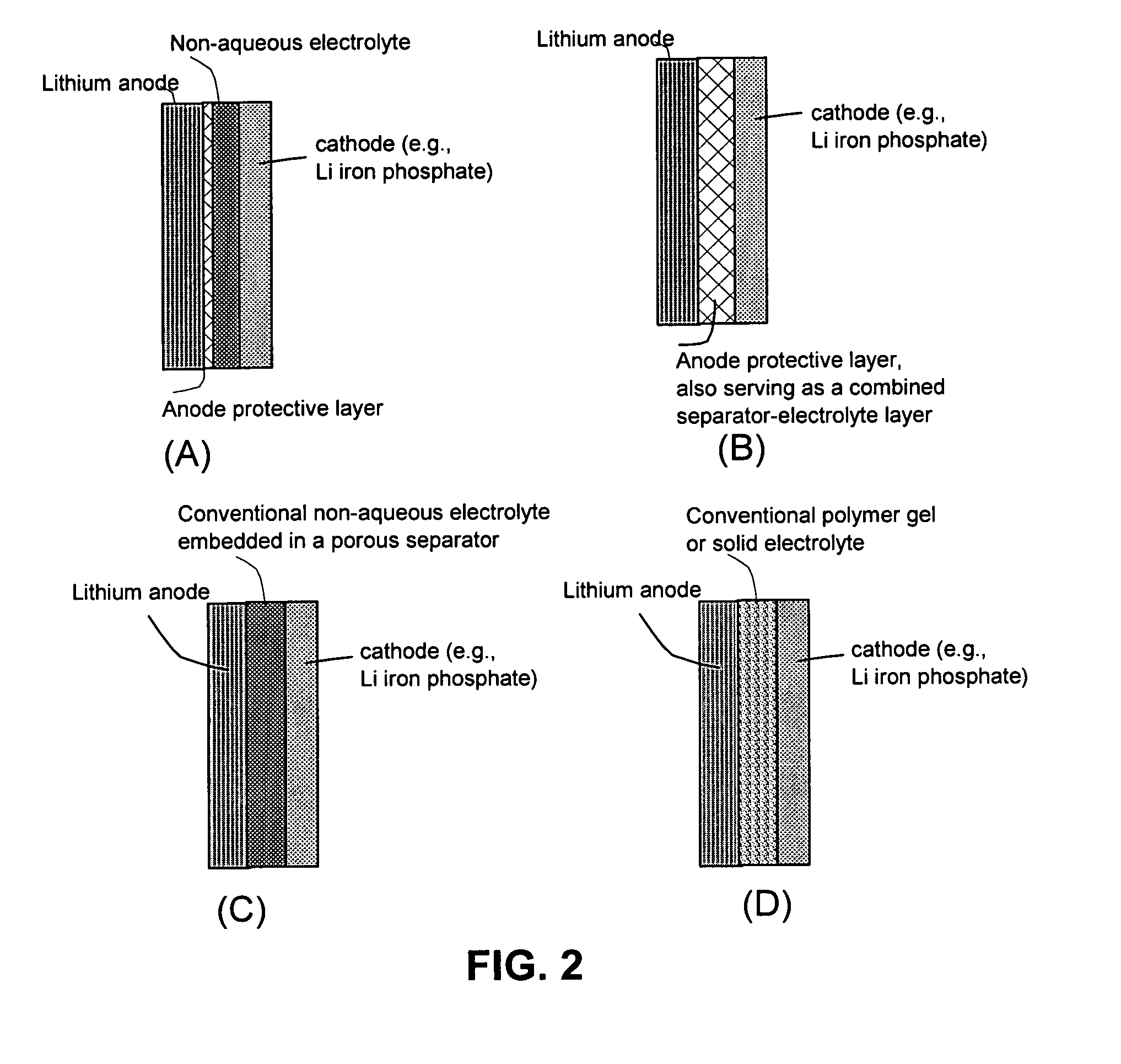

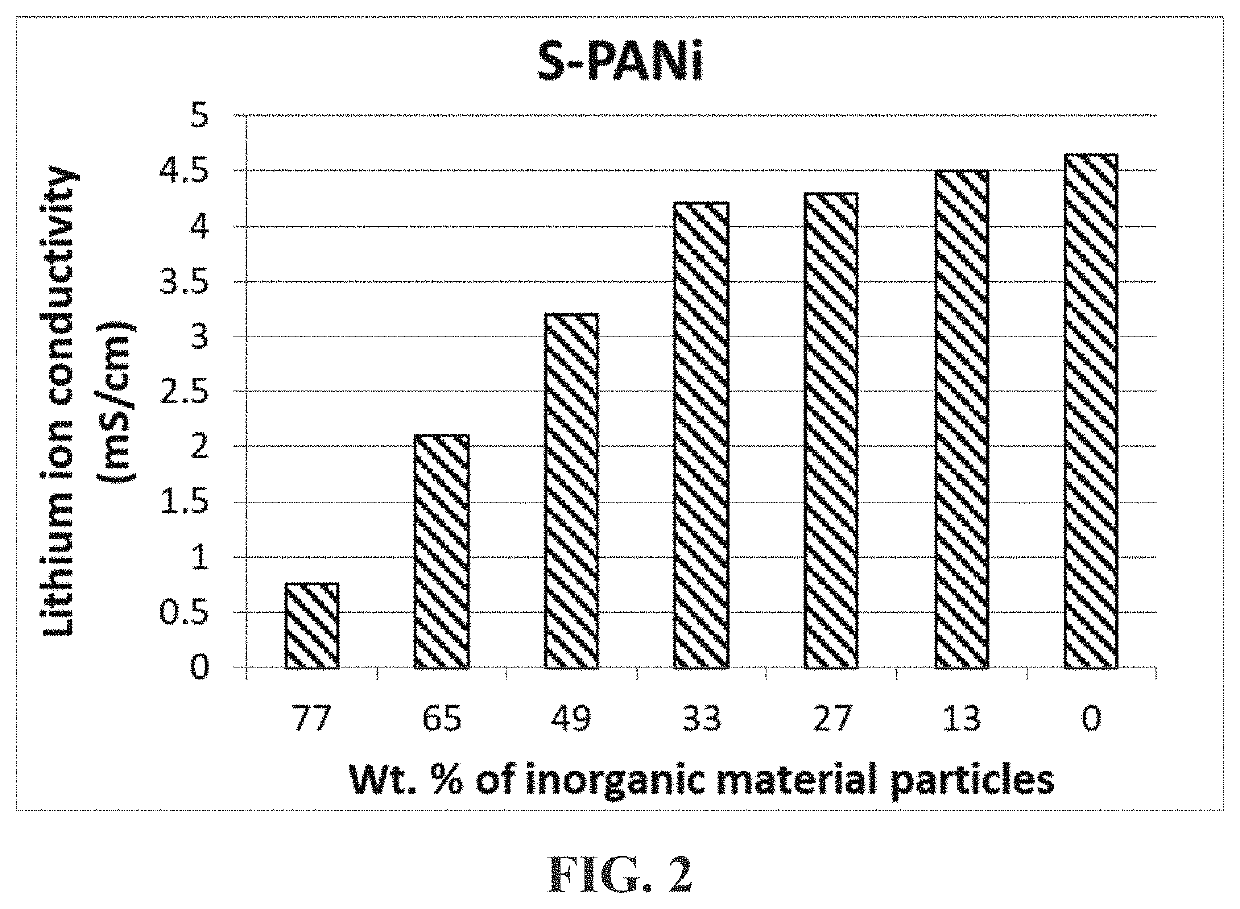

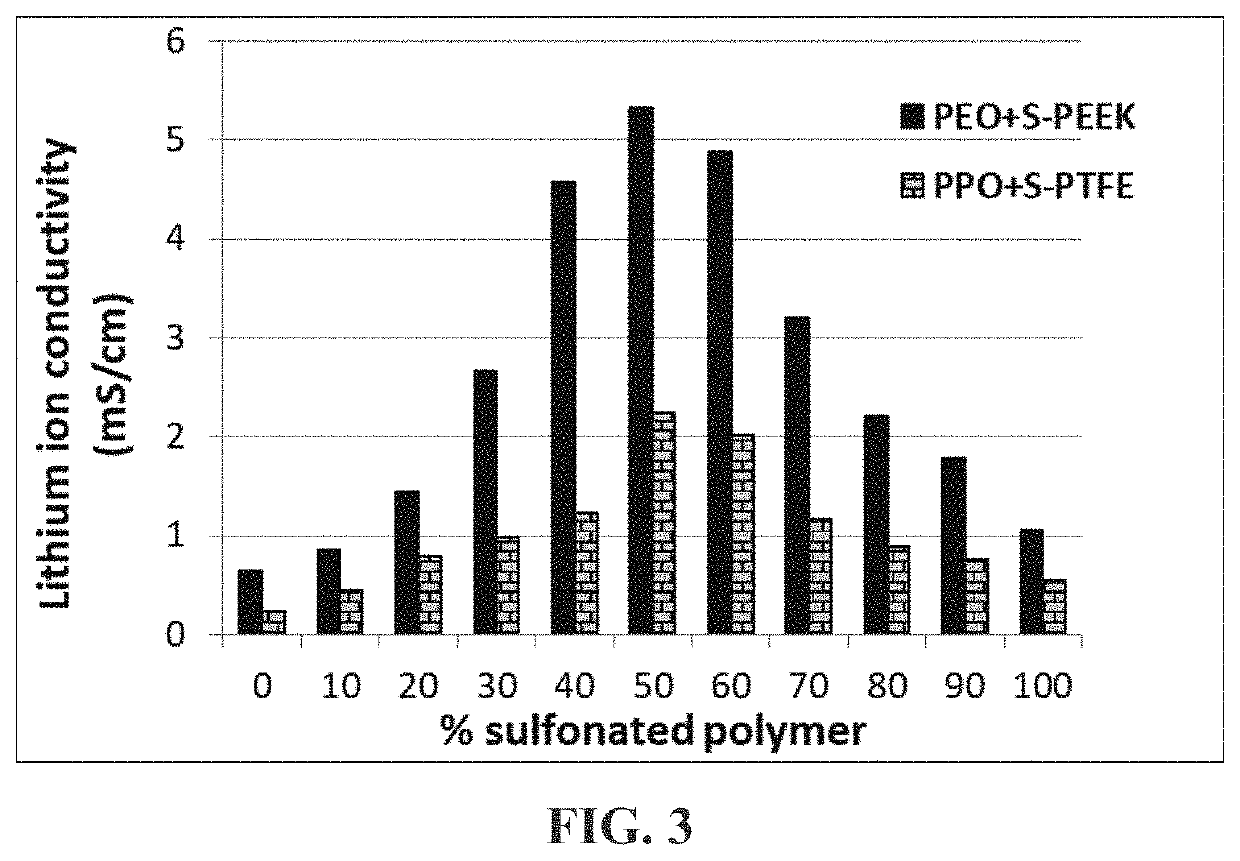

ActiveUS20090155676A1Safe and long and stable cycle lifeLi-accumulatorsCell component detailsLithium metalElectric vehicle

The present invention provides a battery cell, comprising: (a) an anode comprising an active metal or a metal ion storage material (e.g., an intercalation compound that accommodates lithium ion); (b) a cathode structure; and (c) an ionically conductive protective layer on a surface of the anode and interposed between the anode and the cathode structure. This protective layer comprises a porous membrane having pores therein and a soft matter phase disposed in at least one of the pores, wherein the soft matter phase comprises oxide particles dispersed in a non-aqueous alkali, alkaline, or transition metal salt solution. Most preferably, this battery cell is a lithium metal secondary cell that is essentially free from dendrite and exhibits a safer and more stable cycling behavior. Such a high-capacity rechargeable battery is particularly useful for powering portable electronic devices and electric vehicles.

Owner:GLOBAL GRAPHENE GRP INC

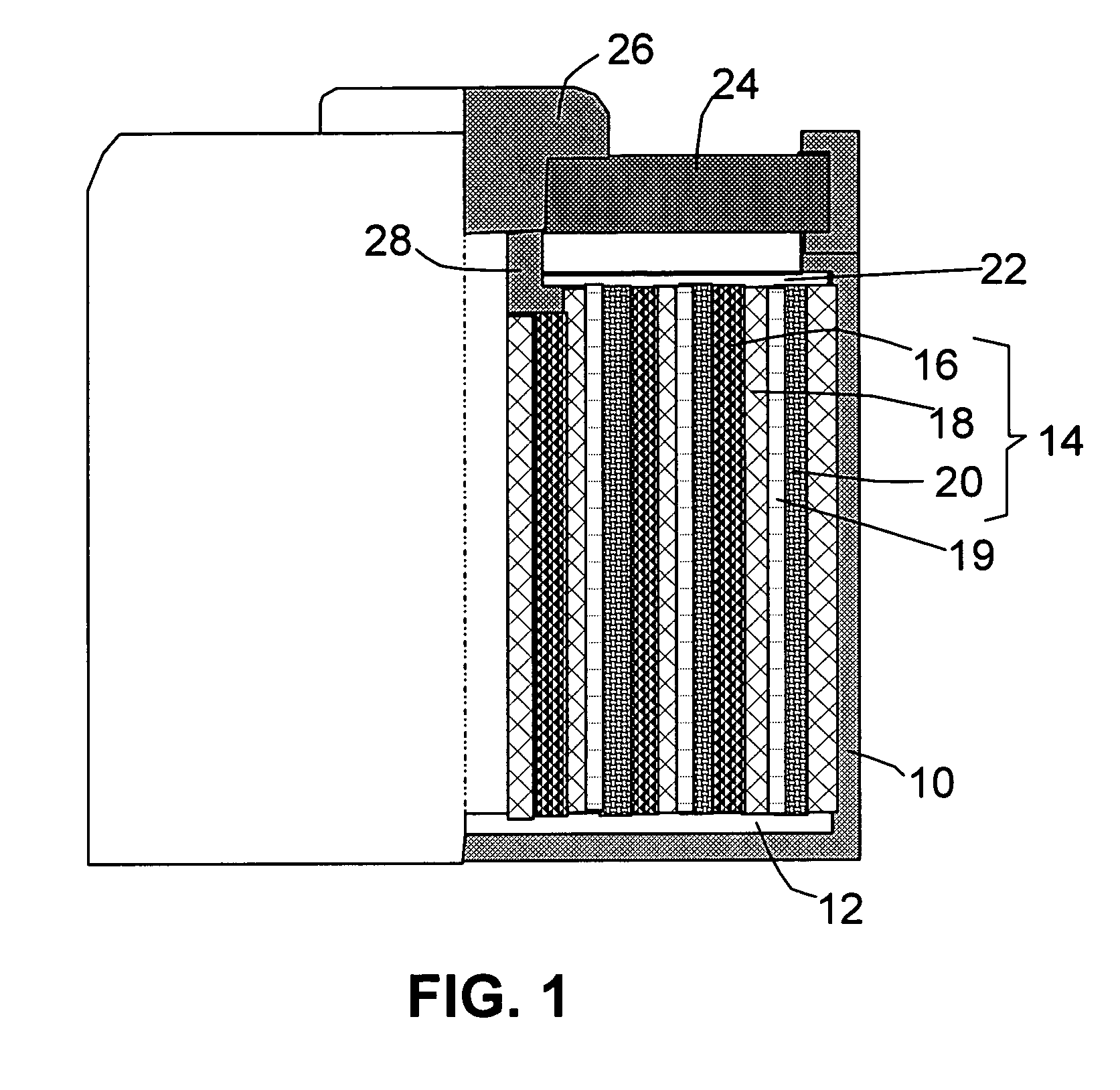

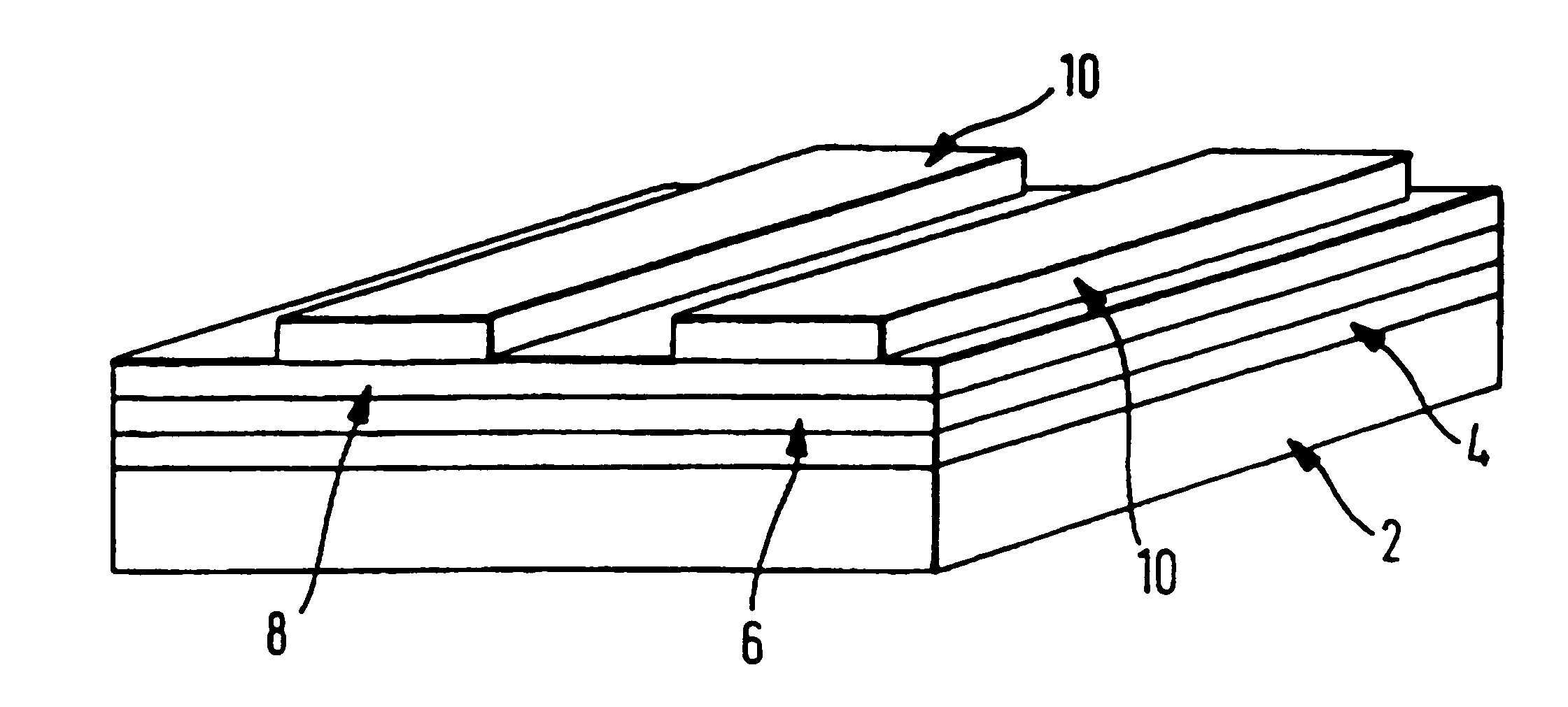

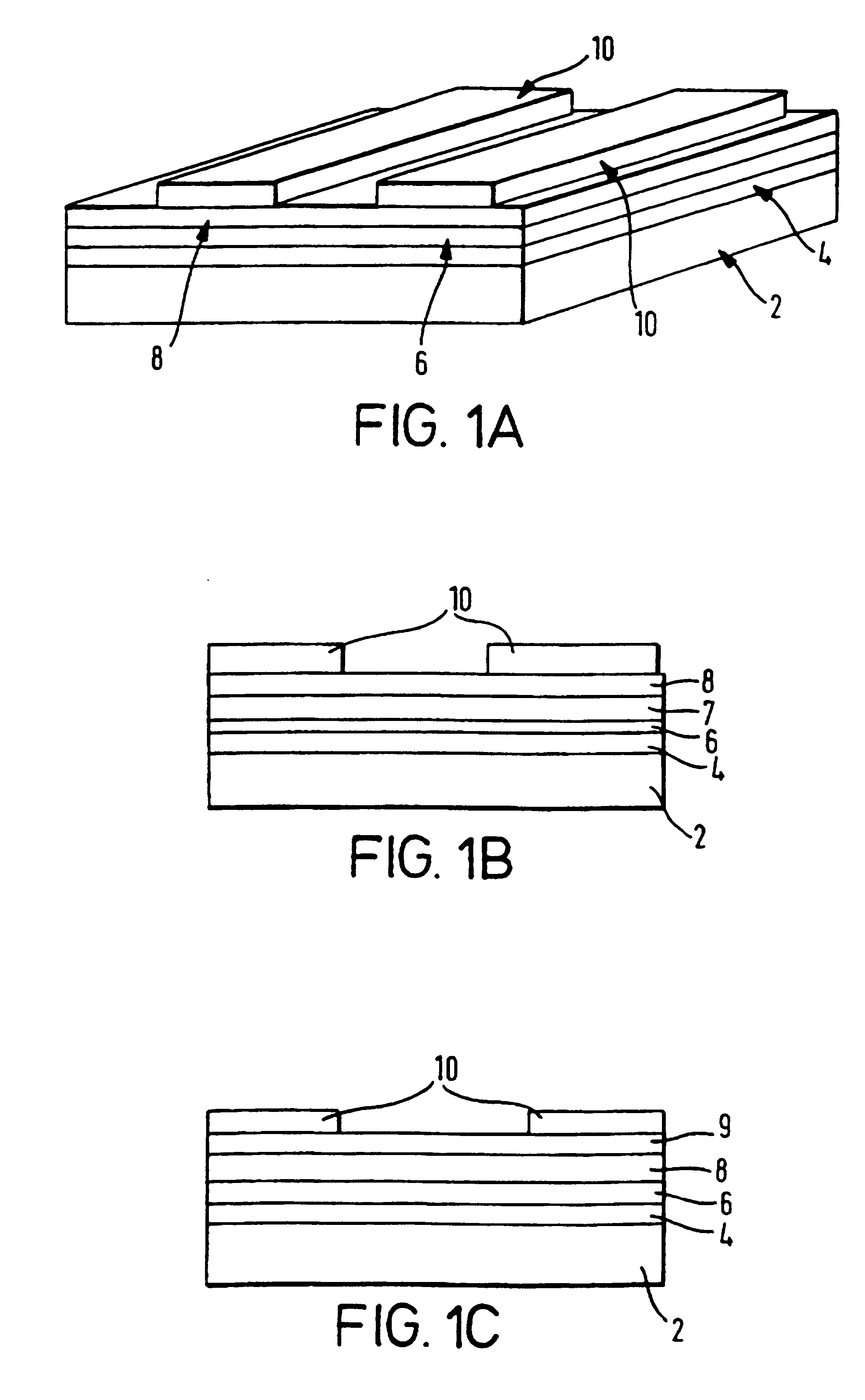

Compliant seal structures for protected active metal anodes

ActiveUS7824806B2Reduced ionic contact areaReduce the total massPrimary cell to battery groupingElectrode manufacturing processesTectorial membraneOptoelectronics

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Compliant seal structures for protected active metal anodes

ActiveCN101313426APrimary cell to battery groupingElectrode manufacturing processesOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholytes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

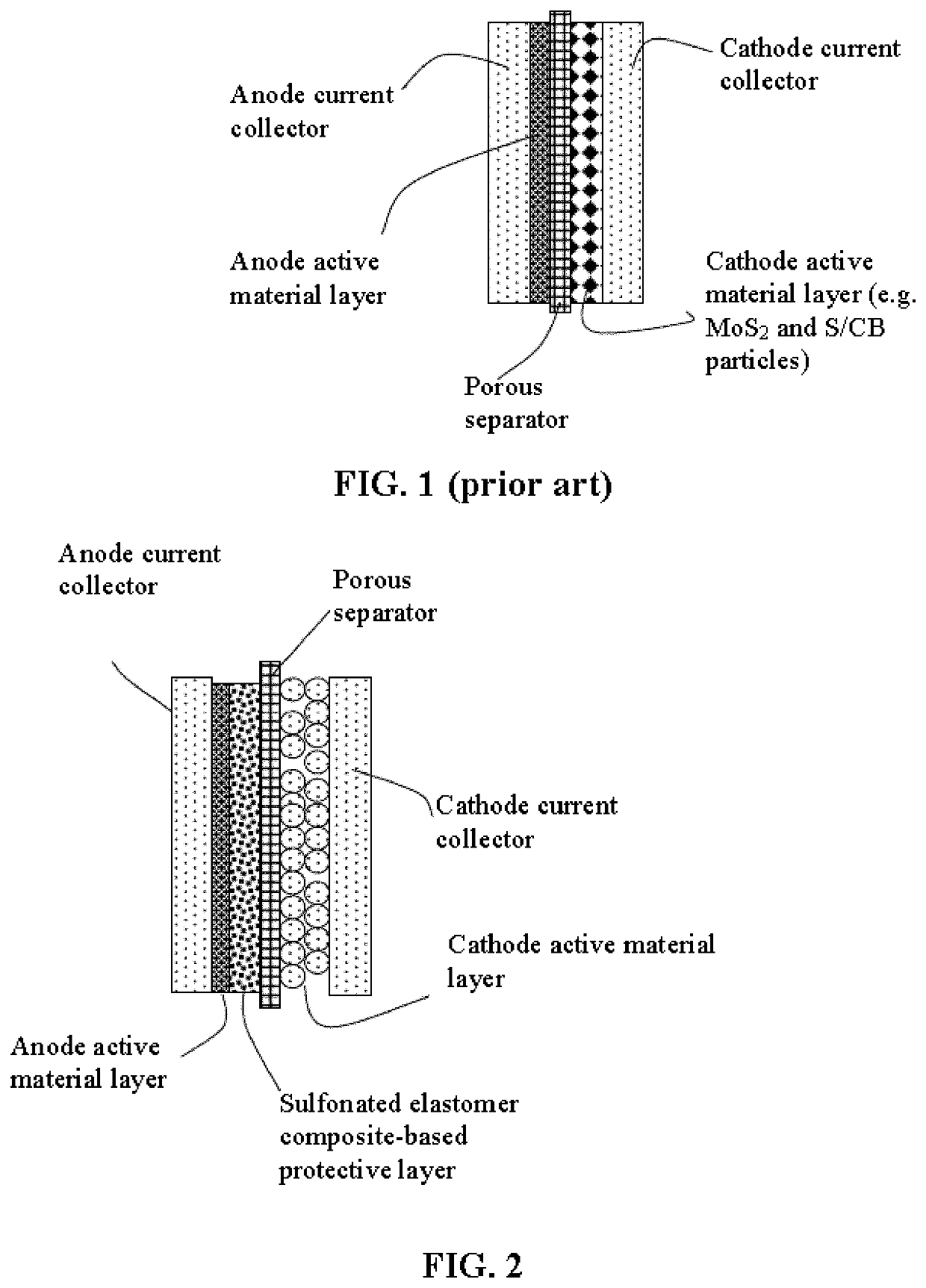

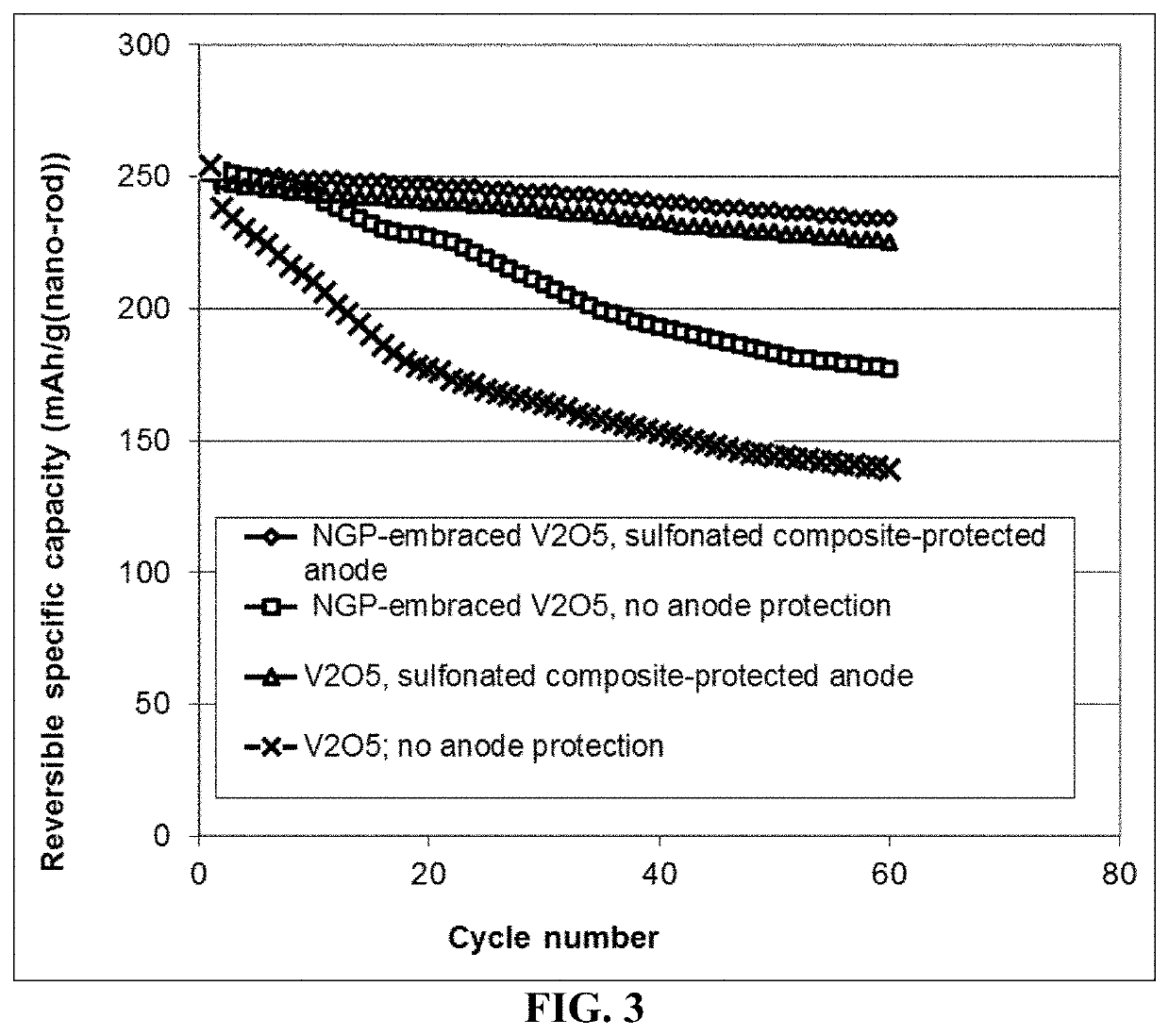

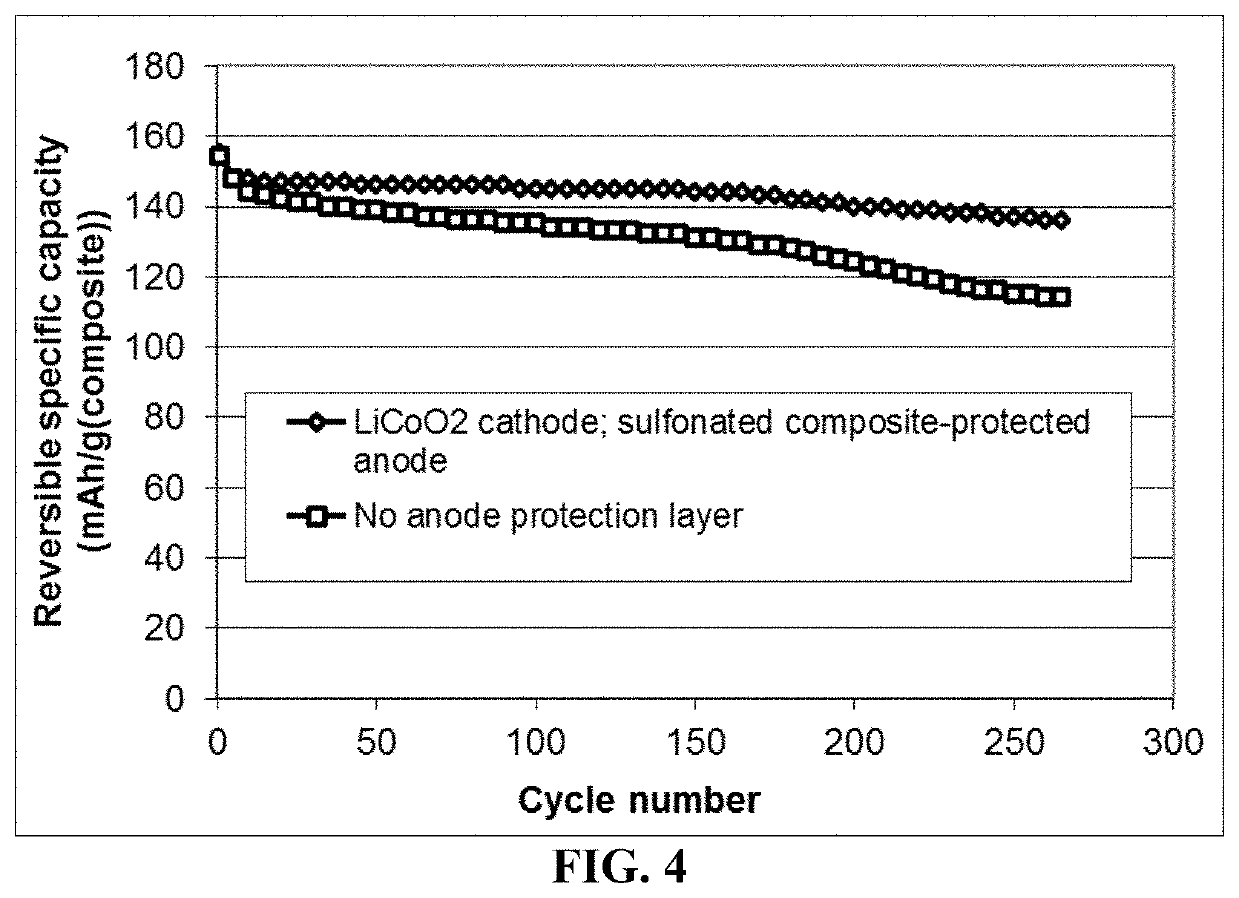

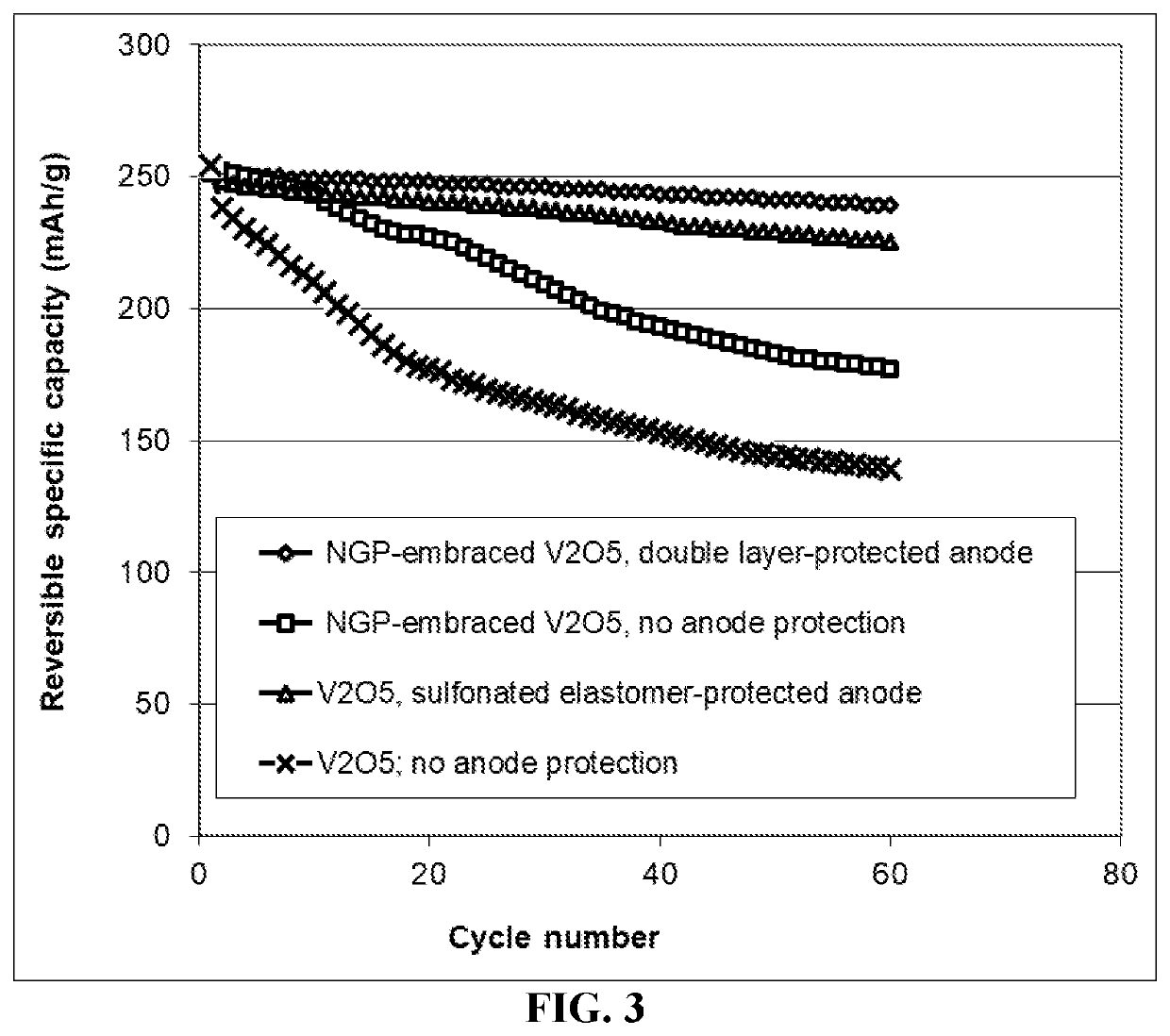

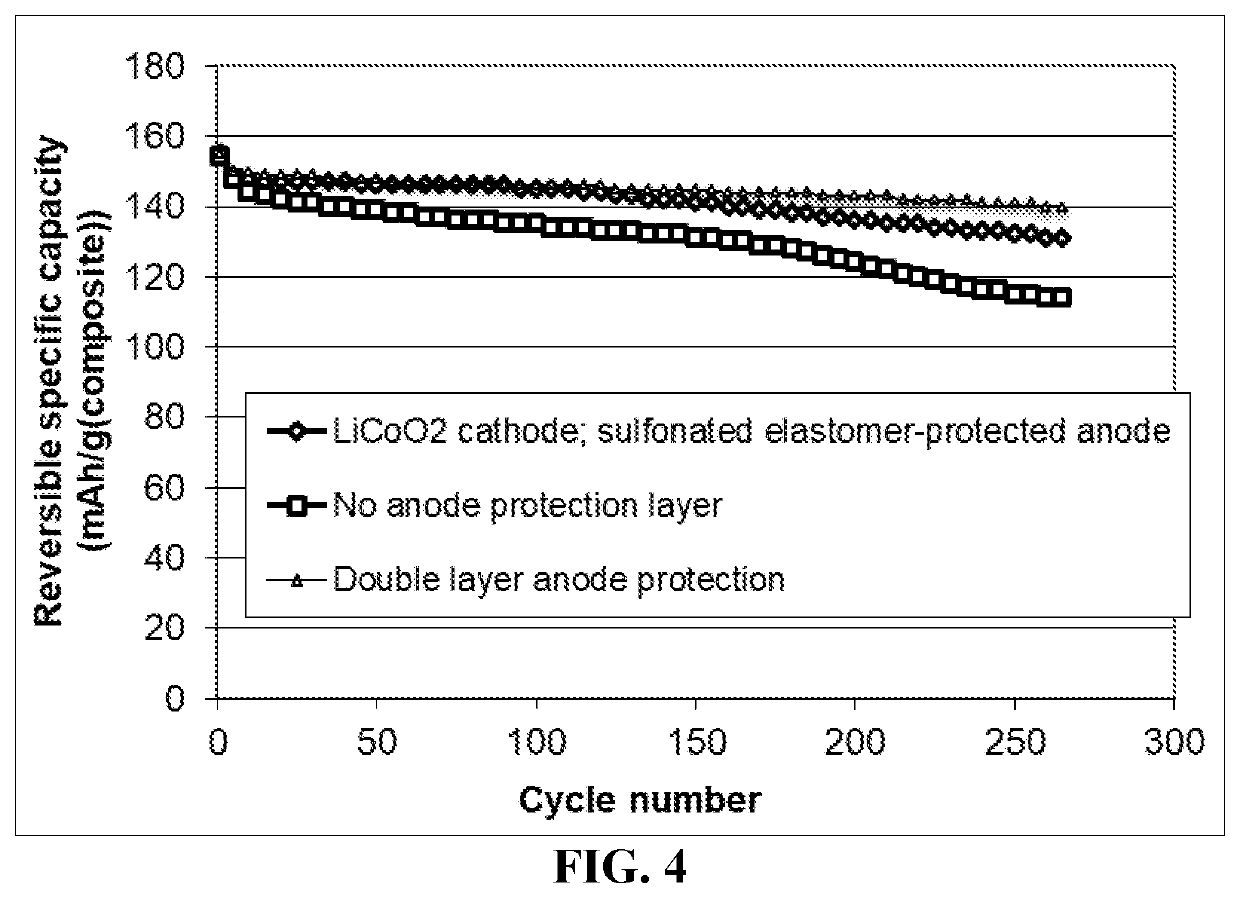

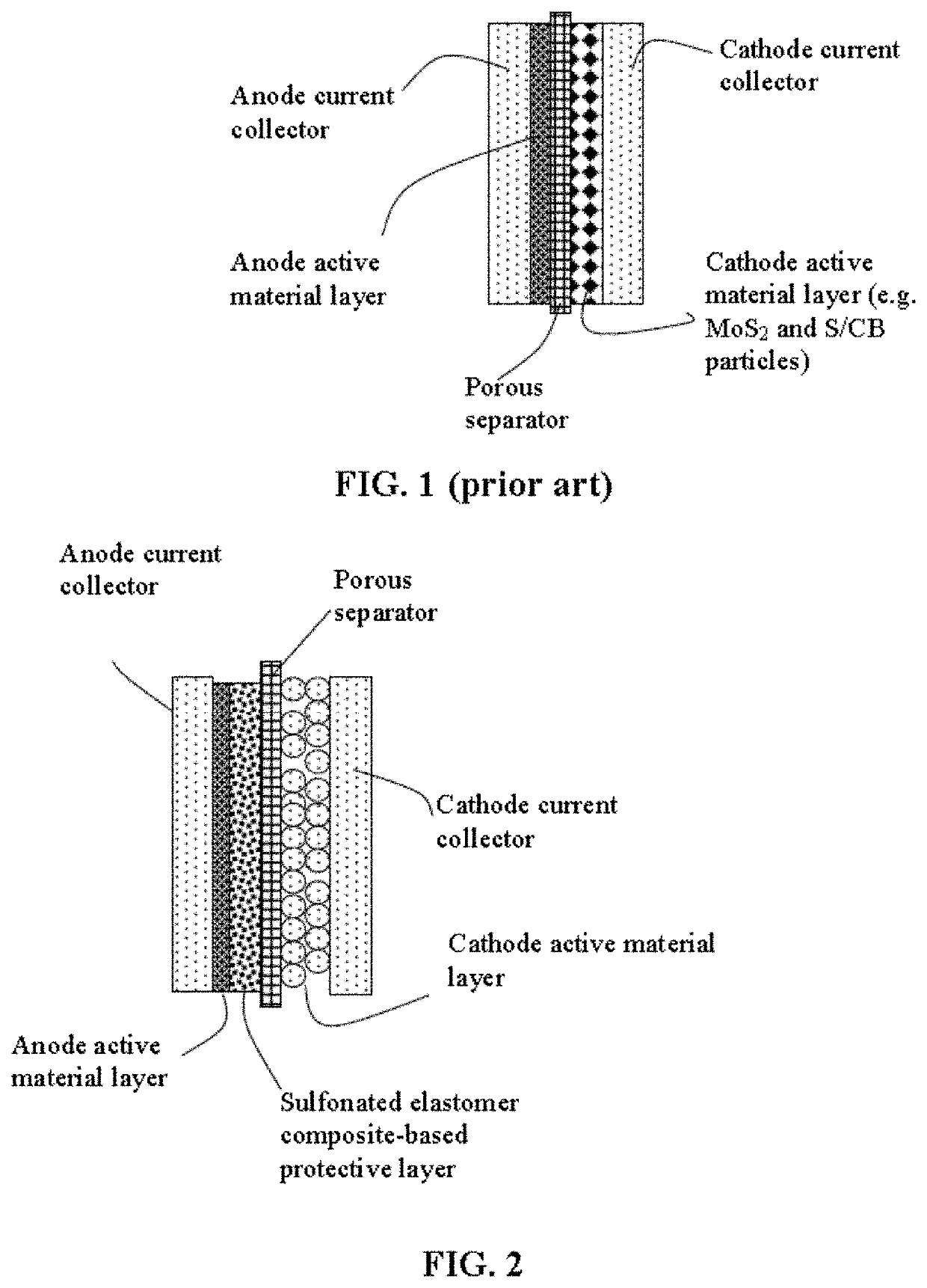

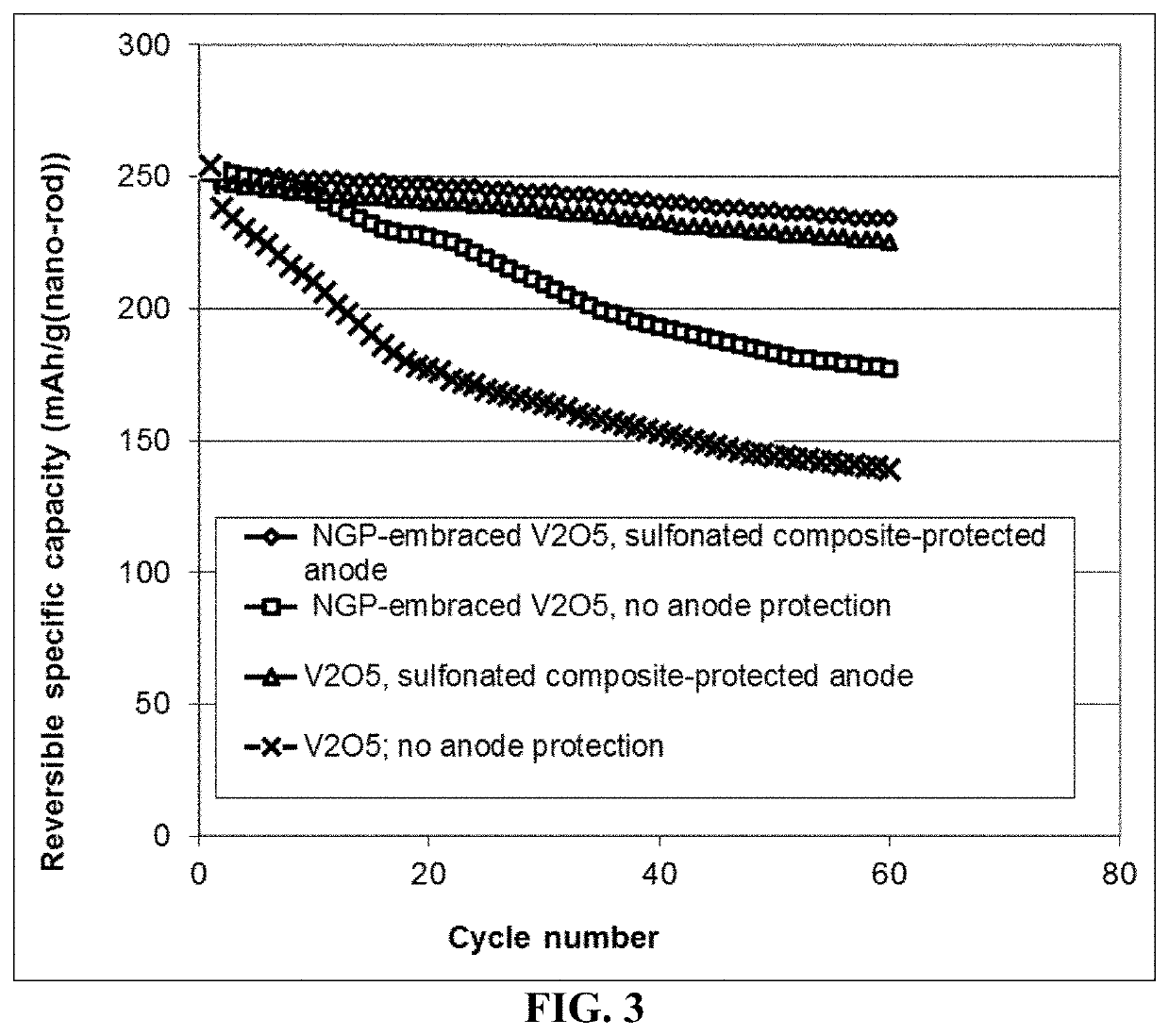

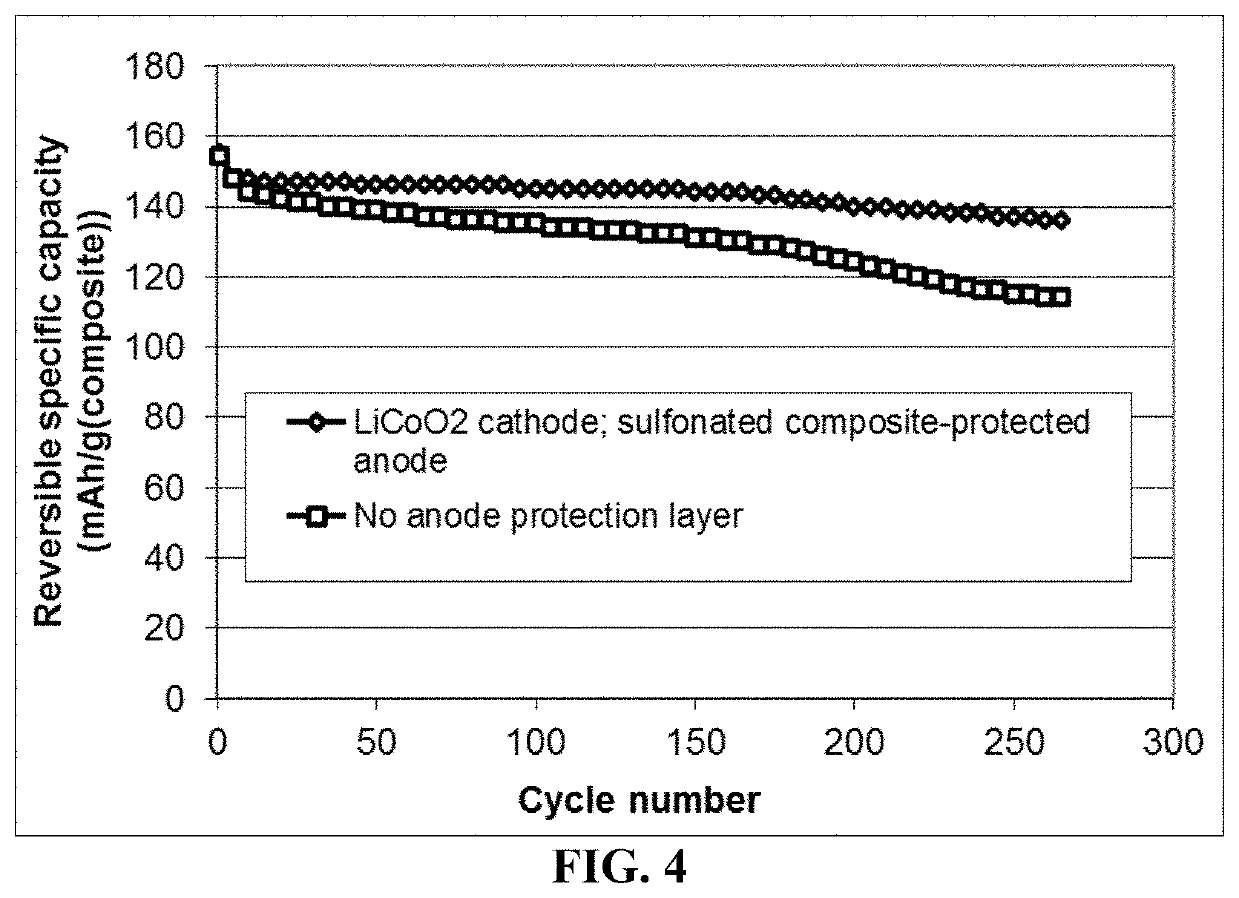

Lithium metal secondary battery containing an electrochemically stable anode-protecting layer

ActiveUS20190393495A1Reduce eliminatePromotes uniform depositionNegative electrodesPositive electrodesElectrical batteryLithium metal

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; and (b) an anode-protecting layer of a conductive sulfonated elastomer composite, disposed between the anode active layer and the separator / electrolyte; wherein the composite has from 0.01% to 40% by weight of a conductive reinforcement material and from 0.01% to 40% by weight of an inorganic filler dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

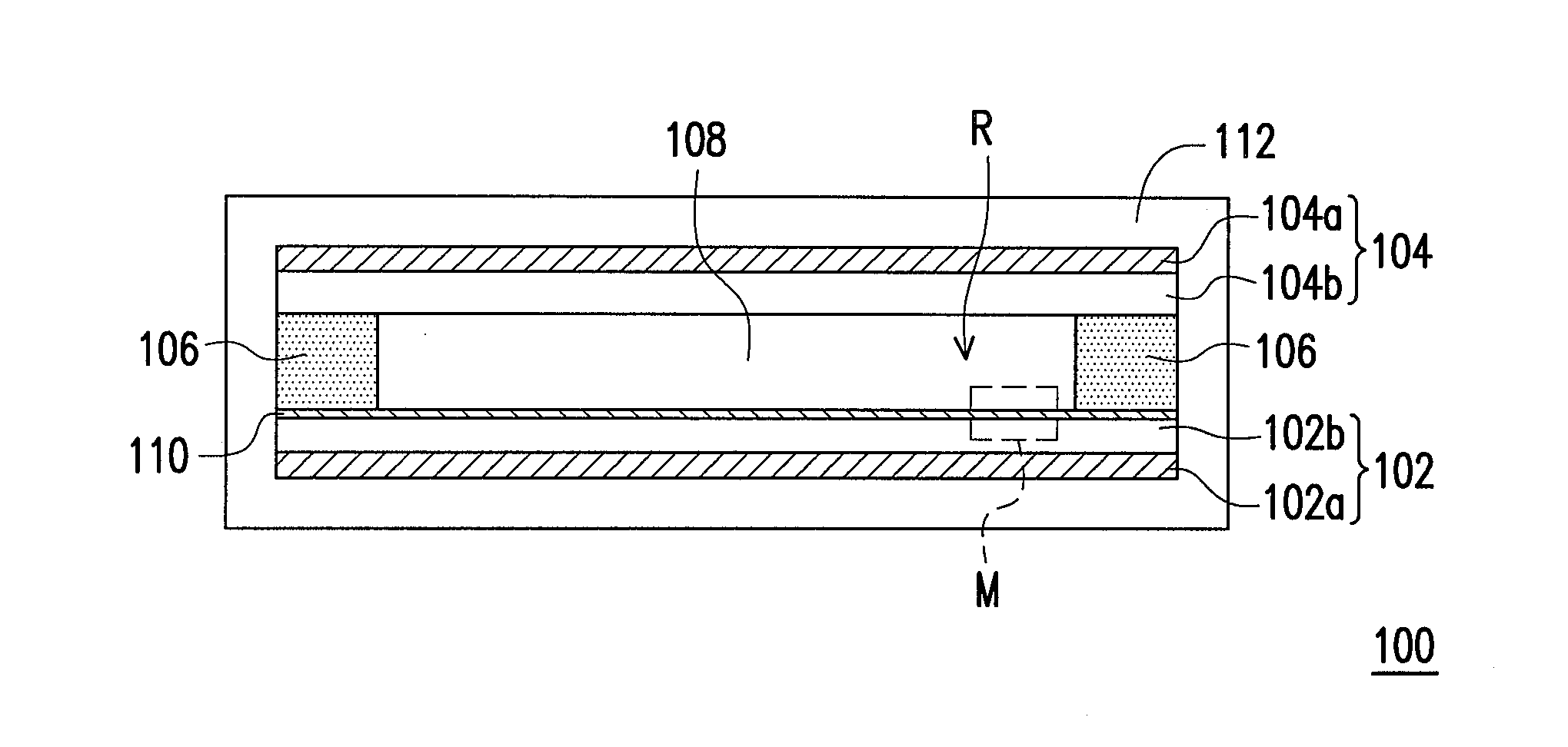

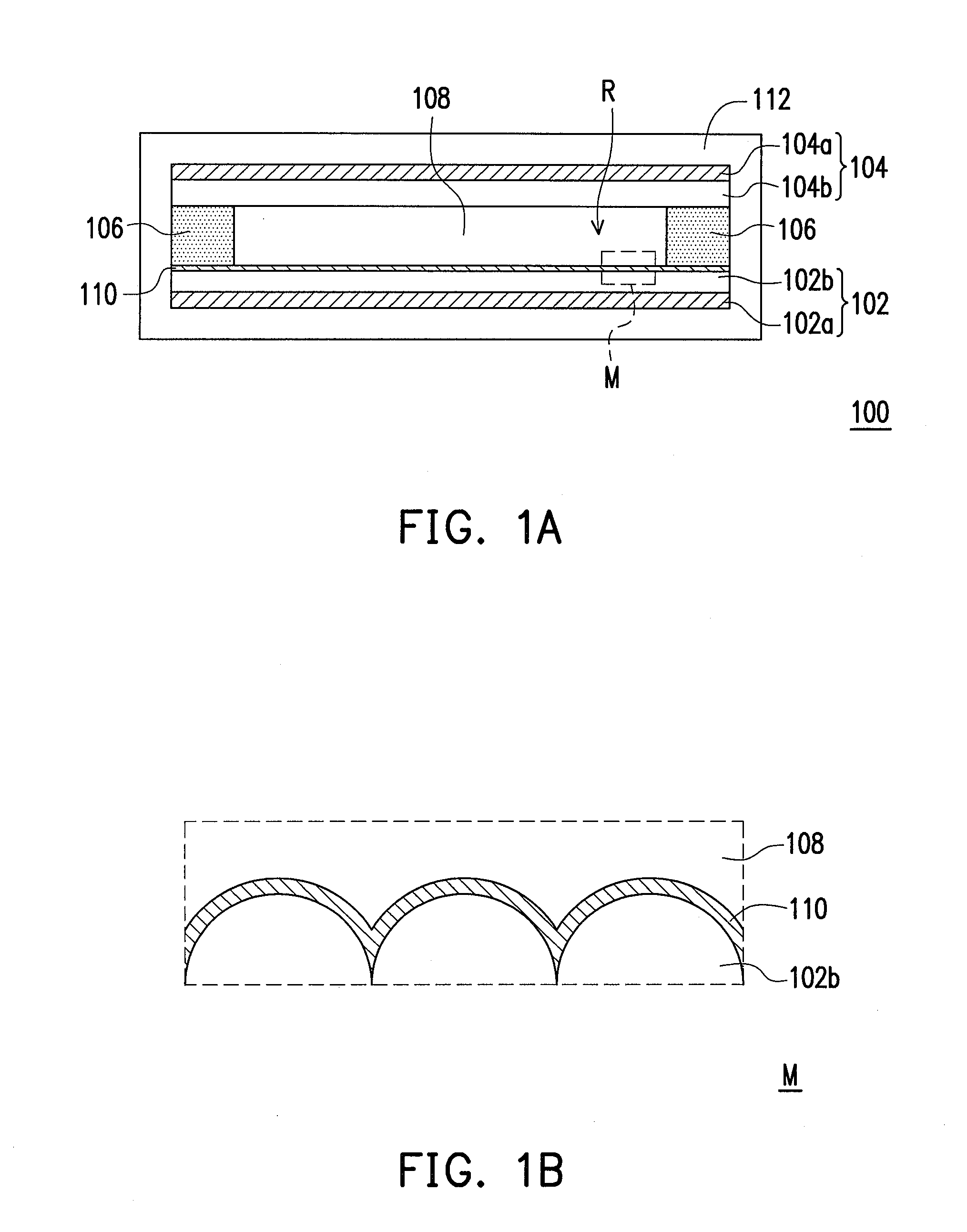

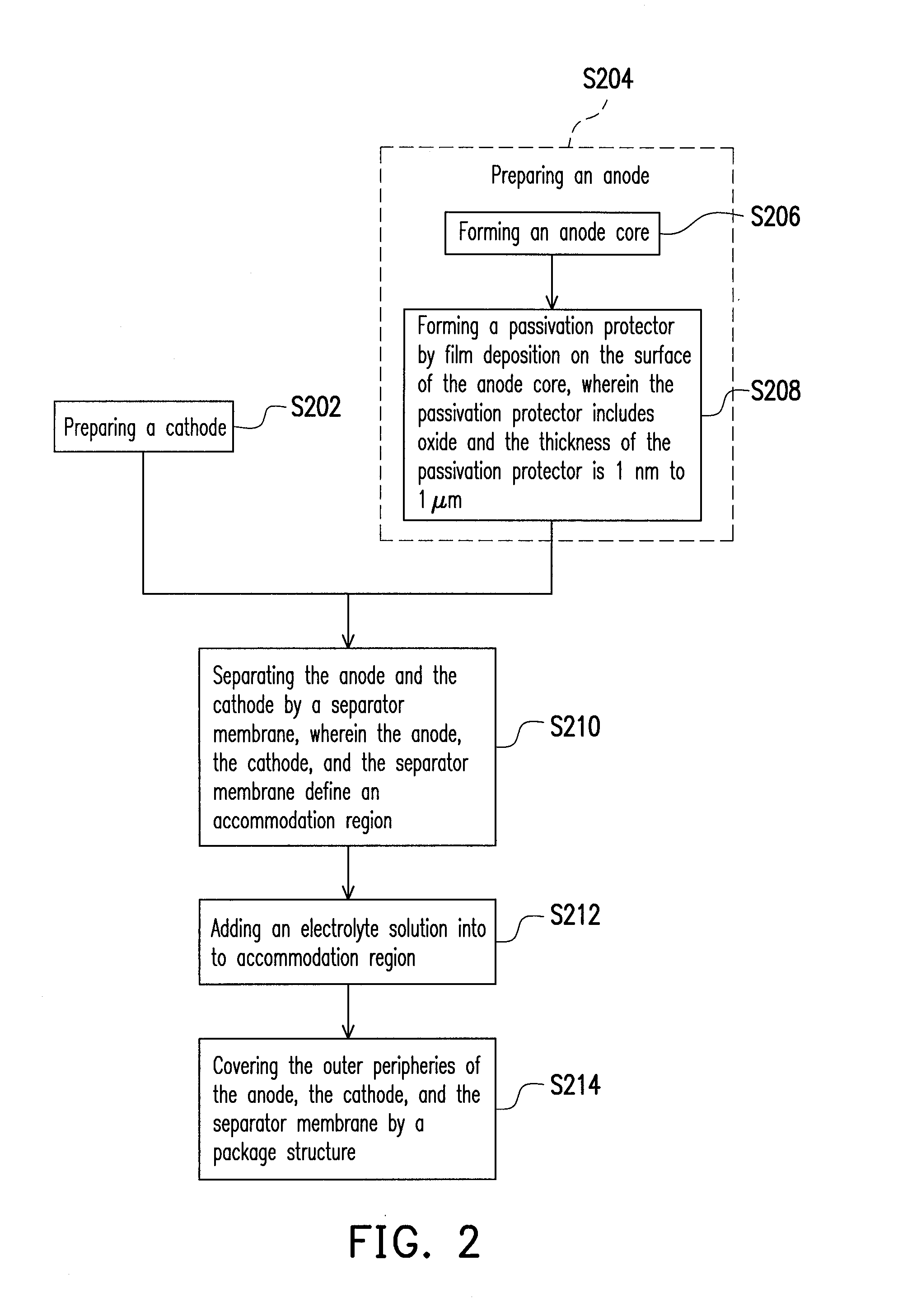

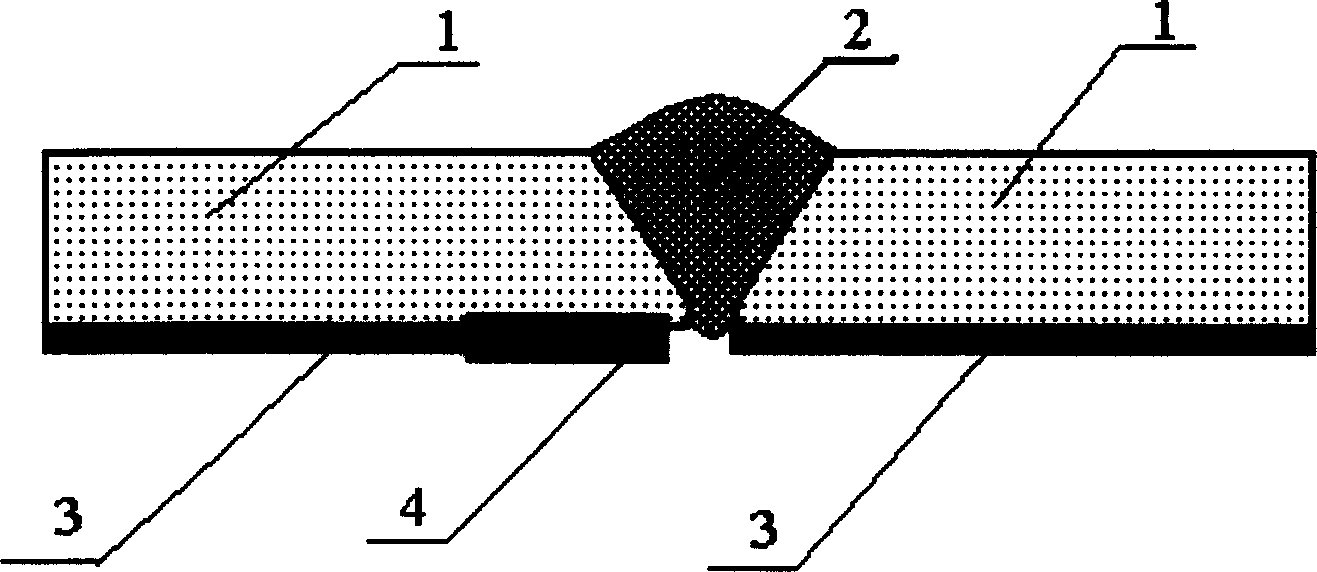

Anode protector of lithium-ion battery and method for fabricating the same

InactiveUS20130177808A1Improve battery efficiencyExtended service lifeSilver accumulatorsMaterial nanotechnologyAnodic protectionLithium-ion battery

An anode protector of a lithium-ion battery and a method for fabricating the same are provided. A passivation protector (110) is formed on a surface of an anode (102) in advance by film deposition, such as atomic layer deposition (ALD). The passivation protector (110) is composed of a metal oxide having three dimensional structures, such as columnar structures. Accordingly, the present invention is provided with effective protection of the anode electrode structure and maintenance of battery cycle life under high-temperature operation.

Owner:NAT TAIWAN UNIV OF SCI & TECH

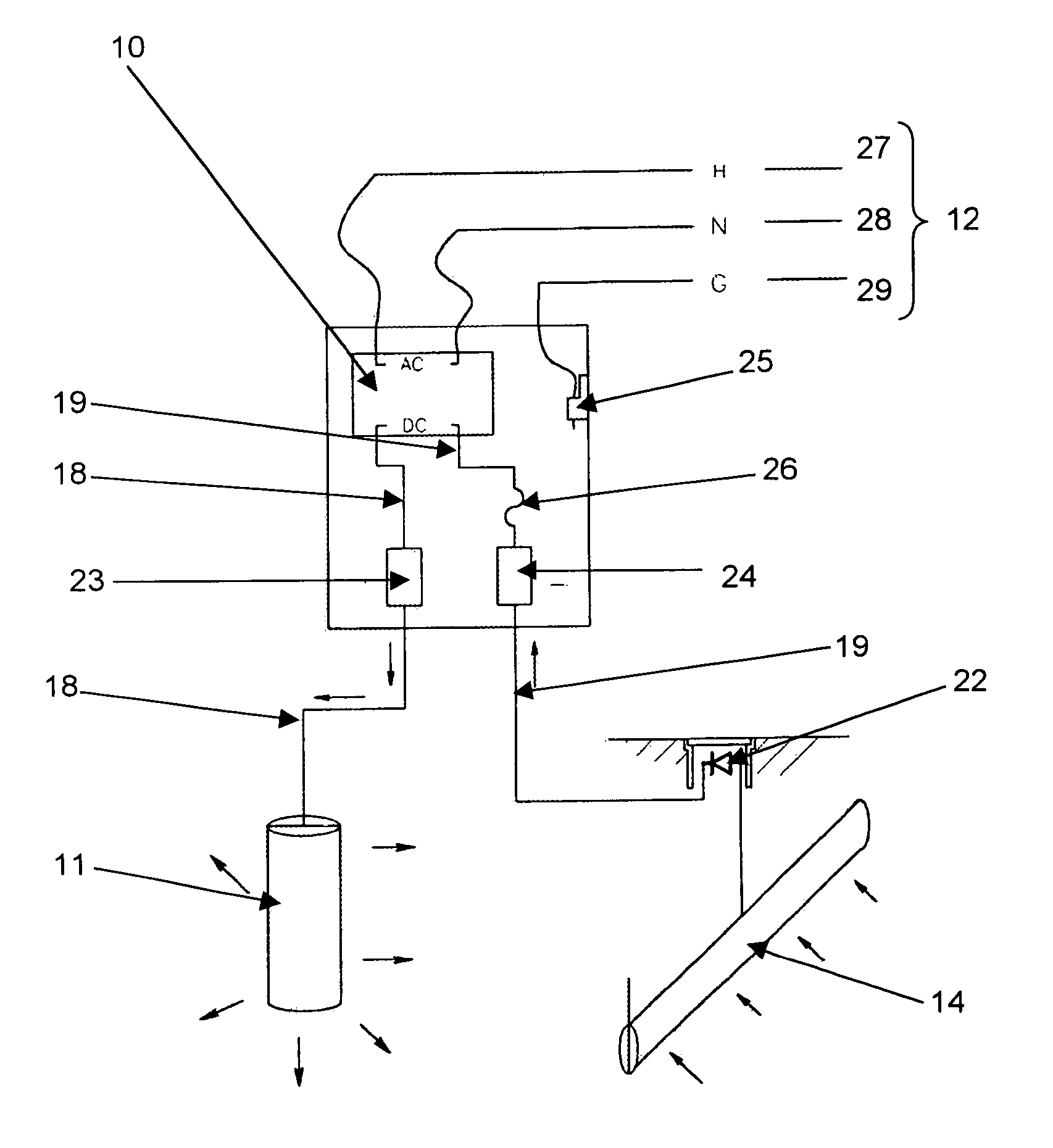

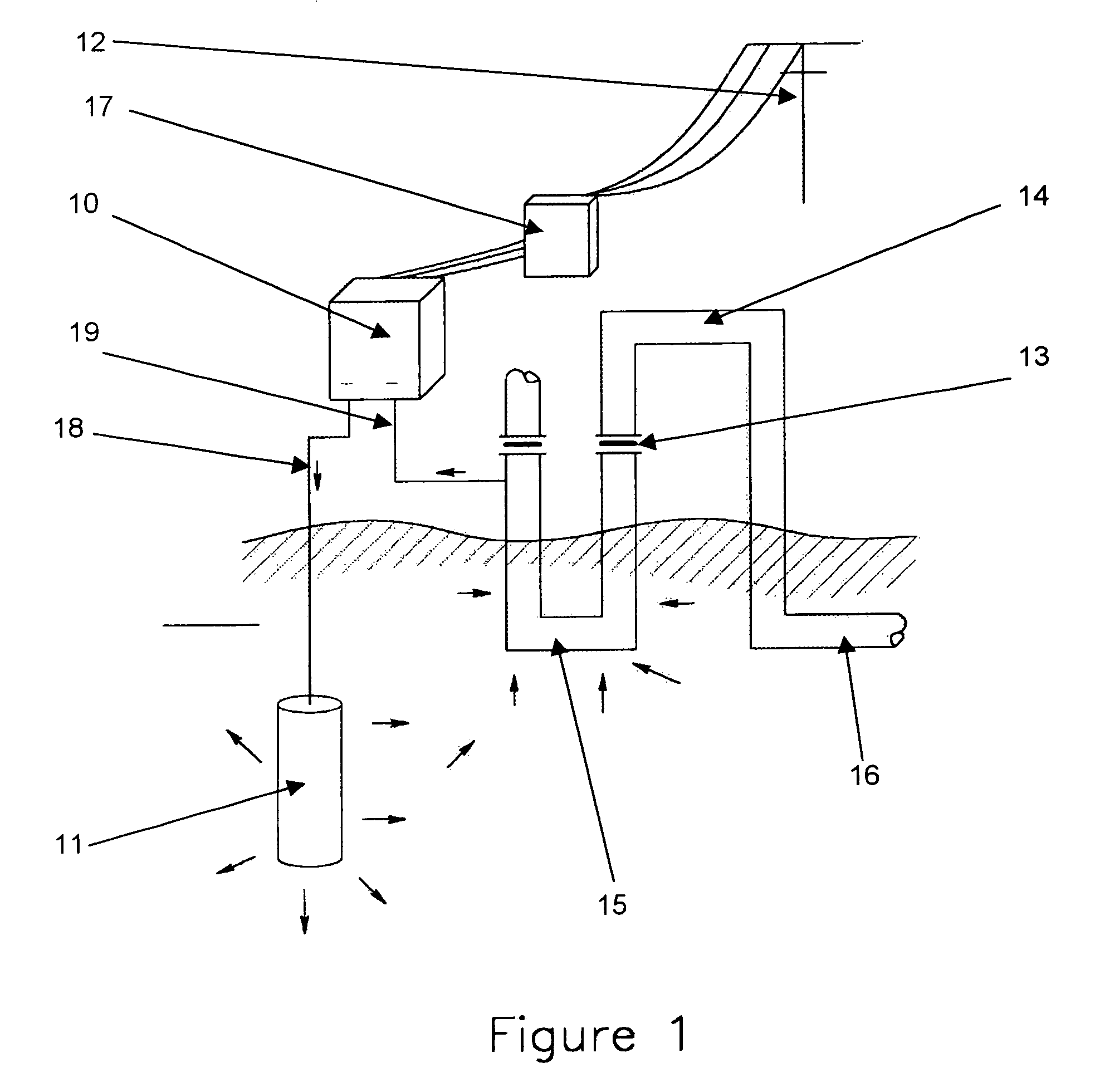

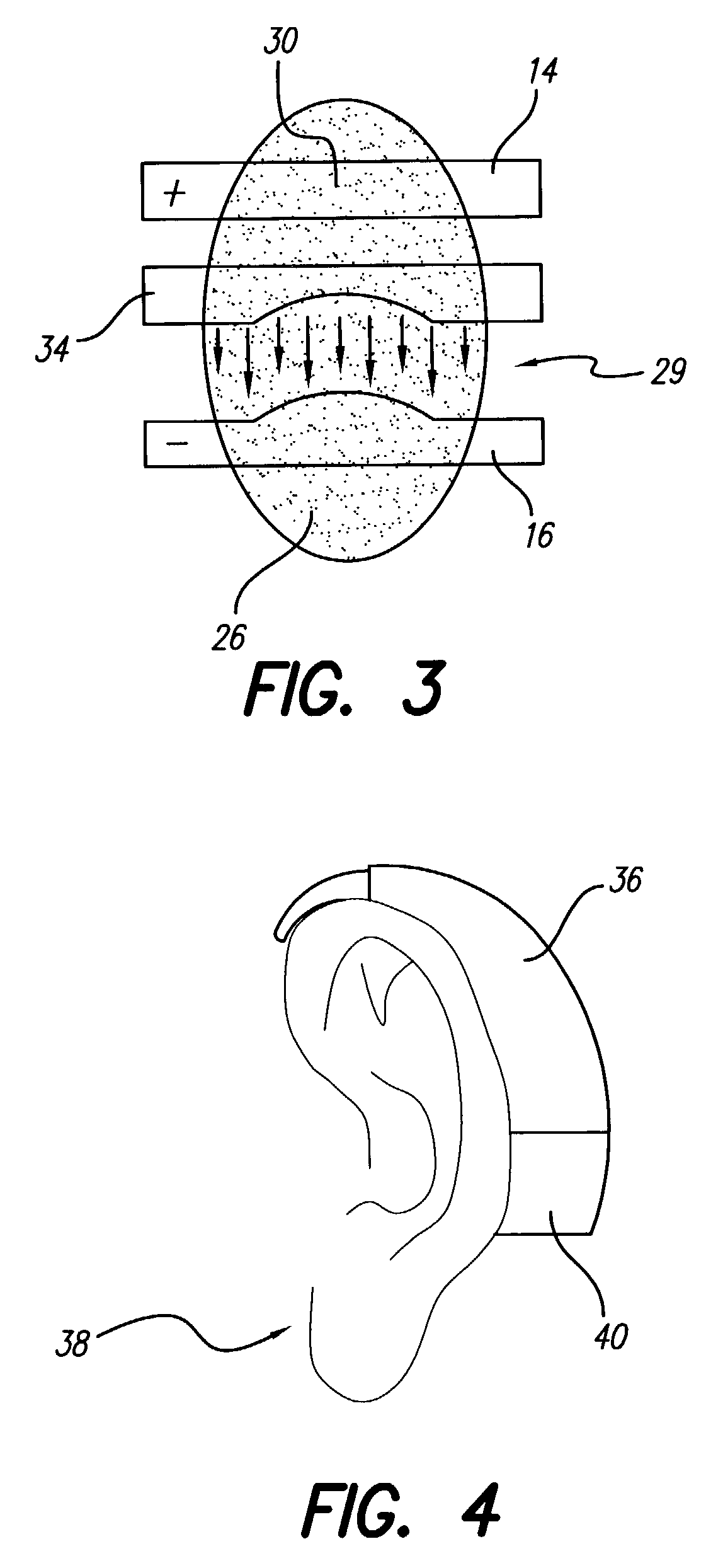

Cathodic protection system for metallic structures

InactiveUS7186321B2Lower resistanceAssist in cleaningAutomatic control devicesAssembly machinesCross connectionElectrical connection

An active cathodic protection system, the apparatus comprising a rectifier element with at least one electrical connection to a source of electrical current, the rectifier element associated with a direct current positive (+) output terminal for electrical connection of via an anode connector to a consumable anode, a direct current negative (−) output terminal for electrical connection via a cathode connector to the structure to be protected, grounding means for electrical grounding of the apparatus and anti-cross connection means for preventing the continuing flow of electrical current when the anode connector is associated with the negative output terminal and the cathode connector is associated with the positive output terminal.

Owner:BENHAM ROGER A

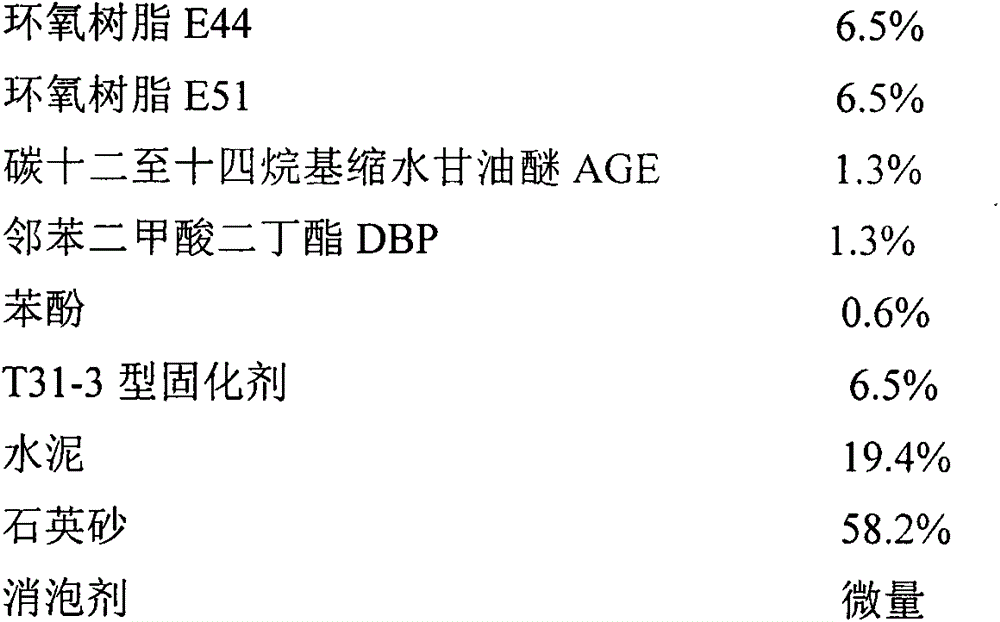

Anodic protection of electrical contacts

ActiveUS7097746B1Reduce morbidityDegree of improvementElectrically conductive connectionsTwo pole connectionsElectricityRechargeable cell

An anode protection device and method are provided. The method includes placing a sacrificial anode in proximity to the positive and negative contacts to shield or distort the field therebetween which provides preferential corrosion of the sacrificial anode, instead of the anode. The protection device is a sacrificial anode having various forms and placed in different configurations. In one form the sacrificial anode is a plate. In another form the sacrificial anode is a ring placed around either the positive contact or negative contact to provide a shield between the negative and positive contacts. In a further device embodiment, the sacrificial anodic plate can be welded to the aluminum case of a rechargeable battery of a behind-the-ear (BTE) hearing device.

Owner:ADVANCED BIONICS AG

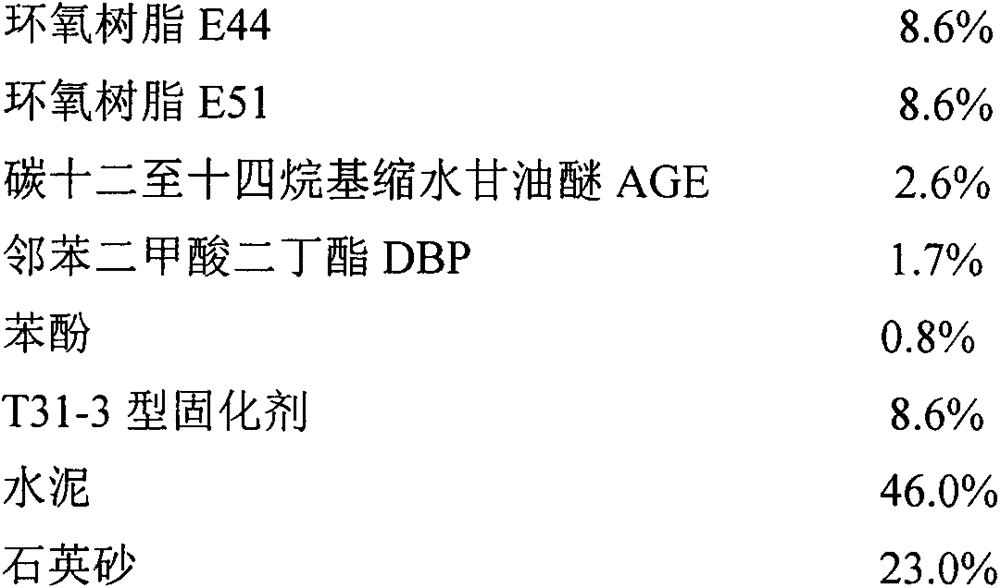

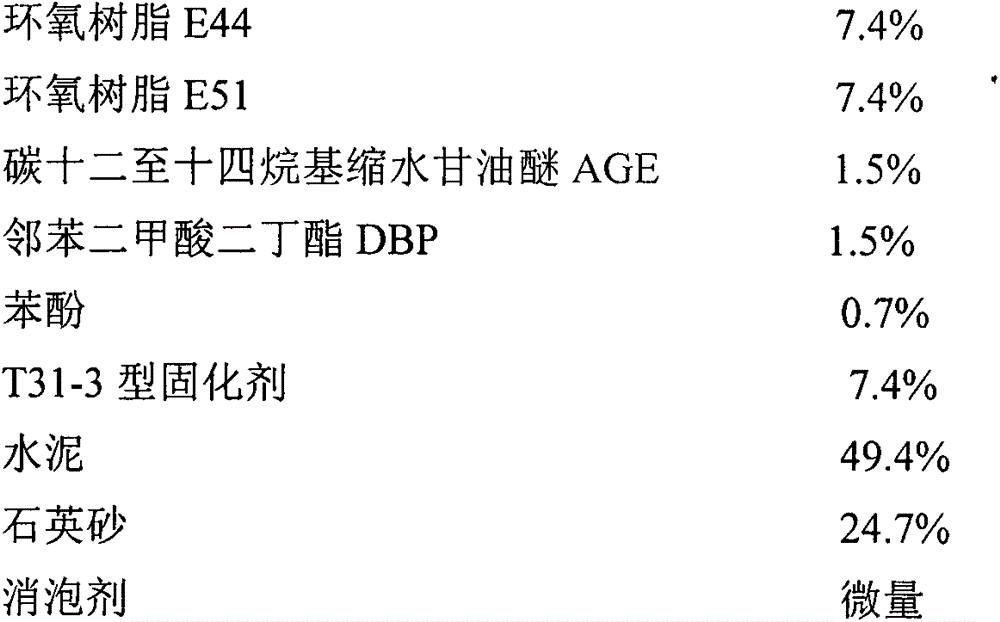

Preparation method of epoxy mortar for filling ocean oil and gas pipeline

InactiveCN103819144ASimple preparation processMeet the replacement requirementsShock resistanceSeawater

The invention belongs to the technical field of application of polymer mortar and particularly relates to a preparation method of epoxy mortar for filling an ocean oil and gas pipeline. The epoxymortar consists of a component A, a component B and a component C, wherein the component A is prepared by defoaming after blending epoxy resin, a reactive diluent, a plasticizer, an accelerator and pigments according to the proper proportion and; the component B is a special underwater T31-3 type curing agent; the component C is aggregate formed by mixing cement with quartz sand according to a certain proportion. When the epoxymortar is used for construction, the component A is heated to 30-50DEG C and stirred to homogeneousphase, and then the component A and the component B are mixed according to certain proportion and uniformly stirred; the component C is subsequently added into the mixture for uniformly blending to obtain an epoxymortar mixture for filling the ocean oil and gas pipeline. The mortar mixture is simple in preparation process; the prepared mixture has the advantages of high curing speed and strong cohesiveness as well as excellent compress and shock resistance and seawater corrosion resistance. The mortar mixture can be used for filling and strengthening an anode protection anticorrosive structure of the ocean oil and gas pipelines.

Owner:TIANJIN UNIV OF SCI & TECH +1

Compliant seal structures for protected active metal anodes

ActiveUS8404388B2Avoid lostReduced ionic contact areaPrimary cell to battery groupingFuel and primary cellsOptoelectronicsAnodic protection

Protected anode architectures have ionically conductive protective membrane architectures that, in conjunction with compliant seal structures and anode backplanes, effectively enclose an active metal anode inside the interior of an anode compartment. This enclosure prevents the active metal from deleterious reaction with the environment external to the anode compartment, which may include aqueous, ambient moisture, and / or other materials corrosive to the active metal. The compliant seal structures are substantially impervious to anolytes, catholyes, dissolved species in electrolytes, and moisture and compliant to changes in anode volume such that physical continuity between the anode protective architecture and backplane are maintained. The protected anode architectures can be used in arrays of protected anode architectures and battery cells of various configurations incorporating the protected anode architectures or arrays.

Owner:POLYPLUS BATTERY CO INC

Method for manufacturing anode protection ring

The invention relates to a production method of an anode protection ring in the electrolytic aluminum production, which is used for producing an anode steel talon protection ring by taking the waste in the electrolytic aluminum production as main raw material and adding coal pitch and coal tar in the waste. The waste includes: residual anode waste, waste paste, waste carbon residue and waste cathode crushed material, different types of waste can produce different types of anode steel talon protection rings, including conventional type protection rings, waste paste protection rings, carbon residue type protection rings and waste cathode block protection rings, and the proportion of various raw materials for producing the anode steel talon protection rings is that: waste : coal pitch : coal tar is equal to 100 : 7-14 : 3-8. The method uses the waste in the electrolytic aluminum production as most raw materials, not only reduces the pollution of overhaul groove solid waste and other waste in the electrolytic aluminum production to the environment, but also effectively utilizes the waste and reduces the production cost of electrolytic aluminum. The plant use proves that the anode steel talon protection rings produced by the method can completely satisfy production requirements.

Owner:河南神火铝业股份有限公司

Method of protecting corrosion proof pipeline joint internal wall using sacrificing anode

Owner:PETROCHINA CO LTD +1

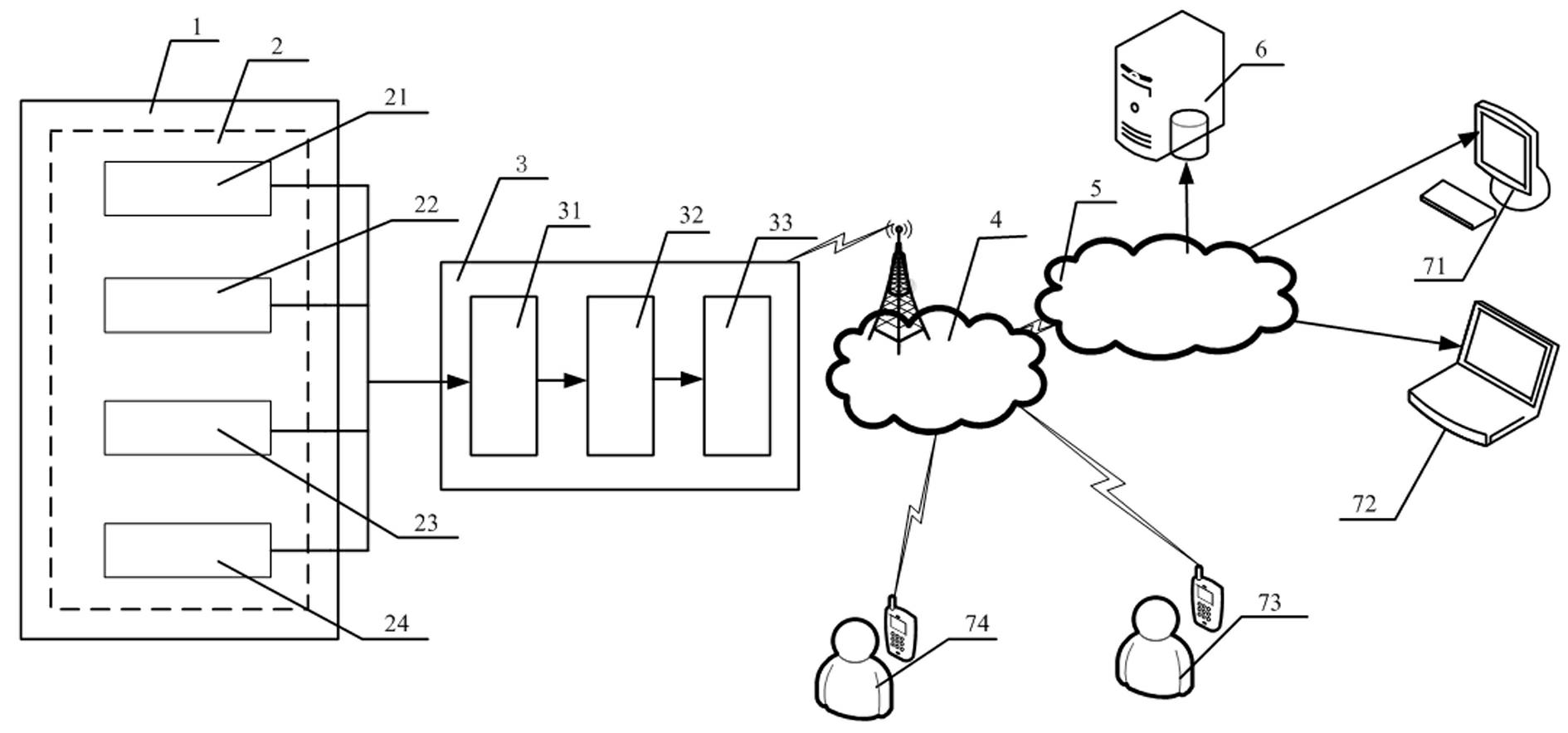

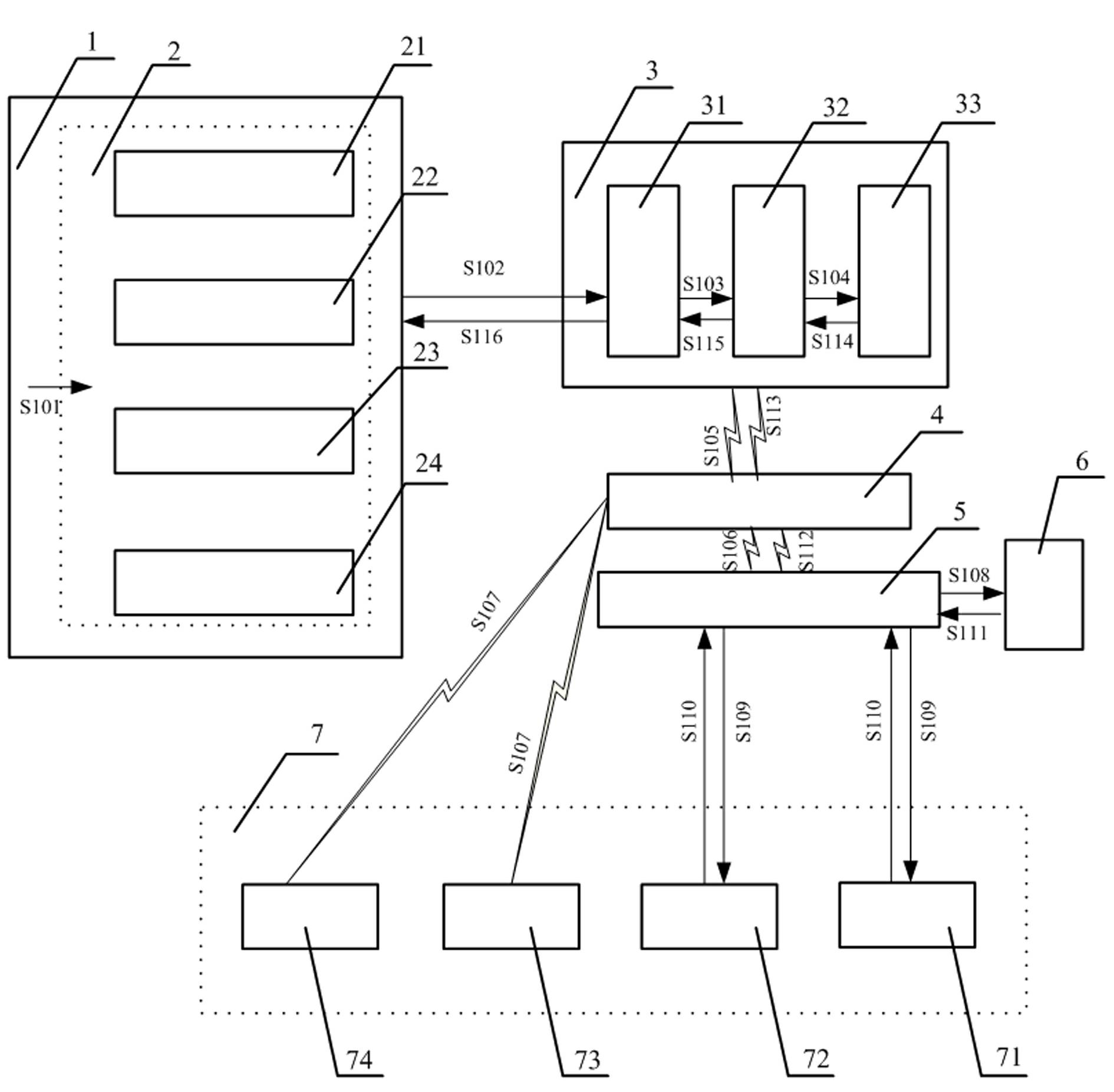

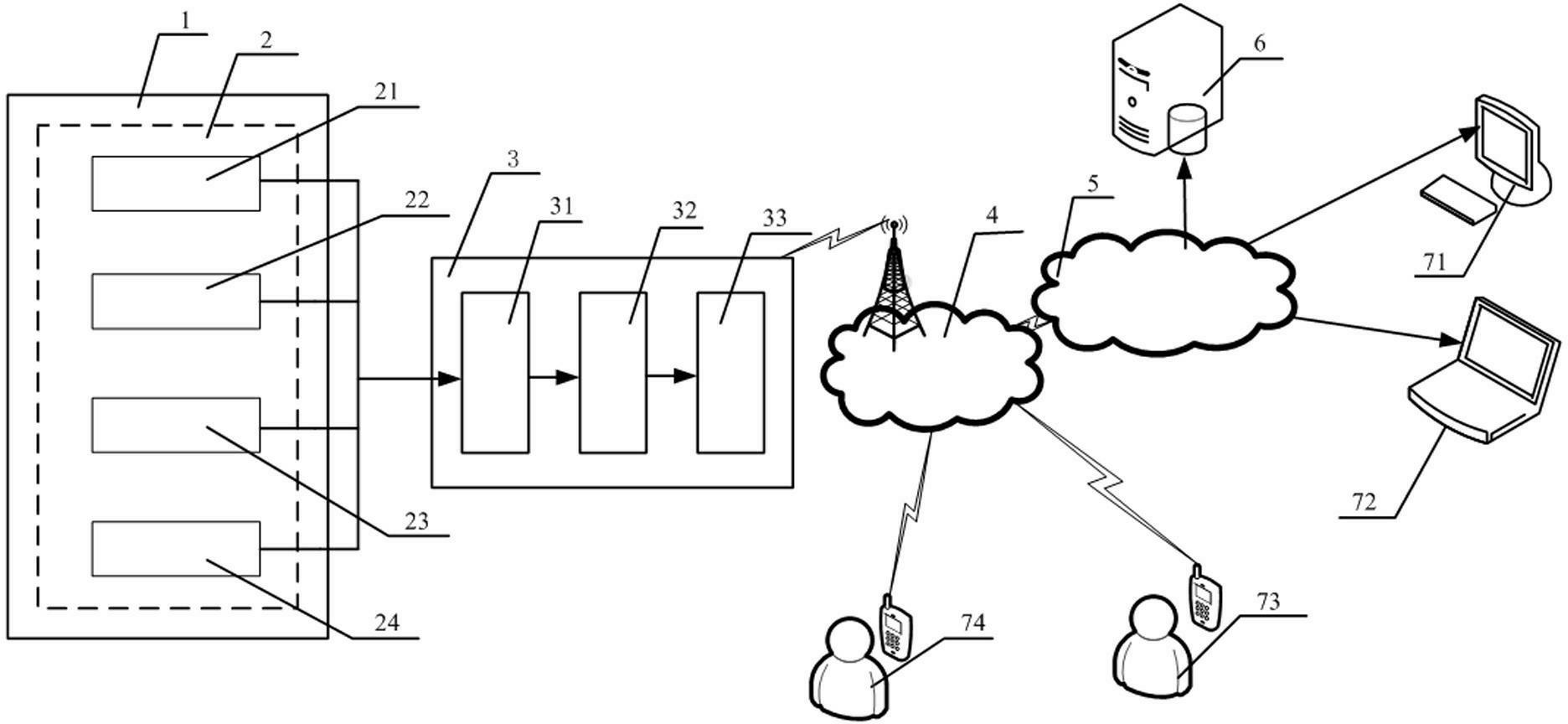

Remote monitoring, early warning and fault-diagnosing system and method for anodic protection device

The invention relates to a remote monitoring, early warning and fault-diagnosing system for an anodic protection device based on an internet of things technology. The system comprises a sensor device, a signal identifying device, a GPRS / CDMA (General Packet Radio Service / Code Division Multiple Access) network, an internet, a database server and a monitoring terminal, wherein the sensor device is connected with the signal identifying device; the signal identifying device is in wireless signal connection with the GPRS / CDMA network; the monitoring terminal comprises an equipment manufacturer monitoring terminal, a client monitoring terminal and an equipment manufacturer engineer and client engineer mobile monitoring terminal; the GPRS / CDMA network is in wireless signal connection with the equipment manufacturer engineer and client engineer mobile monitoring terminal; the GPRS / CDMA network is in wireless signal connection with the internet; the internet is connected with the database server; the internet is connected with the equipment manufacturer monitoring terminal and the client monitoring terminal; and the equipment manufacturer monitoring terminal and the client monitoring terminal are connected with the database server through the internet. The system provided by the invention can be used for remotely monitoring and estimating the state of the anodic protection device in an all-weather way and timely and accurately warning the device exception.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION

Fire-resistant lithium battery containing an electrode-protecting layer

ActiveUS20190372148A1High energyImprove security levelCell seperators/membranes/diaphragms/spacersNegative electrodesChemical LinkageConductive polymer

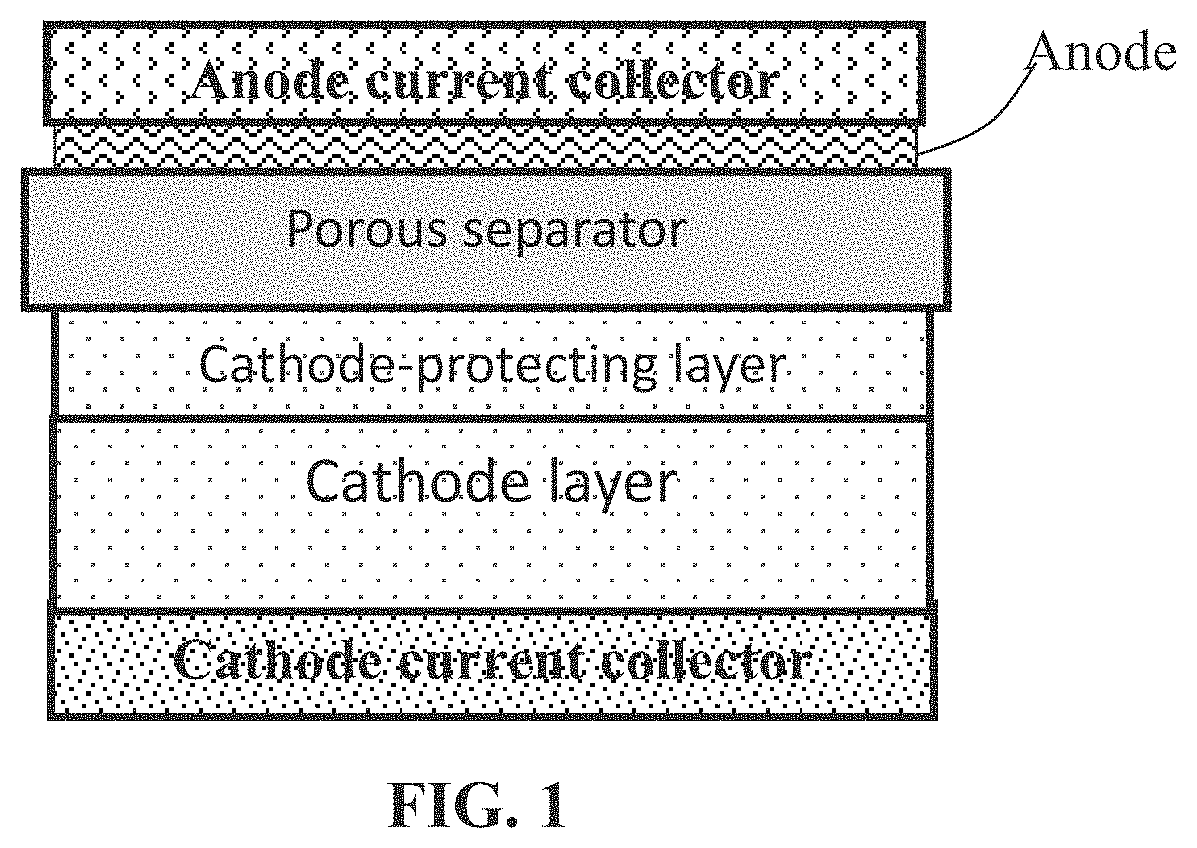

Provided is a lithium secondary battery containing an anode, a cathode, a porous separator / electrolyte element disposed between the anode and the cathode, and a cathode-protecting layer bonded or adhered to the cathode, wherein the cathode-protecting layer comprises a lithium ion-conducting polymer matrix or binder and inorganic material particles that are dispersed in or chemically bonded by the polymer matrix or binder and wherein the cathode-protecting layer has a thickness from 10 nm to 100 μm and the polymer matrix or binder has a lithium-ion conductivity from 10−8 S / cm to 5×10−2 S / cm. Additionally or alternatively, there can be a similarly configured anode-protecting layer adhered to the anode. Such an electrode-protecting layer prevents massive internal shorting from occurring even when the porous separator gets melted, contracted, or collapsed under extreme temperature conditions induced by, for instance, dendrite or nail penetration.

Owner:GLOBAL GRAPHENE GRP INC

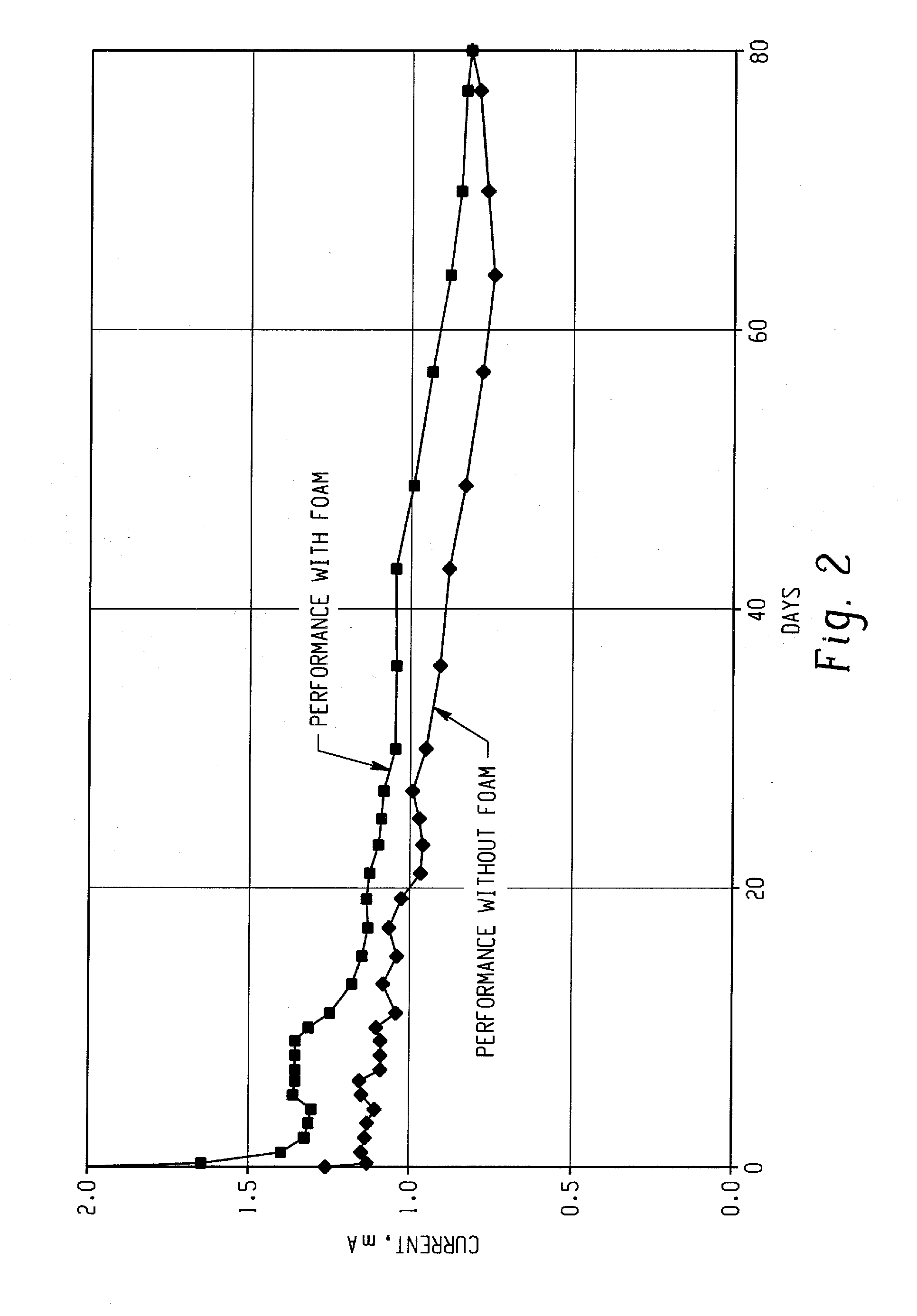

Anode assembly for cathodic protection

The cathodic protection of a reinforced concrete structure utilizes sacrificial anodes such as aluminum or zinc as well as alloys thereof. Each anode is embedded or substantially covered in a material consisting of a hydrophilic non-cementious open-cell foam. An activating agent such as one or more lithium salts is contained within the cells of the foam to maintain the anodes in an electrochemically active state. The activating agent may be immobilized in the cells using an aqueous gel such as agar. One or more metallic conductors electrically connect the anodes to the metal reinforcing members.

Owner:THE EUCLID CHEM CO

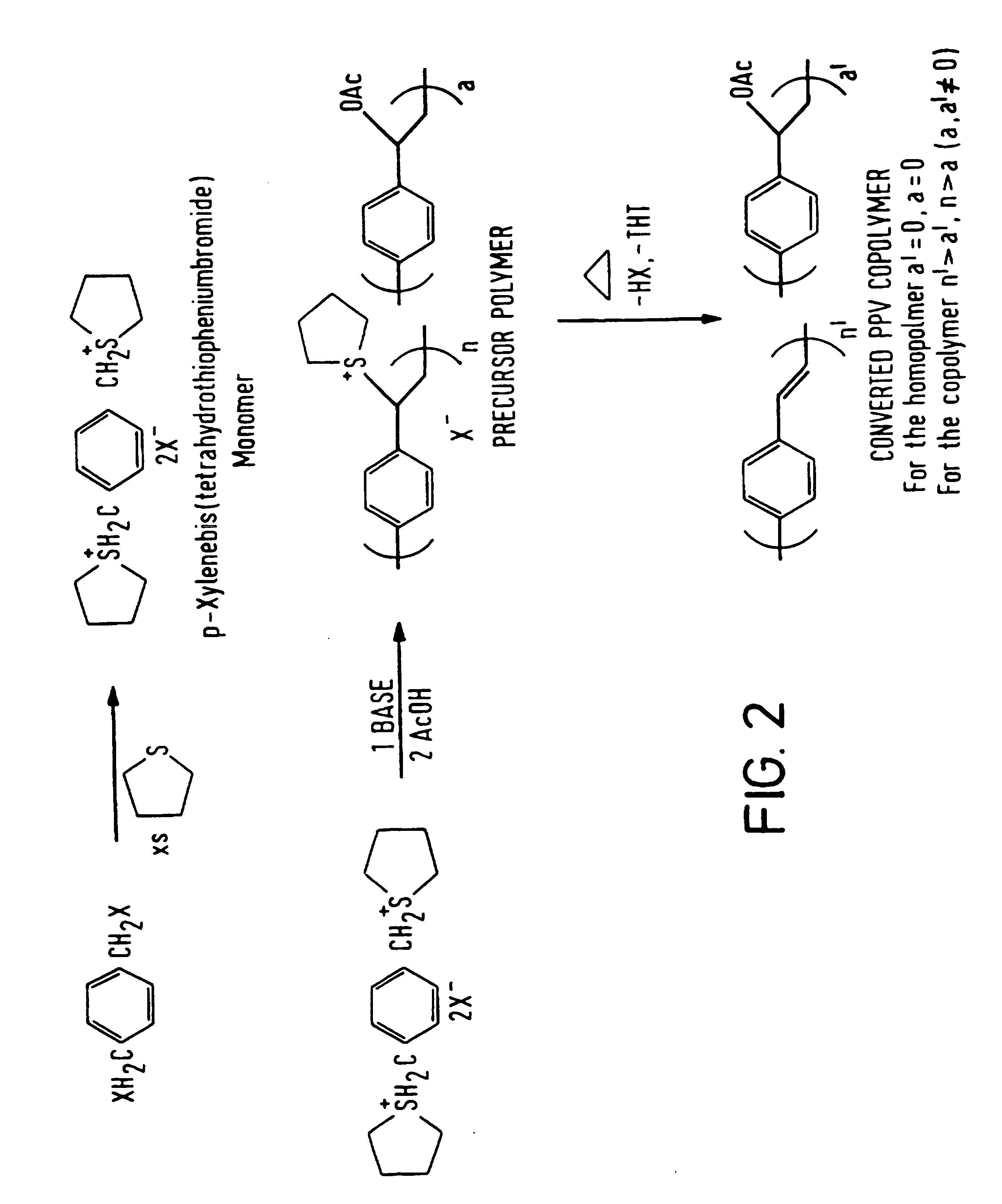

Electroluminescent devices with electrode protection

InactiveUS20060186794A1Easy to disassembleReduce conversionDischarge tube luminescnet screensElectroluminescent light sourcesAnodic protectionProtection layer

A method of manufacturing an electroluminescent device which has an anode and a cathode and arranged between the anode and the cathode a light emissive layer, also includes an anode protection layer which protects the anode against the effects of converting a precursor polymer to a semiconductive conjugated polymer which constitutes the light emissive layer. This has been found to increase the brightness and half-life of devices.

Owner:CAMBRIDGE DISPLAY TECH LTD

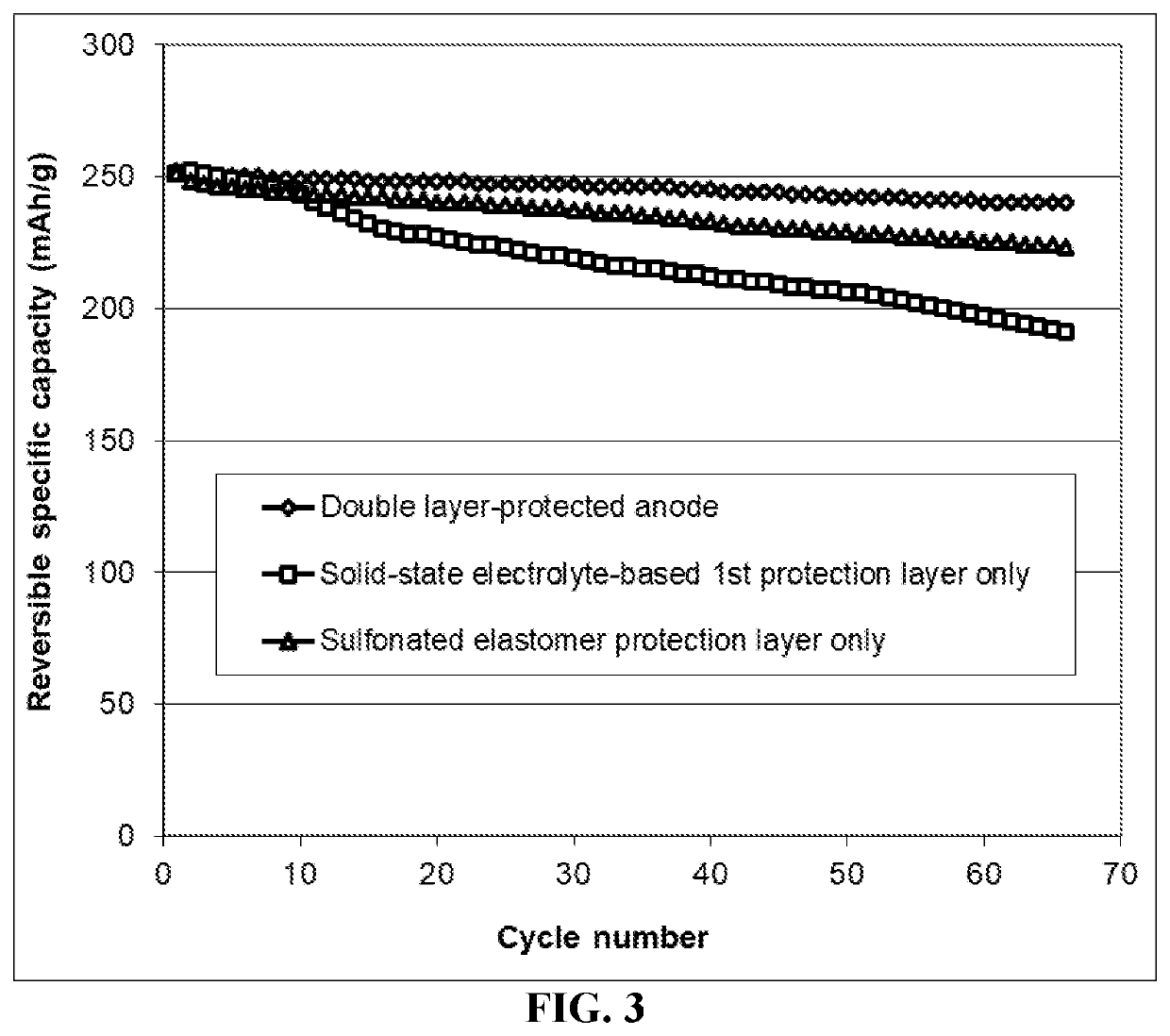

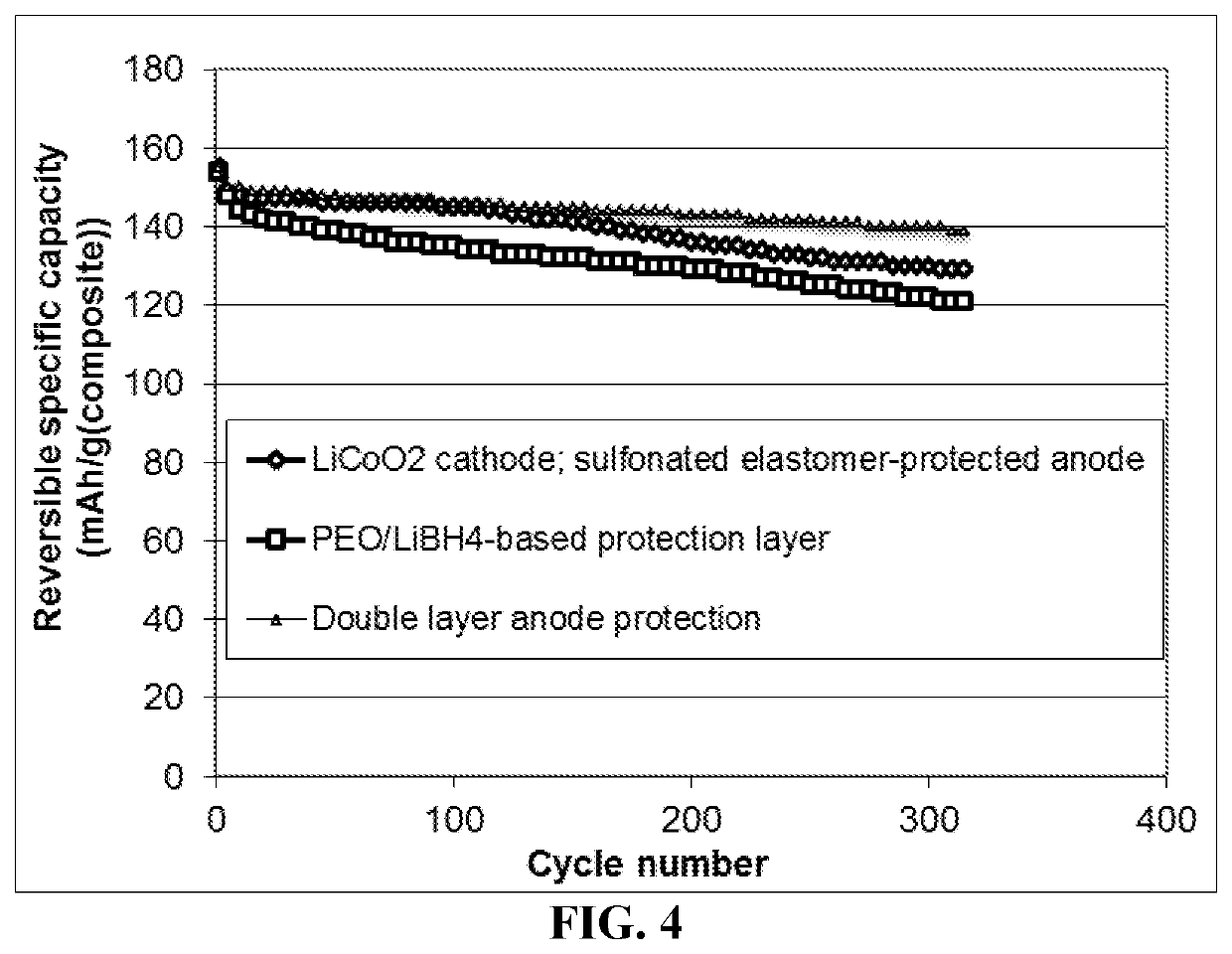

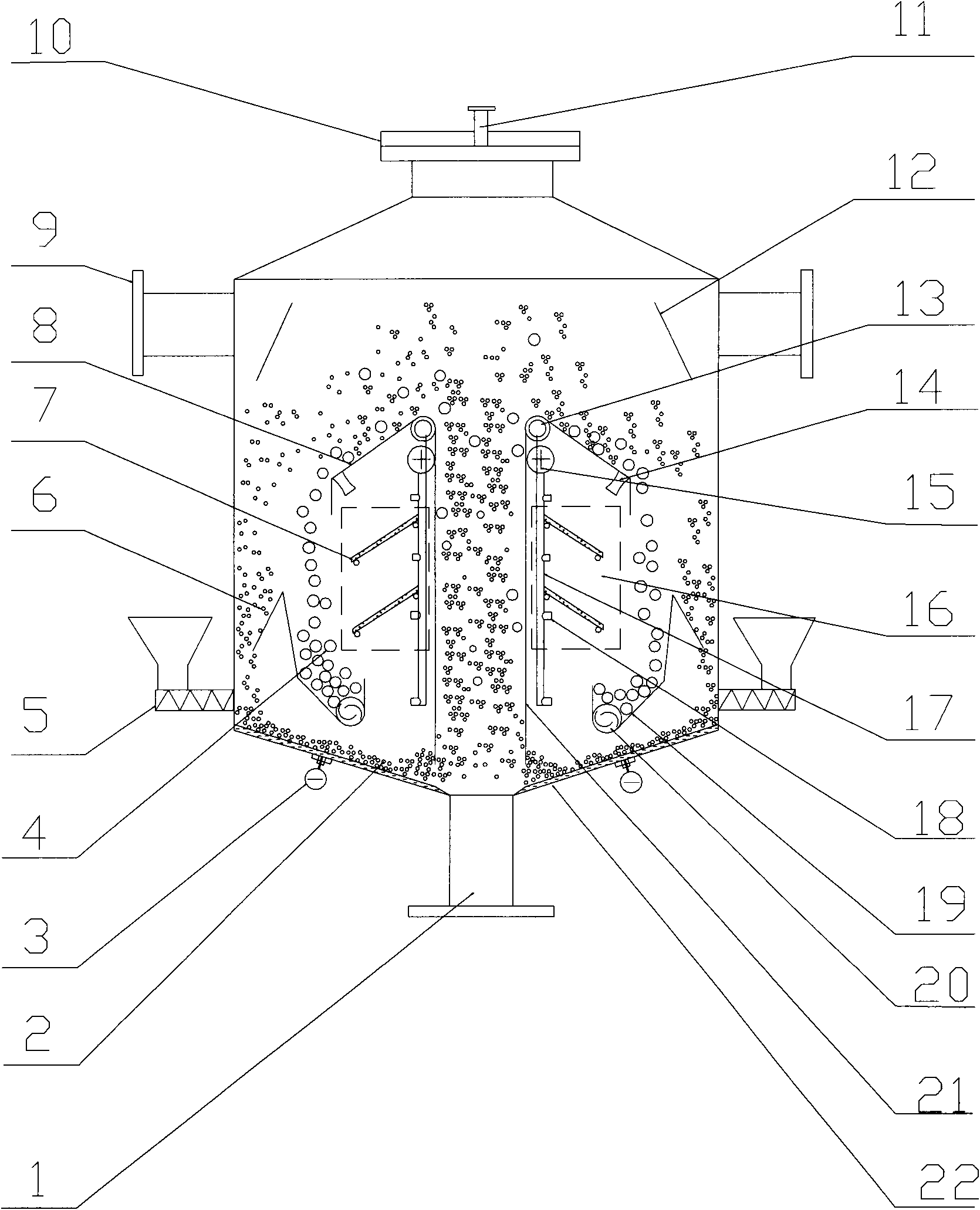

Method of protecting the lithium anode layer in a lithium metal secondary battery

PendingUS20190393482A1Reduce eliminatePromotes uniform depositionSolid electrolytesElectrode manufacturing processesLithium metalPhysical chemistry

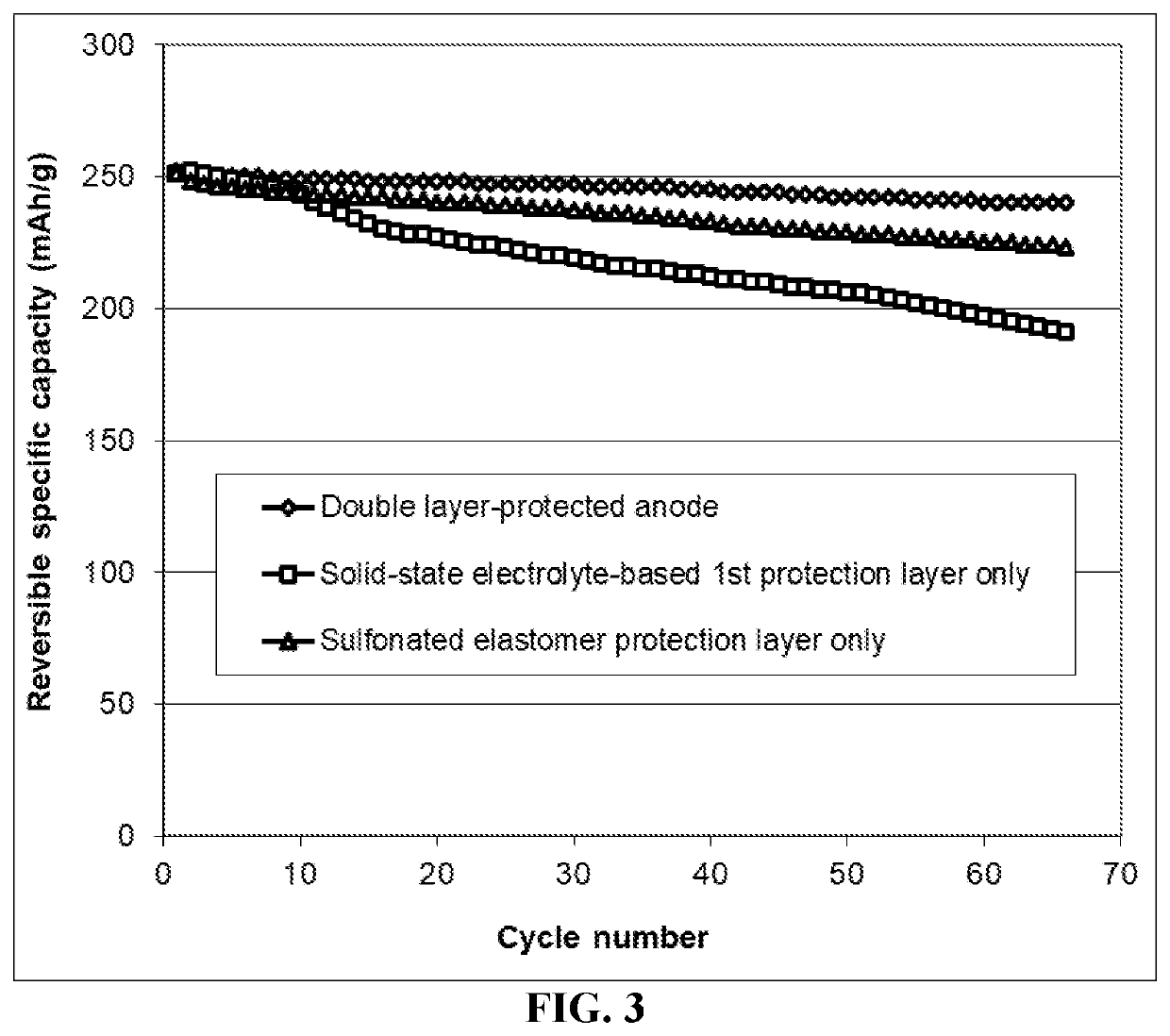

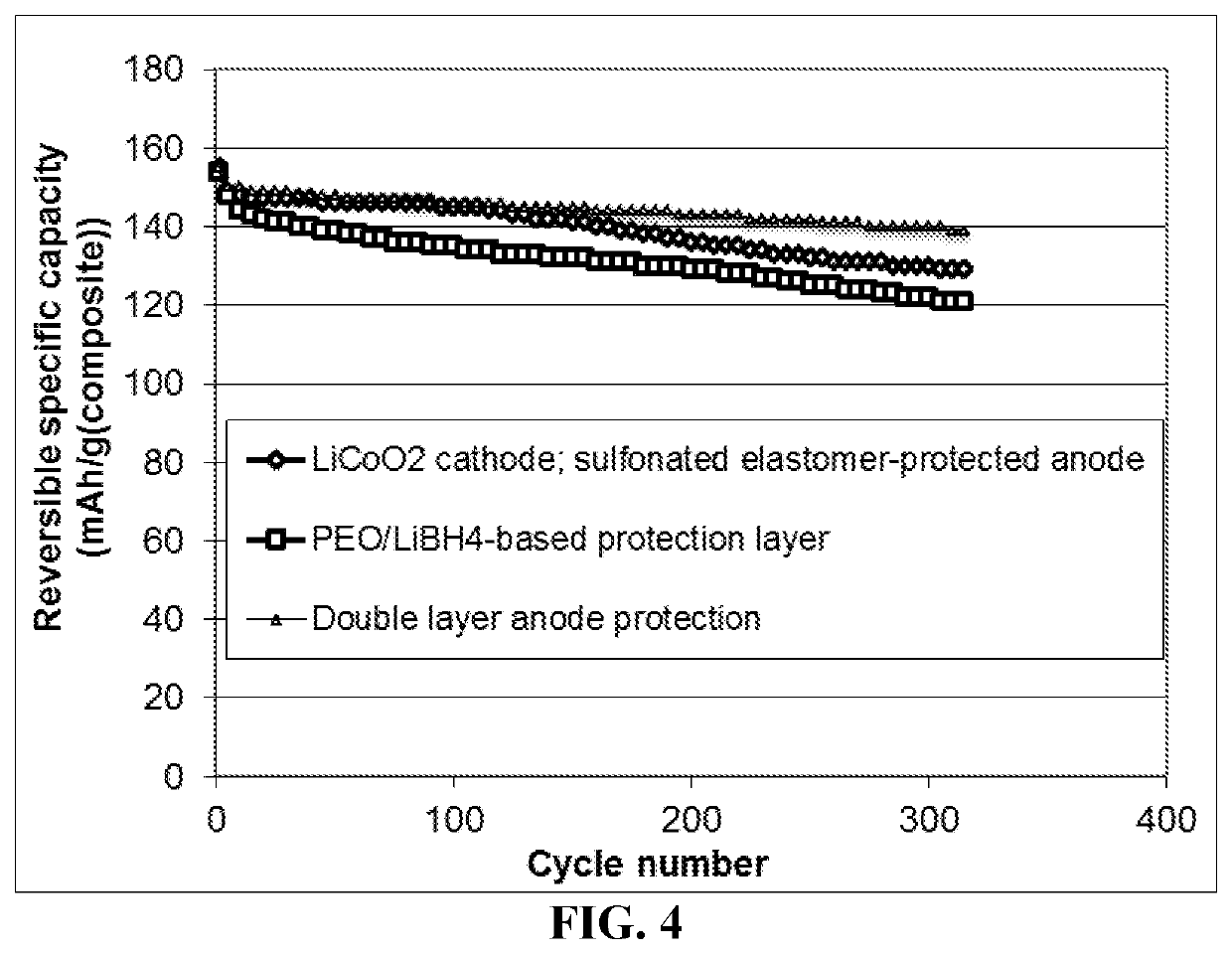

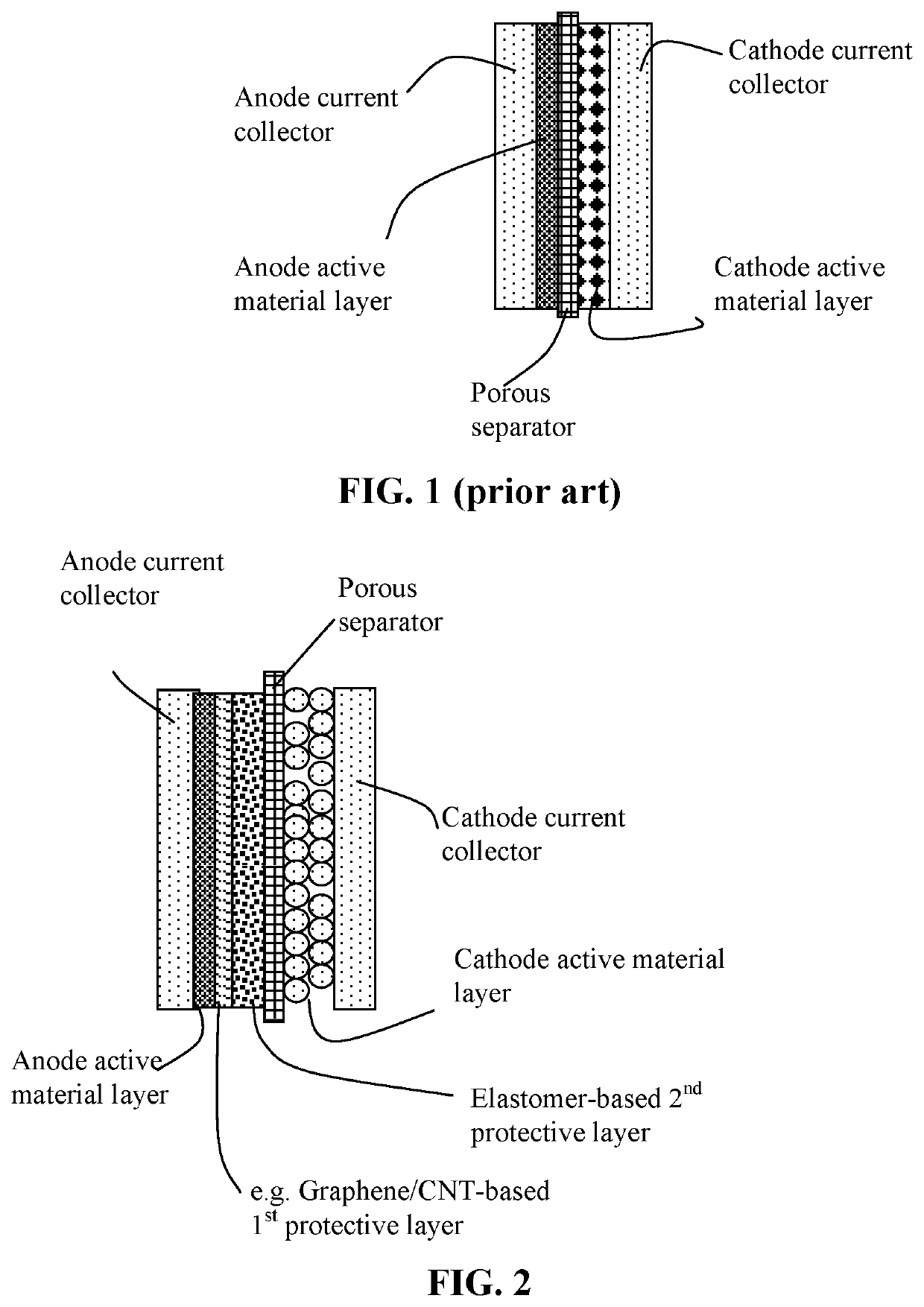

The invention provides a method of improving the anode stability and cycle-life of a lithium metal secondary battery. The method comprises implementing two anode-protecting layers between an anode active material layer and an electrolyte or electrolyte / separator assembly. These two layers comprise (a) a first anode-protecting layer having a thickness from 1 nm to 100 μm (preferably <1 μm and more preferably <100 nm) and comprising a lithium ion-conducting material having a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm; and (b) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% (preferably >10% more preferably >100%) and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

Non-diaphragm electrochemical waste water treatment device

InactiveCN101671066AGuaranteed uptimeLow investment costWater/sewage treatmentWastewaterCathode reaction

The invention relates to a non-diaphragm electrochemical waste water treatment device which comprises an electrode reactor, wherein a waste water guide pipe, an anode, a feed cathode and a large metalparticle collecting device are arranged in the electrode reactor; a waste water inlet is arranged at the bottom of the electrode reactor, the upper side of the waste water inlet is longitudinally provided with the waste water guide pipe, and a space is reserved between the lower end of the waste water guide pipe and the waste water inlet; in addition, the upper end of the waste water guide pipe is provided with an anode protective baffle; the anode is arranged on the outer wall of the waste water guide pipe, and the feed cathode is arranged at the bottom of the electrode reactor; moreover, afeeding device is arranged on the electrode reactor; and the large metal particle collecting device is arranged below the anode protective baffle. Therefore, the non-diaphragm electrochemical waste water treatment device can effectively maintain particles in the electrode reactor to be fluidized and also prevent the metal particles from entering an anode reaction area. Under the condition of no need of a diaphragm, a cathode reaction area and an anode reaction rear are separated, thereby thoroughly solving various problems brought by using the diaphragm.

Owner:SOUTHEAST UNIV

Lithium metal secondary battery containing a protected lithium anode

ActiveUS20190393487A1Reduce thicknessImprove lithium ion conductivityCell seperators/membranes/diaphragms/spacersFinal product manufactureElectrical batteryLithium metal

Provided is a lithium secondary battery, comprising a cathode, an anode, and a porous separator or electrolyte, wherein the anode comprises: (a) an anode active layer containing a layer of lithium or lithium alloy, in a form of a foil, coating, or multiple particles aggregated together, as an anode active material; (b) a first anode-protecting layer having a thickness from 1 nm to 100 μm (preferably <1 μm and more preferably <100 nm) and comprising a lithium ion-conducting material having a lithium ion conductivity from 108 S / cm to 5×10−2 S / cm; and (c) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% and a lithium ion conductivity from 108 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

Ceramic metal oxide composite anode for cathodic protection

The invention relates ceramal oxidate composite anode used for cathodic protection, comprising base body, intermediate layer and surface layer. The base body adopts metallic titanium or niobium; intermediate layer adopts ceramal oxidate IrO2-Ta2O5 in which the proportion of Ir and Ta is (50-90):(10-50); the surface layer is RuO2-IrO2-TiO2 in which the proportion of Ru,Ir and Ti is (15-25):(5-15):(60-70). The composite anode possesses not only the good electrochemistry activity, but also the high stability and low consumption rate. The method suits for impressed current cathodic protection system and other electrochemistry industry.

Owner:SUNRUI MARINE ENVIRONMENT ENG

Method of improving anode stability in a lithium metal secondary battery

PendingUS20190393486A1Decrease exchange current densityPromotes uniform depositionSolid electrolytesElectrode manufacturing processesElastomerFiber

The invention provides a method of improving the anode stability and cycle-life of a lithium metal secondary battery. The method comprises implementing two anode-protecting layers between an anode active material layer and an electrolyte / separator assembly. These two layers comprise (a) a first anode-protecting layer having a thickness from 1 nm to 100 μm, a specific surface area greater than 50 m2 / g and comprising a thin layer of electron-conducting material selected from graphene sheets, carbon nanotubes, carbon nanofibers, carbon or graphite fibers, expanded graphite flakes, metal nanowires, conductive polymer fibers, or a combination thereof; and (b) a second anode-protecting layer having a thickness from 1 nm to 100 μm and comprising an elastomer having a fully recoverable tensile elastic strain from 2% to 1,000% (preferably >10%) and a lithium ion conductivity from 10−8 S / cm to 5×10−2 S / cm.

Owner:GLOBAL GRAPHENE GRP INC

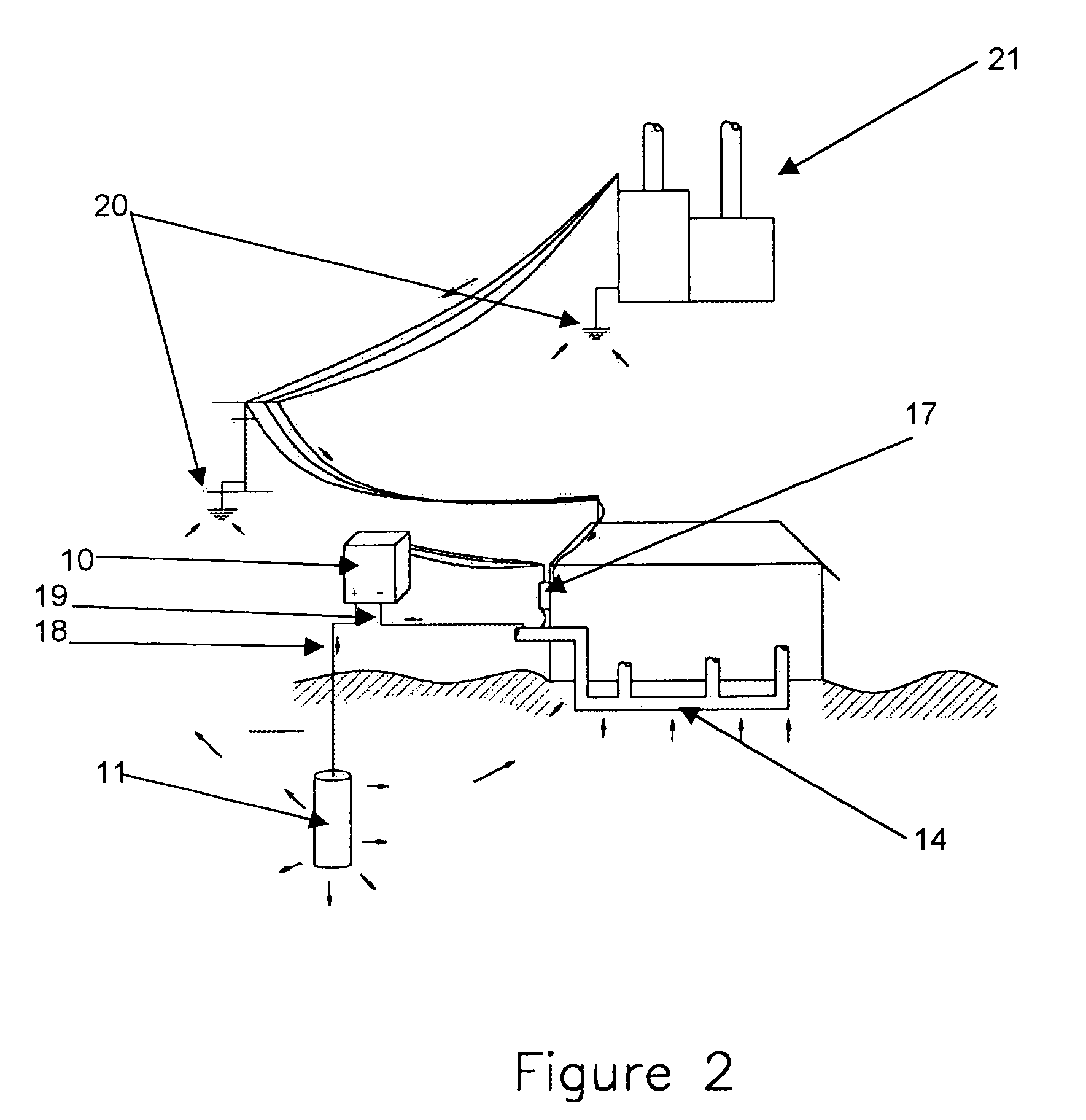

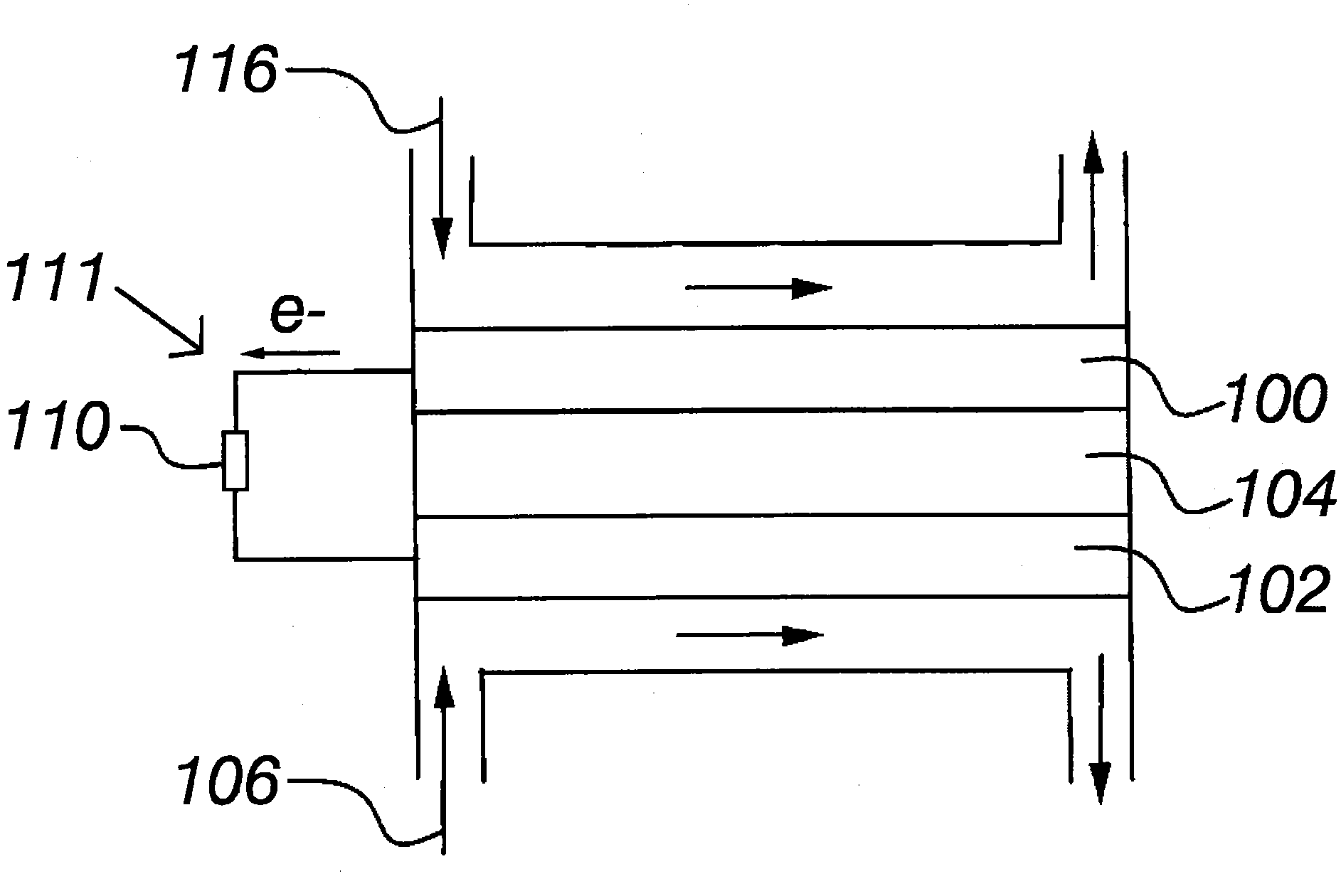

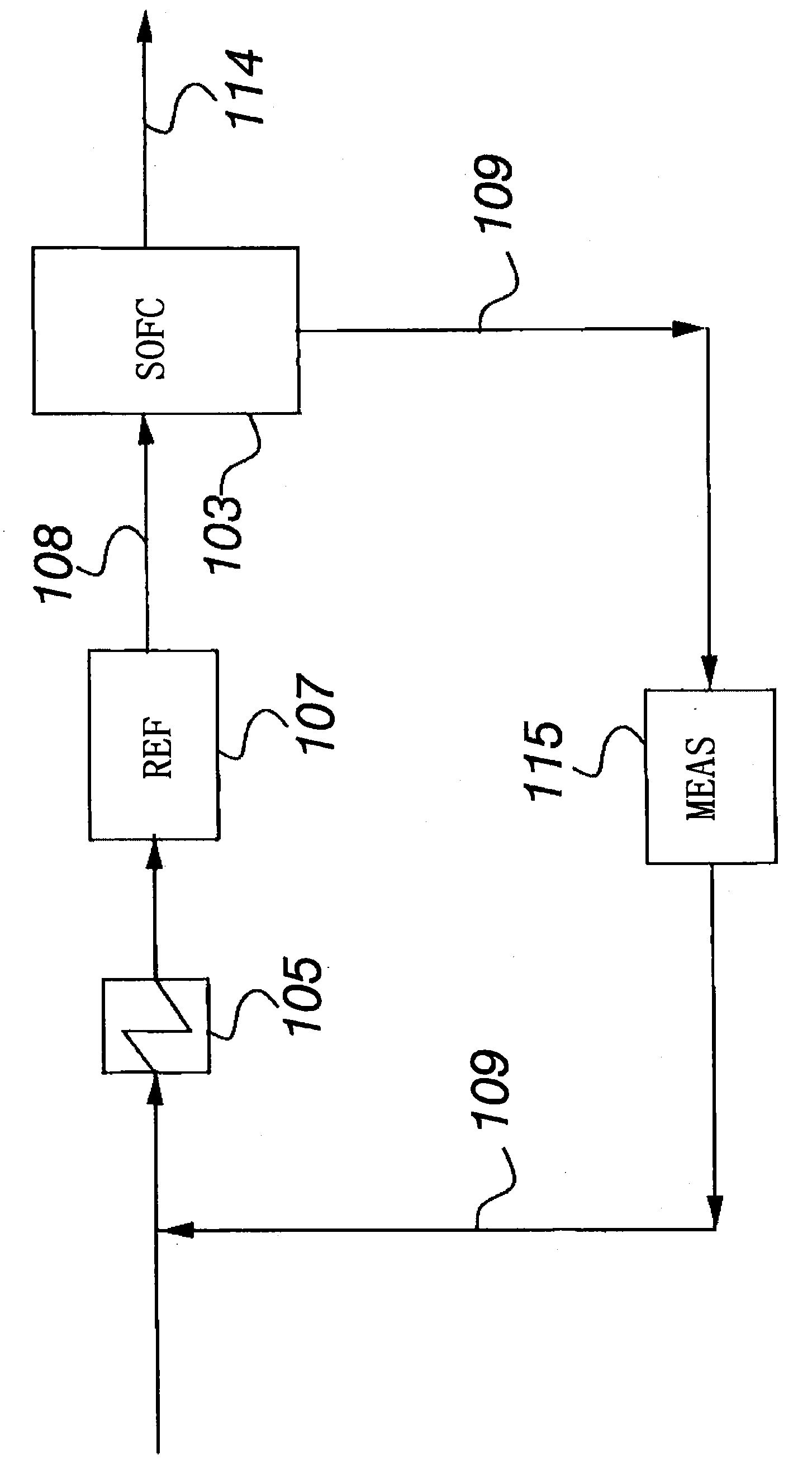

Method and arrangement for minimizing need for safety gases

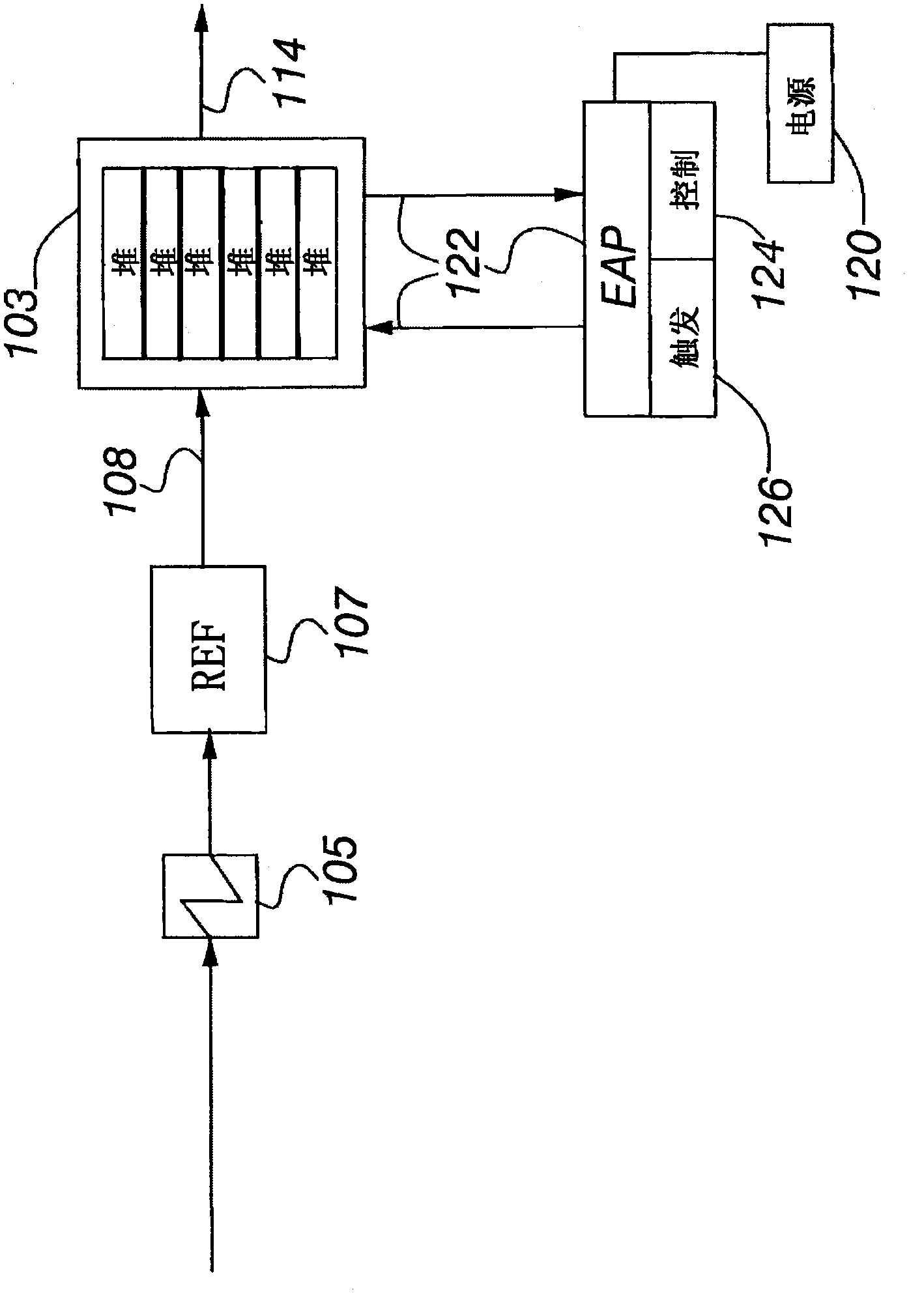

ActiveCN103828111AReduce physical sizeReduce economic costsFuel cells groupingFuel cell auxillariesFuel cellsEngineering

The focus of the invention is an arrangement for minimizing need for safety gases in high temperature fuel cell system, each fuel cell in the fuel cell system comprises an anode side (100), a cathode side (102), and an electrolyte (104) between the anode side and the cathode side, the fuel cells being arranged in fuel cell stacks (103), and the fuel cell system comprises a fuel cell system piping for reactants, and means (108) for feeding fuel to the anode sides (100) of the fuel cells. The arrangement comprises means (122) for electrical anode protection supplying a predefined voltage separately to at least two fuel cell stacks (103) or groups of fuel cell stacks (103) to prohibit oxidation of anodes (100), a source (120) of energy sufficient for providing electrical energy for at least a predetermined minimum time for said means (122) for electrical anode protection, means (124) to reduce said predefined voltage to limit anode protection current to a predefined maximum current value separately for at least two stacks (103) or groups of stacks (103), and means (126) to reliably trigger said means (122) for electrical anode protection in a situation where anode oxidation cannot be prohibited by the means (108) for feeding fuel to the anode sides (100) of the fuel cells.

Owner:CONVION OY

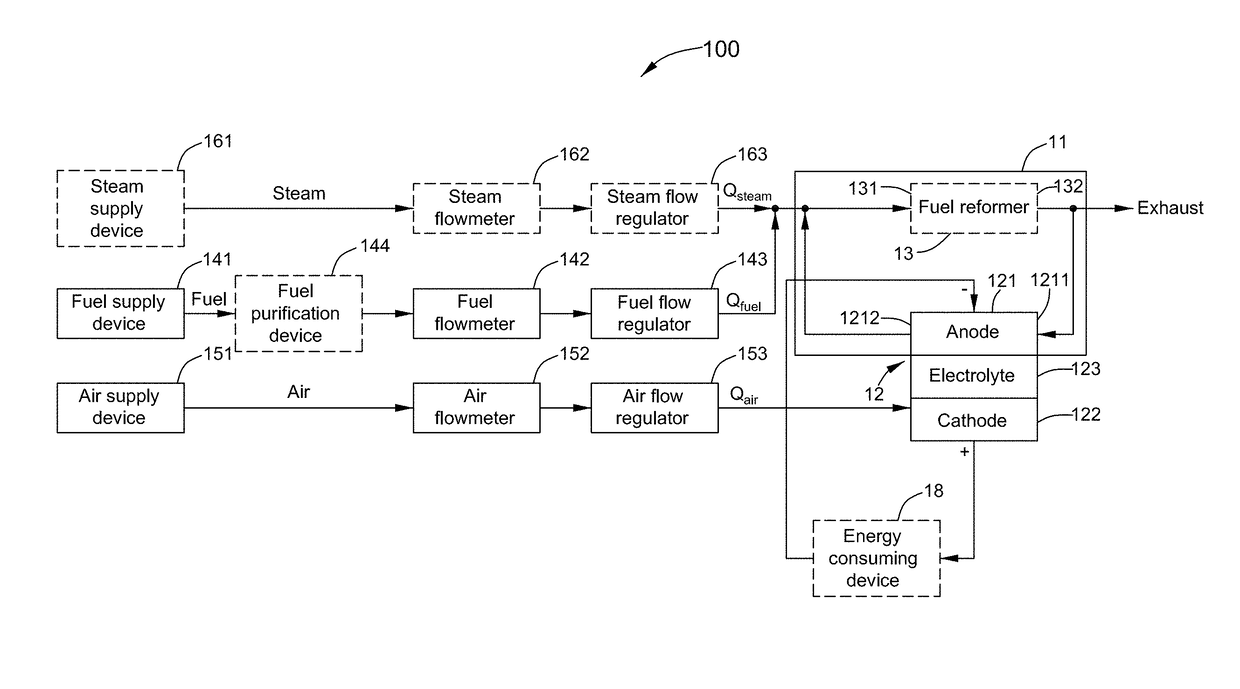

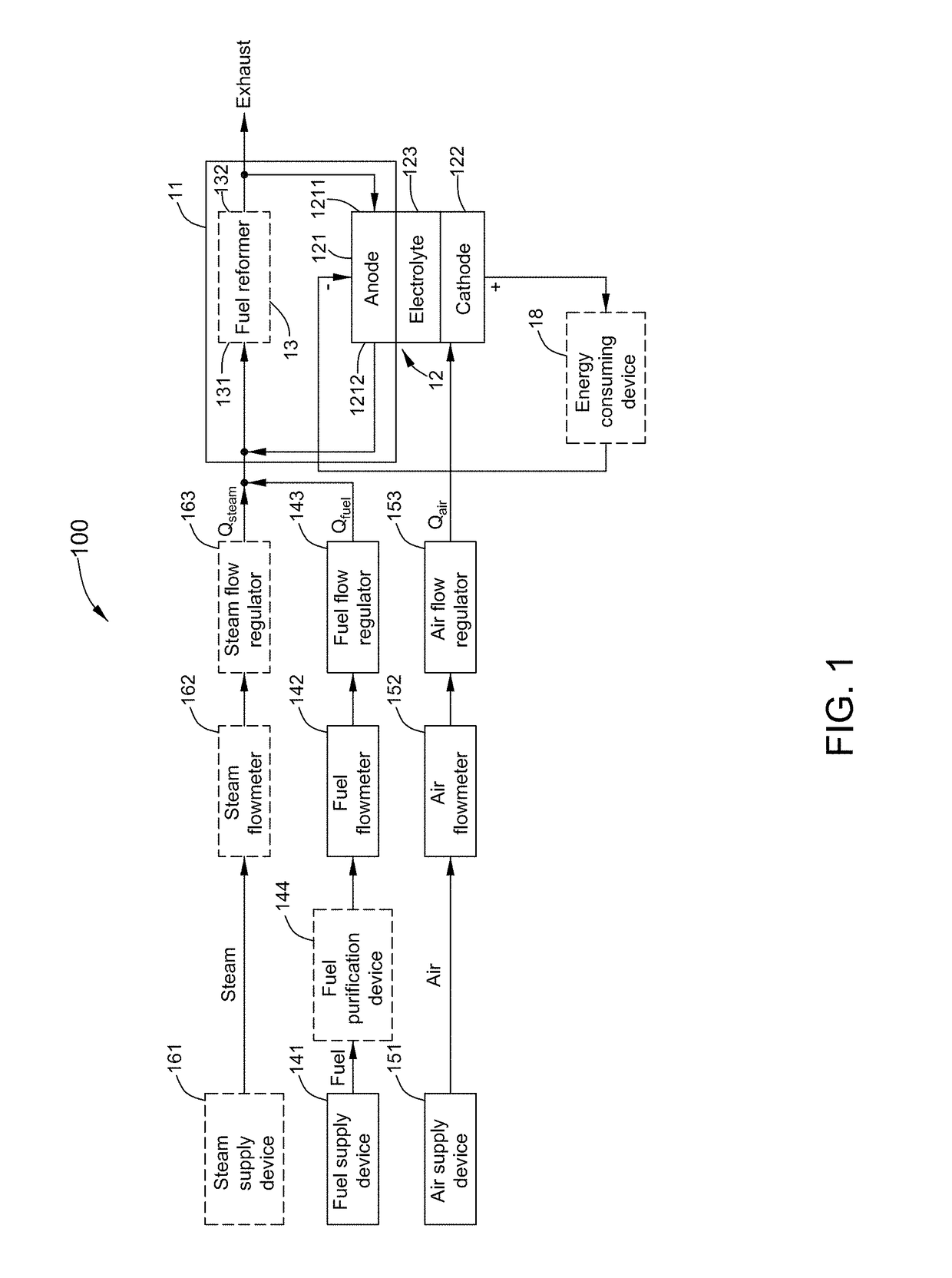

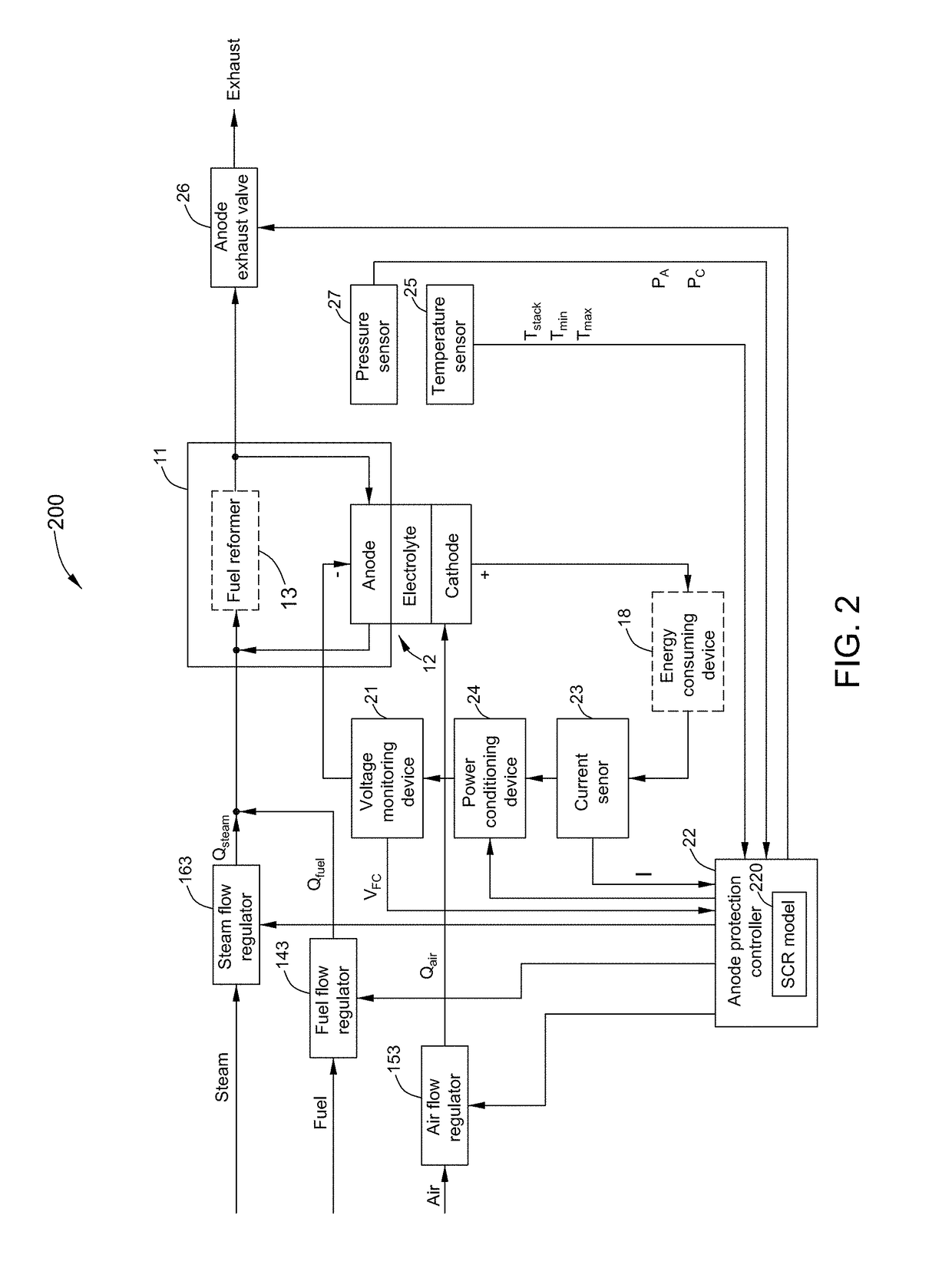

Fuel cell system and shutdown method thereof

A fuel cell system is disclosed, which includes an anode recirculation loop including a fuel cell stack for generating power, a fuel supply device for providing a fuel to the anode recirculation loop, an air supply device for providing air to a cathode of the fuel cell stack, a voltage monitoring device for monitoring a voltage of the fuel cell stack, and an anode protection controller. The anode protection controller decreases a current drawn from the fuel cell stack by a predetermined amount whenever the voltage of the fuel cell stack drops below a predetermined voltage threshold and decreases a fuel flowrate provided to the anode recirculation loop based on the decreased current, so as to maintain a steam to carbon ratio in the anode recirculation loop above a predetermined steam to carbon ratio limit. A shutdown method for the fuel cell system are also disclosed.

Owner:CUMMINS ENTERPRISE LLC

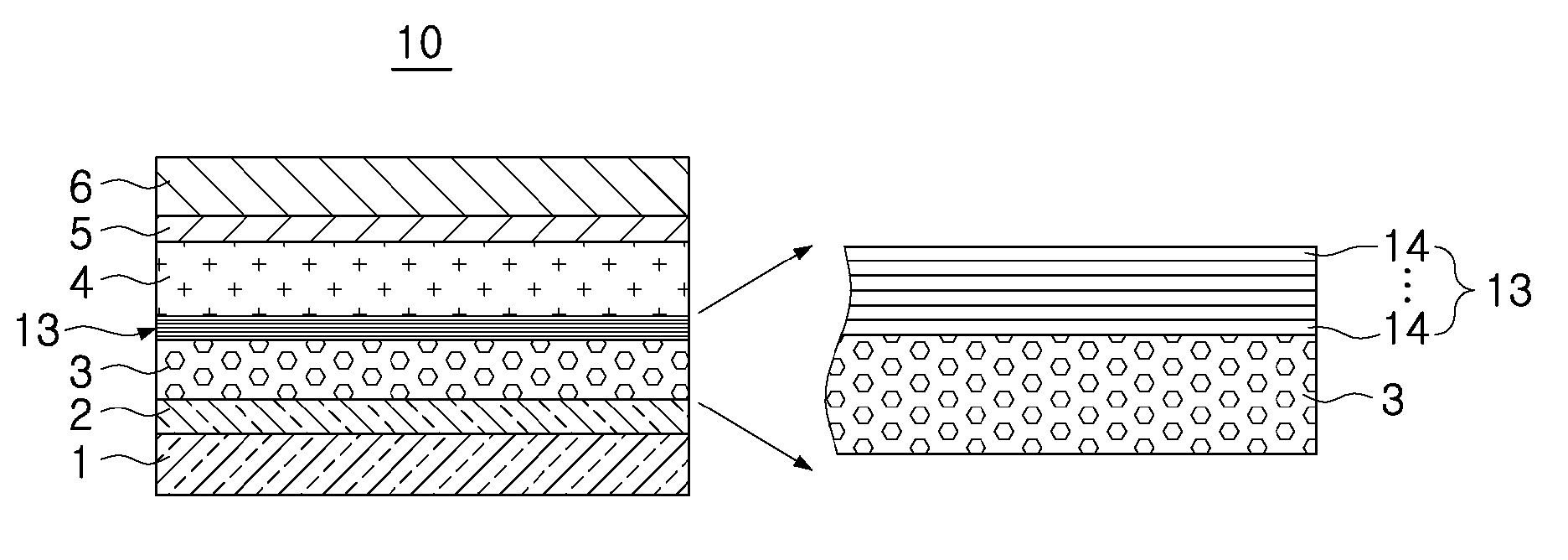

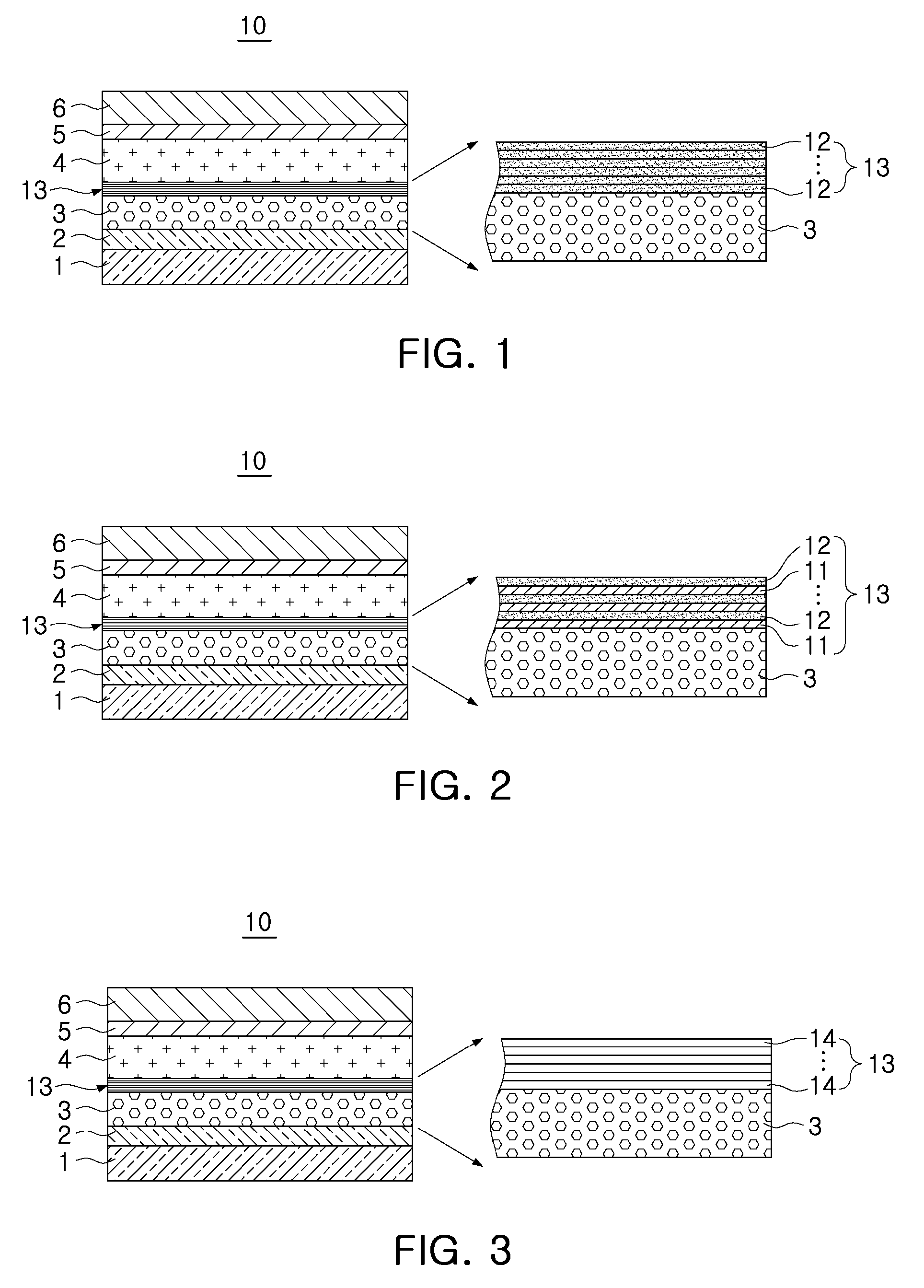

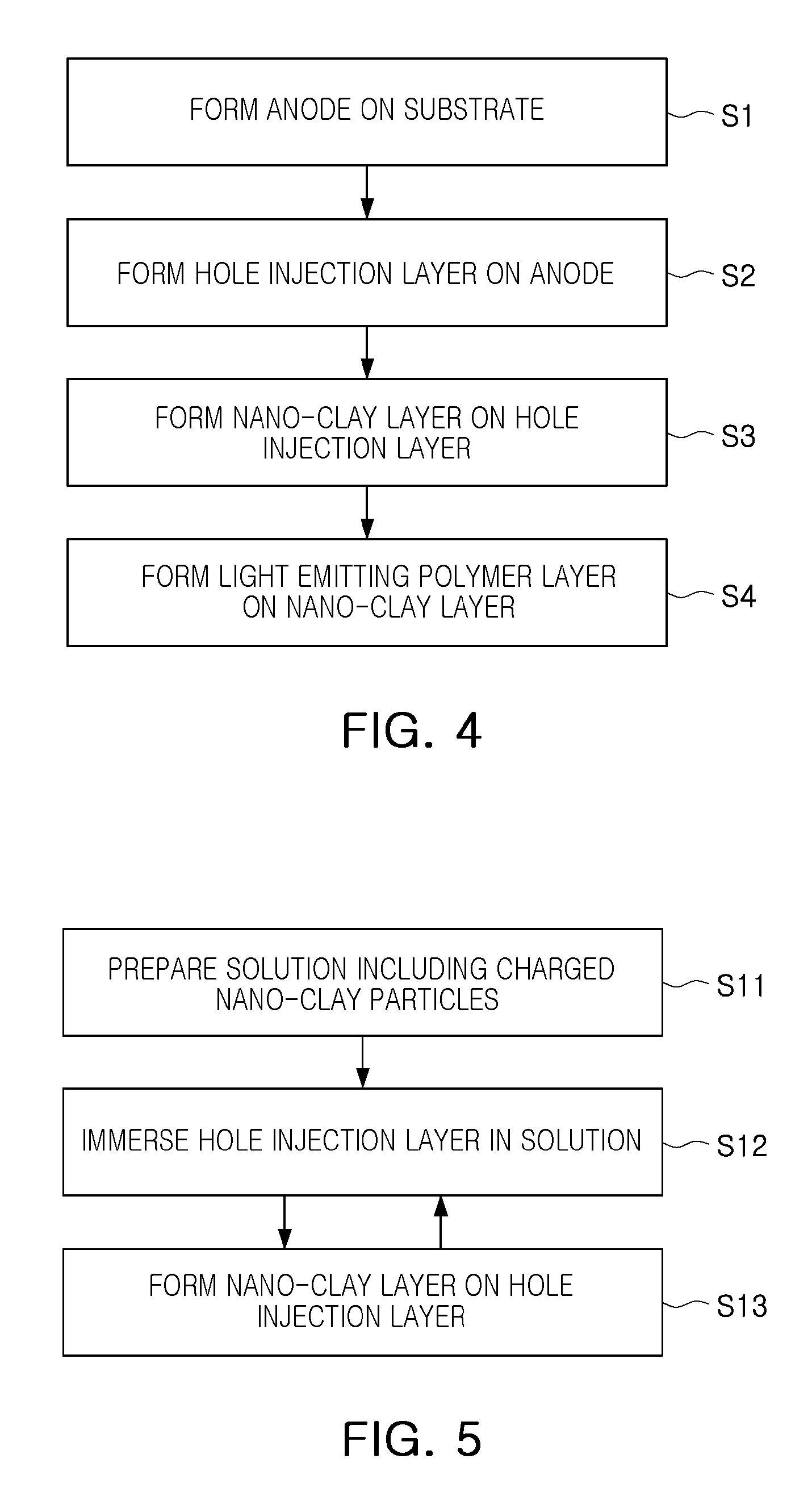

Organic light emitting diode and method of manufacturing the same

InactiveUS20120286248A1Improve stabilitySolid-state devicesSemiconductor/solid-state device manufacturingProtection layerLight-emitting diode

There are provided an organic light emitting diode and a method of manufacturing the same. The organic light emitting diode includes: an anode formed on a substrate; a protective layer having at least one inorganic material layer stacked therein, the at least one inorganic material layer containing at least one of a nano-clay and a graphite oxide; a light emitting polymer layer formed on the protective layer; and a cathode formed on the light emitting polymer layer. In the case of the organic light emitting diode, the injection concentration of holes may be controlled, such that the stability of an element may be improved and the lifespan thereof may be increased.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

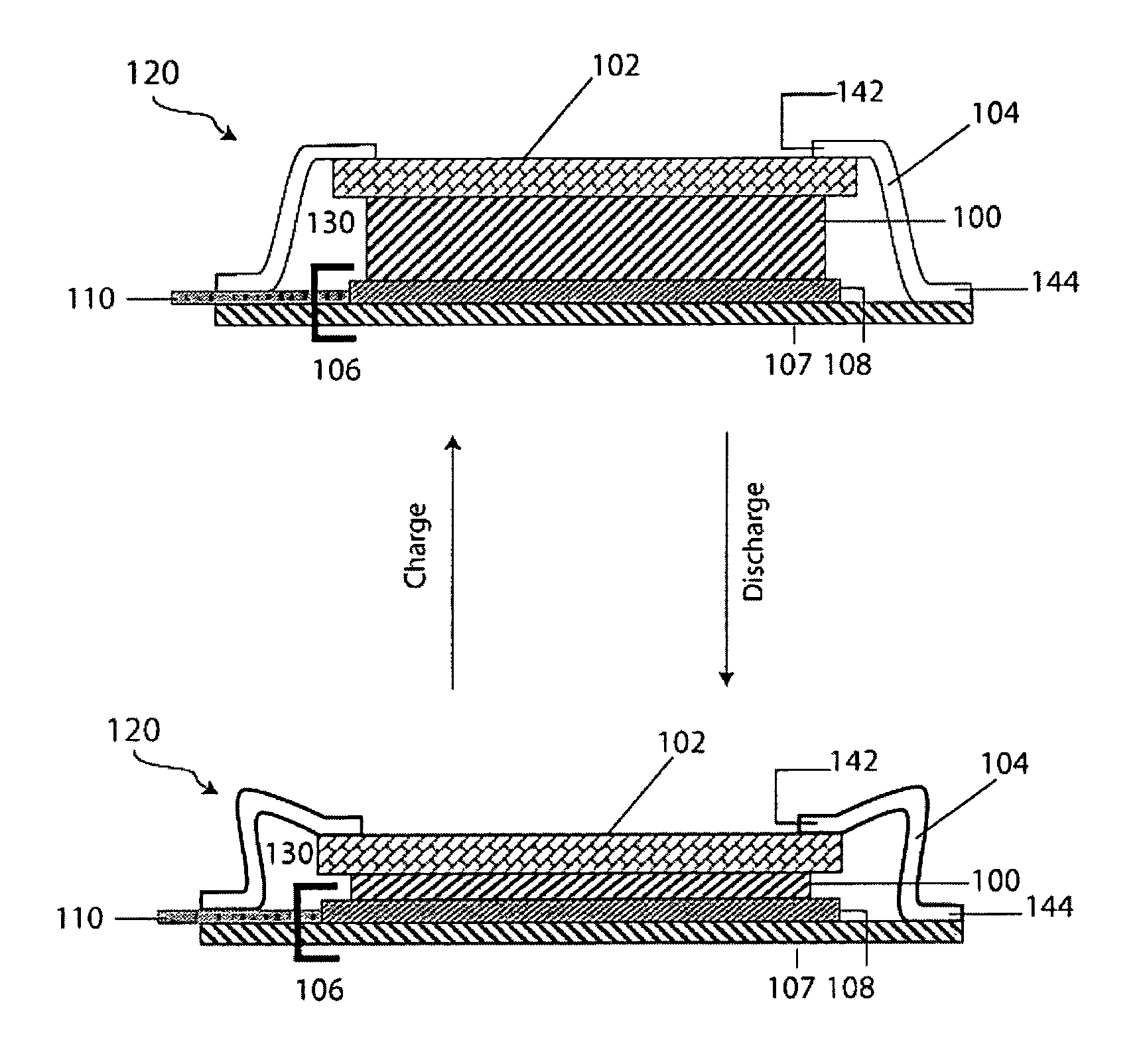

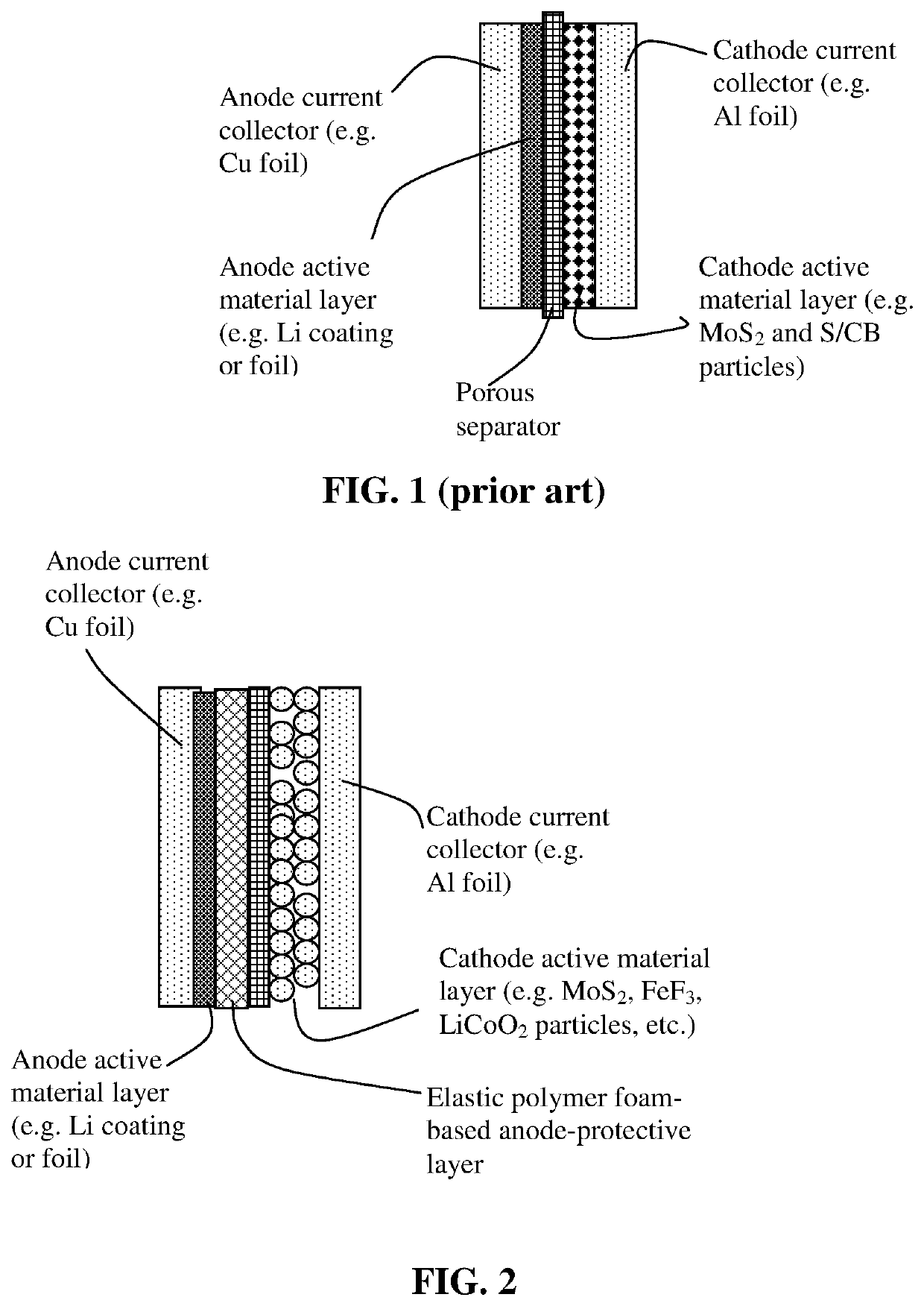

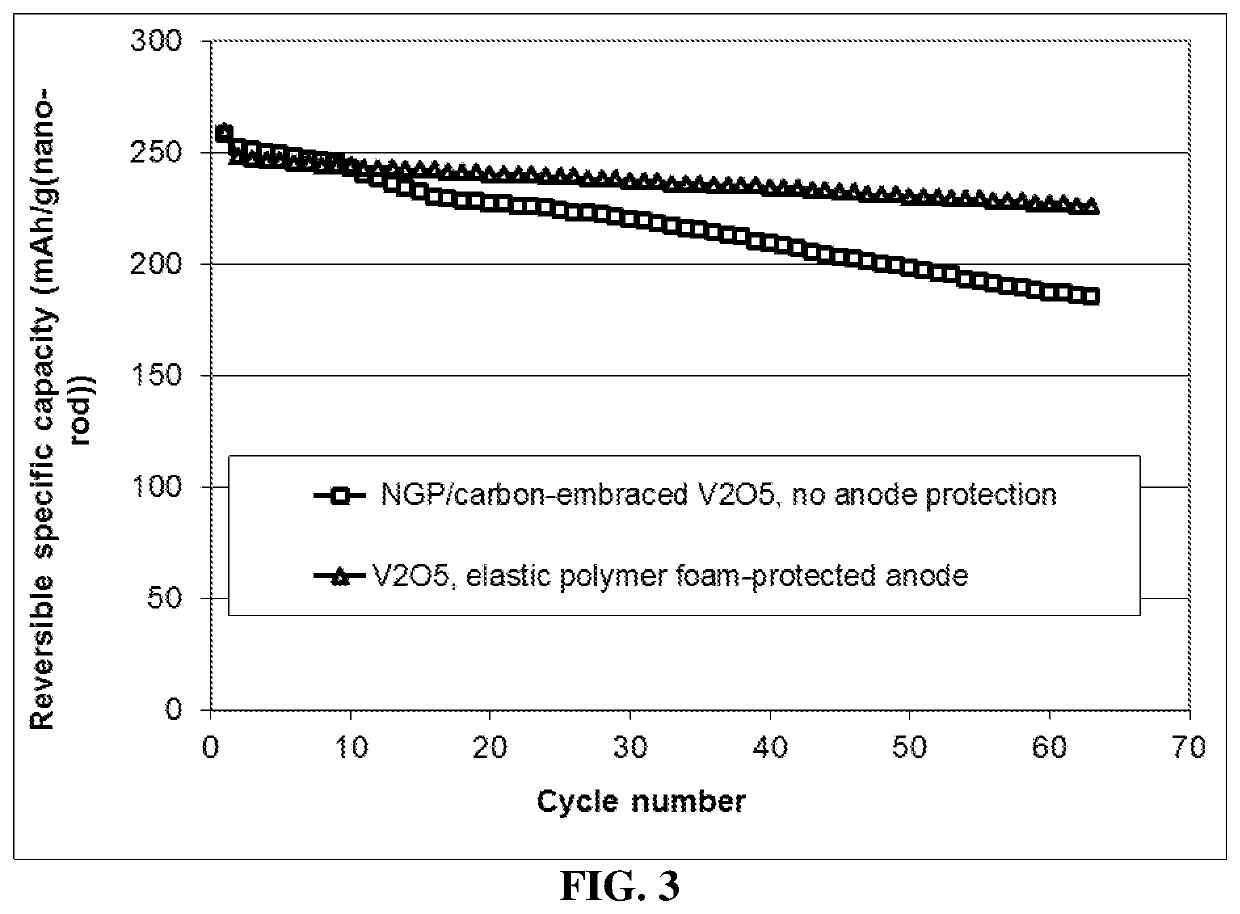

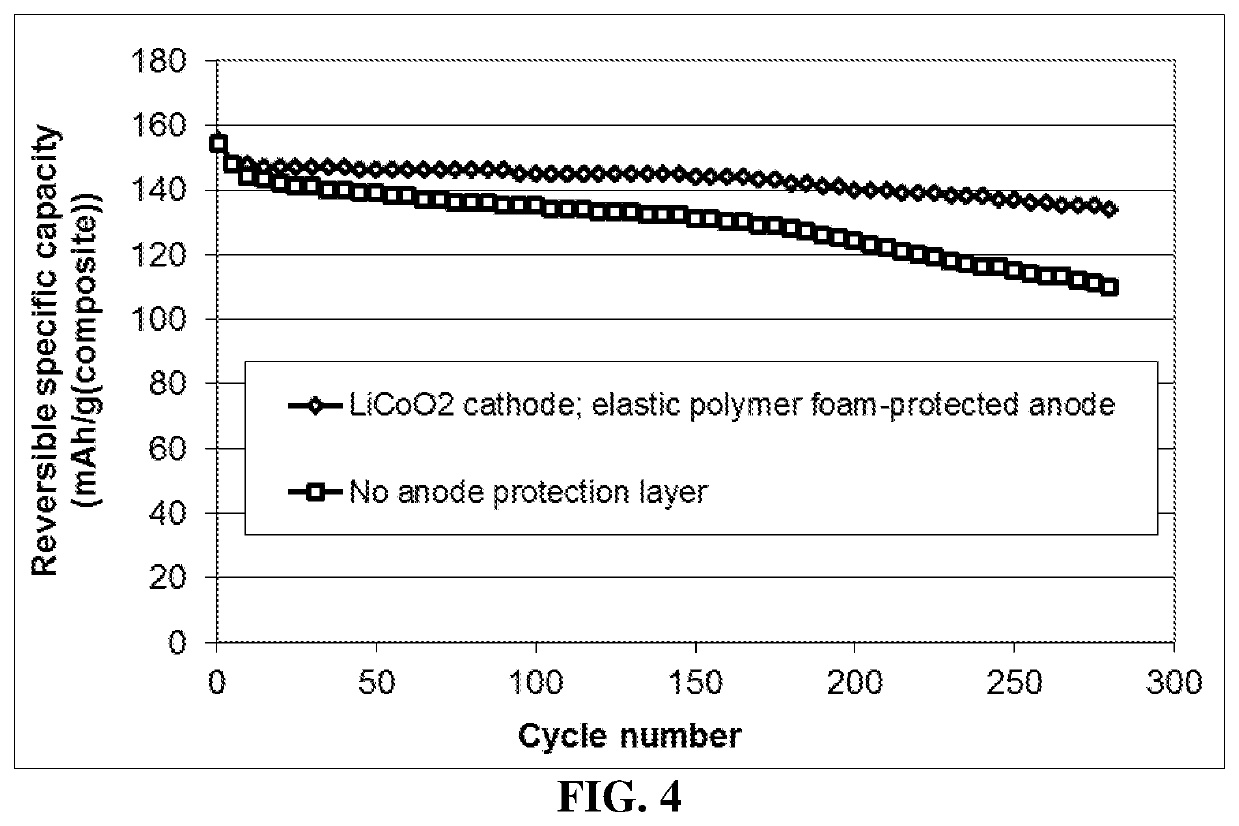

Lithium metal secondary battery containing elastic polymer foam as an anode-protecting layer

ActiveUS20200243854A1Promotes uniform depositionReducing or eliminating the lithium metal dendriteCell seperators/membranes/diaphragms/spacersElectrode carriers/collectorsLithium metalAnodic protection

Provided is a lithium metal secondary battery comprising a cathode, an anode, an electrolyte-separator assembly disposed between the cathode and the anode, wherein the anode comprises: (a) an anode active material layer containing a layer of lithium or lithium alloy optionally supported by an anode current collector; and (b) an anode-protecting layer in physical contact with the anode active material layer and in ionic contact with the electrolyte-separator assembly, having a thickness from 10 nm to 500 μm and comprising an elastic polymer foam having a fully recoverable elastic compressive strain from 2% to 500% and pores having a pore volume fraction from 5% to 95% (most preferably 50-95%); wherein preferably the pores are interconnected.

Owner:GLOBAL GRAPHENE GRP INC

Method of extending cycle-life of a lithium metal secondary battery

PendingUS20190393496A1Reduce eliminatePromotes uniform depositionNegative electrodesPositive electrodesTensile strainLithium metal

The invention provides a method of improving the cycle-life of a lithium metal secondary battery. The method comprises implementing an anode-protecting layer between an anode active material layer and a porous separator / electrolyte, wherein the anode-protecting layer or cathode-protecting layer comprises a conductive sulfonated elastomer composite having from 0.01% to 40% by weight of a conductive reinforcement material and from 0.01% to 40% by weight of an electrochemically stable inorganic filler dispersed in a sulfonated elastomeric matrix material and the protecting layer has a thickness from 1 nm to 100 μm, a fully recoverable tensile strain from 2% to 500%, a lithium ion conductivity from 10−7 S / cm to 5×10−2 S / cm, and an electrical conductivity from 10−7 S / cm to 100 S / cm when measured at room temperature.

Owner:GLOBAL GRAPHENE GRP INC

Anode protective layer compositions for lithium metal batteries

ActiveUS9722275B2Safe and long and stable cycle lifeLi-accumulatorsCell component detailsLithium metalElectric vehicle

Owner:GLOBAL GRAPHENE GRP INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com