Preparation method of epoxy mortar for filling ocean oil and gas pipeline

A technology for oil and gas pipelines and epoxy mortar, which is applied in the field of epoxy mortar for filling offshore oil and gas pipelines and its preparation, can solve the problem of difficult pipeline joints and timely bonding of pipeline anode filling, low bonding strength and compressive impact strength, The mortar mixture is easy to be corroded and other problems, so as to achieve the effect of fast curing speed, reduced fluidity and strong cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

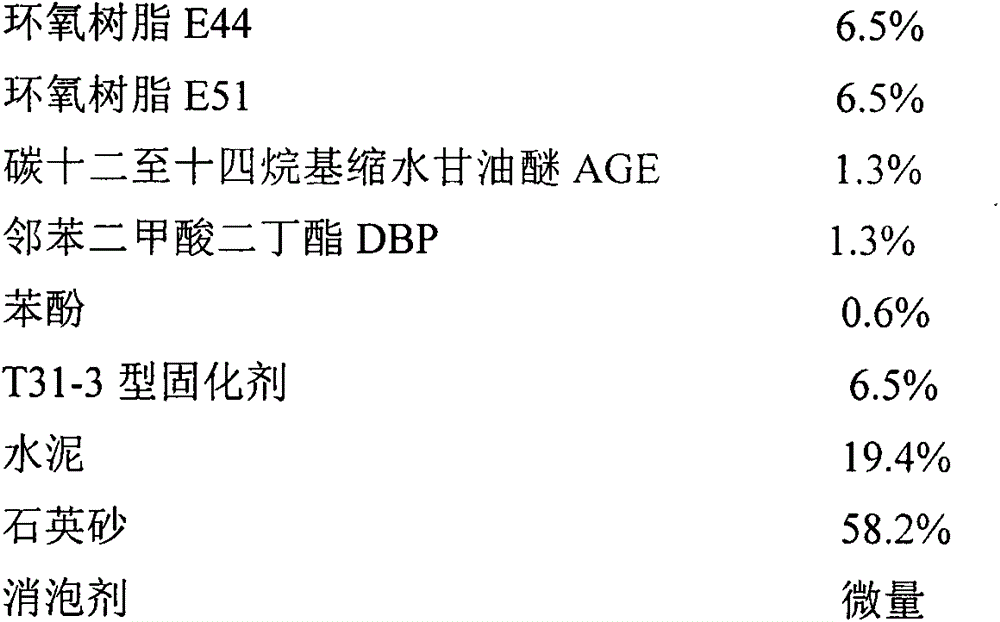

[0017] Example 1: prepare the following substances according to mass percentage:

[0018]

[0019] Mix 6.5% E44, 6.5% E51, 1.3% AGE, 1.3% DBP and 0.6% phenol, stir until homogeneous, heat in a water bath to promote uniform stirring according to temperature conditions, then add a small amount of defoamer and let it stand for 1min to 2min , and then add 6.5% T31-3 type curing agent to it, stir evenly, after a few minutes, pour it into the aggregate and mix for 3min~5min, until it is uniform, the construction operation can be carried out. Aggregate is made of 19.4% cement and 58.2% quartz sand, of which the quartz sand is composed of fine sand with a particle size of 0.3mm to 0.5mm, medium sand with a particle size of 1mm to 2mm and fine sand with a particle size of 2mm to 4mm. Coarse sand is prepared in a ratio of 1:1:1.

[0020] The obtained mortar has the following properties: the initial setting time is 28 minutes, the 1-day compressive strength is 59.6MPa, the 7-day comp...

example 2

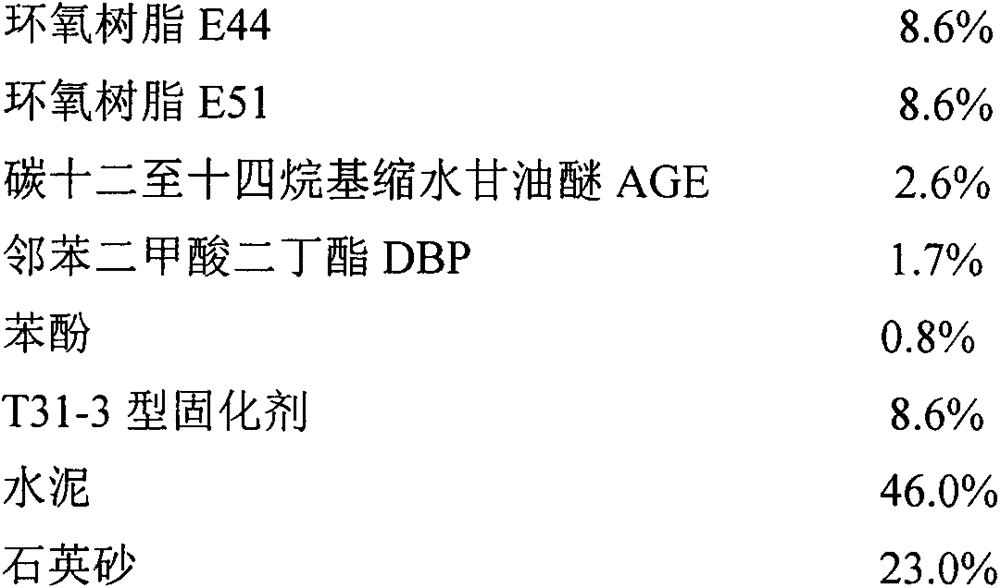

[0021] Example 2: prepare the following substances according to mass percentage:

[0022]

[0023] Mix 8.6% E44, 8.6% E51, 2.6% AGE, 1.7% DBP and 0.8% phenol, heat in a water bath to about 40°C, stir with a mixer until homogeneous, then add a small amount of defoamer and let it stand for 1min to 2min, then Add 8.6% T31-3 curing agent into it, stir evenly, then pour 46% cement and 23% quartz sand mixture into it, and stir for 3-5 minutes to obtain the epoxy mortar of the present invention. Among them, the quartz sand is prepared by fine sand with a particle size of 0.3 mm to 0.5 mm and coarse sand with a particle size of 1 mm to 2 mm in a ratio of 1:1.

[0024] The obtained mortar has the following properties: the initial setting time is 30min, the 1-day strength is 55.1MPa, the 7-day strength is 62.4MPa, the 28-day compressive strength is 72.8MPa, the 28-day flexural strength is 12.9MPa, and the viscoelasticity after 28 days of molding The junction strength is 6.3MPa, the ...

example 3

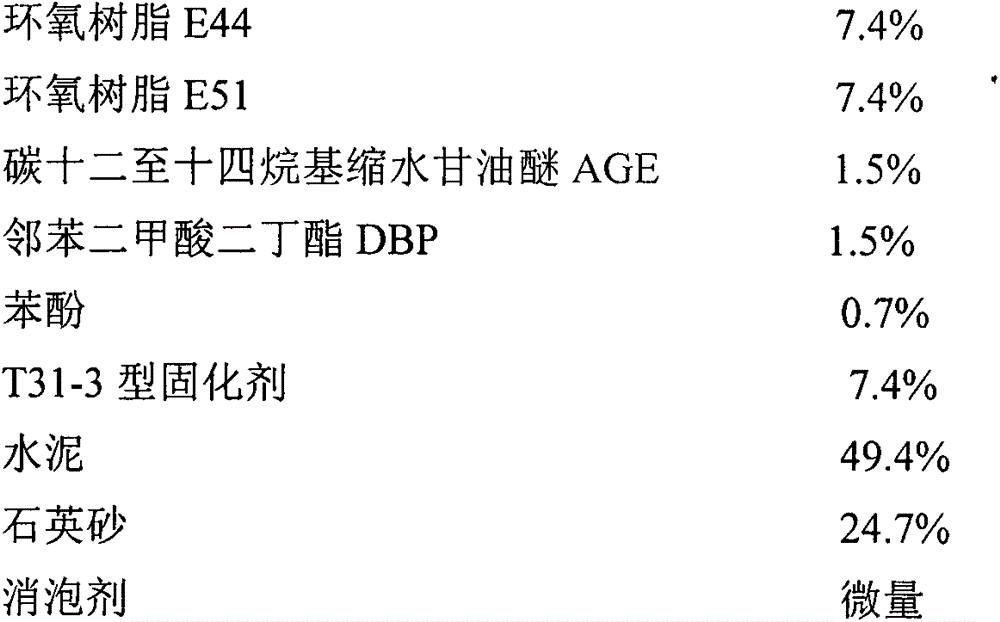

[0025] Example 3: prepare the following substances according to mass percentage:

[0026]

[0027] Mix 7.4% E44, 7.4% E51, 1.5% AGE, 1.5% DBP and 0.7% phenol, stir until homogeneous, heat in a water bath according to temperature conditions to promote uniform stirring, then add a small amount of defoamer and let it stand for 1min to 2min , and then add 7.4% T31-3 type curing agent to it, stir evenly, after a few minutes, pour it into the aggregate and mix for 3min~5min, until it is uniform, the construction operation can be carried out. Aggregate is made by mixing 49.4% cement and 24.7% quartz sand, wherein the quartz sand is prepared in a ratio of 1:1 from fine sand with a particle size of 0.3 mm to 0.5 mm and coarse sand with a particle size of 1 mm to 2 mm.

[0028]The obtained mortar has the following properties: the initial setting time is 25min, the compressive strength is 56.3MPa in 1 day, the compressive strength in 7 days is 61.2MPa, the compressive strength in 28 d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com