Patents

Literature

122results about How to "Strong resistance to seawater corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Seawate-corrosive-resisting steel and its production

Seawater-corrosion-resisting steel consists of C 0.04-0.10wt%, Si 0.40-0.50wt%, Mn 0.75-1.30wt%, Nb<=0.020wt%, Ti<=0.025wt%, Al 0.015-0.040wt%, Cu 0.20-0.50wt%, Cr<=0.95wt%, Mo<=0.25wt%, Ca 0.0015-0.0040wt%, P<=0.020wt%, S<=0.005wt%, O<=0.0040wt%, N<=0.0060wt%, H<=0.00025wt%, F and impurities residues. It has excellent mechanical and welding performances and corrosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

Sea water corrosion resistant steel for ocean drilling/production platform and preparation method thereof

InactiveCN1908217AReduce unevennessAvoid corrosionRoll mill control devicesWelding/cutting media/materialsChemical compositionImpurity

the invention discloses a marine exploiting platform steel of erosion property of sea water resistance, which comprises the following parts: 0.03-0.09% C, 0.90-1.60% Mn, 0.10-0.50% Si, 0.006-0.020% P, 0.004-0.100% Cr, 0.02-0.40% Cu, 0.010-0.060% Als, 0.005-0.060% Nb, 0.005-0.030% Ti, Fe and impurity. the manufacturing method comprises the following steps: desulfurizing; blowing; disposing through vacuum; casting continually; rolling.

Owner:武钢集团有限公司

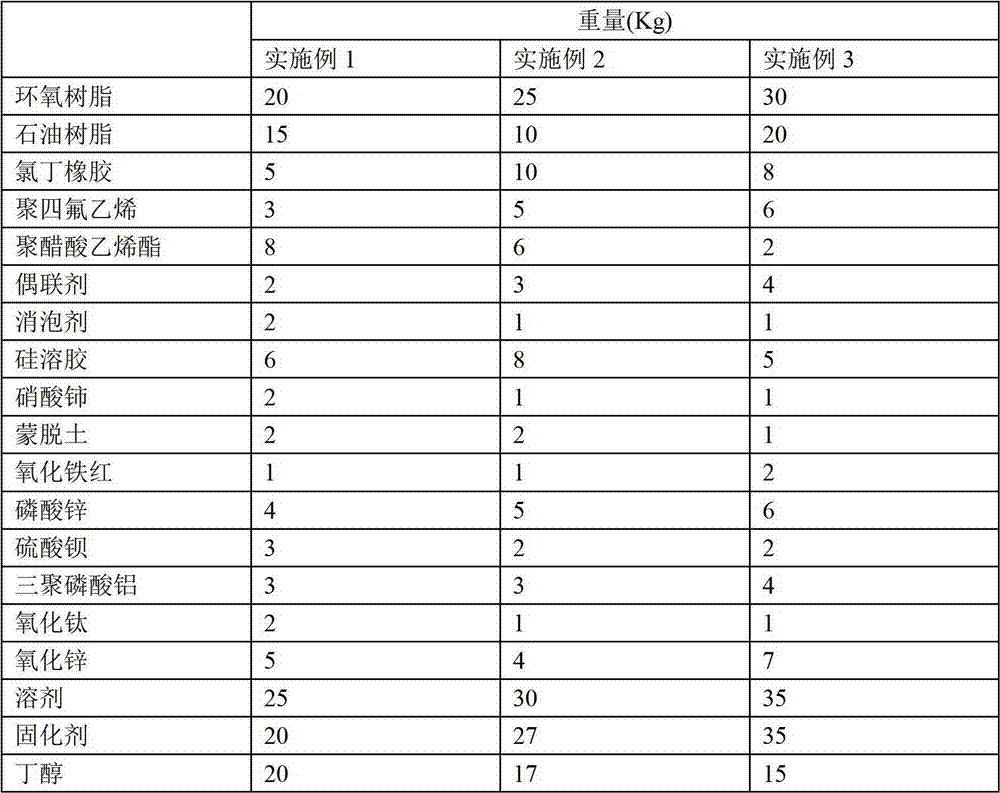

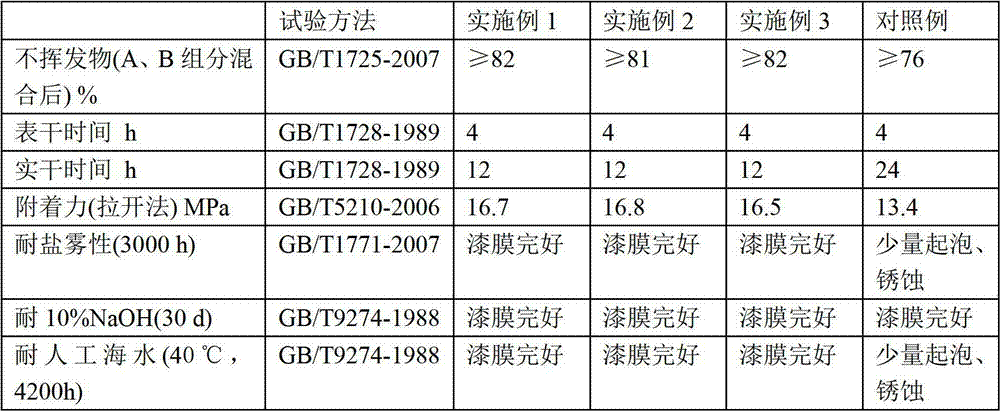

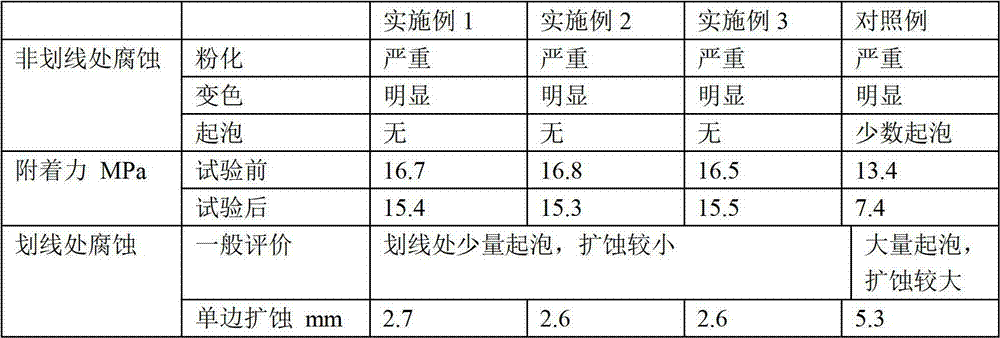

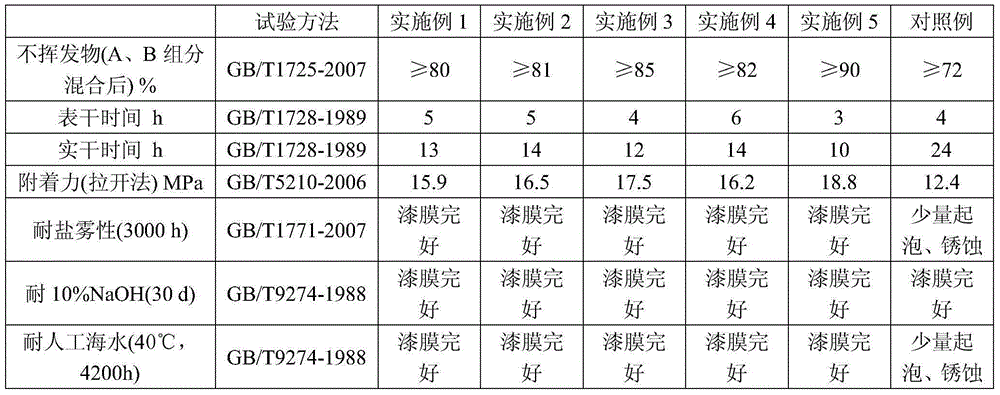

Seawater corrosion-resistant paint

InactiveCN102876192AStrong resistance to seawater corrosionChloropene polymer coatingsAnti-corrosive paintsEpoxyCerium nitrate

The invention provides seawater corrosion-resistant paint which comprises component A and component B. The component A comprises the following materials by weight: 20-30 parts of epoxy resin, 10-20 parts of petroleum resin, 5-10 parts of chloroprene rubber, 3-6 parts of polytetrafluoroethylene, 2-8 parts of polyvinyl acetate, 2-4 parts of a coupling agent, 1-2 parts of a defoaming agent, 5-8 parts of silica sol, 1-2 parts of cerium nitrate, 1-2 parts of montmorillonite, 1-2 parts of iron red, 4-6 parts of zinc phosphate, 2-3 parts of barium sulfate, 3-4 parts of aluminum tripolyphosphate, 1-2 parts of titanium oxide, 4-7 parts of zinc oxide, 25-35 parts of and solvent. The component B comprises the following materials by weight: 20-35 parts of a curing agent, and 15-20 parts of butanol. The inventive paint has excellent seawater corrosion resistance, salt fog resistance above 2,000 hr, 10% NaOH solution resistance above 30 days, and artificial seawater resistance above 4,200 hr.

Owner:WUJIANG HUACHENG COMPOSITE MATERIAL SCI & TECH

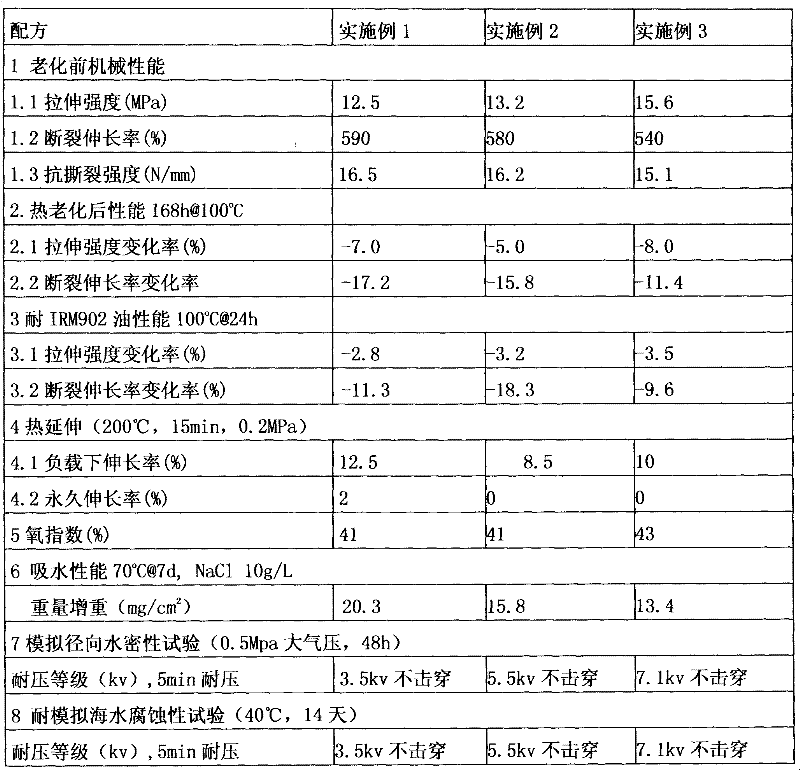

Waterproof and corrosion-resistant sheath material of degaussing cable and production method thereof

InactiveCN102417639AImprove water absorptionImprove mechanical propertiesRubber insulatorsInsulated cablesVulcanizationProcedure Agents

The invention discloses a waterproof and corrosion-resistant sheath material of a degaussing cable, which comprises the following components in part by weight: 100 parts of chloroprene rubber, 5-20 parts of vulcanizing agent, 0.5-5 parts of vulcanization accelerator, 0.5-5 parts of vulcanizing agent, 50-120 parts of filling agent, 15-40 parts of reinforcing agent, 1-5 parts of antiager, 5-15 parts of plasticizer, 5-20 parts of fire retardant, 1-5 parts of coupling agent and 2-6 parts of processing agent. The invention further discloses a production method of the waterproof and corrosion-resistant sheath material of the degaussing cable. Ships which use the sheath material of the invention have good water adsorption resistance, excellent mechanical property, flame resistance, weather resistance, seawater corrosiveness and the like when the ships are in the wet sea surface open-air environments or partially go deeply into the seawater, the performance requirement of the sheath material of the degaussing cable for the ship with the rated voltage of 0.6 / 1kv is satisfied, so the insulating layer of the cable is well protected, and the application of the degaussing cable on the ship is effectively ensured.

Owner:ZHONGTIAN TECH IND WIRE&CABLE SYST CO LTD

Self-compacting powder concrete for ocean engineering as well as preparation method and application

ActiveCN104876500AExtensive self-compactingImprove self-compactingSolid waste managementCalcium hydroxideUltimate tensile strength

The invention discloses self-compacting powder concrete for ocean engineering as well as preparation method and an application. According to the concrete, coal ash and limestone flour are simultaneously added, the precipitation amount of calcium hydroxide is reduced, and the problem in the prior art that the concrete is poor in corrosion resistance can be solved; moreover, the concrete is doped with nano-scale calcium carbonate and silica fume, so that the self-compacting property of the concrete structure is improved. The comprehensive cost of the concrete is low, the material source is wide, and a great amount of industrial wastes can be doped; the seawater corrosion resistance is good, the self-compacting property is good, the expandability is high, hydration heat is low, the adjusting range of the working expandability is large, the early strength is high, the strength of the concrete is greater than 50Mpa at the first day and greater than 130Mpa at the 28th day, and the self-compacting powder concrete is suitable for different types of ocean engineering.

Owner:黄贺明

Super-high-strength martensite aging stainless steel resistant to seawater corrosion

ActiveCN107653421AGuaranteed toughnessGuaranteed corrosion resistanceChemical compositionHigh intensity

The invention belongs to the field of high-strength stainless steel and provides martensite aging stainless steel which is high in toughness and good in corrosion resistance. The strength of the martensite aging stainless steel reaches 2000 MPa or above. The specific chemical constituents of the martensite aging stainless steel comprise, by weight percentage, less than or equal to 0.03% of C, 13.0-14.0% of Cr, 5.5-7.0% of Ni, 5.5-7.5% of Co, 3.0-5.0% of Mo, 1.9-2.5% of Ti, less than or equal to 0.1% of Si, less than or equal to 0.1% of Mn, less than or equal to 0.01% of P, less than or equal to 0.01% of S and the balance Fe. The stainless steel has the excellent seawater corrosion resistance; the pitting potential Epit is greater than or equal to 0.15 V, and high tough fit is achieved; sigma b is greater than or equal to 2000 MPa, sigma 0.2 is greater than or equal to 1700 MPa, delta is greater than or equal to 8%, and psi is greater than or equal to 40%; the martensite aging stainlesssteel is applicable to manufacturing of high-strength and high-toughness structural components used in a chloridion-containing rigorous corrosion environment such as seawater; the content of preciousmetal Co in the steel is low; material production cost is effectively lowered; and wide application prospect is achieved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

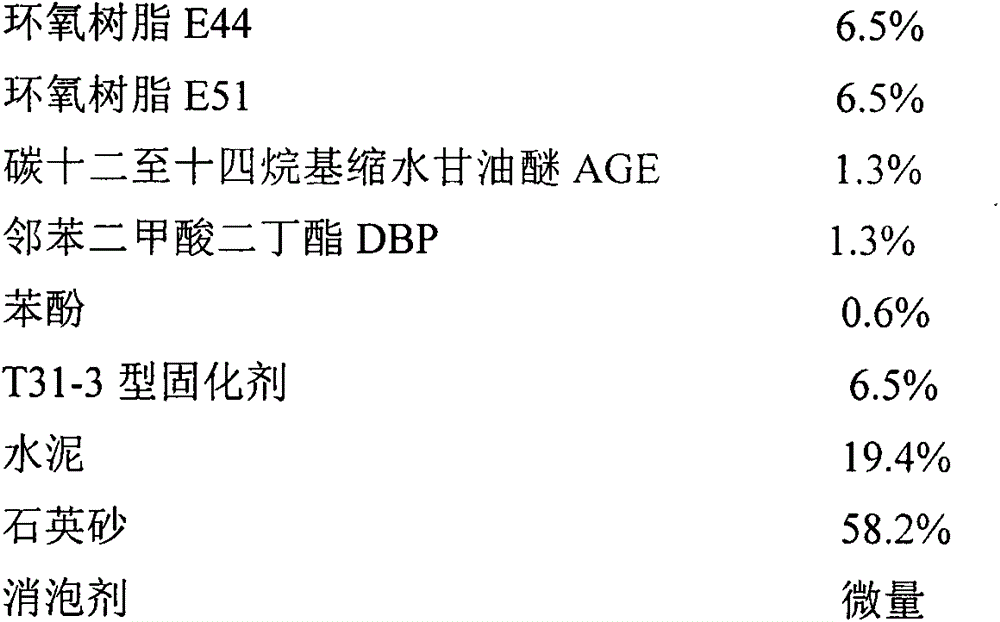

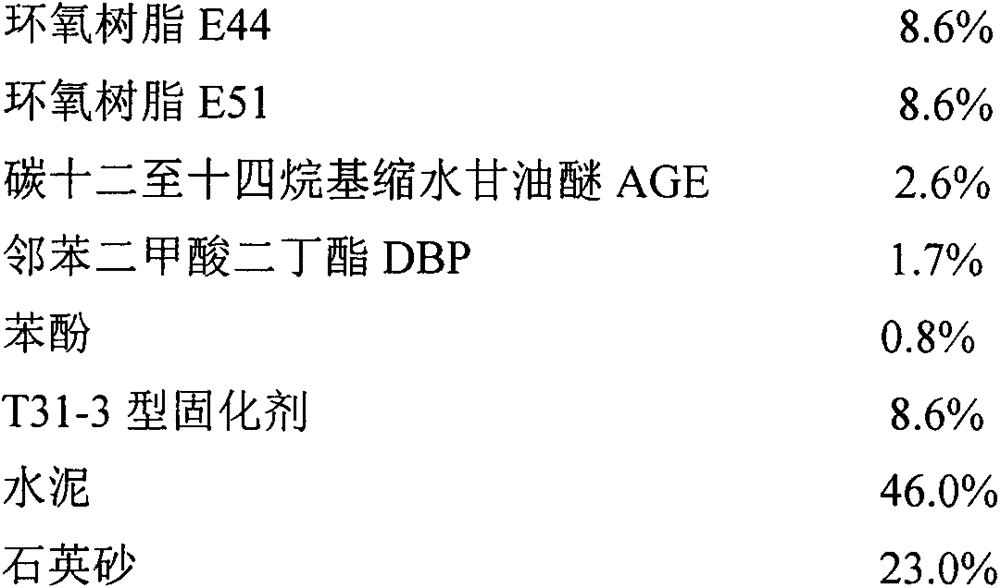

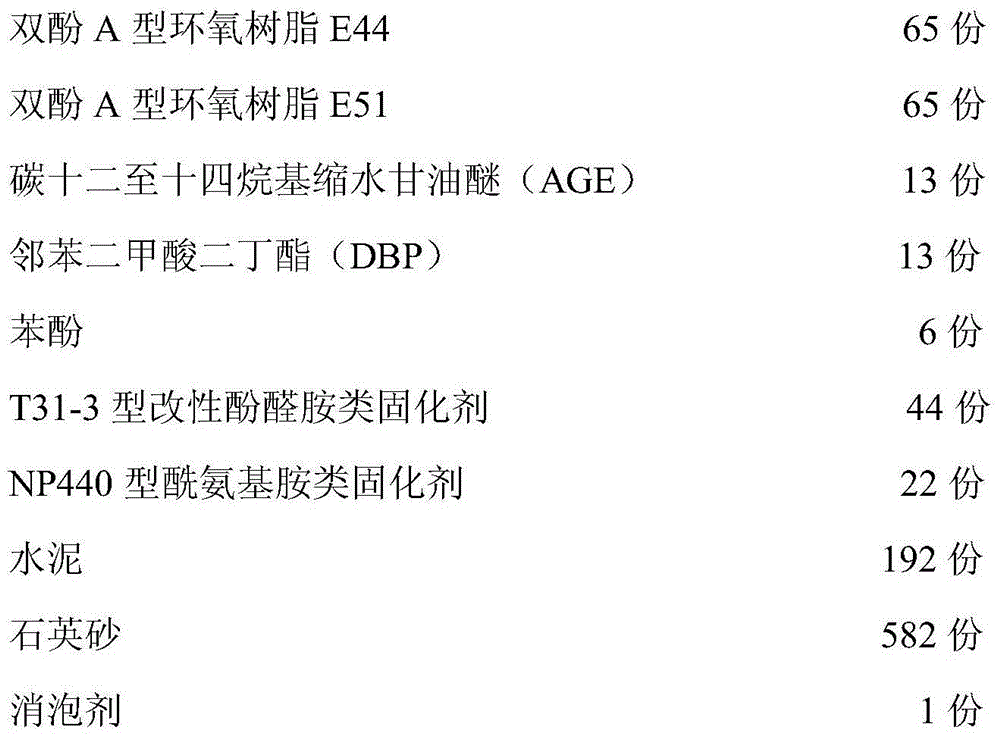

Preparation method of epoxy mortar for filling ocean oil and gas pipeline

InactiveCN103819144ASimple preparation processMeet the replacement requirementsShock resistanceSeawater

The invention belongs to the technical field of application of polymer mortar and particularly relates to a preparation method of epoxy mortar for filling an ocean oil and gas pipeline. The epoxymortar consists of a component A, a component B and a component C, wherein the component A is prepared by defoaming after blending epoxy resin, a reactive diluent, a plasticizer, an accelerator and pigments according to the proper proportion and; the component B is a special underwater T31-3 type curing agent; the component C is aggregate formed by mixing cement with quartz sand according to a certain proportion. When the epoxymortar is used for construction, the component A is heated to 30-50DEG C and stirred to homogeneousphase, and then the component A and the component B are mixed according to certain proportion and uniformly stirred; the component C is subsequently added into the mixture for uniformly blending to obtain an epoxymortar mixture for filling the ocean oil and gas pipeline. The mortar mixture is simple in preparation process; the prepared mixture has the advantages of high curing speed and strong cohesiveness as well as excellent compress and shock resistance and seawater corrosion resistance. The mortar mixture can be used for filling and strengthening an anode protection anticorrosive structure of the ocean oil and gas pipelines.

Owner:TIANJIN UNIV OF SCI & TECH +1

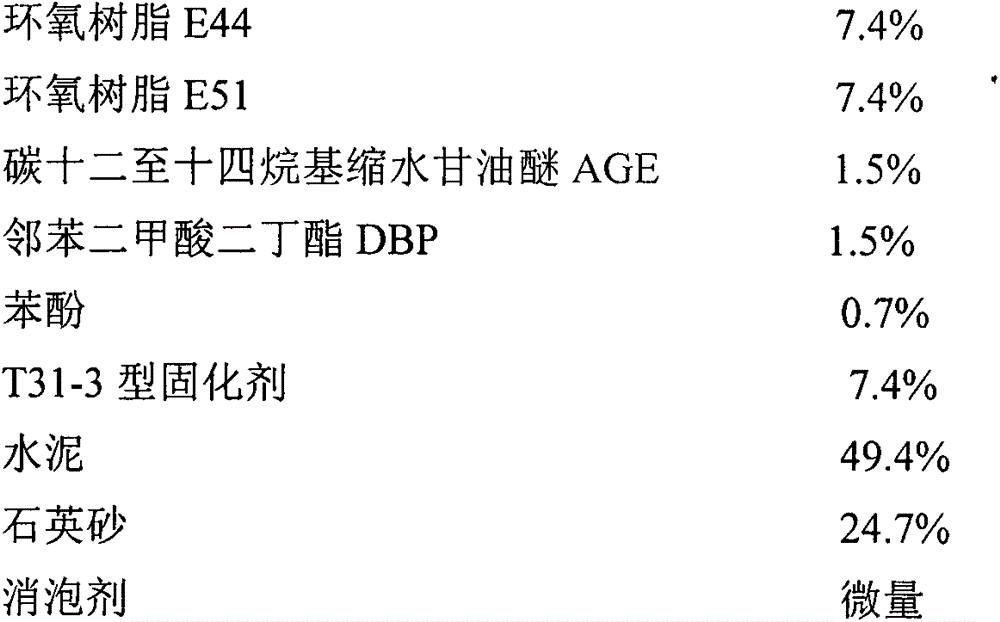

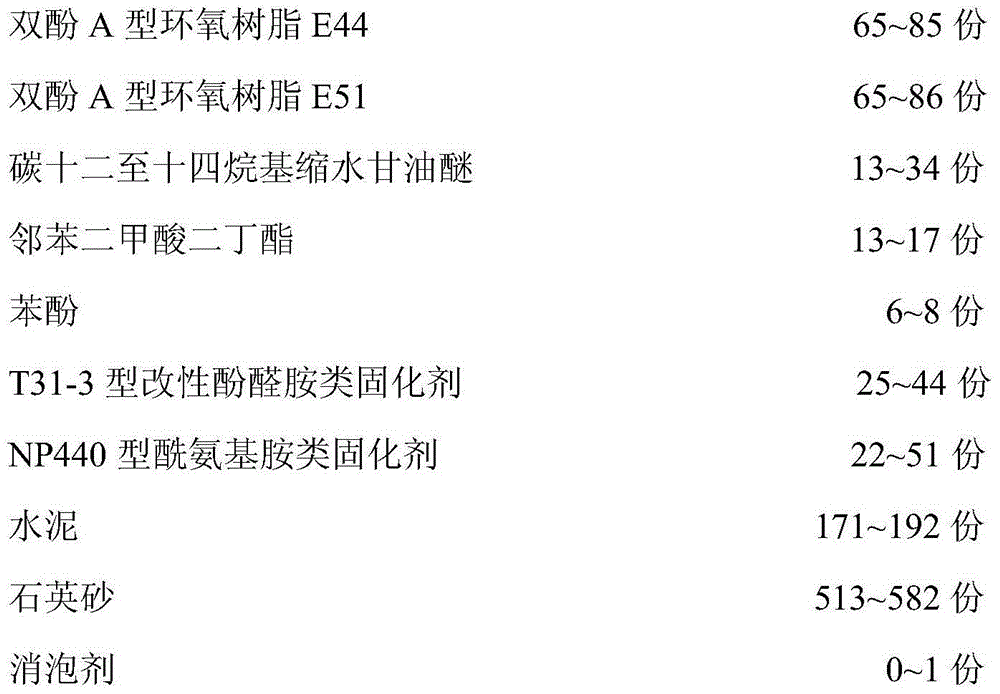

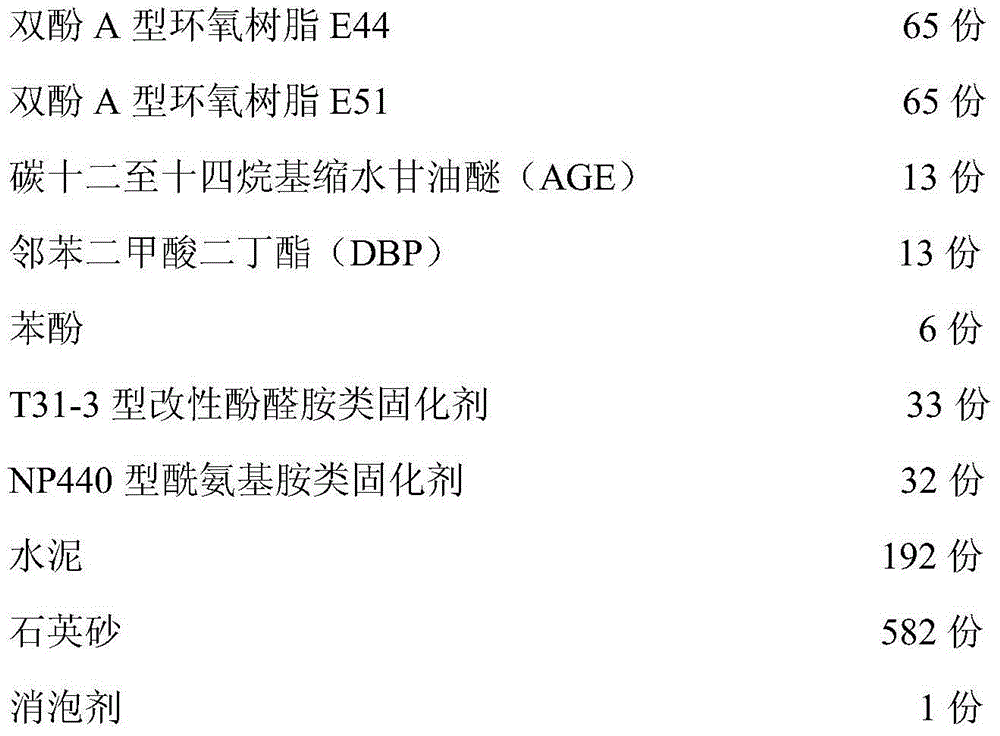

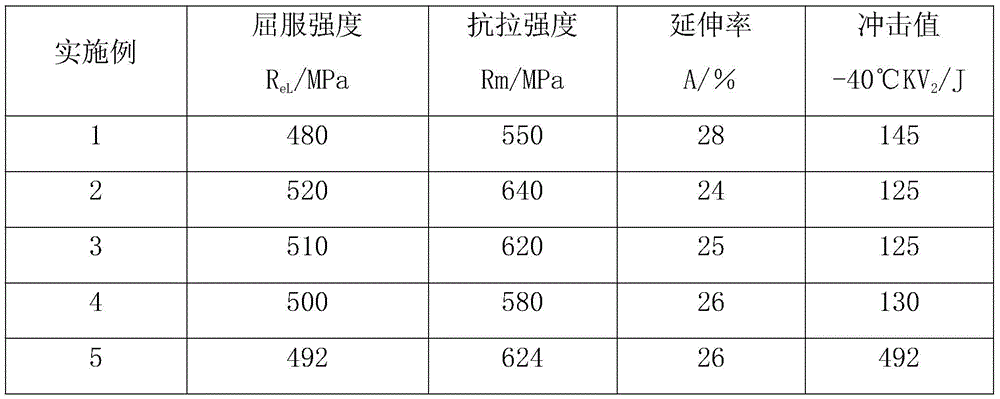

Epoxy mortar used for repairing sea oil gas pipeline and preparation method thereof

The invention discloses an epoxy mortar used for repairing sea oil gas pipeline and a preparation method thereof, which belongs to the technical field of polymer mortar application. The epoxy mortar is composed of a component A, a component B and a component C, the component A is prepared by bisphenol A epoxy resin E44, E51 and a certain amount of auxiliary agent, the component B is prepared by mixing a T31-3 type modified phenolic amine curing agent and a NP440 amidoamines curing agent according to a certain proportion, and the component C is an aggregate by mixing cement and quartz sand according to a certain proportion. The preparation method comprises the following steps: heating the component A to the temperature of 30-50 DEG C, stirring to homogeneous phase, then mixing the component A and the component B according to a certain proportion, uniformly mixing, adding the component C according to a certain proportion, and uniformly blending to obtain the epoxy mortar. The preparation method has simple technology, the epoxy mortar has strong cohesiveness, the epoxy mortar through solidification has excellent anti-compression, anti-punching and anti-seawater corrosion performances, and the epoxy mortar can be used for repairing and reinforcing a concrete coating on the sea oil gas pipeline and a thin layer of an underwater concrete structure.

Owner:TIANJIN UNIV OF SCI & TECH +1

Gas protection welding wire for ocean engineering

InactiveCN105458550AStrong resistance to seawater corrosionImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaSheet steelCrack tip opening displacement

The invention particularly provides a gas protection welding wire for ocean engineering. The gas protection welding wire for ocean engineering is composed of, by mass, 0.09-0.13% of C, 0.8-1.4% of Mn, 0.35-1.20% of Si, 0.08-0.20% of Cr, 0.6-1.3% of Ni, 0.1-0.4% of Mo, 0.01-0.03% of V, 0.20-0.25% of Cu, 0.015% or less of S, 0.025% or less of P, 0.06-0.20% of Ti, 0.002-0.008% of B, and the balance Fe. The composition matching of the welding wire and a welded steel board and influence of protective gas on alloy element burning loss and transition are comprehensively considered, on the basis of an Ni-Cu anti-corrosion alloy system, the compositions and content are controlled and adjusted, and therefore the welding wire has excellent impact toughness, welding performance, corrosion resistance, fatigue resistance, crack-tip opening displacement (CTOD) and other special properties, the board thickness center portion of an ultra-thick board has high strength and low-temperature toughness, and the welding wire can be matched with 460-MPa steel for ocean engineering for welding.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

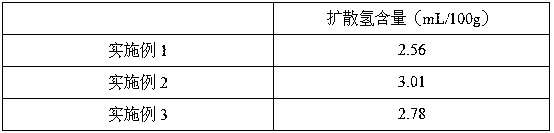

Low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel and preparation method of low-hydrogen high-toughness seamless flux-cored wire

ActiveCN109623193AImprove impact toughnessLow melting pointWelding/cutting media/materialsSoldering mediaSilicon alloyMagnetite

The invention discloses a low-hydrogen high-toughness seamless flux-cored wire for low-temperature steel. The seamless flux-cored wire is composed of low-carbon steel strip skin and flux core powder and used for welding of the low-temperature steel adopted in a LPG ship and a liquefied petroleum storage tank. The low-hydrogen high-toughness seamless flux-cored wire is formed by mixing, by mass percentage, 30-40% of rutile, 0.5-1% of sodium fluoride, 10-16% of manganese-silicon alloy, 1-2% of zircon sand, 5-9% of rare earth silicon iron, 10-12% of nickel powder, 3-5% of magnesium powder, 0.3-0.6% of ferroboron, 1-5% of titanium powder, 2-4% of potassium titanate, 0.5-1% of magnesia, 1-2% of magnetite and 12-14% of iron powder. The seamless flux-cored wire is high in impact toughness at thelow temperature, applicable to all-position welding, good in welding manufacturability and meanwhile good in seawater corrosion resistance and ultralow in diffusible hydrogen; and the low-hydrogen high-toughness seamless flux-cored wire is mainly applied to welding of the low-temperature steel of the LPG ship, the liquefied petroleum storage tank and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

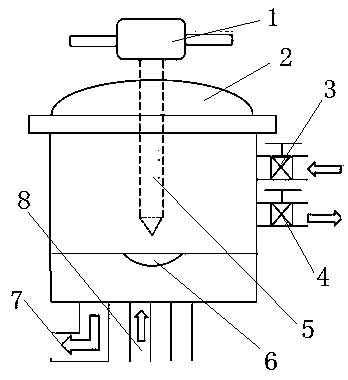

TiCuAlCrMoNb high-entropy alloy and preparing method thereof

The invention provides a TiCuAlCrMoNb high-entropy alloy and a preparing method thereof. The component of the high-entropy alloy is TiaCubAlcCrdMoeNbf, wherein a, b, c, d, e and f separately represent the molar rate of each element, a is larger than or equal to 0.3 and smaller than or equal to 1.5, b is larger than or equal to 0.2 and smaller than or equal to 1.2, c is larger than or equal to 0.2 and smaller than or equal to 1.5, d is larger than or equal to 0.05 and smaller than or equal to 1.2, e is larger than or equal to 0 and smaller than or equal to 1.2, and f is larger than or equal to 0.05 and smaller than or equal to 1.2. Through a non-consumable vacuum electric arc melting technology or electromagnetic levitation melting technology, a high-entropy alloy material which is resistant to seawater corrosion and has a certain anti-fouling function is prepared, the microhardness of the high-entropy alloy material is not lower than 600HV, the defects of traditional high-entropy alloy are compensated, and the application requirements of further ship materials are met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Nylon copper composite material, preparation method and application thereof

InactiveCN106366650ANo pollution in the processSimple ingredientsClimate change adaptationMonocomponent copolyamides artificial filamentCopperSeawater

The invention provides a nylon copper composite material, a preparation method and application thereof. The preparation method of the nylon copper composite material comprises the following steps that 1, nylon powder, a reinforcing agent and copper powder are dried respectively, and the dried nylon powder, the dried reinforcing agent and the dried copper powder are obtained; 2, the dried nylon powder, the dried reinforcing agent, the dried copper powder and a coupling agent are placed into a mixer according to a preset proportion to be mixed and then taken out. The preparation method of the nylon copper composite material is simple, easy to implement and low in preparation cost. The nylon copper composite material is adopted to manufacture a nylon copper composite wire, the nylon copper composite wire is high in tensile strength, the nylon copper composite wire is manufactured into a seawater enclosure culture net cage, and the seawater enclosure culture net cage has the good biology adhesion resistance and also has the good seawater corrosion resistance and long service life.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Aluminum alloy with high seawater corrosion resistance and plate-fin heat exchanger

InactiveCN101191229AExcellent adhesionStrong resistance to seawater corrosionHeat exchange apparatusSuperimposed coating processResin coatingFluorocarbon

An aluminum alloy for use in a plate-fin heat exchanger having a heat transfer portion with seawater as a coolant includes an organic phosphonic acid underlying coating disposed on the surface of the aluminum alloy and a fluorocarbon resin coating disposed on the organic phosphonic acid underlying coating, the fluorocarbon resin coating having an average thickness of 1 to 100 µm after drying. The aluminum alloy has improved durability of coating adhesion and excellent seawater corrosion resistance.

Owner:KOBE STEEL LTD

460 MPa-grade seamless flux-cored wire suitable for full-position welding and manufacturing method

ActiveCN107350659AStable welding arcGood all-position welding processabilityWelding/cutting media/materialsSoldering mediaSilicon alloyFilling rate

The invention relates to a 460 MPa-grade seamless flux-cored wire suitable for full-position welding and a manufacturing method. The flux-cored wire comprises a SPHC steel-tape sheath and filling powder, wherein the filling powder comprises, by weight percentage, 32-42% of rutile, 2-3% of quartz, 1.5-2.5% of sodium fluoride, 2-3% of zircon sand, 3-5% of feldspar, 14-16% of manganese silicon alloy, 3-5% of electrolytic manganese, 3-5% of low-carbon ferromanganese, 2-3% of aluminium magnesium alloy, 0.3-0.5% of ferroboron, 4-6% of nickel powder and the balance iron powder; and the filling rate of the powder is 14-16%. The manufacturing method comprises the steps of carrying out on-line filling and welding, reducing the diameter of the wire to phi 1.2mm-phi 1.6mm by using rollers and a wire drawing die, and carrying out annealing on the wire under the condition that the temperature is 700 DEG C and the time of heat preservation is 3 hours in the diameter reducing process. The 460 MPa-grade seamless flux-cored wire suitable for full-position welding is stable in welding arc under the protection effect of carbon dioxide gas, has good full-position welding manufacturability, and can be used for downhand welding, vertical-up welding, horizontal-position welding and overhead welding; and the formed welding seam is attractive in appearance.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

PE sheath material for submarine cable and preparation method thereof

ActiveCN104829919AGood resistance to seawater corrosionImprove seawater corrosion resistanceMicrobial corrosionElectric cables

The invention provides a PE sheath material for a submarine cable. The PE sheath material comprises, by weight, 100 parts of PE, 8-12 parts of modified hemp fibers, 6-10 parts of modified magnesium oxide, 0.2-0.3 parts of an anti-oxidant, 9-10 parts of EVA, 2-3 parts of carbon black, 3-4 parts of calcium carbonate, 0.1-0.2 parts of a stabilizing agent and 0.1 parts of a coupling agent. The invention also provides a preparation method of the PE sheath material. The PE sheath material for a submarine cable has good sea water corrosion resistance and microbiological corrosion resistance, can effectively reduce corrosion damage and has a long service life.

Owner:青岛宏信塑胶造粒有限公司

High-entropy TiCuAlCrMoNi alloy and preparation method thereof

The invention discloses high-entropy TiCuAlCrMoNi alloy and a preparation method thereof. The high-entropy alloy is composed of TiaCubAlcCrdMoeNif, wherein a, b, c, d, e and f represent molar ratios of corresponding elements, a is greater than or equal to 0.3 but smaller than or equal to 1.5, b is greater than or equal to 0.2 but smaller than or equal to 1.2, c is greater than or equal to 0.2 but smaller than or equal to 1.5, d is greater than or equal to 0.05 but smaller than or equal to 1.2, e is greater than or equal to 0 but smaller than or equal to 1.2 and f is greater than or equal to 0.05 but smaller than or equal to 1.2. The high-entropy alloy with the microhardness not lower than 550 HV, with the seawater corrosion resistance and with the antifouling function can be prepared through the non-consumable vacuum arc smelting technology or the electromagnetic suspension smelting technology, the shortcomings of traditional high-entropy alloy can be overcome, and the application requirements of ship materials in future can be met.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

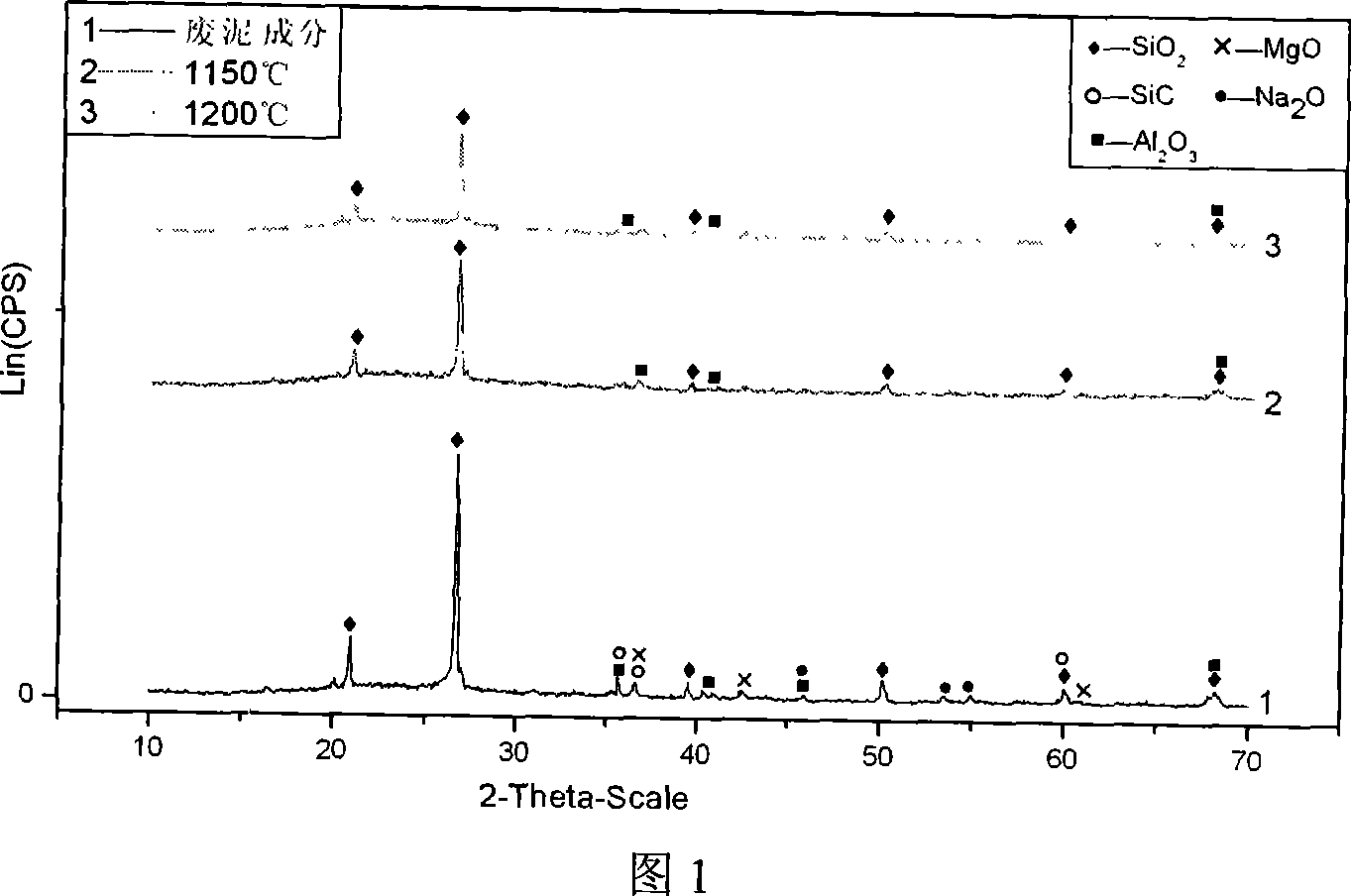

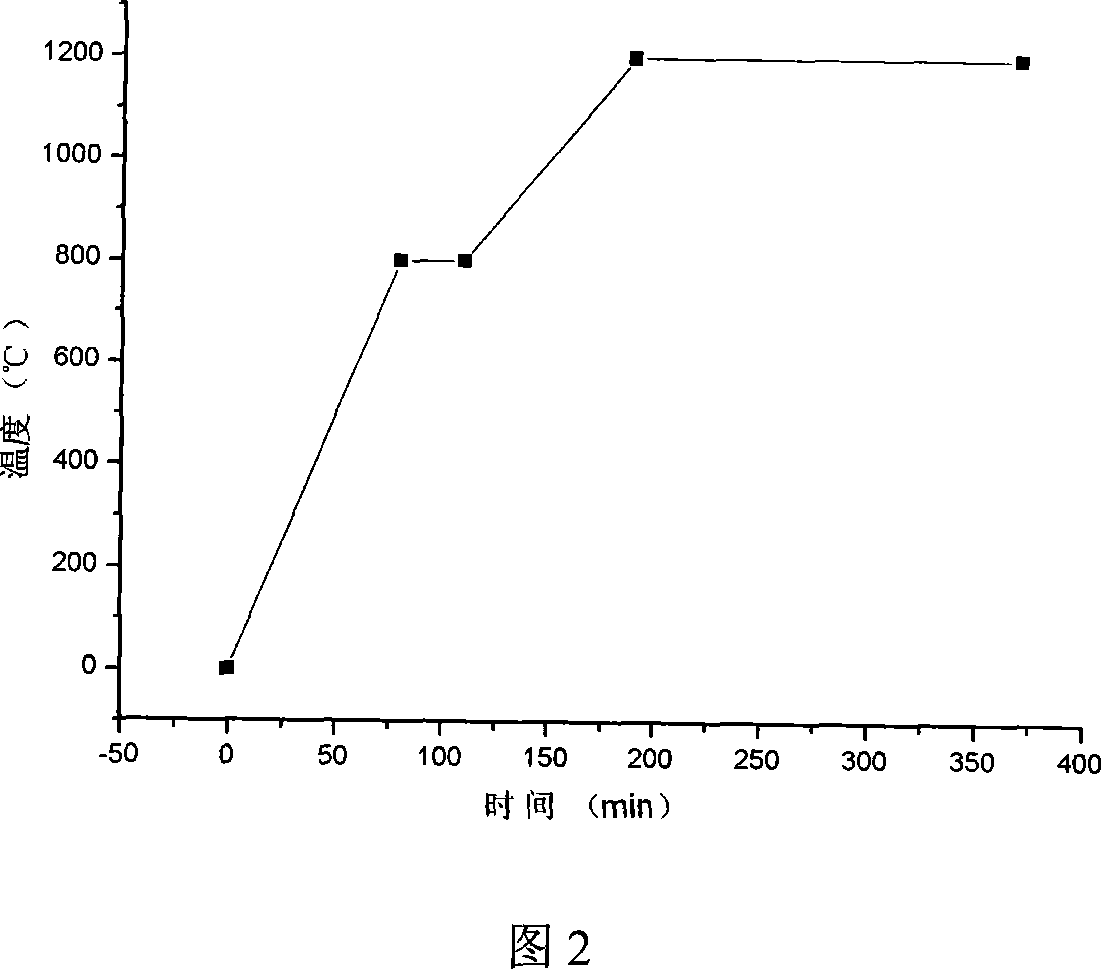

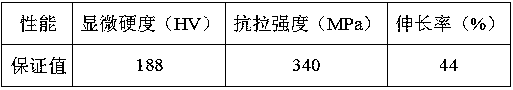

Ceramic-base high-strength lightweight buoyancy material

The present invention discloses a preparation method for new type ceramics-based buoyancy material with light weight and high intensity, wherein the polishing waste sludge from the ceramics factory serves as the main material, the porous ceramic material which has high sealed porosity content and prepared by dry pressing, injection moulding, atmospheric pressure sintering, high temperature chemical blowing process serves as the matrix of the new type ceramics-based buoyancy material, and epoxy resin serves as the fortified outer wall. Compared with the prior art, the buoyancy material of the present invention has excellent endurance and weathering resistance, sea-water corrosion resistance, aging resistance, small specific absorption of volume, high mechanical strength, simple preparation process, low cost and convenience for industrialisation. The internal pore of the porous ceramics has an uniform distribution and the sealed porosity is more than 95% due to the high temperature foaming in situ. The new type buoyancy material has low density and high compression strength. The porous ceramic material prepared by sintering at 1180 DEG C has a density of 0.35g / cm<3> and a compression strength of more than 7 MPa. The buoyancy material which is modified by epoxy resin has a density of 0.52g / cm<3> and a compression strength of more than 20 MPa.

Owner:OCEAN UNIV OF CHINA

High-toughness titanium alkaline type seamless flux-cored wire suitable for full-position welding

ActiveCN108406159ASimple processImprove mechanical propertiesWelding/cutting media/materialsSoldering mediaCrack resistanceSlag

The invention discloses a high-toughness titanium alkaline type seamless flux-cored wire suitable for all-position welding. The flux-cored wire is composed of a low-carbon steel strip at the peripheryand flux core powder inside; and the flux core powder comprises the following components, by weight percentage: 30-40% of rutile, 1-2% of aluminum oxide, 2-4% of dehydrated feldspar, 1-3% of quartz,1-3% of zircon sand, 1-2% of rare earth oxide, 1-2% of silicon powder, 0.2-0.4% of ferroboron, 6-8% of nickel powder, 8-15% of metal manganese, 4-9% of magnesium powder and the balance iron powder andinevitable impurities. According to the flux-cored wire, a titanium alkaline slag system is adopted, the proportion of alloy elements is optimized, the content of mineral powder is adjusted, and under the protection of CO2 gas, horizontal, transverse and vertical position welding can be realized; the mechanical property is stable, the impact power at 40 DEG C below zero reaches 100J, the crack resistance is good, diffusible hydrogen is low, the moisture resistance is strong, the seawater corrosion resistance is good, and the anti-cracking ability is good.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Nylon and copper alloy composite material and preparation method thereof

The invention provides a preparation method for a nylon and copper alloy composite material. The preparation method is characterized by comprising the following steps: 1, drying nylon powder and copper alloy powder in a drying oven to obtain dried nylon powder and dried copper alloy powder; 2, mixing the dried copper alloy powder, the dried nylon powder and a coupling agent in a high-speed mixer to obtain a mixed material, and taking the mixed material out; 3, adding the mixed material into a double-screw extruder, and performing uniform mixing and extrusion to obtain the nylon and copper alloy composite material. The preparation method for the nylon and copper alloy composite material is simple, easy to operate, low in preparation cost and suitable for industrial application. The nylon and copper alloy composite material prepared by the preparation method for the nylon and copper alloy composite material has high microorganism adhesion resistance of copper, high seawater corrosion, strong tensile strength and long service life.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

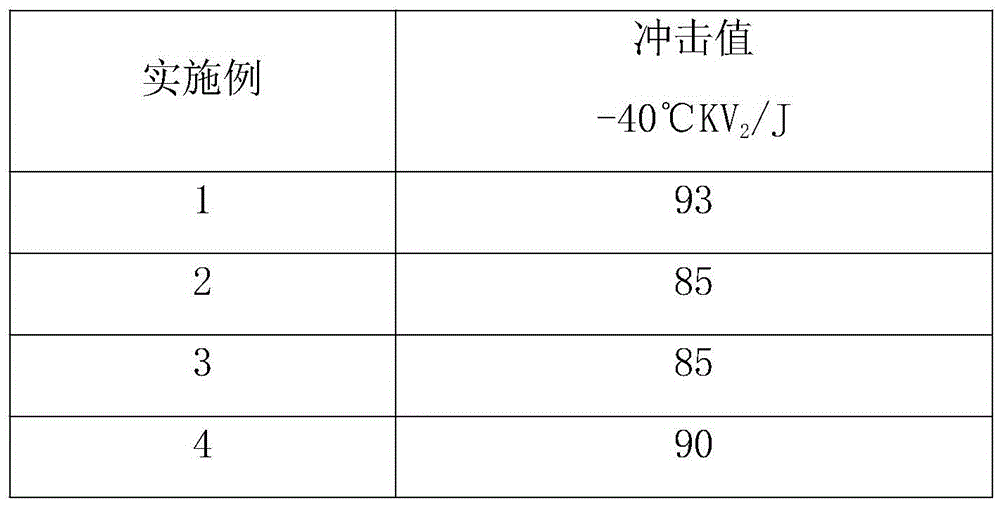

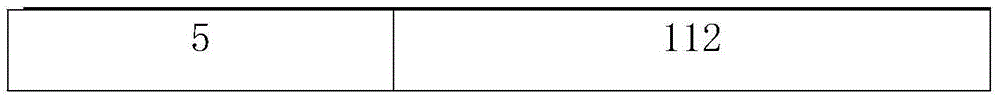

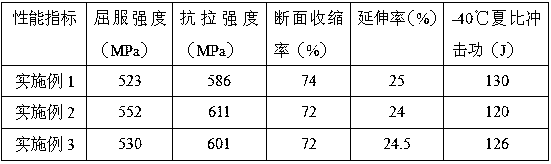

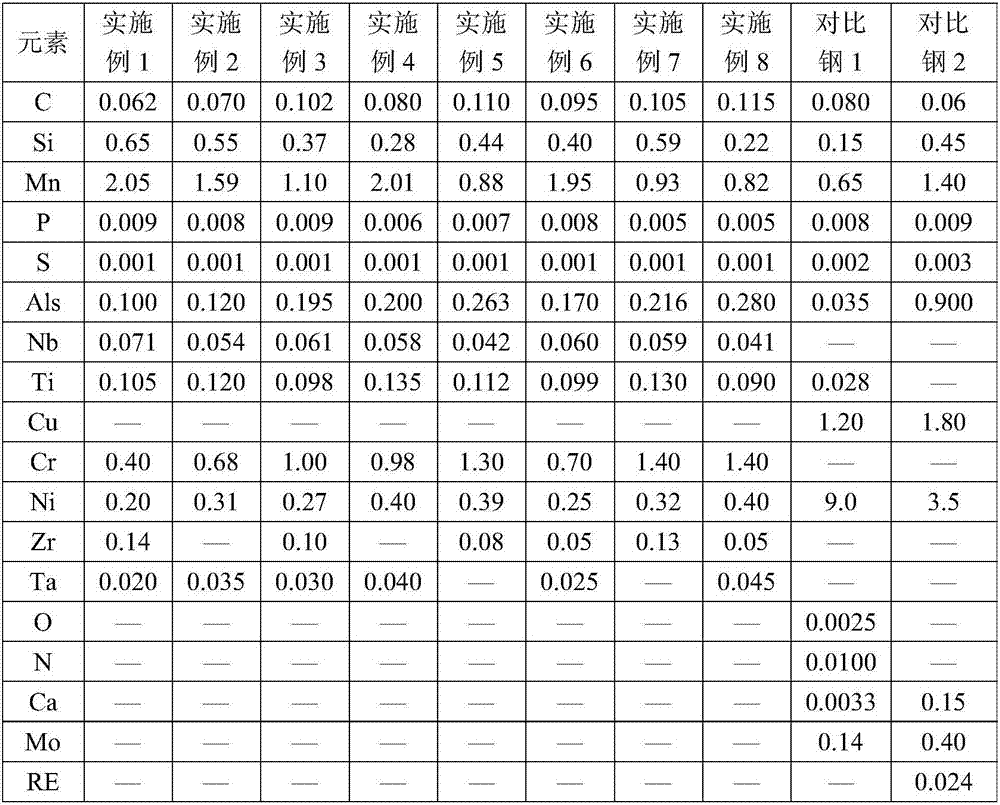

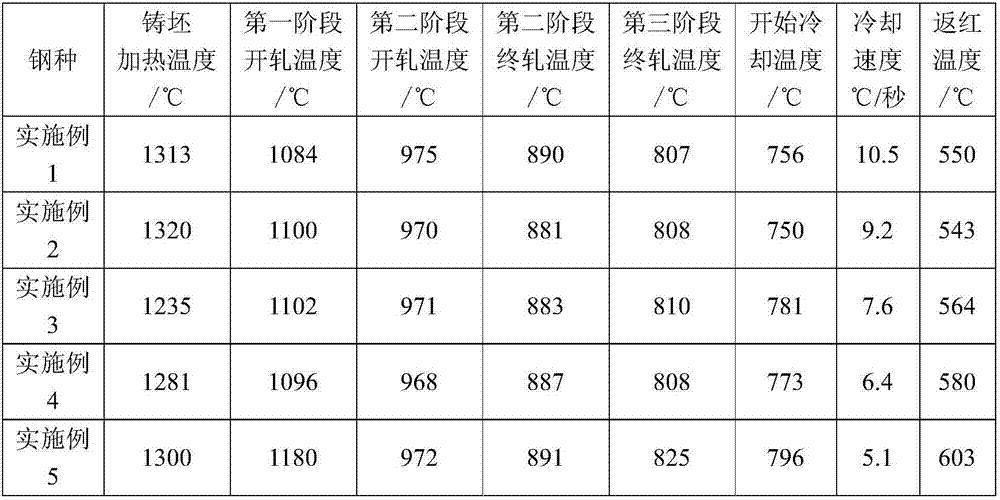

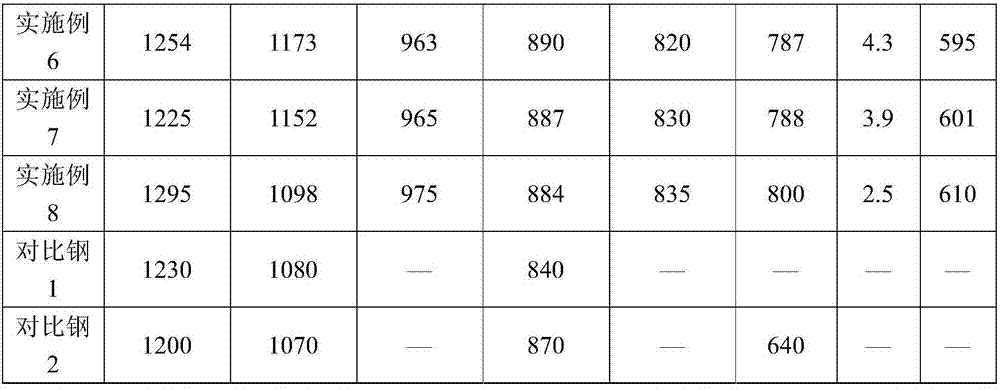

High-strength and high-toughness corrosion-resistant steel capable of being used in low-temperature environment of -60 DEG C, and production method thereof

The invention relates to high-strength and high-toughness corrosion-resistant steel capable of being used in a low-temperature environment of -60 DEG C, and a production method thereof. The steel comprises the following components with contents in percentage by weight: 0.062%-0.115% of C, 0.22%-0.65% of Si, 0.82%-2.05% of Mn, not greater than 0.009% of P, not greater than 0.001% of S, 0.100%-0.280% of Als, 0.041%-0.080% of Nb, 0.090%-0.135% of Ti, 0.20%-0.40% of Ni and 0.40%-1.40% of Cr. The production method of the steel comprises the following production steps: molten iron desulphurization, converter smelting, common continuous casting and heating for a casting blank, three-phase rolling and cooling. With the adoption of the production method disclosed by the invention, the obtained steel has a yield strength of not less than 620MPa, impact toughness KV2 of not less than 100J and excellent seawater corrosion resistance, and can be used as steel for ships, and marine engineering and marine resource transportation equipment used in a low-temperature marine environment of -60 DEG C such as the north pole and having requirements on strength, low-temperature toughness, economical efficiency and use performance to a certain extent.

Owner:武汉钢铁有限公司

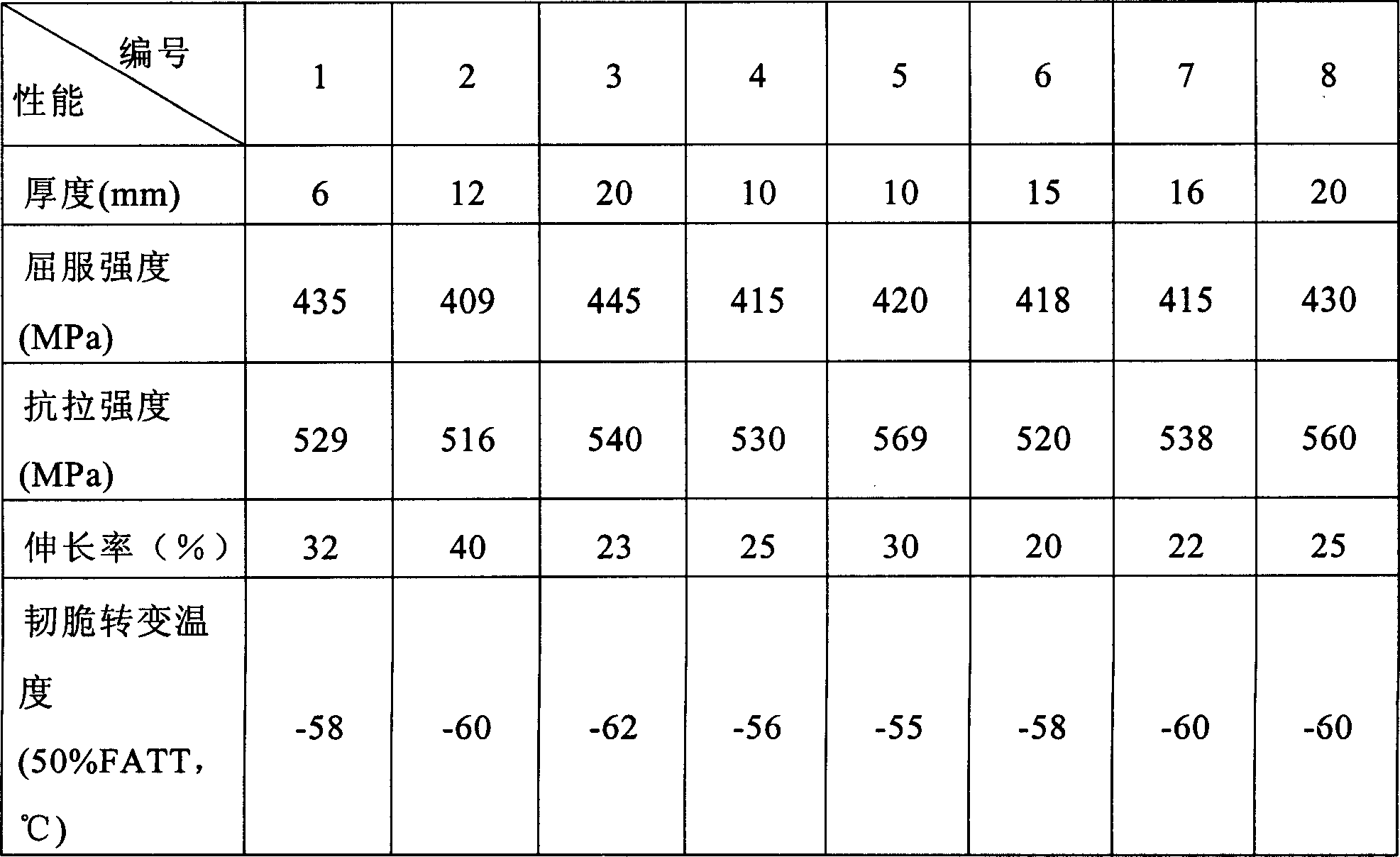

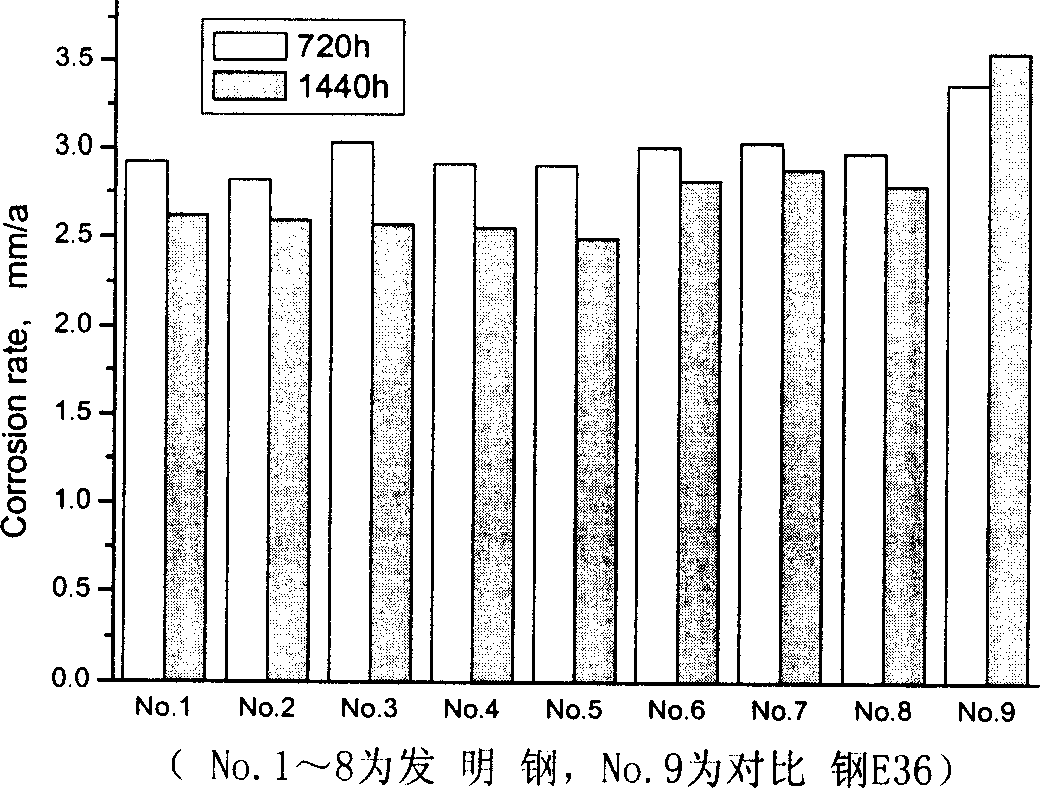

Seawater-corrosion-resistant steel and manufacturing method thereof

The invention discloses seawater-corrosion-resistant steel and a manufacturing method thereof. The mass percentage contents of carbon, silicon, manganese, phosphorus, sulphur, chrome, molybdenum, niobium, titanium and aluminum in the steel are well controlled. Qualified molten steel obtained through converter smelting is subjected to LF + RH + aluminum treatment and then subjected to continuous casting, the obtained billet steel is heated to 1150-1250 DEG C in a heating furnace and then is rolled into a steel sheet, and the final rolling temperature is 850-950 DEG C; and the steel sheet is cooled rapidly at the cooling speed of 100-300 DEG C / s in the first place and then is cooled to 650-750 DEG C in a laminar cooling method at the cooling speed of 10-25 DEG C / s, and the final cooling steel sheet is coiled into a steel coil at the temperature of 650-750 DEG C. The steel coil is spirally welded into a pile pipe through a twin-wire, the pile pipe has good mechanical performance, yield strength is 400-500 MPa, tensile strength is 510-630 MPa, the elongation ratio is larger than 23%, and impact power is larger than 250 J. The pile pipe has good welding performance, the tensile strength obtained after welding is larger than 510 MPa, requirements for 3a and 180 degrees can be met through forward bending, back bending and side bending while integrity is maintained, the impact power obtained after welding is larger than or equal to 110 J, and the corrosion rate of the pile pipe is smaller than 1.30 mm per year.

Owner:WUHAN UNIV OF SCI & TECH

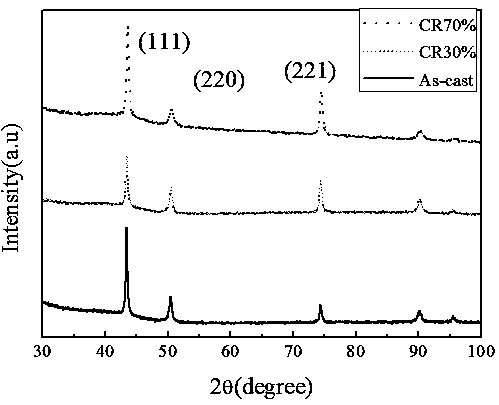

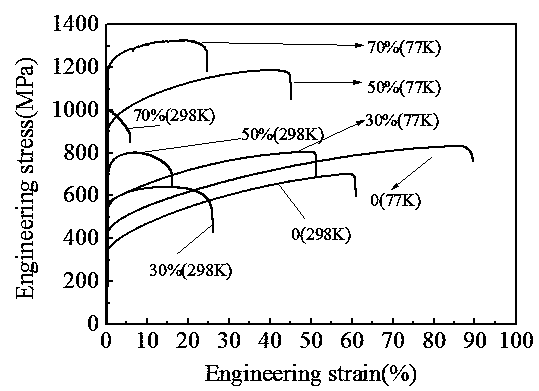

Fe-Mn-Cr-Ni-series medium-entropy stainless steel and preparation method thereof

InactiveCN109913769AReduce manufacturing costImprove low temperature performanceProcess efficiency improvementMarine equipmentMechanical property

The invention discloses a Fe-Mn-Cr-Ni-series medium-entropy stainless steel and a preparation method thereof. The chemical components of the medium-entropy stainless steel are Fe40Mn20Cr20Ni20, and the medium-entropy stainless steel is prepared from raw materials with different qualities of high-purity Fe, high-purity Ni, high-purity Cr and Fe-Mn binary steel with an atomic ratio of 1 to 1; a vacuum arc melting and a copper mold suction casting method are adopted for casting, and the technological process comprises the following steps of smelting, heat treatment, cold working and the like. According to the stainless steel and the method, the medium-entropy stainless steel is designed through parameter calculation, the structure of the medium-entropy stainless steel is a single-phase face-centered cubic crystal structure, the medium-entropy stainless steel not only has good room-temperature strength and plastic deformation capability, and has especially excellent mechanical property atlow temperature; in addition, compared with 304 stainless steel, the medium-stainless steel has more excellent corrosion resistance in a 3.5% sodium chloride solution, in the future, elements such ascarbon, silicon and aluminum can be added into the medium-stainless steel, the comprehensive performance of the material is further enhanced. Therefore, the medium-entropy stainless steel has a very wide application prospect in marine equipment and alpine regions as structural materials.

Owner:TAIYUAN UNIV OF TECH

Preparation method for marine anticorrosive paint

InactiveCN105176286AStrong resistance to seawater corrosionAnti-corrosive paintsEpoxy resin coatingsSolventChemistry

The invention discloses a preparation method for a marine anticorrosive paint. The preparation method comprises the following steps: adding polyvinyl chloride, xylene formaldehyde resin, zinc citrate and epoxy resin into a solvent and carrying out stirring; then adding chloroprene rubber, phosphatidylcholine, sodium sulfoxylate formaldehyde and chlorinated paraffin into the obtained mixture and carrying out stirring; and finally adding rutile titanium dioxide, a dispersant, precipitated barium sulphate, butyl acetate, polymethyl methacrylate and a stirring into the mixture obtained in the previous step and carrying out stirring and grinding so as to obtain the marine anticorrosive paint. The marine anticorrosive paint provided by the invention has excellent resistance to sea water corrosion and can resist salt fog for more than 2000 h, a 10% NaOH solution for more than 30 d and artificial seawater for more than 4200 h.

Owner:ENG EQUIP CO LTD SUZHOU SAI SIDE

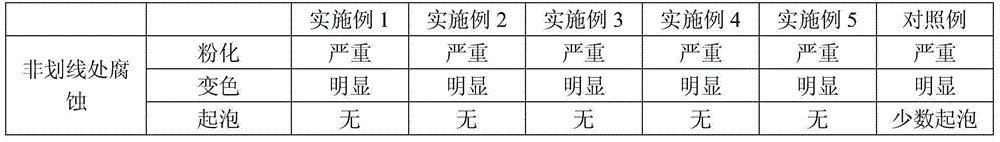

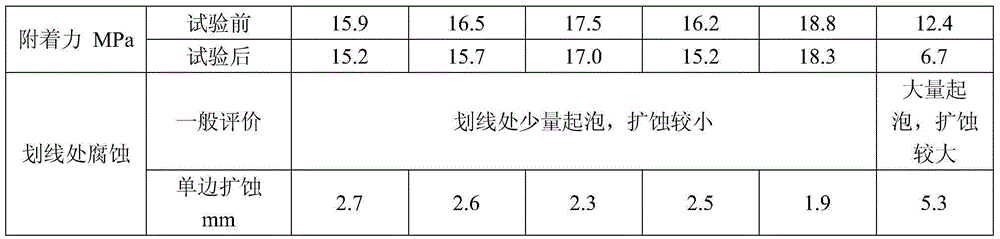

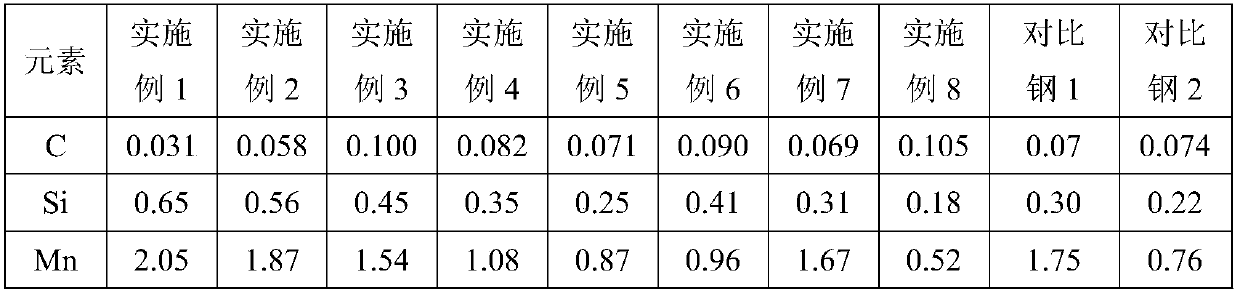

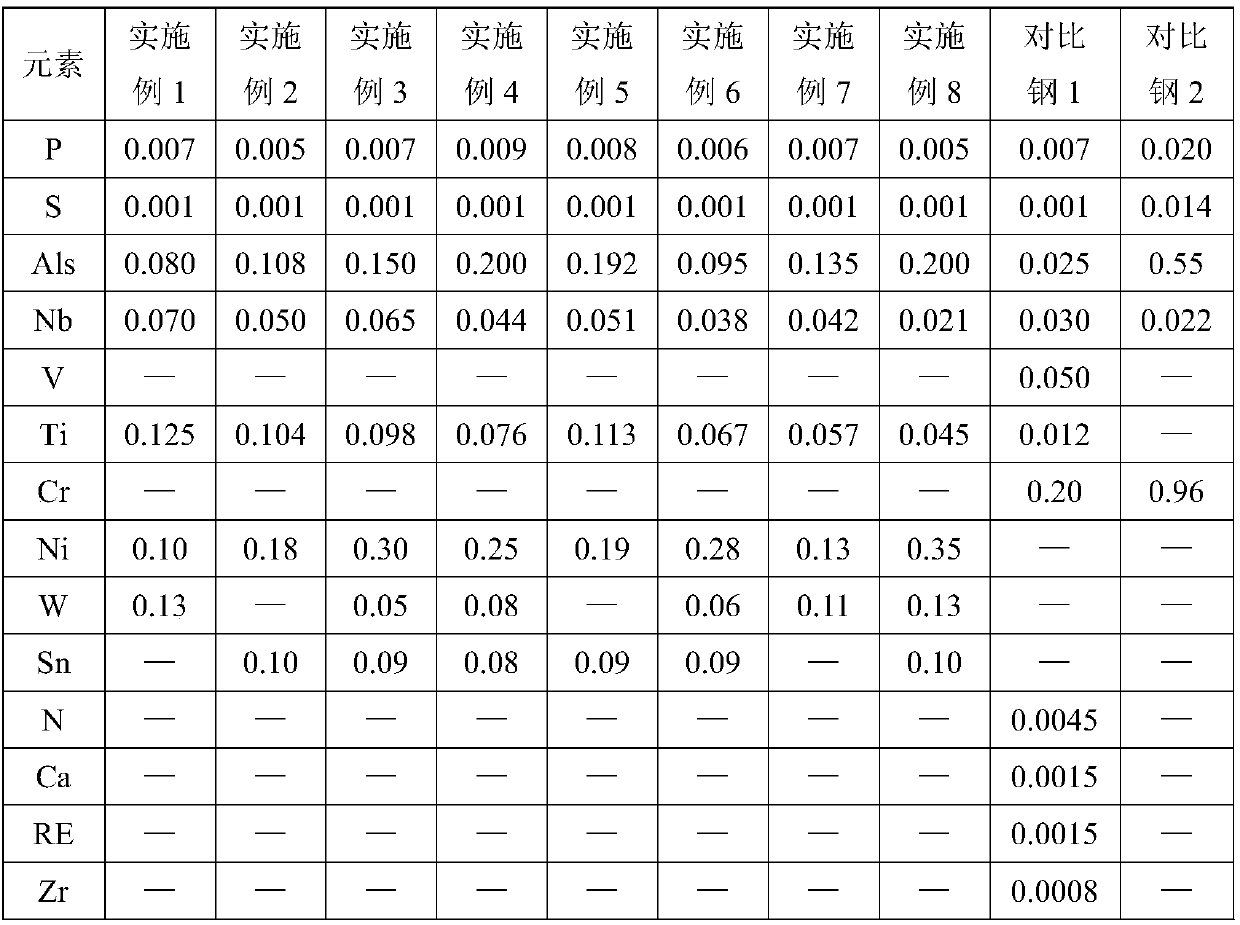

440 MPa corrosion resisting steel for ship at low temperature environment and production method of corrosion resisting steel

The invention discloses a corrosion-resistant steel for 440MPa ships in a low-temperature environment and a production method thereof, belonging to the technical field of material steel. It includes the following components in mass percentage: C: 0.031-0.105%, Si: 0.18-0.65%, Mn: 0.52-2.05%, P≤0.009%, S≤0.001%, Als: 0.080-0.200%, Nb: 0.021 to 0.070%, Ti: 0.045 to 0.125%, Ni: 0.10 to 0.35%, and the balance is Fe and unavoidable impurities. The production method is 1) conventional molten iron desulfurization; 2) converter smelting and RH vacuum treatment; 3) billet continuous casting and heating; 4) section rolling; 5) cooling. The prepared steel plate can be used in an extremely cold and low temperature environment of around ‑80°C. The yield strength of the steel plate is ≥440Mpa, the impact toughness KV2≥100J, and the seawater corrosion performance is better than the traditional seawater corrosion-resistant steel 10CrMoAl.

Owner:武汉钢铁有限公司

High strength anti-corrosion easy processing and low magnetic cast steel for manufacturing ship weldable structure

ActiveCN1928143AFulfil requirementsAvoid pollutionHeat treatment process controlFerrosiliconAluminium

The low magnetism cast steel for making weldable ship structure with high corrosion resistance and easy machining has the chemical components including C 0.05-0.15 wt%, Cr 10.0-22.0 wt%, Mn 3.1-12.0 wt%, Ni 2.0-12.0 wt%, N 0.10-0.28 wt%, and Fe for the rest. It may be produced with waste steel, ferrochromium, metal Mn, electrolytic Ni and recovered 0Cr18Ni9 alloy as material, and through smelting in weak oxidizing atmosphere inside a medium frequency induction furnace. In the smelting process in a medium frequency induction furnace, waste steel and electrolytic Ni is first added and molten down, ferrochromium and metal Mn is then added, metal Al is finally added to deoxidize, ferrosilicon and nitrided ferrochromium and added 5 min before tapping, and the steel is tapped at 1580-1650 deg.c and cast at 1520-1580 deg.c. The low magnetism cast steel may be used in making ship steering and propelling system with less maintenance and high safety.

Owner:中船双瑞(洛阳)特种装备股份有限公司

Seawater corrosion-resistant steel and manufacturing method thereof

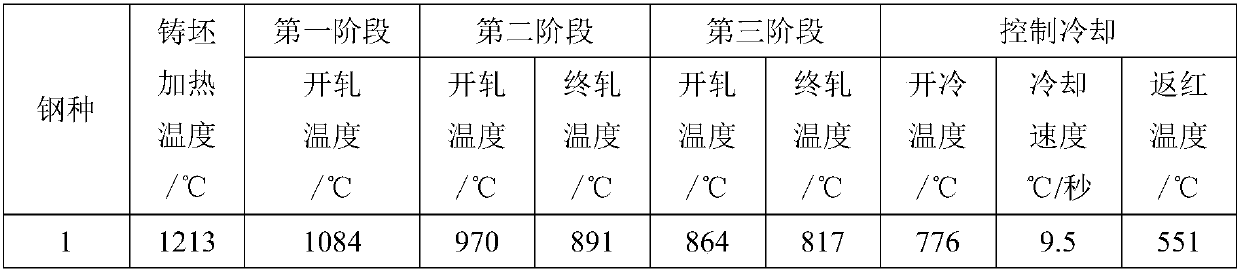

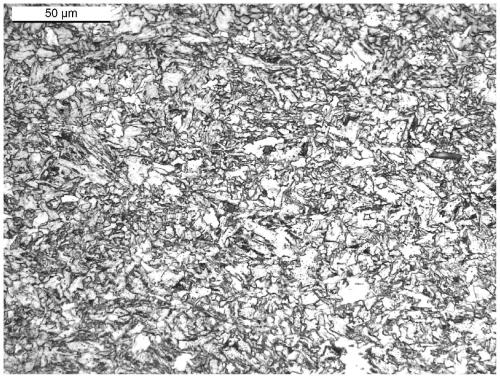

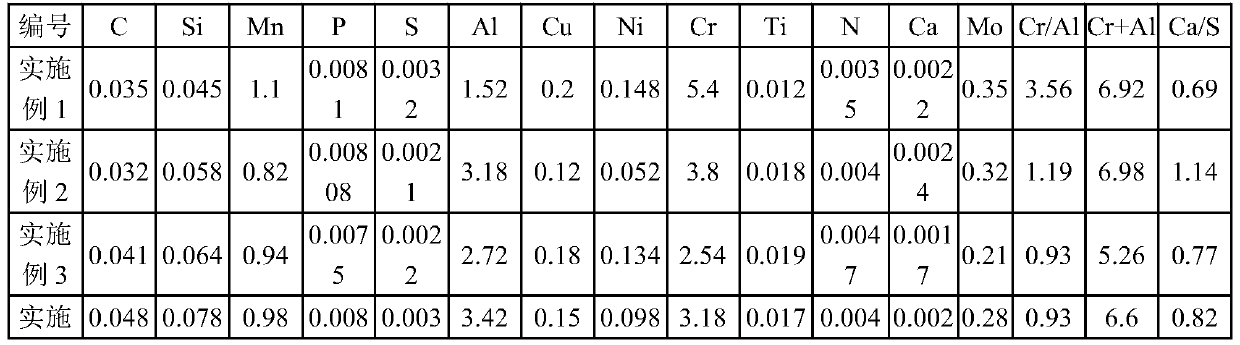

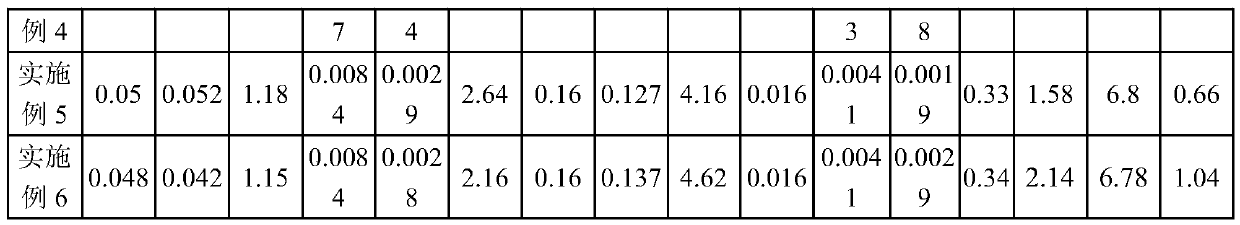

The invention discloses seawater corrosion-resistant steel. The seawater corrosion-resistant steel comprises the following chemical elements in percent by mass: 0.03-0.05% of C, 0.04-0.08% of Si, 0.8-1.2% of Mn, 0.1-0.2% of Cu, 2.5-5.5% of Cr, 0.05-0.15% of Ni, 0.15-0.35% of Mo, 1.5-3.5% of Al, 0.01-0.02% of Ti, 0.0015-0.003% of Ca and the balance Fe and other inevitable impurities. In addition, the invention further discloses a manufacturing method of the seawater corrosion-resistant steel. The manufacturing method comprises the following steps of (1) smelting and casting; (2) reheating: reheating a casting blank to 1200-1260 DEG C; (3) rough rolling; (4) finish rolling; (5) coiling; and (6) carrying out cooling on the casting blank to room temperature. The seawater corrosion-resistant steel has good seawater corrosion resistance and excellent mechanical properties.

Owner:BAOSHAN IRON & STEEL CO LTD

High-strength copper-nickel alloy and preparation process thereof

ActiveCN102644004AImproved corrosion resistance and cavitation resistanceExcellent seawater corrosion resistanceCopper nickel alloyCast iron

The invention discloses a high-strength copper-nickel alloy and a preparation process thereof. The preparation process comprises the following steps: smelting 28-35% of Ni, 0.8-1.5% of Mn, 0.8-1.5% of Fe, 0.2-0.7% of Ag, 2-5% of Mo and 58-65% of Cu in sequence; adding 2-5% of total mass of Al, 0.3-0.6% of Ti, 0.05% of rare earth Ce; continuously cooling; injecting an alloy solution into a cast iron mould when the temperature achieves 1280-1360 DEG C; cooling; heat treating, preserving the temperature in the furnace and carrying out solution treatment to obtain the copper-nickel alloy which comprises the following components by weight percent: 28-31% of Ni, 0.8-1.2% of Fe, 0.8-1.2% of Mn, 2-5% of Al, 1-3% of Mo, 0.3-0.6% of Ti, 0.08-0.12% of Ag, 0.01-0.05% of Ce, 57.83-67.01% of Cu. The copper-nickel alloy is high in strength and toughness and has 2-3 times of tensile strength and yield strength than the tensile strength and the yield strength of B30 copper-nickel alloy.

Owner:TSINGHUA UNIV

High-strength, high-toughness and seawater corrosion-resistant welding rod for ocean engineering

InactiveCN105328363AGood moisture absorptionHigh weld metal strengthWelding/cutting media/materialsWelding/soldering/cutting articlesSeawaterCorrosion resistant

The invention discloses a high-strength, high-toughness and seawater corrosion-resistant welding rod for ocean engineering. The deposited metal of the welding rod comprises the following ingredients in percentage by mass: not greater than 0.05 parts of C, not greater than 0.60 parts of Si, 1.30-1.80 parts of Mn, 0.25-0.40 parts of Cr, 2.20-2.80 parts of Ni, 0.35-0.55 parts of Mo, 0.15-0.40 parts of Cu, not greater than 0.006 parts of S, not greater than 0.010 parts of P, and not greater than 0.005 parts of Re. A preheating temperature can be lowered to 50 DEG C when 800MPa-grade high-strength steel for ocean engineering is welded by adopting the technology of the invention; the coating of the welding rod is high in moisture absorption, the welding toe is smooth, and all-position welding can be carried out; and the welding rod has a high welding joint metal strength (Rm of not less than 780MPa), a low diffusible hydrogen content, a low cold crack sensitivity, a high low-temperature impact strength Kv2 of more than 70J at minus 60 DEG C, extremely low S and P impurity contents, and excellent seawater corrosion resistance.

Owner:SICHUAN XIYE NEW MATERIAL

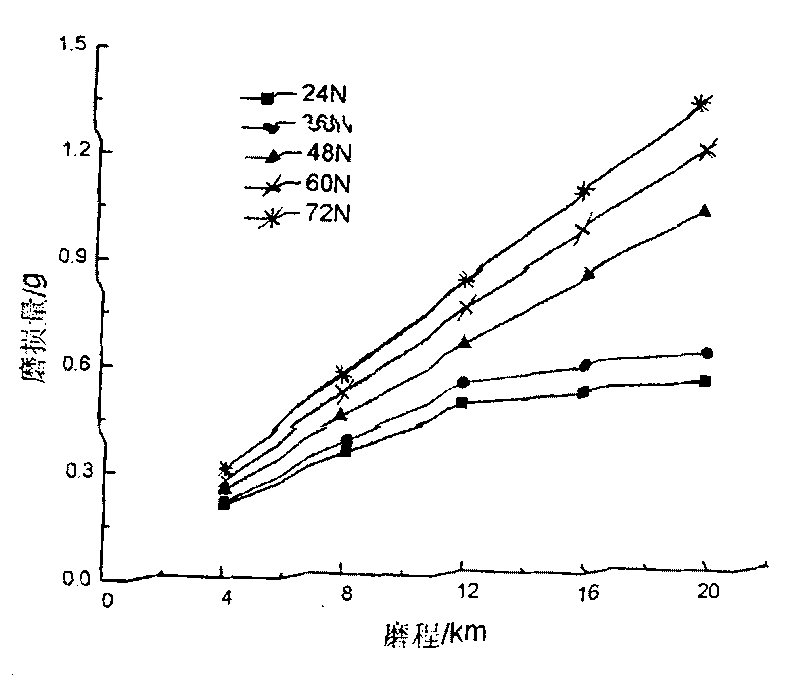

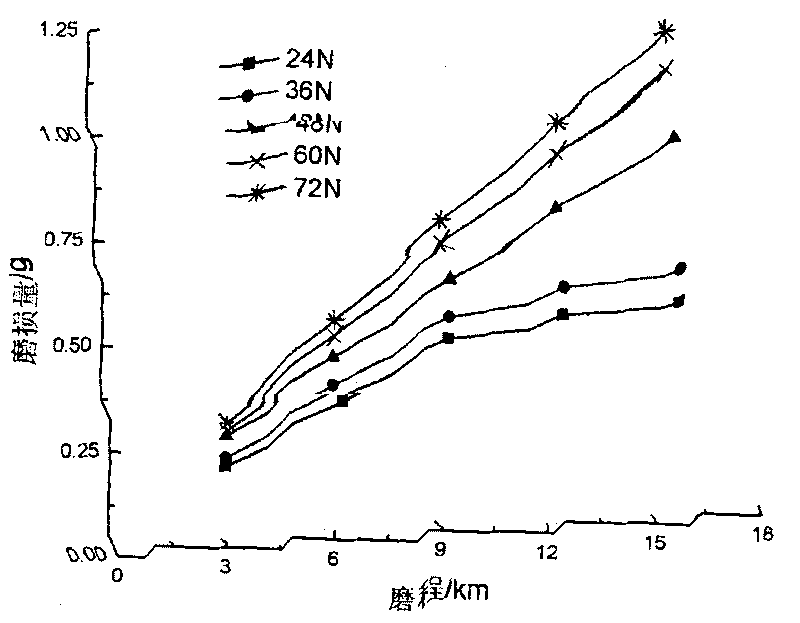

Low-alloy abrasion-proof and corrosion resistant steel and method for producing the same

InactiveCN101423916BImprove corrosion resistanceFix fixesElectric furnaceProcess efficiency improvementWear corrosionWear resistant

The invention relates to low alloy wearing resistance corrosion resistance steel which is suitably used in the ocean mud-sand wearing and corrosive environment, which is produced by the following steps: Mn-Si-Cr-Mo system non-carbide bainite alloy steel is taken as research basis, the carbon content and other alloy element contents are properly adjusted, elements of Al, Nb and rare earth contributing to improving the corrosion resistance of the alloy steel are added for modification, and the Mn-Si-Cr-Mo-Al system non-carbide bainite steel is formed by the progression quenching heat treatment process, so that the low alloy wearing resistance corrosion resistance steel is obtained. The steel has good obdurability, wearing resistant and corrosion resistant comprehensive performance and welding repair performances, and can be used to solve the problem of repairing worn blades of a centrifugal pump of a ship, and can also be applied to other ocean wearing resistance welding parts.

Owner:HOHAI UNIV +1

Polymer-reinforced prestressed concrete cylinder pipe molding technology

ActiveCN107599273AImprove mixing uniformityImprove compactnessTubular articlesPre treatmentWork in process

The invention provides a polymer-reinforced prestressed concrete cylinder pipe molding technology, and belongs to the technical field of pipeline manufacturing. The polymer-reinforced prestressed concrete cylinder pipe molding technology comprises the following steps that (1) manufacturing of a lining mold is conducted, wherein circumferential prestressed wires are wound around a concrete pipe core with a steel cylinder, a PCCP semi-finished product is formed and directly serves as the lining mold, and a reinforcing net is prefabricated in the concrete pipe core; (2) pretreatment of an outer mold is conducted, wherein a release agent coats the inner wall of the outer mold; and (3) construction of a pouring structure is conducted, wherein the lining mold, the reinforcing net and the outer mold are combined in sequence from inside to outside so as to form the pouring structure, polymer concrete is poured into the pouring structure, the outer mold is removed after molding is accomplished,and therefore a polymer-reinforced prestressed concrete cylinder pipeline is obtained. The polymer-reinforced prestressed concrete cylinder pipe molding technology is simple, and the manufactured polymer-reinforced prestressed concrete cylinder pipeline is excellent in performance and has the advantages of being high in sealing performance, strength and anti-permeability and resistant to corrosion.

Owner:江苏致乐管业科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com