Gas protection welding wire for ocean engineering

A marine engineering, gas shielding technology, applied in welding media, manufacturing tools, welding equipment, etc., can solve the problems of undisclosed marine engineering gas shielded welding wire, etc., and achieve good overall crack resistance of welded joints, stable low temperature impact toughness, additional The effect of high value and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

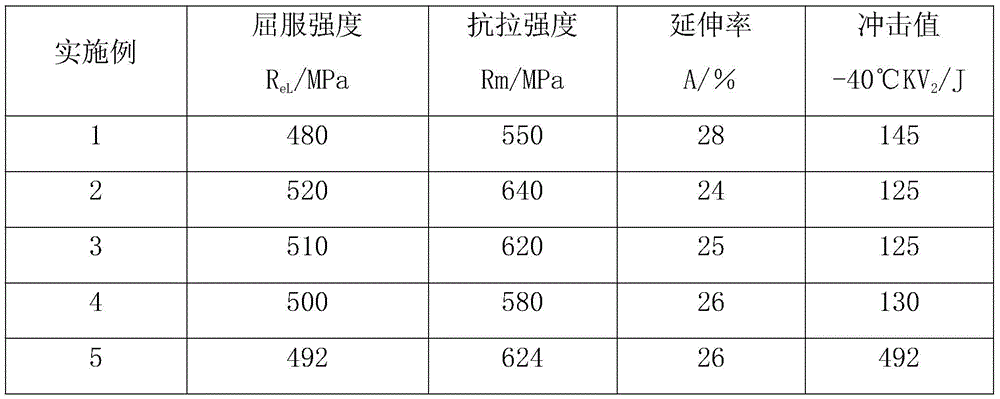

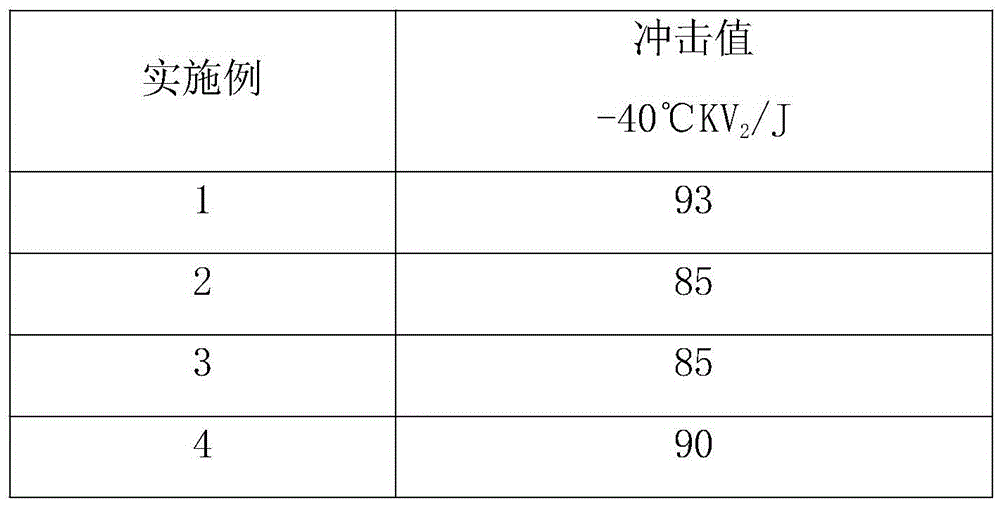

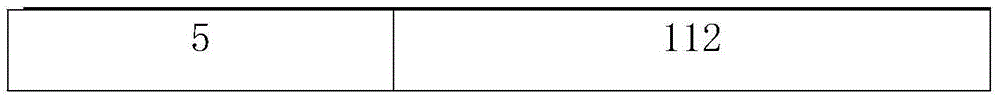

Examples

Embodiment 1

[0031] This embodiment specifically provides a gas-shielded welding wire for marine engineering. The following components are selected according to mass percentage: C: 0.09%, Mn: 0.8%, Si: 0.35%, Cr: 0.08%, Ni: 0.6%, Mo: 0.1%, V: 0.01%, Cu: 0.20%, S: 0.002%, P: 0.008%, Ti: 0.06%, B: 0.002%, and the balance is Fe. The invention uses a converter to make steel. After deoxidation and alloying, the molten steel whose composition meets the requirements is smelted. The molten steel is fully protected and cast into a continuous casting slab by a variety casting machine, and the continuous casting slab is rolled into a Φ6.5mm disc by a high-speed twist-free rolling mill. Wire rods are peeled, pickled, borax-coated, wire-drawn, and copper-plated to make Φ1.2mm finished welding wire.

[0032] The welding wire prepared by this embodiment is matched with 80% Ar+20% CO 2 Deposited metal performance test is carried out with the gas, among which, the base material of the test plate: Q460E, t...

Embodiment 2

[0035] This embodiment provides a gas-shielded welding wire for marine engineering. The following components are selected according to mass percentage: C: 0.13%, Mn: 1.4%, Si: 1.20%, Cr: 0.20%, Ni: 1.3%, Mo: 0.4 %, V: 0.03%, Cu: 0.25%, S: 0.002%, P: 0.010%, Ti: 0.20%, B: 0.008%, and the balance is Fe. The invention adopts converter steelmaking, and after deoxidation and alloying, molten steel whose composition meets the requirements is smelted. The molten steel is fully protected and cast into a continuous casting slab by a variety casting machine, and the continuous casting slab is rolled into a Φ6.5mm disc by a high-speed non-torsion rolling mill. Wire rods are peeled, pickled, borax-coated, wire-drawn, and copper-plated to make Φ1.2mm finished welding wire.

[0036] The welding wire prepared by this embodiment is matched with 80% Ar+20% CO 2 Deposited metal performance test is carried out with the gas, among which, the base material of the test plate: Q460E, the thickness ...

Embodiment 3

[0039] This embodiment provides a gas-shielded welding wire for marine engineering. The following components are selected according to mass percentage: C: 0.11%, Mn: 1.2%, Si: 0.7%, Cr: 0.15%, Ni: 1.0%, Mo: 0.25 %, V: 0.02%, Cu: 0.22%, S: 0.0015%, P: 0.008%, Ti: 0.15%, B: 0.005%, and the balance is Fe. The invention adopts converter steelmaking, and after deoxidation and alloying, molten steel whose composition meets the requirements is smelted. The molten steel is fully protected and cast into a continuous casting slab by a variety casting machine, and the continuous casting slab is rolled into a Φ6.5mm disc by a high-speed non-torsion rolling mill. Wire rods are peeled, pickled, borax-coated, wire-drawn, and copper-plated to make Φ1.2mm finished welding wire.

[0040] The welding wire prepared by this embodiment is matched with 80% Ar+20% CO 2 Deposited metal performance test is carried out with the gas, among which, the base material of the test plate: Q460E, the thickness...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com