Patents

Literature

4548results about "Electric furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

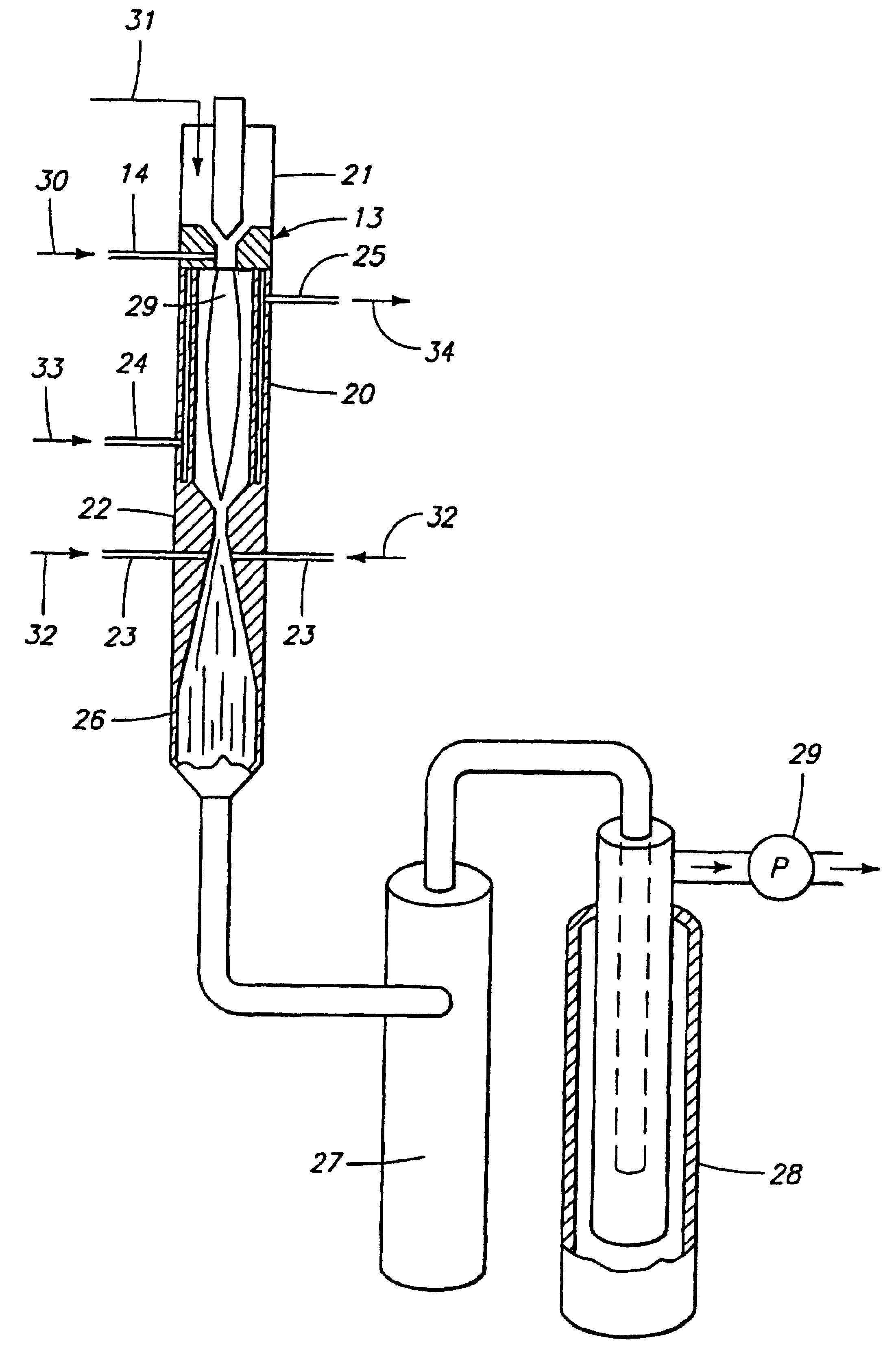

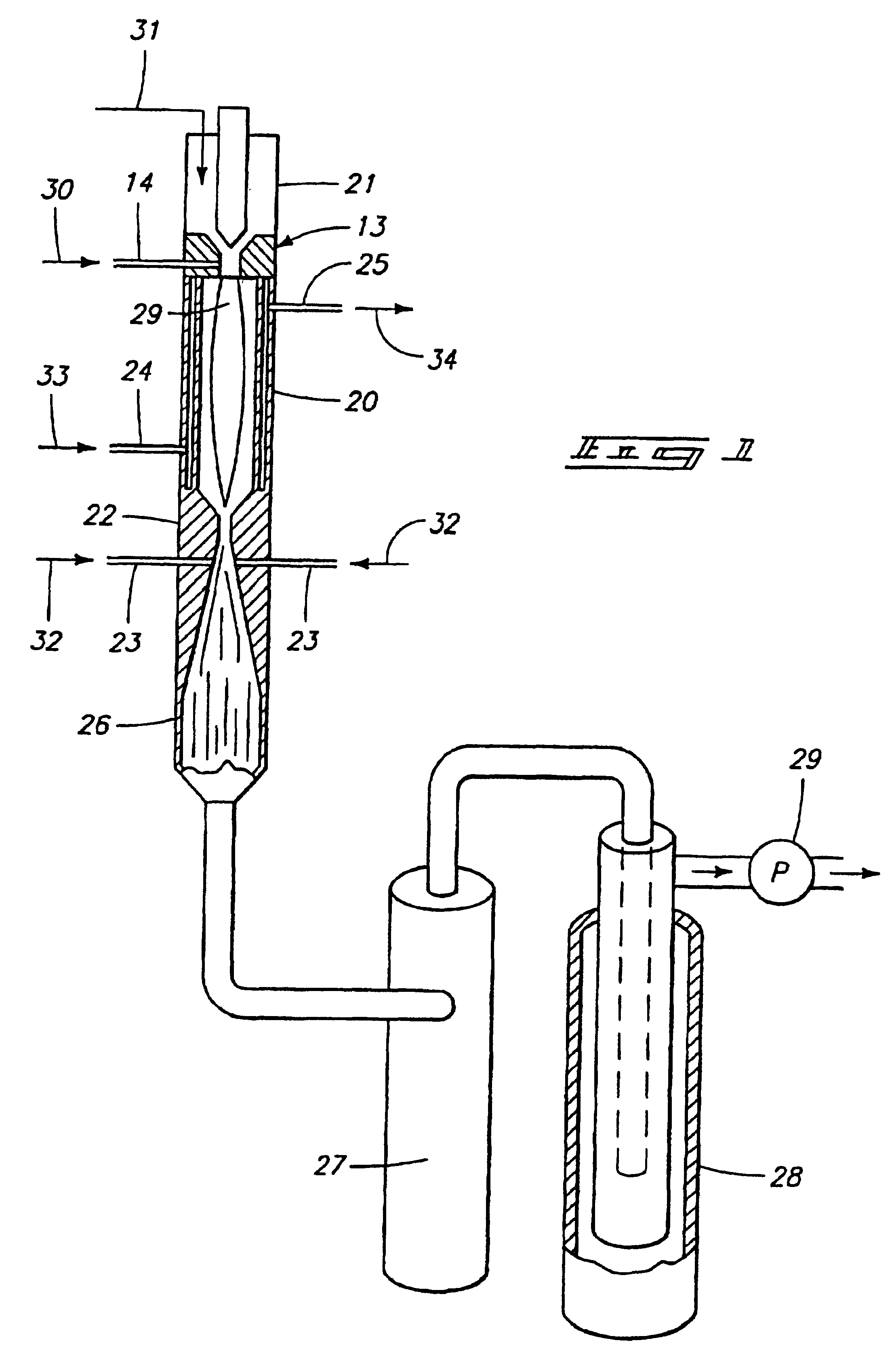

Fast quench reactor and method

InactiveUSRE37853E1Minimizing back reactionRapid coolingMaterial nanotechnologyIndirect heat exchangersThermodynamicsProcess engineering

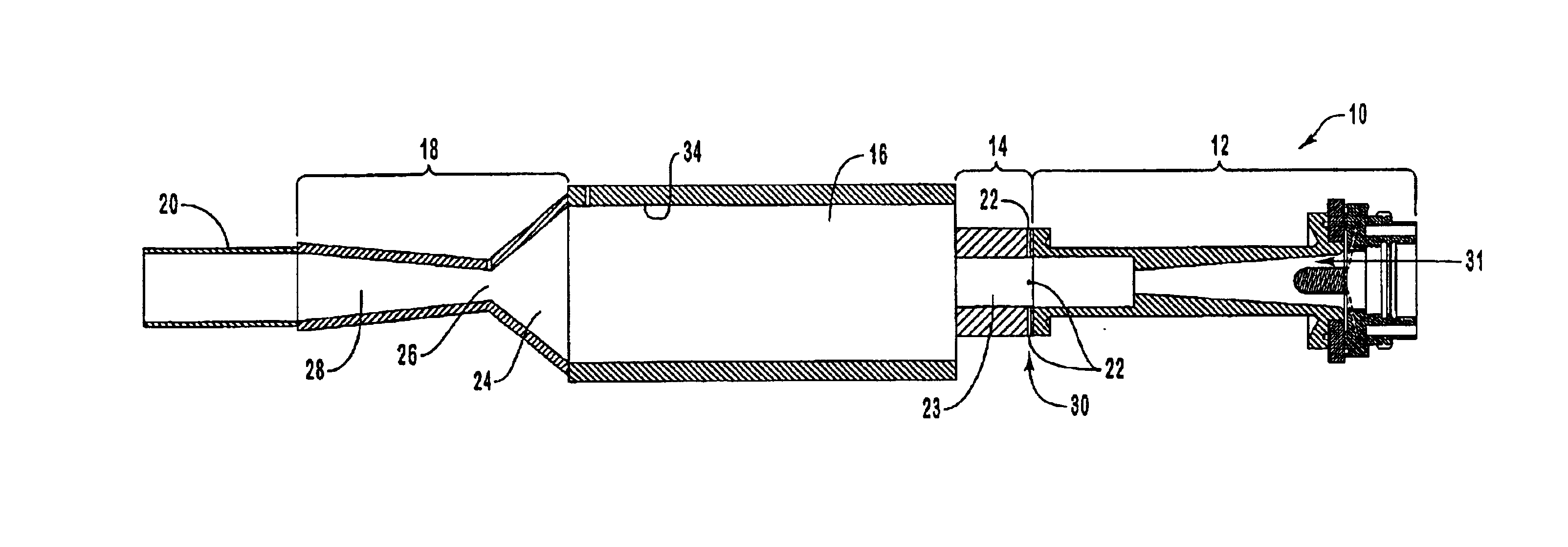

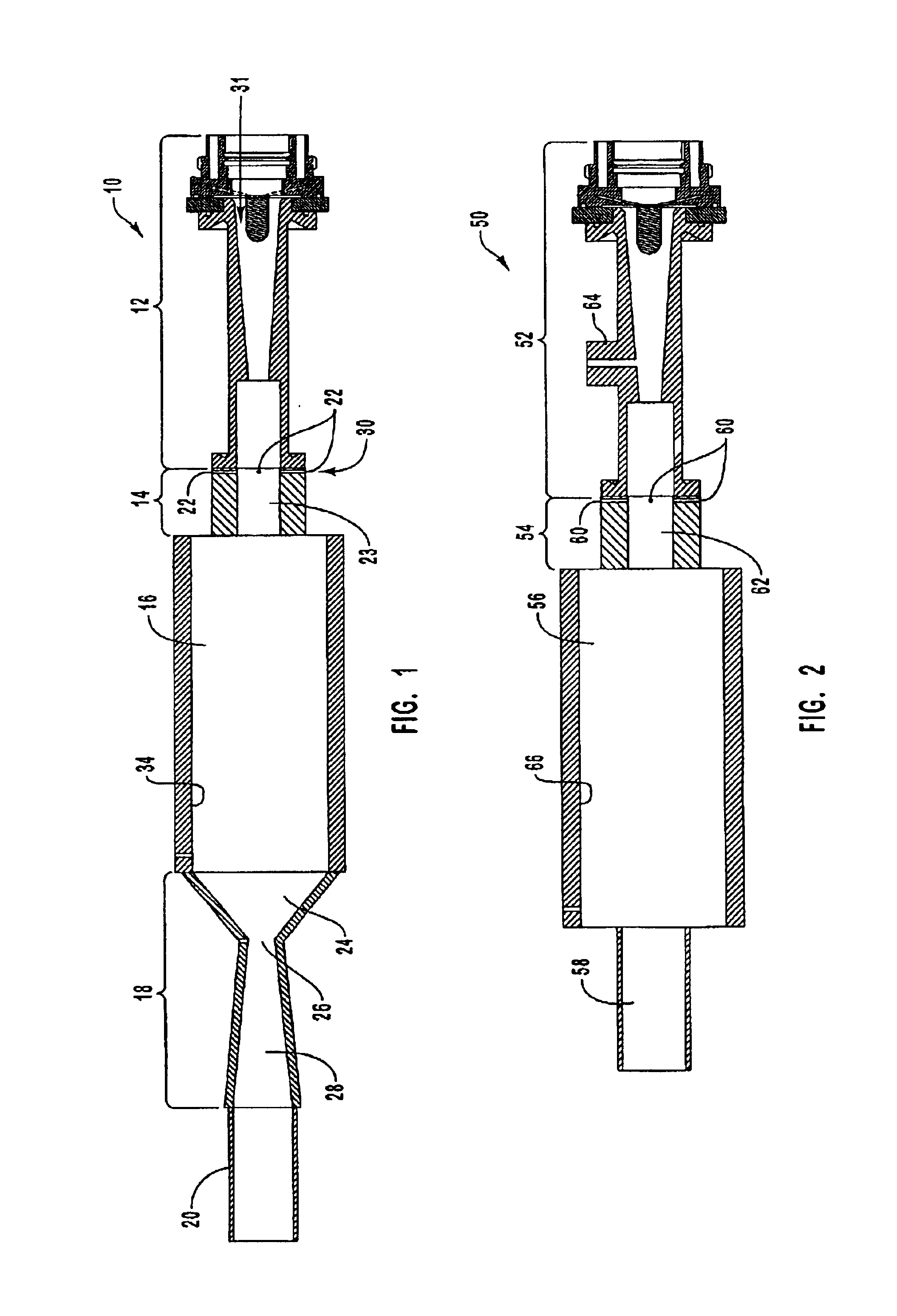

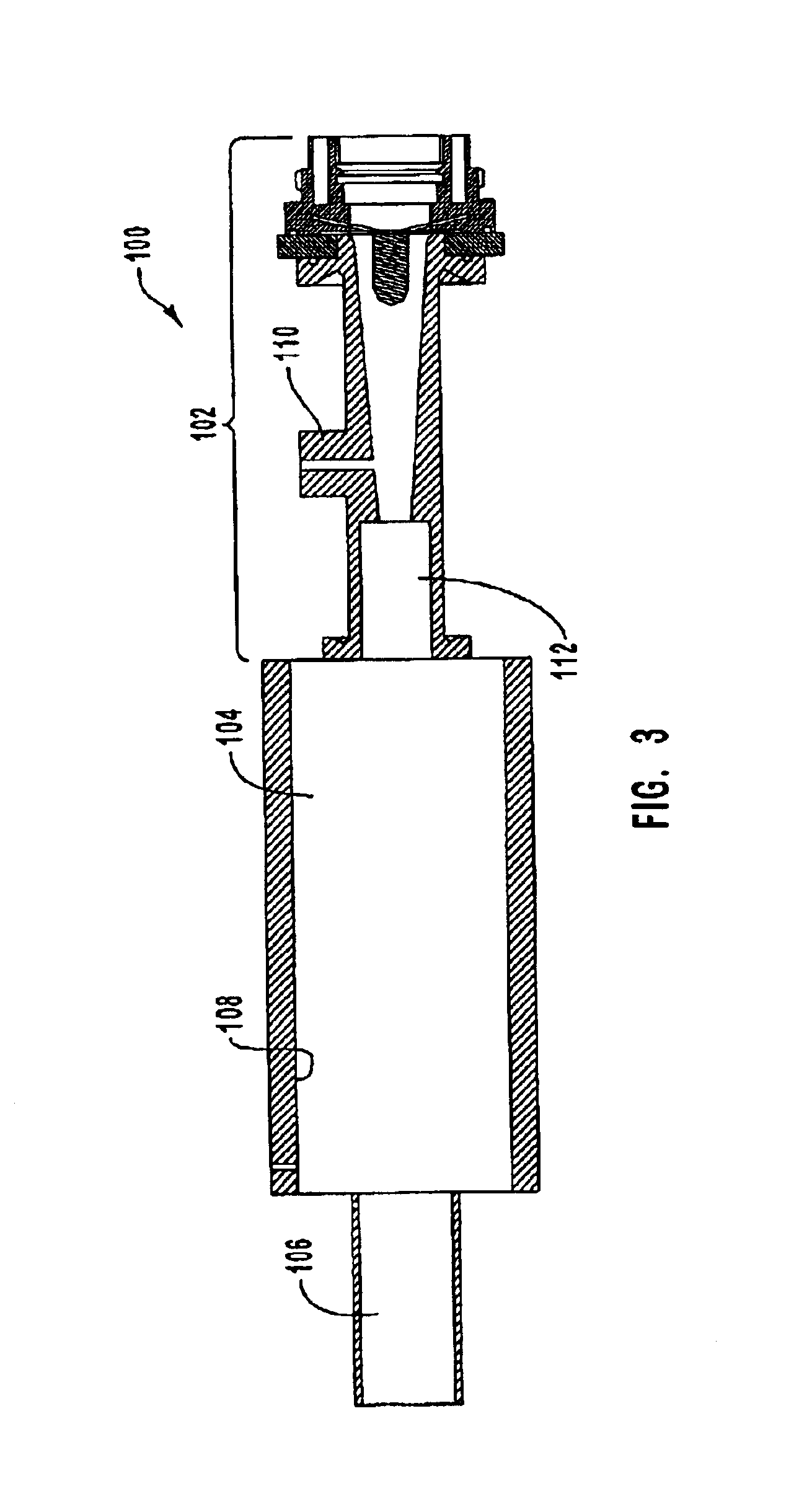

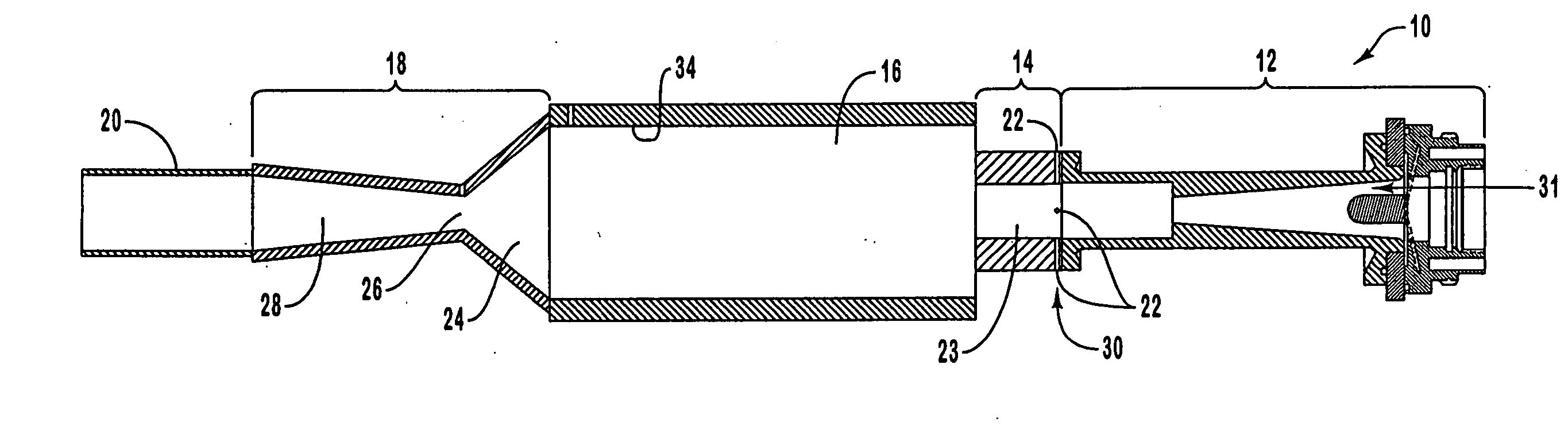

A fast quench reaction includes a reactor chamber having a high temperature heating means such as a plasma torch at its inlet and a restrictive convergent-divergent nozzle at its outlet end. Reactants are injected into the reactor chamber. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle. This "freezes" the desired end product(s) in the heated equilibrium reaction stage.

Owner:BATTELLE ENERGY ALLIANCE LLC

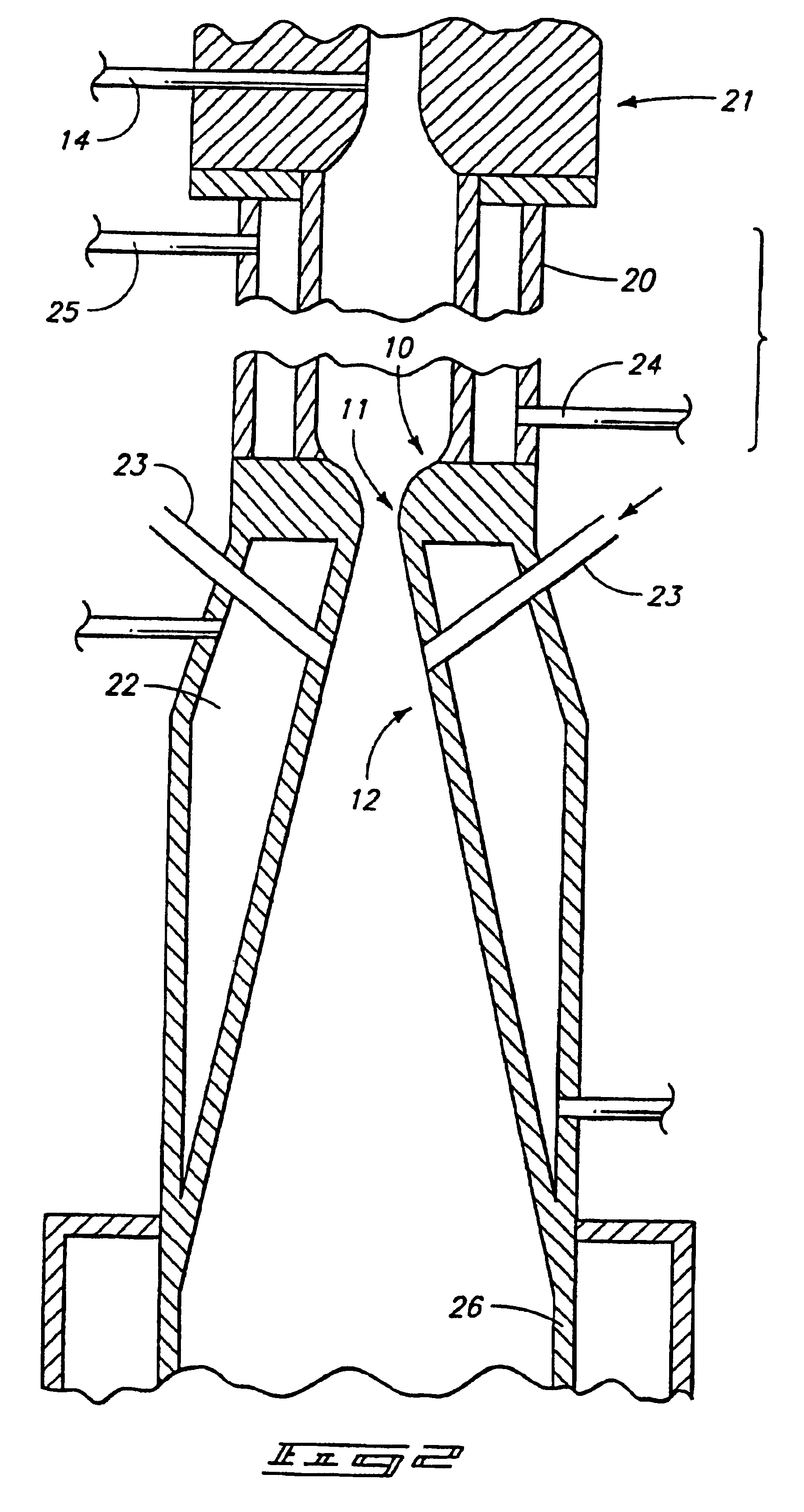

Austenoferritic stainless steel having a very low nickel content and a high tensile elongation

InactiveUS6096441ALow nickel contentImproved general propertyHeat treatment process controlElectric furnaceSulfurManganese

An austenoferritic stainless steel with high tensile elongation includes iron and the following elements in the indicated weight amounts based on total weight: carbon<0.04% 0.4%<silicon<1.2% 2%<manganese<4% 0.1%<nickel<1% 18%<chromium<22% 0.05%<copper<4% sulfur<0.03% phosphorus<0.1% 0.1%<nitrogen<0.3% molybdenum<3% the steel having a two-phase structure of austenite and ferrite and comprising between 30% and 70% of austenite, wherein Creq=Cr %+Mo %+1.5 Si % Nieq=Ni %+0.33 Cu %+0.5 Mn %+30 C %+30 N % and Creq / Nieq is from 2.3 to 2.75, and wherein IM=551-805(C+N)%-8.52 Si %-8.57 Mn %-12.51 Cr %-36 Ni %-34.5 Cu %-14 Mo %, IM being from 40 to 115.

Owner:UGITECH

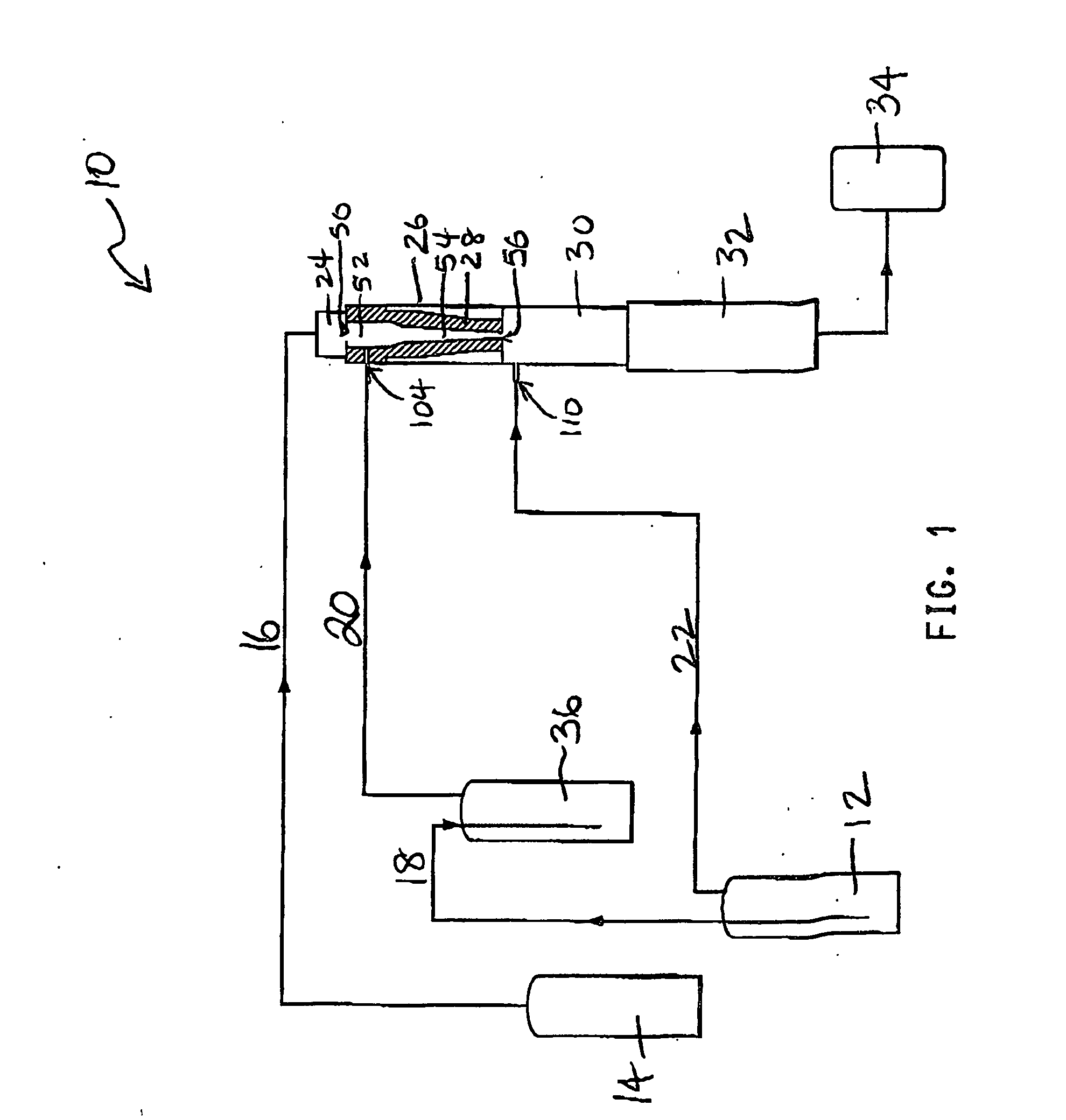

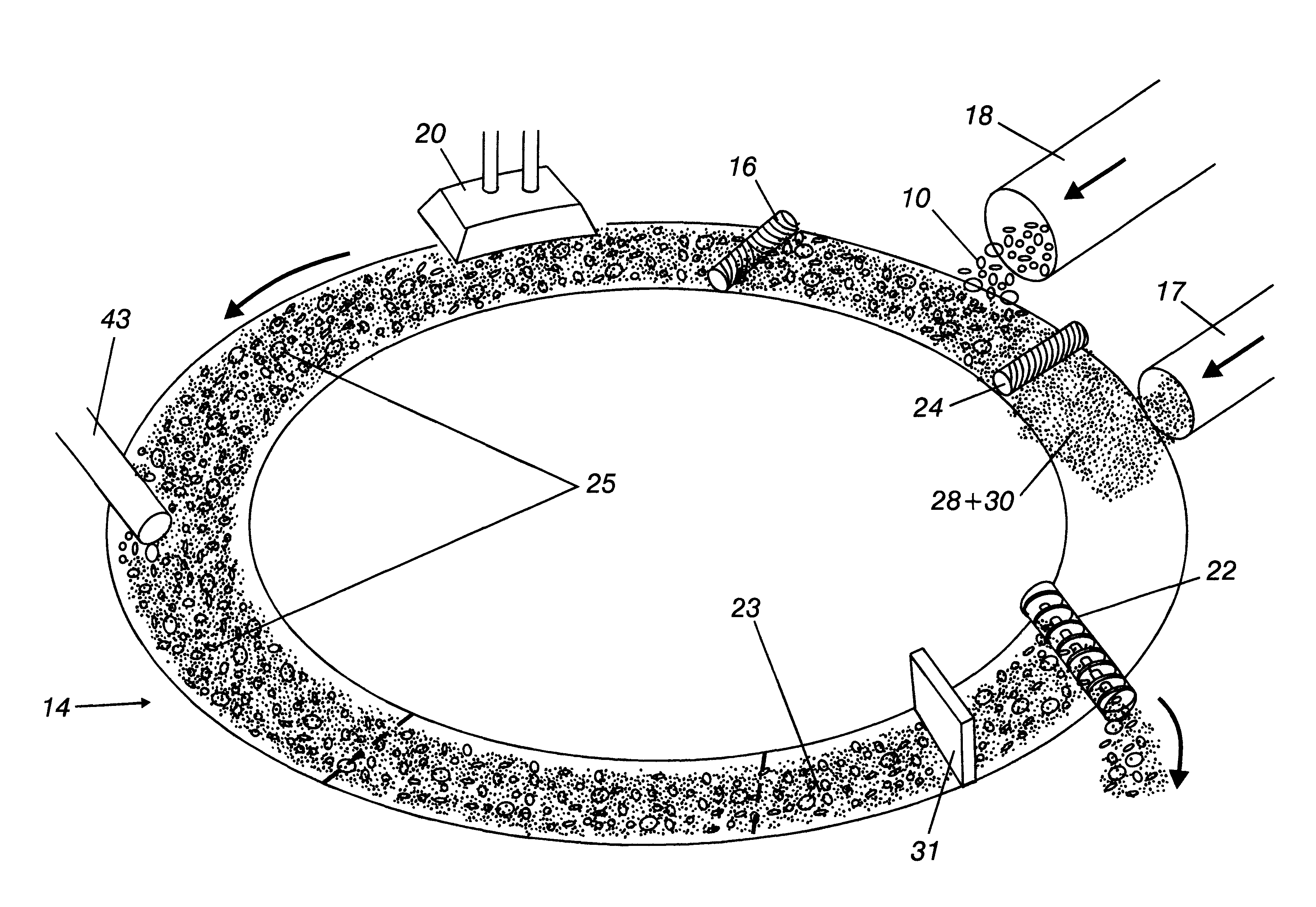

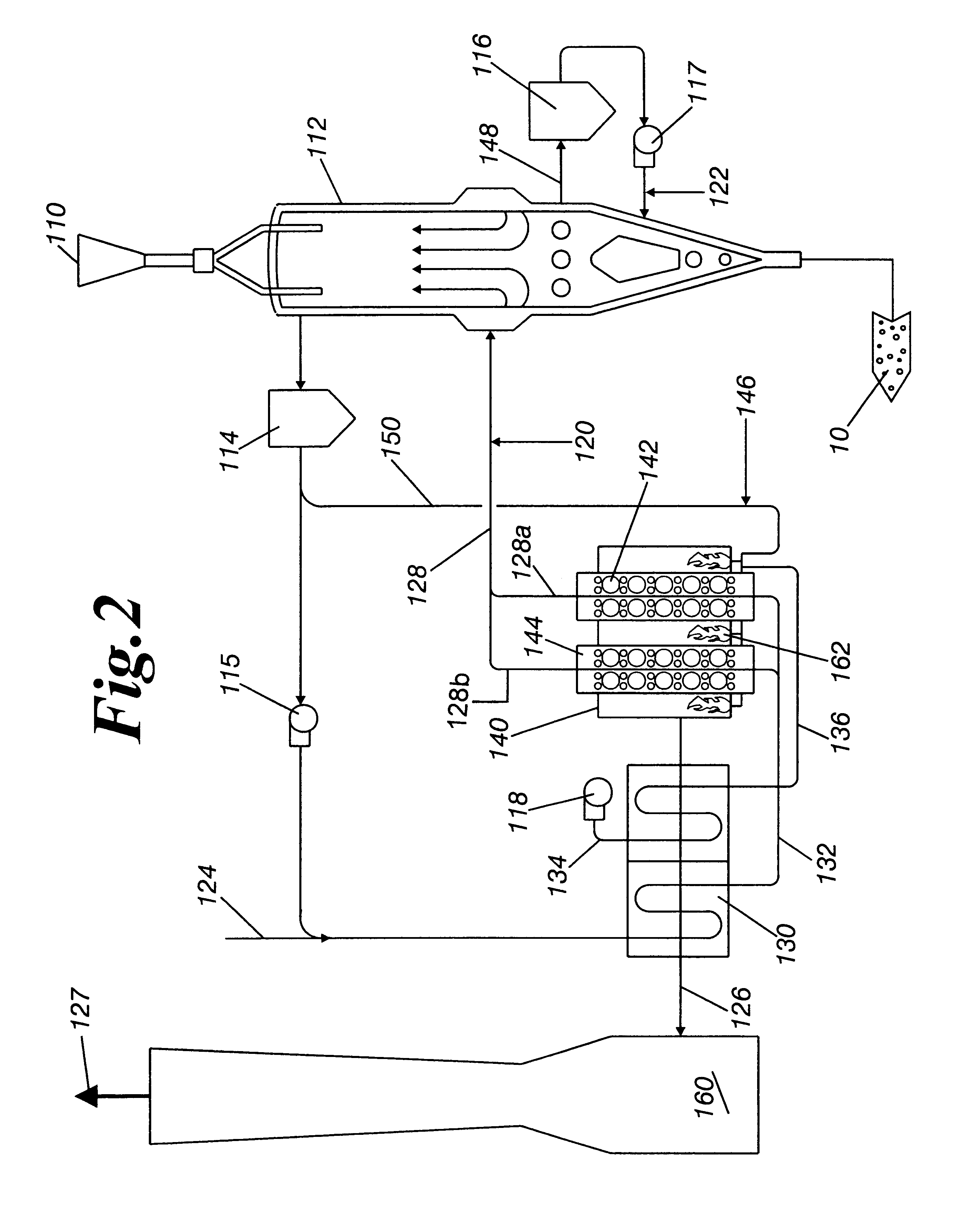

Thermal synthesis apparatus and process

InactiveUS6821500B2Improve efficiencyHigh yieldCarbon monoxideIndirect heat exchangersNuclear engineeringReaction zone

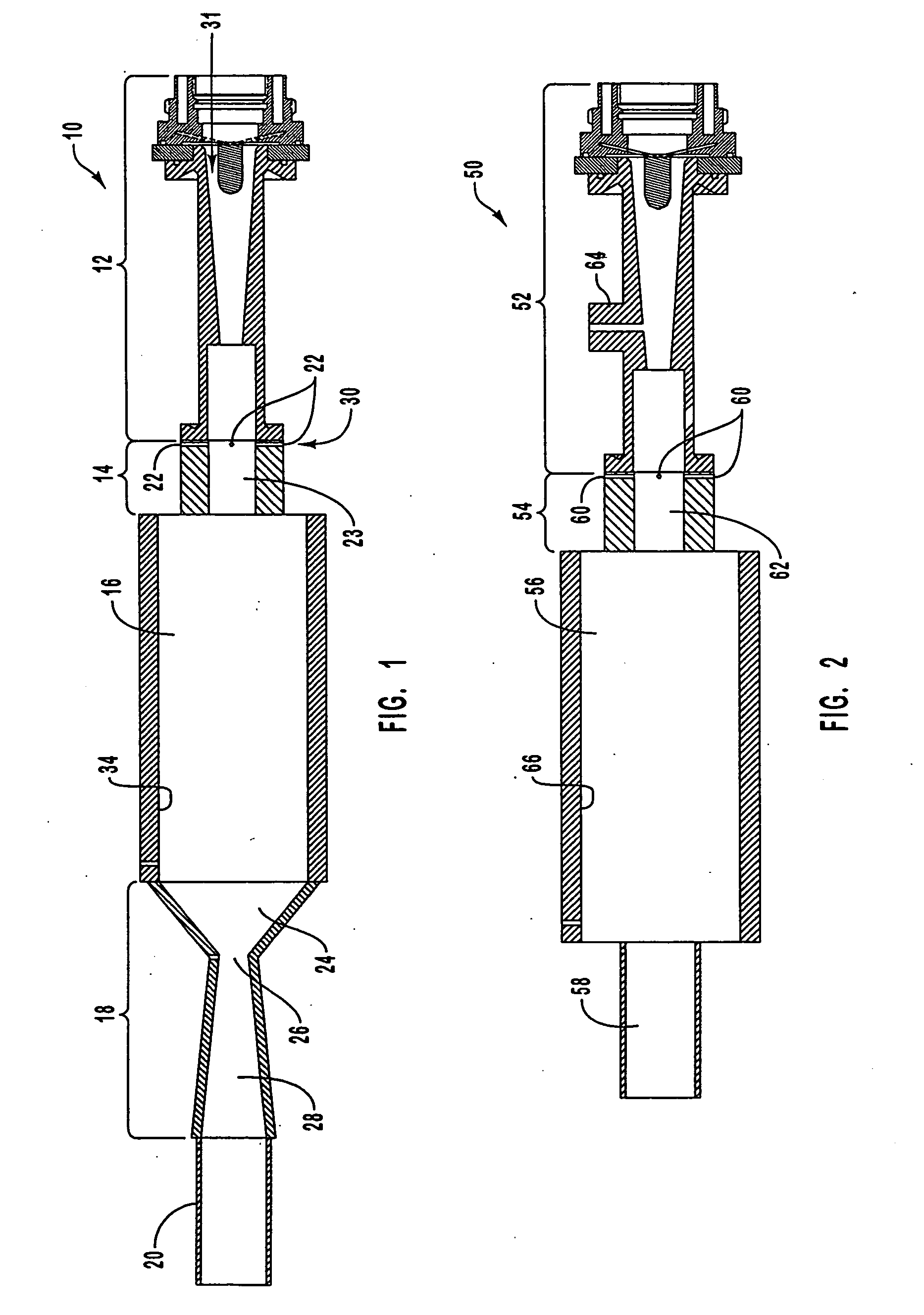

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

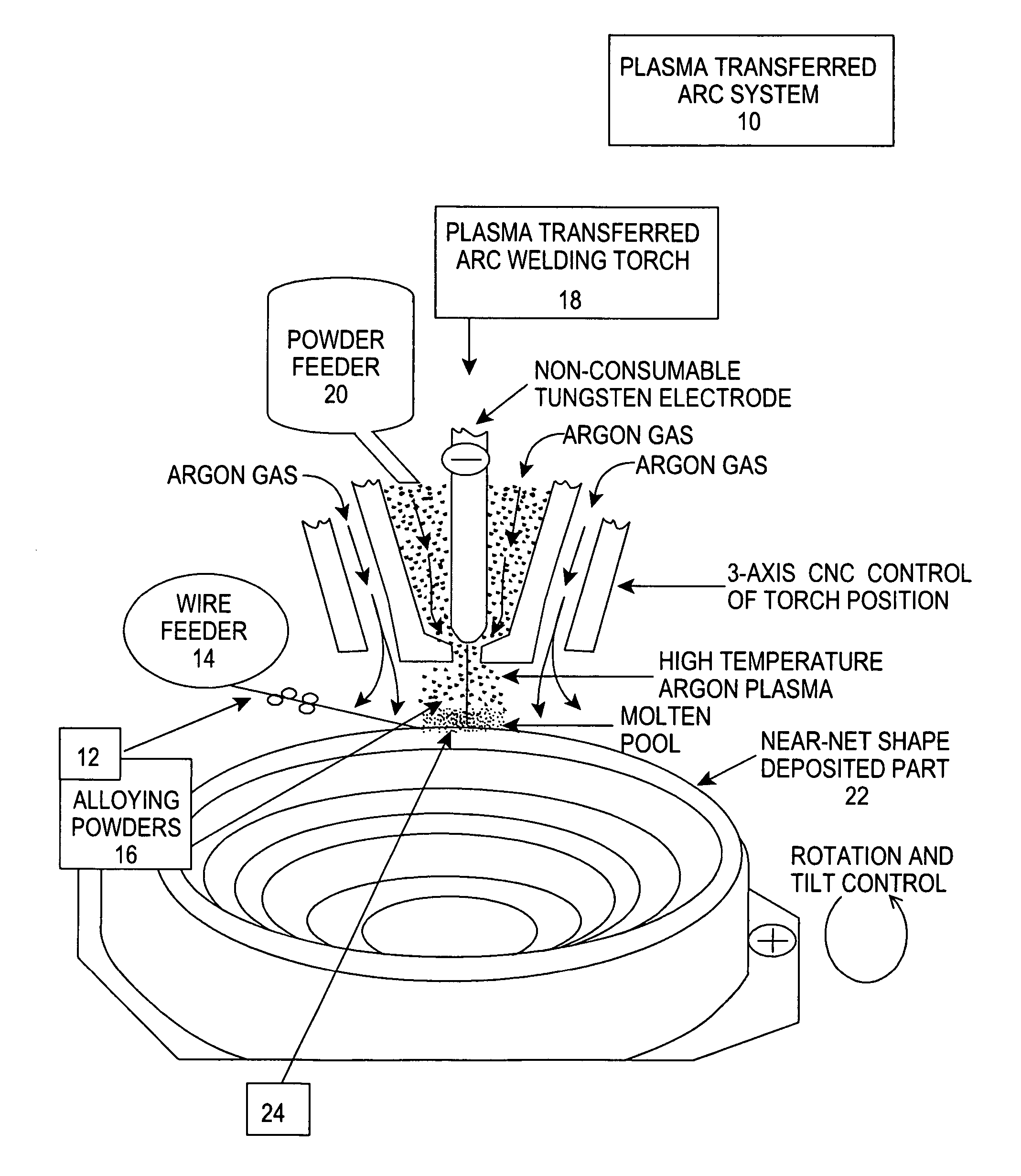

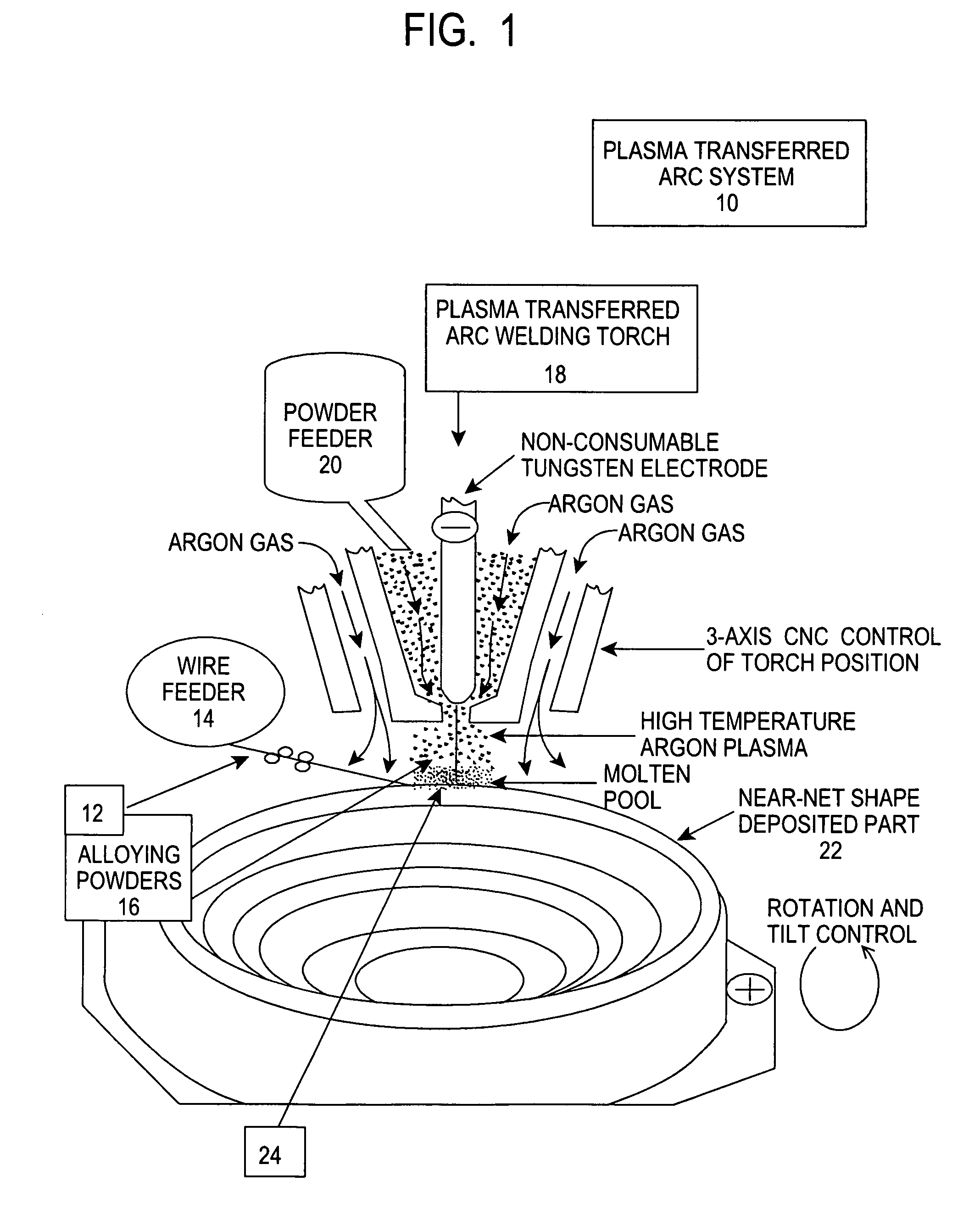

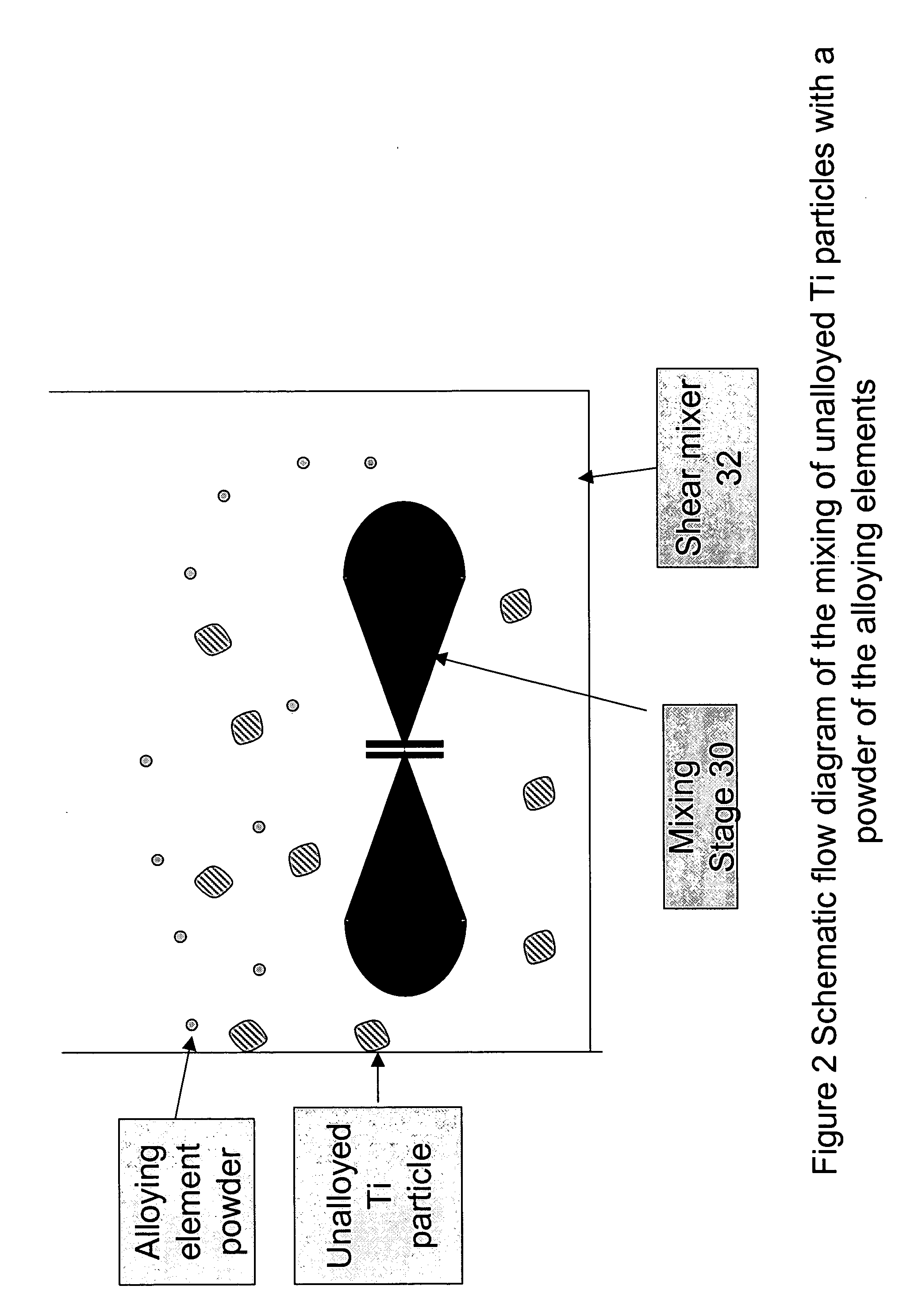

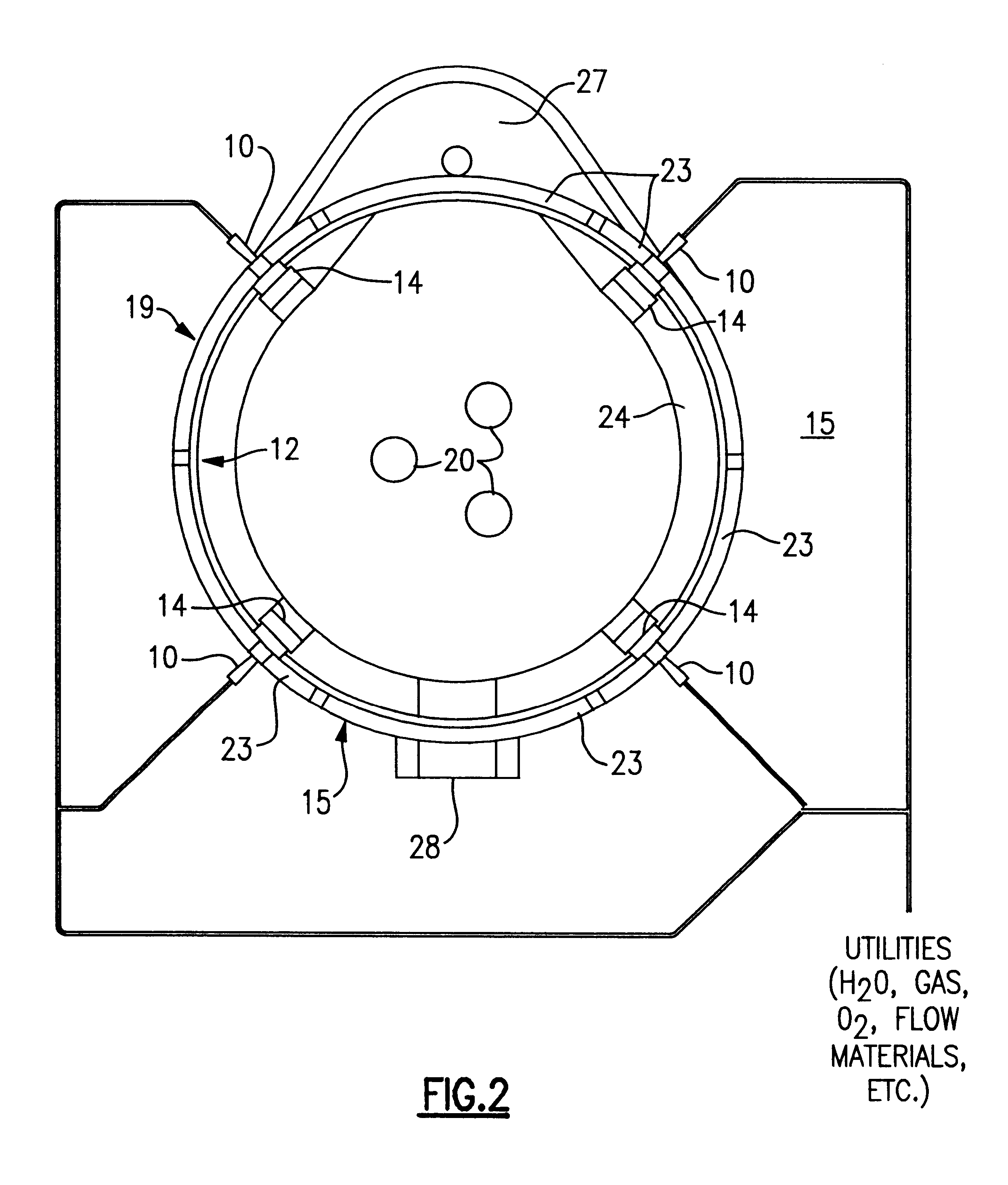

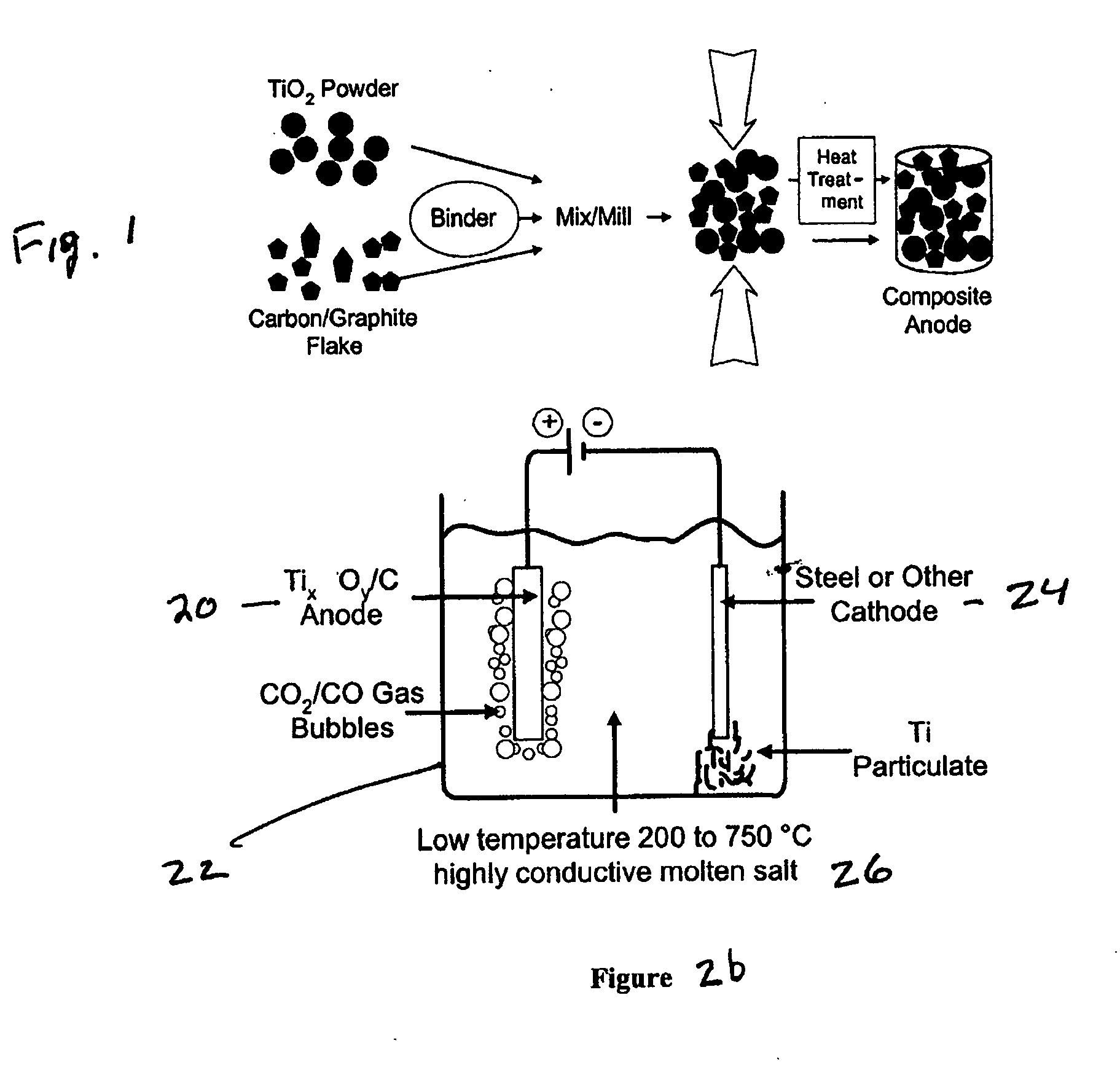

Low cost process for the manufacture of near net shape titanium bodies

InactiveUS20060185473A1Low costAdditive manufacturing apparatusArc welding apparatusHigh energyTitanium

Owner:ATS MER LLC

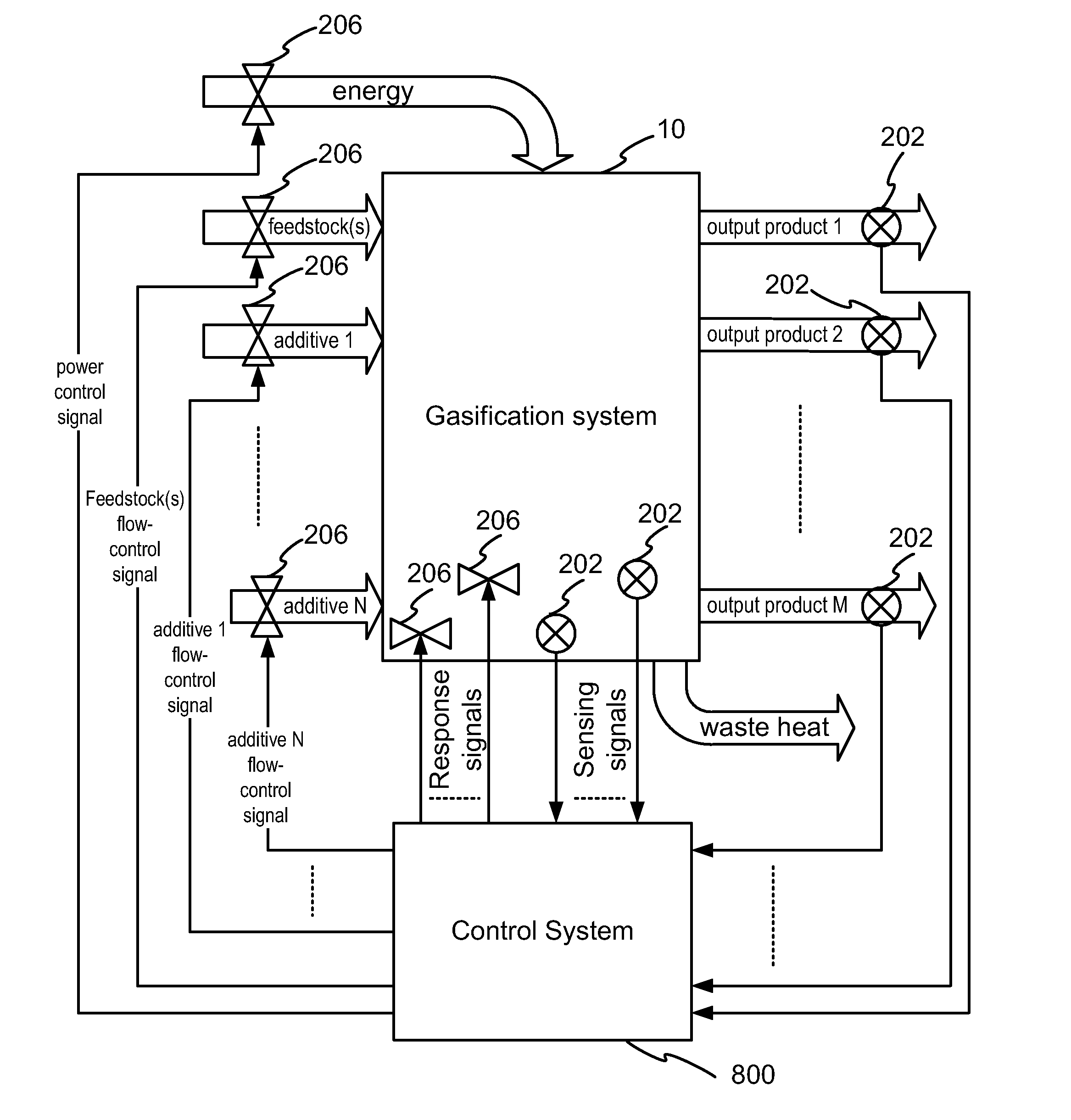

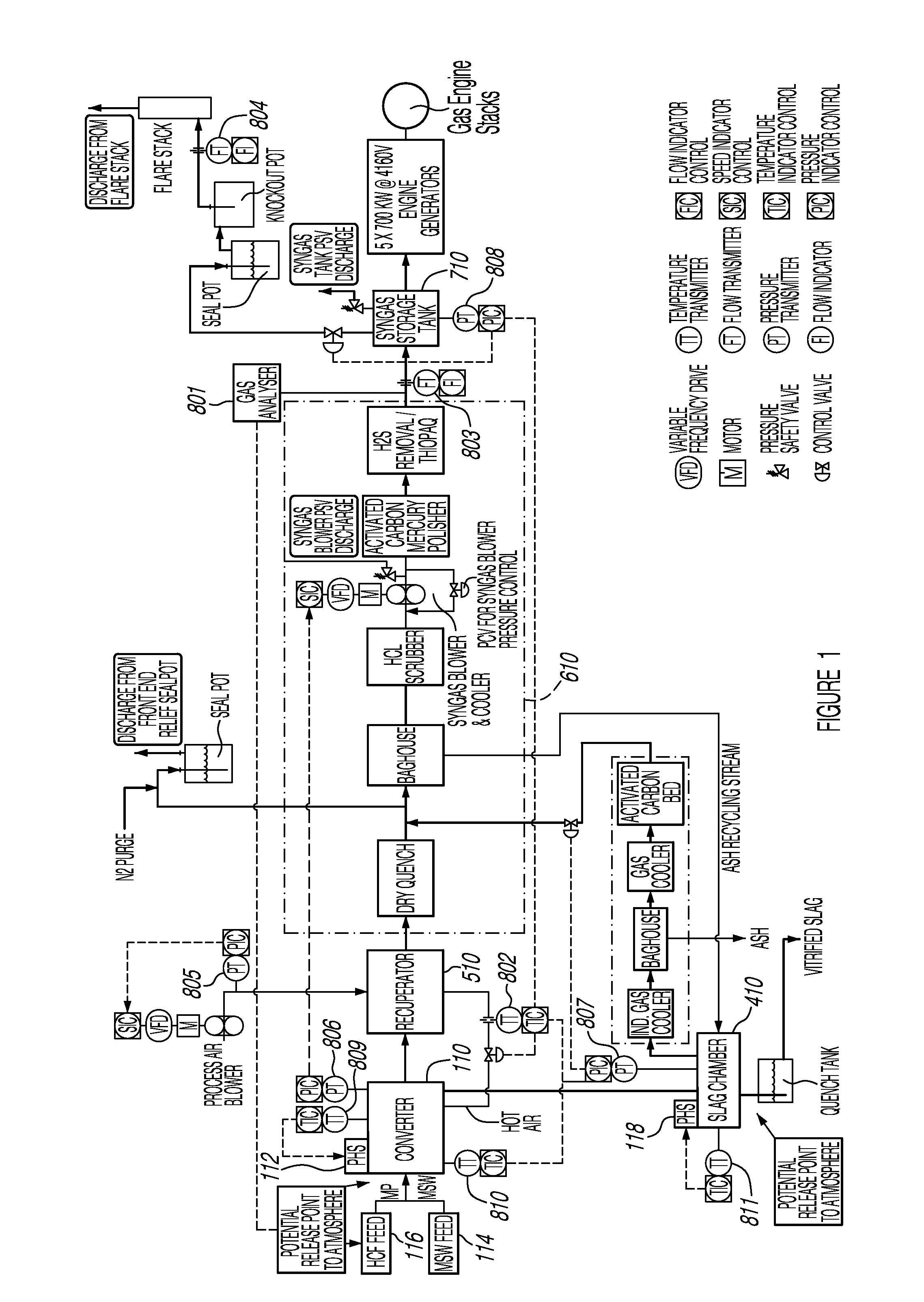

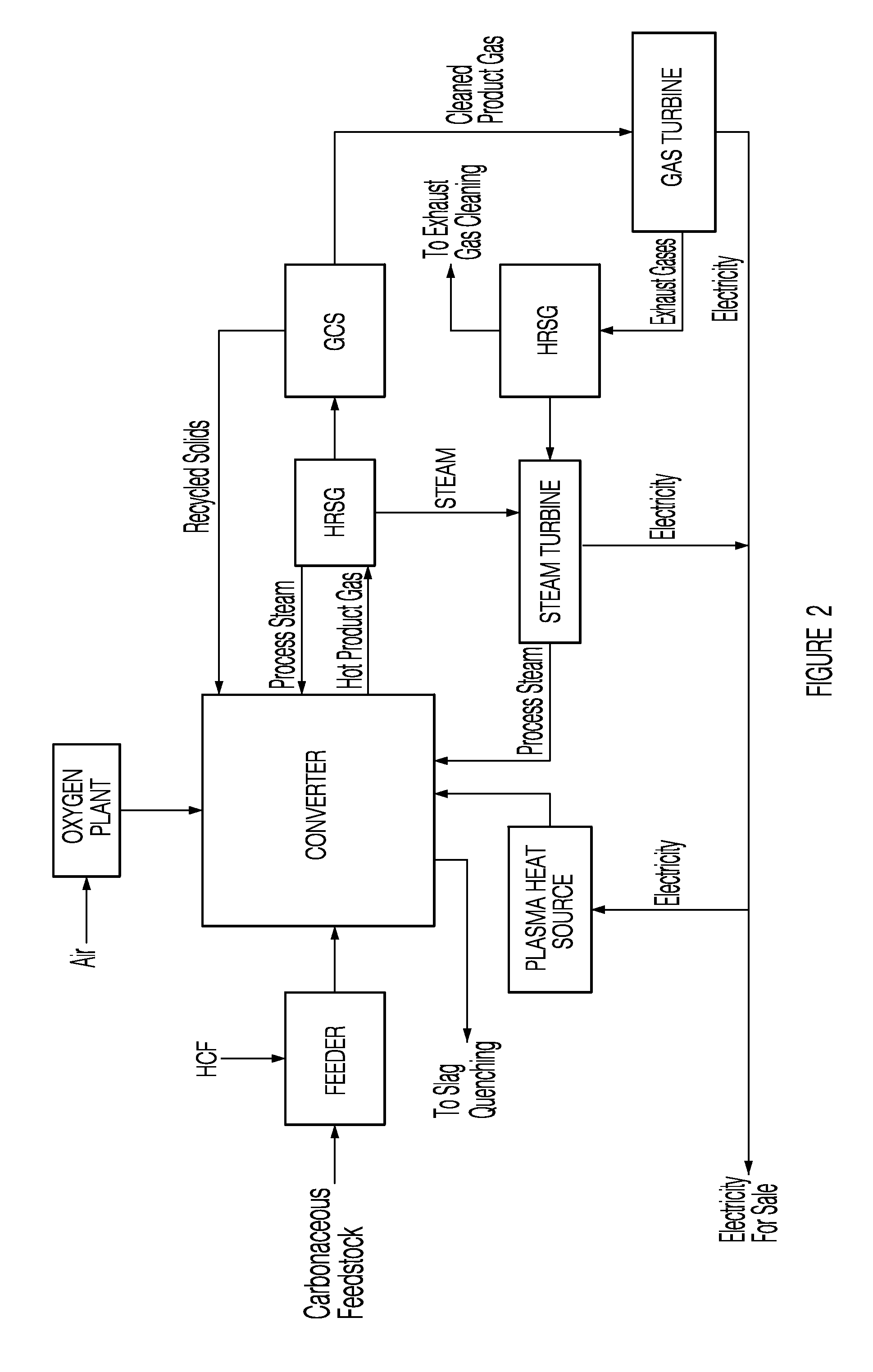

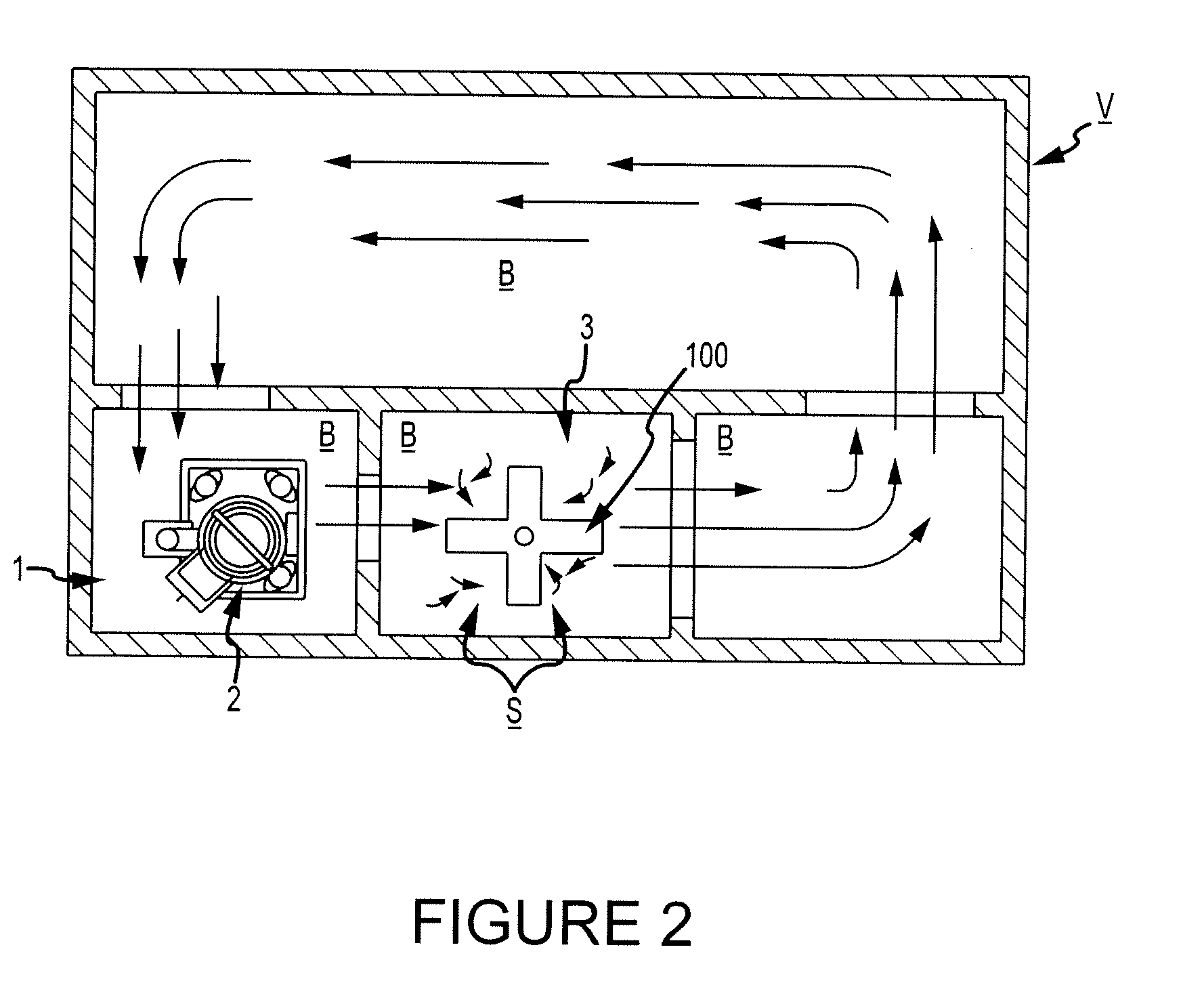

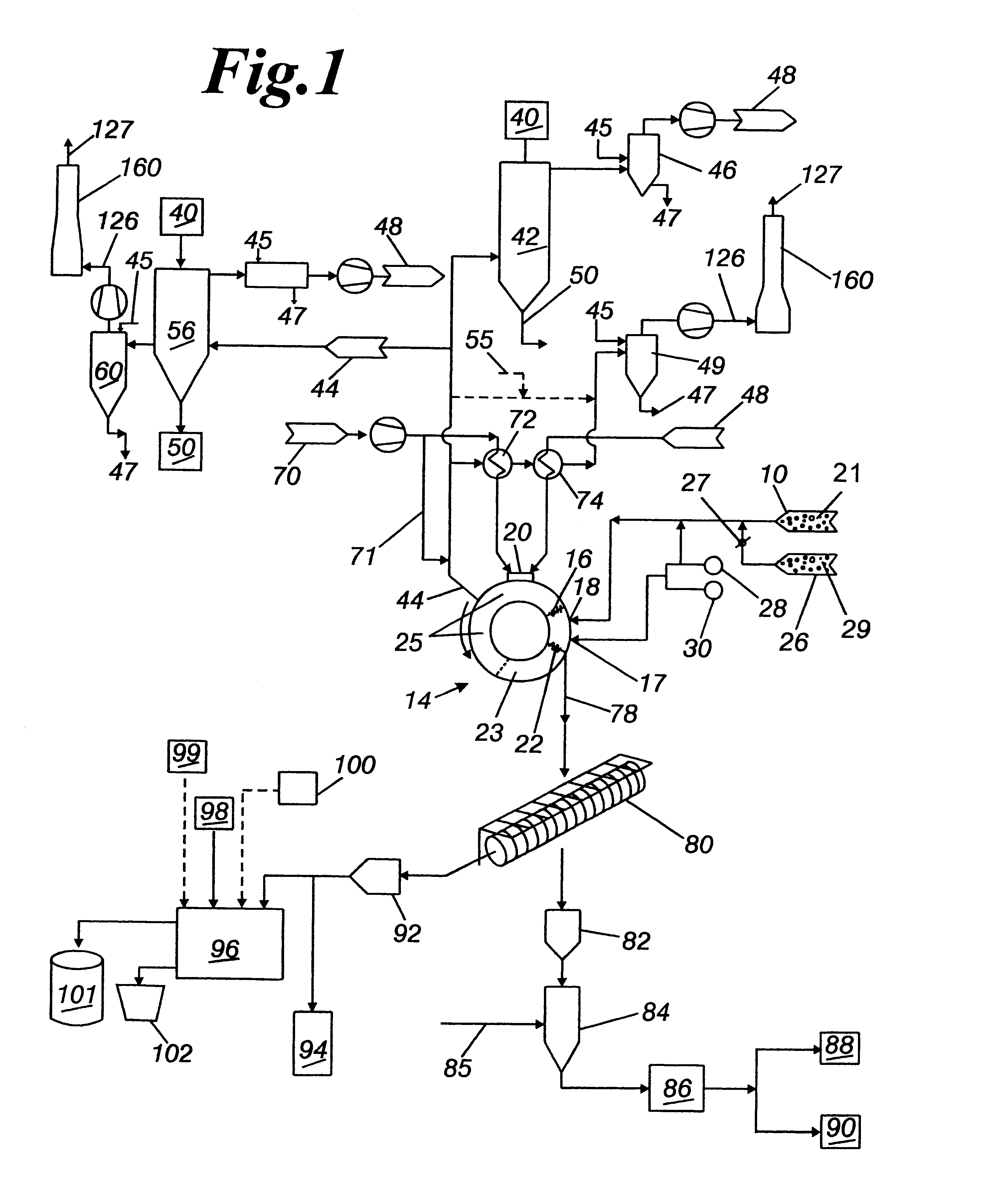

Control System for the Conversion of Carbonaceous Feedstock into Gas

ActiveUS20080147241A1Rapid responseLong responseCombination devicesFunctional valve typesControl systemEngineering

The present invention provides a control system for the conversion of carbonaceous feedstock into a gas. In particular, the control system is designed to be configurable for use in controlling one or more processes implemented in, and / or by, a gasification system for the conversion of such feedstock into a gas, which may be used for one or more downstream applications. Gasification processes controllable by different embodiments of the disclosed control system may include in various combinations, a converter, a residue conditioner, a recuperator and / or heat exchanger system, one or more gas conditioners, a gas homogenization system and one or more downstream applications. The control system operatively controls various local, regional and / or global processes related to the overall gasification process, and thereby adjusts various control parameters thereof adapted to affect these processes for a selected result. Various sensing elements and response elements are therefore distributed throughout the controlled system and used to acquire various process, reactant and / or product characteristics, compare these characteristics to suitable ranges of such characteristics conducive to achieving the desired result, and respond by implementing changes to in one or more of the ongoing processes via one or more controllable process devices.

Owner:PLASCO CONVERSION TECH INC

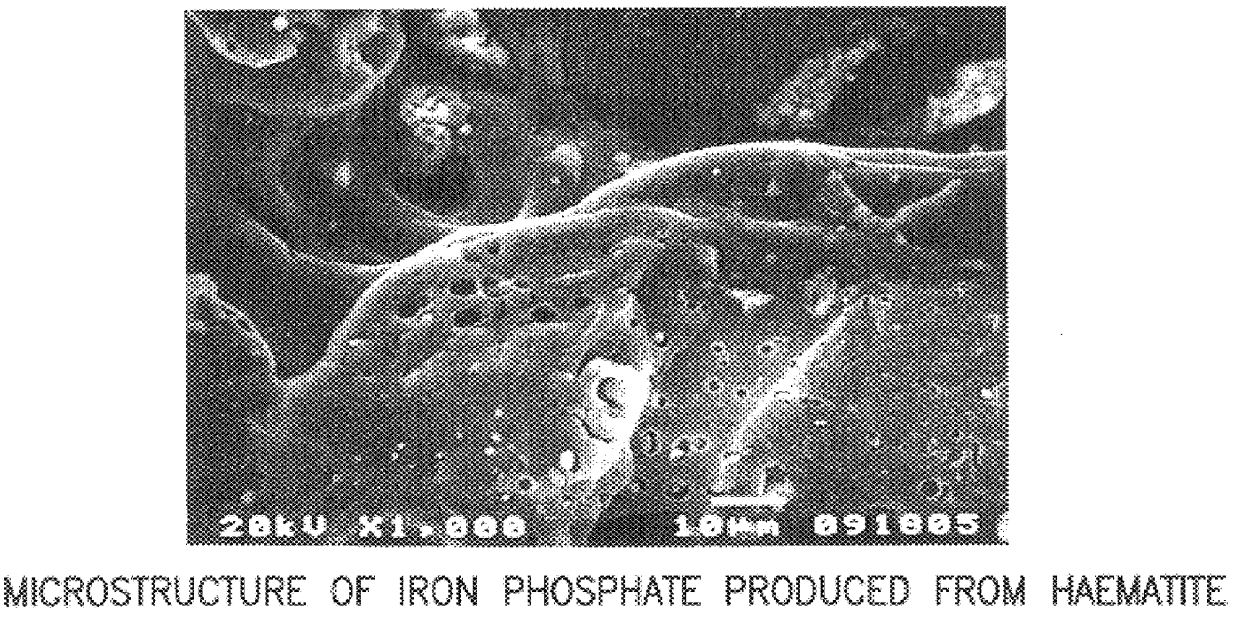

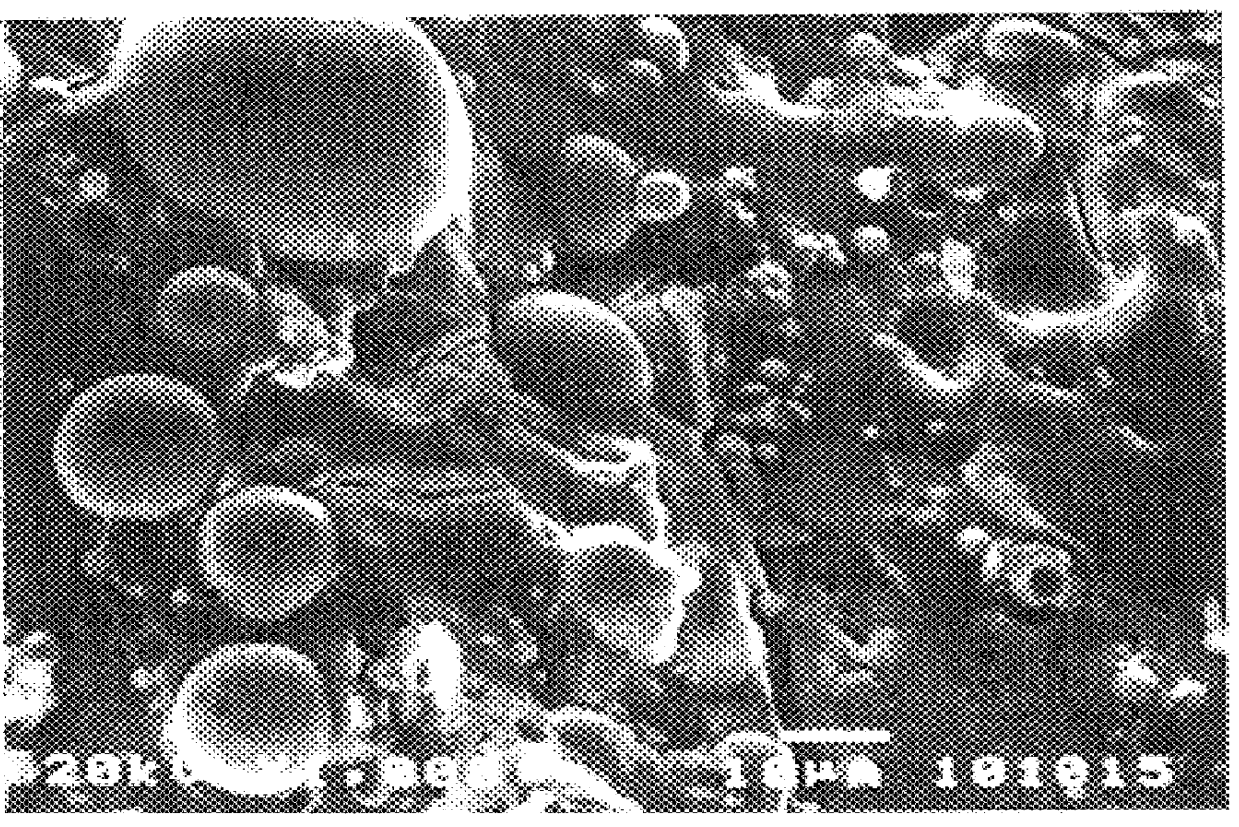

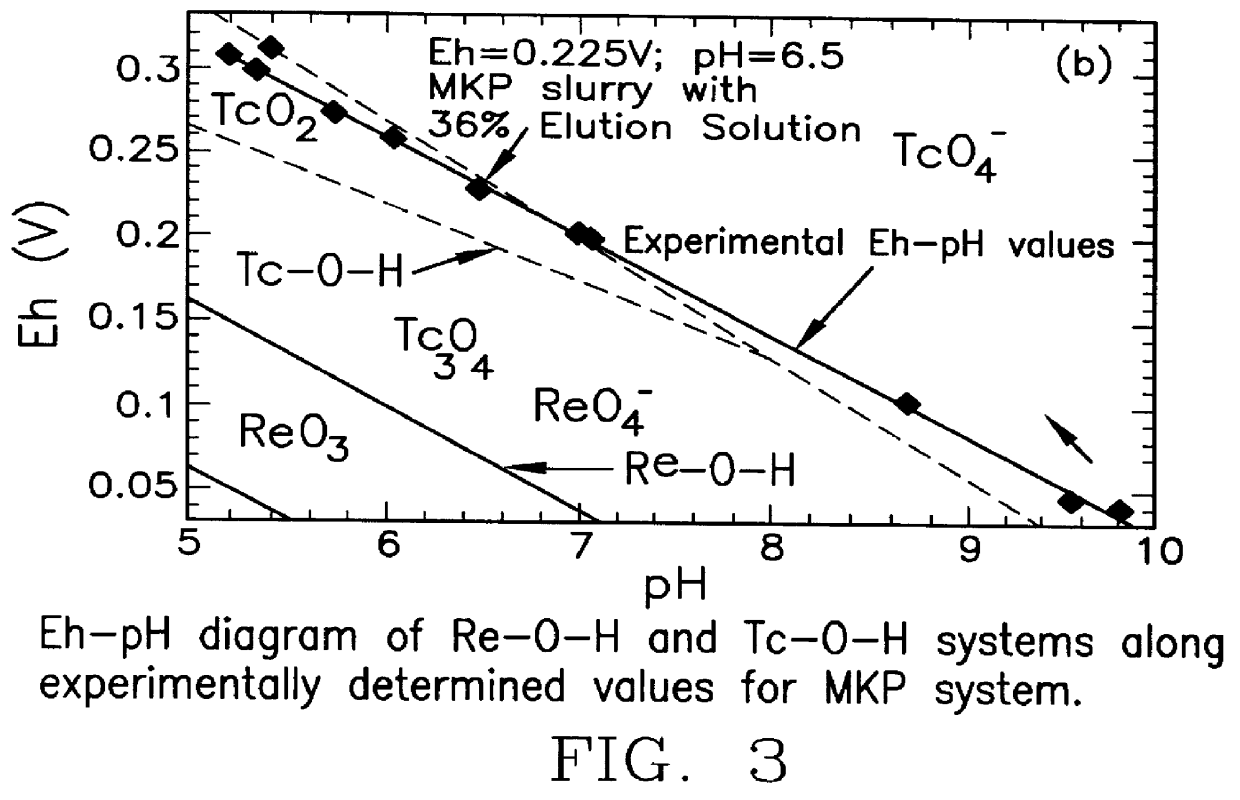

Method for producing chemically bonded phosphate ceramics and for stabilizing contaminants encapsulated therein utilizing reducing agents

Known phosphate ceramic formulations are improved and the ability to produce iron-based phosphate ceramic systems is enabled by the addition of an oxidizing or reducing step during the acid-base reactions that form the phosphate ceramic products. The additives allow control of the rate of the acid-base reactions and concomitant heat generation. In an alternate embodiment, waste containing metal anions are stabilized in phosphate ceramic products by the addition of a reducing agent to the phosphate ceramic mixture. The reduced metal ions are more stable and / or reactive with the phosphate ions, resulting in the formation of insoluble metal species within the phosphate ceramic matrix, such that the resulting chemically bonded phosphate ceramic product has greater leach resistance.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

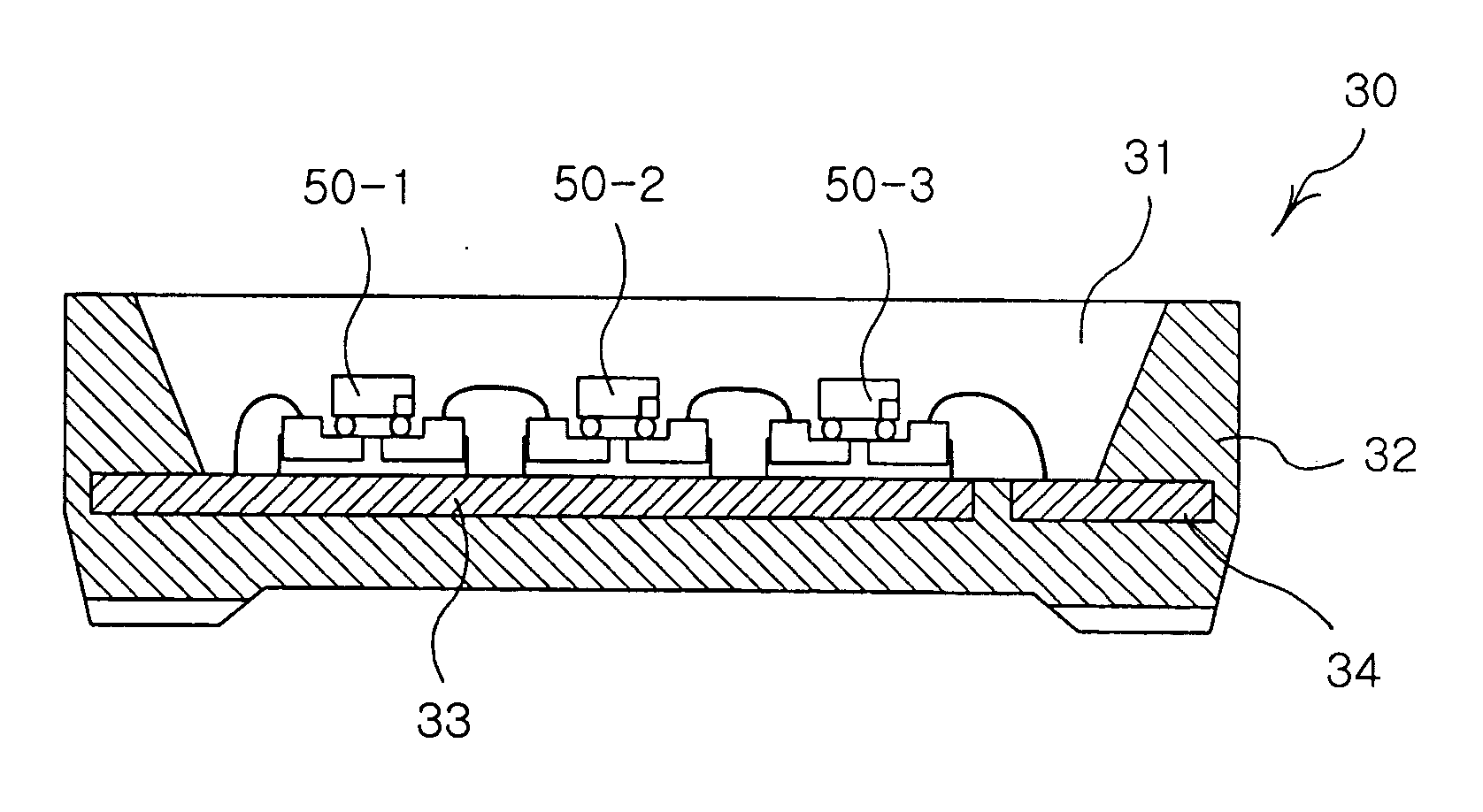

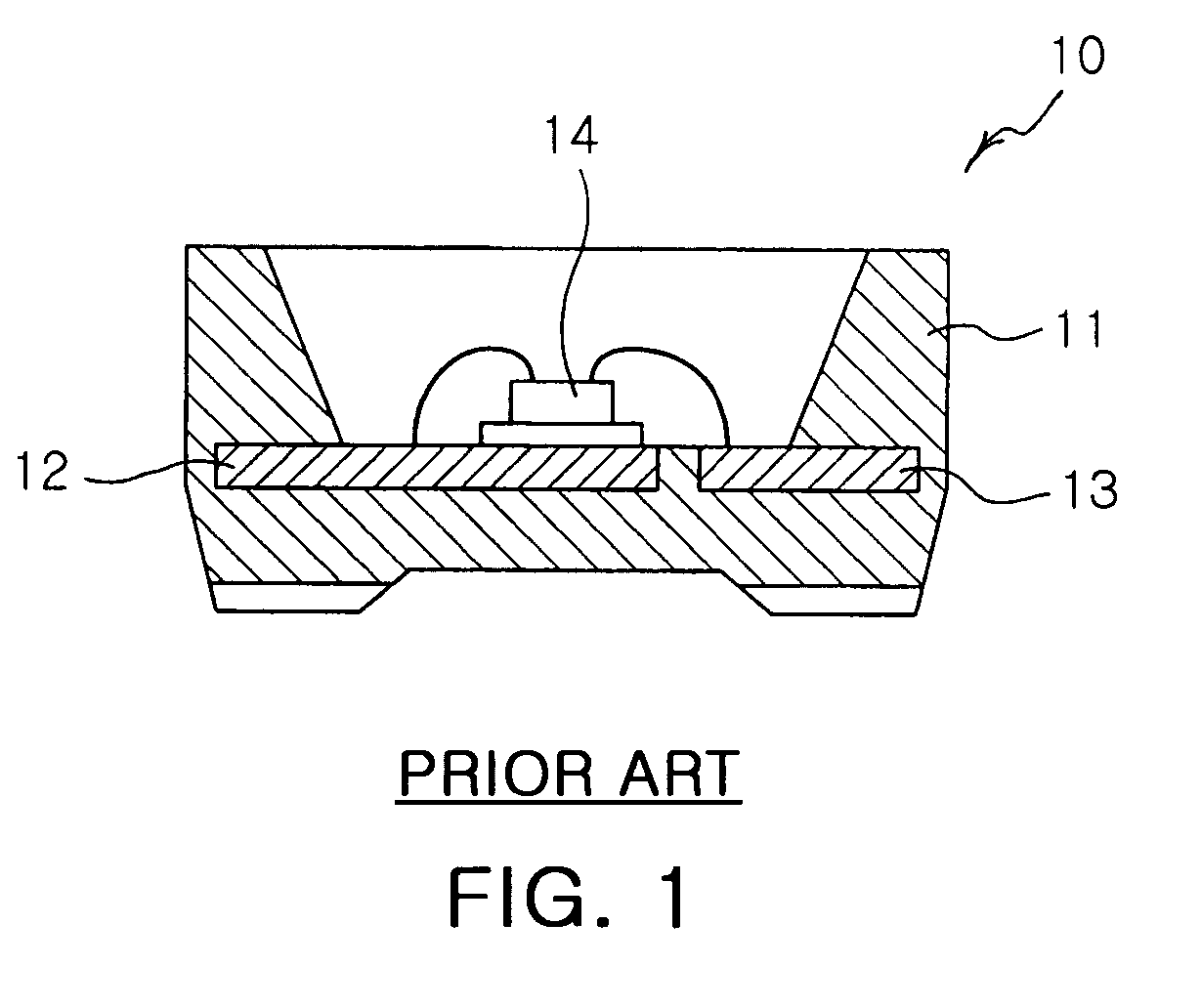

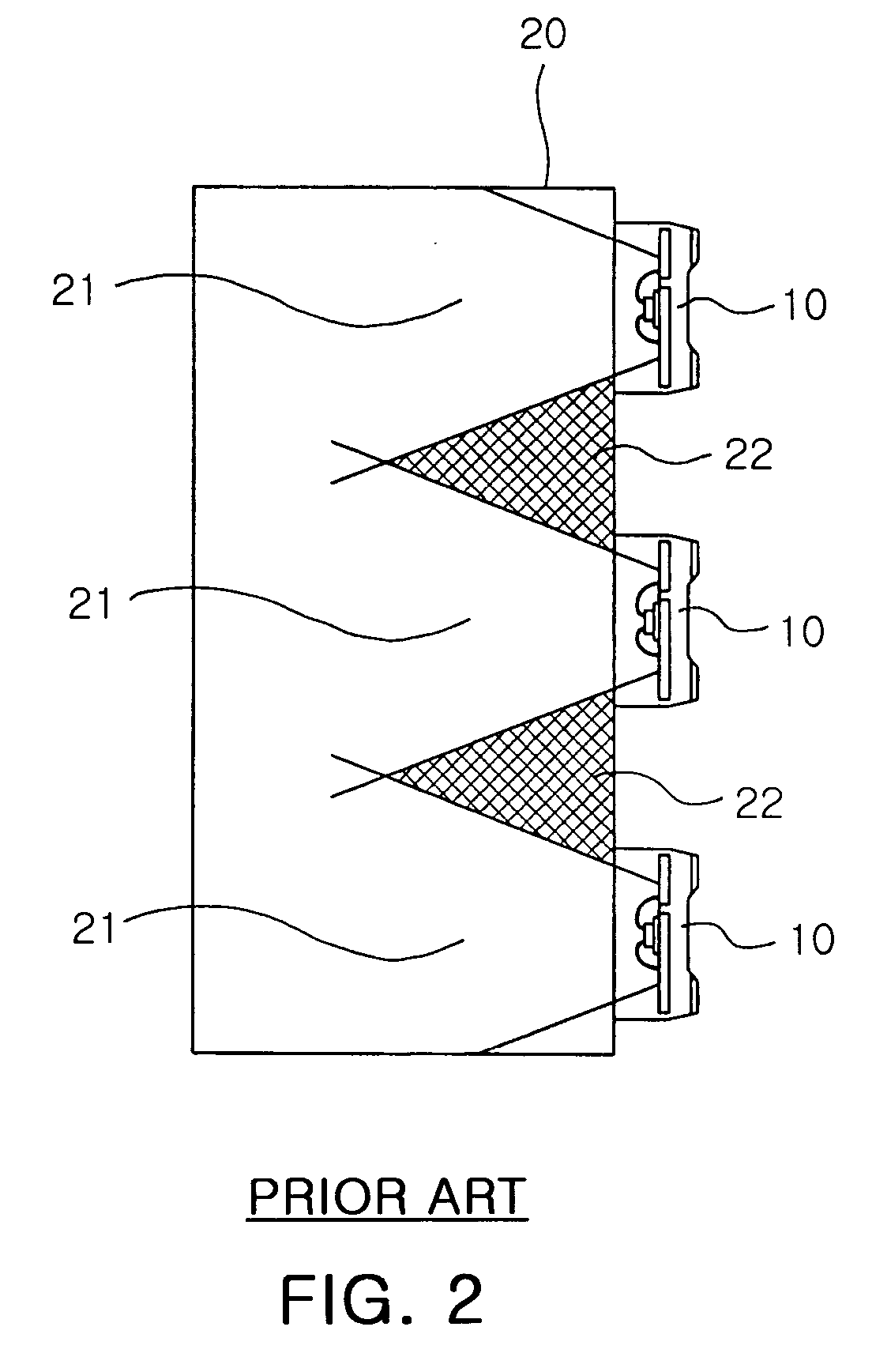

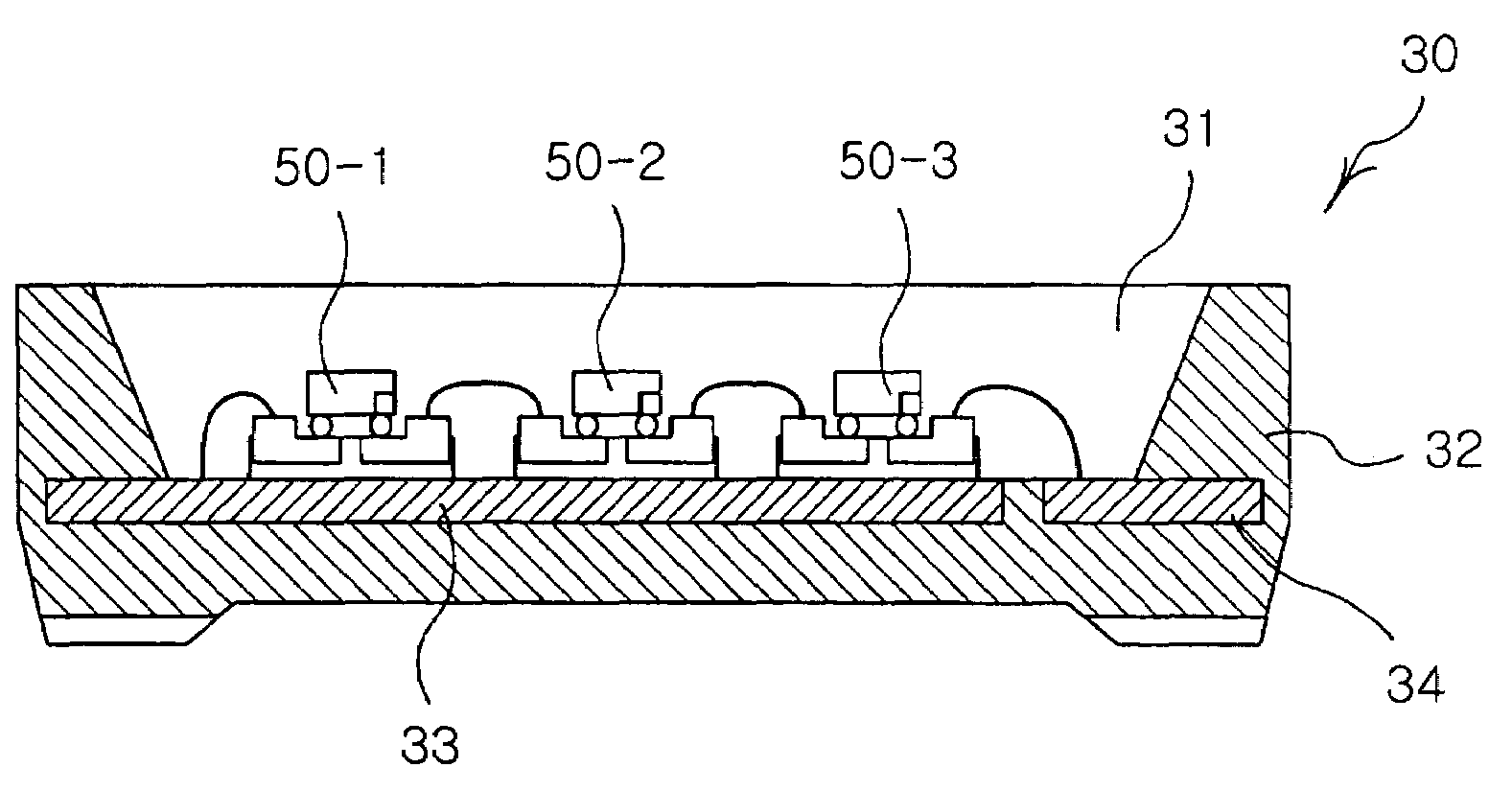

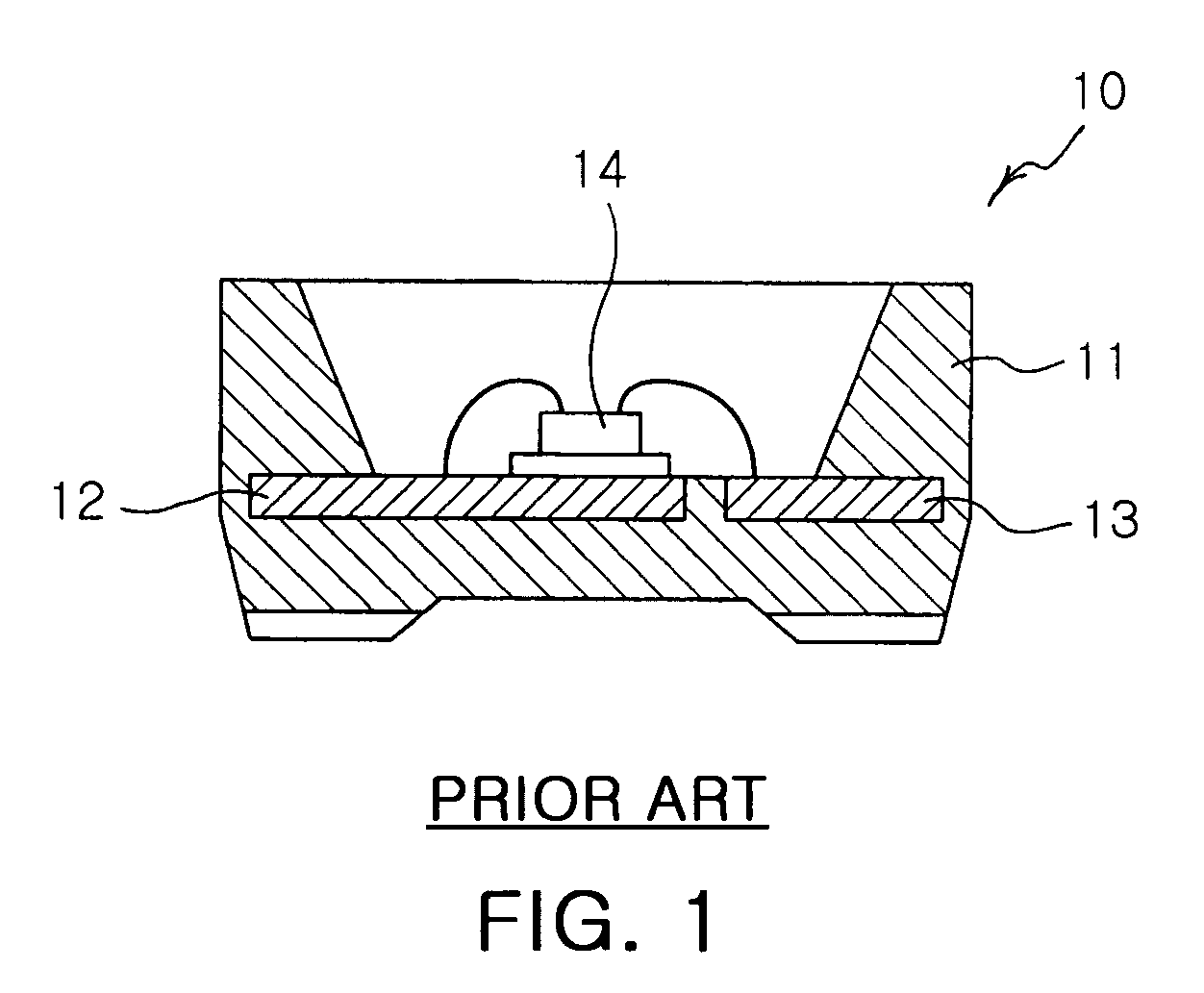

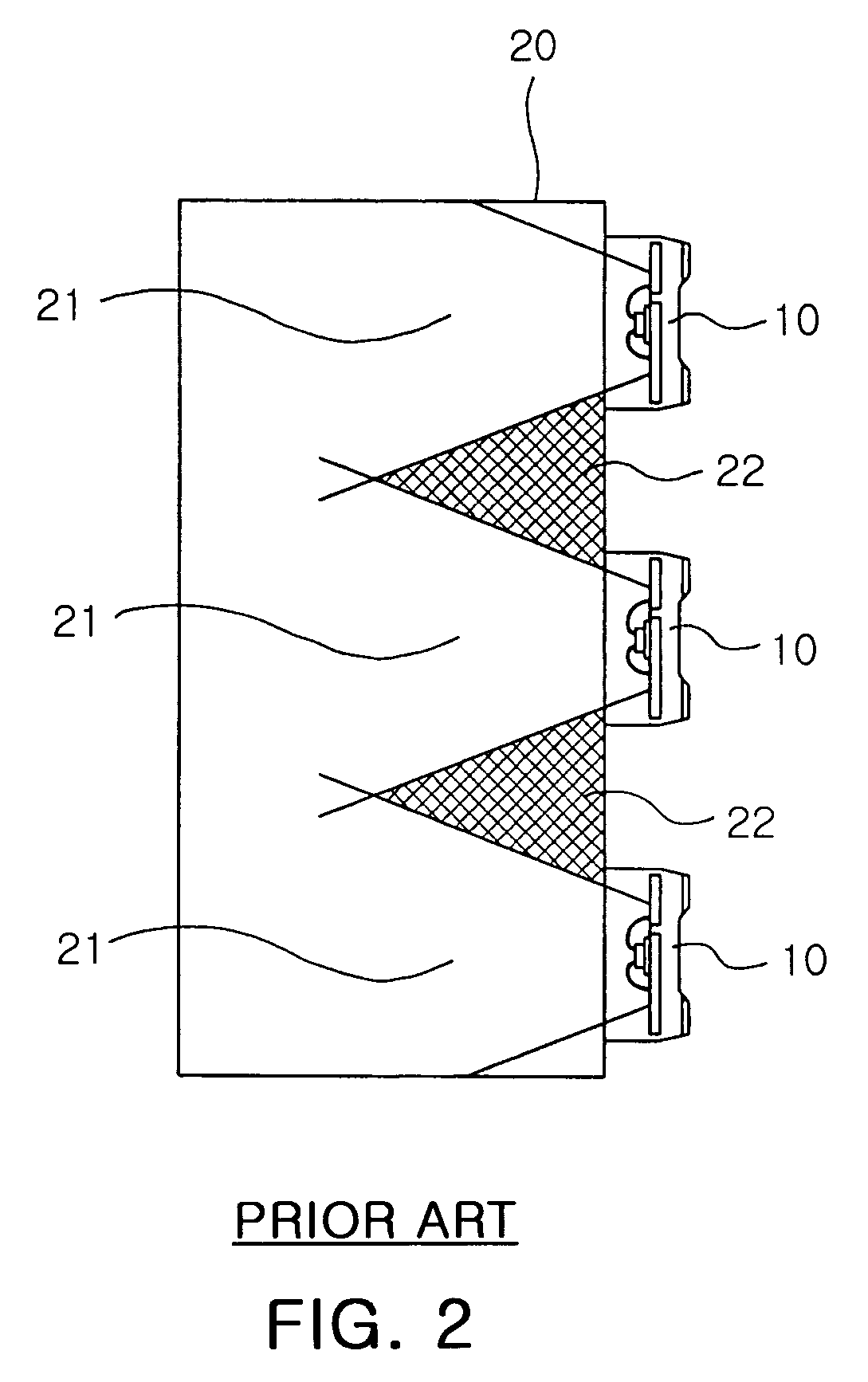

LED package for backlight unit

ActiveUS20060023451A1Avoid deformationImprove image qualityLighting support devicesGlass furnace apparatusEngineeringDie bonding

Disclosed herein is an LED package for a backlight unit. The LED package includes a plurality of LEDs, a die bonding part, a wire bonding part and a body. The die bonding part, on which the plurality of LEDs is arranged, allows the first electrodes of the LEDs to be electrically connected to an external circuit. The wire bonding part is spaced apart from the die bonding part by a predetermined distance to be insulated from the die bonding part and allows the second electrodes of the LEDs to be electrically connected to the external circuit so that the LEDs are operated. The body has a molding cup which is used to fill a space above the LEDs with transparent resin and a base on which the die bonding part and the wire bonding part are arranged.

Owner:SAMSUNG ELECTRONICS CO LTD

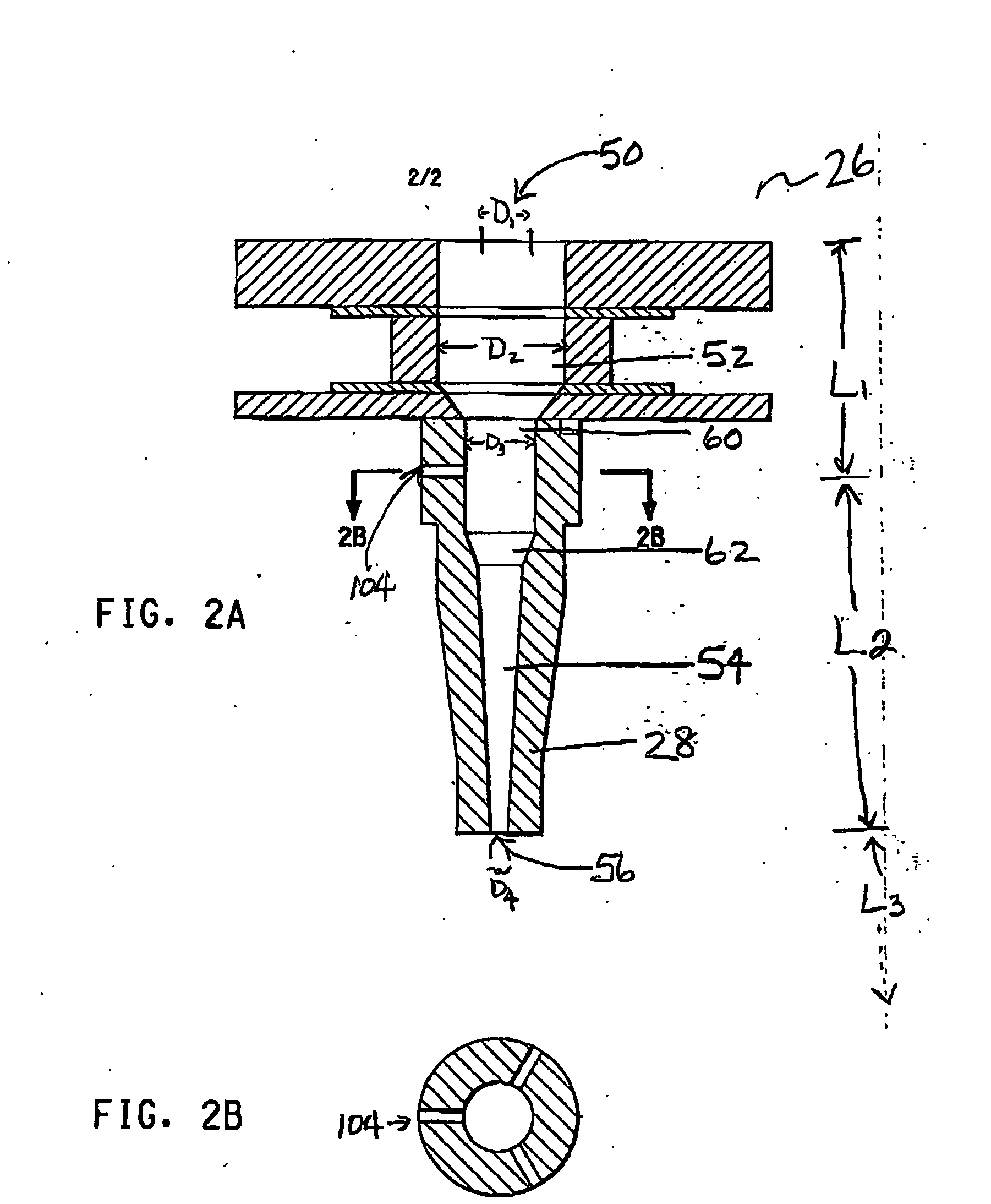

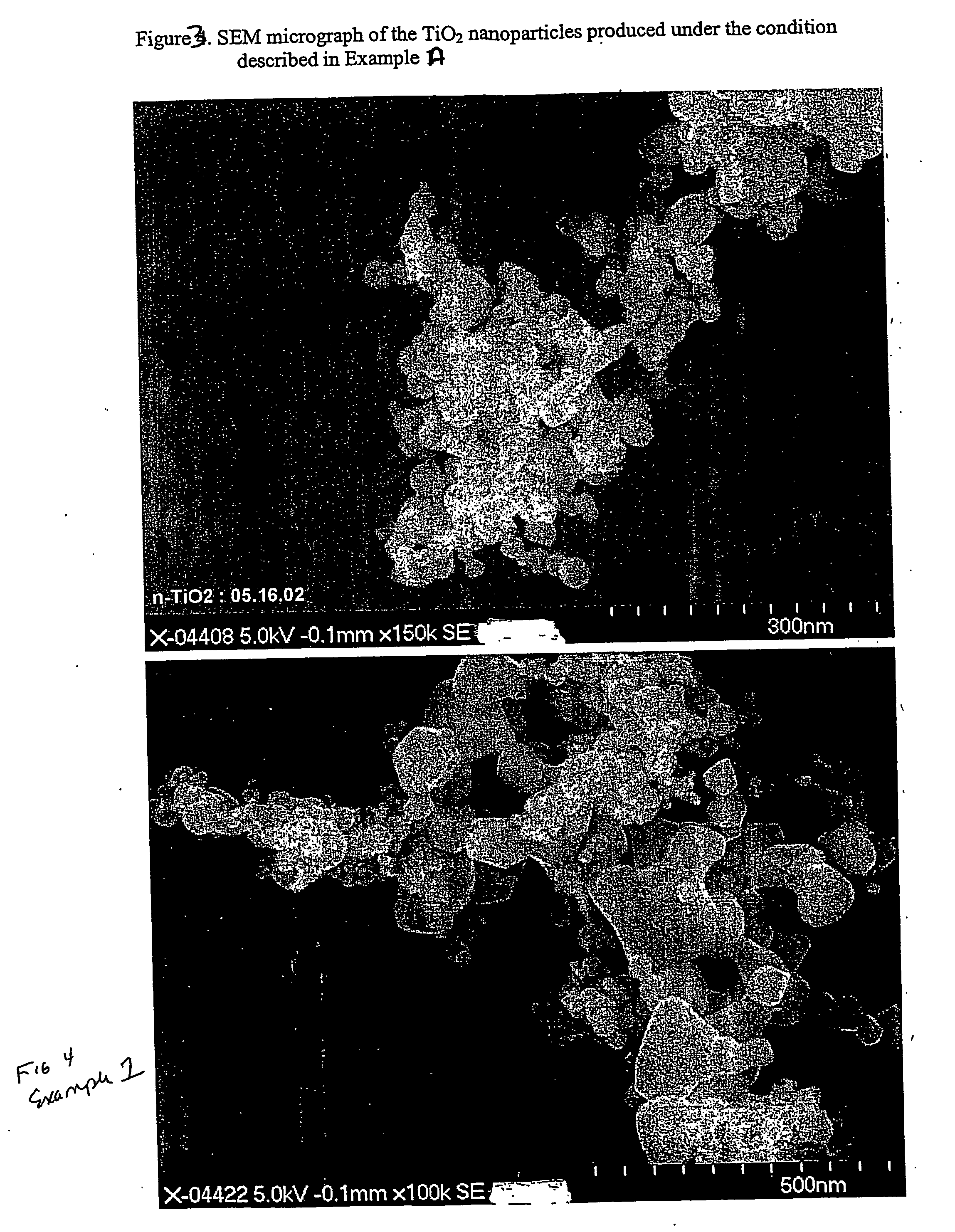

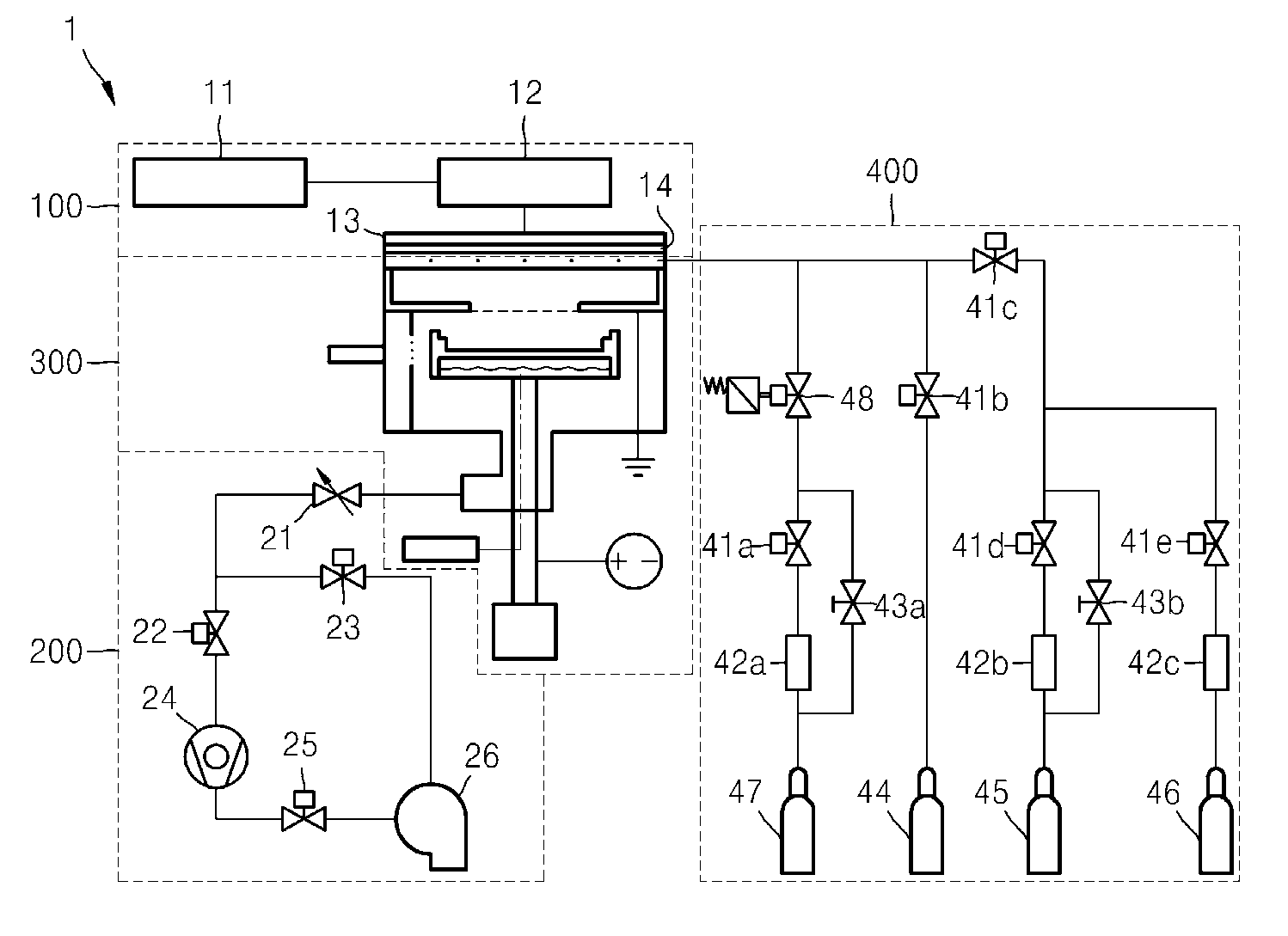

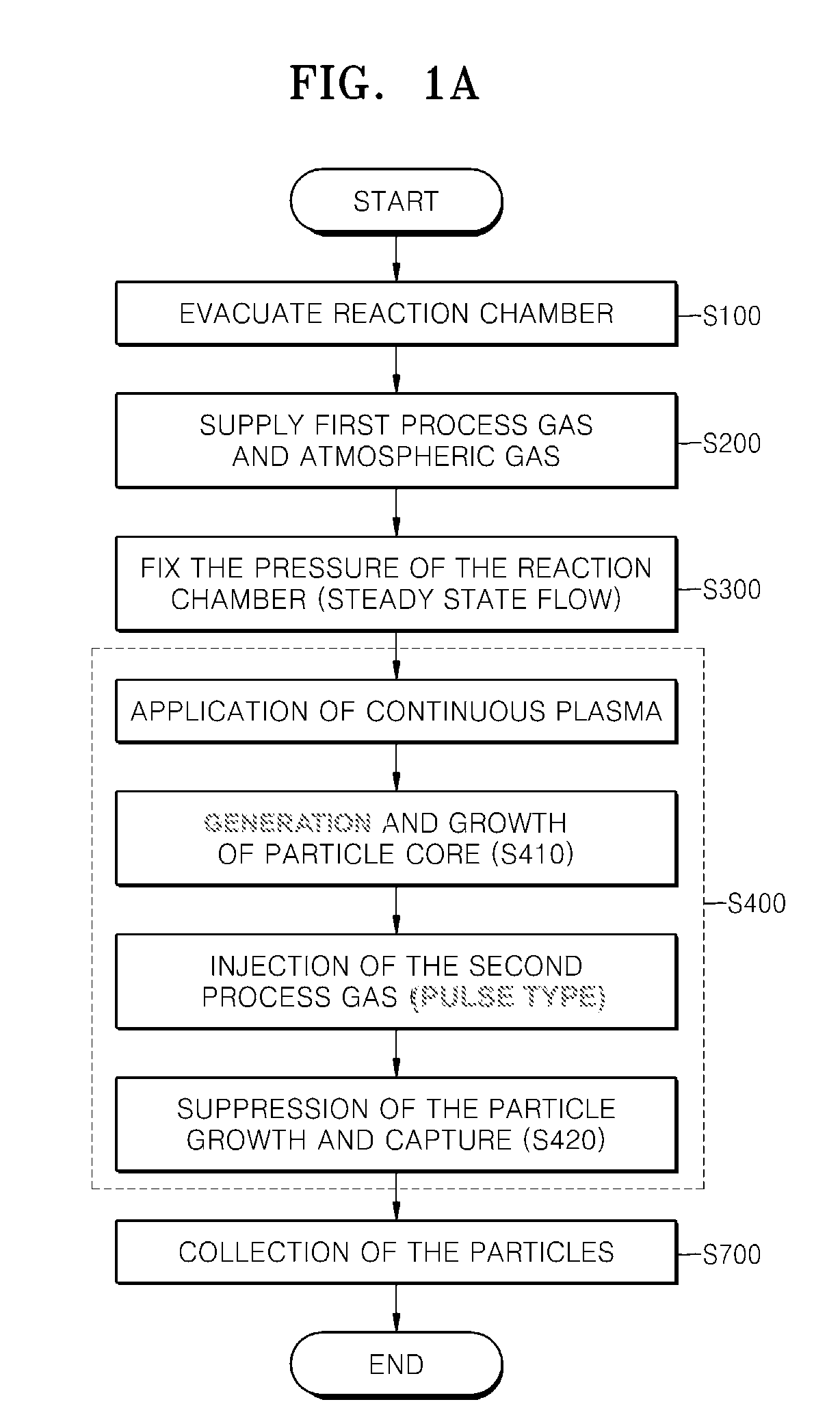

Method of producing nanoparticles using a evaporation-condensation process with a reaction chamber plasma reactor system

InactiveUS20060159596A1Reduce the temperatureMaterial nanotechnologyNanostructure manufactureNanoparticleReaction zone

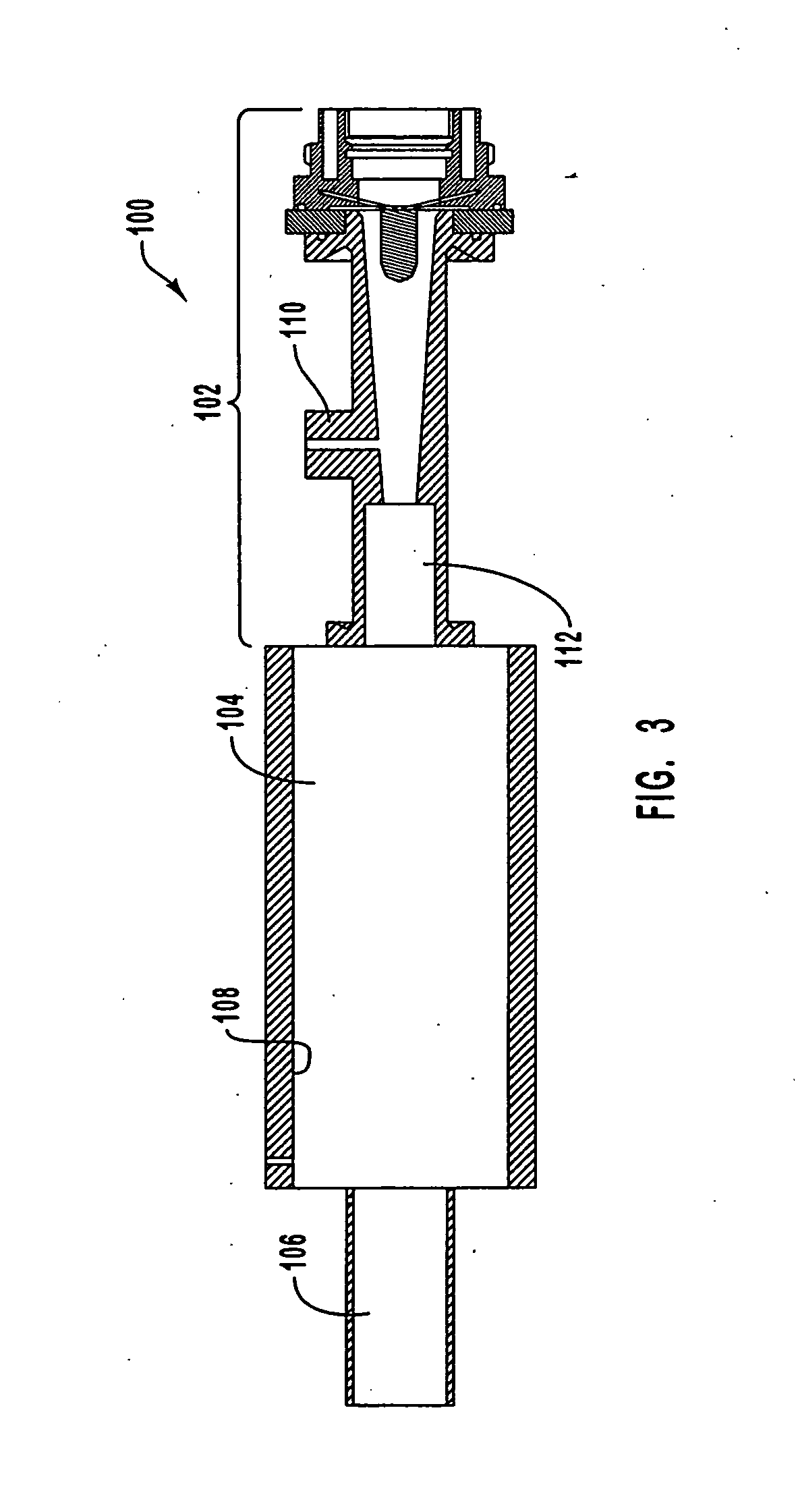

The present invention provides a method and apparatus for the controlled synthesis of nanoparticles using a high temperature process. The reactor chamber includes a high temperature gas heated by means such as a plasma torch, and a reaction chamber. The homogenizer includes a region between the reactant inlets and the plasma (the spacer zone) to ensure that feeds from the reactant inlets are downstream of the recirculation zone induced by the high temperature gas. It also includes a region downstream of the reactant inlets that provides a nearly I dimensional (varying only in the axial direction) flow and concentration profile in the reaction zone to produce nanoparticles with narrow size distribution.

Owner:EI DU PONT DE NEMOURS & CO

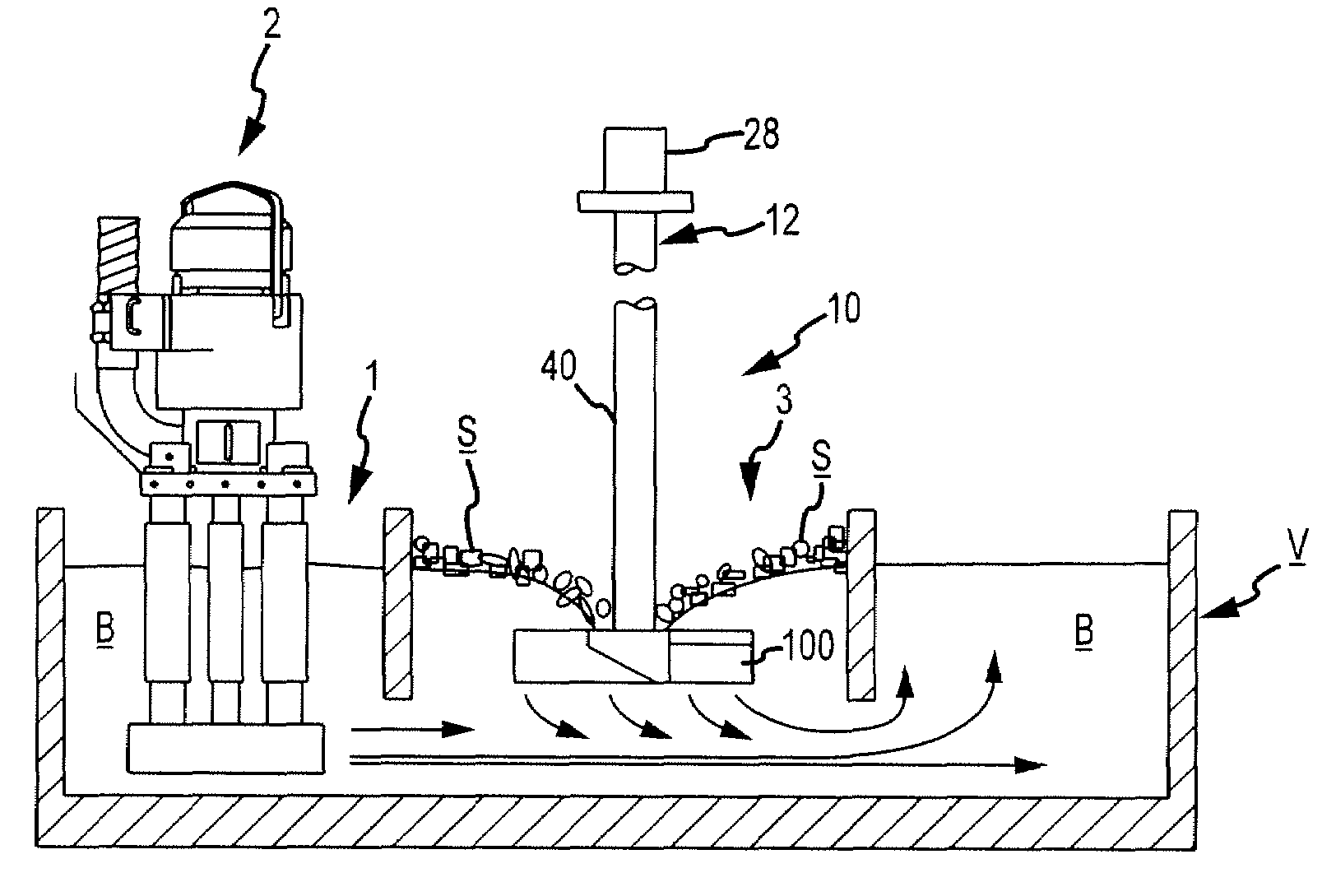

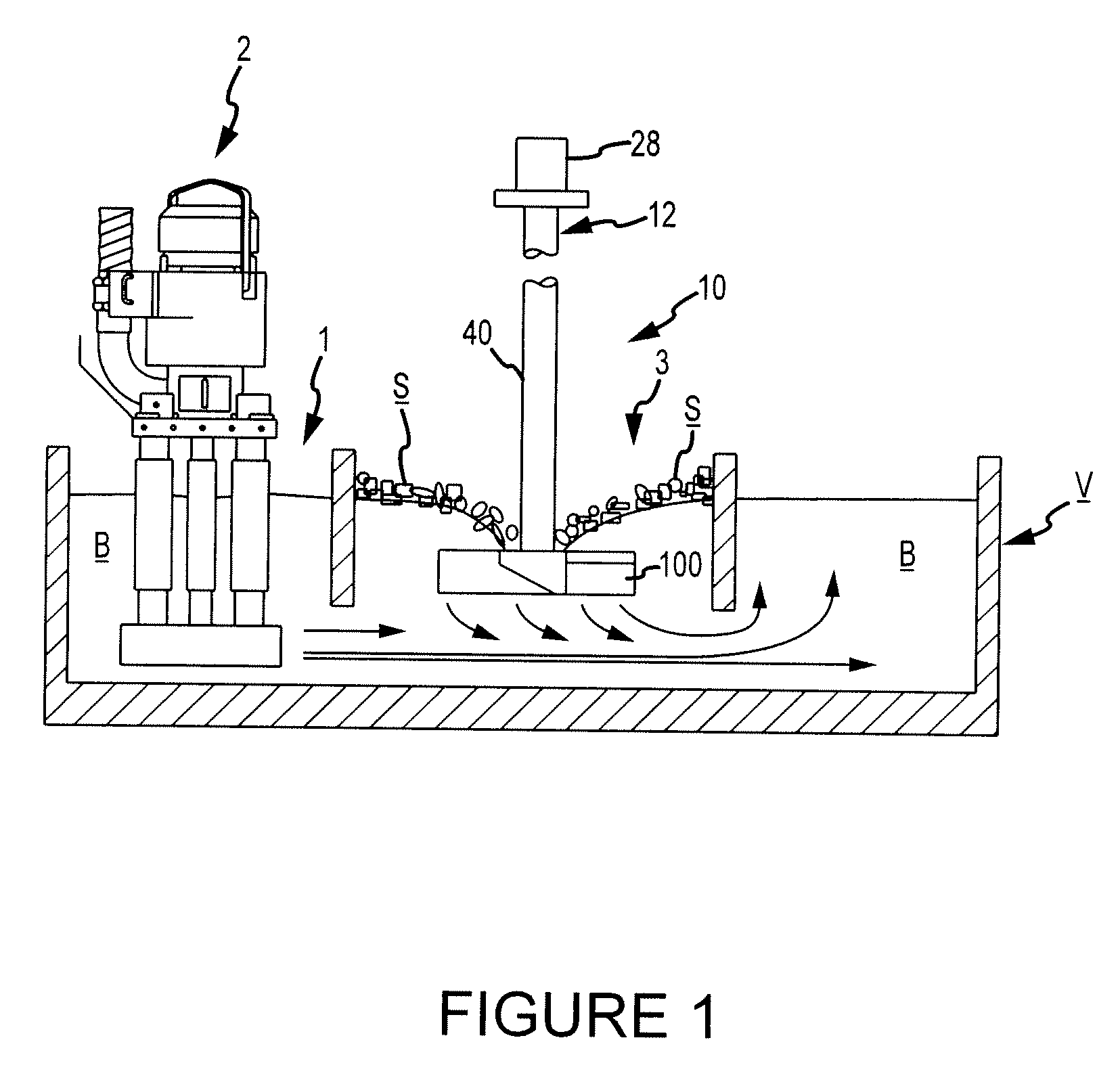

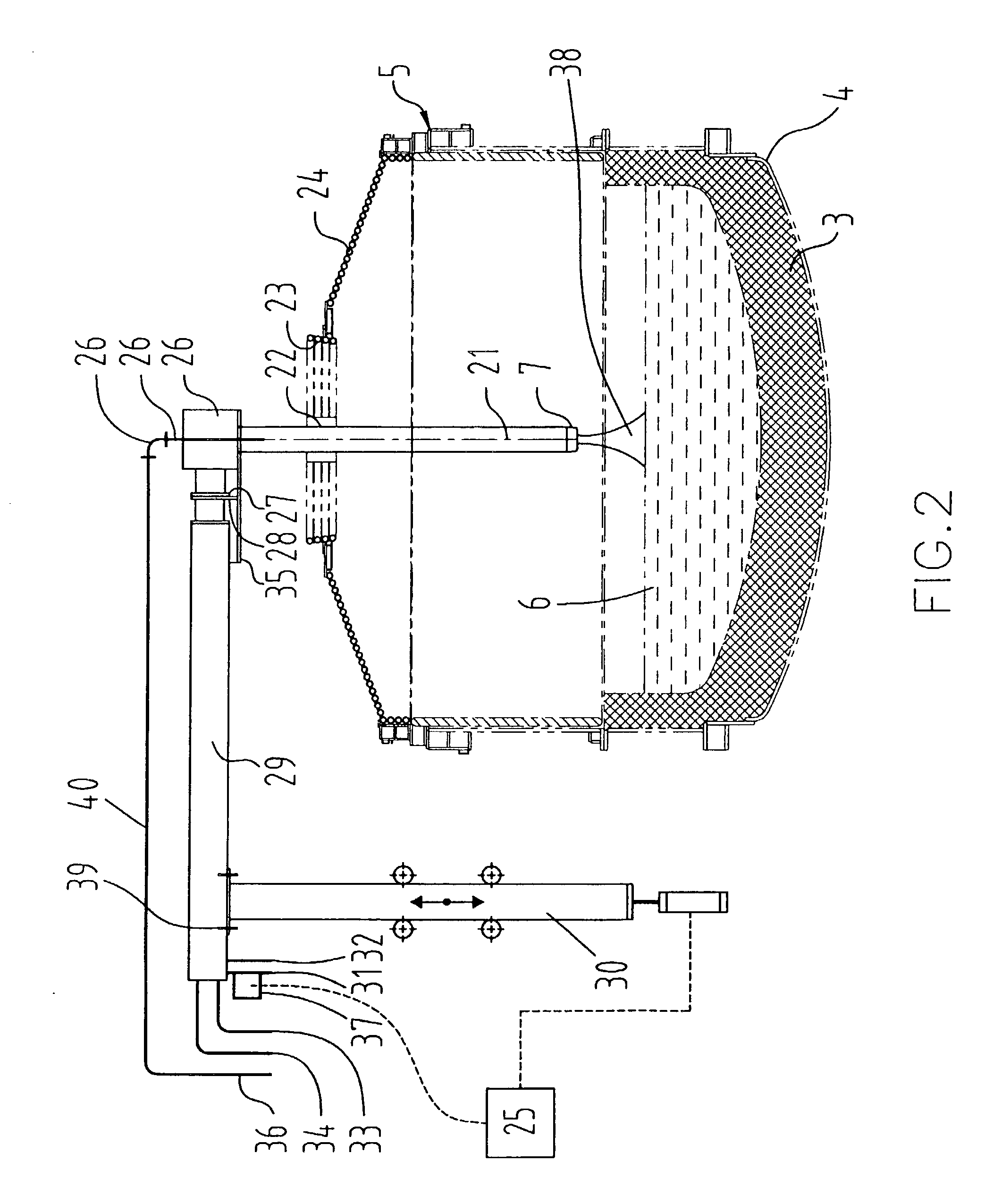

Scrap melter and impeller therefore

InactiveUS20080230966A1Reduce jammingReduce cloggingMelt-holding vesselsStirring devicesImpellerDrive shaft

A device for submerging scrap metal includes: (a) a drive source, (b) a drive shaft having a first end and a second end, the first end being connected to the drive source, and (d) an impeller connected to the second end of the drive shaft, the impeller preferably having two or more outwardly-extending blades. Preferably, each of the blades has a portion that directs molten metal at least partially downward. The impeller design leads to lower operating speeds, lower vibration, longer component life and less maintenance. Additionally, the impeller preferably has a connective portion. The connective portion is used to connect the impeller to the shaft and preferably comprises a nonthreaded, tapered bore extending through the impeller.

Owner:COOPER PAUL V

Method of making iron and steel

InactiveUS6149709AEasy to getLess impurity contentProcess efficiency improvementElectric furnaceHigh energyRefractory

Molten iron is prepared by (1) providing iron oxide and a carbonaceous reducing agent, (2) preparing a shaped product from the carbonaceous reducing agent and the iron oxide, (3) preparing solid reduced iron from the shaped product, wherein the solid reduced iron has a metallization of at least 60%, a specific gravity of at least 1.7, and a carbon content of at least 50% of the theoretical amount required for reducing the iron oxide remaining in the solid reduced iron, and, (4) before substantial cooling occurs, heating the solid reduced iron in an arc heating-type melting furnace at a high temperature. The molten iron can be prepared efficiently from iron ores of relatively low iron content without causing erosion of refractories, at high energy and high reduction efficiencies, and by a simple operation in a simple facility.

Owner:KOBE STEEL LTD

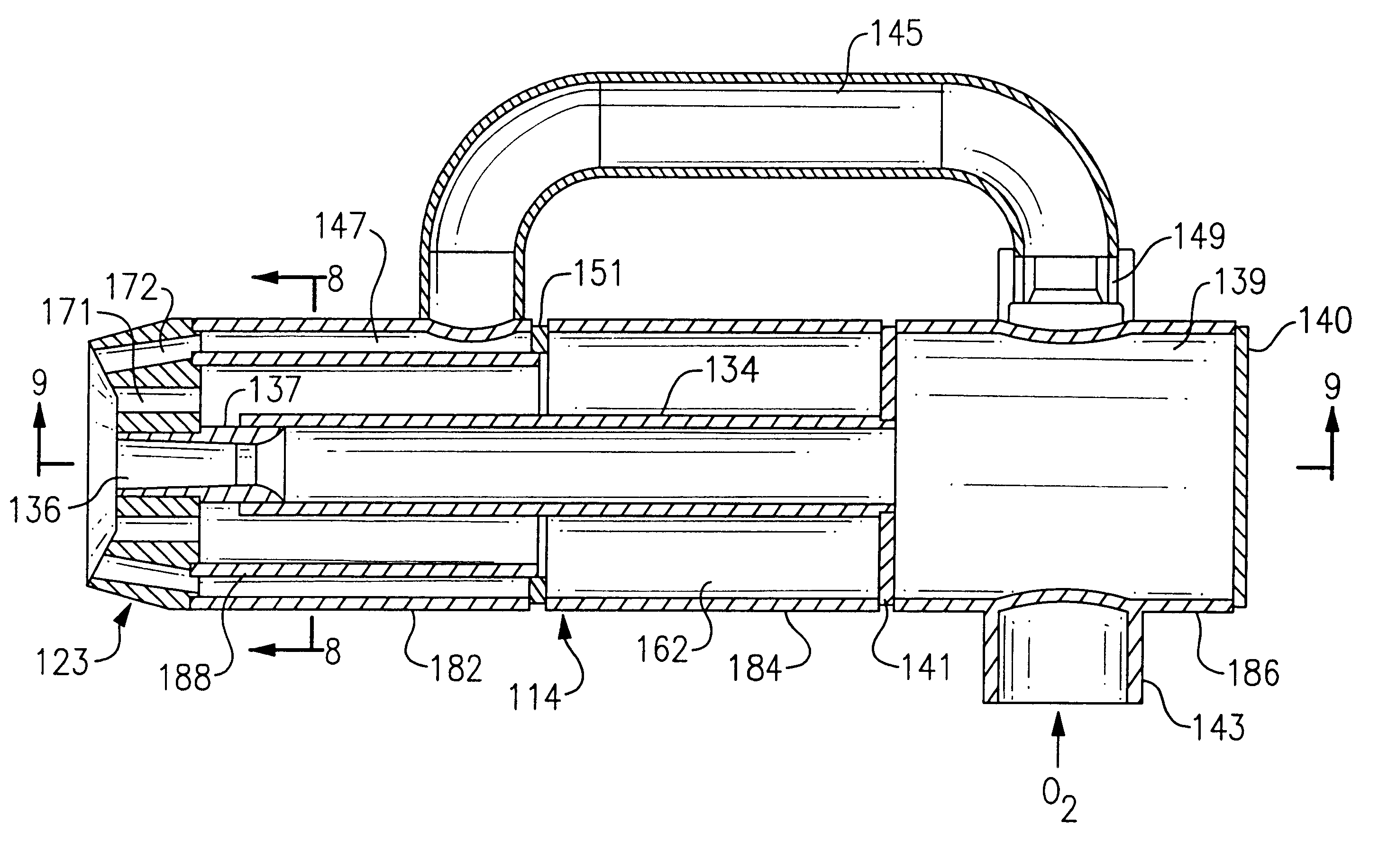

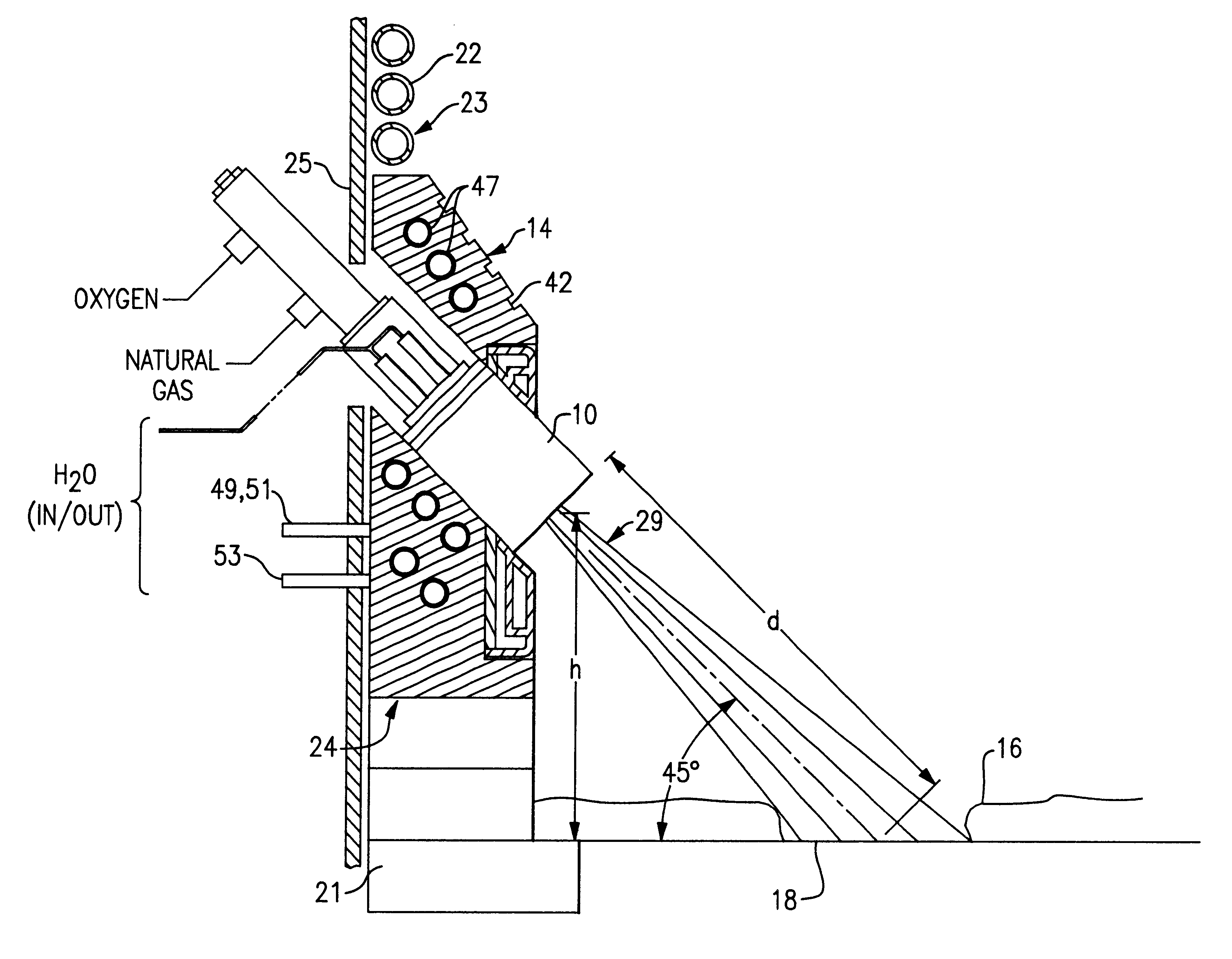

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

Process for production of titanium alloy

InactiveUS6918942B2Inexpensive and reliable in qualityElectric furnaceBeta titanium alloyTitanium aluminum alloy

Owner:TOHO TITANIUM CO LTD

Thermal synthesis apparatus

InactiveUS20040208805A1Smoothly accelerateExpand smoothlyHydrogenCarbon monoxideNuclear engineeringReaction zone

An apparatus for thermal conversion of one or more reactants to desired end products includes an insulated reactor chamber having a high temperature heater such as a plasma torch at its inlet end and, optionally, a restrictive convergent-divergent nozzle at its outlet end. In a thermal conversion method, reactants are injected upstream from the reactor chamber and thoroughly mixed with the plasma stream before entering the reactor chamber. The reactor chamber has a reaction zone that is maintained at a substantially uniform temperature. The resulting heated gaseous stream is then rapidly cooled by passage through the nozzle, which "freezes" the desired end product(s) in the heated equilibrium reaction stage, or is discharged through an outlet pipe without the convergent-divergent nozzle. The desired end products are then separated from the gaseous stream.

Owner:BATTELLE ENERGY ALLIANCE LLC

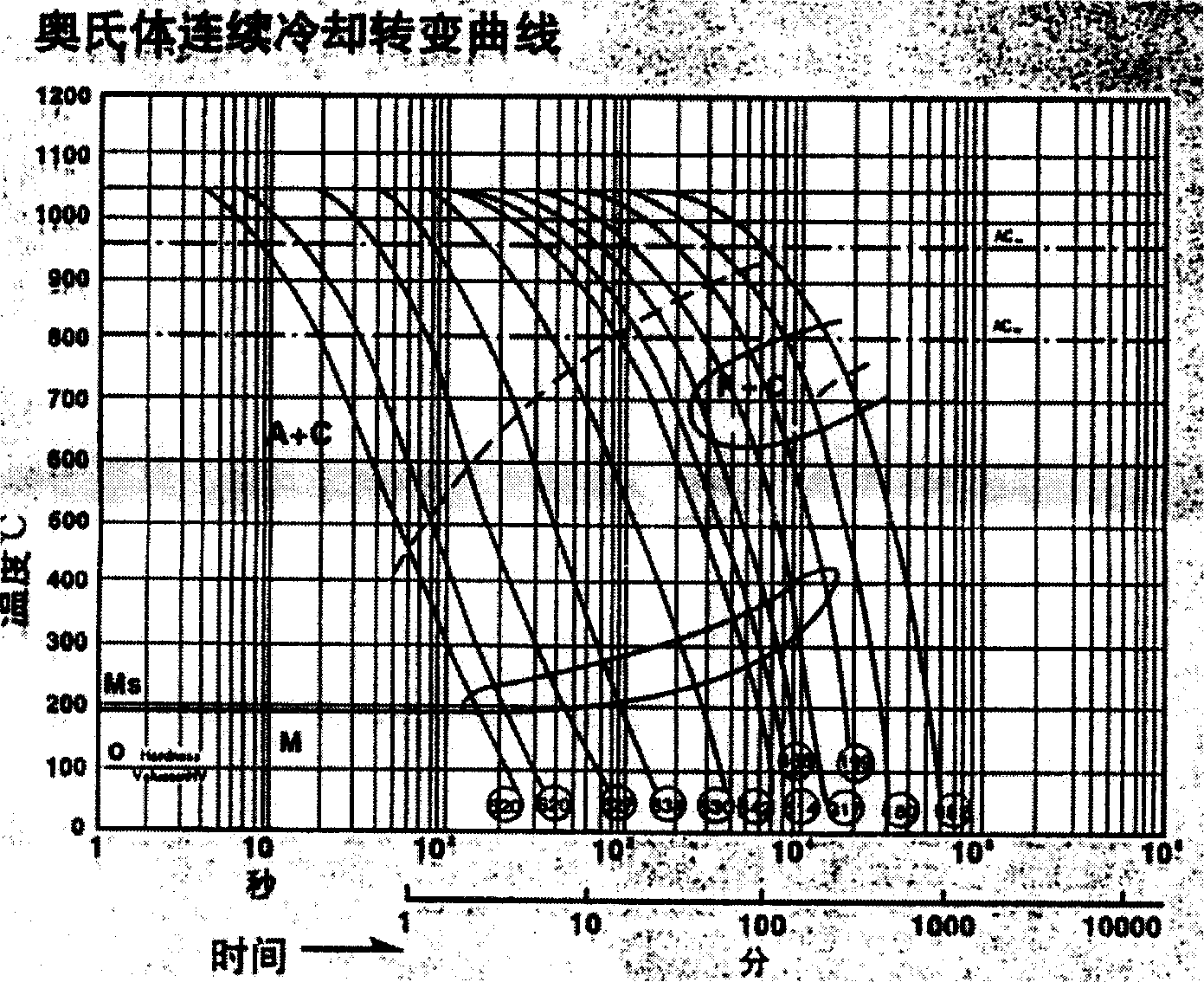

High carbon steel wire rod and preparation method thereof

ActiveCN101649416AImprove mechanical propertiesLess alloying elementsTemperature control deviceManufacturing convertersWire rodTemperature control

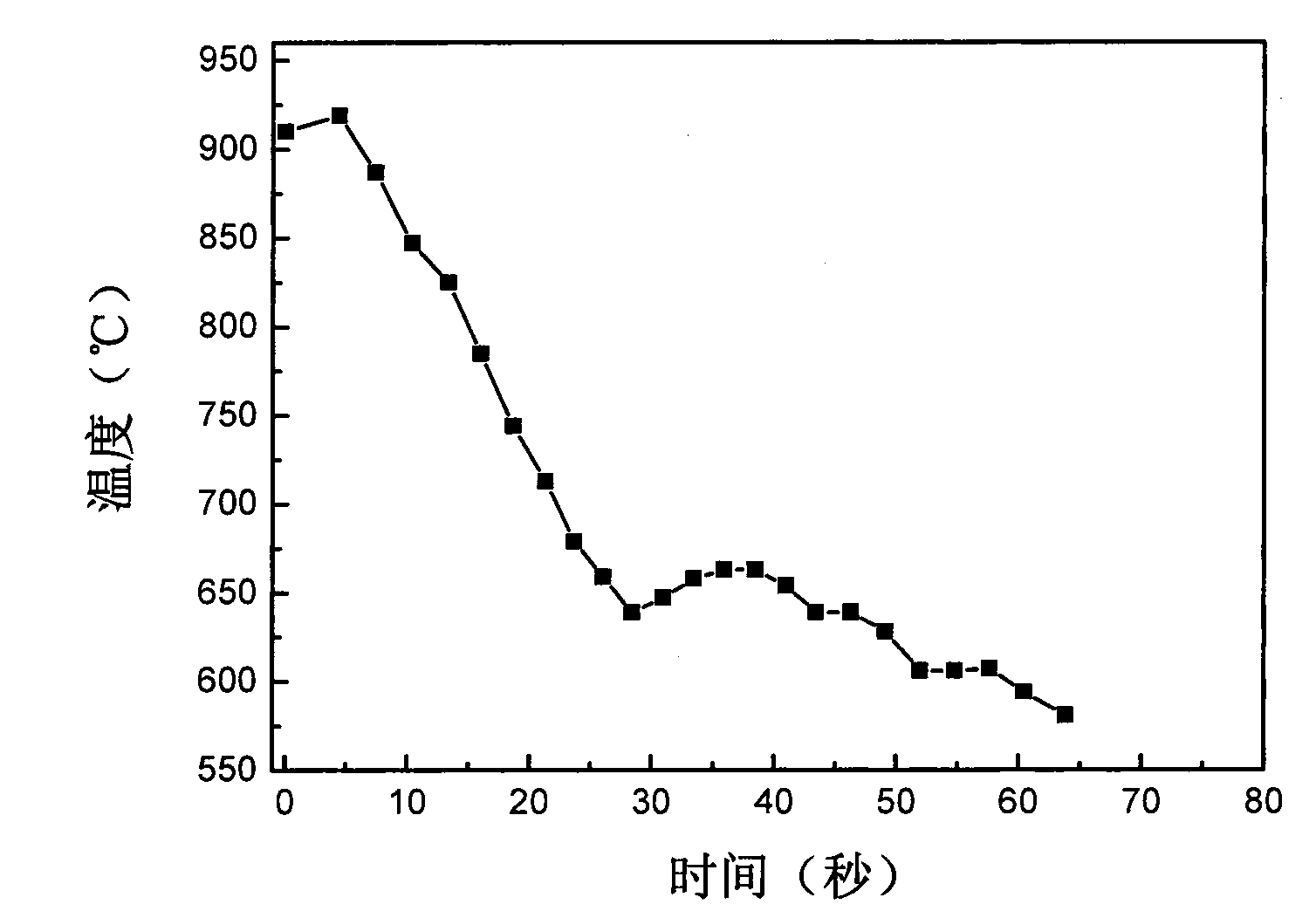

The invention relates to a high carbon steel wire rod with tensile strength of more than 1,200 MPa and surface shrinkage of more than 35 percent and a preparation method thereof. The high carbon steelwire rod comprises the base components of C, Si, Mn, Cr and the like, selective components of Ni, Cu, Al, B, Ti, Nb, Mo and the like, and the balance of Fe and impurities. The preparation method comprises the following procedures of smelting, casting, rolling and cooling control sequentially, wherein the rolling-starting temperature of the rolling procedure is controlled between 1,000 DEG C and 1,100 DEG C, the spinning temperature is 870-930 DEG C, the cooling controlling procedure is carried out by adopting Steyr cooling control, rapid cooling is adopted before the phase change and at the earlier stage of the phase change, and the slow cooling is adopted at the later stage of the phase change. The high carbon steel wire rod has excellent mechanical performance, less alloy elements and low cost; and meanwhile, the preparation method is realized by only less adjusting the prior production process of the high carbon steel wire rod without nearly adding any production cost.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Method of direct iron-making / steel-making via gas or coal-based direct reduction and apparatus

The invention is a method and apparatus for iron-making / steel-making using a modified rotary hearth furnace, that is a finisher-hearth-melter (FHM) furnace. In the method the refractory surface of the hearth is coated with carbonaceous hearth conditioners and refractory compounds, where onto said hearth is charged with pre-reduced metallized iron. The pre-reduced metallized iron is leveled, then heated until molten, and then reacted with the carbon and reducing gas burner gases until any residual iron oxide is converted to iron having a low sulfur content. Nascent slag separates from the molted iron forming carburized iron nuggets. The nuggets are cooled, and then the iron nuggets and the hearth conditioners, including the refractory compounds, are discharged onto a screen, which separate the iron nuggets from the hearth conditioner. The hearth conditioner is recycled, and the iron nuggets are either prepared for sale or for additional treatment, such as alloying, in a final melter, where the final melter is preferably an electric furnace. Exhaust gases from the FHM furnace are recovered for calcining coal into fuel gases and coke.

Owner:KOBE STEEL LTD

Wear-resisting alloy steel with high boron, high chrome and low carbon and preparation method thereof

ActiveCN101660097AReduce manufacturing costElectric furnaceProcess efficiency improvementSilicon alloyCerium

The invention discloses a wear-resisting alloy steel with high boron, high chrome and low carbon and a preparation method thereof, which comprises the following chemical constituents in weight percent: 0.1-0.5% of C, 3-26% of Cr, 0.5-1.2% of Si, 0.5-1.5% of Mn, 0.3-2.8% of B, 0.3-2.6% of Cu, 0.2-0.6% of Ti, 0.02-0.15% of Ca, 0.03-0.25% of Ce, 0.02-0.18% of N, 0.05-0.3% of Nb, 0.04-0.09% of Al, 0.02-0.15% of Mg, 0.04-0.13% of K, less than 0.03% of S, less than 0.04% of P and the balance Fe and unavoidable impurity elements. The method comprises the following steps: melting steel scrap and chromium iron in an electric furnace; adding copper plates, ferrosilicon, ferromanganese into the melted steel scrap and chromium iron, heating the melt to 1560-1620 DEG C after the constituents are adjusted to be qualified in stokehold; adding calcium-silicon alloy and aluminium deoxidation into the melt; and then adding ferrotitanium and ferroboron in sequence, melting and discharging; roasting the compound inoculant composed of granular rare earth magnesium alloy with the diameter being less than 12mm and cerium metal, Si3N4, VN, Nb and K; placing the roasted compound inoculant at the bottom ofa steel ladle; carrying out modification and inoculation processes on the smelted liquid steel by pour-over method in the steel ladle, wherein, the pouring temperature of the liquid steel is 1400-1450DEG C; heating castings to 920-1150 DEG C and preserving heat for 2-4 hours; and air cooling the castings to room temperature to obtain the alloy steel in the invention. The alloy steel of the invention has the advantages of high strength, rigidity and toughness, good thermal fatigue resistance property, wear resistance, and low manufacture cost.

Owner:泰州海天机械配件有限公司

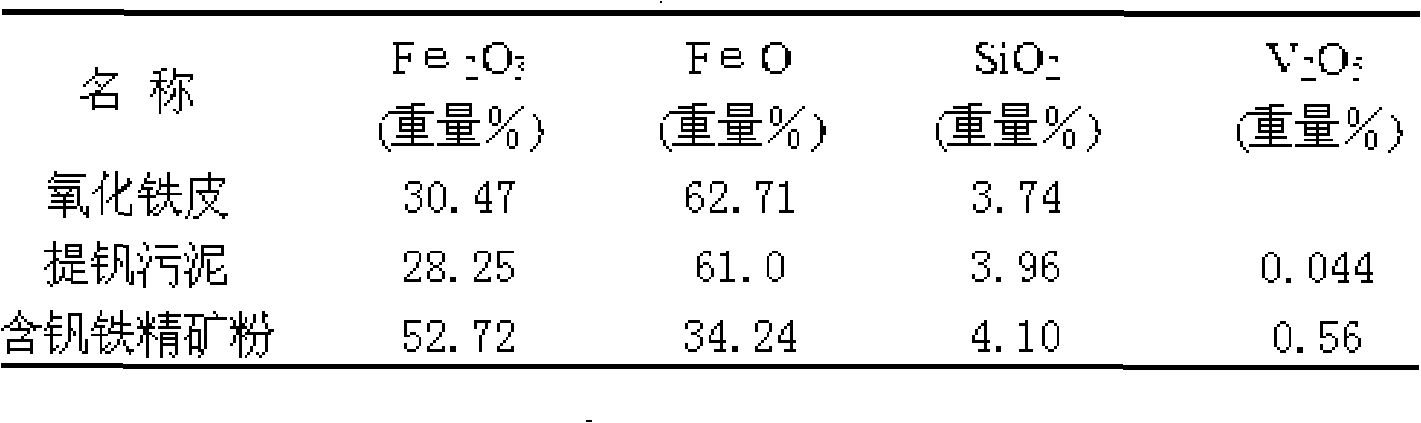

Vanadium-raising cooling agent, method for preparing same and use method

The invention relates to a vanadium extraction coolant and a preparation method and a use method thereof which belong to the field of metallurgy. The invention provides a novel vanadium extraction coolant and overcomes the defects of complex use of the existing coolant and the large operation difficulty of the existing vanadium extraction technique. The vanadium extraction coolant comprises 80 to 95 percent of the oxides of iron, 3 to 6 percent of SiO2, 0.1 to 0.6 percent of V2O5, 1 to 3 percent of MgCl2 and the rest is less inevitable unpurified elements; the total amount is 100 percent. The vanadium extraction coolant of the invention is collocated and pressed by adopting iron concentrate powder containing vanadium and ferric oxide (or vanadium extraction mud) with a bonding agent which not only has a simple preparation method, but also has high cooling intensity; besides, the using method is simple during the process of using the vanadium extraction; the vanadium extraction technique is more smooth; the quality of the vanadium slag and the quality of gun iron are more stable; the invention fully recycles the most resources of iron and vanadium in the coolant simultaneously when achieving the goals of ''removing vanadium and preserving carbon''.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

Method of producing nanoparticles, nanoparticles, and lithium battery comprising electrode comprising the nanoparticles

ActiveUS20090253037A1Material nanotechnologyNanostructure manufactureNanoparticleLow temperature plasma

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV

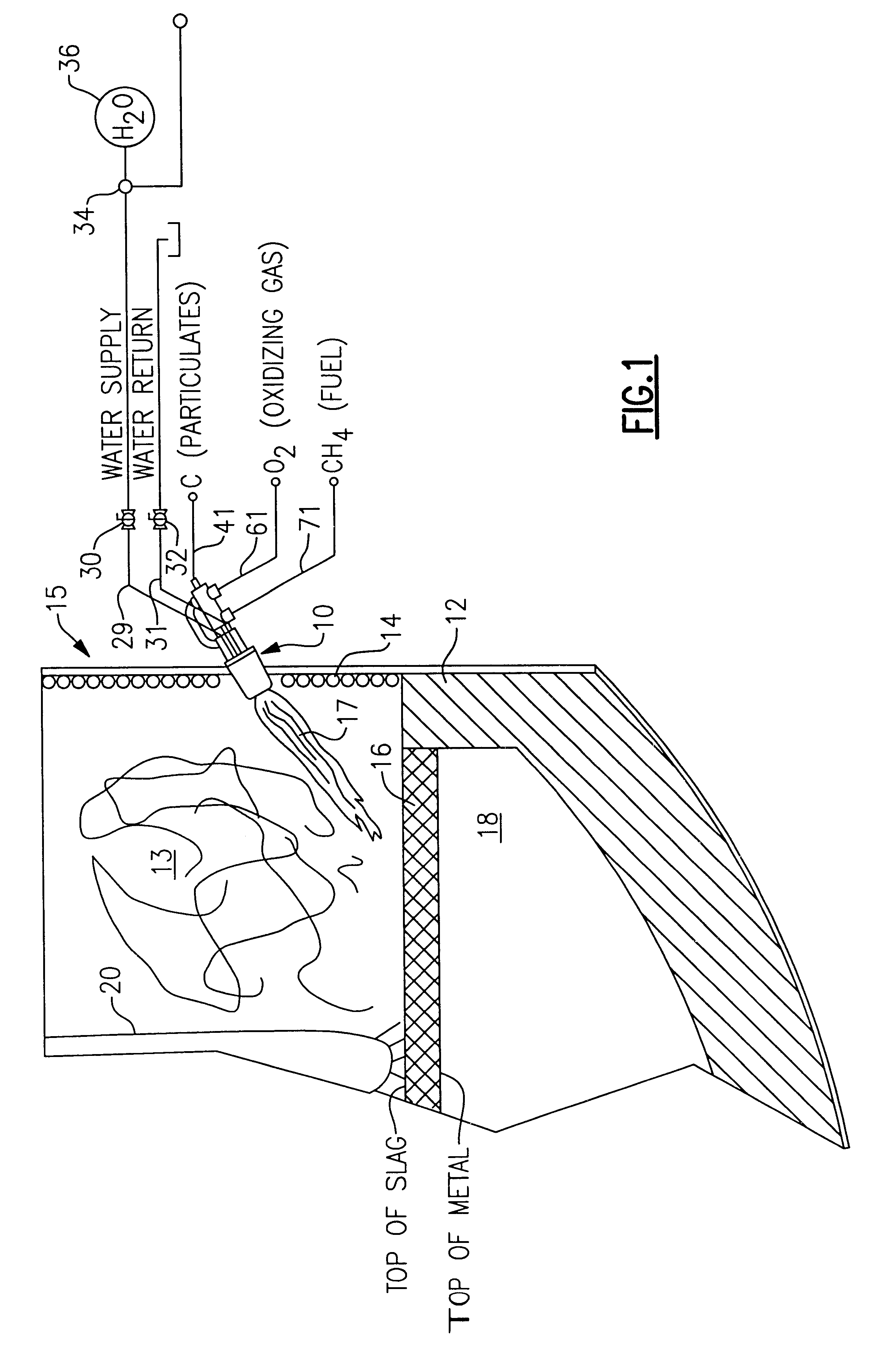

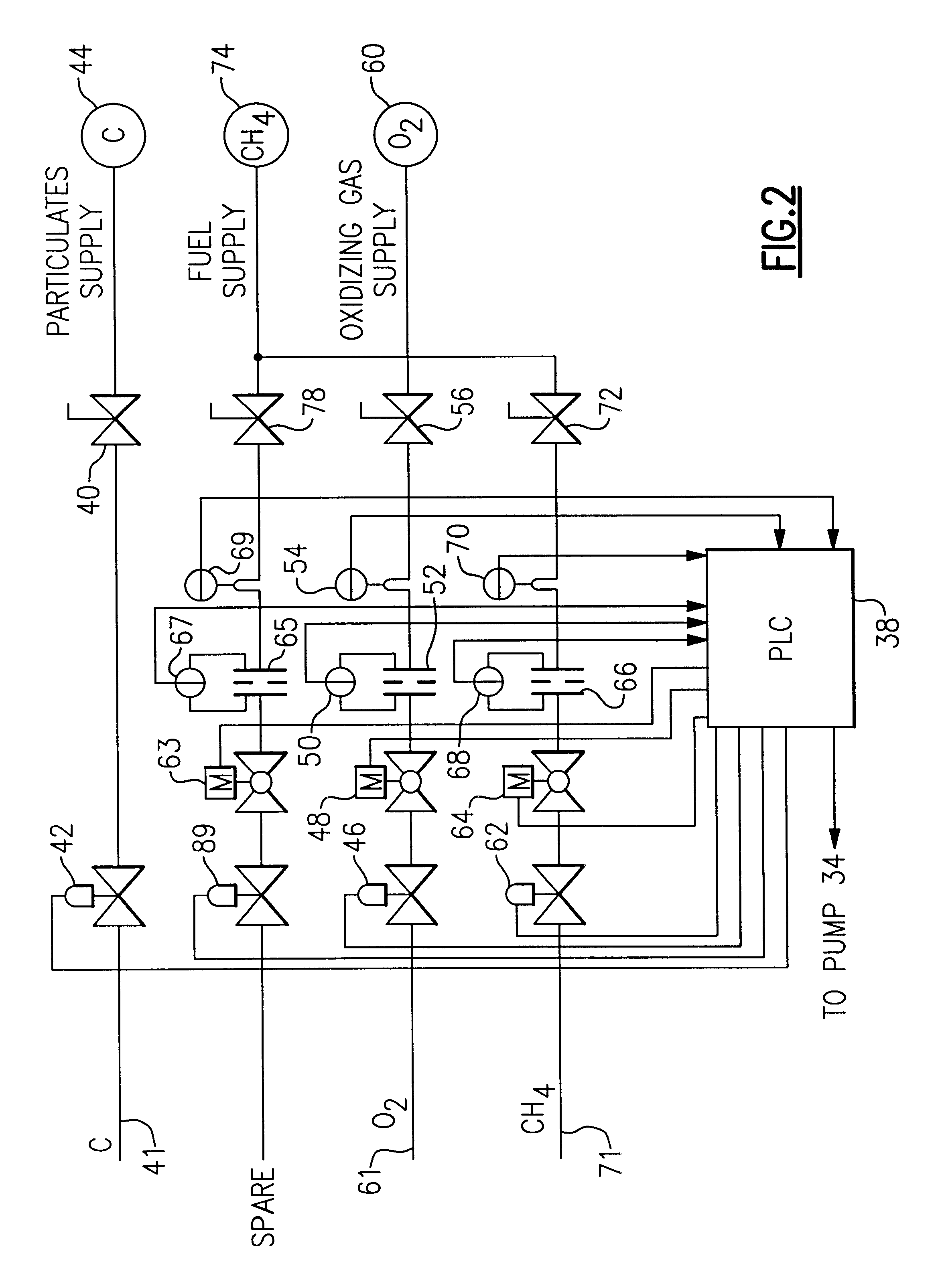

Method for metal melting, refining and processing

An improved method and apparatus for metal melting, refining and processing, particularly adapted to steel making in an electric arc furnace. The method provides auxiliary thermal energy to the steel making process, particulate injection for the formation of slag and foamy slag, and oxygen injection for the decarburization of the melt, for the formation of foamy slag and for post combustion burning of carbon monoxide. The burner includes two injection barrels for providing finely pulverized particles and for providing either a supersonic or a subsonic primary flow of an oxidizing gas. The barrels are positioned side by side in a nozzle at the entrance of a flame shaping chamber of a fluid cooled combustion chamber. The nozzle also contains a plurality of fuel orifices for the providing pressurized fuel to the combustion chamber and a plurality of oxidizing gas orifices for providing a secondary flow of an oxidizing gas around the periphery of the nozzle. Because all of the flows of fuel, oxidizing gas and particulates pass through the flame shaping chamber, they are all substantially directed to the same location in the electric arc furnace. The directionality of the flows allows the burner to heat a localized spot of the slag with thermal energy from the oxidation of the fuel, from the oxidation of oxidizable components in the slag or the melt by the lancing of supersonic oxidizing gas, or from any combination of these. Once a spot in the slag is sufficiently heated, a flow of carbon is directed to the localized hot spot in the slag to reduce the FeO, and other oxides, in the slag to carbon monoxide and produce foamy slag. The particulate carbon introduction can be accompanied by further oxidizing gas injection before, during or after the carbon injection.

Owner:PROCESS TECH INT

LED package for backlight unit

ActiveUS7156538B2Improve image qualityImprove luminous efficiencyLighting support devicesGlass furnace apparatusEngineeringDie bonding

Owner:SAMSUNG ELECTRONICS CO LTD

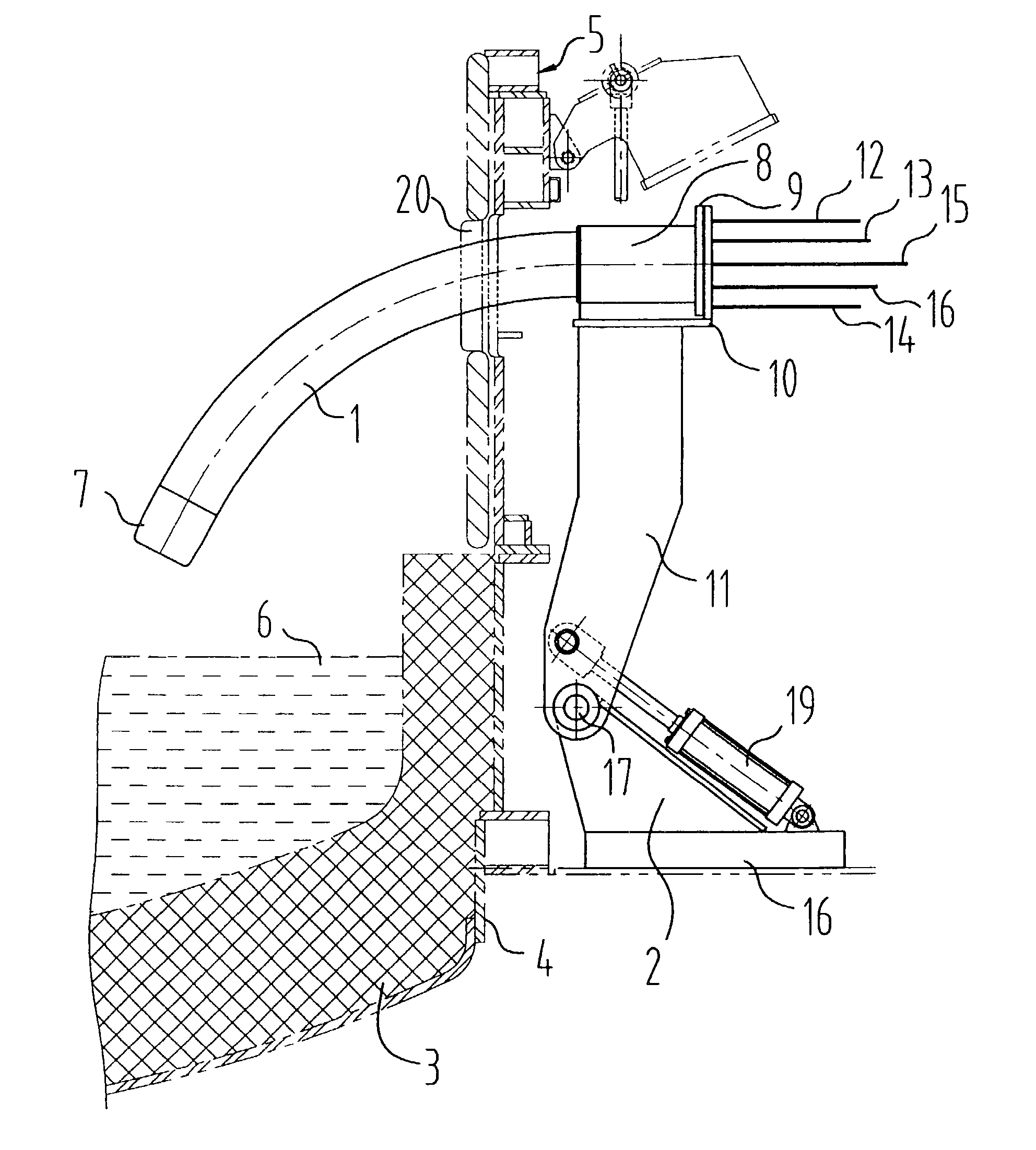

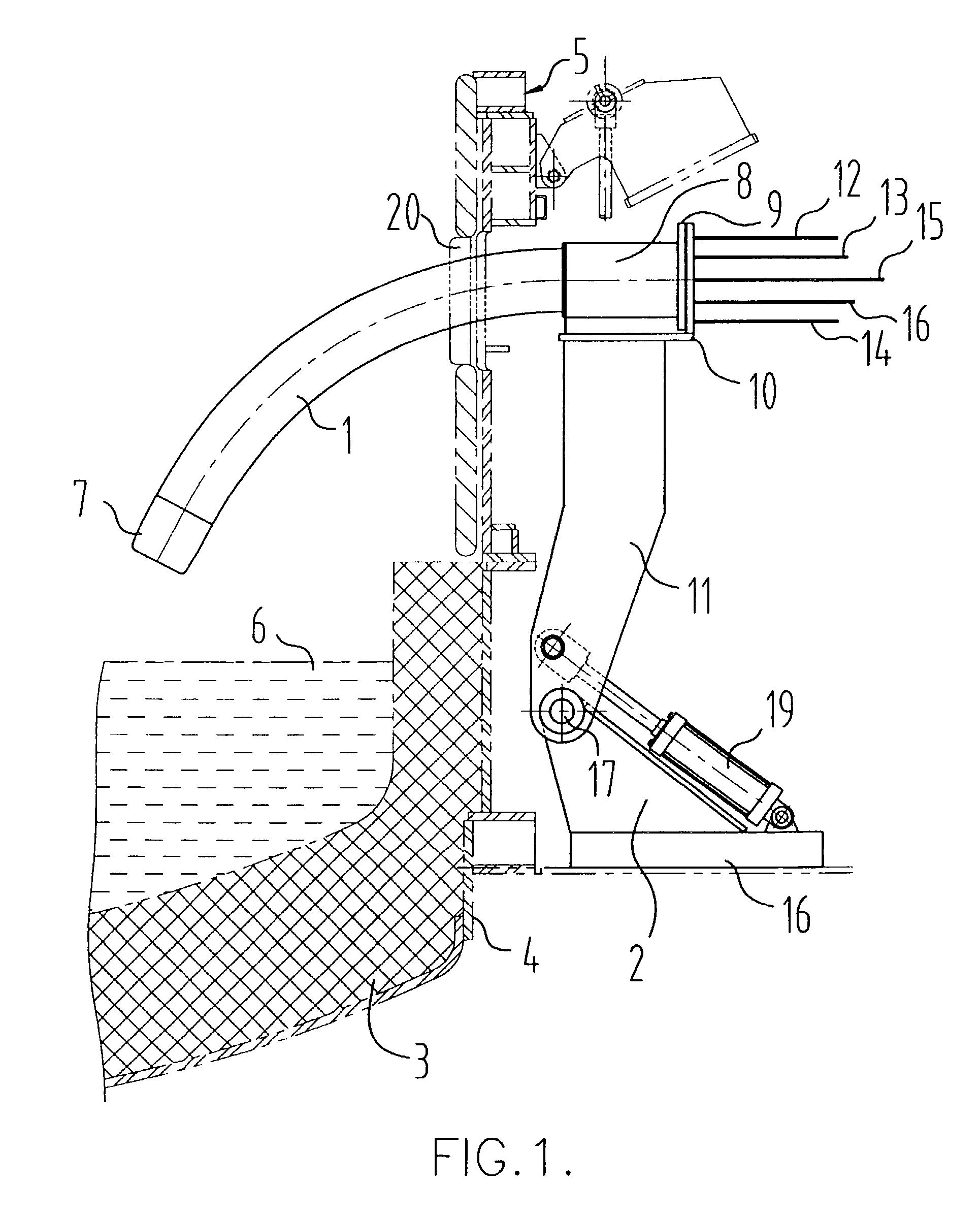

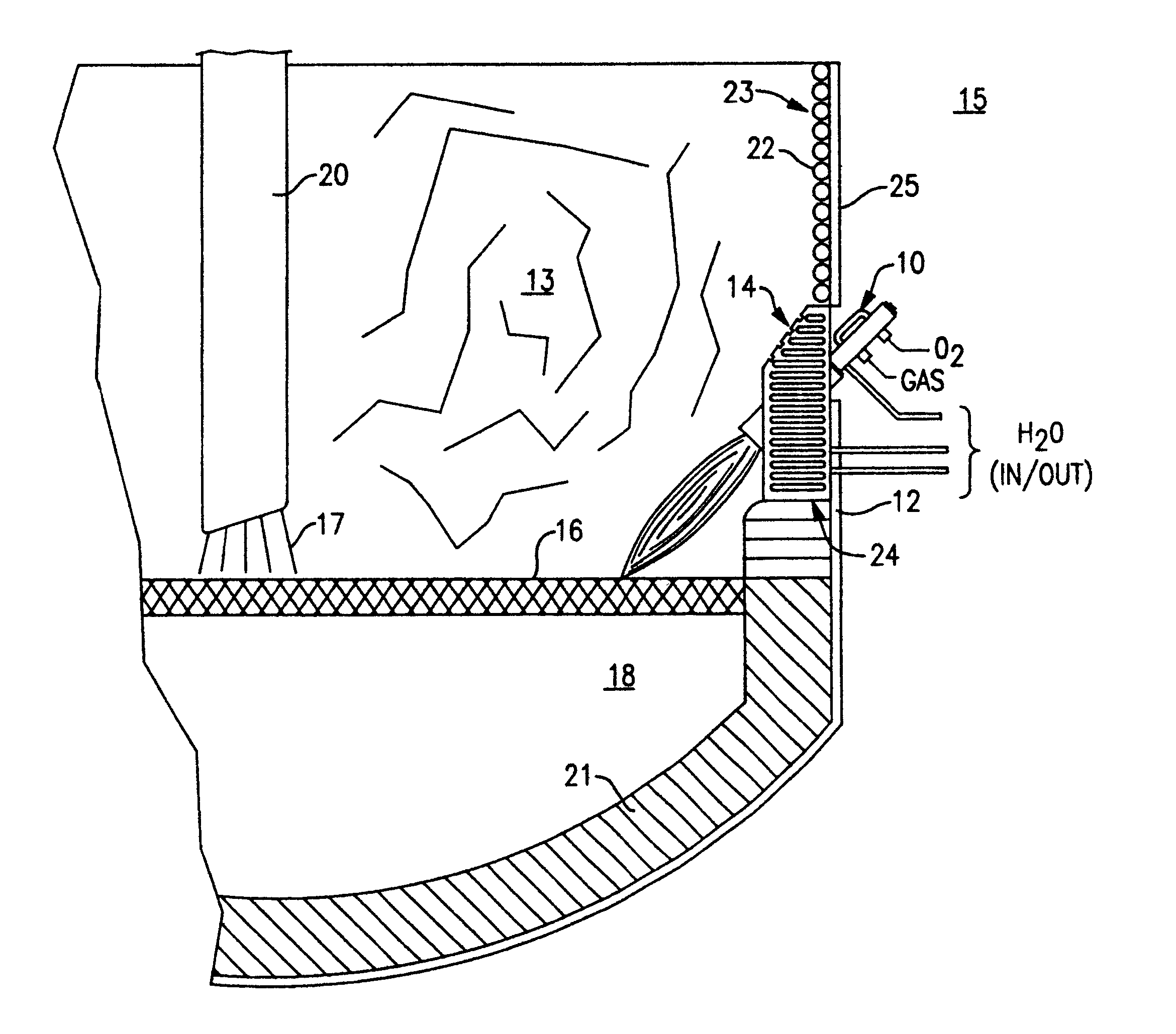

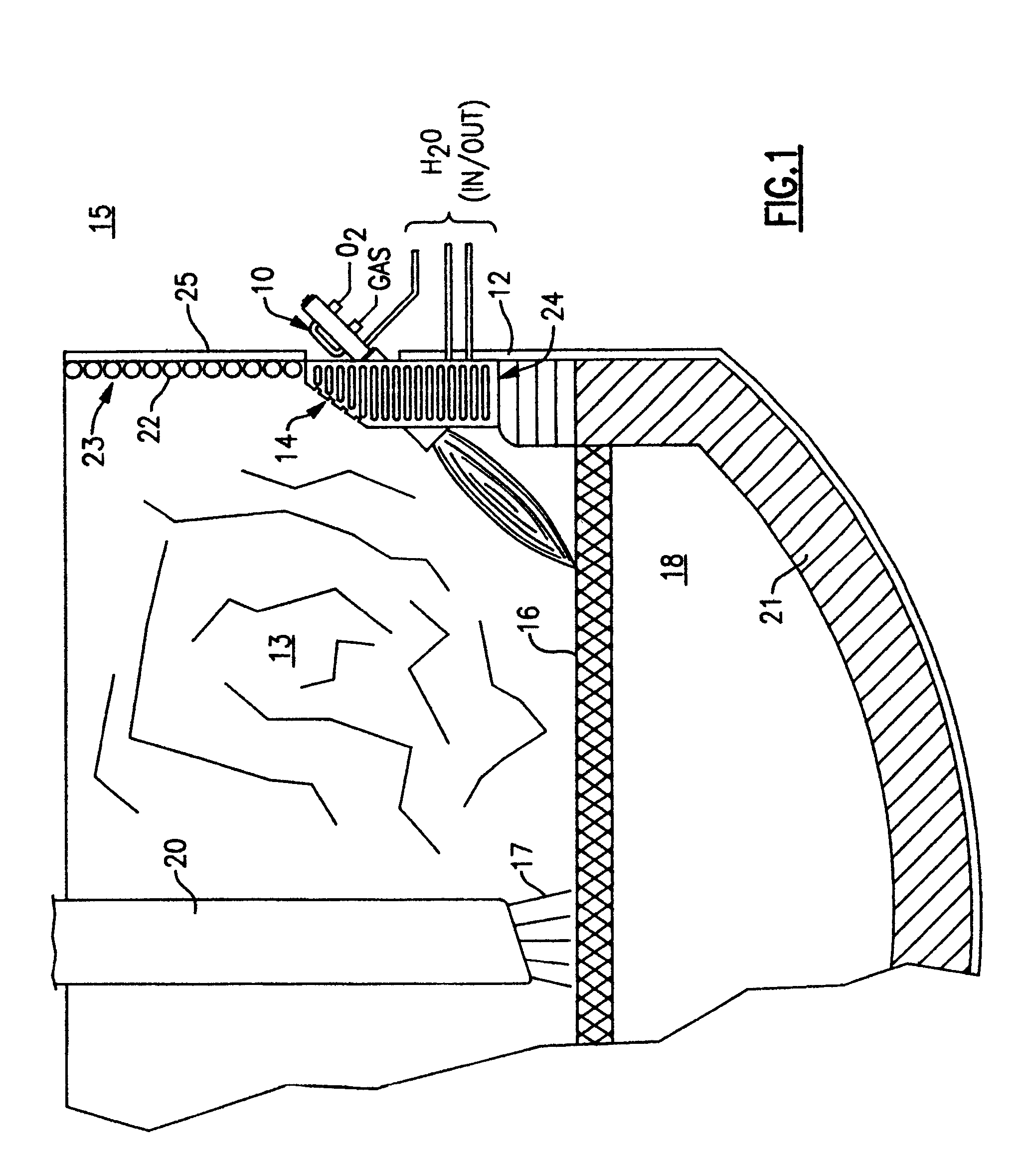

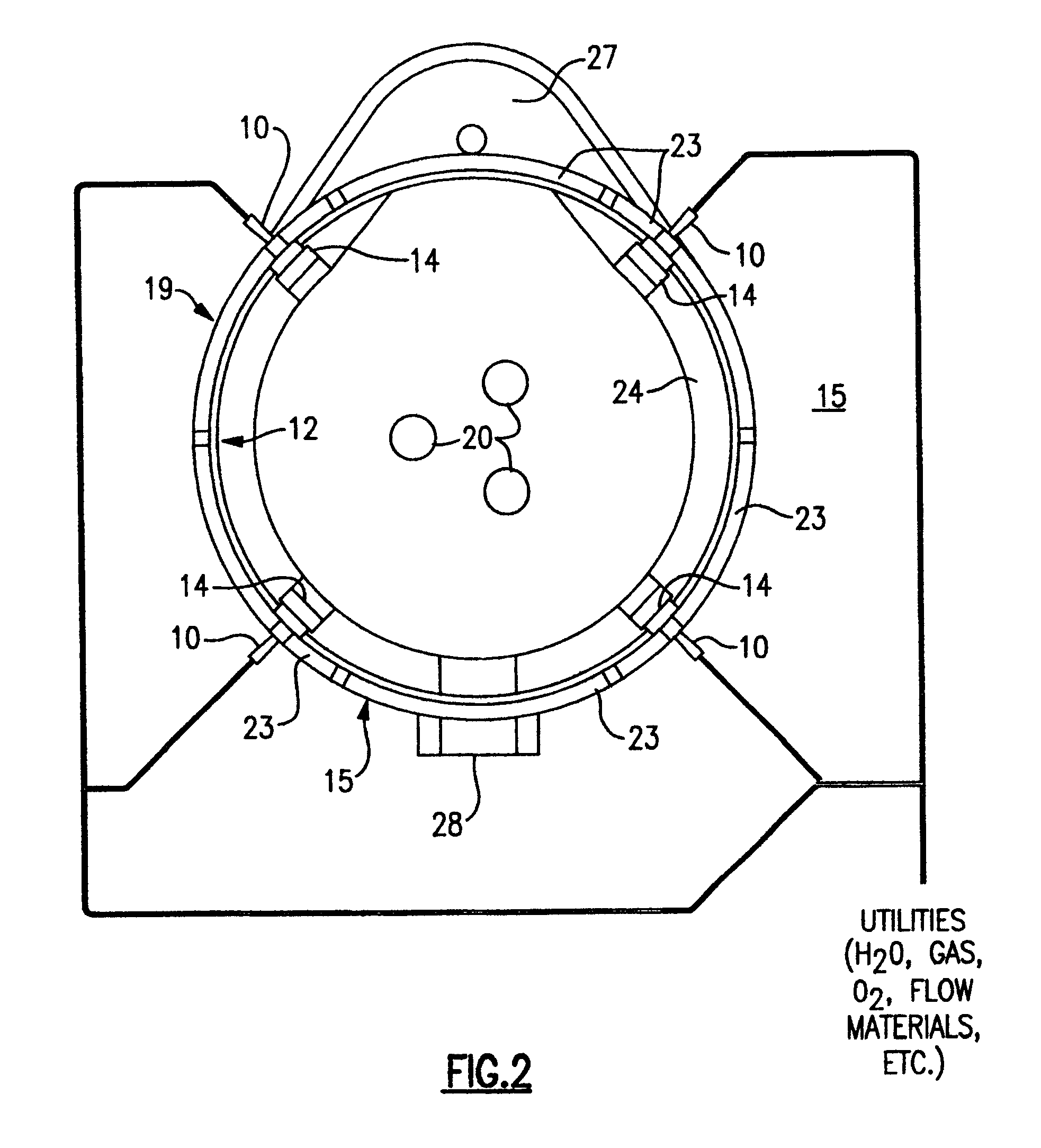

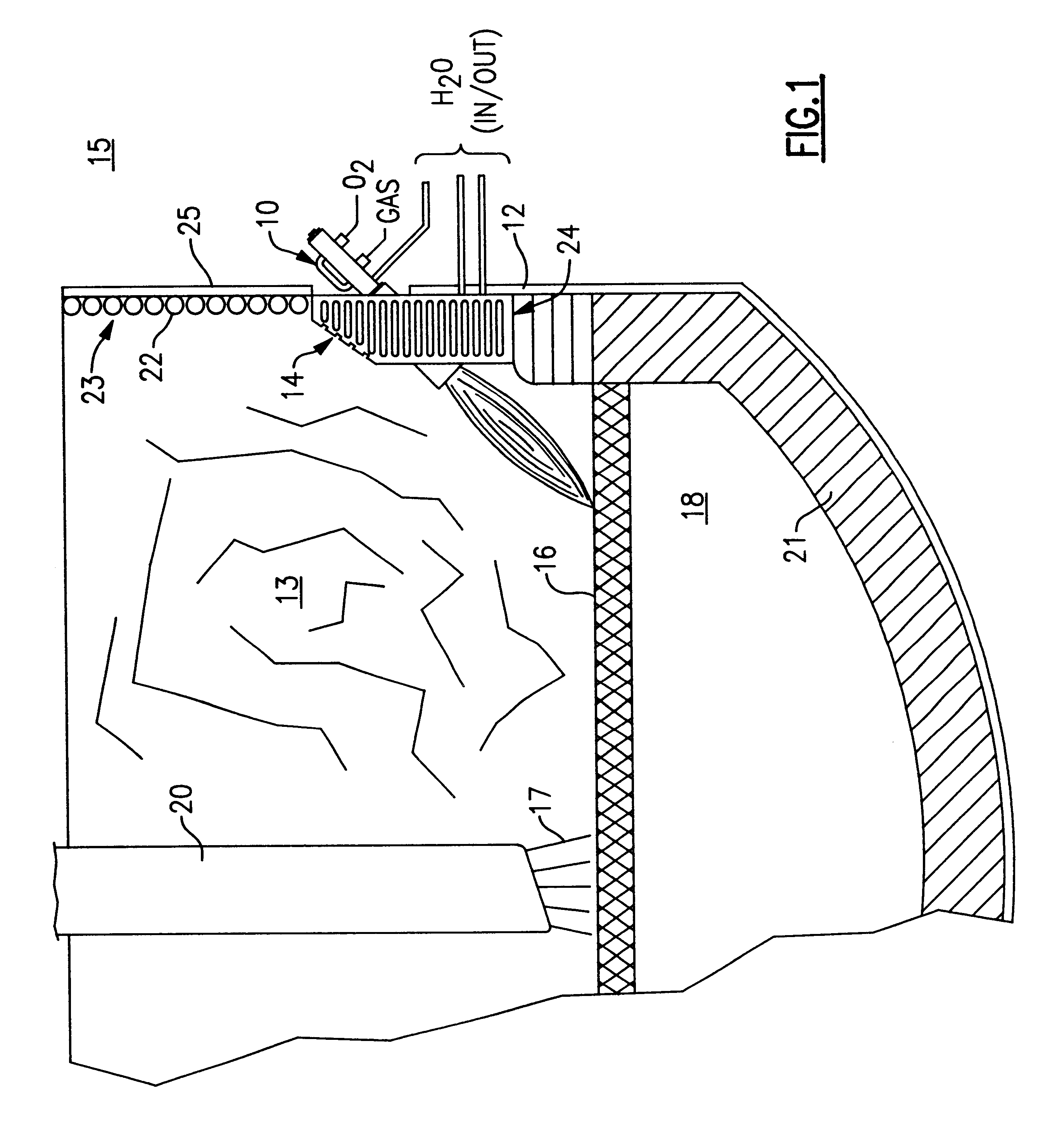

Mounting arrangement for auxiliary burner or lance

InactiveUS6614831B2Easy to produceImprove thermal conductivityElectric discharge heatingPeptide/protein ingredientsParticulatesElectric arc furnace

A mounting enclosure and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted for steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability and injectors or the like for the introduction of particulate matter. The mounting enclosure is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to occupy the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting enclosure comprises a plurality of fluid cooling conduits surrounding an apparatus aperture and an injector aperture which are formed through the enclosure and adapted to mount an apparatus and an injector. The mounting arrangement includes utilizing the mounting enclosure to mount an apparatus with supersonic oxidizing gas lancing capability and an injector for particulate carbon in an electric arc furnace. Because the mounting enclosure is approximately the width of the step, the discharge openings of the apparatus and the injector are moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge openings will now be extended to near the edge of the step so that the oxidizing gas flow pattern of the apparatus does not degrade the hearth material or other furnace equipment mounted nearby and the carbon flow pattern of the injector sufficiently agitates the slag to produce foaming.

Owner:PROCESS TECH INT

Mounting arrangement for auxiliary burner or lance

InactiveUS6289035B1Easy to produceImprove thermal conductivityElectric discharge heatingStirring devicesElectric arc furnaceCombustor

A mounting block and an improved mounting arrangement for apparatus used in metal melting, refining and processing, particularly those apparatus adapted to steel making in an electric arc furnace, such as burners, lances and the like with supersonic oxygen lancing capability. The mounting block is fluid cooled to survive the hostile environment of the electric arc furnace and is designed to rest on the step between the side wall and hearth of the furnace without any substantial change to the structure of the furnace. The mounting block comprises a plurality of fluid cooling conduits surrounding an aperture which is formed through the block and adapted to mount the apparatus. The mounting arrangement includes utilizing the mounting block to mount an apparatus with supersonic oxidizing gas or lancing capability in an electric arc furnace. The apparatus is mounted by passing it through an aperture in a water cooled side panel aligned with the mounting aperture in the mounting block. Because the mounting block is approximately the width of the step, the discharge opening of the apparatus is moved closer to the surface of the melt and toward the center of the furnace thereby providing increased efficiency. The discharge opening will now also extend past the inner edge of the step so that the oxidizing gas flow pattern does not degrade the hearth material and other furnace equipment mounted nearby.

Owner:PROCESS TECH INT

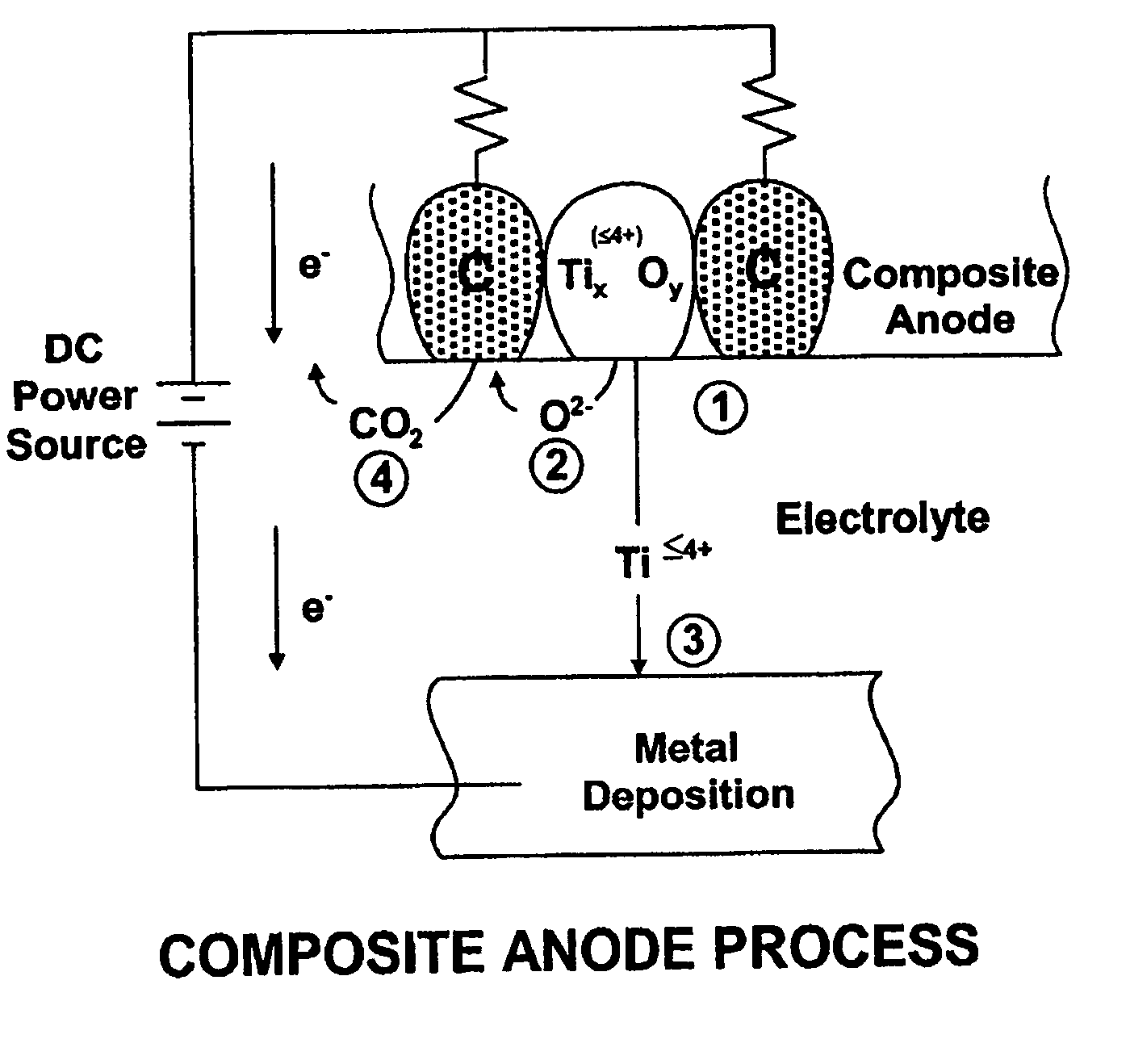

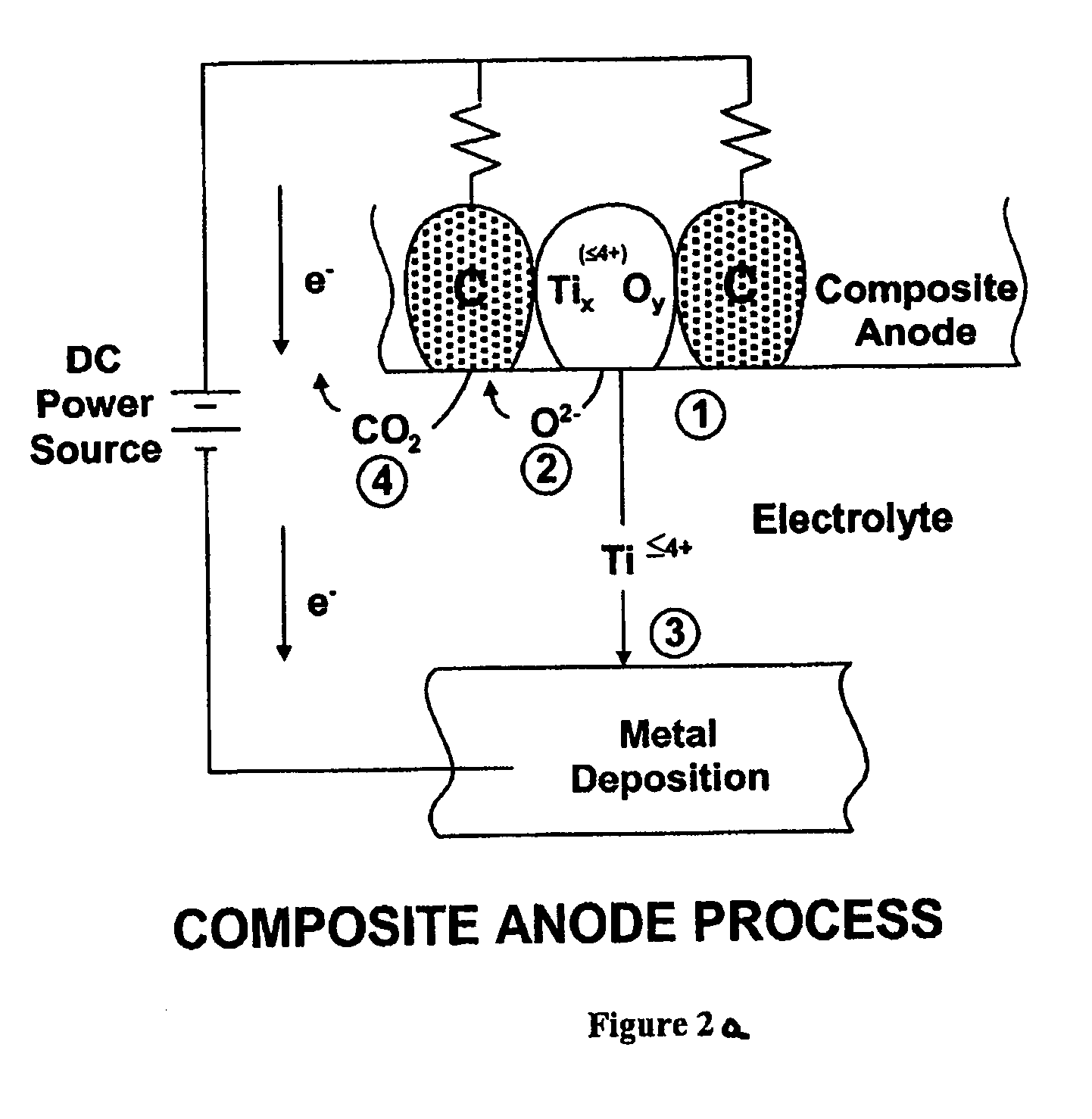

Thermal and electrochemical process for metal production

A system for purification of high value metals comprises an electrolytic cell in which an anode formed of a composite of a metal oxide of the metal of interest with carbon is electrochemically reduced in a molten salt electrolyte.

Owner:ATS MER LLC

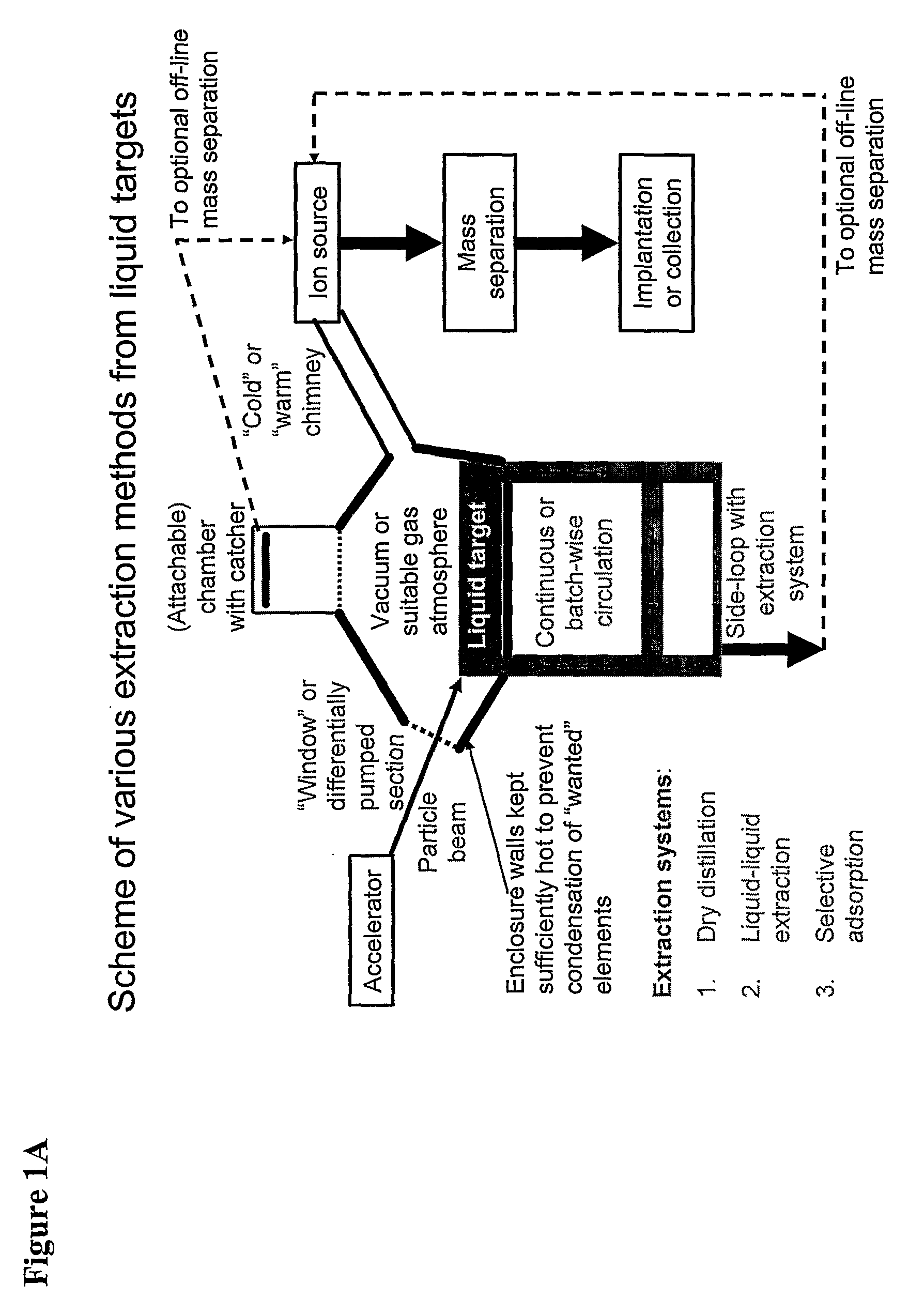

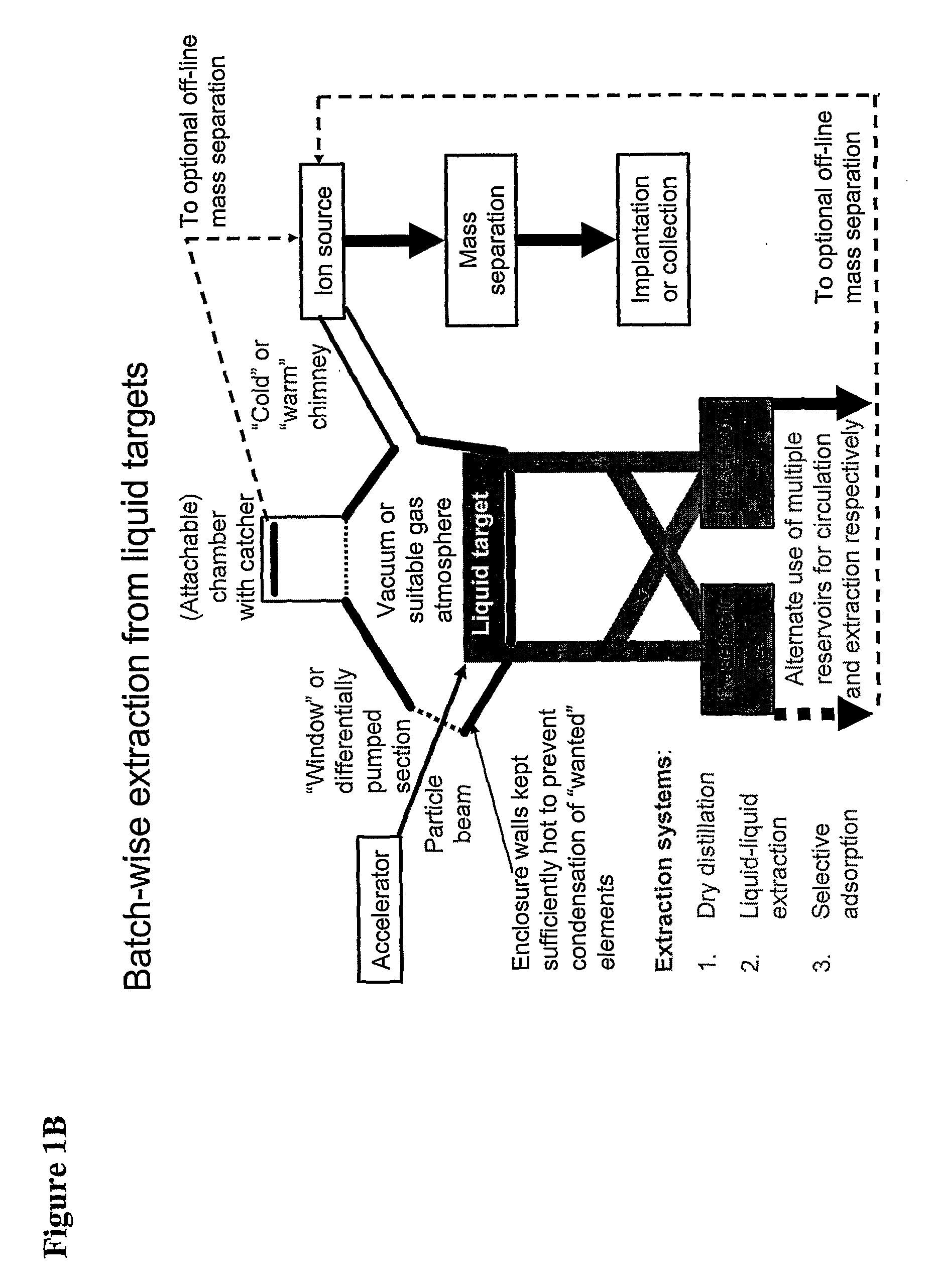

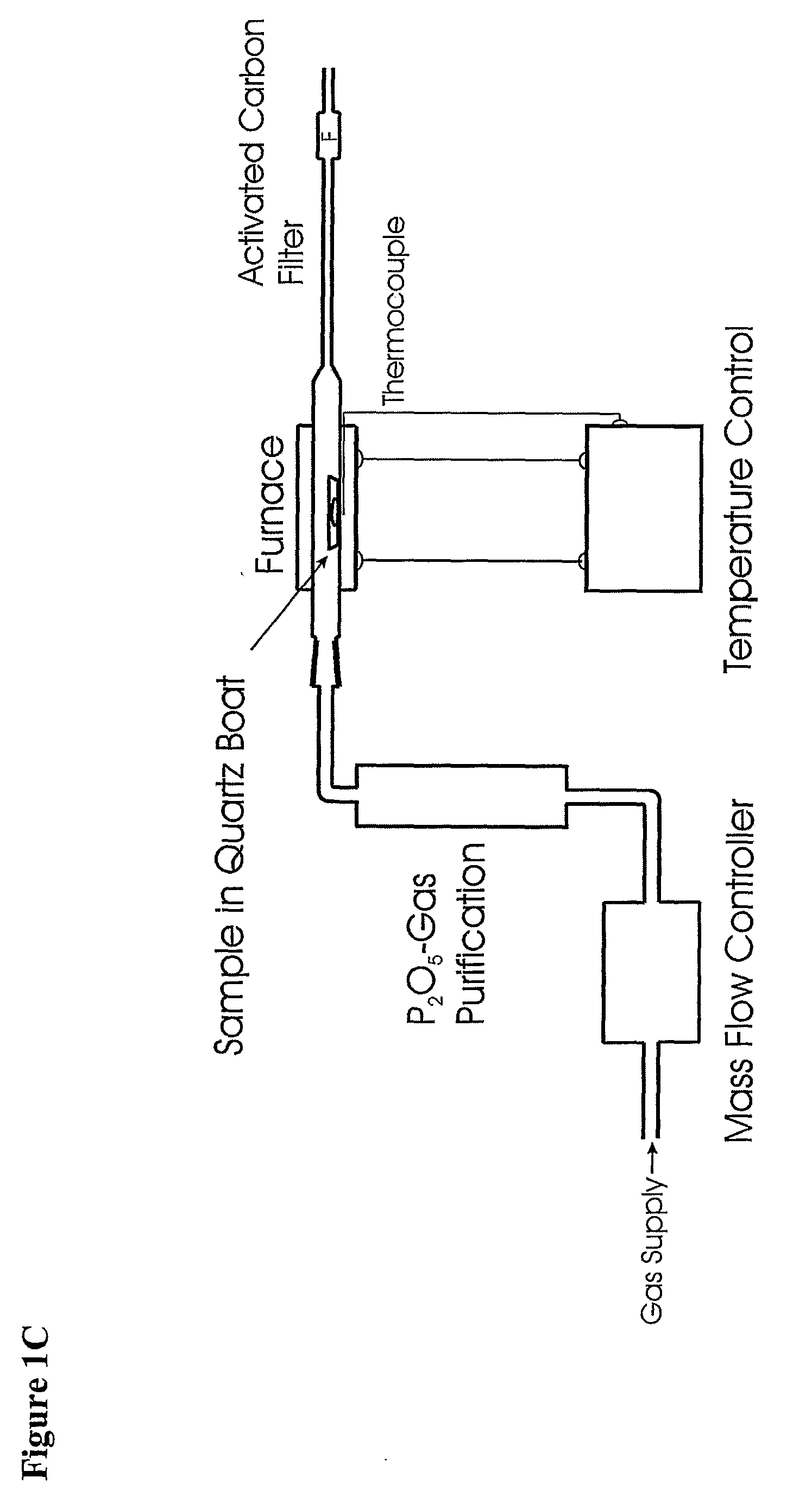

Method for Production of Radioisotope Preparations and Their Use in Life Science, Research, Medical Application and Industry

The present invention relates to an universal method for the large scale production of high-purity carrier free or non carrier added radioisotopes by applying a number of “unit operations” which are derived from physics and material science and hitherto not used for isotope production. A required number of said unit operations is combined, selected and optimised individually for each radioisotope production scheme. The use of said unit operations allows a batch wise operation or a fully automated continuous production scheme. The radioisotopes produced by the inventive method are especially suitable for producing radioisotope-labelled bioconjugates as well as particles, in particular nanoparticles and microparticles.

Owner:EUROPEAN ORGANIZATION FOR NUCLEAR RESEARCH +1

Process for producing high-purity ruthenium

InactiveUS6036741AReduce Particle GenerationVacuum evaporation coatingSolid-state devicesAlkaline earth metalHydrogen atmosphere

A process comprises forming ruthenium tetroxide by blowing ozone-containing gas into crude ruthenium powder while hypochlorous acid is being added to the powder, allowing a hydrochloric acid solution to absorb the ruthenium tetroxide, evaporating the solution to dryness, and roasting the RuOCl3 crystals thus obtained in a hydrogen atmosphere. Thus a high-purity ruthenium material for thin film deposition, typically sputtering targey, is obtained which contains less than 1 ppm each of alkali metal elements, less than 1 ppm each of alkaline earth metal elements, less than 1 ppm each of transition metal elements, less than 10 ppb each of radioactive elements, a total of less than 500 ppm of carbon and gaseous ingredient elements, the material having a purity of ruthenium of at least 99.995% excluding the gaseous ingredient elements.

Owner:JAPAN ENERGY CORP

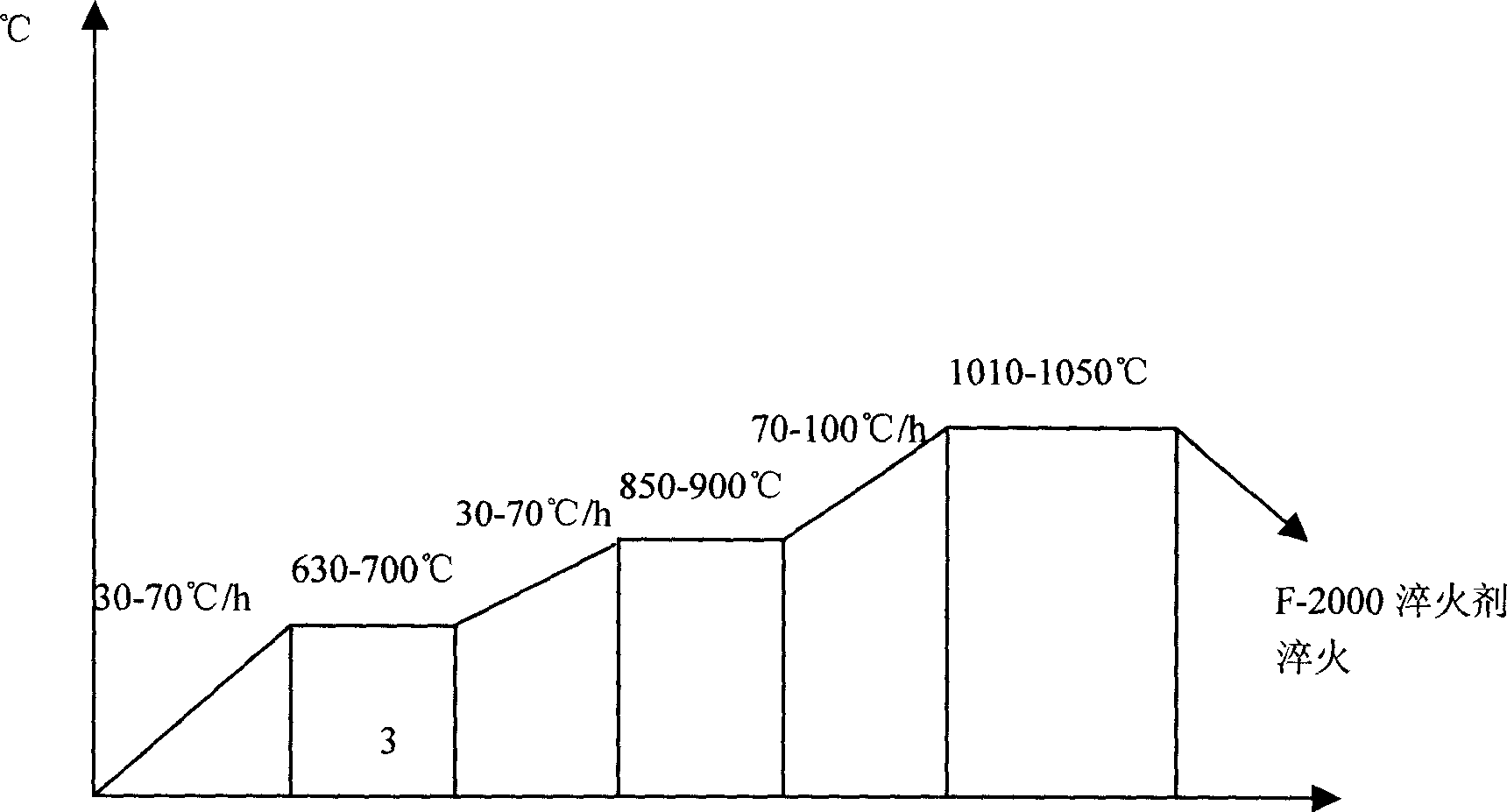

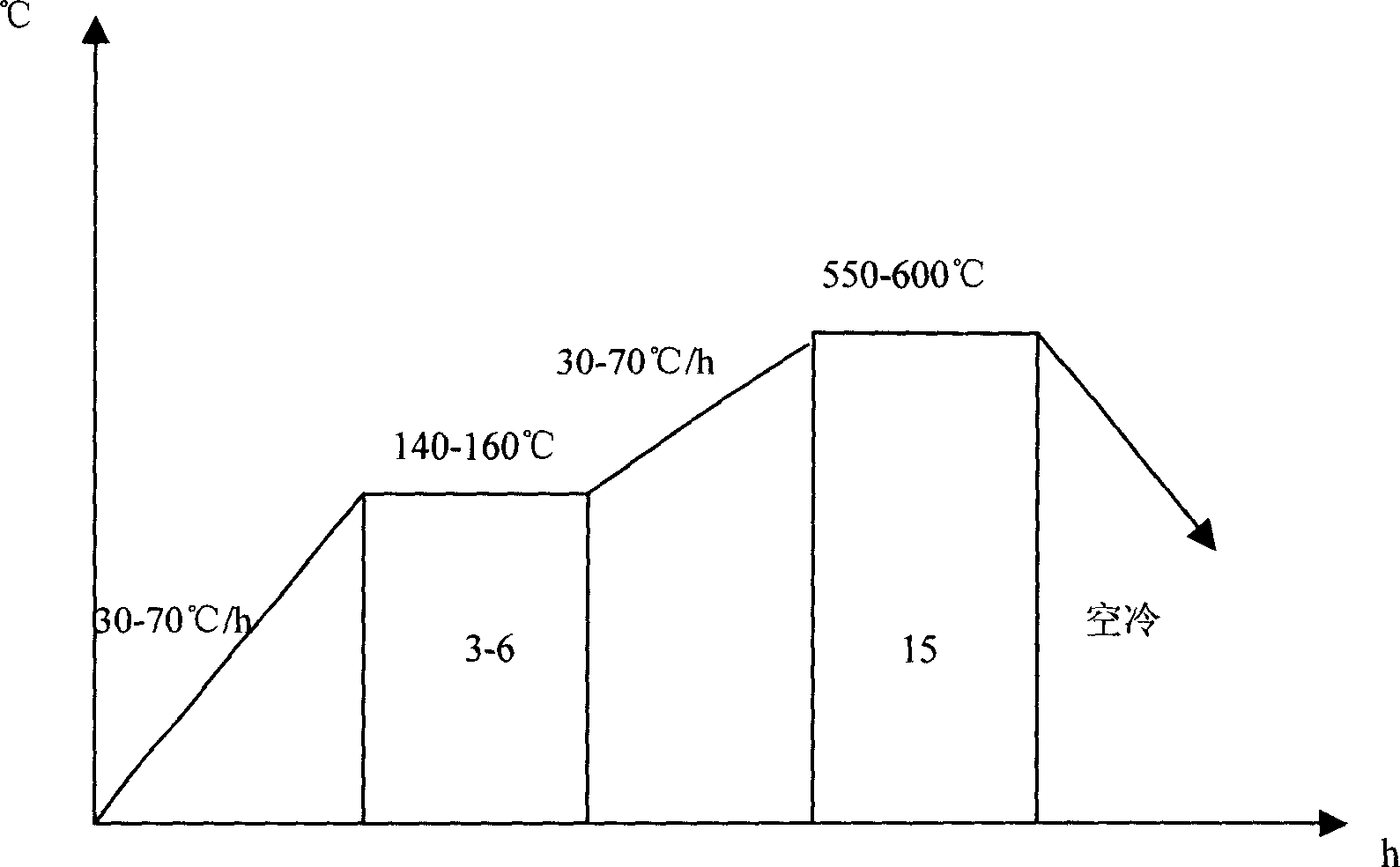

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

Laser Cladding on Low Heat Resistant Substrates

InactiveUS20080226843A1Sufficient powerMolten spray coatingVacuum evaporation coatingMetal alloyLength wave

This invention relates to laser cladding of components used in high temperature-corrosive applications, such as those associated with metallurgical vessels' lances, nozzles and tuyeres, for extending their service life under such severe conditions. In particular, this invention relates to a method for applying a high melting point material onto a substrate, said substrate having a melting point temperature below the melting point temperature of the high melting point material, comprising: (a) moving a laser beam generated from a laser over the surface of said substrate, said laser beam comprised of wavelengths from about 300 to about 10,600 nanometers; (h) providing a metal, alloy, or metal-alloy composite powder to the surface of said substrate; and (c) generating sufficient power to the laser to superficially heat said substrate and to effect a fusion bond between the metal, alloy or metal-alloy composite powder and the surface of said substrate.

Owner:PRAXAIR ST TECH INC

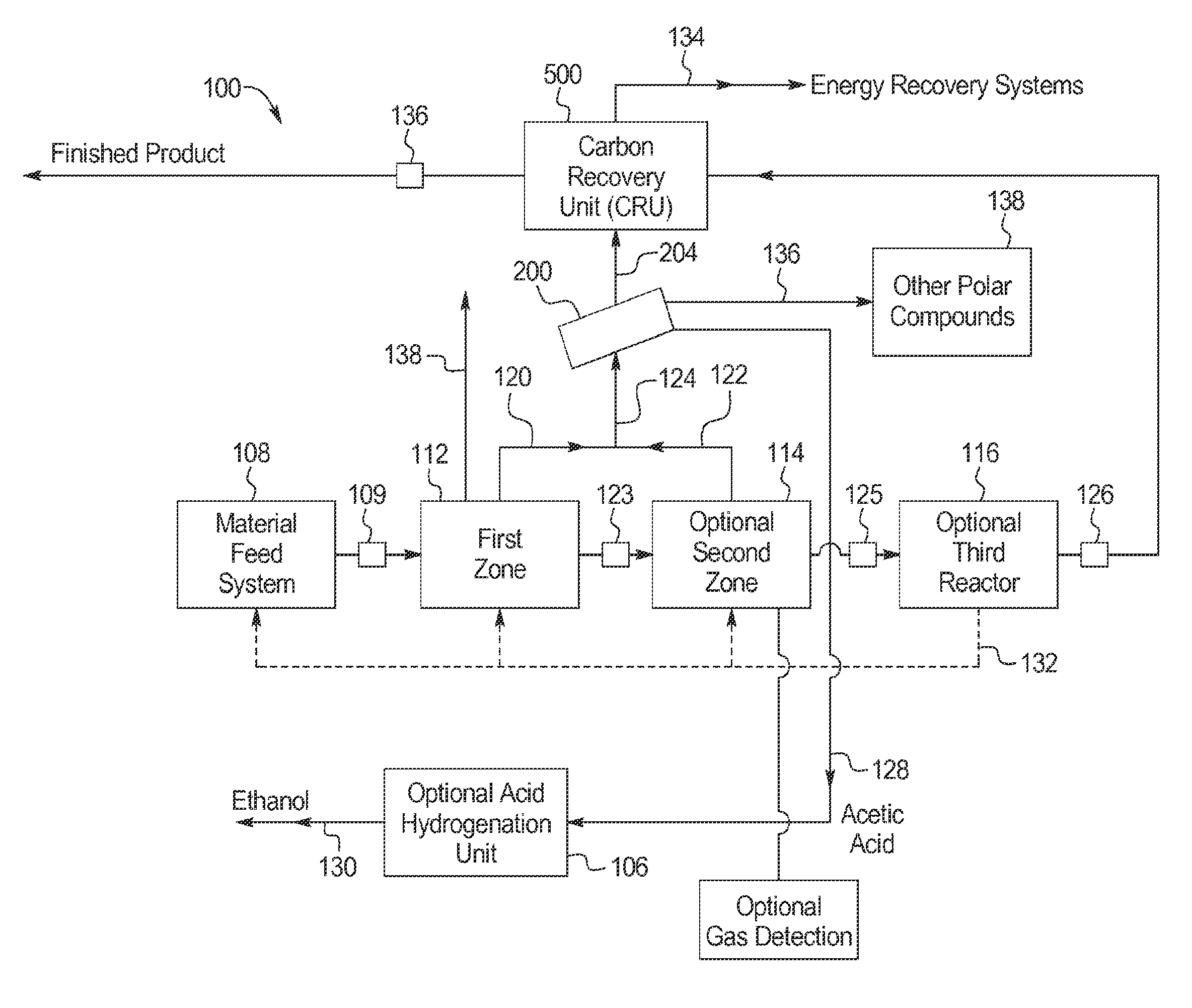

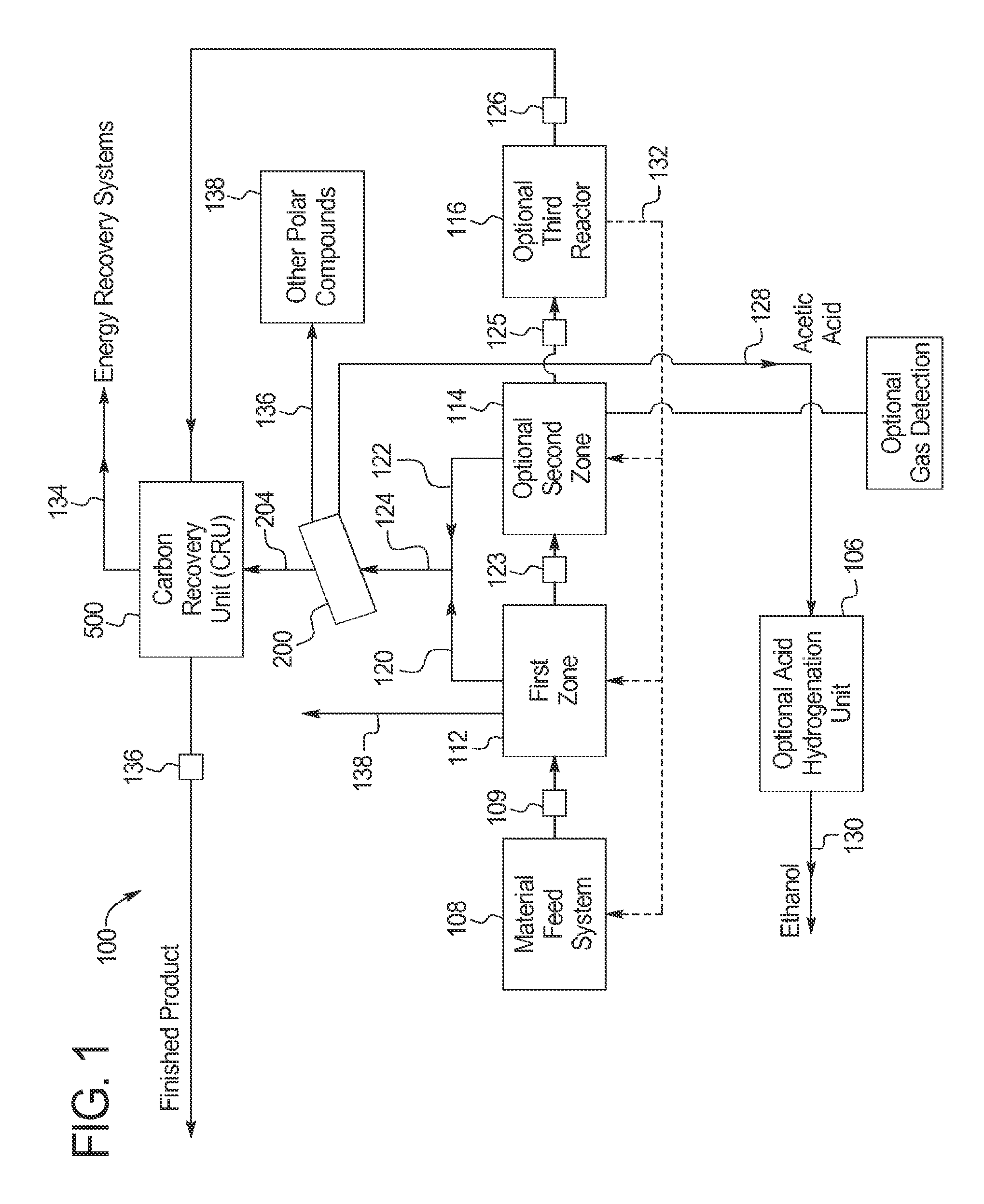

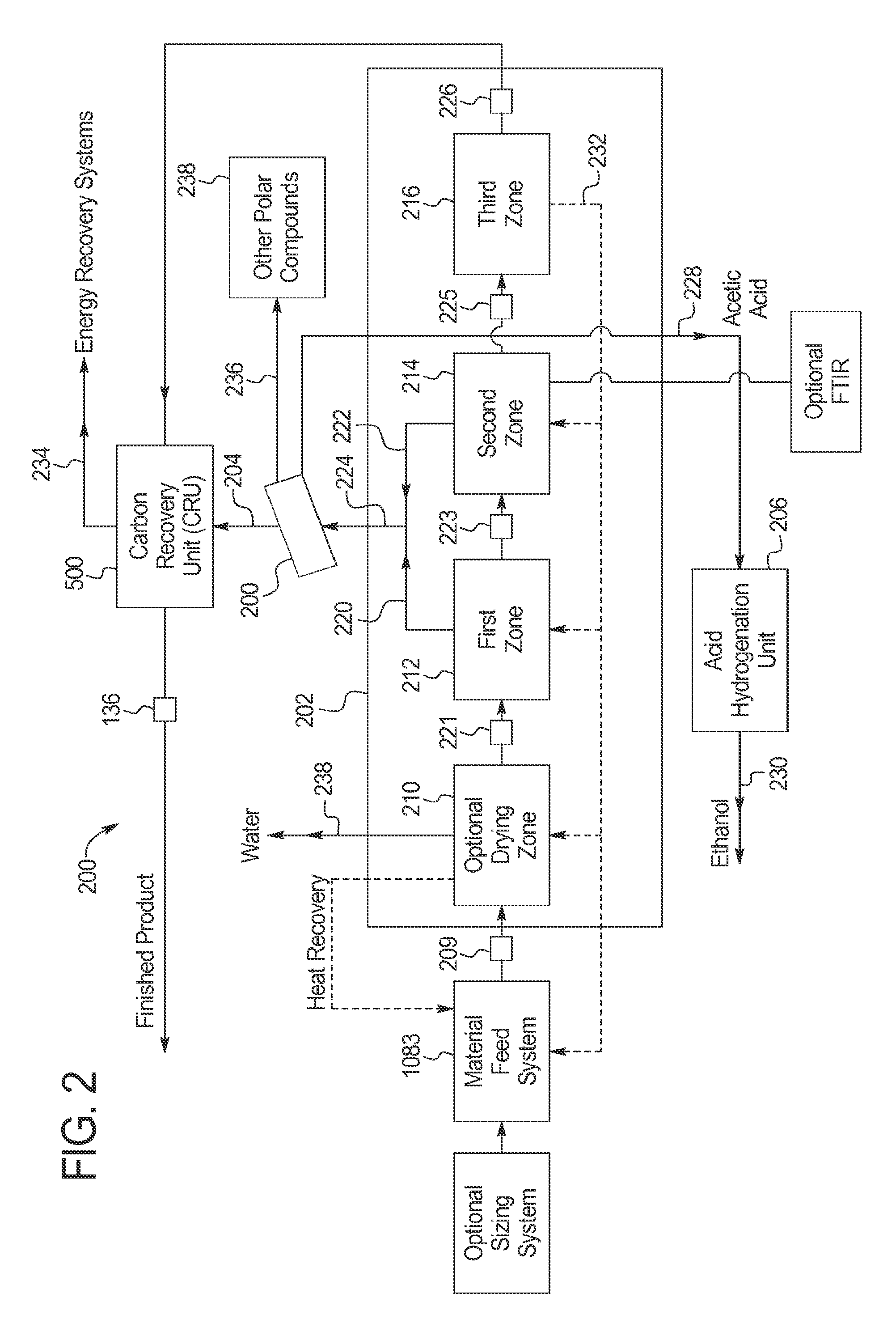

High-carbon biogenic reagents and uses thereof

ActiveUS20120285080A1High carbon contentImprove energy efficiencyCoke quenchingCoke oven safety devicesHigh carbonReagent

This invention provides processes and systems for converting biomass into high-carbon biogenic reagents that are suitable for a variety of commercial applications. High carbon biogenic reagents are also provided.

Owner:CARBON TECH HLDG LLC

Cement compositions comprising improved lost circulation materials and methods of use in subterranean formations

The present invention relates to subterranean cementing operations and, more particularly, to cement composition that include improved lost circulation materials, and methods of using such cement compositions in subterranean formations. In certain exemplary embodiments, the improved lost circulation materials include inelastic particles of polyethylene, polystyrene and / or polypropylene. Optionally, the cement compositions also may include additives such as fly ash, a surfactant, a dispersant, a fluid loss control additive, a conventional lost circulation material, an generator, a retarder, a salt, a mica, fiber, a formation-conditioning agent, fumed silica, bentonite, expanding additives, microspheres, weighting materials, or a defoamer.

Owner:HALLIBURTON ENERGY SERVICES INC

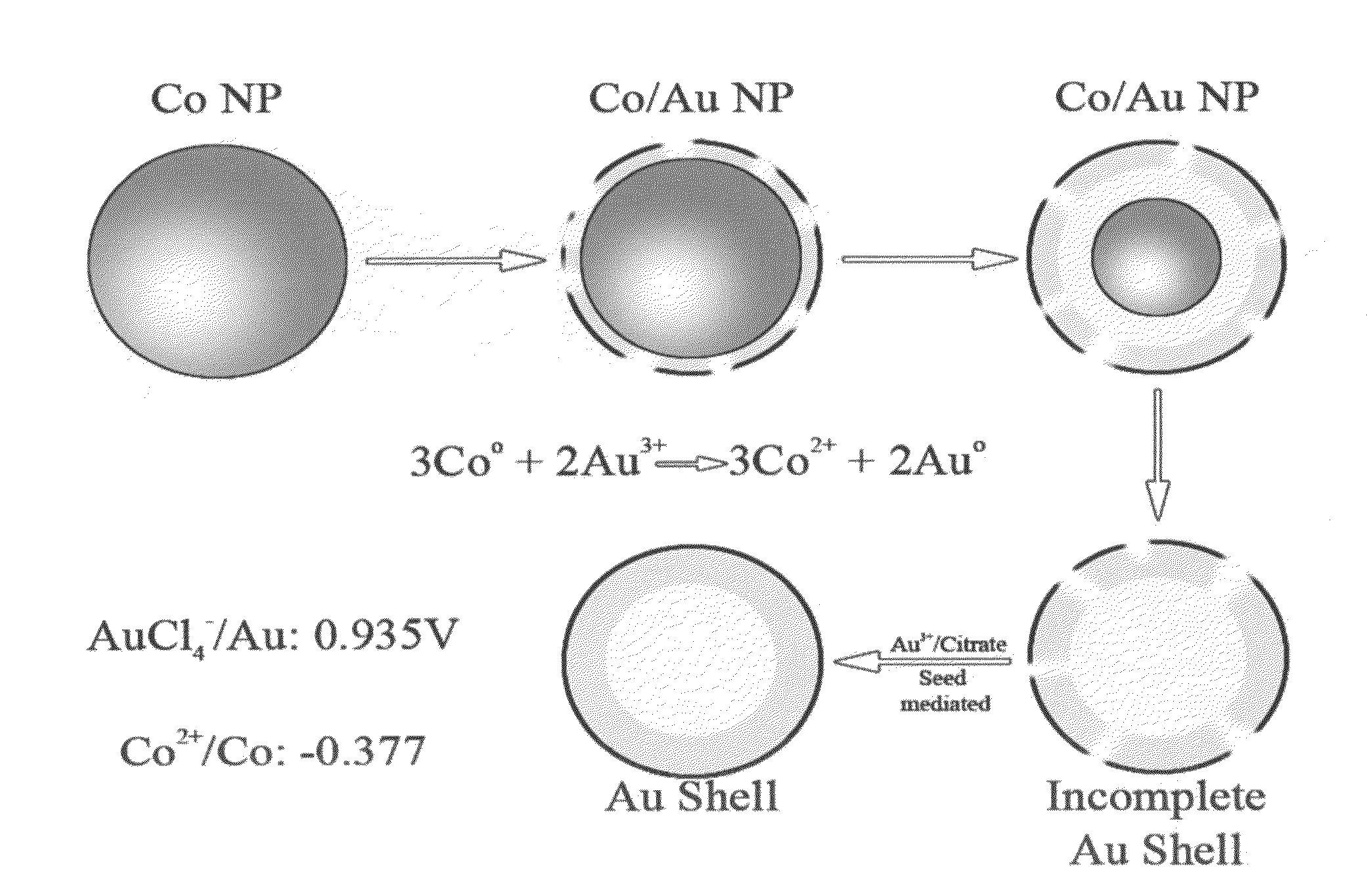

Novel gold nanostructures and methods of use

ActiveUS20100009338A1Material nanotechnologyNon-insulated conductorsElectrical conductorNanostructure

Owner:RGT UNIV OF CALIFORNIA

Popular searches

Hydrocarbon by hydrocarbon condensation Chemical recycling Phosphorus compounds Titanium oxides/hydroxides Hydrocarbon by hydrocarbon cracking Hydrocarbons from unsaturated hydrocarbon addition Hydrocarbons Chemical/physical/physico-chemical nozzle-type rreactors Energy based chemical/physical/physico-chemical processes Halogen/halogen-acids

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com