Patents

Literature

596 results about "Primary energy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Primary energy (PE) is an energy form found in nature that has not been subjected to any human engineered conversion process. It is energy contained in raw fuels, and other forms of energy received as input to a system. Primary energy can be non-renewable or renewable.

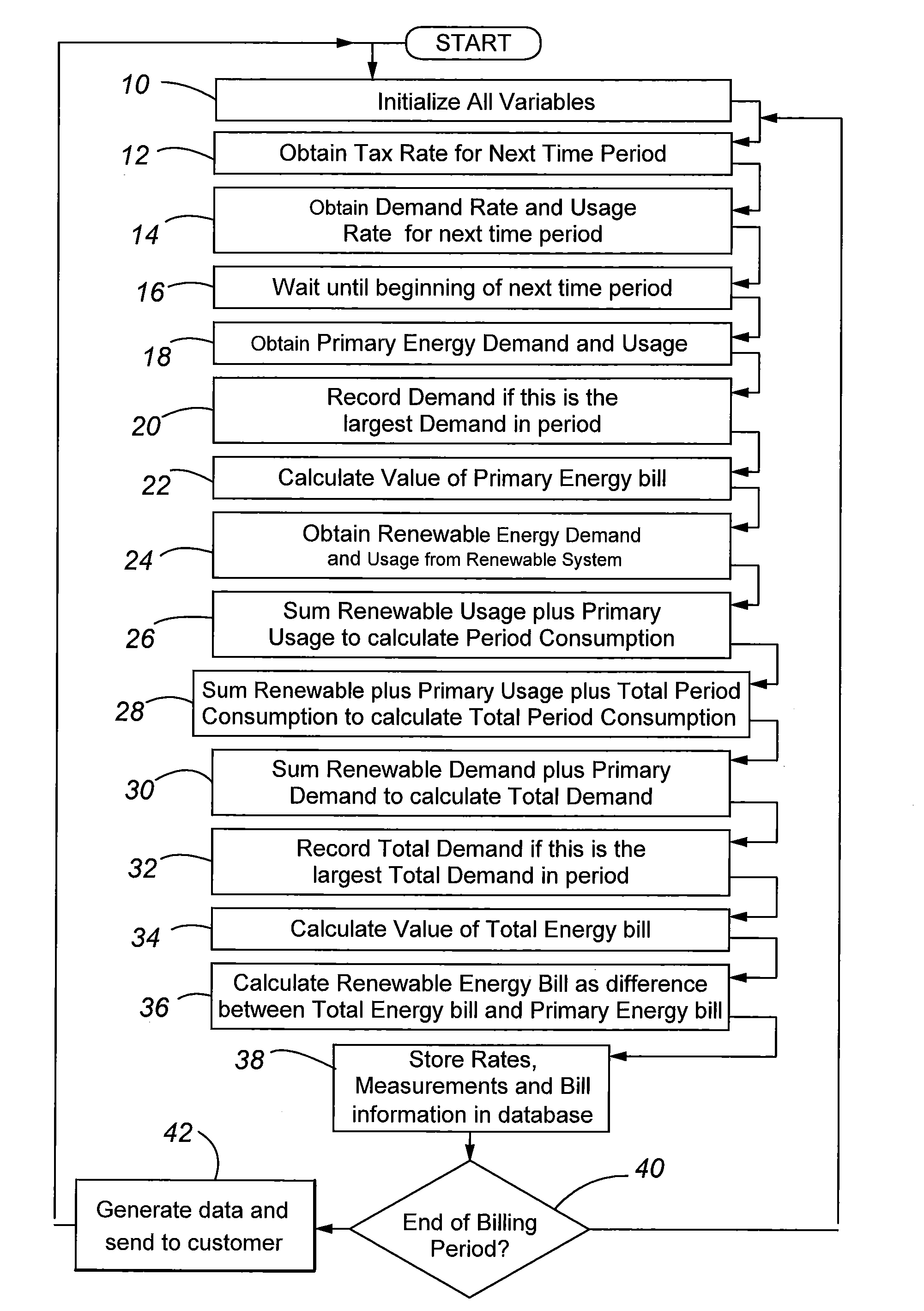

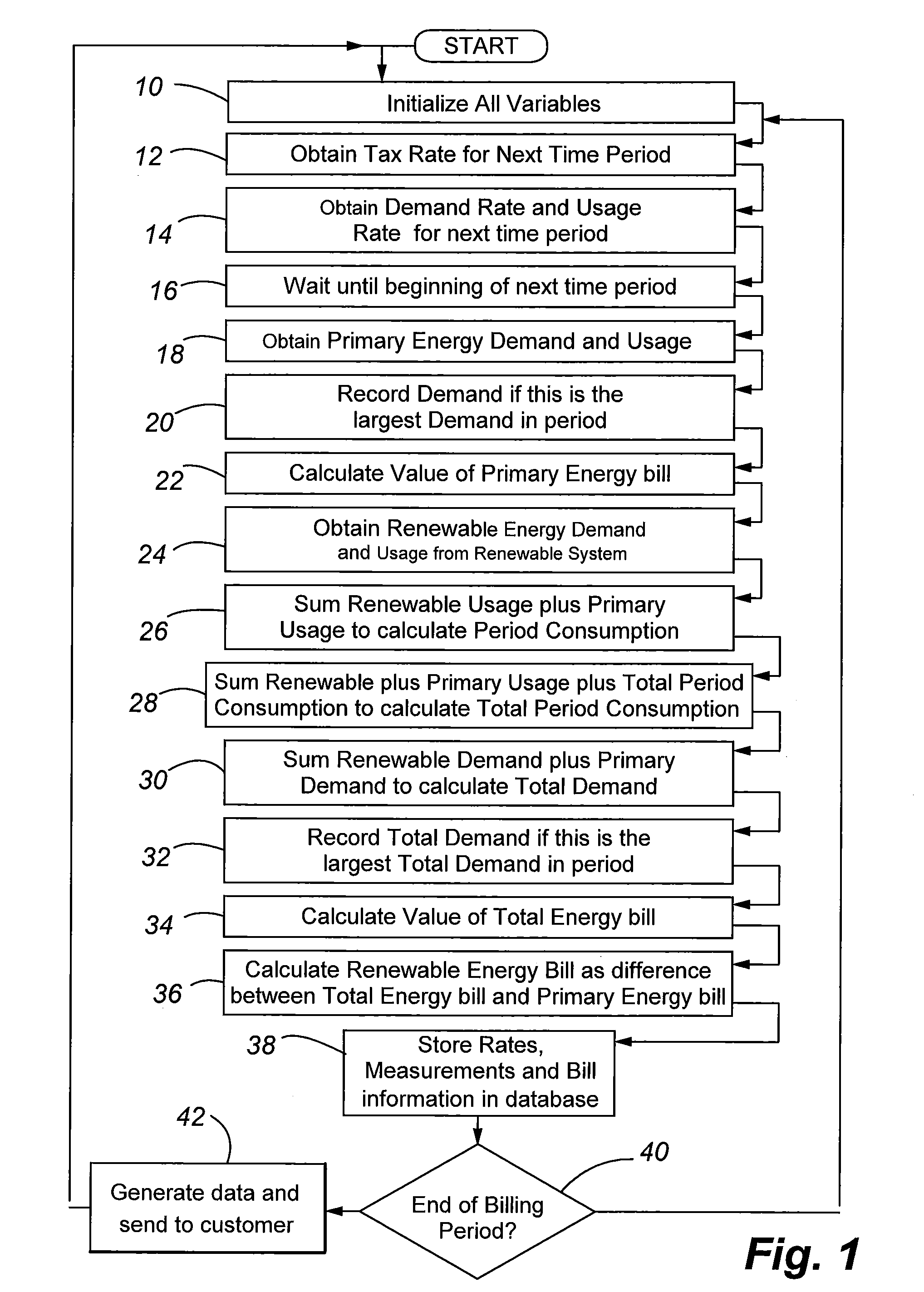

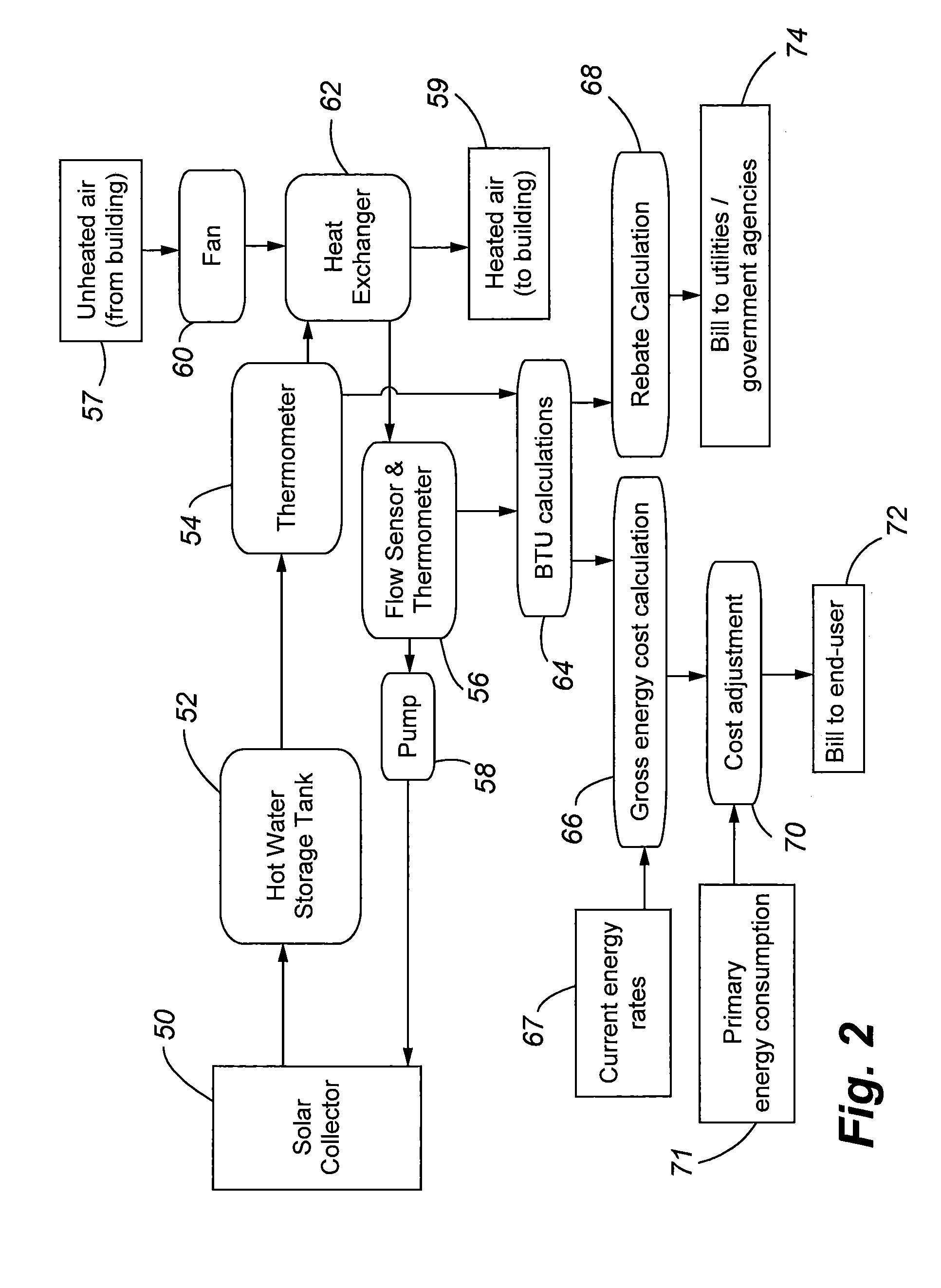

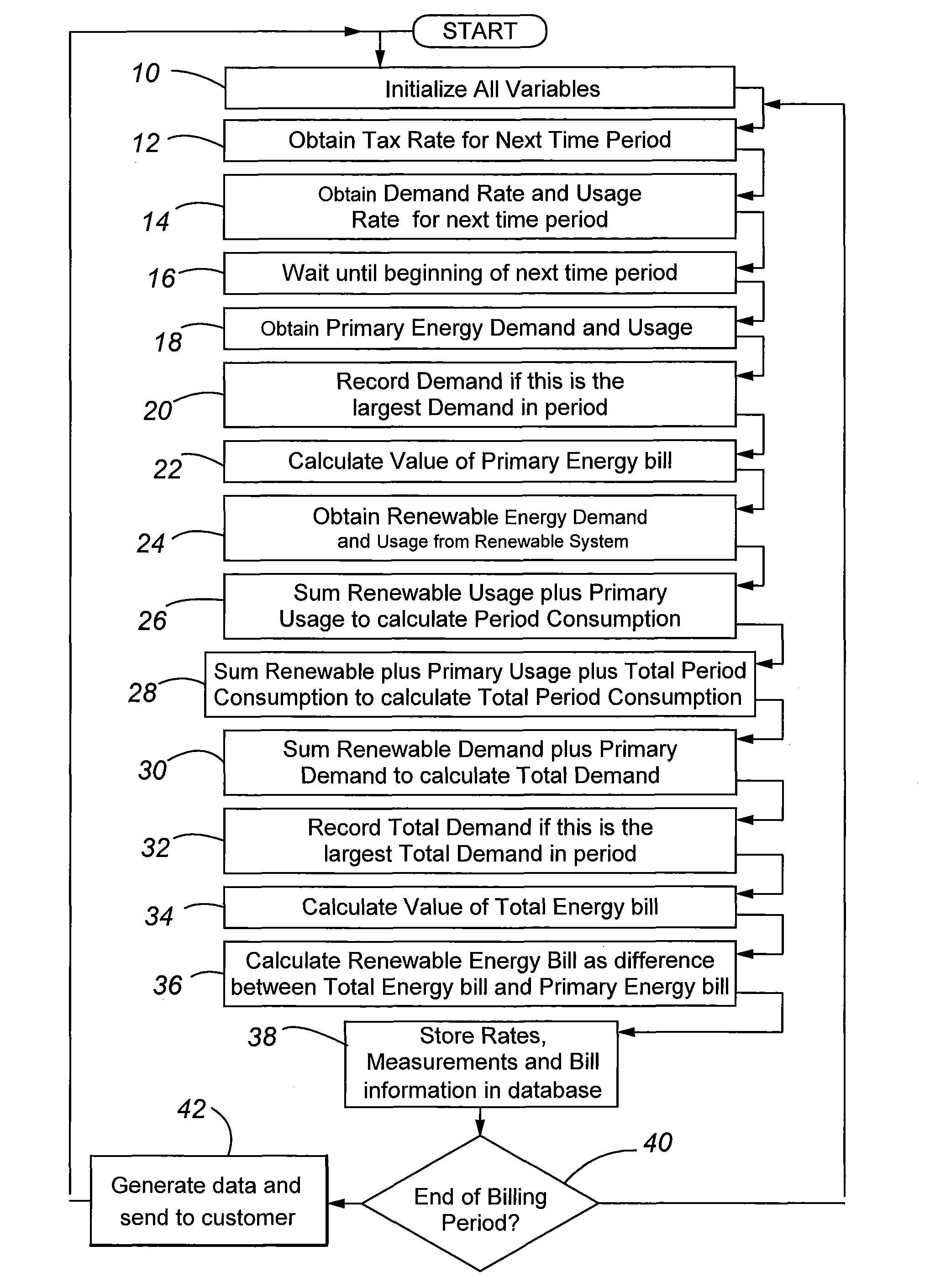

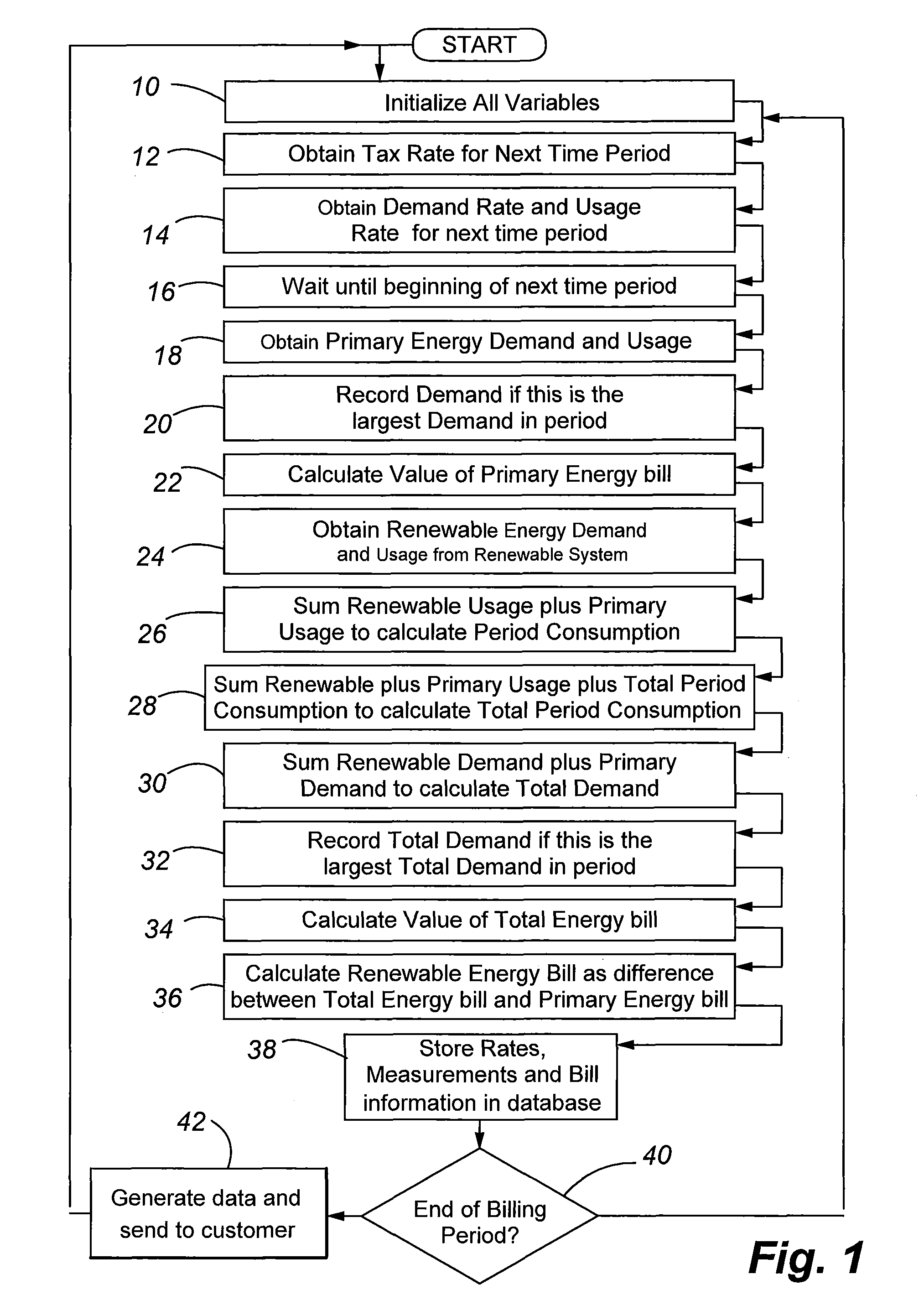

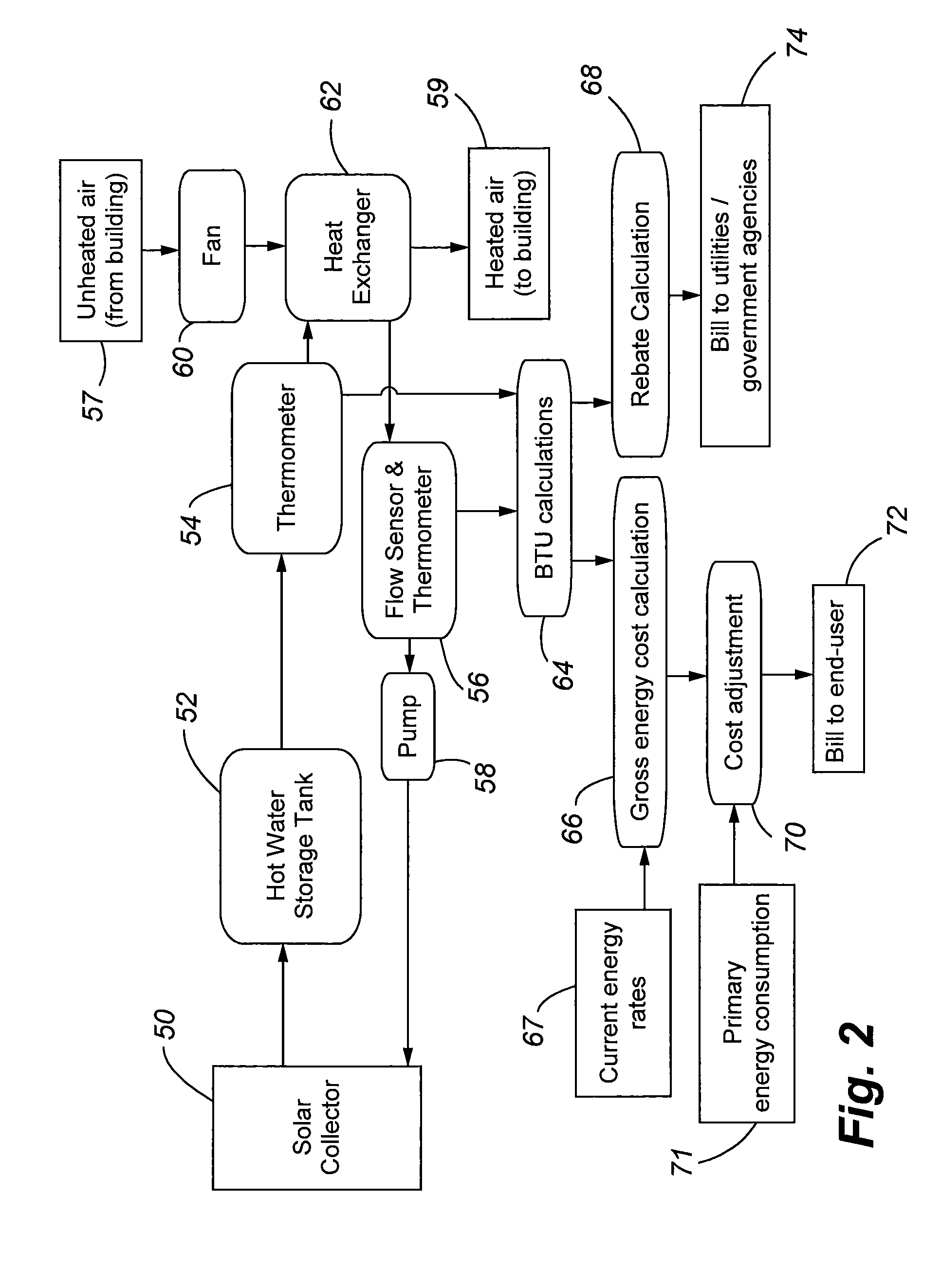

System and method for integrating billing information from alternate energy sources with traditional energy sources

ActiveUS20100174643A1Lower requirementLow costComplete banking machinesElectric devicesEngineeringPredictive analytics

The method and system of the present invention provides for data gathering of energy systems, calculation of billing information for the energy systems to include both traditional energy sources and renewable energy sources, and creation of various outputs to include various user interfaces applicable to overall management of the energy systems. The user interfaces can include integrated, real-time billings to a consumer that measure the cost of the primary energy as well as savings provided by renewable energy sources. The present invention also provides predictive analysis for various aspects of energy use in order to better manage particular facilities that may incorporate renewable energy sources. The gathered data and the various user interfaces enables a user to modify or adjust the use of the renewable energy sources at selected sites to maximize their impact on reducing the cost of the primary energy bill.

Owner:ALSO ENERGY

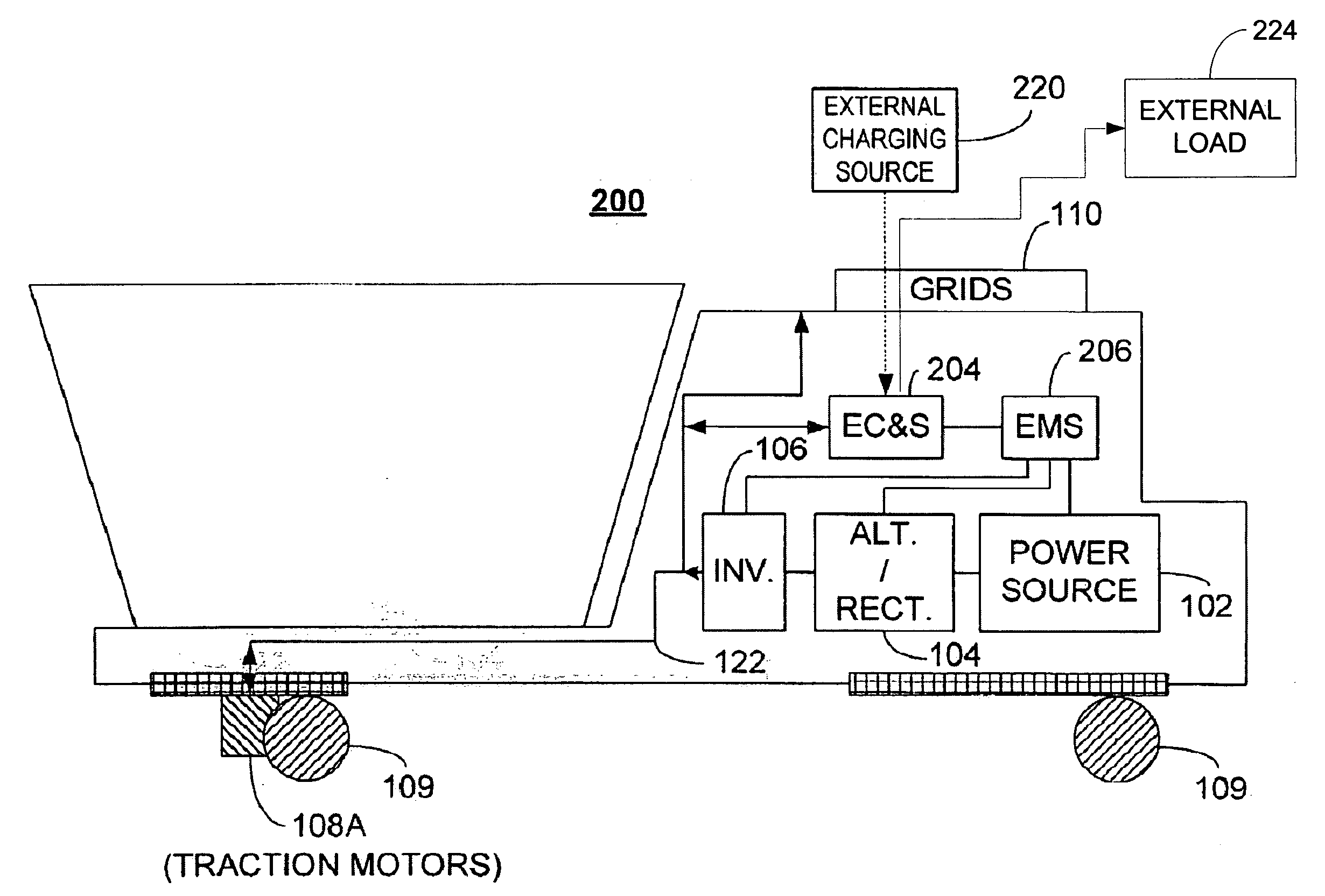

Hybrid energy off highway vehicle electric power management system and method

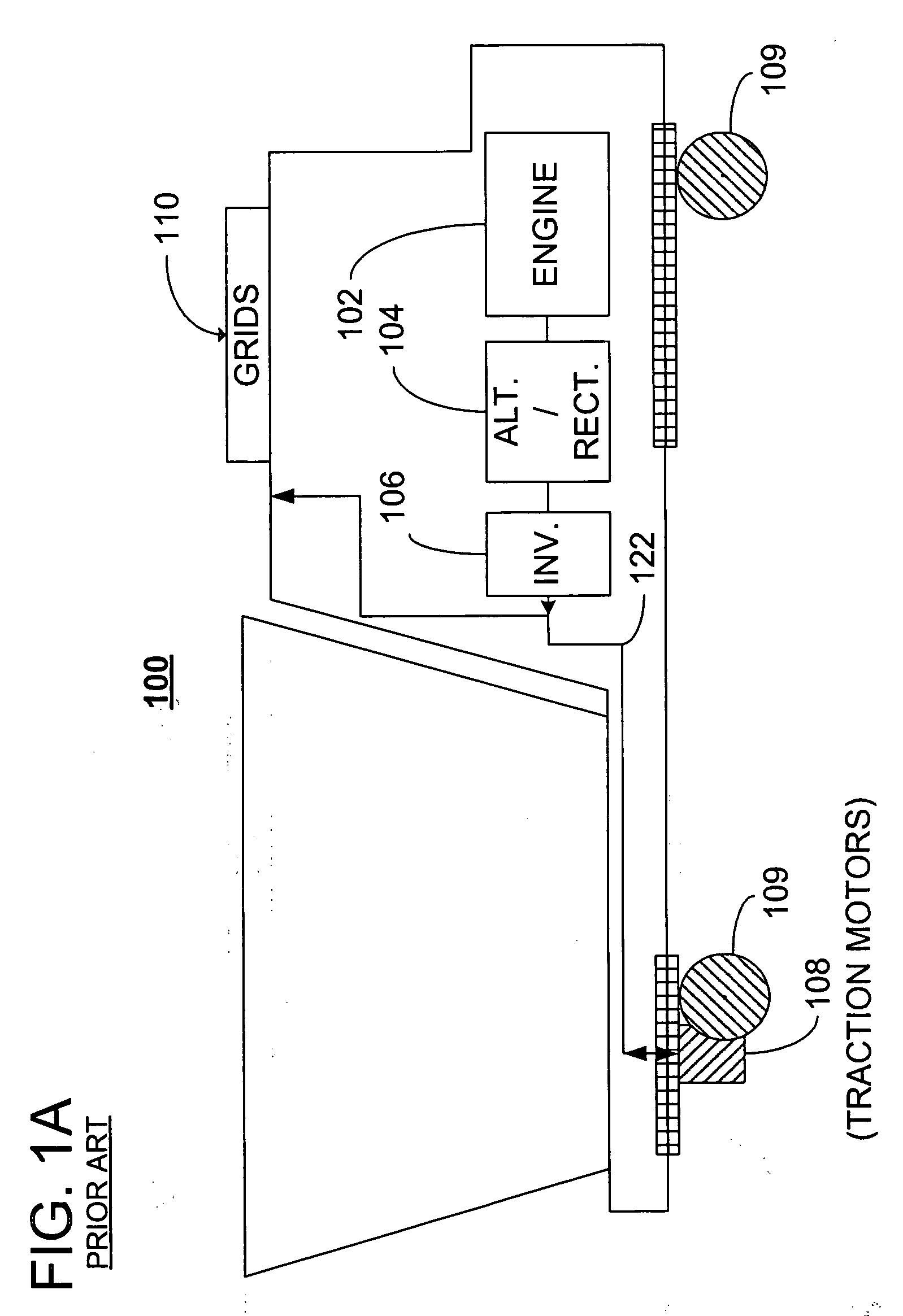

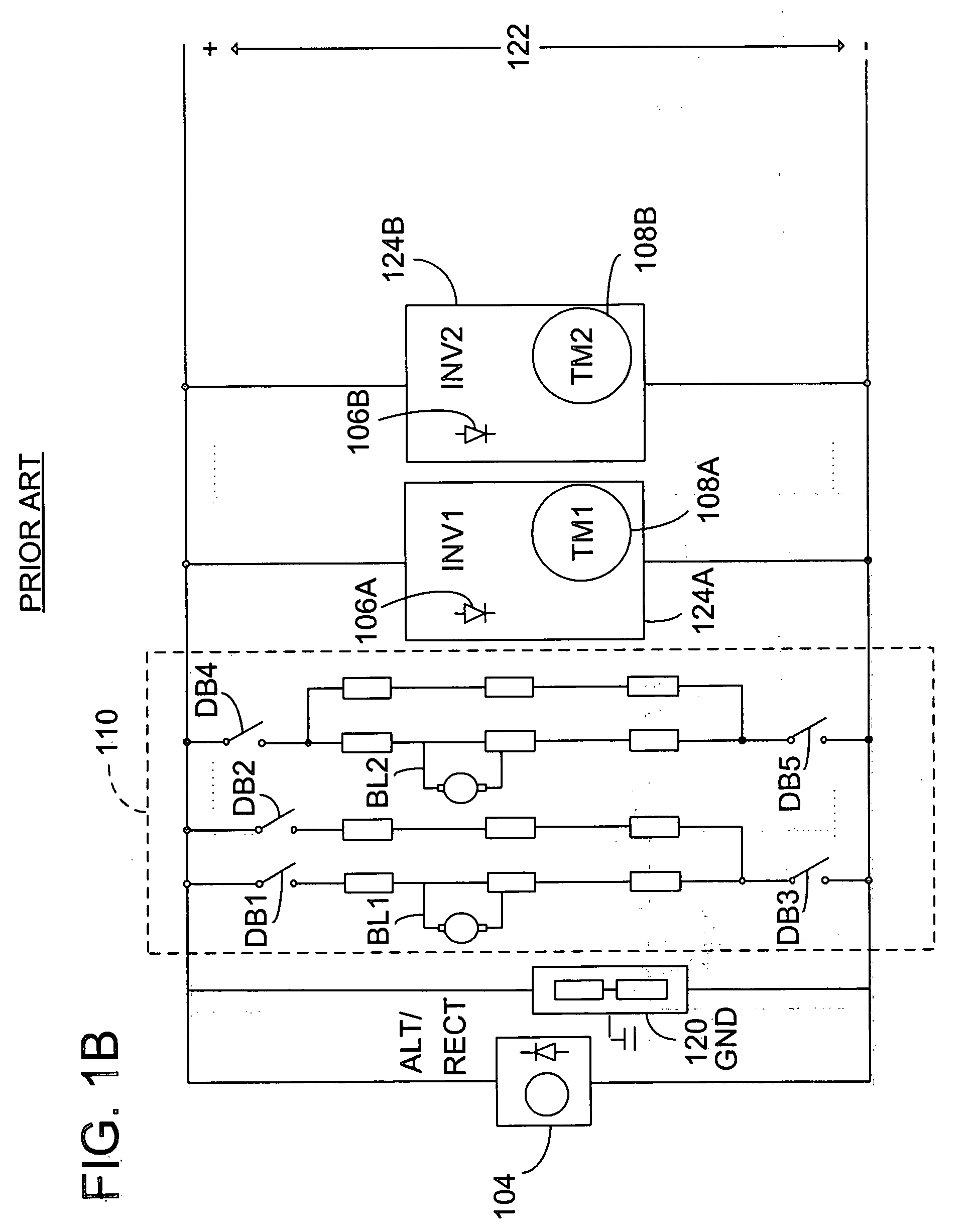

An energy management system for use with a hybrid energy off highway vehicle. The off highway vehicle includes a primary energy source and a power converter driven by the primary energy source for providing primary electric power. A traction bus is coupled to the power converter and carries the primary electric power. A traction drive is connected to the traction bus. The traction drive has a motoring mode in which the traction drive is responsive to the primary electric power for propelling the off highway vehicle. The traction drive has a dynamic braking mode of operation wherein said traction drive generates dynamic braking electrical energy. The energy management system includes an energy management processor for determining a power storage parameter and a power transfer parameter. An energy storage system is connected to the traction bus and is responsive to the energy management processor. The energy storage system selectively stores electrical energy as a function of the power storage parameter and selectively supplying secondary electric power from the stored electrical energy to the traction bus as a function of the power transfer parameter.

Owner:GENERAL ELECTRIC CO

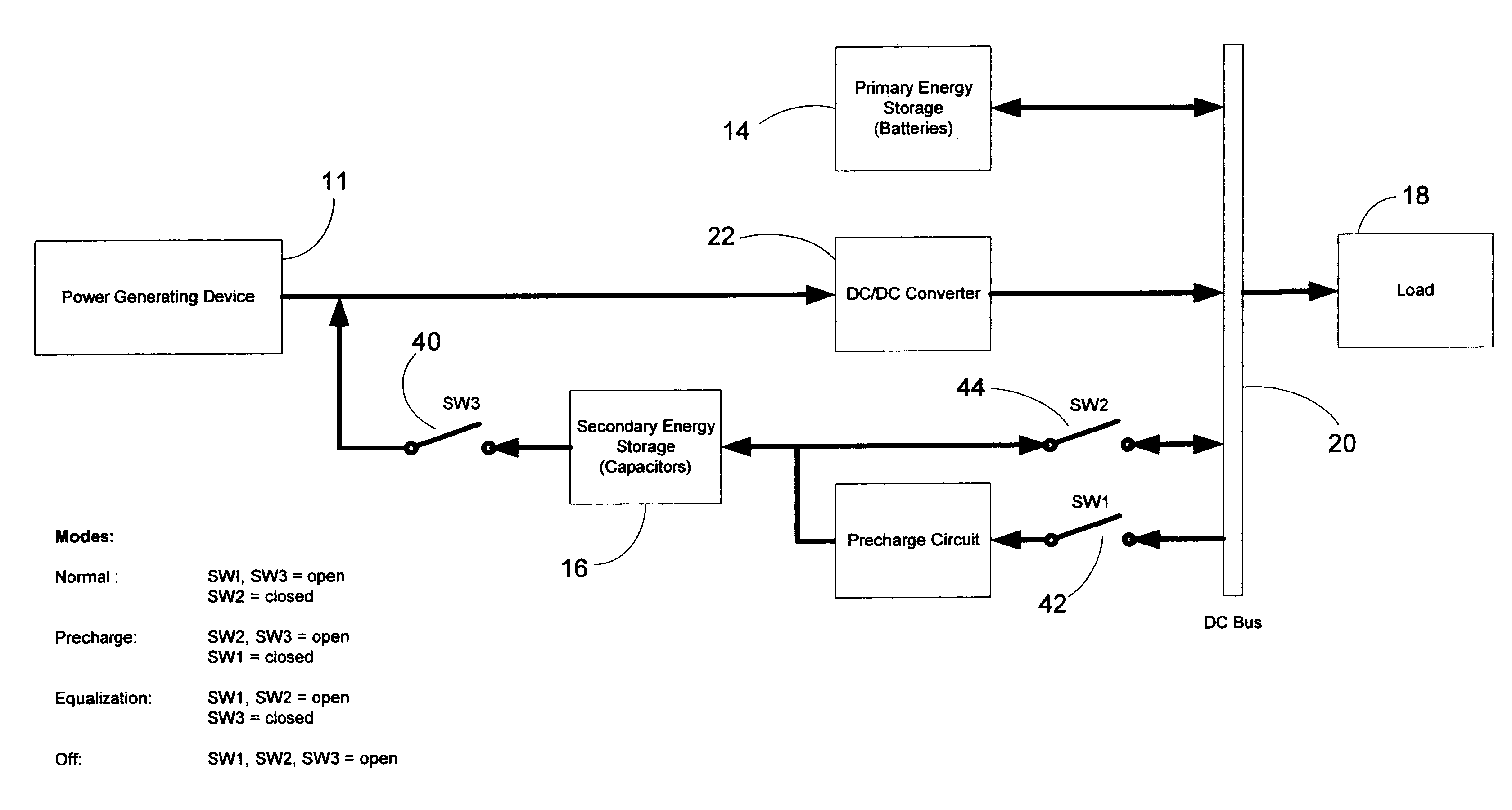

Hybrid energy storage device charge equalization system and method

InactiveUS20020171397A1Avoid excessive dischargeIncreases stored energy availableBatteries circuit arrangementsElectric devicesFuel cellsState of charge

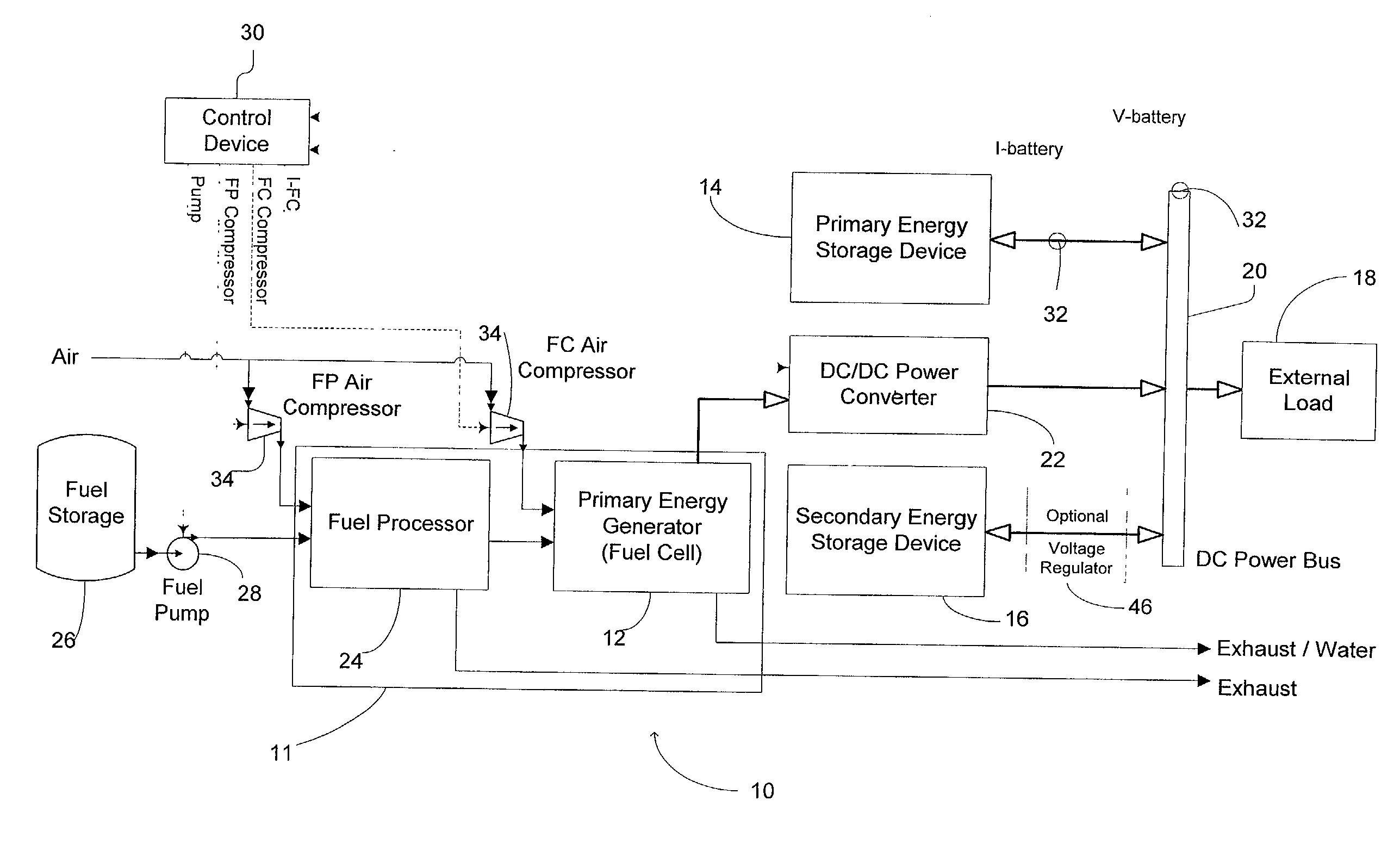

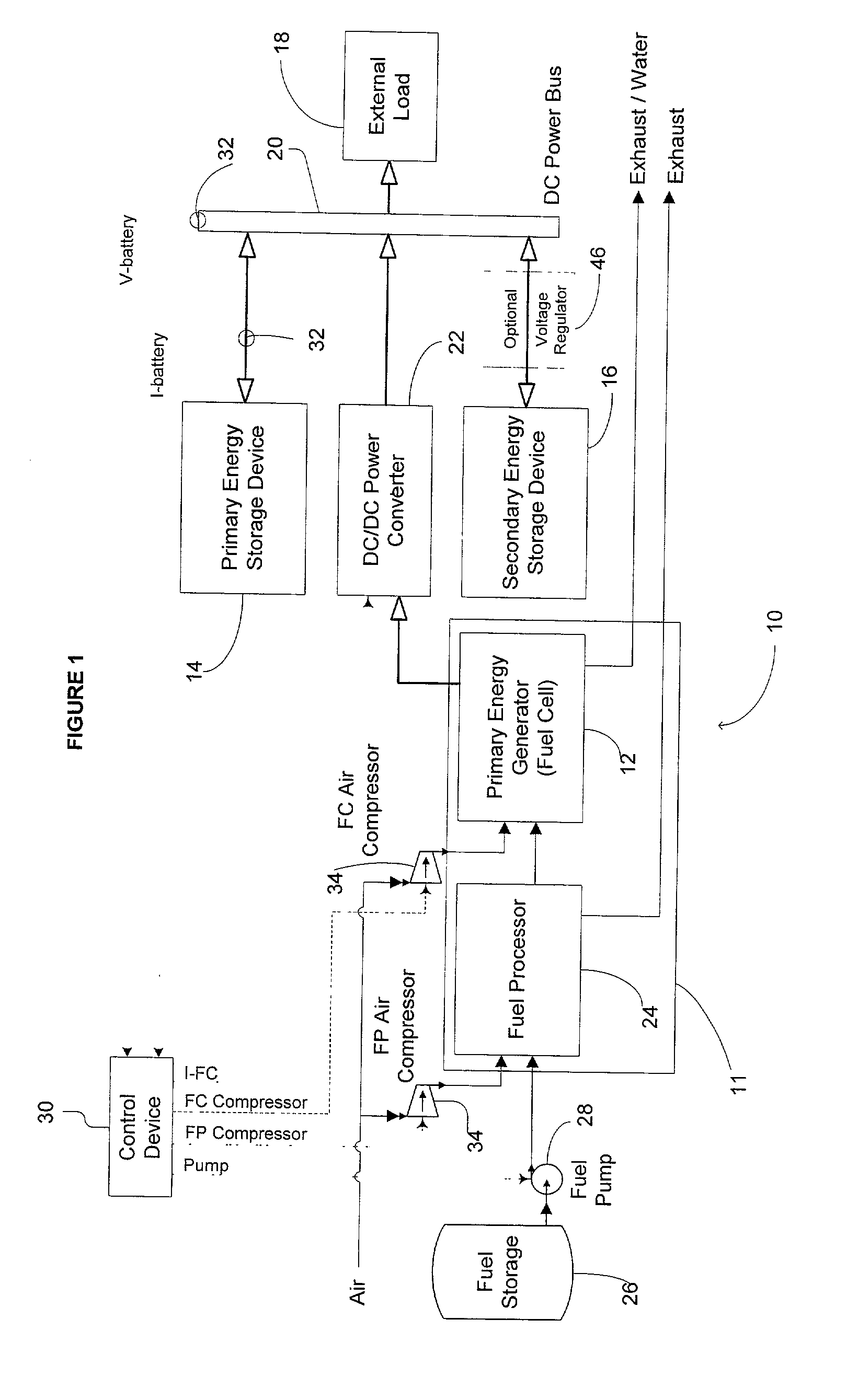

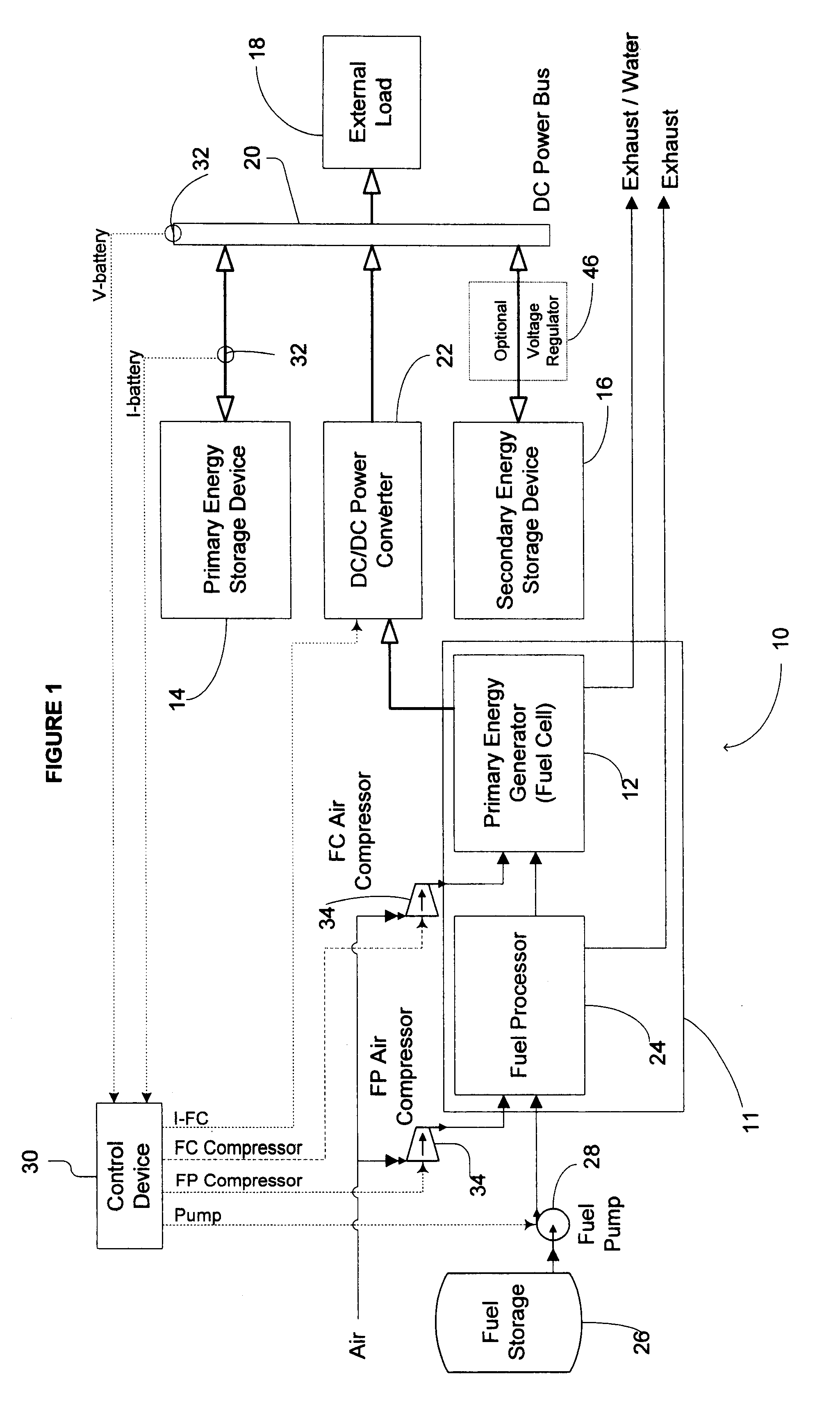

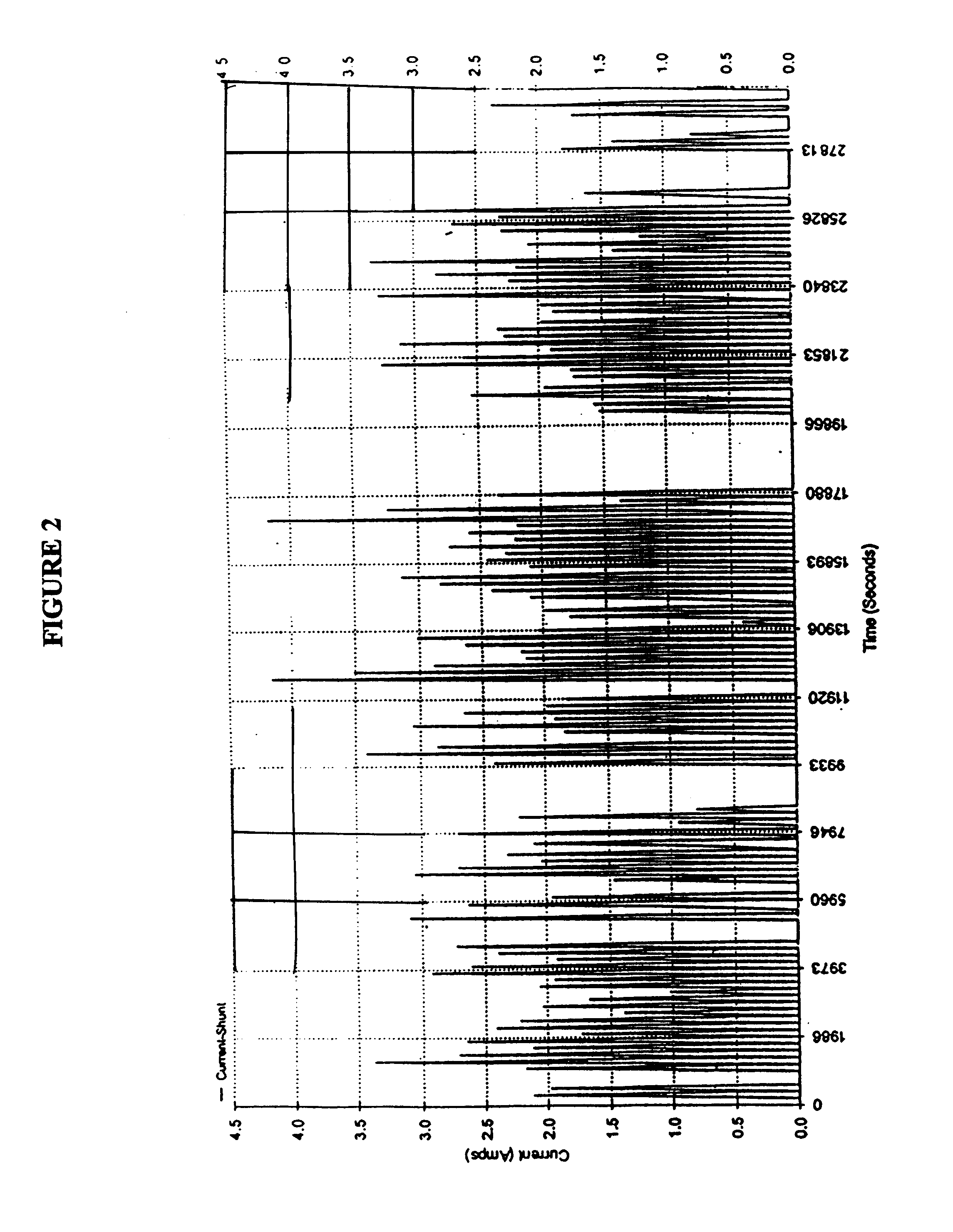

A system and method for improving the performance of a hybrid power supply apparatus comprising a power generating device, such as a fuel cell, and a primary energy storage device, such as a battery. The purpose of the invention is to provide an equalization charge to the battery from a source other than the fuel cell when the battery achieves a predetermined state of charge condition, thereby avoiding the need to operate the fuel cell in a low power output mode. When the predetermined state of charge condition is detected by a controller, the fuel cell is shut-down. In one aspect of the invention the equalization charge is provided to the battery by a secondary energy storage device, such as a plurality of capacitors or secondary batteries. The predetermined state of charge condition may be satisfied, for example, when the state of charge of the battery exceeds a predetermined threshold, such as 80% of the battery's storage capacity, for a predetermined period of time. In some aspects of the invention, the secondary energy storage device may also be connectable to the load. Preferably the system also includes a DC / DC converter for regulating current flow between the fuel cell and the storage devices.

Owner:CELLEX POWER PRODS

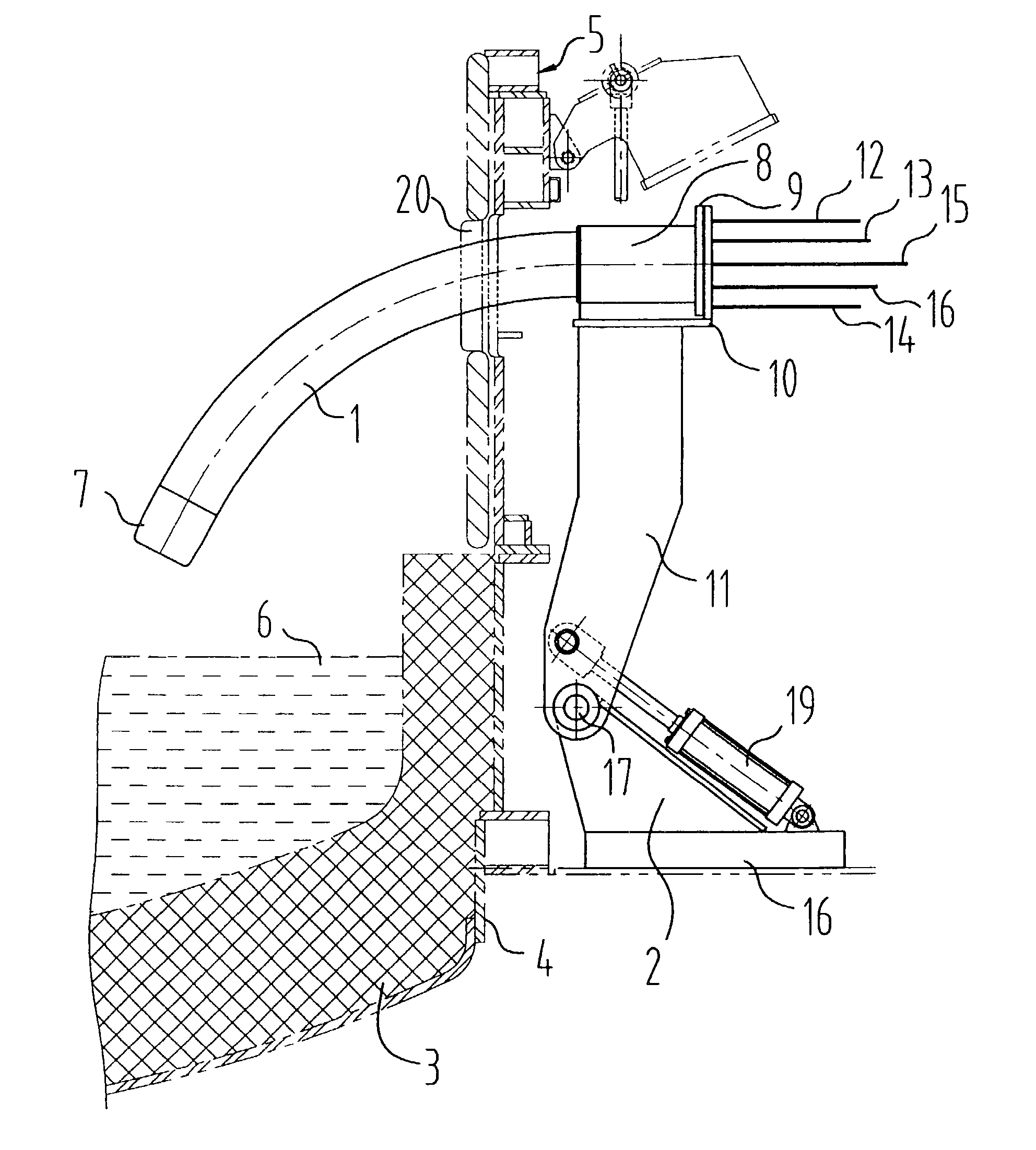

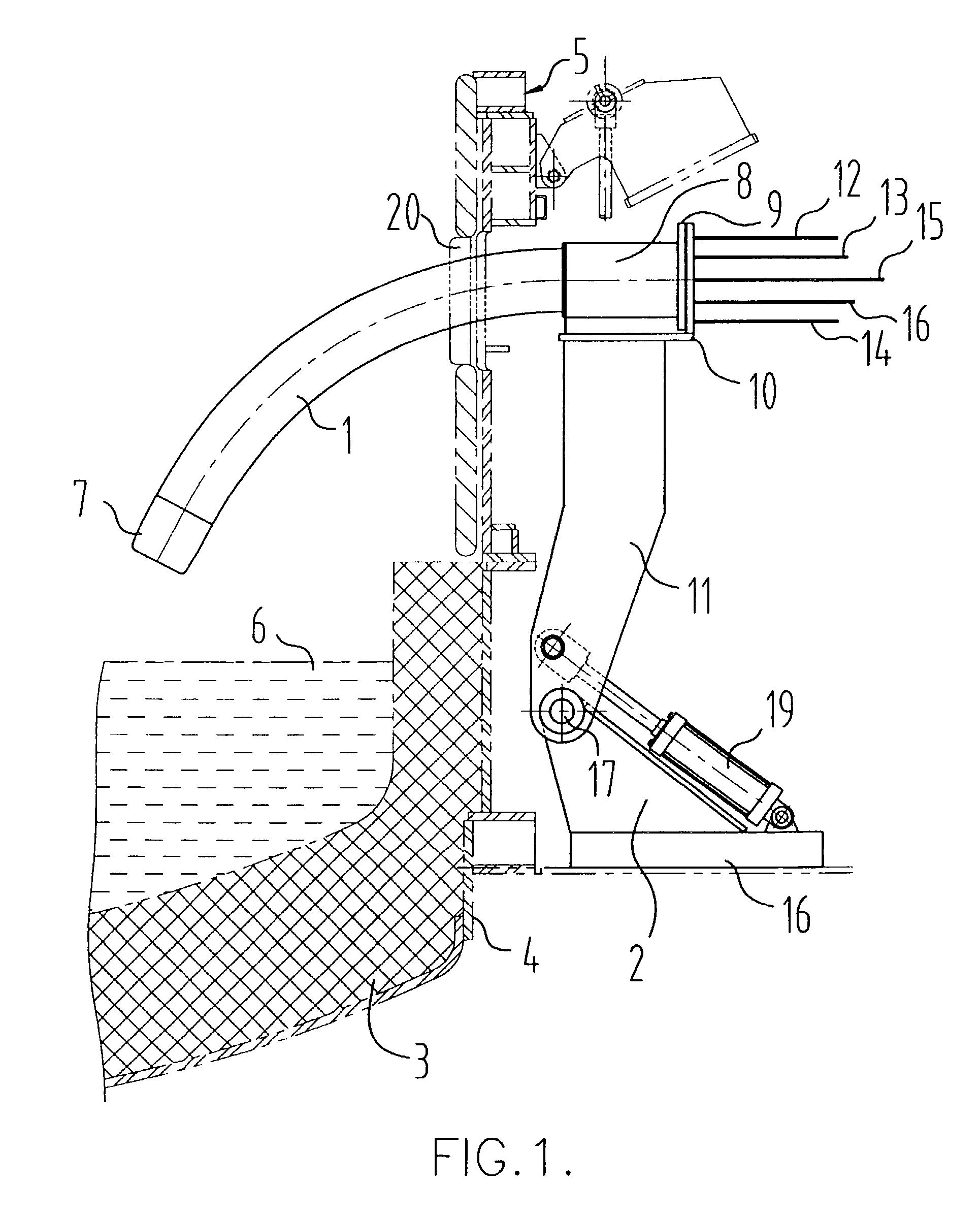

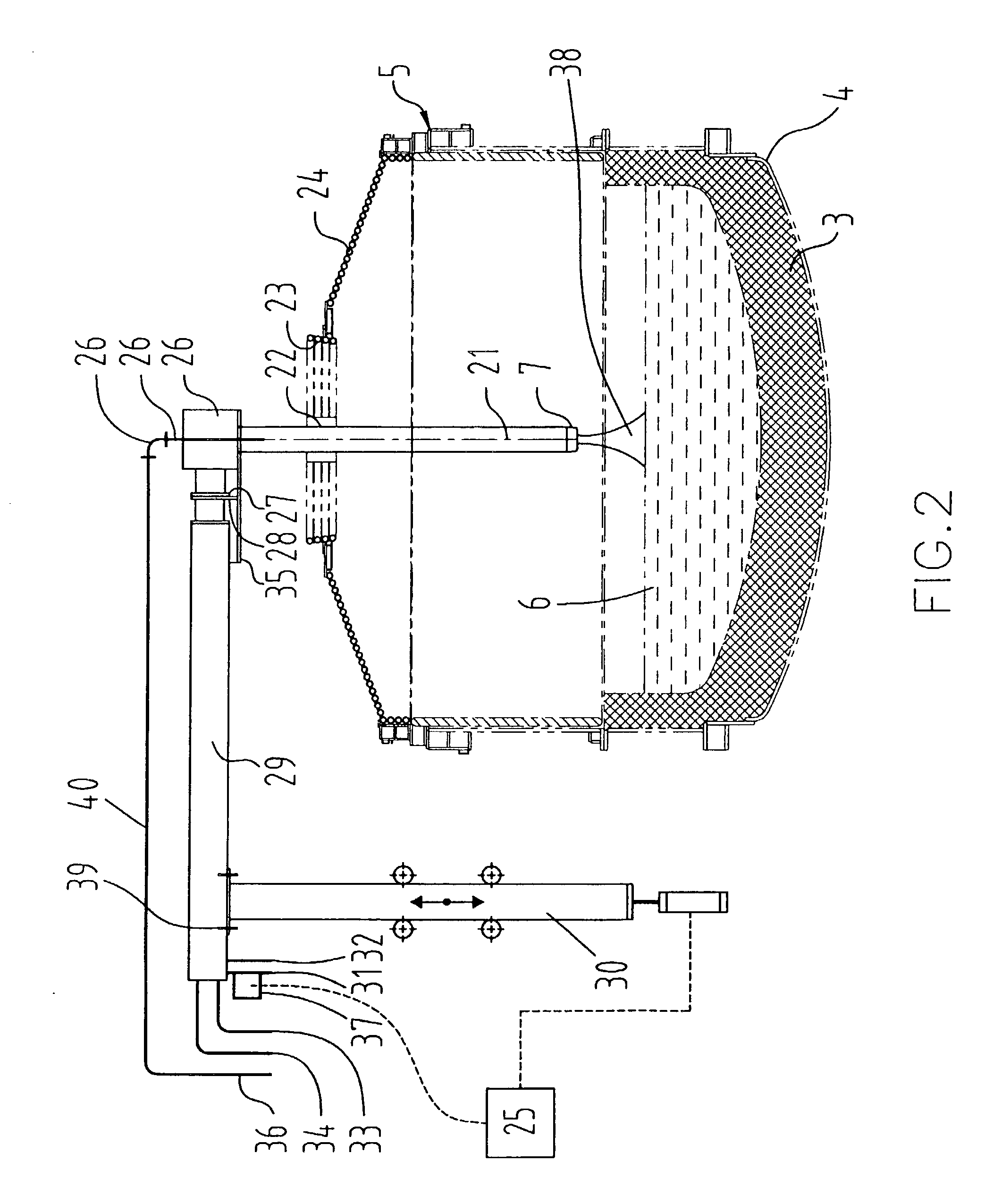

Multi-purpose, multi-oxy-fuel, power burner/injector/oxygen lance device

InactiveUS20030075843A1Reduce the numberSmall sizeTuyeresCharge manipulationSteelmakingLiquid medium

A multi-purpose, multi-oxy-fuel High Temperature Power Burner / Injector / Oxygen Lance, Mechanical System Apparatus Device, for steelmaking from recycled scrap and / or virgin ferrous charge, which can be employed in multi-oxy-fuel (natural gas; pulverized carbonaceous matter; heavy oil), especially by Oxygen Combusted mixture of Natural Gas / Pulverized Carbonaceous Matter in High Temperature Power Burner Mode, for efficient and rapid melting of solid ferrous charge (cold or preheated) in a special steelmaking Metallurgical Furnace or Open Hearth Furnace, Tandem Furnace, BOF, EAF, as its augmenting or only source of thermal energy; more than one Device in Oxygen-Natural Gas / Pulverized Carbonaceous Matter Power Burner Mode, can be employed as the only source of thermal energy in a modified, originally Electric Arc Furnace, as total replacement of Graphite Electrodes and Electric Arc System, the replacement being noticeably more primary energy efficient than the thermal energy provided by Graphite Electrode / Arc System; it also can be employed in an Solid Particles Injector Mode, for injecting of adequately granulated carbonaceous materials or lime into the molten steel for its carburizing or for foamy slag control; further it can be employed in a natural gas shrouded, pulsating oxygen stream, for vertically to the charge oriented soft blow supersonic Oxygen Injection Lance Mode, for decarburization of the molten metal contained in the hearth of the metallurgical furnace and foamy slag control; in one of the embodiments-generally arcuate-pivotally mounted, liquid media cooled composite body, is pivoted into and out of a furnace vessel through a small opening in the shell wall for auto-regulated constant optimal positioning of the Composite Body Tip against solid or molten charge, in each and all multi-purpose modes; furthermore, when inserted into the furnace vessel, the arcuate composite body can be rotated about its longitudinal axis for directing the oxy-fuel high temperature flame towards unmolten charge in the furnace; in an other-generally linear-embodiment, the liquid cooled composite body is attached to the mast type carrier allowing vertical movement of the composite body which enters the furnace vessel through a small opening in the furnace roof; the bimetallic, liquid cooled special tip assembly of both-arcuate and linear embodiments-of the composite body includes easy replaceable, independent, multi-opening nozzles, mounted in a protective, retracted position inside of the liquid cooled special tip assembly.

Owner:EMPCO (CANADA) LTD

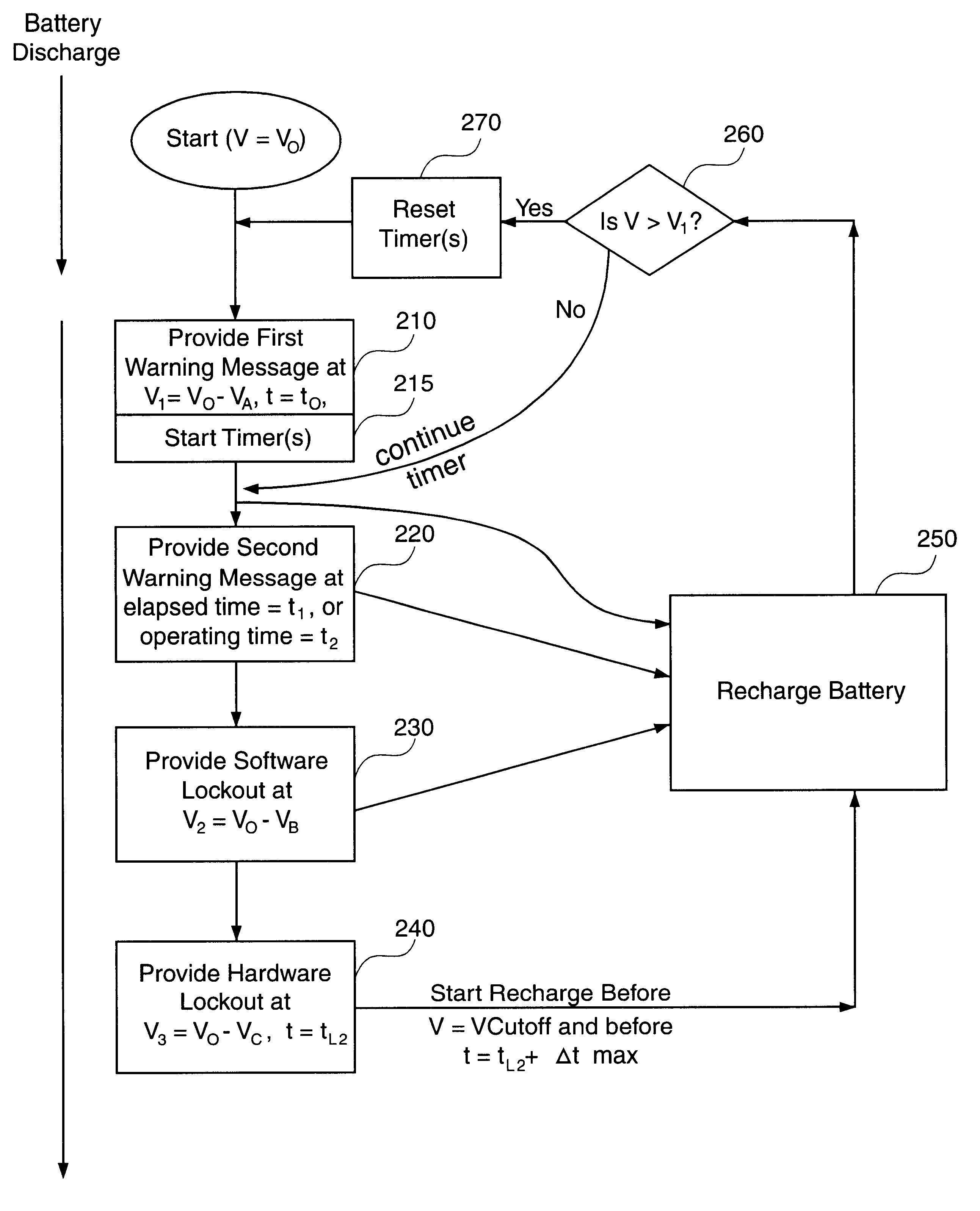

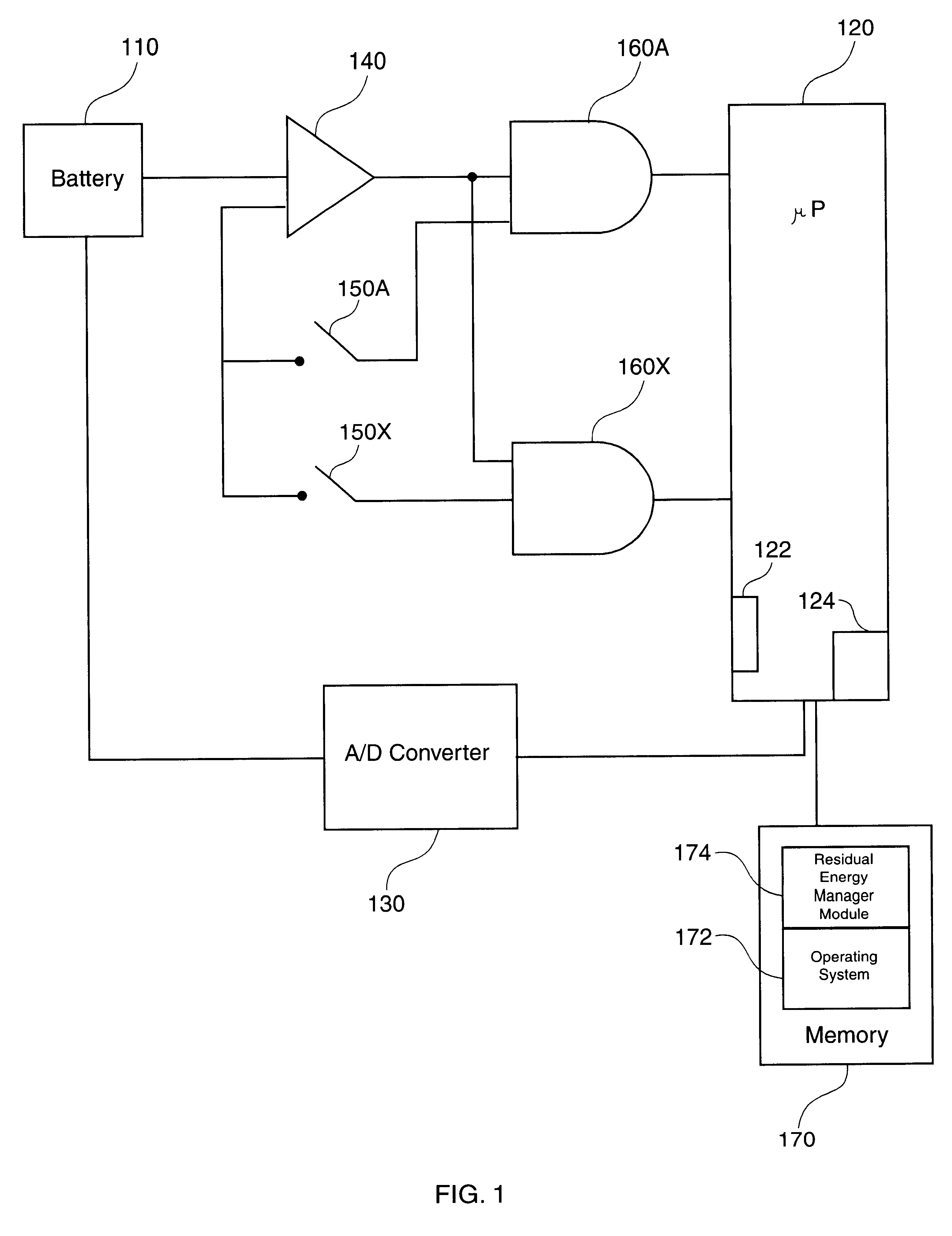

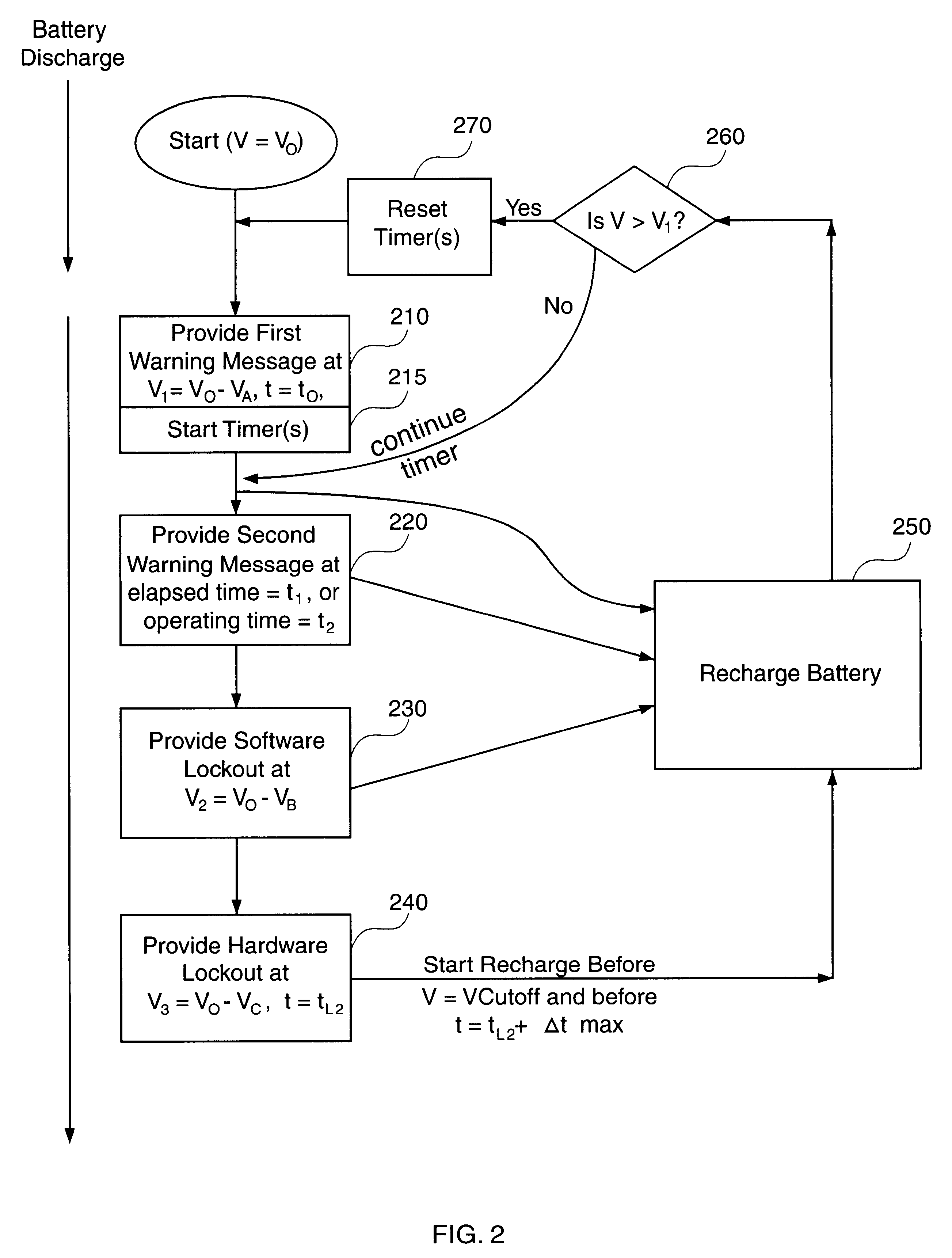

Method and apparatus for using residual energy in a battery-powered computer

InactiveUS6425087B1Avoid lostCost effectiveHardware monitoringPower supply for data processingElectrical batteryCutoff function

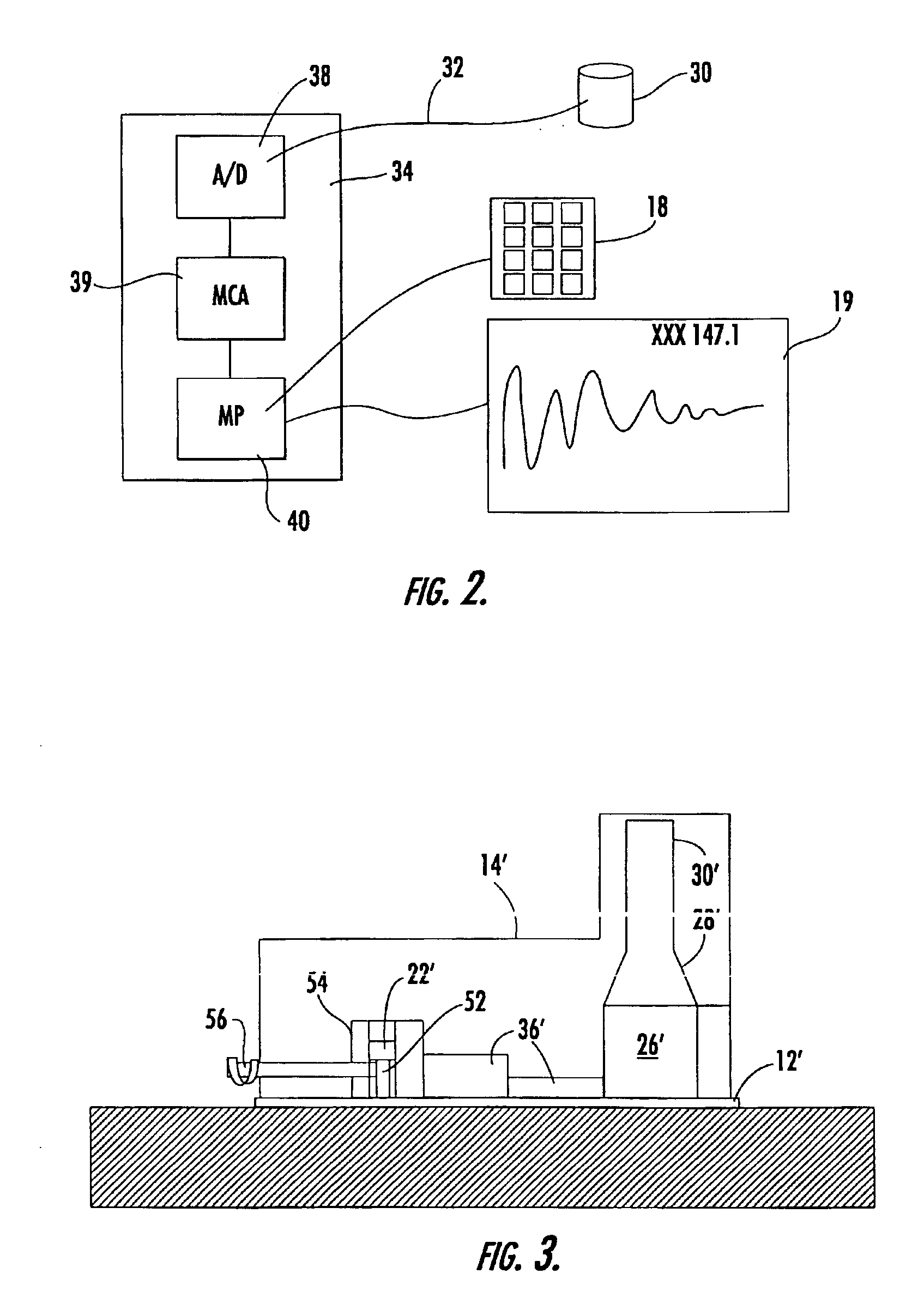

Methods and apparatus are described for providing a time-based warning indicating that the energy capacity of a primary energy source of a battery-powered computer has discharged to a low level, and using residual energy of the primary energy source to perform at least one pre-cutoff function. The time-based warning ensures that the warning is provided in a timely manner by overcoming problems caused by analog to digital converter voltage measurement accuracy limitations and flat battery operating voltage versus discharge curves. The primary energy source can be a rechargeable battery, which can also be the sole energy source for the computer. The battery provides power to operate the computer until the battery voltage discharges to the cutoff voltage. The methods and apparatus provide advantages because they reserve the residual energy in the battery to perform at least one pre-cutoff function within a first duration before the battery discharges to the cutoff voltage. For example, the residual energy can be used to retain data stored in the computer between opportunities to charge the battery. Some embodiments of the invention include hardware resources coupled with the processor to lock out power and application activation when the rechargeable battery has discharged to a predetermined hardware lockout voltage. The value of the hardware lockout voltage can be based on the battery retaining a residual energy sufficient for performing the corresponding pre-cutoff function within an amount of time that is expected to enable the user to perform the function.

Owner:QUALCOMM INC

Hybrid energy storage device charge equalization system and method

InactiveUS6559621B2Reduce stepsAvoid excessive dischargeBatteries circuit arrangementsElectric devicesElectrical batteryEngineering

A system and method for improving the performance of a hybrid power supply apparatus comprising a power generating device, such as a fuel cell, and a primary energy storage device, such as a battery. The purpose of the invention is to provide an equalization charge to the battery from a source other than the fuel cell when the battery achieves a predetermined state of charge condition, thereby avoiding the need to operate the fuel cell in a low power output mode. When the predetermined state of charge condition is detected by a controller, the fuel cell is shut-down. In one aspect of the invention the equalization charge is provided to the battery by a secondary energy storage device, such as a plurality of capacitors or secondary batteries. The predetermined state of charge condition may be satisfied, for example, when the state of charge of the battery exceeds a predetermined threshold, such as 80% of the battery's storage capacity, for a predetermined period of time. In some aspects of the invention, the secondary energy storage device may also be connectable to the load. Preferably the system also includes a DC / DC converter for regulating current flow between the fuel cell and the storage devices.

Owner:CELLEX POWER PRODS

High energy transport gas and method to transport same

InactiveUS8277525B2Increase volumeHigh boiling pointGas modification by gas mixingIndirect heat exchangersThermodynamicsFuel cells

Owner:DALTON ROBERT C

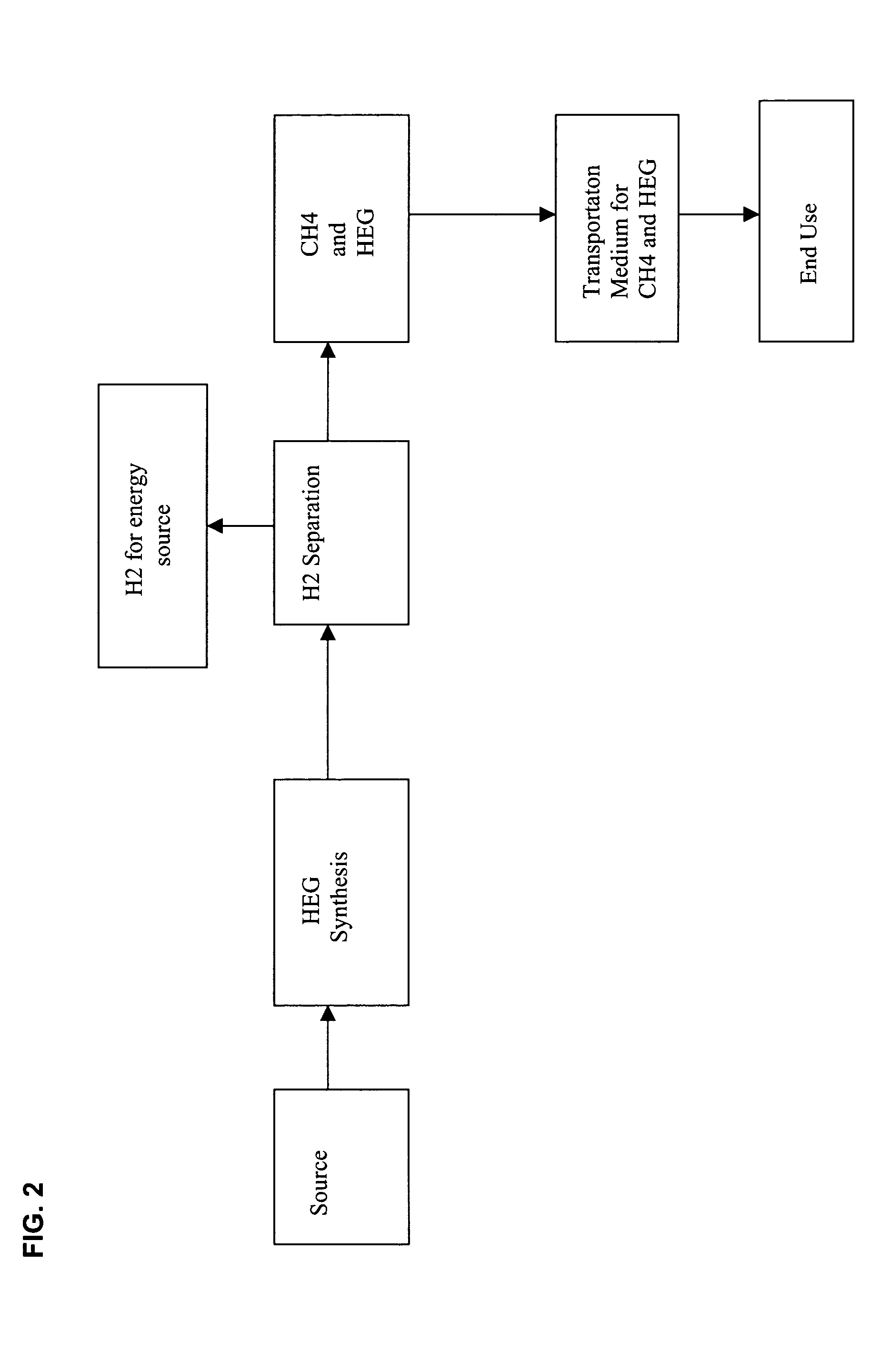

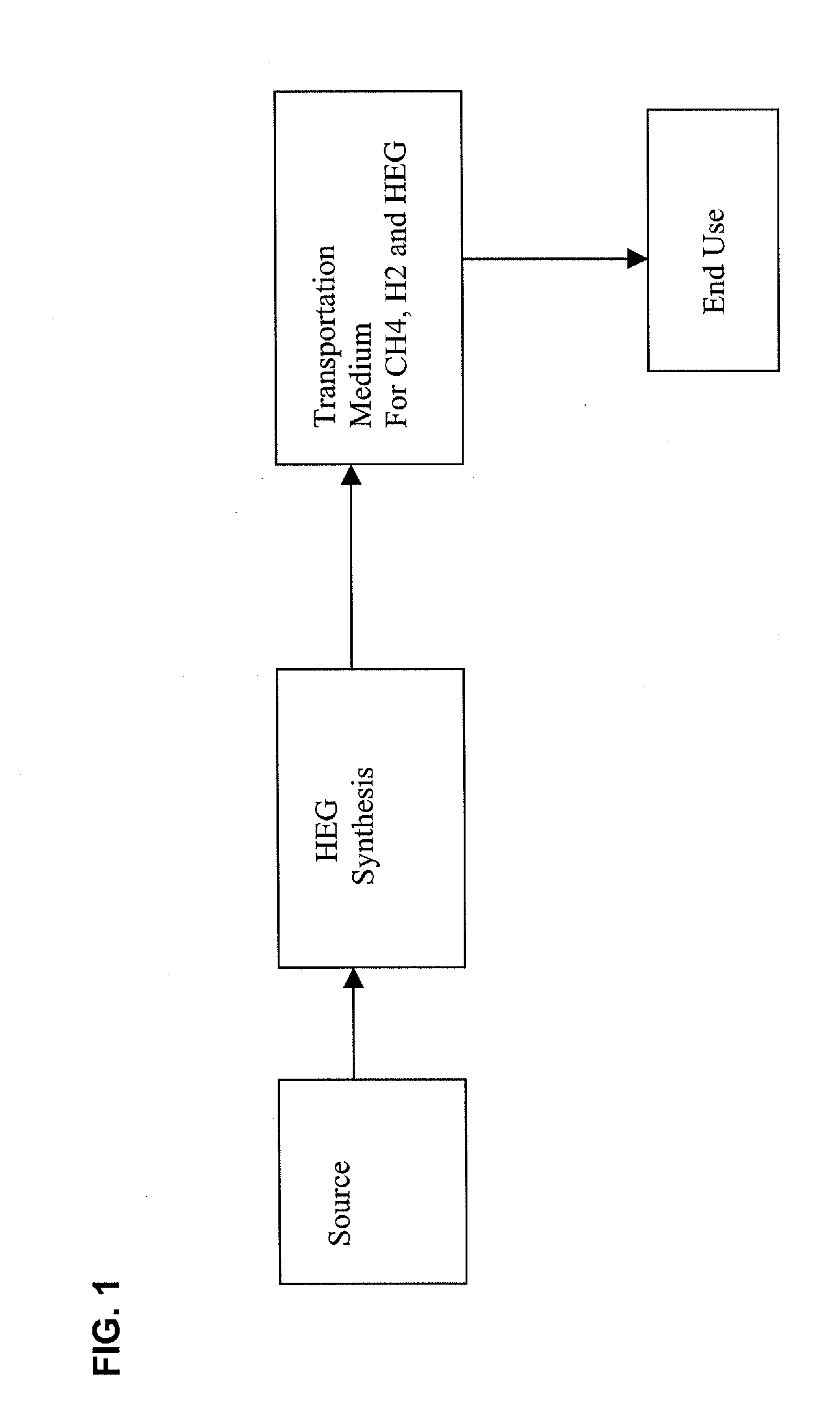

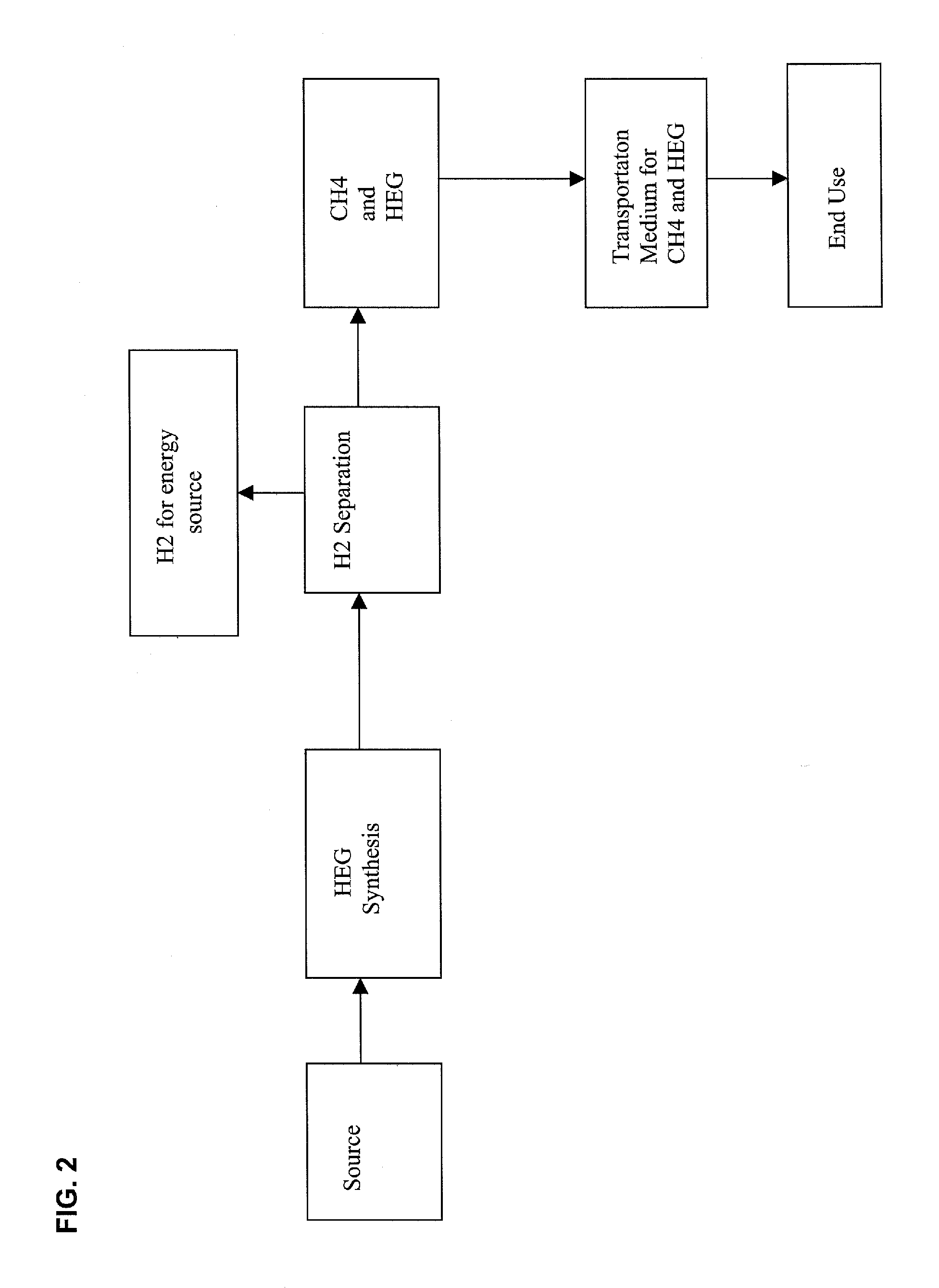

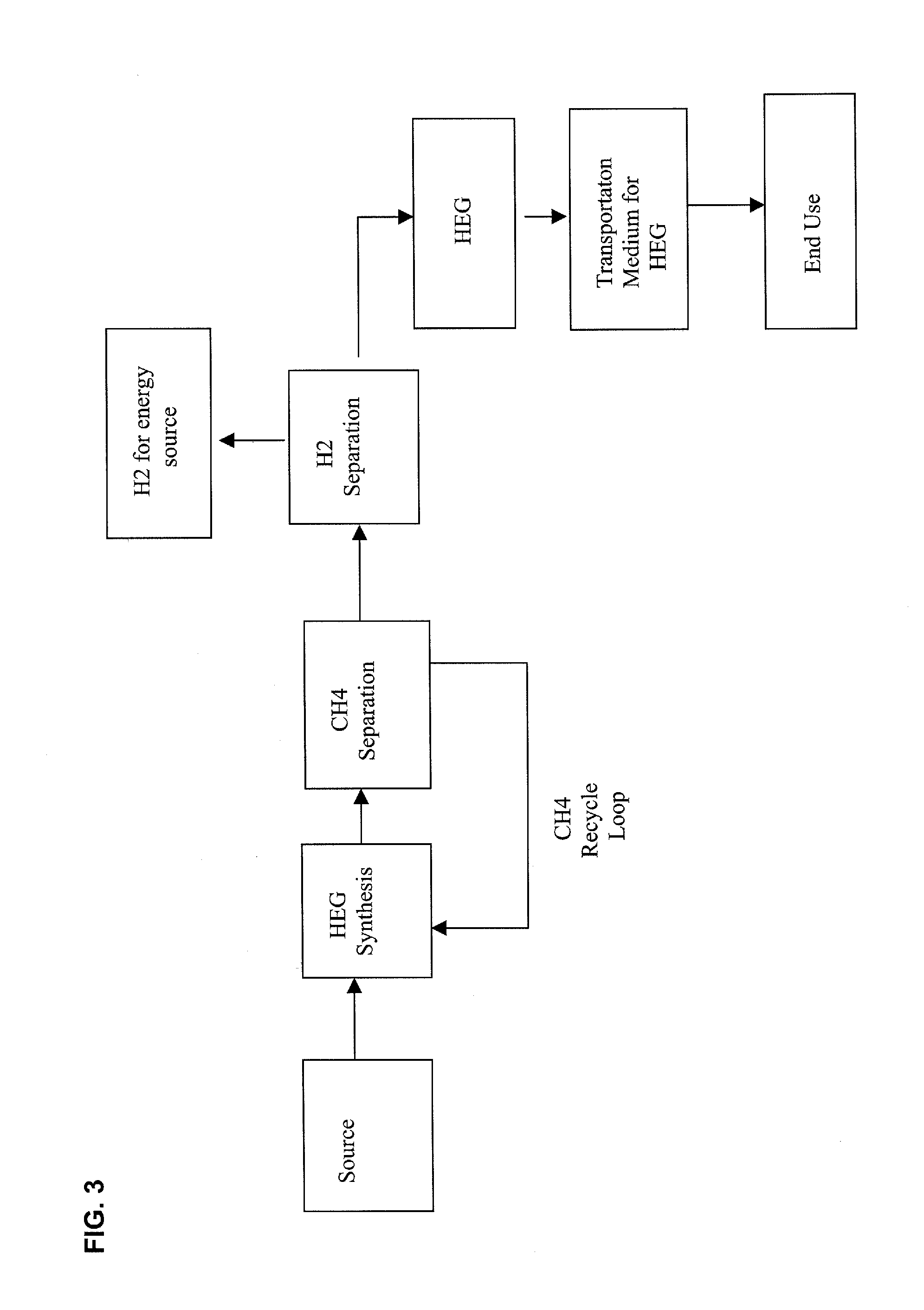

High energy transport gas and method to transport same

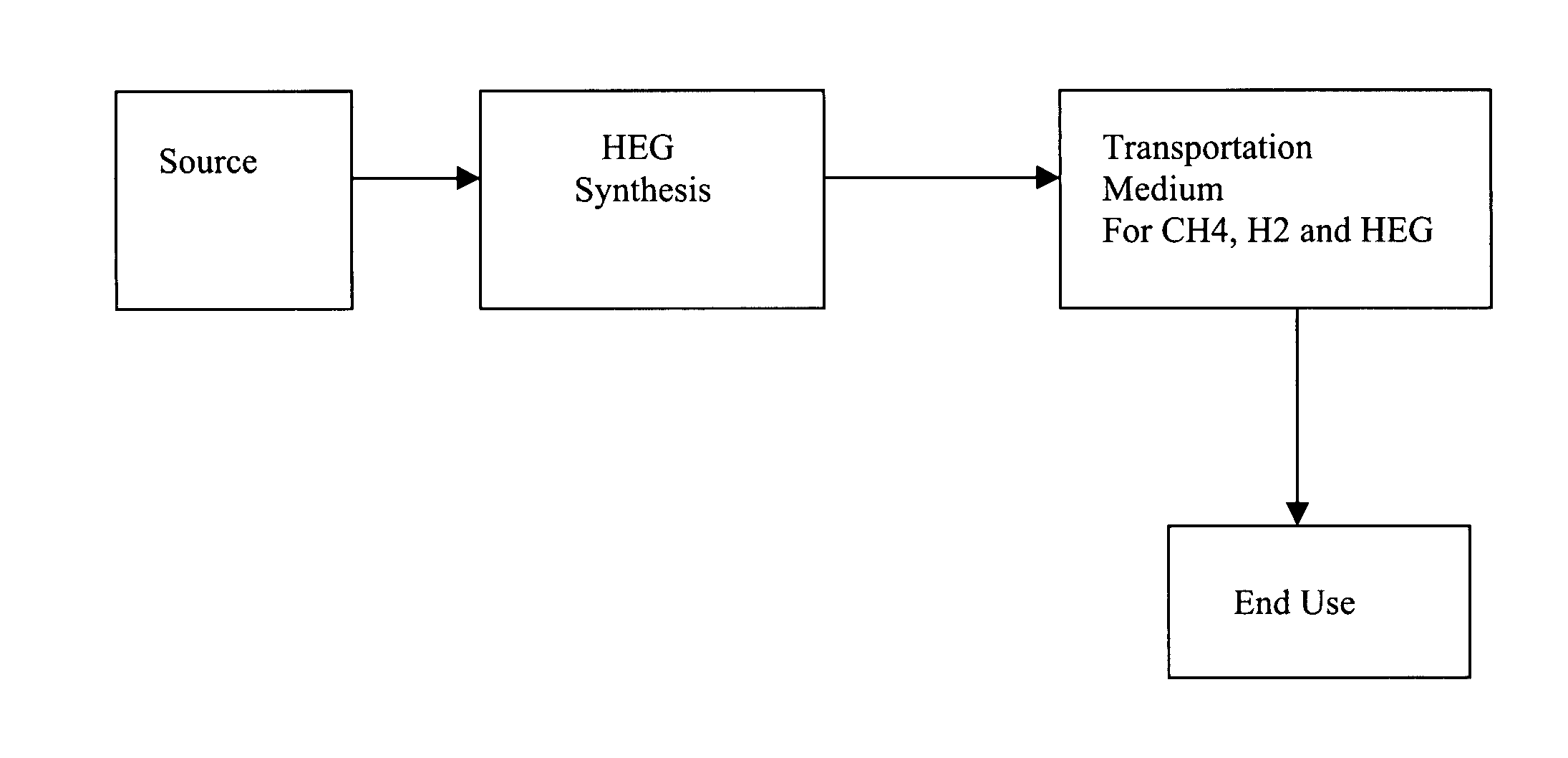

A high energy transport gas and a method to transport the high energy transport gas are used to increase the energy content of a pipeline and other vessels that are designed to carry natural gas under ambient conditions, in a compressed state or in a liquefied state. Methane and other gases are used as the feedstock, with methane from natural gas fields, coal beds or derived from hydrogen reacting with coal being primary energy sources. Also, this gas and method can provide an abundant source for hydrogen production, and the energy from hydrogen can be used for fuel cell applications that generate electricity and power motor vehicles. This gas and method are capable of increasing the energy capacity of current natural gas pipelines and other storage and transport vessels.

Owner:DALTON ROBERT C

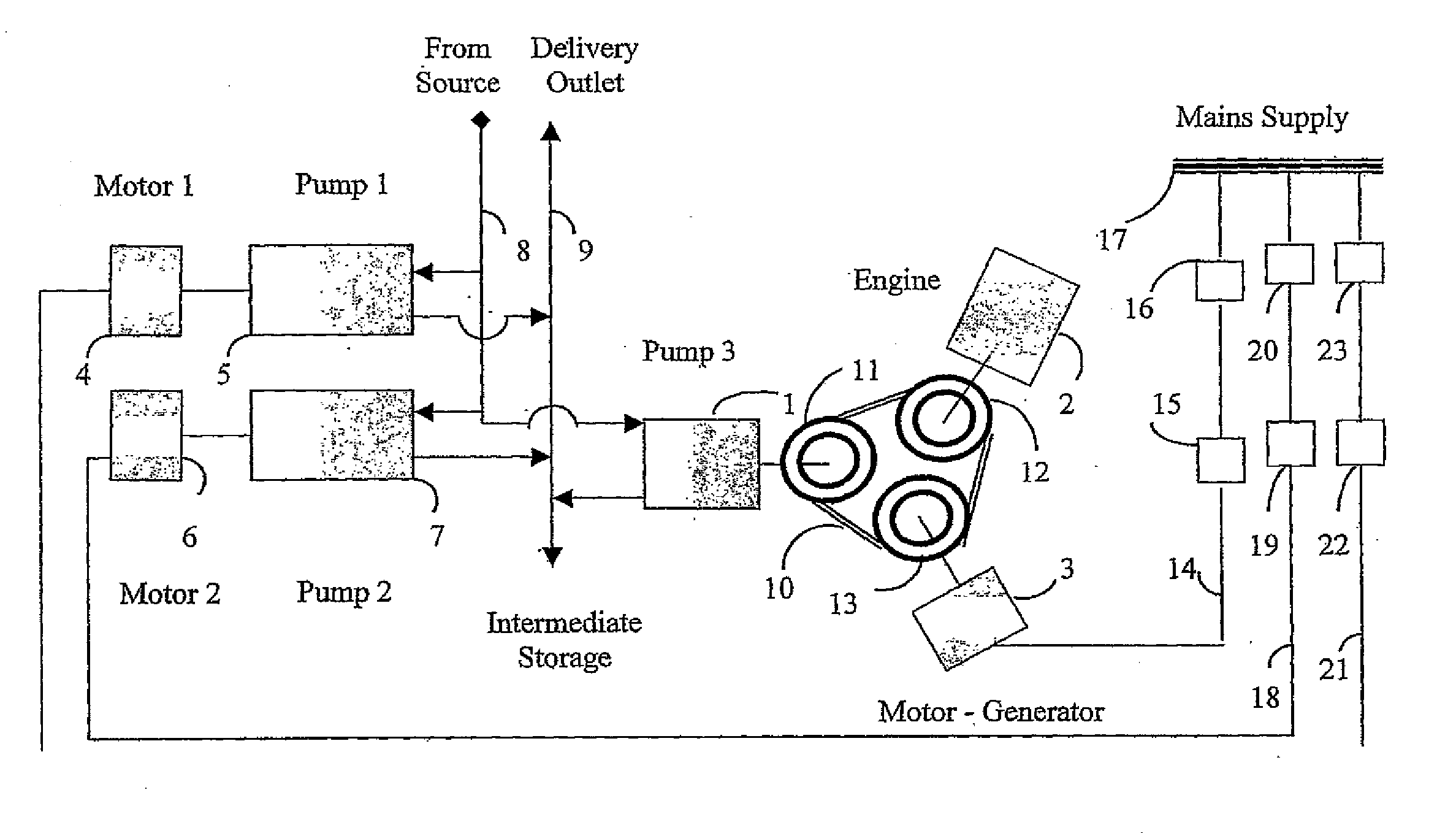

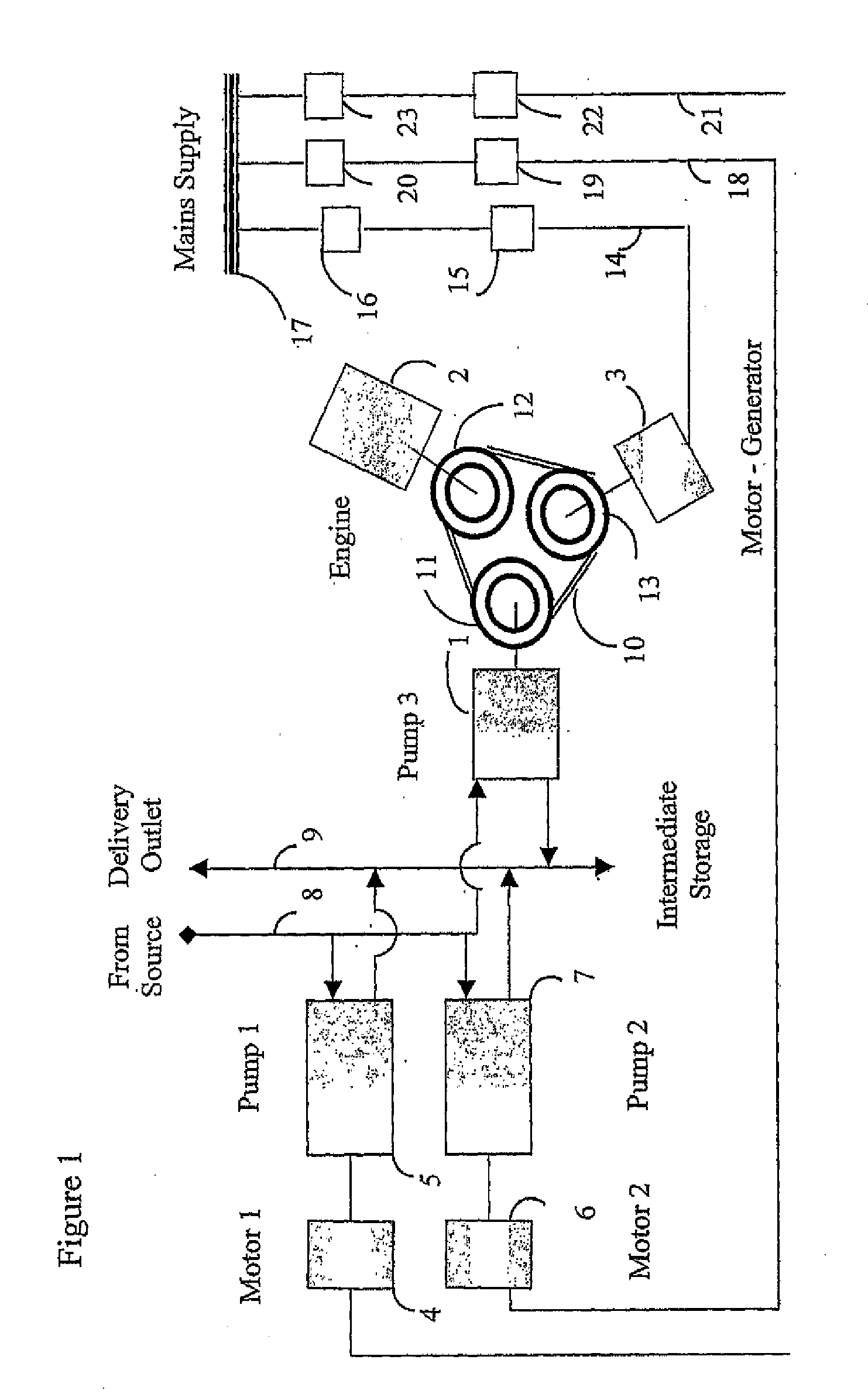

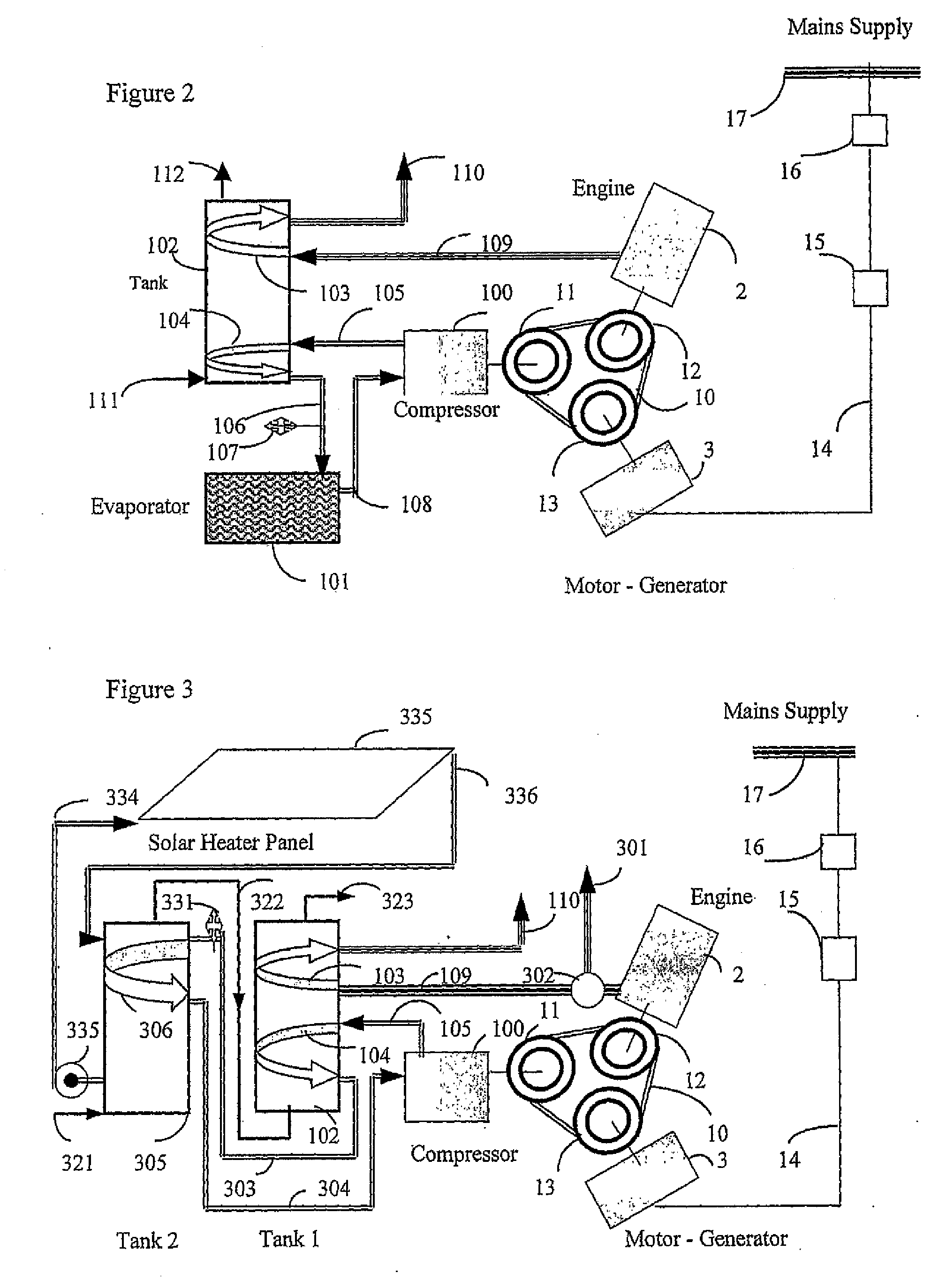

Reducing the Cost of Distributed Electricity Generation Through Opportunity Generation

InactiveUS20080262857A1Economic outcomeLow costElectric power transfer ac networkSingle network parallel feeding arrangementsOperational costsElectricity market

A new disposition of energy use and electricity cogeneration facilities at a customer's premises that enables even a small customer to choose one or more forms of primary energy from among available energy sources, so as to reduce the overall capital and operating costs of meeting own load requirements. Takes into consideration opportunities to save money by way of reducing own load and / or opportunities to earn money by exporting electricity to the mains grid whenever electricity market prices are high, and / or benefiting from payment for network support and ancillary services where such schemes apply. For operations requiring a high level of reliability, opportunity is provided to achieve a desired level of reliability for operations at the premises without recourse to extra cost of duplicate electricity supply connecting lines or expensive stand-by power generation facilities.

Owner:PERERA ANIL L M

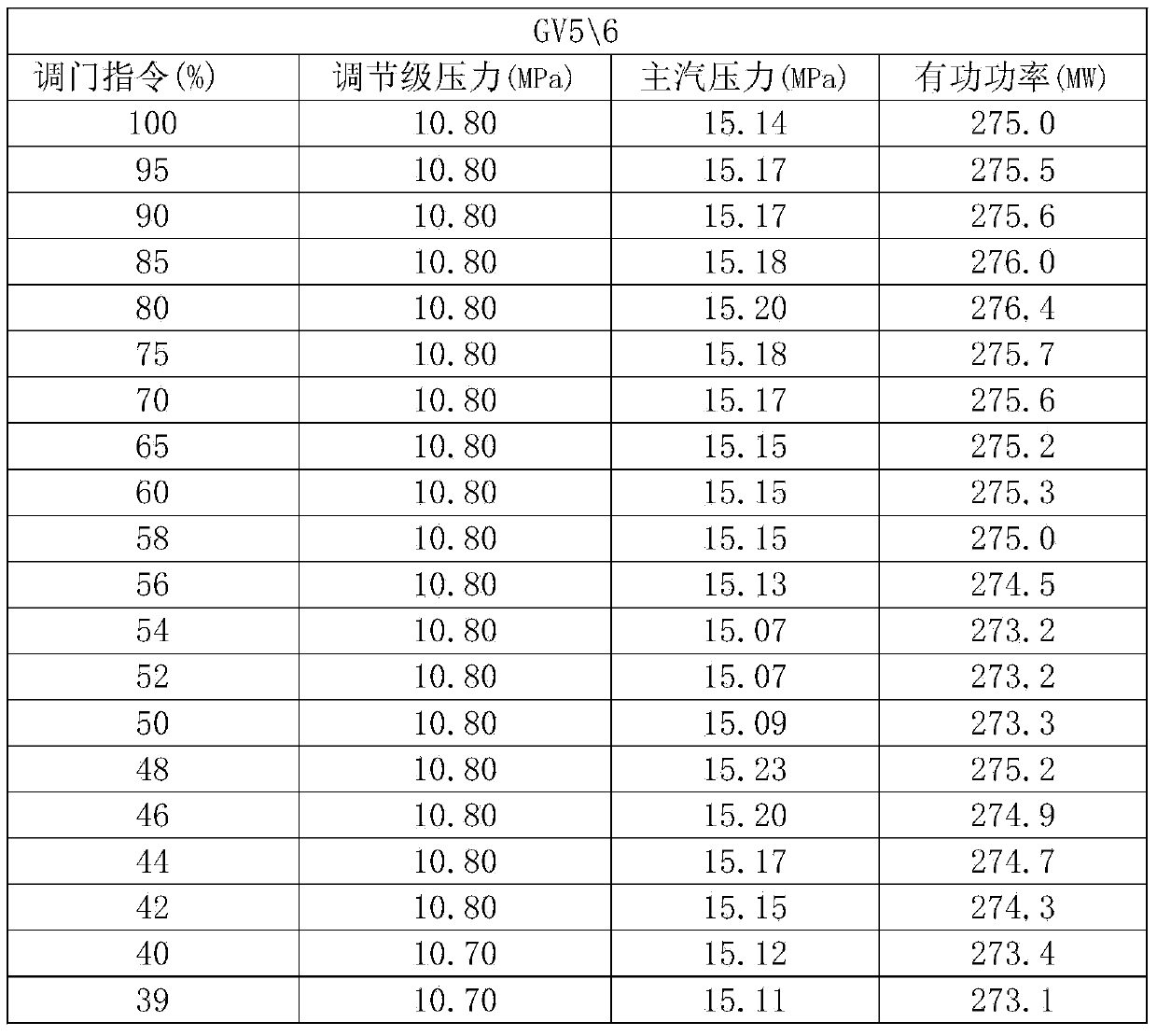

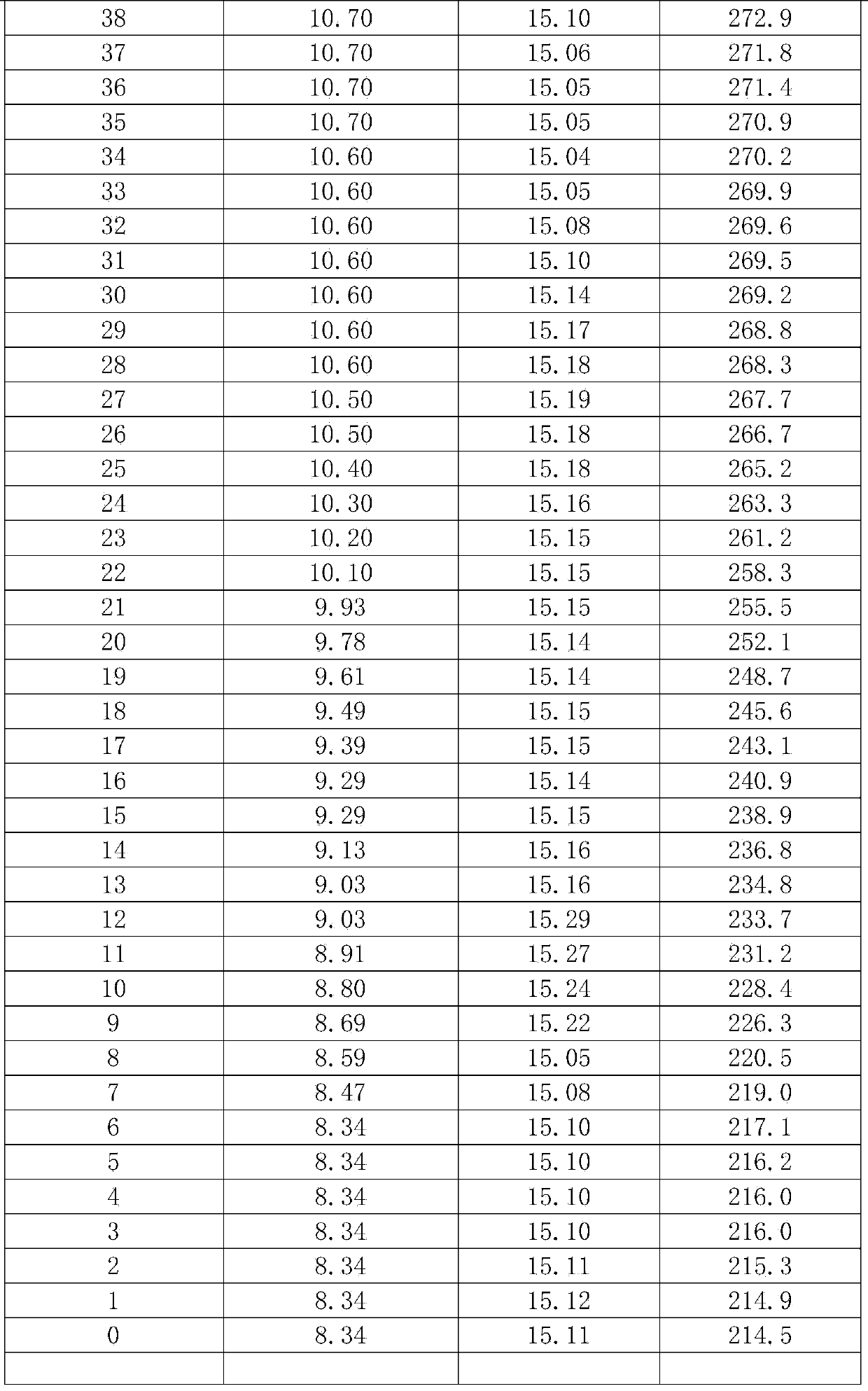

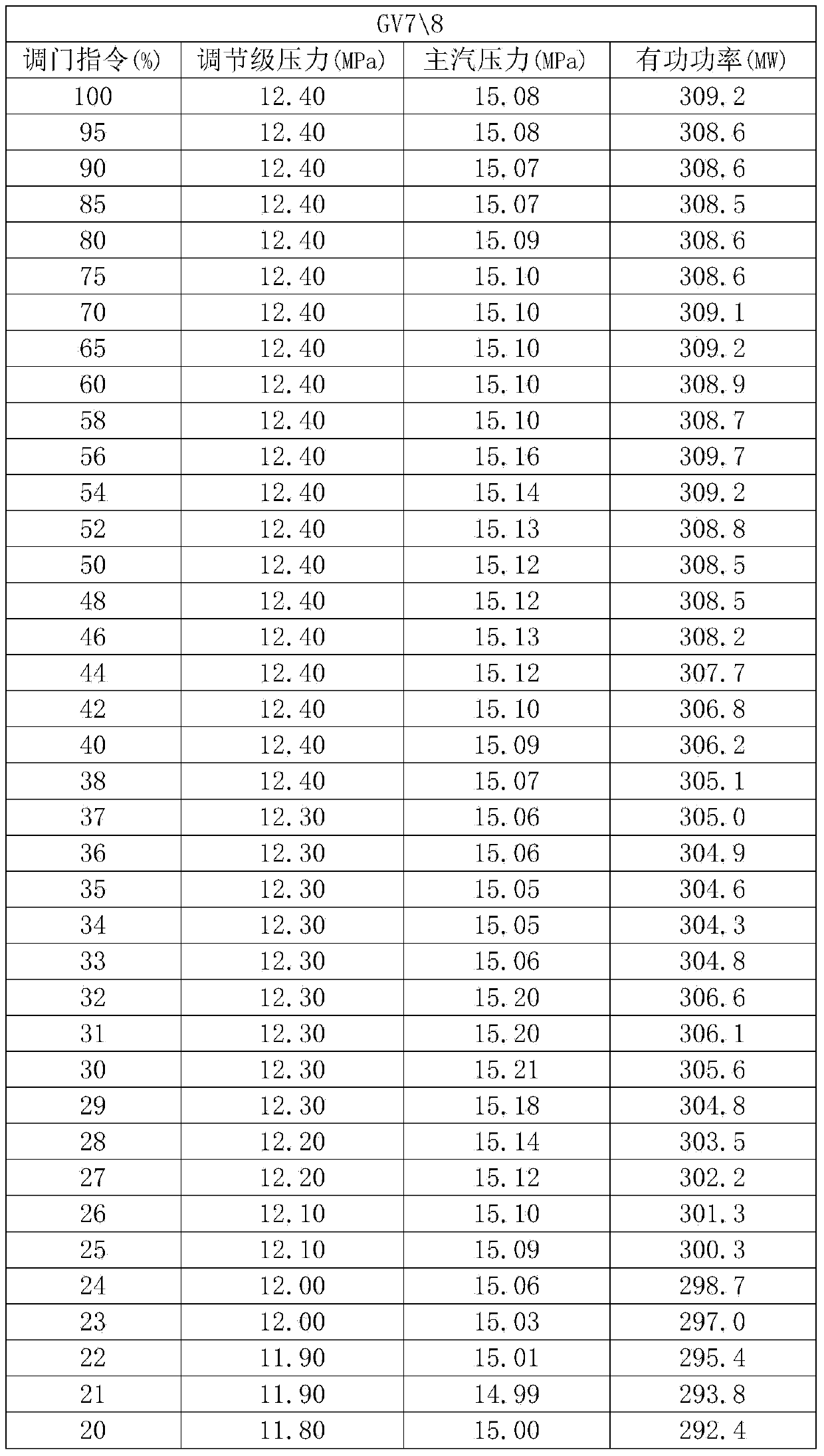

Turbine DEH system high-pressure regulating valve flow characteristic testing and setting method

ActiveCN103743560AImprove control qualityImprove efficiencyMachine part testingSteam pressurePerformance index

The invention discloses a turbine DEH system high-pressure regulating valve flow characteristic testing and setting method, which comprises the steps: relieving the AGC and the primary frequency modulation control method of a DEH system high-pressure adjusting valve, and recording the main steam pressure of a unit; relieving the coordination control method and the DEH remote control method of the DEH system high-pressure adjusting valve, and switching in a DEH valve control method and main steam pressure constant pressure automation; forcedly closing the high-pressure adjusting valve by an instruction according to a specified rule, and recording data; forcedly opening the high-pressure adjusting valve by an instruction according to a specified rule, and recording data; determining a flow characteristic correction curve of the high-pressure adjusting valve according to experimental result data. The testing and setting method has the beneficial effects that the unit efficiency and whole performance indexes are improved, the automation control level is improved, the operation efficiency of the unit is improved, and primary energy is saved.

Owner:STATE GRID CORP OF CHINA +1

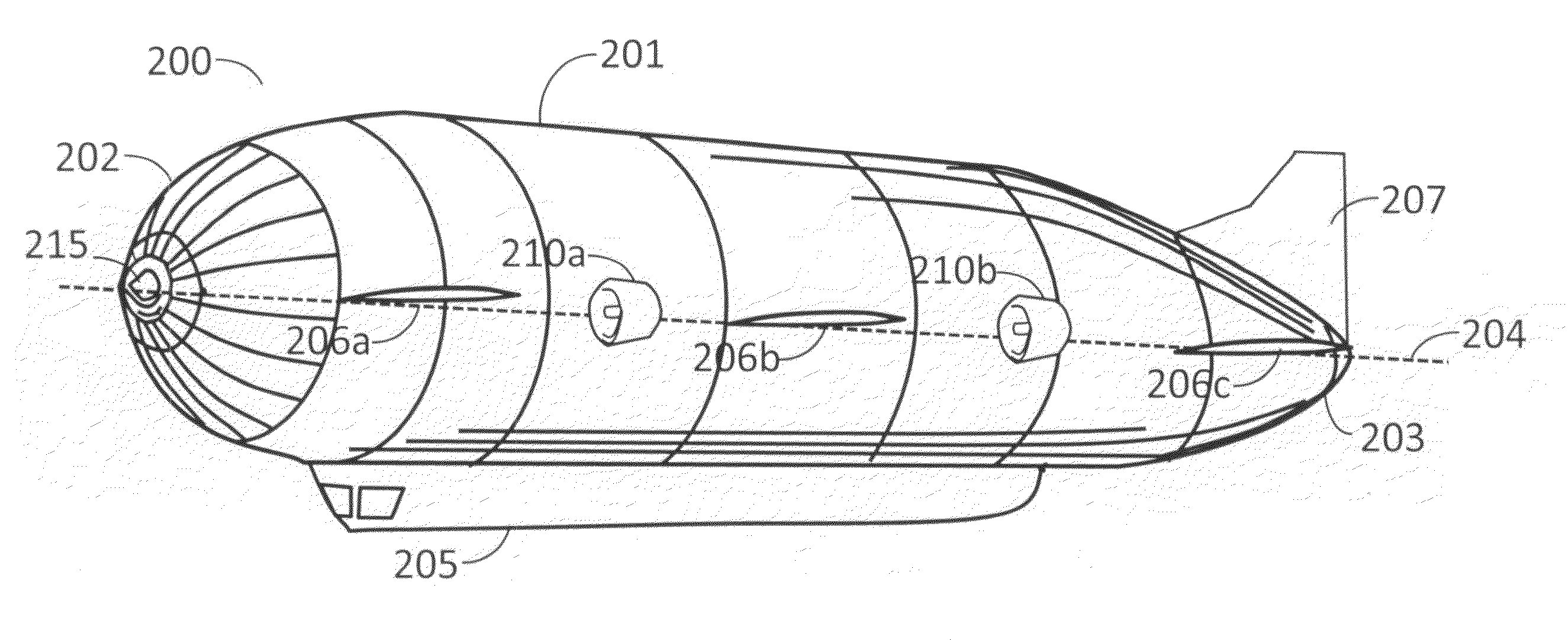

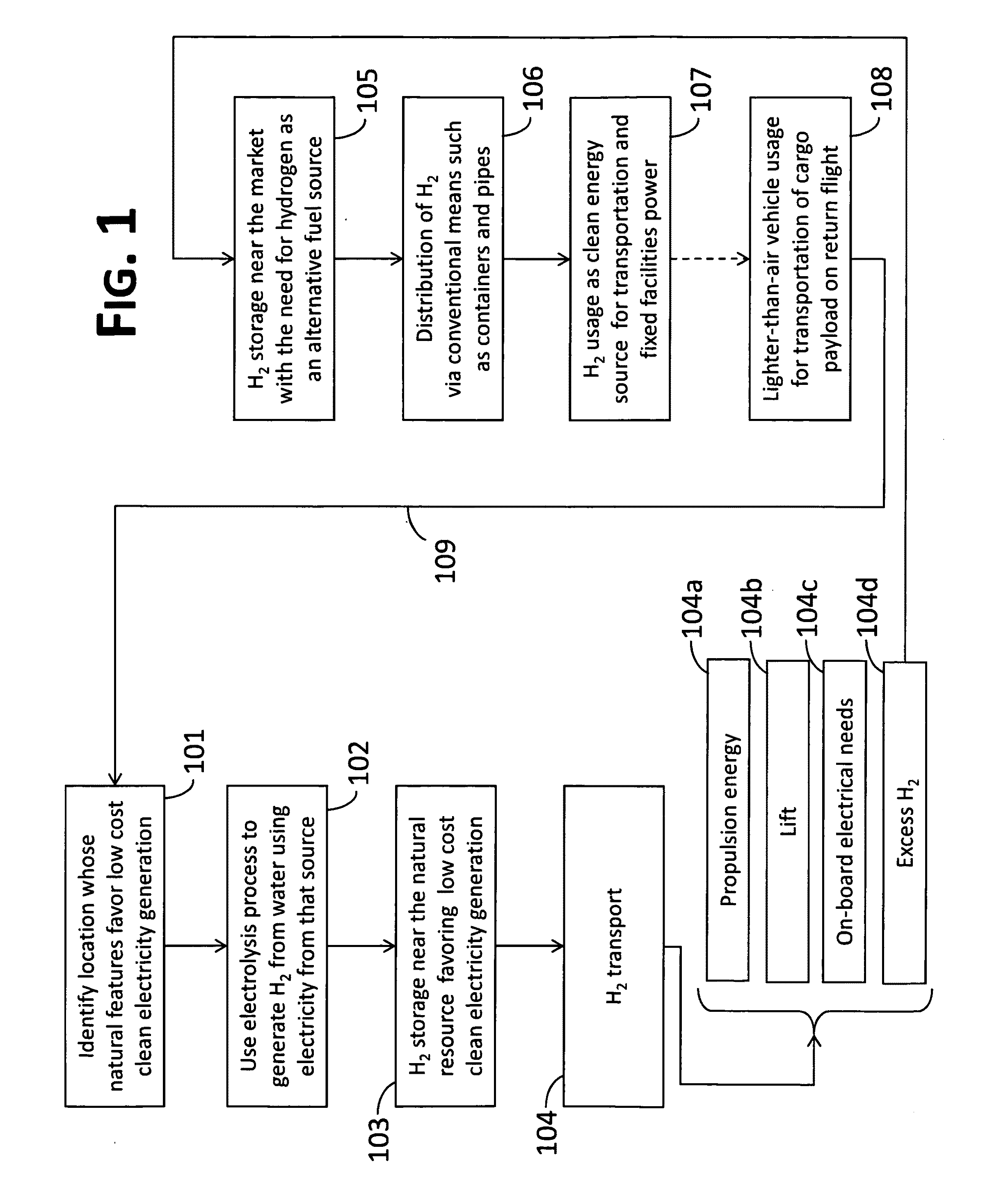

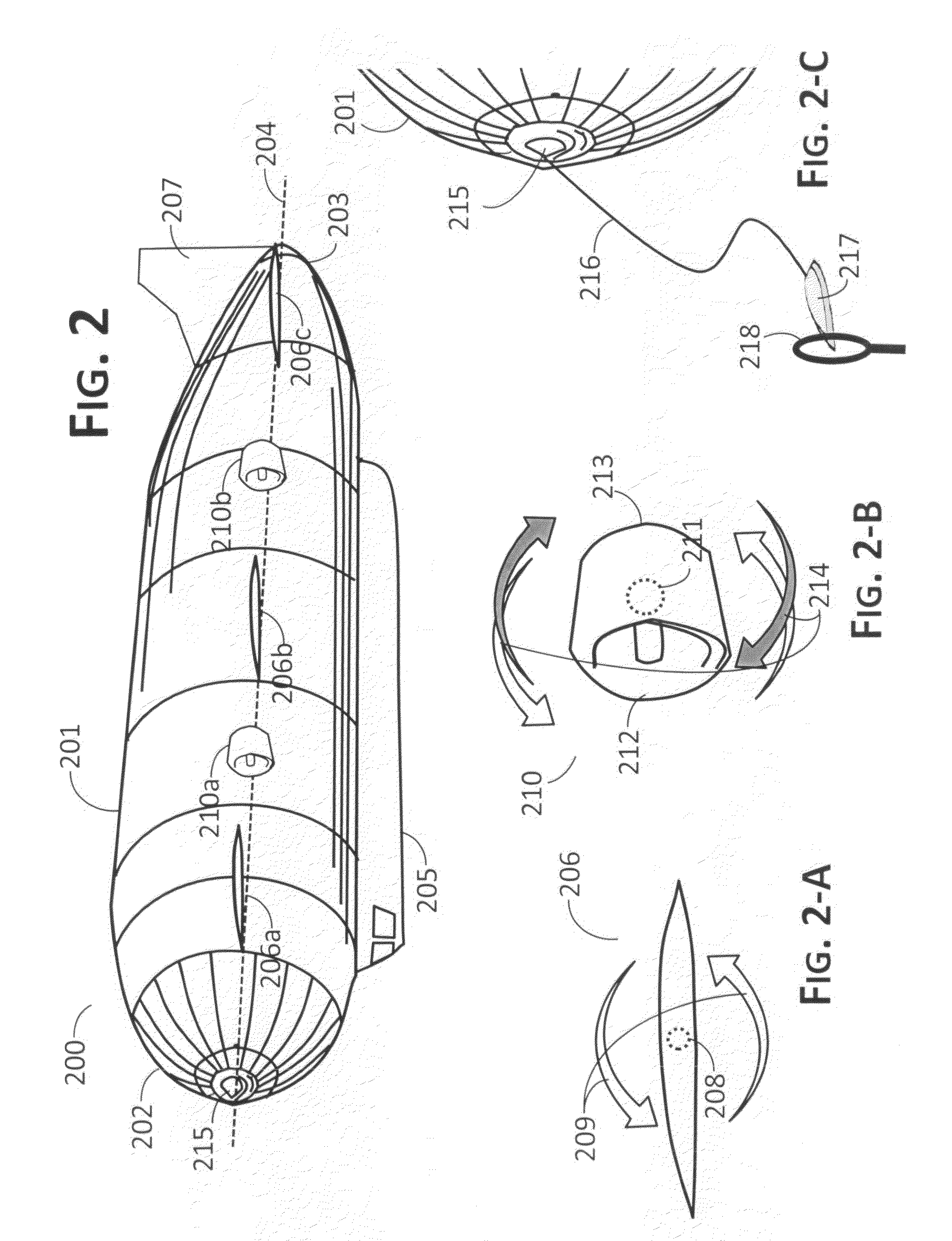

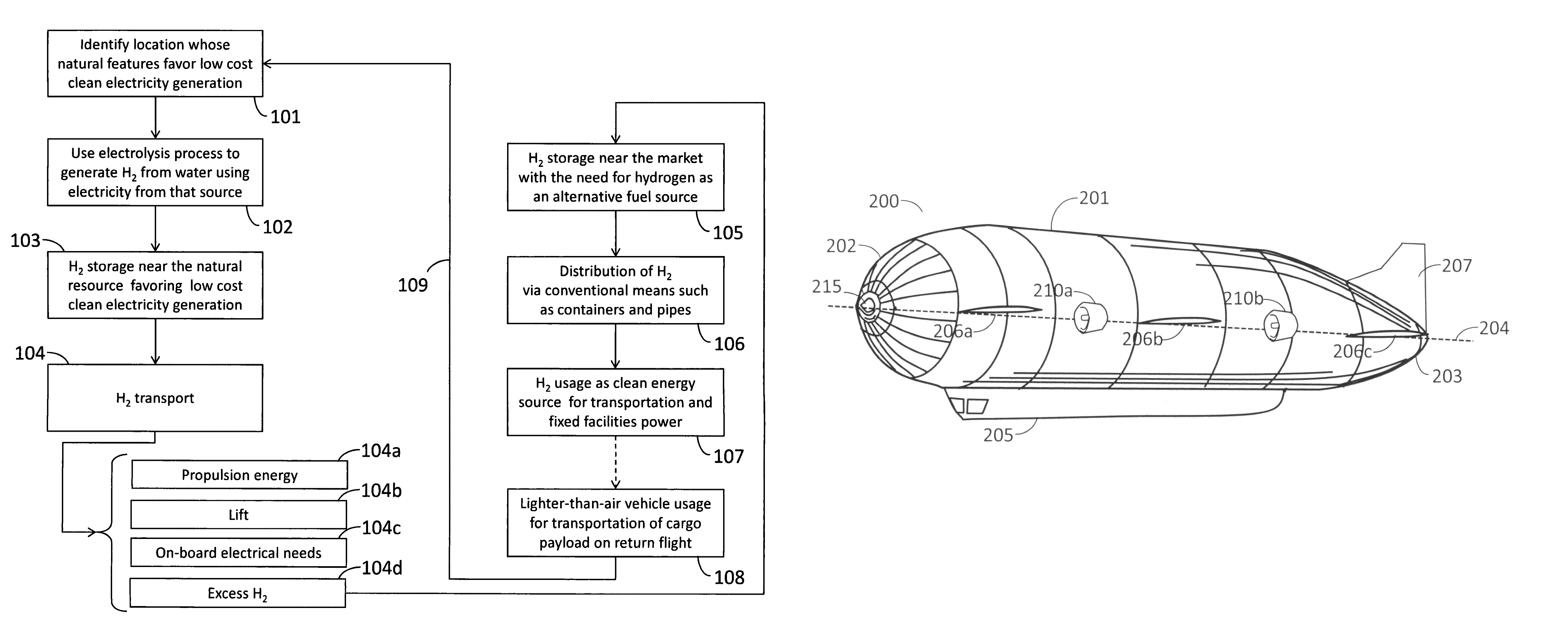

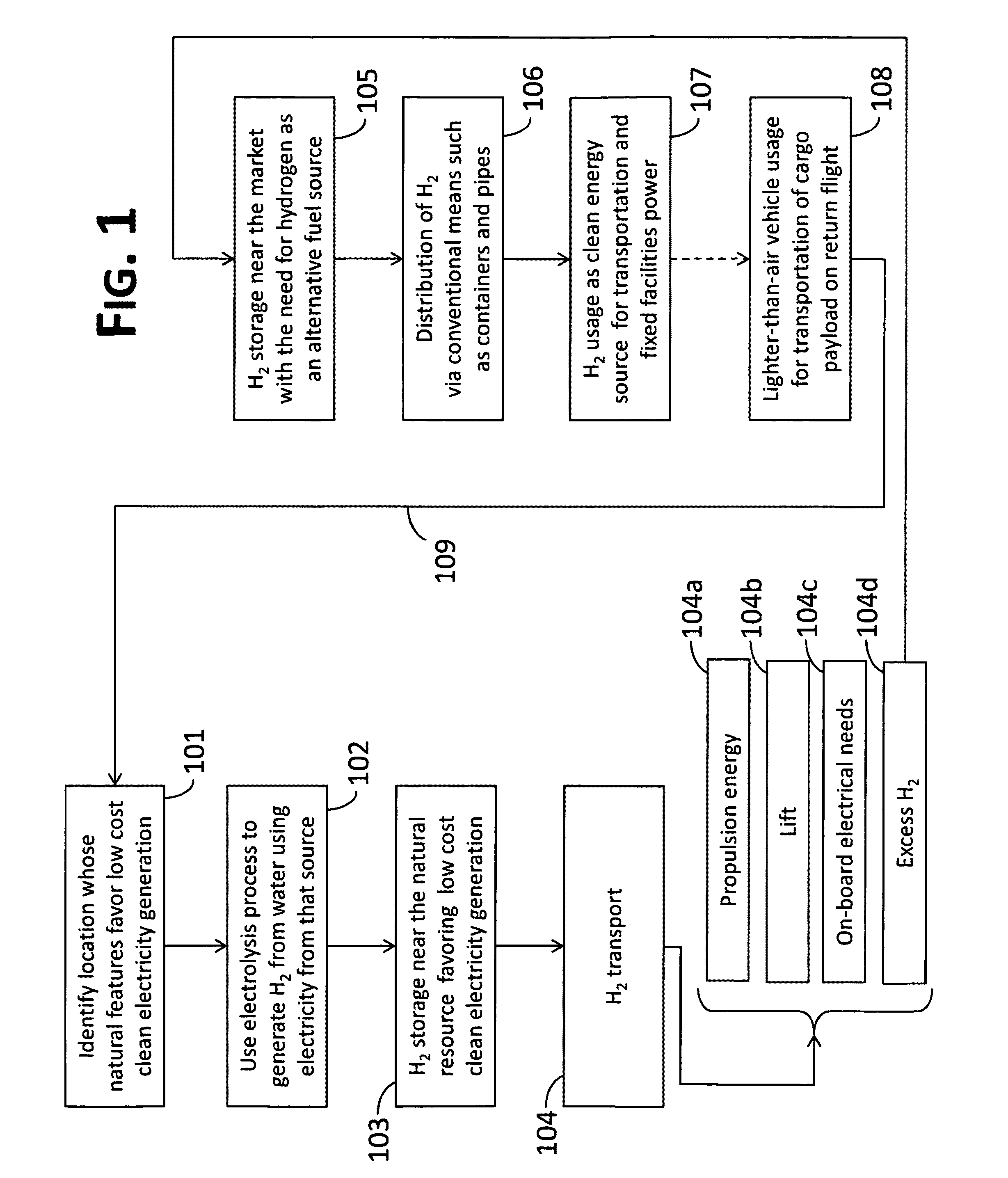

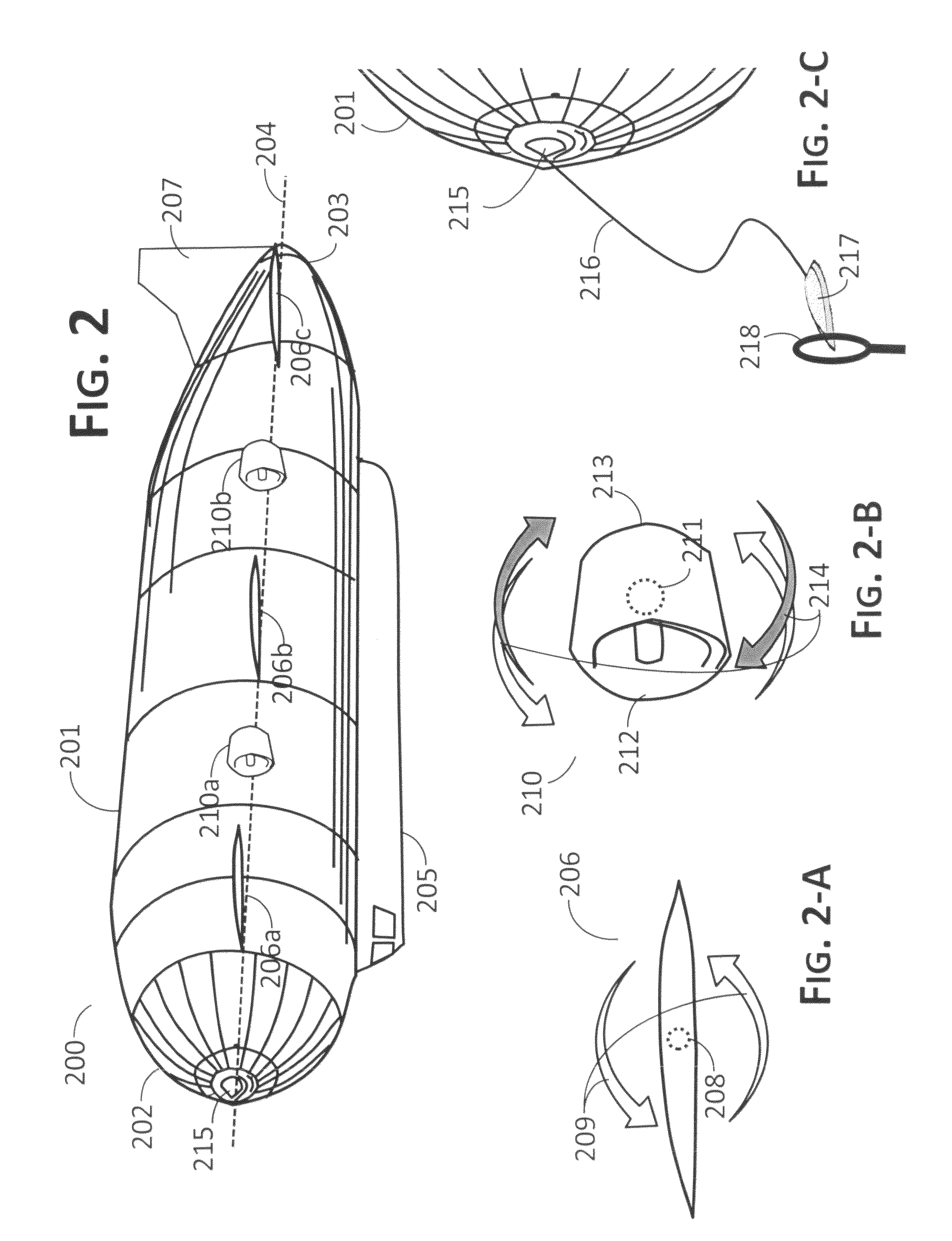

System, method and apparatus for widespread commercialization of hydrogen as a carbon-free alternative fuel source

ActiveUS20100102164A1Reduce shipping costsSave extra spaceArresting gearPower plant arrangements/mountingElectricityHydrogen

A system for efficiently transporting hydrogen from where it can be economically made to where it is most needed using specially designed airships. Technologies such as geothermal, wind, solar, wave tidal or hydropower can be used to generate electricity in-situ or very near to the primary energy sources. This electricity can then be used to produce hydrogen directly from water through various methods known in the art. Hydrogen can be delivered from the place where it is produced to the place where it is needed using an airship in which the hydrogen gas can also be used for generating lift, providing propulsion energy and serving ancillary needs. In other embodiments of the invention, the airship of the present invention can be used to dramatically reduce the cost of transportation of freight, the cost of passenger transportation, and to save on the area required for landing at the points of loading / unloading and embarkation / debarkation. And in another embodiment, the airship of the present invention can be used for transporting water and food to areas where needed. A unique docking system can use a remotely piloted unmanned aircraft flown from the mother craft to carry a guide line into a receiving attachment point.

Owner:H2 CLIPPER INC

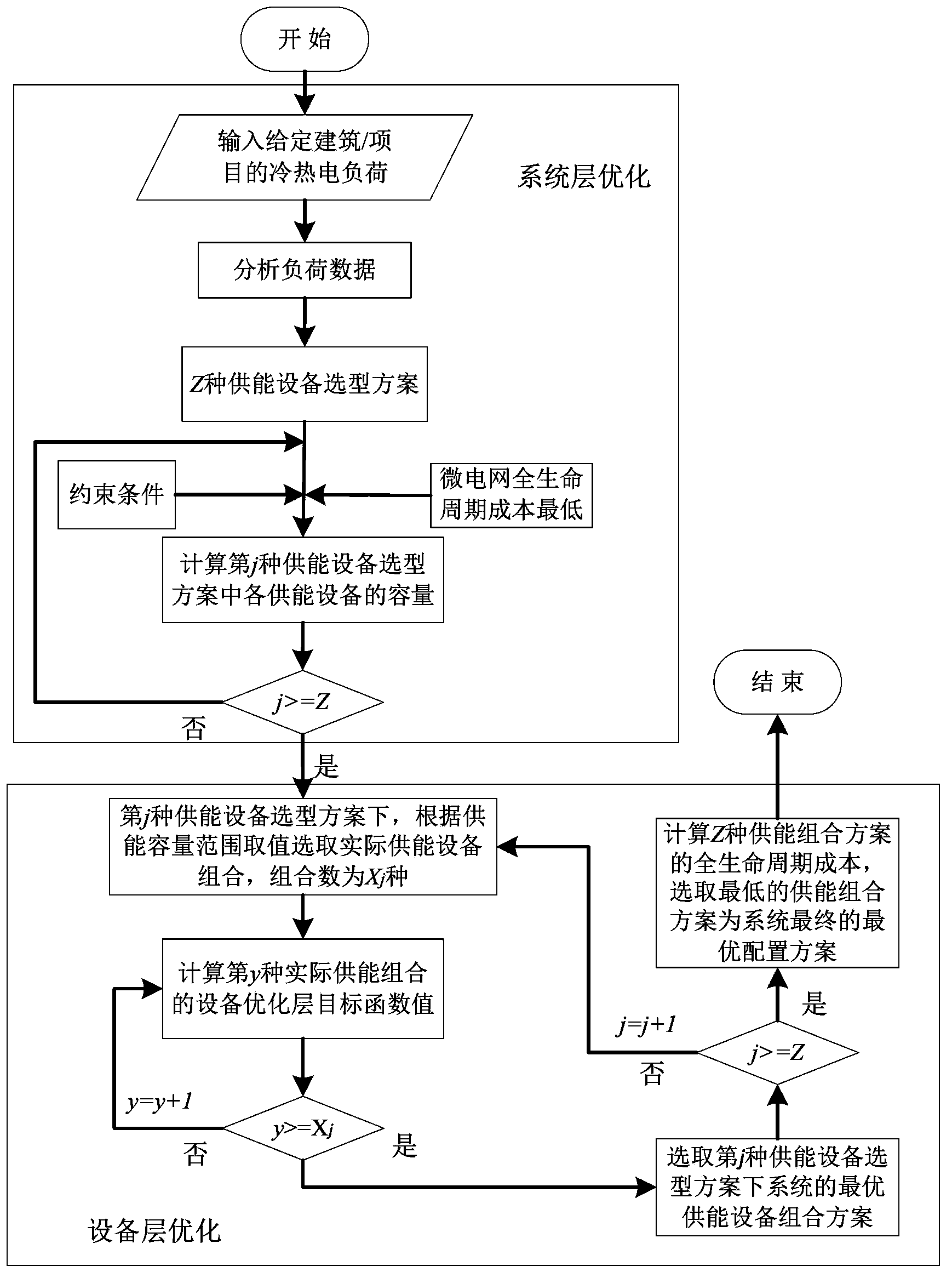

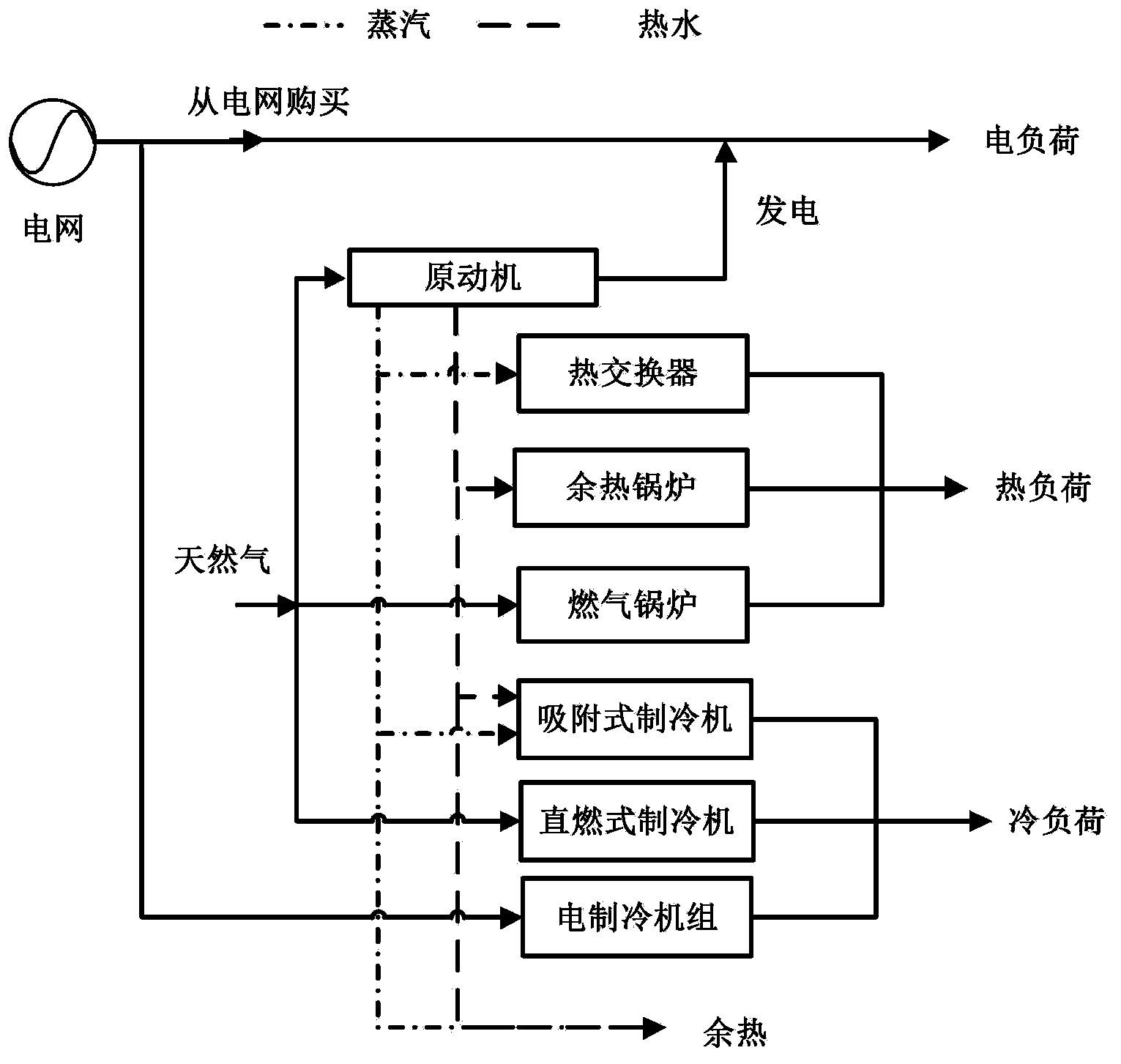

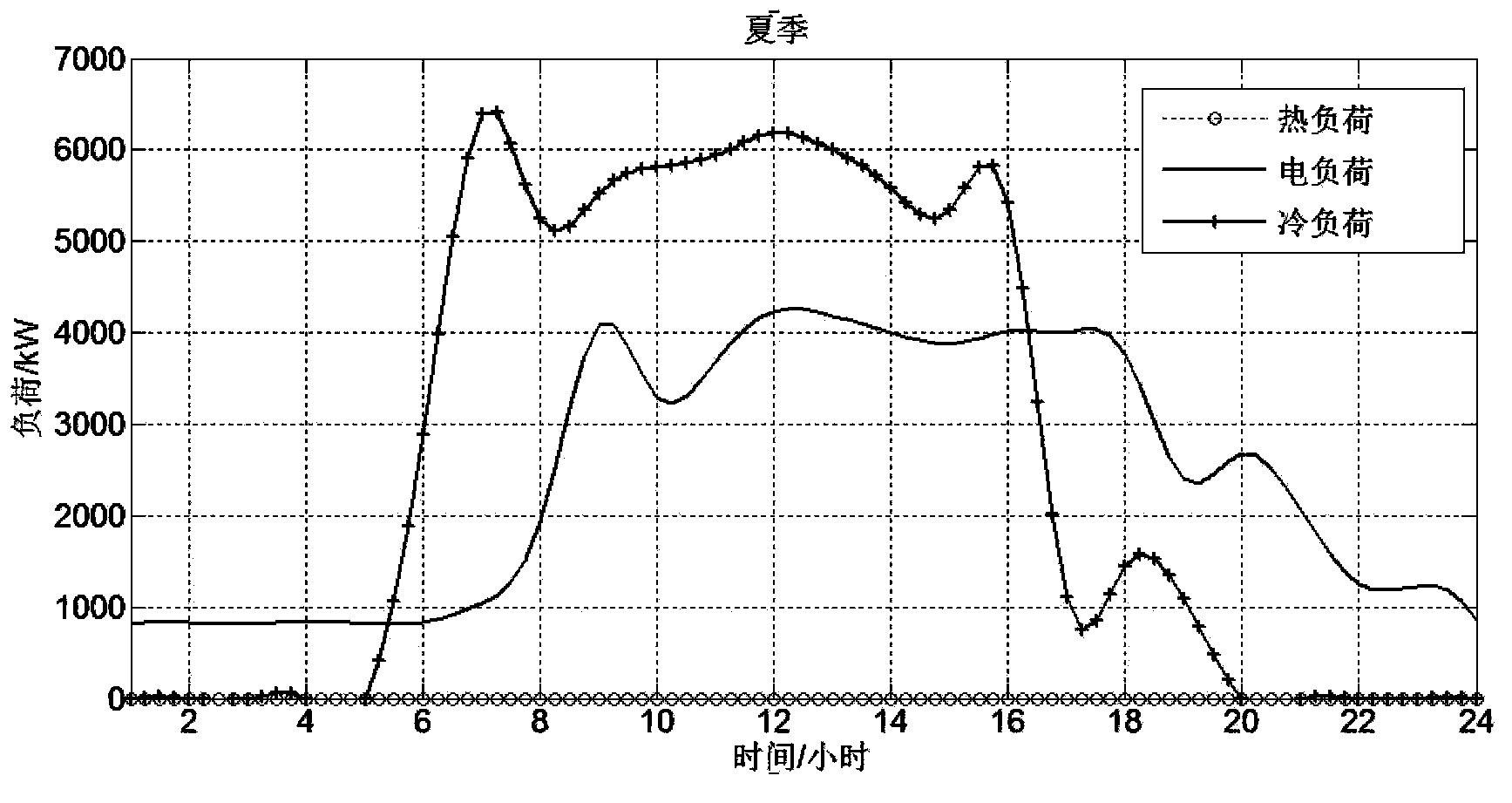

Cool-heat-electricity cogeneration type microgrid optimal configuration method

InactiveCN103400042AImprove utilization efficiencyImprove economyEnergy industrySpecial data processing applicationsElectricity priceMicrogrid

The invention discloses a cool-heat-electricity cogeneration type microgrid optimal configuration method. The method includes the steps of system level optimization and equipment level optimization. Safe and stable operation of electricity, heat and cool generation systems of a system is used as the constraint condition of system level optimization, load data, electrovalence policies and fuel cost in a microgrid region to be planned are used as input, energy supply equipment categories are selected on the basis of load data analysis, the lowest full life circle cost of a microgrid is used as an objective function, the objective function is solved by the adoption of a mixed integer programming approach, and then equipment capacity in the microgrid is acquired. Equipment level optimization is based on a cool-heat-electricity cogeneration equipment scheme library, the capacity value ranges of equipment are set on the basis of the result of system level optimization, solution is calculated in a weighted mode, and then the optimal configuration scheme of the system is obtained. According to the method, capacity of the generation systems can be balanced, utilization efficiency of primary energy and the utilization rate of the equipment are improved, unnecessary investment is avoided, meanwhile, overall economy of the system is improved, and annual operation cost is reduced.

Owner:SOUTHEAST UNIV

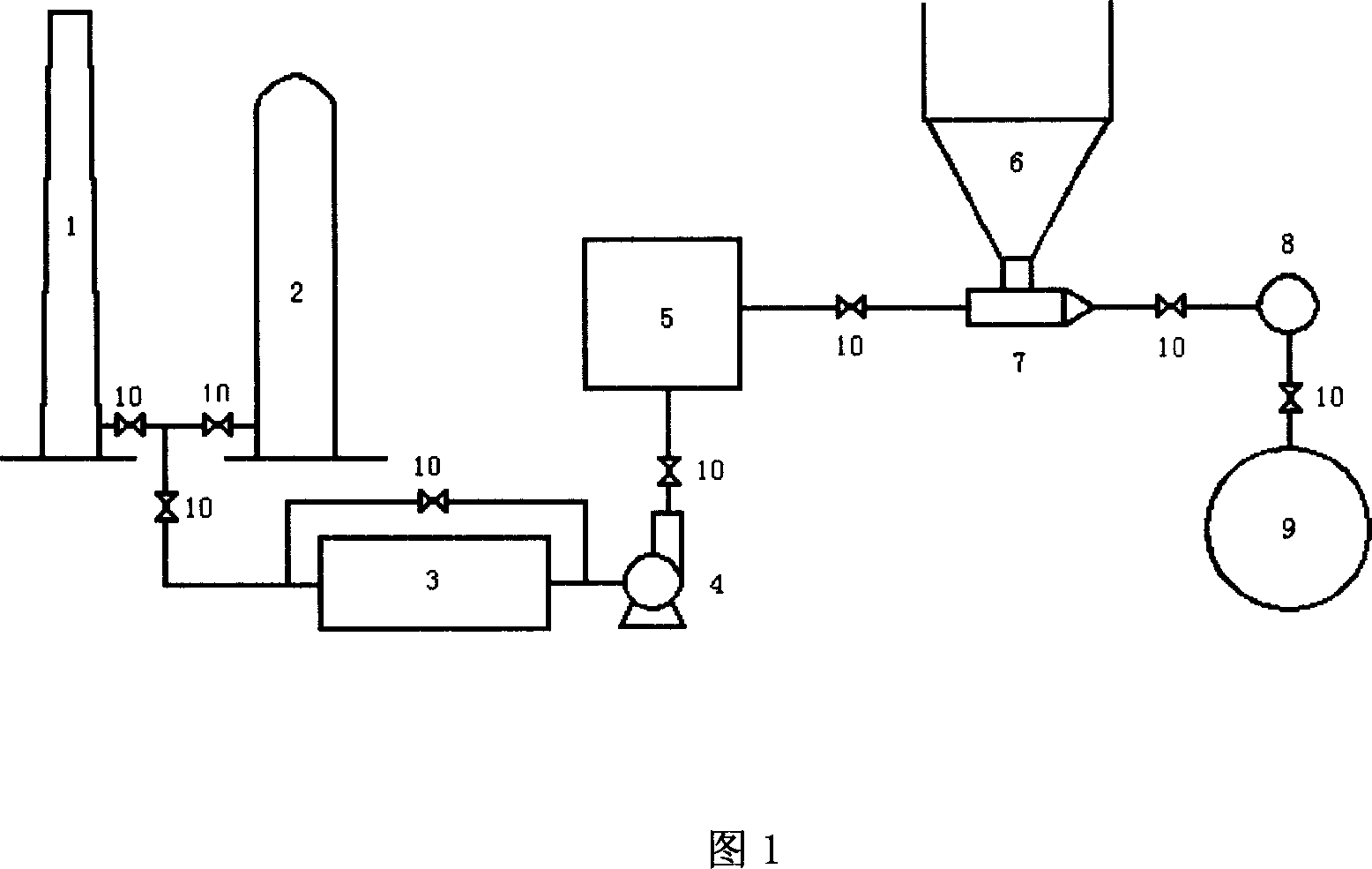

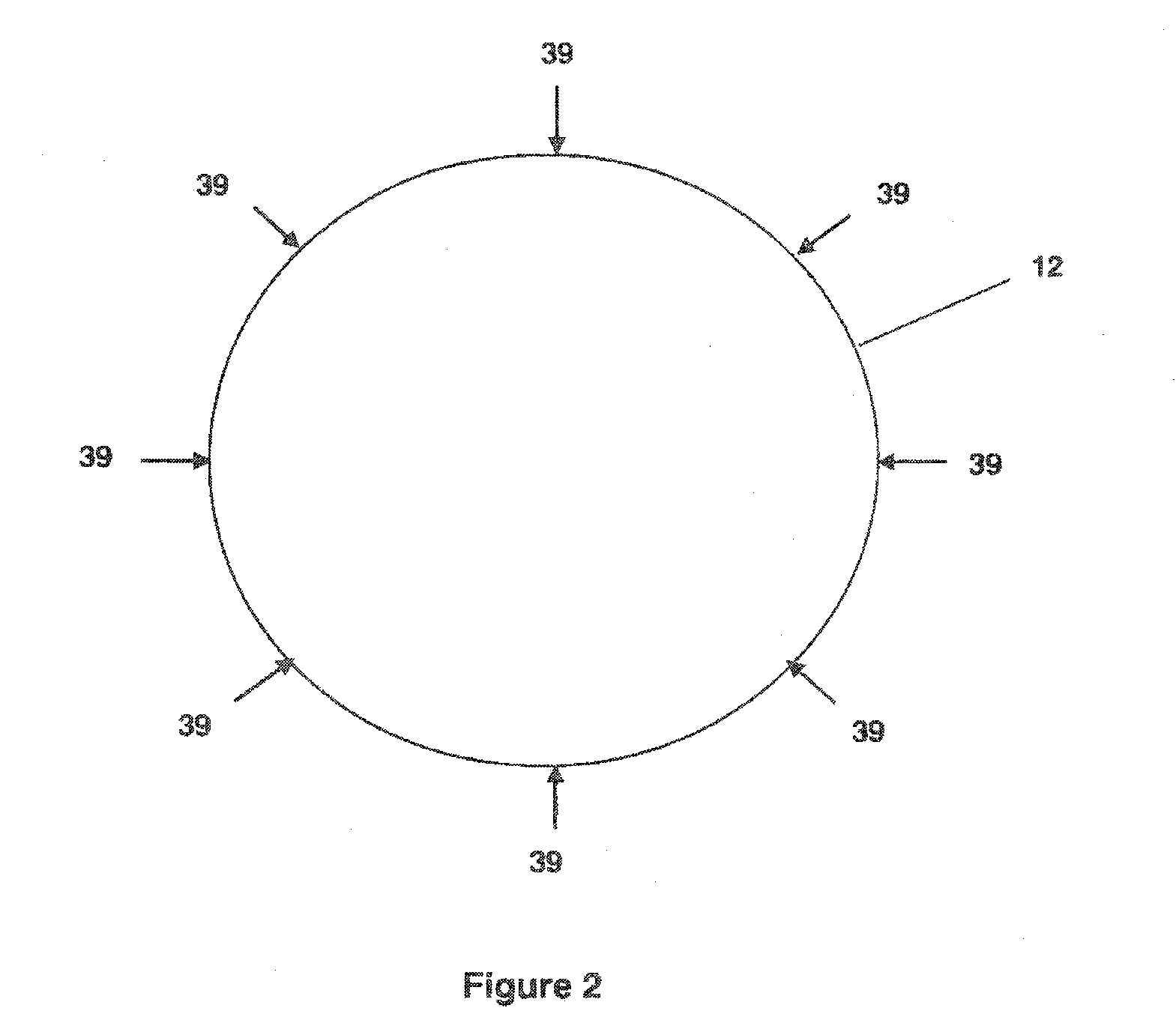

Blast-furnace coal powder injection method using waste gas of hot-blast stove flue as carrier

InactiveCN101000141AAvoid large emissionsReduce pollutionLump/pulverulent fuel feeder/distributionHot blastPrimary energy

The invention provides a blast furnace coal spraying method using flue gas of hot-air furnace, concretely using induced draft fan to draw the flue gas of hot-air furnace through special pipeline and control valve out of the flue, cooling by heat exchanger to enter air compressor, after compression, using coal feeder to blow the pulverized coal inputted by blowing tank to distributor, and thus spraying the pulverized coal into the blast furnace from each tuyere. And it implements waste gas utilization, saving primary energy sources; and helps indirect reduction reaction in furnace, so that secondary energy sources can be utilized; besides, largely avoids waste gas CO2 exhaust, reducing atmospheric pollution; can preheat pulverized coal, increasing combustion speed; and has the same system safety as N2 carrier, especially suitable for large scale blast furnace applications and having extremely remarkable energy saving and environmental protection effects.

Owner:ANGANG STEEL CO LTD

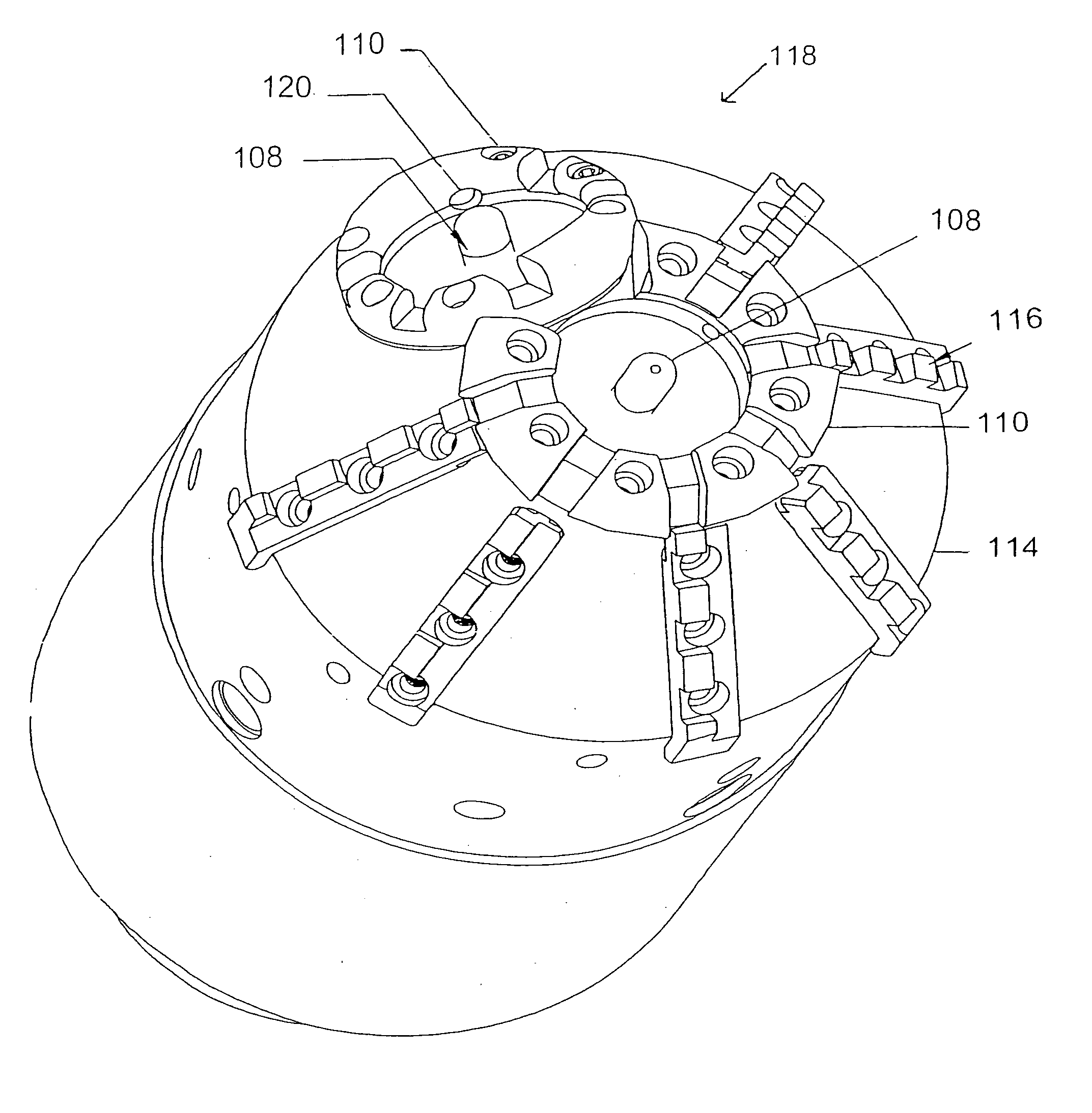

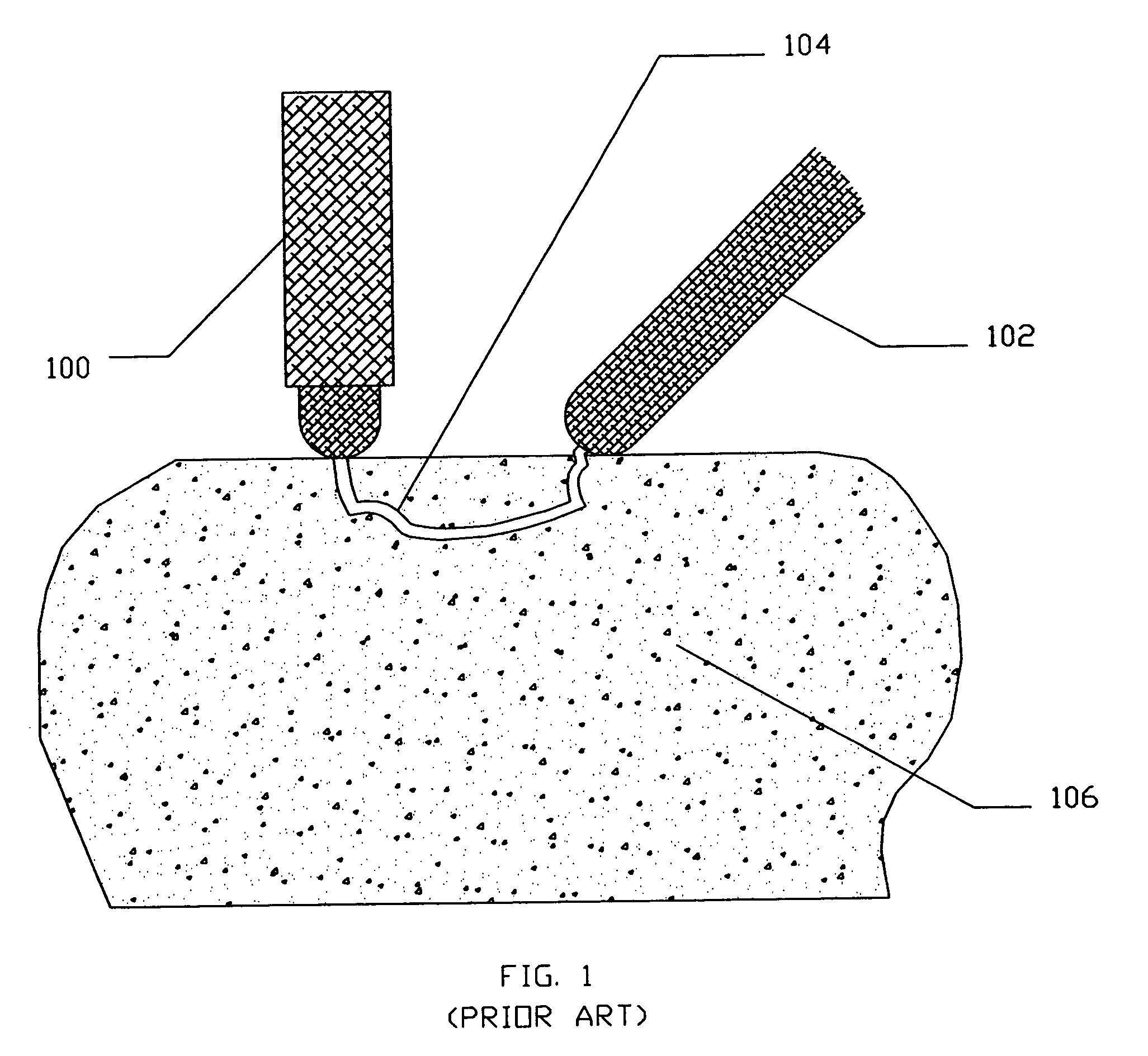

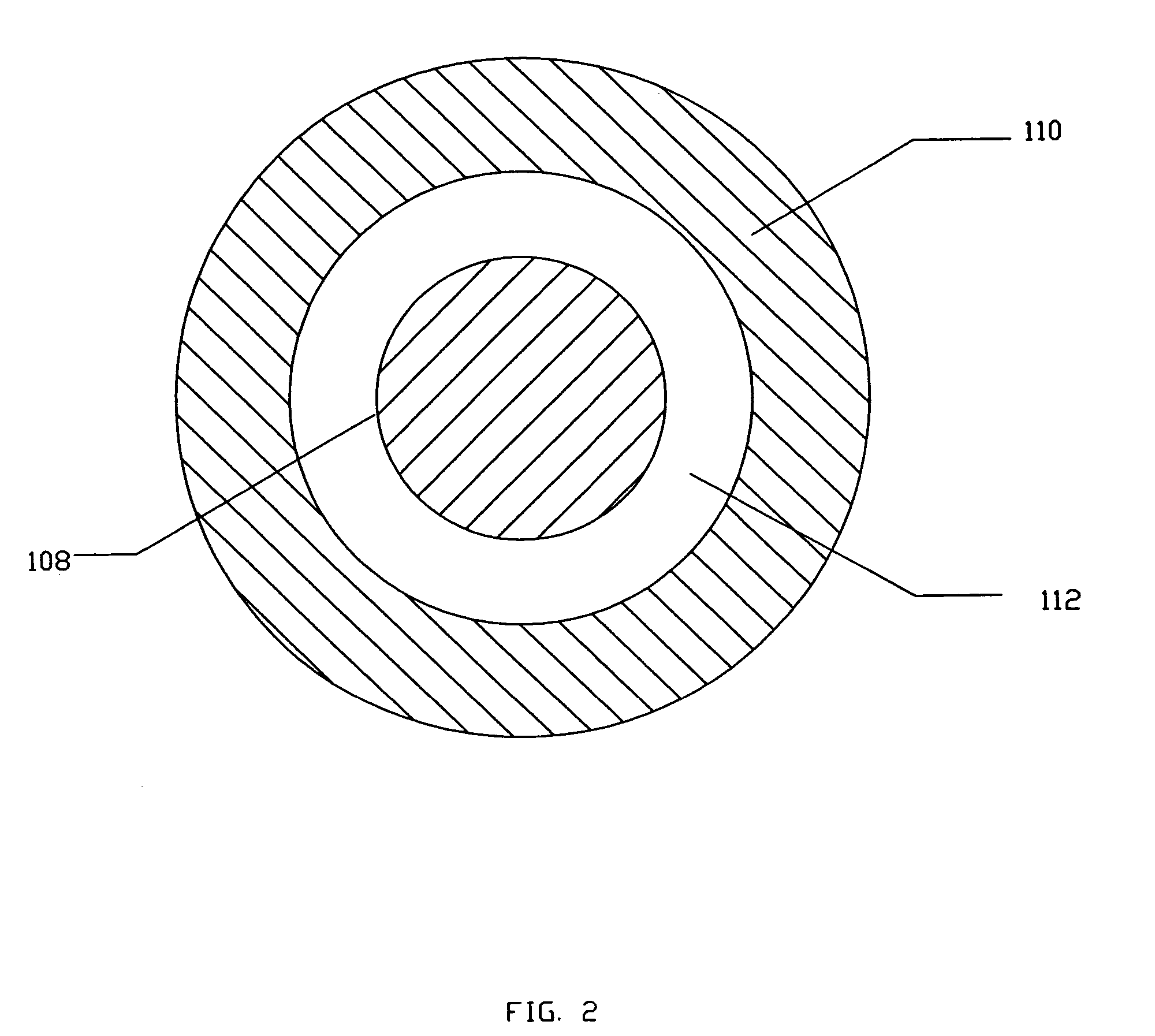

Electrohydraulic boulder breaker

ActiveUS20060038437A1Efficient deliverySolution to short lifeDrill bitsDisloding machinesCouplingTransducer

The present invention provides for an assembly for creating a pressure pulse in a liquid-filled cavity within a fracturable material such as a boulder wherein the primary energy storage element is disposed in a tranducer at the boulder to improve the coupling of energy between the energy storage unit and the fluid in the boulder.

Owner:SDG LLC

System and method for integrating billing information from alternate energy sources with traditional energy sources

ActiveUS8214270B2Reduce needReduce primary energy consumptionComplete banking machinesTelephonic communicationReal-time chargingPredictive analytics

The method and system of the present invention provides for data gathering of energy systems, calculation of billing information for the energy systems to include both traditional energy sources and renewable energy sources, and creation of various outputs to include various user interfaces applicable to overall management of the energy systems. The user interfaces can include integrated, real-time billings to a consumer that measure the cost of the primary energy as well as savings provided by renewable energy sources. The present invention also provides predictive analysis for various aspects of energy use in order to better manage particular facilities that may incorporate renewable energy sources. The gathered data and the various user interfaces enables a user to modify or adjust the use of the renewable energy sources at selected sites to maximize their impact on reducing the cost of the primary energy bill.

Owner:ALSO ENERGY

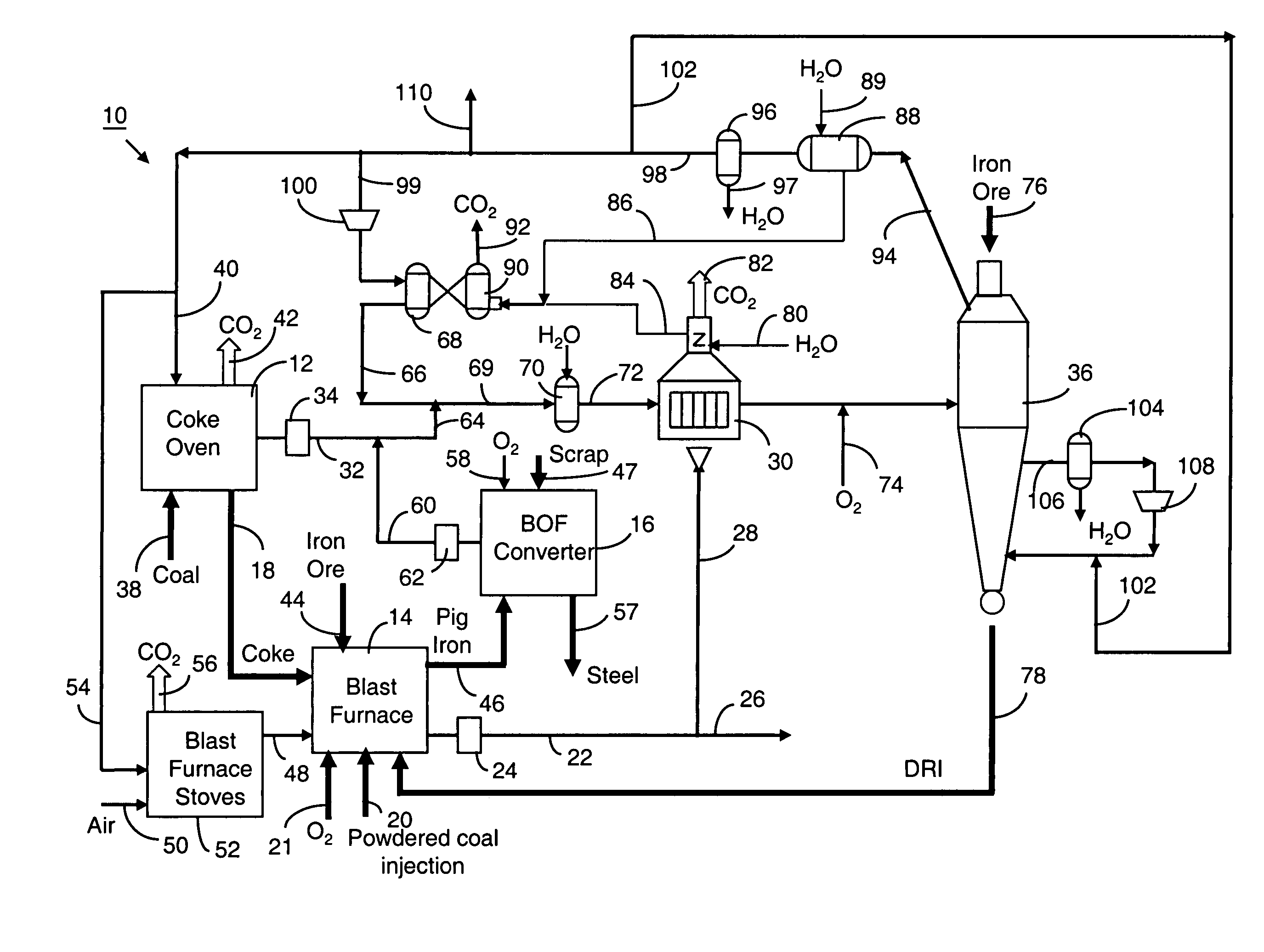

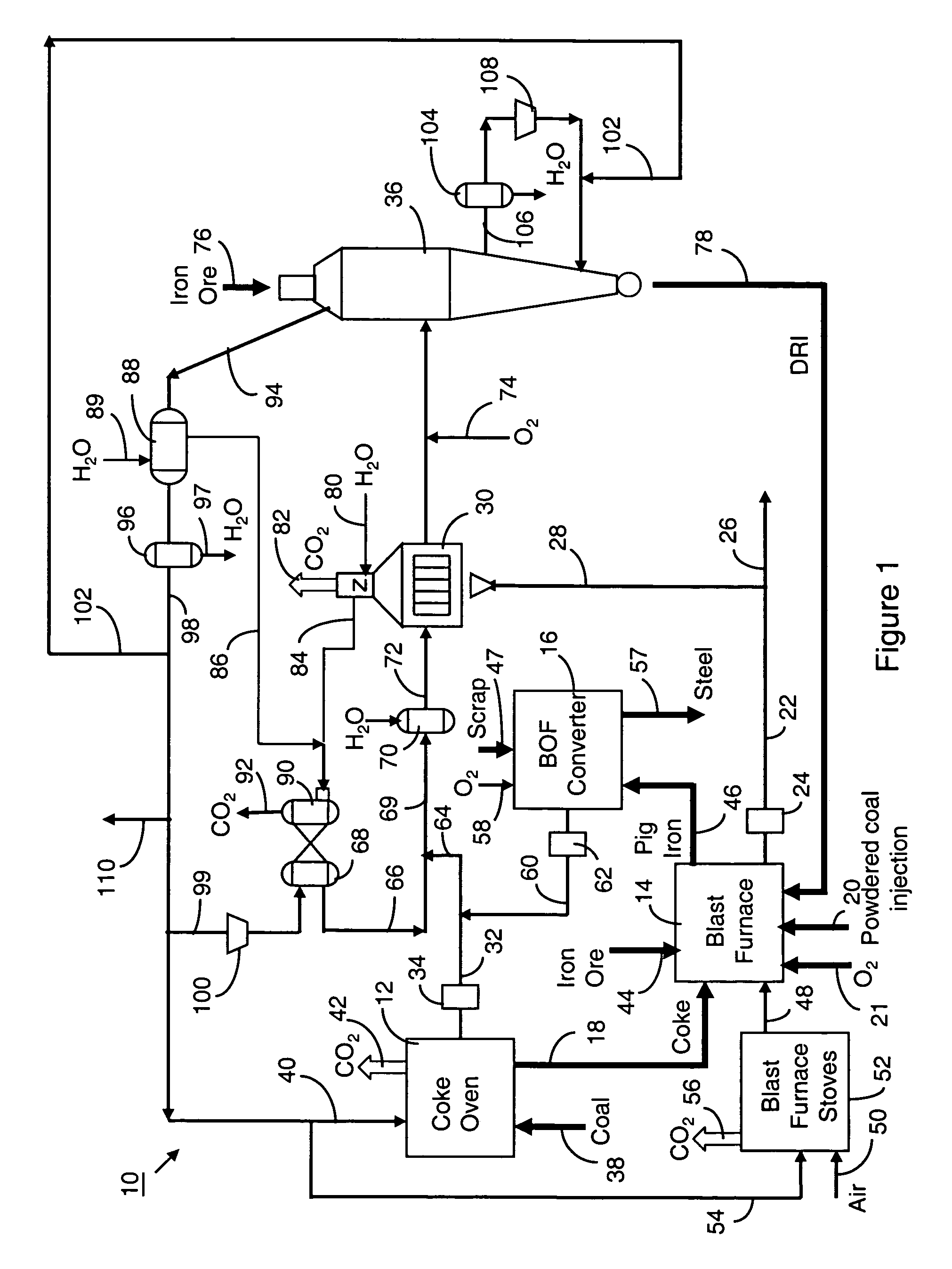

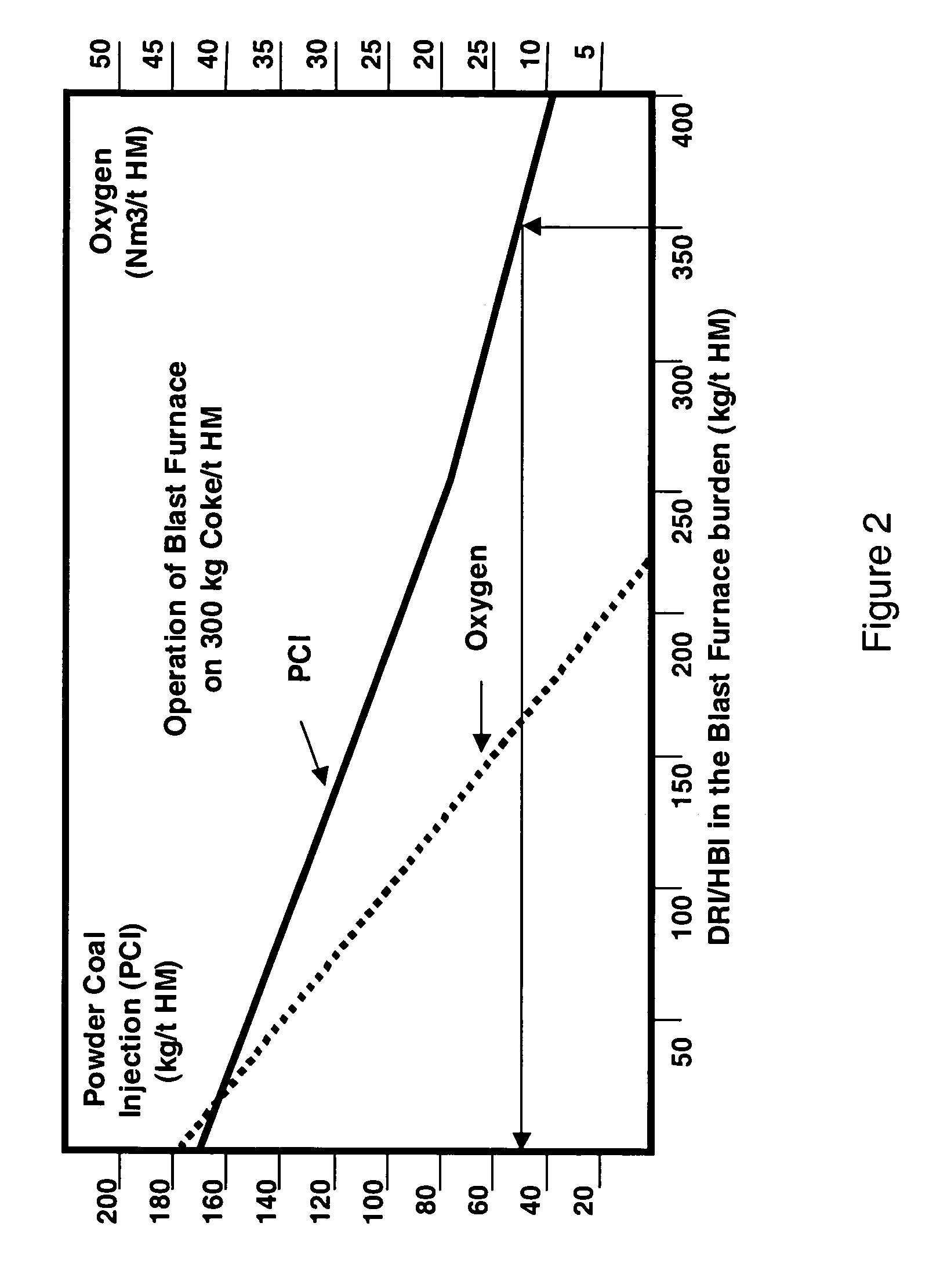

Method and apparatus for improved use of primary energy sources in integrated steel plants

ActiveUS6986800B2Increase productionReduction of fossil fuel specific consumptionBlast furnace detailsManufacturing convertersChemical agentFossil fuel

A method and an integrated steel plant wherein, instead of using coke oven gases, converter gases and blast furnace top gases available as fuel for power generation or other heating purposes, these gases are more efficiently utilized as chemical agents for direct reduction of iron ores producing DRI.DRI is charged to blast furnaces increasing production of crude steel without increasing the capacities of the coke oven plant and blast furnaces and without changes in the quality of the crude steel, or, if production rate is maintained, the fossil fuels specific consumption is significantly reduced.Utilisation of primary fossil energy according to the invention also reduces the specific CO2 emissions per ton of crude steel. The specific CO2 emission in conventional integrated mills is about 1.6 tons of CO2 per ton of crude steel.

Owner:HYLSA SA DE CV

Biomass solid fuel and processing technique thereof

InactiveCN103374427AAchieve innovative resultsAchieving a circular economy modelBiofuelsSolid fuelsAlternative fuelsToxic material

The invention relates to a biomass solid fuel and a processing technology thereof. The biomass solid fuel is prepared by pressing the following raw materials in percentage by weight: 90% of a biomass raw material and 10% of water, wherein the biomass raw material adopts crop derelicts, bamboo-wood processing residues or residual branches and leaves after timber cutting. The biomass solid fuel can replace coal, oil and other primary energy sources and serves as an alternative fuel; because the biomass solid fuel is a renewable energy source, the short supply of energy sources is alleviated; the biomass solid fuel is an environment-friendly fuel, and the combustion emission data reaches the national environmental protection standard, so that the pollution to the air is reduced, and the living environment is improved; and meanwhile, the biomass solid fuel is simple in processing technique, and the production process does not generate toxic substances and can not cause damages to the environment, so that the biomass fuel has an important significance for promoting the construction of a new socialist countryside.

Owner:佛山市三水环能再生能源有限公司

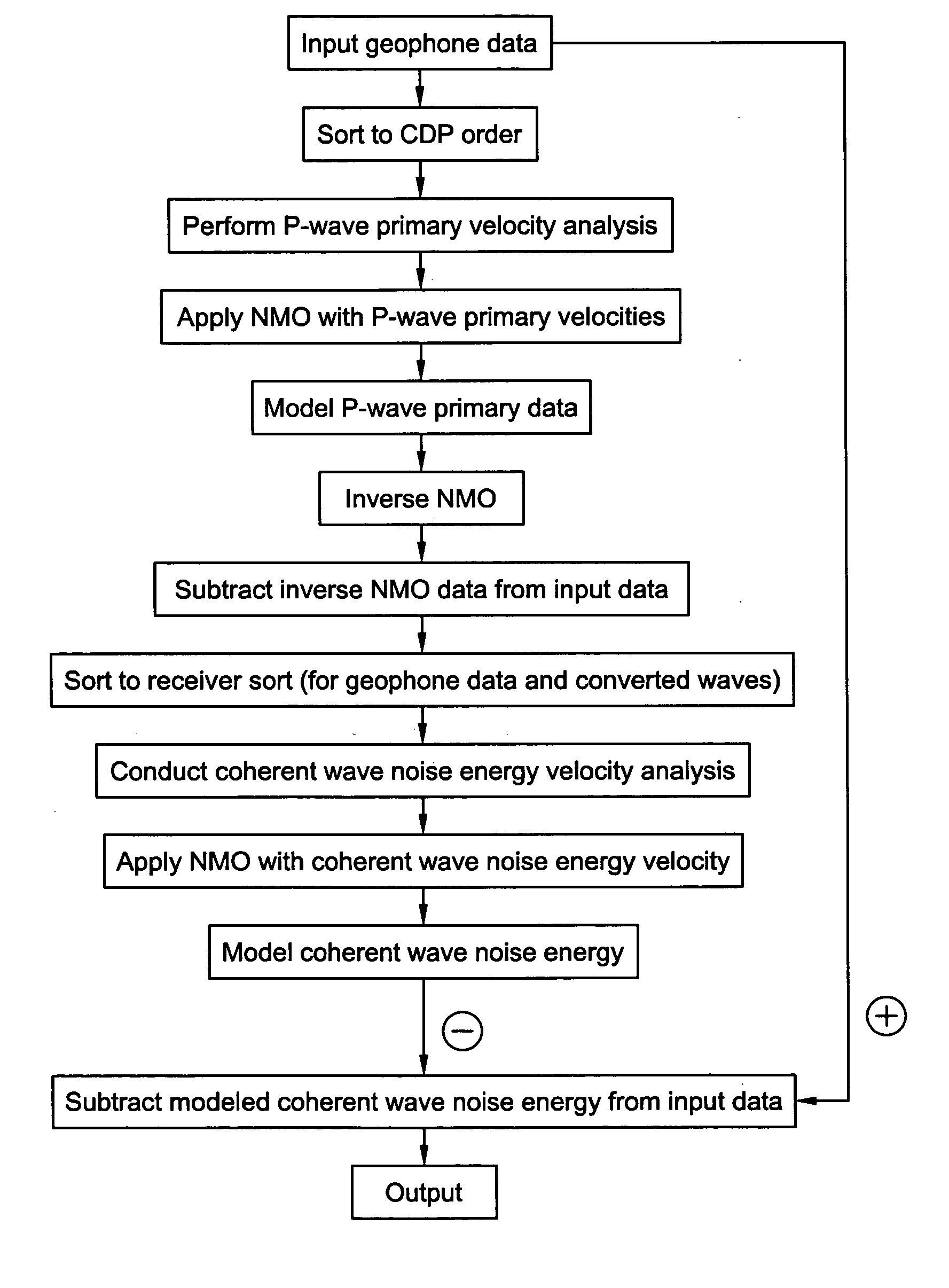

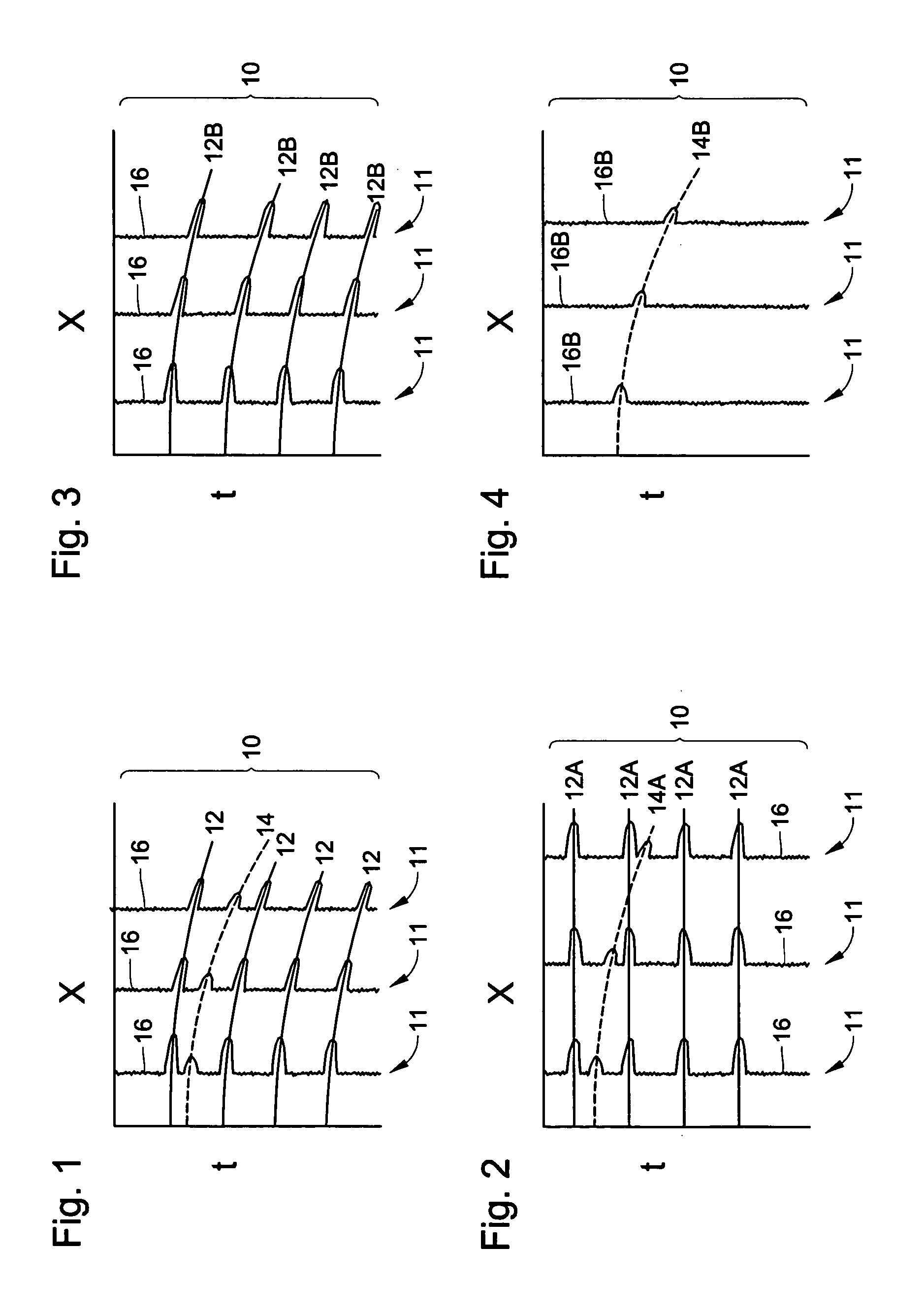

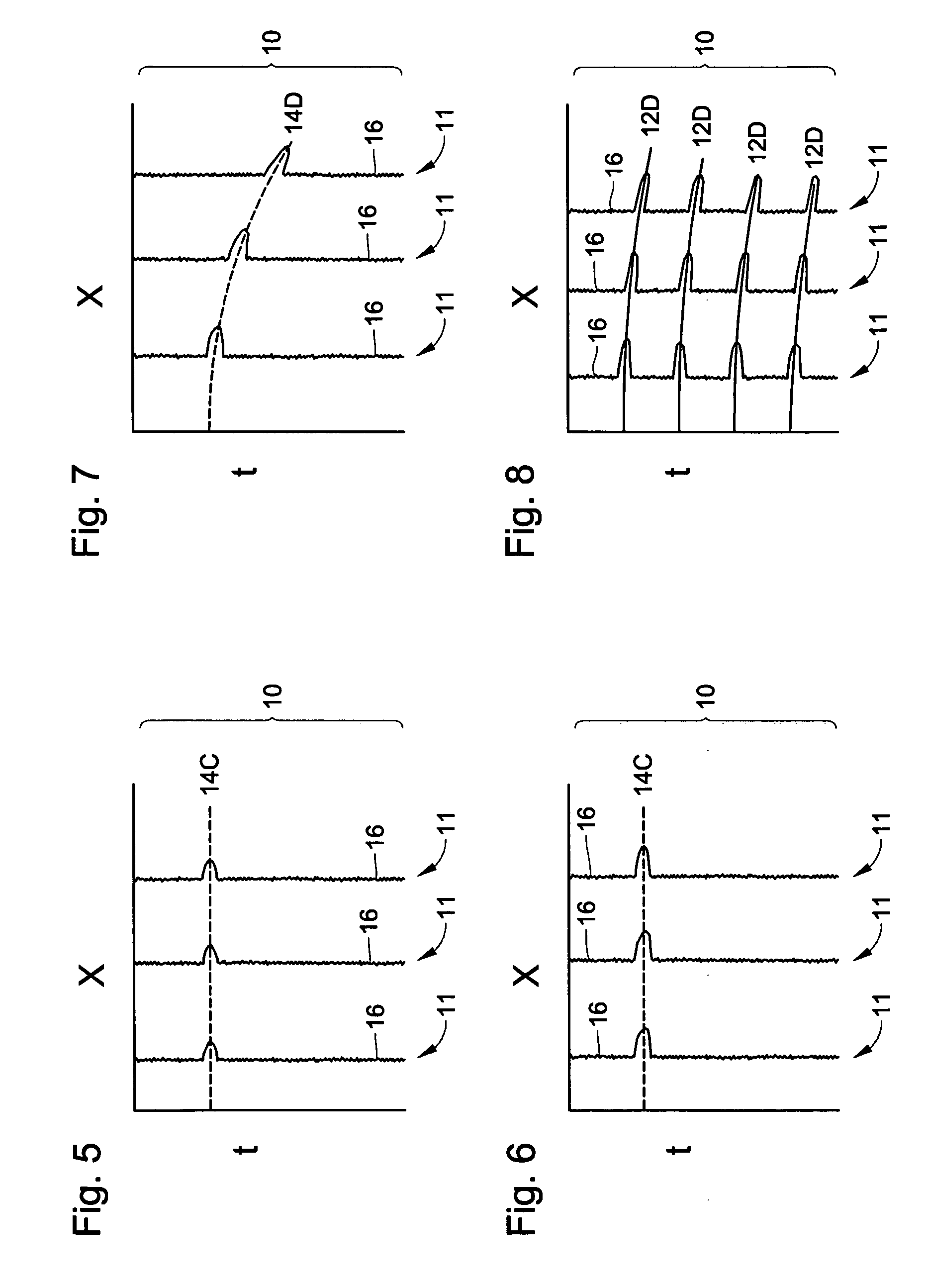

Coherent wave energy removal from seismic data

ActiveUS20070076525A1Efficient modelingRemove coherent wave noise energySeismic signal processingSpecial data processing applicationsData setCoherent wave

Coherent wave noise energy is removed from seismic data by modeling both the P-wave primary energy and the coherent wave noise energy. The P-wave primary energy is modeled first and then subtracted from the input data. The data with the P-wave primary energy removed is used as the input for coherent wave energy removal. The coherent wave energy is modeled and subtracted from the original input data, i.e. the data input into P-wave primary removal. This leaves a dataset with P-wave primary energy and noise energy not related to coherent waves. This method can be utilized to remove all types of coherent noise with a velocity difference to the desired P-wave primary energy or with a different type of moveout (change of time of arrival with source-receiver distance) such as, for example, linear moveout.

Owner:FAIRFIELD INDUSTRIES INC

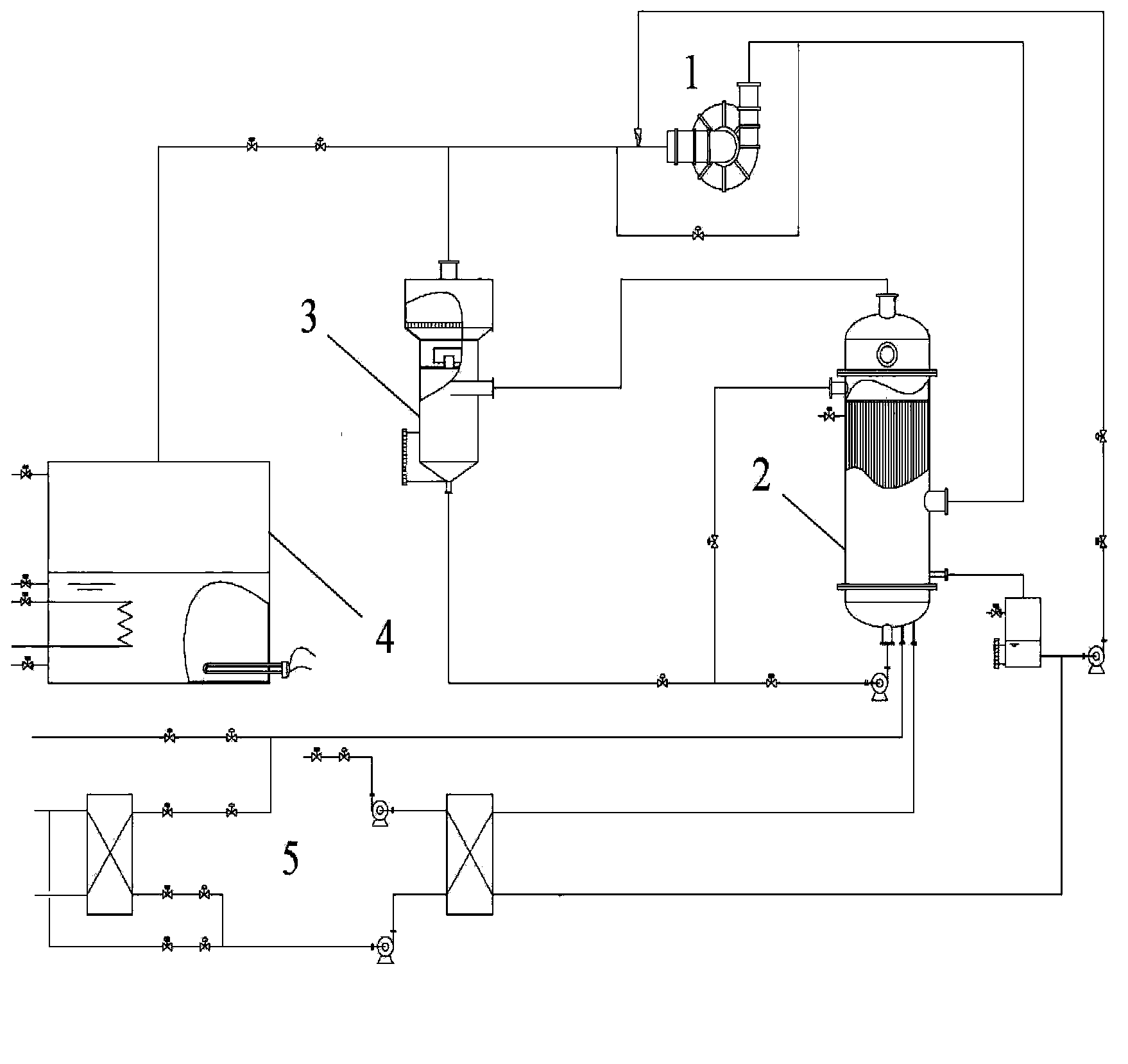

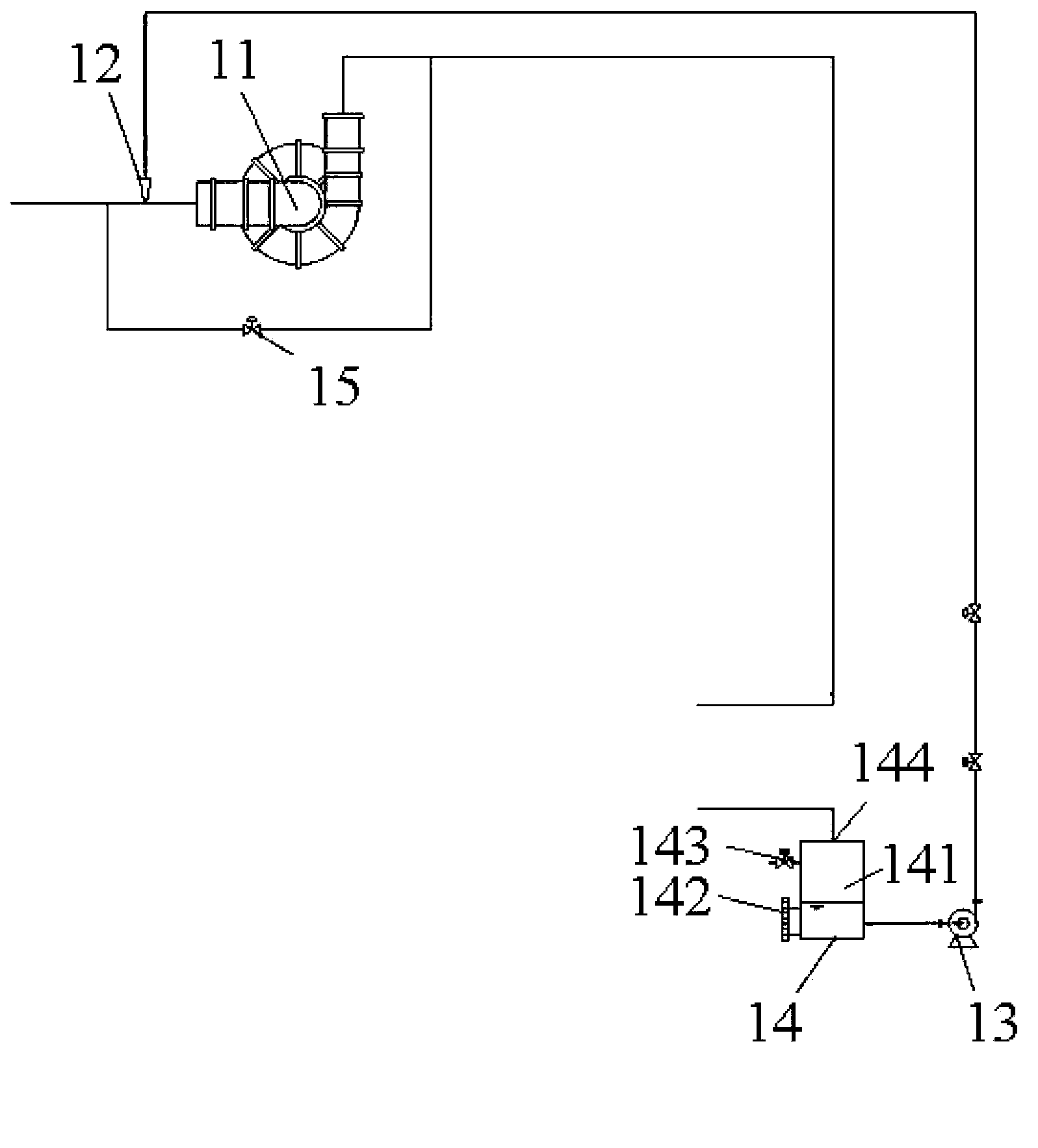

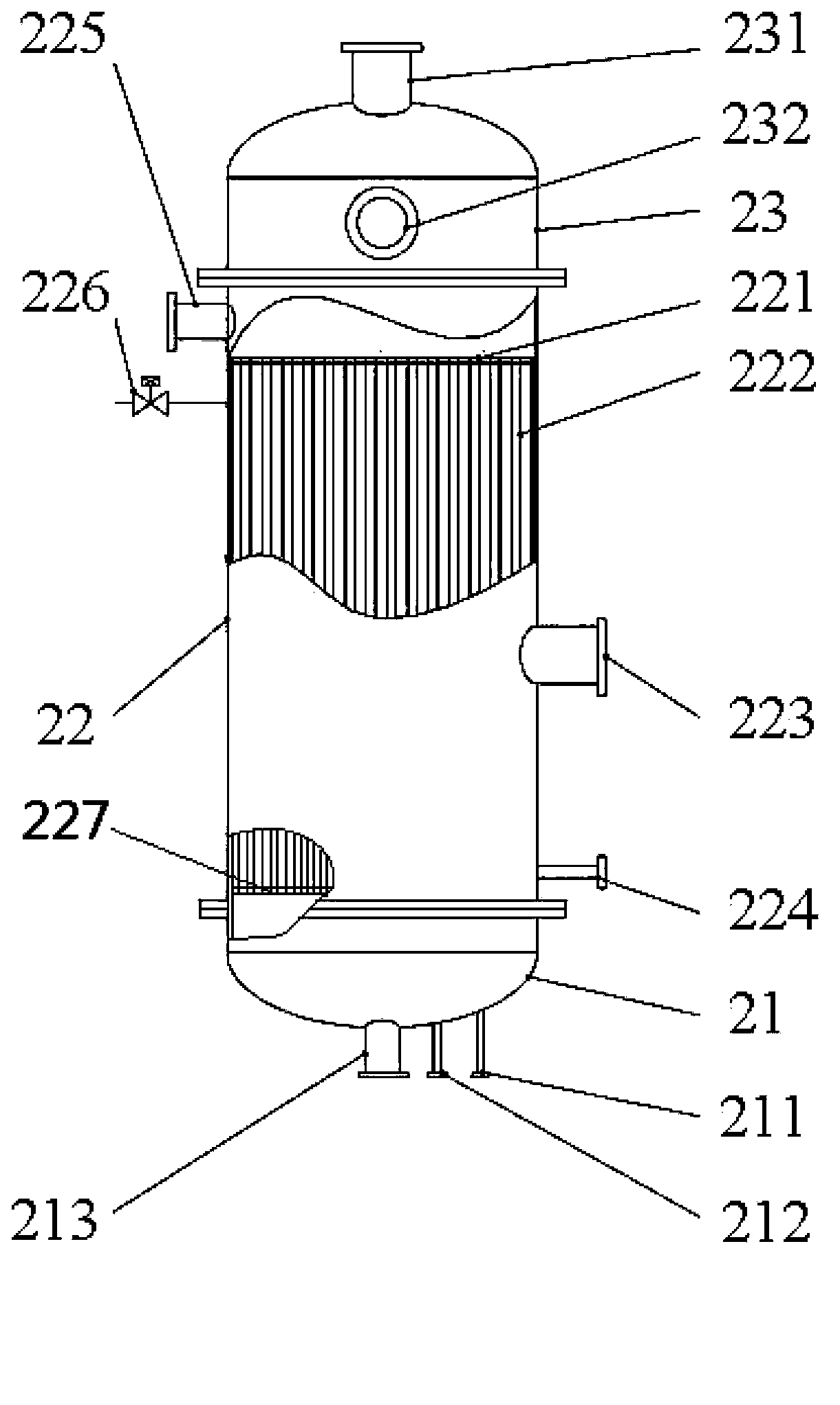

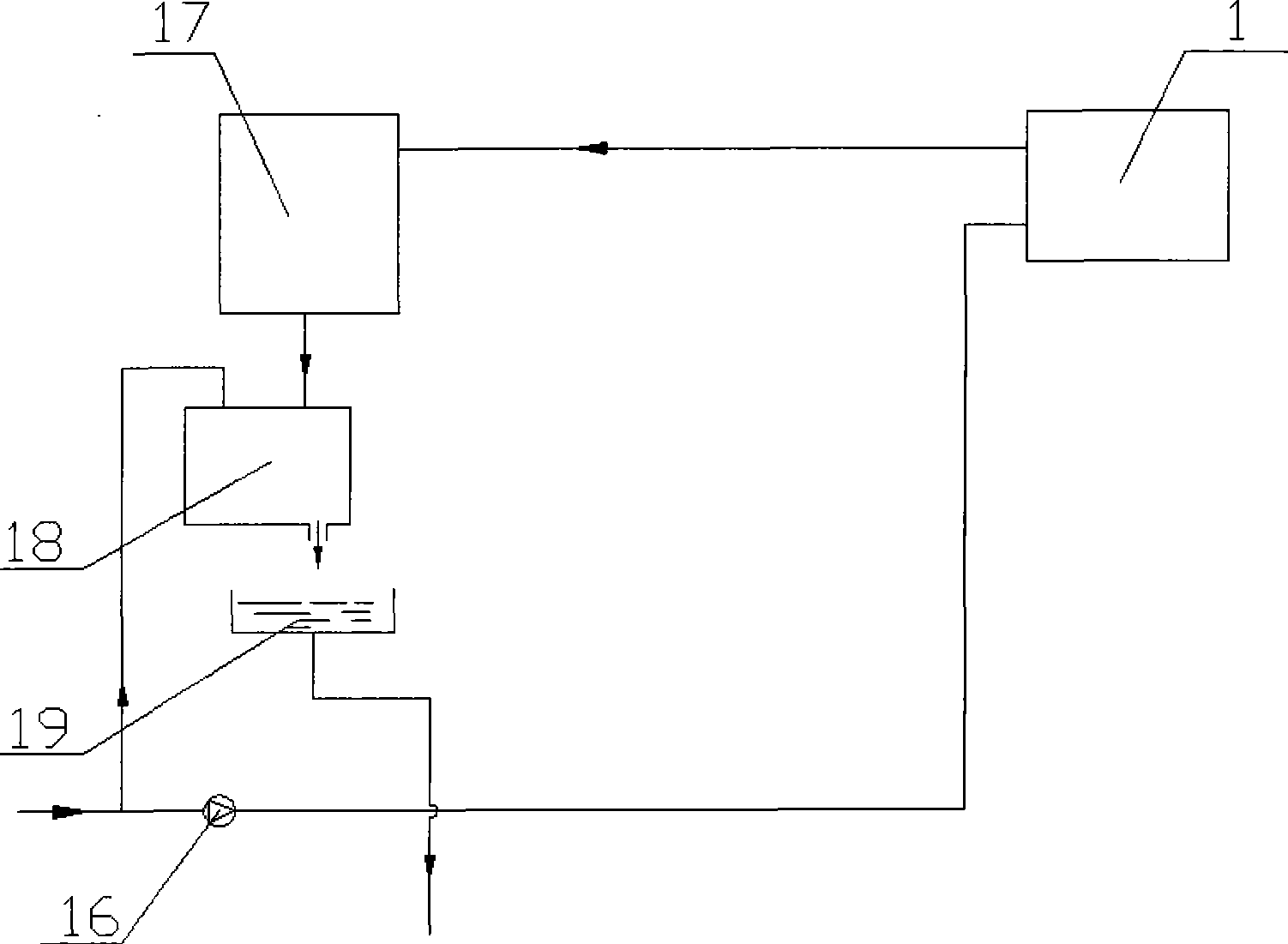

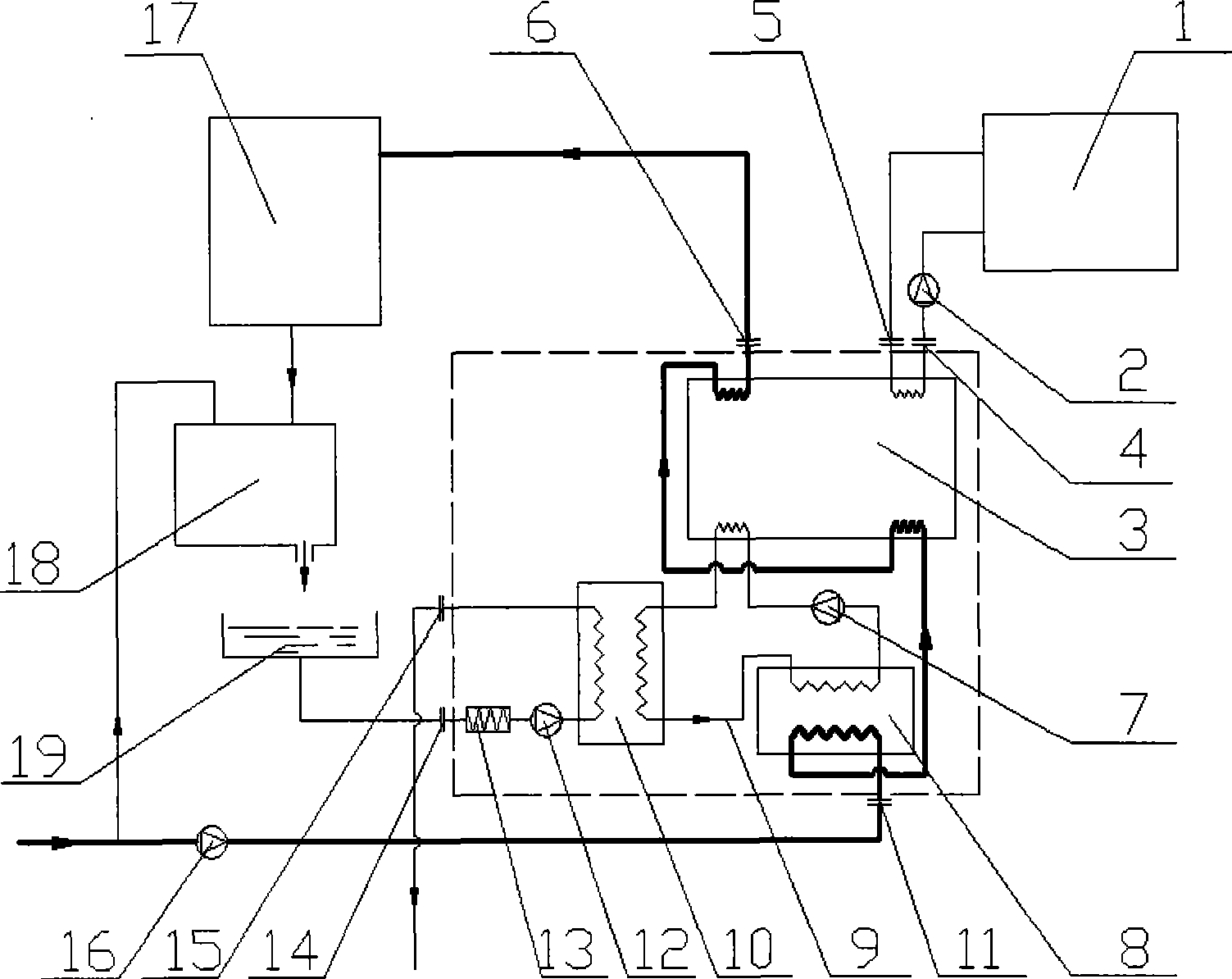

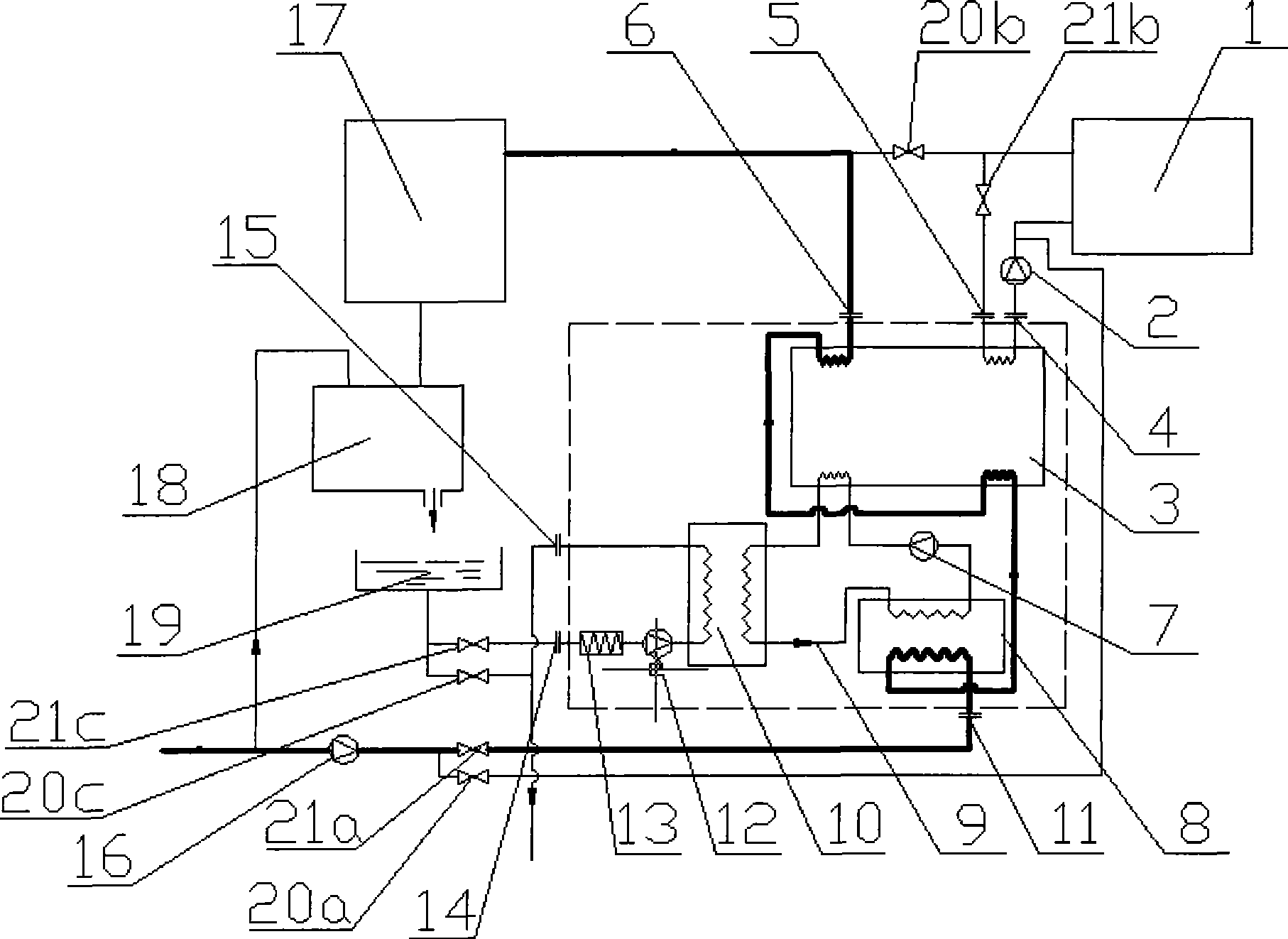

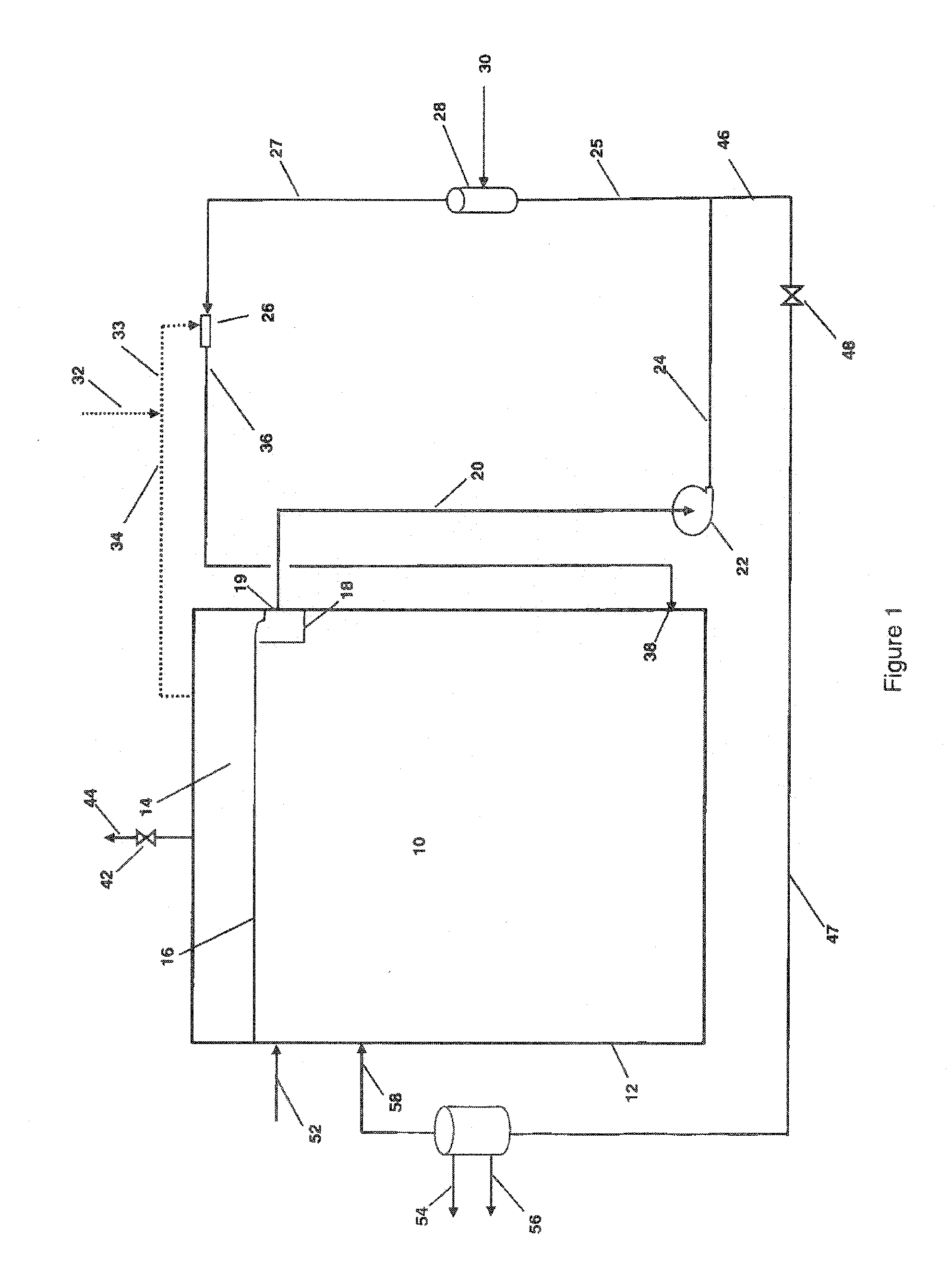

MVR heat pump evaporation system

ActiveCN103908788AReduce consumptionFast startupEvaporator accessoriesEvaporators with vertical tubesWater vaporEvaporation

The invention discloses an MVR heat pump evaporation system, which comprises a water vapor compression system, an evaporator, a separator, an energy storage water tank and a waste heat recovery system. The vapor outlet of the energy storage water tank and the vapor outlet of the separator are both in connection with the vapor inlet of the water vapor compression system, the vapor outlet of which is connected to the vapor inlet of the evaporator. The vapor outlet of the evaporator is connected to the vapor inlet of the separator, and the stock solution inlet and the concentrated solution outlet of the evaporator are both in connection with the waste heat recovery system. The MVR heat pump evaporation system provided by the invention recovers low grade waste heat, i.e. makes use of the energy storage water tank to convert hot water sensible heat into low-pressure vapor latent heat for recycling during starting, thus enhancing the start-up speed of the system, avoiding the influence of non-condensable gas air circulation in the system on compressor performance, recovering all the latent heat of secondary vapor generated in a solution evaporation process, saving primary energy, greatly reducing the energy consumption during solution evaporation, and avoiding pollution.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

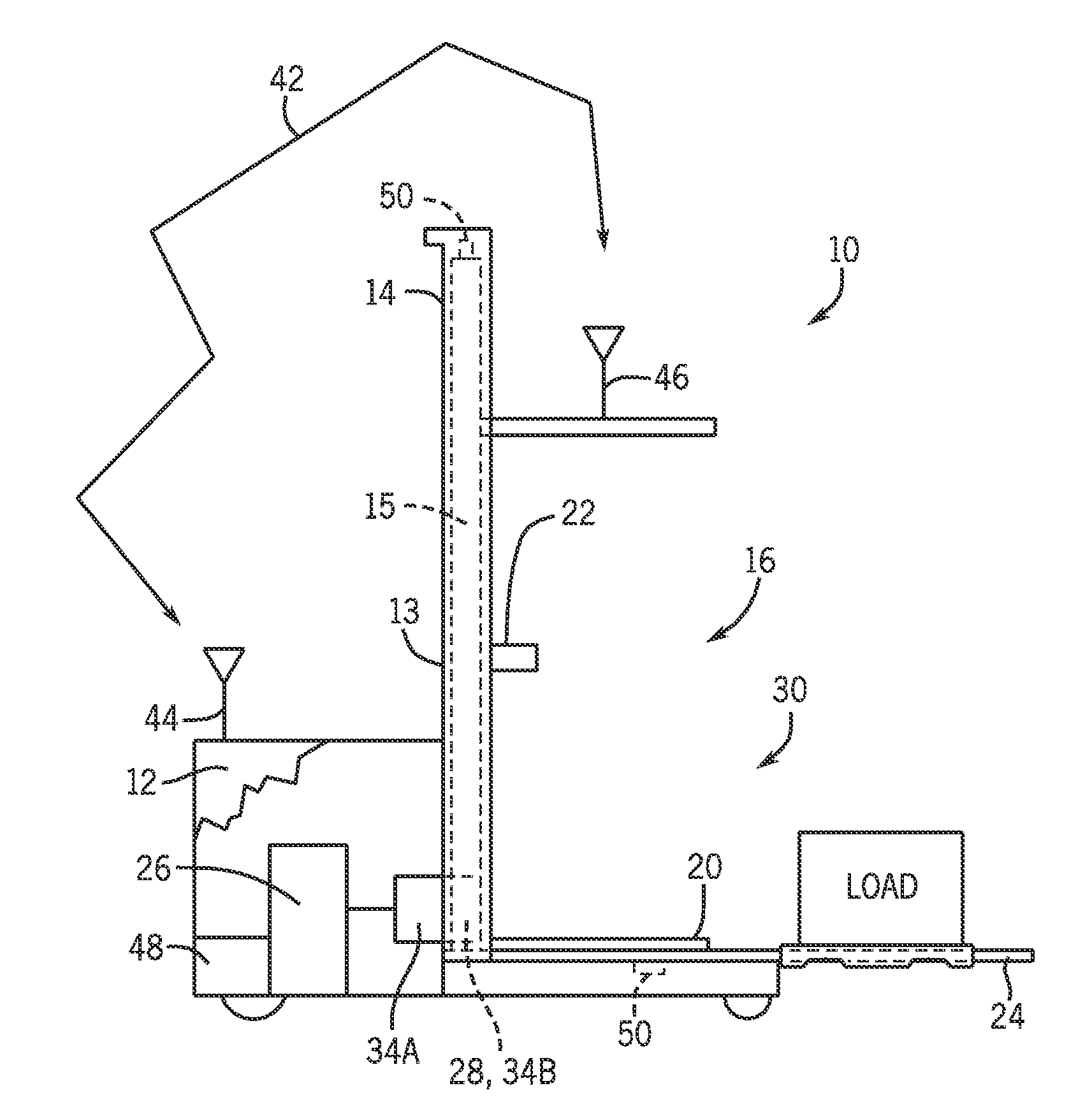

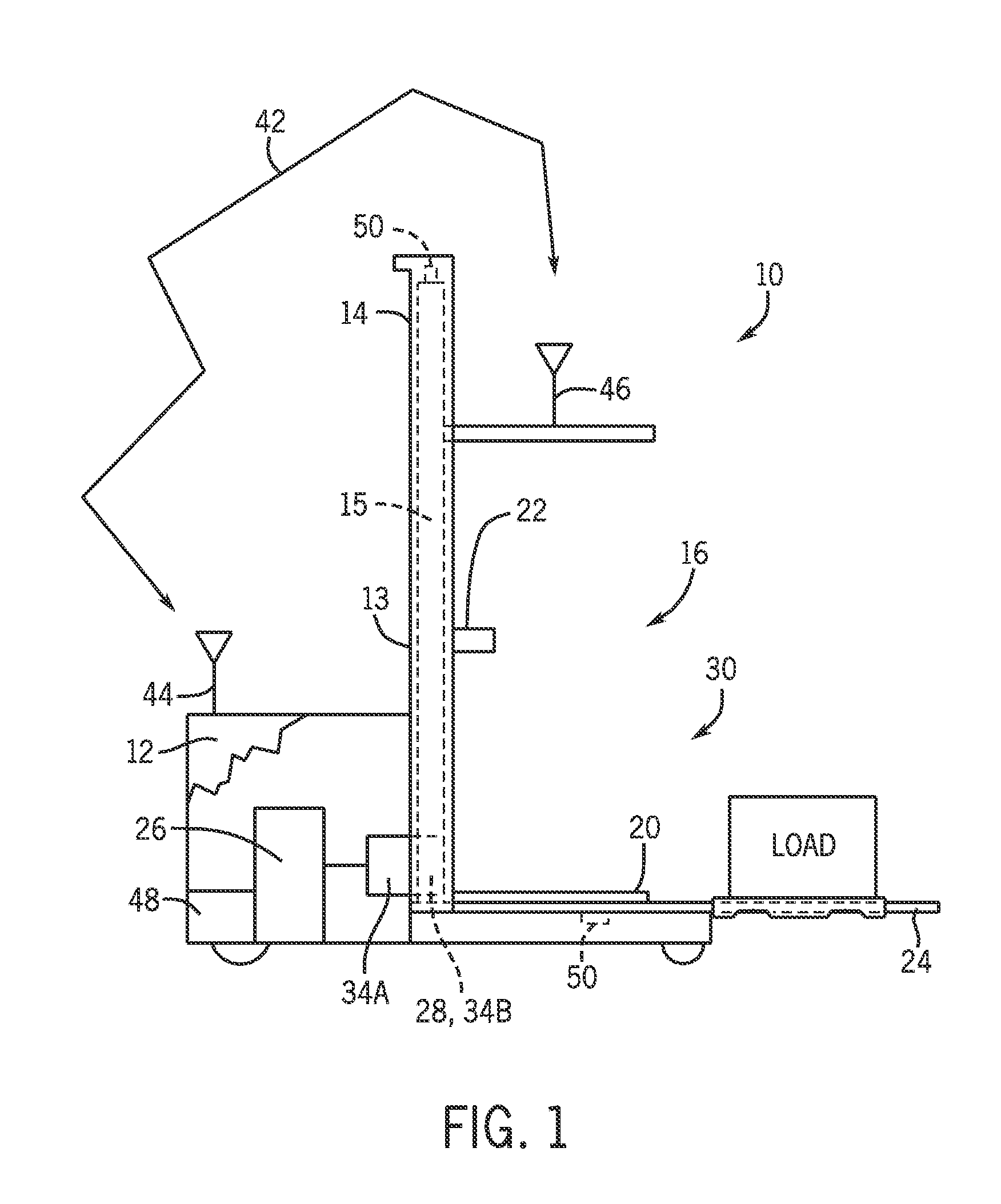

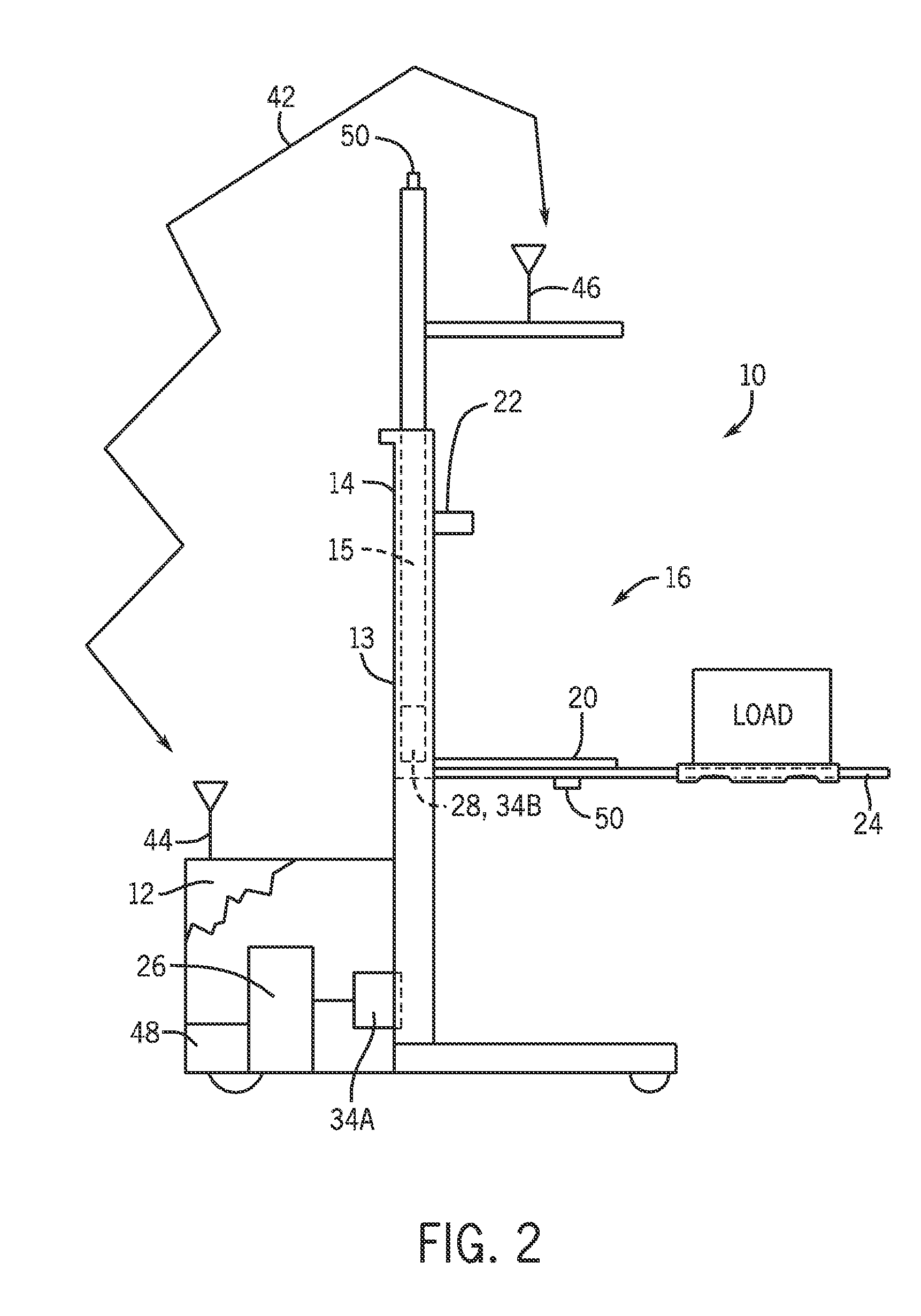

Energy Storage on an Elevated Platform and Transfer Method

ActiveUS20120145485A1Reduce usageOvercomes drawbackBatteries circuit arrangementsElectric devicesTruckElectric power

A lift truck includes a secondary rechargeable energy storage device on a vertically movable platform that is separate from a primary rechargeable energy storage device on the lift truck's main tractor unit. Wires or hoses for transfer of power or controls between the main tractor unit and the platform are reduced or eliminated. The quantity of energy stored in the secondary rechargeable energy storage device is sufficient to power platform electrical loads for a predetermined amount of time until the platform is lowered. When the platform is lowered, the secondary rechargeable energy storage device is recharged by the primary energy storage device.

Owner:RAYMOND LTD

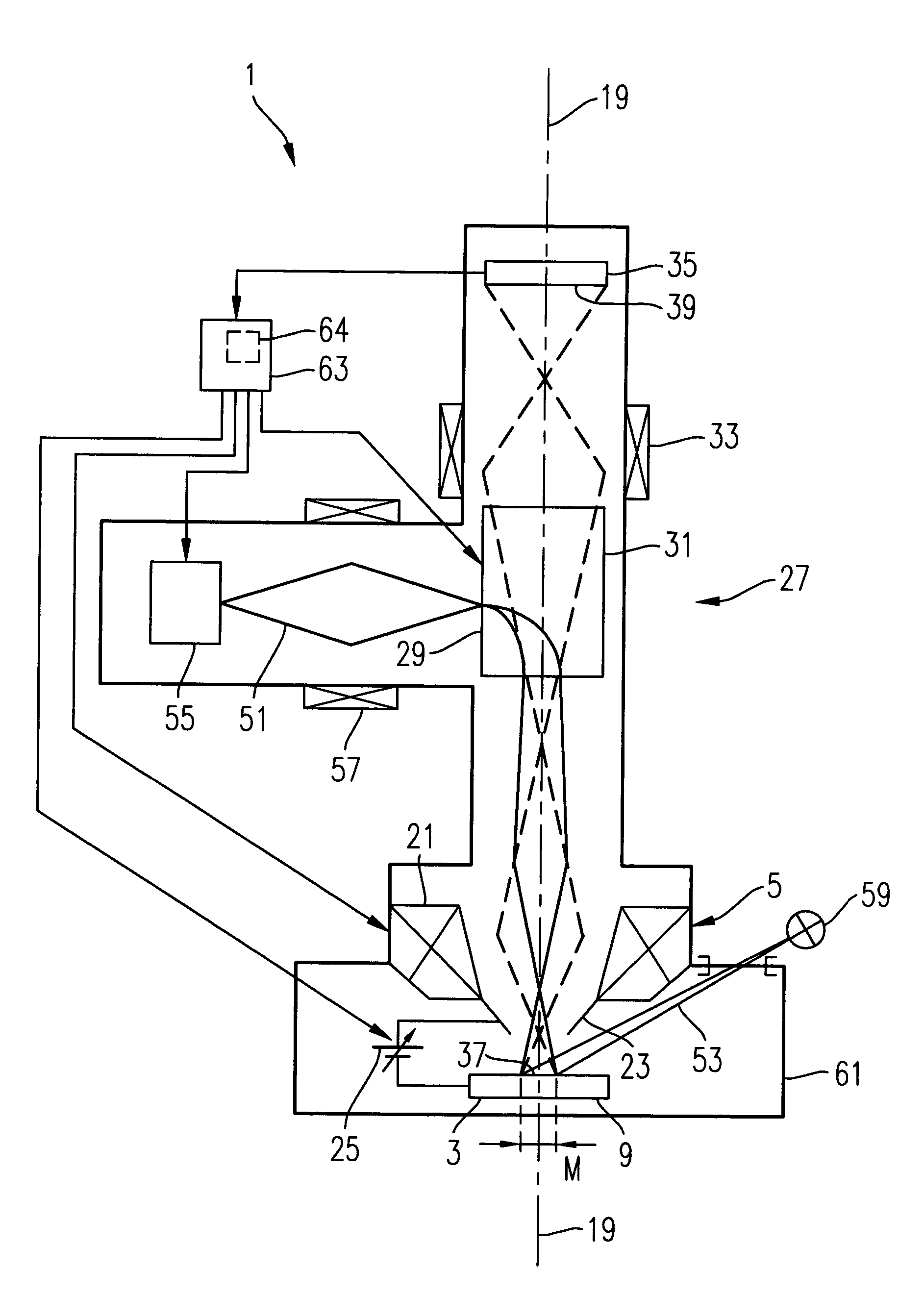

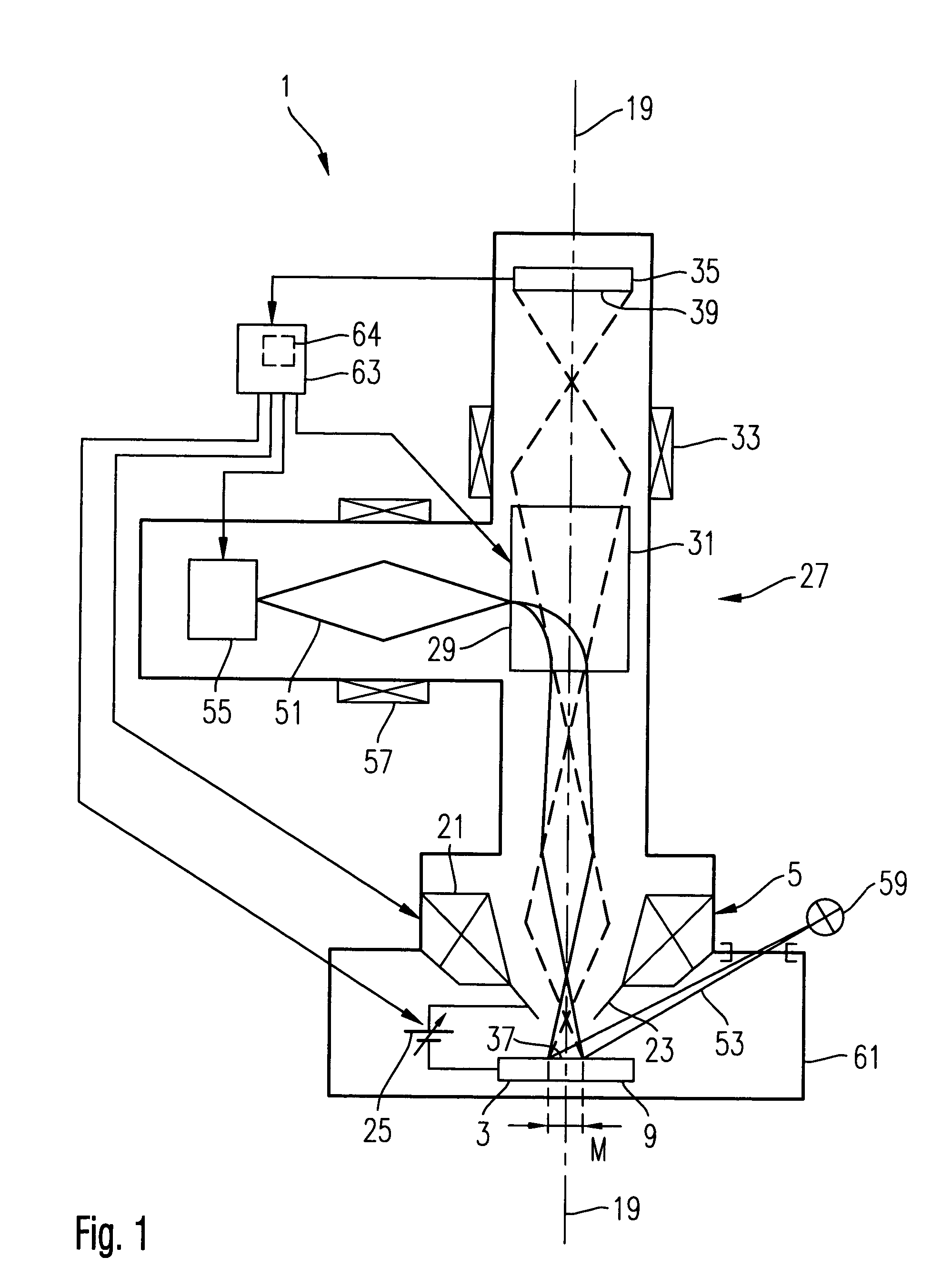

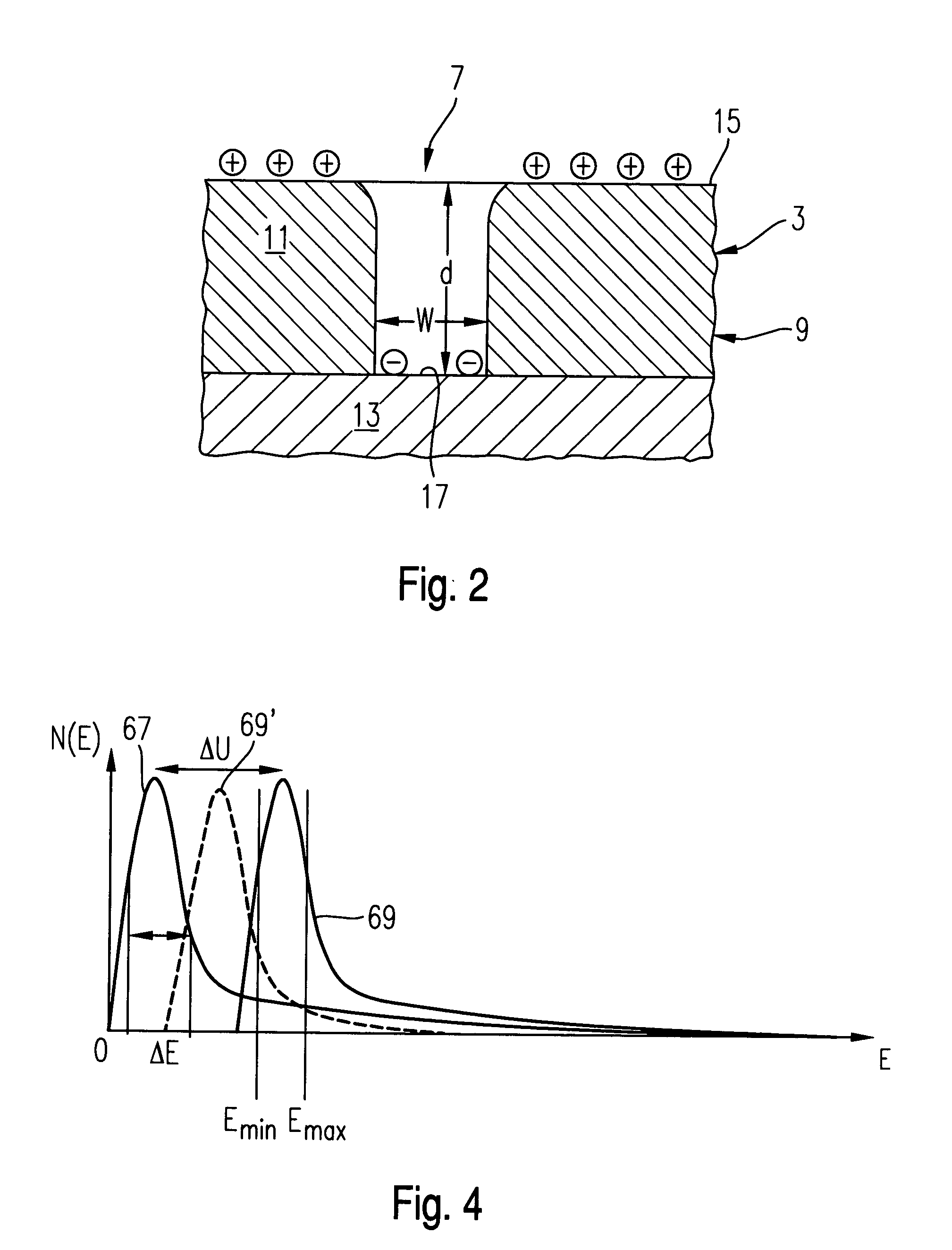

Method for the electron-microscopic observation of a semiconductor arrangement and apparatus therefor

ActiveUS20040065827A1Producing an excessive and uncompensatable image blurHigh resolutionMaterial analysis using wave/particle radiationSemiconductor/solid-state device testing/measurementElectron microscopeSecondary electrons

A method for the electron-microscopic observation of a semiconductor arrangement is provided. It includes providing an electron microscopy optics for imaging secondary electrons emanating from the semiconductor arrangement within an extended object field on a position-sensitive detector, providing an illumination device for emitting a primary energy beam, directing the primary energy beam to at least the object field for extracting there secondary electrons from the semiconductor arrangement. The semiconductor arrangement comprises a region with an upper surface provided by a first material and a recess with a high aspect ratio which is surrounded by the upper surface and has a bottom provided by a second material.

Owner:CARL ZEISS SMT GMBH

Low activity nuclear density gauge

InactiveUSRE38910E1X-ray spectral distribution measurementUsing wave/particle radiation meansLower limitLow activity

Owner:TROXLER ELECTRONICS LAB INC

Starting method and starting device of internal combustion engine, method and device of estimating starting energy employed for starting method and starting device

InactiveUS7096840B2Avoiding unnecessary energy consumptionReliable startPower operated startersElectrical controlCombustionExternal combustion engine

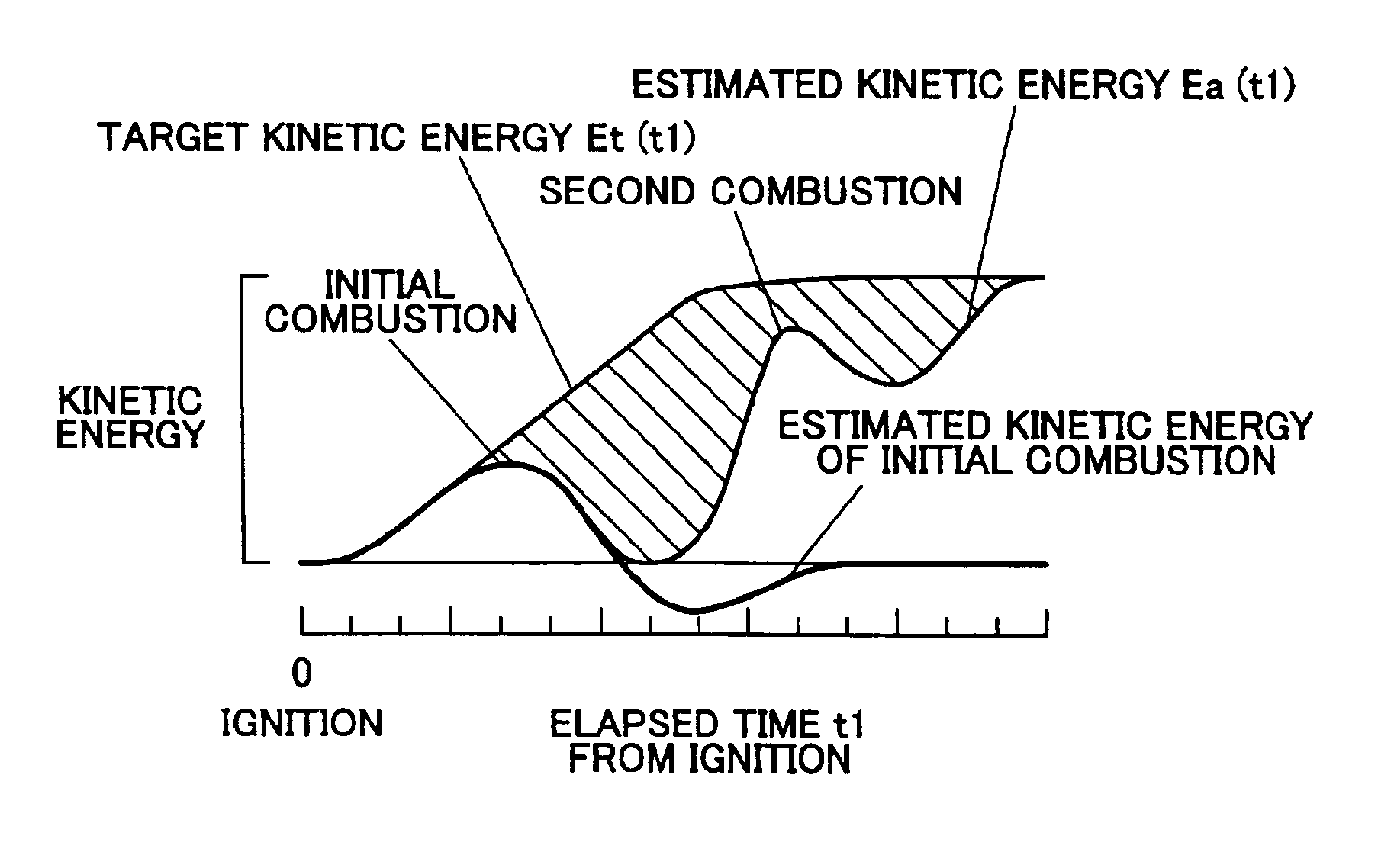

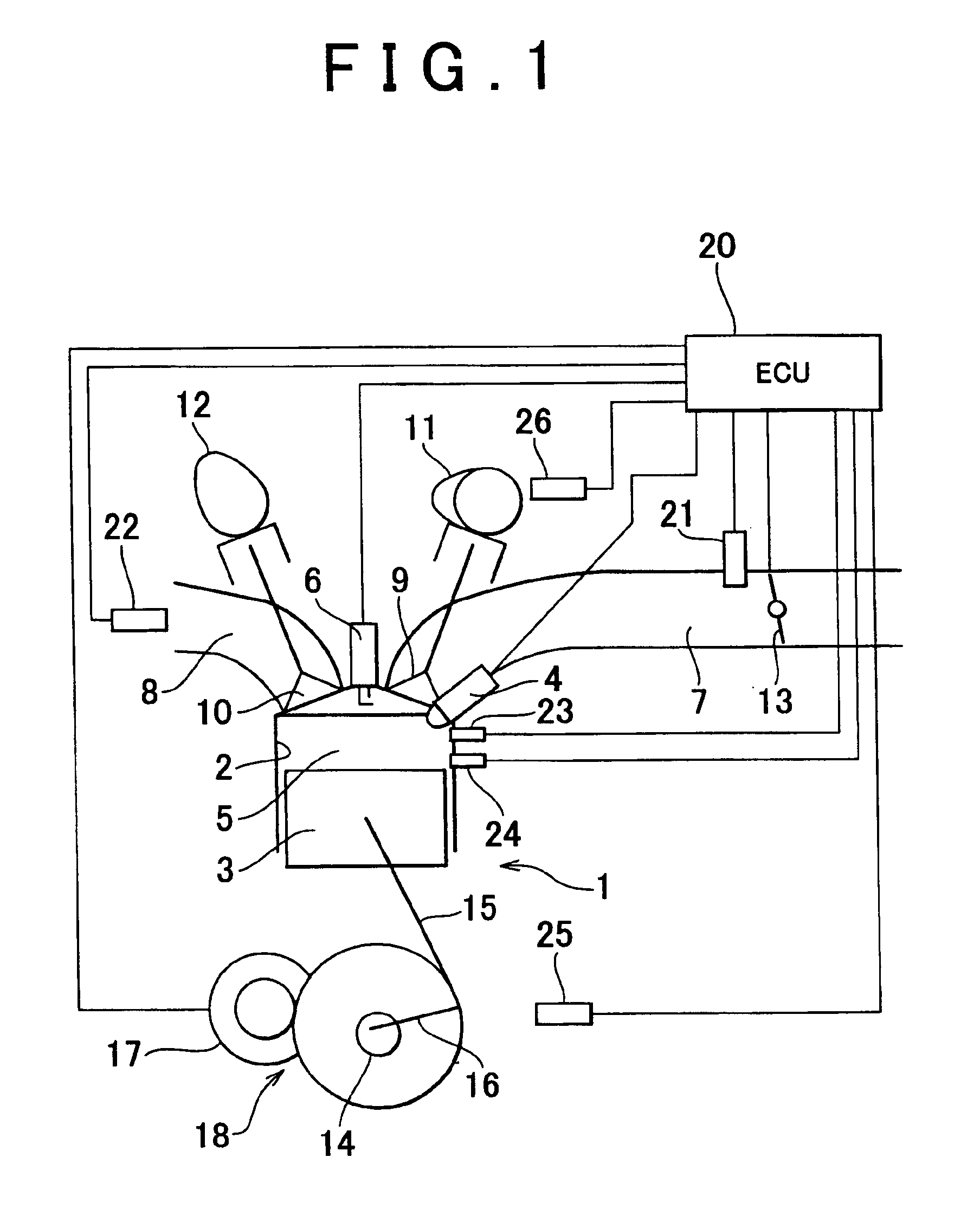

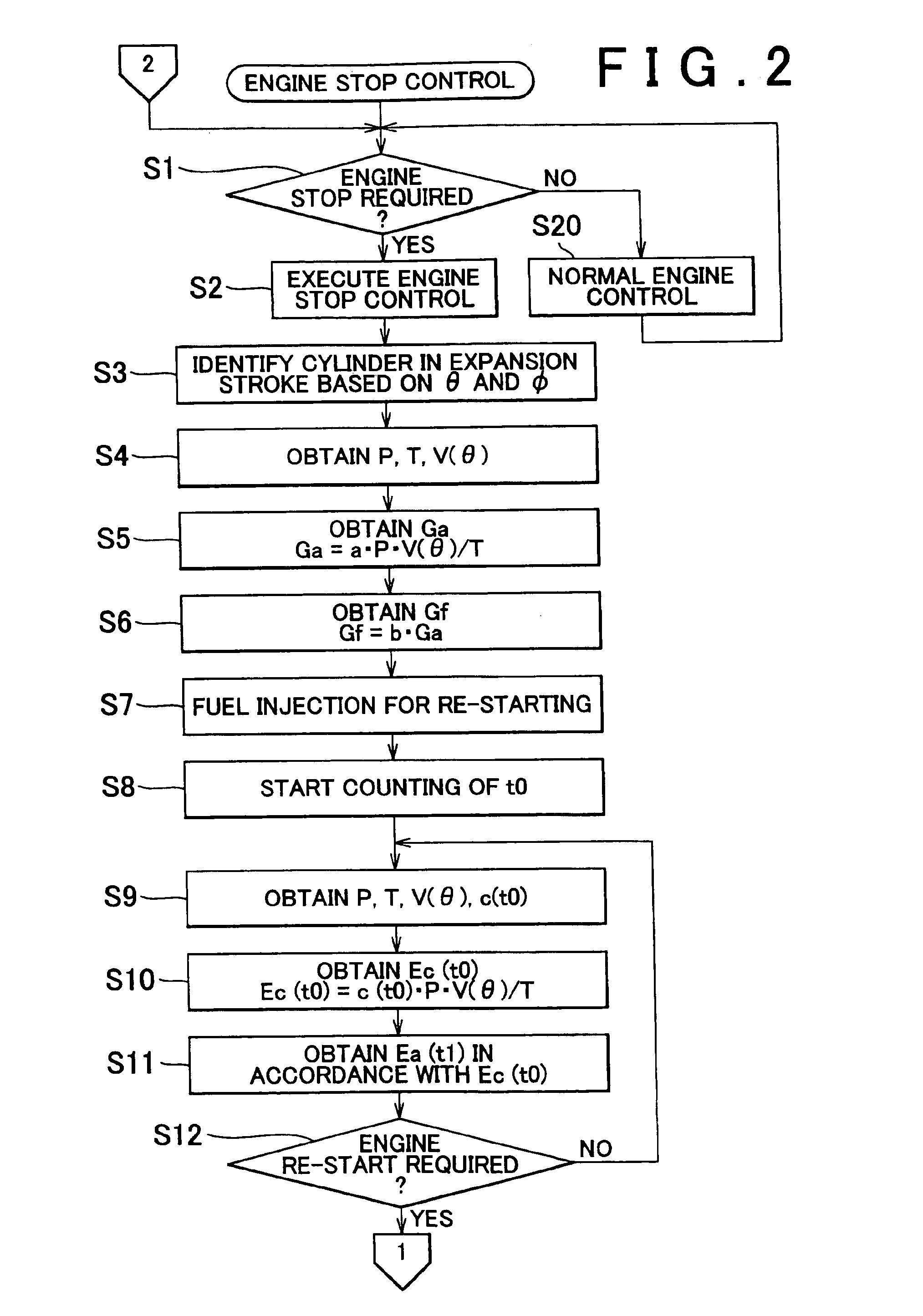

In a method of starting an internal combustion engine, a combustion energy is generated by combusting a fuel that has been injected into a cylinder in an expansion stroke when the internal combustion engine is stopped. In the aforementioned method, the combustion energy generated by combusting the fuel is obtained based on a state of an air / fuel mixture within the cylinder to which the fuel has been injected. Based on the obtained combustion energy, a kinetic energy to be supplied to the internal combustion engine from a primary energy supply source is estimated. A difference between a predetermined target kinetic energy required for starting the internal combustion engine subsequent to the start of combustion and the estimated kinetic energy to be supplied from the primary energy supply source is obtained. The kinetic energy corresponding to the obtained difference is supplied from a secondary energy supply source in the form of a starter motor.

Owner:TOYOTA JIDOSHA KK

Waste heat recovery type hot-water boiler device in bathroom

InactiveCN101520208AIncrease temperatureAvoid wastingEnergy efficient heating/coolingDomestic hot-water supply systemEnergy technologyWastewater

A waste heat recovery type hot-water boiler device in a bathroom comprises a boiler, an absorption type heat pump set, a sewage heat exchanger, a tap water preheater, a heat storage water tank, a sewage pool, a sewage filter, a water-feeding pump, a sewage pump, a circulating water pump and a boiler backwater pump. Water from a tap water pipeline is divided into two paths, wherein one path is normally supplied to the bathroom, and after being heated by the tap water preheater and the absorption type heat pump set, the other path is supplied as bath hot water; waste bath water collected by the sewage pool is discharged after heat exchange by the sewage heat exchanger; and circulating water in a water ring exchanges heat with the sewage in the sewage [heat] exchanger and flows through the tap water preheater and the absorption type heat pump set to exchange heat. The invention sufficiently utilizes the waste heat of waste bath water, reduces the fuel consumption, effectively utilizes primary energy sources, avoids wasting high-grade electric energy, is suitable for places needing hot bath water, such as hotels, schools, gymnasiums, hamams, and the like and belongs to the technical field of energy sources.

Owner:TSINGHUA UNIV

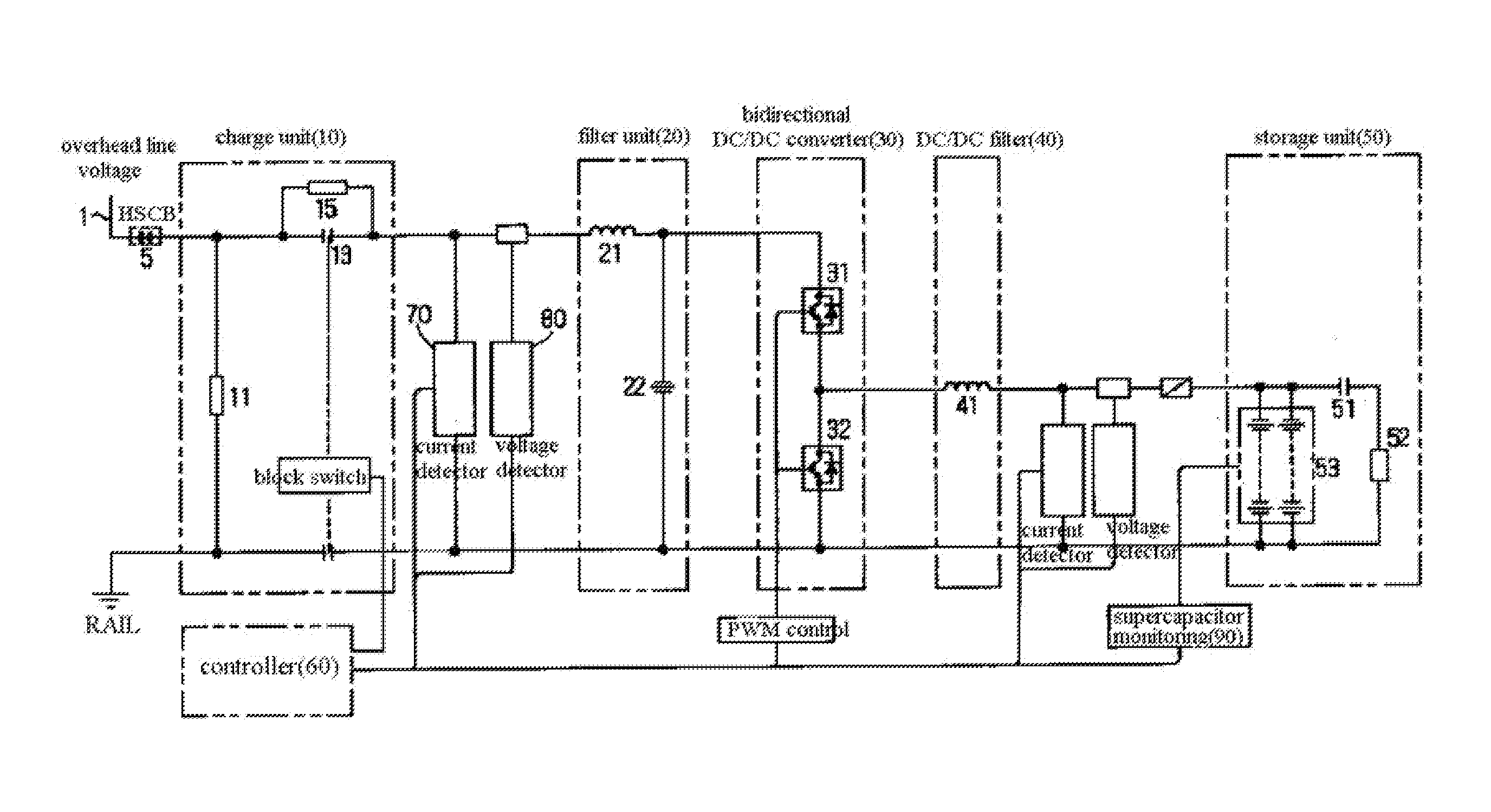

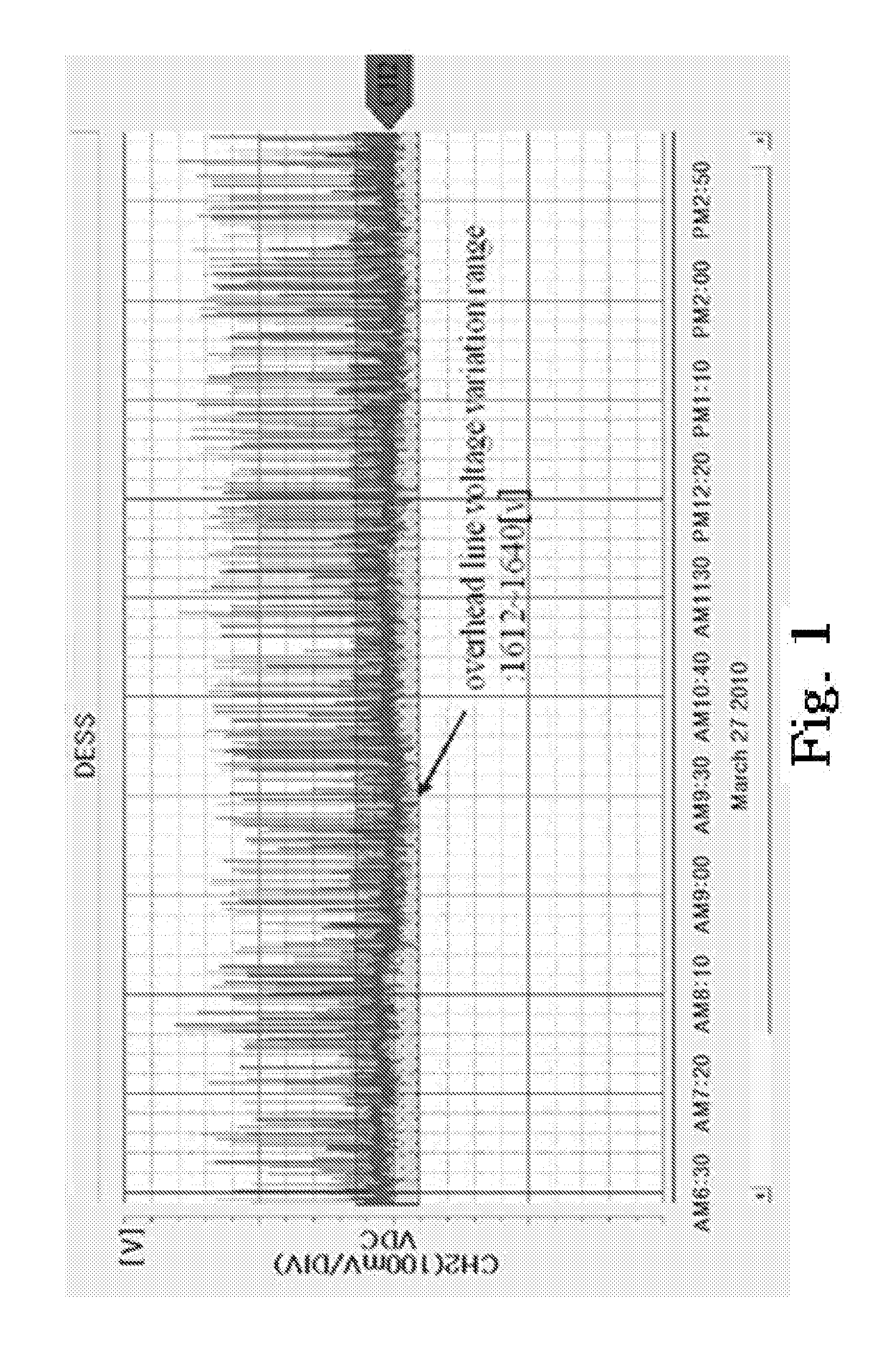

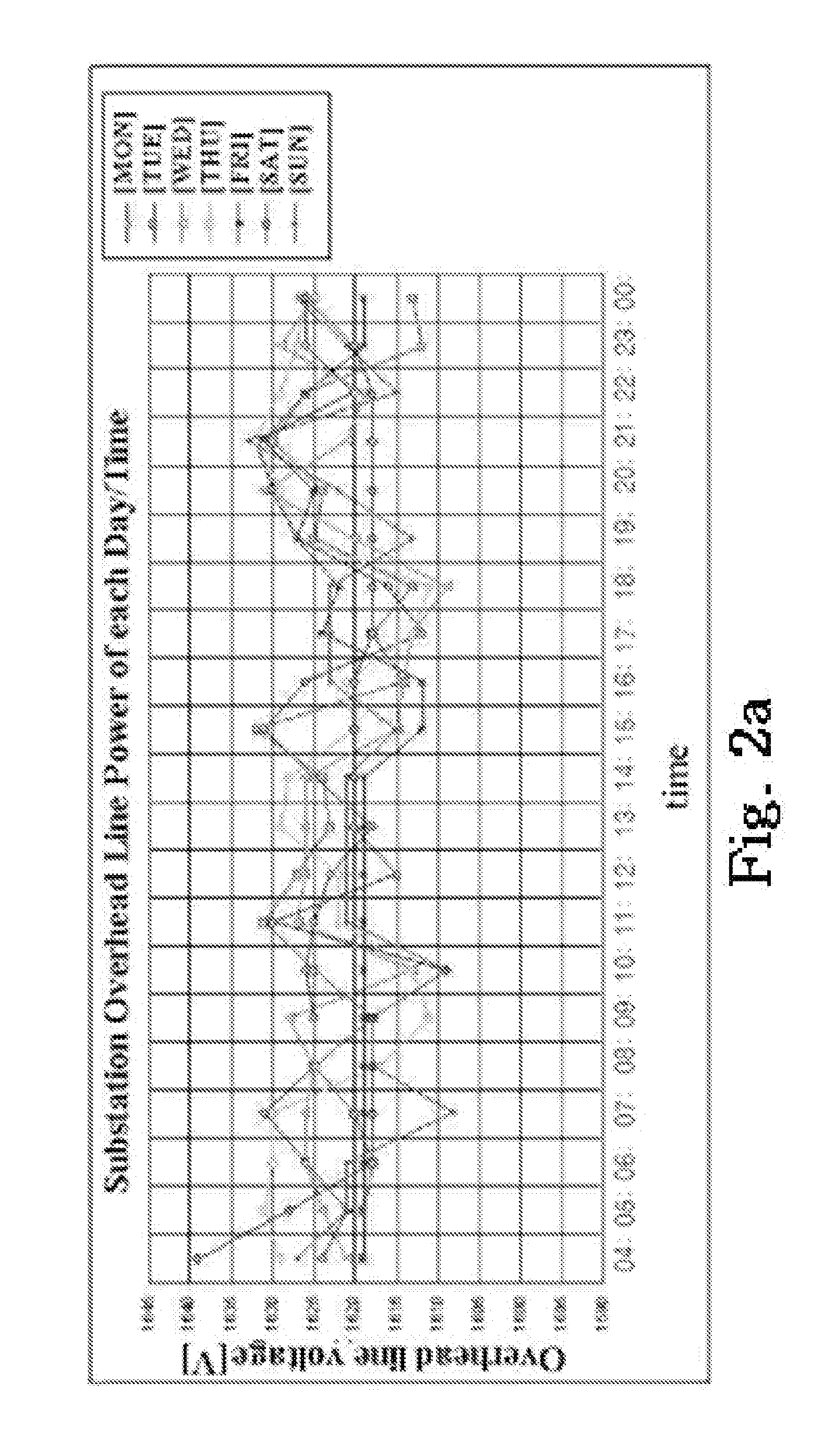

Automatic Tuning Method for Energy Storage System of Railway Vehicle

InactiveUS20130147441A1Improve energy savingEfficiently use regenerative energyInterference suppressionBatteries circuit arrangementsSmart gridMicro grid

An automatic tuning method is developed for an energy storage system of the railway vehicle. The method comprises; an optimal tracking for voltage fluctuation in the overhead line voltage varying with hourly-basis, the voltage variation of the substation and railway vehicle operating pattern. The railway vehicle is automatically performed the tuning to maximize the energy storing efficiency. The railway vehicle can achieve the optimum operation for saving energy effectively by bidirectional DC / DC converter using regenerative energy of DC. The railway vehicle stably operates under the overhead line voltage fluctuation. The energy efficiency is maximized by charging / discharging energy while the power is tracking unstable, which is generated by utilizing natural energies such as wind or solar energy, in real time by applying an automatic tuning algorithm to an energy storage system which is applied to a smart grid or a micro grid that uses renewable energy as a primary energy source.

Owner:LEE EUN KYU +2

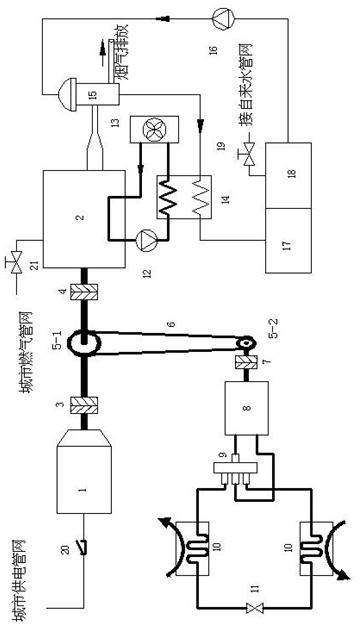

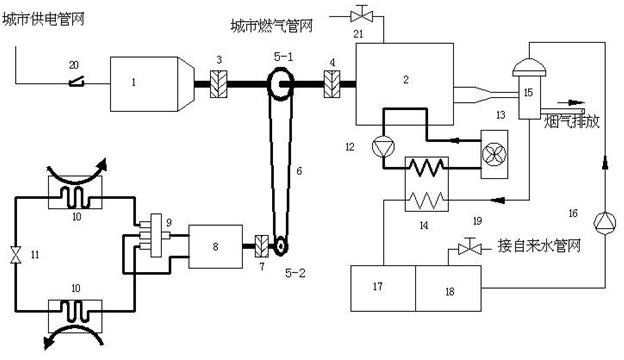

Alternating-current and gas engine parallel dual-drive heat pump device

InactiveCN102563970AAchieve normal operationImprove utilizationHeat pumpsInternal combustion piston enginesElectricityAlternating current

The invention discloses an alternating-current and gas engine parallel dual-drive heat pump device, which comprises a heat pump unit, an alternating-current motor, a gas engine and a transmission unit. An output end of the alternating-current motor is connected with an input end of the transmission unit by an alternating-current motor clutch, an output end of the gas engine is also connected with the input end of the transmission unit by a gas engine clutch, and an input end of the heat pump unit is connected with an output end of the transmission unit by a heat pump clutch. An urban alternating-current pipe network and the gas engine are technically combined, the urban alternating-current pipe network drives the motor, accordingly, load change can be balanced, simultaneously, a unit can be driven to run for a long time during gas shortage due to the fact that an electric driving portion is directly connected into an urban alternating-current grid, six different operating modes can be realized, utilization rate of primary energy can be improved, and carbon emission is reduced relatively.

Owner:SOUTHEAST UNIV

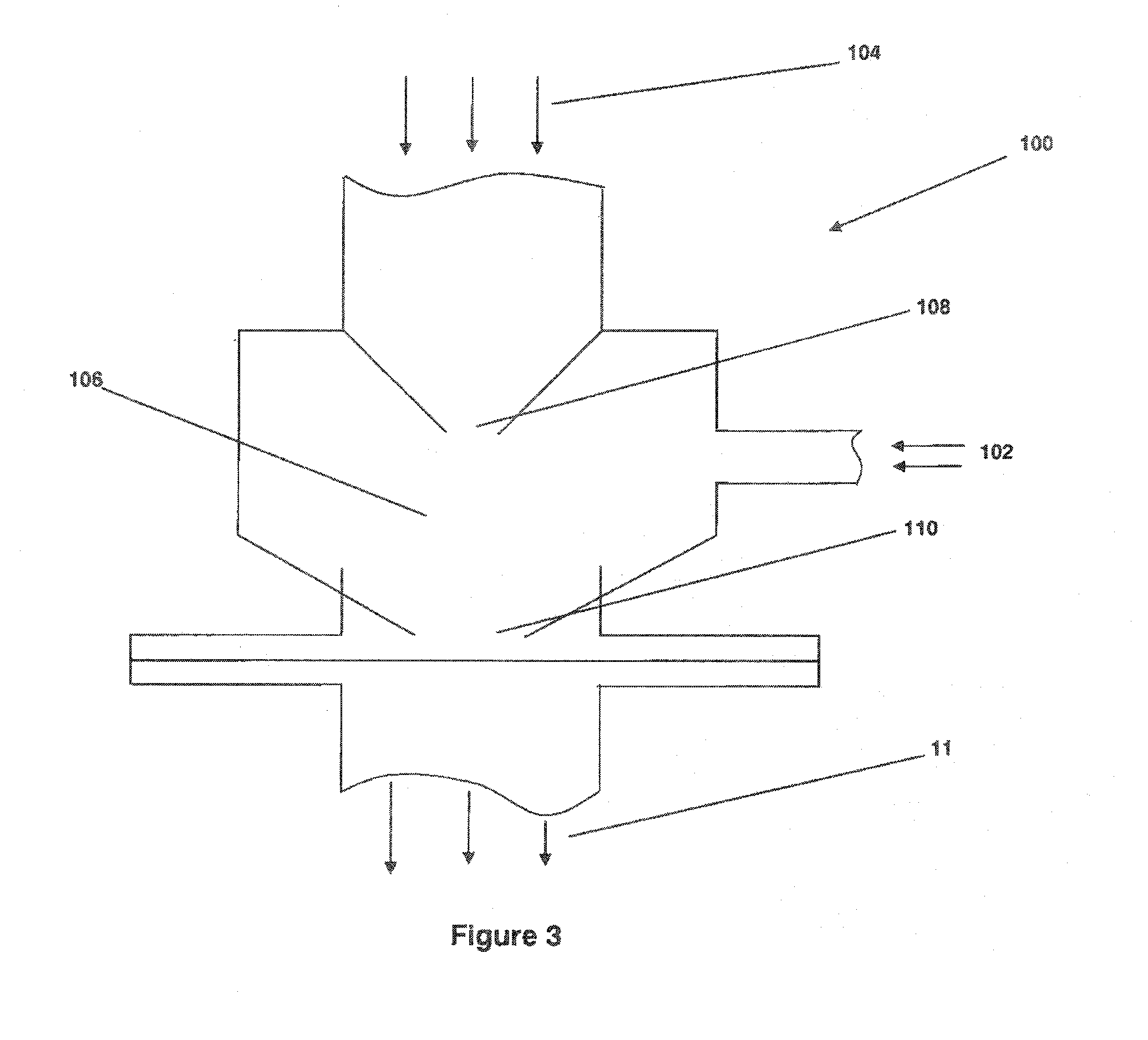

Method for Injecting a Feed Gas Stream into a Vertically Extended Column of Liquid

ActiveUS20120003707A1Reduce surface tensionProfound effect on gas transfer efficiencyBiochemistry apparatusBiofuelsSyngasLiquid product

A process for conversion of syngas to liquid products that serve as surface acting agents uses the gas stream at a relatively low pressure to eliminate the use of a compressor. The process uses a liquid stream as the primary energy input to a gas injector that intensely mixes gas and the liquid with reduced compression costs while the presence of the liquid product maintains the gas-liquid dispersion as it flows downward to build a static pressure head. The process lowers the required gas pressure by adjusting the elevation of the gas injector such that a conduit receives the gas-liquid dispersion from the outlet of the injector and confines it as it travels downward to enter the bottom of a column of liquid. The liquid product provides a surface acting agent that prolongs the creation and duration of microbubbles in the gas-liquid dispersion.

Owner:KLA SYST +1

System, method and apparatus for widespread commercialization of hydrogen as a carbon-free alternative fuel source

ActiveUS8336810B2Reduce shipping costsSave extra spaceArresting gearPower plant arrangements/mountingElectricityHydrogen

A system for efficiently transporting hydrogen from where it can be economically made to where it is most needed using specially designed airships. Technologies such as geothermal, wind, solar, wave tidal or hydropower can be used to generate electricity in-situ or very near to the primary energy sources. This electricity can then be used to produce hydrogen directly from water through various methods known in the art. Hydrogen can be delivered from the place where it is produced to the place where it is needed using an airship in which the hydrogen gas can also be used for generating lift, providing propulsion energy and serving ancillary needs. In other embodiments of the invention, the airship of the present invention can be used to dramatically reduce the cost of transportation of freight, the cost of passenger transportation, and to save on the area required for landing at the points of loading / unloading and embarkation / debarkation. And in another embodiment, the airship of the present invention can be used for transporting water and food to areas where needed. A unique docking system can use a remotely piloted unmanned aircraft flown from the mother craft to carry a guide line into a receiving attachment point.

Owner:H2 CLIPPER INC

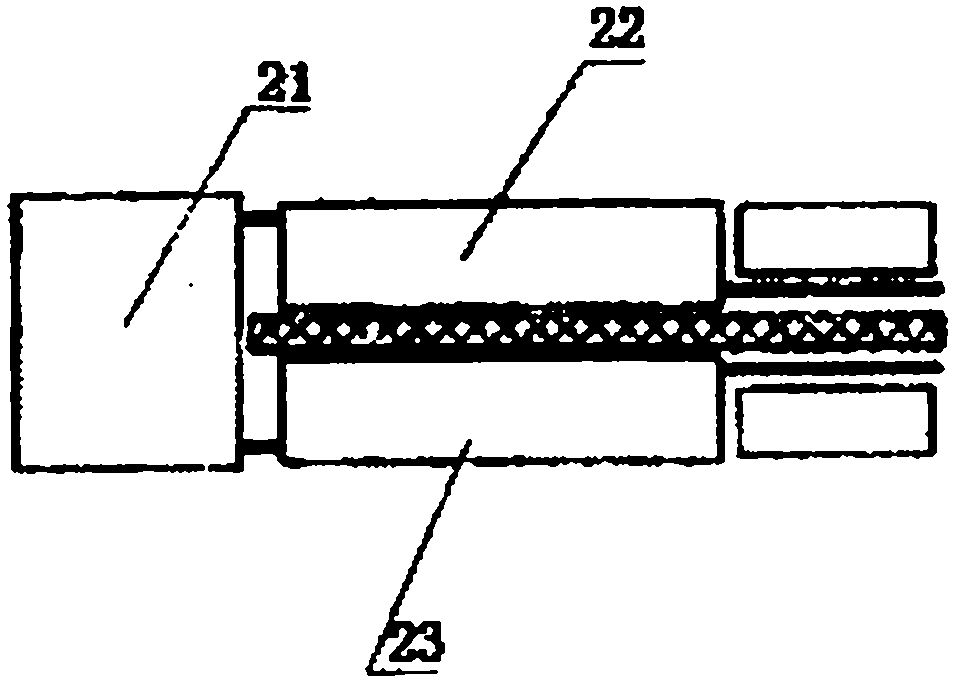

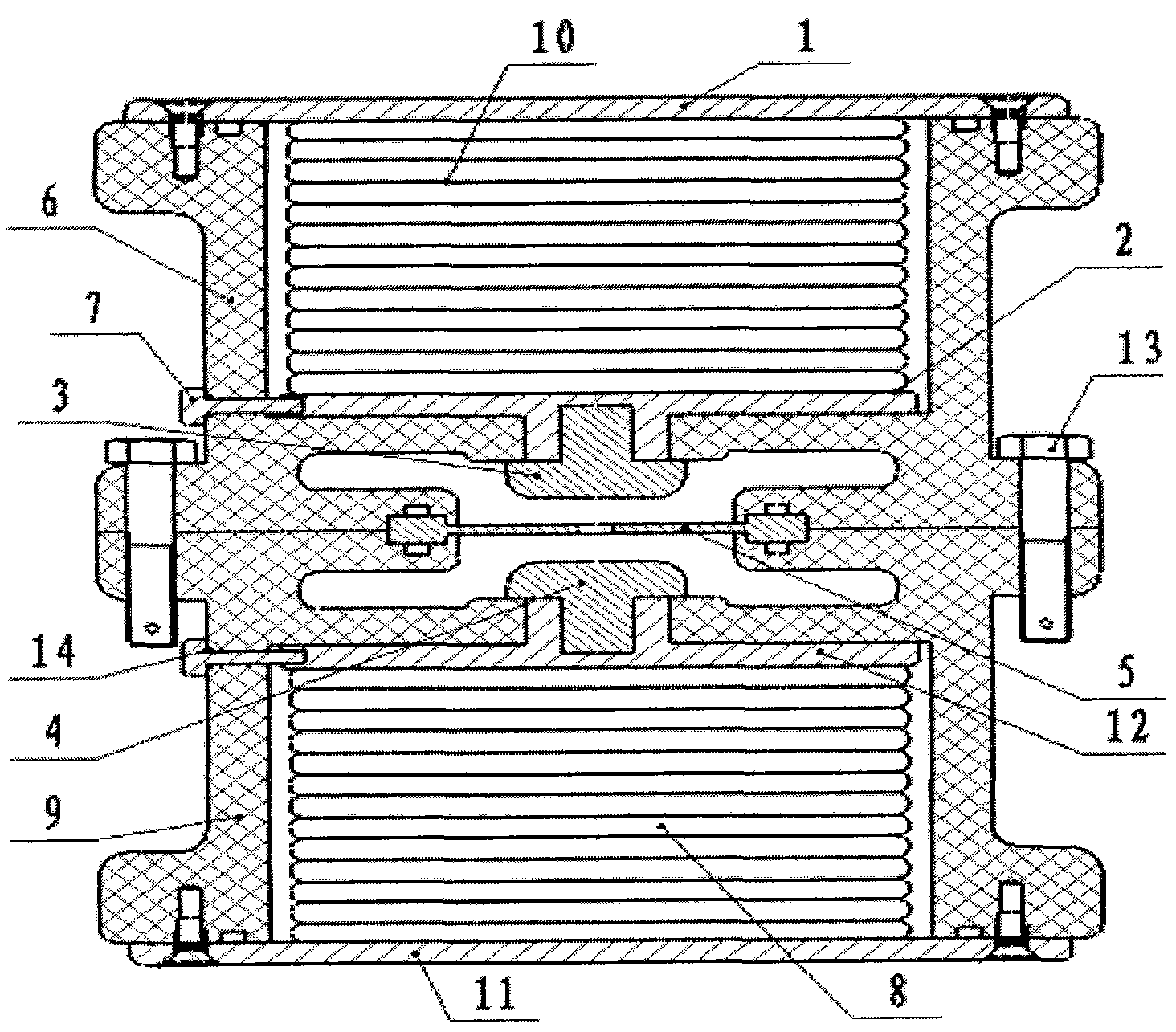

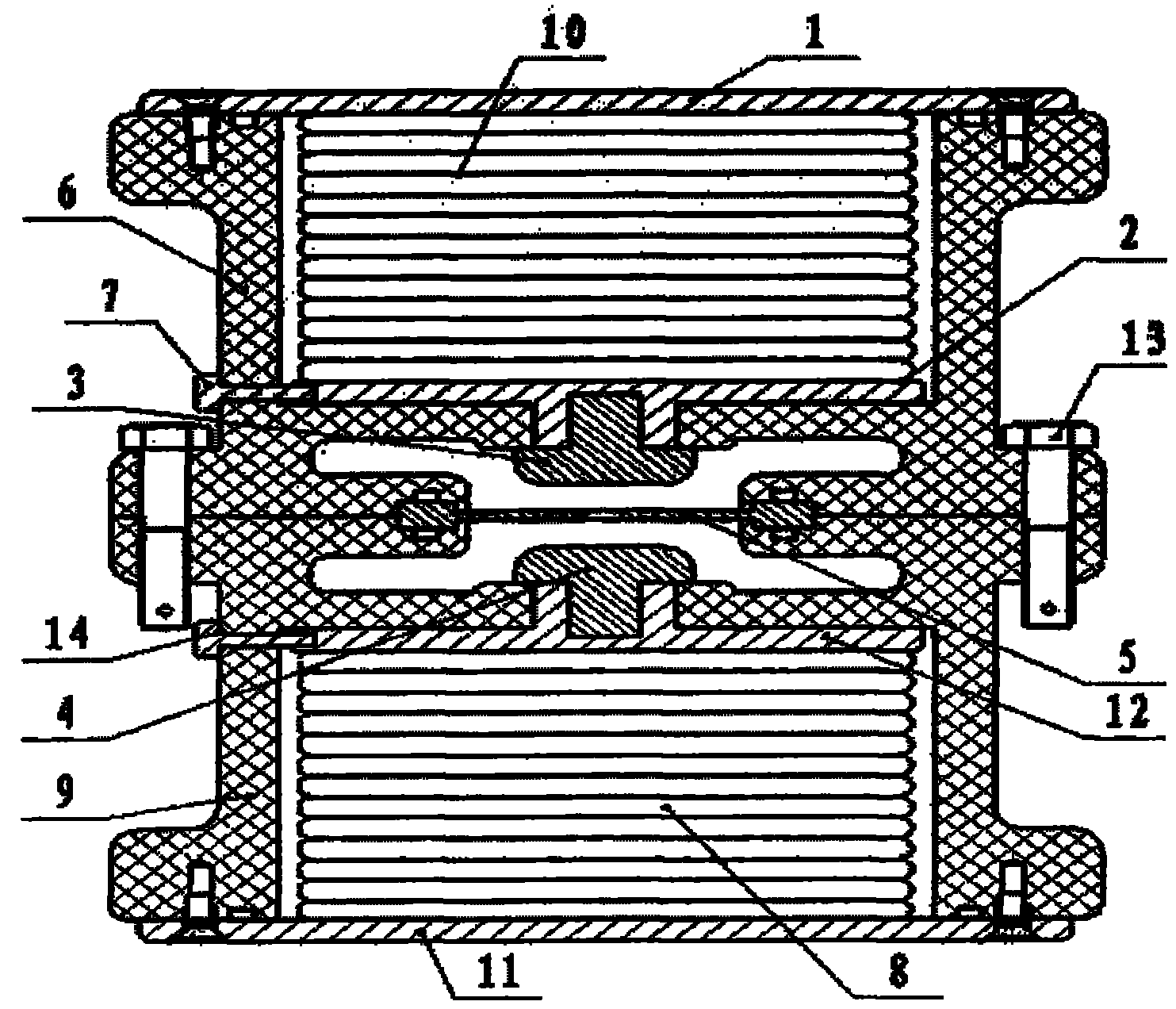

Switch and capacitor integrated quick discharge unit

The invention discloses a switch and capacitor integrated quick discharge unit. Two capacitors and a switch arranged between the two capacitors form a coaxial structure; a high-voltage electrode (2; 12) is led from a capacitor and is simultaneously used as the high-voltage electrode of a gas switch; and the capacitors and the switch commonly share one insulating shell. By adopting the discharge unit, under the same energy storage condition, the module dimension and the branch inductance can be reduced obviously; the output current can be improved; the boosting time can be reduced; the discharge current peak can be improved, the pulse current front can be shortened, and the switch and capacitor integrated quick discharge unit has wide application in pulse power primary energy storage Marx generators and linear pulse transformer driving sources.

Owner:NORTHWEST INST OF NUCLEAR TECH

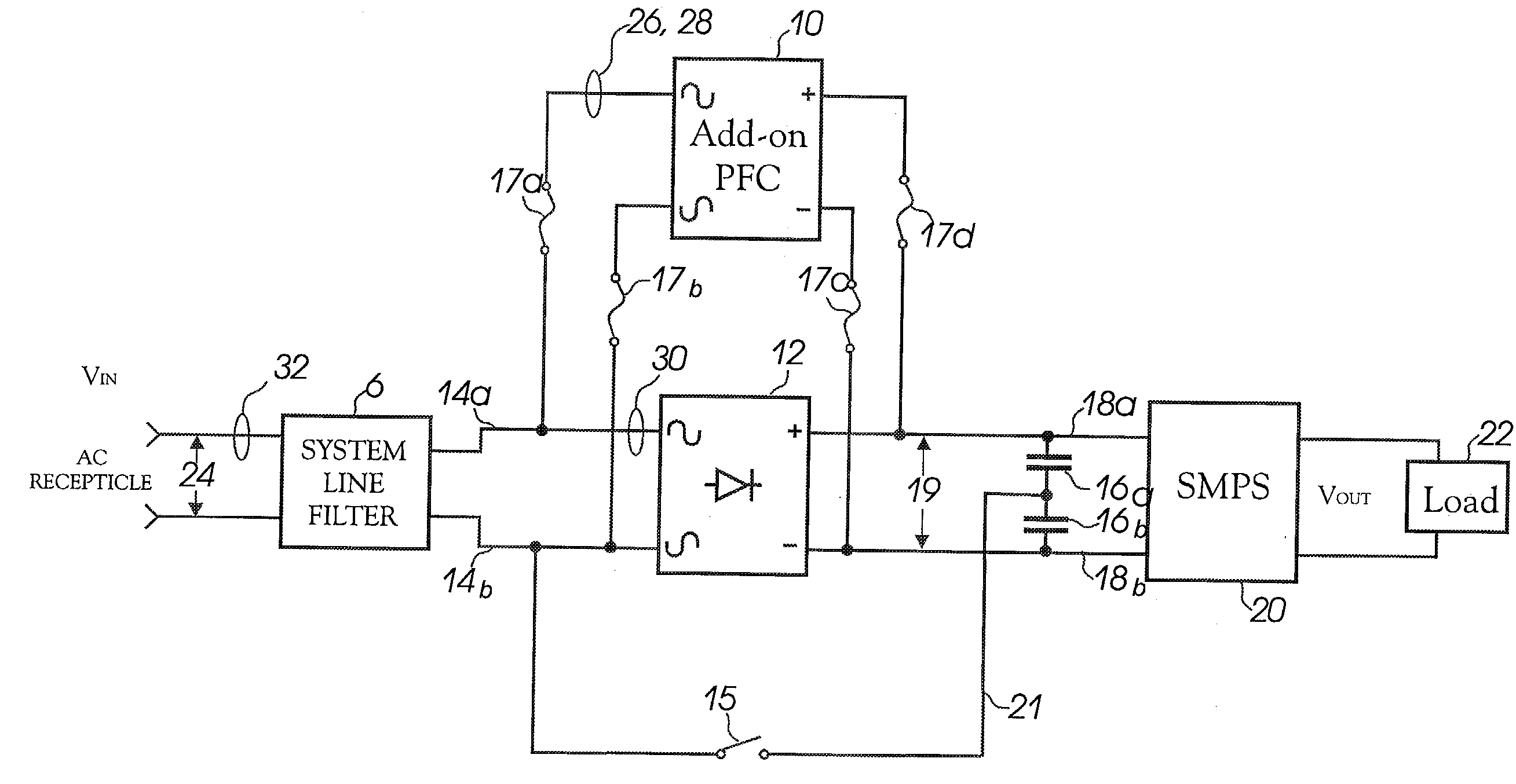

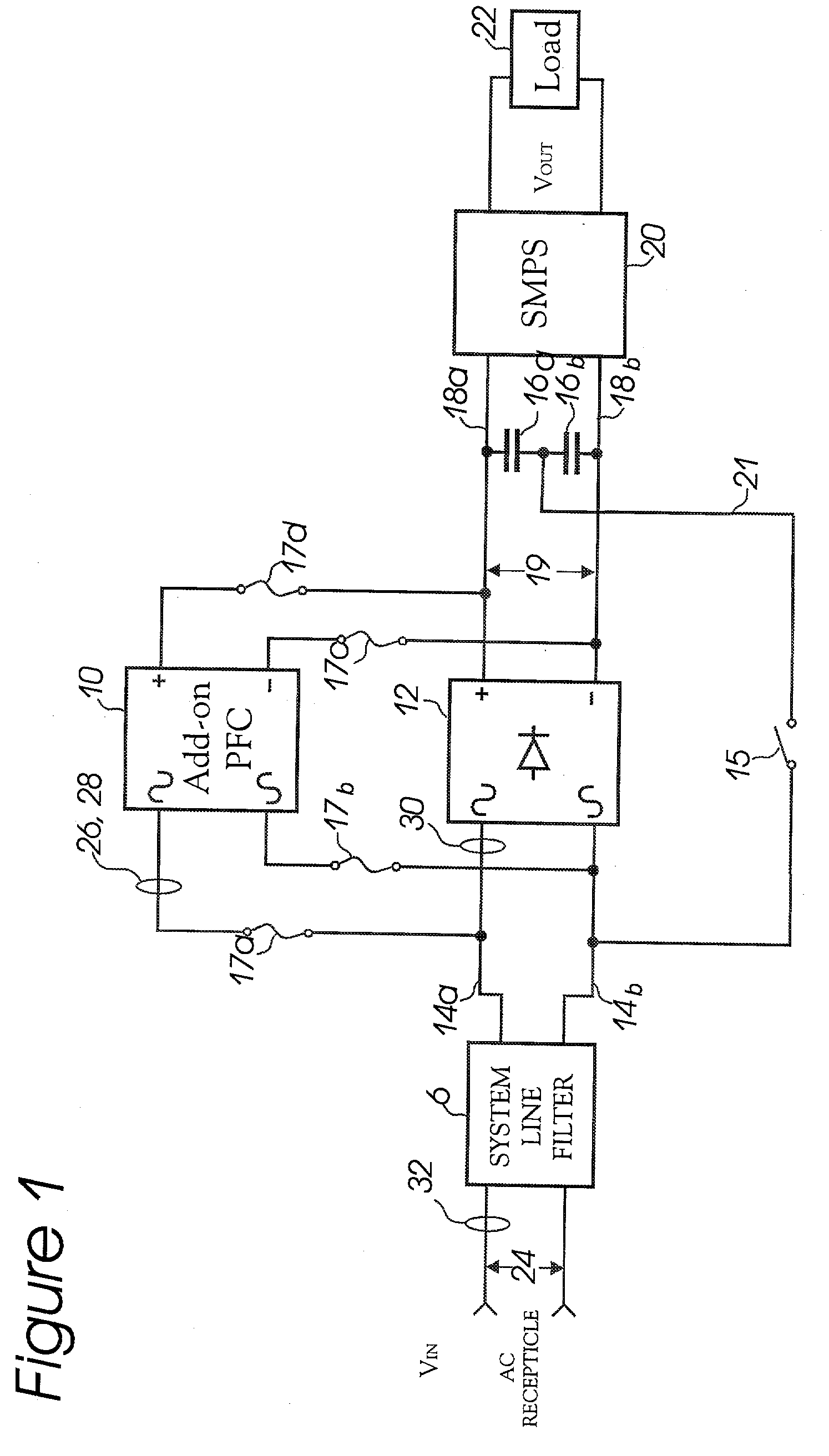

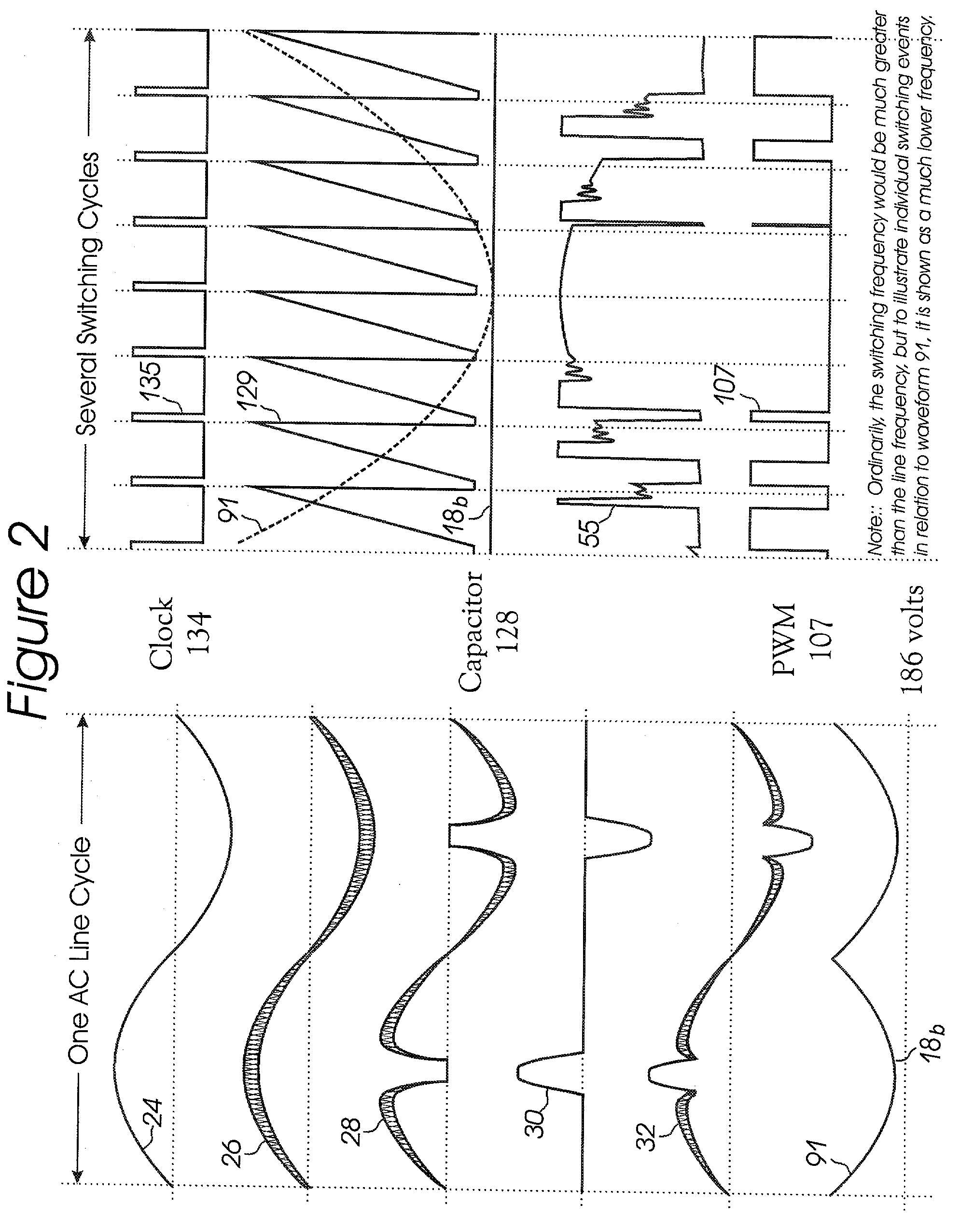

System and method for providing power factor correction

InactiveUS20030202368A1Less expensiveLower capability requirementsEfficient power electronics conversionAc-dc conversionControl systemEngineering

In one embodiment, a power factor correction ("PFC") circuit is adapted to readily being retrofitted to existing power supplies, provided with new power supplies and / or integrated into new power supplies. The PFC circuit, unlike prior circuits, is connected in parallel with a power supply rectifier such as an AC-DC rectifier. In one embodiment the rectifier is a bridge rectifier with a rectifier-fed capacitive primary energy reservoir being used as an electrical power source. In one embodiment of the invention, the PFC circuit uses a boost converter governed by a control system to provide a cycle-completion, current-filling PFC mode above a prescribed average power threshold, and a continuous cycle PFC mode below the prescribed average power threshold.

Owner:QSC AUDIO PRODUCTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com