Turbine DEH system high-pressure regulating valve flow characteristic testing and setting method

A technology for regulating valves and flow characteristics, which is applied in the field of testing and setting the flow characteristics of high-pressure regulating valves in steam turbine DEH systems. The overall performance index, the improvement of automation control level, and the effect of stable load regulation characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In the following, the present invention will be further described in conjunction with the embodiments:

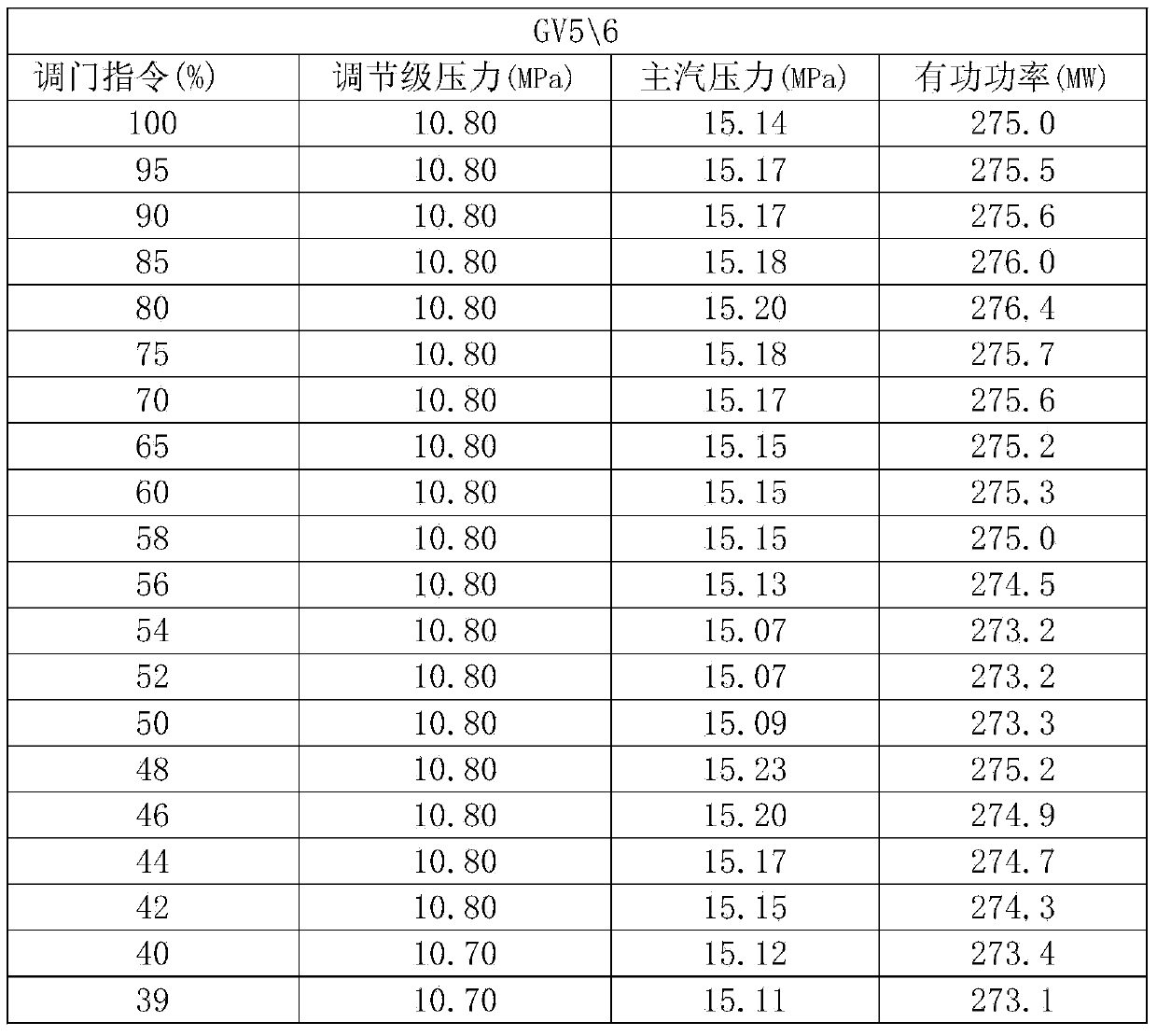

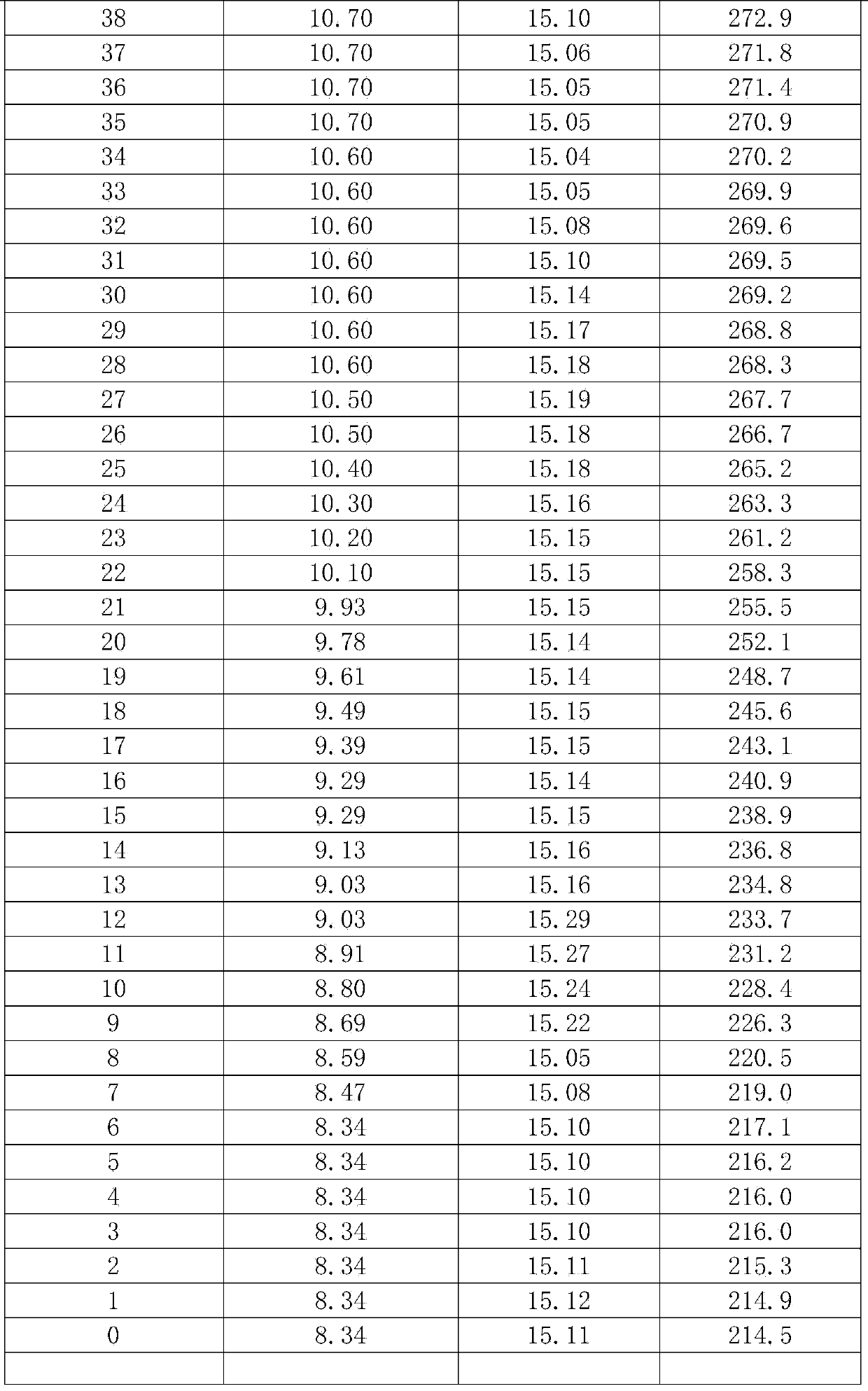

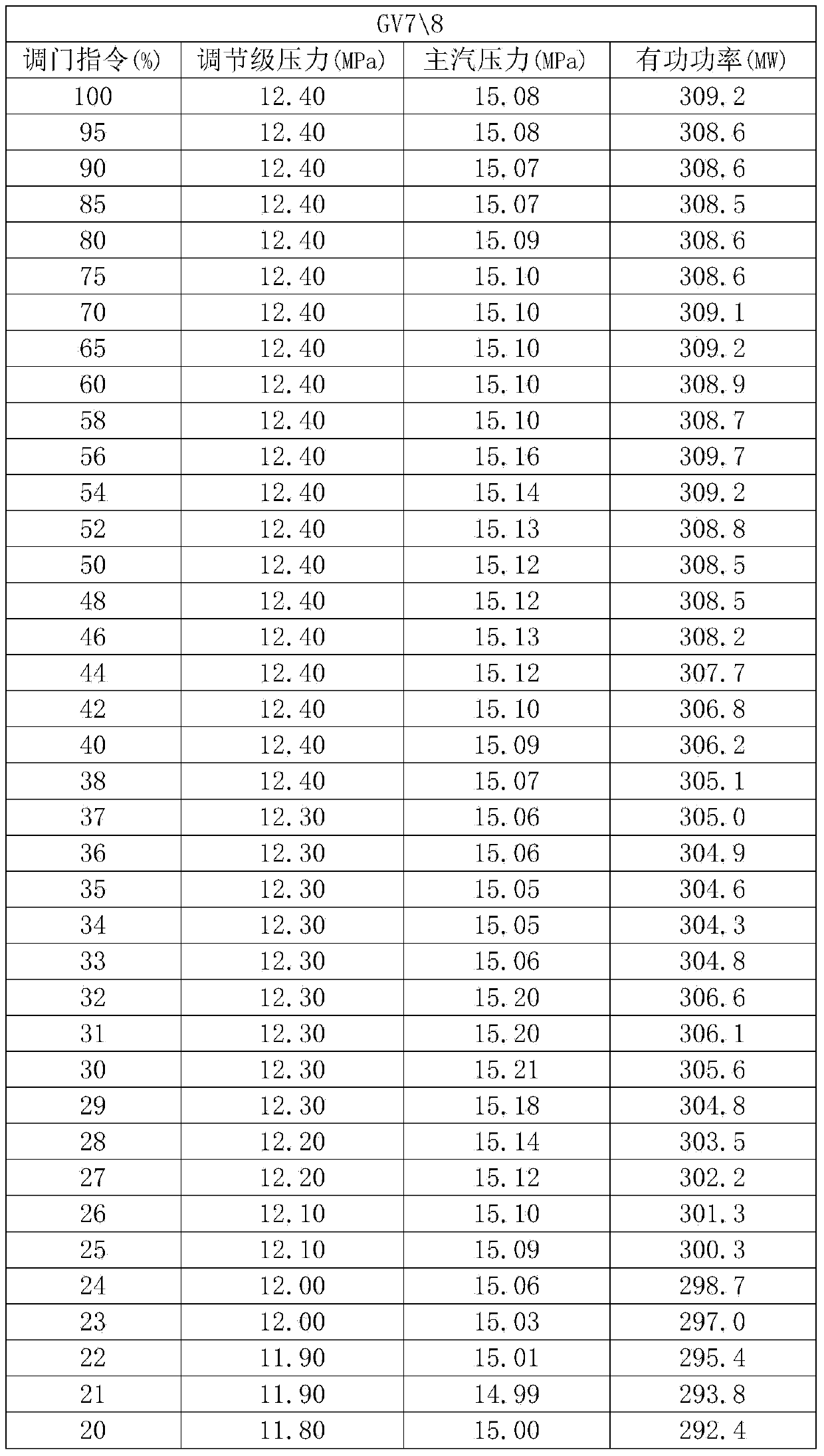

[0029] 1. Phenomena and analysis of valve flow characteristics before test

[0030] The opening sequence of the sequence valve of the steam turbine of this unit is as follows: first, the #1, #2, #3, #4 high pressure regulating valves are opened at the same time to nearly fully open, then #5, #6 high pressure regulating valves are opened to nearly fully open, and finally #7, #8 High-pressure regulating door. The problem lies in the fact that the valve is operating under multi-valve control. When the #5 and #6 valves are opened at about 24% and 31%, the load fluctuates above 9MW, causing severe fluctuations in main steam pressure and boiler combustion, causing unit load The control deviation is large, which cuts off the coordinated control and AGC operation mode, which has a greater impact on the stable operation of the unit. After analysis, the factors of automatically c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com