Method for detecting hearth radiation energy signal and method for controlling boiler combustion by using same

A detection method and radiant energy technology, applied in the control of combustion, radiation pyrometry, optical radiation measurement, etc., can solve the problems of large radiant energy signal pulsation, frequent action of the mechanism, affecting the operation of the unit, etc., to achieve stable radiant energy signal, Improve control quality and more realistic effect of combustion conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

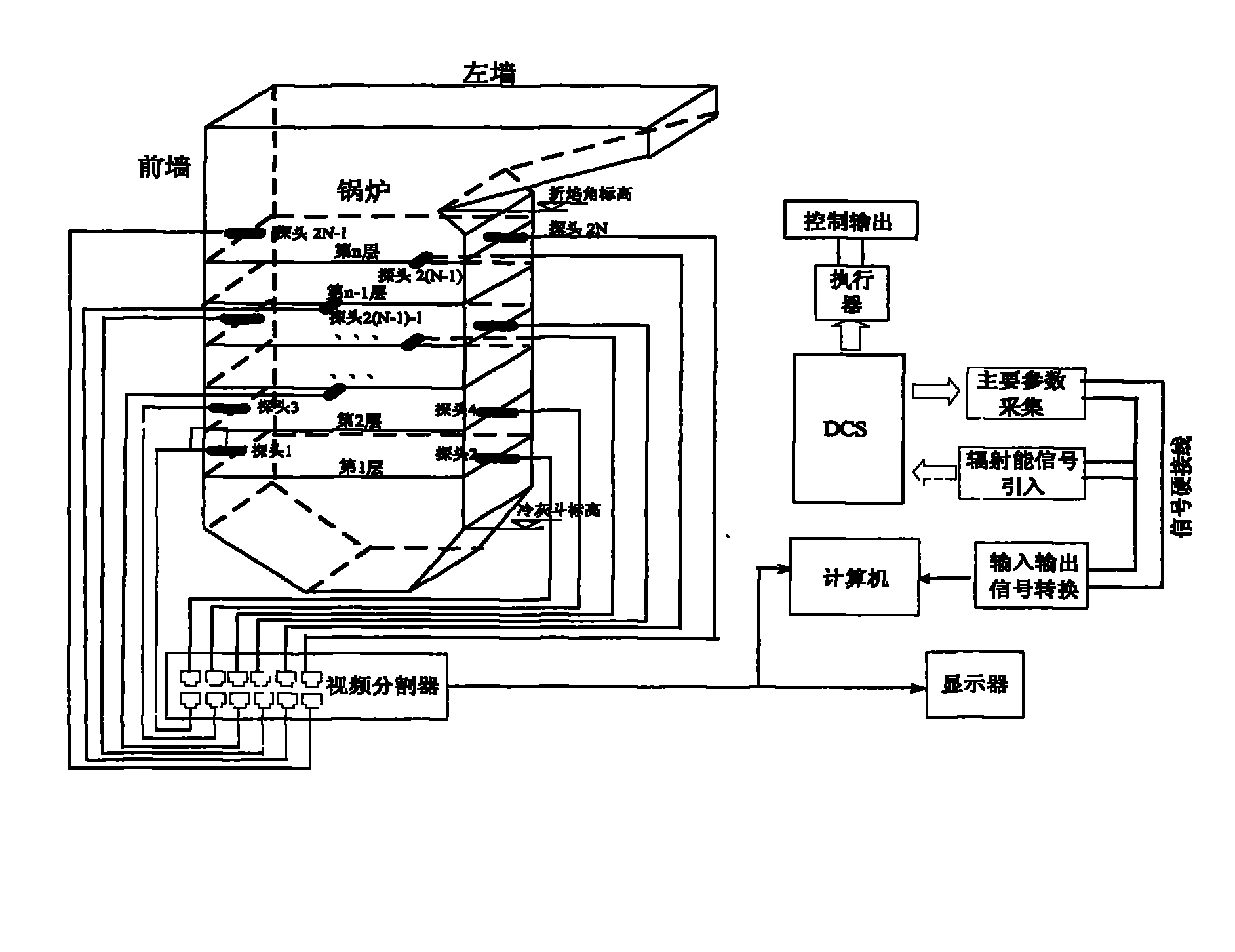

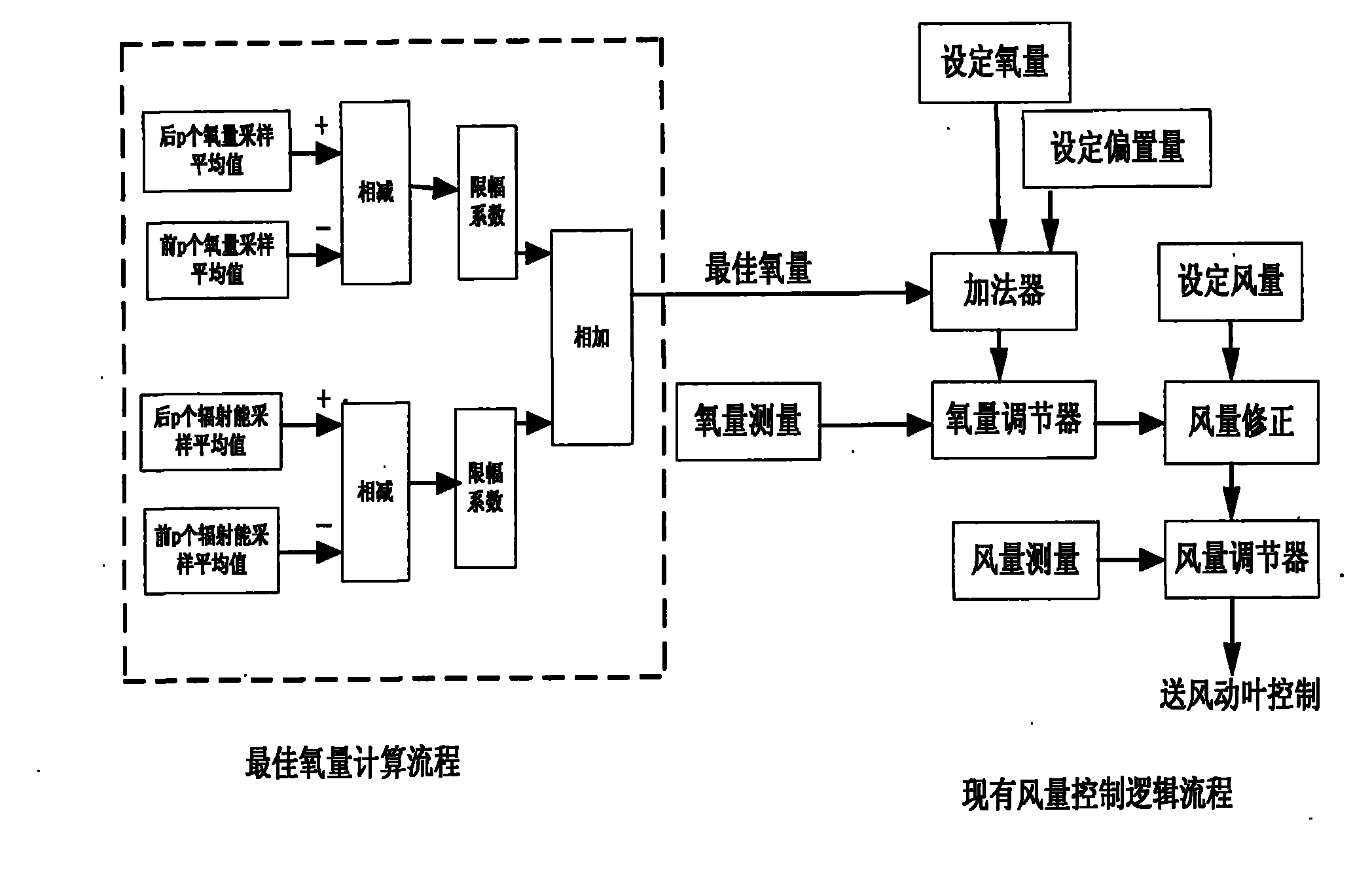

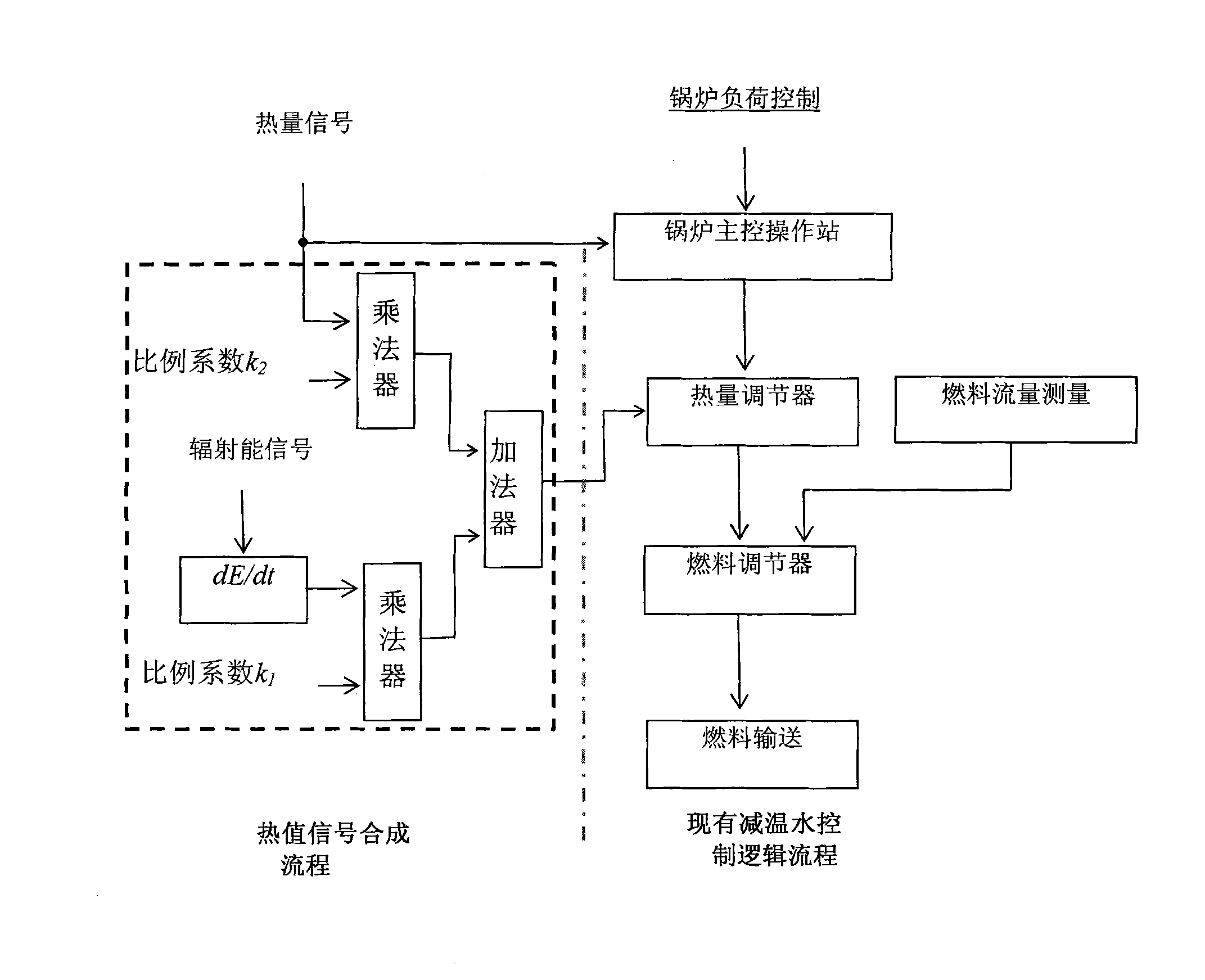

[0040] The detection and control system of the present invention has a structure such as figure 1 As shown, in the boiler furnace space, above the cold ash hopper and below the refraction angle, multiple flame probes are installed along the height, and the flame image is transmitted to the video splitter through the coaxial cable, and then synthesized into one image. Considering the real-time nature of image data processing, the image pixels of each flame probe are set to 30×30, and the synthesized video signal is led to the monitor one way for real-time flame monitoring of the entire furnace, and the other way is led to the computer to extract the furnace radiation can signal. The equipment for optimal control using radiant energy signals includes DCS system, on-site actuators, configuration software, communication lines, air volume and oxygen volume control loops, and desuperheating water control loops, all of which are existing equipment on site.

[0041] For a 300MW quadr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com