A control method for coal-fired units considering the time-space distribution of heat storage

A technology for coal-fired units and space-time distribution, applied in control systems, solid fuel combustion, and combustion equipment, etc., can solve problems such as uneven distribution of boiler heat storage, and achieve the effects of short recovery period, simple implementation method, and improved flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples.

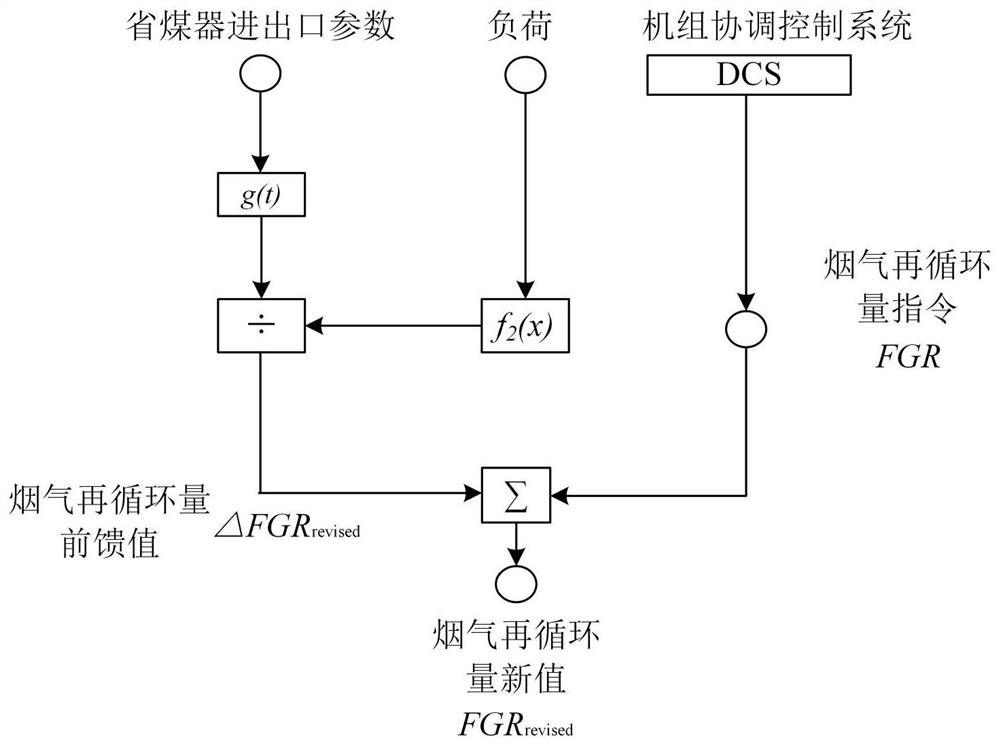

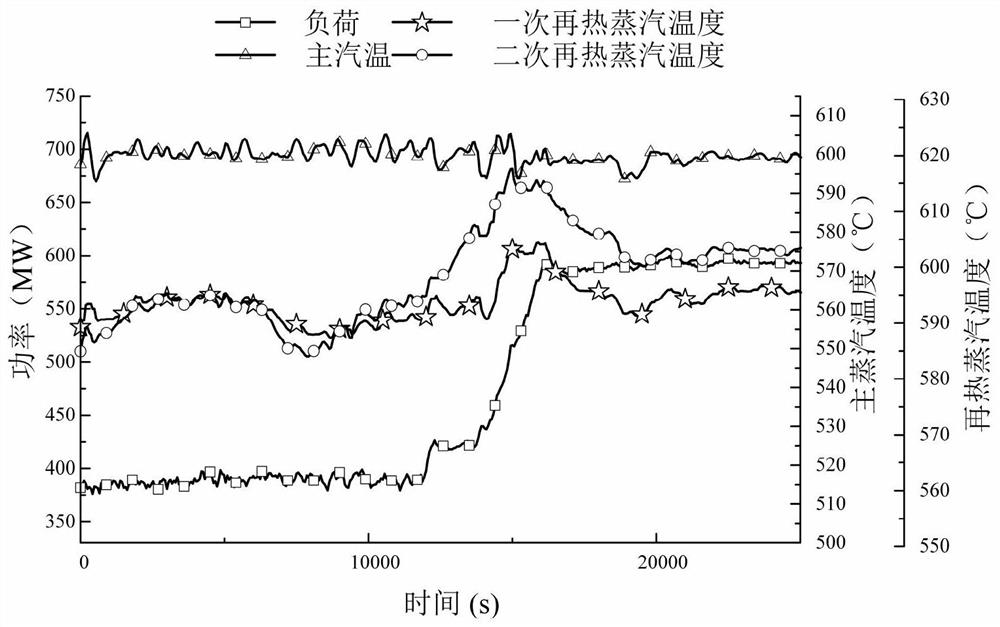

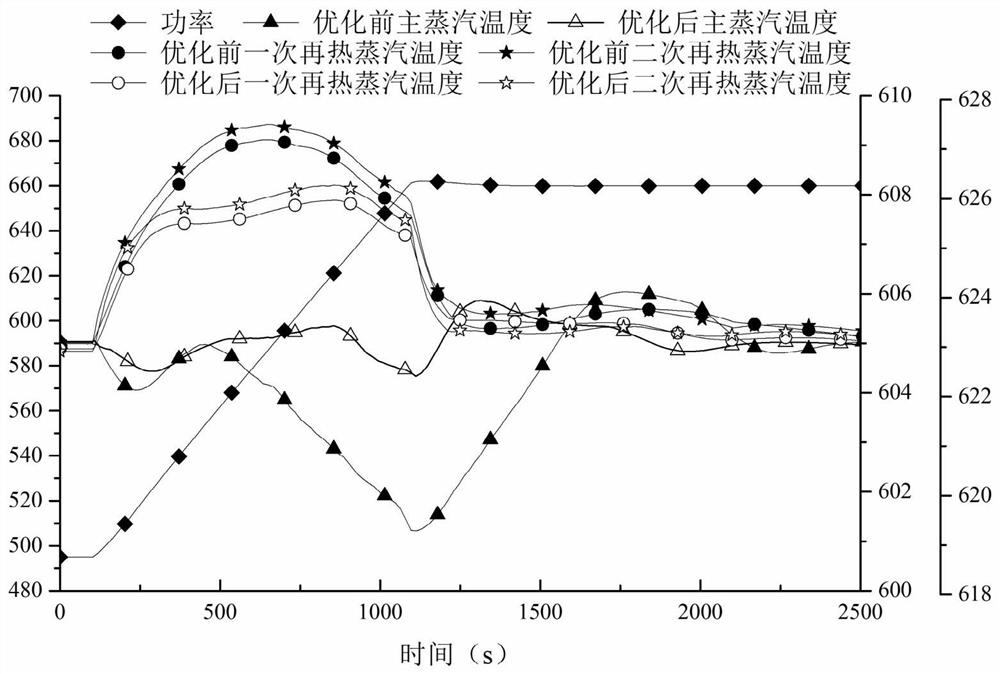

[0055] The invention relates to a control method of a coal-fired unit considering the time-space distribution of heat storage. The double reheat unit is selected as the research object, figure 2 It shows the characteristics of the steam temperature change during the process of increasing the load in the actual power plant. It can be seen that the temperature of the reheat steam is relatively high and the temperature of the main steam is relatively low during the process of increasing the load. The secondary reheating unit adopts flue gas recirculation to adjust the reheating steam temperature. figure 1 The control method shown optimizes the logic. The specific implementation method is as follows:

[0056] 1. Calculation of heat storage variation of economizer

[0057] Temperature measuring points are installed on the metal surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com