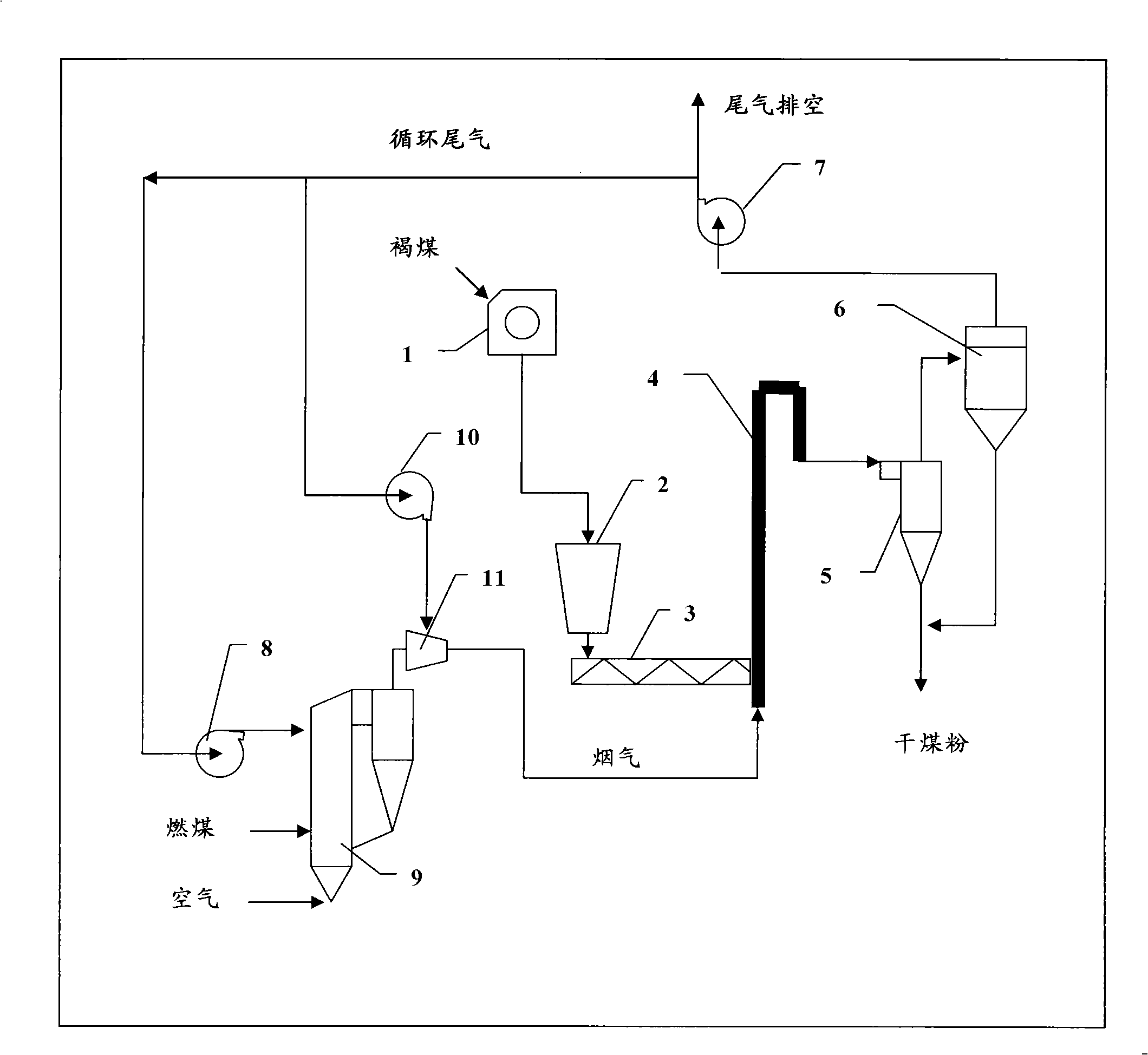

Patents

Literature

7600 results about "Coal fired" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

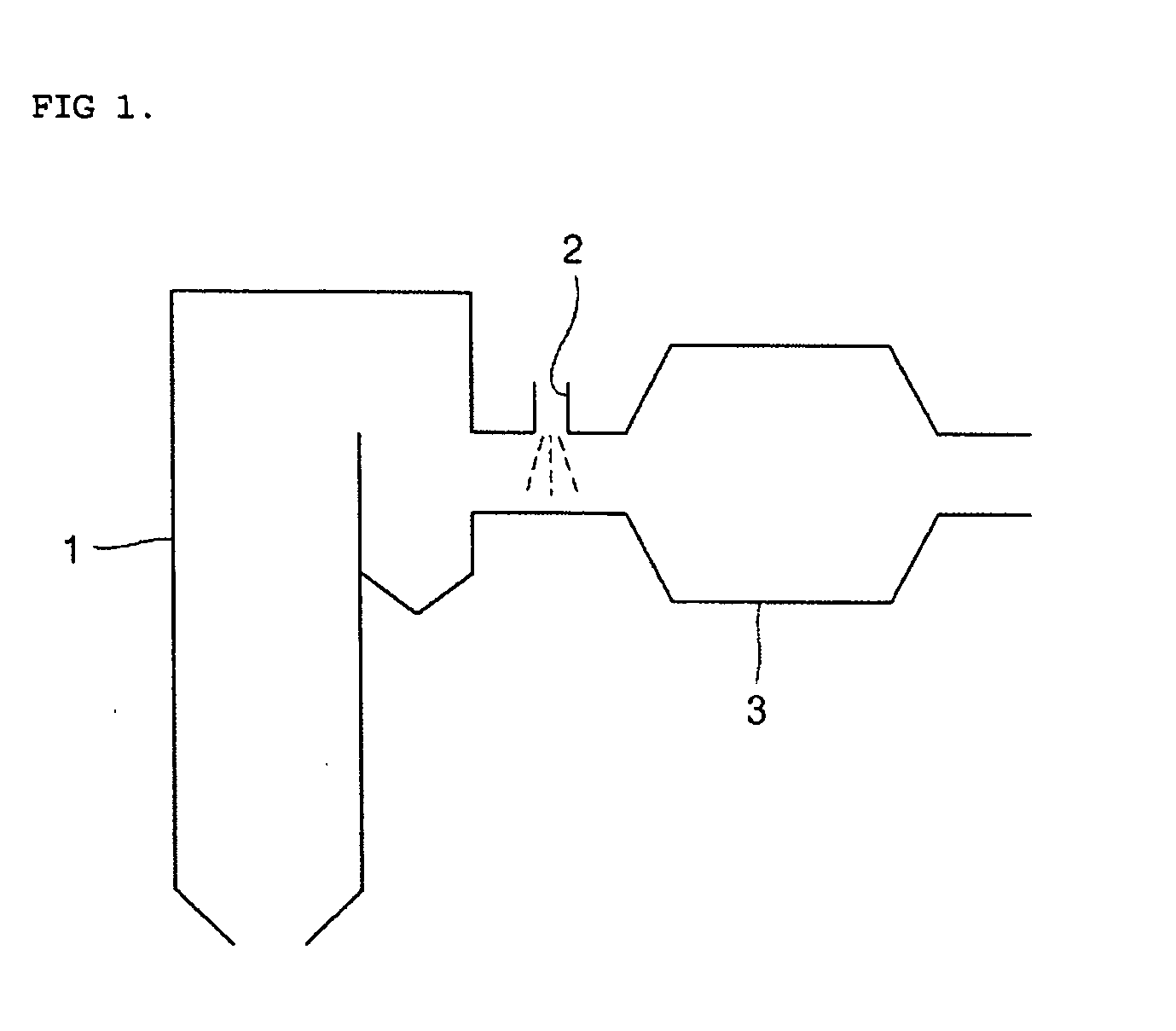

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

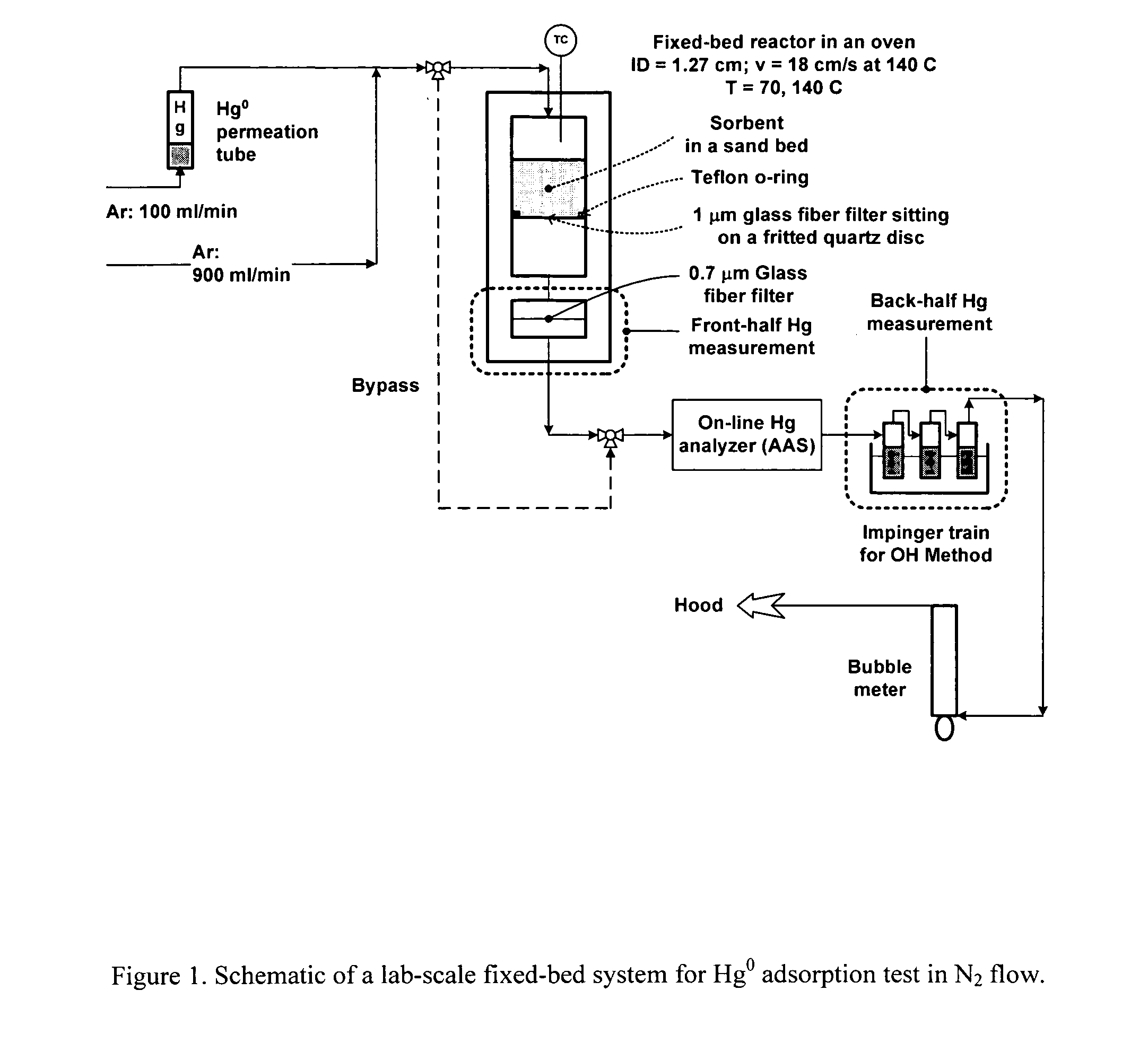

Pollutant emission control sorbents and methods of manufacture

InactiveUS20070122327A1Small particle sizePromotes Hg-captureGas treatmentOther chemical processesSorbentFlue gas

Sorbents for removal of mercury and other pollutants from gas streams, such as a flue gas stream from coal-fired utility plants, and methods for their manufacture and use are disclosed. The methods include mixing sorbent substrate particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the sorbent particles.

Owner:BASF CATALYSTS LLC

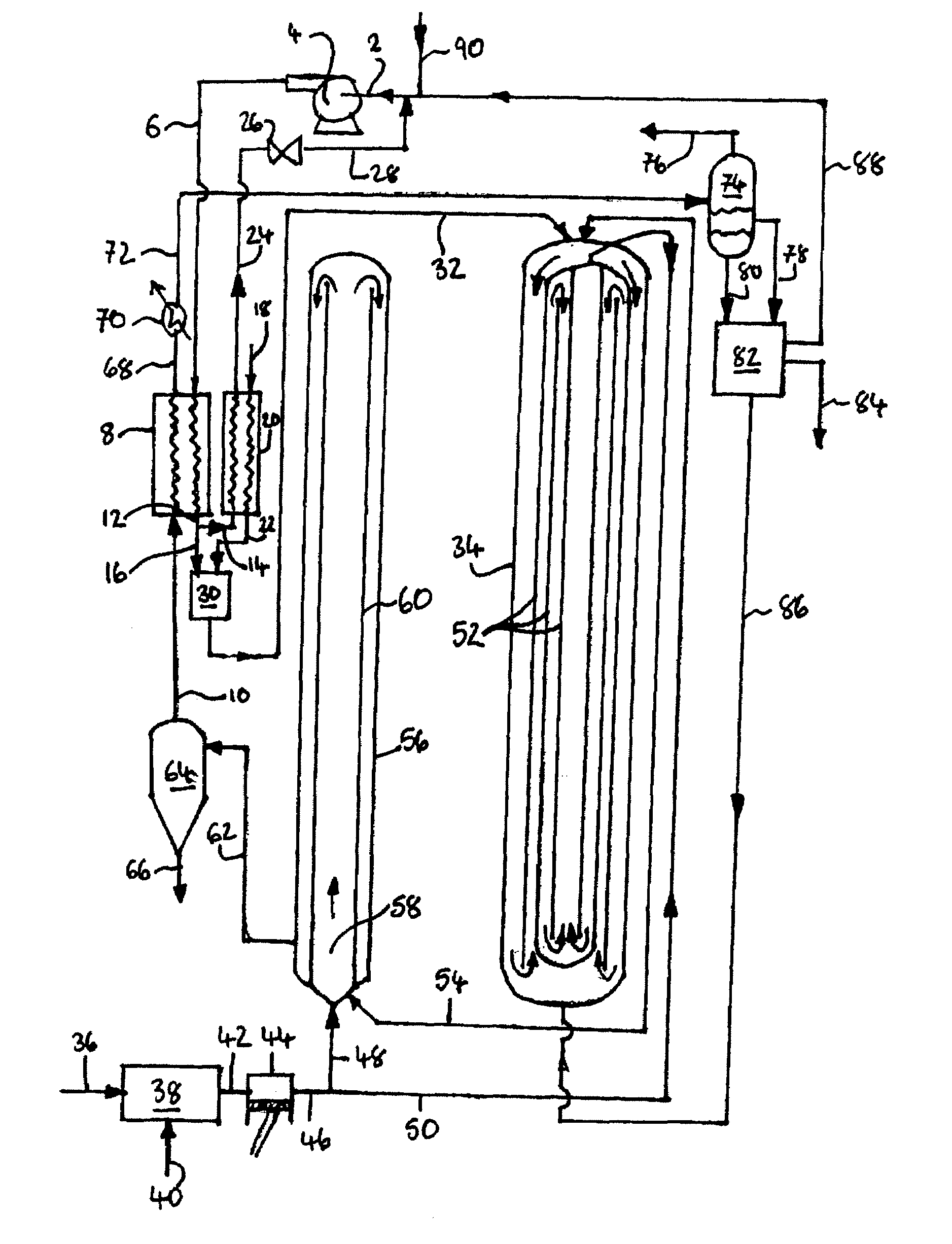

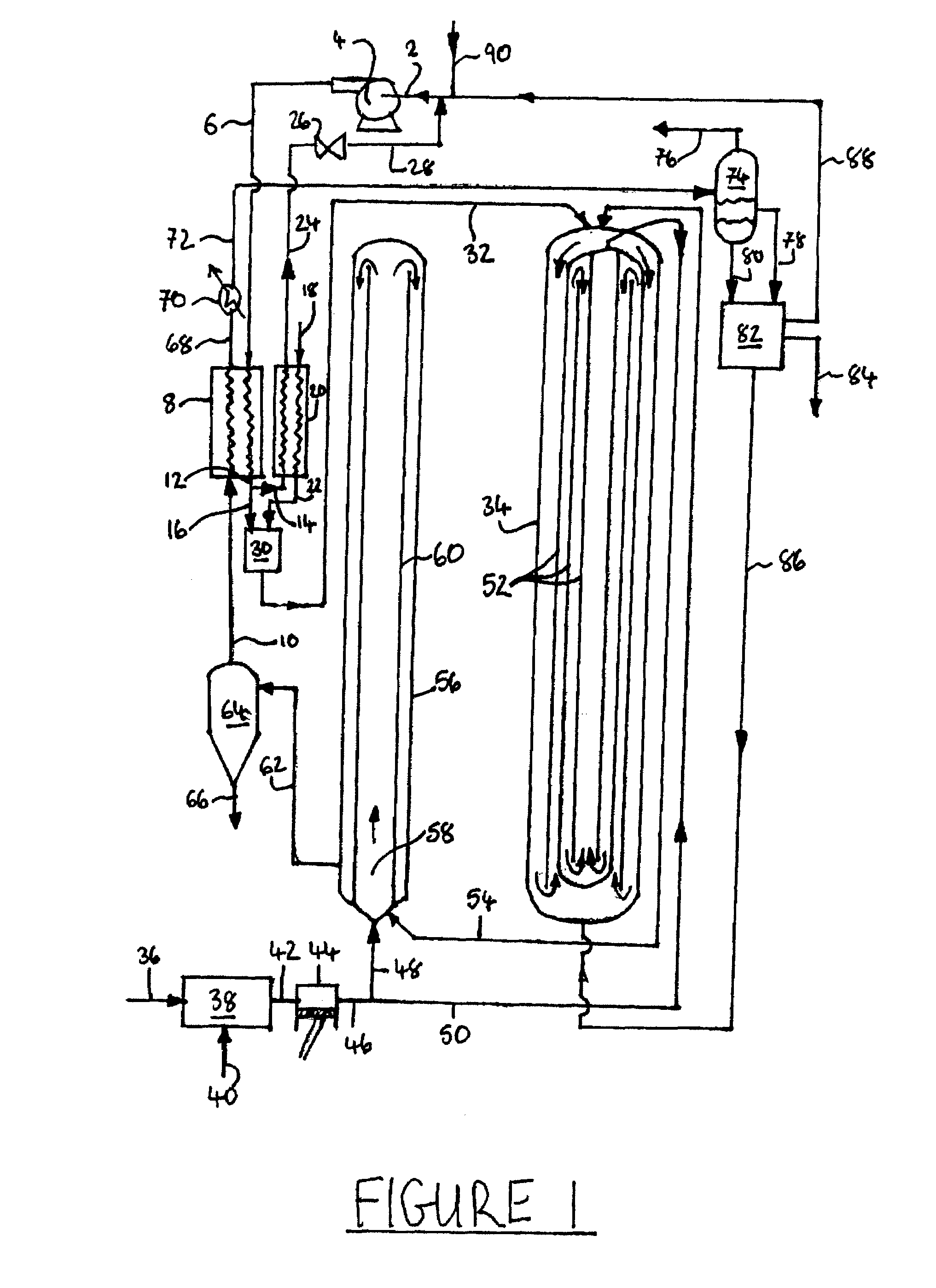

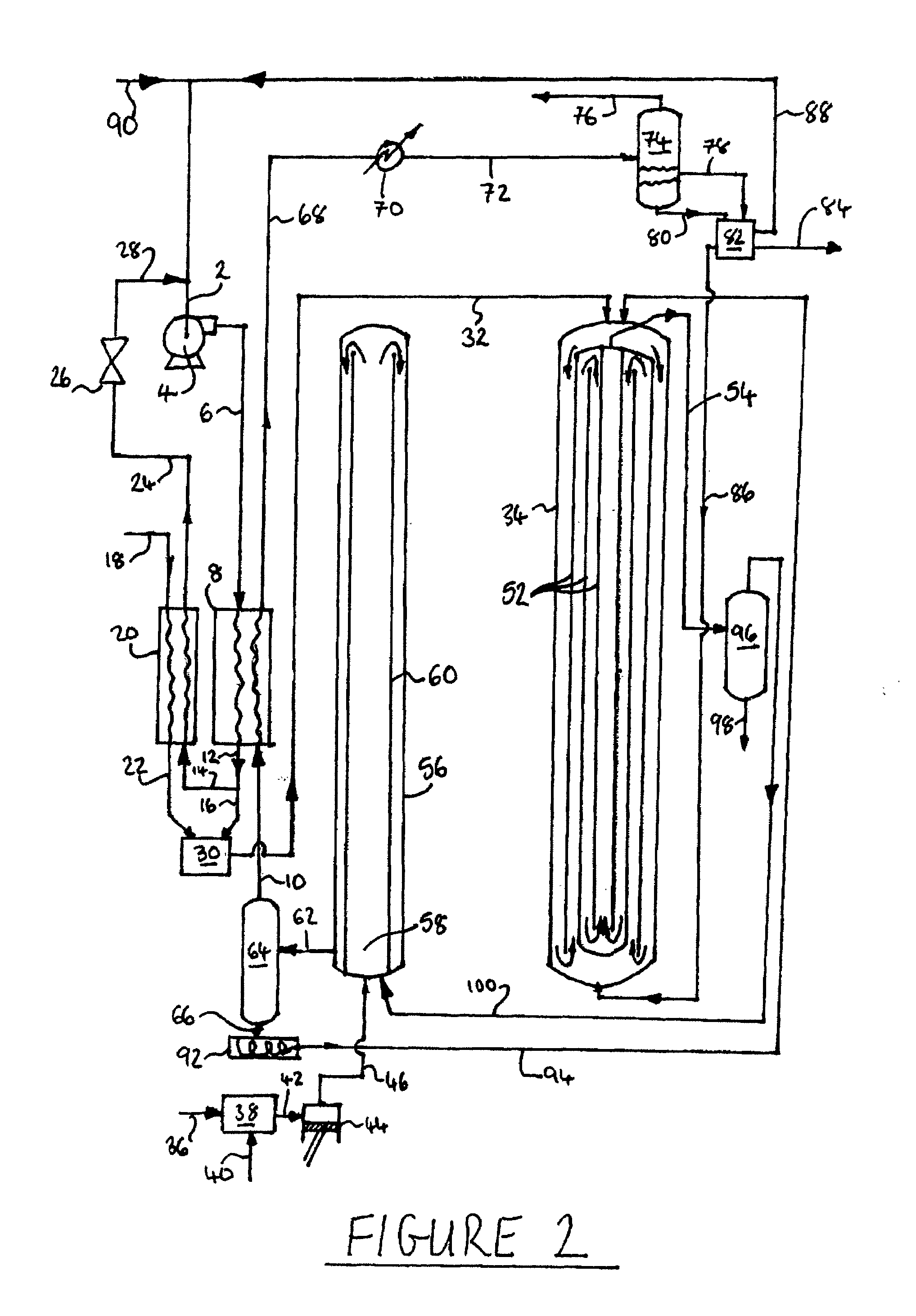

Production of hydrogen and removal and sequestration of carbon dioxide from coal-fired furnaces and boilers

InactiveUS7282189B2Increase ratingsValue maximizationOrganic chemistryNitrogen compoundsHydrogenProcess engineering

Methods for reducing and eliminating carbon dioxide from the emissions of solid fuel fired power plants, particularly coal fired power plants, and to sequester the carbon dioxide, typically by using existing equipment. In some embodiments, the methods involve pyrolyzing the solid fuel to remove volatile matter and using the volatile matter to produce hydrogen. Additionally, the methods may involve burning the solid fuel or pyrolized solid fuel at very fuel rich stoichiometric conditions. Sequestration may include the production of a carbon dioxide-containing solution and the pumping of the solution into the ground, particularly in areas high in limestone.

Owner:ZAUDERER BERT

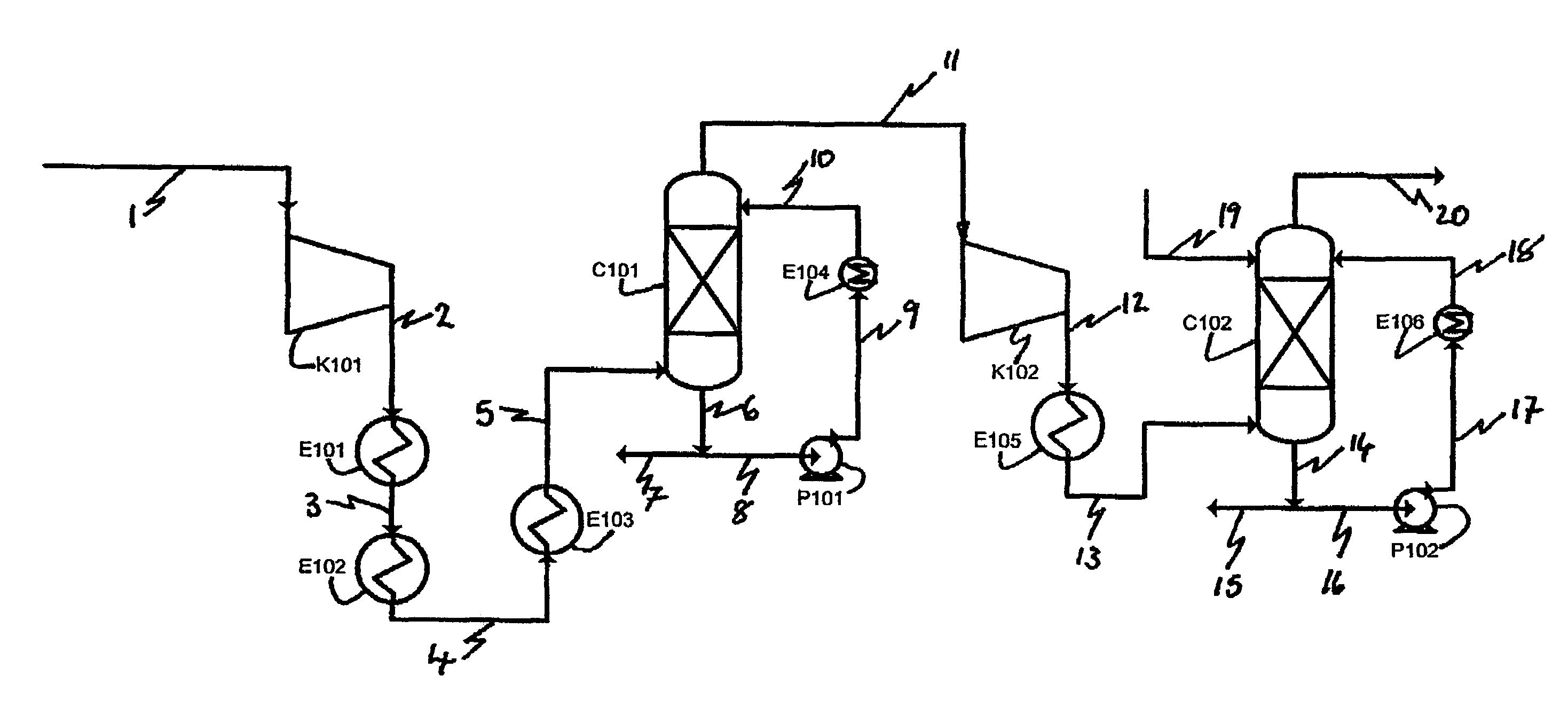

Process and apparatus for upgrading coal using supercritical water

Coal is converted into hydrocarbon compounds using supercritical water. The process involves two stages; a first stage in which carbonaceous material is reacted with supercritical water at above 850K to produce a first supercritical fluid reaction mixture comprising hydrocarbon compounds; and a second stage in which hydrocarbon compounds are extracted from coal mixed with at least a portion of the first supercritical fluid at a temperature within a range of from the supercritical temperature of water to about 695K. Char from the second stage is finely divided and may be either be used outside the process, e.g. in a coal fired power station or a gasifier, or used as at least a portion of the carbonaceous material used in the first stage.

Owner:AIR PROD & CHEM INC

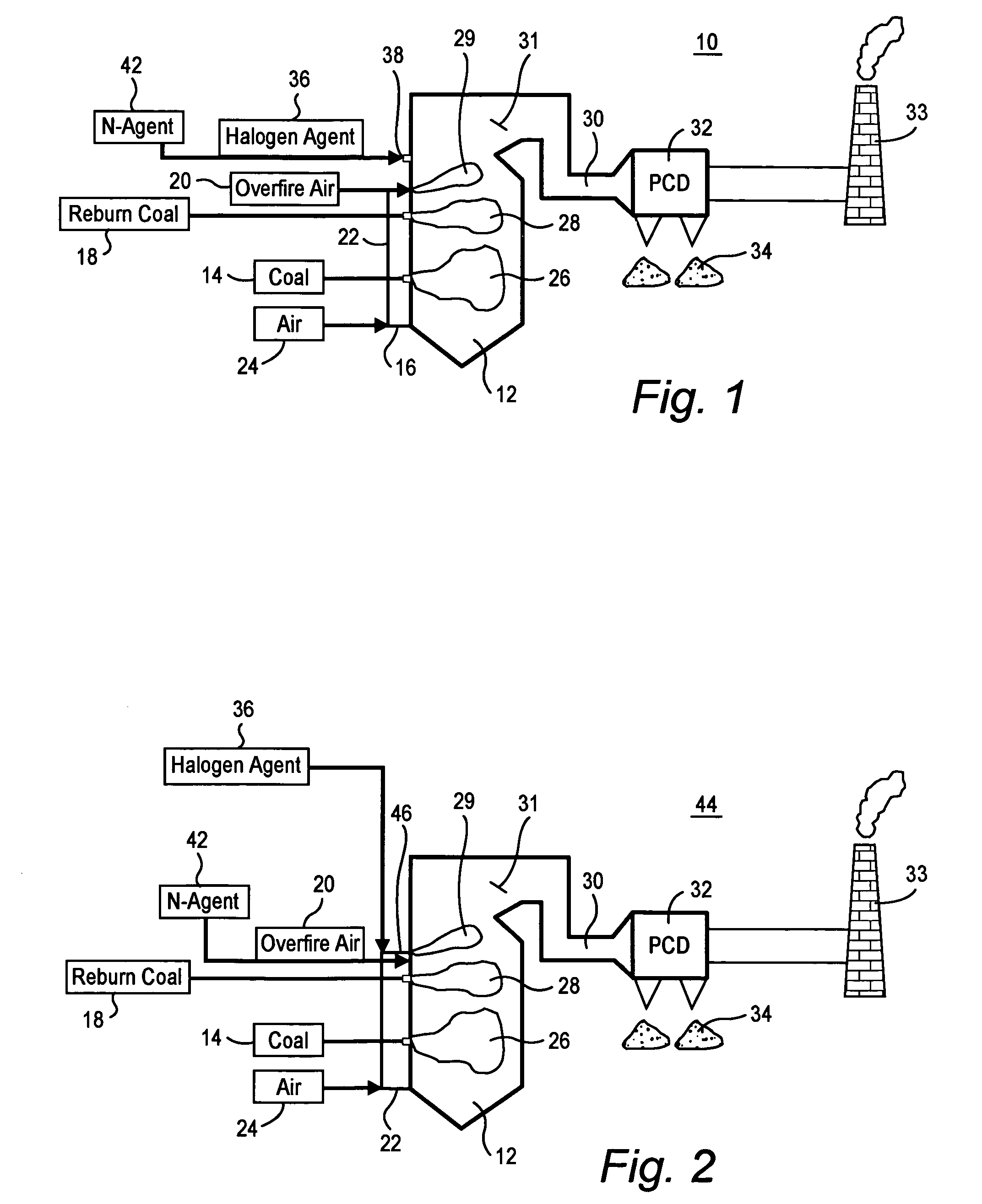

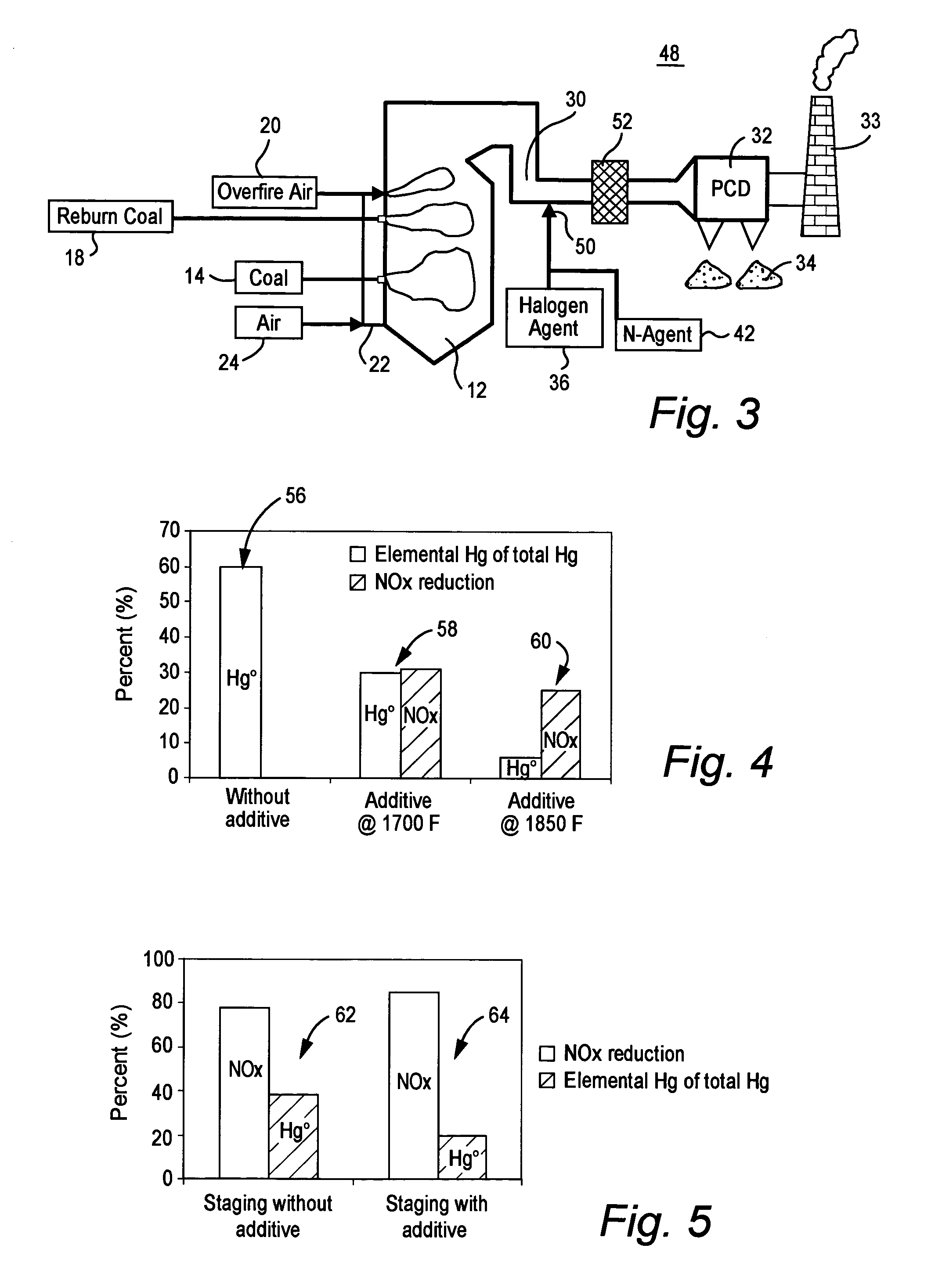

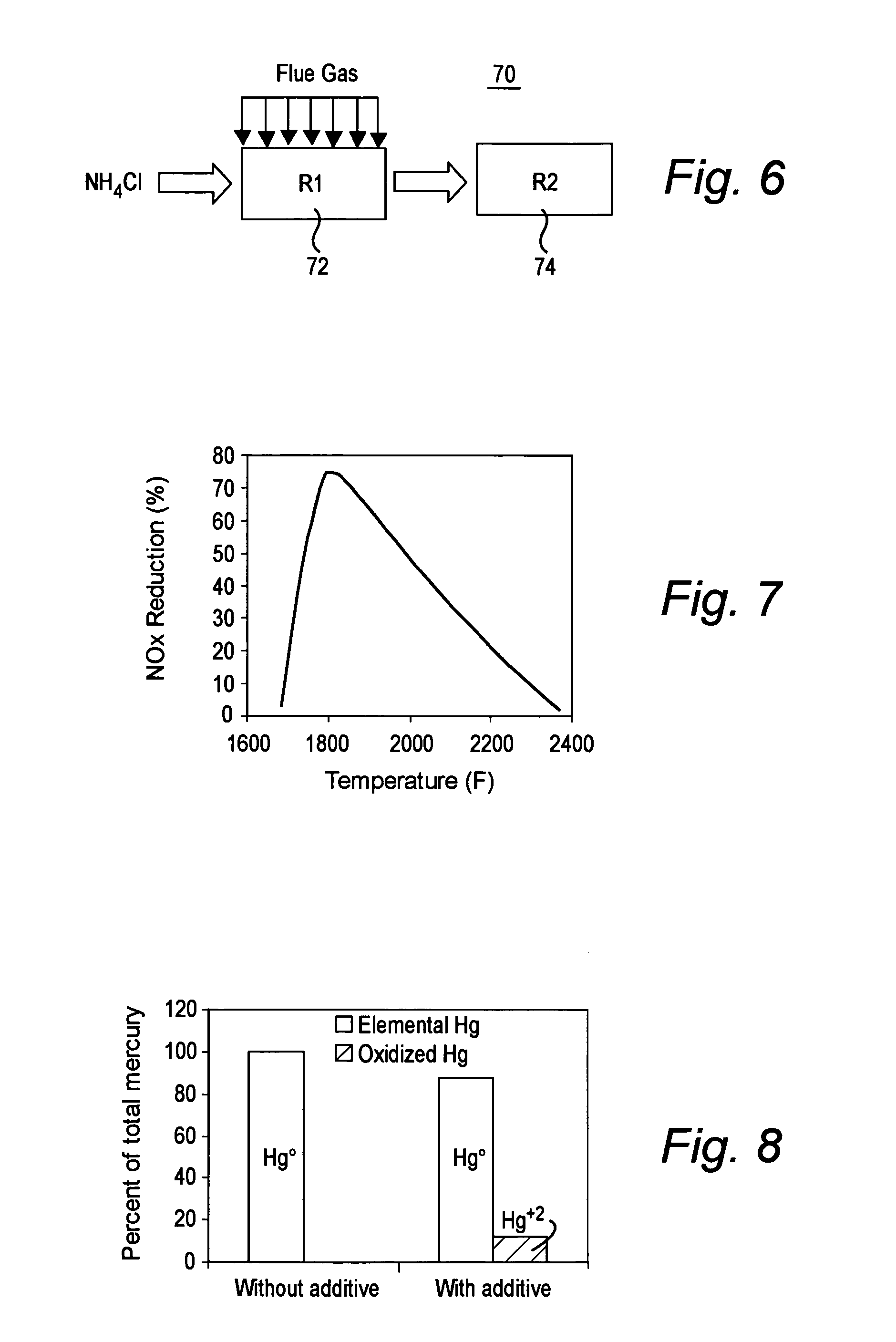

Method for removal of mercury emissions from coal combustion

A method to reduce emissions in flue gas due to combustion of coal in a combustion unit including the steps of: combusting coal in a primary combustion zone of the combustion unit; releasing elemental mercury from the combustion into the flue gas; injecting NH4Cl, NH4Br, or NH4I into the flue gas; oxidizing the elemental mercury with halogen from the additive; adsorbing the oxidized mercury generated by the combustion of the coal with an adsorbent in the flue gas, and collecting the adsorbent with the oxidized mercury in a combustion waste treatment system.

Owner:GENERAL ELECTRIC CO

Methods of operating a coal burning facility

ActiveUS20070168213A1Improve balanceIncrease valueSustainable waste treatmentSolid fuel pretreatmentHalogenSorbent

Methods involve adding sorbent components, such as calcium oxide, alumina, and silica, as well as optional halogens as part of environmental control. Use of the sorbents leads to significant reductions in sulfur and mercury emissions that otherwise would result from burning coal. Use of the sorbents leads to production of waste coal ash that, while higher in mercury, is nevertheless usable as a commercial product because the mercury in the ash is non-leaching and because the coal ash has a higher cementitious nature by virtue of the increased content of the sorbent components in the ash. Thus, the methods involve adding powders having qualities that lead to the production of a cementitious coal ash while at the same time reducing emissions from a coal burning facility.

Owner:NOX II LTD

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

Sorbent for removal of trace hazardous air pollutants from combustion flue gas and preparation method thereof

InactiveUS20070179056A1Low costLow raw material costGas treatmentOther chemical processesSorbentToxic industrial waste

Disclosed is a sorbent for the removal of mercury from combustion flue gas and a preparation method thereof. The sorbent includes an activated heavy oil heavy ash impregnated with 0.1-30% by weight of any chemical substance selected from sulfur, iodine, bromine and chlorine. The sorbent is prepared in an economical manner using heavy oil fly ash, industrial waste generated from heavy oil-fired boilers, and has excellent sorption performance for mercury, so that a low concentration of mercury contained in combustion flue gas discharged from large-scale boilers can be removed by injection of a small amount of the sorbent. Thus, the invention can prevent a reduction in the recycling rate of coal fly ash in coal-fired power plants and minimize operation cost.

Owner:KOREA ELECTRIC POWER CORP

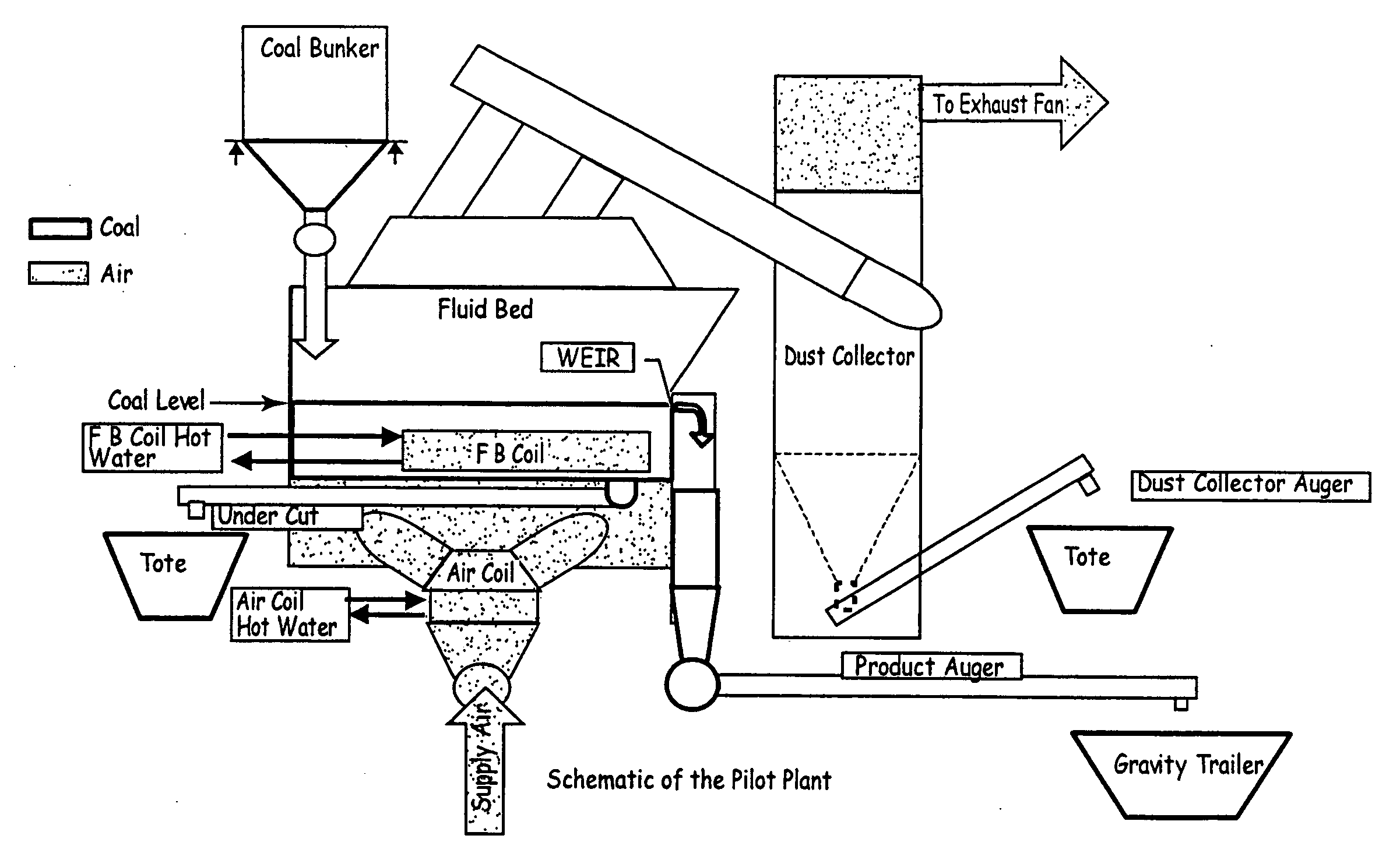

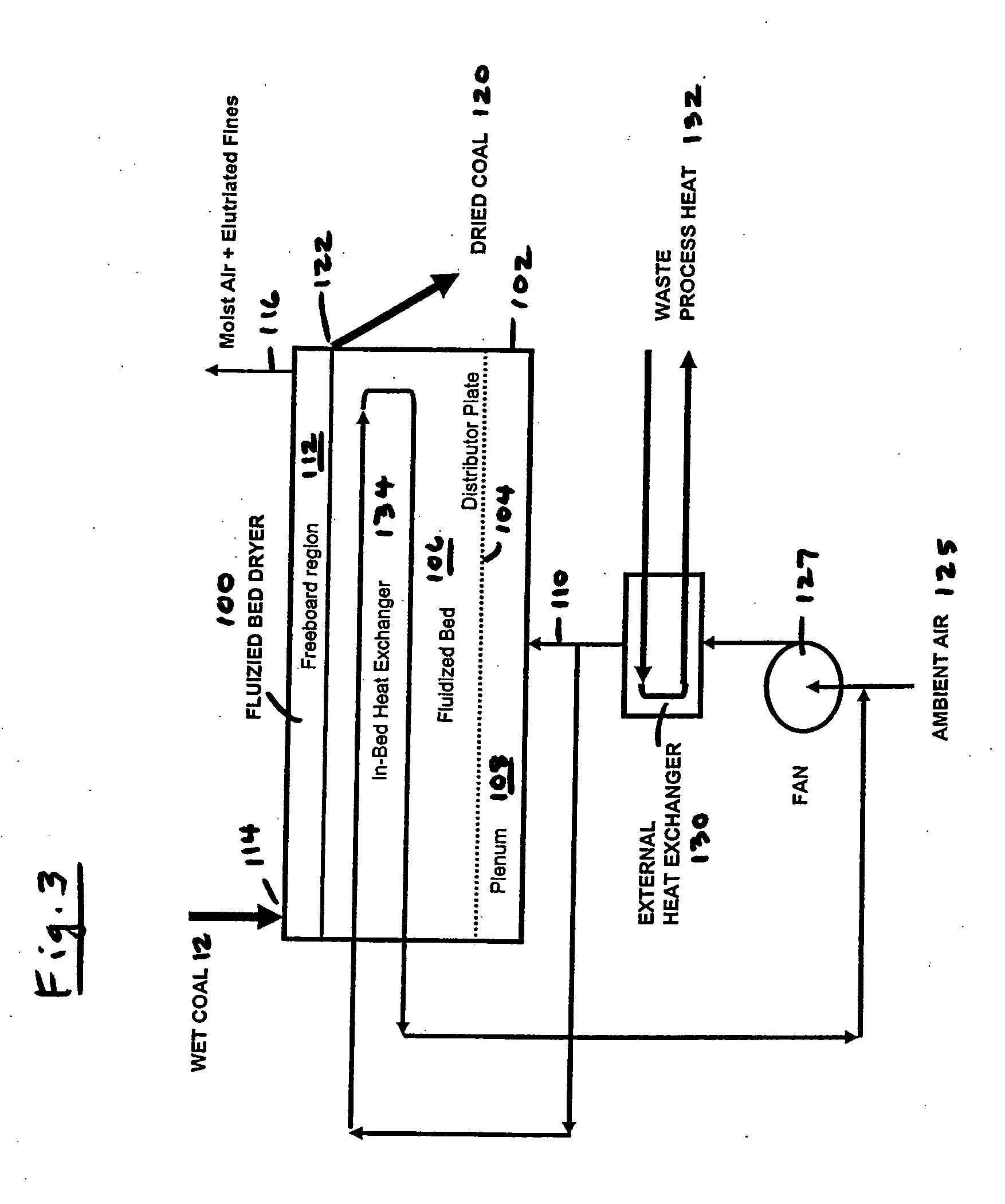

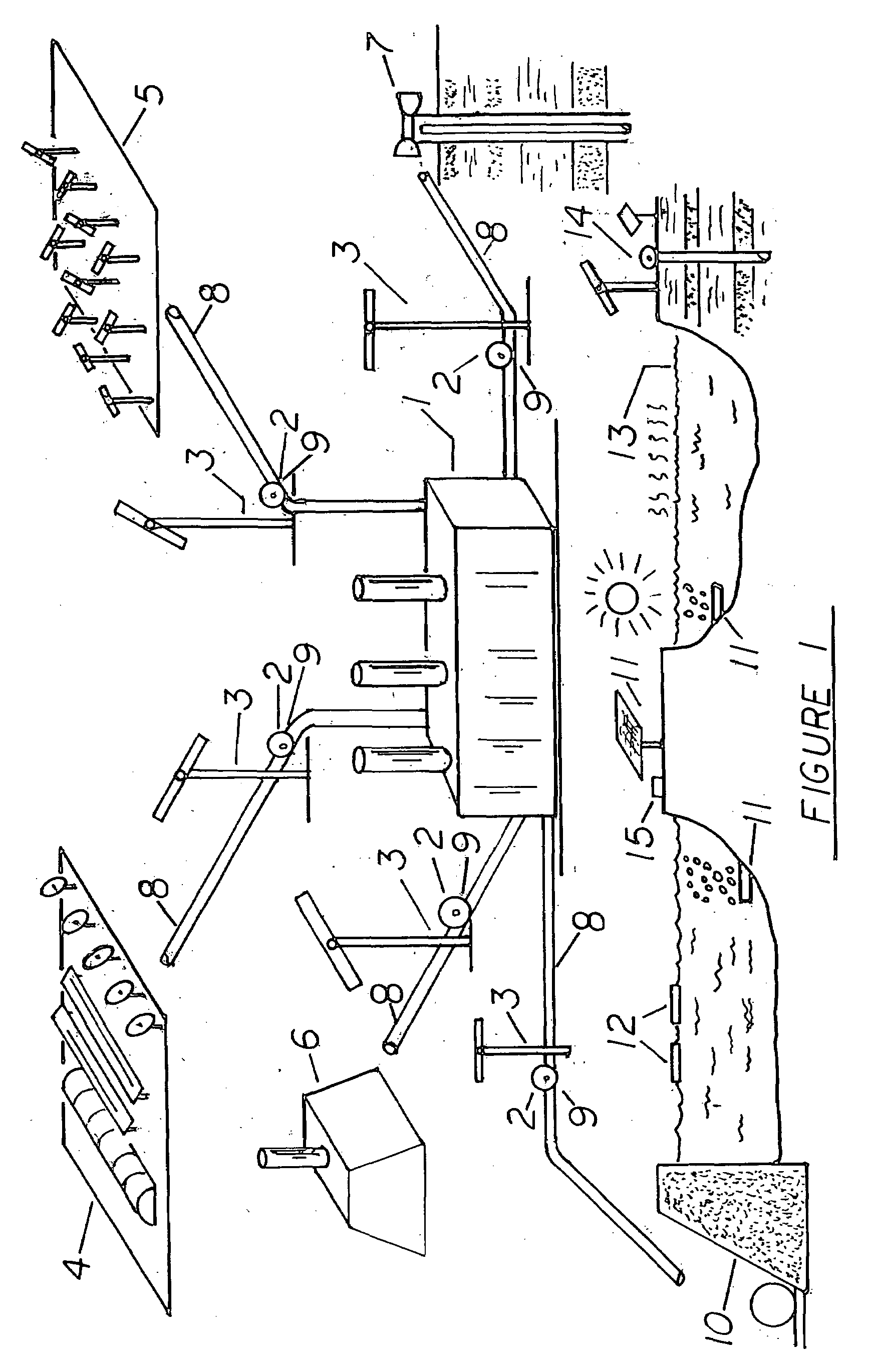

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

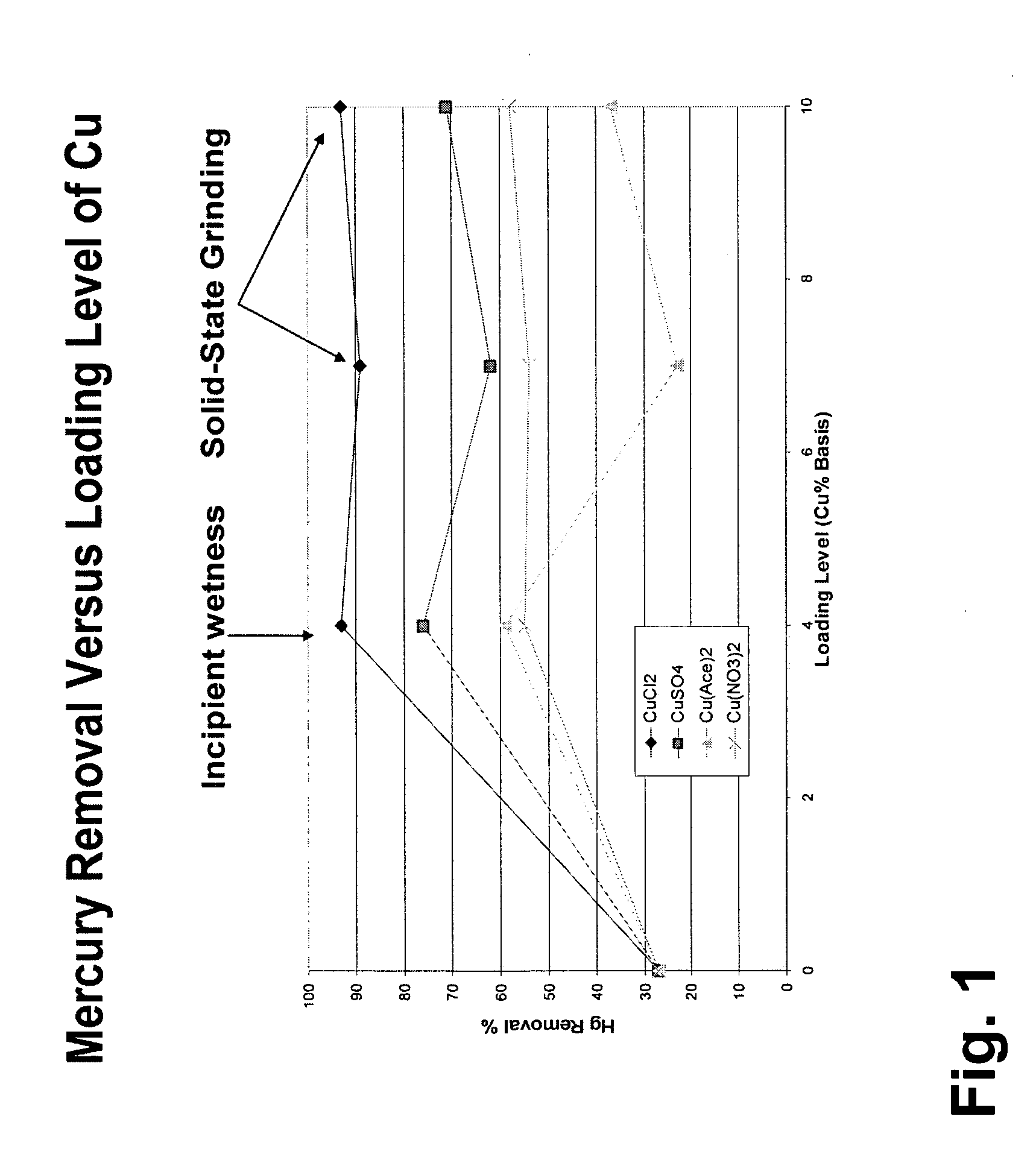

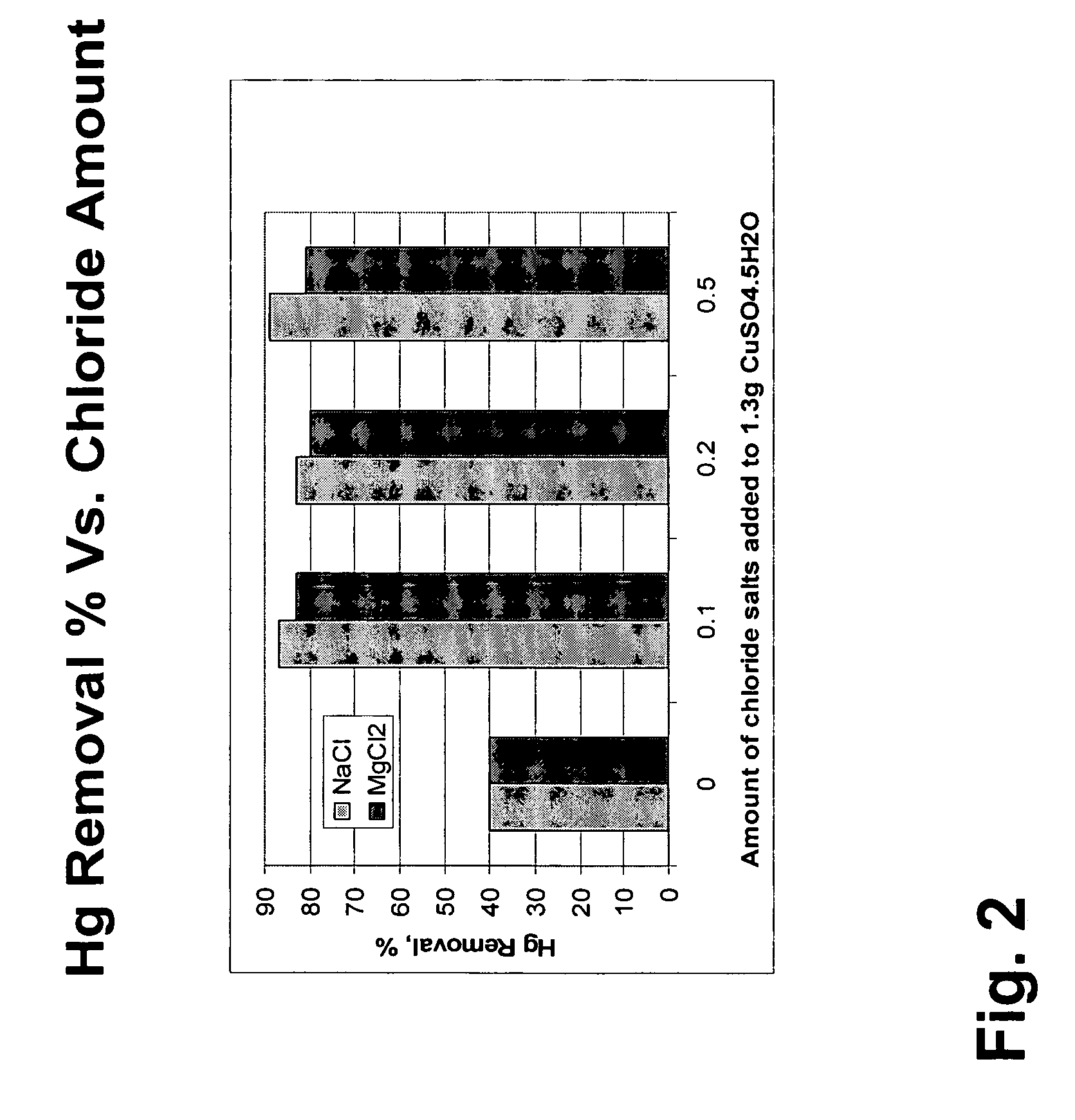

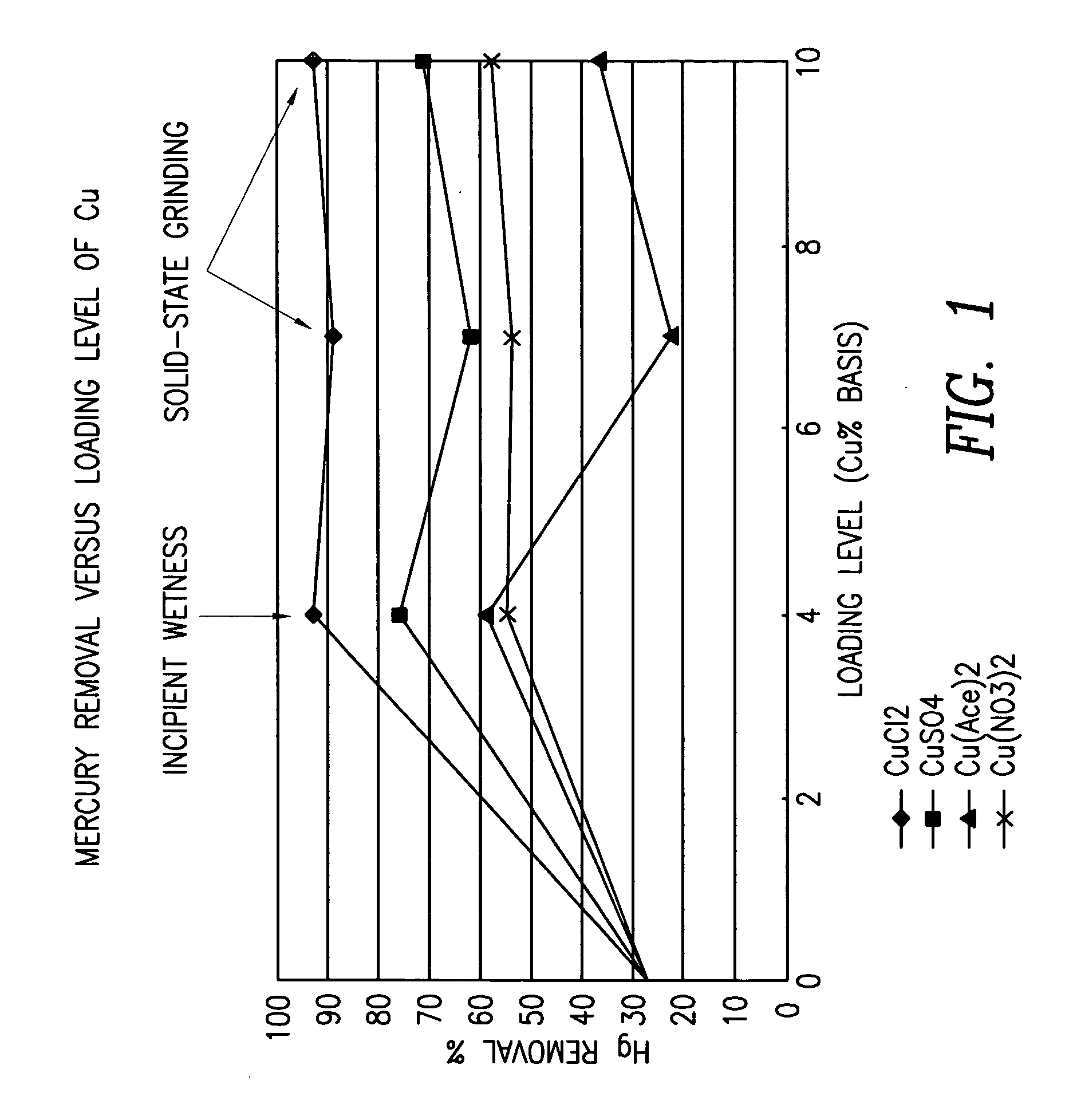

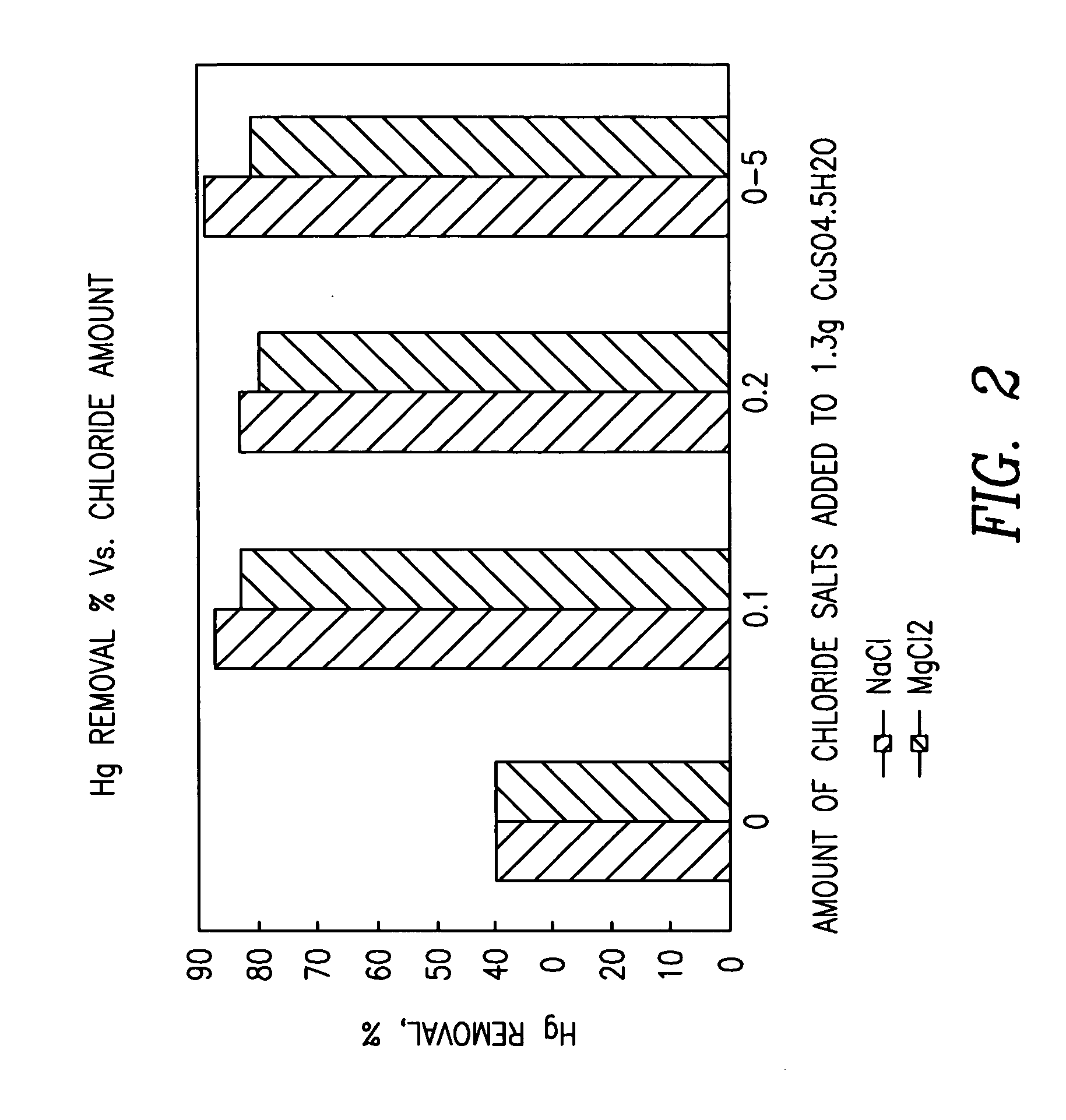

Compositions and methods for removing mercury from mercury-containing fluids

InactiveUS20070140940A1Facilitate mercury removalThe material is lowGas treatmentDispersed particle filtrationSodium BentoniteSorbent

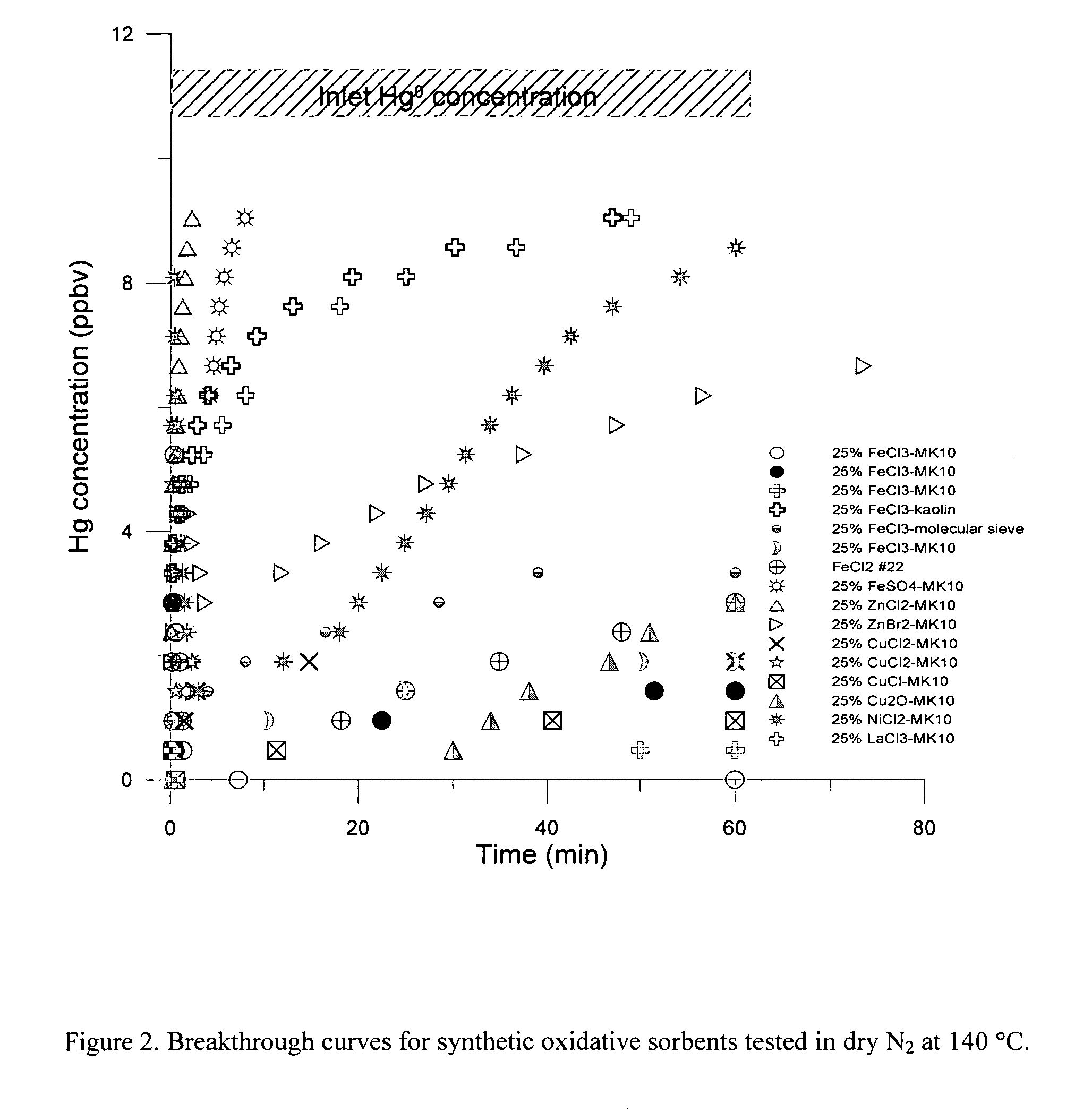

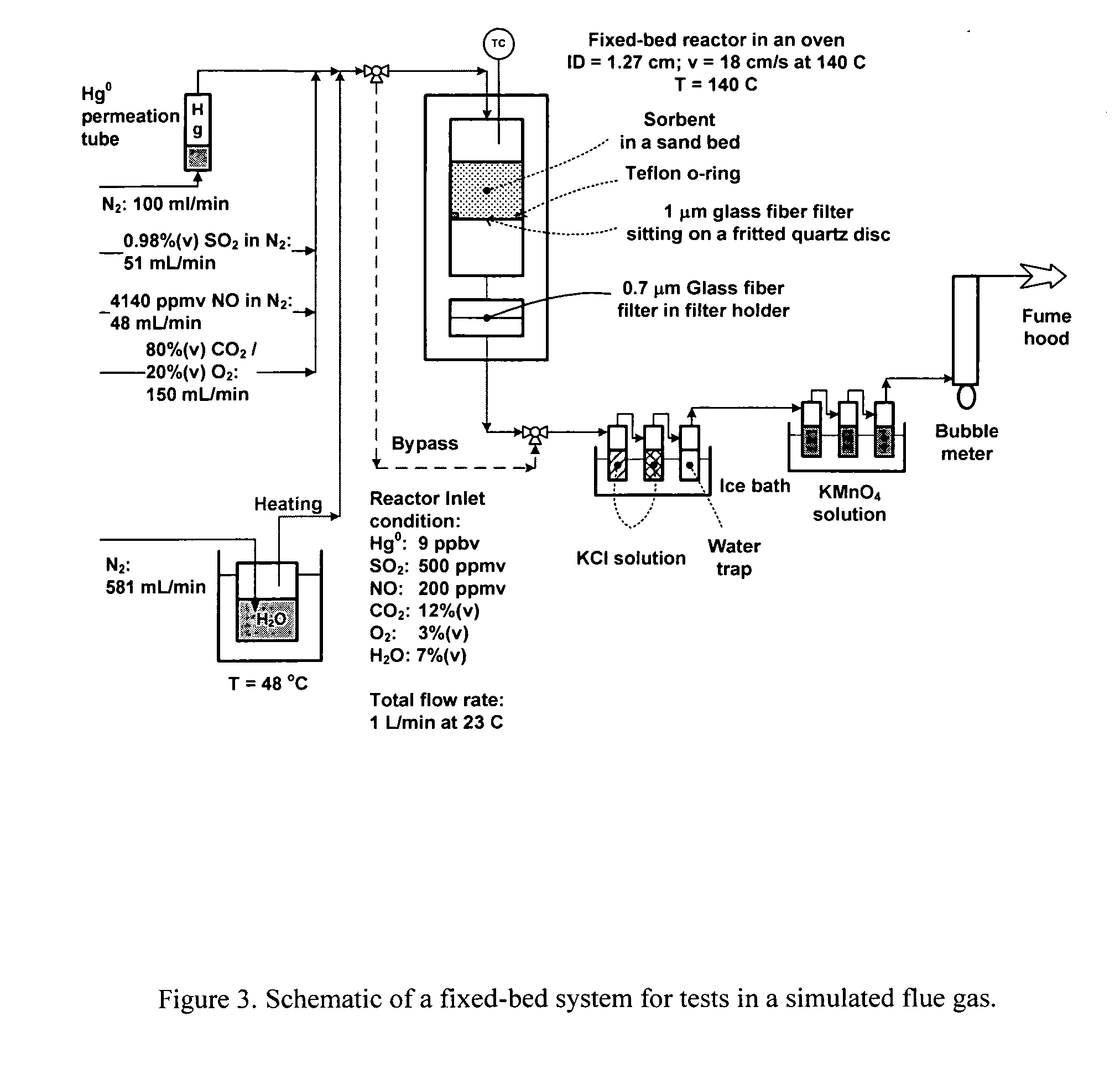

Oxidative sorbents are provided for adsorbing elemental or oxidized mercury from mercury-containing fluids such as flue gas from a coal-burning power utility or the like at a temperature range of about 50 to 350 ° C. The method of preparing and using the oxidative sorbents is also provided. The oxidative sorbent compositions include one or more silicates capable of cation exchange with a plurality of active metal cations and their counter anions. The silicates may include those selected from clays such as montmorillonite, laumonite, bentonite, Mica, vermiculite and kaolinite, and from silica gels, natural and synthetic molecular sieves, zeolites, and ashes from stoker- and pulverized coal-fired boilers. The one or more oxidative metal halides and / or sulfates may be selected from the group consisting of CuCl, CuBr, CuCl2, CuBr2, CuSO4, FeCl2, FeCl3, FeSO4, Fe2(SO4)3, ZnCl2, ZnBr2, NiCl2, and NiSO4. The oxidative sorbents may also include activated carbon.

Owner:U S ENVIRONMENTAL PROTECTION AGENCY UNITED STATES OF AMERICA THE AS REPRESENTED BY THE ADMINISTATOR

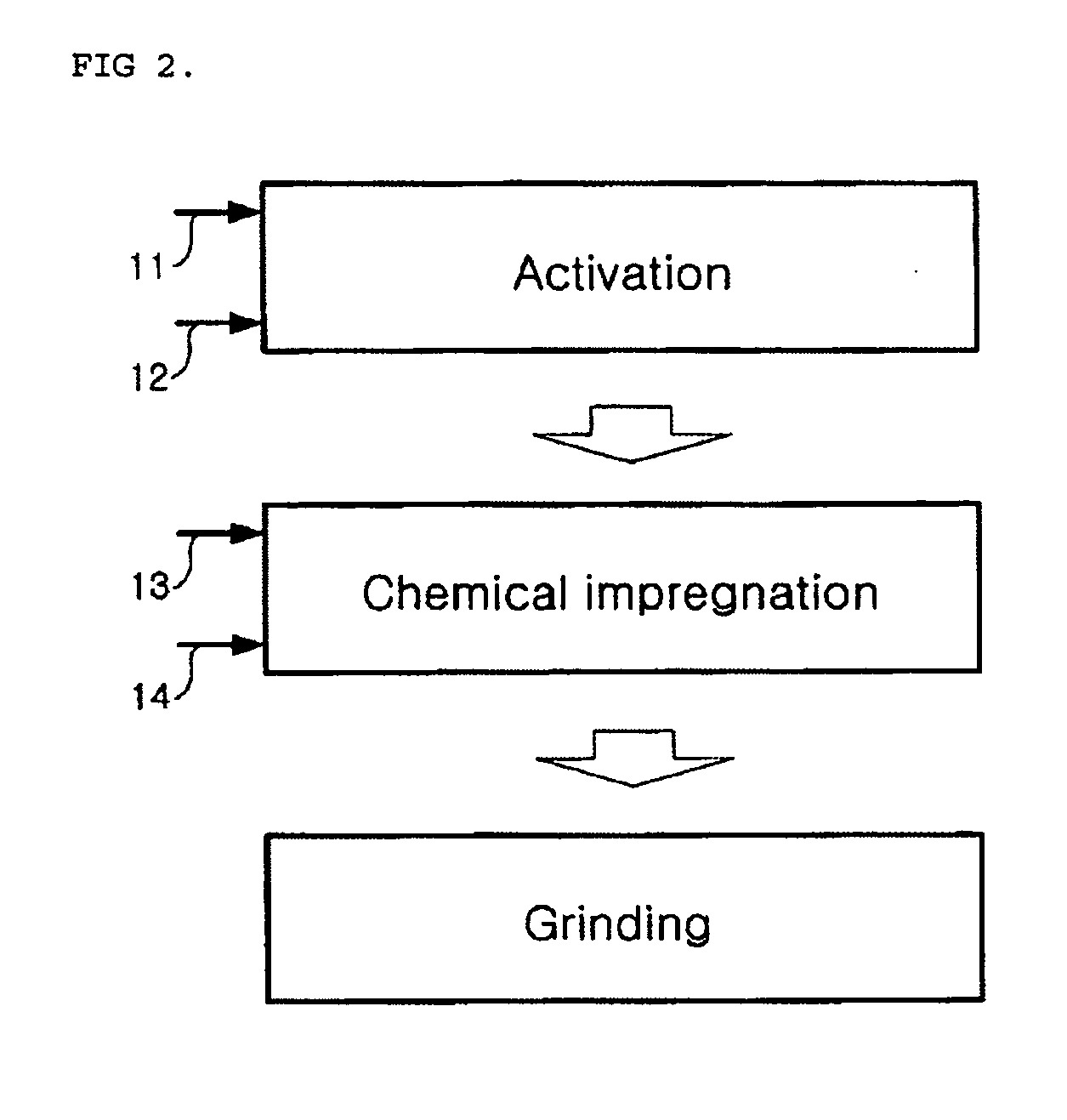

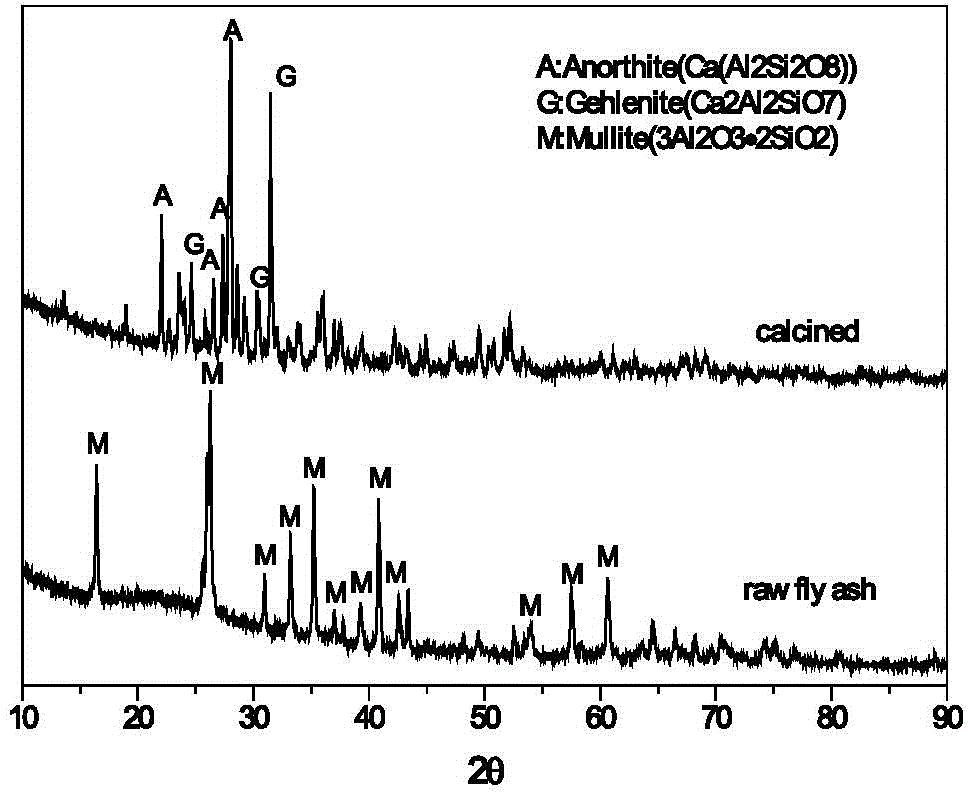

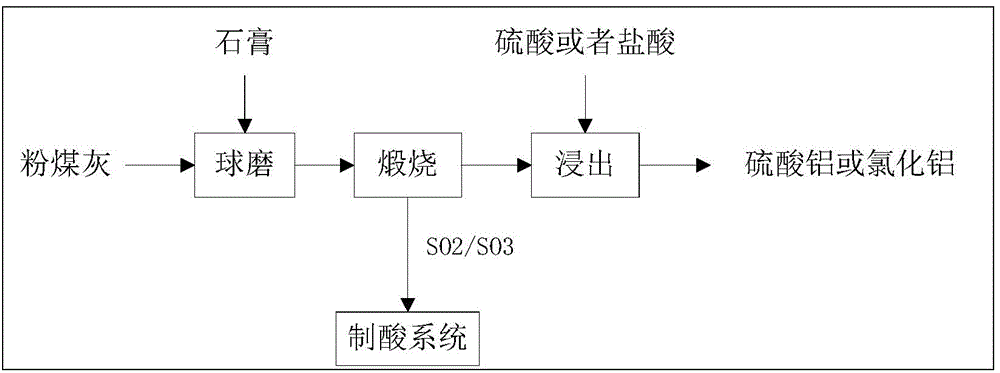

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

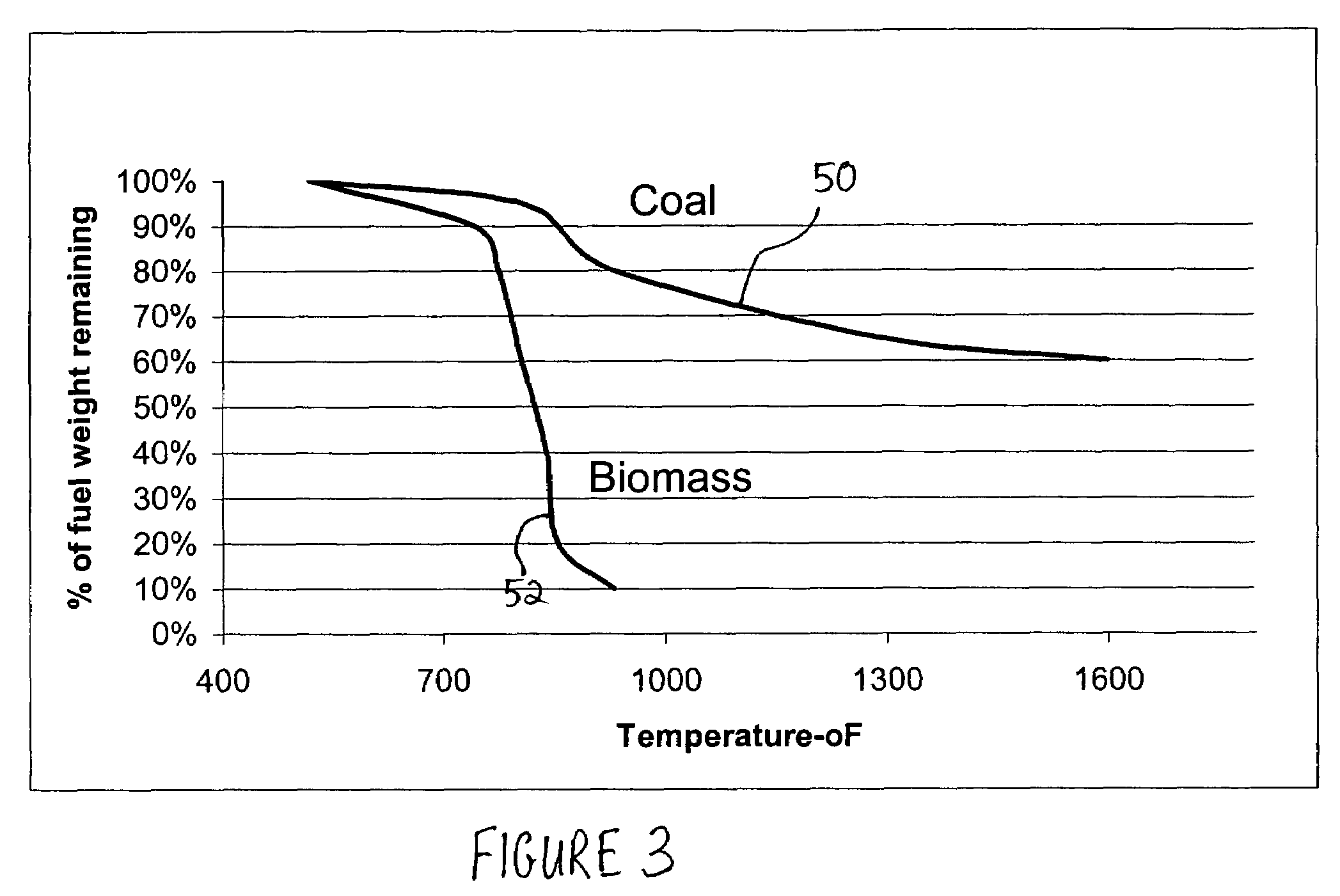

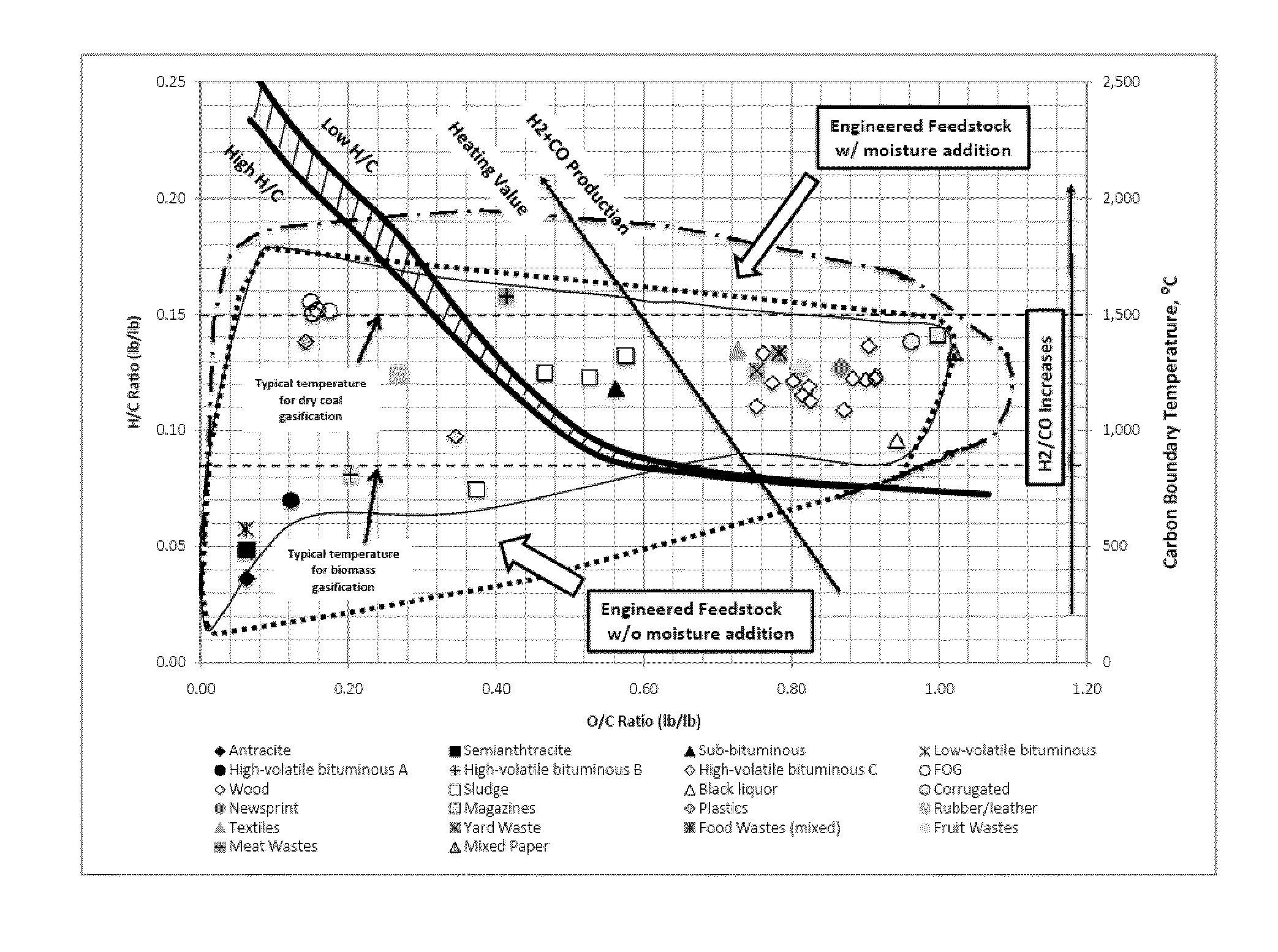

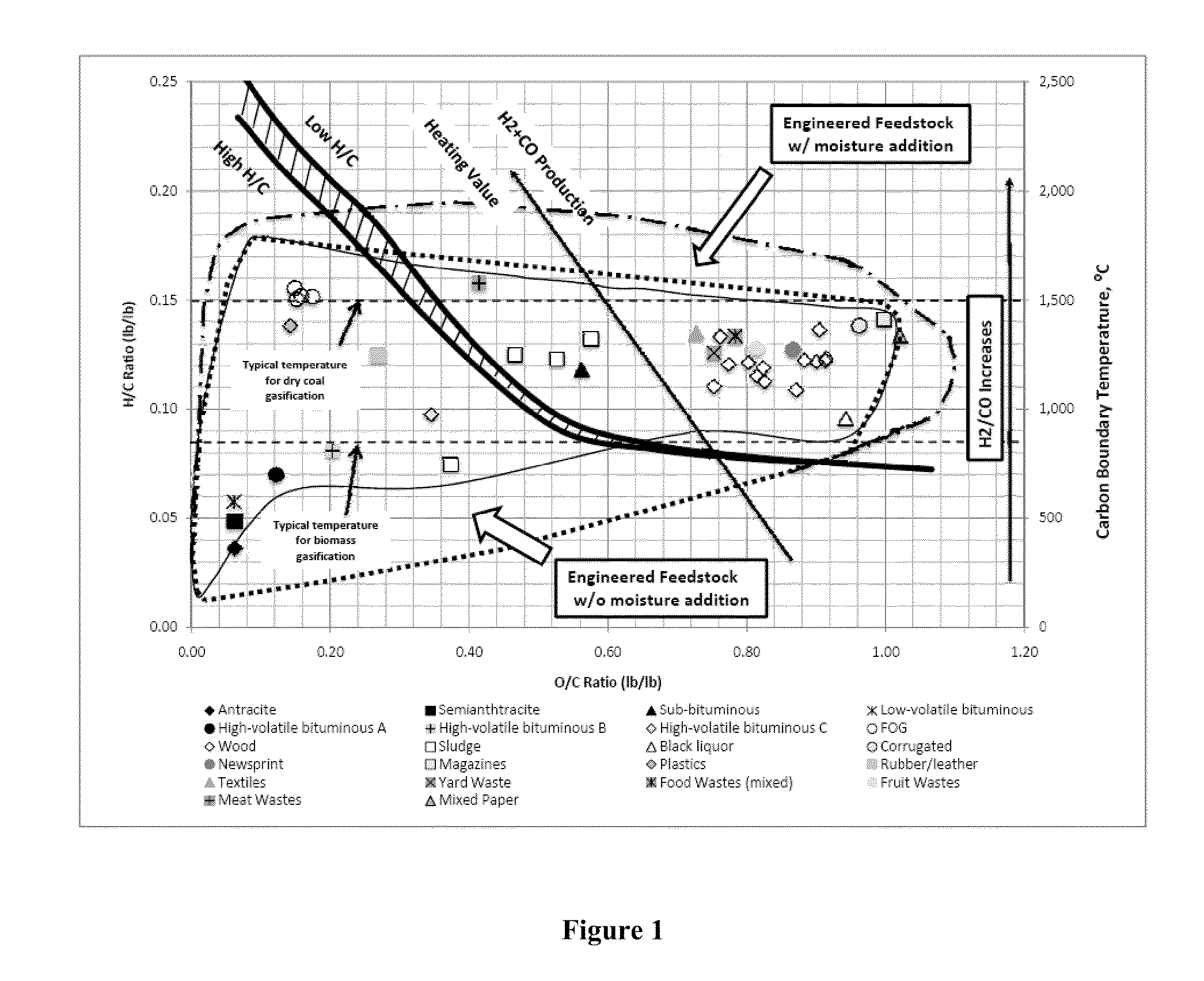

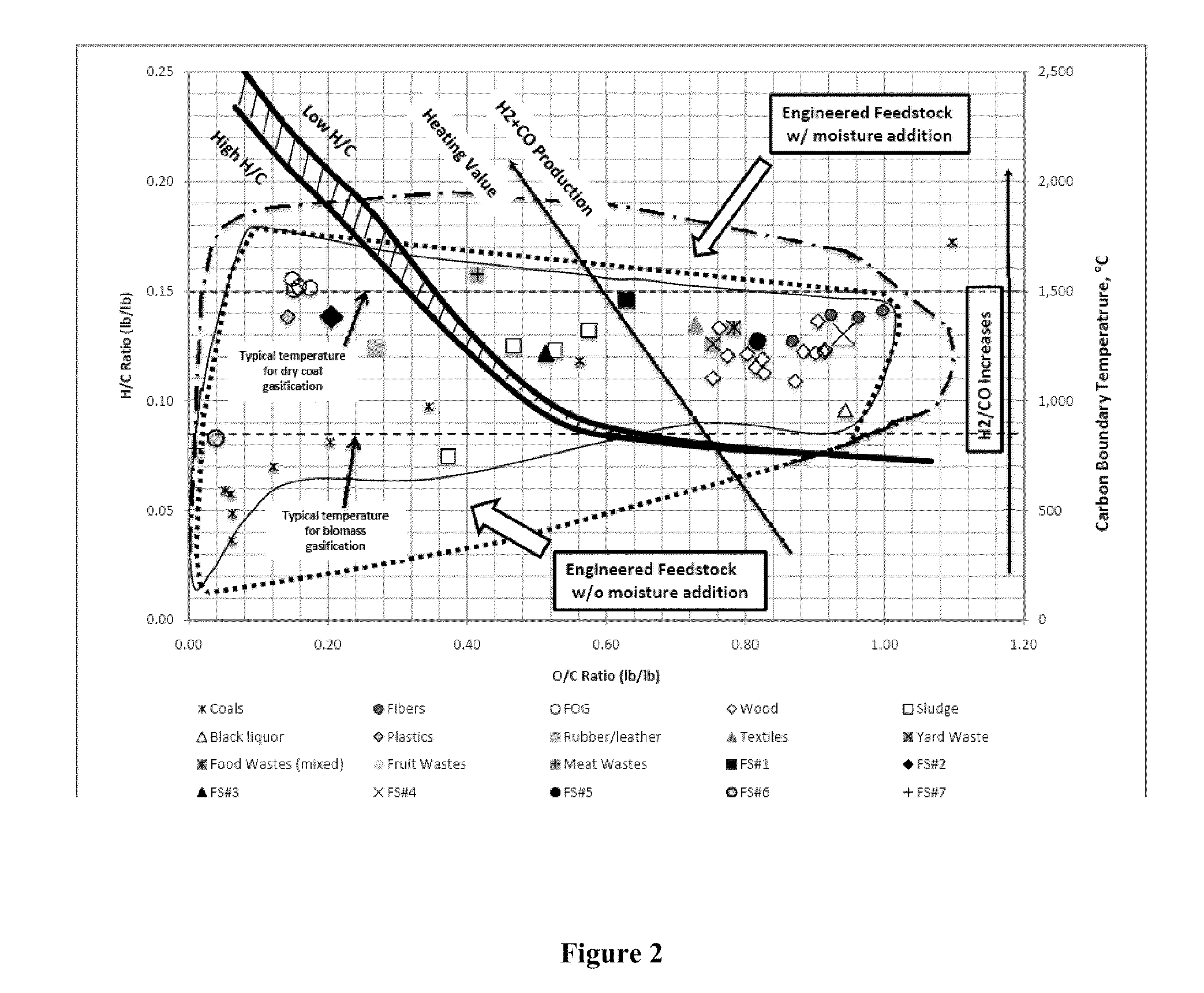

Engineered fuel feed stock useful for displacement of coal in coal firing plants

ActiveUS20100031560A1Reduce harm to the environmentQuality improvementMechanical working/deformationBiofuelsEngineeringCoal fired

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, and methods of making the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles. These feed stocks are useful for a variety of purposes including co-firing with coal and as substitutes for coal.

Owner:REPOWER IP LLC

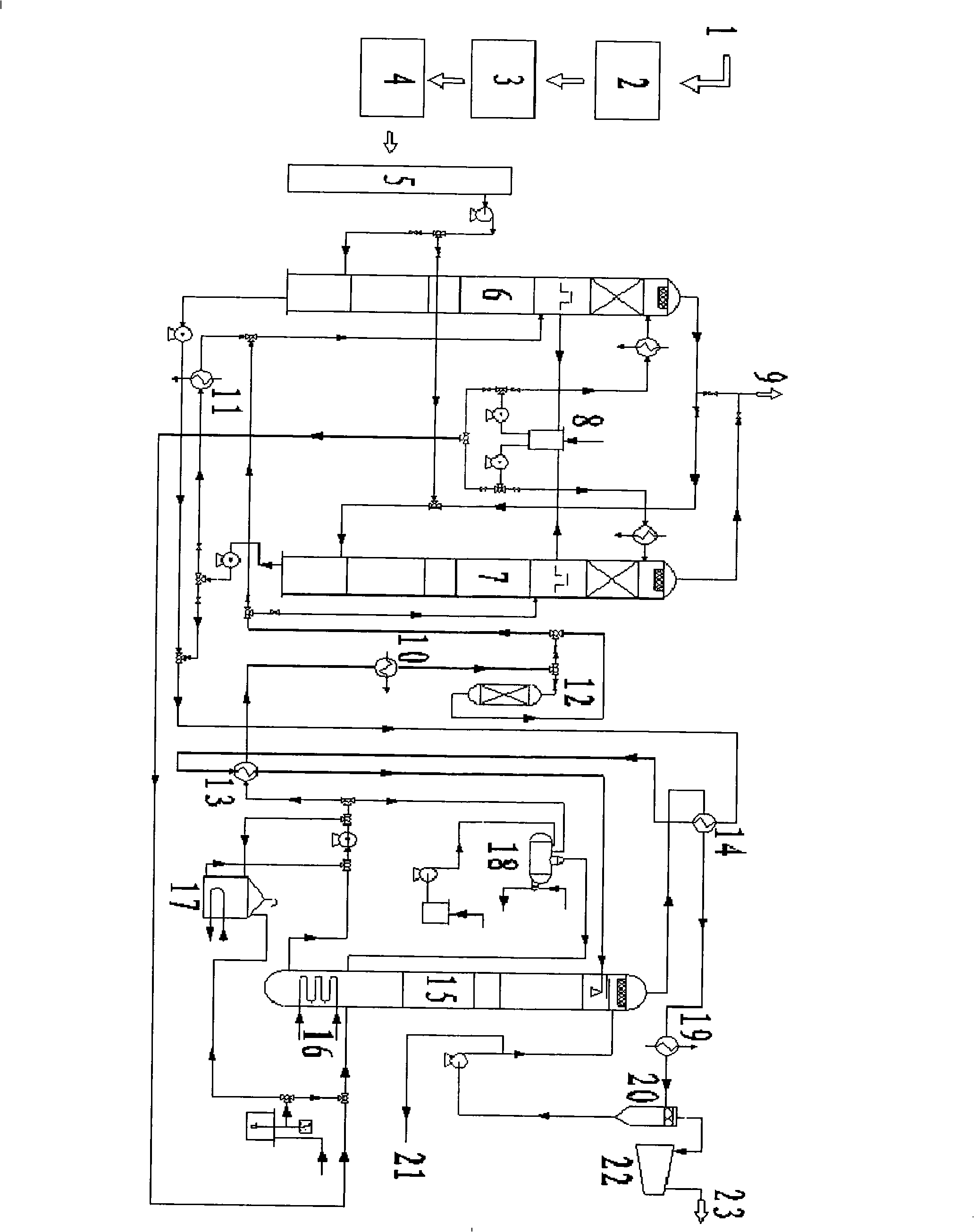

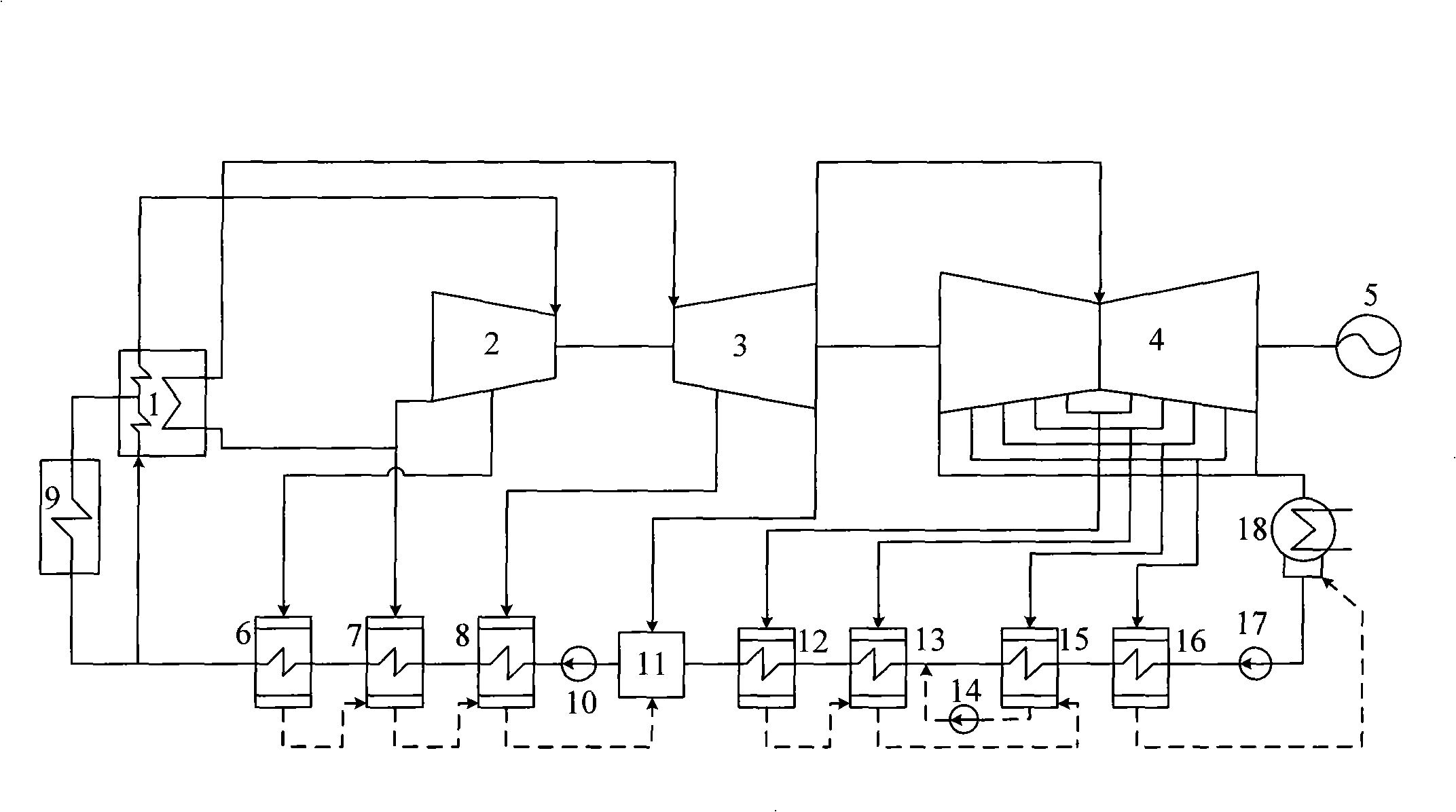

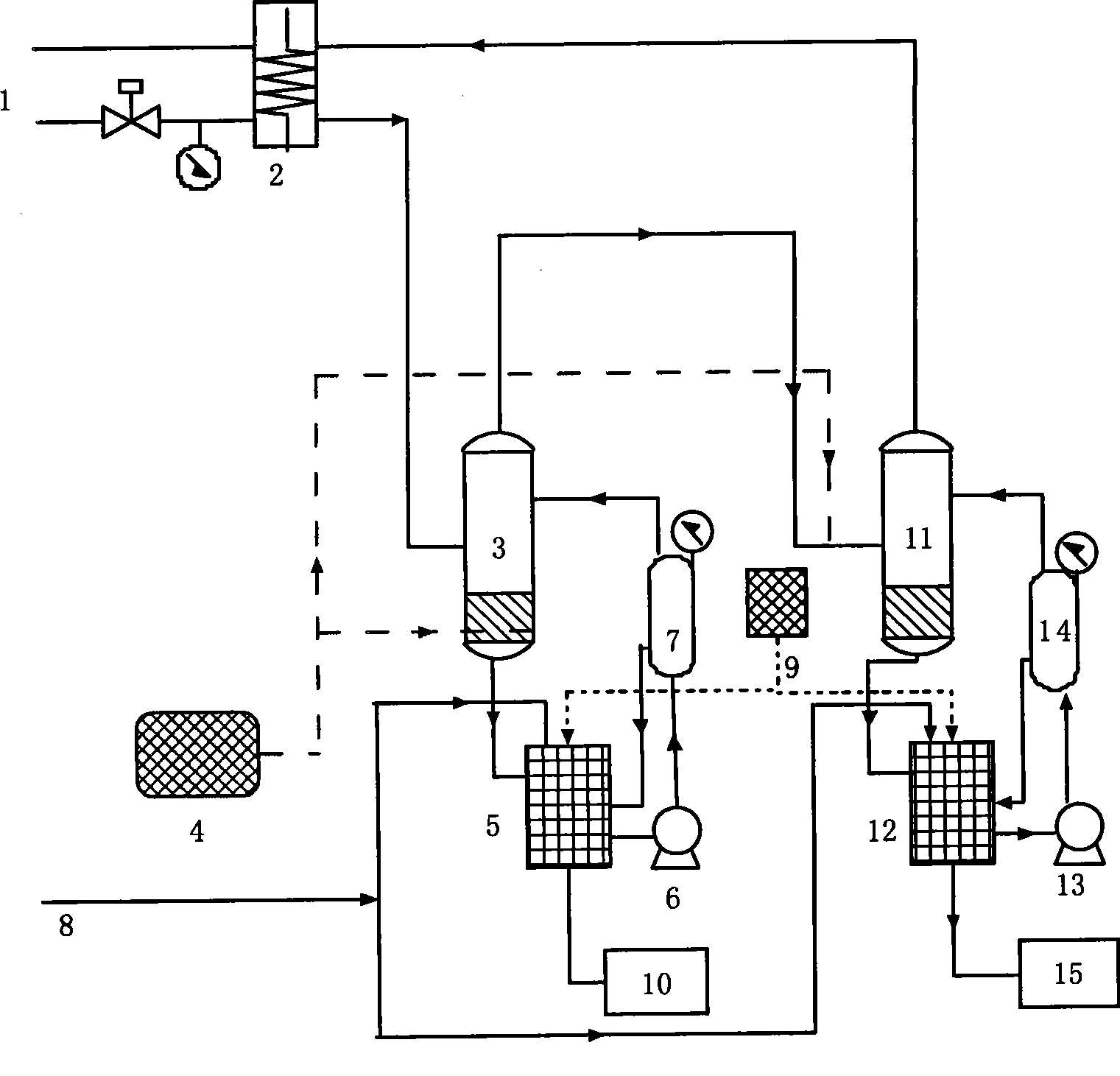

Method and apparatus for collecting carbonic anhydride in coal-fired plant flue gas

The invention provides a method and a device for collecting carbon dioxide in smoke gas of a coal-fired power plant. The device consists of a smoke gas pretreatment system, absorption towers, a regeneration tower, an exhaust scrubbing system, a solution heating recoverer, a product gas processing system (comprising a condenser, a gas-liquid separator and a compressor). The device is integrated with the prior smoke gas purification device of the coal-fired power plant, and is provided with a high-efficiency whirlcone and a chemical absorption system, so that mass carbon dioxide gas exhausted from a coal-fired boiler can be collected, and the emission of greenhouse gas can be reduced; the special arrangement of double absorption towers ensures more flexible operation of a collecting system, and improves the operational reliability; an absorption solution reclaiming process reduces the consumption of the solution; the arrangement of a lean-rich solution heat exchanger and a product gas rich solution heat exchanger reduces the energy consumption of the collecting system; and the steam consumption can be effectively reduced by adopting a built-in solution boiling unit.

Owner:XIAN THERMAL POWER RES INST CO LTD

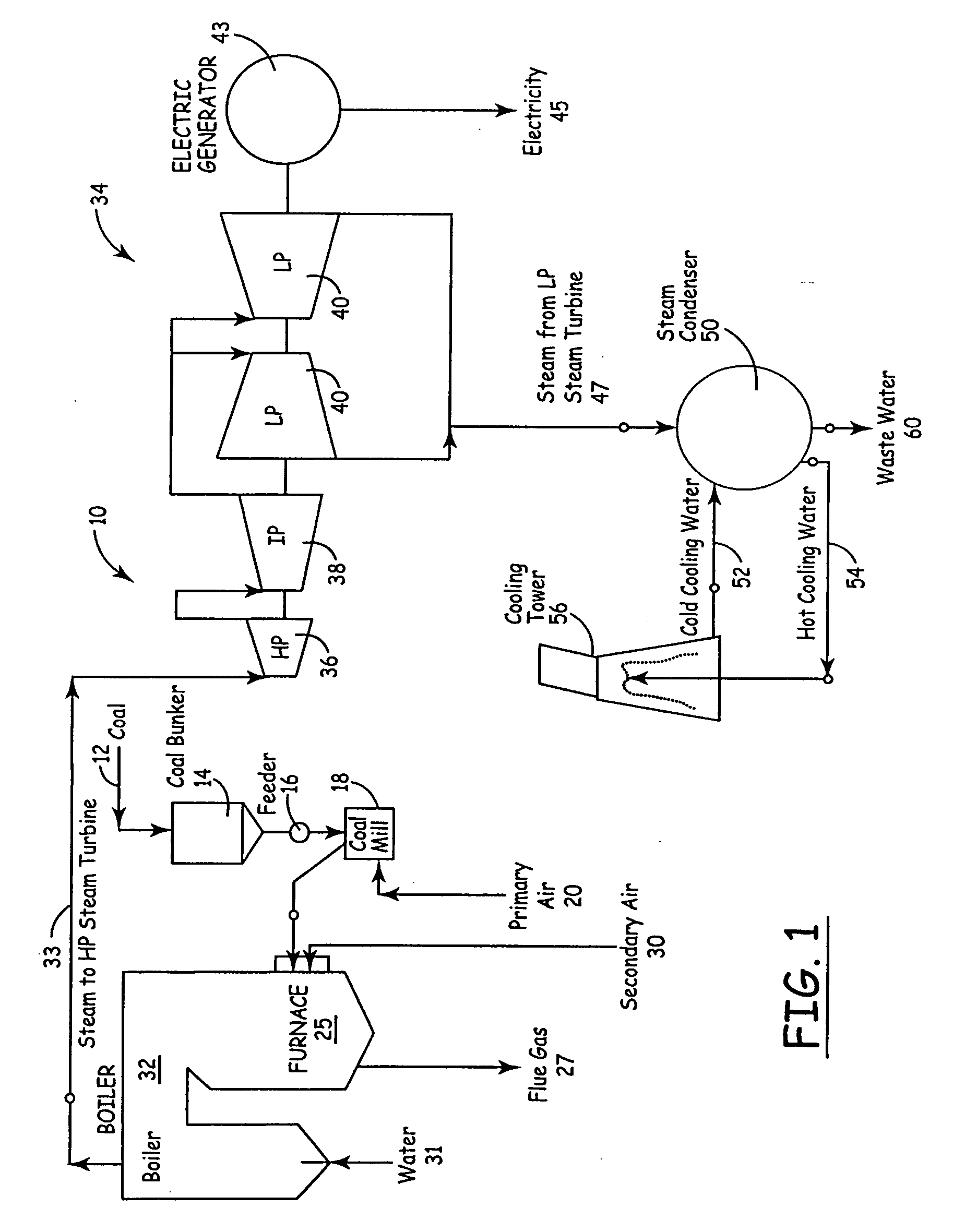

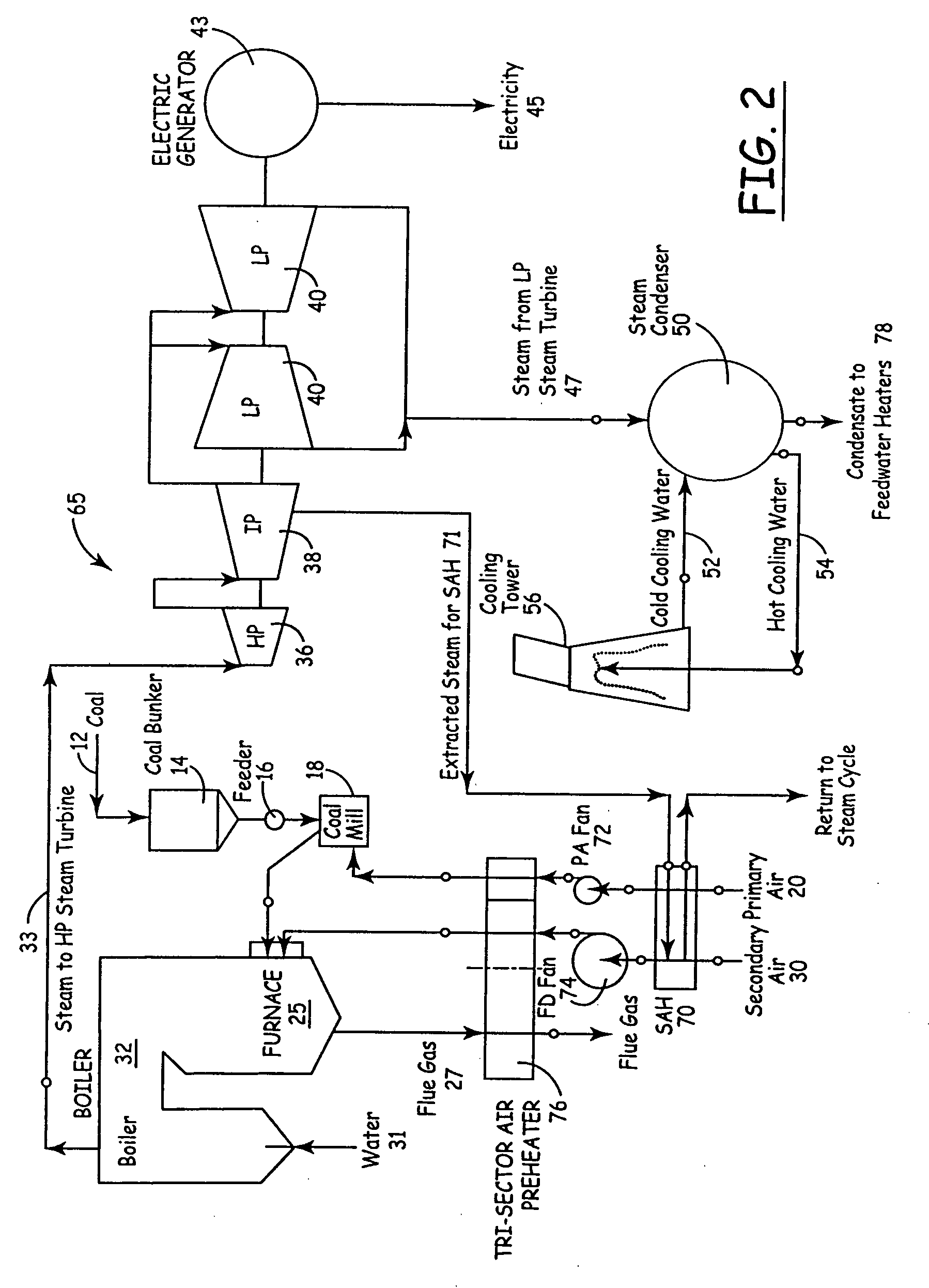

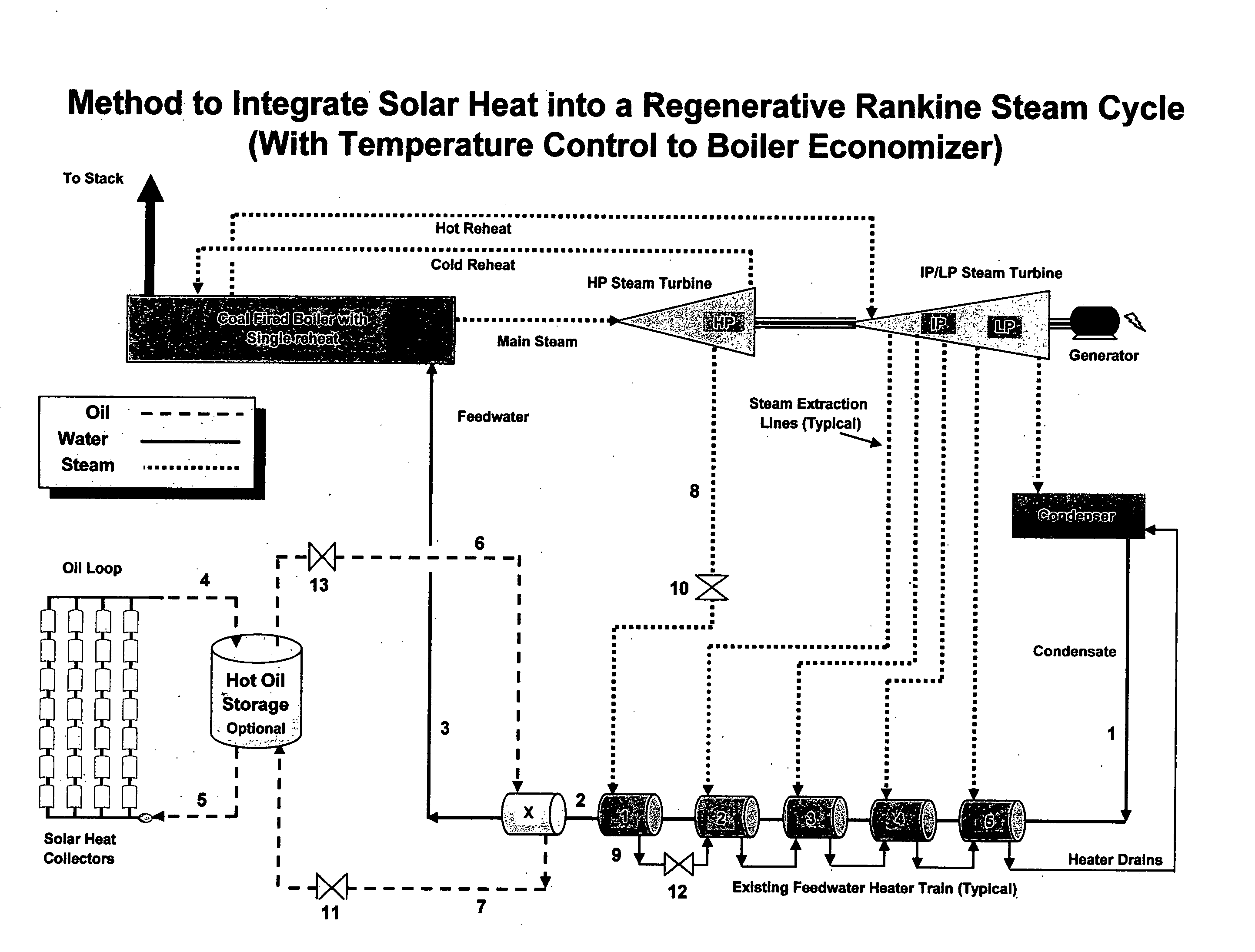

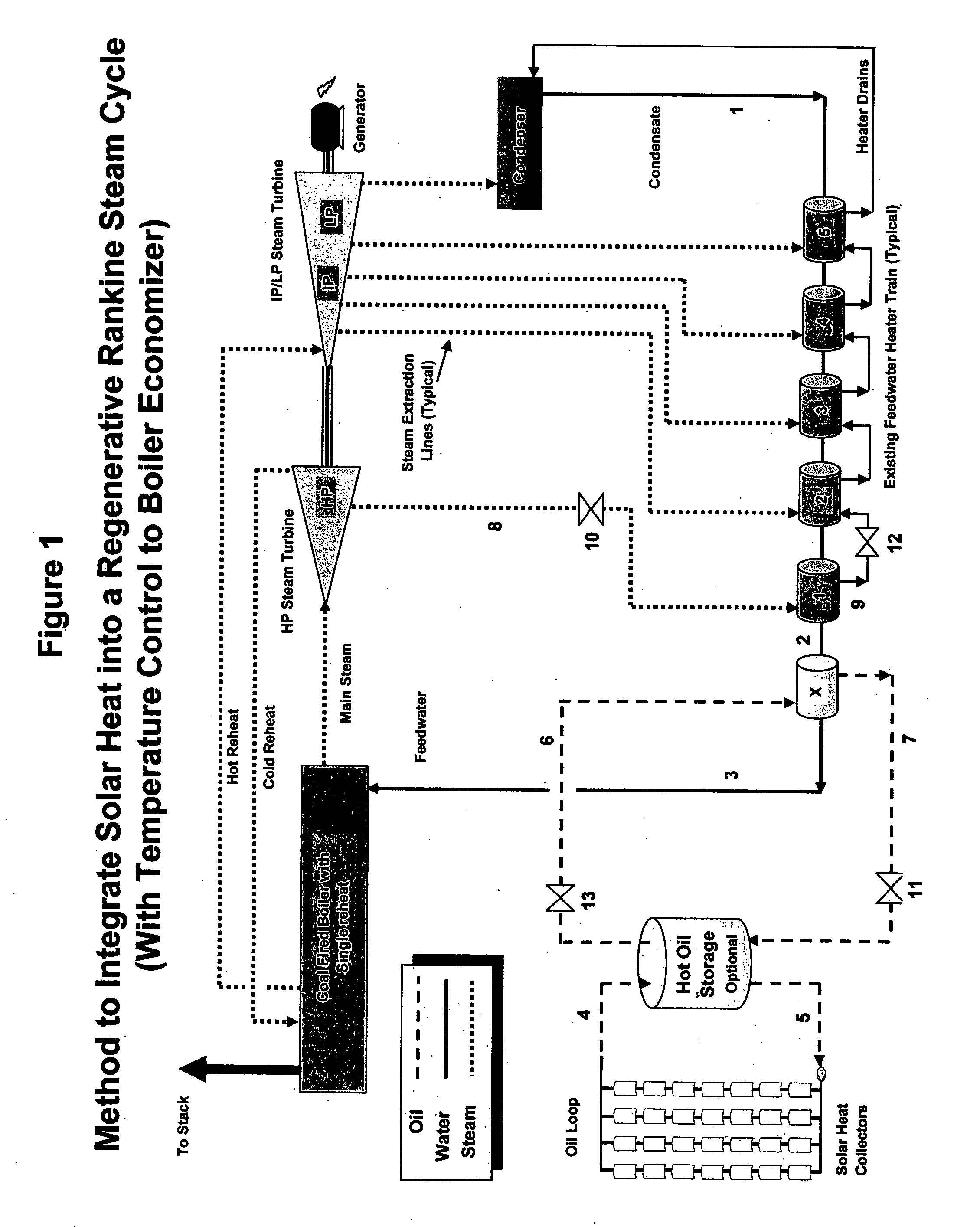

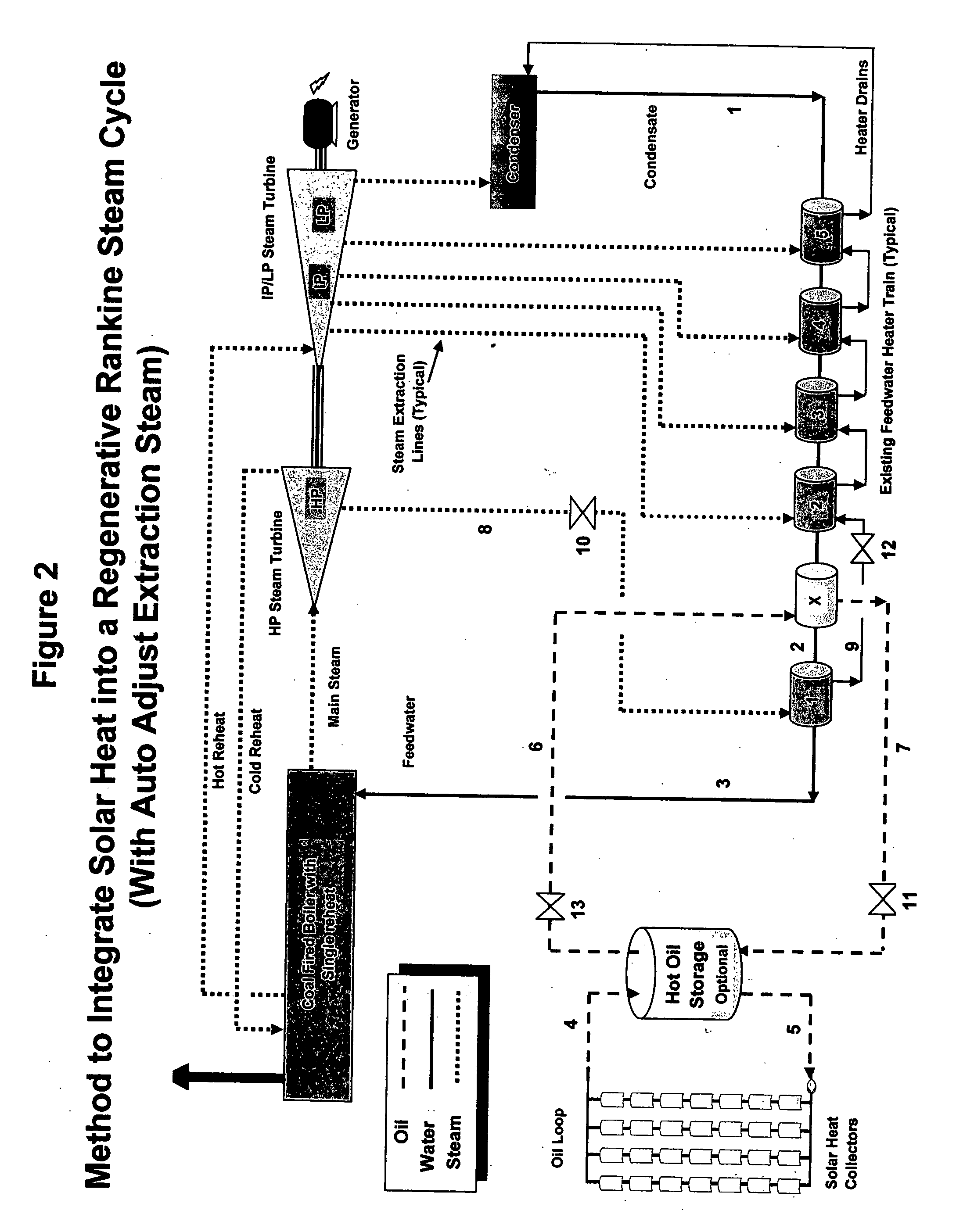

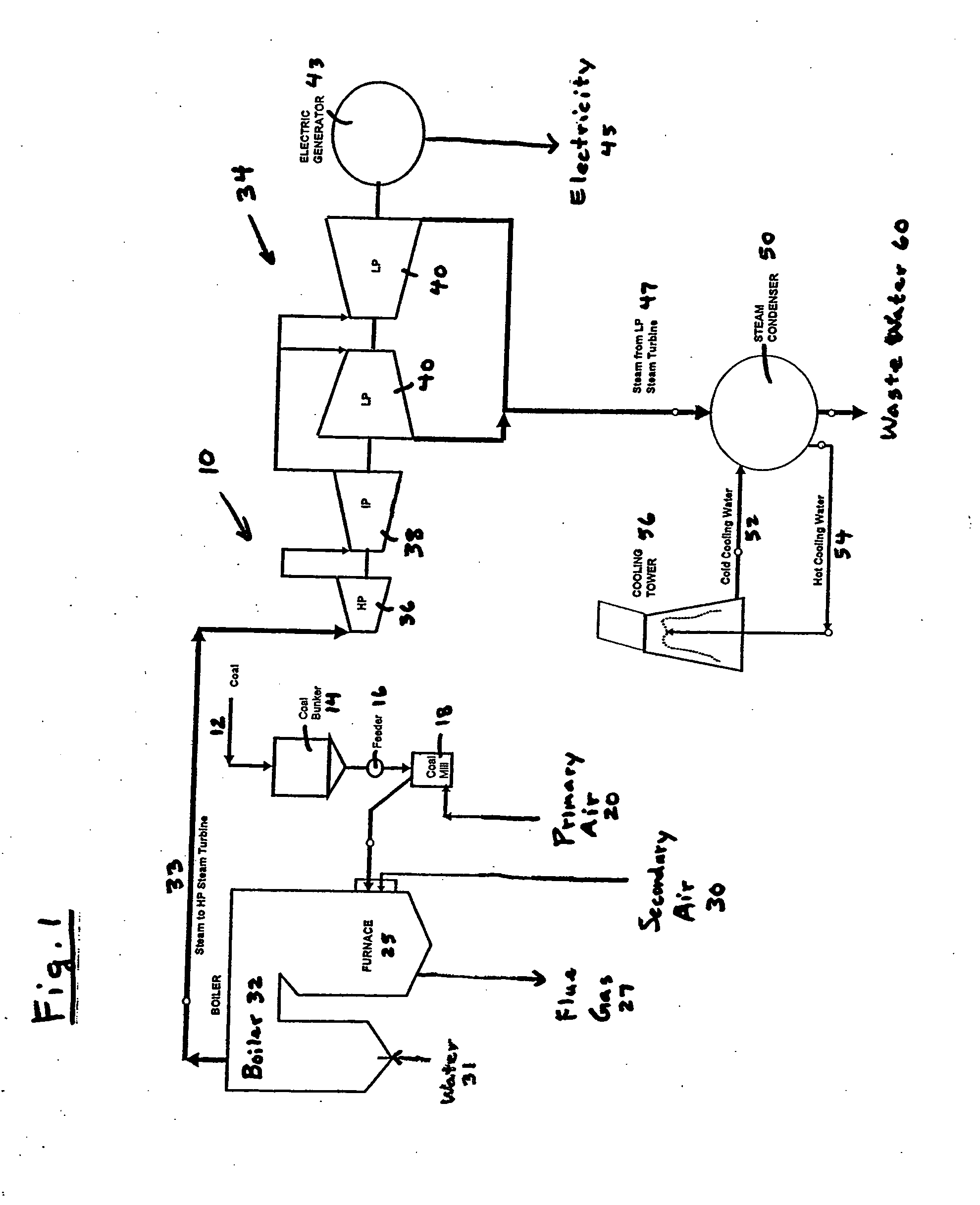

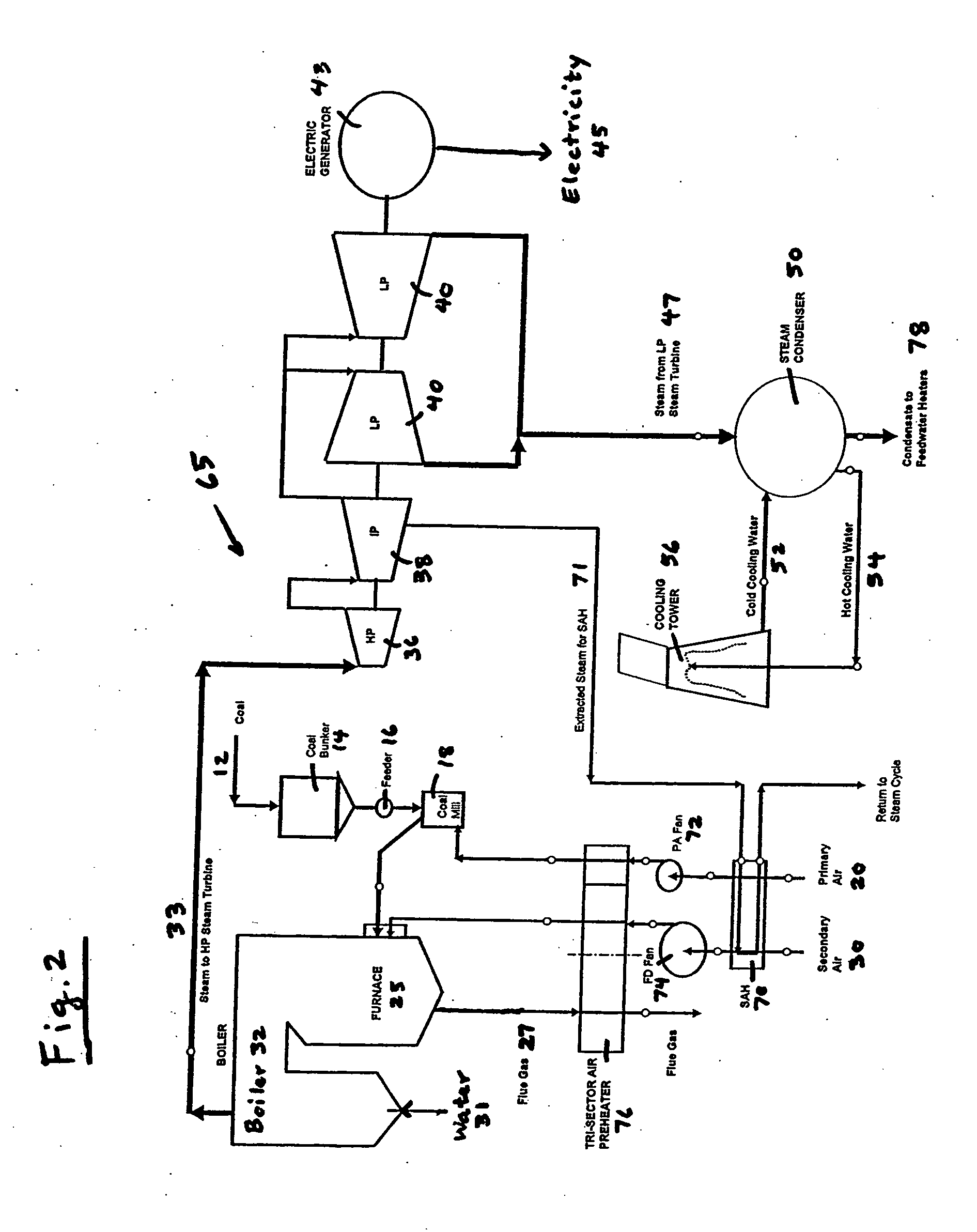

Method and system integrating solar heat into a regenerative rankine steam cycle

InactiveUS20060266039A1High solar system efficiencySmall temperature differenceAuxillary drivesFrom solar energyThermal energyClosed loop

A method to integrate collected solar thermal energy into the feedwater system of a Rankine cycle power plant is disclosed. This novelty uses a closed loop, single phase fluid system to collect both the solar heat and to provide the heat input into the feedwater stream of a regenerative Rankine cycle. One embodiment of this method of integrating solar energy into a regenerative Rankine power plant cycle, such as a coal power plant, allows for automatic balancing of the steam extraction flows and does not change the temperature of the feedwater to the boiler. The concept, depending on the application, allows for the spare turbine capacity normally available in a coal plant to be used to produce incremental capacity and energy that is powered by solar thermal energy. By “piggybacking” on the available components and infrastructure of the host Rankine cycle power plant, considerable cost savings are achieved resulting in lower solar produced electricity costs.

Owner:MARKRON TECH

Methods of manufacturing bentonite pollution control sorbents

InactiveUS20070119300A1Small particle sizeLiquid surface applicatorsGas treatmentSodium BentoniteSorbent

Methods of manufacturing bentonite sorbents for removal of pollutants including mercury from gas streams, such as a flue gas stream from coal-fired utility plants are disclosed. The methods include mixing bentonite sorbent particles with a sulfide salt and a metal salt to form a metal sulfide on the outer surface of the bentonite sorbent particles.

Owner:BASF CATALYSTS LLC

Method of enhancing the quality of high-moisture materials using system heat sources

ActiveUS20060075682A1Eliminates potential harmEmission reductionDrying solid materials with heatSolid fuelsFluidized bed dryingHeat flow

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement. Coal can be intercepted on current coal feed systems ahead of the pulverizers. Drying fuel, such as coal, is done to improve boiler efficiency and reduce emissions. A two-stage bed utilized in the process first “pre-dries and separates” the feed stream into desirable and undesirable feedstock. Then, it incrementally dries and segregates fluidizable and non-fluidizable material from the product stream. This is all completed in a low-temperature, open-air system. Elevation of fan room air temperature is also accomplished using waste heat, thereby making available to the plant system higher temperature media to enhance the feedstock drying process.

Owner:RAINBOW ENERGY CENT LLC

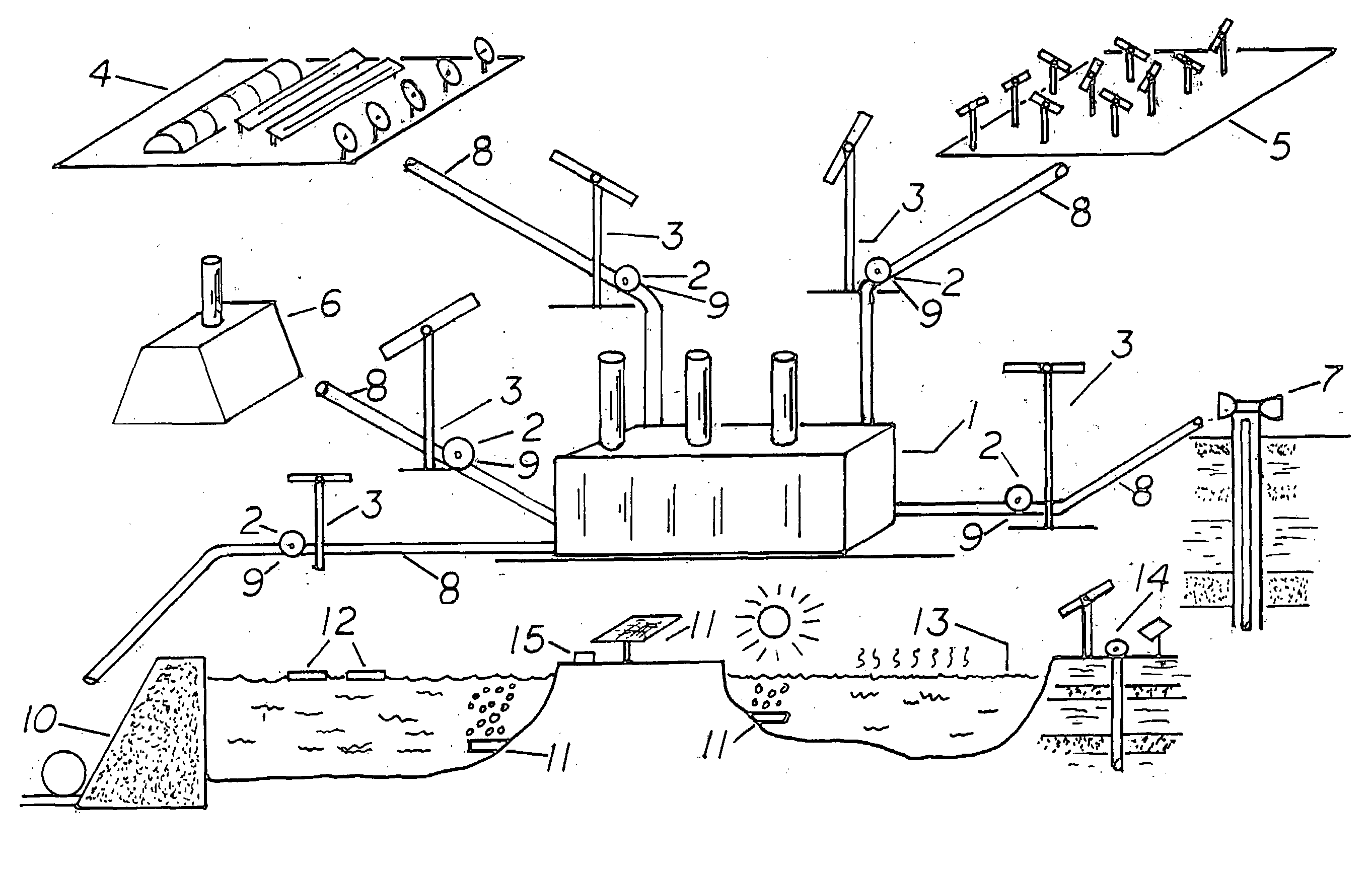

Use of renewable energy like solar, wind, geothermal, biomass, and hydropower for manufacturing combustion air for a fossil fuel burner and firebox

InactiveUS20080131830A1Reduce the amount requiredCarbon reductionSolar heating energyFuel heating with wind energyCombustion chamberEvaporation

Invented is a method of making combustion air for a fossil fuel burner, as a coal burning power plant, oil refinery or gas fired household appliance. Combustion air is made from solar, wind, biomass, hydropower or geothermal. A staged progression using lower cost greenhouses, or flatplates, or solarponds, feed warm air to higher cost concentrator solar collectors. Wind energy, biomass, geothermal energy heat and compress combustion air. Hydropower also heats and compresses combustion air. Solar evaporation from salt or impure water creates water or local rain for the hydropower system. Combustion air thus is made economically hot, compressed and high velocity, and placed into a heavily insulated pipes for long distance transmission to a distant power plant.

Owner:NIX MARTIN E

Reducing mercury emissions from the burning of coal

ActiveUS7758827B2Reduce waste disposal costsReduce concrete costsSolid waste managementUsing liquid separation agentCombustionHalogen

Sorbent components containing calcium, alumina, silica, and halogen are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame, preferably at minimum temperatures to assure complete formation of the refractory structures that result in various advantages of the methods. When used together, the components ● reduce emissions of mercury and sulfur; ● reduce emissions of elemental and oxidized mercury; ● increase the efficiency of the coal burning process through de-slagging of boiler tubes; ● increase the level of Hg, As, Pb, and / or Cl in the coal ash; ● decrease the levels of leachable heavy metals (such as Hg) in the ash, preferably to levels below the detectable limits; and ● make a highly cementitious ash product.

Owner:NOX II LTD

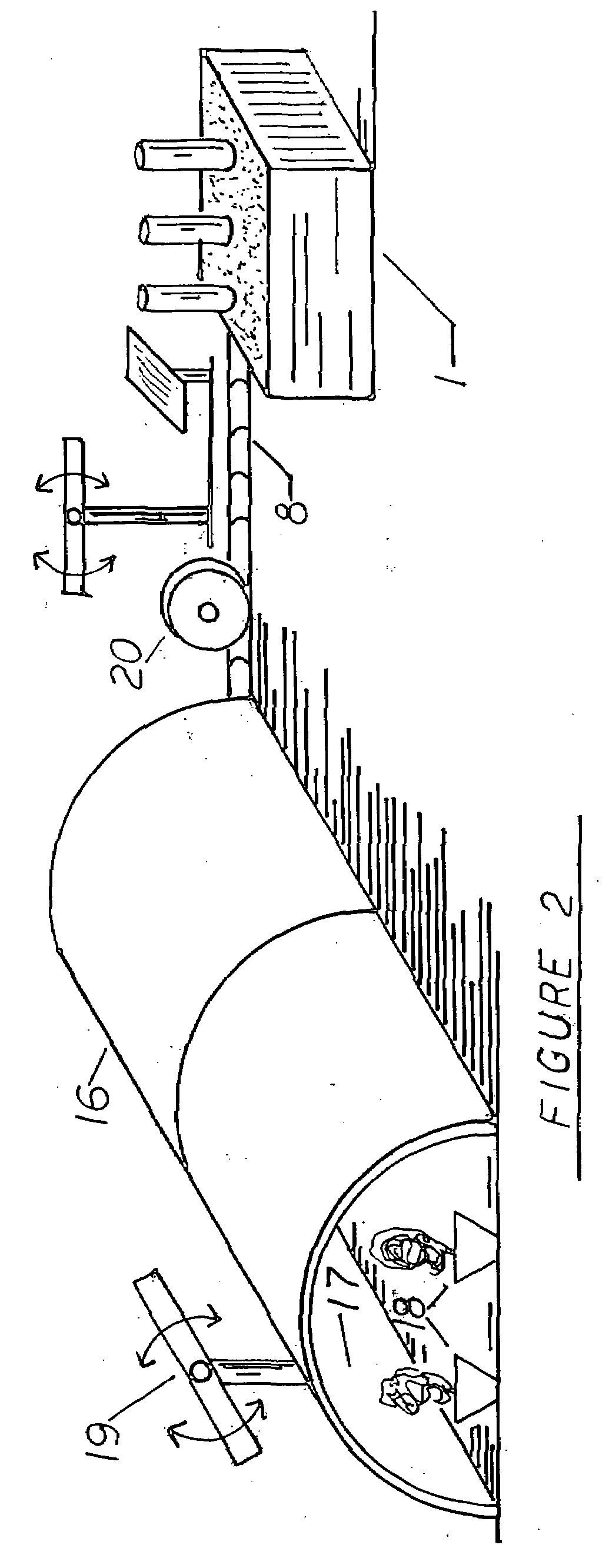

Low rank coal high temperature flue gas drying method and device

The invention relates to a method of high-temperature flue gas drying, which is particularly suitable for drying long flame coal, brown coal or other low rank coal. The coal-fired high-temperature flue gas is used to dry flammable and explosive coal types, such as brown coal in the direct contact method; therefore, the method has less gas exhaust, high thermal efficiency and high drying speed. The internal water content of the dried coal is obviously reduced, and the heating power of the dried coal is greatly increased. The invention also relates to the device using the method.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

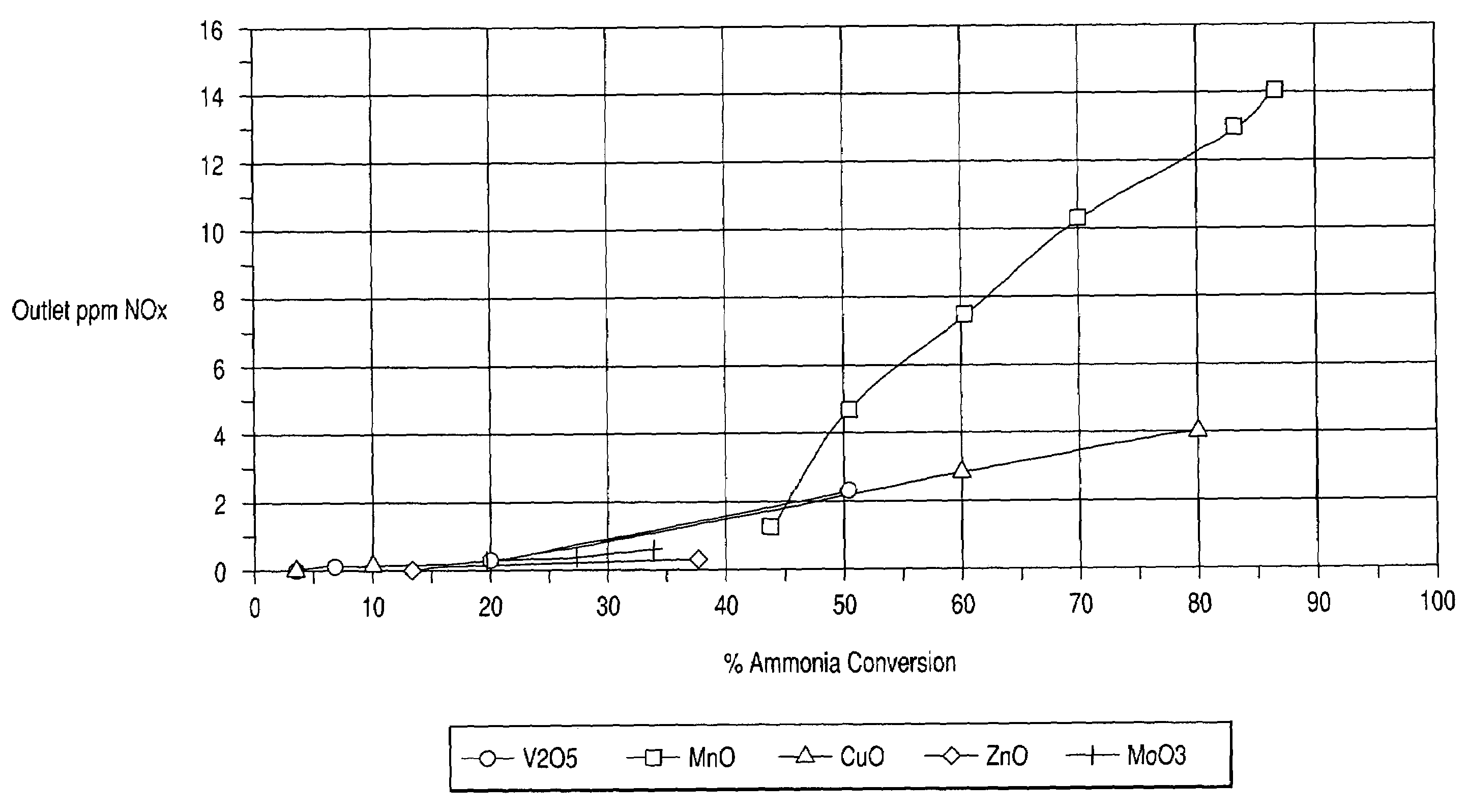

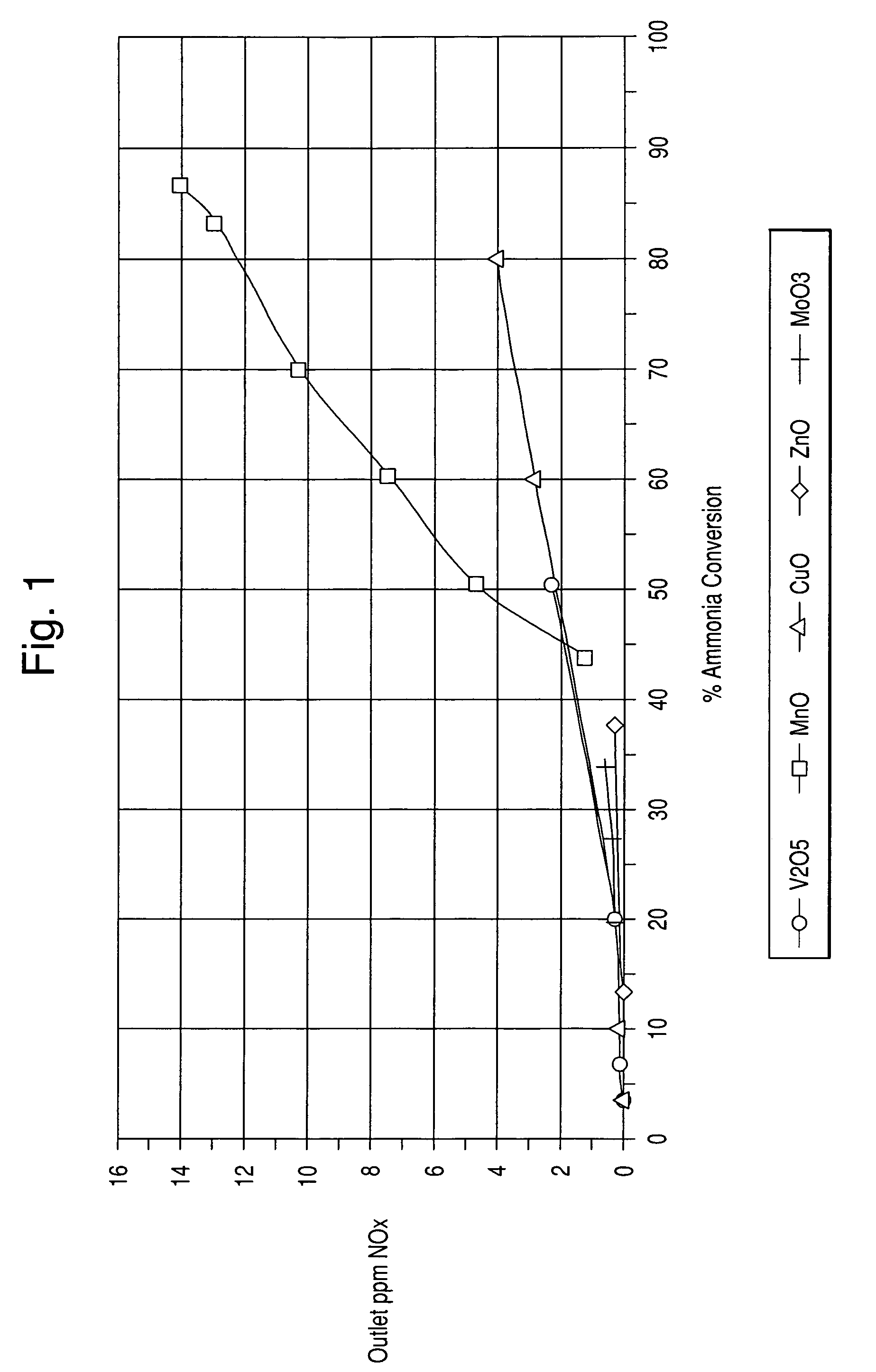

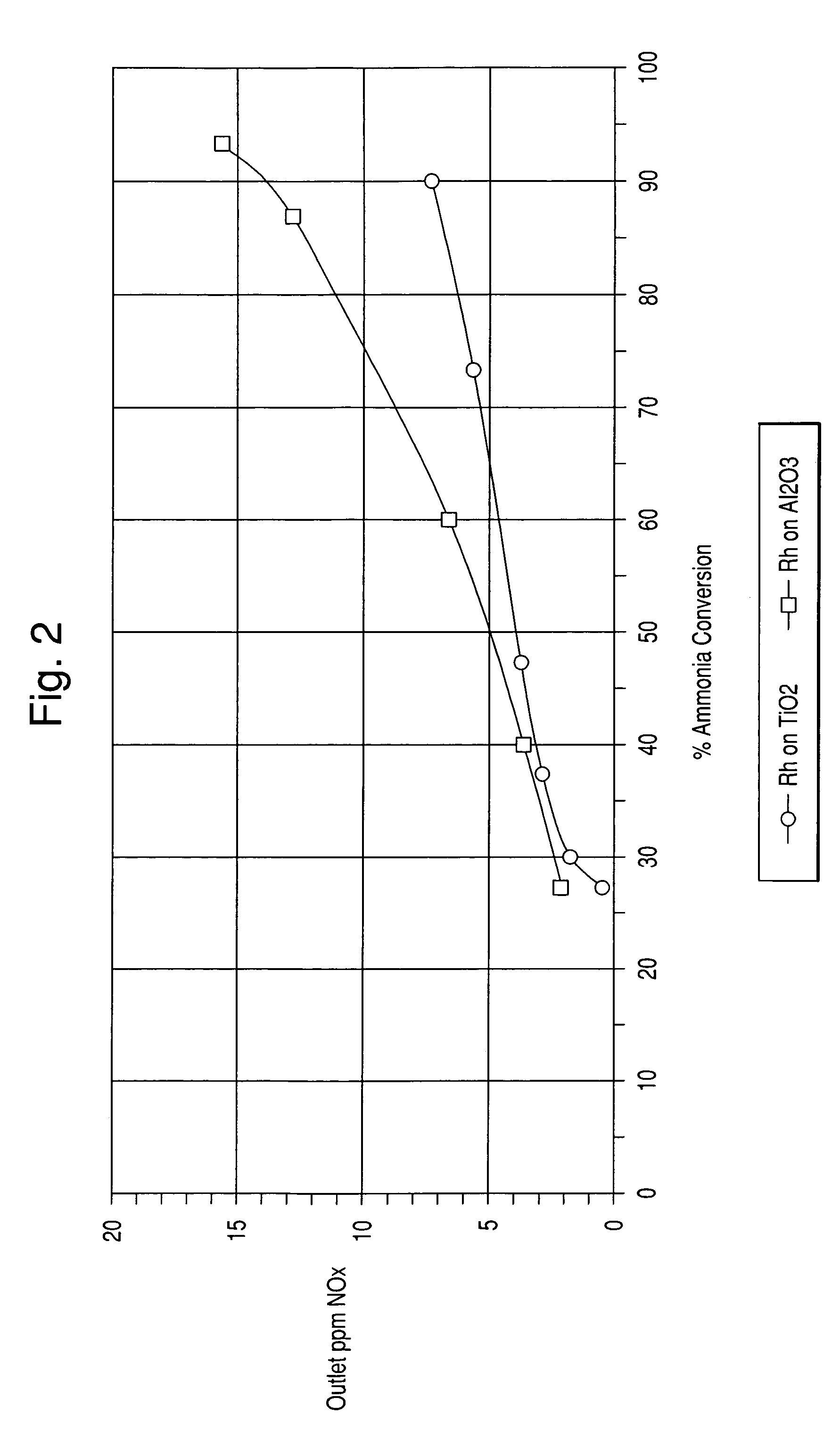

Ammonia oxidation catalyst for the coal fired utilities

InactiveUS7393511B2Undesirable emission levelNo sulfurCyanogen compoundsNitrogen compoundsSulfur dioxideCarbon monoxide

A process is described that removes by oxidation the excess ammonia (NH3) gas from flue gases that have been subjected to selective catalytic reduction (SCR) of oxides of nitrogen (NOx) by ammonia injection. The inventive process incorporates a secondary catalyst of precious metal and vanadia on a metal oxide such as titania to catalyze the oxidation of both ammonia and carbon monoxide (CO) while maintaining sulfur dioxide (SO2) levels.

Owner:BASF CATALYSTS LLC

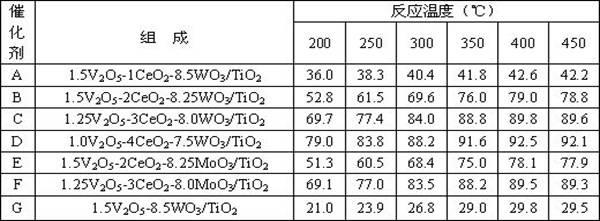

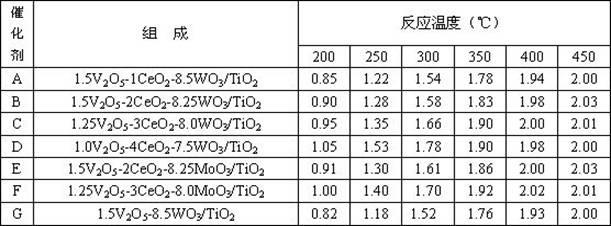

Composite smoke denitration catalyst capable of oxidizing zero-valence mercury

ActiveCN102350340AImprove oxidation capacityRealize collaborative controlDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystVanadate

The invention provides a composite smoke denitration catalyst capable of oxidizing zero-valence mercury. The catalyst is composite oxide V2O5-CeO2-WO3 / TiO2 or V2O5-CeO2-MoO3 / TiO2 based on TiO2 as a carrier, wherein the weight proportion is as follows: the weight percent of TiO2 is 75-100, the weight percent of V is 1-1.5, the weight percent of Ce is 1-5, and the weight percent of W or Mo is 7.5-8.5. The preparation method comprises the following steps: depositing Ce(OH)3 on nano TiO2; dipping ammonium vanadate / ammonium molybdate; and drying and roasting so as to obtain the catalyst; or dipping a commercial SCR (selective catalytic reduction) catalyst in a cerous nitrate aqueous solution, and then drying and roasting. The catalyst provided by the invention maintains the denitraiton efficiency of the original SCR catalyst and simultaneously the oxidation rate of zero-valence mercury is obviously improved, and divalent mercury ions are captured in subsequent dedusting equipment and wet desulphurization system; and the application temperature range of the catalyst is wide, the combination control of emission amounts of nitrogen oxides and mercury in smoke of a fuel coal power plant can be achieved on the promise that the smoke purification facility of the fuel coal power plant is not added.

Owner:GUODIAN SCI & TECH RES INST

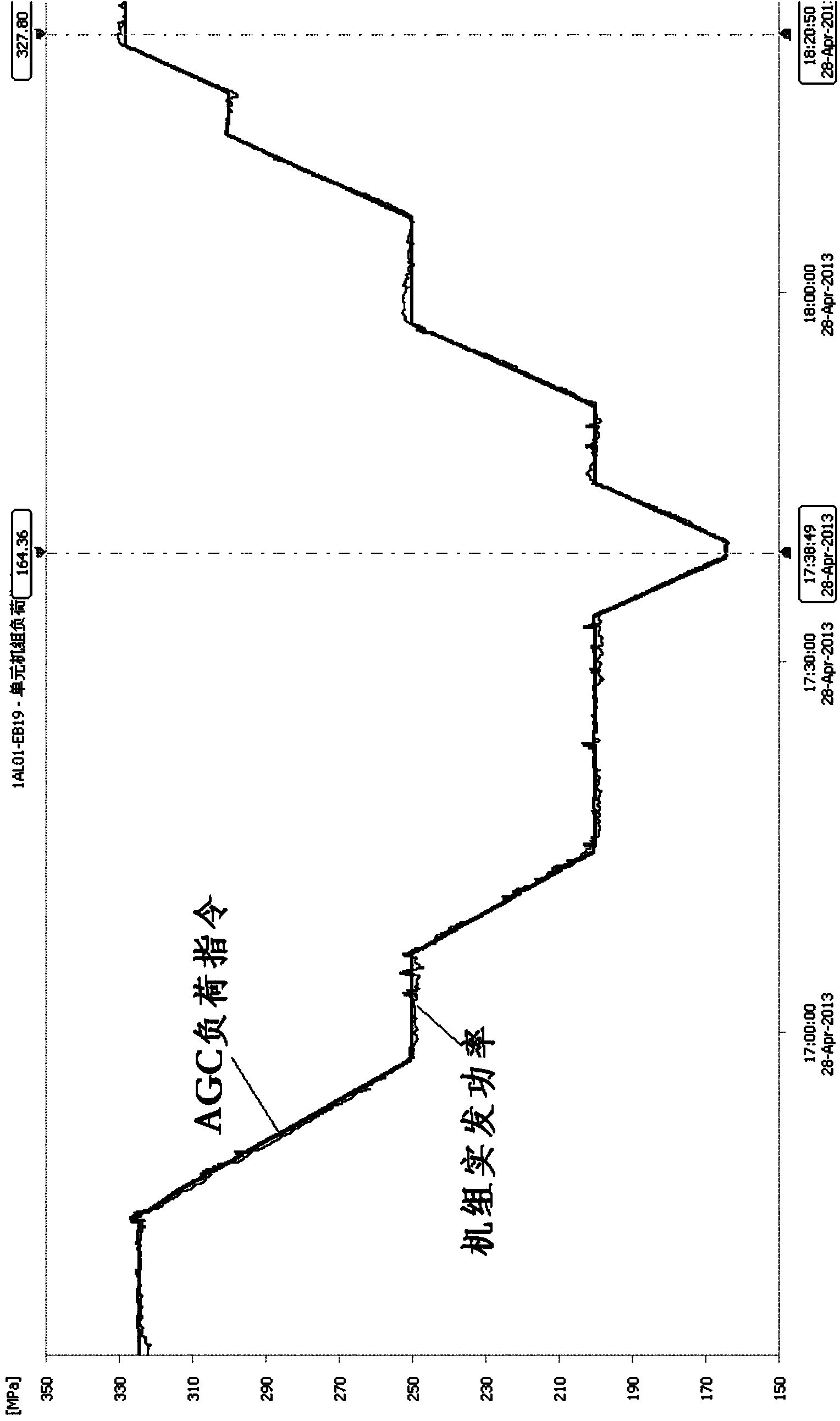

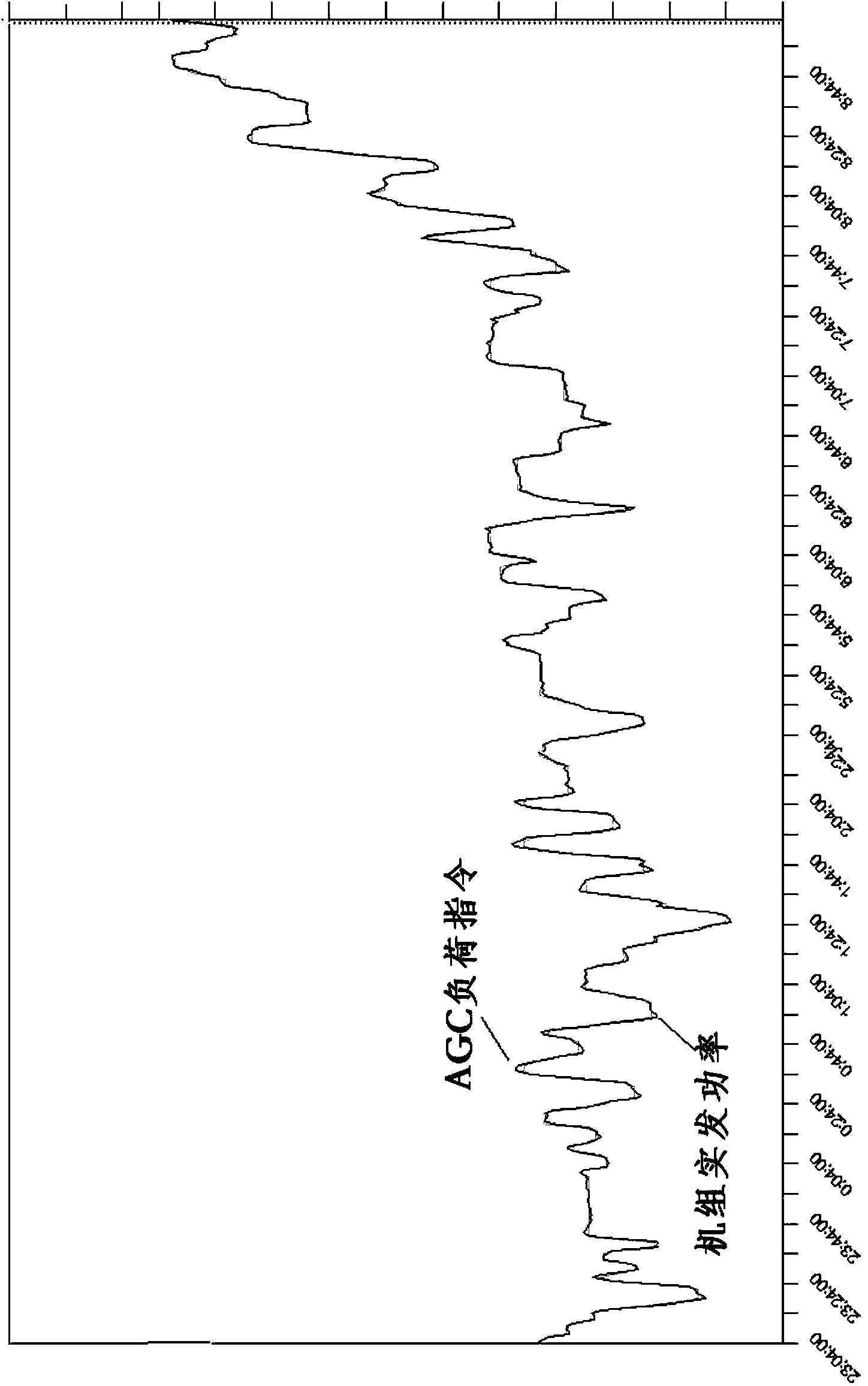

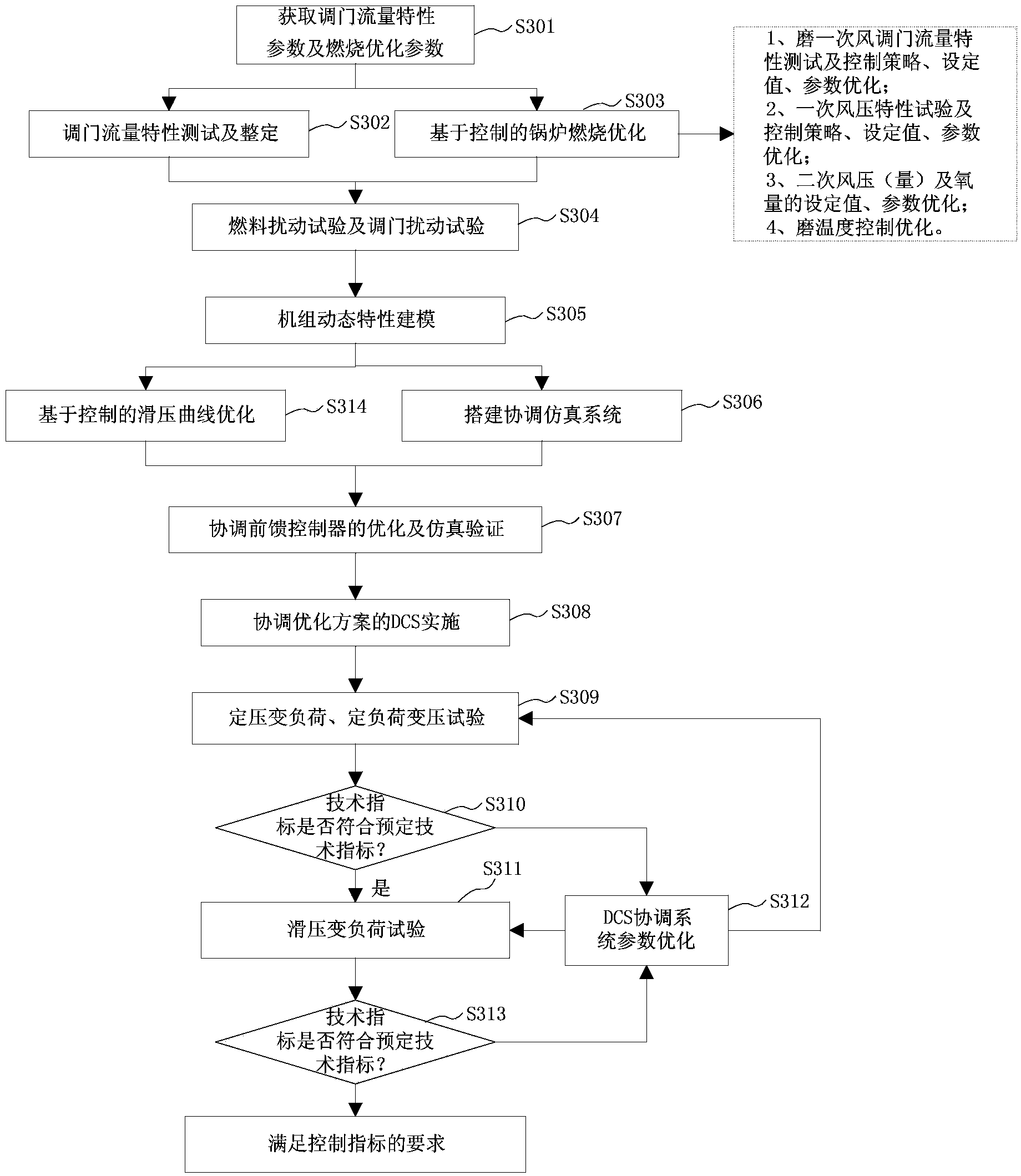

Integral optimization method and system for automatic power generation system of coal-fired unit

ActiveCN103513640AImprove variable load capacityImprove adaptabilityProgramme total factory controlSteam pressureDynamic models

The invention provides an integral optimization method and system for an automatic power generation system of a coal-fired unit. The method comprises the steps of carrying out control valve flow characteristic test and adjustment according to control valve flow characteristic parameters, carrying out combustion optimization on a wind and smoke subsystem and a combustion subsystem, carrying out a fuel disturbance test and a control valve disturbance test to generate typical test parameters, using the typical test parameters to generate a dynamic unit model, constructing a coordinating simulation system according to a coordinating controller and the dynamic unit model, using the dynamic unit model to optimize a feedforward controller and carry out simulation verification on the coordinating simulation system simultaneously, carrying out DCS configuration and parameter debugging in the simulation system, carrying out a constant-voltage slide-voltage variable-load test and a constant-load voltage-transformation test to generate technical indexes of the variable-load rate, the variable-load accuracy, variable-load response time and the main steam pressure accuracy, judging whether the technical indexes meet the preset technical indexes, and if on yes judgment, carrying out a slide-voltage variable-load test to enable the coal-fired unit to operate normally.

Owner:STATE GRID CORP OF CHINA +1

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

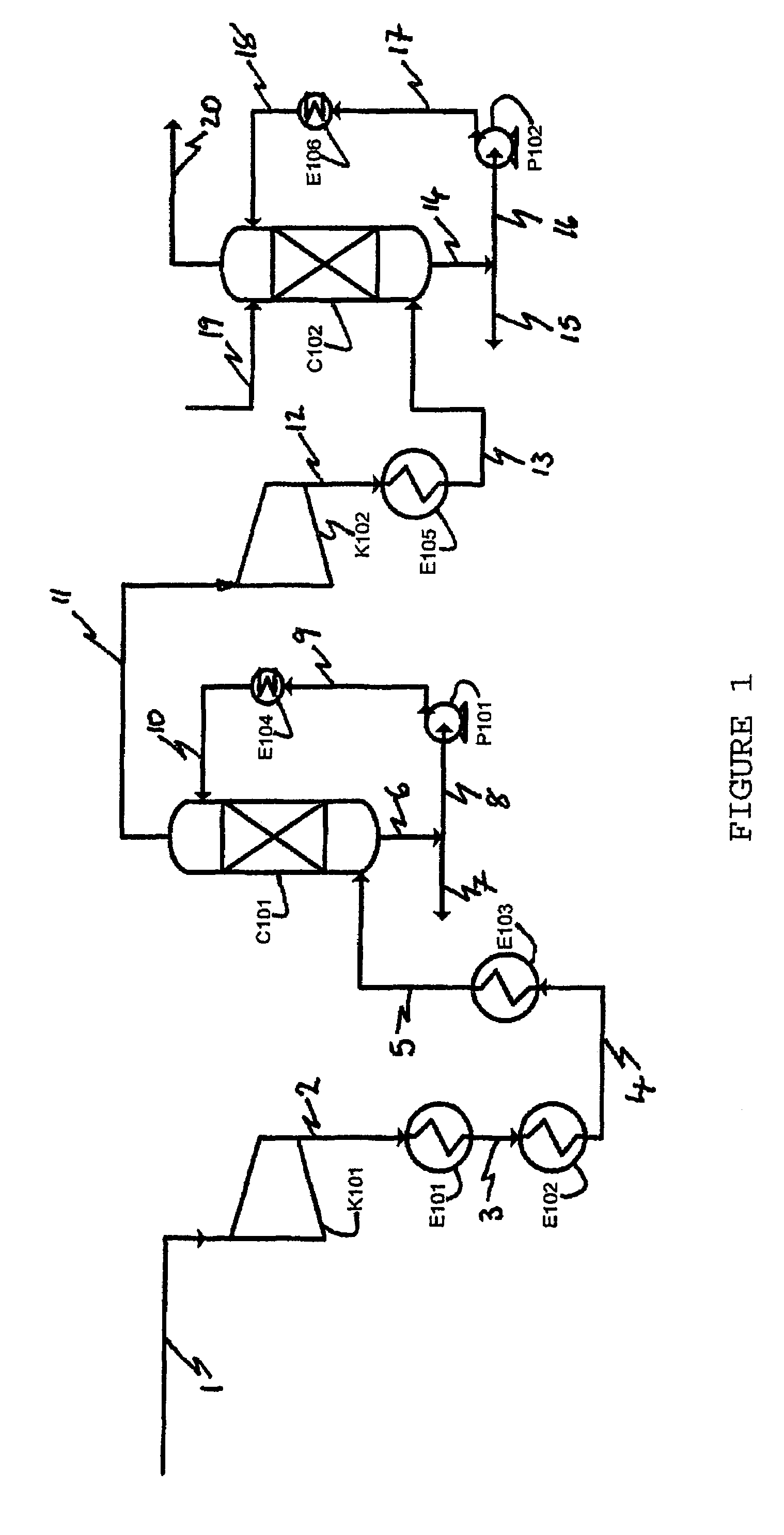

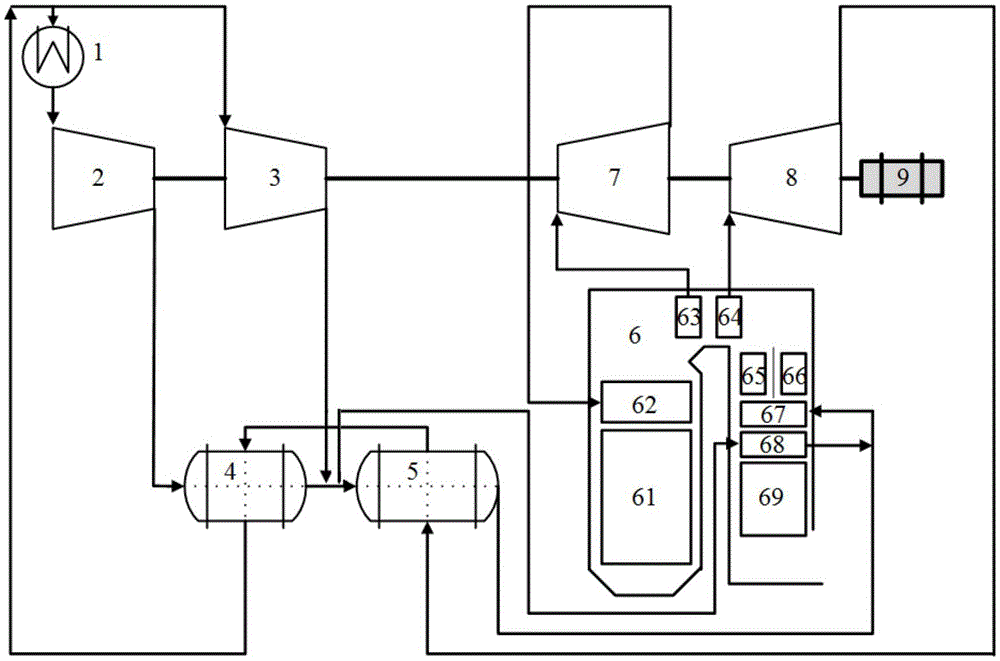

Solar energy and coal-burning unit combined thermal power generation system

InactiveCN101270675AHigh thermal efficiencyImprove thermal efficiencySteam engine plantsDeaeratorEngineering

The invention relates to a generating system, in particular to the heat generating system consisting of a solar heat collector and a coal-fired unit. The heat generating system adopts solar energy to take the place of the partial coal-fired heat energy of a coal-fired unit boiler. A condenser, an extraction pump, a low pressure heater, a deaerator, a water-feeding pump, a high pressure heater and the heat collector, a coal burning boiler and a steam turbine that are connected in parallel are connected in series. The steam turbine drives the generator and discharges gas into the condenser. Condensed water flows into a heater from the condenser to be heated up and pressurized, is deoxidized by the deaerator, then goes through the solar heat collector to be heated to be saturated vapor and goes into the coal burning boiler or directly goes into the coal burning boiler to become the steam with high temperature and high pressure. And then the steam goes into the steam turbine for applying work to drive the generator to generate electricity. The extracted steam of the steam turbine goes into each heater to finish thermodynamic cycle. The thermal efficiency of solar thermal power generation is improved, investment in the trough solar electrical energy generation of single paraboloid is reduced and the coal consumption of the coal-fired unit is decreased.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

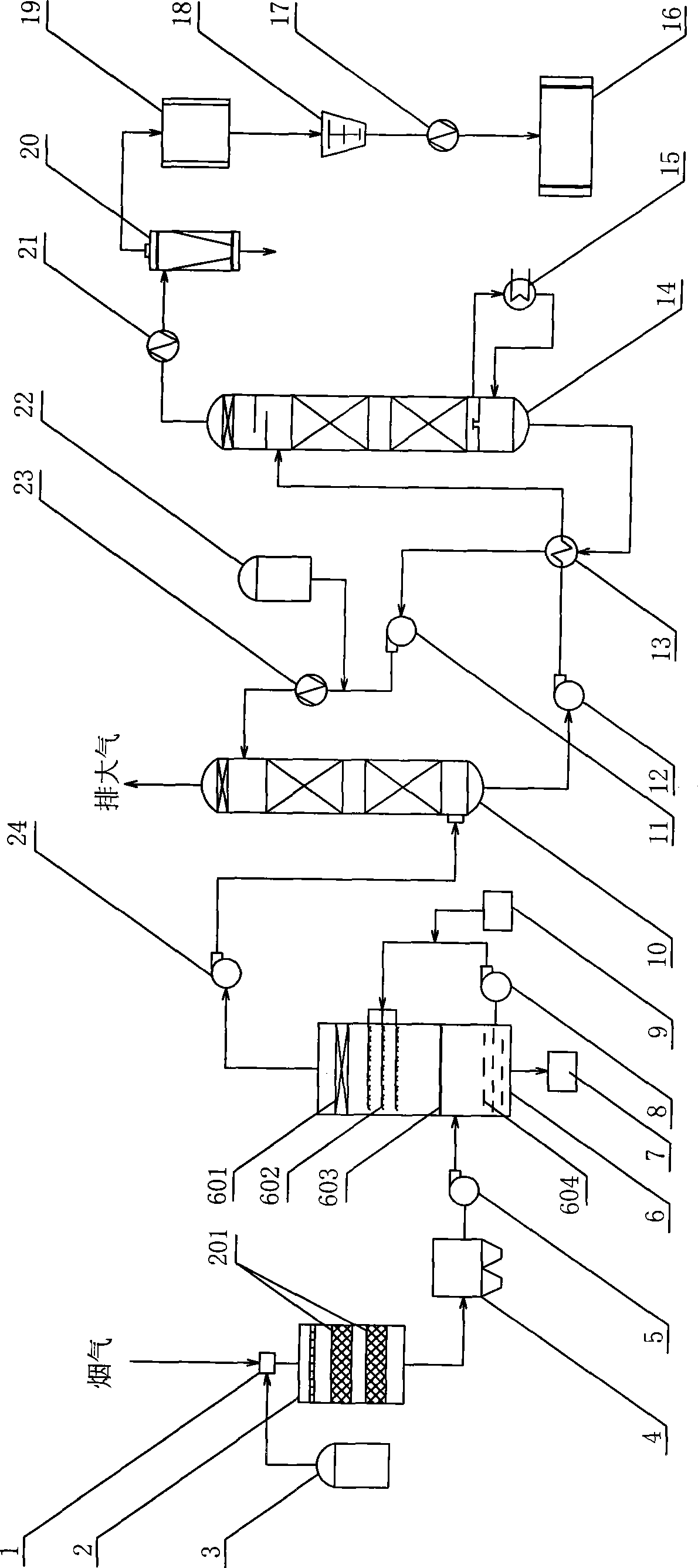

Multi-pollutant removing technique and device of fuel coal smoke

InactiveCN101422691ALow flow resistanceReduce investmentProductsCarbon compoundsHigh concentrationDecarburization

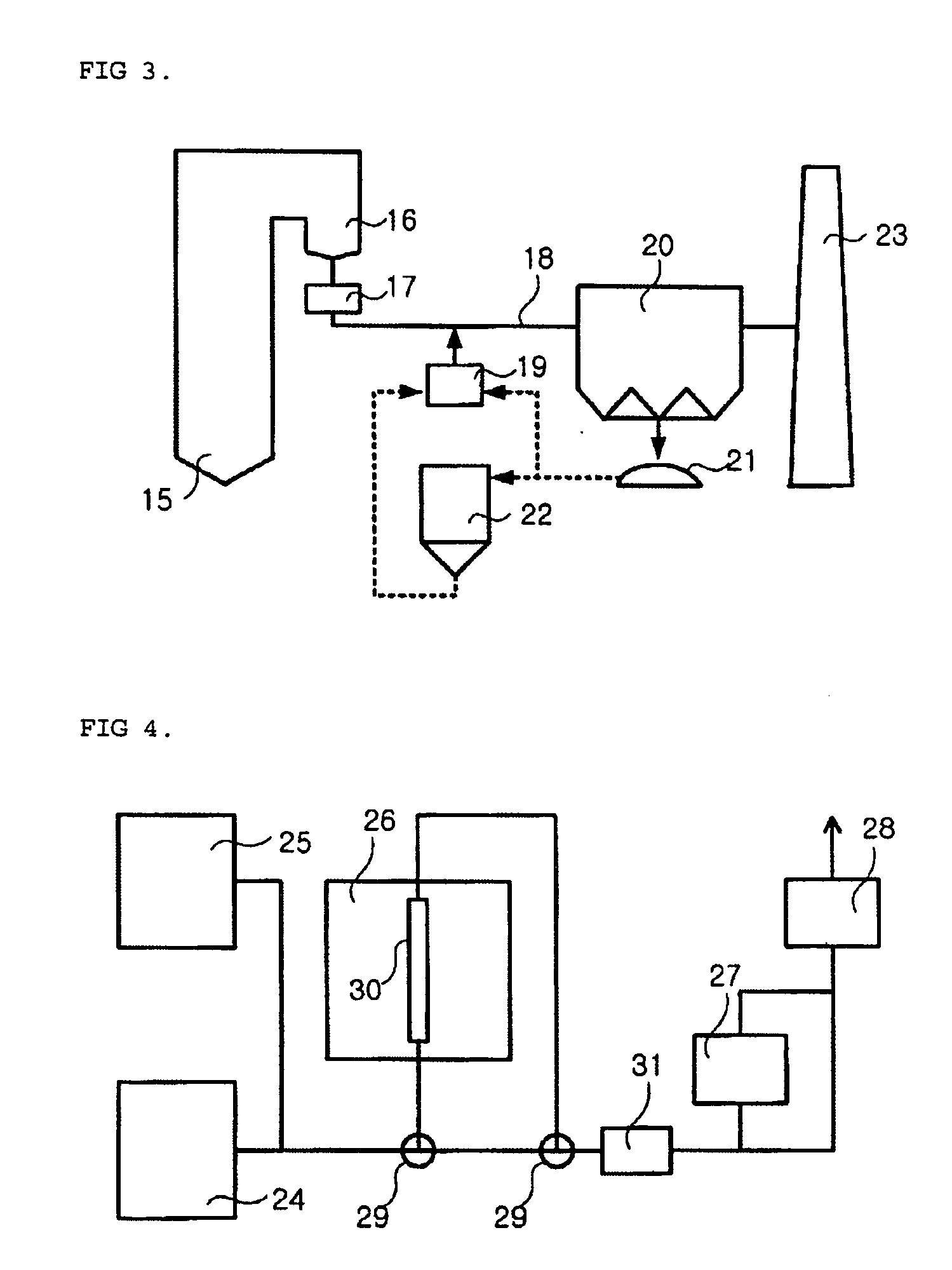

The invention discloses a removal technology of removing coal-fired flue gas pollutants and a device thereof. The technology is as follows: an SCR denitration method is first used for removing NOX in the flue gas; then a dust collector is used for removing dusts and ash particles in the flue gas; then a wet calcium-based desulphurization method is used for removing SO2 in the flue gas; then an MEA decarburization process is used for absorbing the SO2 in the flue gas; simultaneously, a pregnant solution of a generated alkanolamine solution is heated, analyzed and regenerated and the generated barren solution of the alkanolamine solution is continuously and cyclically used; and the analyzed CO2 gas with high concentration is produced to be liquid carbon dioxide of industrial grade with high purity after being cooled, gas-liquid separated, dried, compressed and condensed. The device consists essentially of an SCR denitration reactor, the dust collector, a wet calcium-based desulphurization reactor, an MEA decarburization absorption tower, a regeneration tower, a gas-liquid separator, a dryer, a compressor, a condenser and the like which are connected with each other by pipes. The device has simple and compact overall design, low investment and operation costs, and stable and reliable work and can conduct classified integration processing and highly efficient simultaneous removal on every pollutant in the coal-fired flue gas.

Owner:WUHAN KAIDI ELECTRIC POWER ENVIRONMENTAL

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

Device and method of simultaneous desulfuration and denitration for flue gas using ozone oxygenation combined with double-tower washing

ActiveCN101485957ARealize separate recyclingAchieve denitrification efficiencyDispersed particle separationOzone generatorFlue gas

The invention relates to a technique for processing flue gas of a coal burning boiler, and aims to provide a device and a method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing. The device comprises a flue which is connected with a heat exchanger, an alkali liquor washing tower A, and an alkali liquor washing tower B in sequence, wherein the insides of the alkali liquor washing tower A and the alkali liquor washing tower B are provided with a circular spraying device A and a circular spraying device B respectively; and an ozone generator is connected with a lower liquid phase area of the alkali liquor washing tower A and a pipeline in front of the circular spraying device B respectively. The novel method for desulfurizing and denitrating the flue gas of the coal burning boiler by using ozone oxidation and double tower washing can achieve the denitration efficiency of more than 80 percent and desulfurization efficiency of more than 95 percent, and realize the reclaiming and reusing denitrated and desulfurized products in different devices respectively.

Owner:ZHEJIANG UNIV +1

Method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas

InactiveCN101816886APromote regenerationSolve pollutionDispersed particle separationAir quality improvementMass ratioSorbent

The invention provides a method for simultaneously desulfurating, denitrating and decarbonizing coal-fired flue gas. The method comprises the following steps: dedusting and cooling the coal-fired flue gas containing SO2, NOx and CO2; leading the gas into an adsorbent for saturated adsorption at the adsorption temperature of 50-100 DEG C and the adsorption pressure of 50-10000Pa; evacuating the coal-fired flue gas, desorbing the adsorbent by means of pressure reduction or temperature rise, and then repeatedly using; leading the desorbed gas into ammonia water for absorption treatment, wherein, the mass ratio of the ammonia water to the mixed gas containing SO2, NOx and CO2 is 2-6:1, the absorption temperature is 30-50 DEG C, and the absorption pressure is 5000-12000Pa; and recycling the gas to generate ammonium sulfate, ammonium nitrate and ammonium carbonate. The method can achieve simultaneouse desulfuration, denitration and decarbonization, and has small investment, low cost and low energy consumption; and the method can be widely applied to purification treatment of SO2, NOx and CO2 in the waste gas discharged from fixed fire coal sources such as thermal power plants, smelting plants, oil refinery, chemical plants and the like.

Owner:KUNMING UNIV OF SCI & TECH

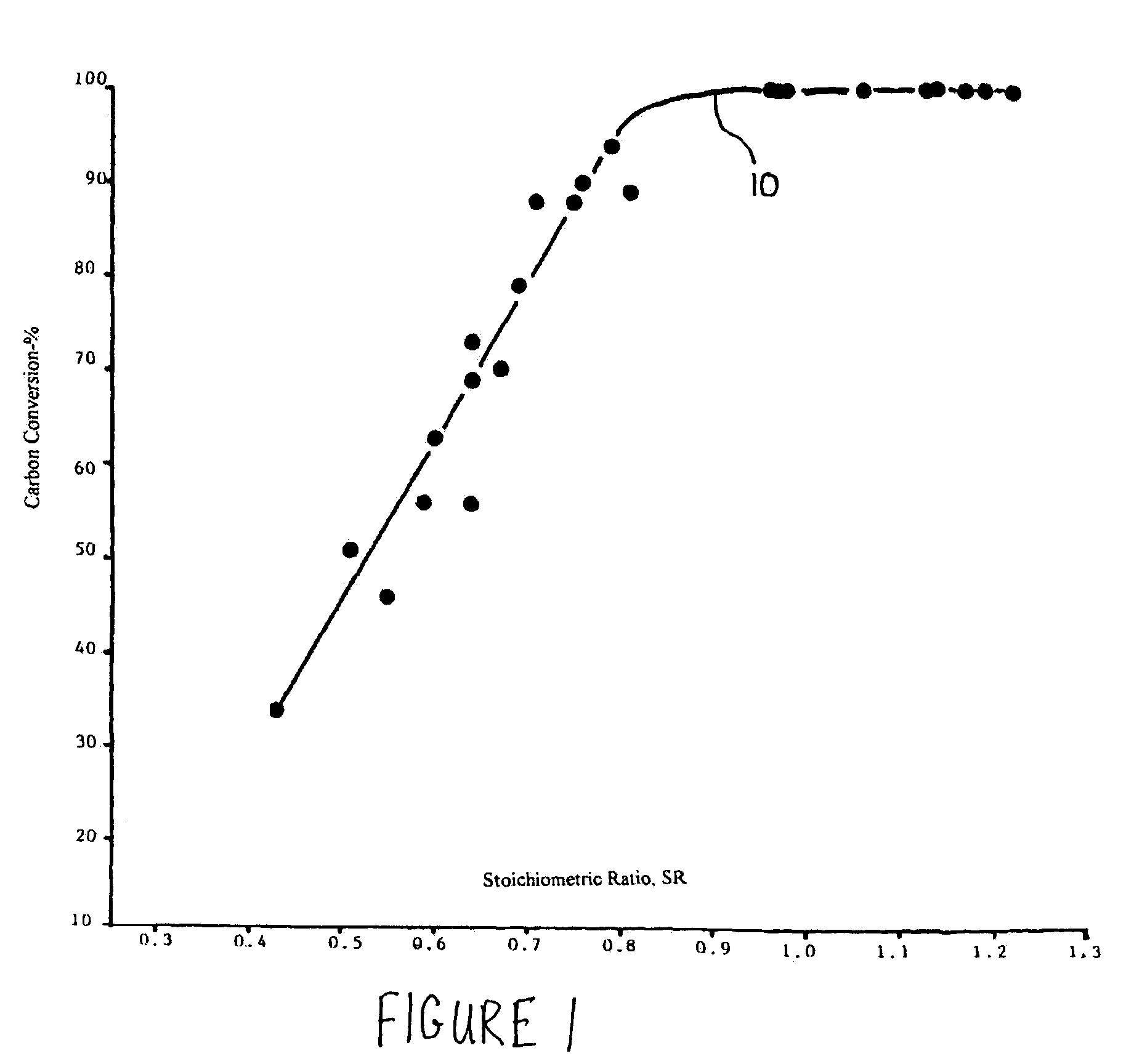

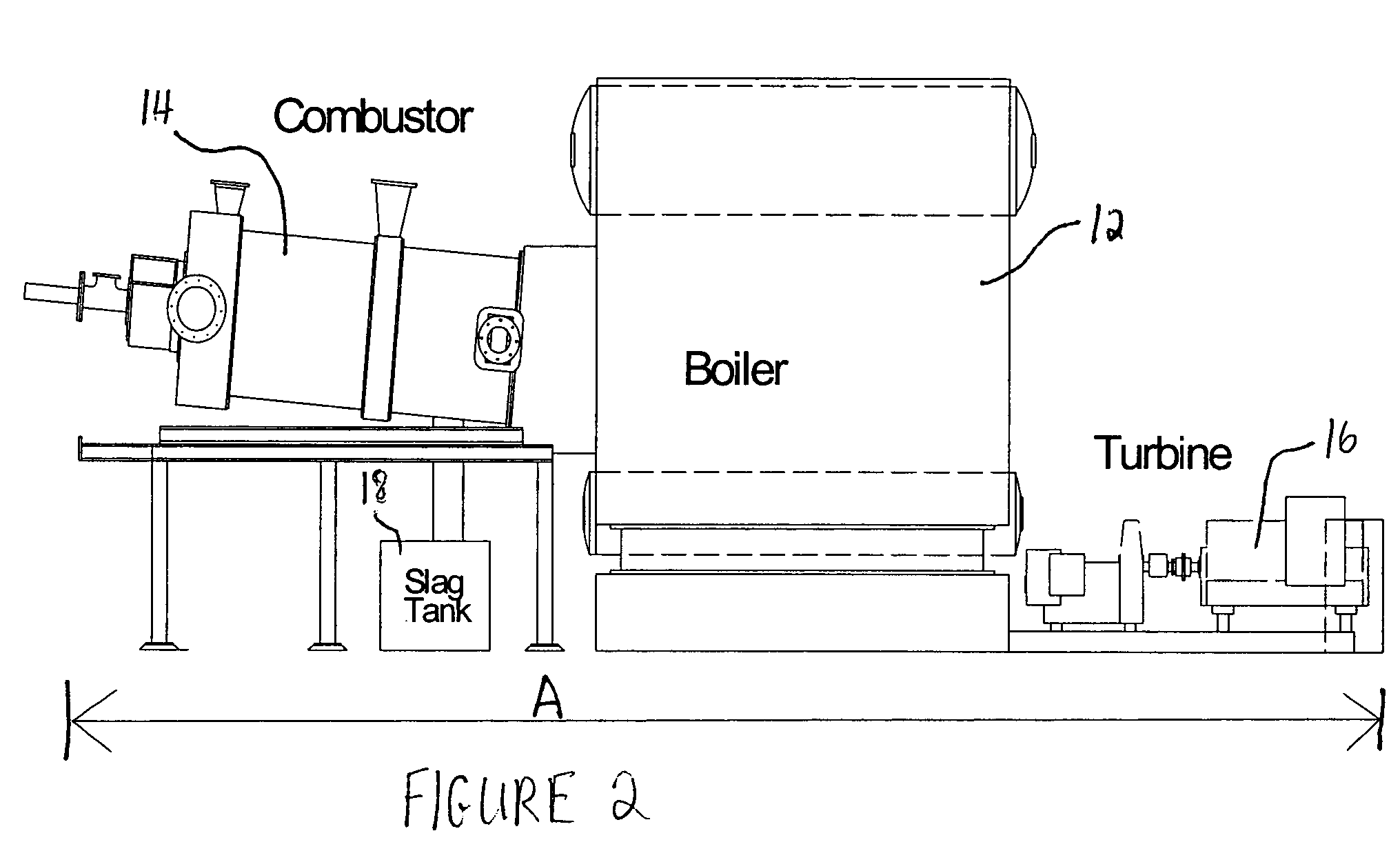

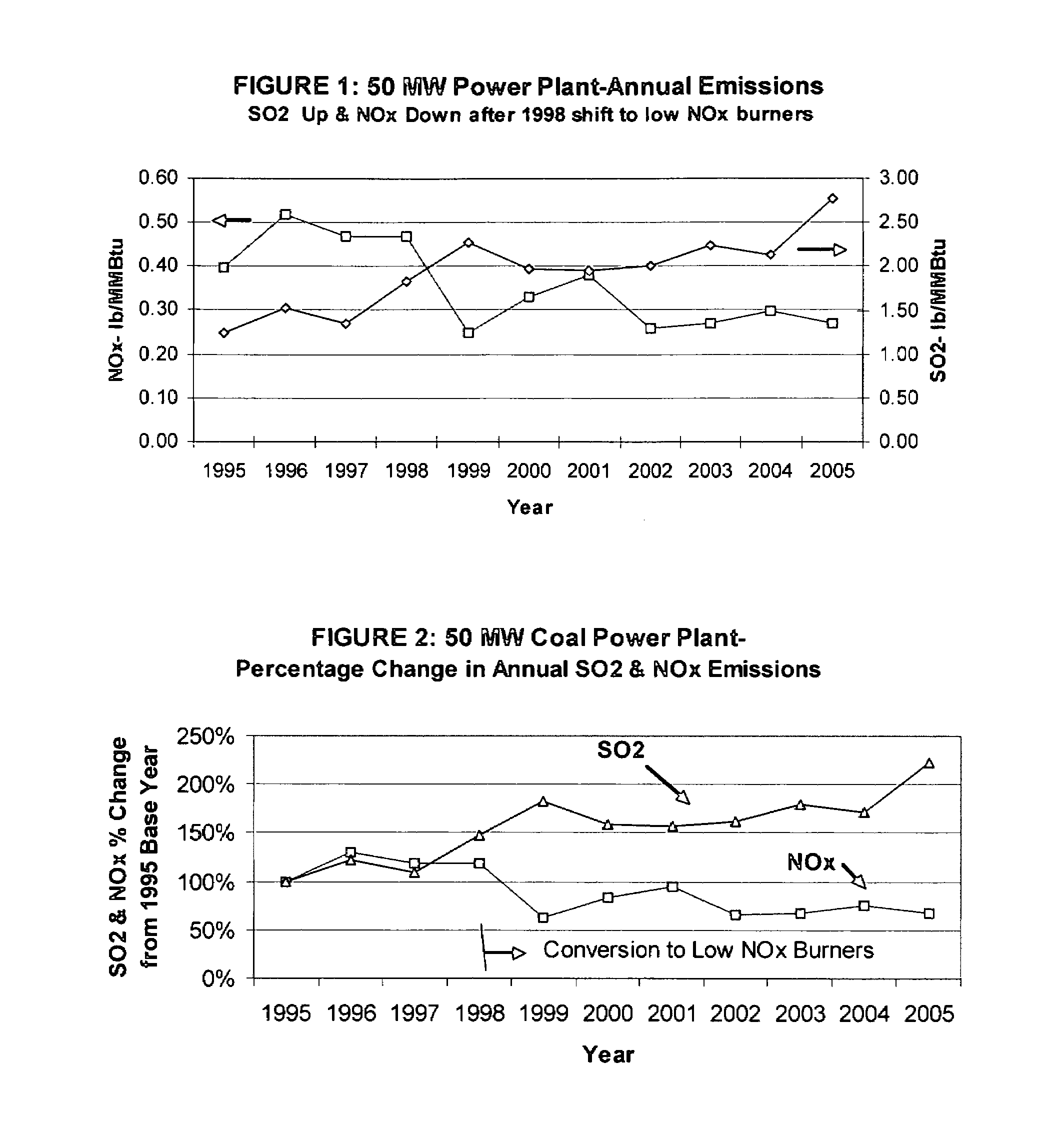

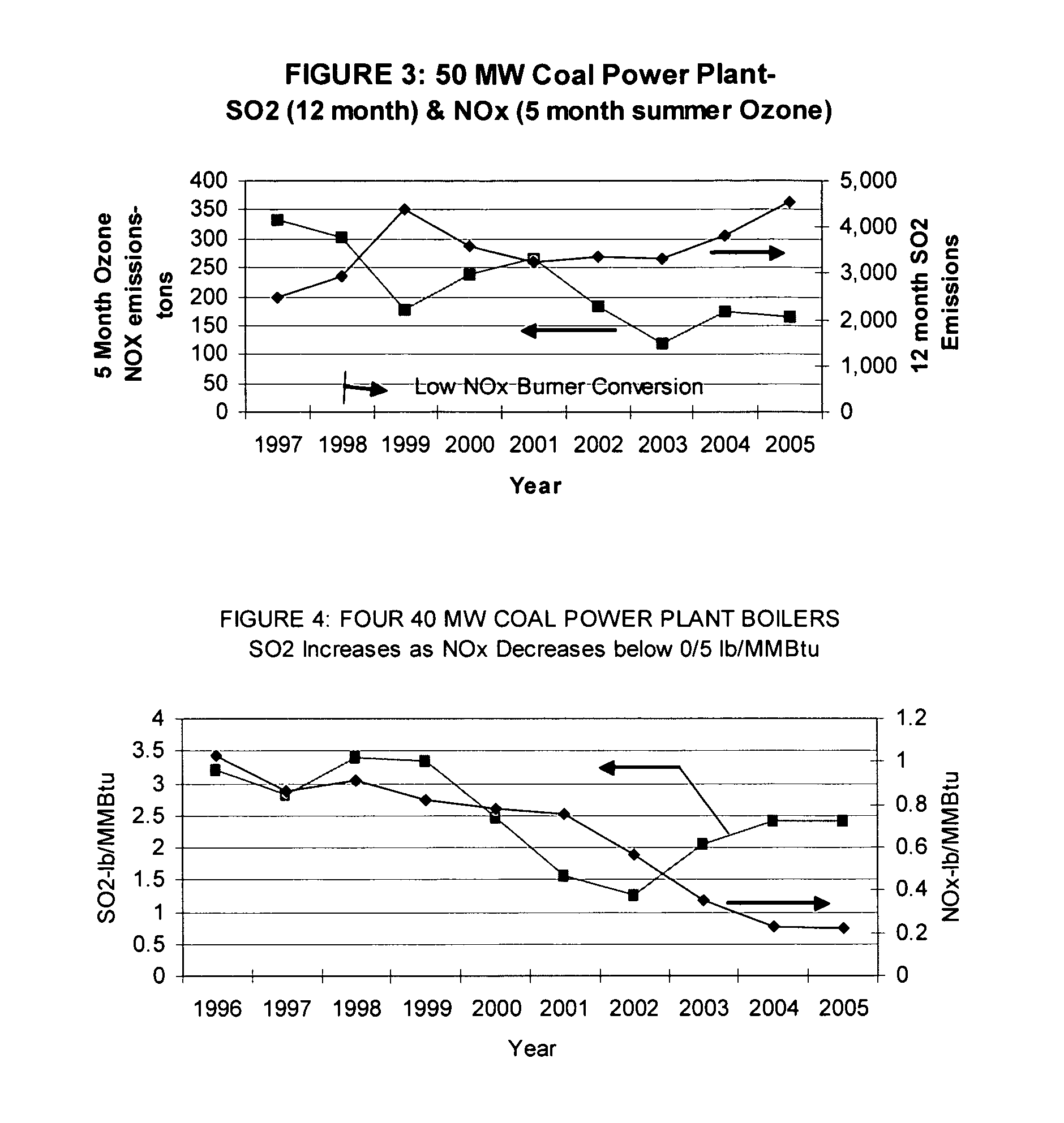

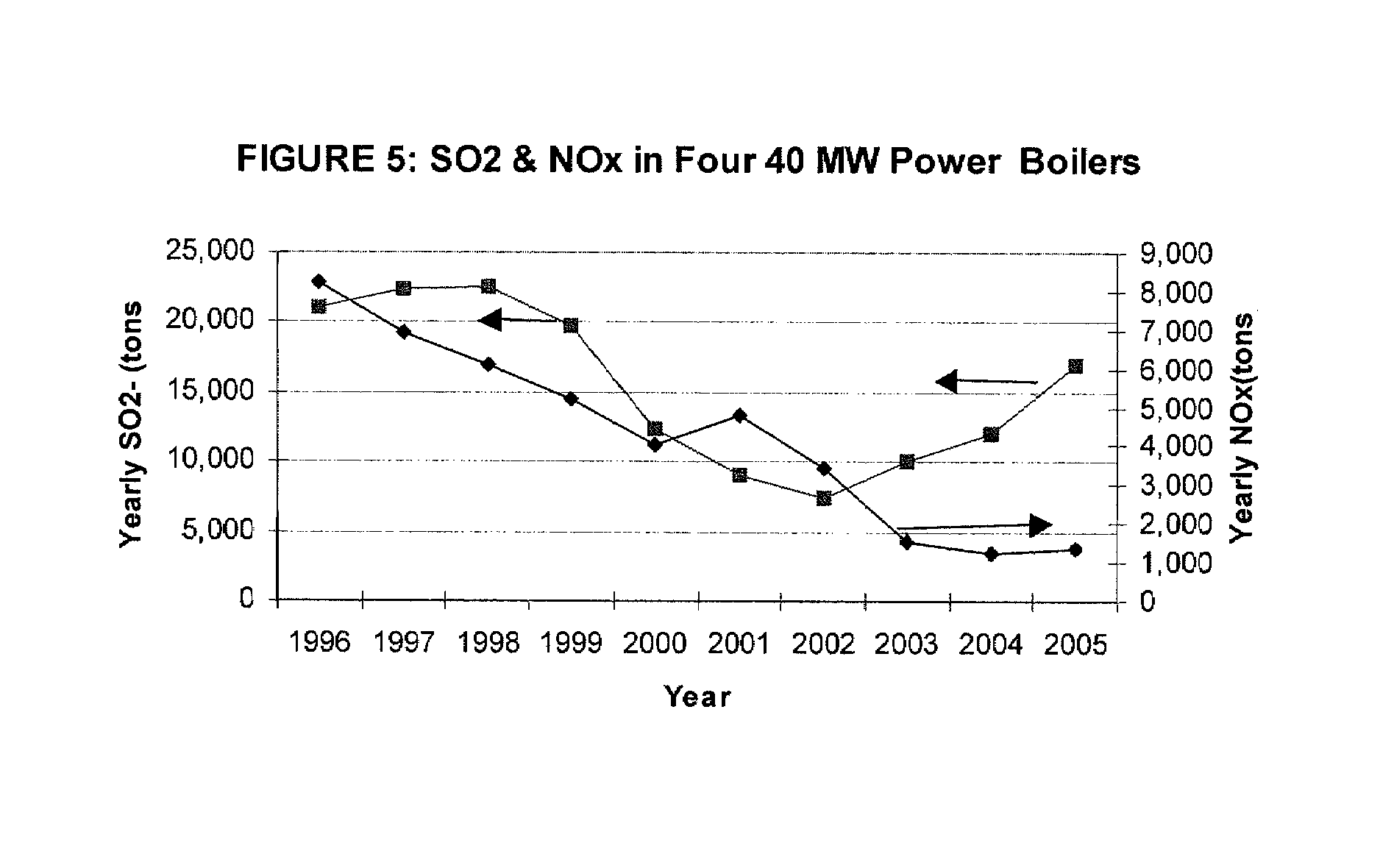

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

Faviform ammonia-method selective-catalytic-reduction denitrified catalyst and preparation method thereof

InactiveCN101676024AGood formabilityHigh strengthDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsDrying timeAmmonia

The invention relates to a faviform ammonia-method selective-catalytic-reduction denitrified catalyst and a preparation method thereof. The invention is characterized in that the catalyst uses TiO2 with a special specific surface area as the carrier and uses V2O5 and WO3 as the catalyst and the cocatalyst, various assistants favorable for the catalyst to form, disperse and perforate are simultaneously added, and the faviform denitrified catalyst is obtained in short drying time and calcination time. The catalyst comprises the following components in weight percent: 80-99% of TiO2, 0.1-2% of V2O5 and 5-10% of WO3. The method selects the TiO2 with the special specific surface area as the carrier, simultaneously adds the proper forming assistants and combines the special preparation techniqueso as to obtain the faviform denitrified catalyst with high strength and favorable forming performance and enhance the denitration activity of the catalyst; when the trial denitration test is carriedout on the faviform denitrified catalyst in a small-size coal burning boiler, the airspeed is 5000 / hr, and the concentration of NOX is about 100 ppmv; when the fume temperature is 350 DEG C, the denitration efficiency reaches 95%; and after long-term operation, the denitration efficiency is still above 80%.

Owner:晶锐瓷业(北京)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com