Patents

Literature

2810results about "Sulfur compounds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbon Dioxide Capture and Mitigation of Carbon Dioxide Emissions

InactiveUS20080031801A1Pressure dropCalcium/strontium/barium carbonatesLiquefactionSorbentSolid surface

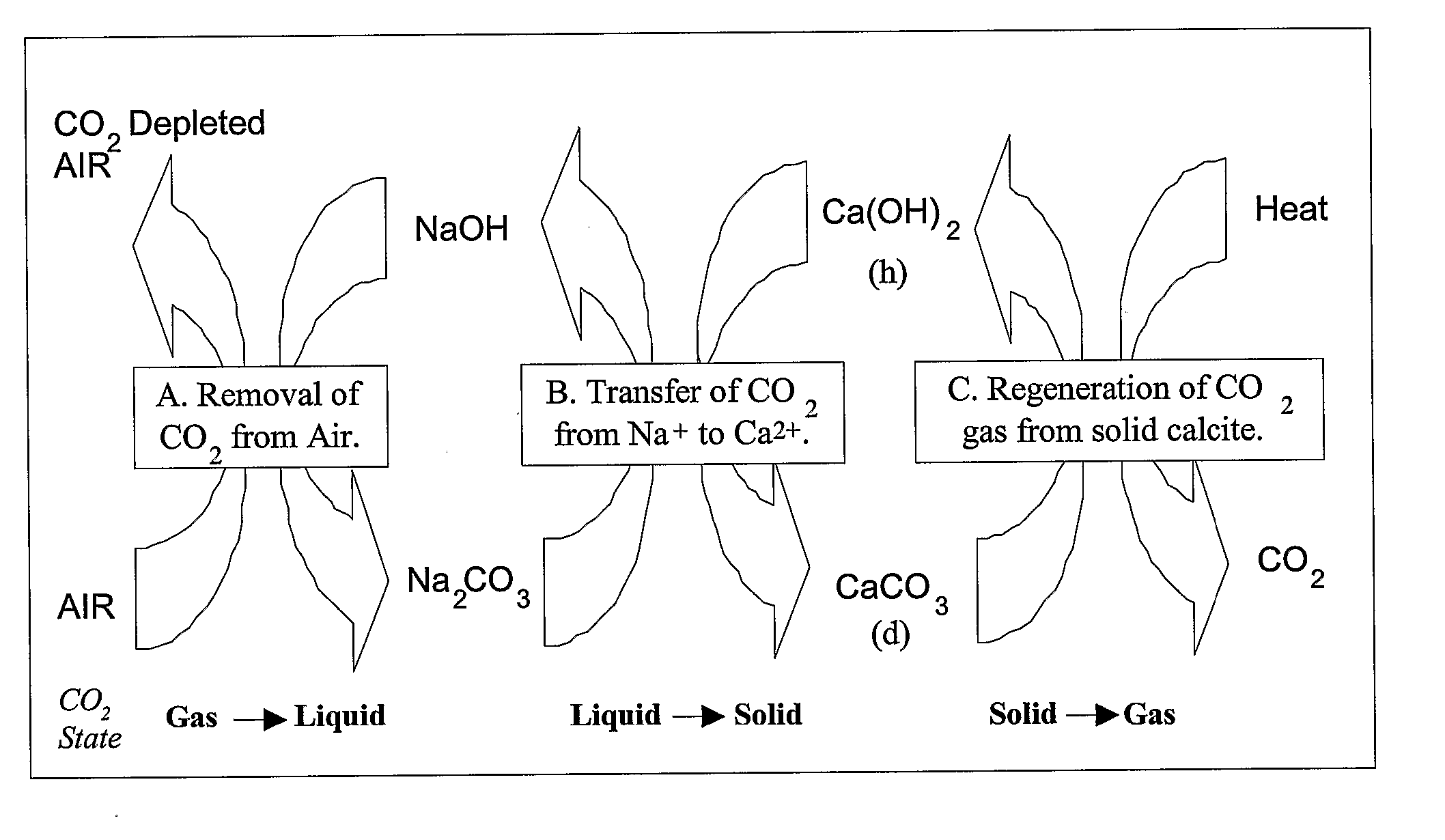

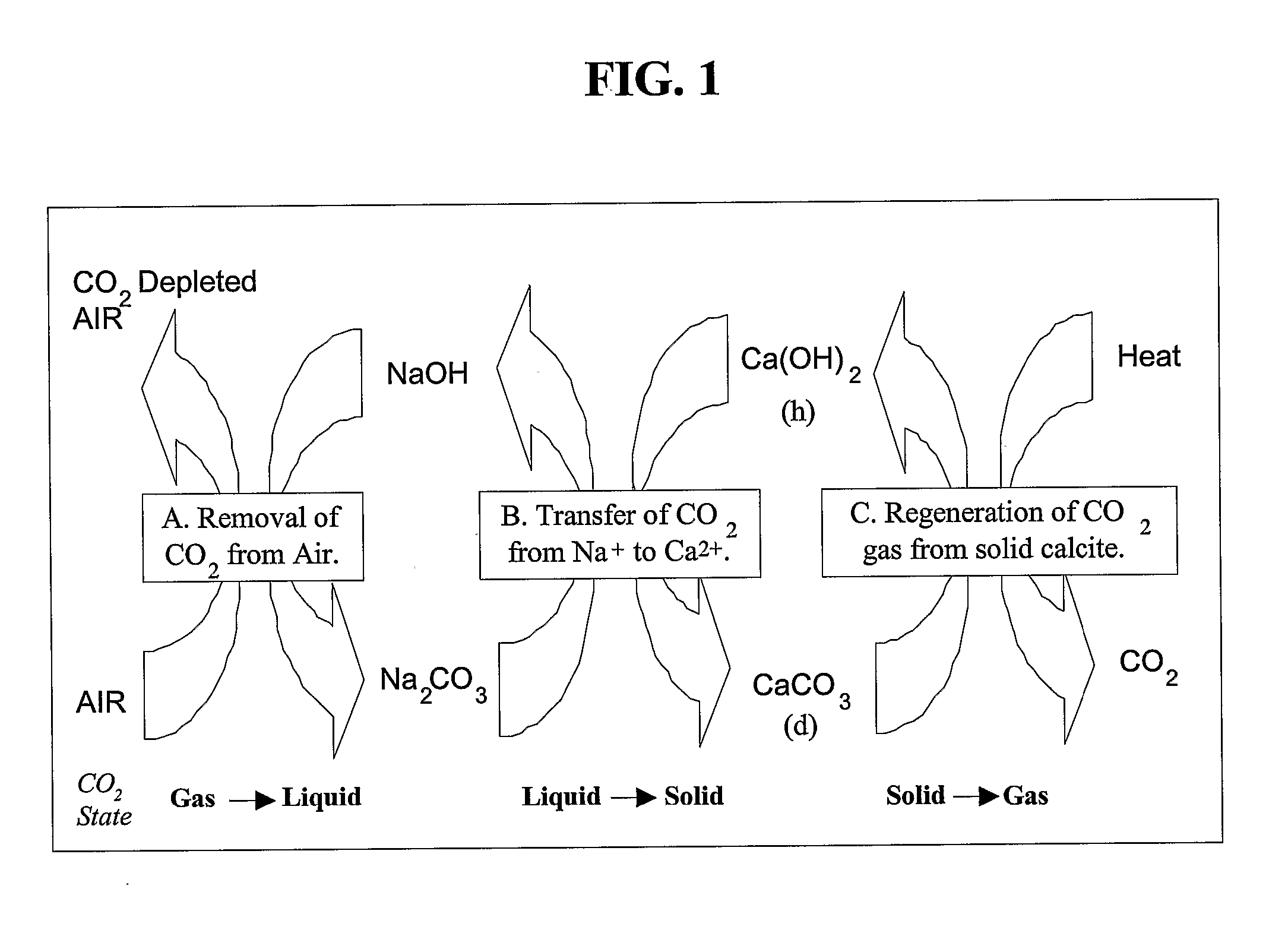

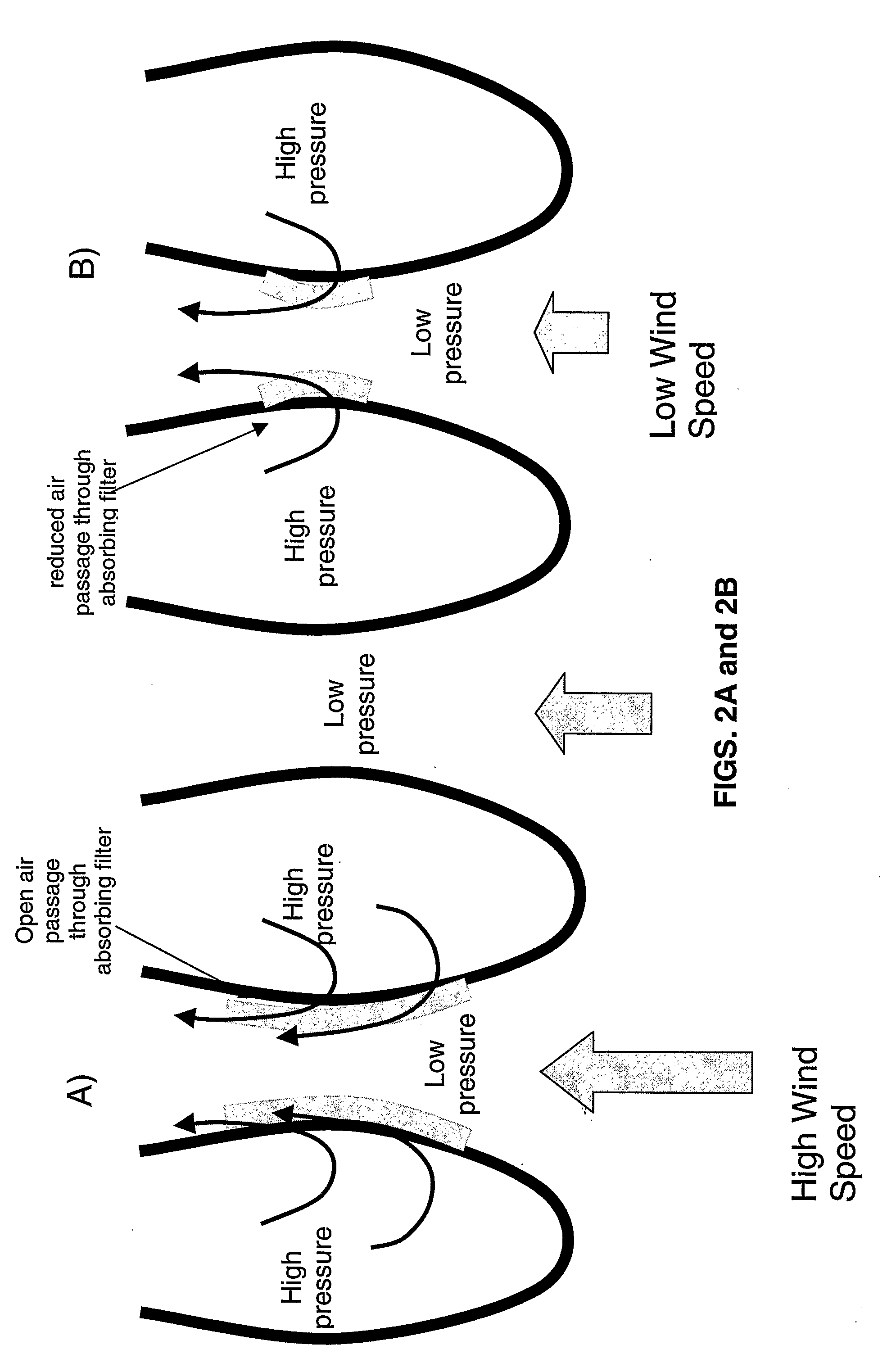

The present invention describes methods and systems for extracting, capturing, reducing, storing, sequestering, or disposing of carbon dioxide (CO2), particularly from the air. The CO2 extraction methods and systems involve the use of chemical processes, mineral sequestration, and solid and liquid sorbents. Methods are also described for extracting and / or capturing CO2 via condensation on solid surfaces at low temperature.

Owner:THE TRUSTEES OF COLUMBIA UNIV IN THE CITY OF NEW YORK +1

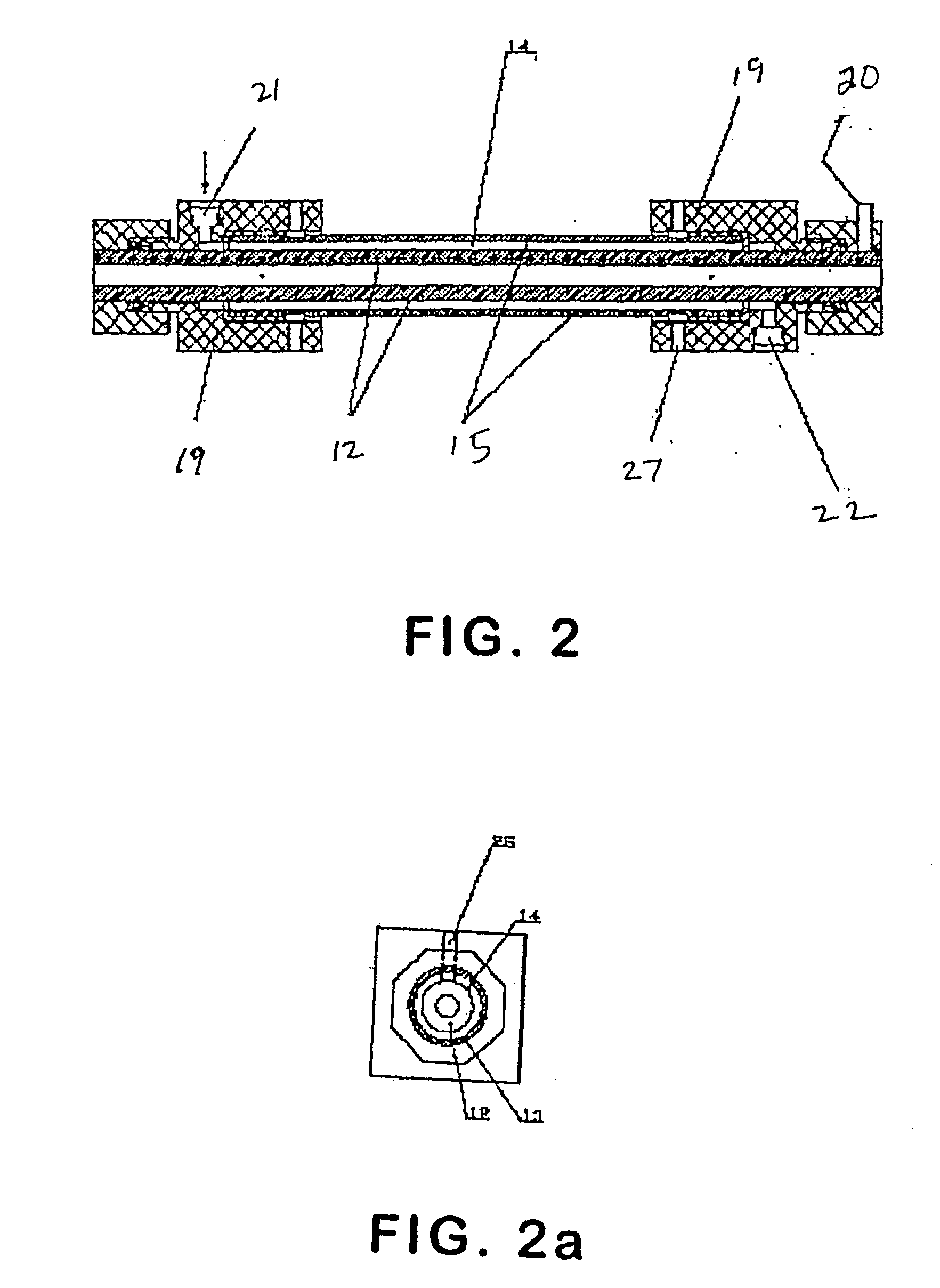

Electrocatalyst powders, methods for producing powders and devices fabricated from same

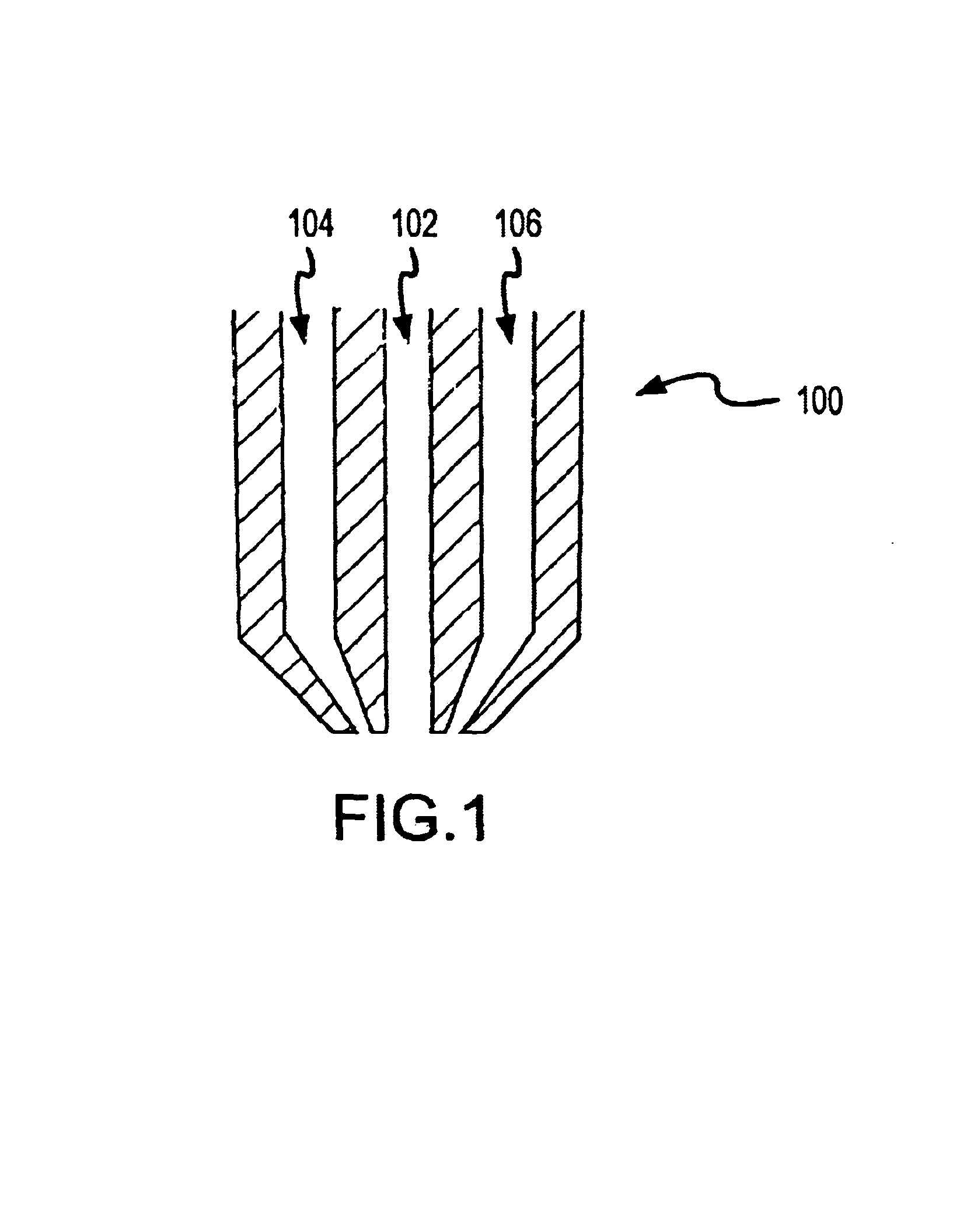

Electrocatalyst powders and methods for producing electrocatalyst powders, such as carbon composite electrocatalyst powders. The powders have a well-controlled microstructure and morphology. The method includes forming the particles from an aerosol of precursors by heating the aerosol to a relatively low temperature, such as not greater than about 400° C.

Owner:CABOT CORP

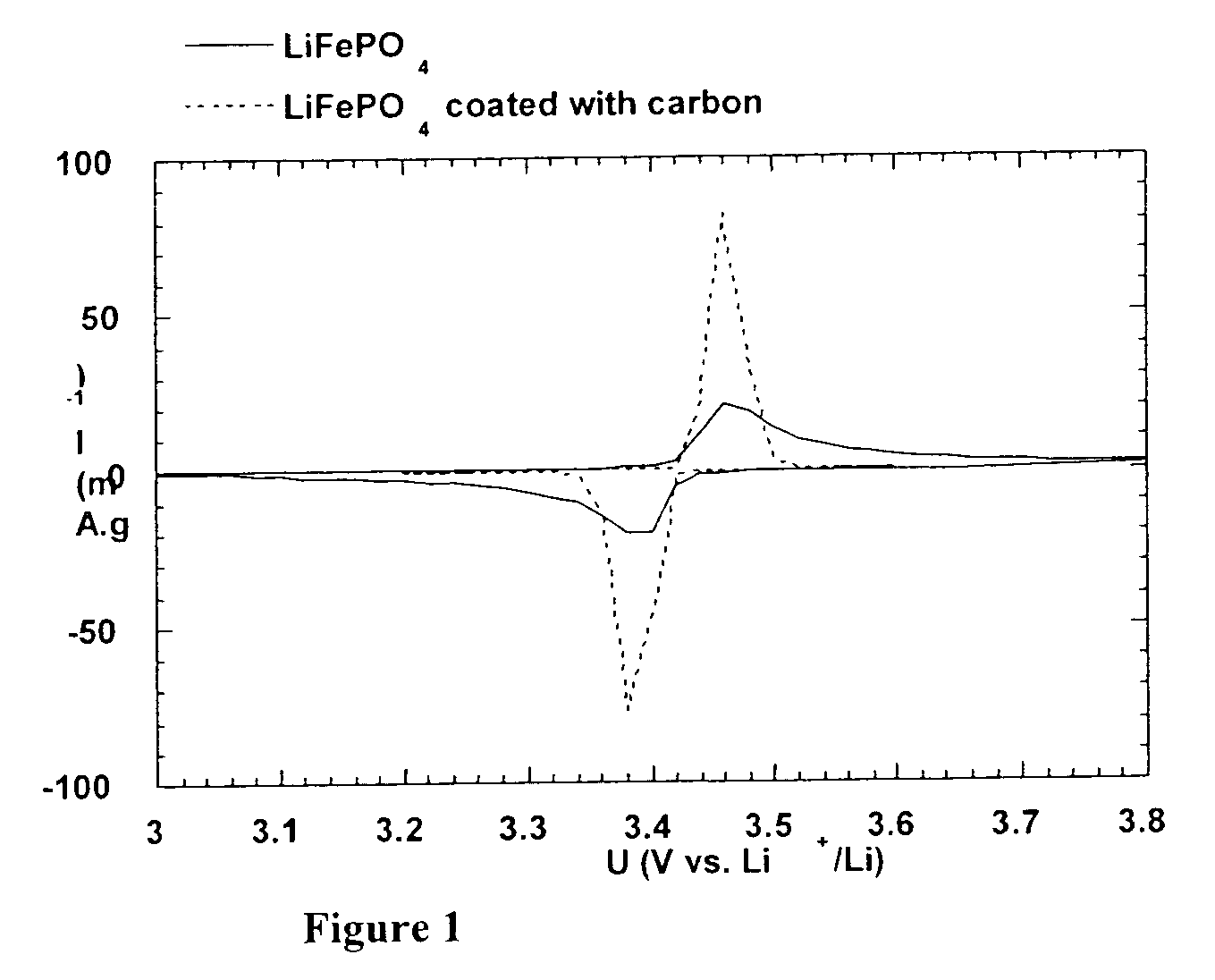

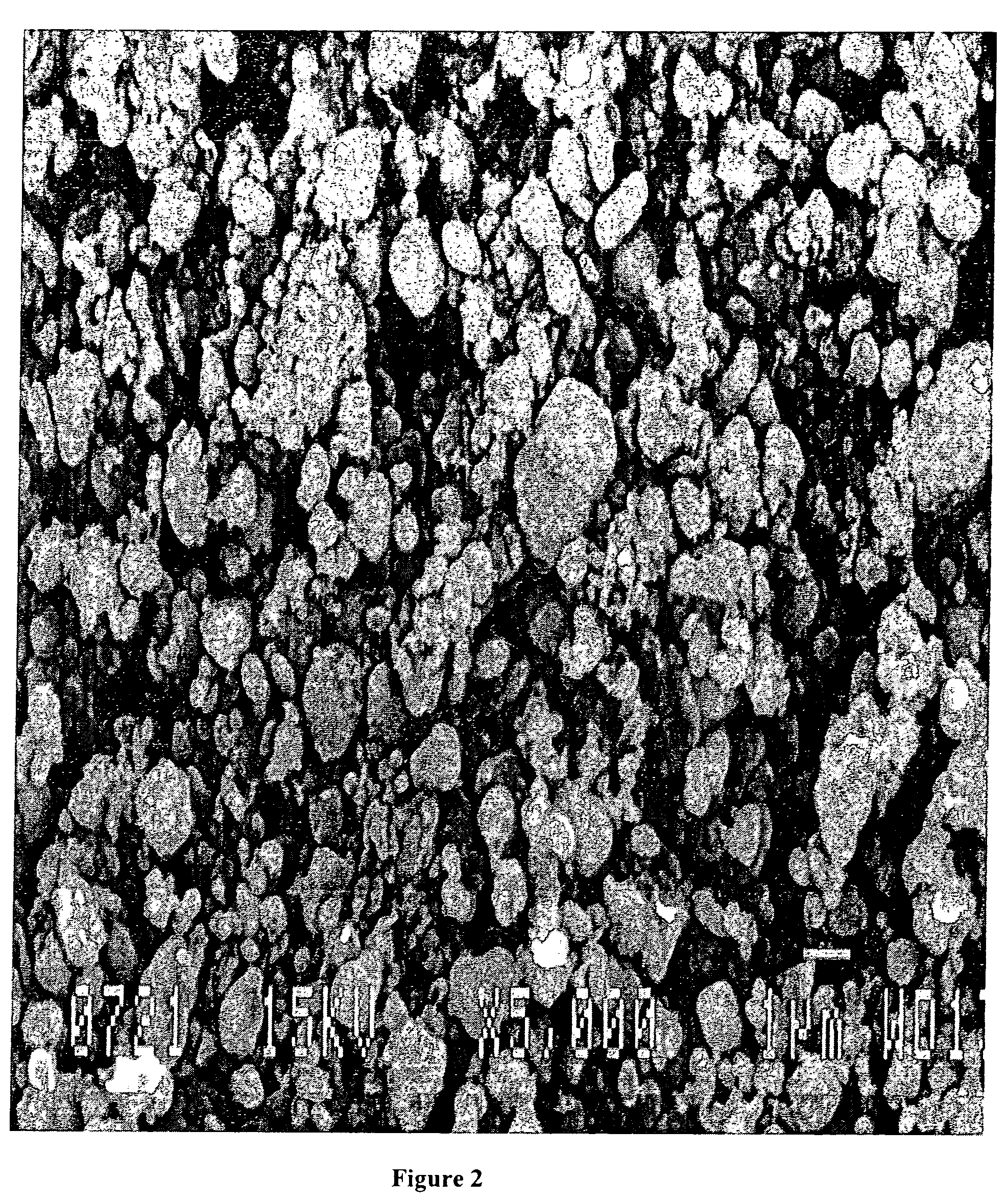

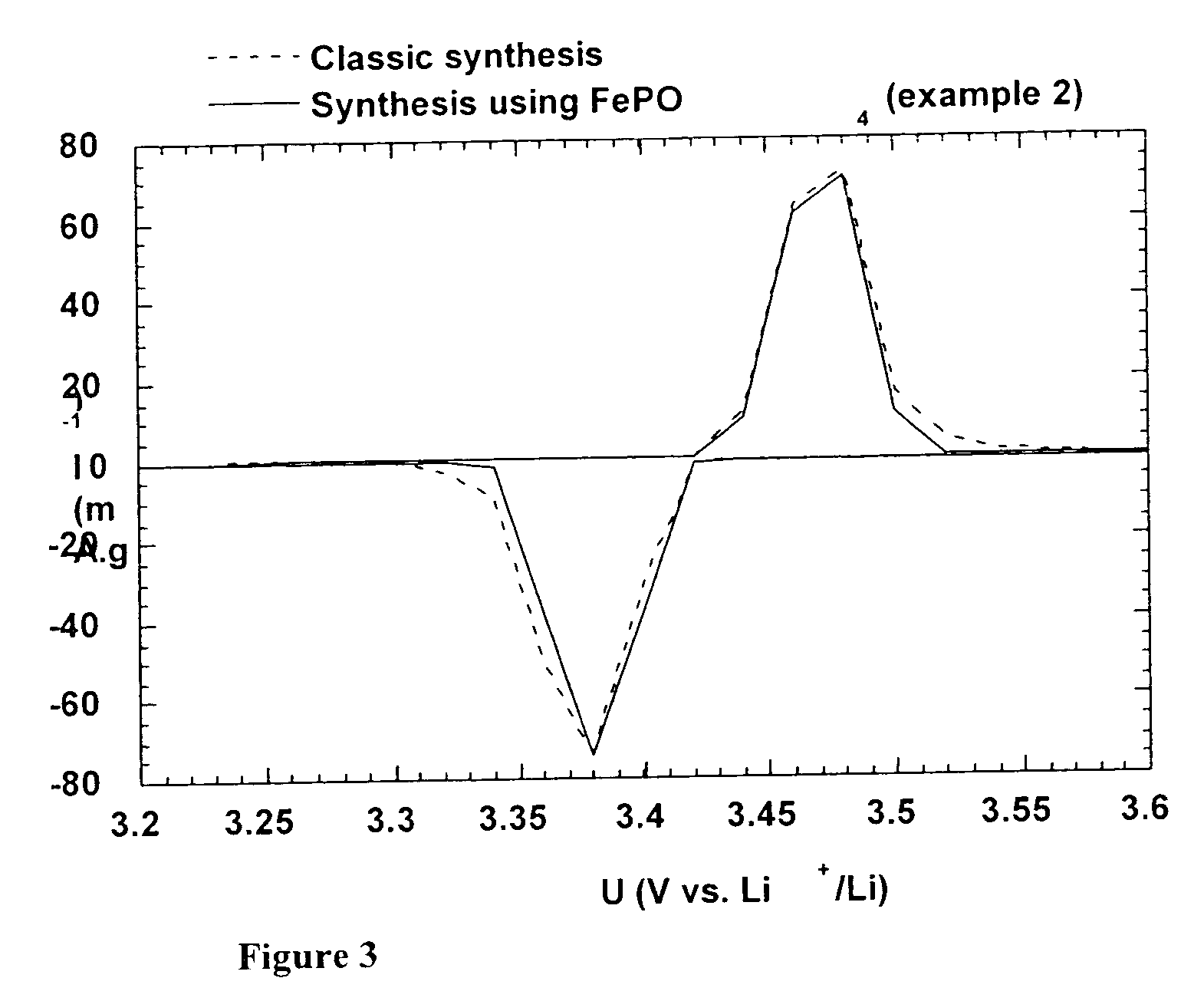

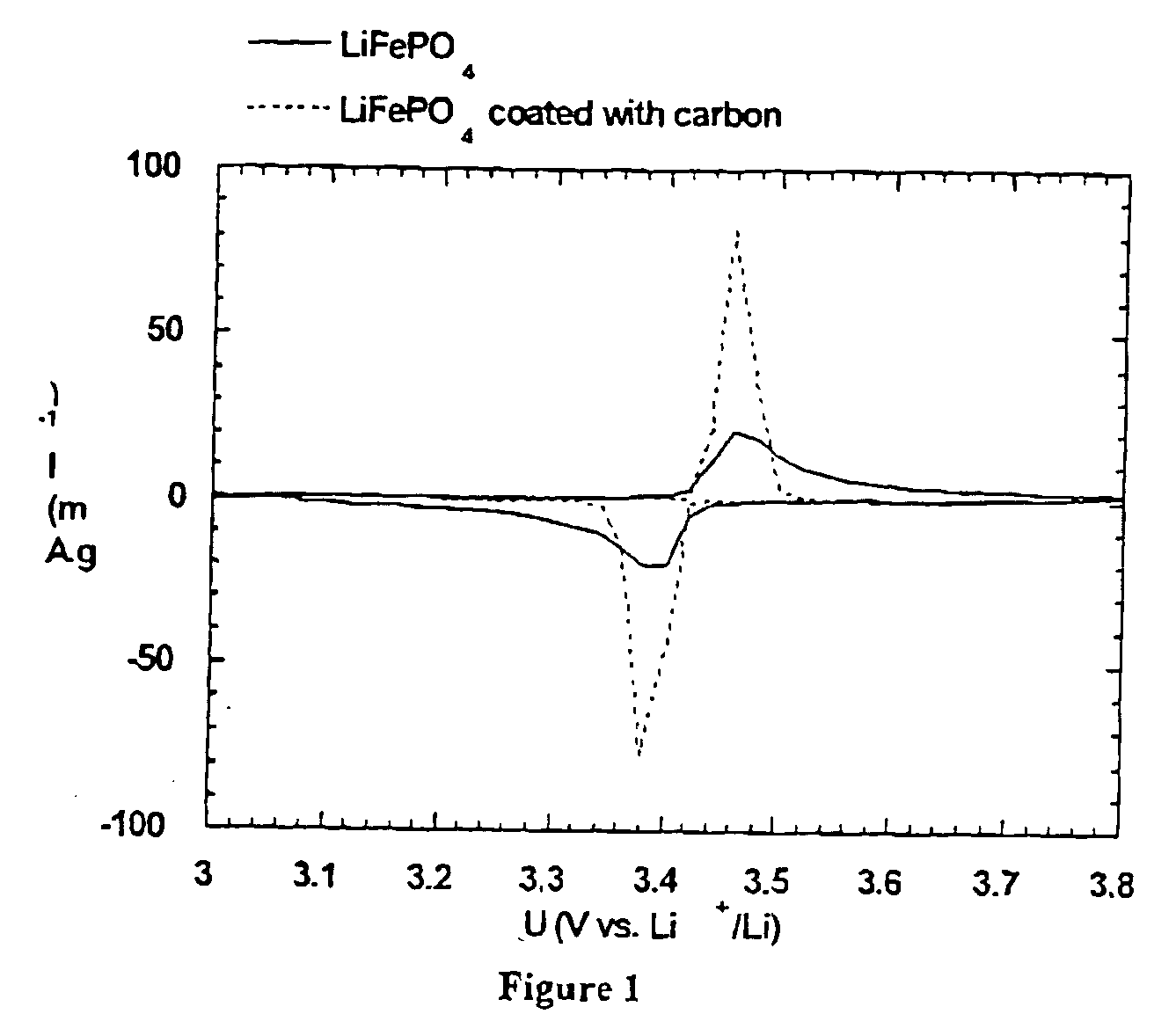

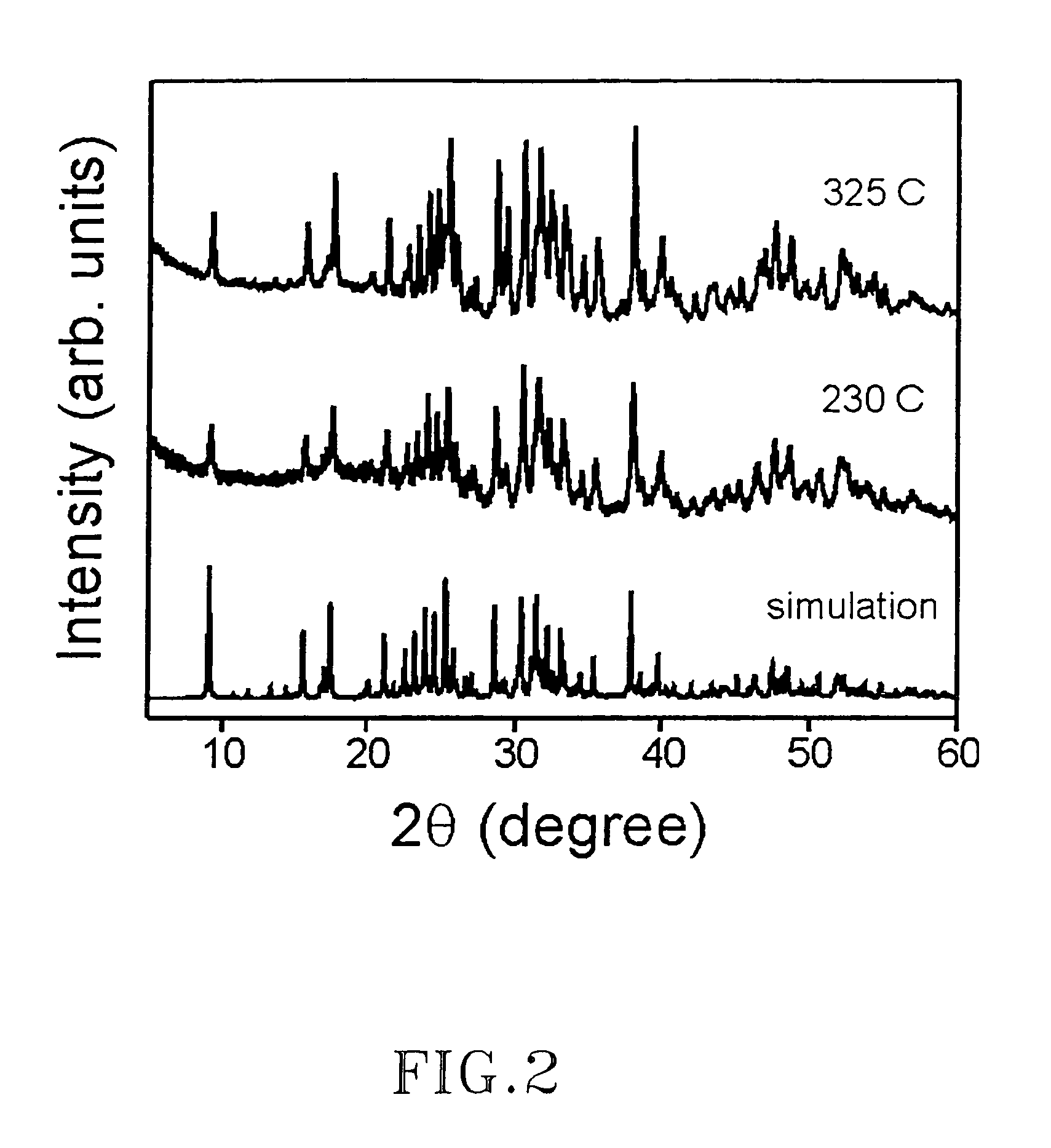

Method for synthesis of carbon-coated redox materials with controlled size

ActiveUS20040033360A1Low costReduce the numberMaterial nanotechnologyHybrid capacitorsCross-linkRedox

A method for the synthesis of compounds of the formula C-LixM1-yM'y(XO4)n, where C represents carbon cross-linked with the compound LixM1-yM'y(XO4)n, in which x, y and n are numbers such as 0<=x<=2, 0<=y<=0.6, and 1<=n<=1.5, M is a transition metal or a mixture of transition metals from the first period of the periodic table, M' is an element with fixed valency selected among Mg<2+>, Ca<2+>, Al<3+>, Zn<2+> or a combination of these same elements and X is chosen among S, P and Si, by bringing into equilibrium, in the required proportions, the mixture of precursors, with a gaseous atmosphere, the synthesis taking place by reaction and bringing into equilibrium, in the required proportions, the mixture of the precursors, the procedure comprising at least one pyrolysis step of the carbon source compound in such a way as to obtain a compound in which the electronic conductivity measured on a sample of powder compressed at a pressure of 3750 Kg.cm<-2 >is greater than 10<-8 >S.cm<-1>. The materials obtained have excellent electrical conductivity, as well a very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

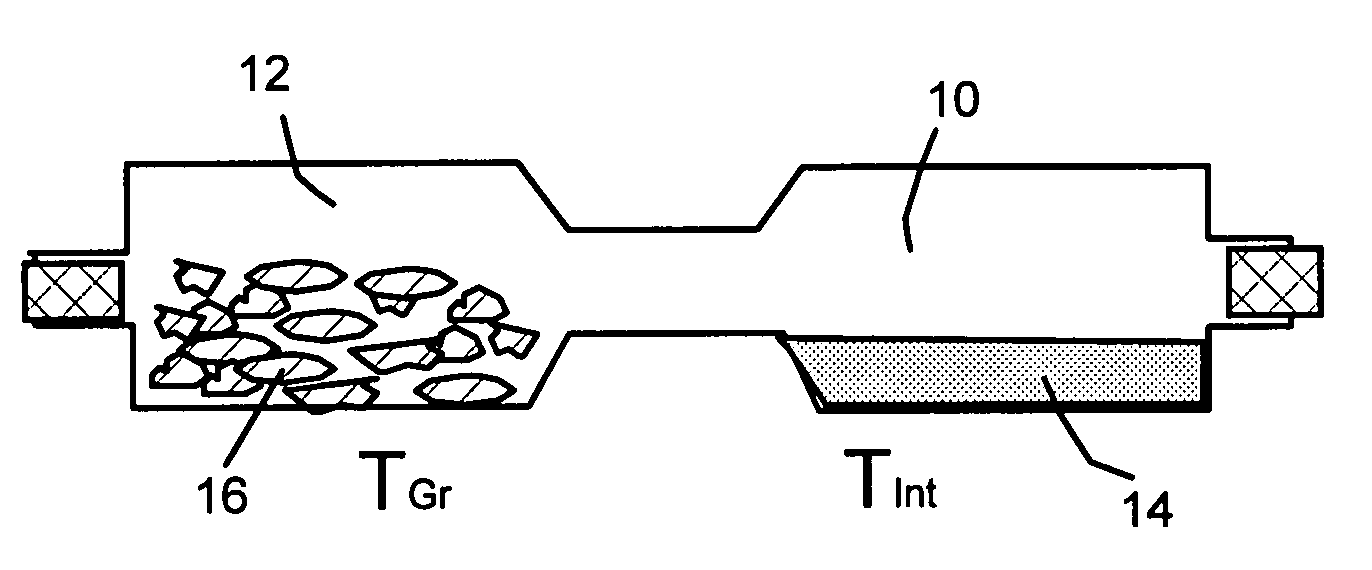

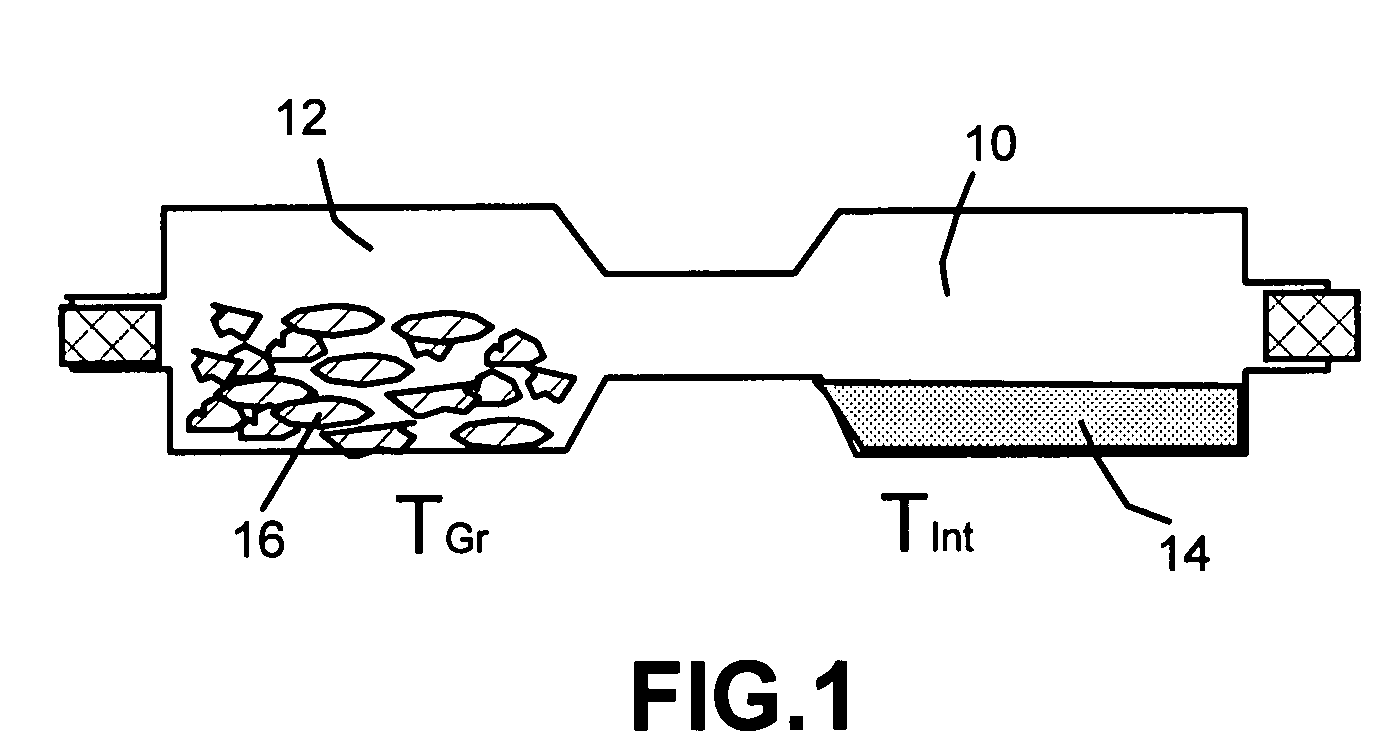

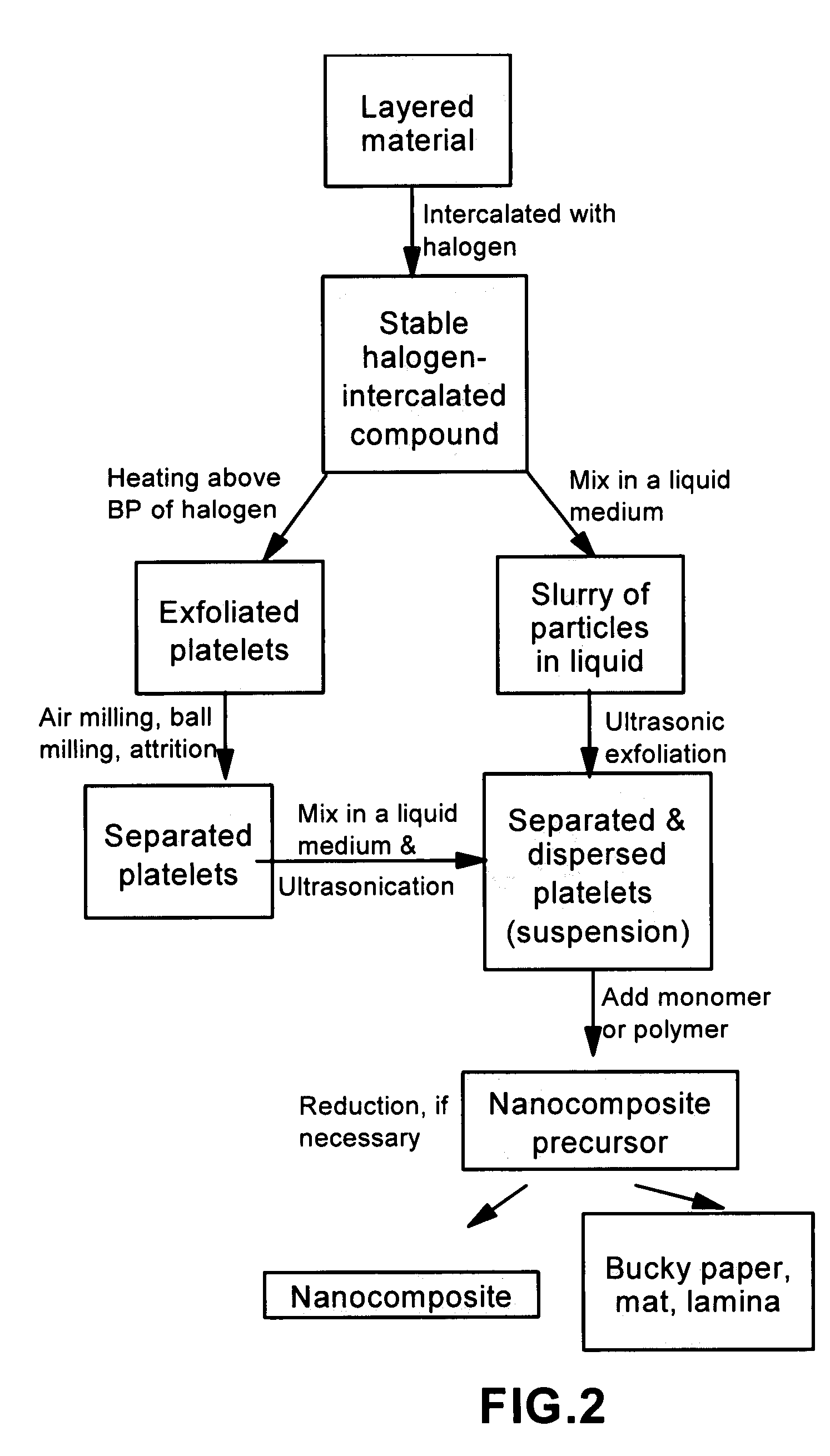

Method of producing nano-scaled graphene and inorganic platelets and their nanocomposites

ActiveUS20080206124A1Readily captured and re-usedReduce impactCarbon compoundsSelenium/tellurium compundsLiquid mediumPhysical chemistry

Disclosed is a method of exfoliating a layered material (e.g., graphite and graphite oxide) to produce nano-scaled platelets having a thickness smaller than 100 nm, typically smaller than 10 nm, and often between 0.34 nm and 1.02 nm. The method comprises: (a) subjecting the layered material in a powder form to a halogen vapor at a first temperature above the melting point or sublimation point of the halogen at a sufficient vapor pressure and for a duration of time sufficient to cause the halogen molecules to penetrate an interlayer space of the layered material, forming a stable halogen-intercalated compound; and (b) heating the halogen-intercalated compound at a second temperature above the boiling point of the halogen, allowing halogen atoms or molecules residing in the interlayer space to exfoliate the layered material to produce the platelets. Alternatively, rather than heating, step (a) is followed by a step of dispersing the halogen-intercalated compound in a liquid medium which is subjected to ultrasonication for exfoliating the halogen-intercalated compound to produce the platelets, which are dispersed in the liquid medium. The halogen can be readily captured and re-used, thereby significantly reducing the impact of halogen to the environment. The method can further include a step of dispersing the platelets in a polymer or monomer solution or suspension as a precursor step to nanocomposite fabrication.

Owner:GLOBAL GRAPHENE GRP INC

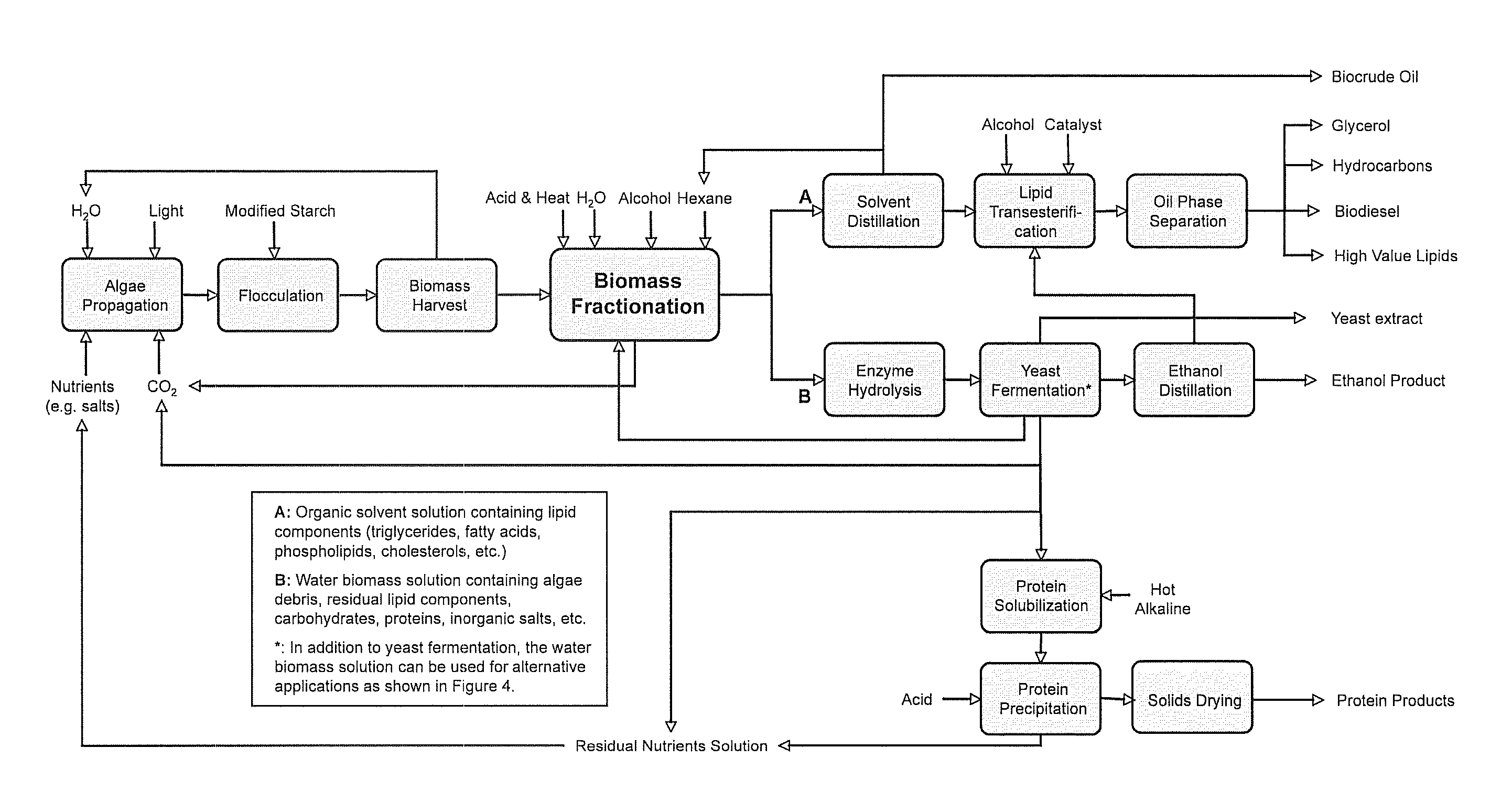

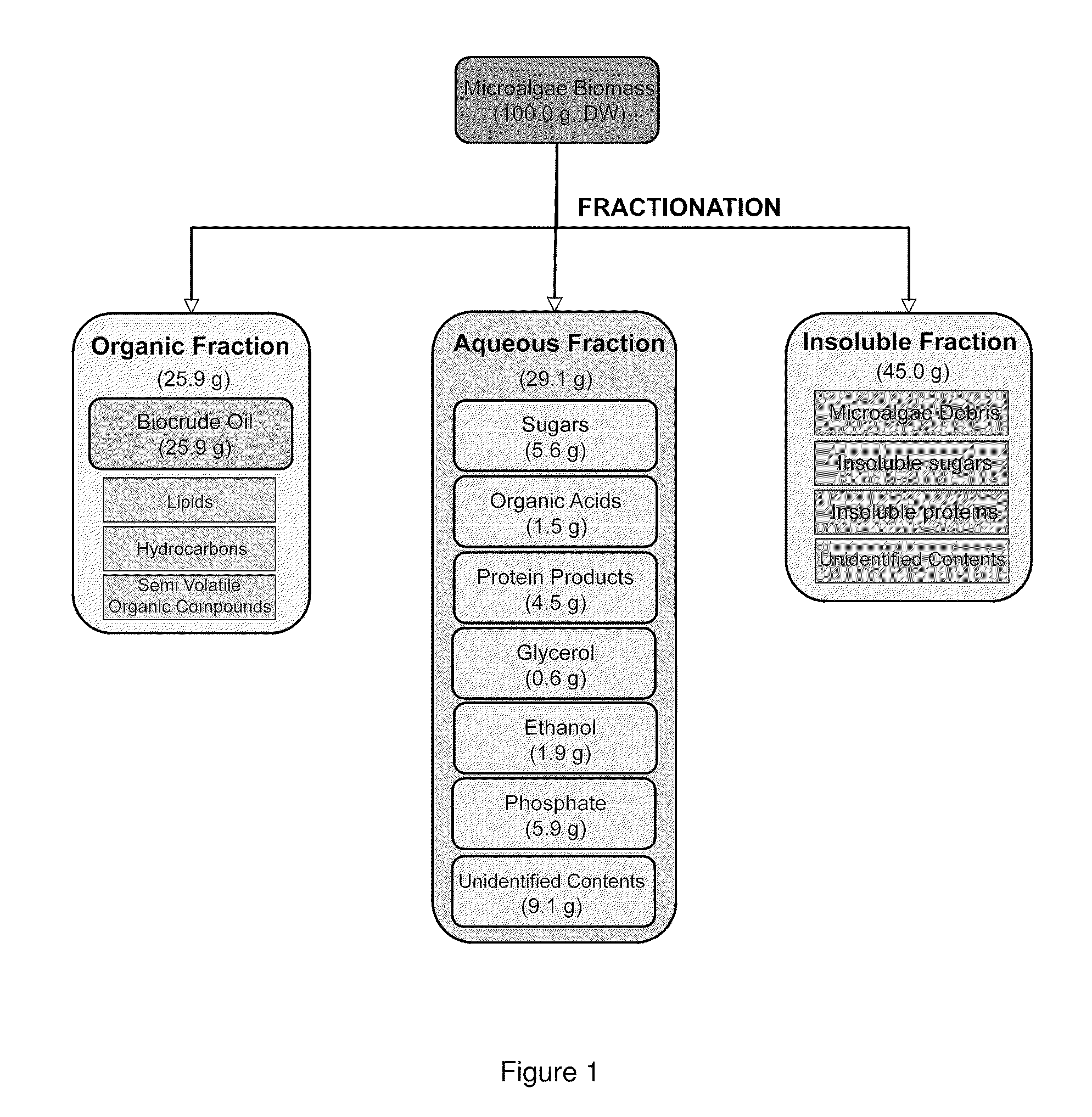

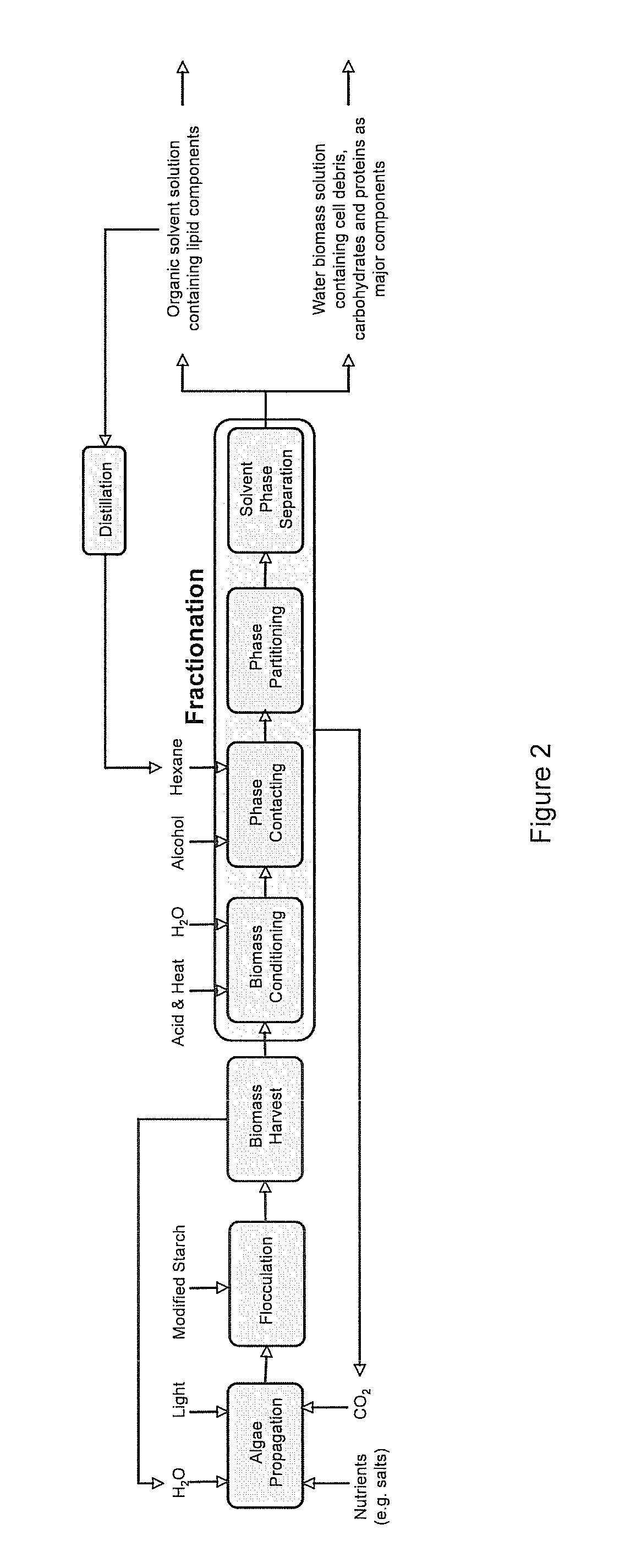

Algae biomass fractionation

A method of fractionating biomass, by permeability conditioning biomass suspended in a pH adjusted solution of at least one water-based polar solvent to form a conditioned biomass, intimately contacting the pH adjusted solution with at least one non-polar solvent, partitioning to obtain an non-polar solvent solution and a polar biomass solution, and recovering cell and cell derived products from the non-polar solvent solution and polar biomass solution. Products recovered from the above method. A method of operating a renewable and sustainable plant for growing and processing algae.

Owner:VALICOR

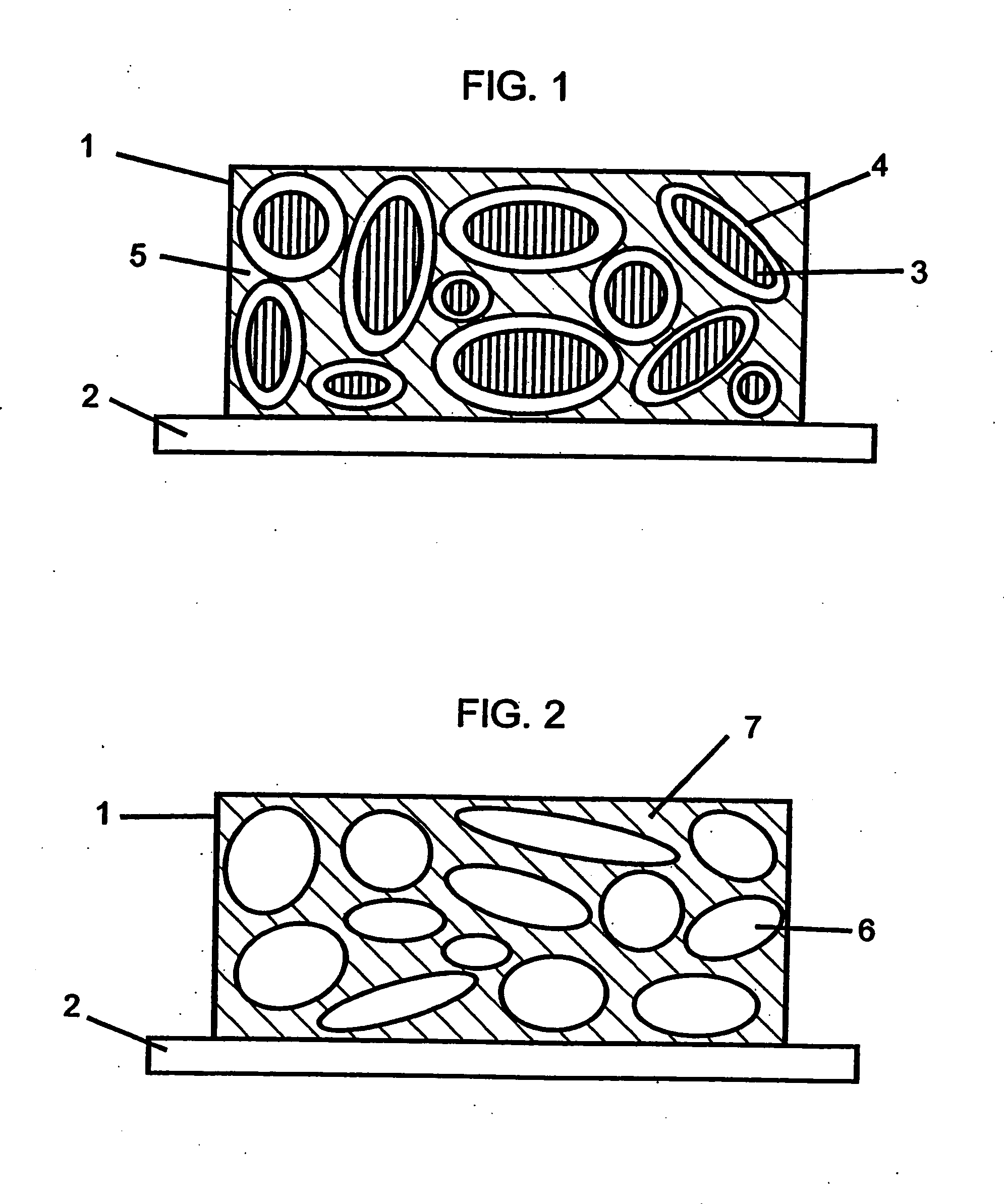

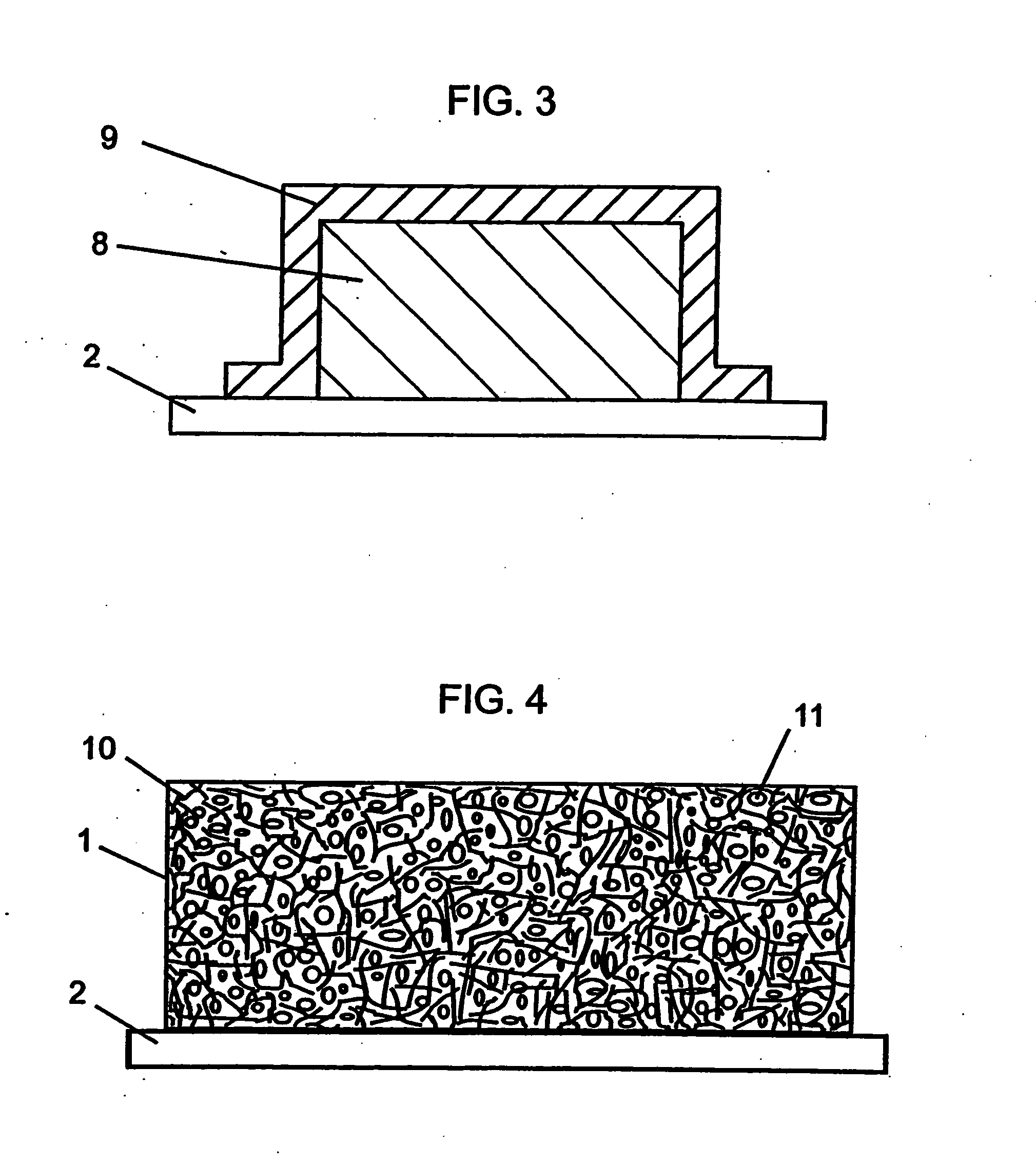

Novel composite cathodes, electrochemical cells comprising novel composite cathodes, and processes for fabricating same

The present invention pertains to composite cathodes suitable for use in an electrochemical cell, said cathodes comprising: (a) an electroactive sulfur-containing cathode material, wherein said electroactive sulfur-containing cathode material, in its oxidized state, comprises a polysulfide moiety of the formula —Sm—, wherein m is an integer equal to or greater than 3; and, (b) an electroactive transition metal chalcogenide composition, which encapsulates said electroactive sulfur-containing cathode material, and which retards the transport of anionic reduction products of said electroactive sulfur-containing cathode material, said electroactive transition metal chalcogenide composition comprising an electroactive transition metal chalcogenide having the formula MjYk(OR)l wherein: M is a transition metal; Y is the same or different at each occurrence and is oxygen, sulfur, or selenium; R is an organic group and is the same or different at each occurrence; j is an integer ranging from 1 to 12; k is a number ranging from 0 to 72; and l is a number ranging from 0 to 72; with the proviso that k and l cannot both be 0. The present invention also pertains to methods of making such composite cathodes, cells comprising such composite cathodes, and methods of making such cells.

Owner:SION POWER CORP

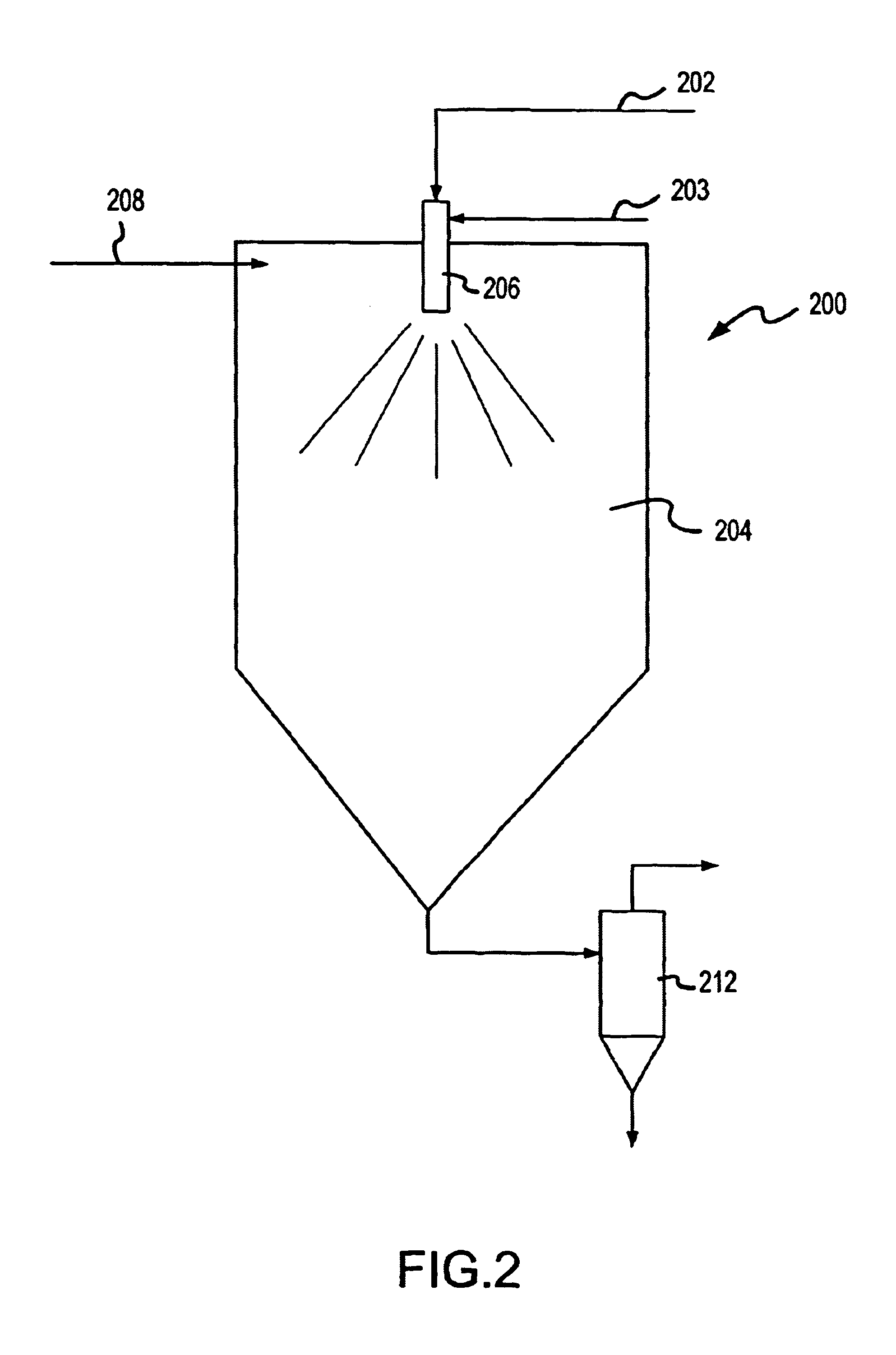

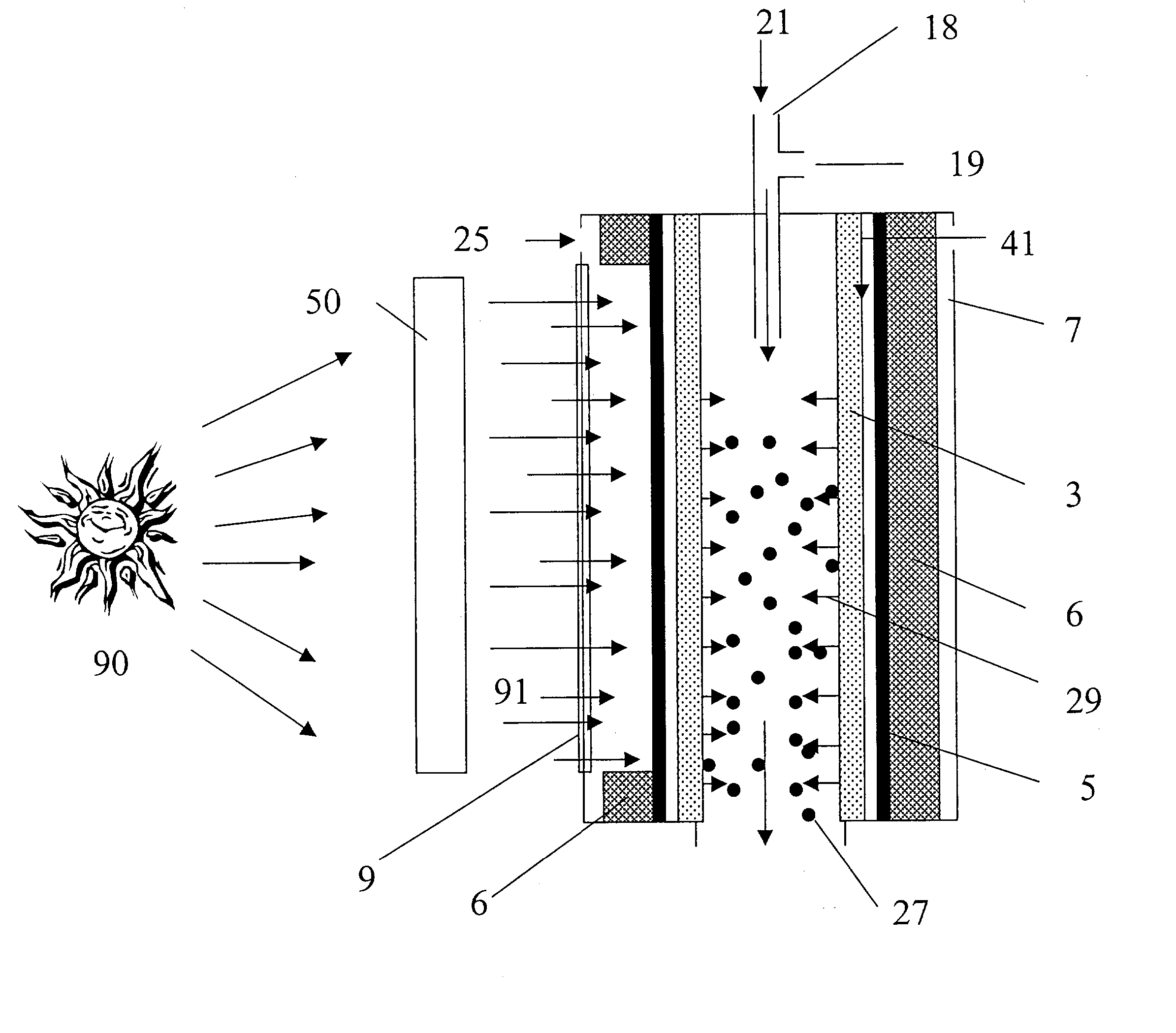

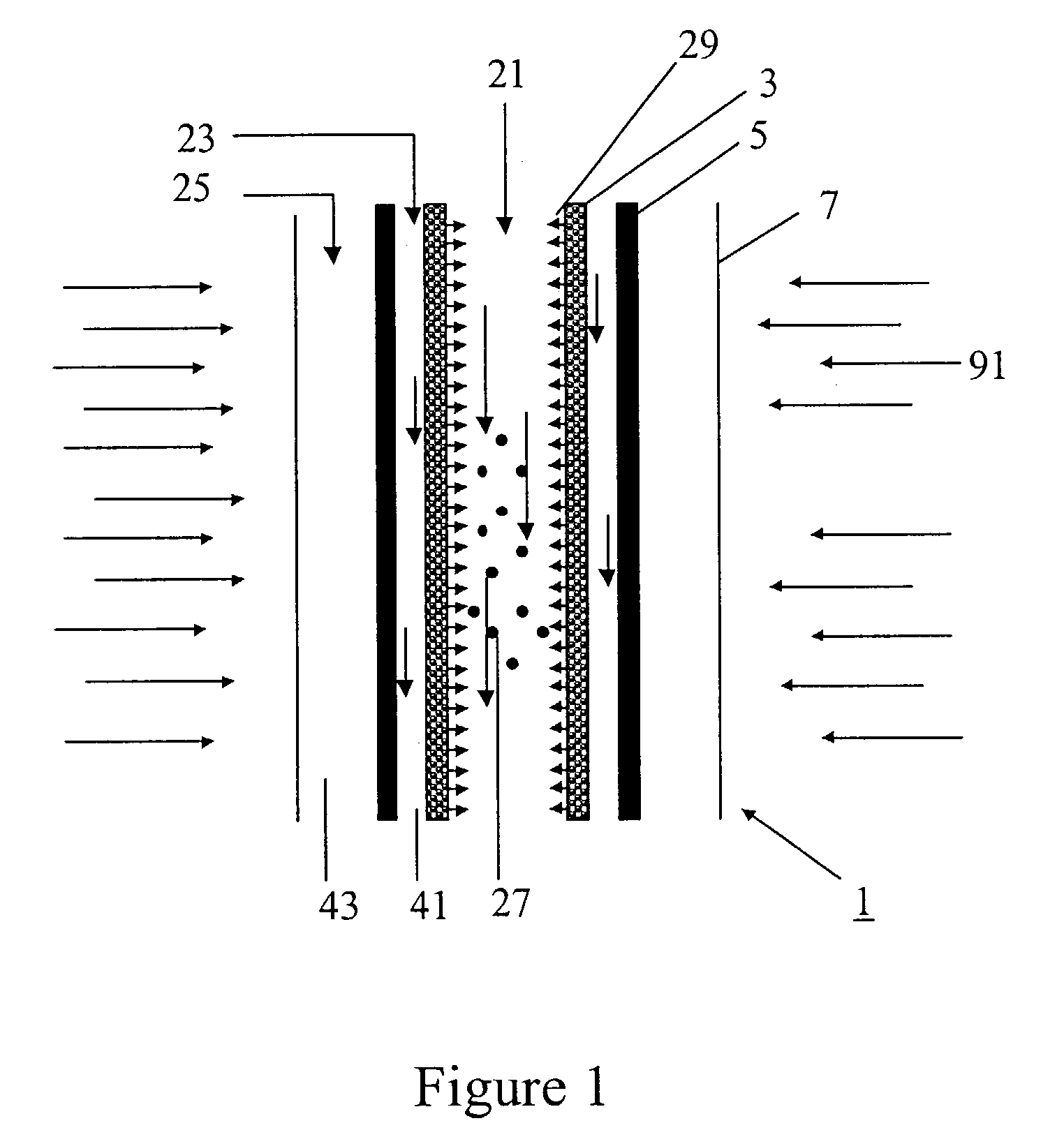

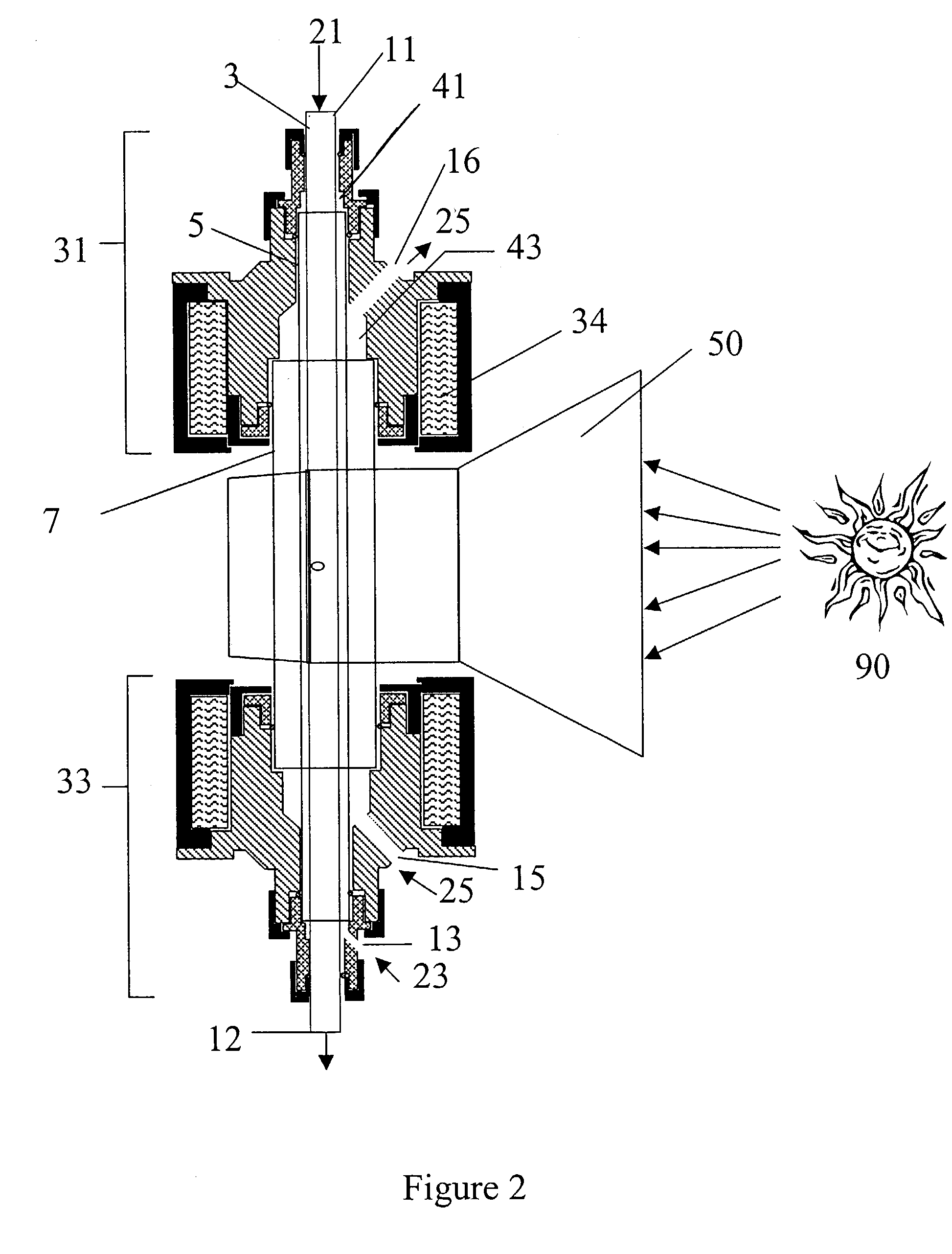

Solar-thermal fluid-wall reaction processing

InactiveUS7033570B2Reduce and preventShort stayThermal non-catalytic crackingSolar heating energyHydrogenReactor system

The present invention provides a method for carrying out high temperature thermal dissociation reactions requiring rapid-heating and short residence times using solar energy. In particular, the present invention provides a method for carrying out high temperature thermal reactions such as dissociation of hydrocarbon containing gases and hydrogen sulfide to produce hydrogen and dry reforming of hydrocarbon containing gases with carbon dioxide. In the methods of the invention where hydrocarbon containing gases are dissociated, fine carbon black particles are also produced. The present invention also provides solar-thermal reactors and solar-thermal reactor systems.

Owner:ALLIANCE FOR SUSTAINABLE ENERGY +1

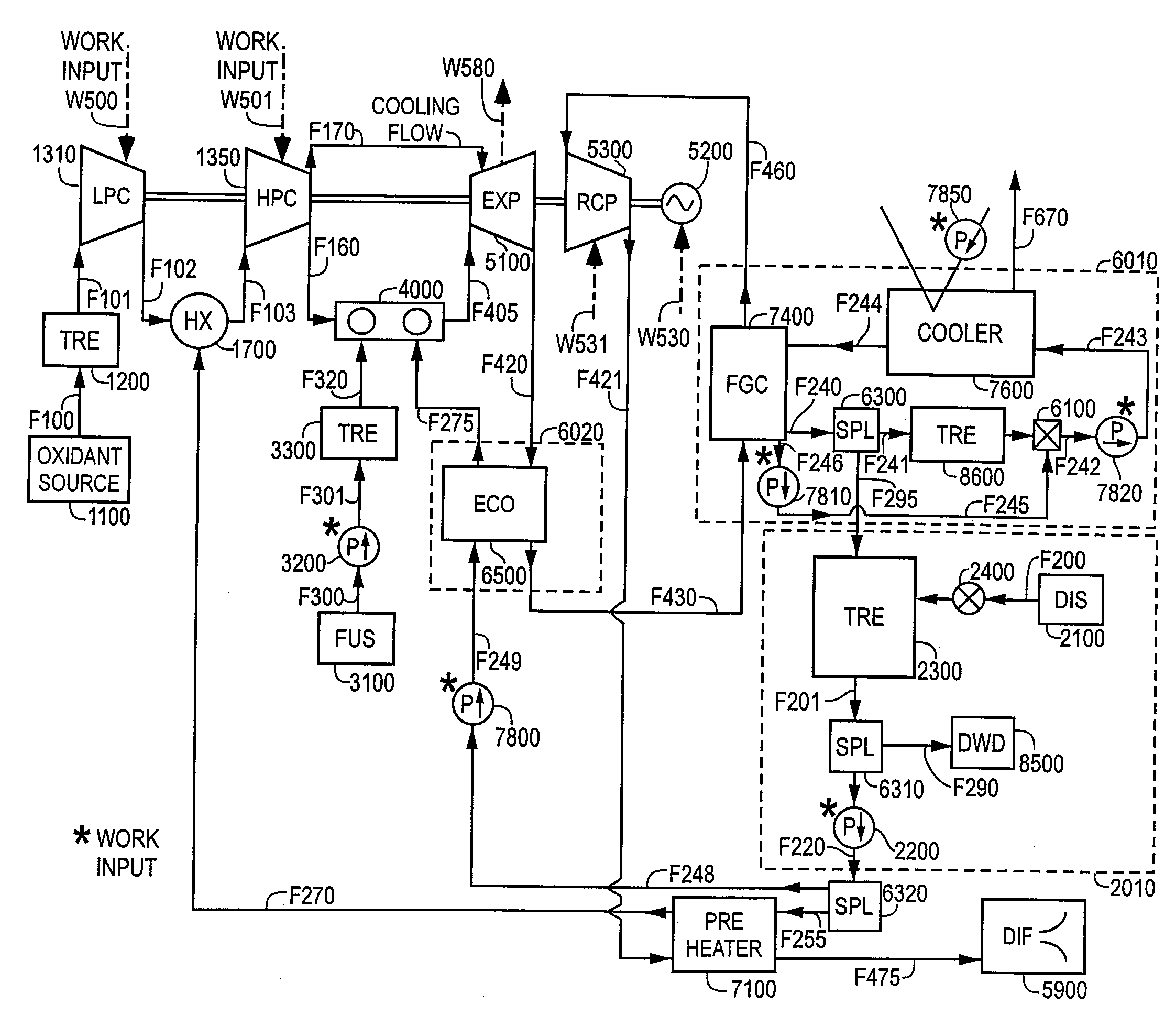

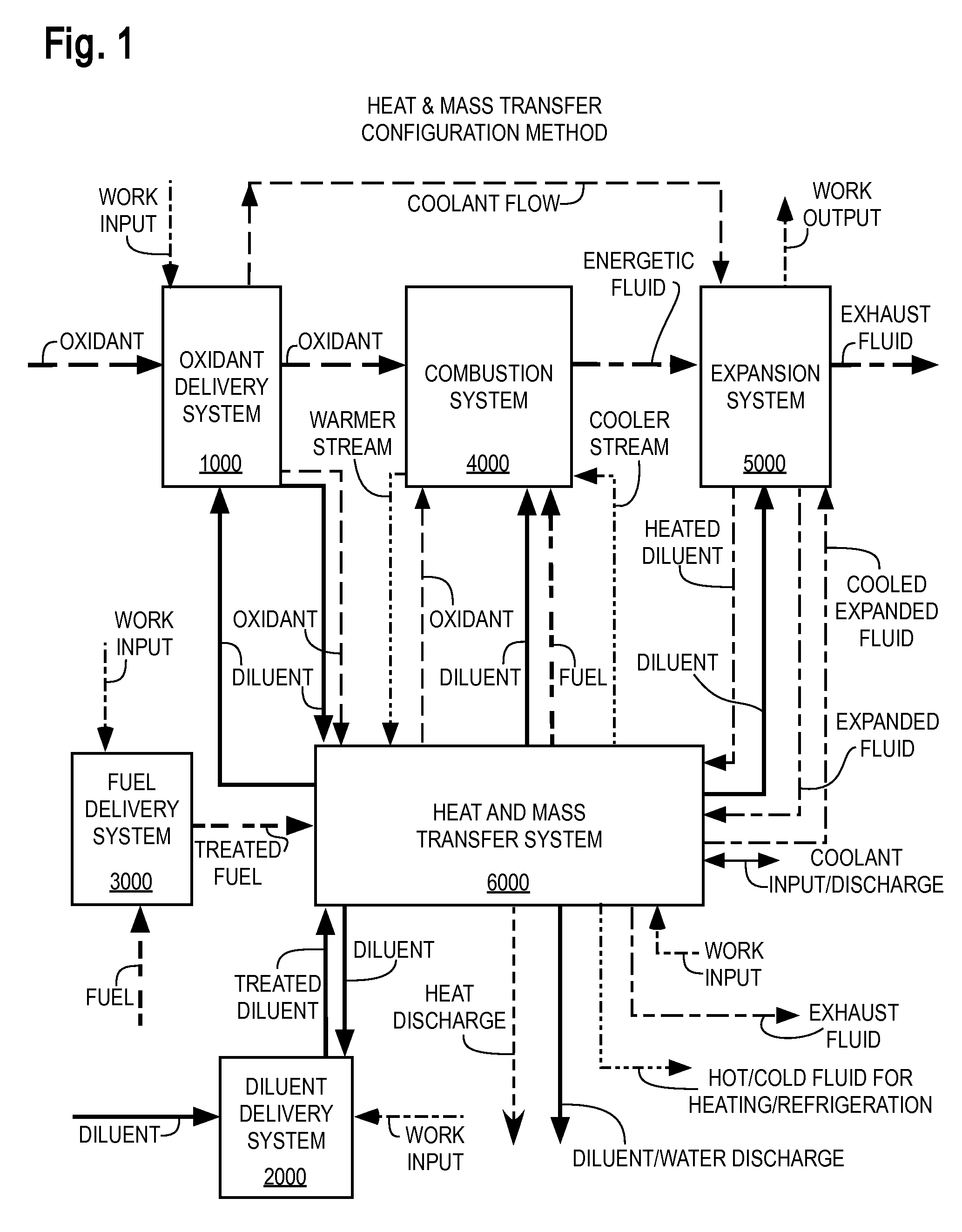

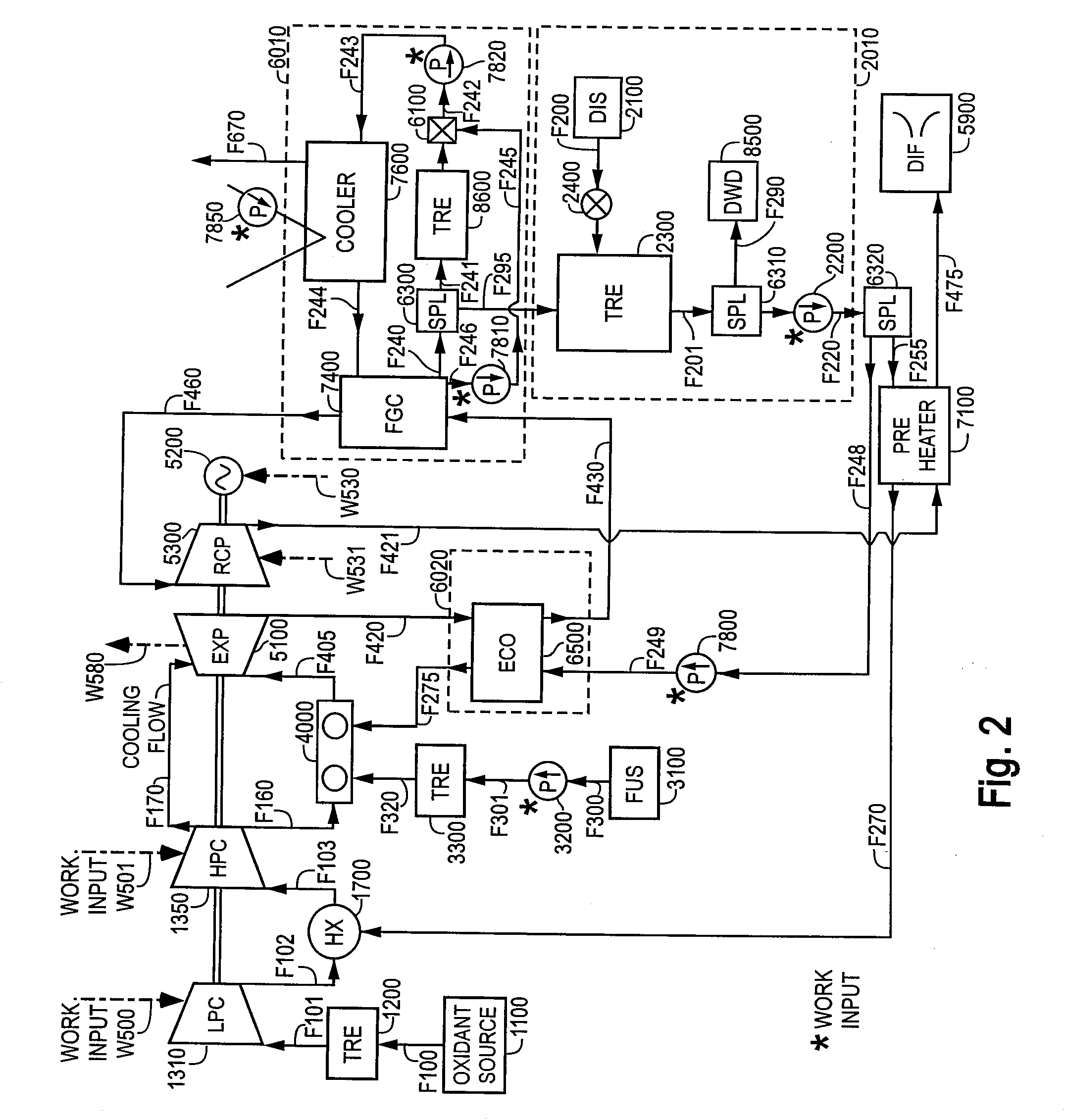

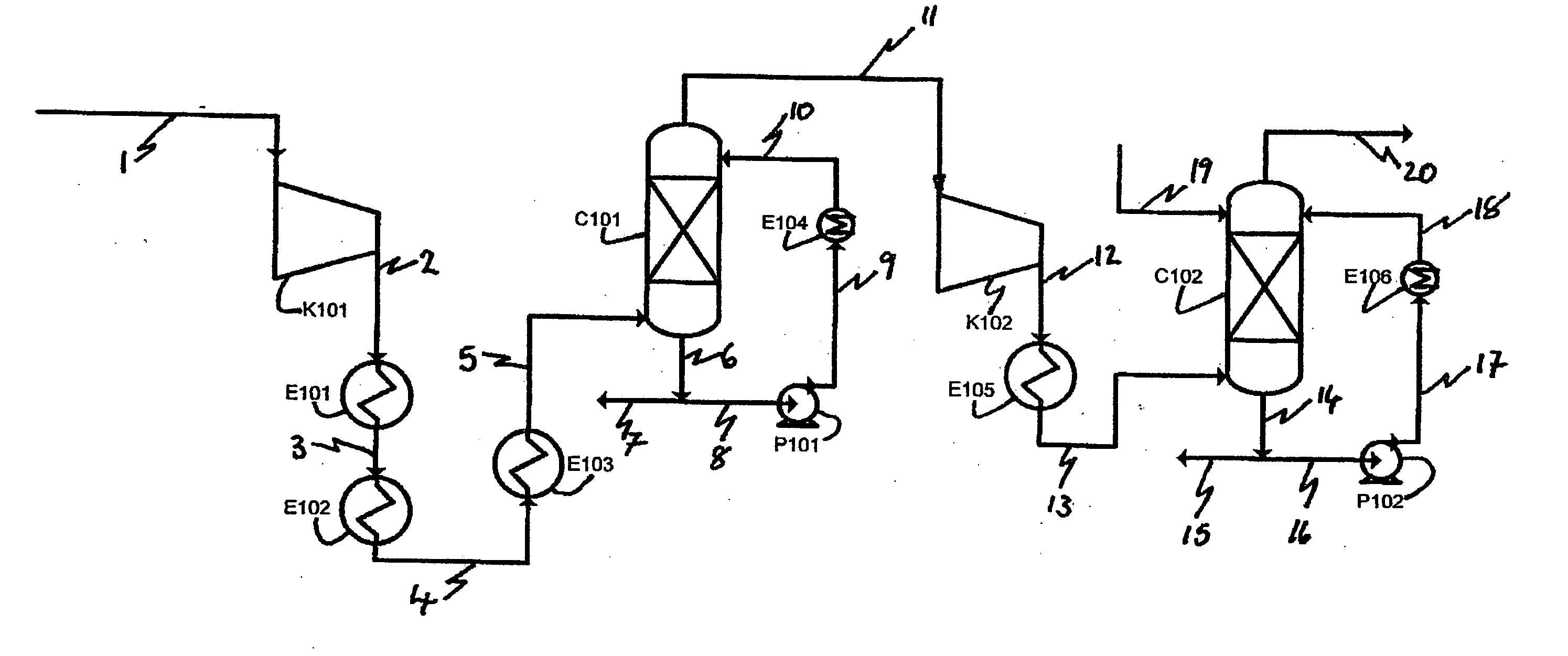

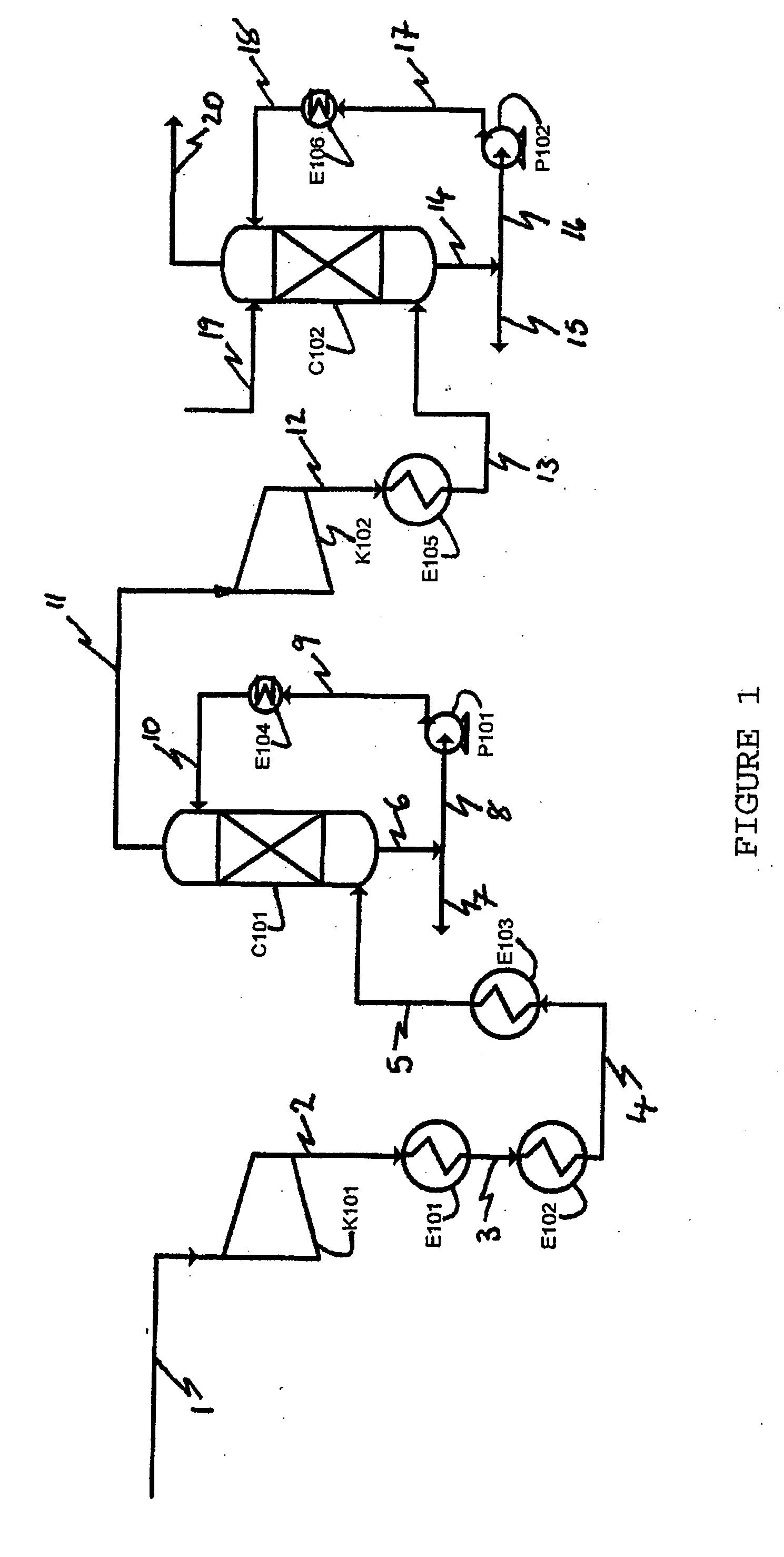

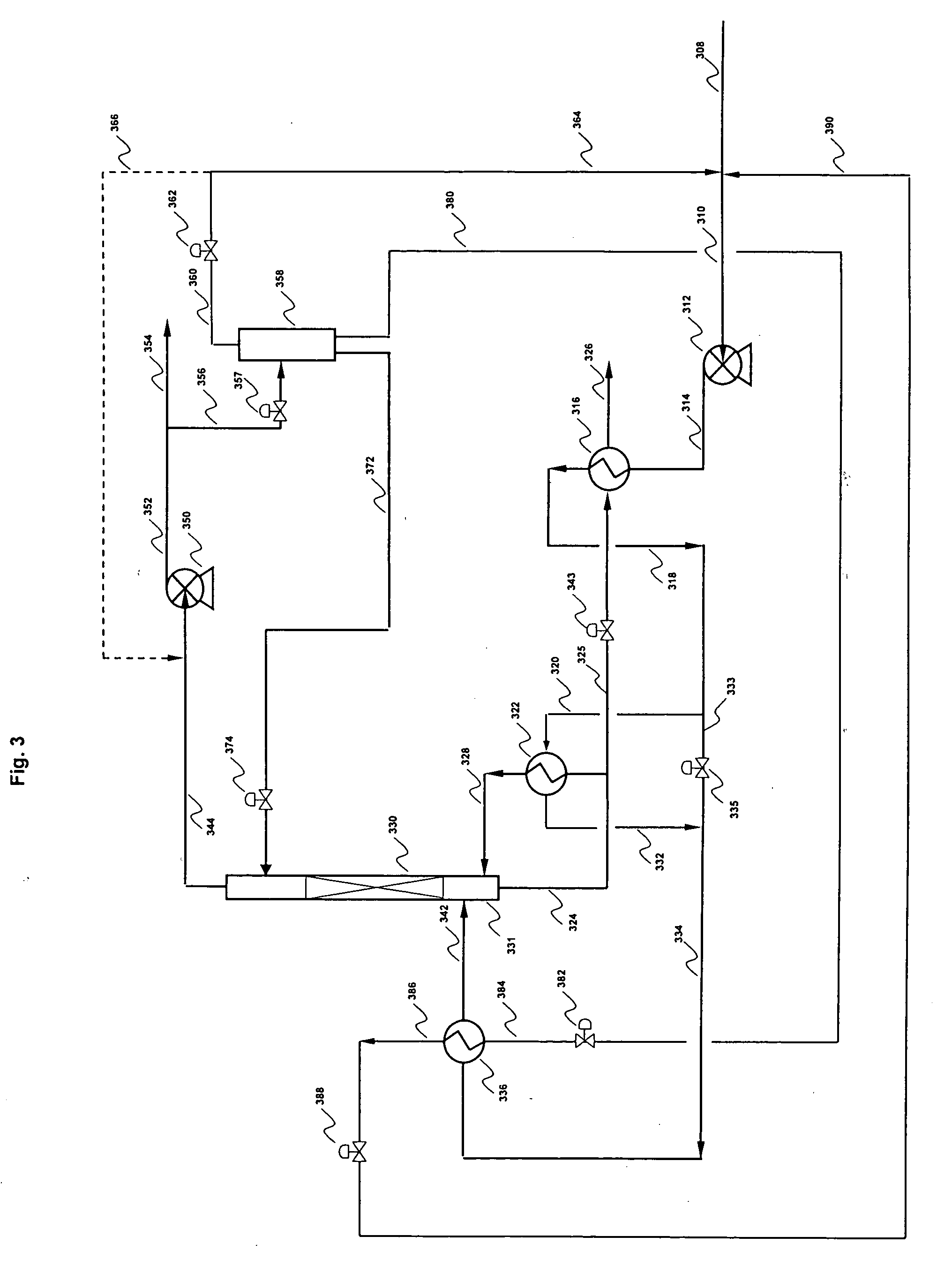

Thermodynamic cycles using thermal diluent

ActiveUS20090071166A1Low costEmission reductionSpace heating and ventilationSulfur compoundsCombustion systemCombustion

A thermodynamic system that produces mechanical, electrical power, and / or fluid streams for heating or cooling. The cycle contains a combustion system that produces an energetic fluid by combustion of a fuel with an oxidant. A thermal diluent may be used in the cycle to improve performance, including but not limited to power, efficiency, economics, emissions, dynamic and off-peak load performance, and / or turbine inlet temperature (TIT) regulation and cooling heated components. The cycle preferably includes a heat recovery system and a condenser or other means to recover and recycle heat and the thermal diluent from the energetic fluid to improve the cycle thermodynamic efficiency and reduce energy conversion costs. The cycle may also include controls for temperatures, pressures, and flow rates throughout the cycle, and controls power output, efficiency, and energetic fluid composition.

Owner:VAST HLDG LLC

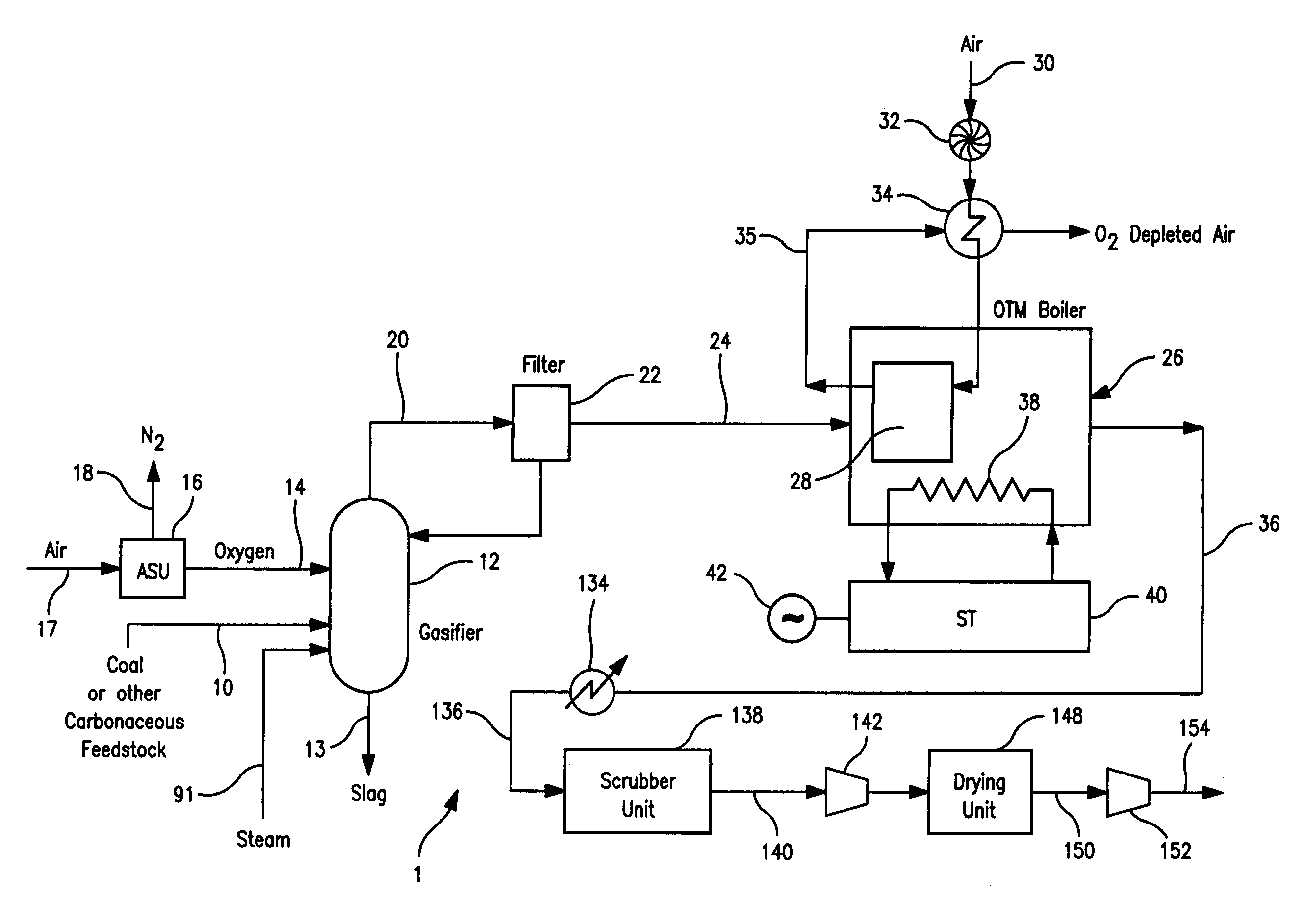

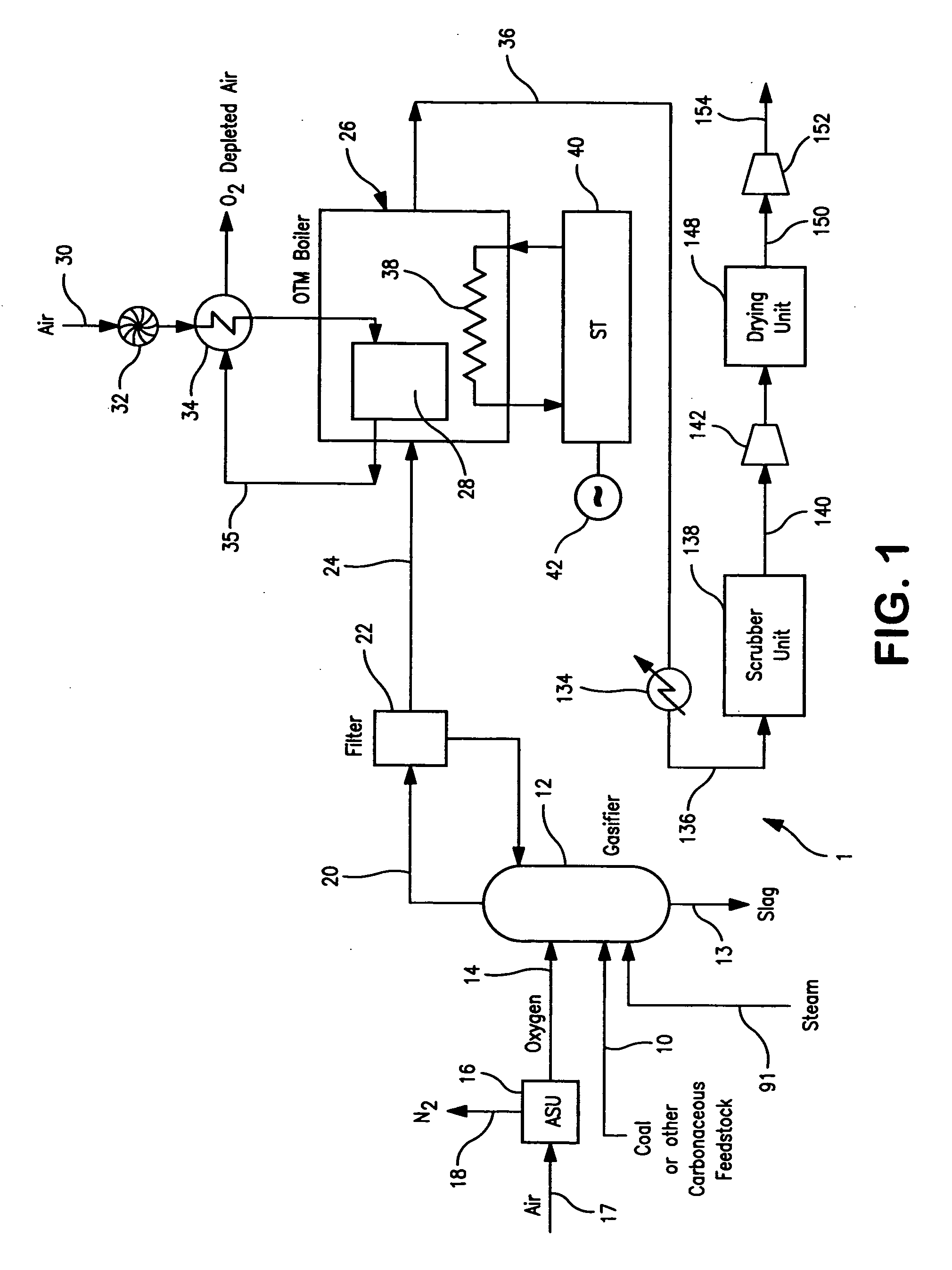

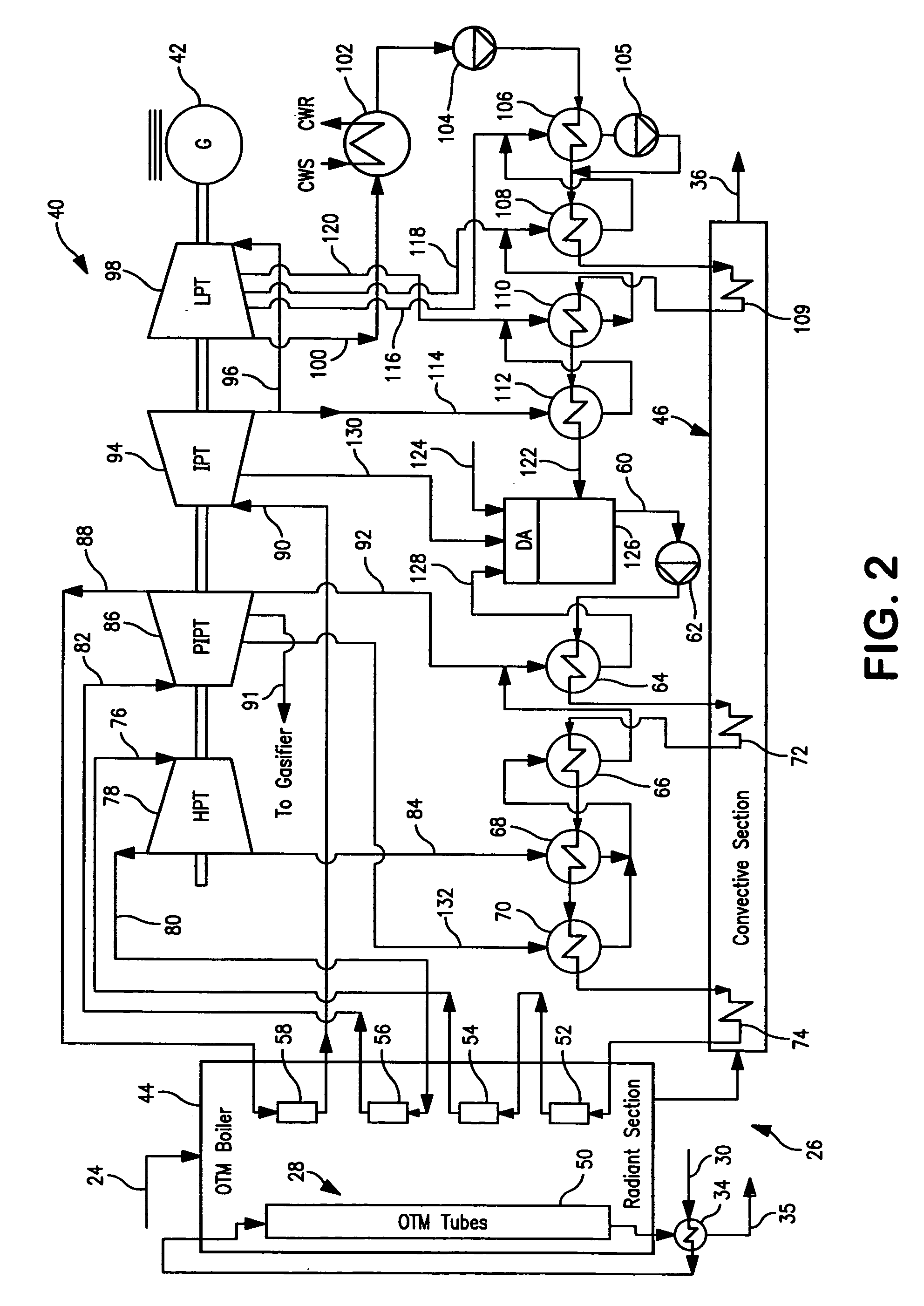

Electrical power generation method

A method of generating electrical power in which a synthesis gas stream generated in a gasifier is combusted in an oxygen transport membrane system of a boiler. The combustion generates heat to raise steam to in turn generate electricity by a generator coupled to a steam turbine. The resultant flue gas can be purified to produce a carbon dioxide product.

Owner:PRAXAIR TECH INC

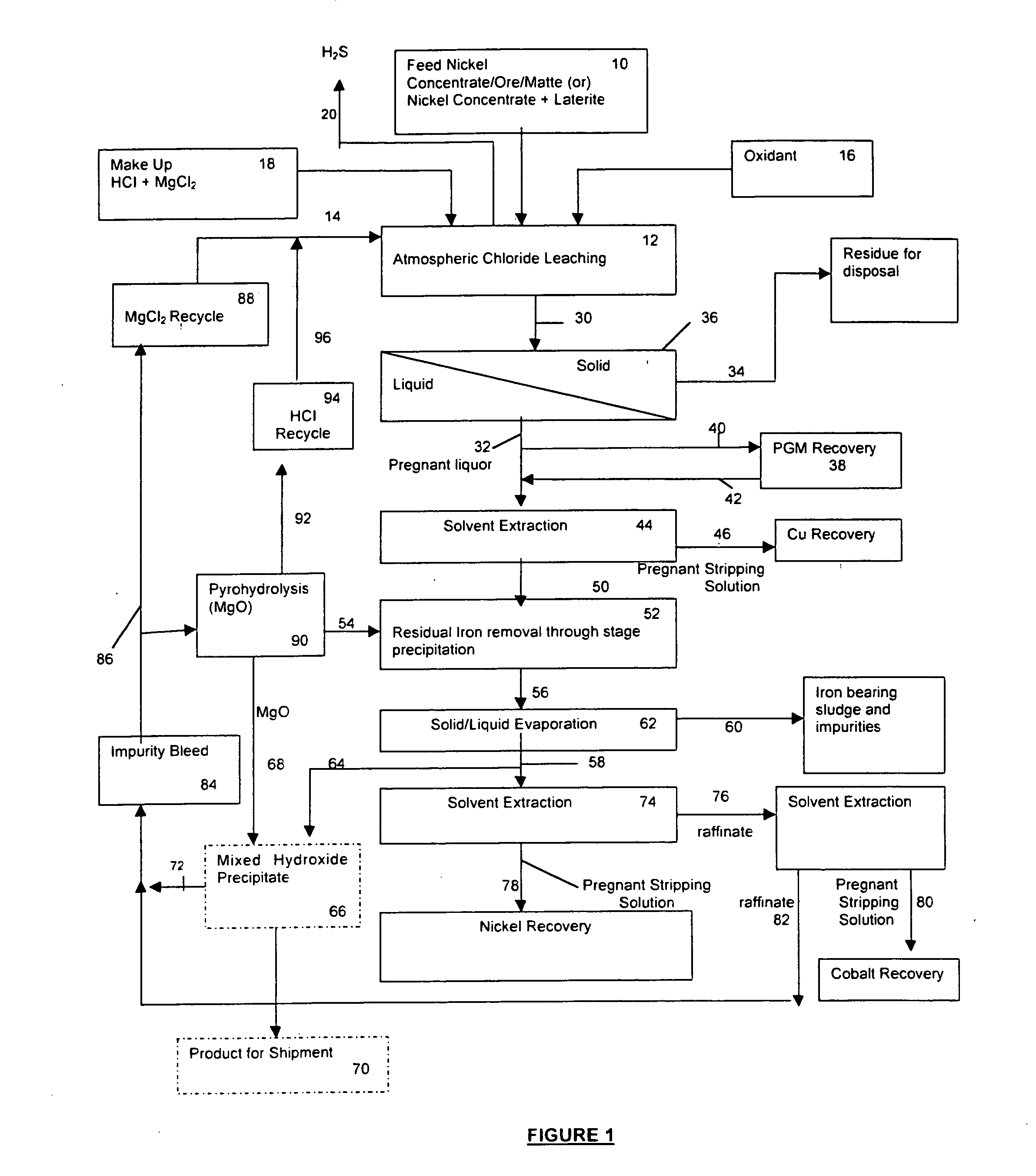

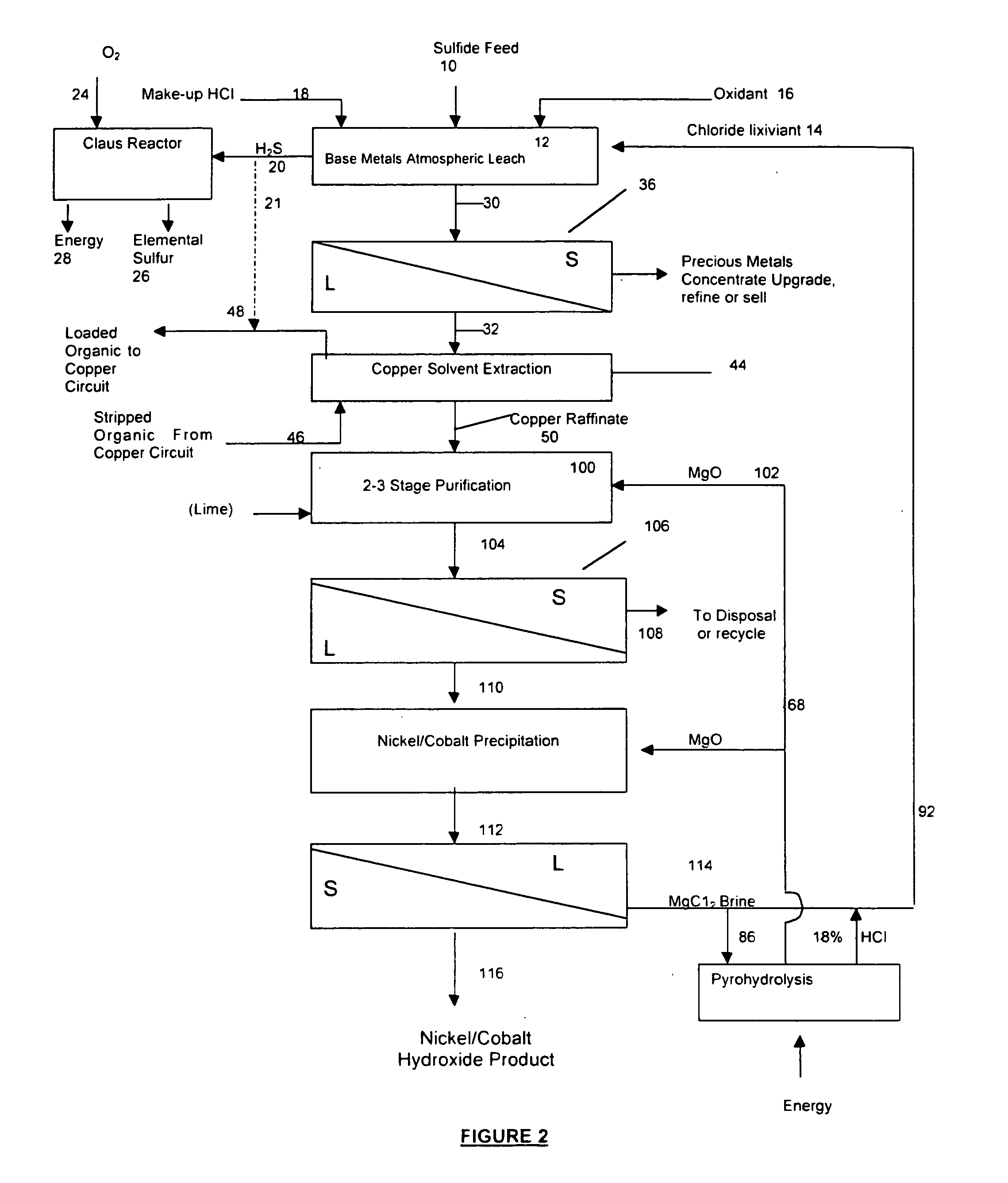

Process for the recovery of value metals from base metal sulfide ores

InactiveUS20050118081A1Simple gas/liquidReduce the amount requiredSulfur compoundsSolid sorbent liquid separationSulfideDissolution

A process for leaching a value metal from a base metal sulfide ore, comprising the step of leaching the ore with a lixiviant comprising a chloride, an oxidant and hydrochloric acid is disclosed. The leaching is controlled, by use of low concentrations of hydrochloric acid and a redox potential, to effect formation of hydrogen sulfide from the base metal sulfide ore. The hydrogen sulfide is stripped from the leach solution, thereby reducing the amount of sulfate generated in the leach to very low levels. The leaching may also be conducted to limit the co-dissolution of platinum group metals and gold with the base value metals. The leach forms a value metal-rich leachate and a solids residue. The solids residue may be subsequently leached to recover the platinum group metals and gold. The value metal-rich leachate can be is oxidized and neutralized to recover the value base metals. In an embodiment, the chloride is magnesium chloride and lixiviant solution is regenerated.

Owner:JAGUAR NICKEL INC

Synthesis method for carbon material based on lixm1-ym'(xo4)n

InactiveUS20040086445A1Improve performanceLow costHybrid capacitorsElectrolytic capacitorsElectrical conductorSynthesis methods

Method of synthesis for a material made of particles having a core and a coating and / or being connected to each other by carbon cross-linking, the core of these particles containing at least one compound of formula LixM1-yM'y(XO4)n, in which x,y and n are numbers such as 0<=x<=2, 0<=y<=0.6 and 1<=n<=1.5, M is a transition metal, M' is an element with fixed valency, and the synthesis is carried out by reaction and bringing into equilibrium the mixture of precursors, with a reducing gaseous atmosphere, in such a way as to bring the transition metal or metals to the desired valency level, the synthesis being carried out in the presence of a source of carbon called carbon conductor, which is subjected to pyrolysis. The materials obtained have excellent electrical conductivity as well as very improved chemical activity.

Owner:CENT NAT DE LA RECHERCHE SCI +2

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

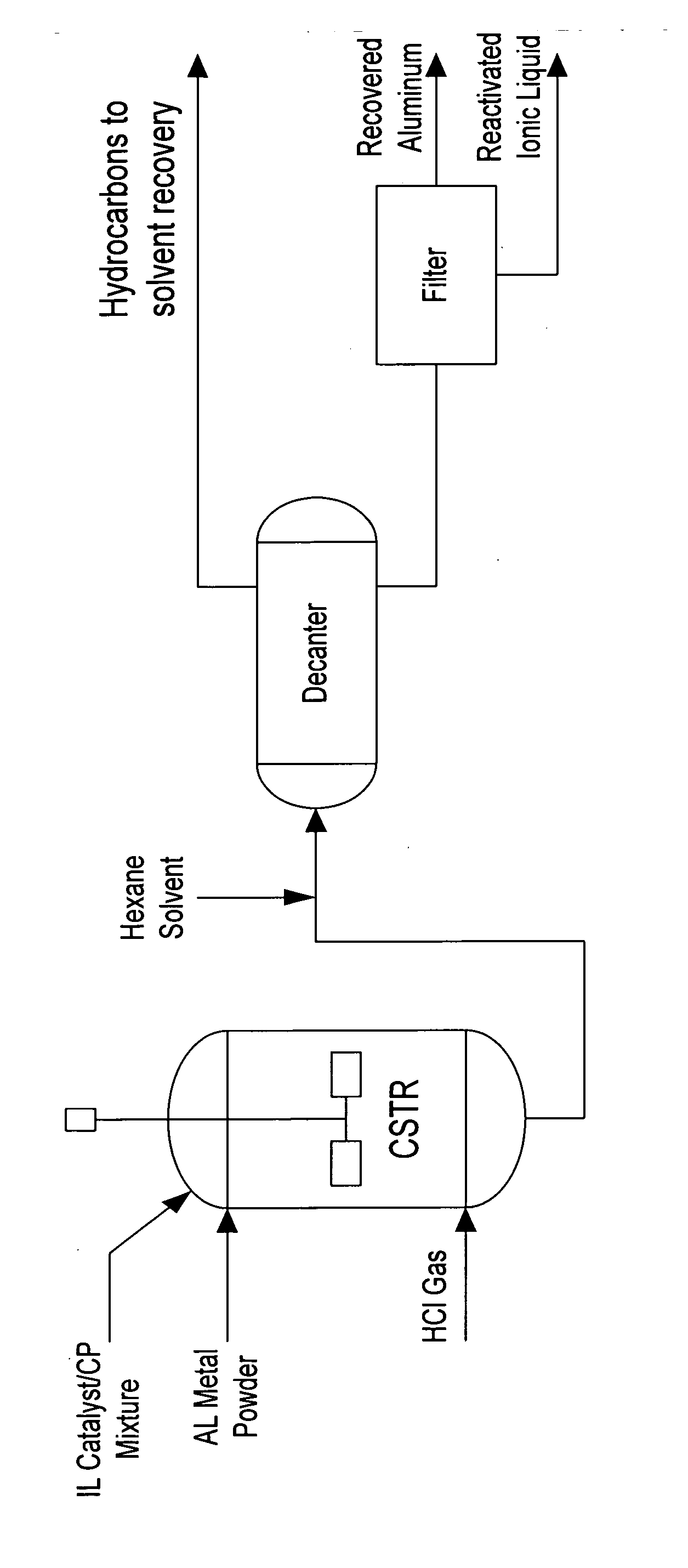

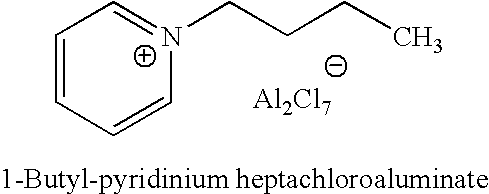

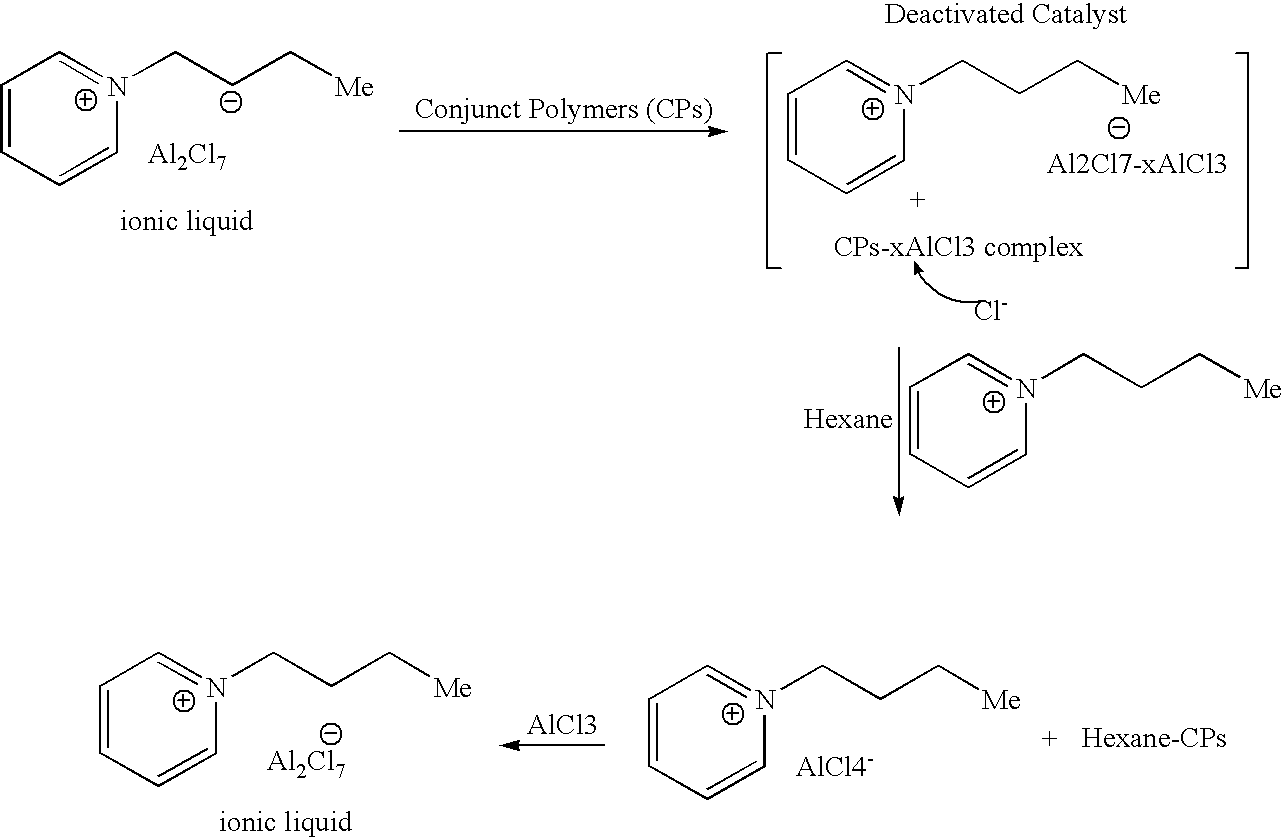

Regeneration of acidic catalysts

ActiveUS20070142213A1High activityChlorine/hydrogen-chloride purificationSulfur compoundsAlkyl transferIonic liquid

A process for regenerating a used acidic catalyst which has been deactivated by conjunct polymers by removing the conjunct polymers so as to increase the activity of the catalyst is disclosed. Methods for removing the conjunct polymers include hydrogenation, addition of a basic reagent and alkylation. The methods are applicable to all acidic catalysts and are described with reference to certain ionic liquid catalysts.

Owner:CHEVROU USA INC

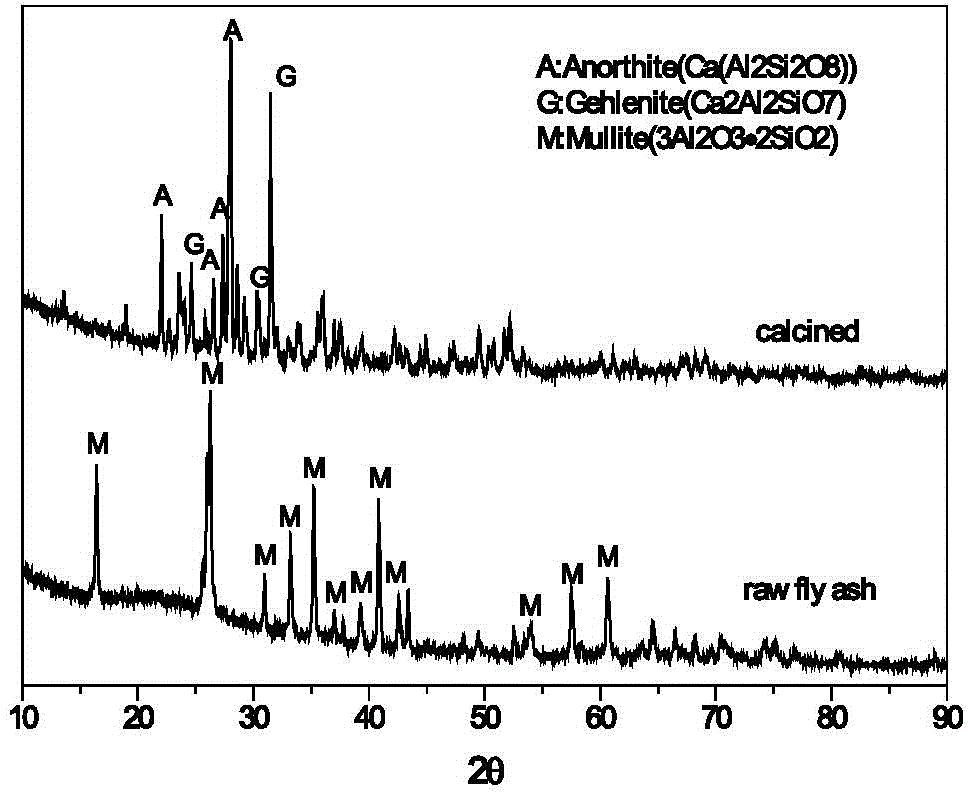

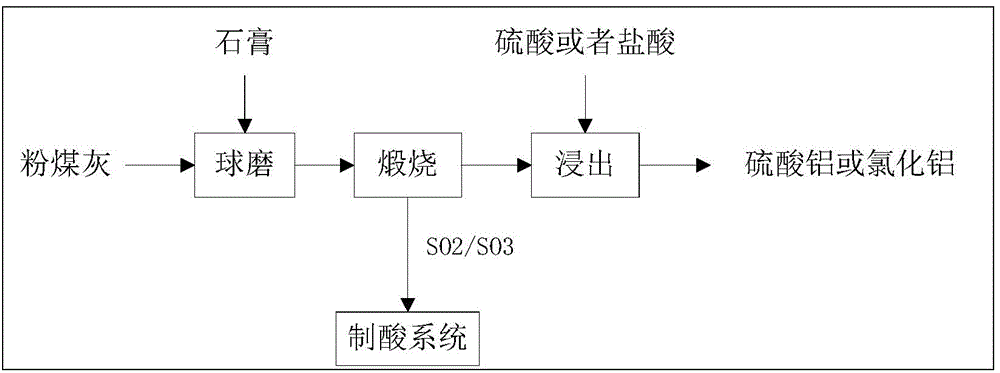

Method for cooperative activation of fly ash and decomposition of gypsum for recovery of sulfur resource

The invention provides a method for cooperative activation of fly ash and decomposition of gypsum for recovery of a sulfur resource. According to the method, solid waste, i.e., fly ash, discharged by a coal-fired power plant or coal-fired boiler is used as a raw material, a certain proportion of desulfurized gypsum discharged by the coal-fired power plant or waste phosphogypsum produced in the phosphorus chemical industry is added and mixed with the fly ash, then the obtained mixture is subjected to ball milling, and activation and calcination at a temperature of 950 to 1450 DEG C are carried out for 5 to 180 min; calcium sulfate in the gypsum are almost totally decomposed after calcination, and produced gas contains sulfur dioxide or sulfur trioxide which can be used as feed gas for preparation of sulfuric acid; and calcination enables solid fly ash to be activated, leaching with a sulfuric acid or hydrochloric acid solution is carried out at a temperature of 50 to 100 DEG C, and the leaching rate of alumina is greater than 80%. The method provided by the invention has the advantages that since all the raw materials are solid waste, the purpose of treating the waste by using the waste is achieved; elemental sulphur in the gypsum can be recovered; and the fly ash can be activated and activity of the fly ash can be improved, so a high alumina recovery rate at a low temperature can be realized. With the method, high-efficiency extraction of alumina in the fly ash is realized; the sulfur resource in the gypsum is recovered; shortage in industrial sulphur in the sulfuric acid industry in China is compensated; and the method has good economic benefits and wide industrial application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

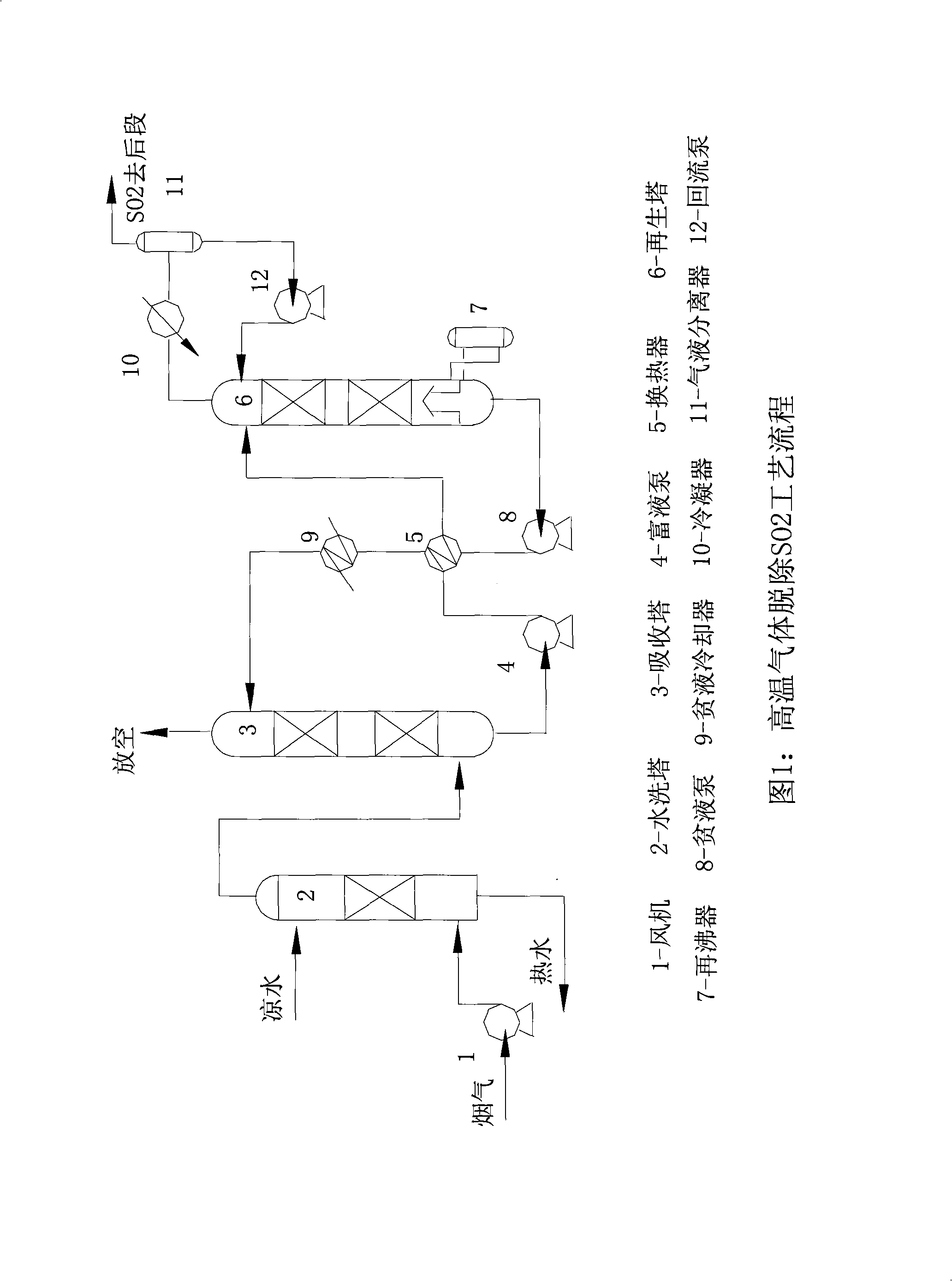

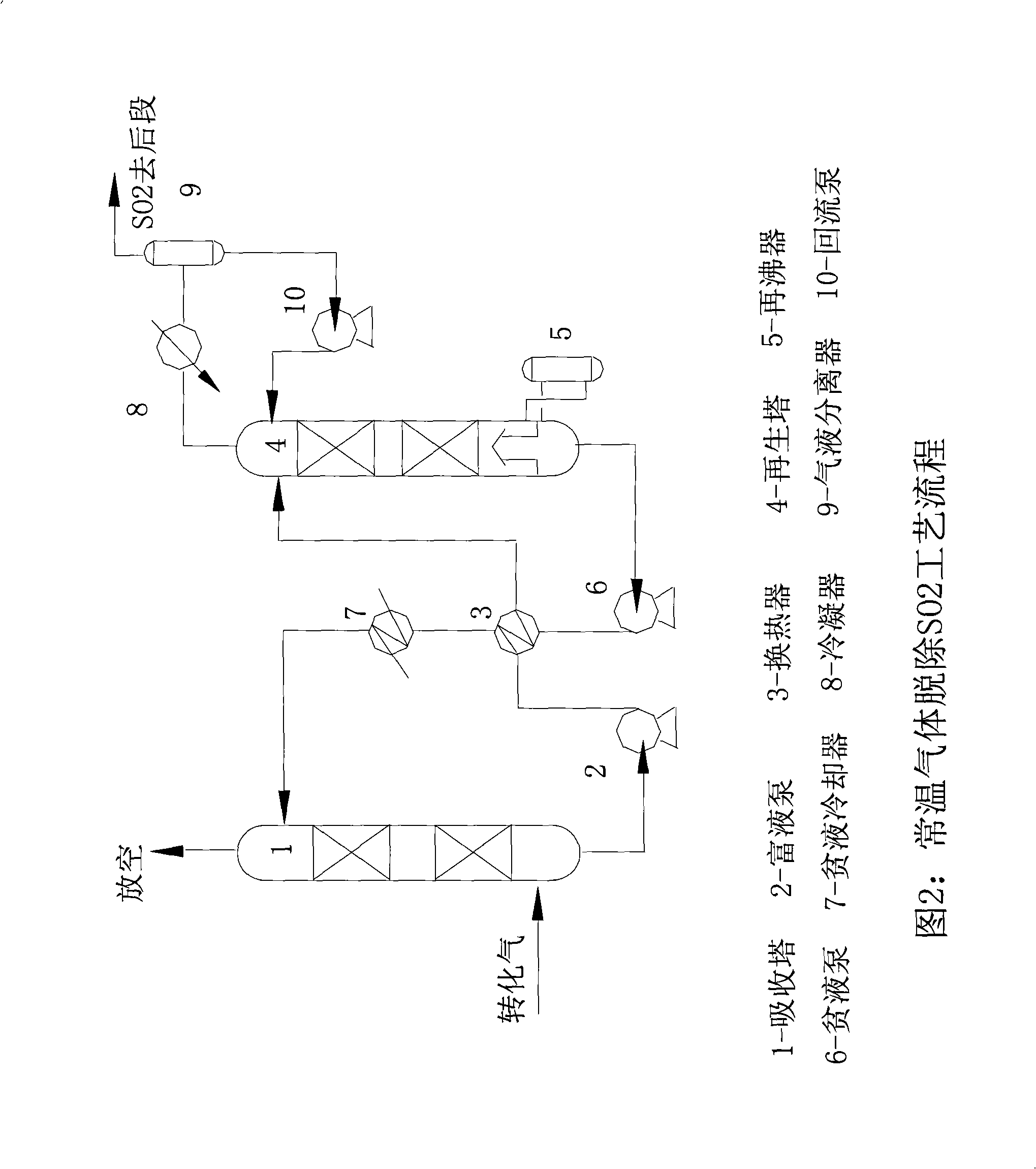

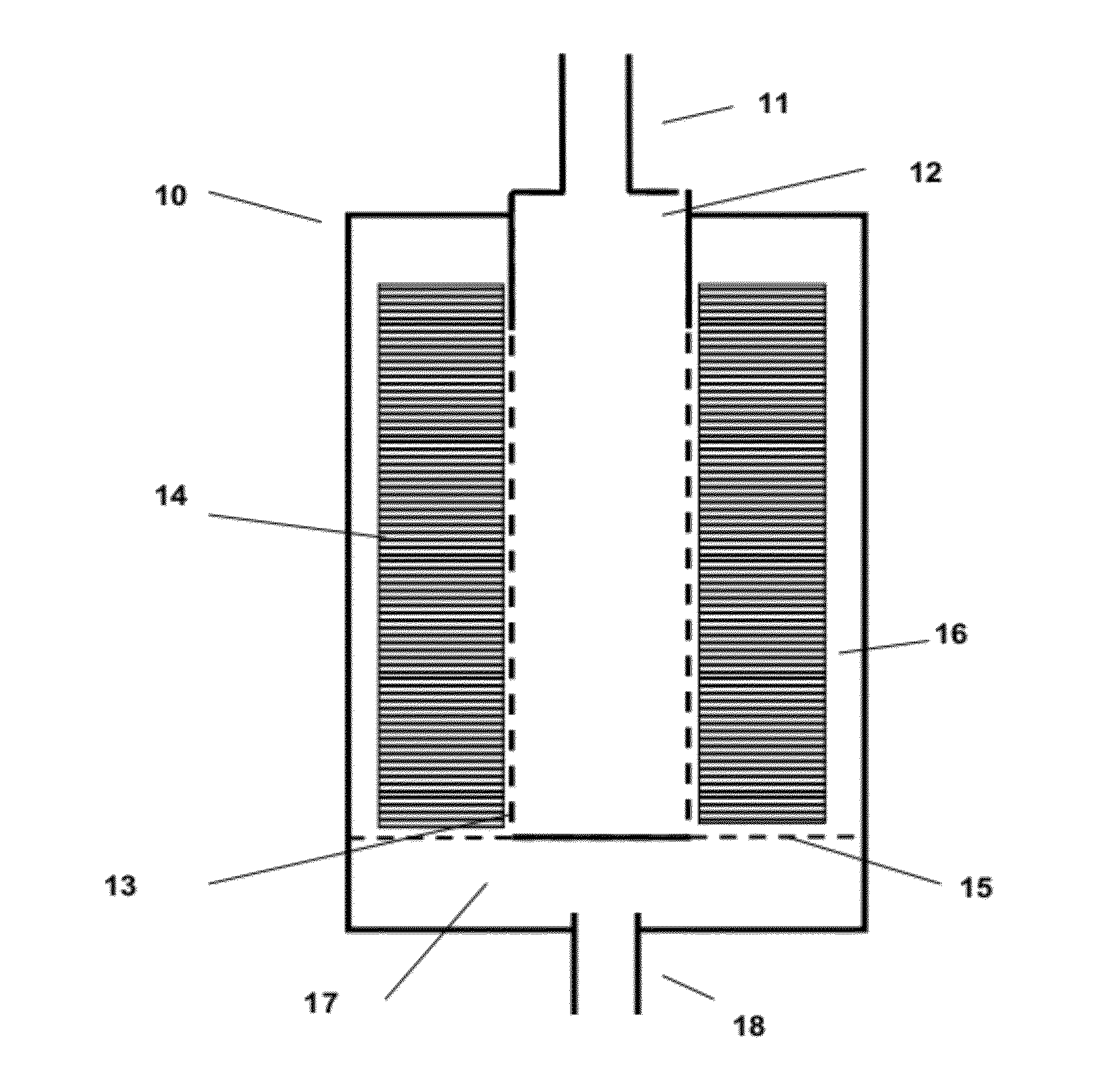

Absorbing agent for removing and recovering sulfur dioxide from gaseous mixture

ActiveCN101274204AReduce operating costsLess investmentSulfur compoundsDispersed particle separationQuinoneAntioxidant

The invention discloses a novel absorbent which can remove SO2 and recover high-consistency SO2 at the same time, aiming at the characteristics of mixed gases such as flue gases of boilers of power plants, metallurgy sintering flue gases, sulfuric acid industrial tail gases, etc. The absorbent provided by the invention has the compositions as follows: (1) the absorbent has substance which contains 2 to 50 percent organic cations and 2 to 50 percent inorganic anions by mass concentration and is used as main component removing the SO2; (2) alkyl alcohol amide with the mass concentration of 0.1 to 3 percent is used as activator for removing the SO2; (3) phenols and quinones with the mass concentration of 0.1 to 0.2 percent are used as antioxidant of the absorbent; (4) metal oxide or inorganic salt with the mass concentration of 0.1 to 0.2 percent is used as corrosion inhibitor of the absorbent; (5) 5 to 95 percent of water is contained. The absorbent absorbs the SO2 gas in the mixed gases under the low temperature of 20 to 80 DEG C, dissolves the SO2 gas under high temperature of 85 to 130 DEG C, and generates the SO2 by-product with the concentration more than 99 percent (dry basis); the absorbent is circularly used.

Owner:HUAXI CHEM INST CHENGDU CITY

Gas Purification Process Utilizing Engineered Small Particle Adsorbents

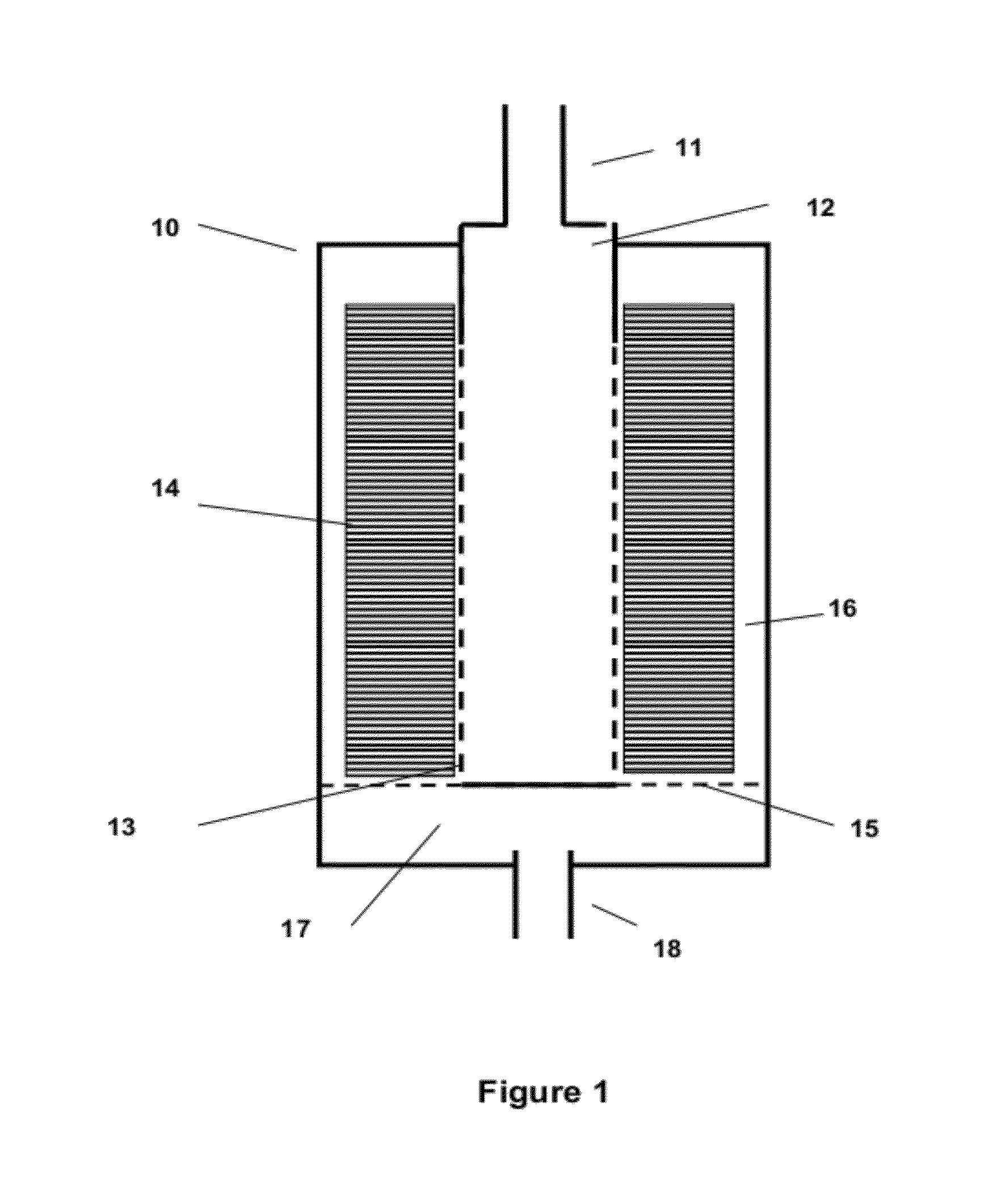

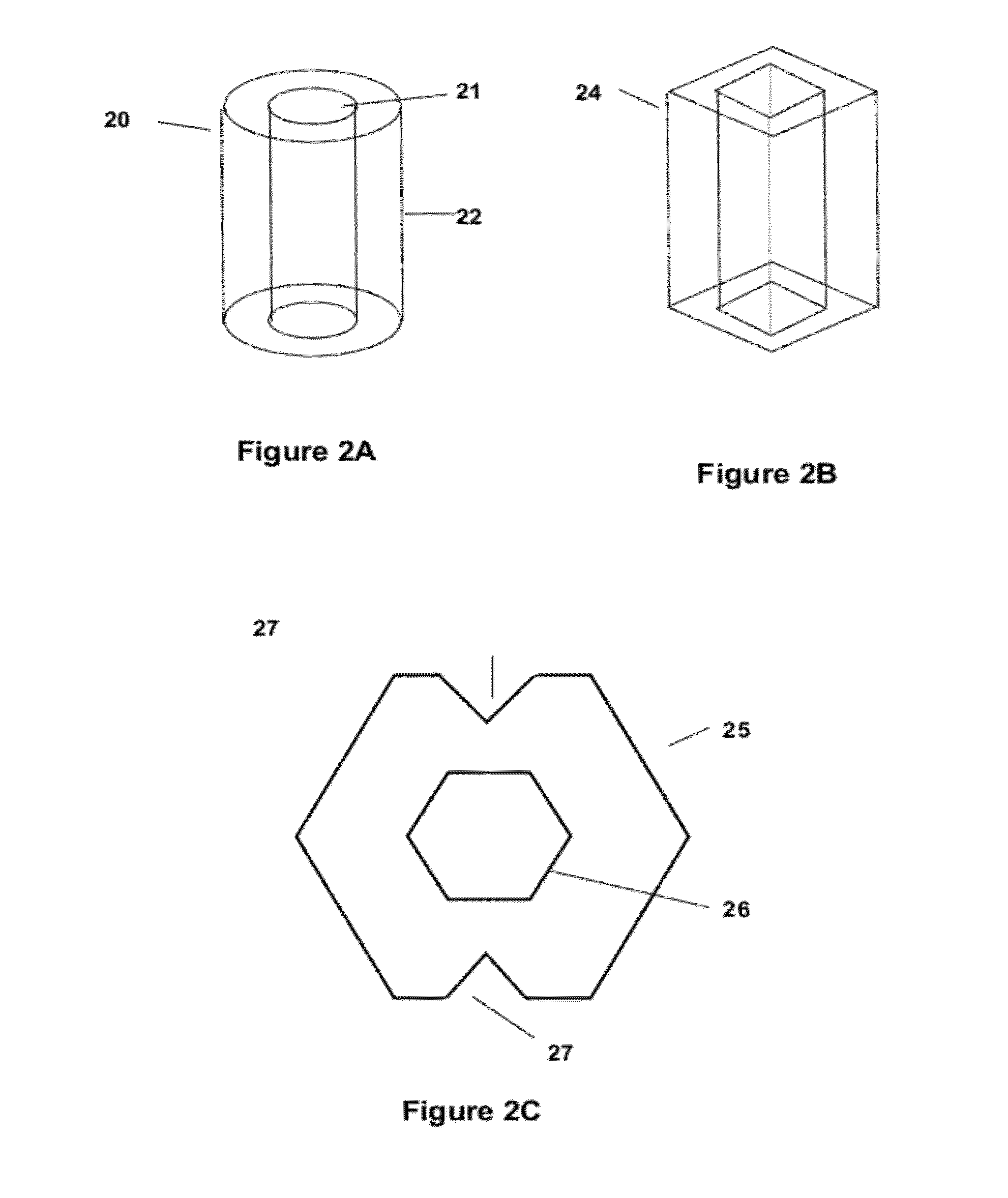

ActiveUS20120222555A1Great diffusion rateLower Level RequirementsCarbon compoundsSulfur compoundsParticulatesSorbent

A gas separation process uses a structured particulate bed of adsorbent coated shapes / particles laid down in the bed in an ordered manner to simulate a monolith by providing longitudinally extensive gas passages by which the gas mixture to be separated can access the adsorbent material along the length of the particles. The particles can be laid down either directly in the bed or in locally structured packages / bundles which themselves are similarly oriented such that the bed particles behave similarly to a monolith but without at least some disadvantages. The adsorbent particles can be formed with a solid, non-porous core with the adsorbent formed as a thin, adherent coating on the exposed exterior surface. Particles may be formed as cylinders / hollow shapes to provide ready access to the adsorbent. The separation may be operated as a kinetic or equilibrium controlled process.

Owner:EXXON RES & ENG CO

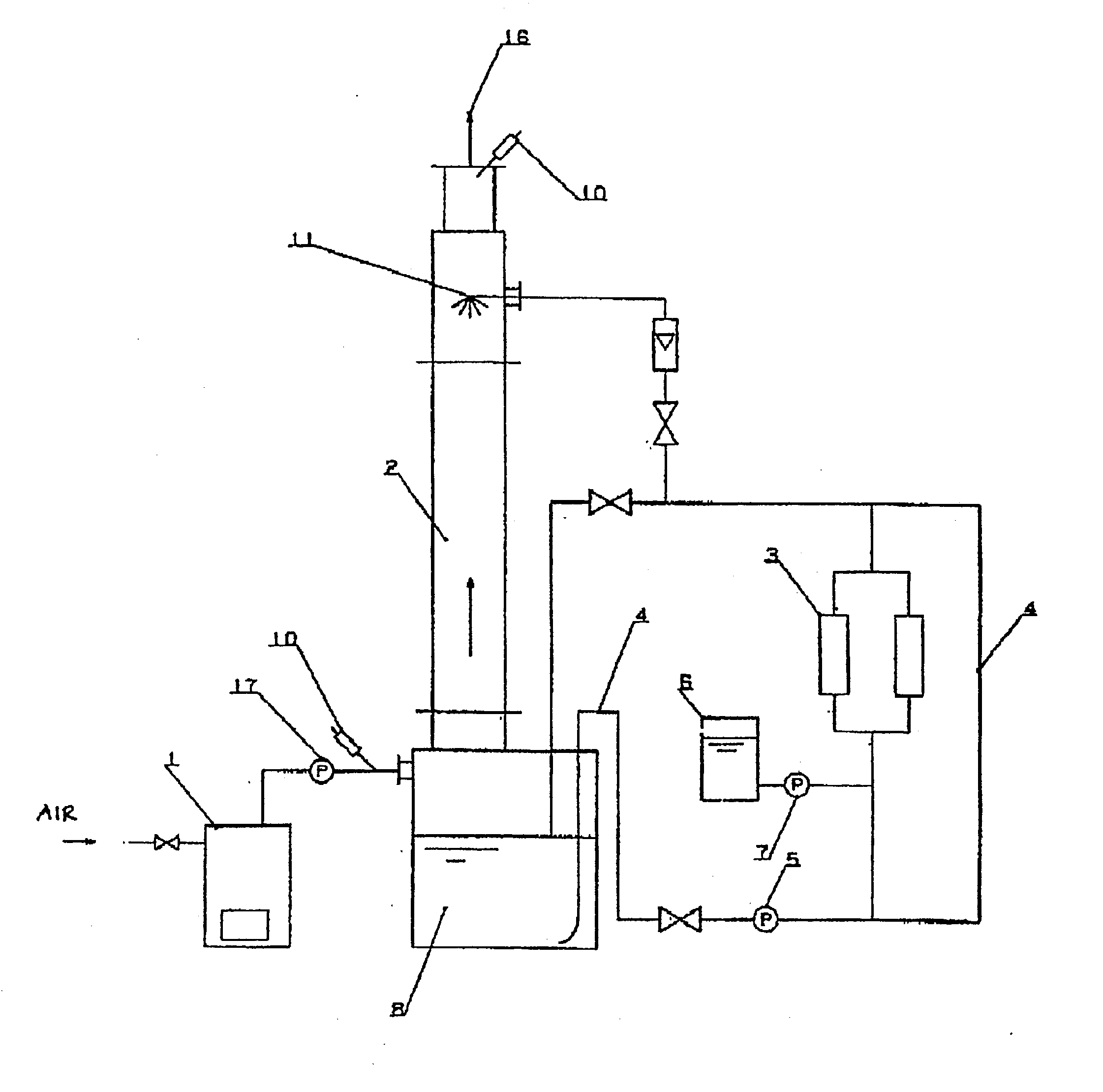

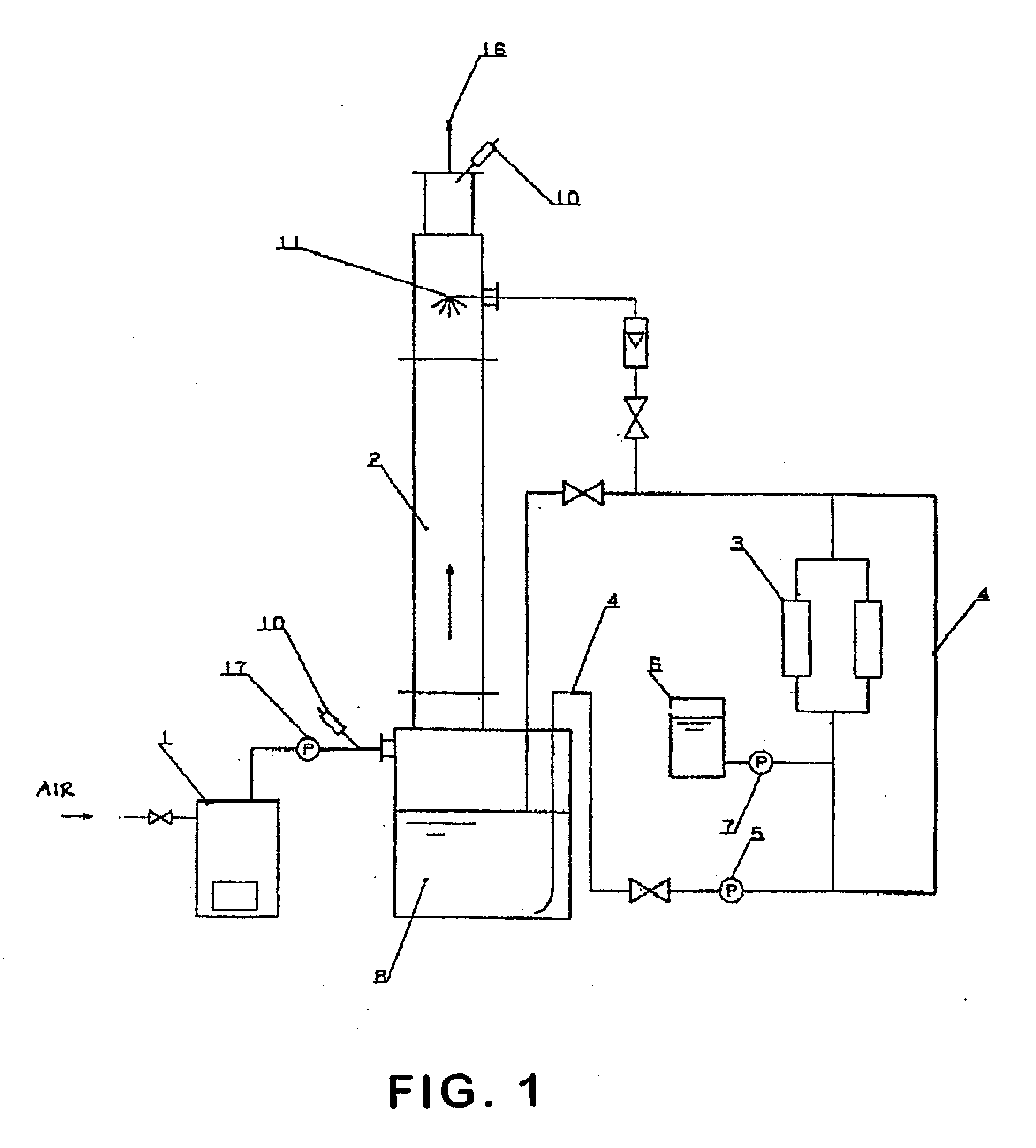

Method and device for deodorization and purification of exhaust gas or flue gas

InactiveUS20030164309A1Easy can be electrolyzedHigh densityCyanogen compoundsLighting and heating apparatusHazardous substancePotassium hydroxide

A method and device for removing, deodorizing and purifying odor, smoke and harmful substances from exhaust gas or flue gas employs a water solution containing hypohalogen acid such as hypochlorous acid soda, an alkaline electrolyte such as potassium hydroxide or sodium hydroxide and a saline electrolyte such as sodium chloride, potassium chloride, sodium bromide or potassium bromide which is electrolyzed to produce an electrolytic water solution which is fed to a deodorizing tower and brought into contact with exhaust gas or flue gas to remove odor, smoke and harmful substances in the exhaust gas or flue gas.

Owner:OMEGA CO LTD

Purification of carbon dioxide

SO2 and / or NOx are removed from gaseous CO2 at elevated pressure(s) in the presence of molecular oxygen and water and, when SO2 is to be removed, NOx, to convert SO2 to sulfuric acid and / or NOx to nitric acid. The sulfuric acid and / or nitric acid is / are then removed from the gaseous carbon dioxide to produce SO2-free, NOx-lean carbon dioxide gas. The invention has particular application in the removal of SO2 and / or NOx from carbon dioxide flue gas produced in an oxyfuel combustion process, for example, in a pulverized coal fired power station.

Owner:AIR PROD & CHEM INC

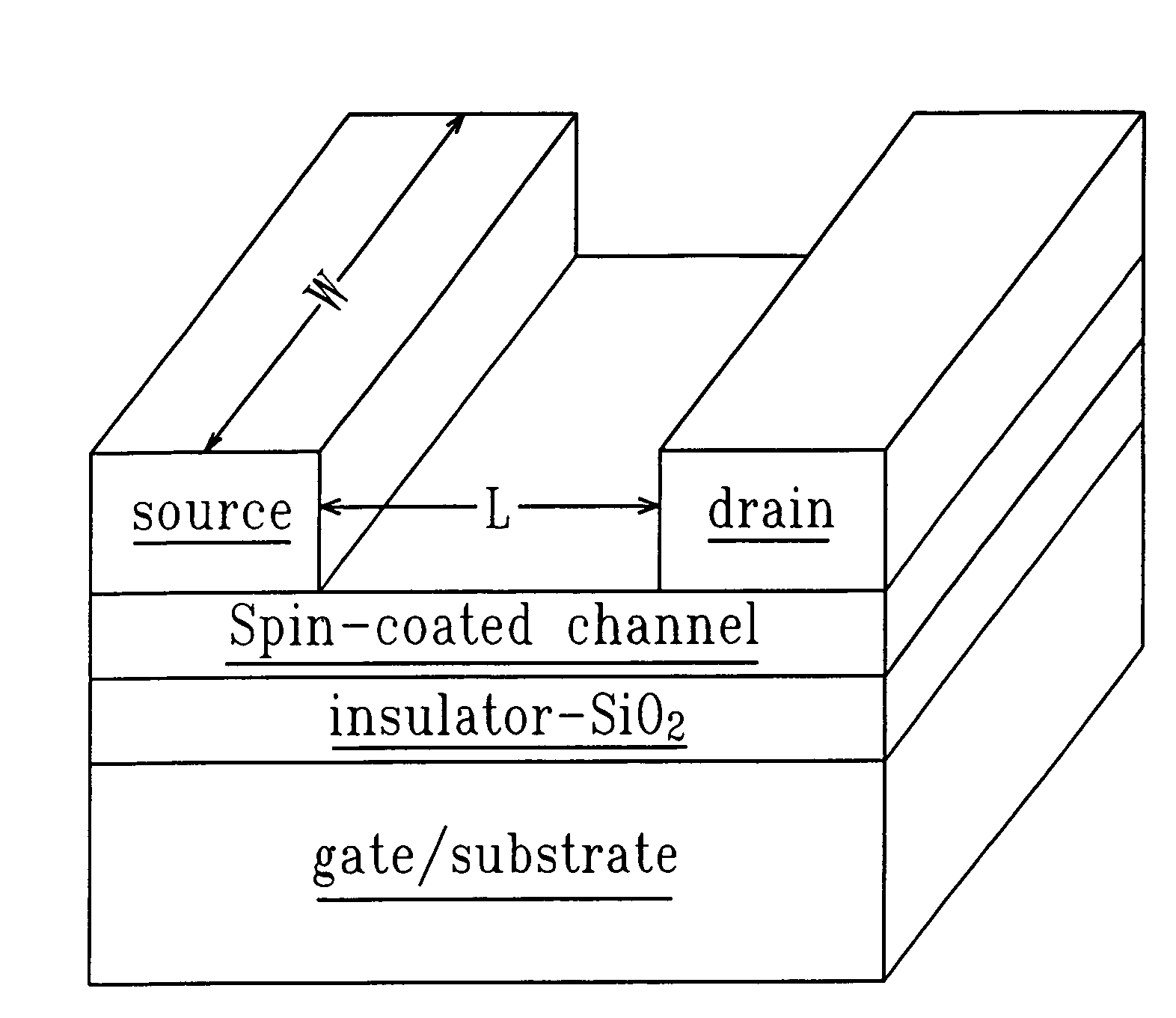

Novel carbon-sulfur compound for lithium-sulfur battery

InactiveCN101587951AIncrease profitIncrease specific energyCell electrodesSulfur compoundsElectric capacityInternal resistance

The invention relates to a novel carbon-sulfur compound for an anode material of a lithium-sulfur battery and a preparation method thereof. Sulfur is filled into a nano and micron hole of a matrix in an elementary substance way by taking a macroporous carbon material with high pore volume, electrical conductivity and specific surface area as the matrix, and the sulfur and carbon can also carry out combination reaction so as to prepare the novel carbon-sulfur compound of which the sulfur exists in one or more chemical states in a carbon material. The novel carbon-sulfur compound used as the anode material of the lithium-sulfur battery has the advantages that the high pore volume has large contained sulfur contents and can ensure high electric capacity; the small granularity of the sulfur can reduce a conductive distance between ions and electrons and increase the utilization ratio of the sulfur; and the adsorption characteristics of the high specific surface of the carbon material can inhibit a discharging intermediate product from dissolving and moving towards a cathode, reduce the self discharge, prevent a nonconductive discharging product, namely lithium sulfide from largely accumulating outside carbon particles and reduce internal resistance, therefore, the material can improve the specific energy, the specific power and the cycle performance of the lithium-sulfur battery.

Owner:NO 63971 TROOPS PLA

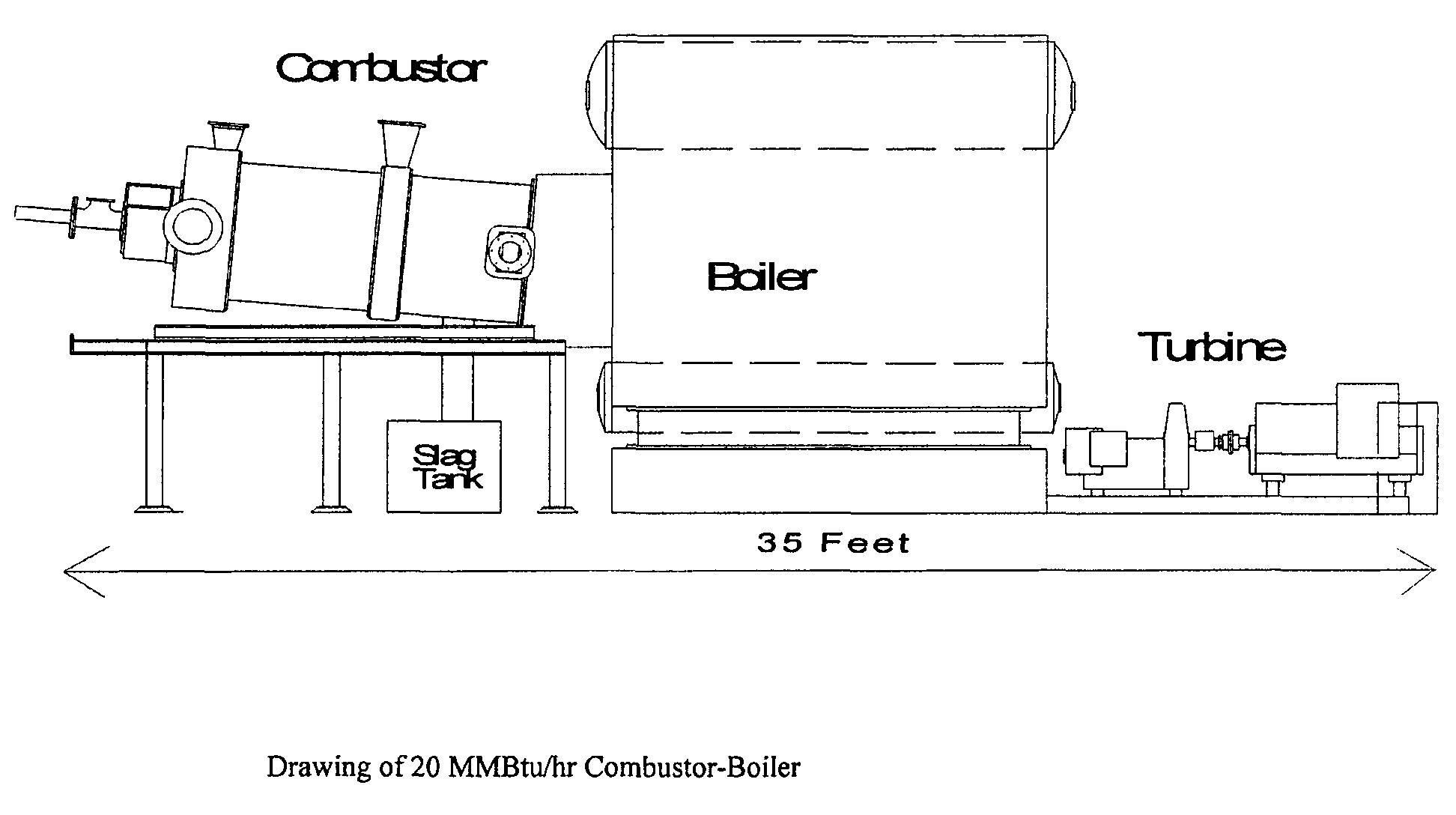

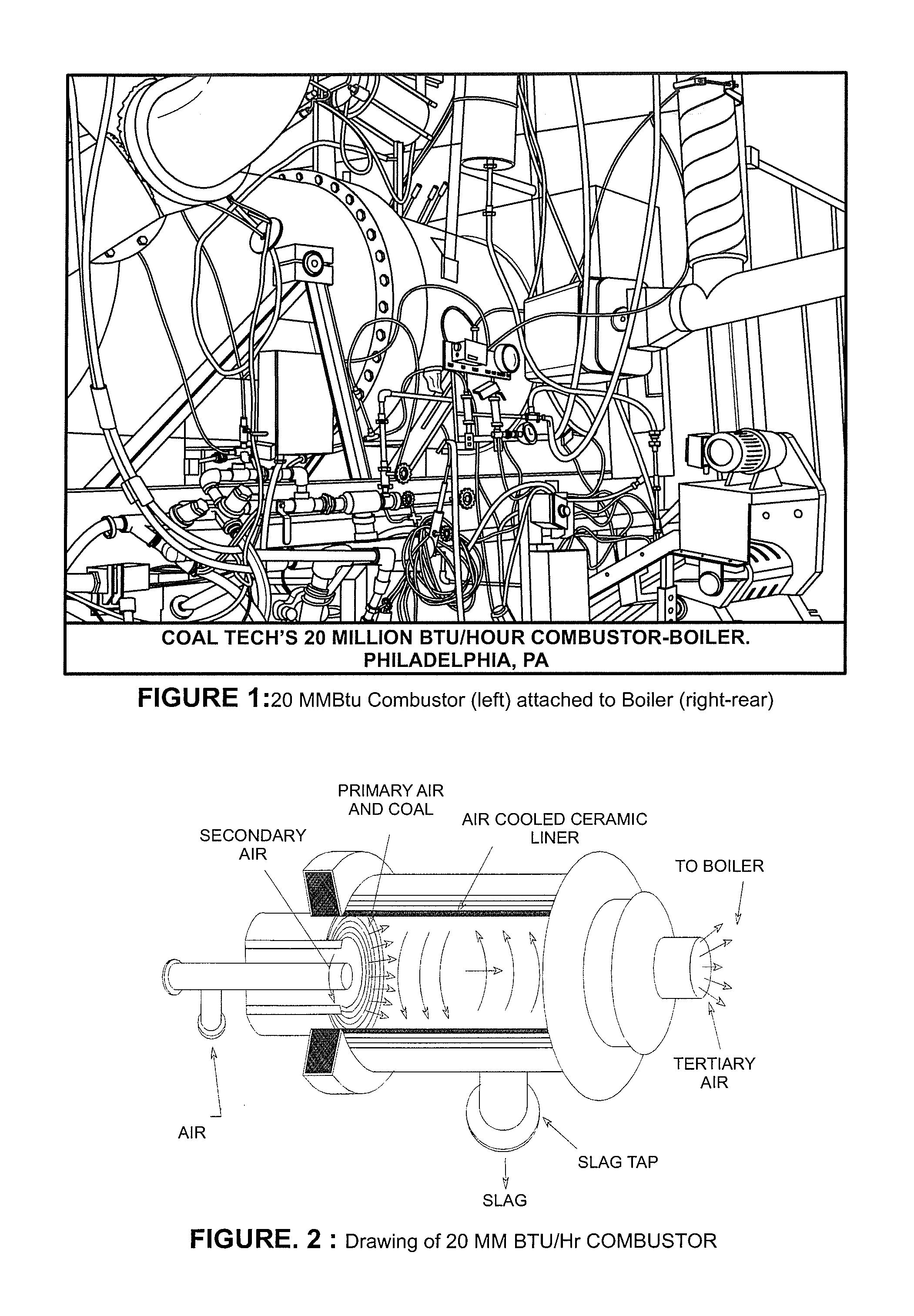

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

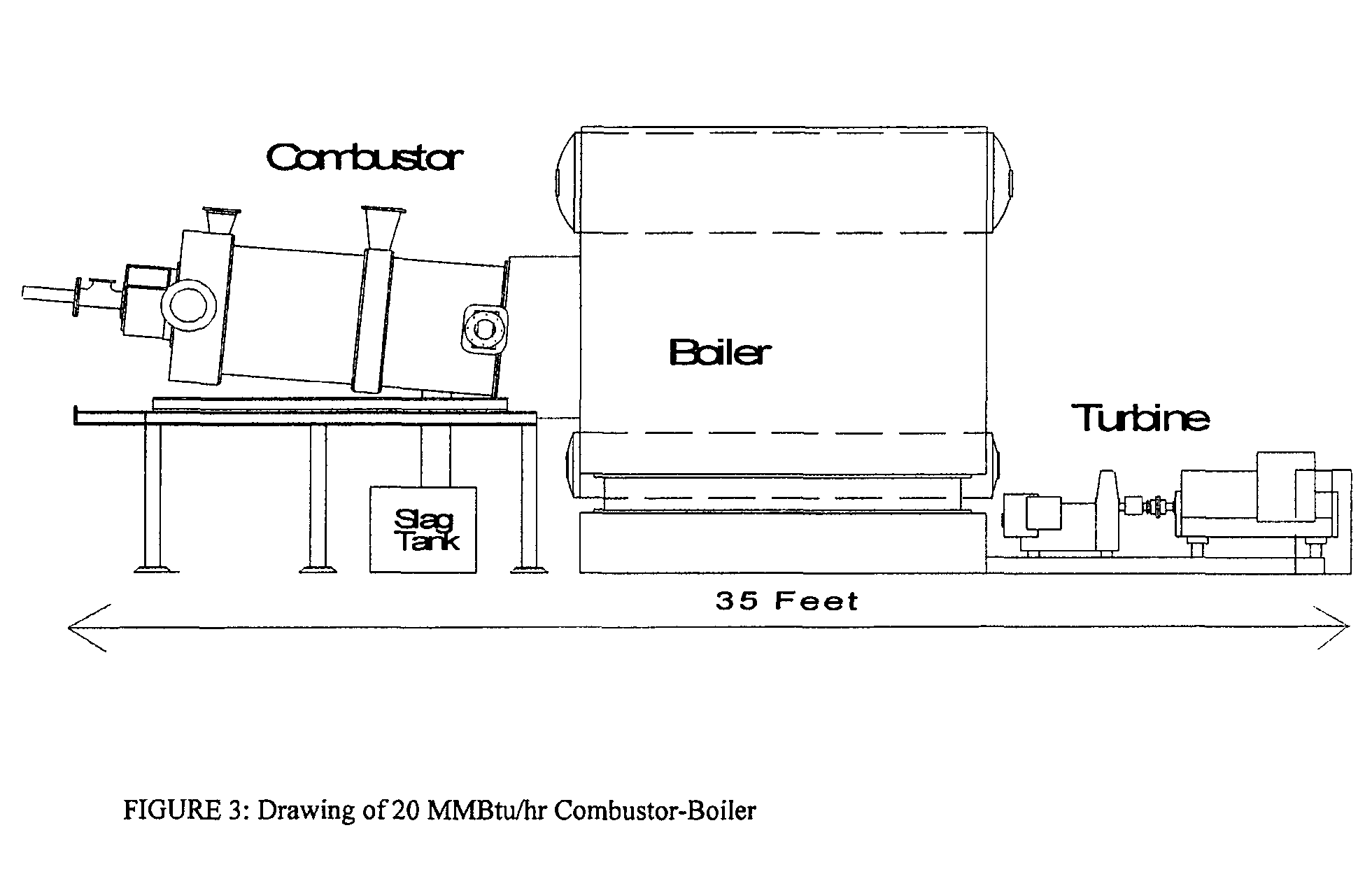

Solution-based deposition process for metal chalcogenides

A solution of a hydrazine-based precursor of a metal chalcogenide is prepared by adding an elemental metal and an elemental chalcogen to a hydrazine compound. The precursor solution can be used to form a film. The precursor solutions can be used in preparing field-effect transistors, photovoltaic devices and phase-change memory devices.

Owner:GLOBALFOUNDRIES U S INC

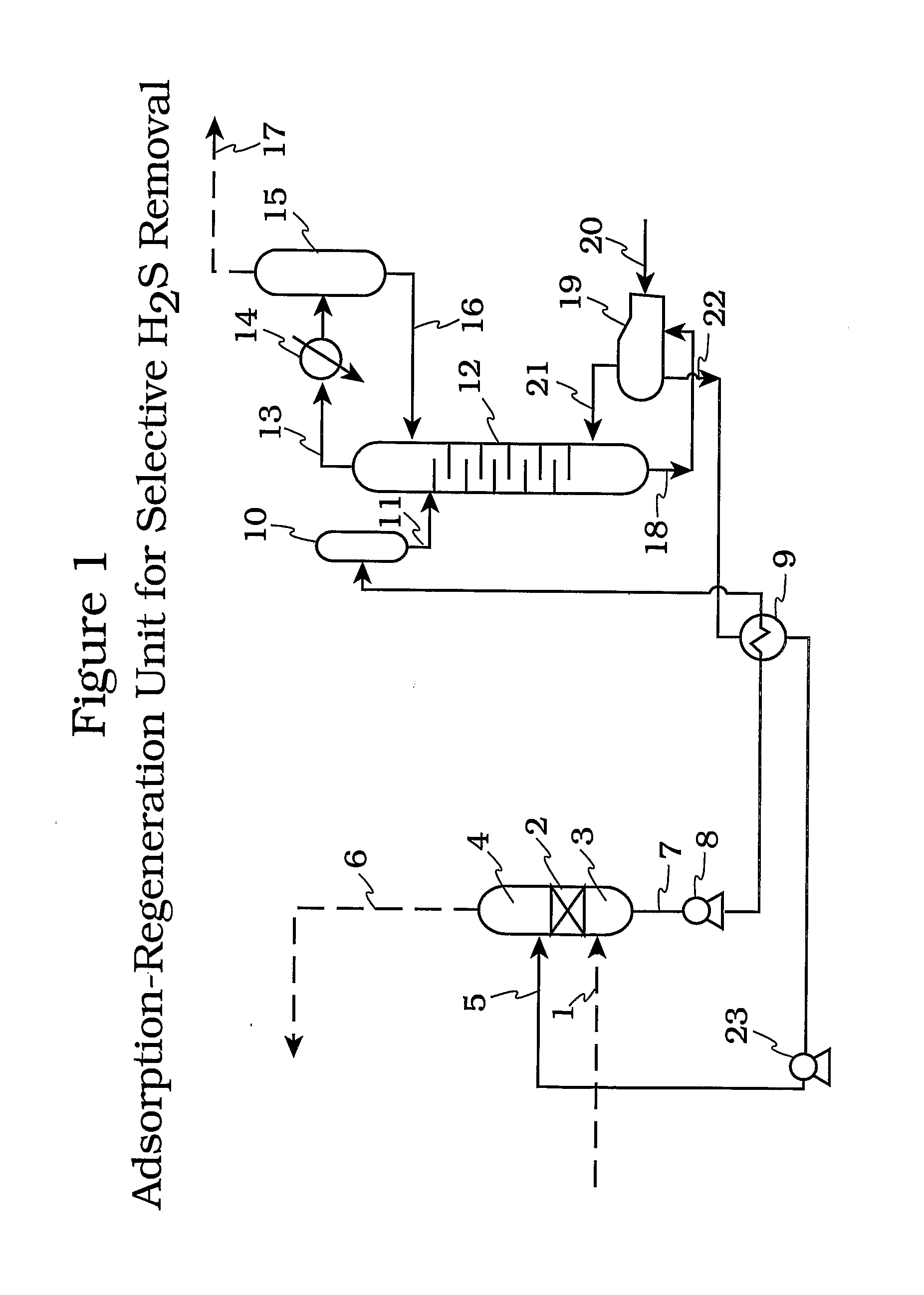

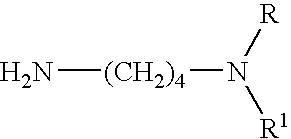

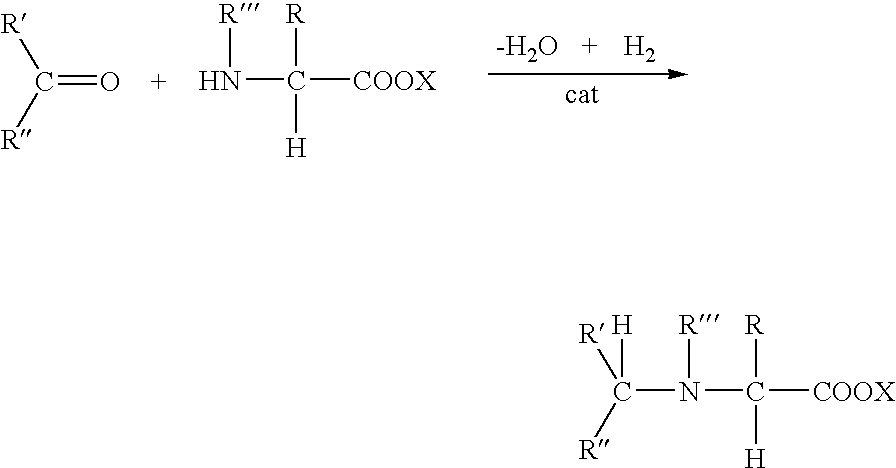

Absorbent composition containing molecules with a hindered amine and a metal sulfonate, phosphonate or carboxylate structure for acid gas scrubbing process

An acid gas absorbent comprising a metal sulfonate, phosphonate or carboxylate of a hindered amine and a process for the selective removal Of H2S as well as other acidic components such as carbon disulfide, carbonyl sulfide and oxygen and sulfur derivatives of C1 to C4 hydrocarbons from mixtures containing such acidic components and CO2 using said absorbent.

Owner:EXXON RES & ENG CO

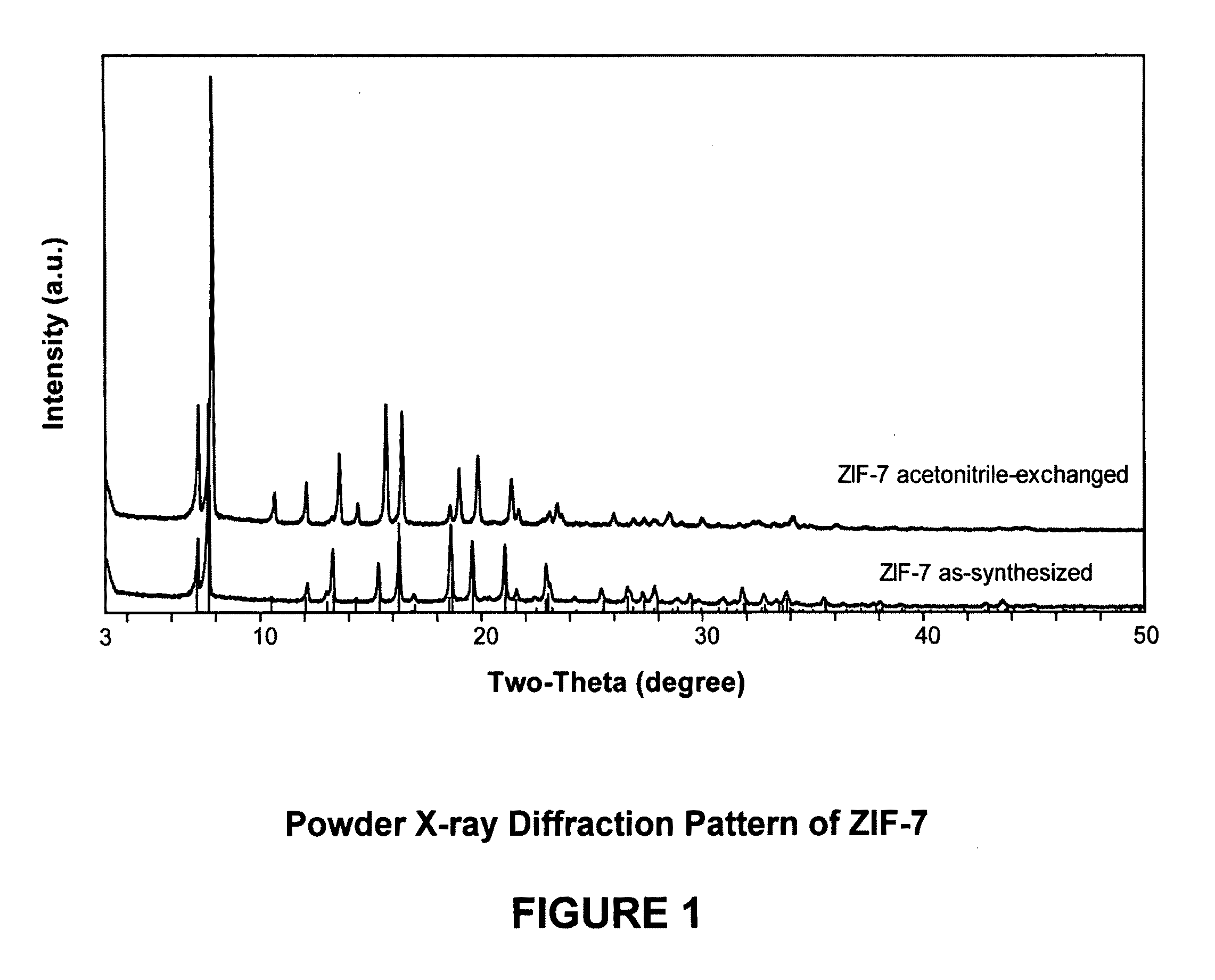

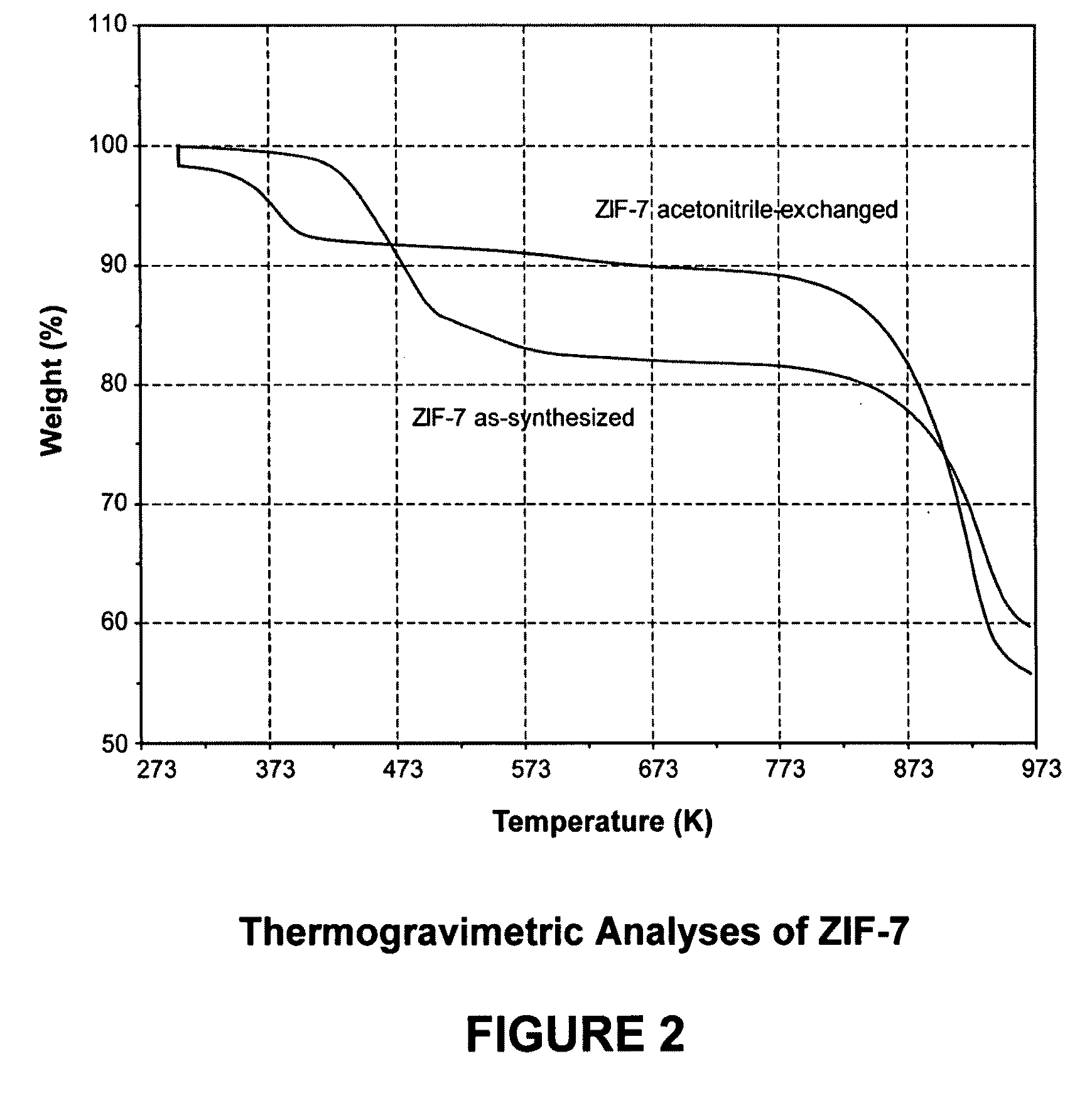

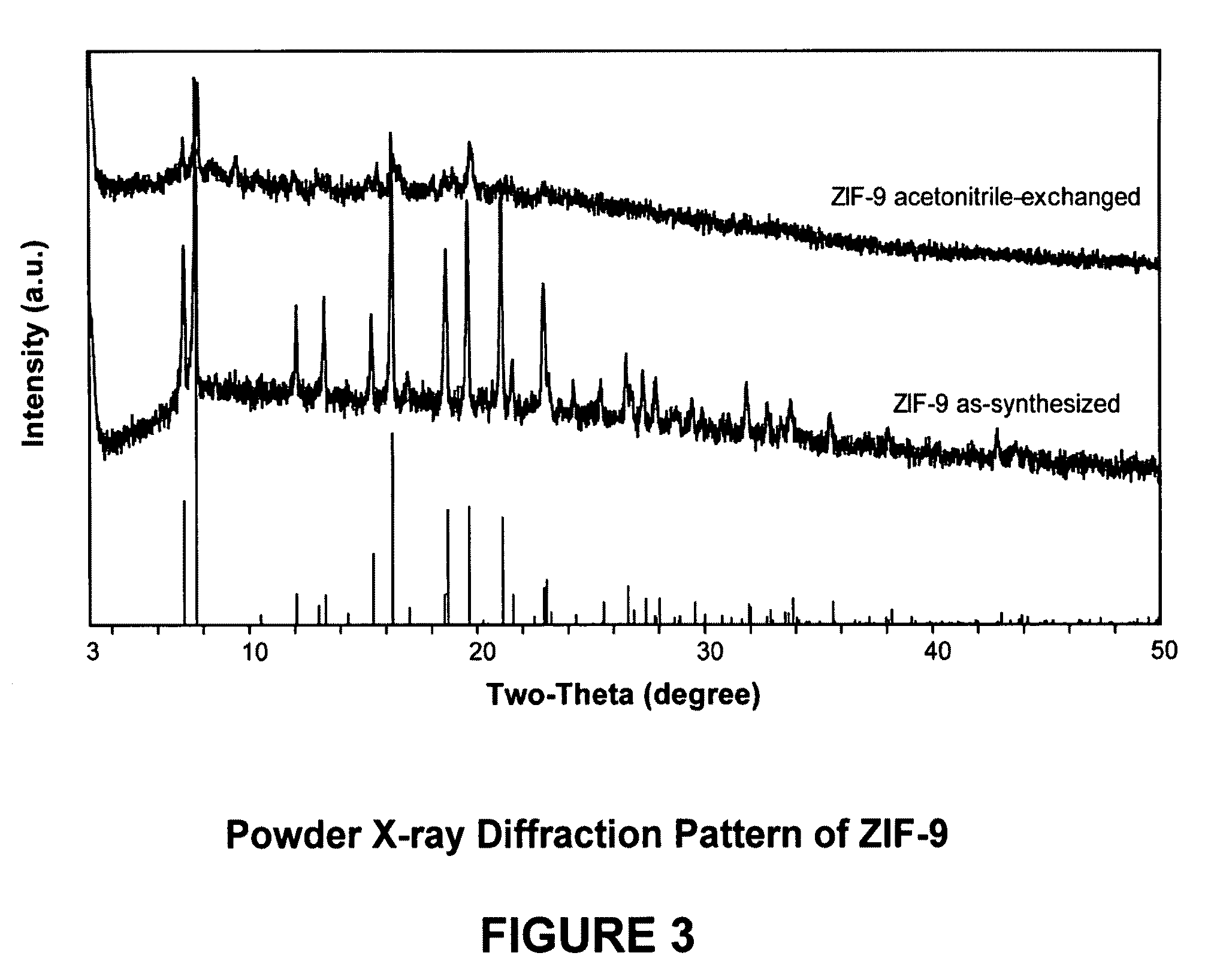

Separation of carbon dioxide from methane utilizing zeolitic imidazolate framework materials

The present invention relates to the selective separation of carbon dioxide (“CO2”) from methane (“CH4”) in streams containing both carbon dioxide and methane utilizing a zeolitic imidazolate framework (“ZIF”) material. Preferably, the stream to be separated is fed to the present process in a substantially gaseous phase. In preferred embodiments, the current invention is utilized in a process to separate carbon dioxide from natural gas streams preferably for sequestration of at least a portion of the carbon dioxide present in the natural gas.

Owner:EXXON RES & ENG CO

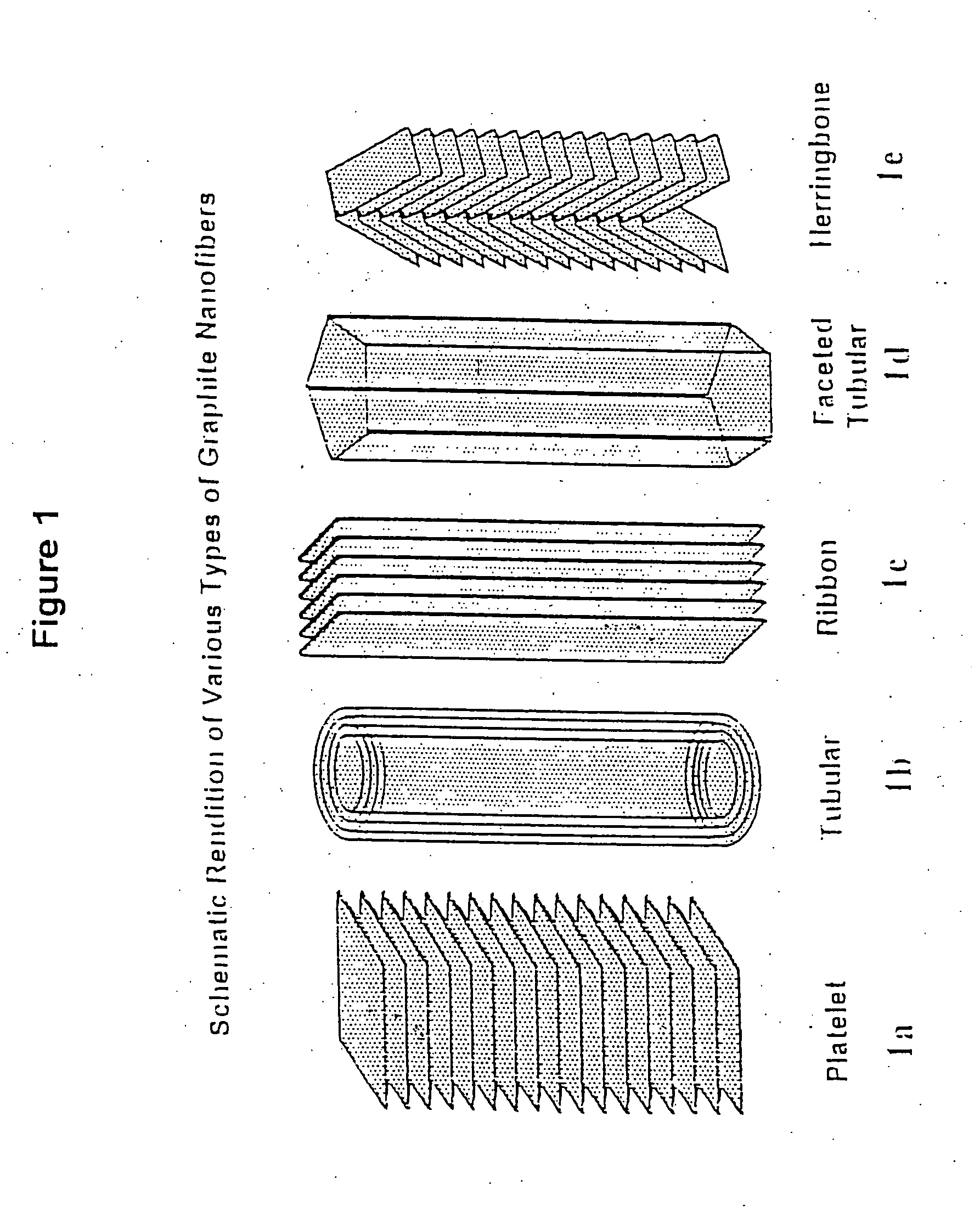

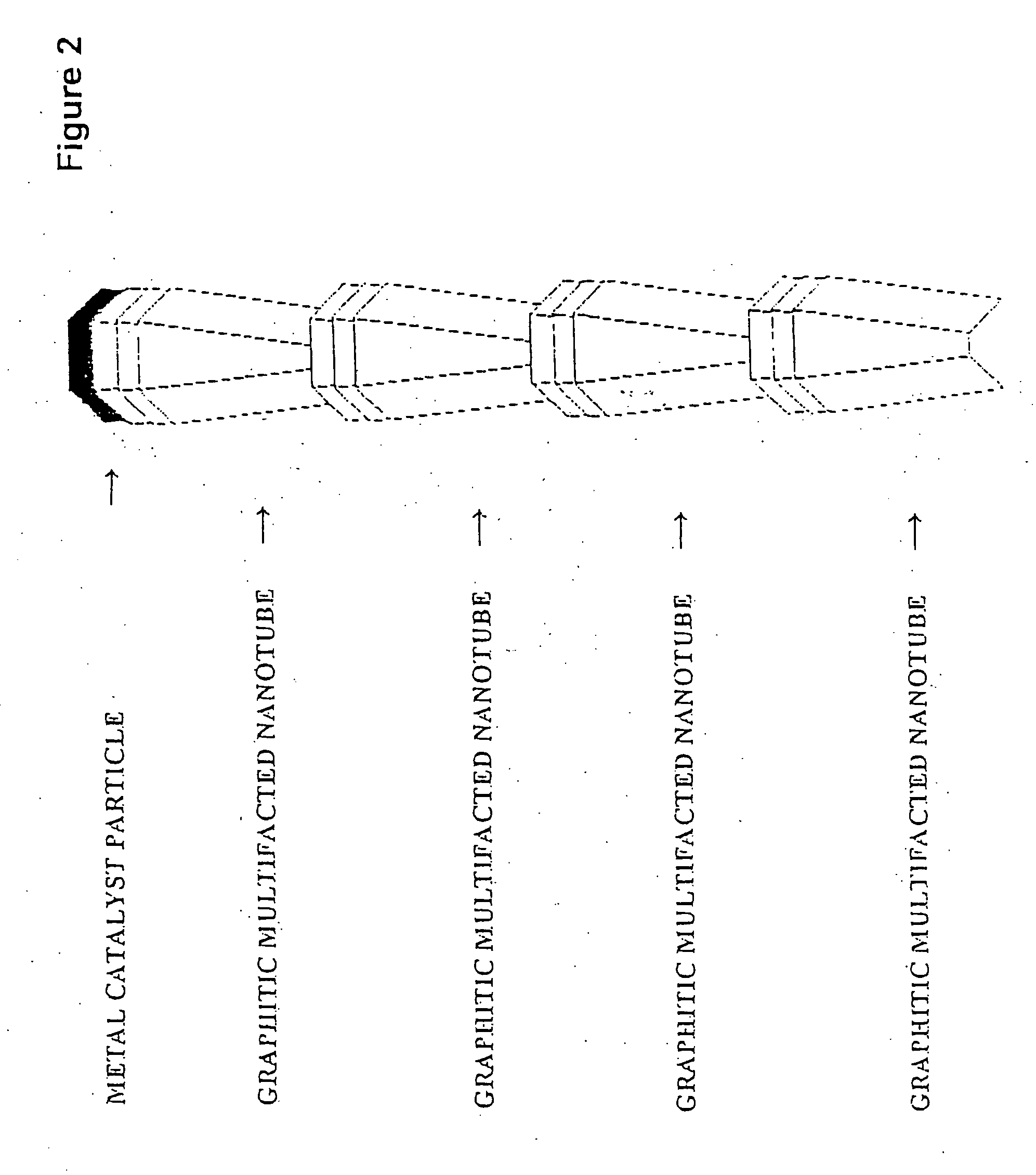

Novel graphite nanocatalysts

Novel catalysts comprised of graphitic nanostructures. The graphitic nanostructure catalysts are suitable for catalyzing reactions such as oxidation, hydrogenation, oxidative-hydrogenation, and dehydrogenation.

Owner:CATALYTIC MATERIALS

Temperature Swing Adsorption Process for the Separation of Target Species from a Gas Mixture

Owner:EXXON RES & ENG CO

Removal of methyl mercaptan from gas streams

InactiveUS20050287056A1Efficient productionGas treatmentDispersed particle separationHigh concentrationThiol

The invention described herein is a method for selectively removing mercaptans such as methyl mercaptan from dry gas mixtures containing high concentrations of carbon dioxide. In the method, the carbon dioxide-rich gas (sour gas) is passed through an absorption vessel or distillation column in which it is contacted with an absorbent such as liquid carbon dioxide in order to selectively absorb the mercaptans. The treated gas, which is now free of mercaptans, leaves the top of the vessel as a sales gas suitable for use in enhanced oil recovery applications. Preferably, a portion of the carbon dioxide in the sales gas is condensed and the liquid is returned to the absorber or distillation column as the scrubbing agent. At least part of this scrubbing agent leaves the bottom of the absorber or distillation column enriched in methyl mercaptan and other sulfur compounds. The stream from the absorption vessel containing the mercaptans can be incinerated or otherwise processed to utilize or dispose of the methyl mercaptan.

Owner:DAKOTA GASIFICATION COMPANY

Process of making hydrophobic metal oxide nanoparticles

InactiveUS7081234B1Uniform coatingSulfur compoundsCopper oxides/halidesMetal oxide nanoparticlesTransport layer

A process of treating metal oxide nanoparticles that includes mixing metal oxide nanoparticles, a solvent, and a surface treatment agent that is preferably a silane or siloxane is described. The treated metal oxide nanoparticles are rendered hydrophobic by the surface treatment agent being surface attached thereto, and are preferably dispersed in a hydrophobic aromatic polymer binder of a charge transport layer of a photoreceptor, whereby π—π interactions can be formed between the organic moieties on the surface of the nanoparticles and the aromatic components of the binder polymer to achieve a stable dispersion of the nanoparticles in the polymer that is substantially free of large sized agglomerations.

Owner:XEROX CORP

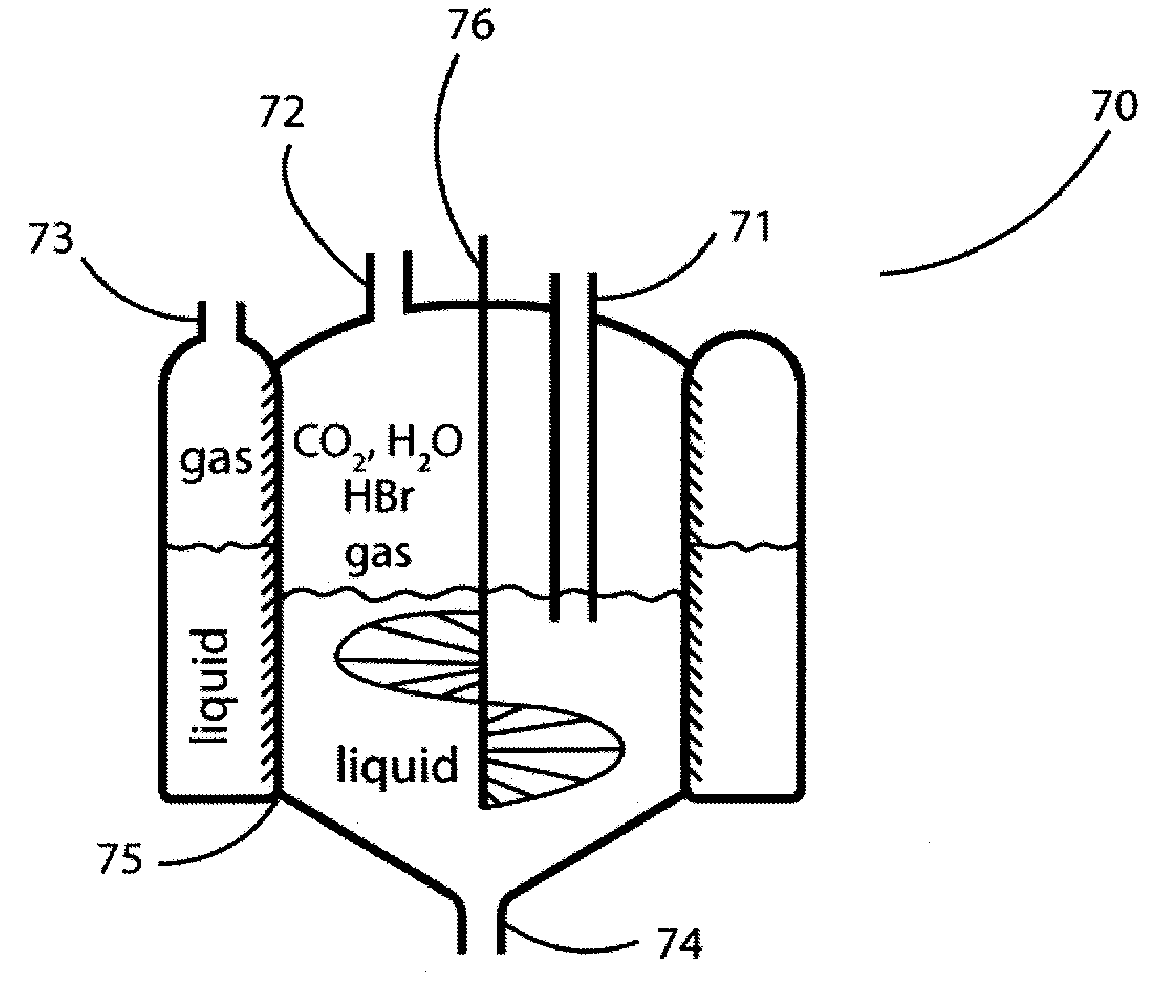

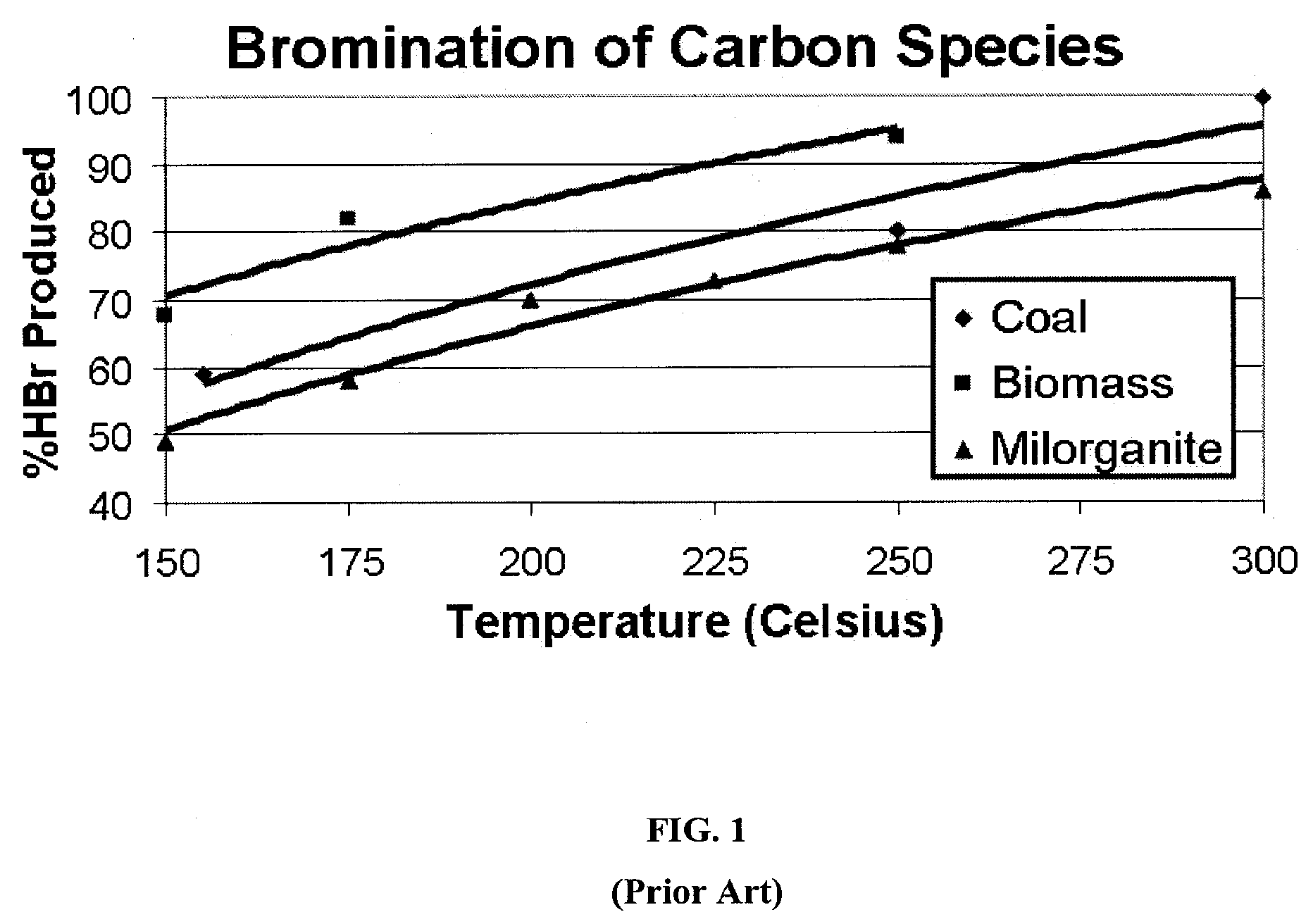

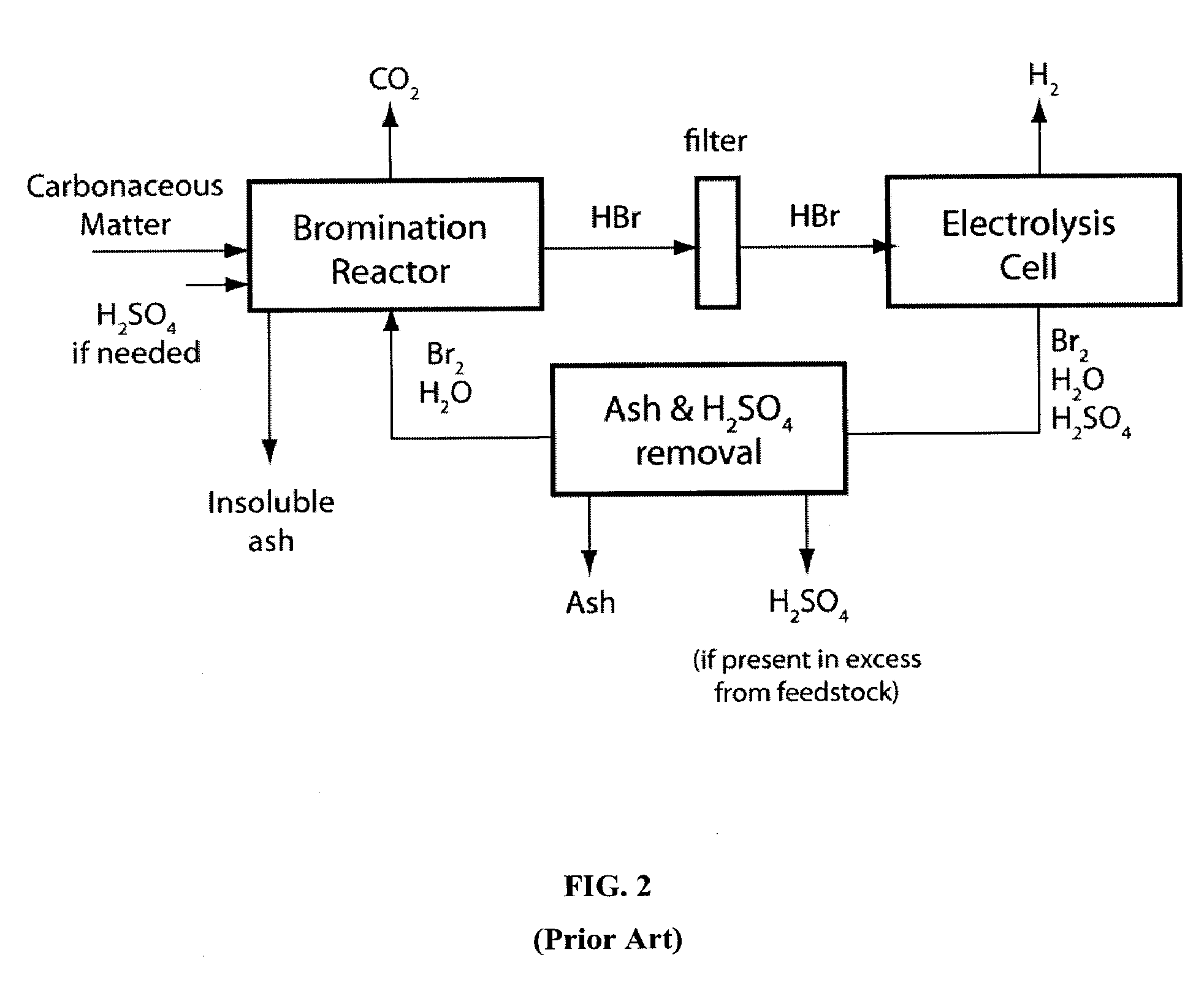

Waste Treatment and Energy Production Utilizing Halogenation Processes

InactiveUS20090028767A1Reduce needEfficient processingPhotography auxillary processesElectrolysis componentsCelluloseEngineering

A method for generating energy and / or fuel from the halogenation of a carbon-containing material and / or a sulfur-containing chemical comprises supplying the carbon-containing material (e.g., coal, lignite, biomass, cellulose, milorganite, methane, sewage, animal manure, municipal solid waste, pulp, paper products, food waste) and / or the sulfur-containing chemical (e.g., H2S, SO2, SO3, elemental sulfur) and a first halogen-containing chemical to a reactor. The carbon-containing material and / or the sulfur-containing chemical and the halogen-containing chemical are reacted in the reactor to form a second halogen-containing chemical and carbon dioxide, sulfur and / or sulfuric acid. The second halogen-containing chemical is dissociated (e.g., electrolyzed) to form the first halogen-containing chemical and hydrogen gas (H2). The first halogen-containing chemical can be Br2 and the second halogen-containing chemical can be HBr. Any carbon dioxide formed during reaction can be directed to a prime mover (e.g., turbine) to generate electricity. Any ash and / or sulfur formed can be removed. In some cases a sulfur-containing chemical can be supplied to the reactor with the carbon-containing material.

Owner:SRT GROUP

Pressure-Temperature Swing Adsorption Process

A pressure-temperature swing adsorption process for the removal of a target species, such as an acid gas, from a gas mixture, such as a natural gas stream. Herein, a novel multi-step temperature swing / pressure swing adsorption is utilized to operate while maintaining very high purity levels of contaminant removal from a product stream. The present process is particularly effective and beneficial in removing contaminants such as CO2 and / or H2S from a natural gas at high adsorption pressures (e.g., at least 500 psig) to create product streams of very high purity (i.e., very low contaminant levels).

Owner:EXXON RES & ENG CO

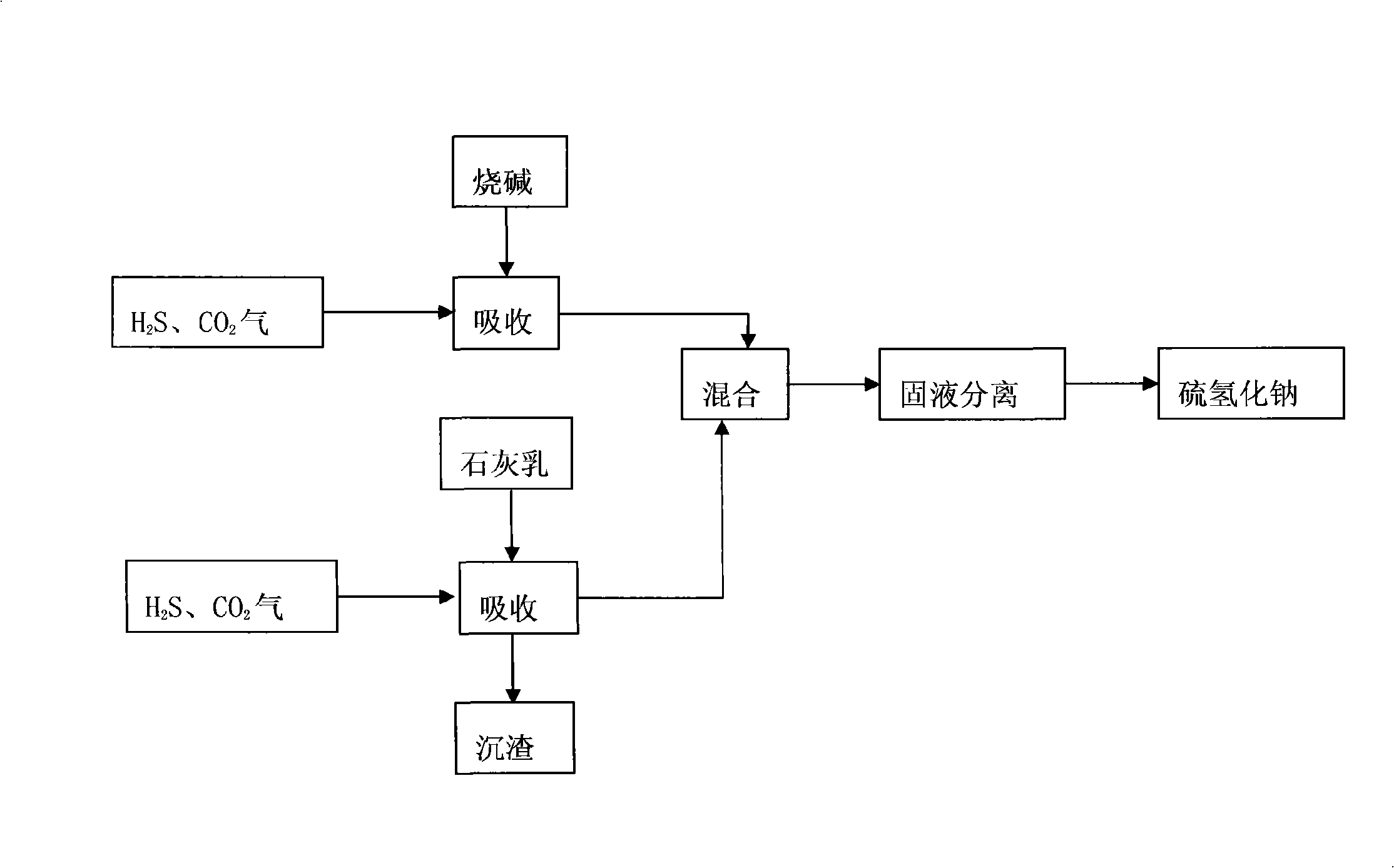

Method for preparing sodium hydrosulfide

InactiveCN101337661AQuality improvementIncrease profitSulfur compoundsHydrogenCALCIUM HYDROXIDE SOLUTION

The invention discloses a method for preparing sodium hydrosulfide. The production process is as follows: introducing a mixed gas containing sulfureted hydrogen H2S with the content larger than 10 percent and carbon dioxide CO2 with the content not larger than 90 percent into lime cream of about 12 percent of concentration, under the condition of a certain temperature and pressure and under agitation; stopping reaction when CaS is less than or equal to 0.5 percent; separating sediments out to obtain a sulfur calcium hydroxide solution; introducing a mixed gas of sulfureted hydrogen and carbon dioxide into a caustic soda solution with concentration larger than 30 percent under the condition of a certain temperature and pressure and under agitation; stopping reaction when Na2S is less than or equal to 0.5 percent to obtain a sodium hydrosulfide solution containing carbonate ions; and adding slightly not enough sodium hydrosulfide solution under agitation according to the amount of the carbonate ions in the sodium hydrosulfide solution, and separating sediments out to obtain sodium hydrosulfide with low carbonate ions.

Owner:褚亚华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com