Patents

Literature

696results about "Solid fuel pretreatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

Reducing mercury emissions from the burning of coal

Processes and compositions are provided for decreasing emissions of mercury upon combustion of fuels such as coal. Various sorbent compositions are provided that contain components that reduce the level of mercury and / or sulfur emitted into the atmosphere upon burning of coal. In various embodiments, the sorbent compositions are added directly to the fuel before combustion; are added partially to the fuel before combustion and partially into the flue gas post combustion zone; or are added completely into the flue gas post combustion zone. In preferred embodiments, the sorbent compositions comprise a source of halogen and preferably a source of calcium. Among the halogens, iodine and bromine are preferred. In various embodiments, inorganic bromides make up a part of the sorbent compositions.

Owner:NOX II LTD

Methods of operating a coal burning facility

ActiveUS20070168213A1Improve balanceIncrease valueSustainable waste treatmentSolid fuel pretreatmentHalogenSorbent

Methods involve adding sorbent components, such as calcium oxide, alumina, and silica, as well as optional halogens as part of environmental control. Use of the sorbents leads to significant reductions in sulfur and mercury emissions that otherwise would result from burning coal. Use of the sorbents leads to production of waste coal ash that, while higher in mercury, is nevertheless usable as a commercial product because the mercury in the ash is non-leaching and because the coal ash has a higher cementitious nature by virtue of the increased content of the sorbent components in the ash. Thus, the methods involve adding powders having qualities that lead to the production of a cementitious coal ash while at the same time reducing emissions from a coal burning facility.

Owner:NOX II LTD

Sorbent containing engineered fuel feed stock

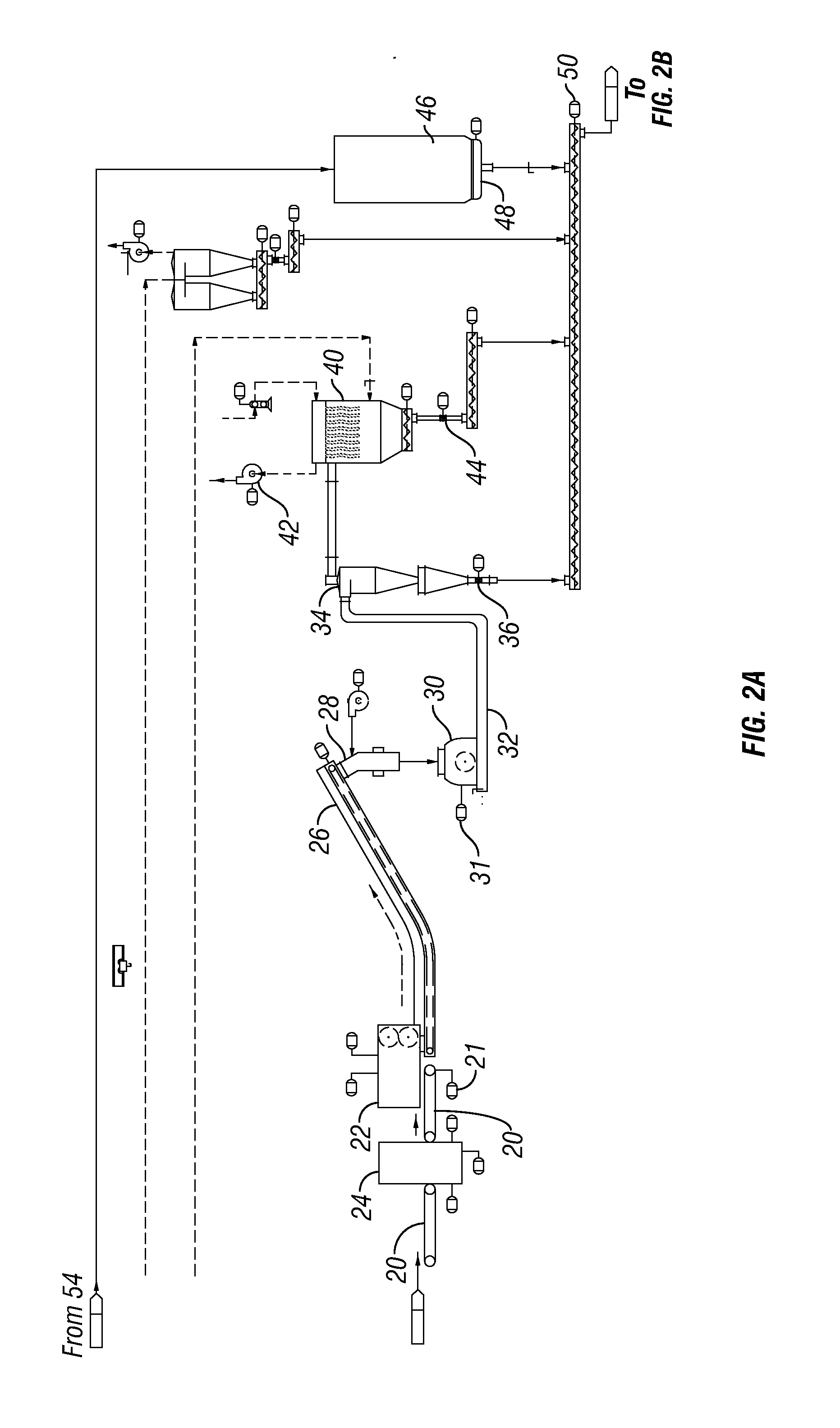

ActiveUS20110099890A1Less-harmful emissionEmission reductionSolid fuel pretreatmentBiofuelsPower stationCombustion

Disclosed are novel engineered fuel feed stocks, feed stocks produced by the described processes, methods of making the fuel feed stocks, methods of producing energy from the fuel feed stocks. Components derived from processed MSW waste streams can be used to make such feed stocks which are substantially free of glass, metals, grit and noncombustibles and contain a sorbent. These feed stocks are useful for a variety of purposes including as gasification and combustion fuels. In addition, one or more sorbents can be added to the feed stocks in order to reduce the amount of a variety of pollutants present in traditional fuel and feed stocks, including, but not limited, sulfur and chlorine. Further, these feed stocks with added sorbent can mitigate corrosion, improve fuel conversion, extend power generating plant lifetime, reduce ash slagging, and reduced operating temperature.

Owner:REPOWER IP LLC

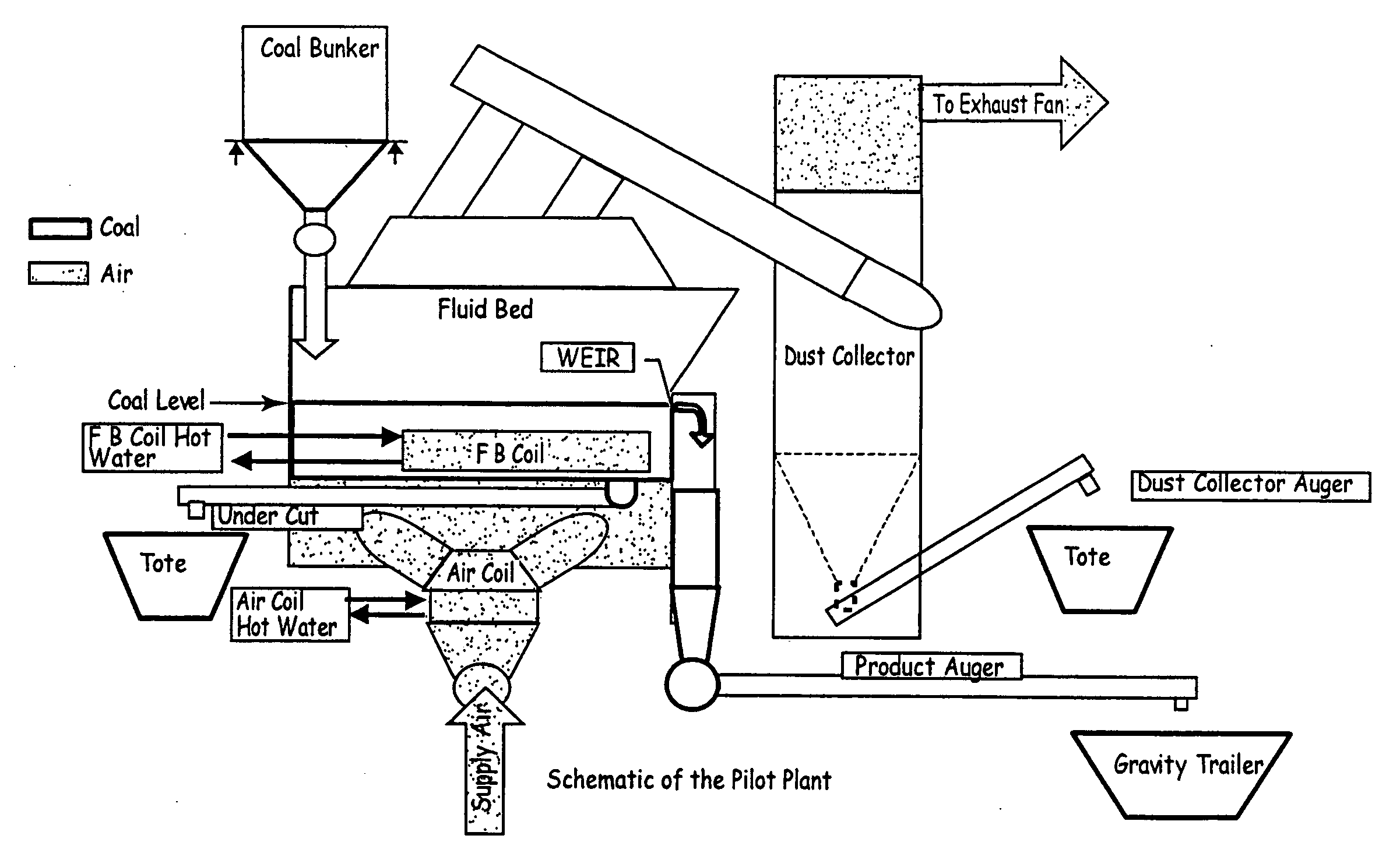

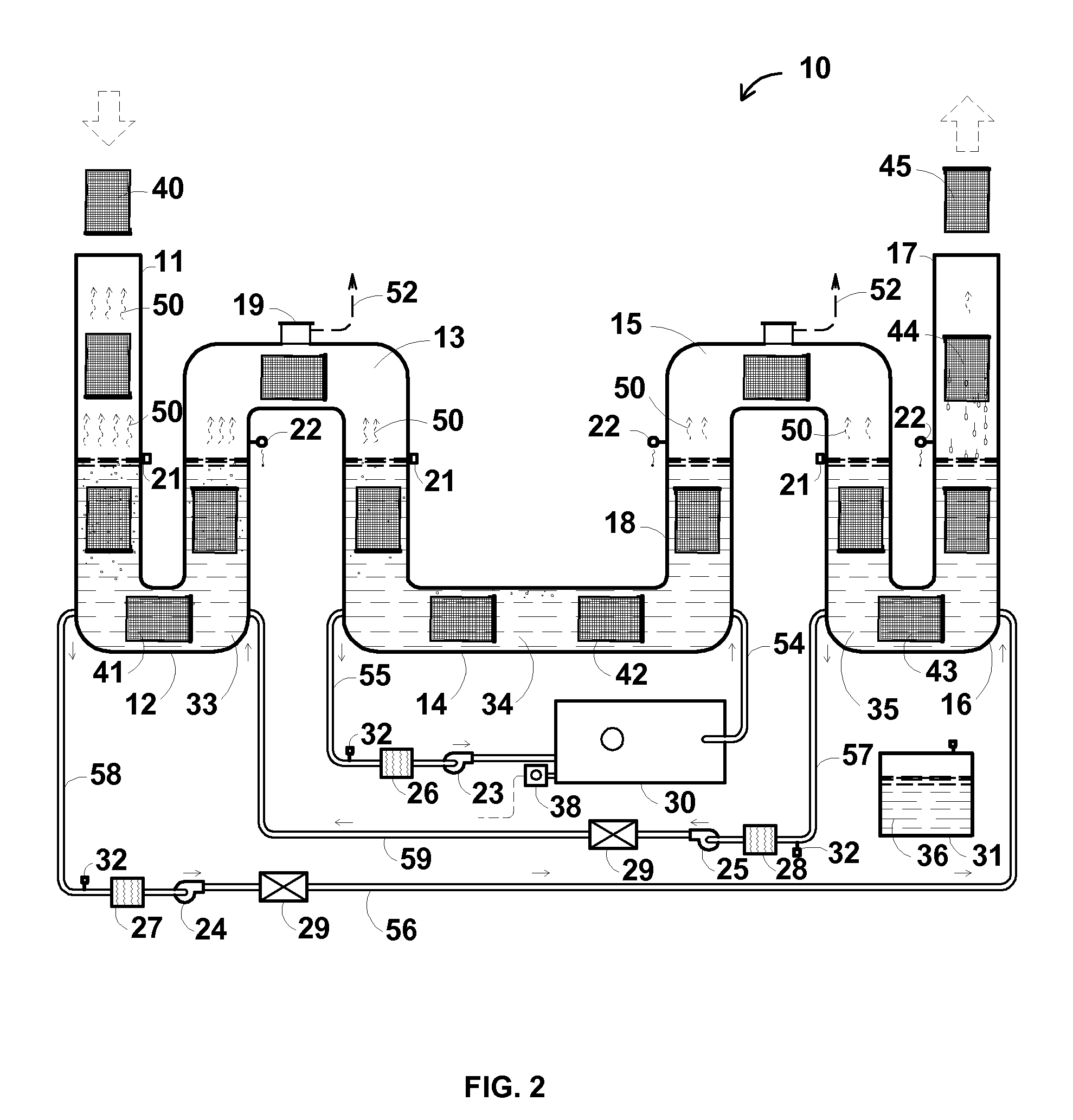

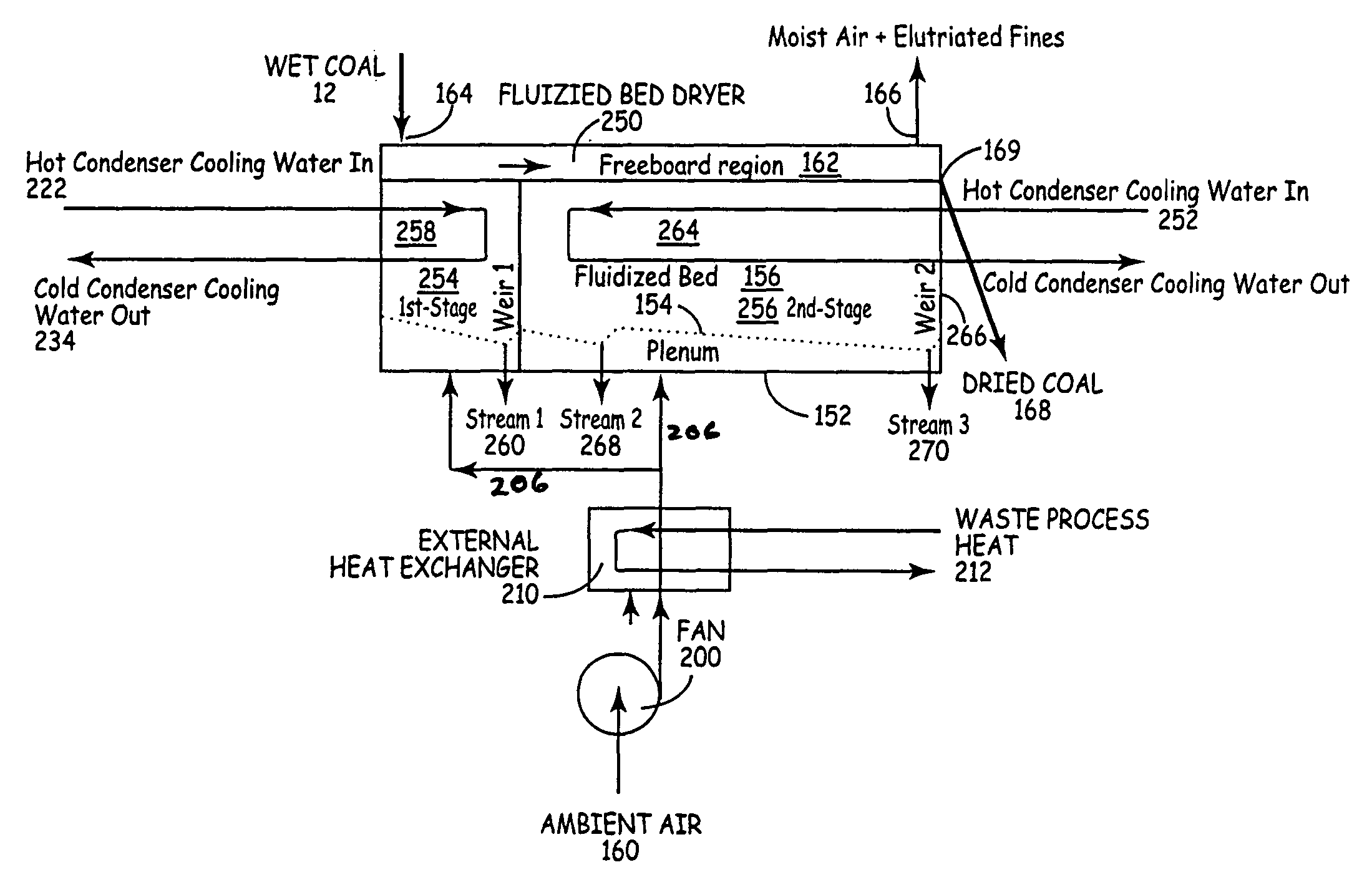

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

ActiveUS20080201980A1Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatSolid fuel pretreatmentParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

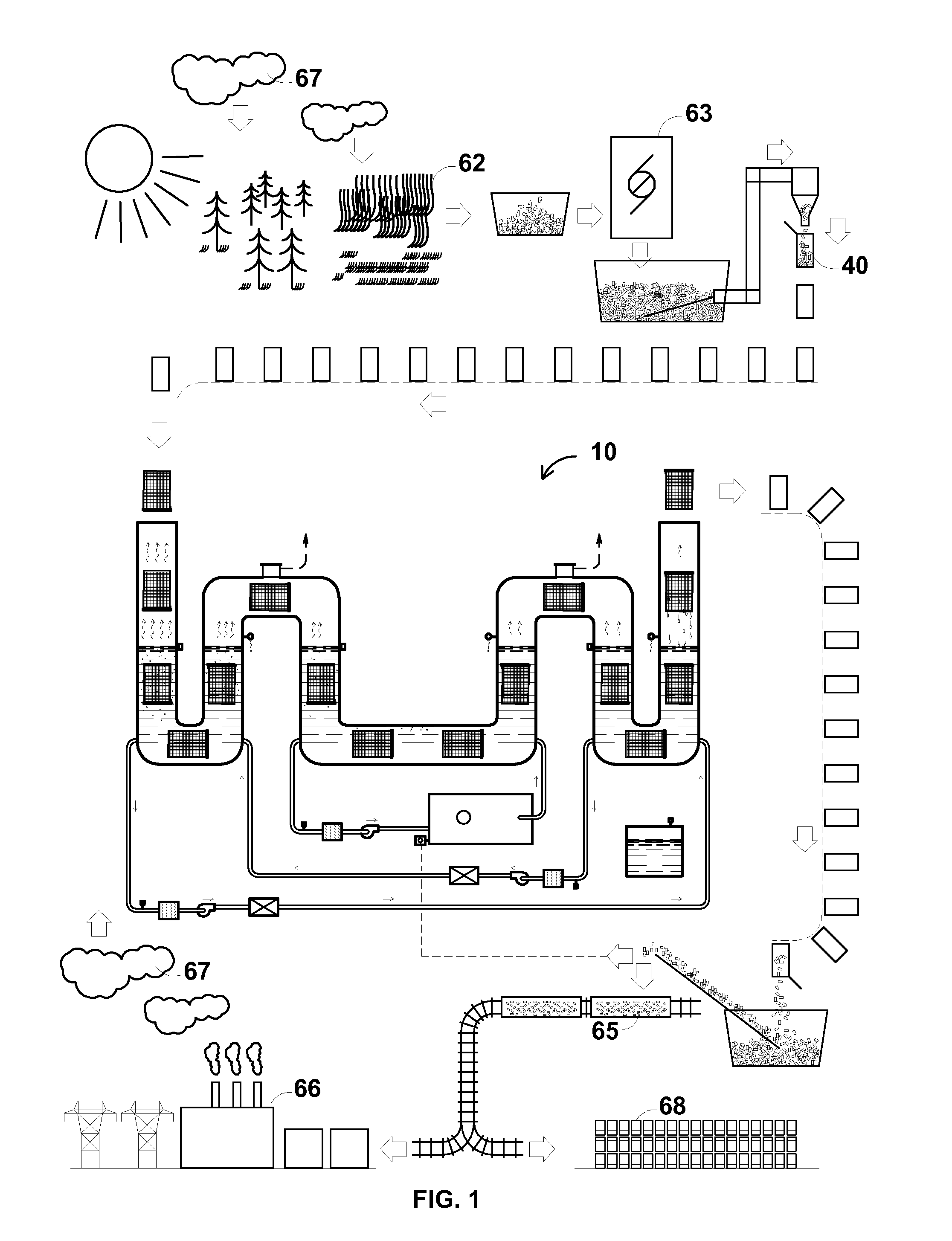

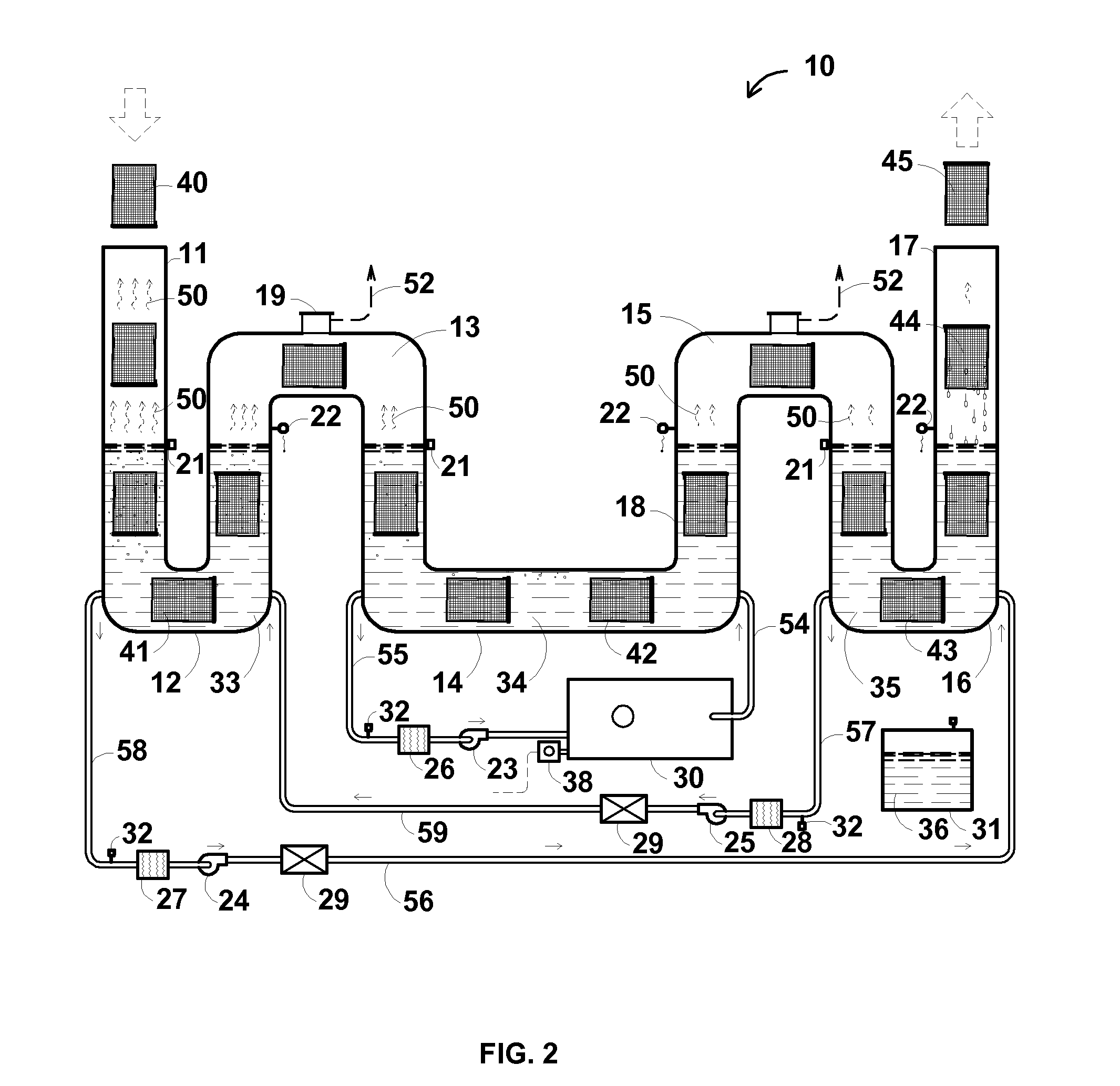

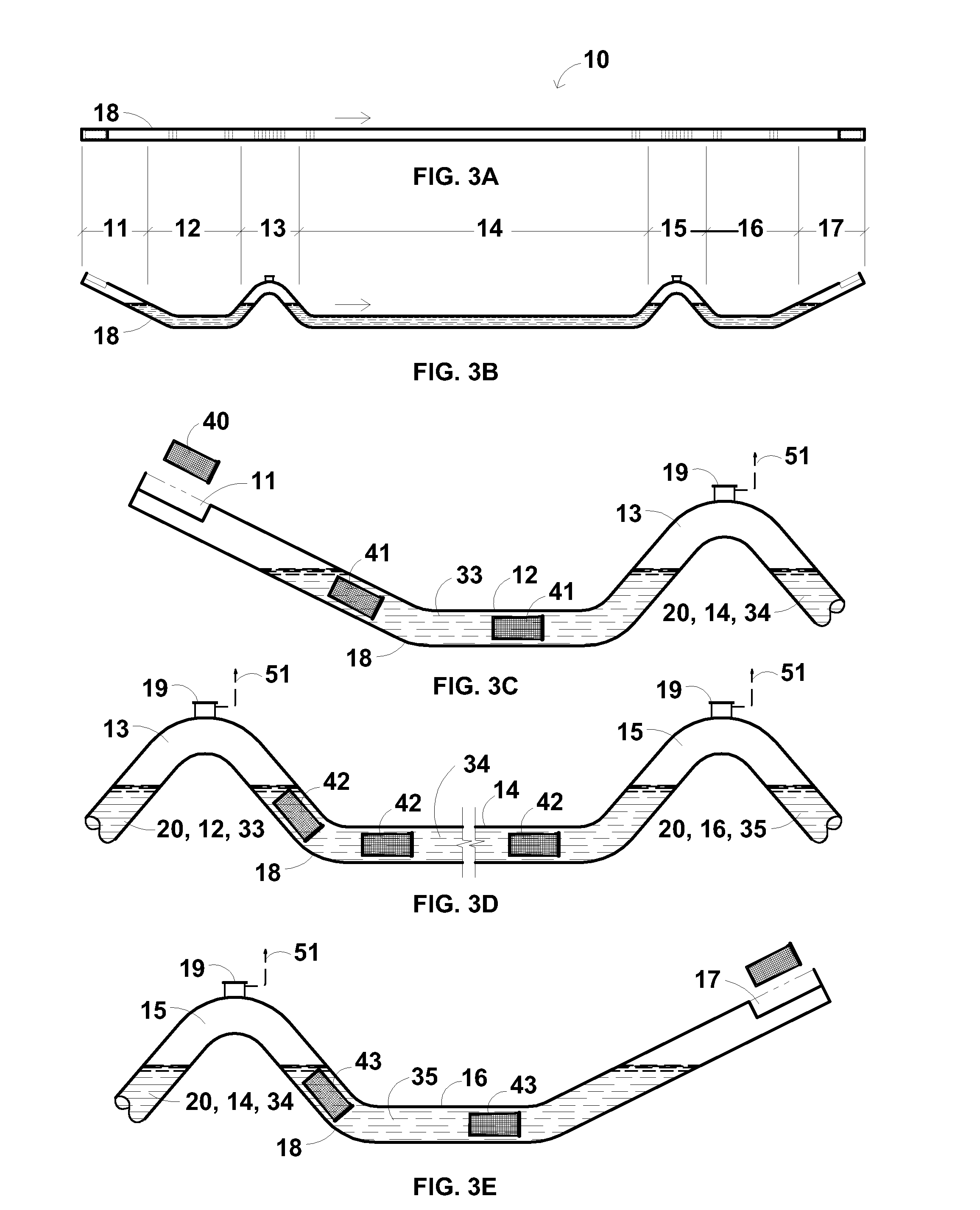

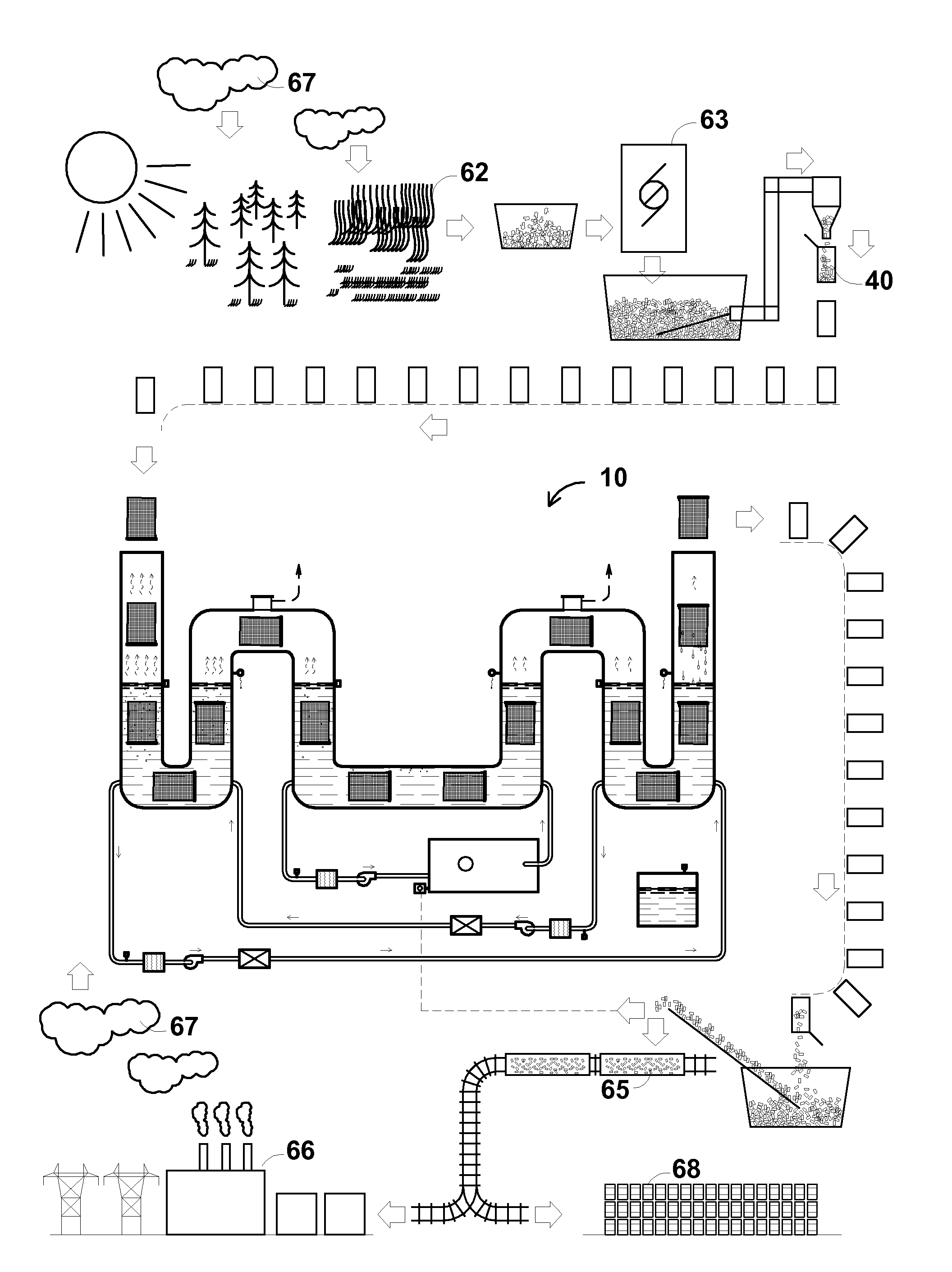

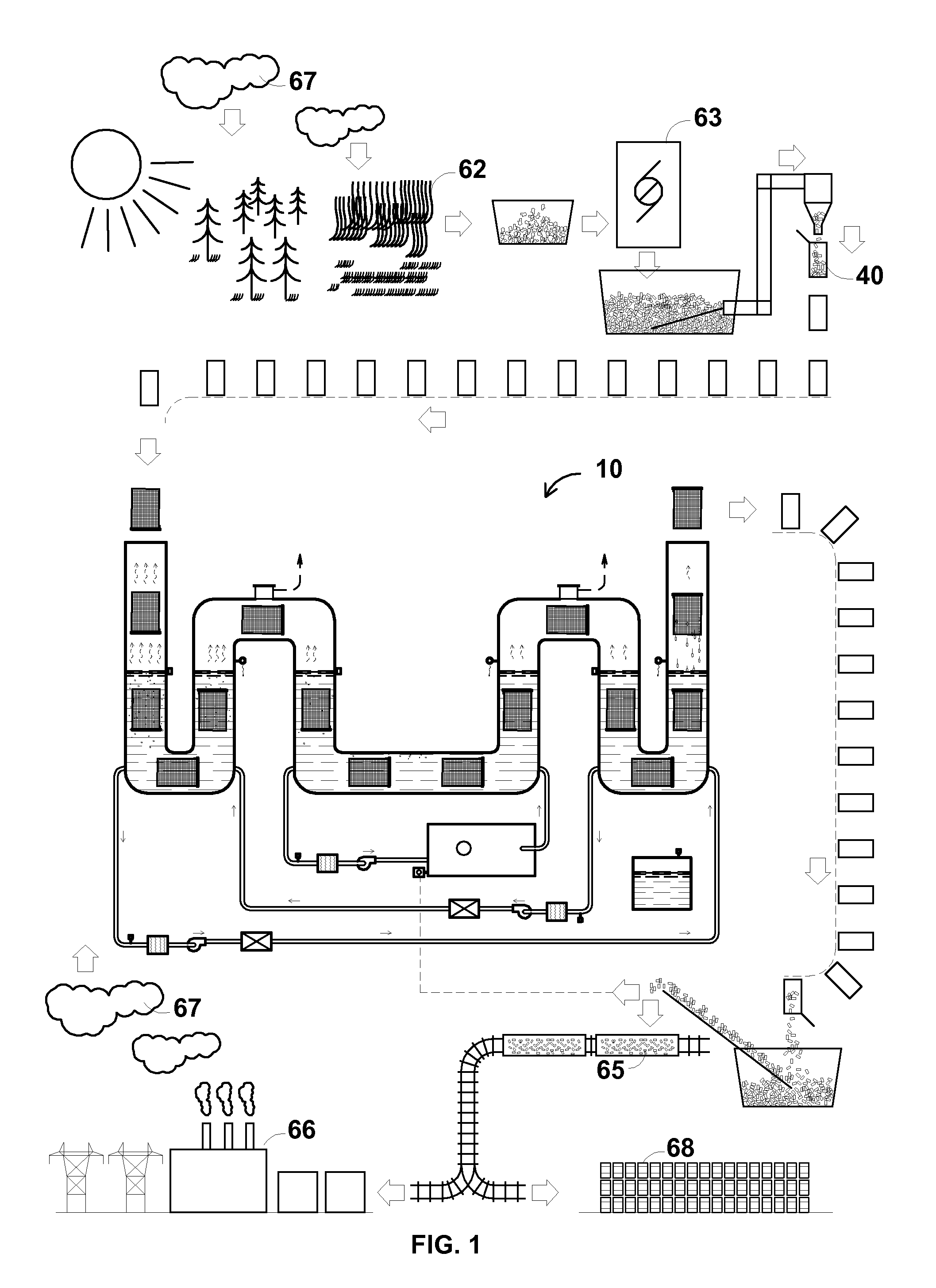

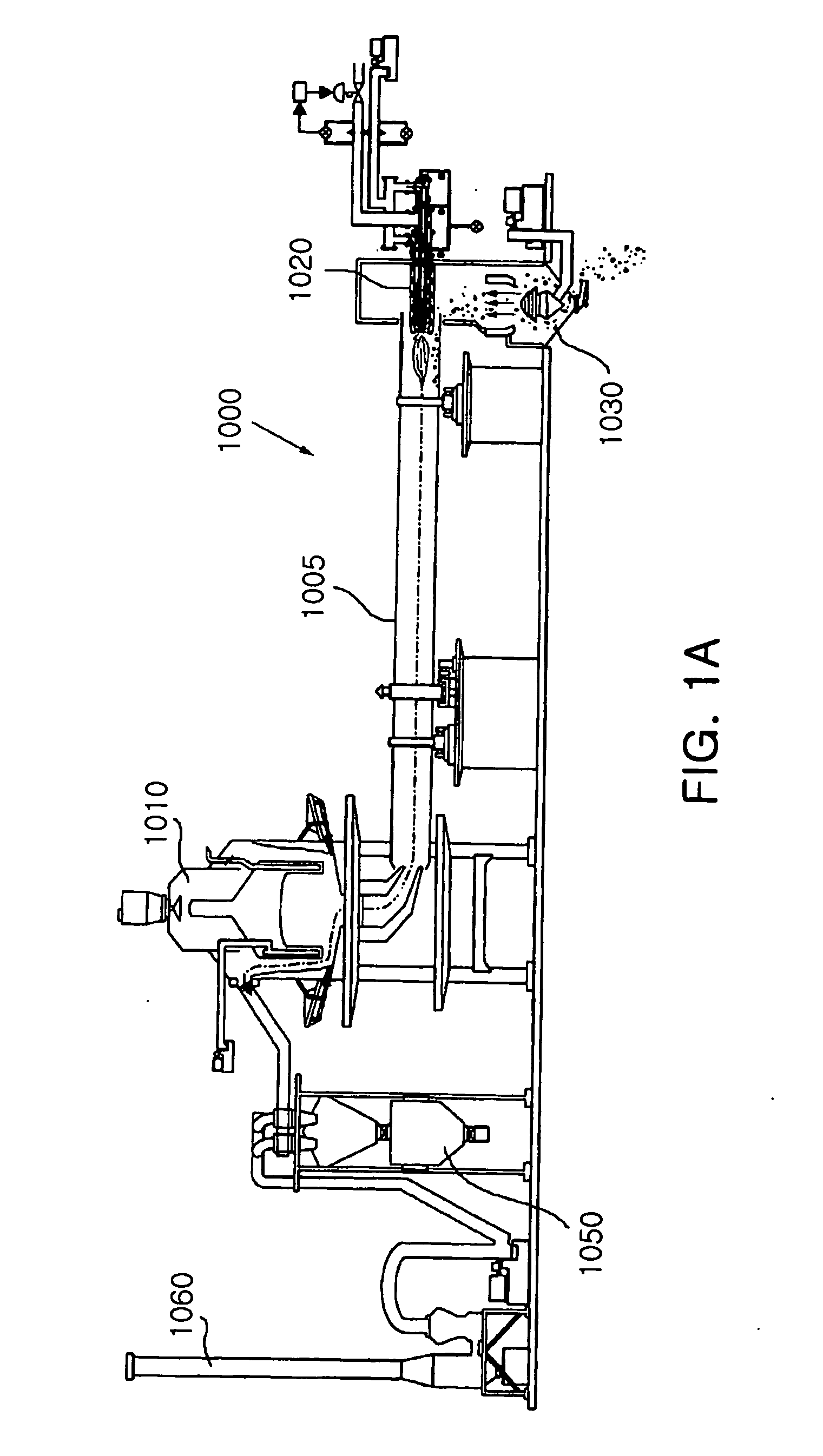

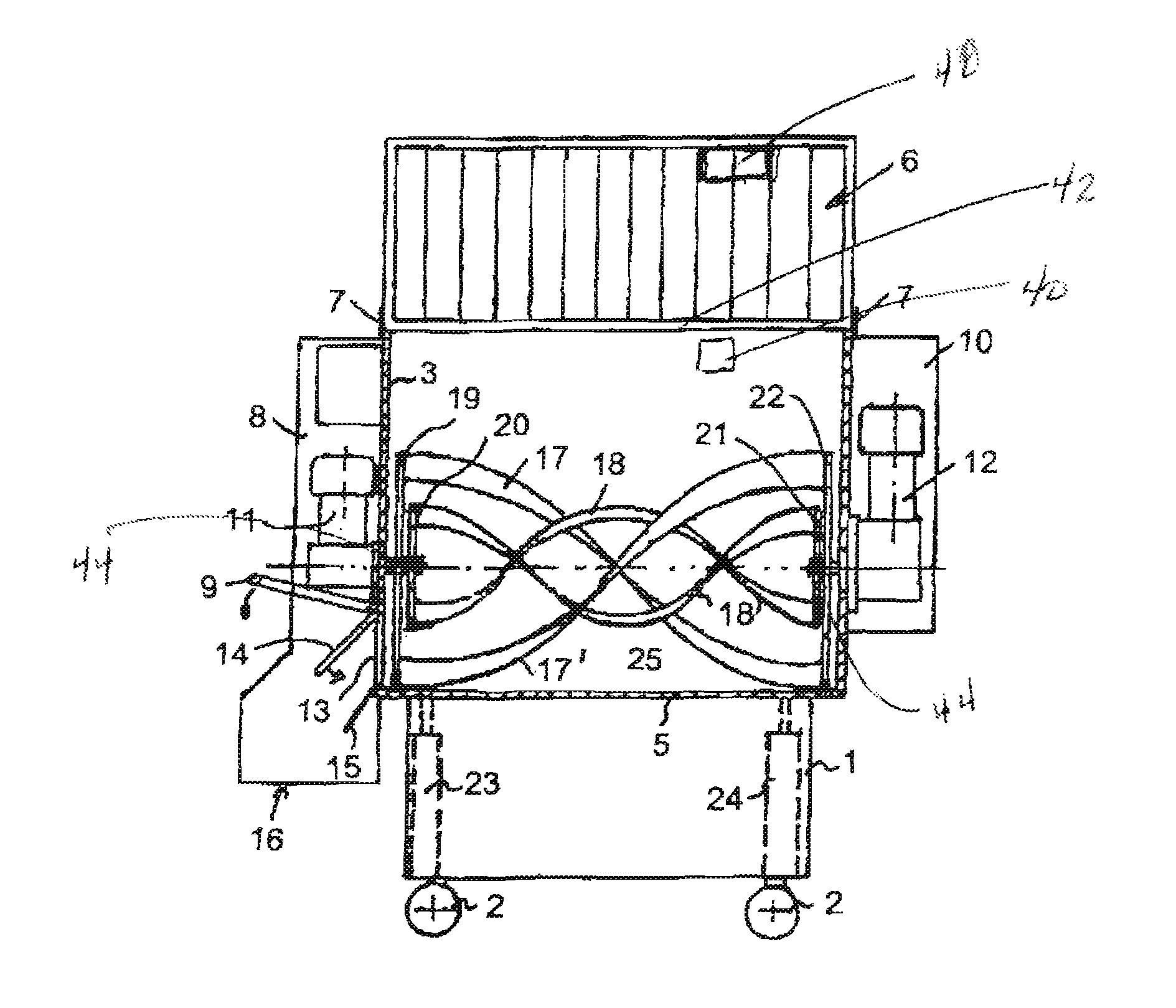

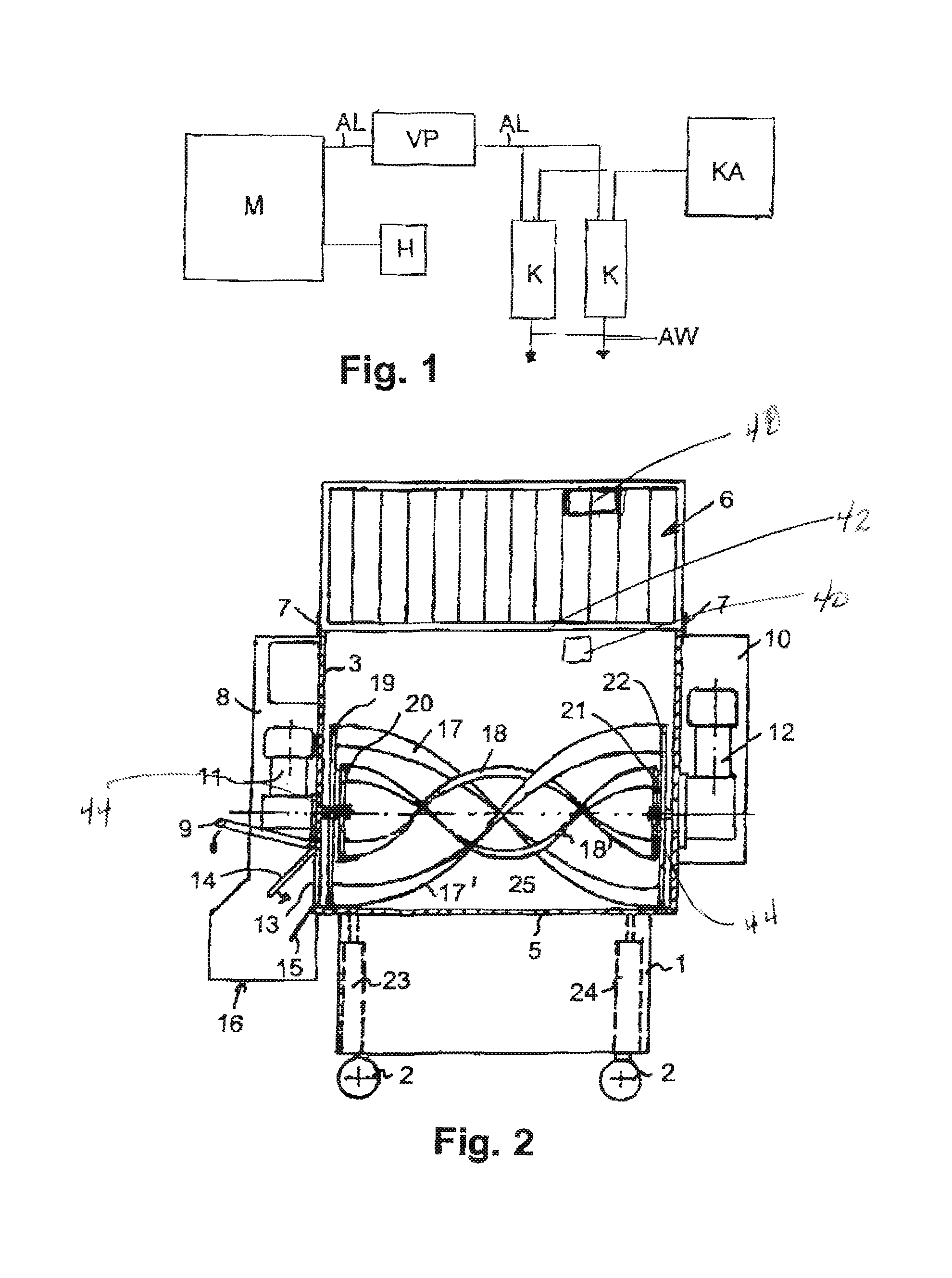

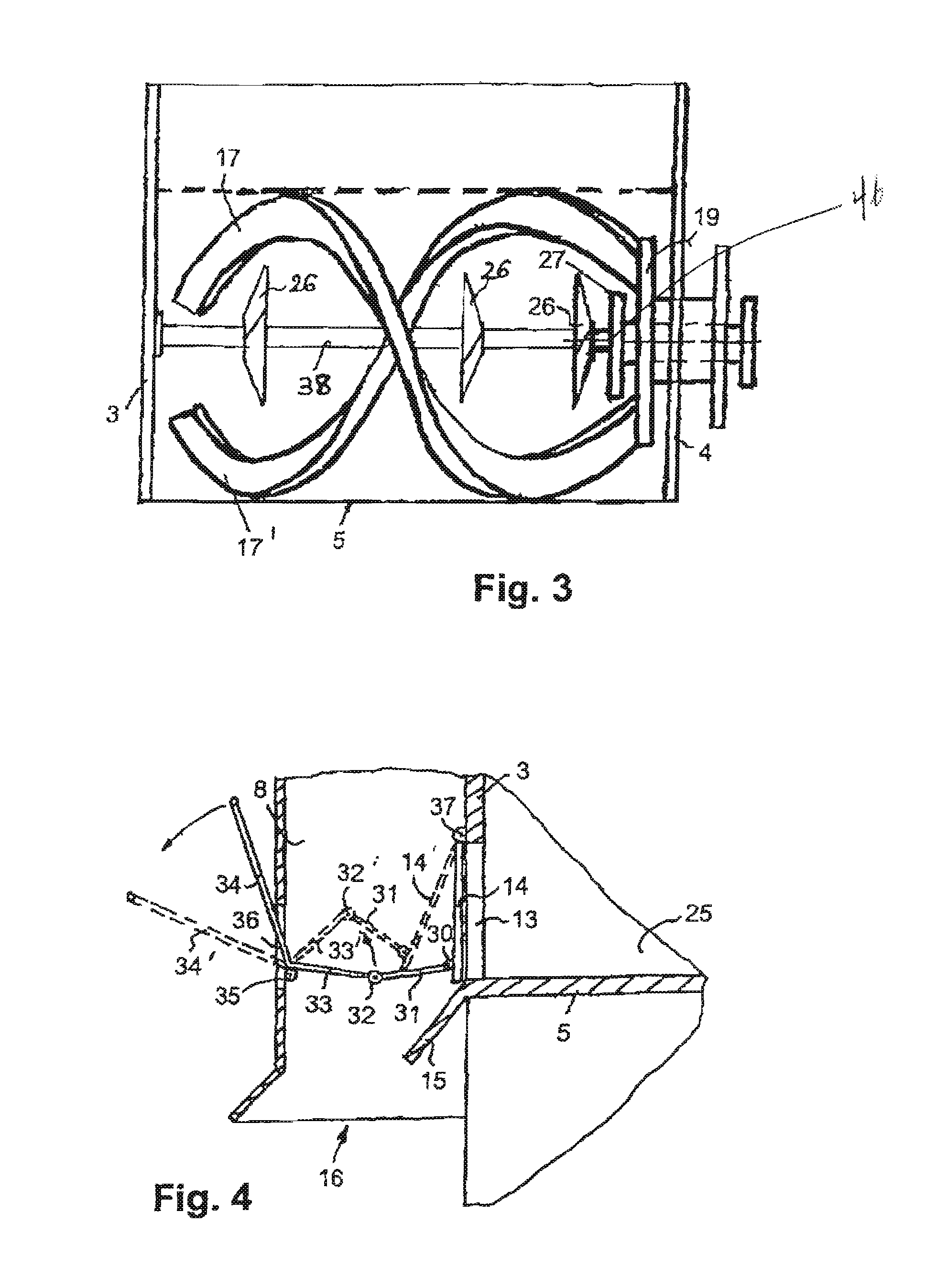

Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and a combustible article of manufacture

ActiveUS20070266623A1Reduce air pollutionEasy to storeSolid fuel pretreatmentBiofuelsHigh elevationManufactured apparatus

Apparatus for biomass torrefaction which includes a serpentine elongated housing, the housing having three generally U-shaped axial portions having first and second axial extremities and an intermediate section, the first and second axial extremities are disposed in normal use at a higher elevation than the first and second axial extremities, the intermediate section being configured for holding a liquid. Other forms of the invention include the method for biomass torrefaction which includes providing a quantity of biomass, providing a liquid heat transfer fluid, providing at least a first housing for holding the heat transfer liquid, elevating the temperature of the liquid heat transfer liquid, heat treating the biomass by passing it through the heat transfer liquid in the first housing at a temperature and duration sufficient to accomplish torrefaction of the wood. In some forms of the method, the process further includes the step of pelletizing the biomass prior to performing the treating step.

Owner:PAOLUCCIO JOHN A

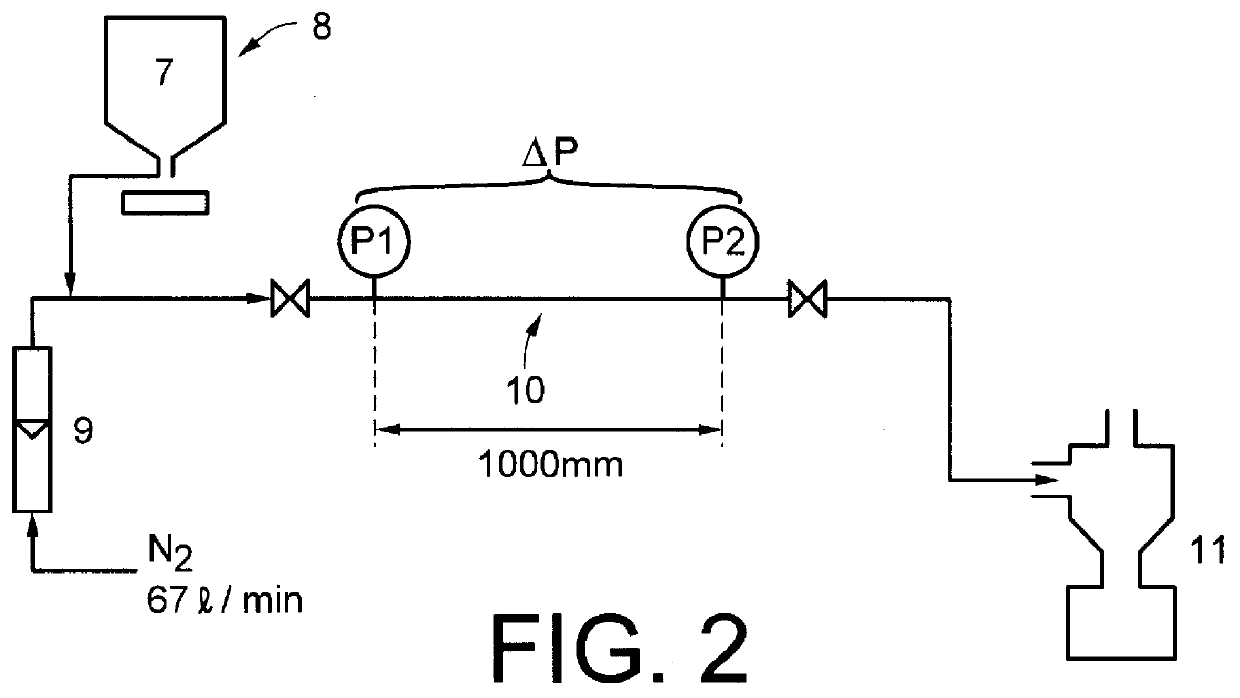

Pulverized coal carriability improver

InactiveUS6083289AGreat varietyImprove liquiditySolid fuel pretreatmentSolid fuelsInorganic saltsCombustion

PCT No. PCT / JP97 / 00668 Sec. 371 Date Sep. 25, 1998 Sec. 102(e) Date Sep. 25, 1998 PCT Filed Mar. 5, 1997 PCT Pub. No. WO97 / 36009 PCT Pub. Date Oct. 2, 1997The use of pulverized coal as the fuel to be injected into metallurgical or combustion furnace becomes possible enabled by improving the transportability thereof. Further, a pulverized coal is provided, which is inhibiting from bridging or channeling in a hopper, or piping choking. A water-soluble inorganic salt having a polar group is made to adhere to pulverized coal which is prepared from raw coal having an average HGI of 30 or above and which is in a dry state at the injection port of a metallurgical or combustion furnace, The inorganic salt is selected from among BaCl2, CaCl2, Ca(NO2)2, Ca(NO3)2, Ca(ClO)2, K2CO3, KCl, MgCl2, MgSO4, NH4BF4, NH4Cl, (NH4)2SO4, Na2CO3, NaCl, NaClO3, NaNO2, NaNO3, NaOH, Na2S2O3, Na2S2O5, HNO3, H2SO4, H2CO3, and HCl.

Owner:KAO CORP

Method and apparatus for biomass torrefaction, manufacturing a storable fuel from biomass and producing offsets for the combustion products of fossil fuels and a combustible article of manufacture

Apparatus for biomass torrefaction which includes a serpentine elongated housing, the housing having three generally U-shaped axial portions having first and second axial extremities and an intermediate section, the first and second axial extremities are disposed in normal use at a higher elevation than the first and second axial extremities, the intermediate section being configured for holding a liquid. Other forms of the invention include the method for biomass torrefaction which includes providing a quantity of biomass, providing a liquid heat transfer fluid, providing at least a first housing for holding the heat transfer liquid, elevating the temperature of the liquid heat transfer liquid, heat treating the biomass by passing it through the heat transfer liquid in the first housing at a temperature and duration sufficient to accomplish torrefaction of the wood. In some forms of the method, the process further includes the step of pelletizing the biomass prior to performing the treating step.

Owner:PAOLUCCIO JOHN A

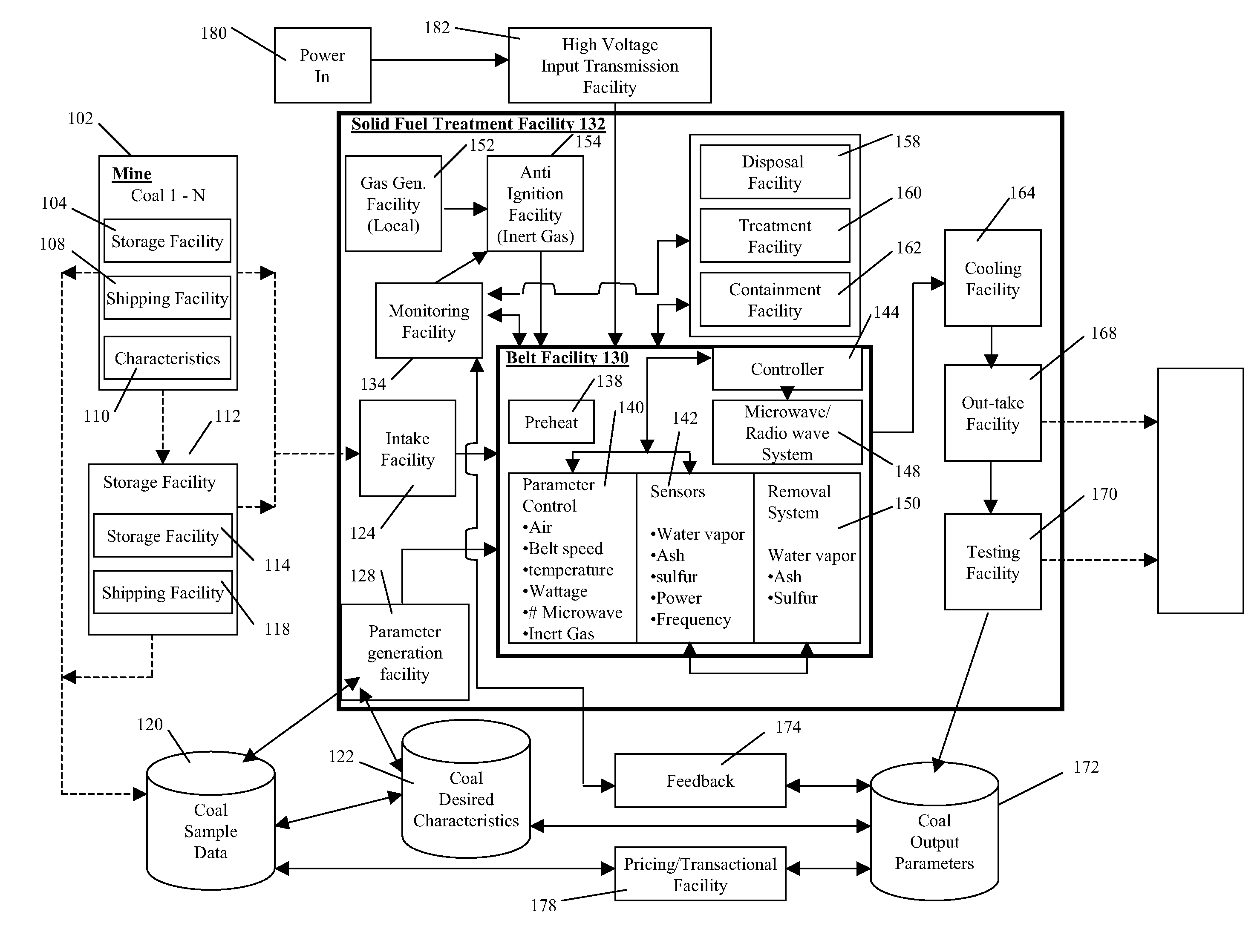

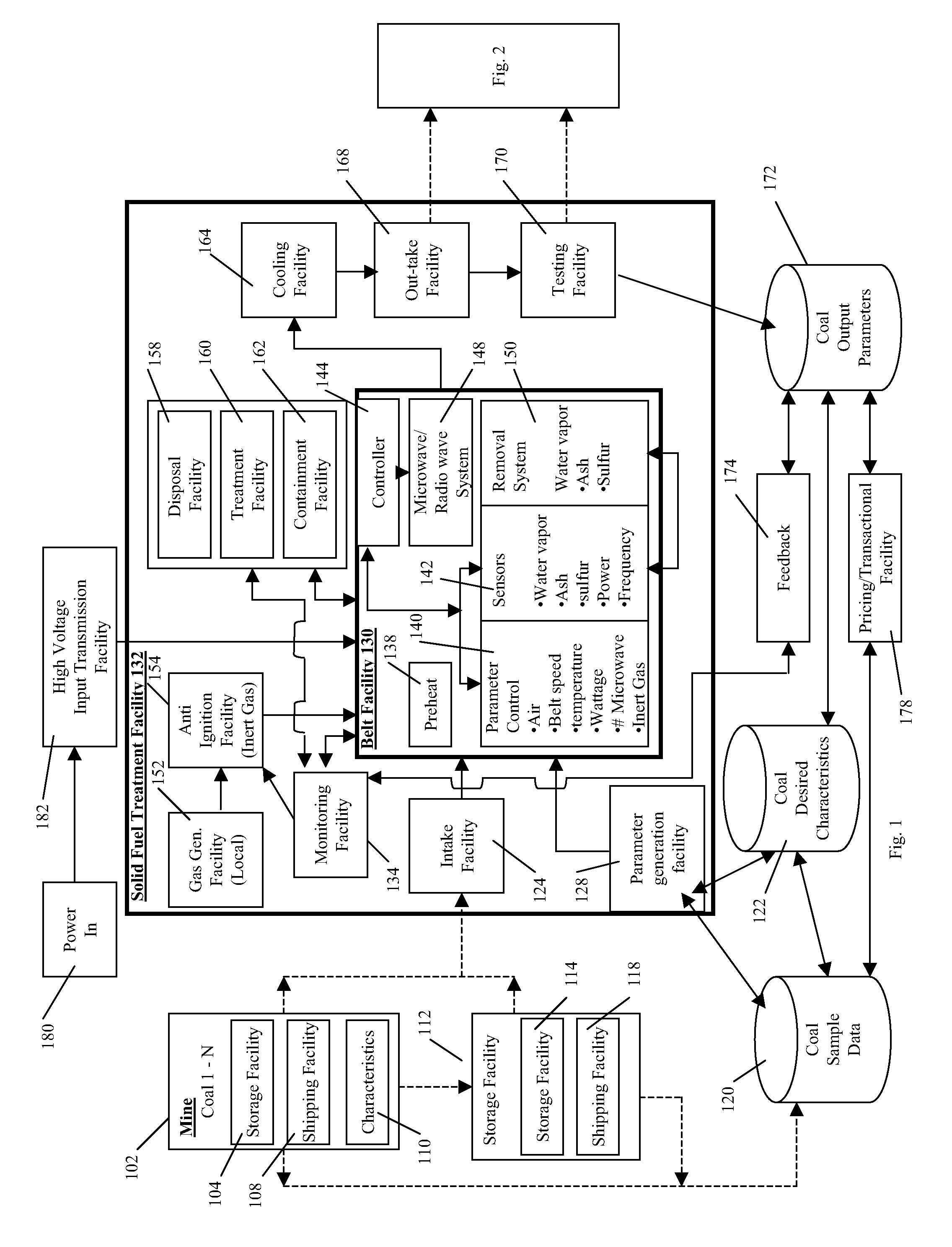

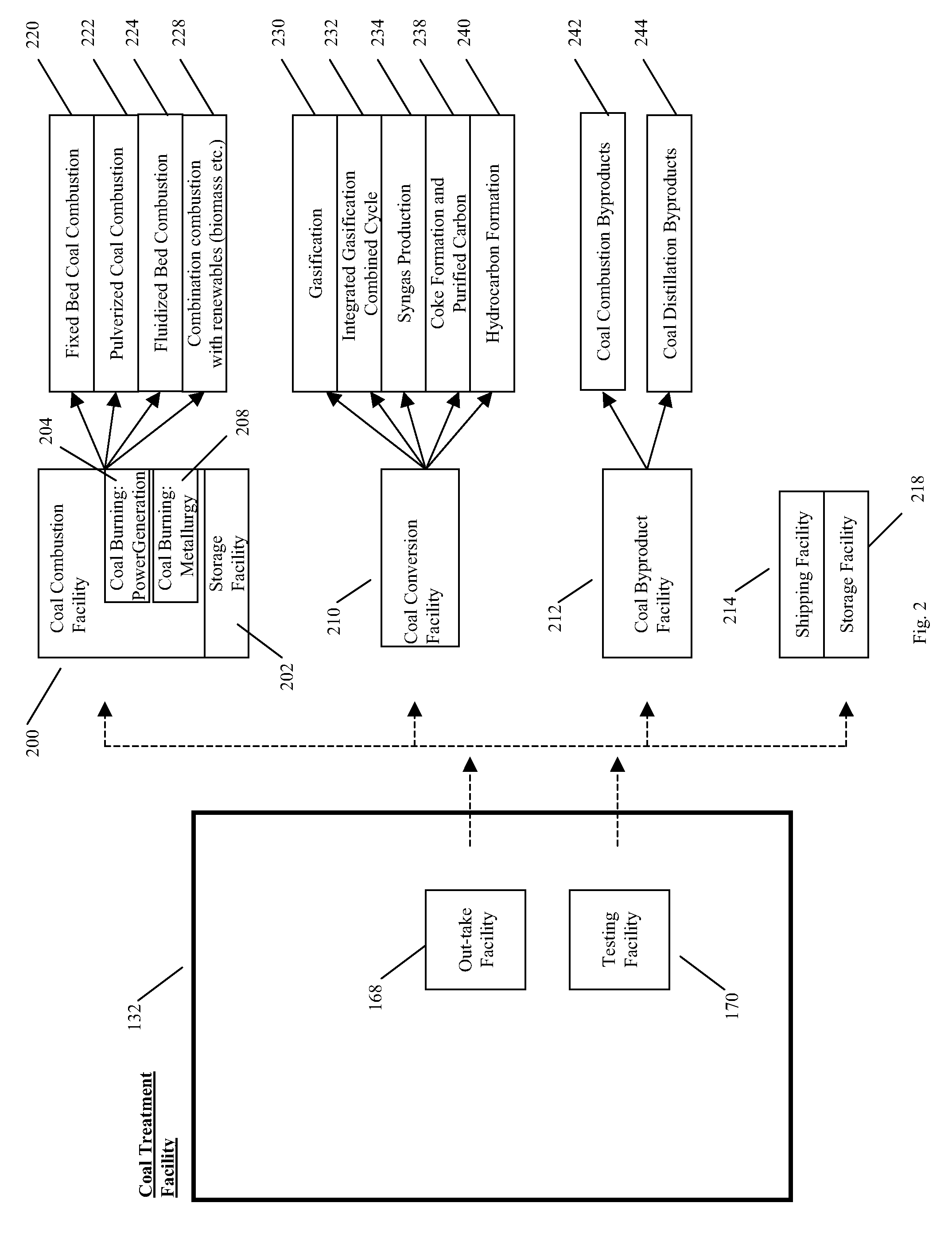

Methods and systems for briquetting solid fuel

InactiveUS20090119981A1Low microwave lossIncrease resistanceSolid fuel pretreatmentSolid fuelsAfter treatmentSolid fuel

In embodiments of the present invention improved capabilities are described for a system and method for briquetting solid fuel before or after treatment with electromagnetic energy. In the system and method, solid fuel is transported through a continuous feed solid fuel treatment facility, treated using electromagnetic energy, and briquetted after treatment.

Owner:COALTEK INC

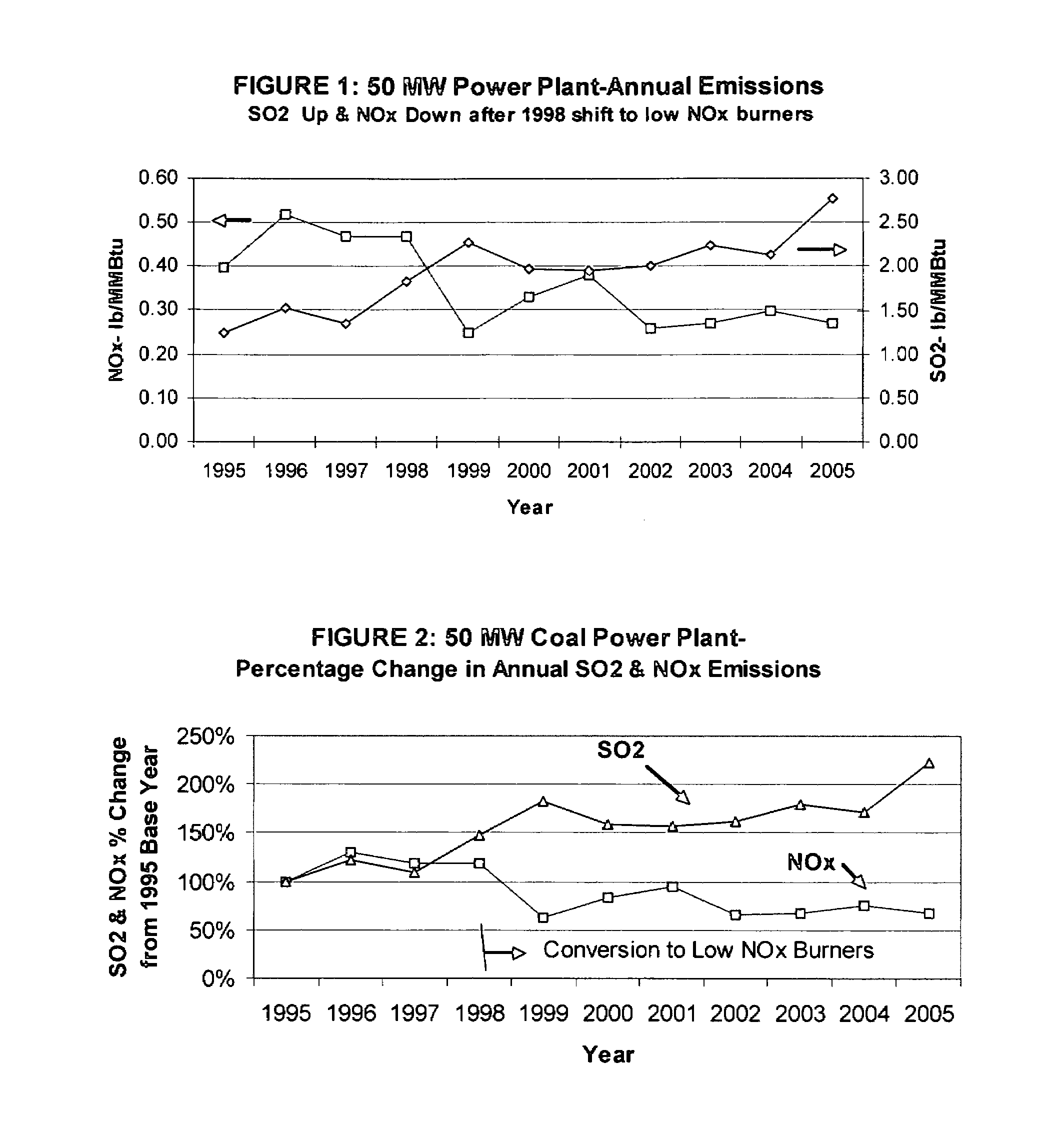

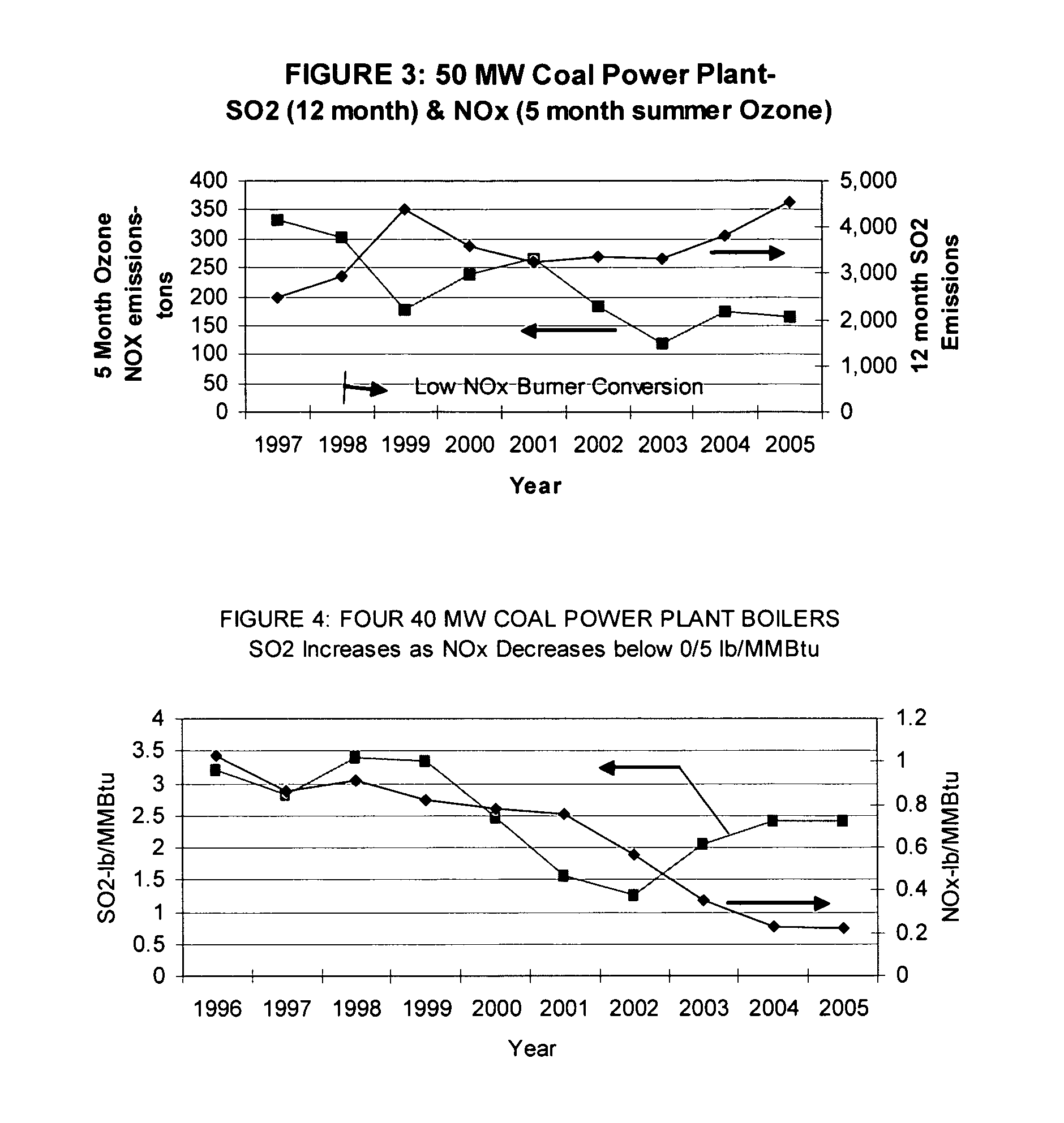

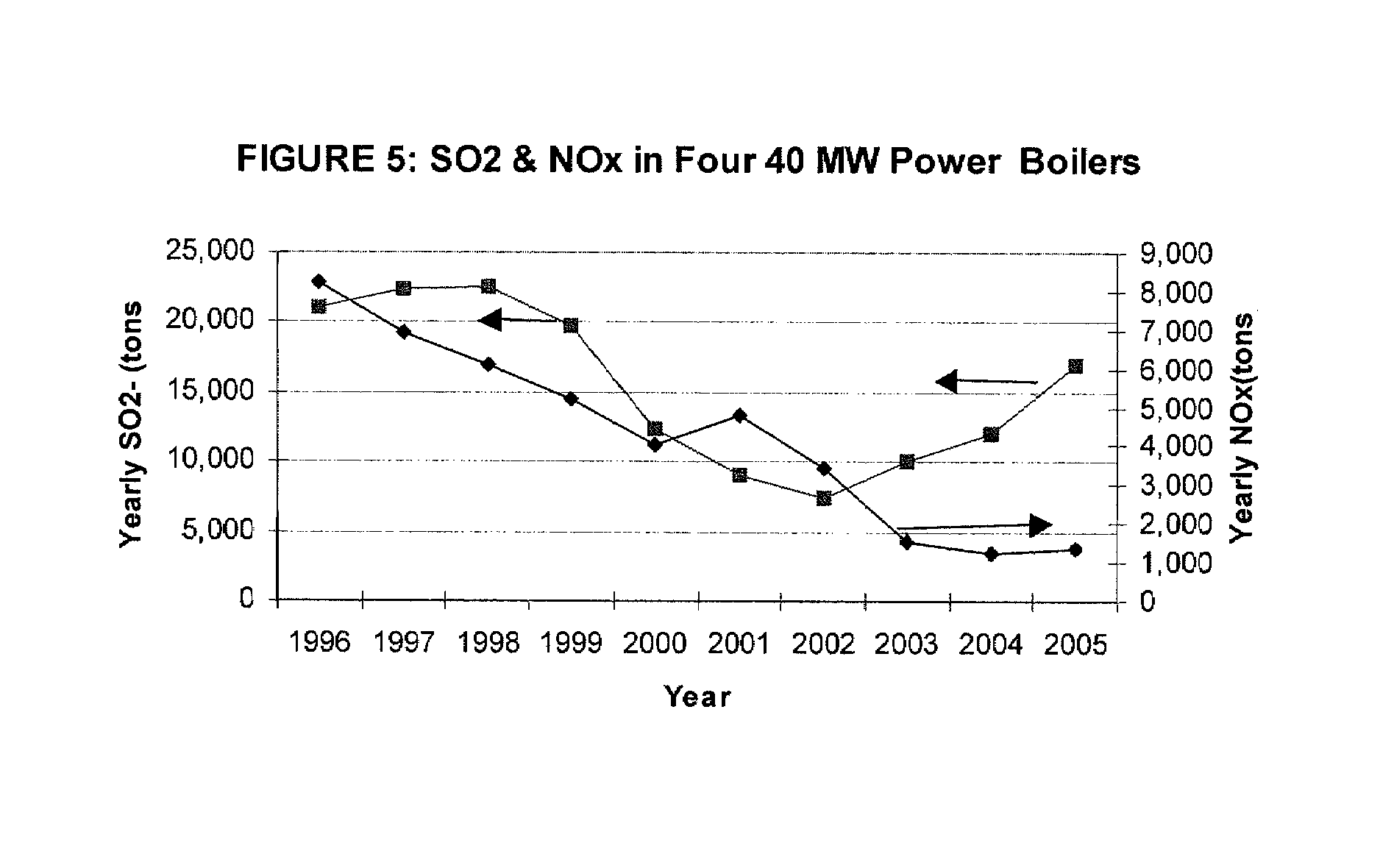

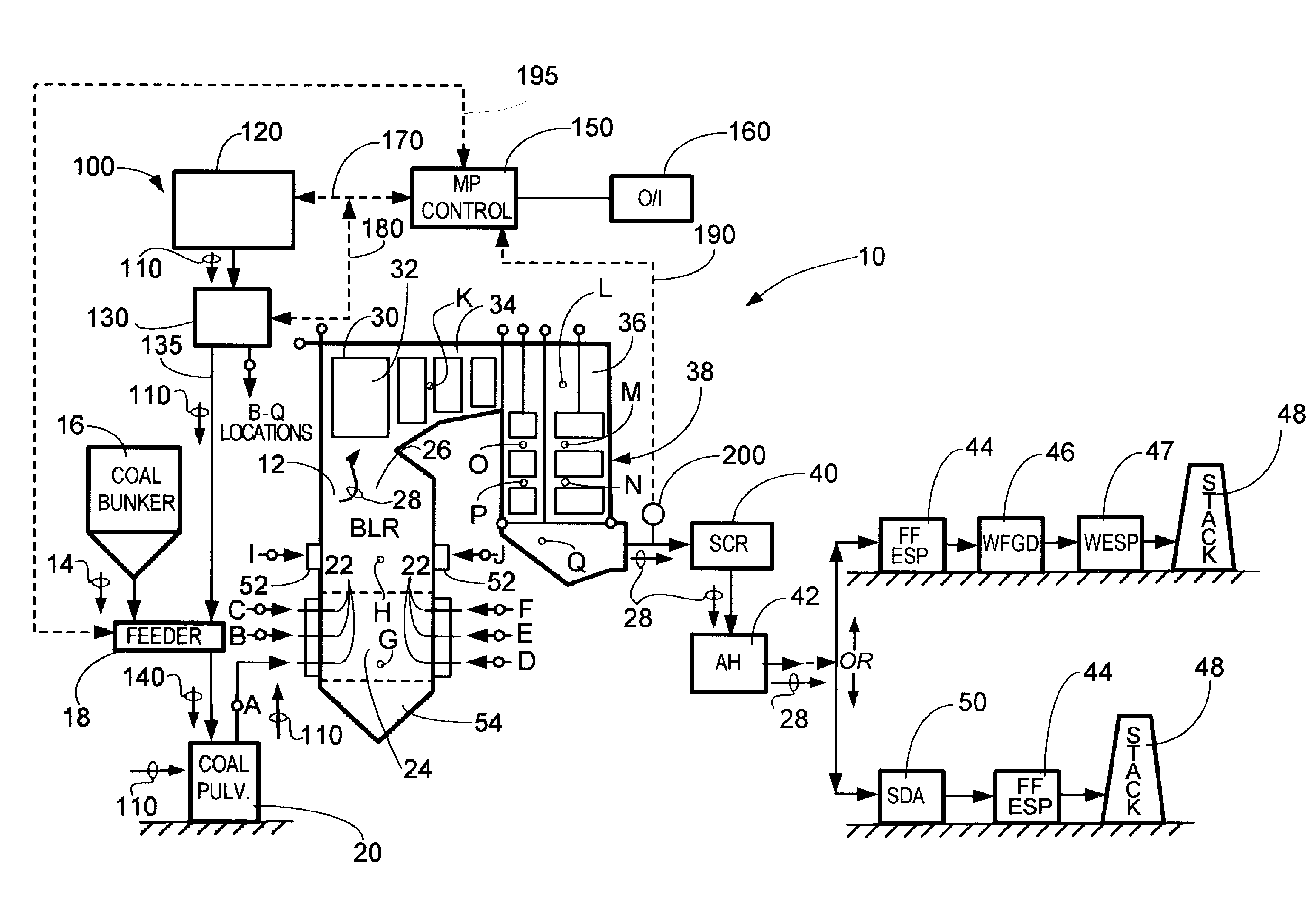

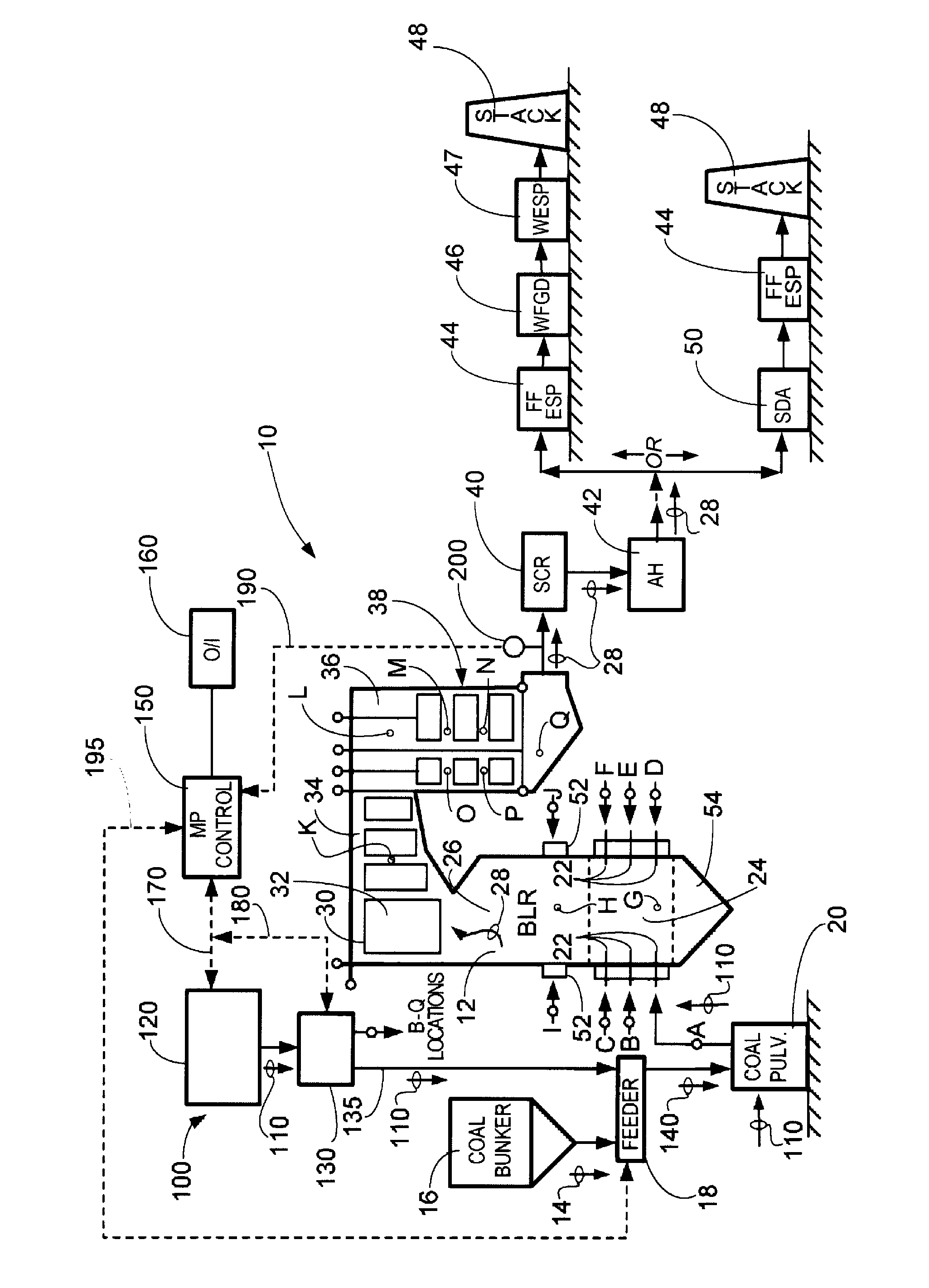

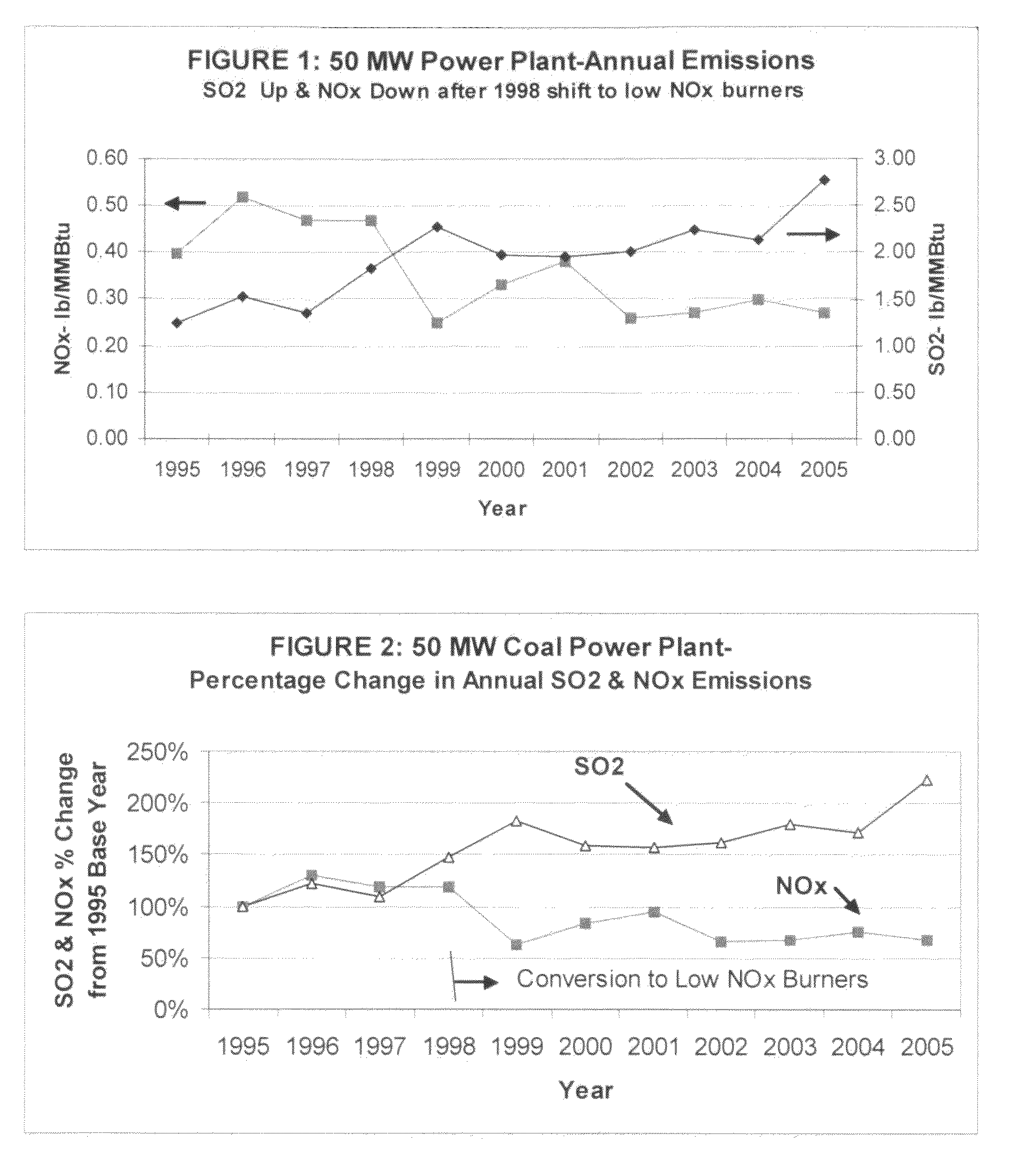

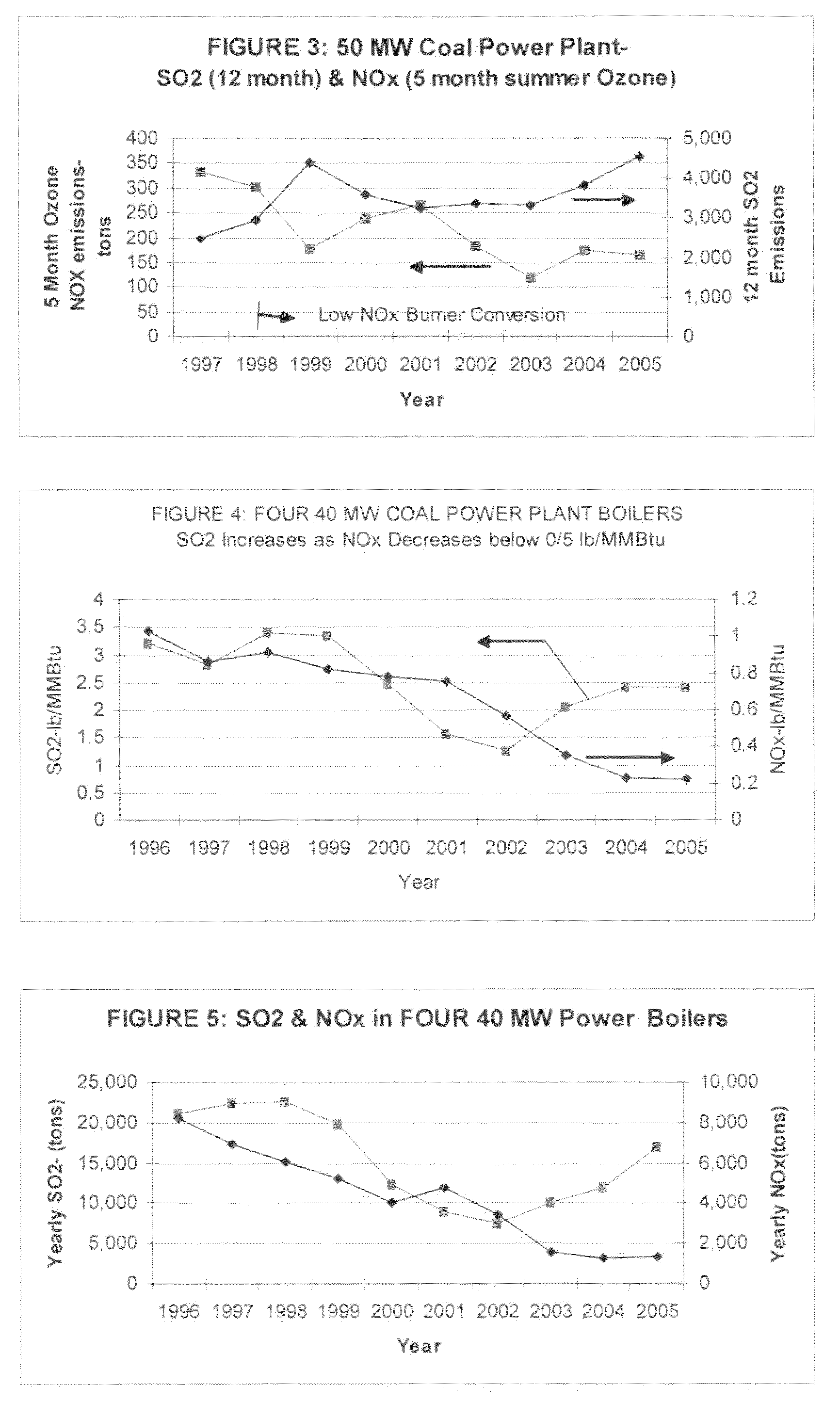

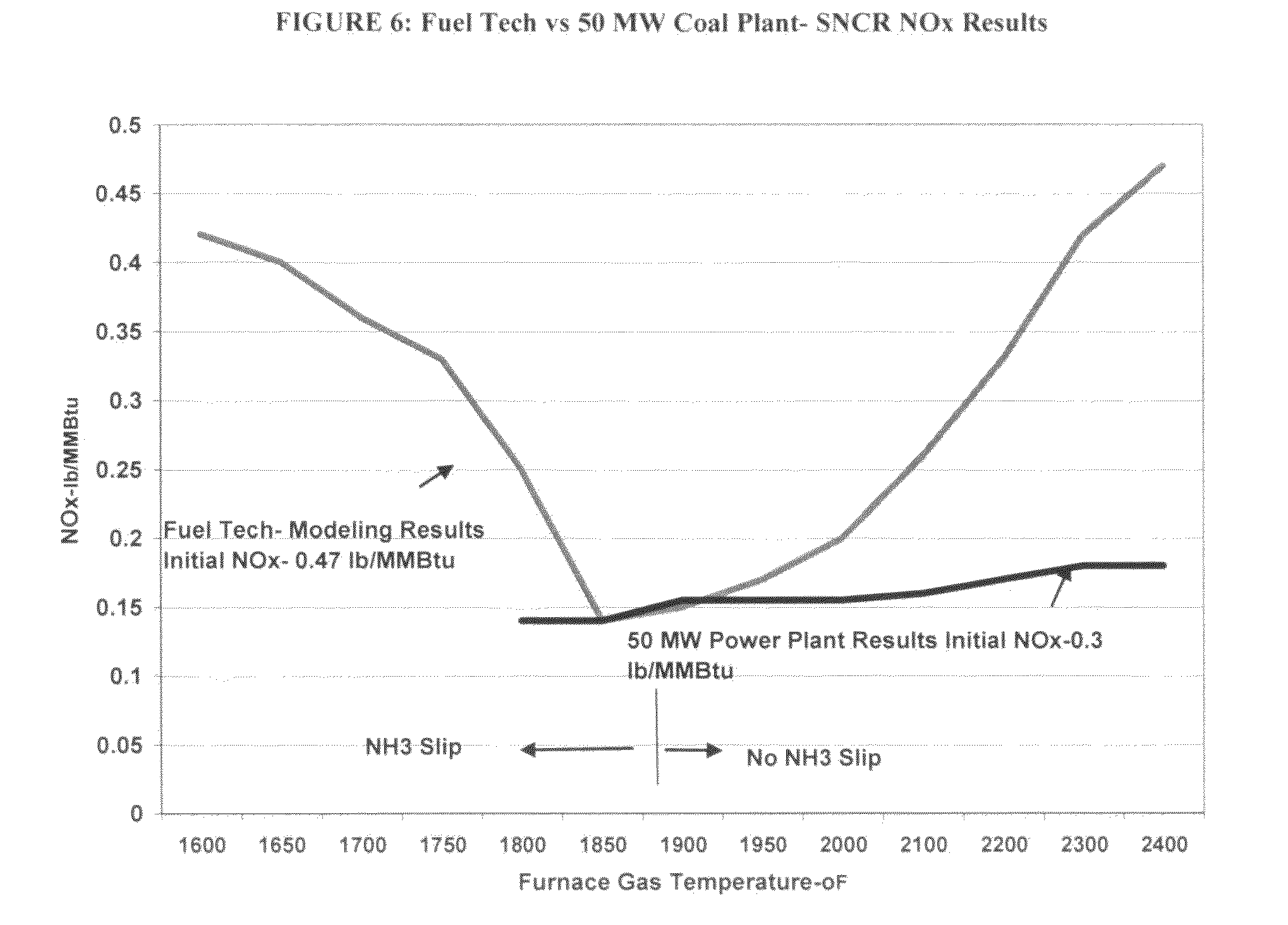

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS7553463B2Minimal equipment costLow costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Methods by which new or used boilers or furnaces ranging from small industrial to the largest utility units that are designed for coal or oil or natural gas or shredded waste or shredded biomass firing can substantially improve their technical operation and sharply reduce their capital and operating costs by implementing component modifications and process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions thereby also facilitating the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) essentially eliminate the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), trace metals, and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide released during combustion and (e) improve the coal and solid fuel combustion efficiency.

Owner:ZAUDERER BERT

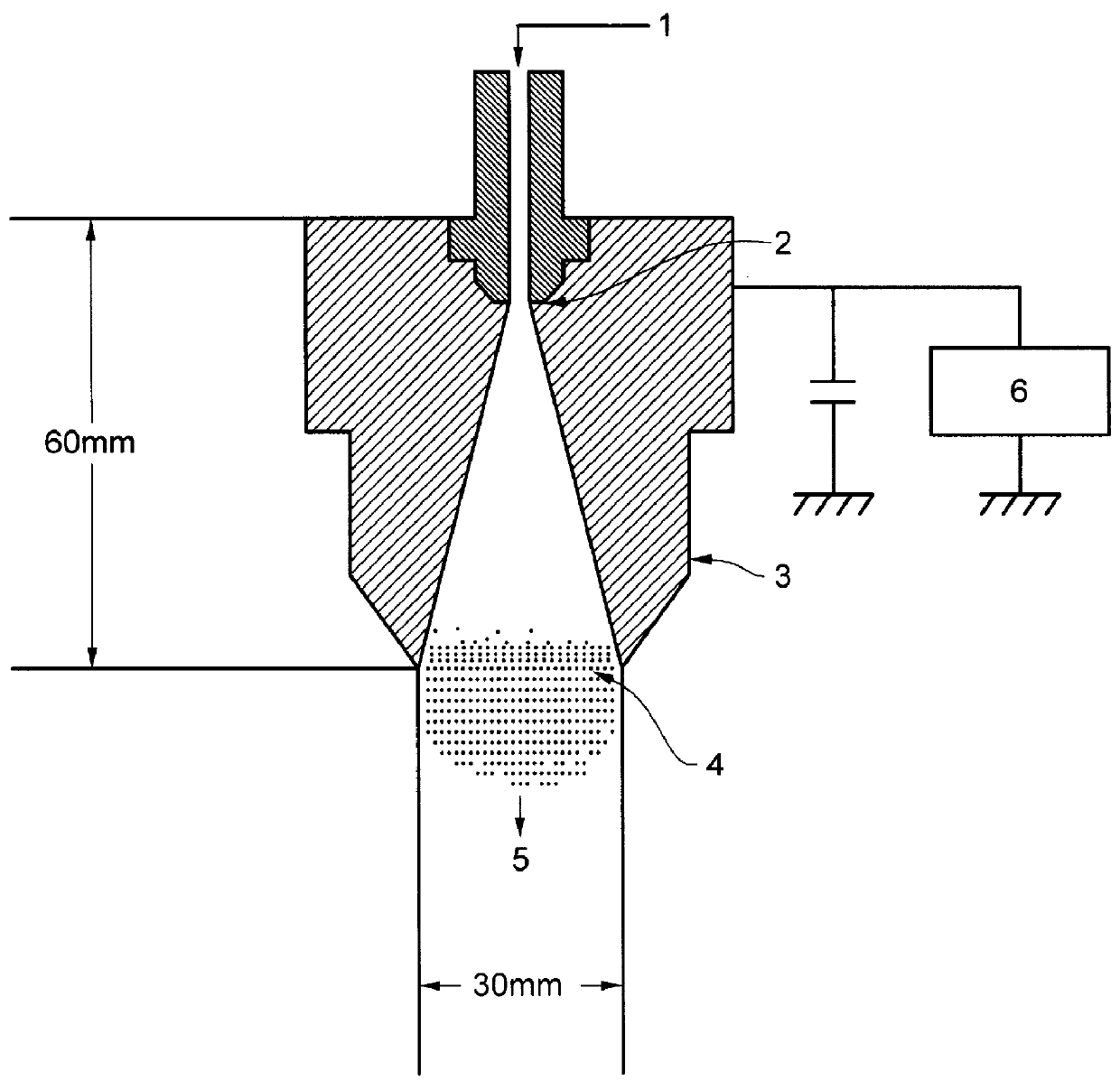

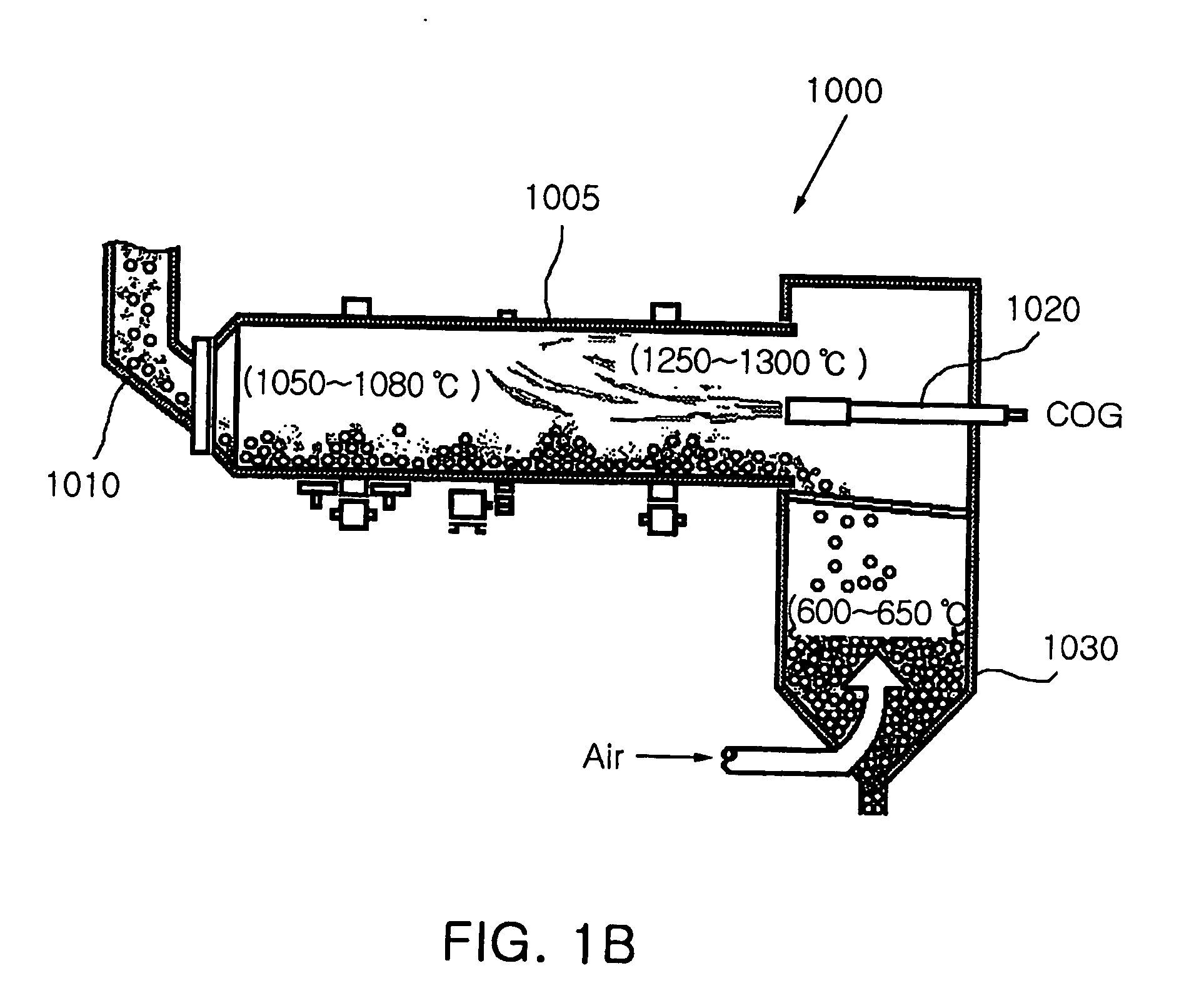

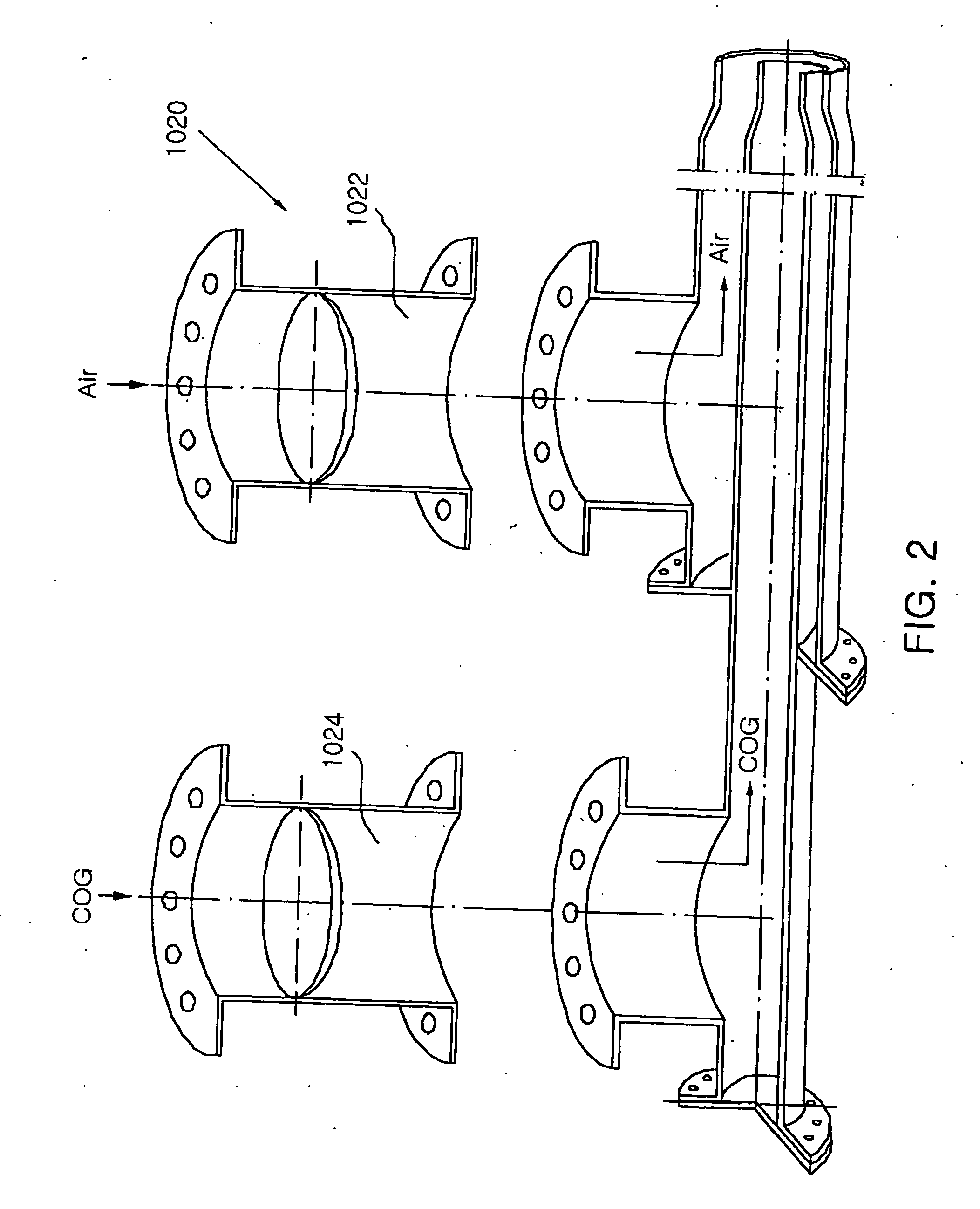

Method and burner apparatus for injecting a pulverized coal into rotary kilns, method and apparatus for producing cao using them

InactiveUS20060169181A1Reduce concentrationMinimize diameter variationPigmenting treatmentSolid fuel pretreatmentCombustorEngineering

The invention relates to a method and burner for injecting pulverized coal into a rotary kiln that uses pulverized coal as fuel in order to produce quick lime of excellent hydration level. The invention calcines lime stone charged into the rotary kiln, and uses pulverized coal as fuel of a heat source applied to the lime stone charged in the rotary kiln. The invention also provides a method and apparatus for producing quick lime by using the pulverized coal. The invention can use pulverized fossil fuel (hereinafter will be referred to as pulverized coal), which is created during coke manufacturing and cooling processes and collected by a dust collector, in order to produce quick lime of excellent hydration level while decreasing SOx (sulfide) and NOx (nitride) generation.

Owner:POHANG IRON & STEEL CO LTD

Reduction of coal-fired combustion emissions

ActiveUS20060034743A1Efficiently and economically capturedReduce in quantityUsing liquid separation agentSolid fuel pretreatmentBruciteMagnesite

A process for mitigation of fouling deposits within a combustion zone, capturing of toxic metal emissions, and reduction of visible sulfur emissions attributable to sulfuric acid mist during coal combustion. SO3 formed during coal combustion is reduced by the addition to the coal of raw, unprocessed magnesium-containing minerals such as magnesite ore or brucite ore. The minerals are pulverized to a fine particle size and combined with pulverized coal to provide a mixture of the particles. The mixture is combusted and the ore particles calcine and decrepitate to very fine magnesium oxide particles that have a significant particle surface area. The magnesium oxide particles react with the SO3 produced during combustion of the coal and also capture toxic metals to reduce the quantity of undesirable stack discharge components.

Owner:PREMIER MAGNESIA

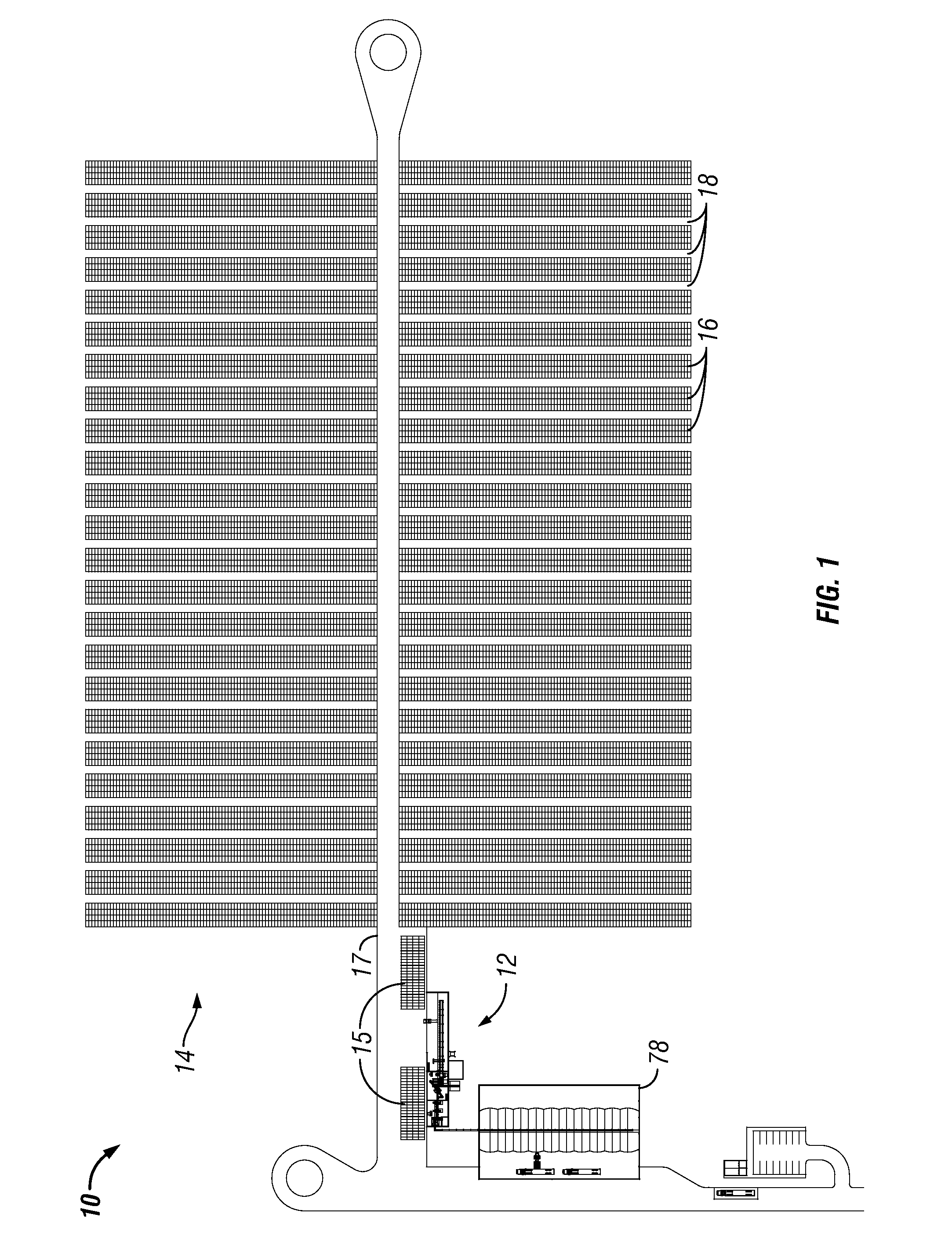

Biomass pelletizing process

ActiveUS20100281767A1Impact soil qualityImpact water useFuel feeding arrangementsSolid fuel pretreatmentAgricultural residueEngineering

A process is provided using non-food or limited-feed agricultural residue and energy crops for energy production, such as ethanol or electricity generation. The agricultural plant material is harvested and baled. The bales are transported to the processing site for storage or immediate processing. The bale strings are first removed, and then the broken bales are shredded. The shredded plant material is then ground to a small size. The ground material is then pelletized to produce densified pellets of the agricultural plant material. The pellets are cooled and then stored or transported to an end user.

Owner:PELLET TECH USA

Method and apparatus for calcining gypsum

The subject invention relates generally to methods and apparatuses for calcining gypsum. The apparatuses and methods place a gypsum particle optimizer in close association with the impact mill so that all the gypsum supplied to the impact mill has to enter the gypsum particle optimizer prior to the gypsum entering the impact mill, and so that heat generated from the impact mill enters into the gypsum particle optimizer from the impact mill. The gypsum particle optimizer utilizes a rotor to disperse the gypsum throughout the gypsum particle optimizer so that the gypsum is exposed to the heat from the impact mill prior to entering the impact mill. The exposure to the heat removes free water from the gypsum prior to the gypsum entering the impact mill.

Owner:GOLD BOND BUILDING PROD LLC

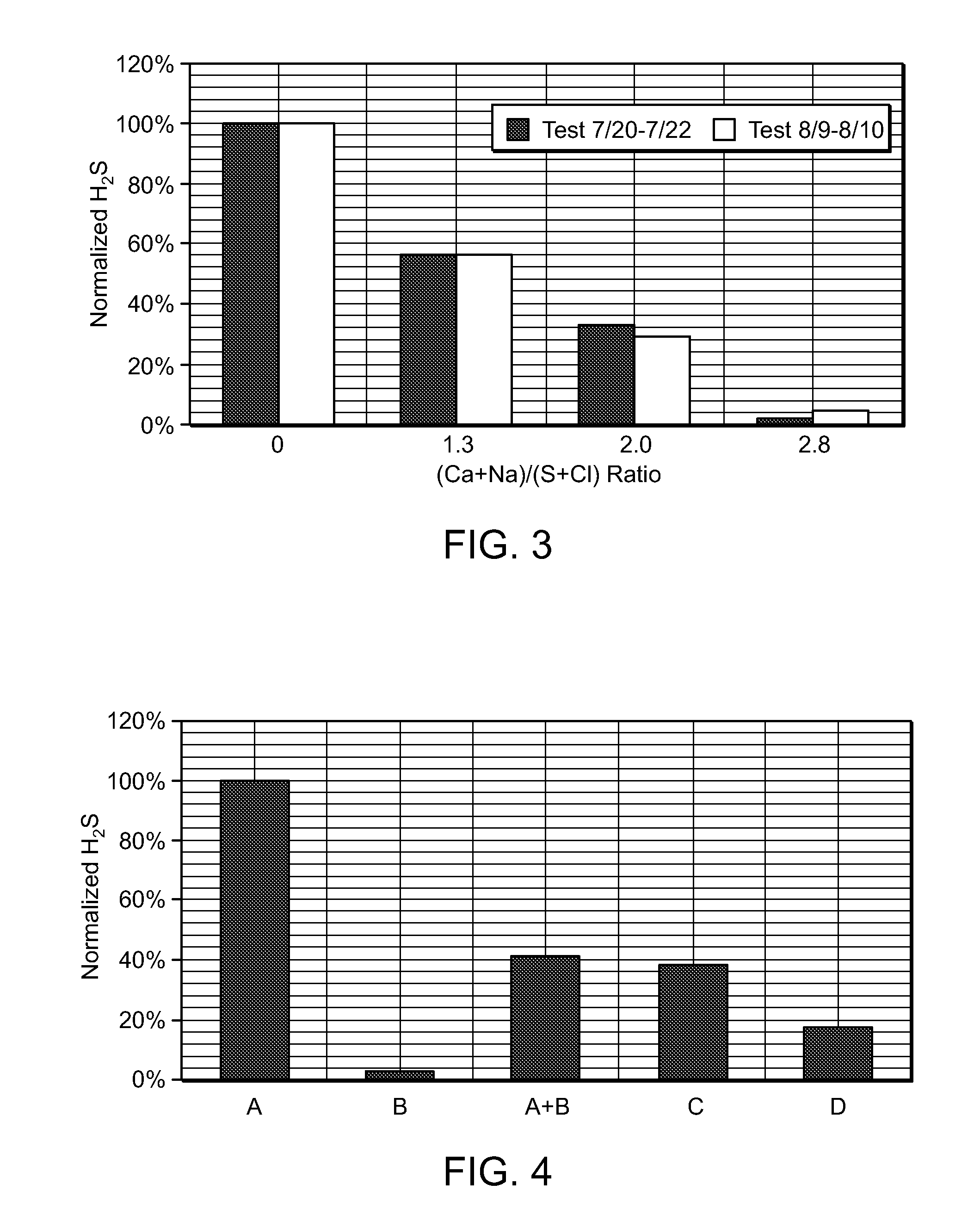

Reducing environmental pollution and fouling when burning coal

InactiveUS20140299028A1Lower Level RequirementsEmission reductionEmission preventionSolid fuel pretreatmentAlkalinityHalogen

Powder components containing calcium, alumina, silica, iron, magnesium, and a halogen sorbent are used in combination during coal combustion to produce environmental benefits. Sorbents are added to the coal ahead of combustion and / or are added into the flame or downstream of the flame. The alkalinity and chlorine of the powder is minimized in order to mitigate unwanted fouling, especially when used with sub-bituminous and lignite coals.

Owner:NOX II LTD

System and method for protection of SCR catalyst and control of multiple emissions

Owner:THE BABCOCK & WILCOX CO

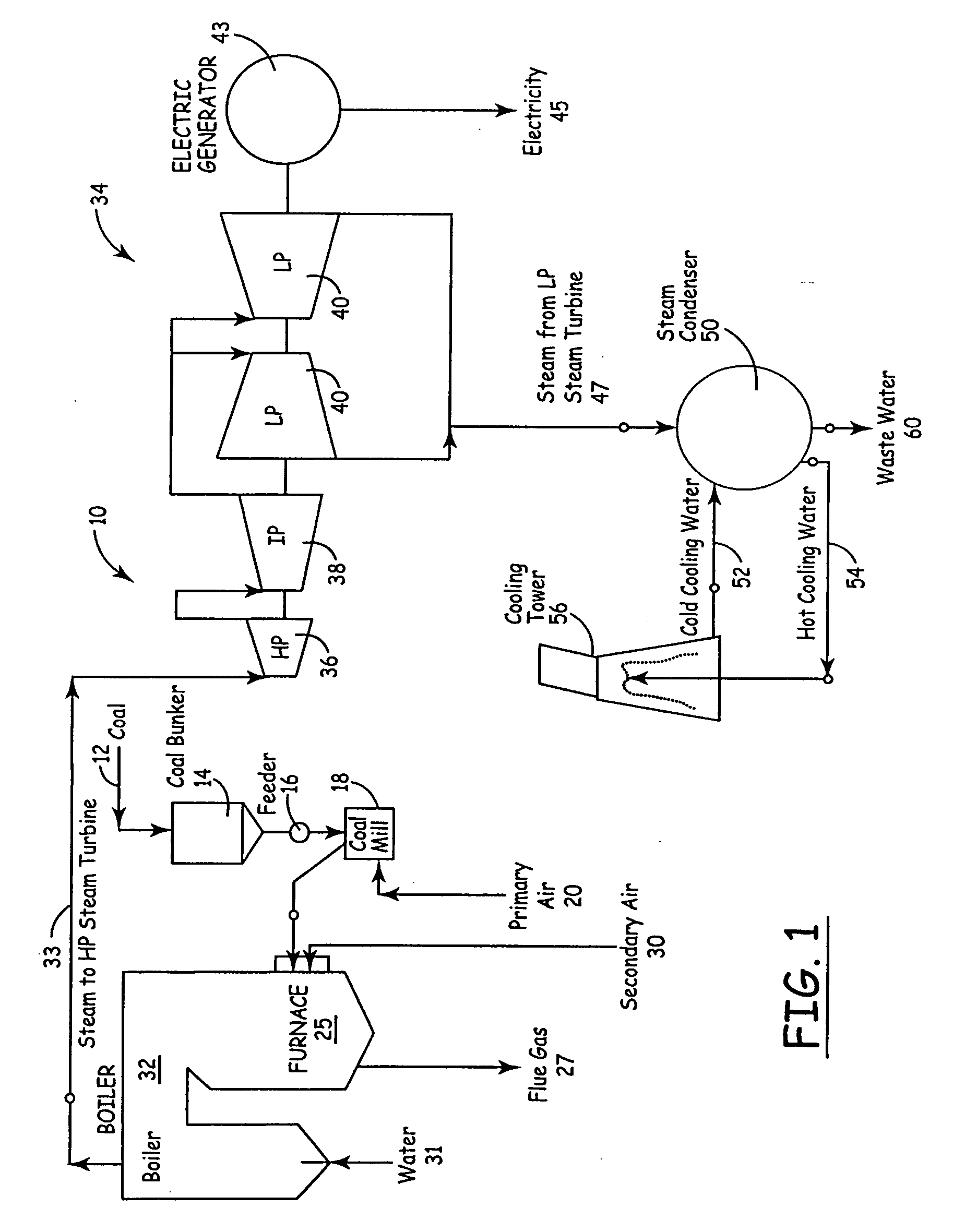

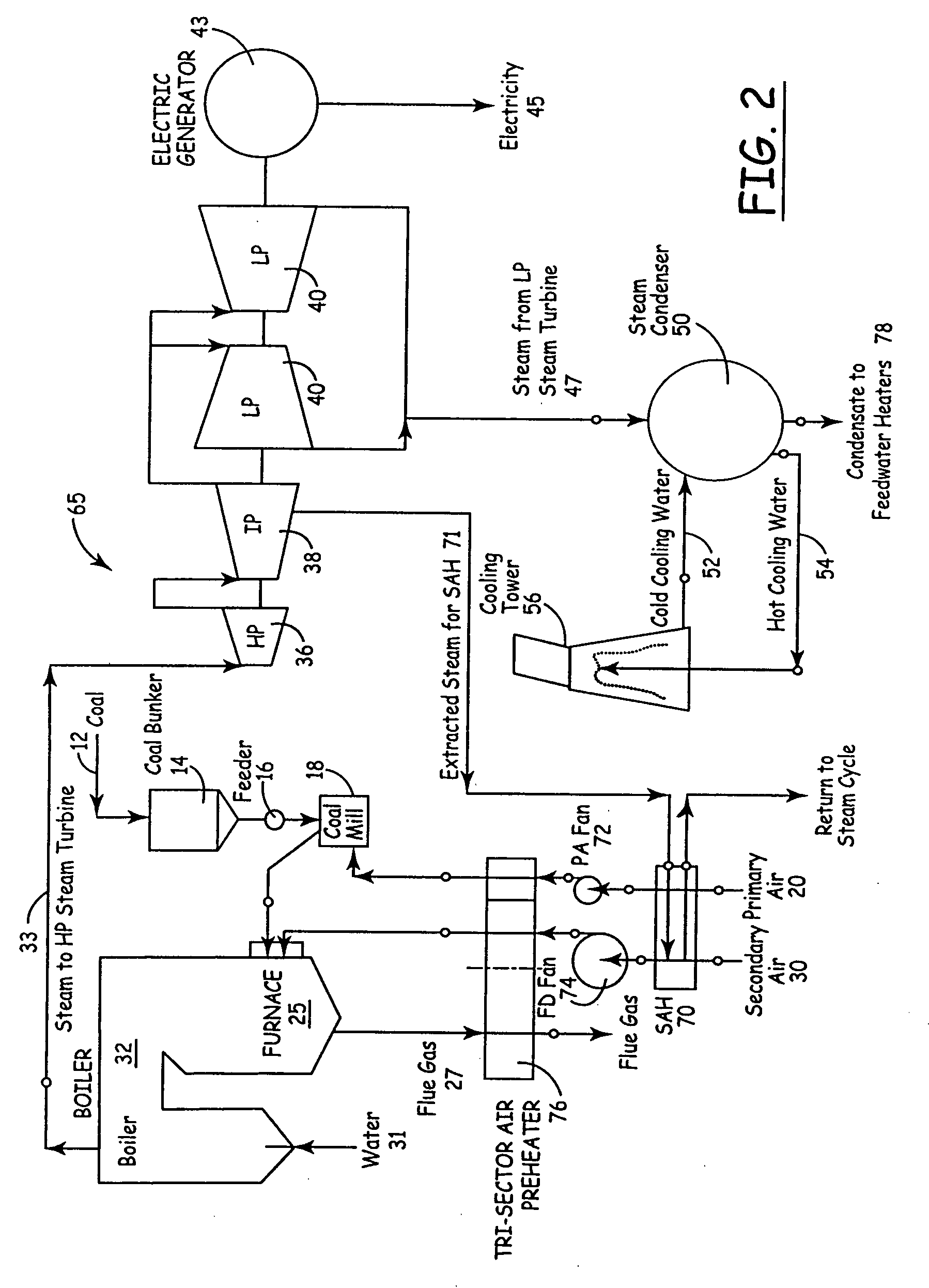

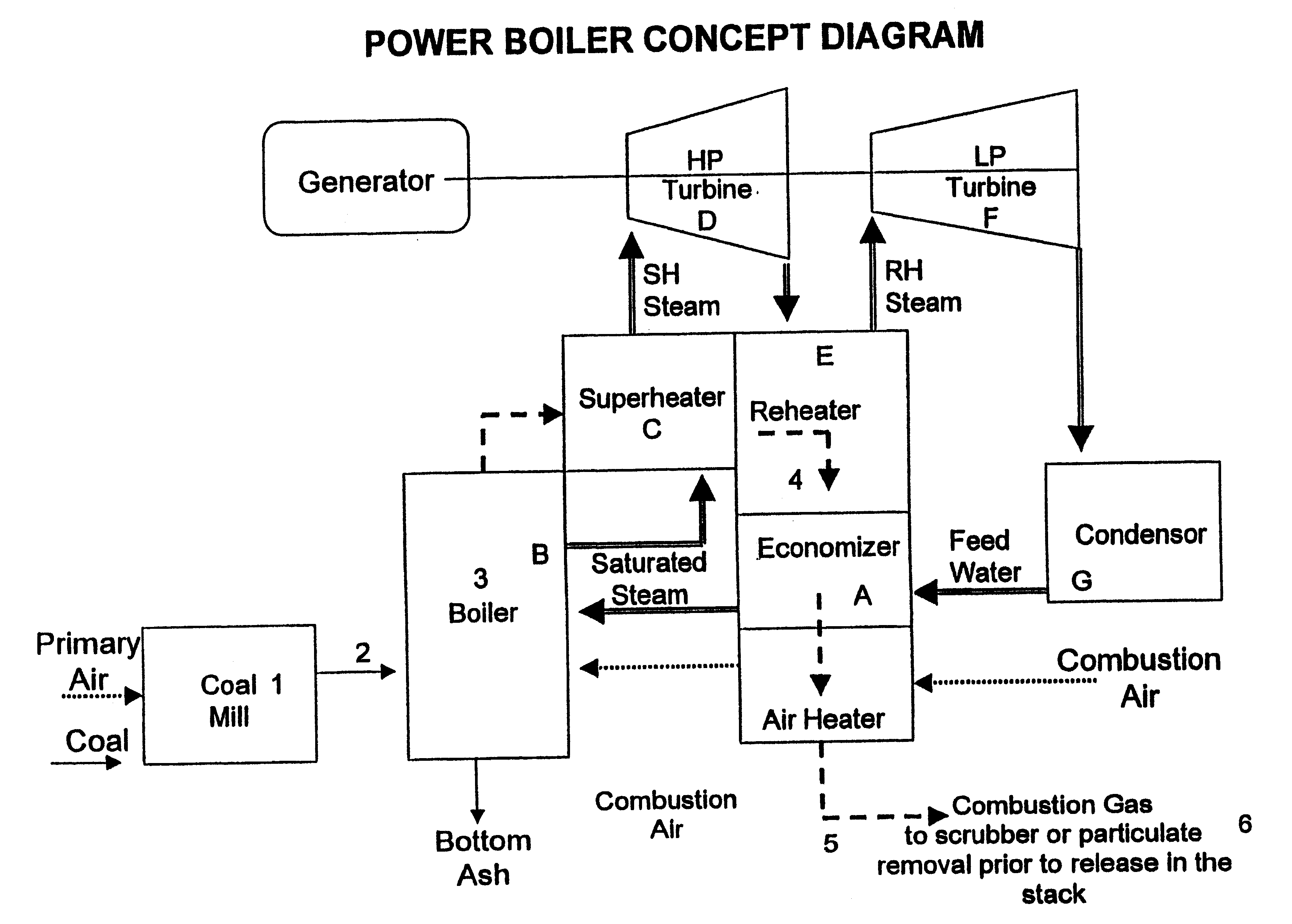

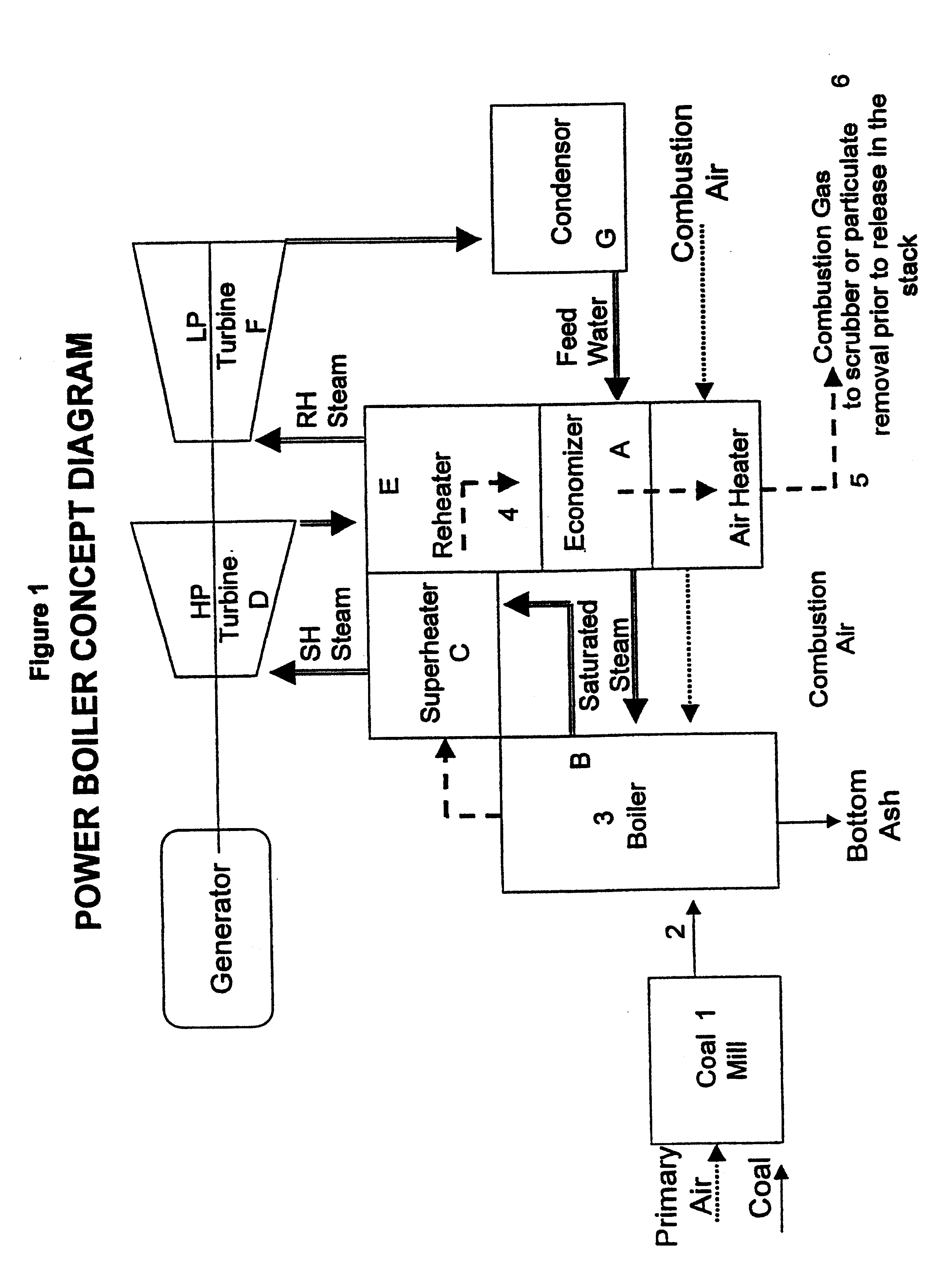

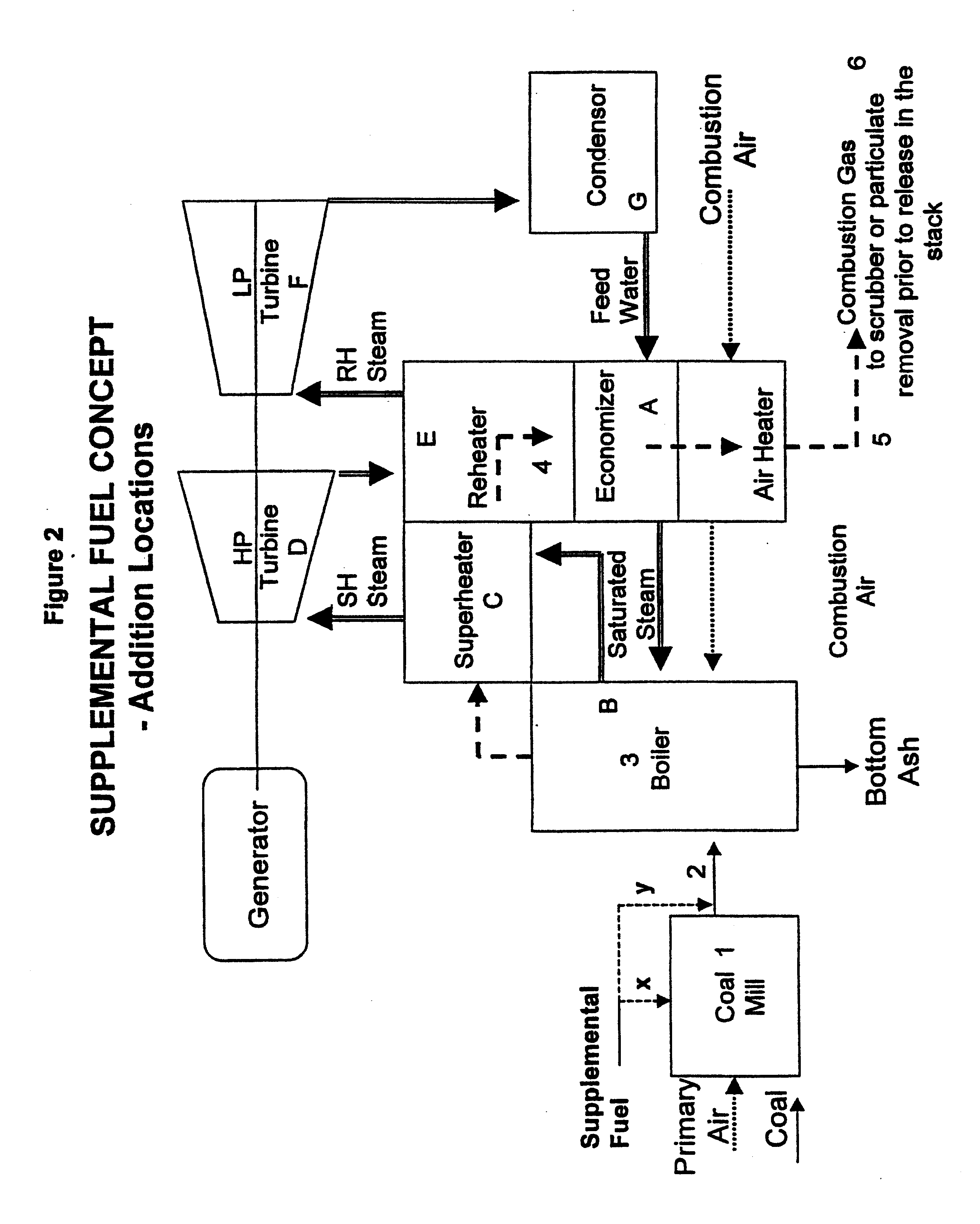

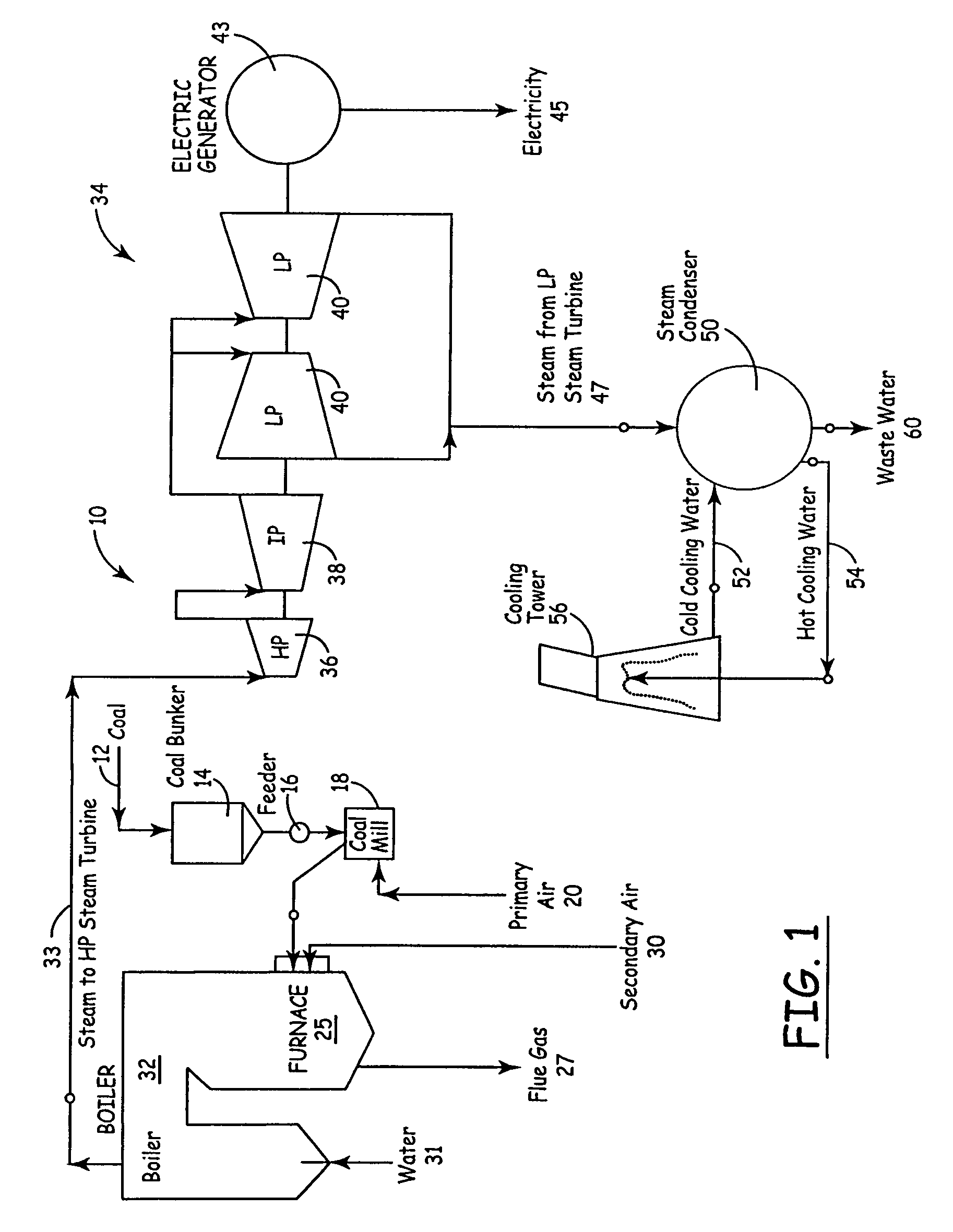

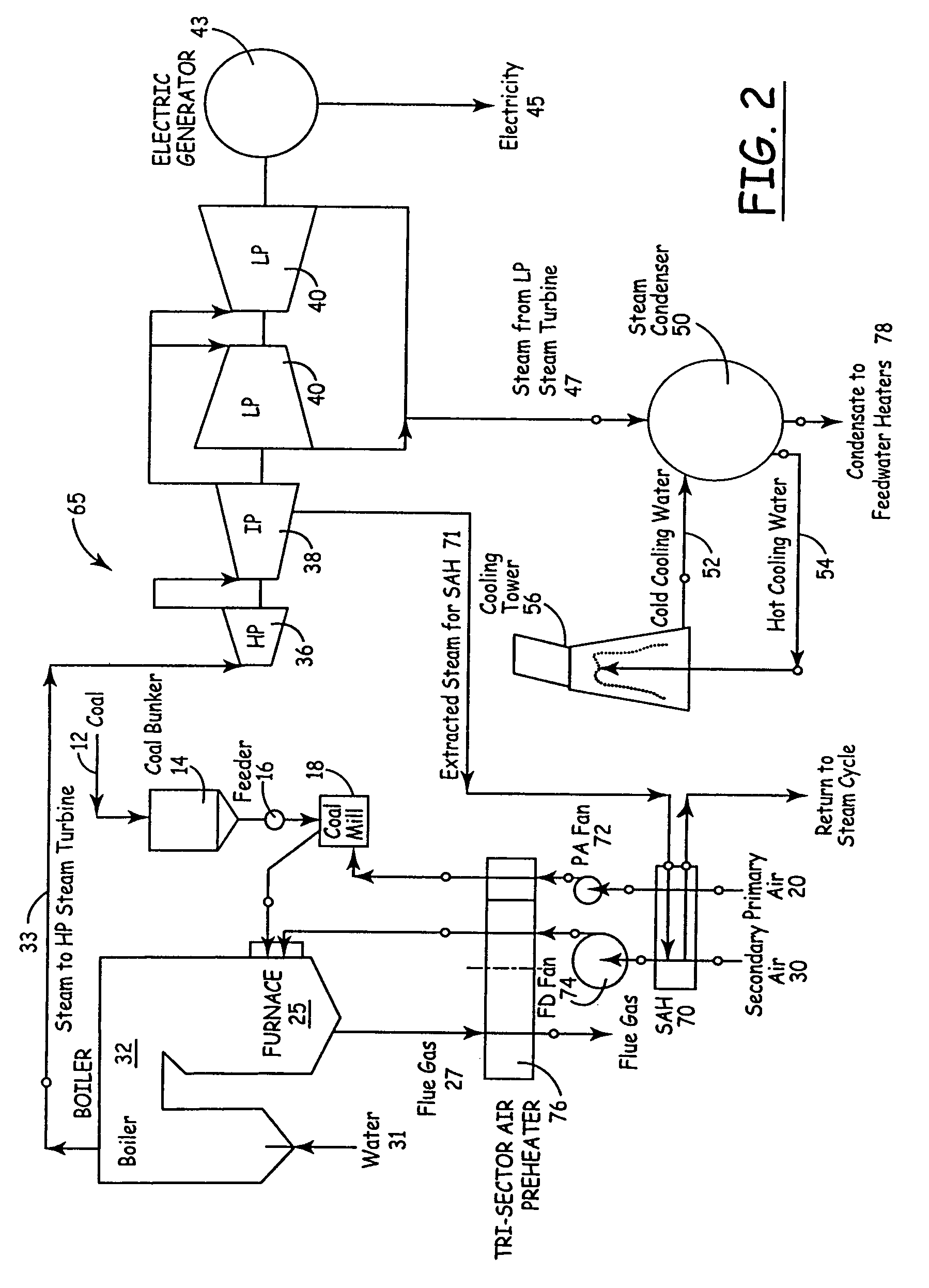

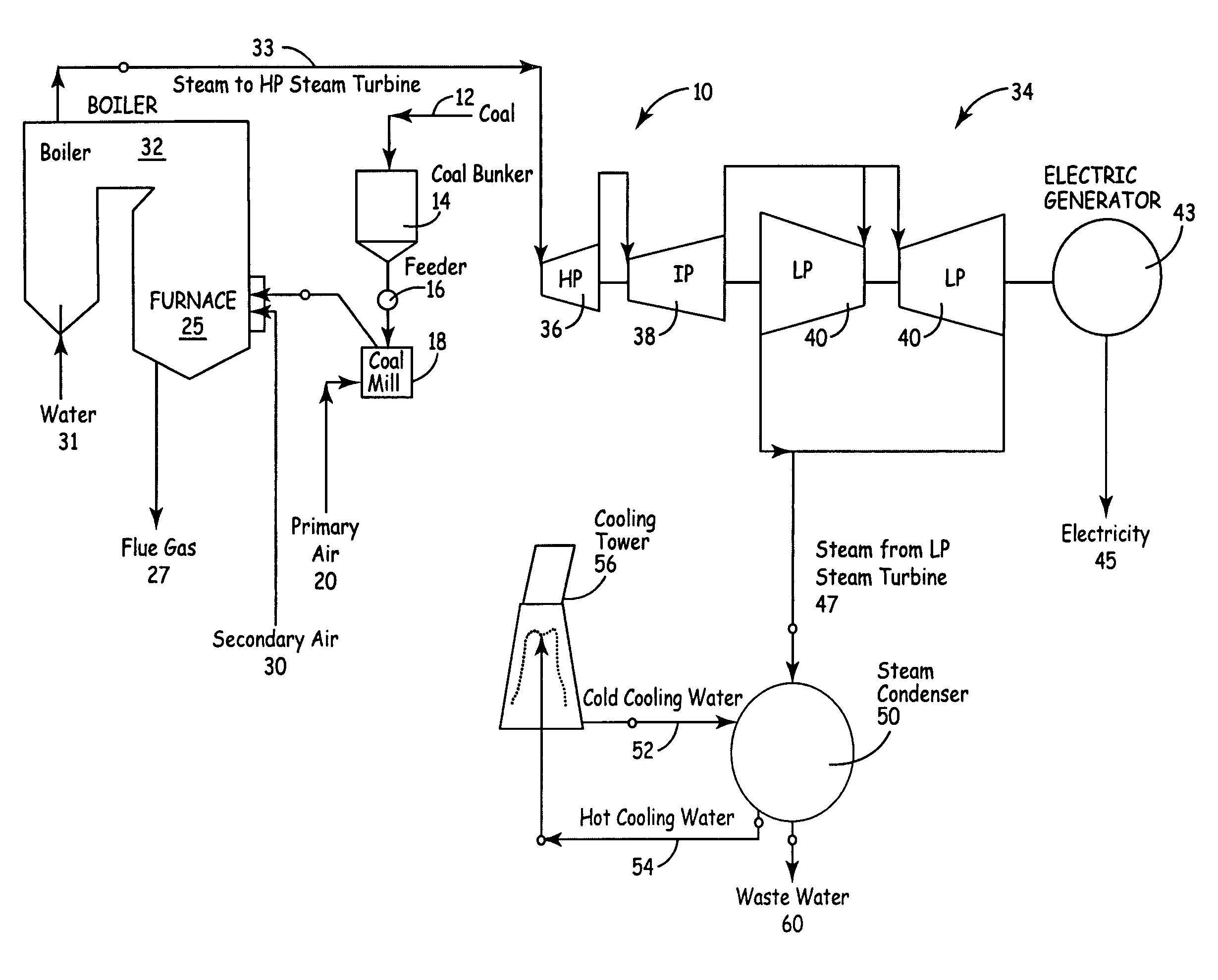

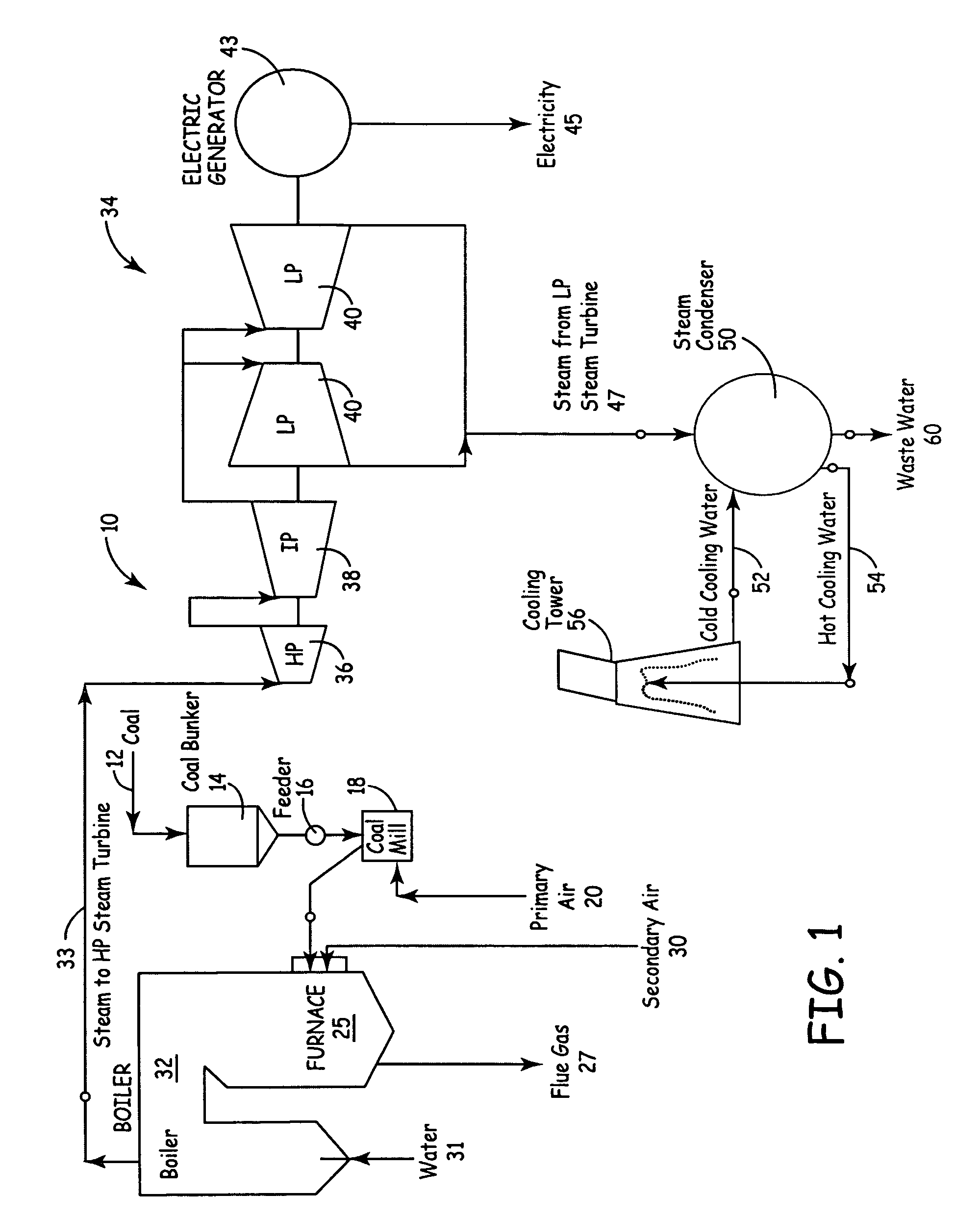

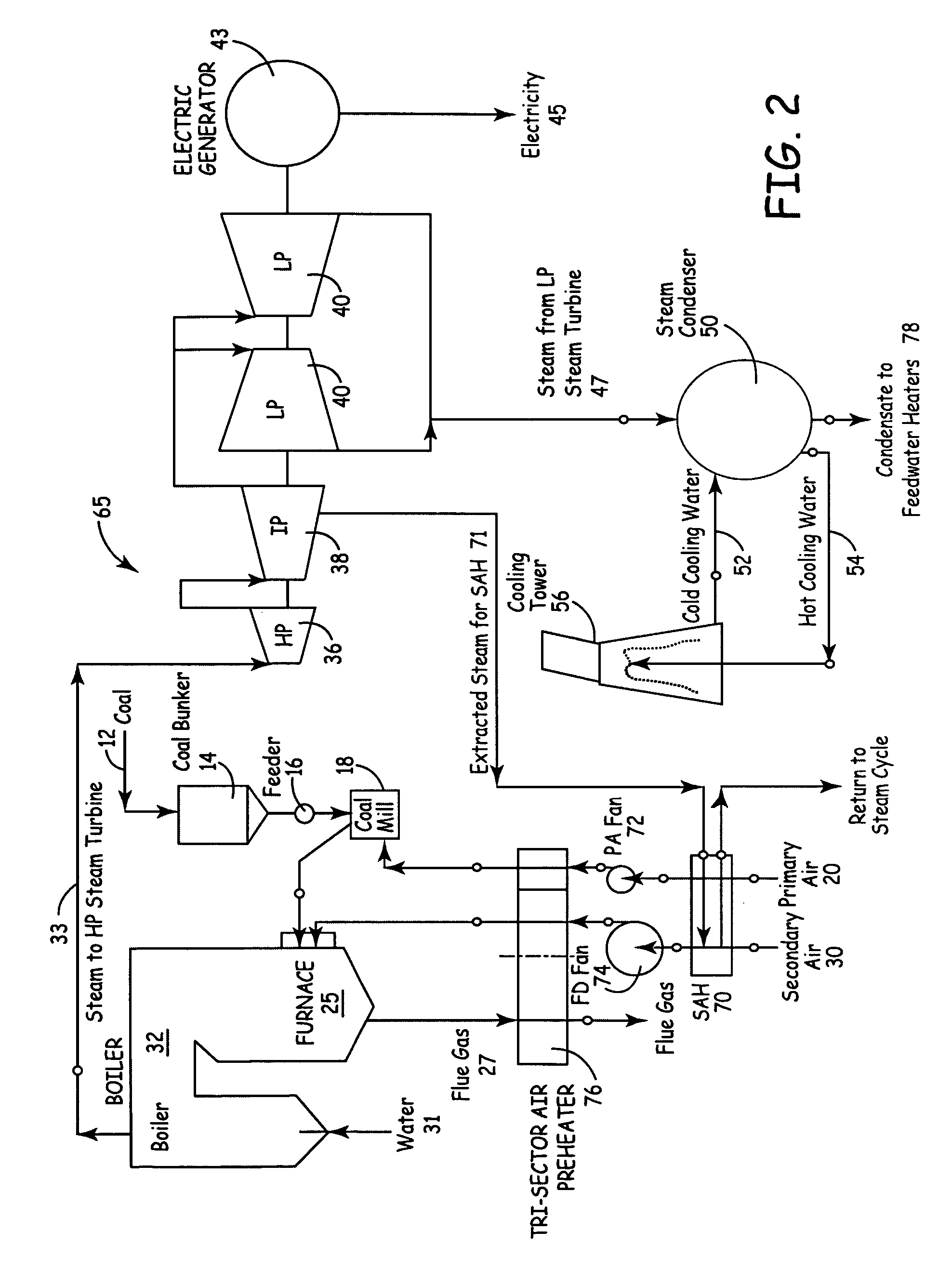

Process to improve boiler operation by supplemental firing with thermally beneficiated low rank coal

InactiveUS6325001B1Improve combustion characteristicsImprove combustion performanceSolid fuel pretreatmentSolid fuelsDevice typeBrown coal

The invention described is a process for improving the performance of a commercial coal or lignite fired boiler system by supplementing its normal coal supply with a controlled quantity of thermally beneficiated low rank coal, (TBLRC). This supplemental TBLRC can be delivered either to the solid fuel mill (pulverizer) or directly to the coal burner feed pipe. Specific benefits are supplied based on knowledge of equipment types that may be employed on a commercial scale to complete the process. The thermally beneficiated low rank coal can be delivered along with regular coal or intermittently with regular coal as the needs require.

Owner:SYNCOAL SOLUTIONS

Inferential pulverized fuel flow sensing and manipulation within a coal mill

Owner:HONEYWELL INT INC

Apparatus and method of enhancing the quality of high-moisture materials and separating and concentrating organic and/or non-organic material contained therein

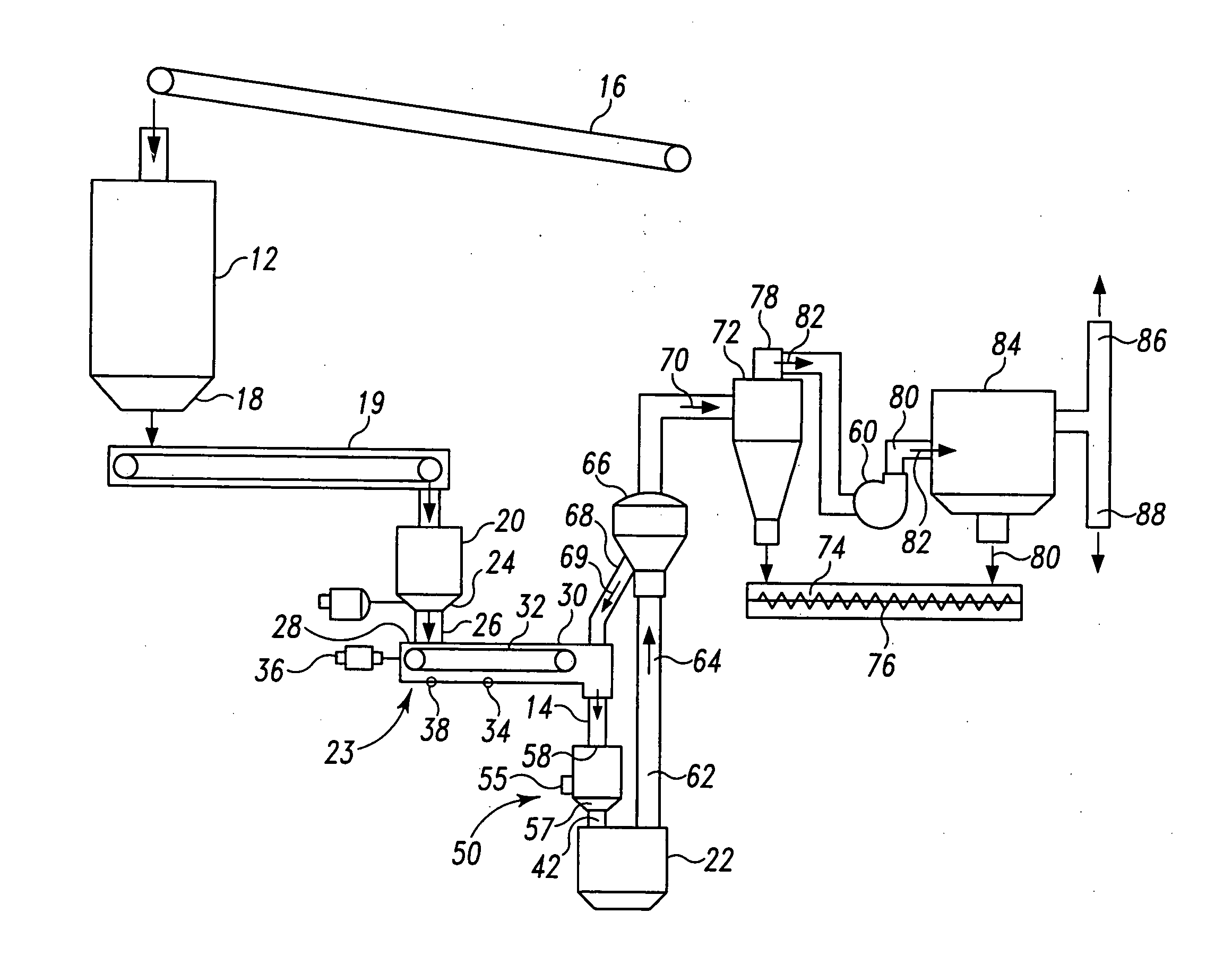

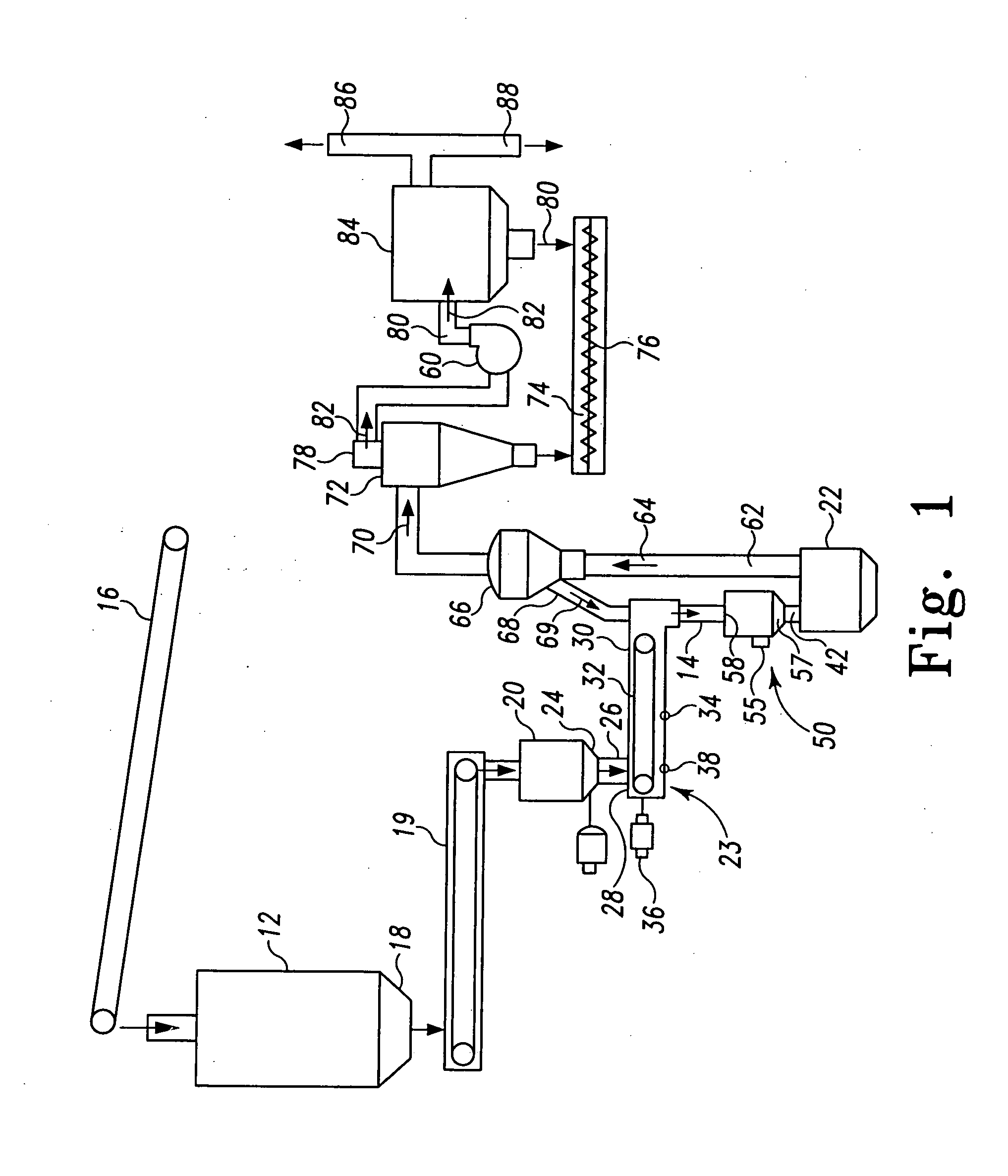

ActiveUS8062410B2Processed evenly and quicklySignificant environmental benefitsDrying solid materials with heatGas current separationParticulatesFluidized bed drying

The present invention harvests and utilizes fluidized bed drying technology and waste heat streams augmented by other available heat sources to dry feedstock or fuel. This method is useful in many industries, including coal-fired power plants. Coal is dried using the present invention before it goes to coal pulverizers and on to the furnace / boiler arrangement to improve boiler efficiency and reduce emissions. This is all completed in a low-temperature, open-air system. Also included is an apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. This is useful for segregating contaminants like sulfur and mercury from the product stream.

Owner:RAINBOW ENERGY CENT LLC

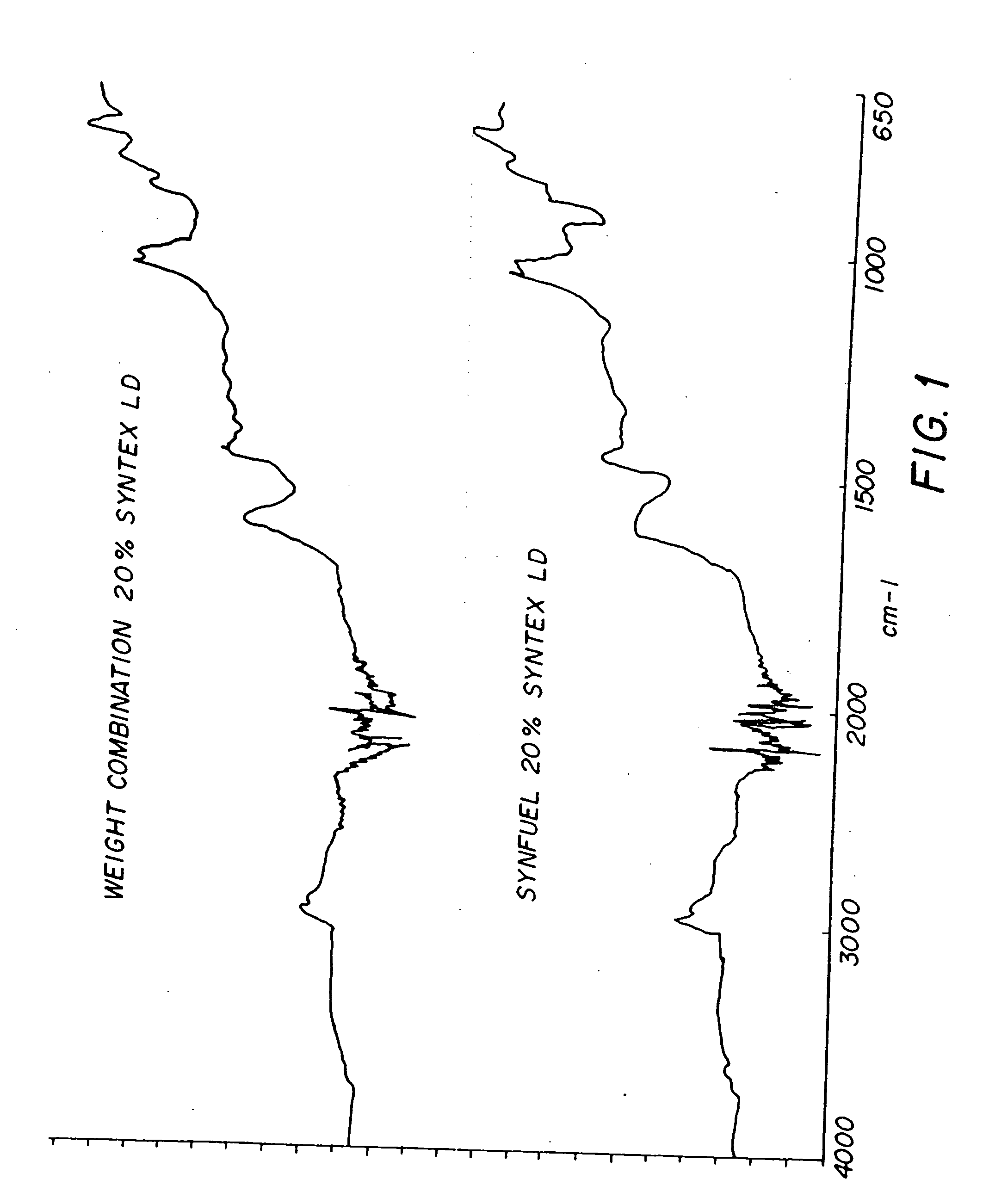

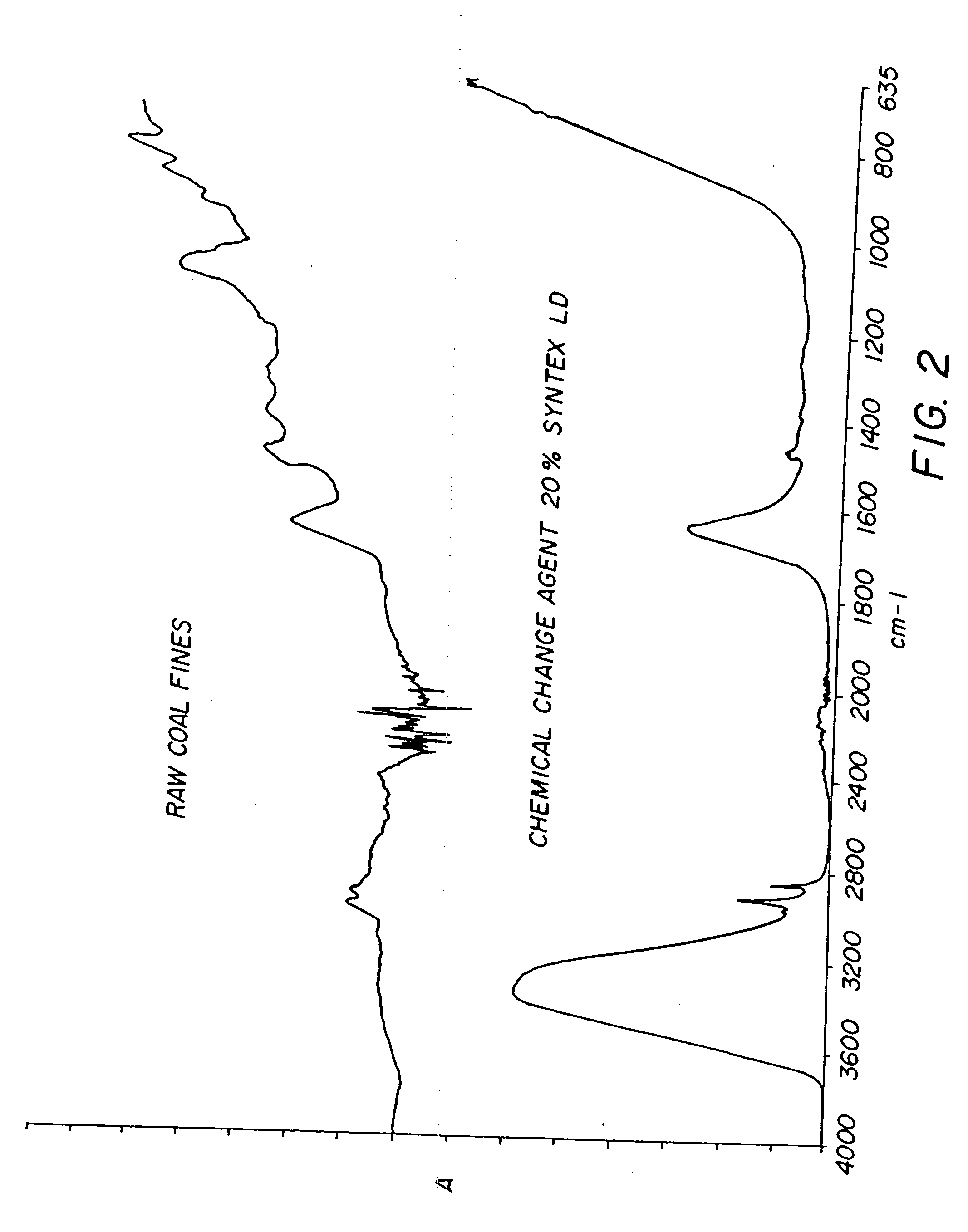

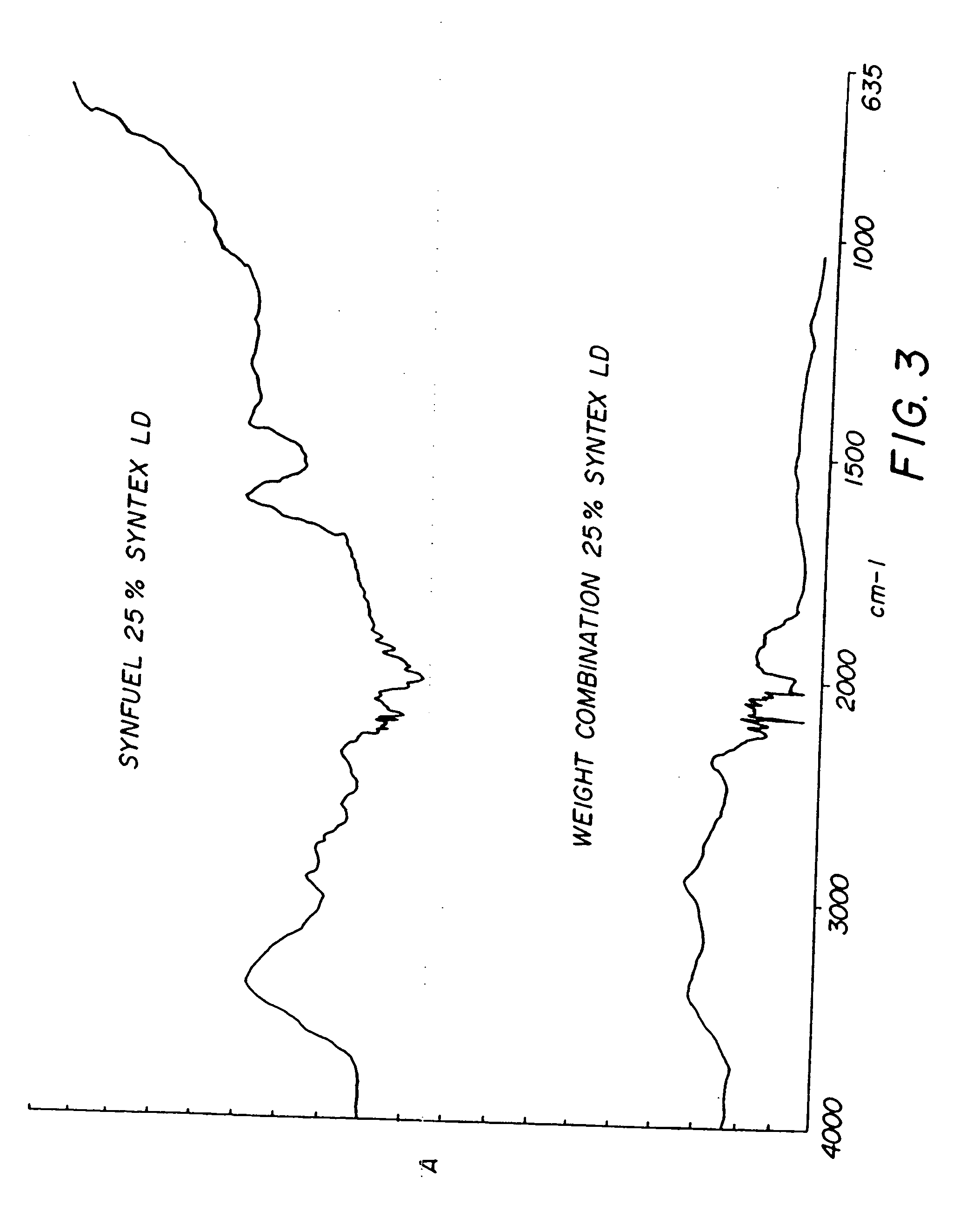

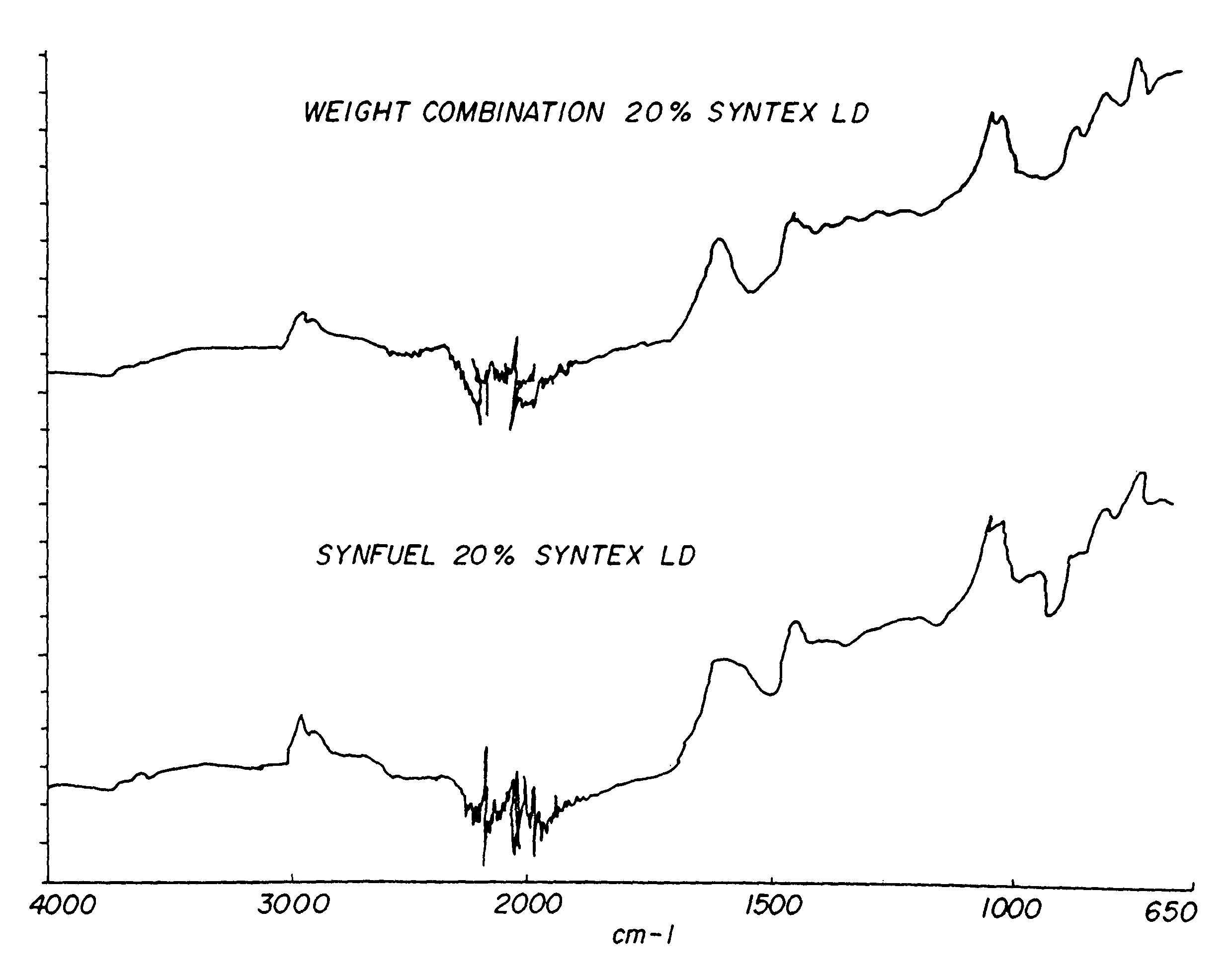

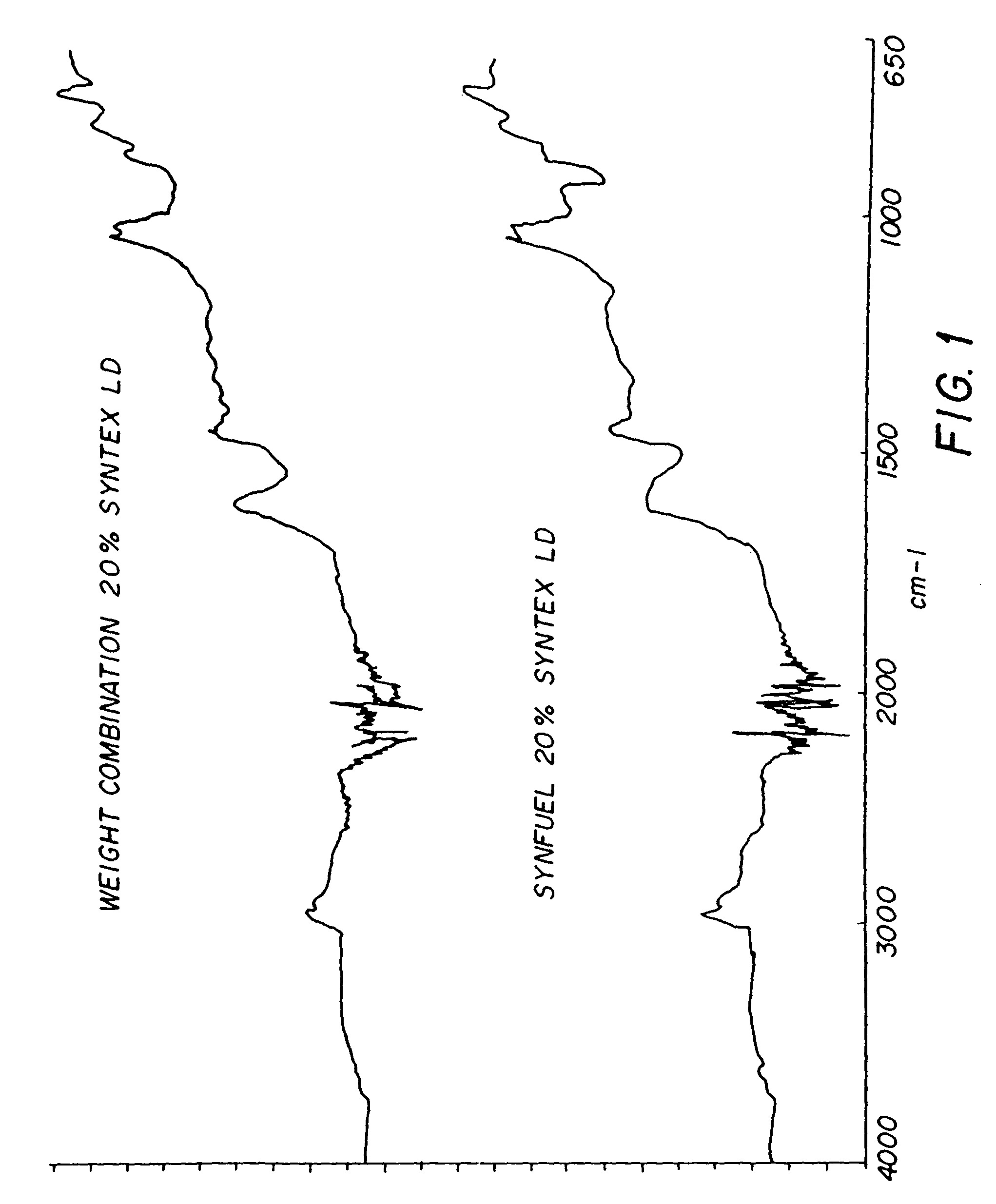

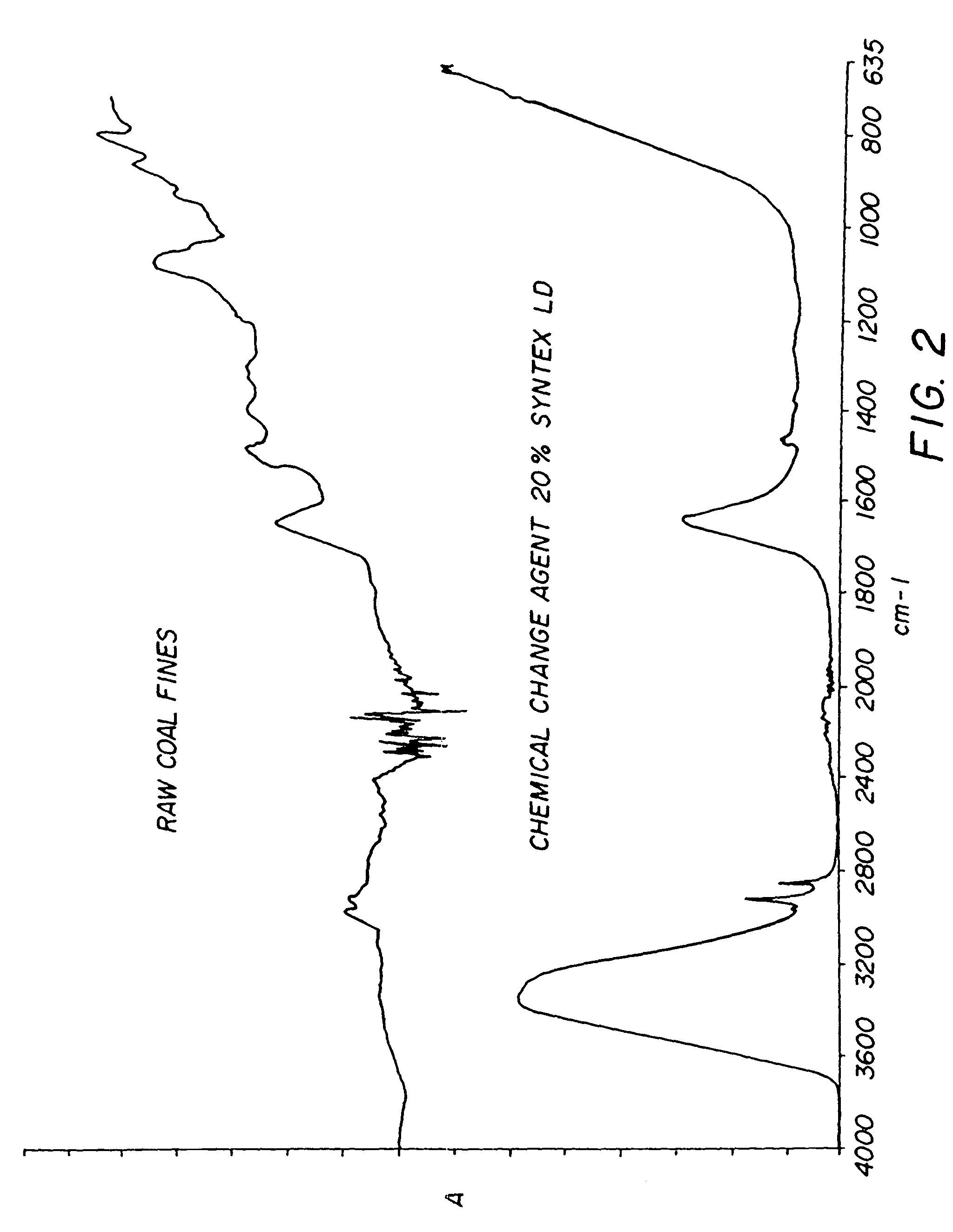

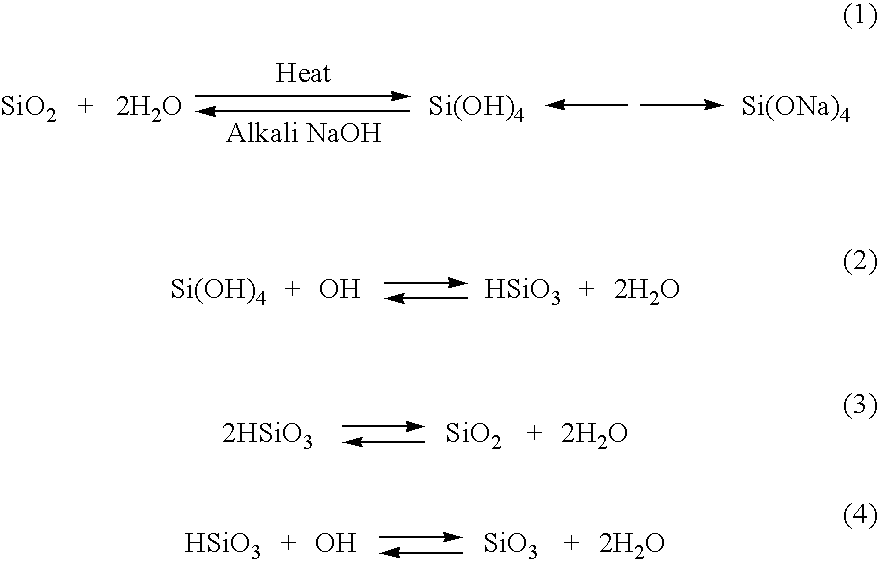

Chemical change agent

InactiveUS20060117651A1Promote combustionEliminate needNitrogen compoundsSolid fuel pretreatmentWaxCombustion

The present invention relates to an improved chemical change reagent which is used as an additive to coal to enhance the complete combustion of the coal after turning it into a synthetic fuel. The composition is a chemical change agent in that it converts the coal / composition mix into a different material which, when burned, results in lower NOx emissions. The composition includes a wax, a base for ph adjustment and water and is mixed with the coal prior to combustion.

Owner:STATE LINE HLDG

Apparatus and method of separating and concentrating organic and/or non-organic material

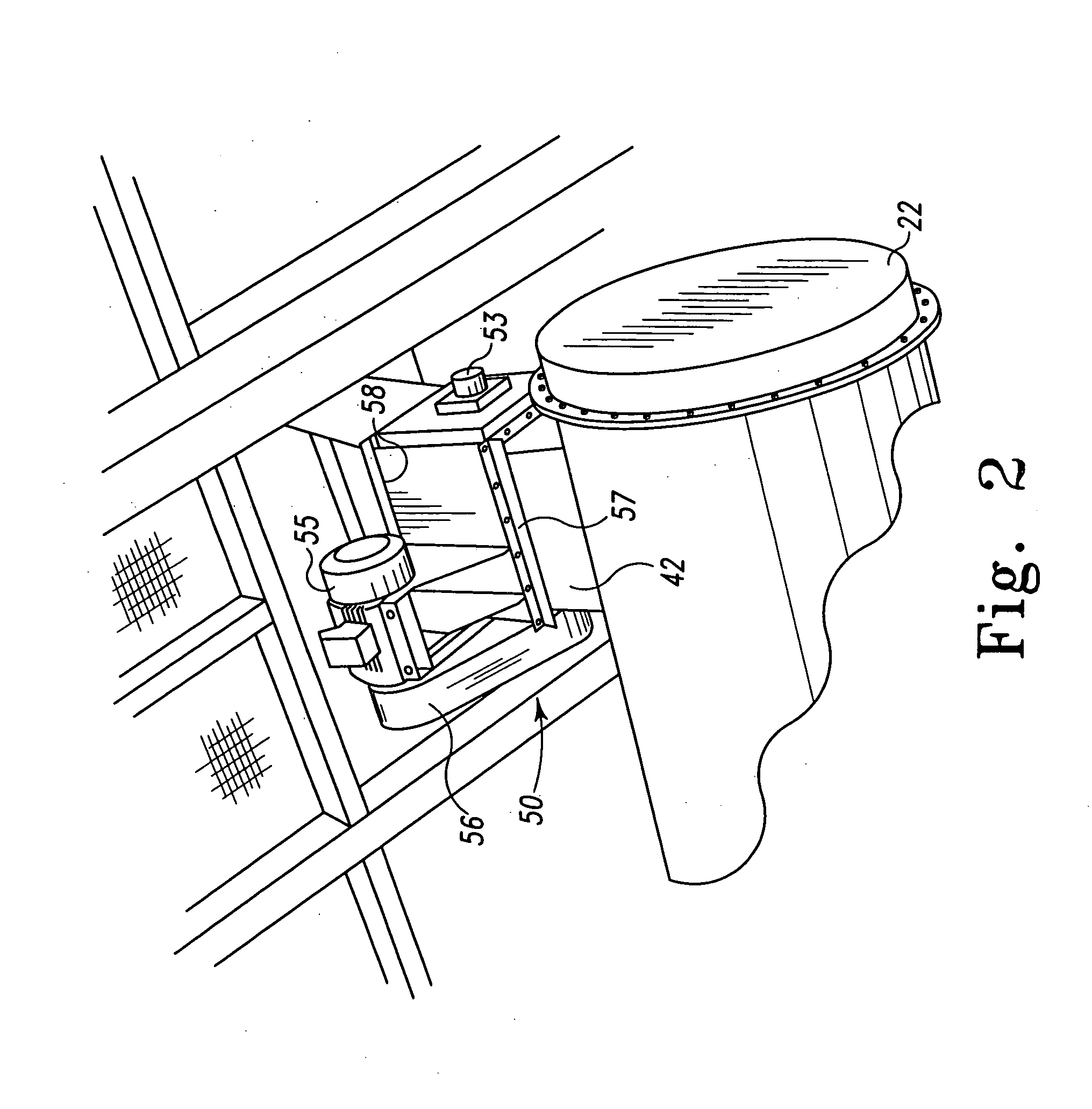

ActiveUS7540384B2Processed evenly and quicklySignificant environmental benefitsGas current separationSolid fuel pretreatmentParticulatesFluidized bed

An apparatus for segregating particulate by density and / or size including a fluidizing bed having a particulate receiving inlet for receiving particulate to be fluidized. The fluidized bed also includes an opening for receiving a first fluidizing stream, an exit for fluidized particulate and at least one exit for non-fluidized particulate. A conveyor is operatively disposed in the fluidized bed for conveying the non-fluidized particulate to the non-fluidized particulate exit. A collector box is in operative communication with the fluidized bed to receive the non-fluidized particulate. There is a means for directing a second fluidizing stream through the non-fluidized particulate as while it is in the collector box to separate fluidizable particulate therefrom.

Owner:RAINBOW ENERGY CENT LLC

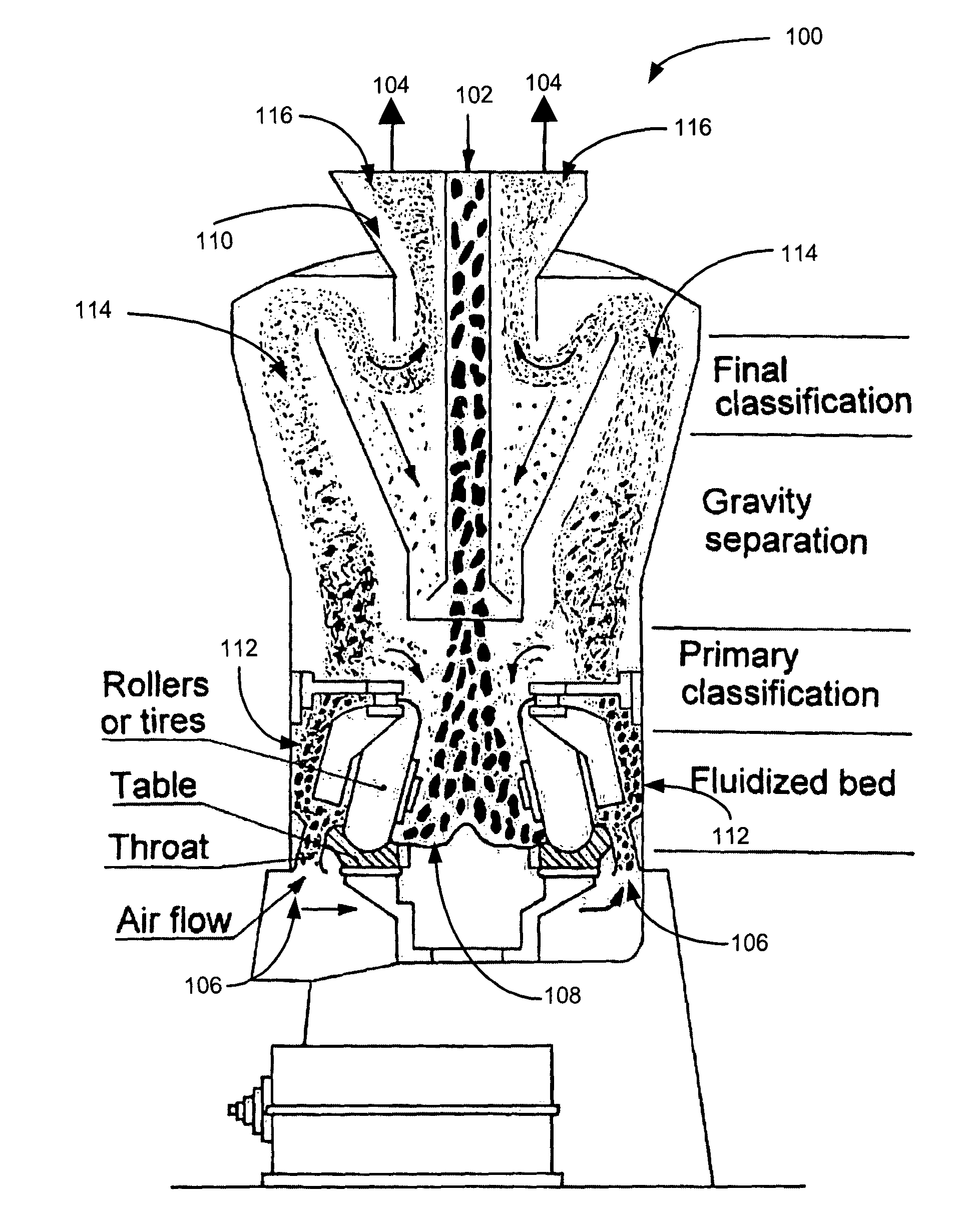

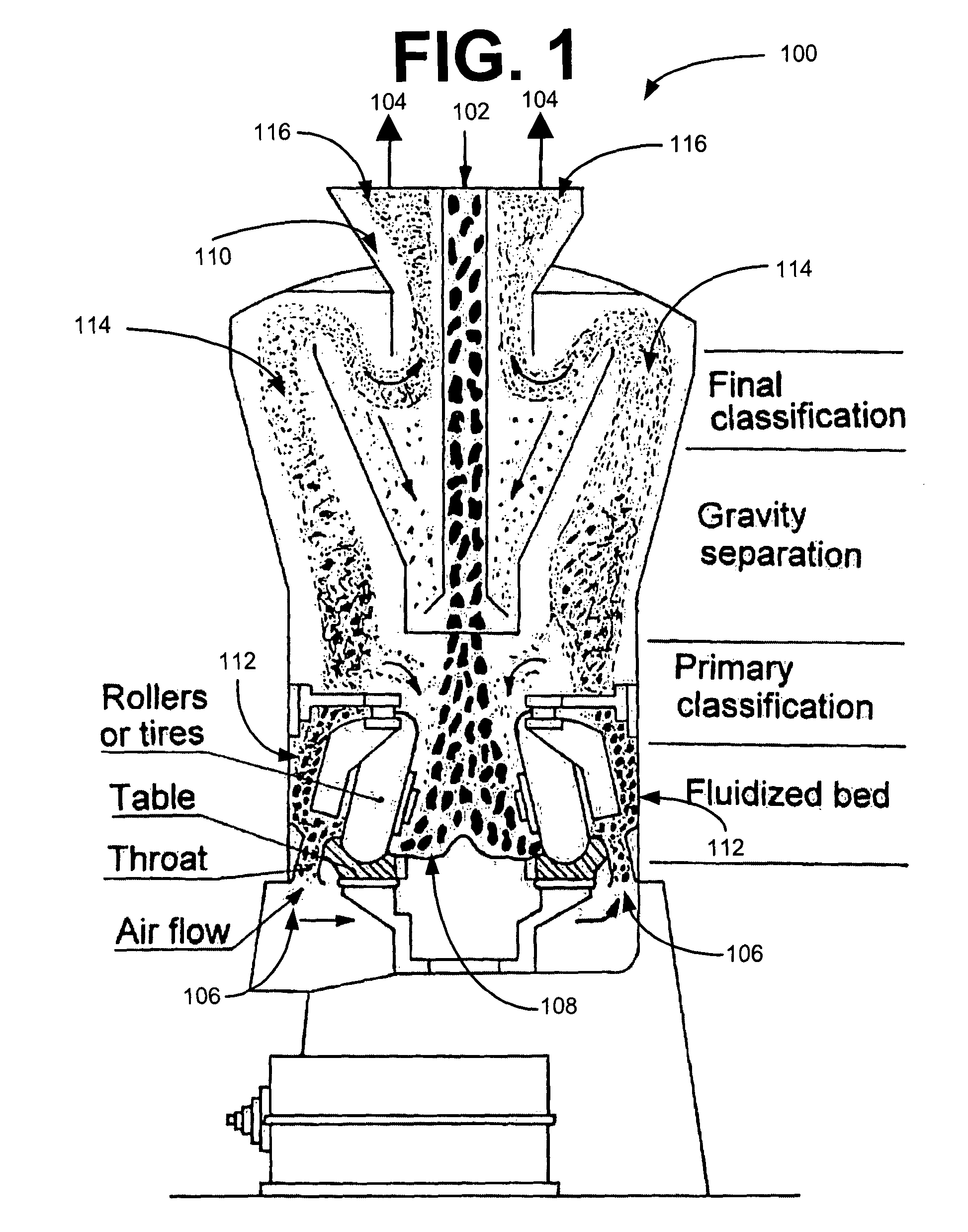

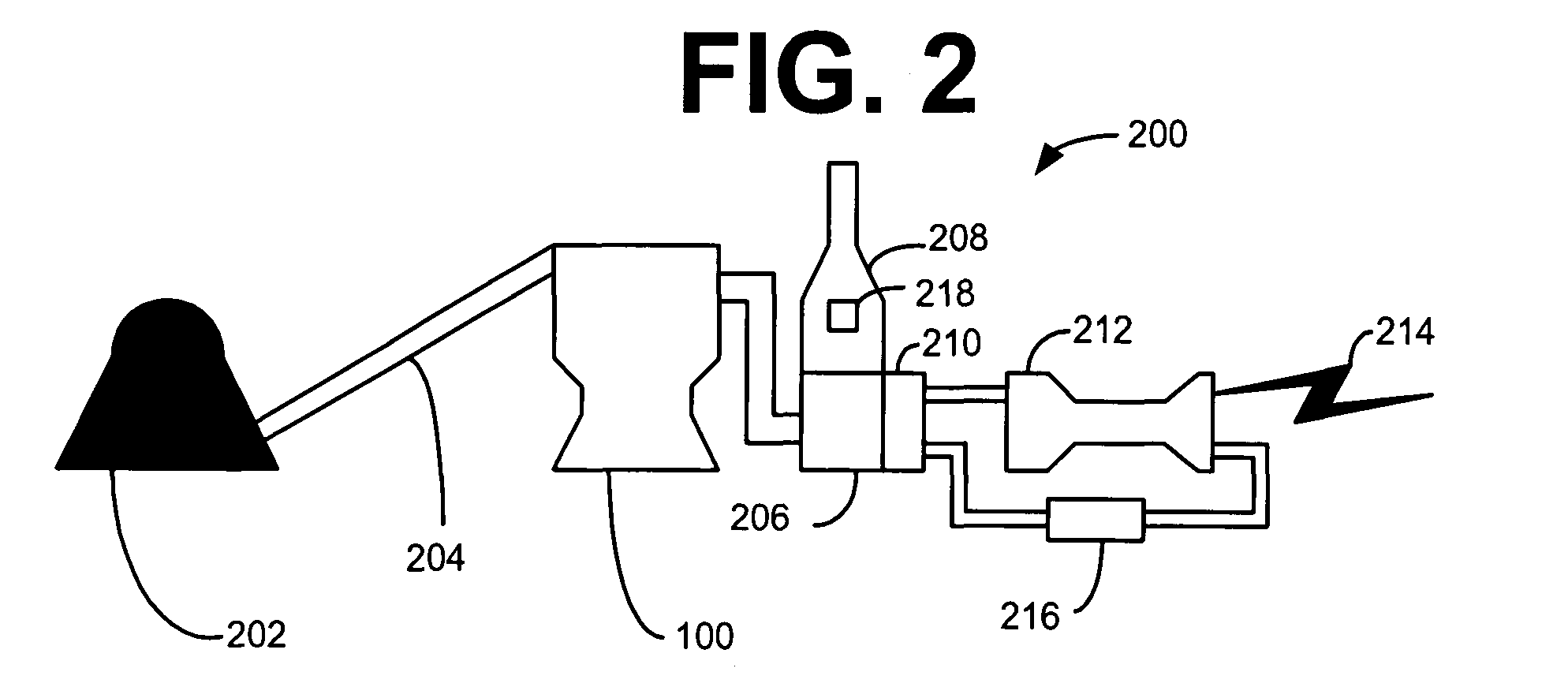

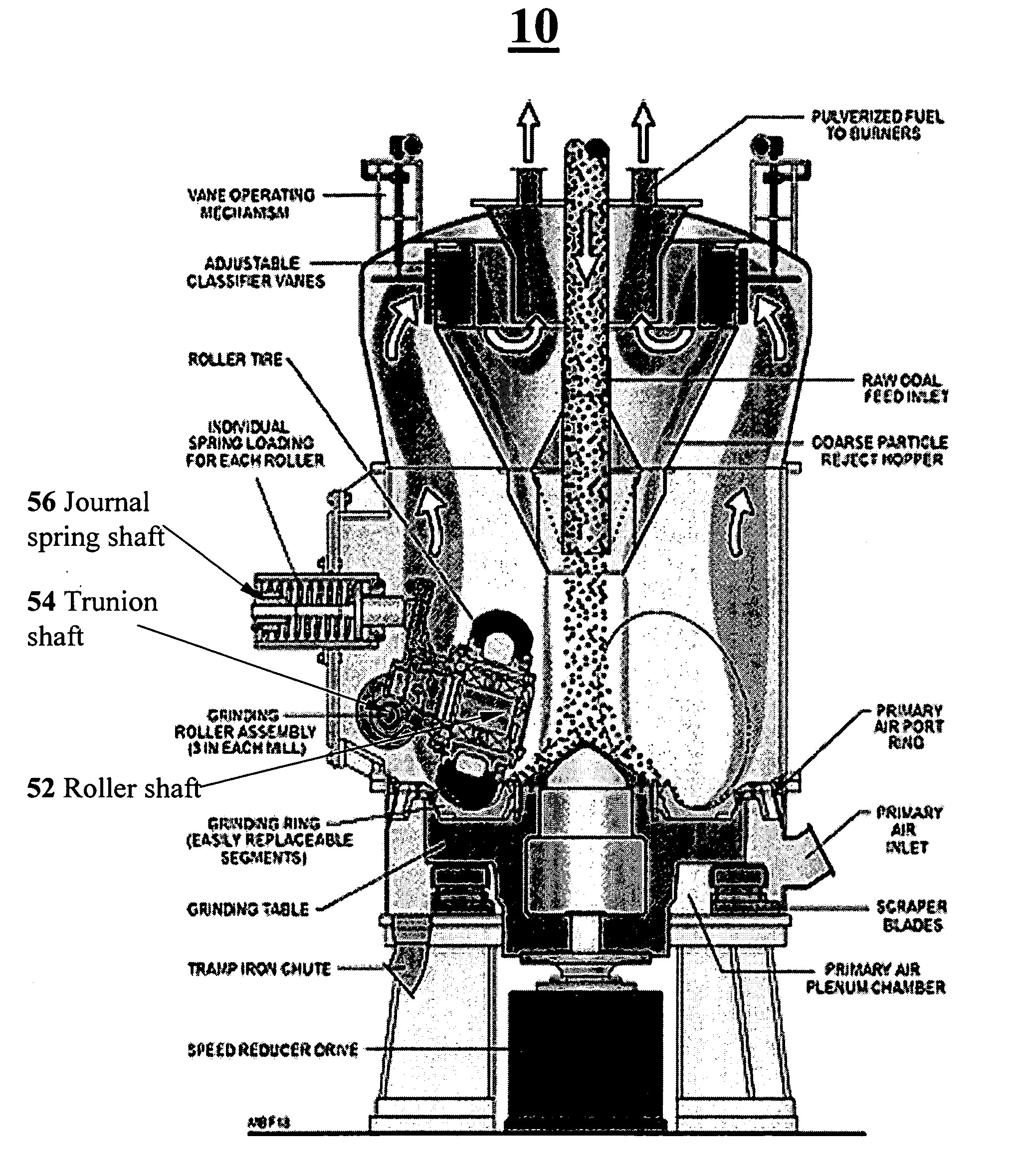

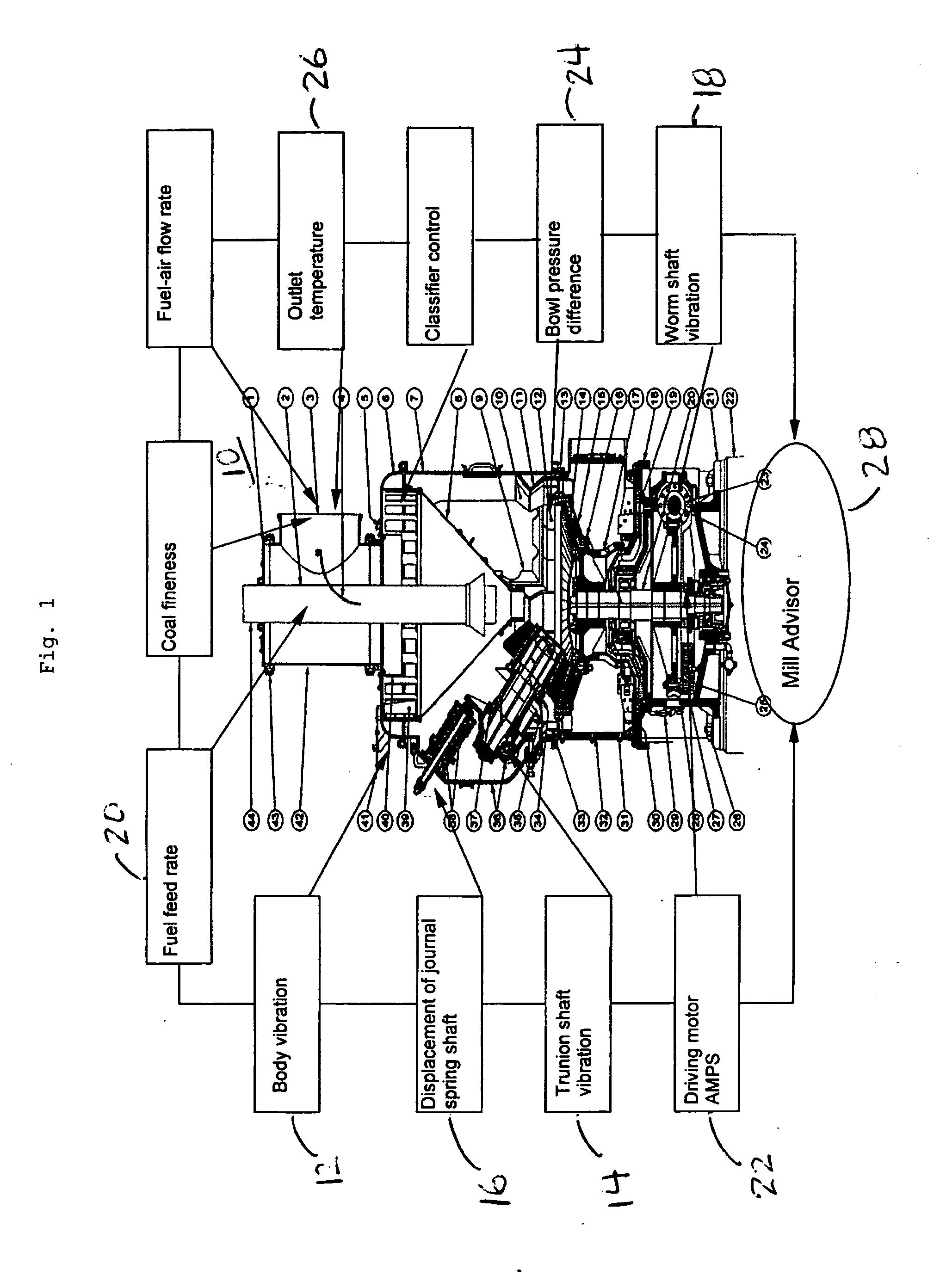

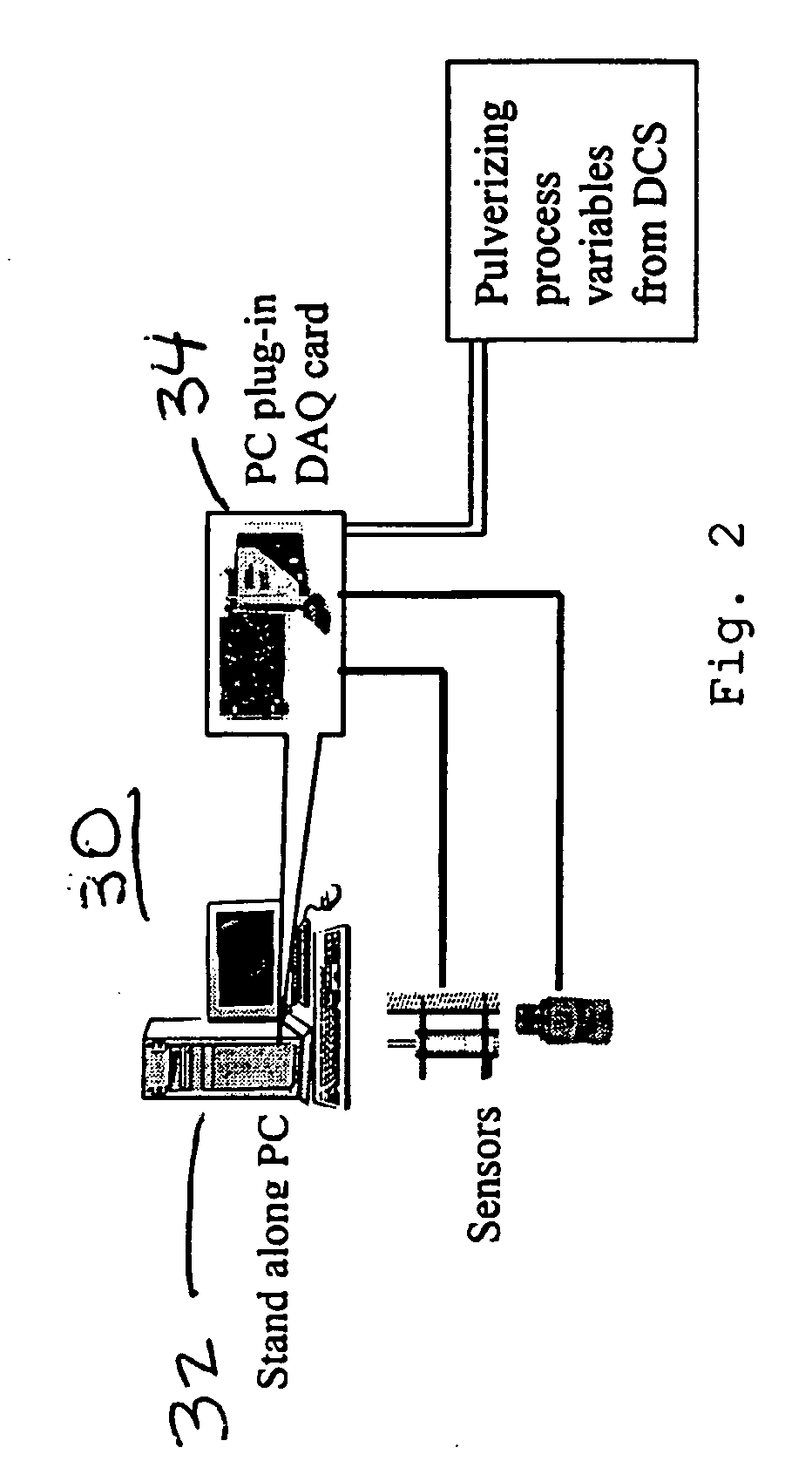

Method and apparatus for solid fuel pulverizing operation and maintenance optimization

A system for use with a roll bowl type mill for the pulverizing of solid fuels such as coal. The system includes hardware in the form of sensors and other components and software to among other things monitor the operating condition of the mill's moving parts and predict their failure. The system can determine the diameter of the mill's rollers, or the reduction and / or depth of cup wear of each of the rollers, the thickness of the solid fuel in the mill, can by analysis determine the wear of each of the one or more roller bearings in the mill and predict their failure and can estimate the mill availability

Owner:ABB TECH AG

Sorbent composition to reduce emissions from the burning of carbonaceous fuels

InactiveUS20070140943A1Efficient sulfur captureHarmful emissionGas treatmentOther chemical processesCombustionFlue gas

Sulfur emissions from combustion of coal and other fuels are reduced by using sugar beet lime as a sorbent during the coal burning process. In various embodiments, the sugar beet lime is added onto the coal before combustion, along with the coal into the furnace, is injected directly into the fire coal, or is added into the flue gases downstream of the furnace. The relatively high calcium content of the sugar beet lime leads to efficient sulfur capture at suitably low treat levels. Excess ash is avoided in the process.

Owner:COMRIE DOUGLAS C

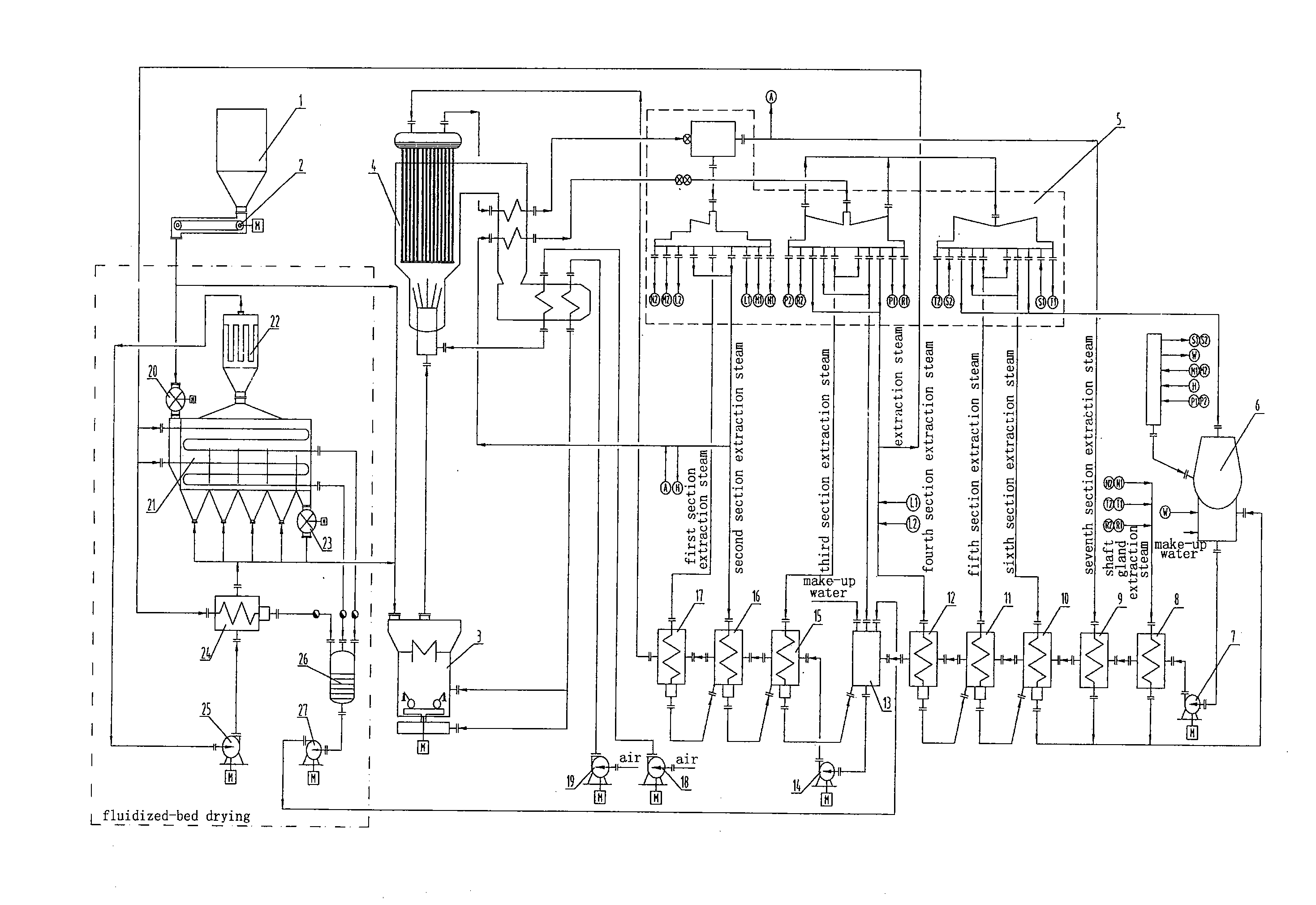

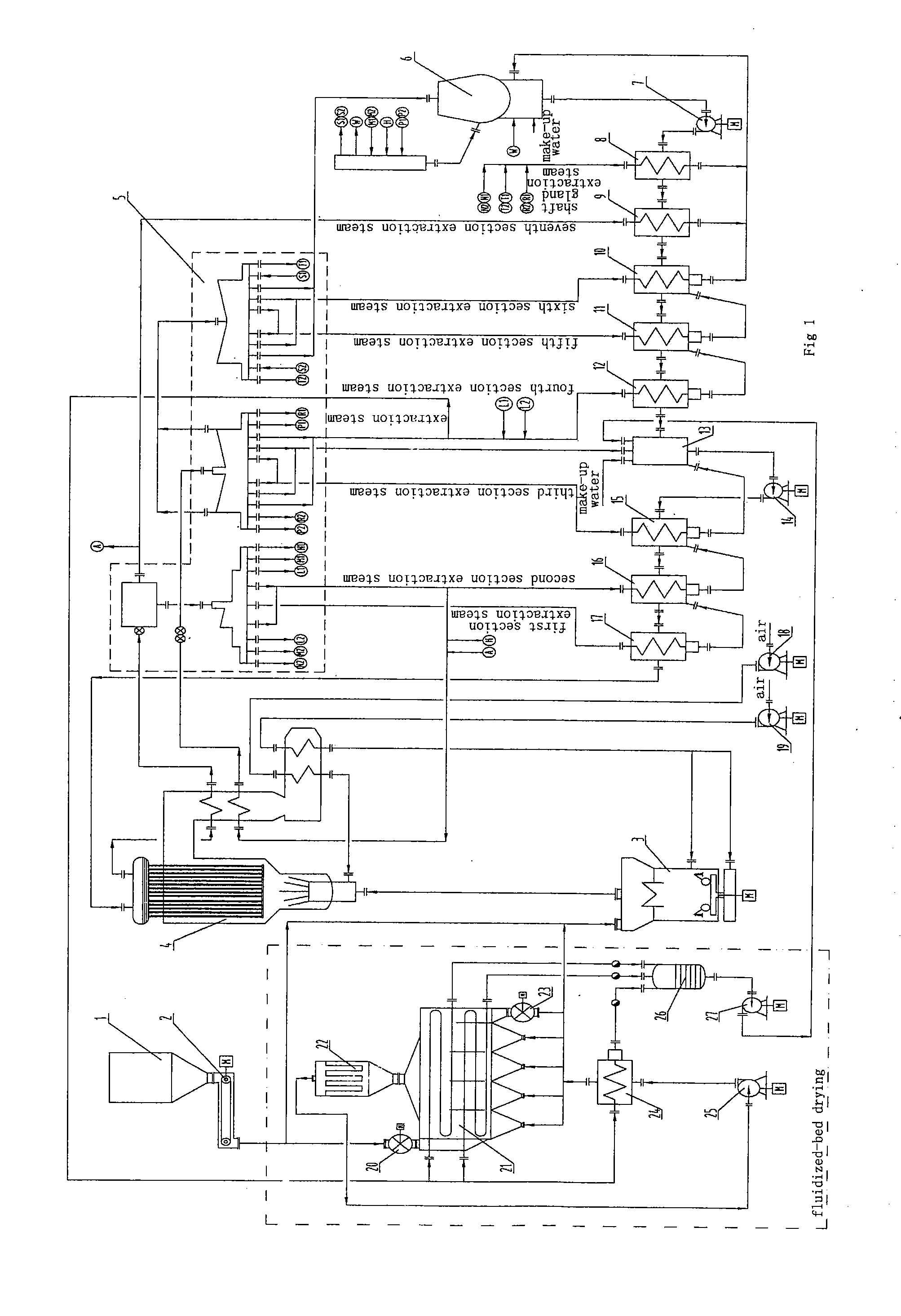

Process for reducing coal consumption in coal fired power plant with fluidized-bed drying

ActiveUS20110220744A1Reduce coal consumptionRemarkable effectFuel feeding arrangementsDrying solid materials with heatFluidized bed dryingProcess engineering

The present invention relates to a process for reducing coal consumption in coal fired plant with fluidized-bed drying, namely a fluidized-bed drying system is provided between a coal powder bunker as well as a weighing belt and a coal grinding mill of the prior coal fired boiler generating set, and superheated steam which has done partial work is extracted from an steam turbine and used as a drying medium, moisture contained in the coal powder is evaporated with sensible heat and latent heat of the superheated steam, water resulted from the condensation of the superheated steam is fed into a deaerator of the steam turbine via a condensate pump for recirculation. The present invention has advantages of reducing coal consumption and saving coal, recovering residual heat, reducing emission of carbon dioxide and adopting to the national industrial policy on energy saving and emission reduction.

Owner:TIANHUA INST OF CHEM MACHINERY & AUTOMATION +1

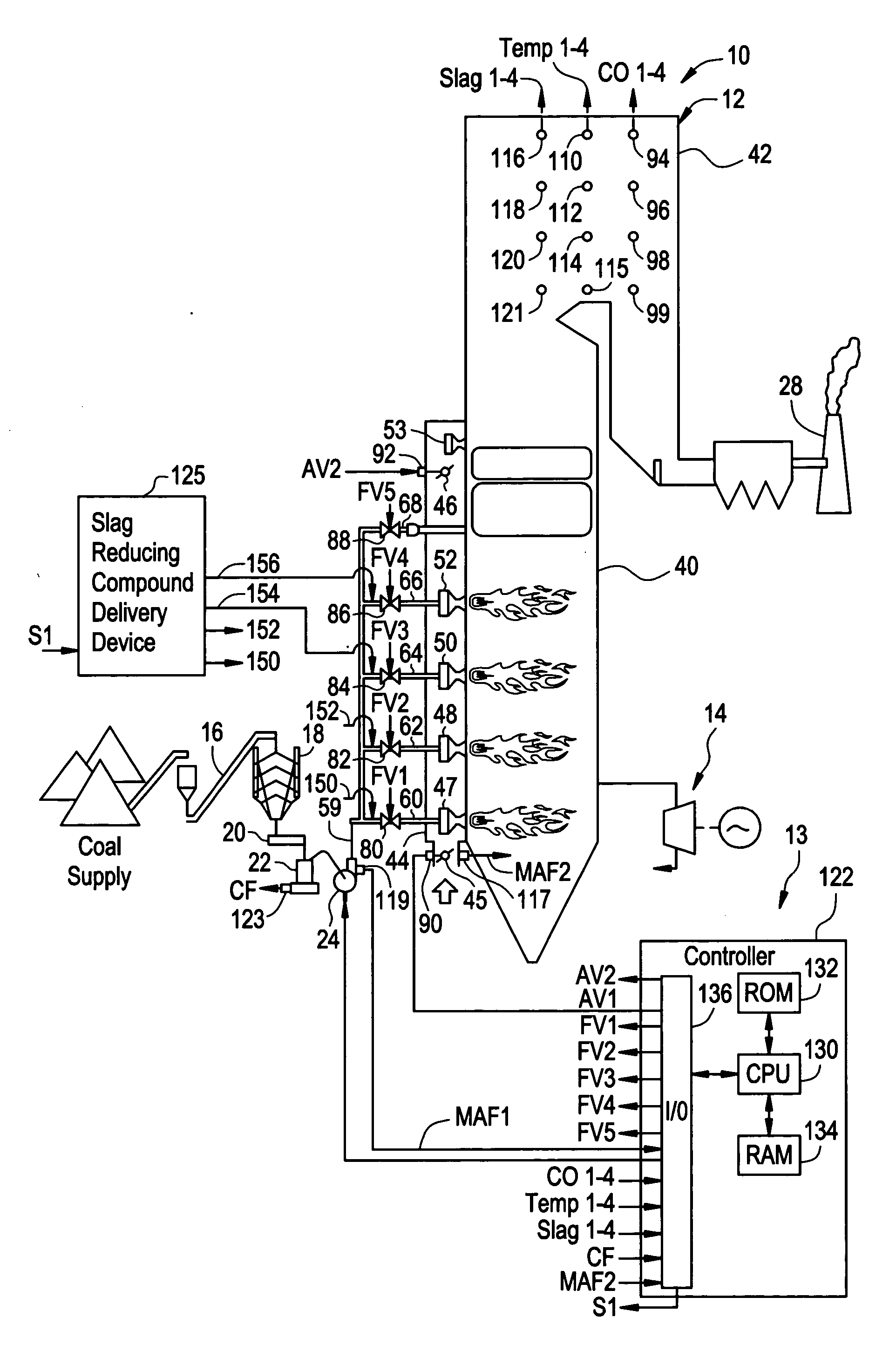

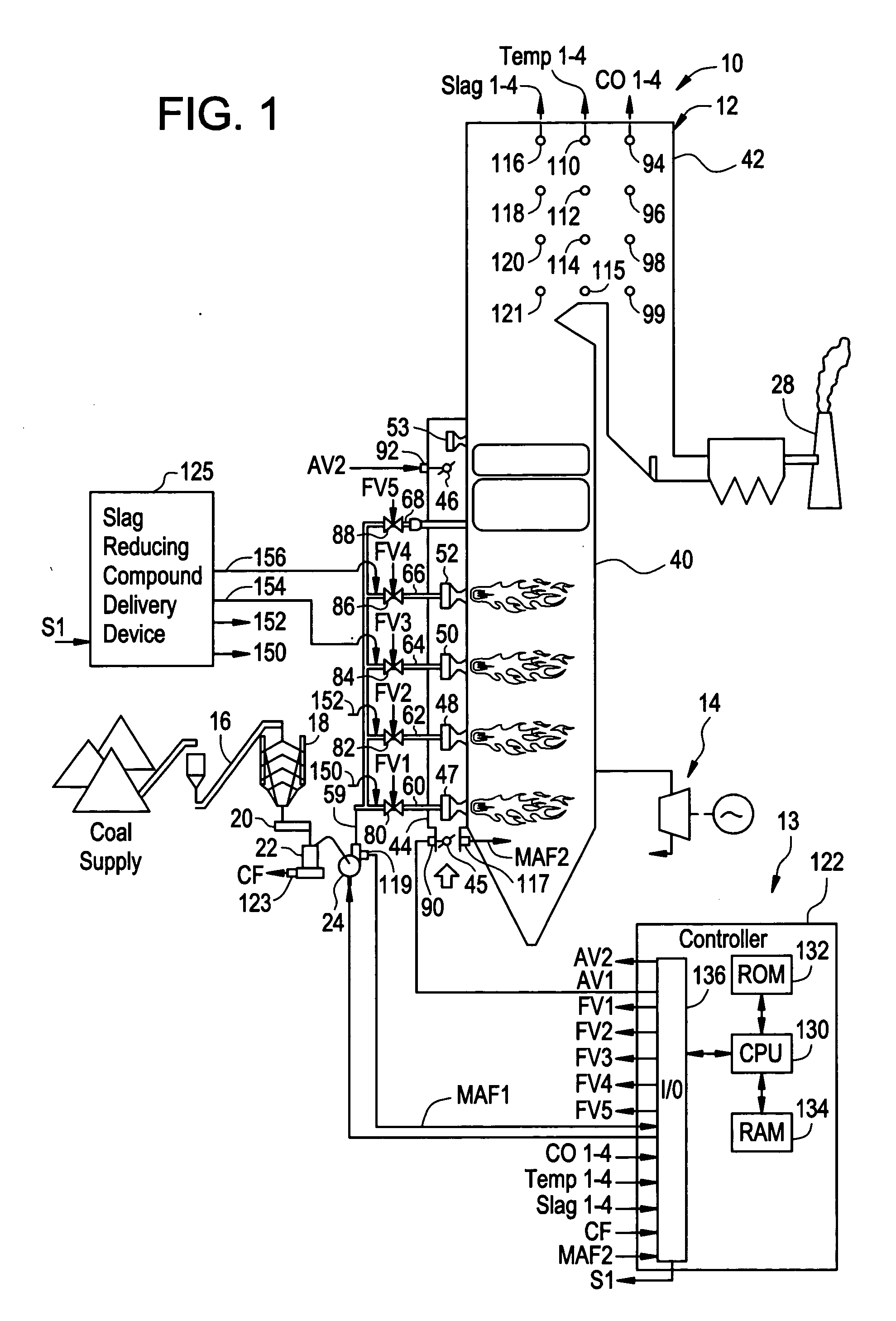

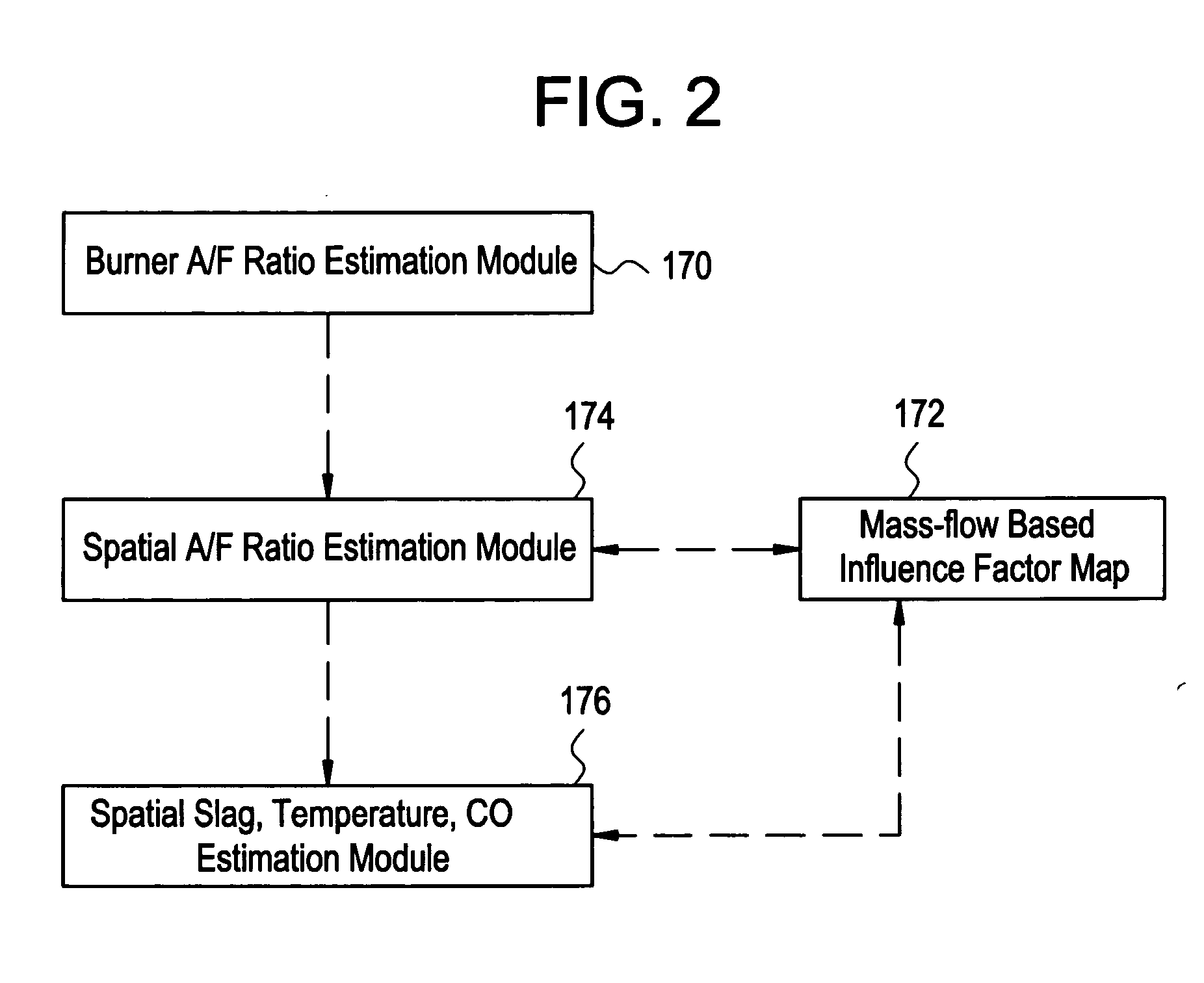

System and method for decreasing a rate of slag formation at predetermined locations in a boiler system

ActiveUS20070119351A1Reduce formation rateReduce slaggingFuel supply regulationMechanical apparatusCombustorSlag

A system and a method for decreasing a rate of slag formation at predetermined locations in a boiler system are provided. The boiler system has a plurality of burners, a plurality of slag detection sensors, a plurality of temperature sensors and a plurality of CO sensors disposed therein. The system determines locations within the boiler system that have relatively high slag thickness levels utilizing the plurality of slag detection sensors and then adjusts A / F ratios or mass flows of burners affecting those locations, or adds slag reducing additives to the burners affecting those locations, to decrease a rate of slag formation at the locations, utilizing signals from the plurality of slag detection sensor, the plurality of temperature sensors, and the plurality of CO sensors.

Owner:GENERAL ELECTRIC CO

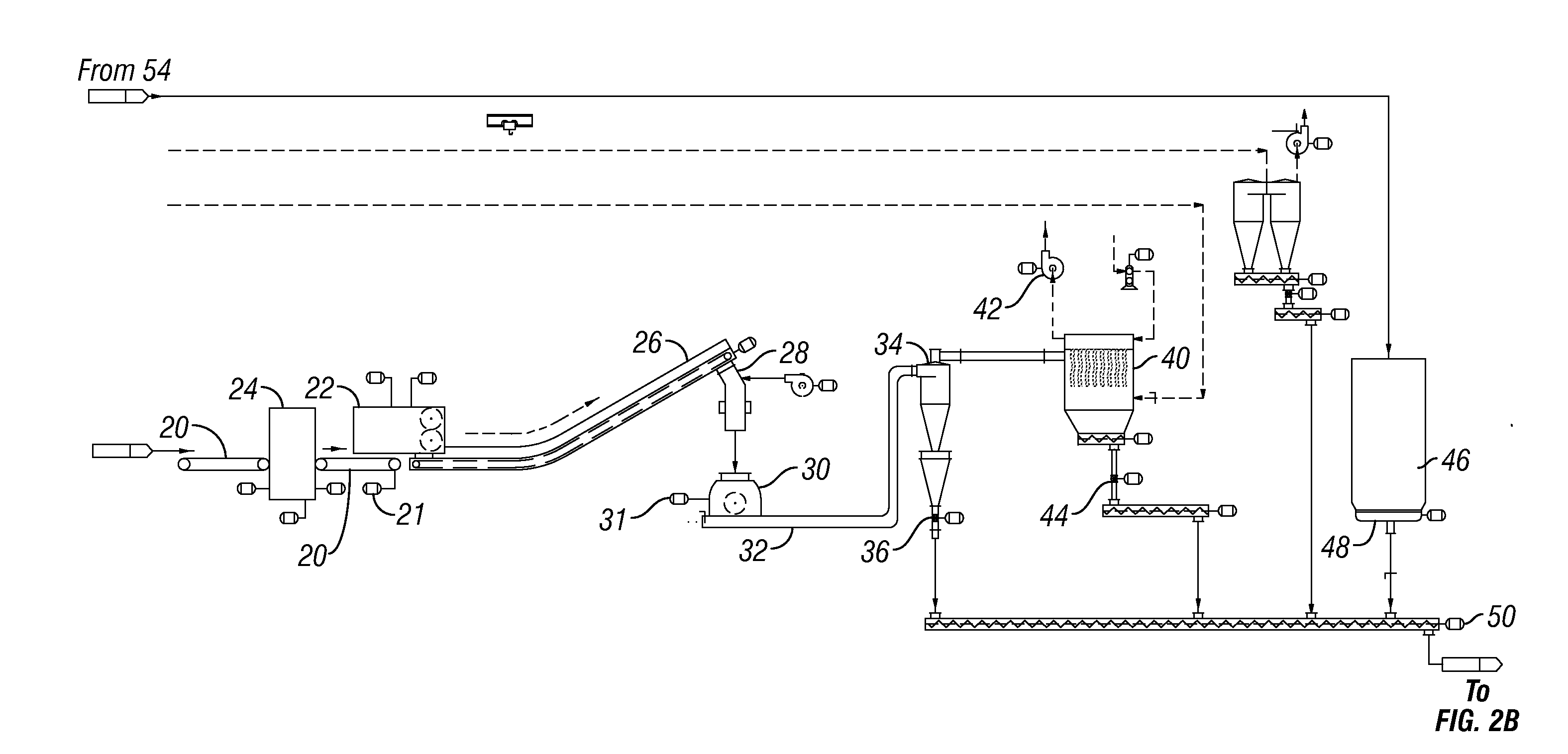

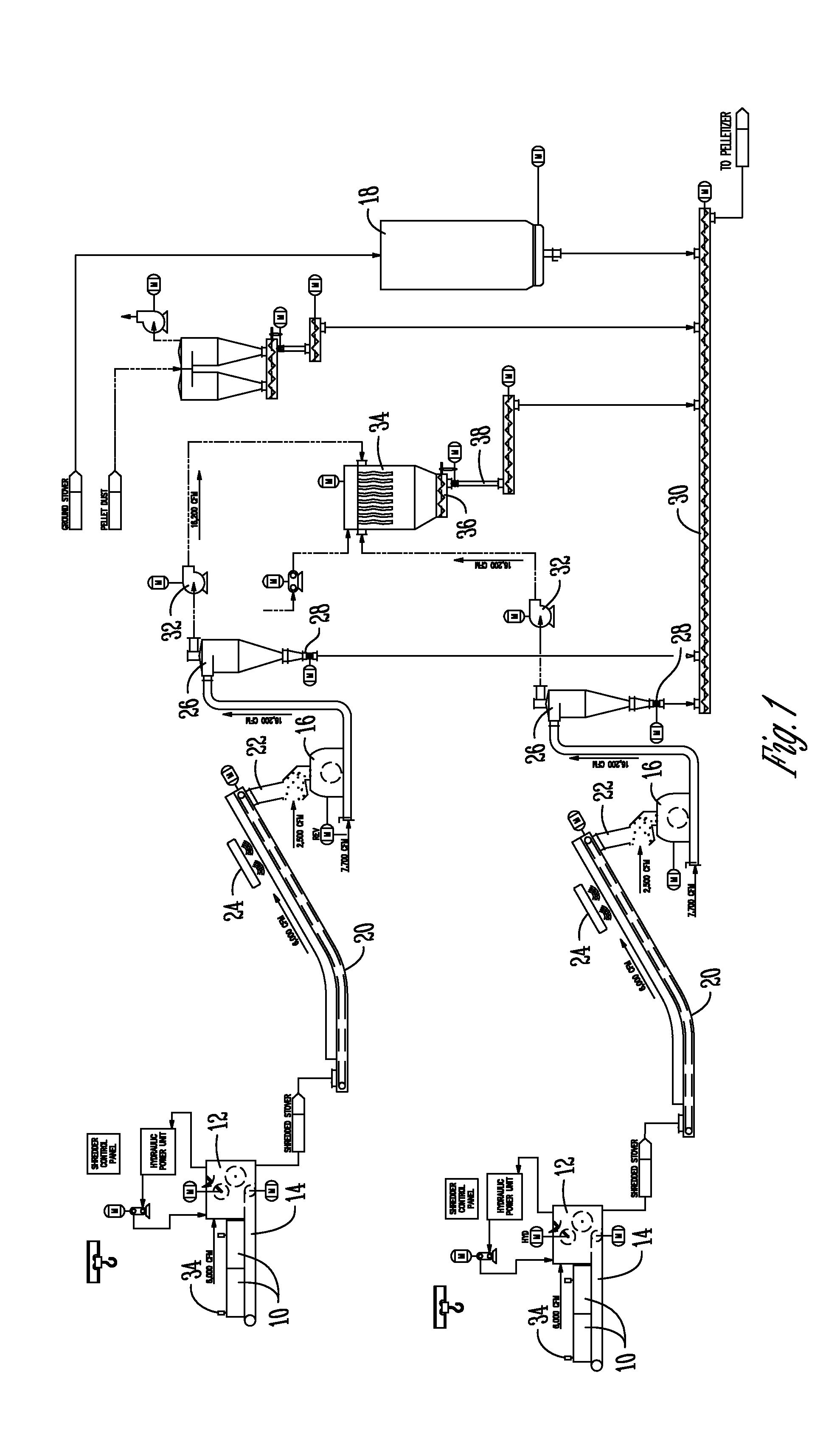

System for shredding and grinding biomass

InactiveUS20140014748A1Efficiently economically shred grindRapid and economic and sustainable developmentFuel feeding arrangementsSolid fuel pretreatmentAgricultural residuePulp and paper industry

A method and system for processing biomass material from harvest to pelletizing includes a continuous shredding stage and grinding stage to reduce the size of the material. A fan pulls air through the shredder and the grinder to assist the movement of the biomass material through the shredder and the grinder. Due to the light weight of the biomass material, the material is transported between the shredding and grinding stages mechanically and pneumatically by a combination auger with air assist. The biomass material may include agricultural residues, such as corn stover. The process and equipment eliminates or minimizes damage to the carbohydrates in the biomass so as to maintain pre-grinding cellulose and hemi-cellulose levels.

Owner:PELLET TECH USA

Technical and economic optimization of combustion, nitrogen oxides, sulfur dioxide, mercury, carbon dioxide, coal ash and slag and coal slurry use in coal fired furnaces/boilers

InactiveUS20080213146A1High capital costMinimal equipment costNitrogen compoundsUsing liquid separation agentParticulatesWater use

Improvements in methods by which new or used coal fired boilers whether designed for coal or oil or natural gas firing can substantially improve their technical operation and reduce their capital and operating costs by implementing process steps that (a) minimize the adverse impacts of coal ash and slag on boiler surfaces and particulate emissions, which will improve coal combustion efficiency and facilitate the use of oil or gas designed boilers for coal firing, (b) drastically reduce the loss of water used to transport coal in slurry form to power plants, (c) minimize the combined total nitrogen oxides (NOx), sulfur dioxide (SO2), mercury (Hg), and carbon dioxide (CO2) emissions, (d) separate and permanently sequester carbon dioxide and (e) improve the coal and solid fuel combustion efficiency. In the method includes whereby slag formed from solid fuel ashes during combustion in boilers or furnaces is suppressed by introducing additional air in a post-primary combustion zone to lower the combustion gas temperatures below temperatures at which the ash softens or liquefies and adheres to boiler or furnace surfaces.

Owner:ZAUDERER BERT

Installation for drying organic matter

ActiveUS8561314B2Efficient heatingFast heatingDrying solid materials with heatDrying solid materials without heatLitterEngineering

An installation for drying organic matter, especially kitchen and food wastes or other biological matter, including matter that contains packaging residues, napkins, straws or the like. The installation comprises the following components: (a) a vacuum mixer (M) having a closable charging opening for introducing the organic matter and a closable discharge opening, disposed at the bottom or laterally towards the bottom, for the dried matter, (b) at least one vacuum pump (VP) for evacuating the air in the mixer to generate the vacuum, the pump being connected to at least one evacuation tube mounted above the maximum filling level in the housing of the mixer (M), (c) a heater (H) for heating the organic matter, (d) at least one condenser (K), connected to the air evacuation duct (AL) of the vacuum pump (VP) and having a cooling unit (KA) connected thereto to condense the evacuated air, and (e) a discharge duct (AW) for the condensate obtained from the evacuated air by cooling in the condenser (K).

Owner:INOTEC MASCHENENTWICKLUNG & VERTRIEB

Chemical change agent

InactiveUS7862630B2Easy to identifyHigh strengthNitrogen compoundsSolid fuel pretreatmentCombustionCoal

The present invention relates to an improved chemical change reagent which is used as an additive to coal to enhance the complete combustion of the coal after turning it into a synthetic fuel. The composition is a chemical change agent in that it converts the coal / composition mix into a different material which, when burned, results in lower NOx emissions. The composition includes a wax, a base for ph adjustment and water and is mixed with the coal prior to combustion.

Owner:STATE LINE HLDG

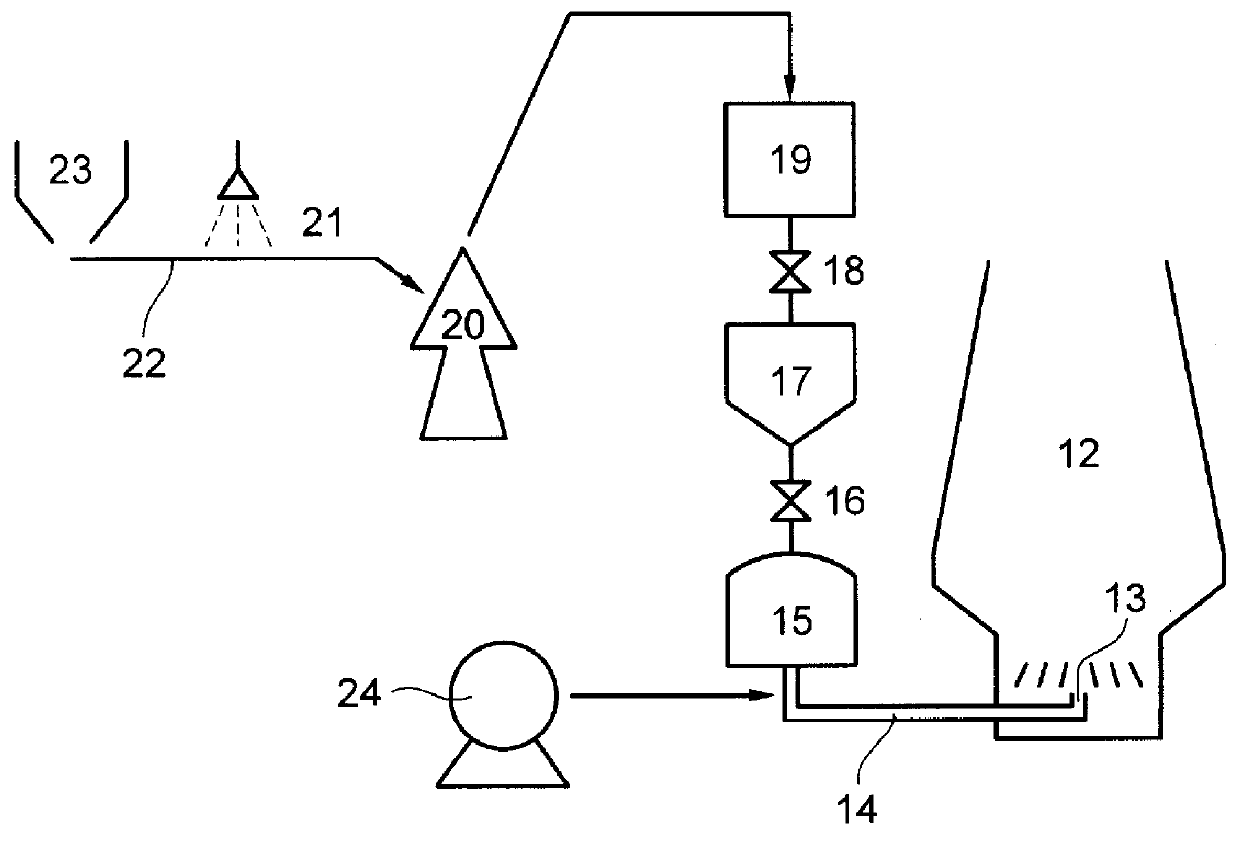

Reducing sulfur dioxide emissions from coal combustion

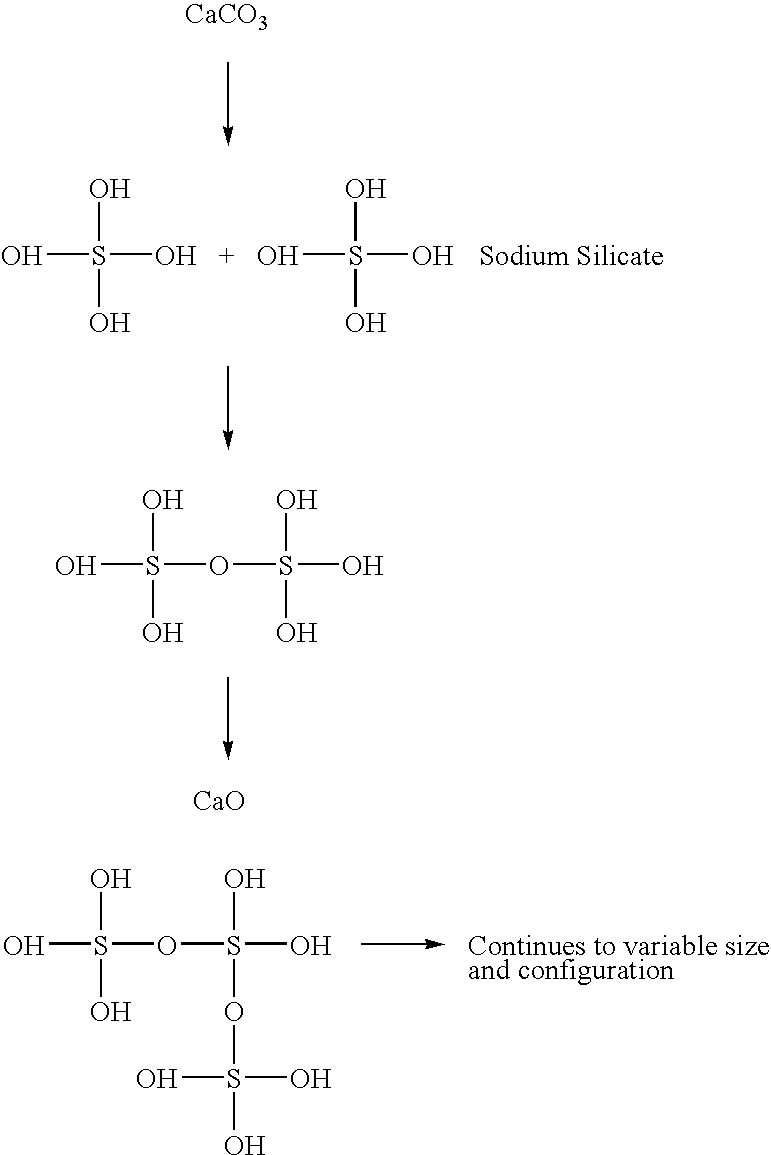

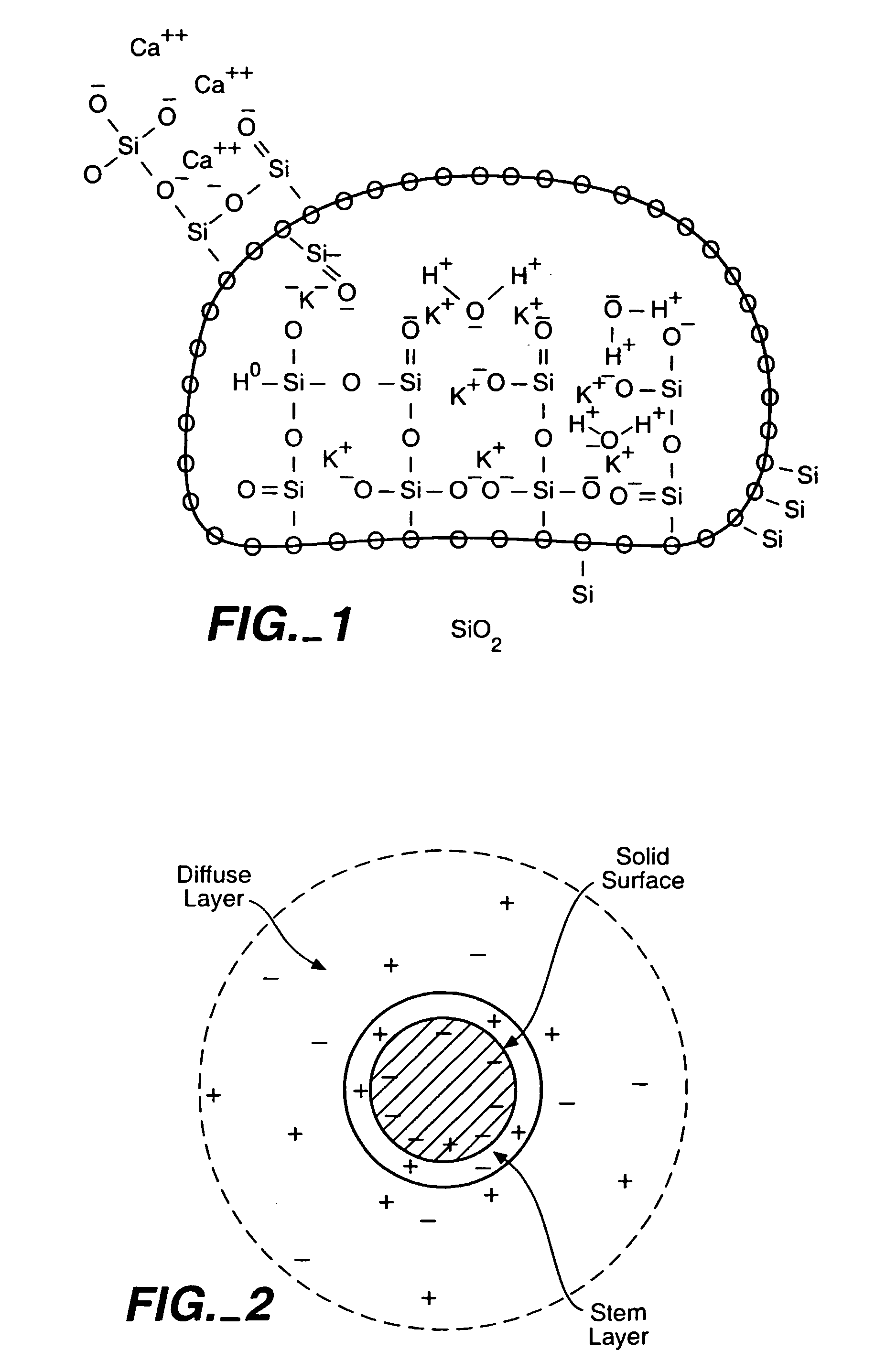

A process of treating high sulfur coal to reduce sulfur dioxide emission when the high sulfur coal is burned comprising placing coal in pressure tank (16) of reduced pressure pressure sufficient to fracture a portion of the coal by withdrawing ambient fluids trapped within the coal. The fractured coal is contacted with an aqueous silica colloid composition supersaturated with calcium carbonate via conduit (21), and the majority of the aqueous composition is then removed from contact with the coal. The aqueous composition-treated coal is pressurized in pressure tank (16) under a carbon dioxide atmosphere for a period of time sufficient for the calcium carbonate to enter fractures in the coal produced in the first step.

Owner:DEMETER SYST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com