Chemical change agent

a technology of chemical change agent and additive composition, which is applied in the direction of solid fuel pretreatment, lighting and heating apparatus, separation processes, etc., can solve the problems that the environment for driesing coal before burning the use of high volume coal is not suitable for the use of technology, so as to facilitate complete combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

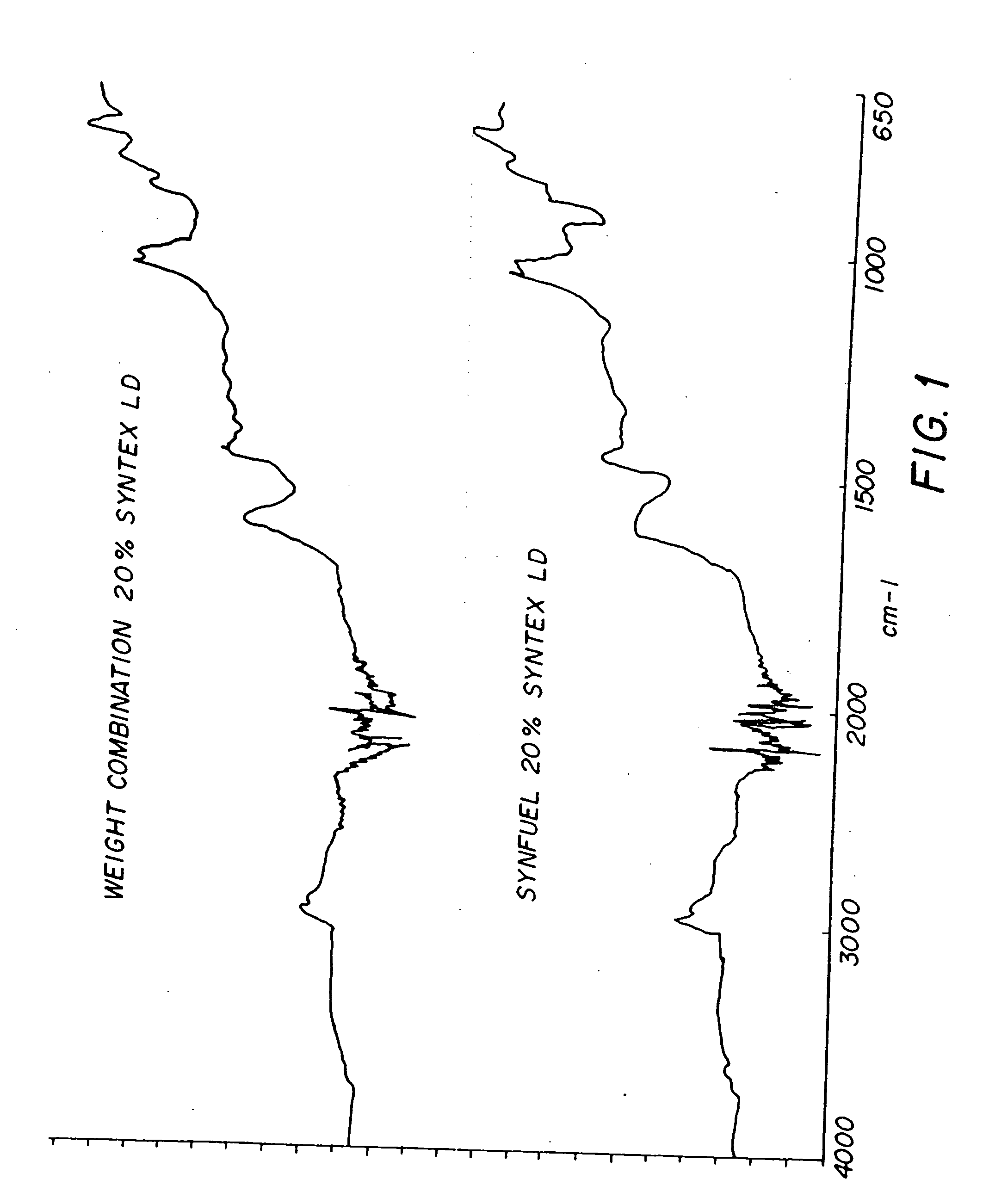

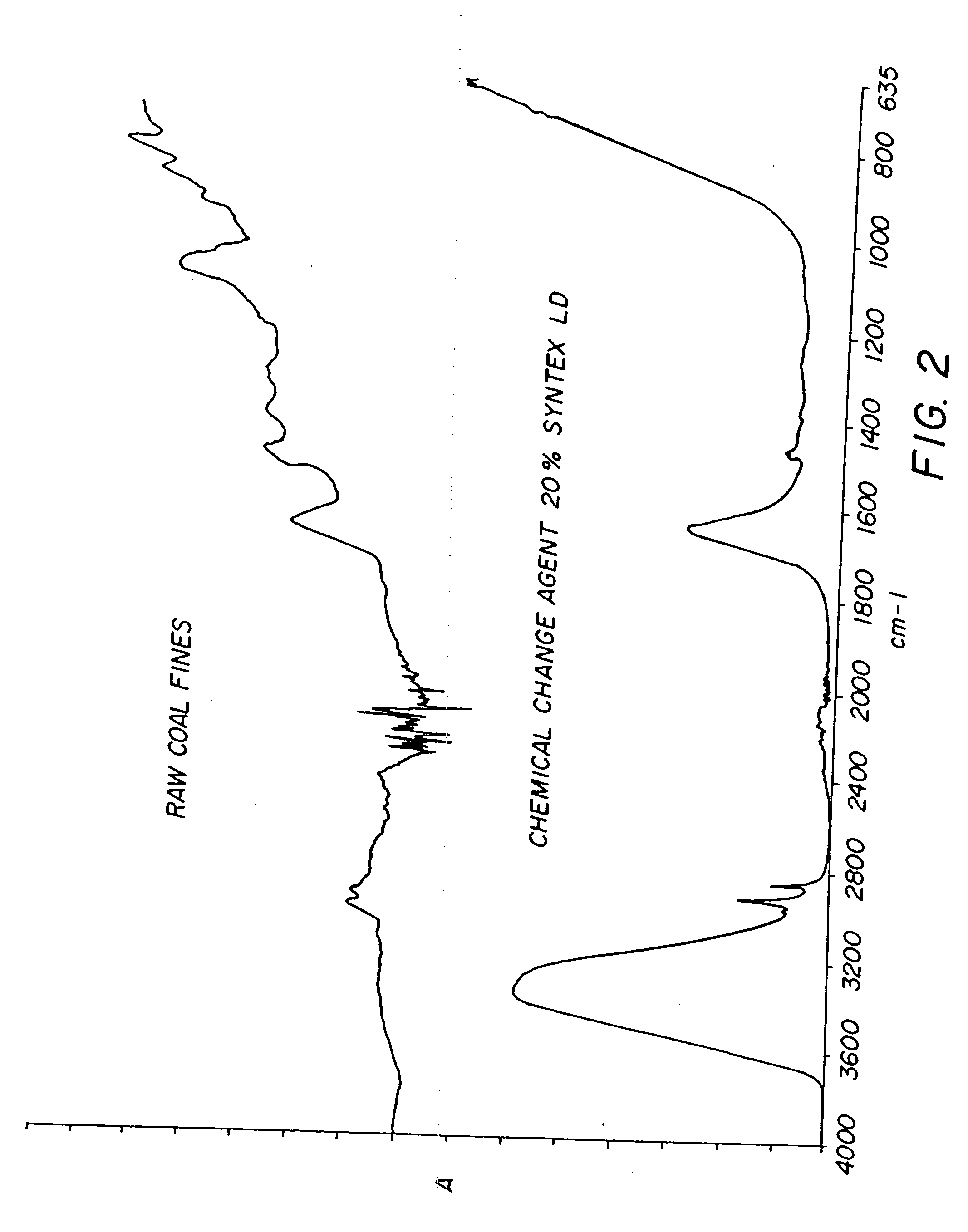

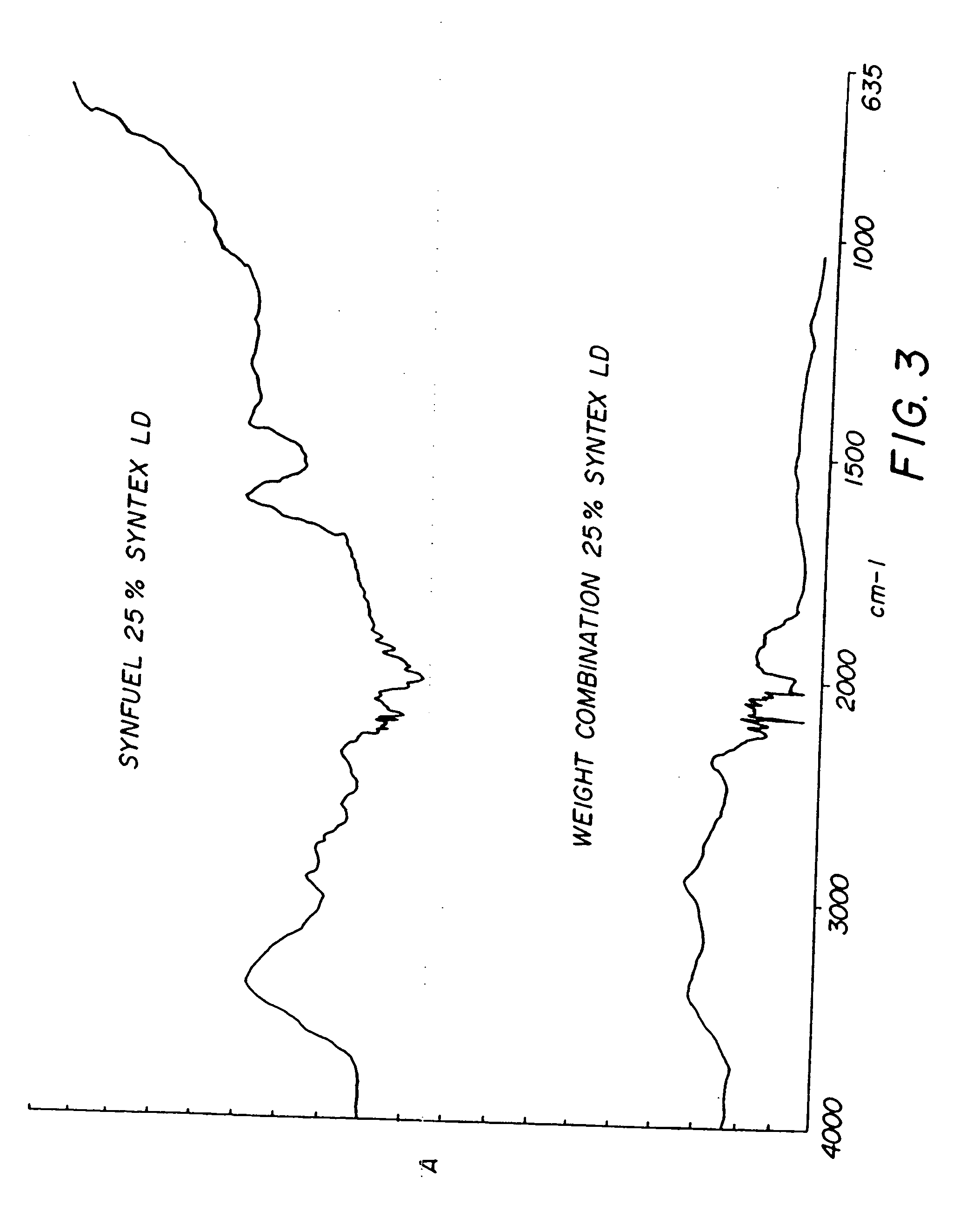

Image

Examples

Embodiment Construction

OF USE

[0015] In addition, this invention seeks to show the applicability of urea to chemical change agents as well as ammonia additives. It illustrates applicability of urea to the fuel itself and not to the flue gases which has been an approach used by industry. The invention also seeks to show that other additives besides titanium dioxide can be used as a chemical change agent and / or as a NOX reduction agent without being a chemical change agent. The invention shows a low NOX formulation which includes urea. It also shows different ways to use titanium dioxide and urea as each works at different temperature ranges to effect NOX reduction and could be said to complement each other.

PRIOR ART

[0016] There is no existing prior art so far as the inventor hereof is aware. There have been fatty acids used in making wax emulsions for the purpose of sealing them against liquid water. There may have been some experimentation with using urea in flue gases to reduce NOX and SOX but applicant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com