Fuel injection method for dual-fuel engine

A dual-fuel engine and fuel injection technology, which is applied in the directions of fuel injection control, engine control, machine/engine, etc., can solve the problems that the power, economy and emission performance of dual-fuel engines cannot be ensured at the same time, and achieve improved economical and Power performance, good combustion and emissions, the effect of improving power performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

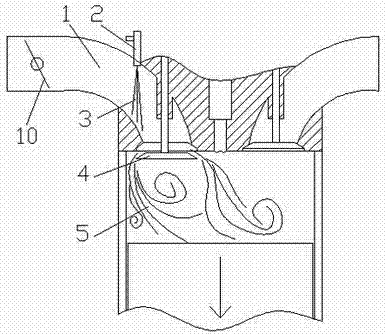

[0023] Such as figure 1 As shown, in the intake stroke, the intake port in the intake port 1 is injected by the pilot fuel nozzle 2 to inject the pilot fuel 3, and enters the cylinder with the air to form the port injection of a mixture 5 of the pilot fuel and air.

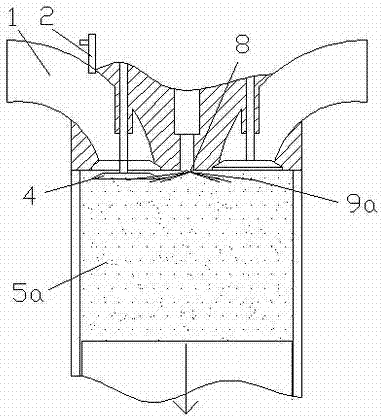

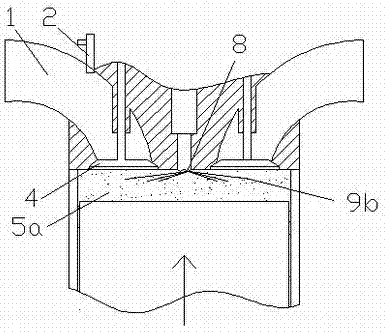

[0024] Such as figure 2 with image 3 As shown, the port injection of the mixture 5 of pilot fuel and air diffuses under the action of the airflow in the cylinder to form a more uniform lean combustible mixture 5a in the cylinder. The pilot fuel nozzle 8 in the cylinder can be exhausted. After the valve is closed, the pilot fuel is injected to the top dead center of the compression stroke, which can form a richer combustible mixture in the upper part of the cylinder close to the fuel injection nozzle 6.

[0025] Such as Figure 4 As shown, at the end of the compression stroke, the fuel injector 6 injects the pilot fuel beam 7 to ignite the combustible mixture near the fuel injector, and the resulting turbulent combusti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com