Patents

Literature

914 results about "Isobutanol" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Isobutanol (IUPAC nomenclature: 2-methylpropan-1-ol) is an organic compound with the formula (CH₃)₂CHCH₂OH (sometimes represented as i-BuOH). This colorless, flammable liquid with a characteristic smell is mainly used as a solvent either directly or as its esters. Its isomers, the other butanols, include n-butanol, 2-butanol, and tert-butanol, all of which are important industrially.

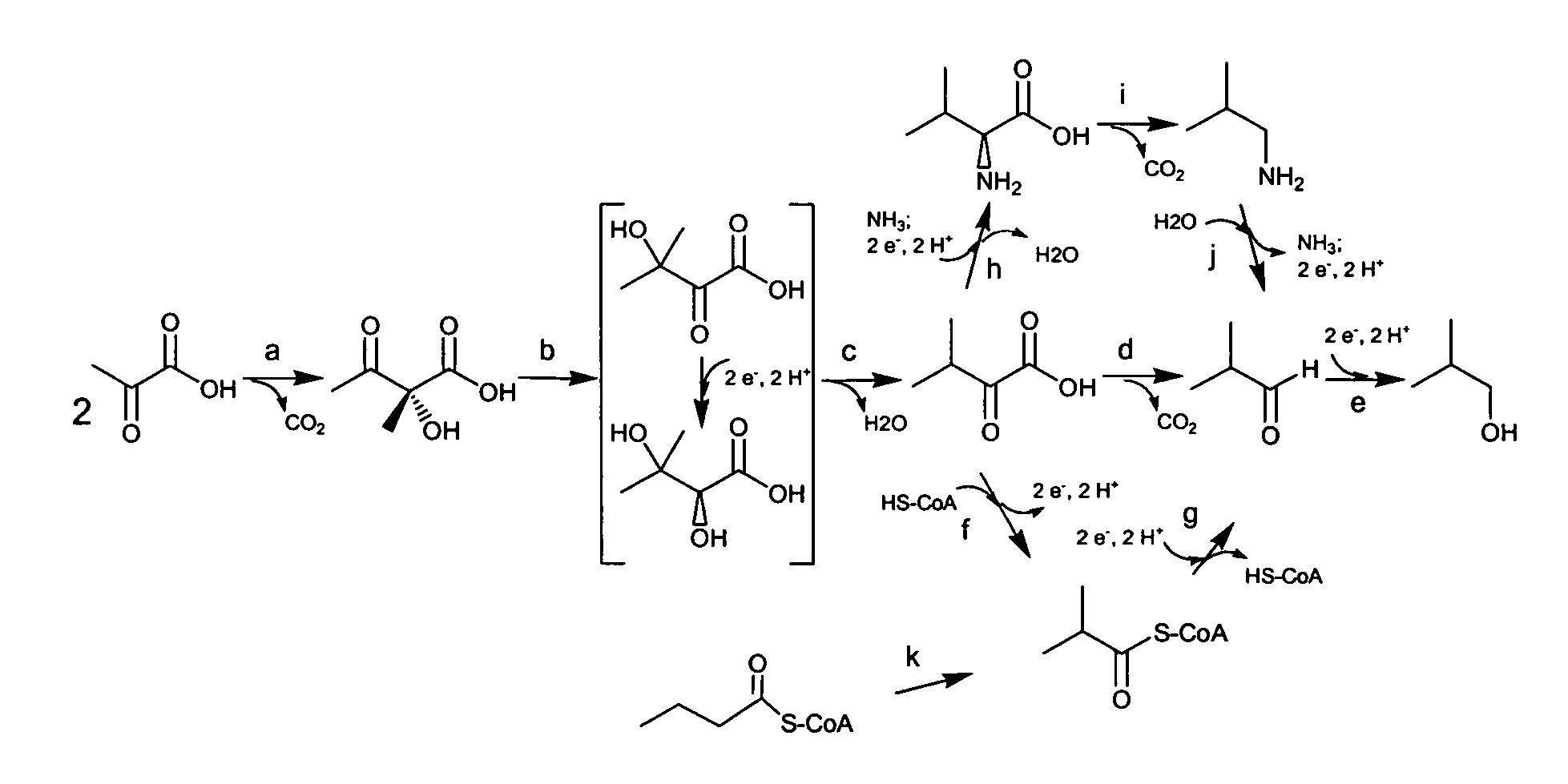

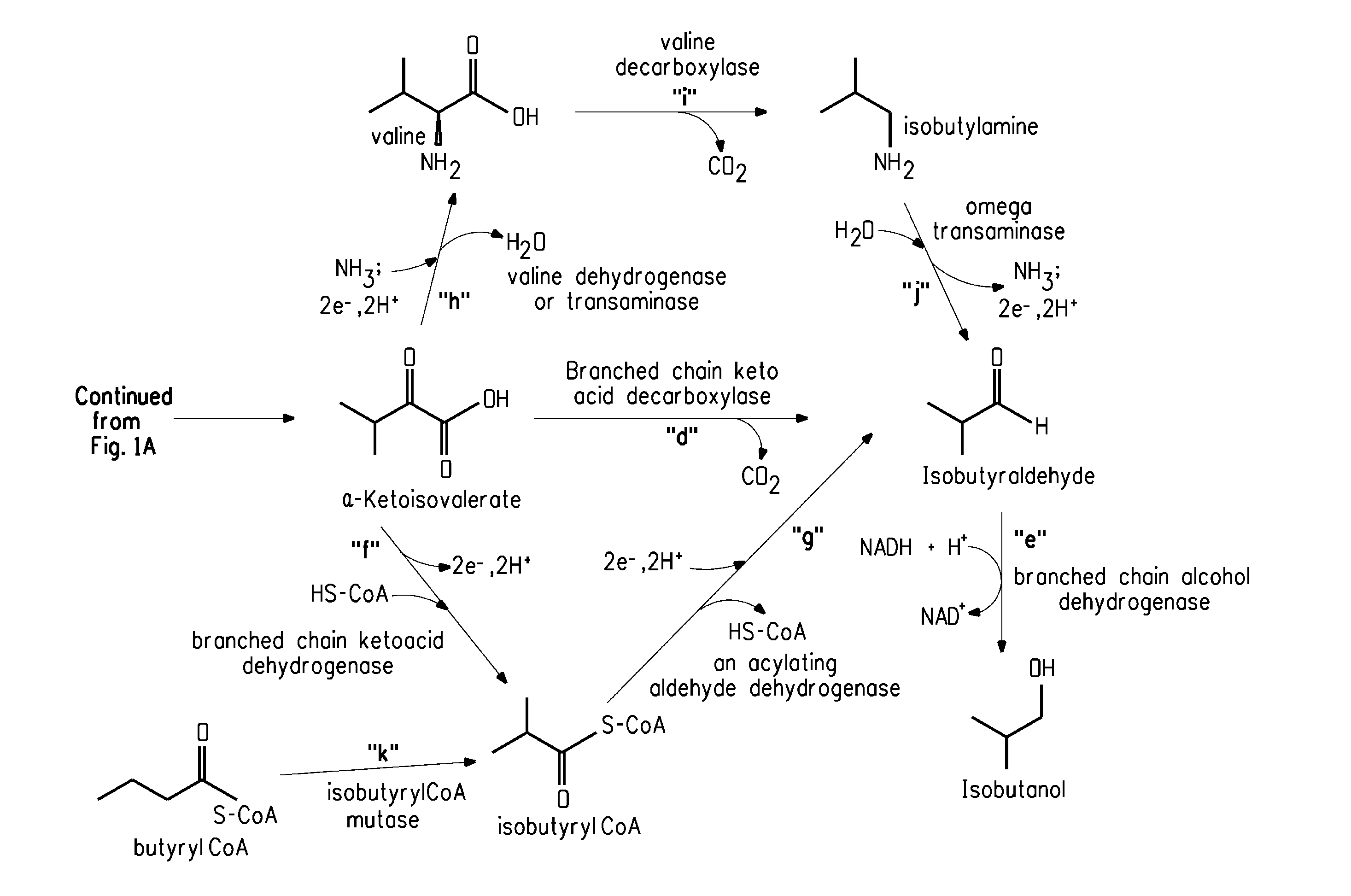

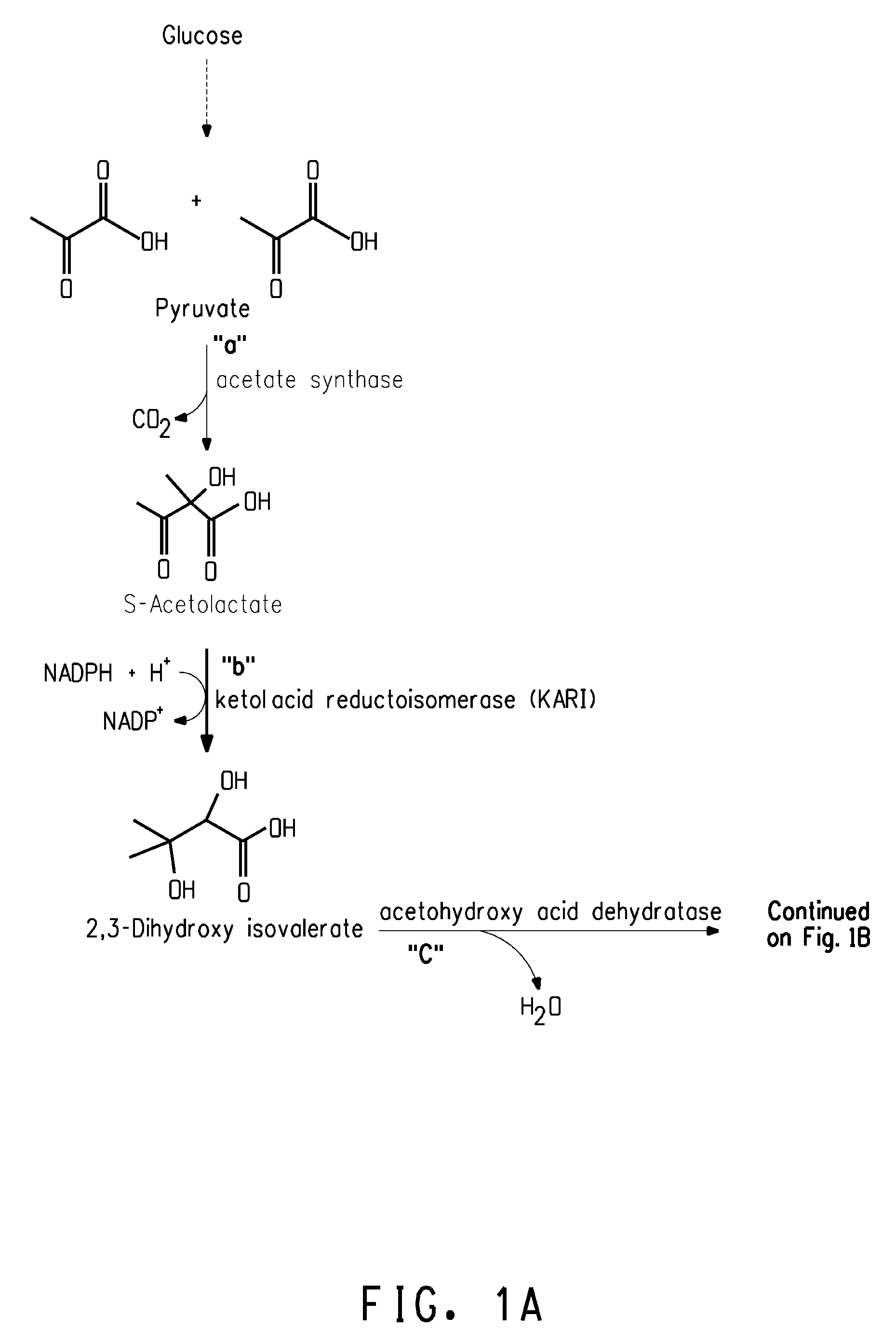

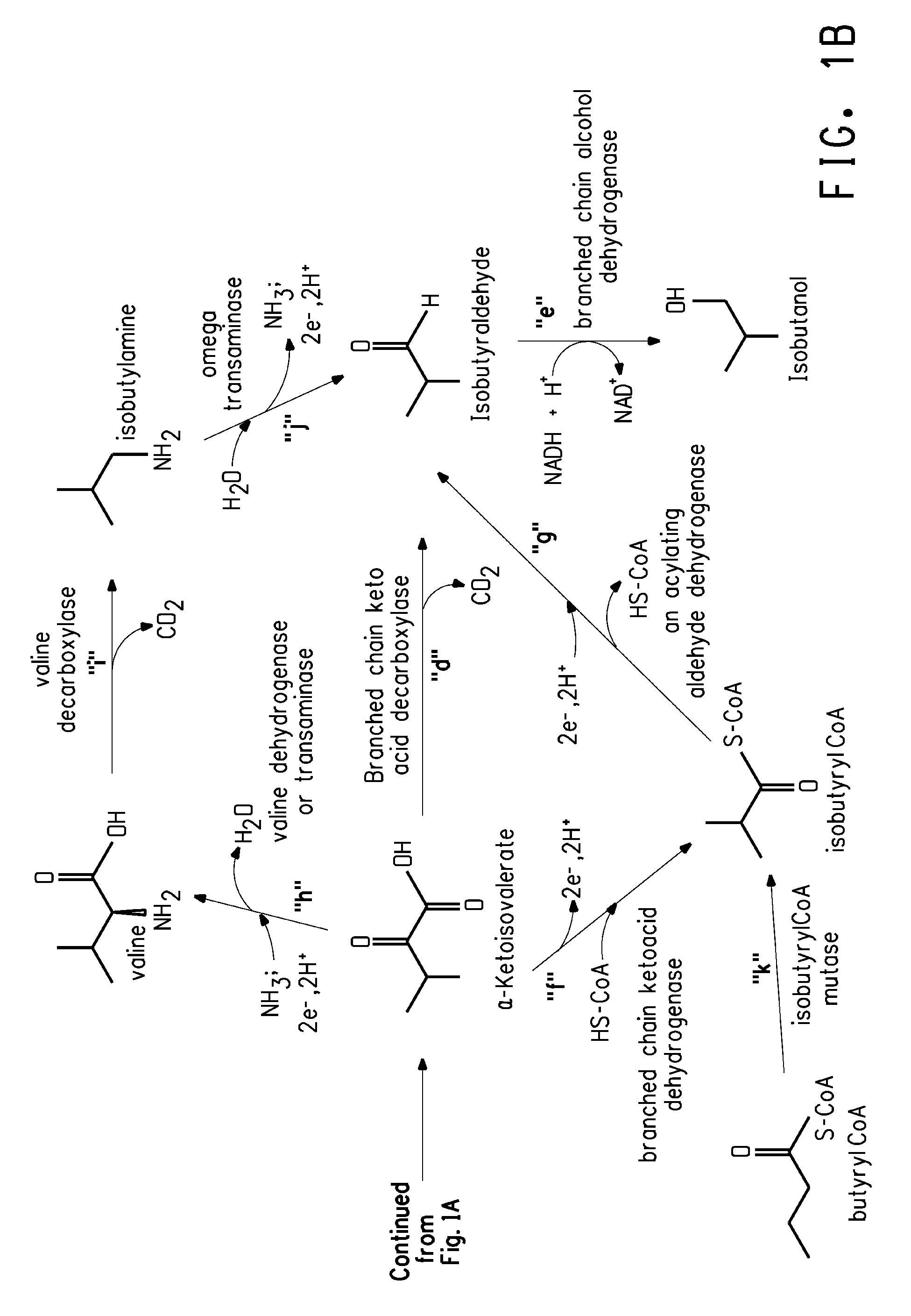

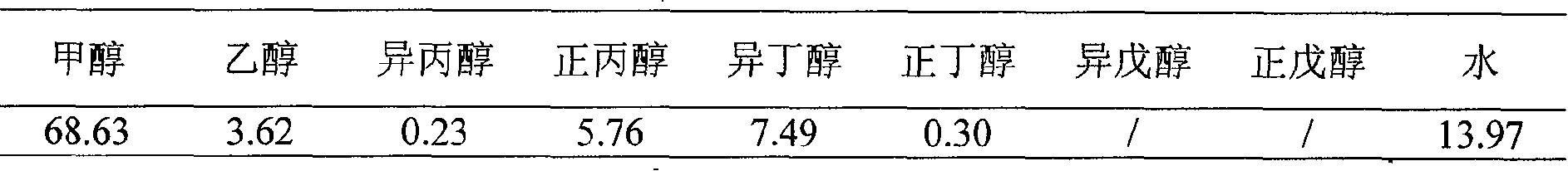

Fermentive production of four carbon alcohols

Owner:GEVO INC

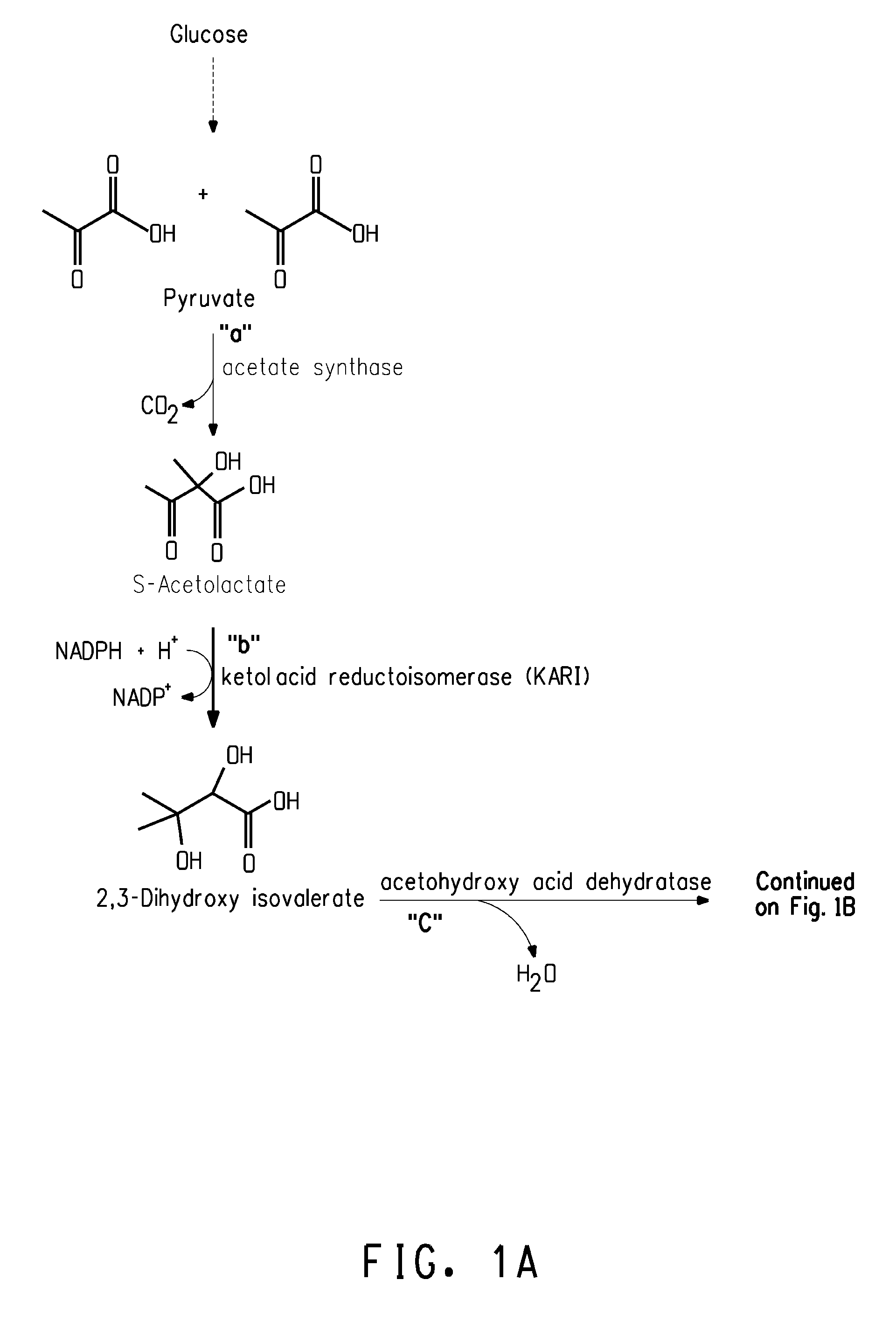

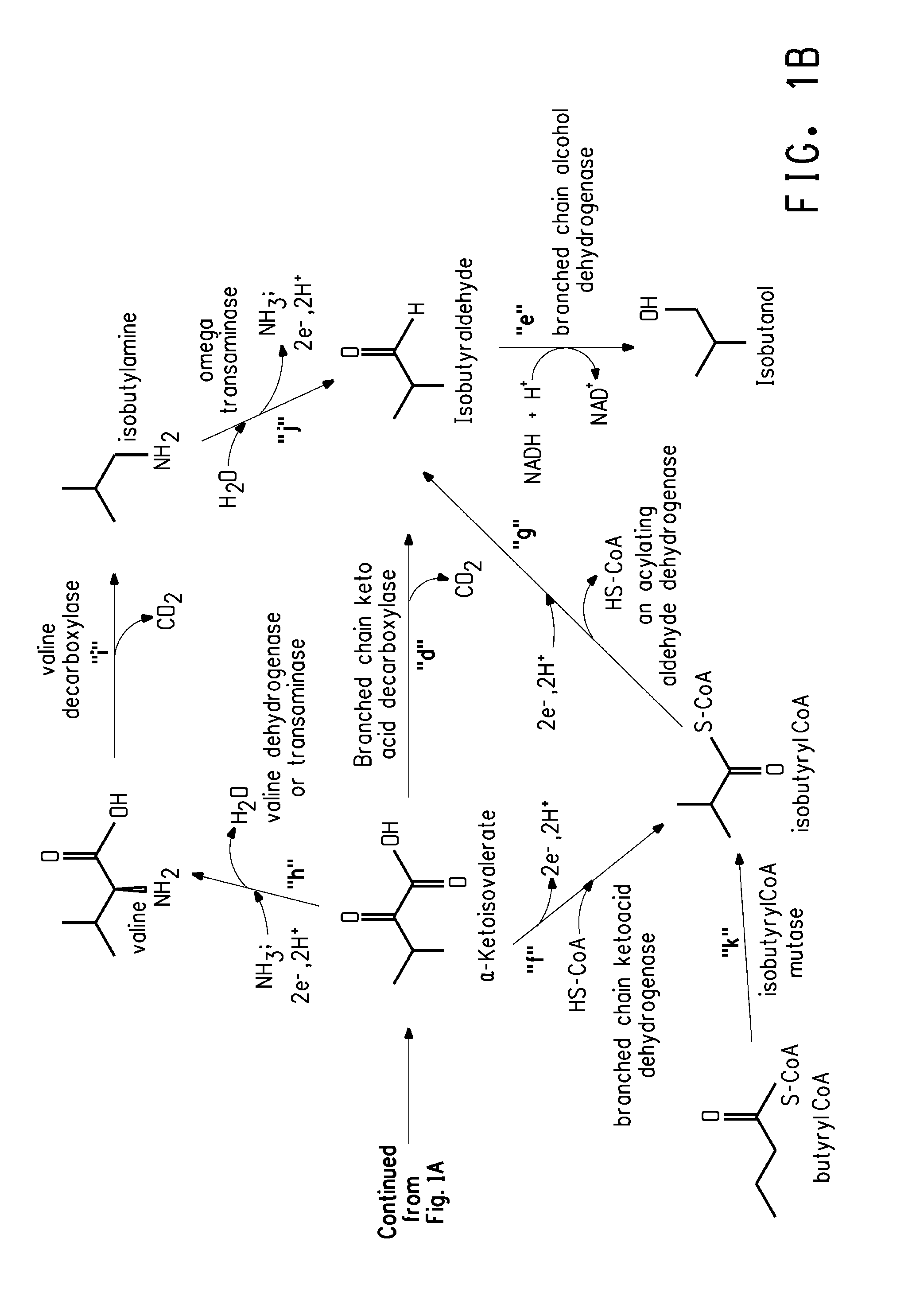

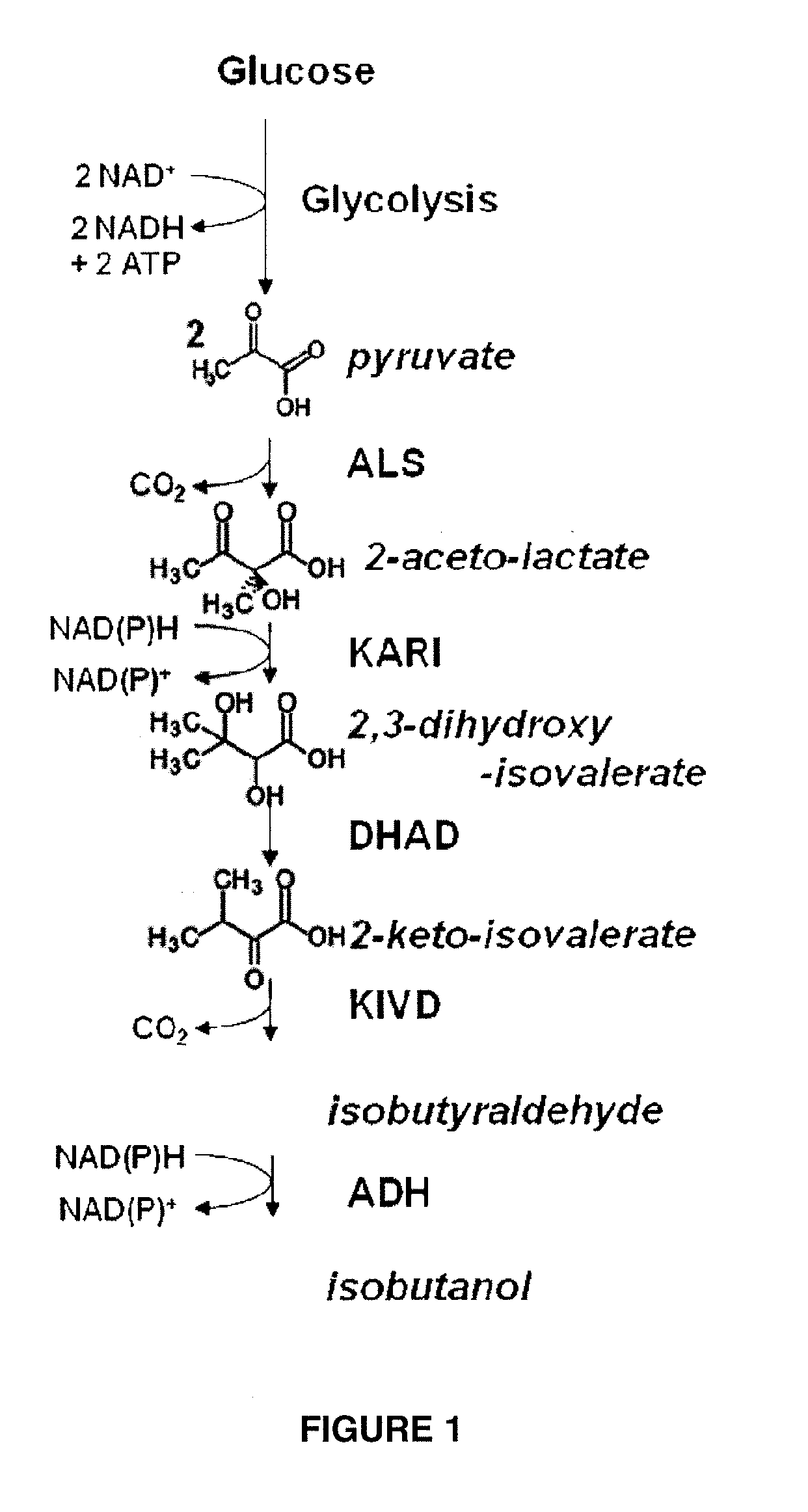

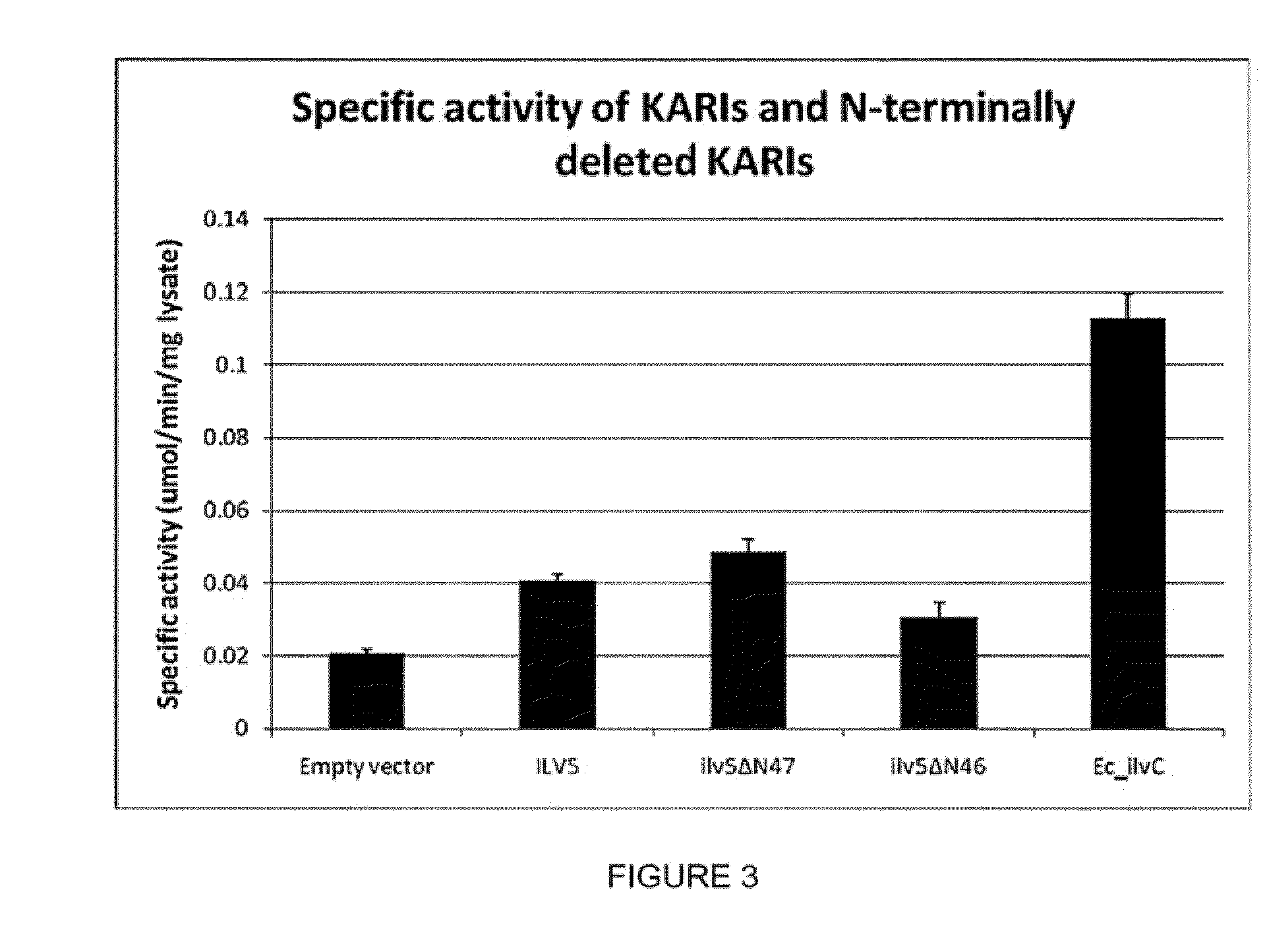

Fermentive production of isobutanol using highly active ketol-acid reductoisomerase enzymes

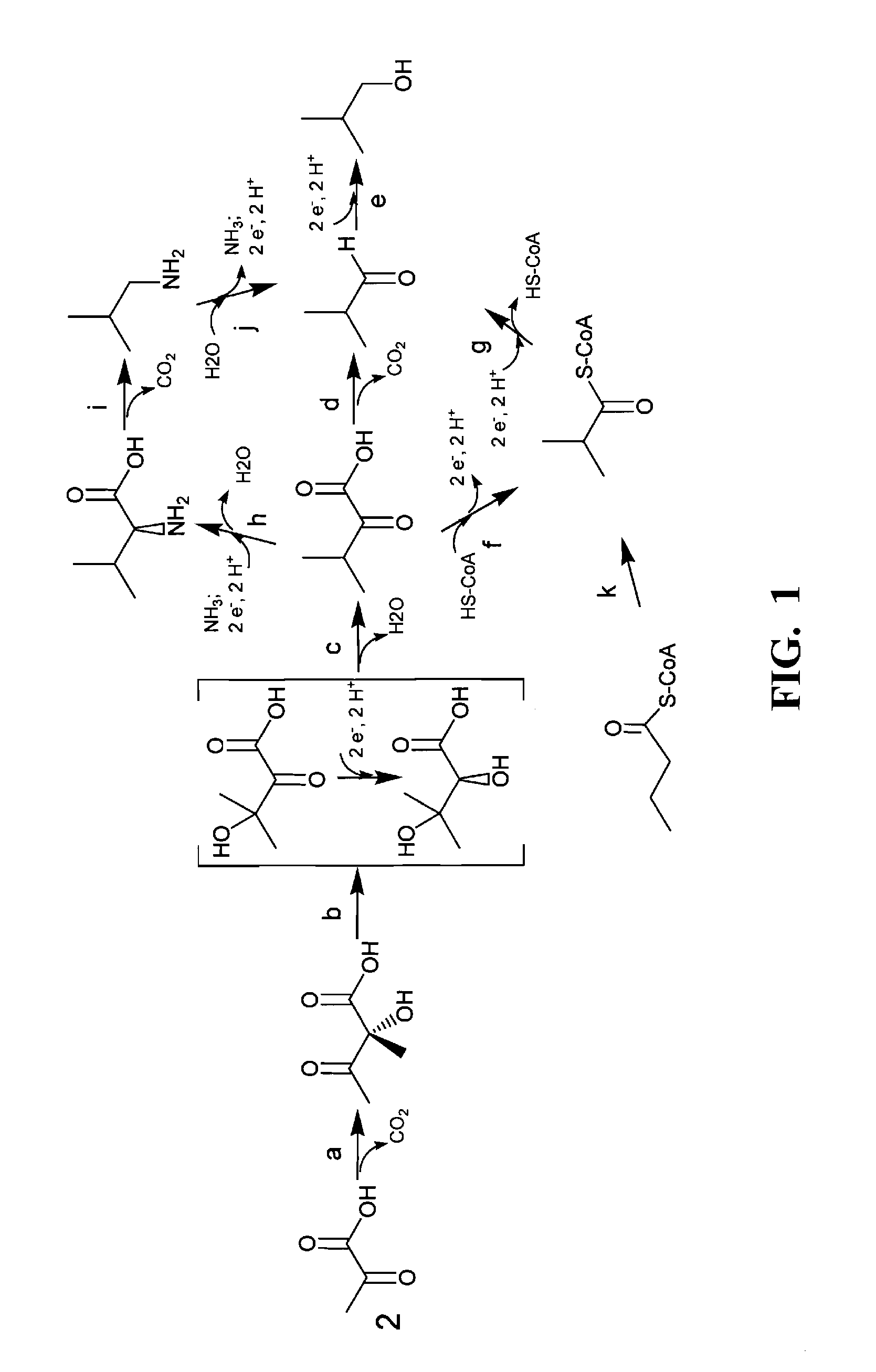

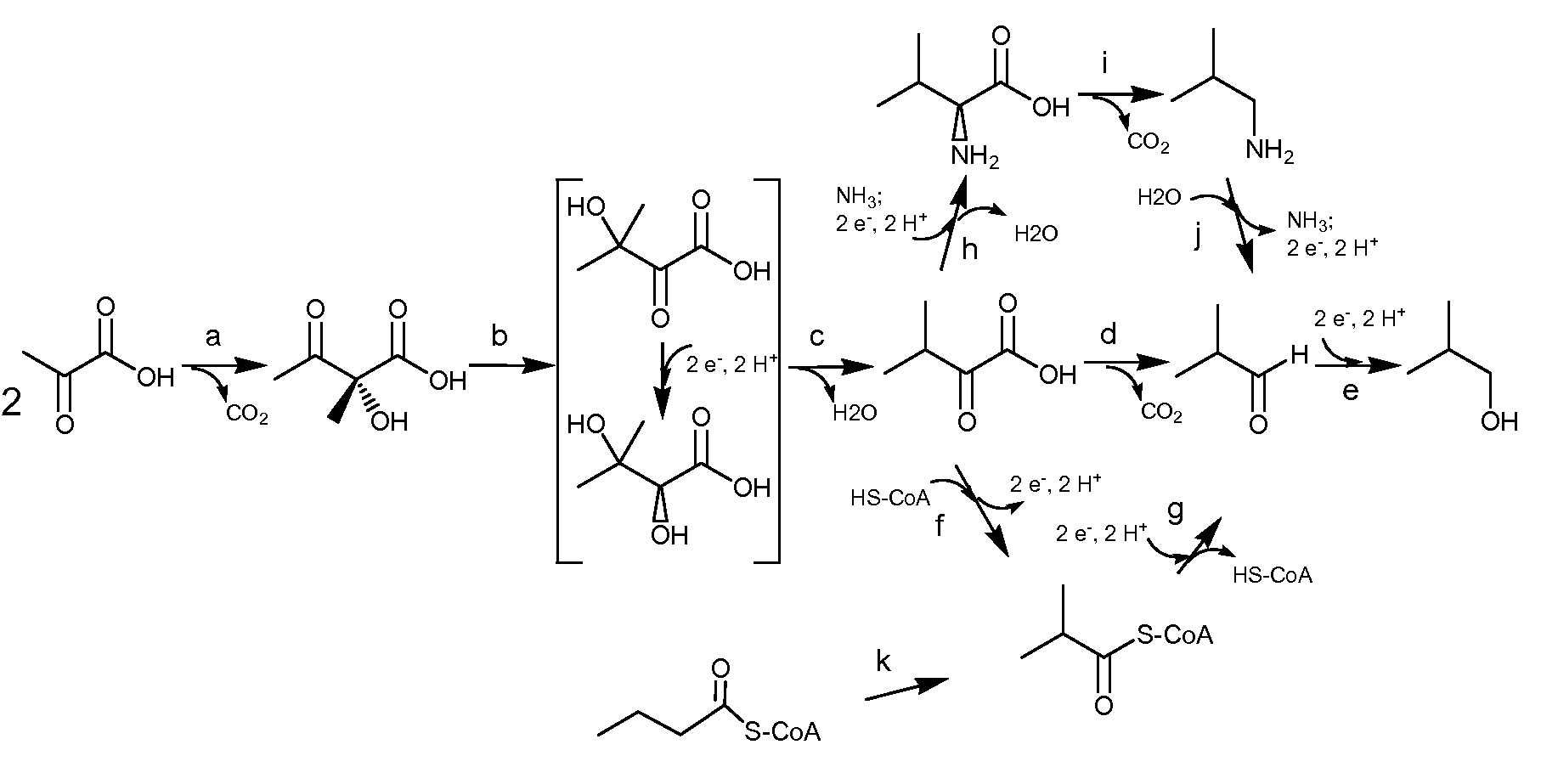

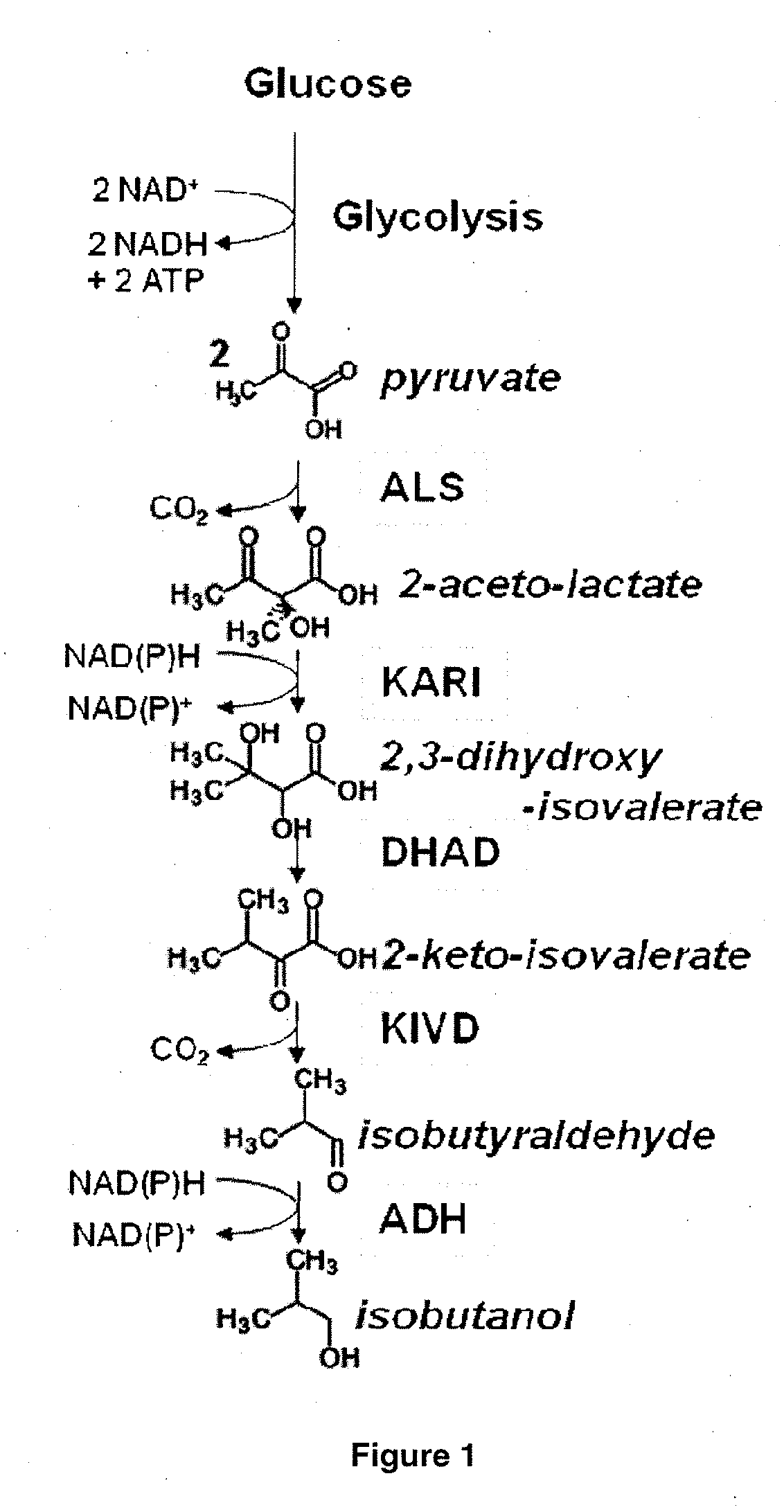

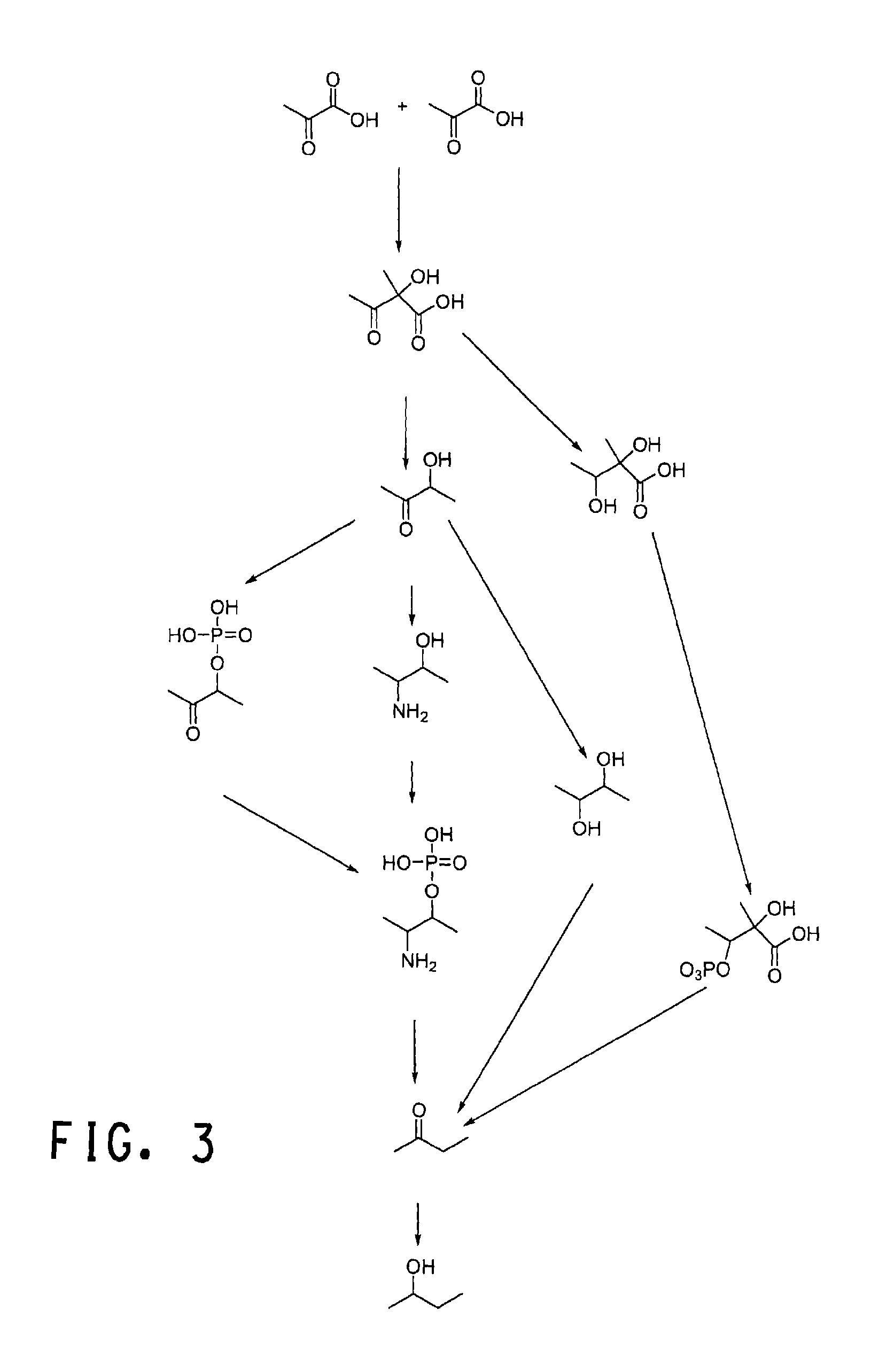

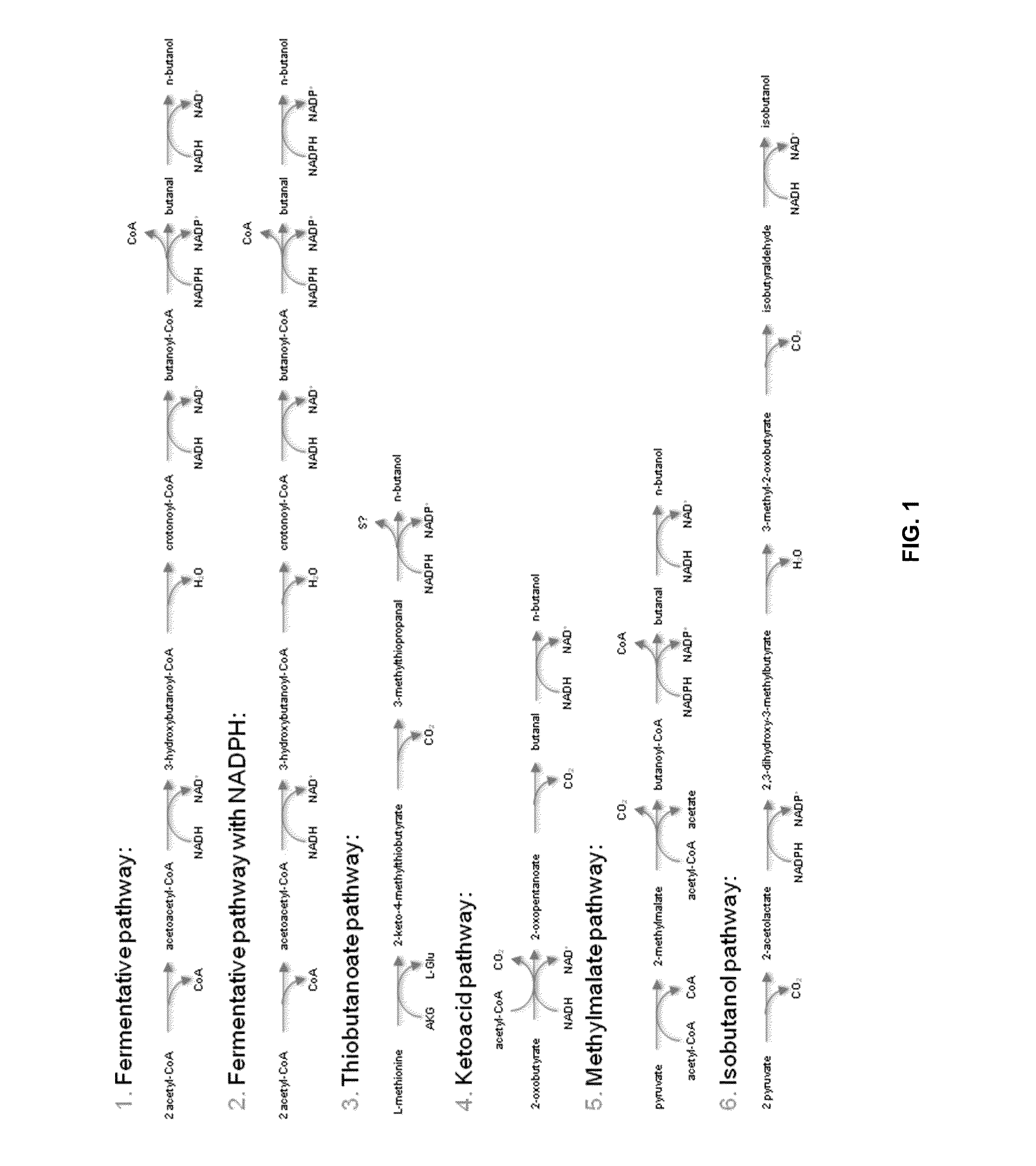

Methods for the fermentative production of isobutanol is provided by the fermentative growth of a recombinant microorganism expressing a highly active ketol-acid reductoisomerase enzyme in addition to other enzymes required for conversion of glucose to isobutanol.

Owner:GEVO INC

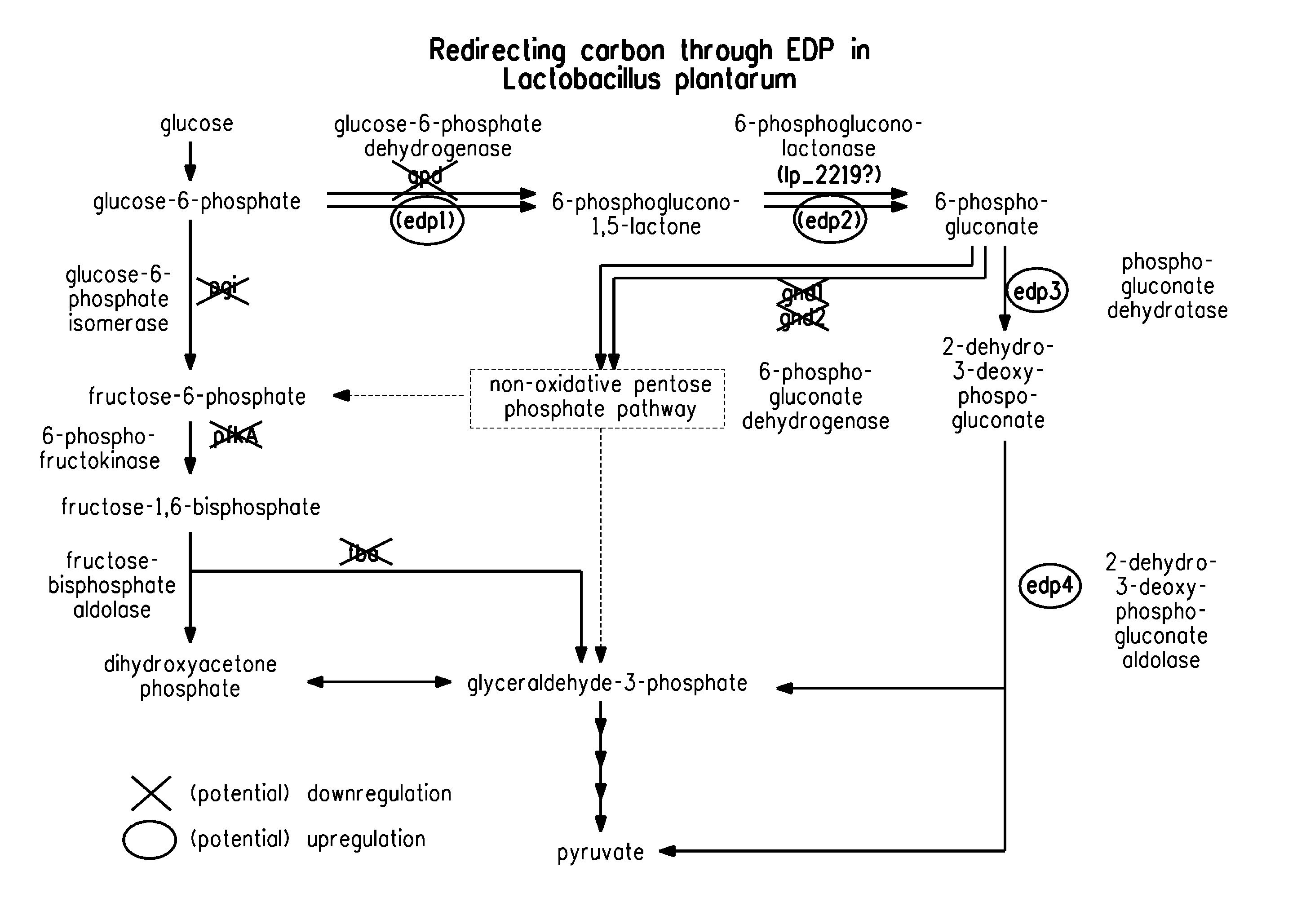

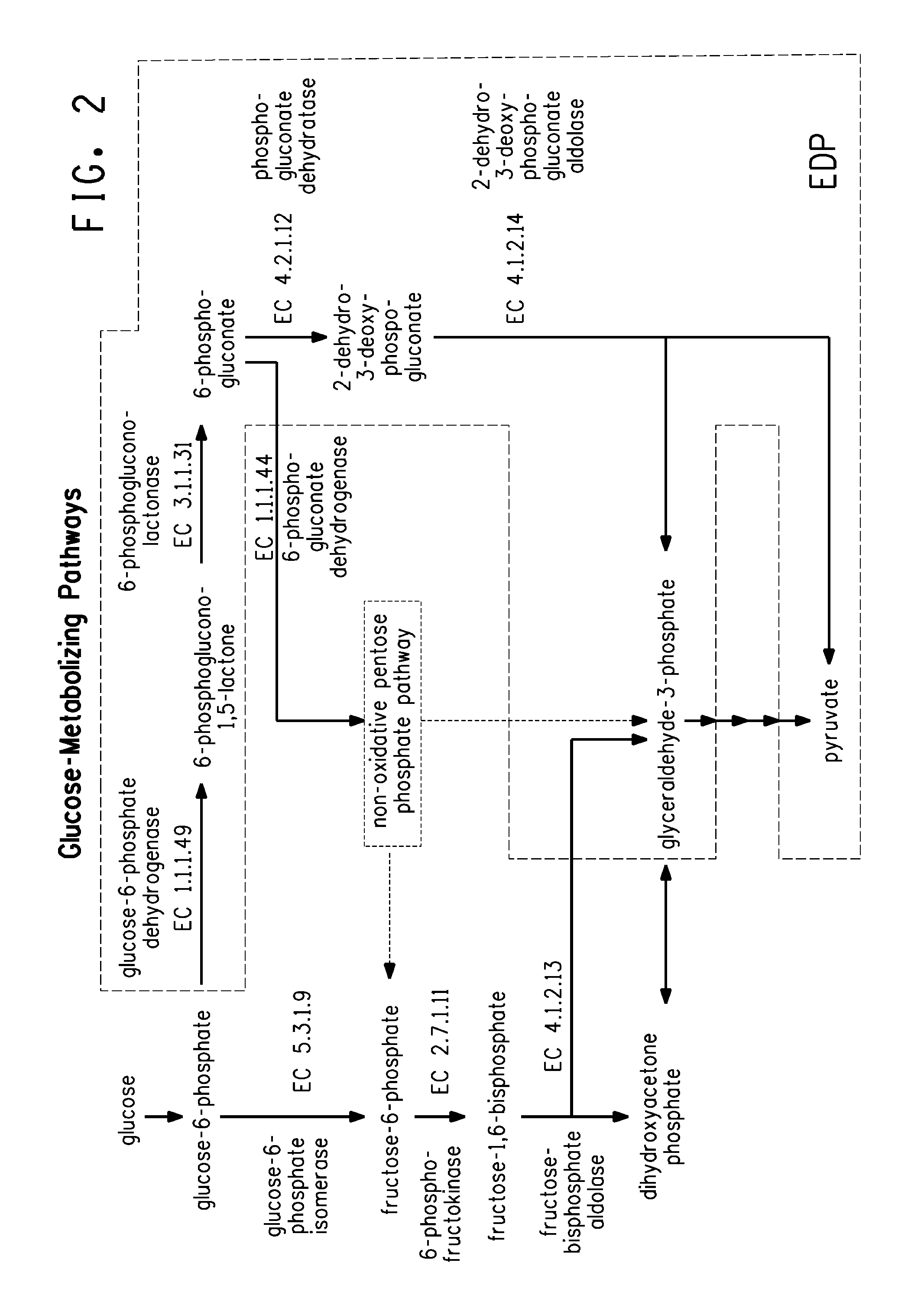

Carbon pathway optimized production hosts for the production of isobutanol

A microbial host cell is provided for the production of isobutanol. Carbon flux in the cell is optimized through the Entner-Doudoroff pathway.

Owner:BUTAMAXTM ADVANCED BIOFUELS

Method for the production of isobutanol

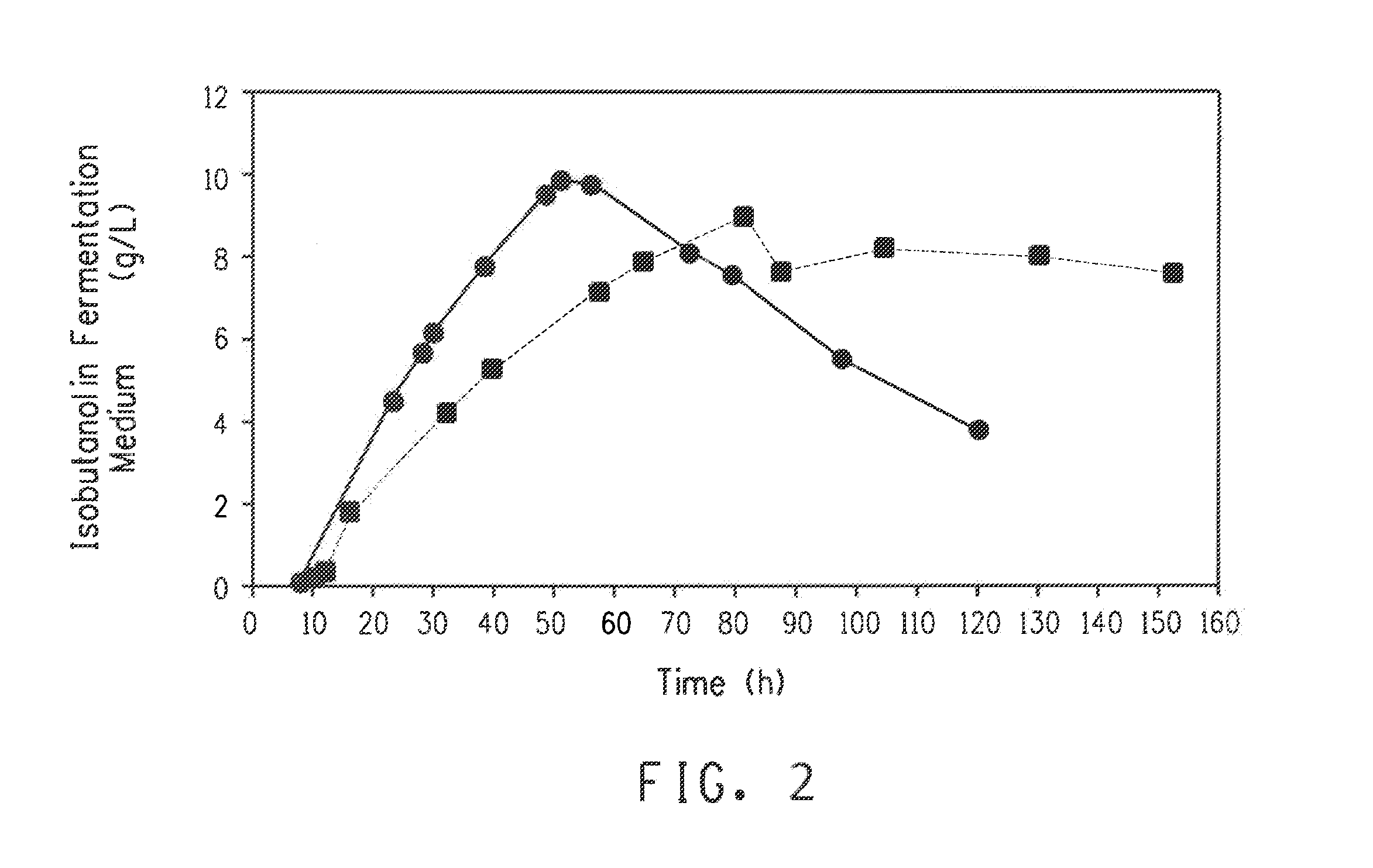

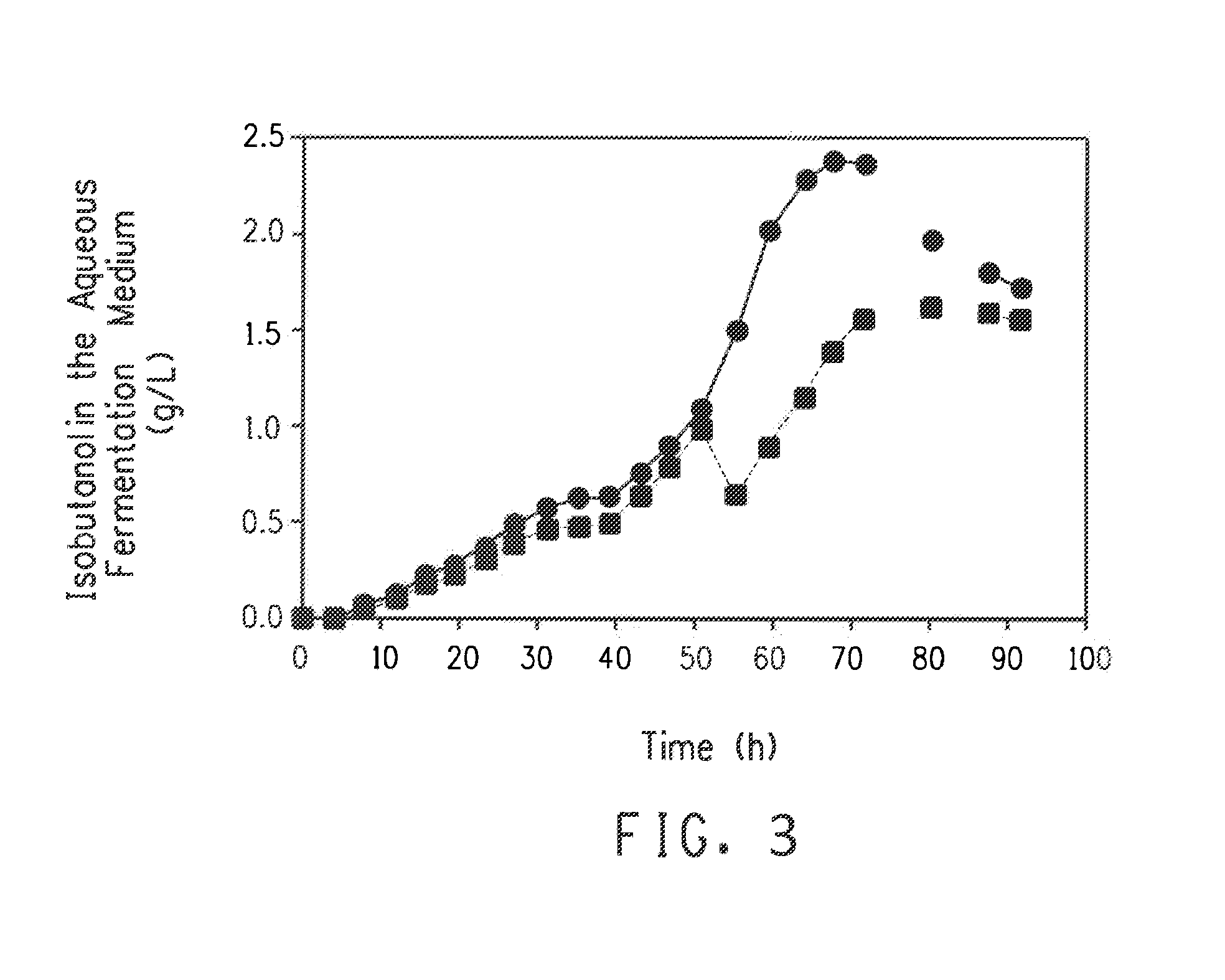

InactiveUS20080274526A1Reduce the temperatureRobust toleranceBiofuelsOxidoreductasesIsobutanolFermentation

A method for the production of isobutanol by fermentation using a microbial production host is disclosed. The method employs a reduction in temperature during the fermentation process that results in a more robust tolerance of the production host to the butanol product.

Owner:BUTAMAXTM ADVANCED BIOFUELS

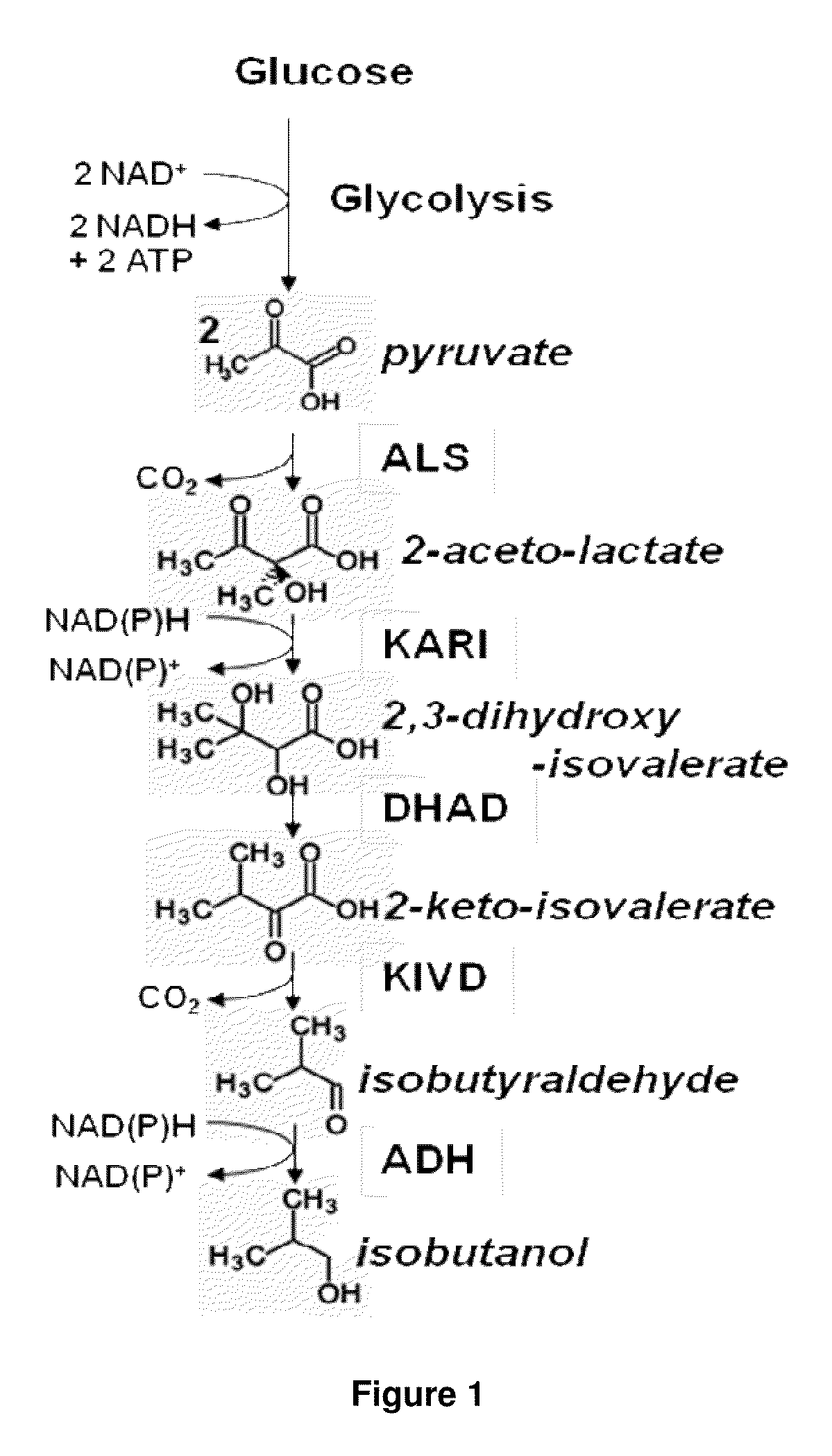

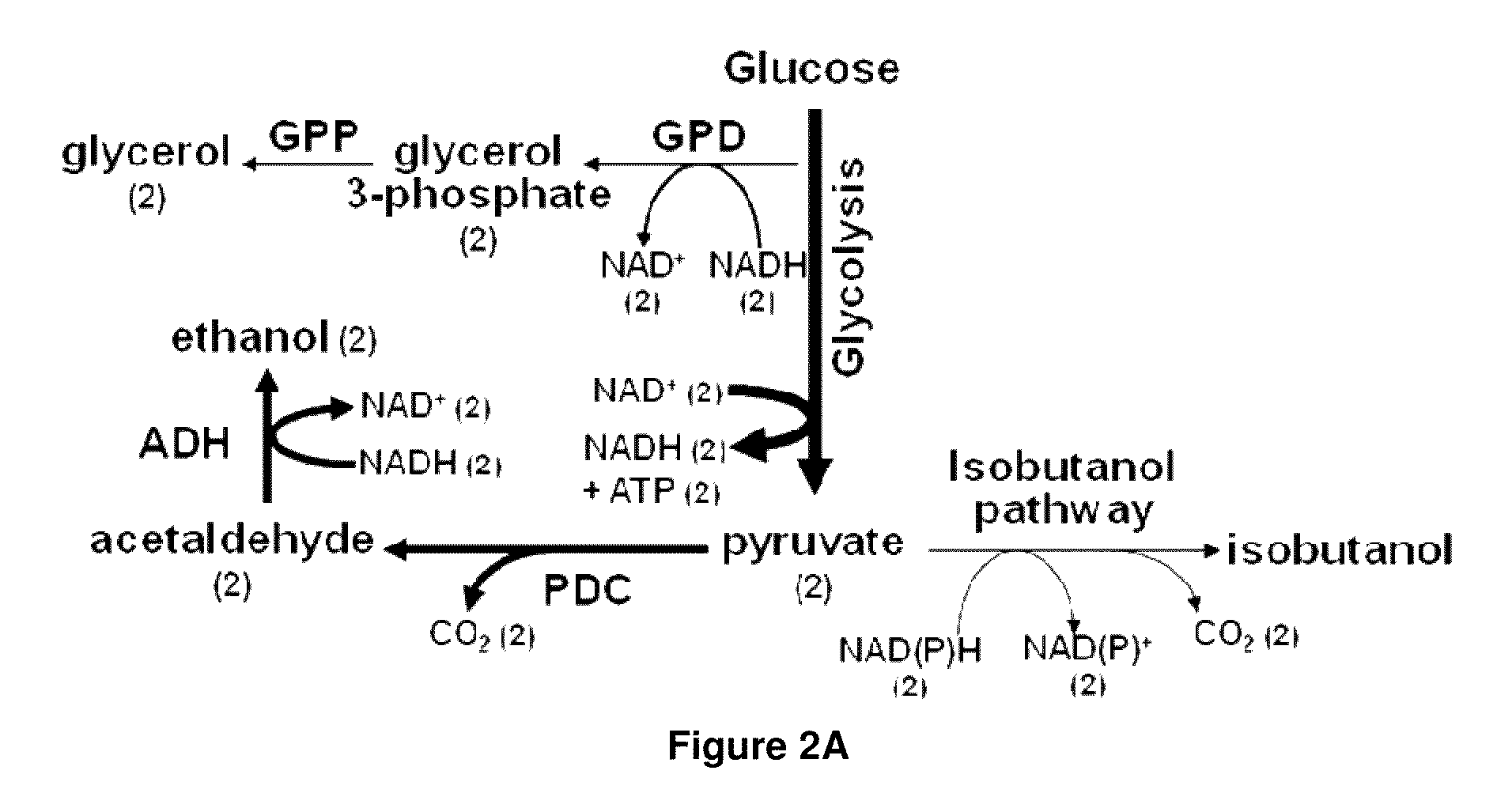

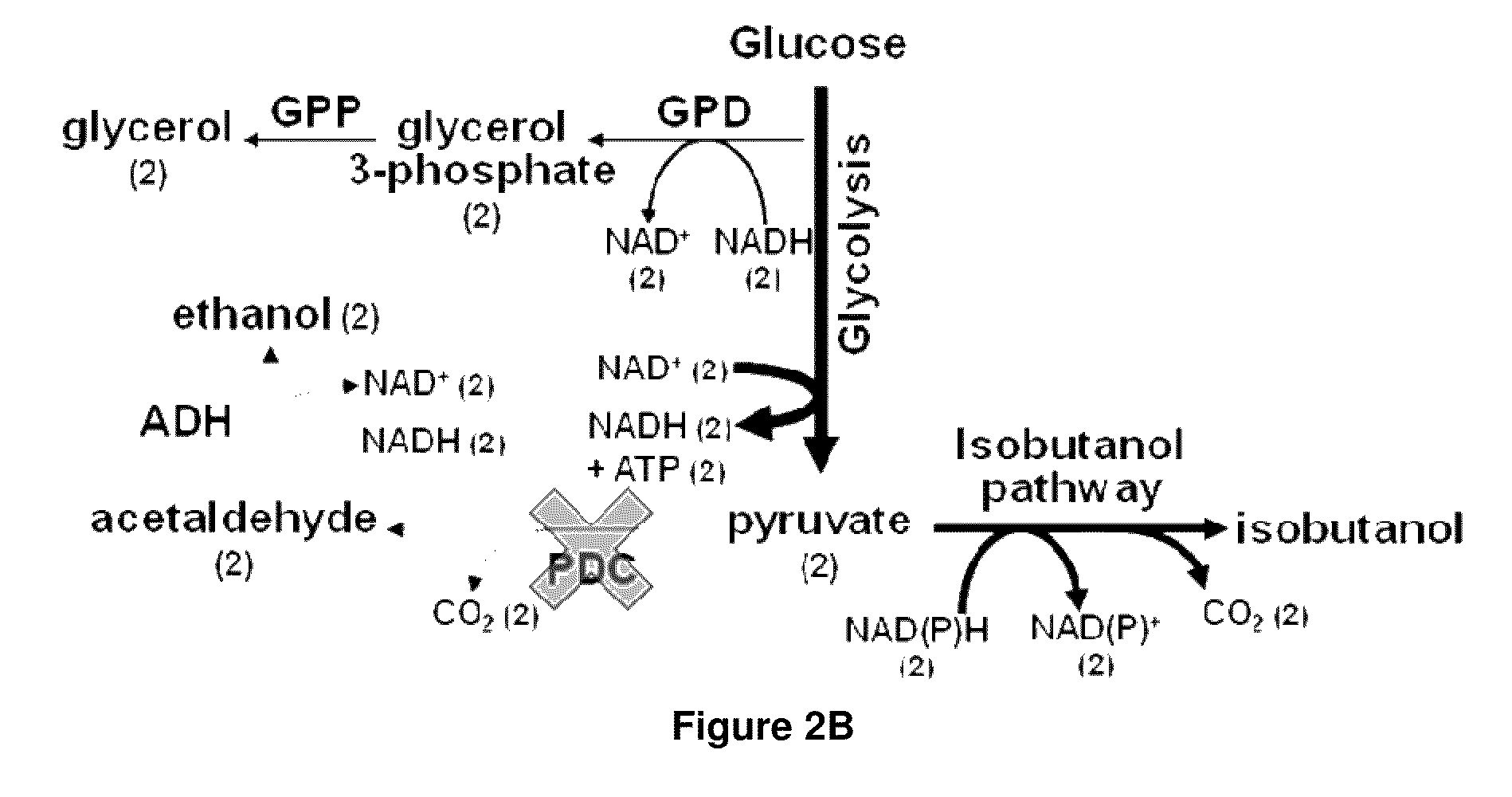

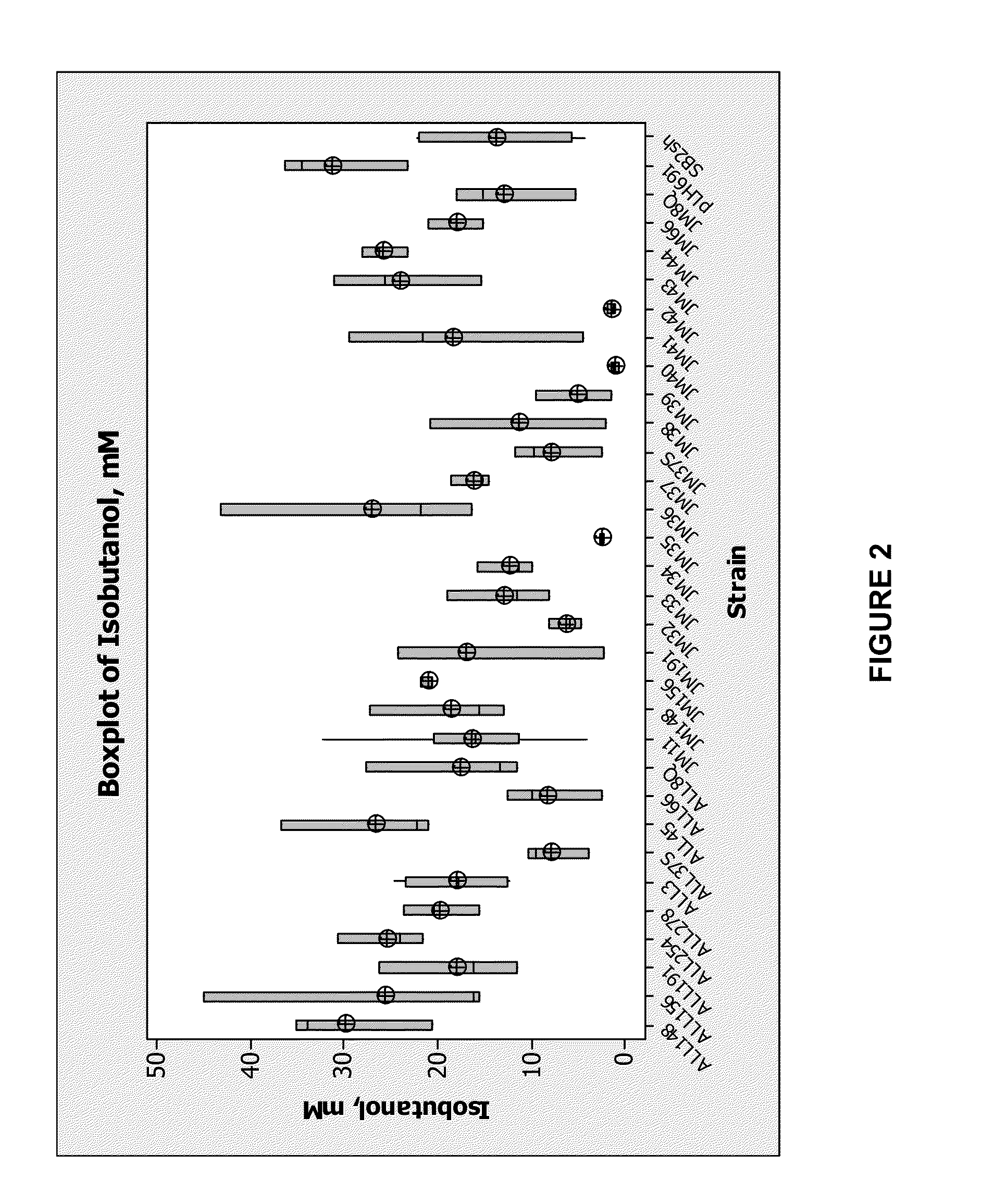

Yeast organism producing isobutanol at a high yield

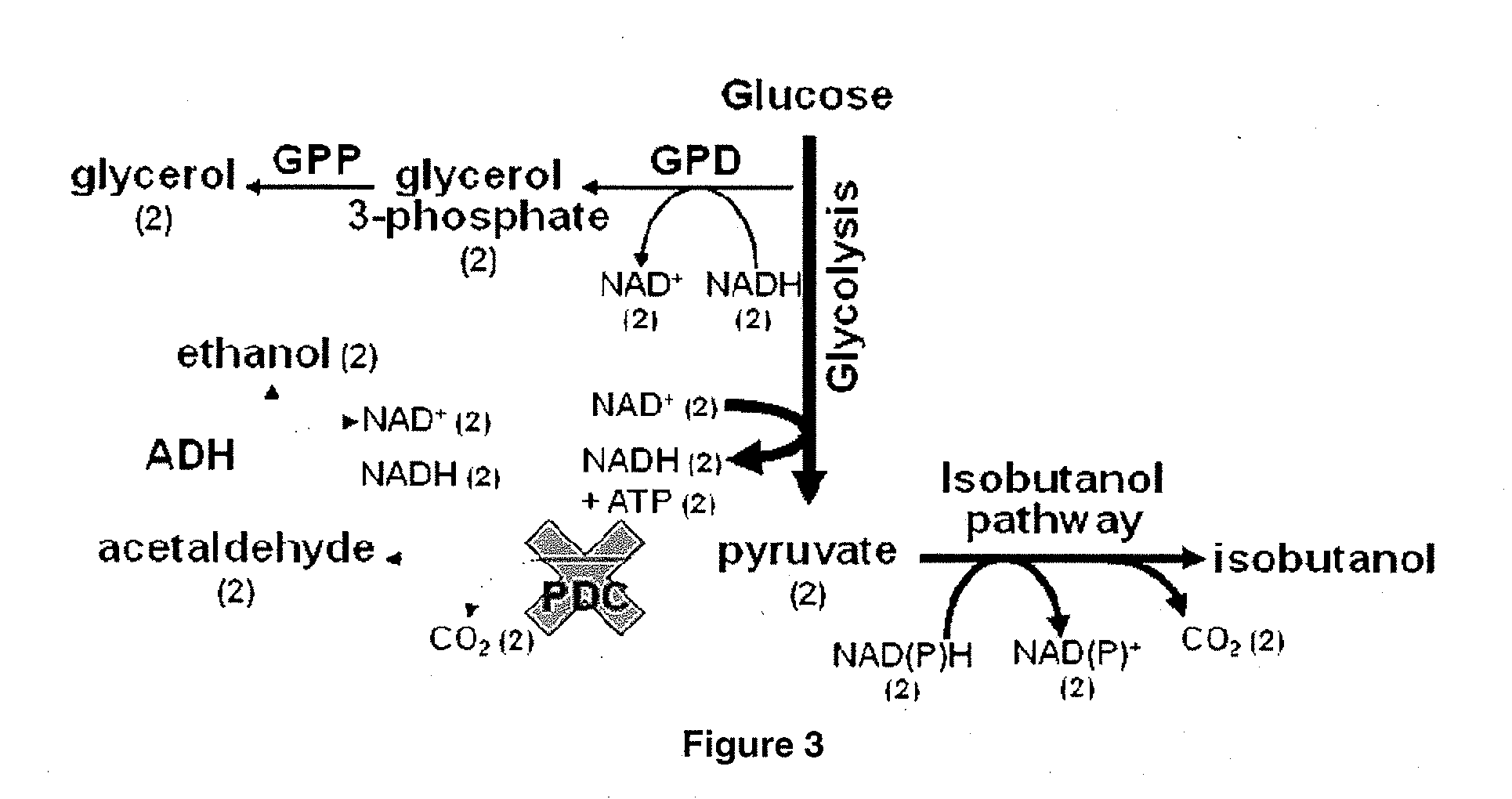

InactiveUS20090226991A1Reduction of pyruvate decarboxylase activityReduce transcriptionFungiBiofuelsBiotechnologyMicroorganism

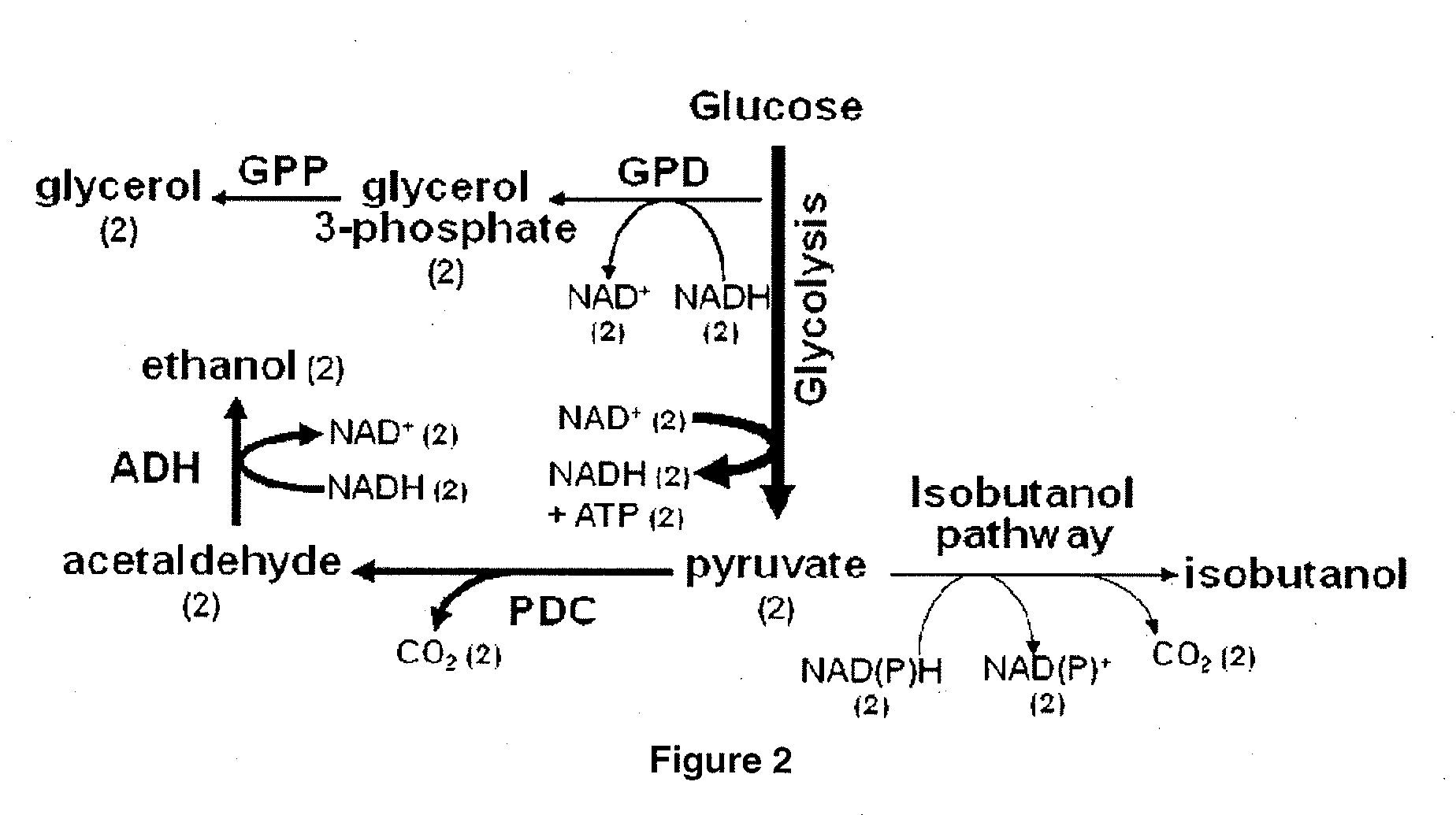

There is disclosed a method of producing isobutanol. In an embodiment, the method includes providing a microorganism transformed with an isobutanol producing pathway containing at least one exogenous gene. The microorganism is selected to produce isobutanol from a carbon source at a yield of at least 10 percent theoretical. The method includes cultivating the microorganism in a culture medium containing a feedstock providing the carbon source, until isobutanol is produced. The method includes recovering the isobutanol. In one embodiment, the microorganism is a yeast with a Crabtree-negative phenotype. In another embodiment, the microorganism is a yeast microorganism with a Crabtree-positive phenotype. There is disclosed a microorganism for producing isobutanol. In an embodiment, the microorganism includes an isobutanol producing pathway containing at least one exogenous gene, and is selected to produce a recoverable quantity of isobutanol from a carbon source at a yield of at least 10 percent theoretical.

Owner:GEVO INC

Fermentive production of isobutanol using highly active ketol-acid reductoisomerase enzymes

Methods for the fermentative production of isobutanol is provided by the fermentative growth of a recombinant microorganism expressing a highly active ketol-acid reductoisomerase enzyme in addition to other enzymes required for conversion of glucose to isobutanol.

Owner:GEVO INC

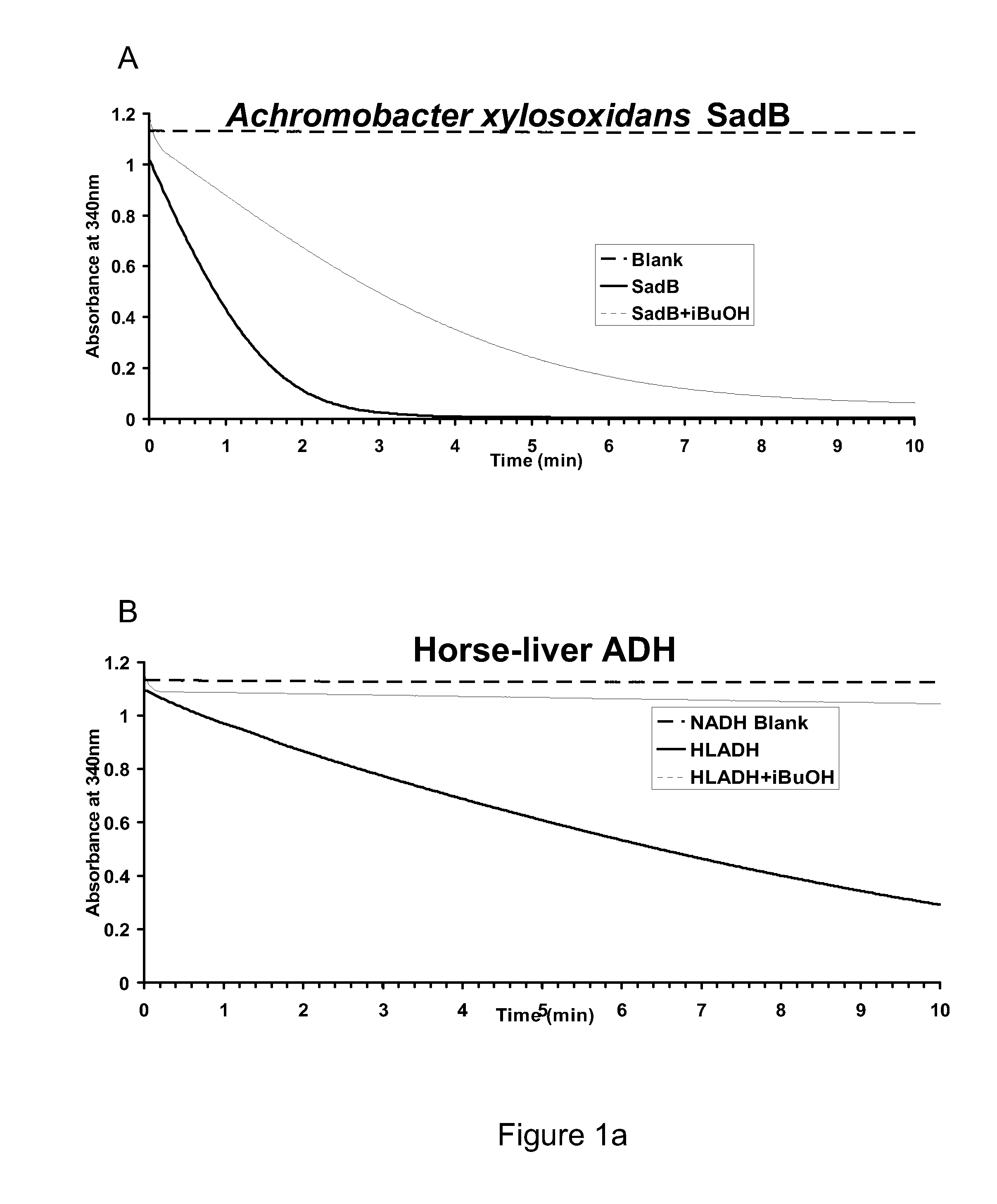

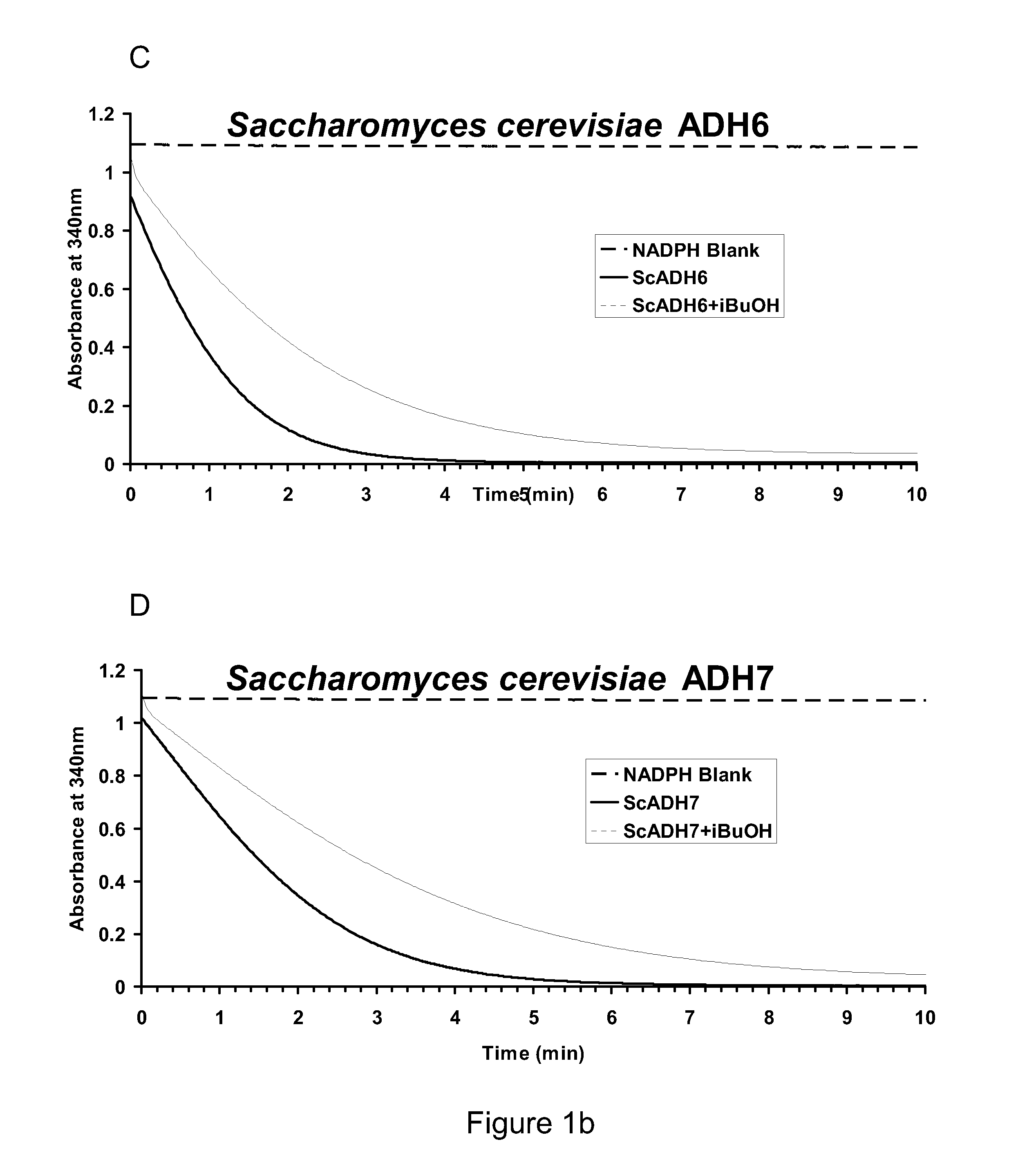

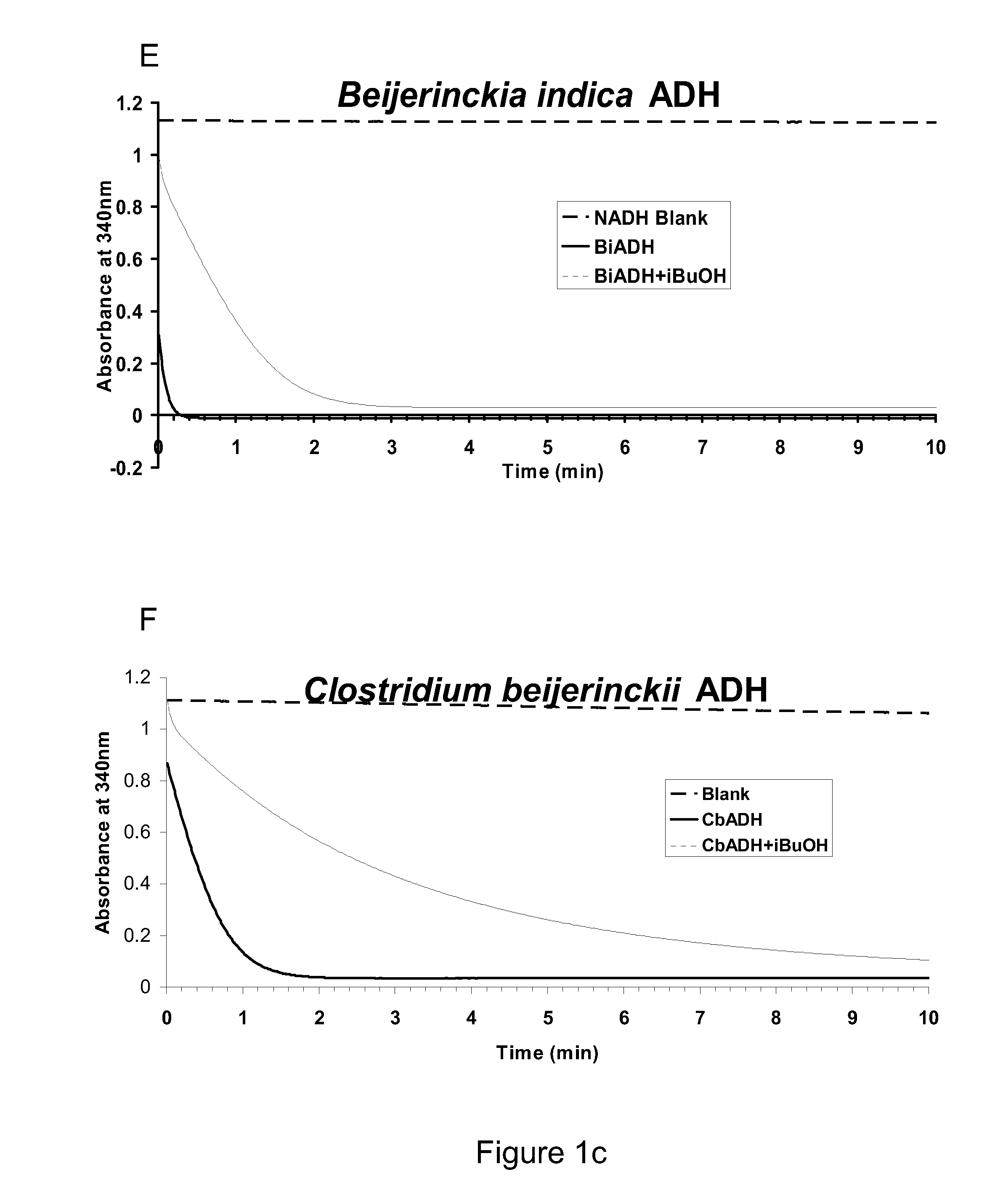

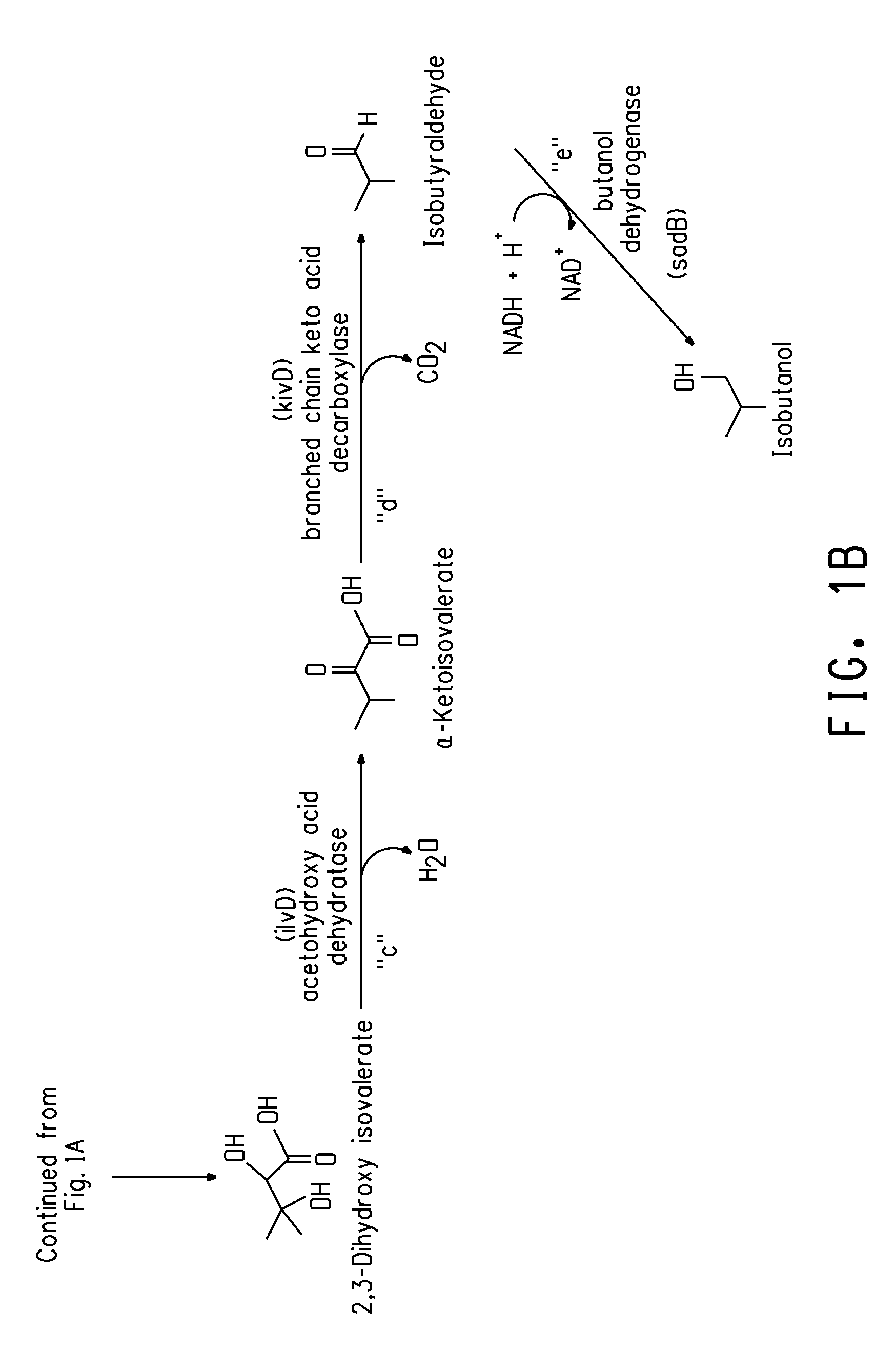

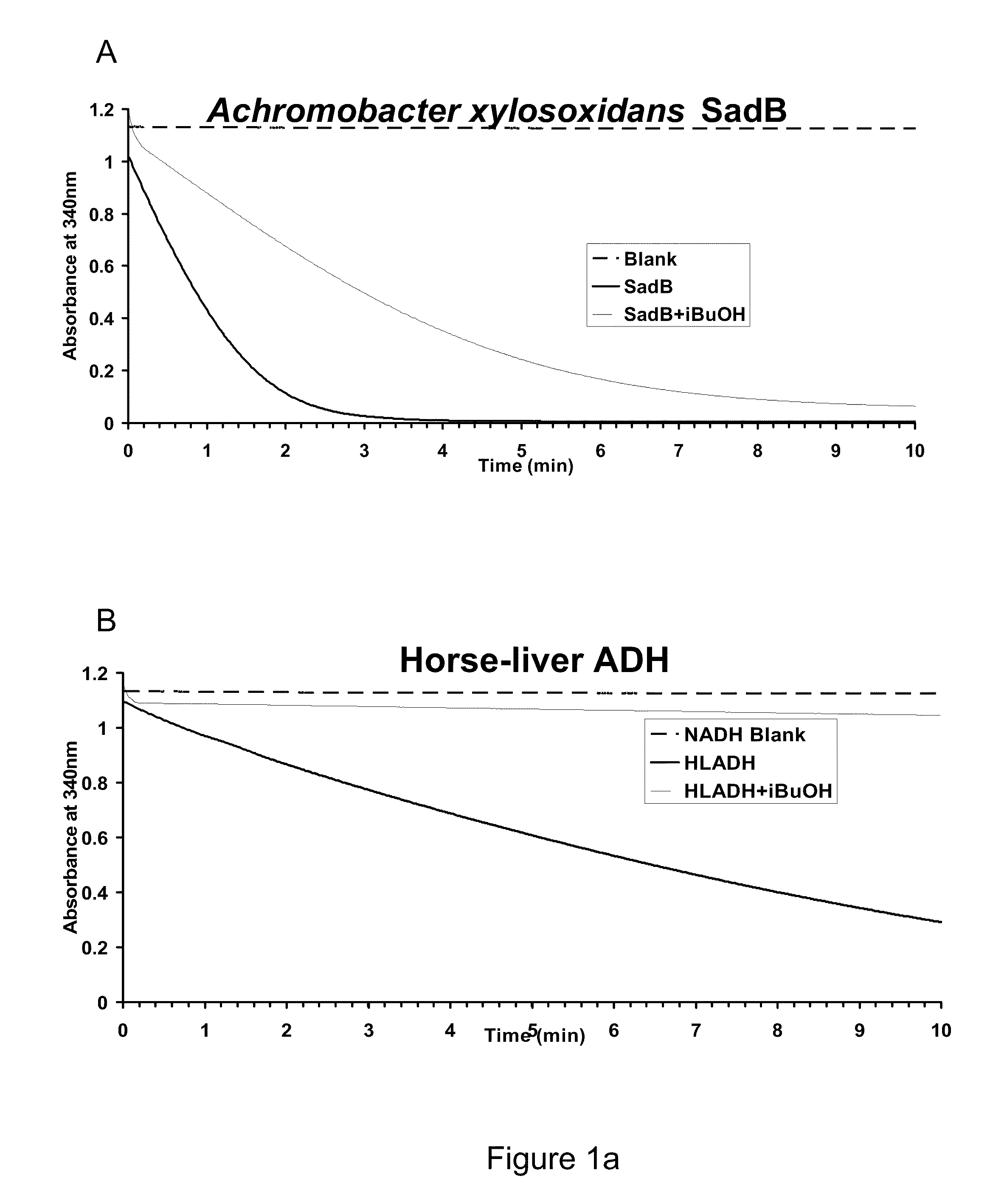

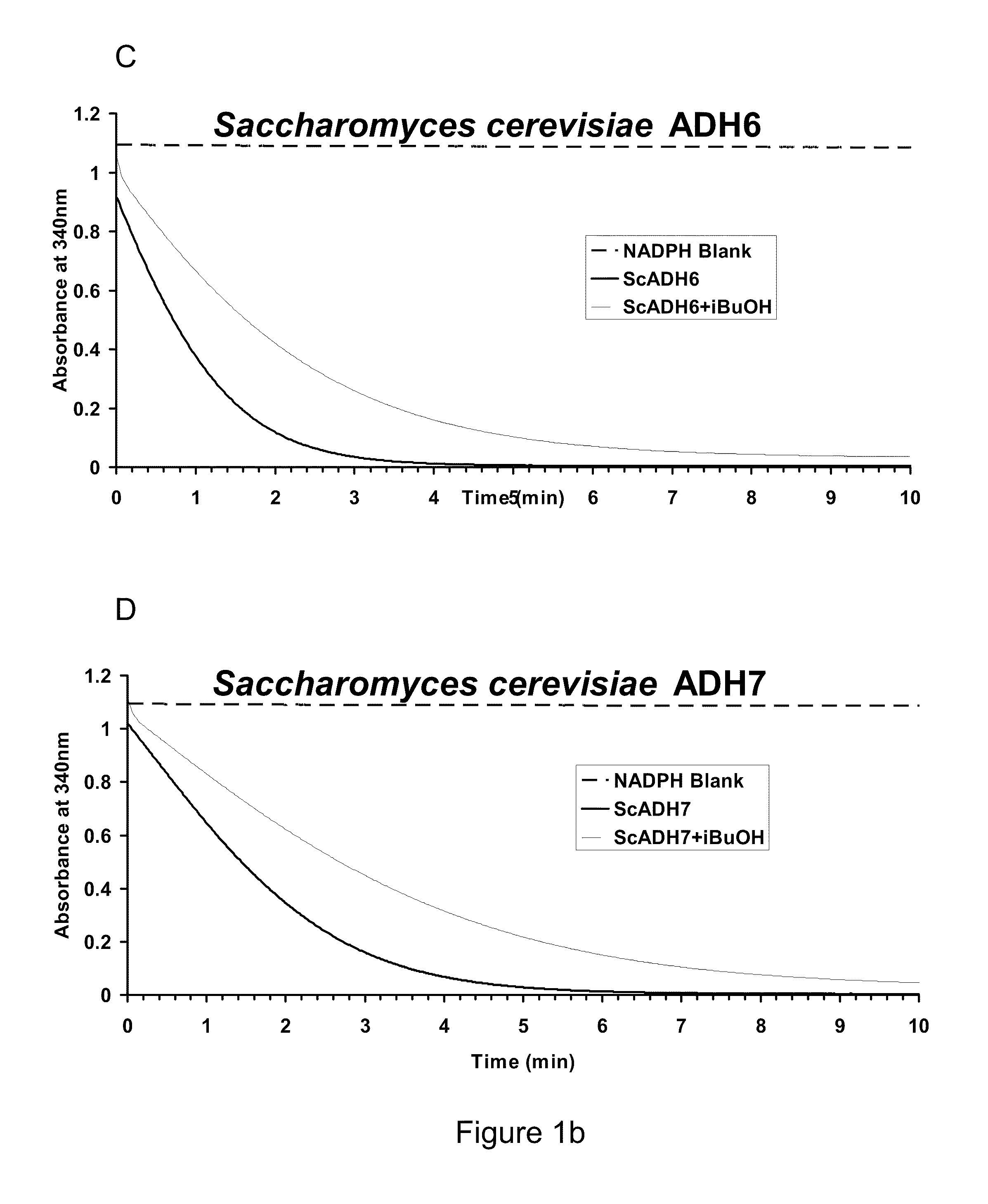

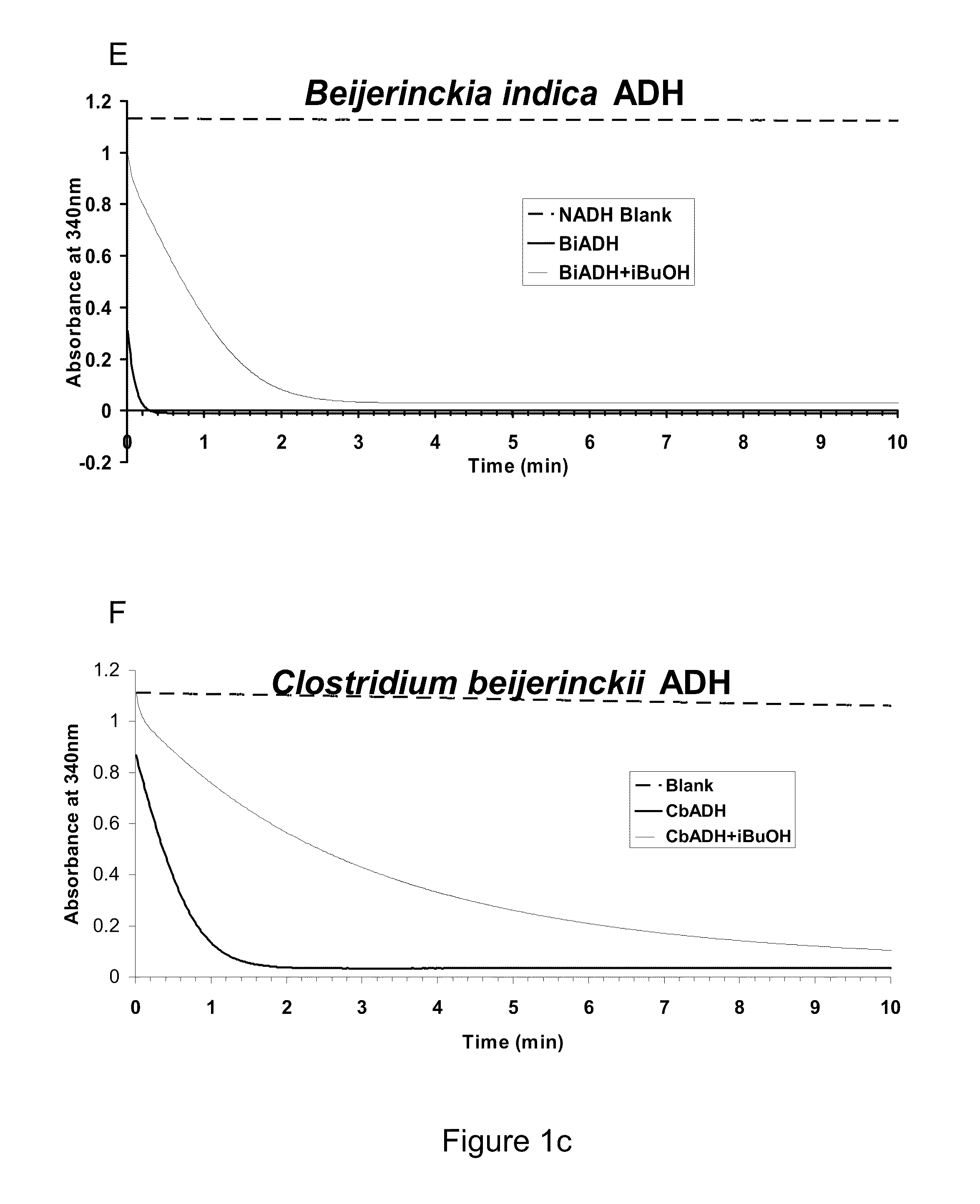

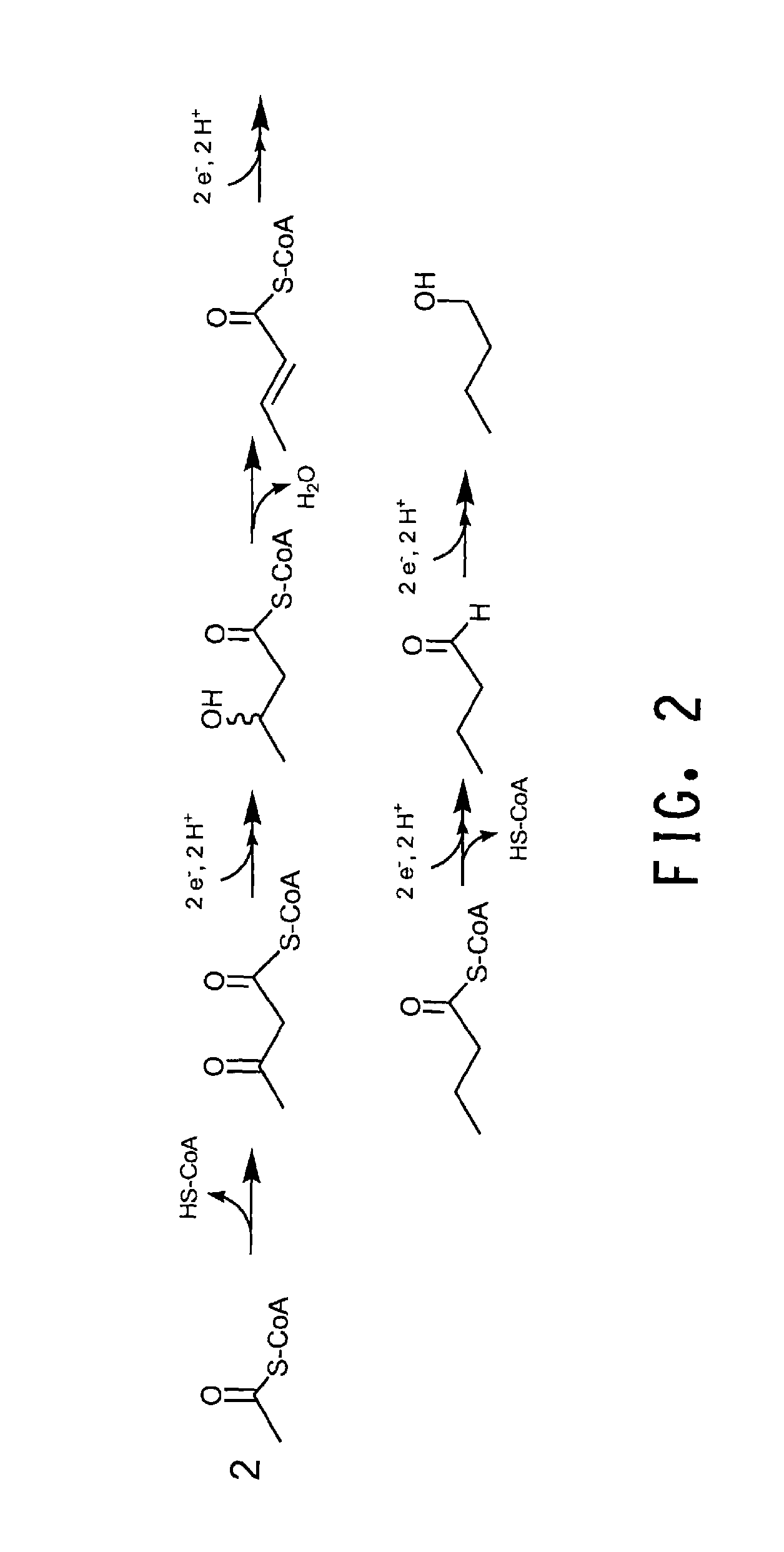

Alcohol dehydrogenases (ADH) useful for fermentive production of lower alkyl alcohols

The invention relates to suitable candidate ADH enzymes for production of lower alkyl alcohols including isobutanol. The invention also relates to recombinant host cells that comprise such ADH enzymes and methods for producing lower alkyl alcohols in the same.

Owner:GEVO INC

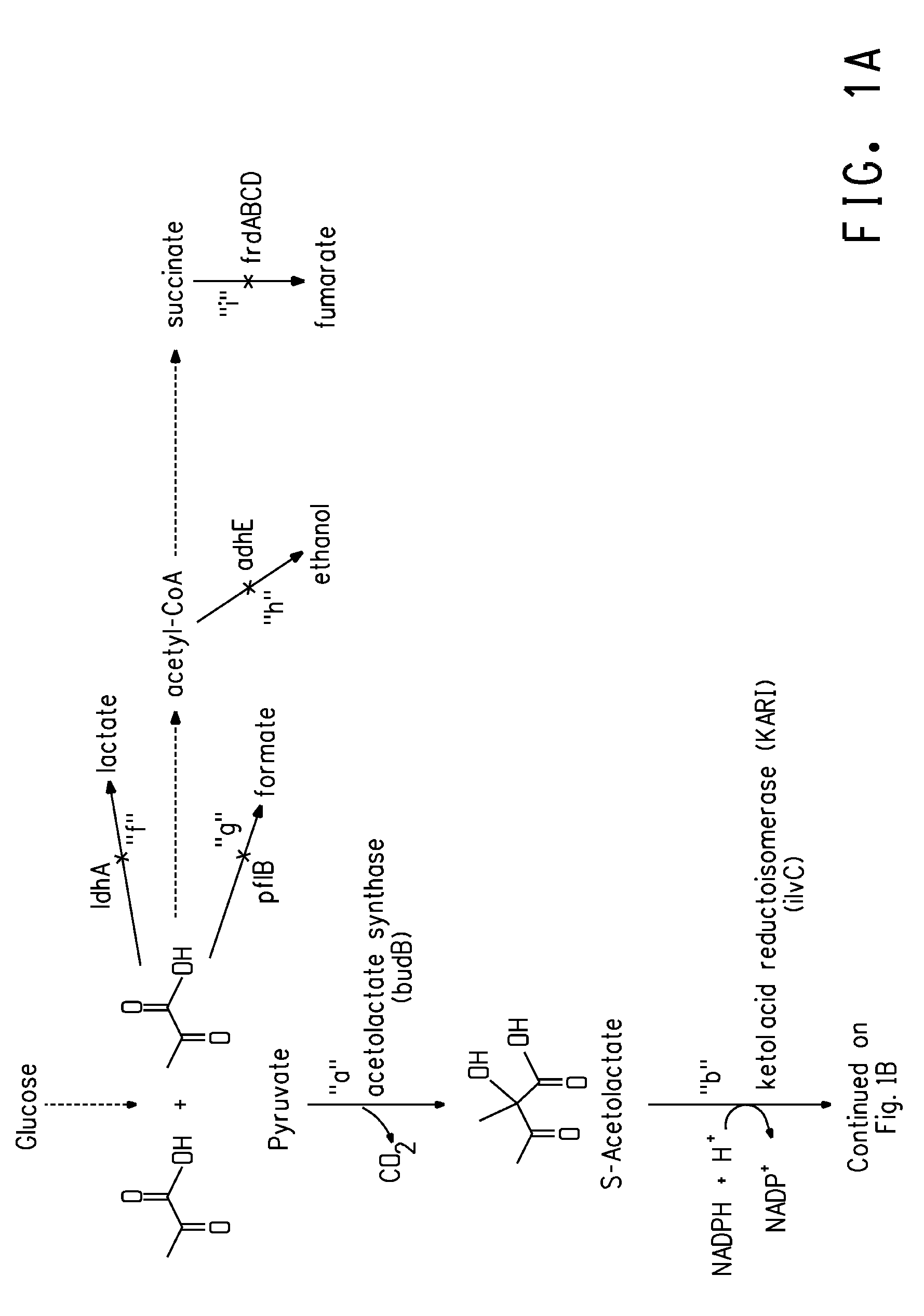

Fermentive production of four carbon alcohols

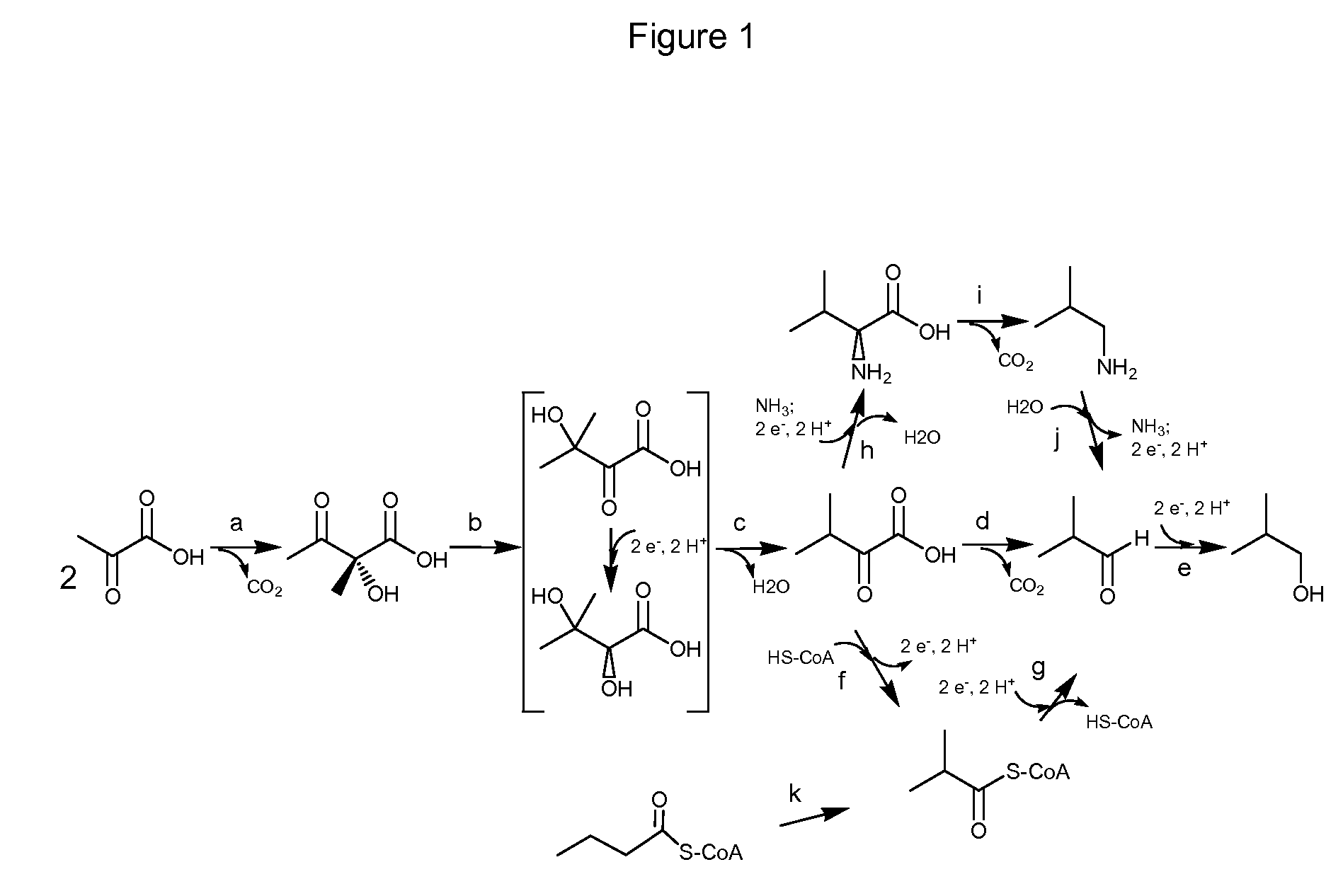

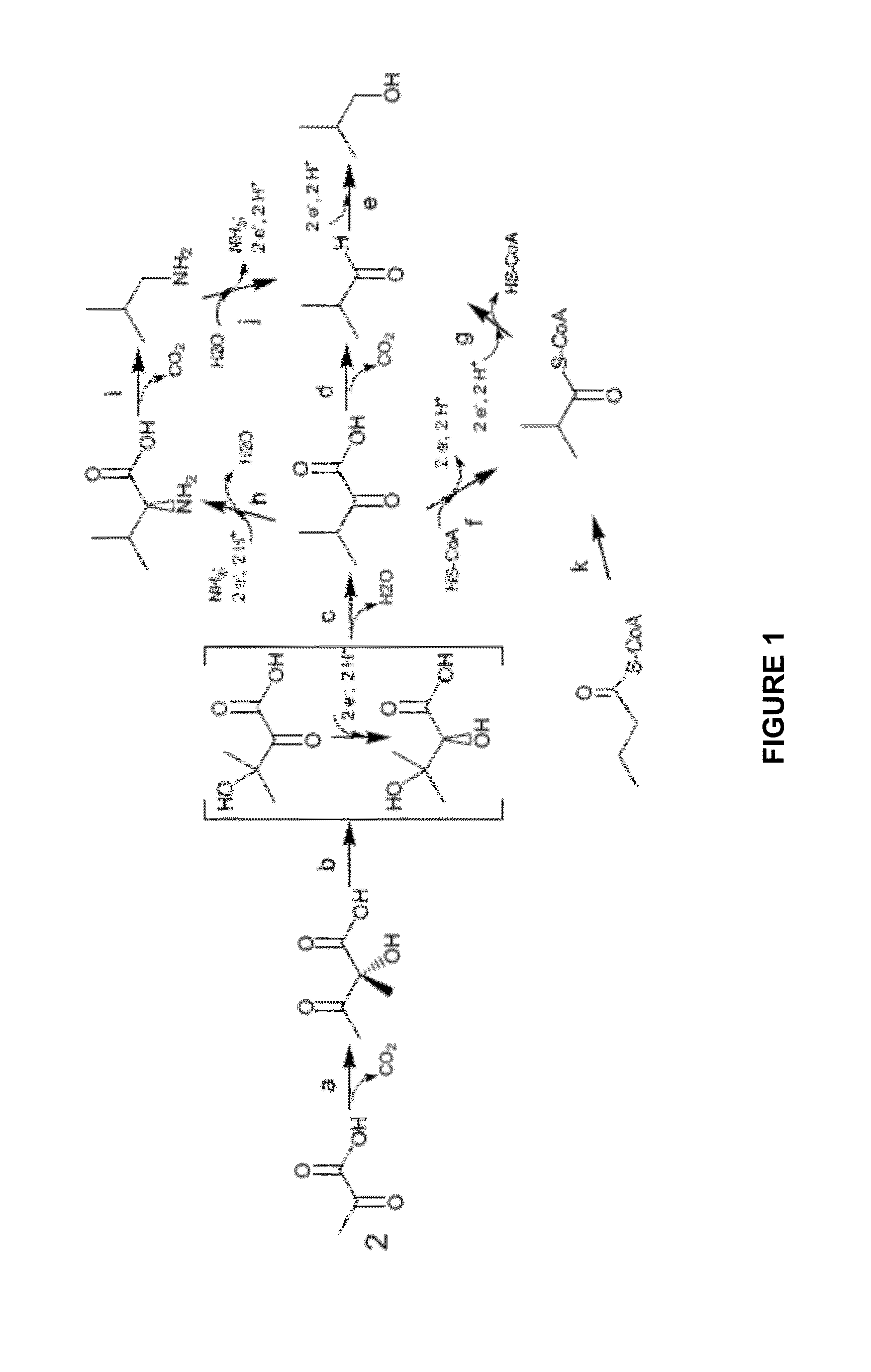

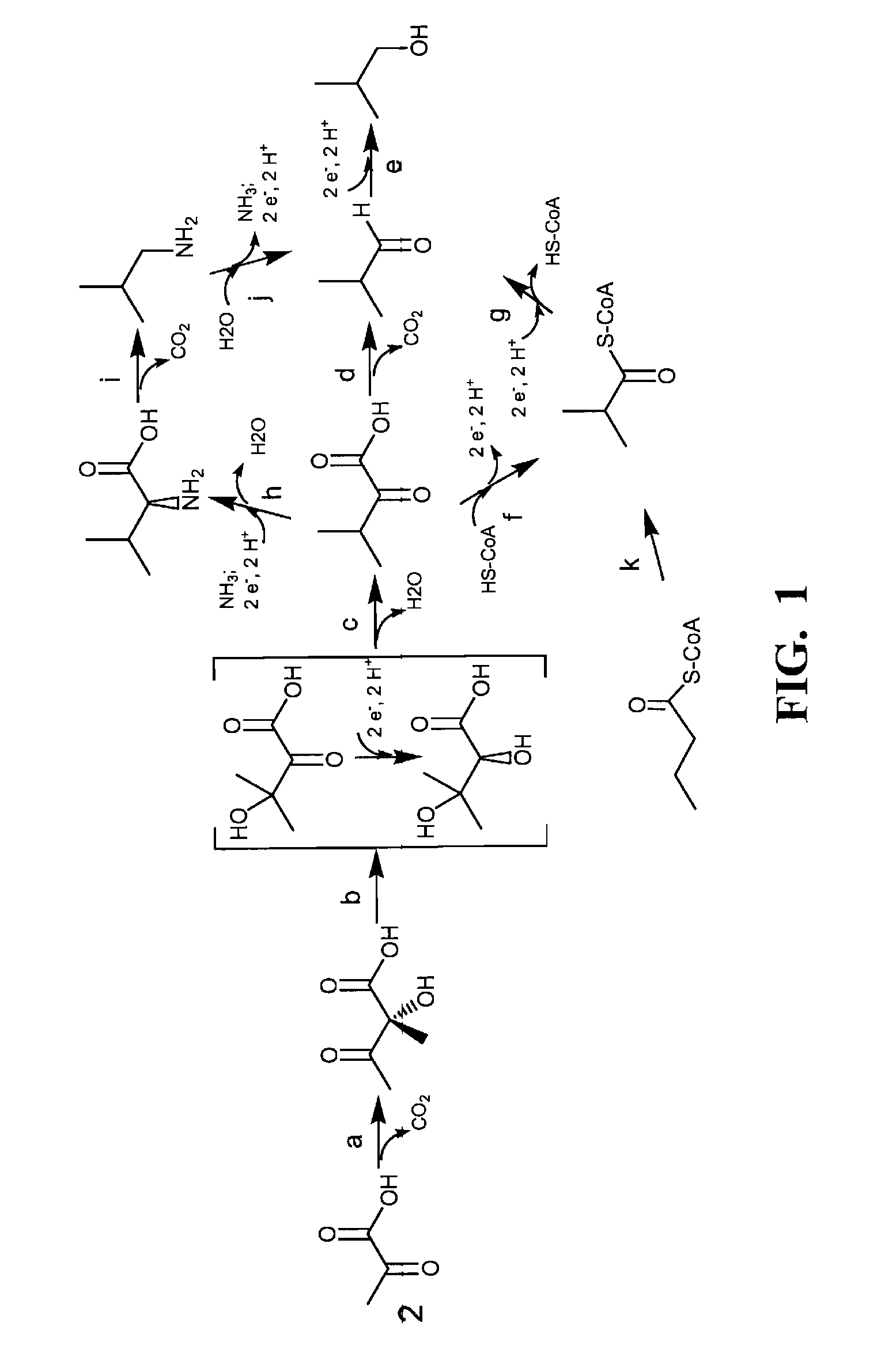

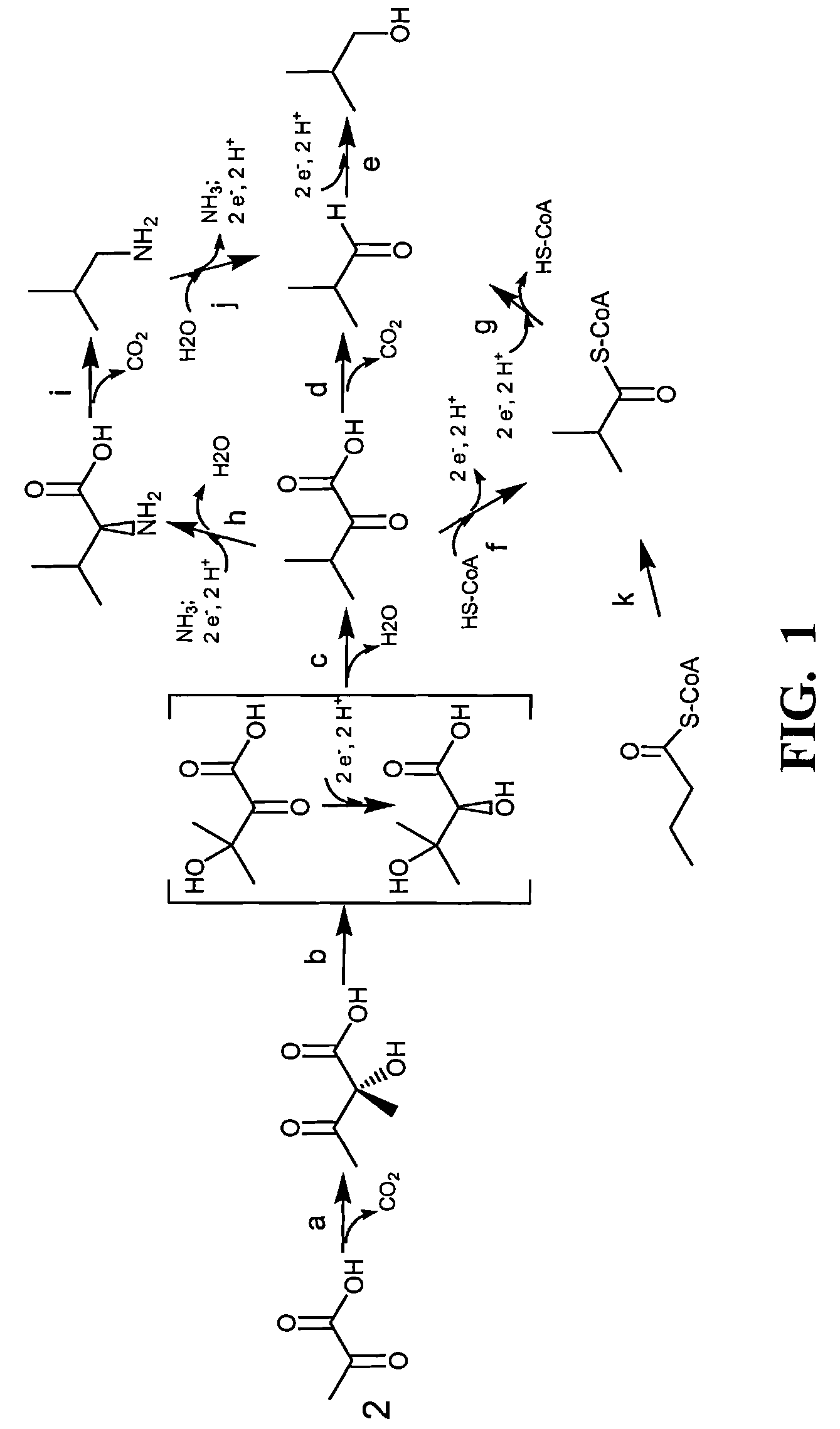

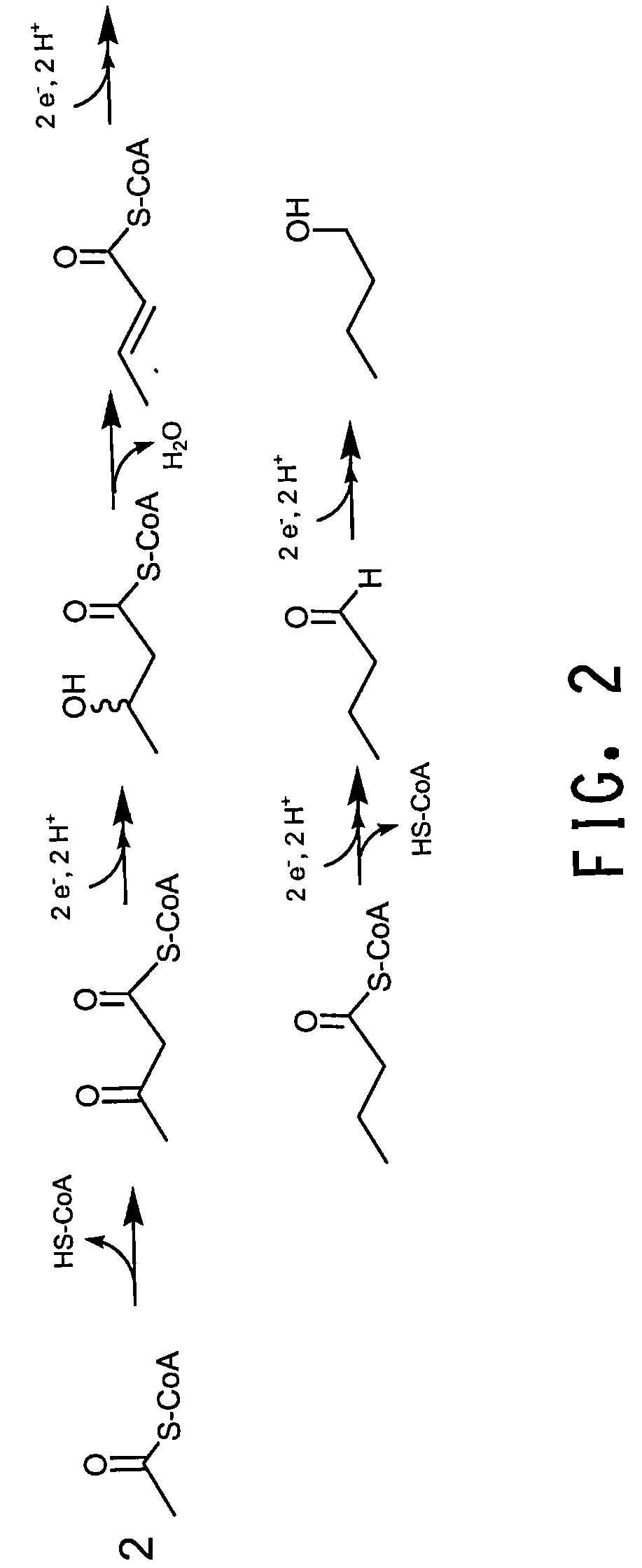

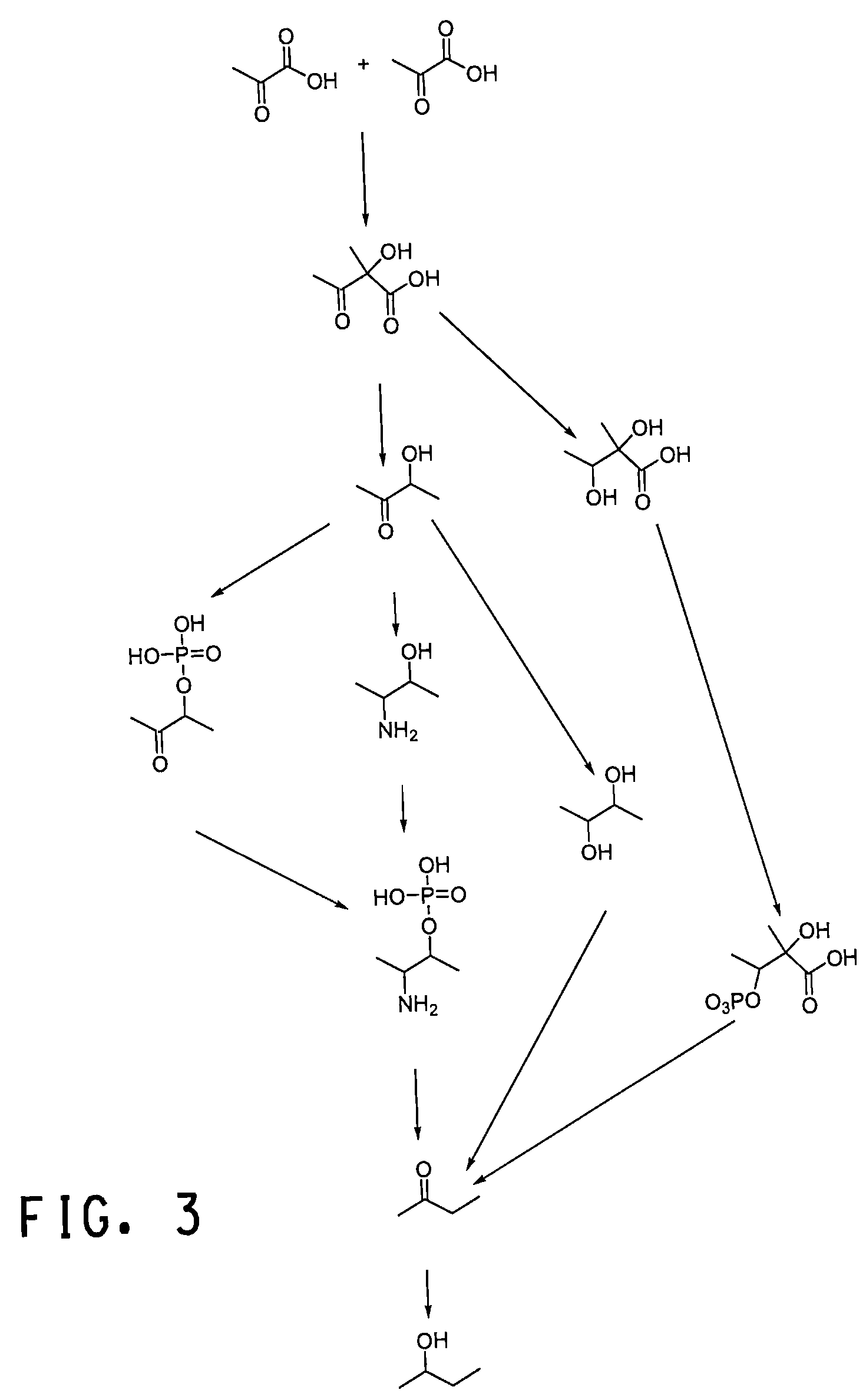

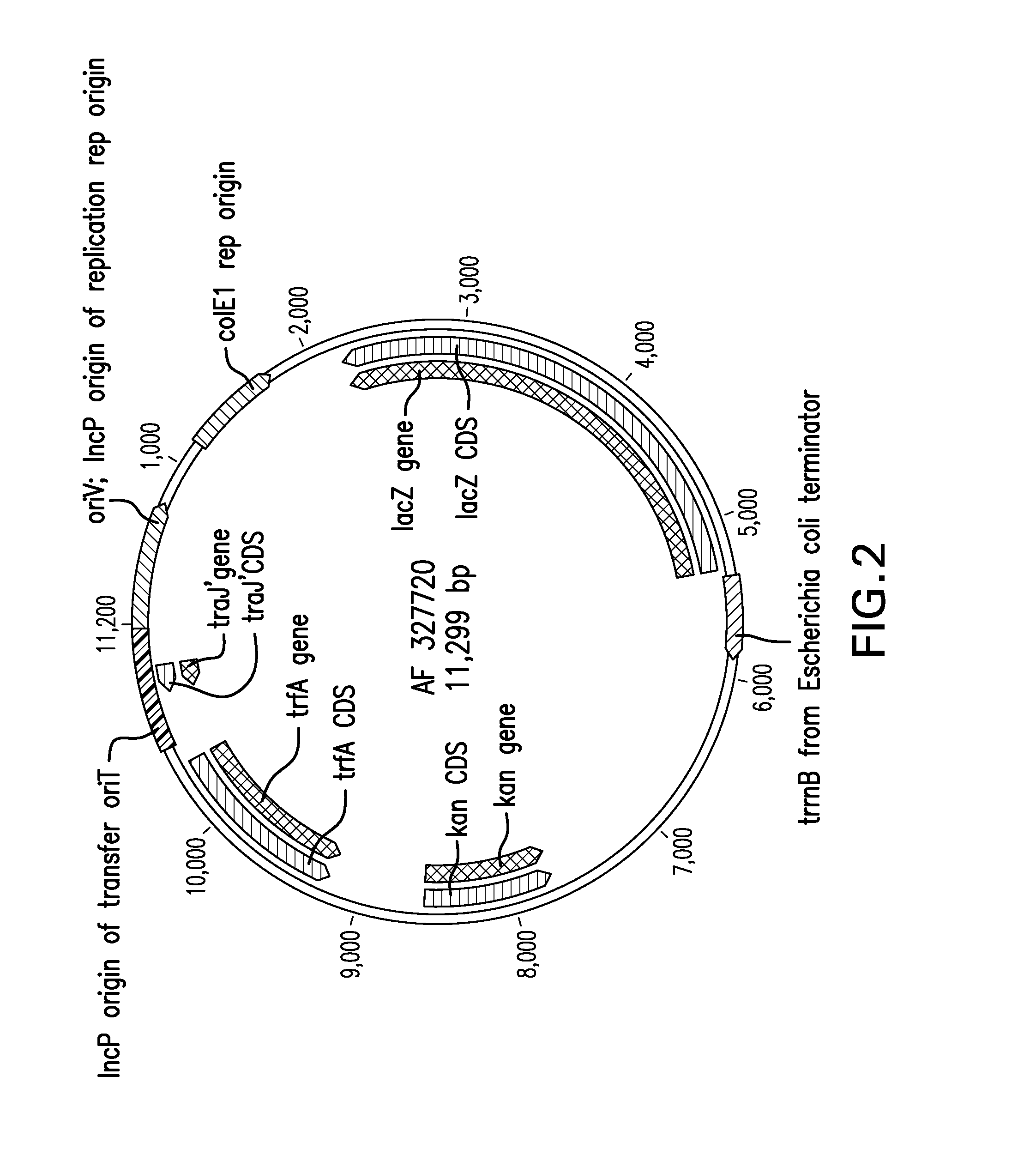

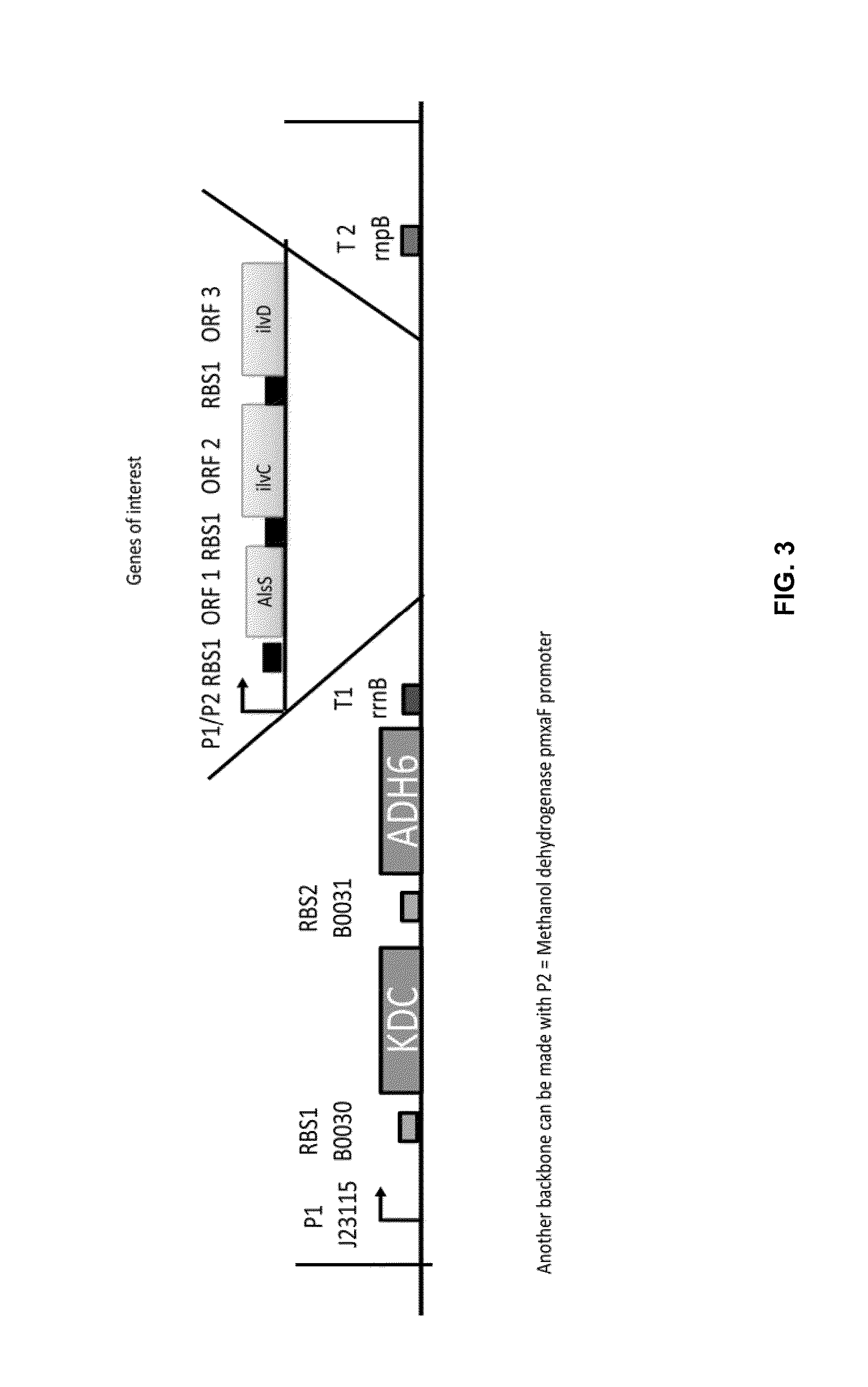

Methods for the fermentative production of four carbon alcohols is provided. Specifically, butanol, preferably isobutanol is produced by the fermentative growth of a recombinant bacterium expressing an isobutanol biosynthetic pathway.

Owner:GEVO INC

Deletion mutants for the production of isobutanol

An E. coli host strain was engineered wherein genes adhE, IdhA, frdB, and pfIB were disrupted and novel butanol dehydrogenase gene, sadB, from Achromobacter xylosoxidans, was added to produce the isobutanol production host.

Owner:BUTAMAXTM ADVANCED BIOFUELS

Yeast organism producing isobutanol at a high yield

The present invention provides recombinant mircoorganisms comprising an isobutanol producing metabolic pathway and methods of using said recombinant microorganisms to produce isobutanol. In various aspects of the invention, the recombinant microorganisms may comprise a modification resulting in the reduction of pyruvate decarboxylase and / or glycerol-3-phosphate dehydrogenase activity. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

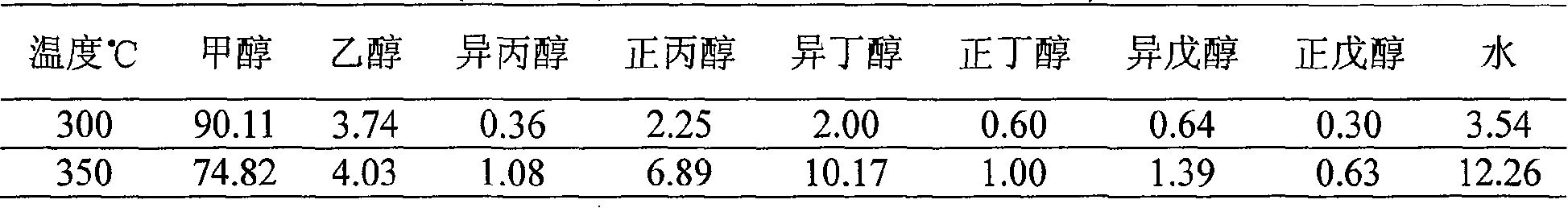

Catalyst for synthesizing low carbon mellow with synthesis gas and preparation method thereof

ActiveCN101185895AHigh conversion rate of COHigh selectivityOrganic compound preparationHydroxy compound preparationIsobutanolPropanol

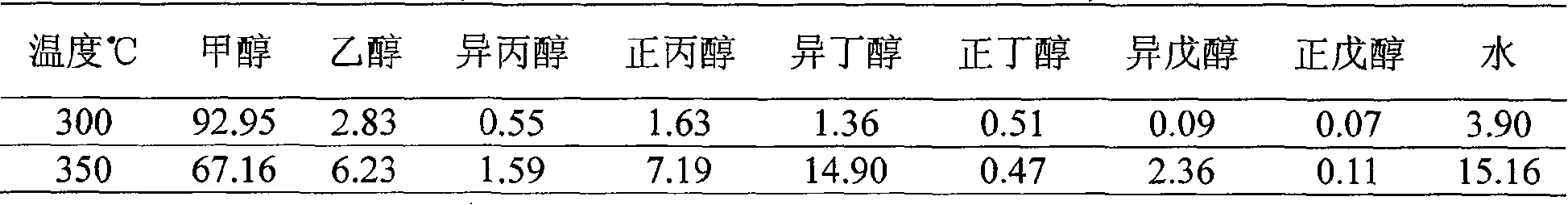

The invention discloses a catalyst for synthesizing low carbon mixed alcohol with synthetic gas and a preparation method. The main components of the catalyst are copper oxide, zinc oxide, chromium oxide, alumina, and an appropriate amount of other assistants, which are expressed by the general formula Cu(Zn)a(Cr)b(Al)c(M)d(A)e(O)x; the catalyst is prepared by coprecipitation, and the assistant is added by impregnation. Under appropriate conditions, the catalyst can lead CO and hydrogen to react to produce a mixture of oxidation compounds which comprises methanol, ethanol, propanol, isobutanol, pentanol, and a small amount of C5.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

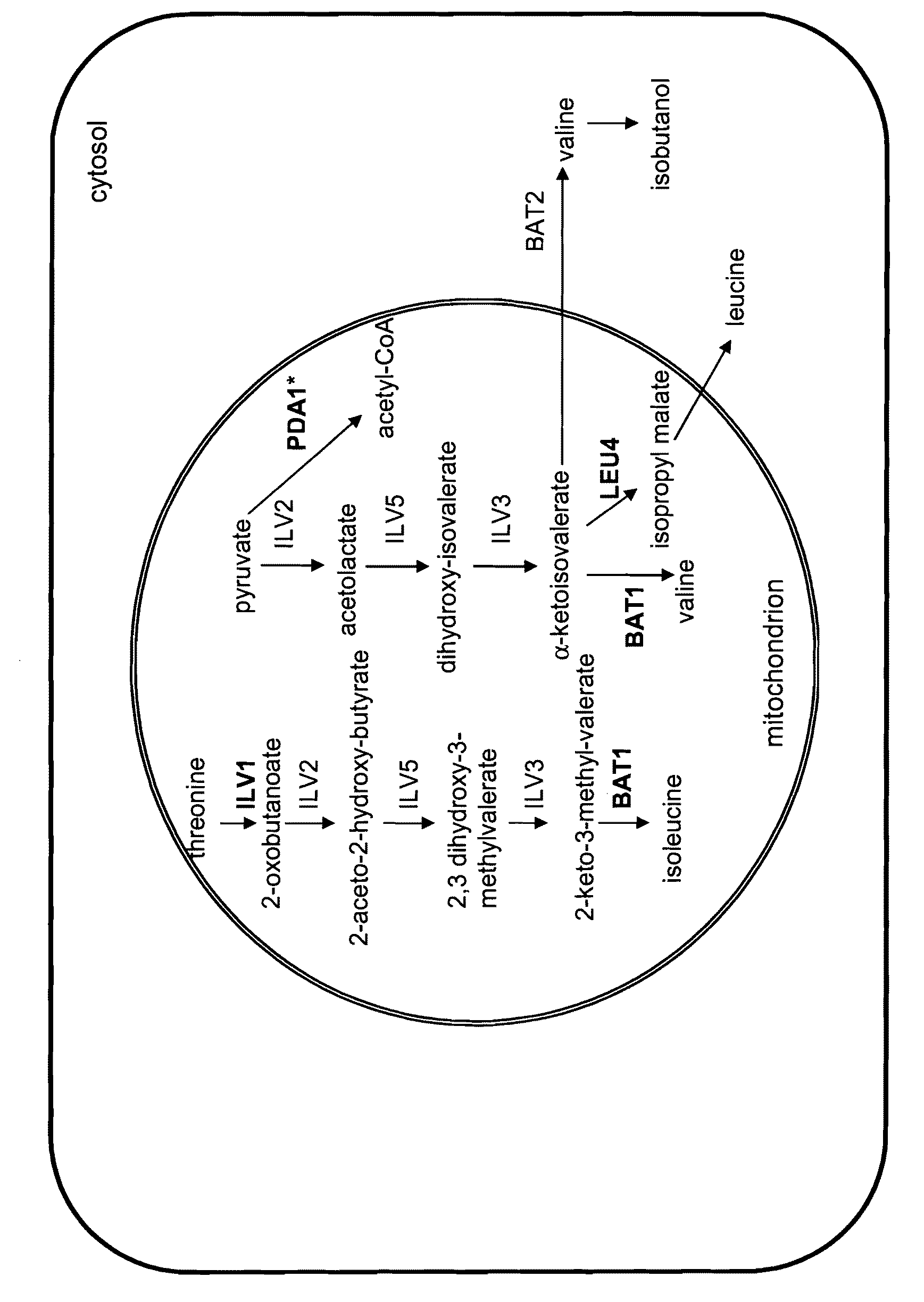

Cytosolic isobutanol pathway localization for the production of isobutanol

ActiveUS20110076733A1Increase cytosolic localizationIncrease cytosolic activityFungiBacteriaYeastIsobutanol

The present invention provides recombinant microorganisms comprising isobutanol producing metabolic pathway with at least one isobutanol pathway enzyme localized in the cytosol, wherein said recombinant microorganism is selected to produce isobutanol from a carbon source. Methods of using said recombinant microorganisms to produce isobutanol are also provided. In various aspects of the invention, the recombinant microorganisms may comprise a cytosolically active isobutanol pathway enzymes. In some embodiments, the invention provides mutated, modified, and / or chimeric isobutanol pathway enzymes with cytosolic activity. In various embodiments described herein, the recombinant microorganisms may be microorganisms of the Saccharomyces clade, Crabtree-negative yeast microorganisms, Crabtree-positive yeast microorganisms, post-WGD (whole genome duplication) yeast microorganisms, pre-WGD (whole genome duplication) yeast microorganisms, and non-fermenting yeast microorganisms.

Owner:GEVO INC

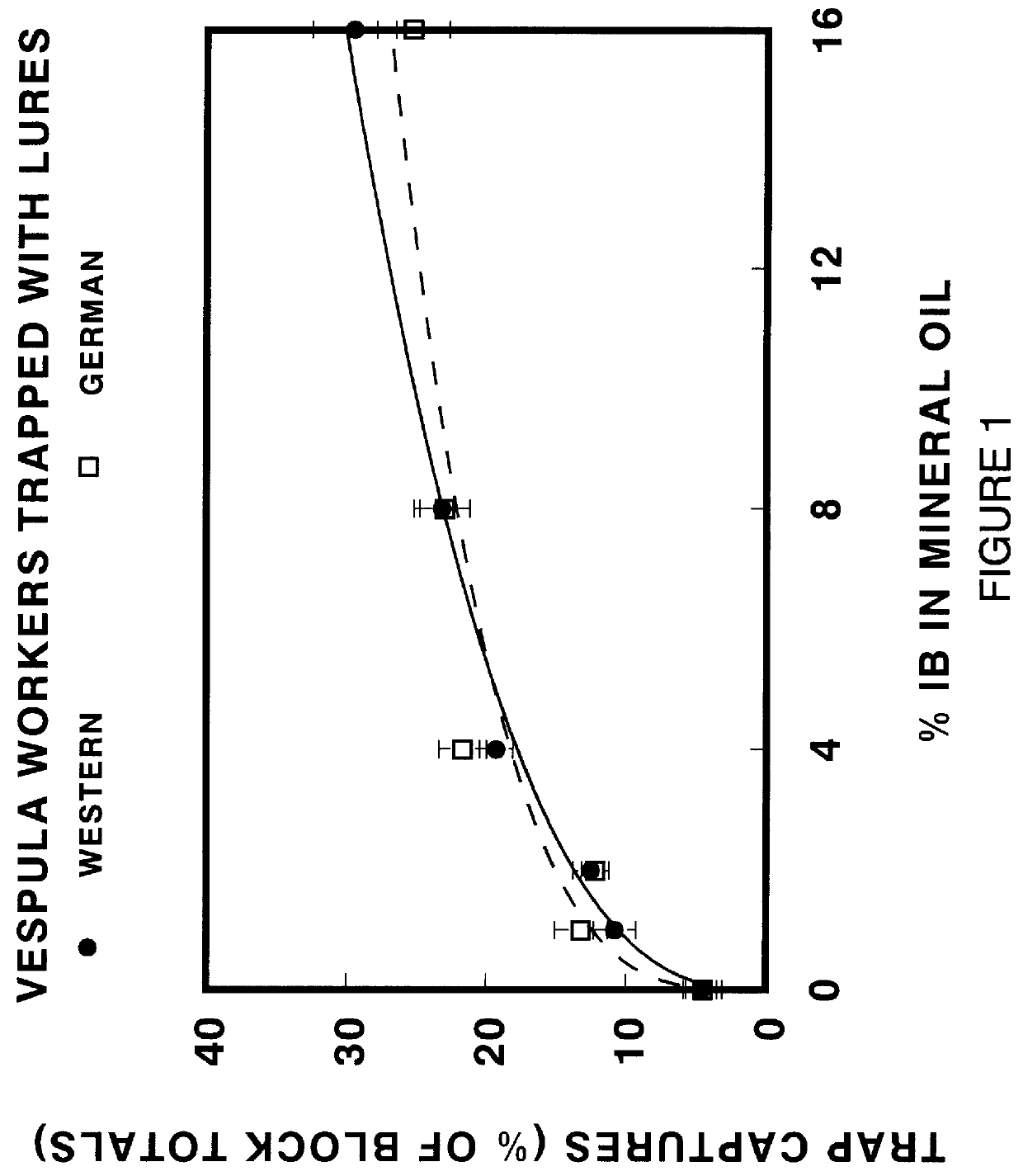

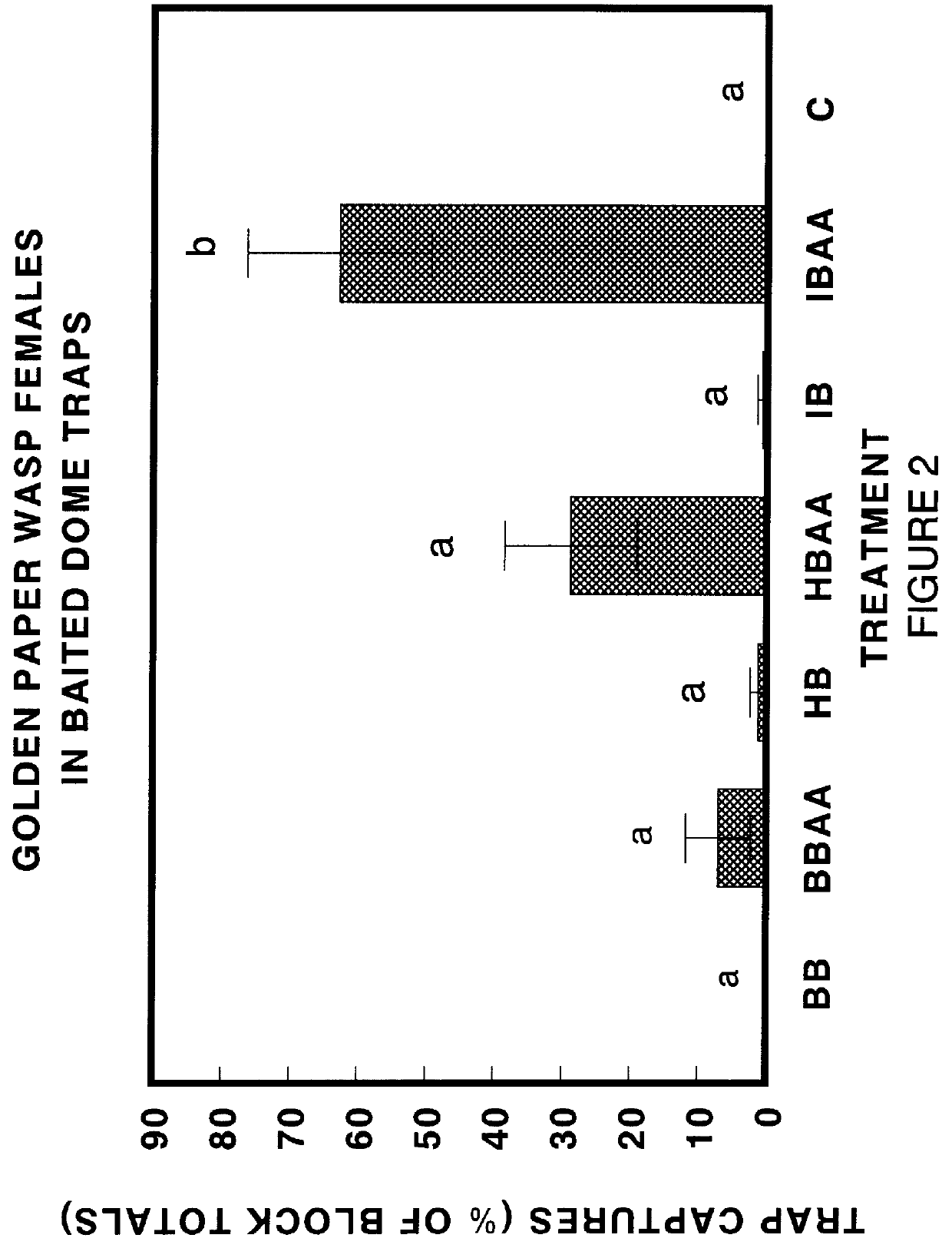

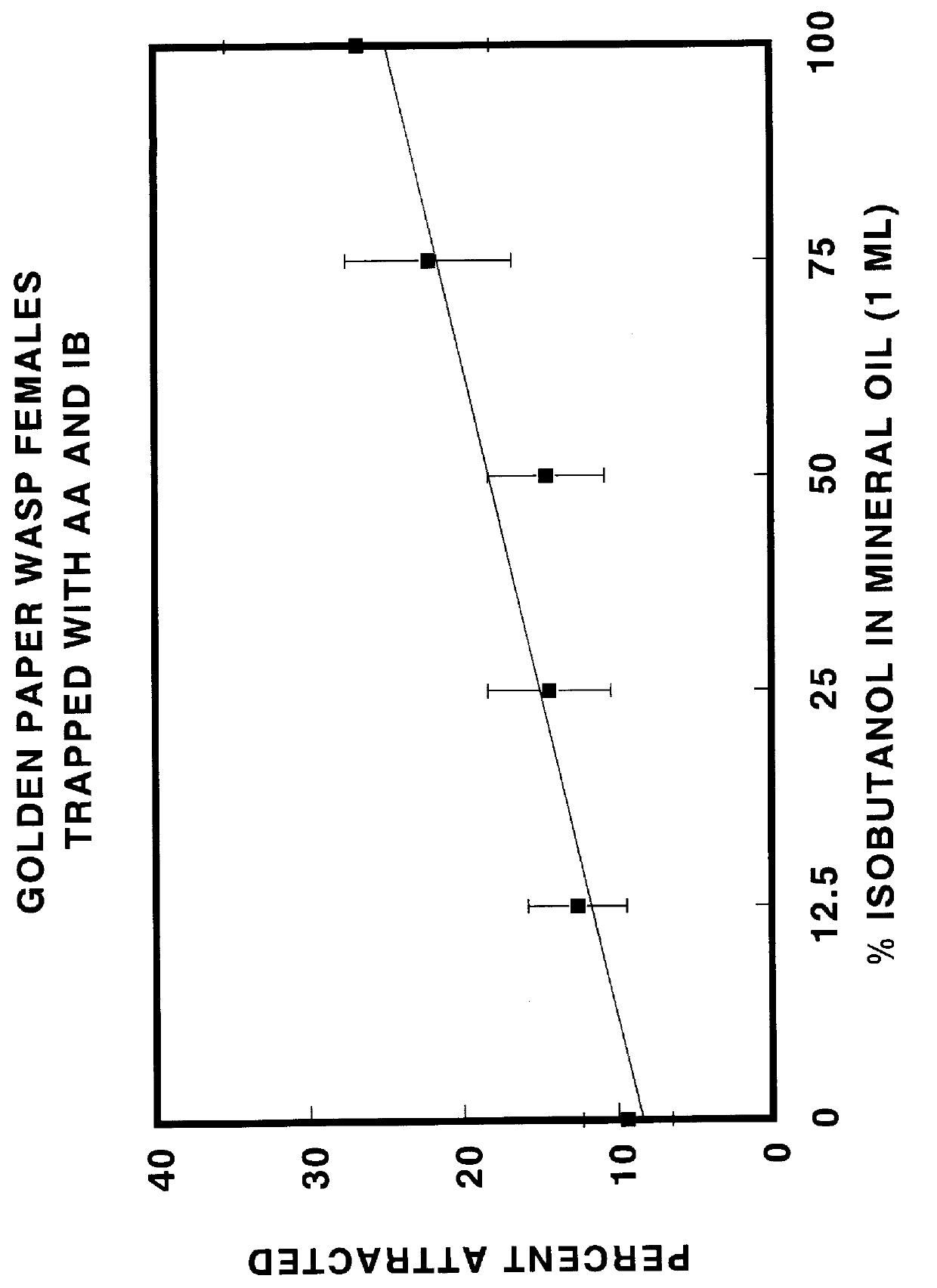

Chemical attractants for yellowjackets and paper wasps

InactiveUS6083498AEnhanced informationEfficient methodBiocidePeptide/protein ingredientsIsobutanolPropanol

Compositions and lures are described which provide vapor blends of acetic acid and one or more compounds selected from the group consisting of isobutanol, racemic 2-methyl-1-butanol, S-(-)-2-methyl-1-butanol, 2-methyl-2-propanol, heptyl butyrate, and butyl butyrate which function as highly effective attractants for yellowjacket wasps and paper wasps. By attracting wasps to traps or baits, the chemical attractants provide a means for detecting, surveying, monitoring, and controlling the wasps.

Owner:US SEC AGRI

Polypeptides with Ketol-Acid Reductoisomerase Activity

ActiveUS20140093930A1Reduced and eliminated acetolactate reductase activityReduced and eliminated dehydrogenase activitySugar derivativesMicroorganismsIsobutanolBiochemistry

Polypeptides having ketol-acid reductoisomerase activity are provided. Also disclosed are recombinant host cells comprising isobutanol biosynthetic pathways employing such polypeptides. Methods for producing isobutanol employing host cells comprising the polypeptides having ketol-acid reductoisomerase activity are also disclosed.

Owner:GEVO INC

High content environmental protection alcohol ether fuel for vehicle

InactiveCN101100618AHigh calorific valueImprove thermal efficiencyLiquid carbonaceous fuelsIsobutanolNitromethane

A high-content environmental-protecting alcohol ether fuel for vehicle consists of additives and methanol or alcohol 75-87 proportion. The additives contain methanol, alcohol, isopropyl alcohol, isobutanol, dimethylcuprate, n-amyl alkyl, dipropyl, cyclopentane, nitro-methane, dimethyl benzene, pinecone oil, cyclopentadienyl, poly-isobutylene, propane diamine, carbomethoxy formate, dimethoxyester carbonate, natural gasoline, hydrocarbon solvent oil, diisopropyl ester, dimethoxy-methane, petroleum ether, methyl tert-amyl ether, tert-amyl tert-butyl ether, lauryl phenol poly-ethenoxy ether, anti-static agent, metal-corrosive inhibitor, rubber plastic swelling inhibitor and anti-oxidant. It's clean and universal; it has excellent burning stability, shock resistance and dynamic character and less oil consumption.

Owner:鲁家政

Increased production of isobutanol in yeast with reduced mitochondrial amino acid biosynthesis

ActiveUS8465964B2Reduced activityCarbon-nitrogen lyasesMicroorganismsIsobutanolBranched-chain-amino-acid transaminase

Owner:GEVO INC

Alcohol dehydrogenases (ADH) useful for fermentive production of lower alkyl alcohols

The invention relates to suitable candidate alcohol dehydrogenase (ADH) enzymes for production of lower alkyl alcohols including isobutanol. The invention also relates to recombinant host cells that comprise such ADH enzymes and methods for producing lower alkyl alcohols in the same.

Owner:GEVO INC

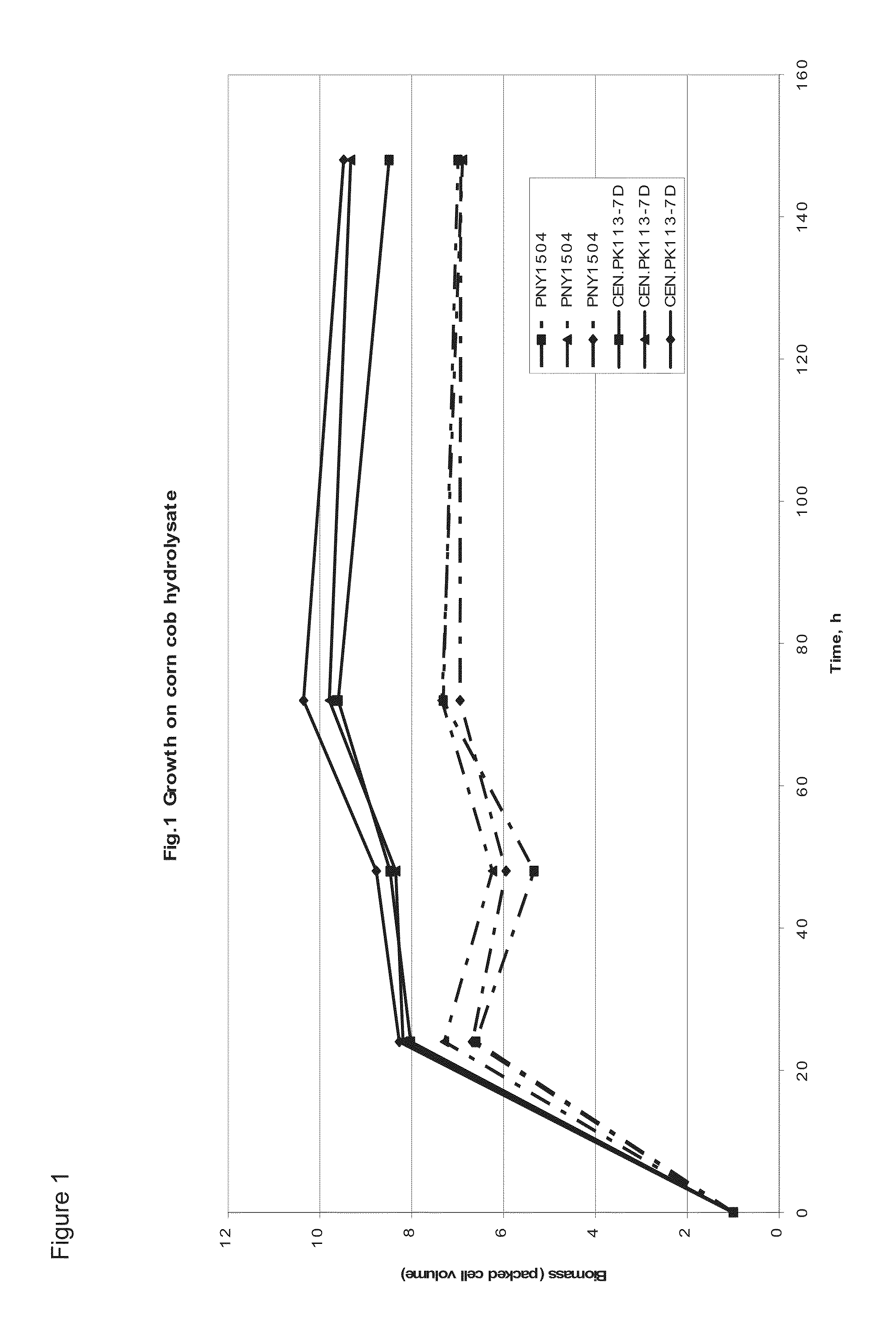

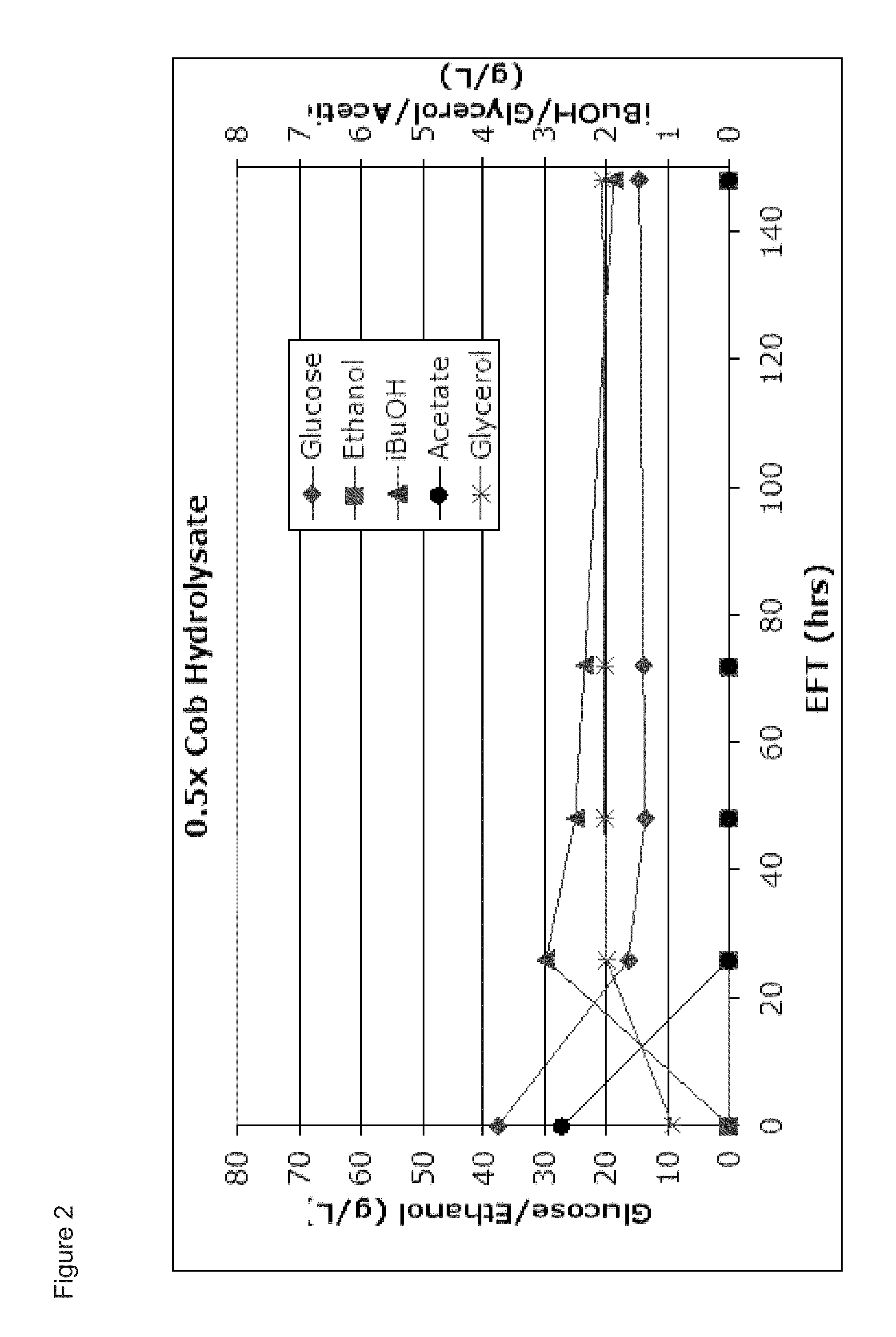

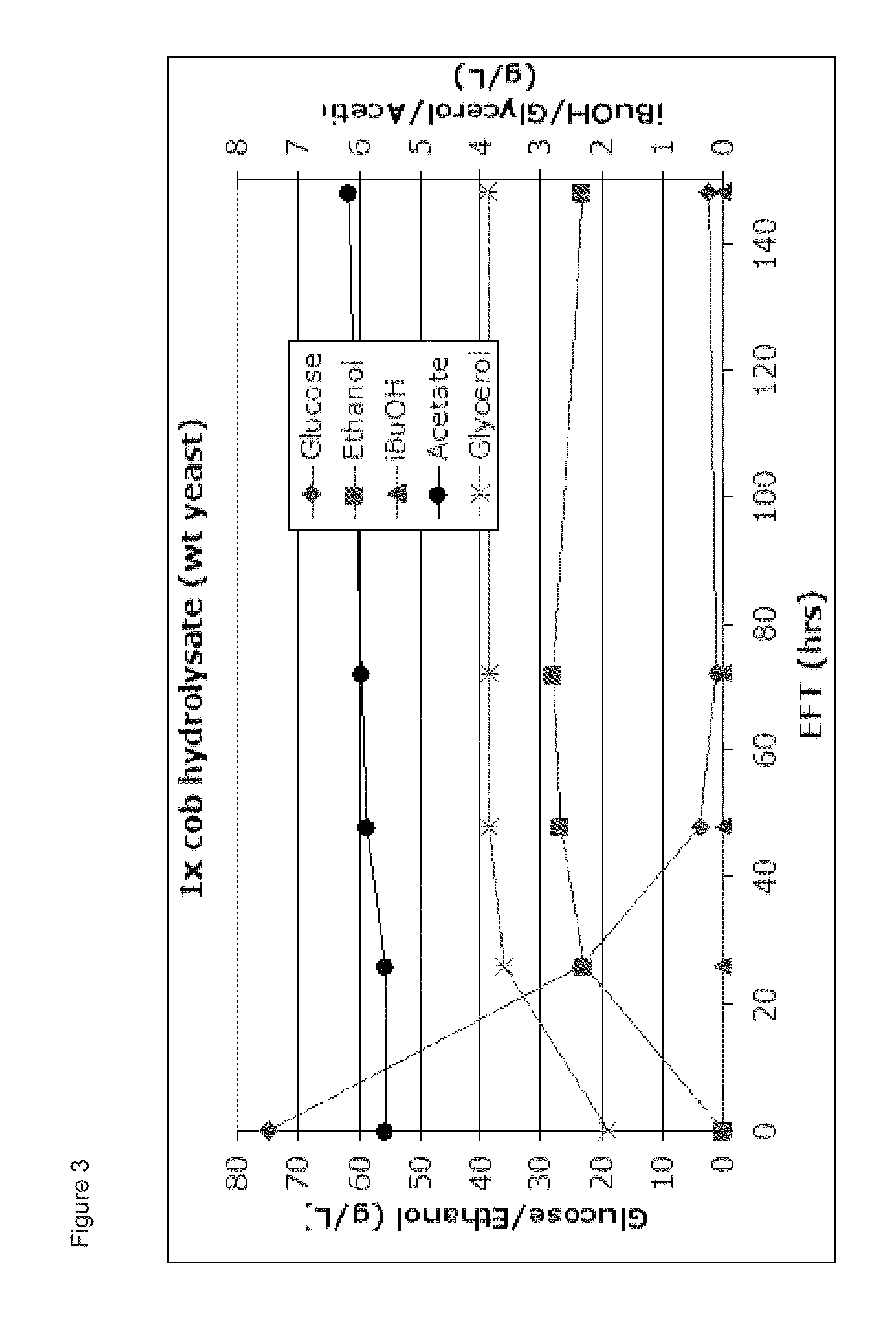

Lignocellulosic hydrolysates as feedstocks for isobutanol fermentation

InactiveUS20130035515A1Improved production of butanolOrganic compound preparationBiofuelsCelluloseIsobutanol

The invention relates generally to the field of industrial microbiology and butanol production from sources of 5-carbon sugars such as lignocellulosic hydrolysates. More specifically, the invention relates to the use of an xylulose or xylulose-5-phosphate-producing enzyme and micro-aerobic or anaerobic conditions to increase butanol production from such sugars and recovery of said butanol through ins situ product recovery methods.

Owner:BUTAMAXTM ADVANCED BIOFUELS

Electroplating effect imitated plastic paint and preparation method, diluent and process of using same

The invention discloses a plastic paint with simulated electroplating effect. The composition and the weight ratio of the invention are as follows: 30 to 45 of acrylic resin with 50 percent of solid content and 70 to 90 DEG C of Tg, 20 to 30 of cellulose acetate butyrate with 20 percent of solid content, 8 to 12 of triad copolymer vinyl chloride-acetate resin with 30 percent of solid content, 6 to 10 of non-floating aluminum and silver pulp with an average diameter less than or equal to 20 Mum, 0.3 to 0.5 of dispersant, 0.2 to 0.4 of flatting agent, 0.4 to 0.6 anti-settling agent, 6.0 to 10.0 of toluene, 3.5 to 6.0 of ethyl acetate, 3.5 to 6.0 methy isobutyl ketone, 3.0 to 5.0 of isobutanol and 4.0 to 7.0 of glycol butyl ether. The special diluent of the invention, according to the weight ratio, is made from the following components evenly mixed: 20 of white gas, 10 of toluene, 22 of ethyl acetate, 15 of acetone, 25 of isobutanol and 8 of glycol butyl ether. The main paint which comprises the composition and the diluent are evenly mixed according to the ratio of 1: 2-3, then the mixture is used for spray coating; the metallic appearance of the paint film obtained is very close to the effect of the electroplating, and the paint film has good alcohol resistance with high hardness and strong wear resistance, and also has simple process. The aluminum and silver pulp used is a common type, the cost of which is only 5 percent to 10 percent of the simulated electroplating aluminum and silver pulp and about 2 percent of electrosilvering.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Vehicle high-methanol content gasoline

InactiveCN102161919AImprove starting performanceCold start problem solvedLiquid carbonaceous fuelsIsobutanolButanedioic acid

The invention discloses vehicle high-methanol content gasoline, relates to carbon-containing fuels and solves the problems of difficult low-temperature startup, serious metal corrosion, inadequate power and susceptibility to generating precipitates of the conventional methanol gasoline. The vehicle high-methanol content gasoline comprises the following components in part by volume: 70 to 86 partsof methanol, 14 to 30 parts of gasoline component oil, 0.5 to 1 part of cosolvent, 0.1 to 0.2 part of antiseptic and rubber swelling inhibitor, 0.2 to 0.3 part of detergent and 0.01 to 0.05 part of coloring agent. The cosolvent consists of isobutanol, isopropyl ether, 2-isobutanol and tetrahydrofuran, the antiseptic and rubber swelling inhibitor consists of propargyl alcohol, butanedioic acid, hexakis(dihydrogen phosphate), N-methyl morpholine, cyclohexane and dimethyl phthalate, the detergent consists of normal propyl alcohol, isopropanol, limonene and cyclohexane, and the coloring agent is Sudan IV solution. The vehicle high-methanol content gasoline has high startability, high dynamic performance, high environmental protection performance, obvious anticorrosion effect and high safety.

Owner:山西丰喜新能源开发有限公司

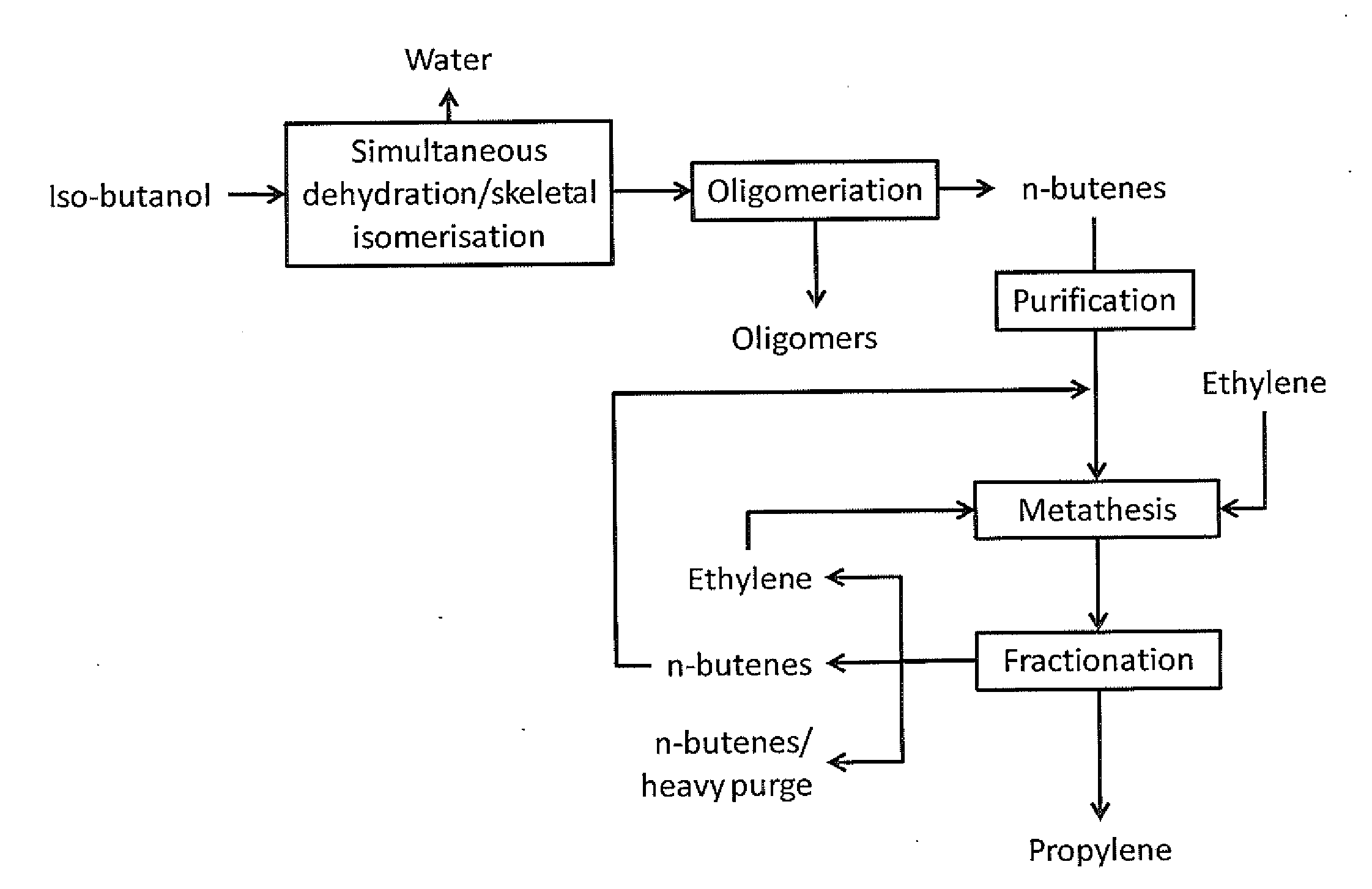

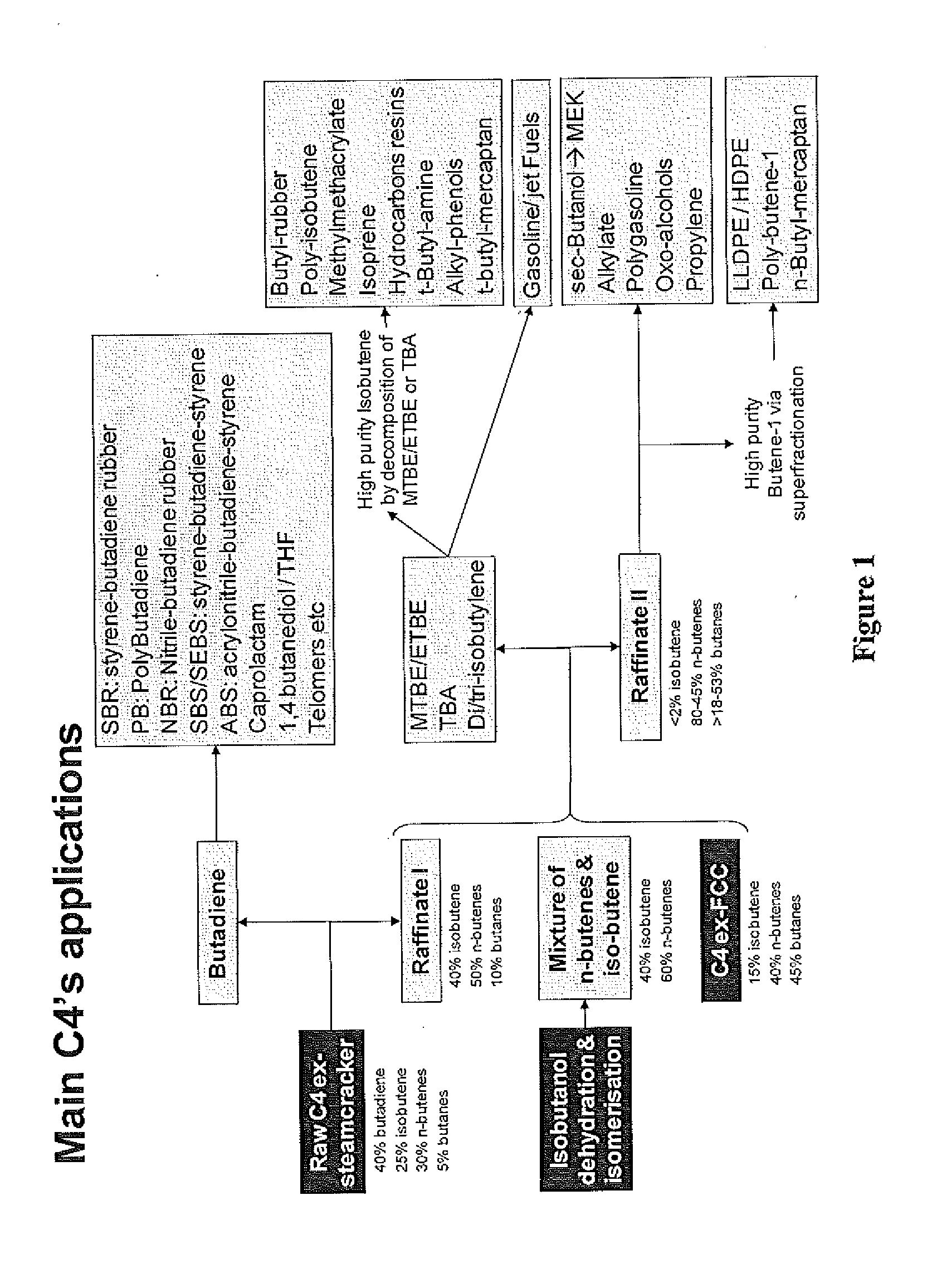

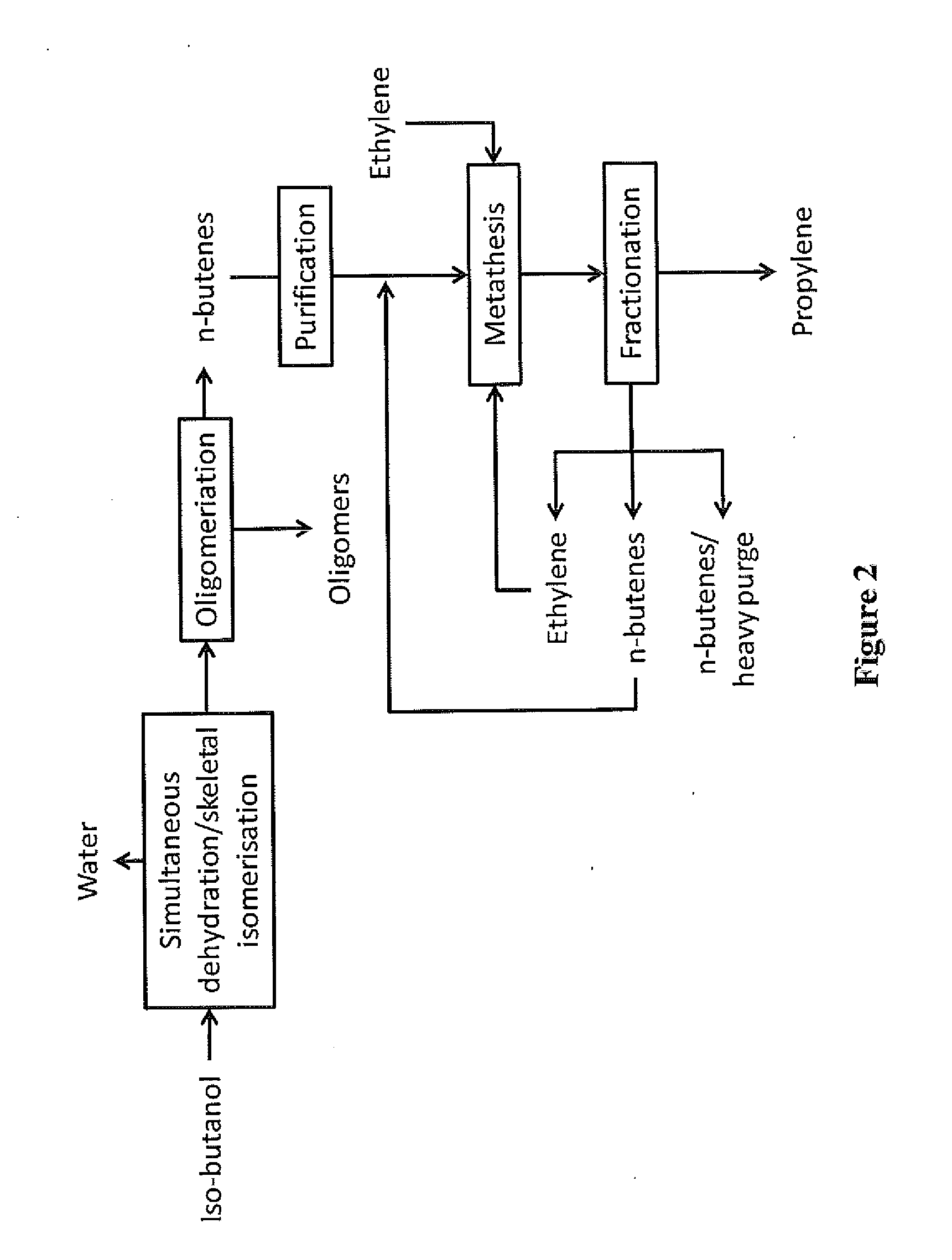

Production of propylene via simultaneous dehydration and skeletal isomerisation of isobutanol on acid catalysts followed by metathesis

ActiveUS20130245348A1High yieldCapital investment can be minimizedMolecular sieve catalystHydrocarbon purification/separationButeneIsobutanol

The present invention relates to a process for the production of propylene in which in a first step isobutanol is subjected to a simultaneous dehydration and skeletal isomerisation to make substantially corresponding olefins, having the same number of carbons and consisting essentially of a mixture of n-butenes and iso-butene and in a second step n-butenes are subjected to methathesis, said process comprising:a) introducing in a reactor a stream (A) comprising isobutanol, optionally water, optionally an inert component,b) contacting said stream with a catalyst in said reactor at conditions effective to dehydrate and skeletal isomerase at least a portion of the isobutanol to make a mixture of n-butenes and iso-butene,c) recovering from said reactor a stream (B), removing water, the inert component if any and unconverted isobutanol if any to get a mixture of n-butenes and iso-butene,d) fractionating said mixture to produce a n-butenes stream (N) and to remove the essential part of isobutene optionally recycled with stream (A) to the dehydration / isomerization reactor of step b),e) sending the stream (N) to a methathesis reactor and contacting stream (N) with a catalyst in said methathesis reactor, optionally in the presence of ethylene, at conditions effective to produce propylene,f) recovering from said methathesis reactor a stream (P) comprising essentially propylene, unreacted n-butenes, heavies, optionally unreacted ethylene,g) fractionating stream (P) to recover propylene and optionally recycling unreacted n-butenes and unreacted ethylene to the methathesis reactor.

Owner:TOTAL RES & TECH FELUY

Yeast with increased butanol tolerance involving filamentous growth response

Increasing tolerance to butanol in yeast has been accomplished by increasing activity of the filamentous growth response. Yeast with increased expression of MSS11p, a transcriptional activator of the filamentous growth response pathway had increased tolerance to isobutanol. These yeast may be used for improved butanol production.

Owner:GEVO INC

Yeast with increased butanol tolerance involving cell wall integrity pathway

Increasing tolerance to butanol in yeast has been accomplished by increasing activity of the cell wall integrity pathway. Yeast with increased expression of SLT2p, a mitogen activated protein kinase of the MAPK module of the cell wall integrity pathway had increased tolerance to isobutanol. These yeast may be used for improved butanol production.

Owner:GEVO INC

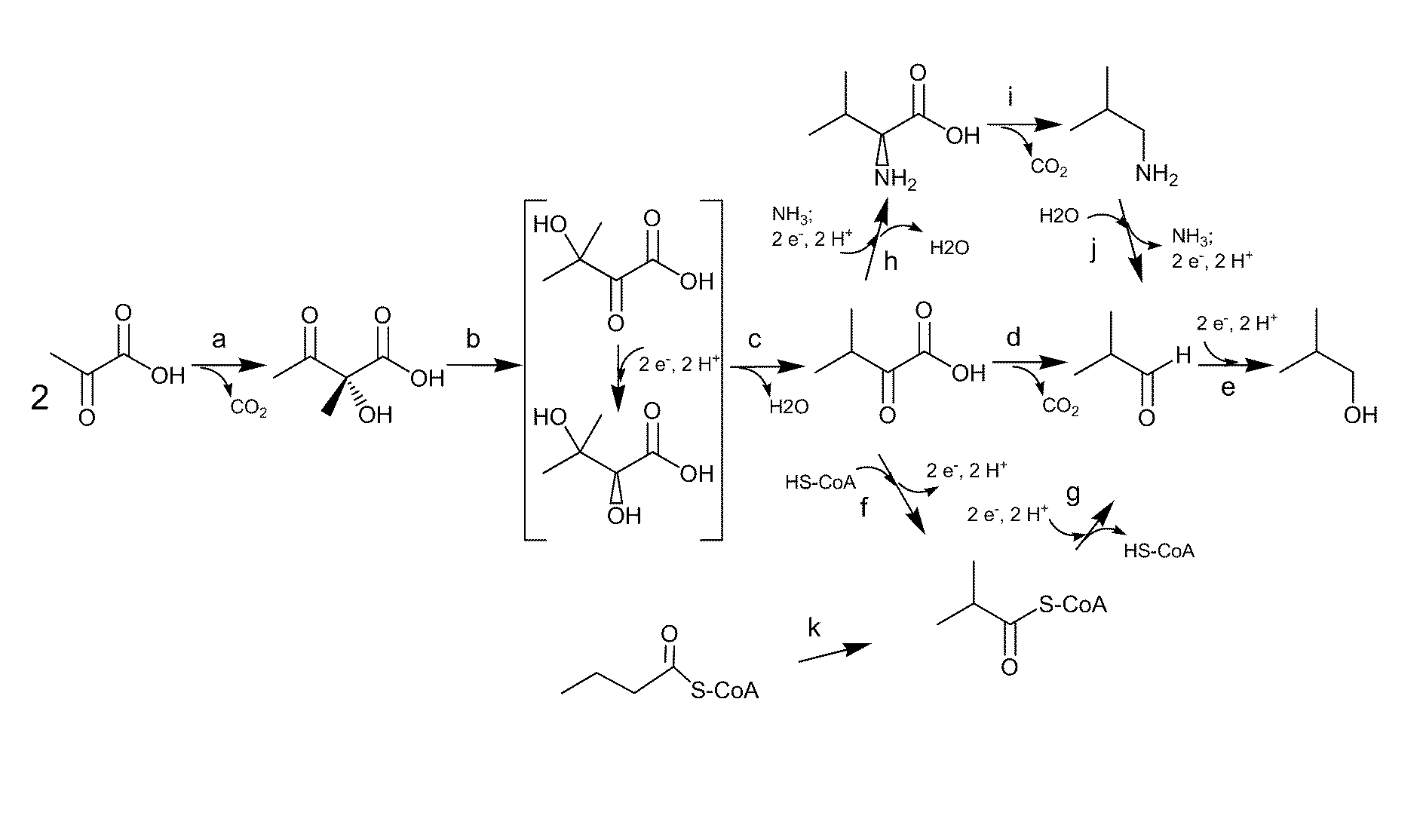

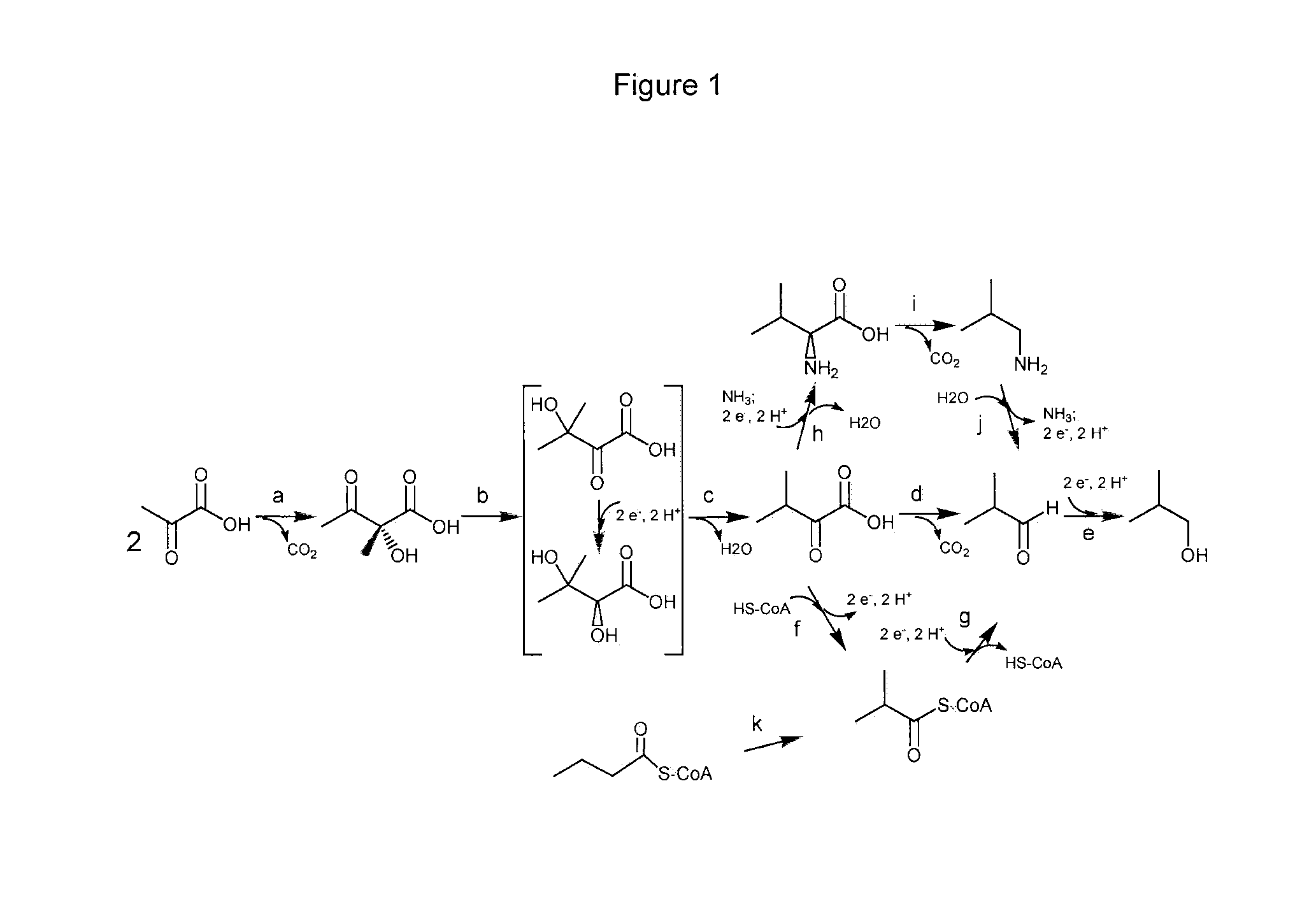

Biological Conversion of Multi-Carbon Compounds from Methane

Multi-carbon compounds such as ethanol, n-butanol, sec-butanol, isobutanol, tert-butanol, fatty (or aliphatic long chain) alcohols, fatty acid methyl esters, 2,3-butanediol and the like, are important industrial commodity chemicals with a variety of applications. The present invention provides metabolically engineered host microorganisms which metabolize methane (CH4) as their sole carbon source to produce multi-carbon compounds for use in fuels (e.g., bio-fuel, bio-diesel) and bio-based chemicals. Furthermore, use of the metabolically engineered host microorganisms of the invention (which utilize methane as the sole carbon source) mitigate current industry practices and methods of producing multi-carbon compounds from petroleum or petroleum-derived feedstocks, and ameliorate much of the ongoing depletion of arable food source “farmland” currently being diverted to grow bio-fuel feedstocks, and as such, improve the environmental footprint of future bio-fuel, bio-diesel and bio-based chemical compositions.

Owner:PRECIGEN INC

High and low voltage power distribution cabinet housing material and preparation method thereof

ActiveCN104151745AImprove performanceImprove insulation performanceDiethylene glycol monobutyl etherIsobutanol

The invention relates to the field of power supply materials, and discloses a high and low voltage power distribution cabinet housing material. The material is prepared from the raw materials of, by weight, 30-40 parts of polyvinyl chloride, 20-25 parts of silicon carbide, 10-12 parts of borax, 8-10 parts of quartz sand, 8-10 parts of phenolic resin, 8-9 parts of glycerol monostearate, 7-8 parts of isobutanol, 7-8 parts of polycarbonate, 5-7 parts of diethylene glycol monobutyl ether, 5-7 parts of decabromodiphenyl ethane, 2-3 parts of graphite, 2-3 parts of aluminum tripolyphosphate, 2-3 parts of antimony trioxide, 1-2 parts of glass fiber, and 1-2 parts of silica gel powder. According to the housing material provided by the invention, good insulation performance can be effectively maintained. Mechanical performance, heat conduction performance, and flame retardant performance of the material are greatly improved.

Owner:SHANDONG MENGQI ELECTRIC CO LTD

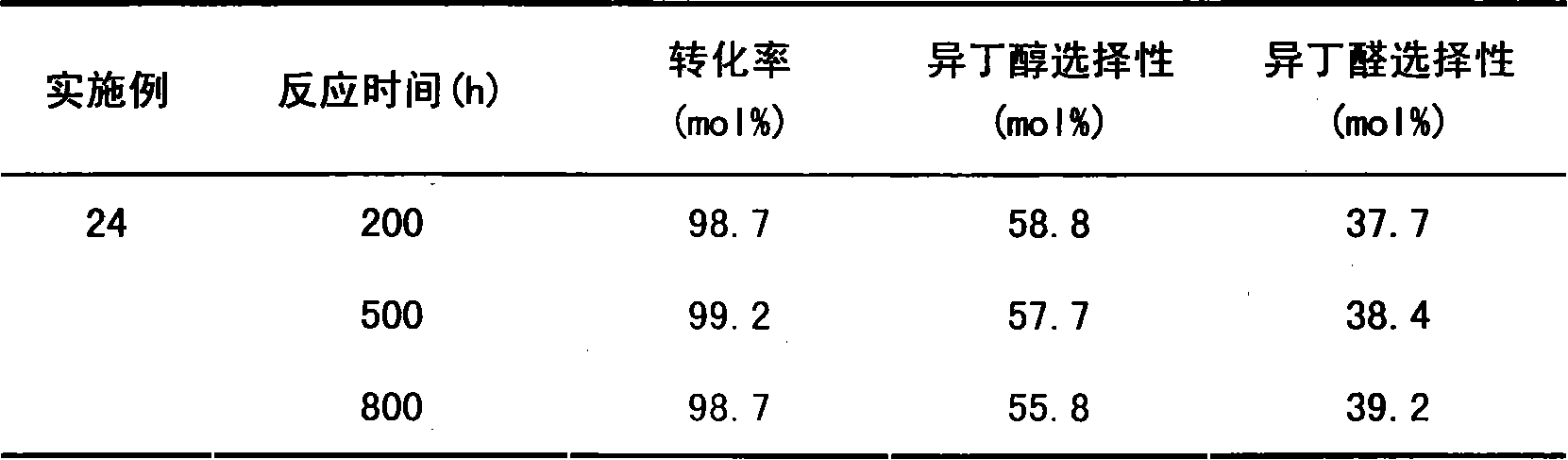

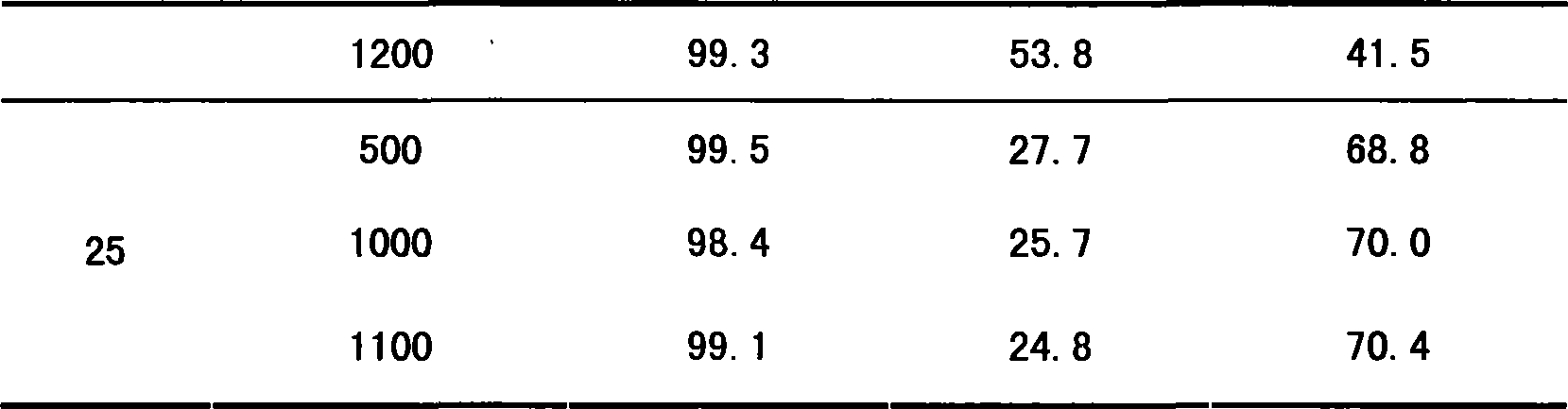

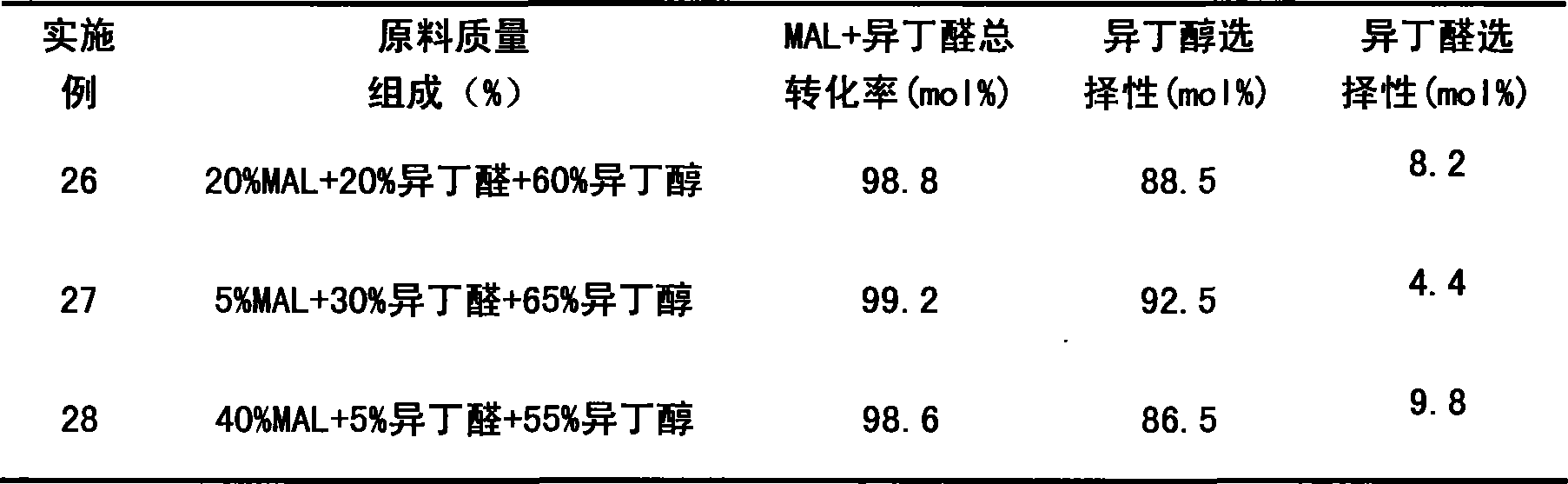

Method for preparing iso-butyraldehyde and isobutyl alcohol by methylacrolein hydrogenation

ActiveCN101239892ALow costHigh selectivityMolecular sieve catalystsOrganic compound preparationIsobutanolMetal catalyst

The invention relates to a method for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein. The method comprises using a supported metal catalyst, and hydrogenating methacrolein obtained by oxidating isobutene under gentle conditions. The invention provides a novel synthesis process for hydrogenation preparing isobutyraldehyde and isobutyl acohol from methacrolein which is obtained by air-oxidating low-utilization C4 material isobutene or tert-butanol. The methacrolein conversion rate is larger than 98%, the total selectivity of isobutyraldehyde and isobutyl acohol is larger than 95%, the performance of the catalyst is stable even the reaction lasts more than 1000 hours. The invention has the advantages of high activity and high selectivity of catalyst, good stability of catalyst, cheap material isobutene, low productin cost of isobutene, environment-protecting process, and suitability of industrialisation production. The process is flexible, can change the proportion of isobutyraldehyde and isobutyl acohol through adjusting the reaction process condition, thereby cogenerating isobutyraldehyde and isobutyl acohol, or only generating isobutyl acohol by cycling and hydrogenating isobutyraldehyde.

Owner:SHANGHAI HUAYI NEW MATERIAL

Silicon tungsten, phosphorus heteropoly tungstic acid load type catalyzer used for esterification reaction, manufacturing method and application thereof

The invention is a silicotungstic and phosphotungstic heteropoly acid load catalyst used for esterification reaction, which comprises the following components: Keggin structure silicotungstic acid H3SiW12O40.xH2O and phosphotungstic H3PW12O40.xH20, the content occupies 10 to 50 quality per centage of the amount of the catalyst; the carrier is H Beta zeolite. The invention adopts soaking method to prepare the solid silicotungstic and phosphotungstic heteropoly acid catalyst load on the H Beta zeolite, which can be used for catalyzing the esterification reaction of etic acid, isobutanol, isobutanol and ethanol, but also can be used for catalyzing esterification reaction of lactic acid and isobutanol to synthesis n-butyl acetate, isobutyl acetate, ethyl acetate and N-Butyl Lactate. The invention has the advantages of good stability, high activity and good selectivity, but also can used as inhomogeneous catalyst which is easy to be separated with reaction product and can use the prepared and formed catalyst powder in the continuous operating fixed bed reactor. The invention is used in the techinics of esterification reaction catalyzing rectifying.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

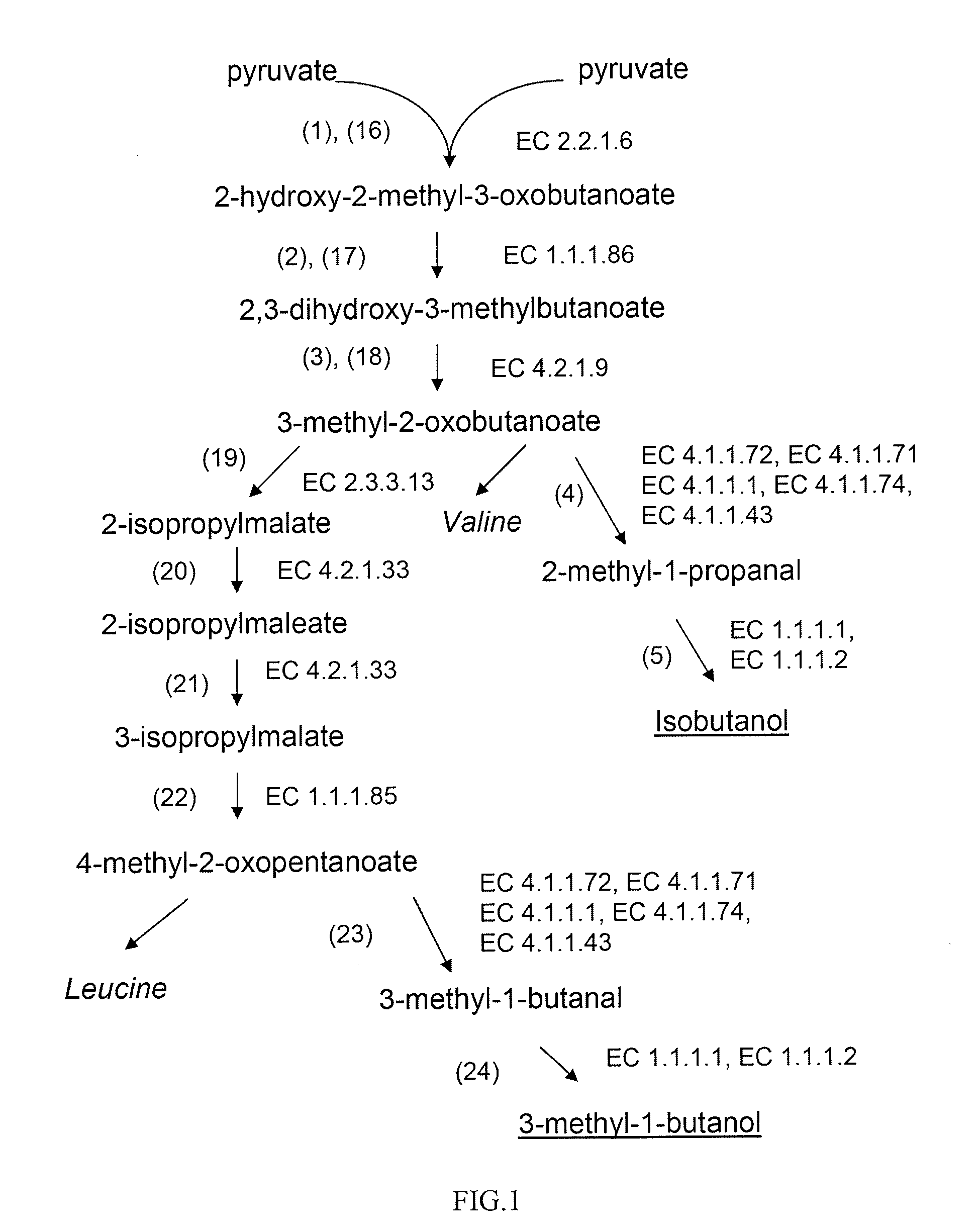

Fermentive production of four carbon alcohols

Methods for the fermentative production of four carbon alcohols is provided. Specifically, butanol, preferably isobutanol is produced by the fermentative growth of a recombinant bacterium expressing an isobutanol biosynthetic pathway.

Owner:GEVO INC

Process for covering water transfer printing on wood plastic, plastic and metallic products

The invention discloses a water-coated transfer printing process for wood, plastic, and metal products, which comprises the following steps: according to the necessary background color, spraying oil paint on the surfaces of the wood, the plastic, and the metal products; spreading a water-coated transfer printing film on the water surface by putting the surface with printing ink patterns to face upwards; spraying an activator on the water-coated transfer printing film evenly through a spray gun when the water-coated transfer printing film is softened and spread levelly; and according to the positions of the patterns floating on the water surface, pressing an obtained product downwards into the water for 2 to 10 seconds and taking out the product, and transferring the patterns on the water-coated transfer printing film to the surface of the product under the action of water pressure. The process further comprises the following steps: washing the obtained product clean by water and then putting the product into a drying furnace to be dried at a temperature between 50 and 70 DEG C; or using a blowing gun to blow off the water, drying the product at room temperature, spraying a layer of transparent oil paint on the surface of the product, putting the product in the drying furnace and curing the product at a temperature between 50 and 160 DEG C. The compositions of the activator are as follows according to percentage by weight: 33 percent of xylene, 15 percent of butyl acetate, 15 percent of methyl acetate, 10 percent of methyl isobutyl ketone, 5 percent of isobutanol, 8 percent of isophorone, 5 percent of methyl methacrylate, 7 percent of cyclo ethyl ketone, and 2 percent of nitrocellulose resin.

Owner:张艳 +1

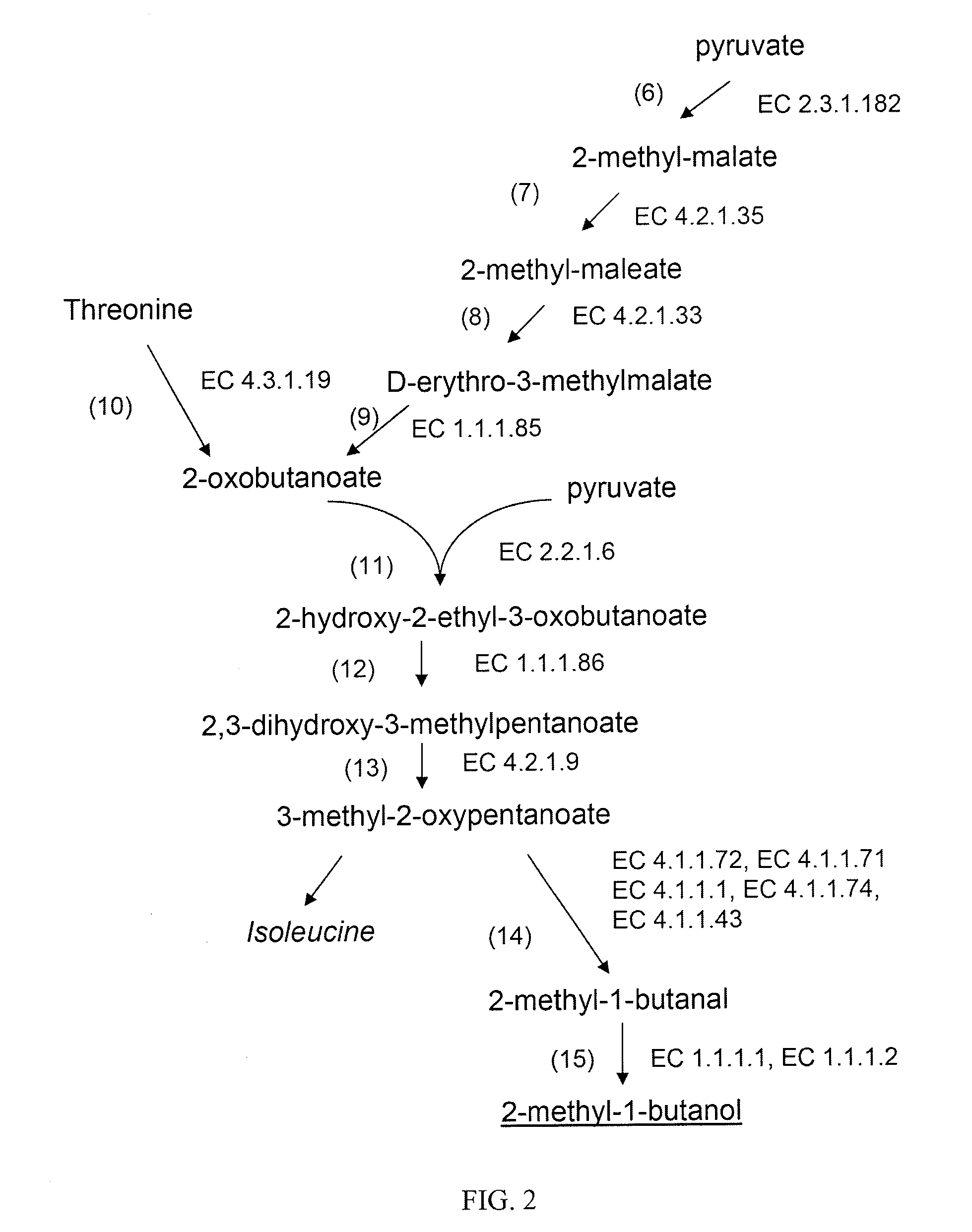

Production of branched-chain alcohols by photosynthetic microorganisms

The present invention provides genes, polypeptides and expression constructs therefor, recombinant photosynthetic microorganisms, and method of use thereof, such as for the production of branched-chain alcohols (including 2-methyl-1-butanol, 3-methyl-1-butanol, and isobutanol) and derivatives thereof for a variety of uses.

Owner:SYNTHETIC GENOMICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com