Patents

Literature

501 results about "Diethylene glycol monobutyl ether" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Environmentally-friendly high-performance water-based woodware paint and using method thereof

ActiveCN102051096AGood weather resistanceGood quick dryingPolyurea/polyurethane coatingsDiethylene glycol monobutyl etherWater based

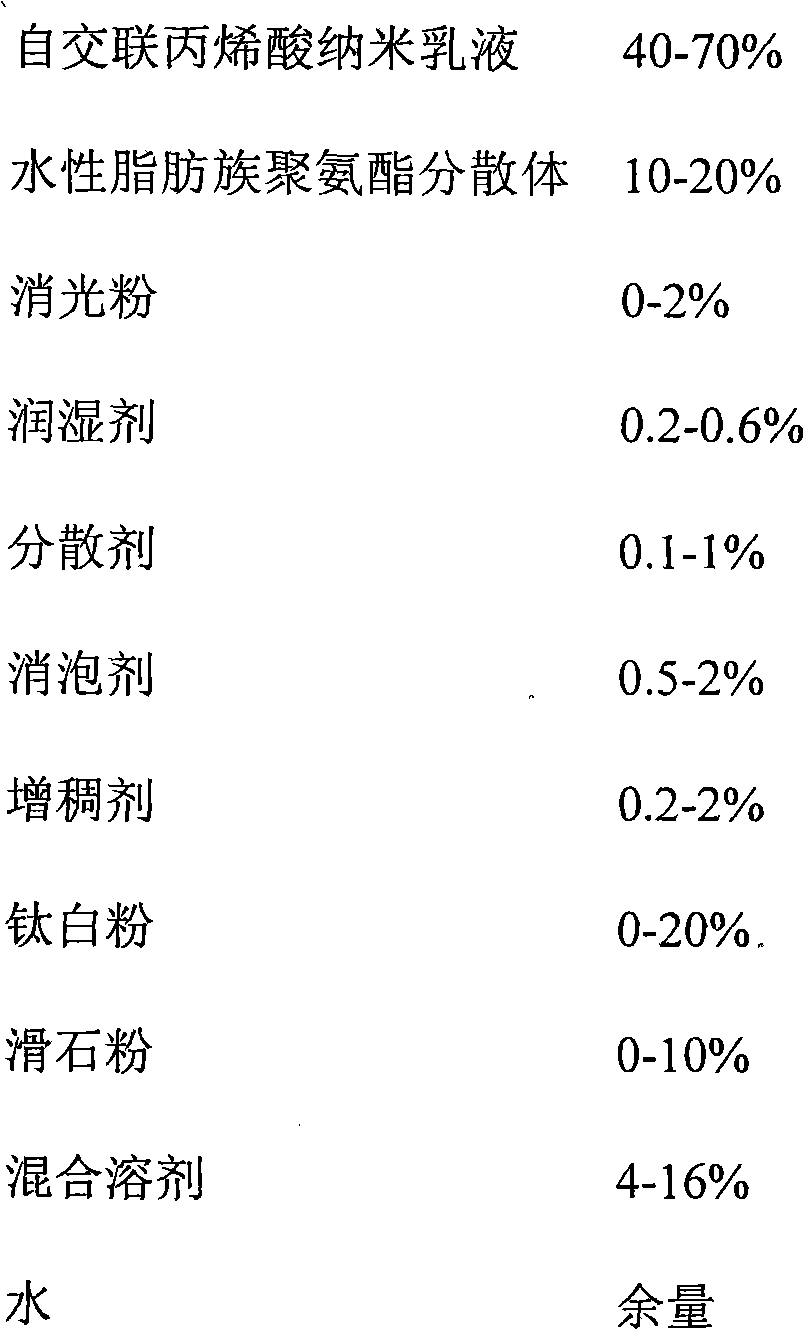

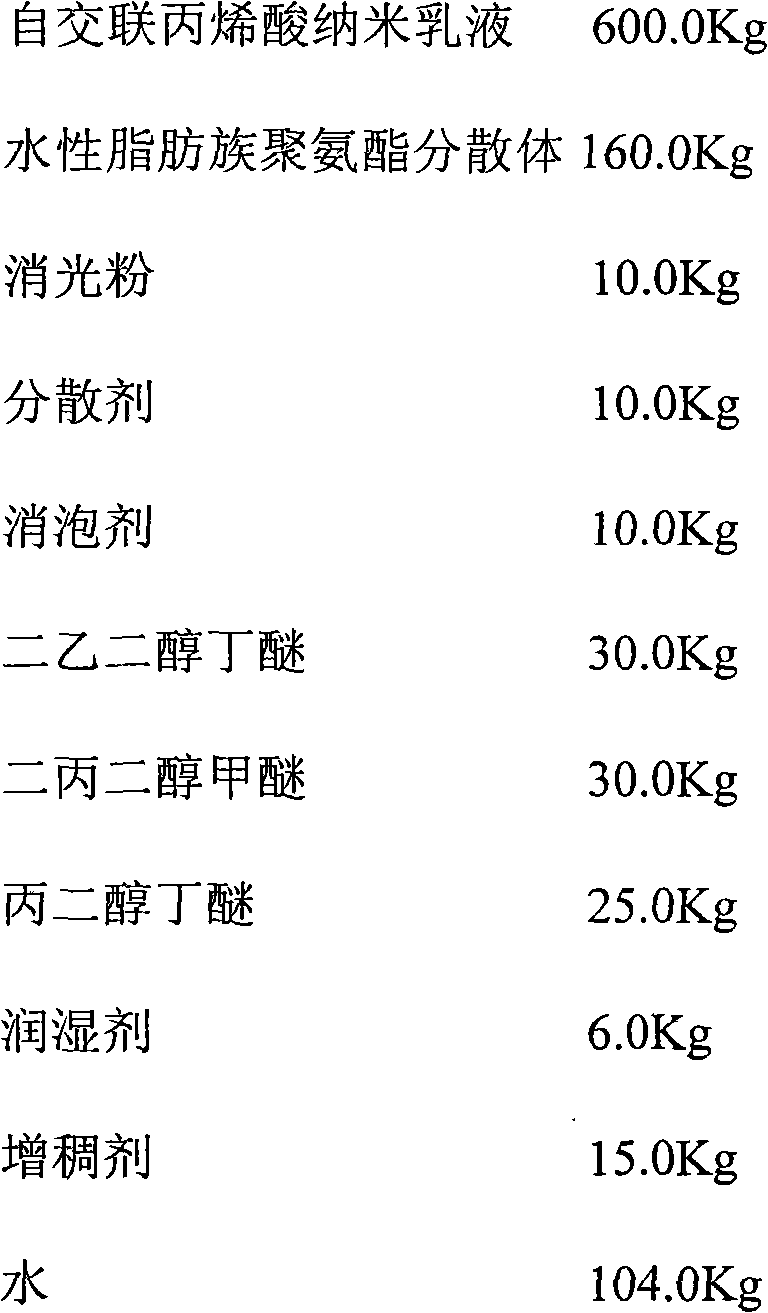

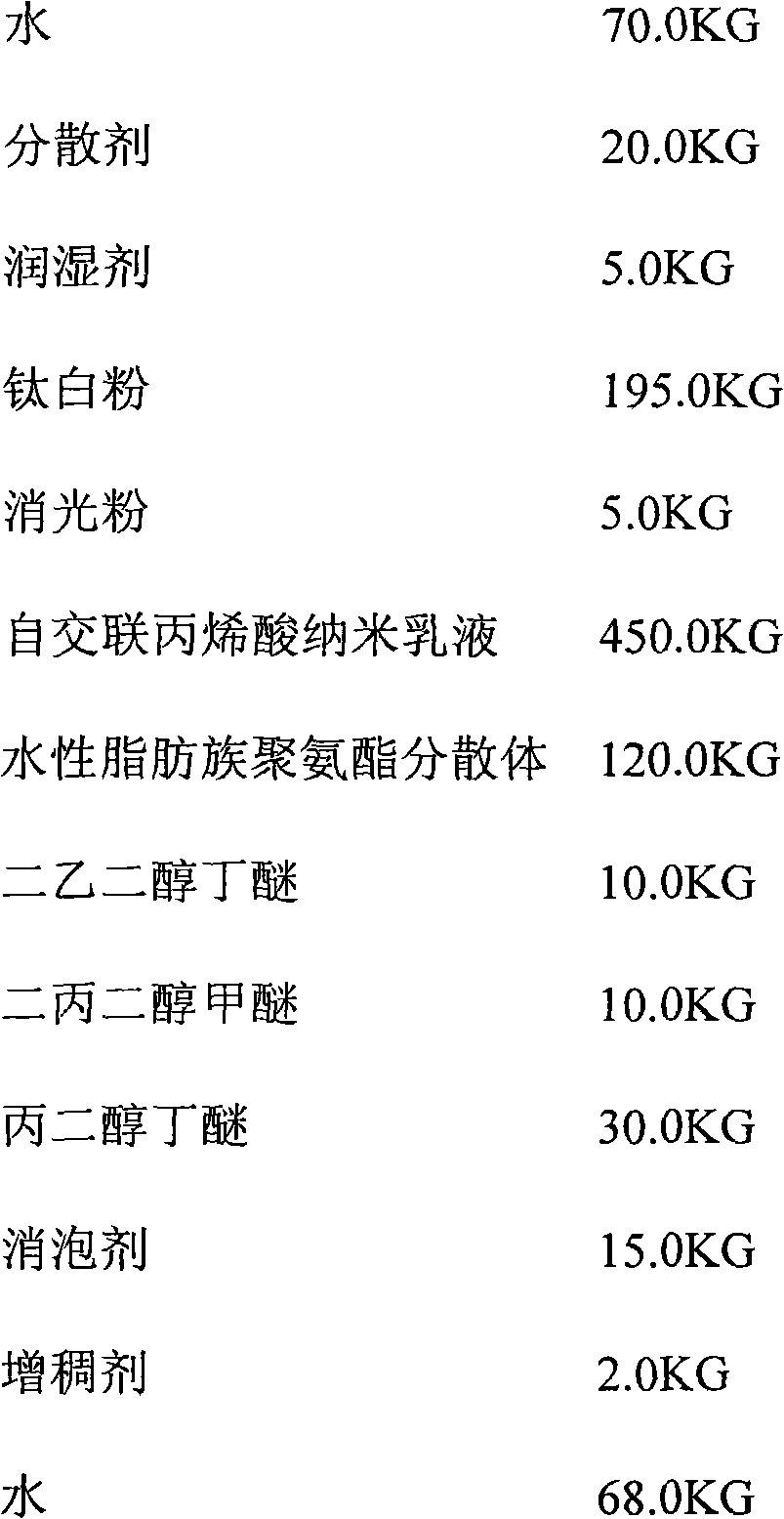

The invention discloses an environmentally-friendly high-performance water-based woodware paint and a using method thereof. The environmentally-friendly high-performance water-based woodware paint comprises 40 to 70 weight percent of self-crosslinking acrylic nano-emulsion and 10 to 20 weight percent of water-based aliphatic polyurethane dispersion. The water-based woodware paint is mainly prepared from the self-crosslinking acrylic emulsion with high triglyceride (Tg) content and weather resistance, so that a paint film has high quick-drying property, chemical resistance and weather resistance, and economy; the self-crosslinking acrylic emulsion is compounded with castor oil modified aliphatic polyurethane dispersion, so that the paint film has high adhesion, hardness, fullness, weather resistance, dry heat resistance and block resistance; and diethylene glycol monobutyl ether is matched with dipropylene glycol methyl ether and propylene glycol monobutyl ether, so that the film forming property of the paint film is ensured, and high drying property is achieved.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

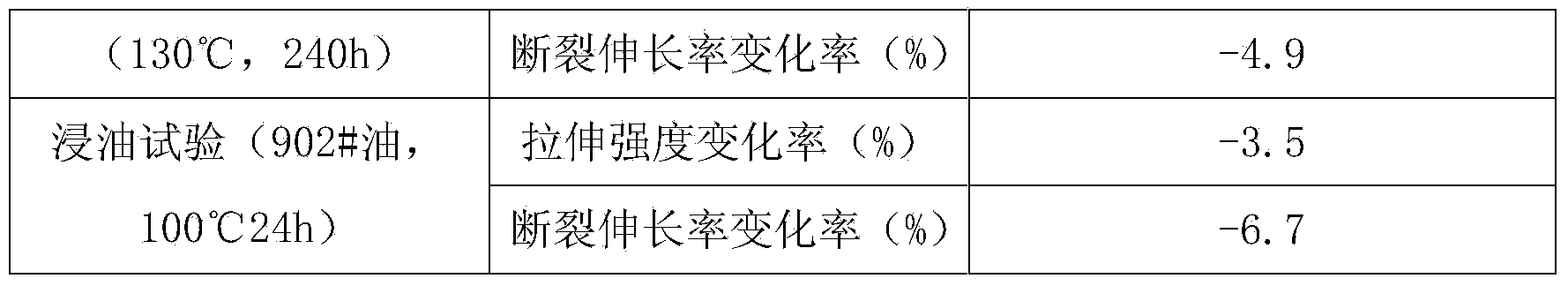

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

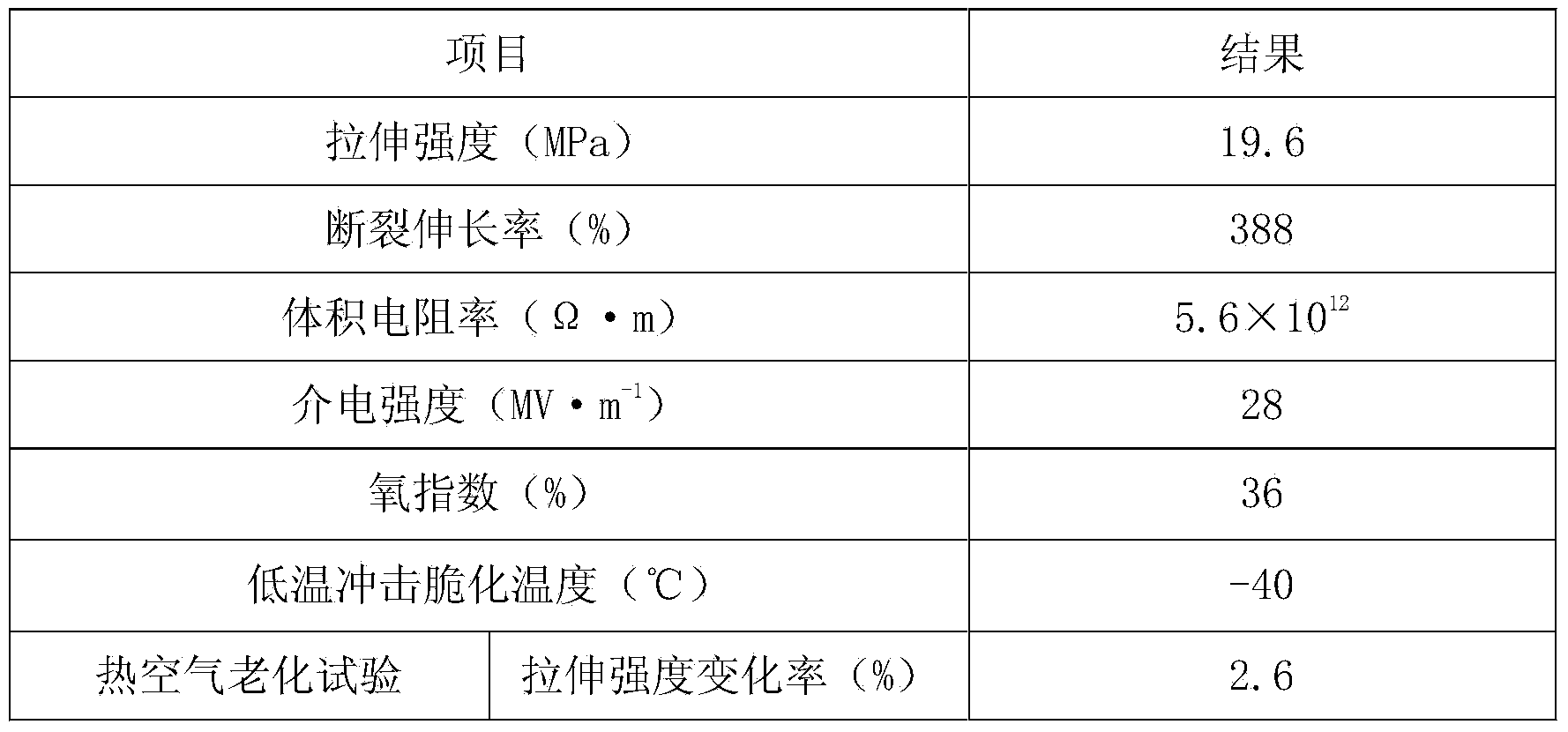

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

Polymerization Inhibitors for Inhibiting the Polymerization of Vinyl Compounds

InactiveCN102295499AReduce dosageReduce consumptionOrganic compounds purification/separation/stabilisationOrganic compound preparationBenzoquinoneDiethylene glycol monobutyl ether

A polymerization inhibitor for inhibiting the polymerization of vinyl compounds, the polymerization inhibitor is a composition, including component A and component B. Wherein: Component A is one or a mixture of two or more of piperidine oxygen free radicals, nitrophenol or benzoquinone; Component B is diethylene glycol monomethyl ether, diethylene glycol dimethyl ether or diethylene glycol One or more mixtures of monobutyl ethers; in parts by weight, component A:component B=1:(0.5-2.0). The polymerization inhibitor may also include solvent dimethylformamide, toluene or xylene. Compared with the prior art, the advantage of the present invention is that when the solution-like polymerization inhibitor is prepared with a solvent, the amount of solvent is reduced, the concentration of effective components is increased, and the consumption of solvent is reduced; component A and component B are compounded and used After that, it has better polymerization inhibition performance, so that the ideal polymerization inhibition effect can be obtained by adding less polymerization inhibitor to the vinyl compound system.

Owner:CHINA PETROLEUM & CHEM CORP +1

High and low voltage power distribution cabinet housing material and preparation method thereof

ActiveCN104151745AImprove performanceImprove insulation performanceDiethylene glycol monobutyl etherIsobutanol

The invention relates to the field of power supply materials, and discloses a high and low voltage power distribution cabinet housing material. The material is prepared from the raw materials of, by weight, 30-40 parts of polyvinyl chloride, 20-25 parts of silicon carbide, 10-12 parts of borax, 8-10 parts of quartz sand, 8-10 parts of phenolic resin, 8-9 parts of glycerol monostearate, 7-8 parts of isobutanol, 7-8 parts of polycarbonate, 5-7 parts of diethylene glycol monobutyl ether, 5-7 parts of decabromodiphenyl ethane, 2-3 parts of graphite, 2-3 parts of aluminum tripolyphosphate, 2-3 parts of antimony trioxide, 1-2 parts of glass fiber, and 1-2 parts of silica gel powder. According to the housing material provided by the invention, good insulation performance can be effectively maintained. Mechanical performance, heat conduction performance, and flame retardant performance of the material are greatly improved.

Owner:SHANDONG MENGQI ELECTRIC CO LTD

Long-acting emulsion-type antirust fluid

InactiveCN101608310AGood oil solubilityGood water solubilityDiethylene glycol monobutyl etherBarium salt

The invention relates to a long-acting emulsion-type antirust fluid used for metal rust prevention. Every 100 parts of the antirust fluid include the following components according to parts by weight: 3-15 oil soluble surfactant, 1-10 alcohol ether type couplant, 1-10 oily-type rust preventive and the balance base oil, wherein the oil soluble surfactant is any one of petroleum sodium sulfonate with molecular weight ranging from 300 to 800, sodium heavy alkylbenzene sulfonate and sodium sulfanilate, the alcohol ether type couplant is any one of ethyl alcohol, ethyl ether, butyl ether, diethylene glycol monobutyl ether, diethylene glycol propyl ether, butyl glycol ether and ethylene glycol propyl ether, the oily-type rust preventive is any one of barium petroleum sulfonate, dinonyl naphthalenesulfonic acid barium salt and barium soap of petroleum ester oxide, and the base oil is any one of cycloalkyl base oil and paraffin base oil. The long-acting emulsion-type antirust fluid has the advantages of meeting the demands of short-term rust prevention of metal and having lower using cost.

Owner:NANJING KERUN LUBRICANTS

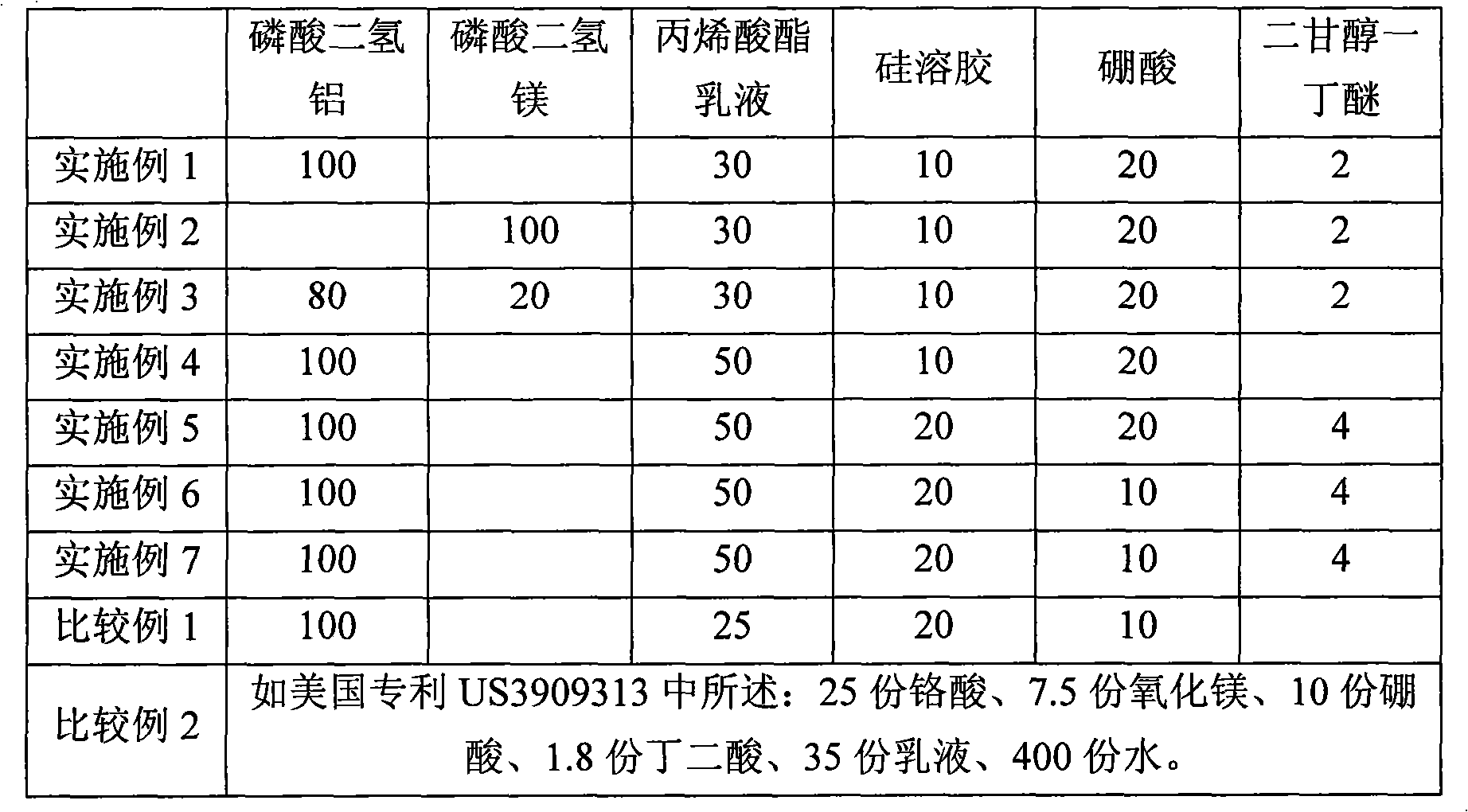

Insulation environment friendly paint for non-oriented electrical steel

ActiveCN101358096AImprove insulation performanceImprove rust resistanceCoatingsDiethylene glycol monobutyl etherEmulsion

The present invention relates to an insulating, environment-friendly coating for non-oriented electrical steel, which belongs to the technical field of electrical steel coatings. The coating contains the following ingredients calculated according to the dry weights of the substances: 20 percent to 60 percent of dihydric phosphate; 20 percent to 40 percent of acrylate emulsion; 2 percent to 20 percent of boracic acid; 0.5 percent to 15 percent of silicasol; 0 percent to 5 percent of diethylene glycol monobutyl ether; all are weight percentages. The coating of the present invention is an environment-friendly coating which does not contain chrome; the coating, the surface of which is shiny and uniform, has good insulating property, adhesive property, rust-resisting property and heat-resisting property; moreover, the coating has good wetting property and is characterized by convenient coating and little foam amount.

Owner:SHOUGANG CORPORATION

Method for purifying ethylenediamine

ActiveCN101723837AHigh purityAvoid corrosionAmino compound purification/separationEthylenediamineDiethylene glycol monobutyl ether

The invention discloses a method for purifying ethylenediamine, comprising the following steps: (1) heating extractant, feeding the extractant in to an extracting tower from the upper part of the extracting tower, gasifying 60.0-92.0% water-bearing ethylenediamine, feeding the ethylenediamine into the lower part of the extracting tower, making the ethylenediamine reversely contact the extractant on the upper part of the extracting tower in the extracting tower, discharging water from the top of the extracting tower and separating the mixture of the ethylenediamine and the extractant at the bottom of the extracting tower, wherein the extractant is diethylene glycol monomethyl ether, diethylene glycol dimethyl ether, triethylene glycol dimethyl ether or diethylene glycol monobutyl ether; and (2) heating the mixture of the ethylenediamine and the extractant, feeding the mixture of the ethylenediamine and the extractant to the middle part of the extracting tower, rectifying the mixture ofthe ethylenediamine and the extractant in a rectifying tower, separating the ethylenediamine on the top of the rectifying tower and discharging the extractant from the bottom of the rectifying tower.The method is mainly used for purifying the ethylenediamine.

Owner:山西玉龙化工有限公司

Cutting fluid containing waste engine oil and preparation method therefor

InactiveCN103710127AImprove the lubrication effectGood extreme pressure and anti-wear propertiesAdditivesBase-materialsDiethylene glycol monobutyl etherPhytic acid

Provided is a cutting fluid containing waste engine oil. The cutting fluid is prepared from the following raw materials, by weight, 12-14 parts of waste engine oil, 1-2 parts of triethanolamine, 4-6 parts of amino-acid ester, 2-3 parts of phytic acid, 2-3 parts of dodecyl dimethyl benzyl ammonium chloride, 1-2 parts of nanoscale graphite micropowder, 14-16 parts of diethylene glycol monobutyl ether, 5-8 parts of propylene glycol, 1-2 parts of sodium laurate, 6-8 parts of auxiliary agents and 200 parts of water. Through application of nanoscale graphite micropowder, the cutting fluid has excellent lubricating property and extreme pressure resistance. Through application of waste engine oil, the cost is lowered. The cutting fluid has good antirust performances, contains no substances of sodium salt, phenol, chlorinated paraffin, mineral oil and the like, has no damage to human body, and is a environmentally friendly and green product.

Owner:MAANSHAN HENGYI MACHINERY MFG

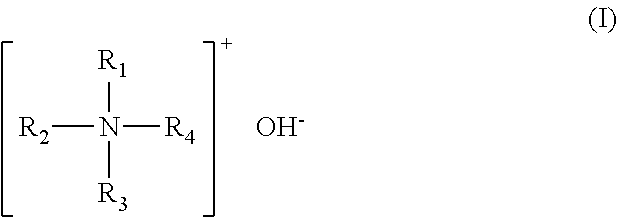

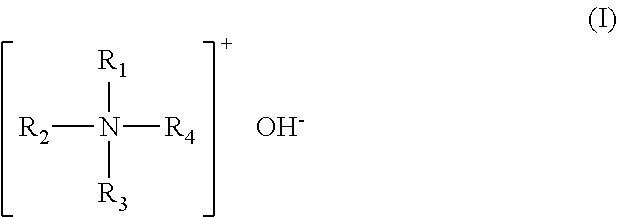

Photoresist stripping solution

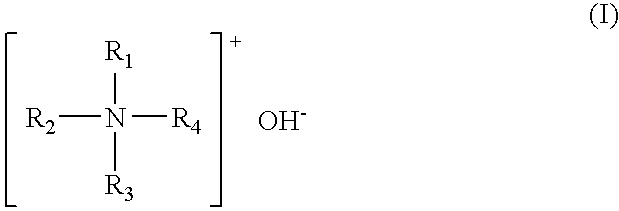

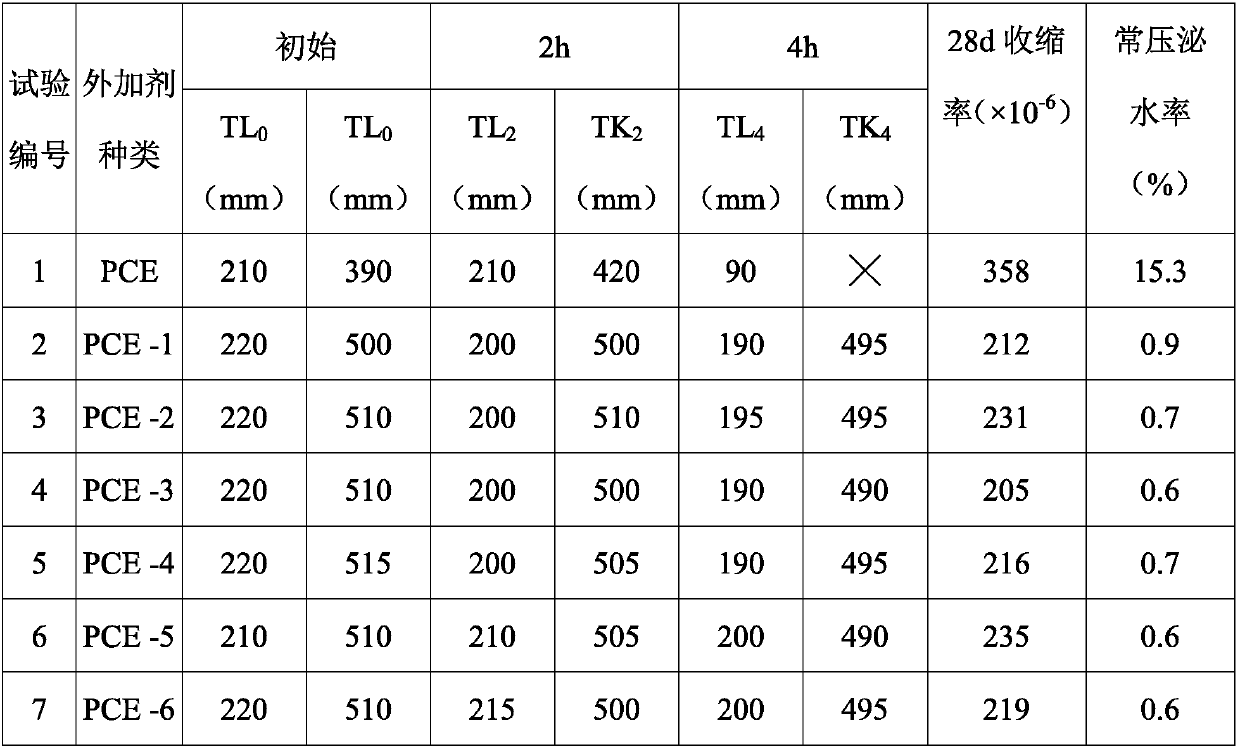

InactiveUS20070078072A1Improve solubilityEasy to useDetergent mixture composition preparationInorganic non-surface-active detergent compositionsTetramethylammonium hydroxideDiethylene glycol monobutyl ether

Disclosed is a photoresist stripping solution consisting essentially of (a) a quaternary ammonium hydroxide (e.g., tetramethylammonium hydroxide), (b) at least one water-soluble organic solvent selected from glycols and glycol ethers (e.g., propylene glycol, ethylene glycol, diethylene glycol monobutyl ether), and (c) a non-amine water-soluble organic solvent (e.g., dimethyl sulfoxide, N-methyl-2-pyrrolidone). The photoresist stripping solution of the invention has an excellent photoresist strippability, not causing damage of swelling / coloration to acrylic transparent films used in production of liquid-crystal panels and not causing damage to electrode materials. In particular, it has an excellent photoresist strippability to remove even a thick-film negative photoresist (photosensitive dry film) used in production of semiconductor chip packages (especially, wafer-level chip size packages, W-CSP), not causing damage to copper.

Owner:TOKYO OHKA KOGYO CO LTD

Aqueous silvery aluminum powder flashing paint

ActiveCN102876167AImproved Rework AttachmentGood metallic glitterPolyurea/polyurethane coatingsPaints with free metalsDiethylene glycol monobutyl etherHydrogen

The invention provides an aqueous silvery aluminum powder flashing paint, belongs to the technical field of coating paint, and solves the problems that aqueous aluminum powder in aqueous paint is imperfect in orientation, hard to apply and easy to rework. The aqueous silvery aluminum powder flashing paint comprises, by weight part, 30-60 parts of watercraft acrylic resin, 3-9 parts of waterborne polyurethane resin, 0.1-0.5 part of neutralizer, 2-6 parts of diethylene glycol monobutyl ether, 0.2-1 part of base wetting agent, 10-20 parts of water, 15-30 parts of metallic pigment orientation additives and 15-30 parts of aqueous aluminum paste. Orientation of the aqueous aluminum powder is affected by the metallic pigment orientation additives, the PH(potential of hydrogen) value, resin and the like, so that the aqueous aluminum powder can be oriented by being parallel to the base to utmost extent, and good metal flashing effect and flip-flop effect are guaranteed. Since watercraft acrylic resin and the waterborne polyurethane resin are combined, rework adhesion of the paint on an oil primer is improved. In addition, the aqueous silvery aluminum powder flashing paint is environment-friendly, energy-saving and safe.

Owner:ZHEJIANG SHENGLIBANG PAINT

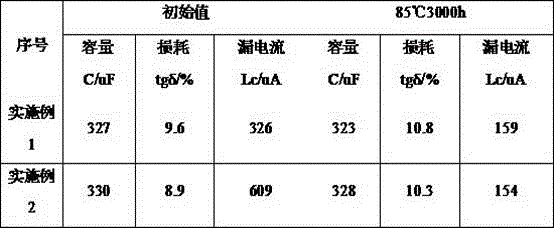

Low-temperature and high-voltage resistant aluminum electrolytic capacitor work electrolyte and preparation method thereof

InactiveCN106783178AImprove solvating powerHigh degree of ionizationElectrolytic capacitorsDiethylene glycol monobutyl etherGlycerol

A low-temperature and high-voltage resistant aluminum electrolytic capacitor work electrolyte comprises by the mass percent: 45-75% of the main solvent, the 15-40% of the secondary solvent, 3-12% of the solute, 0.5-2% of the flash fire promotion additive, 0.2-1.5% of the gas absorption additive; the main solvent is one or more than one of the ethylene glycol, the propylene glycol, the glycerol, the polyethylene glycol 200 and the polyethylene glycol 400. The secondary solvent is one or more than one of the [Gamma]-butyrolactone, the dimethylformamide, the diglycolic simple methyl ether, the diethylene glycol monoethyl ether and the diethlyeneglycol monobutylether. The secondary solvent can be propylene carbonate and one or more than one of the [Gamma]-butyrolactone, the dimethylformamide, the diglycolic simple methyl ether, the diethylene glycol monoethyl ether and the diethlyeneglycol monobutylether. The low-temperature and high-voltage resistant aluminum electrolytic capacitor work electrolyte can resist the -55 DEG C and high voltage of 600V.

Owner:CENT SOUTH UNIV

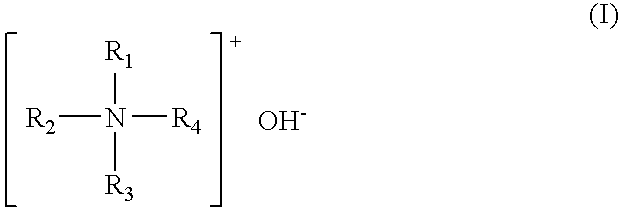

Reducing type concrete fluidity stabilizer preparation method

ActiveCN108047388ALiquidity Stability ControlExcellent initial water reducing rateDiethylene glycol monobutyl etherCarboxylic acid

The invention discloses a reducing type concrete fluidity stabilizer preparation method which comprises the following steps: (1) acylation and esterification reaction; (2) monomer alloying; (3) copolymerization reaction; (4) neutralization reaction. According to the preparation method disclosed by the invention, unsaturated carboxylic acid or unsaturated carboxylic acid anhydride and alcohol amine, diethylene glycol monobutyl ether and / or dipropylene glycol monobutyl ether and compound A are acylated and esterified to prepare unsaturated monomer with an amide structure and an amino structure,unsaturated monomer with an alcohol ether structure and unsaturated monomer with a benzene ring and a carboxylic acid group at the same time; then the unsaturated monomers are copolymerized with excessive unsaturated carboxylic acid and carboxylic acid anhydride, unsaturated sulfonate and polyether macromonomer in acylation and esterification reaction; the monomers are guided into molecule structures, so that the molecule structures have the benzene rings, carboxylic acid groups, sulfonic acid groups, amide groups and amino groups at the same time; thus, a product has an excellent initial water-reducing rate.

Owner:KZJ NEW MATERIALS GROUP CO LTD +1

Water-based ink

ActiveUS20180142110A1Reduce pressureDuplicating/marking methodsInksDiethylene glycol monobutyl etherPolymer science

The present invention relates to [1] a water-based ink including pigment-containing water-insoluble polymer particles A, water-insoluble vinyl-based polymer particles B and an organic solvent C, in which the water-insoluble polymer particles A are obtained by crosslinking polymer particles; the water-insoluble polymer particles B include at least one material selected from the group consisting of water-insoluble vinyl-based polymer particles and the like; the organic solvent C includes at least one compound selected from the group consisting of diethylene glycol monobutyl ether and diethylene glycol monoisobutyl ether, and propylene glycol, in which a total content of diethylene glycol monobutyl ether and diethylene glycol monoisobutyl ether in the water-based ink is not less than 0.8% by mass, and a content of an organic solvent having a boiling point of higher than 250° C. in the water-based ink is not more than 5% by mass; and a content of water in the water-based ink is not less than 45% by mass, and [2] an ink-jet printing method including the step of printing characters or images on a recording medium using the aforementioned water-based ink. The water-based ink of the present invention is excellent in long-term storage stability as well as ejection stability upon ink-jet printing, and can be improved in image quality of printed characters or images, rub fastness, water resistance, solvent resistance and adhesion to a substrate with a high level and a good balance when printed on a non-water absorbing recording medium.

Owner:KAO CORP

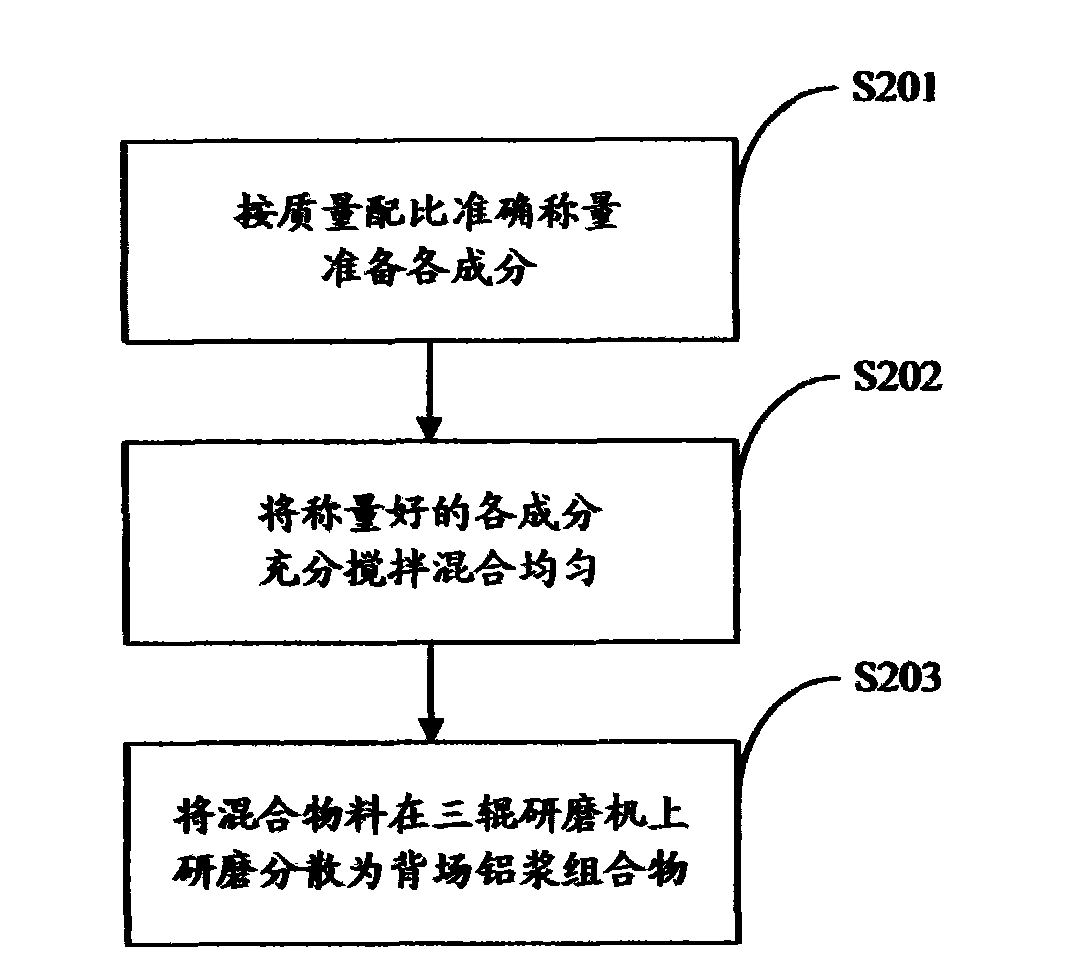

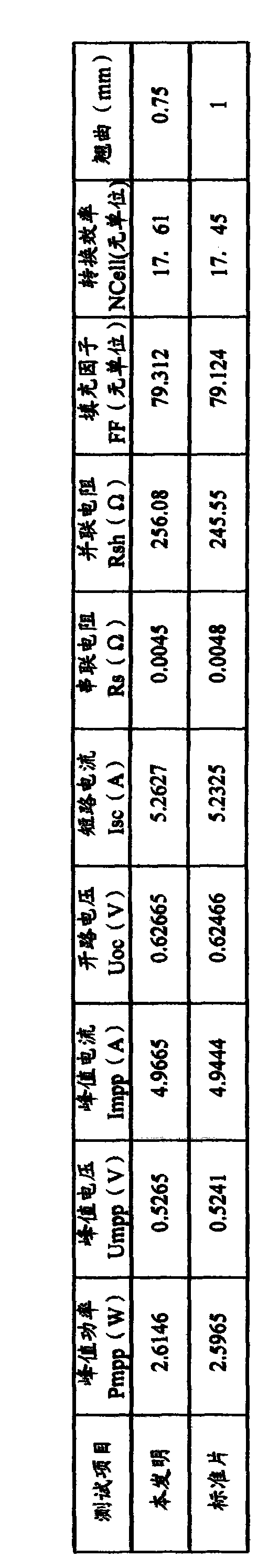

Lead-free silver and aluminum slurry for solar photocell and preparation method of slurry

ActiveCN102708942AImprove conductivityRefined nanocrystalline structureNon-conductive material with dispersed conductive materialCable/conductor manufactureDiethylene glycol monobutyl etherCyclohexanone

The invention discloses lead-free silver and aluminum slurry for a solar photocell. The slurry is prepared from raw materials in percent by mass as follows: 75-80% of silver powder, aluminum powder and copper powder, 15-20% of organic bond, 1-5% of inorganic glass powder, and 1-5% of additive; the purities of the silver powder, the aluminum powder and the copper powder are more than or equal to 99.9%; the organic bond is prepared from the following materials in percent by mass of: 0.5-2% of butyl carbitol, 1-2.5% of resin, 1-4% of rosin, 11-13% of ethylene glycol monomethyl ether, 5-9% of diethylene glycol monobutyl ether, 65-75% of cyclohexanone and 10-20% of n-butyl alcohol; the inorganic glass powder is prepared from the following materials in percent by mass of: 1-3% of titanium dioxide, 55-75% of boric acid, 3-5% of aluminium sesquioxide, 15-25% of antimony oxide and 2-5% of zirconium oxide; and the additive is prepared from the following materials in percent by mass of: 35-45% of span and 55-65% of pump oil. The lead-free silver and aluminum slurry prepared by the raw material has the advantages of good weldability and strong adhesion and meets the lead-free environmental friendless requirement.

Owner:JIANGSU RUIDE NEW ENERGY TECH

Multifunctional water-based cleaning agent

ActiveCN102703256ANo pollutionLess management hassleOrganic non-surface-active detergent compositionsDiethylene glycol monobutyl etherWater based

The invention discloses a multifunctional water-based cleaning agent, which consists of the following raw materials in percentage by weight: 7 to 14 percent of propanediol methyl ether acetate, 5 to 15 percent of diethylene glycol monobutyl ether, 1.5 to 5 percent of monoethanolamine, 0.5 to 2 percent of octyl phosphate, 0.1 to 0.3 percent of defoamer, 1.5 to 5 percent of ethanol and 62.2 to 81.4percent of water. The multifunctional water-based cleaning agent is environment-friendly, high in safety, non-toxic, non-corrosive, pollution-free, low in using cost, safe and stable, has multiple cleaning functions and is used for cleaning red gum, solder paste, rosin, printed circuit board (PCB) carriers and the like.

Owner:东莞优诺电子焊接材料有限公司

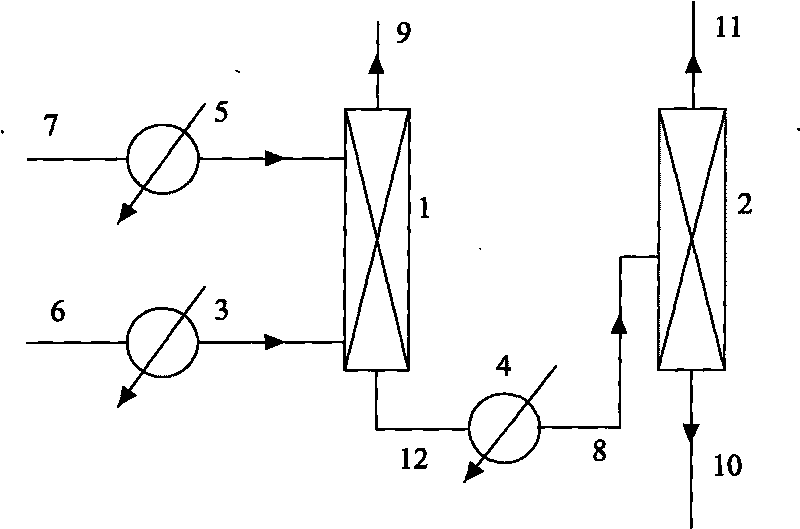

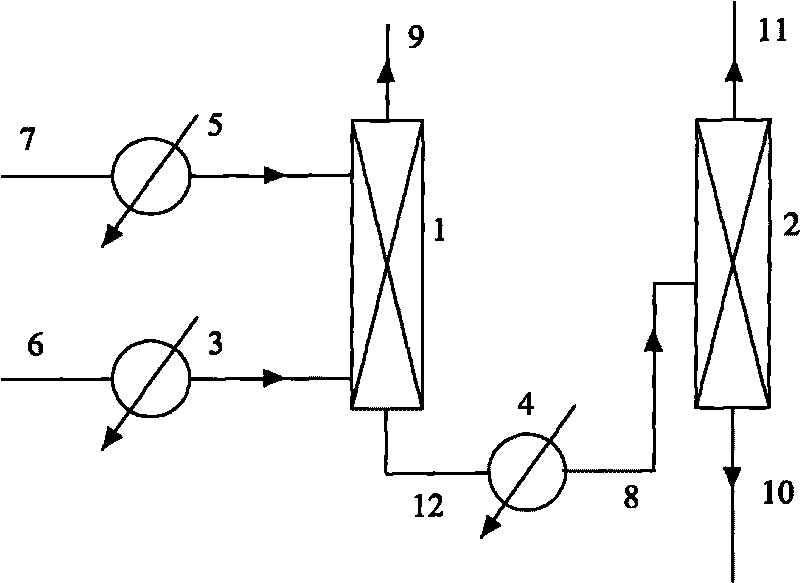

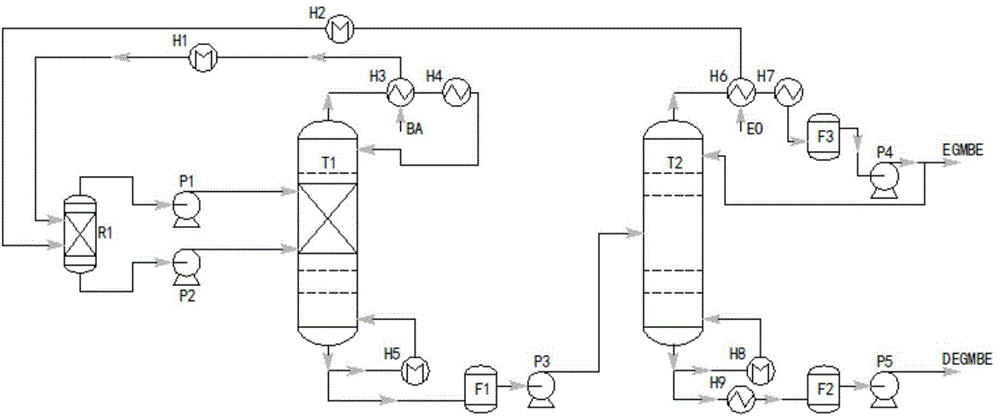

Device and processing method for synthesis of ethylene glycol monobutyl ether through reactive distillation

ActiveCN104788294AEther separation/purificationChemical industryDiethylene glycol monobutyl etherReboiler

The invention provides a device and technological process for synthesis of ethylene glycol monobutyl ether through reactive distillation. The device comprises a reactor, a reactive distillation tower, a treating tower, a condenser, a reboiler, a heat exchanger, a return tank, a kettle outlet tank, a pump and a pipeline. In the technological process, the reactive distillation tower is combined with the reactor and the treating tower. Acidic cation exchange resin or alkali anion exchanger is selected for being used as a catalyst. Preheated ethylene oxide and butanol enter into a reactor for reaction, and unreacted materials pumped into the reactive distillation tower react or are rectified on a tower plate or a filling material on the section; materials flowing down after passing through the reaction section are rectified through a stripping section; total reflux is conducted at the tower top of the reactive distillation tower; materials discharged from the tower kettle of the reactive distillation tower are pressurized to enter into the treating tower for rectification; the ethylene glycol monobutyl ether with the purity higher than 99.9 percent is obtained from the tower top of the treating tower, the yield is greater than 97 percent, and the diethylene glycol monobutyl ether is obtained from the tower kettle of the rectification tower. The device solves the problems that ethylene glycol monobutyl ether produced intermittently is not stable in product quality, the yield is relatively low, the loss of the catalyst is high, and sewage treatment is difficult.

Owner:TIANJIN PULAI CHEM TECH

Electric distribution box outer shell material and application thereof

ActiveCN104151758AImprove performanceImprove insulation performanceDiethylene glycol monobutyl etherIsobutanol

The invention belongs to the field of electric distribution material, and discloses an electric distribution box outer shell material prepared from the following raw materials: kaolin, glass fiber, tetraethyl orthosilicate, butyl acetate, aluminum tripolyphosphate, antimony trioxide, diethylene glycol monobutyl ether, isobutanol, polycarbonate, glycerol monostearate, quartz sand, phenolic resin, borax, silicon carbide and acrylic resin. While effectively maintaining relatively good insulation performance, the electric distribution box outer shell material has mechanical properties, thermal properties and flame retardance improved greatly, and can effectively prevent electric shock; and moreover, produced heat is easy to discharge, so as to avoid potential safety hazards caused by high temperatures of an electric distribution box.

Owner:佛山市艾家电气有限公司

Oil removal cleaning agent for metal surfaces

ActiveCN103334112AGood degreasing effectImprove solubilityDiethylene glycol monobutyl etherEthyleneglycol monobutyl ether

The invention provides an oil removal cleaning agent for metal surfaces. The oil removal cleaning agent is prepared from the following raw materials according to mass proportions: 4-10 of potassium hydroxide, 20-30 of sodium sulfate, 10-20 of trisodium phosphate, 10-15 of sodium carbonate, 5-10 of sodium tripolyphosphate, 1-4 of penetrating agent JFC-M, 6-10 of emulsifier FMES, 3-5 of emulsifier OP-10 and 2-6 of diethylene glycol monobutyl ether. The oil removal cleaning agent can be used at a normal temperature, has good dispersing performance and good cleaning and oil fouling removal effects, is short in oil removal time and does not cause abnomal adhesion pollution.

Owner:LIAONING TIANLONG CHEM

Method for manufacturing powder through neodymium iron boron alloy

ActiveCN103521758ASmooth rotationAvoid contactMagnetic materialsDiethylene glycol monobutyl etherZinc borate

The invention provides a method for manufacturing powder through neodymium iron boron alloy and belongs to the technical field of neodymium iron boron alloy preparation. The method is characterized by including the steps of adding an anti-oxygen lubricant accounting for 0.05-0.5% of neodymium iron boron coarse powder by mass after the neodymium iron boron coarse powder is placed into a powder mixing tank, obtaining fine powder through a jet milling process, then adding a lubricant accounting for 0.05-0.5% of the fine powder by mass, and performing mixing, molding and sintering to obtain the powder. The anti-oxygen lubricant is formed by mixing zinc stearate, diethylene glycol monobutyl ether, myristic acid and megilp according to the mass ratio of (1-50): (1-50): (1-70): (1-70), and the lubricant is formed by mixing isopropyl alcohol, zinc stearate, zinc borate ester and megilp according to the mass ratio of (1-50): (1-50): (1-70): (1-70). According to the method, in the process for manufacturing the powder through the neodymium iron boron alloy, corrosivity of the additives can be eliminated, meanwhile orientation in the compression process is improved, and the powder outgoing velocity in the jet milling process is increased.

Owner:ARCFL TECHNOLOGY LIMITED

650V high-voltage aluminium electrolytic capacitor working electrolyte and preparation method thereof

InactiveCN106531443ALow viscosityLight weightLiquid electrolytic capacitorsDiethylene glycol monobutyl etherPolymer science

A 650V high-voltage aluminium electrolytic capacitor working electrolyte includes, in percentage by mass, 50% to 80% of a main solvent, 20% to 40% of auxiliary solvents, 5% to 15% of solutes, 1% to 8% of a sparking voltage enhancing agent; and the auxiliary solvents are two or more of a gamma-butyrolactone, DMF, polyethylene glycol 200, polyethylene glycol 400, a nano silica solution, glycerol, propylene carbonate, ethylene carbonate, tributyl phosphate, diethylene glycol monobutyl ether, trienthylene glycol dimethacrylate and diethylene glycol. The 650V high-voltage aluminium electrolytic capacitor working electrolyte has the advantages of low viscosity and high conductivity.

Owner:CENT SOUTH UNIV

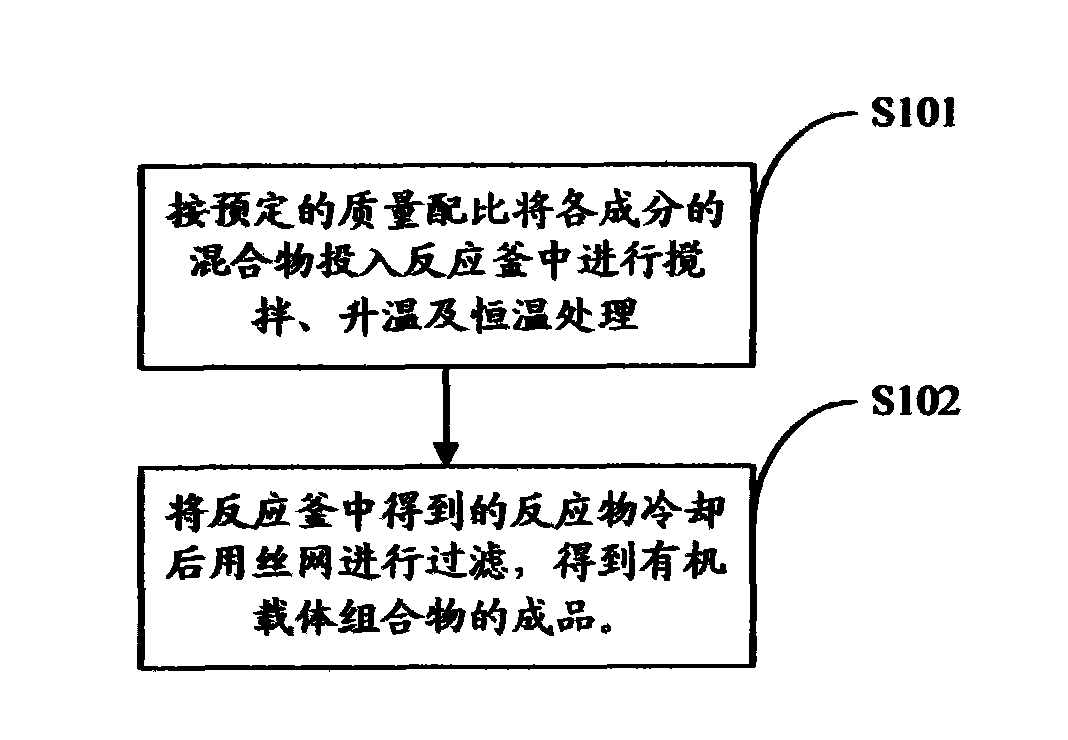

Organic carrier composition for solar cell back surface field aluminium paste and preparation method thereof

InactiveCN101914221AEliminate hazardsGood dry film adhesionFinal product manufactureNon-conductive material with dispersed conductive materialDiethylene glycol monobutyl etherCellulose

The invention relates to an organic carrier composition for solar cell back surface field aluminium paste, comprising a main carrier; wherein the main carrier comprises the following components by mass: 3-5% of methylcellulose, 30-45% of terpinol, 20-40% of diethylene glycol monobutyl ether, 10-20% of diethylene glycol monobutyl ether acetate and 0.2-1% of lecithin. The invention also relates to a method for preparing the organic carrier composition used for solar cell back surface field aluminium paste. In the organic carrier composition for solar cell back surface field aluminium paste and preparation method thereof which are provided by the invention, diethylene glycol monobutyl ether acetate is adopted to substitute the traditional o-benzene compound and is taken as solvent and plasticizer, thus eliminating environmental harm of organic carrier.

Owner:CHANGZHOU YINGDE ENERGY TECH

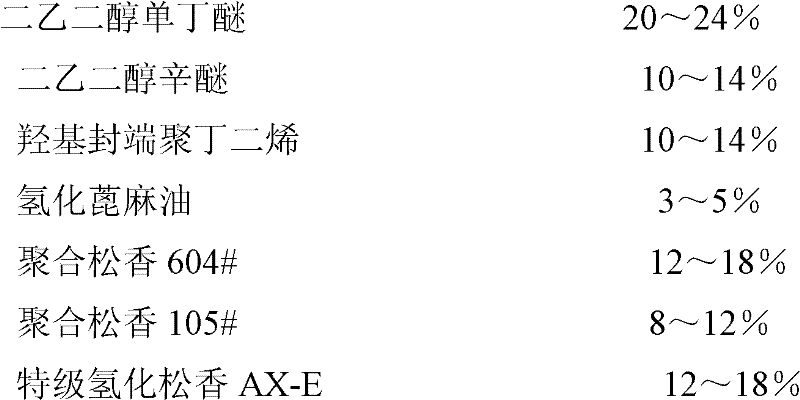

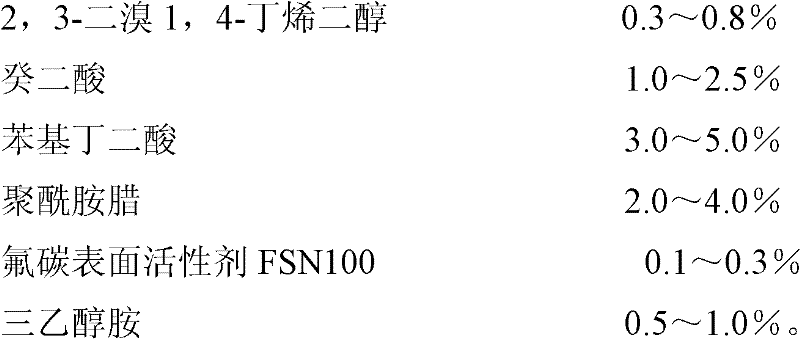

High-temperature lead-free solder paste and preparation method

ActiveCN102528327AImprove adhesionProtects and prevents re-oxidationWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherButanedioic acid

The invention relates to high-temperature lead-free solder paste and a preparation method. The high-temperature lead-free solder paste comprises lead-free electronic grade tin alloy powder and flux. Diethylene glycol monobutyl ether, diethylene glycol octyl ether and hydroxyl-terminated polybutadiene are added into a temperature control emulsifying machine and are heated and mixed, hydrogenated castor oil, polymerized rosin CLEARON105# and hydrogenated rosin are added into the temperature control emulsifying machine and are mixed to obtain primary mixed liquor, the primary mixed liquor is cooled, 2,3-dibromo 1,4-butylene glycol, sebacic acid and phenyl-butanedioic acid are added into the primary mixed liquor and then are mixed to obtain secondary mixed liquor, the secondary mixed liquor is cooled, polyamide wax is added into the secondary mixed liquor and then is mixed to obtain tertiary mixed liquor, the tertiary mixed liquor is cooled, fluorocarbon surfactant and triethanolamine areadded into the tertiary mixed liquor and then are mixed and vacuumized until the temperature returns to room temperature, the lead-free electronic grade tin alloy powder Sn95Sb5 is added into the prepared flux after standing at the temperature of 22-25 DEG C, and the lead-free electronic grade tin alloy powder and the flux are mixed for 15-20 minutes to obtain the high-temperature lead-free solder paste. The high-temperature lead-free solder paste has the advantages of fine solderability and wettability, high solder joint strength, high reliability and solderability in air and nitrogen protection.

Owner:惠州市斯泰尔科技有限公司

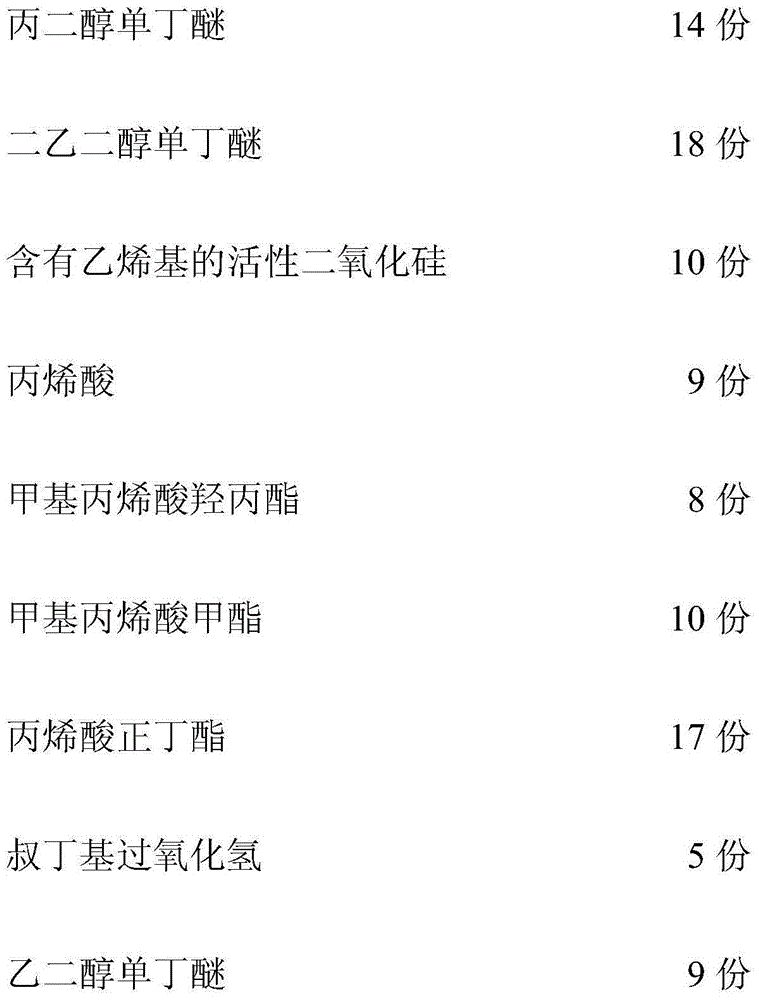

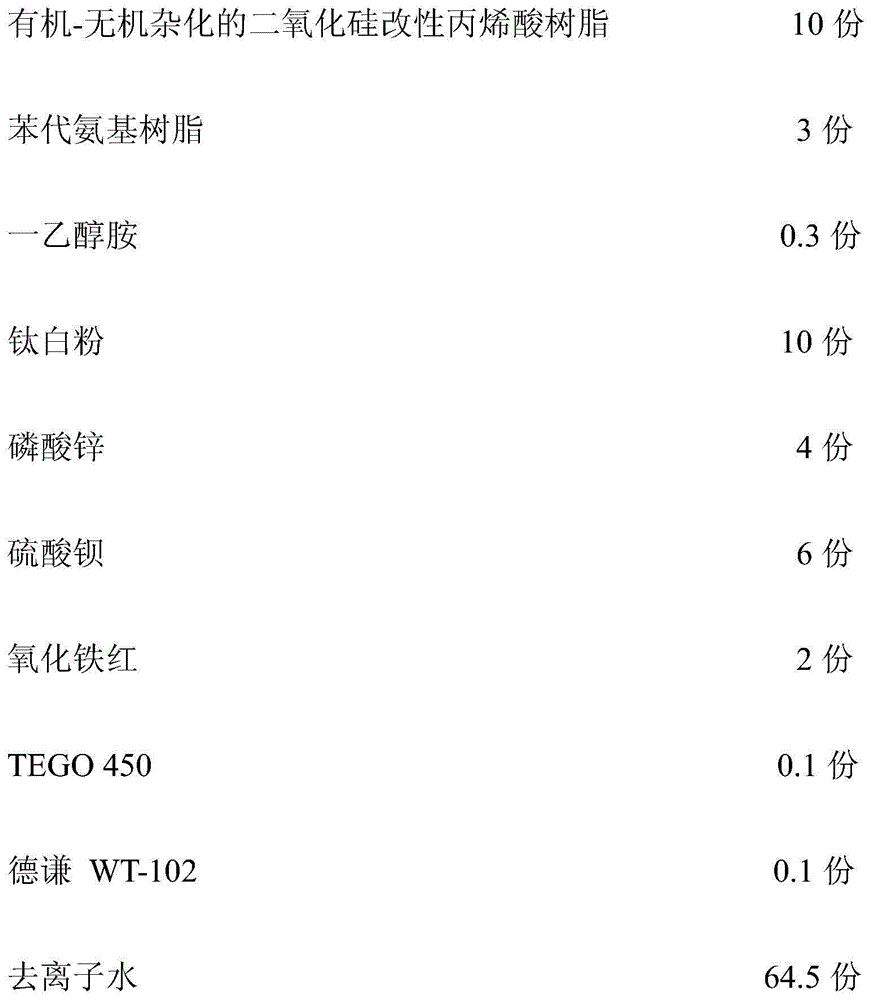

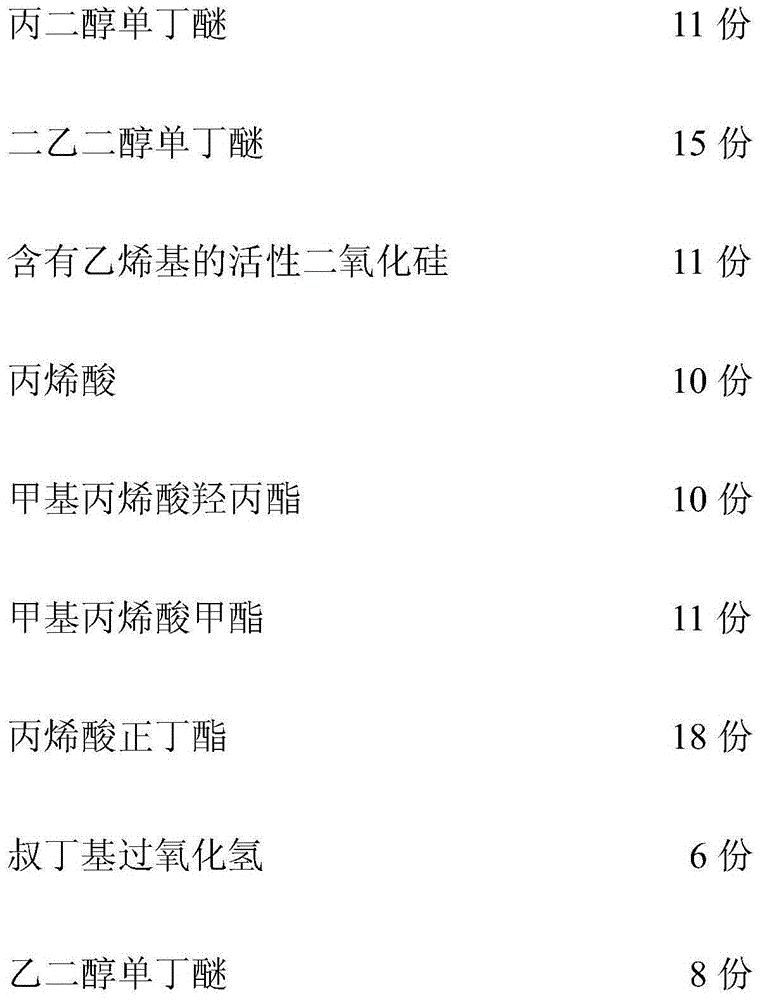

Organic-inorganic hybrid silica modified acrylic resin and coating thereof

ActiveCN105237693AImprove shielding effectFix bugsAnti-corrosive paintsDiethylene glycol monobutyl etherAcrylic resin

The invention relates to an organic-inorganic hybrid silica modified acrylic resin and a coating thereof. The organic-inorganic hybrid silica modified acrylic resin comprises, by weight, 8-14 parts of propylene glycol mono-n-butyl ether, 12-18 parts of diethylene glycol monobutyl ether, 10-12 parts of vinyl group-containing active silica, 9-11 parts of acrylic acid, 8-12 parts of hydroxypropyl methacrylate, 10-12 parts of methyl methacrylate, 17-19 parts of n-butyl acrylate, 5-7 parts of tert-butyl hydroperoxide and 7-9 parts of ethylene glycol monobutyl ether. The coating is suitable for anticorrosion of metal workpieces; and the final hardness of a coating layer obtained by using the coating reaches 2H, the impact strength is 50Kg.cm, the adhesion is 0 grade, the coating layer has very excellent corrosion resistance, the salt spray resistance reaches 1000h, the unidirectional corrosion width is not greater than 2mm, the coating layer has good weatherability, and a result of 1000h QUV ageing test shows that the light loss rate is not greater than 10%, and delta E is not greater than 1.0.

Owner:HAOLISEN COATING SHANGHAI

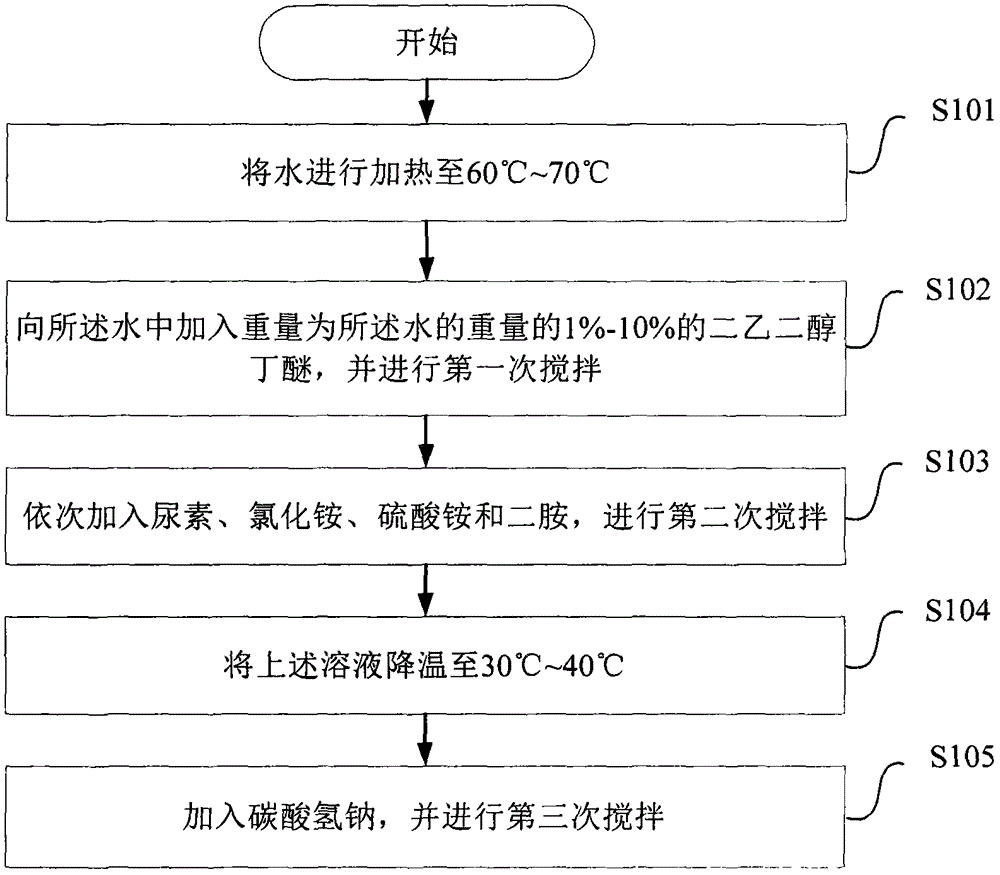

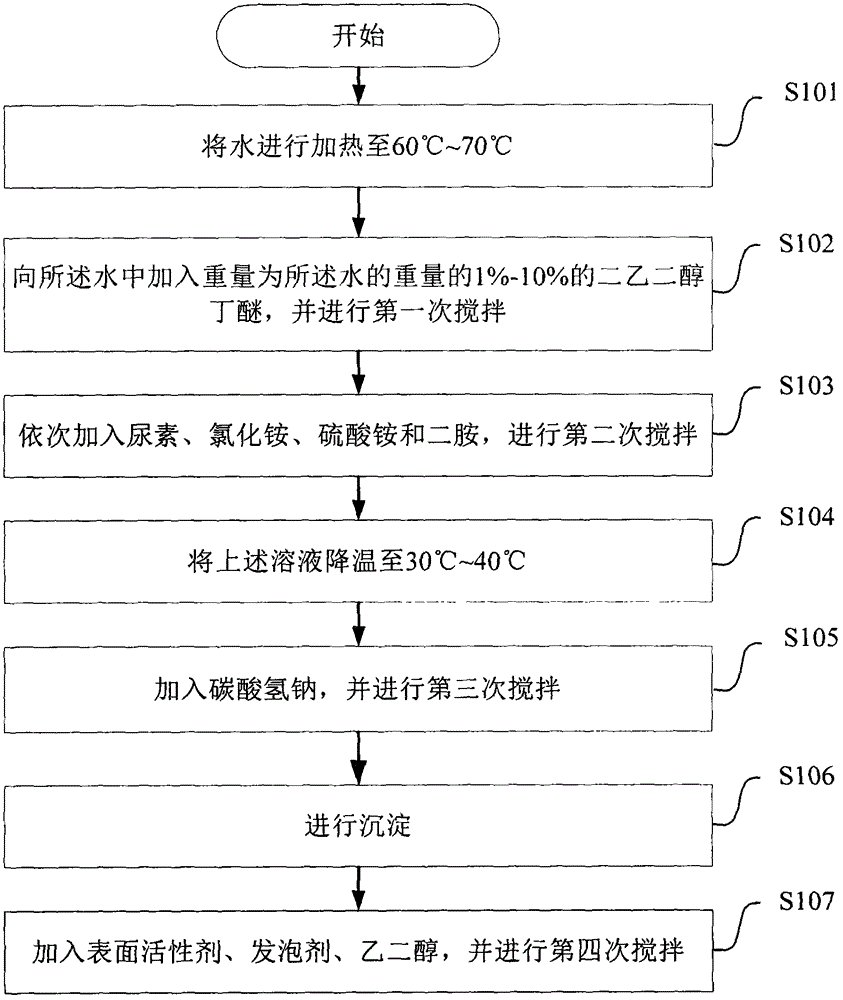

Preparation method of water-based extinguishing agent and water-based extinguishing agent

InactiveCN104436511AHigh fire extinguishing ratingImprove low temperature resistanceFire extinguisherSodium bicarbonateDiethylene glycol monobutyl ether

The invention discloses a preparation method of a water-based extinguishing agent. The preparation method comprises the following steps: heating water to 60-70 DEG C; adding diethylene glycol monobutyl ether the addition of which is 1%-10% of water, and stirring for the first time; sequentially adding urea, ammonium chloride, ammonium sulfate and diamine and stirring for the second time; cooling the solution to 30-40 DEG C; and adding sodium bicarbonate, and stirring for the third time. Correspondingly, the invention also provides a water-based extinguishing agent prepared by the preparation method. According to the water-based extinguishing agent disclosed by the invention, the rapid cooling effect can be achieved; the oxygen can be rapidly isolated; and effects of effectively extinguishing the fire and preventing after-combustion are achieved.

Owner:陈金城

Photoresist stripping solution

ActiveUS20100022426A1Improve solubilityAdvantageously usableDetergent mixture composition preparationPhotosensitive material processingDiethylene glycol monobutyl etherTetramethylammonium hydroxide

Owner:TOKYO OHKA KOGYO CO LTD

Nanometer silver wire inkjet electric conduction ink preparation method

ActiveCN106433316AImprove stabilityEffective dispersionInksDiethylene glycol monobutyl etherDiethylene glycol

The invention discloses a nanometer silver wire inkjet electric conduction ink preparation method, which is characterized in that ultrasonic oscillation and centrifugal separation are combined to obtain the nanometer silver wire with a diameter of 30-60 nm and a length of 2-4 [mu]m; with the application of the nanometer silver wire as the electric conduction component, the high electric conductivity under the low electric conduction component content condition can be achieved, and the good stability and the good rheological behavior can be achieved so as to easily achieve the inkjet printing of the electric conduction line; and the components of the nanometer silver wire inkjet electric conduction ink comprise, by mass, 0.8-2% of nanometer silver wire, 0.01-0.08% of polyvinyl pyrrolidone K90, 78-87% of isopropyl alcohol, 8-15% of diethylene glycol, and 3-6% of diethylene glycol monobutyl ether.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

Tin slag reducer

InactiveCN101613807AReduce formationReduce concentrationProcess efficiency improvementDiethylene glycol monobutyl etherPhosphate

The invention discloses a tin slag reducer. The reducer comprises fatty alcohol polyethenoxy ether phosphate, alkoxy alcohol, silicone oil, ammonium dihydrogen phosphate, diethylene glycol monobutyl ether, cyclohexylamine carbonate, phytic acid, ammonium succinate and phosphorus pentoxide. The tin slag reducer can reduce and reuse the tin slag produced in the electronic processing industry, and improves the welding quality and the product quality.

Owner:黄俊凯

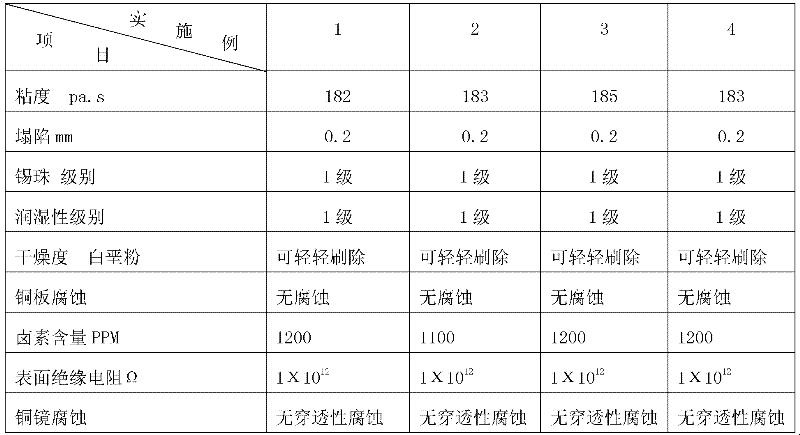

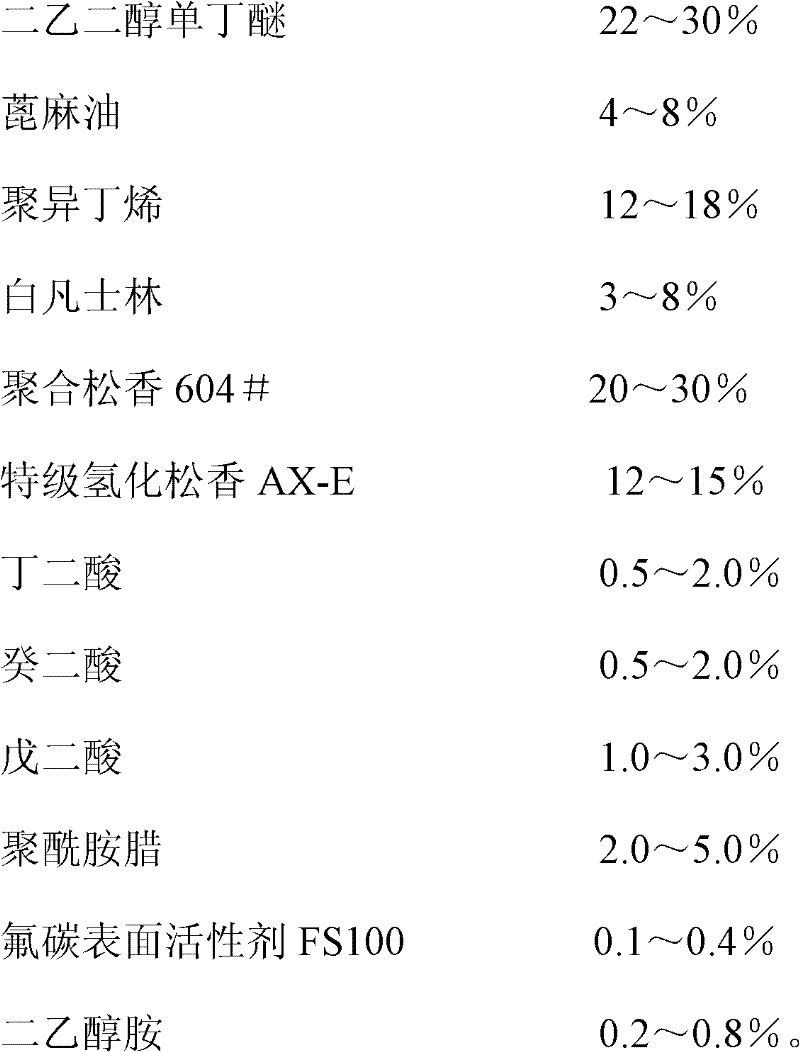

Halogen-free and lead-free solder paste and preparation method

ActiveCN102528329AImprove adhesionAdjustable viscosityWelding/cutting media/materialsSoldering mediaDiethylene glycol monobutyl etherGlutaric acid

The invention relates to a halogen-free and lead-free solder paste and a preparation method. The preparation method is characterized in that the method comprises the steps of adding diethylene glycol monobutyl ether, castor oil and polyisobutene in a temperature control emulsifying machine and mixing, then adding albolene, polymerized rosin and hydrogenated rosin and mixing again to obtain first mixing solution, reducing the temperature of the first mixing solution, adding succinic acid, sebacic acid and glutaric acid, and mixing again to obtain second mixing solution, reducing the temperature of the second mixing solution, adding polyamide wax and mixing again to obtain third mixing solution, reducing the temperature of the third mixing solution, adding a fluorocarbon surfactant and diethanol amine, then stirring and vacuuming until the temperature is restored to the room temperature, standing for 24h with low temperature, then adding lead-free electronic-grade tin alloyed powder Sn96.5Ag3.0Cu0.5, and stirring to obtain the halogen-free and lead-free solder paste. After being welded, the halogen-free and lead-free solder paste has the advantages and effects of fewer residues, extremely high surface insulation resistance, low corrosion, no needing of cleaning, good thixotropic property and electric conductivity, bright welding points after welding and incapability of collapsing easily.

Owner:惠州市斯泰尔科技有限公司

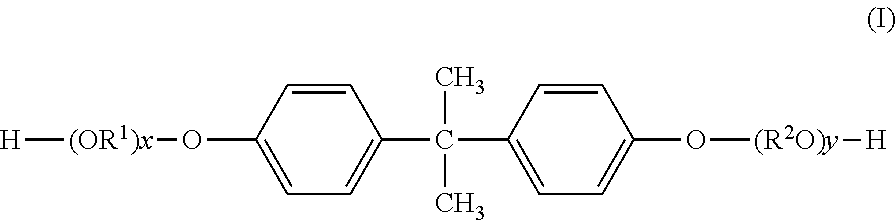

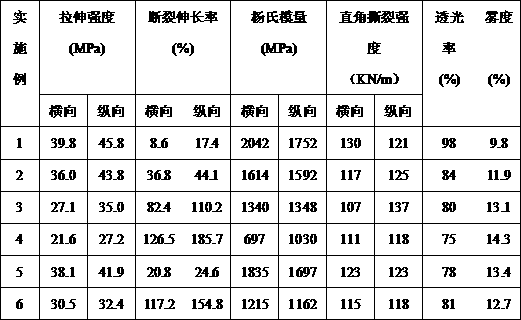

PLA-PBSA blown film and preparation method thereof

InactiveCN108017887AIncreased tensile elongation at breakHigh tear strengthFlat articlesDiethylene glycol monobutyl etherPolymer science

The invention provides a polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film and a preparation method thereof. The blown film comprises a mixture of PLA, PBSA, plasticizer diethylene glycol monobutyl ether adipate, a lubricant, a plastic lubricant and an antioxidant. The PLA, the PBSA, the lubricant, the plastic lubricant and the antioxidant are first mechanically mixed into a premix, the premix is added through a feeding port of a twin-screw extruder, meanwhile the plasticizer diethylene glycol monobutyl ether adipate is metered and added in through a liquid feeding port of the twin-screw extruder, modified polylactic acid blown film special resin is prepared by melt-extruding, water-cooling, pelletizing and drying, the modified polylactic acid blown film special resin is blown by a film blowing machine to form a transparent tear-resistant biodegradable film. The PBSA, the plasticizers, the lubricant, the plastic lubricant and the antioxidant can effectively increase the tensile elongation at break and tear strength of polylactic acid films, maintains the transparency of the polylactic acid, and solves the brittleness defects of the polylactic acid films. The polylactic acid (PLA) / poly(butylene succinate-butylene adipate) (PBSA) blown film has good mechanical properties and excellent transparency, and can replace PE, PP, PVC and the like for preparation of films and sheets.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP +1

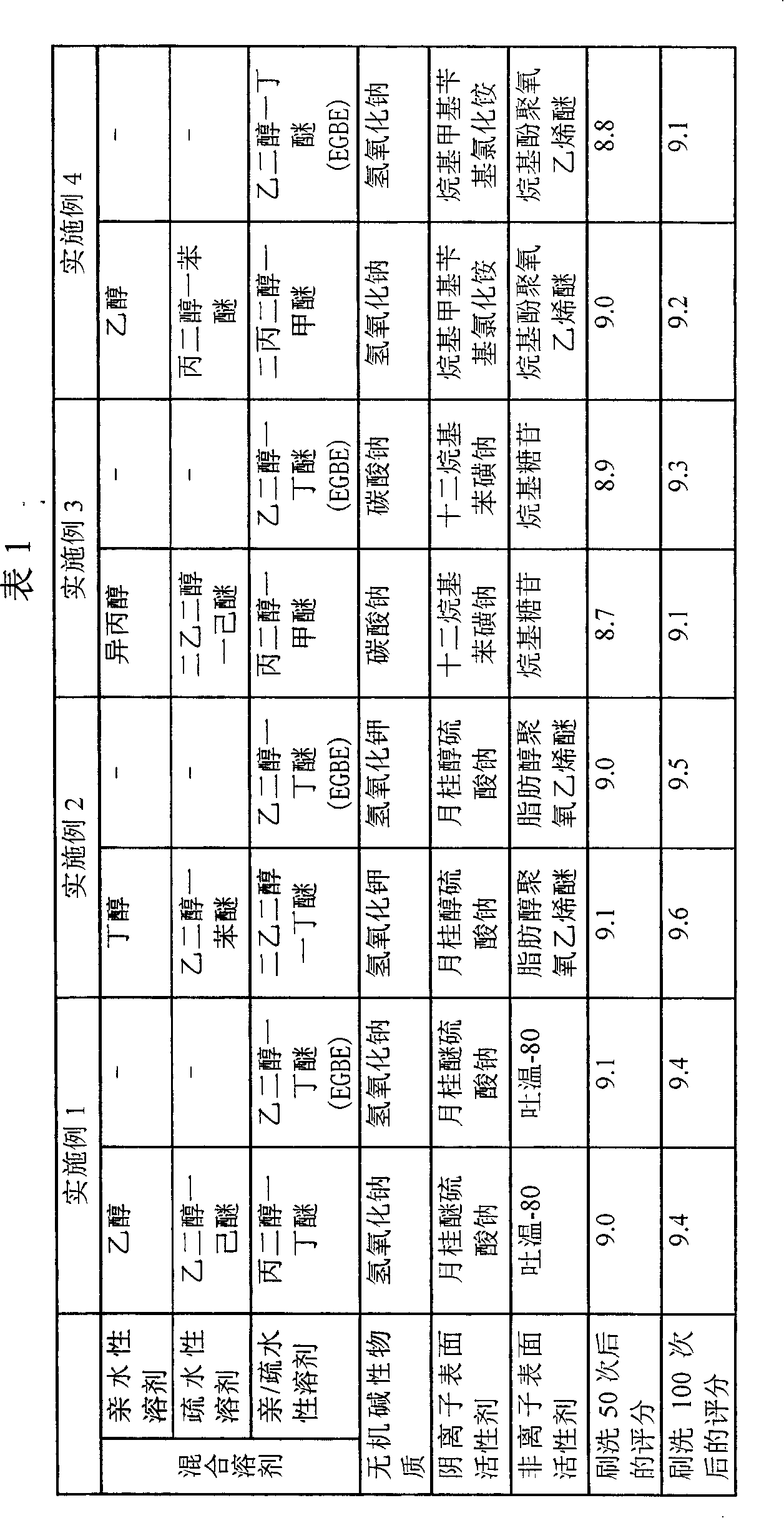

Kitchen detergent composition

InactiveCN101210213ANo toxicityEasy to cleanNon-ionic surface-active compoundsDetergent compounding agentsDiethylene glycol monobutyl etherEthylene glycol monophenyl ether

The invention relates to an alkaline kitchen cleanser composition with no ethylene glycol monobutyl ether (EGBE) for cleaning hard surface with heavy oil stains, and also relates to a mixture solvent capable of substituting for the EGBE solvent in the cleanser composition. The alkaline kitchen cleanser composition mainly comprises (a) a mixed solvent of a hydrophilic solvent and a hydrophobic solvent; (b) an inorganic alkaline substance; and (c) a surfactant. The mixed solvent includes the hydrophobic solvent selected from ethylene glycol monophenyl ether, ethylene glycol monohexyl ether and combination thereof, a hydrophilic diethylene glycol monobutyl ether solvent and a hydrophilic isopropyl alcohol solvent. The alkaline kitchen cleanser composition contains no EGBE, thus eliminating the latent toxicity. Meanwhile, the composition is at low cost and can be mixed to obtain better or more diversified smells.

Owner:SC JOHNSON & SON INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com