Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

A technology of composite cable material and polyvinyl chloride, used in insulated cables, rubber insulators, cables, etc., to achieve the effect of excellent thermosetting rubber appearance, good low temperature flexibility, and excellent thermoplastic elastomer characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

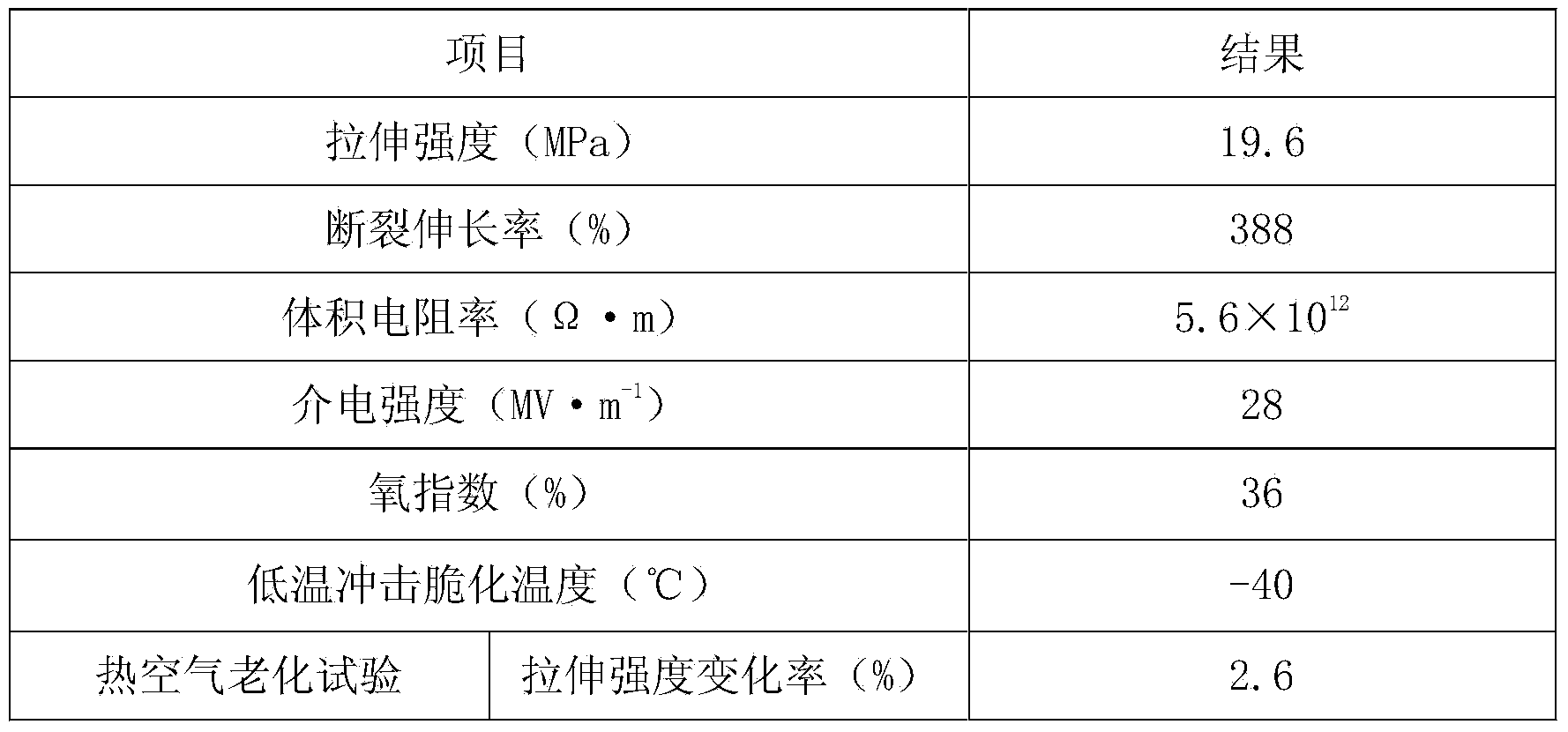

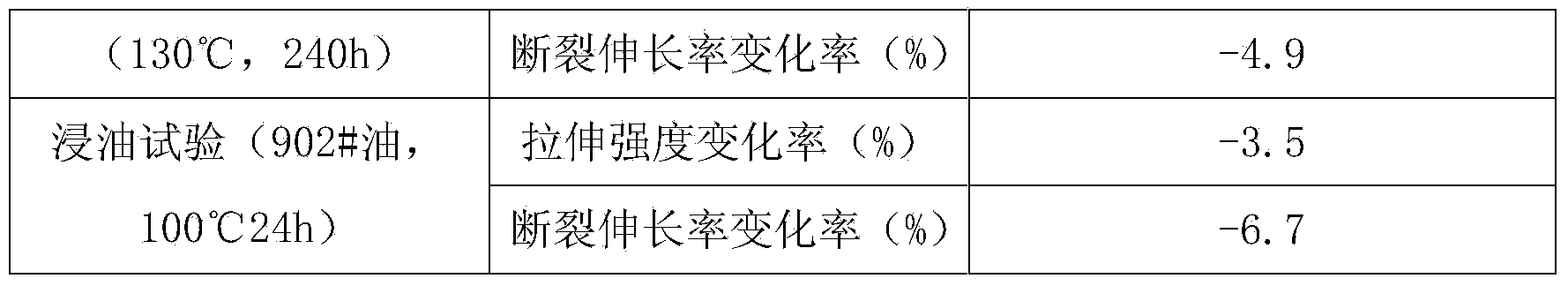

[0013] An oil-resistant, cold-resistant and UV-resistant polyvinyl chloride / nitrile rubber composite cable material, which is made of the following raw materials in weight (kg): SG-2 type polyvinyl chloride 70, POE25, nitrile rubber 40, fluorine rubber 20, o-phthalate Dioctyl diformate 12, diethylene glycol monobutyl ether adipate 8, dicumyl peroxide 0.6, triallyl isocyanurate 2, 2-mercaptobenzimidazole 1.5, di Dibenzothiazole sulfide 2, titanium dioxide 6, paraffin oil 8, zinc oxide 2, microcrystalline paraffin 6, stearic acid 1.5, sodium dehydroacetate 1.5, stearyl benzoyl methane 2, zinc stearate 1.5, Antimony trioxide 16, carbon black N77020, magnesium carbonate 15, nano barite 10, composite filler 6, ultraviolet absorber UV-3271;

[0014] The preparation method of the composite filler is as follows: a. Take the raw materials of the following weight (kg): diatomite 10, wollastonite 8, nano-titanium dioxide 4, nano-silicon carbide 6, vinyl three (β-methoxyethoxy base) sila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com