Patents

Literature

2640results about "Rubber insulators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

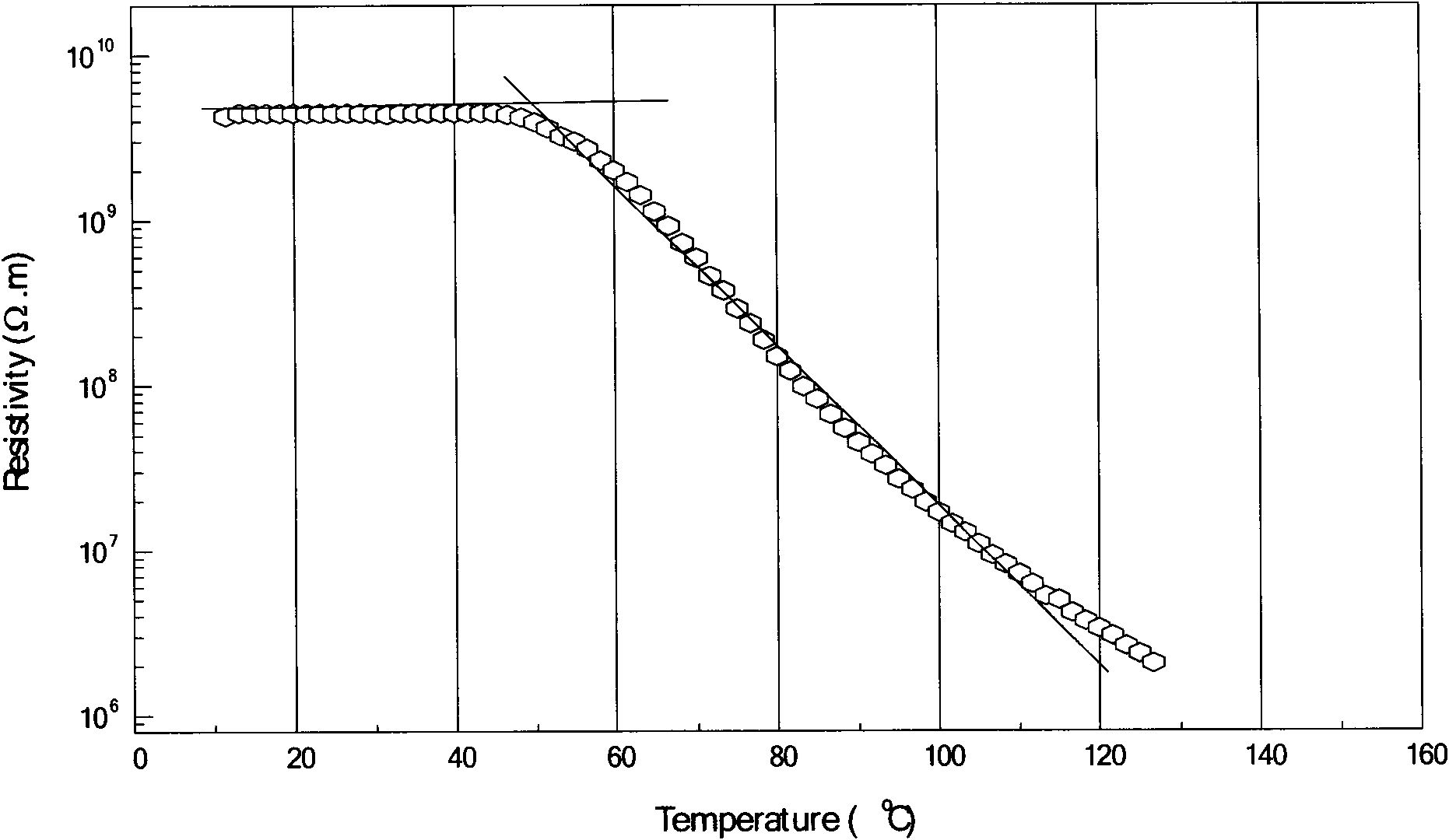

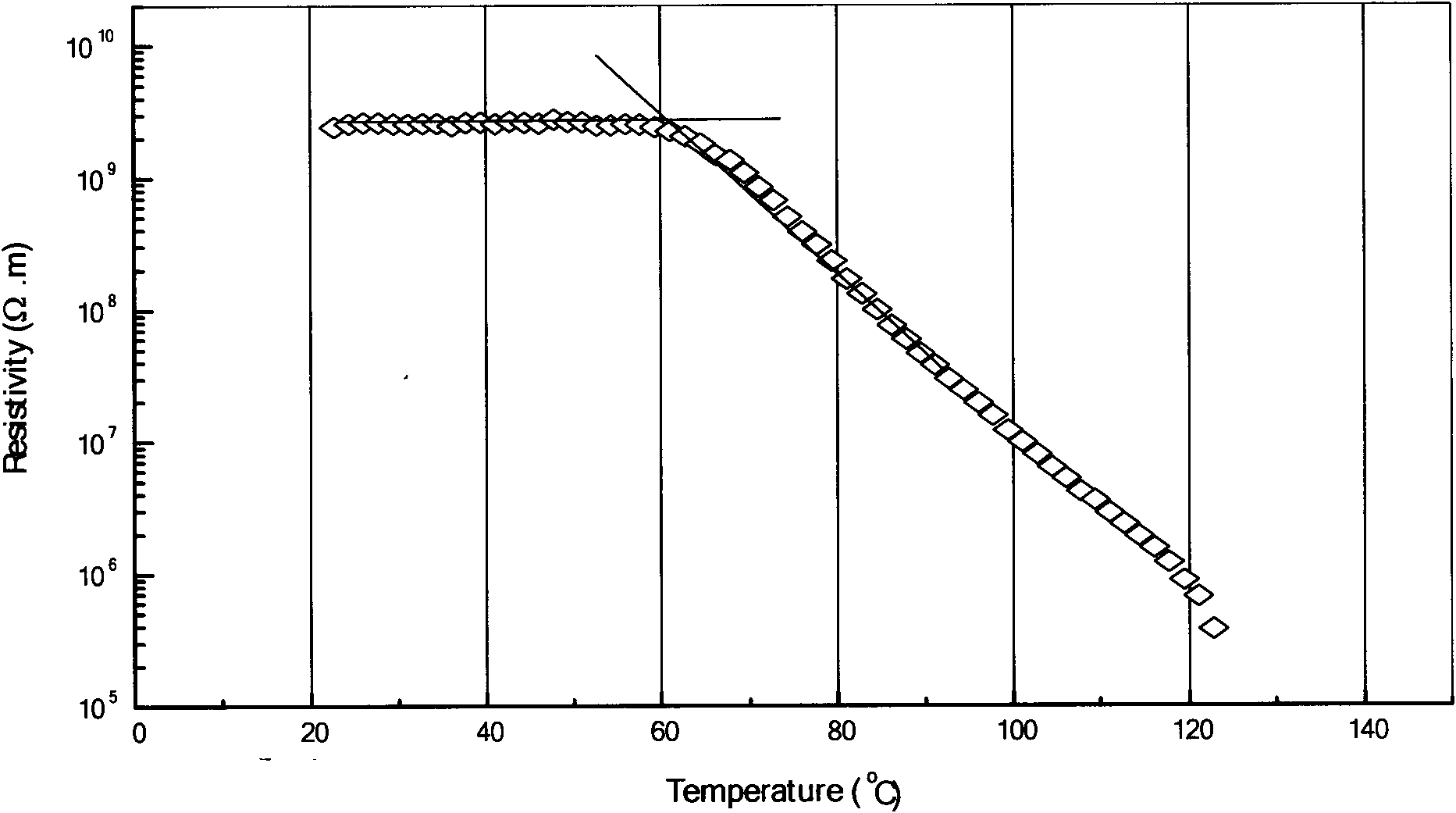

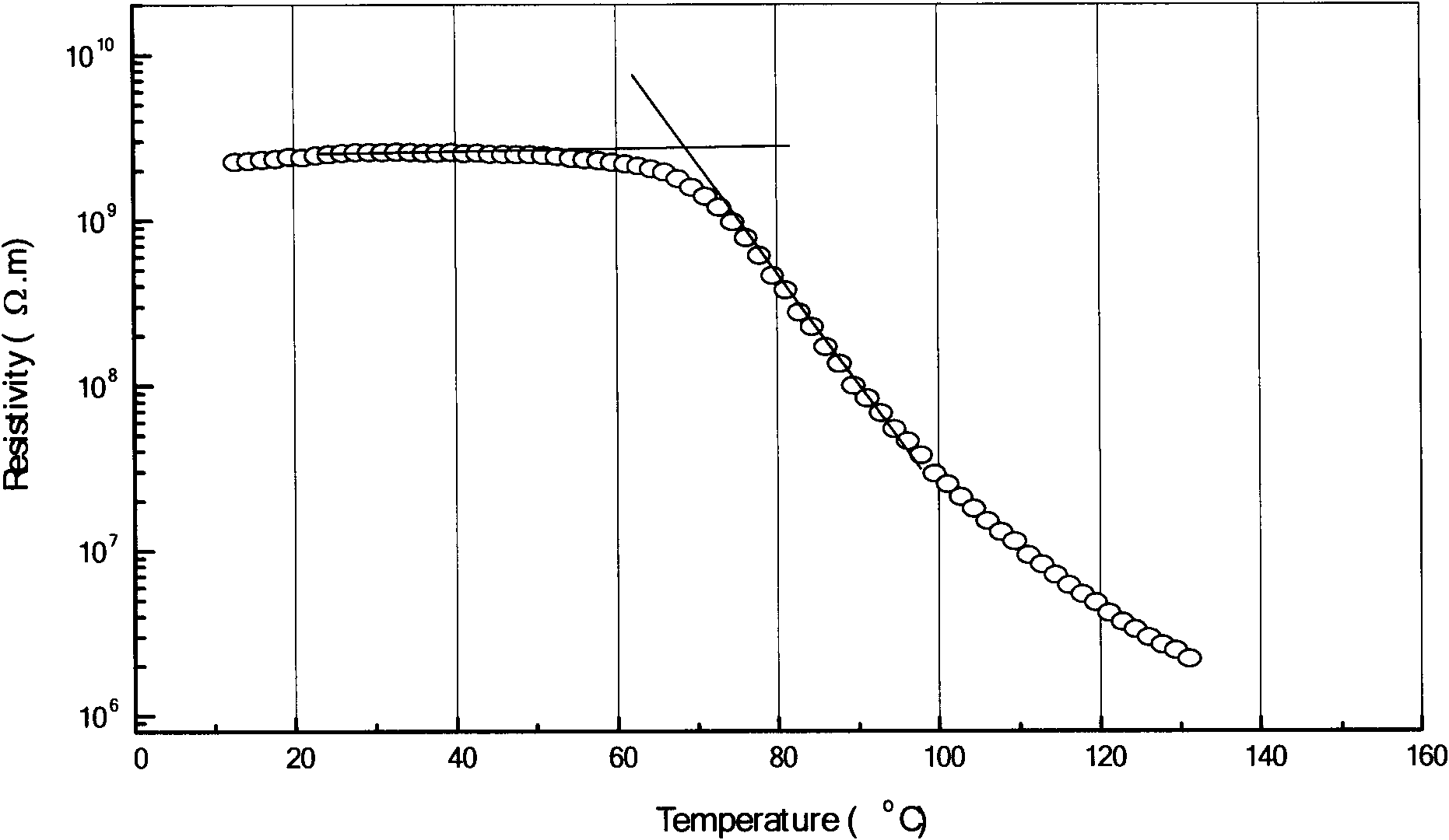

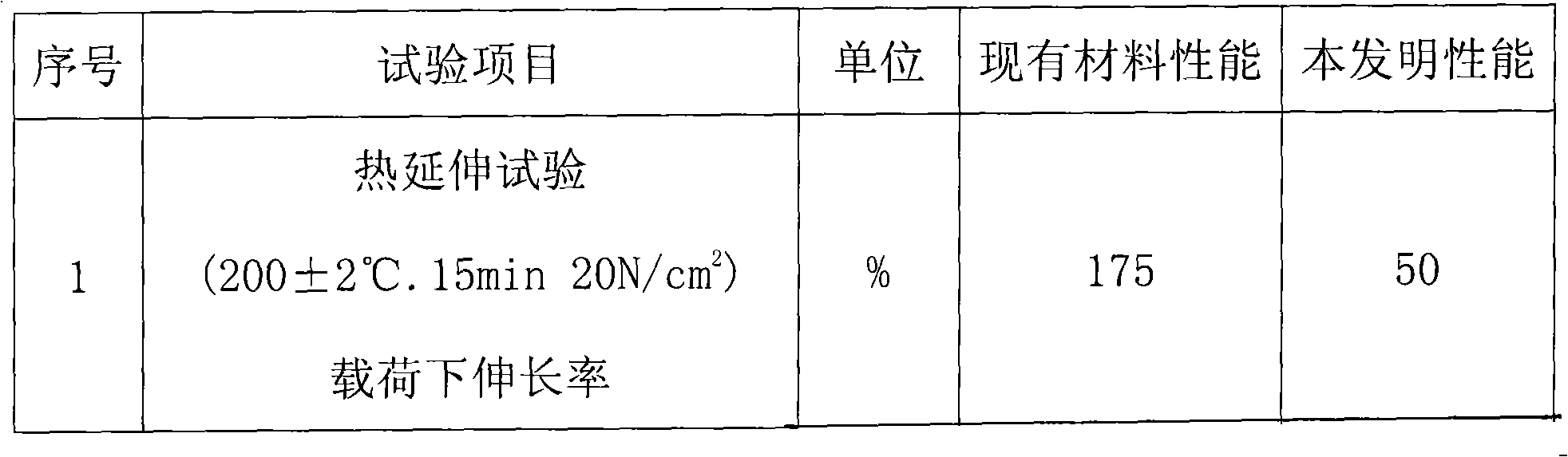

Temperature sensing cable material with CRT characteristics and preparation method thereof

ActiveCN101613504AWith CTR featureFlexibleRubber insulatorsPlastic/resin/waxes insulatorsProcedure AgentsAntioxidant

The invention relates to technical fields of materials, chemical engineering and electronics, in particular to a cable material with a polymer substrate and CTR effect and a preparation method thereof. The temperature sensing cable material with CRT characteristics consists of thermoplastic polymer, a filling agent, a plasticizer, functional additives, a stabilizing agent, a flame retardant, a lubricant, an antioxidant and a processing agent, has the use temperature range between -30 and 150 DEG C, and can be applied on occasions such as recoverable line-type temperature sensing cables, fire prewarning and alarm devices, temperature measurement, overheating alarm and protection and the like. The temperature sensing cable material with the CRT characteristics takes a polymer material as a substrate, and is added with multiple organic and inorganic compounds with special CTR characteristics taken as the functional additives, and has the characteristics of flexibility, and capacities of being continuously processed and being used like a common cable material.

Owner:QINGDAO SUNYFIRE TECHNOLOGE

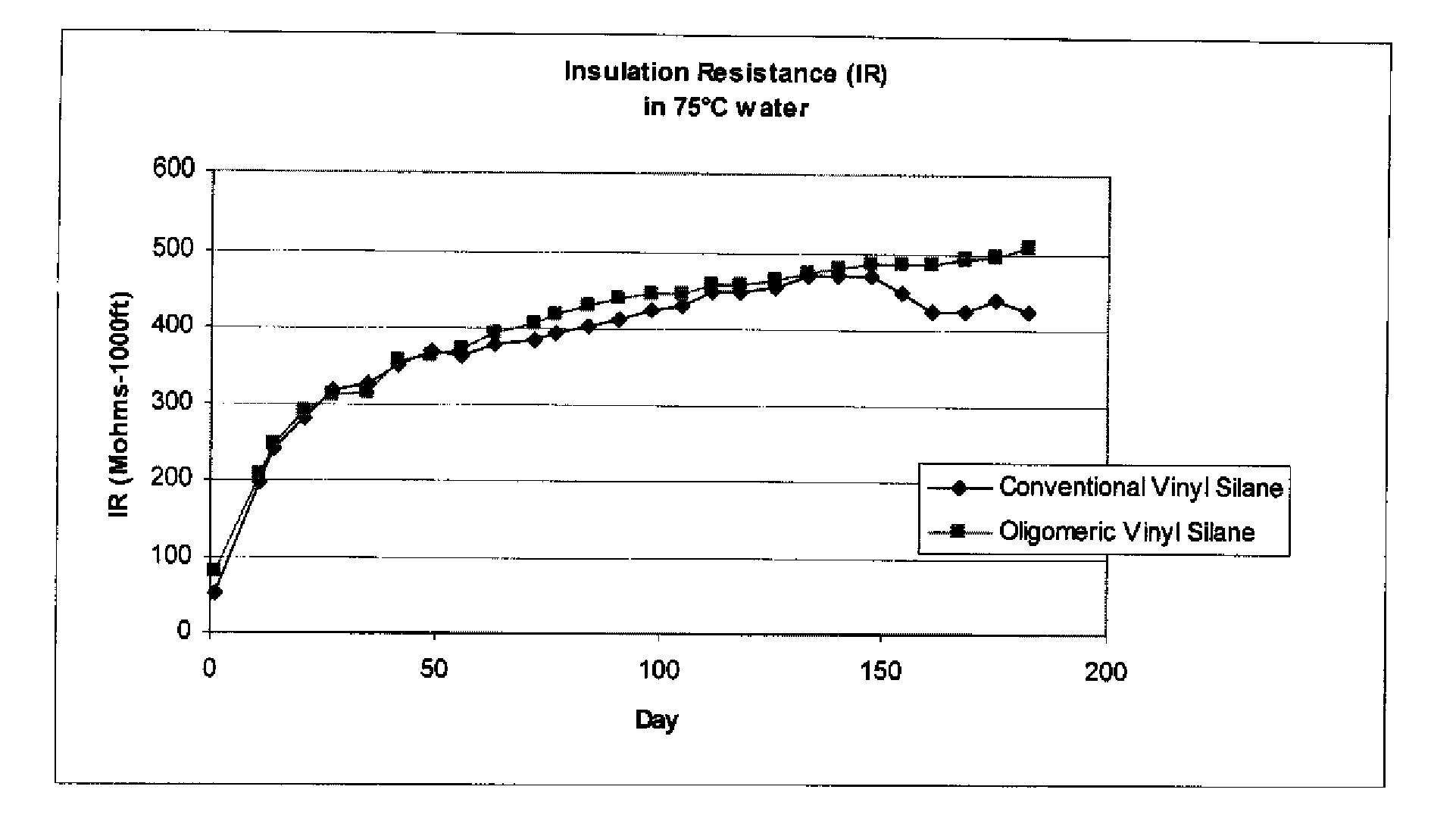

Low smoke, fire and water resistant cable coating

ActiveUS20090238957A1Limited smoke characteristicWet electrical performanceFireproof paintsRubber insulatorsMoisture resistanceOxygen

Cable coatings having effective low-smoke emission, fire resistance and moisture resistance provided by a single layer are described. The cable coatings contain an base polymer, a oxygen containing ethylene copolymer, a fire retardant and a synergistic blend of magnesium hydroxide and aluminum hydroxide. Cables coated with the described coatings have improved wet electrical performance, and satisfactory fire performance and smoke characteristics.

Owner:GENERAL CABLE TECH CORP

Resin composition for wire and cable covering material

A flexible resin composition comprises poly(arylene ether) resin, syndiotactic polystyrene, olefin elastomer, hydrogenated styrene-butadiene copolymer, and a non-halogen fire retardant.

Owner:SABIC GLOBAL TECH BV

Jacket formula for rubber jacketed flame-proof cable and production method thereof

InactiveCN101314654ATightly boundGood flexibilityRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxThiourea

The invention discloses a fire-retardant cable sheath material formulation and the preparation method thereof. The formulation comprises, by weight parts, 15 to 30 parts of chloroprene rubber, 15 to 30 parts of chlorinated polyethylene, 0.5 to 3.0 parts of zinc oxide, 0.5 to 3.0 parts of magnesium oxide, 0.2 to 1.0 parts of ethylene thiourea, 0.5 to 2.0 parts of dibenzothiazyl disulfide, 0.1 to 0.5 parts of tetramethylthiuram disulfide, 0.5 to 2.0 parts of N-phenyl-2-naphthylamine, 0.5 to 2.0 parts of stearic acid, 0.5 to 3.5 parts of paraffin, 1.0 to 5.0 parts of dioctyl phthalate, 5.0 to 15 parts of carbon black with high abrasion resistance, 5.0 to 15 parts of semi-reinforced carbon black, 3.5 to 10 parts of calcium carbonate, 2.5 to 8 parts of bis(pentabromophenyl) ether, 1.0 to 3.0 parts of antimony trioxide, and 1.0 to 8.0 parts of aluminum hydroxide. The preparation method mainly comprises the following steps: plasticating, blending, mixing, thin-passing and calendaring and extruding the sheath.

Owner:JIANGXI CABLE

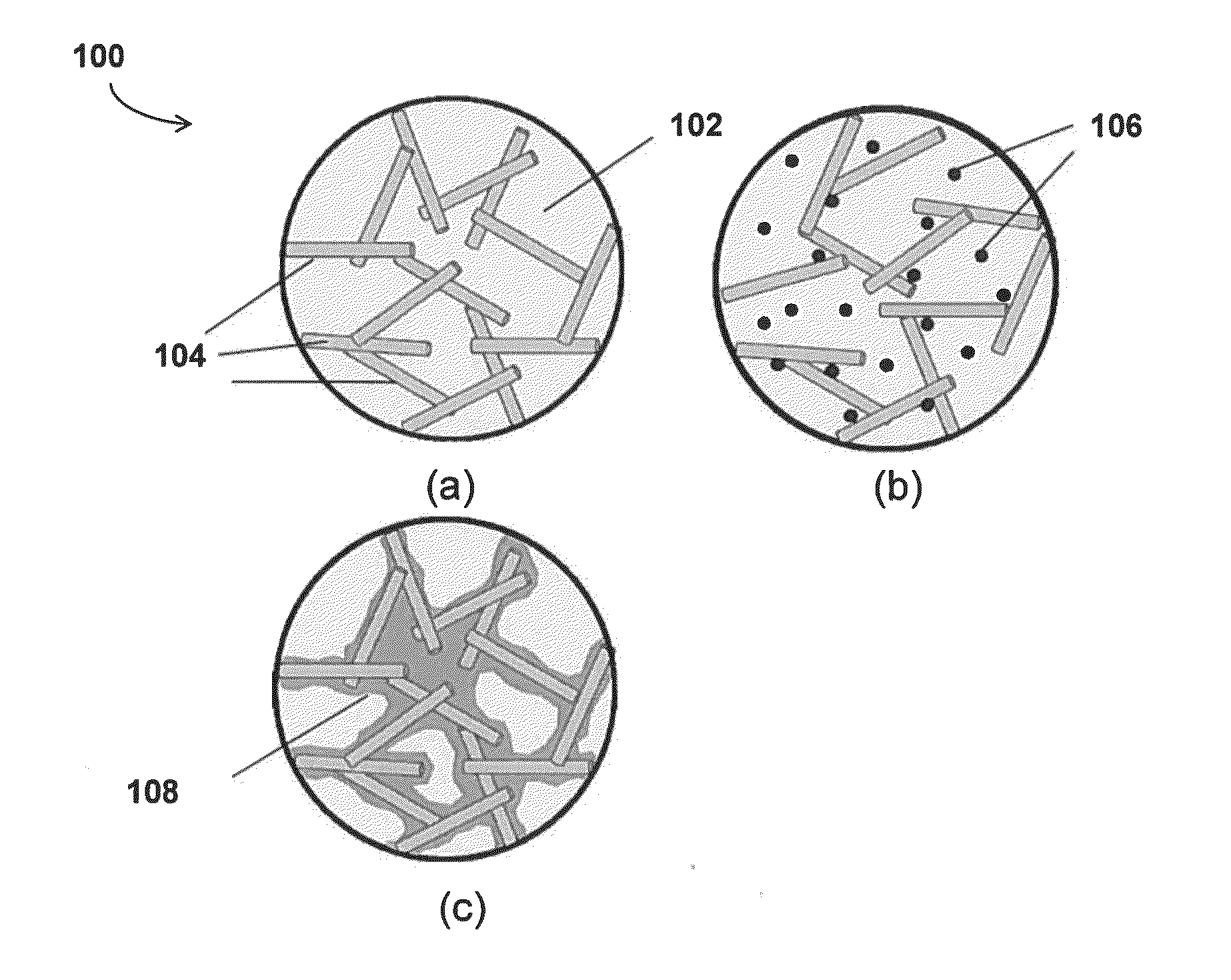

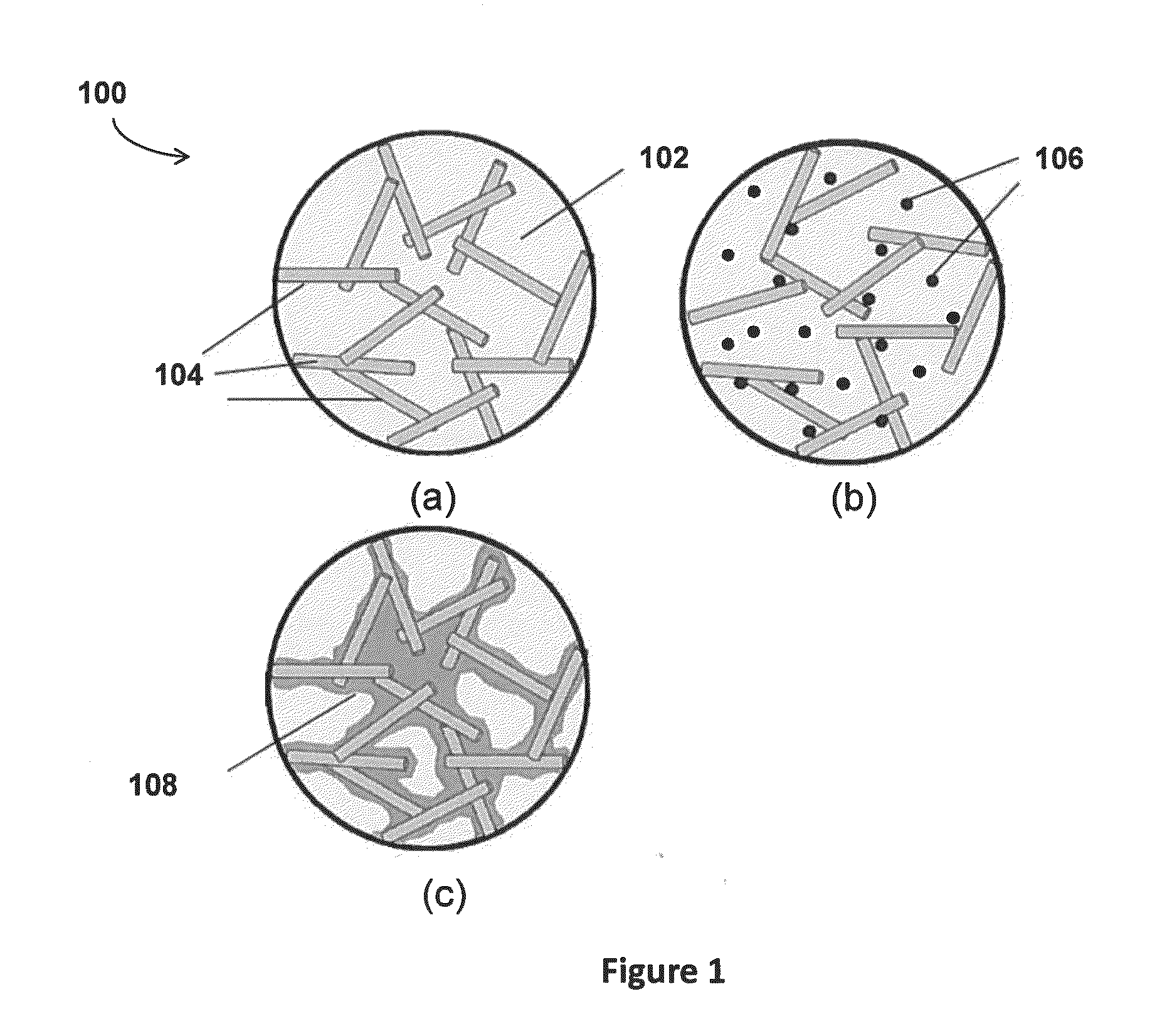

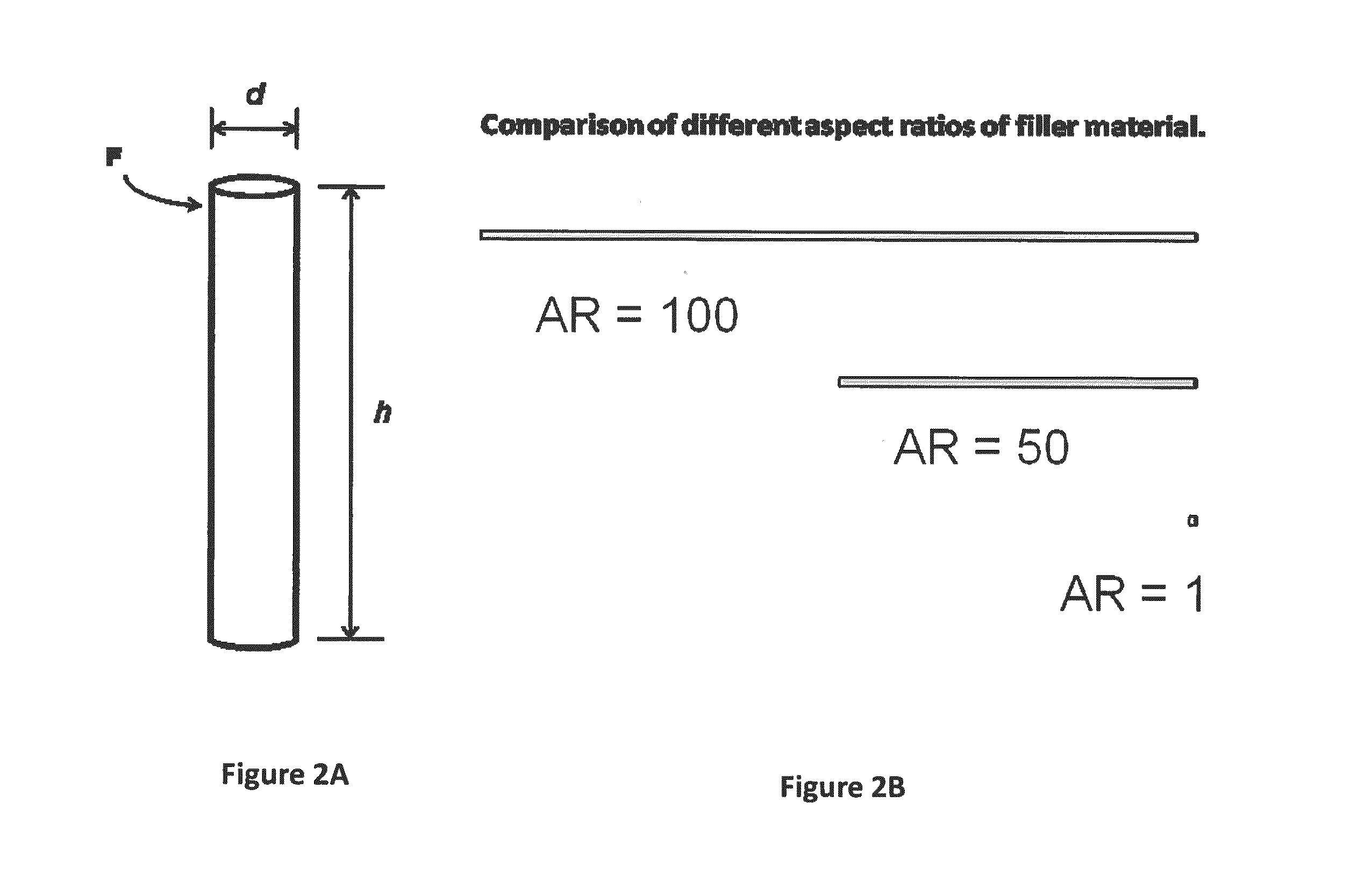

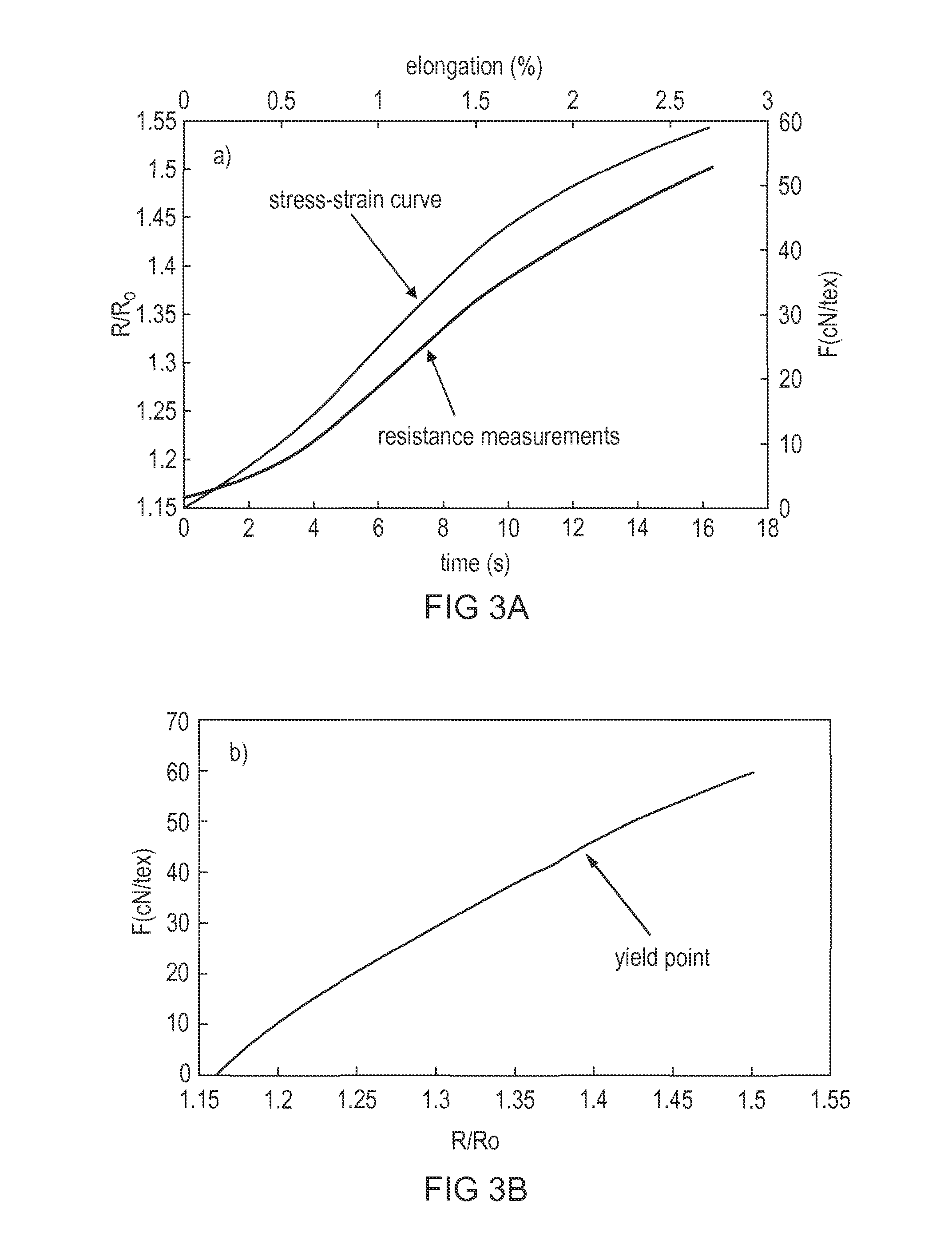

Deformable Elastomeric Conductors and Differential Electronic Signal Transmission

This application generally relates to deformable elastomeric conductors and differential signaling transmission techniques. According to one embodiment, a deformable elastomeric conductor is configured to transmit electrical signals. It comprises: an elastomeric polymer matrix; and conductive filler material uniformly dispersed in the elastomeric polymer matrix sufficient to render the material electrically conductive. The conductive filler material may include substantially non-entangled particles having an aspect ratio sufficiently large to enable the particles to substantially remain in contact and / or in close proximity with adjacent particles so as to maintain conductive pathways in the material when the material is subjected to deformation up to and exceeding 10% strain. Thus, over a transmission distance of an electrical signal through the conductor, the transmission does not suffer greater than about 3 dB of signal attenuation when subjected to the deformation.

Owner:ARMY US SEC THE

Heat-conducting wire cable electric-insulation material or sheath material

InactiveCN104017267AImprove thermal conductivityImprove insulation performanceRubber insulatorsPlastic/resin/waxes insulatorsElastomerHeat conducting

The invention discloses a heat-conducting wire cable electric-insulation material or sheath material which comprises the following components in parts by weight: 100 parts of ethylene and copolymer thereof and / or ethylene propylene diene monomer, 0-25 parts of compatilizer, 0-280 parts of flame retardant, 0.3-8 parts of antioxidant, 0.5-6 parts of lubricant, 0.01-10 parts of crosslinking assistant, 0-30 parts of polymer elastomer, 0-8 parts of coupling agent, 0-12 parts of color master batch and 1-35 parts of heat-conducting material. The heat-conducting wire cable electric-insulation material or sheath material has excellent heat conductivity and electric insulativity; and the cross network formed by piling the heat conducting material, the ethylene and copolymer thereof and other components can effectively perform heat conduction, so that the heat conductivity coefficient is up to 3.305-4.867 w / m.k, and the volume resistivity is 10<14> ohm*cm, thereby ensuring the electric-insulation effect and heat-conducting effect of the wire cable and the, and further ensuring the normal operation of the cable.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +4

Ceramicized silicon rubber, preparation method and application

ActiveCN102964836AEasy to processReduce manufacturing costRubber insulatorsPlastic/resin/waxes insulatorsCouplingOrganic group

The invention relates to a ceramicized silicon rubber, which comprises 1)60-100 parts of silicon rubber, wherein a general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 2)20-100 parts of silicon dioxide; 3)1-20 parts of silicone oil, wherein the general formula is (RnSiO4-n / 2)m, R is an organic group, n is the organic number (1,2,3) connected to silicon atoms, and m is polymerization degree (greater than and equal to 2); 4)0.1-10 parts of coupling agent and 5)20-120 parts of ceramicized powder. The above raw materials are mixed in a kneader and then vacuumized, the ceramicized powder and the coupling agent are added in the kneader and then uniformly mixed to form the bulk ceramicized rubber, and the ceramicized rubber is performed roll mixing and filtered to obtain the ceramicized silicon rubber. The ceramicized silicon rubber has the advantages that the processing is easy, the production cost is low, the ceramicized silicon rubber can be performed ablation to a ceramic shell, and can protect the burned objects from damaging.

Owner:常州市沃科科技有限公司

Flame-retardant ceramic composite material and preparation method thereof

ActiveCN103601954AEasy to processReduce manufacturing costRubber insulatorsInsulated cablesCeramic compositePolyolefin

The invention discloses a flame-retardant ceramic composite material which comprises the following components in parts by weight: 100 parts of polyolefin, 0-100 parts of silicone rubber, 1-100 parts of silica, 0-30 parts of silicone oil, 0.00001-10 parts of platinum complex or platinum compound calculated based on platinum, 0-10 parts of coupling agent, 0-100 parts of flame retardant, 1-250 parts of porcelain powder, 0-10 parts of antioxidant, and 0.01-10 parts of vulcanizing agent. The materials are mixed in a kneading machine, the materials are added into the kneading machine through vacuumizing and then uniformly mixed so as to obtain bulk ceramic rubber, and after being cooled, the cooled rubber is subjected to open milling by adding the vulcanizing agent so as to obtain the flame-retardant ceramic composite material. The flame-retardant ceramic composite material disclosed by the invention is easy to process and low in production cost, and can be ablated into a ceramic shell so as to protect a burnt object from being damaged. Because a platinum complex or a platinum compound is added in the flame-retardant ceramic composite material disclosed by the invention, the sintering temperature of the flame-retardant ceramic composite material can be reduced, the reaction speed of preparation can be increased, the production efficiency is improved, and the production cost is lowered.

Owner:SHANGHAI KETER POLYMER MATERIAL

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

Moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building

ActiveCN103467838AImprove hydrophobicityAvoid short circuit accidentsRubber insulatorsPlastic/resin/waxes insulatorsInsulation layerMoisture absorption

The invention discloses a moistureproof type low-smoke halogen-free flame-retarding wire and cable insulation material used for building. The insulation material comprises components, by weight, 100 parts of vinyl copolymer and / or ethylene propylene rubber, 100-250 parts of halogen-free flame retardants, 1-20 parts of compatilizer, 0.3-5 parts of antioxygen, 0.5-5 parts of lubricants, 0-3 parts of coupling reagents, 0-2 parts of dispersing agents, and 2-20 parts of one or more of vinyl silicone oil, silicone, silicone grease, silicone rubber, and mineral oil. Wires made of the material is low in smoke, free of halogen, incapable of releasing poisonous gas. Flames can be retarded due to the fact that a single stick of wire can vertically combust at combusting time. Moreover, some special addition agents are added in materials of insulation layers or protective sleeve layers, so that the surface hydrophobic property of products is increased and can be used in a high-temperature humid environment for a long time, and short circuit accidents caused by moisture absorption of the wire insulation layers are avoided.

Owner:SHENZHEN WOER HEAT SHRINKABLE MATERIAL +1

Ethylene propylene rubber insulation material for longitudinal high-voltage watertight cable of ships and warships and production method thereof

InactiveCN101831115AMeet the needs of useGuaranteed flexibilityRubber insulatorsParaffin waxPolymer science

The invention discloses an ethylene propylene rubber insulation material for longitudinal high-voltage watertight cables of ships and warships and a production method thereof. The method comprises the following steps: adding the ethylen e-propylene-diene mischpolymere, age resister and fire retardant into a banbury for banburying for 3.5min; adding argil, white carbon black and paraffin wax for continued banburying for 2min; adding active agent, and discharging after banburying for 1.5min; filtering the rubber compound with a three-layer filter screen (namely a 60 mesh filter screen, a 60 mesh filter screen and a 80 mesh filter screen) on a rubber filter; and beating into cornucopla on a double-roller mill, adding vulcanizer and co-crosslinker, then beating into cornucopla for 7 times, grinding and slicing after finishing the steps, and then cooling, wherein the materials are as follows in parts by weight: 100 parts of ethylen e-propylene-diene mischpolymere, 1-5 parts of vulcanizer, 1-4 parts of age resister, 15-70 parts of fire retardant, 0.5-10 parts of active agent, 10-20 parts of argil and 2-4 parts of paraffin. The prepared insulation material has the characteristics of low smoke, no halogen, fire resistance, high machinery strengthen, and high insulation resistance, good flexibility, elasticity and viscosity, and can be used for the ships and warships.

Owner:嘉兴君宏光学有限公司

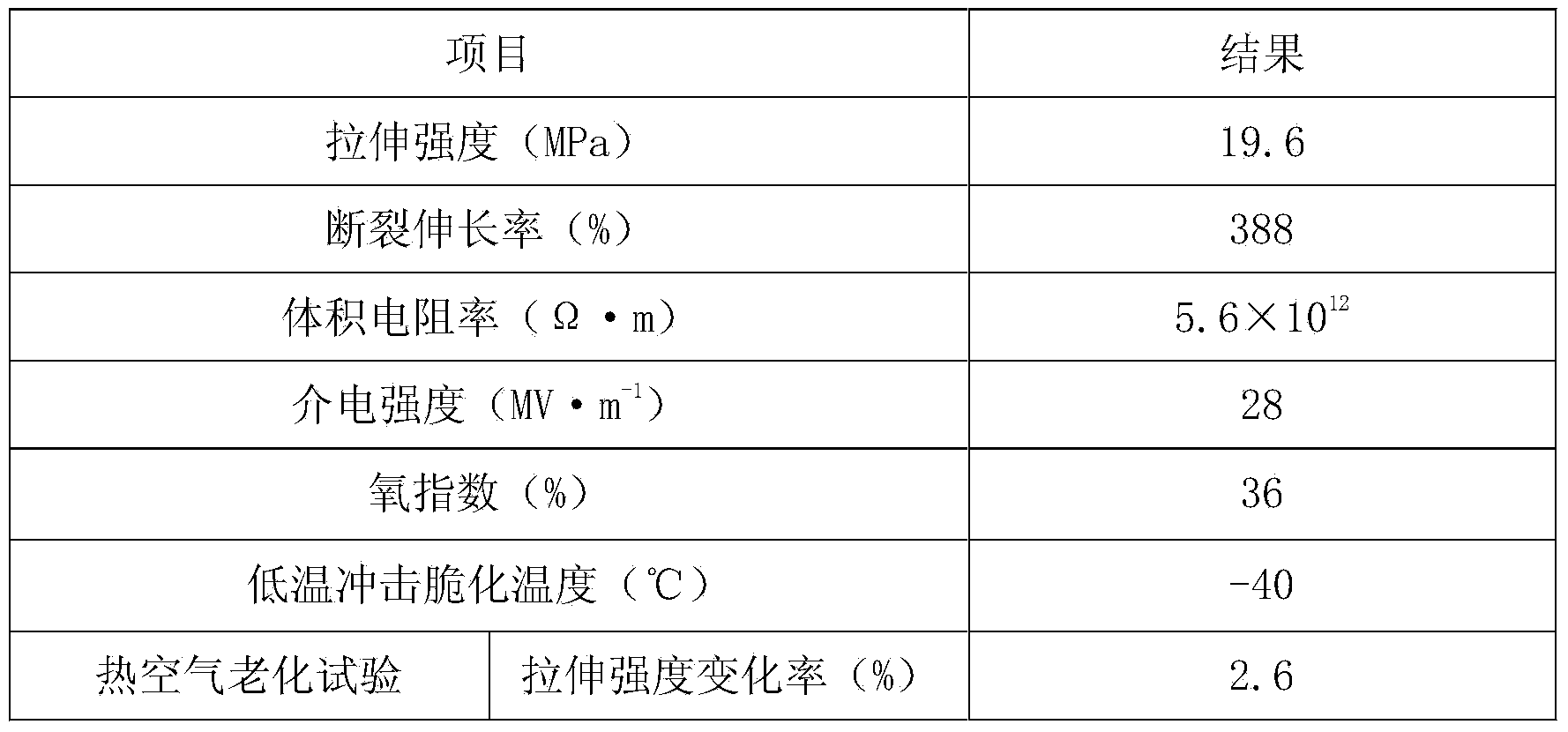

High temperature resistance non halogen flame retardant cable sheath material and preparation method thereof

ActiveCN101613506AImprove temperature resistanceOvercome the problem of not being able to prepare high temperature resistant halogen-free flame retardant cable sheathing materialsRubber insulatorsPolymer scienceVulcanization

The invention discloses a high temperature resistance non halogen flame retardant cable sheath material and a preparation method thereof. The high temperature resistance non halogen flame retardant cable sheath material comprises the following components with the following parts by weight: 100 parts of ethylene-propylene-diene monomer (EPDM), 1.5-6 parts of vulcanizing agent, 1.5-6 parts of co-vulcanization agent, 0.5-5 parts of coupling agent, 4-20 parts of antiager, 4-30 parts of softener and 80-250 parts of inflaming retarding filling agent. In the invention, the halogen-free material is adopted, thick smoke, corrosive halogenide gas and other harmful substances are not generated in the process of burning; the cable sheath of the invention features excellent elasticity and tenacity, not only has obvious inflaming retarding effect, but also improves heat-resisting and anti-aging properties, can resist high temperature, and has high mechanical strength and wide application range; in addition, the production process is easy and is convenient for rubber-producing enterprises to achieve self-sufficiency.

Owner:SICHUAN MINGXING CABLE

High performance rubber sheath rubber material

ActiveCN102796293AExcellent ozone resistanceGood weather resistanceRubber insulatorsInsulated cablesRubber materialNitrile rubber

The invention discloses a high performance rubber sheath rubber material, which comprises the following raw materials by weight part: 30-60 of ethylene propylene diene monomer rubber, 30-70 of nitrile rubber, 25-60 of a reinforcing filler, 5-10 of active agents, 3-5 of anti-aging agents, 0.5-10 of a vulcanizing agent, 0.5-3 of a promoter and 5-20 of plasticizers. The raw materials are subjected to mixing by an open mill and an internal mixer to produce a mixed rubber compound, which is then prepared into a semi-finished product extruder extrusion. The rubber material not only has good ozone resistance and weathering aging resistance, but also has excellent oil resistance and bonding performance. And under the premise of satisfying comprehensive performance, the service life of the rubber material is further improved.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

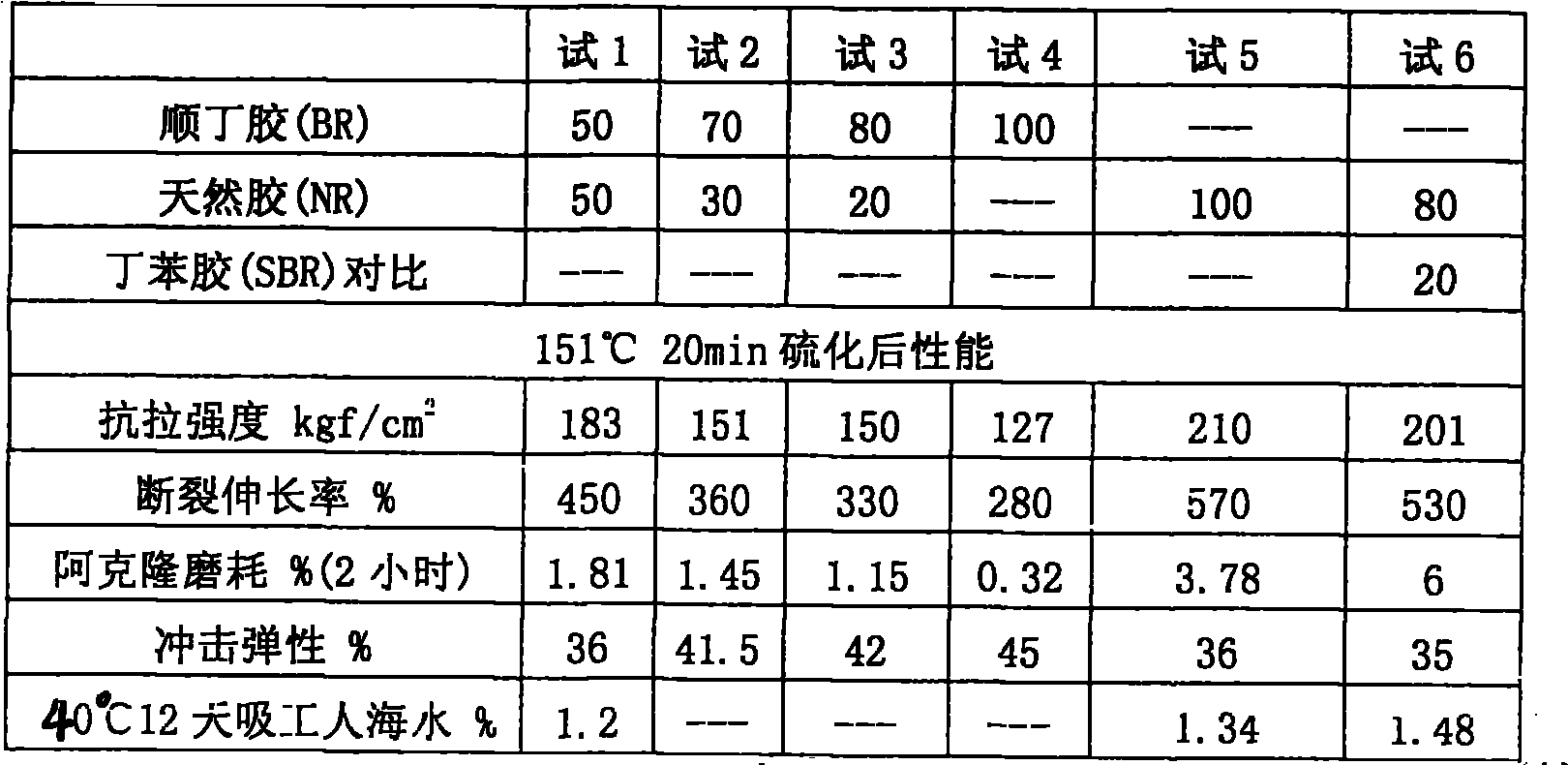

Cable jacket rubber and preparation method

ActiveCN101580606AScorch slowFast vulcanizationRubber insulatorsInsulated cablesTetramethylthiuram disulfideElectricity

The invention relates to a cable jacket rubber and a preparation method, wherein the cable jacket rubber has high elastic resilience, softness and abrasive resistance at a low temperature. The cable jacket rubber is characterized in that a base material of the rubber is formed by mixing 30 to 50 weight percent of natural gum and 50 to 70 weight percent of cis-butadiene rubber; a vulcanizing system in a rubber compounding agent is a low-sulfur high-accelerant vulcanizing system, the addition of sulfur is 0.3 to 0.6 weight percent of that of the base material of the rubbere, the addition of the accelerant tetramethylthiuram disulfide is between 1.0 and 1.3 weight percent, the addition of the accelerant N-cyclohexyl-2-benzothiazole sulfonamide is between 1.8 and 2.2 weight percent, and the addition of the accelerant diphenyl disulfide benzothiazole is between 0.6 and 0.9 weight percent. The cable jacket rubber has wide range of working temperature, and can be bent and distorted randomly without cracking at a long-term usage temperature of between 50 DEG C below zero and 70 DEG C, the impact elasticity is high and can reach 42 percent, the specific elongation is more than 350 percent, and the Akron abrasion loss is less than 2 percent, thus the cable jacket rubber is particularly suitable for wind-power generated electricity tower tube cables.

Owner:WUXI HUAMEI CABLE

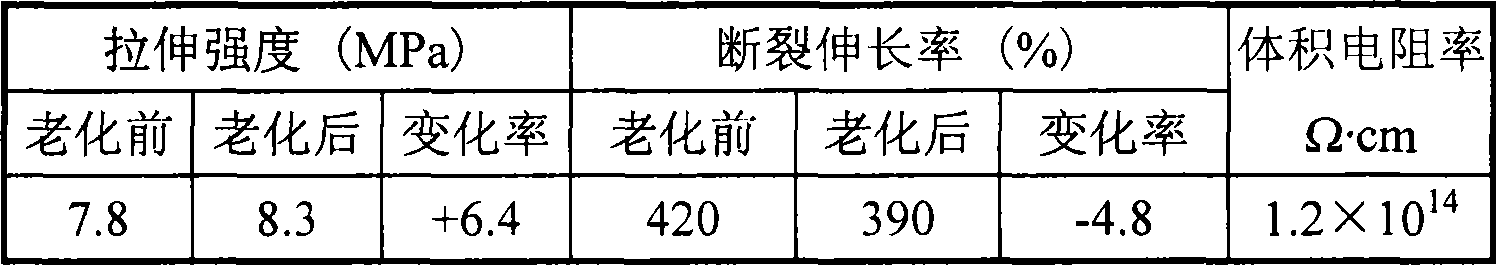

Ultraviolet light crosslinked EPT rubber cable insulation material and preparation thereof

ActiveCN101434728AHigh volume resistivityIncrease productivityRubber insulatorsInsulated cablesCross-linkPolymer science

The invention discloses an ultraviolet cross-linking EPDM (ethylene propylene diene monomer) rubber cable insulation material and a preparation method thereof. The method is characterized in that: by weight, 100 portions of EPDM rubber, 100 portions to 120 portions of inorganic filling, 0.5 portion to 5.0 portions of ultrasonic initiator, 0.5 portion to 5.0 portions of polyfunctional cross-linking agent, 5.0 portions to 10.0 portions of softener, 0.8 portion to 1.2 portions of silane coupling agent and 0.01 portion to 1.0 portion of complex antioxidant are evenly mixed and extruded at the temperature of 100 DEG C to 150 DEG C, thereby obtaining the ultraviolet cross-linking EPDM rubber cable insulation material; then the wire core is fused and extruded coating to form an insulation layer or a protective coating; and ultraviolet cross linking is carried out under 200nm to 400nm of wave length and 400mW / cm<2> to 2000mW / cm<2> of light intensity. The cable insulation material has tensile strength of larger than 6.5MPa, elongation at break of higher than 300 percent and volume resistivity of higher 10<12>Omega question mark cm, and can pass a thermal aging test under the temperature of 135 DEG C for 168h.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

Formula for ceramicized silicon rubber cable material

InactiveCN102040839ASo as not to damageNormal power transmissionRubber insulatorsCombustionRefractory

The invention relates to a refractory and flame-retardant compound, in particular to a silicon rubber cable material ceramicized through combustion. The formula for the ceramicized silicon rubber cable material is characterized by comprising the following materials in parts by weight: 80-120 parts of silicon rubber, 20-50 parts of mineral silicate, 20-50 parts of flame retardant and 40-65 parts of reinforcing filler. A hard shell can be formed on the silicon rubber cable material prepared with the formula after a combustion test, is not easy to fall off, and protects a burned cable from being damaged, therefore, normal transmission is ensured.

Owner:QINGDAO HANHE CABLE

Halogen-free thermoplastic elastomer and manufacturing method thereof and environment-friendly electric wires and cables using halogen-free thermoplastic elastomer

InactiveCN101987902ANon-toxicNo pollution in the processRubber insulatorsPlastic/resin/waxes insulatorsThermoplasticChemistry

The invention discloses a halogen-free thermoplastic elastomer composition, which is characterized by consisting of the following components in percentage by mass: 30 to 40 percent of elastomer, 15 to 30 percent of thermoplastic, 2 to 8 percent of EVA (ethylene-vinyl acetate) resin, 3 to 6 percent of compatilizer, 10 to 25 percent of plasticizer, 2 to 8 percent of inorganic filler and 5 to 10 percent of auxiliary agent. In the halogen-free thermoplastic elastomer composition and a manufacturing method thereof and environment-friendly electric wires and cables using the same, the composition does not contain harmful heavy metals, halogen and chemical substances harming human health and natural environment; and the environment-friendly new material is non-toxic and pollution-free, can be recycled, has the advantage of resisting water, cold, high temperature, oil, acid and alkali, and is widely applied in high-end cables of military industry, ships, nuclear power, wind energy, railway track traffic, magnetic suspension and the like and related fields.

Owner:索肯(上海)科技有限公司

Oil-resistant cold-resistant ultraviolet-proof polyvinyl chloride/nitrile rubber composite cable material and preparation method thereof

InactiveCN103509274AImprove mechanical propertiesImprove toughnessRubber insulatorsPlastic/resin/waxes insulatorsDiethylene glycol monobutyl etherPolymer science

A disclosed oil-resistant cold-resistant ultraviolet-proofpolyvinyl chloride / nitrile rubber composite cable material is prepared from the following raw materials in parts by weight: 60-80 parts of SG-2 type polyethylene, 20-30 parts of POE, 30-50 parts of nitrile rubber, 15-20 parts of fluorubber, 10-15 parts of dioctyl phthalate, 5-10 parts of di(butylcarbitol)adipate, 0.5-1 part of dicumyl peroxide, 2-3 parts of triallyl isocyanurate, 1-2 parts of 2-mercaptobenzimidazole, 4-8 parts of titanium dioxide, 5-10 parts of paraffin oil, 2-3 parts of zinc oxide, 4-8 parts of microcrystalline paraffin and the like. The cable materials of the invention ahs excellent thermoset rubber apparence and thermoplastic elastomer characteristics, and good mechanical properties and low-temperature flexibility; the long-term suitable operation temperature is -40 DEG C to 105 DEG C; the cable material is capable of retarding flame, resisting oil, resisting acid and base, resisting wear, resisting weather, resisting ozone, resisting thermal aging and resisting ultraviolet ray, and is applicable as high-oil-resistance weatherable cable sheath materials.

Owner:安徽天民电气科技有限公司

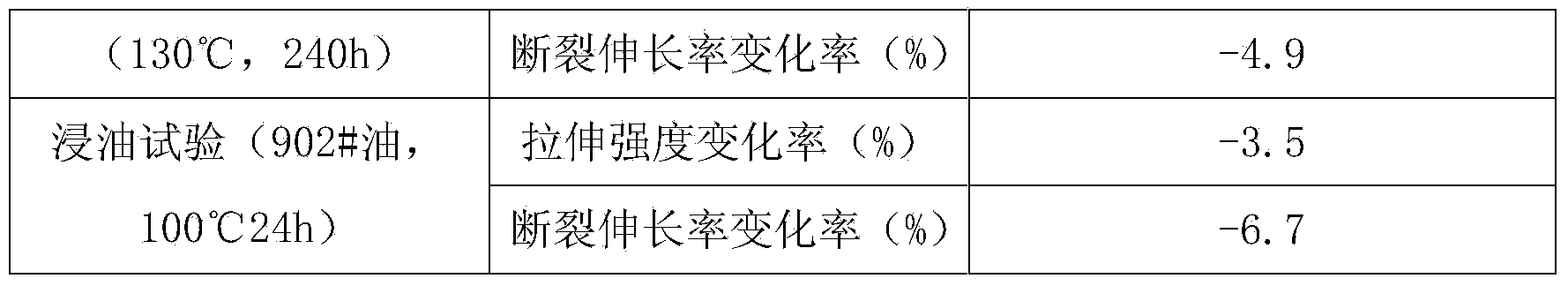

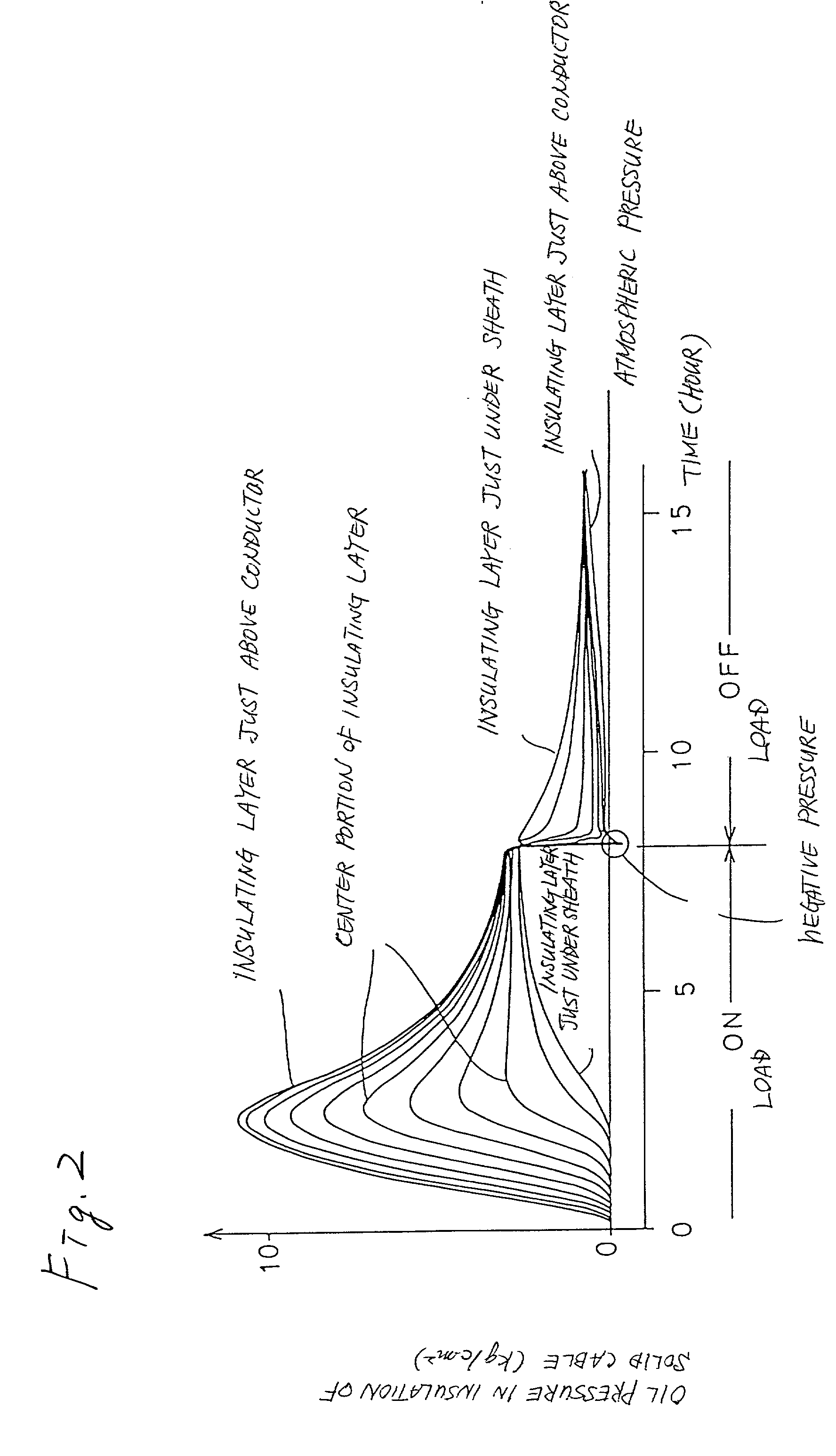

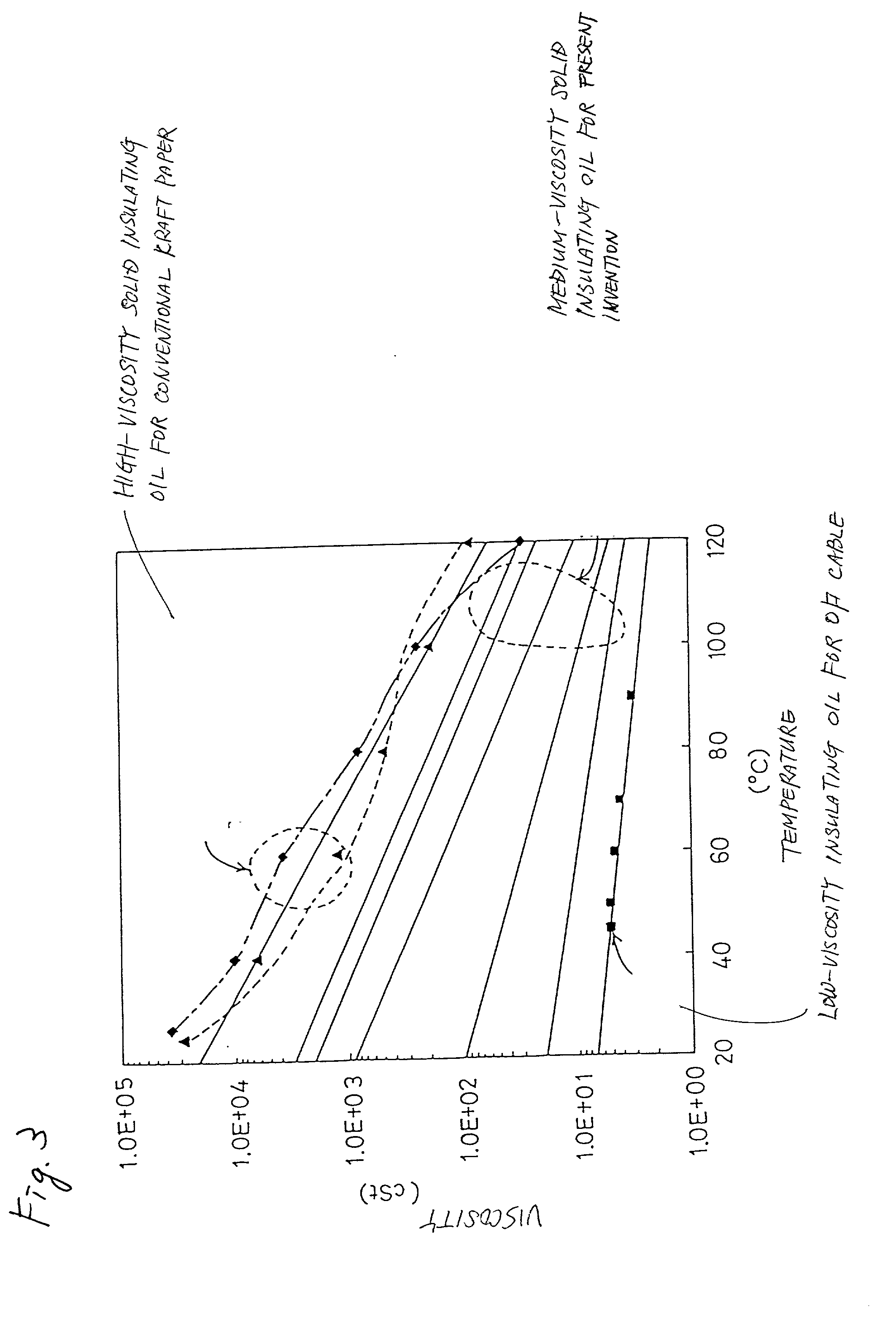

Solid cable, manufacturing method thereof, and transmission line therewith

InactiveUS20010042635A1High tensile strengthRubber insulatorsOil-pressure cablesInsulation layerElectrical conductor

A solid cable provided with an insulation layer on the outer circumference of a conductor, and impregnated with insulating oil in this insulation layer. Medium-viscosity insulating oil the viscosity of which is between not less than 10 cst and less than 500 cst at 60° C. is used as the insulating oil.

Owner:SUMITOMO ELECTRIC IND LTD

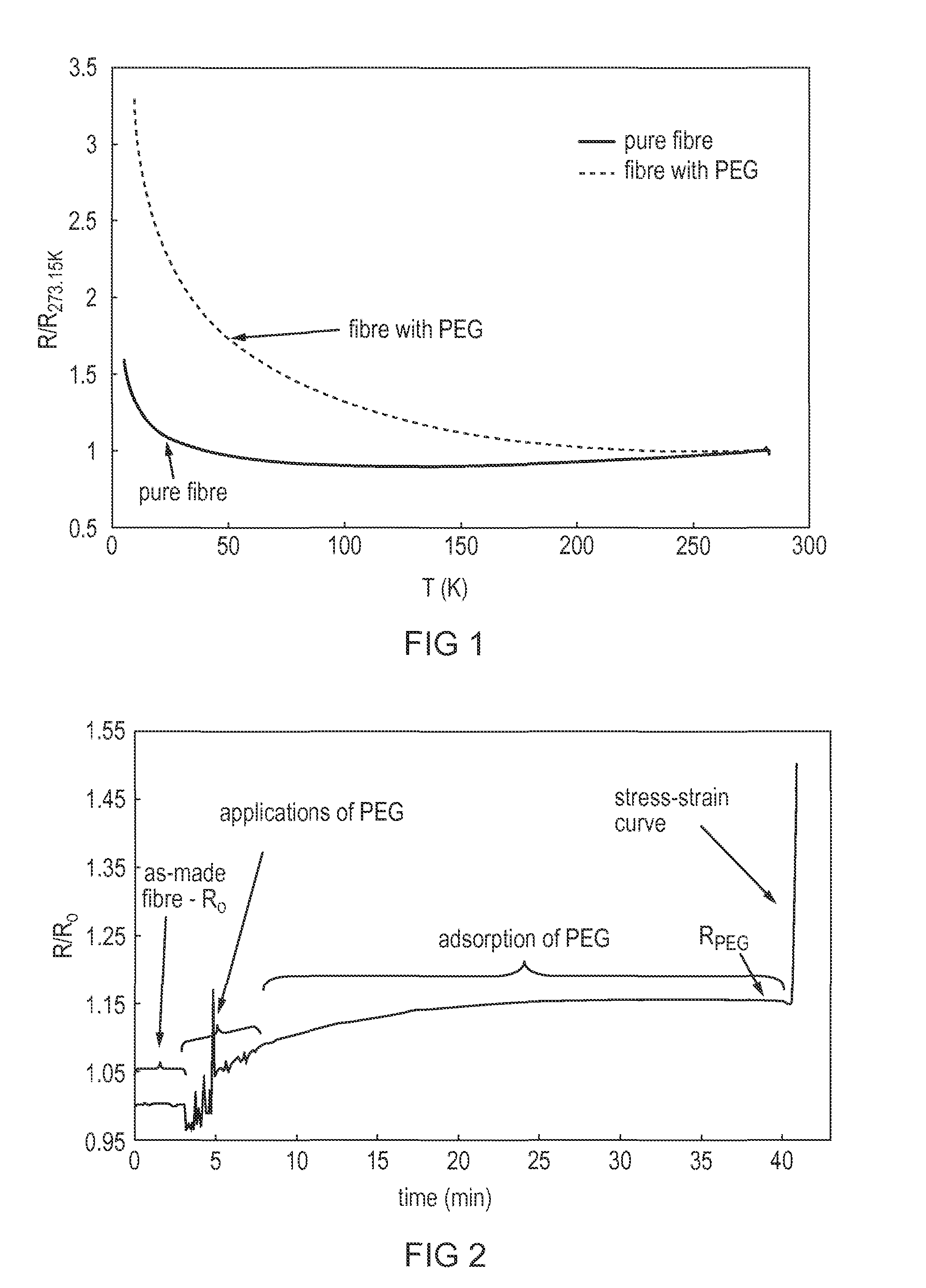

Materials and Methods for Insulation of Conducting Fibres, and Insulated Products

InactiveUS20140231118A1Reduce conductivityAffect conductivityRubber insulatorsMaterial nanotechnologyFiberElectrical conductor

An electrical conductor comprising an electrically conducting fibre comprising carbon nanotubes and / or graphene nanoribbon and a layer of insulating material coated around the electrically conducting fibre. The insulating material substantially does not penetrate the electrically conducting fibre, or penetrates the electrically conducting fibre only to a depth that leaves a continuous conductive path along a remaining part of the electrically conducting fibre.

Owner:CAMBRIDGE ENTERPRISE LTD

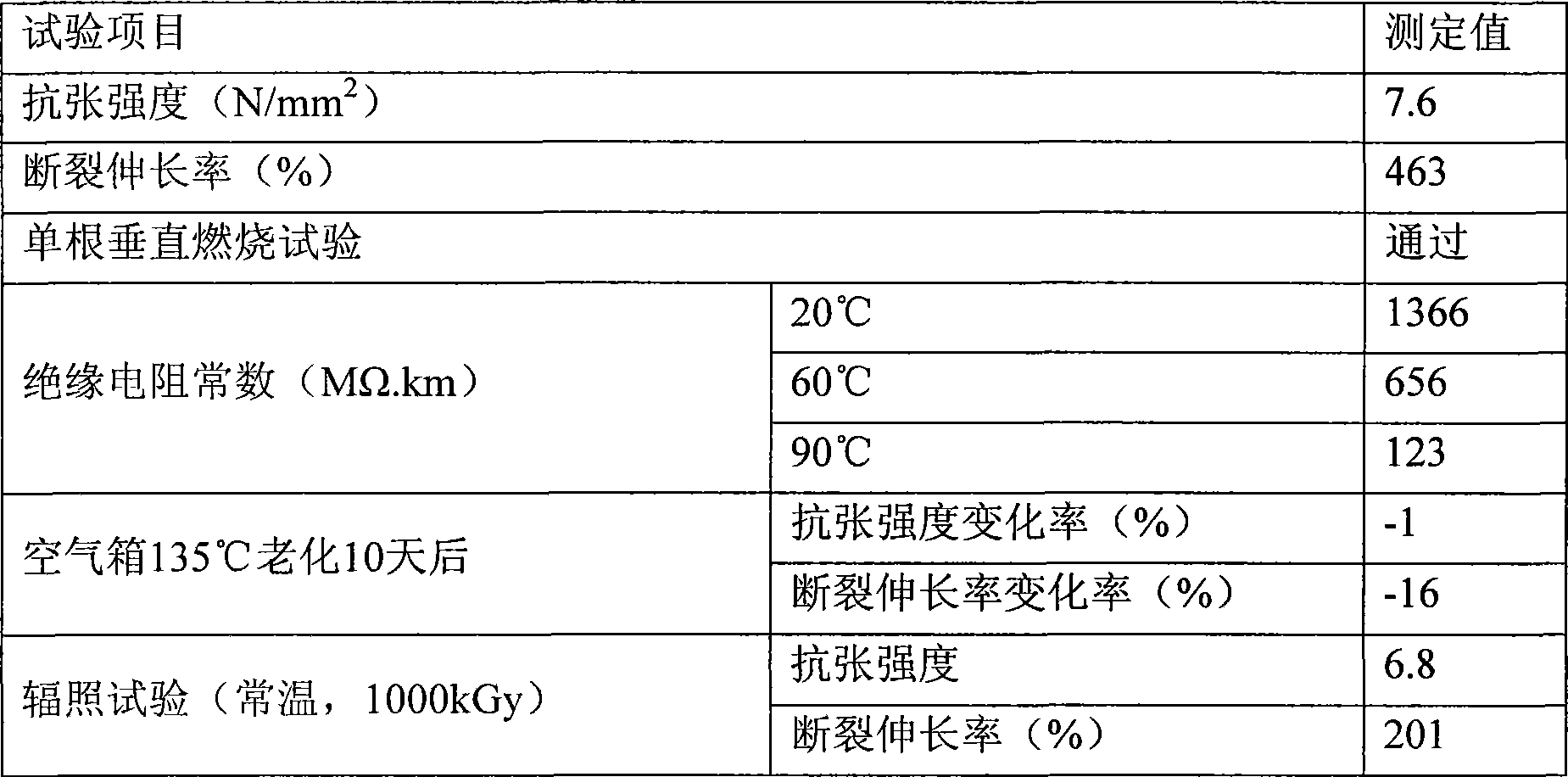

Radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and preparation method

ActiveCN101531789AImprove radiation resistanceThe ratio is scientific and reasonableRubber insulatorsSilanesNuclear power

The invention discloses a radiation-resistant halogen-free low smoke flame retardant insulating material for cables of nuclear power plants and a preparation method. The radiation-resistant halogen-free low smoke flame retardant insulating material is prepared from the following raw materials: ethylene propylene diene rubber, phenyl siloxane rubber, magnesium hydrate, aluminium hydroxide, zinc borate, white carbon black, cerium dioxide, zinc oxide, Bis(tert-butyldioxyisopropyl)benzene, tri allyl cyanurate, 2-mercaptobenzimidazole, 2,2,4-trimethyl-1,2-dihydroquinoline, Aflux A-25, stearic acid, vinyl tris(beta-methoxyethoxy) silane, and paraffin oil by heating and mixing. The formulation and the mixture ratio are scientific and reasonable, and the process is advanced. The prepared insulating material has good radiation resistance, excellent mechanical property, good electrical property and long service life, and is a good radiation-resistant halogen-free low smoke flame retardant insulating material for manufacturing the cables of the nuclear power plants.

Owner:BAOSHENG SCI & TECH INNOVATION

Blends of epdm and metallocene plastomers for wire and cable applications

Power cable coating compounds are disclosed, the coating compounds including an ethylene alpha-olefin diene elastomeric terpolymer, and an ethylene alpha-olefin copolymer having a Melt Index Ratio I10 / I2 of at least 7 and / or a Melt Index Ratio I21 / I2 of at least 20. In various embodiments, the ethylene alpha-olefin copolymer can be present in the coating compound in amounts up to 90 percent by weight, based on the weight of the ethylene alpha-olefin diene elastomeric terpolymer and the ethylene alpha-olefin copolymer. Also disclosed are electrical devices including extruded coating compounds, the extruded compounds having low surface roughness at high extrusion rates.

Owner:EXXONMOBIL CHEM PAT INC

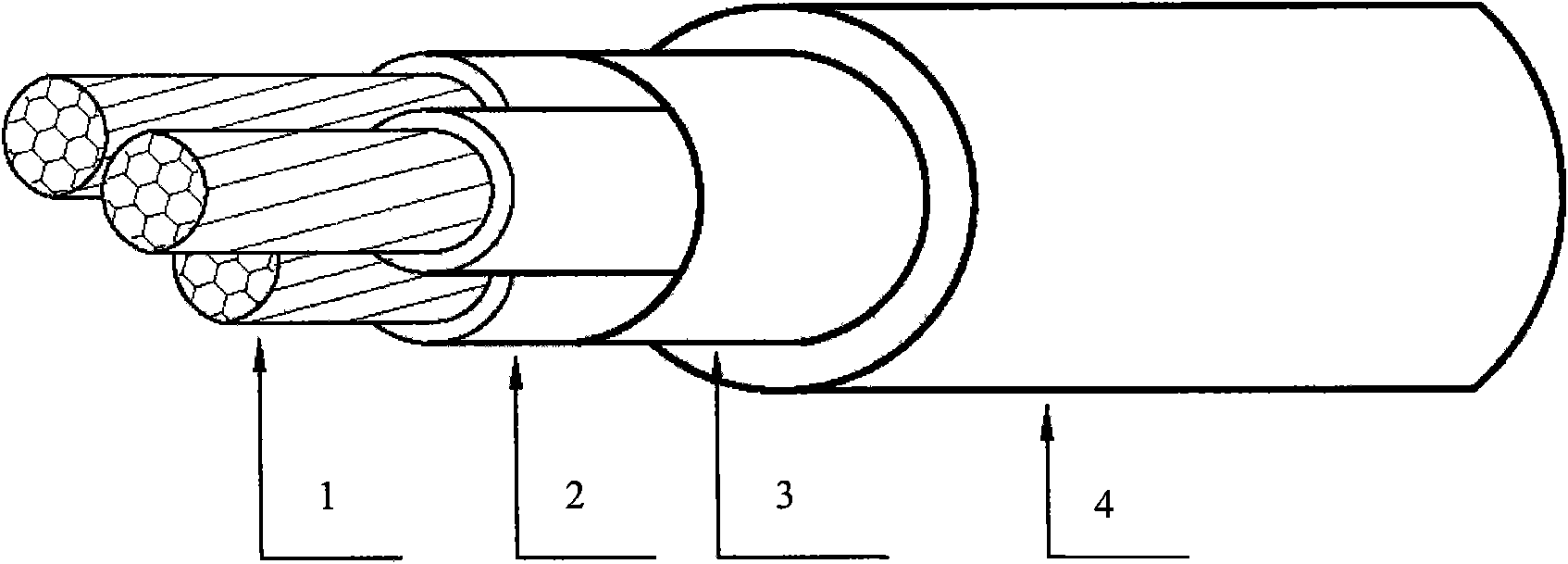

Insulating ethylene propylene rubber LSOH electric power or control cable for ships and warships and processing method thereof

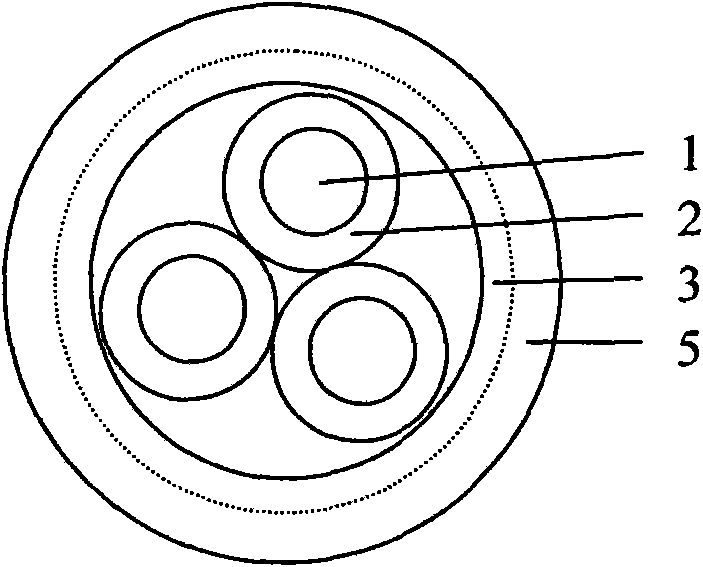

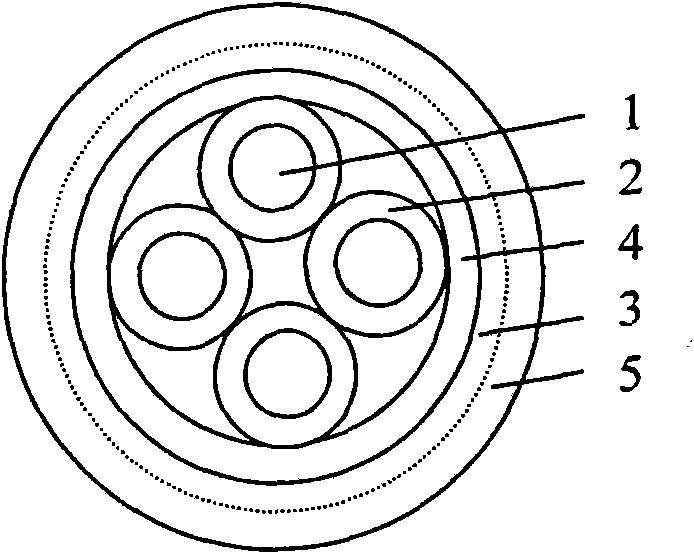

ActiveCN101656124AImprove flexibilityGood softnessRubber insulatorsInsulated cablesCross-linkElectrical conductor

The invention discloses an insulating ethylene propylene rubber LSOH electric power or control cable for ships and warships and a processing method thereof. Multi-strand tinned copper wires twisted conductor is adopted and an extruded ethylene propylene rubber insulating layer is covered on the outer surface of the conductor. Three-core or four-core insulating wires are twisted together. An armorlayer is arranged between three insulating cores and a jacket layer. The outer of the armor layer is provided with the jacket layer. An inner jacket layer is arranged between four insulating cores andthe armor layer. The armor layer is arranged between the inner jacket layer and the jacket layer. The processing method comprises the steps of twisting tinned copper wires with a wire twisting machine to form a conductor, manufacturing the insulating layer outside of the conductor with an extruding machine, irradiating and cross-linking the insulating layer with an electron accelerator, twistingthe insulating cores with a cable-former, braiding the armor layer with a braiding machine, and extruding an oil-proof LSOH jacket layer outside of the armor layer. The invention has the advantages that the products meet the performance demand of the cables for ships and warships, according with the GJB1916-94 general specification for low smoke cable and flexible cord for ships and warships.

Owner:NANJING QUANXIN CABLE TECH

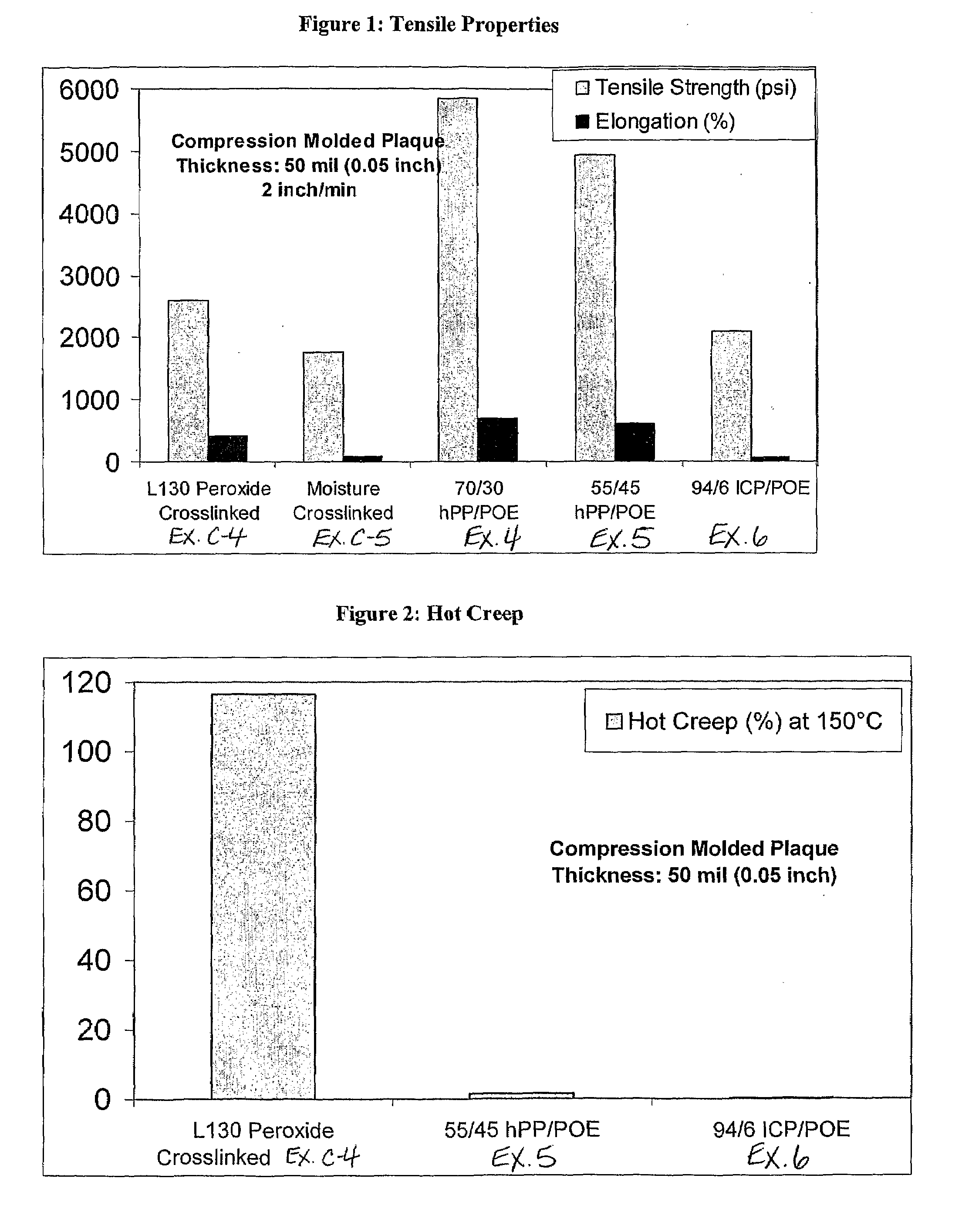

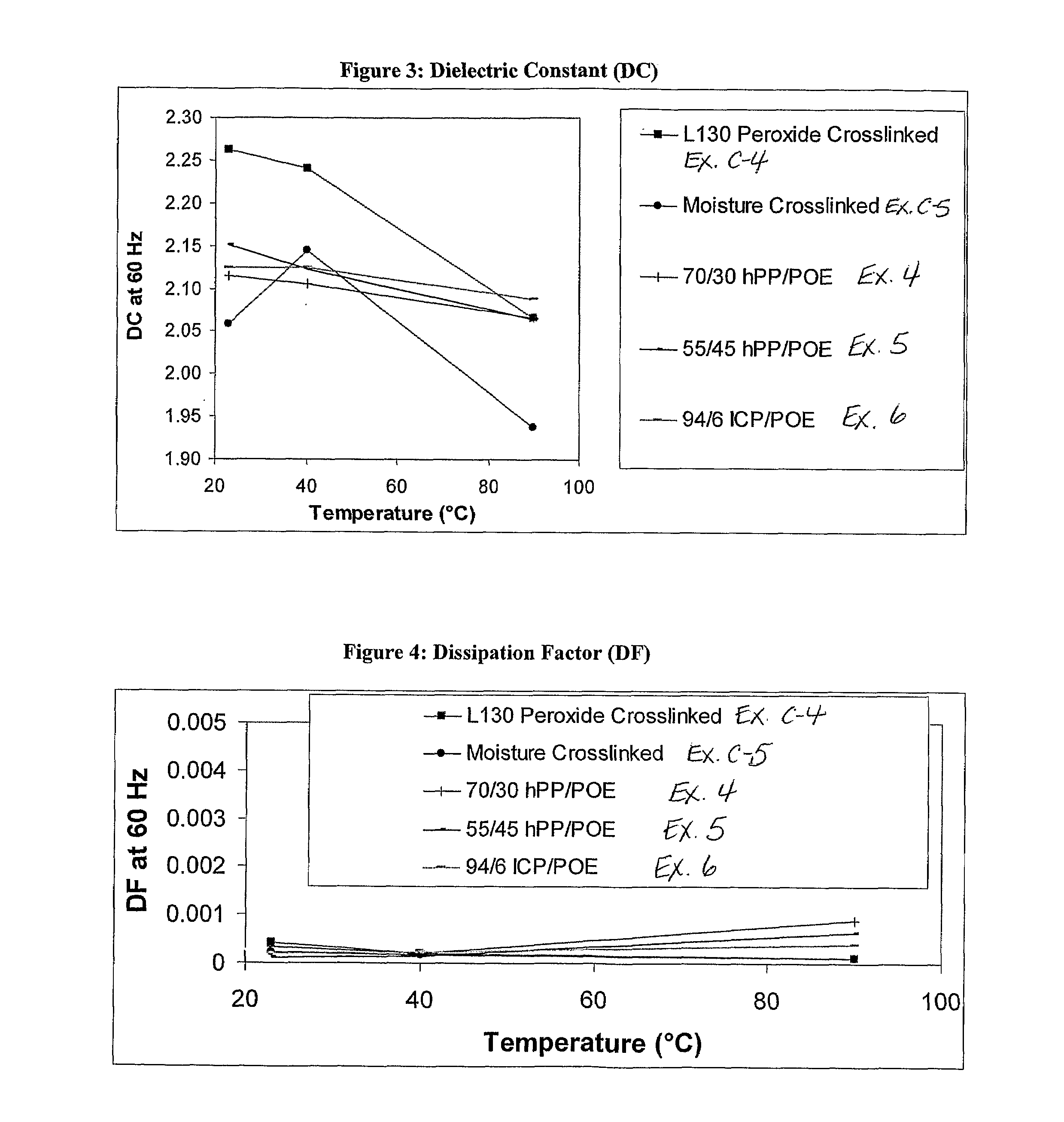

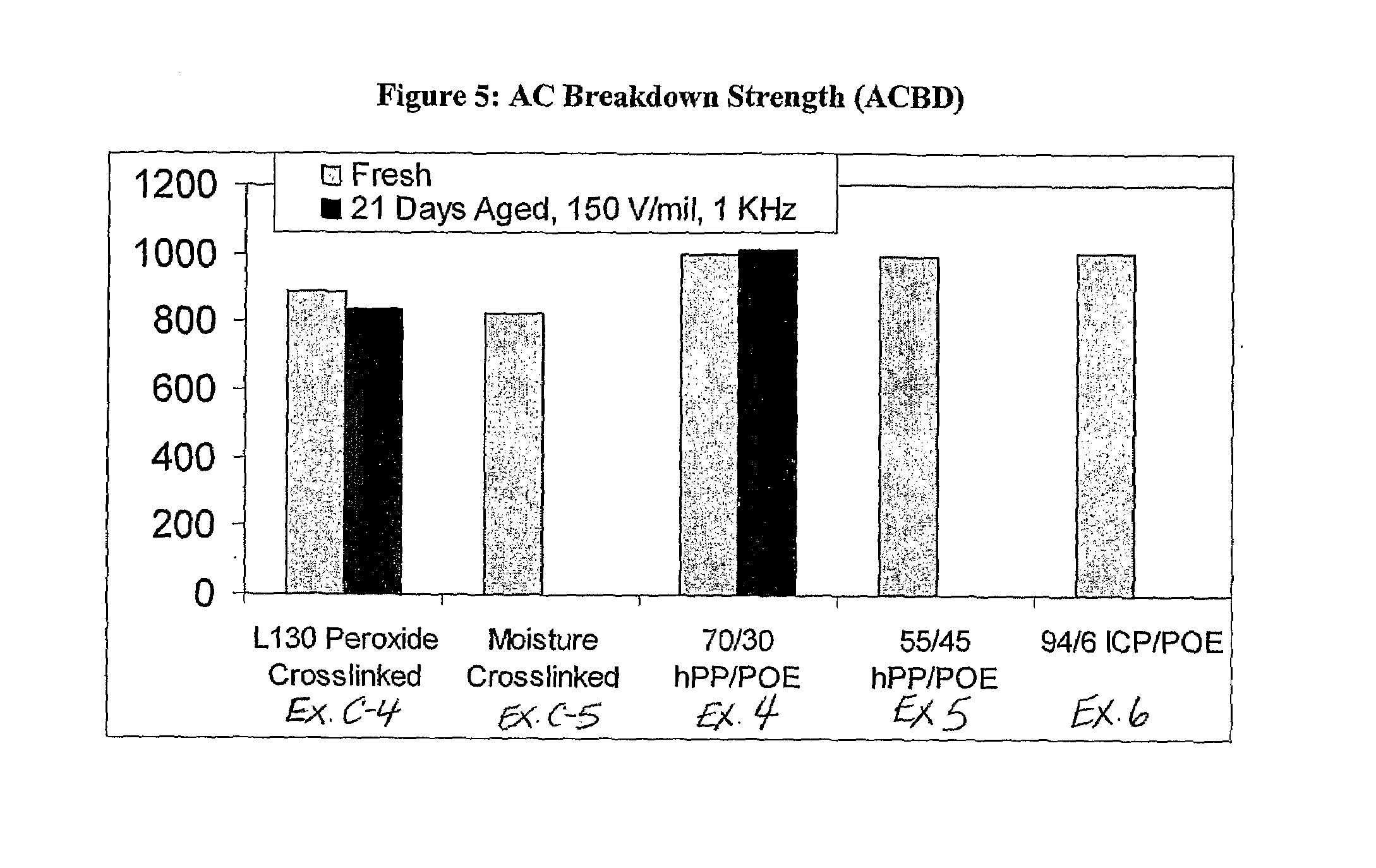

Polypropylene-Based Wire and Cable Insulation or Jacket

The invention is an electrically conductive device, e.g., a wire or cable, having a crush resistance of at least about 18 pounds per square inch (psi), the device comprising: A. An electrically conductive member comprising at least one electrically conductive substrate, e.g., a wire strand or a pair of twisted wire strands; and B. At least one electric-insulating member substantially surrounding the electrically conductive member, e.g., a polymer coating or layer, the electric-insulating member comprising a polymer blend, the polymer blend comprising: 1. At least about 50 weight percent of a polypropylene, and 2. At least about 10 weight percent of an elastomer. In one embodiment, the blend is characterized as having (i) a hot creep of less than 200% at 150 C, (ii) a dielectric constant at 60 Hz and 90 C of less than about 2.5, (iii) a dissipation factor at 60 Hz and 90 C of less than about 0.005, and (iv) an AC breakdown strength of greater than about 600 v / mil.

Owner:KLIER JOHN +2

Butyronitrile-PVC (polyvinyl chloride) compound elastomer insulation material for wires and cables and preparation method of butyronitrile-PVC compound elastomer insulation material

InactiveCN103205034ALower surface energyGood dispersionRubber insulatorsPlastic/resin/waxes insulatorsParaffin waxElastomer

The invention discloses a butyronitrile-PVC (polyvinyl chloride) compound elastomer insulation material for wires and cables and a preparation method of the butyronitrile-PVC compound elastomer insulation material. The butyronitrile-PVC compound elastomer insulation material comprises, by weight, 100-120 parts of butyronitrile rubber, 30-40 parts of PVC resin, 2-3 parts of accelerant TMTD, 1-2 parts of accelerant DM, 1-2 parts of antiager, 2-3 parts of antiager MB, 6-8 parts of paraffin, 8-12 parts of zinc oxides, 1-1.5 parts of stearic acid, 10-15 parts of DOP (dioctyl-phthalate), 2-4 parts of gas-mixed carbon black, 30-40 parts of precipitated white carbon black and 50-60 parts of modified nano calcium carbonate. The insulation material produced has the advantages of good mechanical and physical performance, insulation performance, good high and low temperature resistance, oil resistance, solvent resistance, wear resistance, ozone resistance, ageing resistance and the like, is long-lasting, durable, environment-friendly, pollution-free and capable of meeting the requirements of modern wires and cables completely.

Owner:ANHUI HUAJIN CABLE GROUP

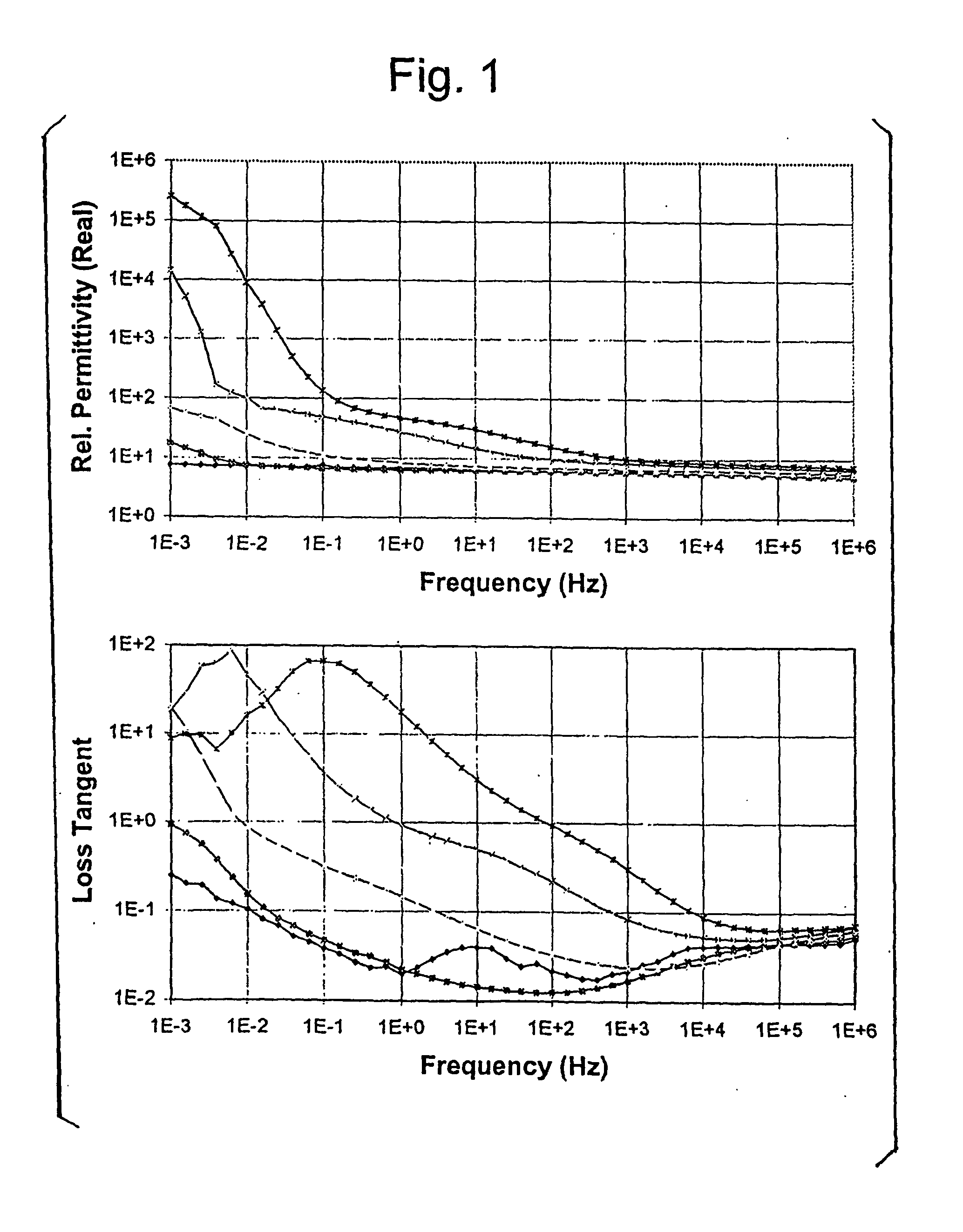

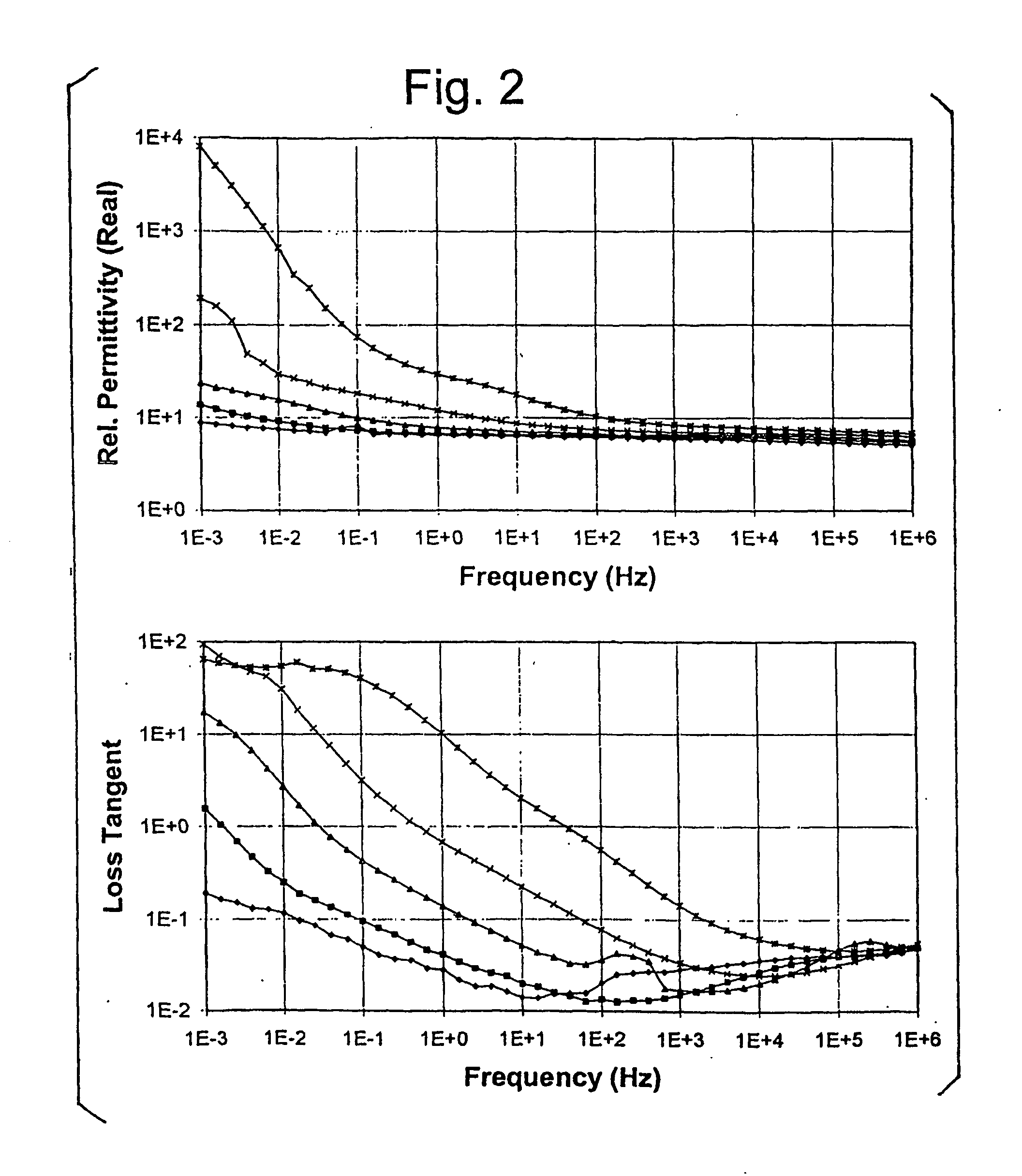

Nanometric composites as improved dielectric structures

InactiveUS20050256240A1Reduce processReduce polarizationRubber insulatorsMaterial nanotechnologyResin matrixInterfacial polarization

A dielectric is provided which possesses high dielectric constant and high dielectric strength, while having the ca-pabilities of a polymer. The dielectric comprises a nanometric composite, which includes a stoichiometric nano-particulate filler embedded in a polymer or resin matrix. Filler particles are reduced in physical size to dimension to the same order as the polymer chain length of the host material and interact cooperatively thereby mitigating the associated Maxwell-Wagner process and reducing interfacial polarization. The internal fields for the new formulation are nearly a factor of 10 lower then for conventional (micro) material. The large changes in the internal field of the composite permit engineering of nanocomposite materials with enhanced electric strength and improved voltage endurance properties.

Owner:RENESSELAER POLYTECHNIC INST

Low temperature resistant anti-crack rubber sleeve flexible cable used for wind power generation

ActiveCN101221836AMeet the torsion resistance requirementsImprove mechanical propertiesRubber insulatorsFlexible cablesPlasticizerFlexion Test

The invention relates to a low-temperature resistant and anti-crack cabtyre flexible cable for the wind power generation and is characterized in that a plasticiser inside a rubber insulation and sheath is a low-temperature resistant plasticizer and is added with 2 to 5 portions of pine tar oil and / or cylinder oil and 3 to 8 portions of coupling agent; the pitch of flexible conductor strands is intertwisted by 8 to 14 times; in the situation of a multiple-core cable, the cable pitch of insulating core is 8 to 10 times. Compared with the prior art, the invention improves the flexility at a low temperature, the anti-crack performance, the mechanical performance at a low temperature and the torsibility of the cable of the rubber insulation and sheath and can satisfy the torsibility requirements of a wind energy cable. The cable of the invention is not cracked in an impact test at a low temperature of 40 DEG C below zero and a flexion test, can maintain the flexility at a very low temperature, satisfies the requirement of the cable used at a low temperature or a maritime climate environment, and can be applicable to the use in the environmental conditions of big difference in environmental temperature, salt mist, moist heat, mould fungus, etc. In addition, an environment-friendly auxiliary material is used and the cable insulation as well as the sheath environment are good; therefore, the invention can satisfy the environment-friendly requirements of PAH such as ROHS and RAHS of the EU.

Owner:JIANGSU ZHONGMEI CABLE

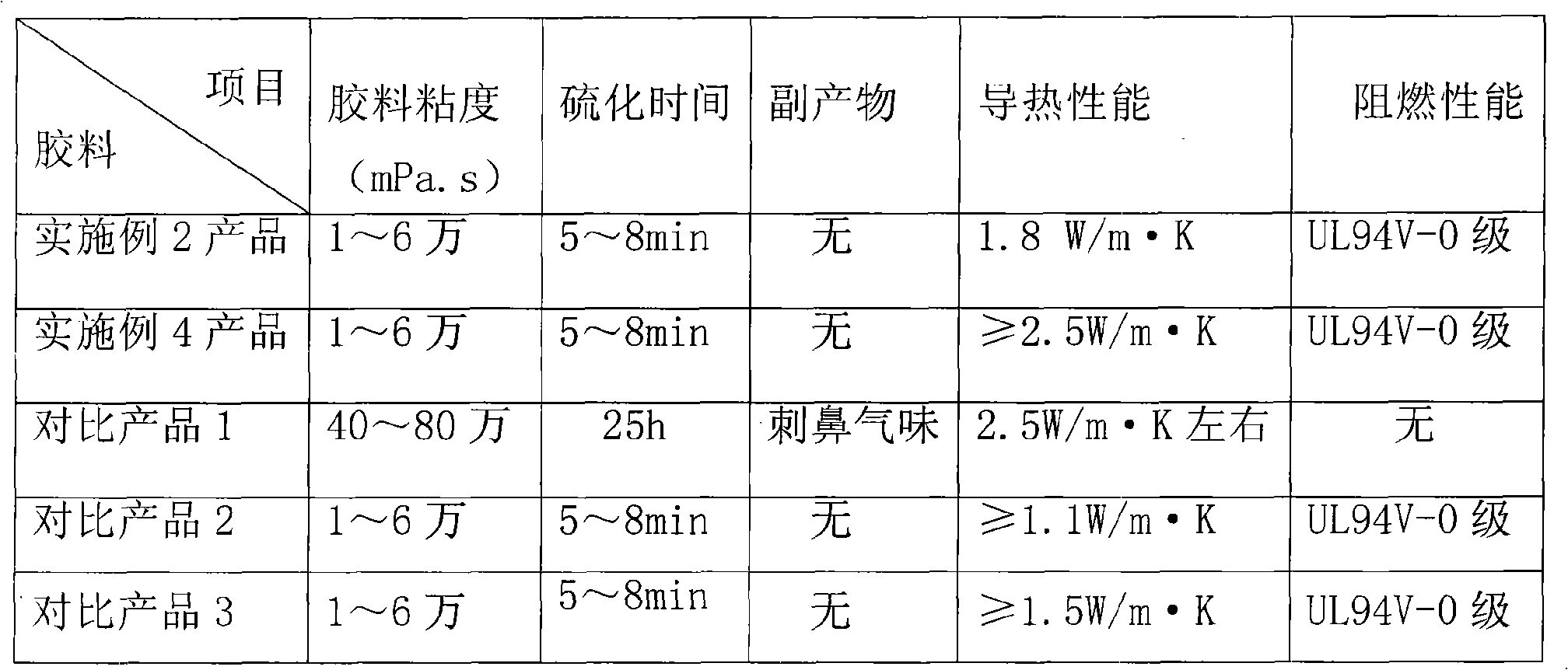

Heat conduction flame-proof liquid silicon rubber for electron and method of producing the same

The invention discloses a heat-conductive anti-flaming liquid silicone rubber used for electrons, which comprises the components with the following parts by weight: ethylene group dead-end organic polysiloxane which has polymer viscosity of 500 to 5000mPa.s and 10000 to 50000mPa.s when reaching 25 DEG C and has a general formula R2SiO(SiRR'O)nSiR2; hydric polysiloxane which has a general formula R'R2SiO(SiR HO)nSiR2R'; alkyldisilazane which has a general formula R3SiNHSiR3; a mixed-powder of Al2O3 and MgO with the surface hydrophobic particle size being respectively 5 Mum and 2 Mum and with the ratio of 4:1between Al2O3 and MgO; an Al(OH)3 powder which has an average particle size of 2 to 10 Mum; an additive solidified catalyst; an alkynol solidified inhibitor; and distilled water. The silicone rubber generates no toxic substance or irritative gas and has no side product and high efficiency; the product obtained is characterized by high thermal conductivity, good storage stability, moderate viscosity and good operability, and can integrate heat conduction, insulation and anti-flaming properties together, thereby meeting higher requirements of electrical appliances industry and having high cost performance.

Owner:兆舜科技(广东)有限公司

EPDM (ethylene propylene diene monomer) rubber insulated/jacketed cable with high strength, oil resistance and aging resistance

InactiveCN105255019AImprove heat resistanceGood weather resistanceRubber insulatorsInsulated cablesCarbon nanotubeEPDM rubber

The invention discloses an EPDM (ethylene propylene diene monomer) rubber insulated / jacketed cable with high strength, oil resistance and aging resistance. The EPDM rubber insulated / jacketed cable comprises following raw materials: EPDM rubber, nitrile butadiene rubber, maleic anhydride grafted polypropylene, an ethylene-vinyl acetate copolymer, diphenyl hexadiphthalein diamine, stearic acid, zinc oxide, superfine fully vulcanized powder nitrile butadiene rubber, tin(II) chloride dehydrate, bromo-octyl-phenolic curing resin, calcined kaolin, zinc methacrylate, carbon nano tubes, superfine silica, calcium sulfate whiskers, polyacrylonitrile fibers, a silane coupling agent, lanthanum glutamic dithiocarbamate, petroleum wax, naphthenic oil, an anti-aging agent and an accelerator. The EPDM rubber insulated / jacketed cable material with high strength, oil resistance and aging resistance serves as insulation and / or a jacket in a cable and has high strength, good oil resistance, aging resistance and combination properties and long service life.

Owner:ANHUI LAND GRP

Halogen-free flame retardant thermoplastic elastomer cable material and preparation method thereof

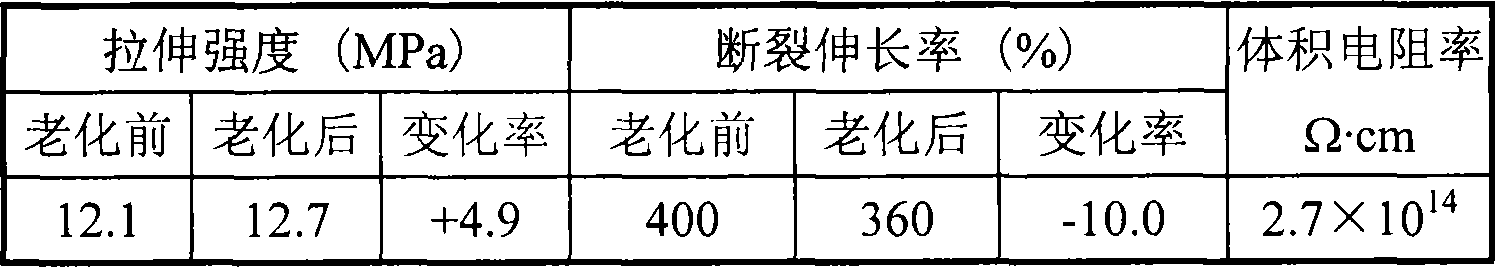

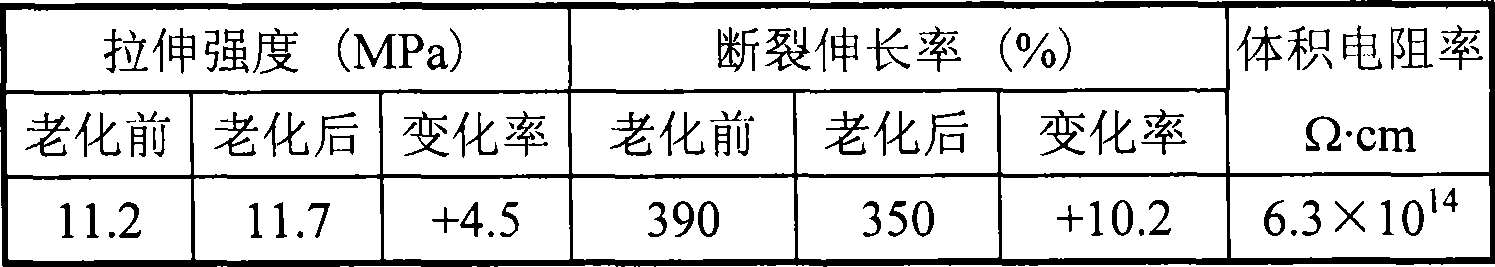

InactiveCN104530626ANo significant change in electrical propertiesGood compatibilityRubber insulatorsPlastic/resin/waxes insulatorsElastomerPolymer science

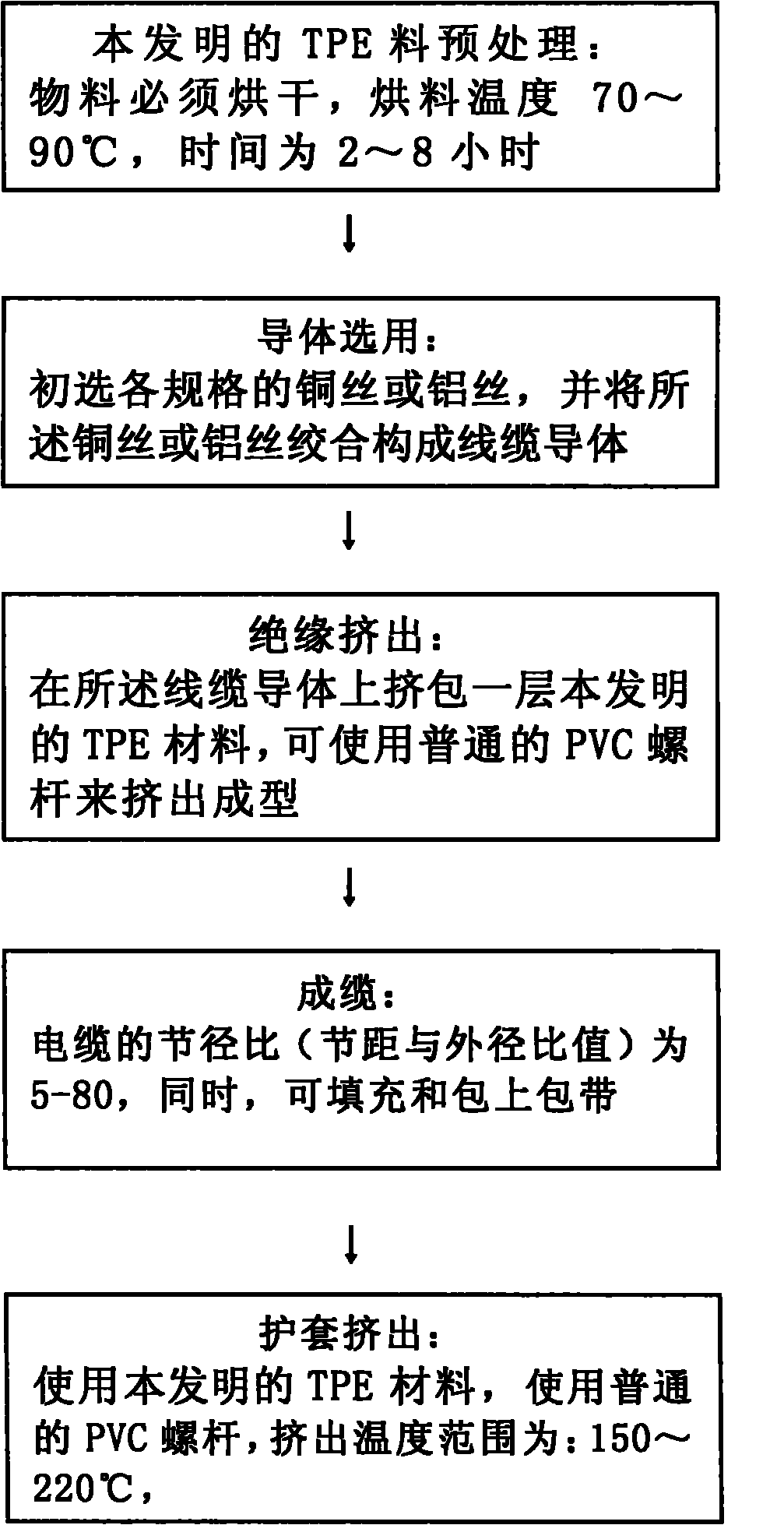

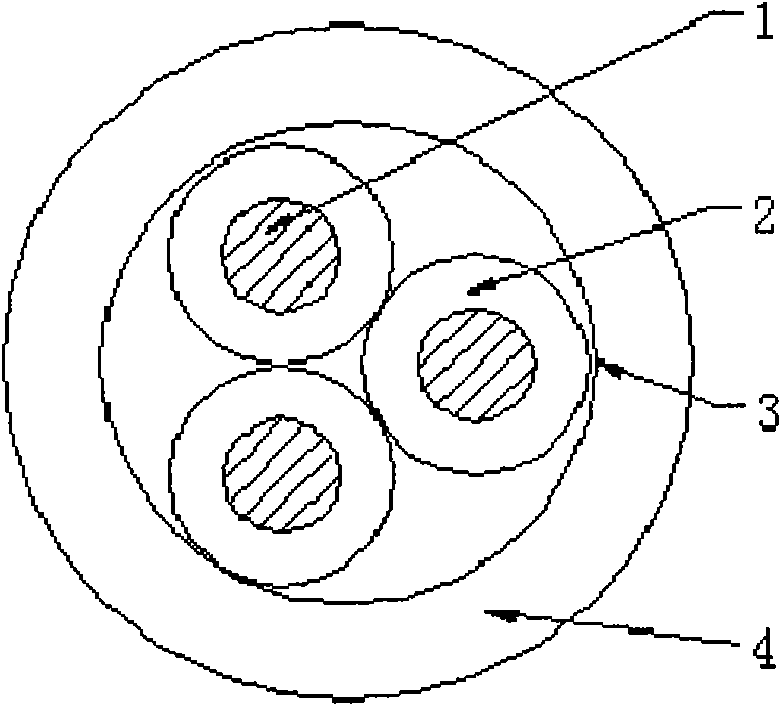

The invention belongs to the technical field of polymer materials and relates to a halogen-free flame retardant thermoplastic elastomer cable material. The halogen-free flame retardant thermoplastic elastomer cable material is characterized by comprising the following raw materials in parts by weight: 20-60 parts of a styrene type elastomer, 20-60 parts of polyphenyl ether resin, 10-40 parts of polyolefin, 10-50 parts of a polyolefin type elastomer, 10-50 parts of a plasticizer, 20-60 parts of a complex phosphorus-nitrogen flame retardant, 1-5 parts of a lubricating agent, 0.1-1 part of an antioxidant and 0.1-1 part of an anti-ultraviolet absorbent. The invention further discloses a preparation method of the cable material. The cable material disclosed by the invention has the characteristics of excellent processing performance, high flame-retardant grade, no toxicity, light density, good anti-tear performance, good acid and alkali resistance, good weather resistance and the like, as well as particularly prominent water resistance and anti-cracking performance. After high-temperature and high-humidity long-term aging, the cable material has no precipitate, the excellent mechanical and physical properties are kept, and the electrical properties do not change obviously.

Owner:JIANGSU ZHONGLI GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com