Patents

Literature

403results about "Unspecified rubber coatings" patented technology

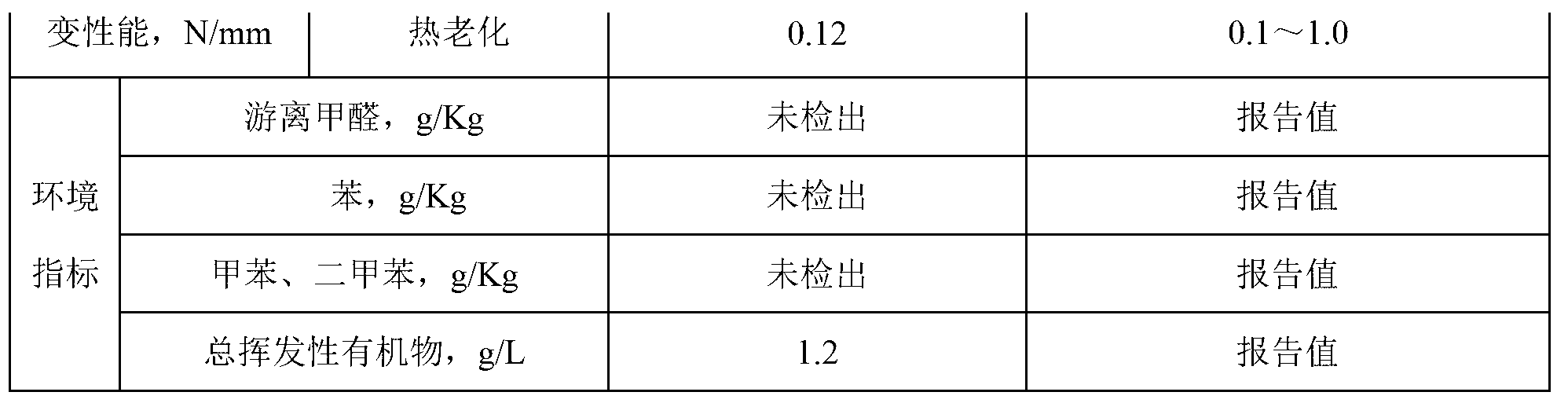

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low smoke, fire and water resistant cable coating

ActiveUS20090238957A1Limited smoke characteristicWet electrical performanceFireproof paintsRubber insulatorsMoisture resistanceOxygen

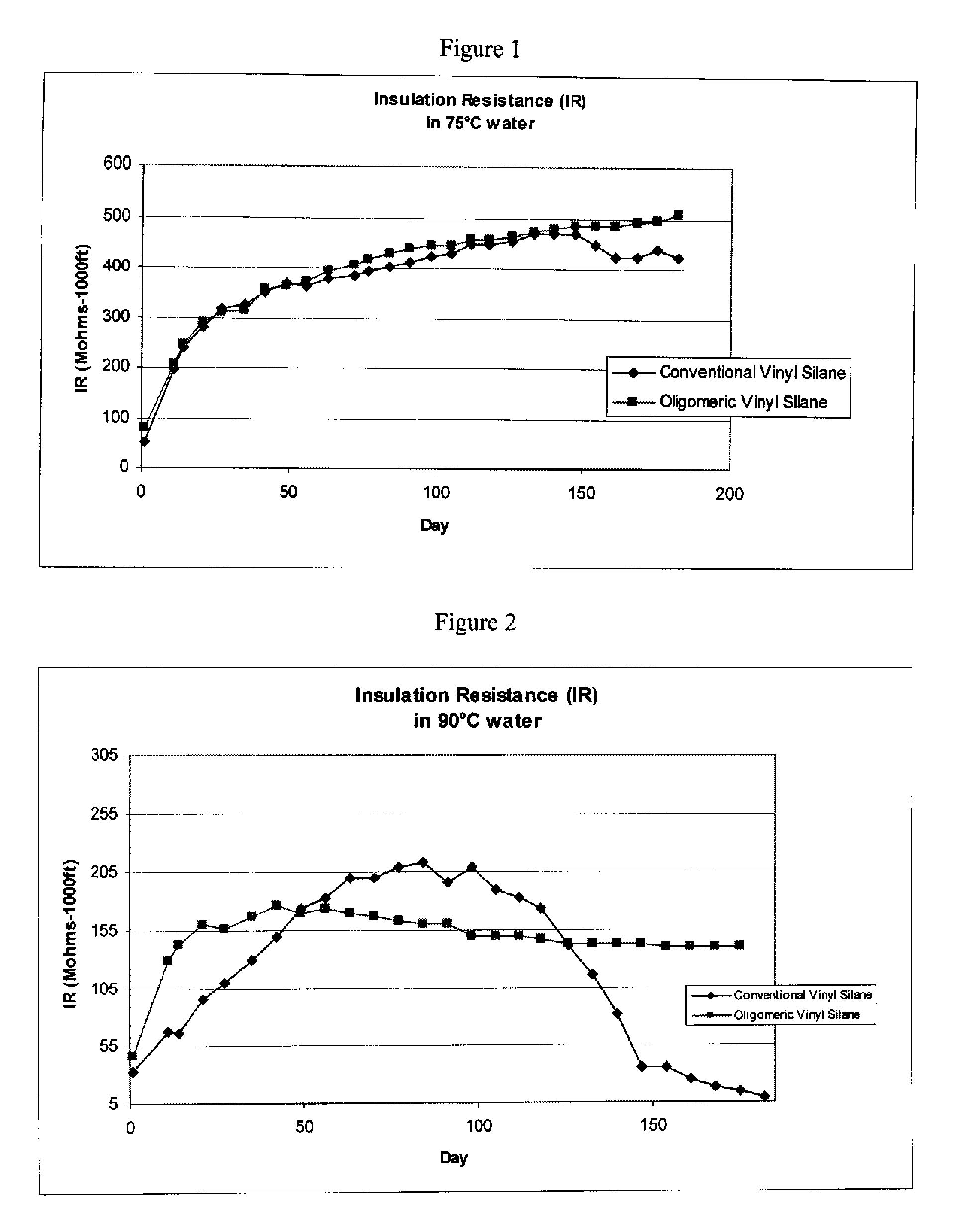

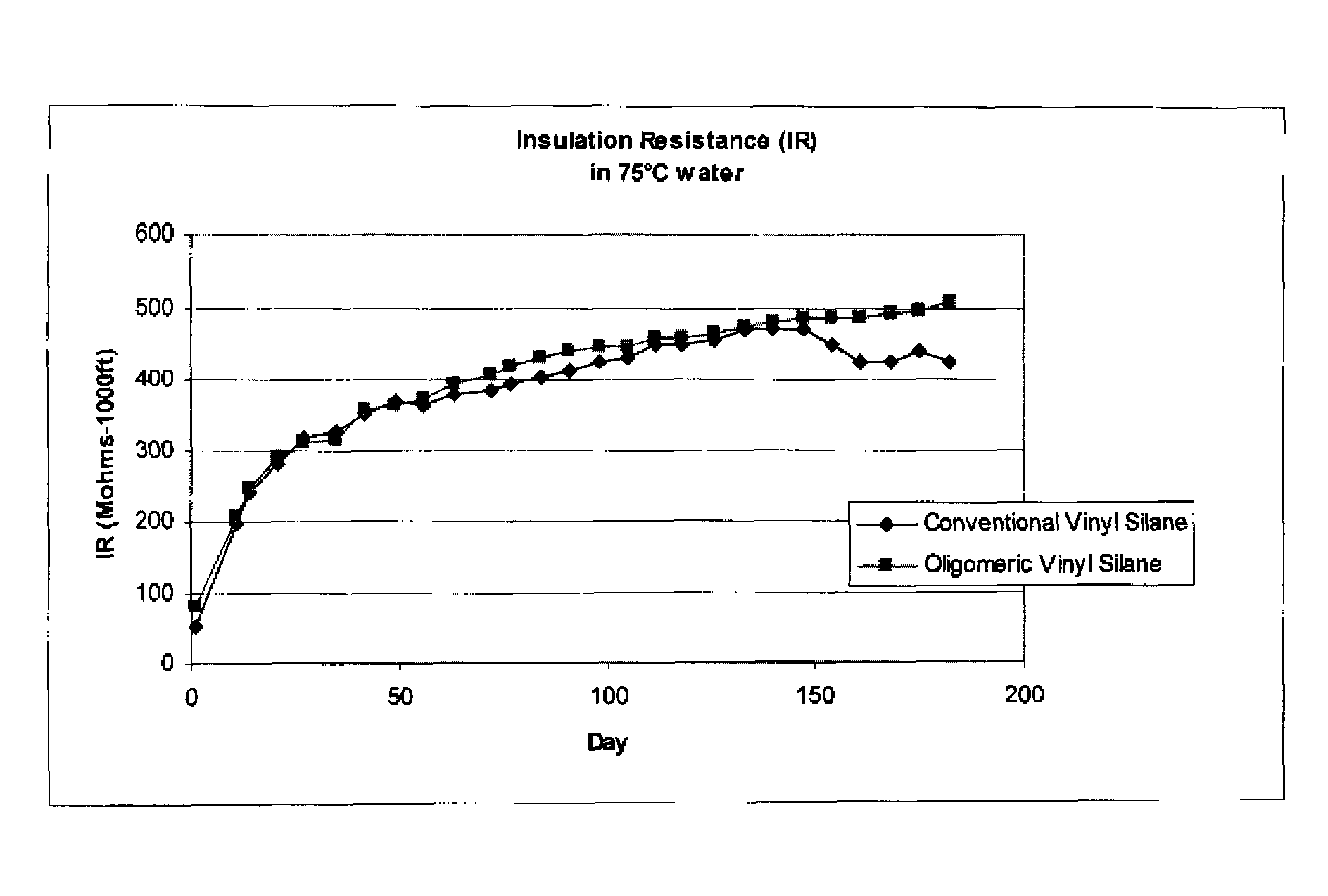

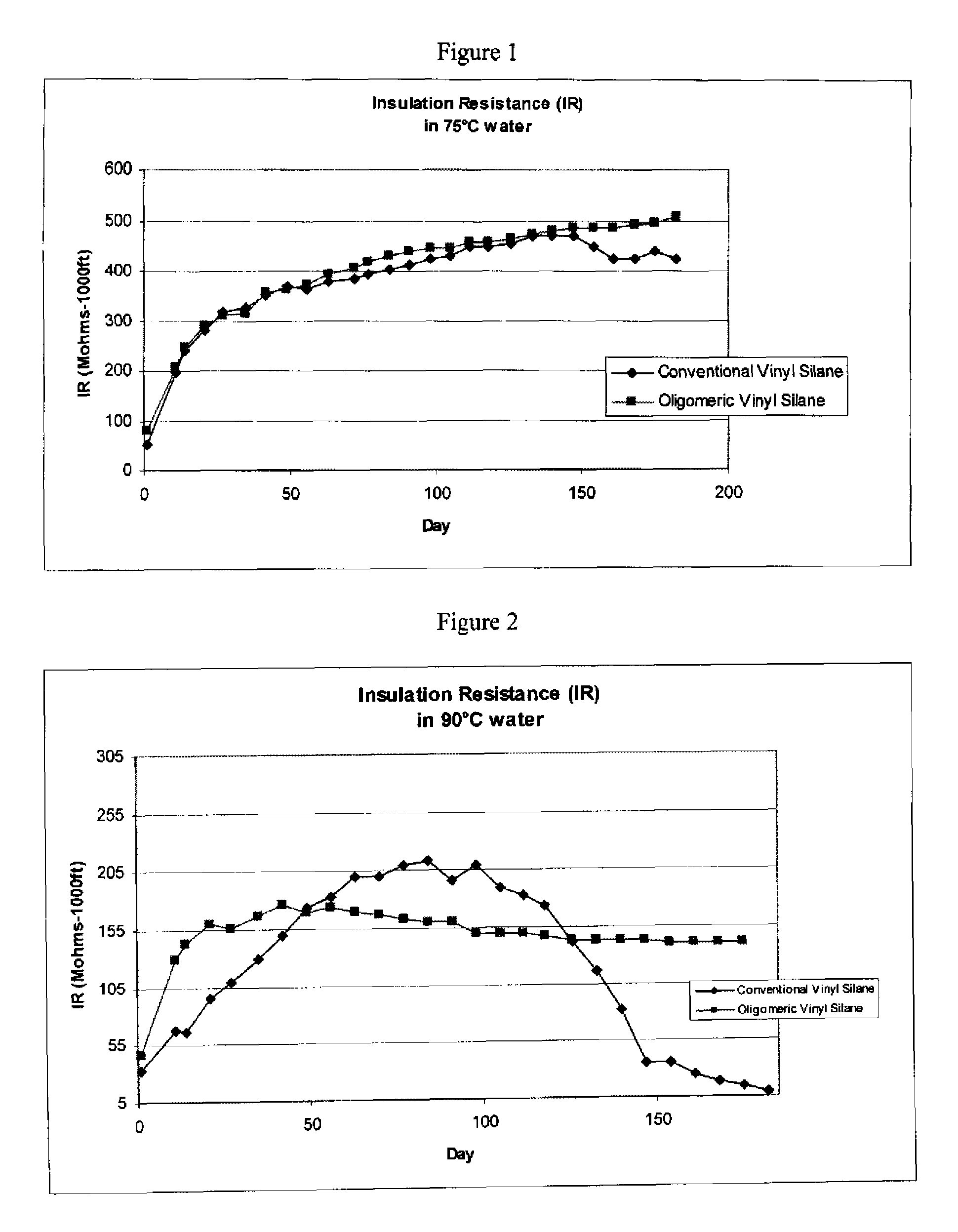

Cable coatings having effective low-smoke emission, fire resistance and moisture resistance provided by a single layer are described. The cable coatings contain an base polymer, a oxygen containing ethylene copolymer, a fire retardant and a synergistic blend of magnesium hydroxide and aluminum hydroxide. Cables coated with the described coatings have improved wet electrical performance, and satisfactory fire performance and smoke characteristics.

Owner:GENERAL CABLE TECH CORP

Reactive surfactants for emulsion polymerization, pigment dispersion, and UV coatings

ActiveUS20130047892A1Reduce the amount requiredIncrease in coating repellencyPigmenting treatmentTransportation and packagingArylEmulsion polymerization

The present invention provides reactive surfactants of the formulaR1O—(CH2CHR2O)x—(CH2CH2O)y—(CH2CHR3O)z—R4 where R1 is either alkyl, aryl, alkylaryl, or aralkylaryl of 8-30 carbon atoms, R2 is —CH2OCH2CH═CH2 (AGE); R3 is either H, CH3, or CH2CH3; R4 is H or —SO3M or —PO3M where M is H or K, Na, NH4, NR4, alkanolamine, or other cationic species and x=2-100; y=4-200 and z=0-50.

Owner:ETHOX CHEM LLC

Microgels in crosslinkable organic media

The present invention relates to a composition which contain a specific organic, crosslinkable medium and at least one microgel which is not crosslinked by high-energy radiation, processes for its preparation, uses of the compositions, microgel-containing polymers prepared therefrom and shaped articles or coatings produced therefrom.

Owner:ZISER TORSTEN +3

Thermal- and chemical-resistant acid protection coating material and spin-on thermoplastic adhesive

New compositions for use as protective coatings and / or adhesives are provided. The compositions comprise a hydrocarbon resin (e.g., terpene rosin) and a rubber (e.g., EPDM) dispersed or dissolved in a solvent system. The solvent system is preferably a single-solvent system, and the compositions are preferably free of surfactants, dyes, and chromophores. The compositions can be cured or dried to form layers or films that are chemically and thermally resistant, but that can be readily dissolved and removed at the appropriate stage in the fabrication process.

Owner:BREWER SCI

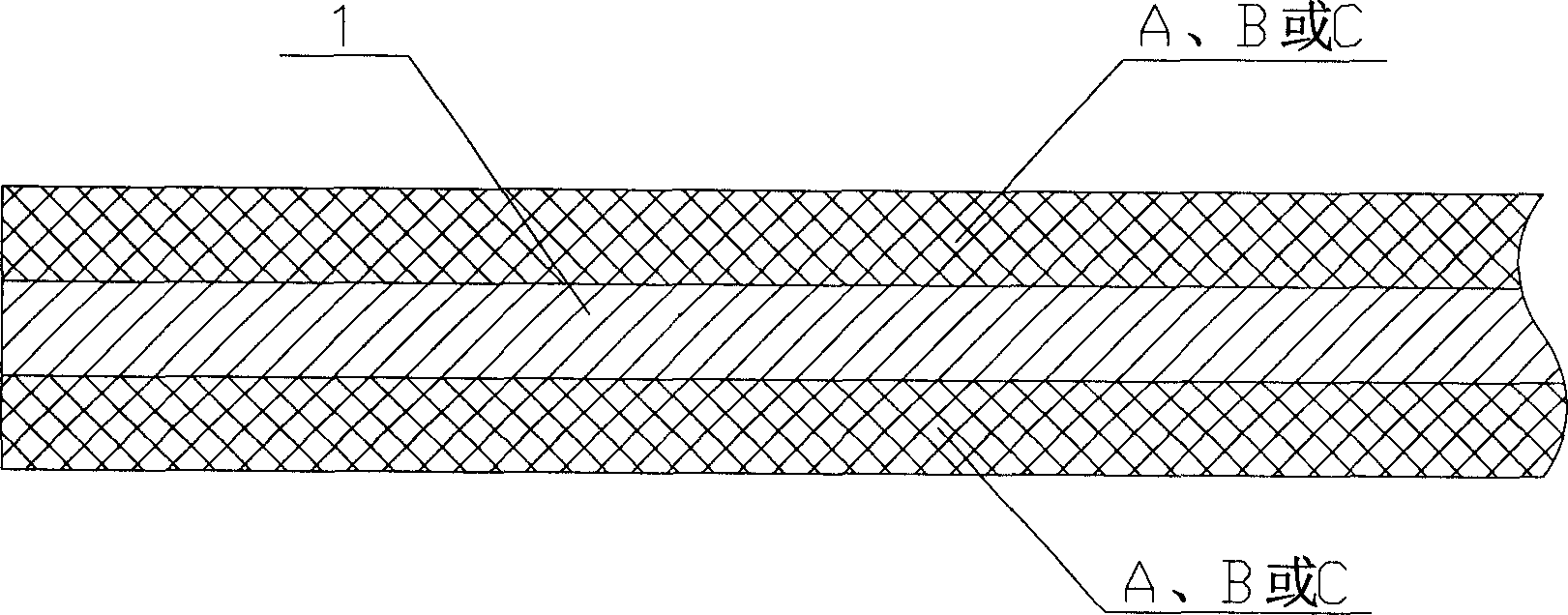

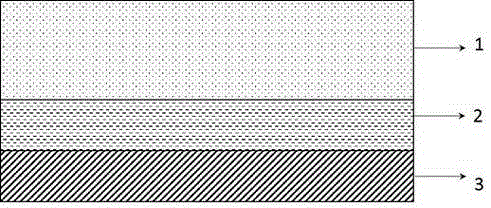

Rubber sealed and shock-reducing sound-absorbent material coated on metal sheet and method for preparing same

InactiveCN1721484AImprove high temperature resistanceGood resistance to various mediaOther chemical processesUnspecified rubber coatingsLiquid mediumMetallic materials

The present invention is sealing, damping and silencing material comprising metal sheet and coating. The coating consists of rubber, stuffing and compound ingredient. The compound ingredient includes sulfur, zinc oxide, stabilizer, etc.; the rubber is one or two selected from fluororubber, NBR, SBR, etc.; and the stuffing may be graphite, carbon black, kaolin, etc. The sealing, damping and silencing material may be machined into sealing washer in required shape, can resist the corrosion of various gas and liquid medium, operate in the temperature up to 400 deg.c and pressure up to 120 kg / sq cm, and possesses reliable sealing.

Owner:舟山海山机械密封材料股份有限公司

Asphalt binder compositions and methods of use

Asphalt binder compositions are formed by combining asphalt with a reclaimed or re-refined oil. The boiling point of the oil may be greater than its flash point. The asphalt may be polymer modified or non-polymer modified. These asphalt binder compositions may be combined with aggregate and / or other matter (e.g., rubber particles) to form cold patch compositions suitable for various applications such as patching potholes, cracks or other defects in roads, driveways, roofs or other paved surfaces.

Owner:RAM TECH GROUP

High-permeability liquid rubber spray coating

InactiveCN102329566AHigh bonding strengthImprove waterproof and anti-seepage performanceUnspecified rubber coatingsConjugated diene hydrocarbon coatingsPolymer scienceSpray coating

The invention discloses a high-permeability liquid rubber spray coating, and relates to the technical field of spray coatings. The high-permeability liquid rubber spray coating comprises a component A and a component B, wherein the component A is anionic liquid rubber asphalt emulsion; the component B is a coagulant solution; the component A has the solid content of liquid rubber asphalt emulsion of 50-75 weight percent, and comprises the following components in percentage by mass: 1 to 35 percent of rubber emulsion, 10 to 50 percent of asphalt emulsion, 0.01 to 2 percent of anionic dispersing agent, 0.01 to 2 percent of anionic surfactant, 0.1 to 10 percent of fatty alcohol-polyoxyethylene ether, 0.1 to 10 percent of alkali resistant wetting agent OEP-70 and 0.1 to 10 percent of alkali resistant wetting agent AEP; and the component B is an aqueous solution at the concentration of 3-18 percent, which is prepared by mixing calcium chloride and composite aluminum-iron polymer in percentage by mass. The wetting agents are added into the spray coating, and the coating has high permeability and wider application range.

Owner:DALIAN MEICHENTE TECH

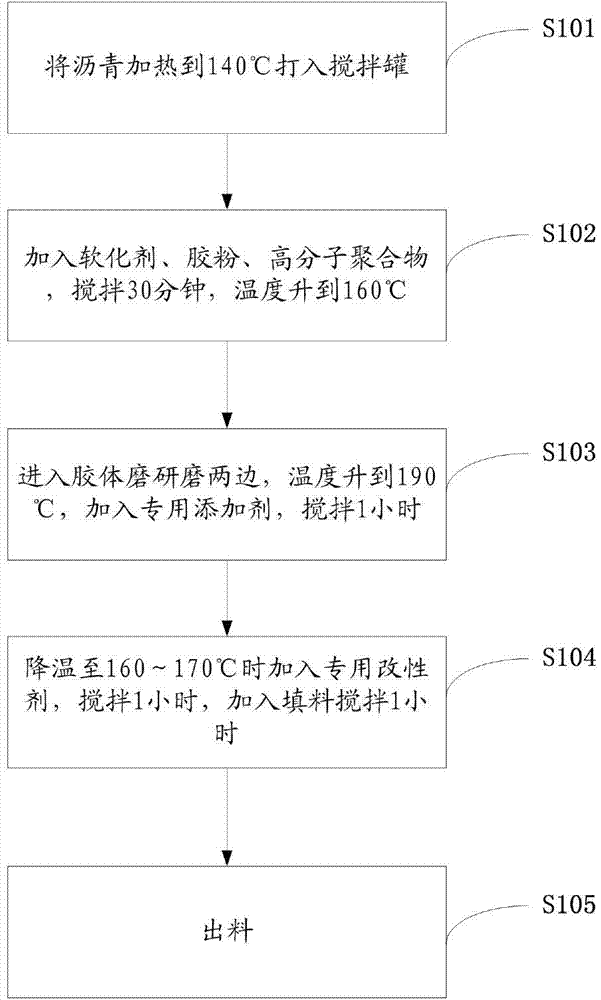

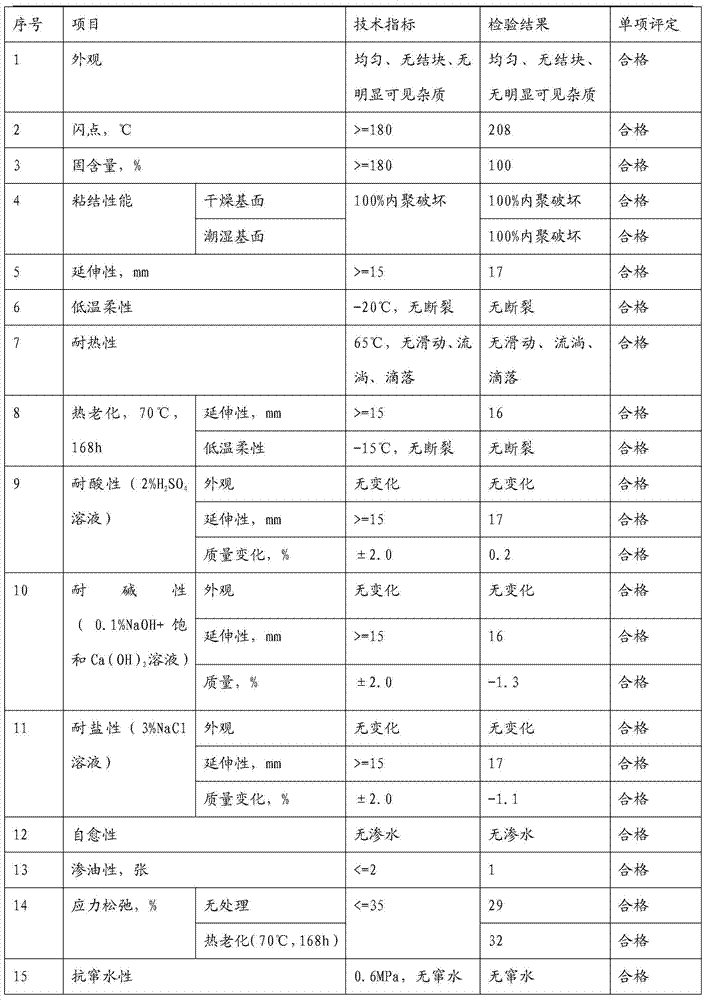

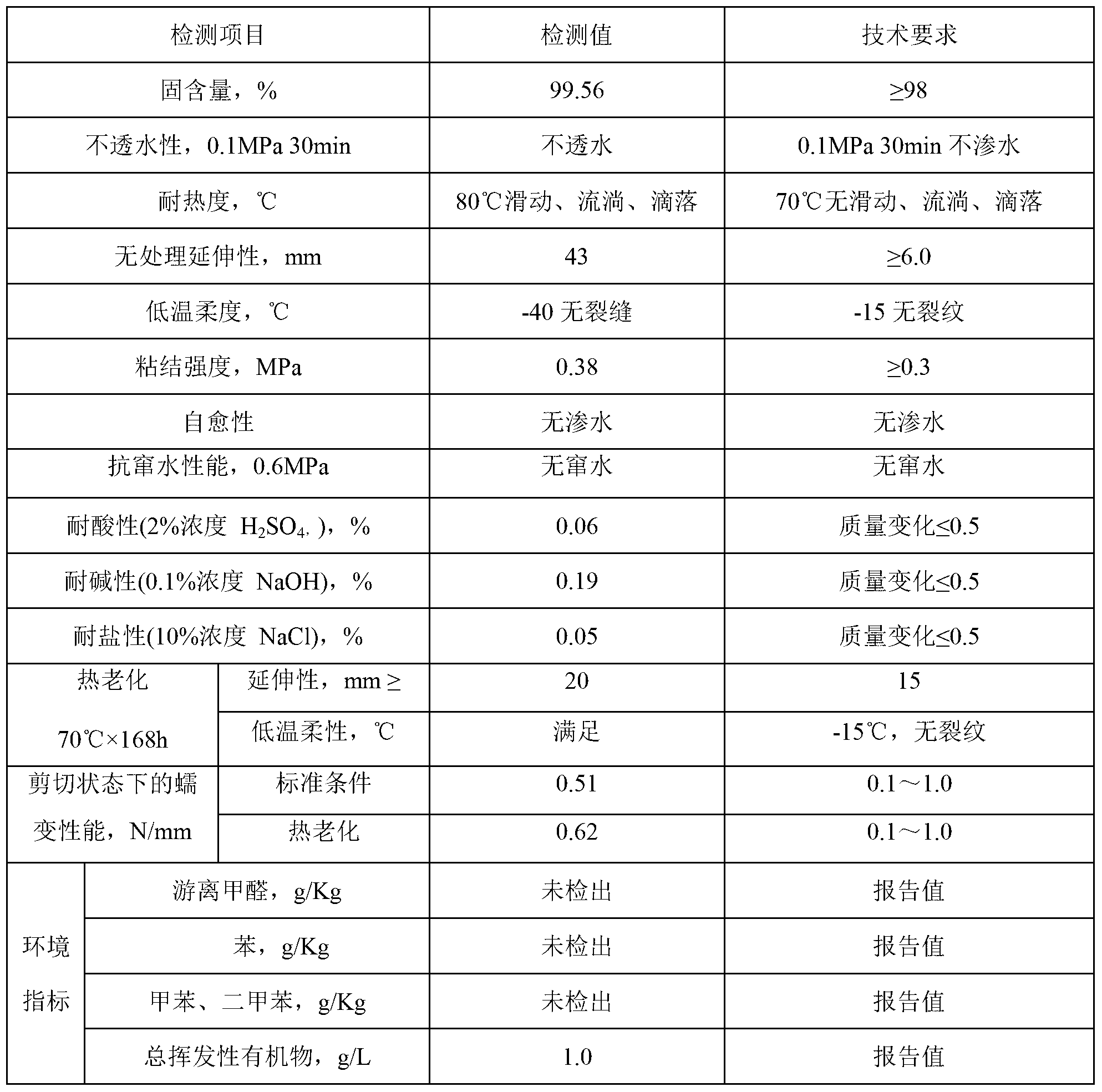

Non-cured rubber asphalt waterproof paint

InactiveCN104119799AWill not harmCompletely sealed and waterproofUnspecified rubber coatingsConjugated diene hydrocarbon coatingsBituminous waterproofingPolymer science

The invention discloses a non-cured rubber asphalt waterproof paint. The preparation technology of the paint comprises the following steps: heating the asphalt to 140 DEG C, loading the heated asphalt into a stirring tank, adding a softening agent, rubber powder, and polymer, stirring for 30 minutes, heating to 160 DEG C, delivering the mixture to a colloid mill to grind the two edges, heating to 190 DEG C, adding a special additive, stirring for one hour, cooling to 160 to 170 DEG C, adding an auxiliary agent, stirring for one hour, adding a filling material, stirring for one hour, and finally discharging. The paint solves the problems of waterproof layer fracture due to the cracking stress, which is transferred from the basic layer to the waterproof layer, and the accelerated aging due to the flexural fatigue and high stress state of the waterproof layer. Moreover, because of the cohesiveness of the paint, the capillary pores and cracks in the basic layer can be perfectly sealed by the paint, thus the problem of water leaking in the waterproof layer is solved, and the waterproof reliability is greatly improved.

Owner:徐立

Surface coating compositions

InactiveUS20080038470A1Great solventHigh strengthUnspecified rubber coatingsPretreated surfacesPolymer modifiedEmulsion

Protective coatings, in particular for the purpose of shielding and waterproofing buildings and engineered outdoor structures are based on mixtures of polymer modified tall oil, in particular mixtures of an aqueous emulsion of tall oil with an aqueous polymeric latex. Waterproofing / coating compositions according to the invention may be made as a two-component sprayable system comprising a first part which is a mixture of a tall oil emulsion and a polymeric latex and a second part which is an aqueous solution of an effective curing agent.

Owner:CANTECH INDAL RES CORP

Asphalt composition containing hydrogenated conjugated diene copolymer

InactiveUS20050107521A1High softening pointHigh modulusOther chemical processesNon-rotating vibration suppressionPolymer scienceDynamic viscoelasticity

An asphalt composition comprising from 0.5 to 50 parts by weight of a hydrogenated conjugated diene copolymer (a) and 100 parts by weight of asphalt (b), wherein the hydrogenated conjugated diene copolymer (a) comprises a polymer block (A) comprising vinyl aromatic monomer units and at least one hydrogenated copolymer block (B) obtained by hydrogenation of a non-hydrogenated random copolymer block comprising conjugated diene monomer units and vinyl aromatic monomer units, the hydrogenated conjugated diene copolymer (a) having the following characteristics (1) to (5): (1) the content of the vinyl aromatic monomer units is more than 30% and not more than 60% by weight per weight of the hydrogenated conjugated diene copolymer; (2) the content of the polymer block (A) is from 5% to 50% by weight per weight of the hydrogenated copolymer; (3) the weight average molecular weight is from 30,000 to 500,000; (4) the percentage of hydrogenation of the double bonds in the conjugated diene monomer units is from 60% to 100%; and (5) at least one peak of the loss tangent (tan δ) is present in the range of from −40° C. to less than −10° C. in a dynamic viscoelastic spectrum obtained with respect to the hydrogenated copolymer.

Owner:ASAHI KASEI CHEM CORP

Pellet From Recycled Waste

InactiveUS20120245257A1Liquid surface applicatorsUnspecified rubber coatingsWaste productCellulose fiber

This invention provides a pellet derived from recycled waste products in particular from a mixture of two or more of cellulose fibers, recyclable plastic, glass and ceramics and other recyclable products such as tetra paks. The pellets can be used to make a variety of extruded or injection molded products including household trim and moldings, decking, shutters, etc.

Owner:GLOBAL PATENTED TECH

Asphalt waterproof paint for building and preparation method thereof

InactiveCN101921545AUnique performanceImprove performanceUnspecified rubber coatingsBituminous coatingsChemical industryBituminous waterproofing

The invention relates to an asphalt waterproof paint for a building and a preparation method thereof, belonging to the technical field of chemical industry. The asphalt waterproof paint for a building comprises the following raw materials according to parts by weight: 20-25 parts of plasticizer, 6-8 parts of modifier, 25-30 parts of asphalt, 20-30 parts of filler, 4-6 parts of tackifier, 0.2-0.3 parts of crosslink coupling agent, and 0.3-0.5 parts of dispersing agent. The invention has the advantages of reasonable compound design, good intensity, safety, environmental protection and stable product quality, and is capable of adapting the climatic conditions at high and low temperatures.

Owner:嘉兴市博豪家纺有限公司

Rubberized-plasticized non-solidified asphalt paint

InactiveCN103305127AImprove adhesionStrong reliabilityUnspecified rubber coatingsConjugated diene hydrocarbon coatingsWaste rubberPliability

The invention discloses a rubberized-plasticized non-solidified asphalt paint. The paint consists of the following components in parts by weight: 30-50 parts of petroleum asphalt, 25-40 parts of waste rubber powder, 5-20 parts of rubber oil, 2-10 parts of a styrene-butadiene segmented copolymer, 3.5-10 parts of butadiene styrene rubber SBR, 2-10 parts of plastic, 0.5-3 parts of a surfactant and 0.5-5 parts of plasticizer. The rubberized-plasticized non-solidified asphalt paint can never be hardened, is greater than 99% in solid content and free from a volatile matter, and the asphalt paint, after construction, is constantly kept in an original colloidal state; the asphalt paint is strong in craking property, and can be constructed on a damp base surface and be stuck with any foreign material; the asphalt paint can be simultaneously used with other waterproof materials to form a composite waterproof layer, thus enhancing the waterproof effect, and the asphalt paint is excellent in flexibility, ductility and deformation following property; the asphalt paint, which is strong in self-healing performance, can self-heal even in case of damage of the waterproof layer in the construction, so as to keep a complete waterproof layer; the asphalt paint is simple to construct, and supports scraping construction, spraying construction and grouting construction. The asphalt paint can construct at a normal temperature and at minus 10 DEG C.

Owner:SHANDONG INNOWIT CHEM

Supported composite photocatalytic coating and preparation method thereof

ActiveCN104830227AImprove photocatalytic efficiencyRealize building environmental protectionMolecular sieve catalystsUnspecified rubber coatingsHigh energyUltraviolet lights

The invention relates to a supported composite photocatalytic coating and a preparation method thereof. A supported photocatalytic coating and a waterproof adhesive layer are adhered to and combined with a substrate; a specially structured supporting material and a composite TiO2 / g-C3N4 photocatalyst are mixed in a high energy ball milling manner so as to effectively improve the supporting rate of the photocatalyst; and the response range can be widened to visible light from ultraviolet light through the composite photocatalyst, thus realizing effective photocatalysis efficiency. The supported composite photocatalytic coating and the preparation method thereof are simple in process, have relatively high economic and environment benefits and belong to high value-added resource utilization.

Owner:江苏倍立达新材料科技有限公司

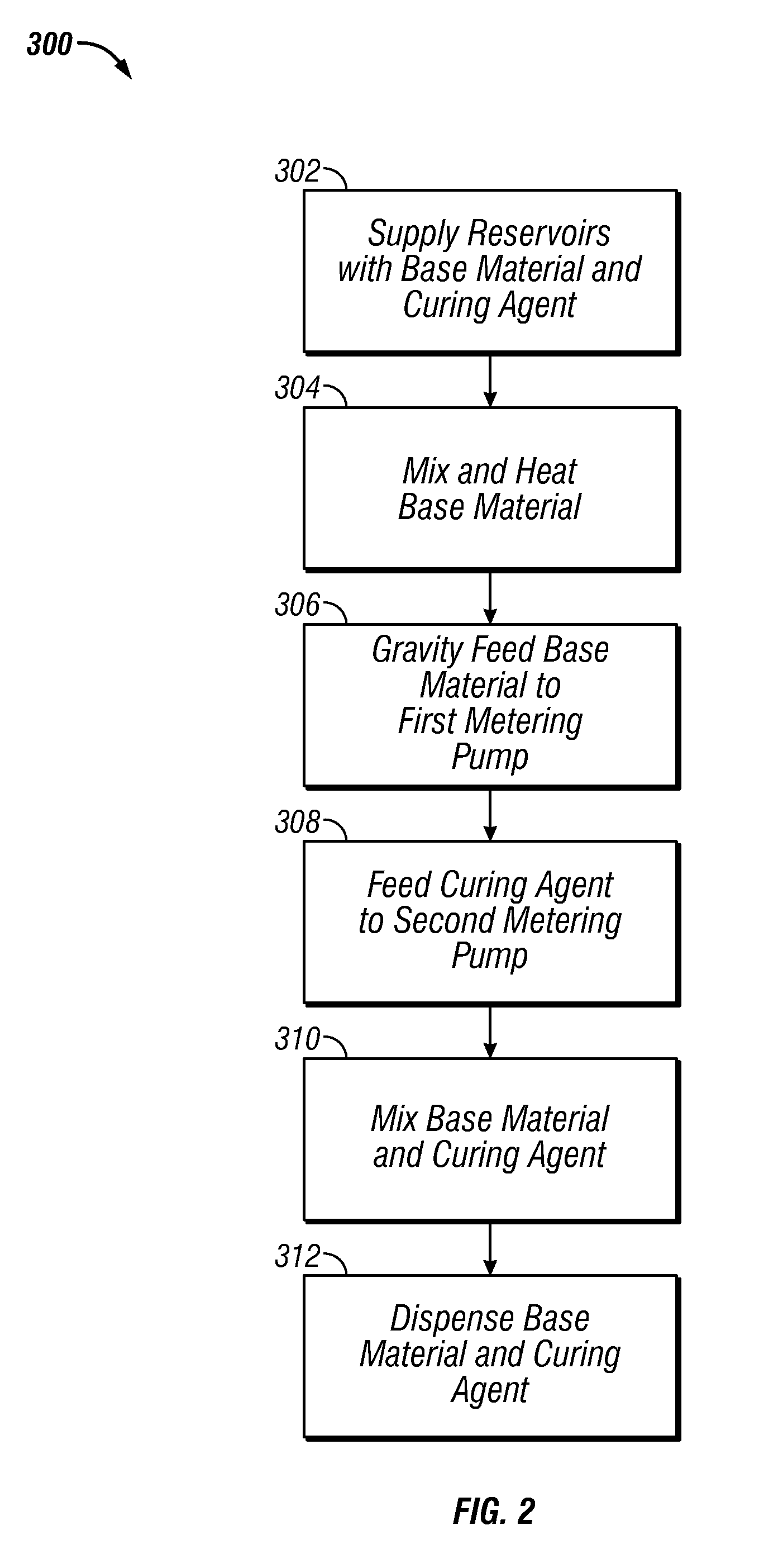

Systems and methods for processing and despensing filled multi-component material

InactiveUS20130045380A1Improve consistencyEnsure a high degree of uniformityUnspecified rubber coatingsSynthetic resin layered productsFilling materialsEngineering

A filled multi-component material applied by a dispensing system is disclosed. The material can be produced by mixing a first reactive component comprising a resin and a filler with a second reactive component comprising a curing agent. The filler can comprise a hard filler and / or an elastic filler such as ground recycled tire material. The first reactive component and the second reactive component can be fed to a dispensing apparatus and mixed by a static mixer, each of which can be disposable. The mixture can then be dispensed onto a surface using air spray, airless spray or extrusion, for example. When applied to a surface, the mixture typically polymerizes and entrains the filler materials to provide a protective layer having improved properties. In certain embodiments, the filler materials can include recycled tires that have been ground into fine particles, providing environmentally friendly new products from old tires that typically end up as landfill.

Owner:RHINO LININGS CORP

Environment protection type single-component polyurethane binder, production and use method of the same

ActiveCN101130680AWon't happenExcellent indicatorsUnspecified rubber coatingsPolyureas/polyurethane adhesivesPolyurethane adhesivePolyol

The invention discloses an environment-friendly type monocomponent polyurethane adhesive to pave gas permeable playground, which comprises the following parts: isocyanate, polyether polyol, age resister, ultraviolet absorbent, dimorpholine ether catalyst and polymerization inhibitor, wherein the polyether polyol is polypropene oxide polyol, which is selected from one or more components of DL-2000, DL-3000, MN-3050 or 330N; the isocyanate is diphenyl methane diisocyanate; the adhesive and rubber particle are blended evenly with weight rate at 15-20: 100 to be paved and solidified (dried). The invention is superior to international index of runway, which is especially for paving indoor playground.

Owner:SHANDONG INOV POLYURETHANE

Sprayable Low-Viscosity Rubber Damping Compounds

ActiveUS20070299193A1Low viscosityUnspecified rubber coatingsAdhesive processes with surface pretreatmentElastomerFiber

Sprayable low-viscosity rubber damping compounds based on liquid rubbers or elastomers and vulcanization agents, which contain small quantities of structure-reinforcing fiber fillers, are notable for the absence of previously usual solid rubbers and have a very low viscosity in the application state. Acoustic compounds of this kind are sprayable with the aid of fully automatic application systems, and are preferably processed at the basic body stage in vehicle construction.

Owner:HENKEL KGAA

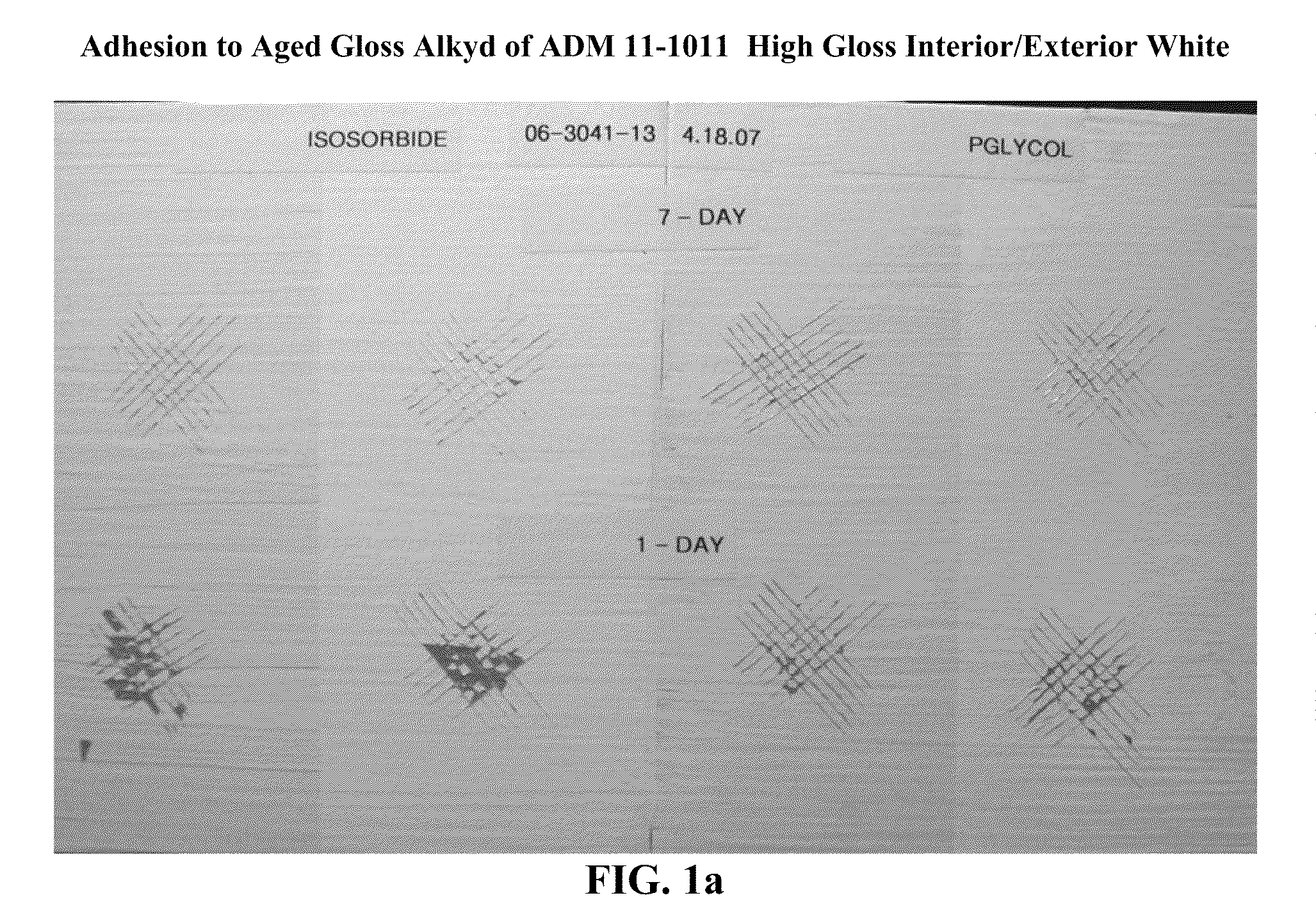

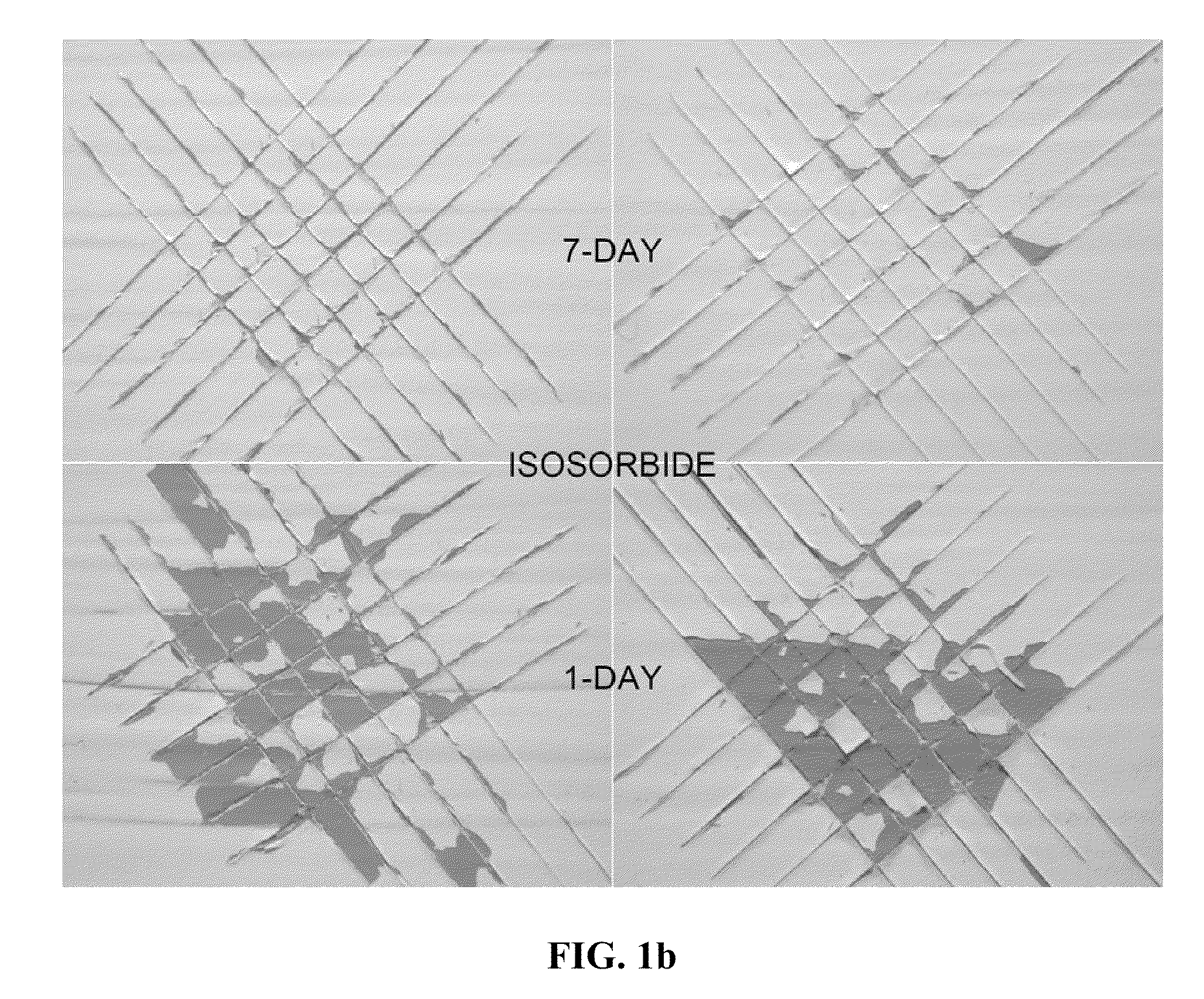

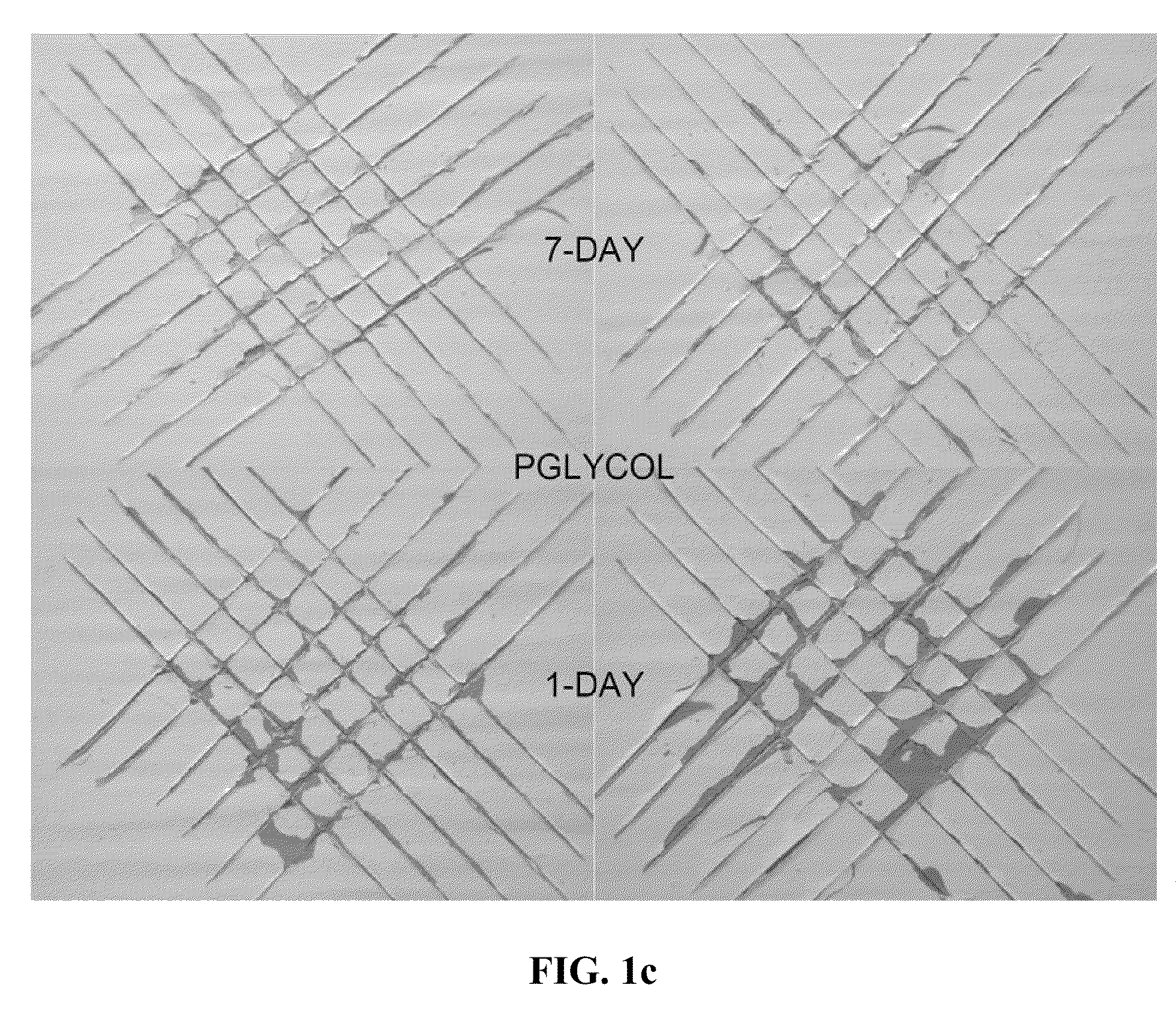

Waterborne Film-Forming Compositions Containing Reactive Surfactants and/or Humectants

ActiveUS20100104884A1Lower Level RequirementsControlled evaporationFireproof paintsUnspecified rubber coatingsCross-linkWater resistant

The present invention is directed to aqueous coating compositions, such as paints, containing a film-forming latex polymer and a reactive surfactant and / or a low VOC humectant. The reactive surfactant, a polyglycerol ester or ether of an unsaturated fatty acid, reduces or eliminates the need for traditional water-soluble additives that lower the water resistance of the dry coating. Additionally, the reactive surfactants of the invention are capable of oxidative cross-linking during the curing process, forming a dry film that is more durable and water-resistant than traditional latex paint composition. The low VOC humectant polyglycerol, isosorbide, or a derivative of isosorbide can replace at least in part traditional humectants such as propylene glycol which contribute to VOCs, while maintaining an effective open time for application of the aqueous coating compositions.

Owner:ARCHER DANIELS MIDLAND CO

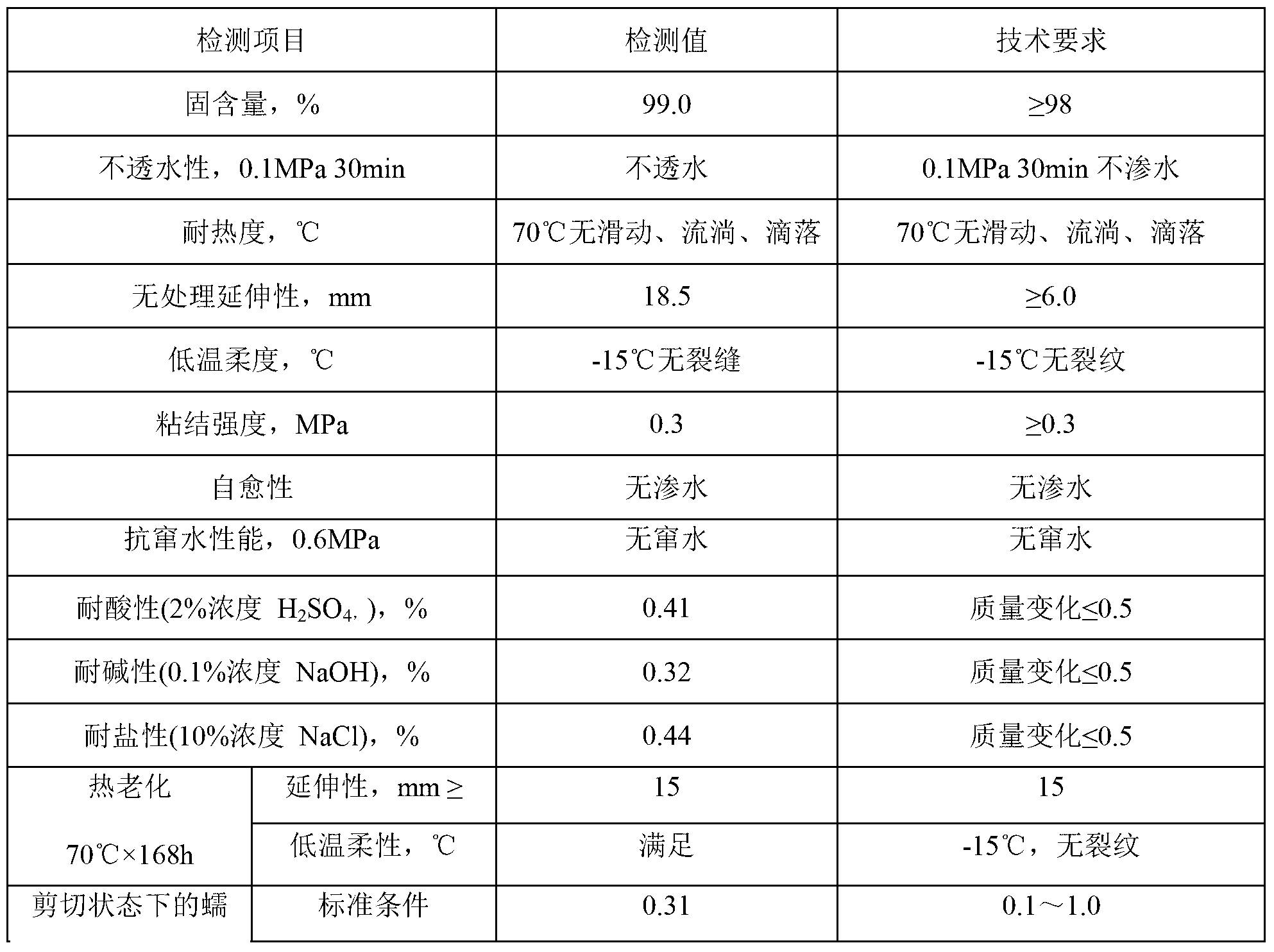

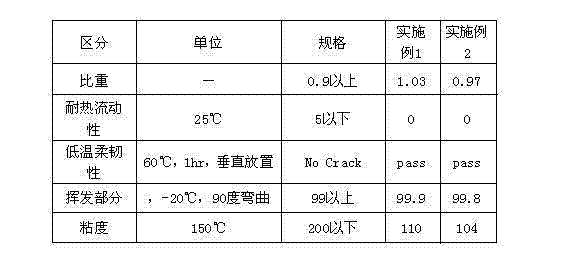

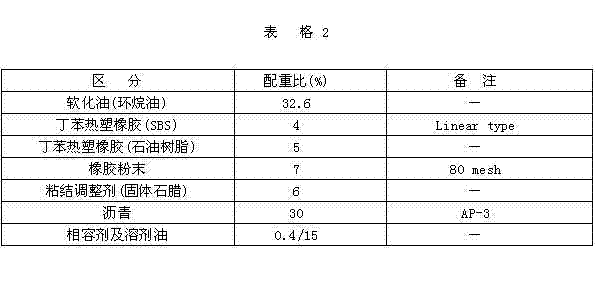

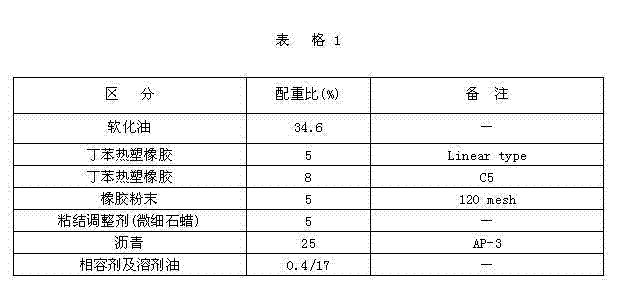

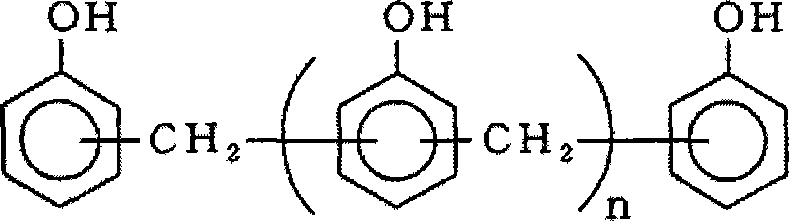

High-solid-content solvent type non-curing rubber asphalt waterproof paint and preparation method thereof

ActiveCN103666261AEasy constructionGood heat resistance and fluidityNatural resin coatingsUnspecified rubber coatingsBituminous waterproofingHeat resistance

The invention discloses a high-solid-content solvent type non-curing rubber asphalt waterproof paint which is prepared by mixing the following ingredients in weight percentage: 20-65 percent of softening oil, 3-20 percent of thermoplastic styrene butadiene rubber, 5-25 percent of rubber powder, 3-20 percent of a bonding modifier, 13-58 percent of asphalt, 10-30 percent of solvent oil and 0.3-1.0 percent of a compatilizer. The waterproof paint can be used under the construction condition of below 30-50 DEG C, the construction is simple, and the high-temperature heat resistance in summer and the low-temperature elasticity in winter are high. The waterproof paint has high heat-resistant liquidity, always keeps in an elastic-plastic colloidal state in the entire service life, is suitable for any forms of underlayer base surfaces, and can cut down the engineering time substantially. The invention further discloses a preparation method of the high-solid-content solvent type non-curing rubber asphalt waterproof paint.

Owner:李崇

Fiber art paint and preparation method thereof

ActiveCN102079905APromote absorptionImprove waterproof performanceUnspecified rubber coatingsFiberMaterials science

The invention discloses a fiber art paint and a preparation method thereof. The fiber art paint comprises the following raw materials in parts by weight: 1-2 parts of gelatin powder, 1.5-4 parts of paper fiber, 0.2-0.5 part of anti-corrosion and mildewproof agent, 0.3-1 part of dispersant, 0.5-1.5 parts of thixotropic lubricant, 0.2-0.6 part of water retaining agent, 2-10 parts of other additives, 0.5-1.2 parts of functional fiber, 40-55 parts of common filler and functional filler and 20-45 parts of pure water. The fiber art paint in the invention is characterized in that the paint can be used to adjust the humidity, absorb formaldehyde and insulate sounds and have rich decorative effects; and the preparation method of the paint is simple and the construction is environment-friendly.

Owner:安徽好思家涂料股份有限公司

Asphalt composition containing hydrogenated conjugated diene copolymer

ActiveUS20070179220A1High softening point and modulus and elongationExcellent in high-temperature storage stabilityOther chemical processesNon-rotating vibration suppressionPolymer scienceDynamic viscoelasticity

An asphalt composition comprising from 0.5 to 50 parts by weight of a hydrogenated conjugated diene copolymer (a) and 100 parts by weight of asphalt (b), wherein the hydrogenated conjugated diene copolymer (a) comprises a polymer block (A) comprising vinyl aromatic monomer units and at least one hydrogenated copolymer block (B) obtained by hydrogenation of a non-hydrogenated random copolymer block comprising conjugated diene monomer units and vinyl aromatic monomer units, the hydrogenated conjugated diene copolymer (a) having the following characteristics (1) to (5): (1) the content of the vinyl aromatic monomer units is more than 30% and not more than 60% by weight per weight of the hydrogenated conjugated diene copolymer; (2) the content of the polymer block (A) is from 5% to 50% by weight per weight of the hydrogenated copolymer; (3) the weight average molecular weight is from 30,000 to 500,000; (4) the percentage of hydrogenation of the double bonds in the conjugated diene monomer units is from 60% to 100%; and (5) at least one peak of the loss tangent (tan δ) is present in the range of from −40° C. to less than −10° C. in a dynamic viscoelastic spectrum obtained with respect to the hydrogenated copolymer.

Owner:ASAHI KASEI CHEM CORP

Rubber composition for coating cord

InactiveCN101045840AExcellent rubber strengthIncreased durabilityUnspecified rubber coatingsYarnCresolRolling resistance

Owner:SUMITOMO RUBBER IND LTD

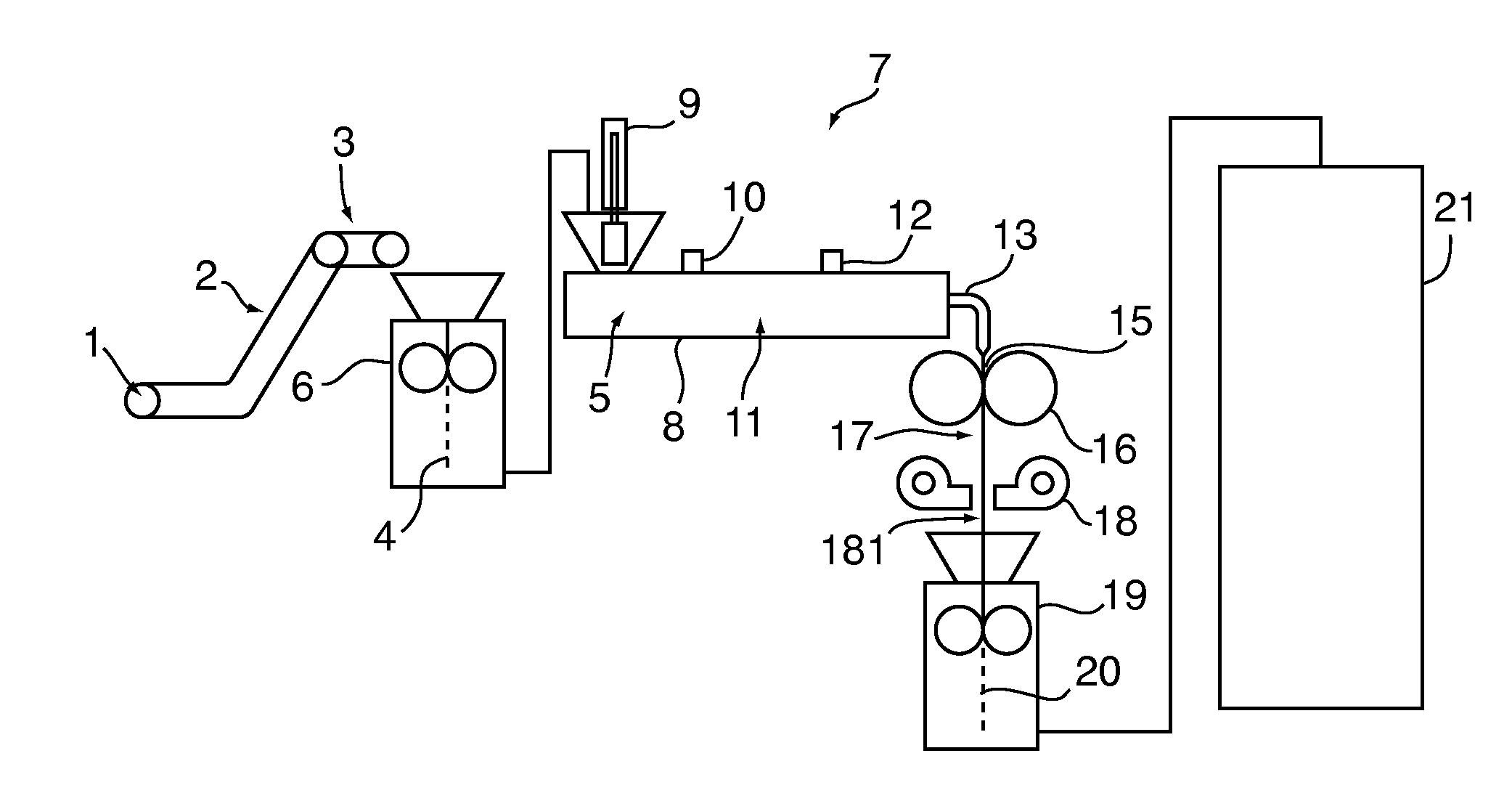

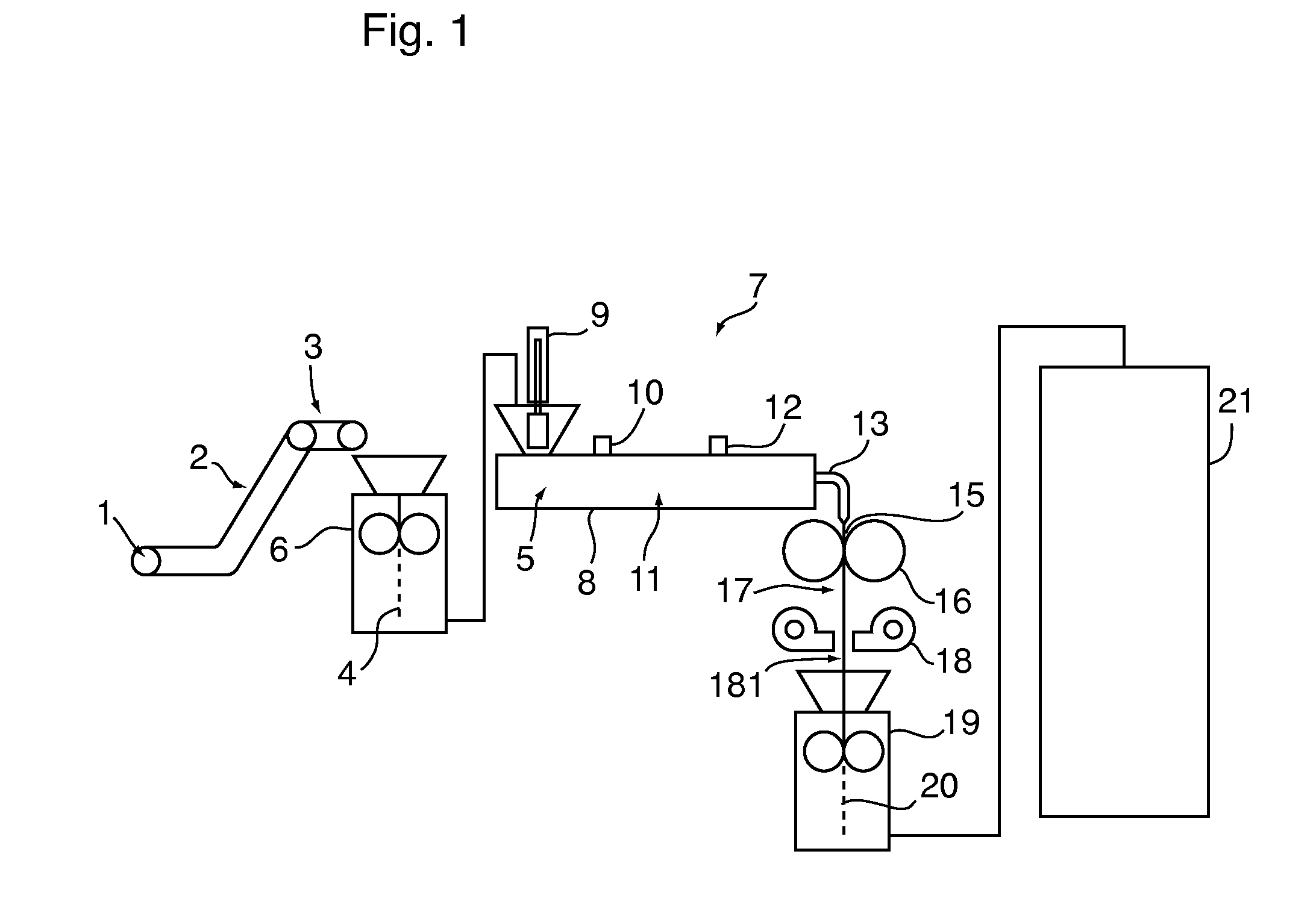

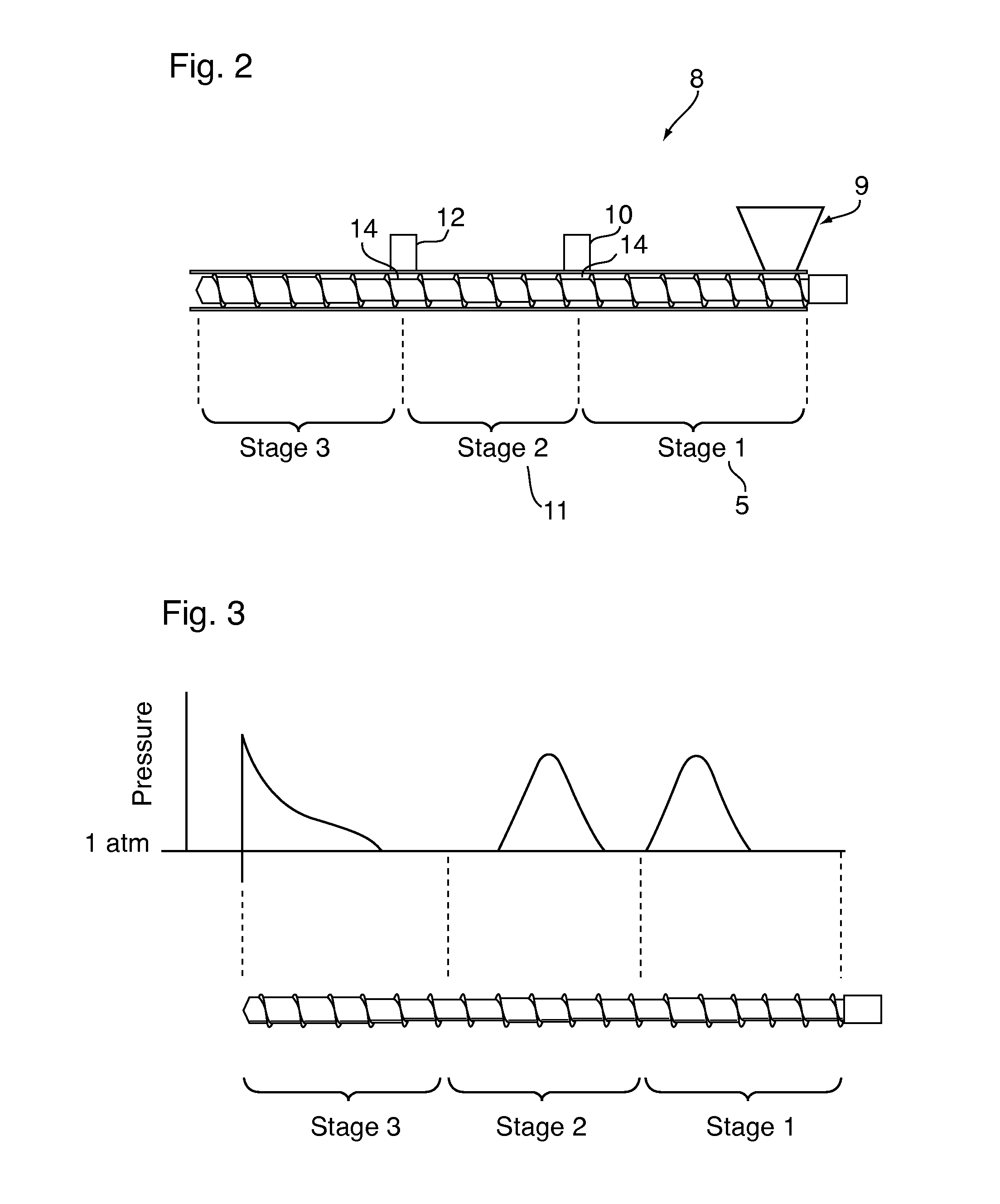

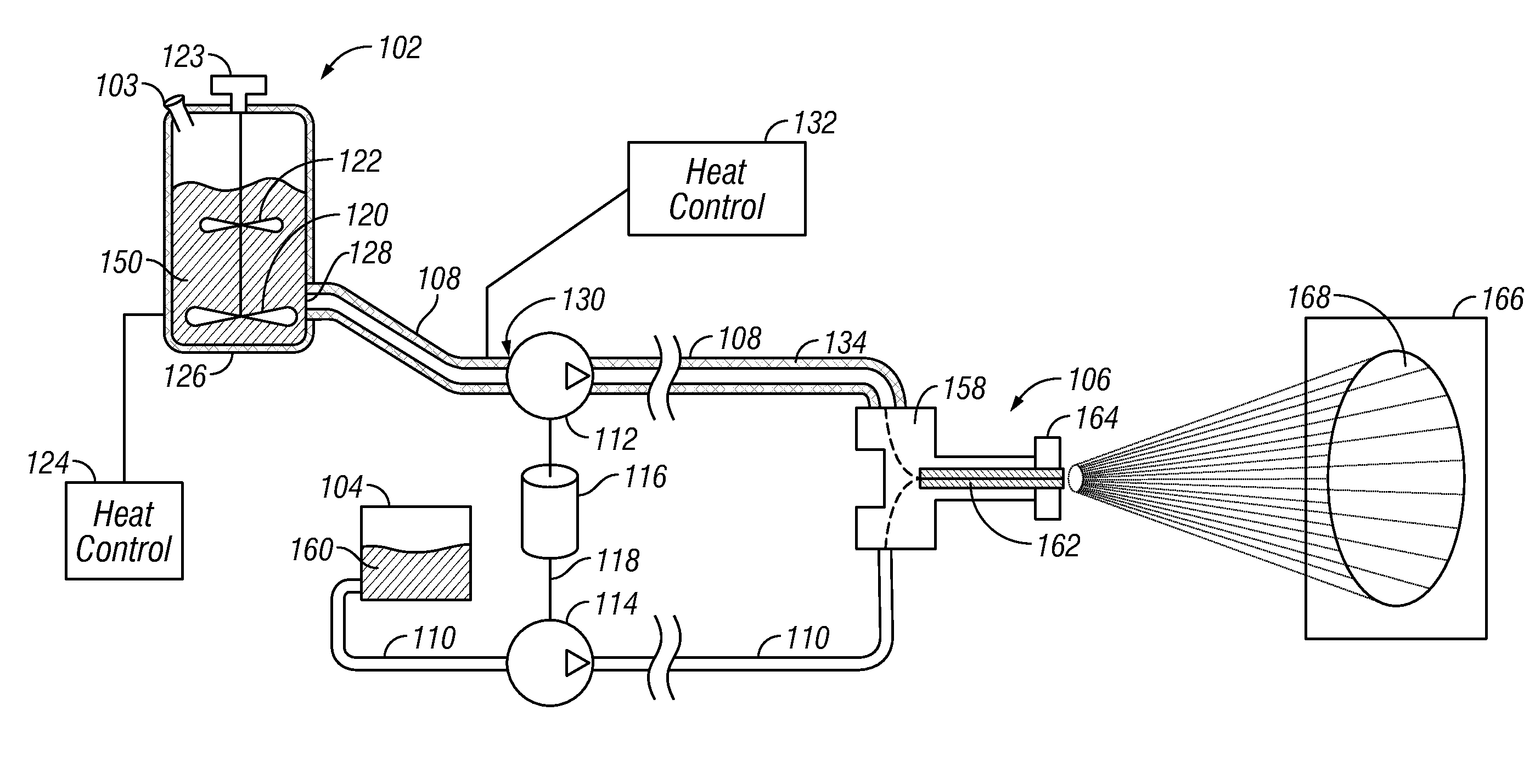

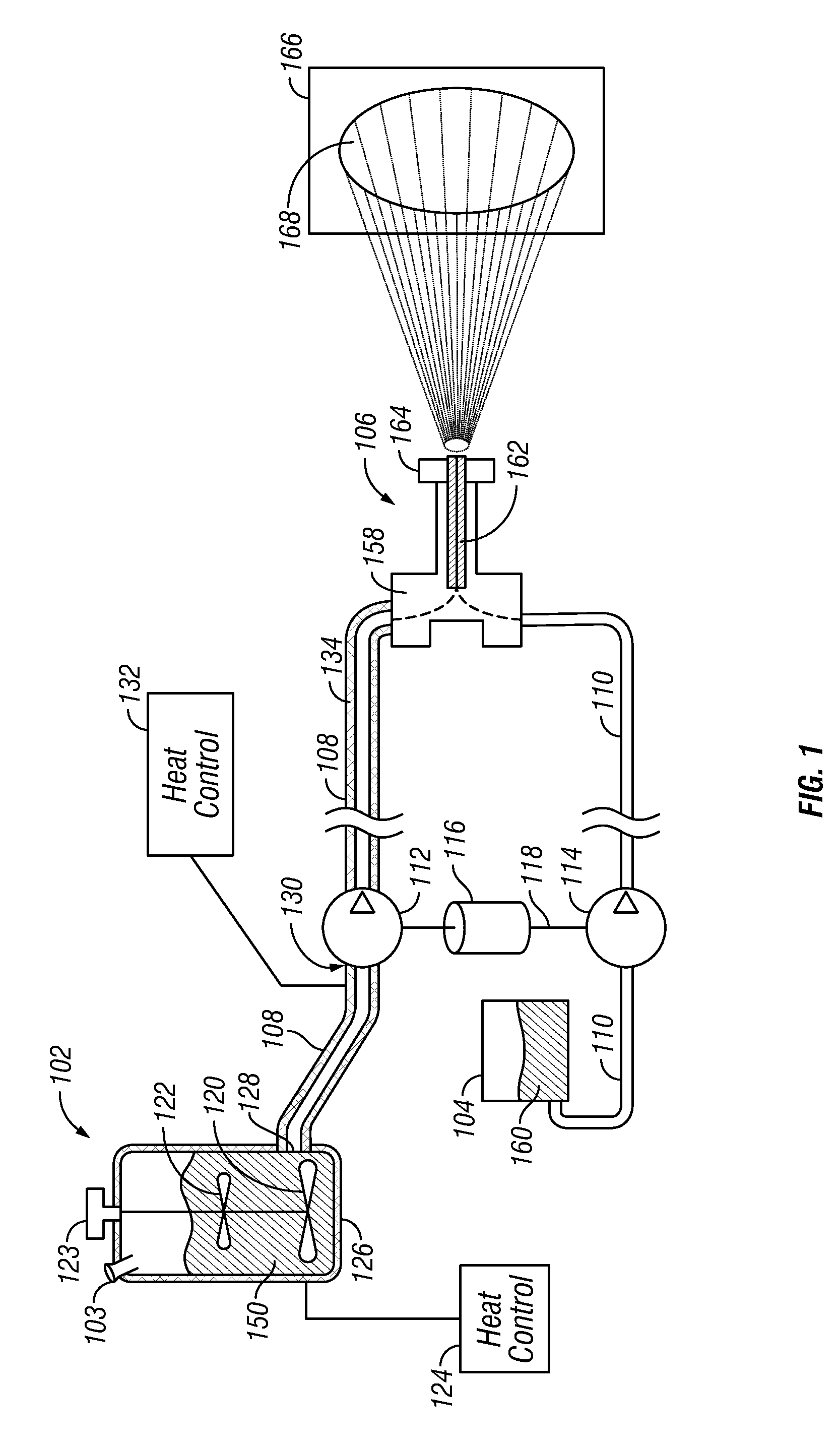

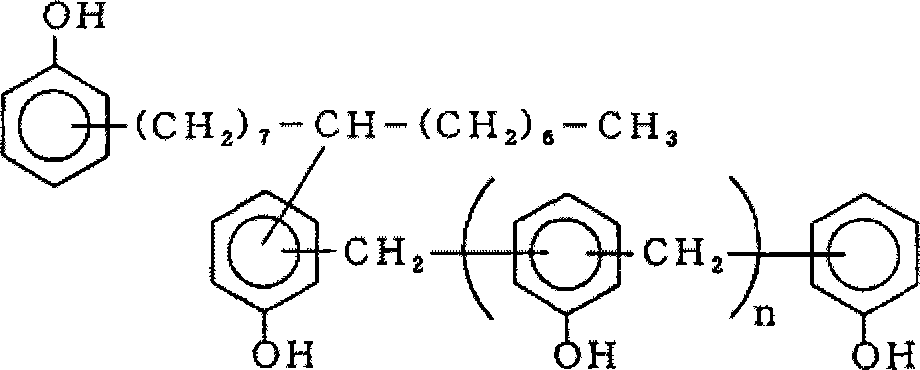

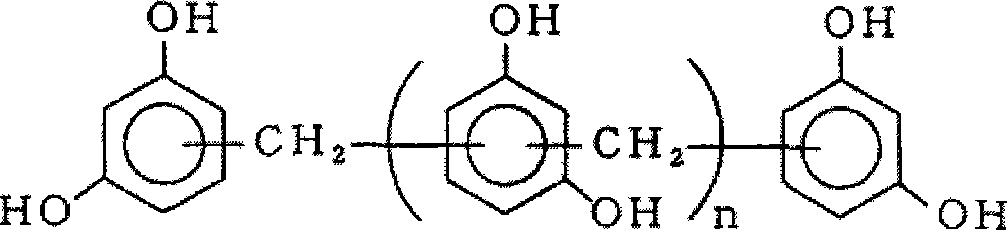

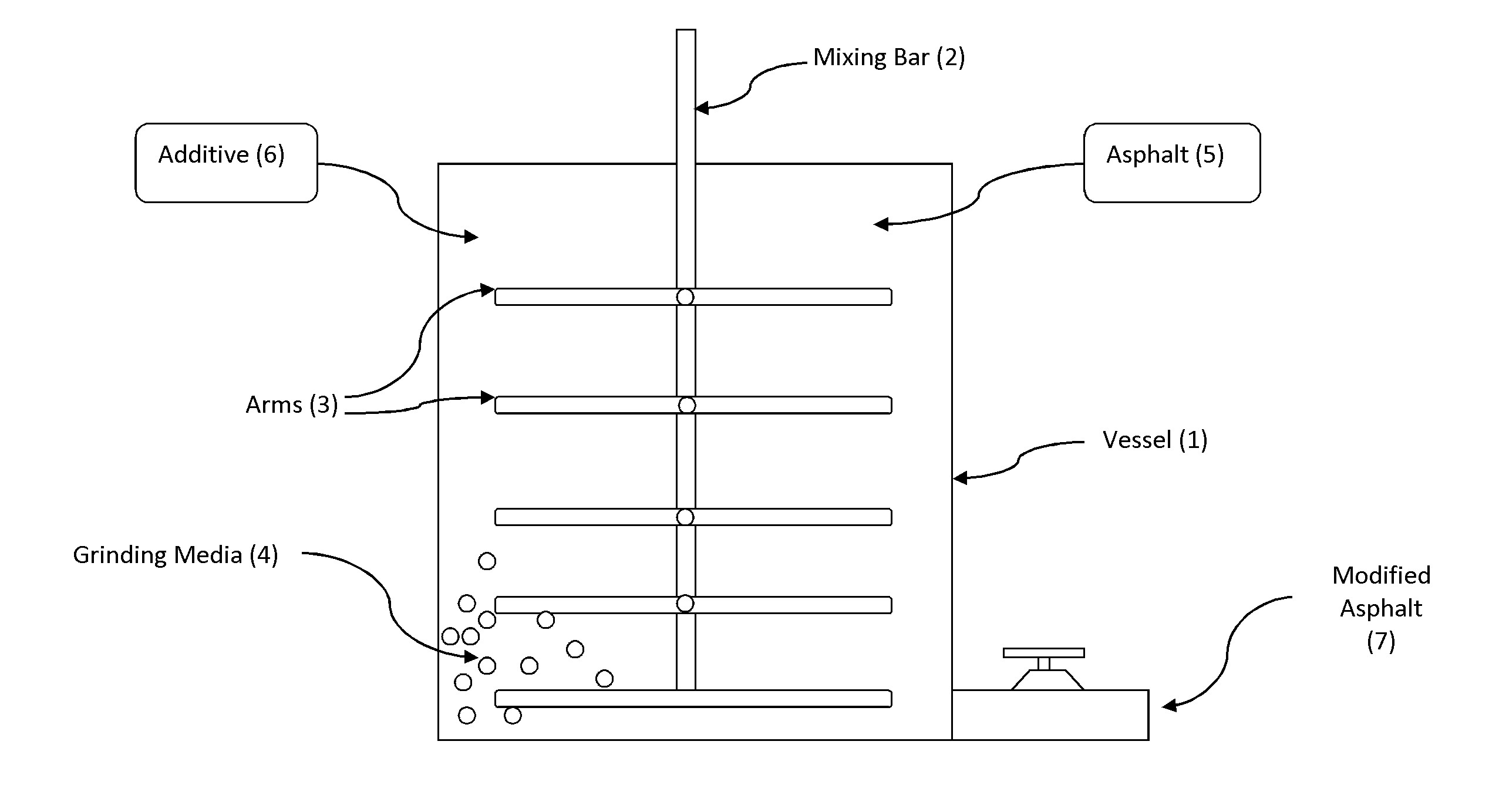

Asphalt modification processing system and method for asphalt additives

InactiveUS20130042793A1Improved performance characteristicsImprove performanceUnspecified rubber coatingsRoads maintainencePolymer scienceAsphalt

Owner:HERITAGE RES GROUP LLC

Rubber powder modified emulsified asphalt waterproof coating

PendingCN103897594AImprove high temperature stabilityGood low temperature crack resistanceUnspecified rubber coatingsBuilding insulationsEmulsionPolymer science

The invention discloses a rubber powder modified emulsified asphalt waterproof coating. The rubber powder modified emulsified asphalt waterproof coating comprises emulsified asphalt and a rubber powder emulsion. Asphalt is prepared into the emulsified asphalt, swelling treatment is performed on rubber powder, the swollen rubber powder is prepared into the rubber powder emulsion, the emulsified asphalt and the rubber powder emulsion are metered, mixed and uniformly stirred, and high-speed shear modification treatment is performed by a colloidal mill to obtain the rubber powder modified emulsified asphalt waterproof coating disclosed by the invention. The waterproof coating keeps the excellent performances of rubber modified asphalt, solves the problem that the rubber modified asphalt can not be saved and used at normal temperature, overcomes the shortcomings of high energy consumption, inconvenience in construction, environmental pollution and the like of the rubber modified asphalt, and overcomes the problems of expensive price, complex manufacturing process and the like of traditional SBS (styrene-butadiene-styrene) and SBR (styrene butadiene rubber) modified emulsified asphalt. The rubber powder modified emulsified asphalt waterproof coating disclosed by the invention takes waste tire rubber powder as a modifying material so as to be in line with the national industrial policy of circular economy and low-carbon economy.

Owner:李志国

Low smoke, fire and water resistant cable coating

ActiveUS8703288B2Wet electrical performanceLimit on characteristicFireproof paintsRubber insulatorsMoisture resistanceWater resistant

Cable coatings having effective low-smoke emission, fire resistance and moisture resistance provided by a single layer are described. The cable coatings contain an base polymer, a oxygen containing ethylene copolymer, a fire retardant and a synergistic blend of magnesium hydroxide and aluminum hydroxide. Cables coated with the described coatings have improved wet electrical performance, and satisfactory fire performance and smoke characteristics.

Owner:GENERAL CABLE TECH CORP

Aqueous damping coating having high acoustical insulation and low density and preparation method thereof

ActiveCN101041755AHigh damping valueWide damping temperature rangeUnspecified rubber coatingsPolyurea/polyurethane coatingsBenzeneWater based

The invention discloses a water-based damping material with high acoustical insulation and low density and preparing method, which comprises the following steps: (1) allocating one kind emulsion or multiple kinds of water-based propyl benzene emulsion, water-based polyurethane and various rubber latex with mass ratio; dissolving into water; setting the solid content at 20-60% in water solution; stirring; mixing; getting water-based emulsion mixture; (2) allocating powder form filler with mass ratio; adding into the allocating water-based emulsion; stirring with high speed; mixing; adding into disperser and deformer; adjusting consistency with thickener; getting the water-based damping paint.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Magnetism-absorbing coating and preparation method thereof

InactiveCN101538437ALow costWaterproofAntifouling/underwater paintsUnspecified rubber coatingsEmulsionFerromagnetism

The invention relates to a magnetism-absorbing coating and a preparation method thereof. The magnetism-absorbing coating comprises 20-70 percent of emulsion, 10-80 percent of ferromagnetic powder of non-magnetite powder and non-iron scurf powder, 0.1-10 percent of preservative and rest percent of water which are all mixed uniformly according to a certain proportion. The coating has no original magnetism, does not influence peripheral electronic products, but utilizes the ferromagnetic powder or a ferromagnetic compound to be diffused to an aqueous or unctuous coating basal body coated on a wall body, and the coating basal body is coated on the surface of an object or the wall body to generate a large-area magnetism-absorbing surface so that blueprints, pictures or notices, and the like can be hung on the wall by stationery magnets. The coating has extremely wide applications, can be coated on the surfaces of glass, wood, wall bodies, cloth, ceramics, plastics, paper, and the like to generate the magnetism-absorbing surfaces and facilitate the suspension of notes, catalogues, and the like. The invention also has the waterproof function and can be applied outdoors.

Owner:张治君

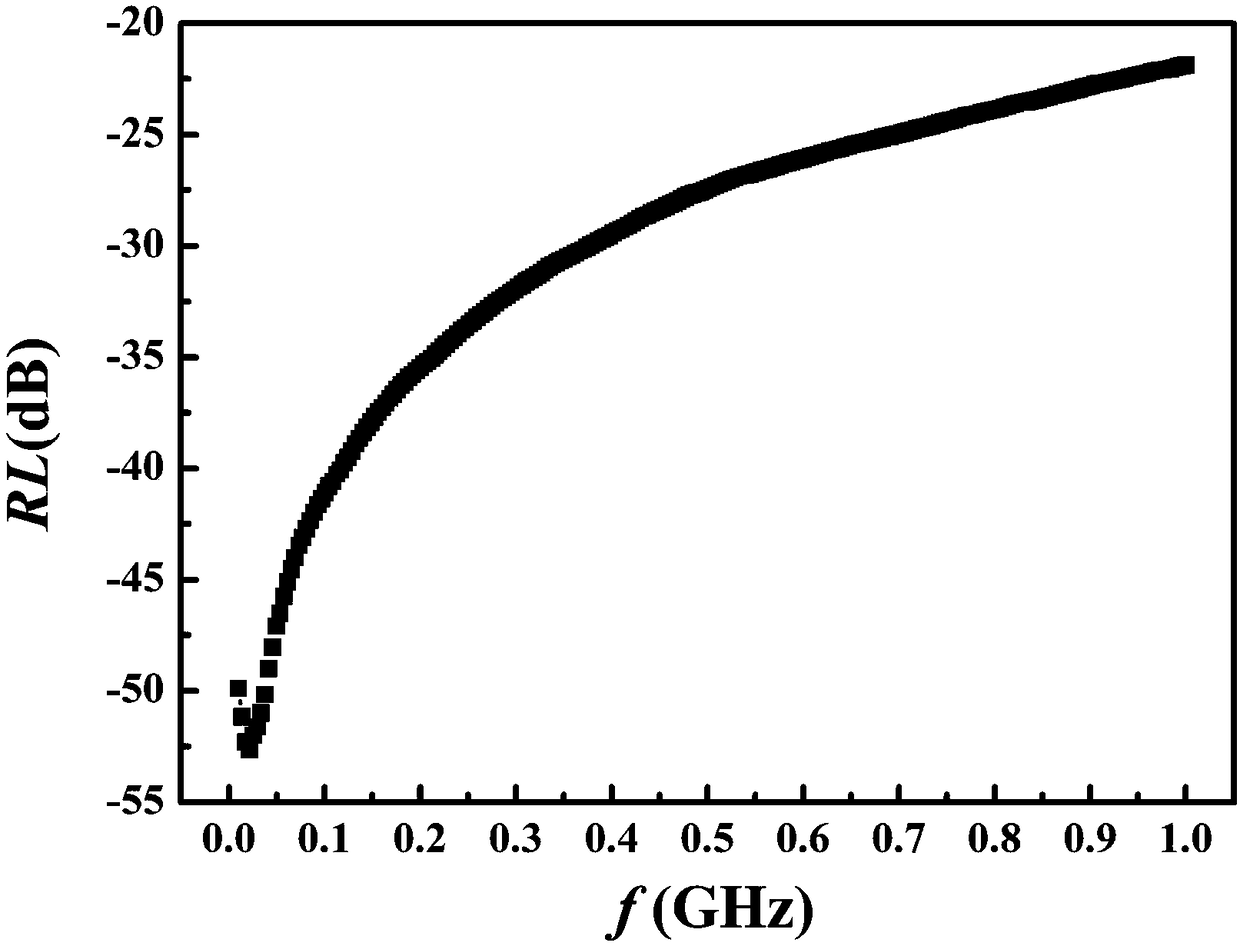

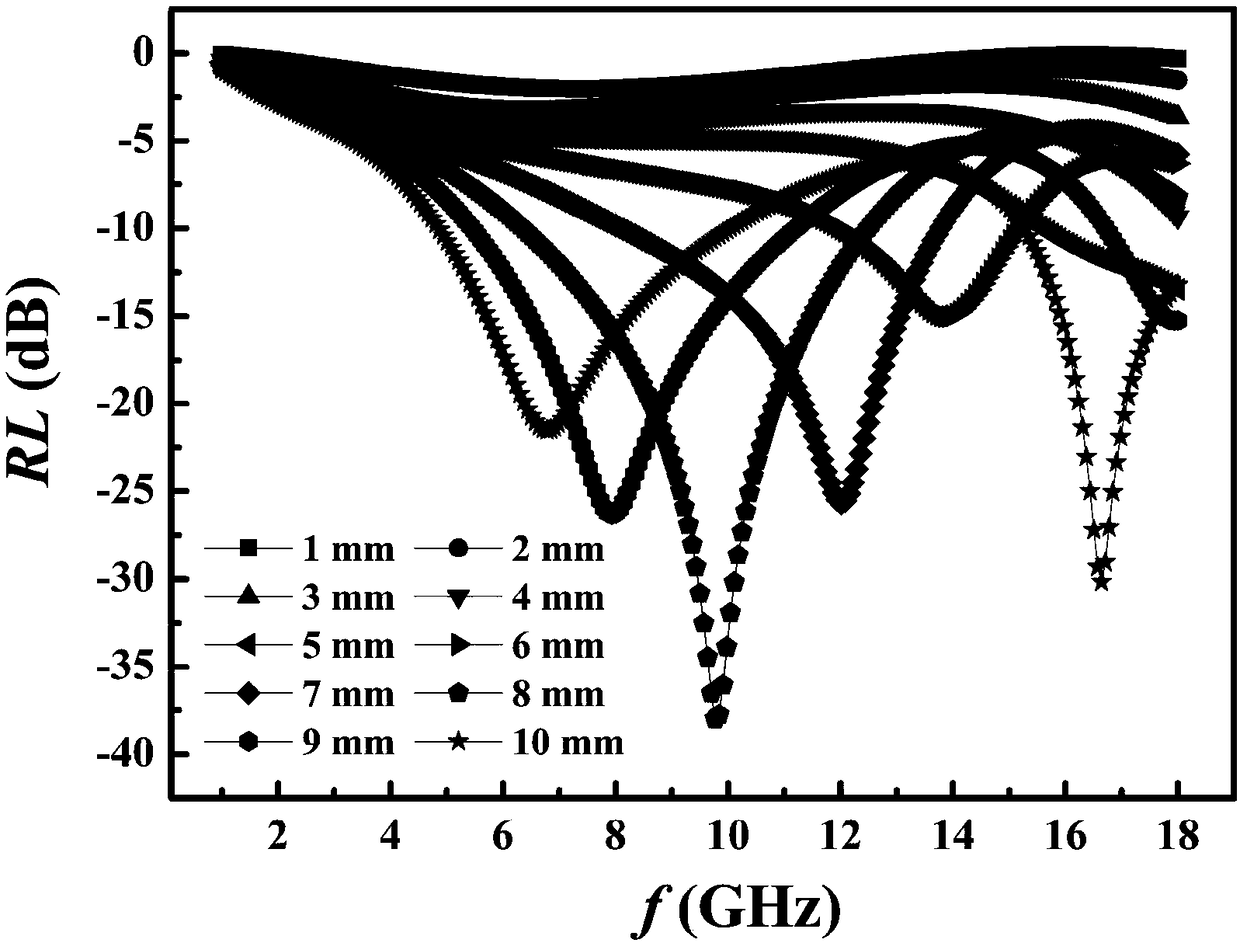

Preparation method of electromagnetic wave absorption material based on ferrite solid wastes

ActiveCN108102393AReduce manufacturing costConducive to environmental protection and recyclingWax coatingsMagnetic/electric field screeningCarbon compositesVolumetric Mass Density

The invention discloses a preparation method of an electromagnetic wave absorption material based on ferrite solid wastes. The electromagnetic wave absorption material with a composite structure is obtained by taking the ferrite solid wastes produced by grinding in a soft magnet magnetic core production link as a magnetic base body and covering carbon on a crystal boundary. A ferrite / carbon composite electromagnetic wave absorption material prepared by the preparation method has anti-oxidization and anti-corrosion capabilities; an interface carbon material is added so that the density of a wave absorption body can be reduced and light and thin wave absorption products are easy to produce; the mechanical properties also can be stabilized and reinforced. The electromagnetic wave absorption material prepared by the preparation method disclosed by the invention has wide applicability, is suitable for being used for absorbing electromagnetic waves with the frequency band of DC-42.5GHz and can be used for products including blocks, patches, pyramids, conoids, coatings, thin films and the like.

Owner:HEFEI UNIV OF TECH

High block, tack and scrub resistant polymer

ActiveUS9611393B2Excellent tack resistance and block resistance and scrub resistanceUnspecified rubber coatingsPolymerColoring agents

The present invention is directed to a coating composition or paint comprising a multistage latex with at least first and second stages, wherein the composition or paint is substantially free of volatile organic compounds (VOC) and capable of film formation even in the absence of coalescent agents. The base paint formulation is capable of being tinted at a point-of-sale (i.e. in-store) using a colorant composition of a type and quantity required to produce a paint of desired color and finish. The paints, including deeply colored paints, show improved block resistance, scrub resistance and tack resistance.

Owner:SWIMC LLC

Waterborne thick rubber-plastic waterproof mortar and method for preparing same

ActiveCN101775249AReach the use thickness requirementBackfill puncture resistantRosin coatingsUnspecified rubber coatingsFiberSodium Bentonite

The invention provides waterborne thick rubber-plastic waterproof mortar and a method for preparing the same. The formula of the mortar comprises the following components in part by weight: 33 to 65 parts of macromolecular emulsion, 2.5 to 6.5 parts of tackifying resin, 0.3 to 1.5 parts of high-strength reinforcement fiber, 20 to 35 parts of waste rubber powder, 3 to 22 parts of filling materials, 1.7 to 5.7 parts of assistant and 2.5 to 7.5 percent of water, wherein the macromolecular emulsion is emulsion of polystyrene-acrylic ester and mainly used as a film forming of the waterborne thick rubber-plastic waterproof mortar; and the filling material is heavy calcium carbonate, talcpowder, plasticizer or bentonite. The waterborne thick rubber-plastic waterproof mortar of the invention can replace part of the waterproof coiled material and meet the application thickness requirement after one-time coating, and has the characteristics of high elasticity, impact resistance and backfill puncture resistance; the mortar can be used for water resistance on the upstream face as well as downstream face, and no other protective layer is added; the mortar is the multi-functional building mortar having the advantages of heat insulation and heat absorption and noise reduction and noise elimination; and in the formula, a large amount of waste tire rubber powder is used, so that the method for preparing the mortar makes an active contribution to environmental protection and resource recovery.

Owner:KESHUN WATERPROOF TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com