Patents

Literature

120results about How to "Wide damping temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acid-resistant and alkali-resistant waterborne damping coating with wide temperature range and high damping capacity and method for preparing same

InactiveCN106009961AWide damping temperature rangeHigh dampingAnti-corrosive paintsEmulsionDefoaming Agents

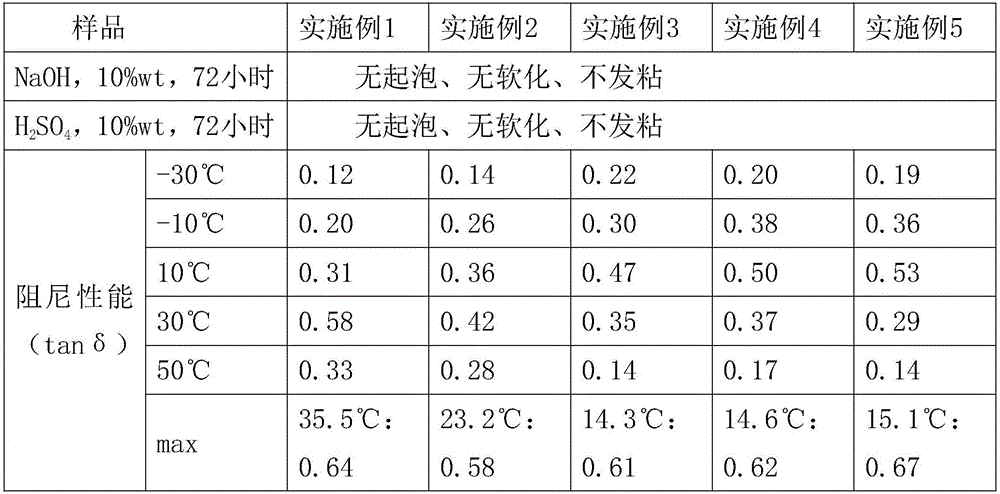

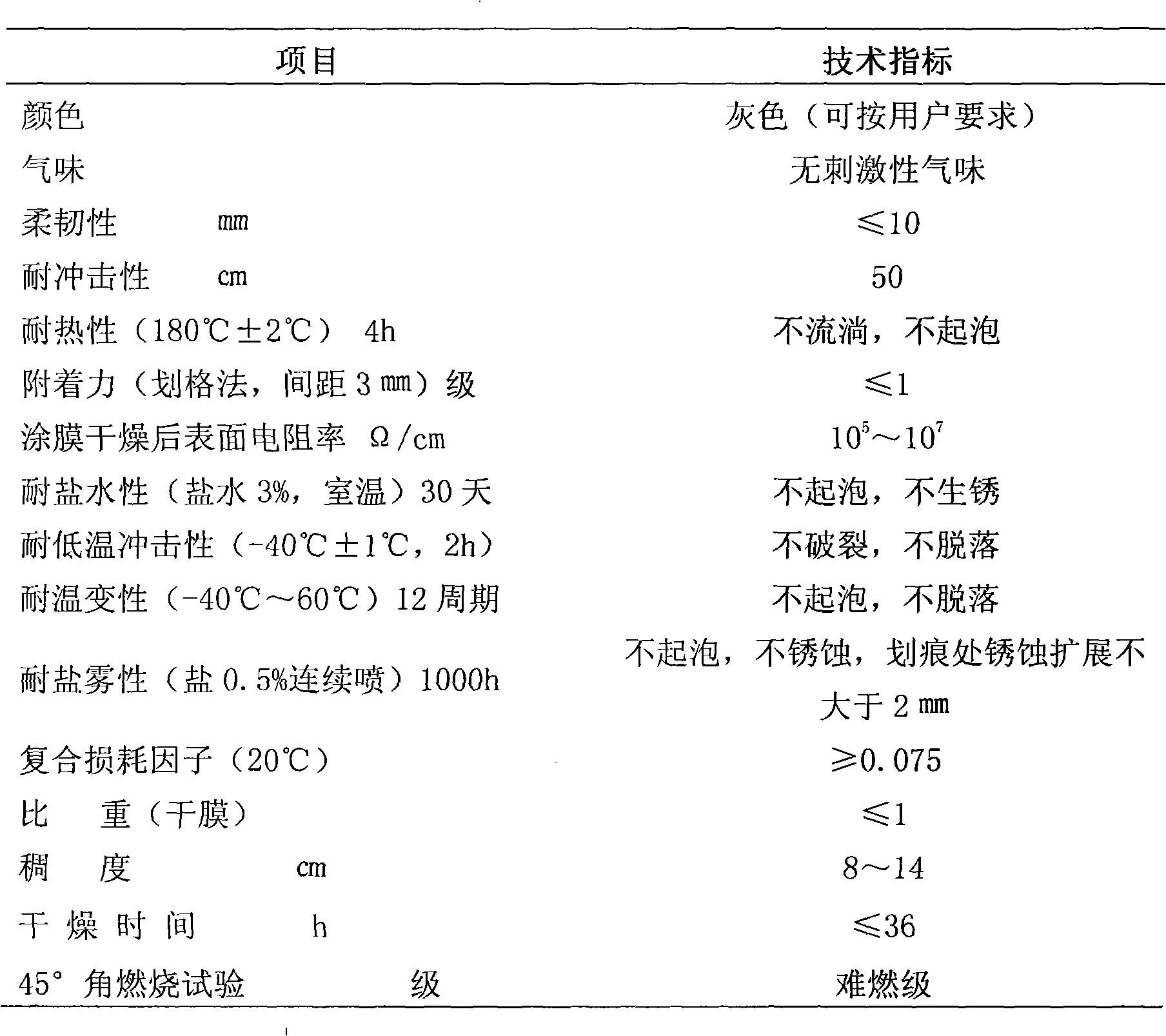

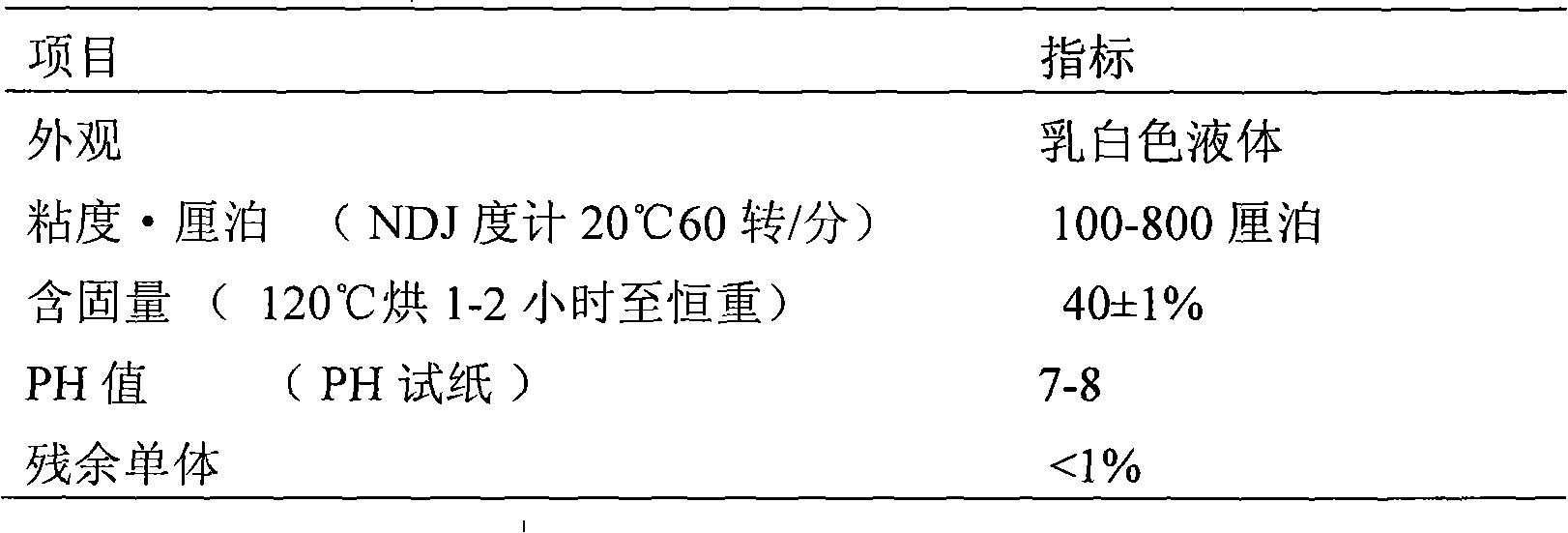

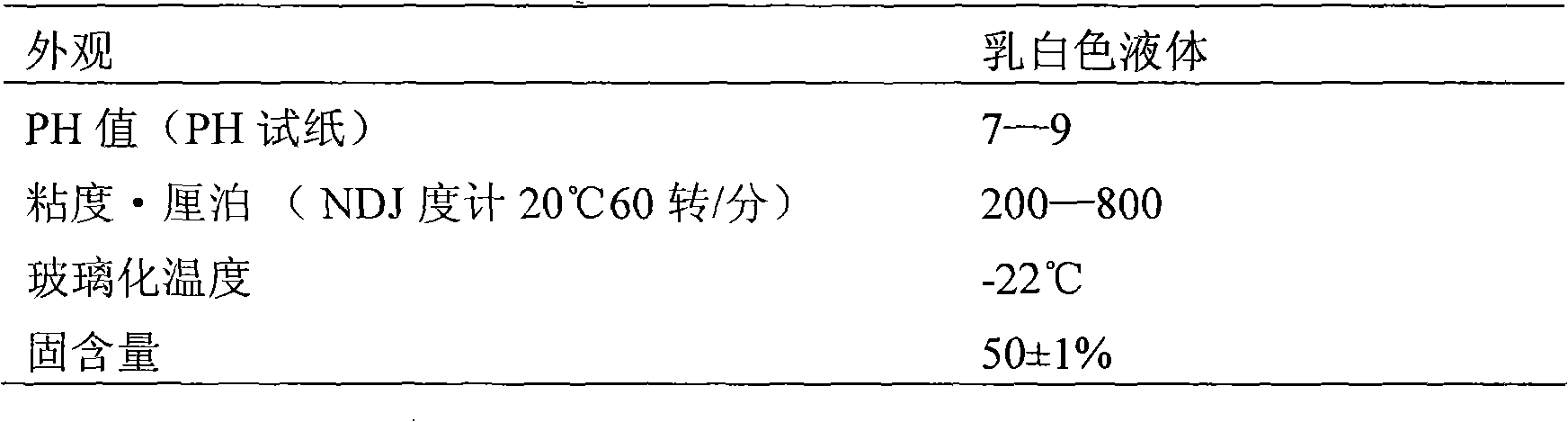

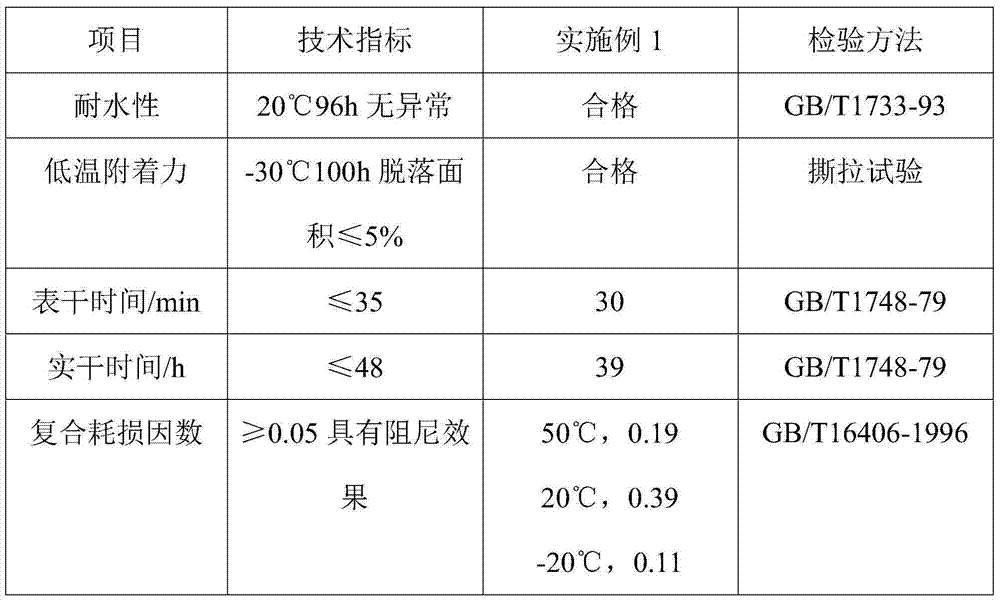

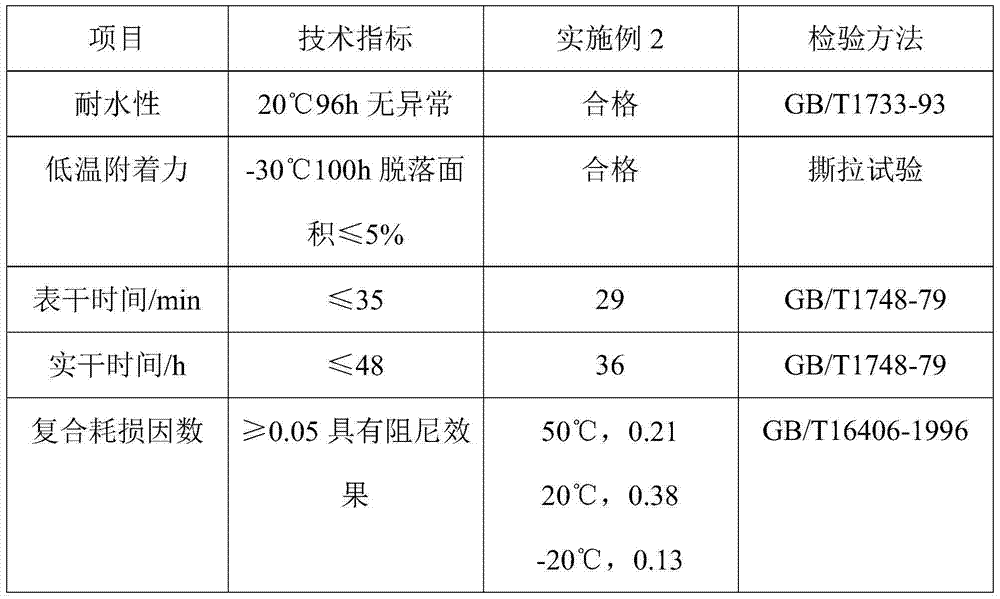

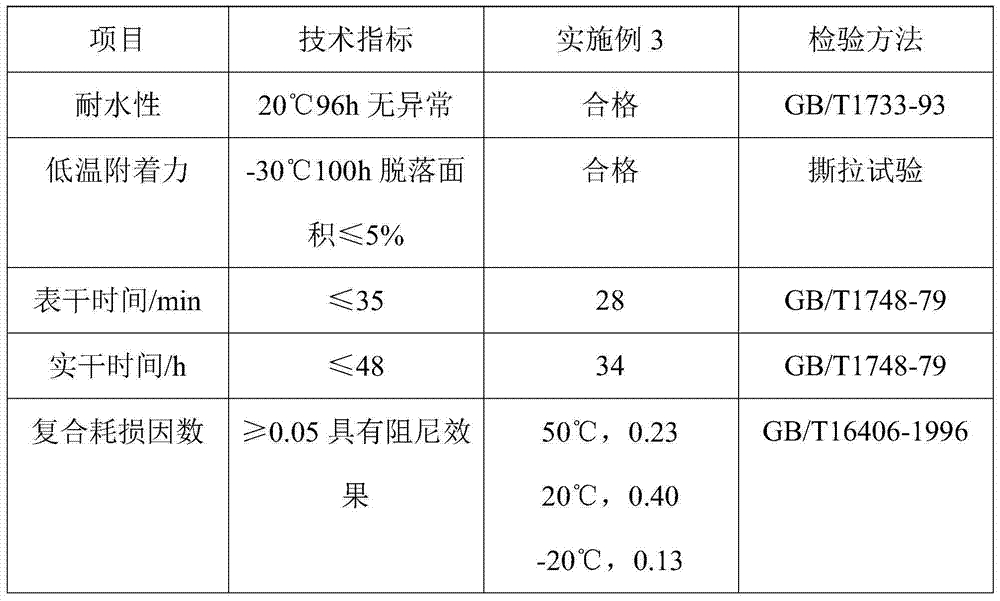

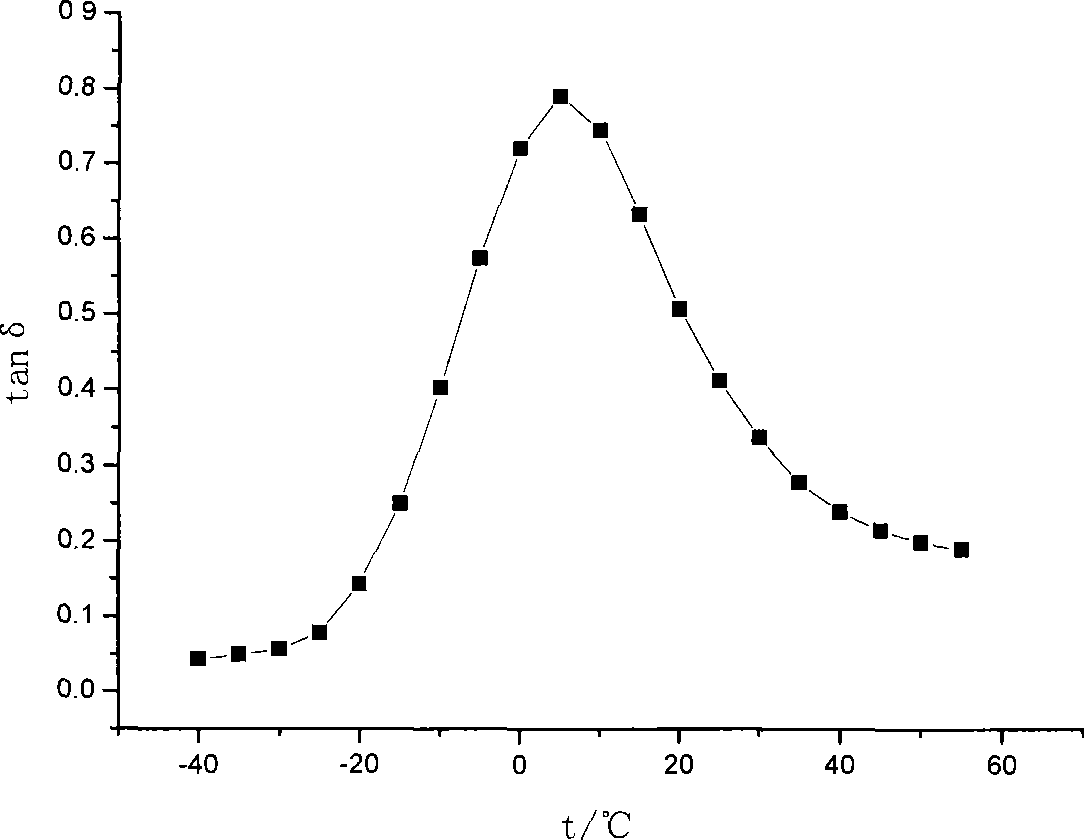

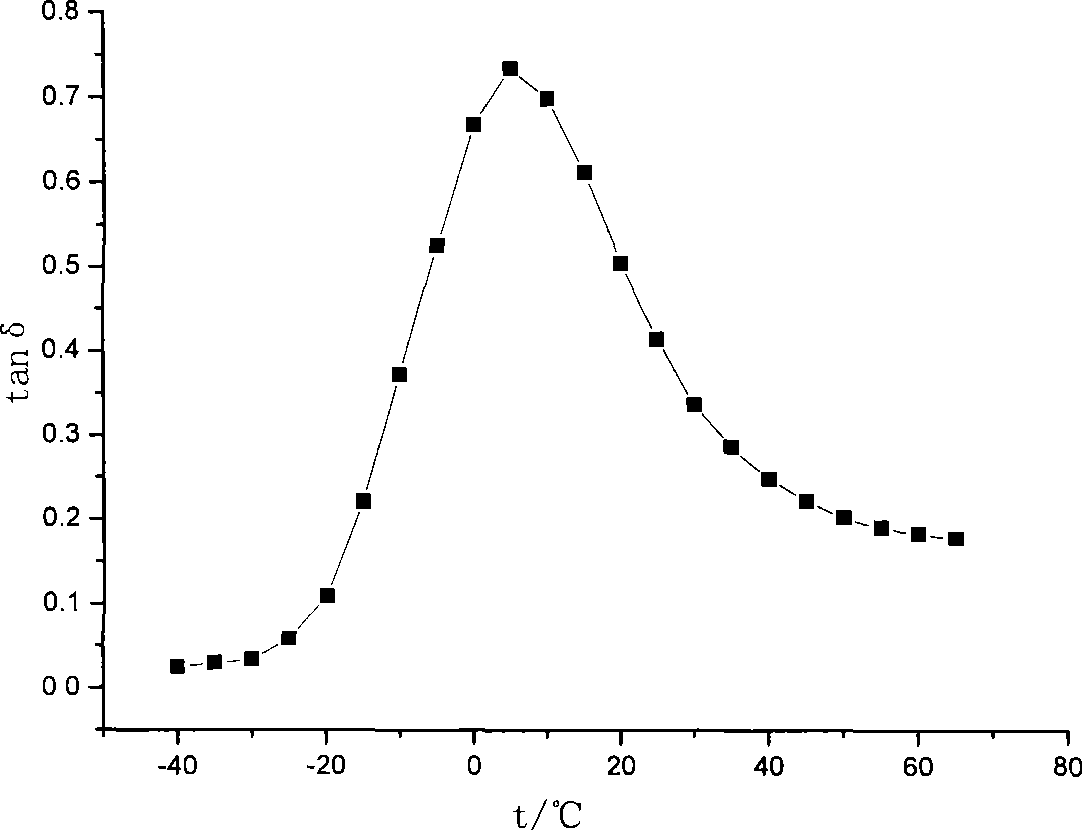

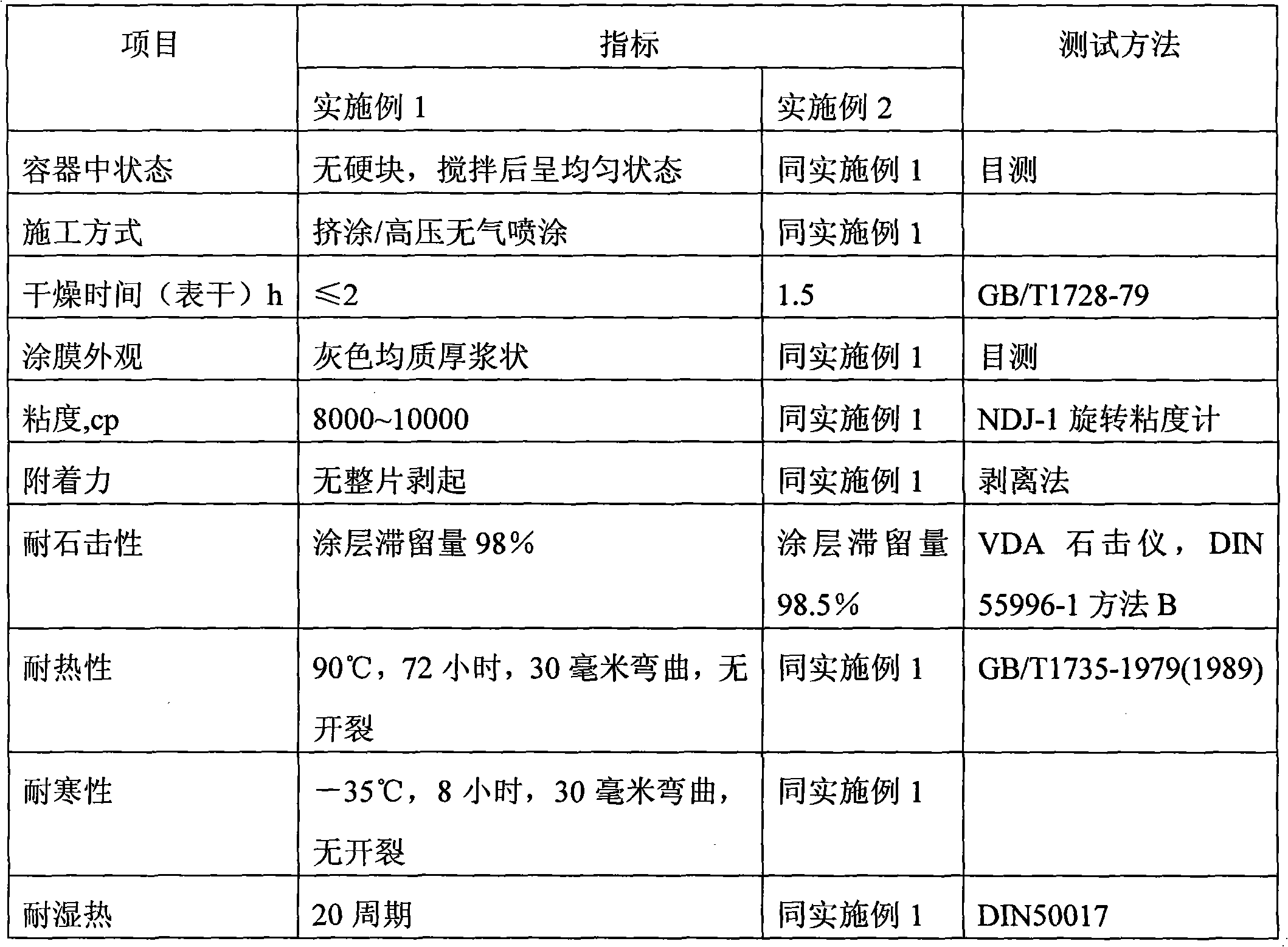

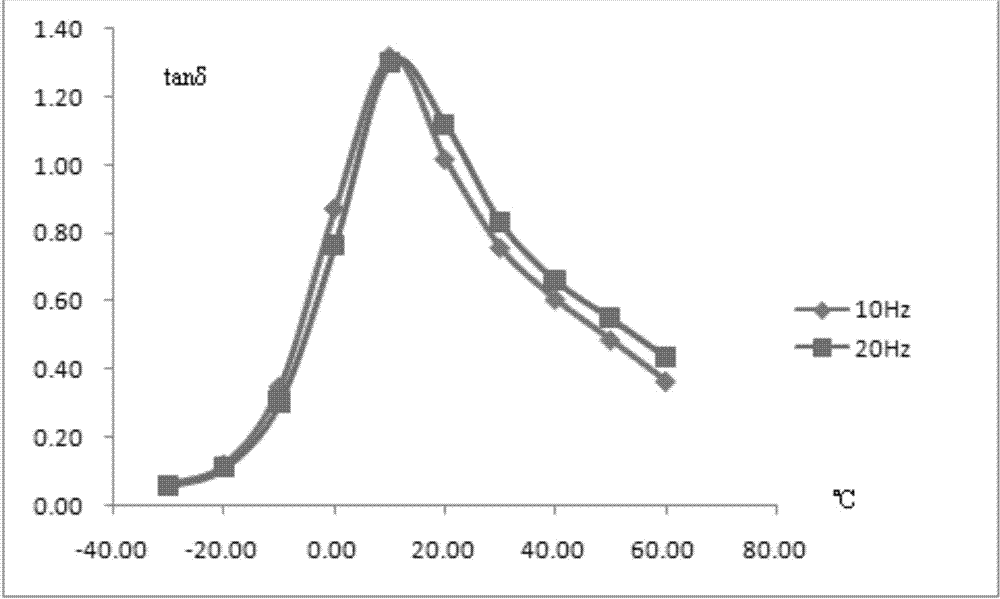

The invention discloses an acid-resistant and alkali-resistant waterborne damping coating with a wide temperature range and high damping capacity, comprising, by weight, 30-65 parts of a waterborne emulsion, 15-45 parts of a filler, 10-35 parts of a flame retardant, 0.1-2 parts of fibers, 0-5 parts of a film-forming agent, 0.1-1.5 parts of a dispersing agent, 0.1-1.5 parts of a defoaming agent, 0-4 parts of an antifreeze agent, 0.2-3 parts of a thickening agent and 1-8 parts of a multifunctional aid. The acid-resistant and alkali-resistant waterborne damping coating with wide temperature region and high damping capacity has the advantages that the acid-resistant and alkali-resistant waterborne damping coating is high in damping performance, wide in damping temperature range and excellent in acid resistance and alkali resistance; loss factors of materials in the temperature range ranges from -30 DEG C to 50 DEG C reach 72 hours as shown by acid-resistant and alkali-resistant tests on the materials by the aid of 10% NaOH solution and 10% H2SO4 solution, and the acid-resistant and alkali-resistant waterborne damping coating is free of foaming, softening and sticking and excellent in acid resistance and alkali resistance.

Owner:安徽贝卫新材料科技有限公司

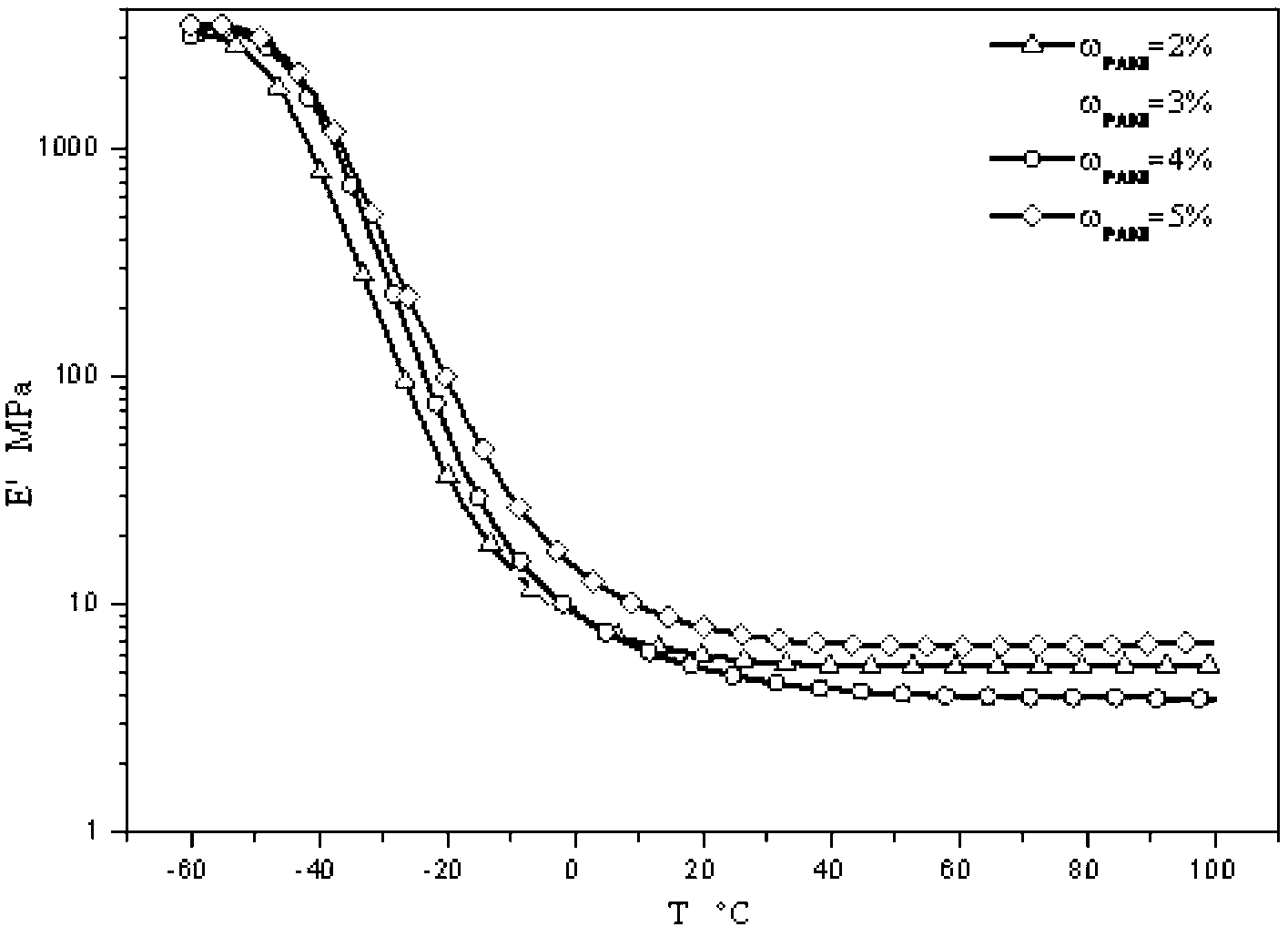

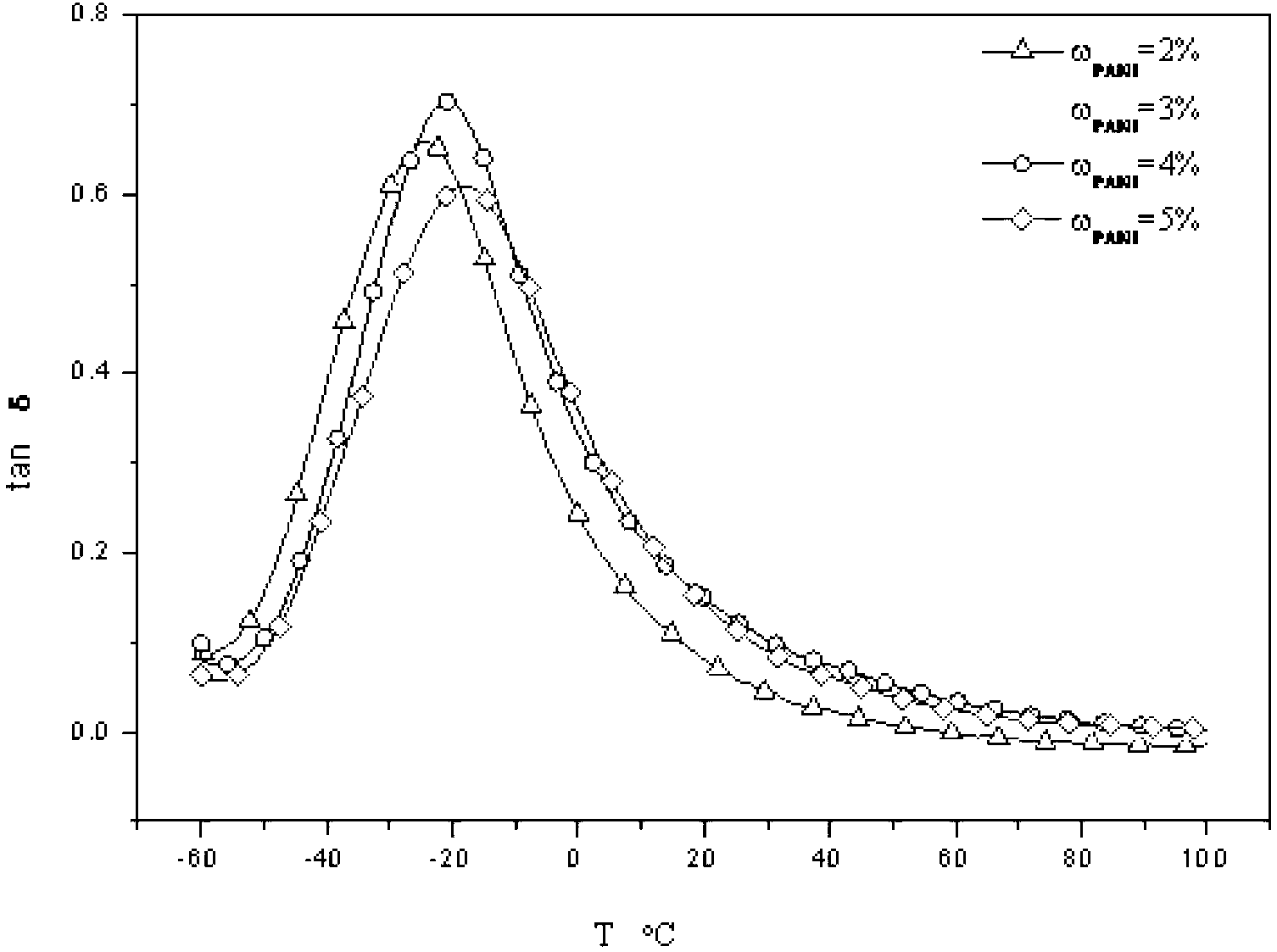

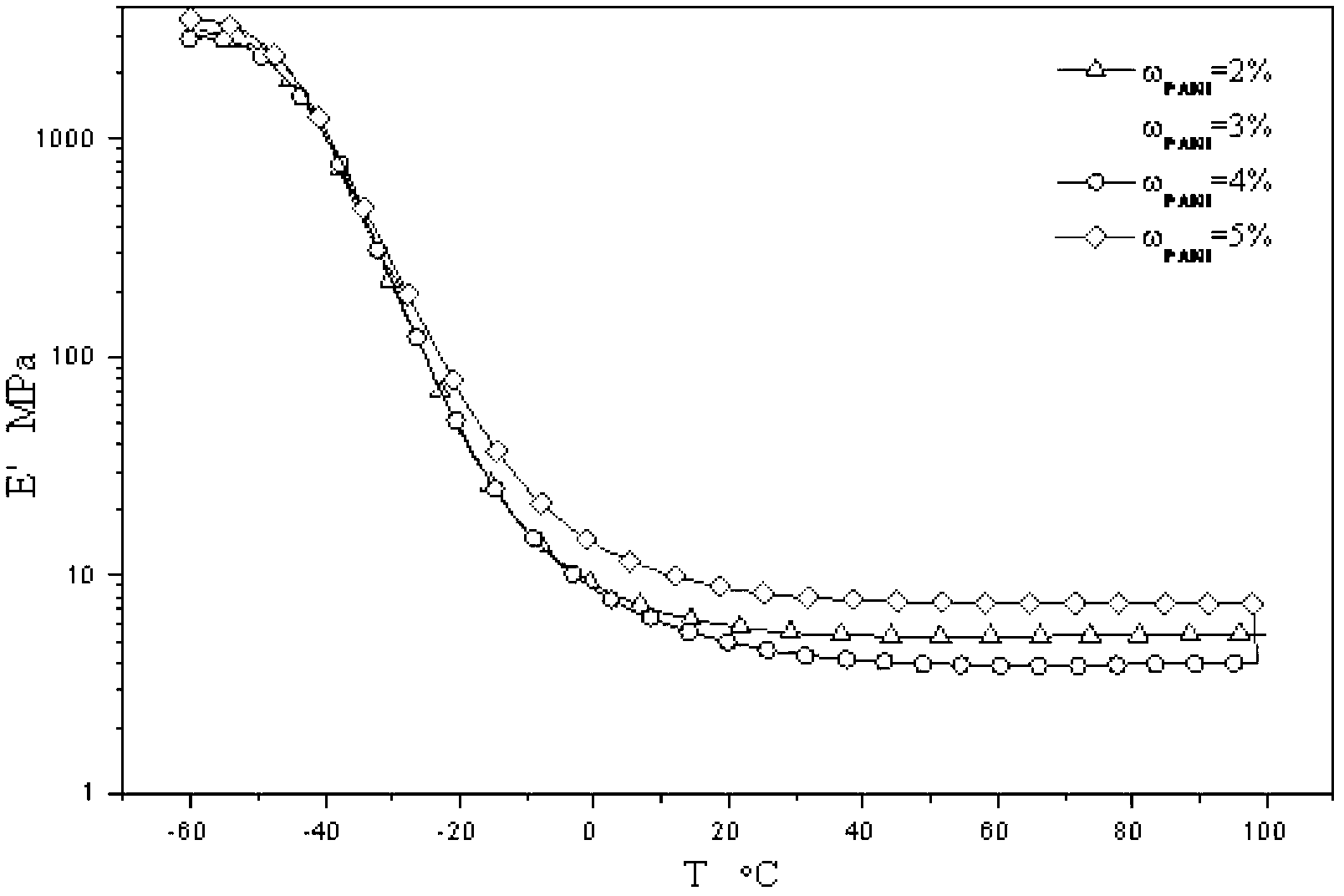

Water-soluble conducting polyaniline static-free damping paint and preparation method thereof

InactiveCN101633809ANo pollutionWide damping temperature rangeAntifouling/underwater paintsPaints with biocidesWater basedVibration absorption

The invention relates to a water-soluble conducting polyaniline static-free damping paint and a preparation method thereof, belonging to a static-free damping paint. The water-soluble conducting polyaniline static-free damping paint contains the following raw materials in portions by weight: 20-40 portions of basic materials commixed by styrene-acrylic emulsion and water-based elastic acrylic emulsion dedicated for the water-based damping paint; 20-50 portions of fillers being several ones of lamellar mica powder, precipitated calcium carbonate, zinc phosphate, talc powder, titanium pigment, precipitated barium sulfate and silica sand; 25-50 portions of static-free fillers being water-soluble conducting polyaniline solution; 1-5 portions of fire retardants; and 2-6 portions of film forming assistants. The invention has the advantages that water-soluble emulsions are used as basic materials to ensure that the paint has such features as no position, no smell, incombustibility, no environmental pollution and easy construction; excellent damping effect and vibration-absorption effect are guaranteed; besides, as water-soluble conducting polyaniline solution is used as the static-free filler, the water-soluble conducting polyaniline static-free damping paint has the static-free function not available in the damping paint.

Owner:JILIN ZHENGJI TECH DEV

Preparation and application of thermal conductive wide temperature range damping coating

ActiveCN106590203AImprove thermal conductivityLarge specific surface areaPolyurea/polyurethane coatingsPreservativeFilm-forming agent

The invention provides preparation and application of a thermal conductive wide temperature range damping coating. The thermal conductive wide temperature range damping coating is prepared from the following components in parts by mass: 75-125 parts of a main material and 14-39 parts of additive; the main material is prepared from the following components in parts by mass: 30-50 parts of acrylic emulsion, 35-55 parts of filler, 10-20 parts of thermal conducting filler and 10-25 parts of deionized water; the additive is prepared from the following components in parts by mass: 1-5 parts of dispersant, 1-3 parts of anti-sedimentation agent, 0.2-1 part of defoamer, 0.1-1.5 parts of thickener, 0.5-1.8 parts of film forming agent and 0.06-0.2 part of preservative. According to the preparation and the application, the acrylic emulsions with a core-shell structure and an IPN structure are adopted, the structures can enable a polymer to have a micro-phase separation structure after film formation, and the problem of mutual separation of damping peaks due to phase separation easily caused by blending of traditional polymers is overcame; and in addition, various polymerized emulsions are blended and are in gradient Tg distribution, so that a damping temperature range can be widened to the greatest extent, the prepared damping coating is wide in damping temperature range, can be suitable for variation of air temperature and reaches a wide temperature range from 20 DEG C to 100 DEG C.

Owner:BMF NANO MATERIAL TECHNOLOGY CO LTD

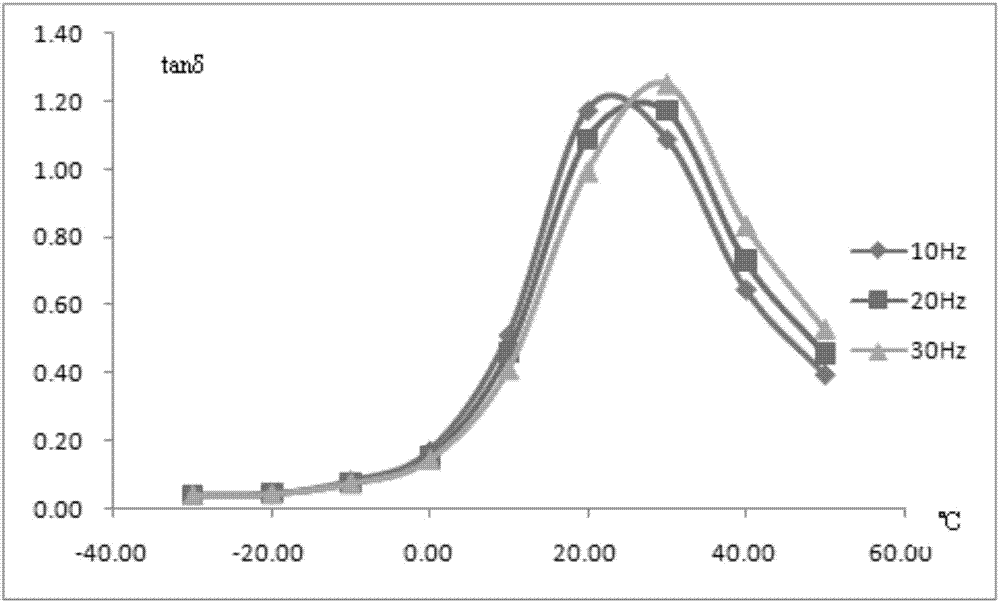

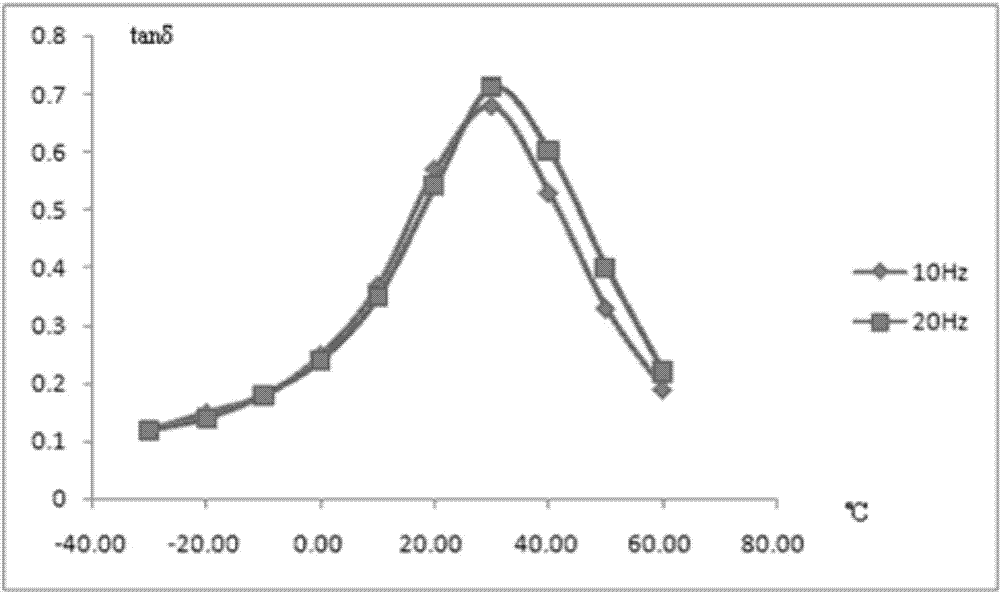

Aqueous damping coating having high acoustical insulation and low density and preparation method thereof

ActiveCN101041755AHigh damping valueWide damping temperature rangeUnspecified rubber coatingsPolyurea/polyurethane coatingsBenzeneWater based

The invention discloses a water-based damping material with high acoustical insulation and low density and preparing method, which comprises the following steps: (1) allocating one kind emulsion or multiple kinds of water-based propyl benzene emulsion, water-based polyurethane and various rubber latex with mass ratio; dissolving into water; setting the solid content at 20-60% in water solution; stirring; mixing; getting water-based emulsion mixture; (2) allocating powder form filler with mass ratio; adding into the allocating water-based emulsion; stirring with high speed; mixing; adding into disperser and deformer; adjusting consistency with thickener; getting the water-based damping paint.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

Cold-resistant and water-proof damping coating

InactiveCN104263224AGood chemical compatibility and stabilityWide damping temperature rangePolyurea/polyurethane coatingsIonPerlite

The invention discloses a cold-resistant and water-proof damping coating which is characterized in that raw materials comprise the following components in parts by weight: 40-60 parts of waterborne polyurethane / polyacrylate latex, 5-16 parts of sericite modified by a coupling agent, 5-15 parts of talcum powder, 3-10 parts of hollow glass beads, 3-8 parts of mica powder, 5-12 parts of perlite, 5-17 parts of kieselguhr, 4-10 parts of nanometer acrylate rubber powder, 0.3-0.9 parts ofphosphate modified amine compound, 3-6 parts of magnesium hydroxide, 5-12 parts of aluminium hydroxide, 3-10 parts of glass fibre, 1-3 parts of boron-containing phenolic resin, 2-5 parts of organic solvent, 2-7 parts of a film coalescing aid, 2-5 parts of aids, and 20-30 parts of deionized water. The cold-resistant and water-proof damping coating provided by the invention has good damping performance, cold resistance and water-proof property.

Owner:WUHU SHUANGBAO BUILDING MATERIAL

Polyester type polyurethane damping material and preparation method

The invention provides a polyester polyurethane damping material with dimethyl structure with the same carbon number on main chain and a preparation method thereof. The preparation method comprises the following steps: A. allowing polyester glycol dehydrated in vacuum to react with diisocyanate to synthesize a prepolymer; and B. allowing the prepolymer to react with a chain extender or block and graft to synthesize the polyester polyurethane damping material with dimethyl structure with the same carbon number on the main chain; choosing 3,3'-dichloro-4,4'-diaminodiphenylmethane, 3,5- dimethythiotoluene diamine, 1,4-butanediol or trimethylolpropane as the chain extender for room temperature vulcanization. The polyester polyurethane damping material has good thermal stability, acid and alkali resistance, hydrolytic resistance, weatherability and high damping property. Meanwhile, the polyester main chain contains ester group with strong polarity, and forms a plurality of hydrogen bonds with urethane group to improve intermolecular acting force, thus the polyester polyurethane has good mechanical property. High-performance damping materials for use under different temperature can be obtained by adjusting position of damping peak by changing molecular weight of the polyester glycol and by adding liquid packing. The preparation method is simple with low energy consumption.

Owner:HEBEI ENERGY RES INST

Aqueous damping paint and preparation method thereof

InactiveCN102337061AEasy to prepareGood compatibilityPolyurea/polyurethane coatingsGlass transitionInterpenetrating polymer network

The invention provides an aqueous damping paint, comprising the following ingredients: 25-35 wt% of acrylic acid emulsion, 8-10 wt% of PUD, 4-6 wt% of protective colloid, 40-50 wt% of filling material, and 5-15 wt% of deionized water. The invention also provides a method for preparing the aqueous damping paint. The aqueous damping paint is a multi-ingredient damping paint, wherein, the base material comprises two polymers, latex interpenetrating polymer network (LIPN) is used for preparing, so that some defects of polymer blend are overcome, compatibility of ingredients is improved, and the damping temperature range is widen. According to the invention, water is used as the diluent, so that poisonous organic solvent causing environmental pollution is avoided, and the preparation method is simple. The glass transition temperature transition region is larger than the actual used temperature range of the aqueous damping paint, and the paint has high elastic modulus, large elongation at break, and large tensile strength in the used temperature range, and can form a thick coating.

Owner:上海天地涂料有限公司

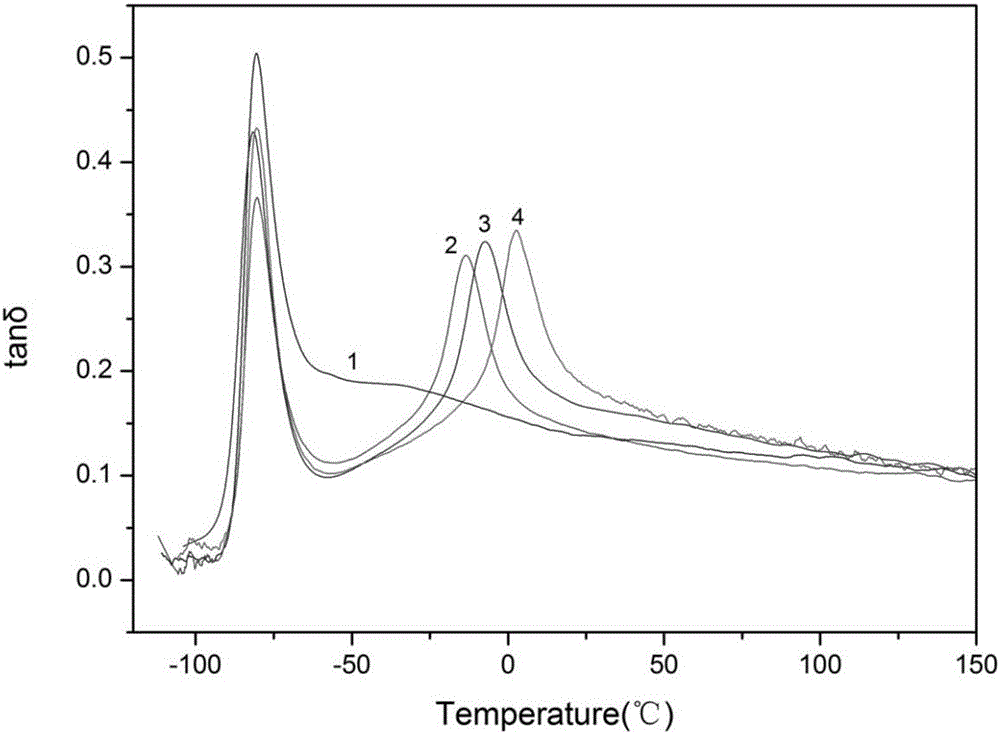

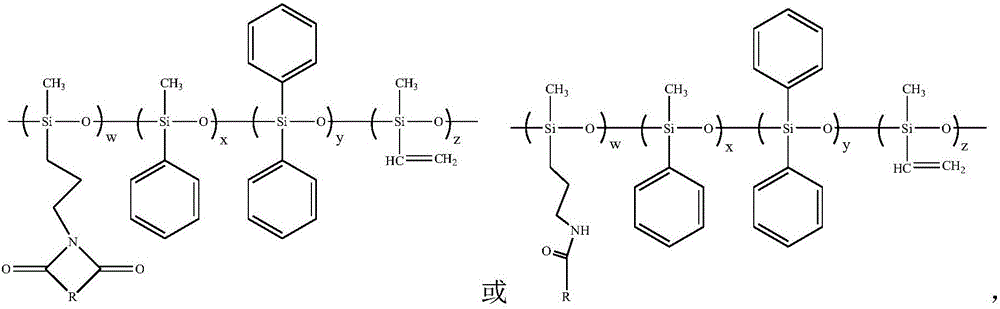

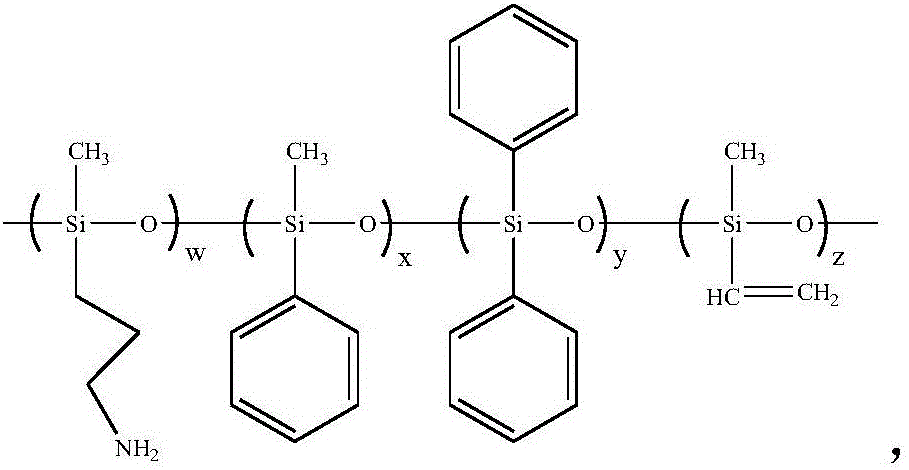

Organic silicon damping additive and preparation method thereof

The invention discloses an organic silicon damping additive. The molecular structure formula of the organic silicon damping additive is as shown in the description, wherein R is an aromatic group; w / (w+x+y+z)*100%=1%-40%;z / (w+x+y+z)*100%=0.1%-5%; and (x+y) / (w+x+y+z)*100%=55%-98.9%. According to the organic silicon damping additive disclosed by the invention, the volume of a polysiloxane side group of an aromatic imide side group contained in a side chain is larger than that of phenyl, internal friction resistance between chain segments is large, and the damping effect can be improved. In addition, the molecular weight of the organic silicon damping additive and the content of the imide side group are adjusted, so that the damping temperature range is widened. In addition, the organic silicon damping additive disclosed by the invention also contains vinyl chain links and can realize covulcanization with methyl phenyl silicone rubber, so that not only is the migration problem of a low molecular weight damping additive solved, but also the influence on the mechanics of silicone rubber is reduced.

Owner:SHANDONG UNIV

Environmental-friendly heat-isolating high-performance aqueous damping coating and preparation method thereof

The invention belongs to the technical field of coatings and discloses an environmental-friendly heat-isolating high-performance aqueous damping coating and a preparation method thereof. The coating is prepared from the following components in parts by weight: 30-45 parts of an aqueous emulsion, 5-20 parts of a damping pigment and filler, 10-20 parts of rigid polyurethane foam, 15-25 parts of inorganic filler, 5-10 parts of a flame retardant, 1-5 parts of an antifreezing agent, 0.5-1.0 part of a base material wetting agent, 1.0-5.0 parts of an aqueous wetting dispersing agent, 0.5-2.0 part of an aqueous defoamer, 0.5-3.0 parts of a coupling agent, 0.5-2.0 parts of a coalescing agent, 0.5-1.5 parts of a thickener and 5-10 parts of water. The aqueous emulsion is a self-crosslinked acrylate emulsion. The coating provided by the invention has the advantages of being high in damping value, wide in damping temperature domain, good in heat-isolating property and the like and is good in covering force to a base material and strong in decorativeness. The method provided by the invention is simple and easy to operate, and green and environmental-friendly.

Owner:SOUTH CHINA UNIV OF TECH

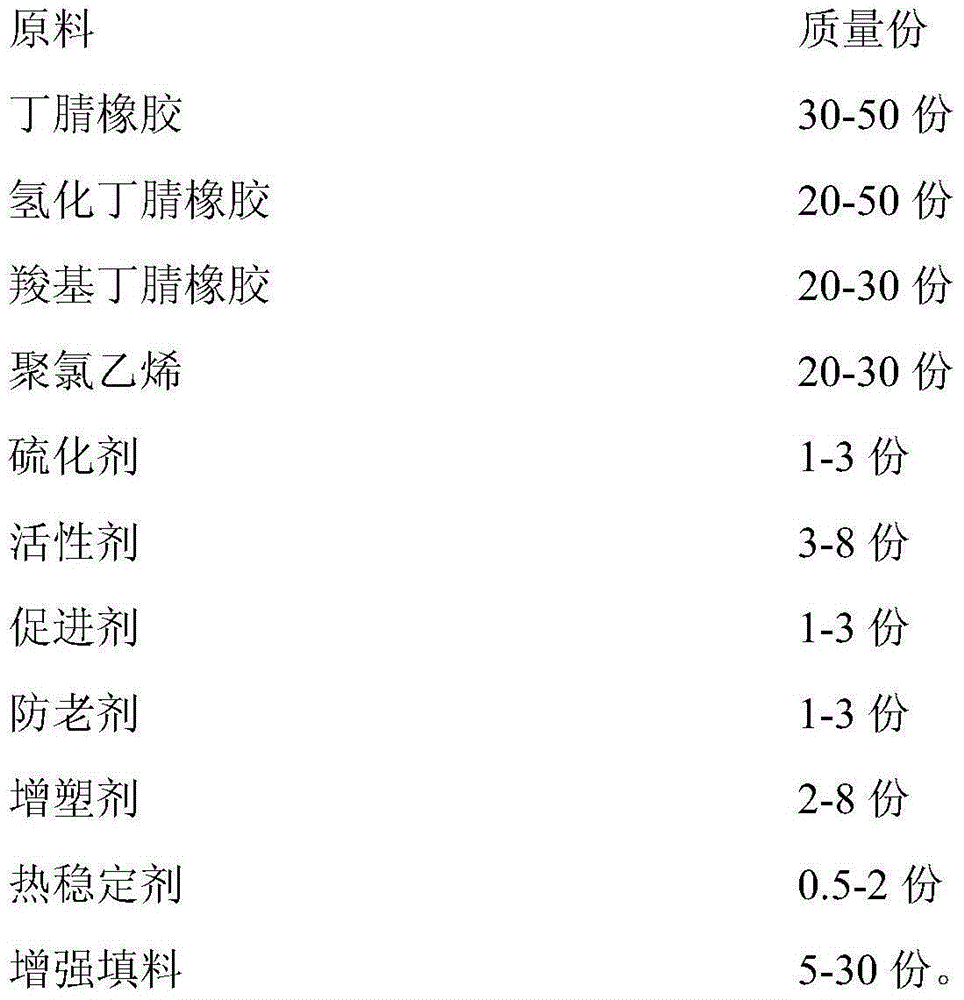

Shock absorbing rubber material used for transformer

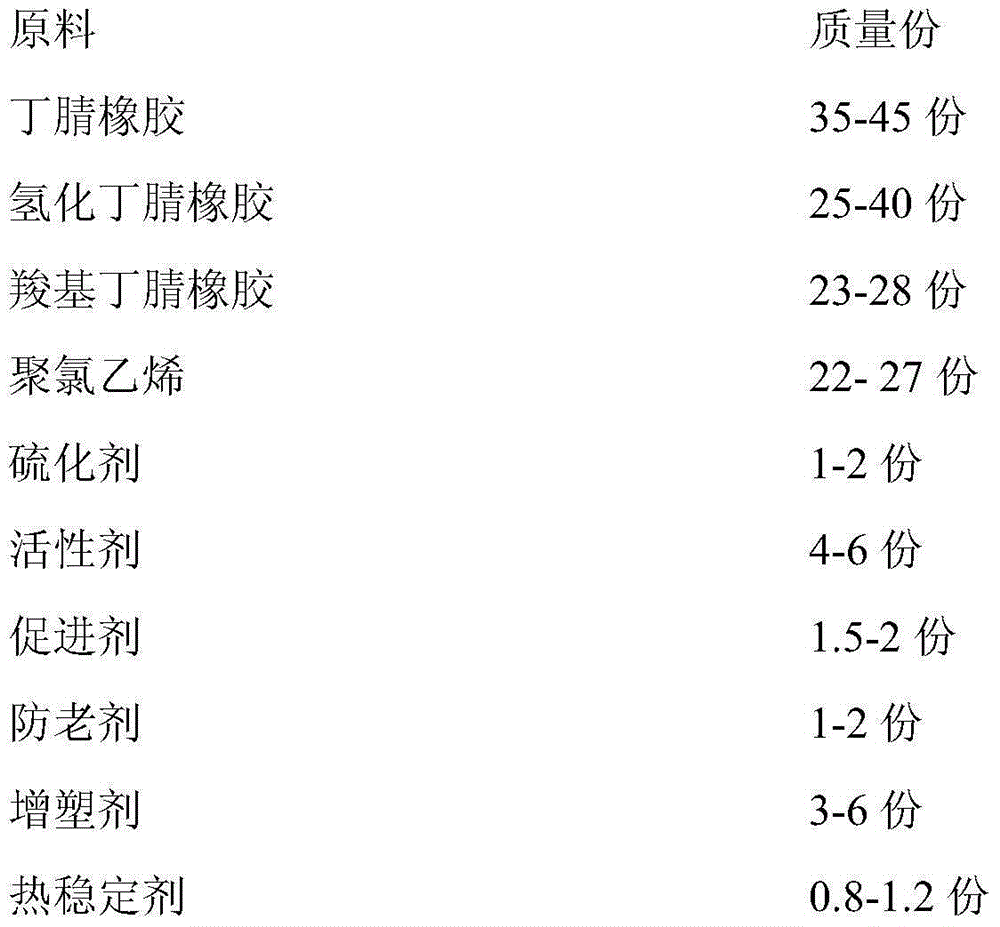

The invention provides a shock absorbing rubber material used for a transformer. The rubber material is prepared from, by mass, 30-50 parts of butadiene-acrylonitrile rubber, 20-50 parts of hydrogenated butadiene-acrylonitrile rubber, 20-30 parts of carboxylic acrylonitrile butadiene rubber, 20-30 parts of polyvinyl chloride, 1-3 parts of vulcanizers, 3-8 parts of active agents, 1-3 parts of accelerators, 1-3 parts of anti-aging agents, 2-8 parts of plasticizers, 0.5-2 parts of heat stabilizers and 5-30 parts of reinforcing filler. The rubber material is resistant to oil and high temperature, and has a wide damping temperature range and excellent mechanical performance.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +4

Composite damping coating

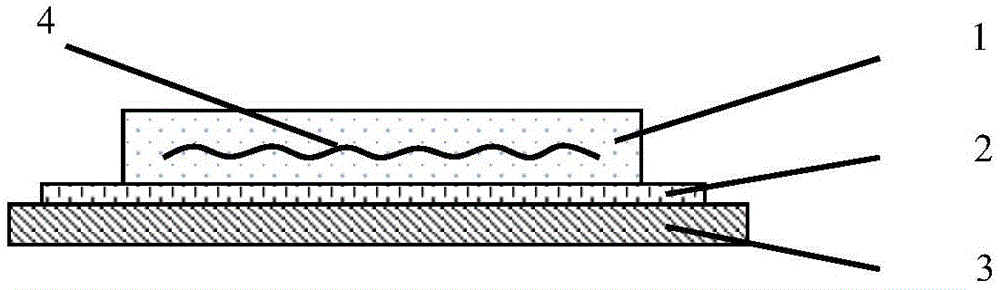

ActiveCN104129132AWide damping temperature rangeImprove damping performanceSynthetic resin layered productsMetal layered productsEpoxyOrganic solvent

The invention discloses a composite damping coating comprising a damping layer and a constraining layer. The damping layer is a solvent-free modified polyurethane damping coating, and the constraining layer is a solvent-free modified epoxy resin constraining coating. According to the composite coating provided by the invention, the constraining layer is used for reducing sound, and the damping layer is used for insulating sound, such that frequency from a sound source can be reduced, and muting and noise reduction purposes can be achieved. The coating provided by the invention has the characteristics of wide damping temperature range, high loss factor after being combined with a metal plate material, good damping effect, and the like. Also, the coating does not contain an organic solvent. The coating has the advantages of normal-temperature curing and convenient and fast construction. The coating is non-toxic and flame-retardant.

Owner:GUANGZHOU POWER SUPPLY BUREAU GUANGDONG POWER GRID CO LTD

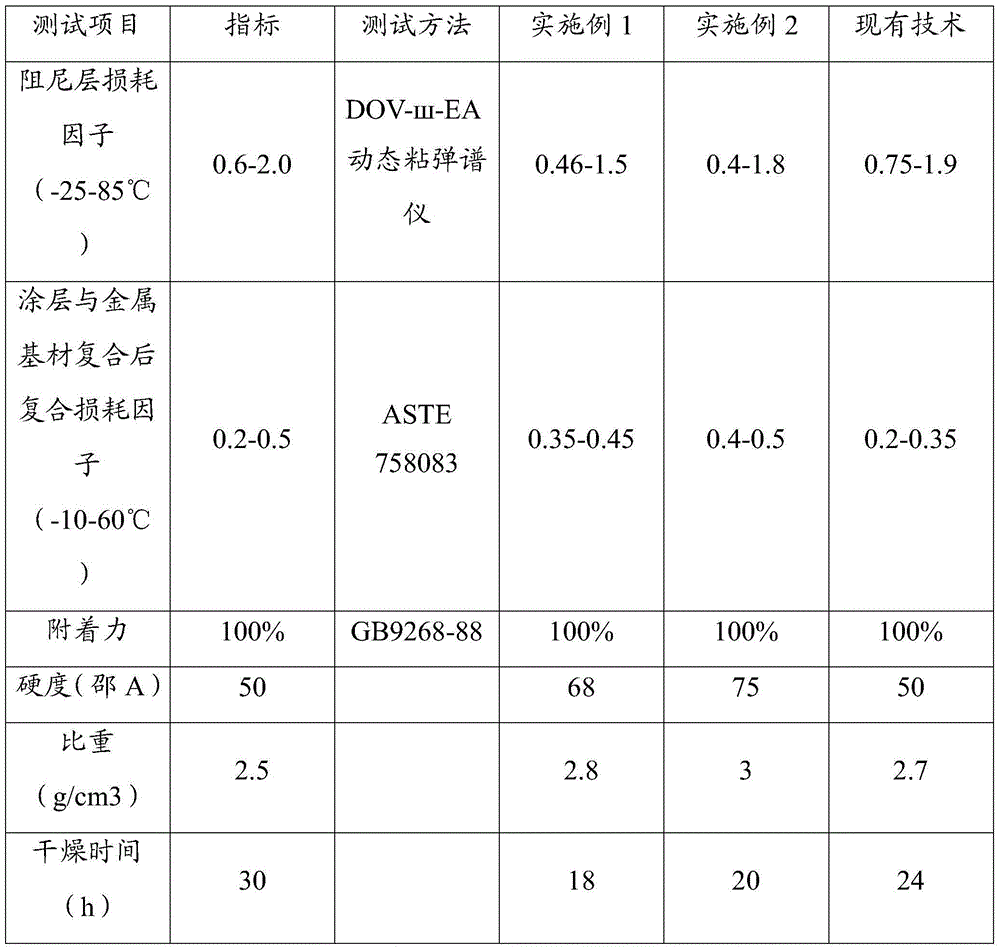

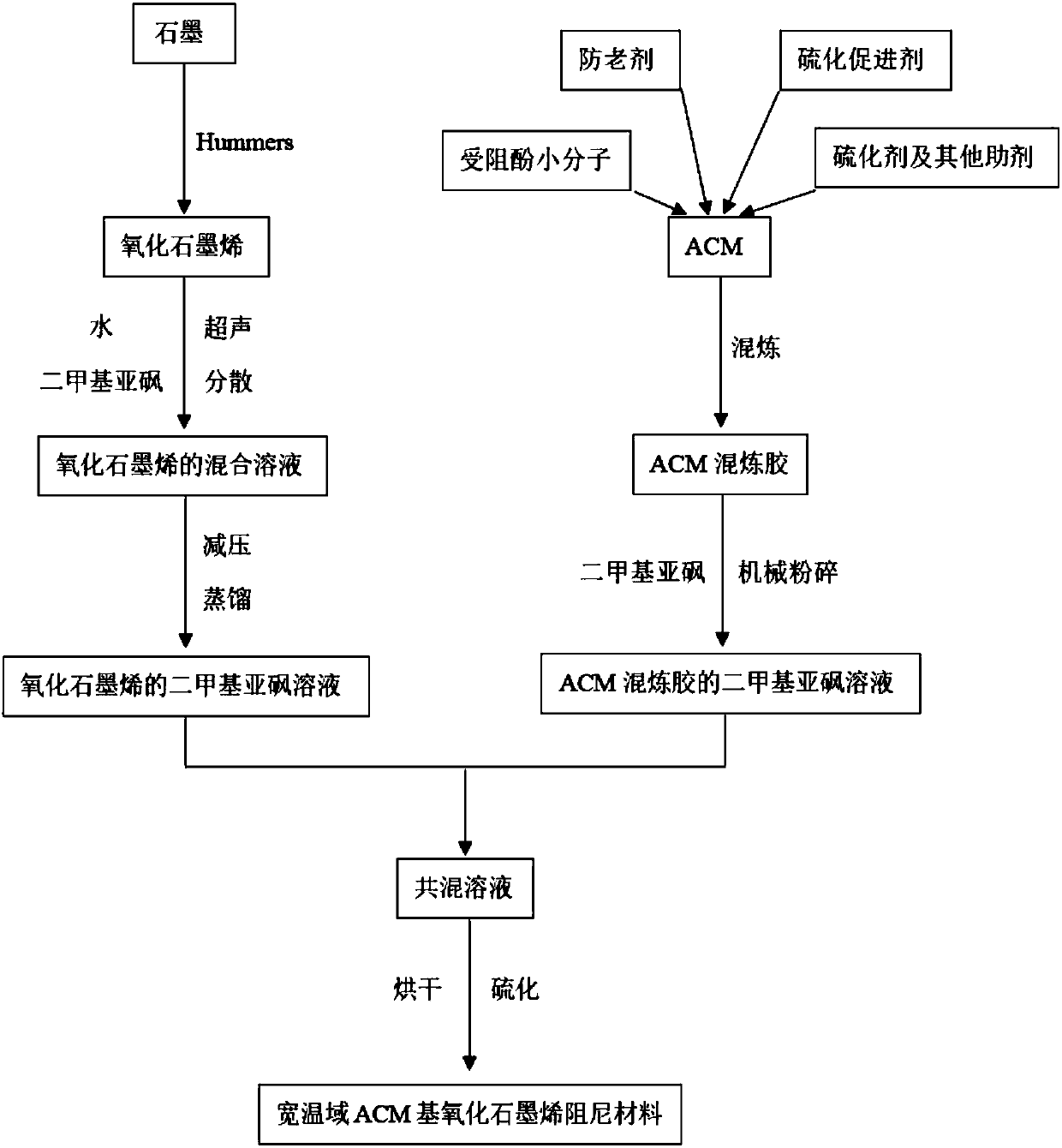

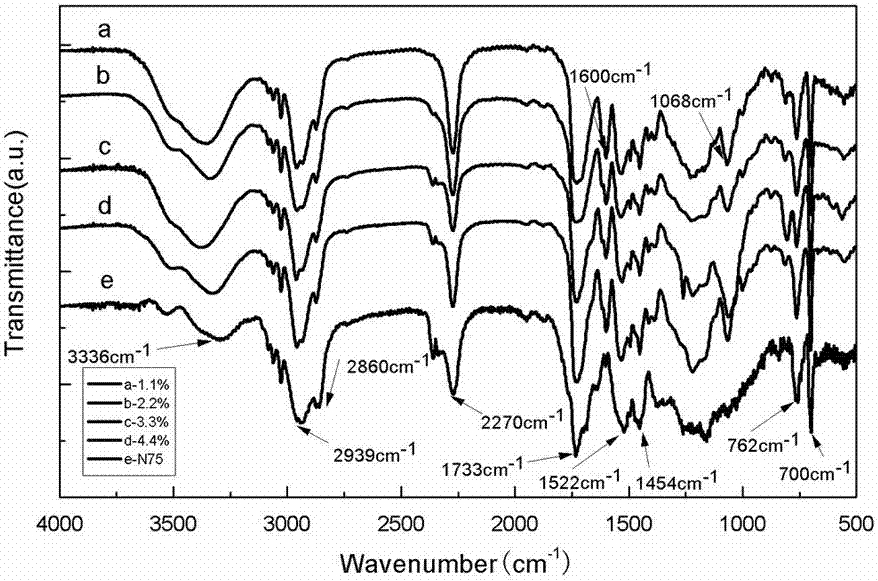

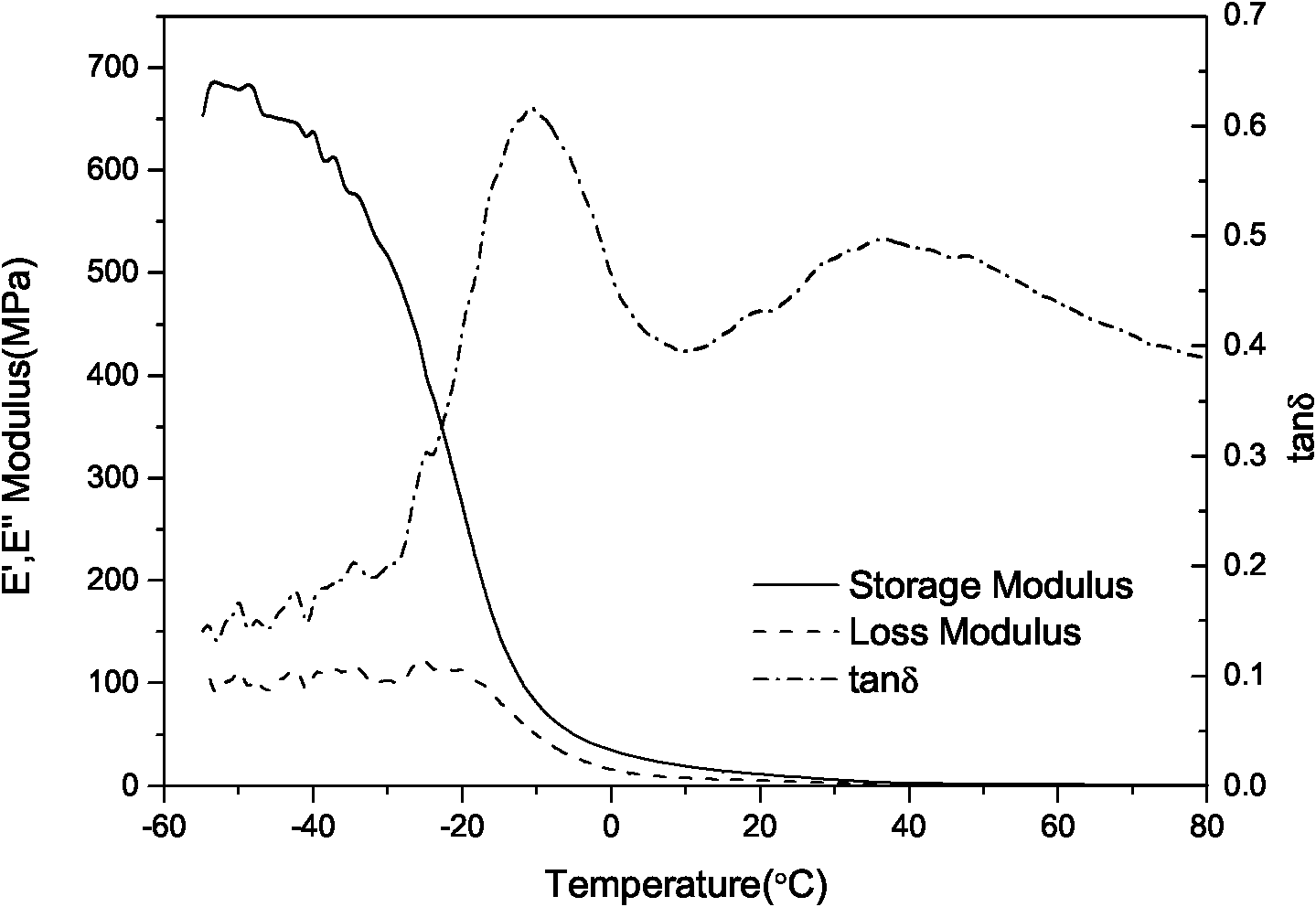

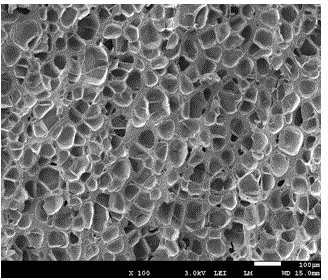

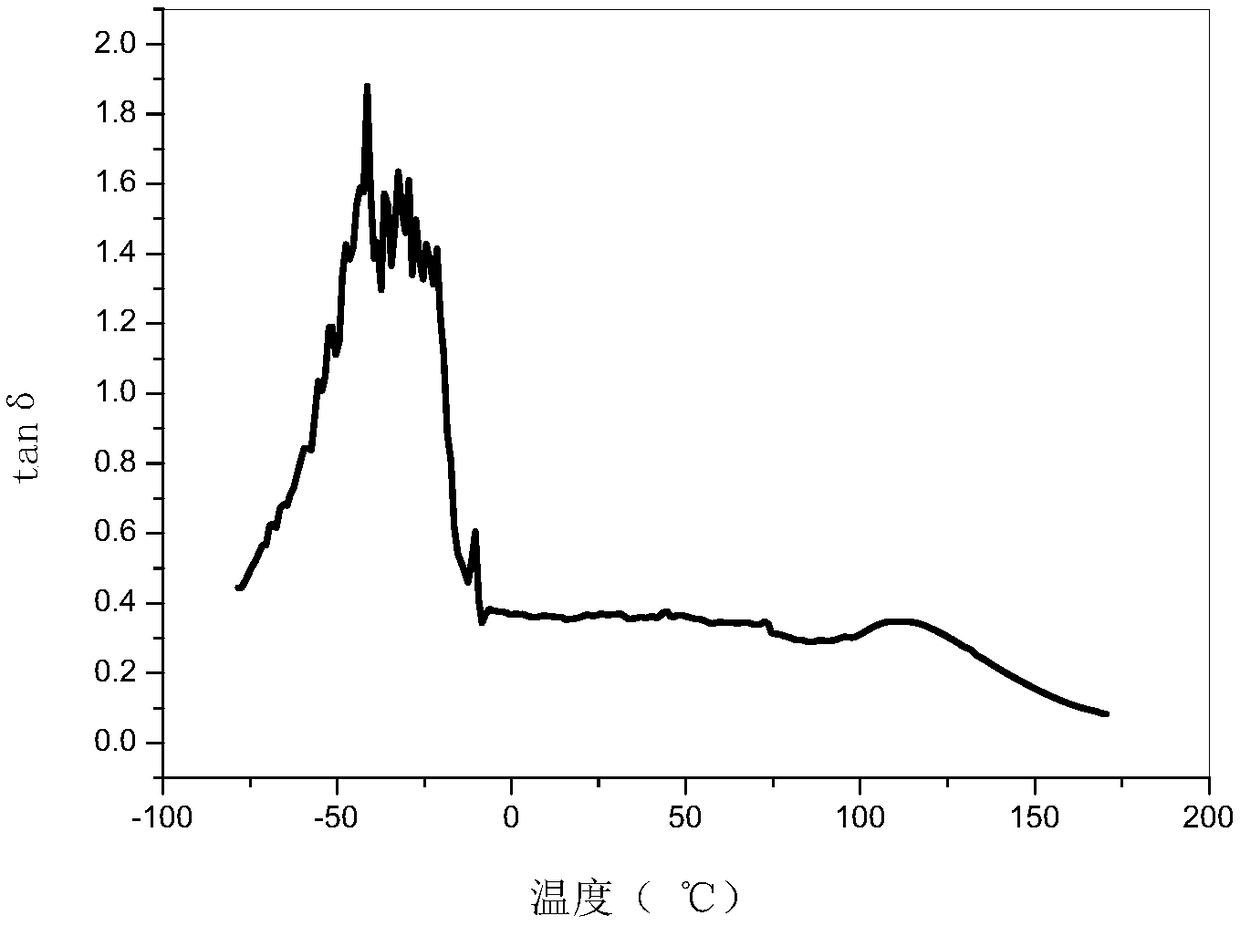

Wide temperature range acrylate rubber based graphene oxide damping material and preparation method thereof

The invention discloses a wide temperature range acrylate rubber (ACM) based graphene oxide damping material and a preparation method thereof. The method comprises the steps of: adjusting the dosage of oxidant to prepare of a graphene oxide dispersion liquid with certain size and a lot of polar groups on the surface; using mechanical blending method to blend ACM with hindered phenol small molecules, a curing agent and other compounding agents, then performing mixing with graphene oxide by solvent blending method, and conducting drying and vulcanizing so as to obtain the wide temperature rangeACM based damping rubber containing graphene oxide. According to the invention, graphene oxide with a lot of polar groups on the surface, hindered phenol small molecules and ACM are utilized to form astrong hydrogen bond, at the same time, the barrier properties of graphene oxide are utilized to greatly improve the effective damping temperature range of the ACM based graphene oxide damping material (with tan delta being greater than or equal to 0.3) and the damping properties after aging.

Owner:NANJING UNIV OF SCI & TECH

Preparation method of curing agent for high temperature damping polyurethane

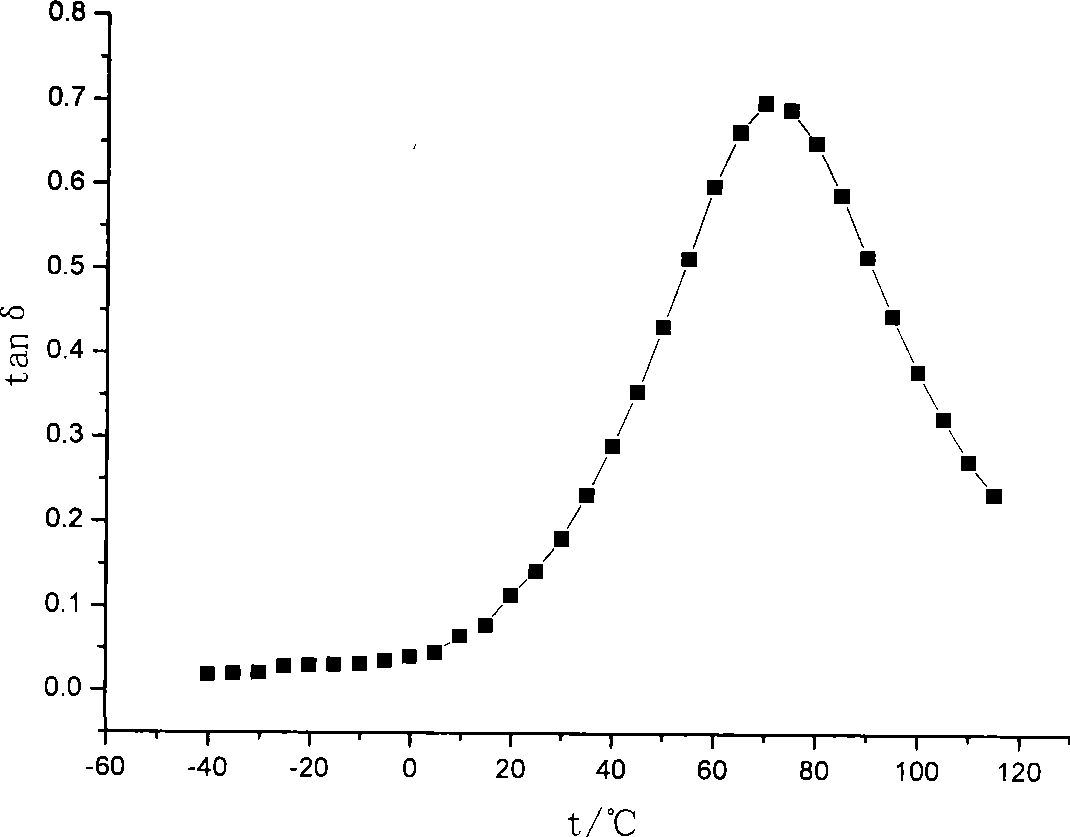

ActiveCN107383304AImprove high temperature stabilityImproved high temperature damping performanceDamping factorSide chain

The invention discloses a preparation method of a curing agent for high temperature damping polyurethane. The dinitrogen bisfluorene in the structure comprises a special large spatial configuration; the spatial configuration, as a side chain of a polymer, can strengthen the friction steric hindrance between molecular chains, meanwhile, the fused heterocycle structure containing pyridine and the like is utilized to improve the proportion of a rigid segment of polyurethane, so that the damping performance of a polyurethane material in the high temperature environment and the stability of the damping performance are improved. The prepared curing agent is applied to the curing of a polyurethane resin, compared with the traditional curing agent, the curing agent increases the glass transition temperature of the polyurethane material and the damping factor at the medium-high temperature, expands the damping temperature range of the material, and improves the damping performance of the material in the medium-high temperature environment.

Owner:FUZHOU UNIV

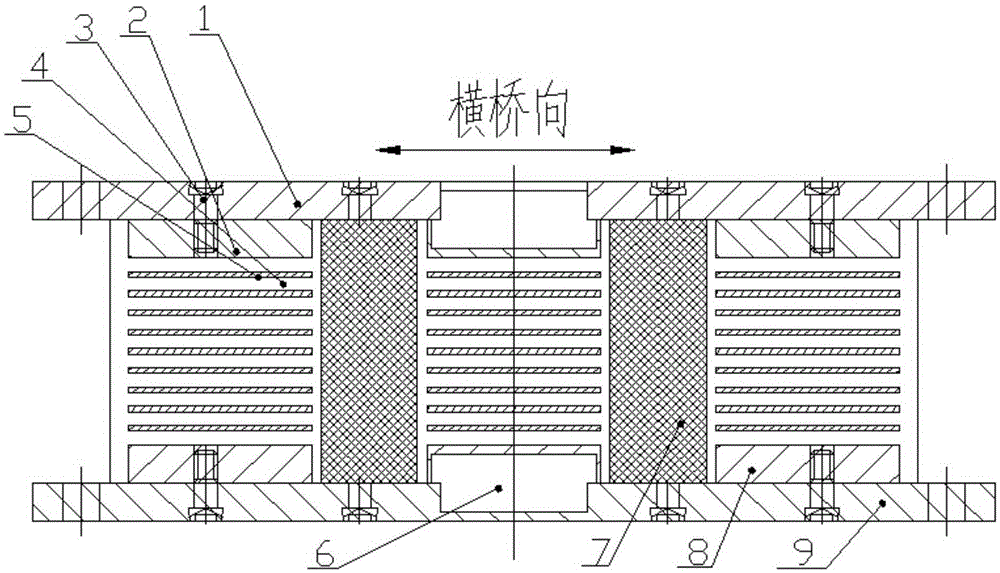

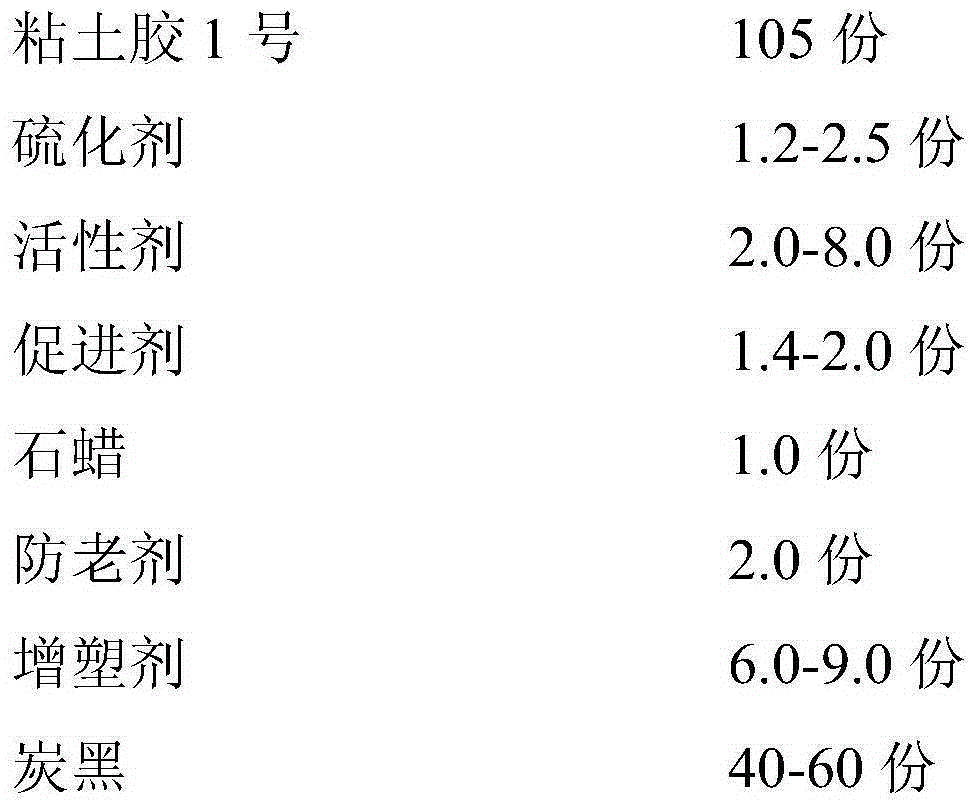

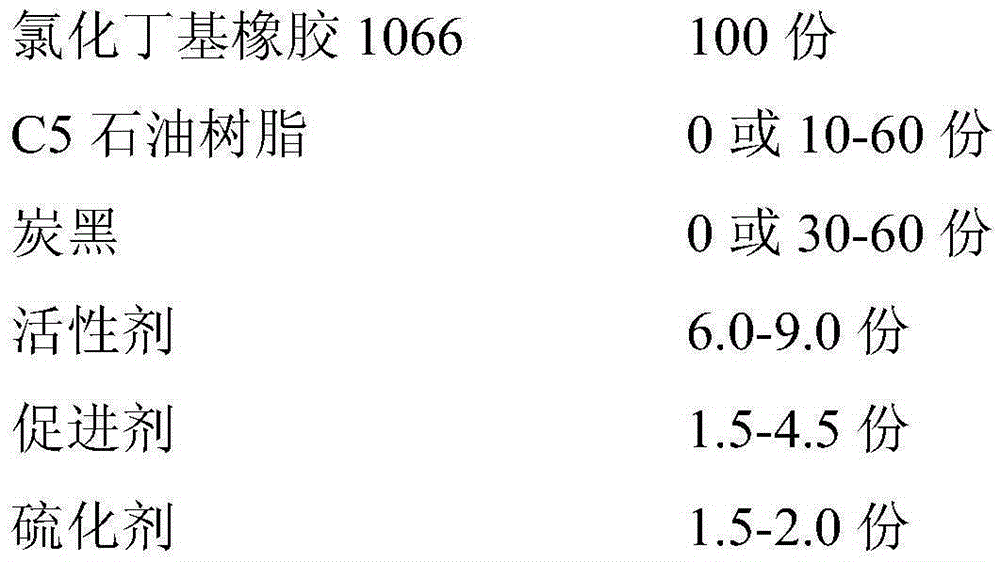

High-performance rubber composite for bridge damping support and preparation method thereof

ActiveCN105295121AImprove damping performanceWide damping temperature rangeBridge structural detailsRubber technologyPressure resistance

The invention relates to a high-performance rubber composite for a bridge damping support and a preparation method thereof and belongs to the technical field of rubber. Two novel rubber materials are used for the damping support. One material is an organic clay rubber composite having high tensile strength, elongation at break and compression modulus and is suitable for laminated rubber of the support. The other material is a novel rubber composite, has high damping performance, can greatly improve damping ratio of the support and effectively broaden damping temperature range of the rubber support. A crosslinked core material has a certain elasticity and pressure resistance. The damping support prepared by adopting the material has the advantages of being excellent in damping performance and low in equivalent horizontal stiffness and deforming easily under low seismic waves, the actual application requirements of a bridge are met, and the replacement of a lead core in the support is achieved.

Owner:BEIJING UNIV OF CHEM TECH

Water-based viscoelastic damping soundproof sealant

ActiveCN102424714AViscoelastic PersistenceIncrease dampingOther chemical processesWater basedFire retardant

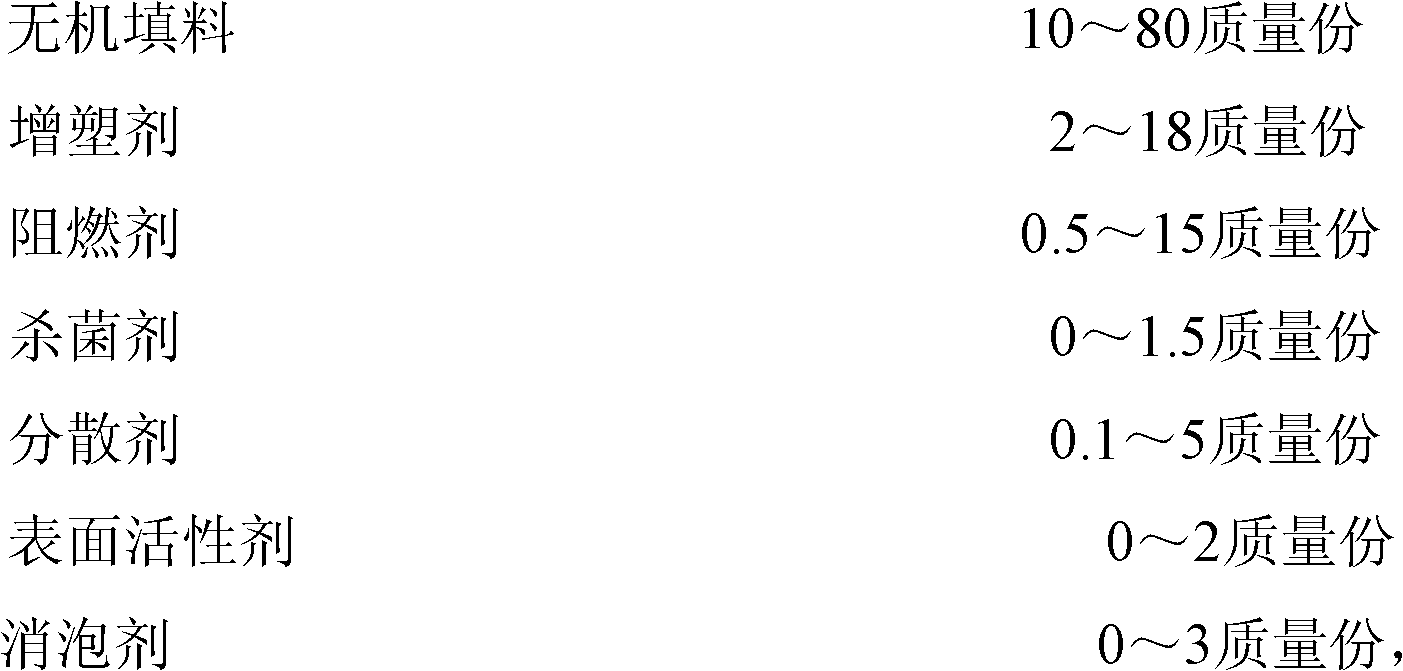

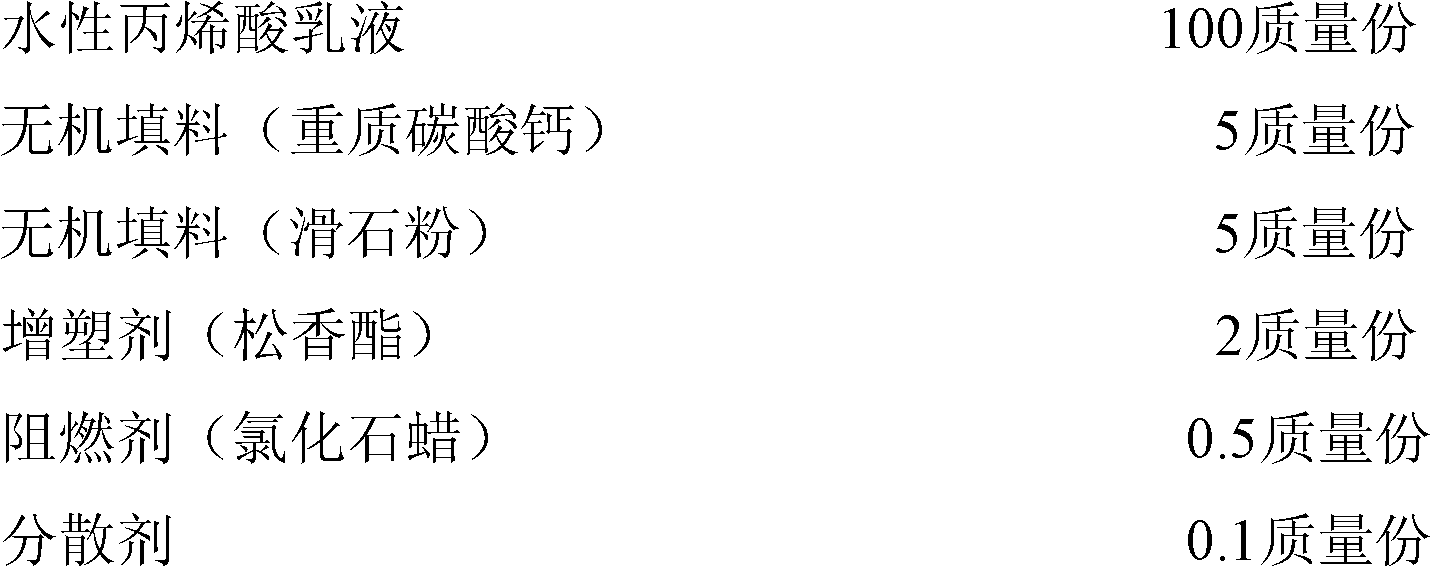

The invention discloses a water-based viscoelastic damping soundproof sealant which comprises the following components: 100 parts by mass of waterborne acrylic acid emulsion, 10-80 parts by mass of fillers, 2-18 parts by mass of plasticizers, 0.5-15 parts by mass of fire retardants, 0-1.5 parts by mass of bactericides, 0.1-5 parts by mass of dispersants, 0-2 parts by mass of surfactants, 0-3 parts by mass of antifoaming agents; the waterborne acrylic acid emulsion is an interpenetrating network polymer emulsion. The water-based viscoelastic damping soundproof sealant of the invention has the advantages of high damping capacity, wide damping temperature range, high bonding property, no solidification, no contraction, long-lasting viscoelasticity, and the like, can form a damping platform with a damping value of above 0.7 and a temperature range of up to above 75 DEG C, reaches a bonding strength of not less than 0.6 Mpa, can absorb sound vibrational energy which is converted into heat energy and is released, can be used for sealing and joint filling, and has excellent soundproof effect.

Owner:SHANGHAI HOOSUN INTELLIGENT TECH CO LTD

Inorganic whisker-modified adhesive sheet for damping and noise reducing

InactiveCN107083223AIncrease dampingRaw materials are easy to getNon-macromolecular adhesive additivesFilm/foil adhesivesWhiskersButyl rubber

The invention relates to an inorganic whisker-modified adhesive sheet for damping and noise reducing. The inorganic whisker-modified adhesive sheet comprises two parts, namely a damping adhesive layer and an isolated reflection layer; according to the damping adhesive layer, butyl rubber is taken as a matrix, an inorganic whisker is added for modification, and tackifying resin and a filler are adopted for improving the combination property. In addition, a refection layer is arranged on the damping adhesive layer; and the reflection layer is capable of carrying out strength supplementation on the adhesive layer and dispersing noise. Only the adhesive sheet needs to be pasted on the surface of a base material during construction, and sulfuration treatment is not needed. The product is simple in preparation, convenient to construct and obvious in damping and noise-reducing effects.

Owner:三友(天津)高分子技术有限公司

Rubber base damping material and preparation method thereof

The invention relates to a rubber base damping material and a preparation method thereof, belonging to the technical field of damping materials. The damping material prepared by a method of rapid blending and hot-press forming comprises the following components: ethylene propylene rubber, butadiene nitrile rubber, petroleum resin, phenolic resin, a peroxide vulcanizing agent and a plasticizer; and the rubber base damping material can effectively widen the damping temperature range while keeping the original damping peak value not to obviously drop.

Owner:SHANGHAI JIAO TONG UNIV

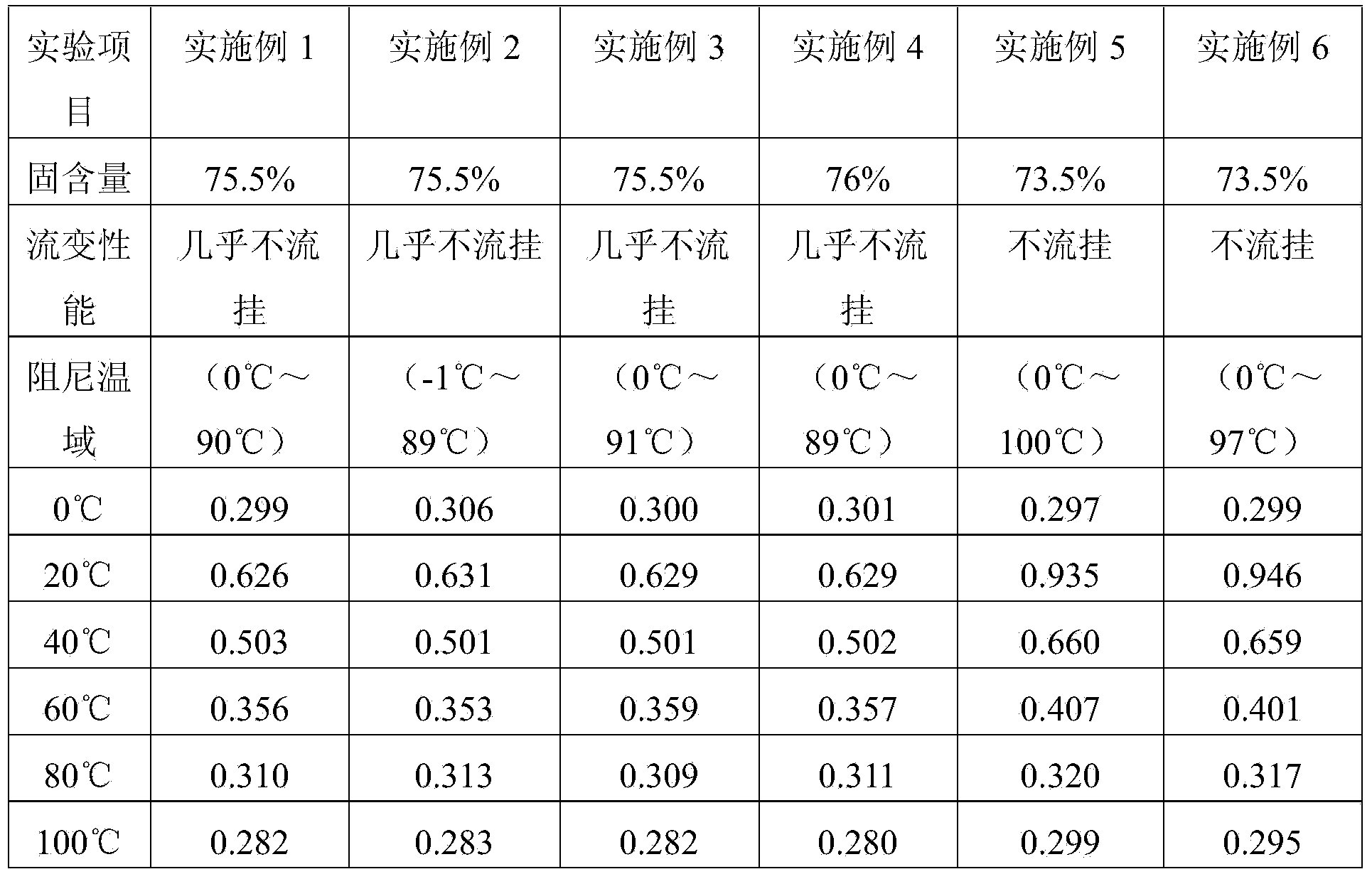

High-solid content high-build water-based damping coating and preparation method thereof

The invention relates to a high-solid content high-build water-based damping coating and a preparation method thereof. The water-based damping coating comprises the following components in parts by weight: 20-40 parts of emulsions, 1-5 parts of curing agents, 50-60 parts of inorganic fillers, 5-10 parts of water, 1-2 parts of film-forming auxiliary agents, 1-6 parts of thickening agents, 0.5-2 parts of water-based dispersing agents, 0.5-3 parts of water-based wetting agents and 0.5-1.5 parts of water-based defoaming agents, wherein the emulsions are high-solid content styrene-acrylic emulsions with lower glass temperature. The high-solid content high-build water-based damping coating is prepared through the following three steps of: preparation of a water-based emulsion, addition of a filler and an auxiliary agent and paint blending. The product disclosed by the invention has the advantages of wider damping temperature domain, better damping property and very good low-temperature damping property especially. The high-solid content high-build water-based damping coating disclosed by the invention can be coated in a scratching way and a spraying way, can realize the thickness of a paint film more than 3 mm through one-pass construction, is obvious in shear thinning, has the advantages of good sag resistance, no curling or cracking in a drying and solidifying process and good mechanical property, can be applied to an automobile and various mechanical equipment and achieves the effects of vibration reduction, sound insulation and noise reduction.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of wide-temperature-range and high-damping rubber and plastic blended foam material

InactiveCN103951921AHalogen Free Flame RetardancyWide damping temperature rangePolymer scienceVulcanization

The invention discloses a preparation method of a wide-temperature-range and high-damping rubber and plastic blended foam material. The preparation method comprises the following steps of carrying out first-stage mixing by using an internal mixer, adding polylactic acid firstly, then, adding ethylene-polyvinyl acetate rubber and white carbon black, and mixing; carrying out second-stage mixing by using a two-roll mixing mill, sequentially adding zinc oxide, stearic acid, a foaming agent and a vulcanizing agent BIPB into a first-stage rubber compound at normal temperature, thinning and batching off to prepare a rubber compound a; standing the rubber compound a for 8-16h, then, molding, vulcanizing and foaming by using a plate vulcanizing machine to prepare a wide-temperature-range and high-damping blended material with uniform foam holes. The preparation method has the beneficial effects of effectively widening the damping temperature range and increasing damping factors; and in addition, the material prepared by using the preparation method disclosed by the invention is uniform in foam holes, smooth in surface, attractive in appearance and excellent in mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH

Polyurethane-base piezoelectric conductive intelligent composite damping material and preparation method thereof

InactiveCN103289363AWide damping temperature rangeSimple preparation processElectricityMechanical energy

The invention provides a polyurethane-base piezoelectric conductive intelligent composite damping material and a preparation method thereof. The polyurethane-base piezoelectric conductive intelligent composite damping material contains a polyurethane base body, a piezoelectric ceramic, a conducting particle and a curing agent, wherein the content of the piezoelectric particle accounts for 60% of the weight of the polyurethane base body, and the content of the conducting particle accounts for 2%-5% of the weight of the polyurethane base body. The composite damping material provided by the invention can be used for controlling the modulus and damping property of a composite material by controlling the proportion of the conducting particle and the piezoelectric particle in a polymer. The principle of the composite damping material is as follows: the piezoelectric damping composite material regulates the mechanical energy to transform the mechanical energy into electric energy by introducing the piezoelectric particle and the conducting particle to the polymer and regulating the proportion of the conducting particle and the piezoelectric particle, then the electric energy is transformed into heat energy in a certain conductive network to be consumed, and the viscoelasticity of the material is enhanced and the capacity of transforming mechanical vibration energy into the heat energy is enhanced through the addition of the piezoelectric particle and the conducting particle.

Owner:HARBIN ENG UNIV

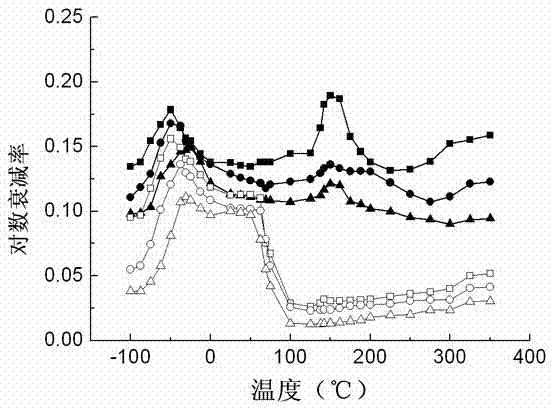

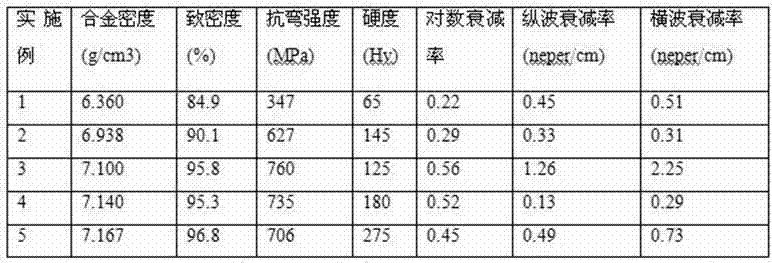

High-damping MnCu alloy and powdery metallurgy preparation technology thereof

The invention discloses a high-damping MnCu alloy and a powdery metallurgy preparation technology thereof. According to the high-damping MnCu alloy, Mn, Cu, Al, Ni and Fe are used as main components, the damping property can be enhanced by adding one or more of strongly magnetic particles Co3B, Co2B, Fe2B, FeB and MnB, and the sintering performance of the high-damping MnCu alloy can be effectively improved by adding one or more of Bi, Si, Sn and B as a sintering auxiliary. Compared with the traditionally cast MnCu-based damping alloy, the high-damping MnCu alloy has the characteristics of being higher in damping property, wider in damping temperature range, more flexible in formability and the like, and further the energy consumption can also be decreased. The formability of the prepared high-damping alloy is more flexible, so that the processing load of the subsequence procedures of rolling, grinding, cutting and the like can be reduced, and the cost reduction and mass production can be facilitated.

Owner:TIANJIN YINLONG HIGH TECH NEW MATERIAL RES INST

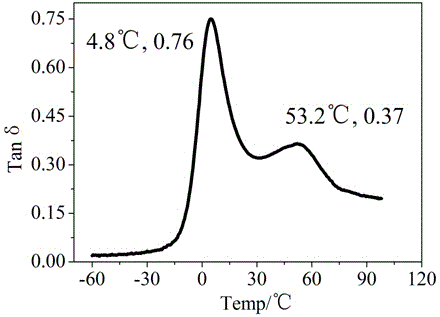

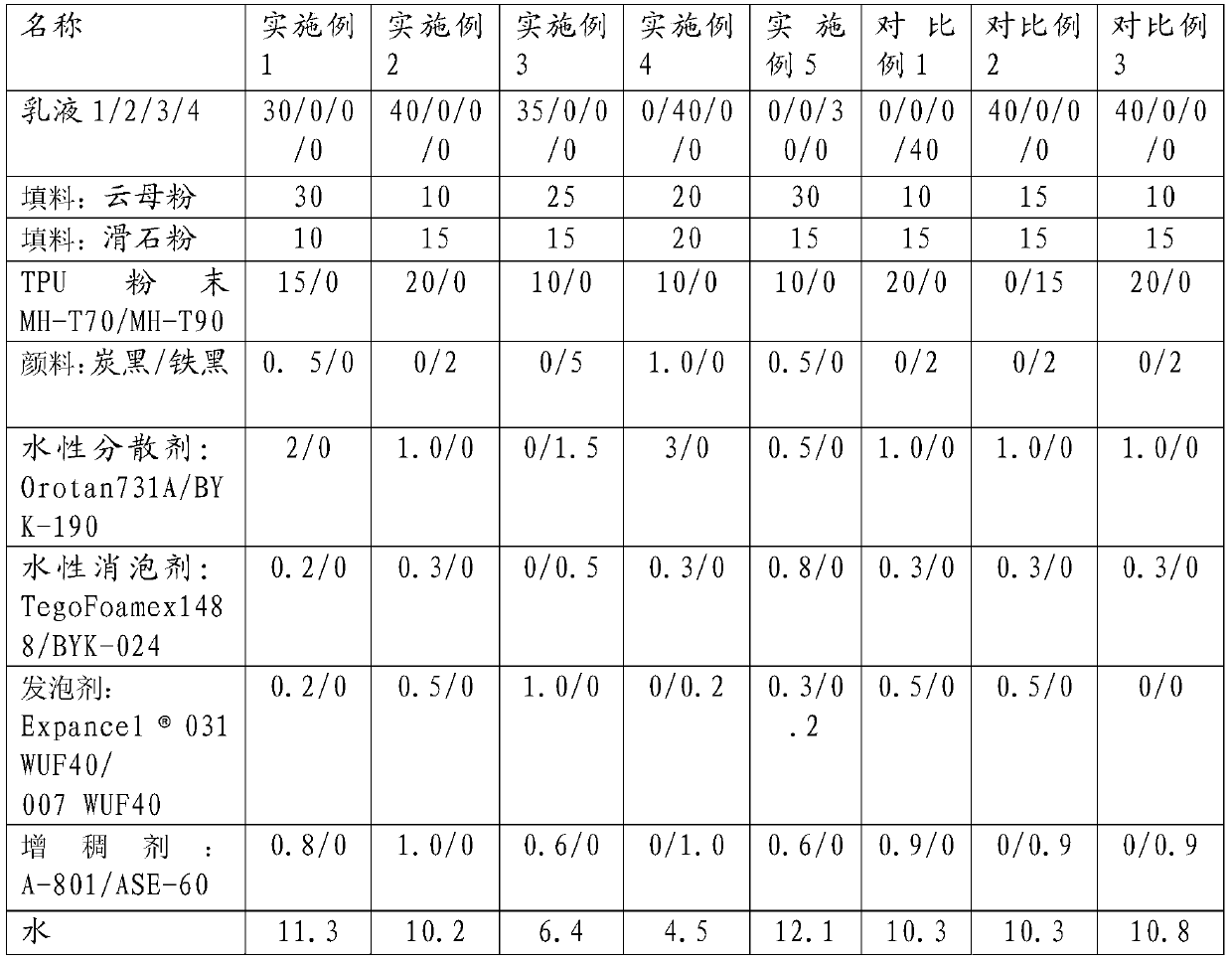

Water-based damping paint and application thereof in automobile field

ActiveCN109749552AExcellent shock resistance and noise reduction effectIncrease resistancePretreated surfacesPolyurea/polyurethane coatingsWater basedEmulsion

The invention provides water-based damping paint and an application thereof in the automobile field. The water-based damping paint is mainly prepared by using the following raw materials according toa mass percentage of a total mass of the raw materials: 30-40% of water-based acrylic emulsion, 10-20% of TPU powder, 20-50% of filler, 0.5-3.0% of a water-based dispersant, 0.2-1.0% of a water-baseddefoamer, 0.2-1.0% of a foaming agent, and 0.2-1.0% of a thickener, wherein a glass-transition temperature of the water-based acrylic emulsion is -20 DEG C to 30 DEG C, preferably -10 DEG C to 10 DEGC; and a melting point of the TPU powder is 70-110 DEG C, preferably 80-90 DEG C. The provided water-based damping paint is capable of realizing a wider damping temperature domain and better chemicalresistance of the damping paint while paint film strength is guaranteed.

Owner:WANHUA CHEM GRP CO LTD +1

Damping coating forming multi-layer compound structure

ActiveCN107722814AComposite loss factor peak highWide damping temperature rangeFireproof paintsLiquid surface applicatorsCompound structurePeak value

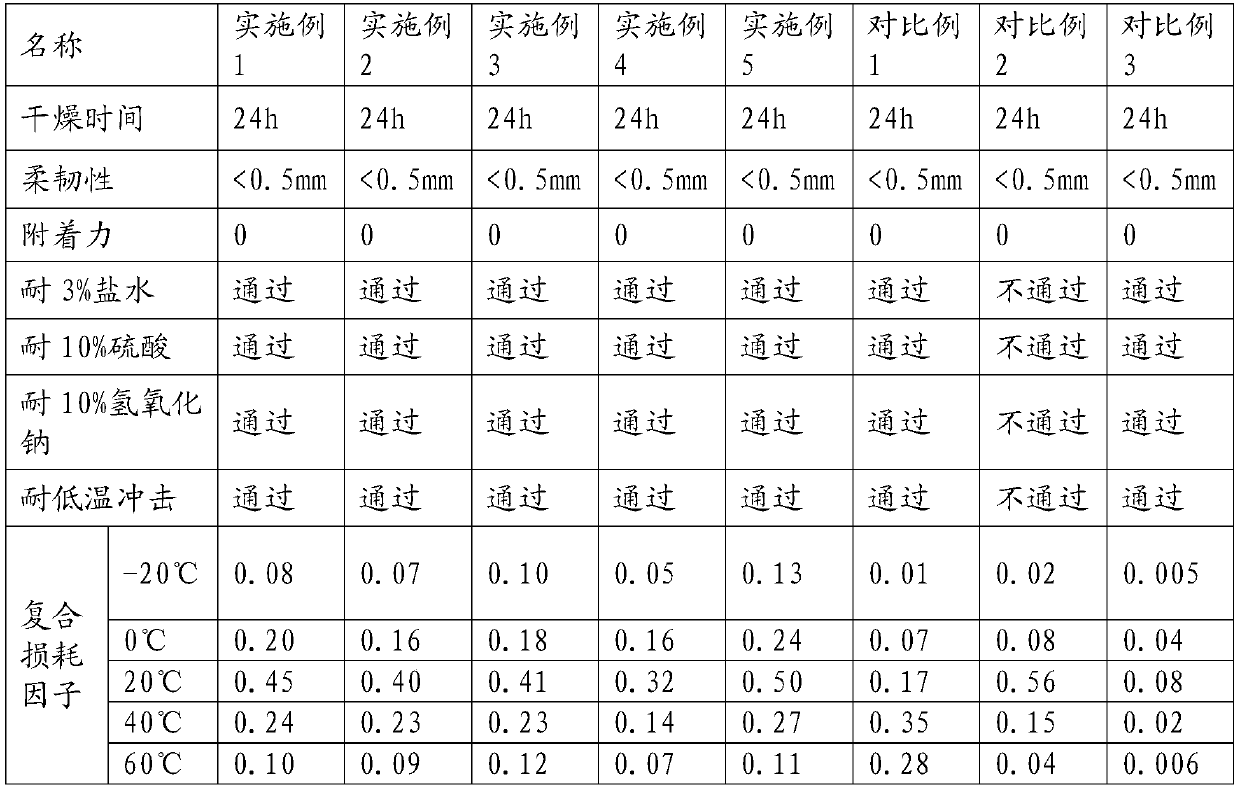

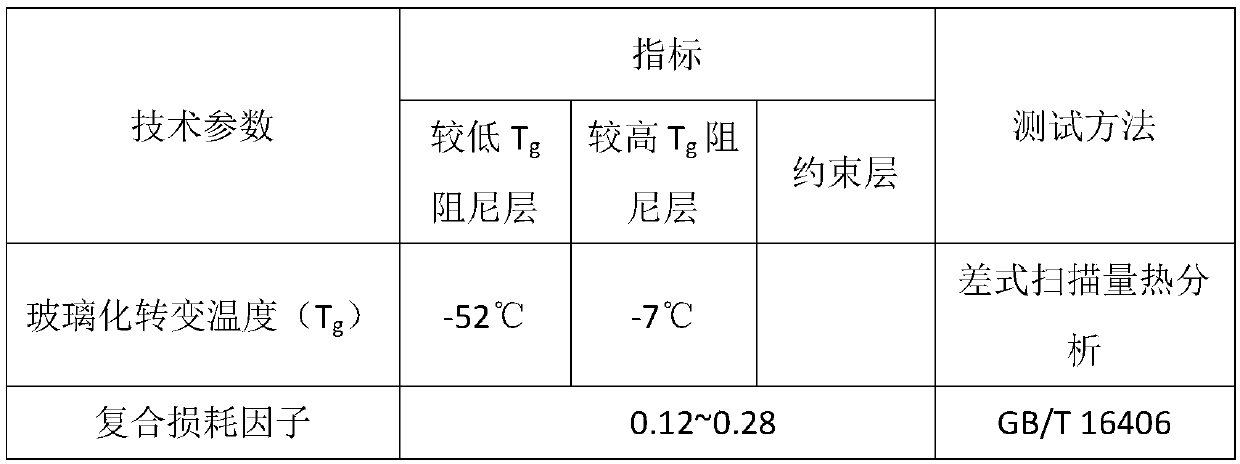

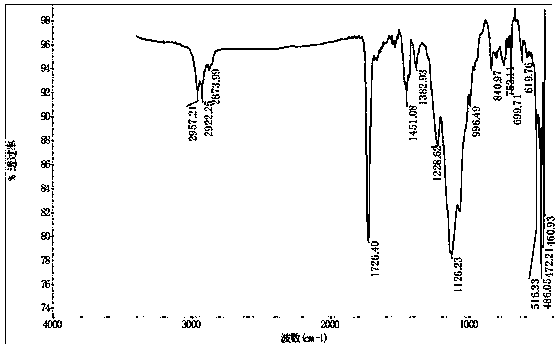

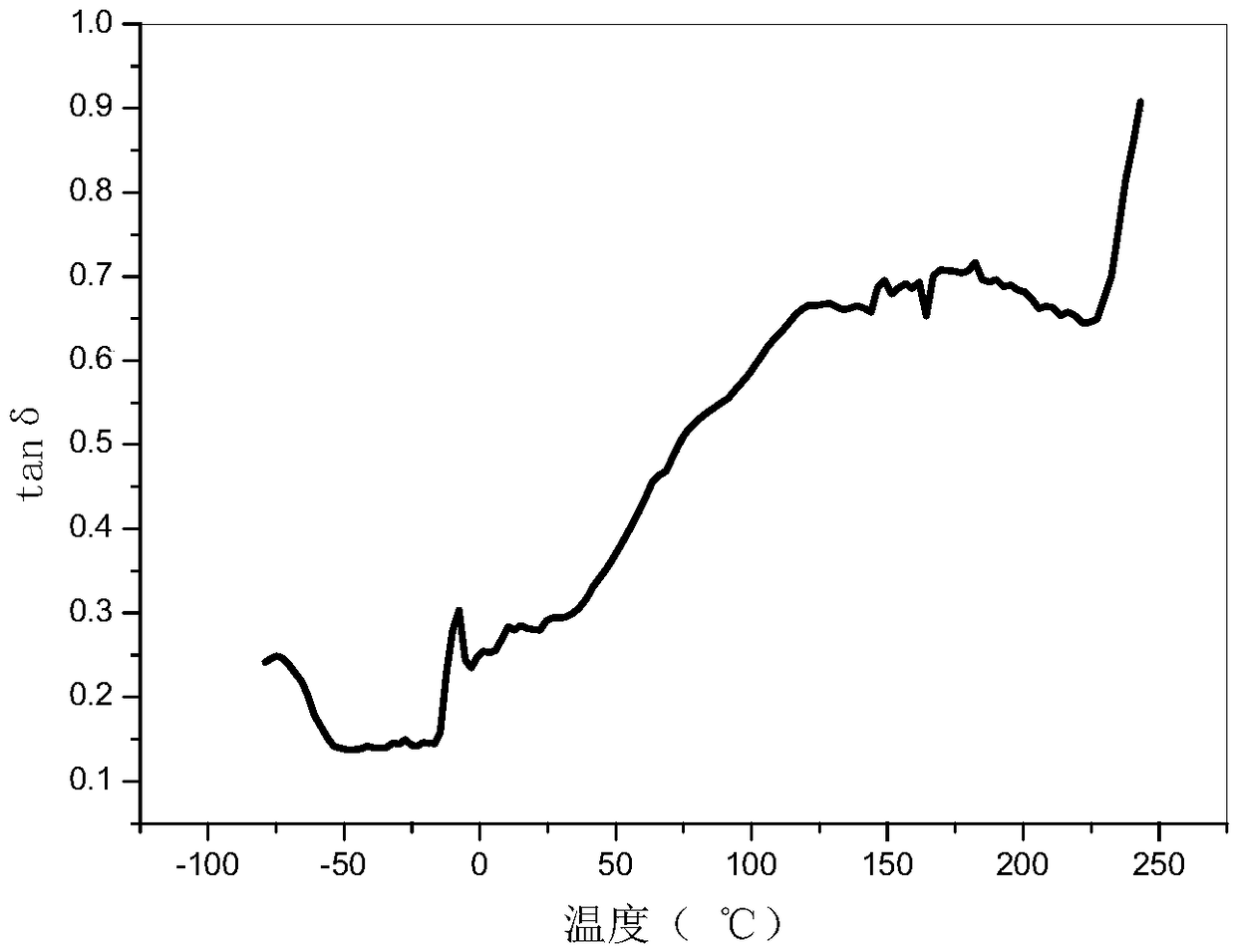

The invention discloses a damping coating forming a multi-layer compound structure. The damping coating is compounded of a polyurethane damping coating layer and an epoxy-resin restrained coating layer which have different glass-transition temperatures (Tg); the damping coating layer with the Tg (which is from -60 DEG C to -40 DEG C) is composed of a polyurethane prepolymer, a chain extender, a fire retardant and lamellar padding; the restrained coating layer with the Tg (which is from -20 DEG C to 0 DEG C) is composed of epoxy resin with low molecular weight, a curing agent, a reactive diluent and a fire retardant. When the thicknesses of the two layers of the damping coating with different Tg are 0.8 mm-1.2 mm respectively, and the ratio of the total thickness of the restrained coating layer and the damping coating layer to the thickness of a substrate is 1.8-2.2, compound loss factors in a range of 0.12-0.28 in the temperature range of -40-80 DEG C can be obtained. The damping coating is high in peak value of the compound loss factors, wide in damping temperature range and mainly used for reducing vibration and noise of ships; meanwhile, the coating has high mechanical performance, processing performance and fire retardant performance.

Owner:QINGDAO ADVANCED MARINE MATERIAL TECH

Polymer-based multilayer foaming composite damping material and preparation method thereof

InactiveCN109664562AIncrease dampingImprove mechanical propertiesSynthetic resin layered productsThermoplastic elastomerUltimate tensile strength

The invention relates to a polymer-based multilayer foaming composite damping material and a preparation method thereof. The damping material is formed by alternately arranging structural polymer layers and foaming polymer layers in a layered manner so as to form a high damping performance material having high strength and good toughness, wherein the structural layer comprises a strong rigidity polymer, and is used for controlling the size of gas bubble, limiting the thickness of the foaming layer and ensuring the good mechanical property of the whole material, the foaming layer comprises a thermoplastic elastomer, and can form uniform and dense gas bubbles so as to form the good damping performance polymer foaming layer, a large number of contact interfaces are formed between the foaminglayer and the structural layer, the layer structure remains good, and the interface improves the damping performance of the material through interlayer shearing. According to the present invention, the number of the micro-layers can be controlled and adjusted from two layers to thousands of layers, and the volume ratio of the structural layer to the foaming layer can be controlled as needed; and through the co-action of the foaming layer and the interlayer interface, the damping performance of the material is improved, and the material has characteristics of good mechanical property, no toxicity, no harm, environment protection and low cost of the required raw material.

Owner:苏州上品嘉新材料科技有限公司

Damping resin emulsion and preparation method thereof

The invention provides damping resin emulsion. The damping resin emulsion is characterized by being prepared from, by weight, 10-50 parts of a functional acrylic monomer, 100-150 parts of an acrylic monomer, 4-20 parts of a cross-linking monomer 1, 1-10 parts of a cross-linking monomer 2, 4-20 parts of an emulsifying agent, 0.3-1 part of an initiator and 200-400 parts of deionized water. The functional acrylic monomer is prepared from hydroxyethyl acrylate, isophorone diisocyanate, an antioxidant 1010, an acetone and butanone mixed solvent and a catalyst according to a weight ratio of (50-60):(110-150):(170-210):(100-200):(0.01-1), wherein the acetone and butanone mixed solvent is a mixed solvent made from acetone and butanone according to a mass ratio of (1-3):10, and the catalyst refersto dibutyltin dilaurate. The damping resin emulsion is great in film forming performance, wide in damping temperature range and excellent in damping effect and can be widely applied to vibration damping and noise reduction of airplanes, ships, buildings, transportation and various machines.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

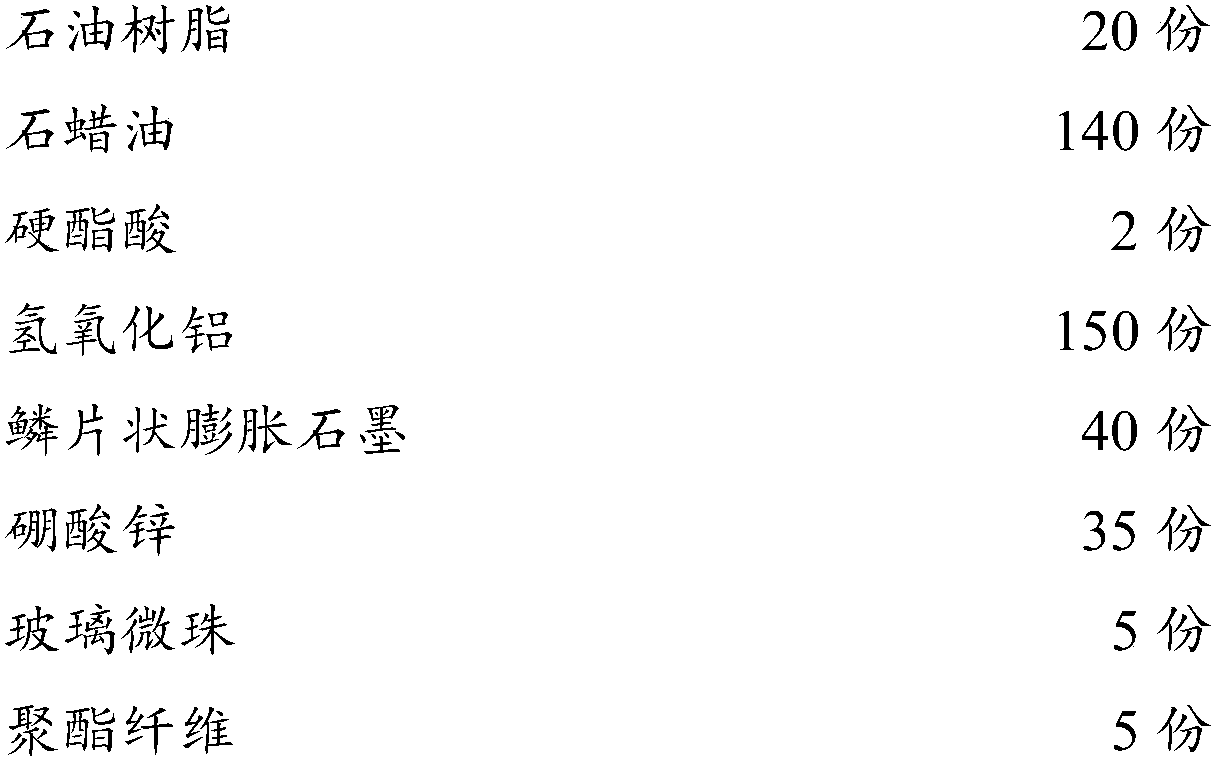

Flame-retardant vibration reduction and sound insulation material and preparation method thereof

InactiveCN108250598AGood damping and sound insulation performanceApplicable temperature range wideLaminationLamination apparatusEnvironmental resistanceZinc borate

The invention discloses a flame-retardant vibration reduction and sound insulation material which comprises the following components in parts by weight: 90-120 parts of butyl rubber, 5-15 parts of ethylene propylene diene monomer, 20-30 parts of petroleum resin, 150-180 parts of aluminum hydroxide, 40-60 parts of expanded graphite and 35-55 parts of zinc borate. The flame-retardant vibration reduction and sound insulation material disclosed by the invention has the advantages of being highly flame retardant, environmental-friendly, excellent in damping and sound insulation performances, wide in applicable temperature range, aging-resistant and the like and can be applied to the field of automobile industry. Moreover, the invention further provides a preparation method of the flame-retardant vibration reduction and sound insulation material.

Owner:GUANGZHOU JUNYIHUI AUTOMOBILE TECH

Room-temperature curable epoxy resin based high damping material and preparation method thereof

The invention provides a room-temperature curable epoxy resin based high damping material and a preparation method thereof. The room-temperature curable epoxy resin based high damping material is mainly composed of a bisphenol A epoxy resin, a polyurethane modified epoxy resin, a silane coupling agent, a mixed amine curing agent and a curing accelerant as major components; liquid materials are divided into components A and B; the resins are heated at a constant temperature in an electric heating air-blast drying box firstly, thoroughly and evenly mixed, and then blended; the components are mixed independently in a mixing tank, stirred evenly by use of a stirrer, barreled in groups, and sealed, and therefore, the preparation of the room-temperature curable epoxy resin based high damping material is completed. The room-temperature curable epoxy resin based high damping material has the characteristics of high damping property, wide damping temperature range, long construction period, natural curing in a room-temperature environment and the like.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Water-based damping coating as well as preparation method and application thereof

InactiveCN111518445ALow priceImprove performanceConjugated diene hydrocarbon coatingsBasalt fiberFire retardant

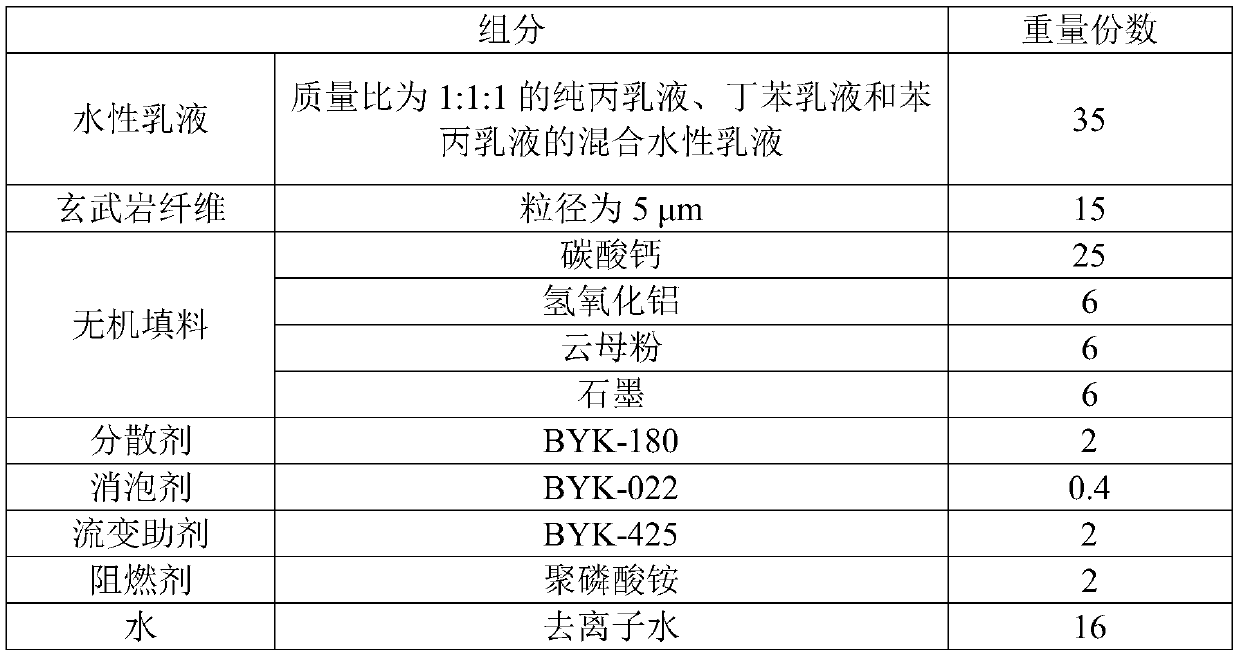

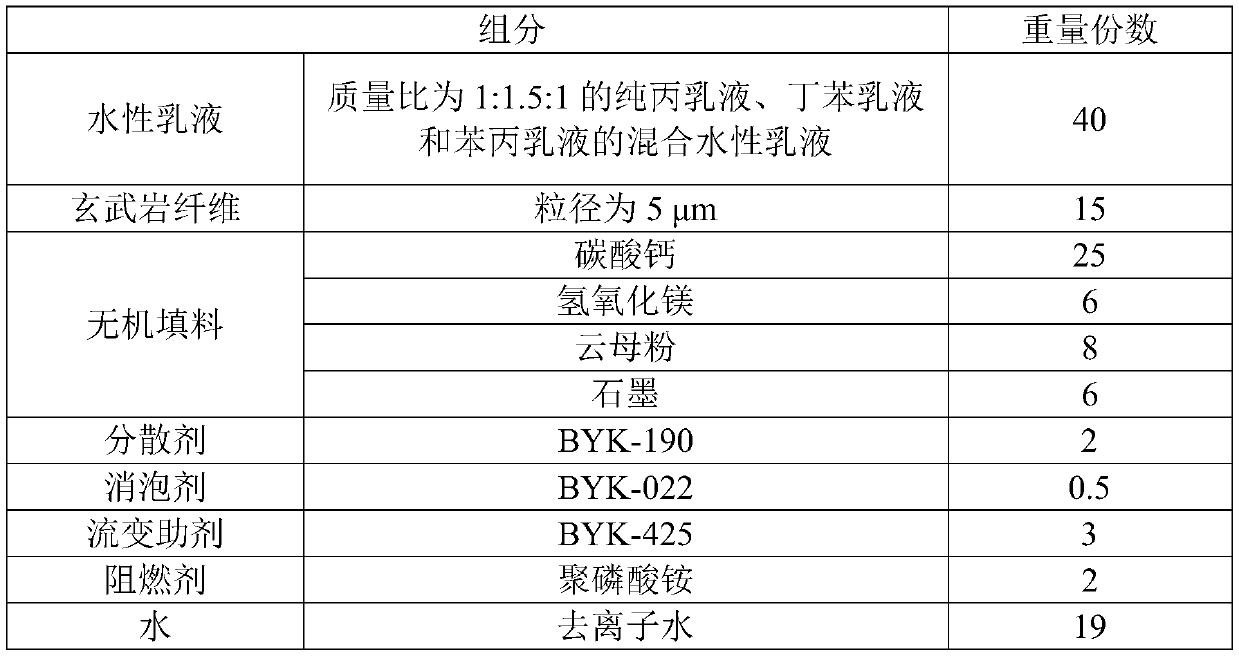

The invention provides a water-based damping coating as well as a preparation method and an application thereof. The water-based damping coating is prepared from the following components in parts by weight: 30 to 60 parts of water-based emulsion, 10 to 20 parts of basalt fiber, 30 to 60 parts of inorganic filler, 1 to 5 parts of dispersing agent, 0.3 to 1.5 parts of defoaming agent, 1 to 6 parts of rheological additive, 2 to 6 parts of flame retardant and 30 to 60 parts of water. According to the water-based damping coating, the basalt fiber fibers are added, so that the mechanical property, especially the ductility, of the water-based damping coating is enhanced, the damping coefficient is increased, the anti-cracking and anti-bubbling effects can be achieved in the actual application process, and a better appearance effect and a better use effect are obtained.

Owner:CHINA FIRST AUTOMOBILE

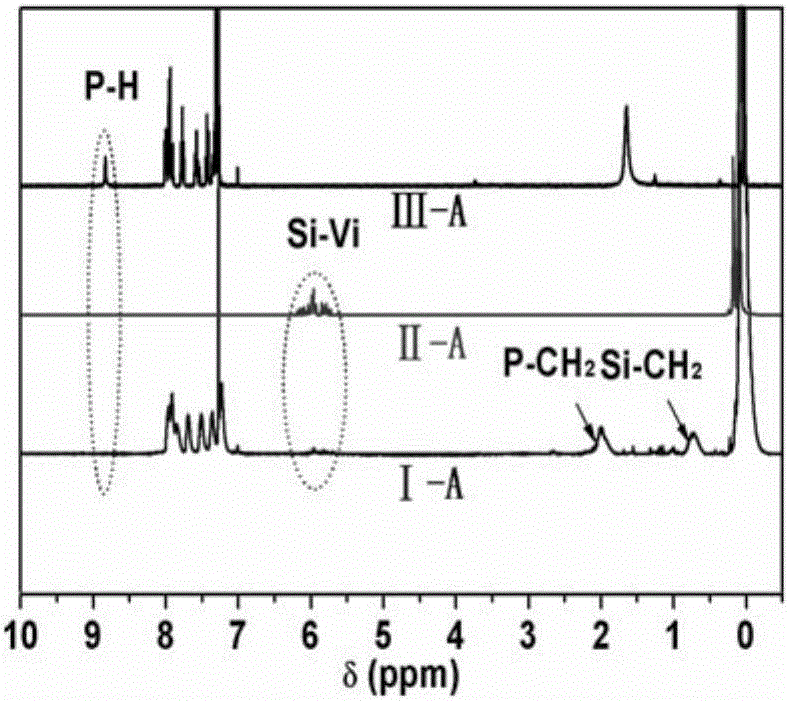

DOPO derivative modified organosilicon damping additive and preparation method and application thereof

The invention discloses a DOPO derivative modified organosilicon damping additive and a preparation method and application thereof. The structural formula of the damping additive is as shown in the formula I. in the formula I, R1, R2, R3, R4, R5, R6, R7 and R8 are respectively selected from C2-C5 alkenyl group, aryl group, halogenated aryl group, amino-group, C1-C5 alkyl group, C1-C5 cyanogen alkyl group, C1-C5 halogenated alkyl group and C1-C5 aminoalkyl group; R5, R9 and R10 are respectively selected from C0-C5 alkylene group; R11, R12, R13, R14, R15, R16, R17 and R18 are respectively selected from hydrogen atom, aryl group, halogenated aryl group, nitro group, C1-C5 cyanogen alkyl group, C1-C5 halogenated alkyl group, hydroxyl group, halogen and C1-C5 alkyl group; m is any integer from 0-200; n is any integer from 0-200; q is any integer from 0-200; and m, n and q are not 0 at the same time. The damping additive of the invention will not migrate in silicone rubber base, has good compatibility with silicone rubber, is efficient, is easy to add, and will not influence mechanical properties of silicone rubber.

Owner:INST OF CHEM CHINESE ACAD OF SCI

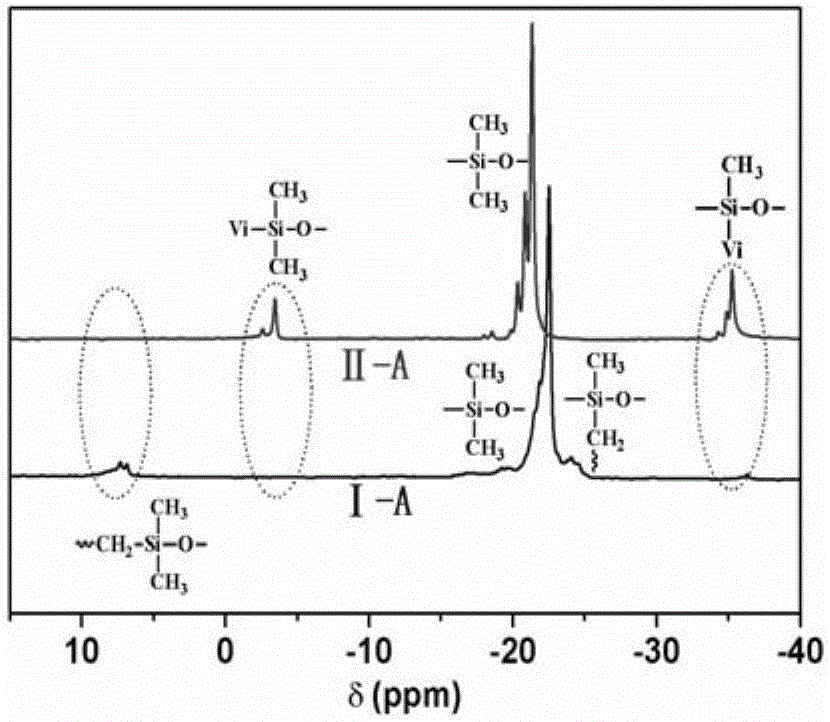

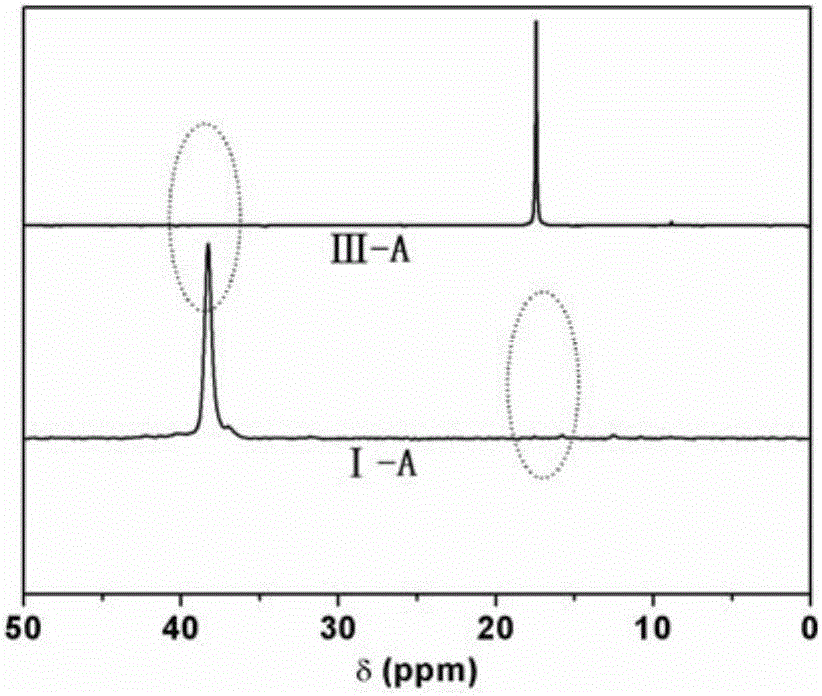

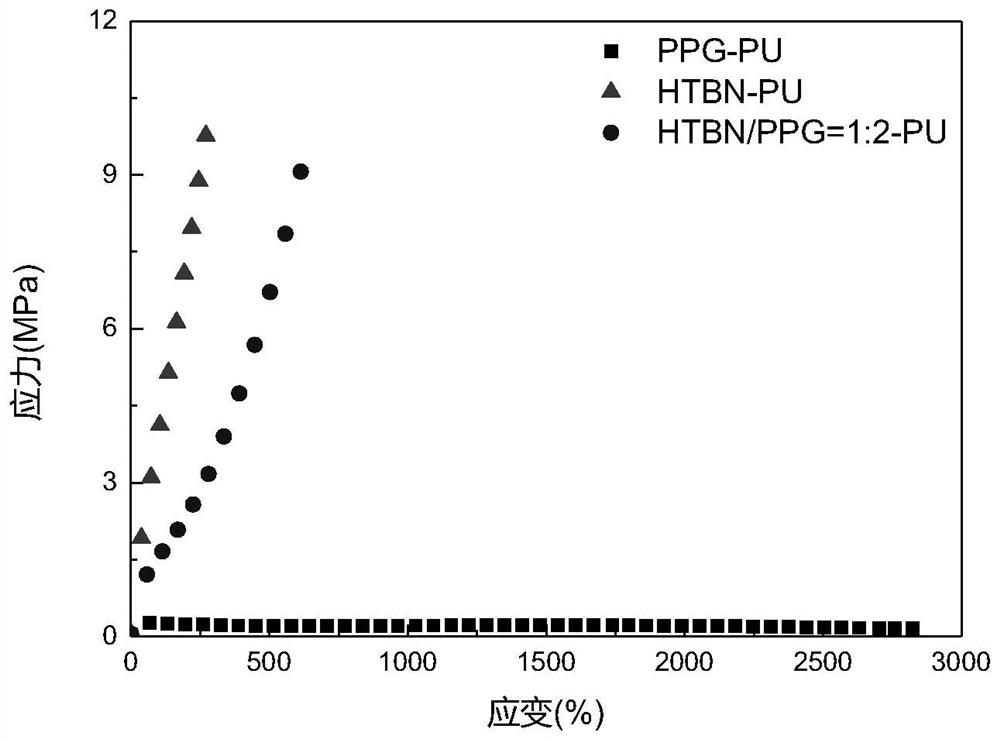

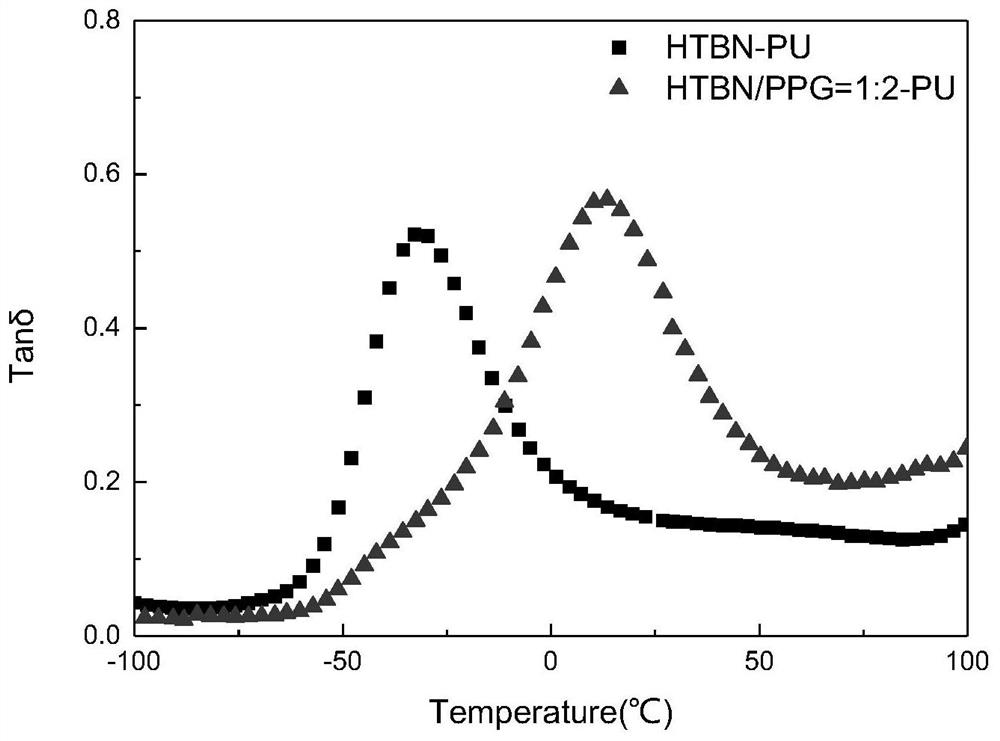

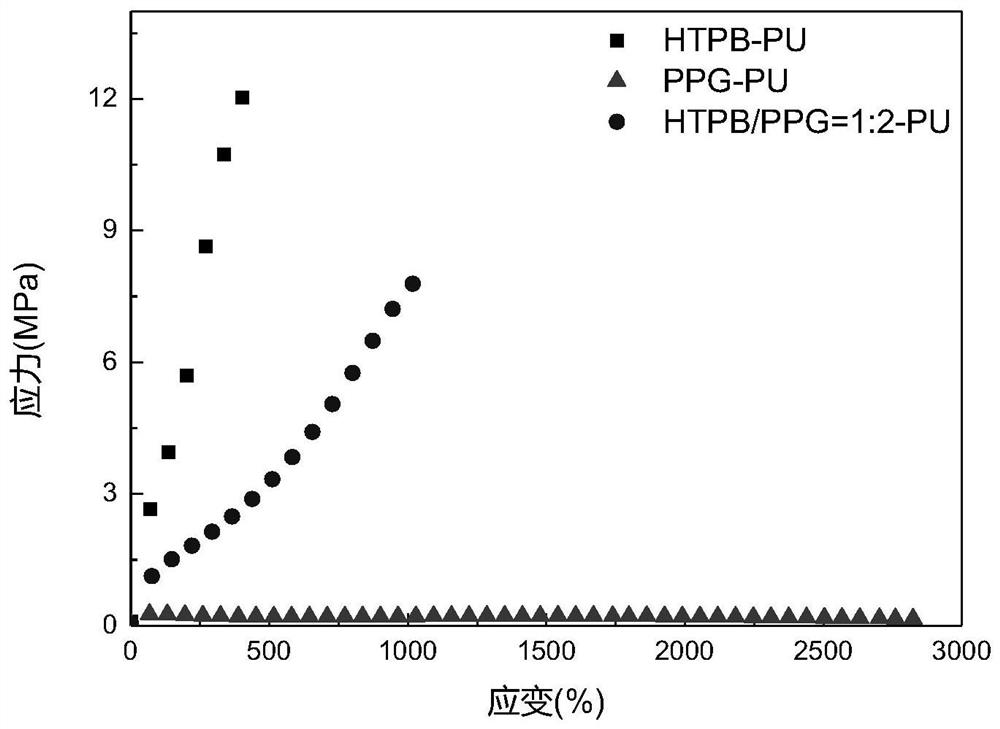

Mixed soft segment type polyurethane damping material and preparation method thereof

The invention provides a mixed soft segment type polyurethane damping material and a preparation method thereof. The soft segment of the polyurethane damping material comprises olefin oligomer dihydric alcohol and polyether dihydric alcohol. The preparation method comprises the following steps of uniformly mixing olefin oligomer dihydric alcohol and polyether dihydric alcohol, and carrying out a prepolymerization reaction with diisocyanate to obtain a biisocyanate-terminated prepolymer, and adding a chain extender into the obtained biisocyanate-terminated prepolymer, and carrying out a chain extension reaction to obtain the polyurethane damping material. The polyurethane damping material disclosed by the invention has excellent properties of two soft segments, the damping temperature rangeis improved compared with that of a single soft segment, and the polyurethane damping material has better hydrolysis resistance; meanwhile, the preparation method is simple, high in repeatability andbeneficial to industrial production.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com