Room-temperature curable epoxy resin based high damping material and preparation method thereof

An epoxy resin, room temperature curing technology, which is applied in the field of room temperature curing epoxy resin-based high damping materials and their preparation, can solve the problems of unknown and unmentioned characteristics of materials in a wide temperature range, and achieve a wide and high damping temperature range. The effect of damping, long construction pot life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0062] The specific embodiment of the present invention is shown in the following table. When using, first dry the resin in an electric blast drying oven at 50°C for 2 hours, weigh according to the proportion, mix the resin, stir evenly, add glycidyl ether and silane coupling agent, Continue to mix well to form component A of the material. Use aliphatic amines, amino-terminated polyethers, and low-molecular-weight polyamides alone or in combination, scale up according to the proportion, weigh, batch, stir and mix them evenly in advance, and then weigh, batch, and mix the three materials according to the proportion Stir well. Finally, add the curing accelerator DMP-30 according to the proportion, and continue to stir evenly to form the B component of the material. Before use, accurately weigh components A and B according to the mass ratio of 1:1, fully stir and mix, vacuumize at room temperature to remove air bubbles, and pour products or use them for other purposes. Naturall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

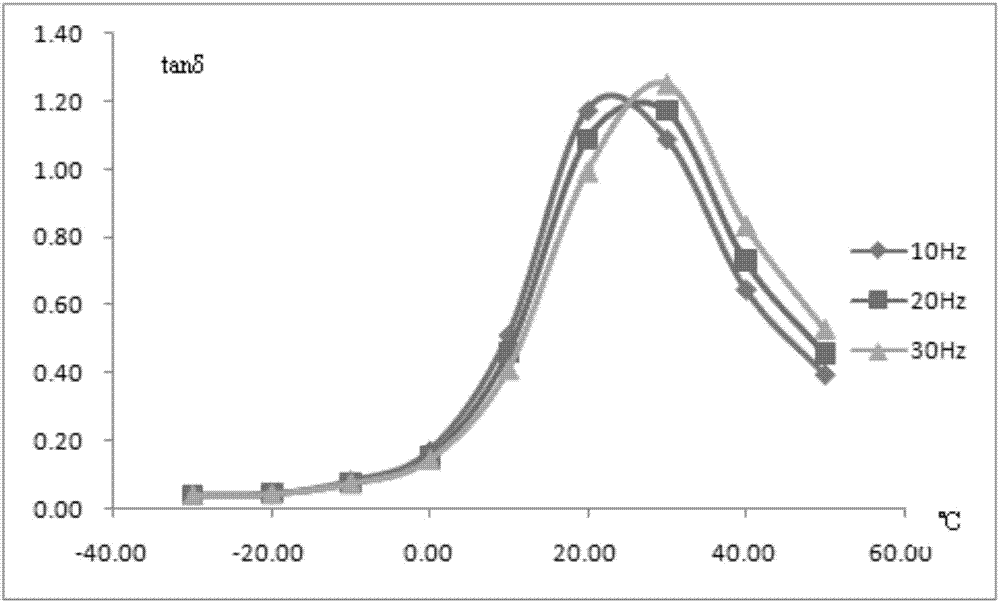

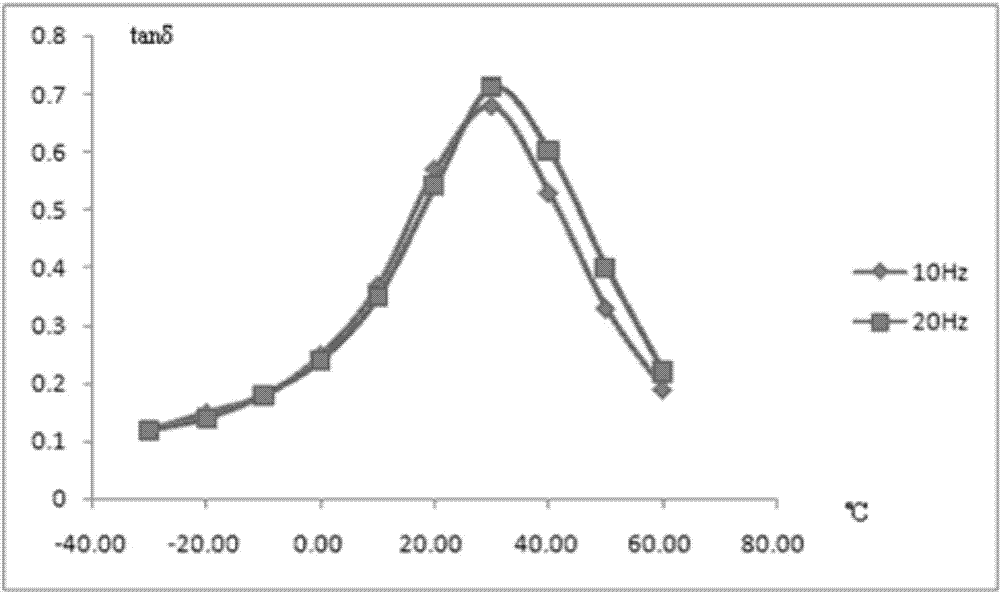

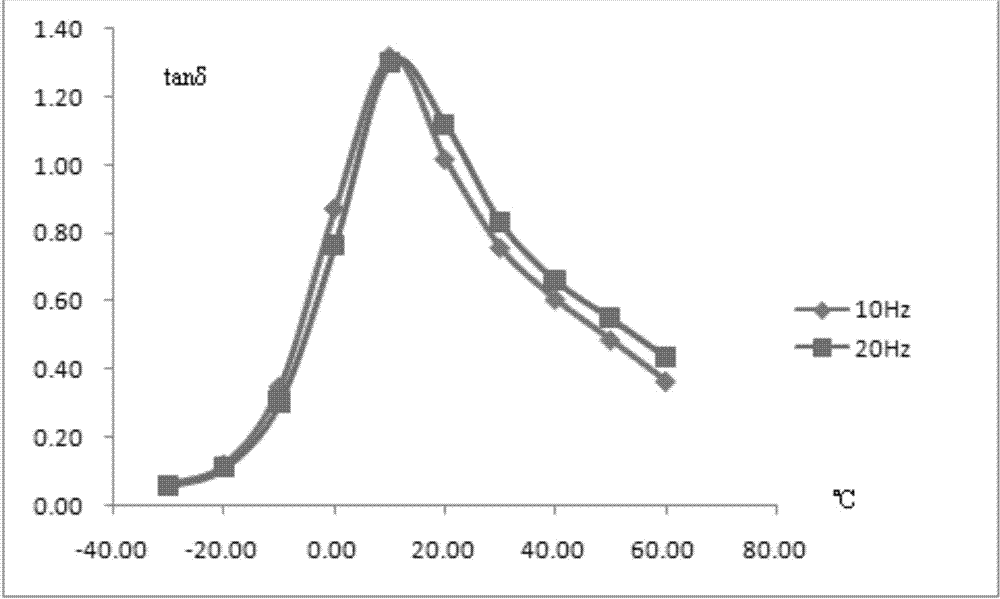

| dielectric loss factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com