Patents

Literature

3836 results about "Air blast" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

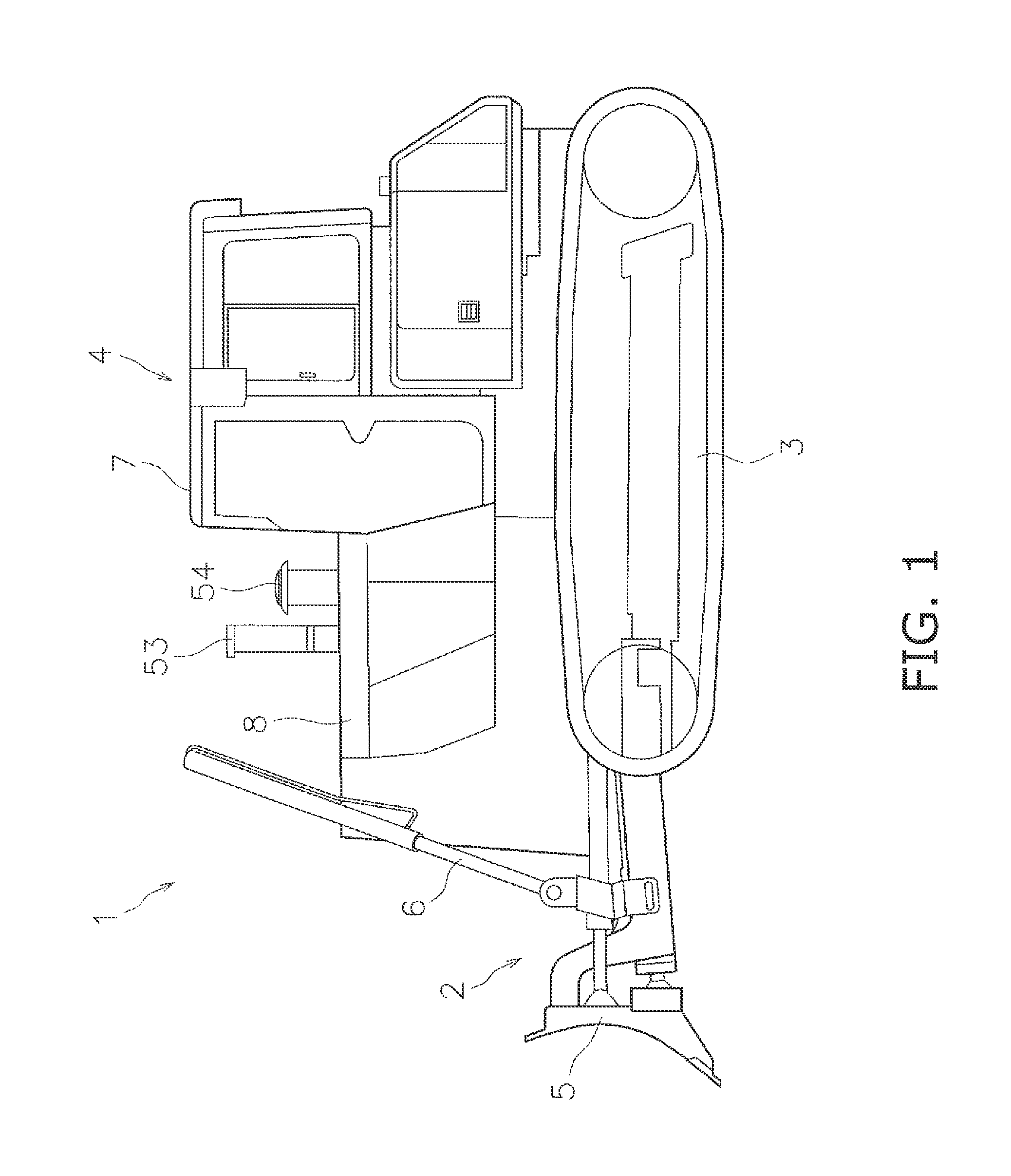

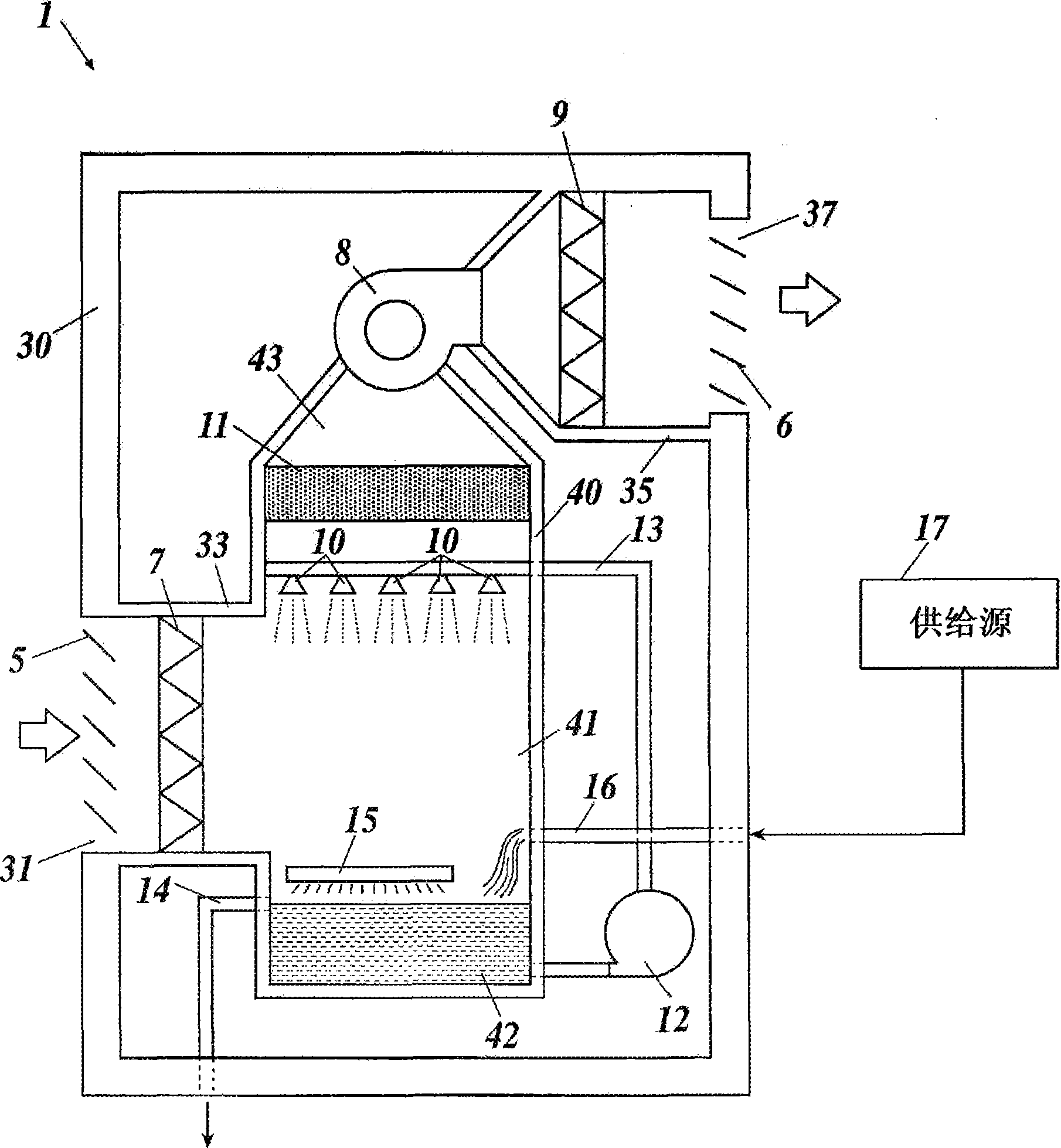

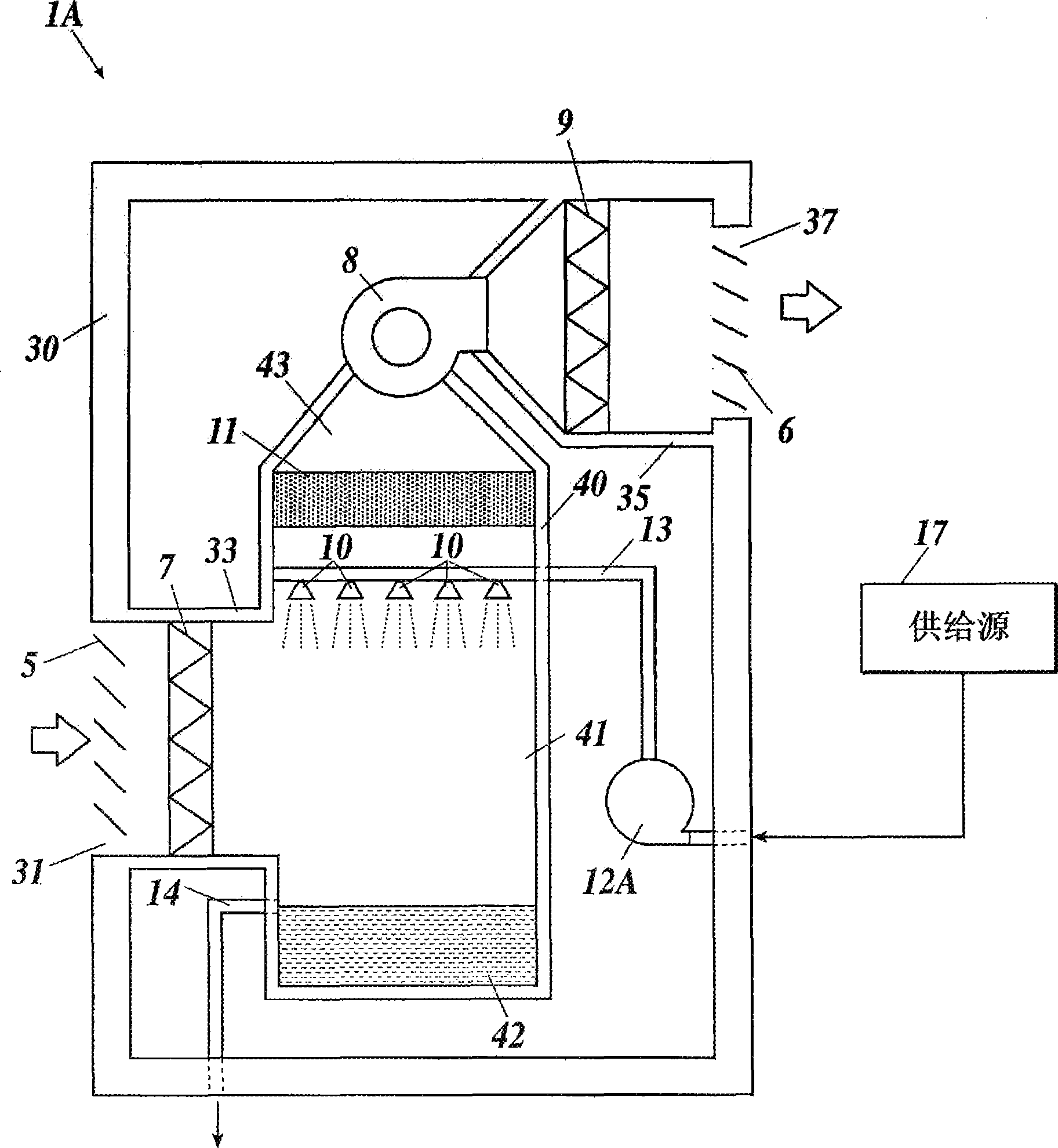

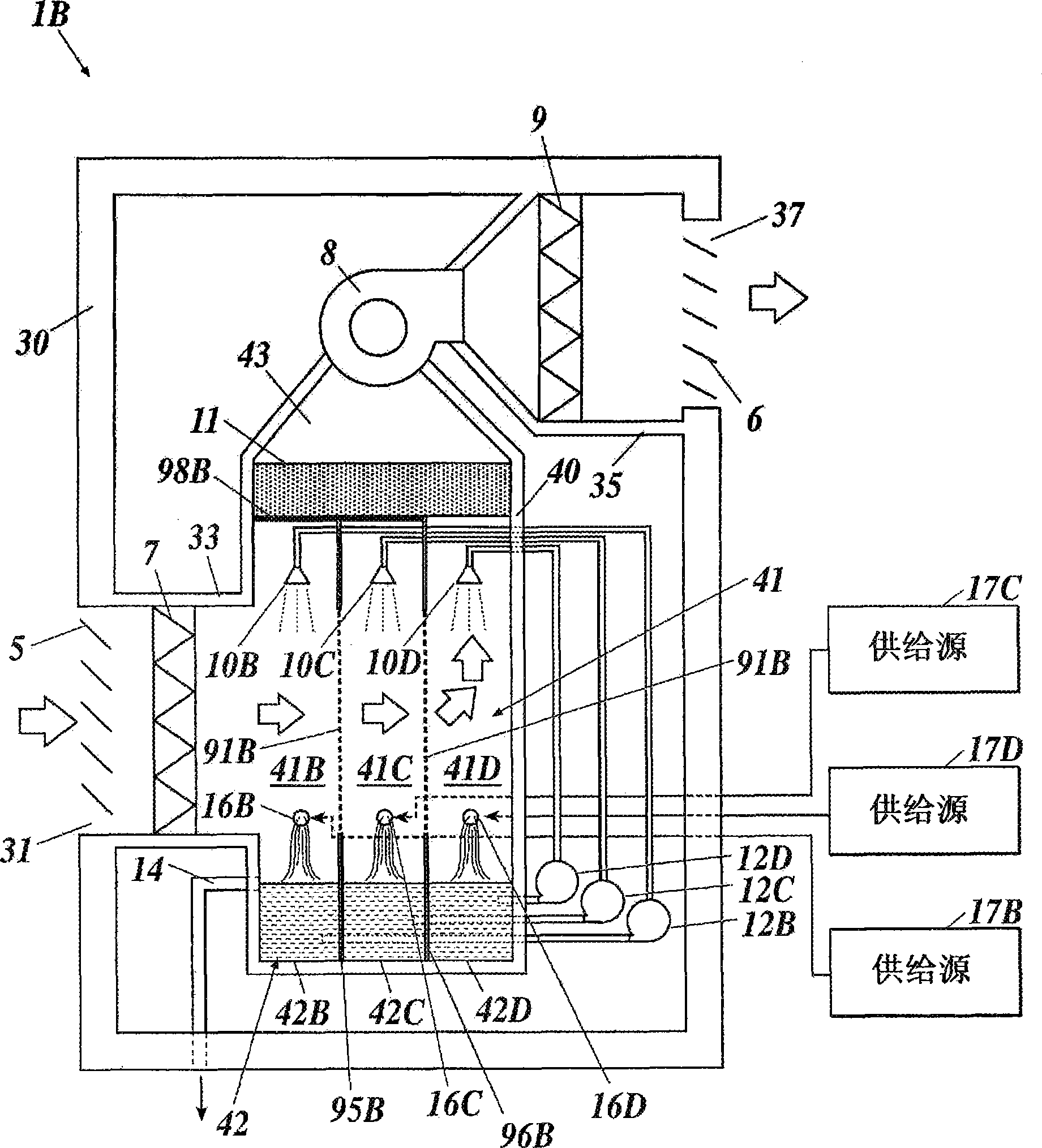

Air purifier

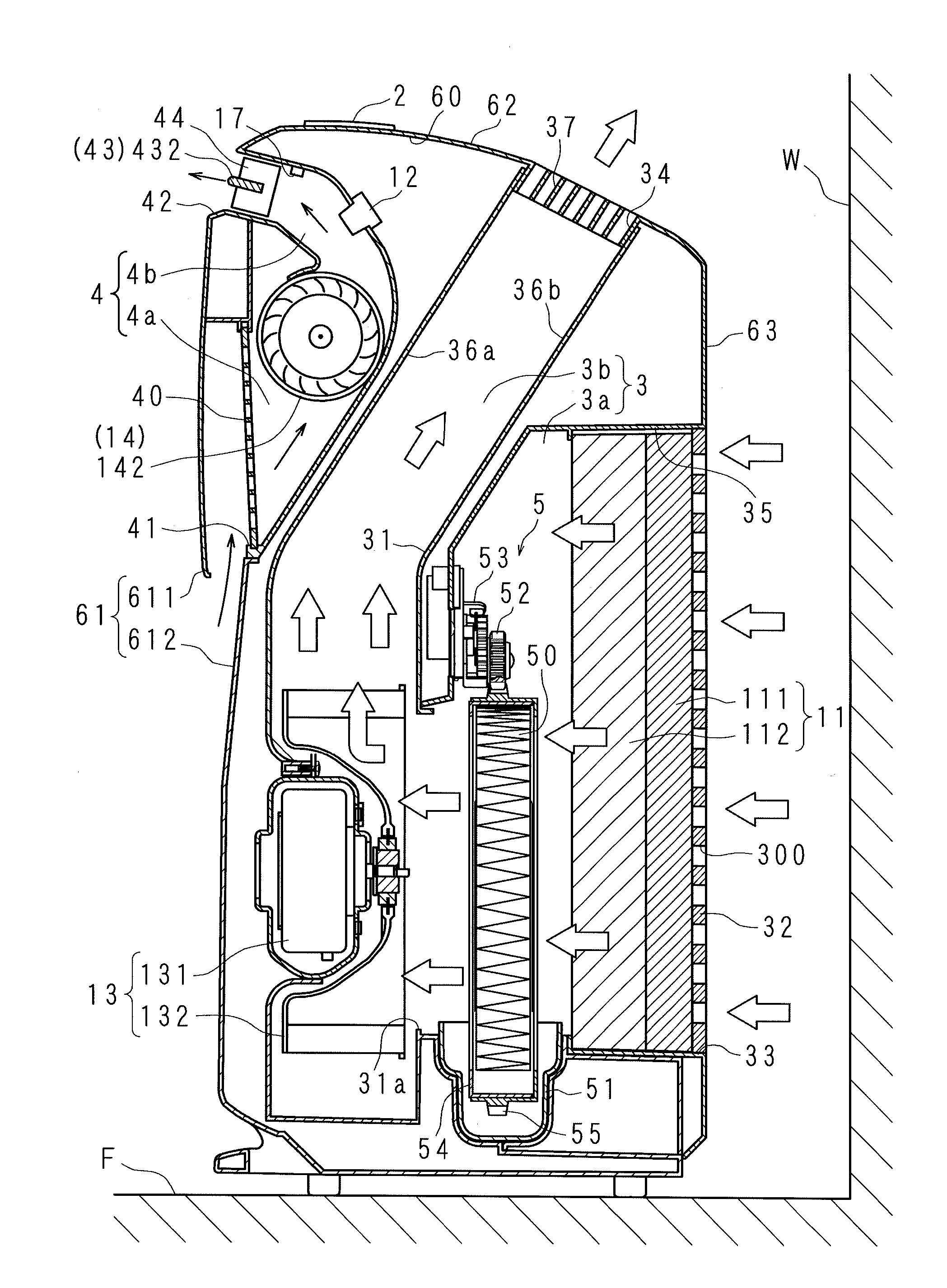

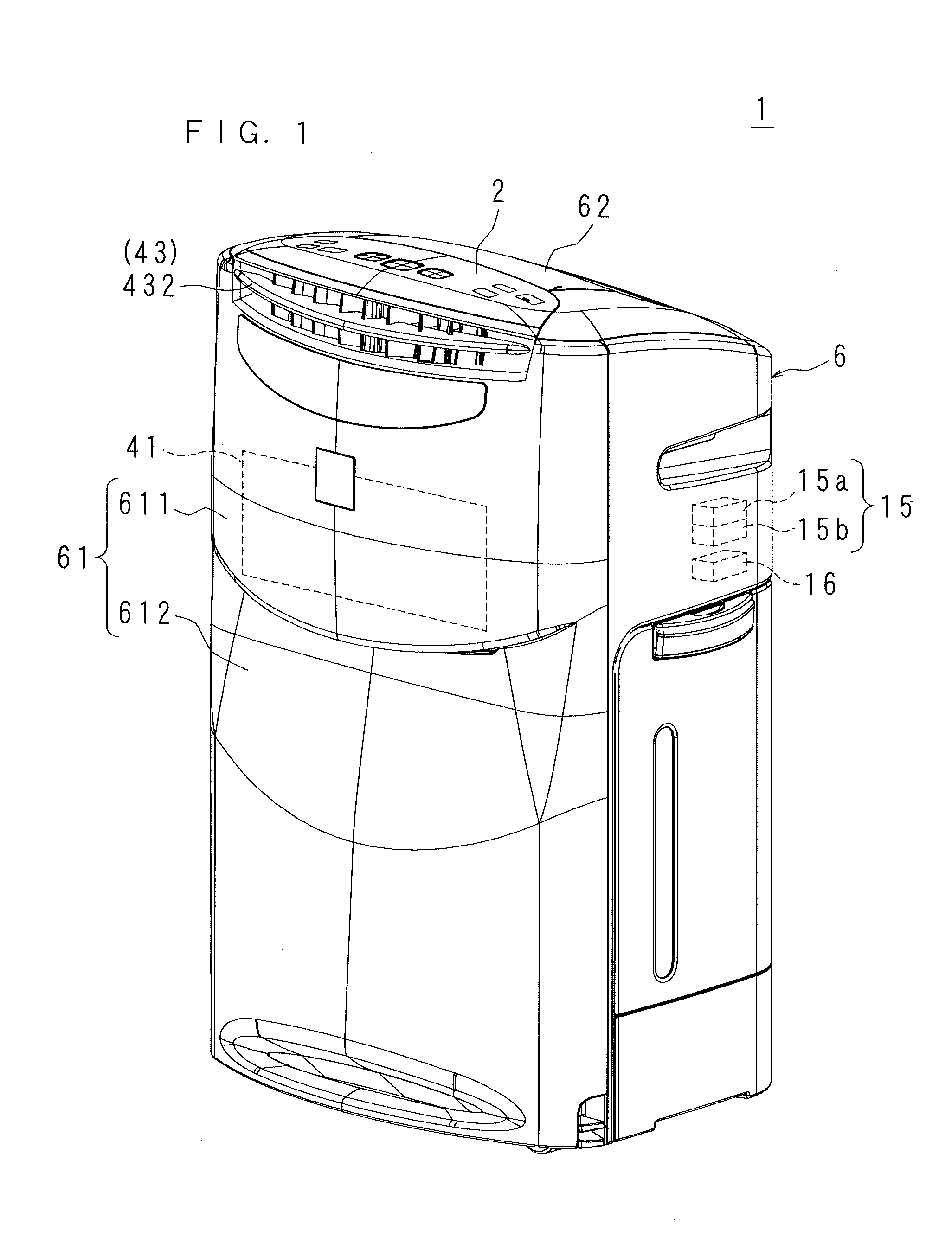

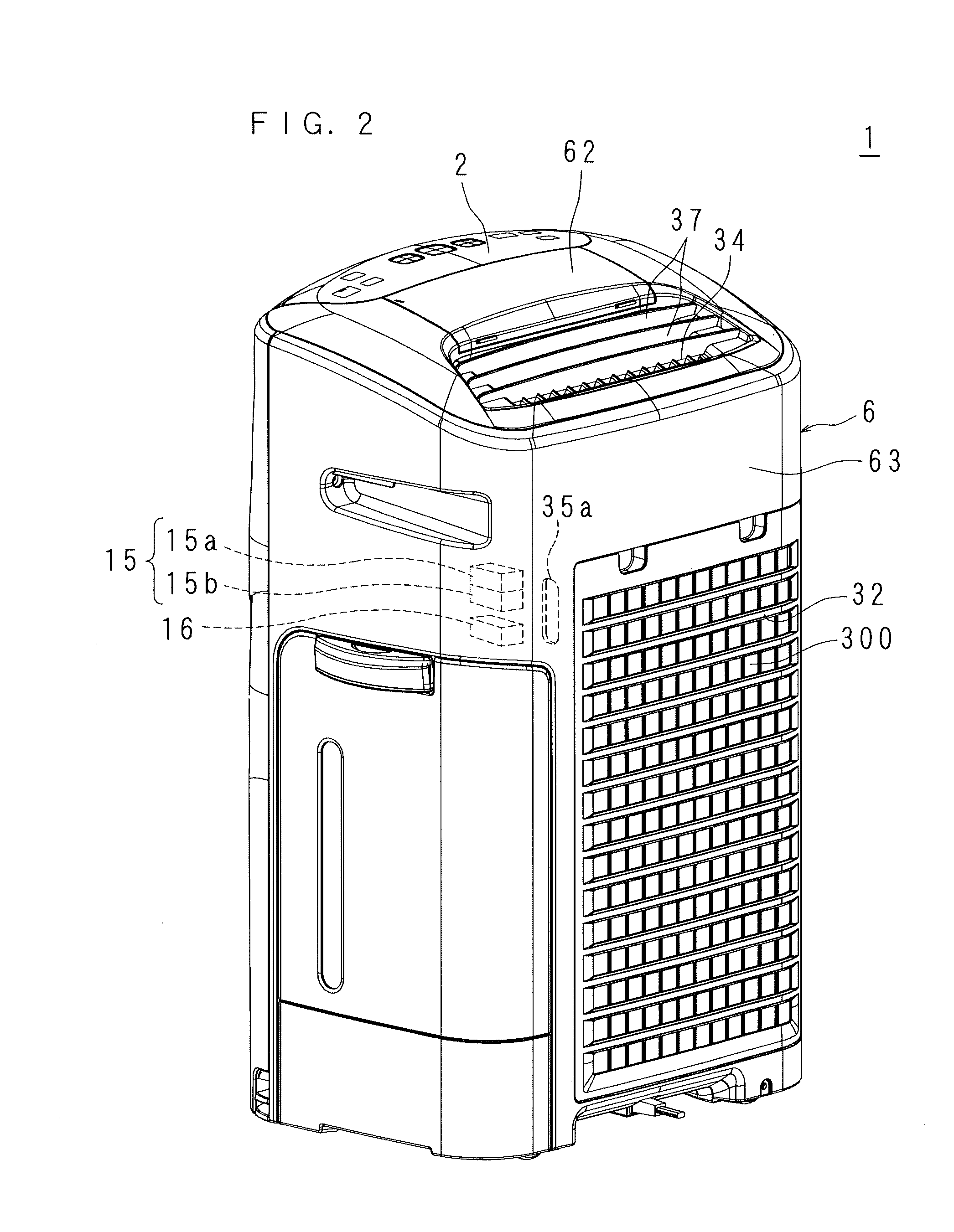

InactiveUS20140216259A1High densityIncrease rotation speedMechanical apparatusSpace heating and ventilation safety systemsAir purifiersEngineering

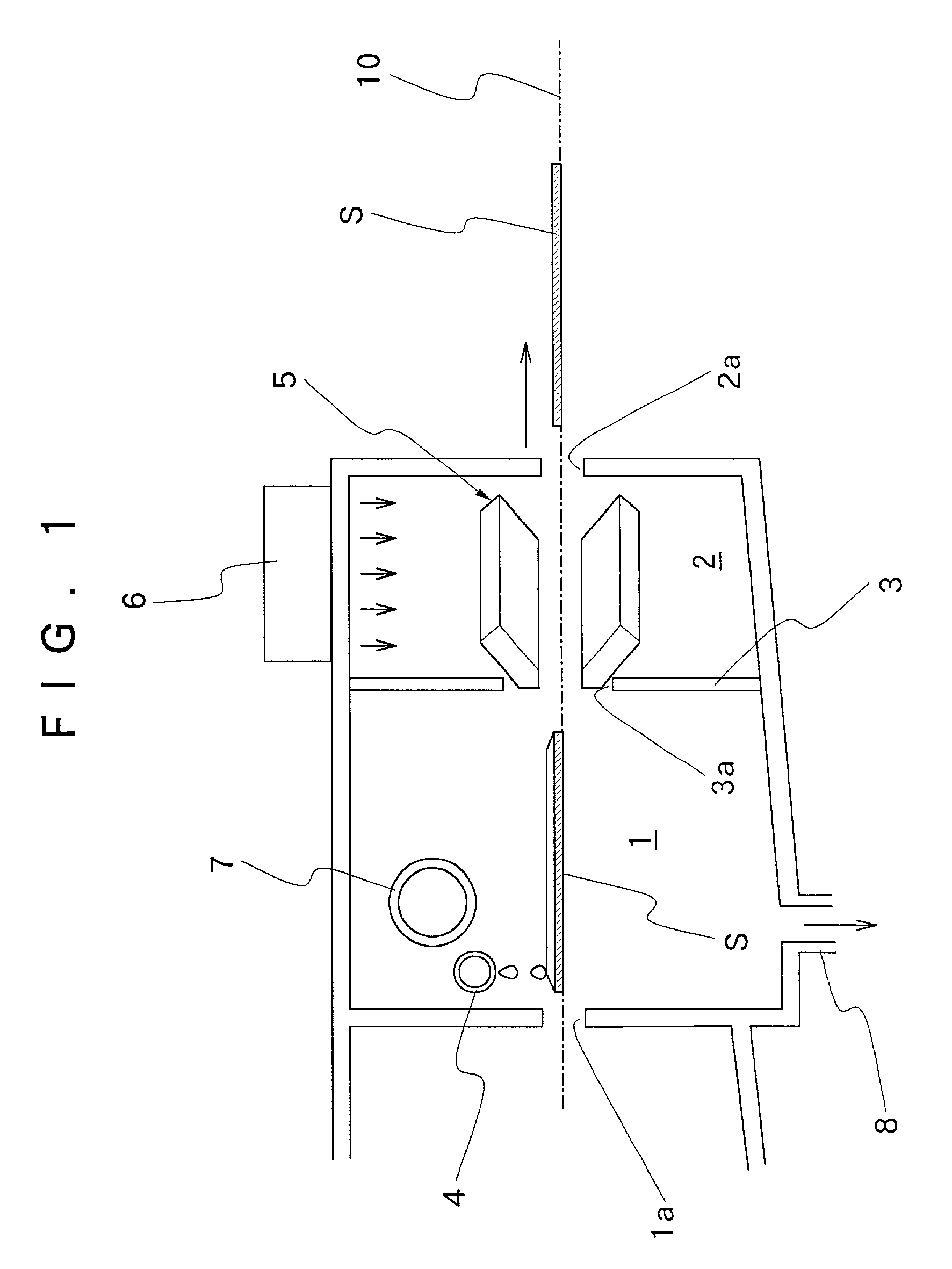

Provided is an air purifier capable of increased air purification properties due to charged particles being blown out. A first air-blower blasts air, thus drawing air in from the outside to a first air-flow path, and an air-purification unit purifies the air and blows out same. A second air blower blasts air, thus drawing air in from the outside to a second air-flow path, and the air is blown out together with charged particles generated by a charged particle generator. A control unit controls the amount of air blasted by the second air-blower, according to the amount of air blasted by the first air-blower. Alternatively, the control unit controls the angle to be adjusted by the regulator, according to the amount of air blasted by the first air-blower.

Owner:SHARP KK

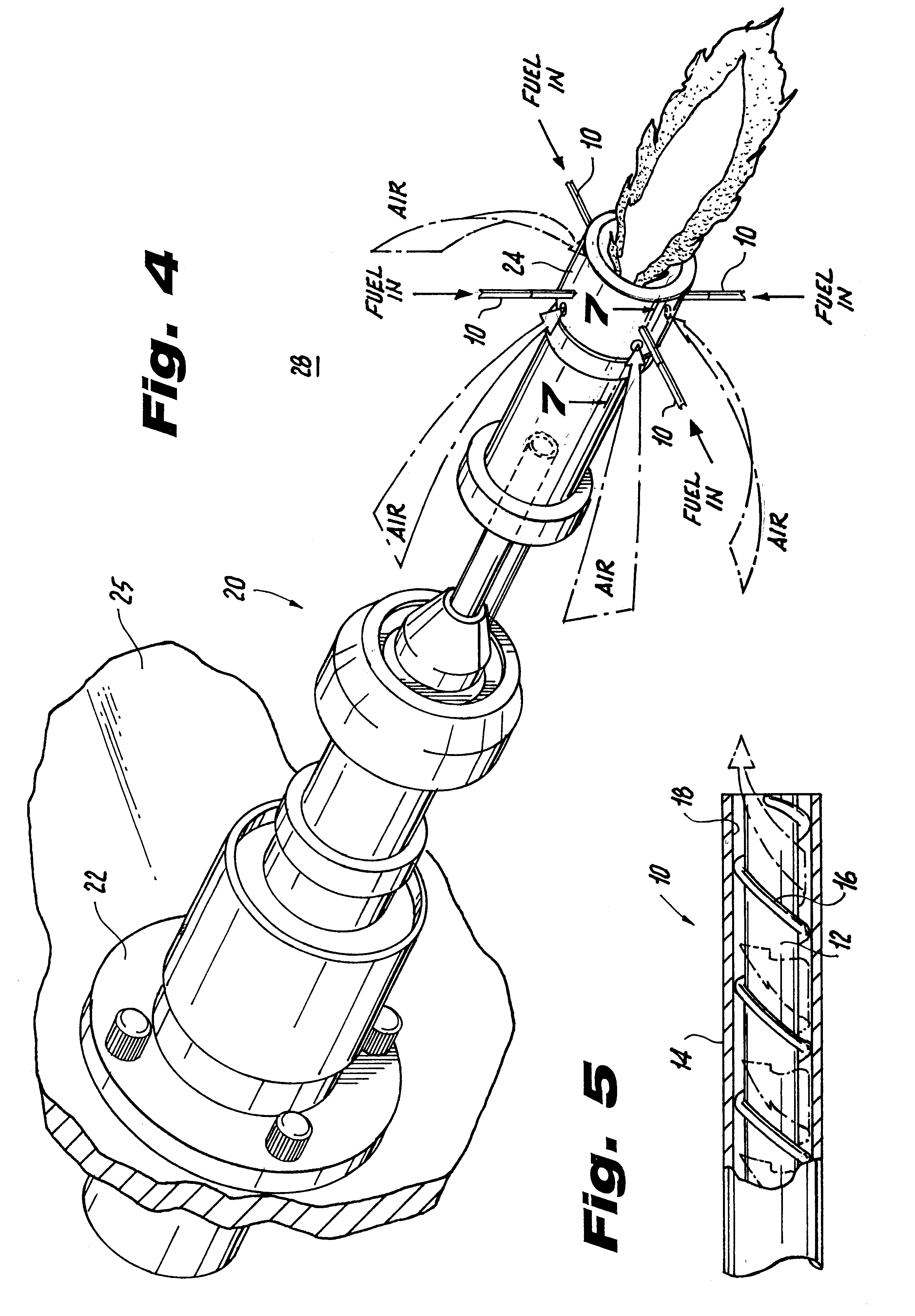

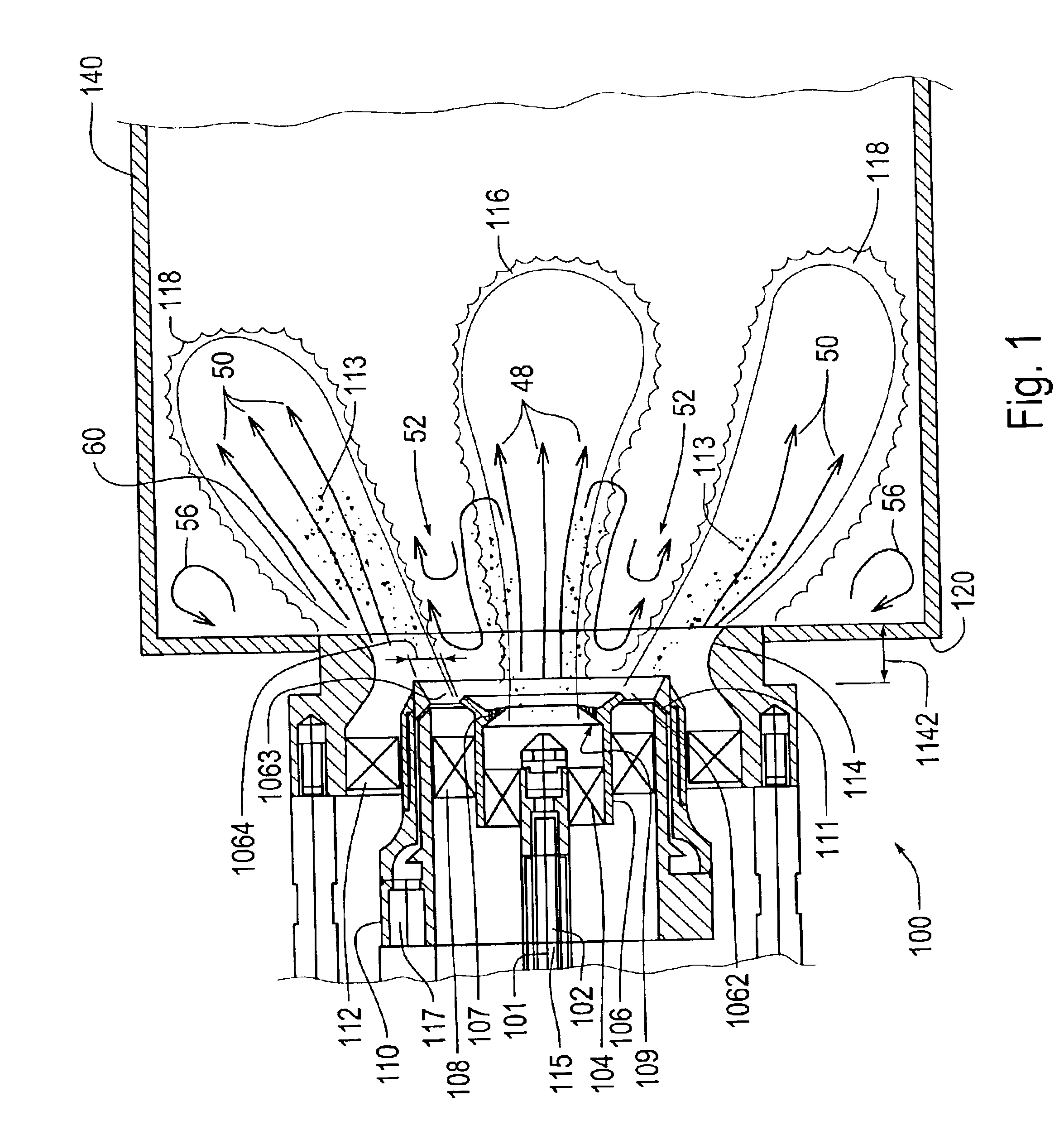

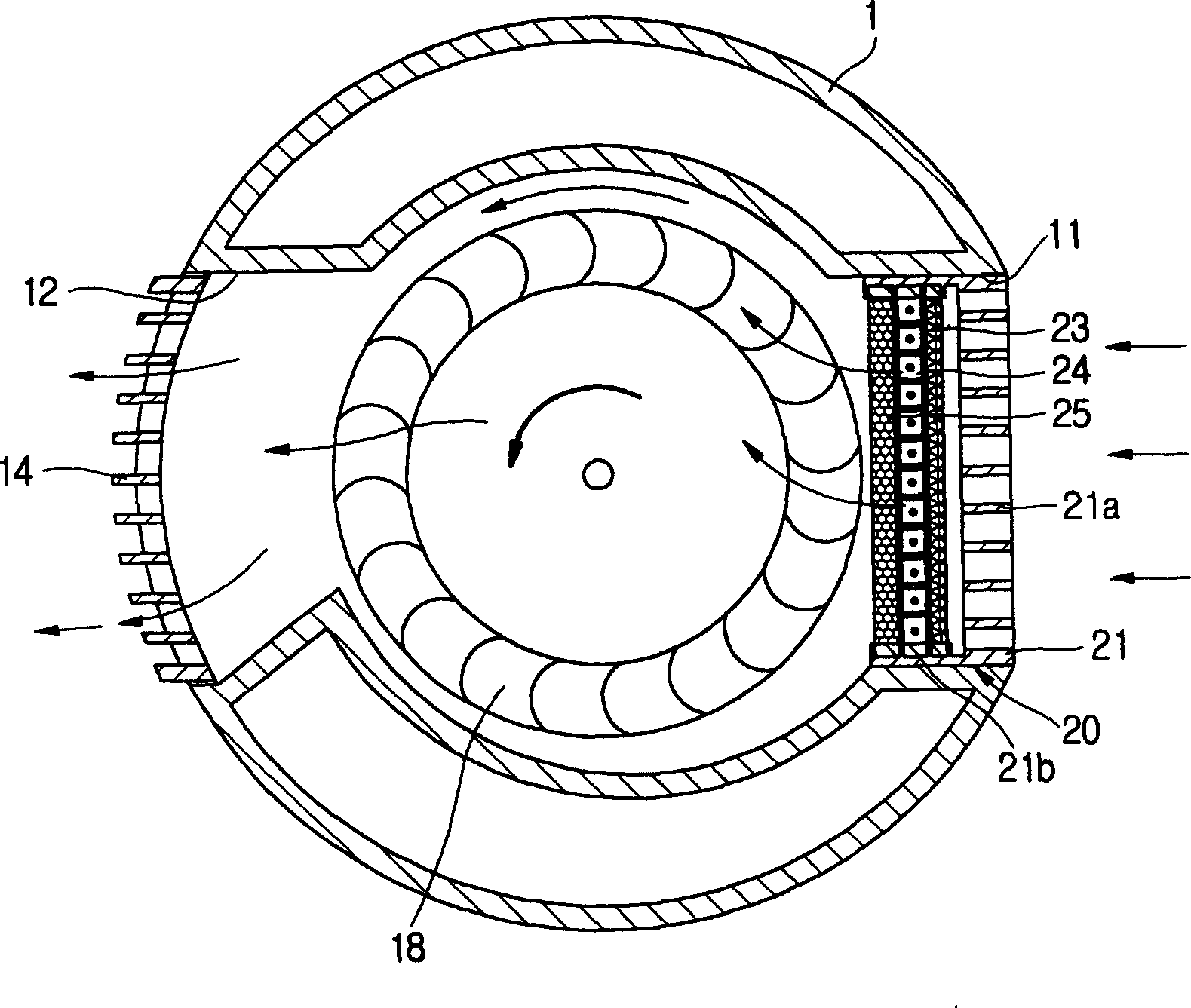

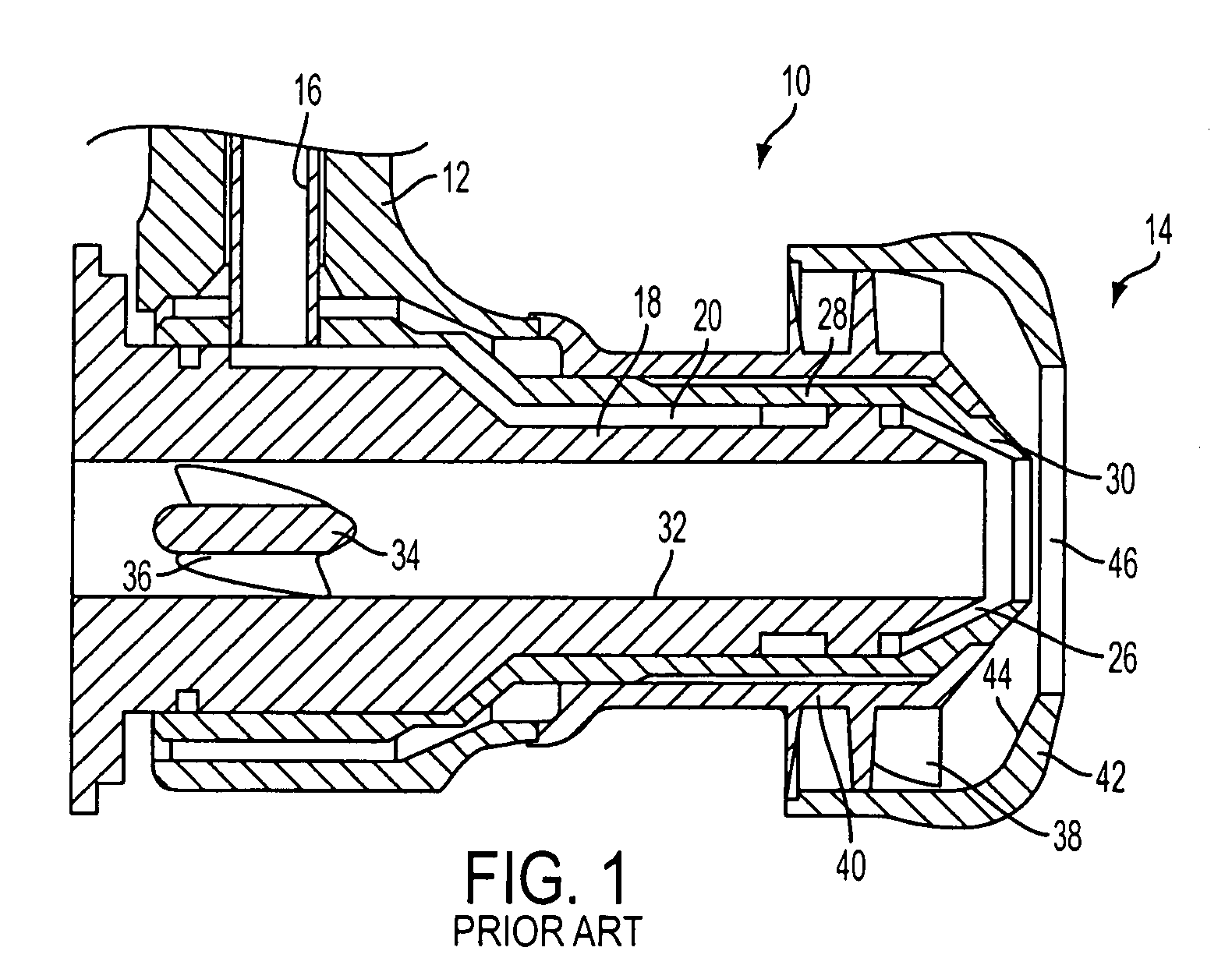

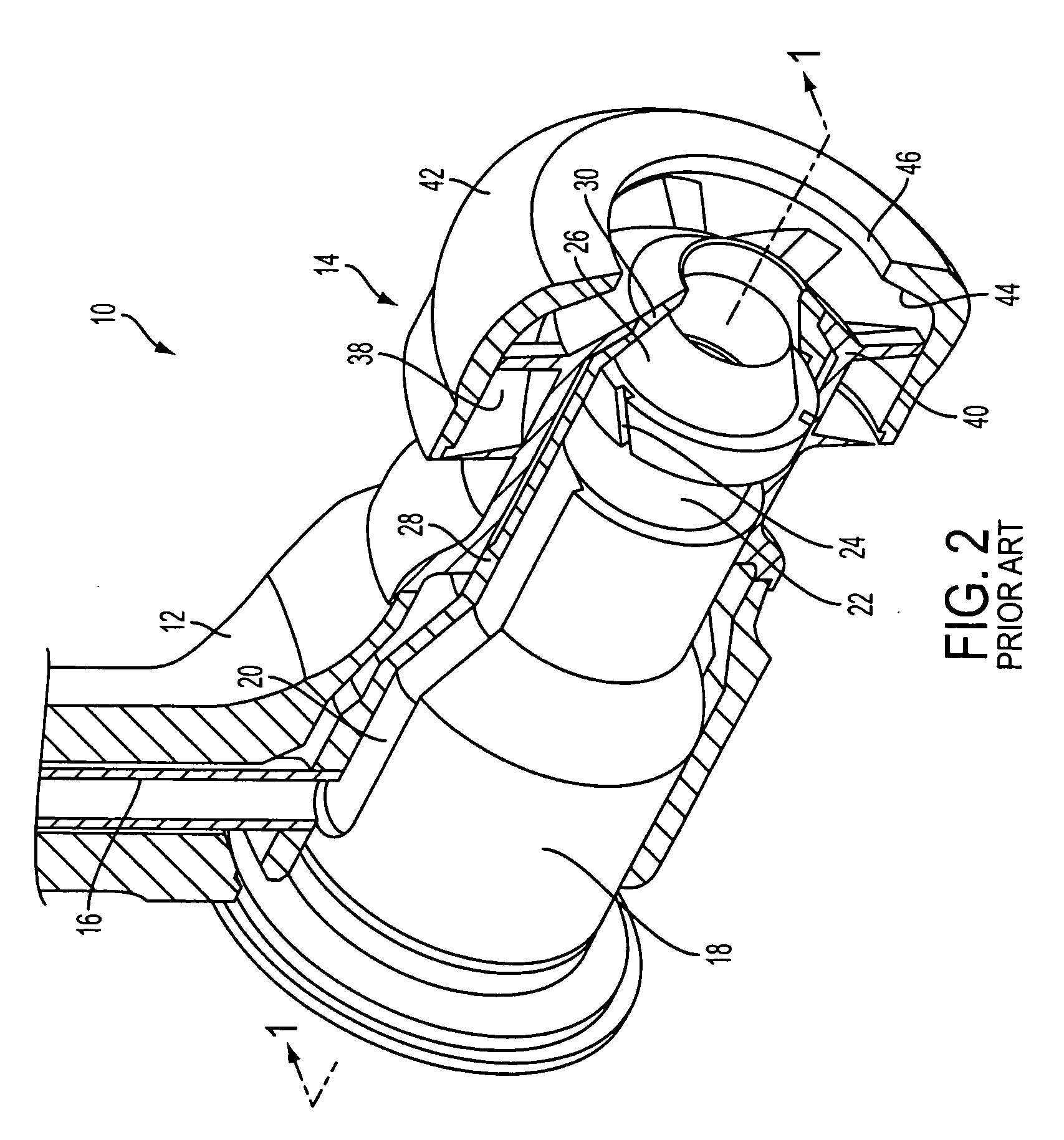

Fuel injector with bifurcated recirculation zone

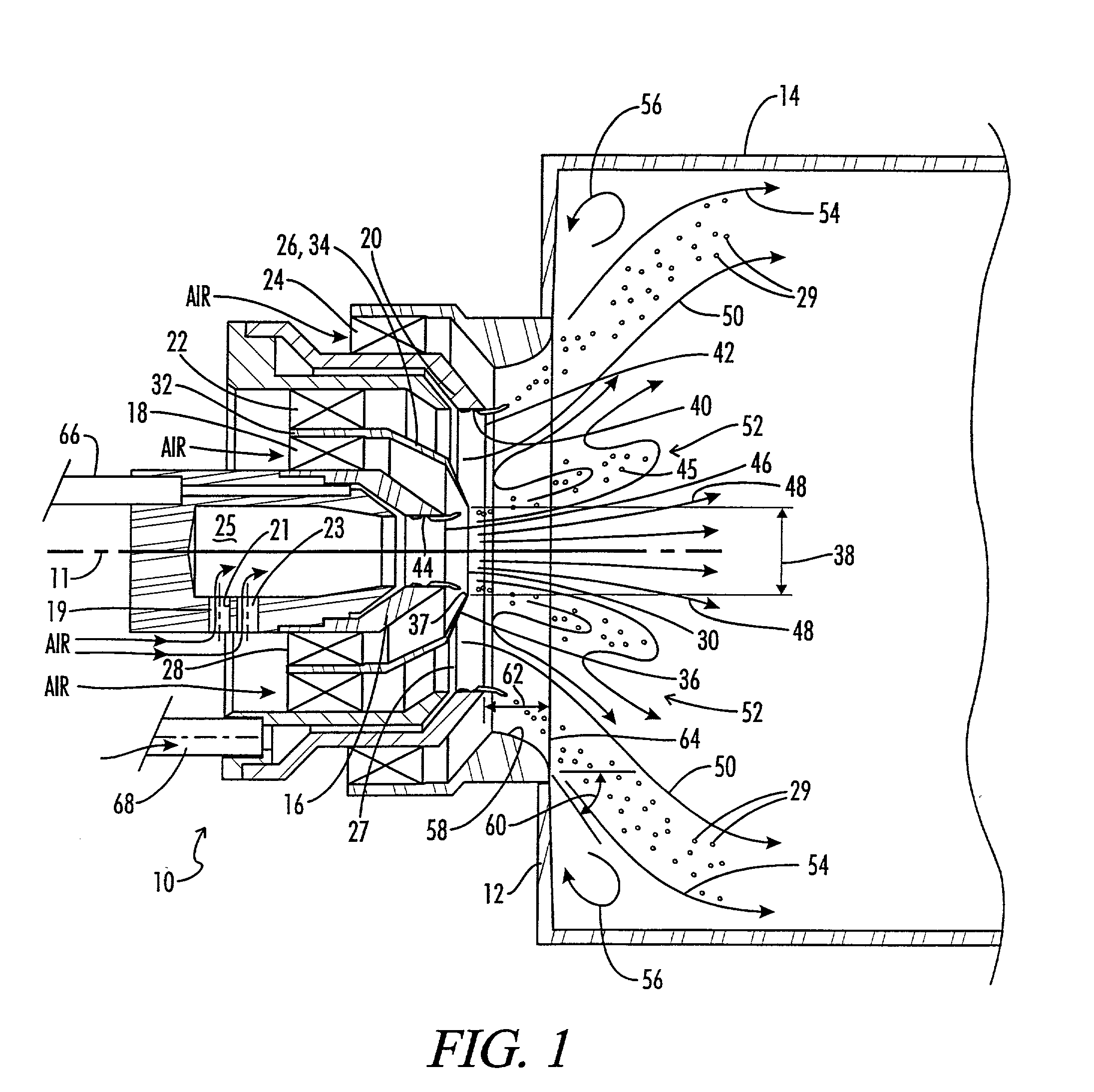

InactiveUS20020011064A1Low pollutant emissionReduce nitrogen oxide emissionsBurnersTurbine/propulsion fuel supply systemsProcess engineeringNitrous oxide

A gas turbine fuel injection system of the lean direct injector type designed to reduce nitrous oxide (NOx) emissions is provided. The configuration includes a pilot fuel injector for injecting a pilot fuel stream, and a pilot swirler for providing a swirling pilot air stream to atomize and entrain the pilot fuel stream. A main airblast fuel injector is located concentrically about the pilot fuel injector, for injecting a main fuel stream concentrically about the pilot fuel stream. Inner and outer main swirlers provide a swirling main air stream to atomize and entrain the main fuel stream. An air splitter is located between the pilot swirler and the main swirler. The air splitter is so arranged and constructed as to divide the pilot air stream exiting the pilot swirler and the air splitter, from the main air stream exiting the inner main swirler, whereby a bifurcated recirculation zone is created.

Owner:CROCKER DAVID S +2

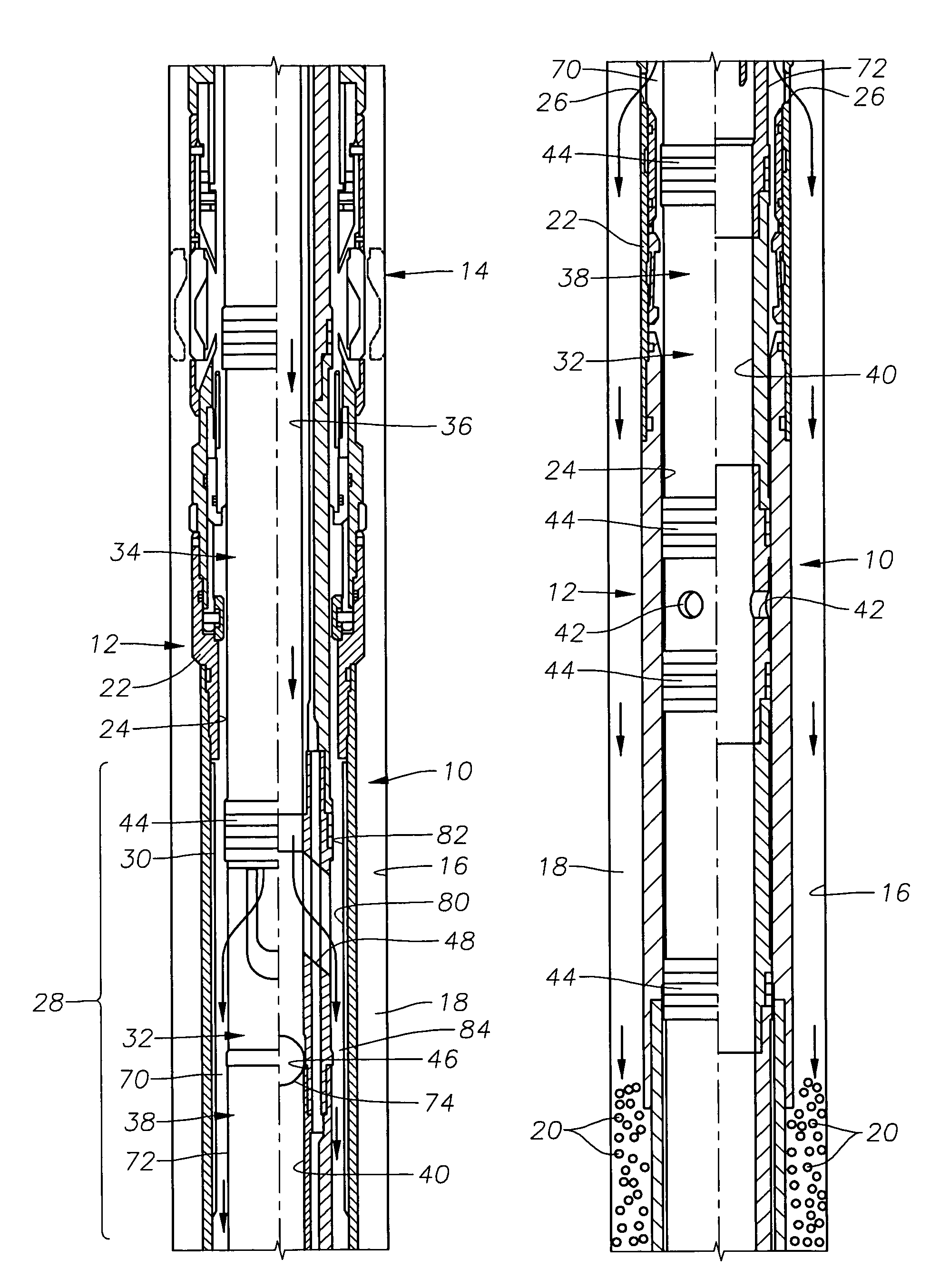

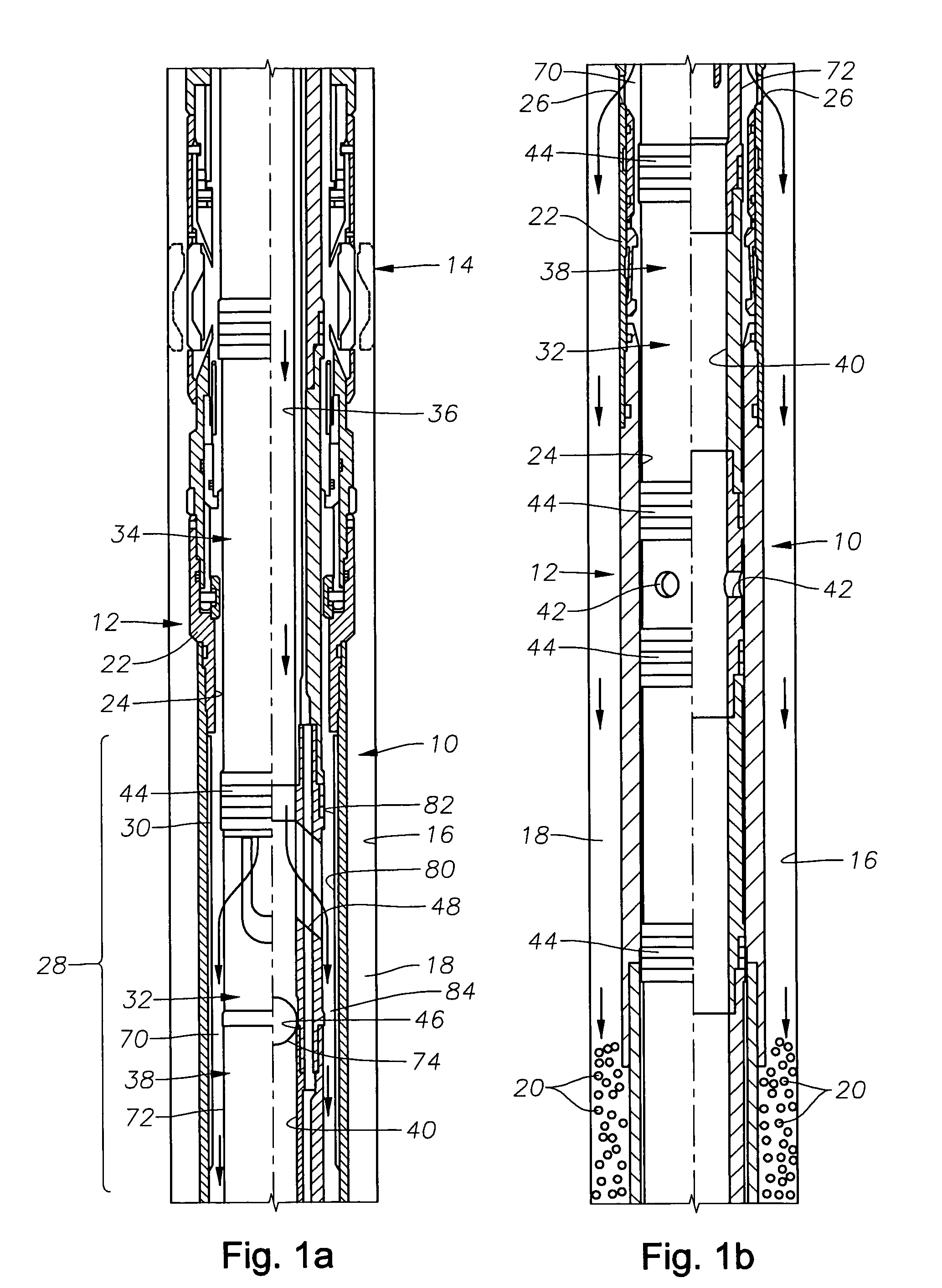

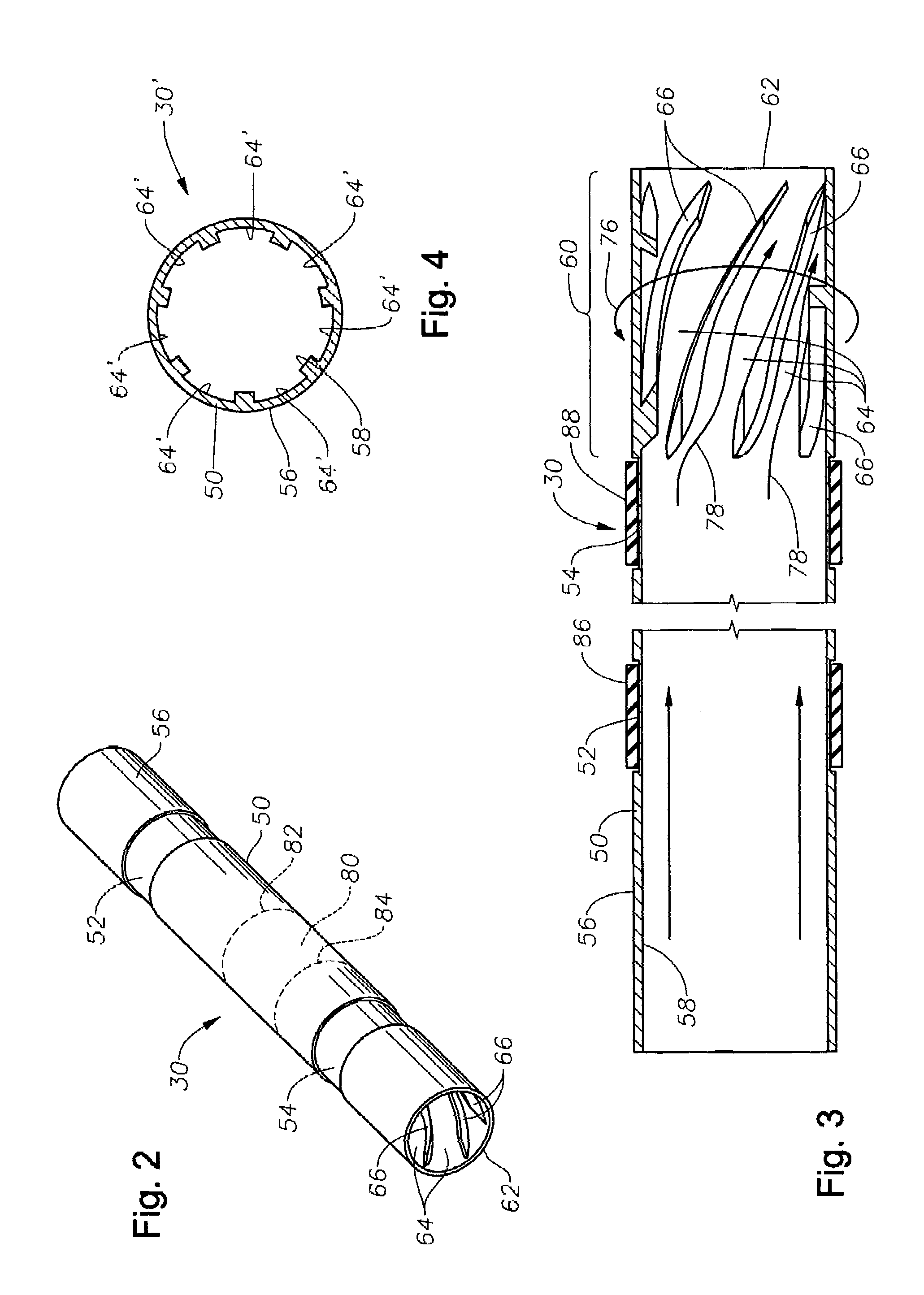

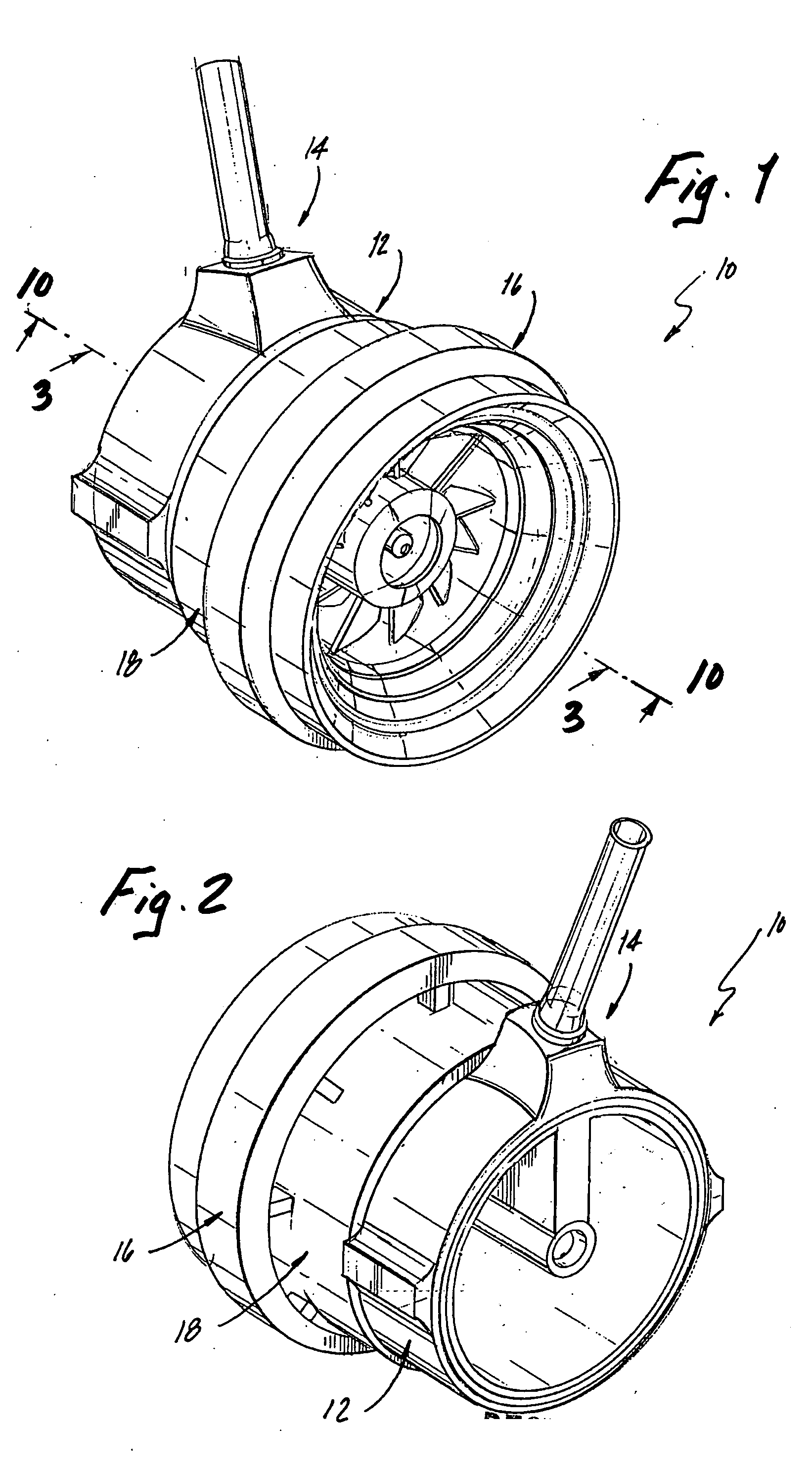

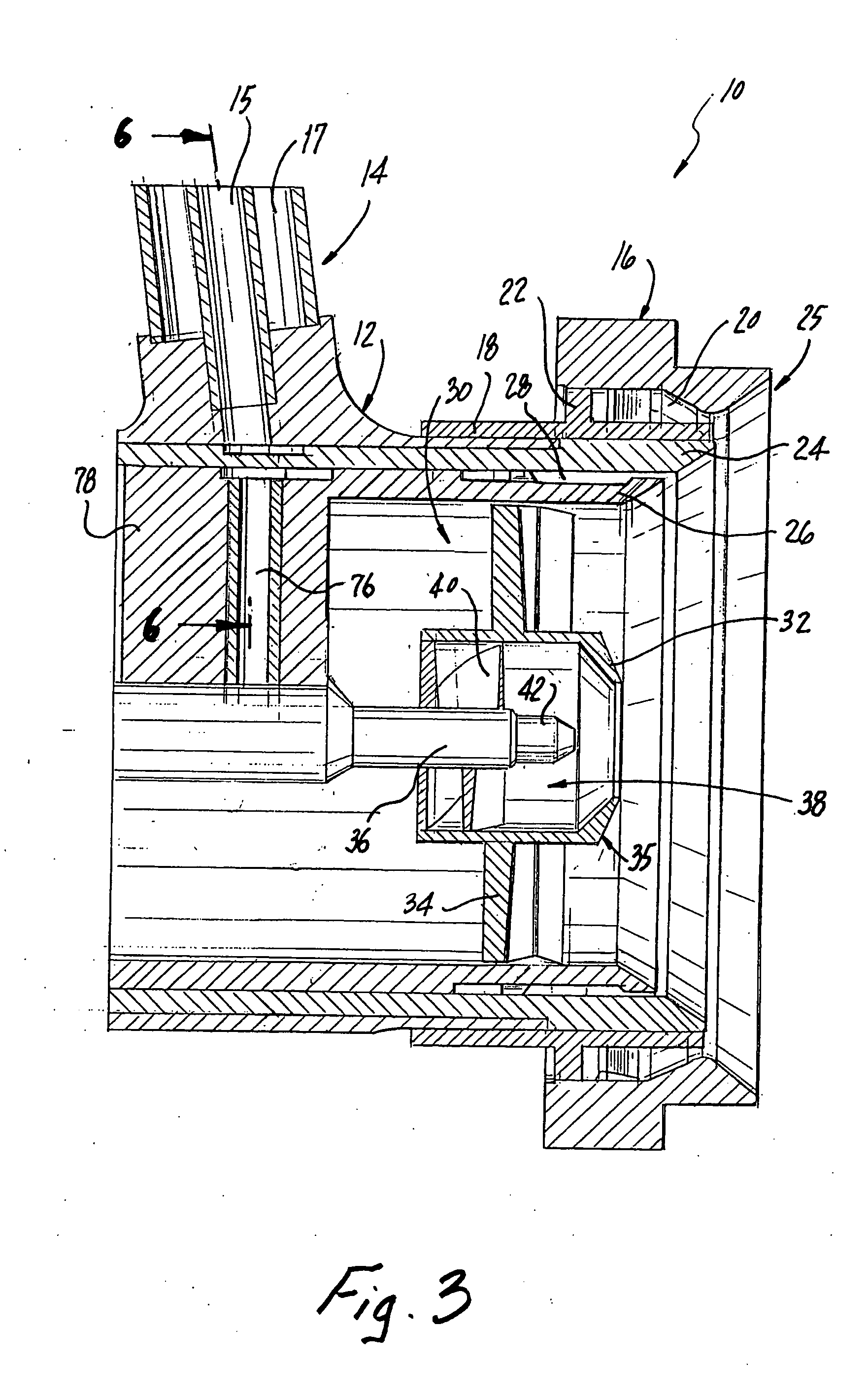

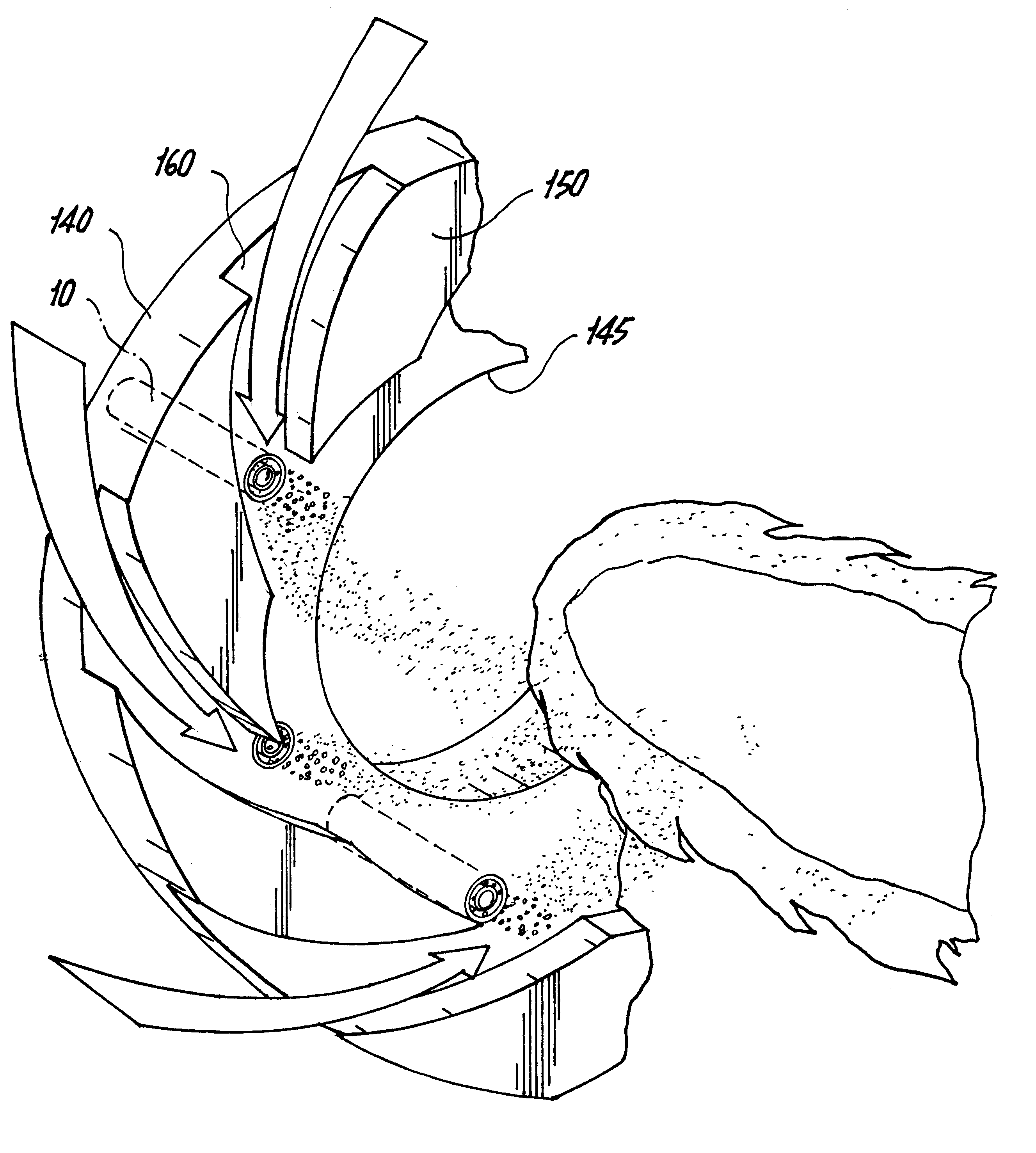

Rotating blast liner

InactiveUS7096946B2Increase the areaProlong lifeDrilling rodsFluid removalAbrasive blastingEngineering

An improved blast liner assembly for use in gravel packing or fracturing operations wherein solid materials, in slurry form, are flowed out of the flowbore of a working tool and into the annulus of a wellbore. The blast liner is a cylindrical member that provides a protective shield to the interior retaining section. An angular flow diverter is provided within the blast liner and has a plurality of angled flow diversion channels formed into the inner surface of the blast liner body. Flow of slurry through the blast liner will cause the blast liner to rotate within the retaining section due to the reaction forces imparted to the blast liner from diverting the slurry flow. In this manner, the impingement area presented by the blast liner is increased, and the life of the blast liner extended. The blast liner may also be caused to move axially within the retaining section to further increase the impingement area.

Owner:BAKER HUGHES INC

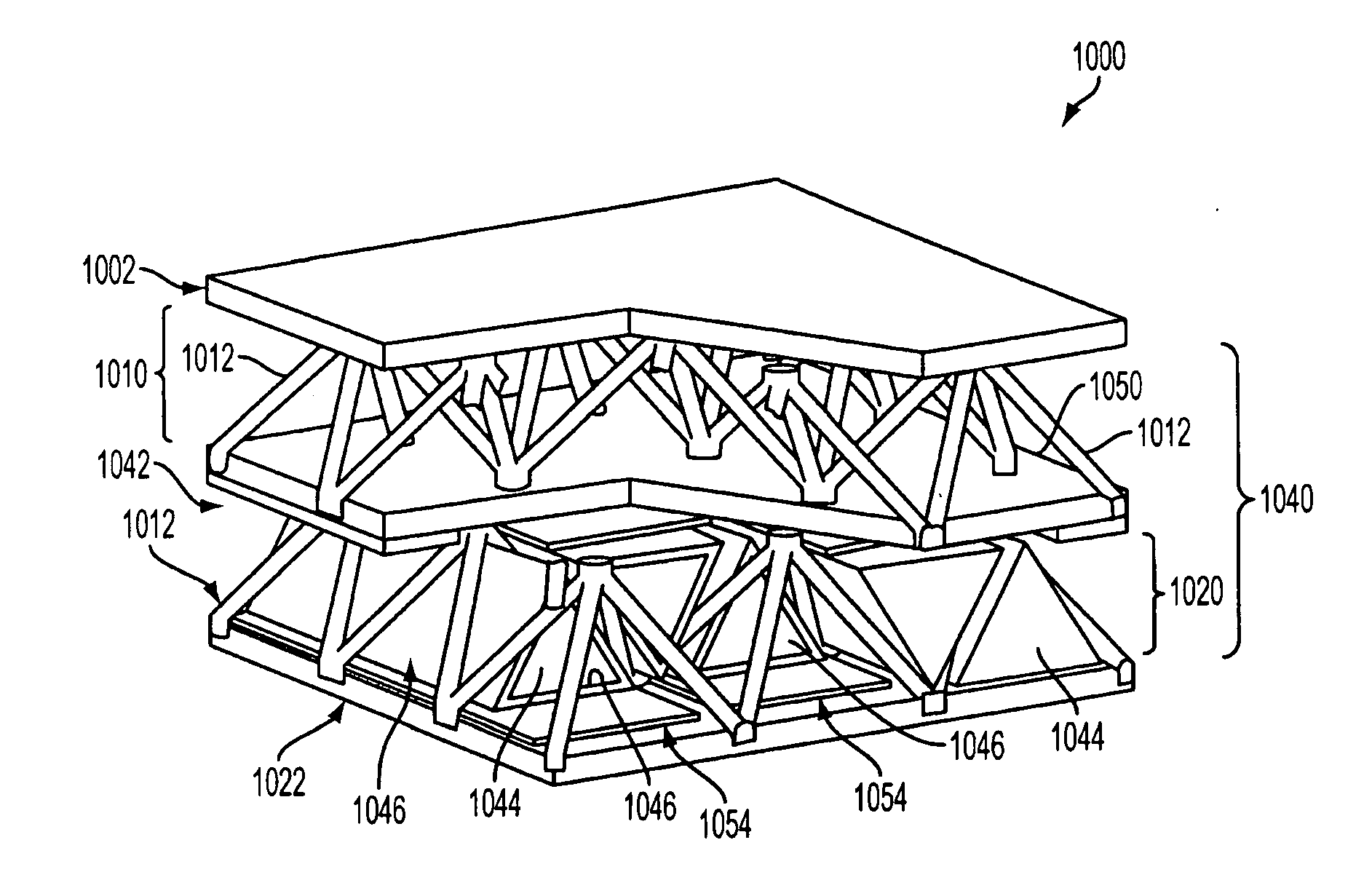

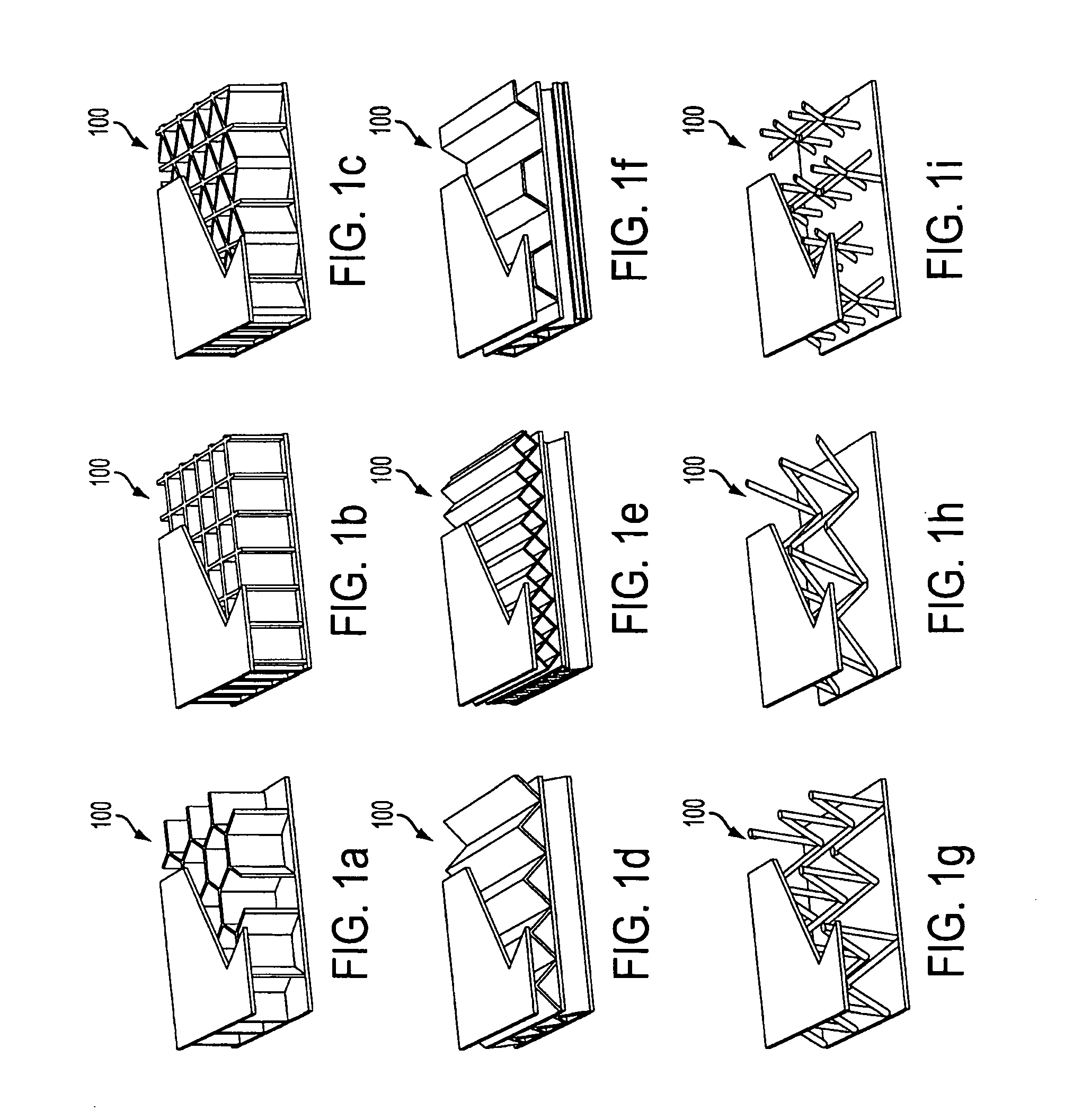

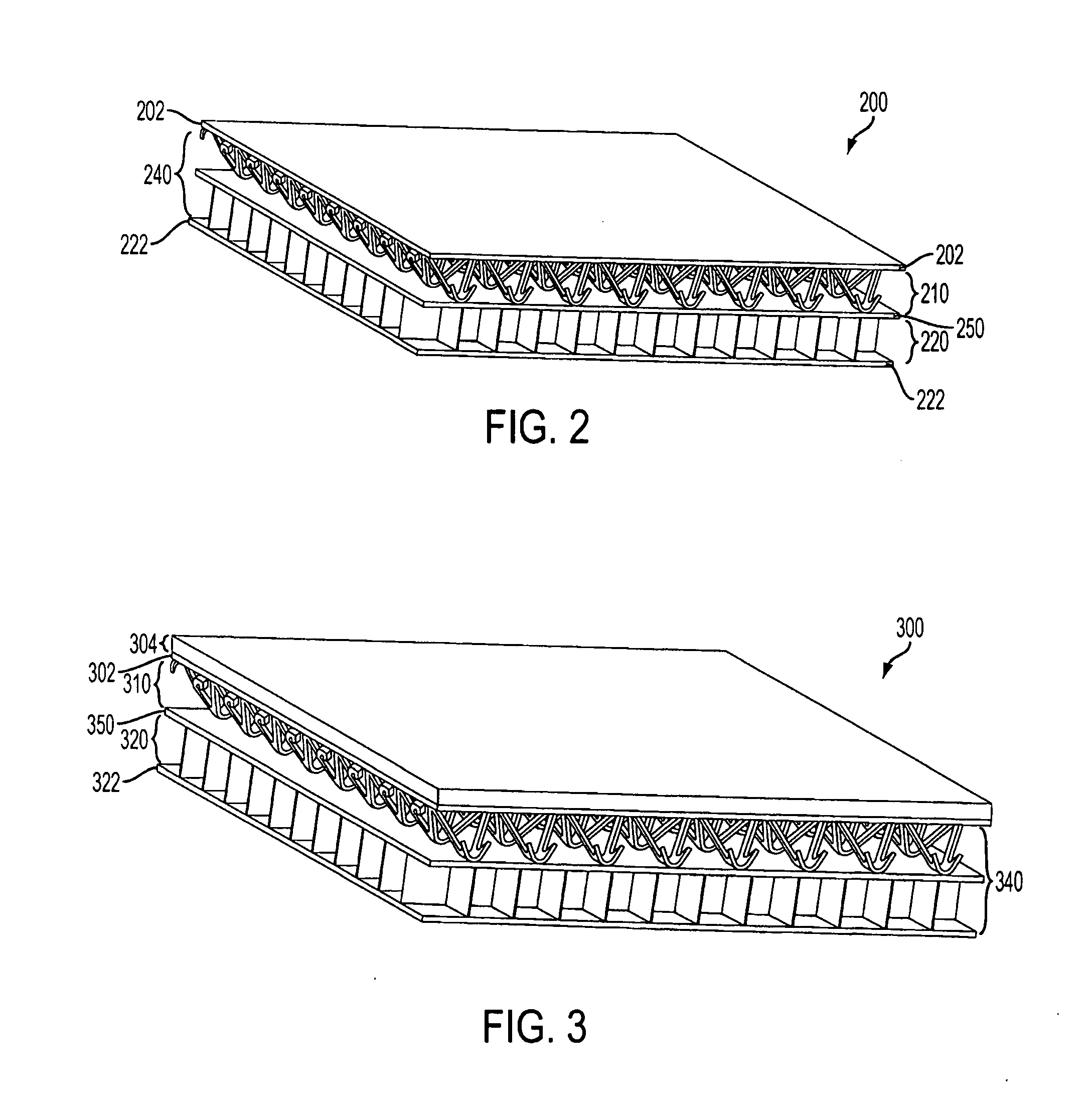

Hybrid Periodic Cellular Material Structures, Systems, and Methods For Blast and Ballistic Protection

ActiveUS20110283873A1More structurally efficientLarge structureArmoured vehiclesAxle-box lubricationProtection systemUltimate tensile strength

Structures based upon periodic cellular materials that provide a potential for defeating combinations of both air blast loading and ballistic attack either sequentially or simultaneously, or combination of both. The cellular structures may also be configured to meet the stiffness and strength support requirements of particular vehicle or other applications, systems or structures. The armor is therefore potentially able to support normal service loads and defeat blast and ballistic threats when necessary. The structure provides for using efficient load support capabilities of the material (without a high armor protection level) in low threat conditions, as well as the ability to modify the system to increase its level protection to a desired or required level. This would reduce the weight of the protection system in normal (low threat) conditions which reduces vehicle wear and tear, as well as cost savings in fabrication of applicable structures or systems.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

Lift, propulsion and stabilising system for vertical take-off and landing aircraft

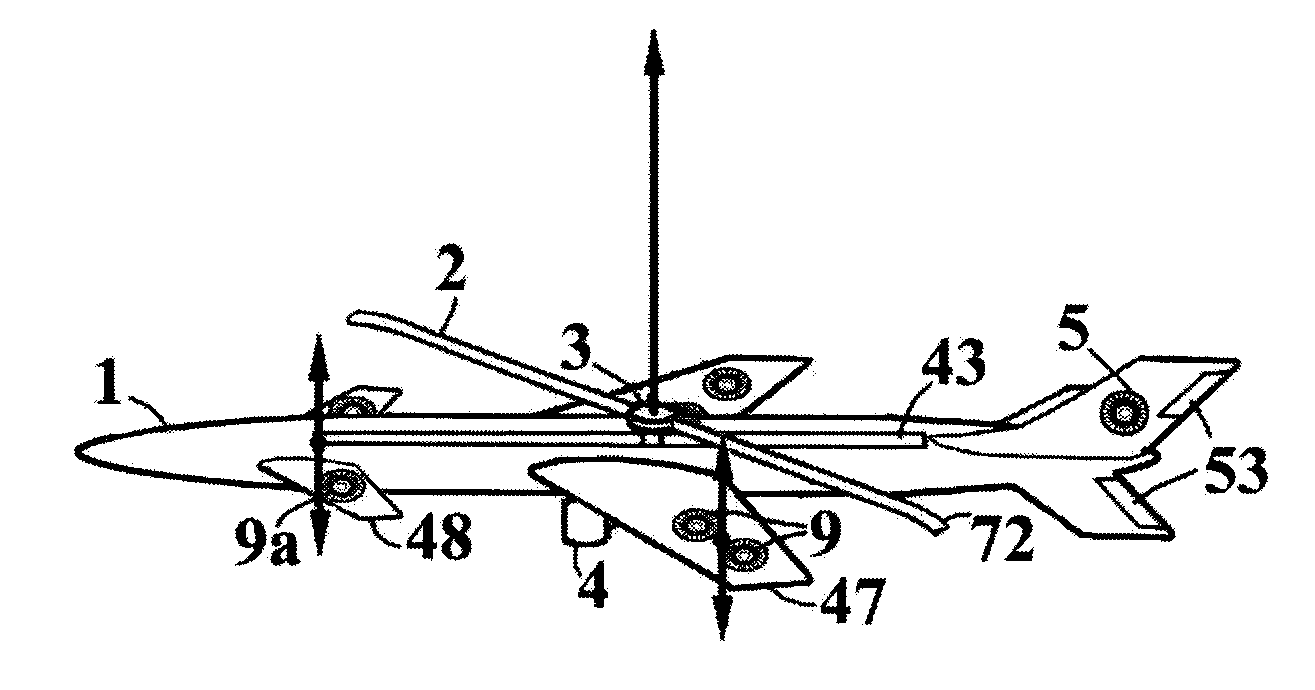

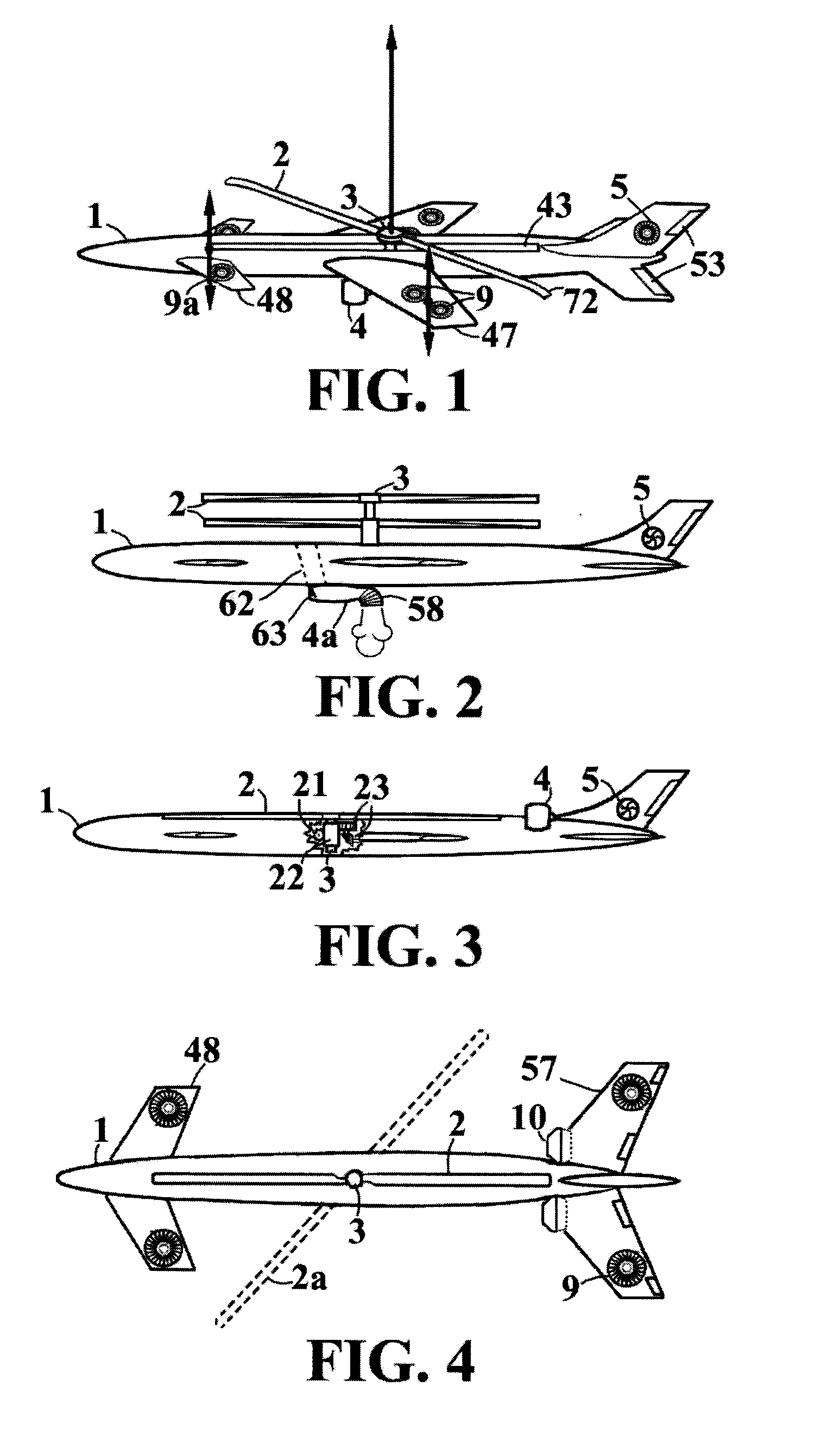

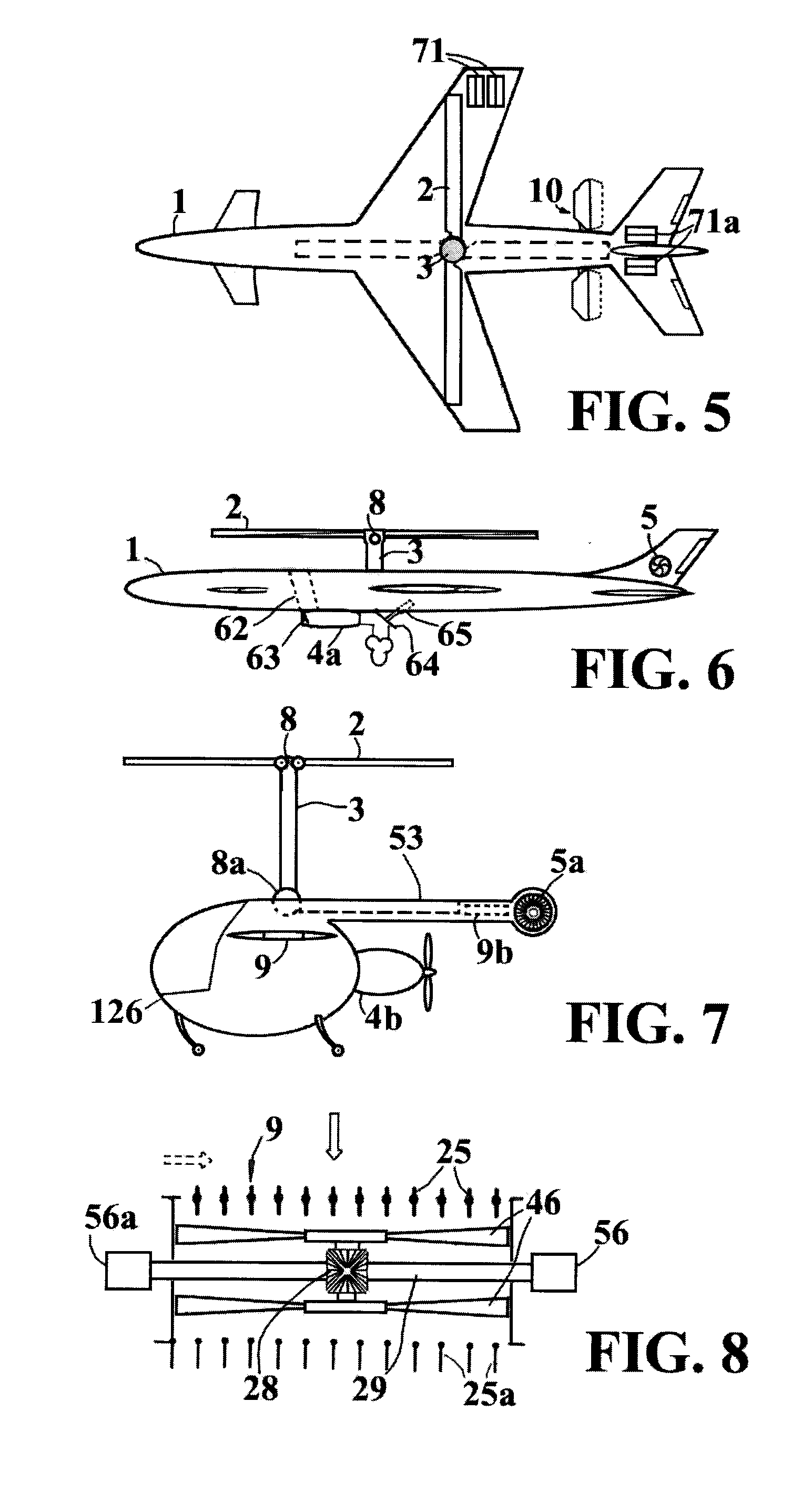

InactiveUS20120280091A1Streamlined shapeImprove stabilityAircraft navigation controlVertical landing/take-off aircraftsTransverse axisFixed wing

The lift, propulsion and stabilising system for vertical takeoff and landing aircraft of the invention consists of applying during vertical flight on, below or in the interior of the fixed-wing aircraft one or more rotors or large fans each one with two or more horizontal blades, said rotors are activated by means of turboshafts, turbofans or turboprops with a mechanical, hydraulic, pneumatic or electrical transmission, and the respective motors. Using lifting and / or stabilising and / or controlling fans and / or oscillating fins and / or air blasts. Placing the horizontal lifters near at least one end of the longitudinal axis and of the transverse axis of the aircraft. Generally said stabilising elements form 90° with one another and with the central application point of the rotor or application of that which results from the lift forces.

Owner:SALZ MANUEL

System and method for cooling a staged airblast fuel injector

A staged fuel injector is disclosed that includes a main fuel circuit for delivering fuel to a main fuel atomizer and a pilot fuel circuit for delivering fuel to a pilot fuel atomizer located radially inward of the main fuel atomizer. The pilot fuel circuit is in close proximity to the main fuel circuit enroute to the pilot fuel atomizer so that the pilot fuel flow cools stagnant fuel located within the main fuel circuit during low engine power operation to prevent coking.

Owner:ROLLS ROYCE PLC

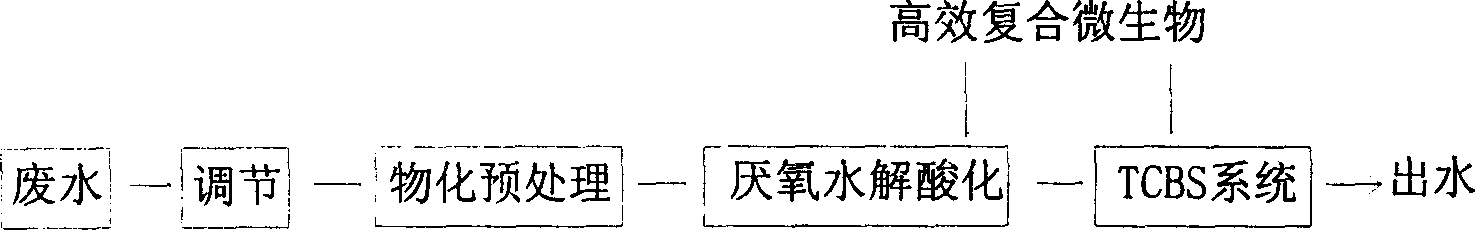

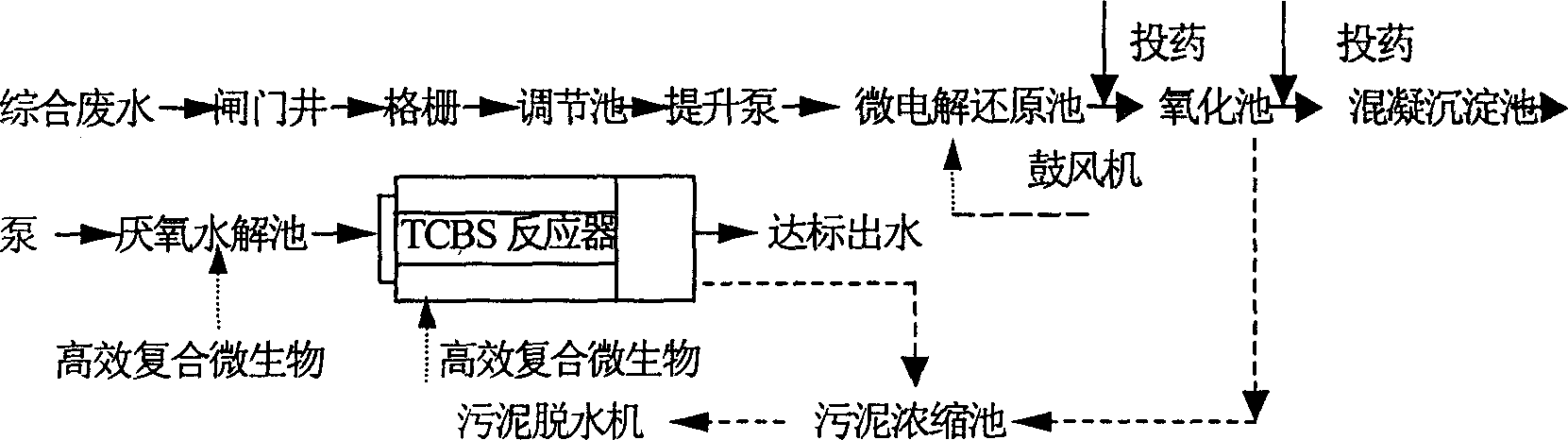

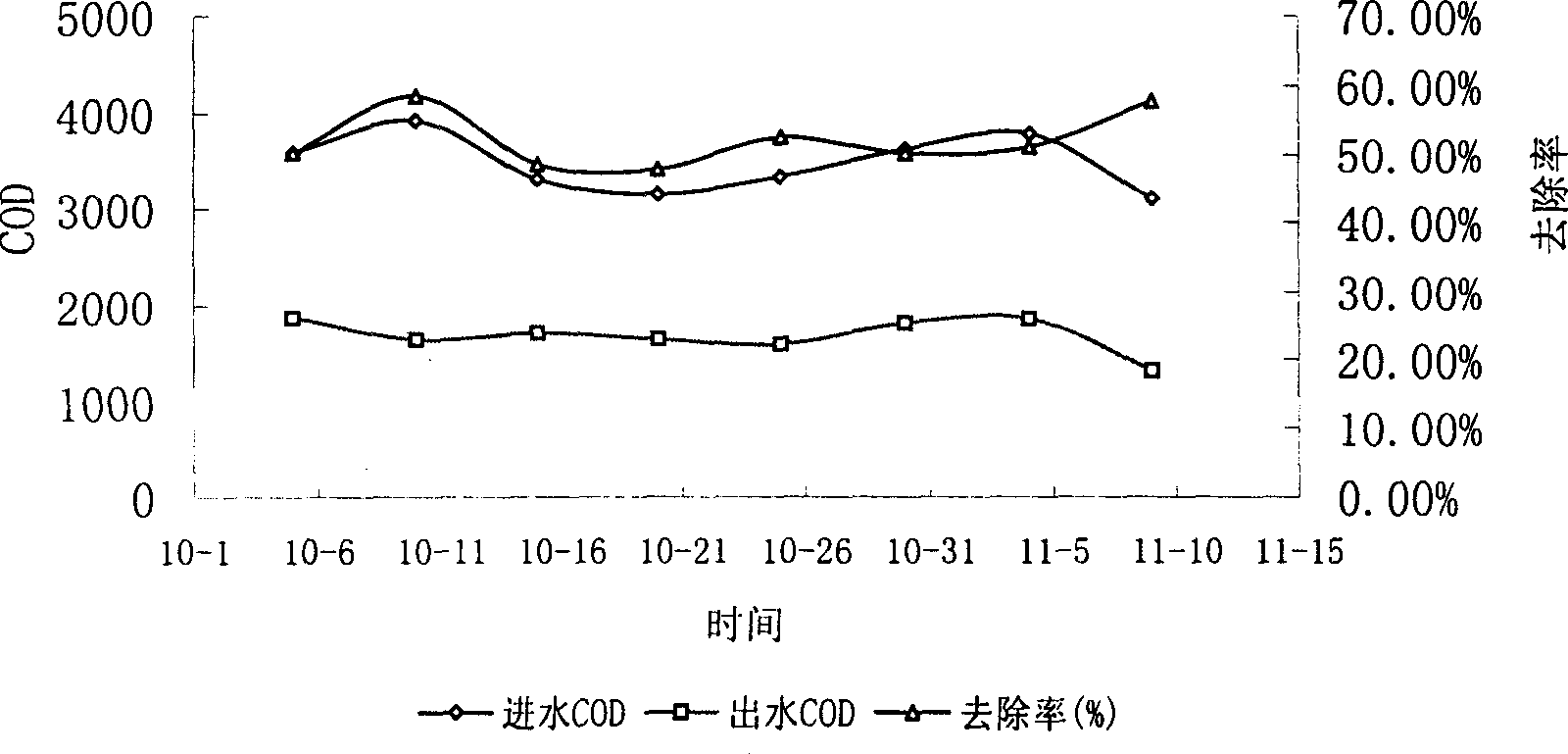

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

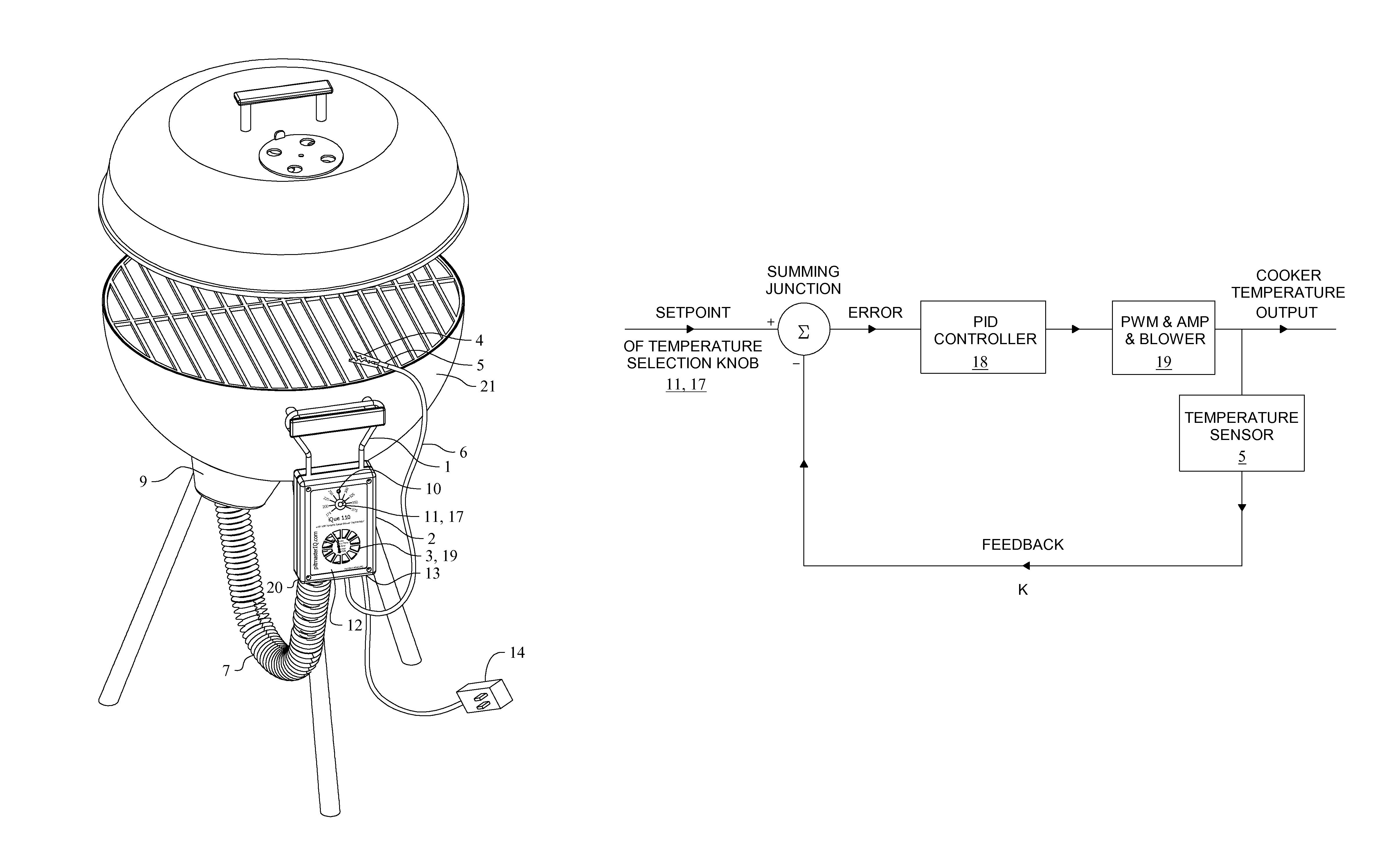

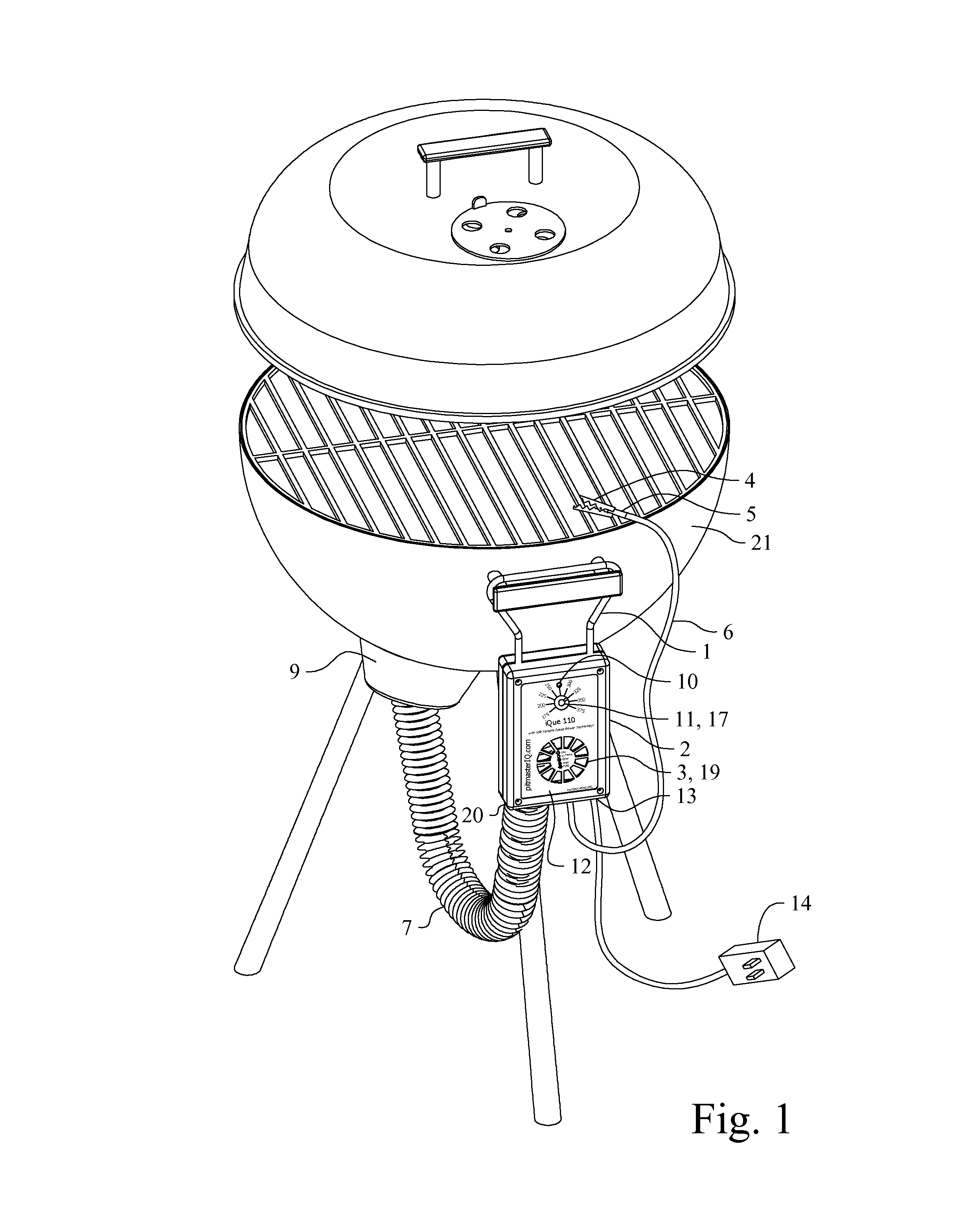

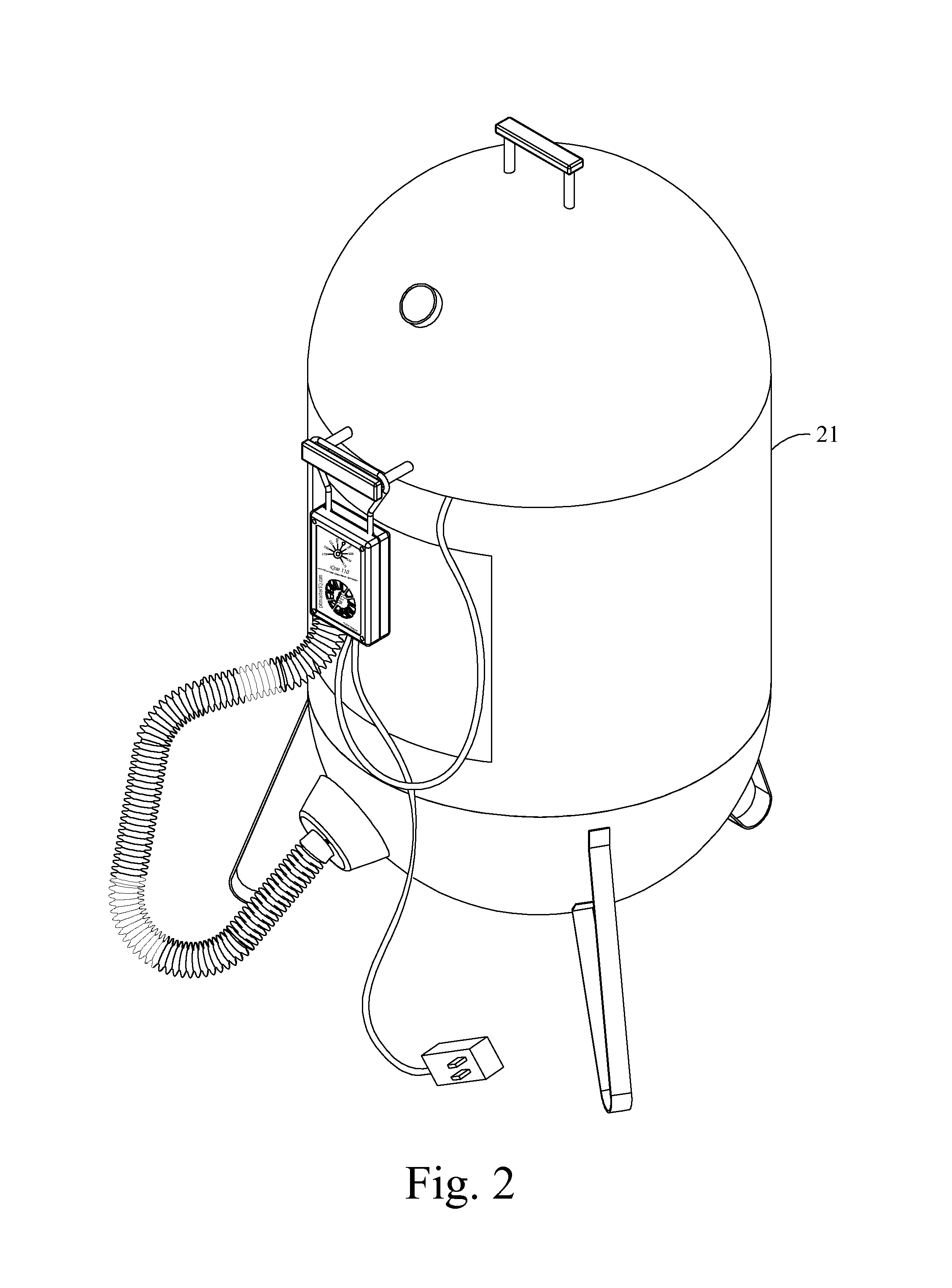

Automatic temperature control device for solid fuel fired food cooker

ActiveUS8800542B1The process is simple and easy to understandQuick installationDomestic stoves or rangesBoiling over preventionTemperature controlCore component

An automatic temperature control device for solid fuel fired food cooker fueled by wood, charcoal, or other solid fuels which is capable of operation with any type of cooker without utilization of different sized blowers and conserves solid fuel usage. The present invention serves to regulate cooking temperature by controlling or optimizing the amount of combustion air reaching the fuel. The present invention also allows an outdoor barbecue grill or smoker of any reasonable size to be retrofitted with the invention in order to allow a chef to cook foods at stable and precise temperatures. The core components of the invention are an air blower to provide combustion air to the burning fuel, an electronic controller to control the amount of air delivered by the air blower via a unique algorithm embedded within the electronic controller, a temperature sensor to sense the temperature inside of the cooker in the vicinity of the cooking food and provide feedback to the electronic controller, and an air tube and air manifold to get or direct the combustion air from the air blower inside the blower box to the burning fuel inside the cooker. Alternative embodiments utilize an automatic damper connected with said electronic controller whereby convection air currents may be precisely controlled.

Owner:KENNINGTON JOHN MATTHEW

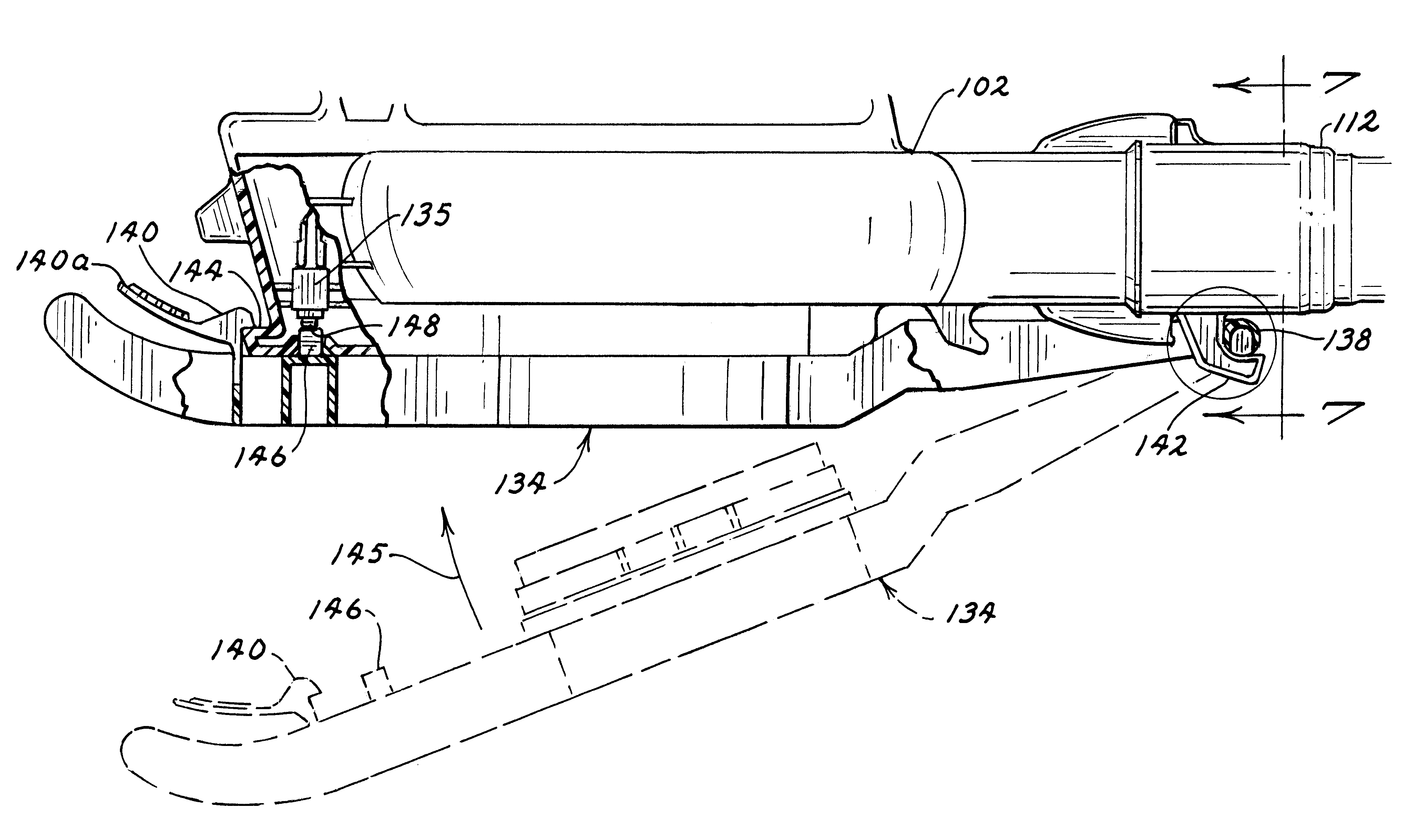

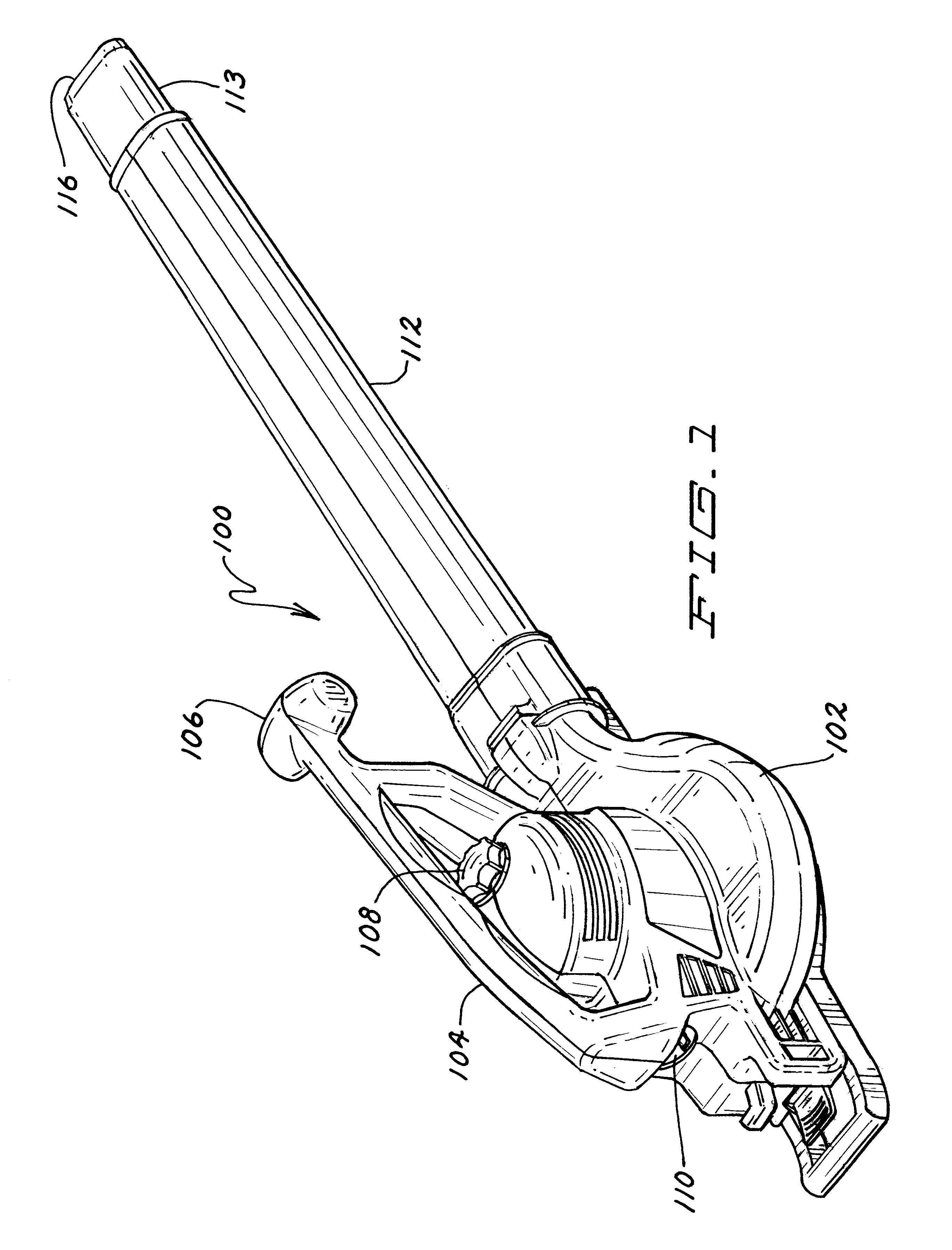

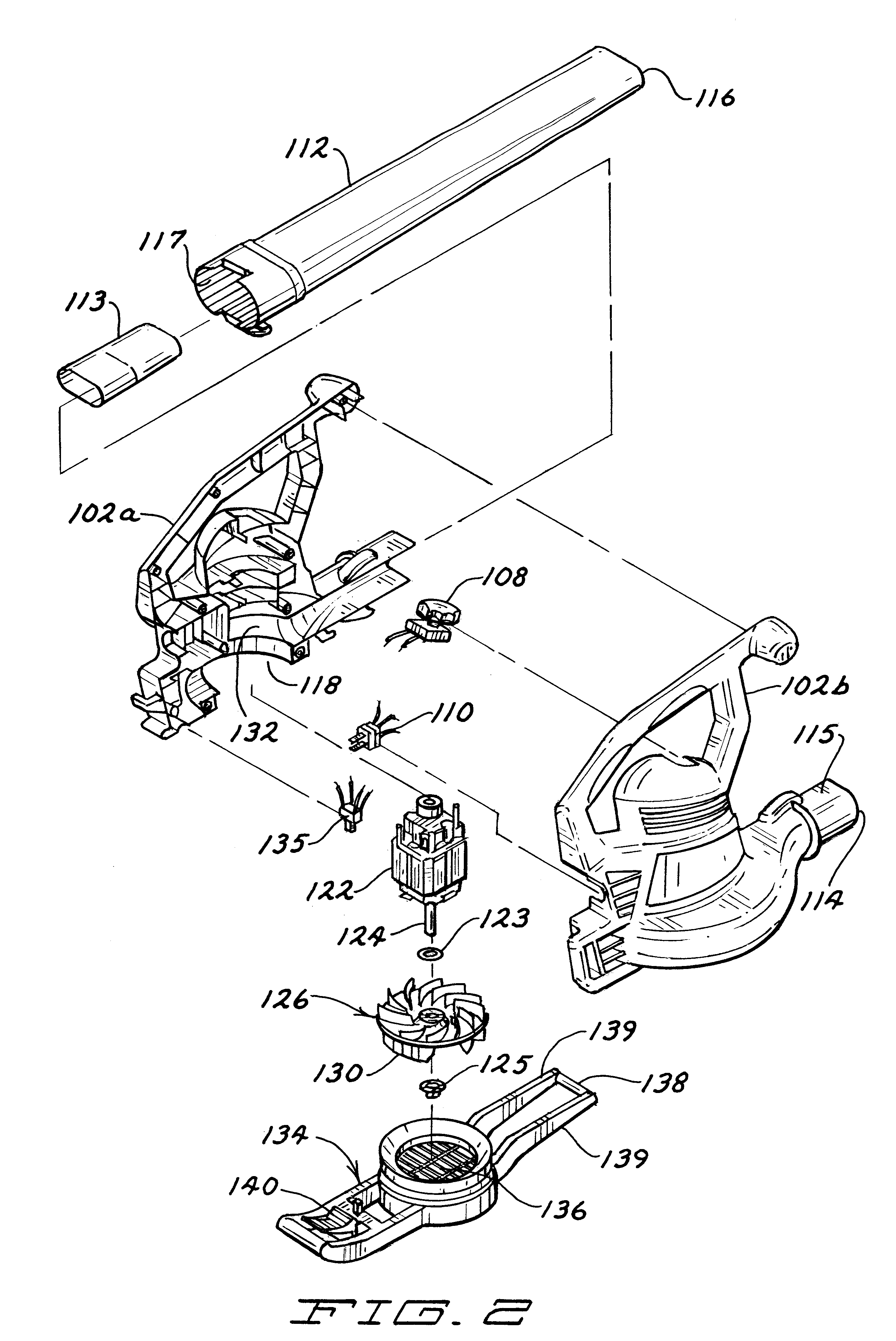

Portable blower/vacuum having air inlet cover attachable to blower tube

A blower / vacuum having an air inlet cover and a blower tube, both of which attach to a blower housing for operation in a blower mode. The air inlet cover is preferably able to removably attach to the blower housing and the blower tube. Blower / vacuums of the present invention may generally prohibit operation unless both the blower tube and the air inlet cover are first installed. The blower / vacuum is further adapted to operate in a vacuum mode by removing the air inlet cover and blower tube and replacing the same with a vacuum tube assembly and a vacuum collection container, respectively.

Owner:TORO CO THE

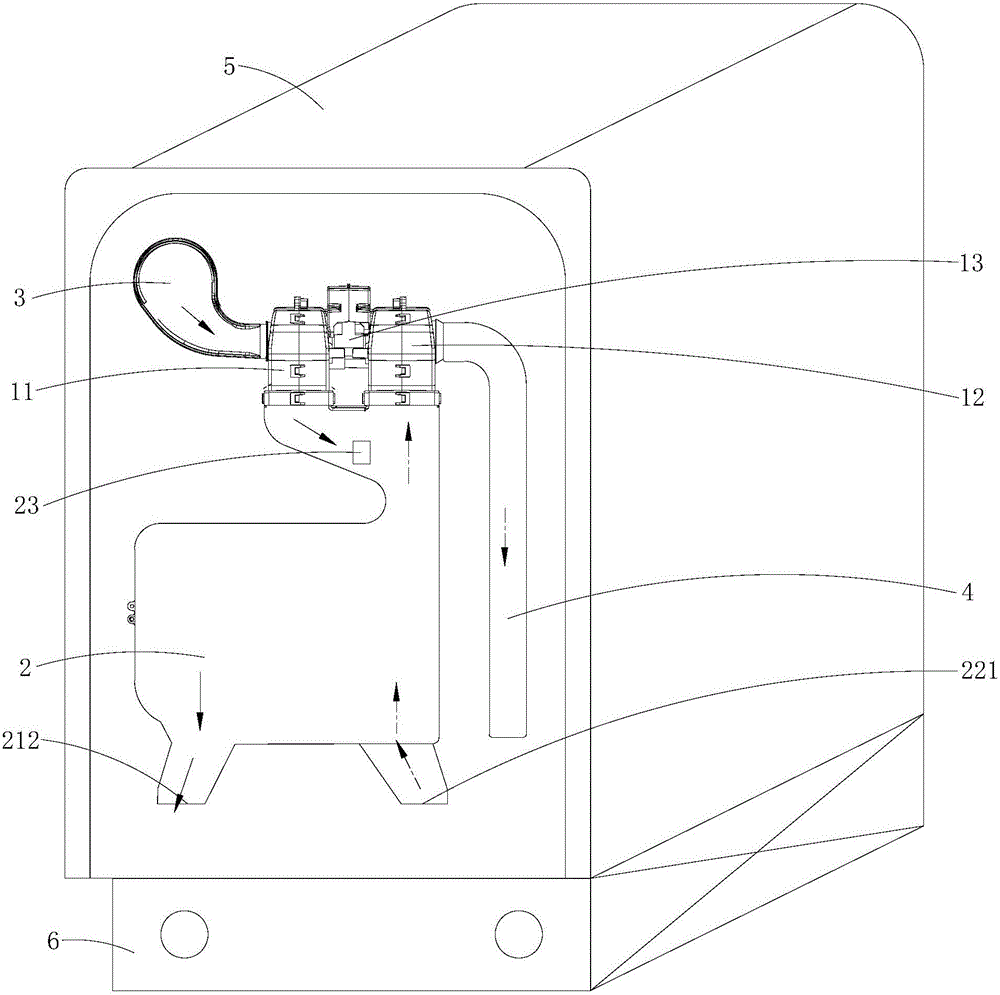

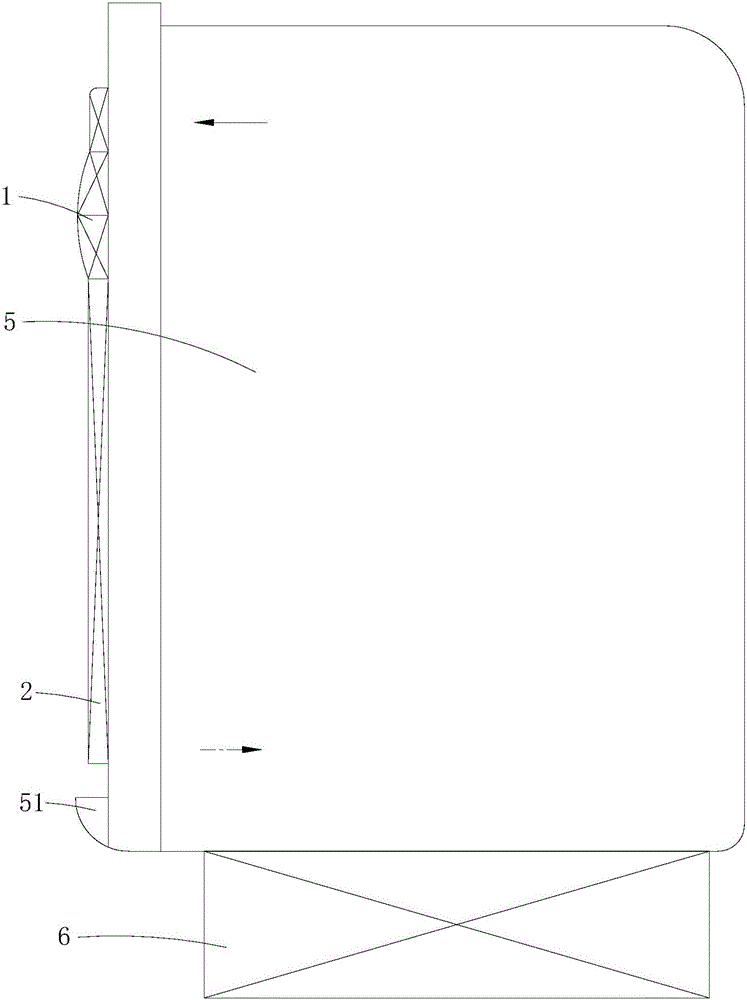

Condensing and drying device of dish-washing machine and dish-washing machine

InactiveCN105796033AKeep dryImprove drying efficiencyTableware washing/rinsing machine detailsHome appliance efficiency improvementWater flowEngineering

The invention is applicable to the field of dish-washing machines, and discloses a condensing and drying device of a dish-washing machine and the dish-washing machine. The condensing and drying device of the dish-washing machine is installed between an inner door and an outer door of the dish-washing machine and comprises an air-blasting assembly and a heat exchange component; a condensing cavity and a heating cavity are formed in the heat exchange component side by side, the air-blasting assembly comprises a first air-blasting component, a second air-blasting component and a power component, wherein the first air-blasting component can suck humid and hot air in an inner container of the dish-washing machine into the condensing cavity and outwards exhaust the air subjected to condensation of the condensing cavity, the second air-blasting component can suck external air located in front of the outer door into the heating cavity and exhaust the external air heated by the heating cavity into the inner container, and the power component is used for driving the first air-blasting component and the second air-blasting component to operate. According to the condensing and drying device of the dish-washing machine and the dish-washing machine, the situation that due to the fact that air exhausted from the dish-washing machine forms condensed water on the outer surface of the dish-washing machine, the condensed water sags on the outer surface of the dish-washing machine or drips onto the ground is prevented, necessary energy consumption in the drying process of the dish-washing machine is reduced, and meanwhile the internal hygiene condition of the dish-washing machine is effectively improved.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD +1

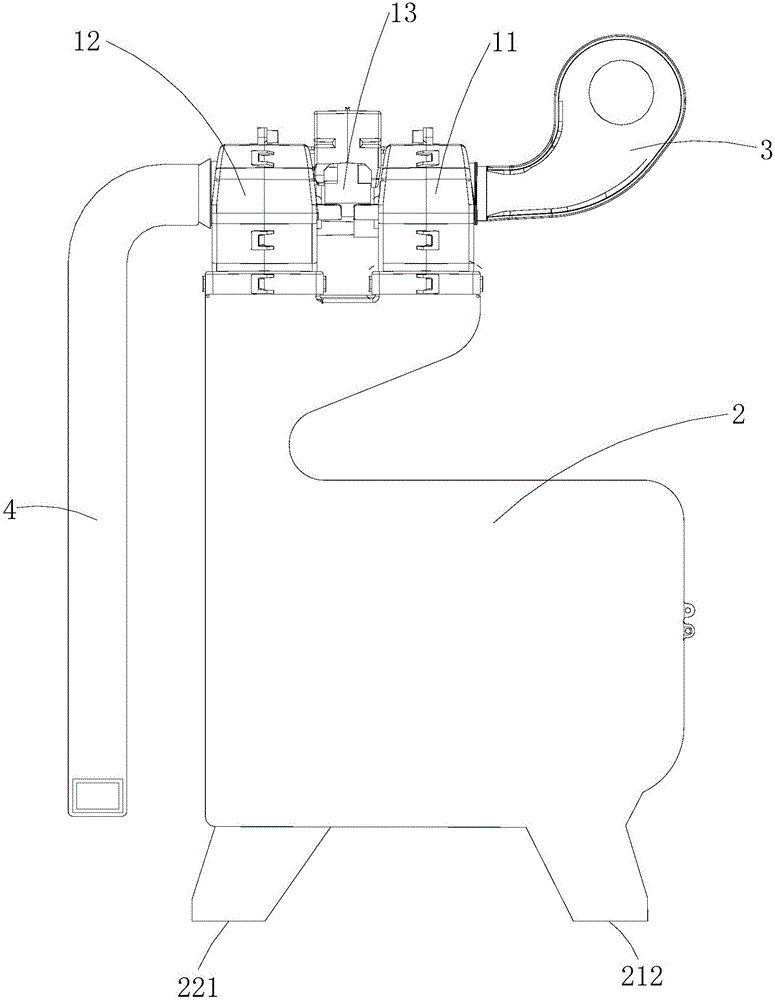

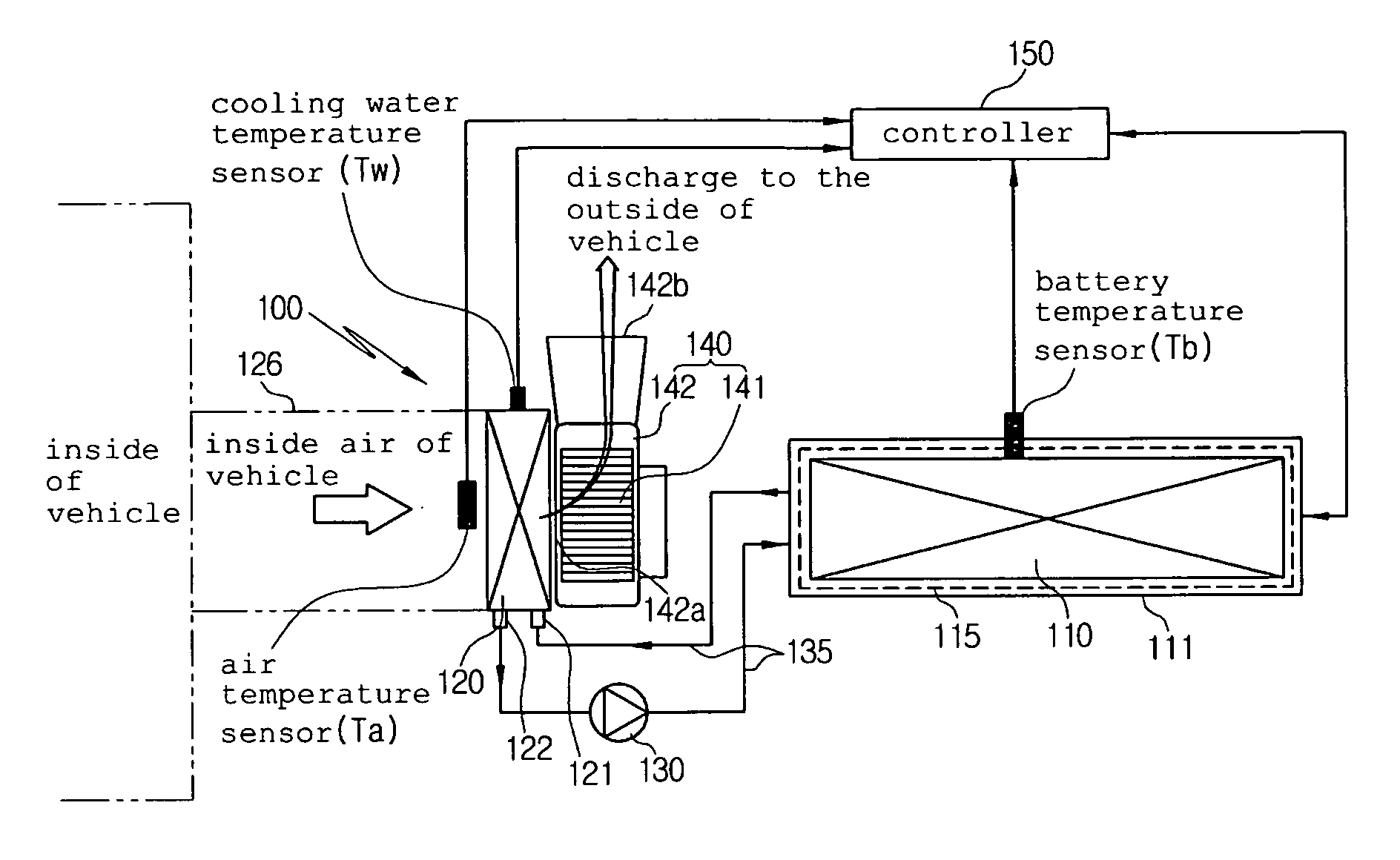

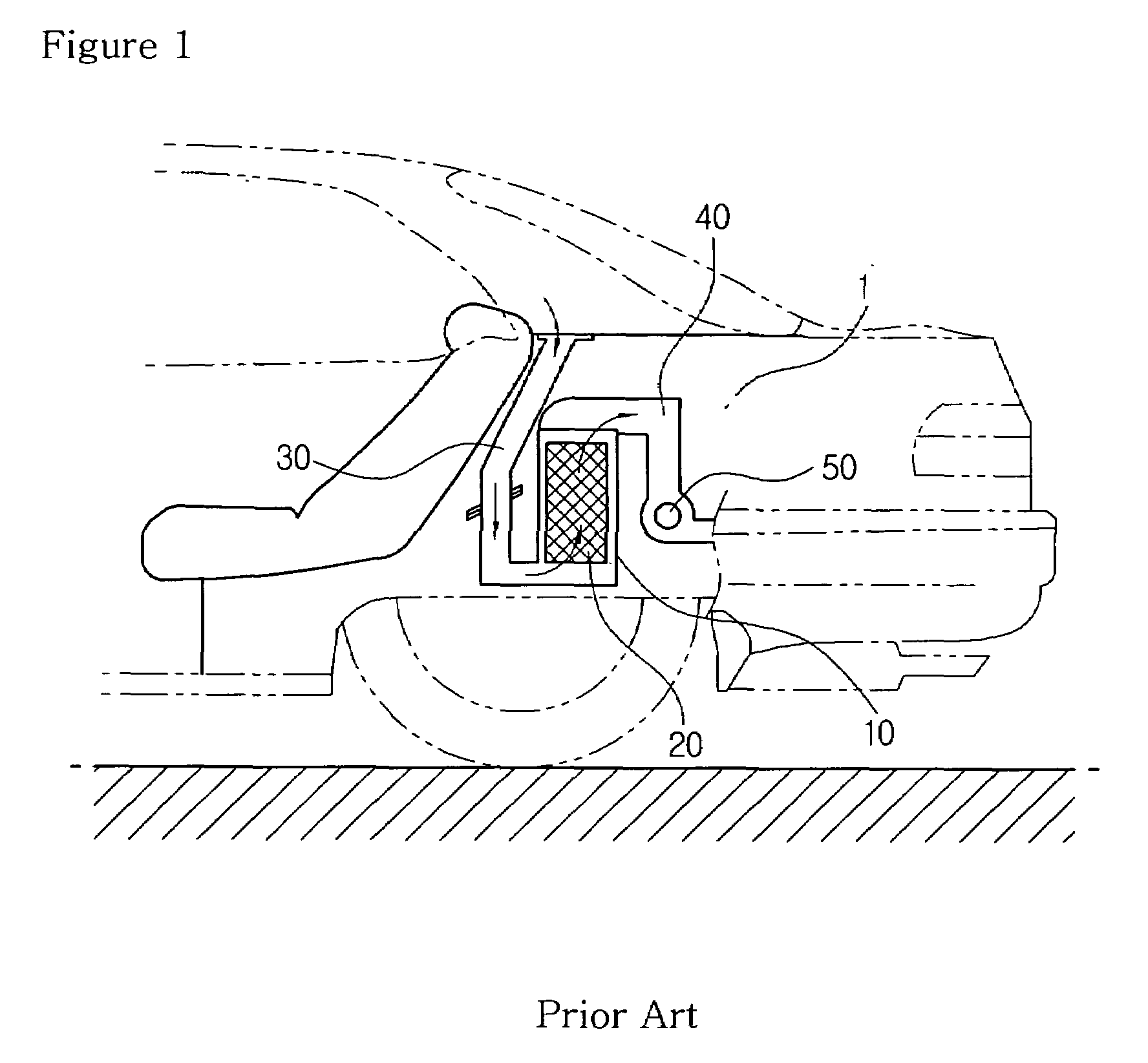

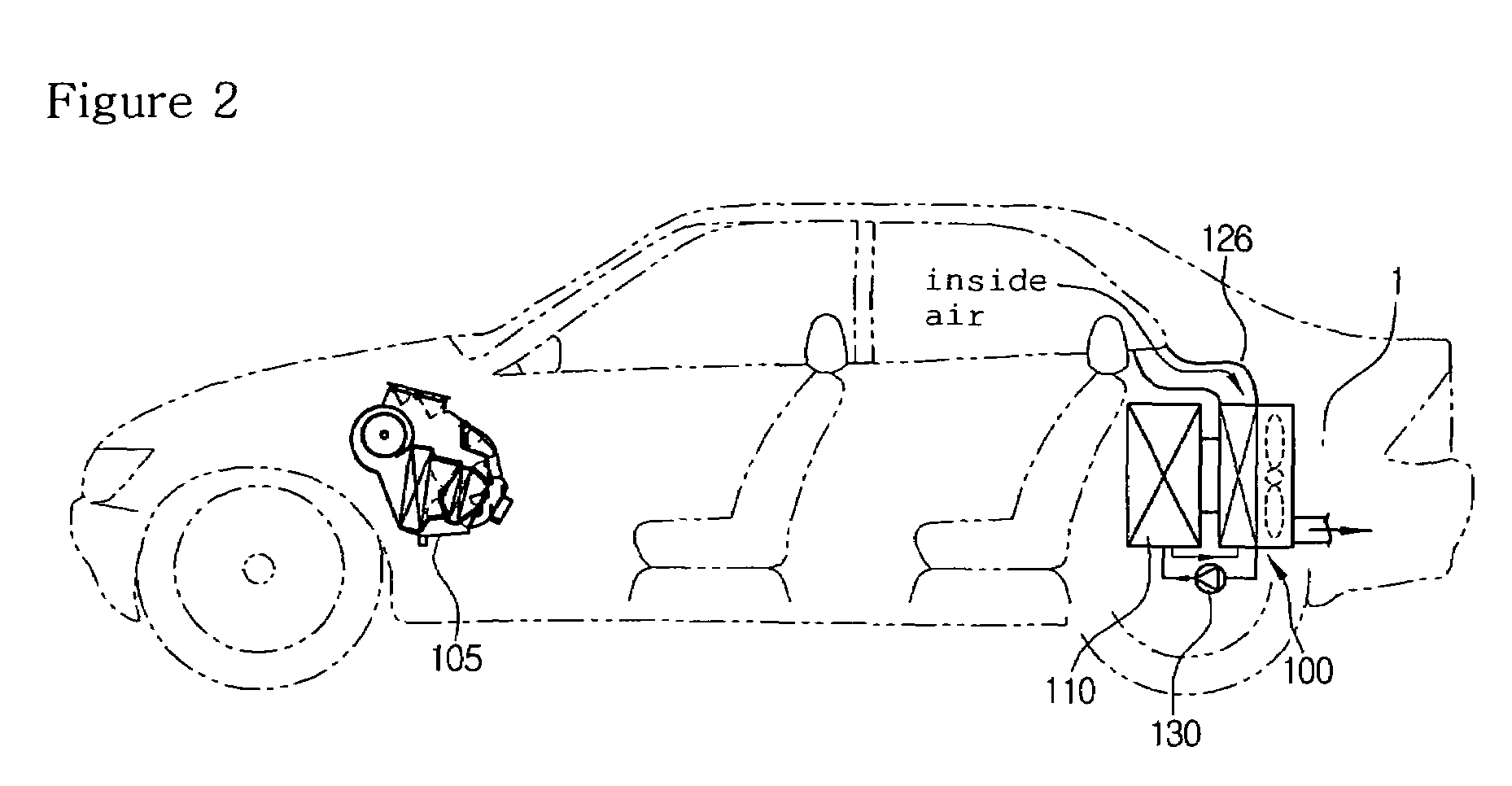

Battery cooling device for vehicles and control method thereof

InactiveUS20080202741A1Improve efficiencyReduce noiseTemperatue controlElectric propulsion mountingElectrical batteryEngineering

The present invention relates to a battery cooling device for vehicles and a method for controlling the battery cooling device, which compactly includes battery heat exchanging means mounted on a battery to cooling the battery in a water cooling type, and a heat exchanger, air blowing means and cooling water circulating means connected with the battery heat exchanging means. Operations of the air blowing means and the cooling water circulating means are controlled in such a way as to compare battery temperature, cooling water temperature and inside air temperature of the vehicle with one another, whereby the battery cooling device can enhance efficiency of the battery by properly controlling the battery temperature, reduce power consumption and noise by properly operating the air blowing means and the cooling water circulating means, and satisfy necessary inside temperature conditions while cooling the battery using the inside air of the vehicle.

Owner:HALLA CLIMATE CONTROL

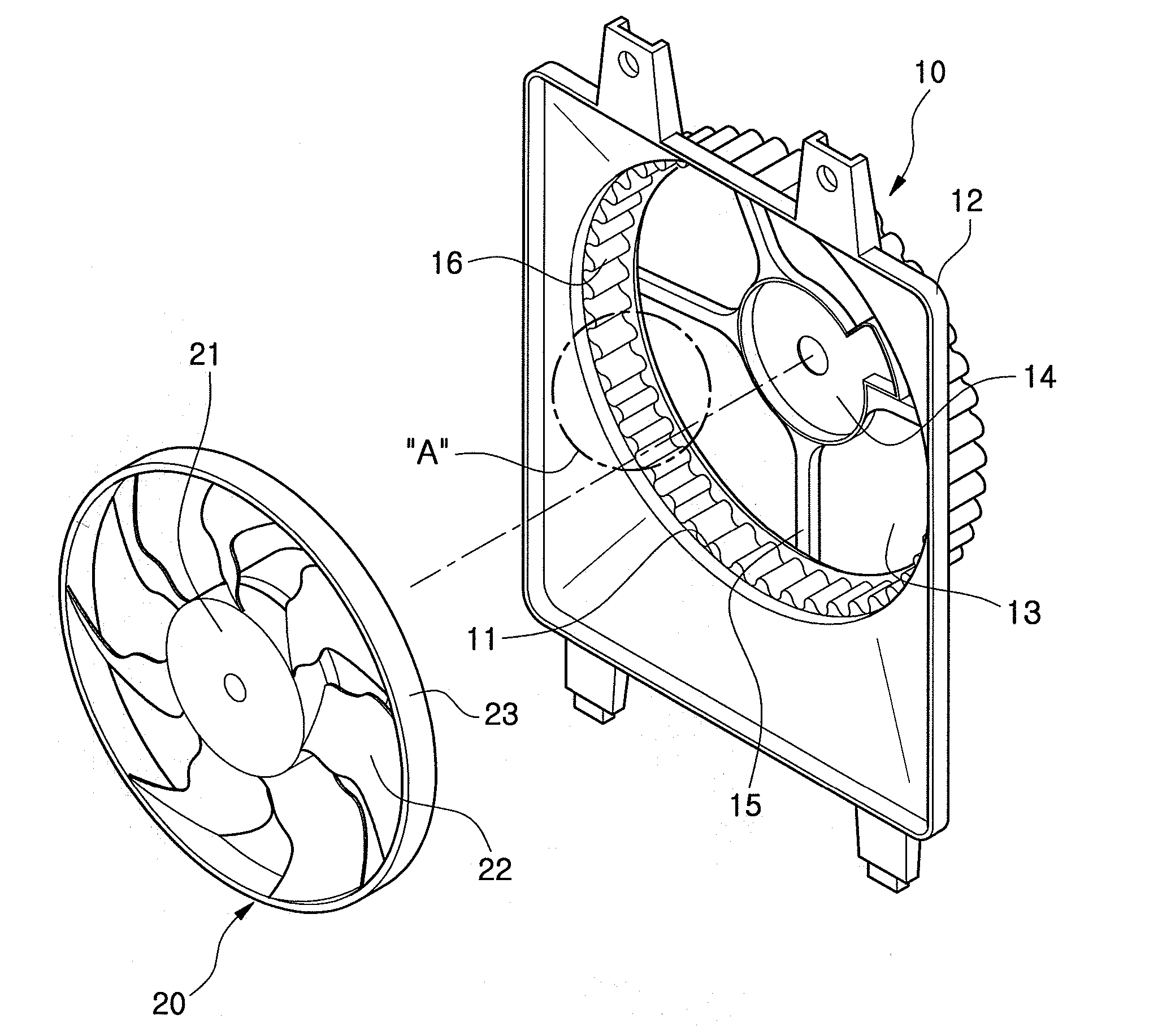

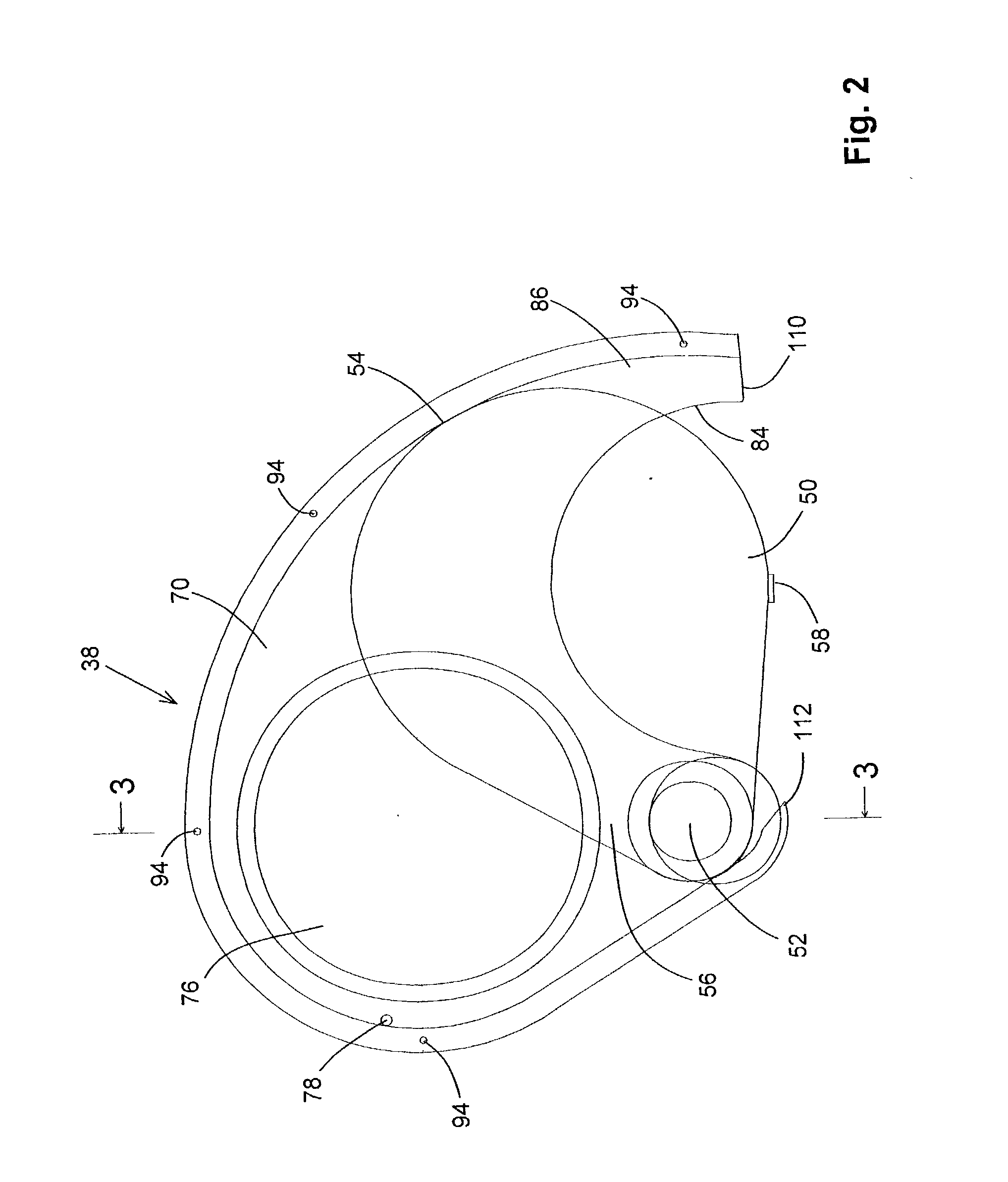

Fan and shroud assembly

InactiveUS20060216147A1Improve noise reductionPreventing swirling airflowPropellersReaction enginesEngineeringNoise reduction

Disclosed herein is a fan and shroud assembly comprising: a fan having a hub rotating on a shaft and a plurality of blades extending outward from the hub; and a shroud surrounding the fan for controlling air blast by rotation of the fan, wherein the shroud comprises: a guide ring part spaced apart at a predetermined interval from the periphery of the fan which connects ends of the blades; and swirl preventing means formed on the guide ring part for preventing swirling airflow along the periphery of the fan connecting the ends of the blades. The fan and shroud assembly can minimize generation of swirling airflow and backflow and provide improved noise-reduction effect.

Owner:HANON SYST

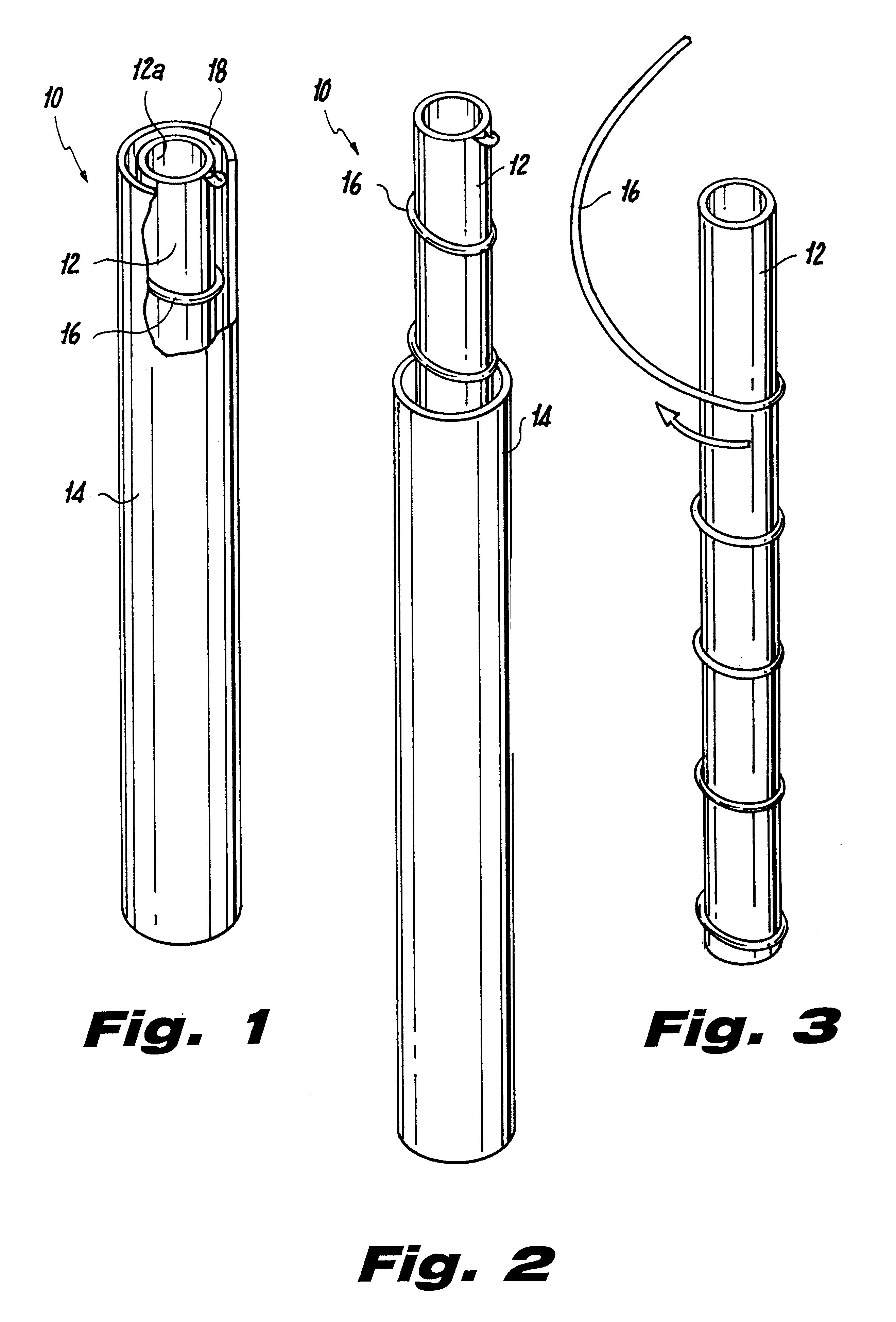

Airblast fuel atomization system

An airblast fuel injector assembly for use in conjunction with a gas turbine is disclosed which includes an elongated tubular body having first and second concentric tubes separated from one another by a helical spacer wire so as to define a fuel passage therebetween. The injector assembly is situated such that fuel flow exiting the fuel passage is intersected by an air flow at a predetermined angle of incidence so as to atomize the fuel flow.

Owner:DELAVAN +1

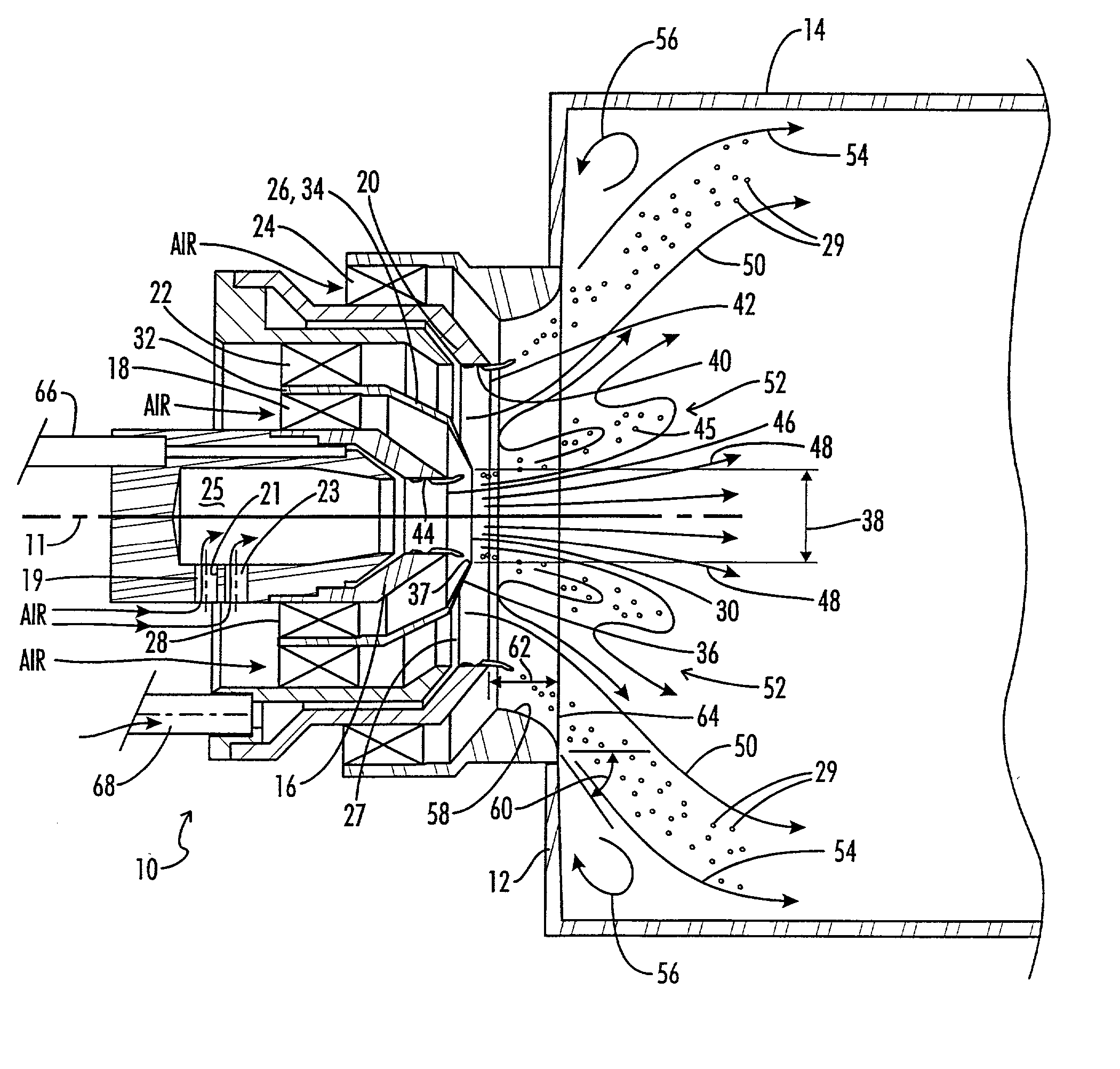

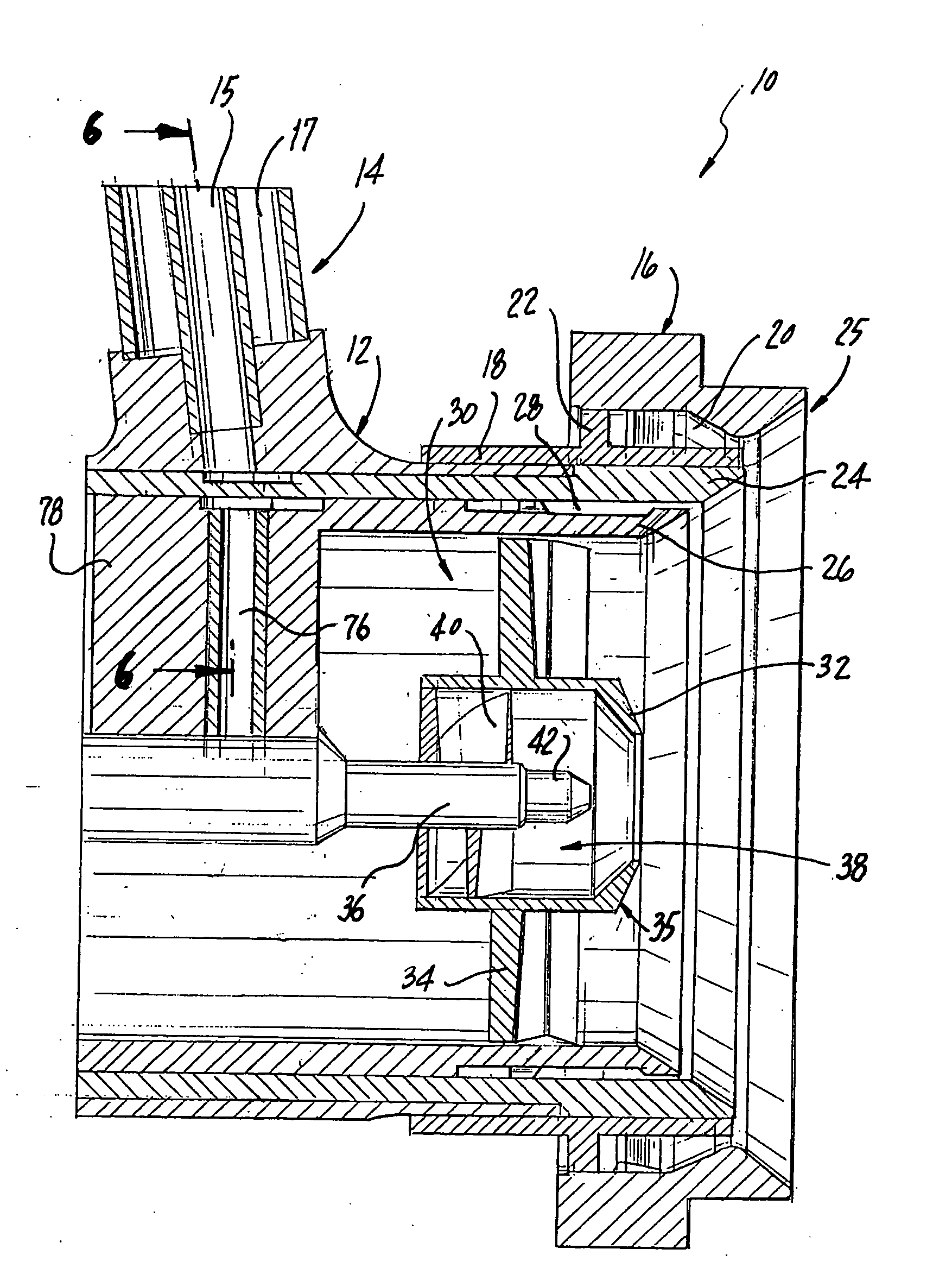

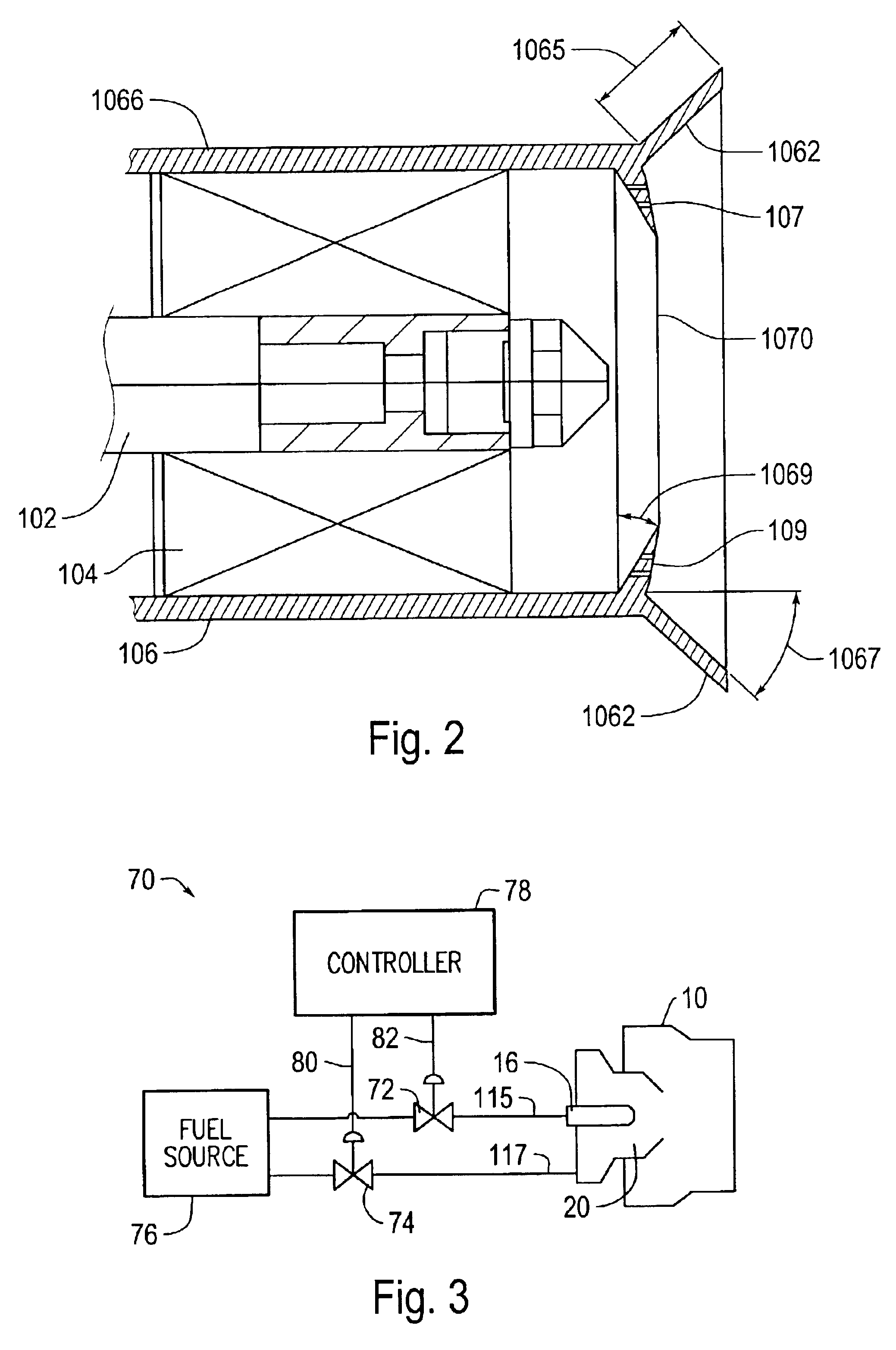

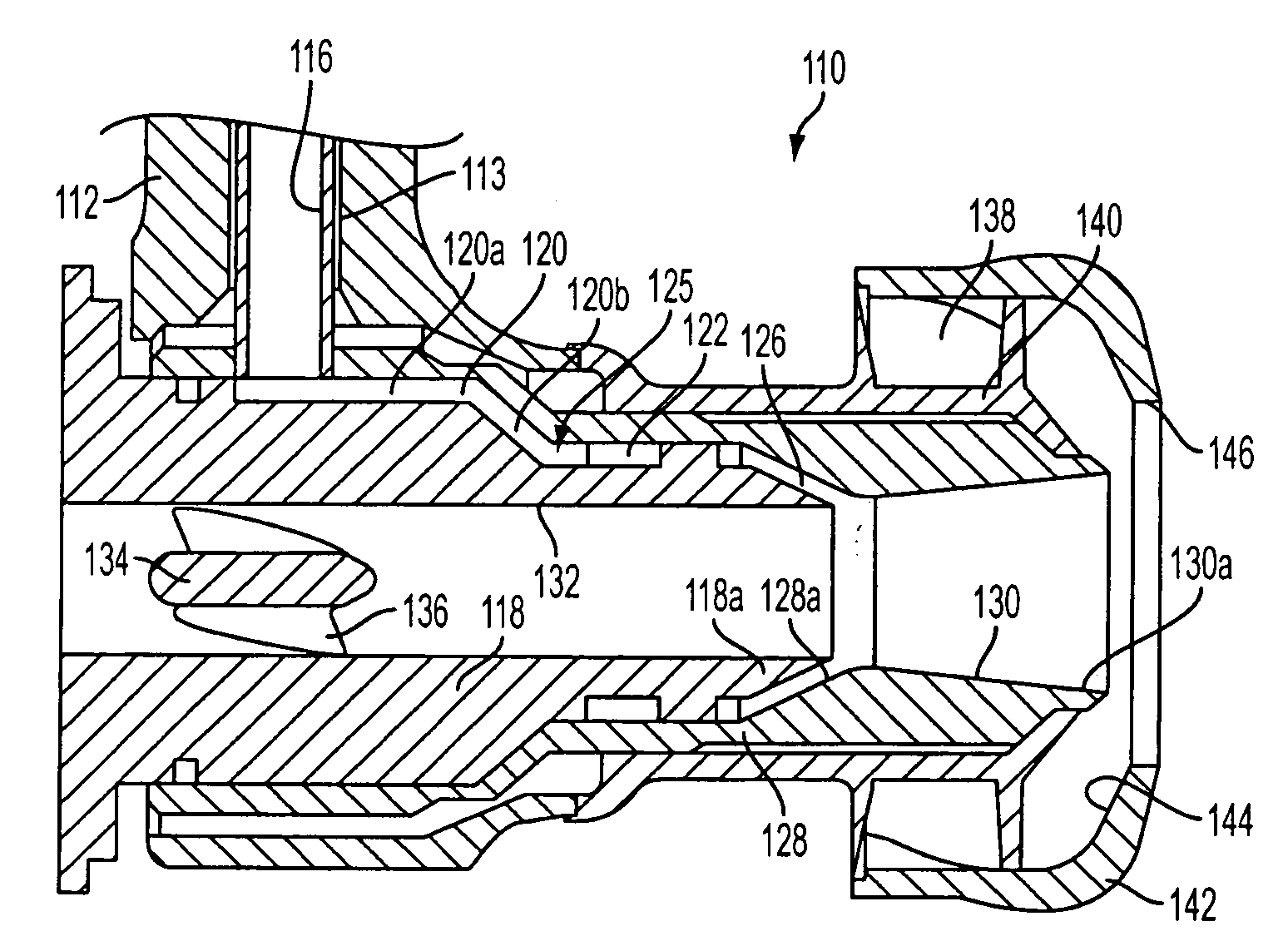

Piloted airblast lean direct fuel injector with modified air splitter

ActiveUS6986255B2Improve combustion efficiencyEmission reductionBurnersContinuous combustion chamberCombustion instabilityInjector

A fuel injector system that reduces and / or eliminates combustion instability. The fuel injector system includes a pilot fuel injector, a pilot swirler that swirls air past the pilot fuel injector, a main airblast fuel injector having an aft end, inner and outer main swirlers that swirl air past the main airblast fuel injector, and an air splitter located between the pilot swirler and the inner main swirler. The air splitter includes at least one aft end cone angled radially outboard and axially positioned downstream of the main airblast fuel injector aft end. The air splitter divides a pilot air stream exiting the pilot swirler from an inner main air stream exiting the inner main swirler to create a bifurcated recirculation zone.

Owner:ROLLS ROYCE PLC

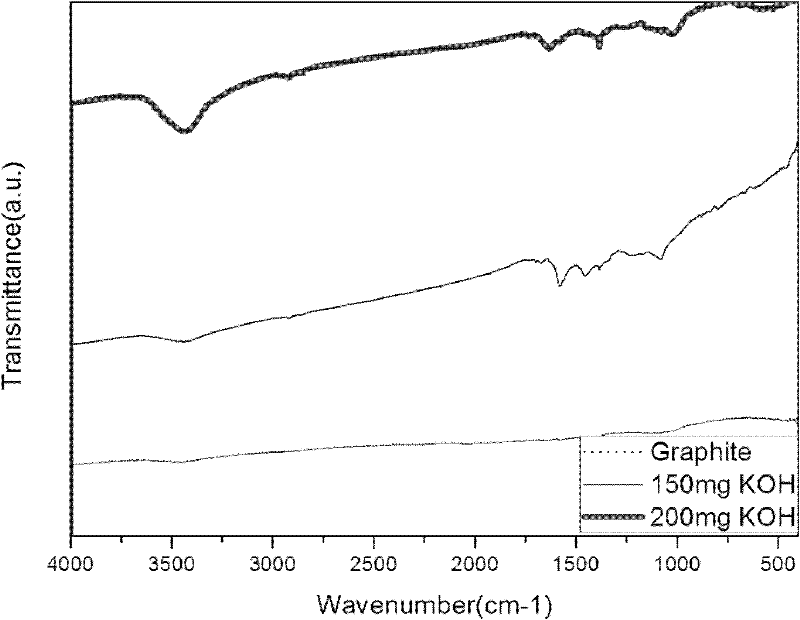

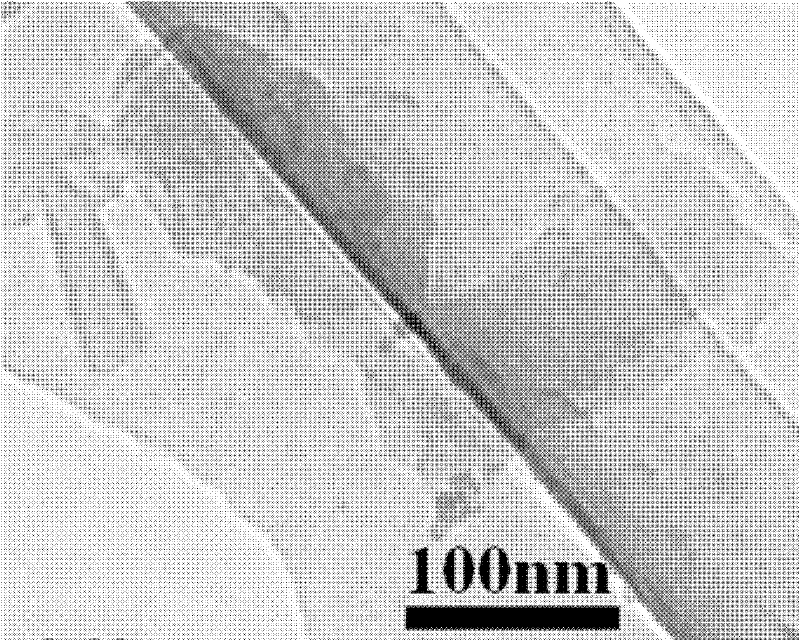

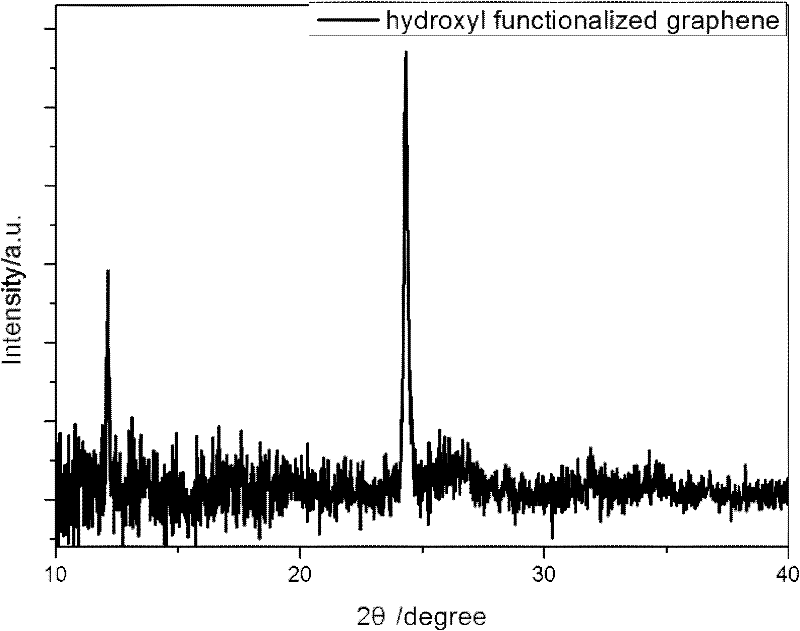

Low-temperature preparation method of hydroxy-functionalized graphene

InactiveCN102225759AThe internal structure is intactHigh degree of crystallinityNanotechnologyPotassium hydroxideEngineering

The invention relates to a novel and simple low-temperature preparation method of hydroxy-functionalized grapheme, belonging to the field of novel carbon nanomaterials. The preparation method provided by the invention comprises the following steps of: adding graphite powder and potassium hydroxide solid to a ball milling tank, then adding milling balls to the ball milling tank, placing the ball milling tank in a ball mill, continuously ball-milling under air blast and room temperature conditions at a speed of 200-400 r / min for 10-16 hours, transferring the ball-mill product to a sample bottle by deionized water, and then removing unreacted potassium hydroxide by deionized water until the solution was neutral. By using the preparation method provided by the invention, hydroxy-functionalized grapheme can be prepared at room temperature, and the hydroxy-functionalized grapheme has a lamellar structure, contains a large number of hydroxyl groups on the surface, well remained internal structure and a high crystallinity.

Owner:WENZHOU MEDICAL UNIV

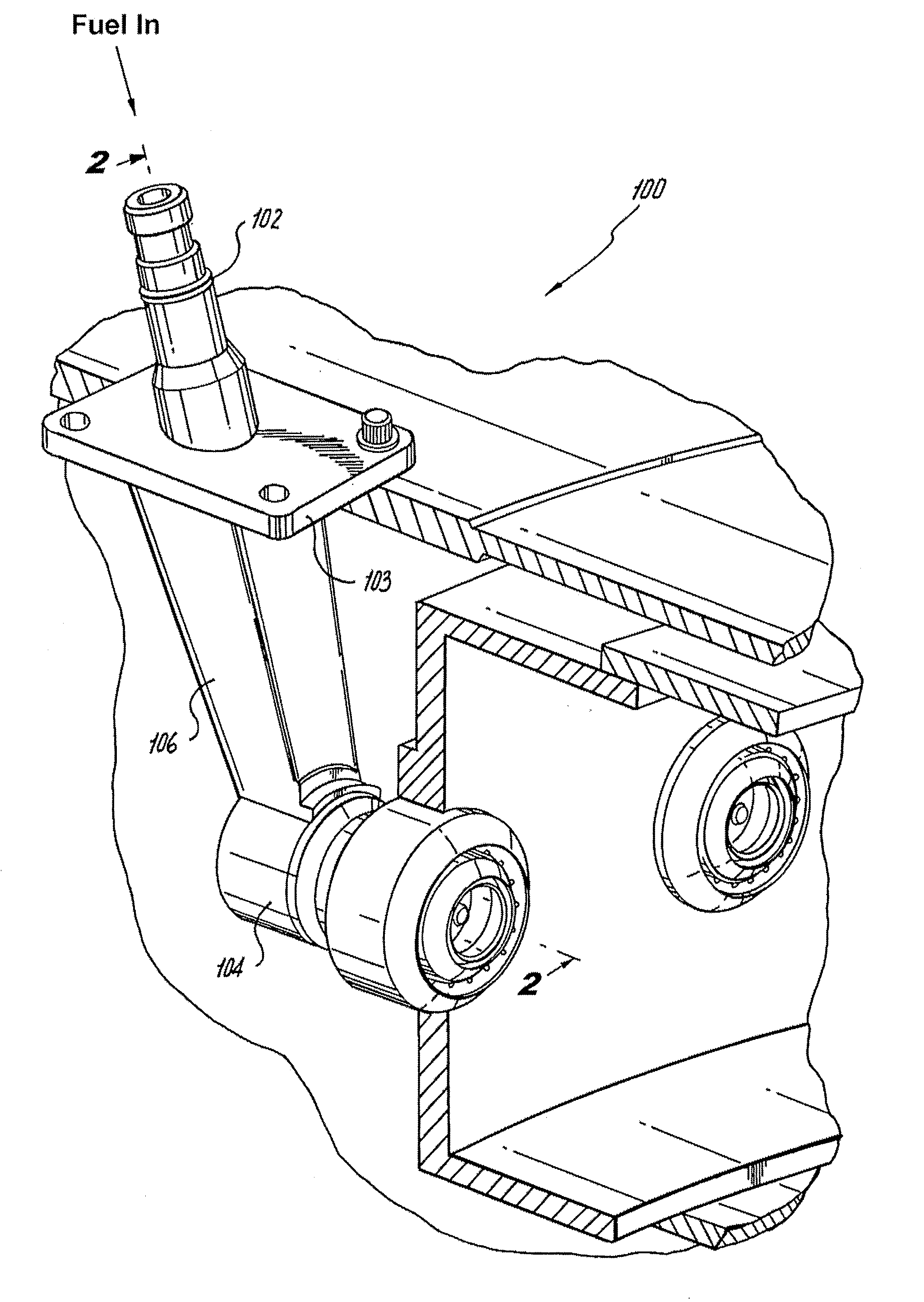

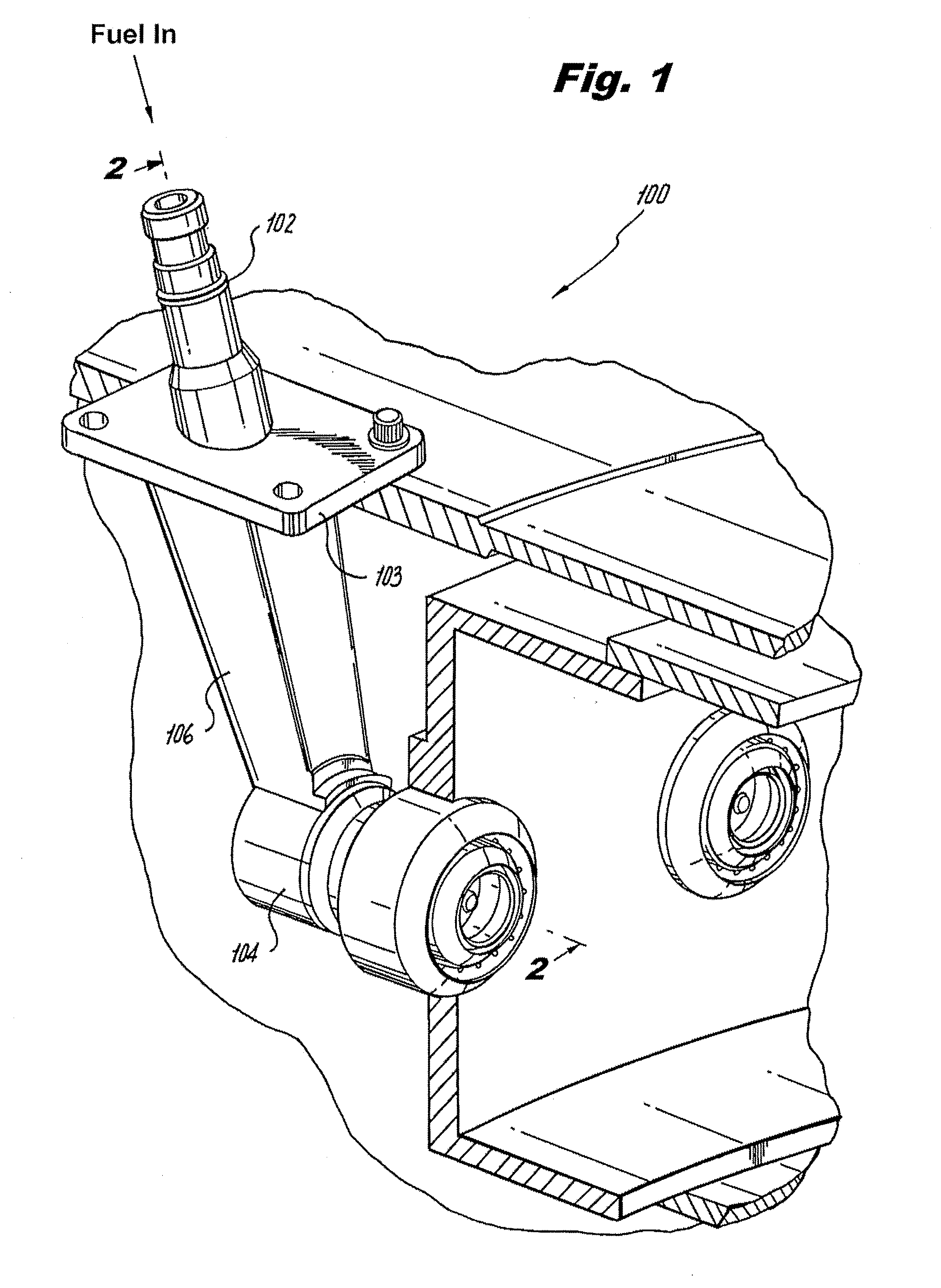

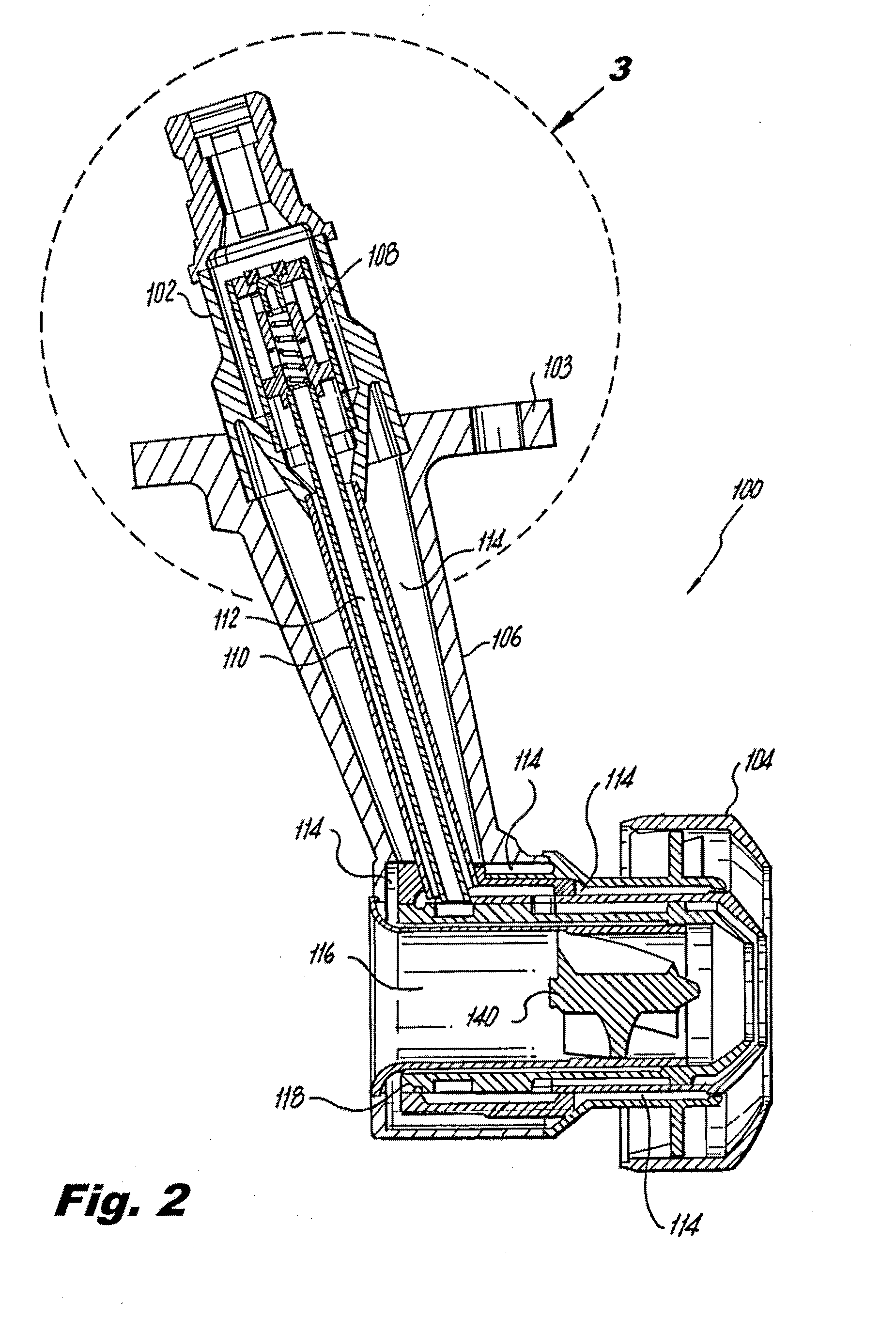

Pure air blast fuel injector

An air blast fuel injector for a gas turbine engine includes an elongate feed arm having an inlet fitting for receiving fuel and for distributing the fuel to first and second fuel delivery conduits extending through the feed arm. A nozzle body is operatively connected to the feed arm. The nozzle body includes an on-axis inner air circuit and fuel circuitry radially outboard of the inner air circuit for delivering fuel to a fuel swirler outboard of the inner air circuit. The fuel circuitry includes a first fuel circuit configured and adapted to deliver fuel to the fuel swirler from the first fuel conduit of the feed arm and a second fuel circuit configured and adapted to deliver fuel to the fuel swirler from the second fuel conduit of the feed arm.

Owner:ROLLS ROYCE PLC

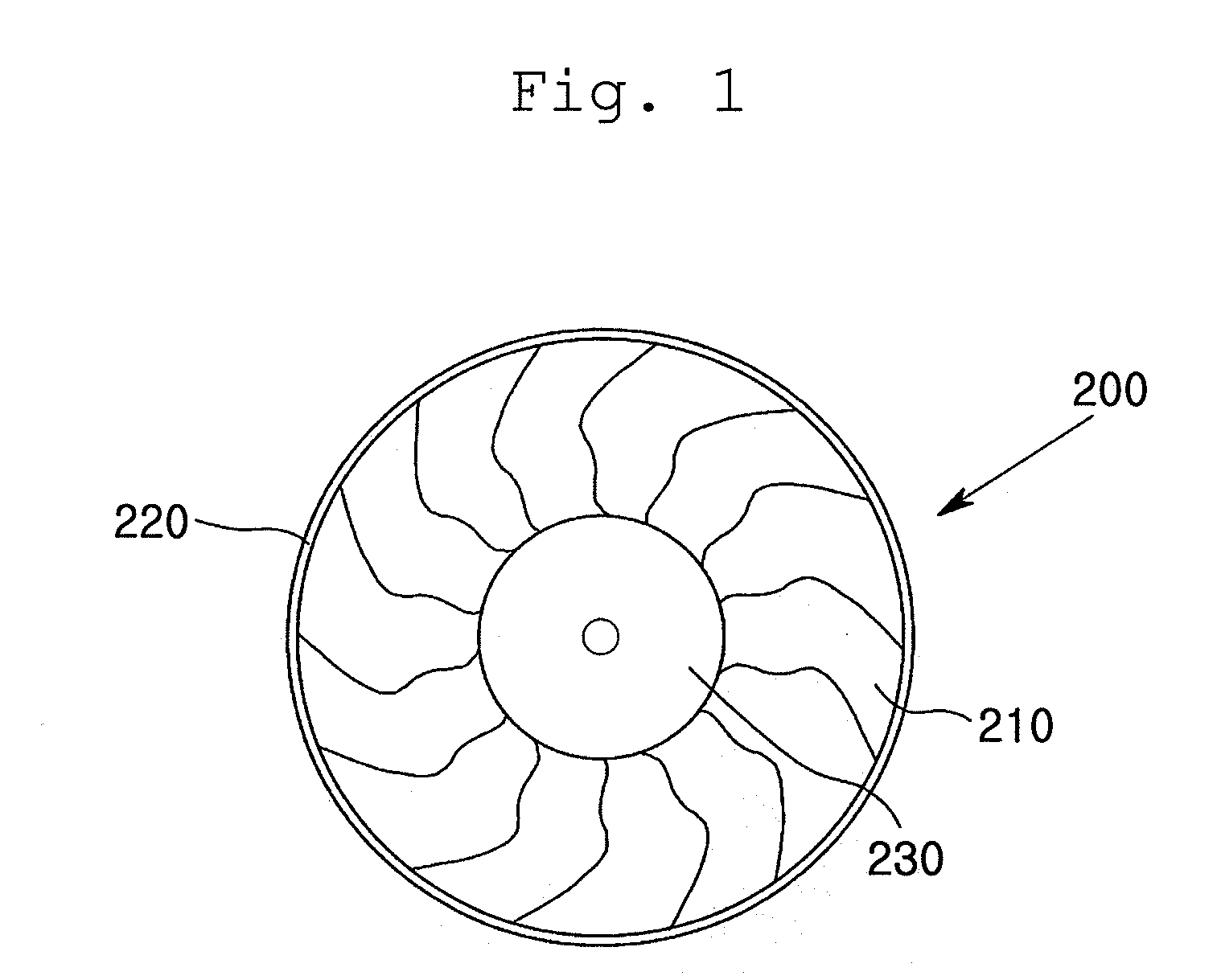

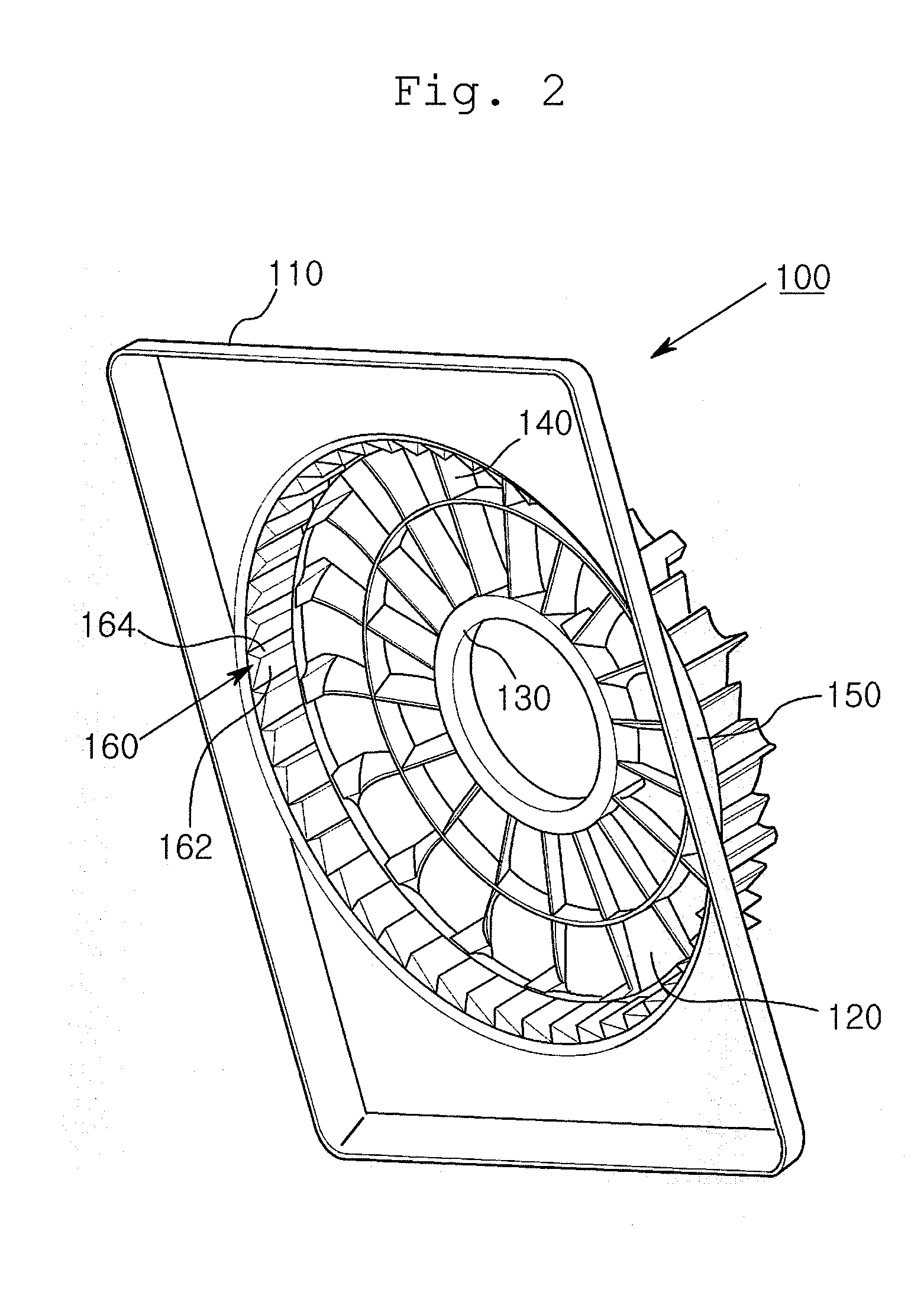

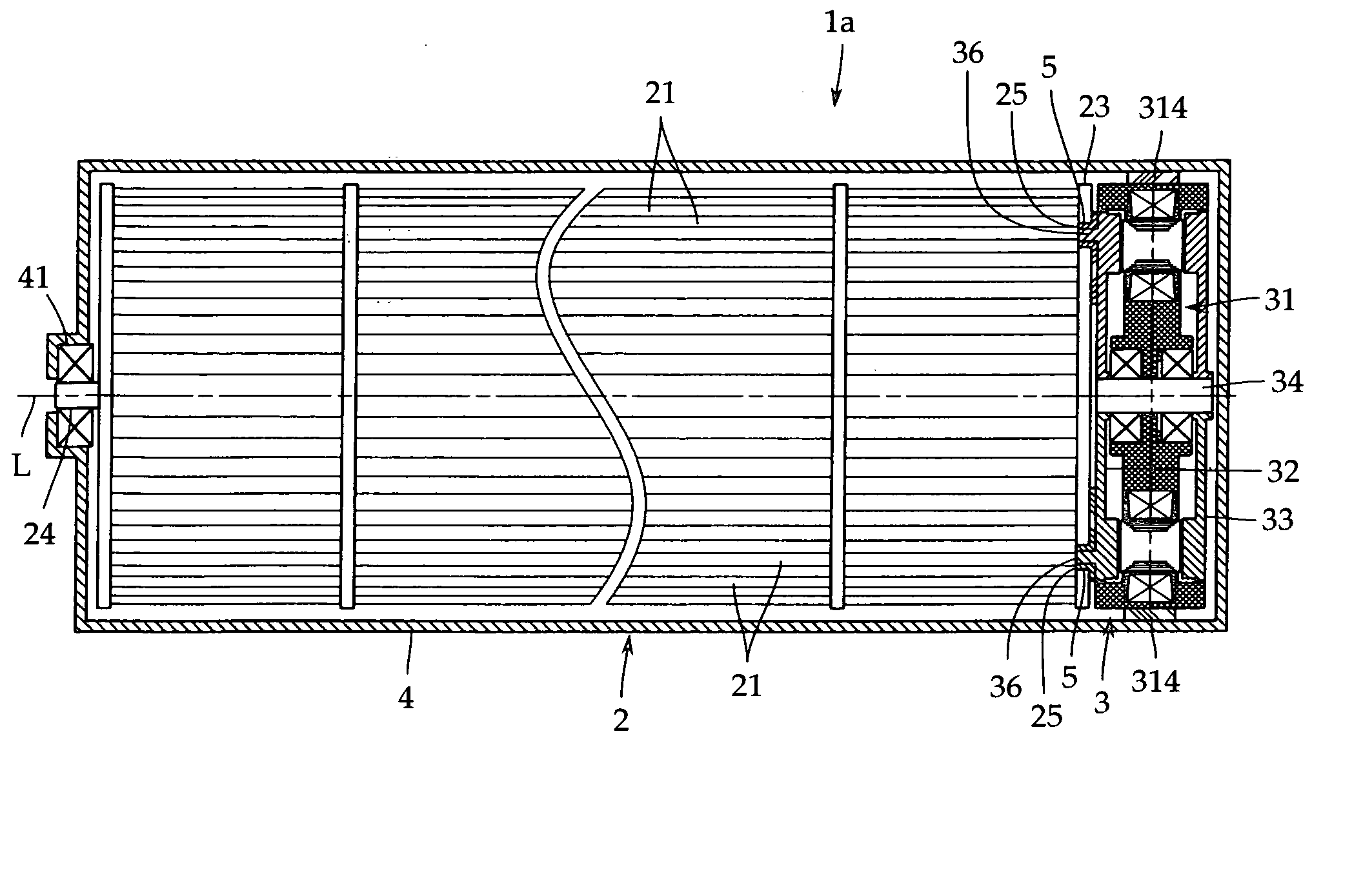

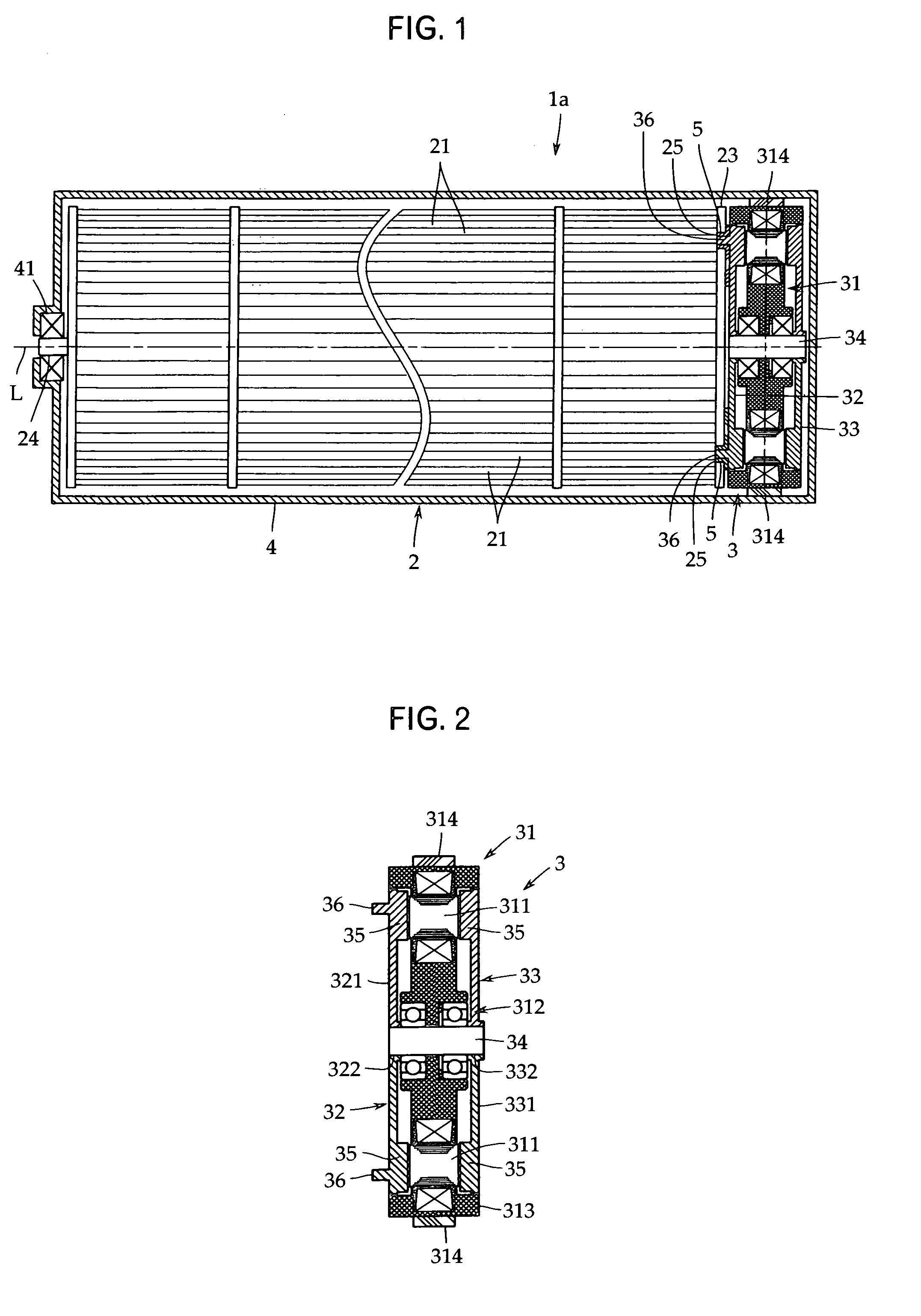

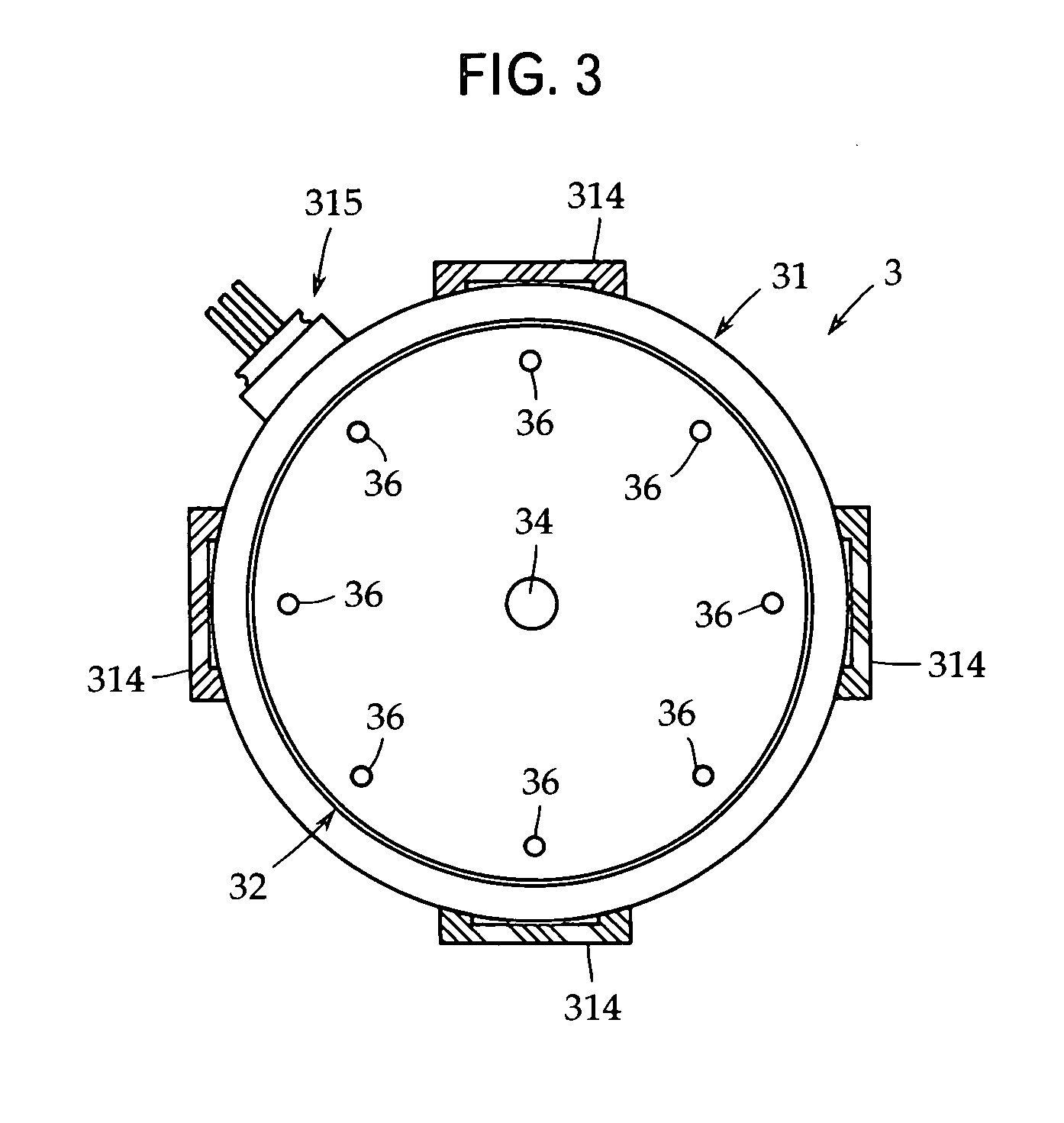

Air blower apparatus

InactiveUS20050140233A1Increase in sizeLow costPump componentsLighting and heating apparatusAir blowerAir blast

There is provided, at a low cost, an air blower apparatus capable of increasing the air blowing capability without an increase in size of an electronic motor, and having a high assembling ability. An electronic motor 3 is an axial gap electronic motor in which a rotor 32 and a stator 31 of the electronic motor are arranged opposedly with a predetermined gap along the rotation axis direction of the rotor, and coaxially supports an air blowing fan 2 on an attaching surface of the rotor 32 opposite to the stator.

Owner:FUJITSU GENERAL LTD

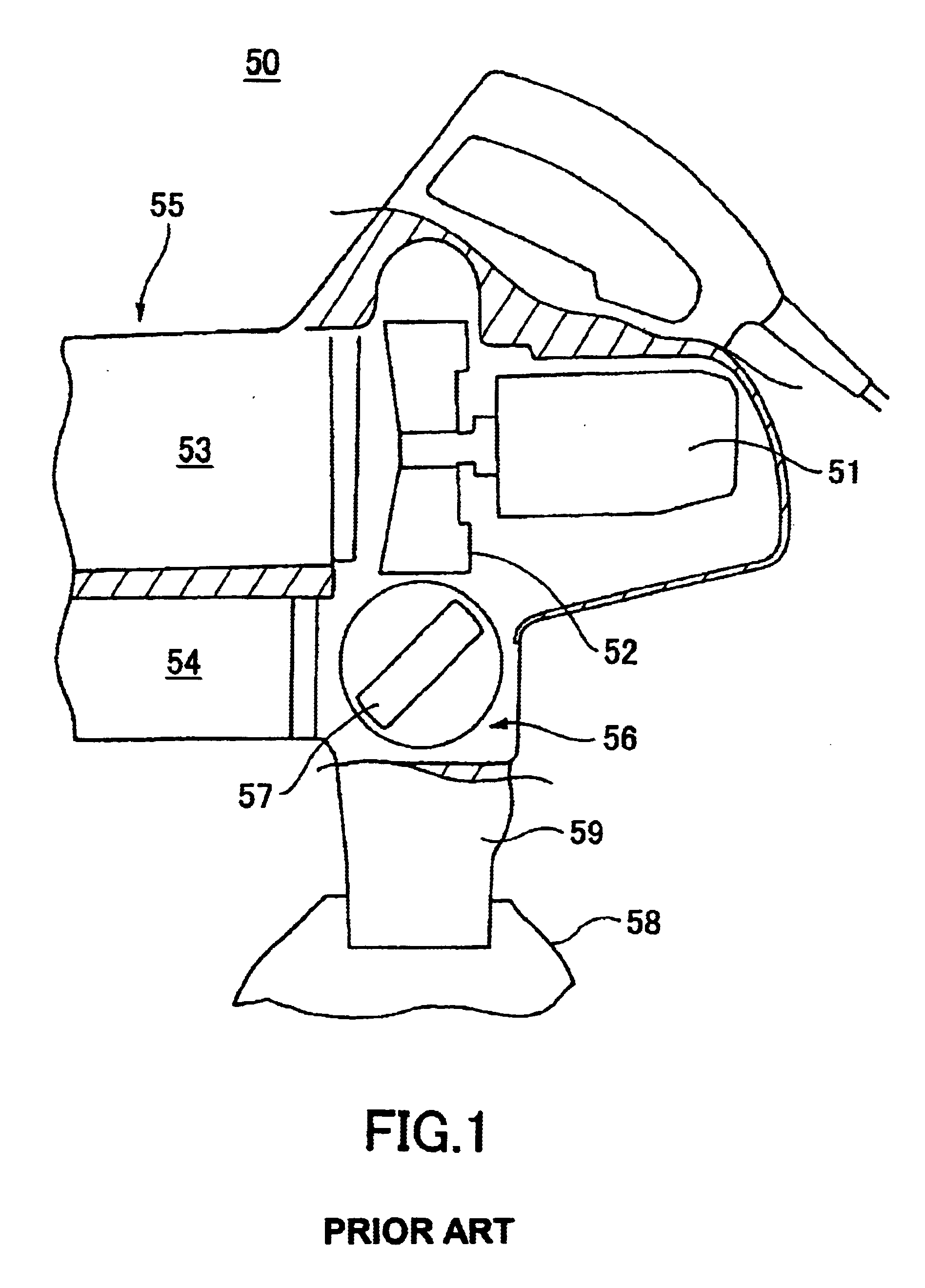

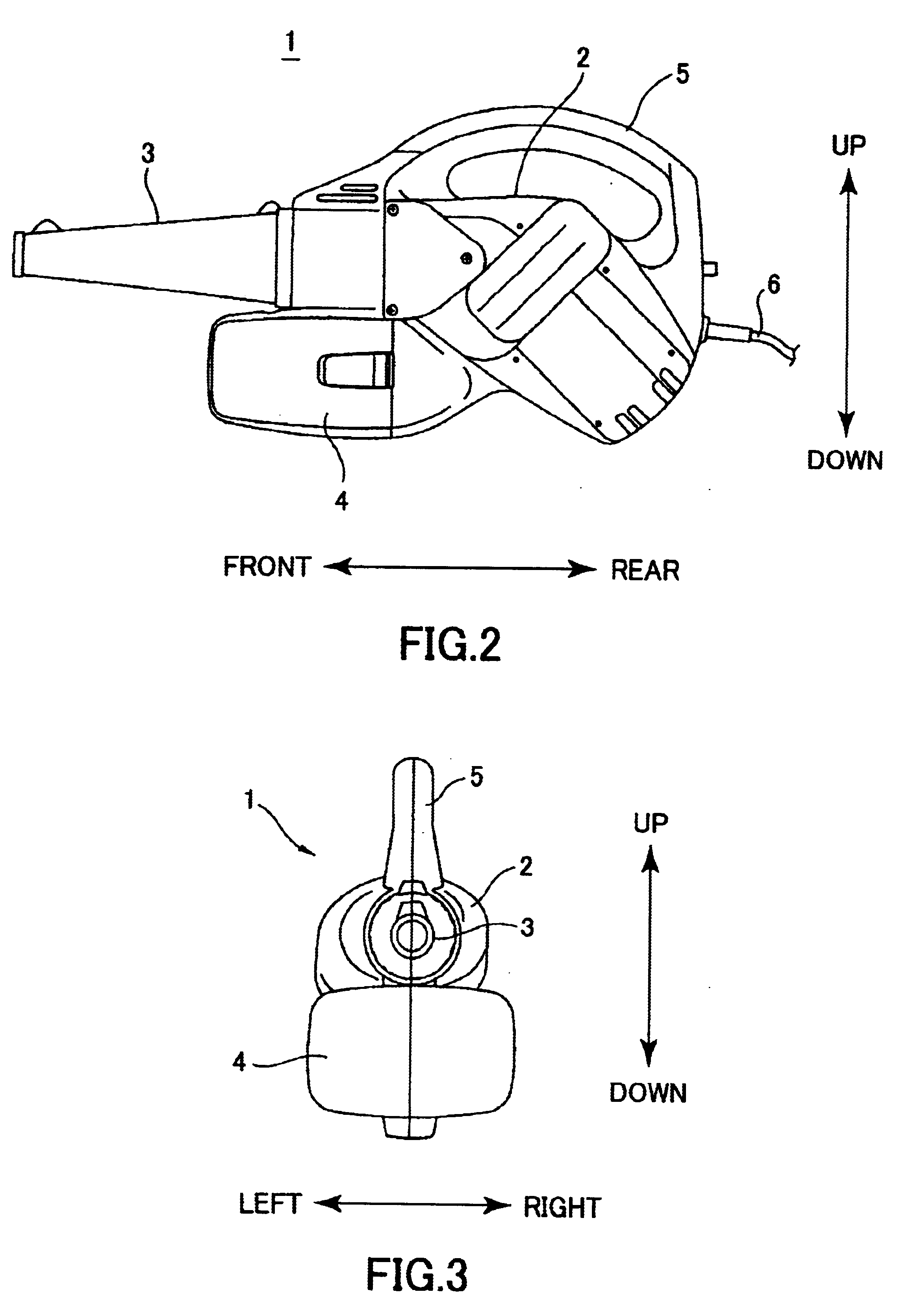

Mechanism for switching airflow mode of air blower/vacuum

InactiveUS6735813B2Easy to switchConfiguring an air blower/vacuumSuction cleanersAir blowerAir blast

An air blower / vacuum includes a nozzle, a fan, and a main body. The main body is formed with a vacuum pathway and a blower pathway, located upstream and downstream, respectively, from the fan with respect to the flow of air. The main body is also formed with an attachment hole in fluid communication with both the vacuum pathway and the blower pathway. The attachment hole supports the nozzle rotatable between a vacuum mode orientation and a blower mode orientation. In the vacuum mode orientation, the pathway of the nozzle is in fluid communication with the vacuum pathway. In the blower mode orientation, the pathway of the nozzle is in fluid communication with the blower pathway.

Owner:RYOBI

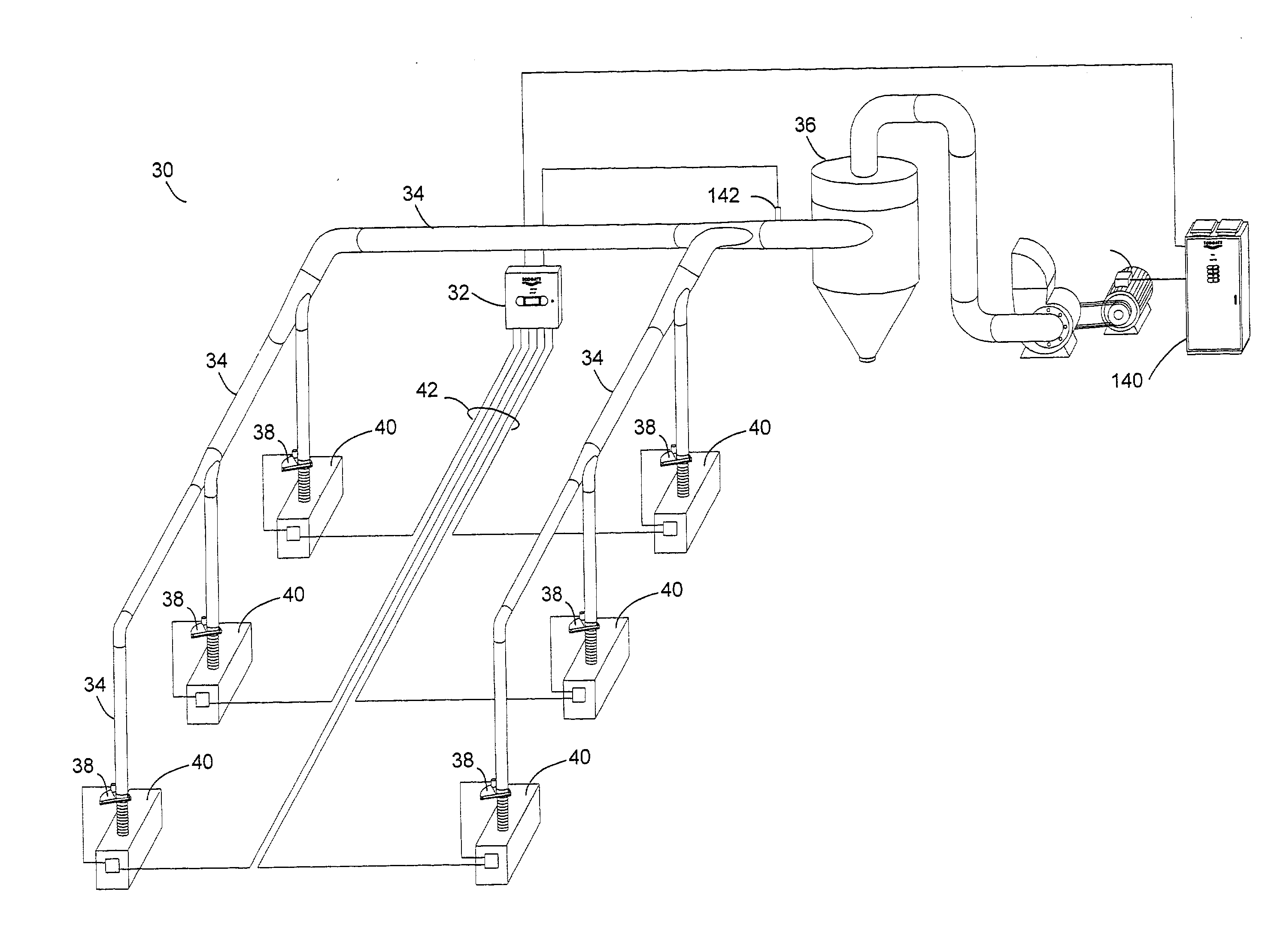

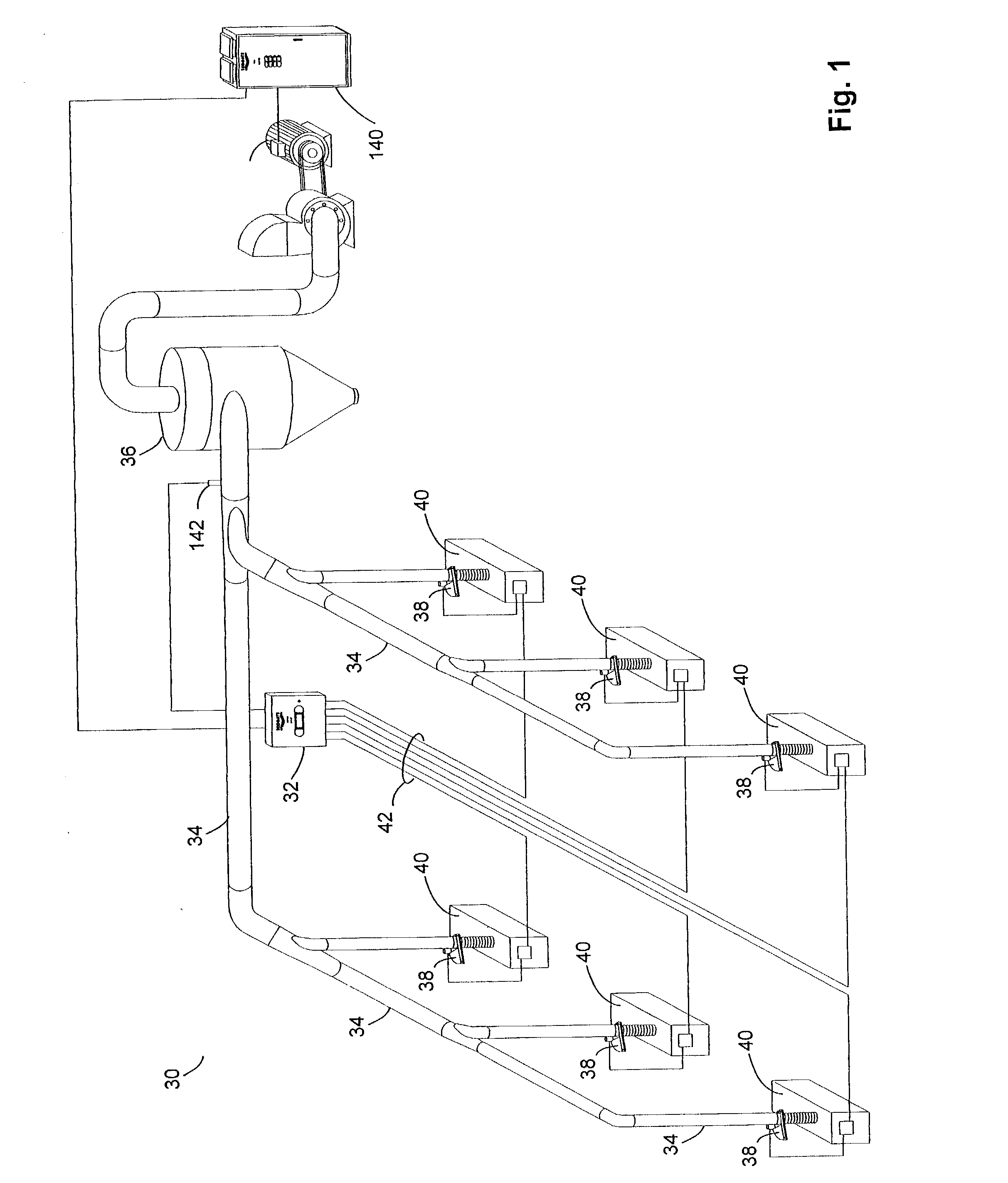

Energy saving vacuum system for particle, mist, and fume collection

ActiveUS20040093682A1High ratio leverageGuaranteed uptimeMetal sawing accessoriesVehicle cleaningMachine shopCollection system

An improved energy-efficient vacuum system for machine shop dust, particulate matter, and the like. Blast gates, including large-diameter blast gates, control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch, an increased current feedback system, a biasing-spring assembly or otherwise to limit the rotation driving of the rotating blade. In one embodiment, the blast gate blade bears teeth about its perimeter. The DC motor engages the perimeter blade teeth with a gear. Greater mechanical advantage is achieved over the blast gate blade and less torque arises in contrast to a driving system located at the blade's central pivot point. Additionally, sensing apparatus or system calculation allow the dust collecting vacuum system to operate in an energy-efficient manner. By supplying only the vacuum needed to collect present dust, energy is saved in comparison with a dust collection system operating continuously at full capacity.

Owner:LITOMISKY IVAN +2

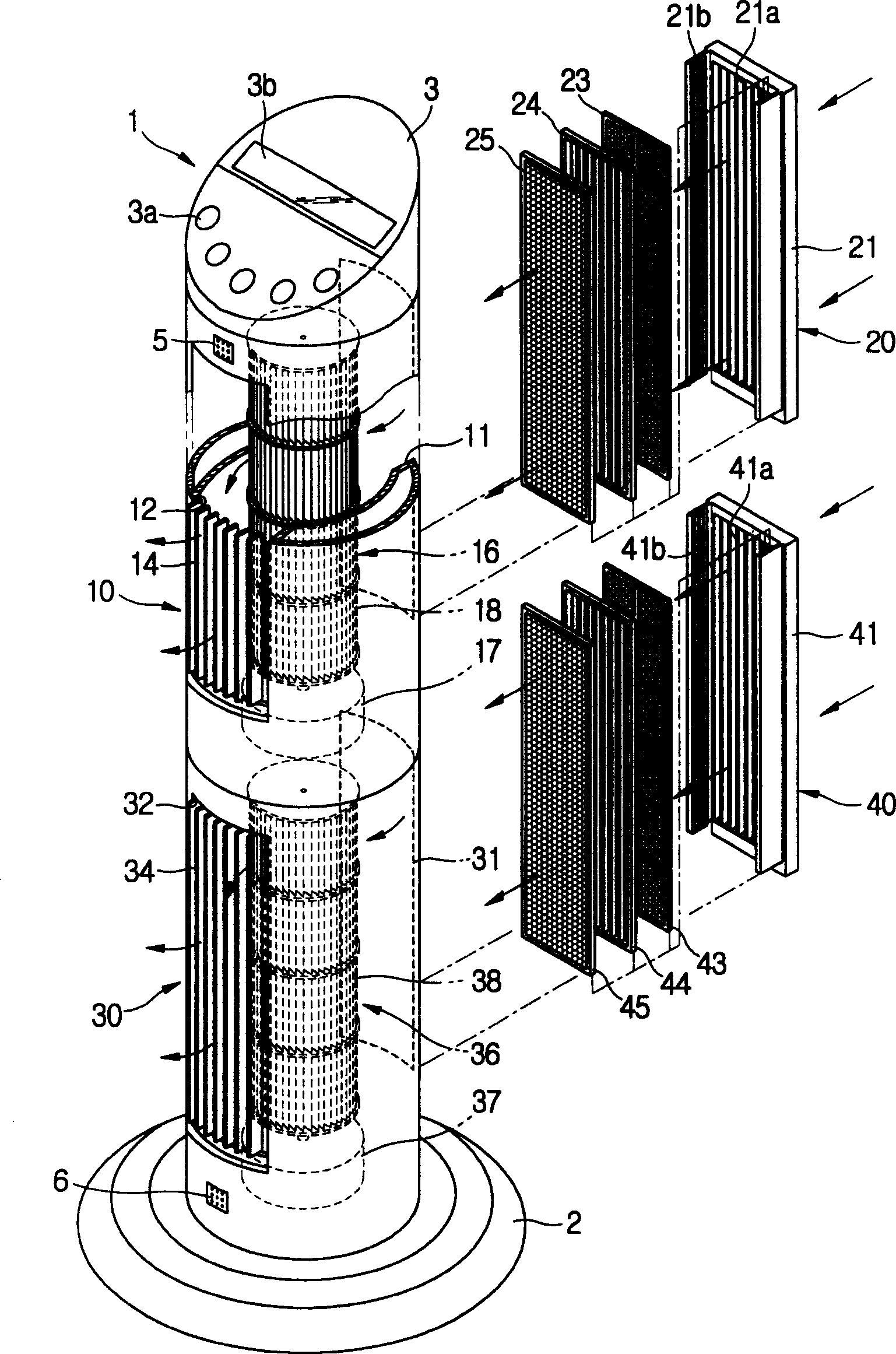

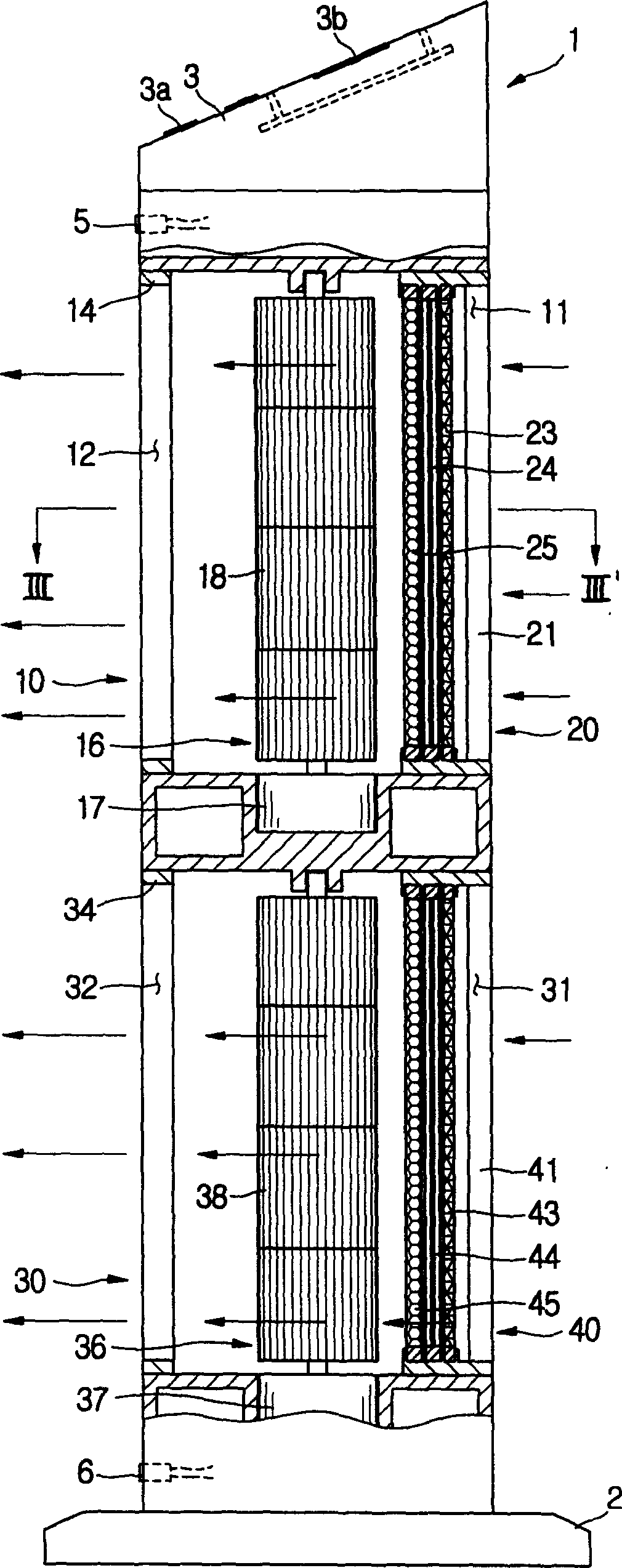

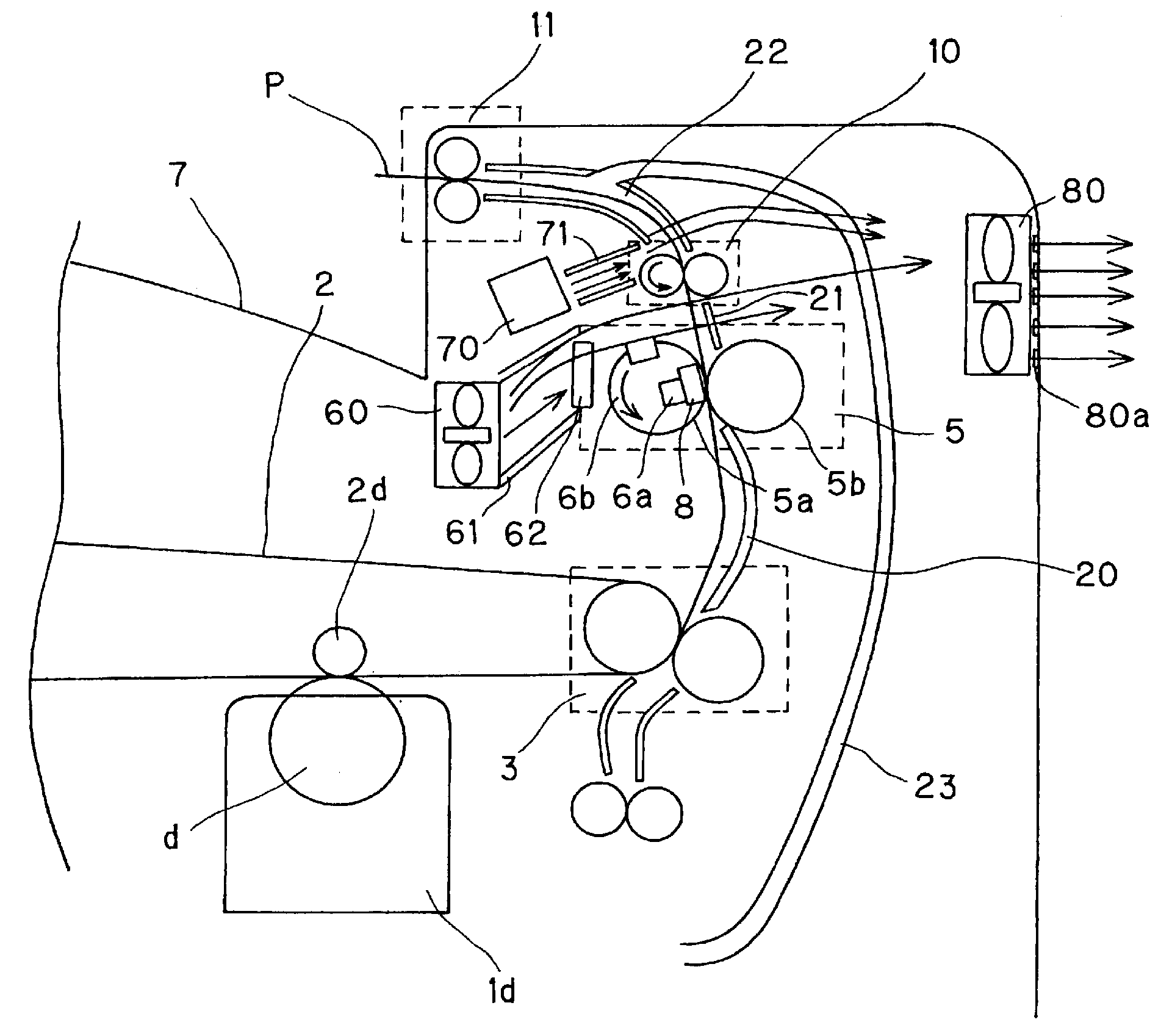

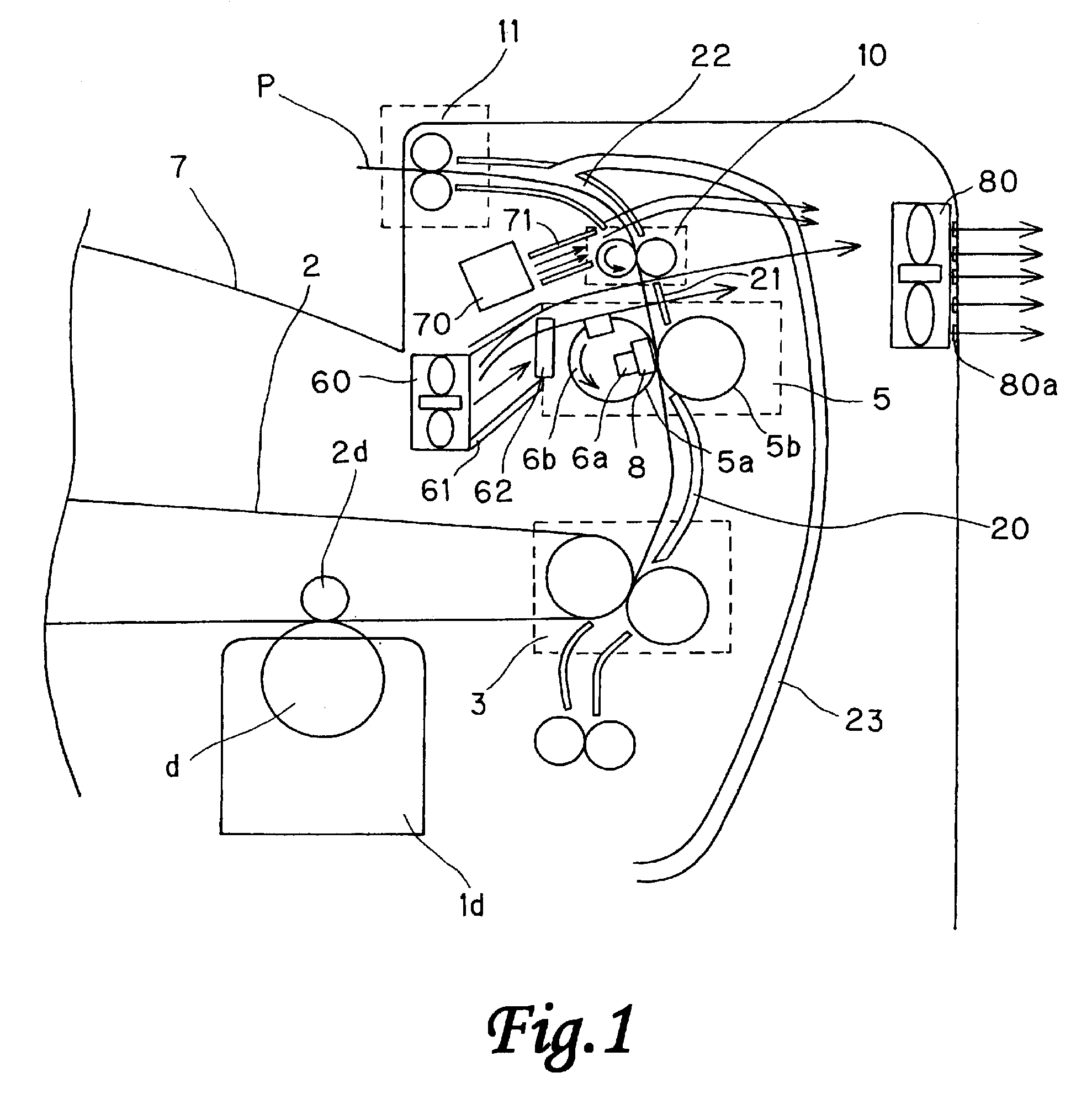

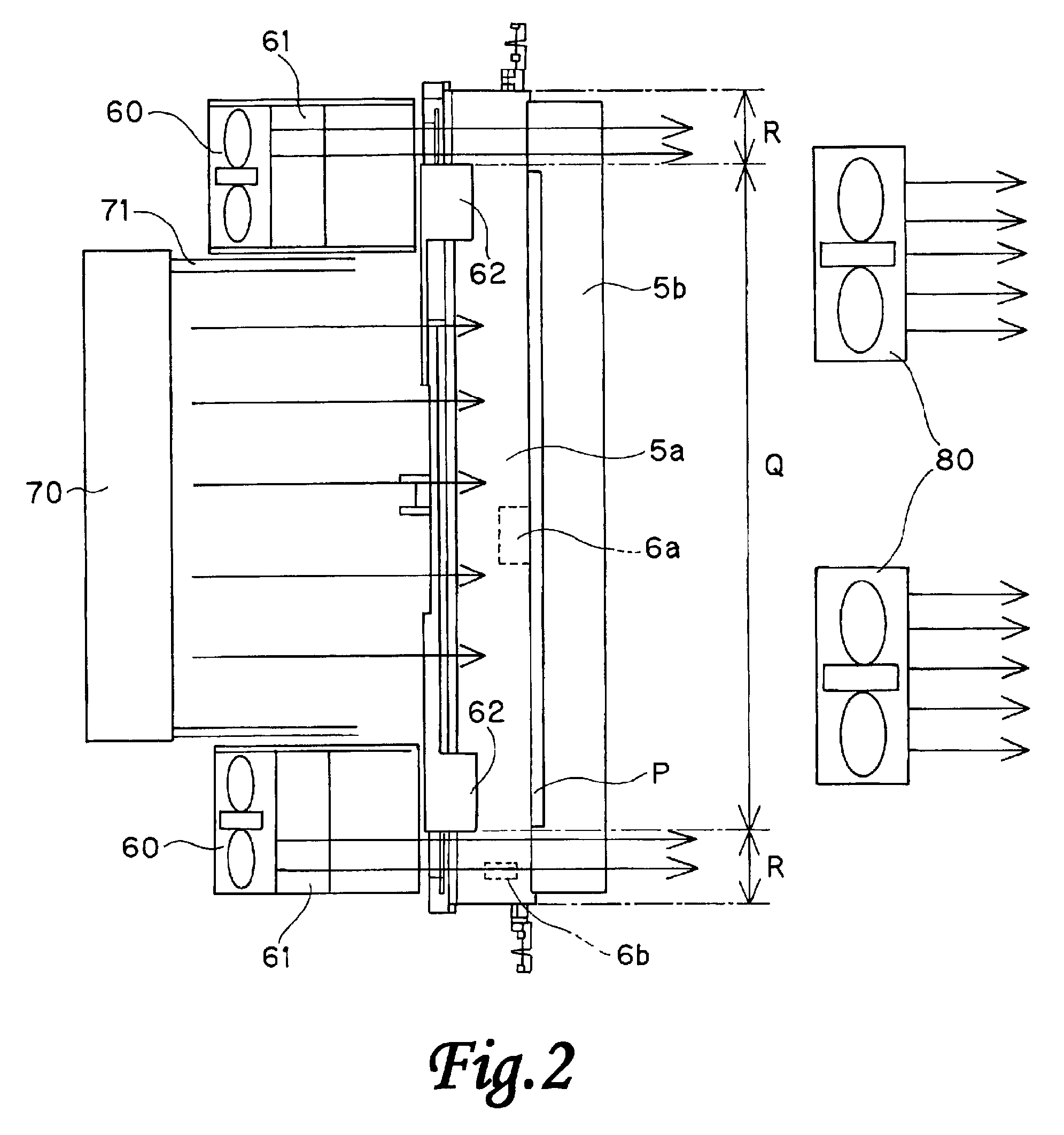

Air purifier

An air cleaning apparatus includes an air cleaning unit at its upper and lower portions thereof which are independently operated to effectively and uniformly clean room air in a short period of time. The air cleaning apparatus includes a cabinet provided with first and second air cleaning units. The first and second air cleaning units are connected to each other, and are provided with a blowing unit and a filtering unit. First and second sensors are provided on the cabinet in such a way as to be spaced apart from each other, and to sense air pollution levels at opposite sides of a room. The air cleaning apparatus also includes a control unit. The control unit controls the first and second air cleaning units so that both the first and second air cleaning units are operated or either of the first and second air cleaning units is operated, according to data obtained from first and second sensors.

Owner:SAMSUNG ELECTRONICS CO LTD

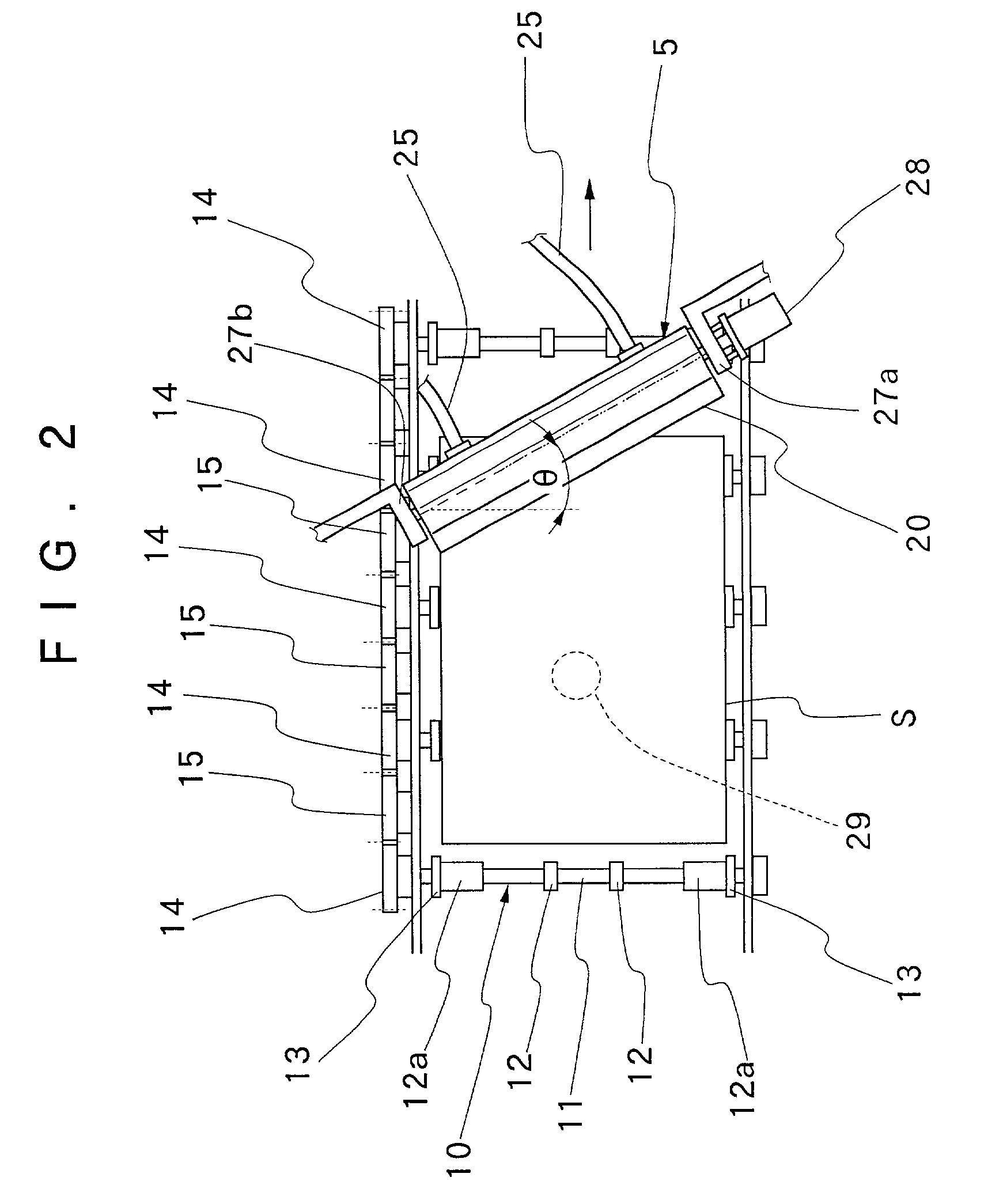

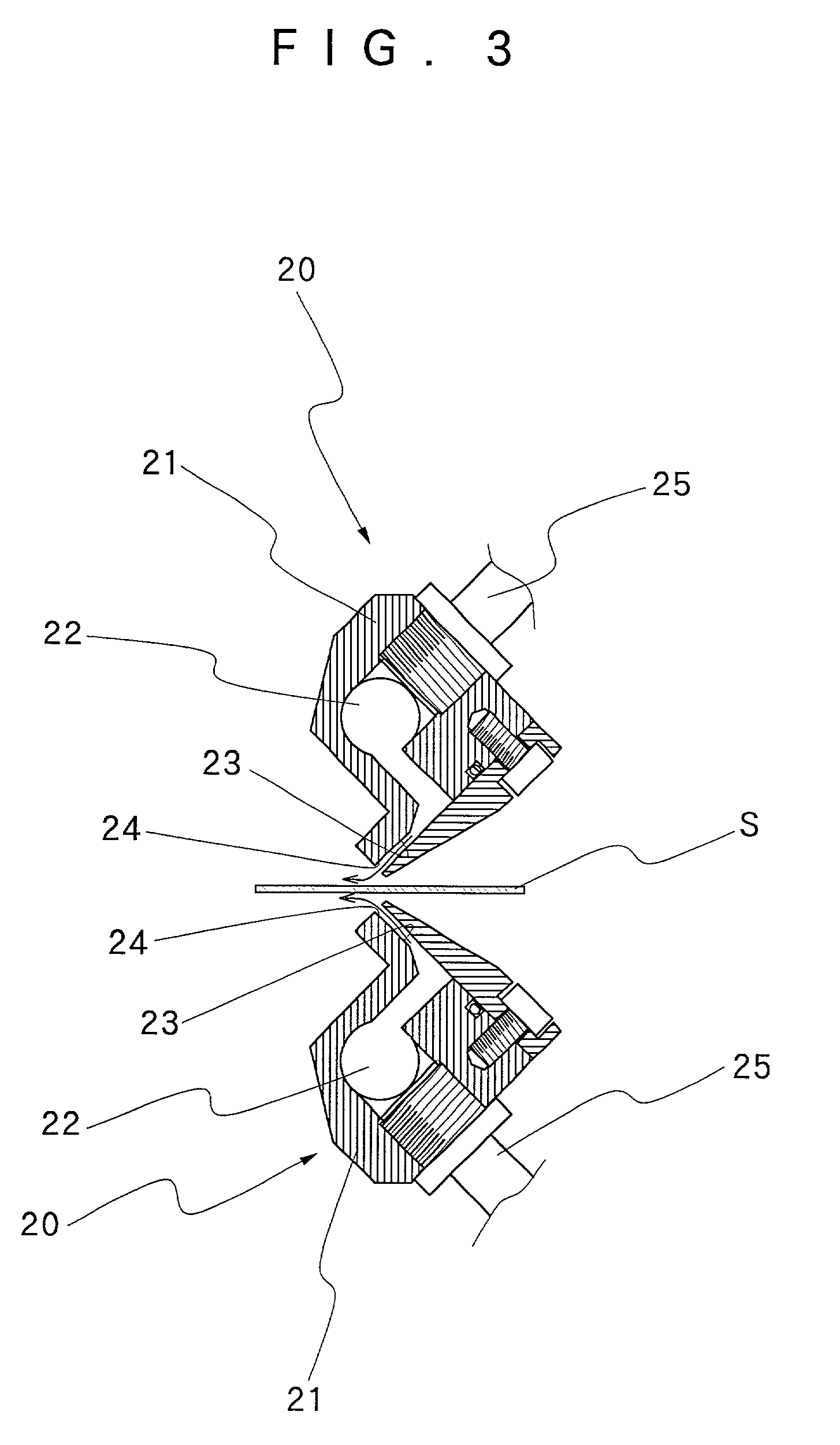

Method and apparatus for drying substrate plates

InactiveUS20010015021A1Fast dryingDrying solid materials with heatDrying solid materials without heatAngle of incidenceEngineering

While being transferred in substantially horizontal state along a predetermined path of transfer by a conveyer means, a substrate plate is dried by a jet of compressed air which is spurted out from a slit-like mouth of an air knife nozzle crosswise of the entire width of the substrate plate and at a predetermined angle of incidence with respect to a drying surface of the substrate plate to scrape off a liquid. The angle of incidence of jet air is made shallower as soon as the substrate on the conveyer means comes to a point of entry to an air blasting zone and is made deeper at latest when the substrate plate comes to a position immediately before a point of disengagement from the air blasting zone.

Owner:HITACHI ELECTRONICS ENG CO LTD

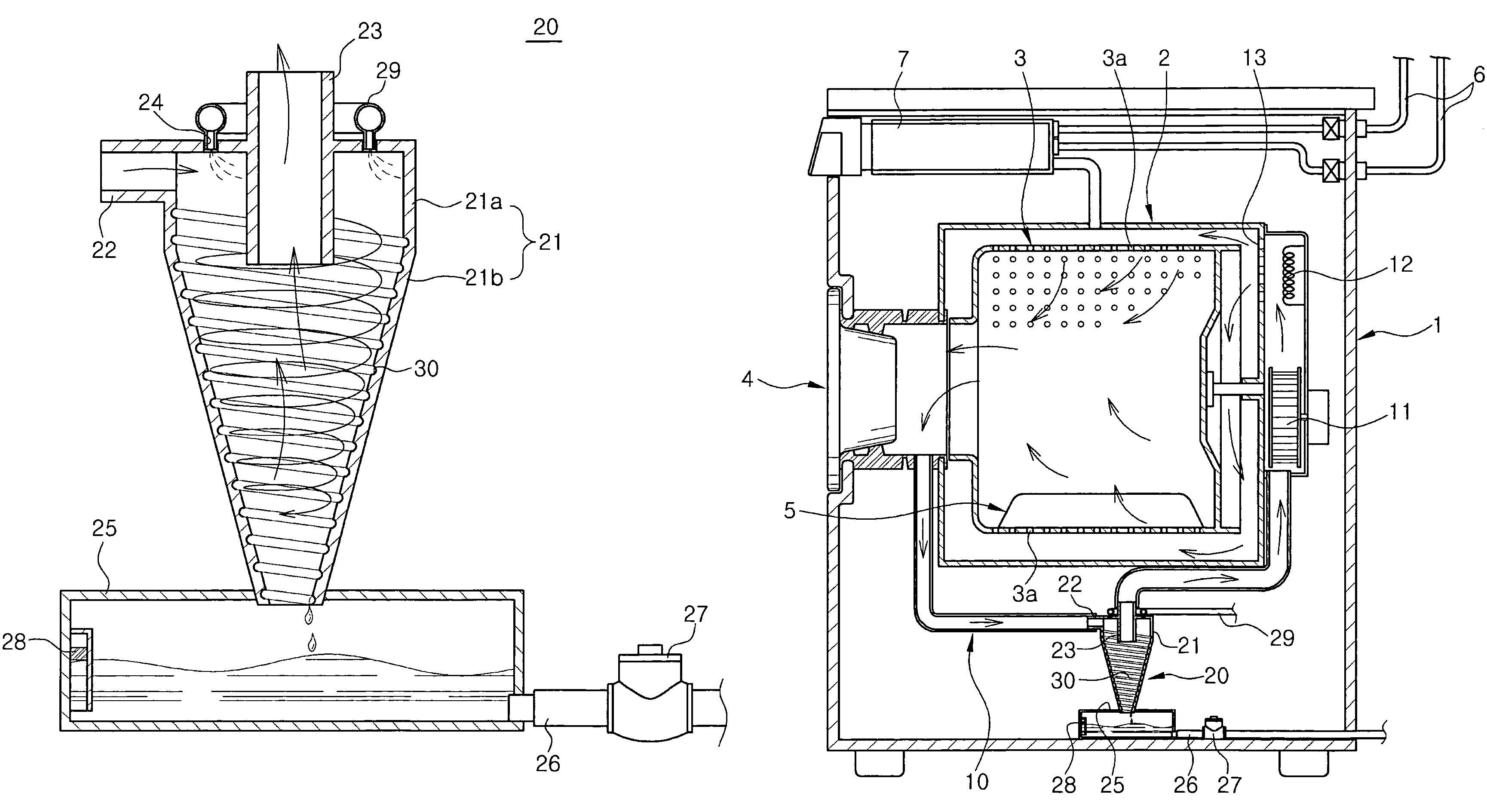

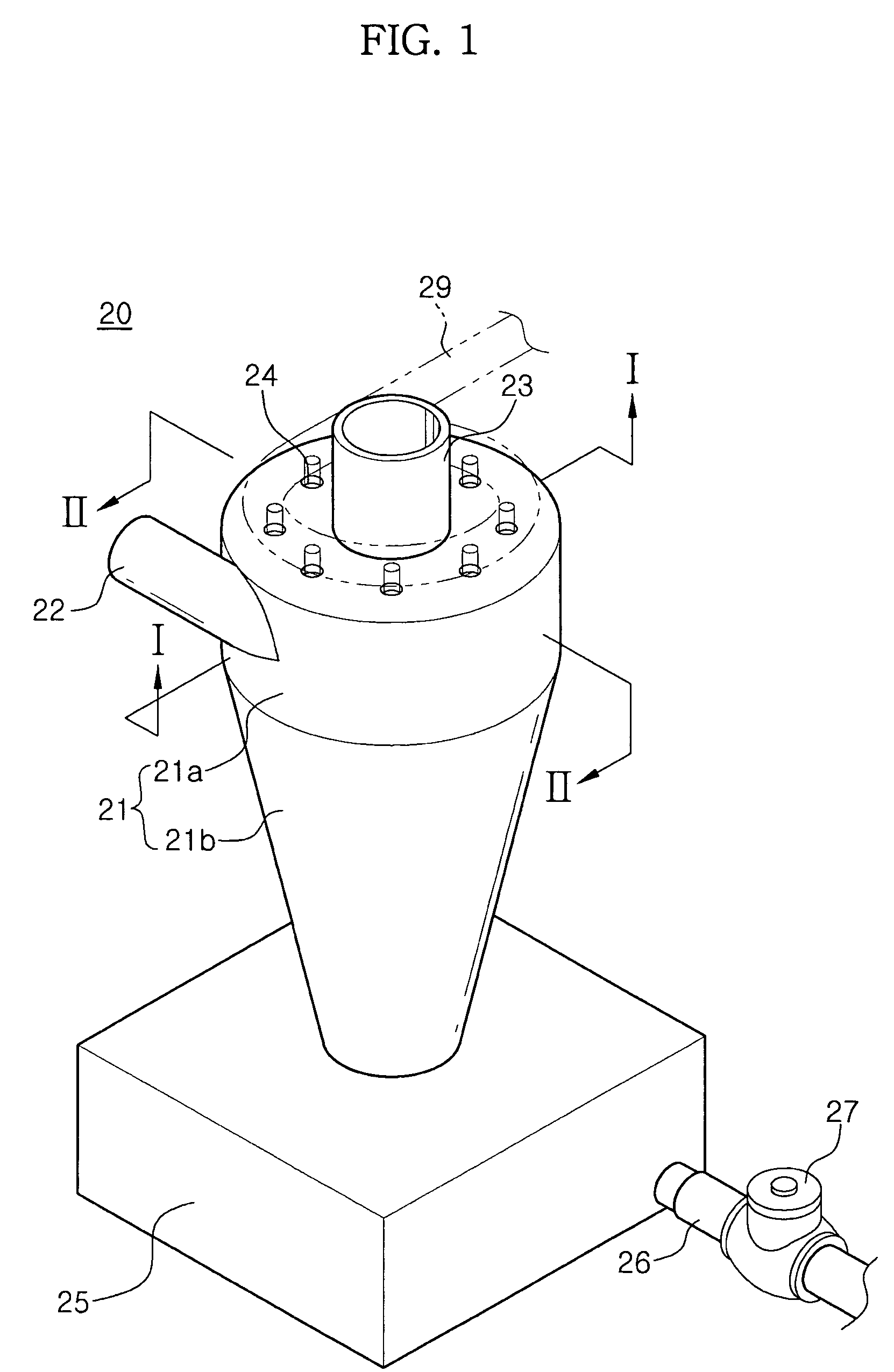

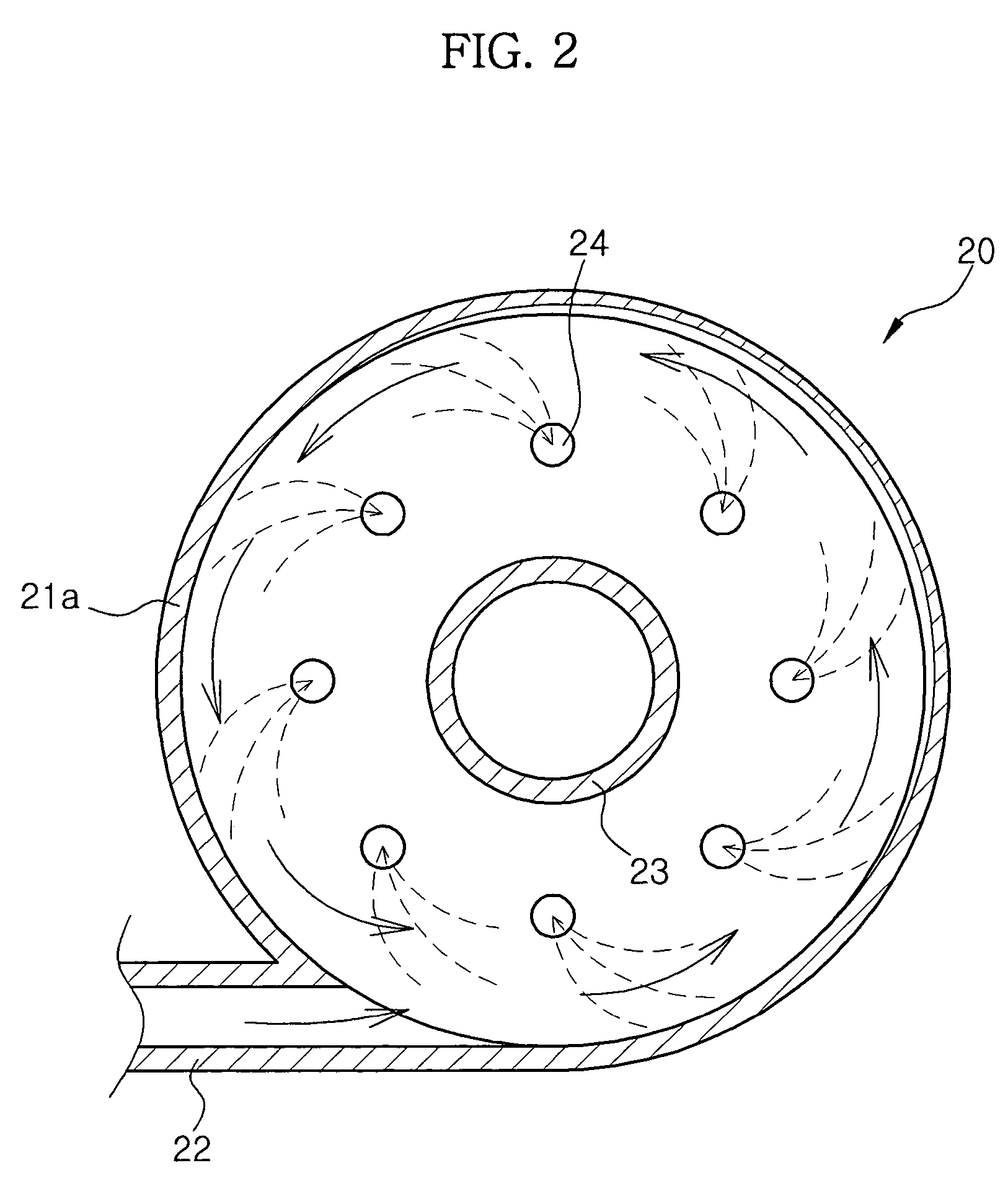

Cyclone condensing apparatus and washing/drying machine having the same

ActiveUS7448146B2Efficient dischargeReversed direction vortexDispersed particle separationAir cycleCyclone

A cyclone condensing apparatus having a structure in which air of high-temperature and high-humidity sufficiently contacts cooling water, and condensed water is efficiently discharged to the outside, and a washing / drying machine having the cyclone condensing apparatus. The cyclone condensing apparatus includes an air inlet connected to the upper part of a casing having a conical shape along a tangential direction; an air outlet disposed along the central line of the casing, and a plurality of cooling water spray nozzles disposed along the circumferential direction of the casing. A spiral groove for guiding condensed water downwards is formed in the inner circumferential surface of the casing, and a water-collecting container for collecting the condensed water is connected to the lower end of the casing. The cyclone condensing apparatus further includes an air blast fan and a heater in the washing / drying machine, and is connected to an air circulating duct forming a closed circuit together with a dry tub, thereby condensing water from air of high-temperature and high-humidity passed through the dry tub.

Owner:SAMSUNG ELECTRONICS CO LTD

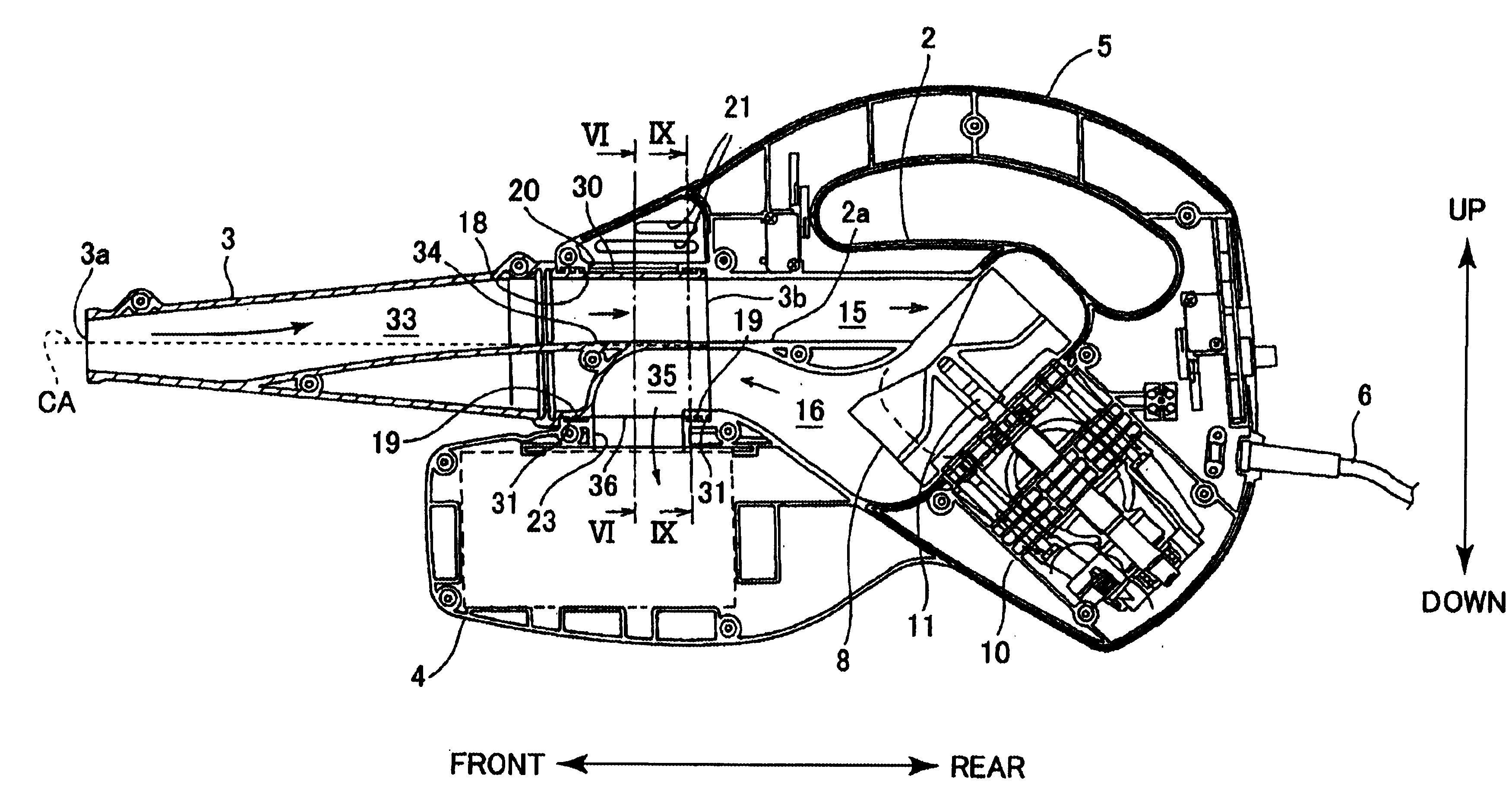

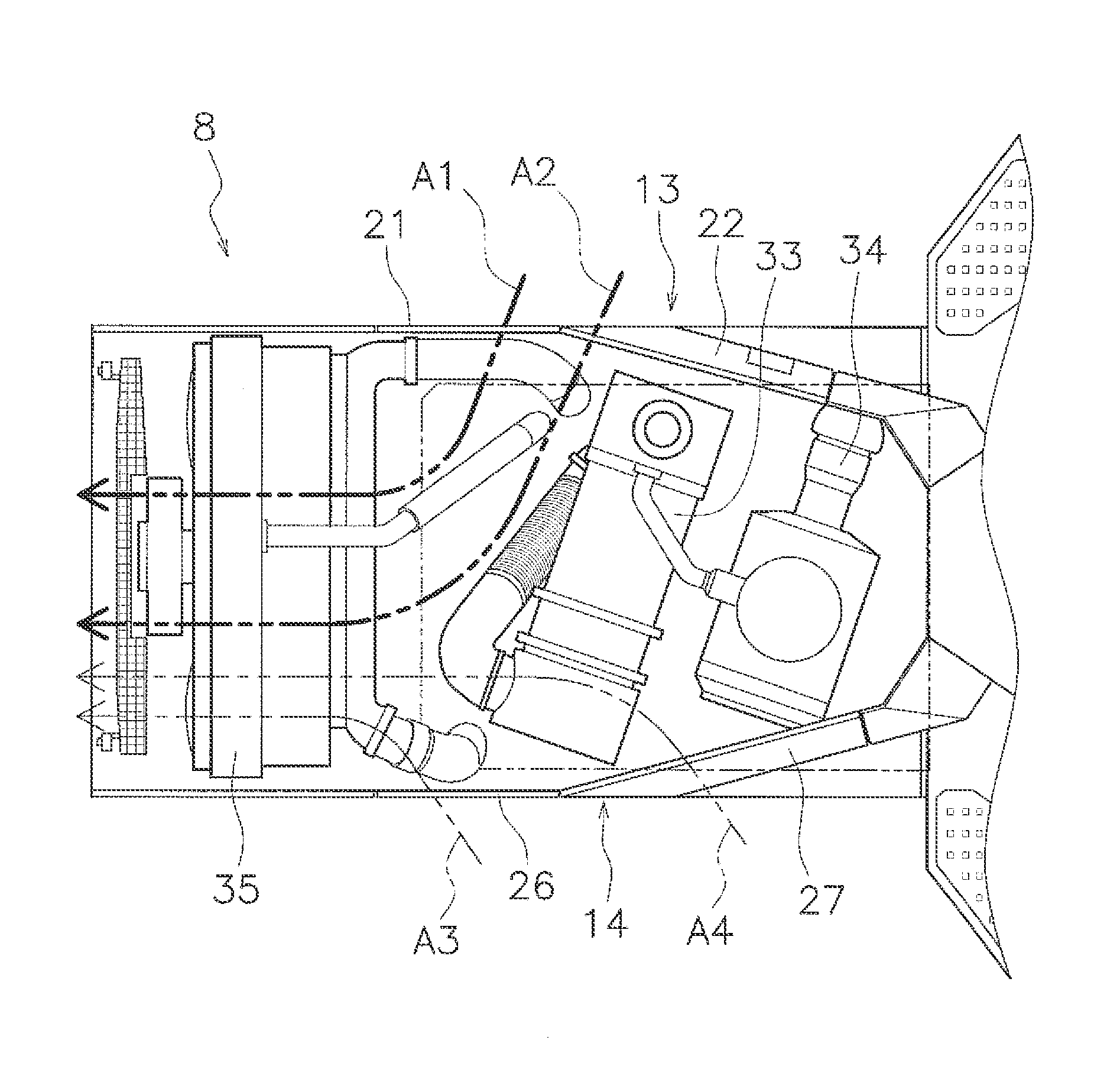

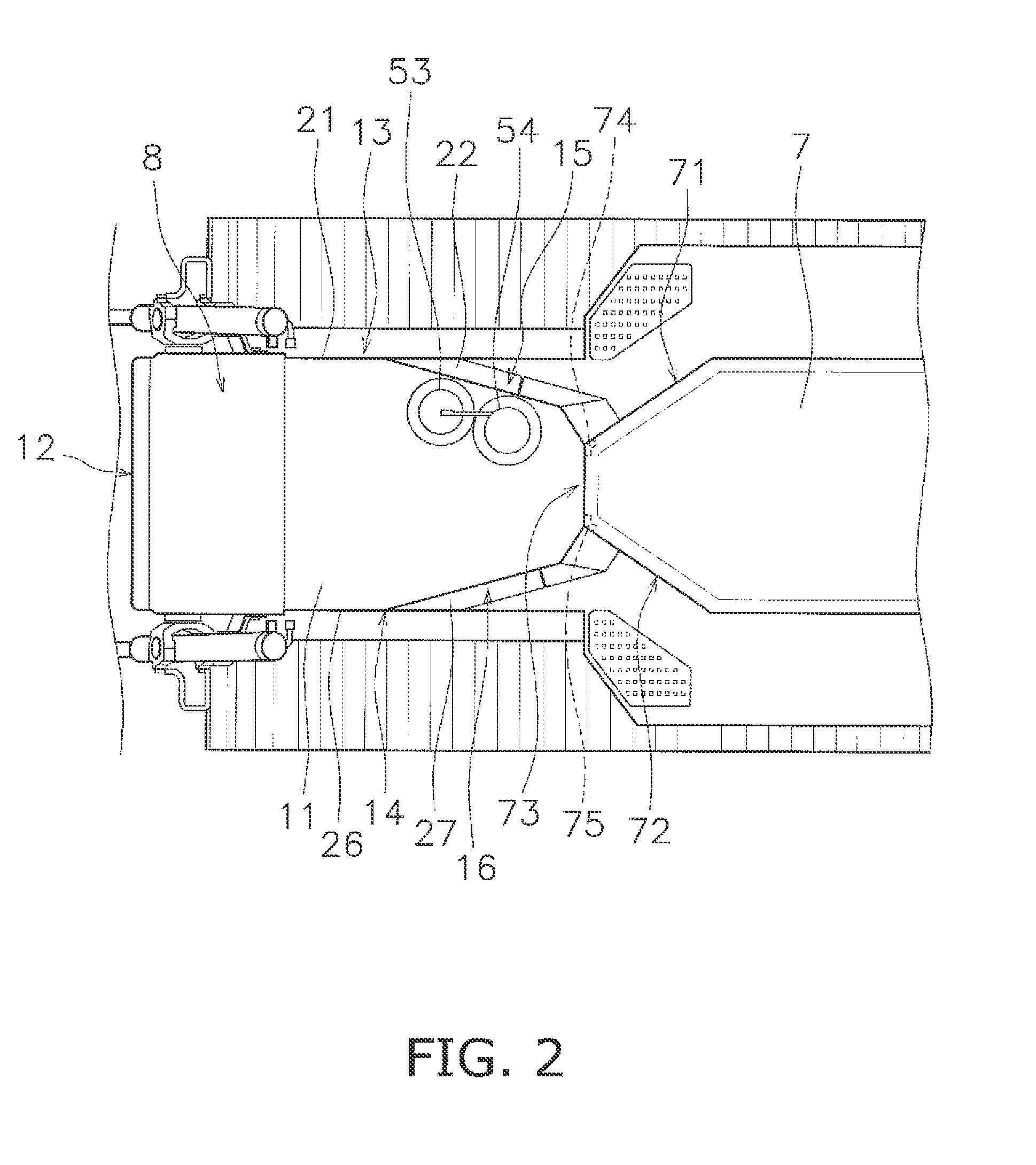

Work vehicle with engine compartment and exhaust gas treatment arrangement

ActiveUS8505661B2Reduce cooling efficiencySufficient reliabilityExhaust apparatusSilencing apparatusExhaust fumesAir blast

In a work vehicle, an engine compartment is disposed forwards of a cab. An exhaust gas treatment device is disposed over an engine in the engine compartment. A radiator is disposed forwards of the exhaust gas treatment device (33) in the engine compartment. A blower is configured to generate an airflow passing through the radiator from back to front of the radiator. The exhaust gas treatment device is slanted with respect to a vehicle width direction for increasing a distance between the exhaust gas treatment device and the radiator towards a first lateral face portion. Further, the first lateral face portion includes air inlets facing a space between the exhaust gas treatment device and the radiator.

Owner:KOMATSU LTD

Image forming apparatus

Owner:CANON KK

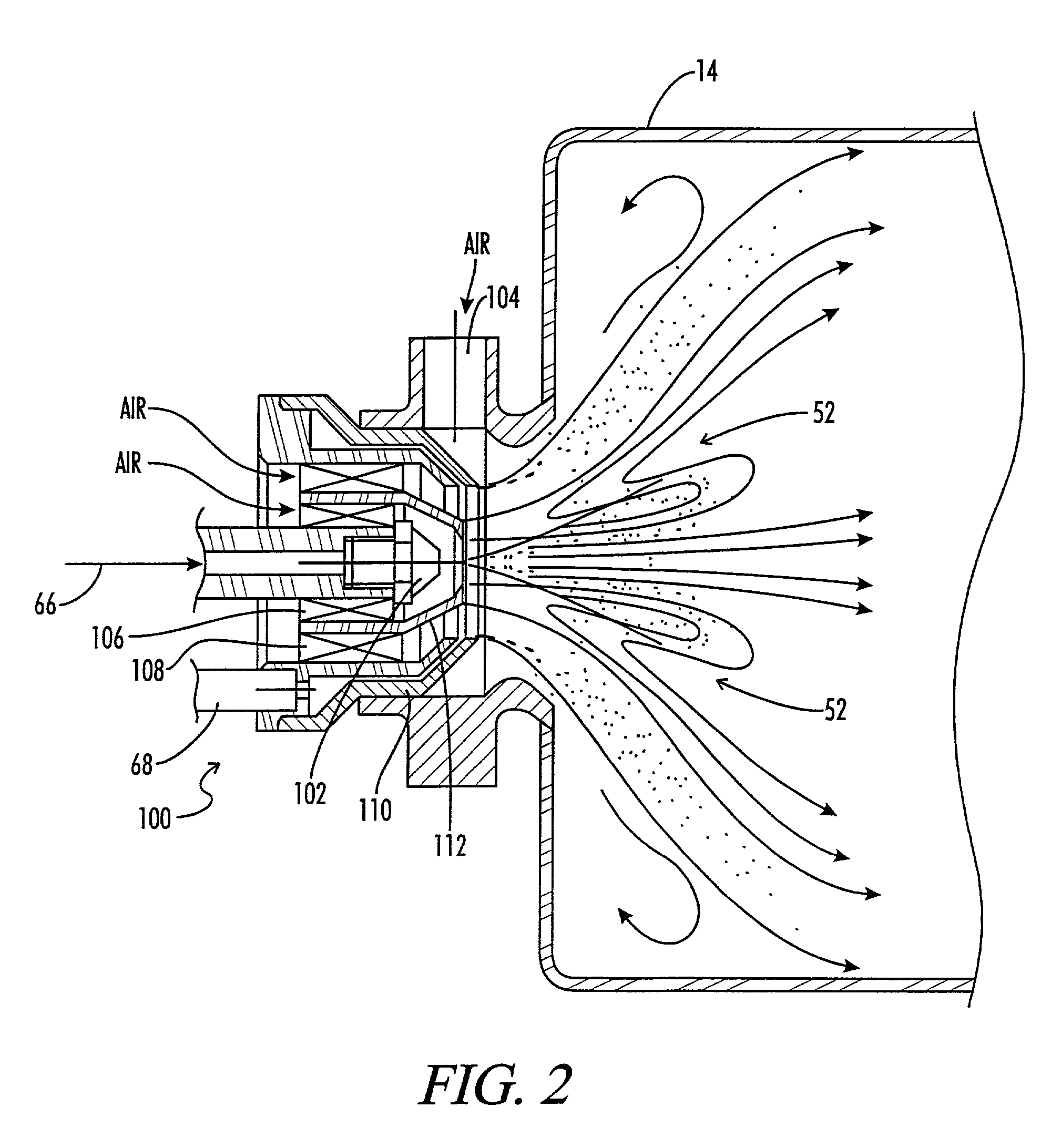

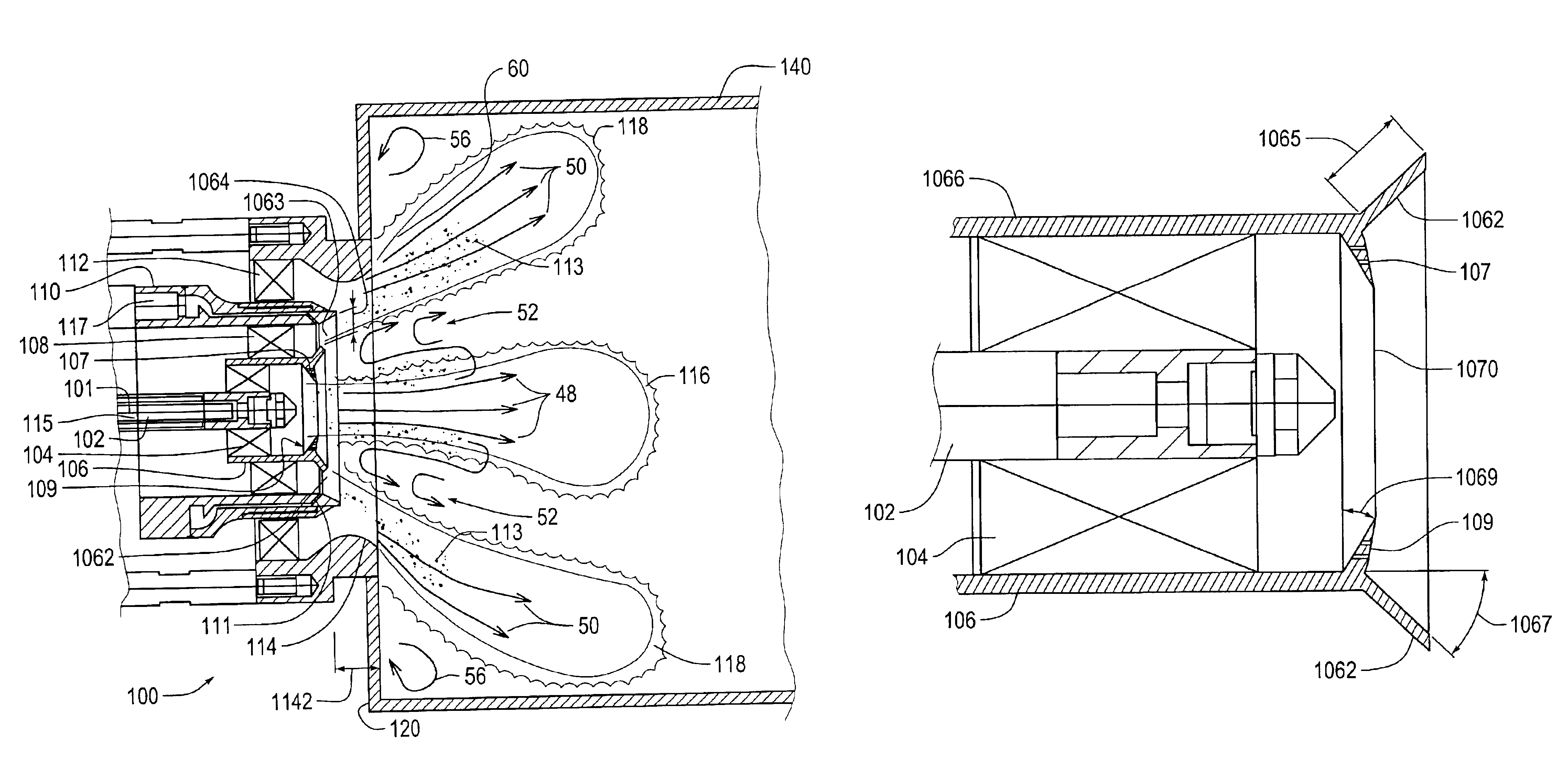

Pre-filming air-blast fuel injector having a reduced hydraulic spray angle

InactiveUS20090255258A1Reduced spray angleDecreased fuel momentumBurnersContinuous combustion chamberInjection airAir blast

An air-blast fuel injector is disclosed that includes an on-axis inner air circuit, a fuel circuit radially outboard of the inner air circuit, the fuel circuit having an axially converging pre-filming chamber and an axially diverging pre-filming surface extending from the pre-filming chamber to an exit annulus and an outer air circuit radially outboard of the fuel circuit communicating with the exit annulus of the axially diverging pre-filming surface.

Owner:DELAVAN

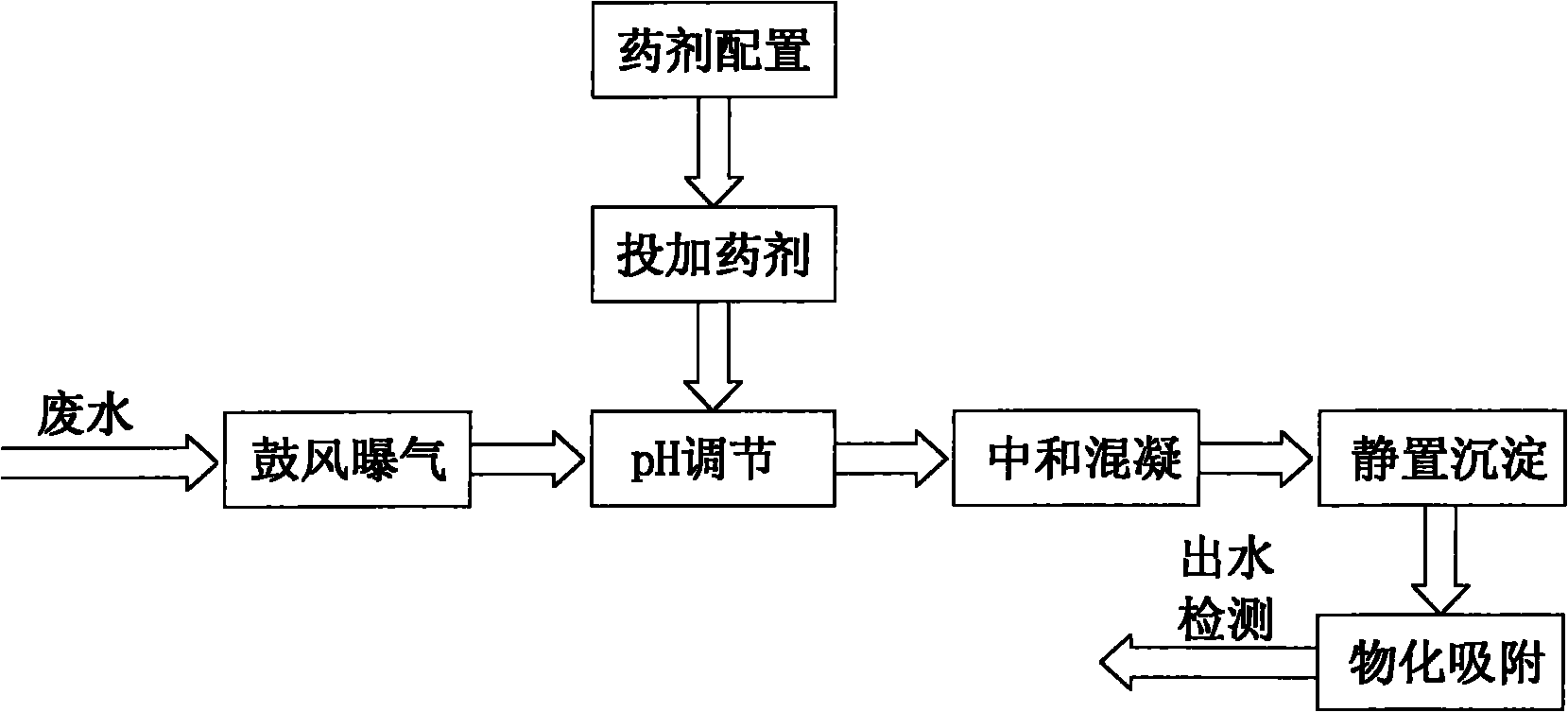

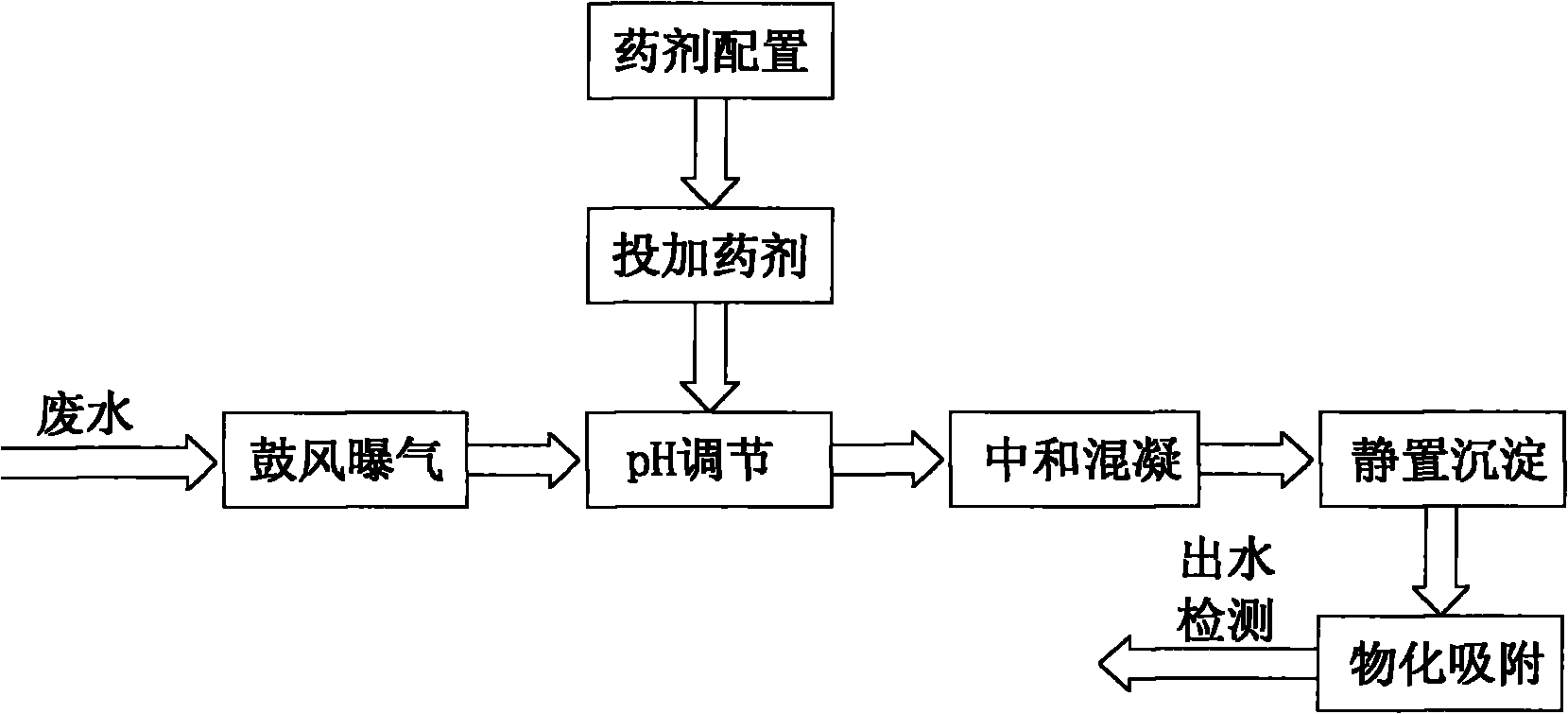

Process for treating mine wastewater containing sulfur minerals, As, Pb and Cd

InactiveCN101805084APrevent precipitationSolve the smellWaste water treatment from quariesEnergy based wastewater treatmentActivated carbon filtrationChemical adsorption

The invention discloses a process for treating mine wastewater containing sulfur minerals, As, Pb and Cd, which comprises the following steps: (1) performing blast aeration and oxidation treatment on the mine wastewater containing the sulfur minerals, As, Pb and Cd in an aeration tank; (2) neutralizing and coagulating the wastewater after the aeration and oxidation in a neutralization tank and controlling the pH to be between 8.6 and 9.5; (3) standing and depositing the wastewater after the neutralization and the coagulation treatment in a sedimentation tank; and (4) after the wastewater is clear after standing for a certain period of time, performing advanced treatment on heavy metal in a supernatant in a physical and chemical adsorption device and an activated carbon filtering system to obtain clean water meeting the environmental-protection or agricultural requirement. Through the process, peculiar smell in the mine wastewater can be eliminated, the wastewater color is changed to be normal, and the requirement of the quality of mine wastewater containing the discharged sulfur minerals, As, Pb and Cd in 'Standards for irrigation water quality' (GB5084-2005) can be met.

Owner:SINOSTEEL MAANSHAN INST OF MINING RES

Air purifier

An air purifier comprises a cleaning tower having an internal space communicating with a suction port and a discharge port, a blower for taking air from the suction port into the internal space of the cleaning tower and send it from the discharge port to the outside of the cleaning tower, and nozzles disposed in the internal space of the cleaning tower and spraying water in the internal space of the cleaning tower. The water sprayed from the nozzles is brought into contact with the air supplied by the blower in the cleaning tower.

Owner:MISAWA HOMES CO LTD +1

Tiltable vacuum loader and receiver with blow-back

InactiveUS8753432B2Improve reliabilityEasy to cleanCombination devicesAuxillary pretreatmentEngineeringMaterials processing

A vacuum loader for providing granular resin material to resin material processing equipment has a loader housing, a vacuum motor, a dust filter, an air blast generator, a dump flap, and a pivoting manually releasable latch for retaining the lateral web and the loader from tilting rotation of the loader about the shaft and supporting the loader when placed in a tilted orientation; the latch being weighted to pivotally return to a web-retaining position when released by an operator.

Owner:MAGUIRE STEPHEN B

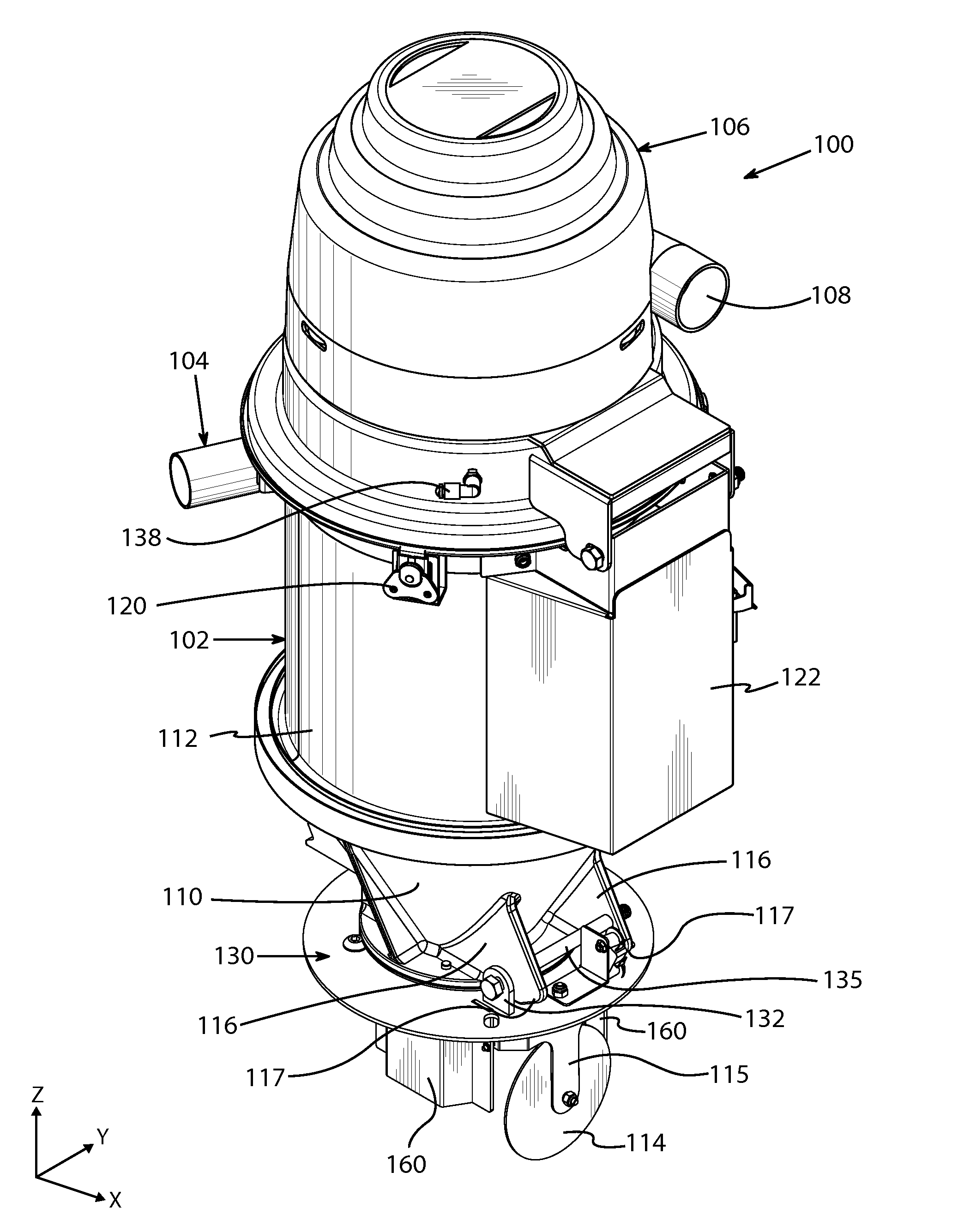

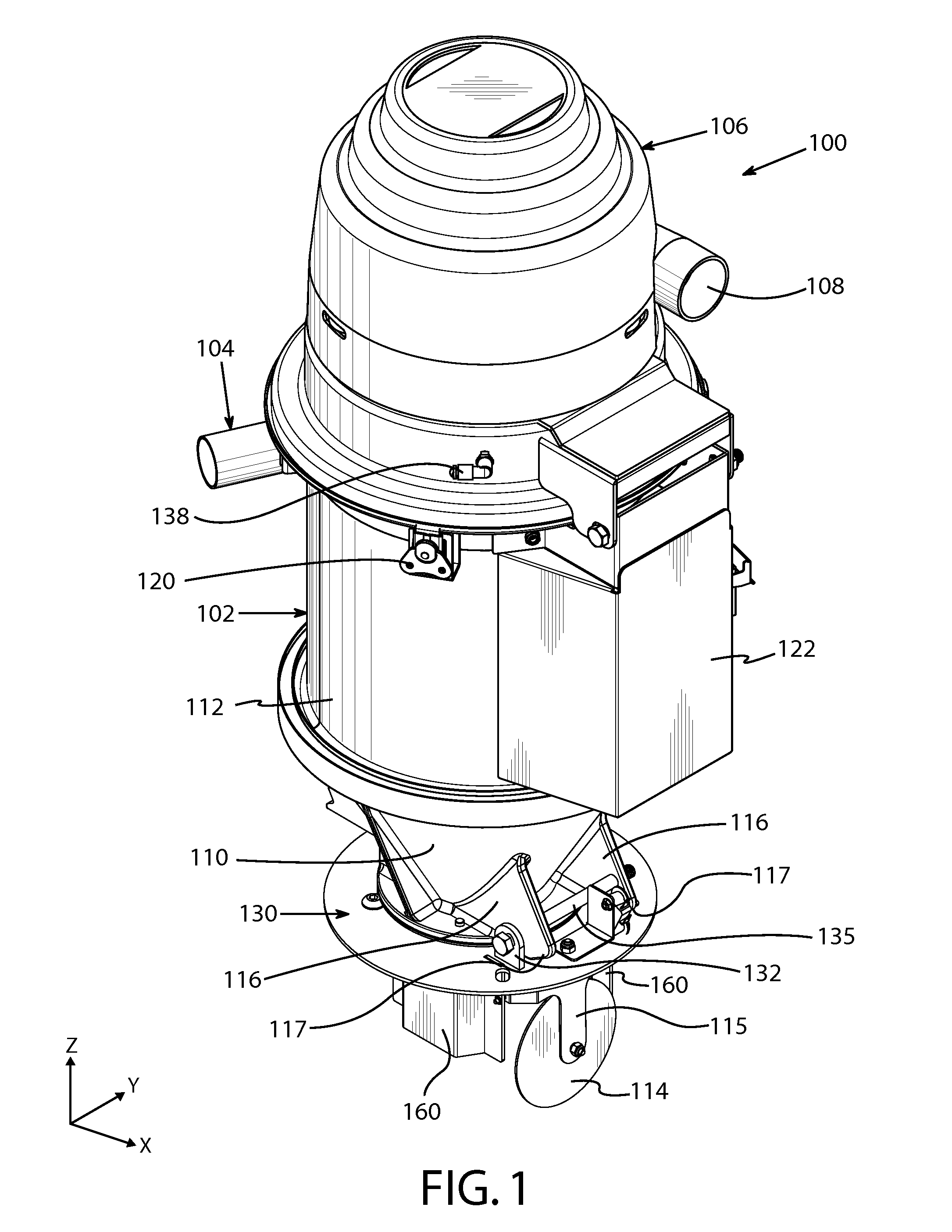

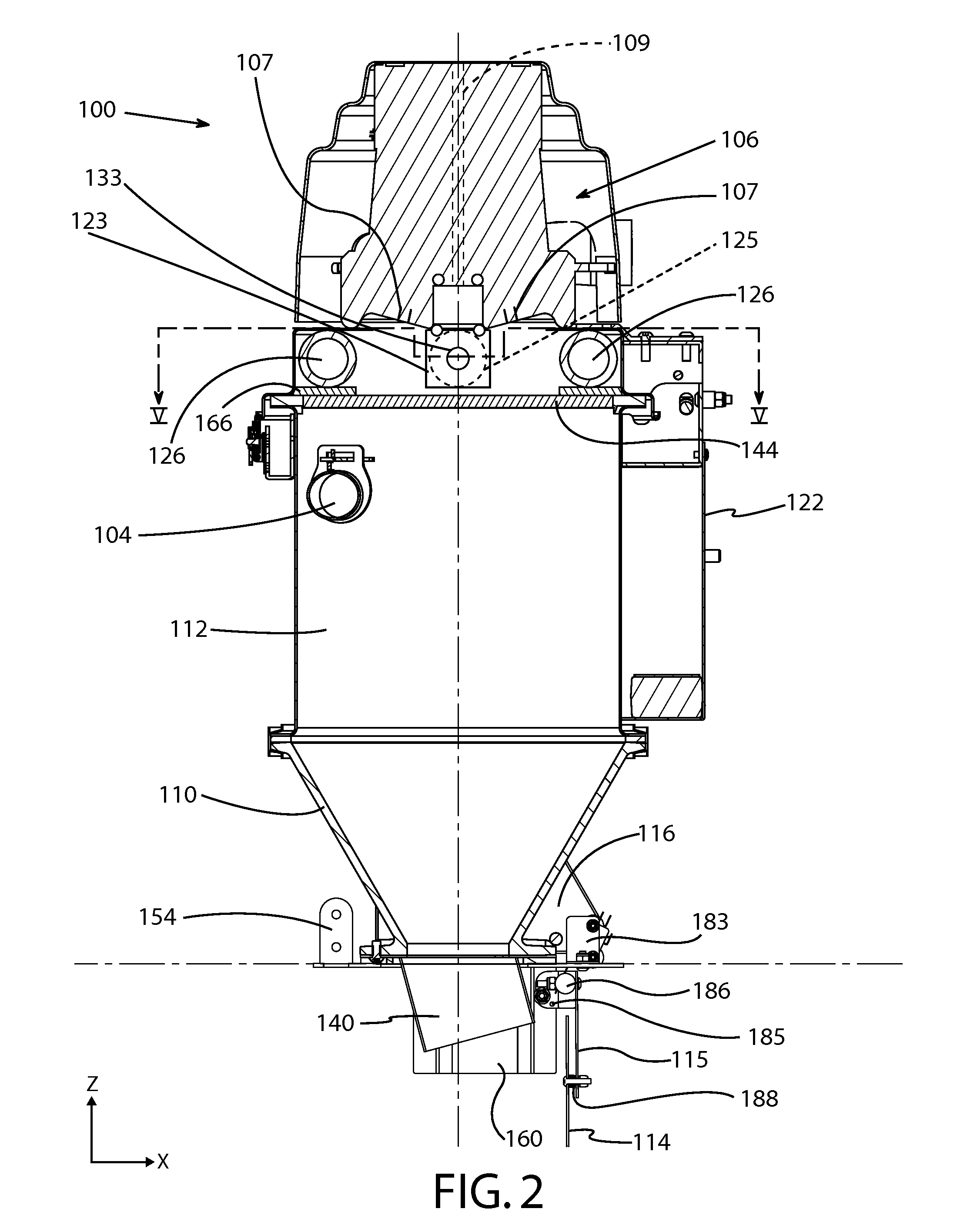

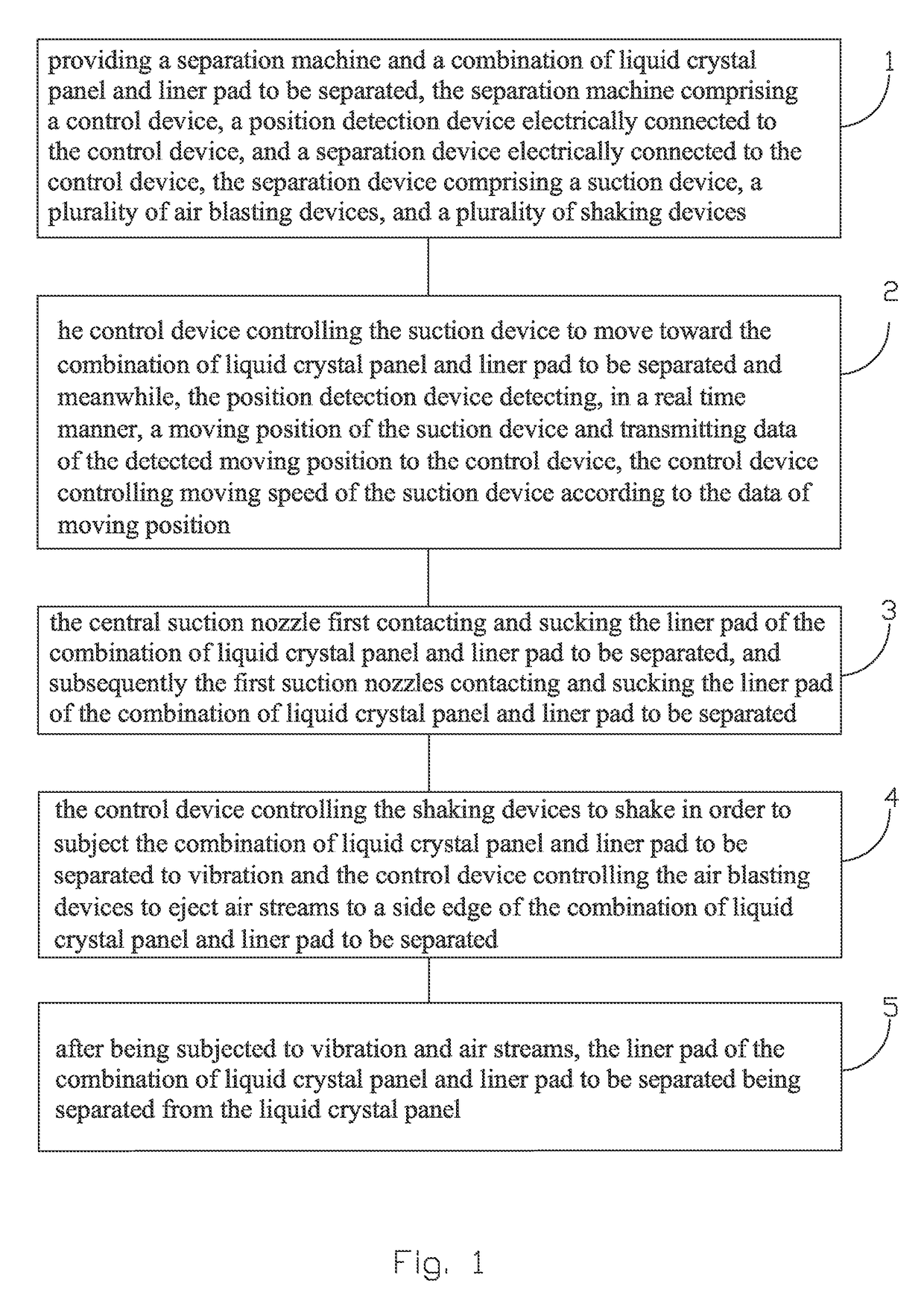

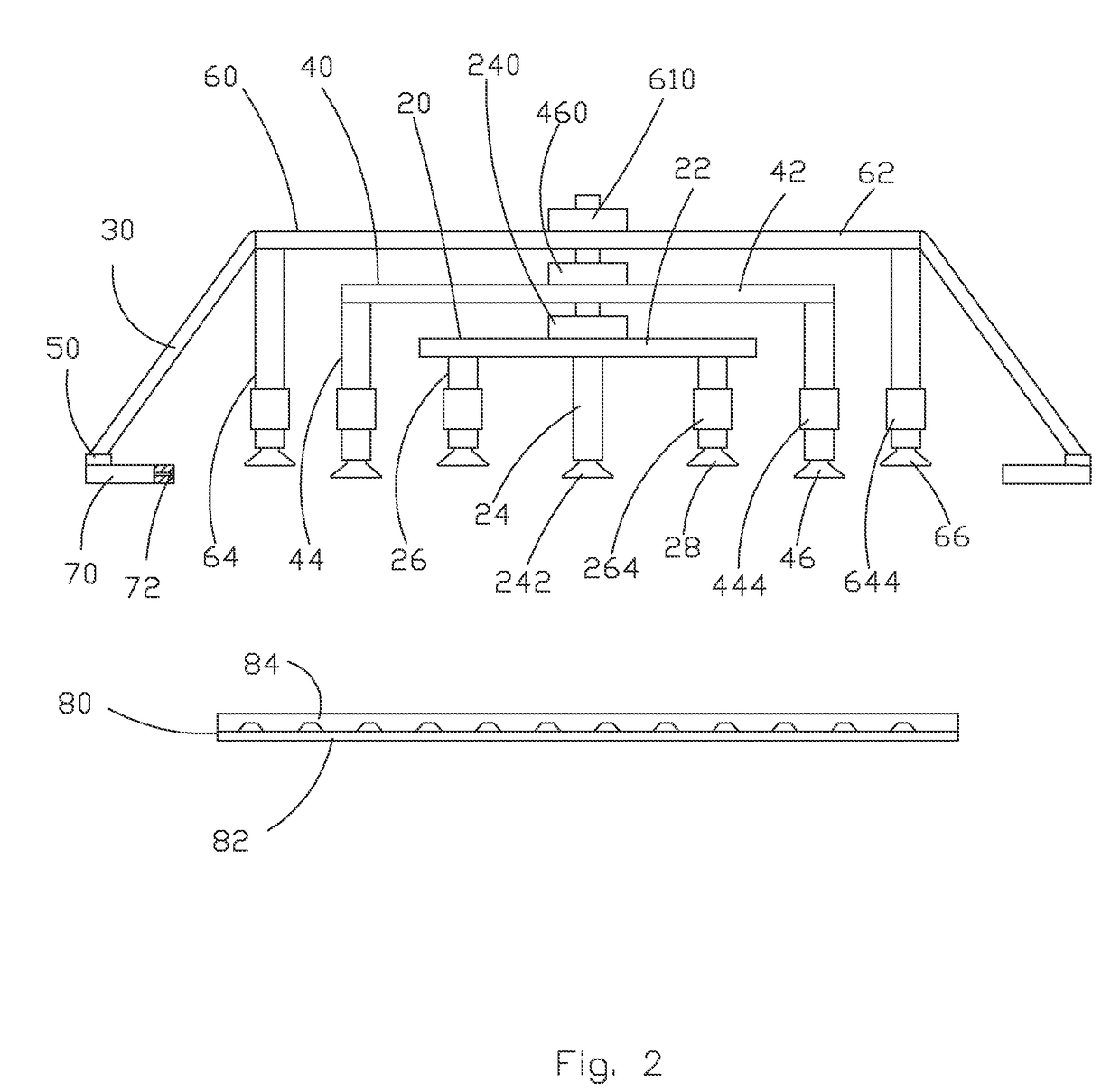

Method and machine for separating liquid crystal panel and liner pad

ActiveUS8470129B1Efficient separationShorten the time periodLamination ancillary operationsLayered product treatmentEngineeringLiquid crystal

The present invention provides a method and machine for separating a liquid crystal panel and a liner pad. The method includes (1) providing a separation machine and a combination of the liquid crystal panel and liner pad to be separated, the separation machine including a separation device that includes a suction device, air blasting devices and shaking devices; (2) the suction device moving toward the combination; (3) a central suction nozzle first engaging and sucking a liner pad of the combination and later the first suction nozzles engaging the sucking the liner pad of the combination; (4) the shaking devices being operated to subject the combination to vibration and the air blasting devices being operated to eject air streams to side edges of the combination; and (5) the combination, after being subjected to vibration and air streams, being separated so as to realize separation of the liquid crystal panel and liner pad.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

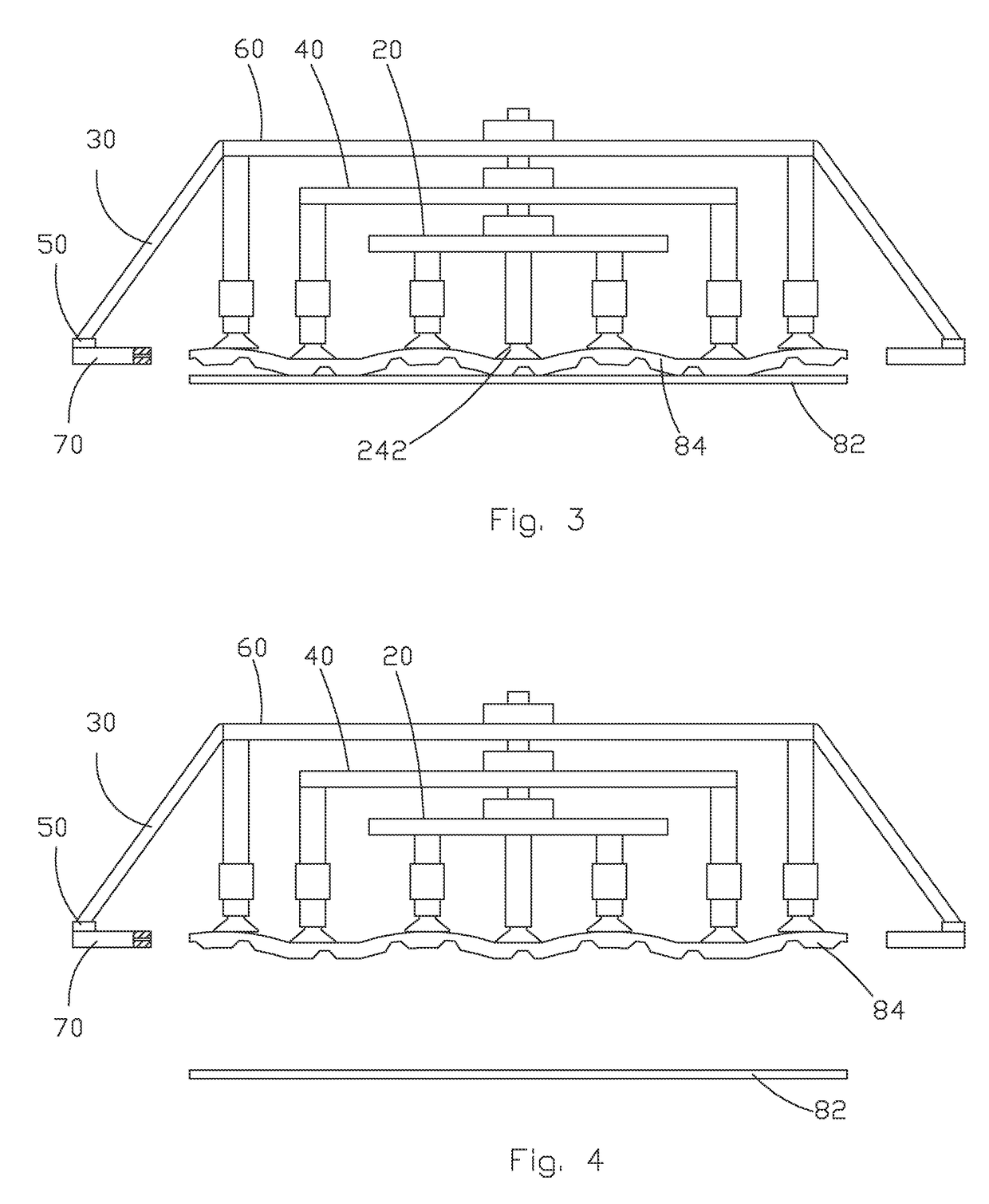

High iron aluminate-belite-sulfoaluminate cement clinker and preparation method thereof

ActiveCN107721214AIncrease iron oxide contentImprove wear resistanceCement productionCalcium in biologyWear resistance

The invention discloses a high iron aluminate-belite-sulfoaluminate cement clinker and a preparation method thereof. The high iron aluminate-belite-sulfoaluminate cement clinker comprises the following components in percentages by mass: 25 to 35% of C4A3S<->, 32 to 42% of C2S, 10% to 30% of C4AF and 15 to 25% of f-CaSO4; and besides, the cement clinker also comprises CT. The invention also discloses a preparation method for the cement clinker. The preparation method comprises the following steps: respectively subjecting a calcareous raw material, a salic raw material, a ferruginous raw material and a gypsum component to drying, crushing and grinding, and carrying out weighing and mixing in proportion, adding a certain amount of water and carrying out uniform mixing, carrying out press molding so as to obtain sample blocks, then carrying out calcination at 950 DEG C for 30 min, then immediately transferring the calcined sample blocks into a high-temperature furnace with a temperature of1275 DEG C to 1350 DEG C, continuing calcination for 30 to 60 min, and carrying out air-blast cooling so as to obtain the clinker. The preparation method provided by the invention gets rid of the modulus limit of traditional sulfoaluminate cement, and improves the content of free gypsum on the basis of high iron aluminate and high belite; and the clinker prepared by using the preparation method provided by the invention has mechanical properties capable of meeting requirements of sulfoaluminate cement 525, and has good wear resistance.

Owner:BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com