Patents

Literature

98 results about "Machine shop" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A machine shop is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plastic (but sometimes of other materials such as glass or wood). A machine shop can be a small business (such as a job shop) or a portion of a factory, whether a toolroom or a production area for manufacturing. The parts produced can be the end product of the factory, to be sold to customers in the machine industry, the car industry, the aircraft industry, or others. In other cases, companies in those fields have their own machine shops.

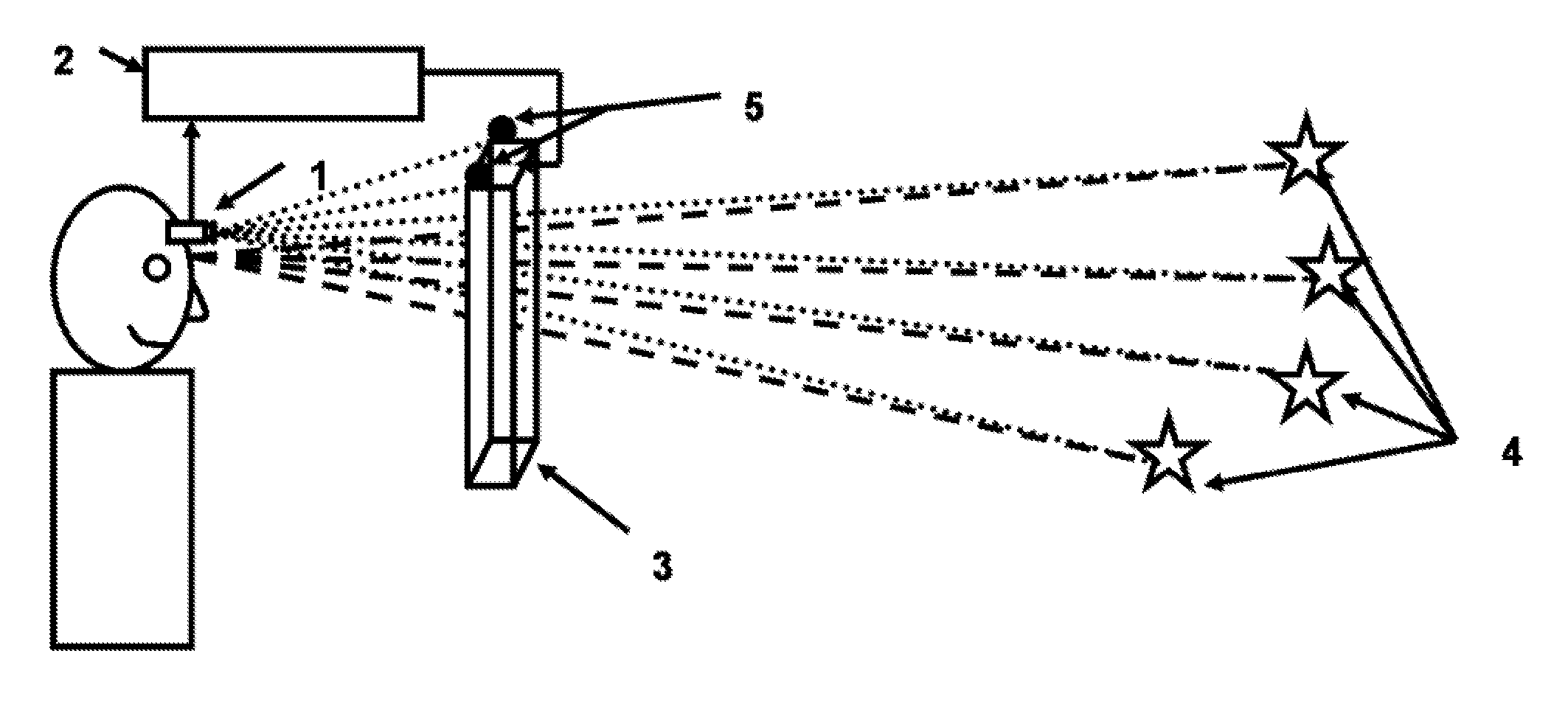

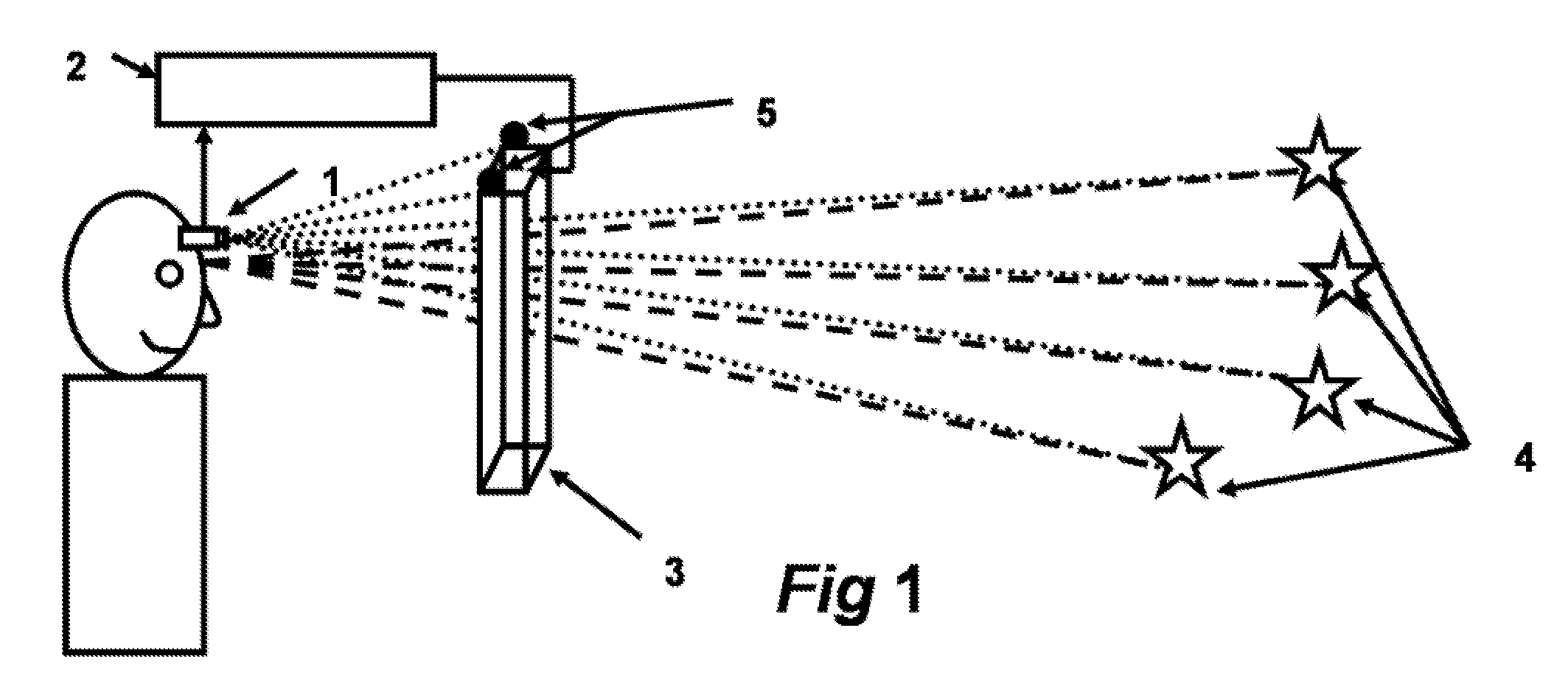

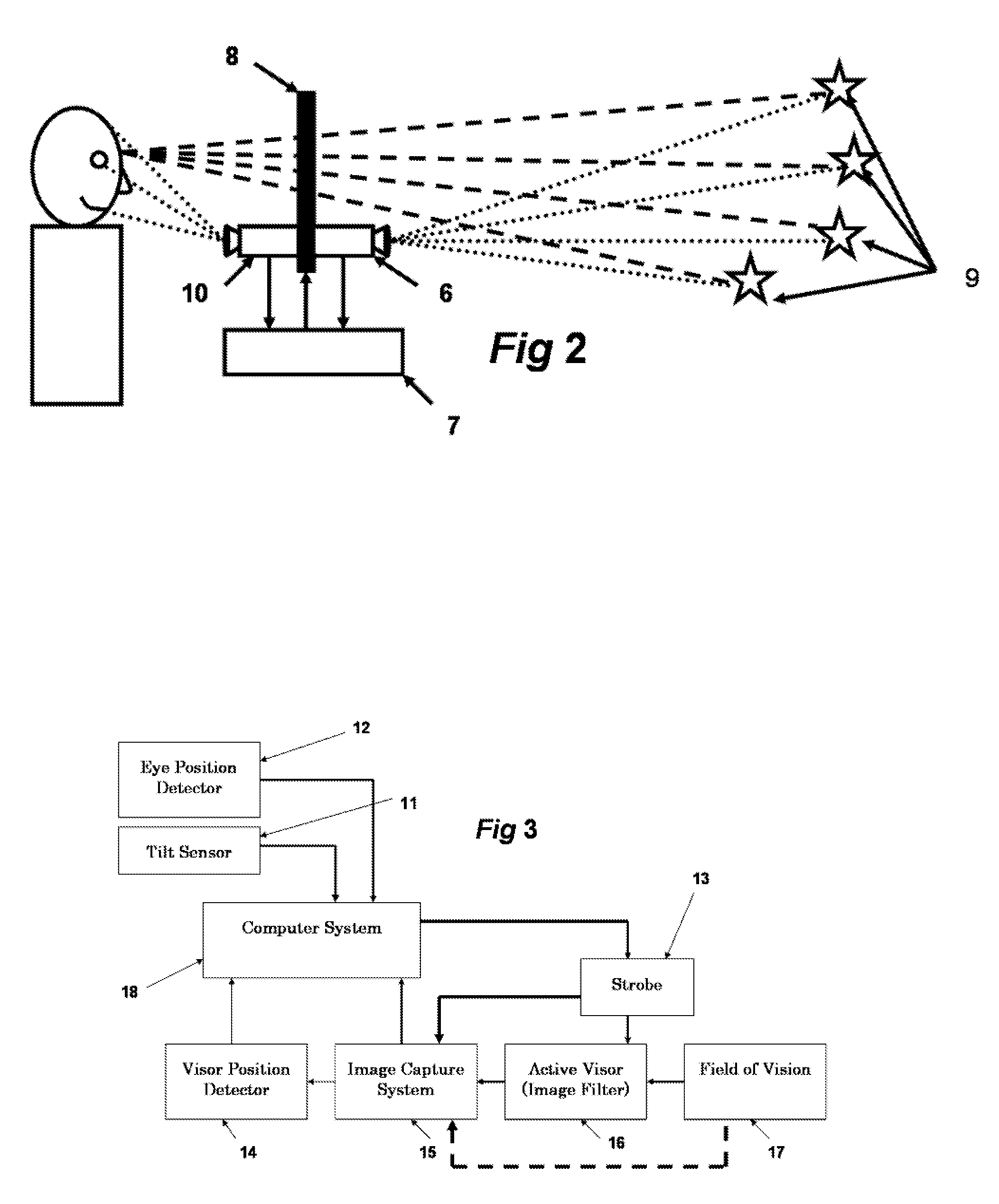

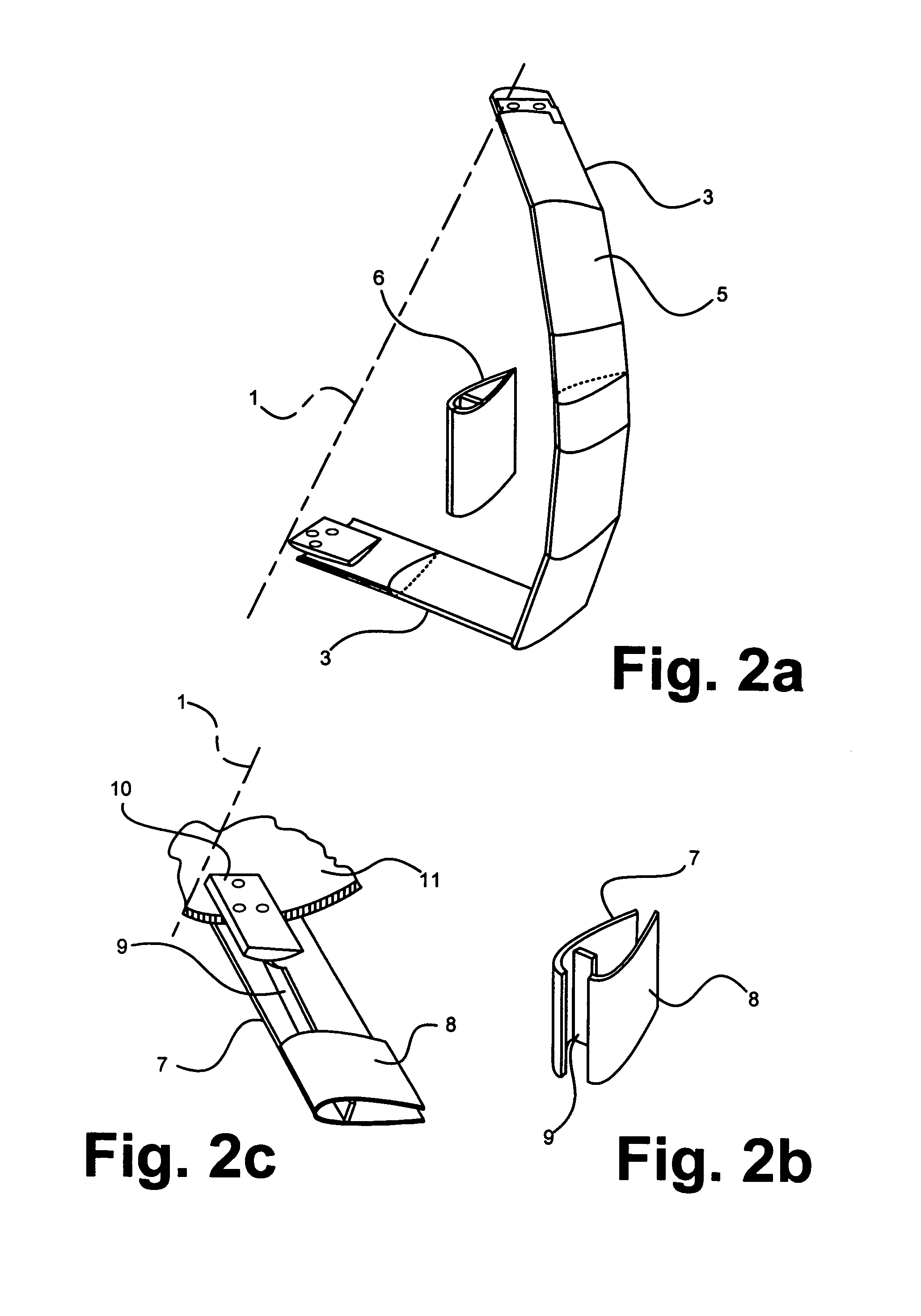

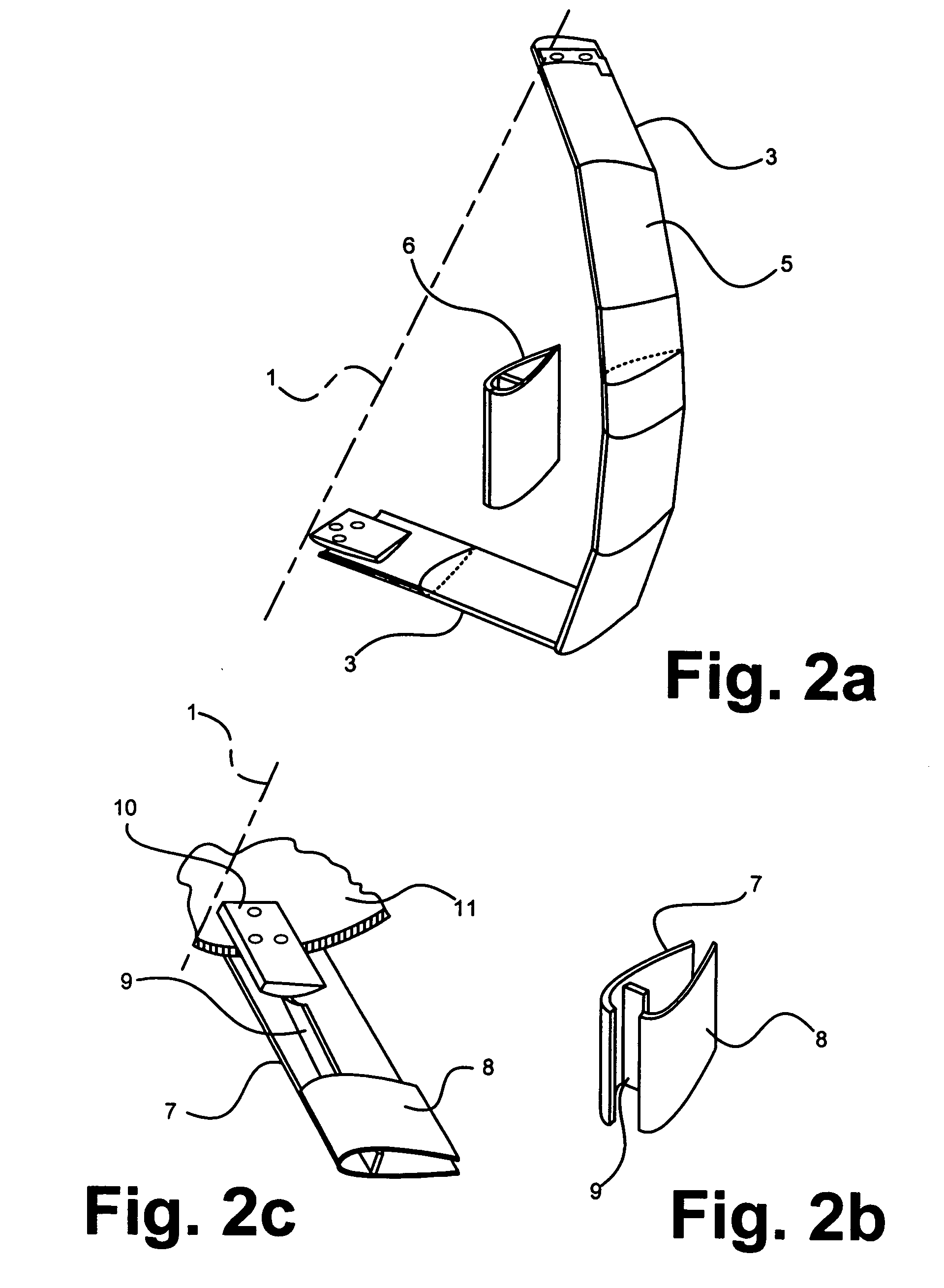

Active visor system for eliminating glare in field-of-vision from mobile and transient light sources and reflective surfaces

InactiveUS20060140502A1Reduce the amount requiredAntiglare equipmentCharacter and pattern recognitionVision processingMachine shop

A field-of-vision processing and filtering system for eliminating glare from mobile and transient light sources and reflective surfaces, using image recording, eye-position detection, and a active matrix screen functioning as a dynamically controllable visor, for modifying the field of vision appropriately. The system filters out high light intensity points from the field of vision, without seriously affecting the relevant parts of the field of vision. One embodiment of the system can be used by drivers for filtering glare from oncoming headlight at night, as well as during day time to block glare from the sun. Another embodiment of the system can be used for protection from glare of welding iron in a machine shop.

Owner:TSENG ALLAN S +1

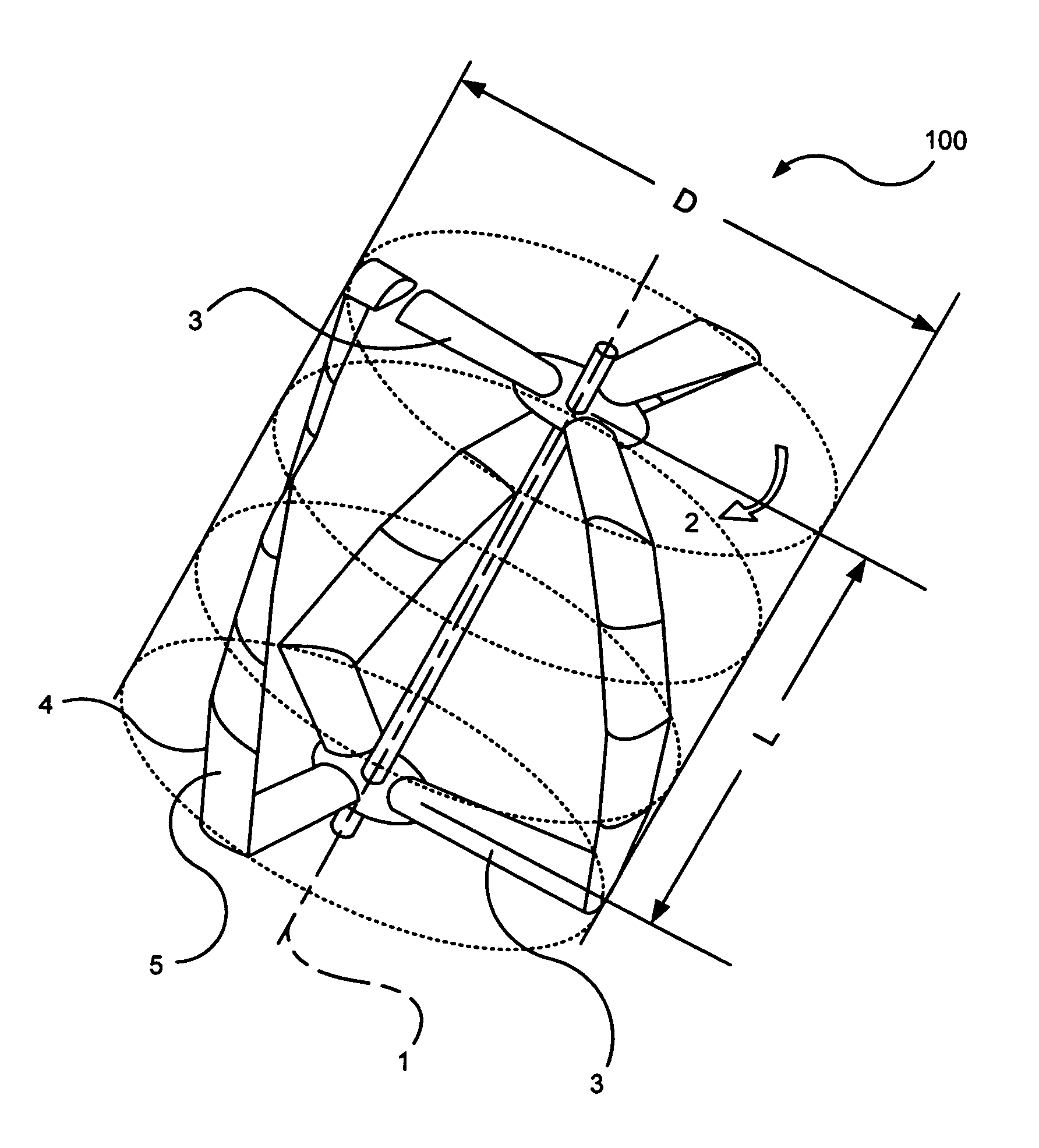

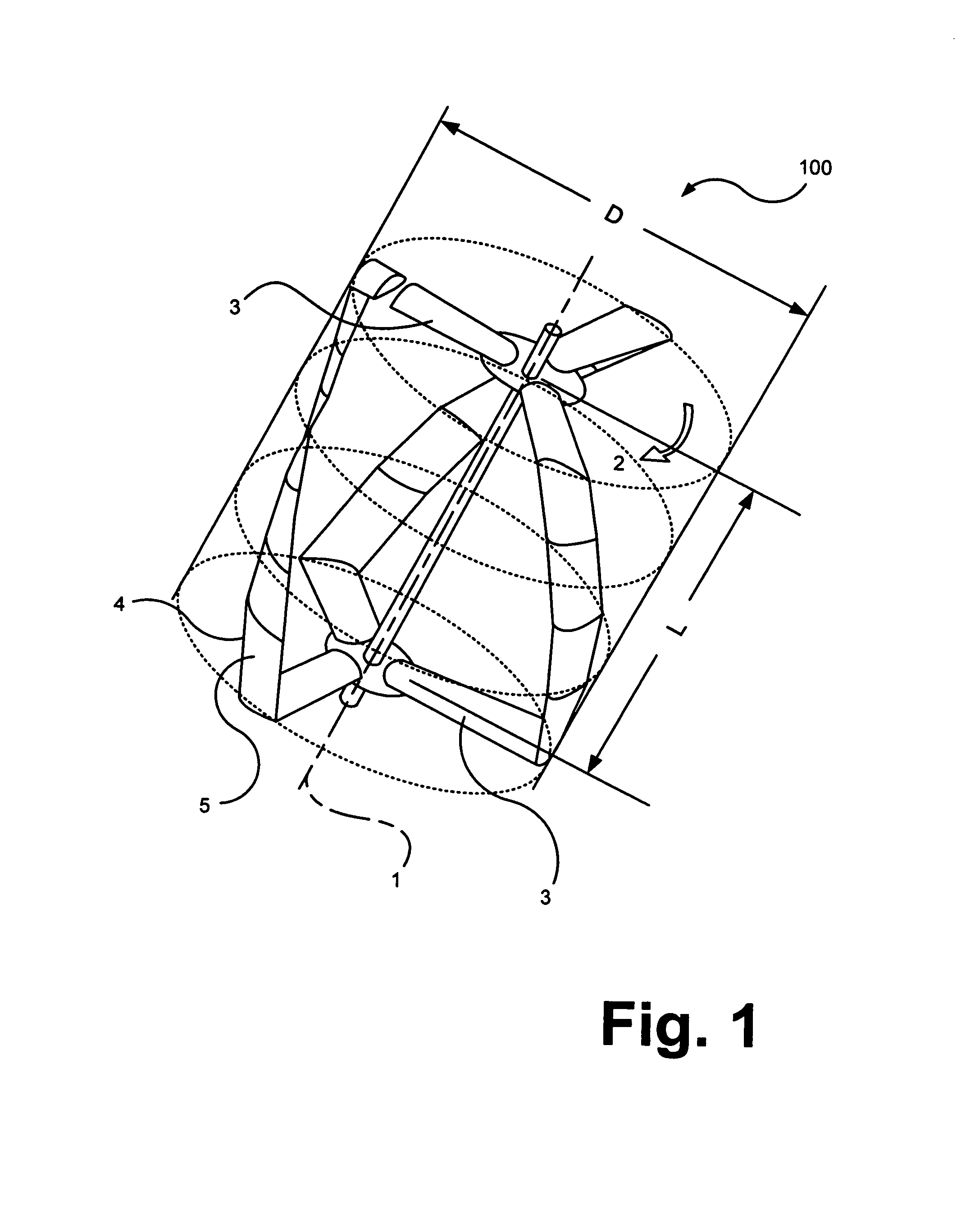

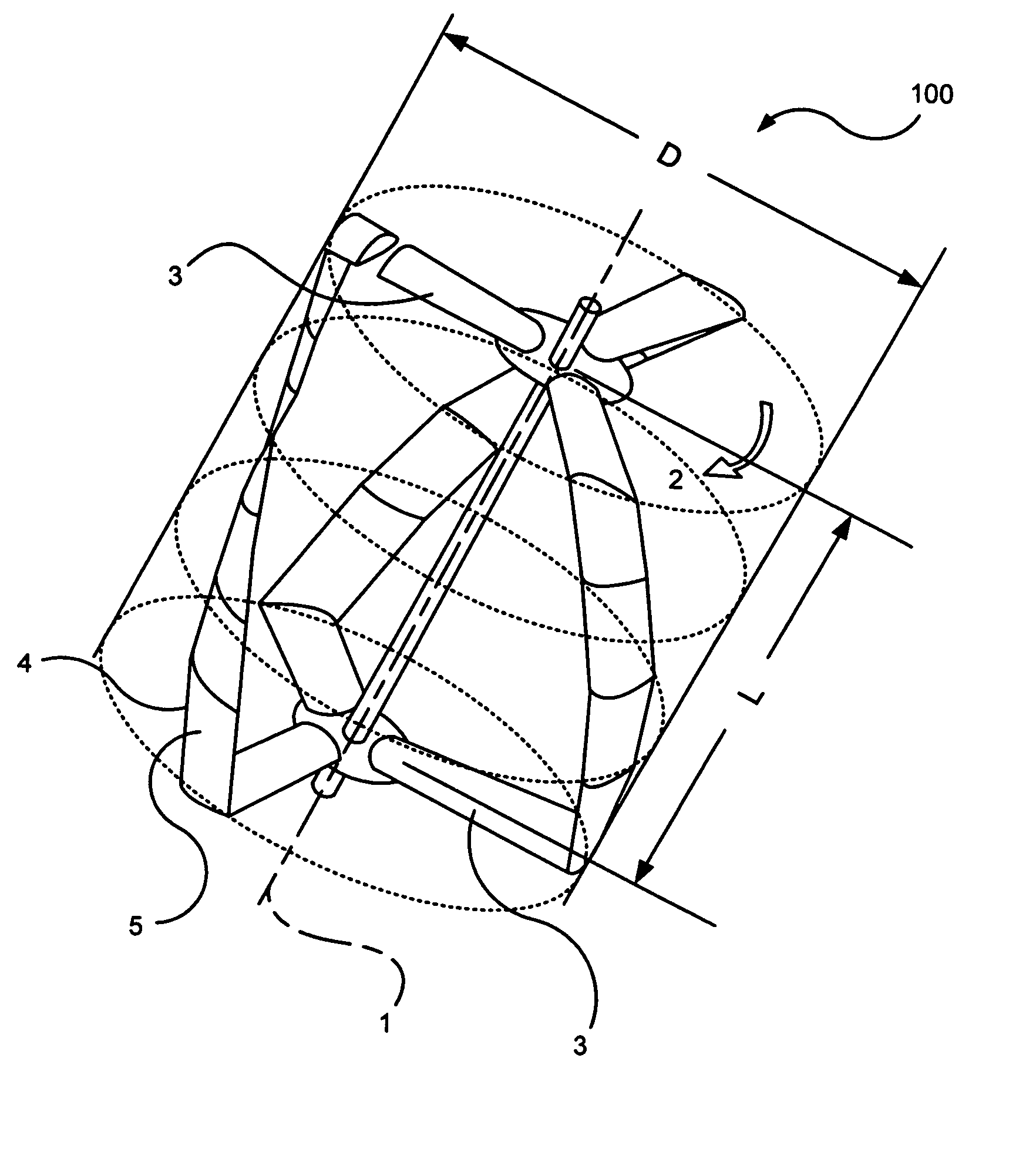

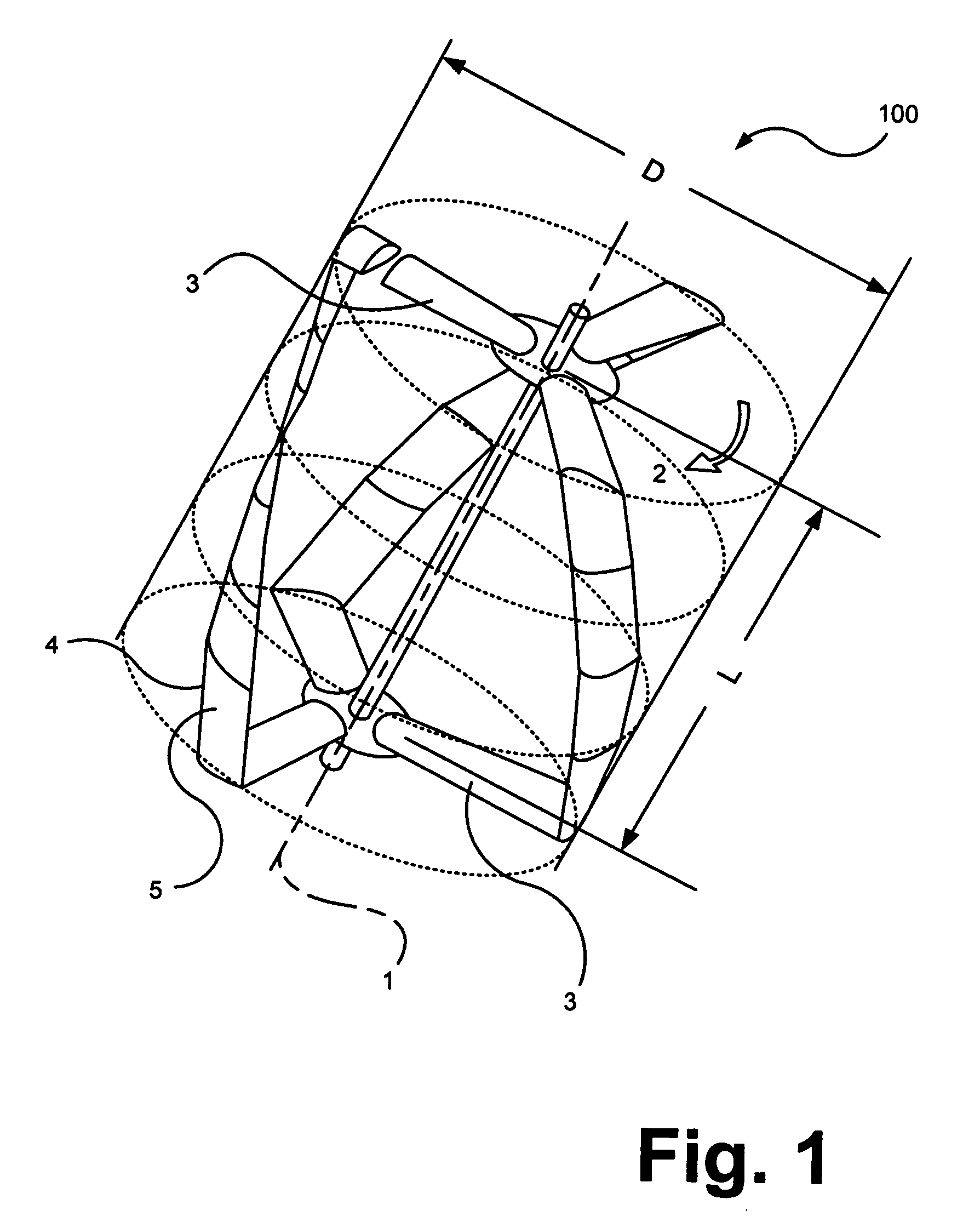

Method of making complex twisted blades with hollow airfoil cross section and the turbines based on such

InactiveUS7156609B2Improve efficiencyPropellersWind motor controlMachine shopManufacturing technology

A reactive turbine, each blade of which approximates a helical shape that is constructed with readily available conventional manufacturing techniques. The blades are constructed in discrete straight sections that, when joined, approximate a helix or any other efficient turbine shape. Each section is manufactured with the well known and readily available machine shop techniques of shaping, forming, and joining with welds or fasteners.

Owner:GCK

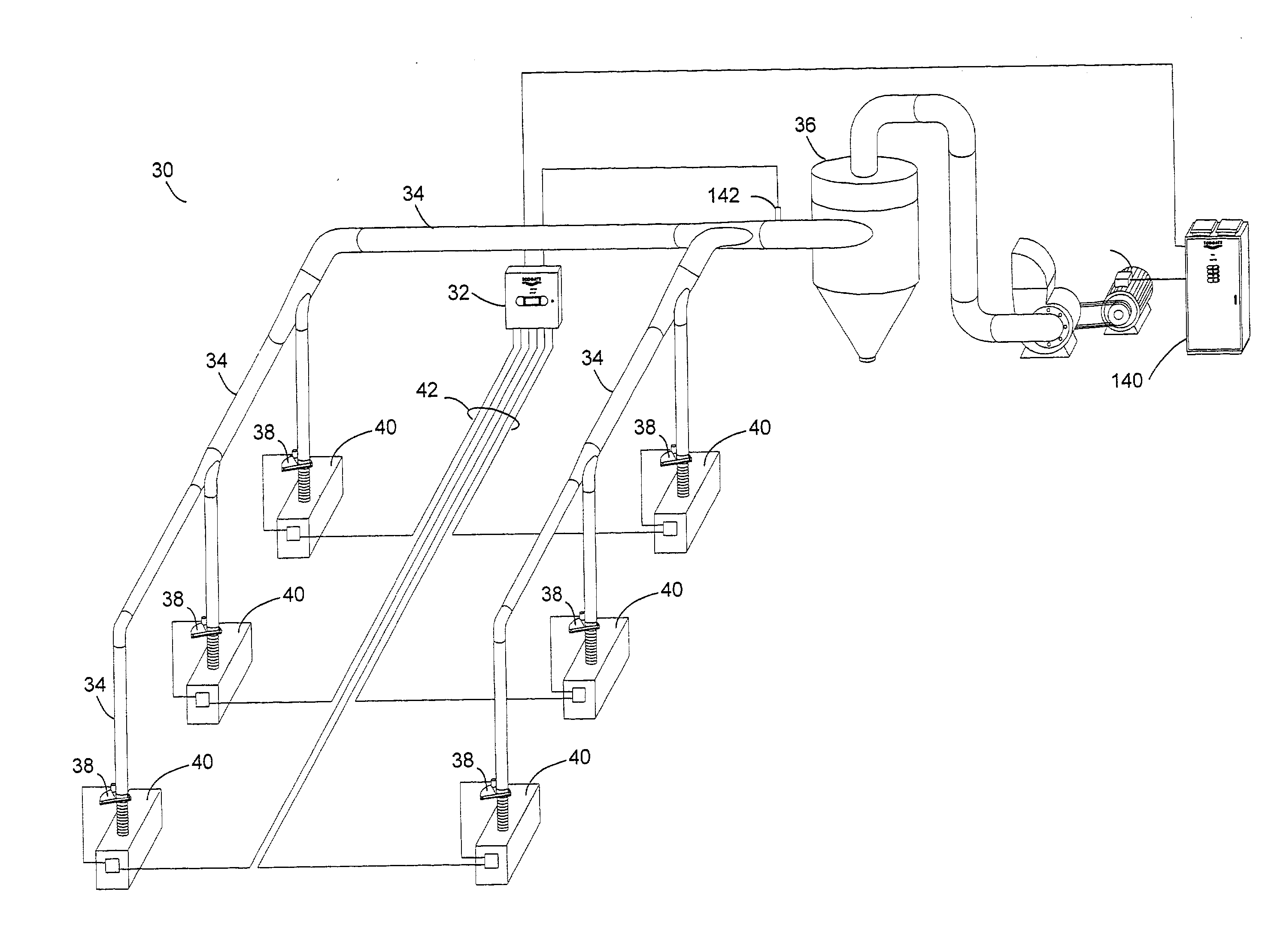

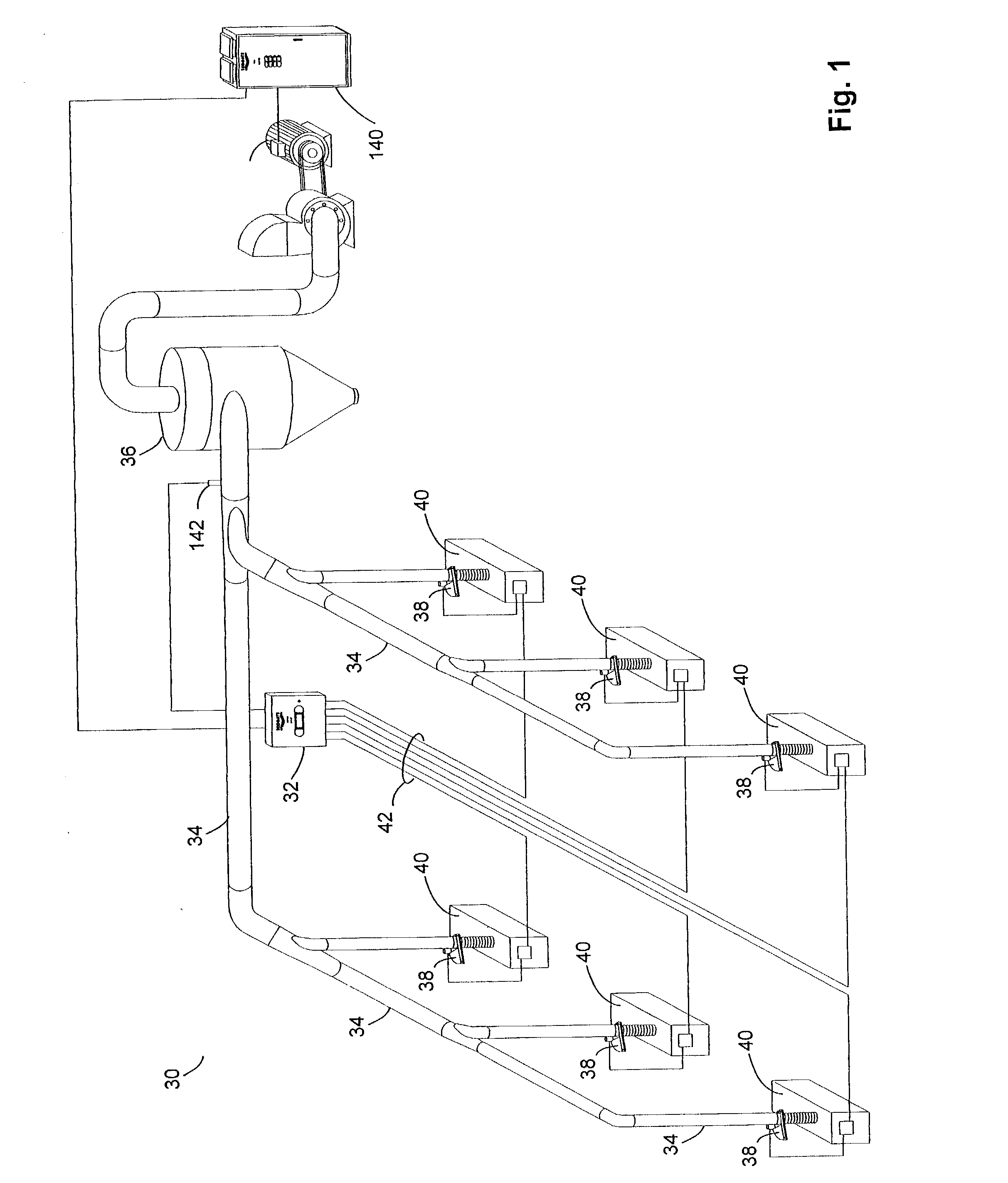

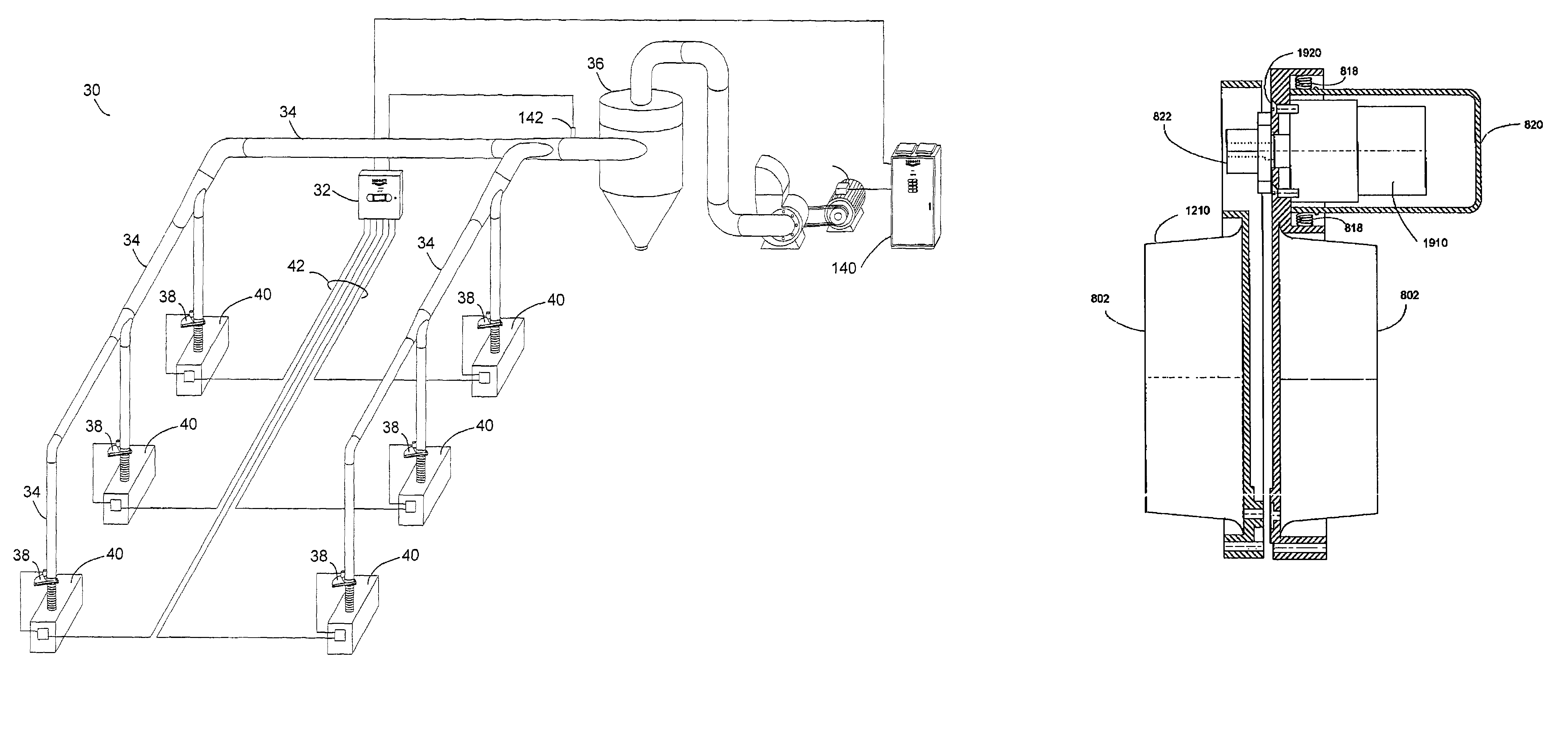

Energy saving vacuum system for particle, mist, and fume collection

ActiveUS20040093682A1High ratio leverageGuaranteed uptimeMetal sawing accessoriesVehicle cleaningMachine shopCollection system

An improved energy-efficient vacuum system for machine shop dust, particulate matter, and the like. Blast gates, including large-diameter blast gates, control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch, an increased current feedback system, a biasing-spring assembly or otherwise to limit the rotation driving of the rotating blade. In one embodiment, the blast gate blade bears teeth about its perimeter. The DC motor engages the perimeter blade teeth with a gear. Greater mechanical advantage is achieved over the blast gate blade and less torque arises in contrast to a driving system located at the blade's central pivot point. Additionally, sensing apparatus or system calculation allow the dust collecting vacuum system to operate in an energy-efficient manner. By supplying only the vacuum needed to collect present dust, energy is saved in comparison with a dust collection system operating continuously at full capacity.

Owner:LITOMISKY IVAN +2

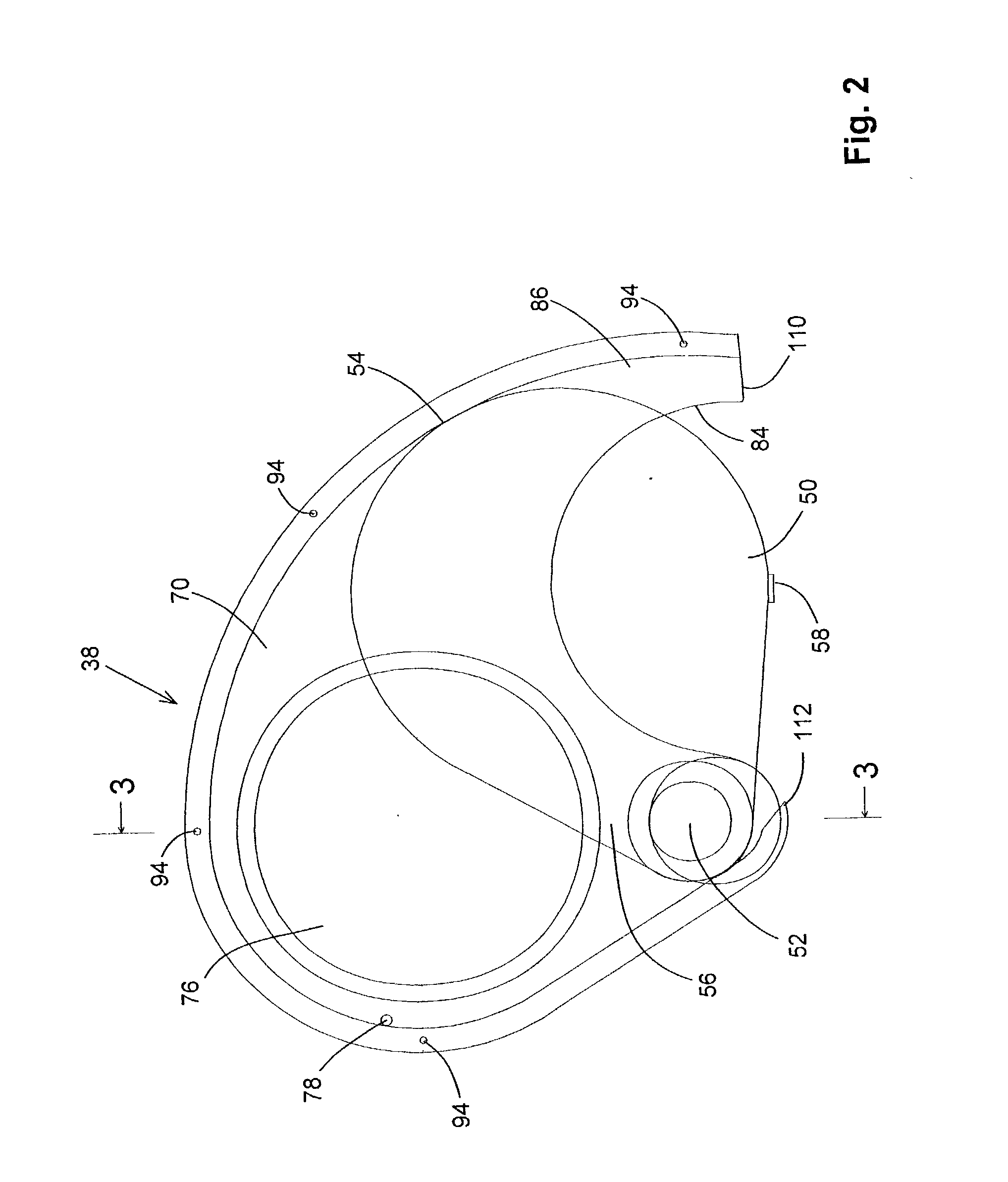

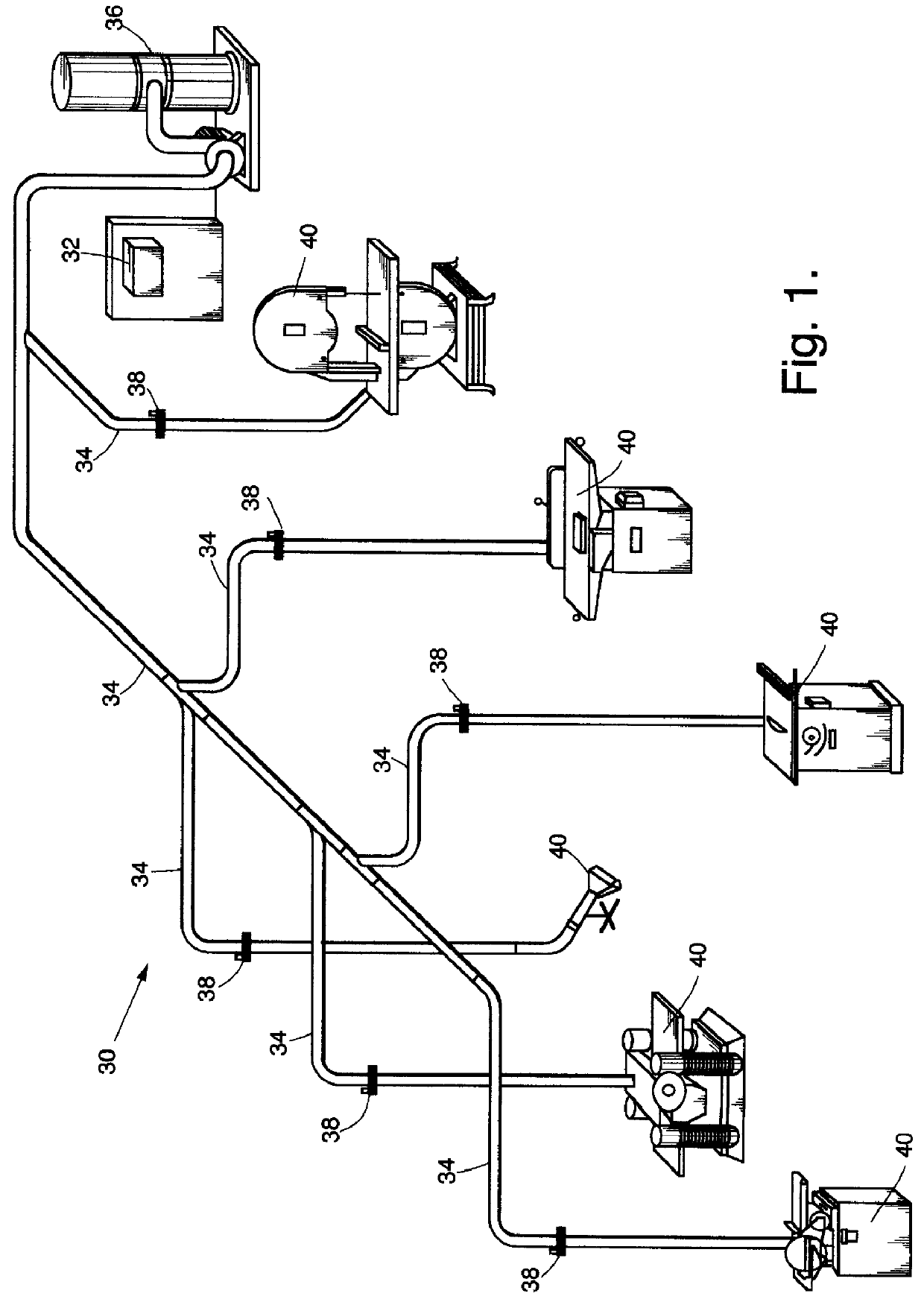

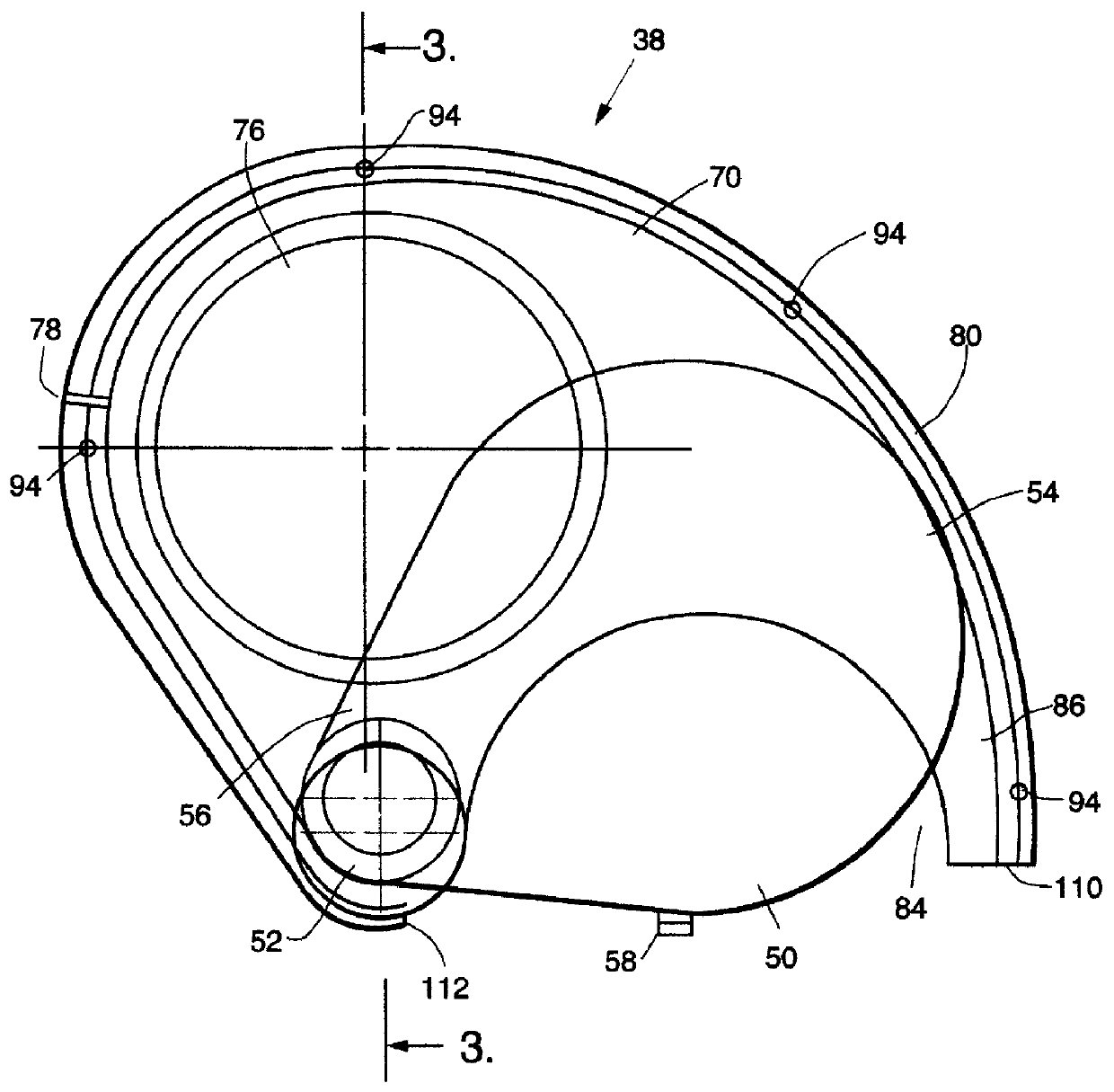

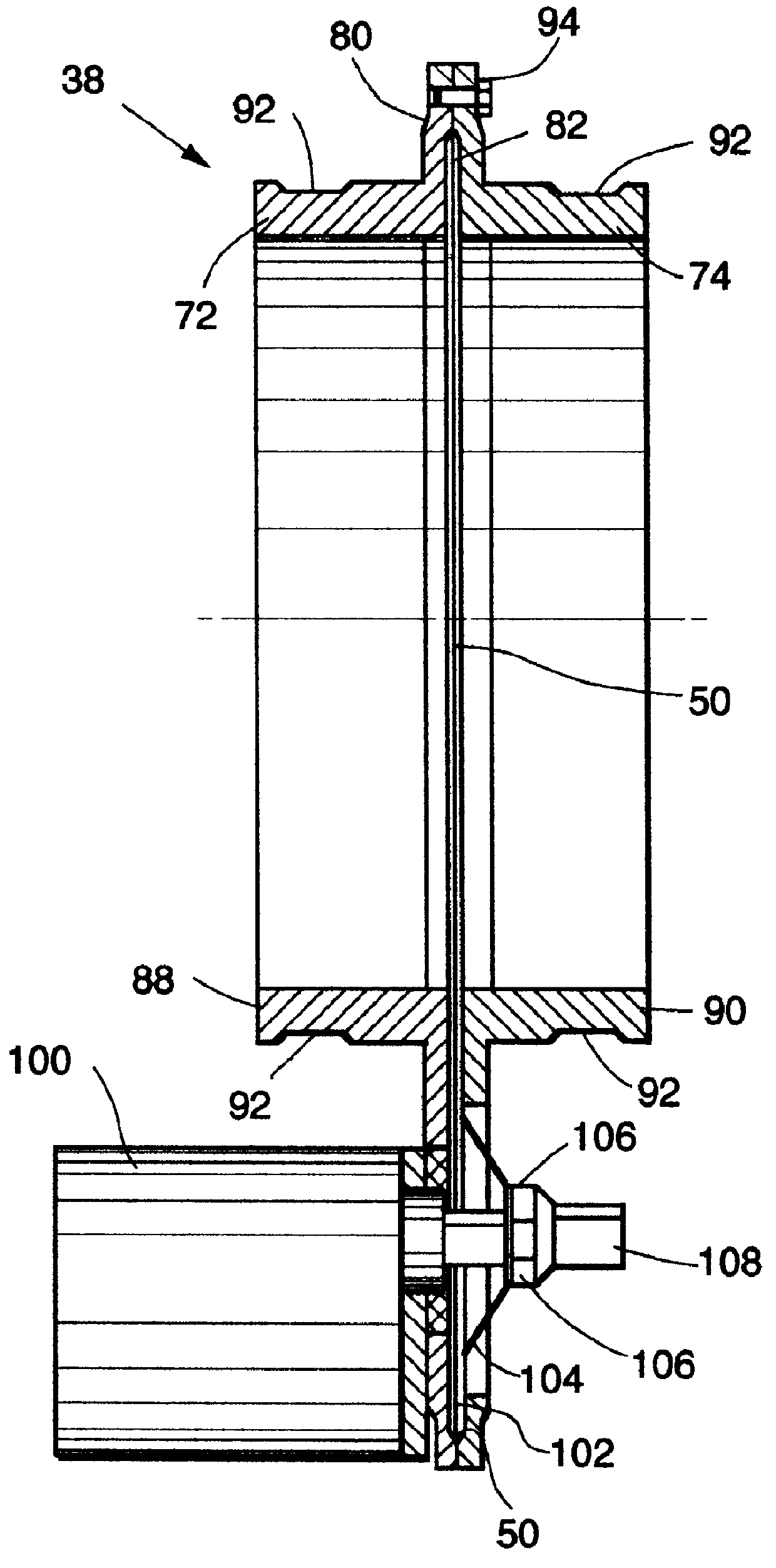

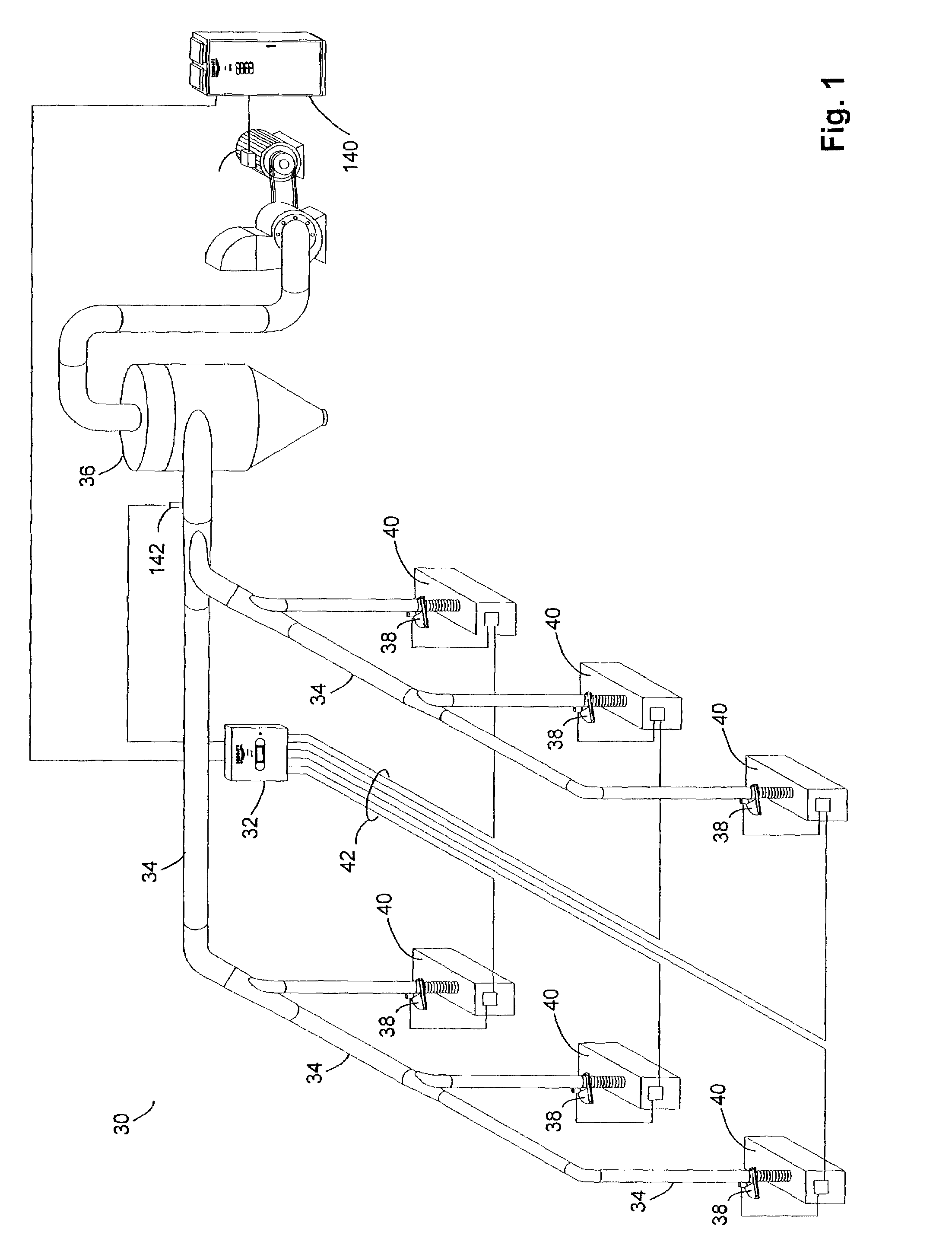

Refuse vacuum system for machine shops

InactiveUS6012199AInexpensiveEfficient mannerMetal sawing accessoriesLighting and heating apparatusParticulatesMachine shop

A vacuum system for machine shop dust, particulate matter, and the like. Blast gates control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch or an increased current feedback system to limit the rotation driving of the rotating blade. Importantly, a small aperture serves to allow air flow into the chassis gap through which the rotating blade rotates in order to ensure the particular matter does not lodge inside the chassis thereby preventing the proper operation of the rotating blade. A central controller having a microprocessor or the like may be programmed or programmable and serve to individually control a selected number of blast gates based upon a feedback mechanism. A piezoelectric sensor or the like senses the vibration arising from the turning on of the associated machinery, indicating the demand for vacuum power to collect particulate matter. In response to the piezoelectric sensor's signal, the blast gate is opened and the dust collector is either turned on or stepped up to accommodate the increase load upon the vacuum system. The reverse situation occurs when the machinery is turned off. The piezoelectric sensor ceases signalling the central controller of the machine "on" condition. The central controller then steps down the dust collector / vacuum system and closes the associated blast gate. Alternative embodiments are set forth whereby additional features provide for enhanced utility, including a computer operation, control, monitoring, and feedback.

Owner:LITOMISKY PETR +1

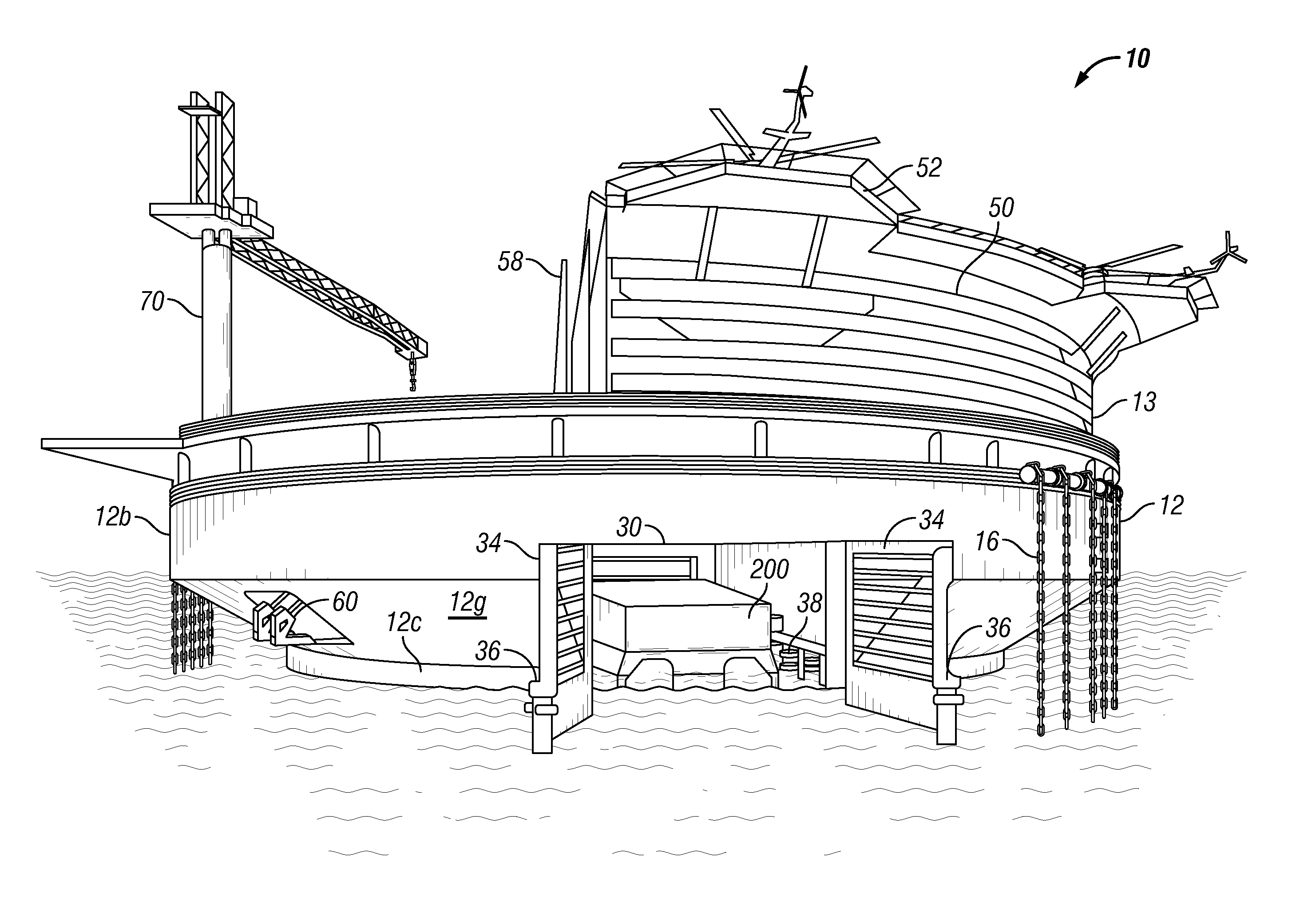

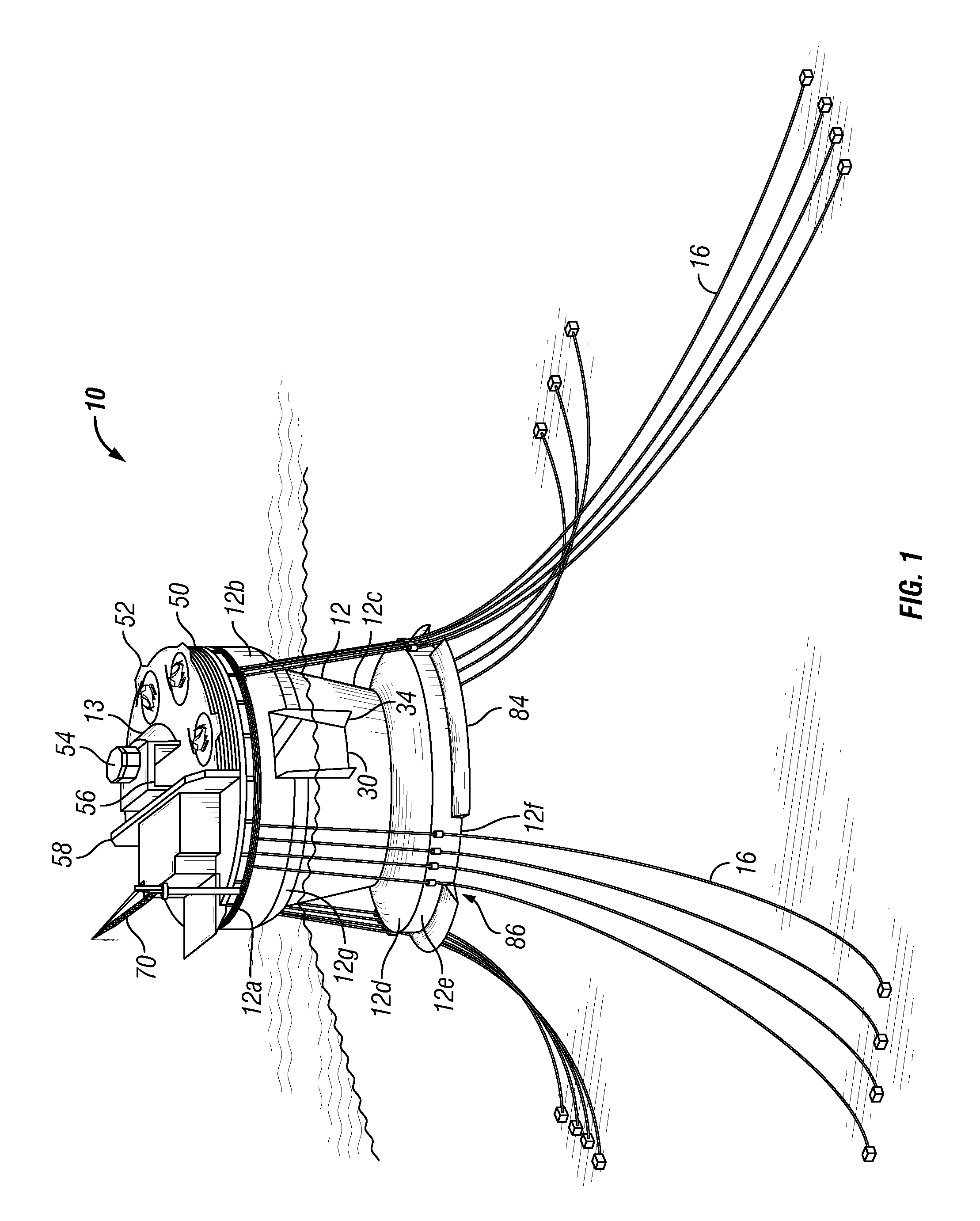

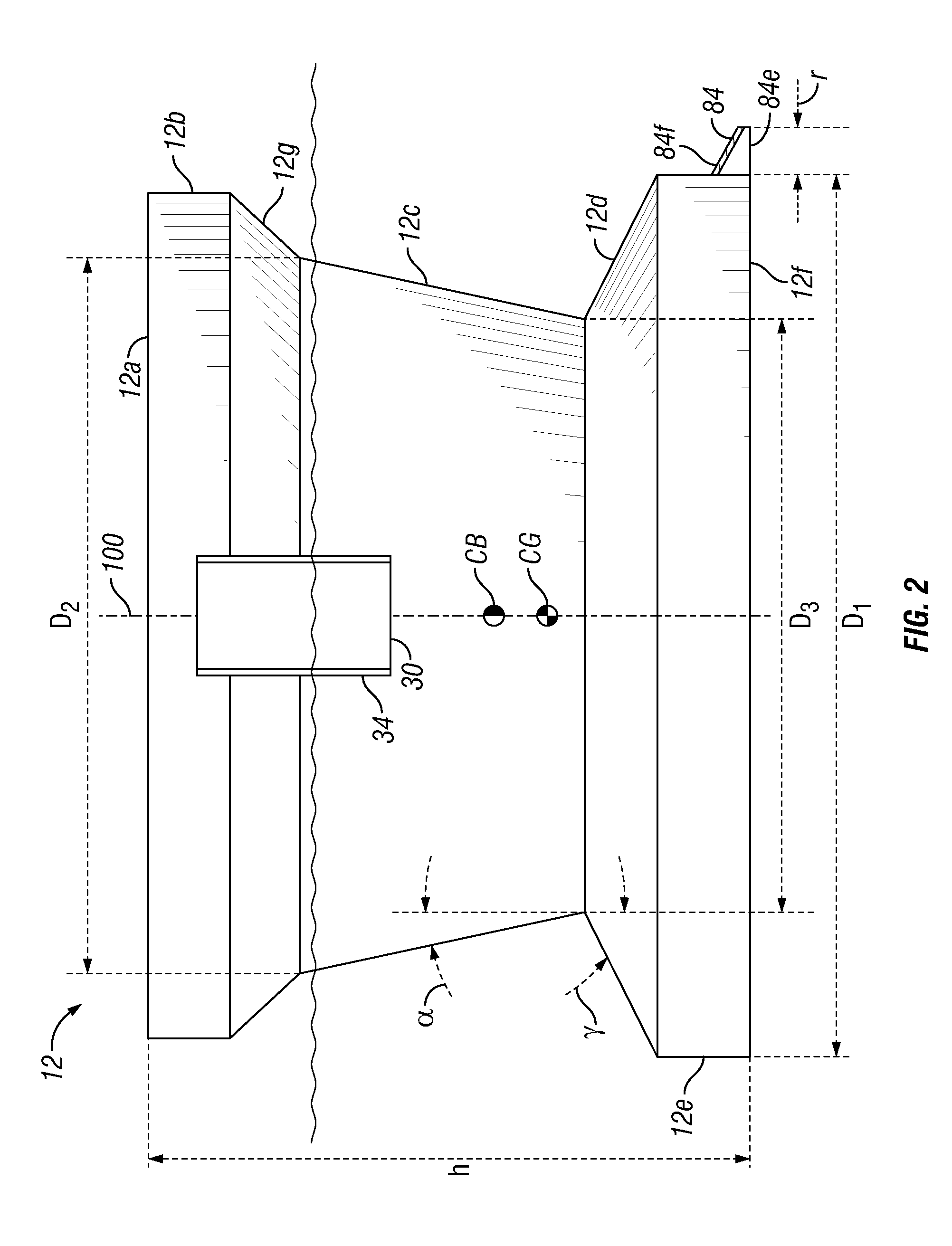

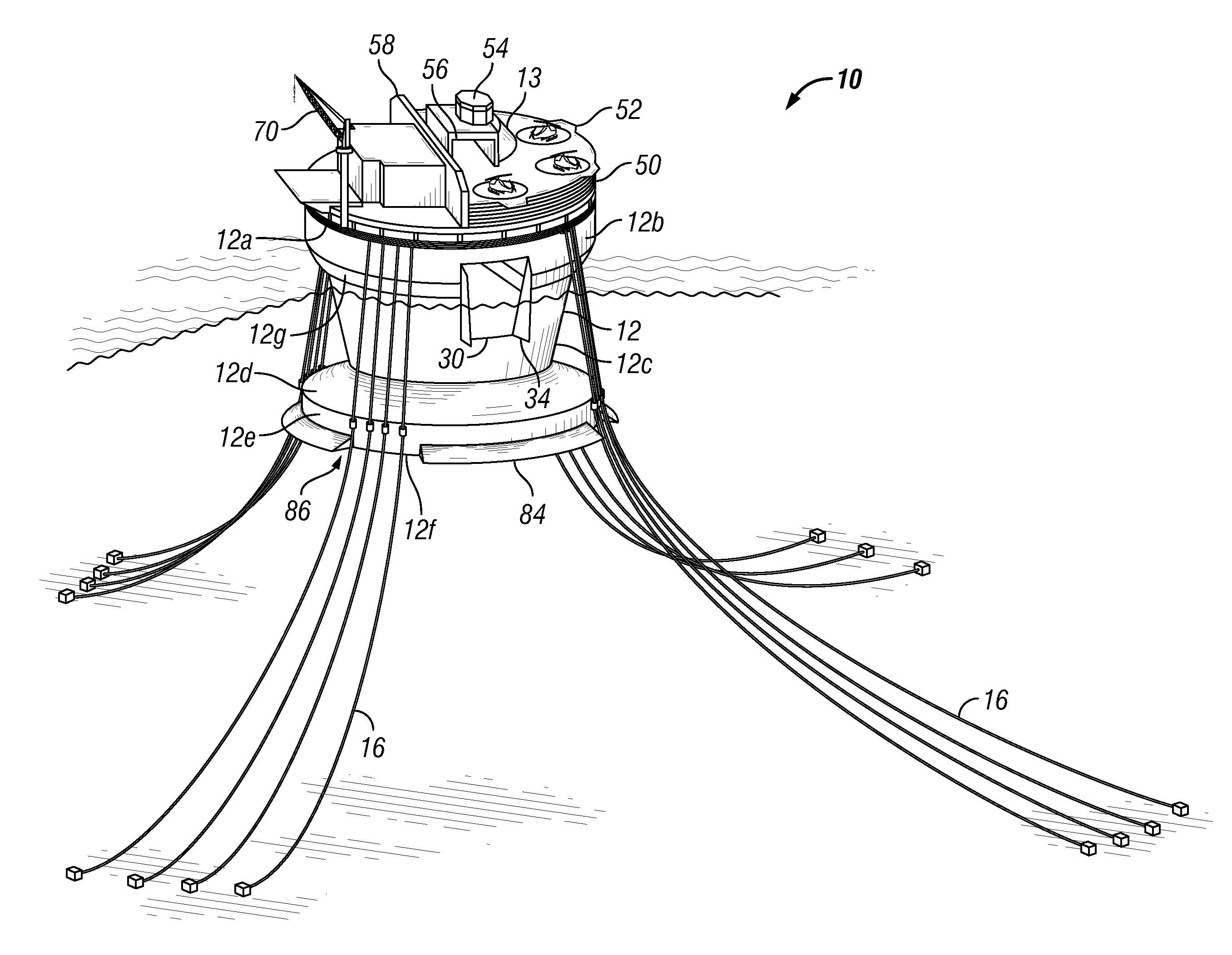

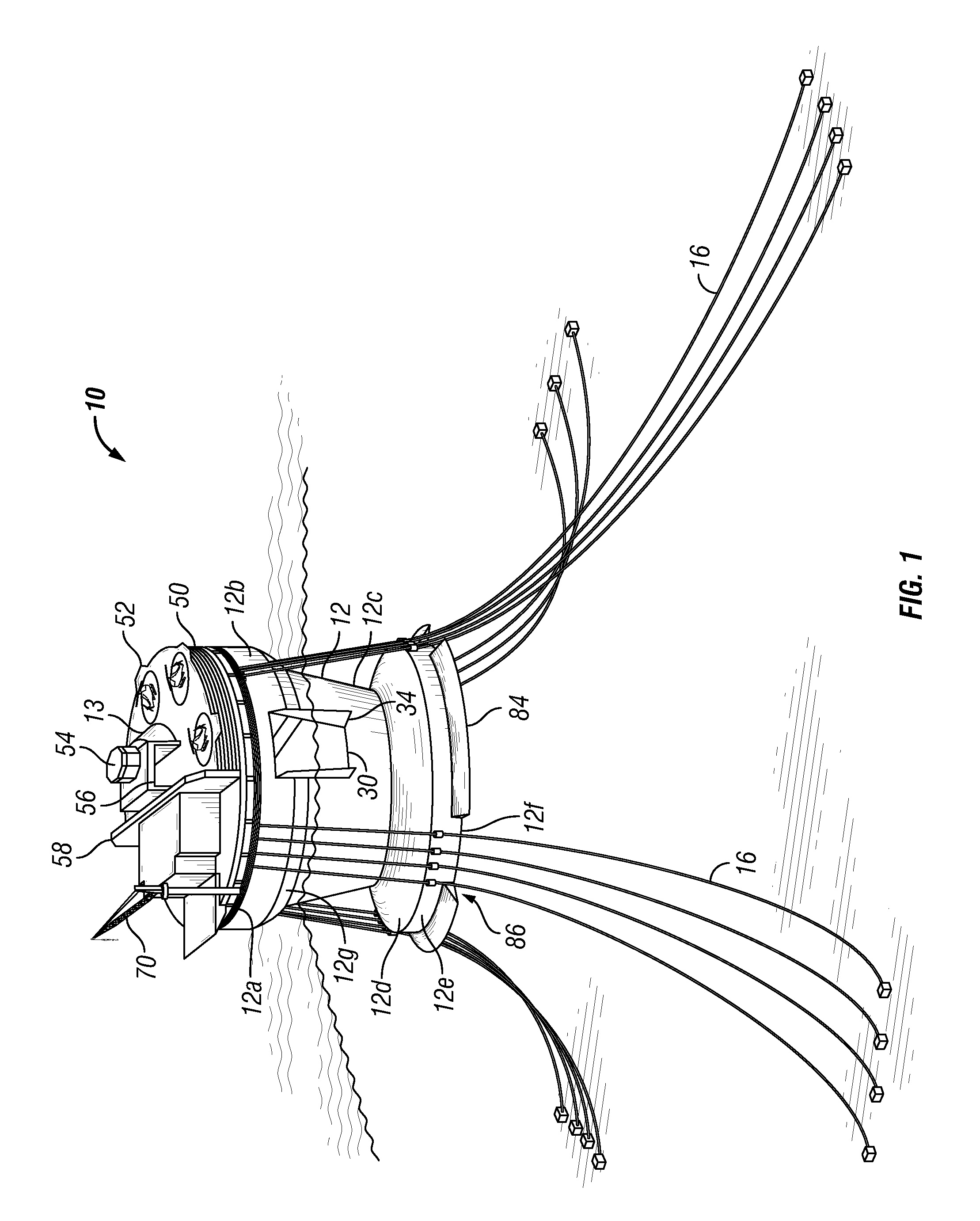

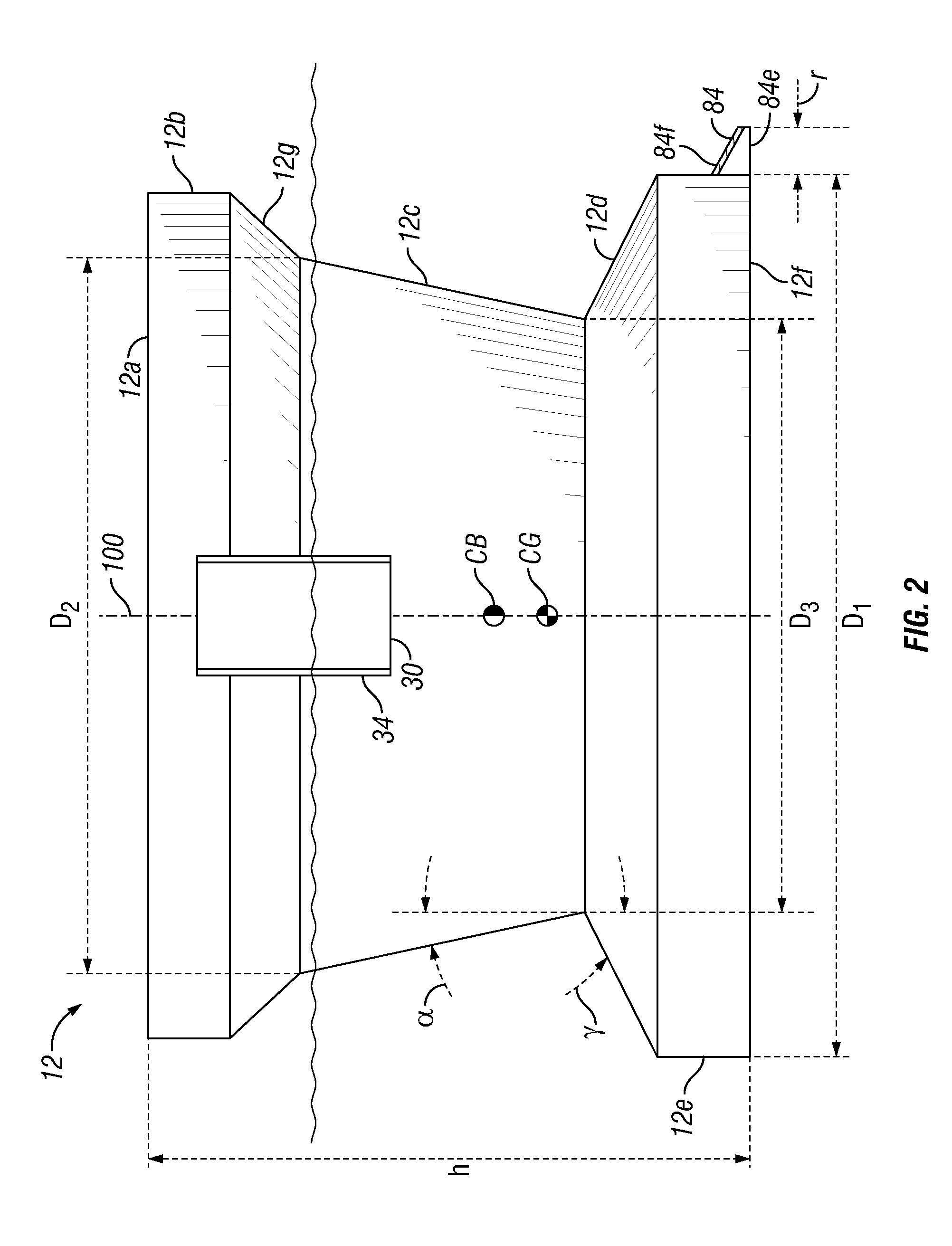

Stable offshore floating depot

ActiveUS8662000B2Exceptional heave damping characteristicsSteering by propulsive elementsAircraft carriersMachine shopMarine engineering

An offshore depot having a vertically symmetric hull, an upper inwardly-tapered wall and a lower outwardly-tapered wall that produce significant heave damping in response to heavy wave action. Ballast is added to the lower and outermost portions of the hull to lower the center of gravity below the center of buoyancy. The offshore depot includes a tunnel formed within or through the hull at the waterline that provides a sheltered area inside the hull for safe and easy launching / docking of boats and embarkation / debarkation of personnel. When the watertight tunnel doors are all shut, the tunnel may be drained to create a dry dock environment within the hull. The offshore depot includes berthing and dinning accommodations, medical facilities, workshops, machine shops, a heliport, and the like.

Owner:JURONG SHIPYARD

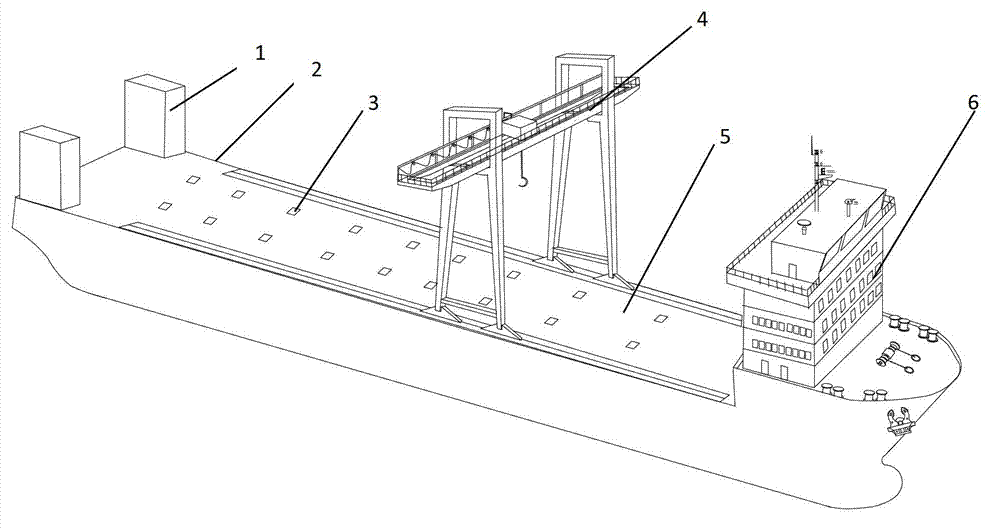

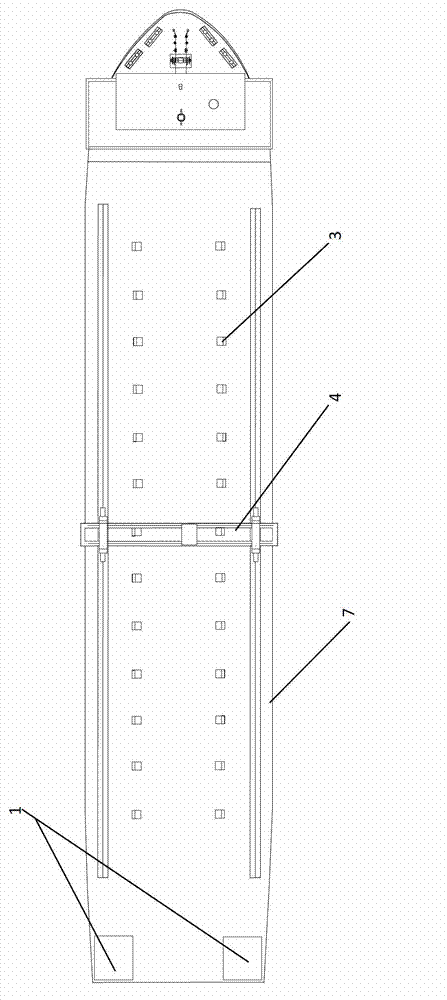

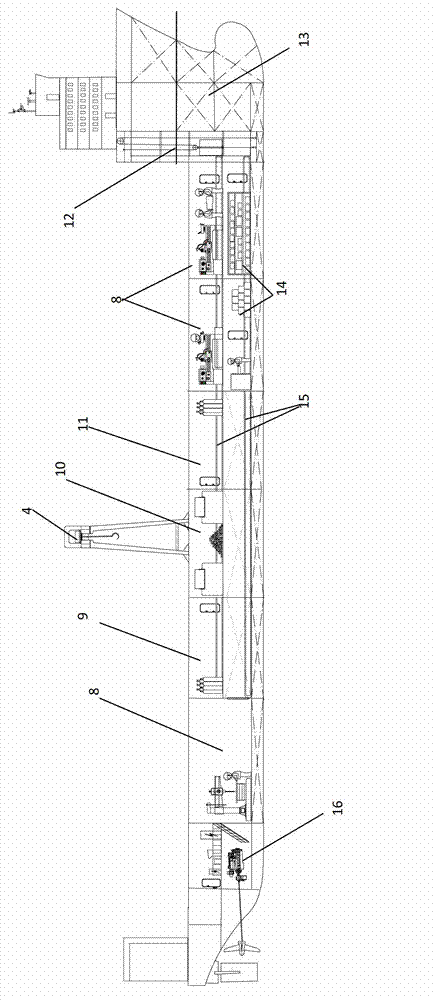

Self-propelled semi-submersible type maintenance vessel

ActiveCN103112553AReduce dependenceRapid sinking and floating loading and unloadingWaterborne vesselsSpecial purpose vesselsButtressMachine shop

A self-propelled semi-submersible type maintenance vessel is provided with an engine room system and a propelling system, wherein the two sets of systems are respectively and independently controlled. A main deck is a flat and wide deck, and support buttresses and a crane running rail are arranged on the main deck. A crane is arranged on the rail. A water tight side tank, a steering engine room, a chain locker, an engine room, an oil tank, a water ballast space, a fresh water tank, a tool and a machining workshop, an oxygen room, an acetylene room, a waste material recycling room, a salvage equipment room, a spare part warehouse and a goods transfer device are arranged below the main deck. A forecastle is arranged. Ballast water is also loaded in the water tight side tank, and the total capacity of the water ballast space can enable the main deck of the self-propelled semi-submersible type maintenance vessel to dive 1-30 meters under water. The self-propelled semi-submersible type maintenance vessel has the advantages of having an offshore maintenance function, being capable of maintaining on the sea, capable of quickly sailing, diving, floating, loading and unloading, having functions salvation salvage and special heavy bulk transport, and being capable of being used for loading and transporting large-scale marine equipment or engineering structure works which are oversized, overweight and indivisible.

Owner:DALIAN MARITIME UNIVERSITY

Energy saving vacuum system for particle, mist, and fume collection

ActiveUS7146677B2Cost effectiveEnergy efficiencyMetal sawing accessoriesLighting and heating apparatusMachine shopCollection system

An improved energy-efficient vacuum system for machine shop dust, particulate matter, and the like. Blast gates, including large-diameter blast gates, control the flow of vacuum generated by a dust collector to individual machines that may or may not accommodate vacuum ductwork and the like. The blast gate has a rotating blade inside a chassis with a DC motor effectively using a slip clutch, an increased current feedback system, a biasing-spring assembly or otherwise to limit the rotation driving of the rotating blade. In one embodiment, the blast gate blade bears teeth about its perimeter. The DC motor engages the perimeter blade teeth with a gear. Greater mechanical advantage is achieved over the blast gate blade and less torque arises in contrast to a driving system located at the blade's central pivot point. Additionally, sensing apparatus or system calculation allow the dust collecting vacuum system to operate in an energy-efficient manner. By supplying only the vacuum needed to collect present dust, energy is saved in comparison with a dust collection system operating continuously at full capacity.

Owner:LITOMISKY IVAN +2

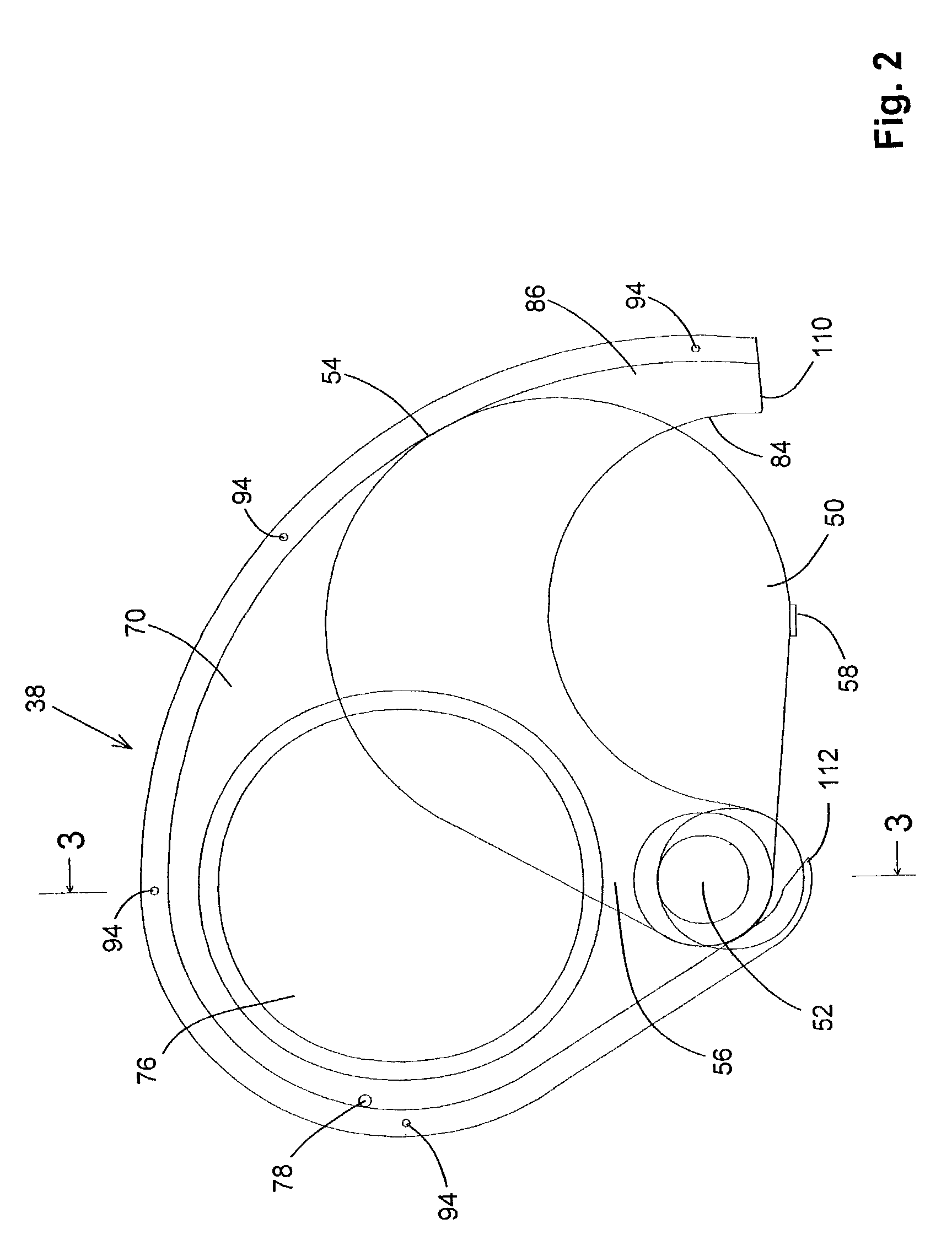

Stable offshore floating depot

ActiveUS20120132122A1Exceptional heave damping characteristicsVessels for aircraftLifeboat handlingMachine shopMarine engineering

An offshore depot having a vertically symmetric hull, an upper inwardly-tapered wall and a lower outwardly-tapered wall that produce significant heave damping in response to heavy wave action. Ballast is added to the lower and outermost portions of the hull to lower the center of gravity below the center of buoyancy. The offshore depot includes a tunnel formed within or through the hull at the waterline that provides a sheltered area inside the hull for safe and easy launching / docking of boats and embarkation / debarkation of personnel. When the watertight tunnel doors are all shut, the tunnel may be drained to create a dry dock environment within the hull. The offshore depot includes berthing and dinning accommodations, medical facilities, workshops, machine shops, a heliport, and the like.

Owner:JURONG SHIPYARD

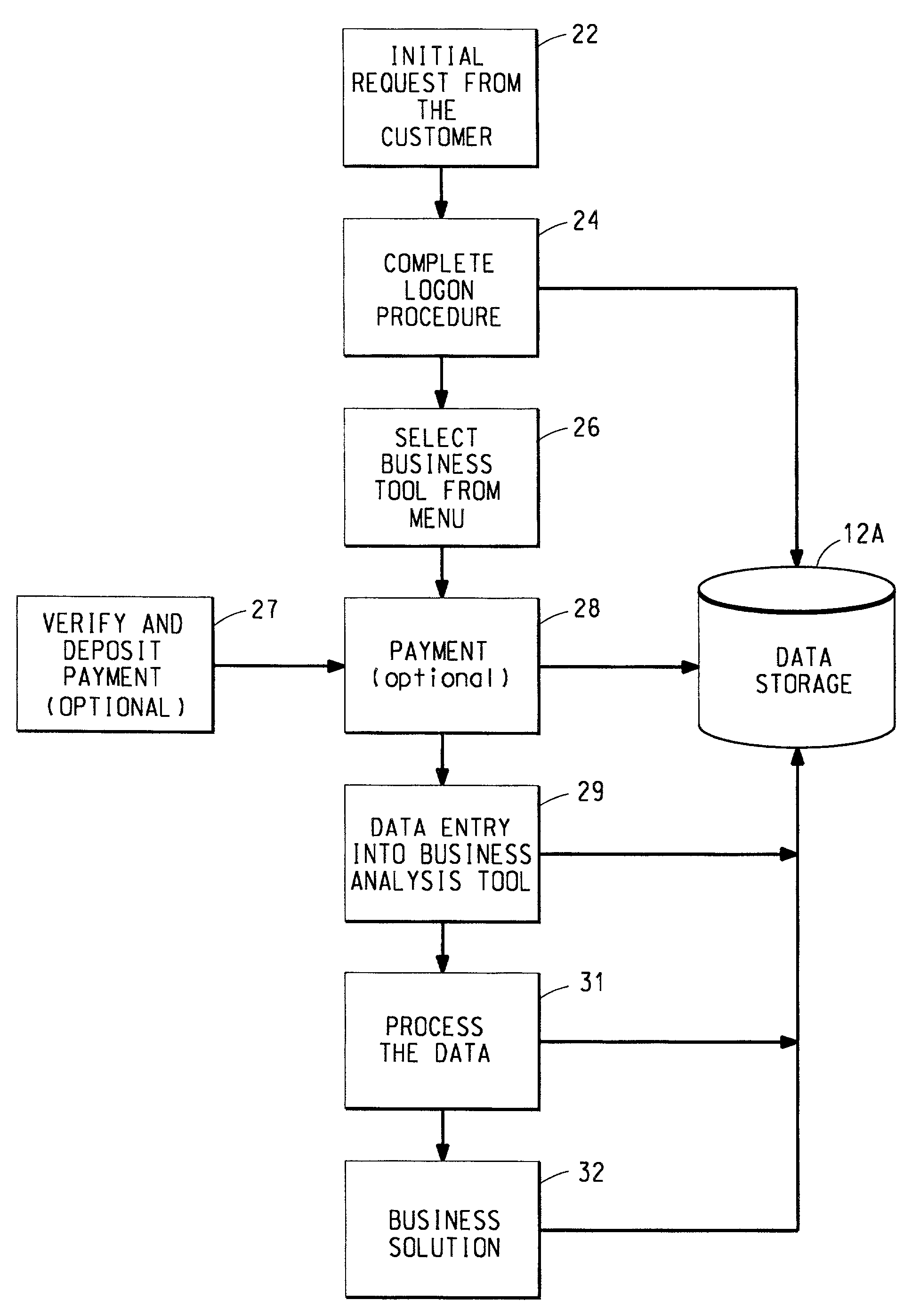

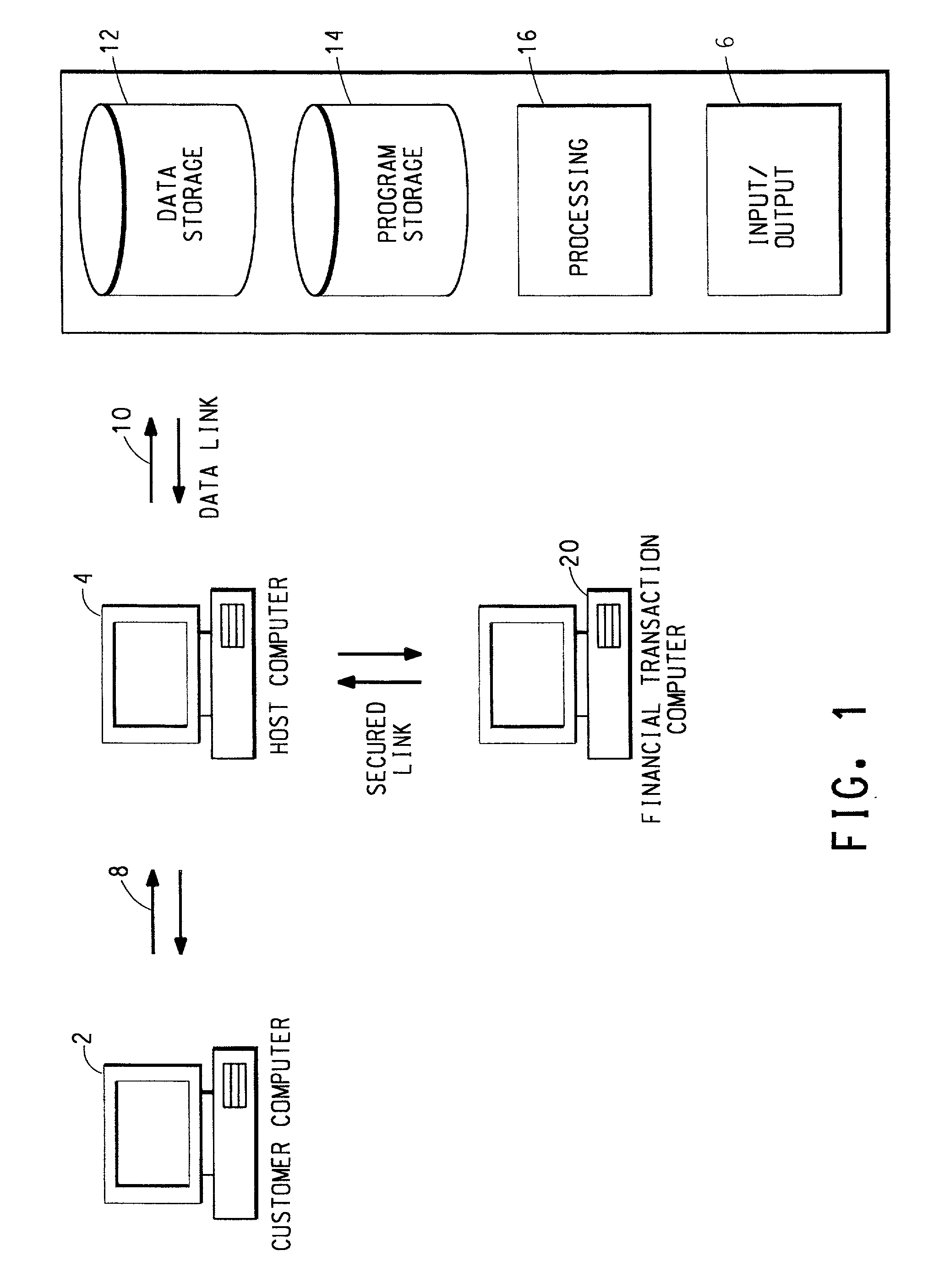

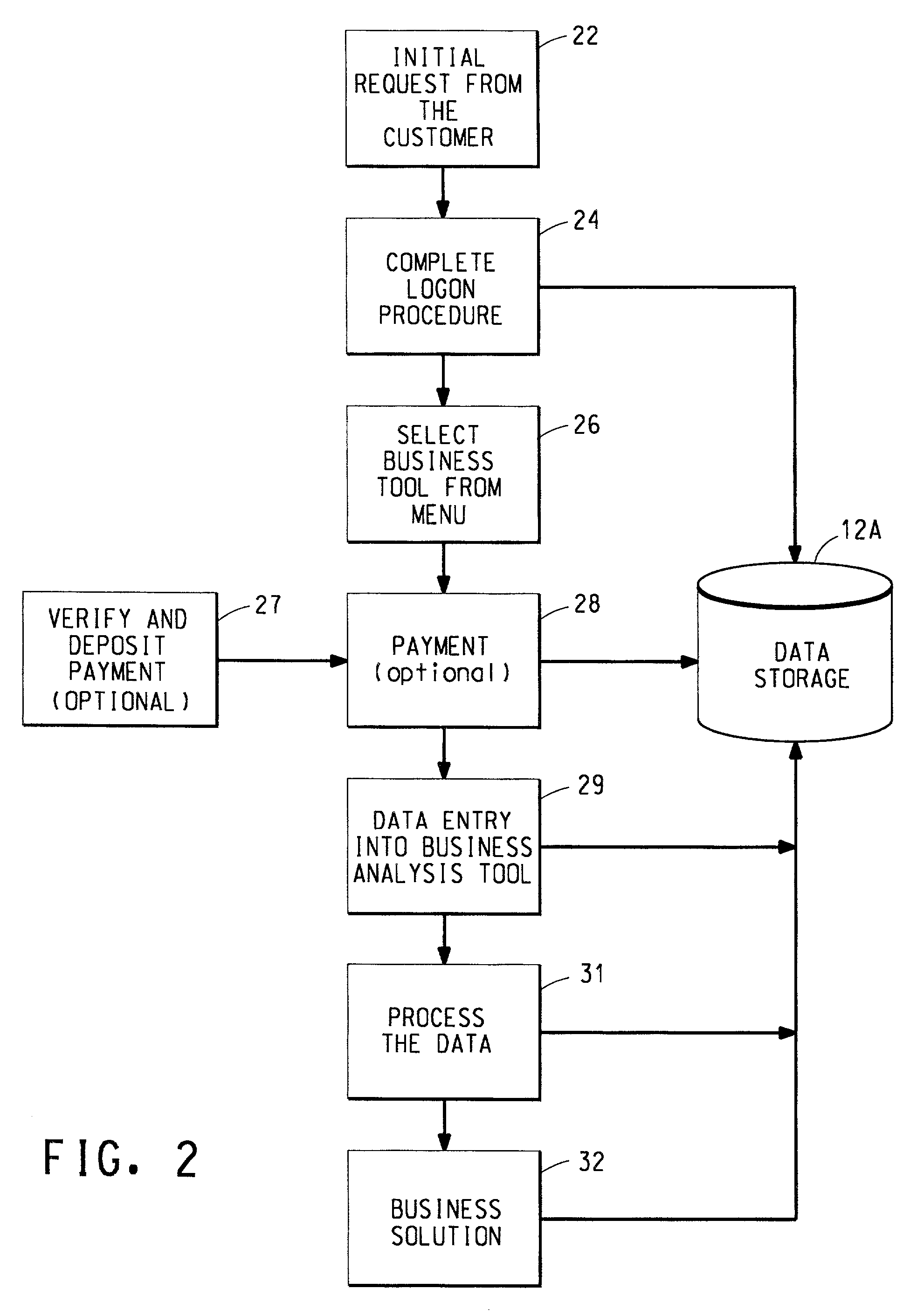

Network-based business process for improving performance of businesses

InactiveUS20080059279A1Improve performanceOffice automationSpecial data processing applicationsMachine shopRepair shop

The present invention relates to a network-based business process. The process allows a business owner through a logon procedure on his computer to access, preferably via a website, the process of the present invention loaded on a host computer. The customer then accesses a main menu having one or more business tools suitable for improving the performance of businesses and is then requested to choose one of the business tools. The customer then enters customer business data as per instructions provided on the web page of the selected business tool. The process of the present invention then processes the entered data and provides a business solution to the customer. The menu includes several important business tools, such as plant capacity planner, determining optimal sales potential of the business, run charts, plant layout, business evaluation, sales & production tracker, work-in-process, etc. The process of the present invention is suitable for any business, but it is especially suitable for small businesses that may not be able to afford expensive consultants or personnel to run sophisticated programs necessary to improve business efficiency and profit margins. Some of the suitable businesses include, an auto collision repair shops, machine shops, grocery stores, butcher shops, barber shops, and manufacturing plants.

Owner:EI DU PONT DE NEMOURS & CO

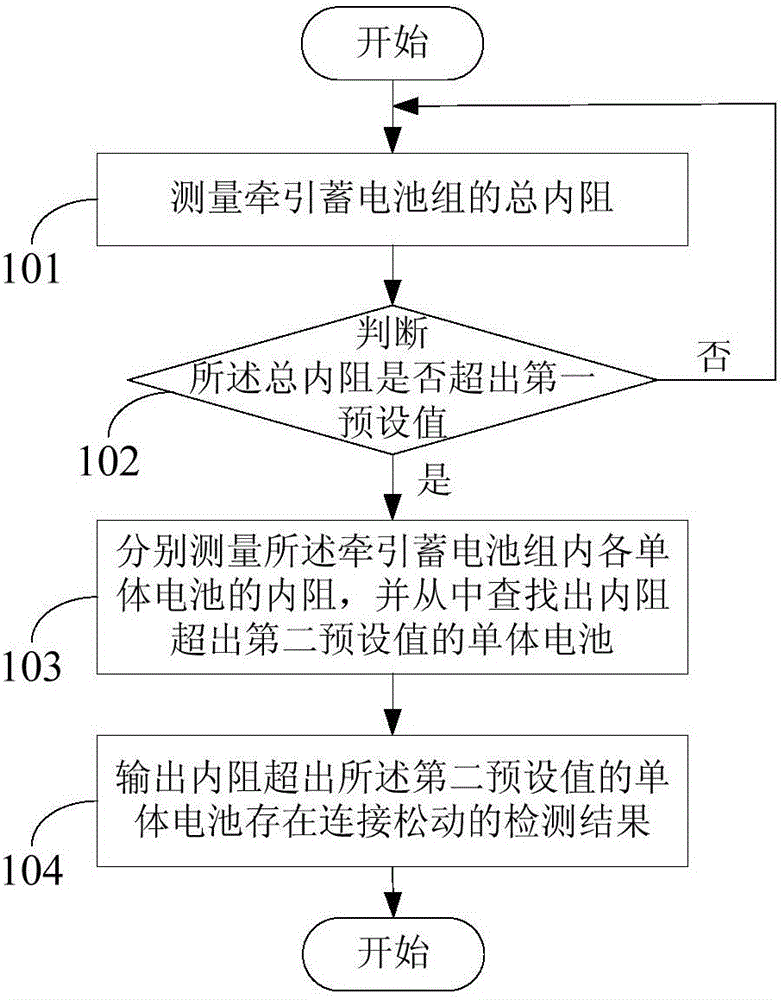

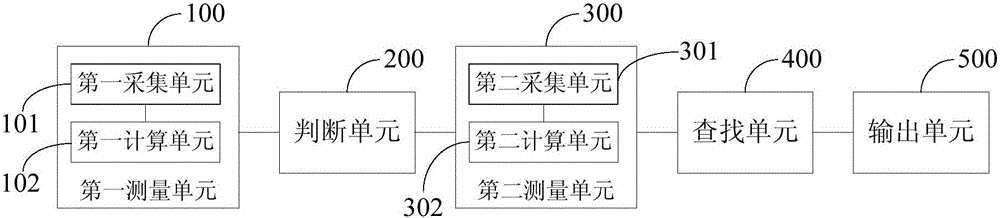

Traction storage battery connection state detection method, apparatus, managing system and machine shop truck

ActiveCN105807229APrecise positioningGuaranteed operational safetyElectrical testingMachine shopElectrical battery

The invention discloses a traction storage battery connection state detection method, an apparatus, a managing system and a machine shop truck. The method is performed through the following steps: measuring the total internal resistance of a traction storage battery set; checking if the total internal resistance is beyond a first preset value; measuring all the batteries in the set to get their individual internal resistances in an attempt to find the individual batteries with internal resistances that are beyond a second preset value if the total internal resistance is beyond the first preset value; outputting a test result that shows individual batteries with internal resistances beyond the second preset value are in loose connection. With such invention, online check can be done to determine if the individual batteries in a traction storage battery set are well connected and the loosening parts can be accurately positioned.

Owner:ZHUZHOU ELECTRIC LOCOMOTIVE CO

Method of making complex twisted blades with hollow airfoil cross section and the turbines based on such

InactiveUS20050106023A1Improve efficiencyLow costPropellersWind motor controlMachine shopEngineering

A reactive turbine, each blade of which approximates a helical shape that is constructed with readily available conventional manufacturing techniques. The blades are constructed in discrete straight sections that, when joined, approximate a helix or any other efficient turbine shape. Each section is manufactured with the well known and readily available machine shop techniques of shaping, forming, and joining with welds or fasteners.

Owner:GCK

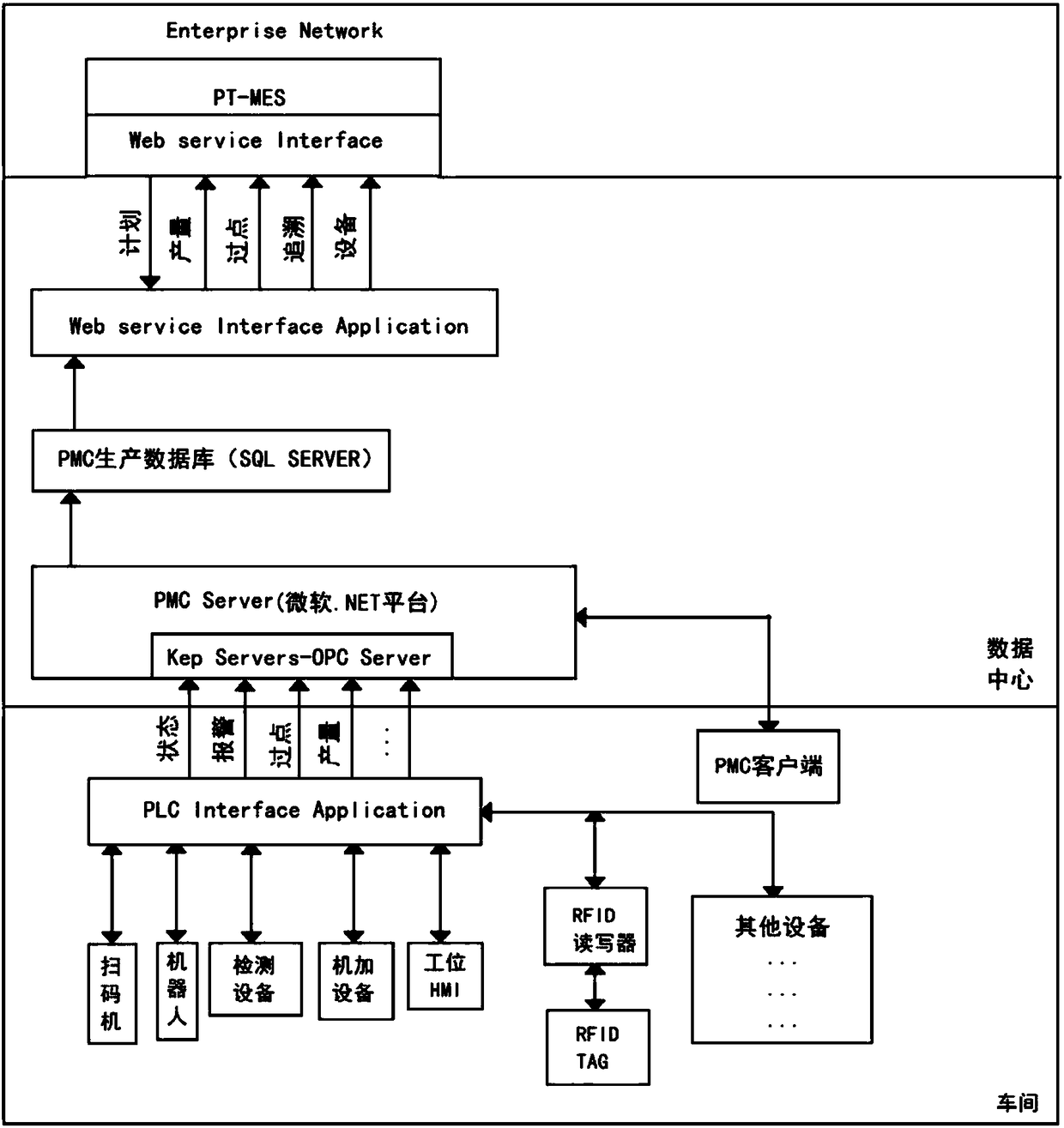

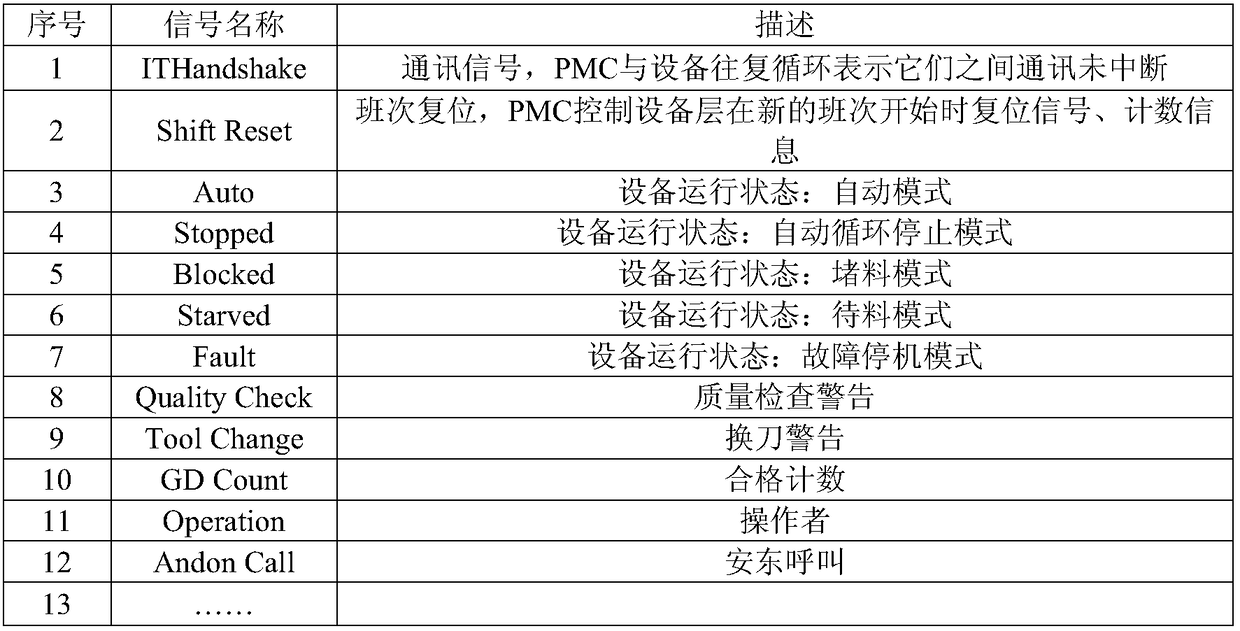

Distributed remote monitoring system and monitoring method for machining workshop

InactiveCN108415381APrevent control misuseEnsure safetyTotal factory controlProgramme total factory controlMachine shopModel management

The invention discloses a distributed remote monitoring system and monitoring method for a machining workshop. The monitoring system is connected to and communicates with a device to be monitored andcomprises an operating state real-time monitoring module, a production data real-time acquisition module, a data analysis module, an equipment early warning control module and a remote access and control module. According to the system and the method, the overall monitoring of equipment in different areas of the workshop can be achieved, the running state of the workshop equipment is monitored, analarm is timely emitted when a key problem occurs, and relevant personnel is notified to solve the problem. The operating parameters of the equipment are collected in real time to carry out dynamic data analysis, an equipment early warning mechanism is achieved, and a fault is eliminated at the beginning of the problem. The consumption of monitoring equipment is low, resources are mobilized in time to maintain and improve the equipment, and finally, the model management and global control of the equipment are realized.

Owner:苏州宏软信息技术有限公司

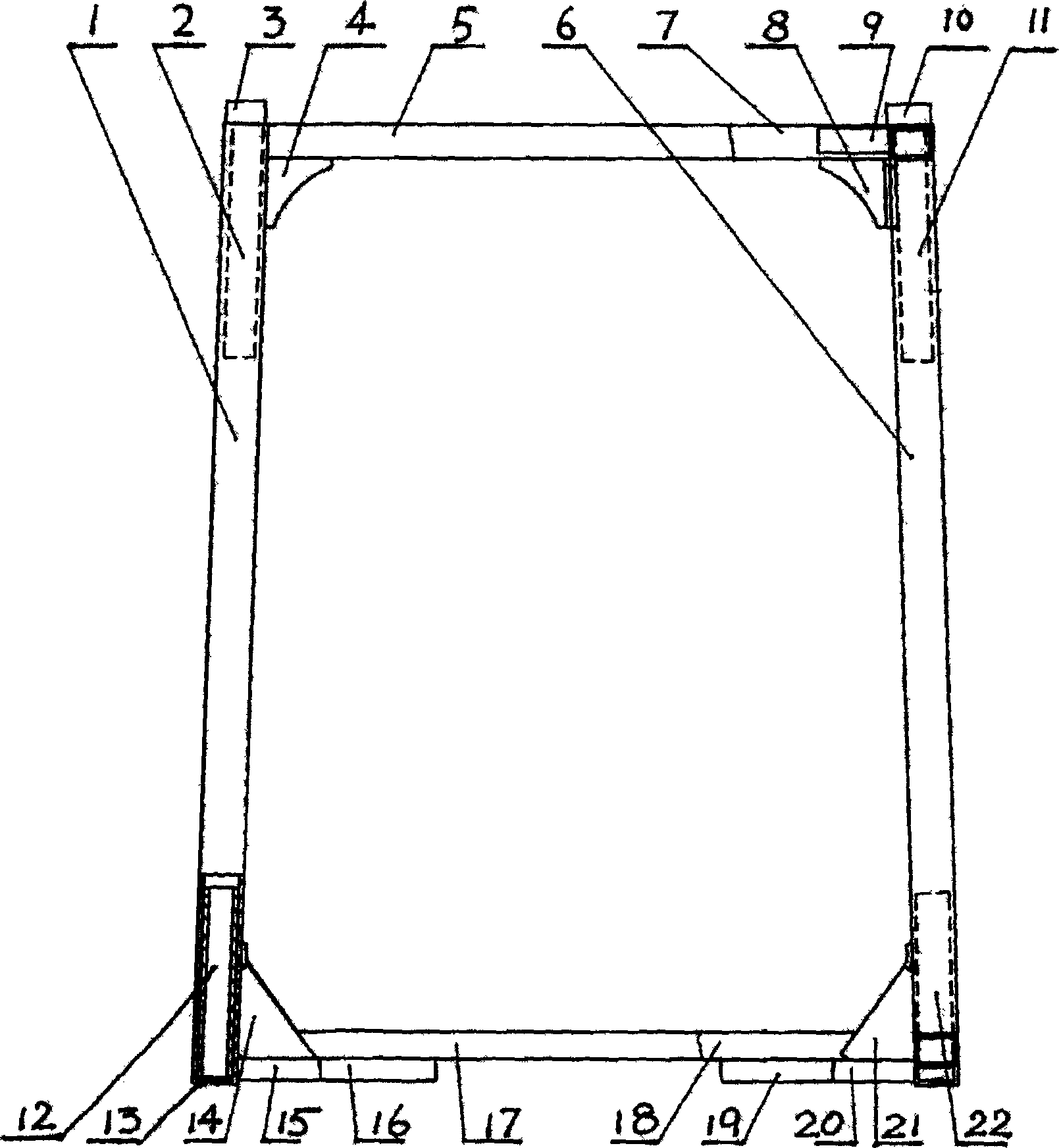

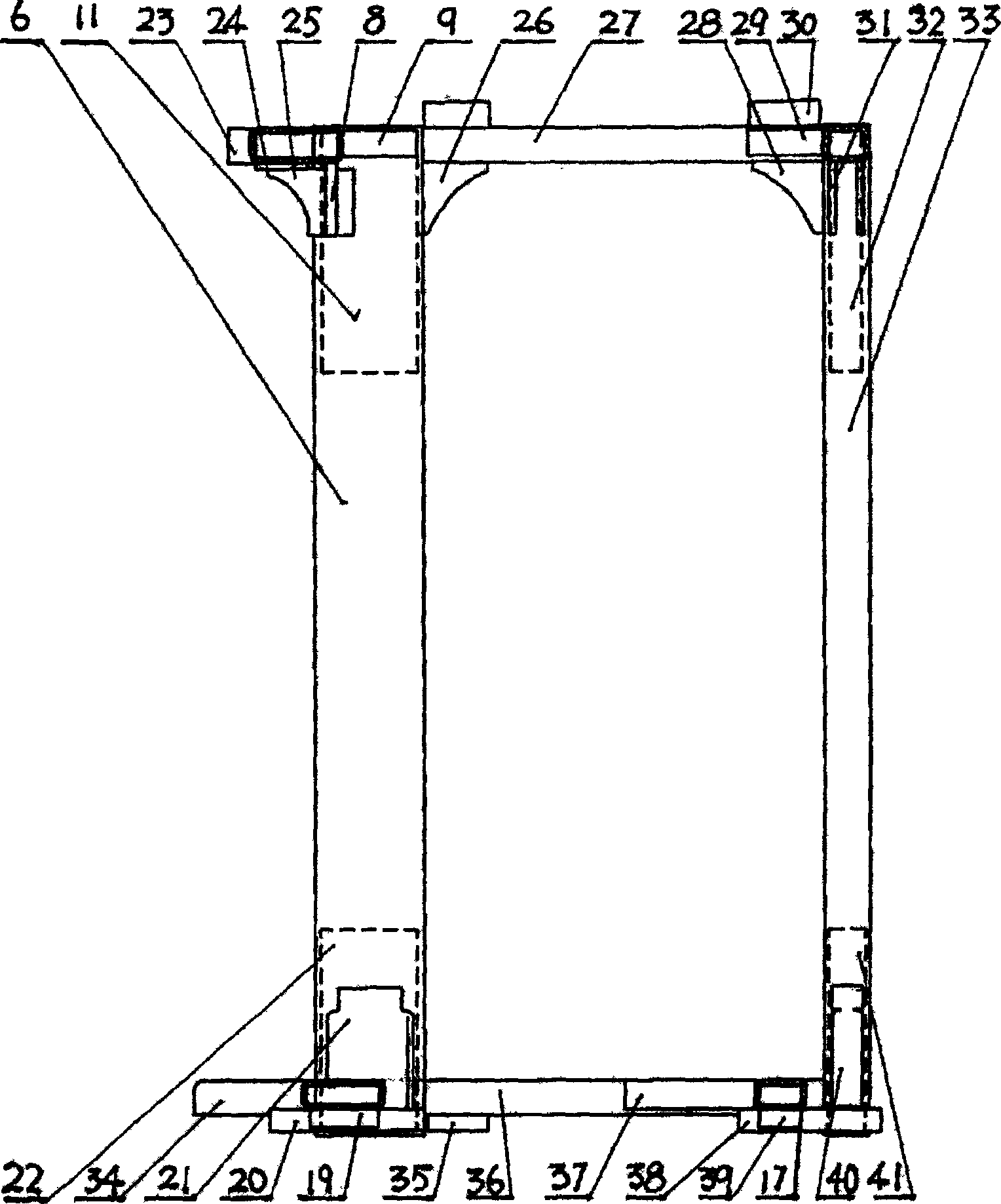

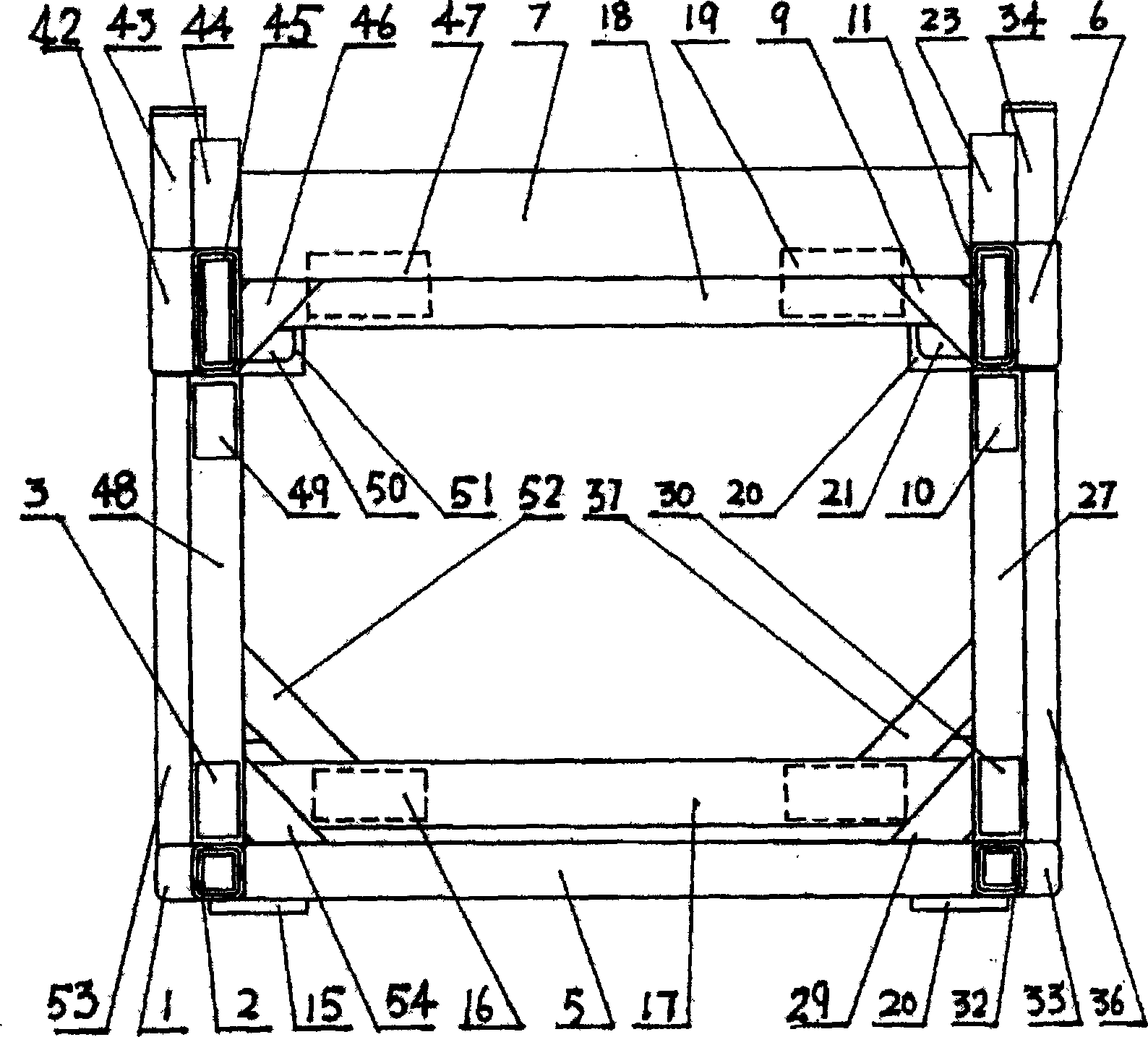

Machineshop truck driver's cab with reinforced turnover protection device

InactiveCN1775607AHigh degree of generalizationReduced Shock Concussion DamagePedestrian/occupant safety arrangementLoading-carrying vehicle superstructuresMachine shopEnergy absorption

The invention discloses a machine-shop truck cab with reinforced turnover protector, characterized in that the special structural positions of the cab framework are added with combined beams for raising plastic deforming force, i.e. the upper and lower ends of each of the front, rear, left and right pillars are added with combined beams, separately, changing the bearing force of the pillars, and making the invention have ROPS protector and able to largely improve the universal degree of machine-shop truck cab and as the vehicle turns over, the ROPS component can bear the impact force of the ground plane, assuring any part of the deformed ROPS and the ground plane do not enter in human body limit safety region and simultaneously the ROPS has a certain energy absorbing ability to reduce impact and vibration damage to the driver. The invention has the characters of simple structure and convenient application and use.

Owner:TIANJIN LIUGONG MACHINERY

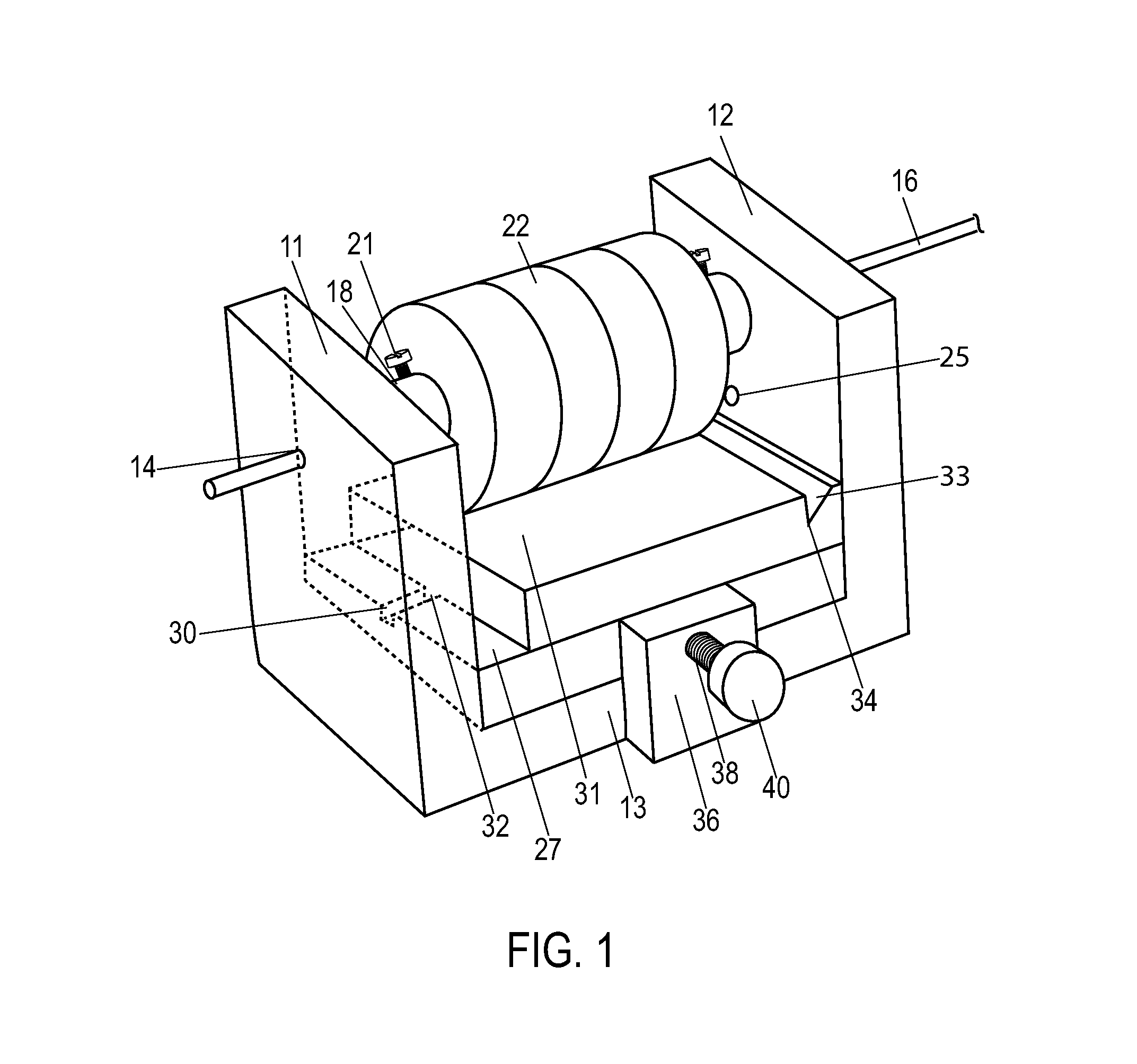

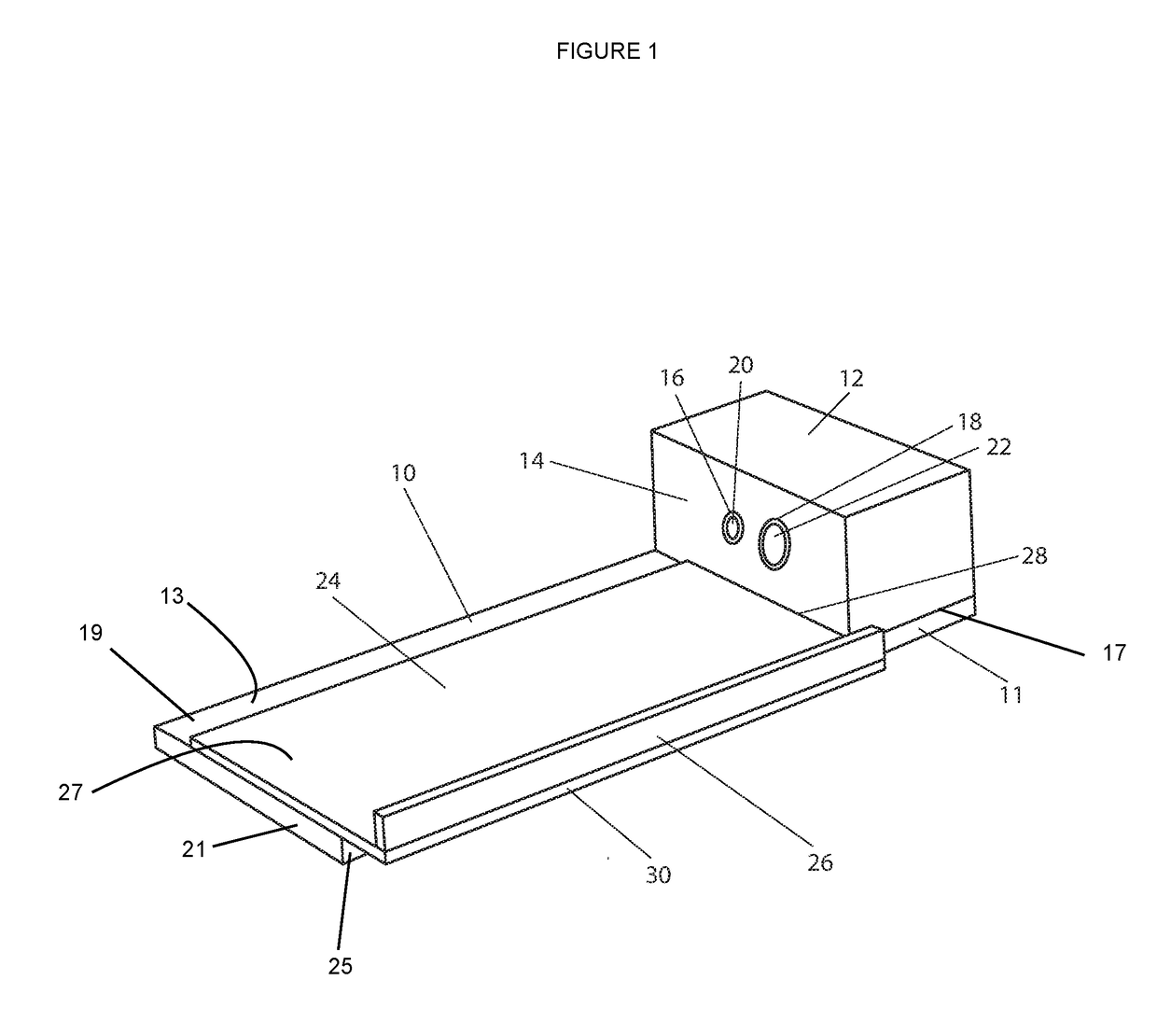

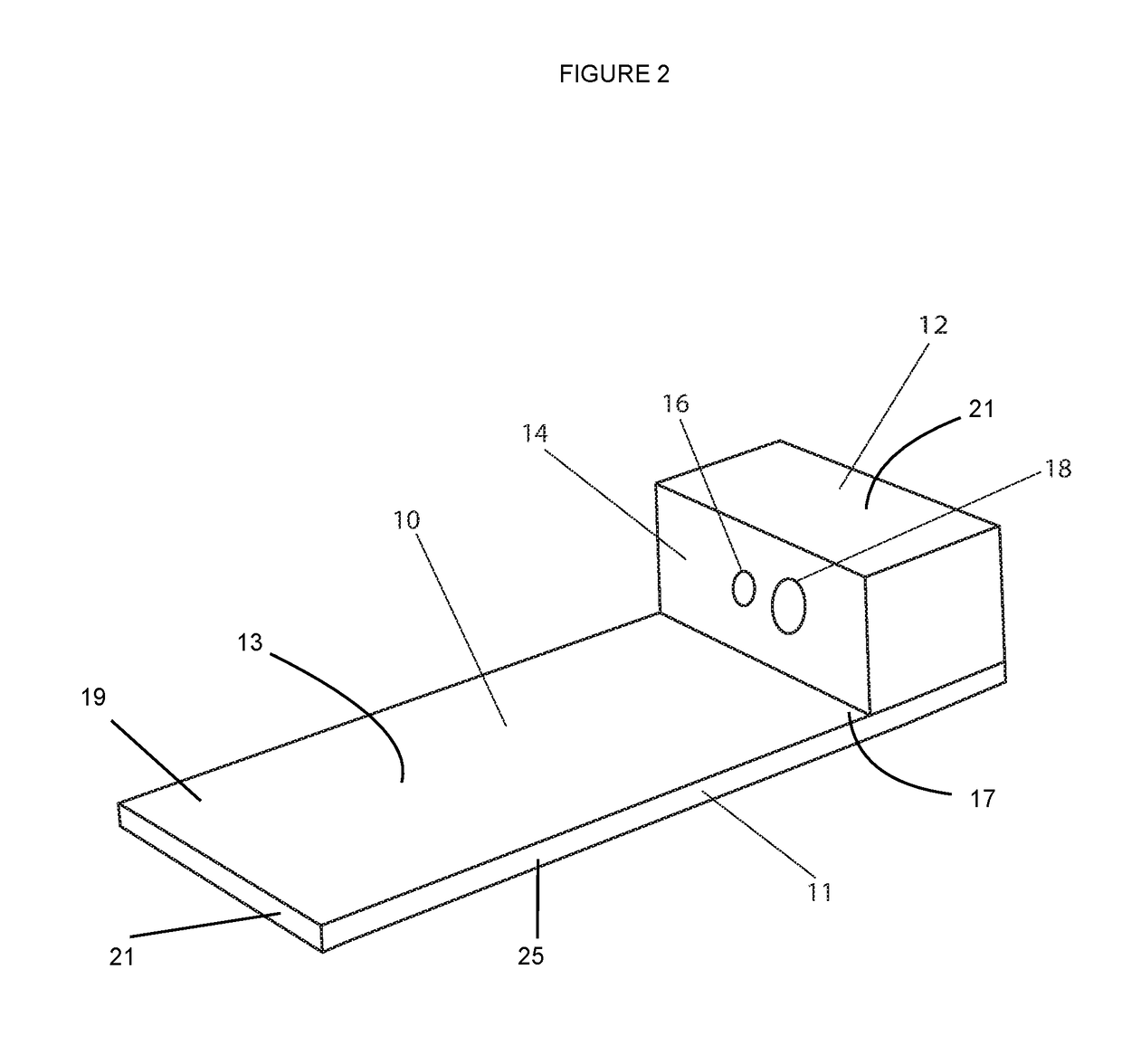

Slidable platform abrasion workstation device for truing model car wheels and axles

ActiveUS8465346B1Easy to useRevolution surface grinding machinesGrinding drivesMachine shopRotational axis

The device is a U-shaped housing comprising slidable platform embodiments providing defined and directed platform movements toward the task of shaping a rotating workpiece substantially at 90 degrees and 180 degrees to the axis of rotation. The device provides for sliding surface planes configured to accept abrasive materials and implements at predetermined angles for the purpose of trimming imperfections and truing model car wheels and axles. As an alternative to more complex machine shop equipment, the child, applying sandpaper to the platform surfaces and a triangular file or rectangular file on platform insets is enabled to effectively direct an abrasive surface which is configured at 90 degrees and 180 degrees to the axis of rotation for the purpose of truing the model car wheel and axle. To further enhance the child's participation, the workpieces can effectively be manually rotated in the slidable platform abrasion workstation device.

Owner:CATTANEO STEPHEN MICHAEL

Cutting fluid recovery system for high-speed tool steel

InactiveCN102837262AImprove purification effectEasy to recycleFiltration circuitsLubricant compositionMachine shopMagnetic separator

The invention relates to a cutting fluid recovery system for high-speed tool steel. The cutting fluid recovery system comprises a settling tank, a magnetic separator, a filter unit and a water tank, wherein the settling tank and the water tank are respectively communicated with a lathe of a grinding machine shop. The cutting fluid recovery system for the high-speed tool steel is capable of better purifying and recovering cutting fluid containing impurities to increase service life and application value of the cutting liquid, protect environment from being polluted, and reduce production cost; in addition, the cutting fluid recovery system for the high-speed tool steel further guarantees the performance of the cutting fluid, and avoids deterioration failure after the cutting fluid is polluted.

Owner:JURONG HENGXIANG TEXTILE

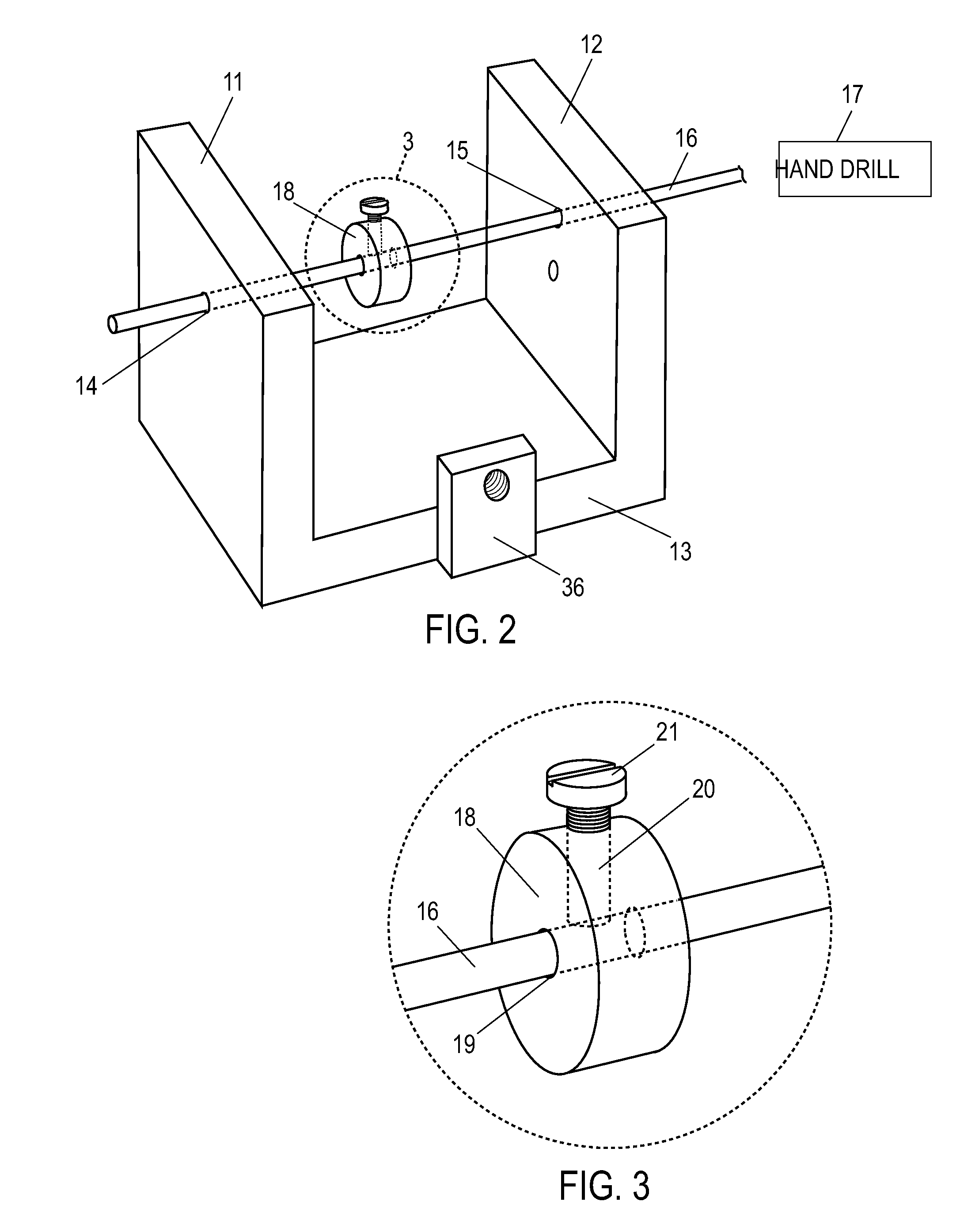

Three dimensional workpiece support and drill jig alignment device for placement of weight loading channels in the body of a model car

The embodiment is an L-shaped housing with a configuration that provides both for support to a small hand-held workpiece and to specific drill bit alignment toward the task of placing multiple, immediately adjacent, aligned channels within the body of a model car. To optimize car speed in the Pinewood Derby event, the child can specifically align and strategically place channels in the model car for the optimal loading of cylindrical weights. As an alternative to free-hand drilling with an attempt at sighting drill bit direction in two planes, the device provides for precise drill bit alignment to small hand-held workpieces. As an alternative to more complex drill jig and machine shop equipment, the device enables a child to safely and effectively introduce multiple, aligned channels with precision into the model car.

Owner:CATTANEO STEPHEN

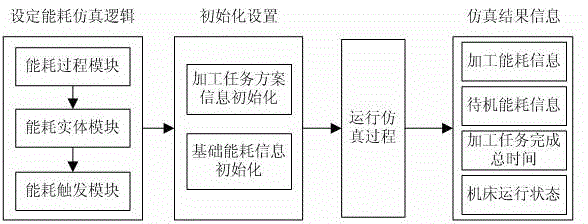

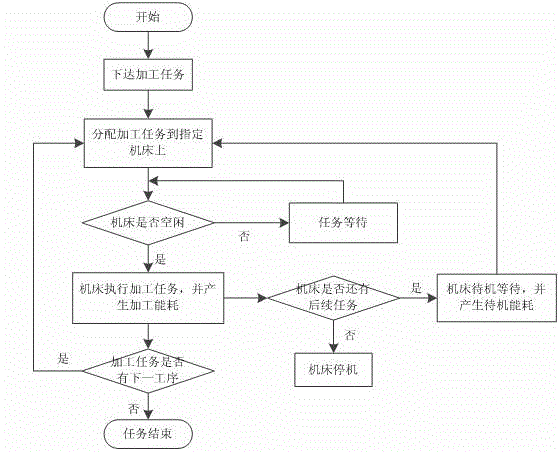

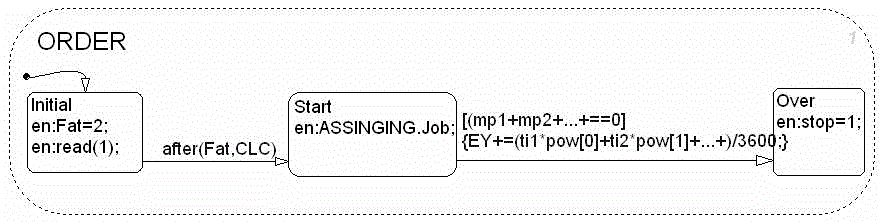

Energy consumption simulating method orienting machining task of machine shop

ActiveCN103150634AAchieve energy-saving optimizationReduce manufacturing costResourcesManufacturing computing systemsMachine shopSystems analysis

The invention provides an energy consumption simulating method orienting a machining task of a machine shop. According to the method disclosed by the invention, the energy consumption process logic of the machining task of the machine shop is firstly set, and an energy consumption process module, an energy consumption entity module and an energy consumption triggering module are arranged to be used for simulating the energy consumption process of the machining task of the machine shop; then machining task scheme information in the energy consumption process logic and basic energy consumption information of the machining task are initially set; and finally a simulation process is operated to obtain rich information such as machining energy consumption and stand-by energy consumption in spare time of the machine shop when executing the machining task, the total implementation time for executing the machining task and the operating state of a machine tool for executing the machining task. The method can be used for the system analysis of energy consumption in dynamic variable production running processes of the machine shop and the assessment of energy consumption of the elaborated machine shop, and can provide energy saving optimized decision support for various machining schemes particularly for multi-task flexible machine shops.

Owner:CHONGQING UNIV

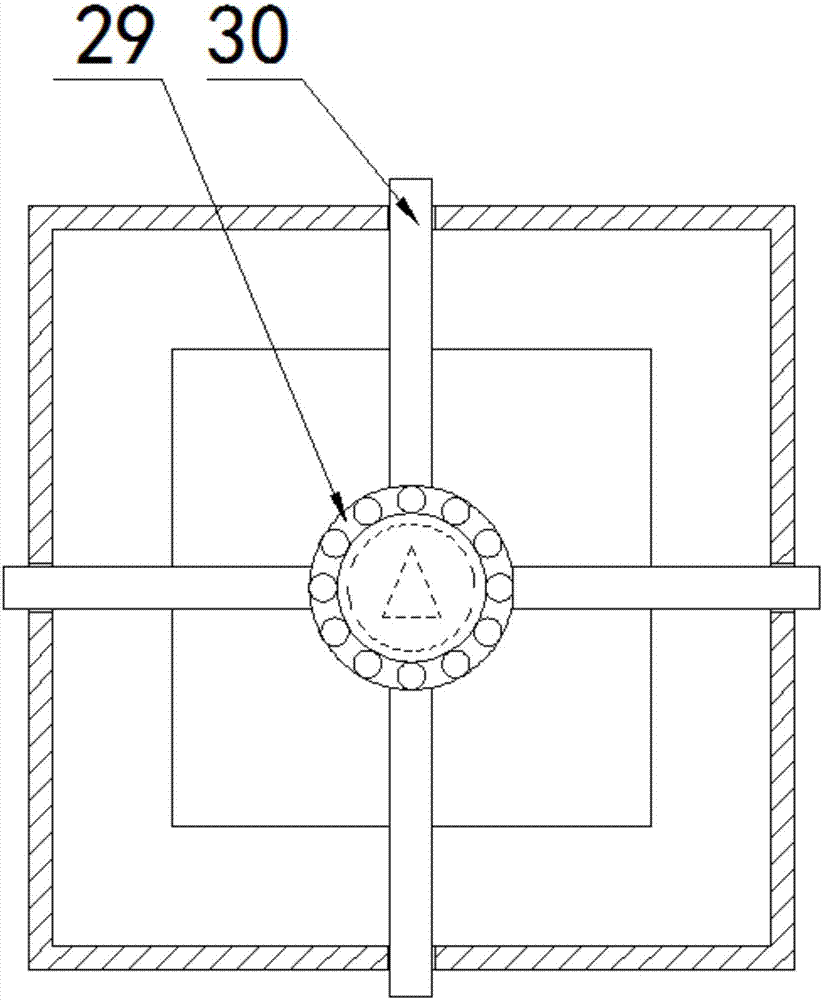

Ceramic tile cement slurry laying machine with stirring device

InactiveCN107322801AEasy to installAchieve the effect of mixing and stirringDischarging apparatusBuilding constructionsMachine shopScreed

The invention discloses a ceramic tile cement grouting machine with a stirring device, which comprises a shell, a traction device, a detachable stirring device, a cement scraping device, a spring movable door, a hand push rod and a first pulley; the cement scraping The device is set on the lower left side of the shell; the bottom of the detachable stirring device is fixed with the triangular fixed bump on the top of the turntable; the device of the present invention realizes the effect of mixing and stirring cement and water through the setting of the detachable stirring device, saving It is possible to mix cement and water manually or by machine, and at the same time, it is inlaid with the triangular fixed bump at the bottom of the turntable, which is convenient for disassembly and installation of the mixing device; through the cooperation of the traction device and the spring movable door, it is convenient Control the outflow of cement slurry and the flow of cement slurry; through the setting of the telescopic cement scraper and the cement scraper fixing device in the cement scraping device, the effect of controlling the thickness of the cement slurry paved by the machine is realized.

Owner:HUIAN HUACHEN TRADE CO LTD

Treatment agent and treatment method for regeneration and recycling waste water-based metal working fluid

PendingCN110846119AImprove the lubrication effectEasy to cleanLubricant compositionMachine shopMetalworking fluid

The invention discloses a treatment agent and treatment method for regeneration and recycling waste water-based metal working fluid. The treatment agent comprises the following raw materials in percentage by weight: 20-30% of an emulsifier, 10-15% of an alkali regulator, 3-5% of an antibacterial agent, and 2-5% of a non-ferrous metal corrosion inhibitor, with the balance being deionized water, summing to 100%, wherein the emulsifier is one or a mixture of two or more selected from the group consisting of NEUF192, self-emulsifying ester Priolube, T-80, castor oil polyoxyethylene ether, polyethylene glycol laurate and polyethylene glycol oleate. According to the invention, residual effective components are effectively utilized to emulsify and dissolve invaded lubricating oil and to convert the lubricating oil into effective components of the metal working fluid for utilization, and effective components in the waste working fluid are not damaged; the regenerated waste metal working fluidcan stably operate in a machine tool for a long time and guarantees that metal processing process is smoothly carried out; and the regenerated fluid returns to a machining workshop to be continuouslyused, so emission is truly avoided, and no secondary pollutants are generated.

Owner:HUBEI CHENGXIANG TECH

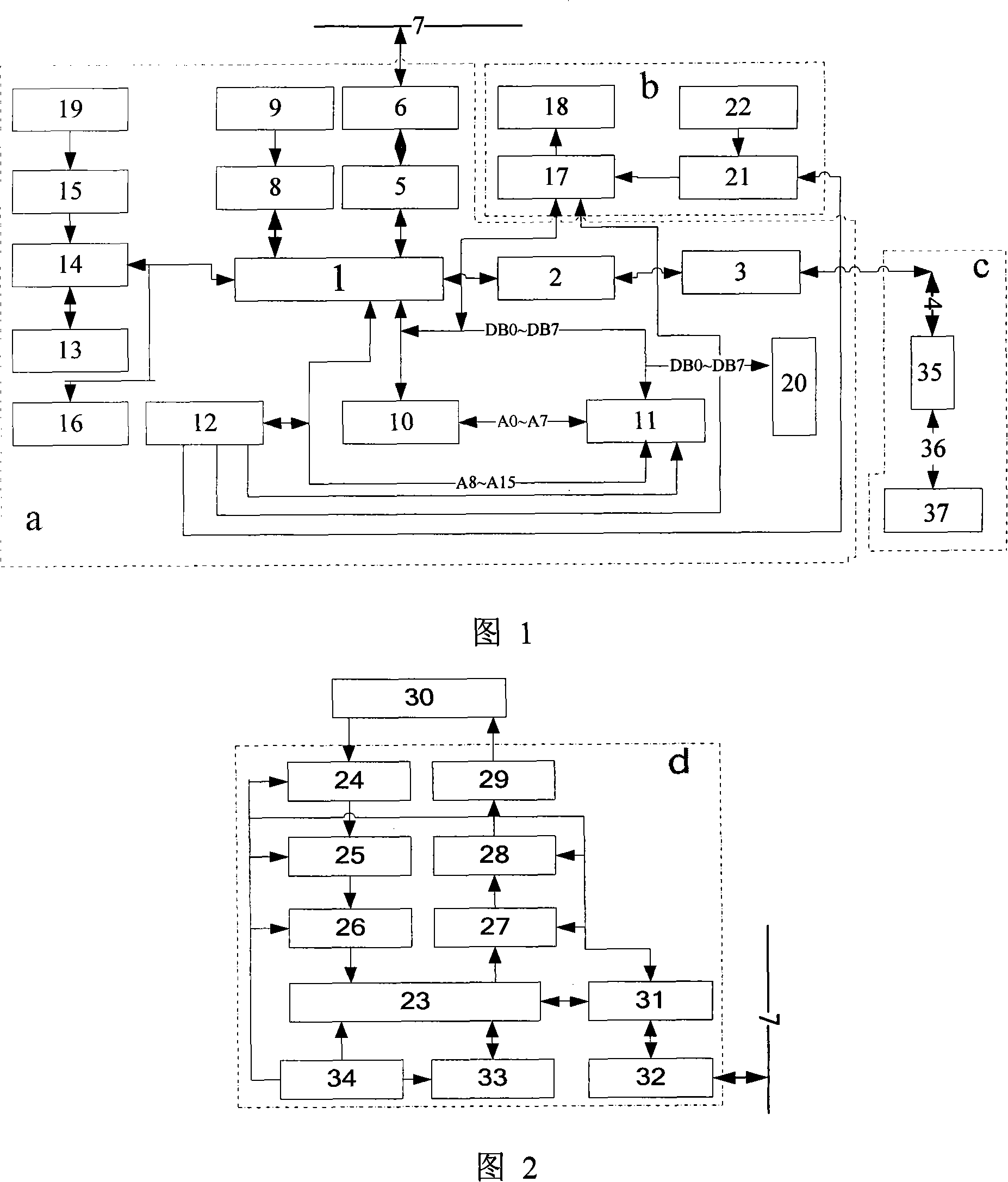

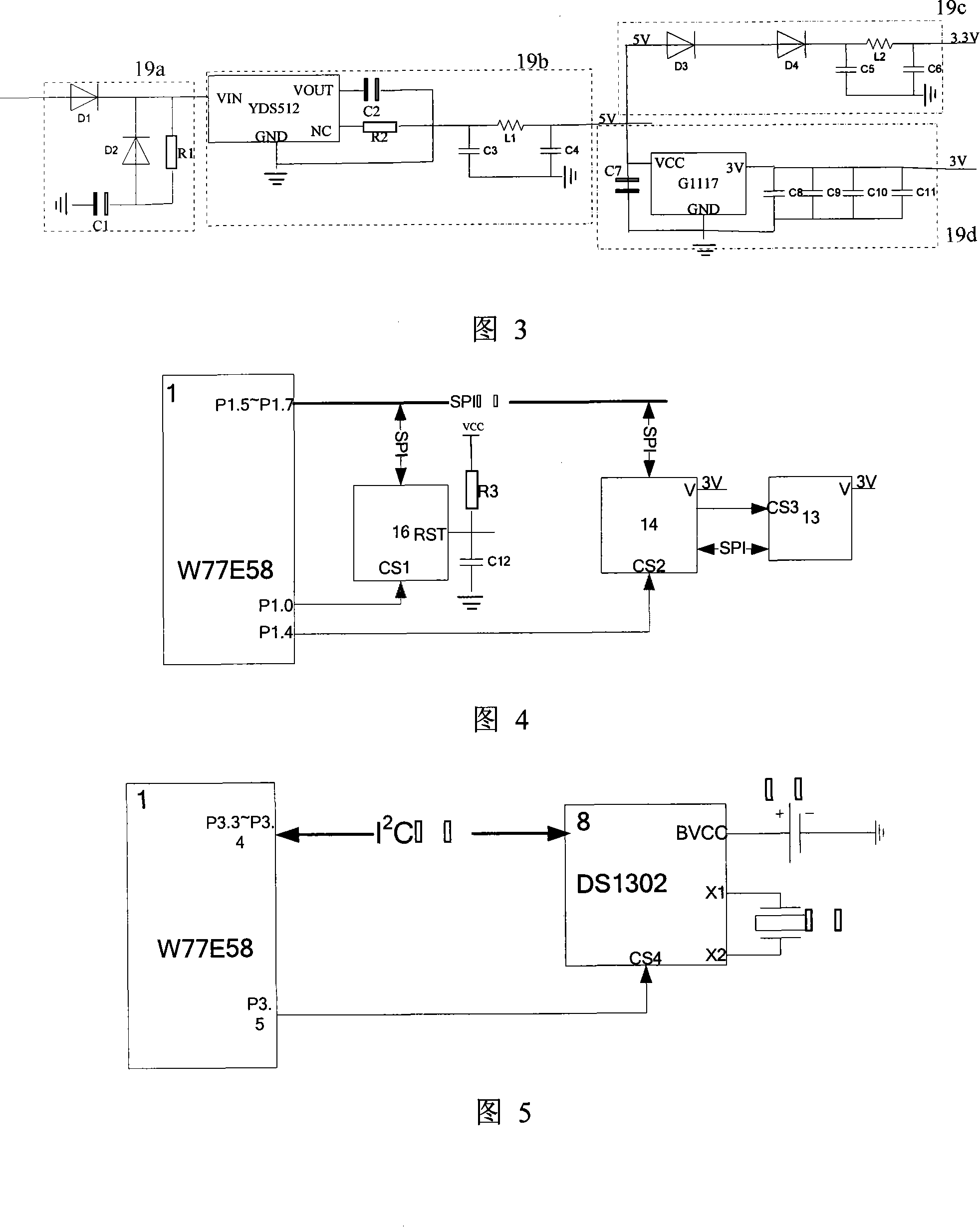

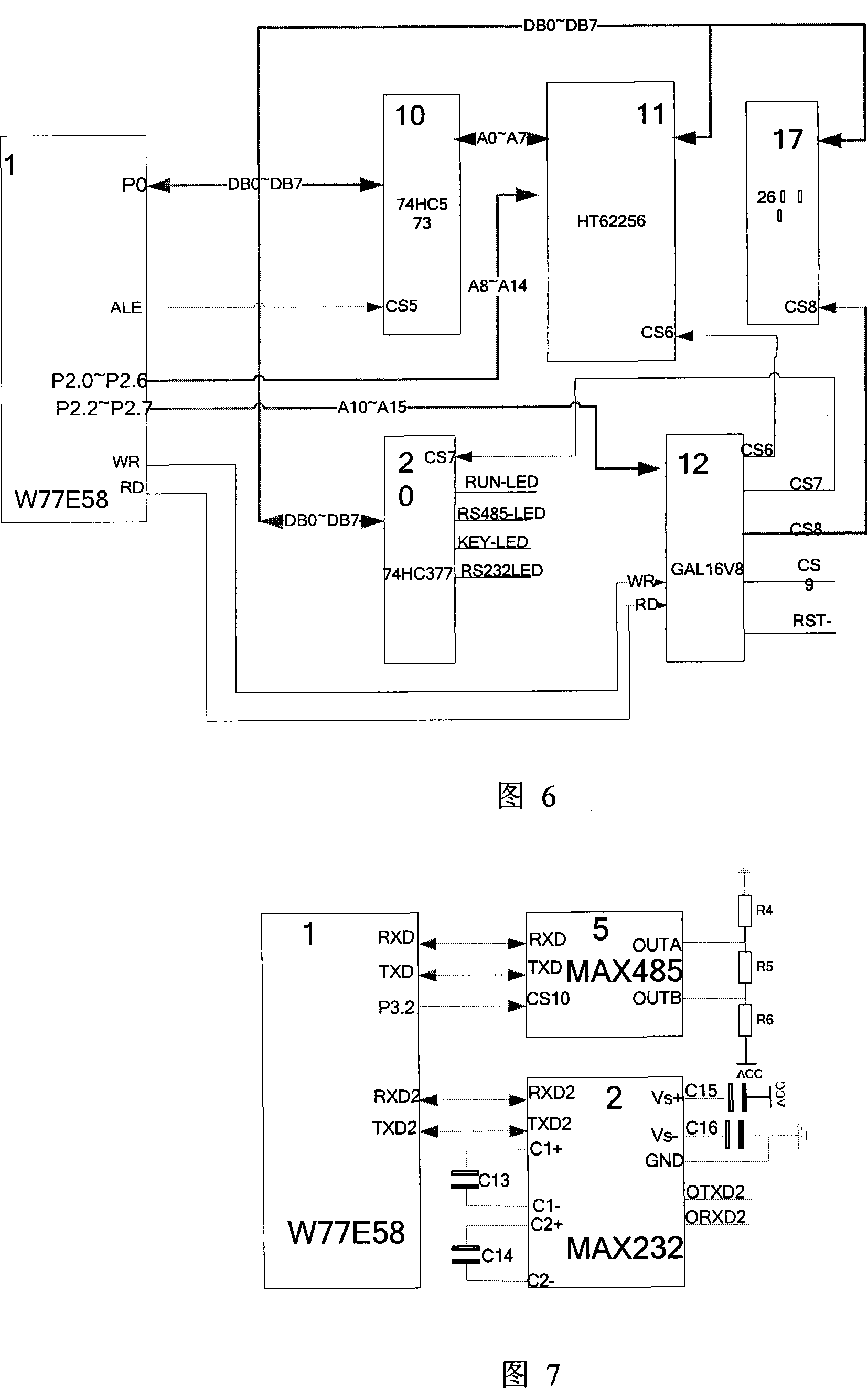

Self-possessed type production monitoring and supervision system facing bearing ring grinding and machining shop

InactiveCN101126925APrecision assistWith field data protection functionNumerical controlData compressionMachine shop

The utility model discloses an autonomous production monitoring system for bearing ring grinding workshop, comprising a monitor master and a monitor slave of machine tools. The monitor master takes responsibility for coordinating and controlling a plurality of monitor slave for machine tools, realizing the online data compression, transmitting the compressed data to the information server of enterprises through Ethernet and enabling the integration of field data and enterprise information system. The dot matrix liquid crystal screen is arranged on the monitor master, the managerial personnel of workshop can observe the operating condition of every machine tool in real time; the monitor slaves of machine tools are in charge of collecting the operating condition of machine tools, judging the operating condition of machine tools according to the collected data, if the abnormal operating condition of the machine tool is found, the enforced shutdown treatment for the machine tool can be taken; the monitor slave of machine tool can transmit the collected data to the monitor master via RS 485 bus. The user can set the system parameter via PC and change the control regulations of machine tool; the communication between the monitor master and the monitor slave of the machine tool is carried out via the RS 485 bus.

Owner:ZHEJIANG UNIV +1

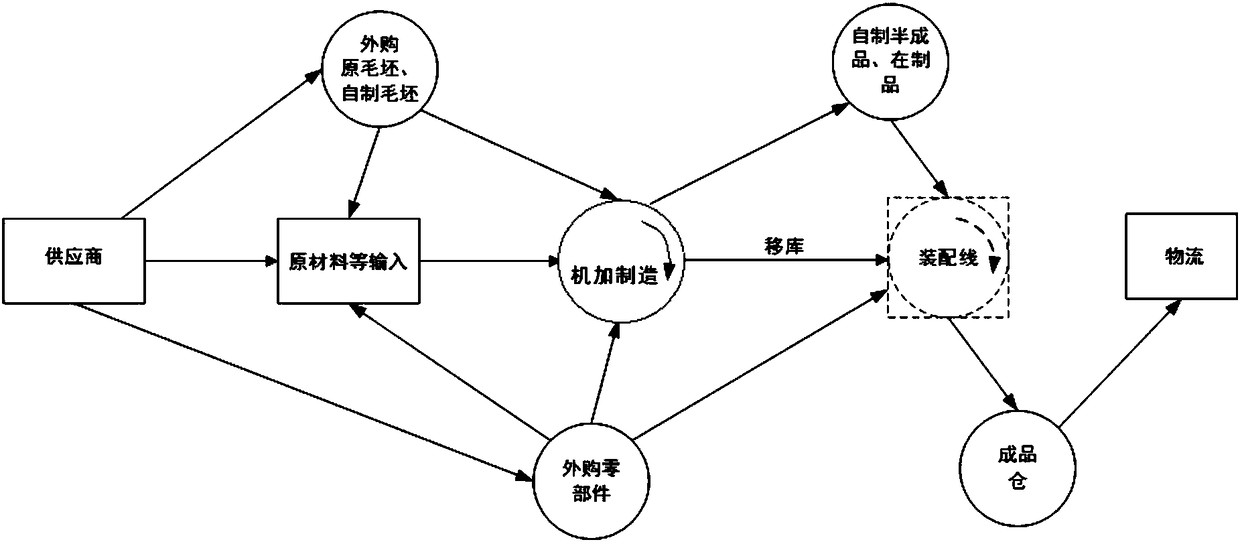

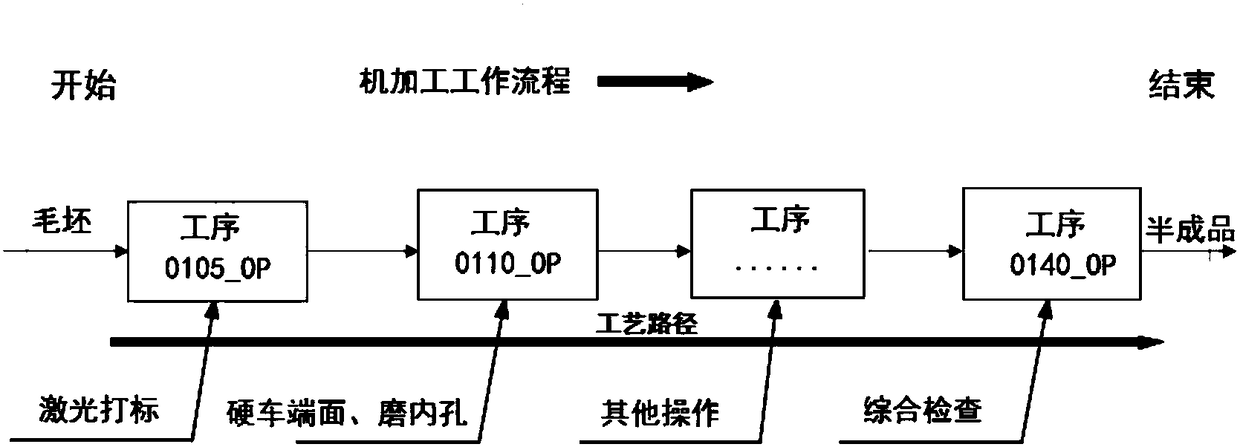

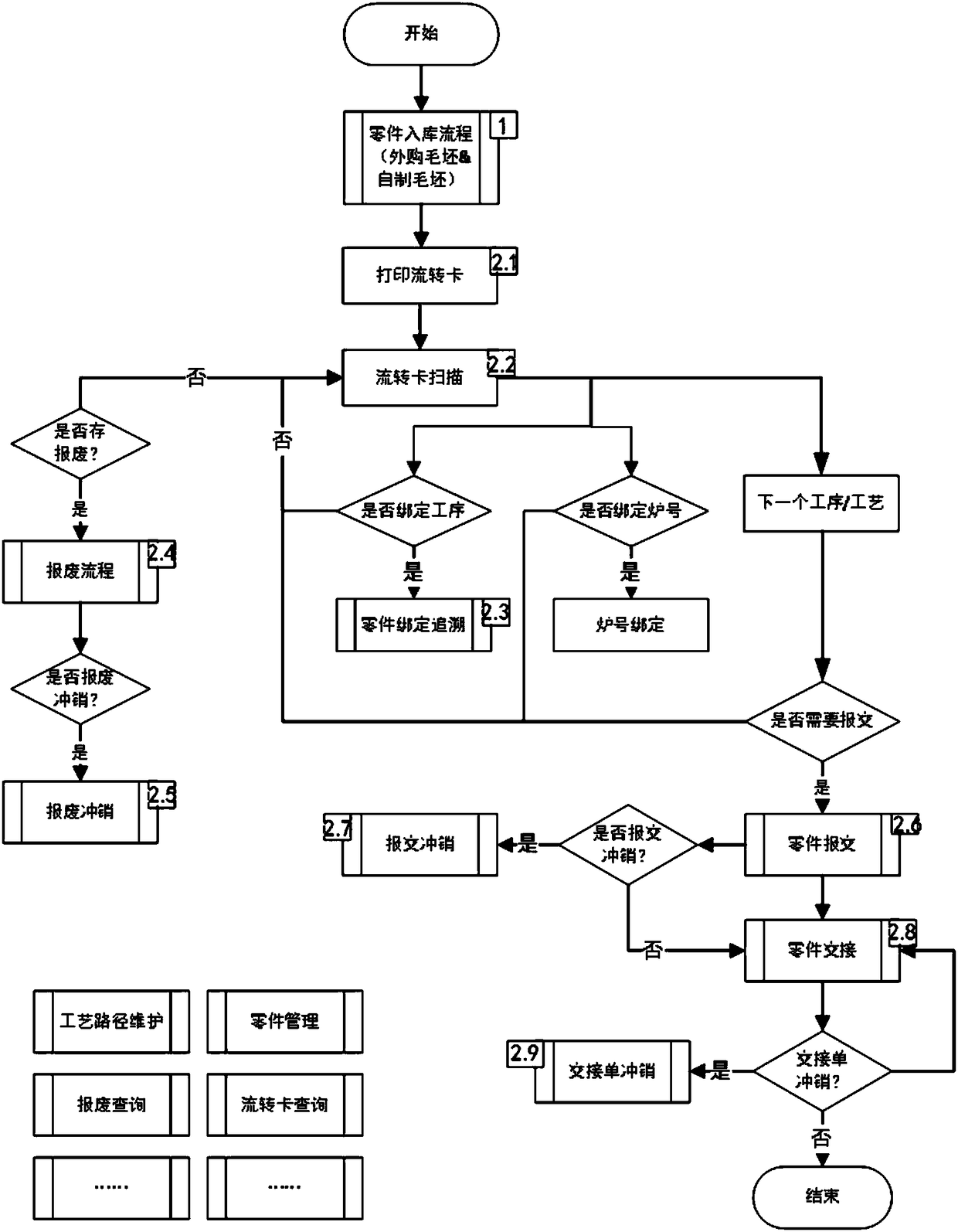

Machining workshop part manufacturing management method

The invention discloses a machining workshop part manufacturing management method which solves a series of production problems by setting details of the production link. In the invention, all complicated repetitive works executed by labor are replaced, and workshop management and management mode in modernized management are integrated, real-time acquisition and quick transmission of information can be realized automatically, remote control of production process management can be realized, then the workshop part manufacturing management method becomes a necessary tool as well as an important means for realizing informationized production management of an enterprise, and the production efficiency is greatly improved.

Owner:苏州宏软信息技术有限公司

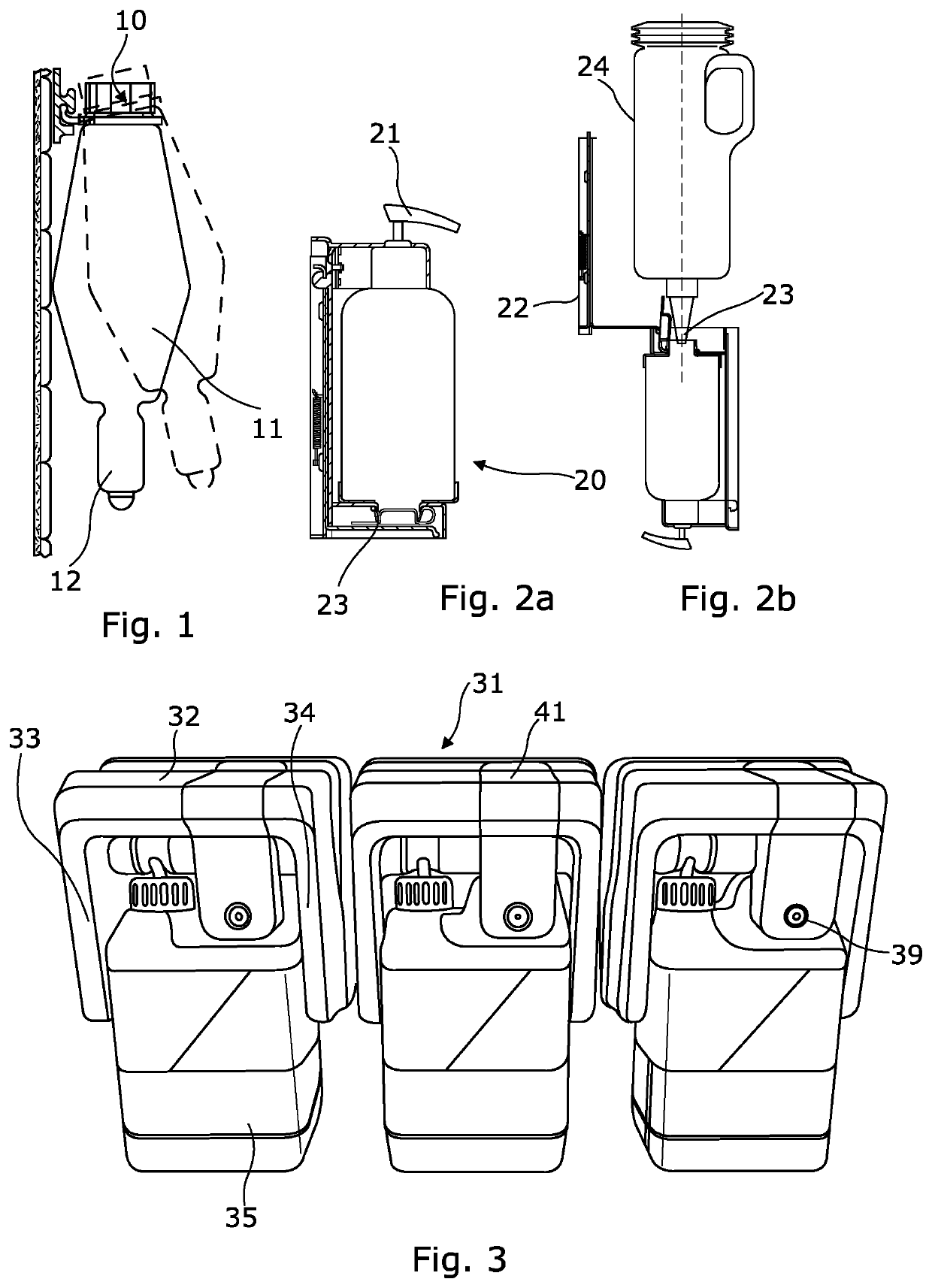

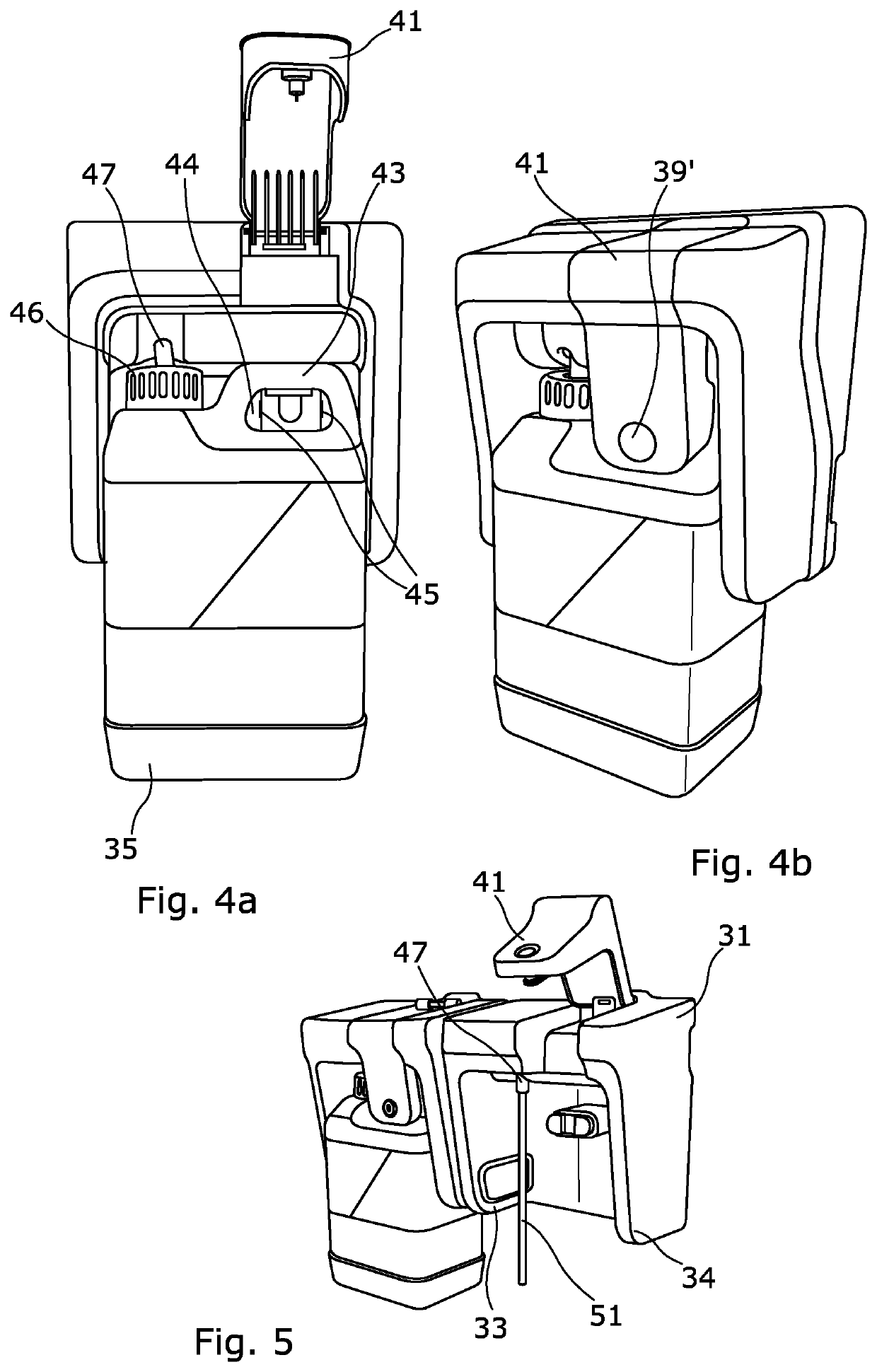

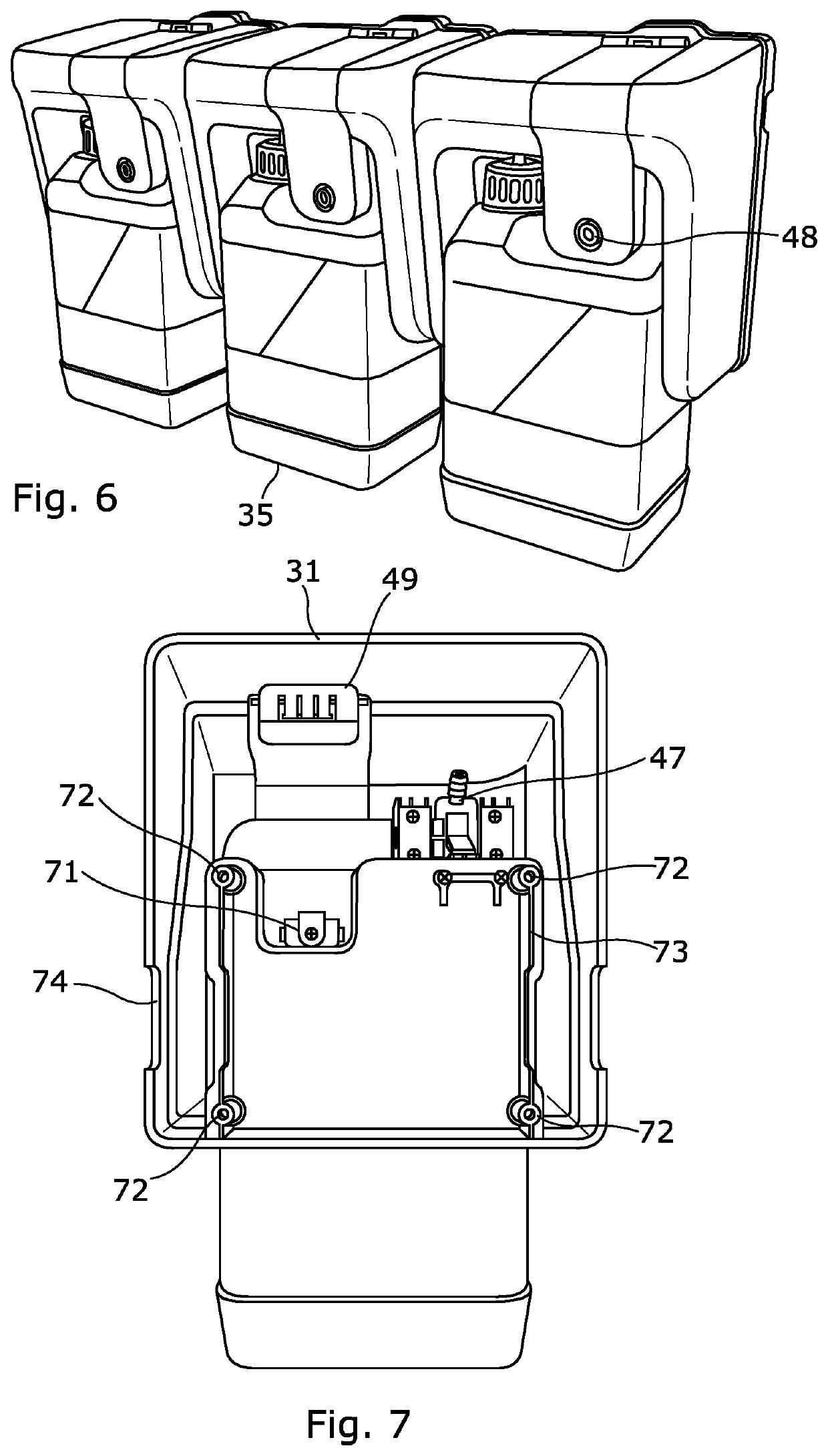

Dispensing System

ActiveUS20200029748A1Easy to cleanForm evenlyBottlesHolders and dispensersMachine shopProcess engineering

The present invention relates to dispensing systems that include containers used to contain fluids that need to be dispensed in controlled quantities. In particular, the present invention relates to a dispensing system which can be readily and securely fastened to the walls and other operating surfaces associated with bathrooms, changing rooms, machine shops and the like. In water closets at places of work, hospitals, laboratories, workshops and similar places, there are many individuals who require access to liquids such as liquid soap, oils and production process chemicals etc. usually have a reservoir that must be filled from a larger supply container. The filling operation tends to be complicated and thus time-consuming and with the likelihood of the creation of a mess. It is often difficult to feed the product directly into the dispenser container by pouring the liquid from a big supply tank. It is important that the fluids—whether for lubricating, cleaning or production processes—are managed such that only the correct fluids are. In the installation of a liquid dispensing system, factors of convenience in ensuring that the dispensers are maintained at a suitable level must be weighed against security of product. Many “universal” systems relinquish security and stock control and / or are complex to utilise. The present invention seeks to provide a solution to the problems addressed above. The present invention seeks to provide a dispensing system and a container that enables simple checking of fluid levels and simple re-filling thereof.

Owner:BRADLEY MARK ANTHONY

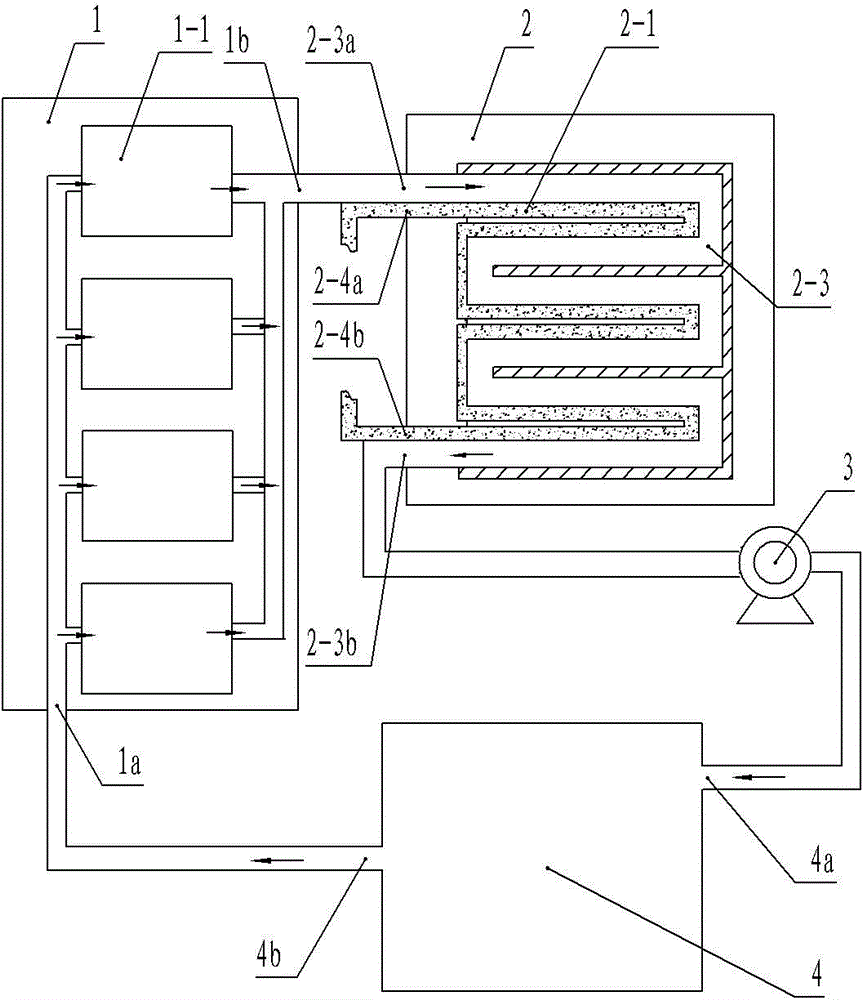

Water cooling system of machining workshop

InactiveCN104359276AImprove cooling effectReduce manufacturing costLighting and heating apparatusCooling fluid circulationMachine shopCooling effect

The invention discloses a water cooling system of a machining workshop, and belongs to the technical field of a cooling device. The water cooling system of the machining workshop comprises a water tank and a circulation pipeline, wherein the circulation pipeline is used for supplying water to the workshop, a water cooling tank is communicated with a pipeline arranged between a water outlet of the workshop and a water returning opening of the water tank, the water cooling tank comprises a U-shaped passage communicated with the circulation pipeline, and a cold medium passage is embedded and connected between the U-shaped passage. The water cooling system can solve the problems of poor cooling effect and water resource waste.

Owner:LIUZHOU KAITONG MACHINERY

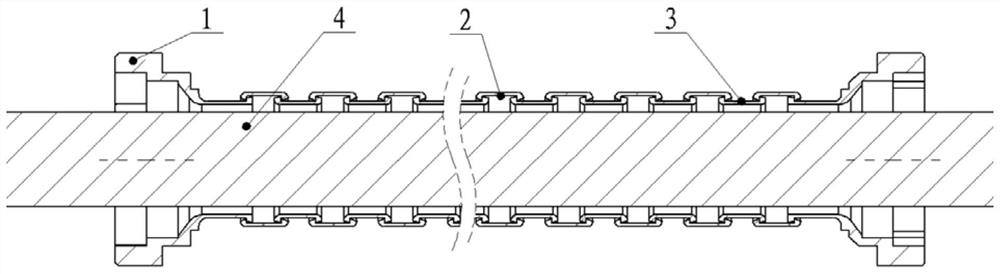

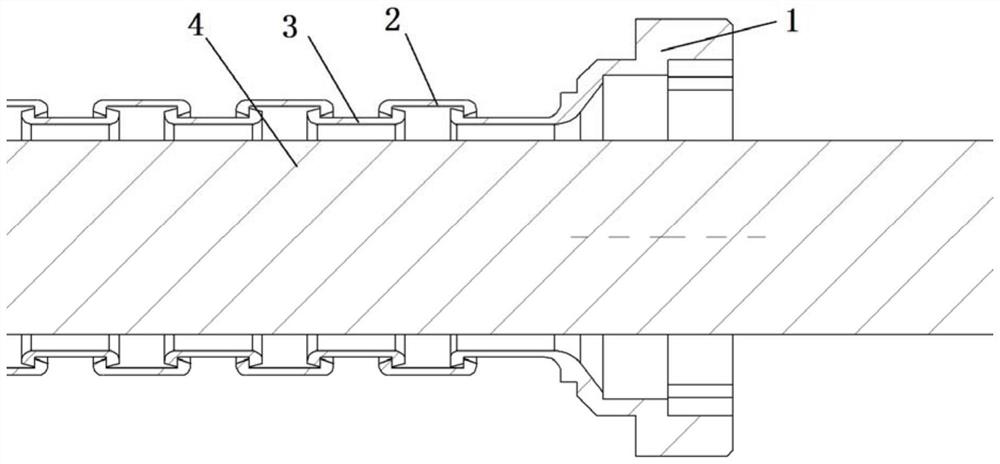

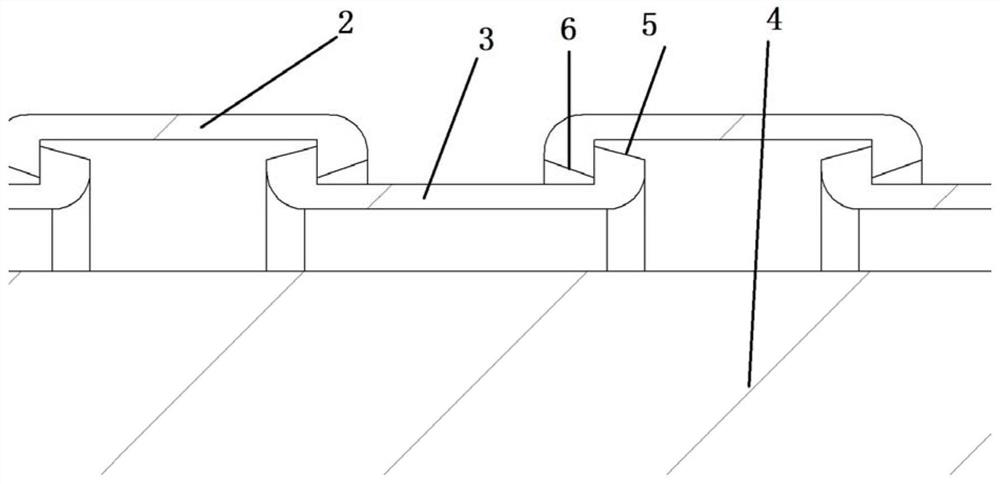

Flexible armor structure for protecting cable and assembly method

PendingCN112054443ARealize the twistAdjust the bend lengthElectrical apparatusFlexural torsionalMachine shop

The invention discloses a flexible armor structure for protecting a cable and an assembly method, and the structure mainly comprises a flexible armor interface, a flexible armor outer ring, a flexiblearmor inner tube, a cable structural part, and a flexible armor inner tube and a flexible armor outer ring which are sleeved outside the cable structural part and are hooked and embedded end to end.The two ends of the flexible armor outer ring and the two ends of the flexible armor inner tube are fixed through flexible armor connectors, and the flexible armor connectors are connected with equipment in a butt joint mode. According to the invention, the multiple inner tubes and the multiple outer tubes are buckled, bending and twisting of the flexible armor can be achieved, the bending lengthof the flexible armor can be adjusted, and finally flexible connection is achieved; the manufacturing is simple and can be realized in a common machining workshop; under the condition that bending torsional deformation is met, load acting force in the axial direction can be achieved; and strong cable protection capability is achieved.

Owner:杭州瑞声海洋仪器有限公司

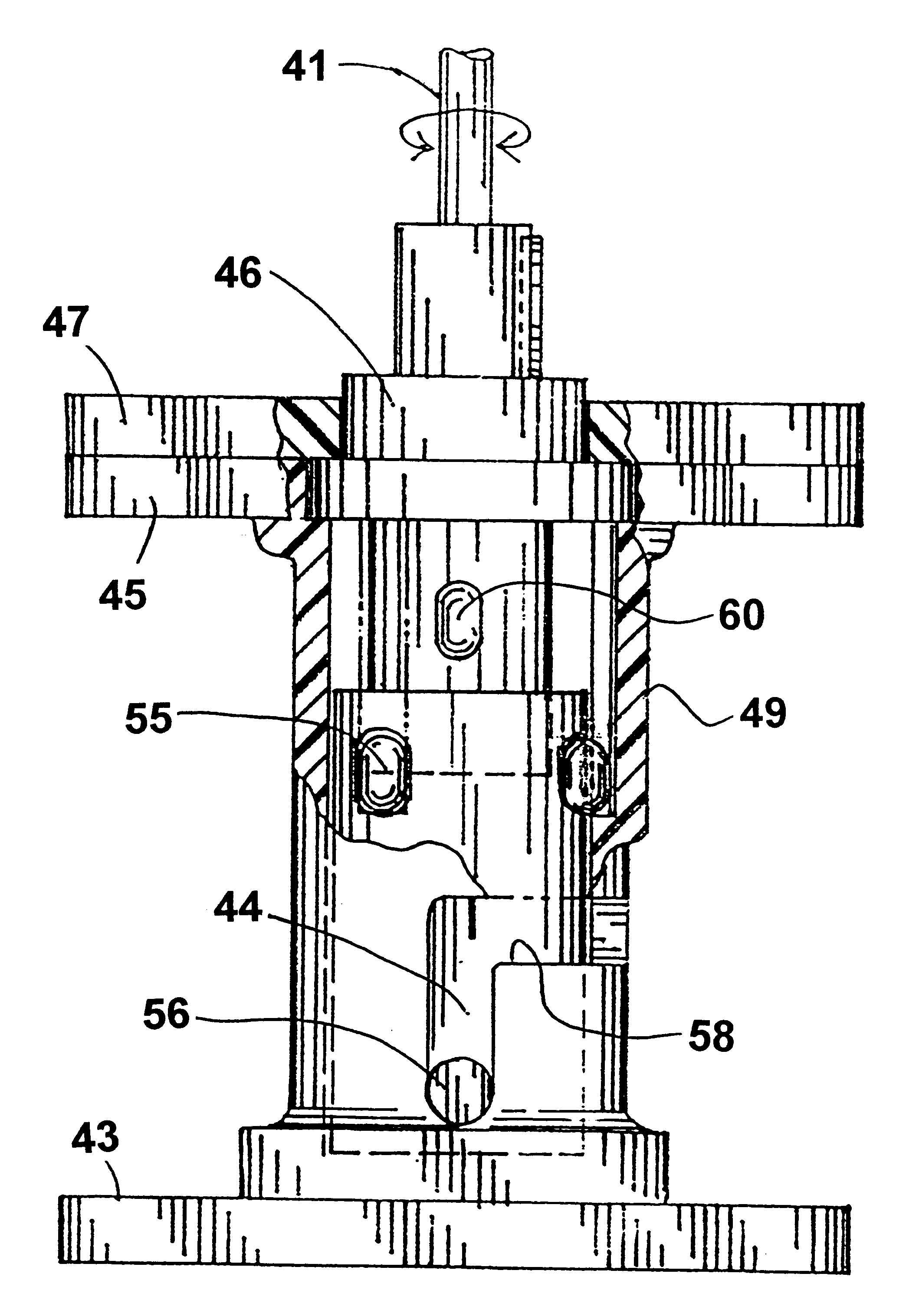

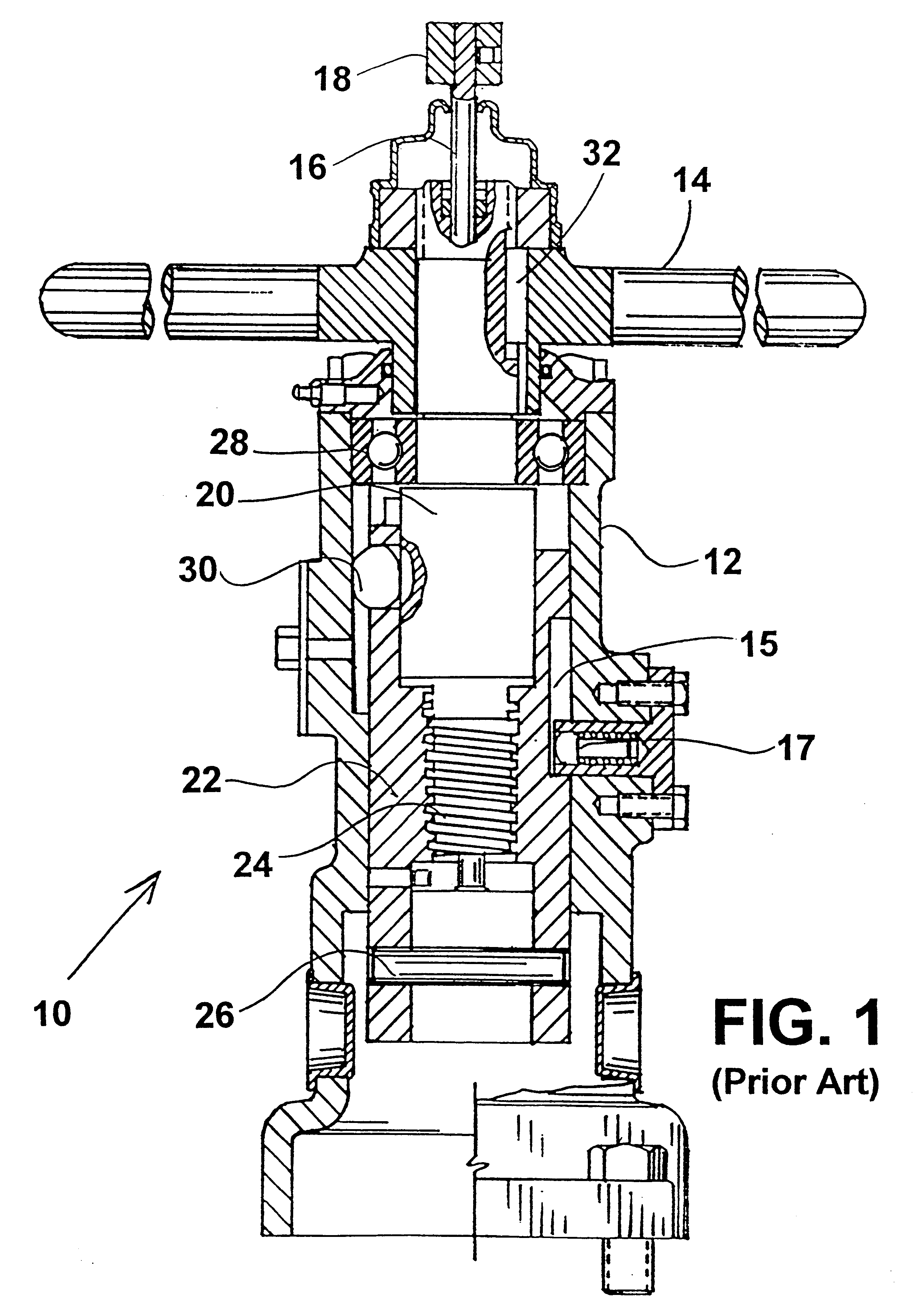

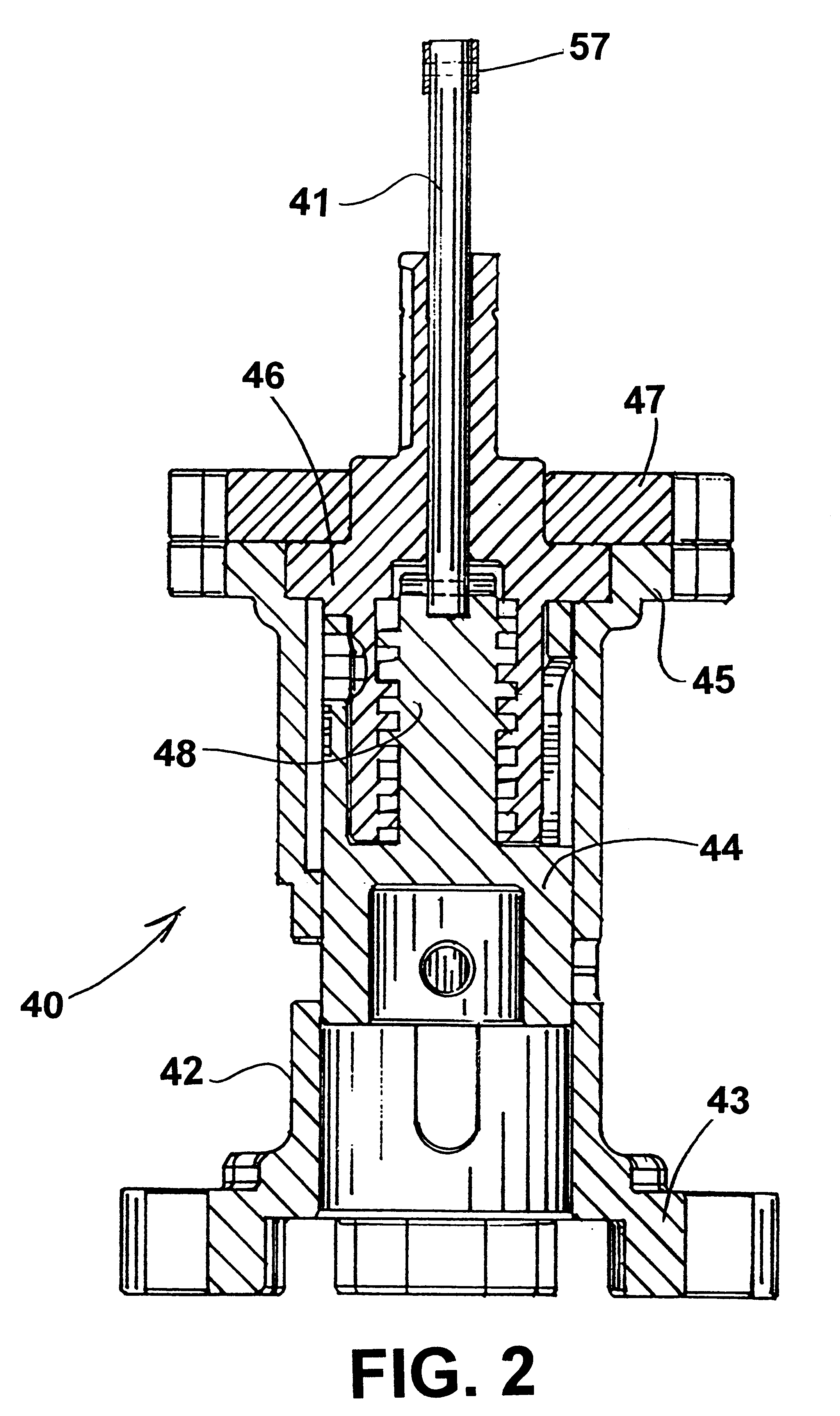

Compact stem set with load-balanced rollers for non-lubricated double block and bleed plug valves

InactiveUS6276394B1Operating means/releasing devices for valvesPipeline systemsMachine shopInvestment casting

In the stem set configuration for a double block and bleed plug valve, the improvement provides an operator which can be significantly shorter and more compact than conventional operators for such valves. The invention makes use of a novel nesting of the threading section whereby a conventional female thread is replaced by a nested male thread surrounded by the translation section. The translation section, in turn, houses the indication section inboard of the nested male threads thereby compacting three functions into one location. This design lends itself nicely to investment casting technology obviating conventional machine shop practices. The invention also combines by use of a long plug stem pin, the plug connection and L slot functions into one location. The input function still remains separate, however, combining ultimately all functions in only three discrete locations and what appears at this time to be the ultimate compacted or nested arrangement.

Owner:GENERAL VALVE INC

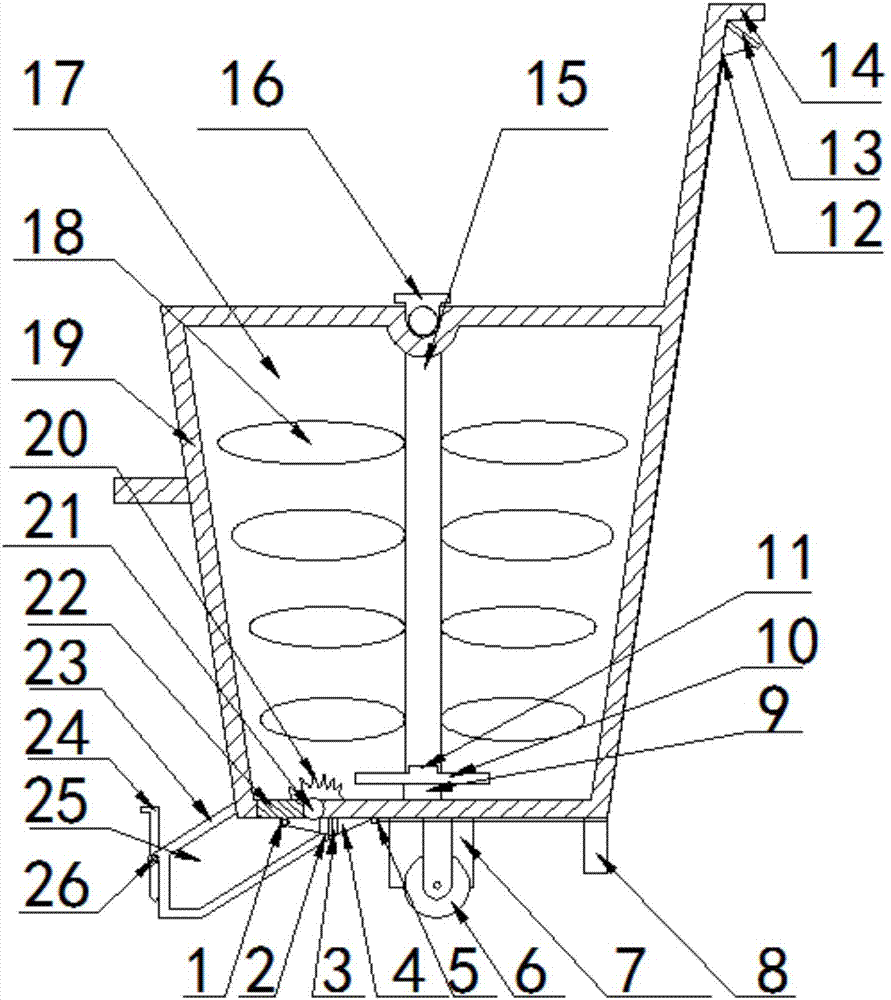

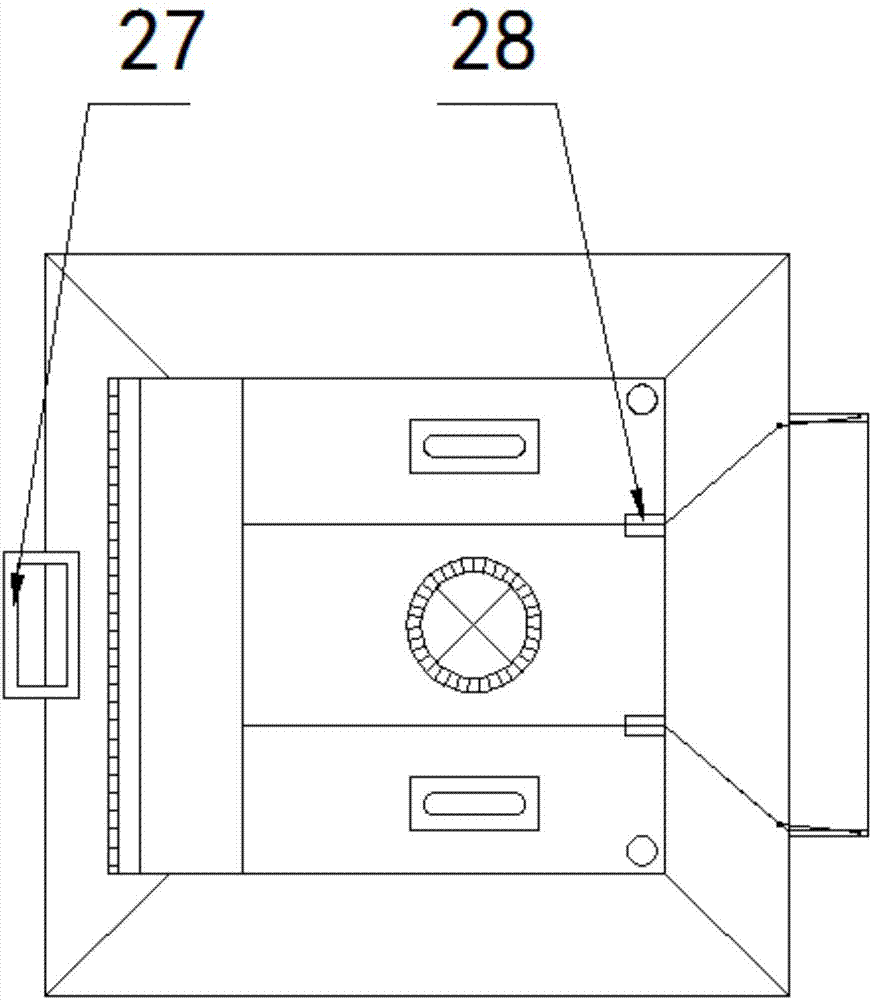

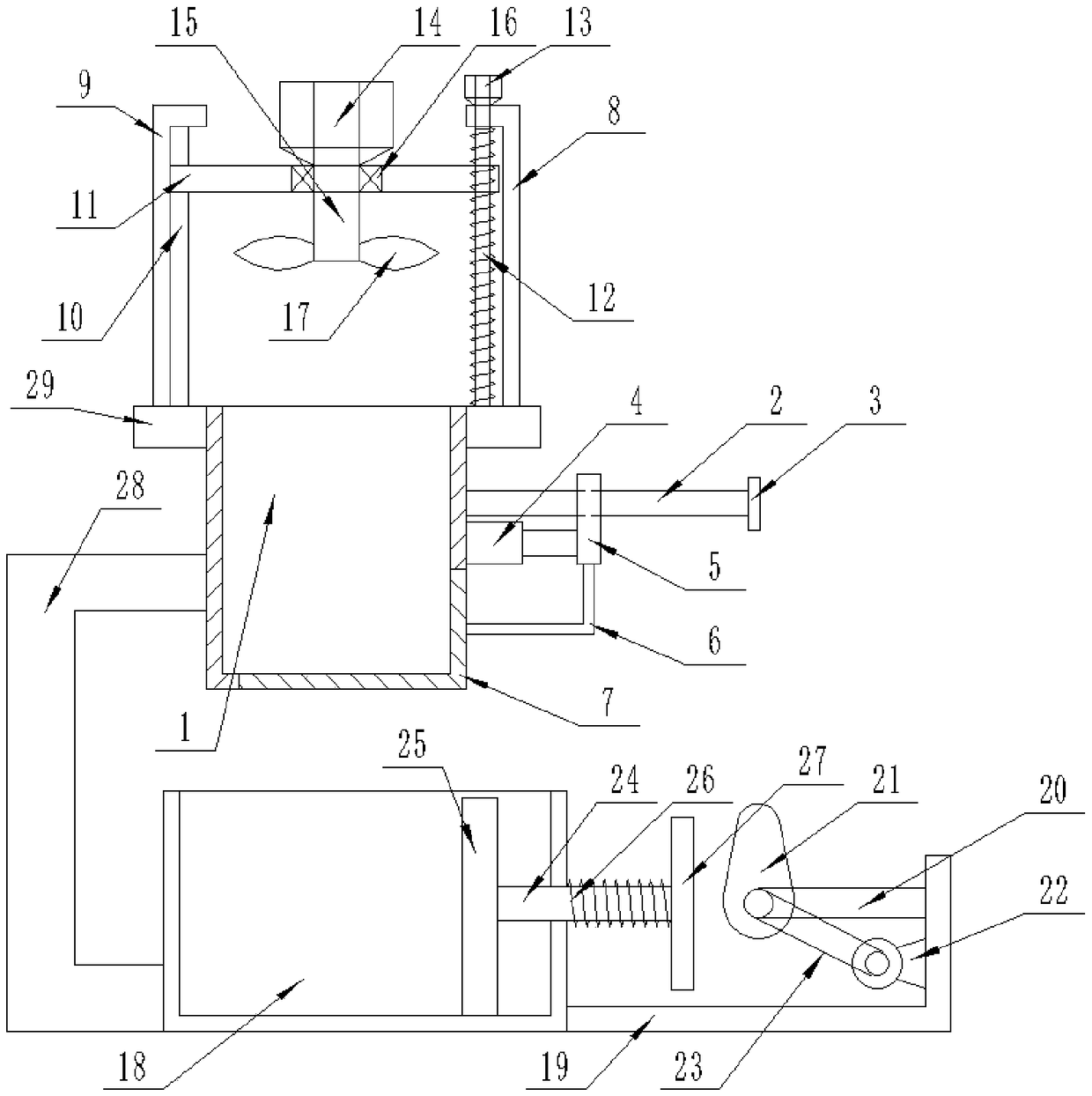

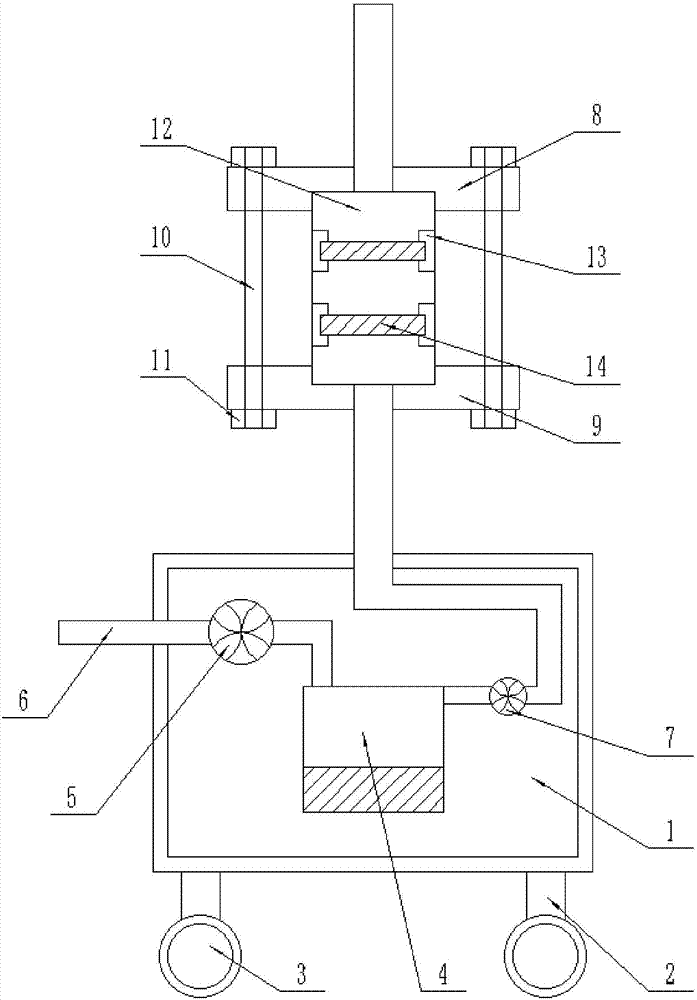

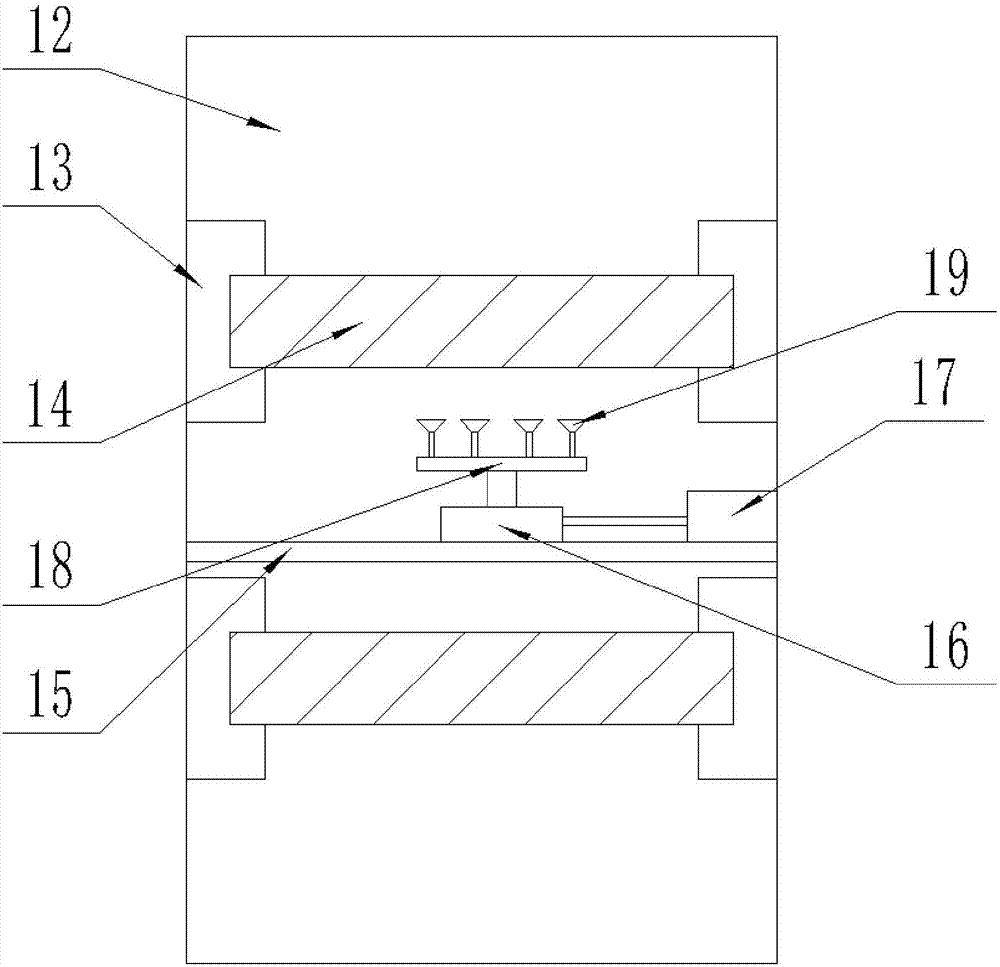

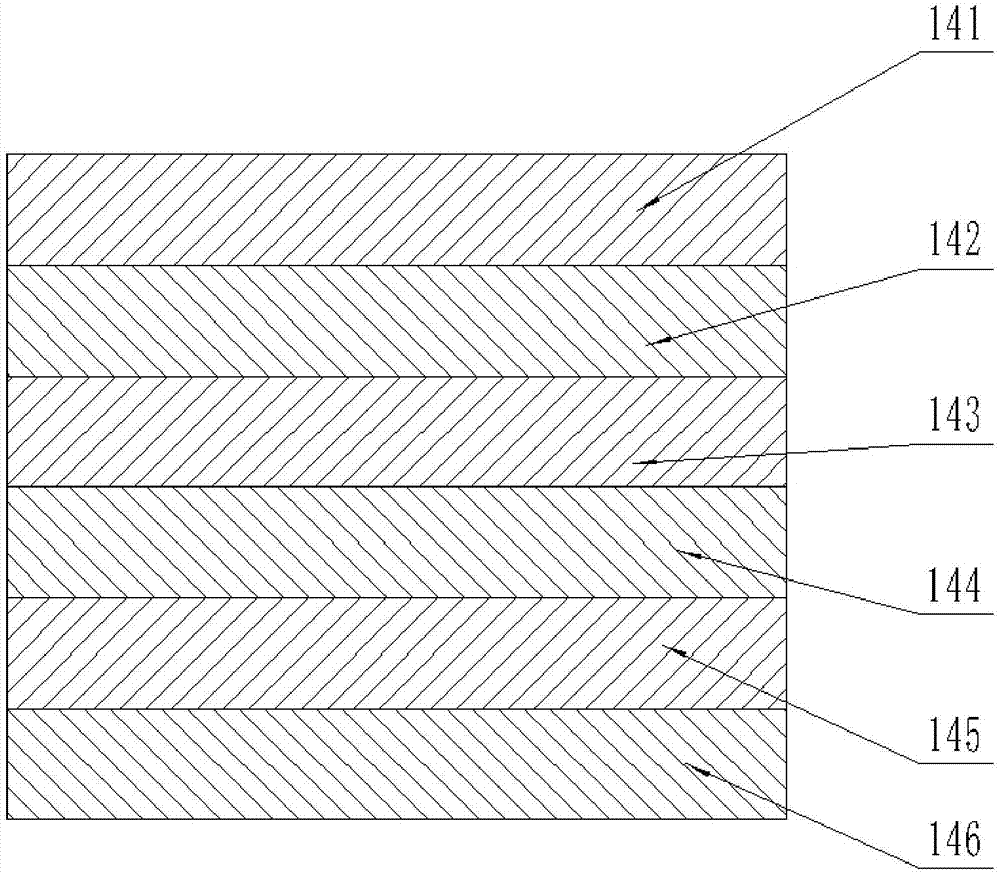

Scrap iron compression equipment for machining workshop

PendingCN109225504ASimple structureReduce manufacturing costGrain treatmentsPressesMachine shopHydraulic cylinder

The invention discloses scrap iron compression equipment for a machining workshop. The scrap iron compression equipment has a reasonable and simple structure, low production cost, convenient mountingand complete functions, and can effectively crush and compress scrap iron to facilitate handling and transportation later. The scrap iron compression equipment is characterized in that the scrap ironis put into a crushing chamber, then a lead screw is driven by a first motor to rotate, the height of a lifting platform is controlled, so a crushing cutting blade extends into the crushing chamber; arotating shaft is driven by a second motor to rotate, the scrap iron is crushed by the crushing cutting blade on the rotating shaft, a hydraulic cylinder operates after crushing to propel a shaft sleeve, so a bottom cap is separated from the crushing chamber, and the crushed scrap iron in the crushing chamber enters a compression chamber; and a third motor drives a cam to rotate by a belt, the cam knocks a contact plate, and meanwhile, under the action of a spring, a press block moves from left to right to realize reciprocating compression of the scrap iron. By the technical scheme, defects in the background art are effectively solved.

Owner:NANTONG INST OF TECH

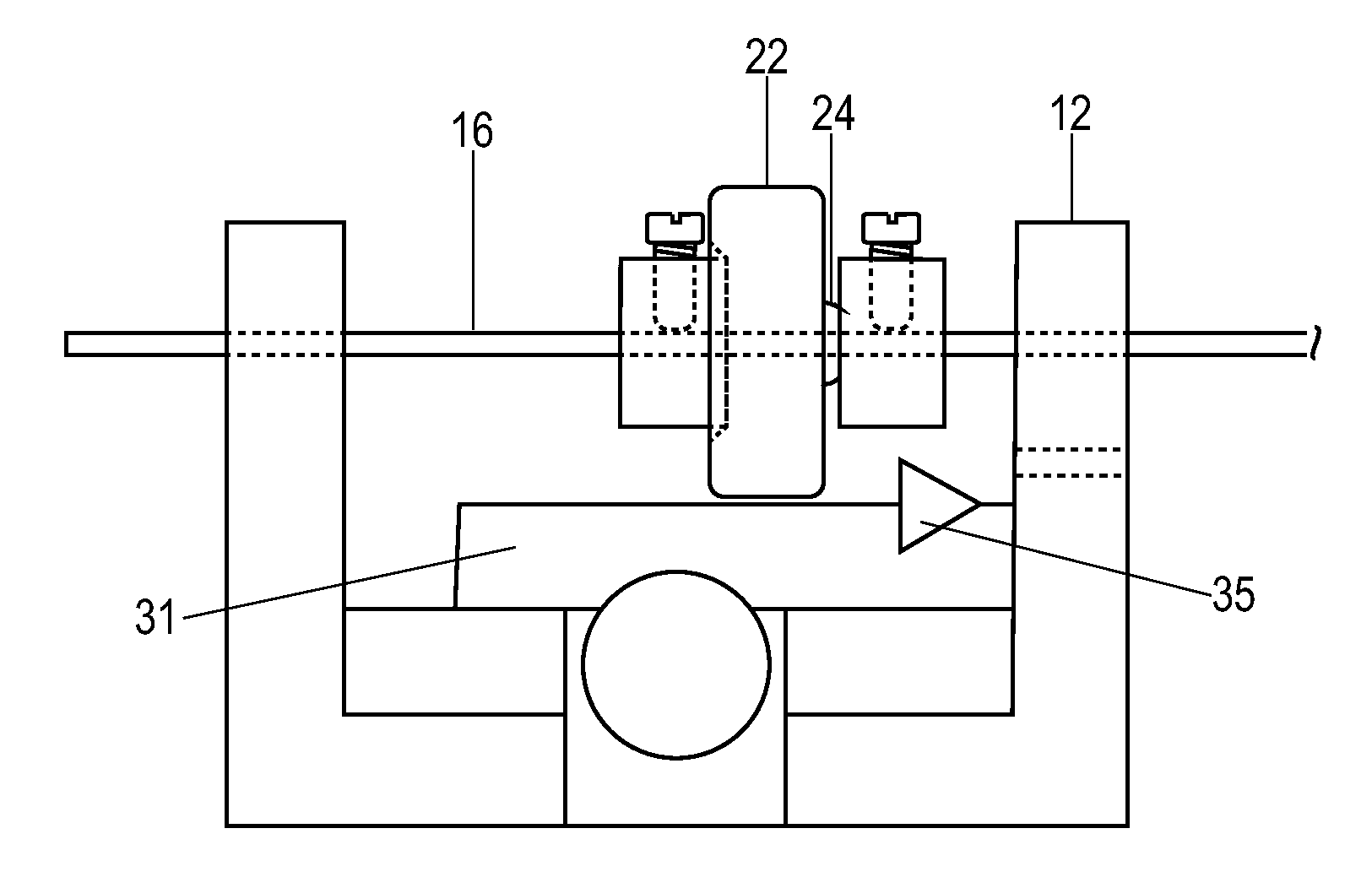

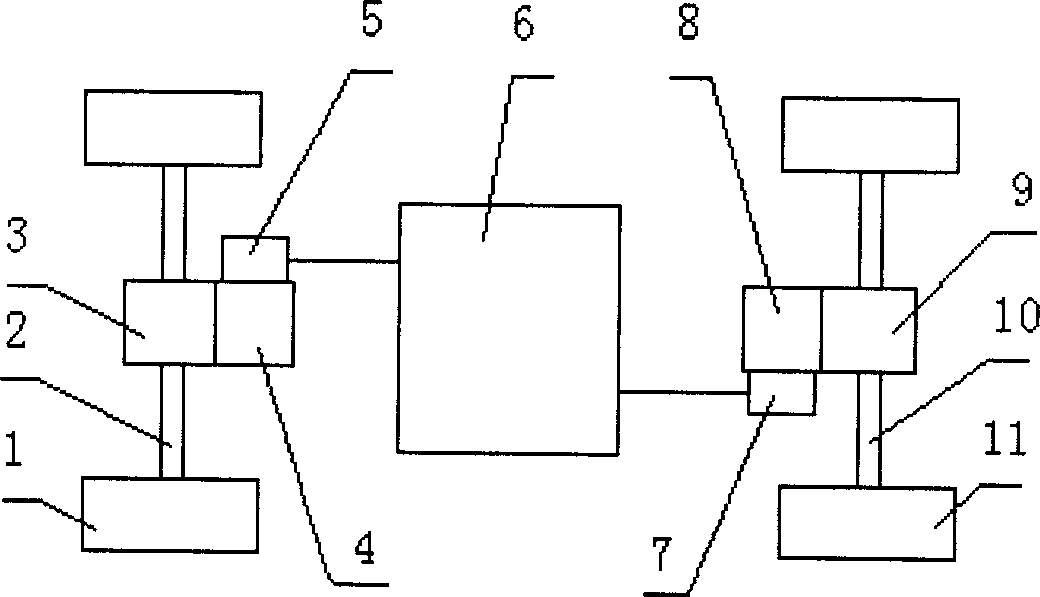

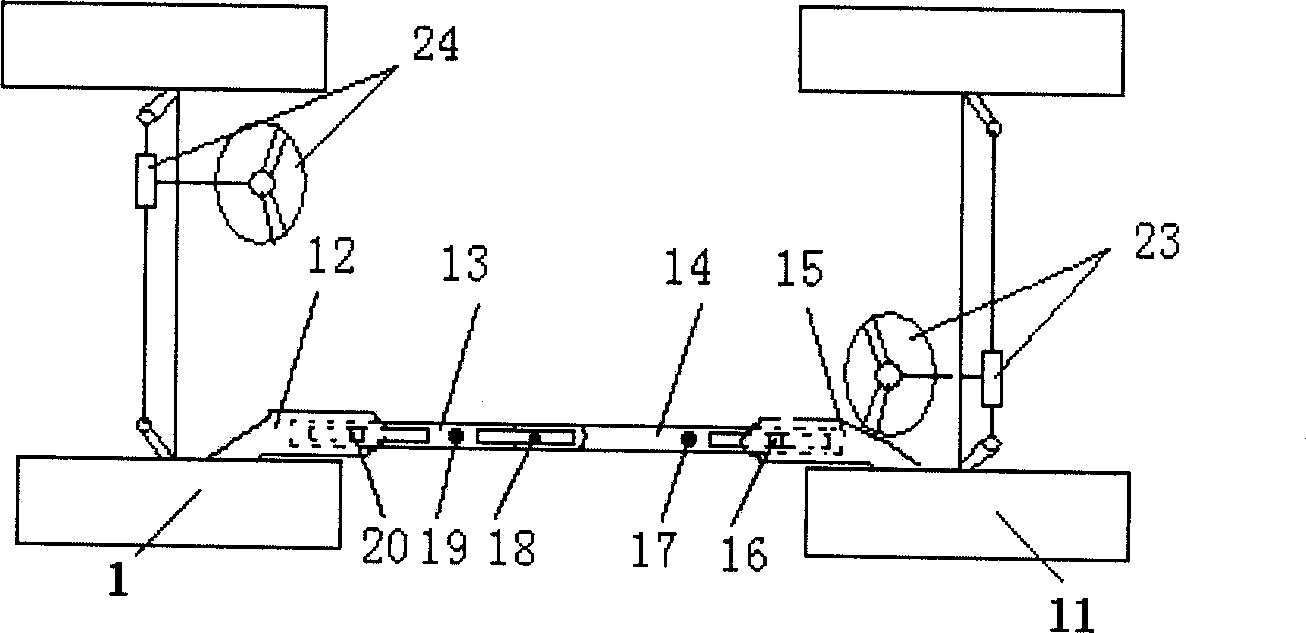

Bidirectionally steering electric machineshop car

ActiveCN1799915AGuaranteed synchronicitySmall turning radiusAlternative steering controlVehiclesMachine shopElectric machine

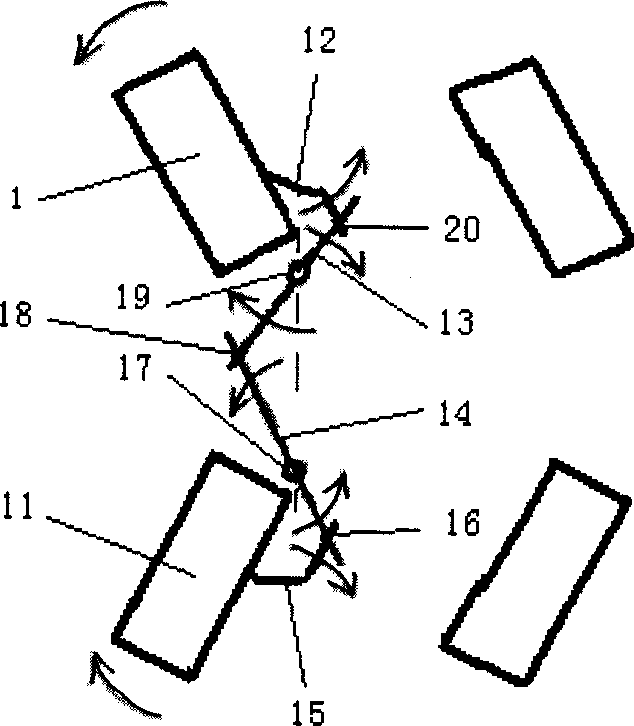

The invention relates to a bidirectional electric machine-shop car, which comprises a chassis, a car body, a carrier battery, a front main reducer, a front motor, a back motor and a back main reducer. It is characterized in that: four wheel steering linked device are mounted at the same side of front and back wheel (1, 11); the four wheel steering linked device comprises a first fixing connection rod (12), a first transmission connection rod (13), a second transmission connection rod (14), a second fixing connection rod (15), a second power pin (16), a second rotational pin (17), a third power pin (18), a first rotational pin (19) and a first power pin (20). The invention has the character of small steering radius, which can apply small and micro low-sped vehicle (comprising machine-shop car), display several parameters of carrier information, charge the battery and avoid the sliding between solid rubber tyre and circular rim.

Owner:武汉经开科创运营有限公司

Machining workshop air supply device

InactiveCN104676807APrevent subsidenceInhibit aggregationMechanical apparatusSpace heating and ventilation safety systemsMachine shopMachining

The invention discloses a machining workshop air supply device, belonging to the technical field of machining. The machining workshop air supply device comprises at least one suction ventilator, wherein an exhaust inlet of the suction ventilator is communicated with multiple suction heads at the upper part in a machining workshop, an air outlet of the suction ventilator is communicated with an air inlet of at least one dust remover, an air outlet of the dust remover is communicated with an air inlet of at least one tempering room, an air outlet of the tempering room is communicated with an air inlet of at least one blower, and an air outlet of the blower is communicated with multiple air outlets of the lower part in the machining workshop. The machining workshop air supply device can be used for solving the problems of incomplete metal dust clearing and single function in the machining workshop.

Owner:黎雅伟

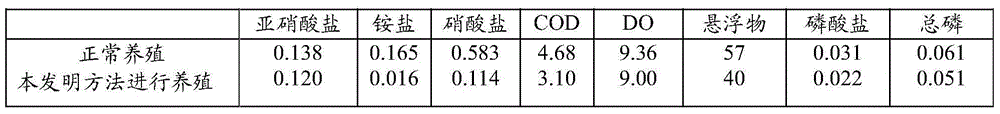

Fish farming system and method for water treatment of fish farming

InactiveCN106614218AWith water saving and pollution reductionReduce productionPisciculture and aquariaMachine shopZoology

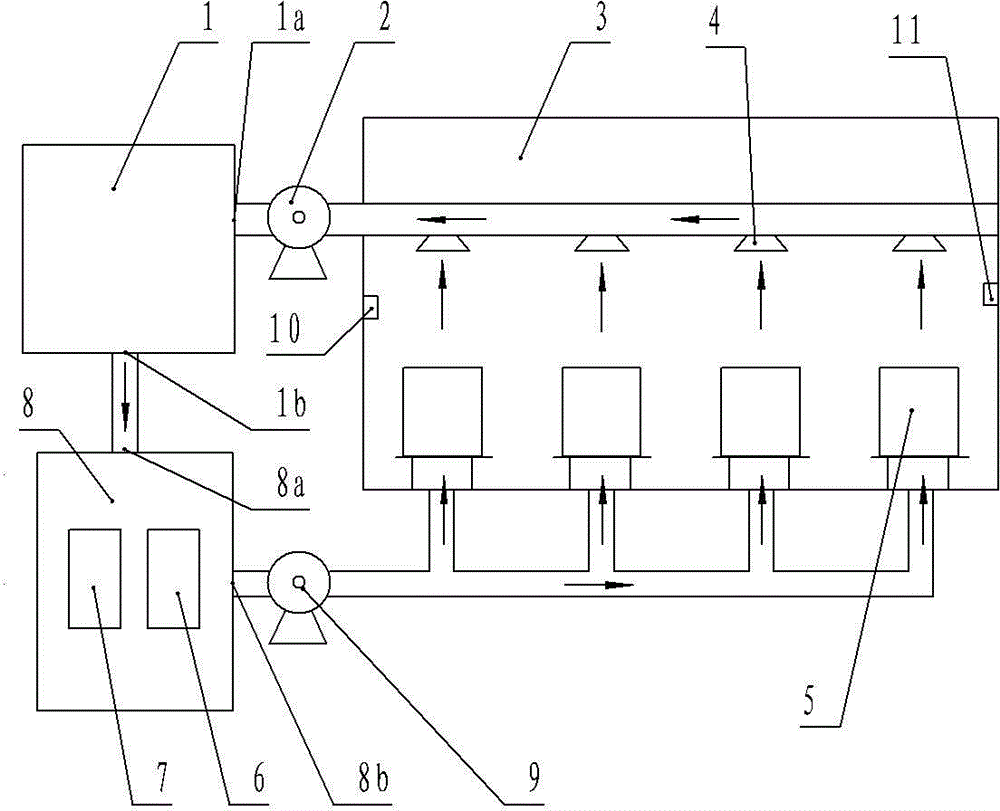

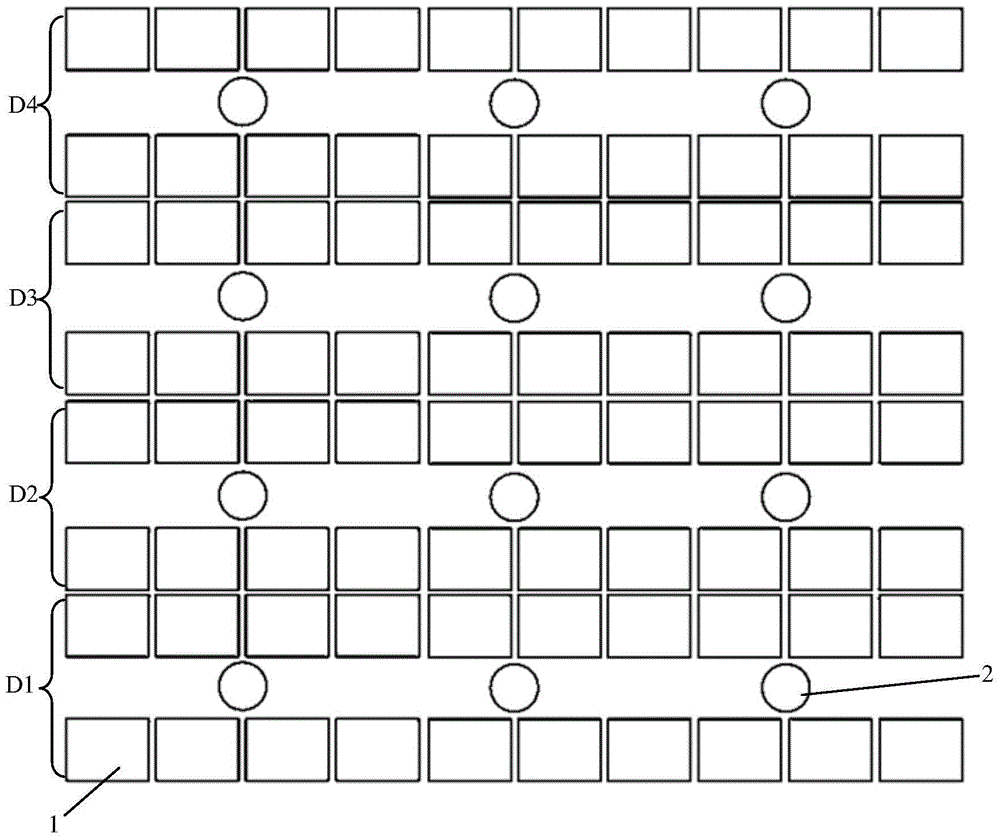

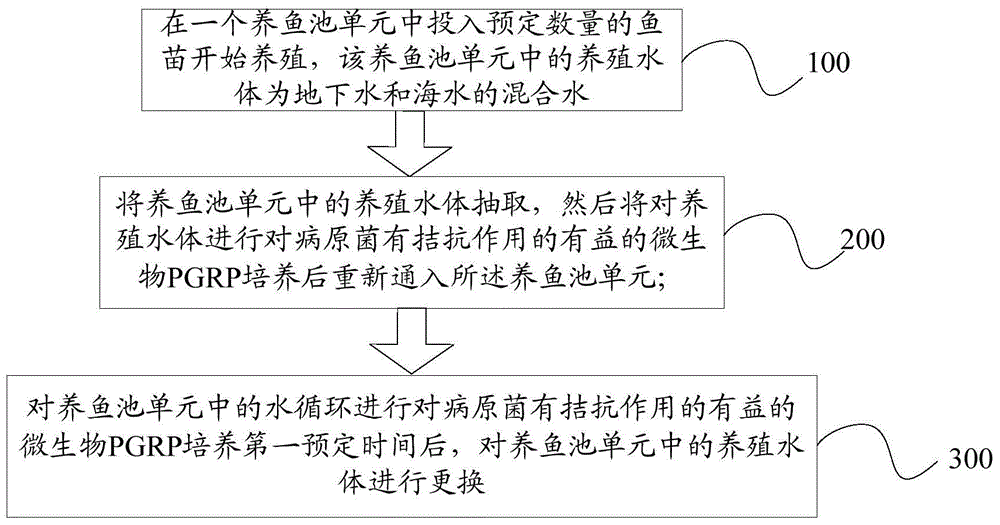

The invention provides a fish farming system and a method for water treatment of fish farming. The fish farming system includes a machine shop which is provided with multi-row fishpond groups and every row of the fishpond group is provided with a plurality of fishpond units, and a plurality of microbial treatment systems are connected with the fishpond units. The microbial treatment systems utilize the aquaculture water in the fishpond units to cultivate beneficial microorganism PGRP which has antagonistic effect on the pathogen. And then return the clean water to the fish pond units. A water outlet is arranged at the bottom of each fishpond unit. Every fishpond unit is provided with two inlets, wherein one of the inlets is connected with a high-level reservoir containing a mixture of groundwater and seawater, and the other inlet is connected with the microbial treatment system. The fish farming system and method for water treatment of fish farming has the advantages of water saving and pollution reduction, which is capable of effectively reducing the intakes of seawater and underground hot water, decreasing the amount of aquaculture waste water, achieving the effect of water-saving and pollution-reducing. The fish farming system and method for water treatment of fish farming provides strong support for the implementation of water ecological civilization construction in coastal areas.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES

Air filtering device for machining workshop

The invention discloses an air filtering device for a machining workshop. The air filtering device has the advantages that the structure is reasonable and simple; the production cost is low; the installation is convenient; air in the workshop can be effectively filtered; a first exhaust fan and a second exhaust fan work; the air enters a clean water chamber; dust in the air is removed; then, impurities are filtered out through two filtering cores; a fiber layer, a nonwoven fabric, a composite nanometer fiber layer, a glass fiber layer, chinlon and an air filtering material body are used in each filter core; the impurities can be effectively removed; universal wheels are installed, so that moving is convenient; an air pressure rod drives a slide block to slide; the filter cores are cleanedthrough hair brushes arranged on a turntable.

Owner:NANTONG INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com