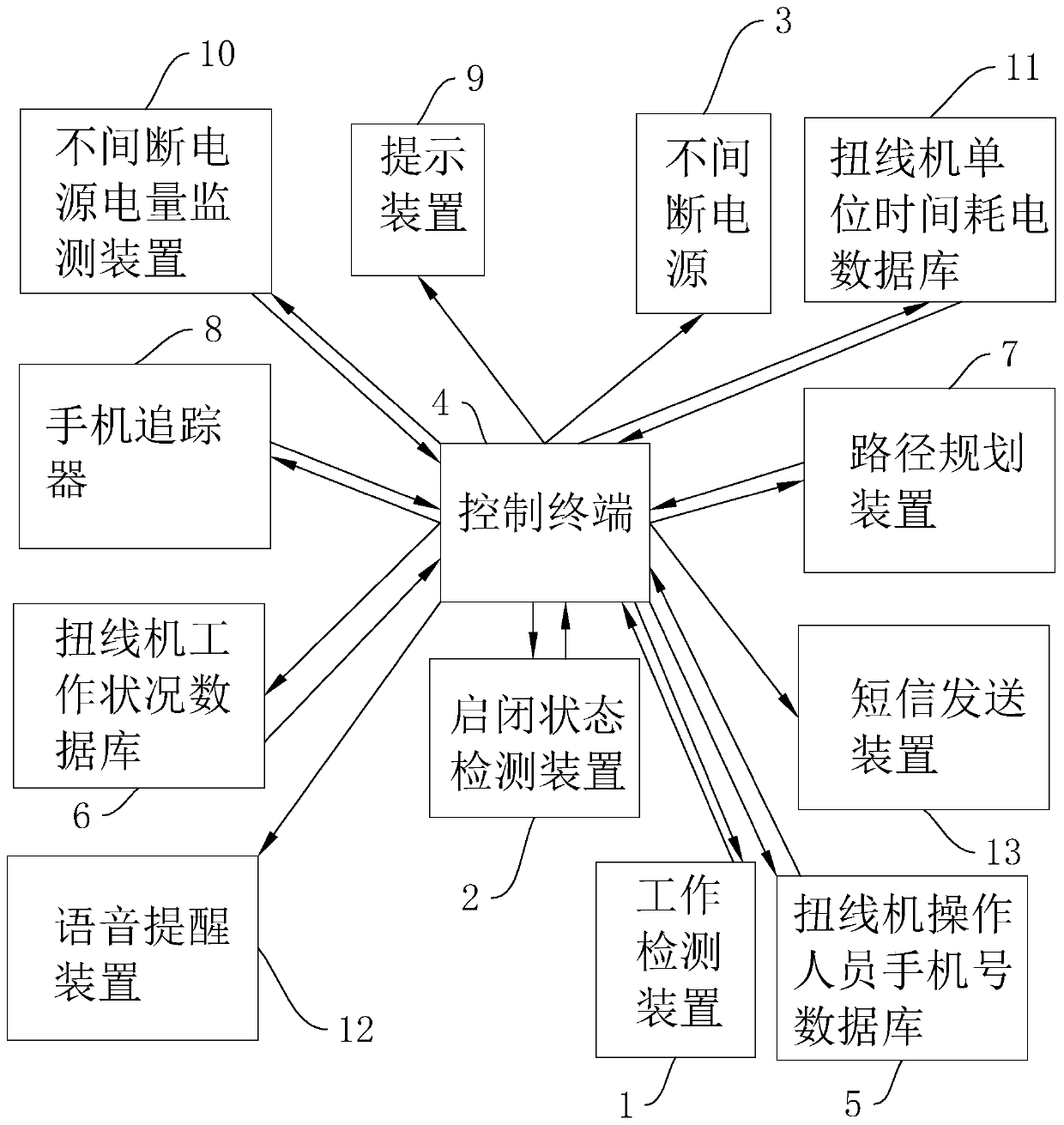

Patents

Literature

53results about How to "Realize the twist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

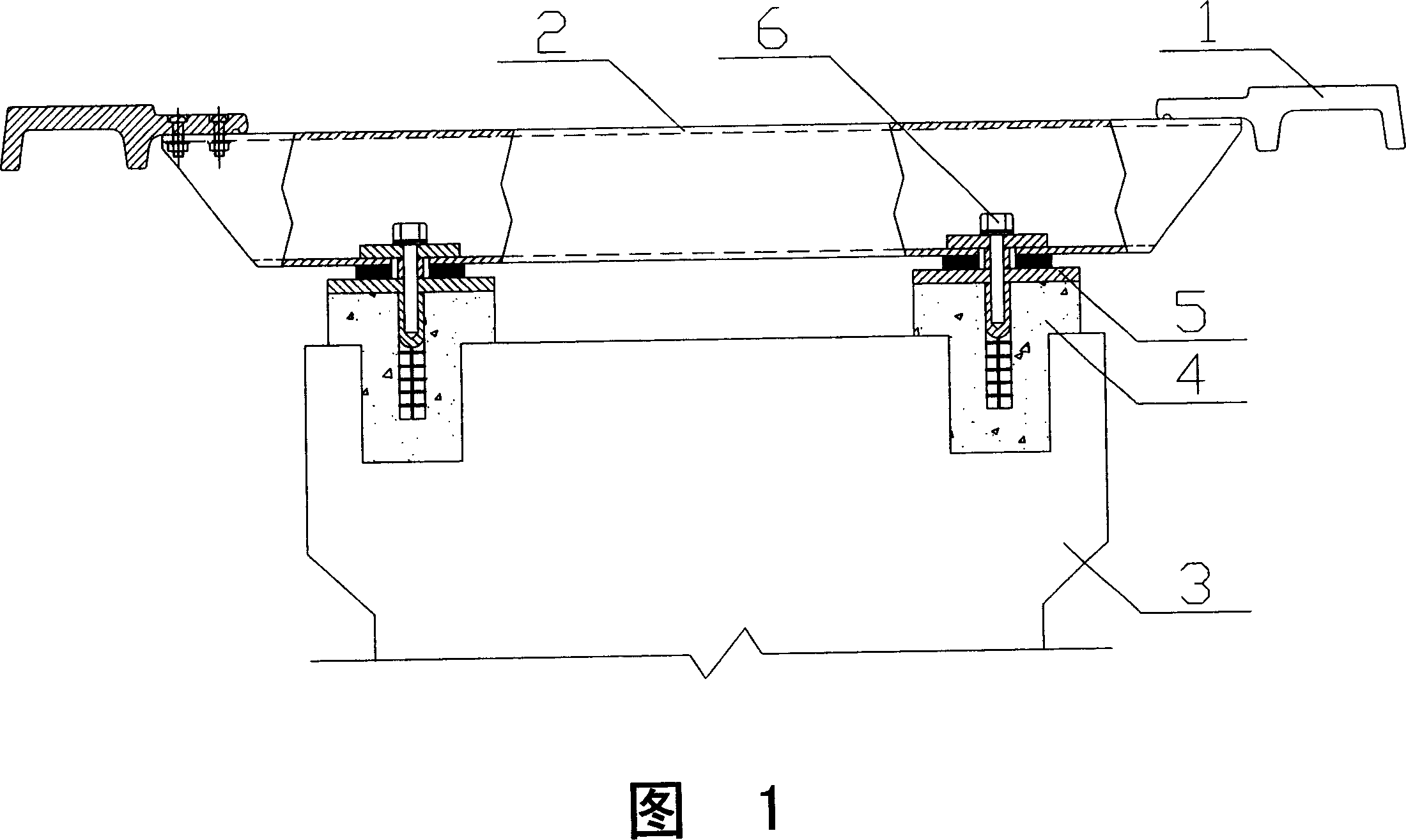

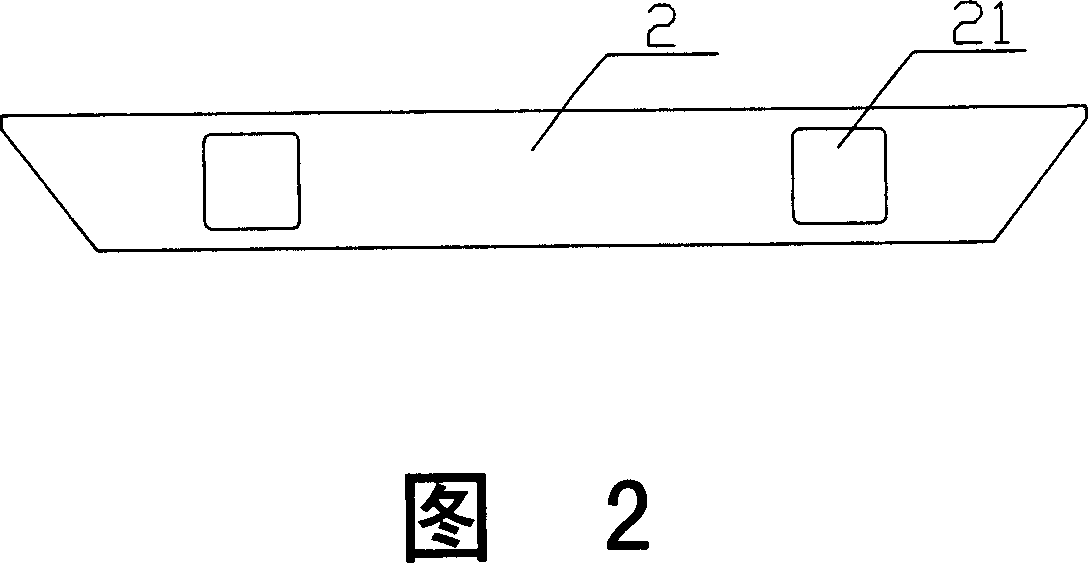

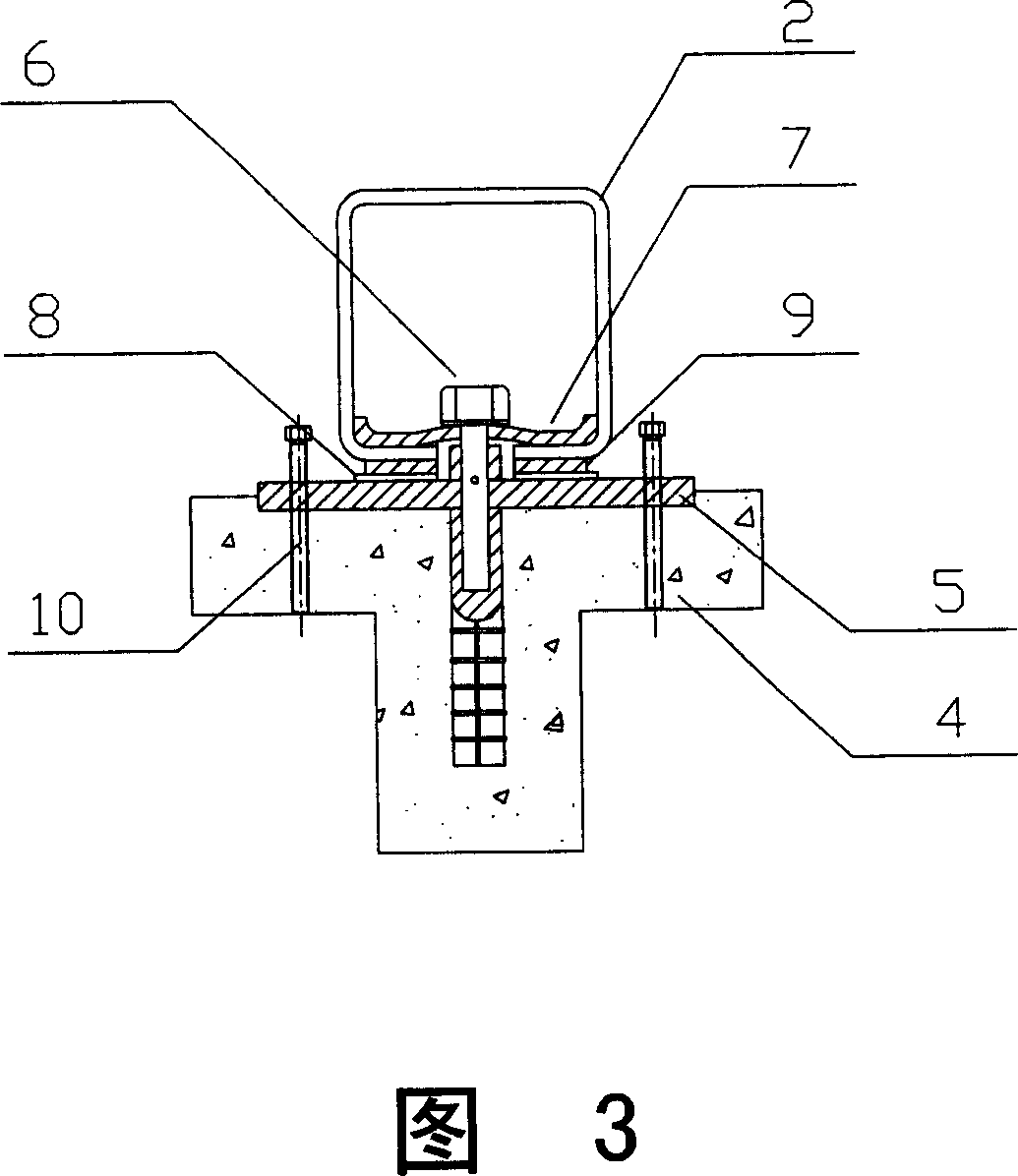

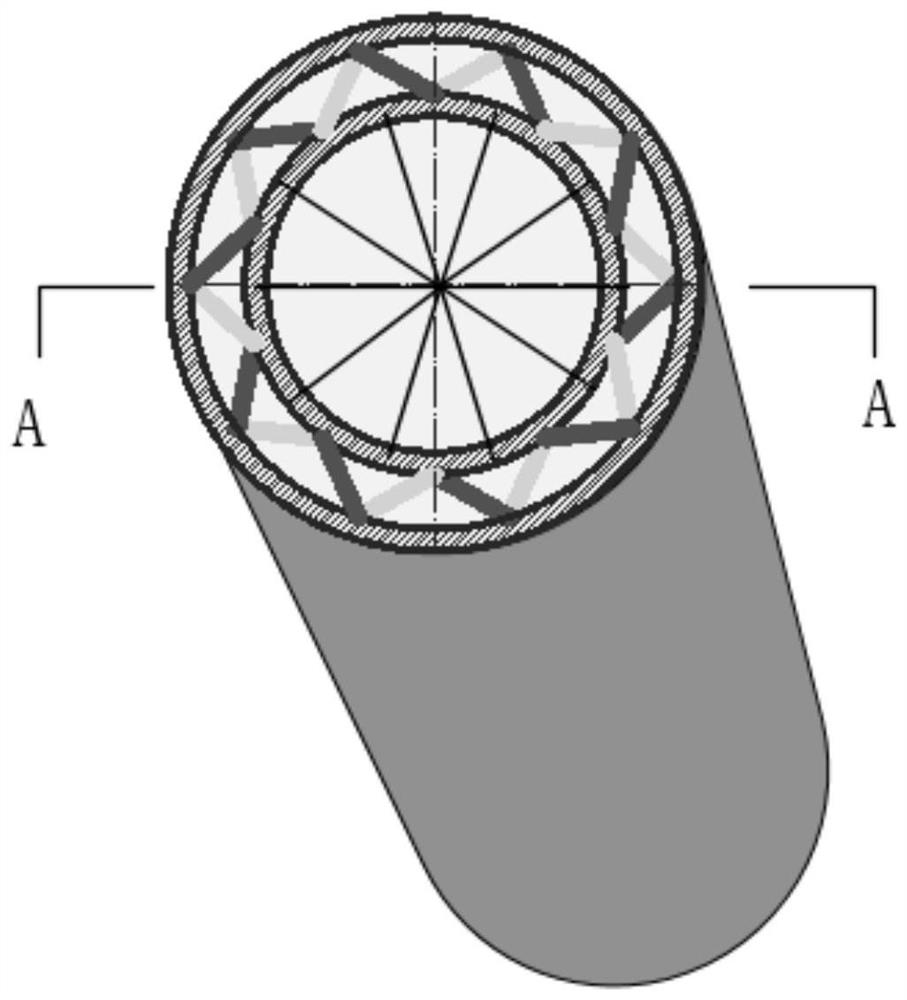

Track structure of magnetic floating traffic and manufacturing method therefor

InactiveCN101063286AImprove safety and reliabilityImprove rigidityRailway tracksDistortionSteel tube

The invention provides a track structure of magnetic floating traffic, comprising a track beam, railroad ties supported and fixed on the track beam via a connecting structure and a track supported and fixed at two sides of the upper surface of the railroad ties, wherein the connecting structure comprises a fixer and a concrete block, the railroad tie is made from hollow square steel tube. The invention also provides a relative production, comprising that preparing the track beam with preformed holes, preparing a track arranger formed by a track and railroad ties, while the railroad tie is made from hollow square steel tube, connecting and fixing the arranger on the track beam via the connecting structure, while the connecting structure comprises a fixer and a concrete block. The invention uses square tubular steel railroad ties to improve the rigidity, distortion resistance, and longitudinal deformation resistance, to improve the safety and reliability of the track, and uses a novel flexible buckle plate to make installment easy and improve vibration proof ability.

Owner:SHANGHAI MAGNETIC SUSPENSION COMM ENG TECH RES CENTE

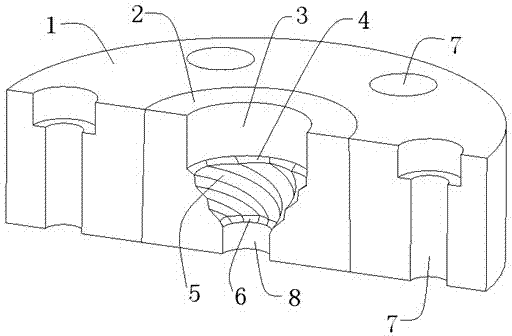

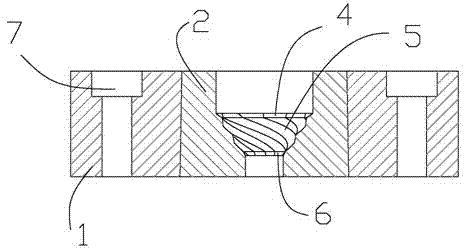

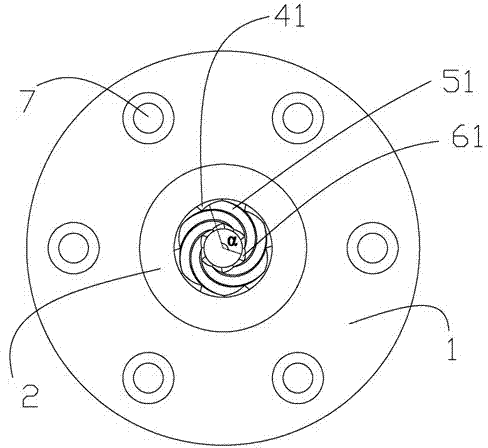

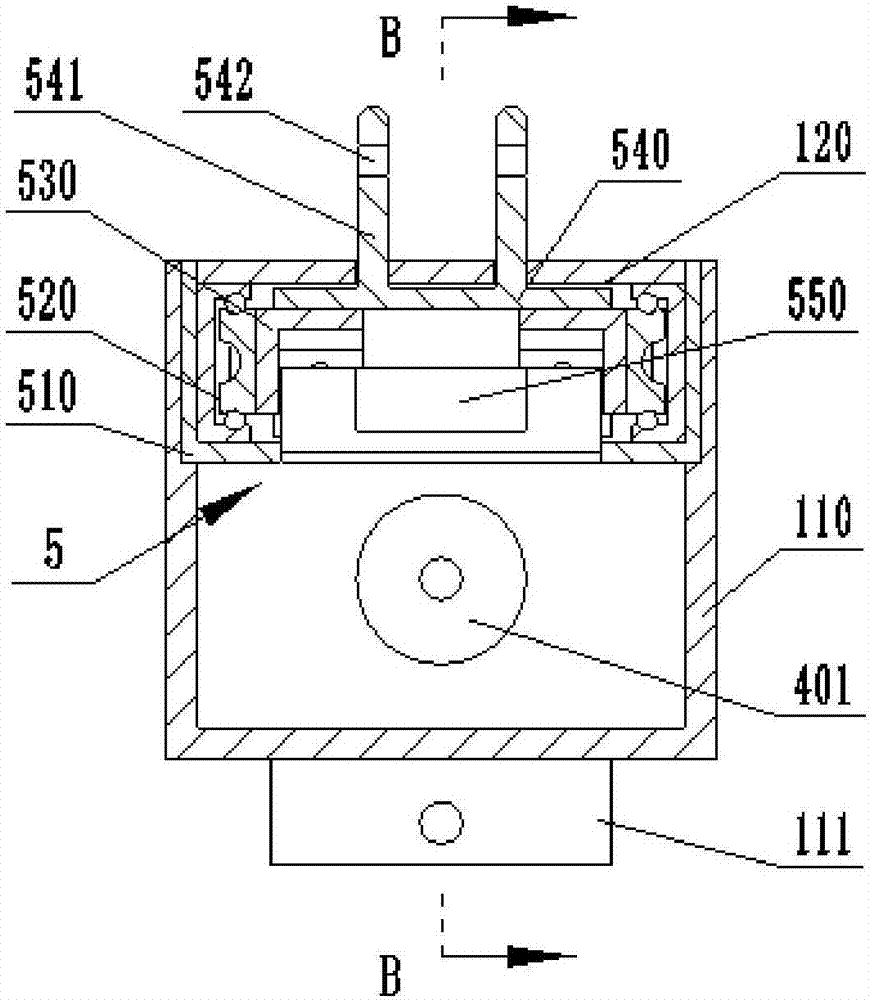

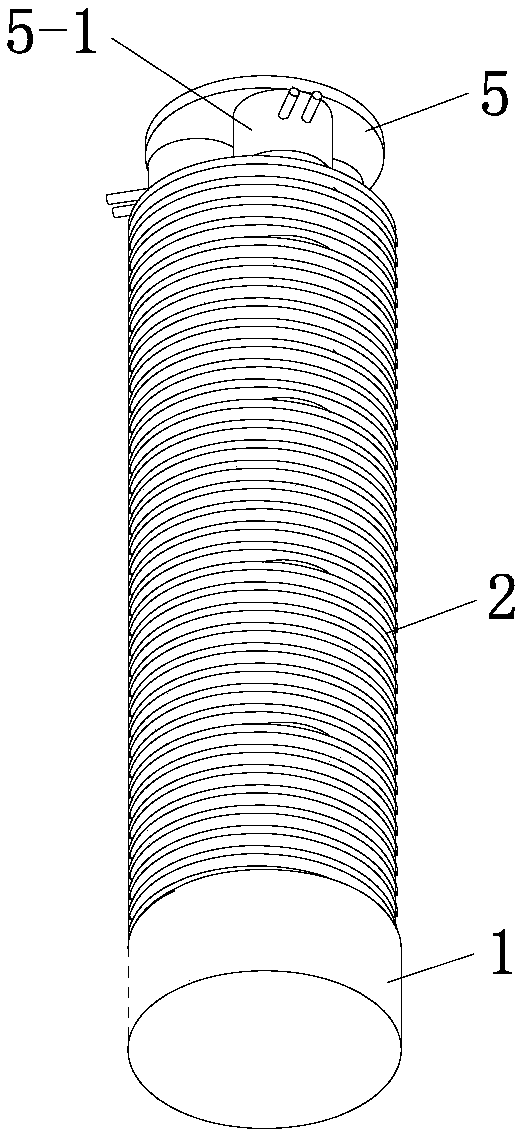

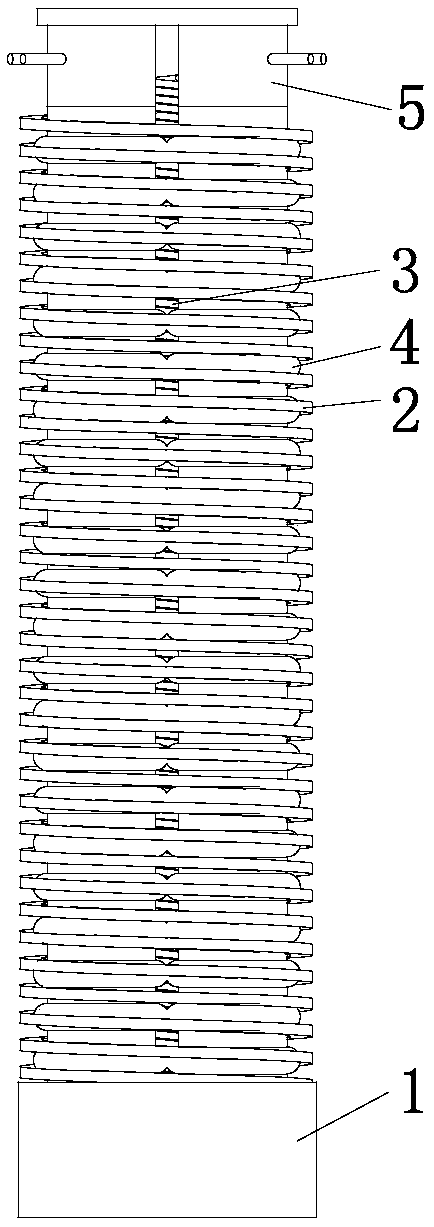

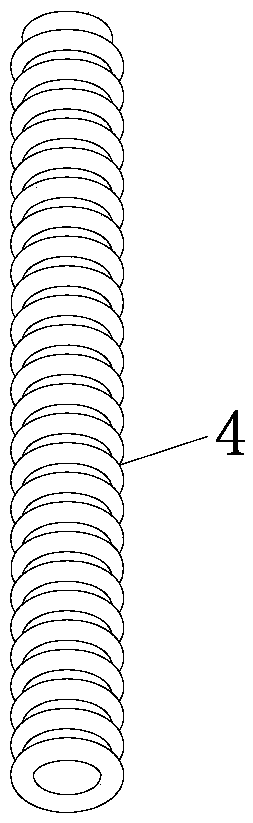

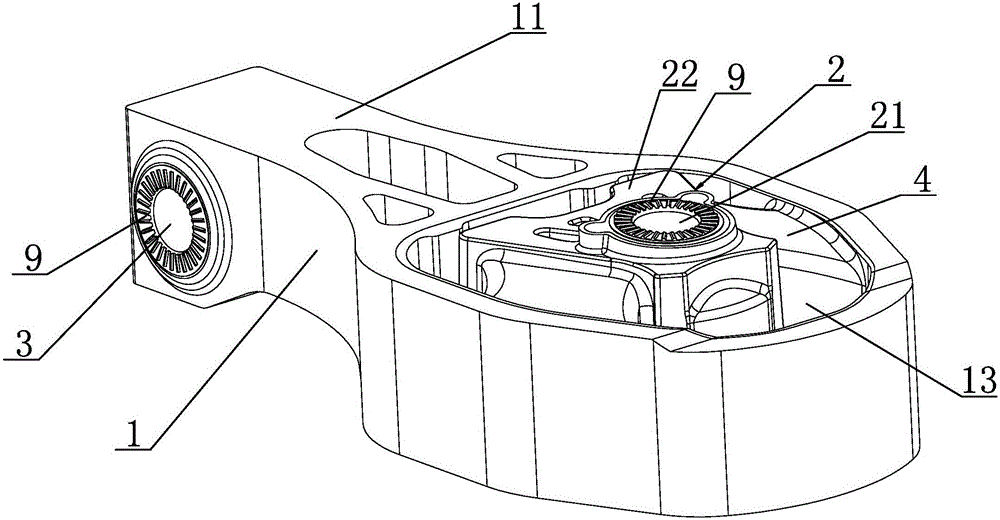

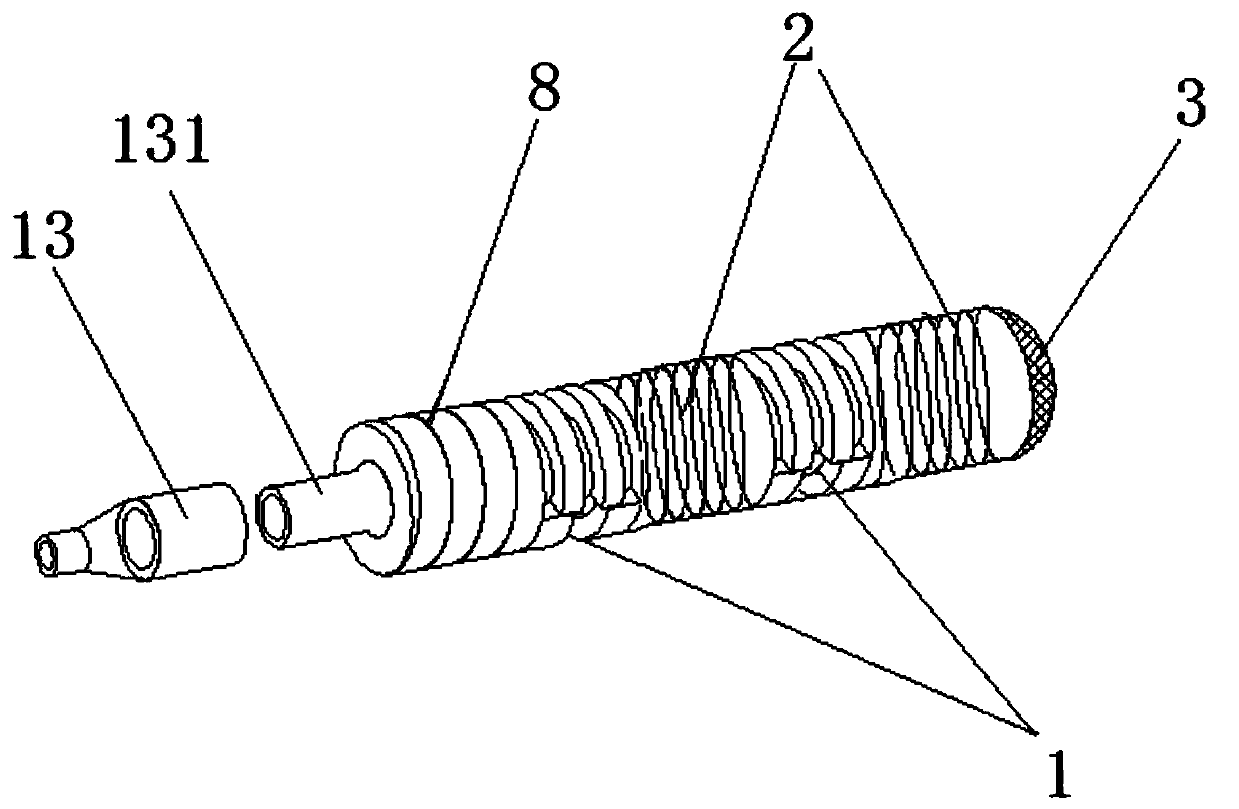

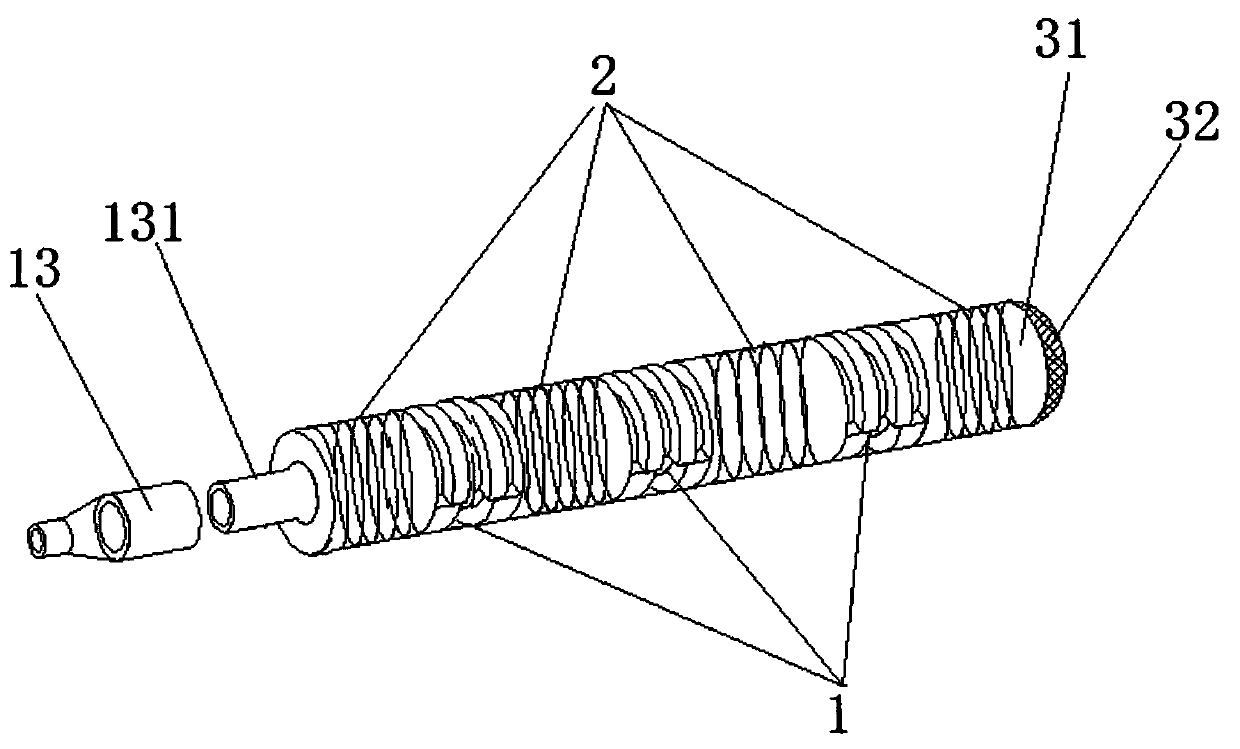

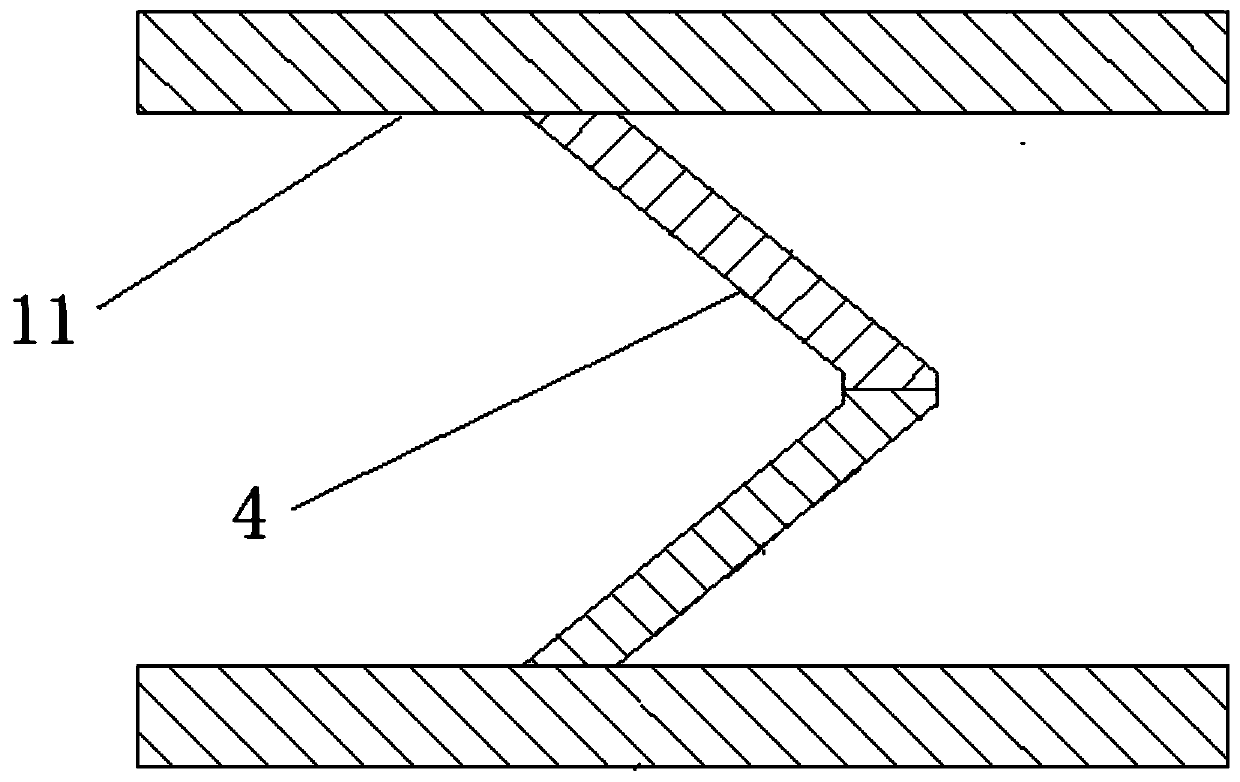

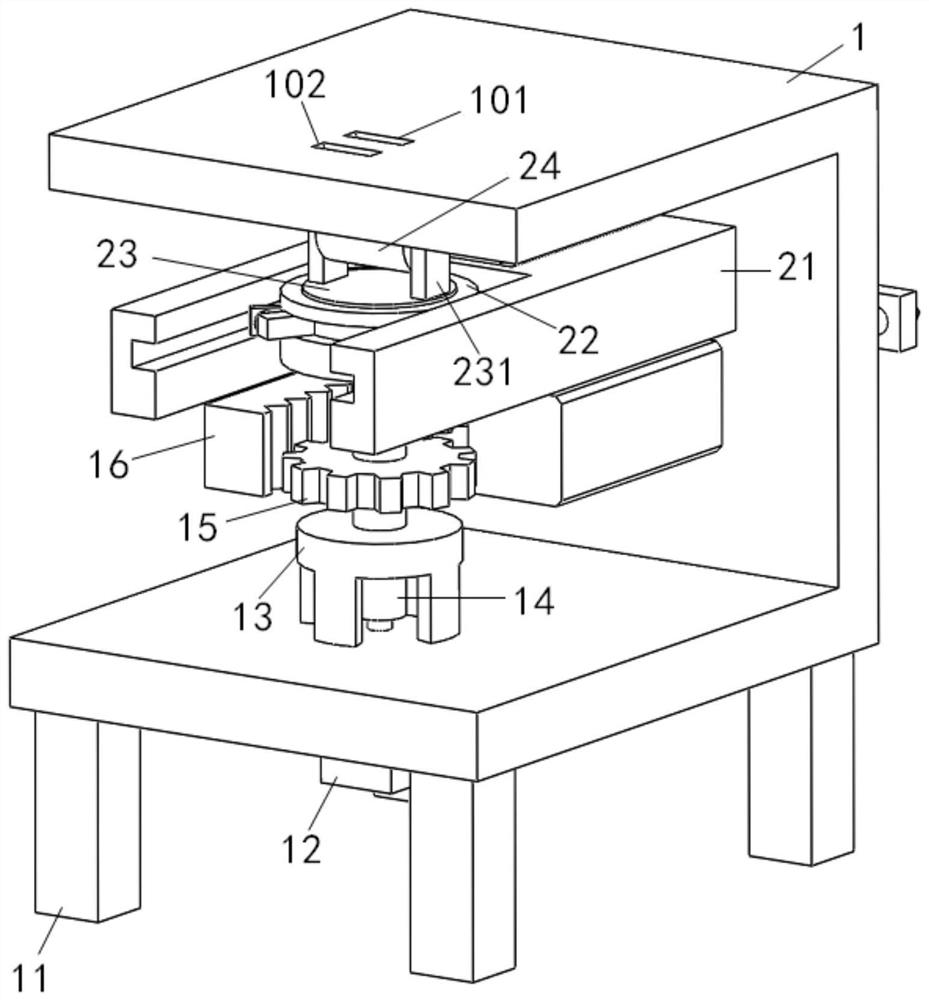

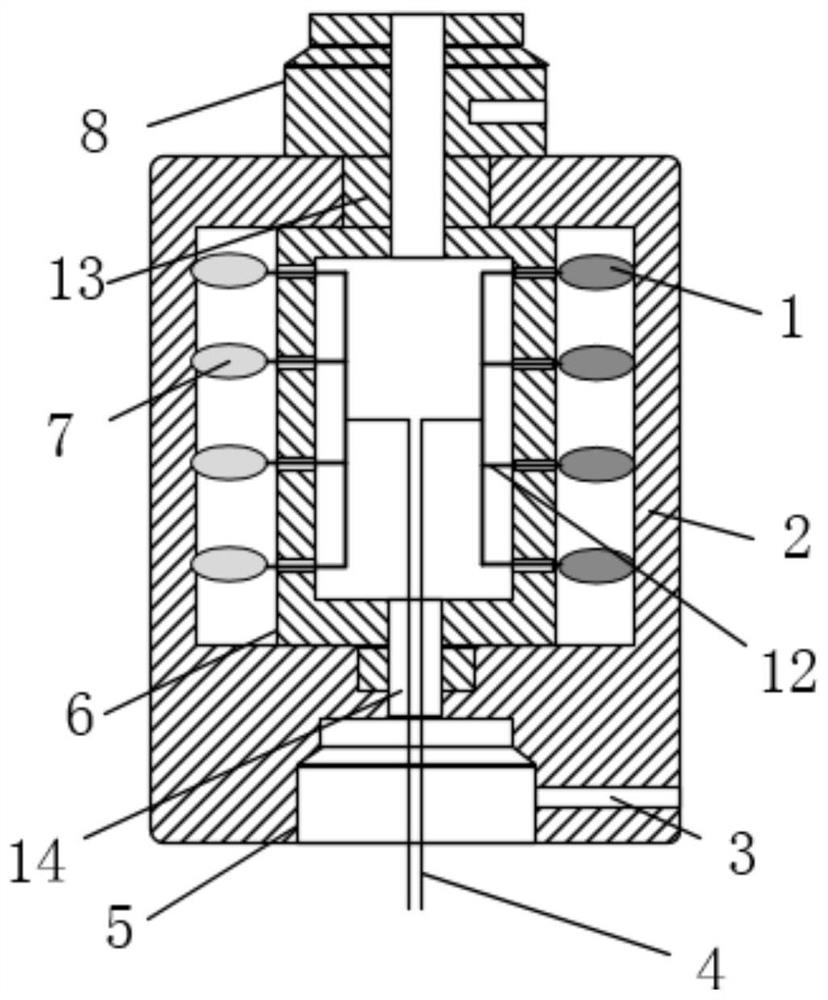

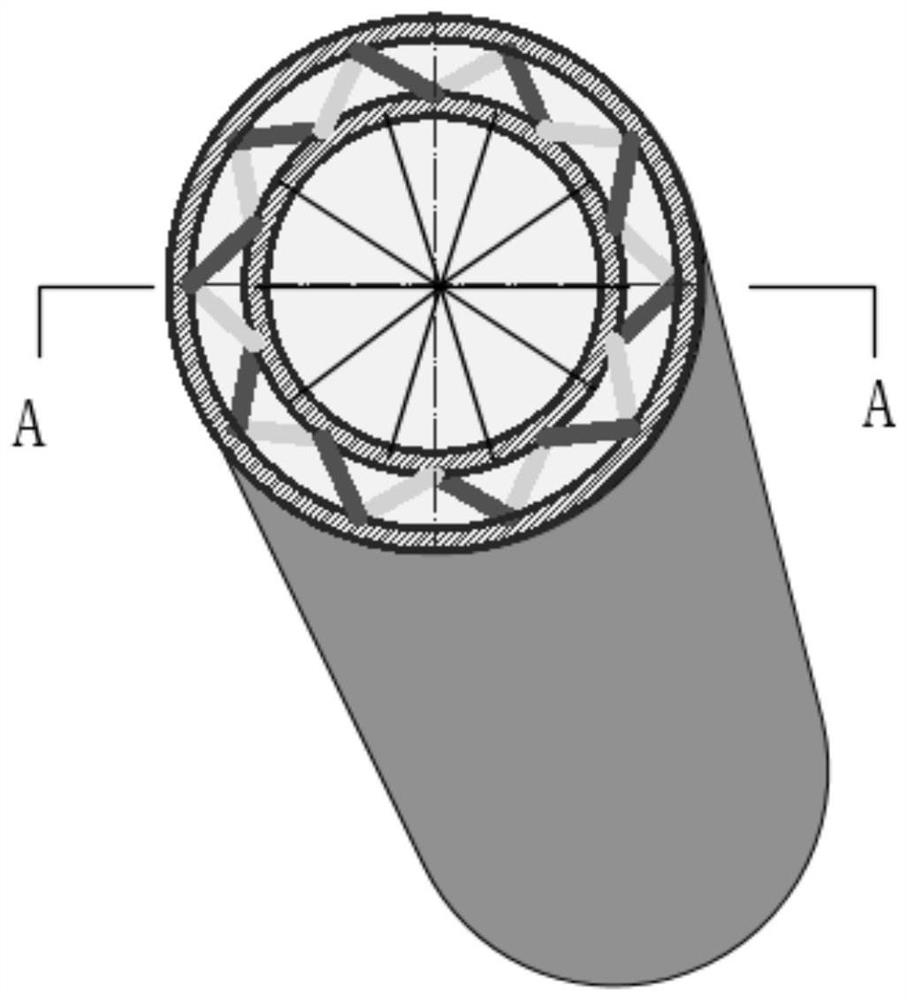

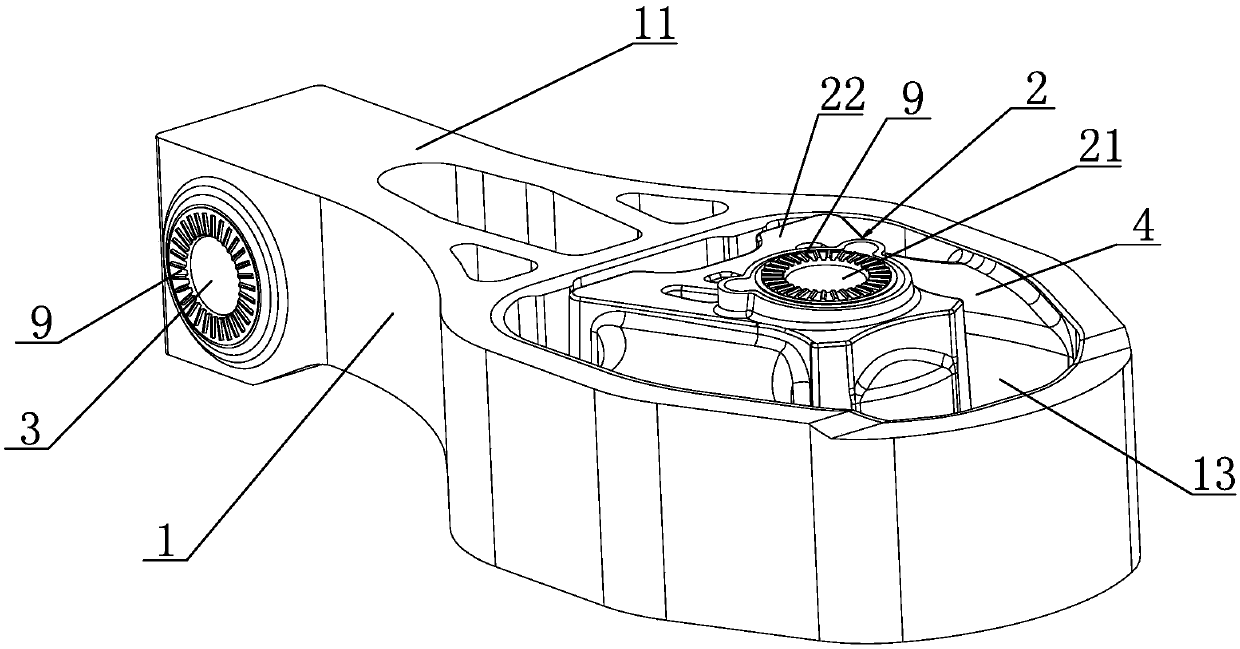

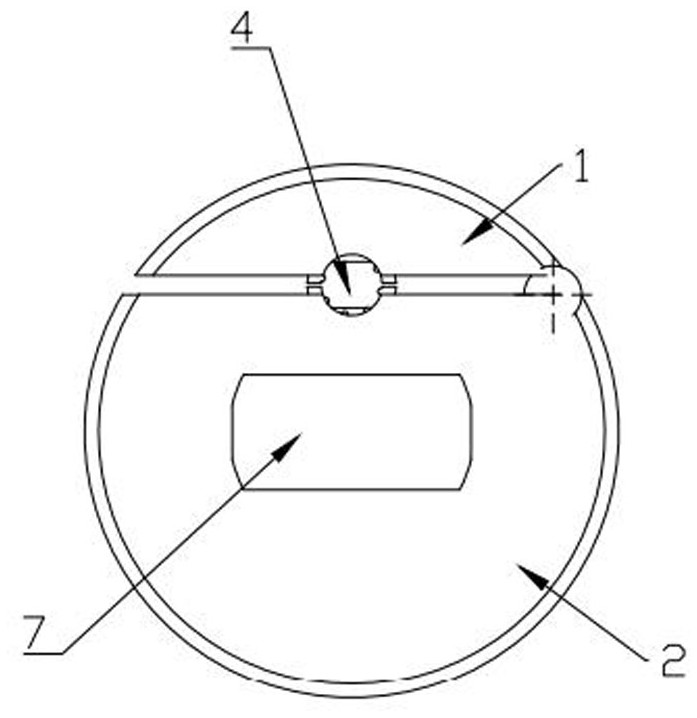

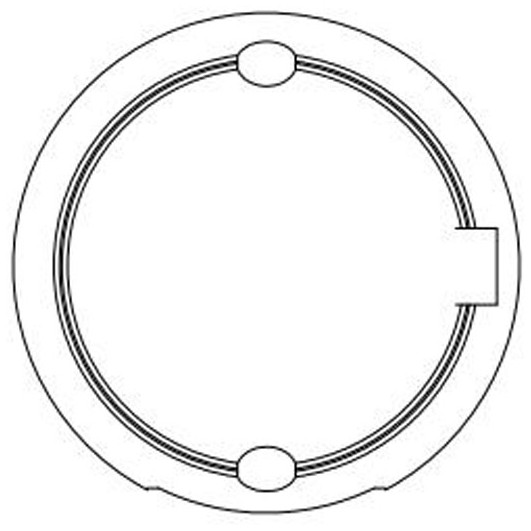

Vortex extrusion type large-plastic deformation device

ActiveCN103785702AIncrease work intensityRealize the twistExtrusion diesExtrusion mandrelsInterference fitExtrusion

The invention discloses a vortex extrusion type large-plastic deformation device which comprises a device main body, wherein the device main body comprises an outer-layer reinforcing ring and an inner-layer concave die in interference fit with the outer-layer reinforcing ring, the inner-layer concave die is provided with a twisting extrusion chamber which is necked from the upper port to the lower port, a twisting extrusion deformation region is formed in the twisting extrusion chamber and comprises a deformation band composed of a plurality of stripe projections or a plurality of stripe grooves, the upper end portions of the stripe projections or the stripe grooves are capable of extending to the upper port of the twisting extrusion chamber, and the lower end portions of the stripe projections or the stripe grooves are capable of extending to the lower port of the twisting extrusion chamber. The vortex extrusion type large-plastic deformation device integrates twisting and extrusion techniques, so that the device is capable of realizing twisting of a material without rotating the die with an extra device and capable of achieving the same effect only through structural design; besides, the device is capable of preventing sliding between the material and the die while twisting; moreover, the device is simple and convenient in design.

Owner:HEFEI UNIV OF TECH

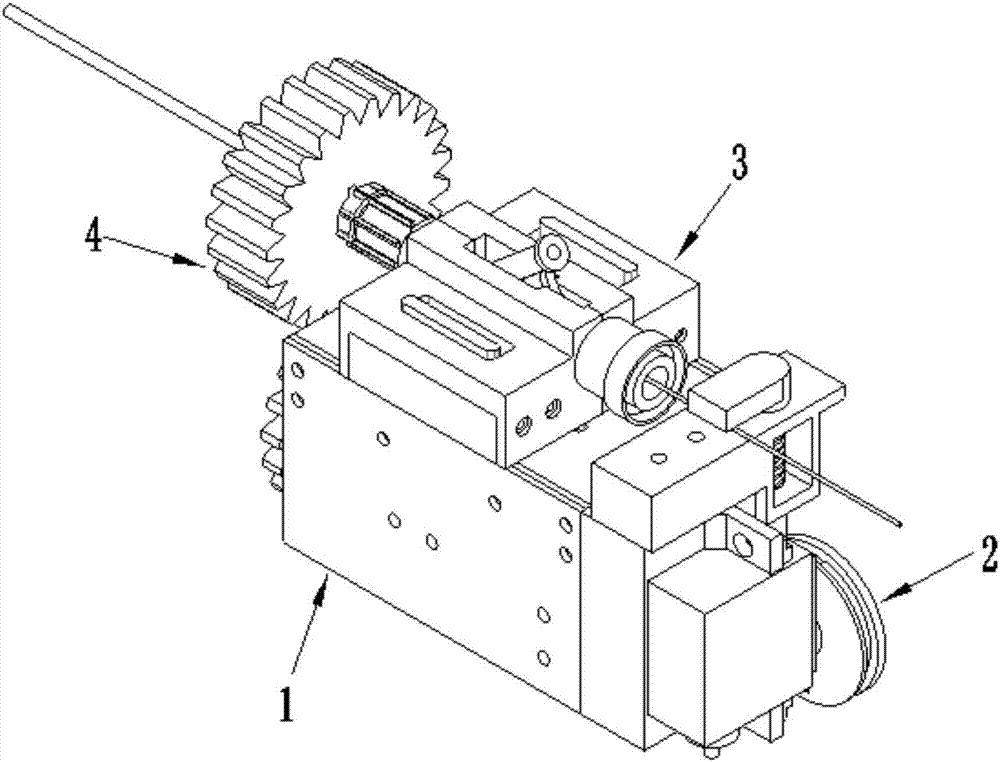

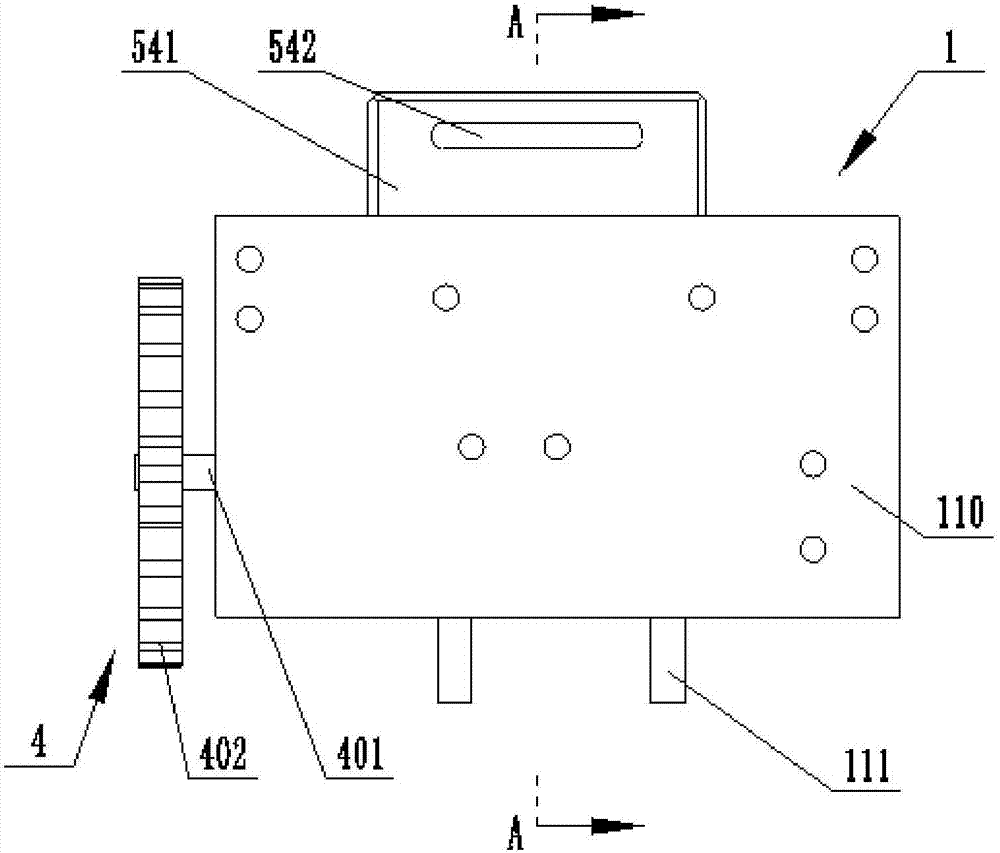

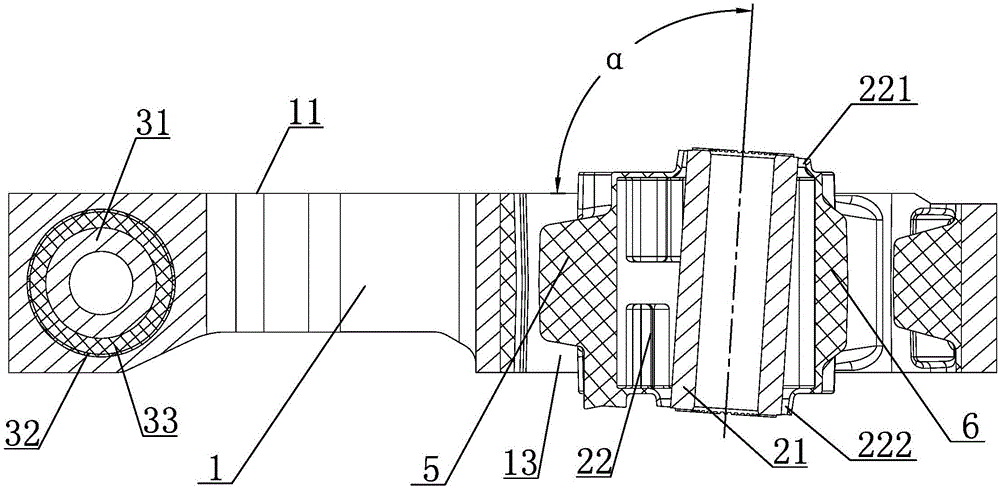

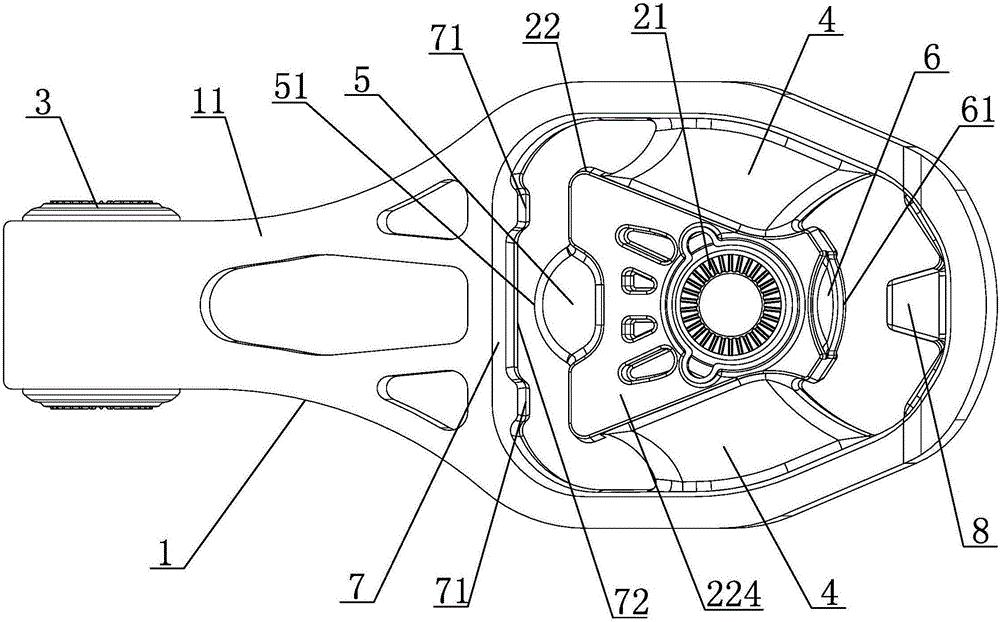

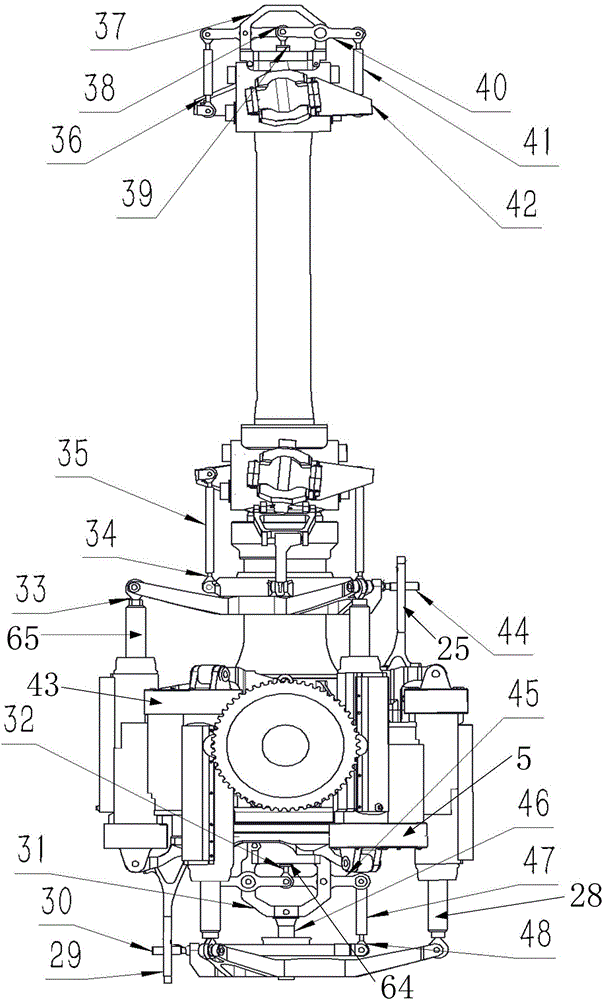

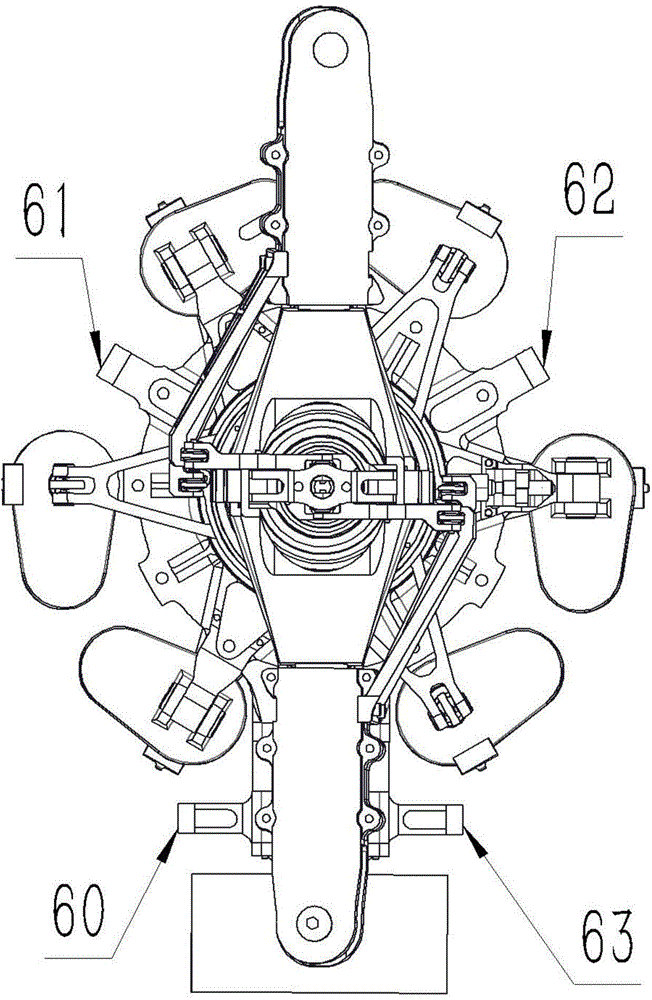

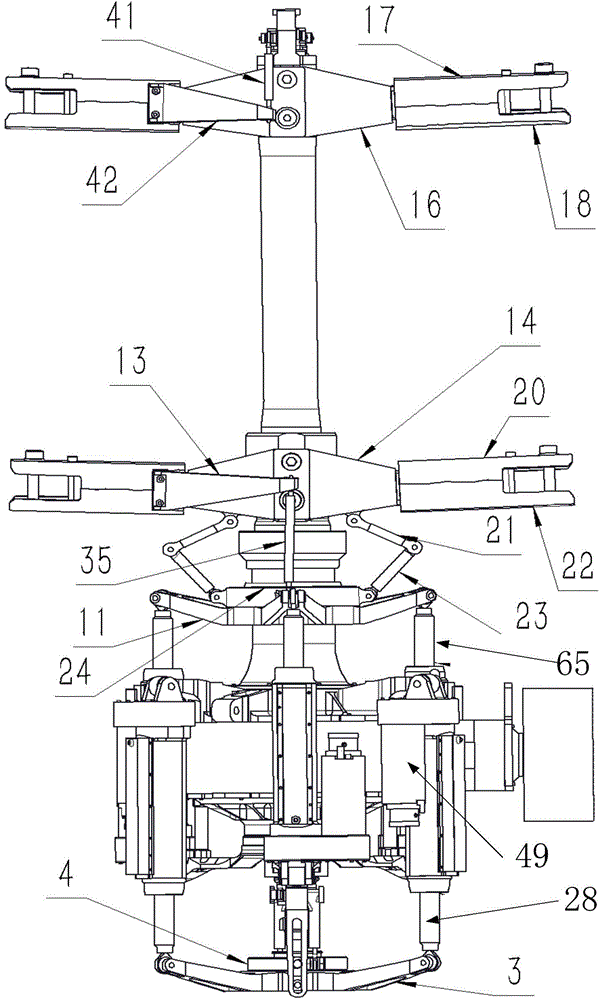

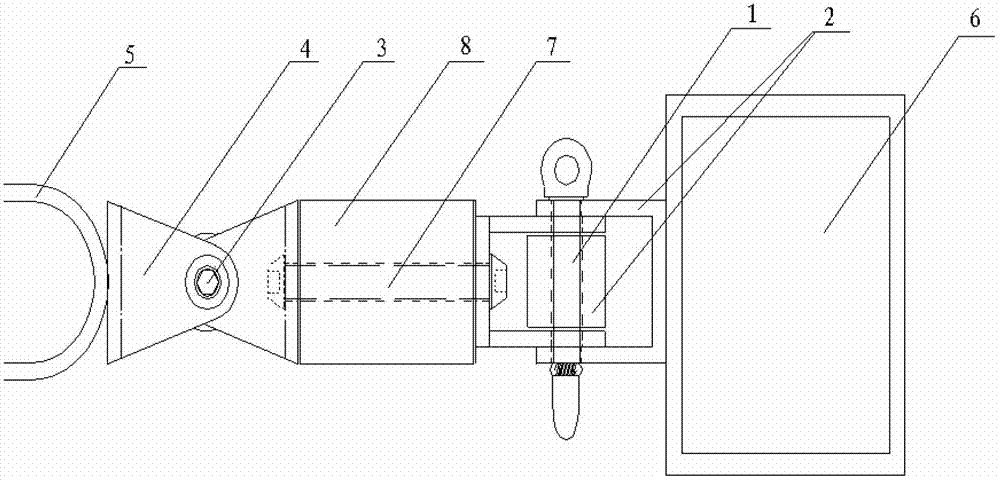

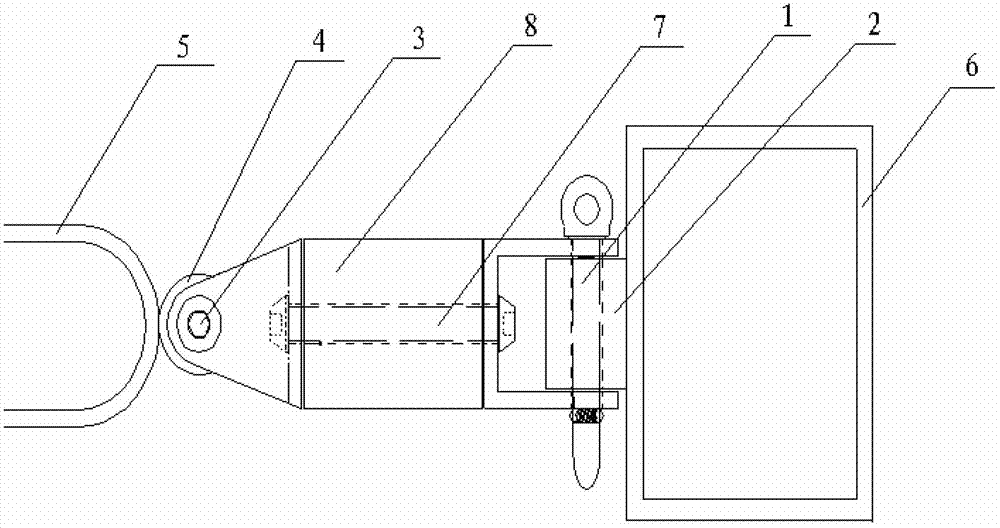

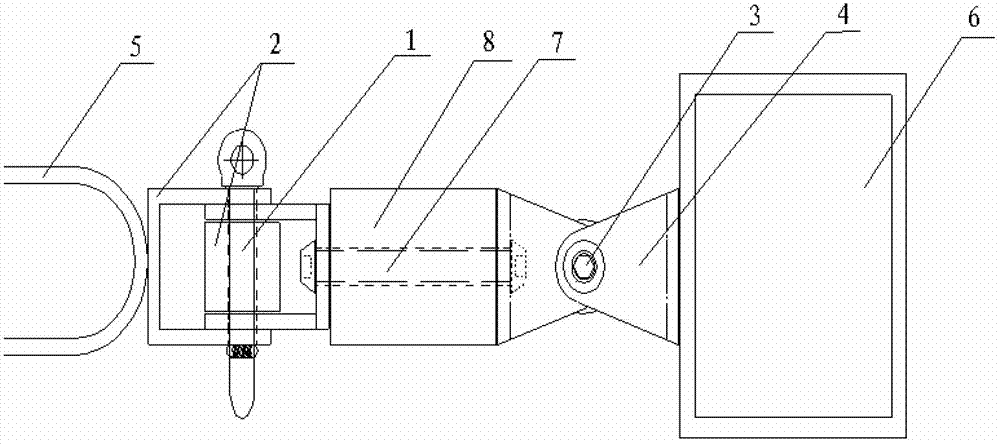

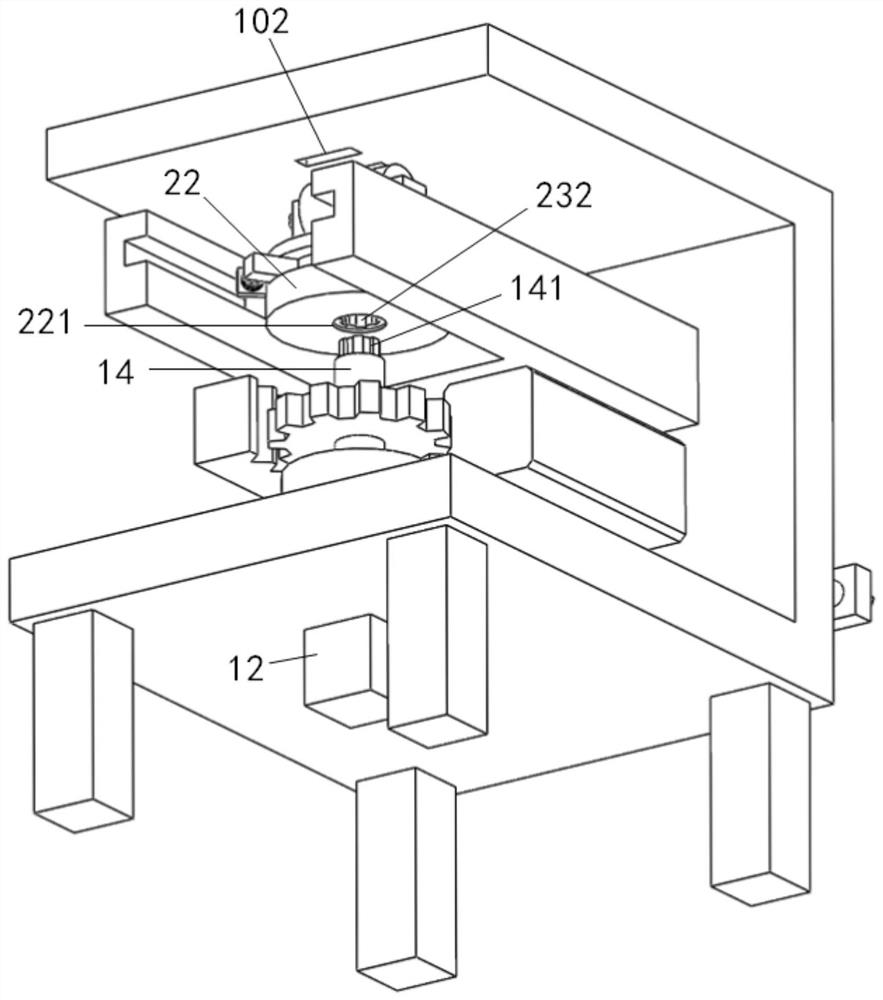

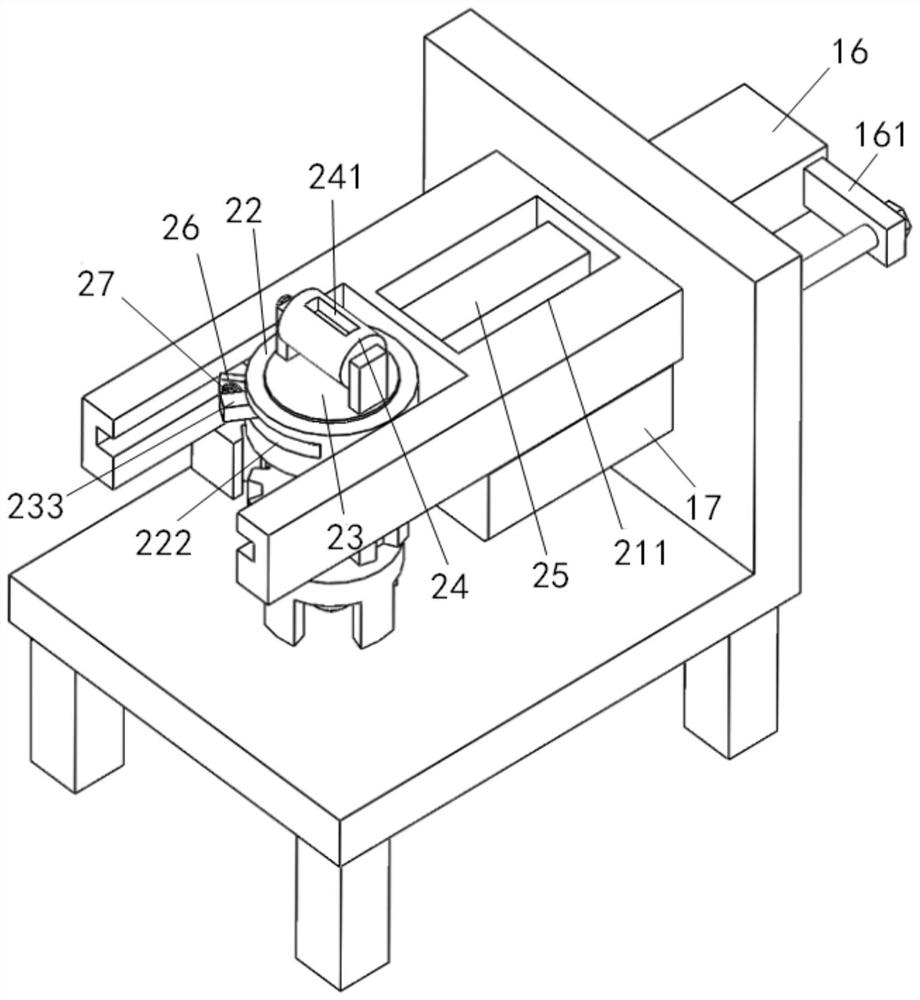

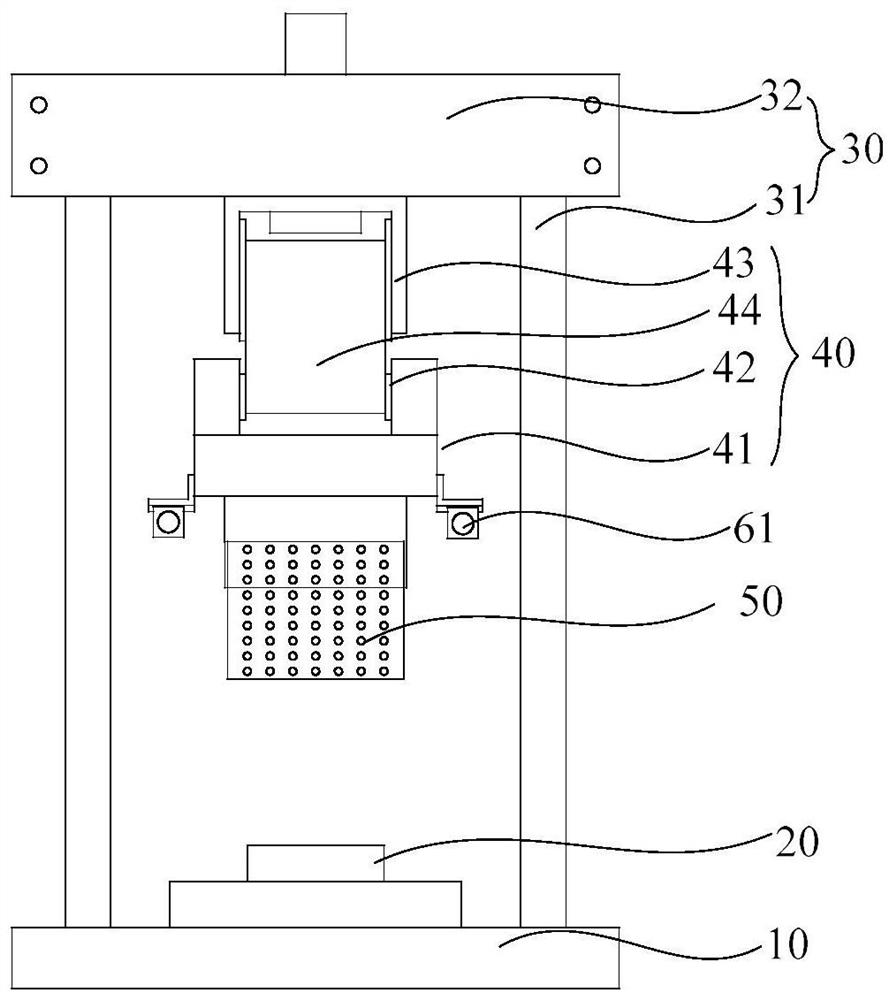

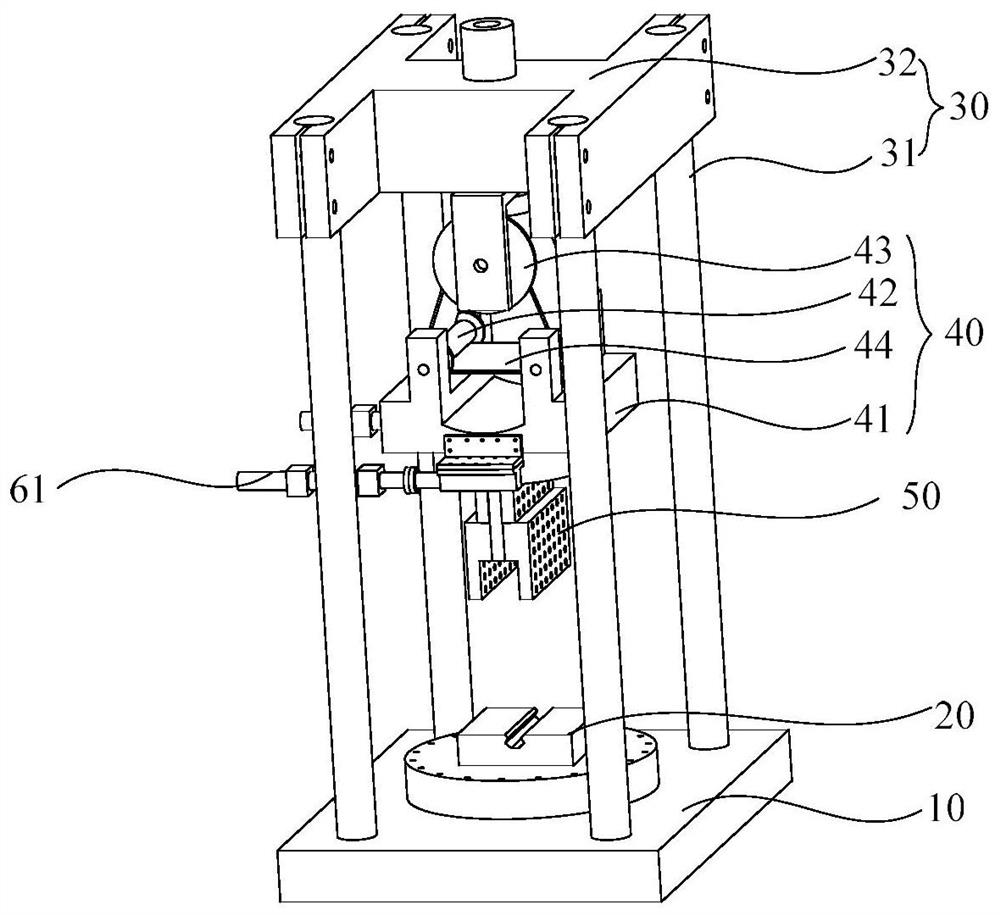

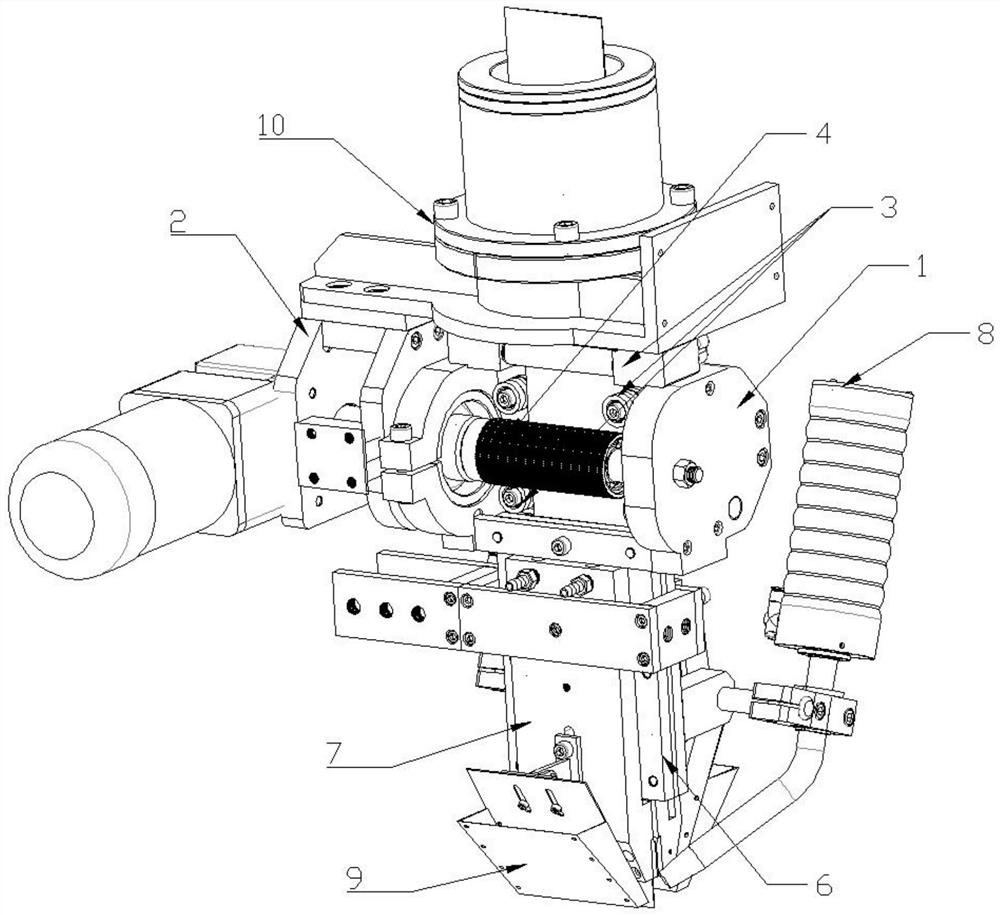

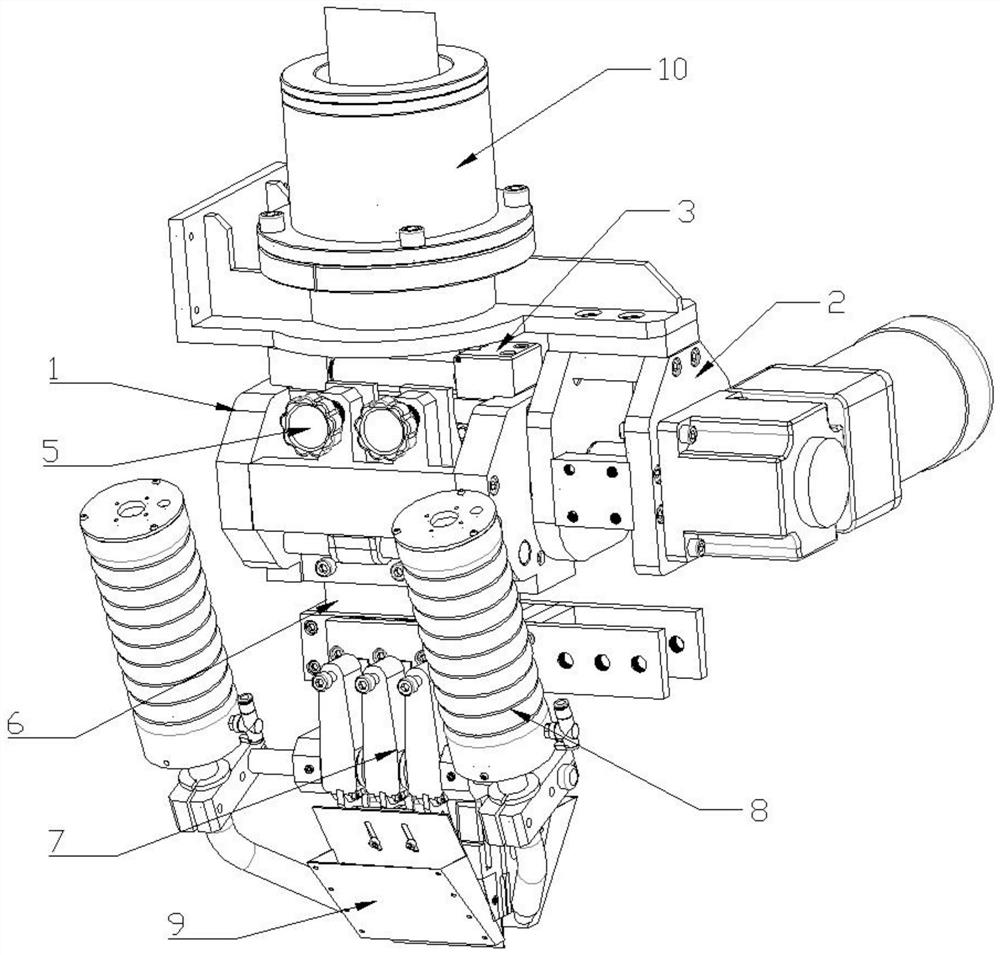

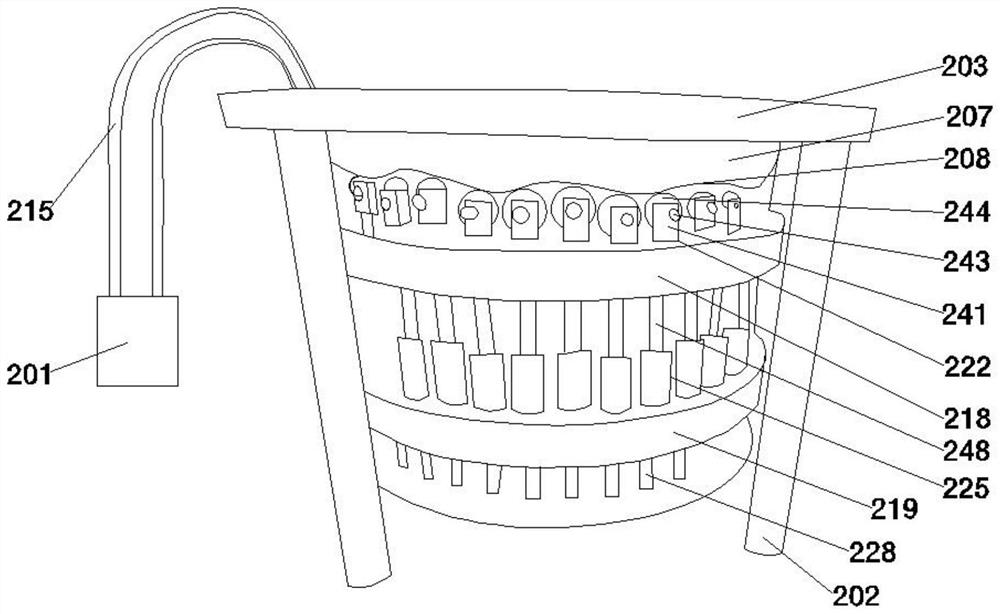

Interventional surgical robot subordinate end device and control method thereof

The invention discloses an interventional surgical robot subordinate end device and a control method thereof and belongs to the technical field of minimally invasive blood vessel interventional operations. The device comprises a main body, a catheter clamp holder, a guide wire clamp holder, a torsional component and a force measurement component; the catheter clamp holder is used for clamping catheters, the guide wire clamp holder is used for tightly clamping or loosening guide wires, and the catheter clamp holder and the guide wire clamp holder are both detachably mounted on the main body; the catheter clamp holder comprises a medical three-way valve and a clamping component, and the medical three-way valve is used for connecting the catheters and is fixed to the main body through the clamping component; the torsional component is used for driving a screw cap of the medical three-way valve to drive the catheters to rotate; the force measurement component is used for detecting push force of the catheters. The subordinate end device can clamp the catheters and tightly clamp or loosen the guide wires, achieves co-operating operation of the catheters and the guide wires, and is simple in structure and convenient to disassemble and assemble. According to the control method, the subordinate end device is controlled so that clamping, pushing, torsion and force measurement of the catheters and clamping of the guide wires can be completed, and accordingly co-operating of the catheters and the guide wires is achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

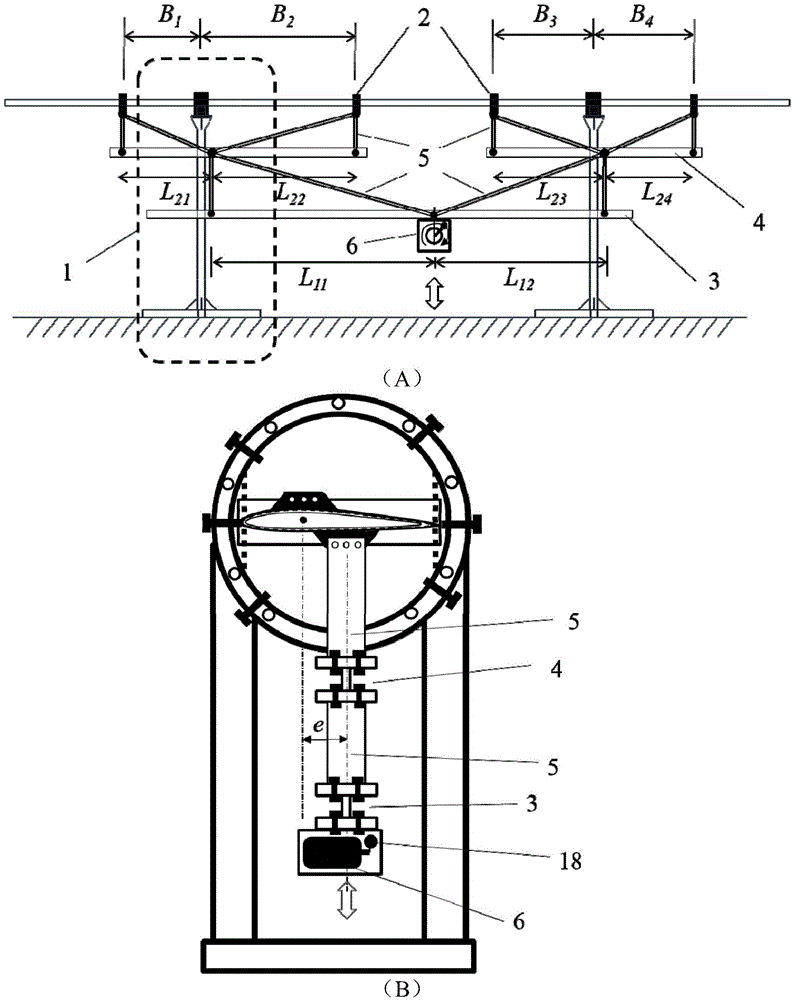

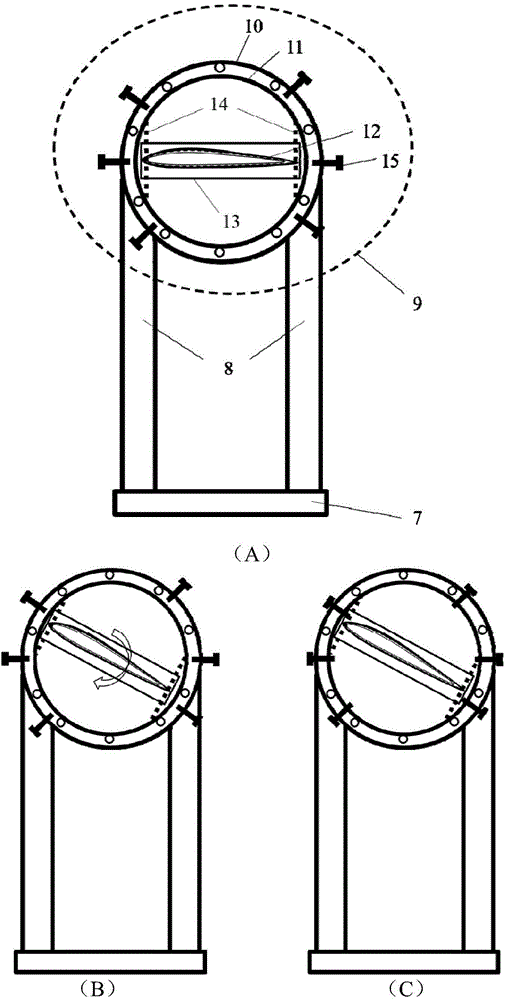

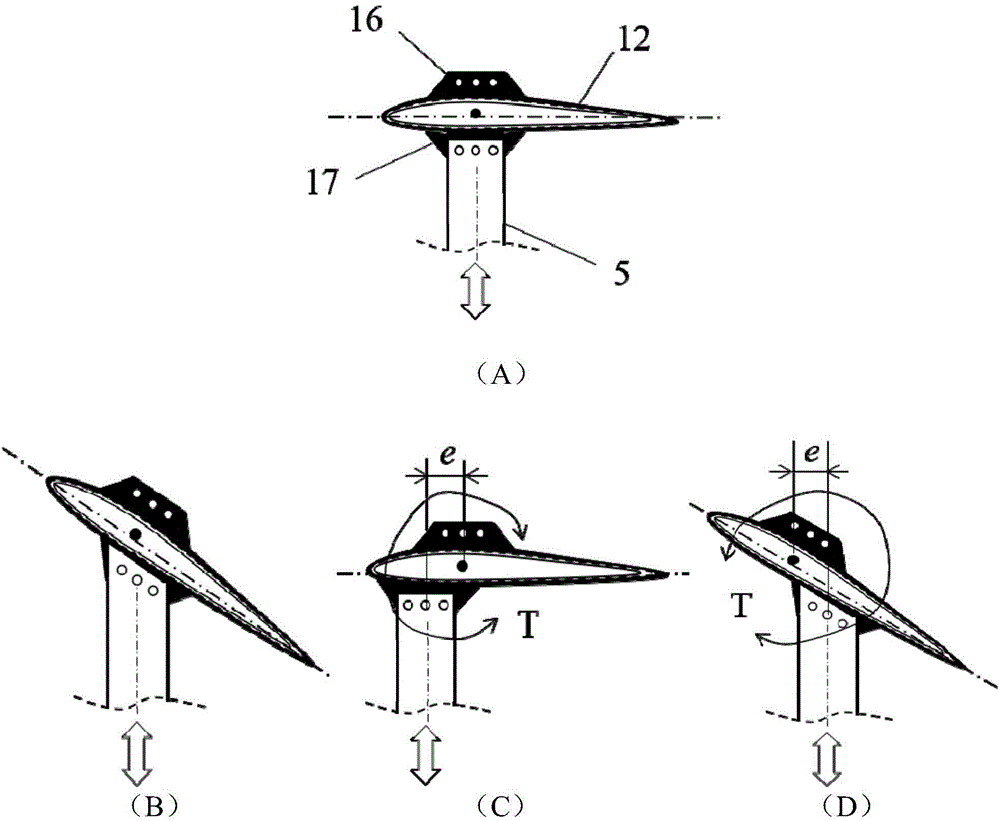

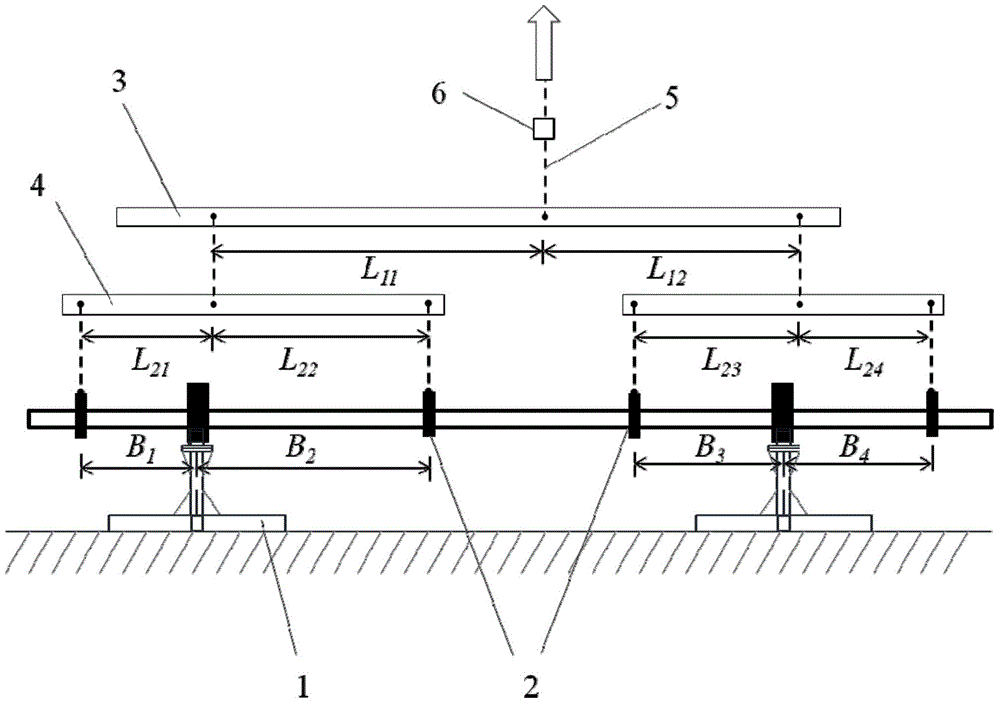

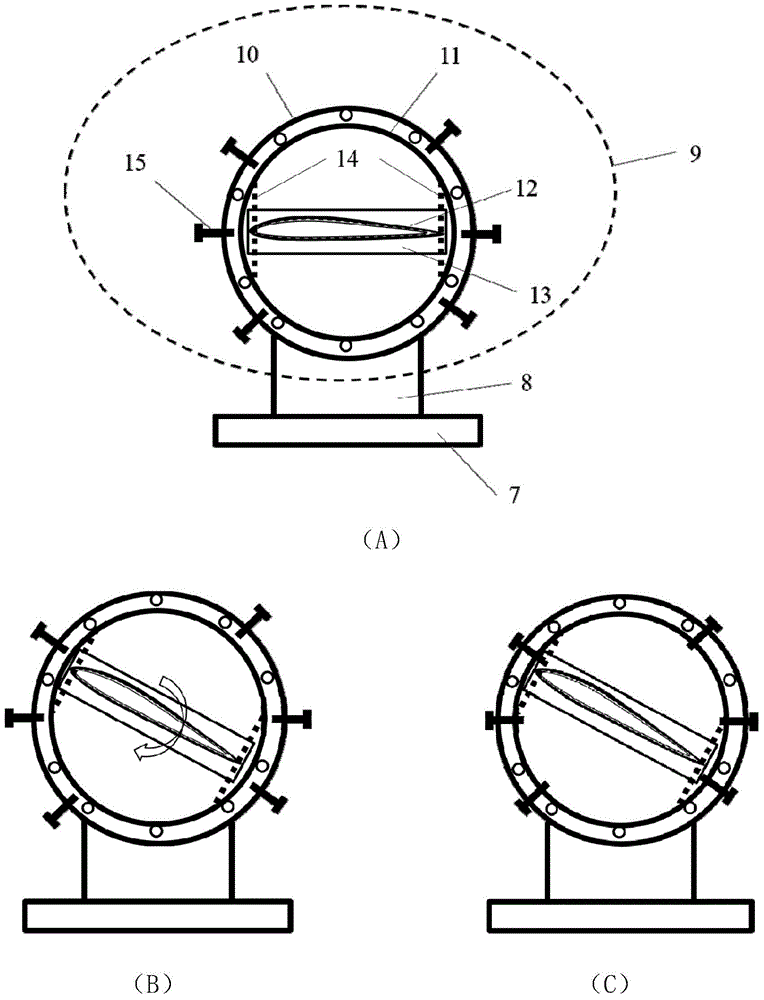

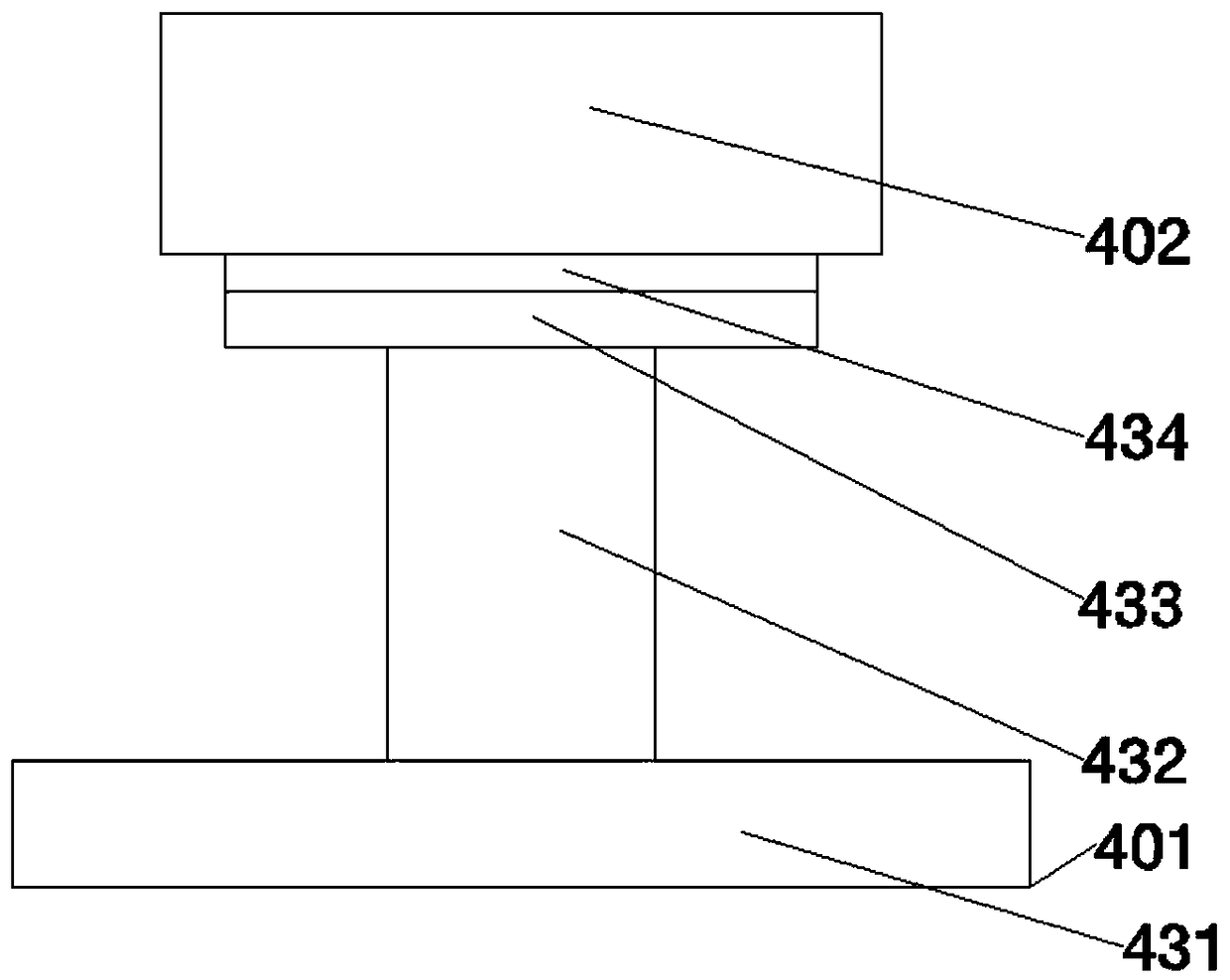

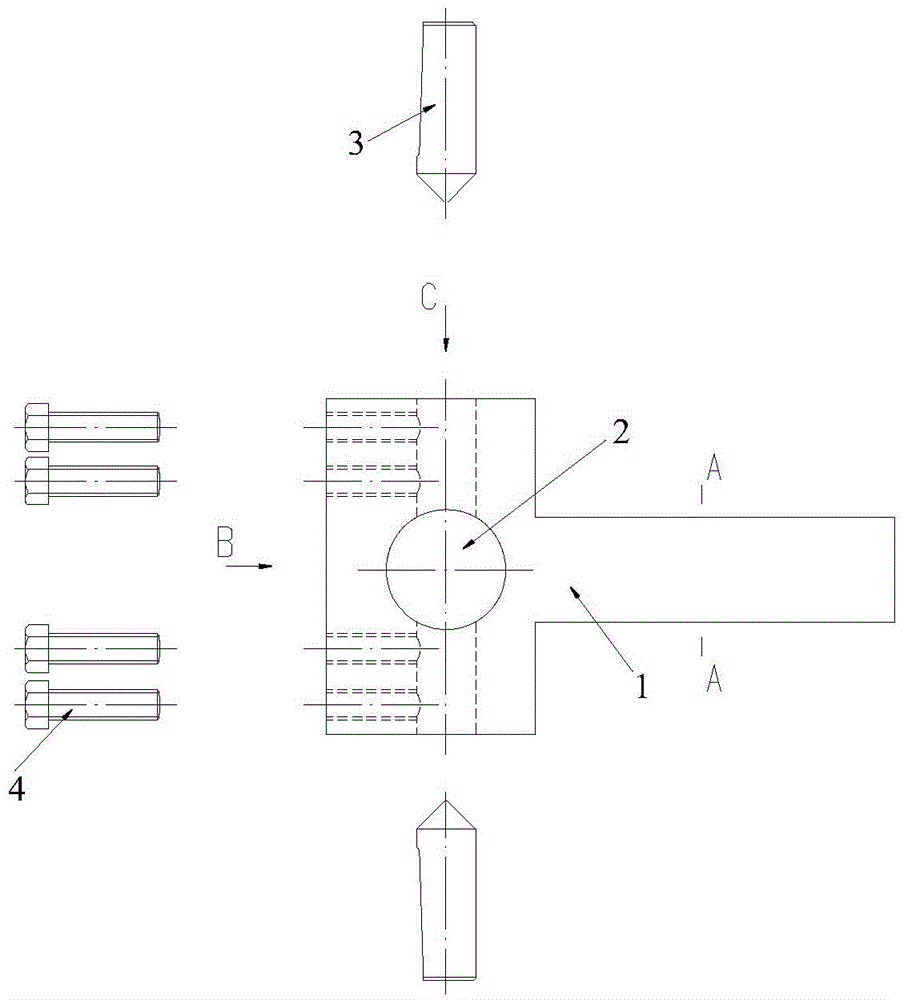

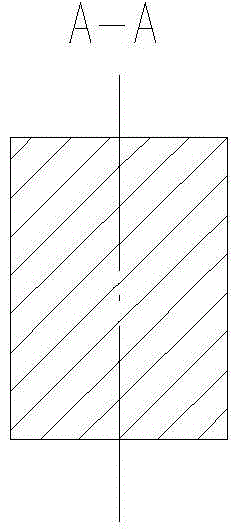

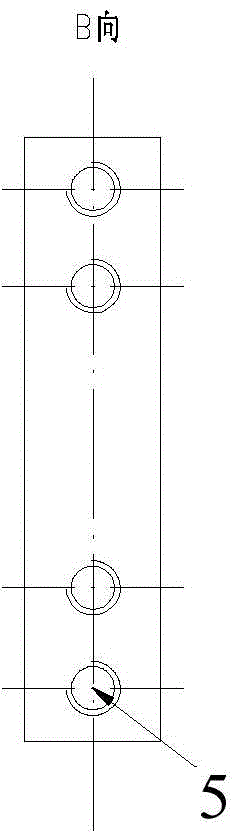

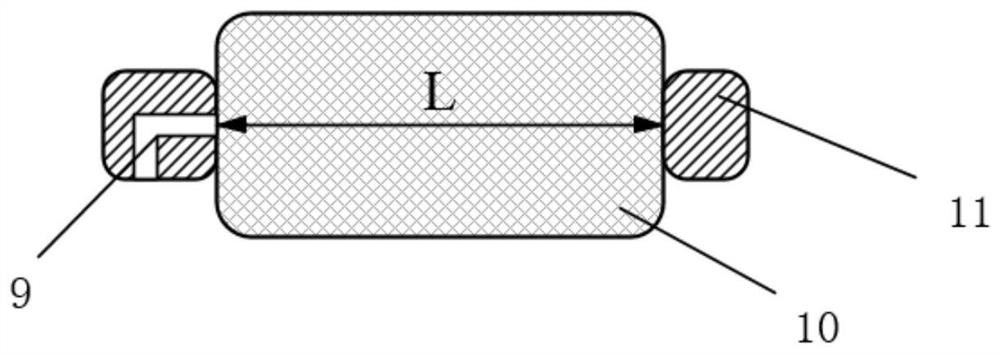

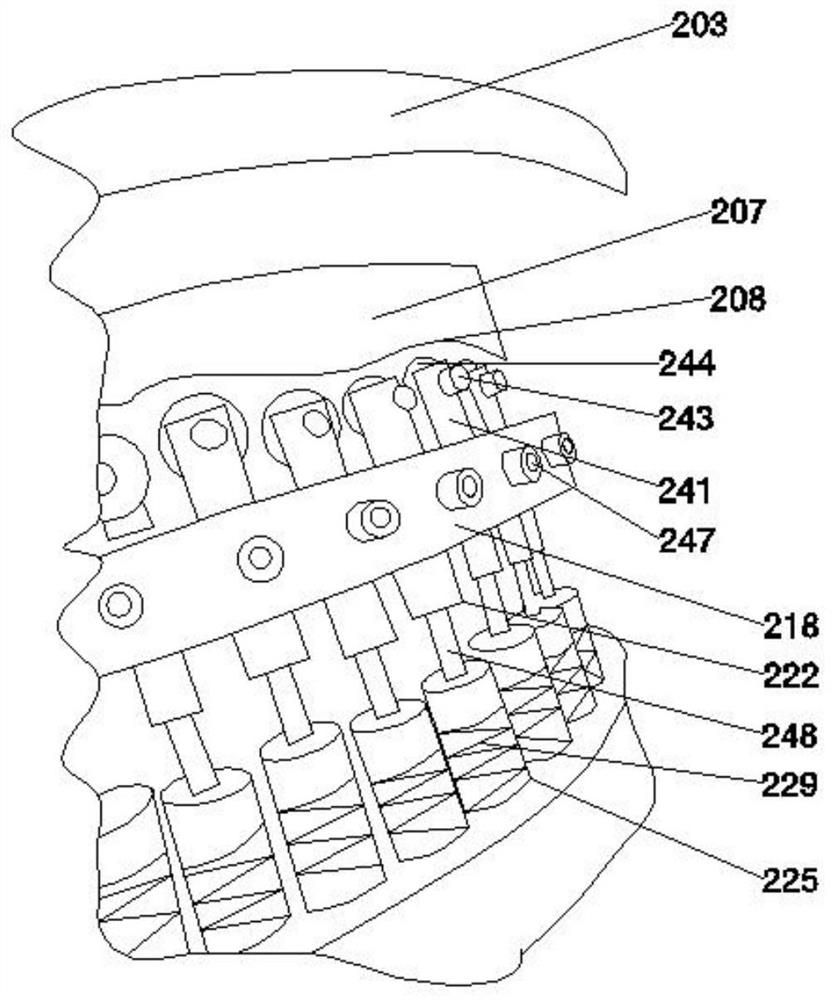

Device and method for testing structural fatigue of H-shaped vertical shaft wind turbine blade

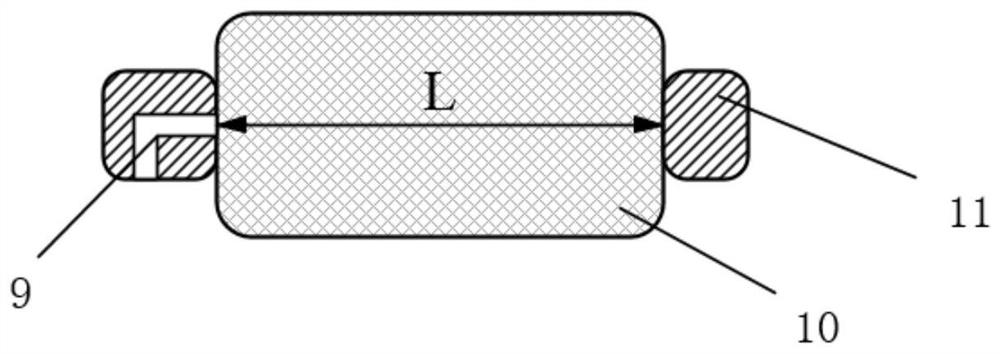

ActiveCN104792516ATo reverse the realizationEvaluate fatigue structural performanceMachine part testingFatigue loadingStructural fatigue

The invention relates to a device and a method for testing the structural fatigue of an H-shaped vertical shaft wind turbine blade. The device comprises a support base component, a distribution beam, a loading hoop, a support connecting rod and an eccentric motor, wherein the distribution beam, the loading hoop and the support connecting rod are connected together by using bolts so as to form a whole load distribution system, so that the fatigue load which acts in an upper and lower reciprocation manner can be effectively conducted. When the device is used for experiment, the fatigue bending moment distribution of the blade under various working conditions can be simulated by adjusting the length L of the distribution beam and the position B of the loading hoop, and the fatigue stress state of the blade in axial torsion and multiple attack angles can be simulated by adjusting the structural modes of the support base component and the loading hoop; the strain distribution of the blade under the fatigue loaded condition can be measured, and furthermore, the fatigue structural property of the blade can be evaluated; by only exerting one external fatigue load to the device, combined fatigue loading modes such as bending, torsion and multiple attack angles of the blade can be achieved, and the device is simple and convenient to operate, accurate and reliable in result and relatively high in universality.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

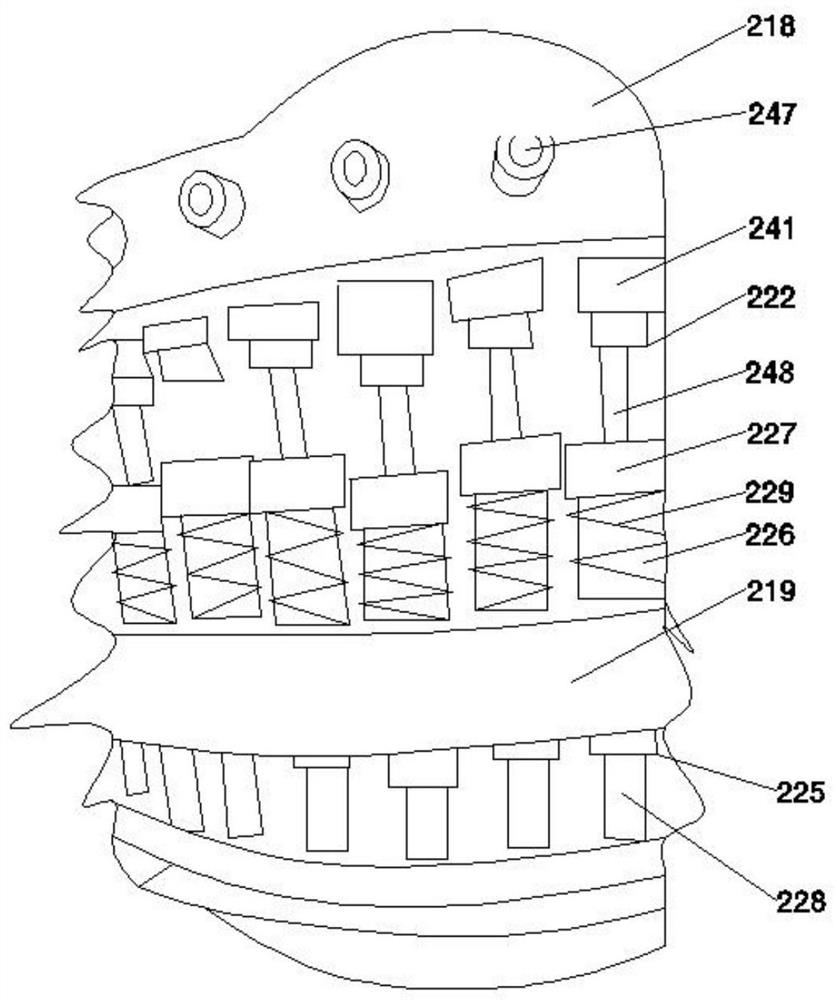

H-shaped vertical axis wind turbine blade static force structure test device and method

ActiveCN104807630AEasy to operateThe result is accurate and reliableMachine part testingBending momentStatic force

The invention relates to an H-shaped vertical axis wind turbine blade static force structure test device and a method. The device comprises a supporting seat component, a loading hoop, a distribution beam, a connecting component, a force sensor, a displacement sensor and a strain gauge. During a test, the length L of the distribution beam is adjusted and the position B of the loading hoop is loaded, so the actual bending moment distribution of a blade under various work conditions can be simulated; the supporting seat component is adjusted and the structural form of the loading hoop is loaded, so the stress state of the blade under axial torque and multiple angles of attack can be simulated. The deformation and the strain distribution of the blade under a loading condition can be measured, so that the structural performance of the blade can be assessed. The invention applies an external load to the device, the combined loading forms of bending, torqueing and having multiple angles of attack of the blade can be realized, the operation is simple and convenient, the result is accurate and reliable, and the universality is stronger.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Wearable flexible auxiliary operating arm

ActiveCN108673471AAchieve elongationAchieve shorteningProgramme-controlled manipulatorEngineeringGas chamber

The invention discloses a wearable flexible auxiliary operating arm, and relates to a flexible operating arm. The wearable flexible auxiliary operating arm comprises a gas chamber cover, a base, an inner spring and three flexible inflatable gas tubes, wherein each flexible inflatable gas tube is a guide tube which is sealed in one end and is open in the other end; the inner spring is arranged on the middle part of the base; the three flexible inflatable gas tubes are arranged in the peripheral direction of the spring; the sealed ends of the flexible inflatable gas tubes abut against the base;a gas chamber which is matched with the flexible inflatable gas tubes is arranged on the gas chamber cover; opening ends of the flexible inflatable gas tubes are fixedly arranged in the gas chamber; and a gas inlet and a gas outlet are formed in the gas chamber. The wearable flexible auxiliary operating arm is flexible in structure, can realize various motion forms, has very good convenience, is convenient to expand, and can be applied to different occasions according to the needs.

Owner:HARBIN INST OF TECH

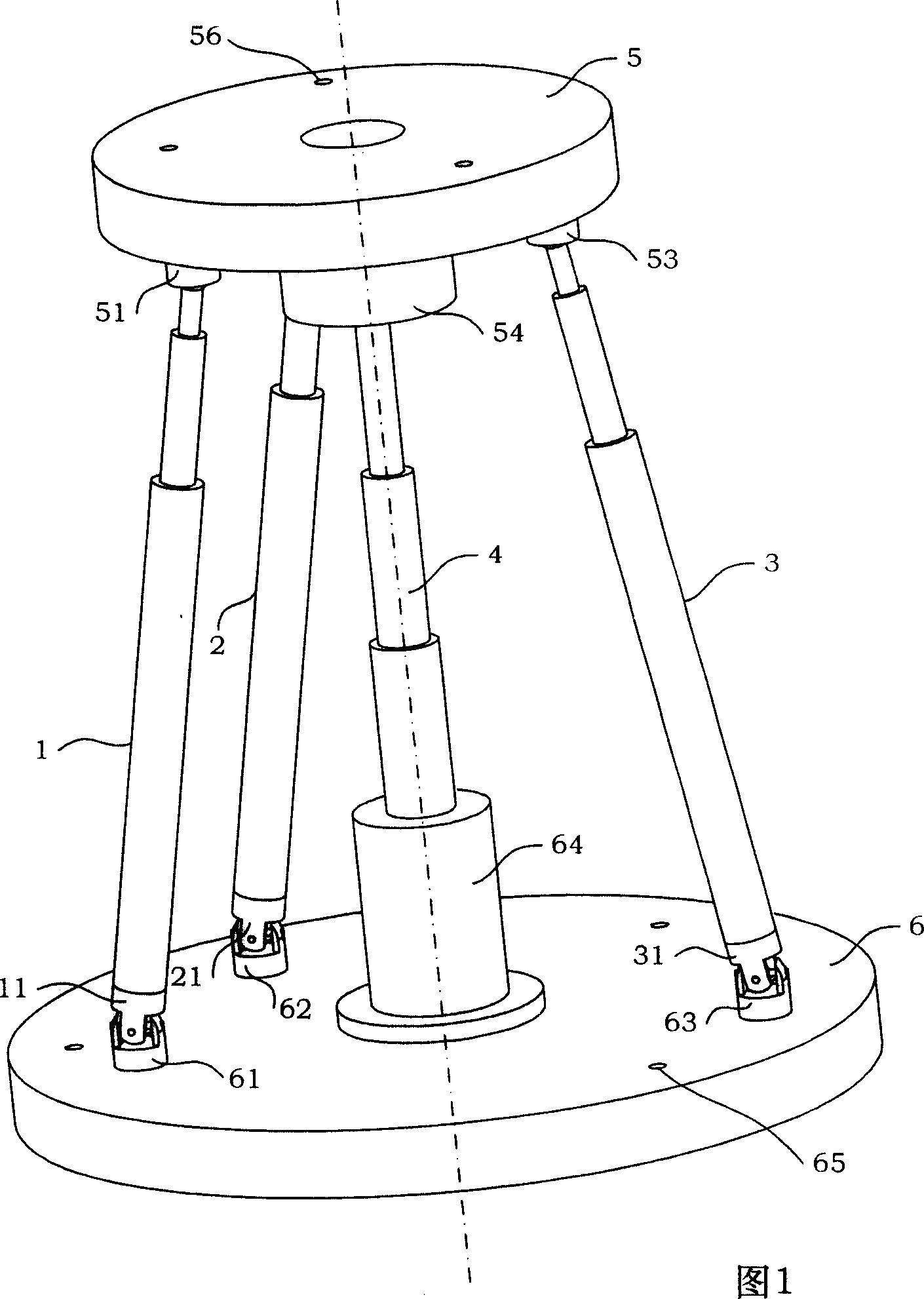

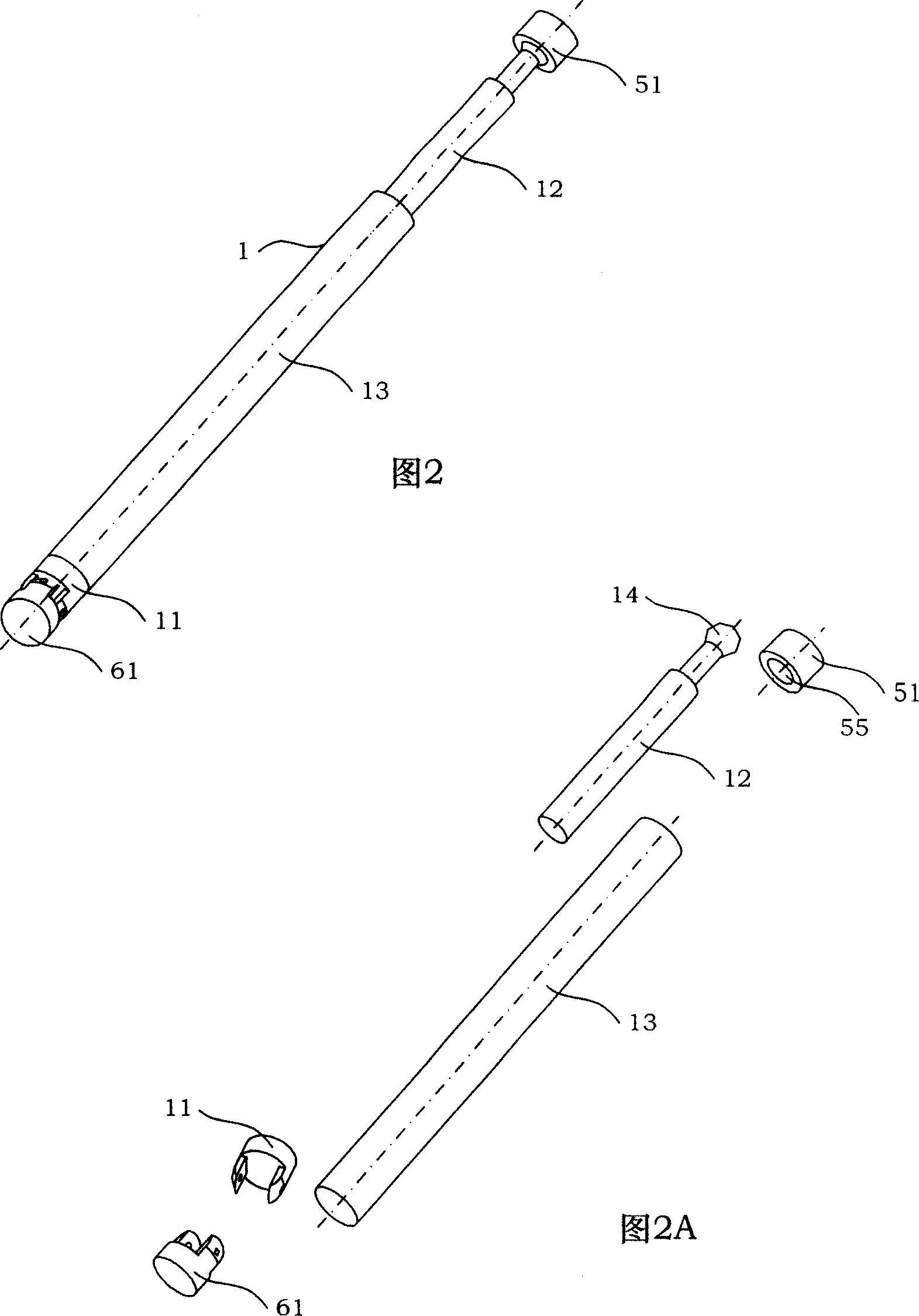

Three-freedom active ball-baring

InactiveCN101025248ARealize the twistWide range of exercise spaceDollsStands/trestlesBall bearingArchitectural engineering

The invention discloses a three-freedom active ball bearing, comprising first branch chain, second branch chain, third branch chain, support shaft, dynamic platform and static platform, where the three branch chains have the same structure and are uniformly distributed between the dynamic and static platforms; the support shaft is equipped in the center between the dynamic and static platforms, and one end of the support shaft is equipped in a support seat of the static platform, and the spherical end of the support shaft is equipped in the ball socket of a ball bearing. And the invention adopts extensional movement of branch chains to drive the platforms to move up and down and right and left, implementing large-range motional space; and it adopts the combined structure of branch chains and dynamic platform to implement ball joint function.

Owner:BEIHANG UNIV

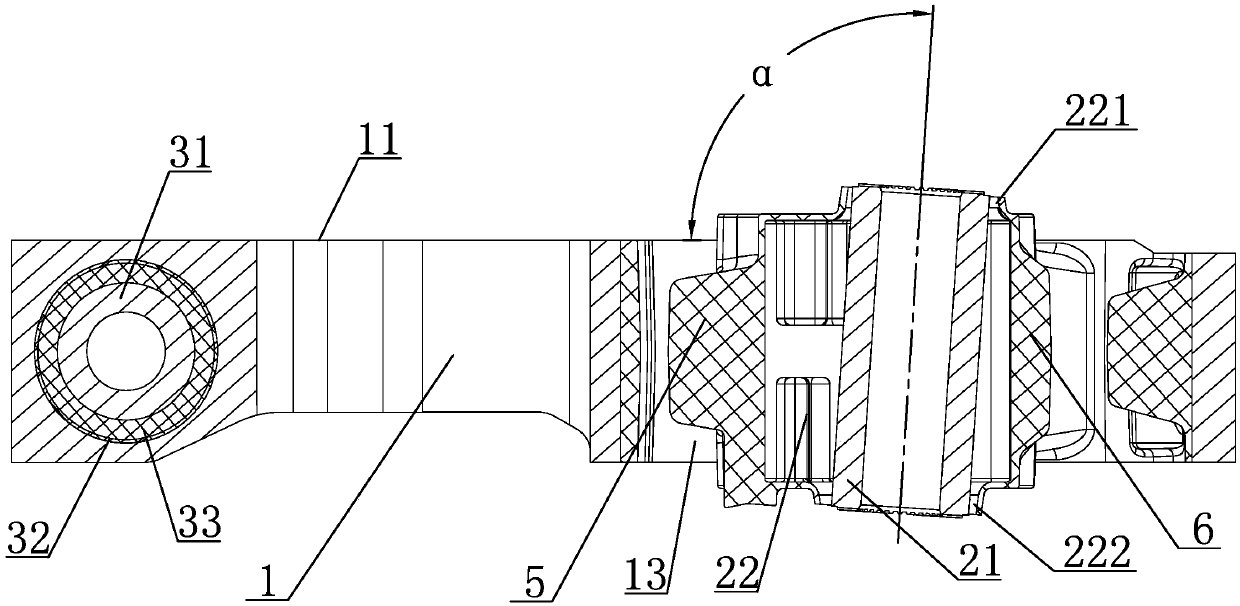

Torsion resistant pull rod of power assembly

ActiveCN106427516AControl installation angleGuaranteed stabilityJet propulsion mountingInternal combustion mountingVehicle frameAcute angle

The invention discloses a torsion resistant pull rod of a power assembly. The torsion resistant pull rod comprises a pull rod bracket, a large liner bushing and a small liner bushing, wherein the large liner bushing and the small liner bushing are respectively arranged at two ends of the pull rod bracket; the large liner bushing comprises a large liner bushing inner pipe; and the small liner bushing comprises a small liner bushing inner pipe. The torsion resistant pull rod is characterized in that the upper surface of the pull rod bracket is a flat end surface; the central axis of the small liner bushing inner pipe is parallel to the upper surface of the pull rod bracket; an oblique obtuse angle is formed between the central axis of the large liner bushing inner pipe and the upper surface of the pull rod bracket; when one end of the pull rod bracket is connected with the power assembly through the small liner bushing, an oblique acute angle is formed between the upper surface of the pull rod bracket and a level surface; and the difference between the oblique obtuse angle and the oblique acute angle is 90 degrees. The torsion resistant pull rod disclosed by the invention has the advantages that after the pull rod bracket of the torsion resistant pull rod is mounted in a preset angle, the upper surface or the lower surface of the large liner bushing inner pipe can be mounted on a vehicle body or a sub vehicle frame in a flat clinging manner, so that the mounting stability and the whole using stability of the torsion resistant pull rod are guaranteed.

Owner:NINGBO TUOPU GROUP CO LTD

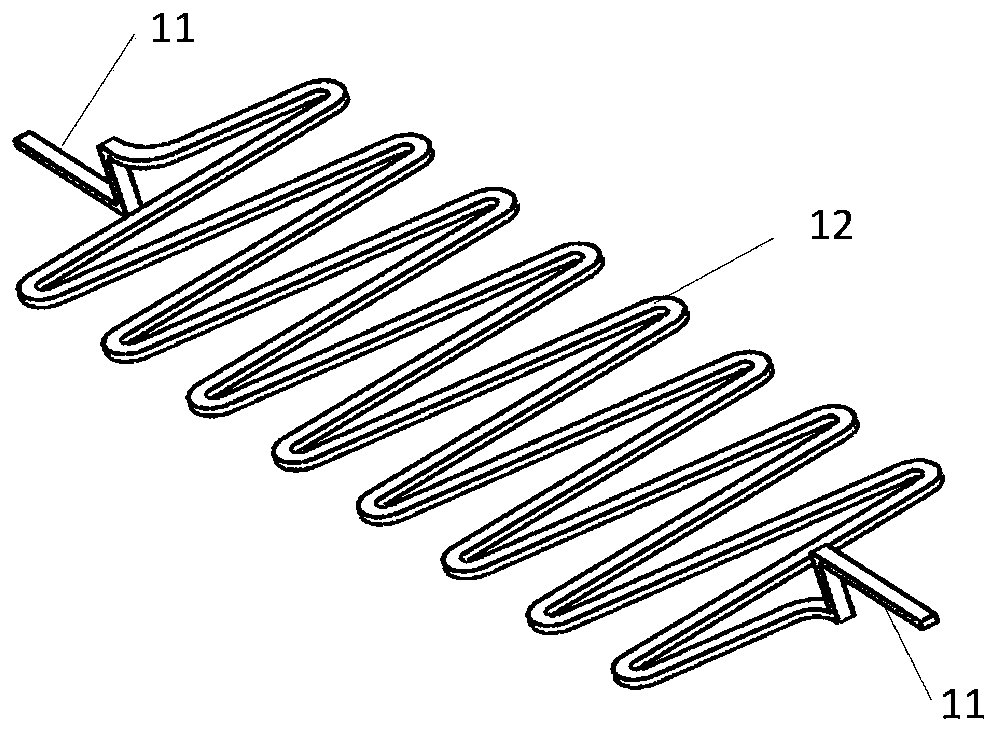

Flexible LED lamp strip

InactiveCN106322190ARealize the twistSimple structureElongate light sourcesElectric circuit arrangementsLED lampRectifier

The invention discloses a flexible LED lamp strip. The flexible LED lamp strip comprises a lamp strip body and a power socket connected with the lamp strip body. The lamp strip body comprises a strip-shaped FPC (flexible printed circuit) board. The two sides of the FPC board are each provided with multiple concave portions. The power socket comprises two shells, a first insulating fixed body and two conductive needles, wherein the two shells are closed by being covered with each other; the first insulating fixed body is fixedly connected with the shells; and the two conductive needles are fixed to the first insulating fixed body. A circuit board is further arranged in the power socket. A rectifier and multiple bonding pads are arranged on the circuit board. The two conductive needles are welded to the circuit board through the bonding pads correspondingly. A protrusion vertically protrudes out of the end face, facing the circuit board, of the first insulating fixed body. A groove matched with the protrusion is formed in the circuit board. The power socket is further connected with two or more wires. One end of each wire is welded to the corresponding bonding pad, and the other end of each wire is connected with the lamp strip. The flexible LED lamp strip has the beneficial effects that the structure is simple; connection is conducted firmly; and a circuit cannot be damaged when the FPC board is bent and twisted.

Owner:GUANGDONG COOPER OPTOELECTRONICS INC

Flexible driver

The invention discloses a flexible driver. A bending driving unit and an extension driving unit are alternatively connected to form a combined driving unit, a flexible seal cover is connected to one end of the combined driving unit, and a tubular structure with one closed end and one opened end is formed; the opening end of the tubular structure communicates with an air inlet guide pipe, a partition board is arranged in the tubular structure, an inner cavity of the tubular structure is divided into an upper cavity and a lower cavity, flexible valves are arranged on openings of the upper cavityand the lower cavity, an opening is formed in the partition board on the flexible seal cover area, a flexible valve is arranged on the opening, a torsion driving unit is connected between the open end of the tubular structure and the air inlet guide pipe, under extension, bending and torsion of the driver, fingers or limb joints are driven to move within the proper angle range, long-term rigidityof the hand is avoided, hand functional rehabilitation actions of hand bending, extension, inward buckling, outward extending, limb extension and the like can be finished, physical ergonomics are met, flexible degree is high, and the comfort is good.

Owner:JILIN UNIV

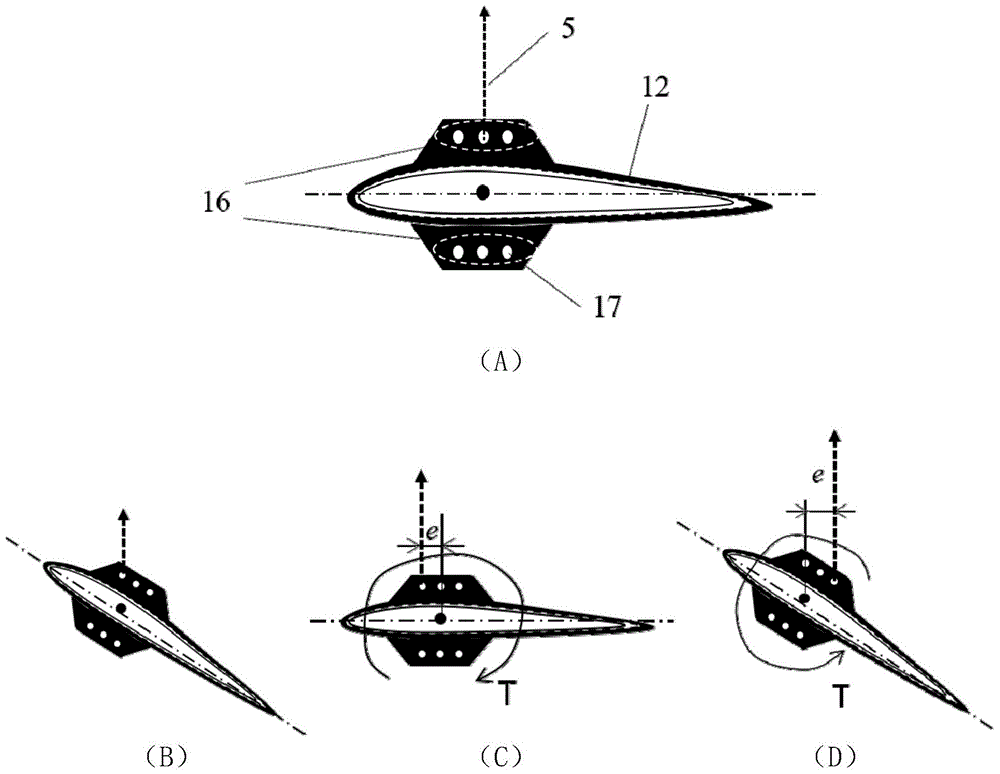

Rotor wing driving method and device

The invention discloses a rotor wing driving method and device. The method comprises the following steps: receiving a flight control command; acquiring the current rotation status of a first motor corresponding to a first steering engine, and the current rotation status of a second motor corresponding to a second steering engine; determining the first rotation status needed by the first motor according to the flight control command and the current status of the first motor; determining the second rotation status needed by the second motor according to the flight control command and the current status of the second motor; controlling the first motor to rotate at the corresponding second rotation status, thus realizing the torsion of a first paddle clamping body relative to a lower rotor hub; and controlling the second motor to rotate at the corresponding second rotation status, thus realizing the torsion of a second paddle clamping body relative to an upper rotor hub. Therefore, the defect that driving process of the existing rotor wing driving system is complicated by adopting the corresponding rotor wing driving method can be solved.

Owner:BEIJING ZHZ TECH

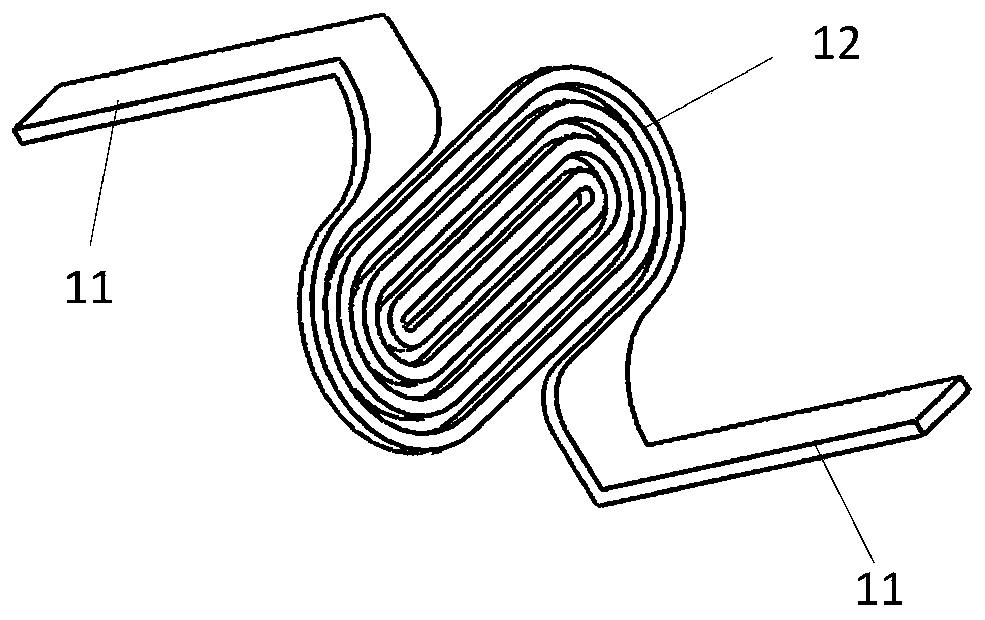

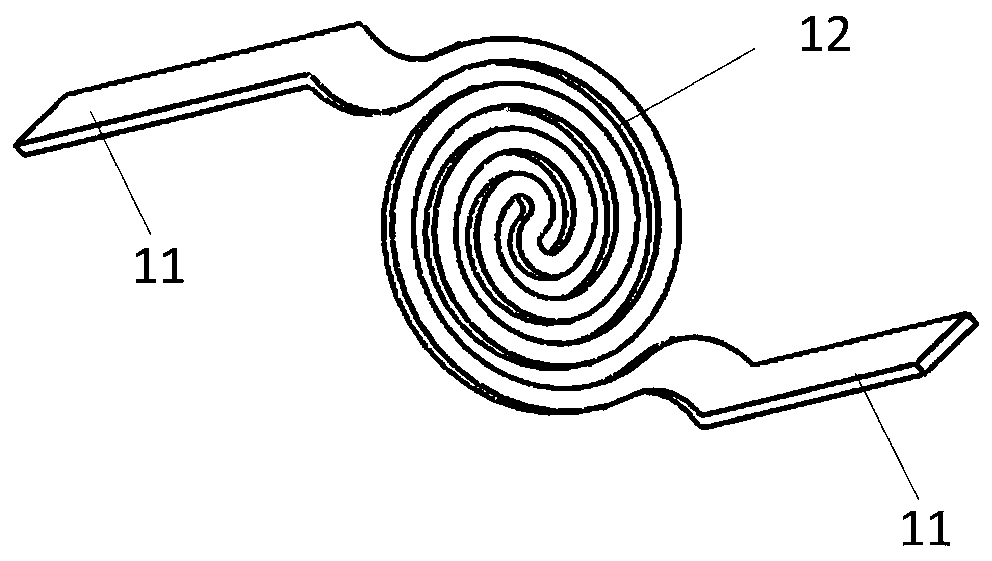

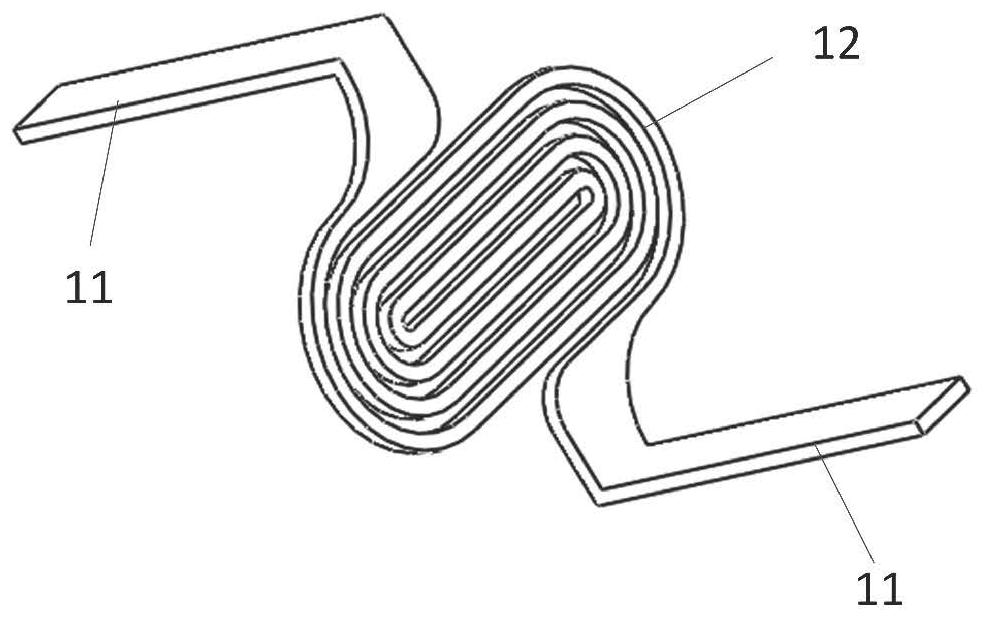

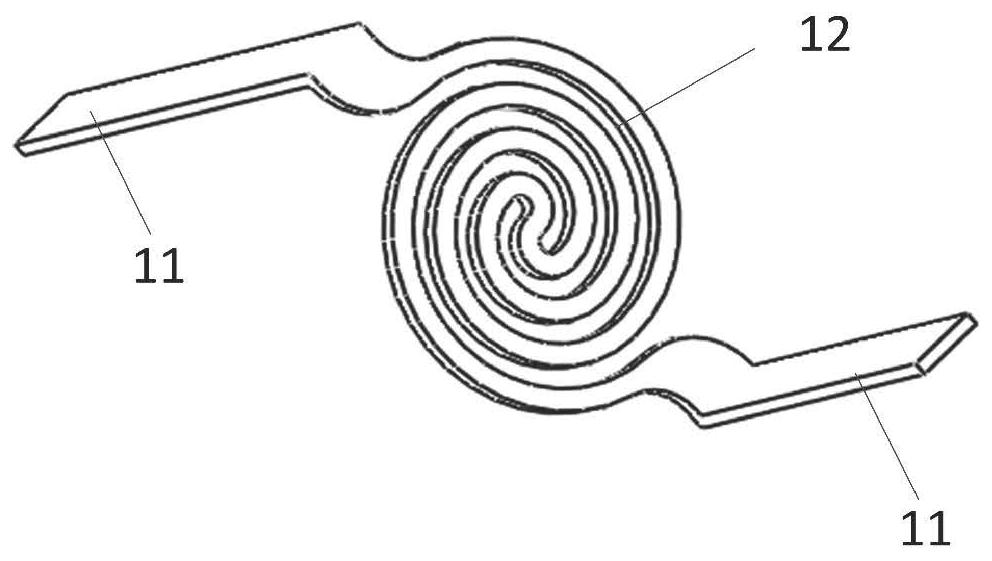

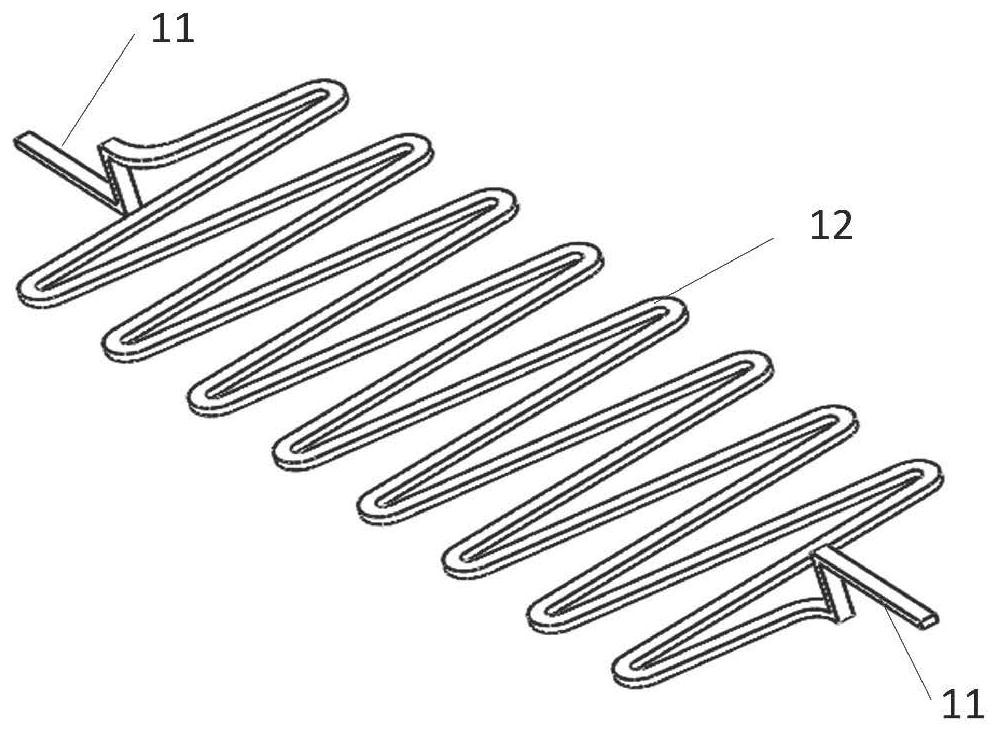

Flexible battery pack

ActiveCN111129383ACan be stretched to achieveAchieve bendableCurrent conducting connectionsStructural engineeringMechanical engineering

The invention discloses a flexible battery pack. The flexible battery pack comprises a flexible stretchable battery cell assembly and a flexible stretchable protective shell for accommodating the battery cell assembly; the battery cell assembly comprises at least two battery cells and a flexible connecting piece for electrically connecting the adjacent battery cells; and the protective shell comprises at least two main shells and an inter-shell structure for connecting the adjacent main shells, the main shells are used for accommodating and protecting the battery cell, and the inter-shell structure can be stretched, bent or twisted and is used for protecting the flexible connecting piece. According to the flexible battery pack disclosed by the invention, the battery cells are connected into the flexible stretchable battery cell assembly through the flexible connecting piece, and then the flexible stretchable battery cell assembly is accommodated in the flexible stretchable protective shell, so that the stretchable, bendable, twistable and conductive effects are realized, the capacity of the battery pack can reach 100mAh or above, and the safety is higher.

Owner:嘉兴极展科技有限公司

Traction steering device

InactiveCN103204182ARealize the twistIncrease flexibilityTowing devicesTrailer steeringEngineeringTractor

The invention discloses a traction steering device. The traction steering device comprises a first vertical rotating shaft, a first connecting piece rotationally connected with the first rotating shaft, a second rotating shaft, a second connecting piece rotationally connected with the second rotating shaft, a third rotating shaft and a third connecting piece rotationally connected with the third rotating shaft, the second rotating shaft is horizontal and perpendicular to the vehicle running direction, the first connecting piece is mounted on one of a tractor and a trailer, the second connecting piece is mounted on the other of the tractor and the trailer, the third rotating shaft is parallelly arranged and perpendicular to the second rotating shaft, and one end of the third connecting piece is fixedly connected with the first connecting piece while the other end thereof is fixedly connected with the second connecting piece. By the aid of the three rotating shafts, multidirectional relative movement of the trailer relative to the tractor is achieved, and accordingly flexibility during turning and traveling is improved.

Owner:立大自行车(句容)有限公司

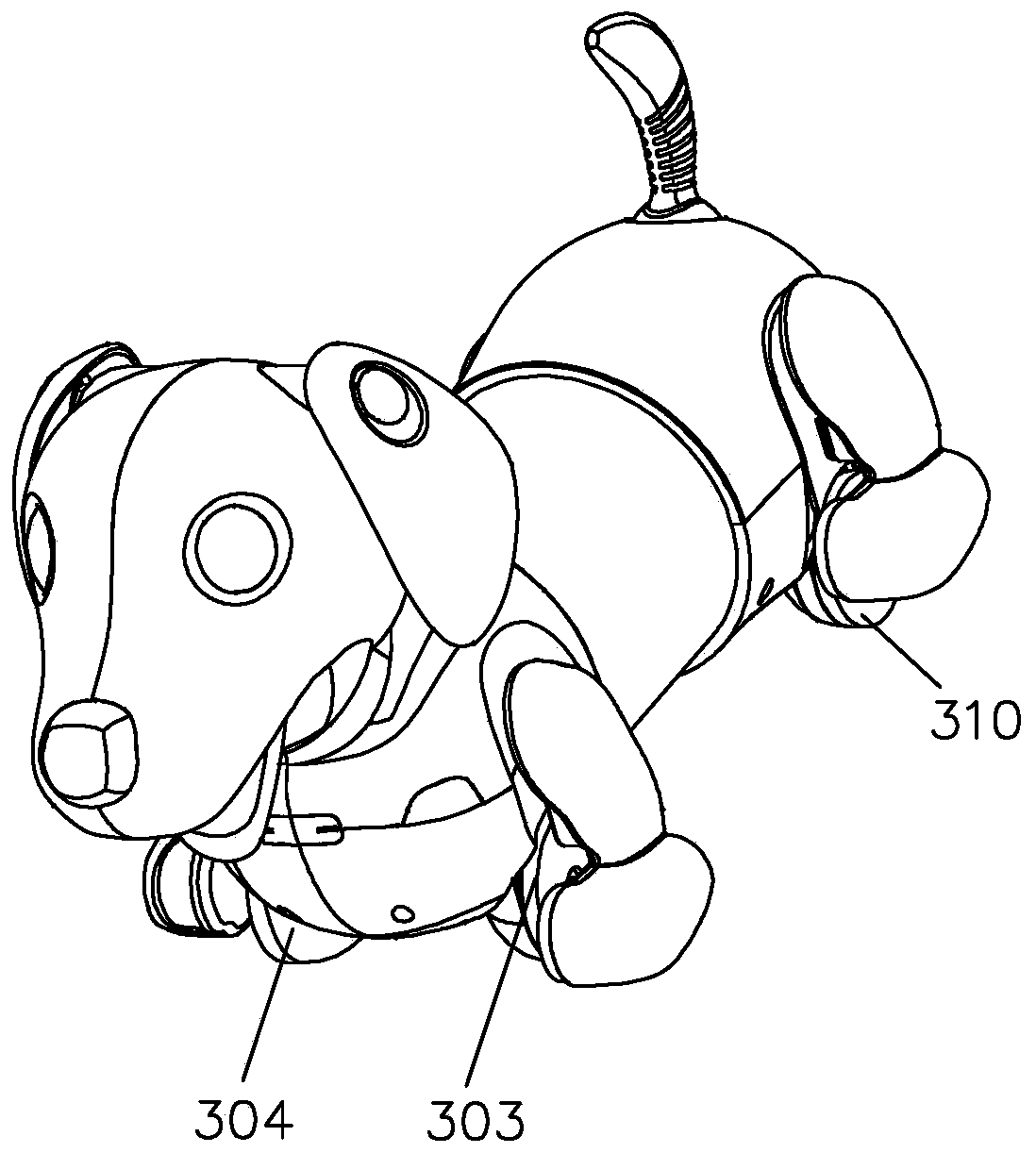

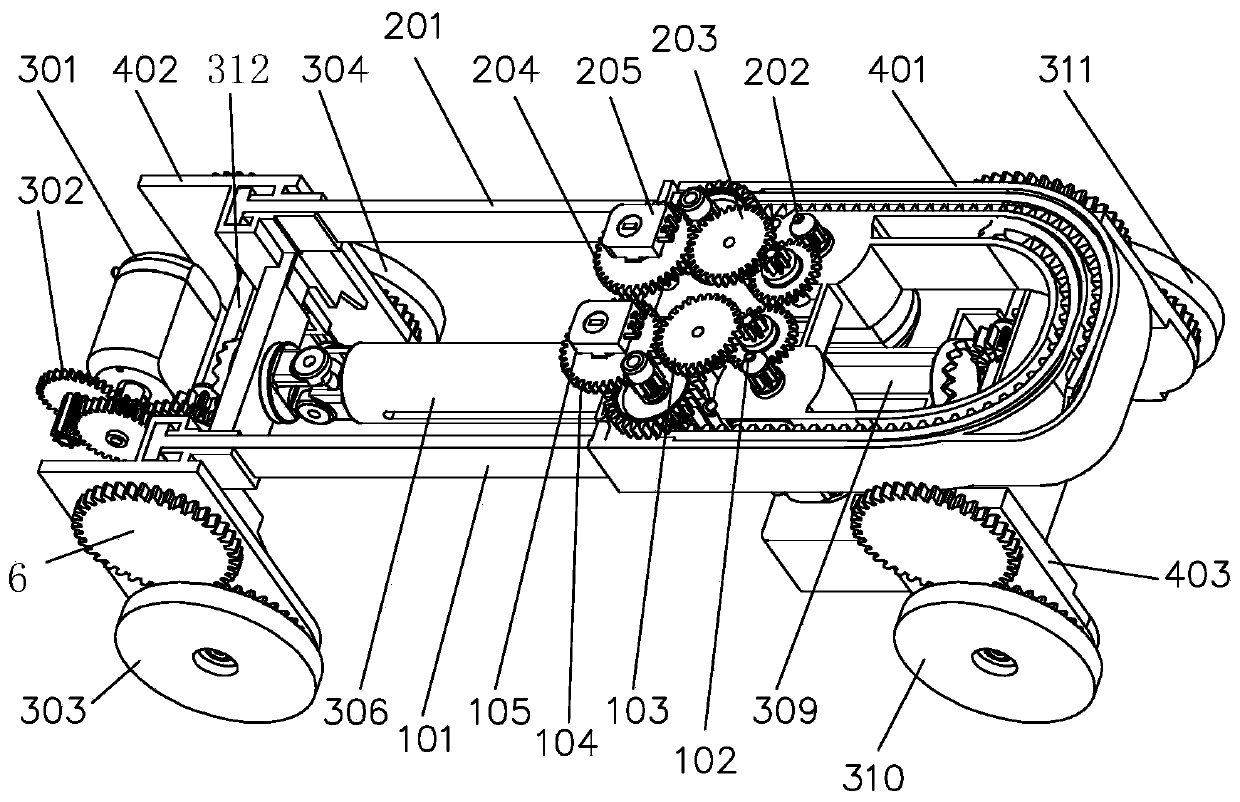

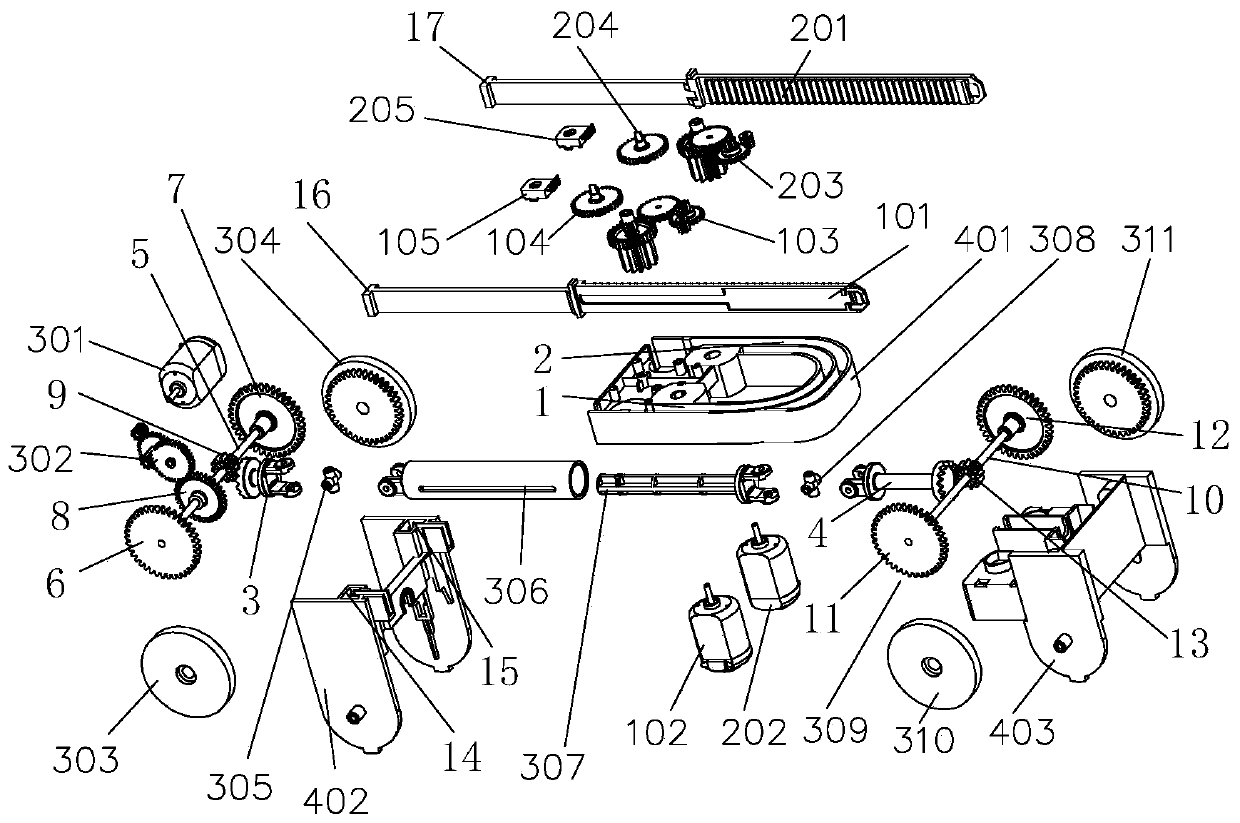

Telescopic and torsional toy structure

The invention relates to the technical field of toy structures, in particular to a telescopic and torsional toy structure. The telescopic and torsional toy structure comprises a front fixed support, arear fixed support, a left rack, a right rack, a telescopic transmission assembly, a rack fixed support, a wheel driving mechanism, a front wheel transmission assembly and a rear wheel transmission assembly, wherein the wheel driving mechanism and the front wheel transmission assembly are arranged on the front fixed support; the rear wheel transmission assembly is arranged on the rear fixed support; a left front wheel and a right front wheel are rotationally arranged on the left side and the right side of the front fixed support respectively; a left rear wheel and a right rear wheel are rotationally arranged on the left side and the right side of the rear fixed support respectively; the front wheel transmission assembly is in transmission connection with the rear wheel transmission assembly through the telescopic transmission assembly; the rack fixed support is fixed on the rear fixed support; and the rack fixed support is provided with a left rack driving mechanism used for driving the left rack to move, and a right rack driving mechanism used for driving the right rack to move. The structure is novel and can realize the telescopic and torsional motion of the toy.

Owner:东莞银辉玩具有限公司

Aluminum alloy plate machining all-in-one machine with rotatable rolling wheel

The invention discloses an aluminum alloy plate machining all-in-one machine with a rotatable rolling wheel. The aluminum alloy plate machining all-in-one machine comprises a construction frame and supporting legs, wherein a concave horizontal base is fixed to the inner wall of a side plate of the construction frame, a movable circular base is arranged between two convex plates of the horizontal base in a sliding mode, a rotary circular base capable of resetting is rotationally arranged in the rotary circular base, a pair of vertical fixing plates is arranged on the top face of the rotary circular base, the resettable rolling wheel is rotationally arranged between the two vertical fixing plates, and a rotary containing groove is formed in the top face of the rolling wheel. The aluminum alloy plate machining all-in-one machine has the advantages that by arranging the rolling wheel which can move front and back and rotate, an aluminum alloy plate can be bent and further be twisted, so that connecting plates in different shapes are machined, and the aluminum alloy plate machining all-in-one machine is simple in structure, low in cost and good in effect.

Owner:吴根生

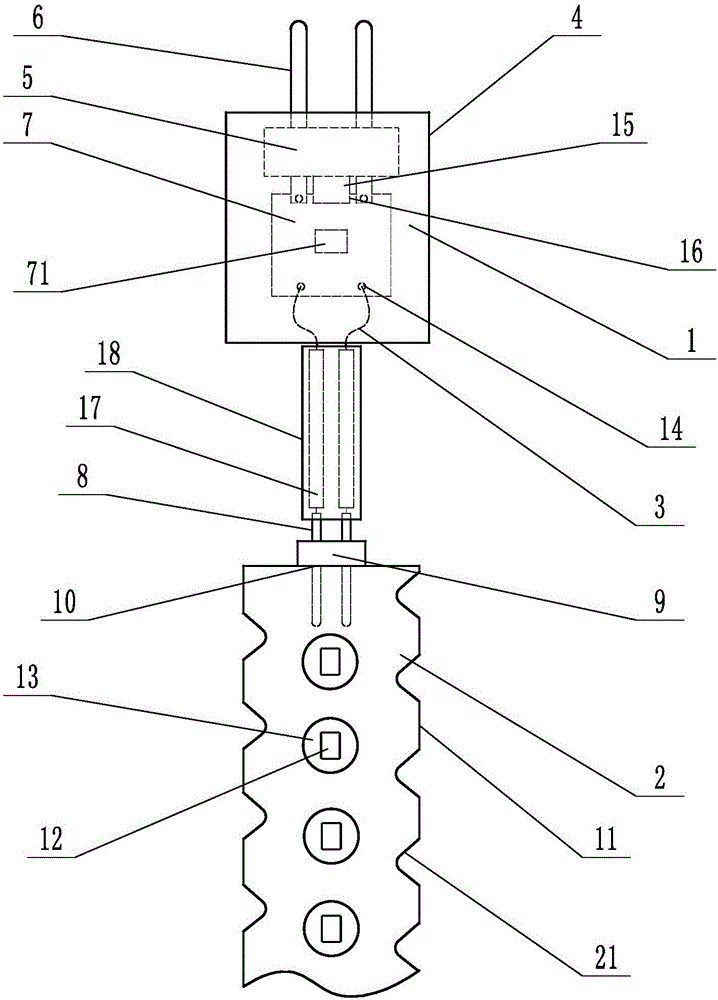

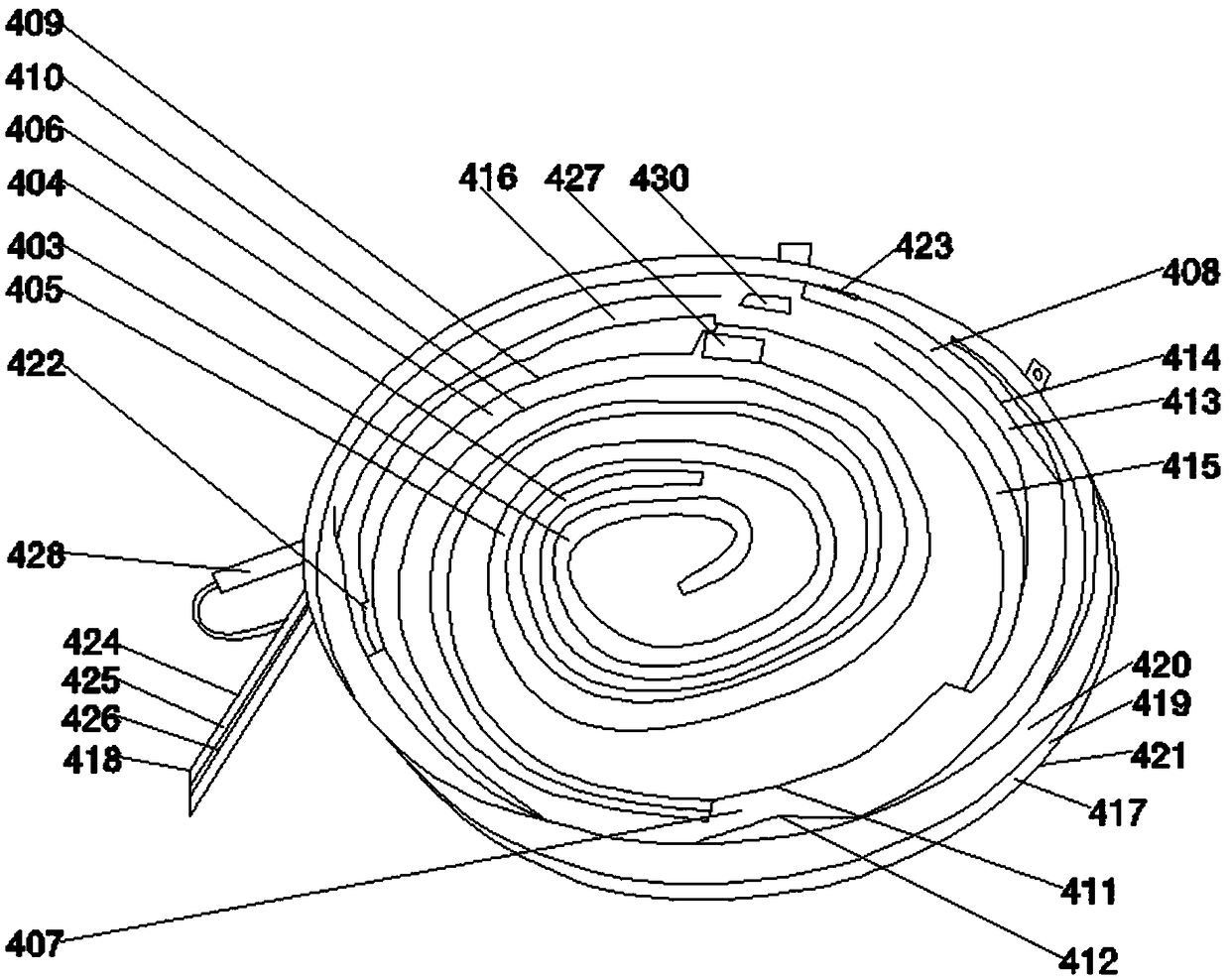

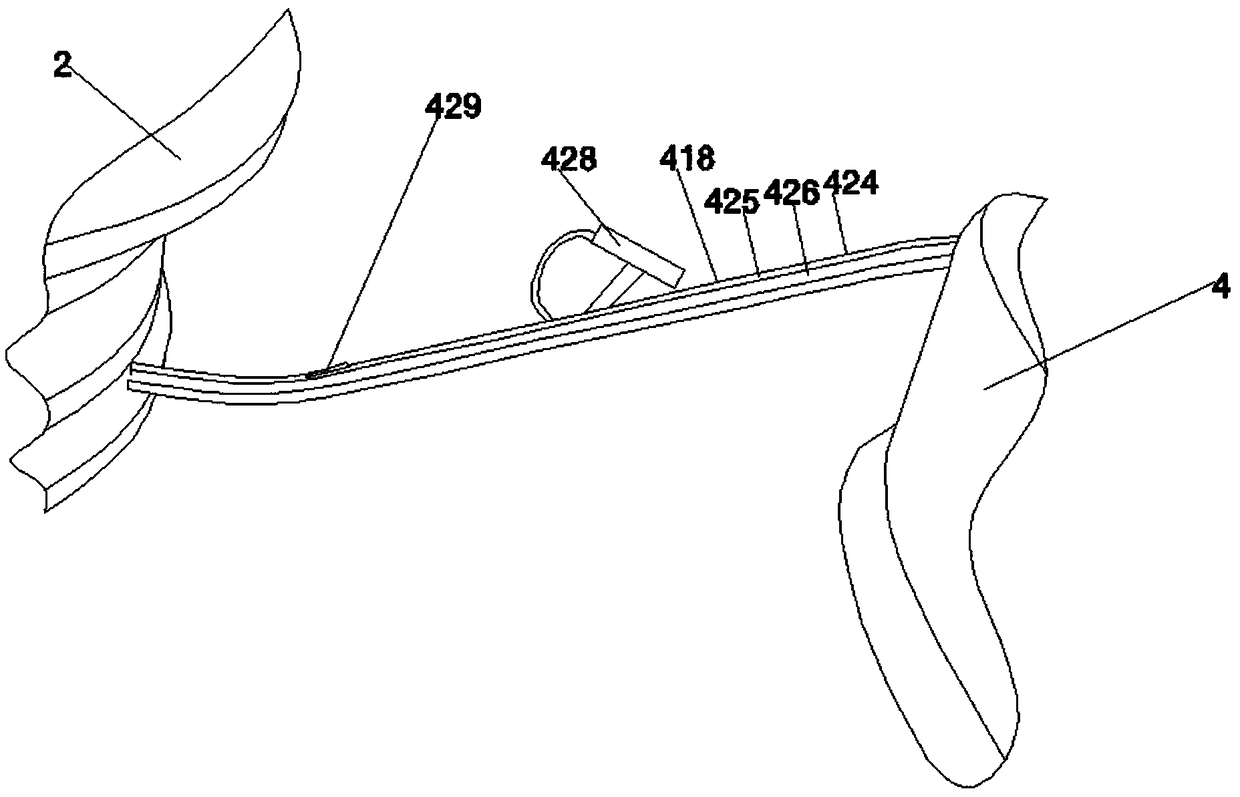

Automatic feeding mechanism for oral liquid bottle aluminum caps

The invention relates to the technical field of medical packaging products, and particularly discloses an automatic feeding mechanism for oral liquid bottle aluminum caps. The mechanism comprises a first vibrating assembly and a first conical tray; the first conical tray is provided with a first a spiral conveying track and a second spiral conveying track; the first spiral conveying track comprises a first spiral conveying section, a second spiral conveying section, a first torsion section and a third spiral conveying section which are sequentially connected; the first torsion section is composed of a first inner wall plate and a first torsion bottom plate; the third spiral conveying section is composed of a third inclined bottom plate and a third side plate; the second spiral conveying track comprises a first spiral feeding section, a second spiral feeding section, a third spiral feeding section and a fourth feeding section which are sequentially connected; the third spiral feeding section comprises a third bottom plate, a third upper plate and a third lower plate; and the fourth feeding section is composed of a fourth feeding bottom plate and a fourth L-shaped side plate. The mechanism has the characteristics of high degree of automation, low labor cost and good safety.

Owner:浙江冠利新材料股份有限公司

Bolt type twisting handle

InactiveCN104801730ASmooth dischargeImprove drilling effectAuxillary equipmentBoring/drilling componentsPrismDrill bit

The invention relates to a bolt type twisting handle, which comprises a handle body, bolts and fastening screws, wherein the handle body is of a T-shaped structure, and comprises a left head and a right tail, the tail is of a quadrangular prism structure, the head is provided with a round hole for the mounting of a bit body along the longitudinal direction, the head is provided with a bolt hole for the mounting of the bolts along the vertical direction, the bolt hole is communicated with the round hole, the left side of the head is provided with threaded holes for the mounting of the fastening screws from the left to the right, and the threaded holes are communicated with the bolt holes. The bolt type twisting handle can be applied to ordinary lathes, and by means of a transmission mechanism of a machine tool, the bolt type twisting handle can implement the twisting of constant lead; the helical chip groove of the body of a crown bit can be obtained by twisting, an optimized groove design can be achieved with only a small amount of grinding, and the bolt type twisting handle has the advantages of high mechanical strength, high cutting efficiency and the like, and is particularly suitable for the machining of crown bit bodies with helical internal cooling holes.

Owner:SUZHOU AHNO PRECISION CUTTING TECH CO LTD

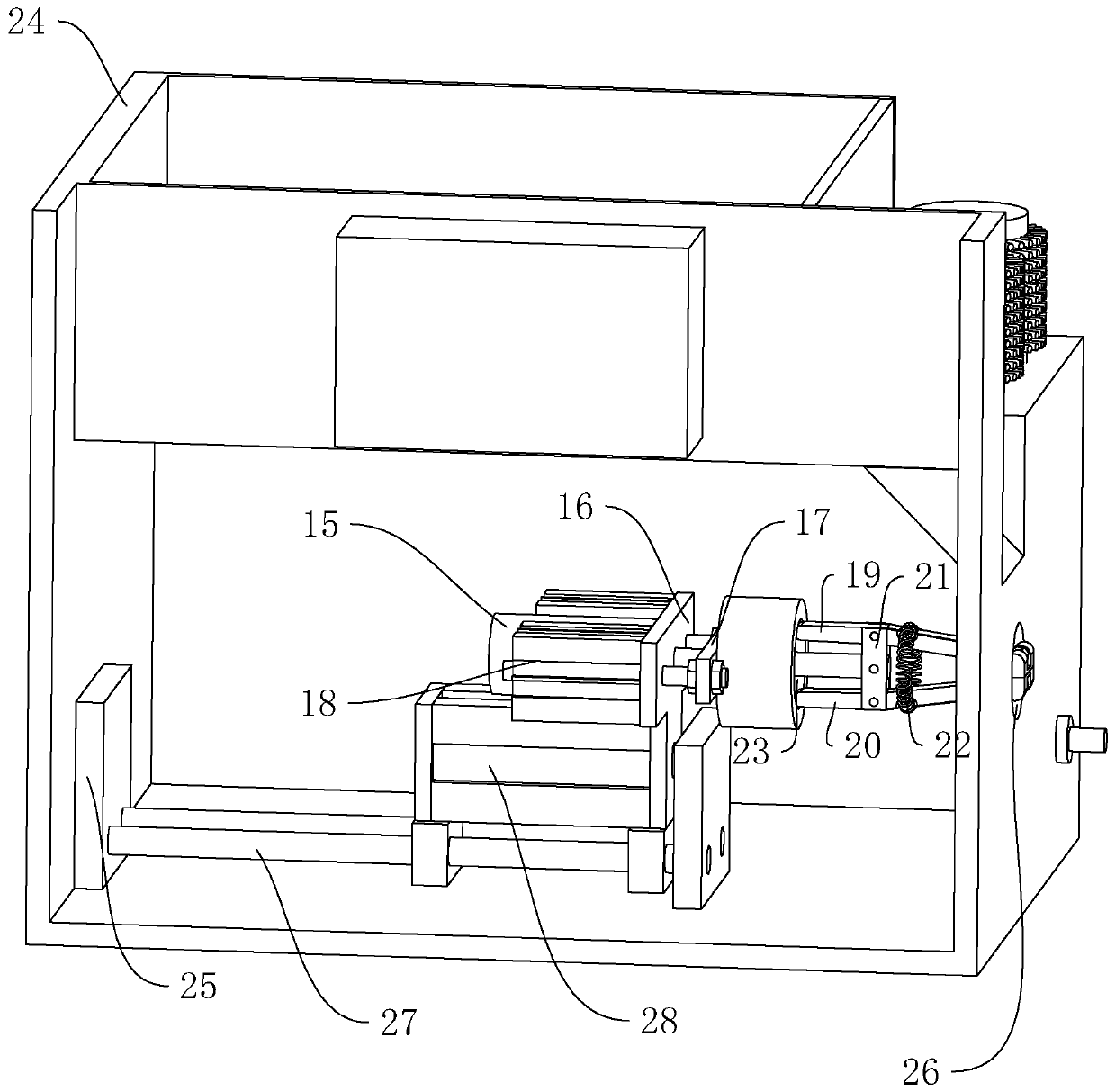

Automatic welding device of color band

ActiveCN108501391ASolve problems that require manual twisting of the ribbonImprove work efficiencyDomestic articlesEngineeringConductor Coil

The invention discloses an automatic welding device of a color band, and relates to the technical field of processing of color bands. The automatic welding device comprises a box body, wherein a transverse plate is fixedly connected between two opposite sides of the inner wall of the box body; the top part of the transverse plate is rotationally connected with a driving roller through a rotary frame; the inner wall of the box body is rotationally connected with a color band winding roll through a fixed seat and a rotary sleeve; the top part of a movable plate is fixedly connected with a firstelectric telescopic rod; the working end of the first electric telescopic rod is fixedly connected with a first rotary device through a connecting block; the top end of the box body is fixedly connected with a second movable block through a second electric telescopic rod; the bottom part of the second movable block is fixedly connected with a turnover device through a third electric telescopic rod; the top part of the inner wall of the box body is fixedly connected with a welding device through a fourth electric telescopic rod; one side of the top part of the transverse plate is fixedly connected with a shearing device through a support plate. The automatic welding device of the color band solves the problem of artificial torsion of the color band in the welding process, and improves the welding efficiency.

Owner:绍兴柯桥兴旺印纸印花有限公司

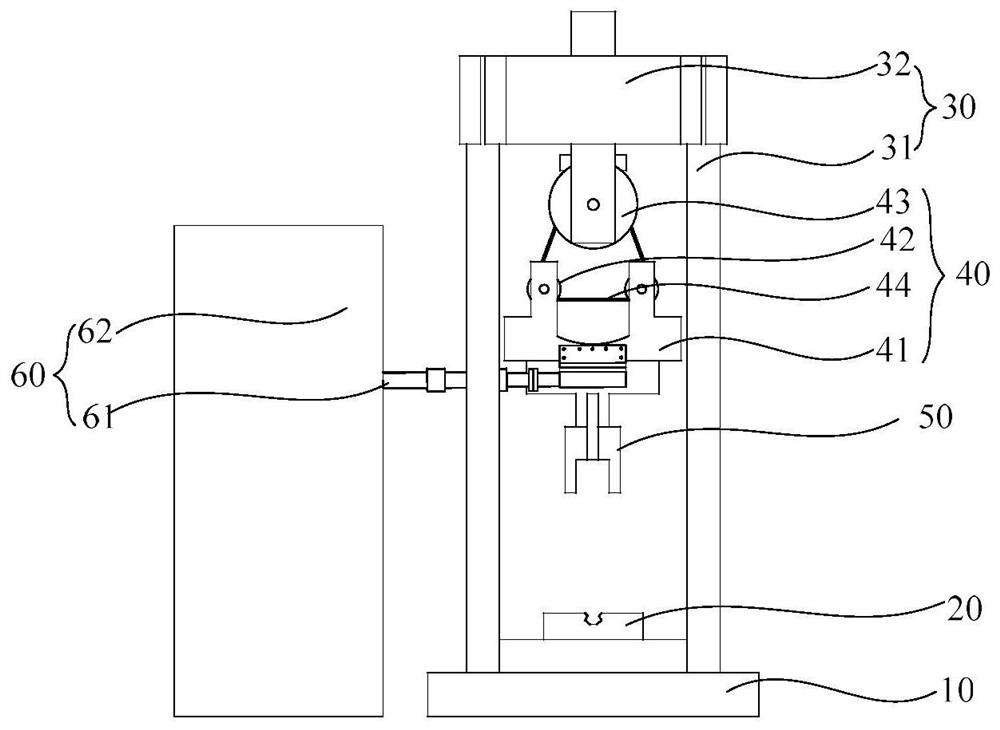

Low-cycle fatigue composite test device

InactiveCN113176088AAchieve bendingFully bentMachine part testingWind energy generationFatigue loadingPull force

The invention provides a low-cycle fatigue composite test device. The low-cycle fatigue composite test device comprises a base, a first chuck, a support, a lifting device, a rotating device, a horizontal moving device, a second chuck, a load applying device and a control device. The horizontal moving device is fixed to the rotating device and can move in the horizontal direction relative to the support. According to the load applying device, a horizontal pushing force or pulling force is applied to a blade through the horizontal moving device, the lifting device can apply a vertical pulling force and pressure to the blade, the rotating device can apply rotating forces in different directions to the blade, and an external force can be applied to the blade in multiple directions; and bending, twisting and multi-angle combined fatigue loading forms of the blade can be realized, and through the fatigue load and the strain distribution, the structural performance of the blade under the fatigue load can be evaluated. Therefore, the fatigue test can be fully performed on the blade.

Owner:HARBIN INST OF TECH

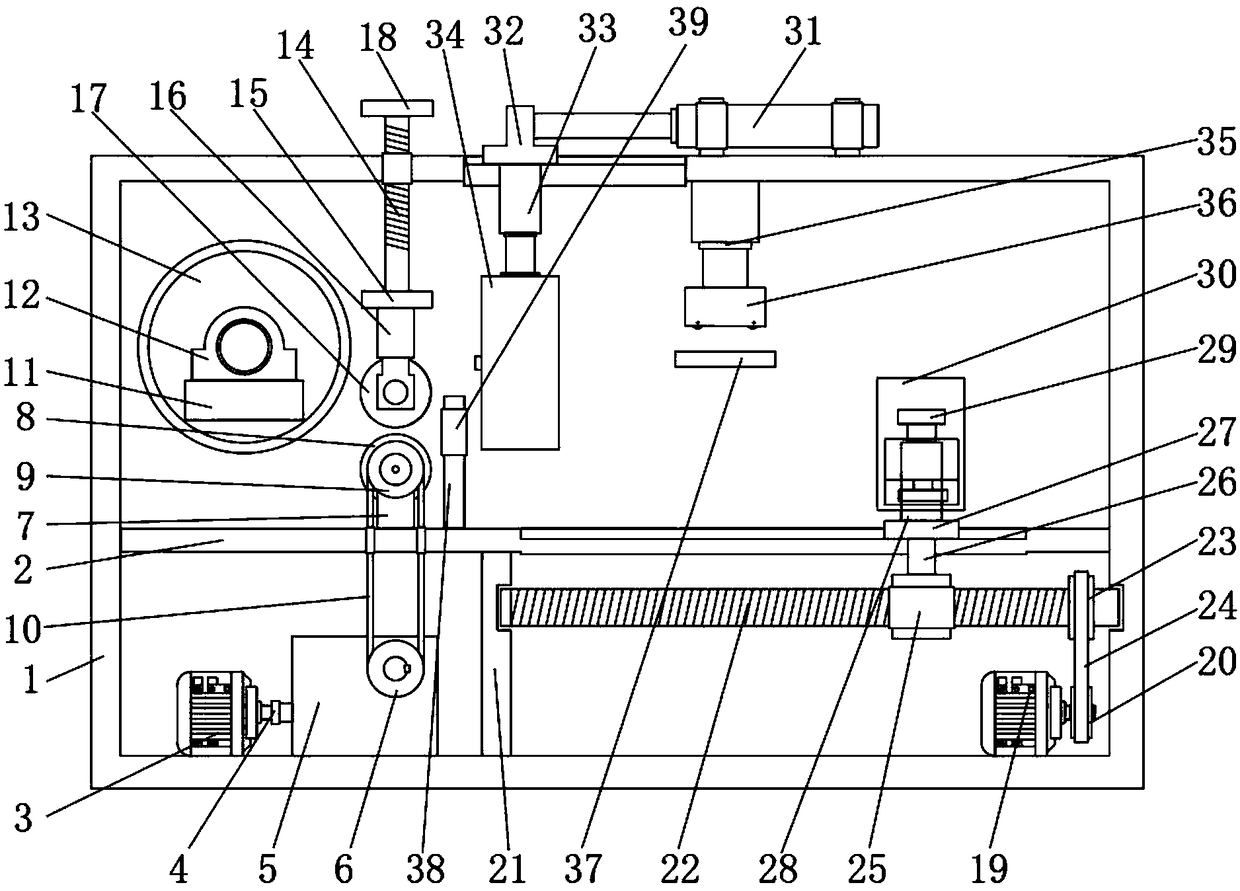

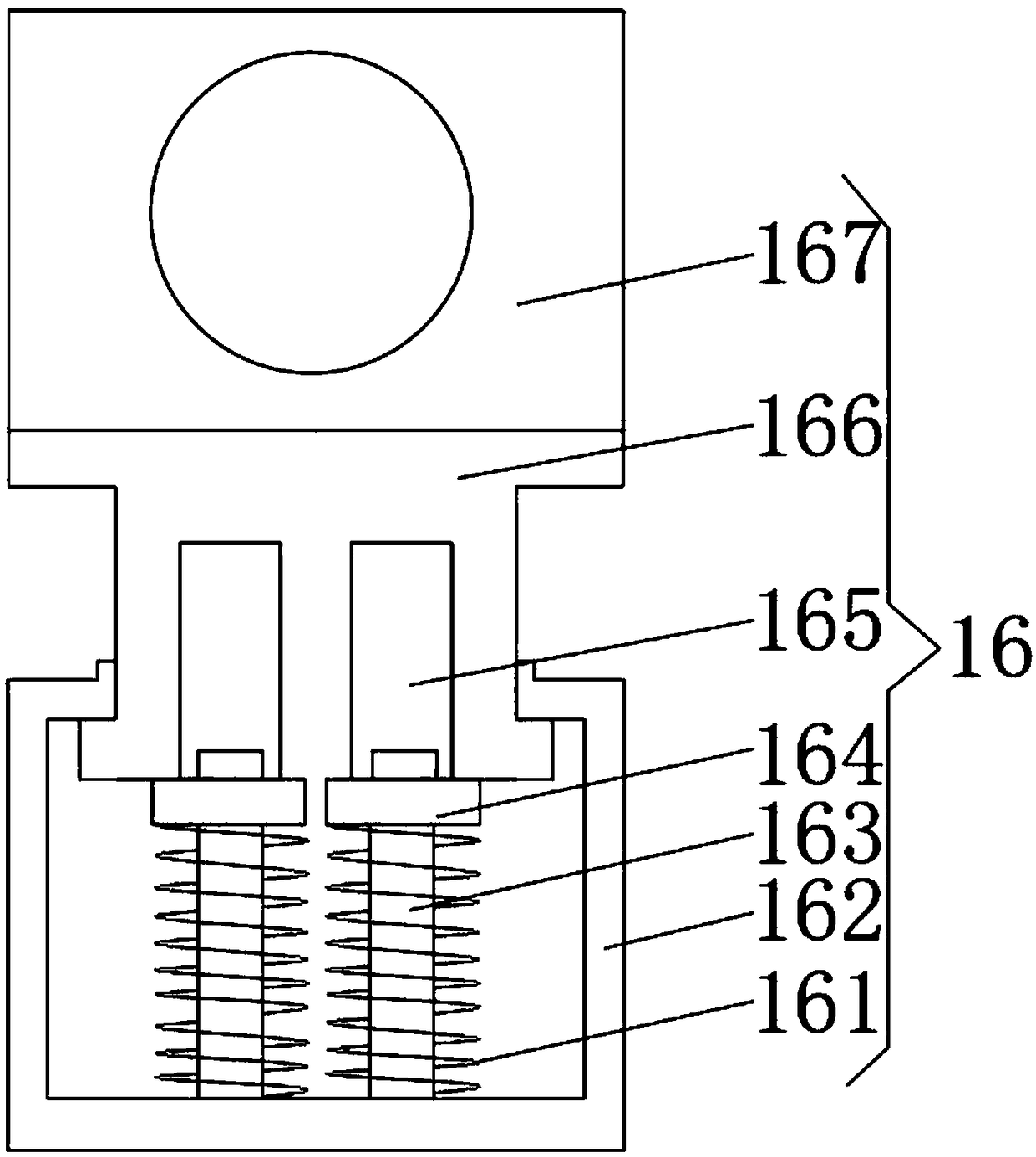

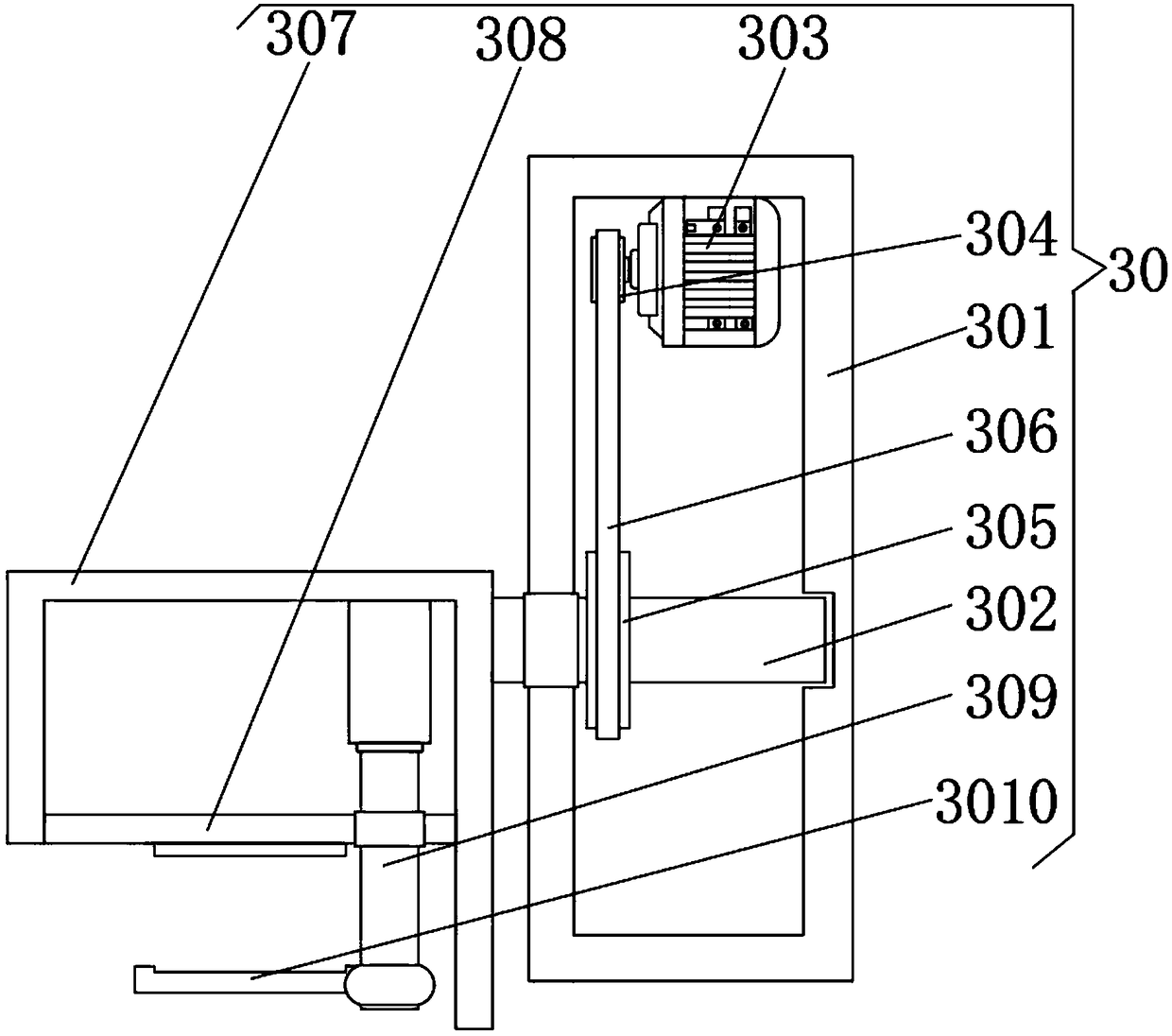

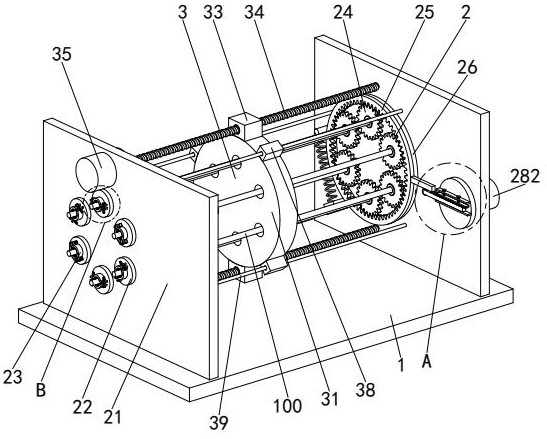

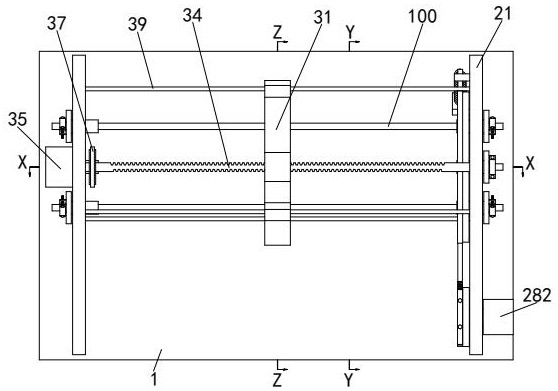

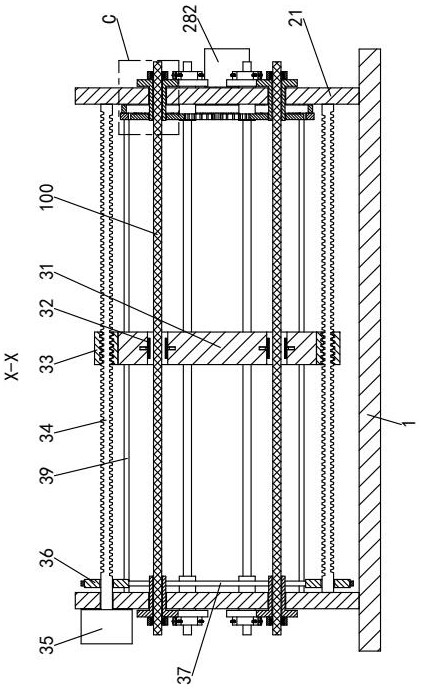

Batch testing machine for torsion durability of wires and cables

ActiveCN113504106AControl twist angleImprove testing capabilitiesMaterial strength using steady torsional forcesMaterial strength using repeated/pulsating forcesTorsion testStructural engineering

The invention relates to the technical field of wire and cable testing and particularly relates to a wire and cable torsion durability batch testing machine. The testing machine comprises a workbench, a torsion detection device and a wear resistance detection device, wherein the torsion detection device is arranged on an upper end face of the workbench, and the wear resistance detection device is arranged in the middle of the torsion detection device. According to the testing machine, distortion resistance test detection and wear resistance test detection can be carried out on wires and cables, that is to say, a torsion test or a wear test can be carried out on the wires and cables independently, and the torsion test and the wear test can also be carried out on the wires and cables step by step, so the application range of the device is widened; batch test detection can be carried out on wires and cables in an annular distribution mode, test efficiency is improved, a torsion angle of the wires and cables can be controlled when the torsion test is carried out on the wires and cables, and the test effect of detecting the wires and cables is further improved.

Owner:徐州盛丰电子科技有限公司

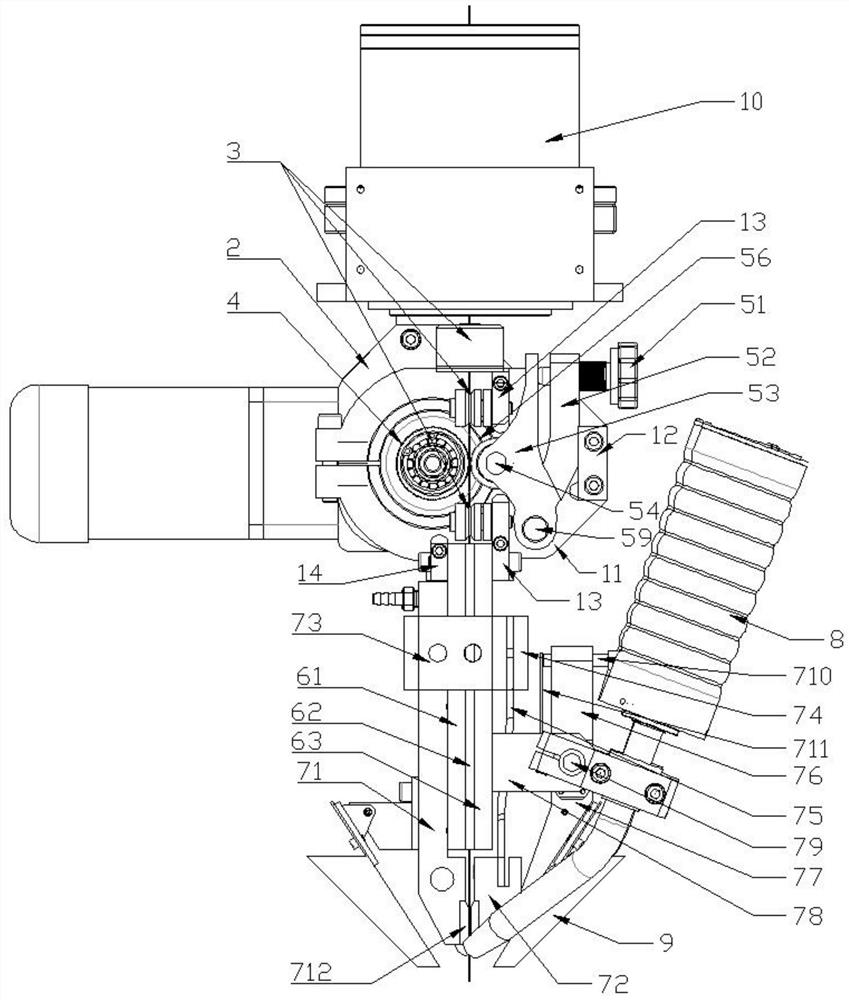

Strip electrode submerged arc build up welding equipment

PendingCN111774704ARealize the twistRealization of surfacingWelding accessoriesEngineeringMechanical engineering

The invention provides strip electrode submerged arc build up welding equipment, and relates to the field of strip electrode build up welding equipment. Problems in the prior art can be solved, the equipment comprises a machine head mounting base and a strip electrode submerged arc build up welding machine head, the machine head mounting base is provided with an upper connecting base and a lower connecting base which are coaxially mounted and can oppositely rotate around the axis, the lower connecting base is fixedly connected with a hanging base assembly with the strip electrode submerged arcbuild up welding machine head, the equipment is divided into an upper part and a lower part which can oppositely rotate, 90-degree torsion of a welding strip can be achieved, and build up welding intwo directions is achieved.

Owner:张敏

Flexible battery pack

ActiveCN111129383BCan be stretched to achieveAchieve bendableCurrent conducting connectionsStructural engineeringMechanical engineering

The invention discloses a flexible battery pack, comprising: a flexible and stretchable cell assembly and a flexible and stretchable protective case for accommodating the cell assembly; the cell assembly includes at least two electric cells A core and a flexible connector for electrically connecting adjacent electric cores; the protective case includes at least two main shells and an inter-shell structure for connecting adjacent main shells, and the main shell is used to accommodate and protect the battery core, the inter-shell structure can be stretched, bent or twisted and used to protect the flexible connector. In the flexible battery pack of the present invention, the cells are connected through flexible connectors to form a flexible and stretchable cell assembly, and then accommodated in a flexible and stretchable protective case, which realizes stretchable, bendable and twistable , Conductive, and the capacity of the battery pack can reach more than 100mAh, and the safety is higher.

Owner:嘉兴极展科技有限公司

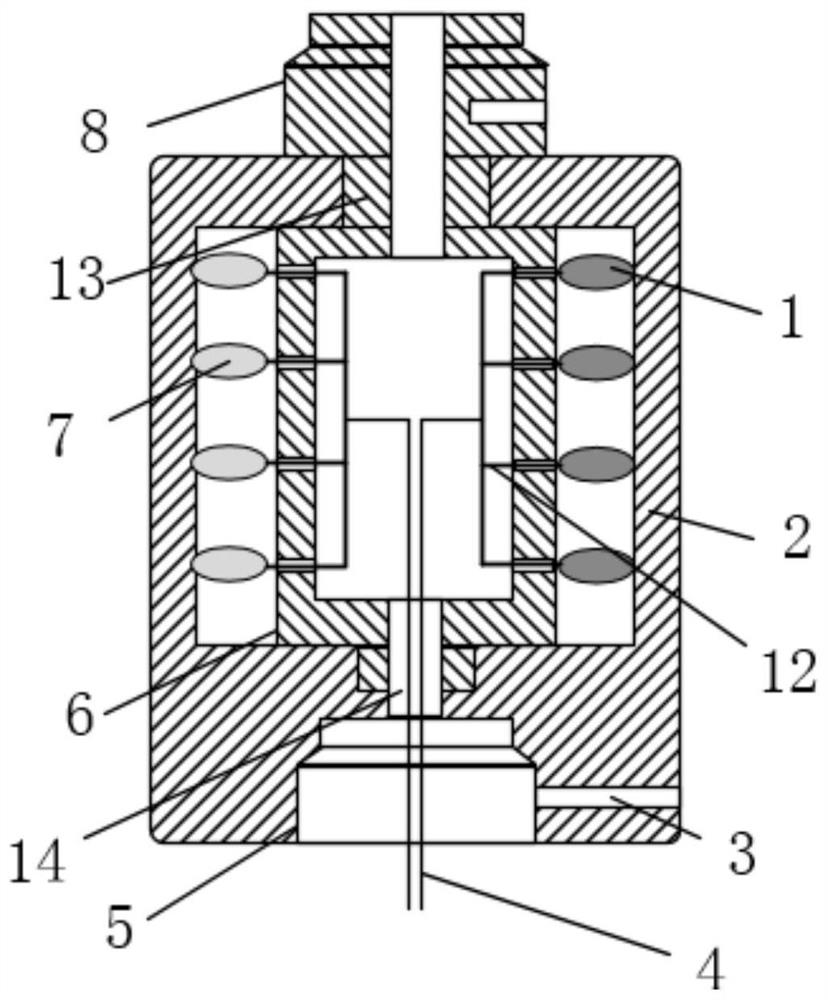

Modular flexible torsion joint based on air bag inflation and deflation actuation

The invention provides a modularized flexible torsion joint based on air bag inflation and deflation actuation, which includes a torsion joint shell, a torsion joint inner shell and a built-in air circuit. The outer shell and the inner shell of the torsion joint are installed coaxially, and the outer shell of the torsion joint and the inner shell of the torsion joint are arranged to rotate relative to each other; between the outer shell of the torsion joint and the inner shell of the torsion joint, several groups of reversely distributed airbag groups and several groups of forwardly distributed airbag groups are fixed. The airbag group, the built-in air circuit is installed in the internal through hole of the torsion joint inner shell and the torsion joint shell, all the airbags distributed in the reverse direction and all the airbags distributed in the forward direction are respectively connected to a built-in air circuit, and the airbags with the same distribution direction are inflated at the same time Deformation is generated to realize the relative rotation between the torsion joint inner shell and the torsion joint outer shell. The invention utilizes the inflated deformation of the airbag to trigger the rotation between the inner and outer shells of the torsion joint, and has the characteristics of low triggering, low impact and high flexibility.

Owner:HARBIN INST OF TECH

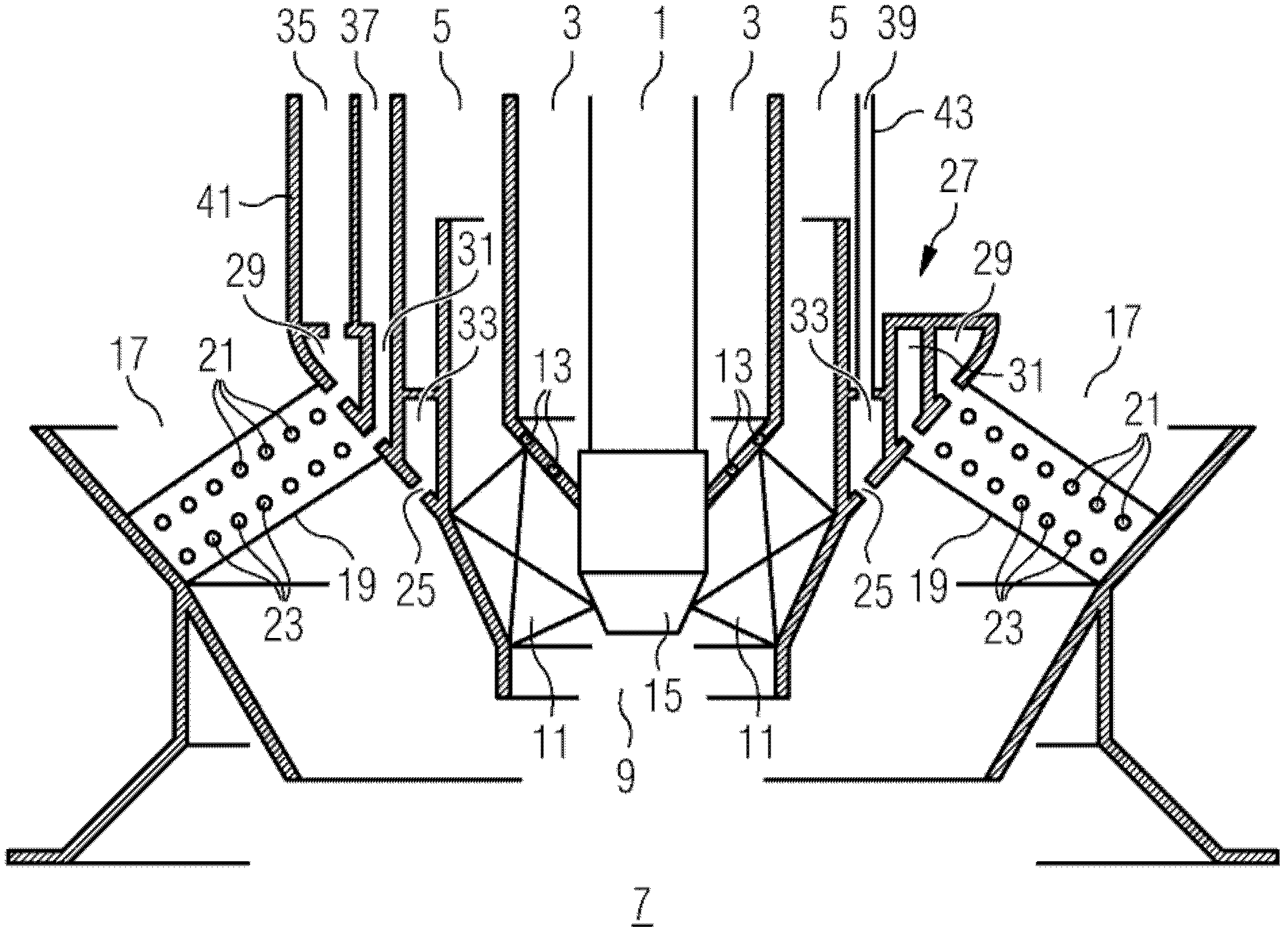

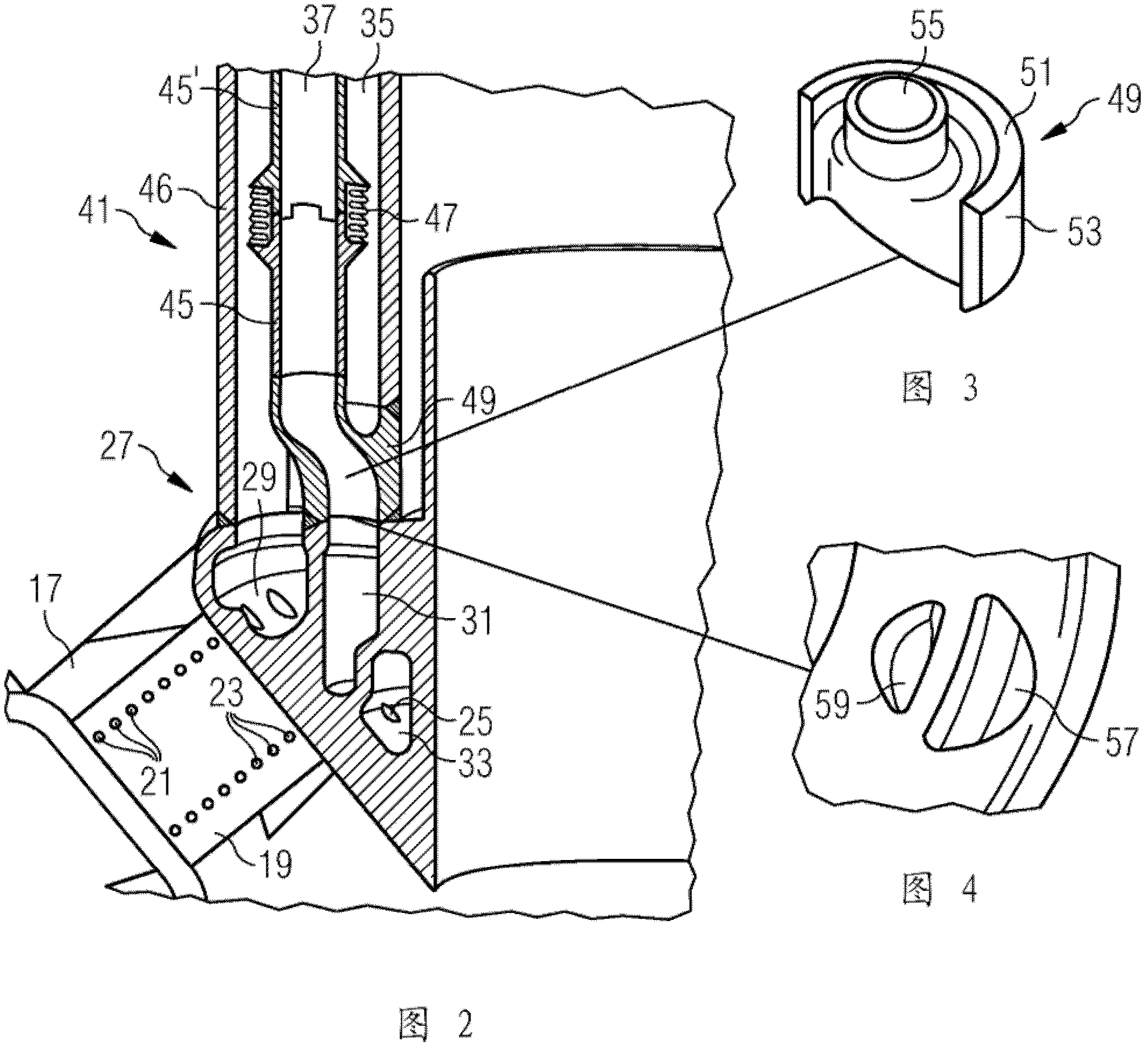

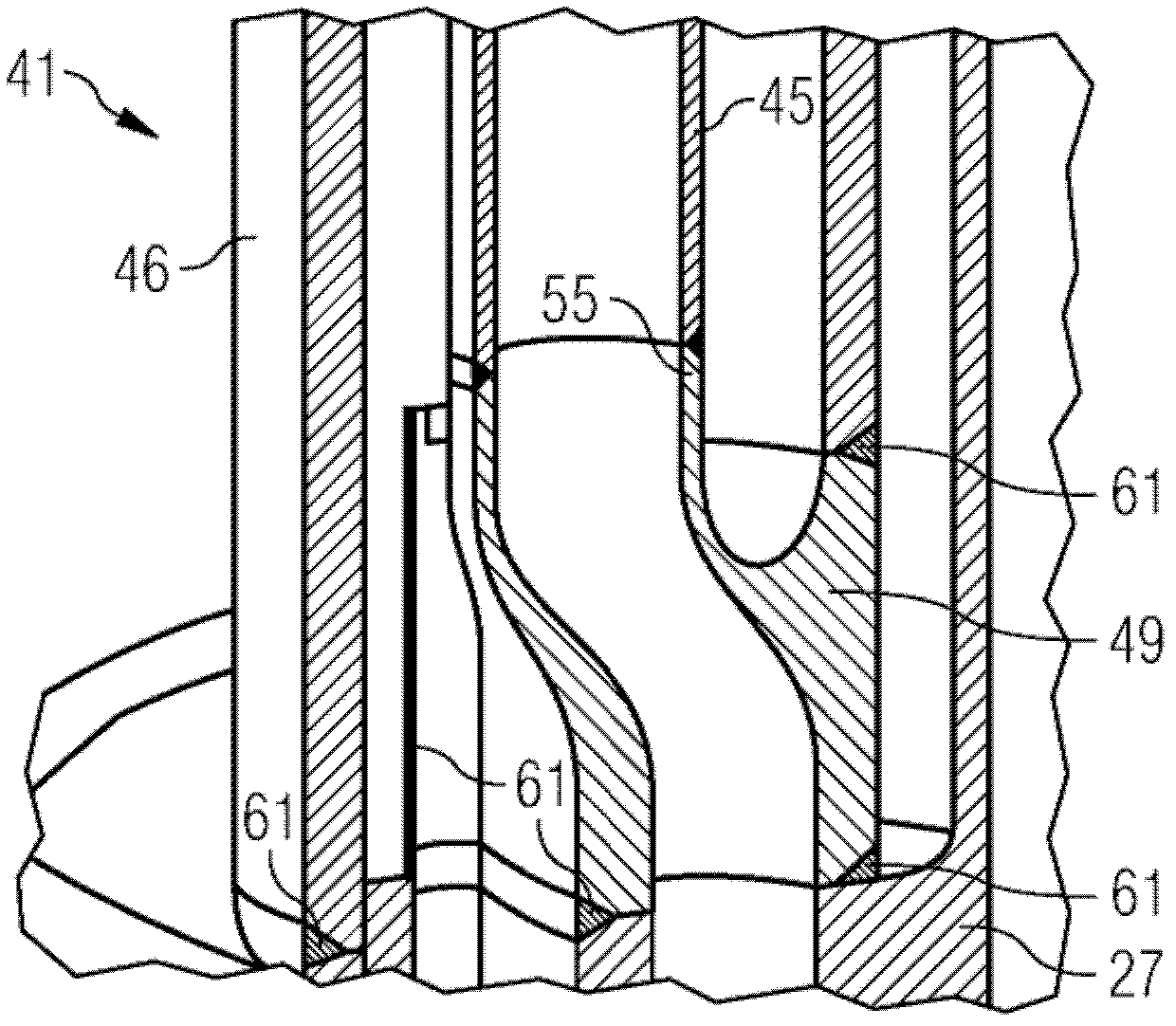

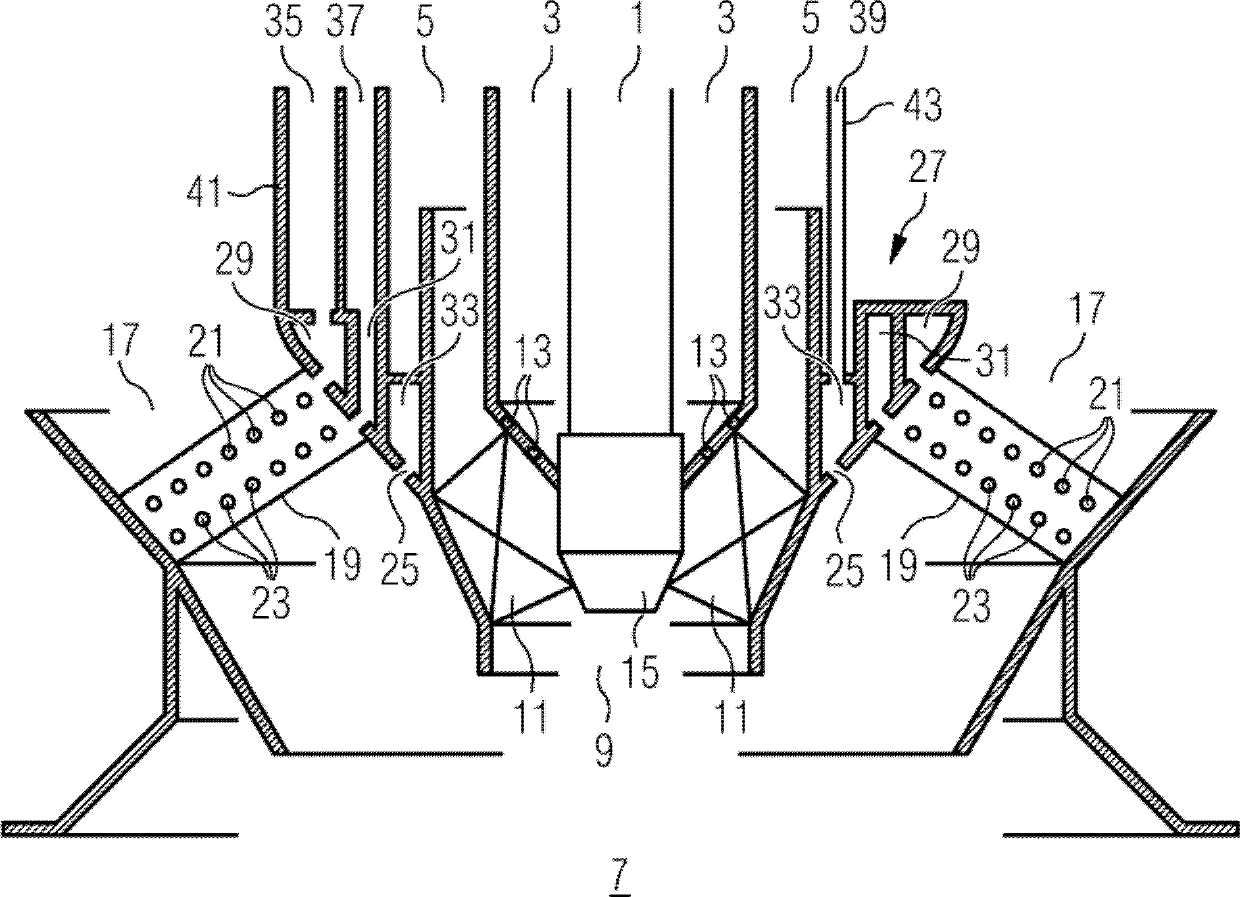

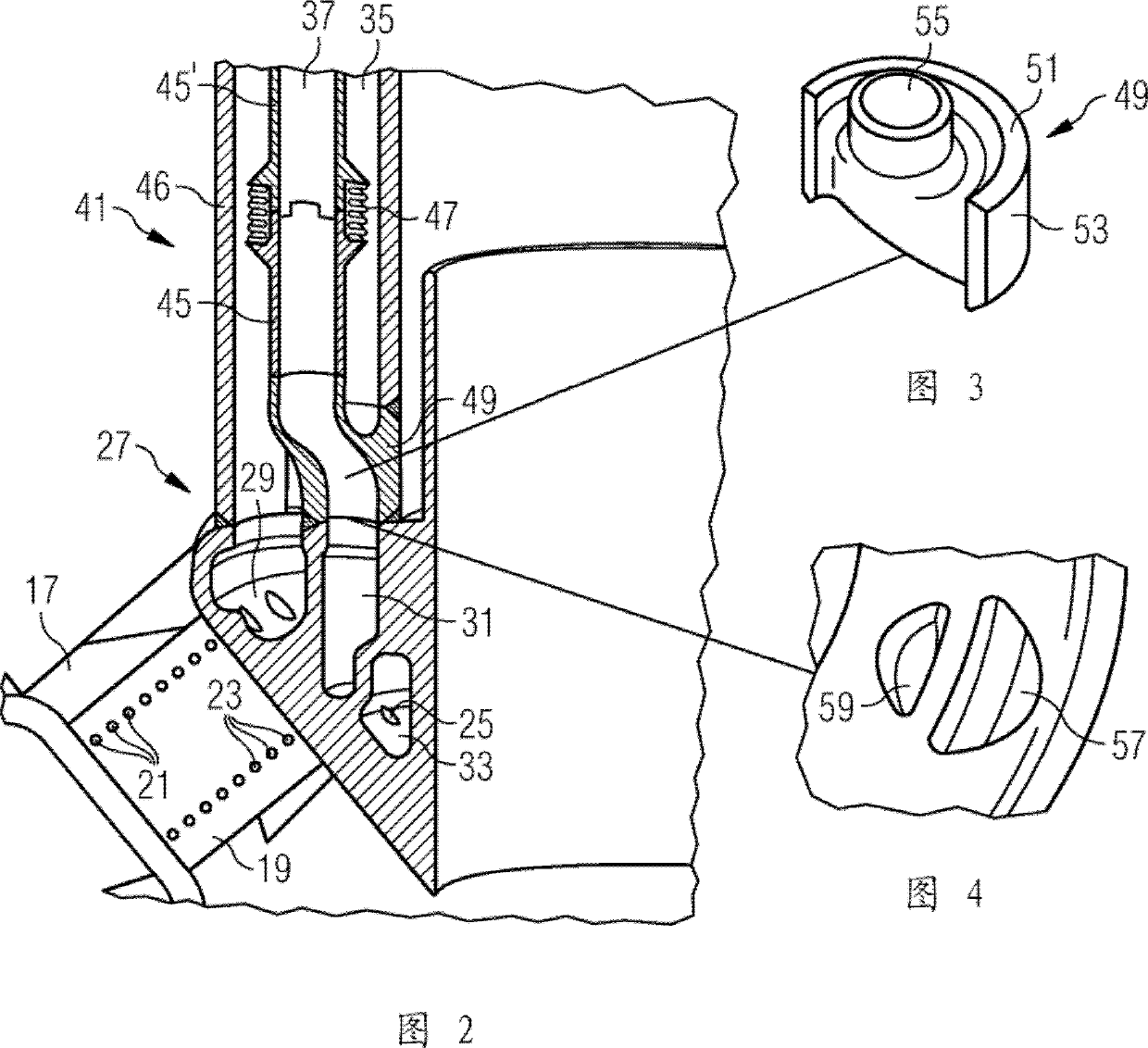

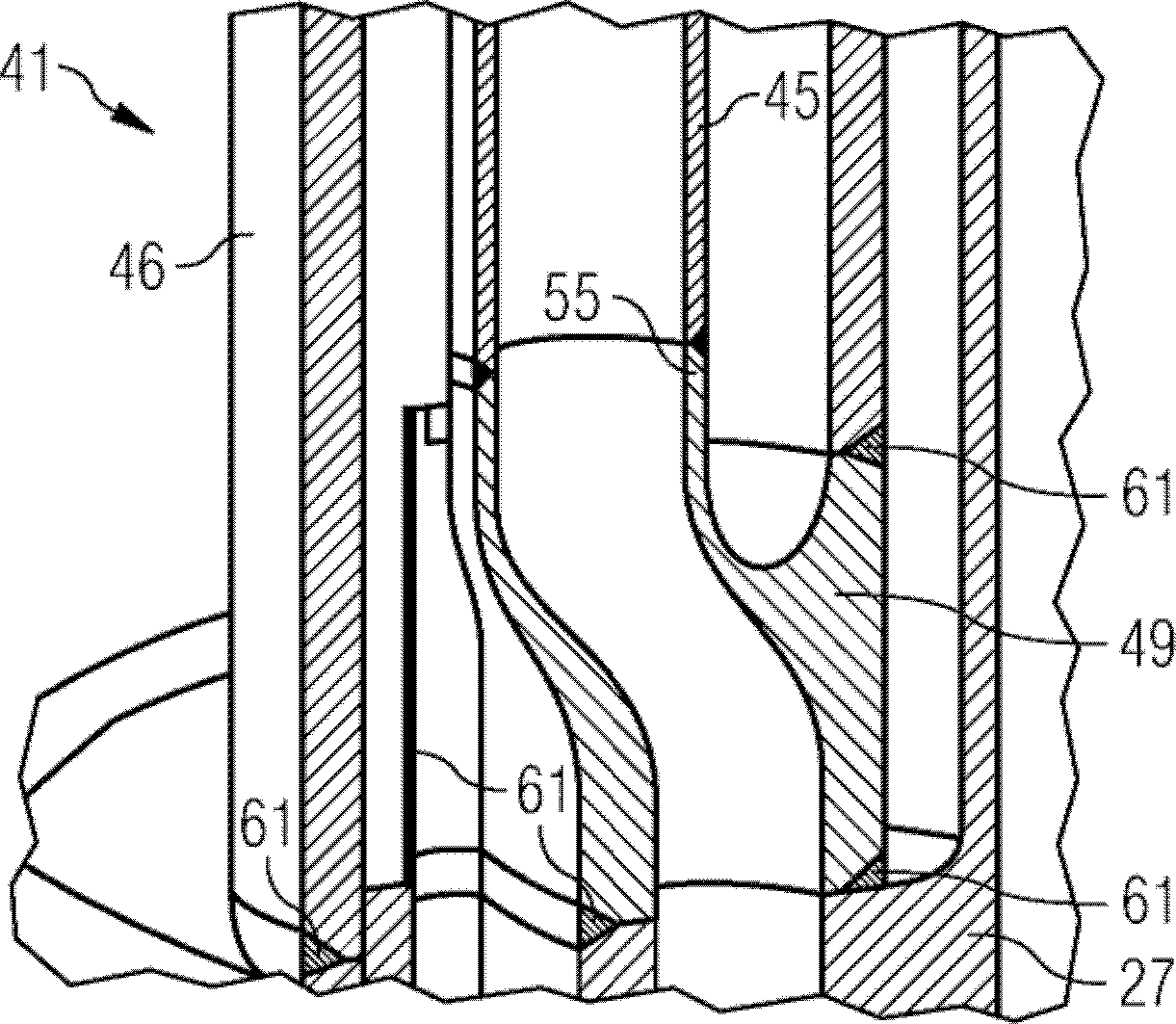

Burner, in particular for gas turbines

ActiveCN102472494ARealize the twistConstant wall thicknessBurnersContinuous combustion chamberCombustorGas supply

Provided is a burner with a central fuel supply arrangement (27), an annular air channel (17) surrounding the central fuel supply arrangement (27) for supplying combustion air, and swirl vanes (19) disposed in the annular air channel (17). The swirl vanes (19) have first gas nozzles (21) for injecting a gaseous fuel into the combustion air, and second gas nozzles (23) for injecting a gaseous fuel into the combustion air. The first gas nozzles (21) are fed from a first gas distribution channel (29) in the fuel supply arrangement (27), and the second gas nozzles (23) are fed from a second gas distribution channel (31) in the fuel supply arrangement (27). The first gas distribution channel (29) and the second gas distribution channel (31) are supplied with combustion gas from a gas supply pipe (41) which has a first gas supply channel (35) and a second gas supply channel (37), the first gas supply channel (35) being connected to the first gas distribution channel (29) and the second gas supply channel (37) being connected to the second gas distribution channel (31).

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

Modularized flexible torsion joint based on air bag inflation and deflation actuation

ActiveCN112338958ANo pollution in the processGuaranteed stabilityJointsEngineeringStructural engineering

The invention provides a modularized flexible torsion joint based on air bag inflation and deflation actuation. The modularized flexible torsion joint comprises a torsion joint outer shell, a torsionjoint inner shell and built-in air channels, wherein the torsion joint outer shell and the torsion joint inner shell are each of a cylindrical structure; the torsion joint outer shell and the torsionjoint inner shell are coaxially installed and are arranged in a relative rotation mode; a plurality of air bag sets distributed reversely and a plurality of air bag sets distributed forwards are fixedbetween the torsion joint outer shell and the torsion joint inner shell; the built-in air channels are installed in through holes in the torsion joint inner shell and the torsion joint outer shell; all the air bags distributed reversely and all the air bags distributed forwards are connected with the built-in air channels correspondingly; and the air bags distributed in the same direction are inflated at the same time to deform, and relative rotation between the torsion joint inner shell and the torsion joint outer shell is achieved. Rotation between the torsion joint inner shell and the torsion joint outer shell is triggered through inflation deformation of the air bags, and the modularized flexible torsion joint has the characteristics of being low in triggering and impact and high in flexibility.

Owner:HARBIN INST OF TECH

Burner, in particular for gas turbines

ActiveCN102472494BCompensation for thermal expansionGood inflowBurnersContinuous combustion chamberCombustorProcess engineering

Owner:SIEMENS ENERGY GLOBAL GMBH CO & KG

A powertrain anti-torsion tie rod

ActiveCN106427516BOverall light weightReduce weightJet propulsion mountingInternal combustion mountingVehicle frameAcute angle

The invention discloses a torsion resistant pull rod of a power assembly. The torsion resistant pull rod comprises a pull rod bracket, a large liner bushing and a small liner bushing, wherein the large liner bushing and the small liner bushing are respectively arranged at two ends of the pull rod bracket; the large liner bushing comprises a large liner bushing inner pipe; and the small liner bushing comprises a small liner bushing inner pipe. The torsion resistant pull rod is characterized in that the upper surface of the pull rod bracket is a flat end surface; the central axis of the small liner bushing inner pipe is parallel to the upper surface of the pull rod bracket; an oblique obtuse angle is formed between the central axis of the large liner bushing inner pipe and the upper surface of the pull rod bracket; when one end of the pull rod bracket is connected with the power assembly through the small liner bushing, an oblique acute angle is formed between the upper surface of the pull rod bracket and a level surface; and the difference between the oblique obtuse angle and the oblique acute angle is 90 degrees. The torsion resistant pull rod disclosed by the invention has the advantages that after the pull rod bracket of the torsion resistant pull rod is mounted in a preset angle, the upper surface or the lower surface of the large liner bushing inner pipe can be mounted on a vehicle body or a sub vehicle frame in a flat clinging manner, so that the mounting stability and the whole using stability of the torsion resistant pull rod are guaranteed.

Owner:NINGBO TUOPU GROUP CO LTD

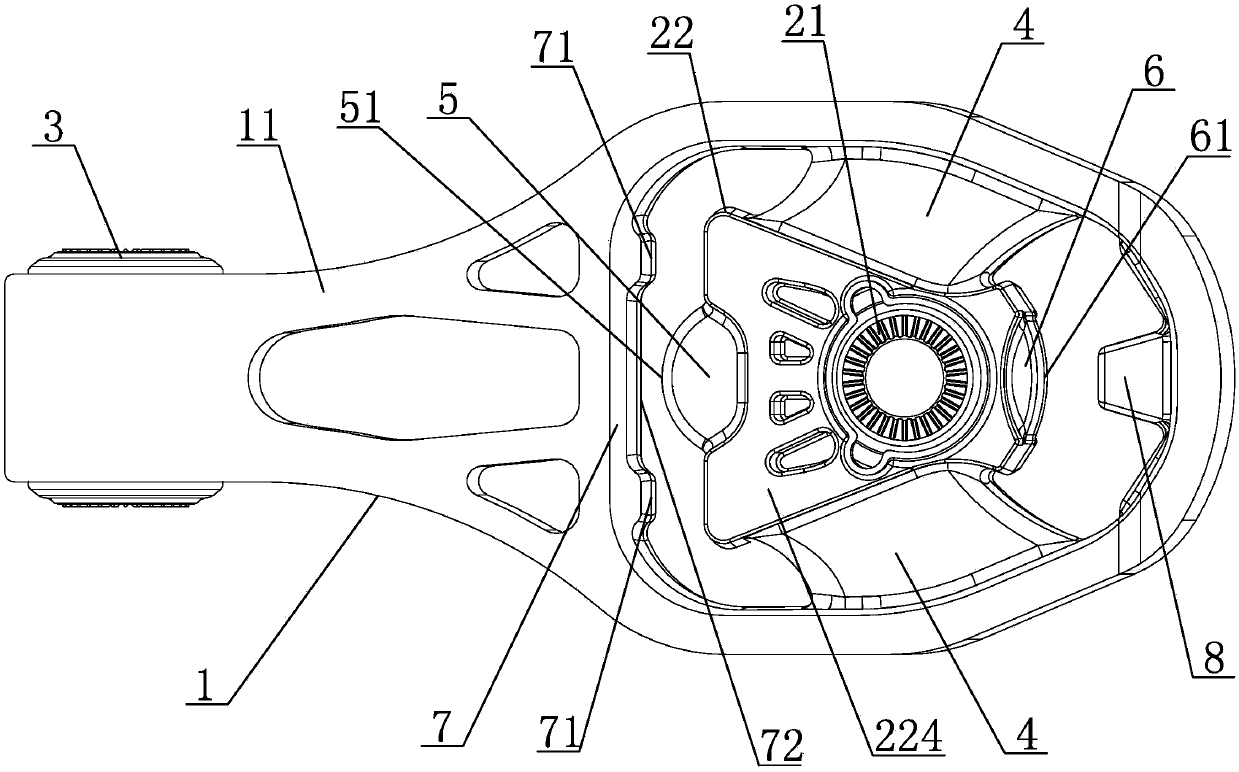

a twisting machine

ActiveCN109903932BRealize the twistEffective clampingCable/conductor manufactureElectric machineryEngineering

The invention relates to a twister and relates to the technical field of mechanical equipment. Through the twister, the problem that even though equipment capable of automatically twisting a core wireis available in the prior art, the existing equipment only can realize simple twisting operation, manual operation is still needed for clamping the core wire, and the situation is troublesome is solved. The twister comprises a wire clamping component, a rotation driving motor, an installation base plate, an adjustment plate and a clamping port adjustment cylinder. The twister has the effects thatthe core wire can be clamped and twisted, and the trouble of manual clamping is avoided.

Owner:深圳市新杰斯锐电子科技有限公司

High-efficiency assembly mechanism for bottle caps

ActiveCN109175928BEasy to adjustConvenient supplementMetal working apparatusPharmaceutical packagingBottle cap

The invention relates to the technical field of pharmaceutical packaging supplies, and particularly discloses a bottle cap high-efficiency assembly mechanism comprising a bracket, an insertion and plugging mechanism and a first feeding mechanism; the first feeding mechanism comprises a first vibration component and a first tapered charging tray which is provided with a first screw conveyer track and a second screw conveyer track, and the first screw conveyer track comprises a first screw conveyer section, a second screw conveyer section, a first torsion section and a third screw conveyer section; the second screw conveyer track comprises a first screw feeding section, a second screw feeding section, a third screw feeding section and a fourth screw feeding section; and the insertion and plugging mechanism comprises a vacuum pump, a top tray, a base tray, a semicircular guide block, a regulating part, a first driving disk, a second driving disk, a conveying fluted disk, first driving parts and second driving parts. The high-efficiency assembly mechanism has the characteristics of higher automation degree and assembly efficiency, better assembly effect, product quality guarantee, lower labor cost and higher safety.

Owner:浙江冠利新材料股份有限公司

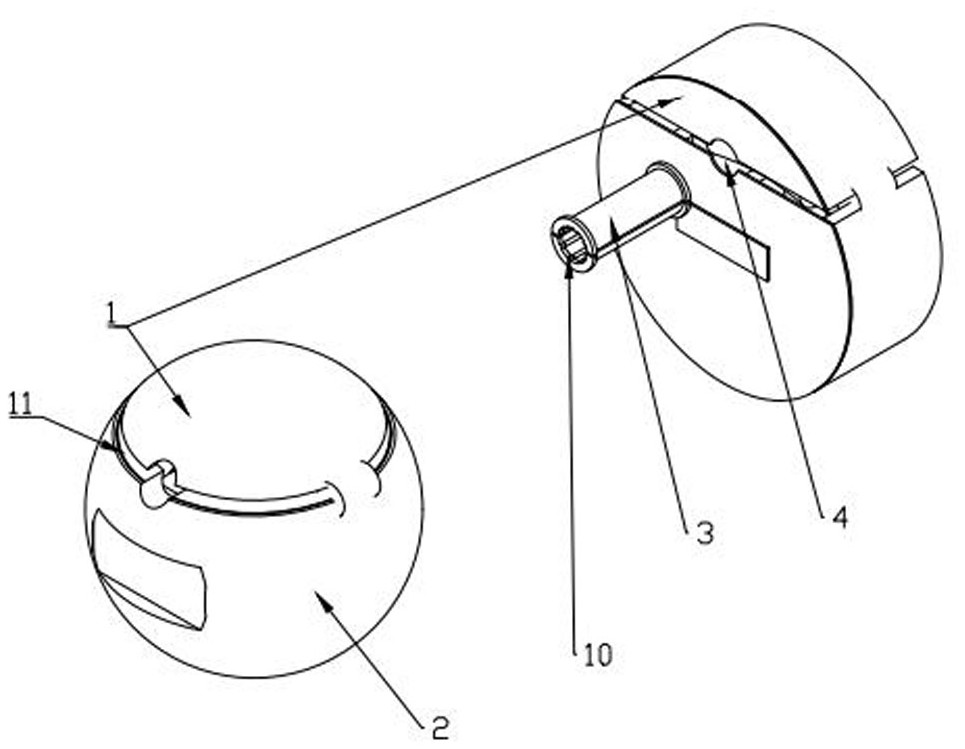

Cable length metering device in tunnel construction

PendingCN114279382ASimple structureRealize length measurementTesting dielectric strengthShort-circuit testingArchitectural engineeringHand held devices

The invention relates to the field of measuring equipment in tunnel construction, in particular to a cable length metering device in tunnel construction. The problems that cable length measurement is difficult and equipment is numerous and jumbled in tunnel construction at the present stage are solved. The device comprises at least one spherical or cylindrical shell, the shell comprises an upper cover and a lower base which are hinged and connected, cable through holes are formed in the center positions of the upper cover and the lower base, a top pressing roller tangent to a cable is arranged in the upper cover, a bottom top roller is arranged in the lower base, and the bottom top roller is connected with a meter counter for recording the rotating speed of the bottom top roller. The device has the advantages that the whole device serves as a handheld device, is small in size, convenient to carry and diversified in function, and can have multiple functions in tunnel construction occasions.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com