Burner, in particular for gas turbines

A technology for burners and combustion appliances, which is applied in the directions of burners, combustion chambers, and combustion methods, and can solve problems such as changing the design of the burner.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

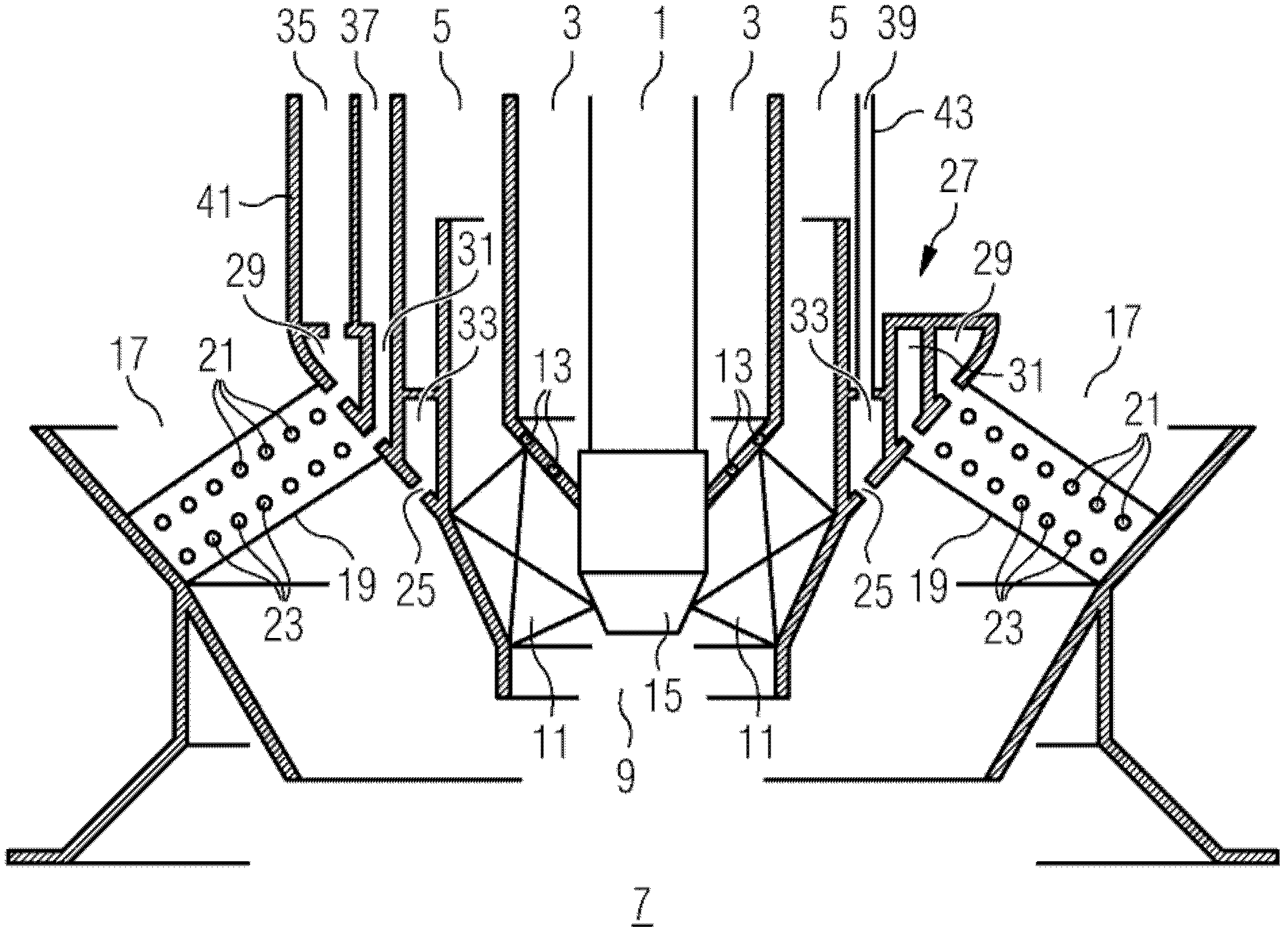

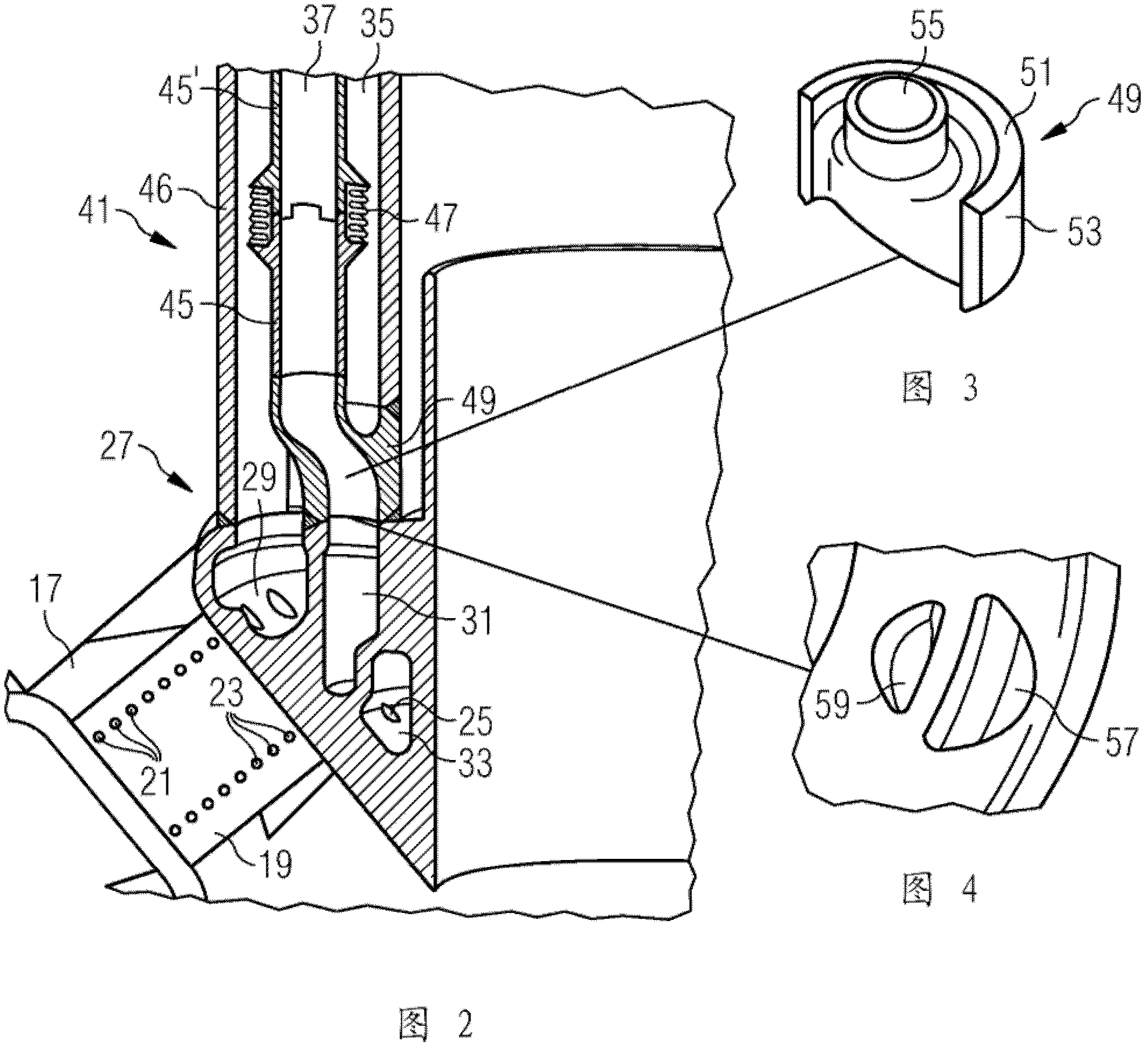

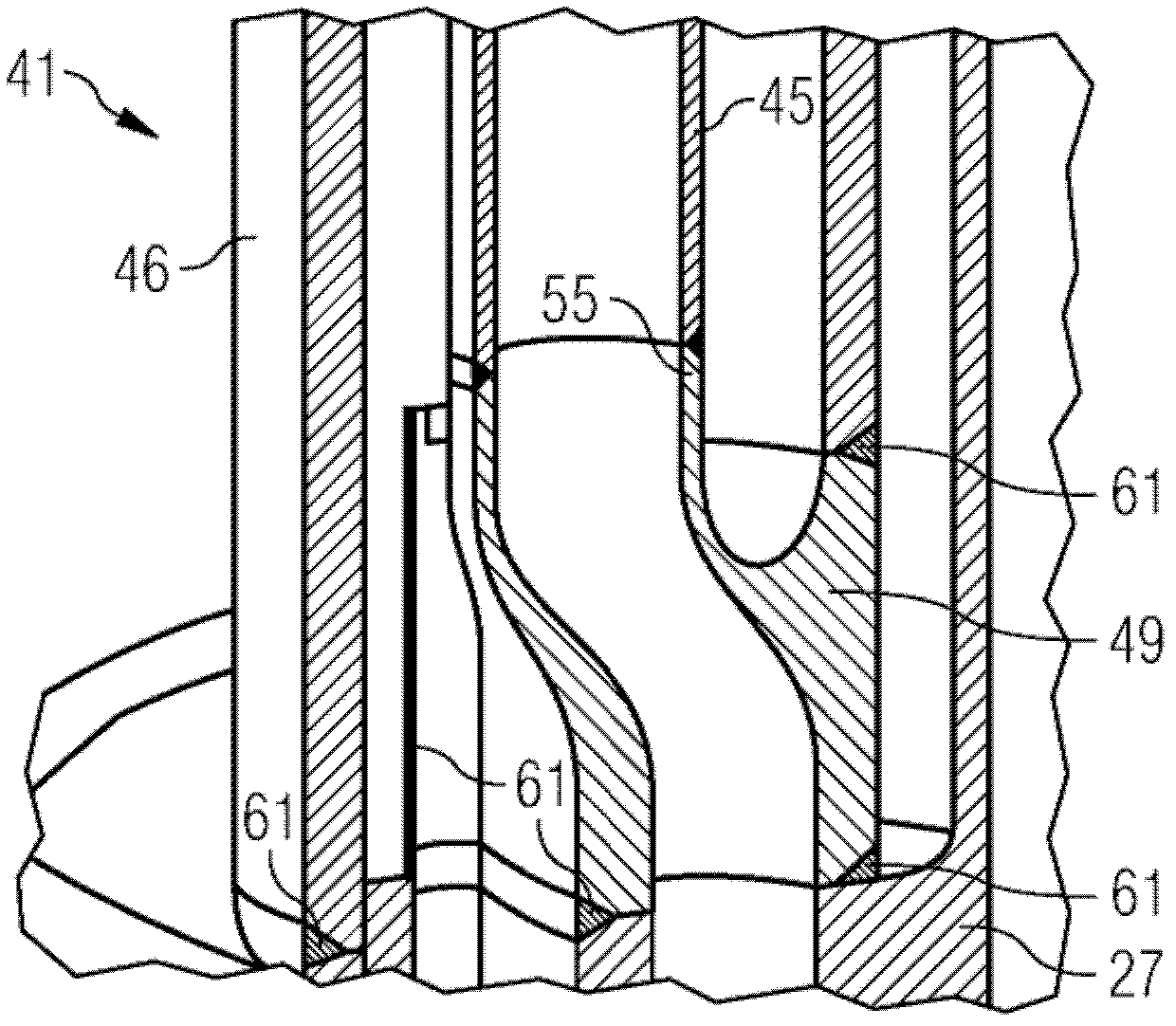

[0028] The burner according to the invention is shown in a clearly schematic schematic diagram below with reference to figure 1 Describe the scheme that is the basis for the burner.

[0029] A burner according to the invention can optionally be arranged in combination with several burners of the same type in the combustion chamber of a gas turbine plant, the burner comprising an inner pilot burner system and a main combustion chamber concentrically surrounding the pilot burner system device system. Both the pilot burner system and the main burner system can optionally be operated with gaseous and / or liquid fuels such as natural gas or fuel oil.

[0030] The pilot burner system comprises an inner oil delivery channel 1 which is concentrically surrounded by an inner annular gas delivery channel 3 . This gas delivery channel is in turn surrounded concentrically by the inner air delivery channel or inert gas delivery channel 5 . Furthermore, a suitable ignition system (not show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com