Patents

Literature

1531results about How to "Effective clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

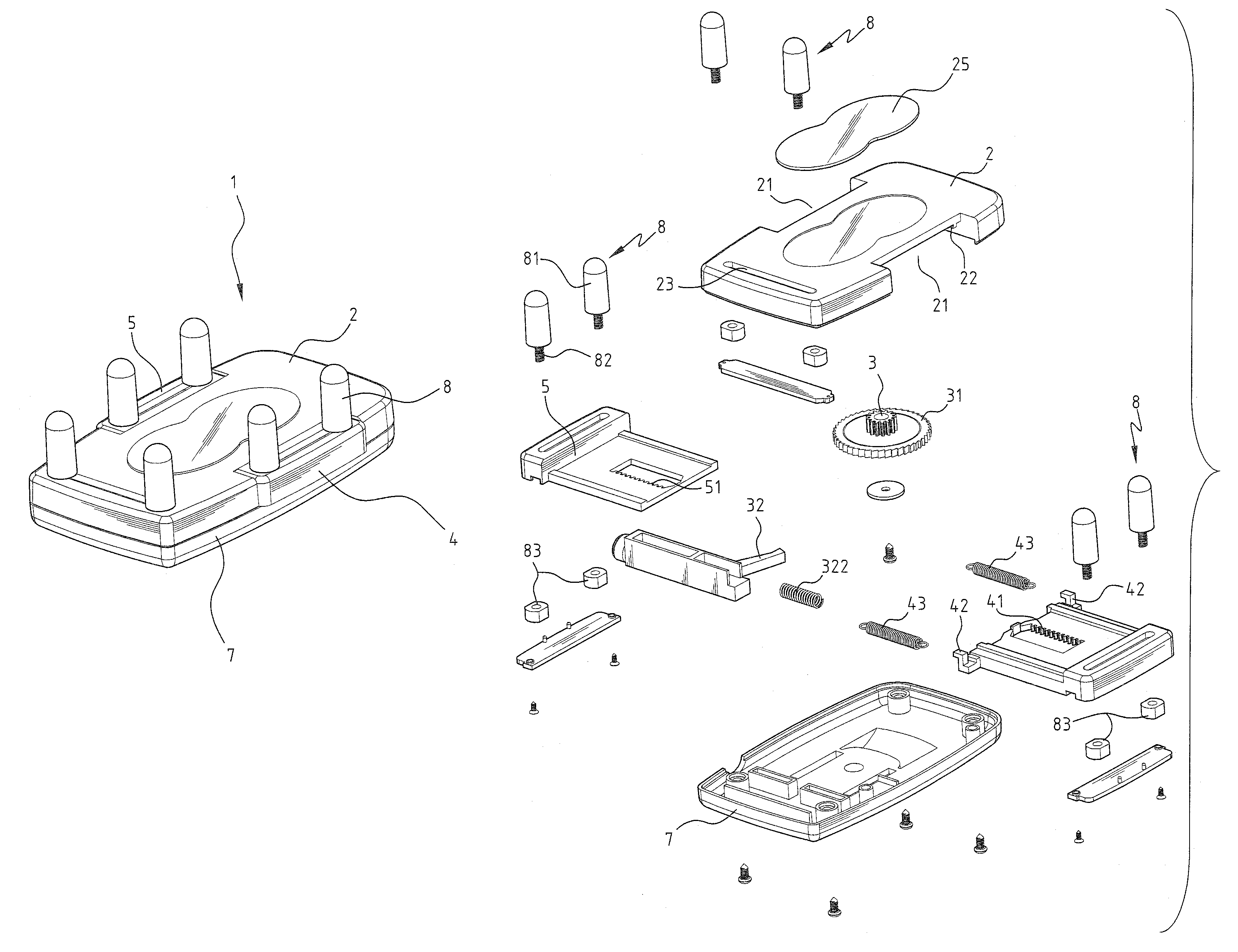

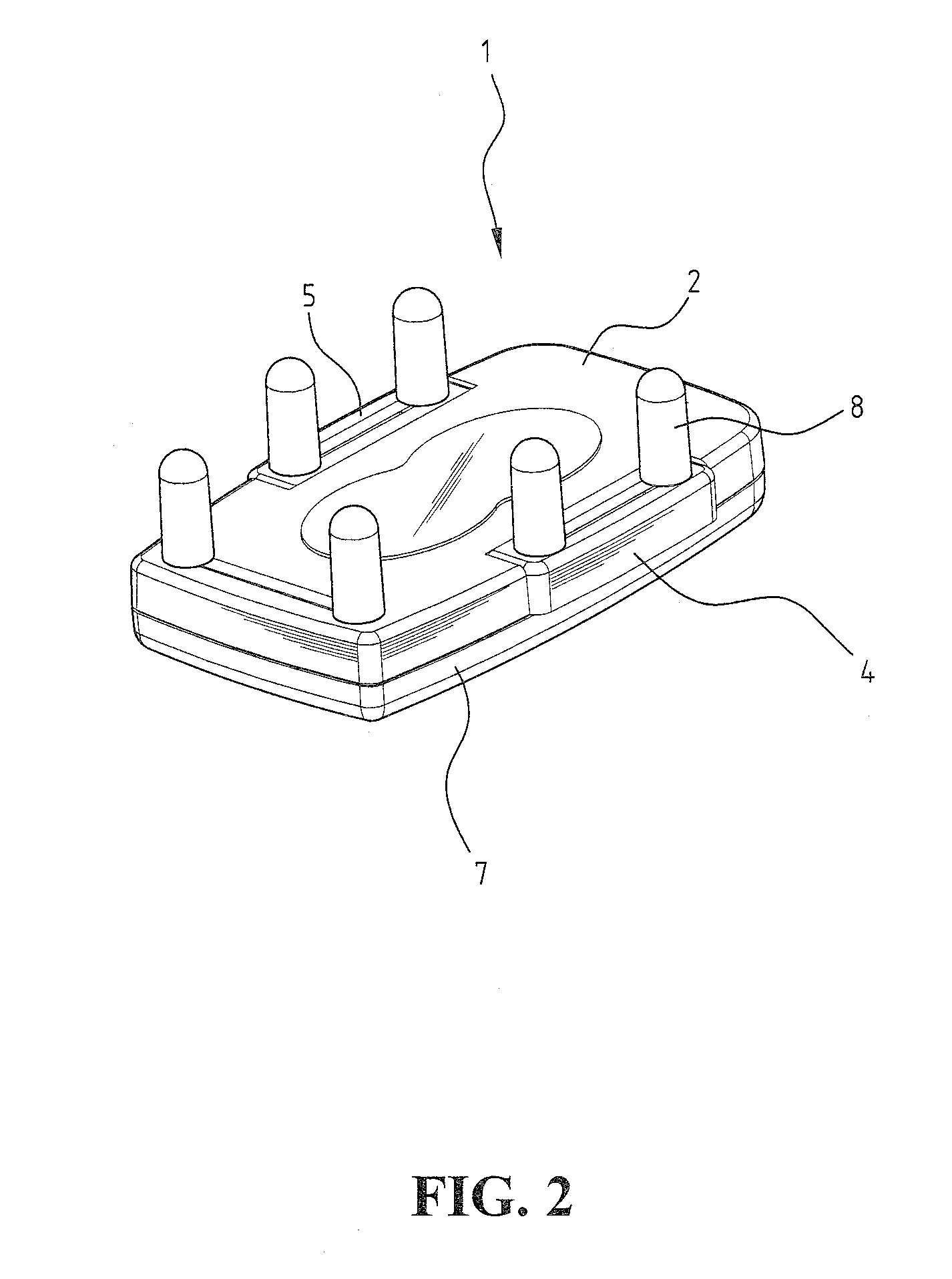

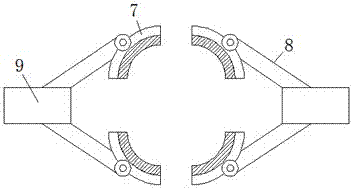

Communication device holder for vehicles

InactiveUS7407143B1Increase flexibilitySimple structurePicture framesDomestic mirrorsRight flankCommunication device

A communication device holder for vehicles includes an upper cover and a lower cover cooperating with the upper cover; a left wing member and a right wing member, which are horizontally displaceable, are disposed in between the upper cover and the lower cover; one end of the left wing member is formed with at least one clamping jaw, and the other end of the left wing member is formed with a horizontal rack; one end of the right wing member is formed with at least one clamping jaw, and the other end of the right wing member is formed with the horizontal rack and at least one raised portion, and the raised portion is connected with a post formed on the upper cover through a spring; the spring pushes the right wing member to displace towards the outside of the upper cover.

Owner:SUPA TECH

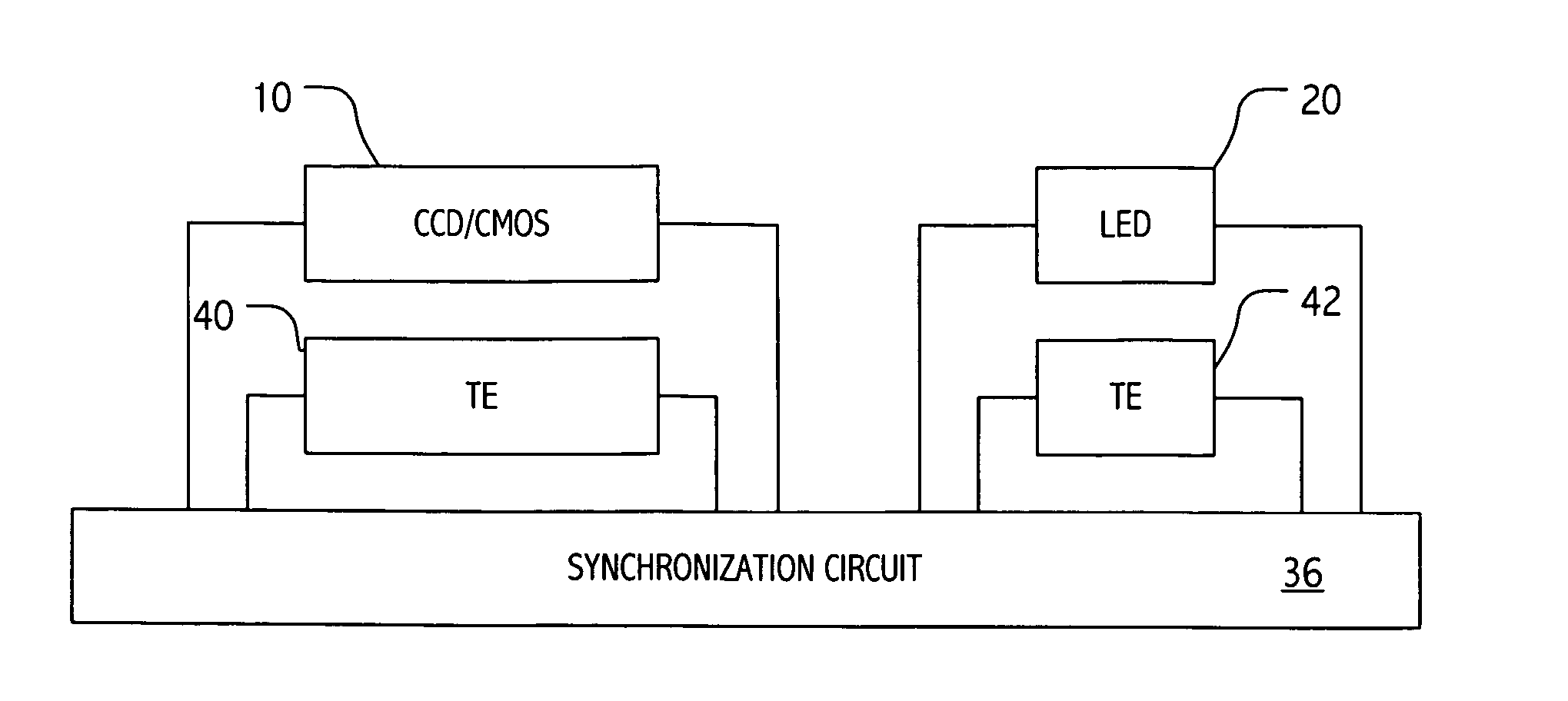

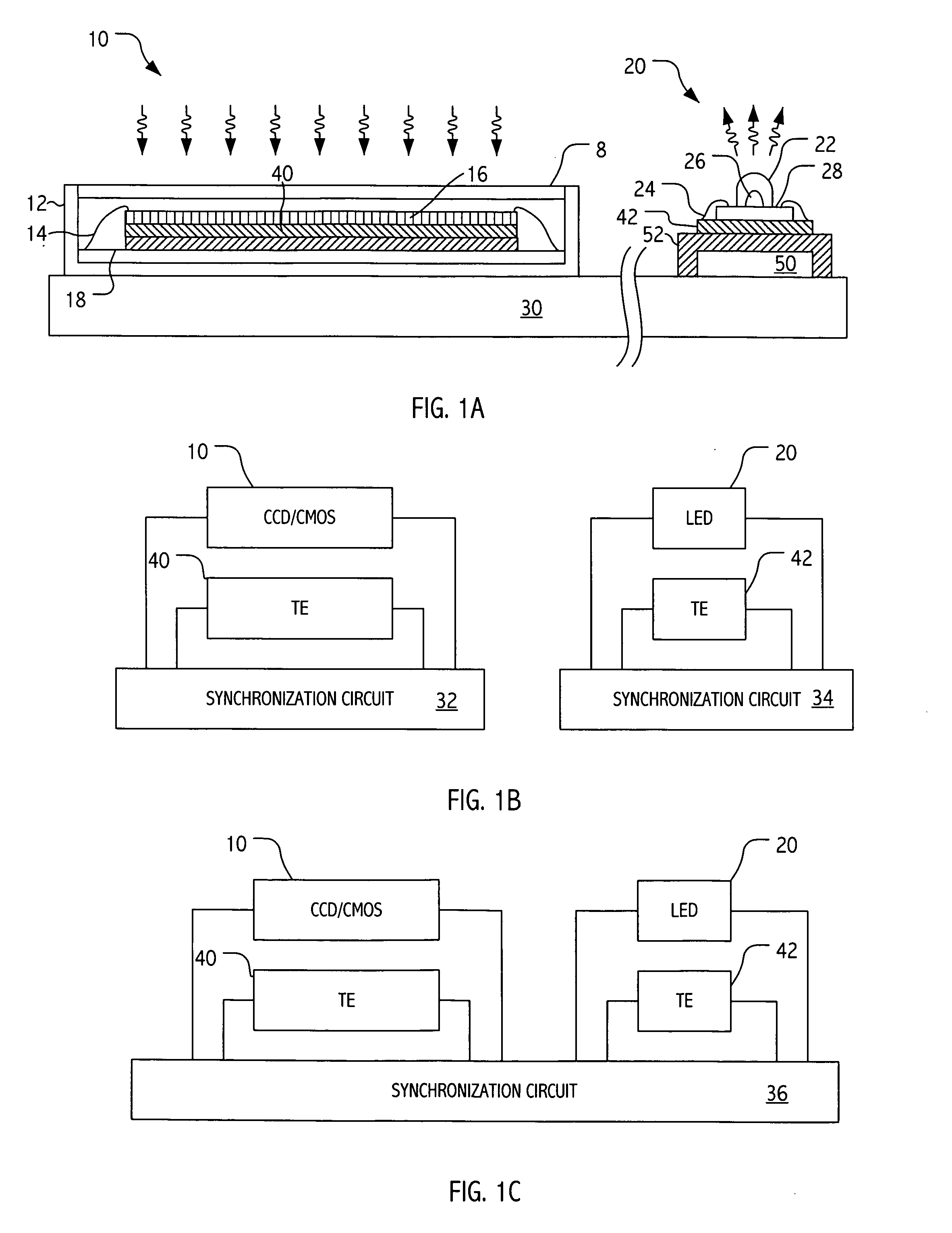

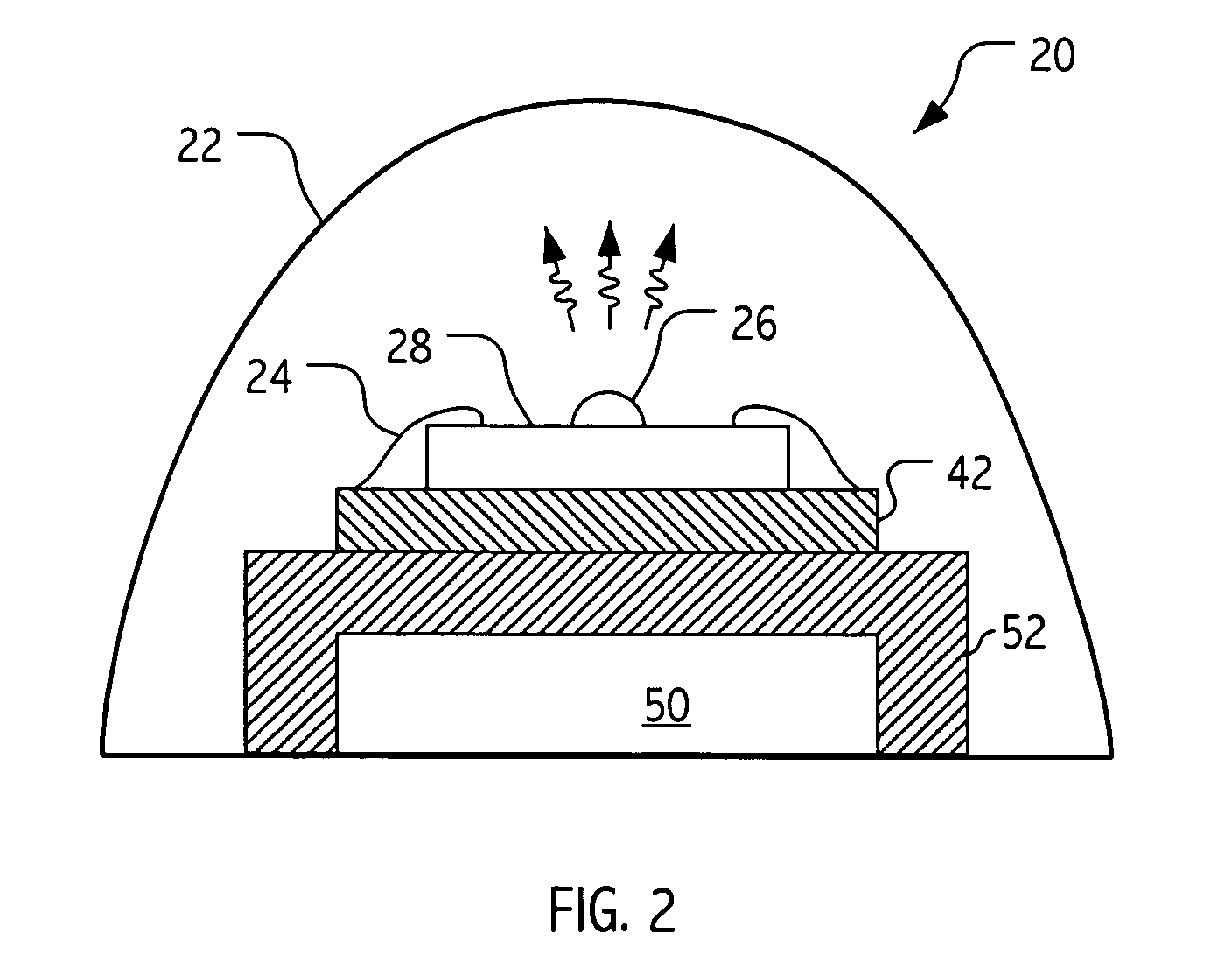

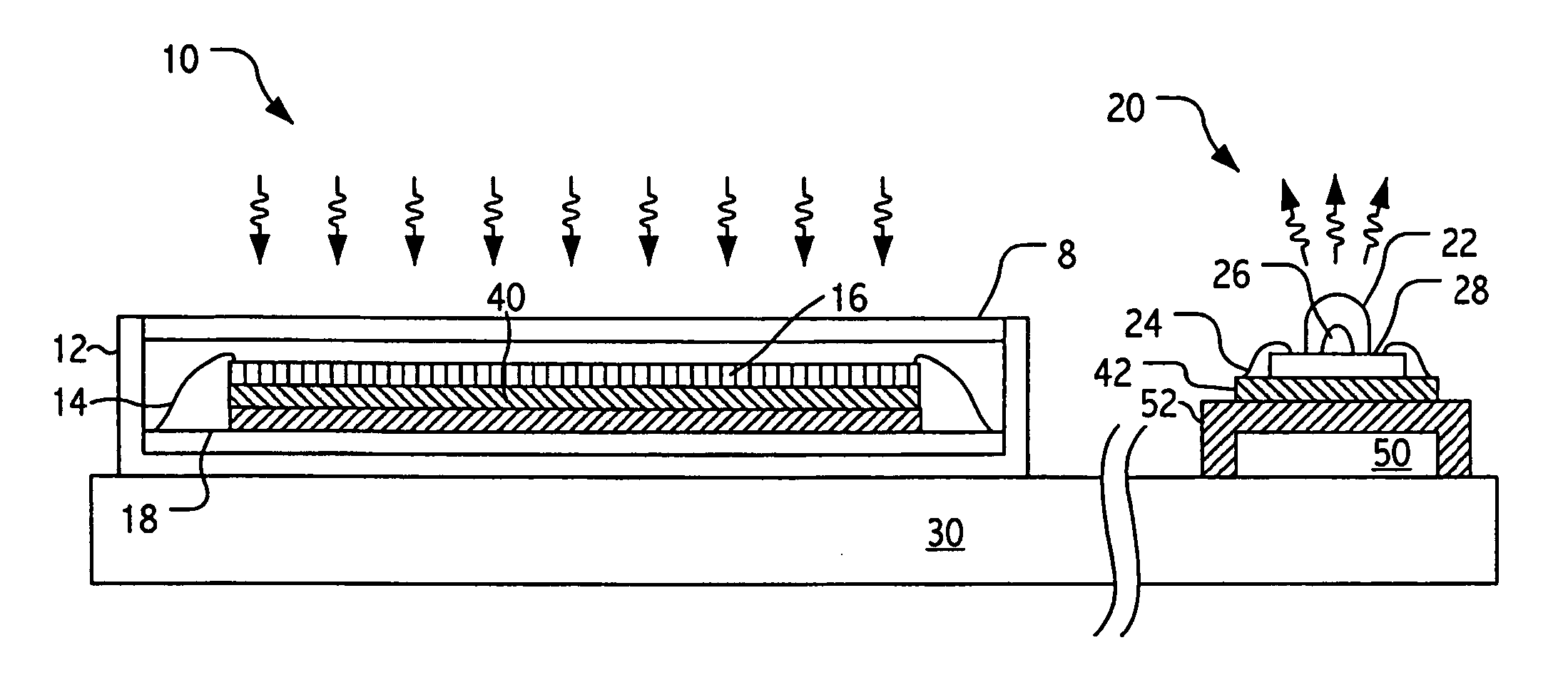

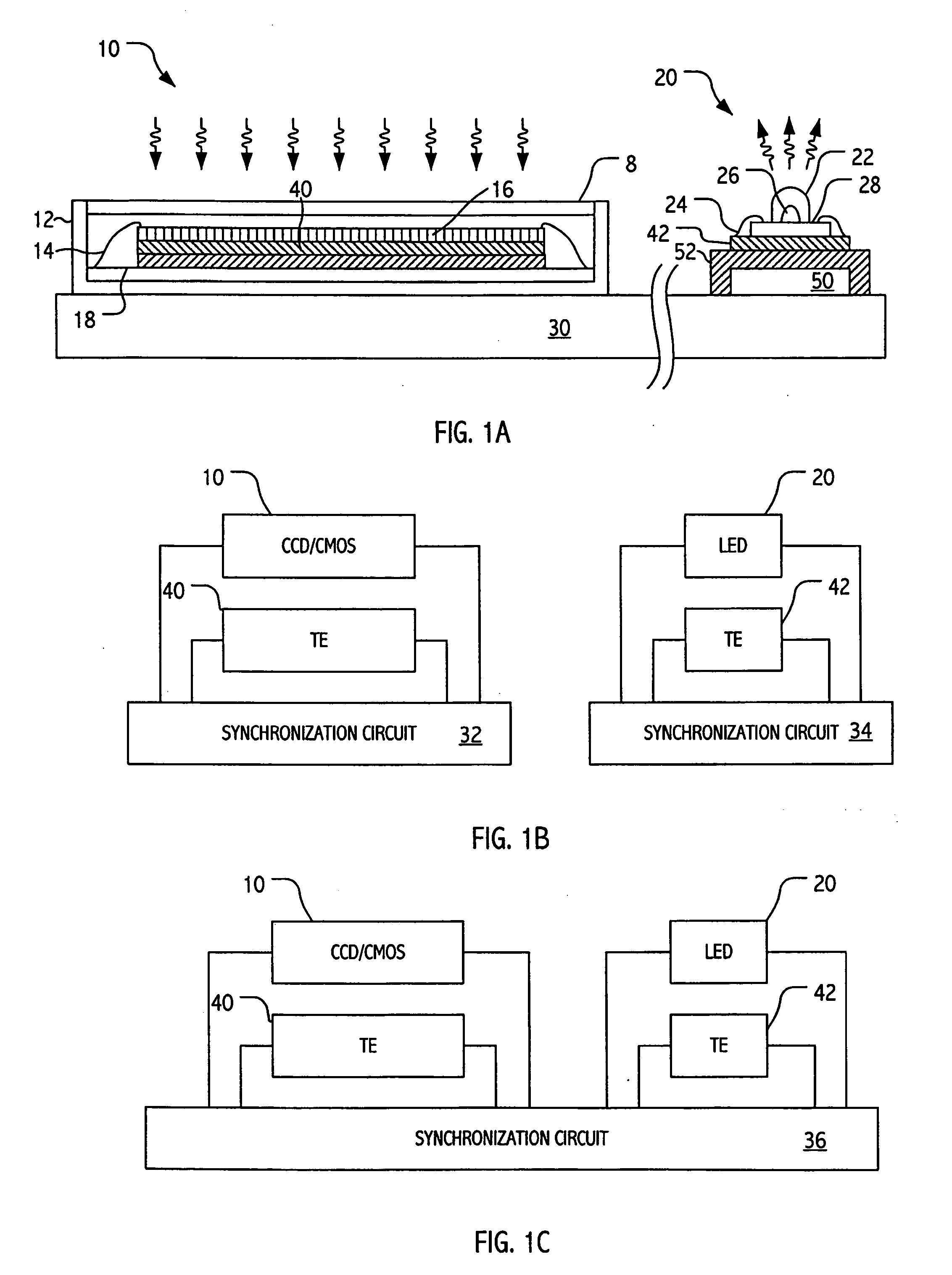

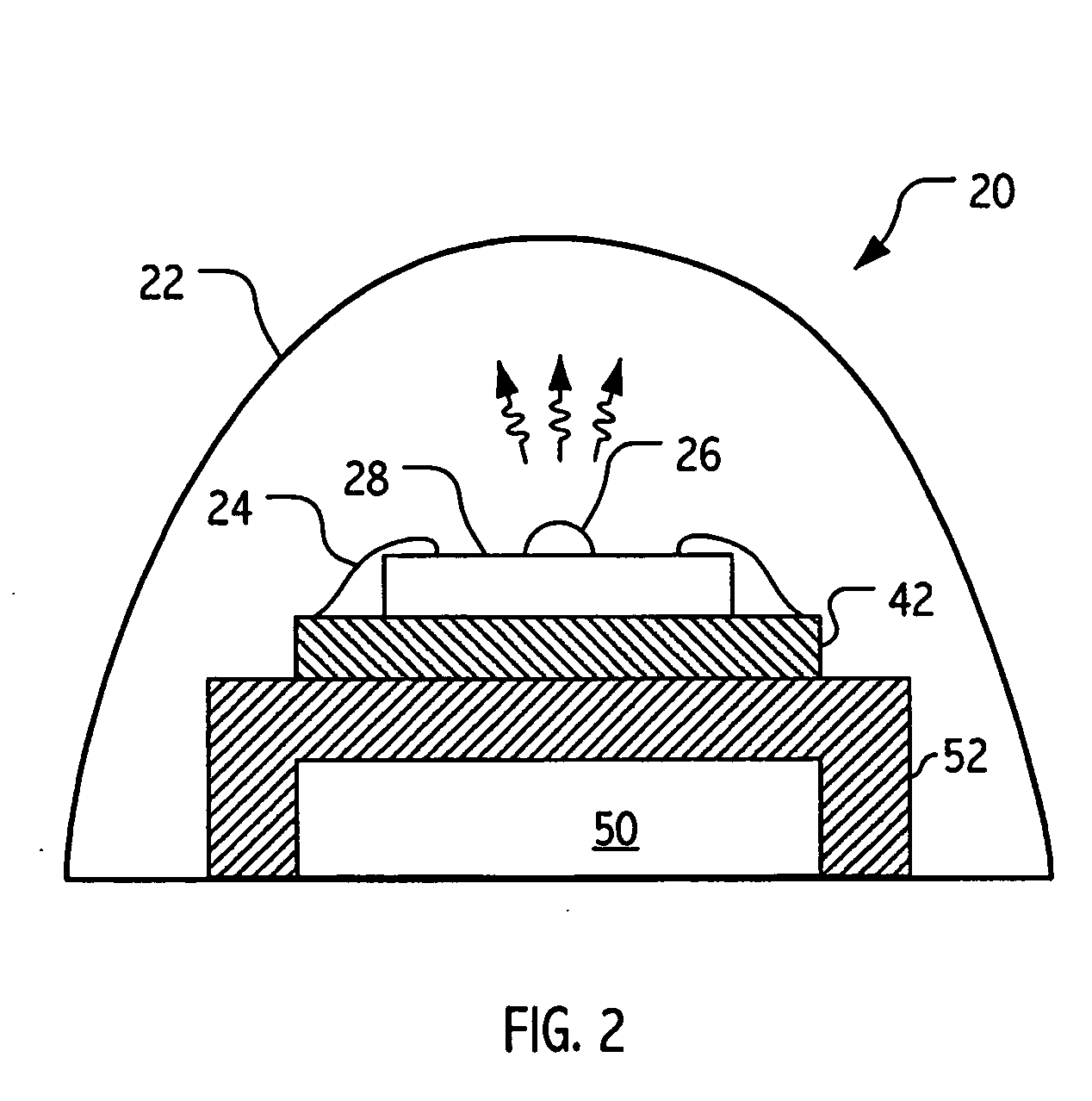

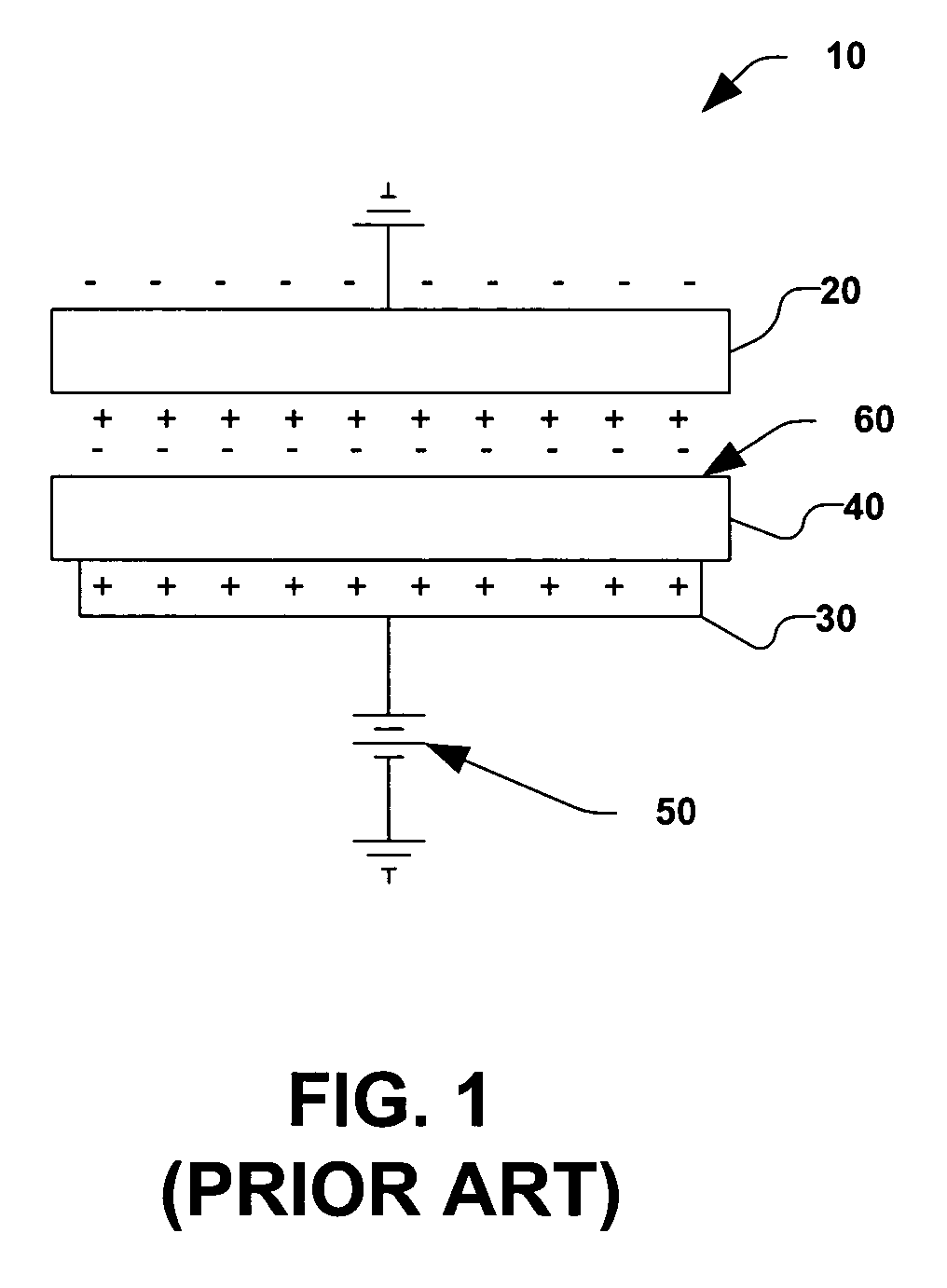

Transient thermoelectric cooling of optoelectronic devices

InactiveUS20060088271A1Reduce the temperatureEffective clampingPrinted circuit aspectsSolid-state devicesThermoelectric coolingHeat flux

A thermoelectric cooler may be transiently operated in substantial synchronization with operation of an optoelectronic device to provide extremely high density and intensity spot cooling when and where desired. The invented techniques described and illustrated herein can permit high luminous flux and / or longer lifetimes for a class of emissive device configurations and / or uses that generate intense highly localized, but transient heat flux. For example, certain Light Emitting Diode (LED) applications, e.g., white LEDs for flash illumination, certain solid state laser configurations and other similar configurations and uses may benefit from the developed techniques. In addition, the invented techniques described and illustrated herein can be employed in sensor configurations to provide greater device sensitivity. For example, in photosensitive device applications, e.g., CCD / CMOS imagers, the invented techniques may be employed to provide greater photon sensitivity and lower dark currents.

Owner:NANOCOOLERS

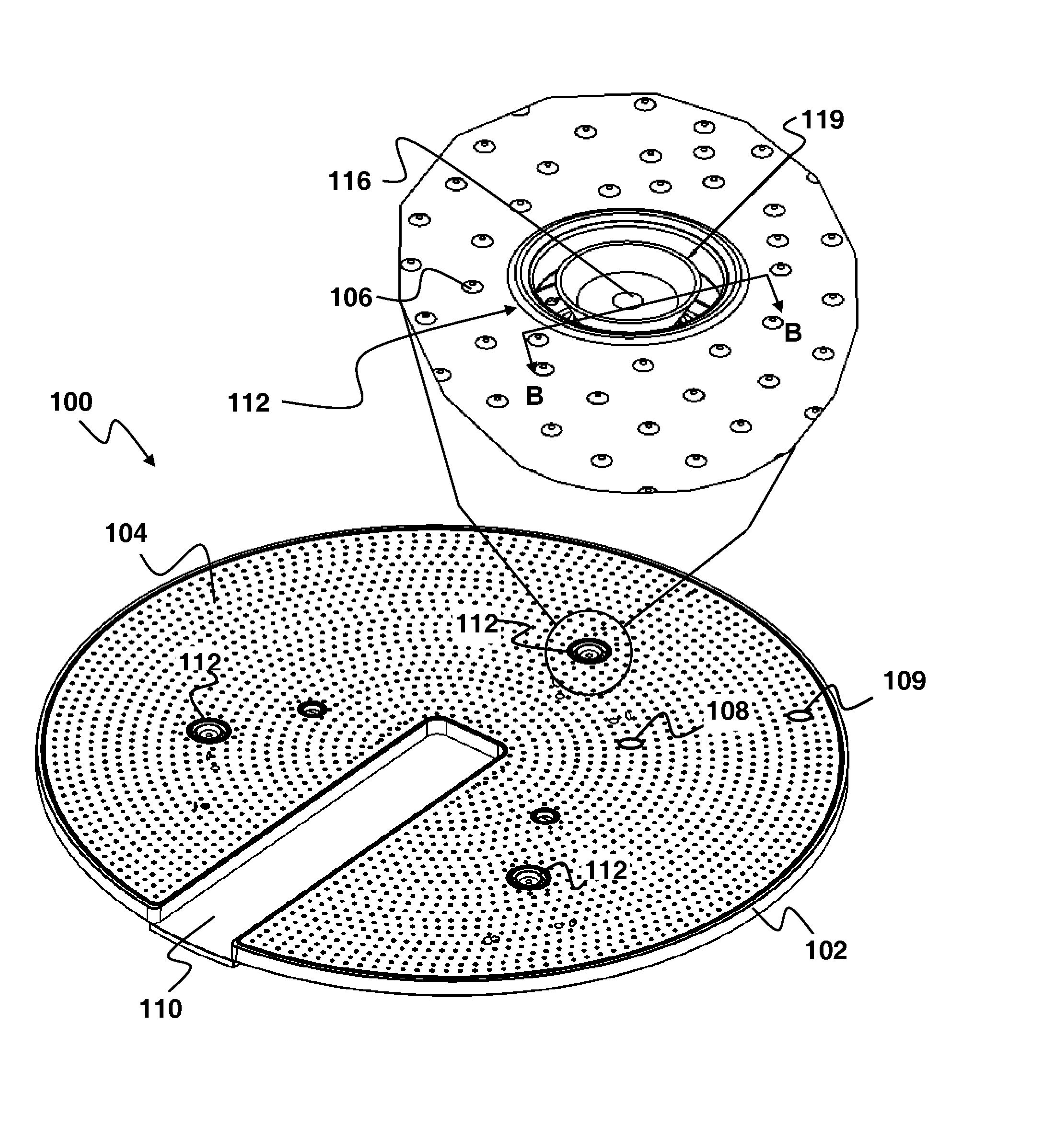

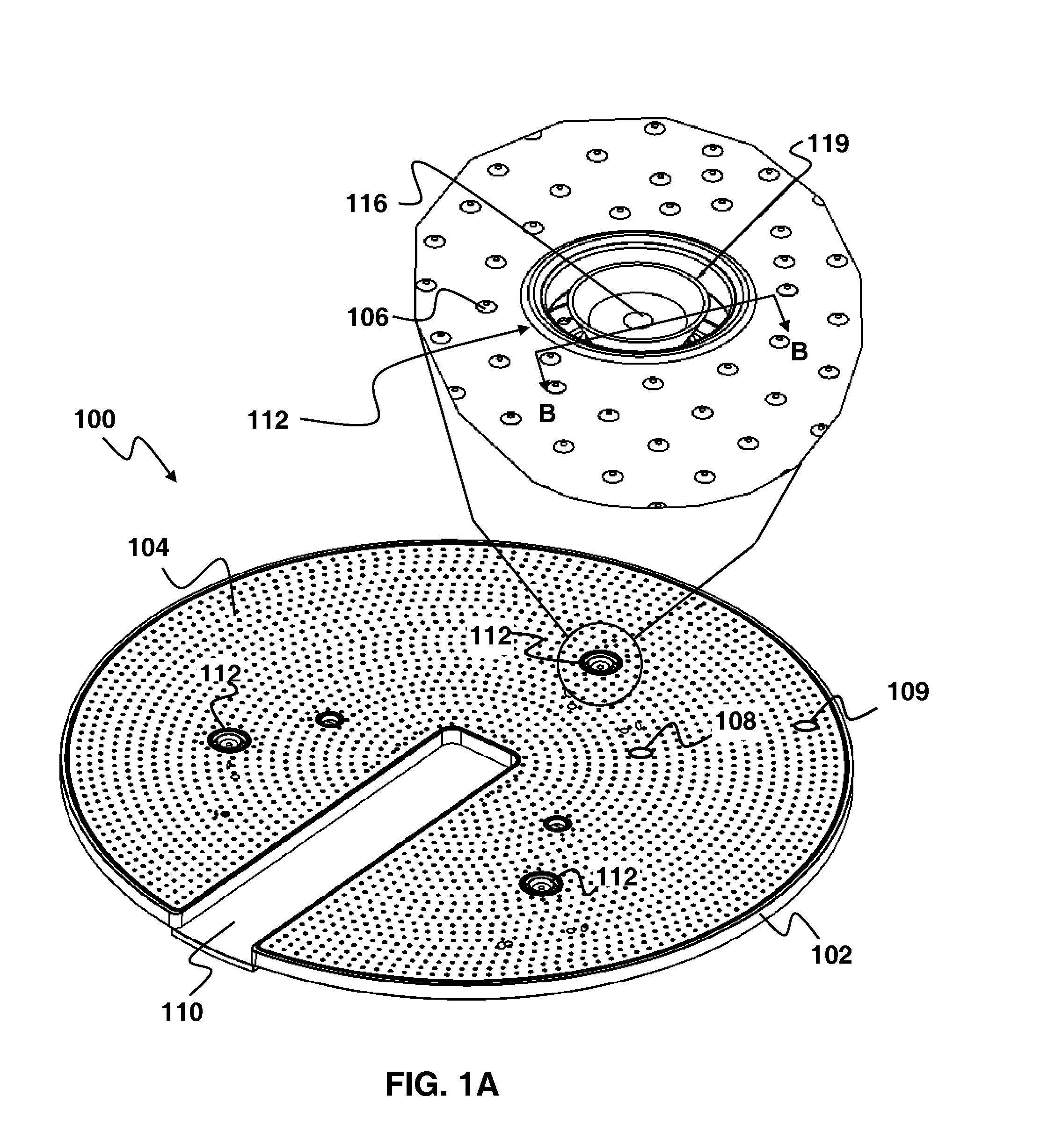

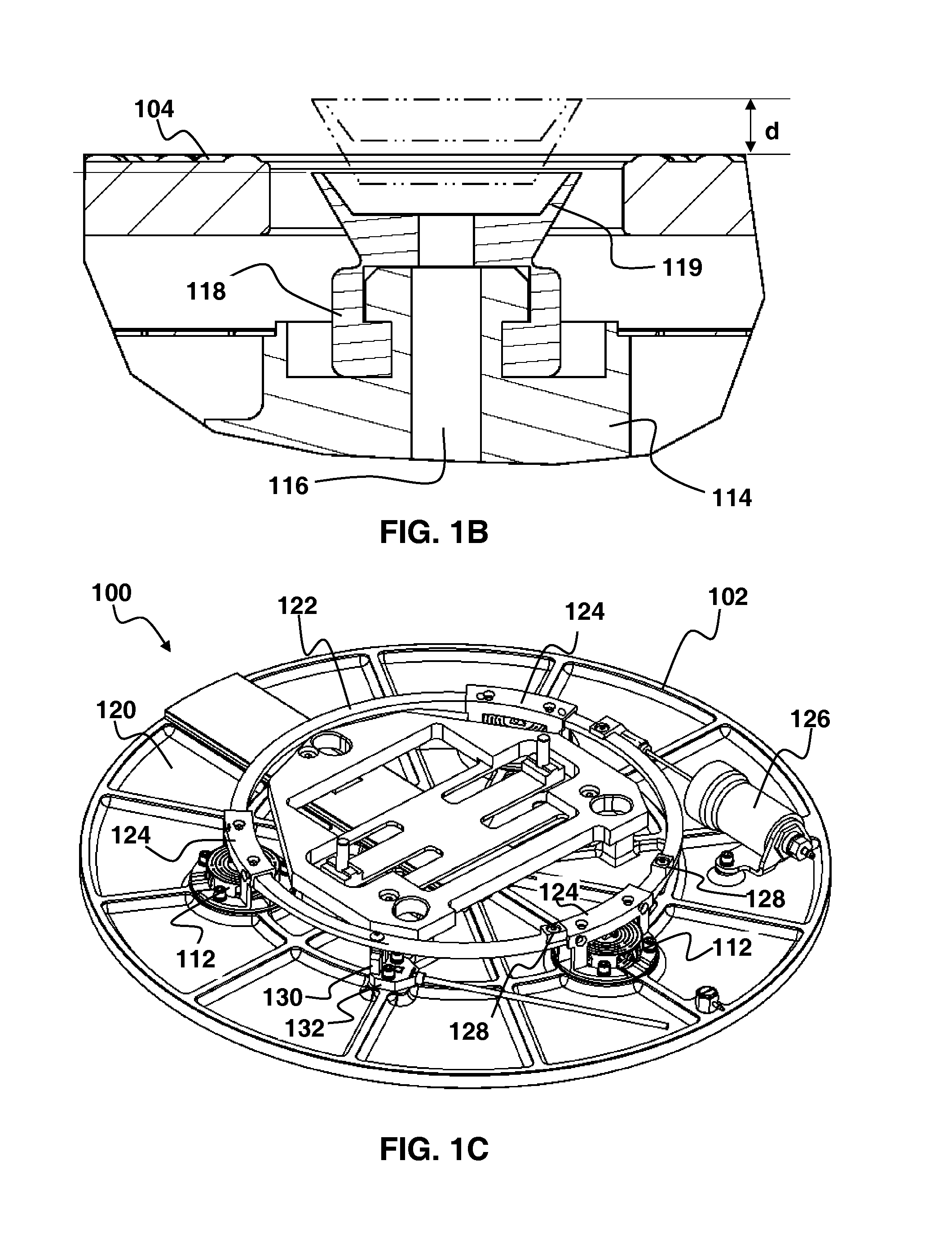

Pin lift chuck assembly for warped substrates

ActiveUS7292427B1Effective clampingSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

Owner:KLA TENCOR TECH CORP

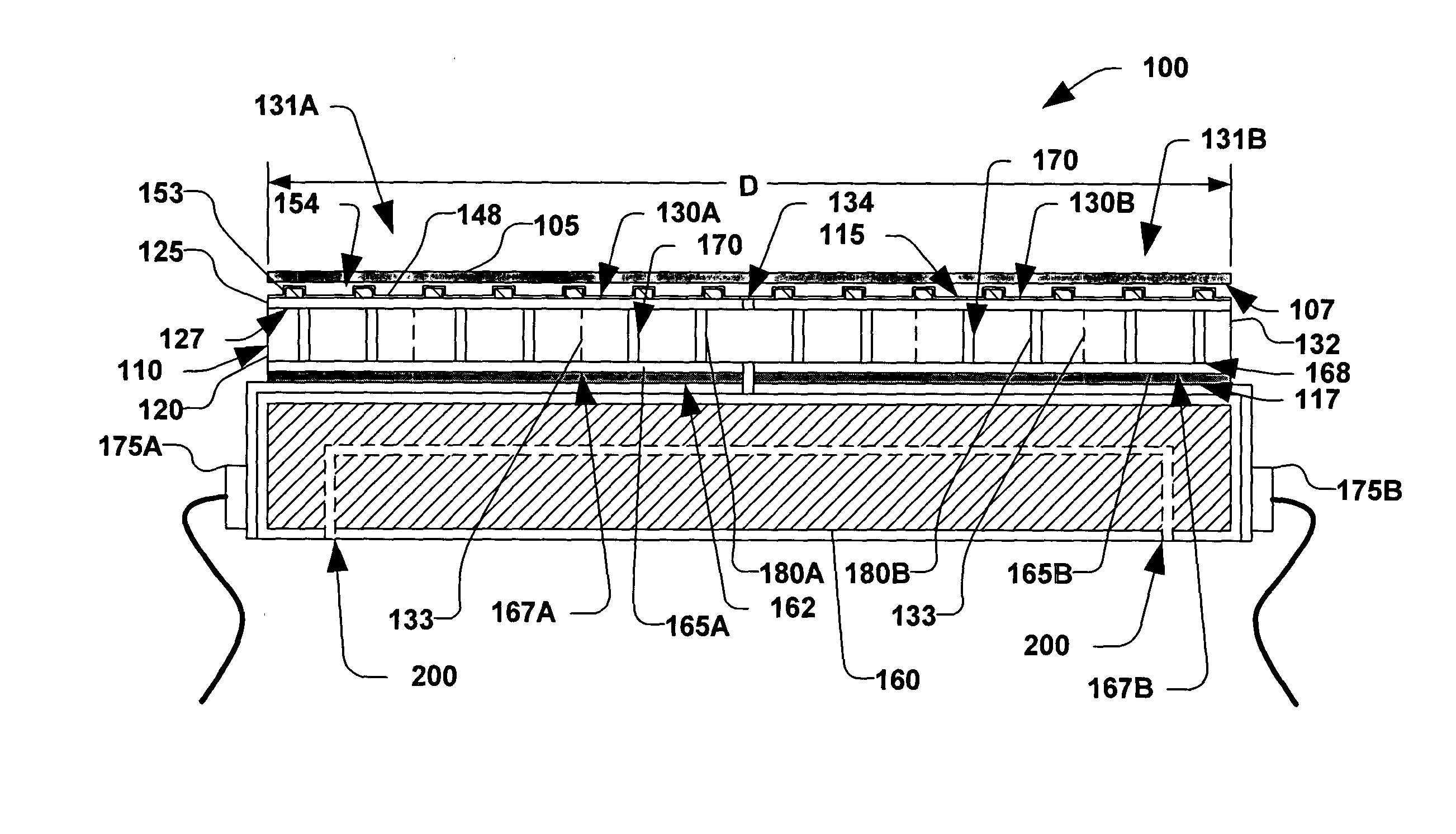

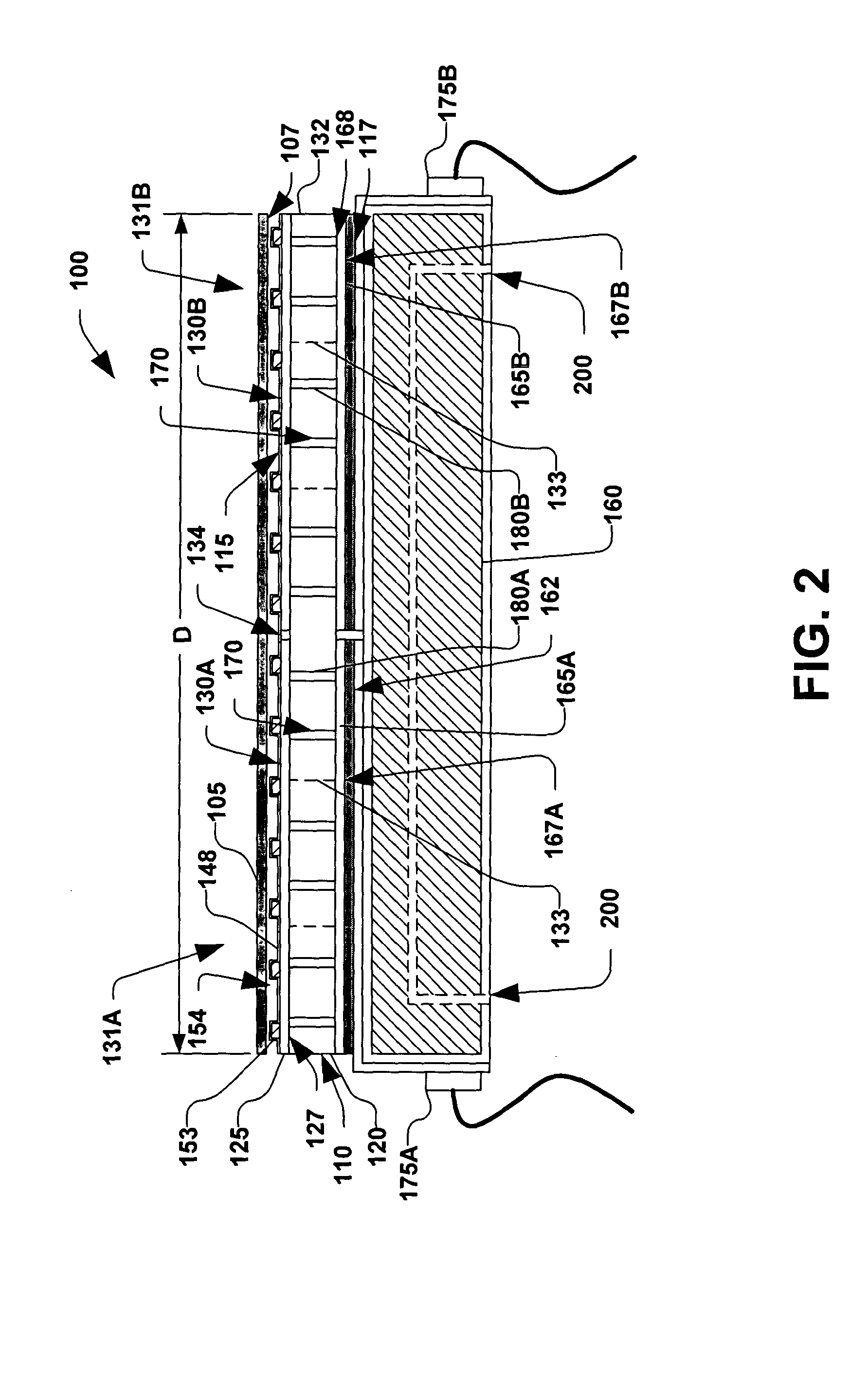

Mems based multi-polar electrostatic chuck

InactiveUS20050041364A1Effective clampingEasy to controlEmergency protective arrangement detailsSemiconductor/solid-state device manufacturingMean free pathSemiconductor

The present invention is directed to a semiconductor processing apparatus and a method for clamping a semiconductor substrate and controlling a heat transfer associated therewith. According to one aspect of the present invention, a multi-polar electrostatic chuck and associated method is disclosed which provides a controlled and uniform heat transfer coefficient across a surface thereof. The multi-polar electrostatic chuck comprises a semiconductor platform having a plurality of protrusions that define gaps therebetween, wherein a distance or depth of the gaps is uniform and associated with a mean free path of the cooling gas therein. The electrostatic chuck is permits a control of a backside pressure of a cooling gas within the plurality of gaps to thus control a heat transfer coefficient of the cooling gas. The plurality of protrusions further provide a uniform contact surface, wherein a contact conductivity between the plurality of protrusions and the substrate is controllable and significantly uniform across the substrate.

Owner:AXCELIS TECHNOLOGIES

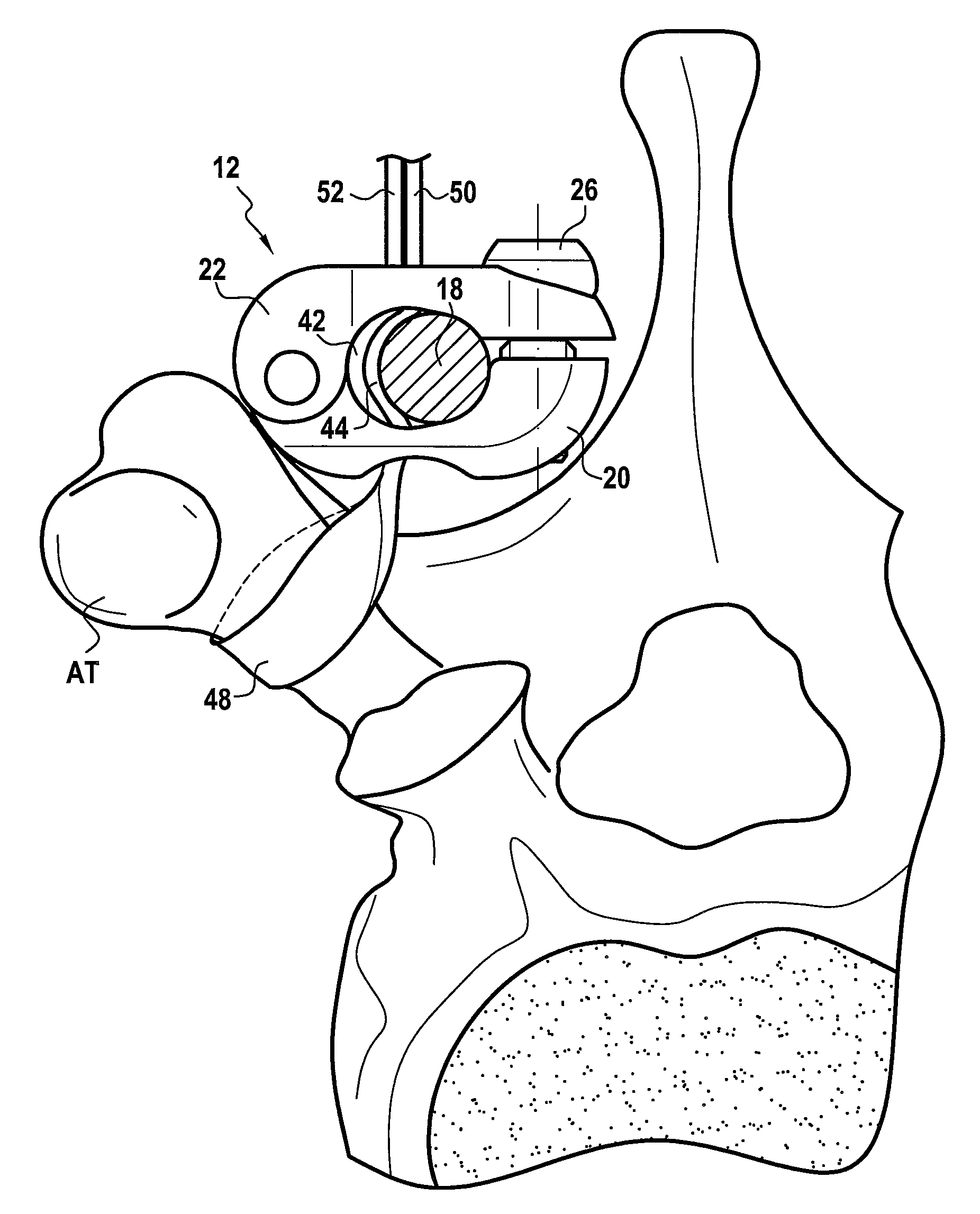

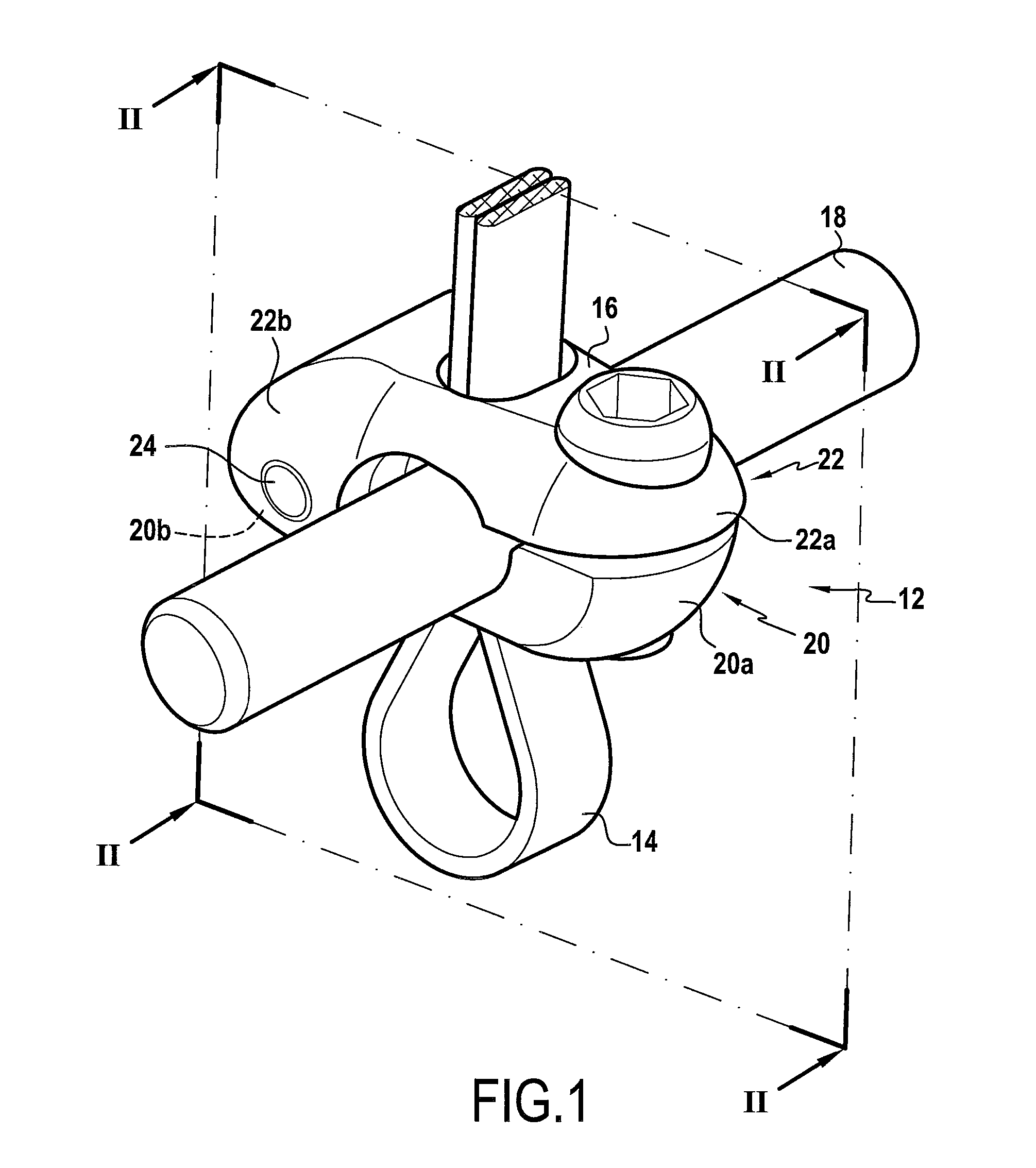

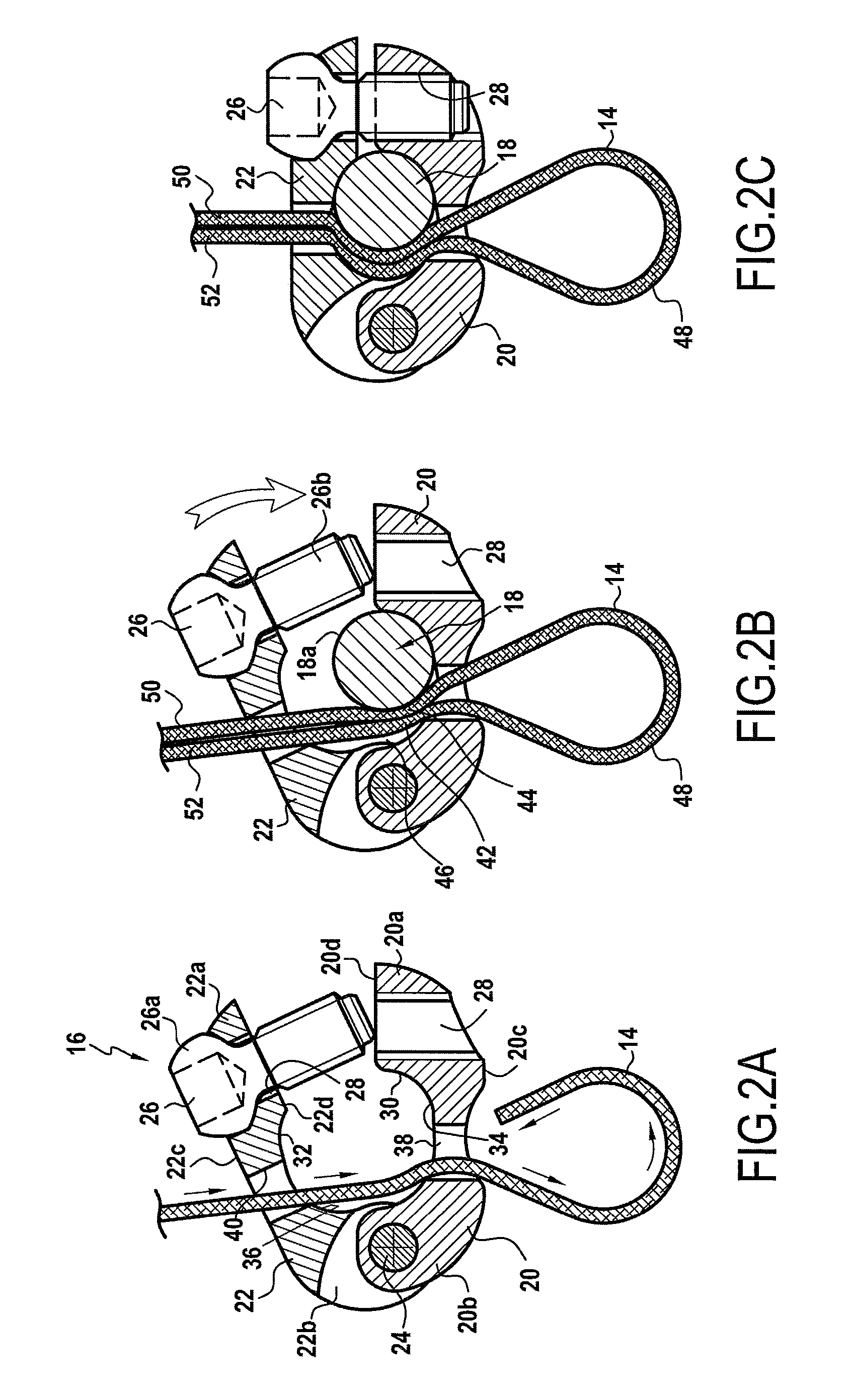

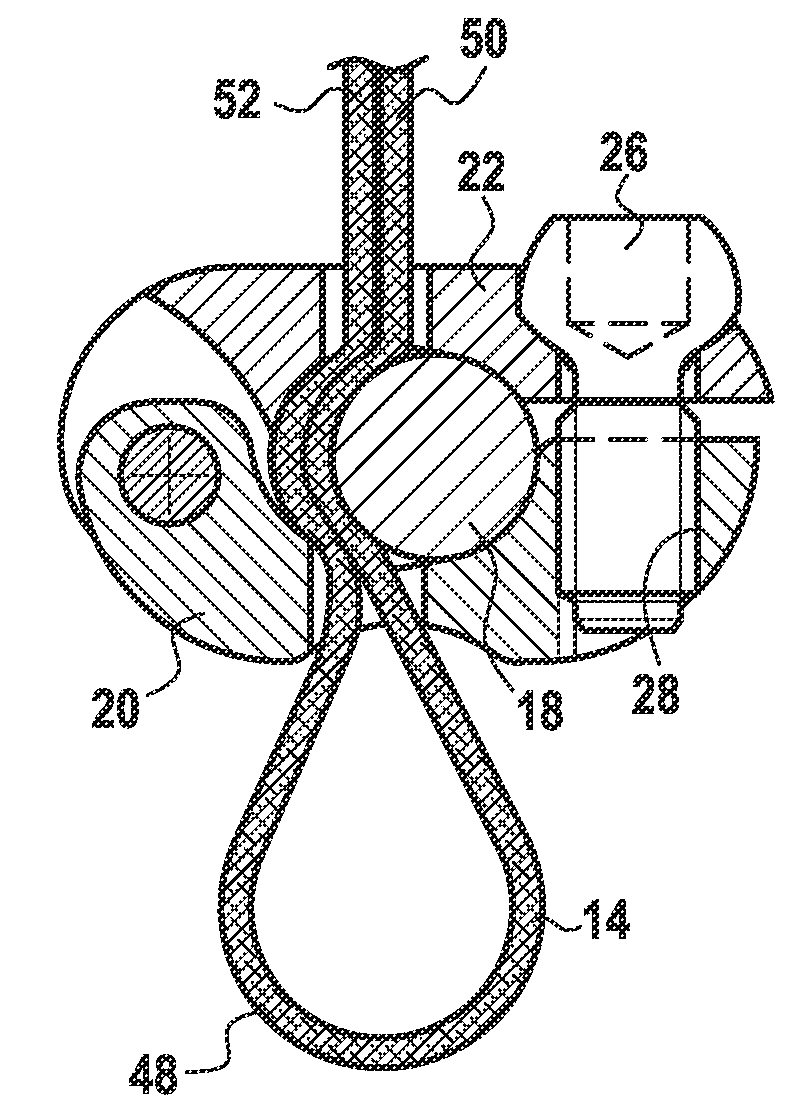

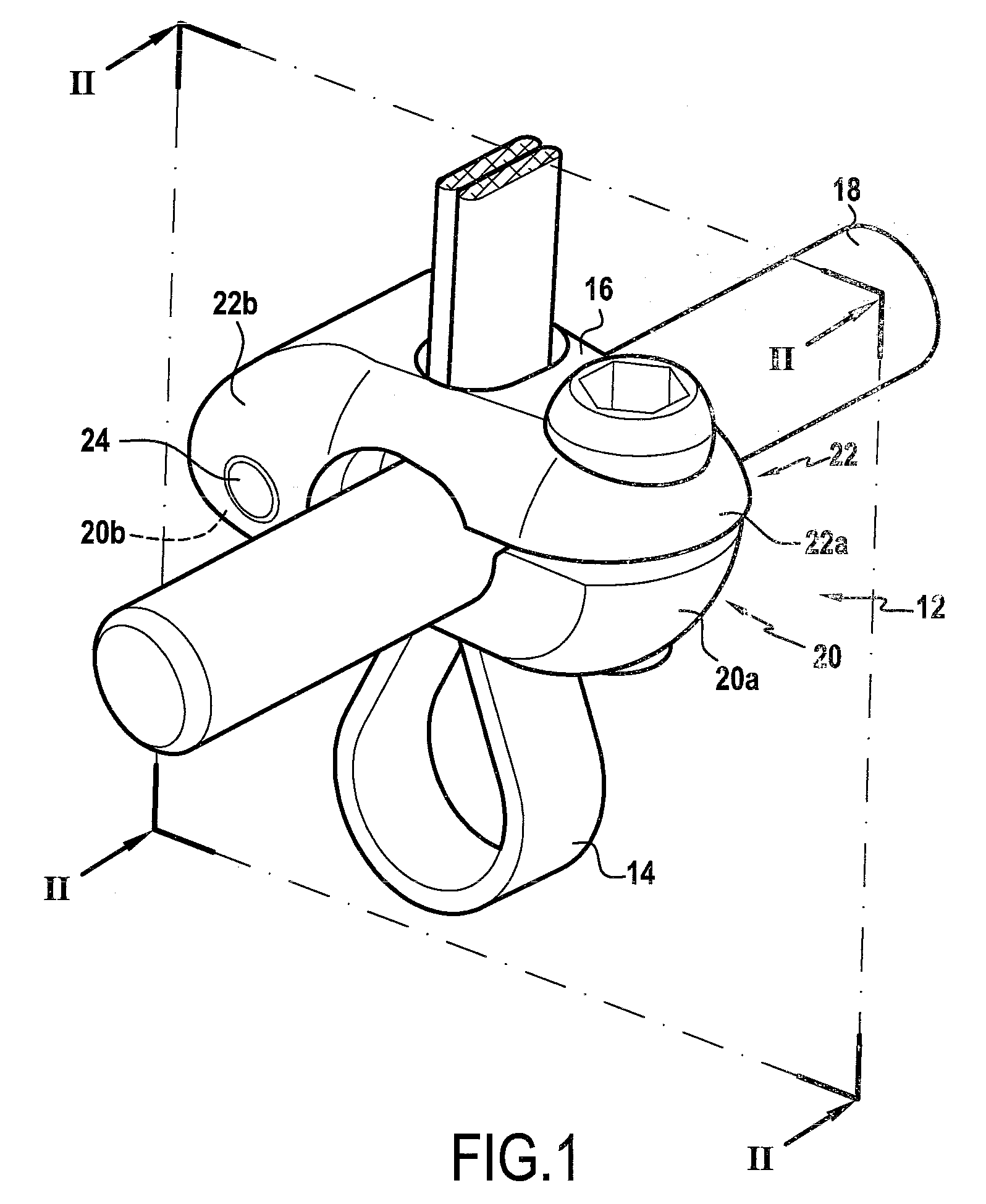

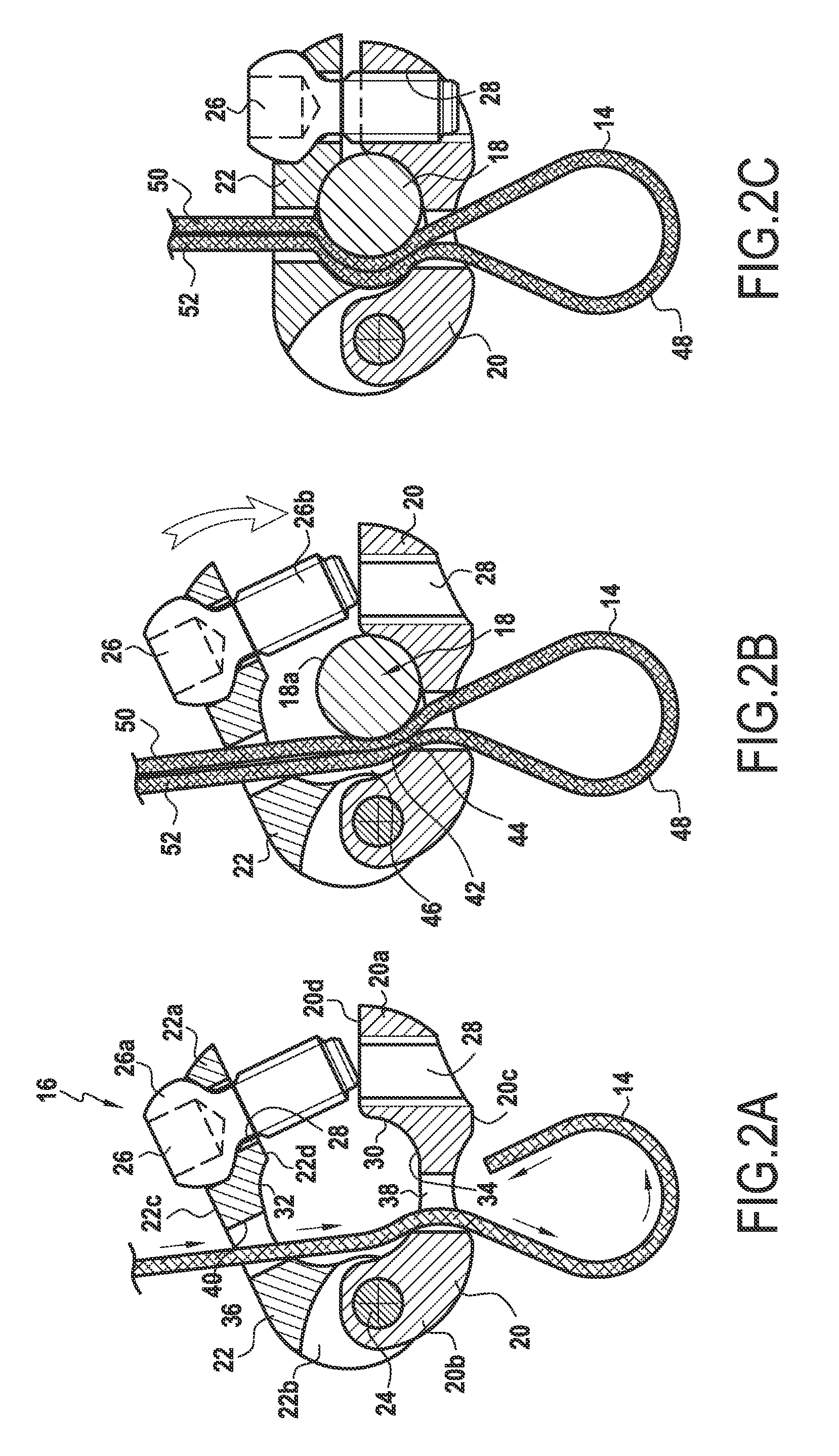

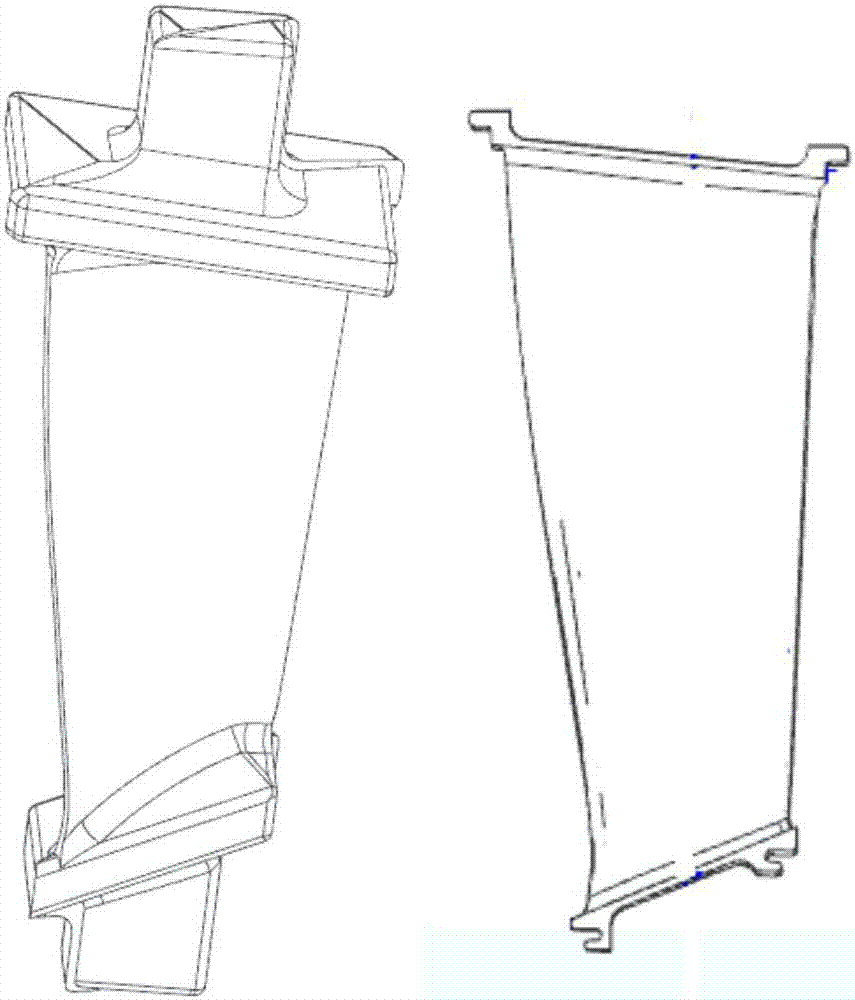

Vertebral fixing system

ActiveUS20120022591A1Effective clampingAvoid displacementInternal osteosythesisJoint implantsEngineeringMechanical engineering

A vertebral fixing system comprising a connecting part with two longitudinal elements coupled to each other at a first end and having mutually facing recesses for receiving a rod. A portion of a flexible ligature extends through orifices of the two longitudinal elements to define a loop opposite two free ends of the flexible ligature. The two longitudinal elements are engaged at a second end of the connecting part via a locking means. When the two longitudinal elements of the connecting part are locked at the second end of the connecting part, two strands of the flexible ligature are pinched between the rod and a wall of the mutually facing recesses of the two longitudinal elements of the connecting part, preventing the flexible ligature from moving in translation relative to the connecting part.

Owner:ZIMMER SPINE SAS

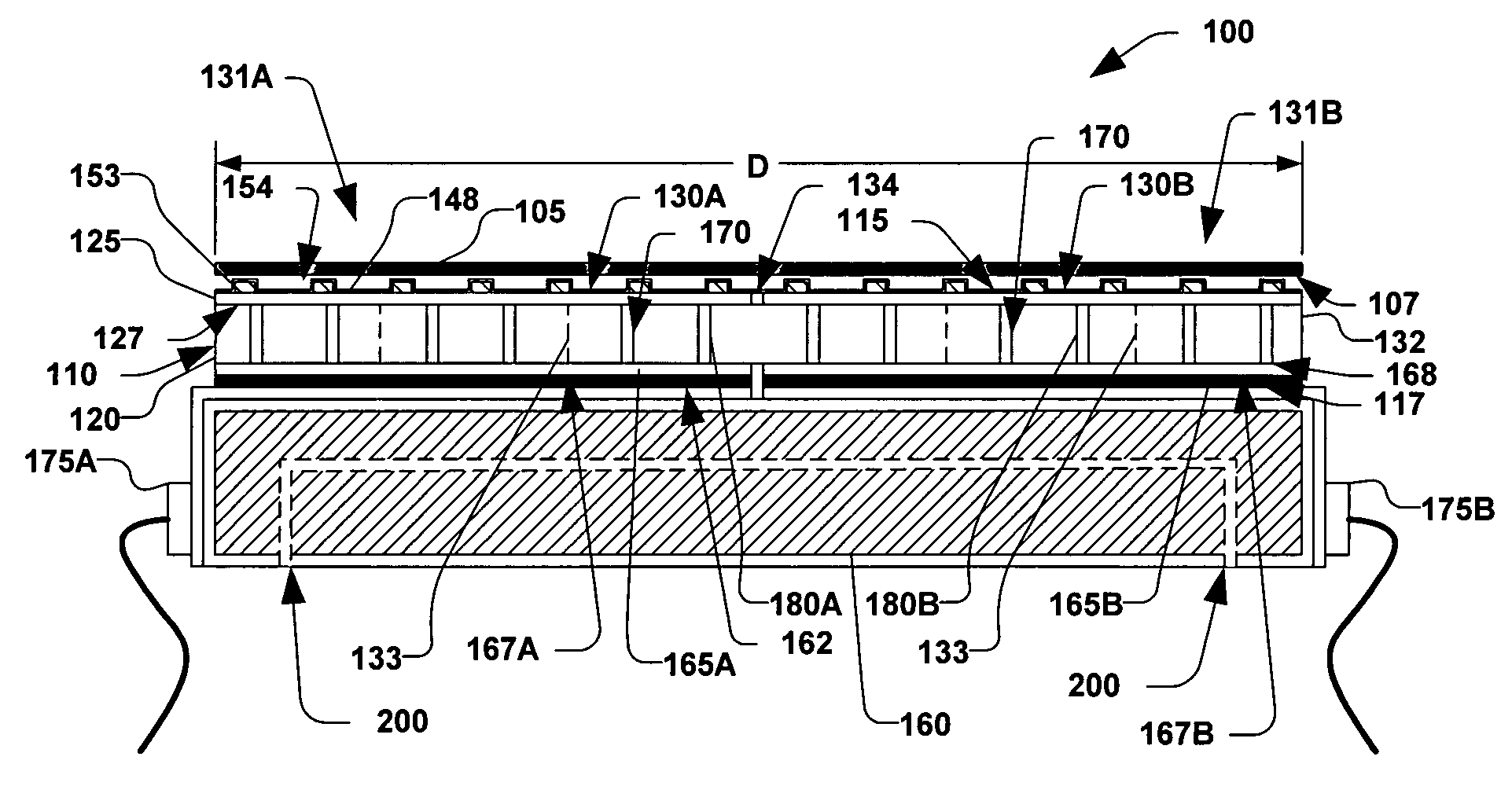

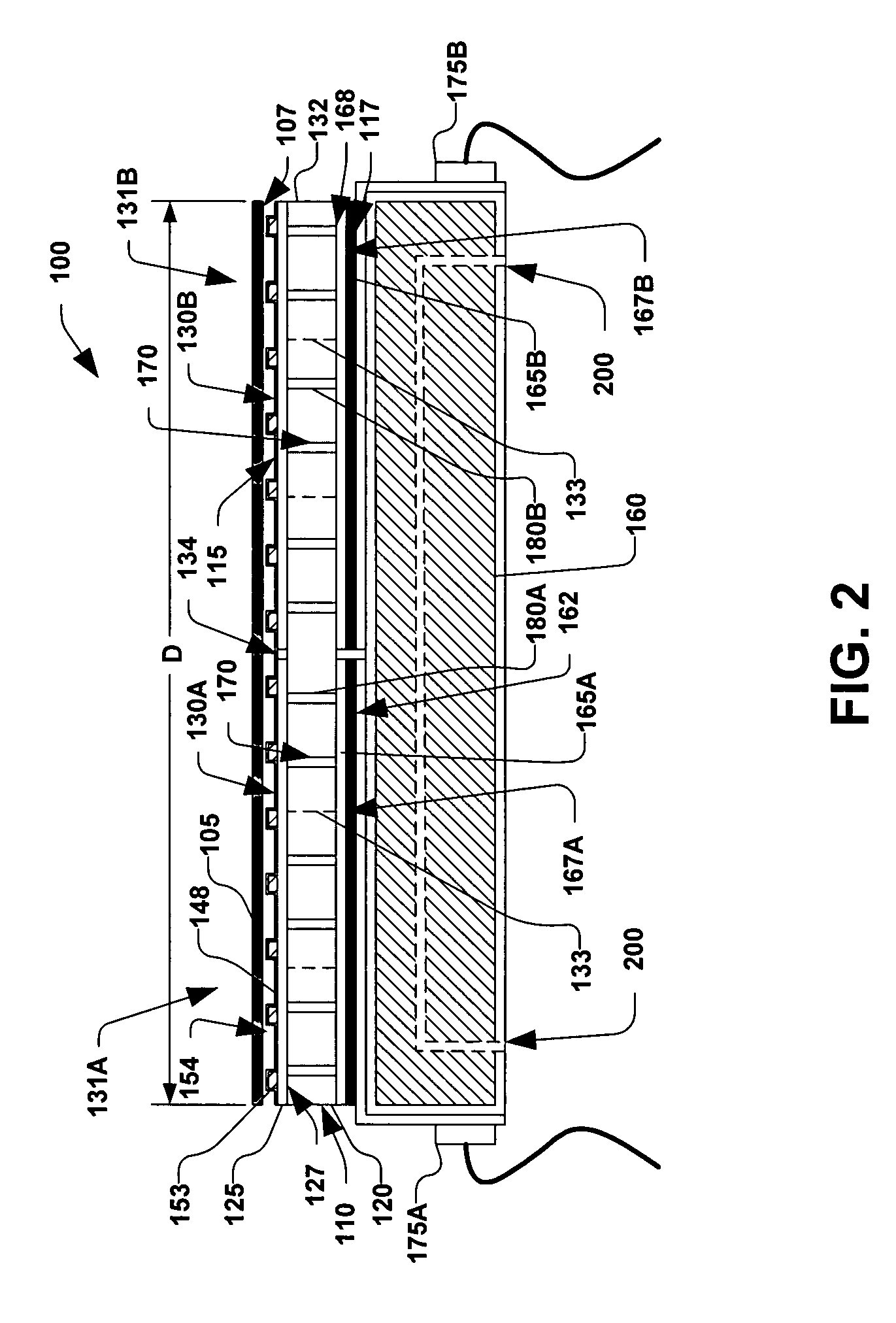

Thermoelectric cooling and/or moderation of transient thermal load using phase change material

InactiveUS20060086096A1High densityEffective clampingDomestic cooling apparatusPrinted circuit aspectsThermoelectric coolingHeat flux

Techniques described and illustrated herein can permit high luminous flux and / or longer lifetimes for a class of photoemissive device configurations and / or uses that generate intense highly localized, but transient heat flux. For example, certain Light Emitting Diode (LED) applications, e.g., for flash illumination, certain solid state laser configurations and other similar configurations and uses may benefit from the developed techniques. In particular, it has been discovered that by locating an amount of appropriate phase change material in close thermal proximity to such a photoemissive device, substantial generated heat fluxes may be “absorbed” into a phase transition of the phase change material. In some configurations, a thermoelectric is employed in conjunction with the phase change material. For example, the thermoelectric may at least partially define a heat transfer path from the photoemissive device to the phase change material. Similar configurations may be employed for photosensitive devices. In such configurations, the phase change material may effectively clamp one side (typically the hot side) of the thermoelectric as heat transferred across the thermoelectric is absorbed into the transition of at least some of the phase change material from a first state thereof to a second state. The thermoelectric may be transiently operated in substantial synchrony with operation of the photoemissive or photosensitive device to provide extremely high density spot cooling when and where desired.

Owner:NANOCOOLERS

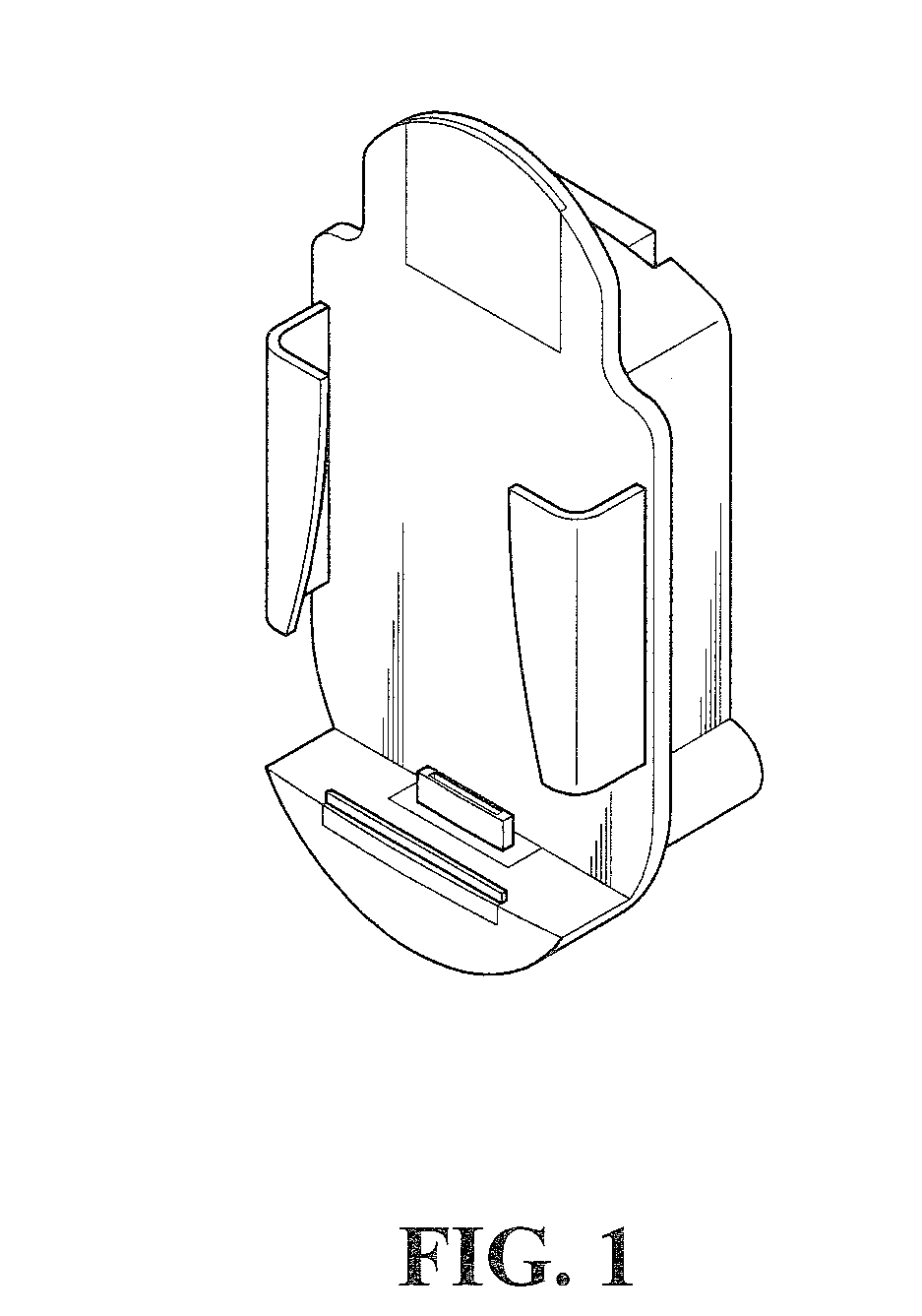

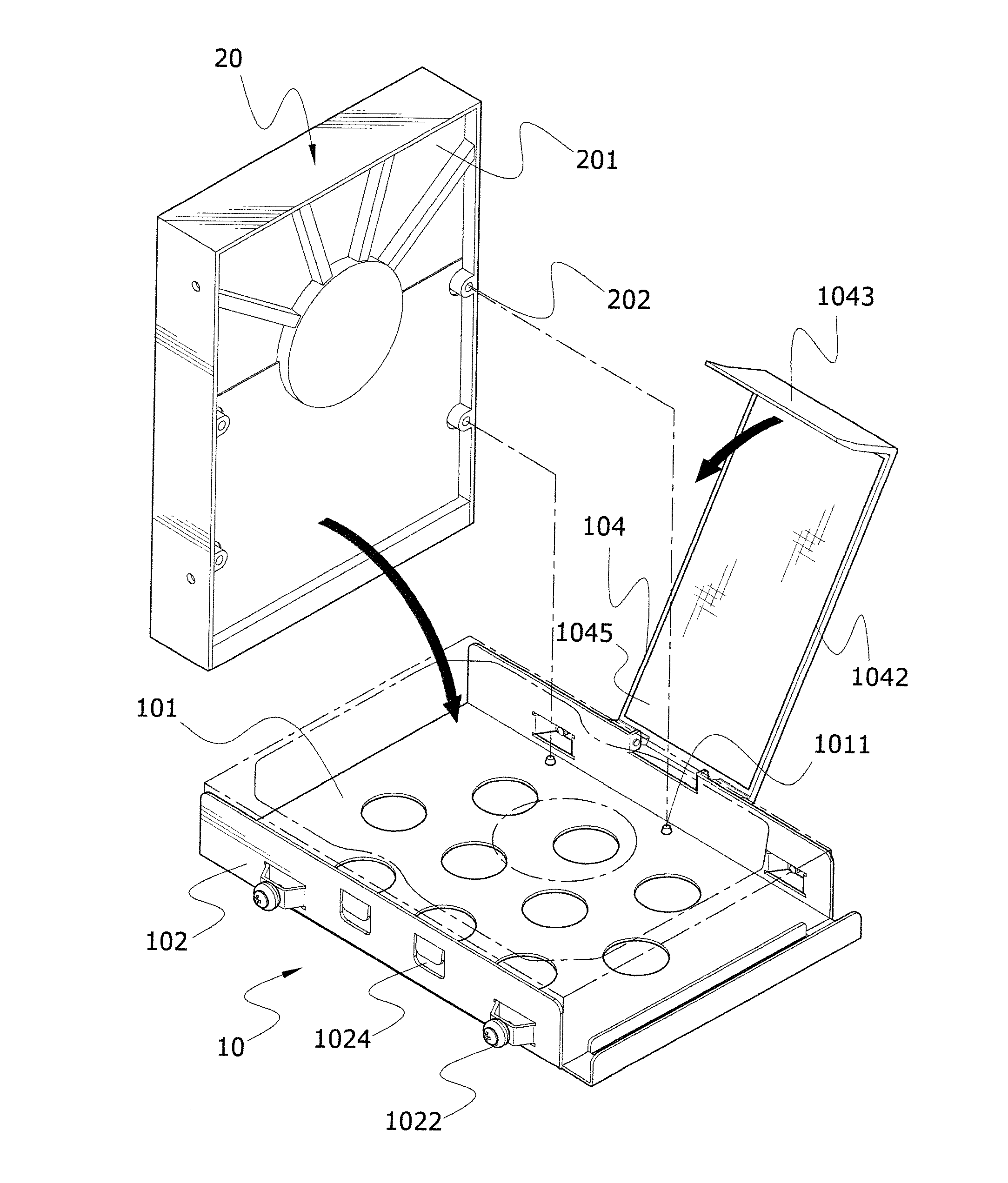

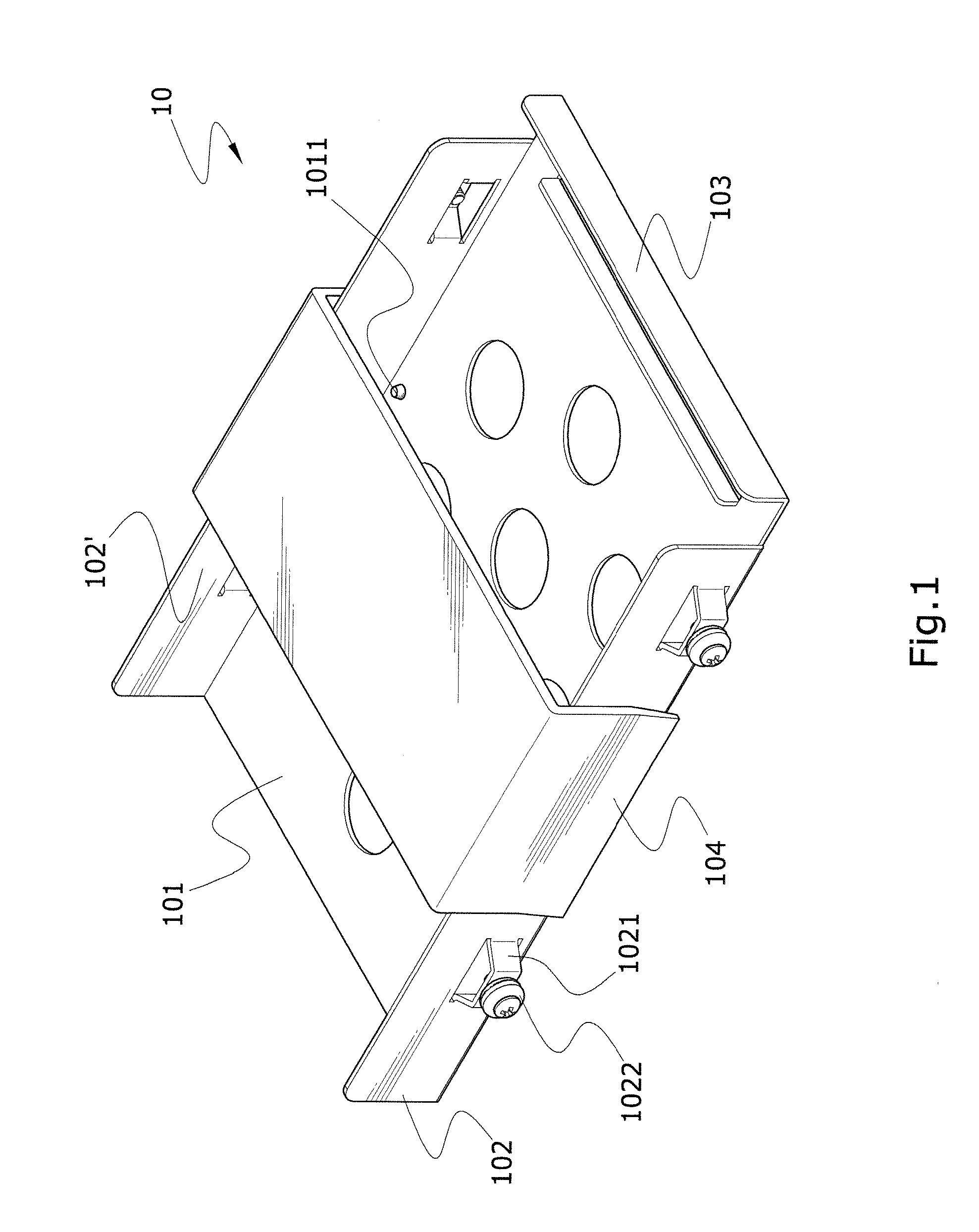

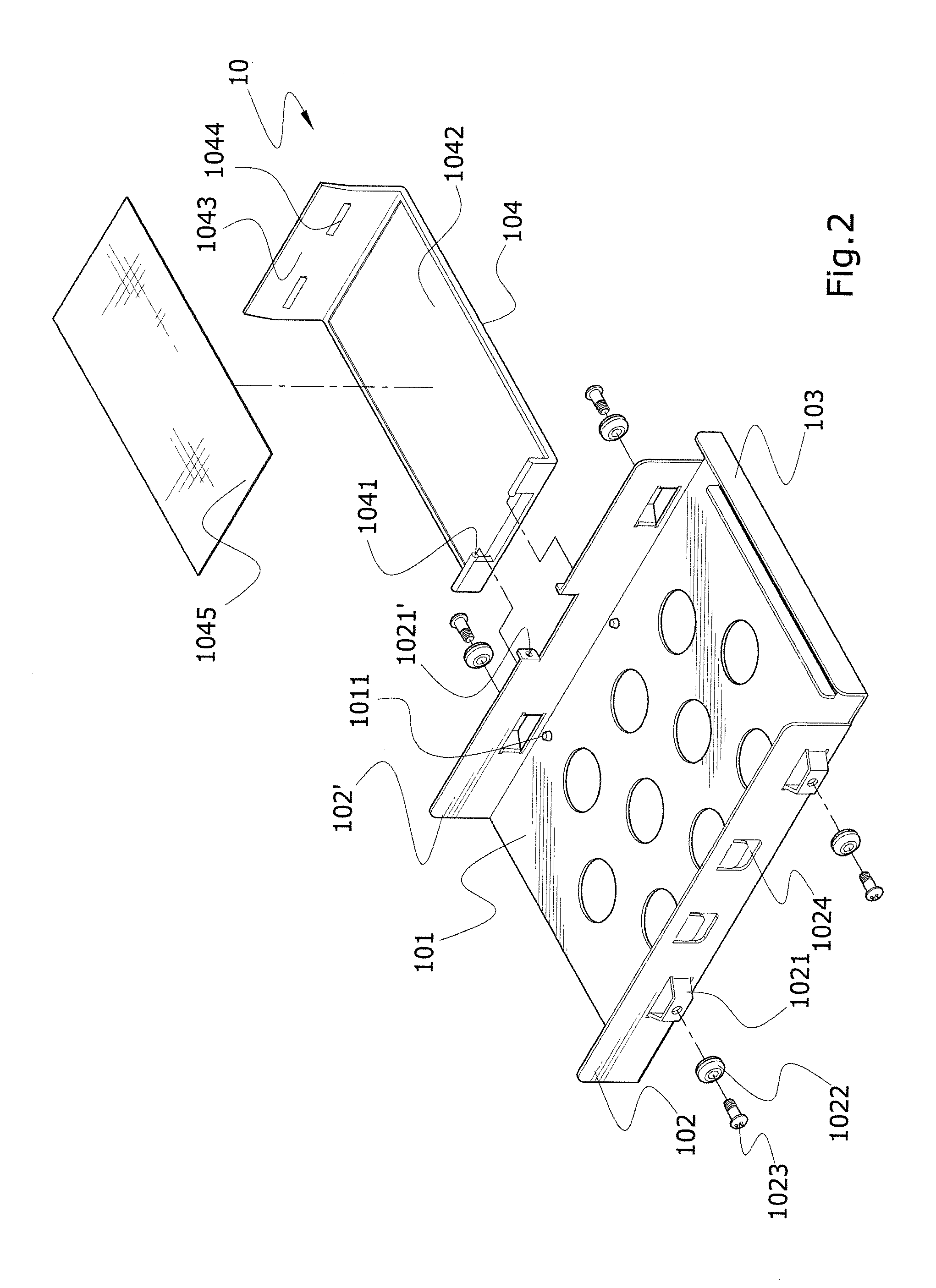

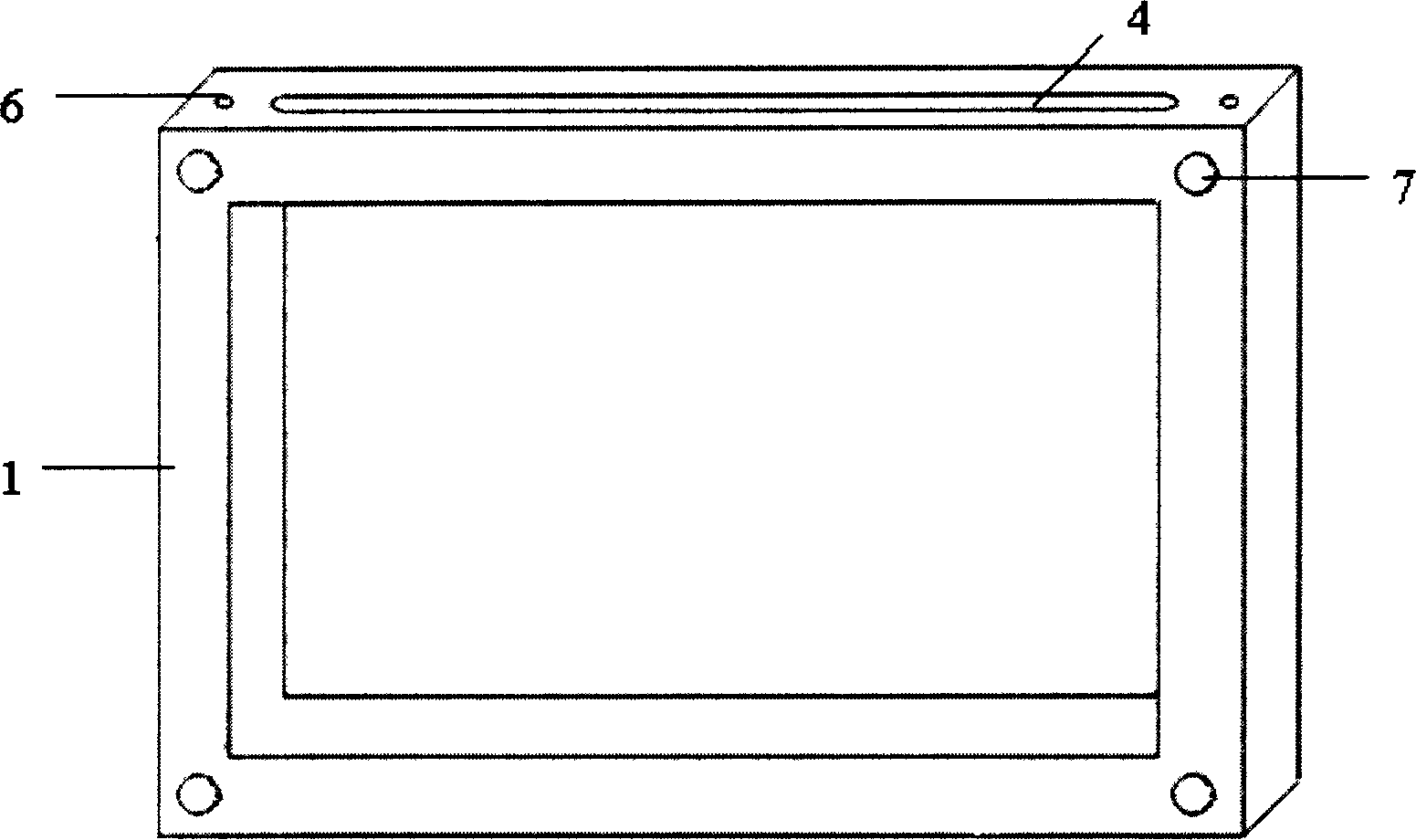

Disk Drive Case

InactiveUS20110255235A1Easy to assemble and disassembleSimple designDigital data processing detailsElectrical apparatus contructional detailsEngineeringComputer engineering

A disk drive case is used to hold a disk drive and is then assembled into a corresponding slot in a computer case. The disk drive case provides a carrier to effectively protect the disk drive, allowing the disk drive to be quickly inserted into and pulled out of the slot of the computer case, such that the computer assembly operation can be faster and more convenient.

Owner:LIAN LI IND CO LTD

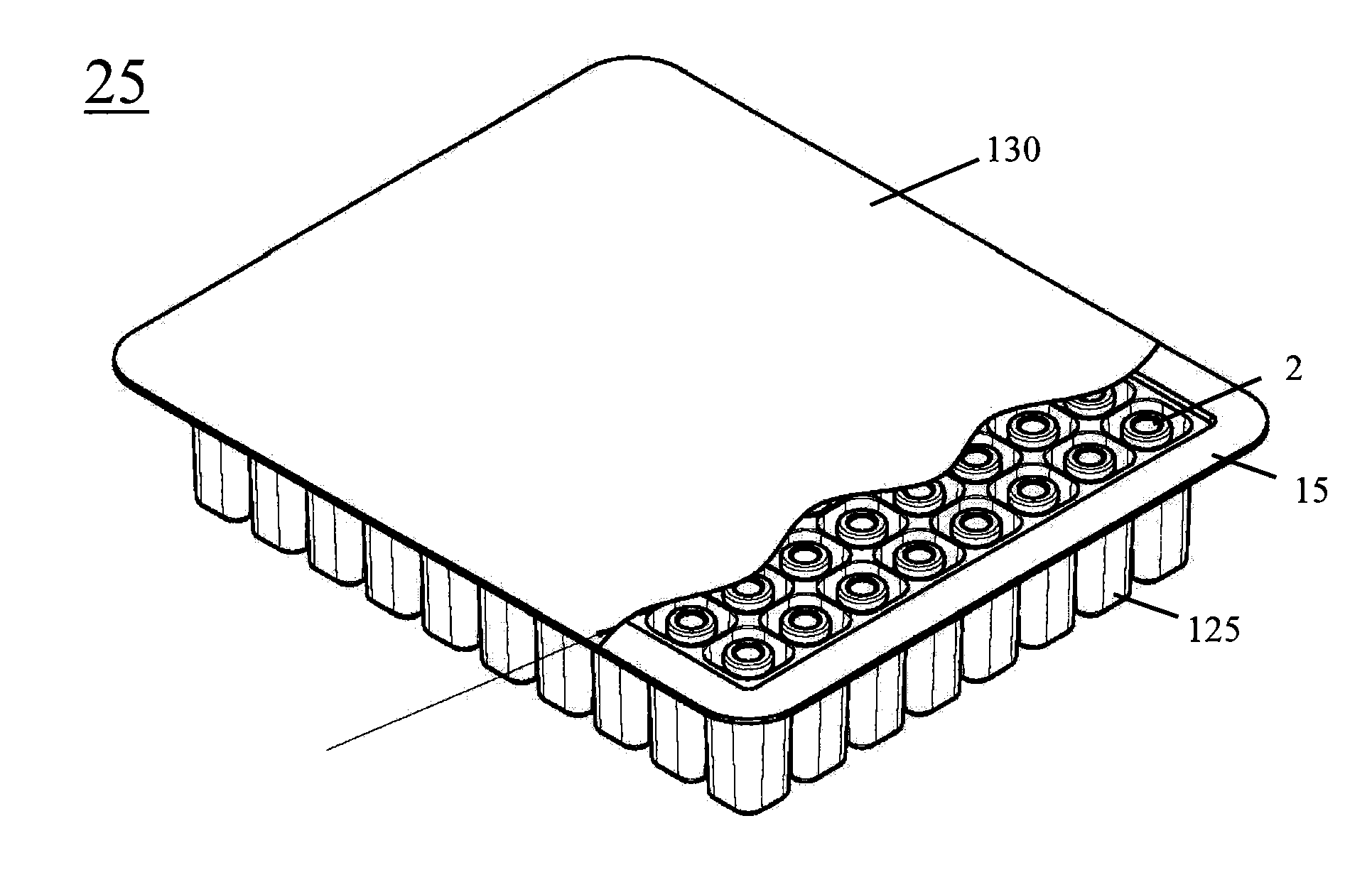

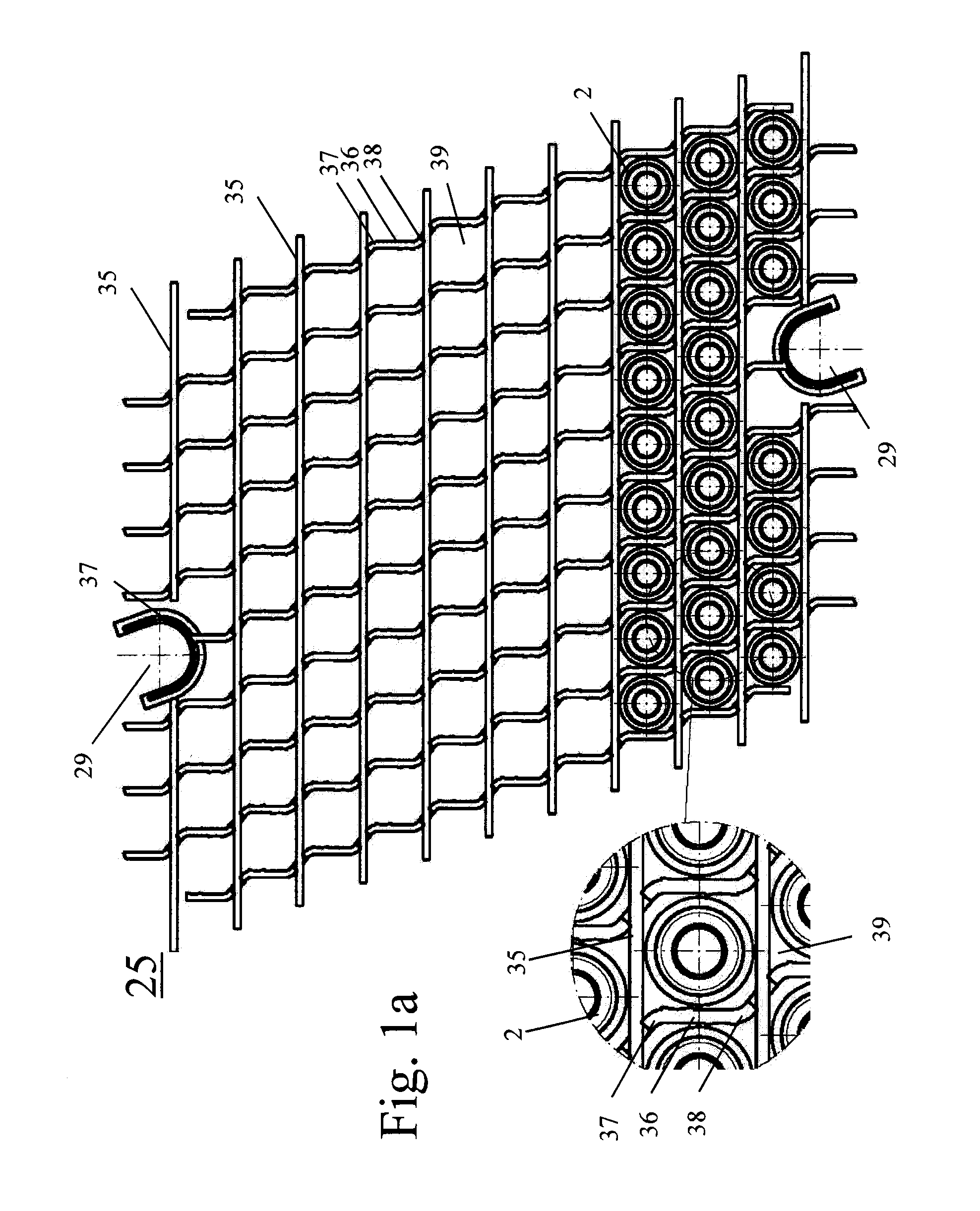

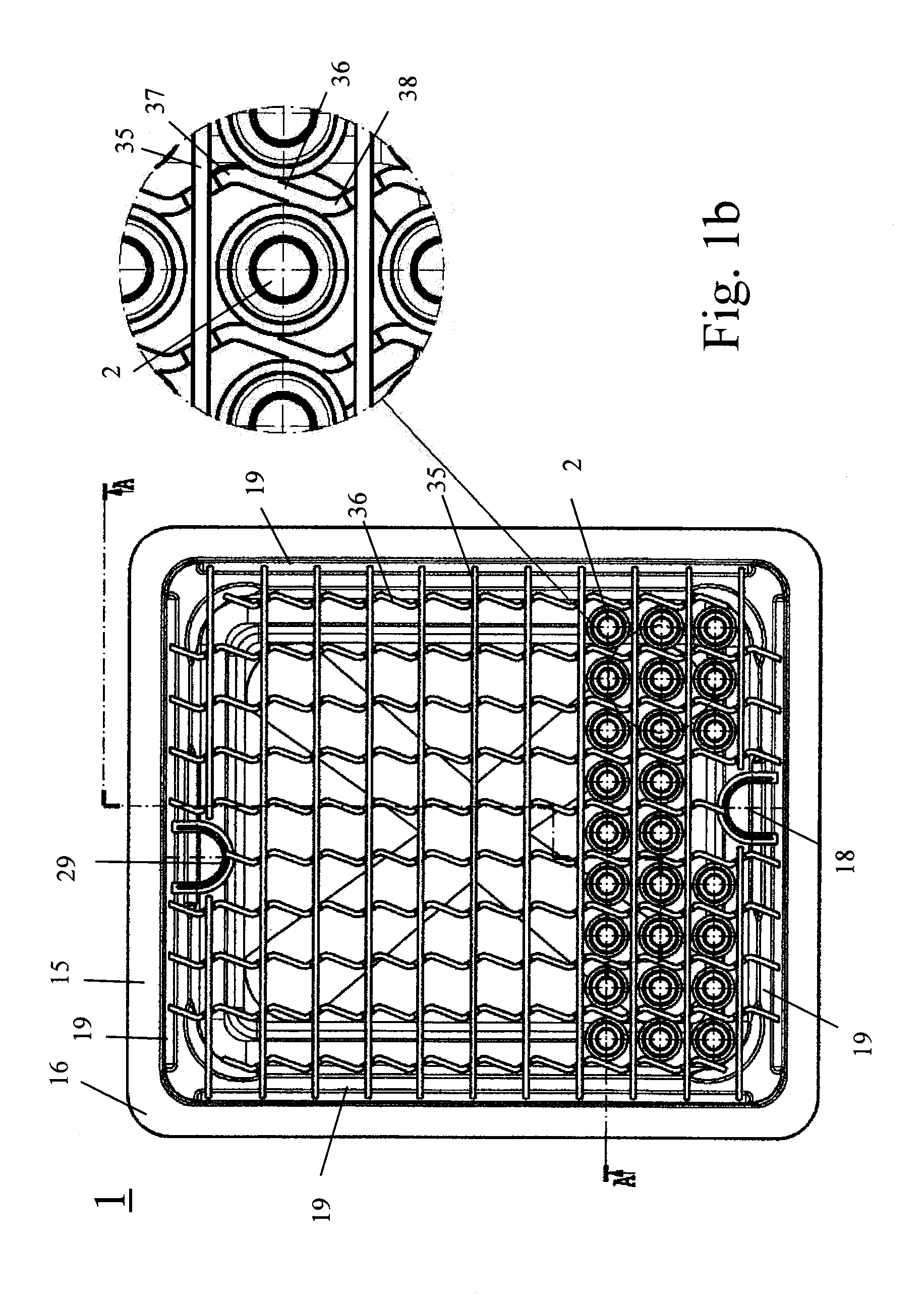

Holding structure for simultaneously holding a plurality of containers for medical, pharmaceutical or cosmetic applications and transport or packaging container comprising such a holding structure

InactiveUS20140027333A1Increase heightAdd support structureDiagnosticsSurgical needlesEngineeringMechanical engineering

Owner:SCHOTT AG

Vertebral fixing system

ActiveUS8172843B2Reduce operational riskSmall sizeSuture equipmentsInternal osteosythesisOrthodontic ligatureMechanical engineering

A vertebral fixing system comprising a connecting part with two longitudinal elements coupled to each other at a first end and having mutually facing recesses for receiving a rod. A portion of a flexible ligature extends through orifices of the two longitudinal elements to define a loop opposite two free ends of the flexible ligature. The two longitudinal elements are engaged at a second end of the connecting part via a locking means. When the two longitudinal elements of the connecting part are locked at the second end of the connecting part, two strands of the flexible ligature are pinched between the rod and a wall of the mutually facing recesses of the two longitudinal elements of the connecting part, preventing the flexible ligature from moving in translation relative to the connecting part.

Owner:ZIMMER SPINE SAS

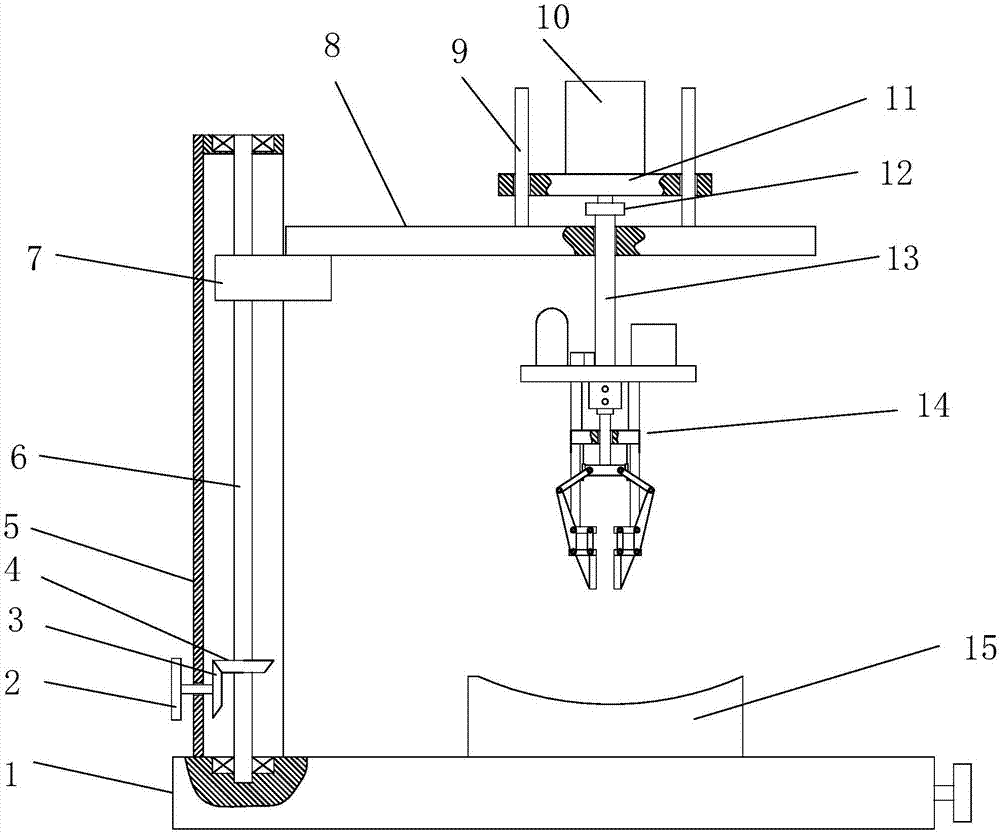

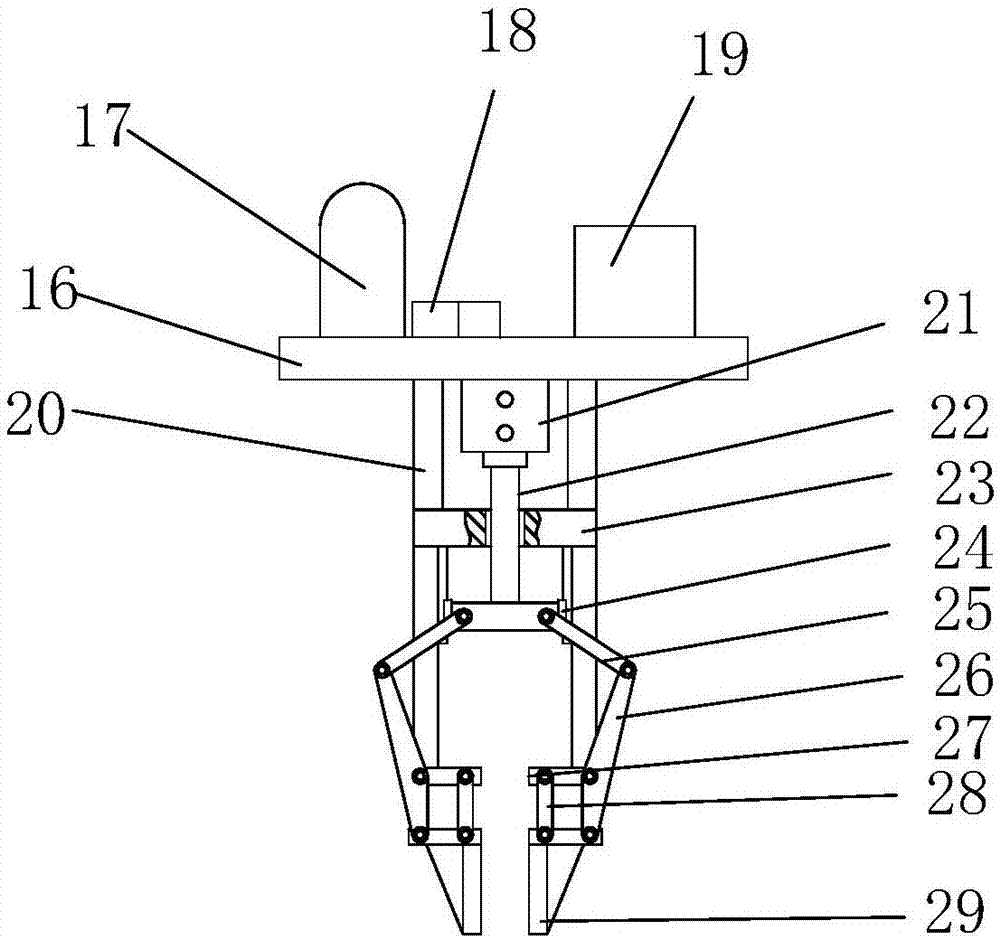

Nail taking device used in orthopedics department

InactiveCN107485442AEffective clampingTake it out and save effortOsteosynthesis devicesCouplingOrthopedic department

Owner:SHANGHAI TENTH PEOPLES HOSPITAL

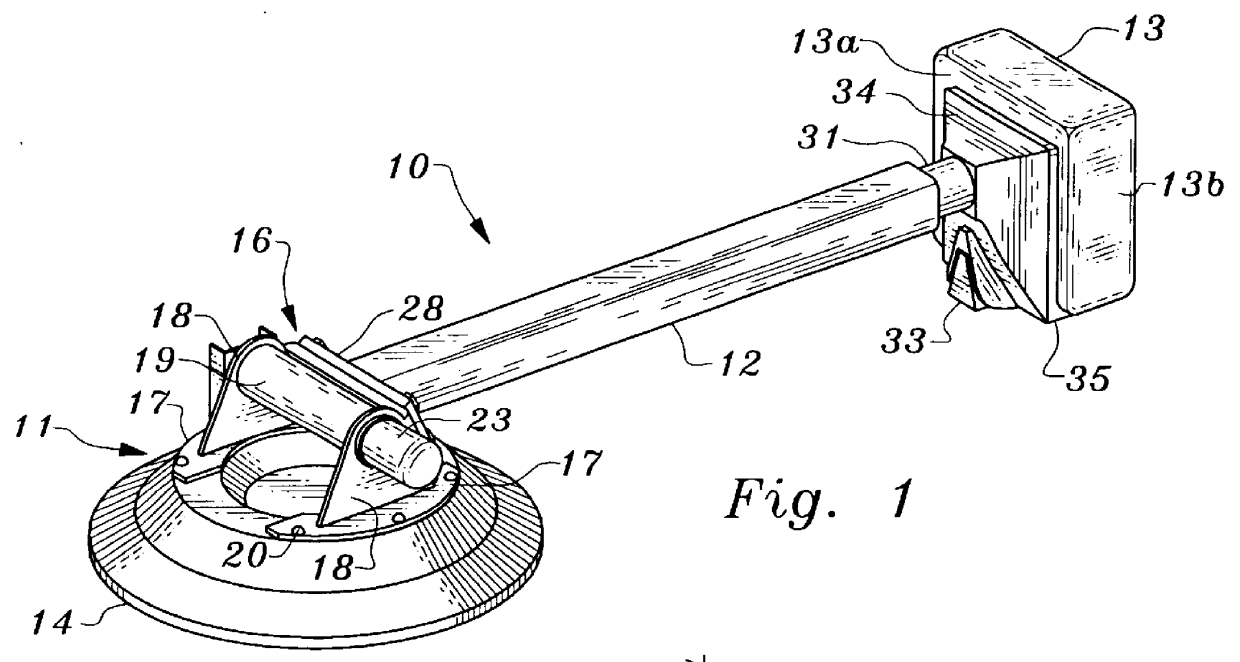

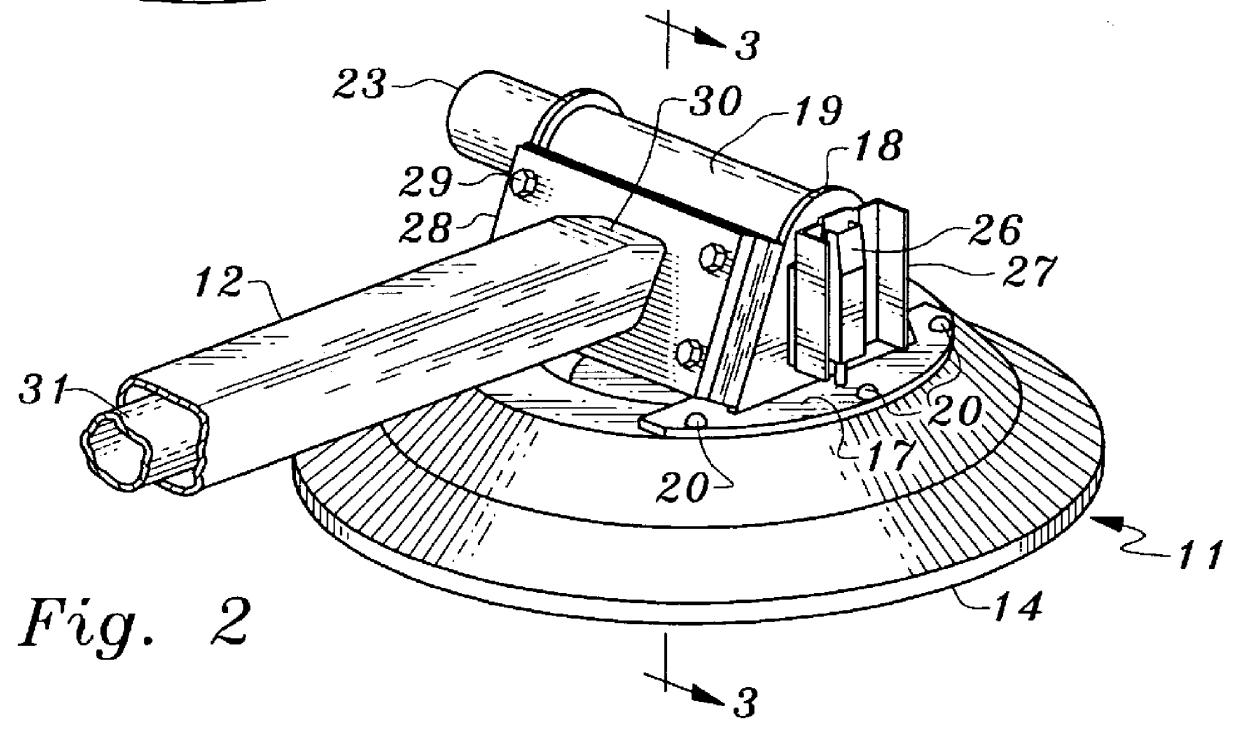

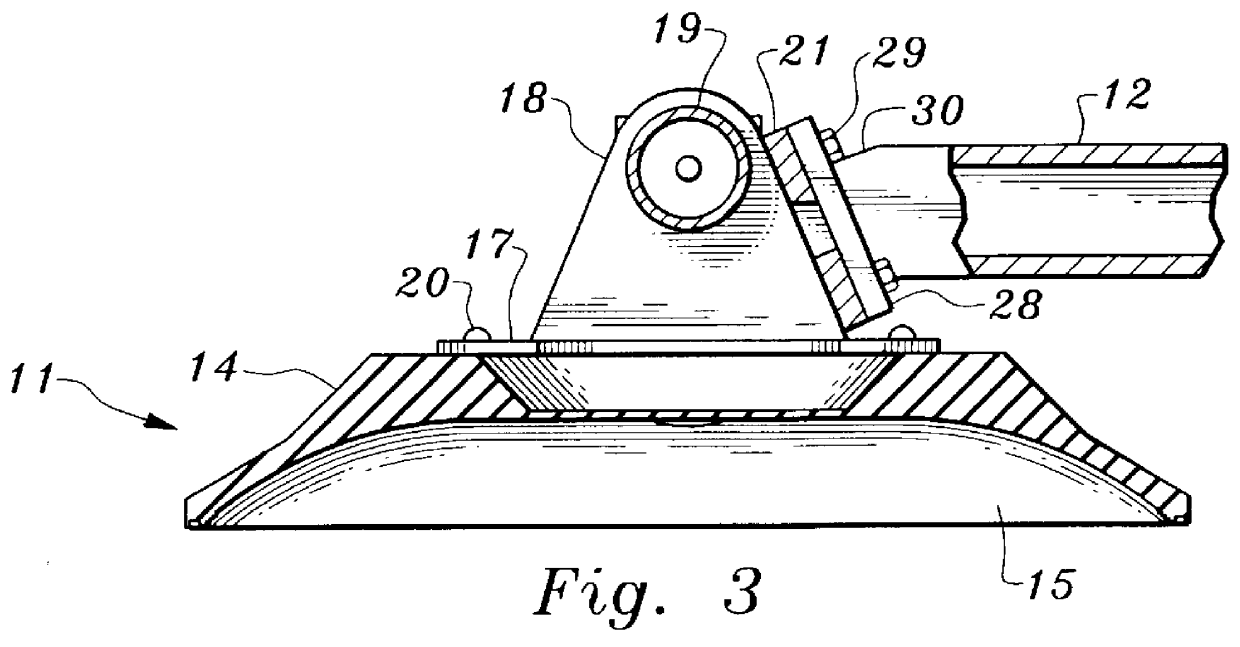

Vacuum stretching and gripping tool and method for laying flooring

A vacuum pump operated suction cup is utilized to form tools to assist the installer in laying flooring. In one embodiment, the suction cup is provided with a bracket which supports the vacuum pump and a handle having a knee pad at the end. In use, the suction cup is vacuum bonded to the flooring and pressed against the floor by hand while the knee pad is kicked with the knee to smooth out any irregularities. In another embodiment the flooring is stretched by pushing the vacuum bonded suction cup with a jack. In another embodiment, a tacking strip is utilized in lieu of adhesive to secure the flooring to a substrate with the assistance of the vacuum pump.

Owner:SMITH MARK

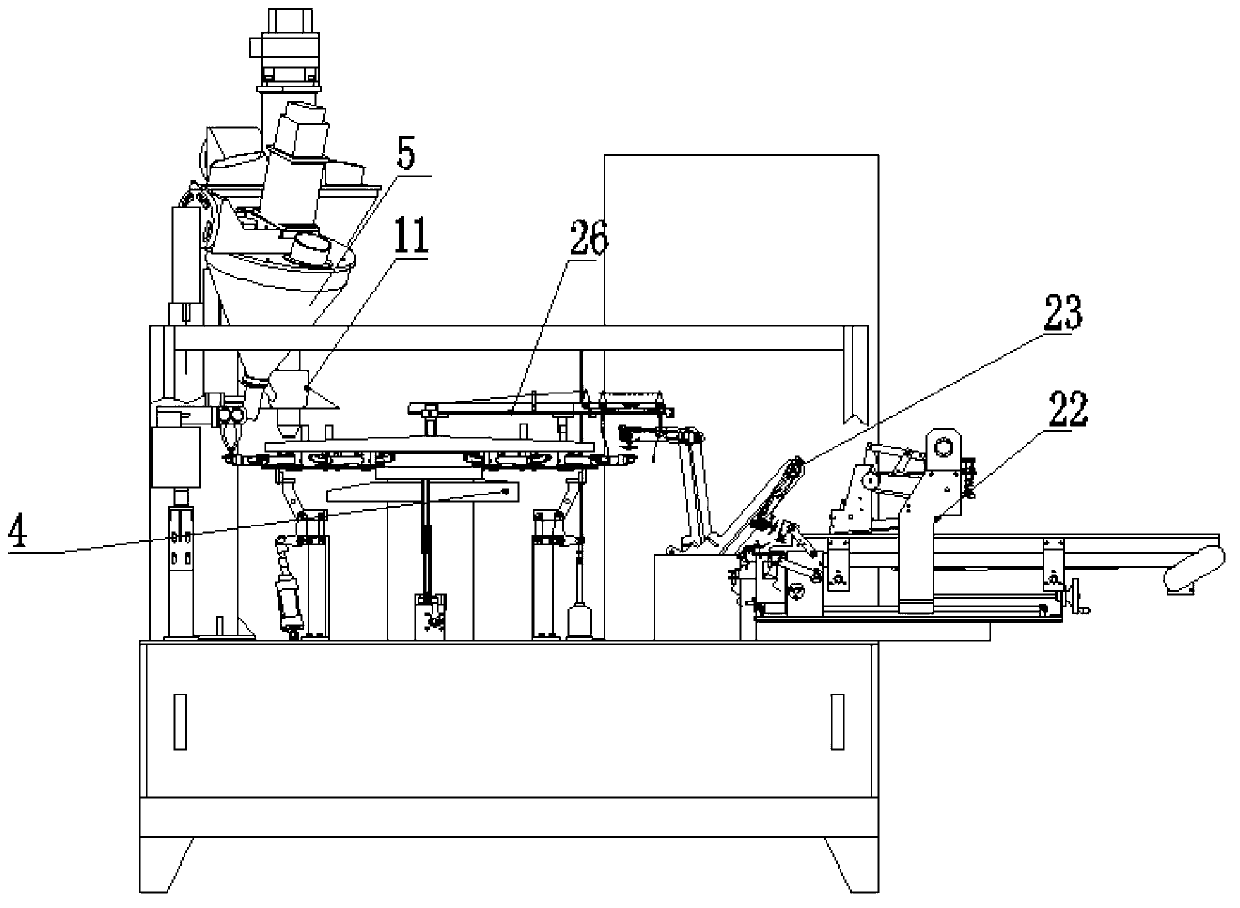

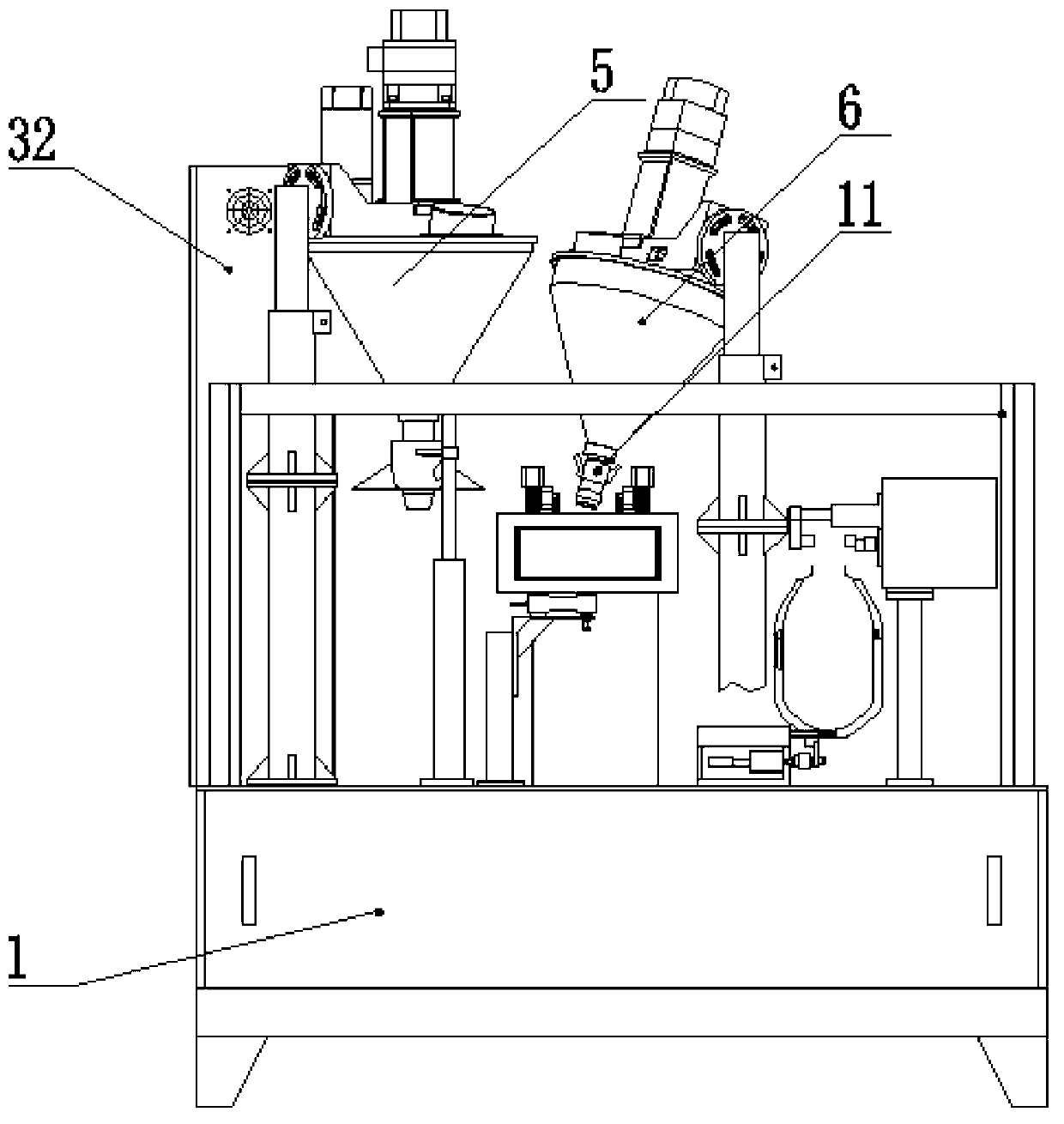

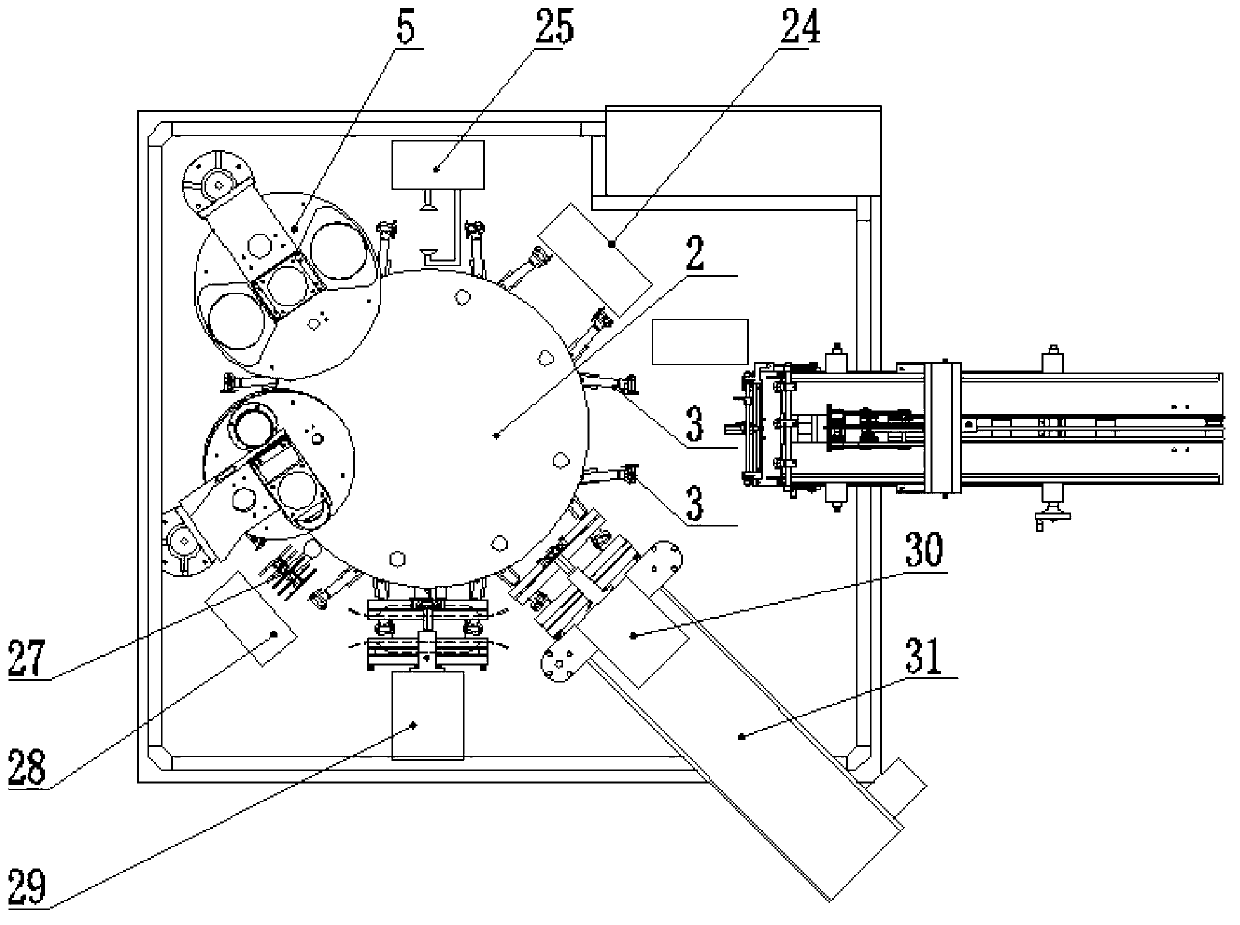

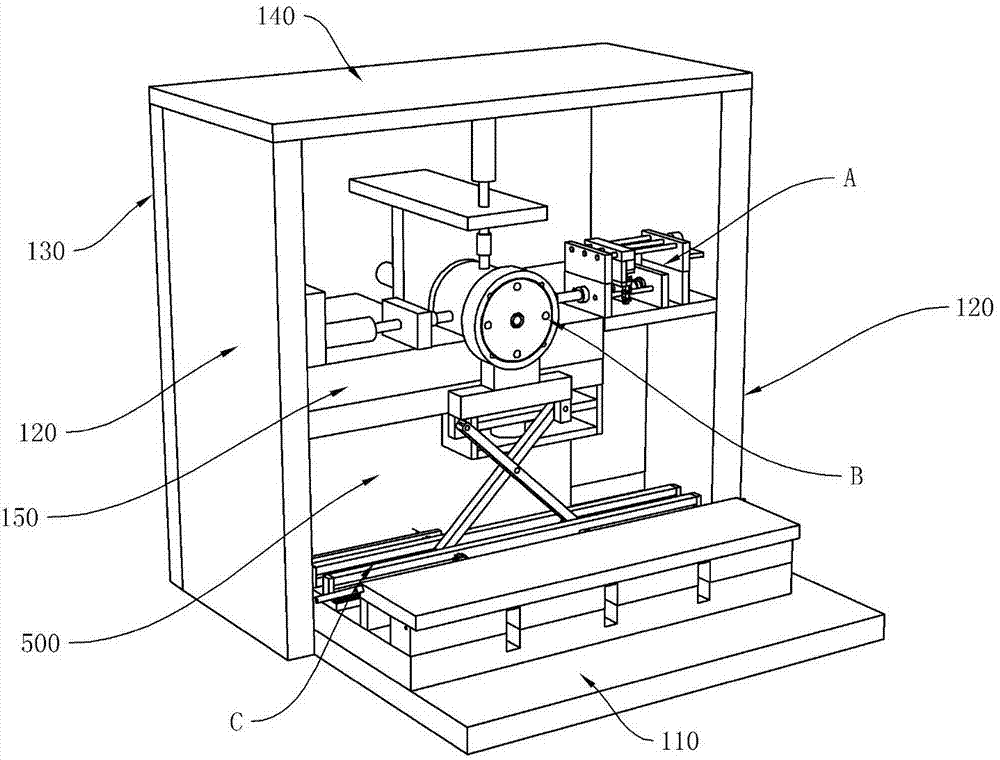

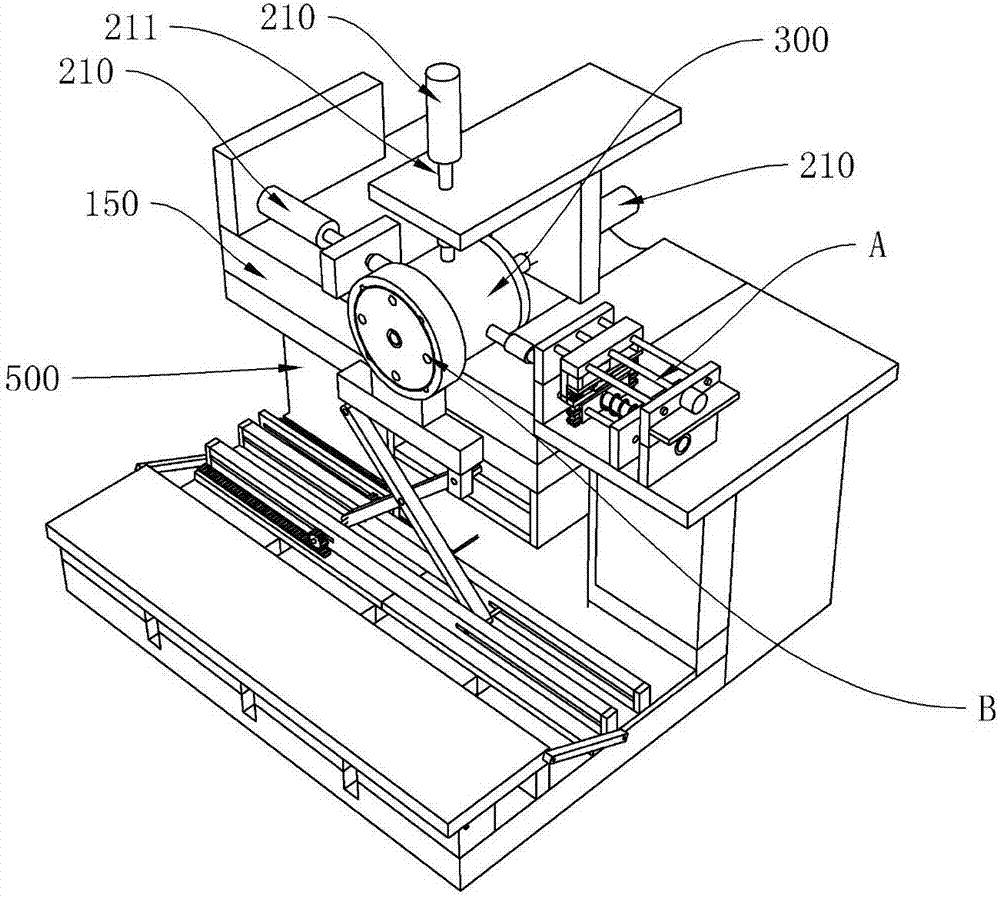

Full-automatic packaging machine

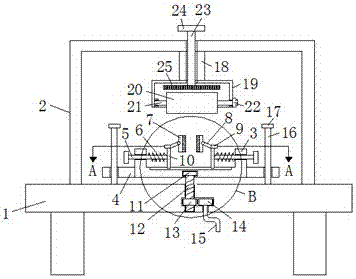

ActiveCN102991734AGuaranteed accuracyIngenious structureWrapper twisting/gatheringSolid materialEngineeringDrive shaft

The invention discloses a full-automatic packaging machine. The full-automatic packaging machine comprises a stander, a driving device and a packaging executing device, wherein the driving device is arranged at the lower part of the stander, and the packaging executing device is arranged at the upper part of the stander; the packaging executing device comprises a driving disc, anchor arms, an anchor arm guide rail, stations and a transmission shaft; the number of the anchor arms is eight pairs, and the anchor arms are arranged at eight equal diversion positions of the driving disc in pairs; the anchor arms are glidingly connected with the anchor arm guide rail; the driving device drives the driving disc to rotate by the transmission shaft and drives the anchor arms arranged on the driving disc to slide on the anchor arm guide rail; and the number of the stations is eight, each station corresponds to a pair of the anchor arms, and the stations sequentially include a bagging station, a code printing station, a bag opening station, a rough filling station, a fine material supplementing station, a dust extraction station, an exhausting and heat-seal station and a cold-compacting reshaping station according to an anticlockwise sequence. According to the full-automatic packaging machine, the filling manner is simple and flexible, powders in different forms can be automatically adjusted, the dose precision and the filling speed of various materials are guaranteed, and the full-automatic packaging machine is simultaneously suitable for liquids, particles and irregular materials.

Owner:JIANGSU TOM PACKAGING MACHINERY

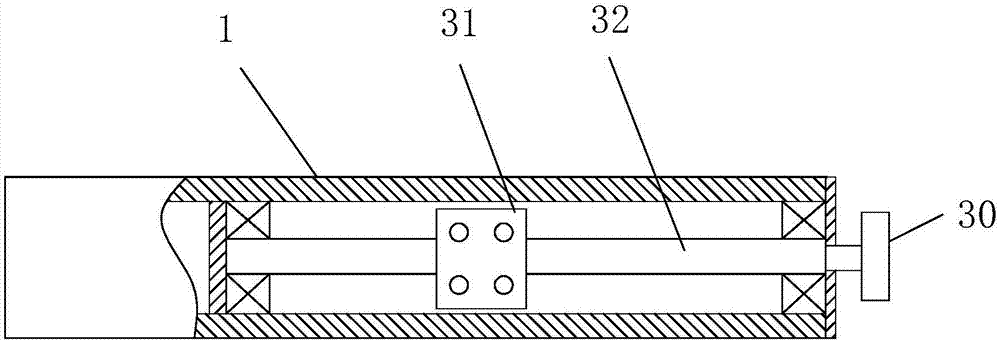

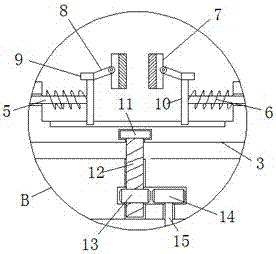

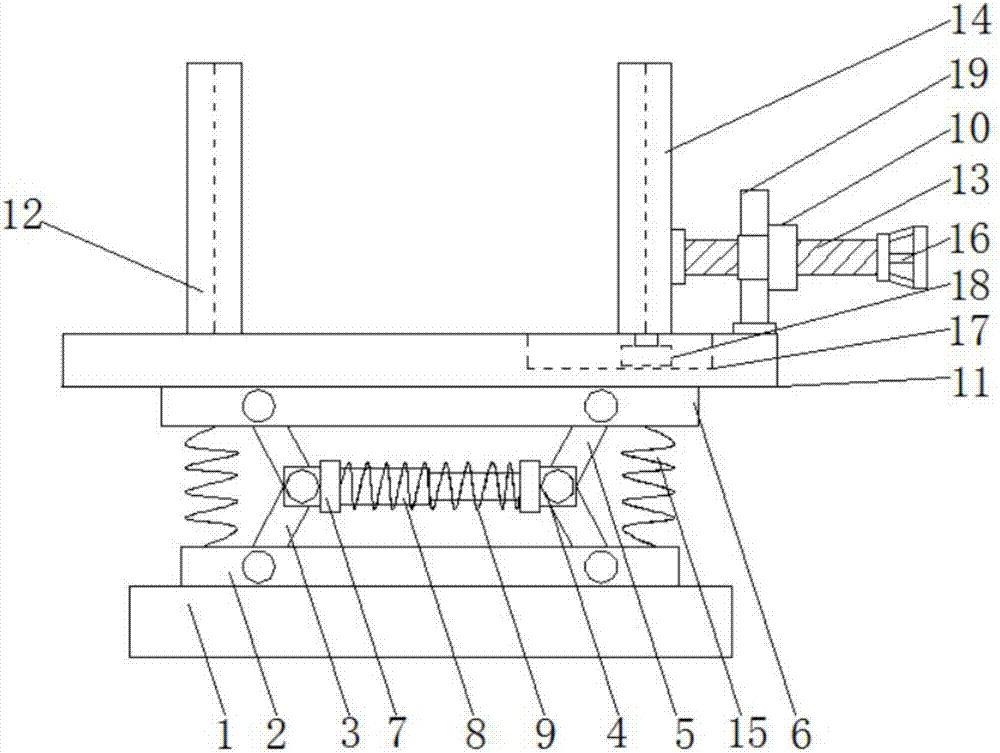

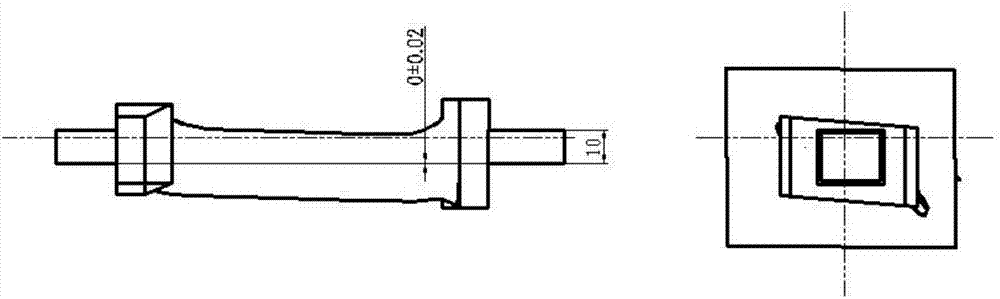

Catheter and guide wire control device for interventional operation and control method of catheter and guide wire control device

PendingCN107349514AEffective clampingAccurate clampingGuide wiresMedical devicesEngineeringGuide wires

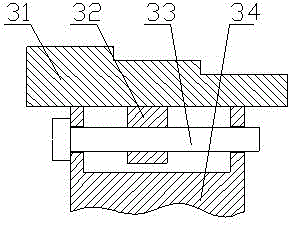

The invention discloses a catheter and guide wire control device for an interventional operation and a control method of the catheter and guide wire control device, belonging to the technical field of minimally invasive vascular interventional operations. The device comprises a clamping mechanism, a sleeve driving assembly and a brake braking assembly, wherein the clamping mechanism comprises a sleeve, a braking part and a clamping part, after the clamping part with a clamping end is mounted in the braking part, the braking part is in threaded connection with the sleeve, a notch is formed in one end, with the clamping end, of the clamping part, and the clamping end is in conical fit with the sleeve; the sleeve driving assembly is used for driving the sleeve to rotate; the brake braking assembly is used for clamping or loosening the braking part. With the method, a catheter or a guide wire can be clamped, pushed and twisted, and force measurement also can be realized; the efficient, accurate and nondestructive clamping and loosening for the guide wire and the catheter can be realized, and the catheter and the guide wire can be cooperatively operated.

Owner:SHENZHEN INST OF ADVANCED BIOMEDICAL ROBOT CO LTD

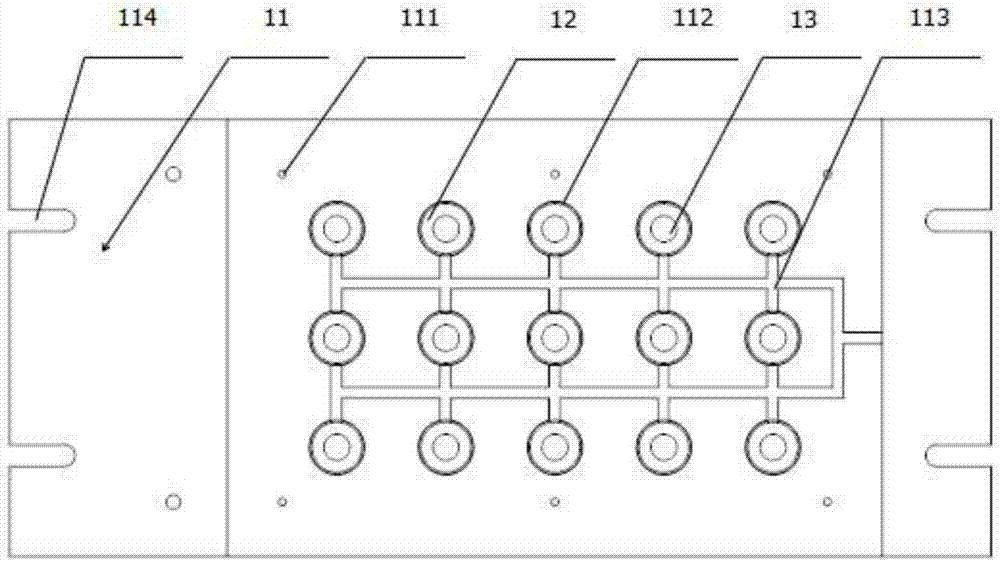

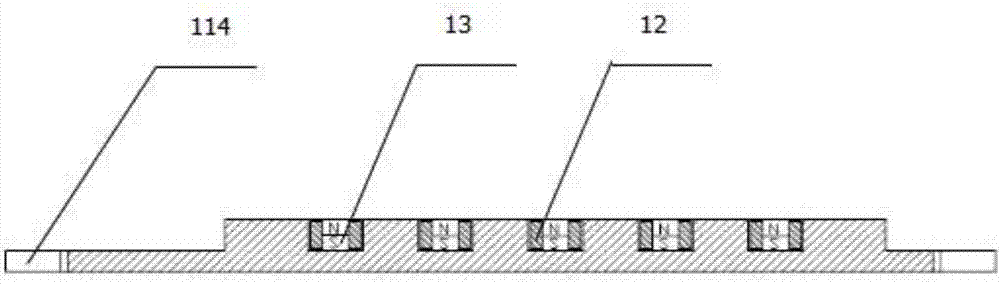

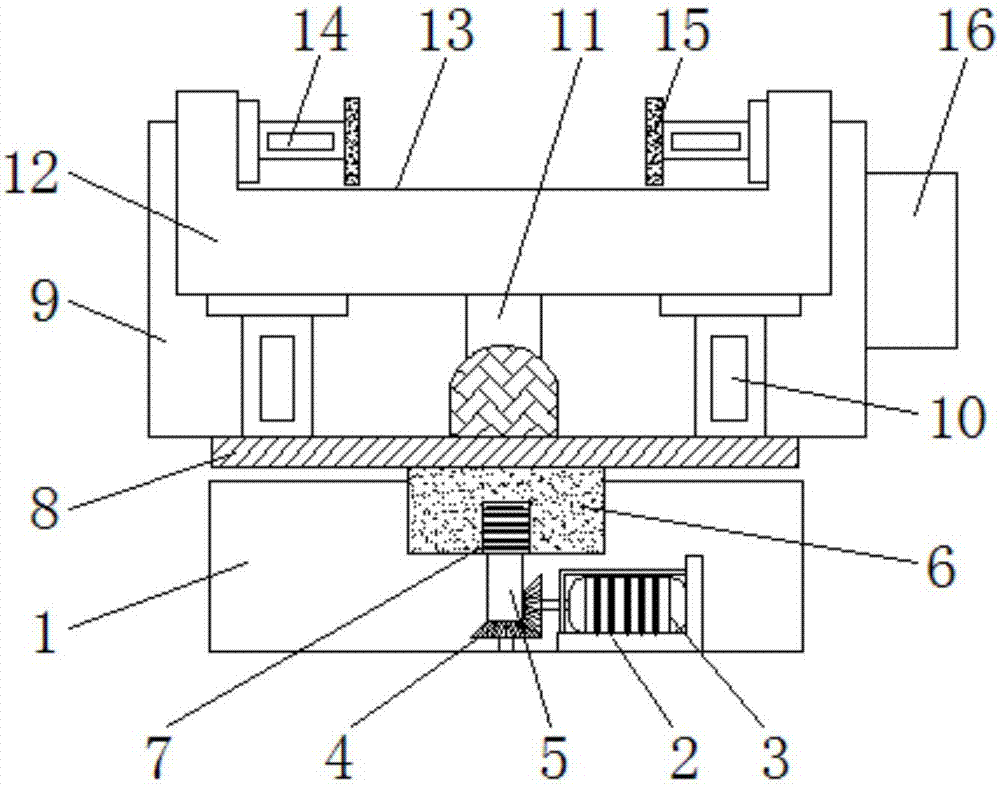

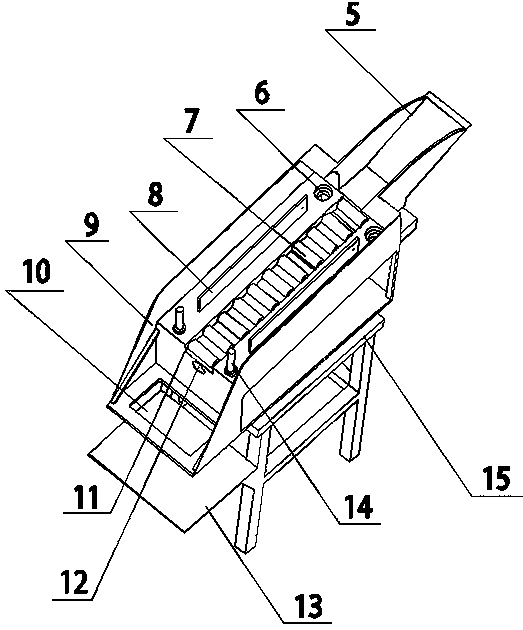

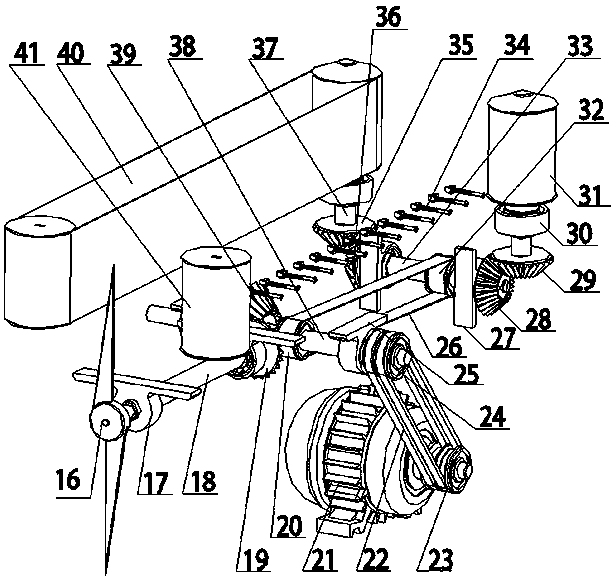

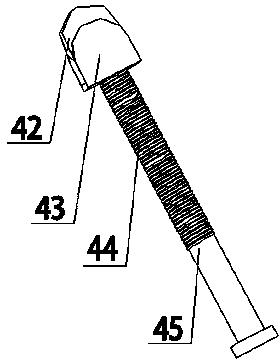

Positioning fixture for testing of digital tube display screen

Owner:湖南新融创科技有限公司

MEMS based contact conductivity electrostatic chuck

InactiveUS20050079737A1Effective clampingEasy to controlSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingContact pressureControl system

The present invention is directed to a method for clamping and processing a semiconductor substrate using a semiconductor processing apparatus. According to one aspect of the present invention, a multi-polar electrostatic chuck and associated method is disclosed which provides heating or cooling of a substrate by thermal contact conduction between the electrostatic chuck and the substrate. The multi-polar electrostatic chuck includes a semiconductor platform having a plurality of protrusions that define gaps therebetween, wherein a surface roughness of the plurality of protrusions is less than 100 Angstroms. The electrostatic chuck further includes a voltage control system operable to control a voltage applied to the electrostatic chuck to thus control a contact heat transfer coefficient of the electrostatic chuck, wherein the heat transfer coefficient of the electrostatic chuck is primarily a function of a contact pressure between the substrate and the plurality of protrusions.

Owner:AXCELIS TECHNOLOGIES

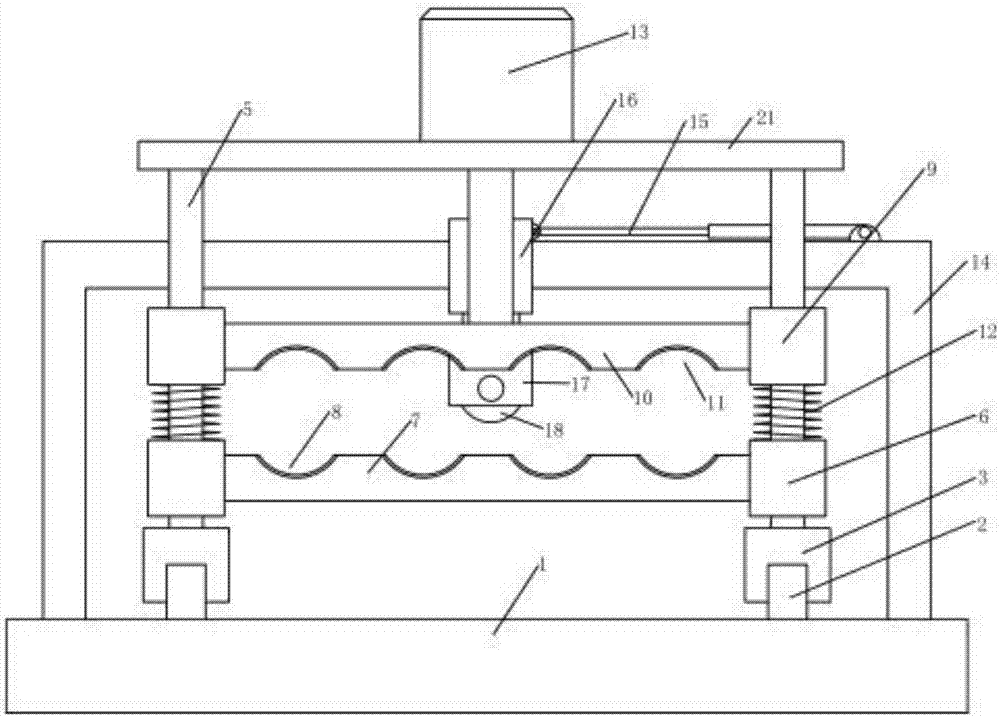

Automatic cutting machien for cutting pipe fittigns

InactiveCN107962225AEasy feedingEffective clampingTube shearing machinesShearing machine accessoriesArchitectural engineeringSteel tube

The invention discloses an automatic cutting machine for cutting pipe fittings, and relates to the techcnial field of steel pipe processing equipment. The automatic cutting machine comprises a workbench, and two sliding rails arranged in the length direction of the workbench; the two sliding rails are both provided with sliding blocks, and the workbench is hinged with a first telescopic cylinder used for driving the sliding blocks to slide; the two sliding blocks are both provided with vertical screw rods, and a lower fixed block is fixedly connected between the two screw rods; the lower fixedblock is provided with a plurality of lower pressing slots; the upper ends of the two screw rods are both provided with movable sleeves in a sleeving manner, and an upper fixed block is connected between the two movable sleeves; the lower surface of the upper fixed block is provided with a plurality of upper pressing slots corresponding to the lower pressing slots; and the two screw rods are further provided with compression springs in the sleeving manner. According to the automatic cutting machine disclosed by the invention, a plurality of steel pipes can be clamped between the upper fixed block and the lower fixed block without manual operation required, so that the feeding and cutting of the steel pipes can be finished, and the cutting efficiency and safety are improved greatly; and the automatic cutting machine is applicable for mass production.

Owner:四川精通机械科技有限公司

Universal fixture in use for supersound cleaning

InactiveCN1562506AReduce areaImprove work efficiencyWork holdersCleaning using liquidsFixed frameBiomedical engineering

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Novel functional flexible clamp and application method thereof

ActiveCN107322347AVersatileEnergy savingPositioning apparatusMaintainance and safety accessoriesPhysicsMagneto

Owner:HEBEI UNIV OF TECH

Precise indexing clamp special for turning

InactiveCN105583421AImprove clamping efficiencyEasy to holdMeasurement/indication equipmentsChucksEngineeringMachining

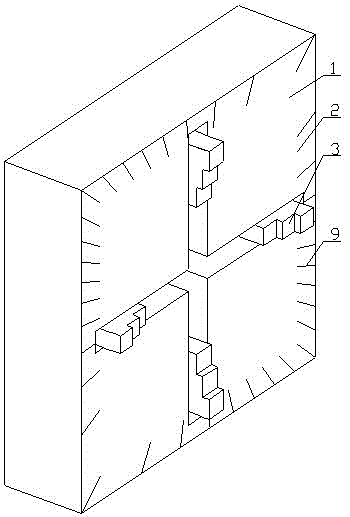

The invention discloses a precise indexing clamp special for turning, and belongs to clamps special for turning in the technical field of machining equipment. According to the precise indexing clamp special for turning, multipoint stress is achieved, and the clamp is suitable for clamping workpieces of multiple sizes. According to the technical scheme, the clamp comprises a clamp body, and a cross sliding groove is formed in the clamp body; a clamping jaw is arranged in each sliding groove body of the cross sliding groove, and a clamping jaw drive mechanism is arranged on the back face of the clamp body and comprises a large conical gear and a plurality of sets of lead screws; the large conical gear is mounted on the clamp body, and each lead screw is arranged at the position corresponding to the position of the corresponding clamping jaw; the lead screws are sleeved with threaded holes of the clamping jaws, and are in threaded connection with the clamping jaws; and a small conical gear is arranged on one side, close to the large conical gear, of each lead screw, and the small conical gears on the lead screws are meshed with the large conical gear. The precise indexing clamp is suitable for being used in turning.

Owner:新都区大丰鹏宇机械厂

Artware polishing grinding device bringing convenience to positioning

InactiveCN107350951AIncrease frictionGood positioning and clamping effectPolishing machinesGrinding drivesEngineering

The invention discloses a handicraft polishing and polishing device which is convenient for positioning, which comprises a fixed frame and a workbench. A grinding cover is fixedly connected to the lower end of the grinding cover, and a grinding roller is arranged inside the grinding cover. The limit rod is fixed on the upper end of the fixed frame. A pull rod is connected, the outer wall of the pull rod is sleeved with a spring, and the end of the pull rod is fixedly connected with a movable rod, the upper end of the movable rod is fixedly connected with a fixed block, and the outer wall of the fixed block is symmetrically provided with connecting rods, The end of the connecting rod away from the fixed block is rotatably connected with a clamping block. The invention is simple in structure, easy to operate, can effectively locate handicrafts, has good clamping effect, and avoids damage during polishing.

Owner:浙江千鹤工艺品有限公司

Rock disturbance generating mechanism and relaxation-disturbance integrated experiment device

ActiveCN107221236AQuick assemblyEffectively fixedMaterial strength using tensile/compressive forcesEducational modelsEngineeringElectric machinery

The invention discloses a rock disturbance generating mechanism, which comprises a first vertical plate and a third vertical plate. A second guide rod is fixed between the first vertical plate and the third vertical plate, and the second guide rod passes through a driving frame; a driving screw rod passes through the driving frame, the first vertical plate and the third vertical plate and is in screwing assembling with the driving frame through thread; the driving screw rod passes through one end of the third vertical plate and is connected with the output shaft of a loading motor; an impact plate can slide on the first guide rod; the back of the impact plate is provided with an impact disc, one end surface is connected and fixed with one end of an impact guide rod; the impact guide rod is sleeved with an impact spring, and the other end of the impact guide rod is provided with an impact guide end; an automatic loading mechanism is arranged on the driving frame; the bottom part of the loading motor is provided with a motor supporting plate; one end of an impact shaft is provided with a peripheral mounting head, the other end passes through the first vertical plate, and the end, passing through the first vertical plate, is provided with an auxiliary impact disc; and the impact shaft is connected with the loading shaft through a connection shaft assembly. The invention also discloses a relaxation-disturbance integrated experiment device applying the above rock disturbance generating mechanism.

Owner:ANHUI UNIV OF SCI & TECH

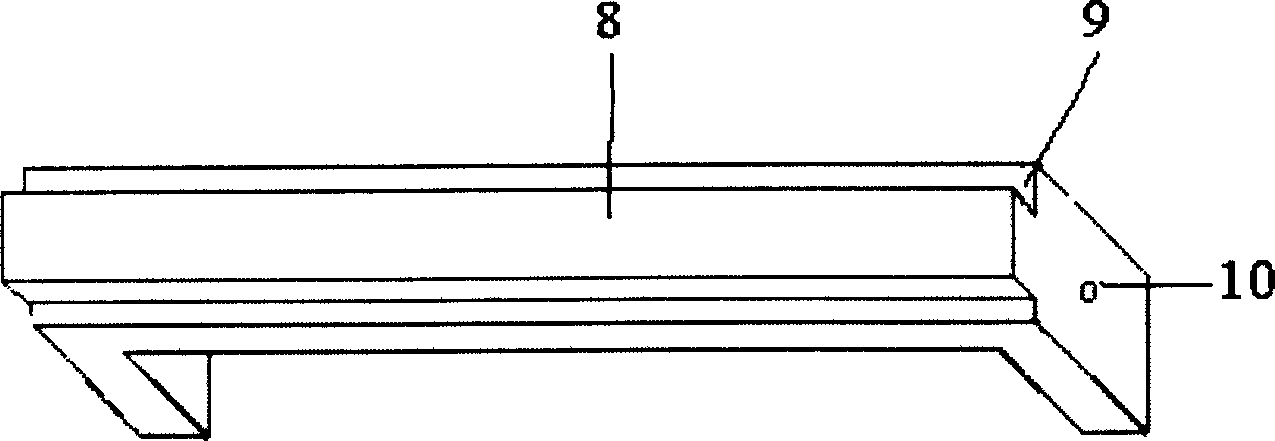

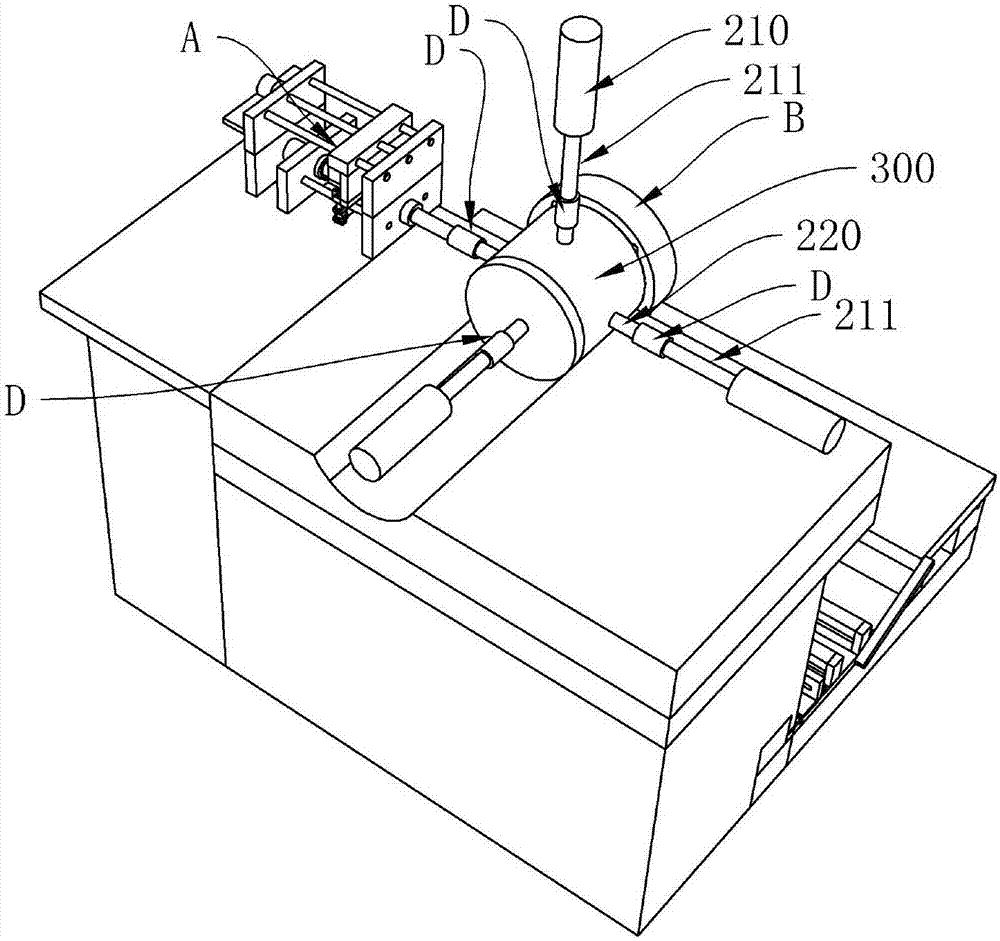

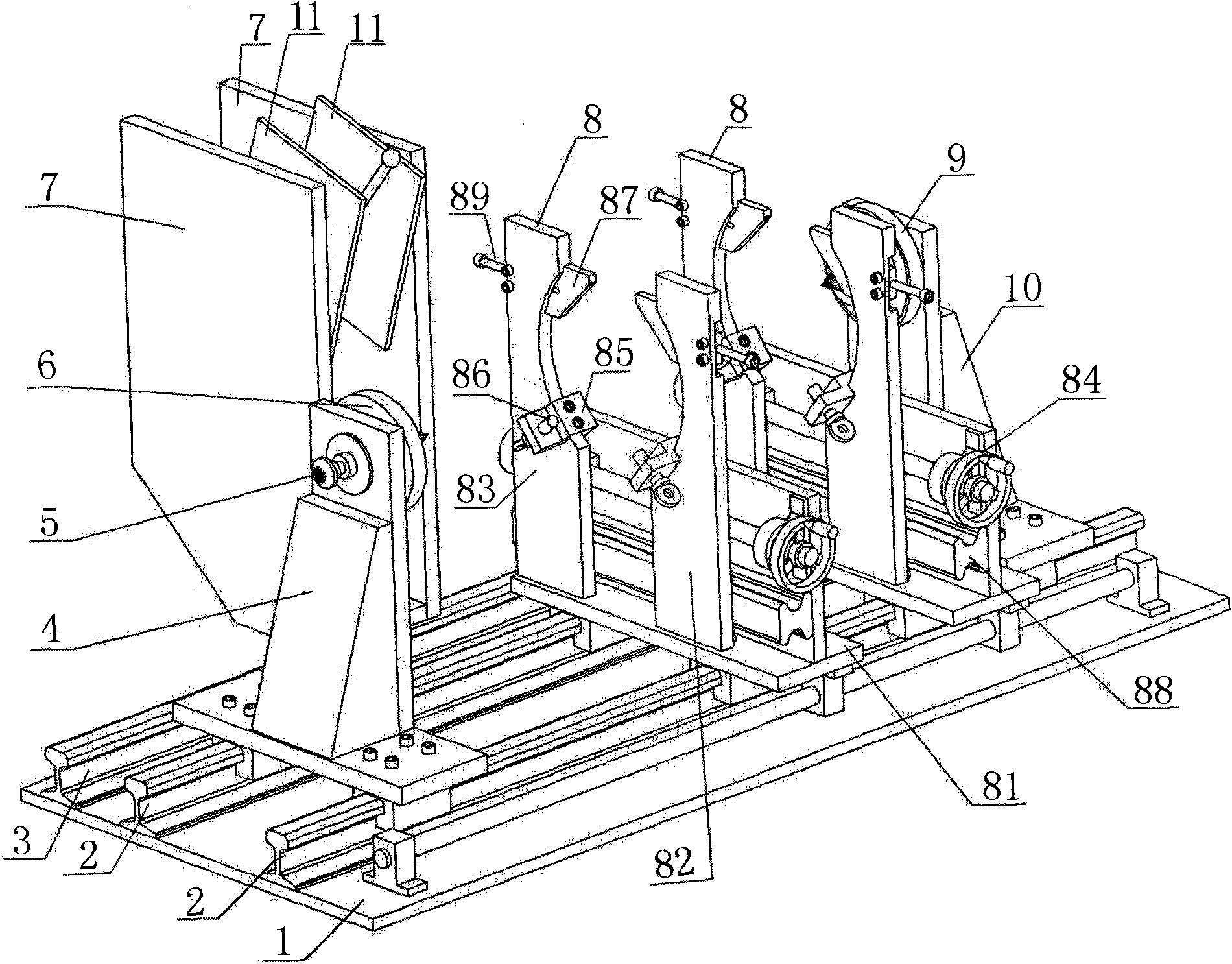

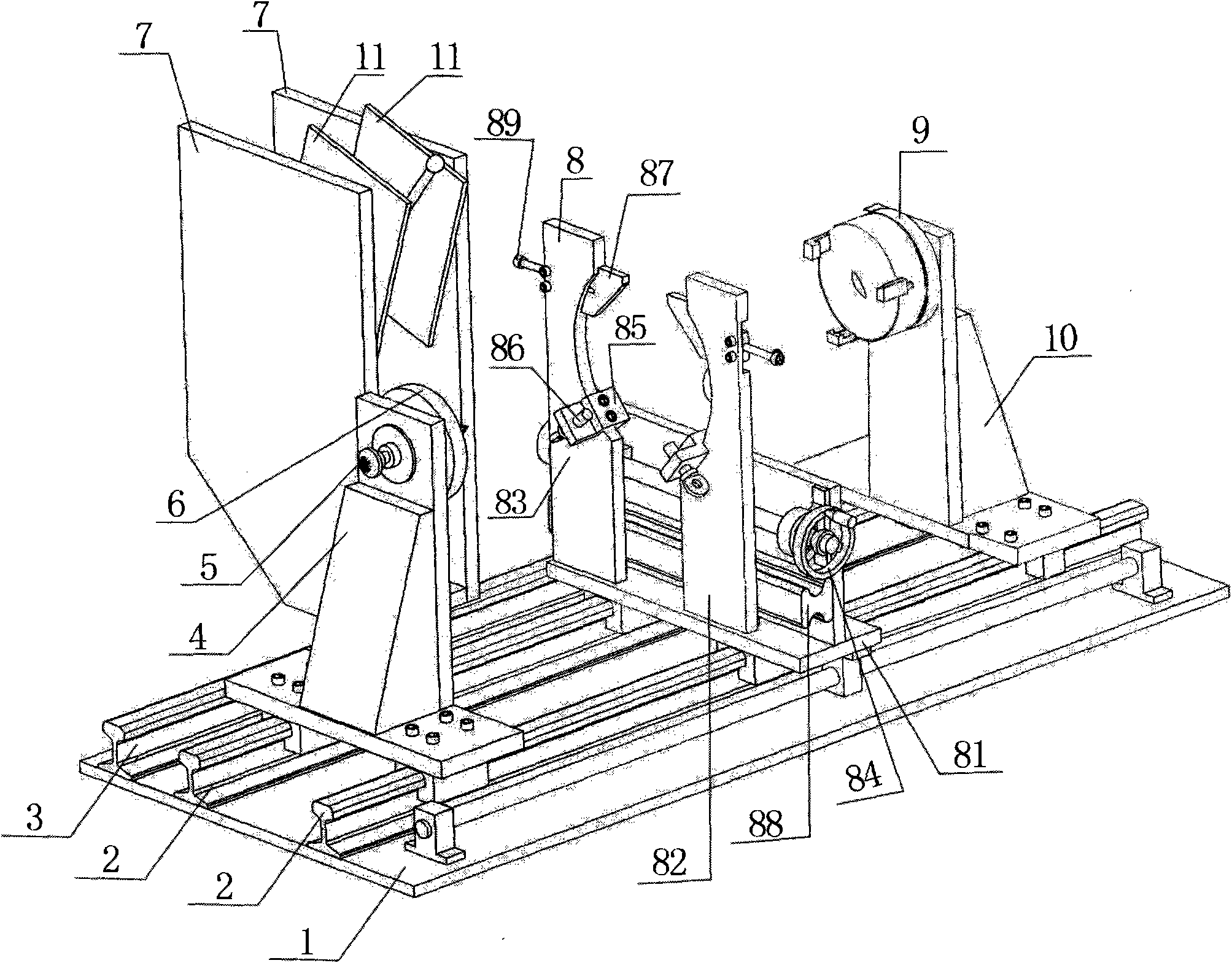

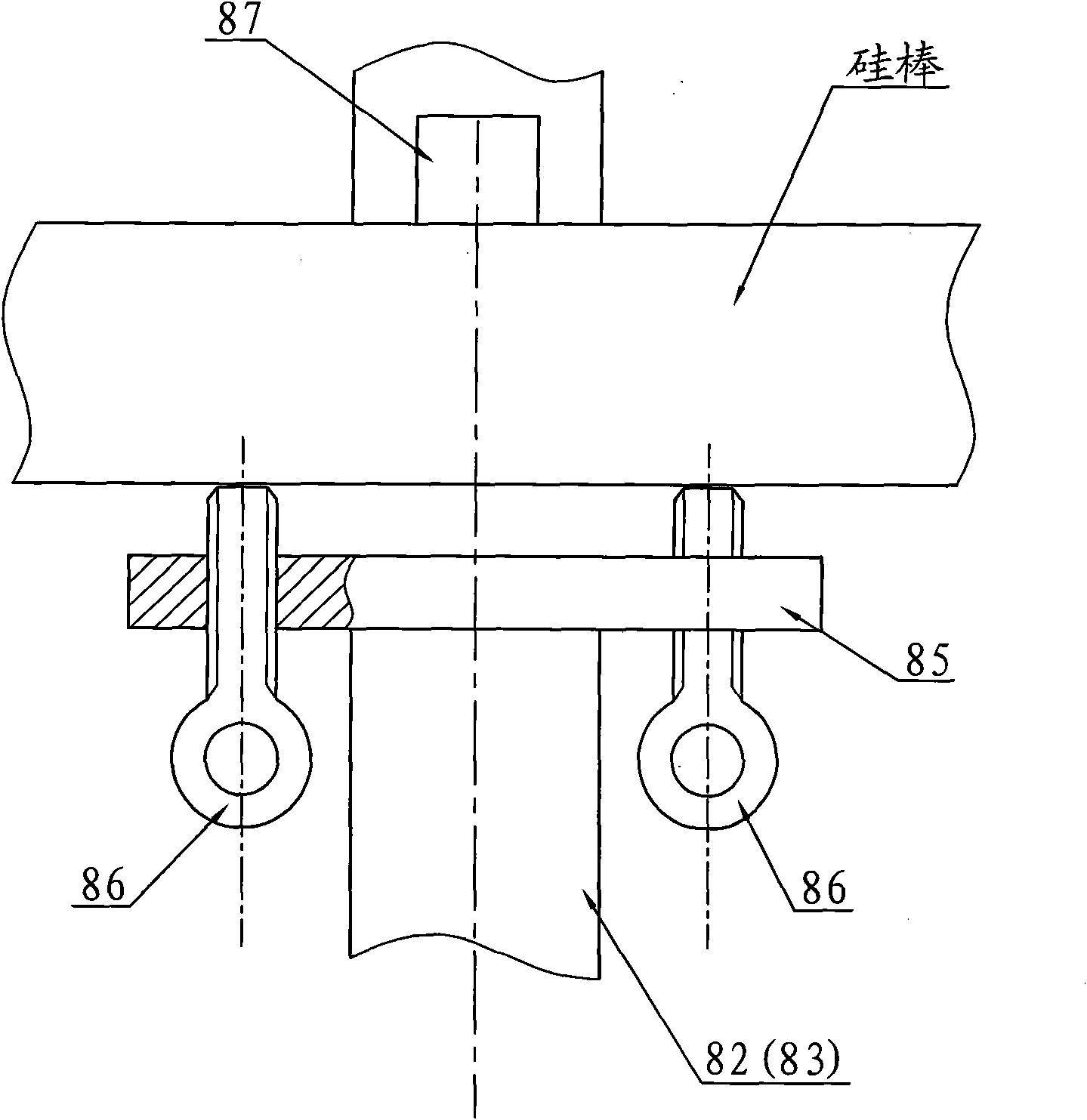

Silicon rod glue joint machine with single clamping bracket

InactiveCN101973074AReduced adjustment distanceSimple structureWorking accessoriesFine working devicesEngineeringCrystal base

The invention relates to a silicon rod glue joint machine with a single clamping bracket which comprises a silicon rod clamping mechanism. Two adjusting screws are symmetrically arranged on a locating block, and a distance between the two adjusting screws is 30-100cm. The silicon rod clamping mechanism can stably support a silicon rod only by placing the gravity center of the silicon rod to be adhered between the two adjusting screws. Compared with the prior art, an adjusting distance between a left slide carriage and a right slide carriage is further reduced only by the silicon rod clamping mechanism; and as long as the length of the silicon rod to be adhered can satisfy the clamping of a three jaw chuck and the silicon rod can be placed on the silicon rod clamping mechanism, the silicon rod can be effectively clamped, and adhesion of the silicon rod with a crystal base can be ensured. The silicon rod adhesive machine is enabled to have more compact structure, is more convenient to operate, and can effectively adhere the silicon rod with smaller liner dimension, and the silicon rod which cannot be subjected to normal cutting and slicing processing can be fully utilized.

Owner:EGING PHOTOVOLTAIC TECHNOLOGY CO LTD

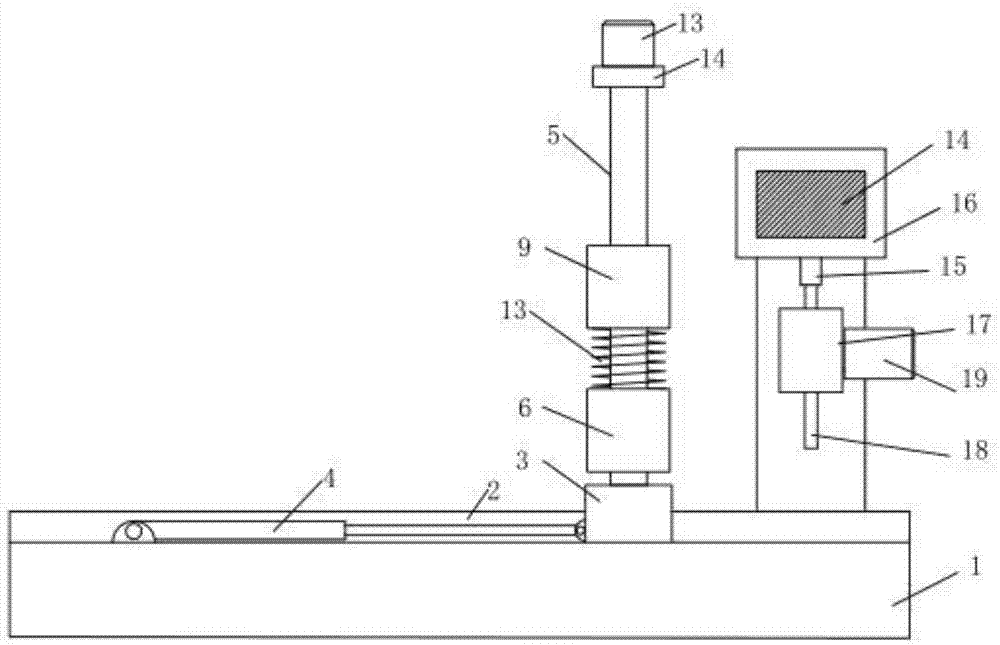

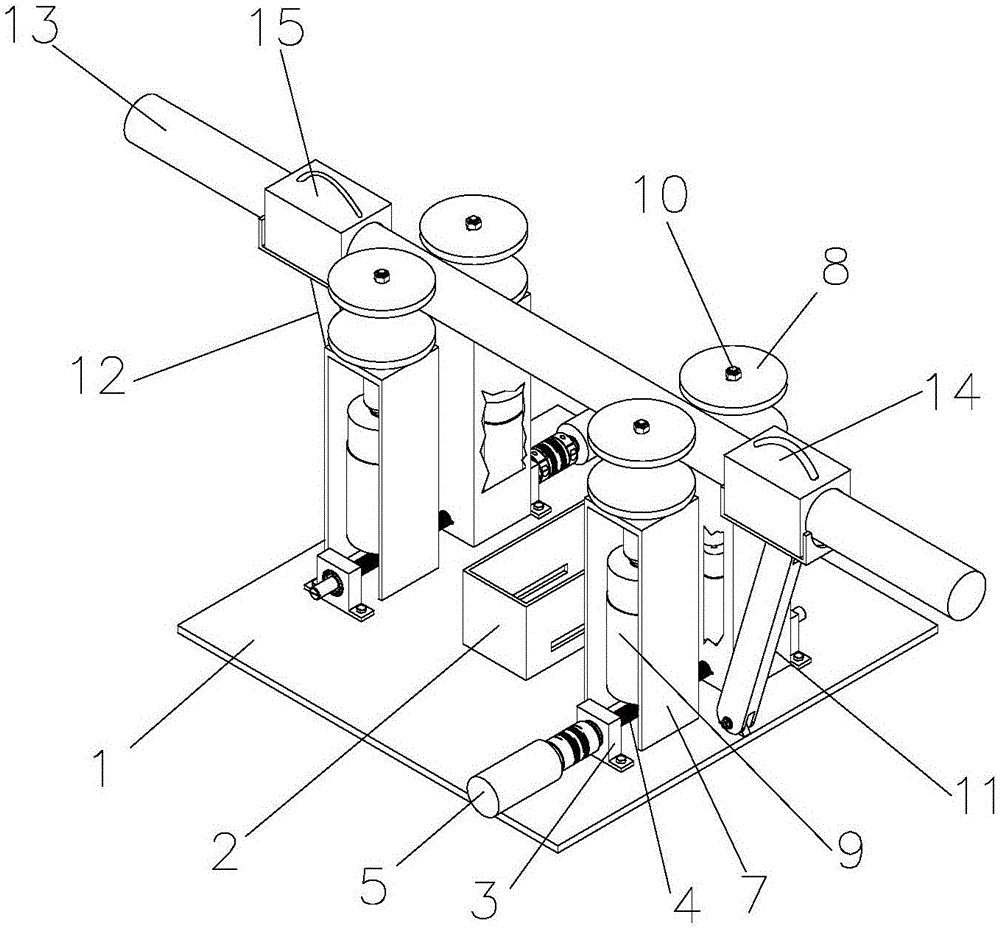

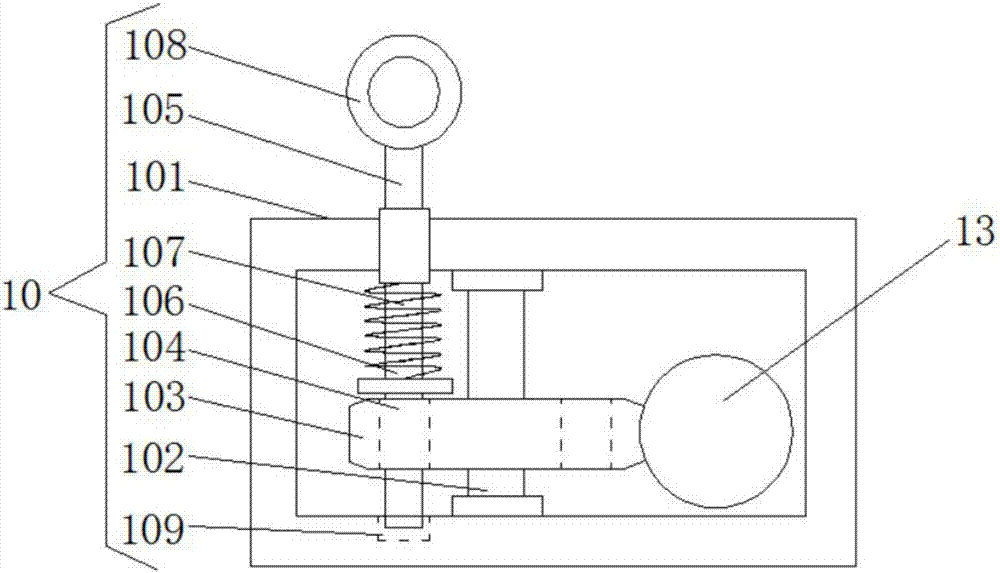

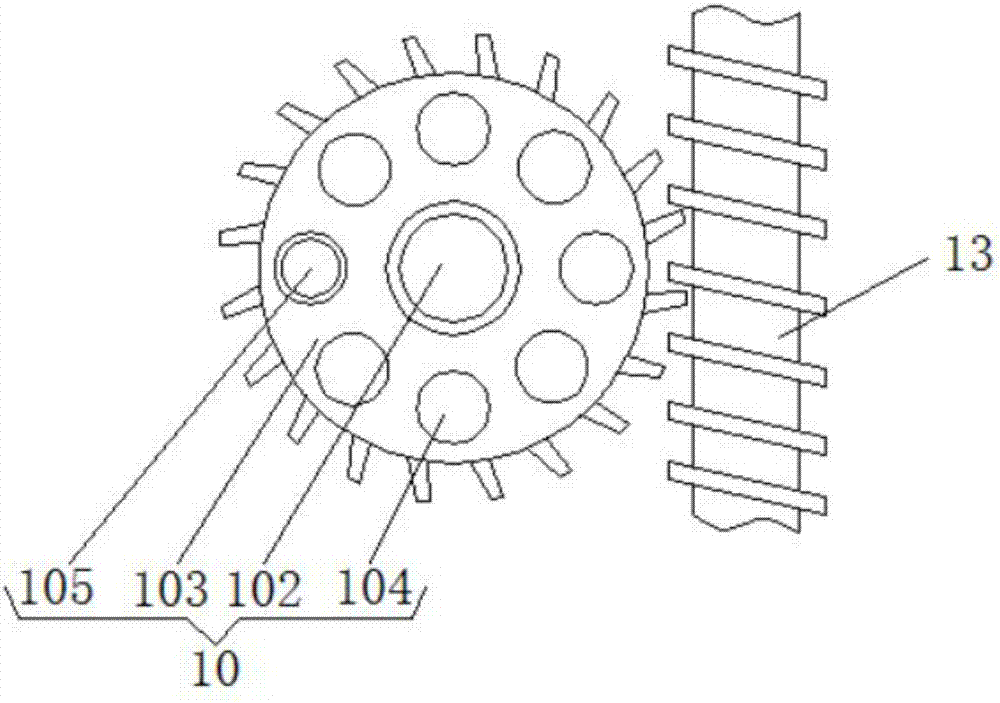

Suspension bridge steel wire rope damage patrolling robot

ActiveCN107175665AJudging the degree of damageEasy for daily maintenanceProgramme-controlled manipulatorMaterial magnetic variablesRemote controlEngineering

The invention discloses a suspension bridge steel wire rope damage patrolling robot. The suspension bridge steel wire rope damage patrolling robot comprises a base, a patrolling device arranged on the base and conducting patrolling on suspension bridge steel wire rope damage, and a control device controlling the patrolling device. The process for patrolling a steel wire rope includes the steps that firstly, the patrolling device is installed; secondly, the patrolling robot conducts patrolling on the suspension bridge steel wire rope; thirdly, after the robot finish patrolling, the robot returns to the initial end of the suspension bridge steel wire rope; fourthly, the first step, the second step and the third step are repeatedly conducted many times; and fifthly, damage state data are obtained. The suspension bridge steel wire rope damage patrolling robot is novel and reasonable in design, low in using cost, easy to operate, good in safety and capable of conveniently and rapidly finishing the suspension bridge steel wire rope damage patrolling operation; through the arrangement of the control device, a user remotely controls the patrolling robot to conduct high-altitude detection through a wireless remote control transmitter, and safety hidden danger of workers during high-altitude operation is avoided; and design is ingenious and reasonable, reliability and stability are achieved, the size is small, and practicability is high.

Owner:XIAN UNIV OF SCI & TECH

Displayer base having protective function

ActiveCN107239107AWith protective functionEasy to useDigital data processing detailsTransverse planeDisplay device

Owner:SHANDONG JINXIN TEXTILE FAN AIR CONDITIONING EQUIP

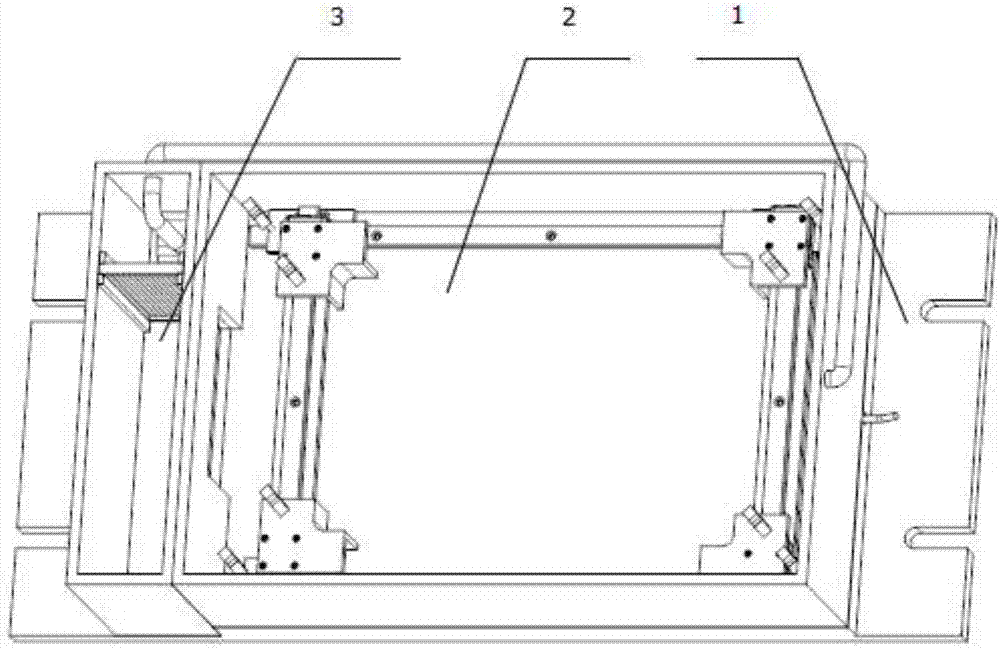

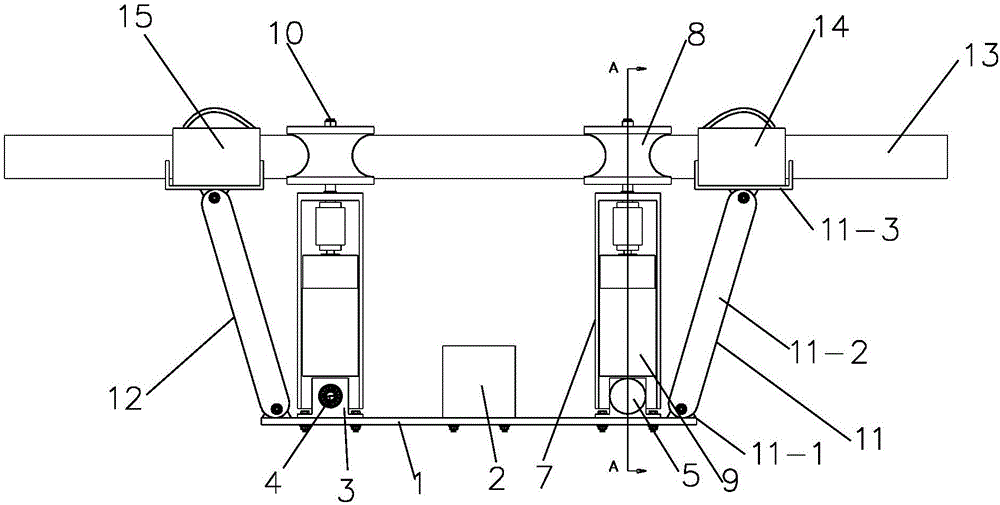

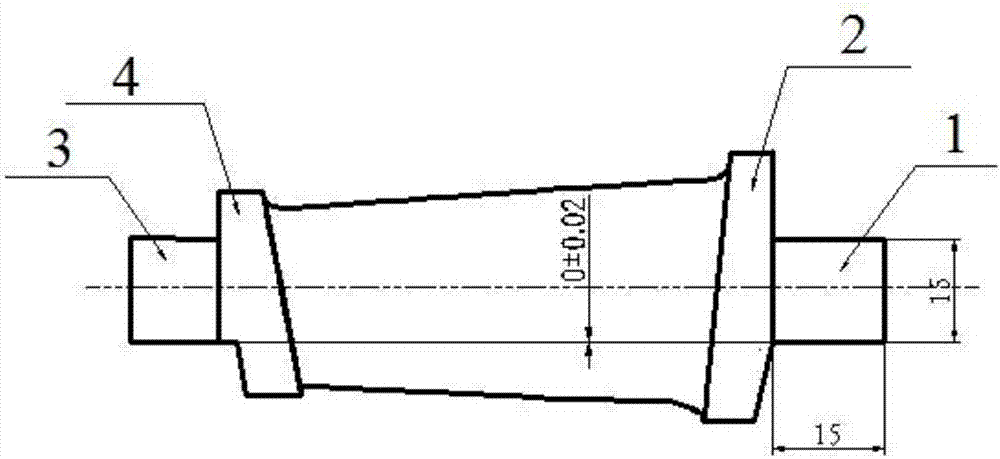

Centering clamping mechanism of CNC (Computerized Numerical Control) drilling machine of pipe fittings

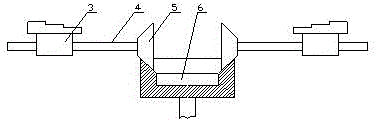

InactiveCN101954600AEffective clampingAvoid shockPositioning apparatusBoring/drilling componentsHydraulic motorNumerical control

The invention relates to a centering clamping mechanism of a CNC (Computerized Numerical Control) drilling machine for pipe fittings, arranged on a drilling platform of the CNC drilling machine. The centering clamping mechanism of the CNC drilling machines for pipe fittings comprises two clamping blocks which are arranged at both sides of the circumference of a pipe fitting and can move along the horizontal diameter direction of the pipe fitting, nuts are arranged at the lower parts of the two clamping blocks and engaged with a positive and negative screw mandrel which has two sections of opposite threads and is supported by the middle of a supporting seat, the supporting seat is fixedly connected with the drilling platform, and a rotating motion driving mechanism is arranged at one end of the positive negative screw mandrel. According to the invention, the positive negative screw mandrel is driven to rotate by adopting a hydraulic motor, the clamping blocks at both sides are driven to simultaneously homodromously or oppositely move and rapidly finish the centering and clamping action to the symmetrical outer walls of a cylinder, a hydraulic motor controls and drives the centering and clamping action through a hydraulic station, the action and the speed can be accurately controlled through a CNC console and the automation requirement with high efficiency is accurately satisfied, and the pipe fitting can be slowly and effectively clamped hydraulically to prevent mechanical clamping from causing impact and damage to the pipe fitting.

Owner:WUXI HUALIAN PRECISION MACHINERY

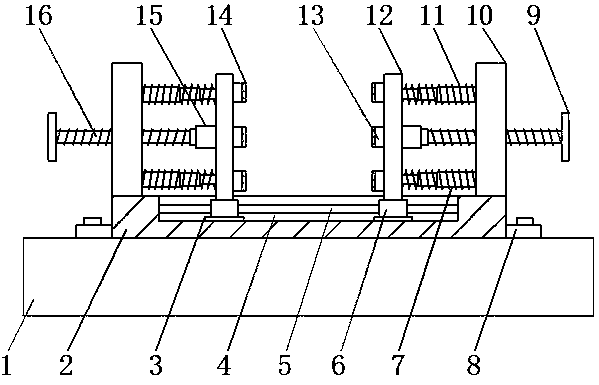

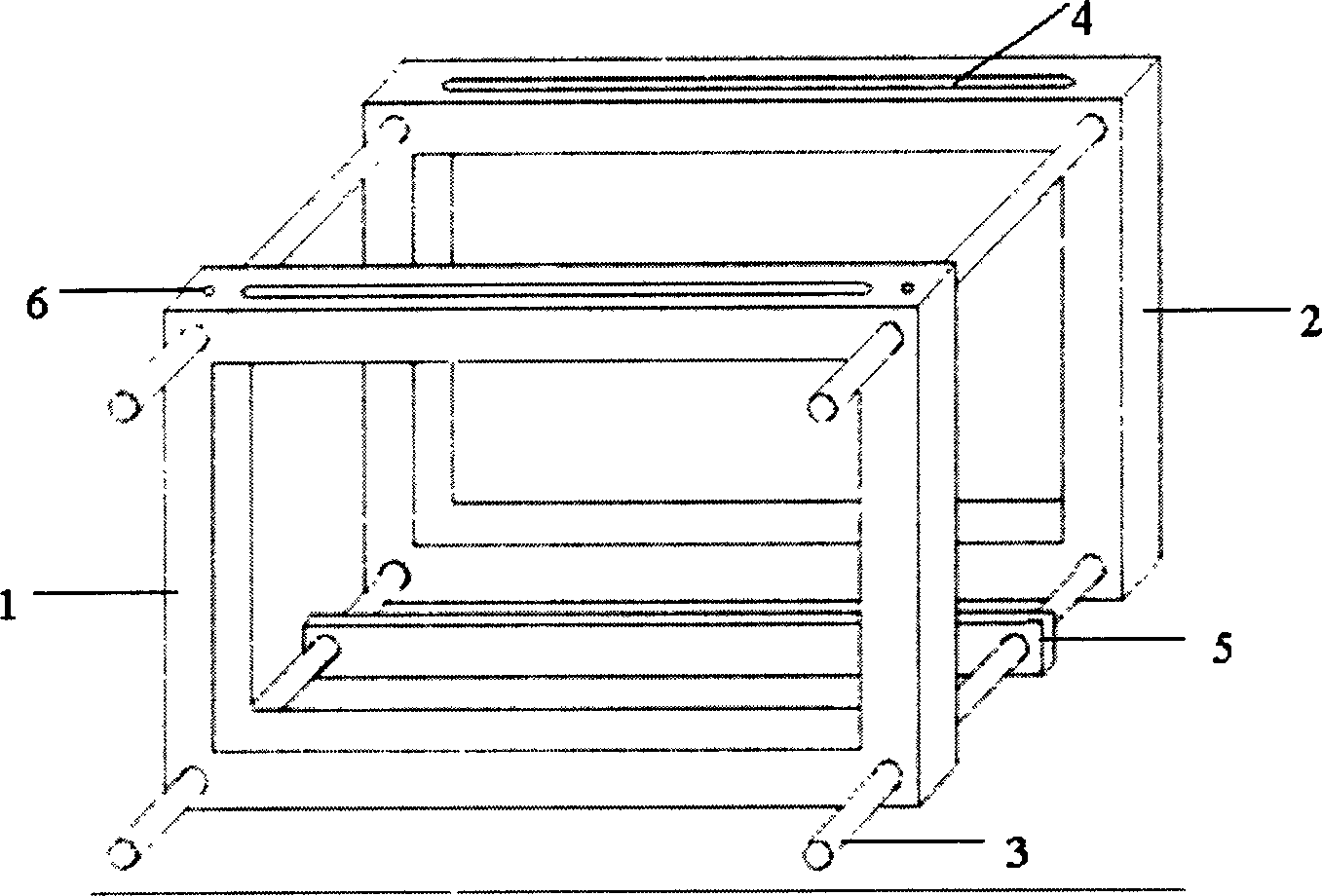

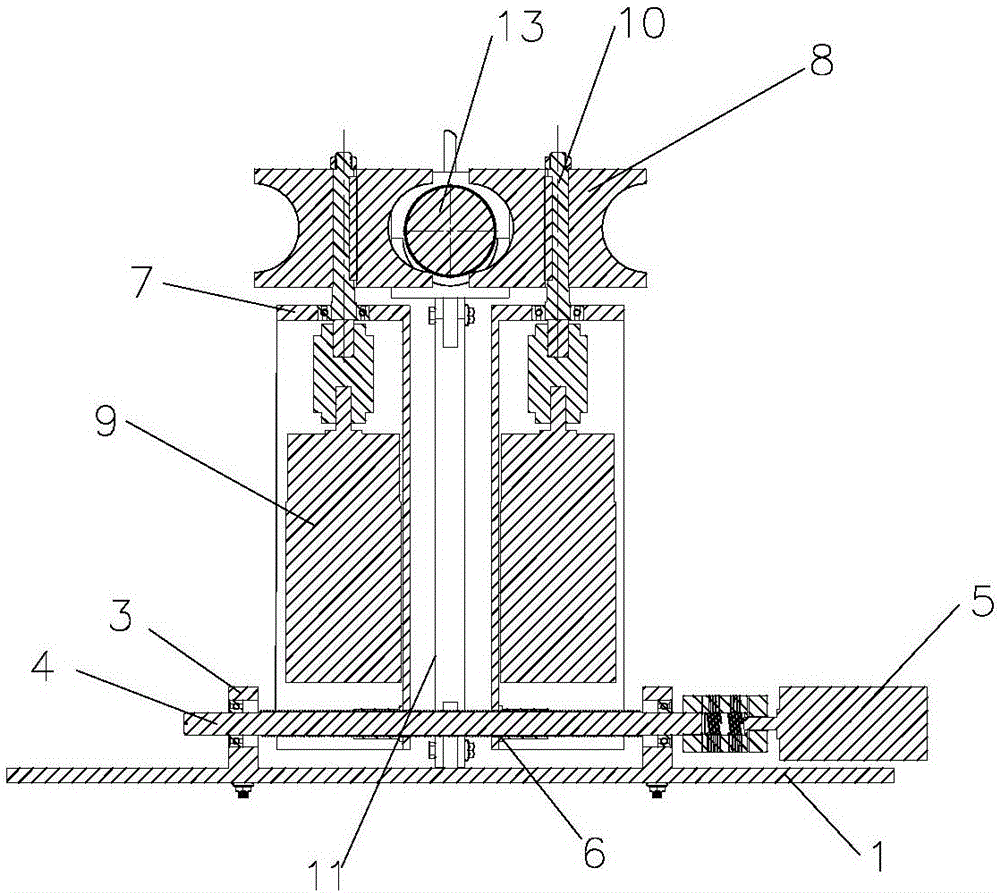

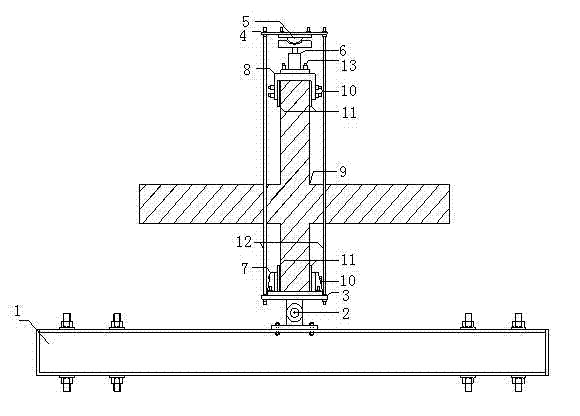

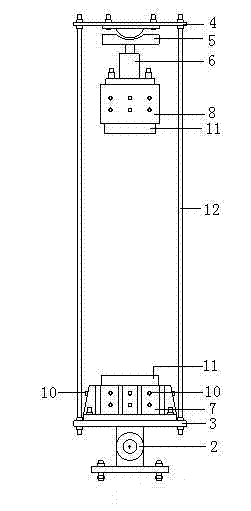

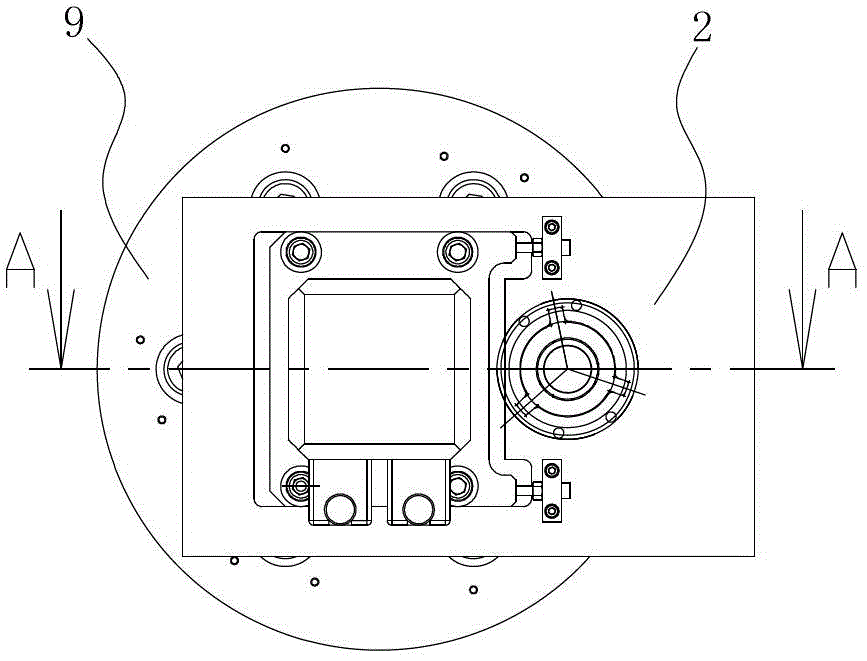

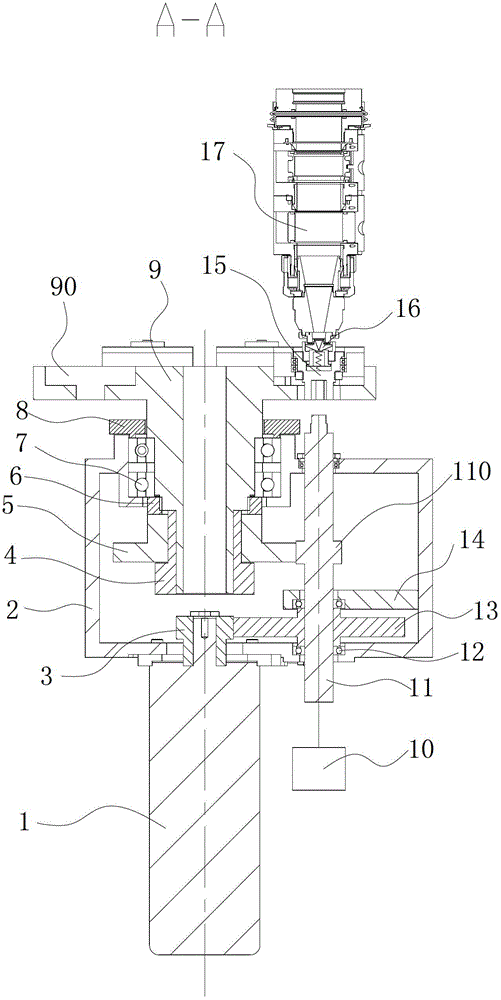

Constant-axial-force self-balanced loading device for different column section joints

InactiveCN103207121AConstant vertical axial forcePrevent axial force from changingMaterial strength using repeated/pulsating forcesAxial pressureMaterial consumption

The invention discloses a constant-axial-force self-balanced loading device for different column section joints. The constant-axial-force self-balanced loading device comprises a bottom beam, a bottom spherical hinge, a lower reaction plate, a lower clamping structure, a beam-column joint test piece, an upper clamping structure, a hydraulic jack, an upper-end hinge support and an upper reaction plate which are sequentially connected with one another from bottom to top. The upper reaction plate is connected with the lower reaction plate by reaction draw bars, adjusting bolts are respectively mounted on the left side and the right side of the upper clamping structure and the left side and the right side of the lower clamping structure, and steel clamp plates are mounted among the clamping structures and the column-beam joint test piece. The constant-axial-force self-balanced loading device has the advantages that the device can be self-balanced in a test procedure, the axial pressure keeps constant in the test procedure, and the device is simple in structure, convenient to detach, low in material consumption and applicable to tests for hysteretic behavior of the different column section beam-column joints under the condition of low-cycle repetitive load.

Owner:HOHAI UNIV +1

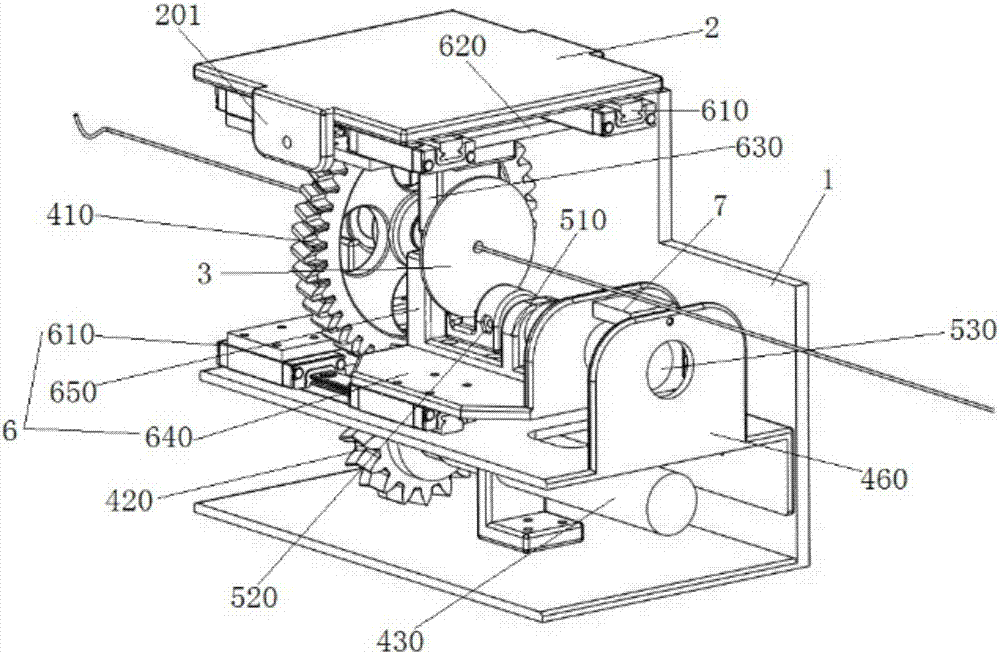

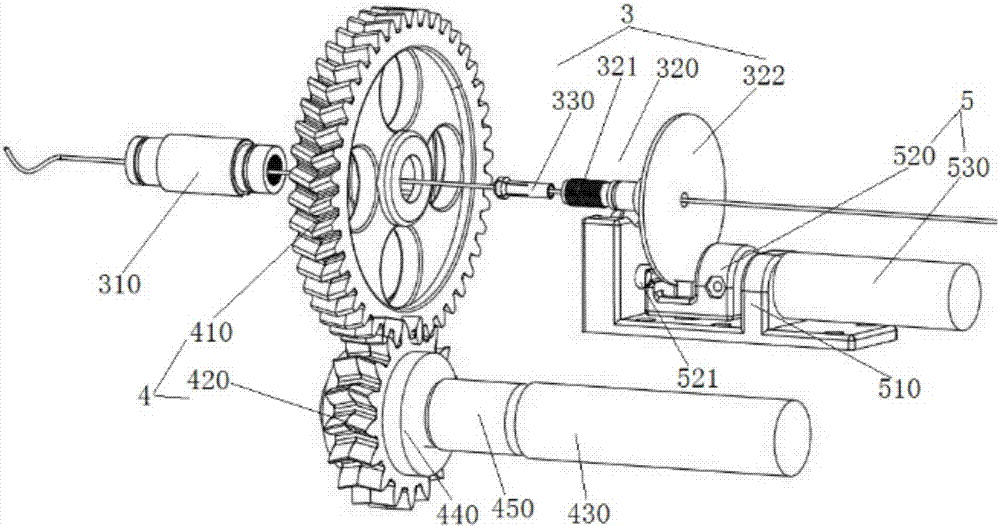

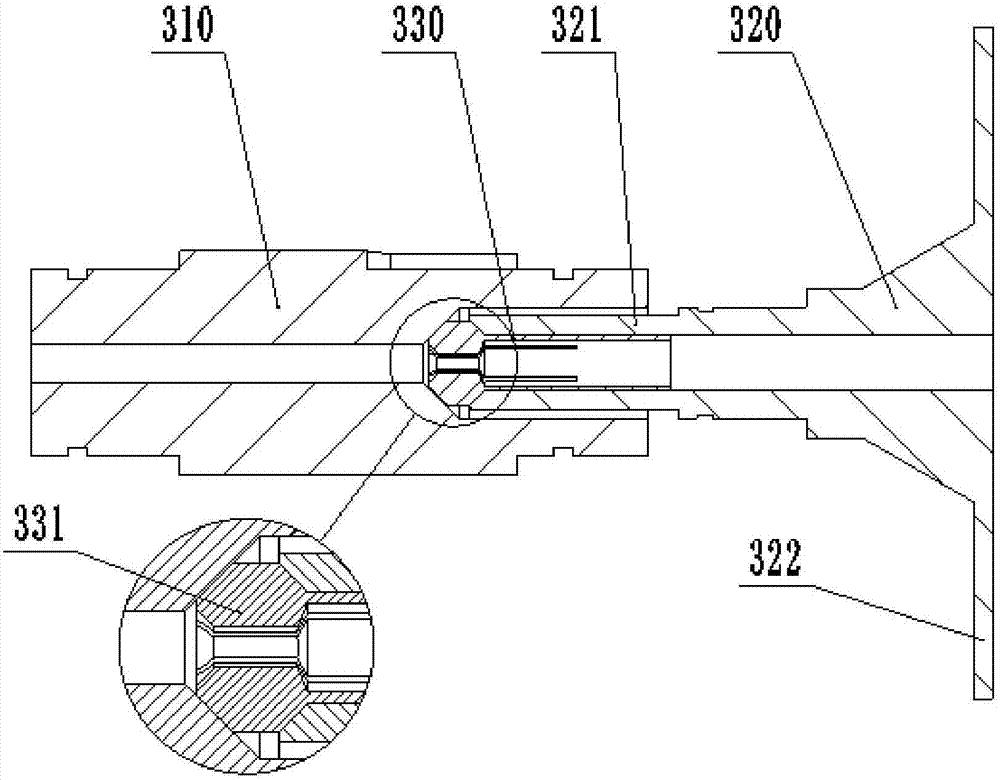

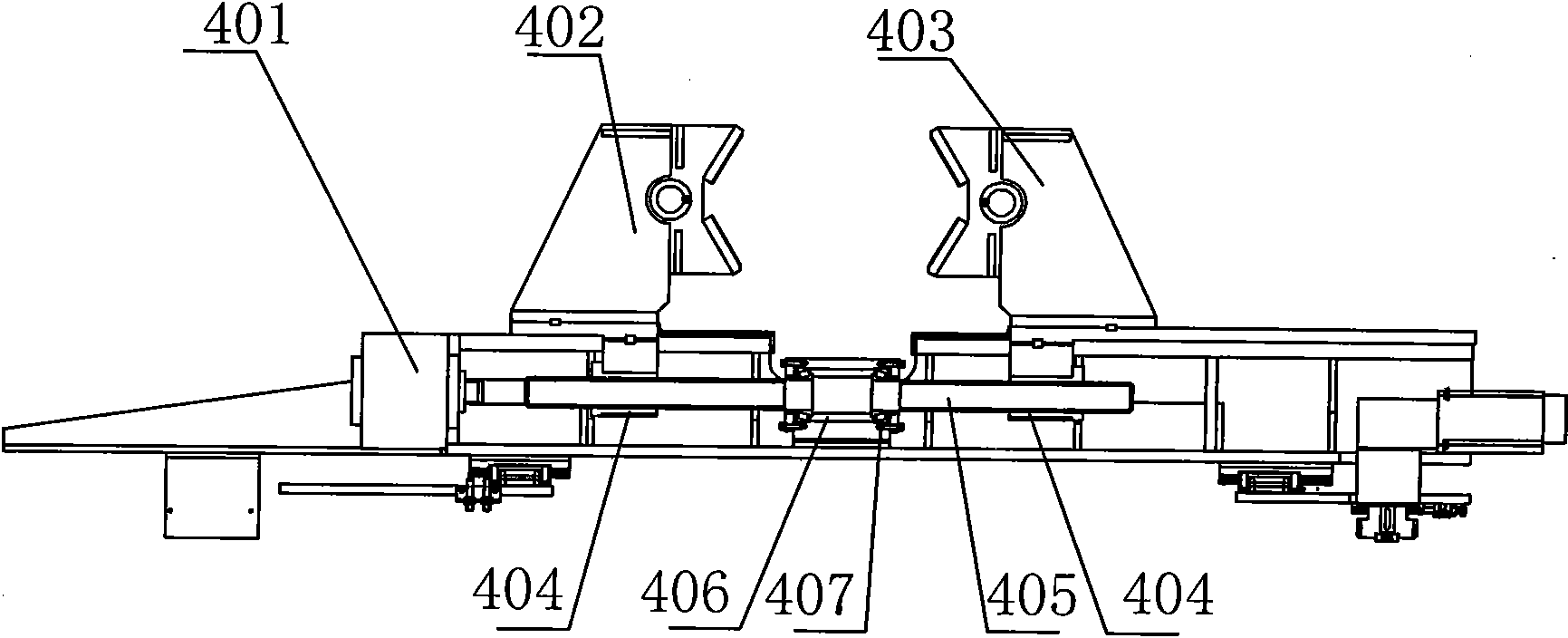

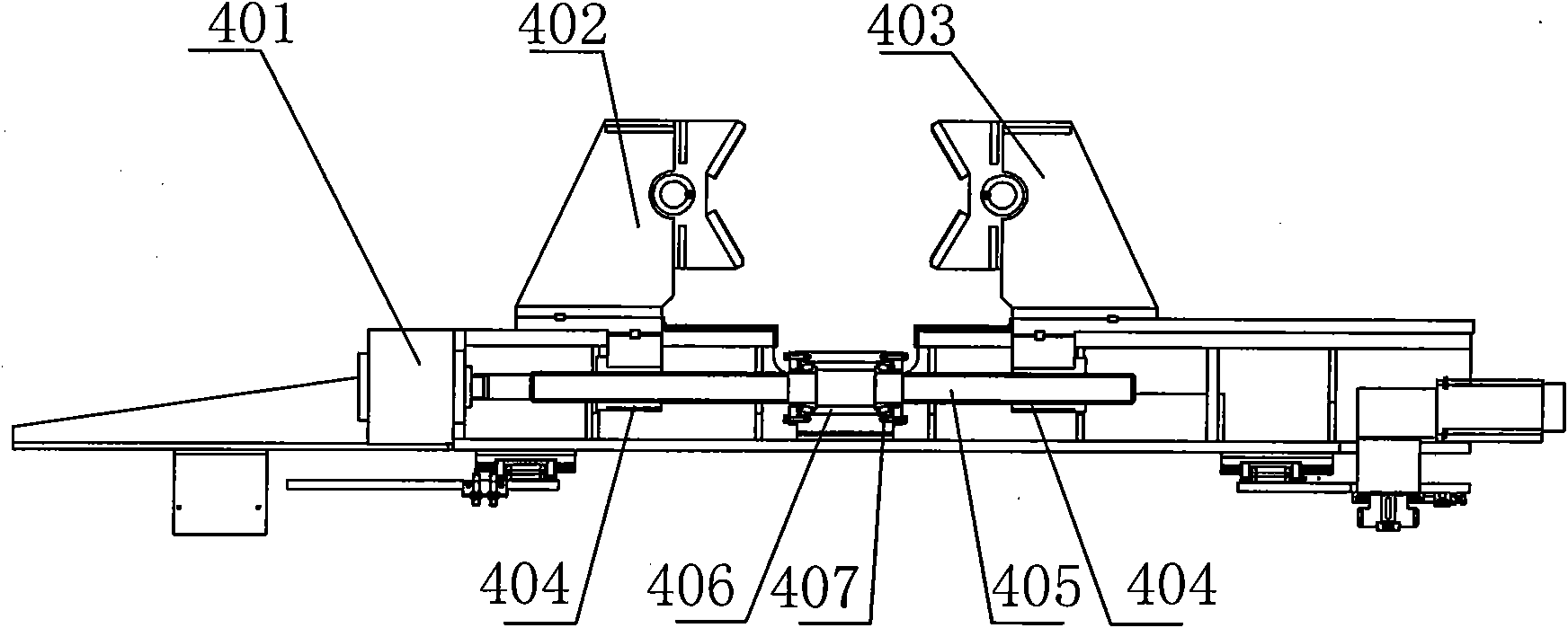

Automatic turret-type nozzle replacing device of laser cutting machine

ActiveCN103143846AGuaranteed reliabilityReduce non-productive timeLaser beam welding apparatusGear transmissionEngineering

The invention relates to an automatic turret-type nozzle replacing device of a laser cutting machine, in particular to an automatic turret-type nozzle replacing device which is simple in structure, convenient and rapid for replacing a nozzle and capable of increasing the working efficiency. The laser cutting machine comprises a worktable, a cutting head and a nozzle, wherein the nozzle is detachably connected onto the cutting head; and any corner of the worktable is provided with the automatic nozzle replacing device, and the automatic nozzle replacing device comprises a turntable, a nozzle receiving component, a box body, a transmission shaft, an elevation air cylinder and a gear transmission mechanism. The automatic turret-type nozzle replacing device is unnecessary to operate by an operator, especially under an automatic running mode, so that the non-production time is shortened, the working efficiency is increased, and the cost is saved.

Owner:江苏扬力数控机床有限公司

Method for quickly preparing double-mounting plate blade

The invention provides a method for quickly preparing a double-mounting plate blade. The method comprises the specific technological processes of (1) processing upper and lower technological tables: one technological table is processed at each of the upper and lower ends of a blade blank, the upper technological table is connected to a blade tenon or the outer side surface of an upper mounting plate, and the lower technological table is connected with the outer side surface of a lower mounting plate of the blade; (2) designing a clamping structure with the upper and lower technological tablesadopted as a datum; (3) carrying out rough / finish milling on the mounting plates and a blade body profile with the upper and lower technological tables adopted as the datum; (4) polishing the blade body profile; and (5) removing the upper and lower technological tables of the blade. According to the method, the problems that during conventional machining for complex-structure blades of an air compressor, the technology is complex, clamping is difficult, precision is hard to guarantee, procedures are long, quality efficiency is low, and the like, are solved.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Maintaining worktable and method for capacitor

Owner:长兴恒业达电子股份有限公司

Feeding type automatic lotus root slicing machine

InactiveCN104385338ASlicing is stable and efficientClamp firmlyMetal working apparatusMechanical engineeringLotus root

The invention relates to a feeding type automatic lotus root slicing machine, in particular to novel lotus root processing equipment. The feeding type automatic lotus root slicing machine consists of a frame, a lotus root conveying unit, a lotus root clamping unit, a lotus root slicing unit and a lotus root slice collecting unit, wherein the lotus root conveying unit and the lotus root clamping unit are embedded together; and the lotus root clamping unit is contacted with a conveying belt on the lotus root conveying unit through a roller on a pressurizing chuck, so that processed lotus roots can be smoothly fed in the lotus root slicing unit through the lotus root conveying unit. The lotus root slicing unit is positioned at the tail end of the lotus root conveying unit; and the lotus root slice collecting unit is positioned rightly below the lotus root slicing unit. The feeding type automatic lotus root slicing machine adopts the pressurizing chuck to perform the point clamping for the lotus roots through flexible transition of the conveying belt, the lotus root conveying unit and the lotus root clamping unit are embedded together, and the lotus root conveying unit and the lotus root slicing unit are linked, so that the structure is compact, and the stability is enhanced; and all the component units of the whole machine are higher in working coordination degree, facilitate automatic production control, are excellent in use effect, and are strong in practicability.

Owner:WUHAN TEXTILE UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com