Patents

Literature

78results about How to "Reduce non-productive time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

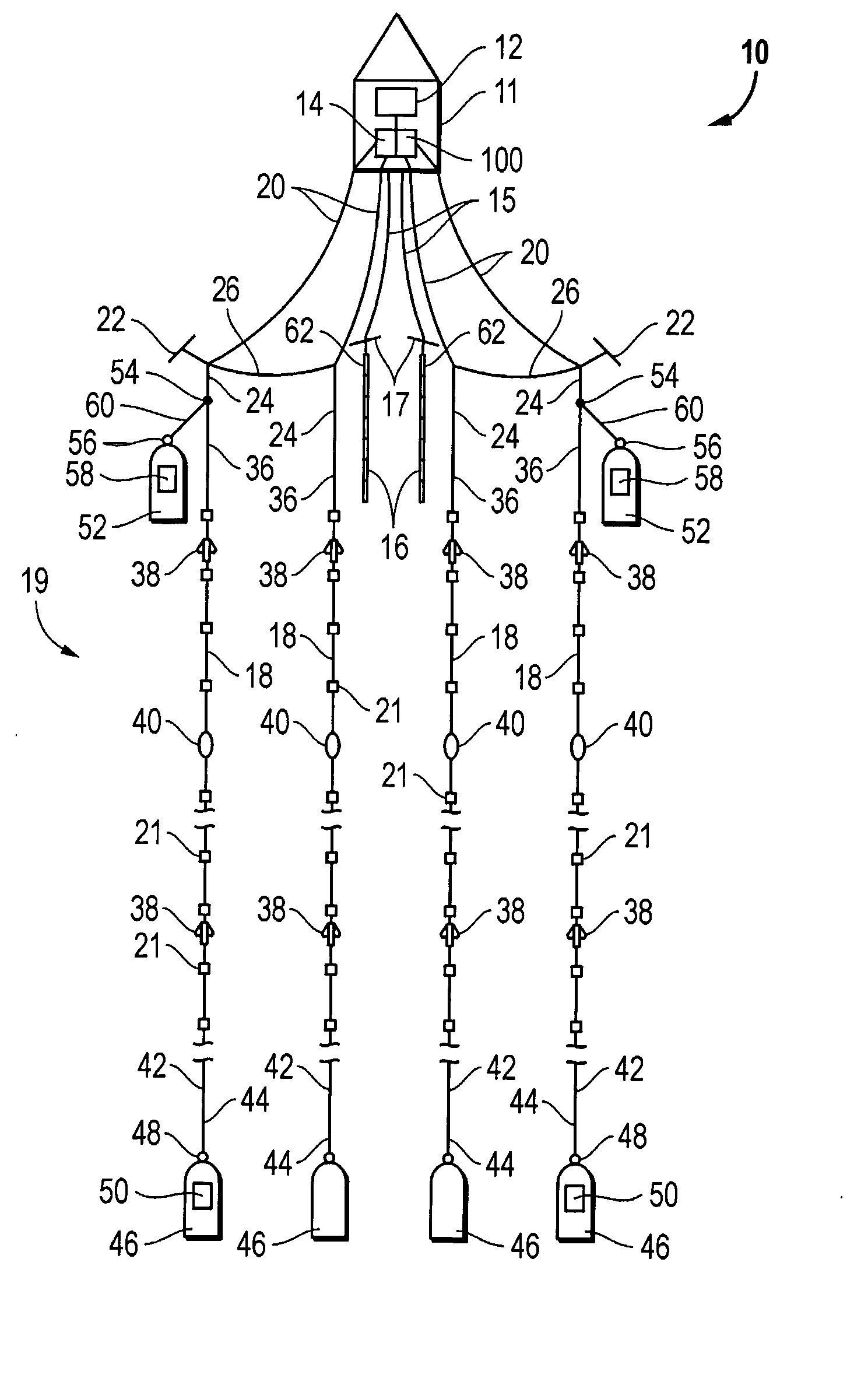

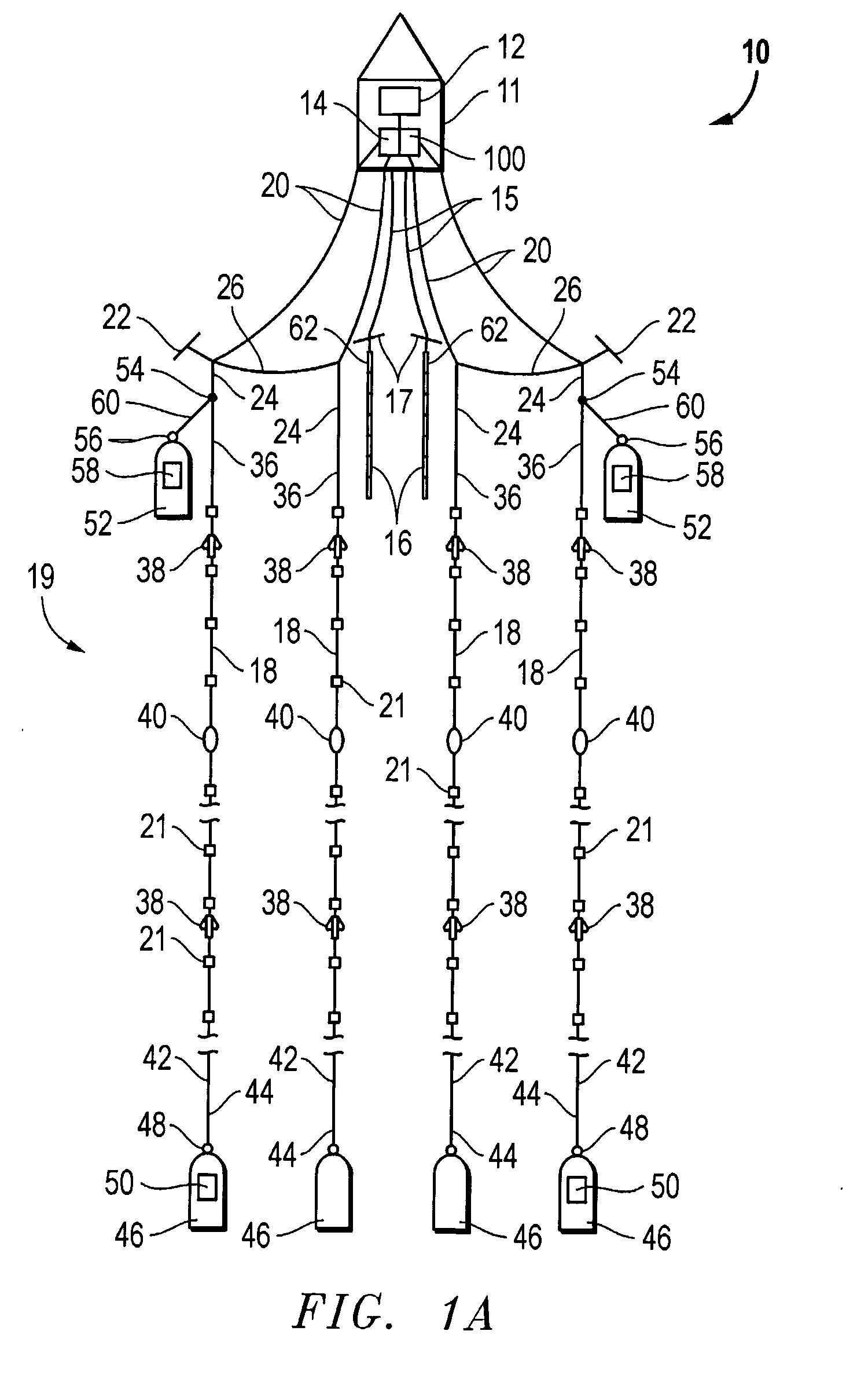

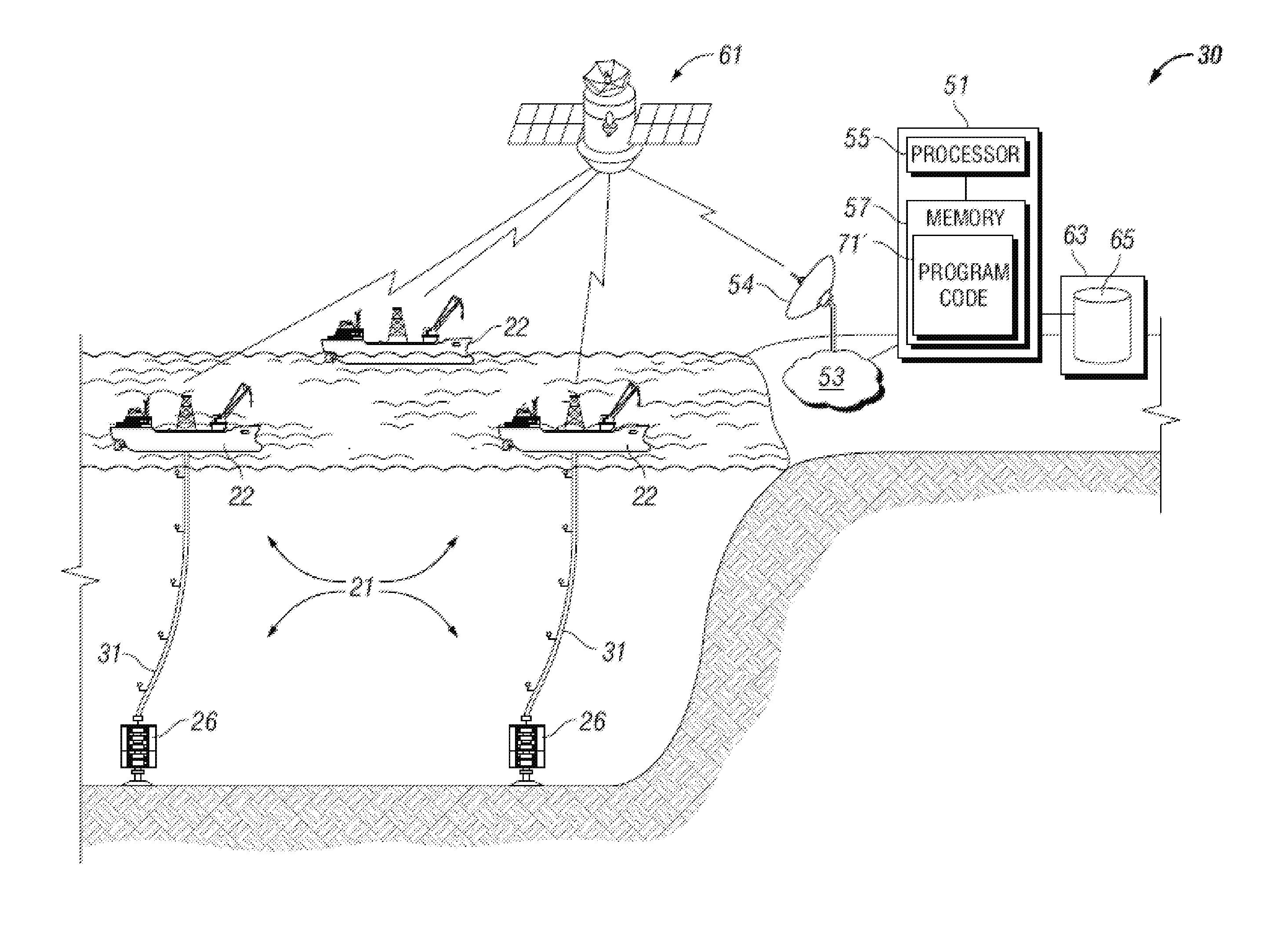

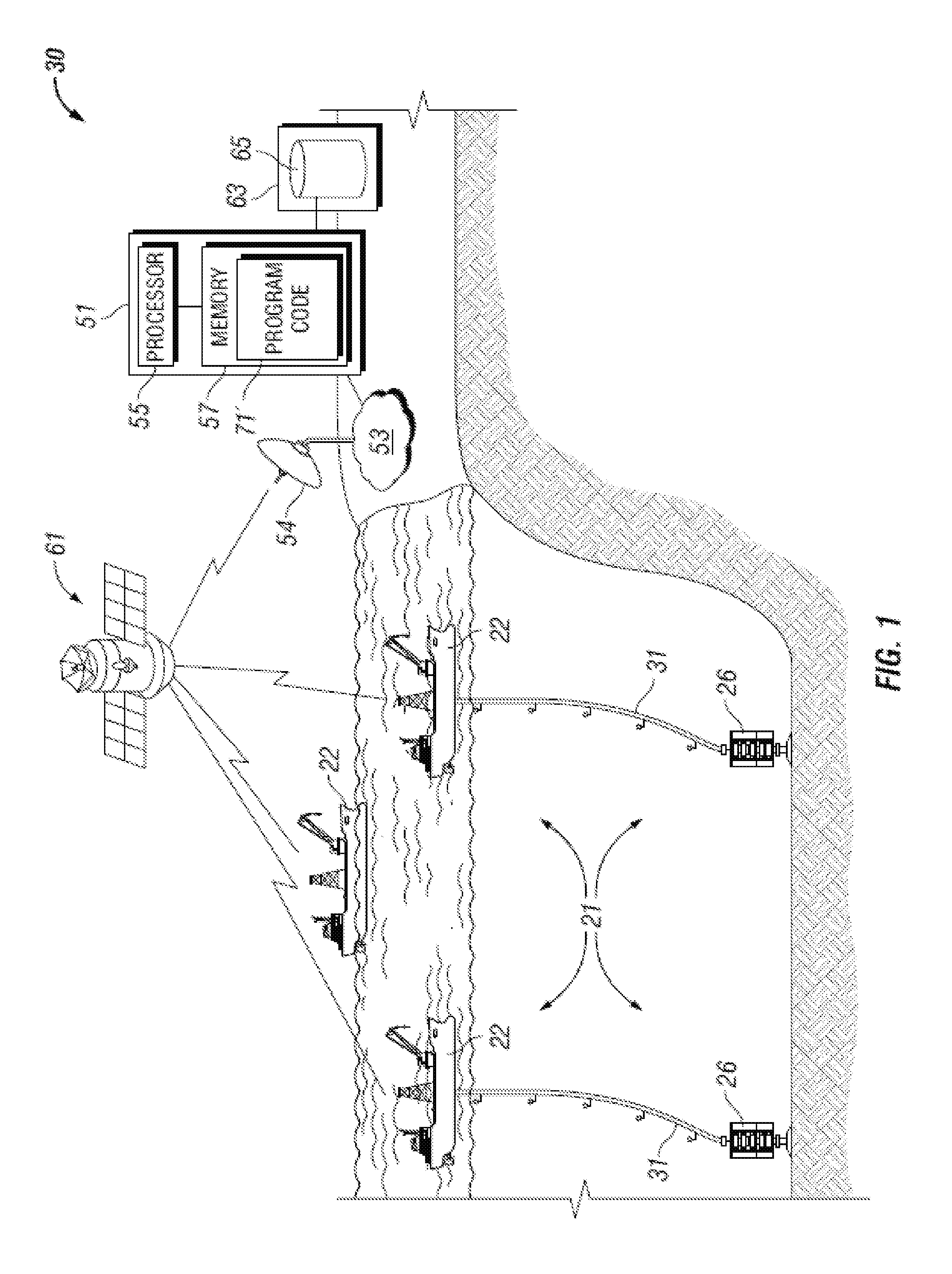

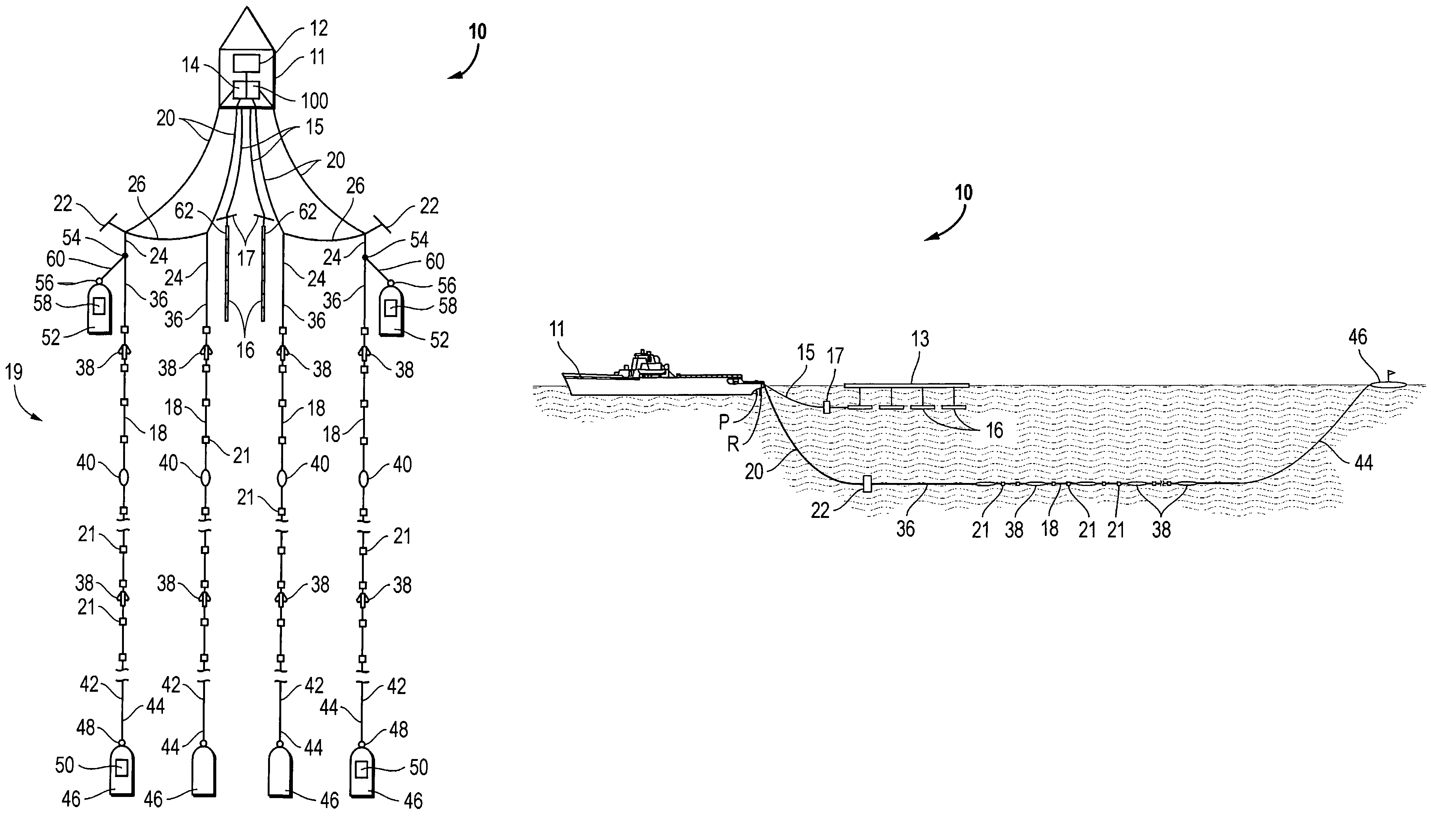

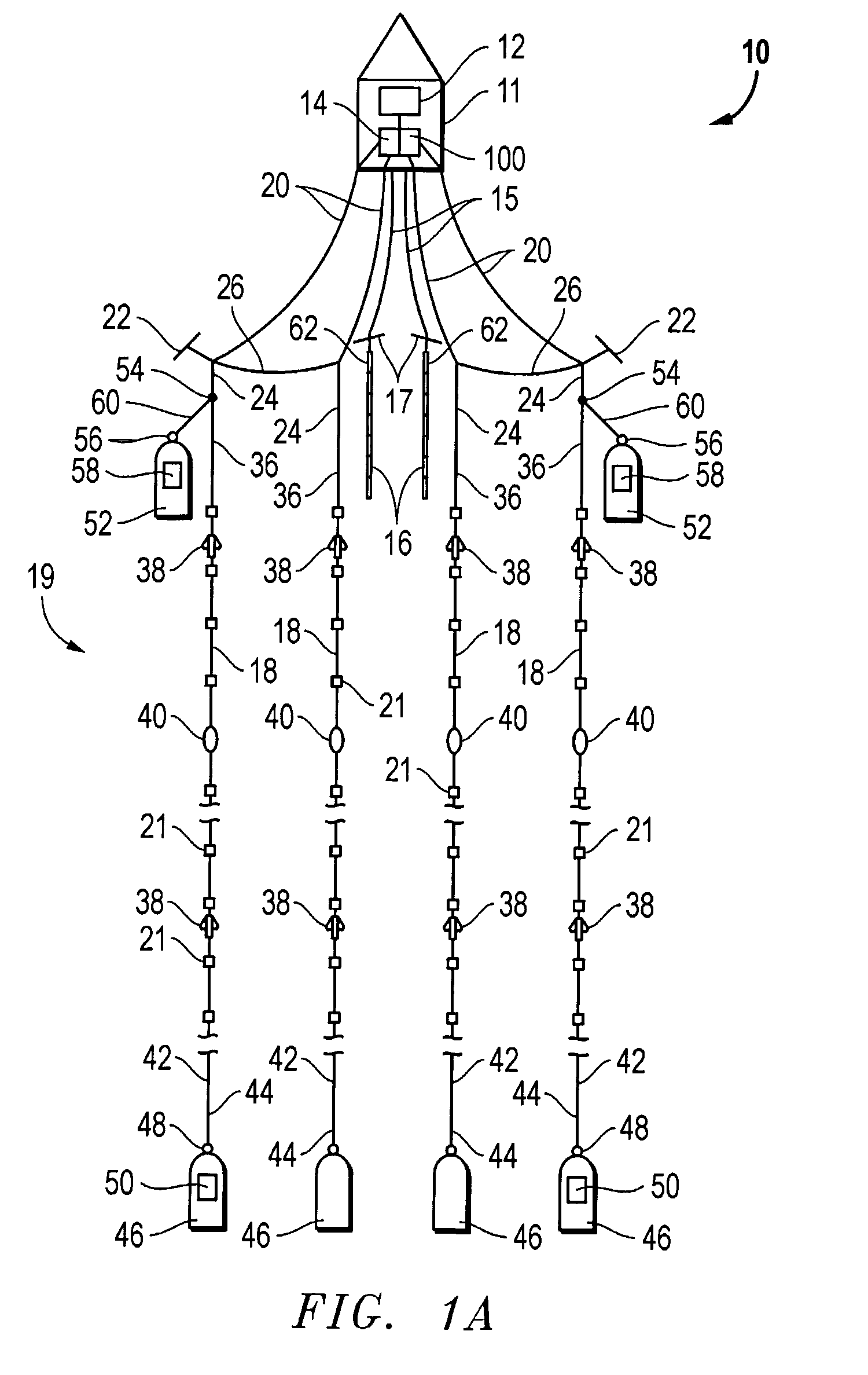

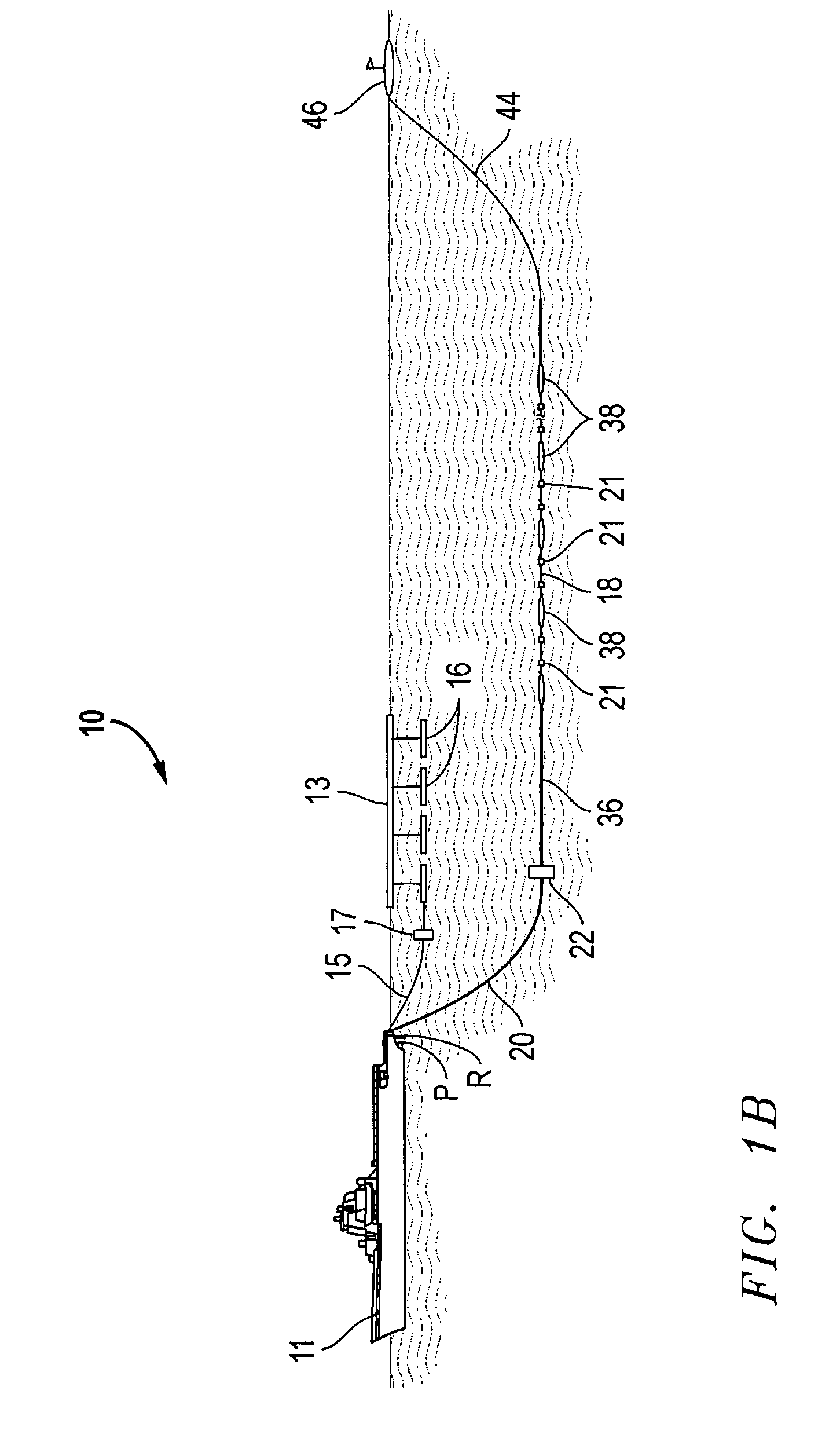

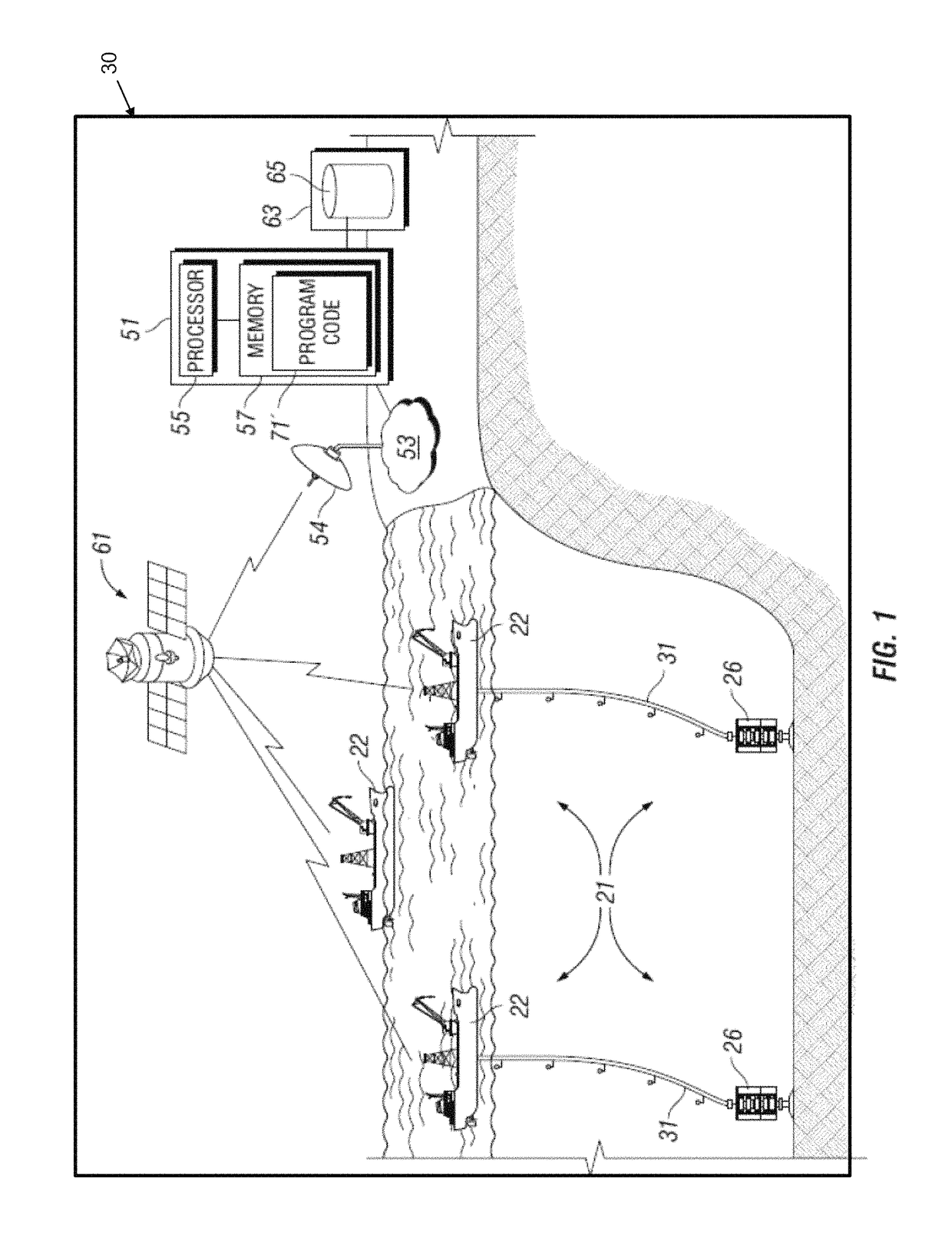

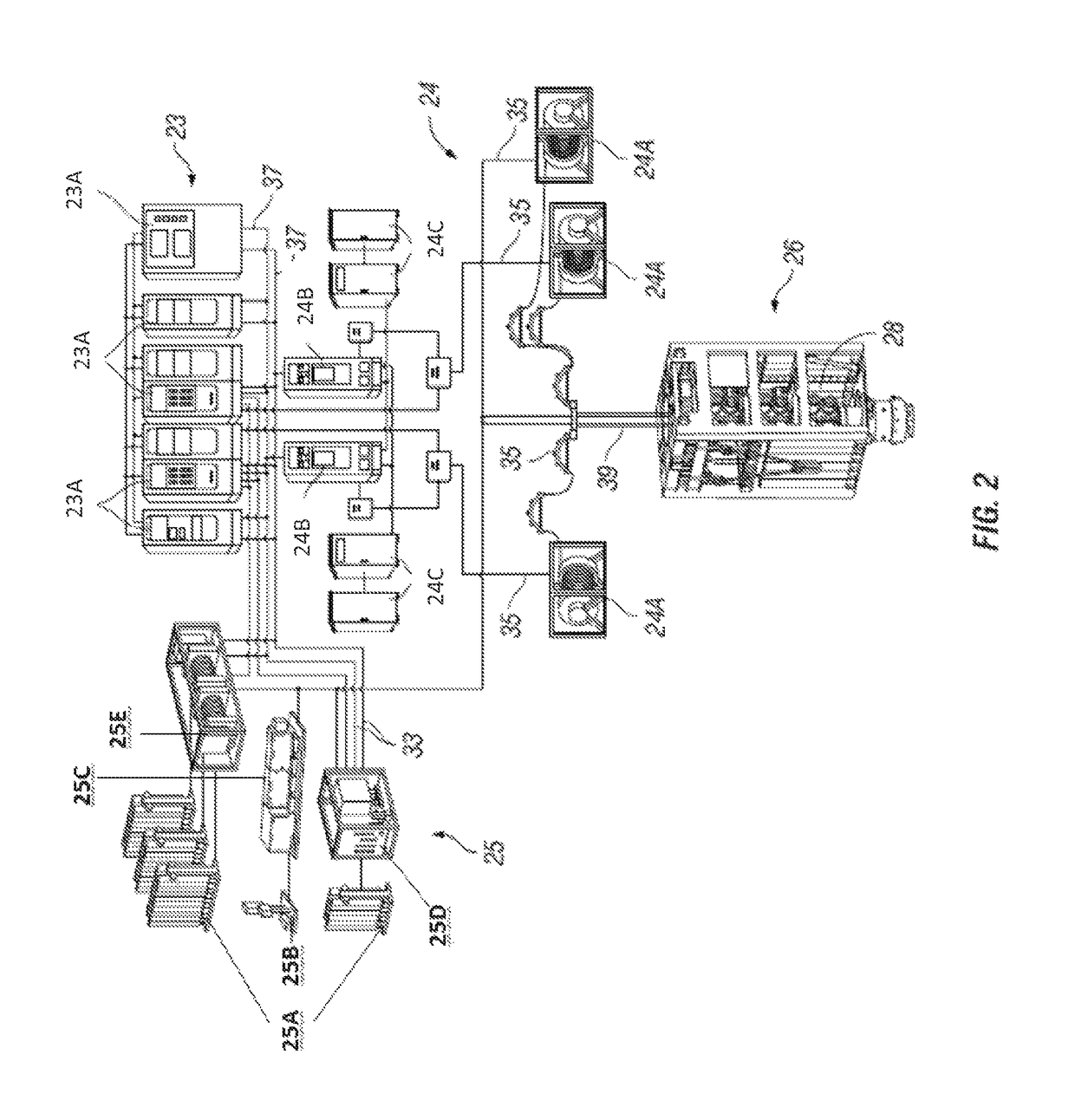

Marine seismic survey method and system

ActiveUS20090141587A1Reduce non-productive timeSeismic signal recordingSeismology for water-covered areasSeismic surveyEnvironmental data

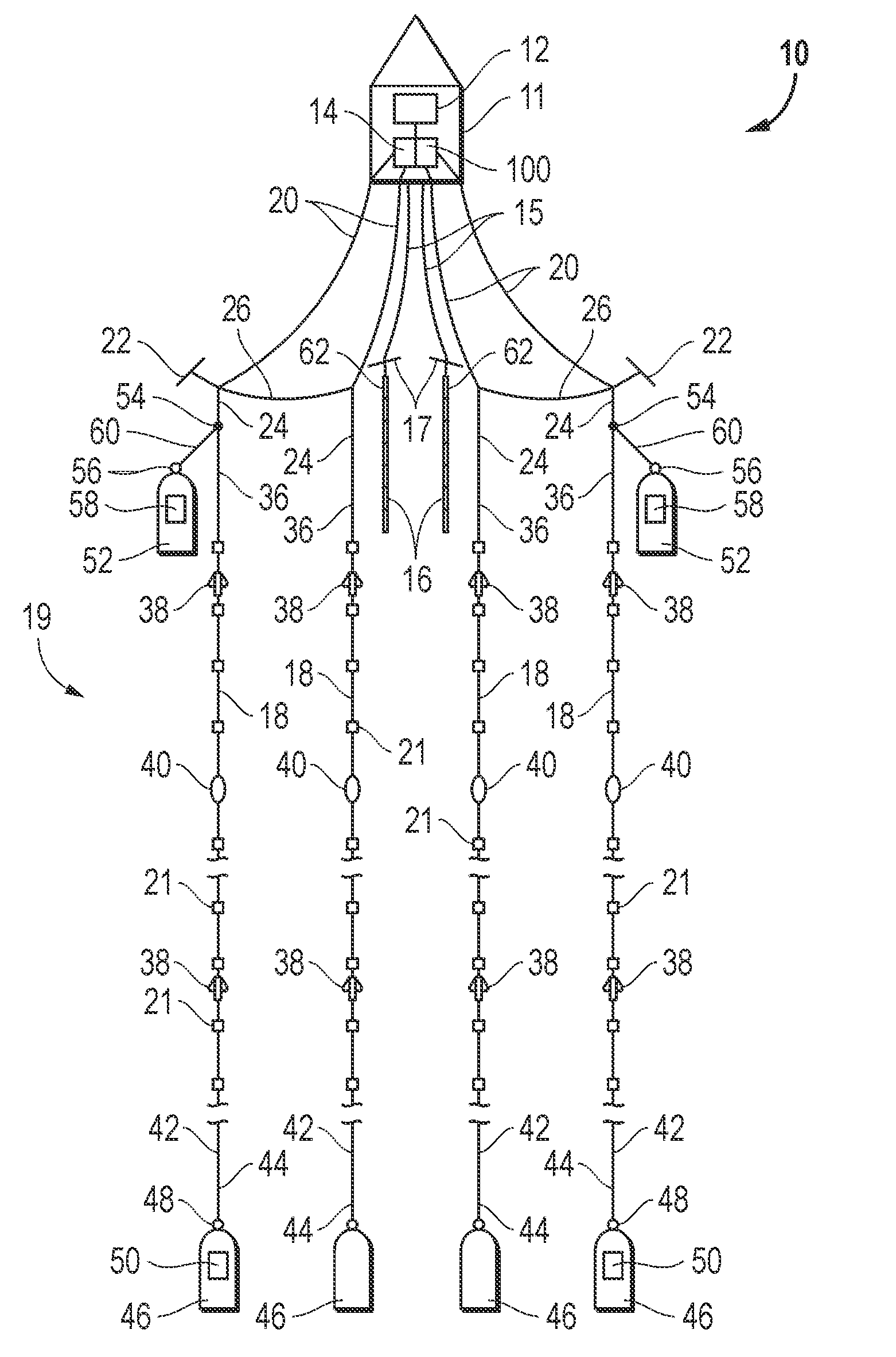

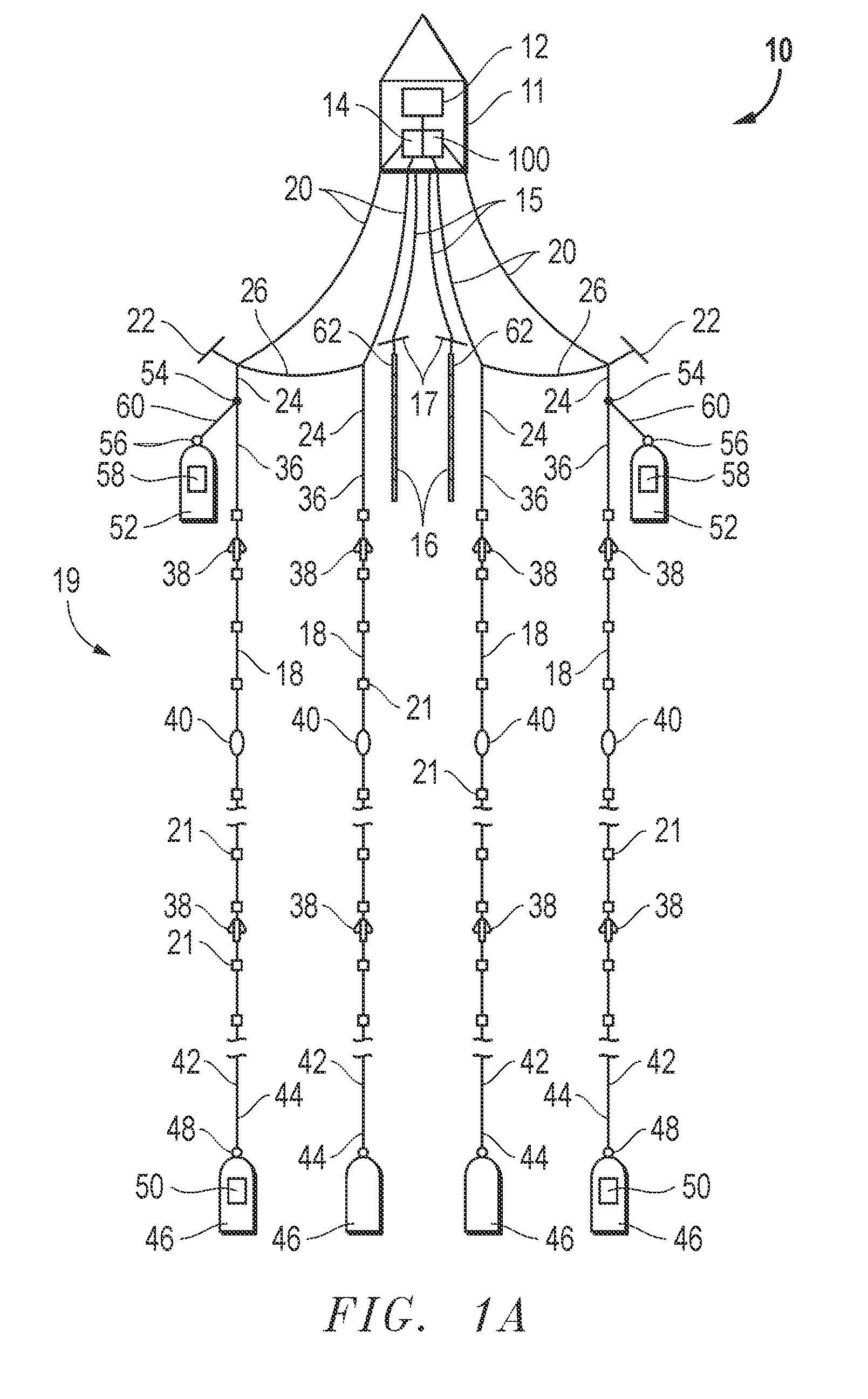

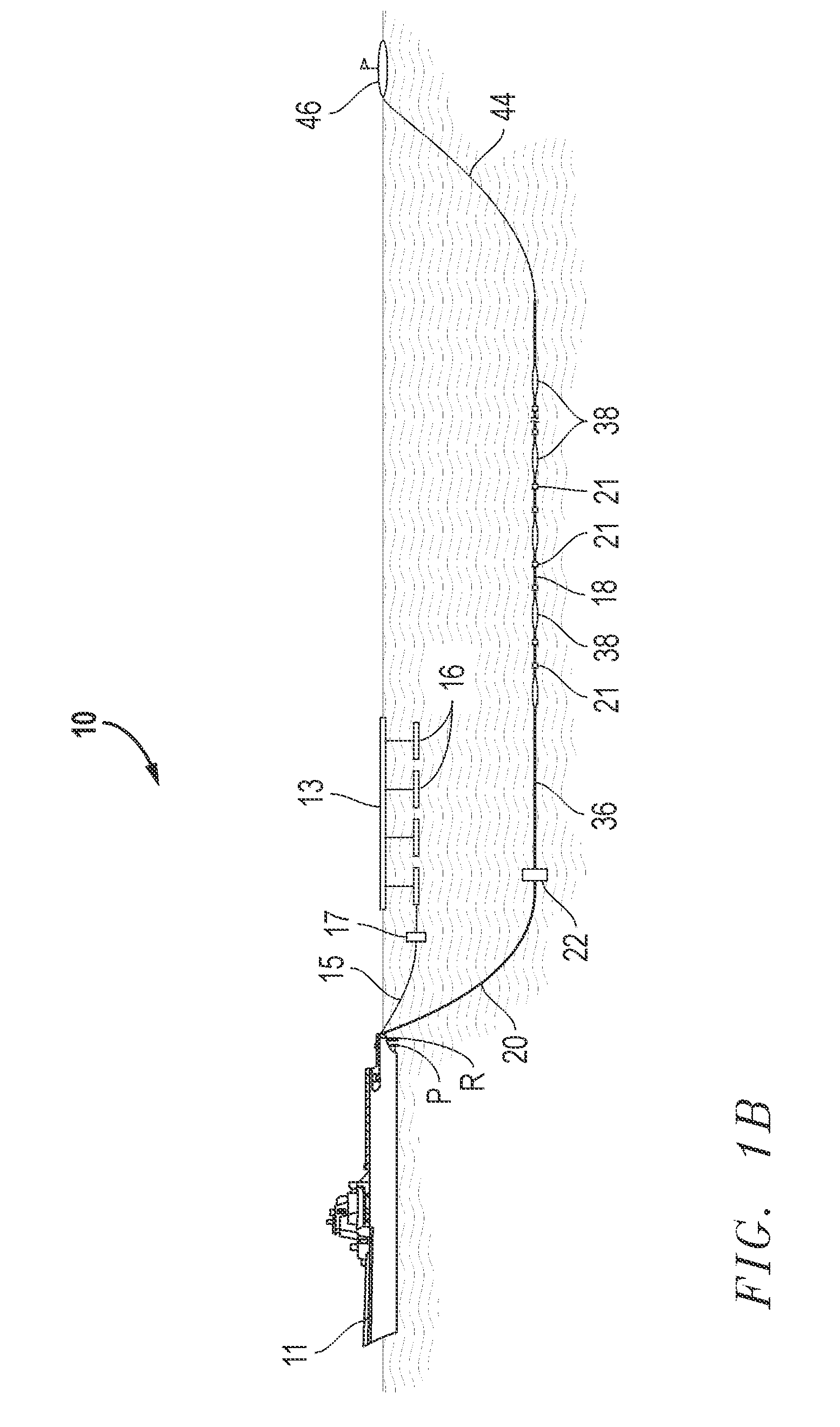

An inventive method provides for control of a seismic survey spread while conducting a seismic survey, the spread having a vessel, a plurality of spread control elements, a plurality of navigation nodes, and a plurality of sources and receivers. The method includes the step of collecting input data, including navigation data for the navigation nodes, operating states from sensors associated with the spread control elements, environmental data for the survey, and survey design data. The positions of the sources and receivers are estimated using the navigation data, the operating states, and the environmental data. Optimum tracks for the sources and receivers are determined using the position estimates and a portion of the input data that includes at least the survey design data. Drive commands are calculated for at least two of the spread control elements using the determined optimum tracks. The inventive method is complemented by an inventive system.

Owner:WESTERNGECO LLC

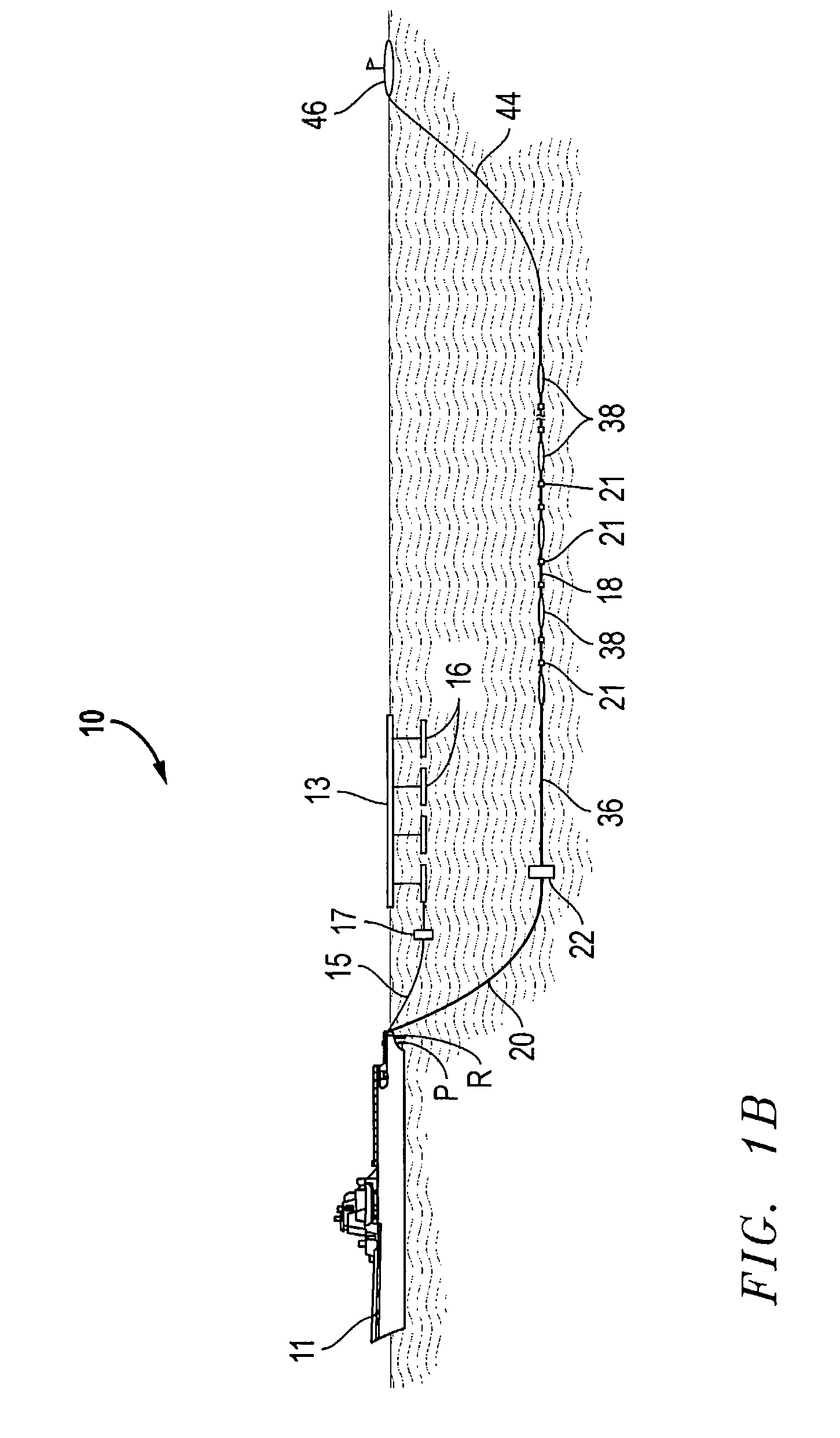

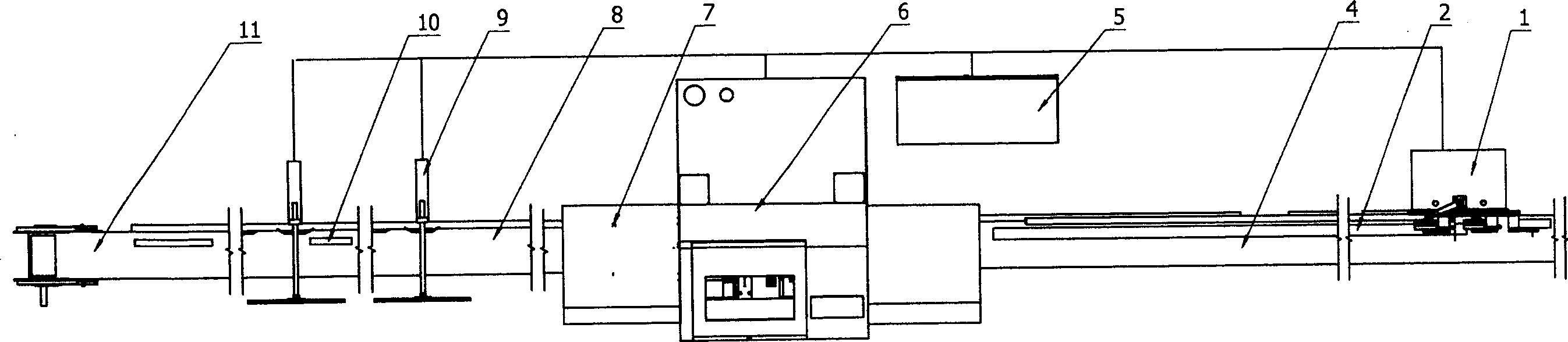

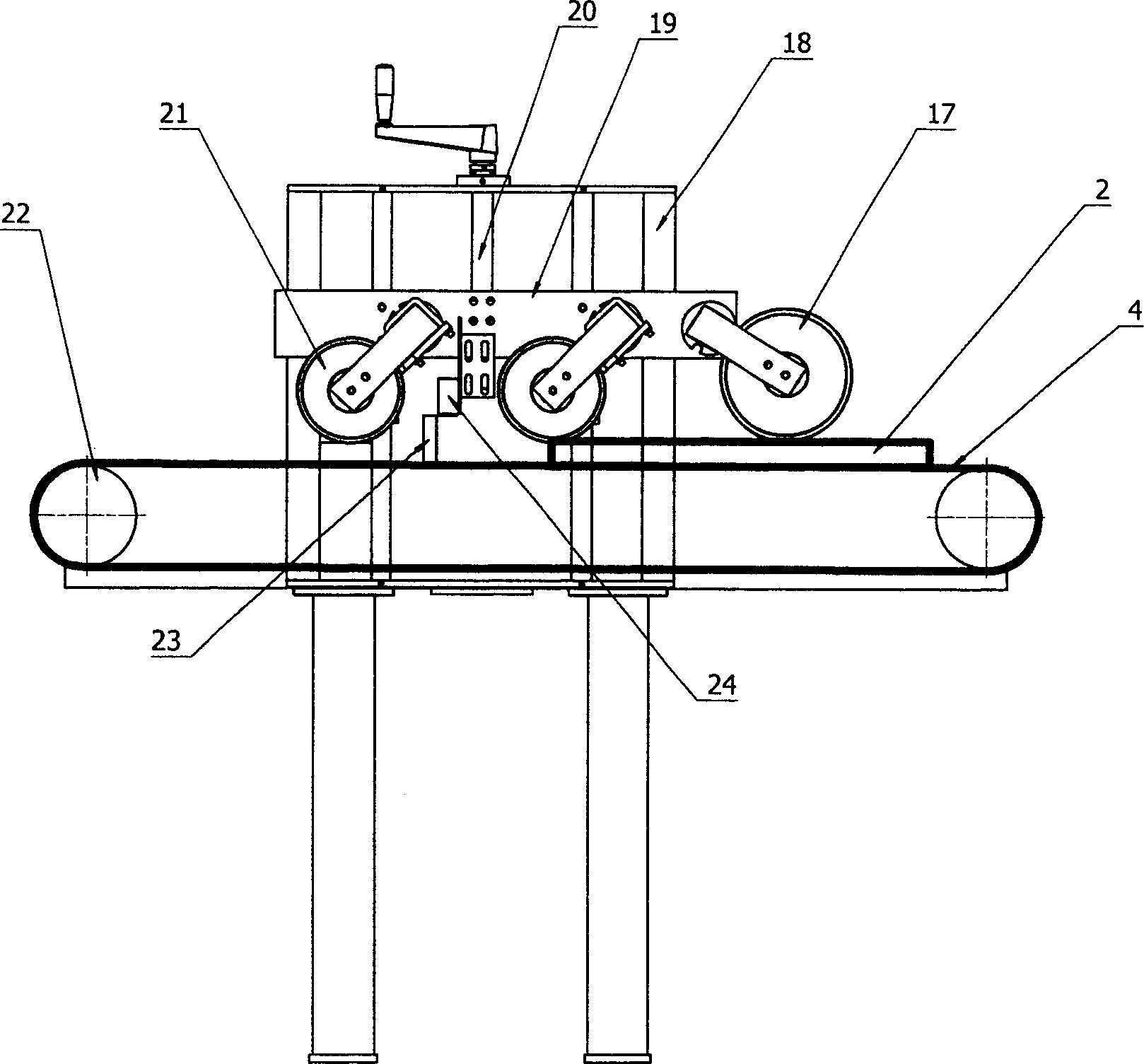

Timber selecting and chopping method and selection chopping saw therefor

InactiveCN1827319AIncrease productivityImprove operating rateLoading equipmentAdjusting equipmentComputer science

The invention discloses a timber optimized truncate method and relative optimized truncate saw. First, inputting the saw data list which comprises target saw length and quality parameters into the computer; when the sawed timber that longitudinally supplied passes the position relative to the detecting device, the detecting device reads the information of sawed timber into the computer, and the computer according to the input saw data list and said information to select the optimized sawing method; the saw machine according to said method processes truncating on the timber. Two sides of said truncate machine individually have a feeding platform and a finished product classifying platform; wherein, said feeding platform has a detecting device; said finished product classifying platform has a finished product classifying device; and a waste removing device is arranged between them.

Owner:JIANGSU JIANGJIA MACHINERY

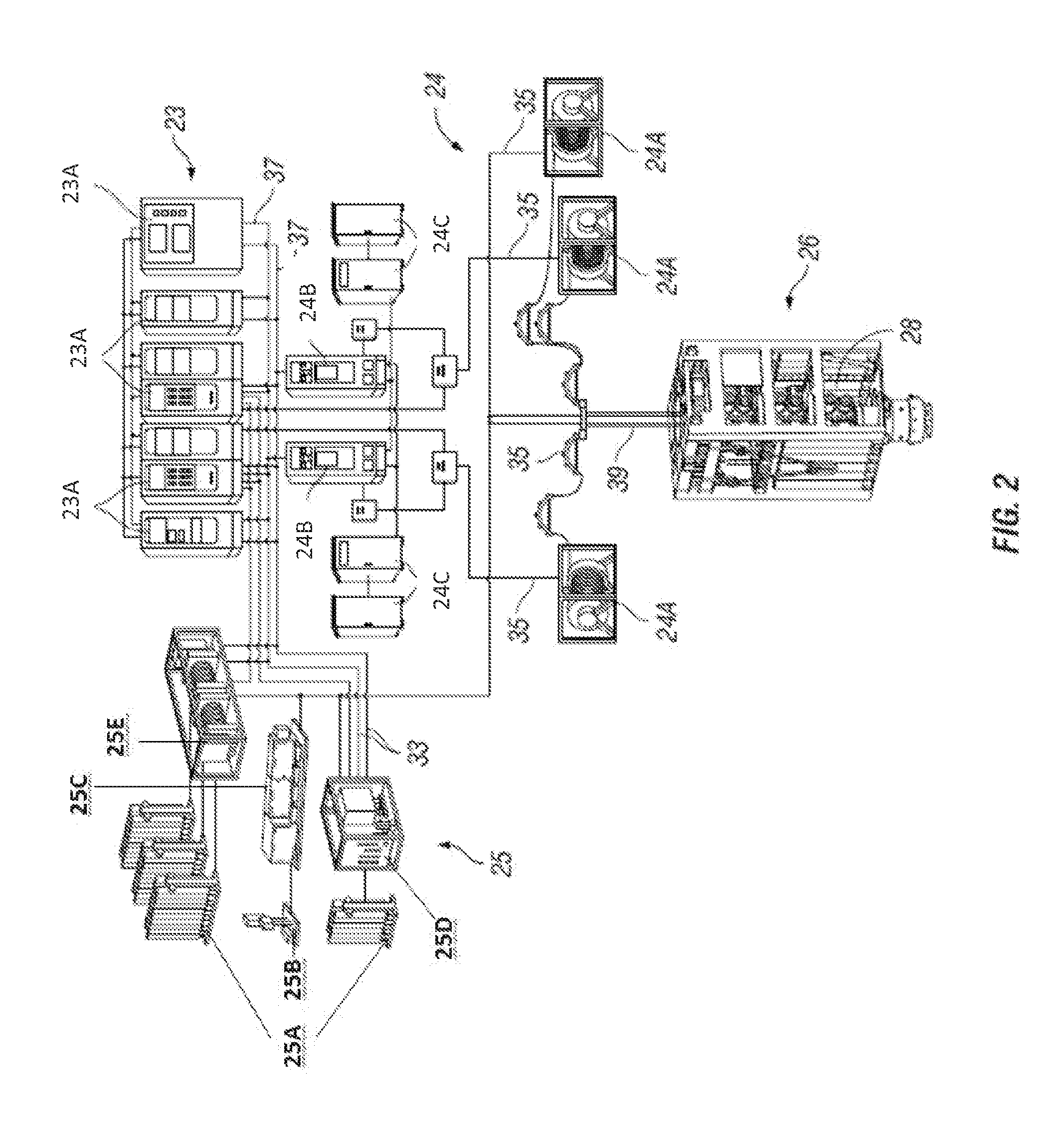

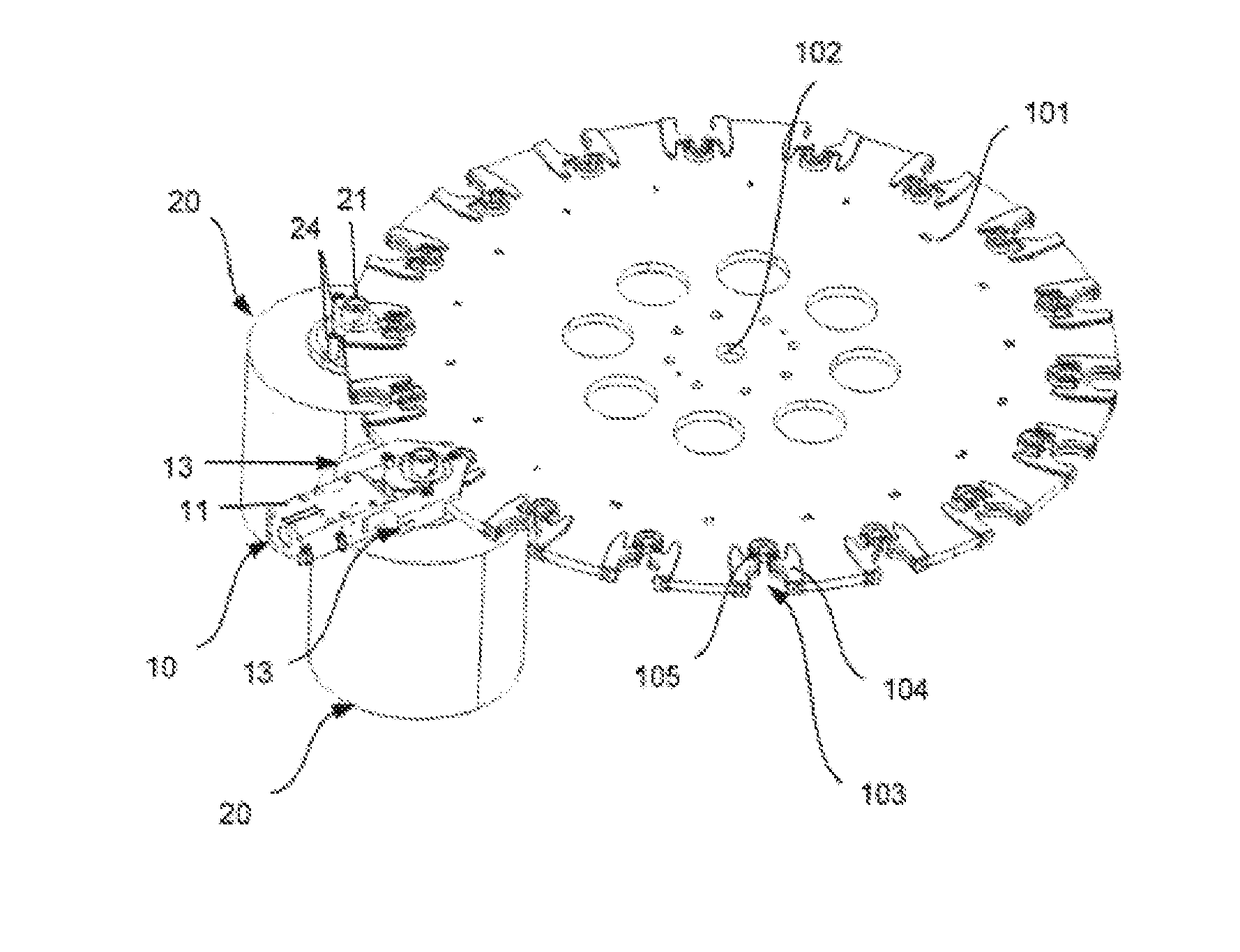

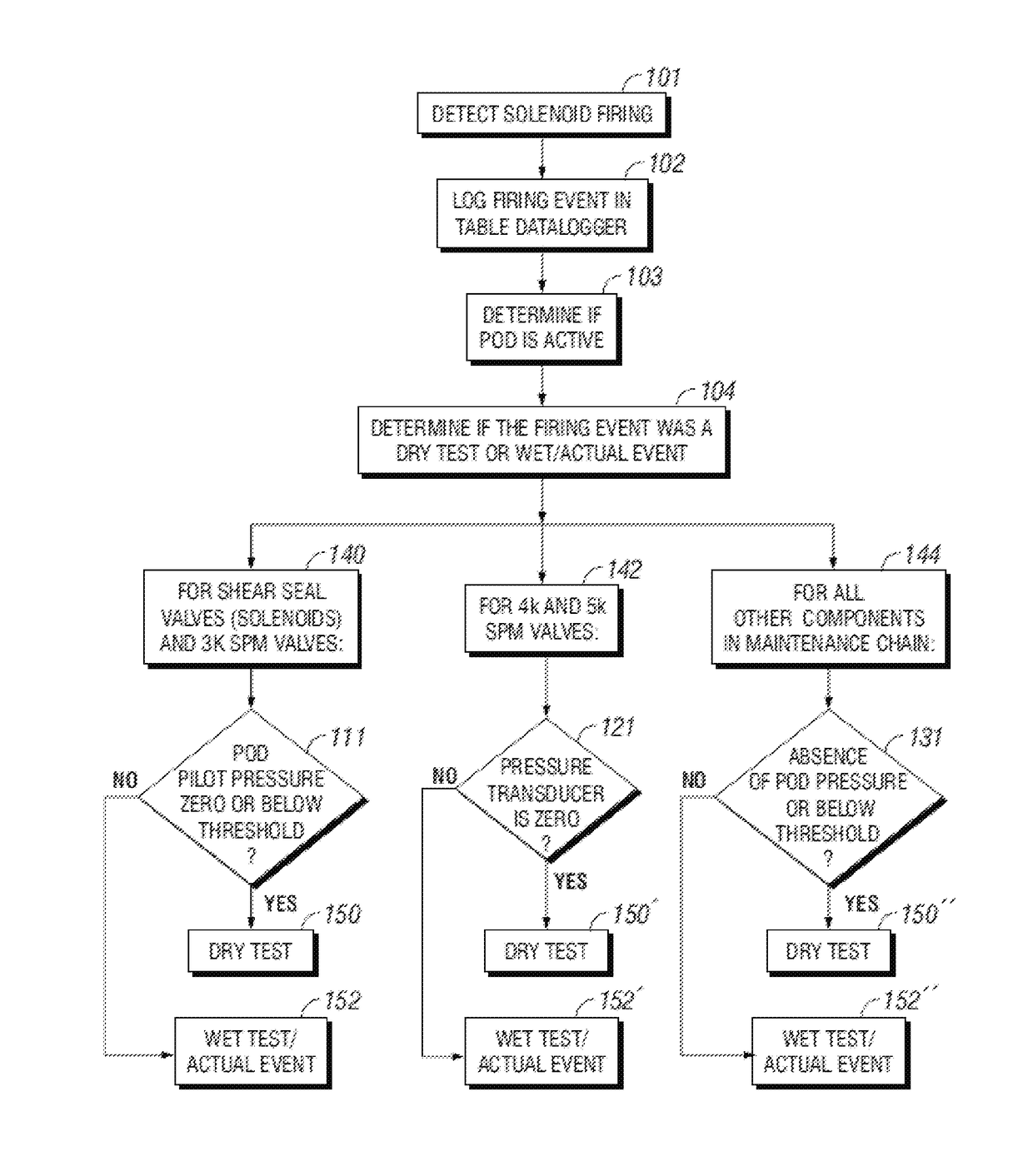

Systems and methods to visualize component health and preventive maintenance needs for subsea control subsystem components

ActiveUS20150184505A1Easy to identifyImprove visualizationElectric/magnetic detection for well-loggingSurveyOcean bottomGraphics

Systems and methods to visualize component health and preventive maintenance needs for subsea control subsystem components are provided. Embodiments can include energizing one or more solenoids, detecting a solenoid firing event, detecting activity in blowout preventer components downchain from the solenoids, and incrementing a cycle count for the one or more solenoids and each downchain blowout preventer component activated. Embodiments can include projecting a replacement date for the solenoid or any of the downchain blowout preventer components based on the cycle count and user-defined thresholds. In embodiments, a user is provided with an interactive graphical representation of a blowout preventer including selectable blowout preventer components thereby to visualize component health and preventive maintenance needs.

Owner:HYDRIL USA DISTRIBUTION LLC

Marine seismic survey method and system

ActiveUS8824239B2Reduce non-productive timeSeismic signal recordingSeismology for water-covered areasSeismic surveyEnvironmental data

An inventive method provides for control of a seismic survey spread while conducting a seismic survey, the spread having a vessel, a plurality of spread control elements, a plurality of navigation nodes, and a plurality of sources and receivers. The method includes the step of collecting input data, including navigation data for the navigation nodes, operating states from sensors associated with the spread control elements, environmental data for the survey, and survey design data. The positions of the sources and receivers are estimated using the navigation data, the operating states, and the environmental data. Optimum tracks for the sources and receivers are determined using the position estimates and a portion of the input data that includes at least the survey design data. Drive commands are calculated for at least two of the spread control elements using the determined optimum tracks. The inventive method is complemented by an inventive system.

Owner:WESTERNGECO LLC

Marine seismic survey method and system

InactiveUS20150016218A1Reduce non-productive timeSeismic signal recordingSeismology for water-covered areasSeismic surveyEnvironmental data

An inventive method provides for control of a seismic survey spread while conducting a seismic survey, the spread having a vessel, a plurality of spread control elements, a plurality of navigation nodes, and a plurality of sources and receivers. The method includes the step of collecting input data, including navigation data for the navigation nodes, operating states from sensors associated with the spread control elements, environmental data for the survey, and survey design data. The positions of the sources and receivers are estimated using the navigation data, the operating states, and the environmental data. Optimum tracks for the sources and receivers are determined using the position estimates and a portion of the input data that includes at least the survey design data. Drive commands are calculated for at least two of the spread control elements using the determined optimum tracks. The inventive method is complemented by an inventive system.

Owner:WESTERNGECO LLC

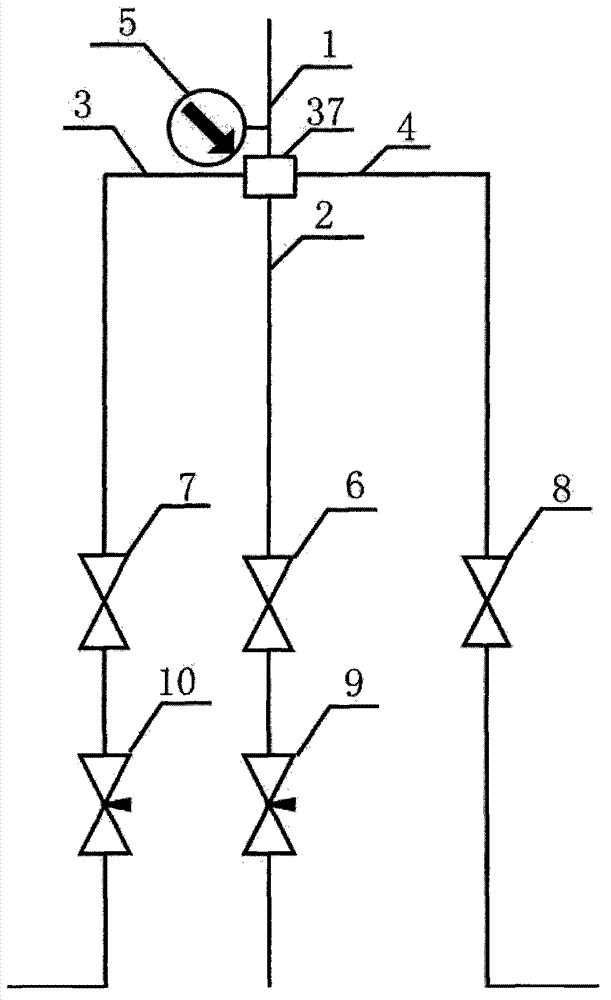

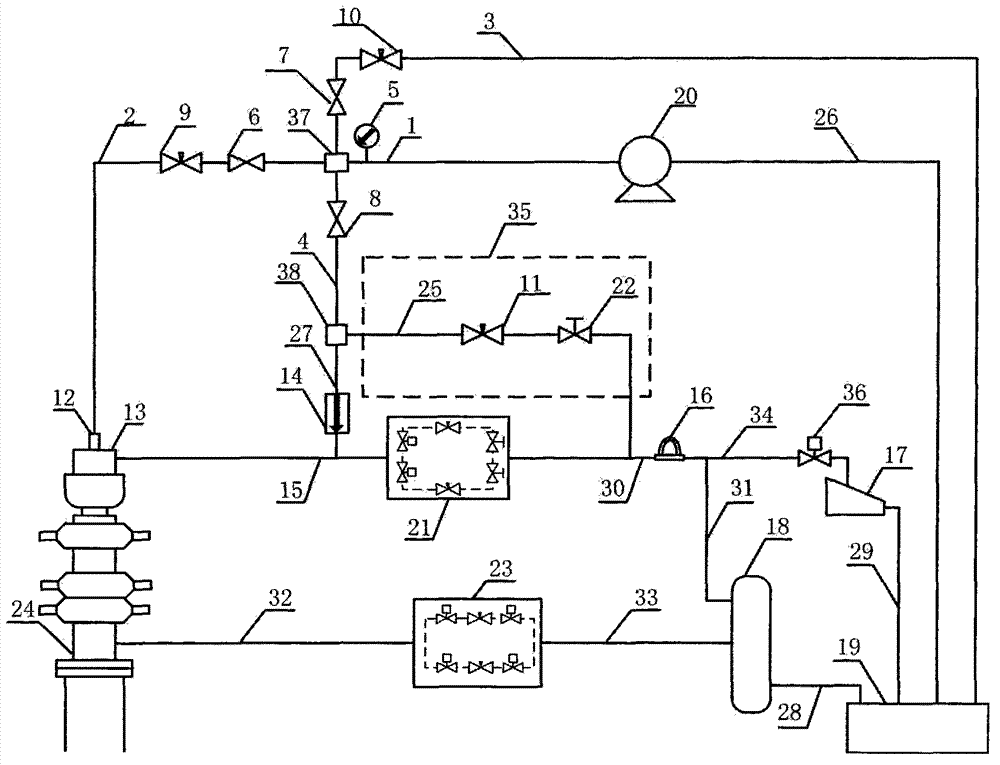

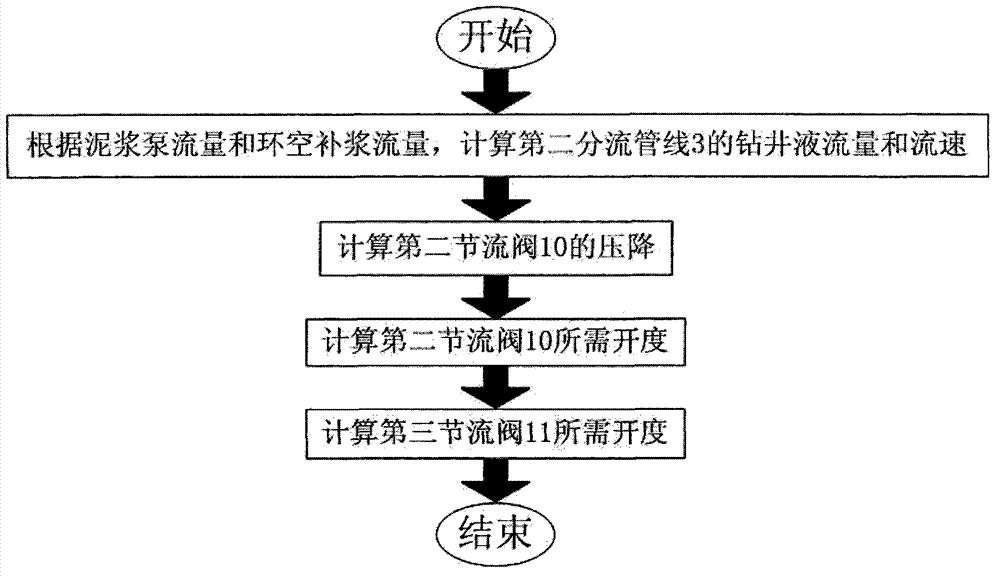

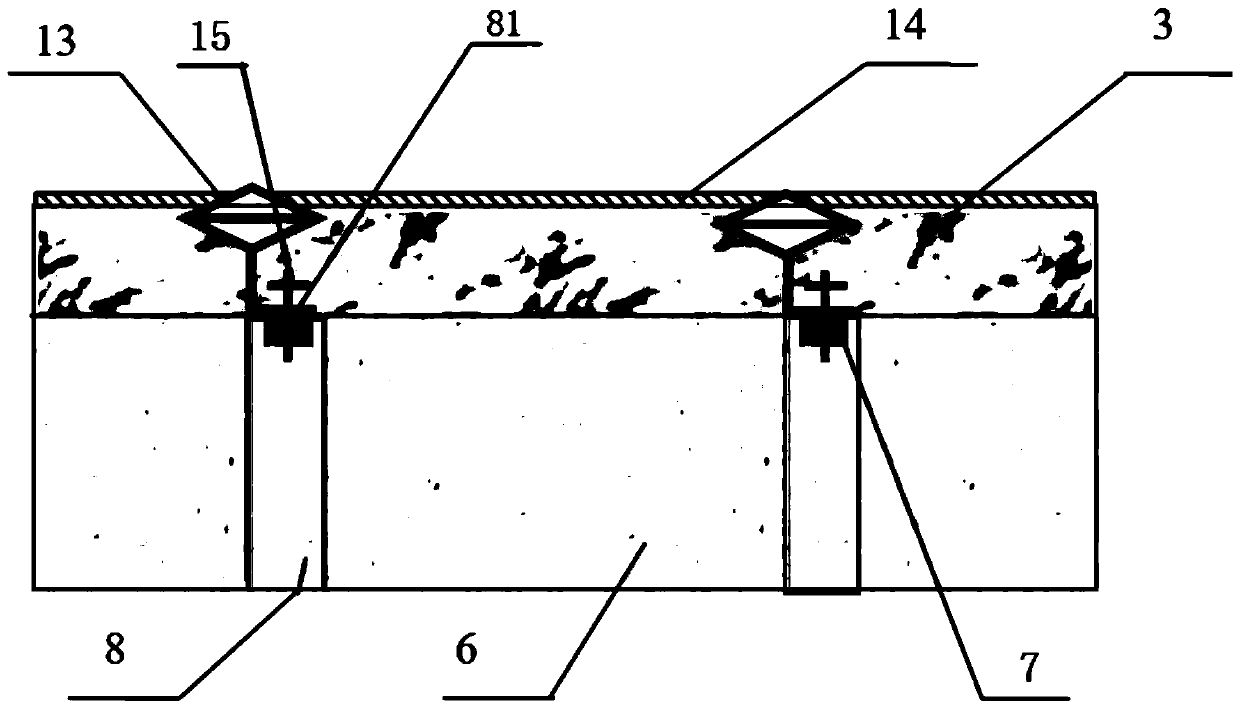

Double-throttle control slurry pump distributing manifold for applying wellhead back pressure and method

The invention belongs to the technical field of oil drilling, and relates to a double-throttle control slurry pump distributing manifold for applying wellhead back pressure and a method. The double-throttle control slurry pump distributing manifold for applying the wellhead back pressure comprises a main pipe, a manifold four-way joint, a first distributing pipeline, a second distributing pipeline and a third distributing pipeline; the manifold four-way joint is respectively connected with the main pipe, the first distributing pipeline, the second distributing pipeline and the third distributing pipeline; a pressure gauge is installed on the main pipe; and the first distributing pipeline is provided with a first stop valve and a first throttling valve, the second distributing pipeline is provided with a second stop valve and a second throttling valve, and the third distributing pipe is provided with a third stop valve. The pump is unnecessary to stop and start in the connecting process, the pulling out process and the drilling down process, so that the pressure fluctuation on the bottom of a well can be reduced, and the control capacity for the bottom pressure can be improved; a back pressure pump is not needed, so that additional work caused by the back pressure pump is avoided, the nonproduction time can be reduced, and the drilling cost can be reduced; the pollution caused by the leakage of the back pressure pump can be avoided; and the energy and the floor area can be saved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

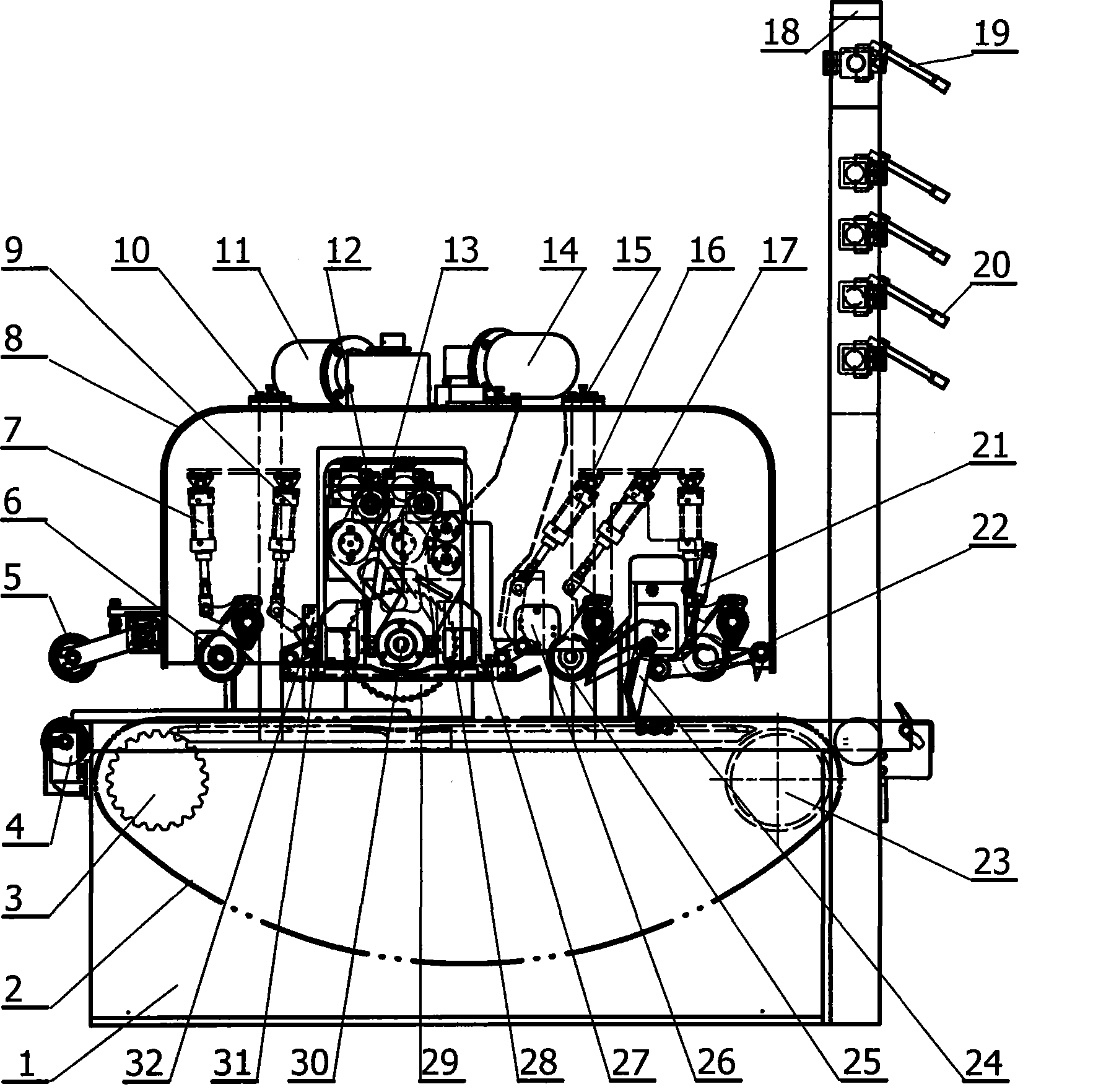

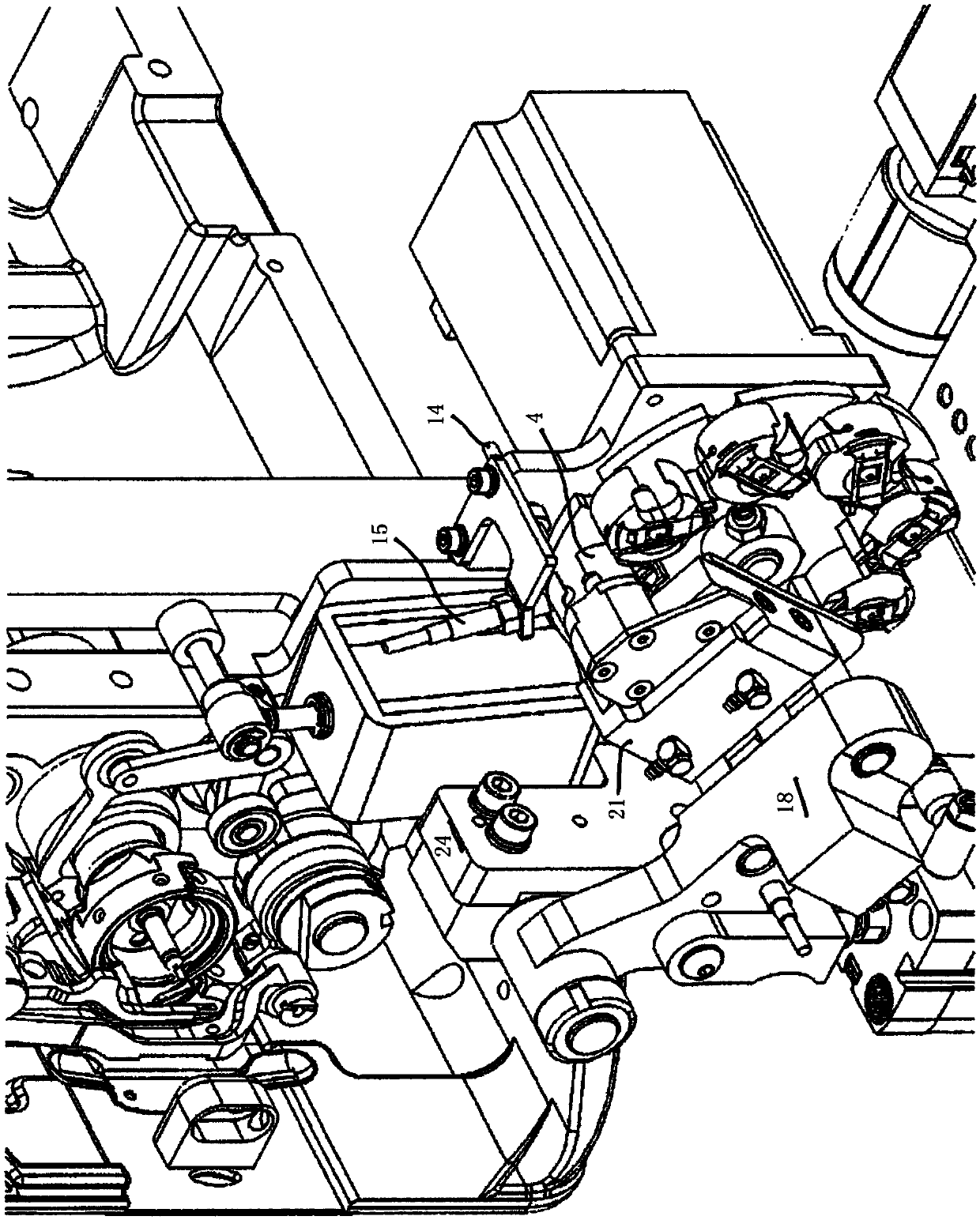

Method for preferably cutting timber in longitudinal direction and circular saw machine for preferably cutting timber in longitudinal direction

The present invention discloses a method for longitudinally optimizing cutting timber. The method comprises the following steps: inputting a cutting data list into a computer device beforehand, selecting a width reference border of sawtimber to be cut for confirming the maximum width of sawtimber to be cut, transmitting the information to the computer device for selecting an optimal cutting plan through analyzation and calculation, axially moving the circular saw blade of saw cutting machine to a cut line position corresponding with the sawtimber to be cut according to instruction of computer device for longitudinally cutting the sawtimber to be cut to finished sawtimber and waste edge material. The timber cutting optimizing circular sawing machine for realizing the method of the invention comprises a circular sawing machine base, a feeding chain plate, a sawblade main shaft, a front compression roller and a back compression roller, wherein the front compression roller and the back compression roller are positioned at the front side and the back side. The marking-off equipment stand which is fixedly installed at the front end of engine base is installed with follower marking-off equipment. A moving circular saw blade is installed on the main shaft of sawblade. The main shaft assembly and the upper frame are respectively supported on the front lifting upright post and the back lifting upright post with a liftable mode. The method of the invention can greatly increase the material yielding rate and production efficiency and has the advantages of high automatization degree and wide application sphere.

Owner:JIANGSU JIANGJIA MACHINERY

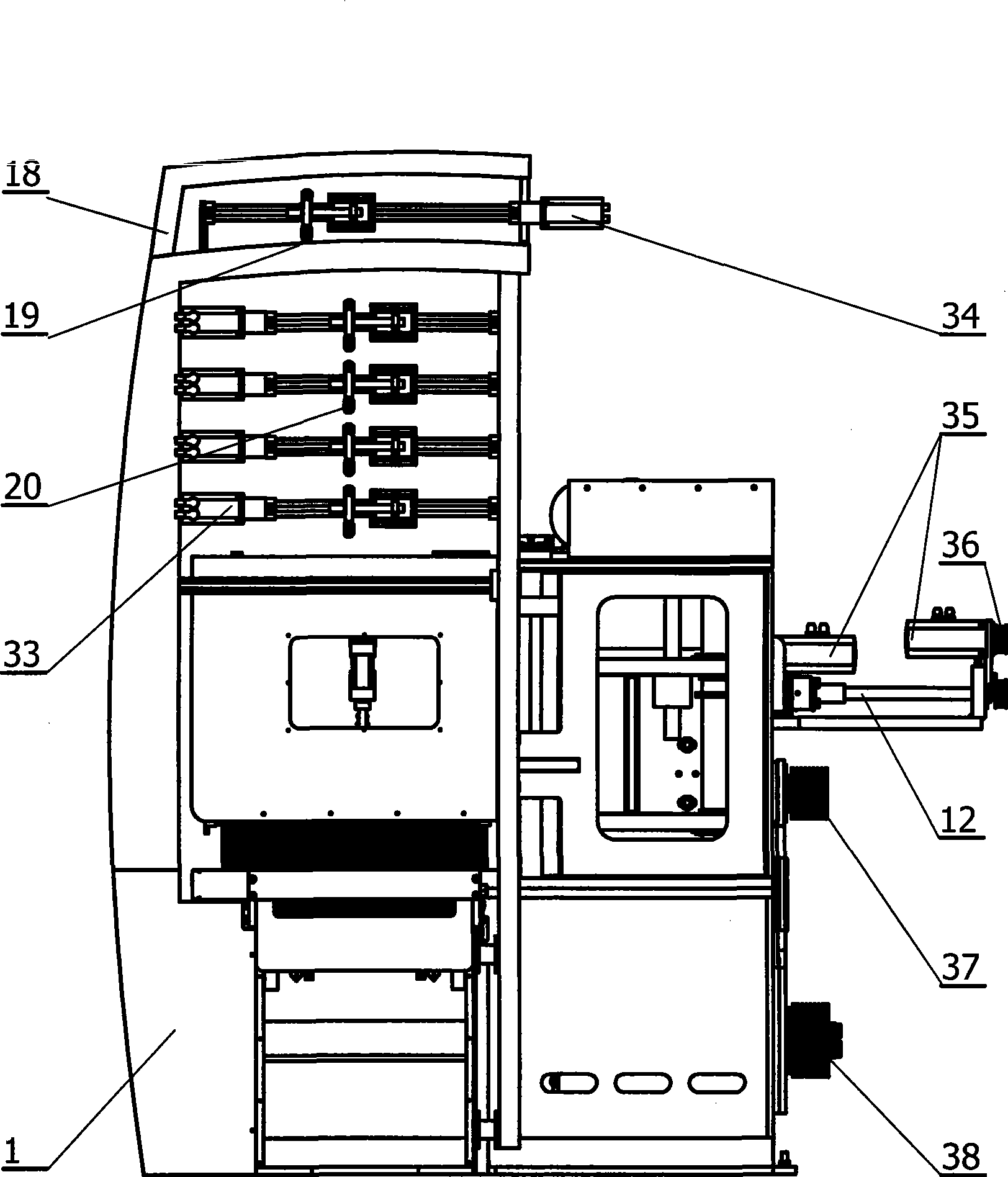

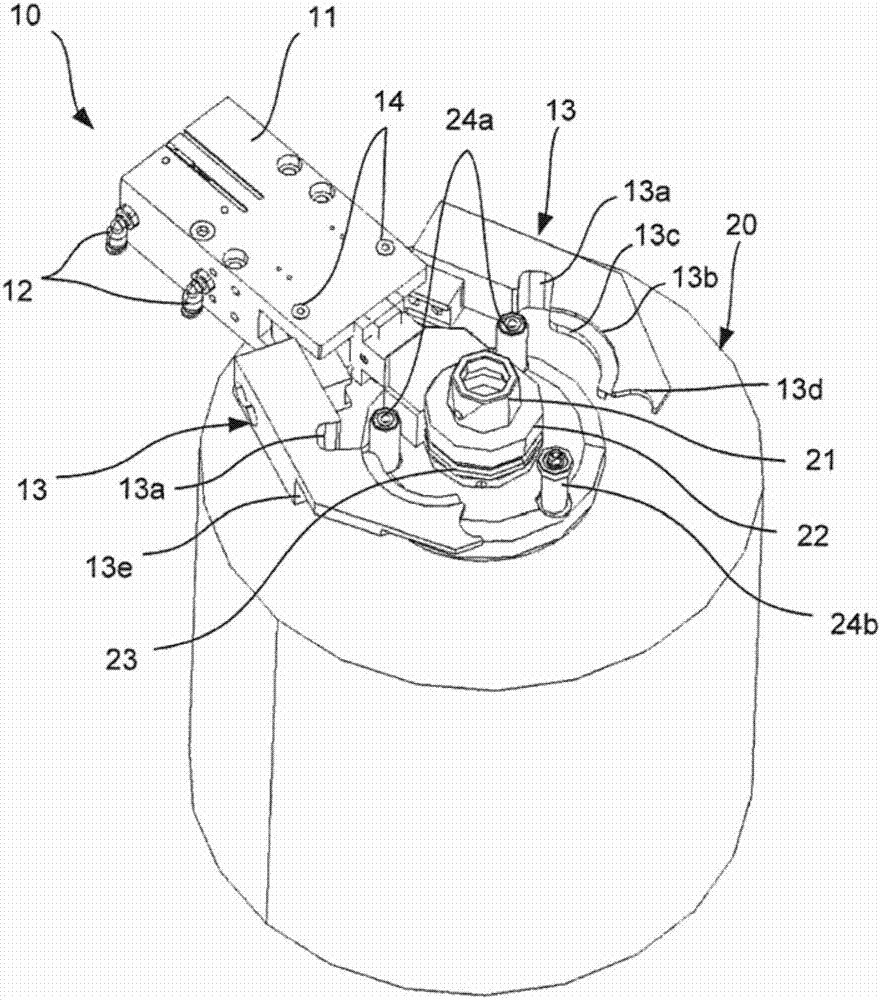

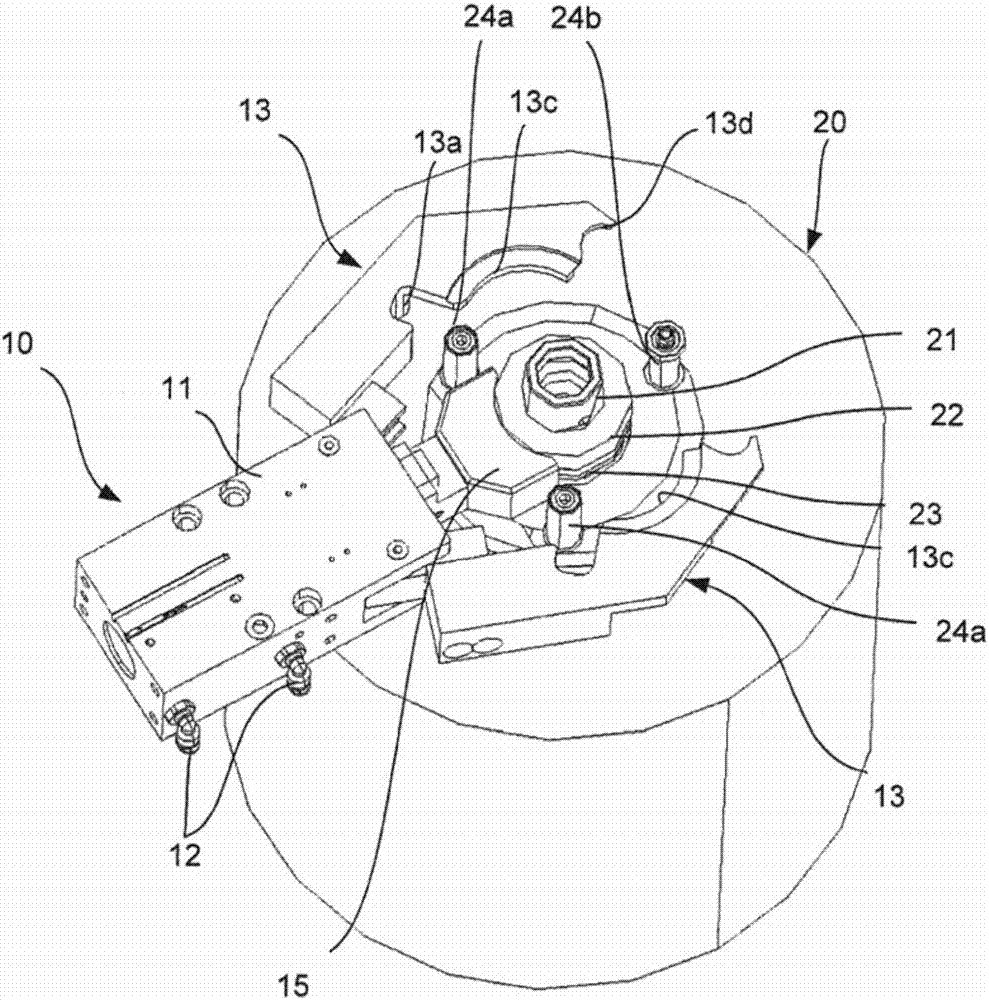

Automatic turret-type nozzle replacing device of laser cutting machine

ActiveCN103143846AGuaranteed reliabilityReduce non-productive timeLaser beam welding apparatusGear transmissionEngineering

The invention relates to an automatic turret-type nozzle replacing device of a laser cutting machine, in particular to an automatic turret-type nozzle replacing device which is simple in structure, convenient and rapid for replacing a nozzle and capable of increasing the working efficiency. The laser cutting machine comprises a worktable, a cutting head and a nozzle, wherein the nozzle is detachably connected onto the cutting head; and any corner of the worktable is provided with the automatic nozzle replacing device, and the automatic nozzle replacing device comprises a turntable, a nozzle receiving component, a box body, a transmission shaft, an elevation air cylinder and a gear transmission mechanism. The automatic turret-type nozzle replacing device is unnecessary to operate by an operator, especially under an automatic running mode, so that the non-production time is shortened, the working efficiency is increased, and the cost is saved.

Owner:江苏扬力数控机床有限公司

Process for preparing polyvinyl chloride in 70.5 mcube polymeri reactor

A process for preparing polyvinyl chloride in 70.5 cu.m polymer reactor includes such steps as isolating oxygen, flushing inner surface of reactor by water, spraying detackifier by steam, flushing with water, sequentially adding buffering agent, vinyl chloride, hot water, disperser, composite trigger and chain transferring agent, polymerizing for 10 min, adding low-temp water to make reaction temp to be 49-64 deg.C, reacting until the conversion rate reaches 80%, adding stopping agent, terminating reaction, discharging slurry, recovering excessive vniyl chloride, steam stripping, dewatering and drying.

Owner:航锦锦西氯碱化工有限公司

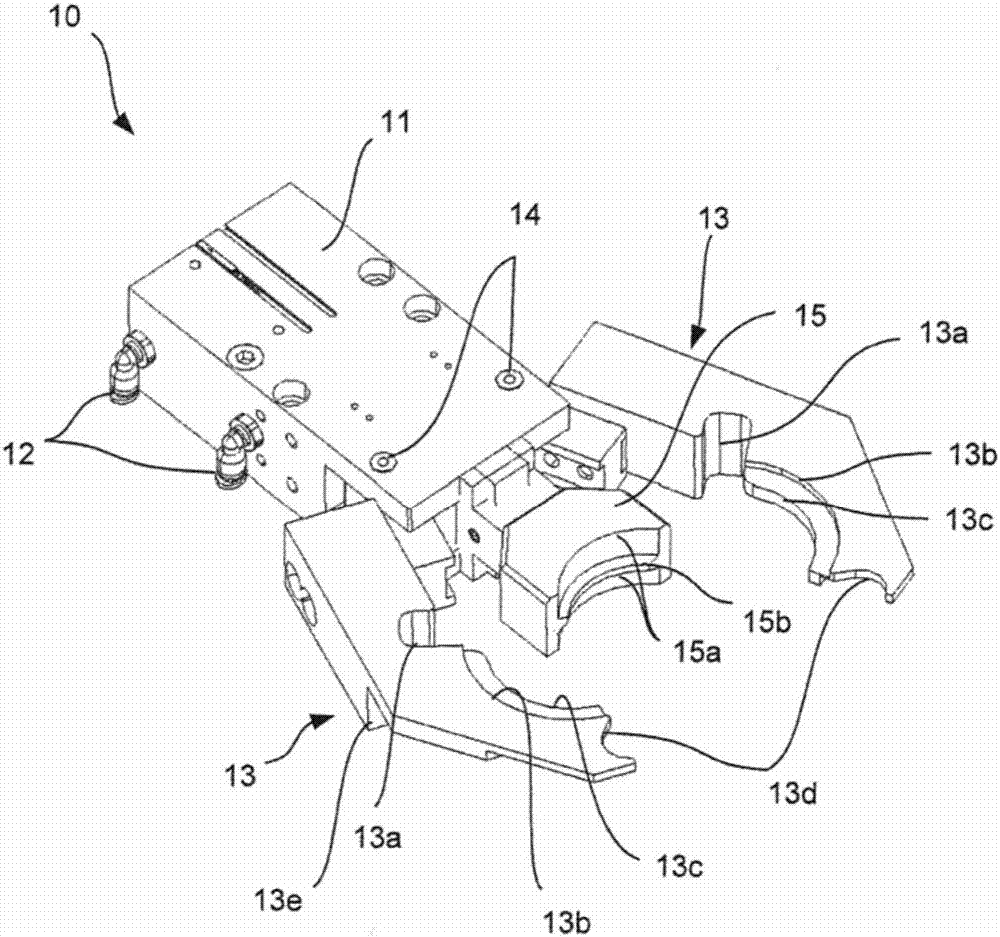

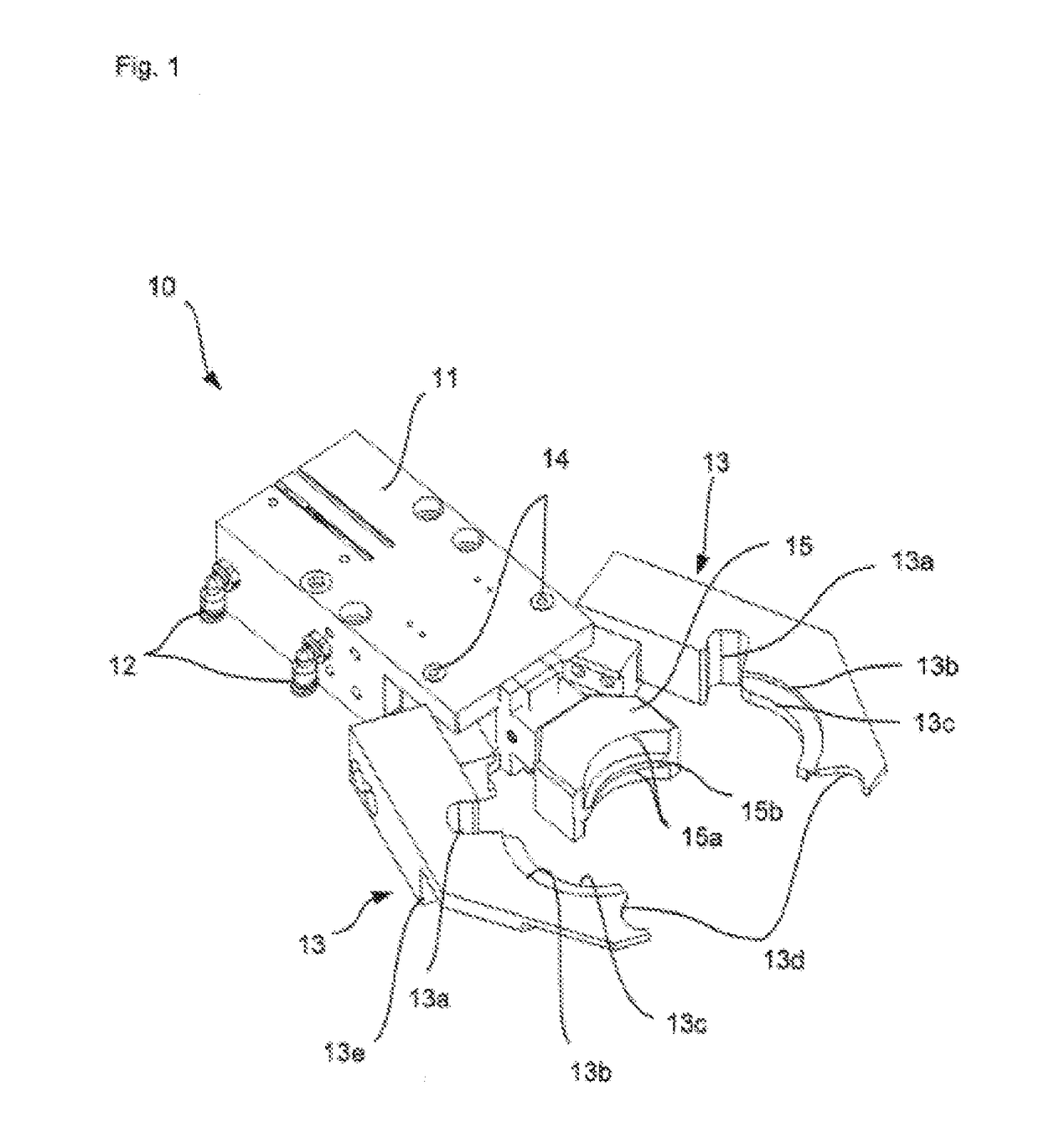

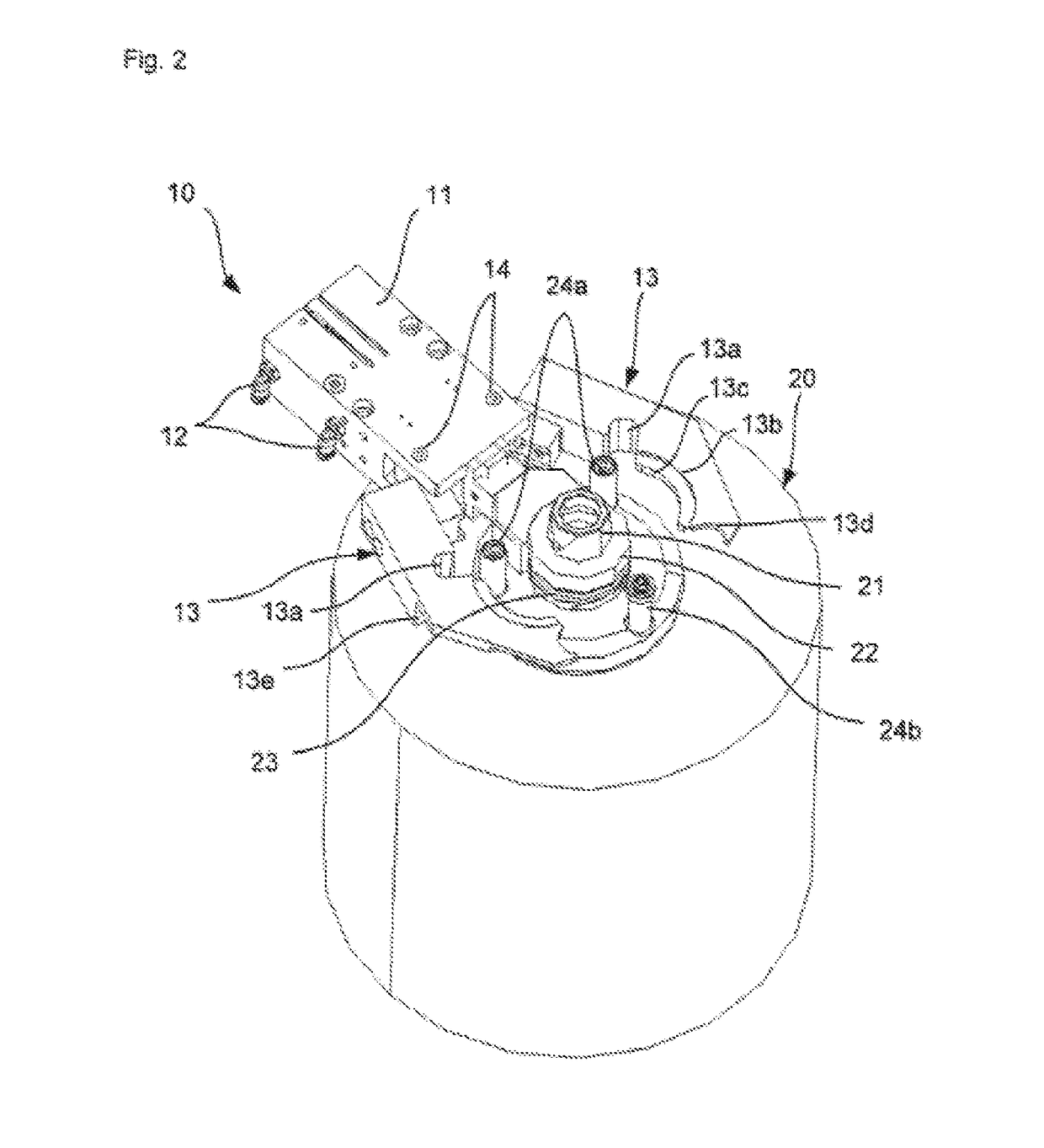

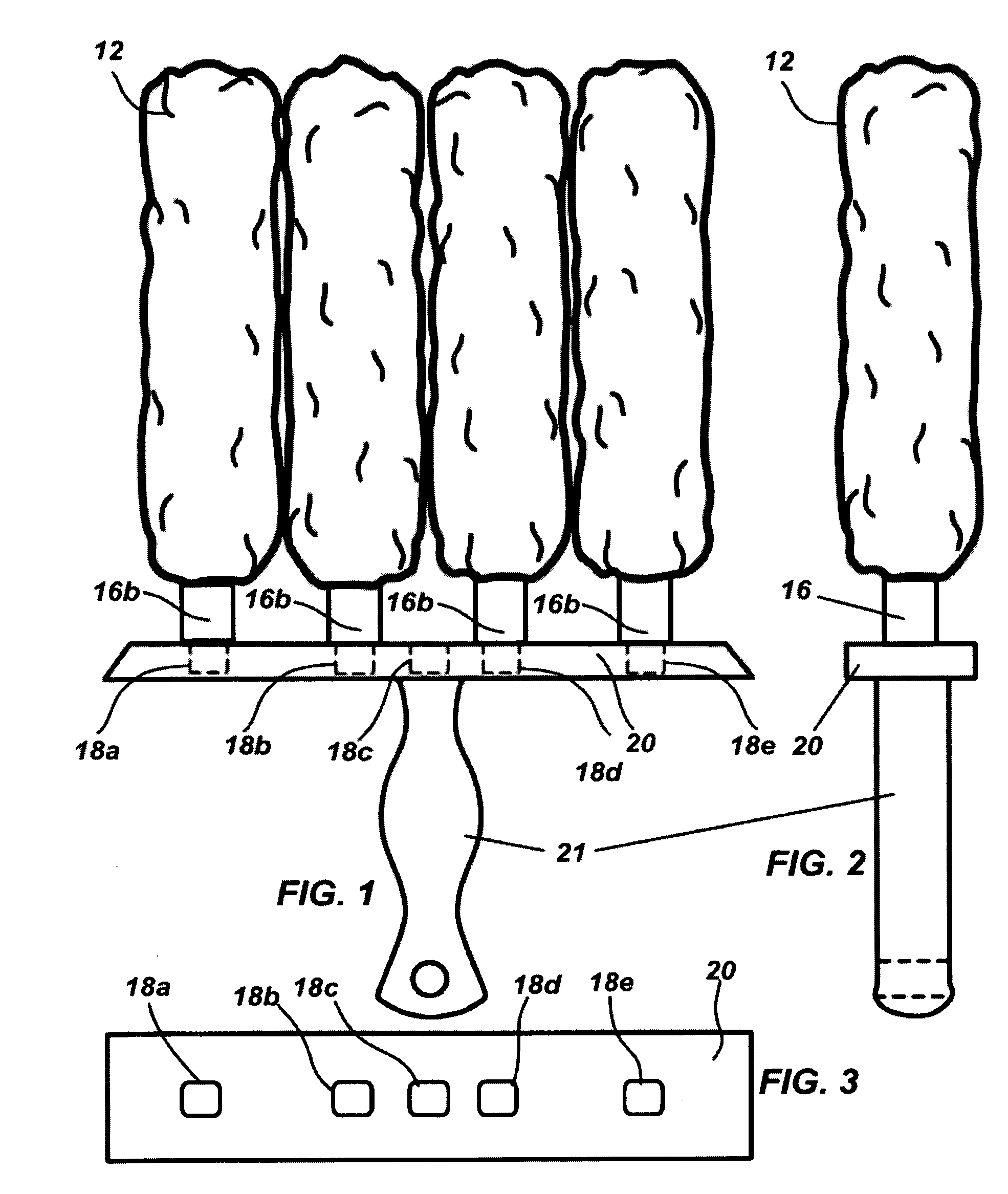

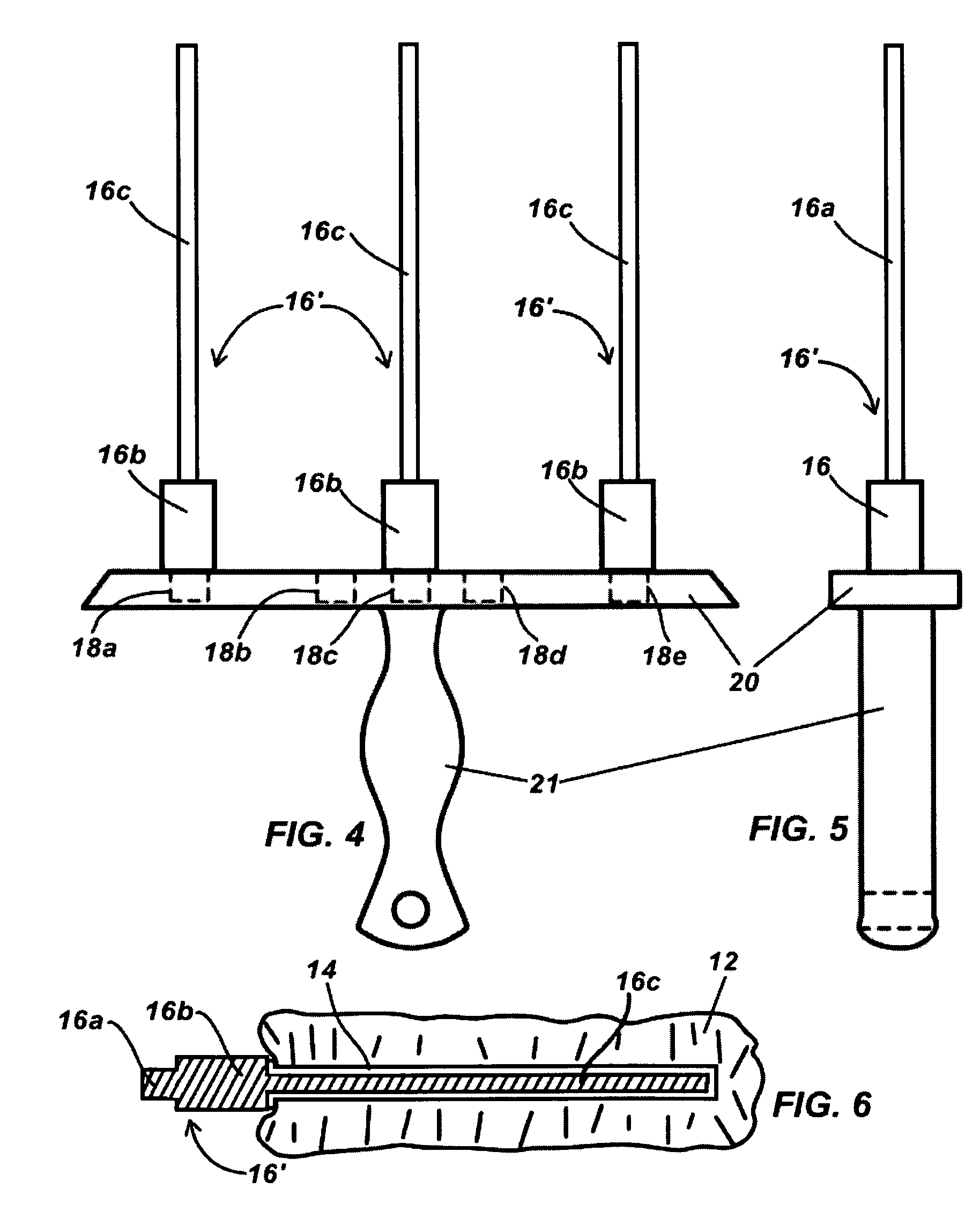

System for gripping a processing tool, storage system and method

InactiveCN107000146AShort switching cycleReduce non-productive timePositioning apparatusMulti-purpose toolsComputer scienceMachine tool

The present invention relates to a gripping system for receiving a processing tool, and to a storage system. These processing tools are used, for example, in processing machines or centers in the woodworking industry. The present invention also relates to a processing machine with the above-mentioned storage system. This processing machine is used, in particular, for processing elongate pieces of wood.

Owner:HOMAG HOLZBEARBEITUNGSSYST

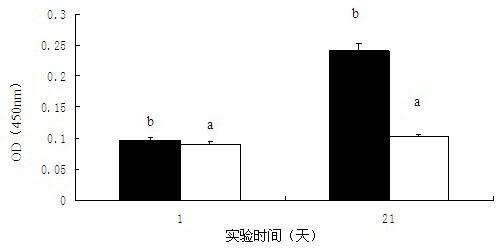

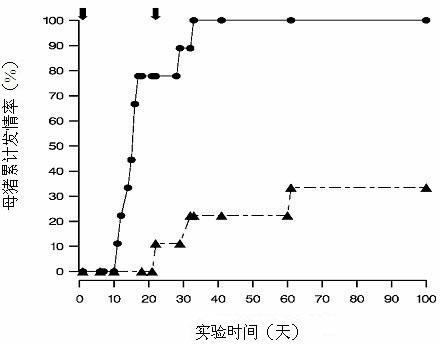

Application of inhibin recombinant fusion protein to preparing medicines for promoting oestrus and hybridization of sows

InactiveCN102166348ANo toxicityNon-pathogenicPeptide/protein ingredientsRecombinant DNA-technologyMedicinePharmaceutical drug

The invention discloses an application of an inhibin recombinant fusion protein to preparing medicines for promoting oestrus and hybridization of sows. When inhibin is used for the sows: 0.5-1mg of the inhibin recombinant protein is used for initial immunization; and after 15-21 days, 0.25-0.5mg of the inhibin recombinant protein is used for second immunization. The immune inhibin can increase the estrus rate and the litter sizes of the sows. The invention has obvious effects on overcoming anestrus of the sows, caused by heat stress in summer, promoting the breeding activities of breeding sows, and particularly on promoting oestrus of breeding sows and back-up sows and increasing litter sizes. Thus, the non-productive time of the breeding sows is shortened, the breeding performance of thebreeding sows is improved, and the economic benefit of sow raising is increased.

Owner:SOUTH CHINA AGRI UNIV

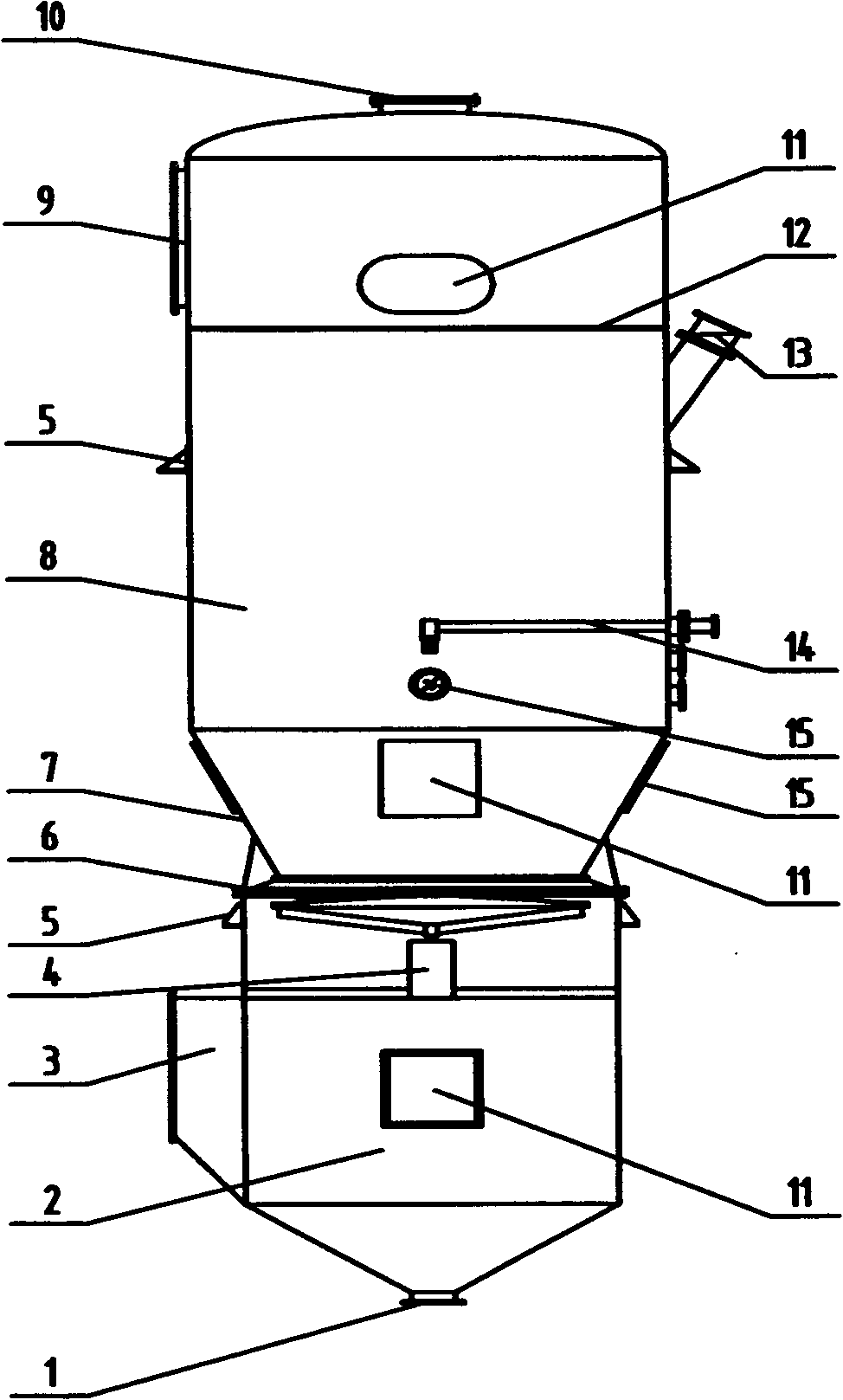

Vertical type control-releasing fertilizer membrane wrapping fluidized-bed

ActiveCN101357863AContinuous operationIncrease production capacityFertilizer mixturesControlled releaseAutomatic control

The invention discloses a controlled release fertilizer coated fluidized bed which consists of an automatic control valve of a material outlet, a discharging bin at bottom, a fluidizing gas inlet, an automatic discharging device, an air distribution plate, a middle cone, a top cylinder body, a fluidizing gas outlet, a filter screen, an automatic control valve of the material inlet and a spray gun; the upside of the middle cone is connected with the top cylinder body which is internally provided with the filter screen and the spray gun; the filter screen is arranged under the fluidizing gas outlet; the distance between the spray gun and the air distribution plate is 140 to 350cm; the middle cone is connected with the discharging bin at bottom by the air distribution plate and the automatic discharging device; the automatic control valve of a material outlet is arranged under the discharging bin at bottom; the sidewall of the top cylinder body is provided with the automatic control valve of a material inlet. The technology effect is that the fluidized bed of the invention can charge and discharge materials automatically, thereby reaching the purpose of continuous operation and greatly reducing energy consumption.

Owner:KINGENTA ECOLOGICAL ENG GRP

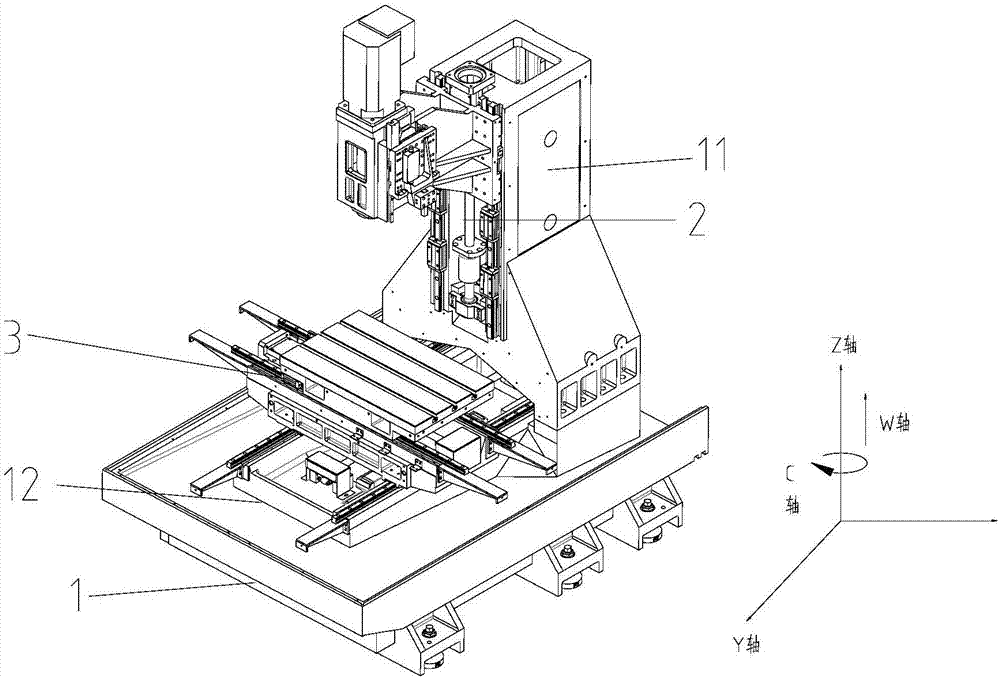

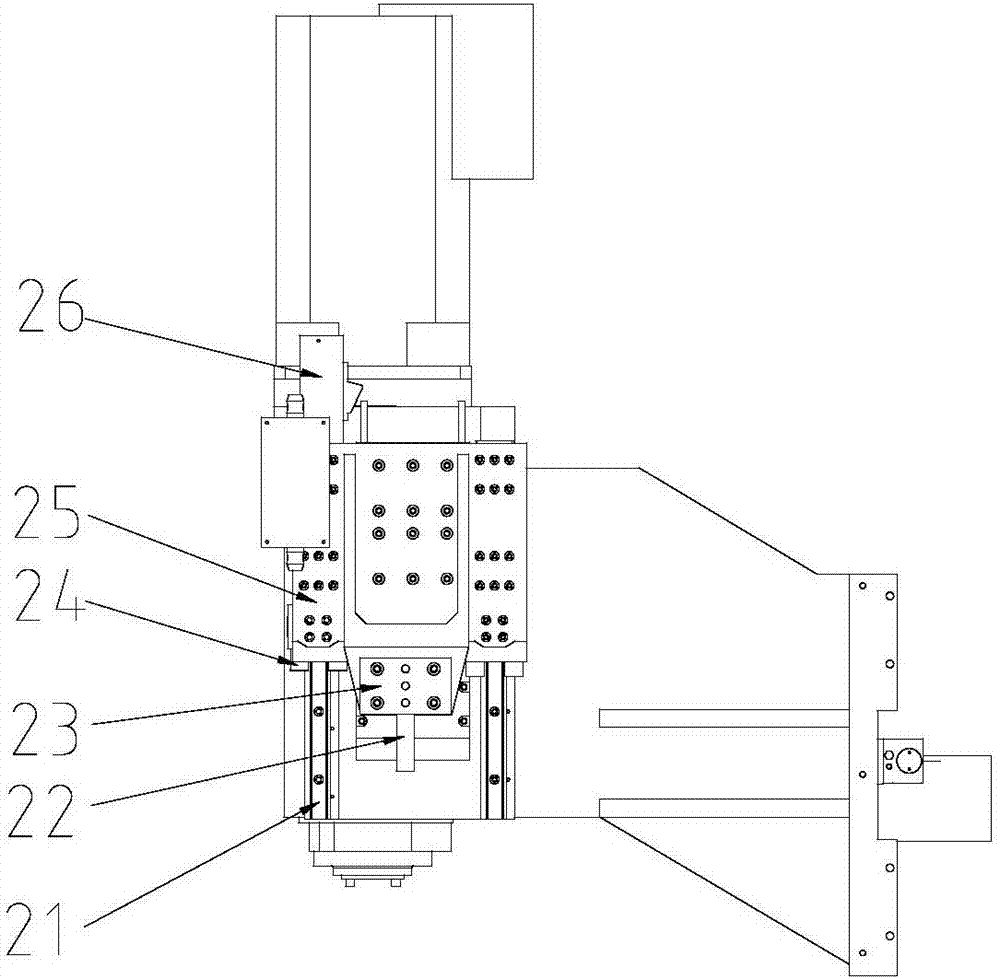

Turn-milling combined-type drilling and tapping center

PendingCN107214521AFacilitate batch industrializationSimple and flexible structureOther manufacturing equipments/toolsRotational axisMachine tool

The invention relates to a turn-milling combined-type drilling and tapping center which comprises a milling machine tool, a turning head and a turn-milling rotary table; the turning head is installed on the side face of a milling head of the milling machine tool, and the turn-milling rotary table is installed on the surface of a workbench of the milling machine tool; the movement axes of the turn-milling combined-type drilling and tapping center are the X axis, the Y axis, the Z axis, the C axis and the W axis, and the W axis is in parallel with the Z axis; the X axis is the directional axis of perpendicular feeding movement of the turning head, the C axis rotates around the Z axis and is the rotary directional axis of the turn-milling rotary table; when the turning head moves, the turn-milling rotary table rotates at the preset rotary speed and the preset torque, the turning function is started, and the milling function is stopped; when the milling head moves, the turn-milling rotary table serves as a milling workbench, the milling function is started, and the turning function is stopped; a part is machined through cooperation of turning and milling, through one-time clamping, the working procedures such as turning, milling, drilling and tapping can be completed, machining of the overall complex part is completed, the machining precision is high, the economic and practical effects are achieved, and the production efficiency of a product is greatly improved.

Owner:GUANGDONG HARVEST START TECH CO LTD

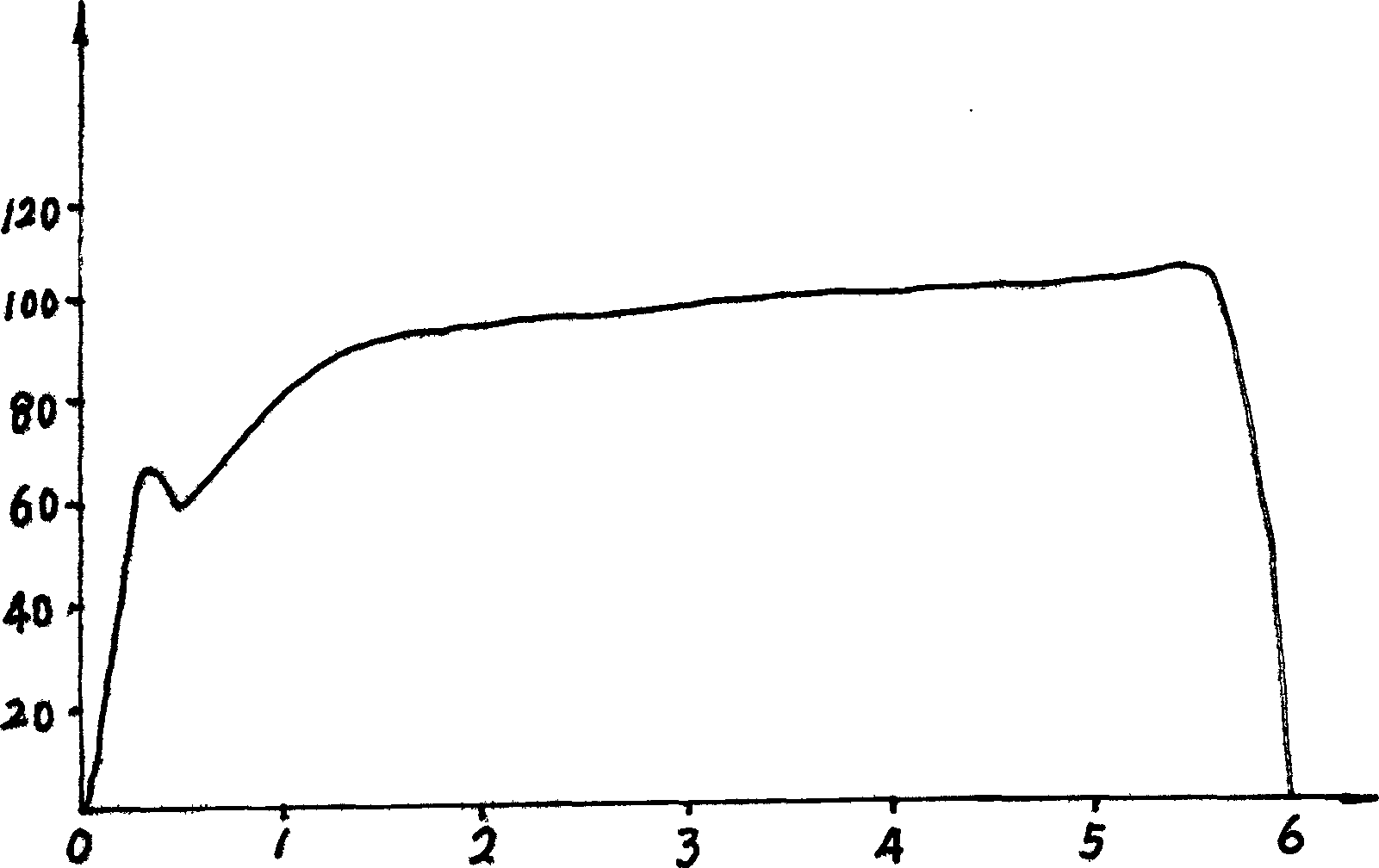

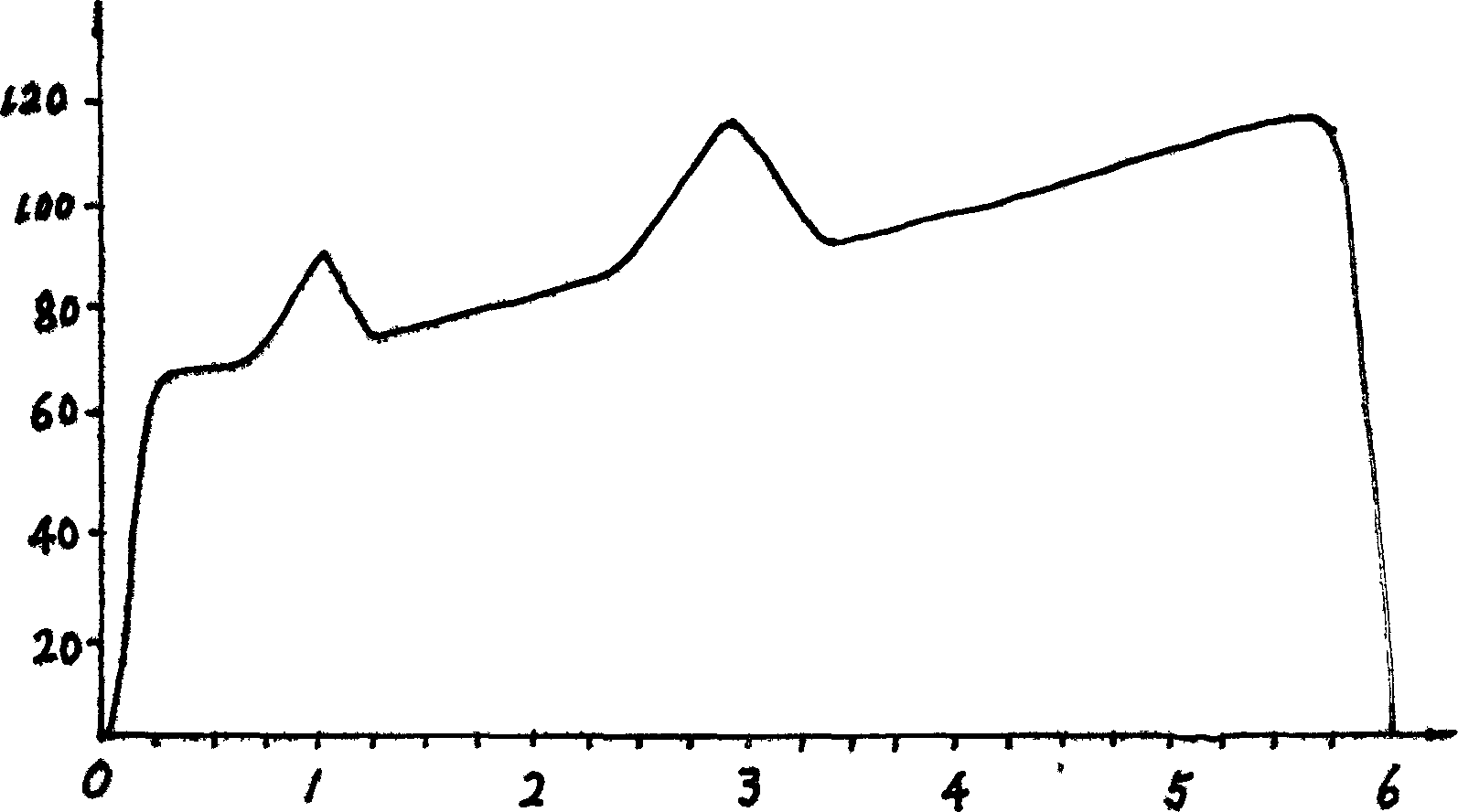

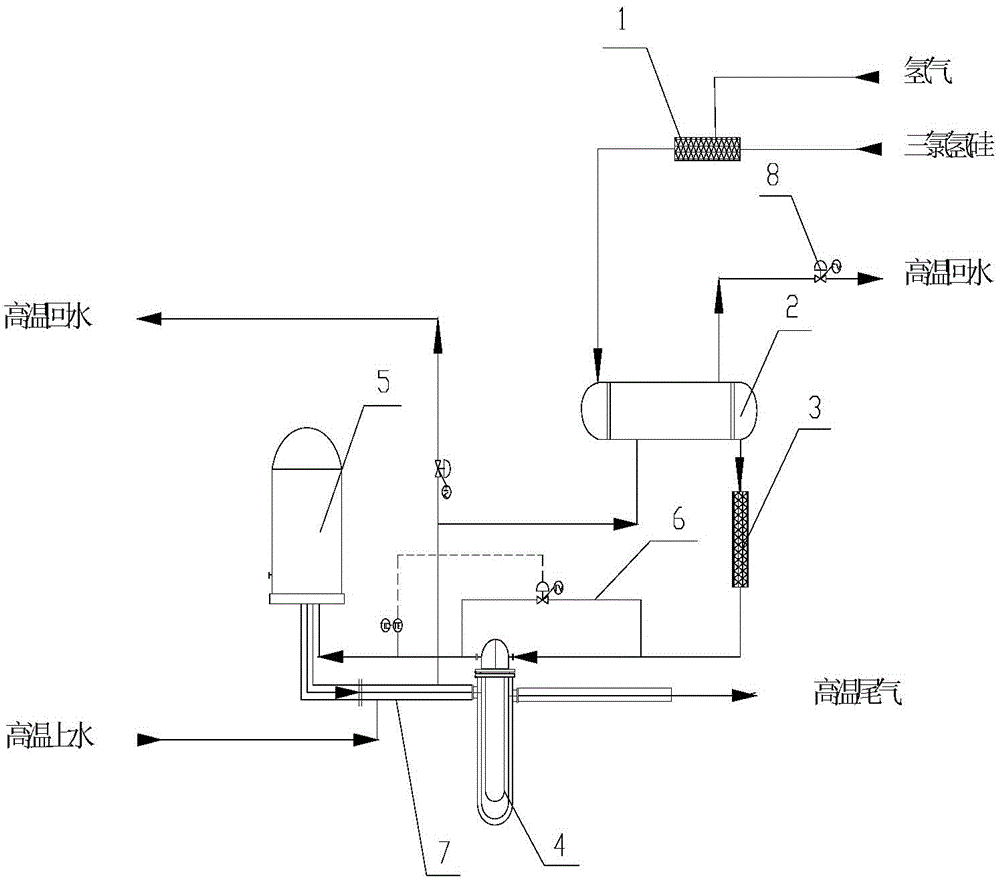

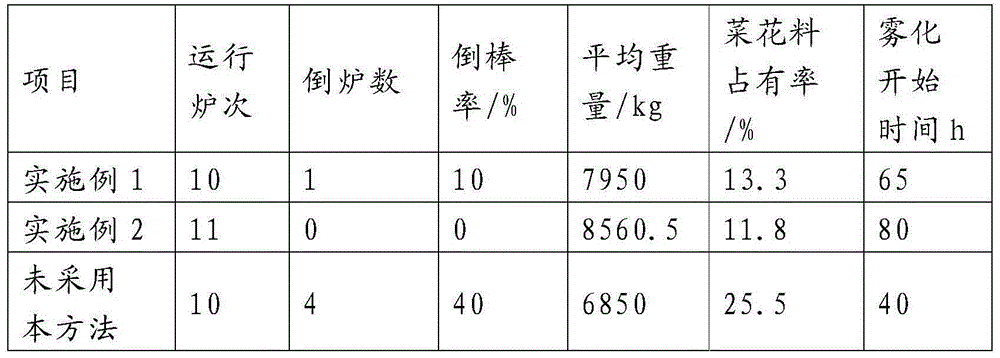

Reduction furnace operation control method

ActiveCN104860315AReduce non-productive timeImprove effective utilizationAuxillary controllers with auxillary heating devicesSilicon compoundsTemperature controlFurnace temperature

The invention provides a reduction furnace operation control method. The method comprises setting initial pressure in a range of 0.45-0.6MPa in a reduction furnace, setting an initial temperature in a range of 1120-1150 DEG C, continuously feeding trichlorosilane and hydrogen to form mixed gas, continuously conveying the mixed gas into the reduction furnace in reduction furnace operation, carrying out a continuous reaction process on the mixed gas in the reduction furnace, controlling a reduction furnace temperature in a range of 900-1100 DEG C in 0-5h after conveying of the mixed gas into the reduction furnace, when the mixed gas undergoes a reaction in the reduction furnace for 30-60h, according to distribution of a hot field and a gas field in the reduction furnace, applying different intensity of currents for all layers of silicon rods in the reduction furnace at time intervals so that equalization of the hot field and the gas field in the reduction furnace are kept, and keeping a reduction furnace temperature in a range of 900-1100 DEG C until the reduction furnace is stopped.

Owner:XINTE ENERGY

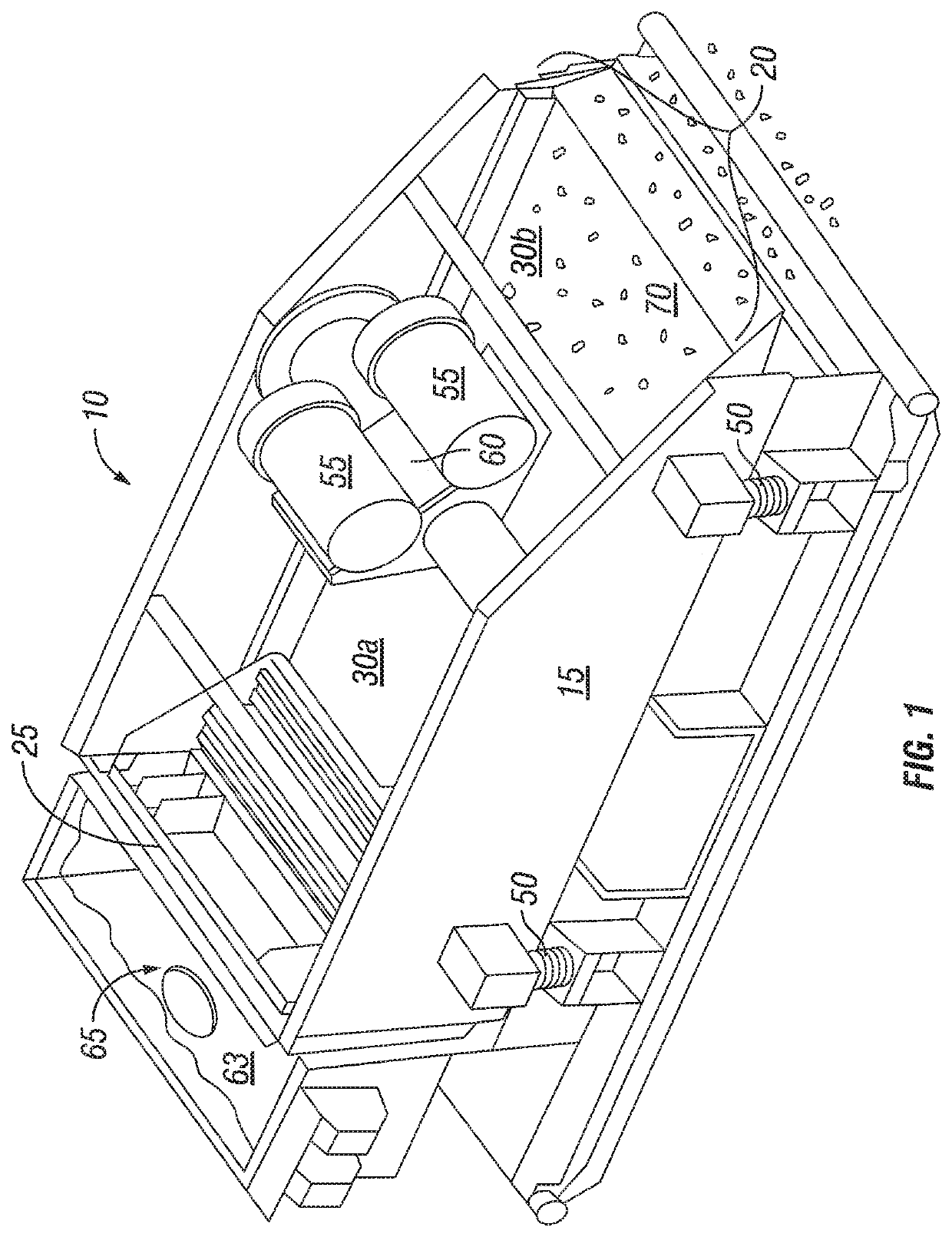

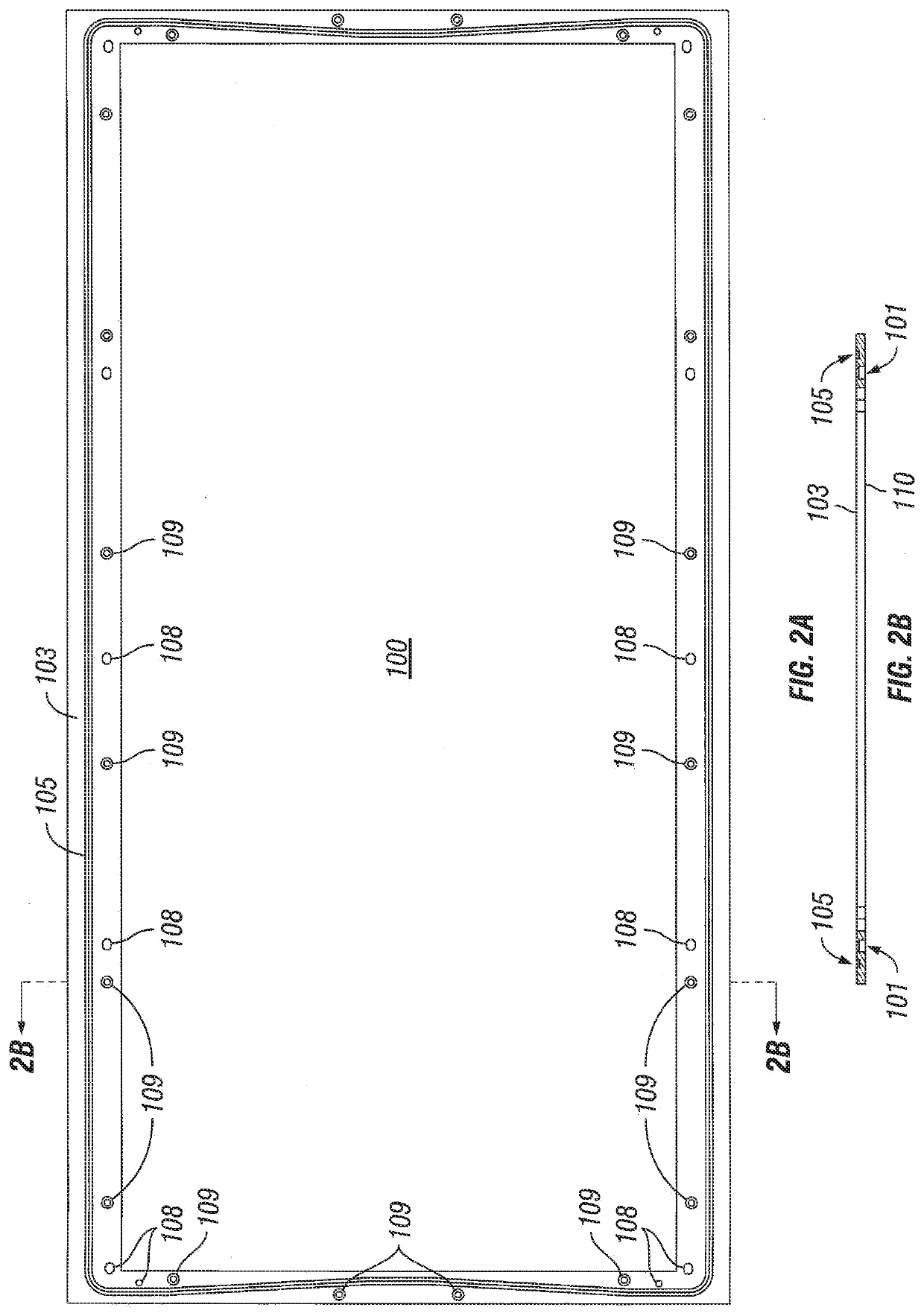

Shale Shaker Buffer Wear Item and Method for Use

ActiveUS20190374976A1Increased durability and longevityImprove efficiencySievingScreeningEnvironmental geologyMining engineering

A shale shaker buffer and wear reduction barrier, placed between a shale shaker filter screen, shale shaker wear items and a shale shaker deck of a shale shaker for the prevention of vibratory and friction-induced wear that is reversibly adhered, placeable and replaceable to a shale shaker filter screen, shale shaker wear items and a shale shaker deck of a shale shaker basket to decrease wear on a shale shaker's functional components, singularly and in combination. The buffer and wear reduction barrier that is the present invention serves the additional function of a solids control barrier as an operable seal between a shale shaker filter screen, wear items and deck of a shale shaker to obviate entrance of solids into mud pits via wear induced areas of separation between shale shaker filter screen, wear items and a deck of a shale shaker.

Owner:HERRINGTON BRETT

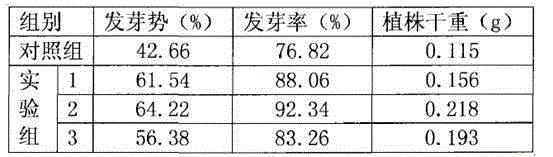

Seedling raising method of tomato seed

InactiveCN104663382ASpeed up germinationImprove germination rateSeed and root treatmentFertilising methodsSalicylic acidSeedbed

The invention discloses a seedling raising method of a tomato seed. The seedling raising method is characterized by comprising the following steps: (1) selecting the seed; (2) accelerating germination; (3) preparing a seedbed; (4) performing seedling raising management; (5) transplanting; (6) applying fertilizer; (7) performing final period management. The development of adventitious roots is promoted by adding salicylic acid, so the root system is more developed, and the success rate after transplantation of a seedling is greatly improved. The method has a simple process and is convenient to operate; the tomato seed germination speed, the germination rate and the uniformity can be effectively improved by combining germination and the seedling raising mode, the seedling quality is improved, robust seedling is cultivated, the tomato non-production time is shortened, and an efficient method is provided for large-scale seedling production required by the tomato planting industry.

Owner:QINGDAO XINRUNTU NURSERY STOCK SPECIALIZED COOP

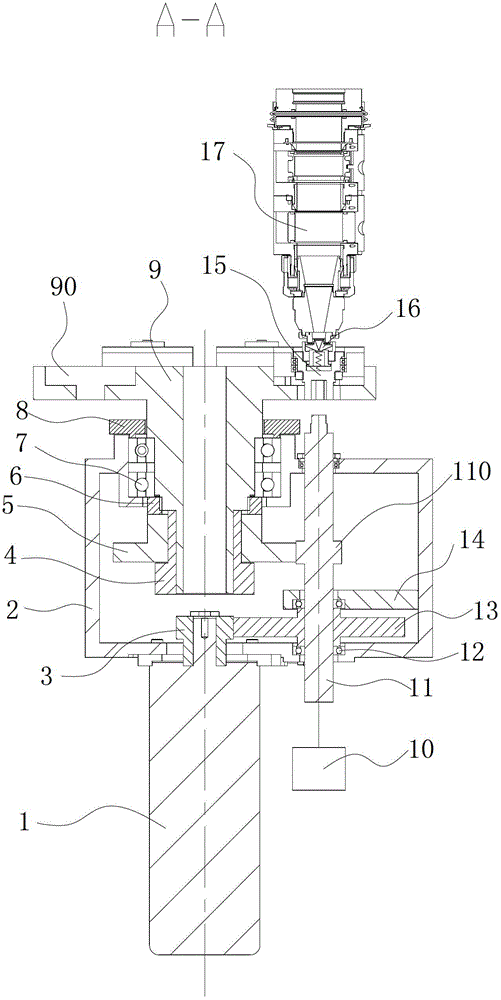

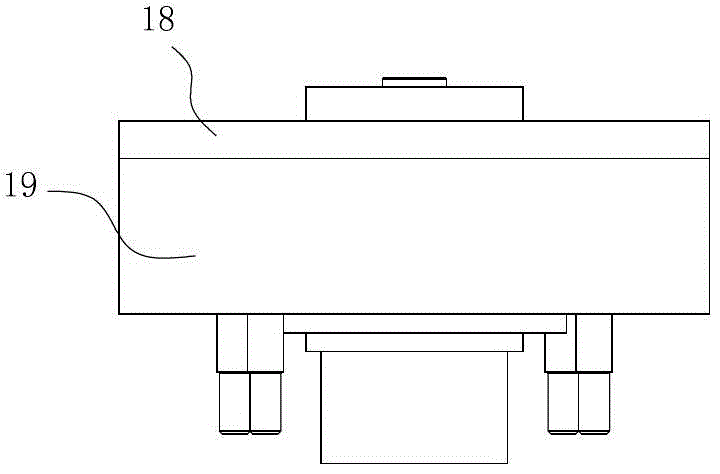

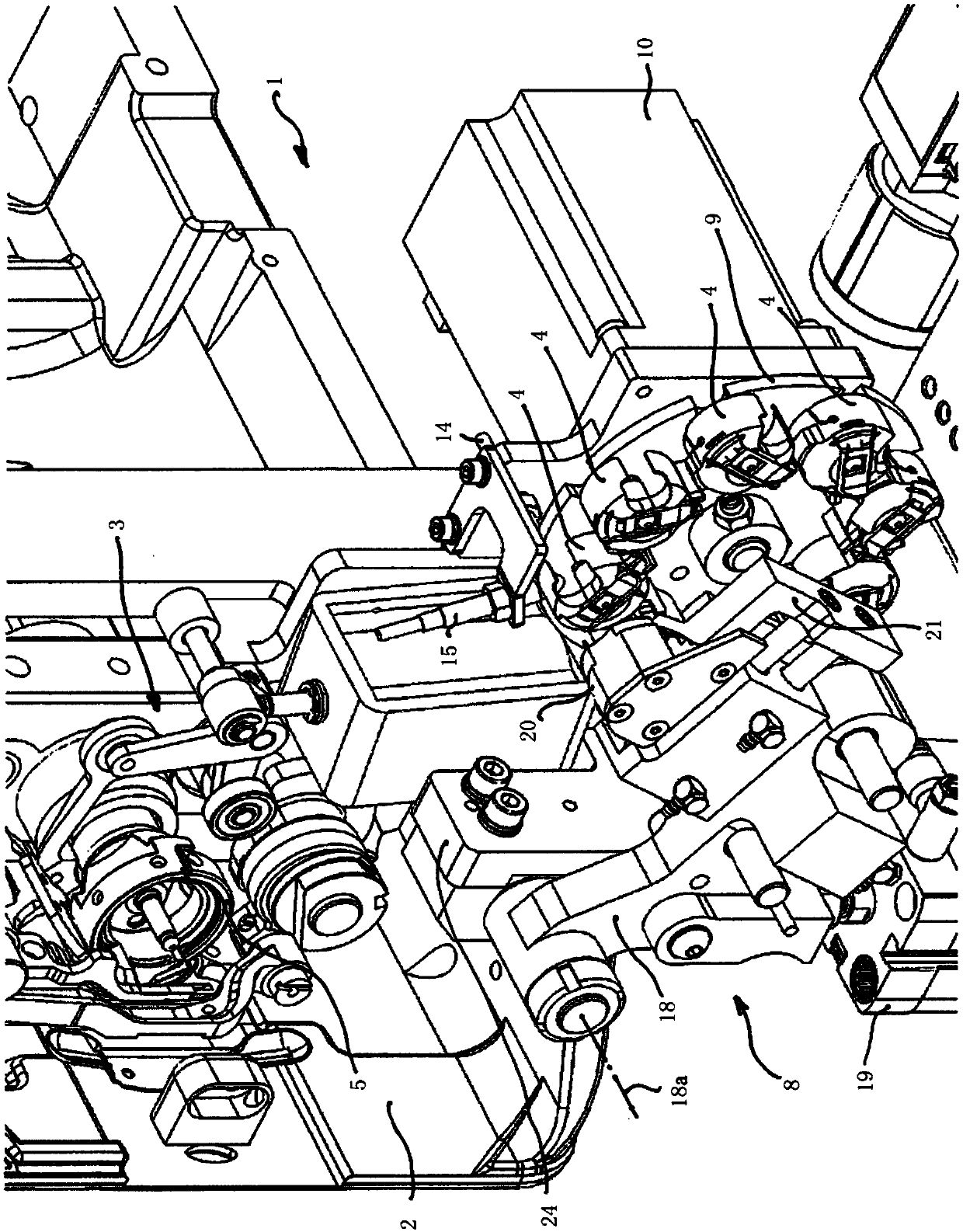

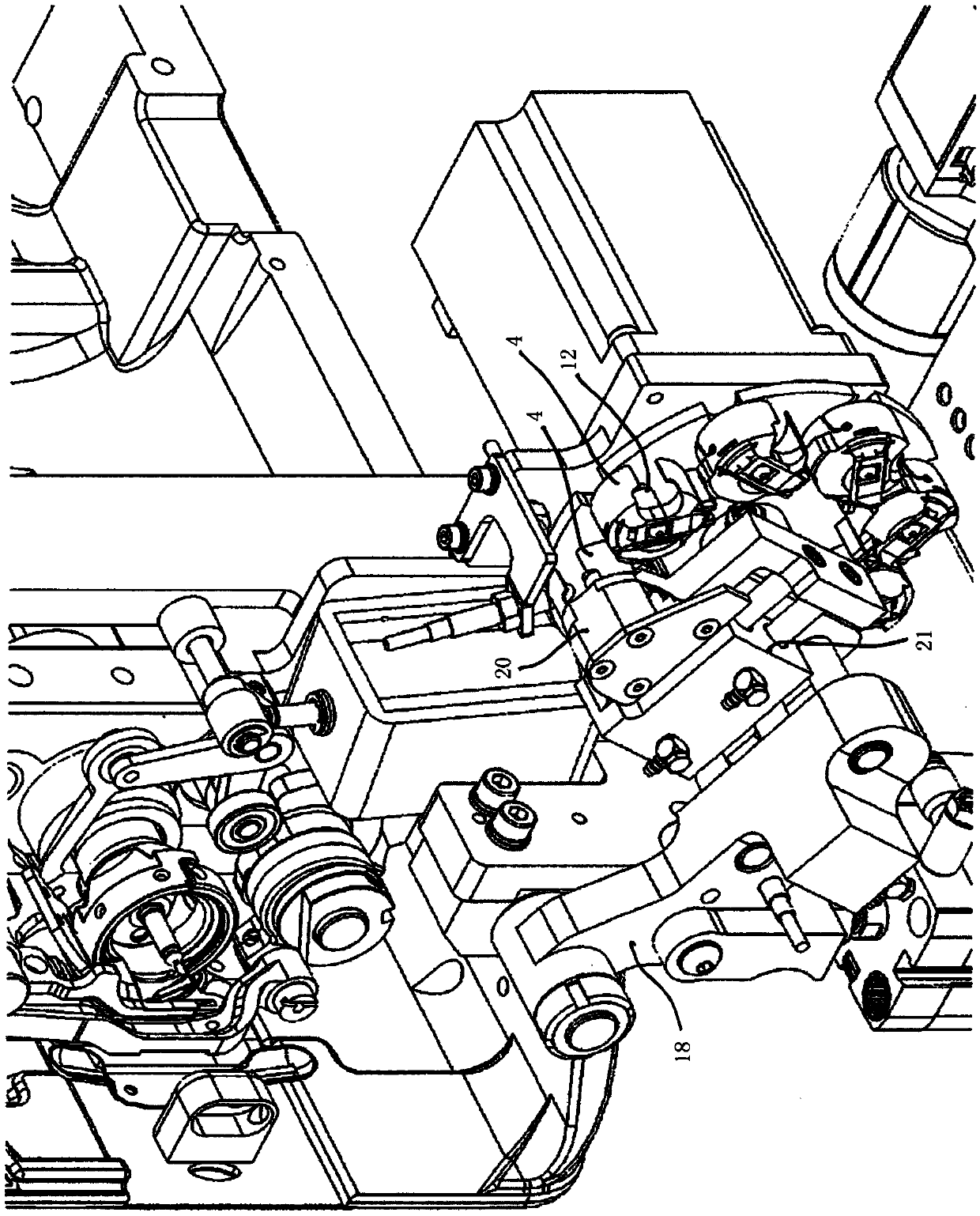

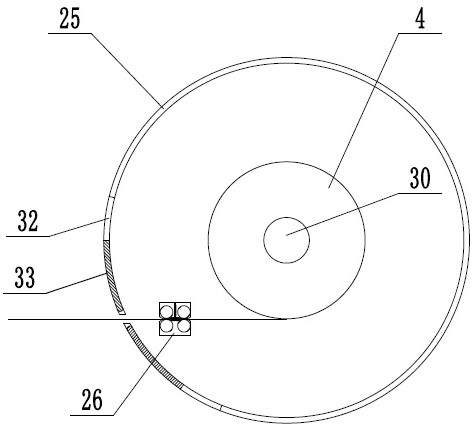

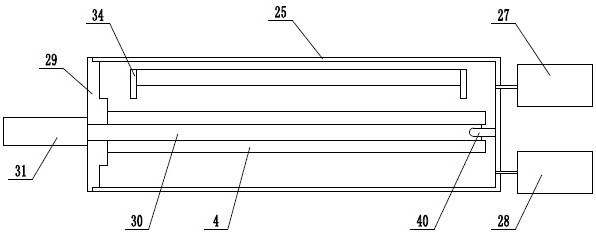

Sewing machine with a bobbin case changing device

ActiveCN109563664AReduce non-productive timeBobbin-winding devicesEmbroidering machines apparatusNeedle guideManufacturing engineering

The invention relates to a sewing machine for stitching back stitches, provided with a needle bar for receiving a needle guiding an upper thread, and comprising a rotary shuttle (5) in which a bobbincase (4) comprising a bobbin guiding a lower thread can be accommodated, said sewing machine also comprises a bobbin case changing device (8) enabling a bobbin case (4) to be removed from a housing (9) and to be introduced into the rotary shuttle (5). The aim of the invention is to improve the functional reliability of said type of sewing machine with a bobbin case changing device, such that the bobbin case changing device (8) is secured to an upper part of the machine frame (2) of the sewing machine.

Owner:PFAFF INDUSTRIESYSTEME & MASCH AG

Alloyed aluminum-nickel-chromium-iron composite alloy for final deoxidizing in steel-making

The invention relates to an alloy for steel in the metallurgical field, in particular to an aluminum nickel chrome copper iron composite alloy for final deoxidation and alloying in steelmaking. The aluminum nickel chrome copper iron composite alloy solves the problems that Cr, Ni and Cu are difficult to smash and process and troublesome in use, influence the steelmaking time, has large yield fluctuation, influence the smelting yield of steel grades, etc. The composite alloy simultaneously meets the smelting steel grade needs of a steel grade containing acid-soluble aluminum (Als) and Ni, Cr, Cu and other elements. The aluminum nickel chrome copper iron composite alloy comprises the following compositions in percentage by weight: less than or equal to 0.5 percent of C, less than or equal to 3 percent of Si, less than or equal to 0.05 percent of S, less than or equal to 0.05 percent of P, 3 to 70 percent of Al, 1 to 60 percent of Ni, 1 to 60 percent of Cr, 1 to 65 percent of Cu and the balance being Fe. The aluminum nickel chrome copper iron composite alloy has low melting point, large specific gravity, no pulverization, no impurity, convenient smelting operation, good and stable deoxidation effect, the Ni and Cu yield of 100 percent, the Cr yield of between 90 and 95 percent and high smelting yield of the steel grade.

Owner:李兴有

Gripping device for a processing tool, storage system and method

InactiveUS20170282316A1Quick tool changeReduce non-productive timePositioning apparatusMulti-purpose toolsOperating system

Disclosed is a gripping system for receiving a processing tool, and to a storage system. These processing tools are used in processing machines or centres in the woodworking industry. Also disclosed is a processing machine with the above-mentioned storage system. This processing machine is used for processing elongate pieces of wood.

Owner:HOMAG GMBH

Systems and methods to visualize component health and preventive maintenance needs for subsea control subsystem components

ActiveUS10018007B2Easy to identifyImprove visualizationConstructionsWell/borehole valve arrangementsOcean bottomGraphics

Systems and methods to visualize component health and preventive maintenance needs for subsea control subsystem components are provided. Embodiments can include energizing one or more solenoids, detecting a solenoid firing event, detecting activity in blowout preventer components downchain from the solenoids, and incrementing a cycle count for the one or more solenoids and each downchain blowout preventer component activated. Embodiments can include projecting a replacement date for the solenoid or any of the downchain blowout preventer components based on the cycle count and user-defined thresholds. In embodiments, a user is provided with an interactive graphical representation of a blowout preventer including selectable blowout preventer components thereby to visualize component health and preventive maintenance needs.

Owner:HYDRIL USA DISTRIBUTION LLC

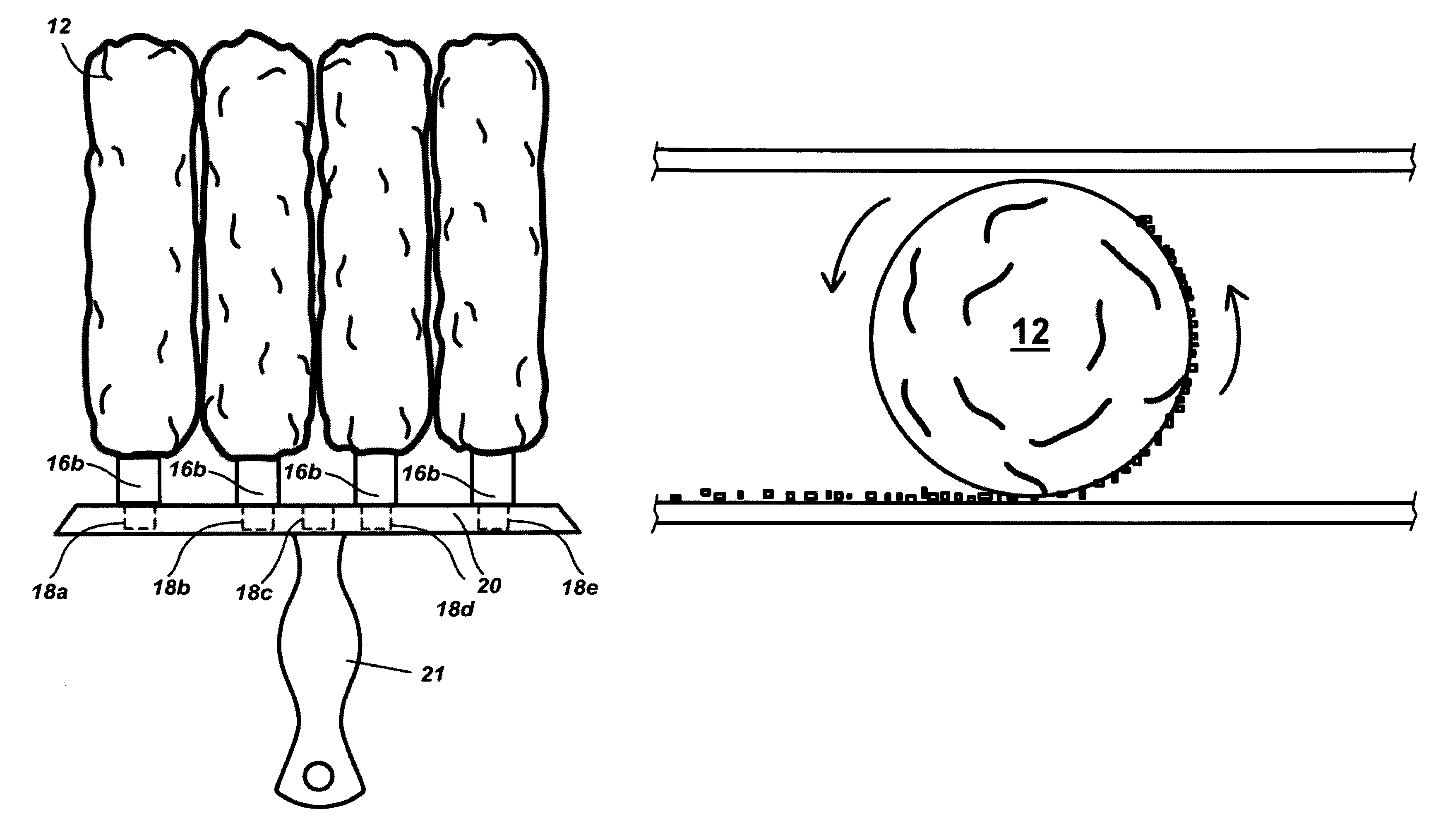

Duster for blinds and plantation shutters

InactiveUS7735181B1Less frequent cleaningReduce non-productive timeLiquid surface applicatorsWindow cleanersFree rotationEngineering

An improved duster for venetian blinds and plantation shutters is disclosed including a handle and cross member with a number of rigid repositionable pins about which a dusting finger freely rotates when drawn lengthwise between the slats of blinds. The process of rotating prevents the bunching of dust unevenly on the dusting finger and provides for a greater removal of dust from the blinds, the dust being evenly distributed about the dusting finger. The dusting fingers may be treated with an anti-static compound to ease intermittent clearing of the dusting finger of dust.

Owner:THOMAS BRETT LOWELL

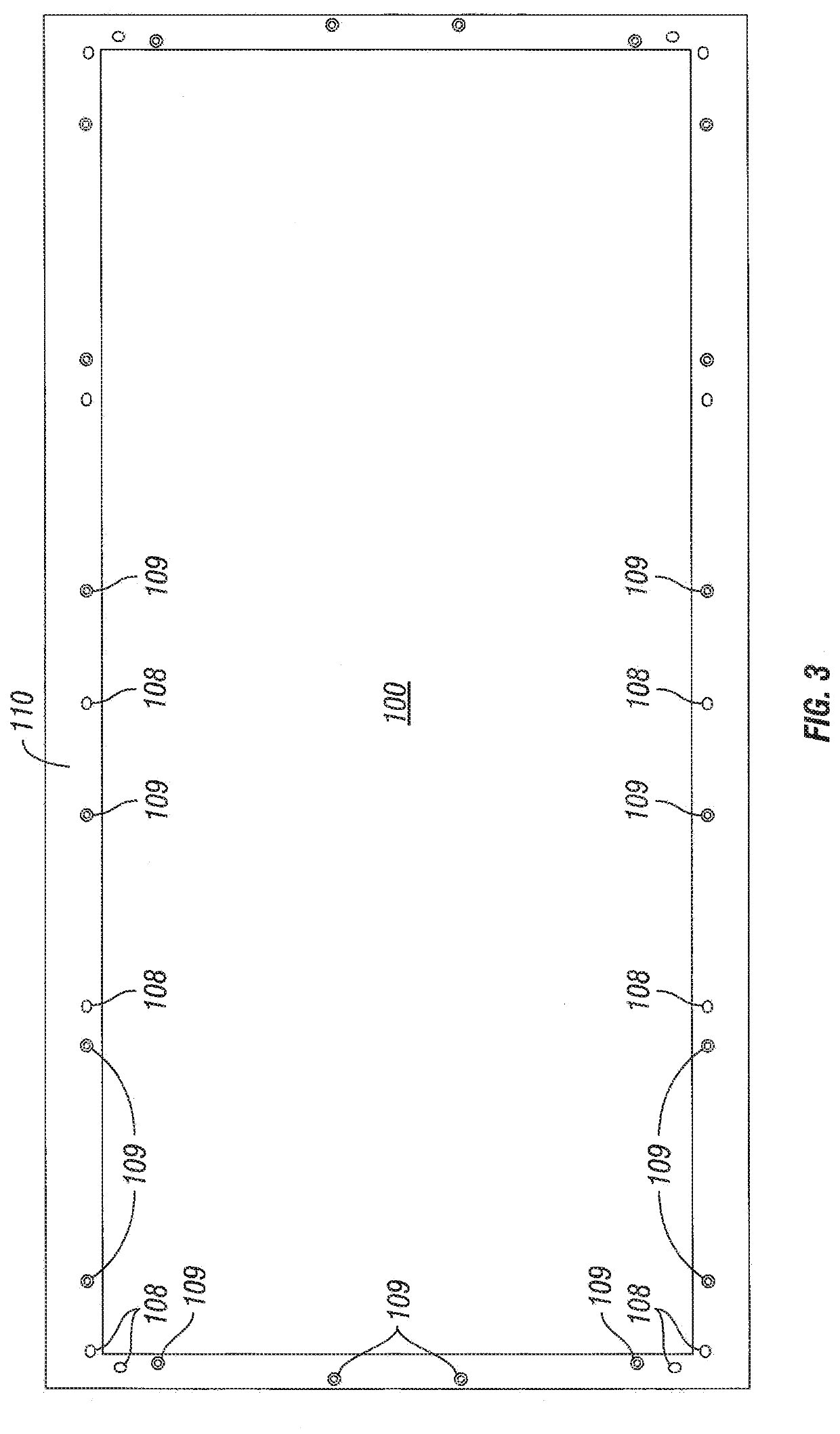

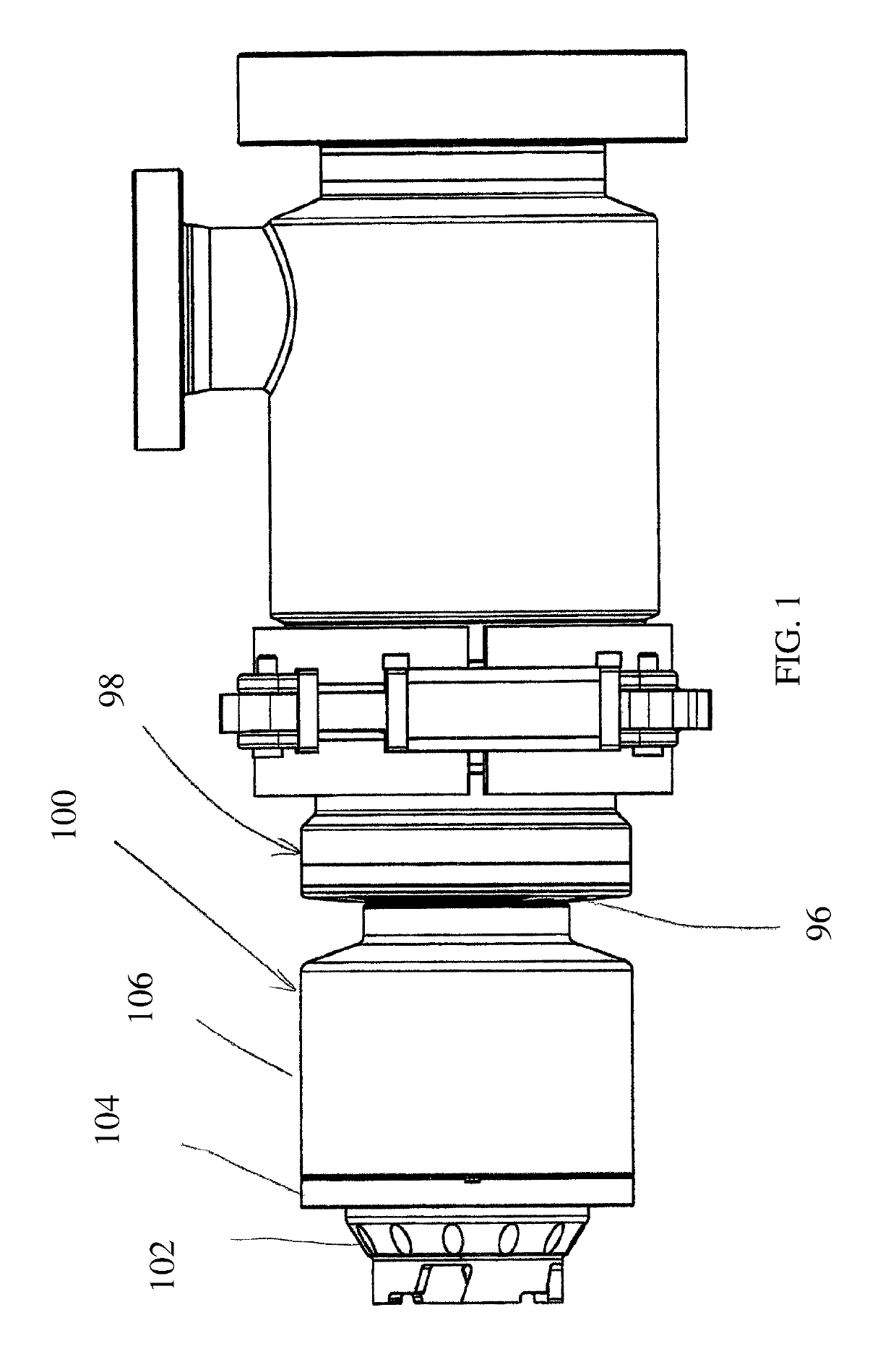

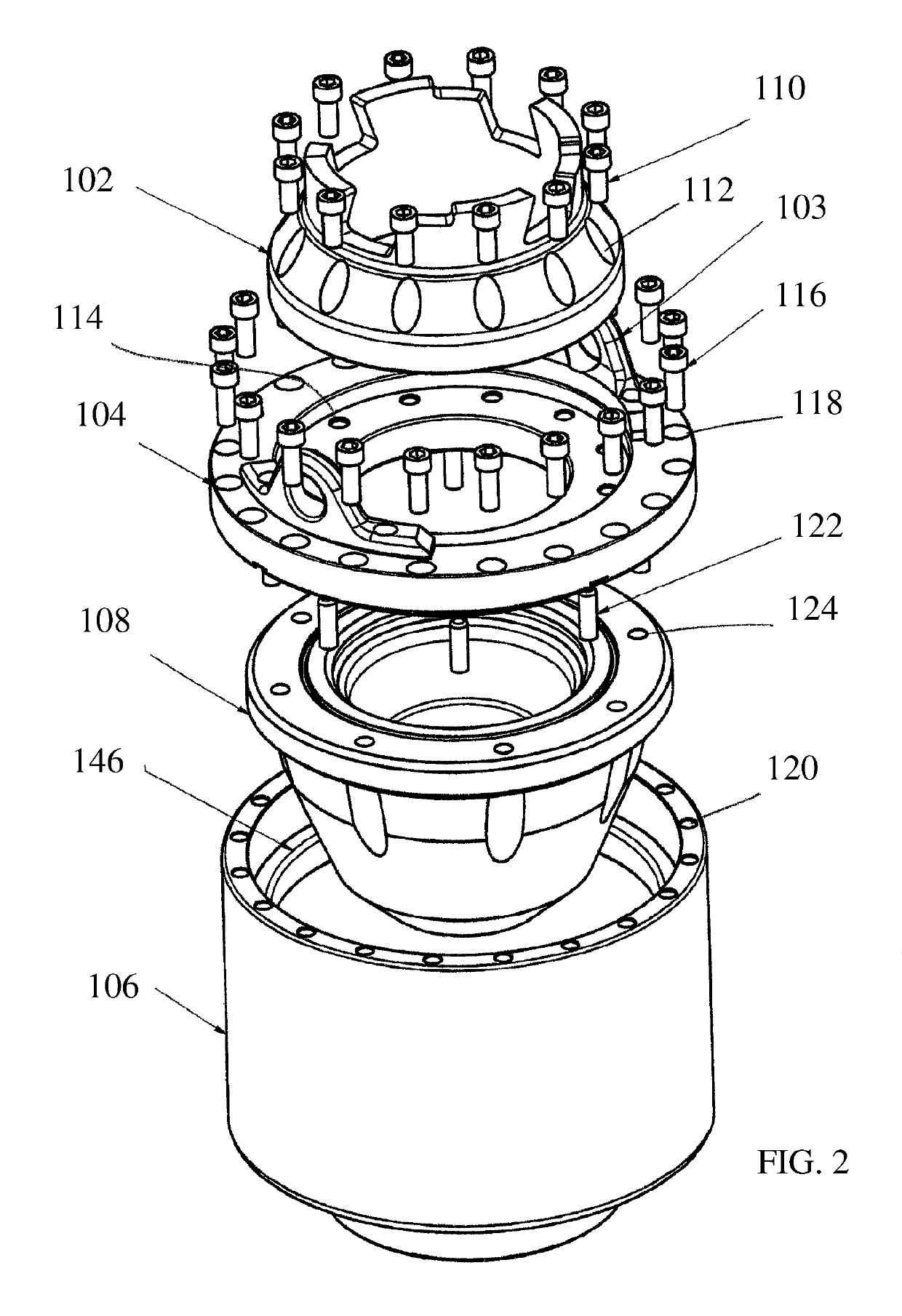

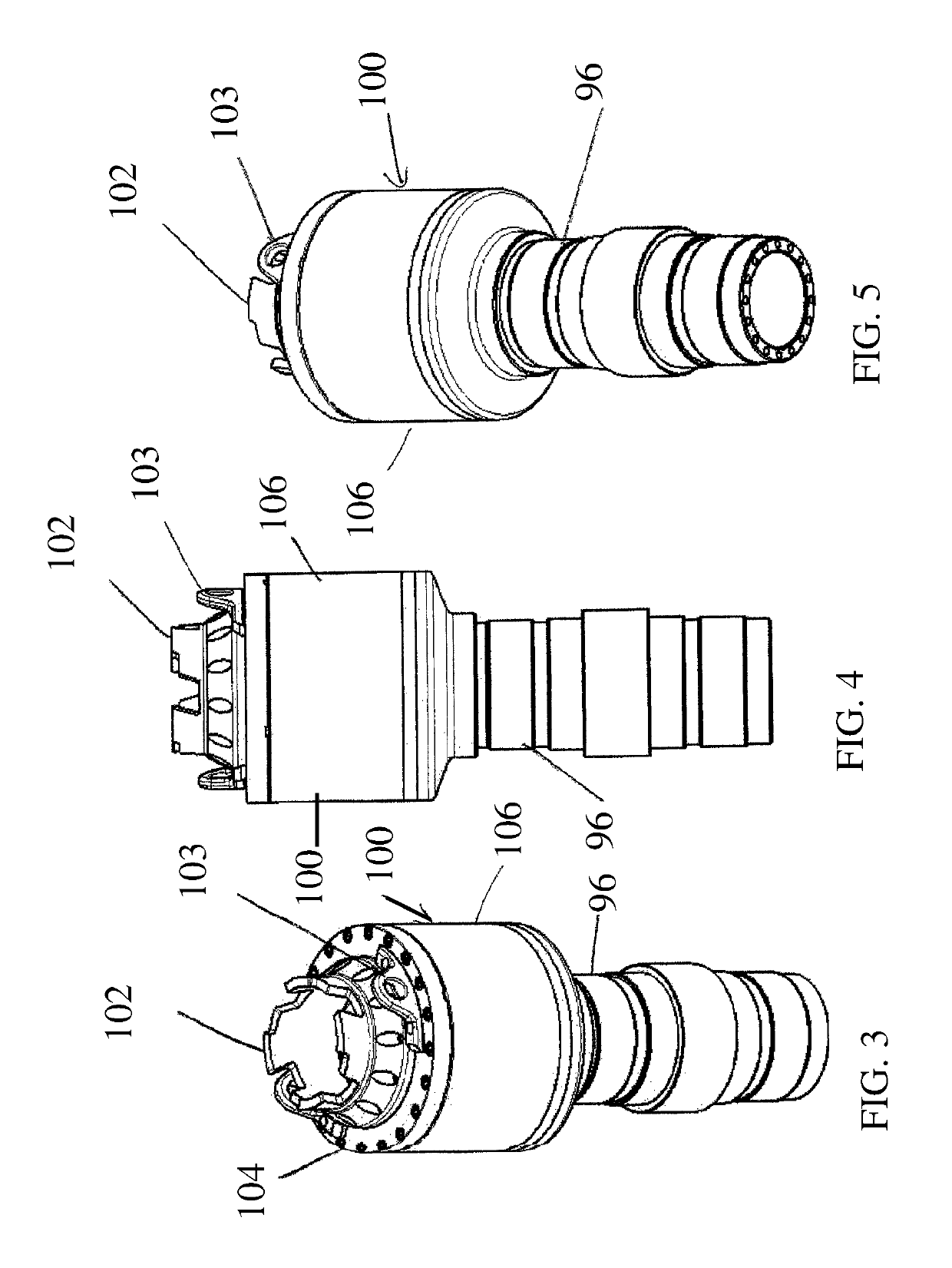

Top pot assembly

ActiveUS10392891B1Improve efficiencyReduce the amount requiredSealing/packingEngineeringMechanical engineering

An improved top pot assembly utilizes an attachment body for attaching the rubber to a bearing assembly for rotation with the inner barrel. The attachment body simplifies the replacement of the rubber on the drilling assembly. The attachment body provides a guide that slopes downward into the central aperture and the bore to guide the mandrel and drilling string towards the bore. The attachment body also provides a stripper receiver for attachment of the rubber to the attachment body. The attachment body attaches to the housing which attaches to the bearing assembly for rotation of the rubber and the inner barrel.

Owner:PRUITT TOOL & SUPPLY

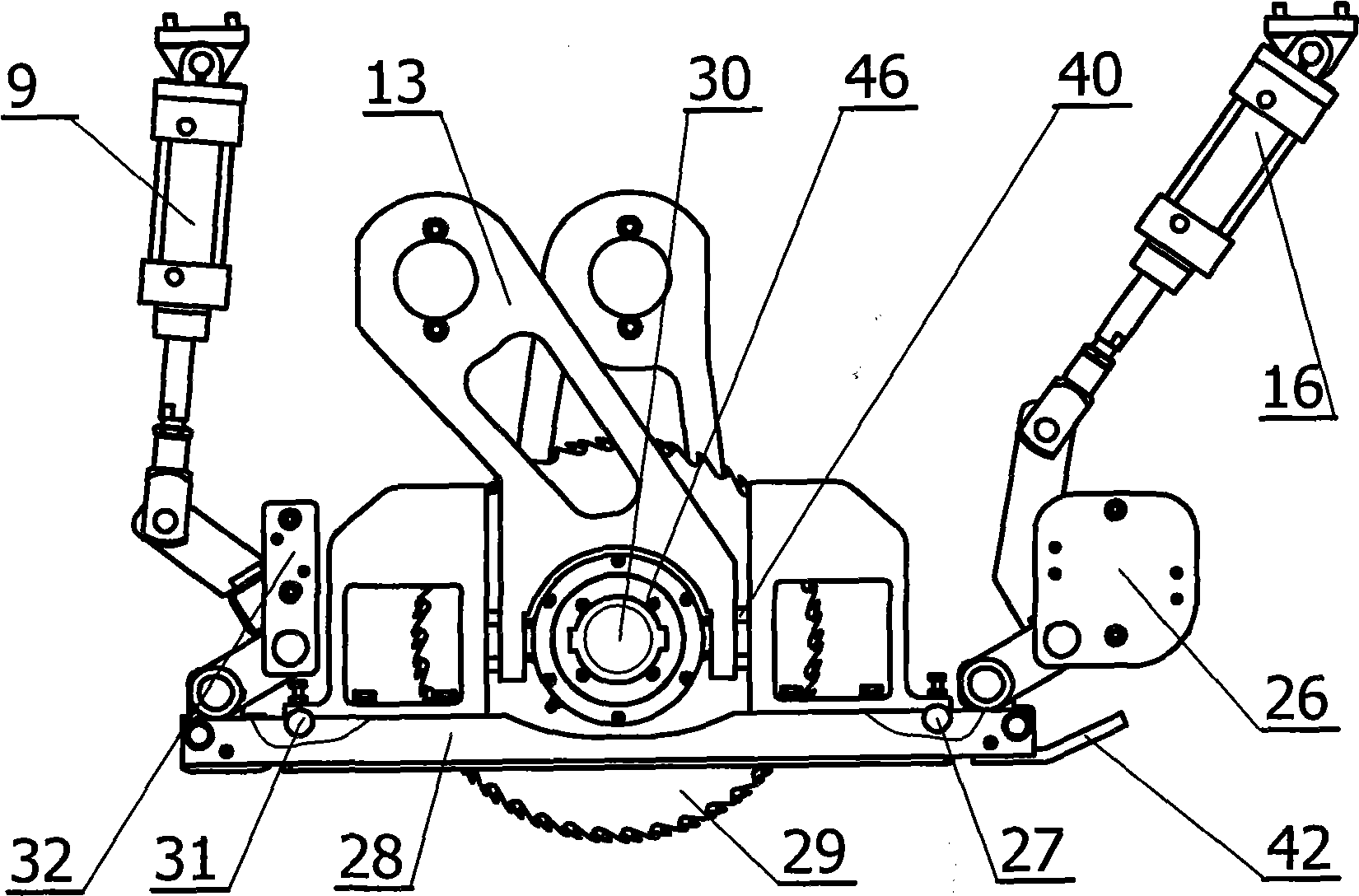

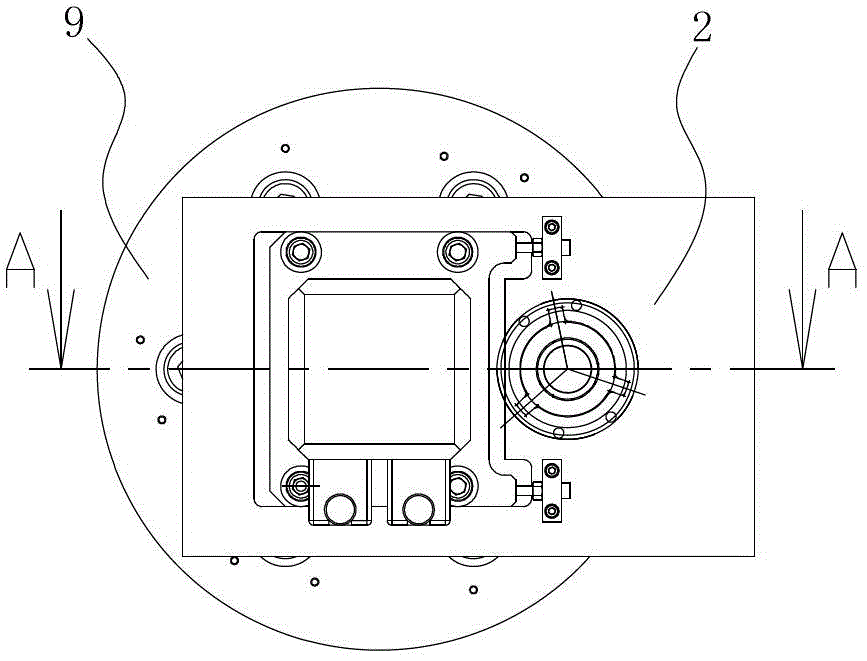

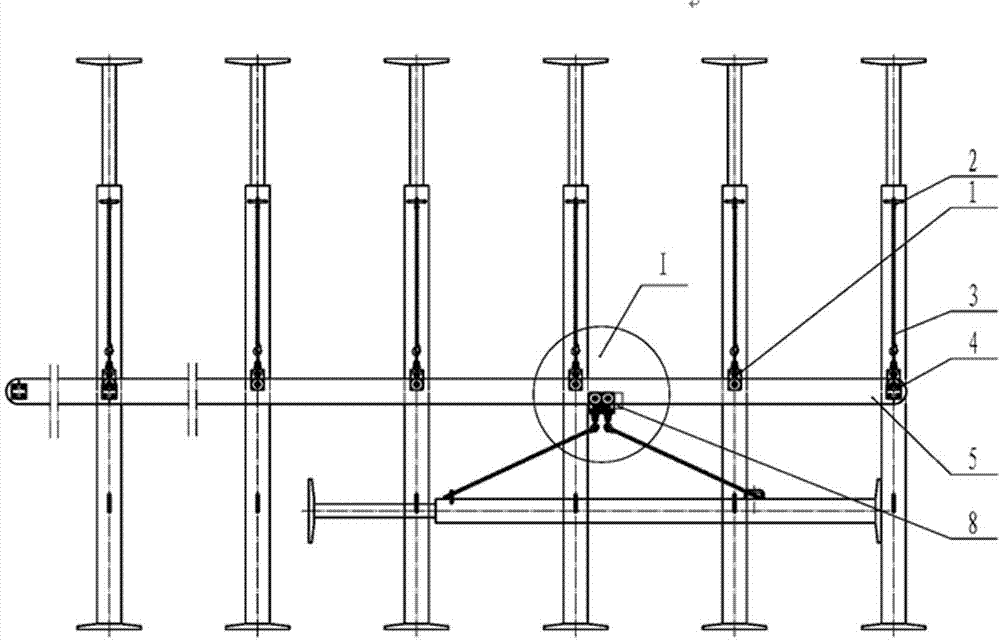

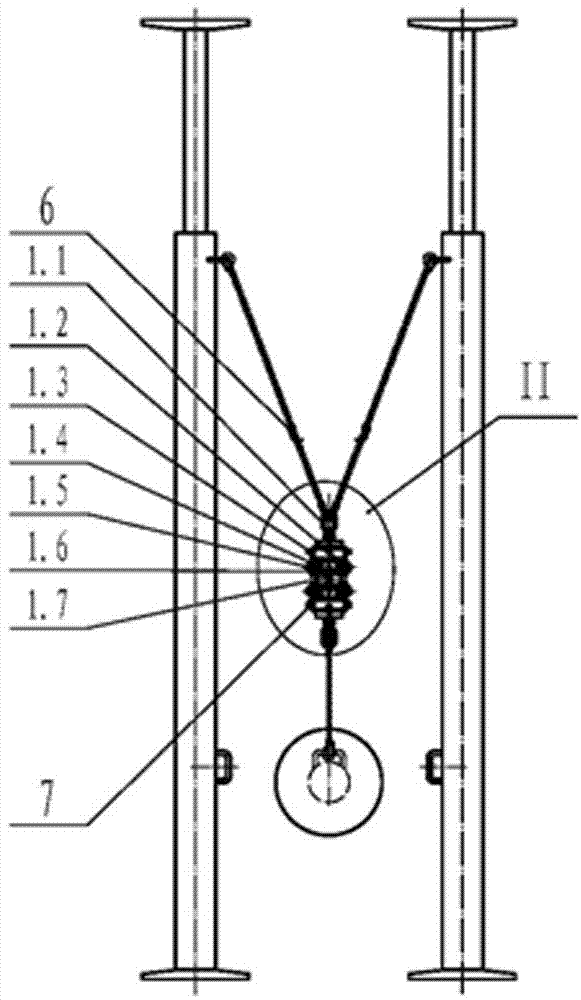

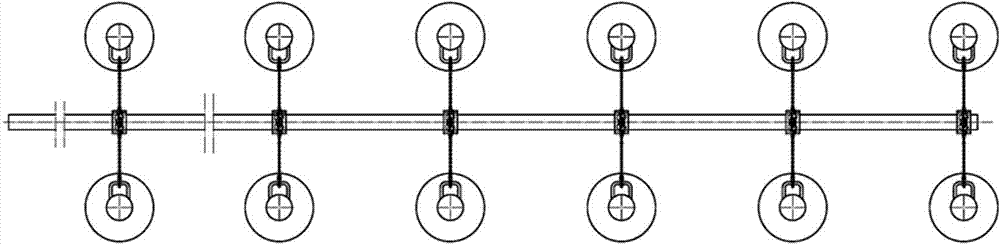

Rapid transporting device for underground single hydraulic prop and transporting method finished thereof

ActiveCN104279003ASolve long-distance transportationMove quicklyRailway componentsEarth drilling and miningDrive wheelUltimate tensile strength

The invention belongs to the technical field of coal-mine underground single hydraulic-prop transportation, particularly relates to a rapid transporting device for an underground single hydraulic prop and a transporting method finished by the rapid transporting device and solves the problems of great worker labor intensity and difficult safety guarantee of traditional single hydraulic-prop support. The device comprises a plurality of main-wheel groups, a driving-wheel group, a chain, a plate-bending assembly and a track. According to the transporting method, a double-end closed-type railway is adopted, and the plurality of main-wheel groups can be recycled in the processes of hanging a transporting railway and transporting the single hydraulic prop, so that the rapid transportation of the single hydraulic prop is realized. According to the transporting device and the transporting method, the requirement on the rapid transportation of the single hydraulic prop at a mining area can be met; in addition, the time and the labor are saved, the labor intensity of workers is lowered, the auxiliary time is shortened, the safety is improved, and the production efficiency of a fully-mechanized coal-mining surface is improved.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

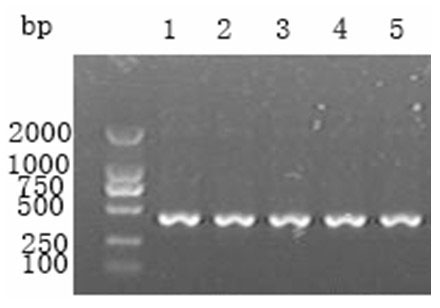

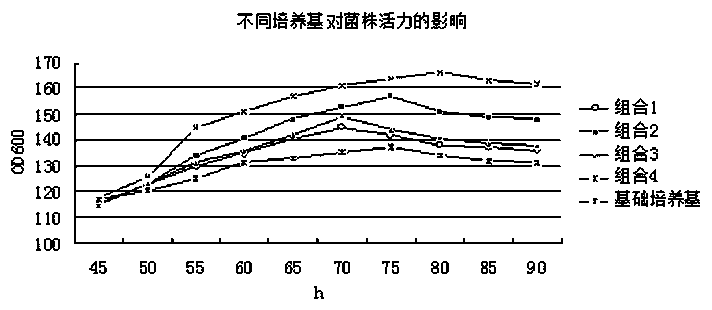

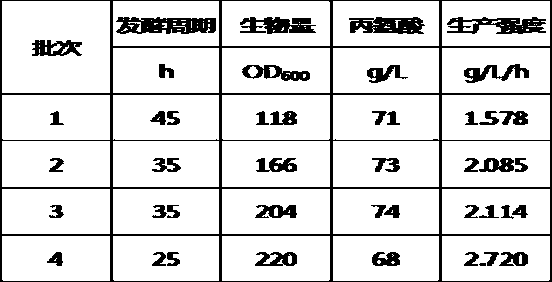

Method for producing neutral phytase through immobilized bacillus fermentation

PendingCN111057701AIncrease the effective apertureImprove adsorption capacityHydrolasesMicroorganism based processesBiotechnologyContinuous fermentation

The invention provides a method for producing neutral phytase through immobilized bacillus fermentation. The method comprises the following steps: (1) preparing a seed solution; (2) carrying out pretreatment of a carrier: modifying a ceramsite carrier with an alkali liquor; (3) preparing immobilized cells: filling the carrier into a fixed bed reactor, and immobilizing thallus cells on the carrierthrough an adsorption effect; (4) carrying out pre-culturing: culturing the immobilized cells for 30-40 hours by using a fermentation culture medium; and (5) carrying out continuous fermentation culture: enabling the fermentation culture medium to flow into a fixed bed reactor at a certain dilution rate for continuous fermentation. The bacillus is immobilized by adopting the alkali-modified carrier, and the method has the advantages of being low in cost, stable in property, non-toxic and good in adsorption effect. According to the method, the immobilized cell technology is combined with the continuous fermentation process, so that the purpose of continuously producing neutral phytase at high intensity is achieved, the fermentation efficiency and the phytase yield are greatly improved, andindustrial production is facilitated.

Owner:陈东浩

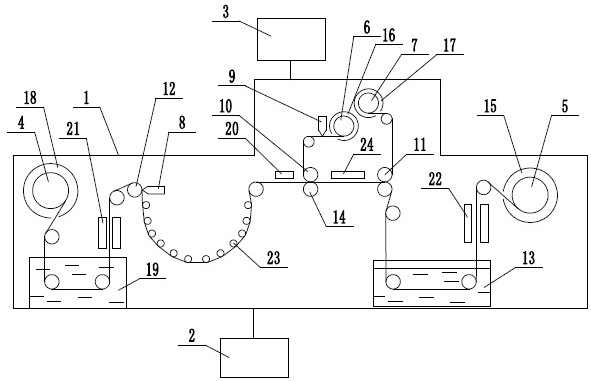

Reel-to-reel equipment for preparing nano-silver wire electrode film

ActiveCN113441340AHigh optical transmittanceReduce the chance of oxidationLiquid surface applicatorsSolid-state devicesThin membraneEngineering

The invention discloses reel-to-reel equipment for preparing a nano-silver wire electrode film. The reel-to-reel equipment comprises a vacuum chamber, a first unwinding roller, a first winding roller, a second unwinding roller, a second winding roller, a nano-silver wire groove mold, a Meyer rod group, a high-molecular polymer groove mold, an impressing roller, a separating roller and a coating roller, and the unwinding rollers and the winding rollers are both arranged in a roller replacing device. According to the device, replacement of the rollers can be achieved under the condition that the vacuum chamber is not exposed to the atmosphere. A PI flexible film coiled material is loaded on the first unwinding roller, and the coating roller, the MeiYer rod group, the impressing roller, a nano-silver wire recycling pool and the first winding roller are sequentially arranged on the downstream portion of the first unwinding roller. A PET flexible film coiled material is loaded on the second unwinding roller, and the high-molecular polymer groove mold, the impressing roller, the separating roller and the second winding roller are sequentially located on the downstream of the second unwinding roller. The PI flexible film and the PET flexible film are subjected to impressing compounding at the impressing roller and an impressing supporting roller, are separated at the separating roller and are finally wound by the first winding roller and the second winding roller respectively.

Owner:辽宁分子流科技有限公司

Method for raising seedling of oil palm seed

InactiveCN102084774BSpeed up germinationImprove germination rateSeed and root treatmentHorticultureOil palmSeedbed

The invention belongs to the technical field of plant sprout breeding, in particular to a method for raising a seedling of an oil palm seed, which comprises the following steps of: (1) seed harvesting and accelerating germination; (2) seedbed preparing; (3) sowing and seedling-growing managing; and (4) transplanting. The invention has a simple process, is convenient for operation, increases the oil palm seed germinating speed, the germinating rate and the uniformity through combining accelerating germination with seedling-growing manners, improves the sprout quality, cultivates robust sprouts, shortens the oil palm period of immaturity, and provides a high-efficiency method for mass sprouts required by the oil palm planting industry.

Owner:COCONUT RES INST OF CHINESE ACAD OF TROPICAL AGRI SCI

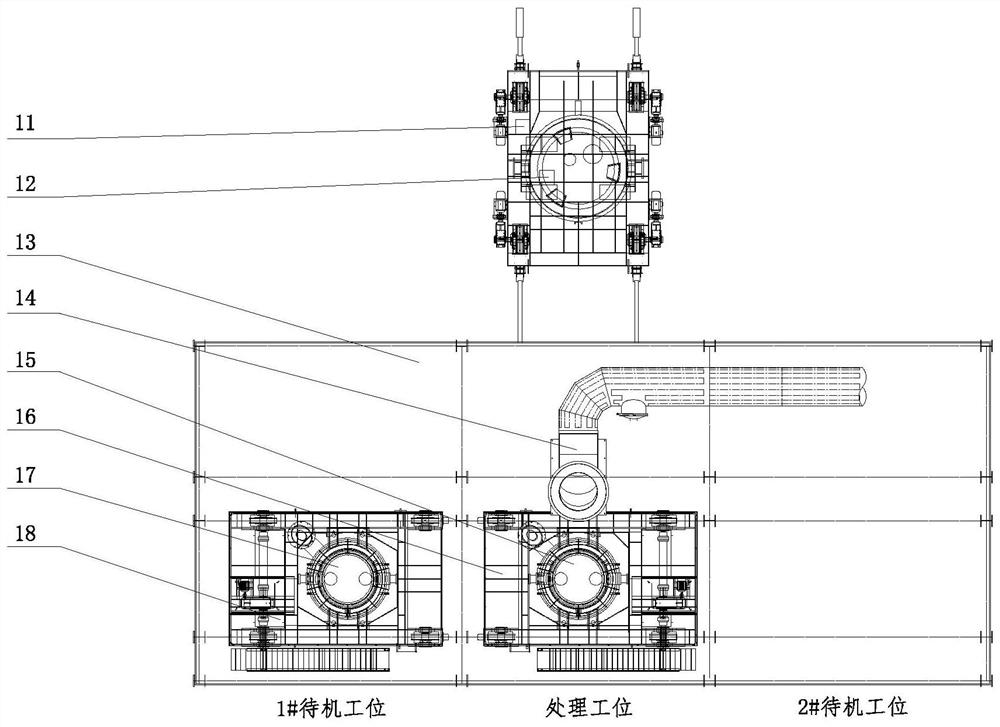

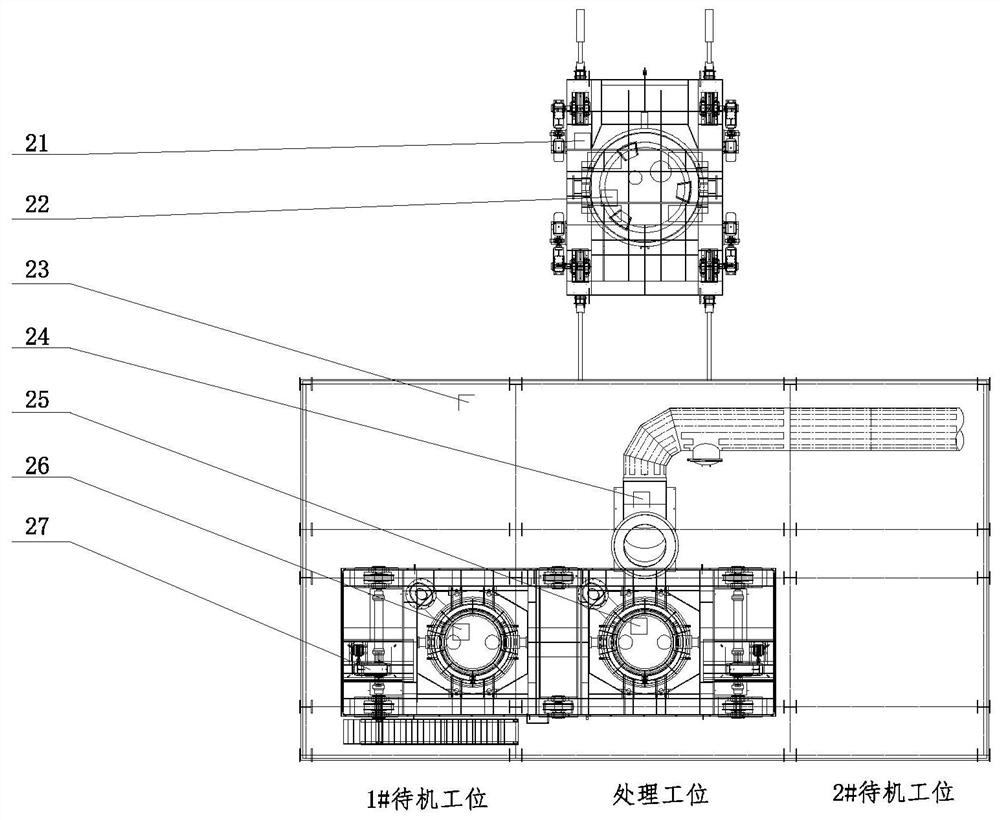

Method for shortening replacement time of single-station RH vacuum chambers and RH vacuum chamber replacement device

PendingCN113373280AShorten the lengthReduce non-productive timeProcess engineeringManufacturing engineering

The invention relates to a method for shortening the replacement time of single-station RH vacuum chambers and an RH vacuum chamber replacement device. According to the method, two original vacuum chamber transporting vehicles of the single-processing-station RH are combined into a long double-vacuum-chamber transporting vehicle, the action that one of the two vacuum chambers operates from a processing station to a standby station and the action that the other of the two vacuum chambers operates from the standby station to the processing station can be completed at the same time, the non-production time of an RH vacuum refining furnace is shortened, and the RH vacuum refining furnace has the advantages of being light in equipment weight, small in total length and large in operation area.

Owner:WISDRI ENG & RES INC LTD

Efficient environmentally-friendly production and extraction process of amino acid

InactiveCN111574390AShorten the fermentation cycleIncrease production intensityBacteriaOrganic compound preparationActivated carbonCentrifugation

The invention belongs to the technical field of bioengineering, and relates to an amino acid efficient environmentally-friendly production extraction process. The process comprises the following stepsof: collecting an L-alanine fermentation broth, performing centrifuging, and collecting a supernatant; carrying out microfiltration on the supernatant through a ceramic membrane, and collecting filtrate; adding activated carbon into the filtrate for decolorization, performing filtering by a plate frame, and collecting a decolorized solution; exchanging L-alanine onto resin through strongly acidiccation exchange resin, then completely eluting the L-alanine on the resin with ammonia water, and carrying out concentration crystallization, centrifugation and drying to obtain a finished product. According to the process, fermentation production intensity can be improved, so that the production cost of fermented alanine is reduced.

Owner:赵兰坤

Modular structure wall body of high-temperature heating furnace and mounting method

PendingCN110455082AImprove heat transfer efficiencyDelay the aging processFurnace liningsMonolithic liningsFiberHeat transfer efficiency

The invention provides a modular structure wall body of a high-temperature heating furnace, and the modular structure wall body greatly increases a furnace wall inner wall radiation coefficient of thehigh-temperature heating furnace, obviously strengthens in-furnace heat transfer efficiency, achieves energy conservation and emission reduction, slows down a furnace wall ageing process, and prolongs the service life of a furnace wall. The modular structure wall body comprises a preset furnace wall main truss and a furnace top truss. The modular structure wall body is characterized in that corresponding connecting inverted-H-shaped steel is fixedly arranged on the bottom surface of the furnace top truss separately, wherein the bottom of the connecting inverted-H-shaped steel is connected with a top blocking structure of a hoisting outer screw; the hoisting external screw which is upwards bulged is uniformly distributed on the upper surface of a ceramic fiber cotton module; the ceramic fiber cotton module is mounted on the lower surface of the furnace top truss through the hoisting external screw; a gap is reserved in the lower surface of the connecting inverted-H-shaped steel; a ceramic fiber cotton felt spreads on a gap area between the ceramic fiber cotton module and the lower surface of the connecting inverted-H-shaped steel; and the lower surface of the ceramic fiber cotton module is fixedly equipped with a furnace wall inner protective liner.

Owner:RISHANG (SUZHOU) LIGHT CHEM TEXTILE HIGH TECH CO LTD

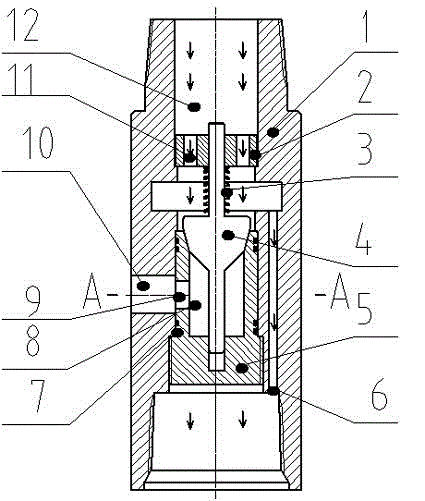

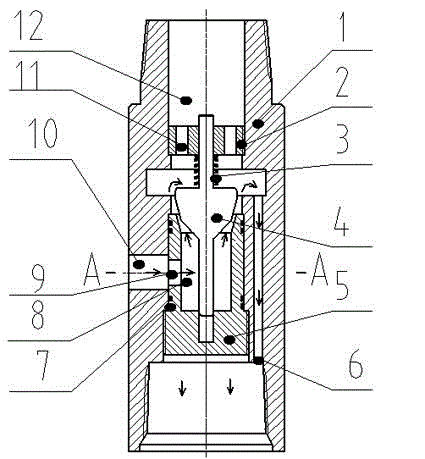

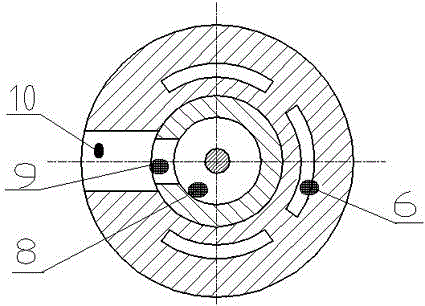

Uninterrupted circulating valve

The invention discloses an uninterrupted circulating valve. The uninterrupted circulating valve comprises a casing, a main channel and a bypass channel, wherein the casing is cylindrical, threads are formed in the upper end and the lower end of the casing, a through hole A and hole channels A are axially formed in the casing, and a hole channel B is radially formed in the casing; a spring seat, a spring, a valve element and a valve seat are mounted in the through hole A from top to bottom; a through hole B is processed in the axial center of the spring seat, and axial through holes C are formed in the outside part of the through hole B; the middle of the valve element adopts a conical structure and forms a taper angle seal with a conical chamfer at the upper part of the valve seat. The uninterrupted circulating valve has the advantages that with the adoption of a manure one-way valve seal form, the fluid sealing reliability of the uninterrupted circulating valve is improved. Through continuous circulation in the drill pipe connection period, pressure fluctuation of a wellbore due to drill pipe connection operation is effectively avoided, the wellbore quality and cleanness are improved, the probability of leakage, well kick, pipe sticking and other complicated problems is reduced, the non-productive time is reduced, and a stratum which cannot be drilled previously is drilled.

Owner:CHINA PETROCHEMICAL CORP +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com