Patents

Literature

326results about "Monolithic linings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

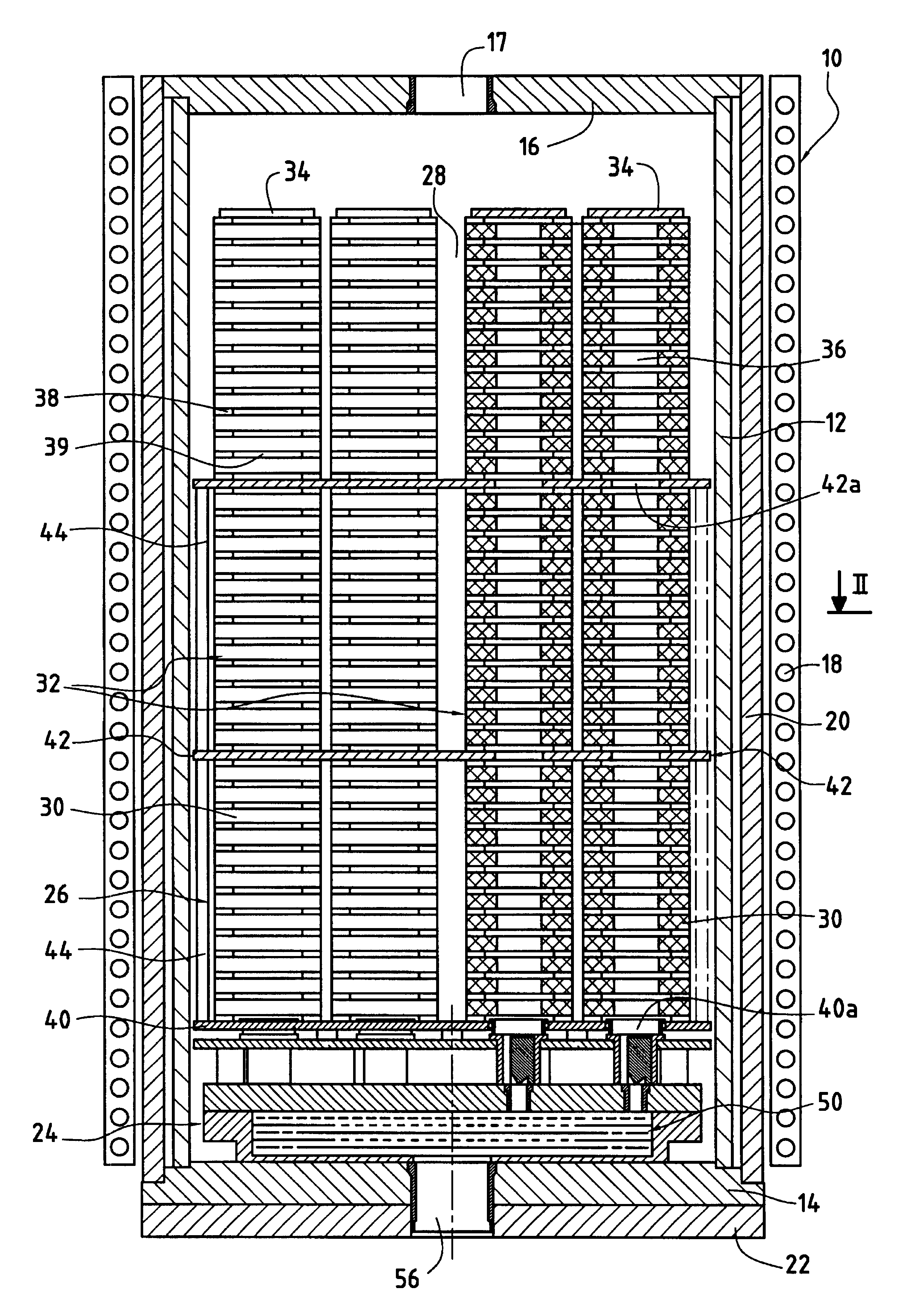

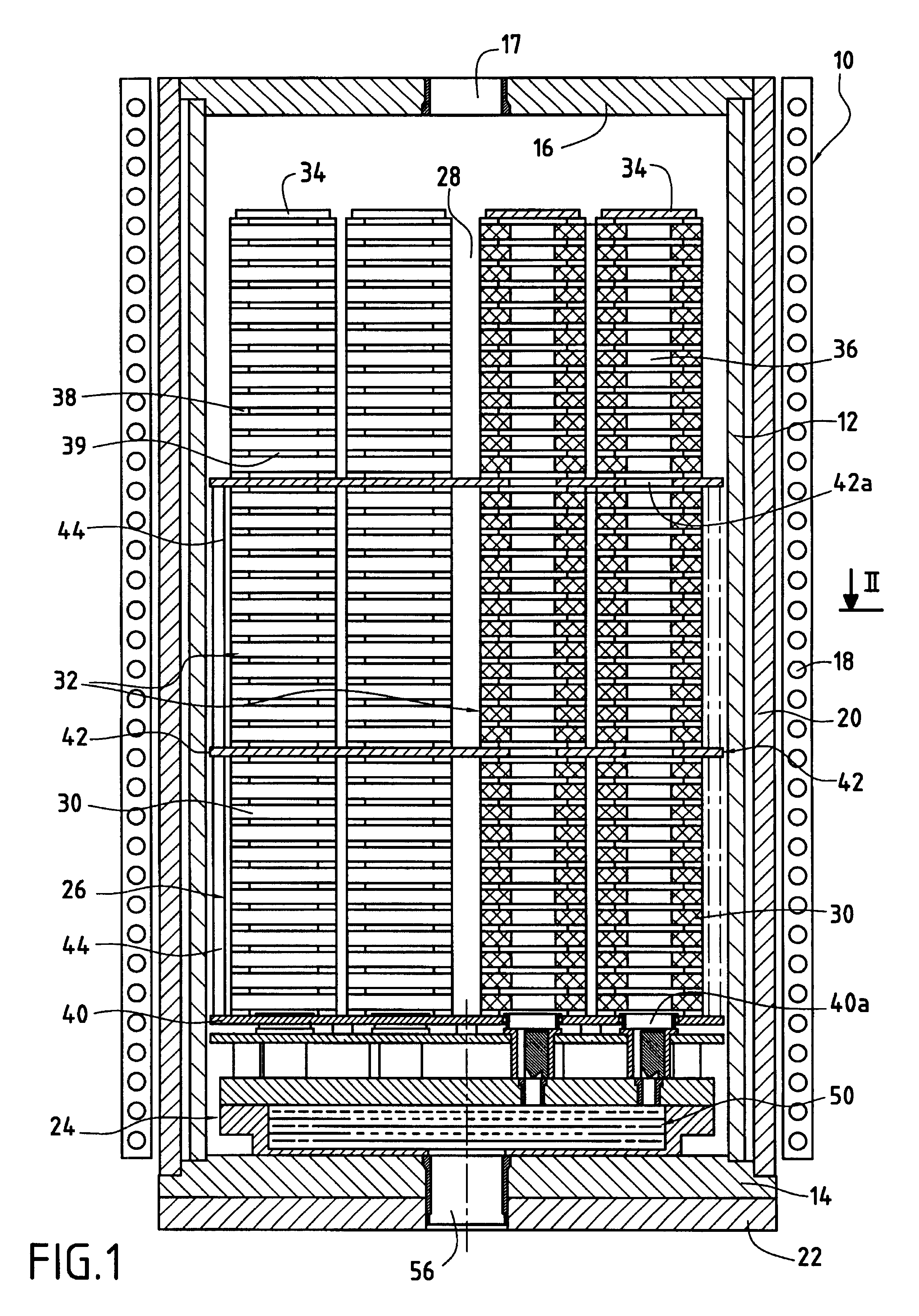

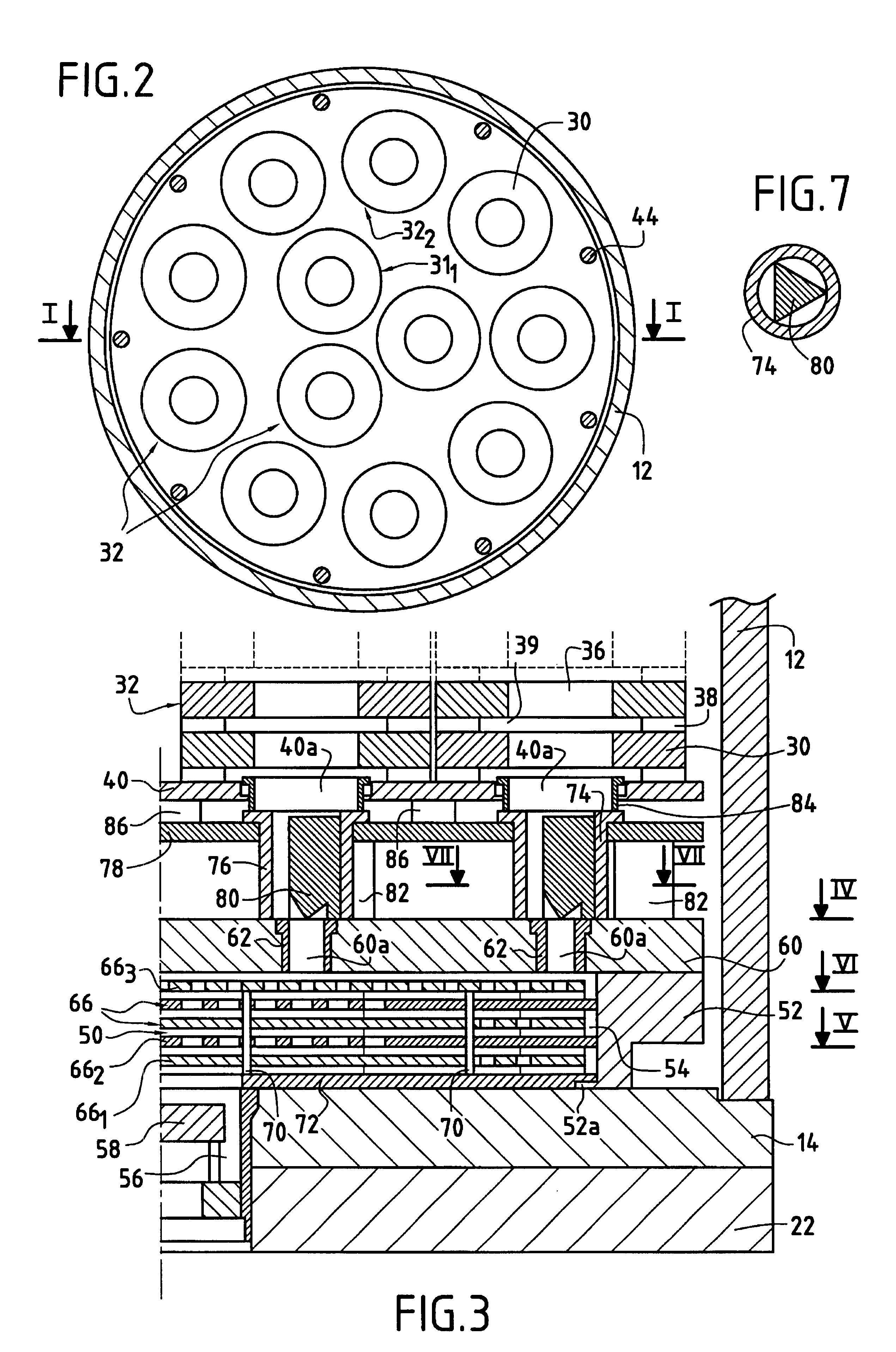

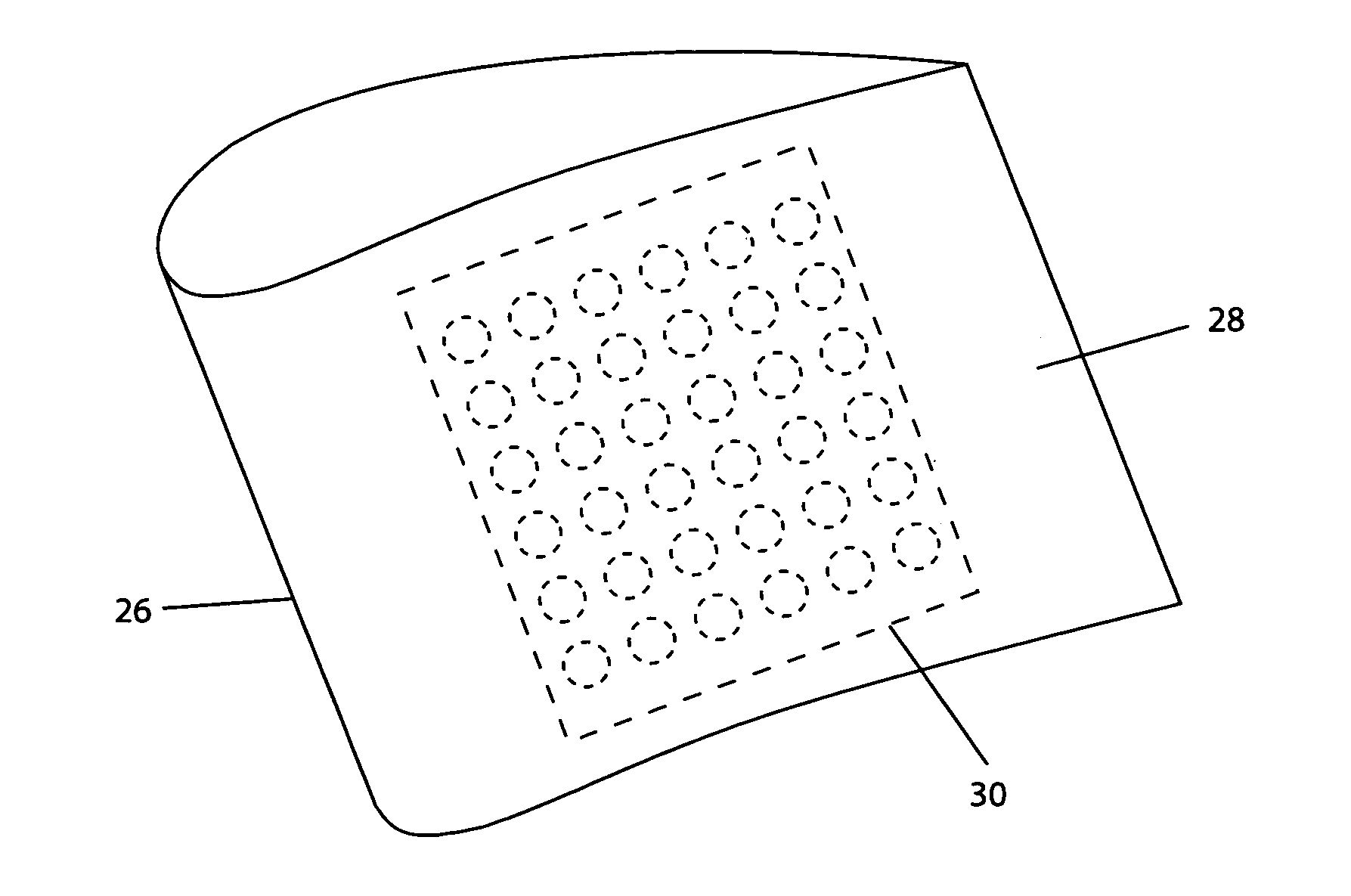

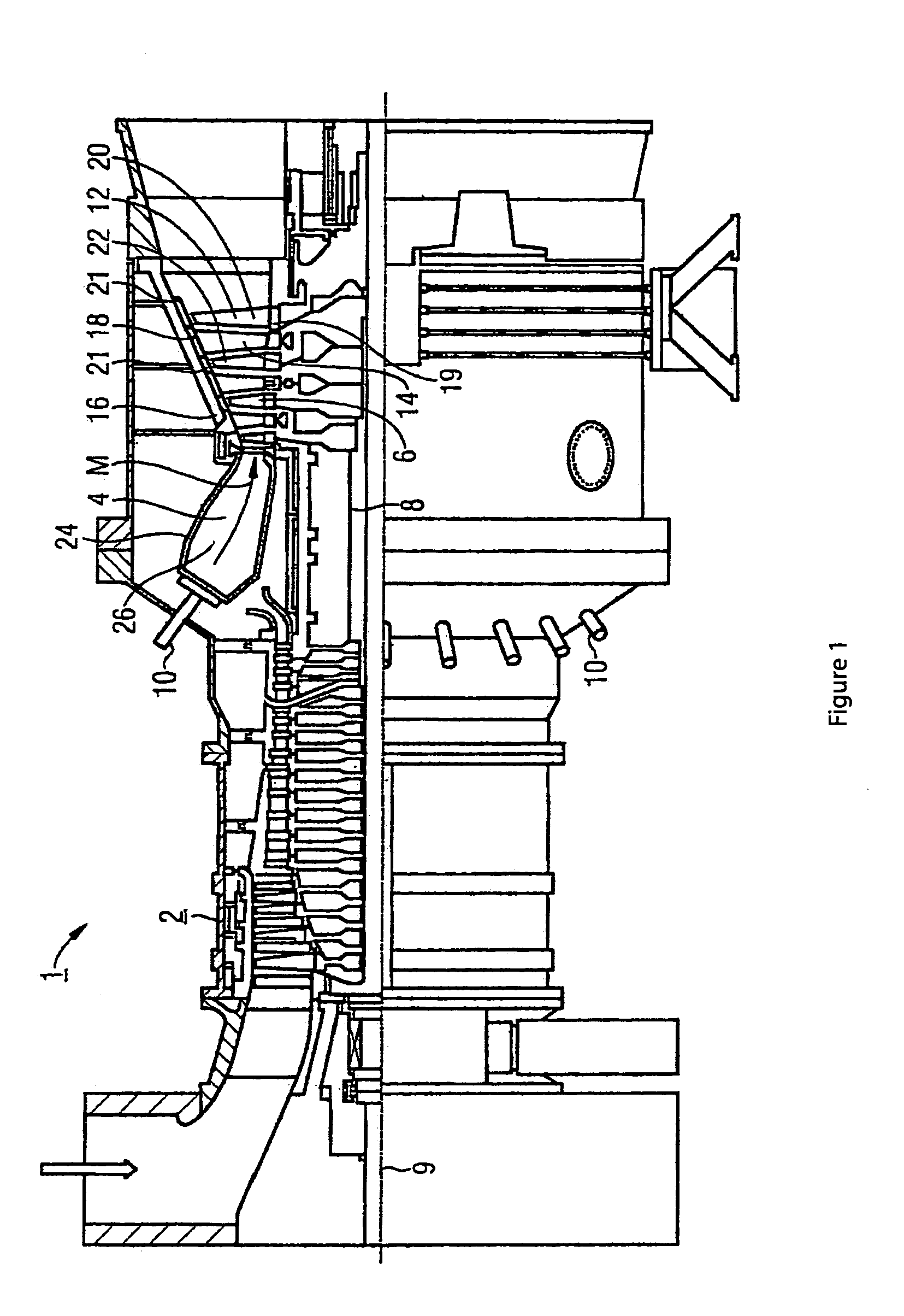

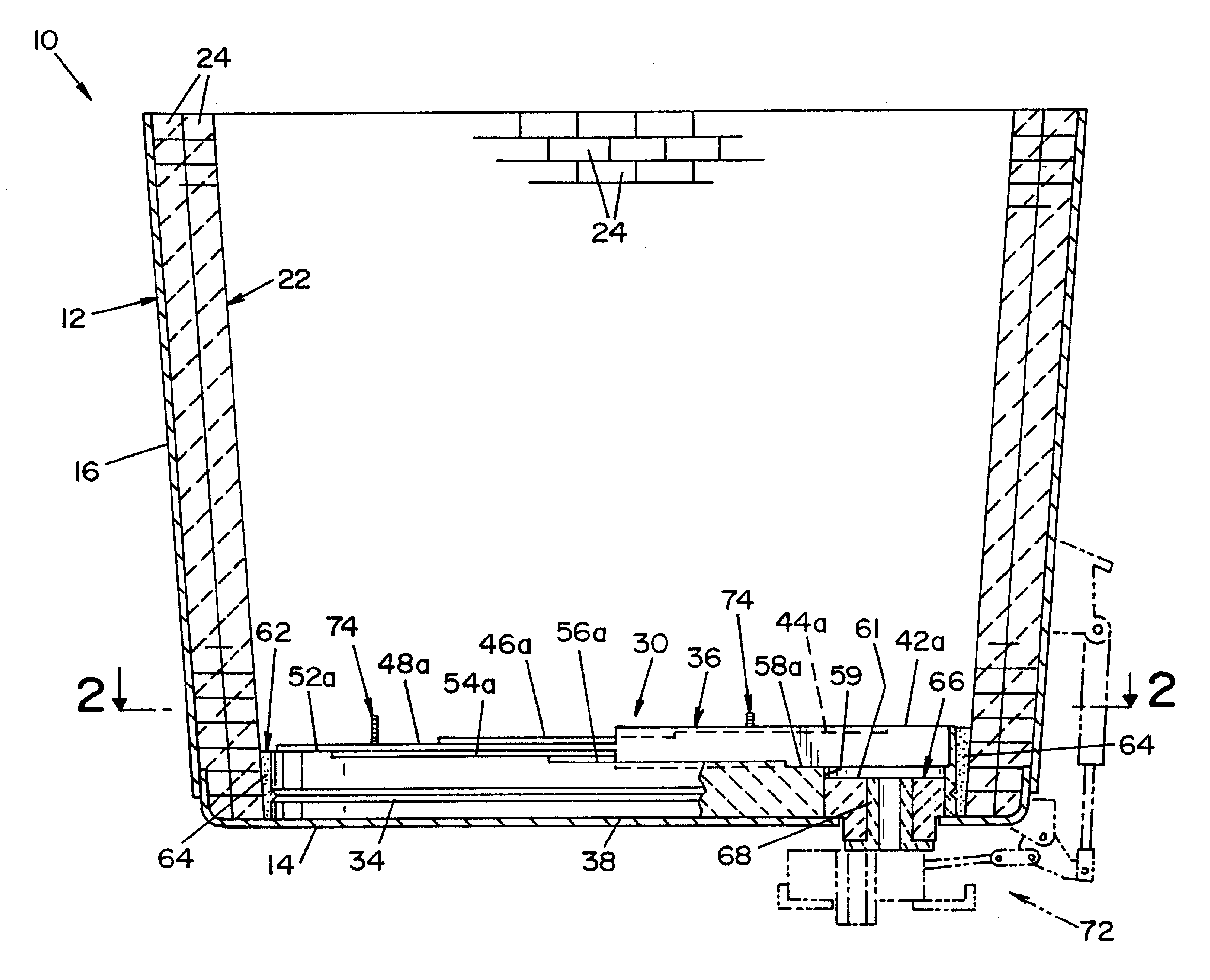

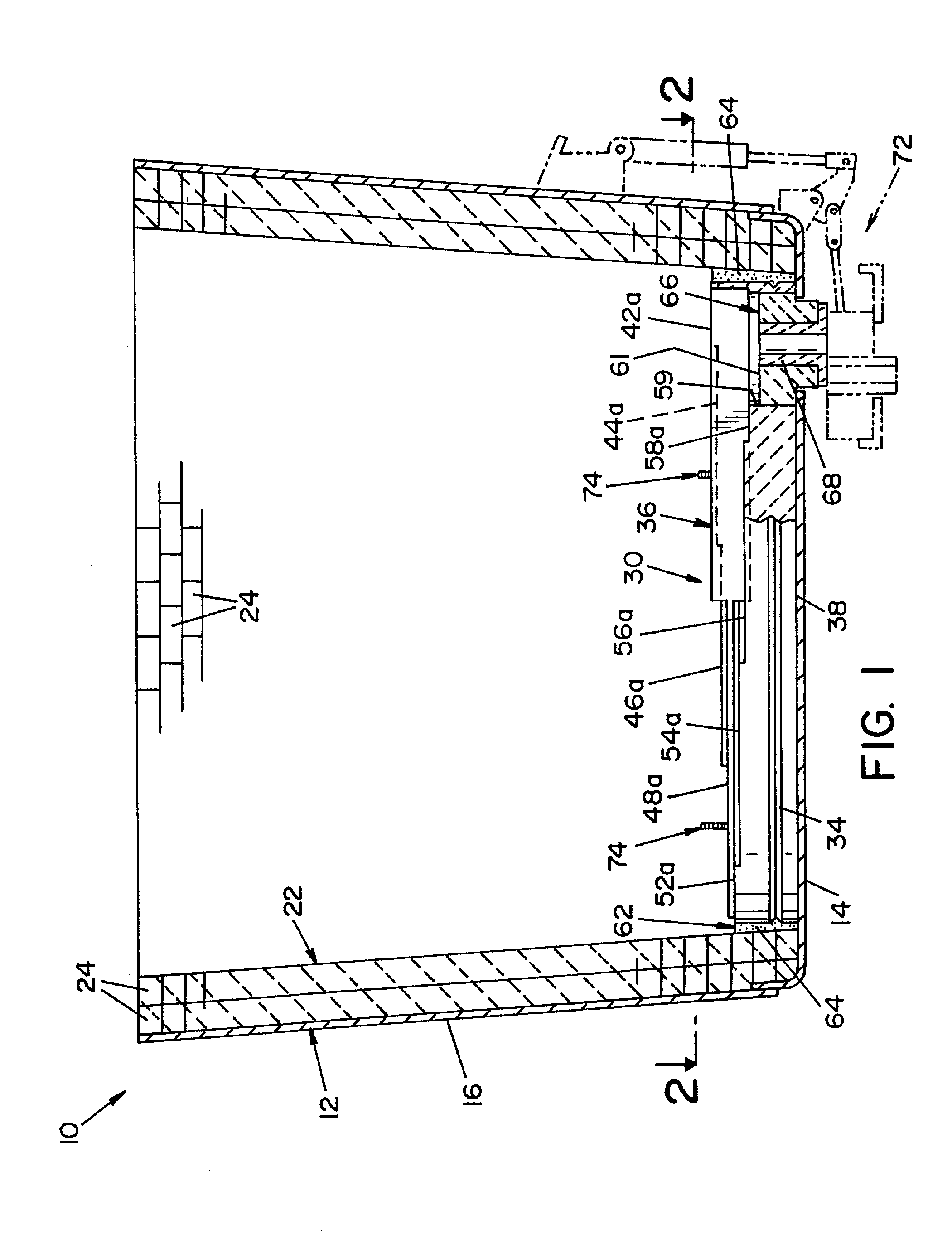

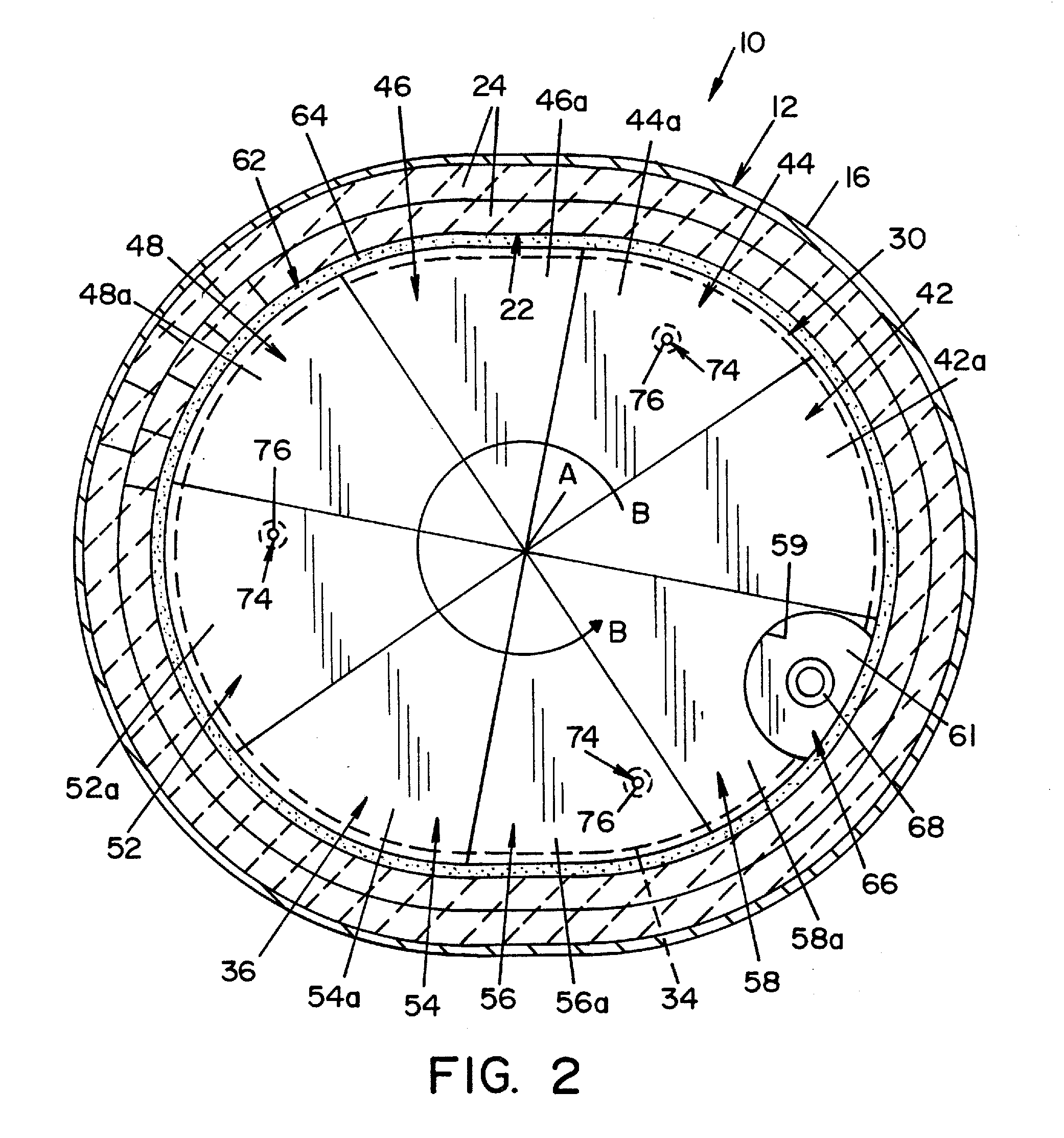

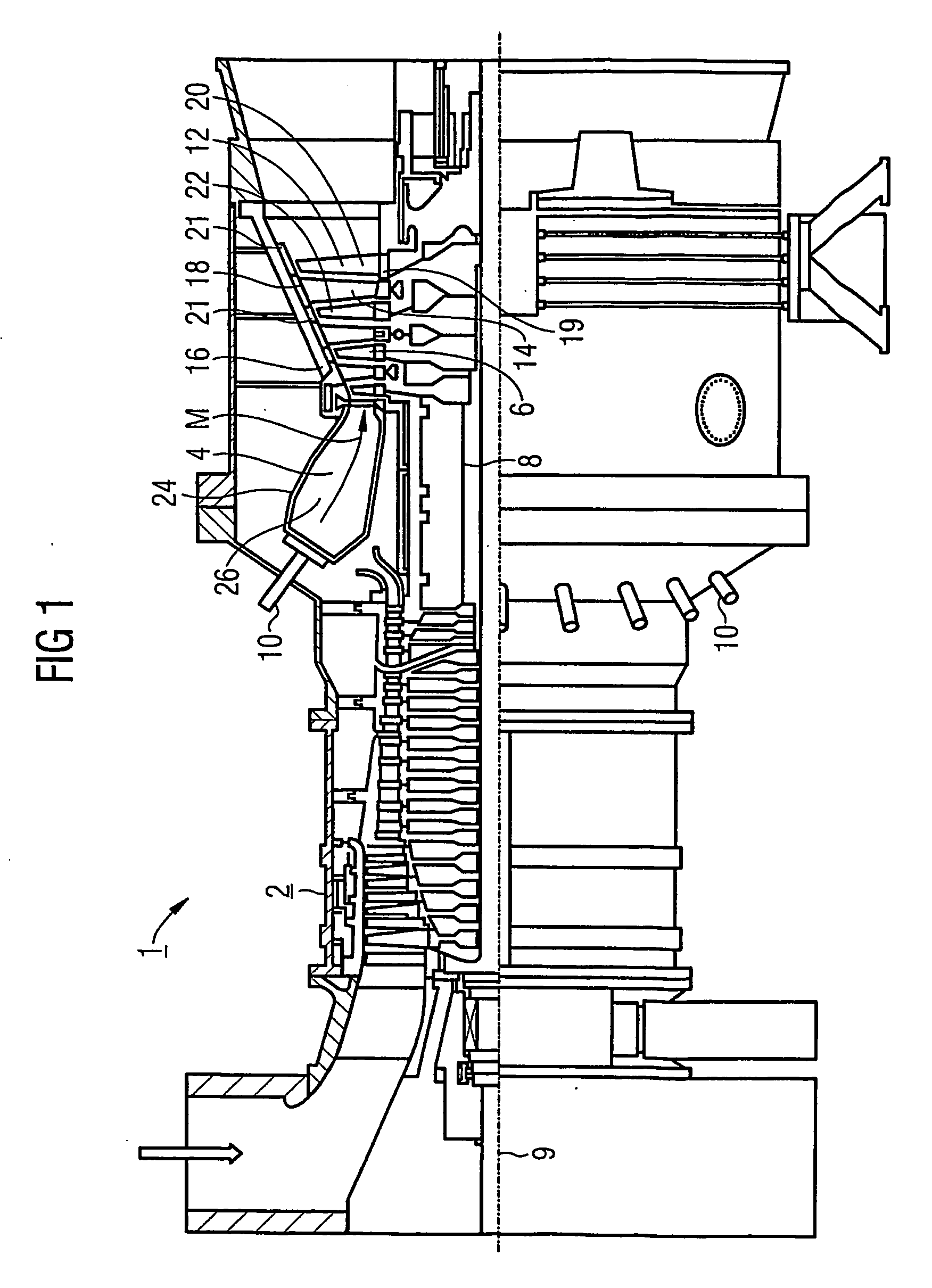

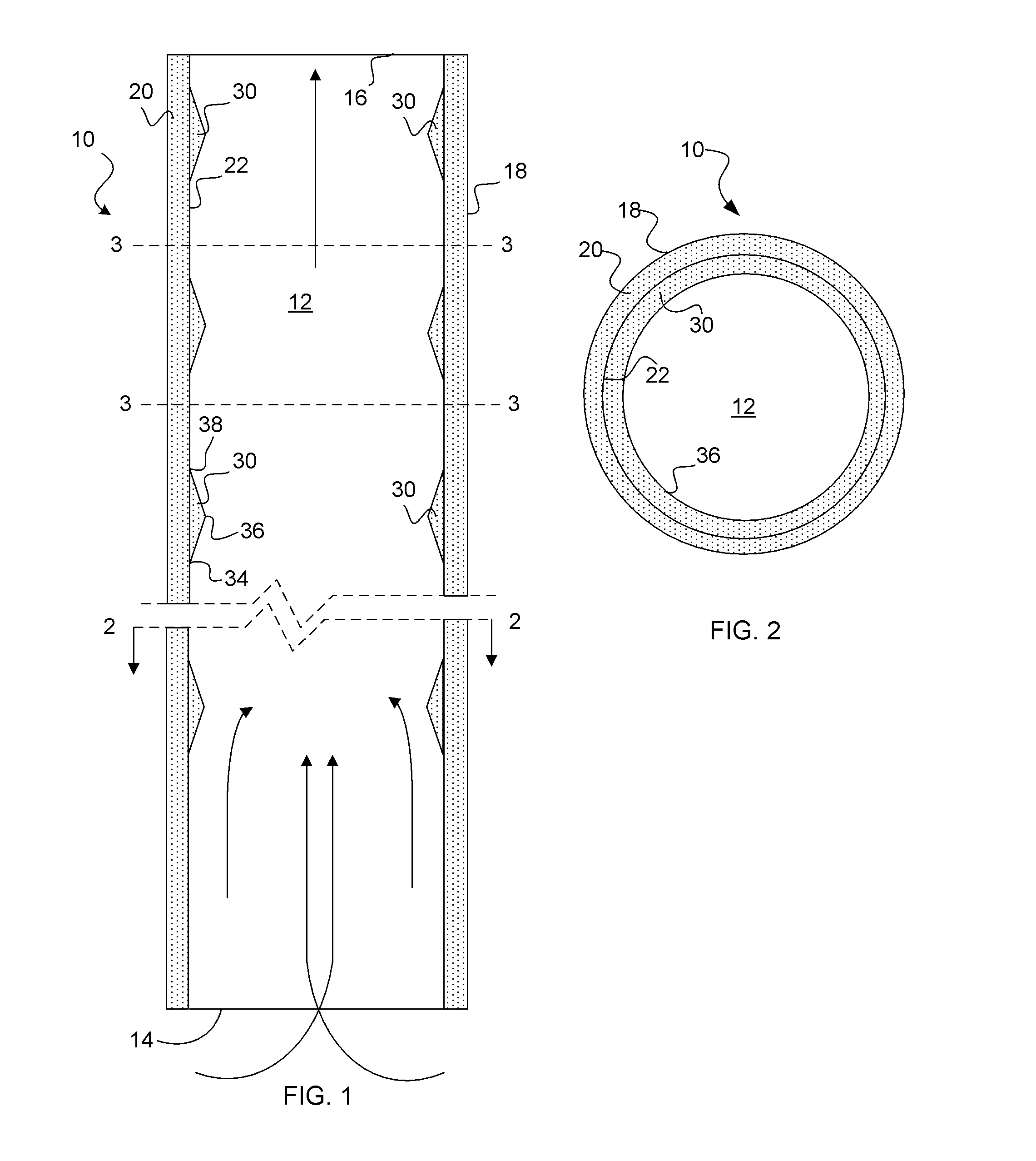

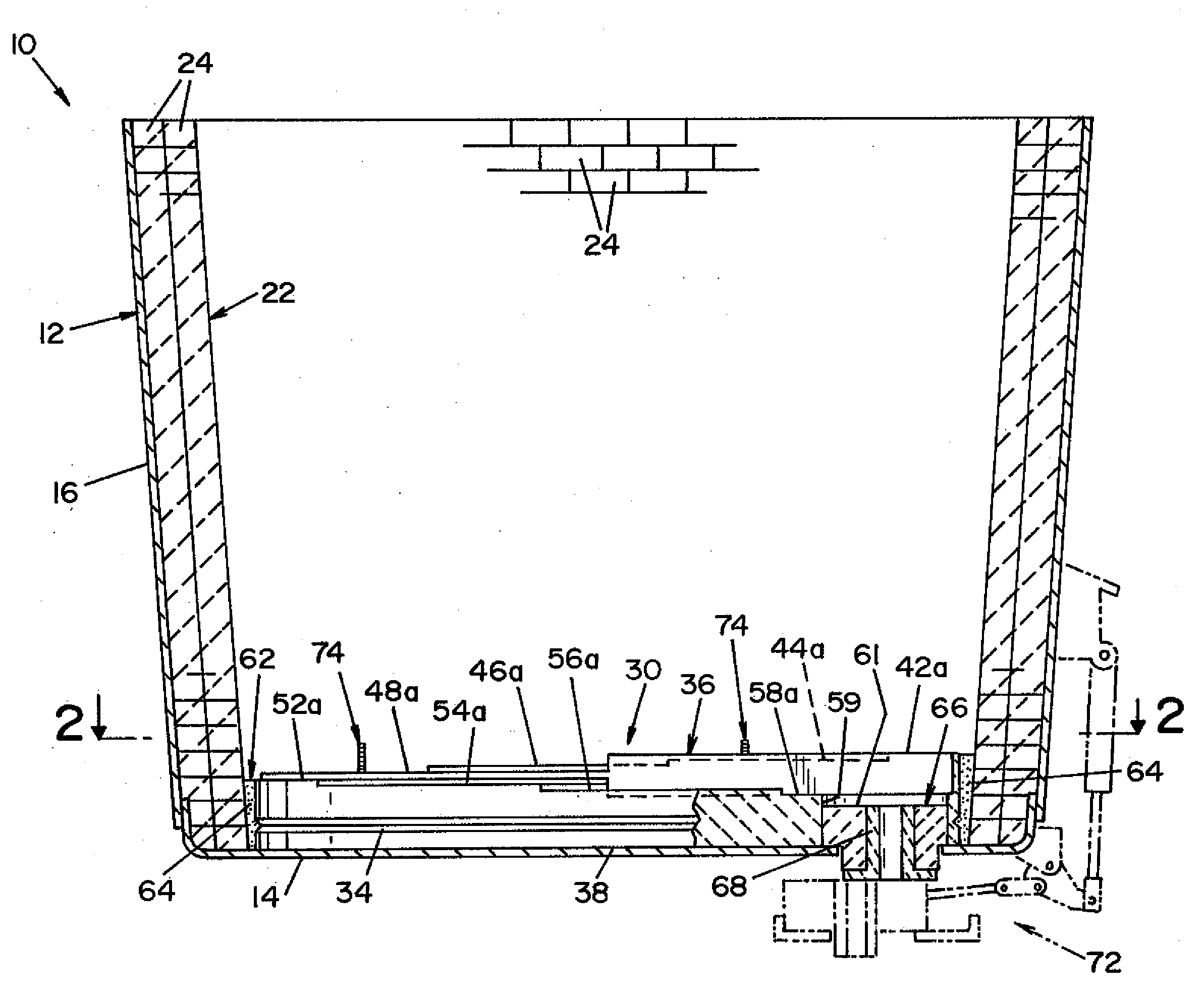

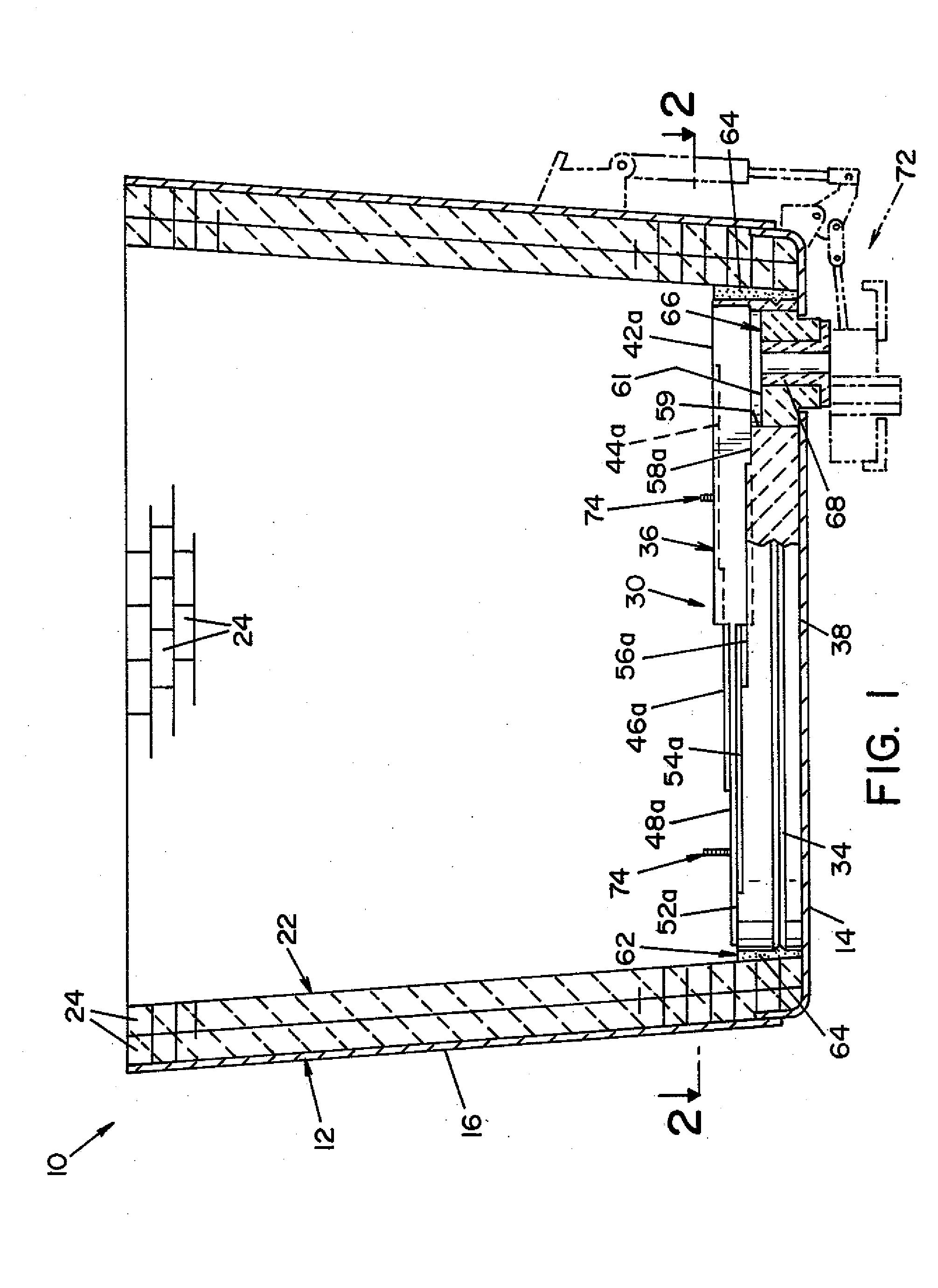

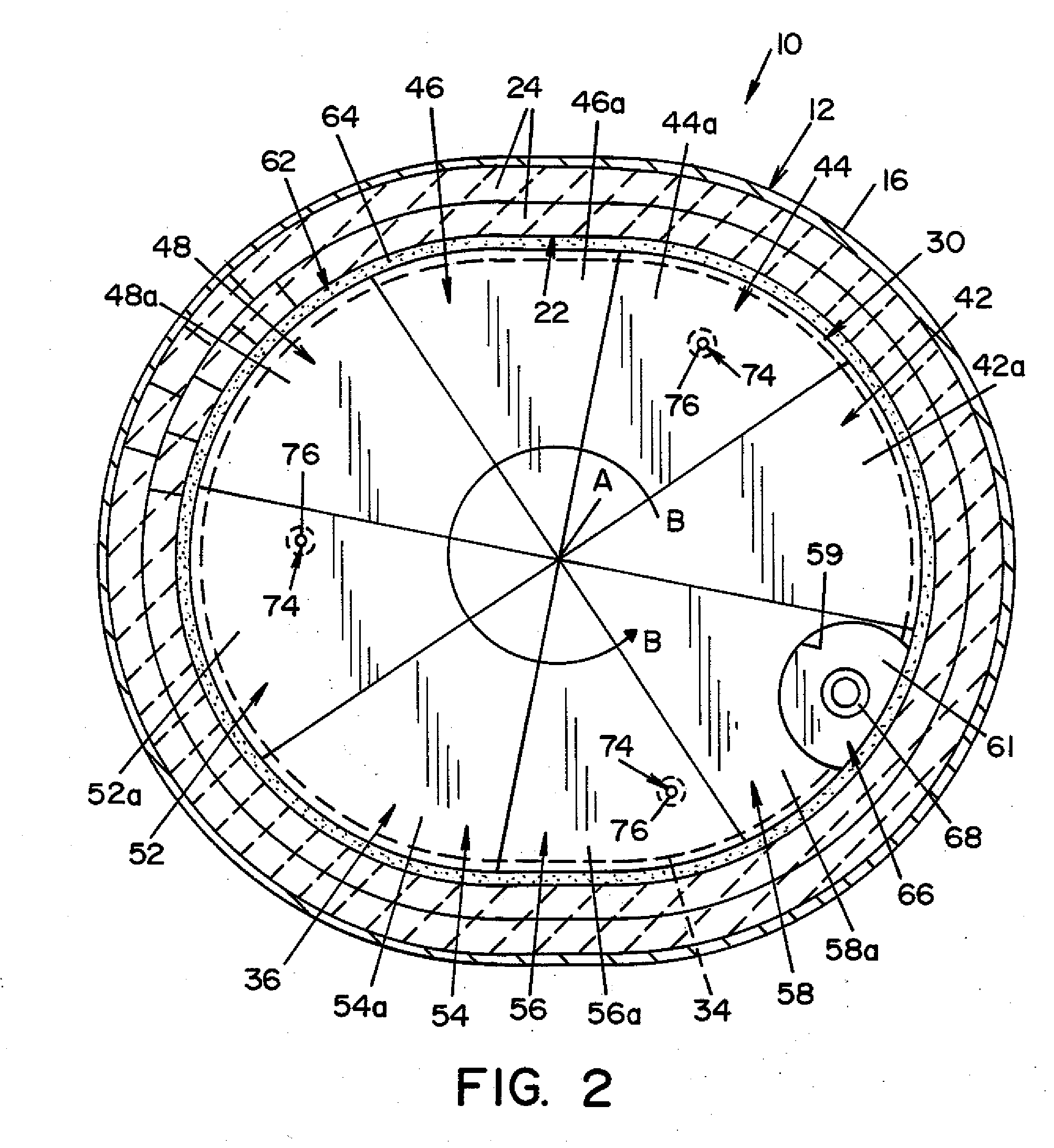

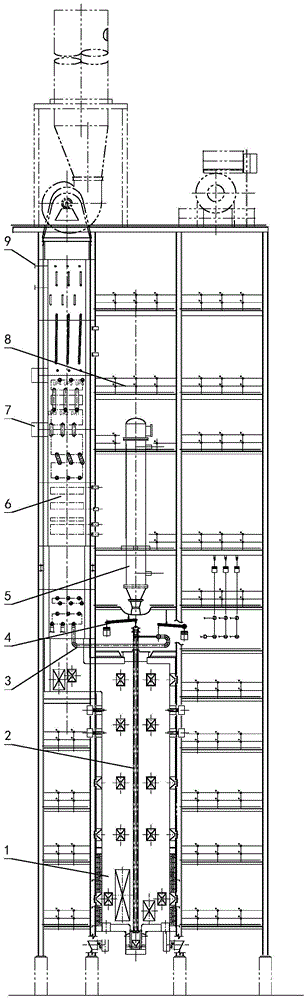

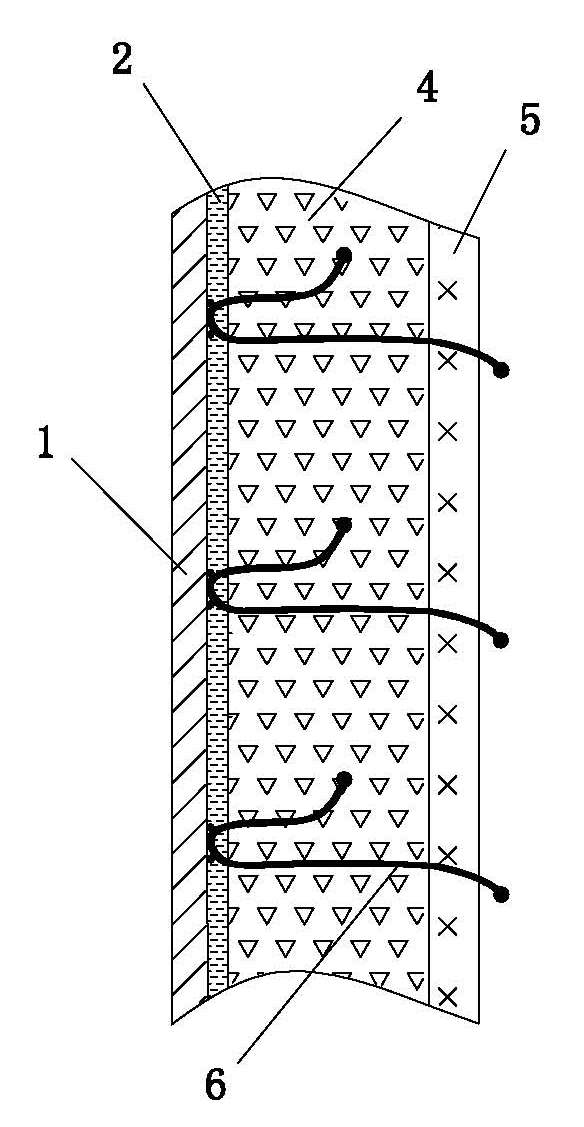

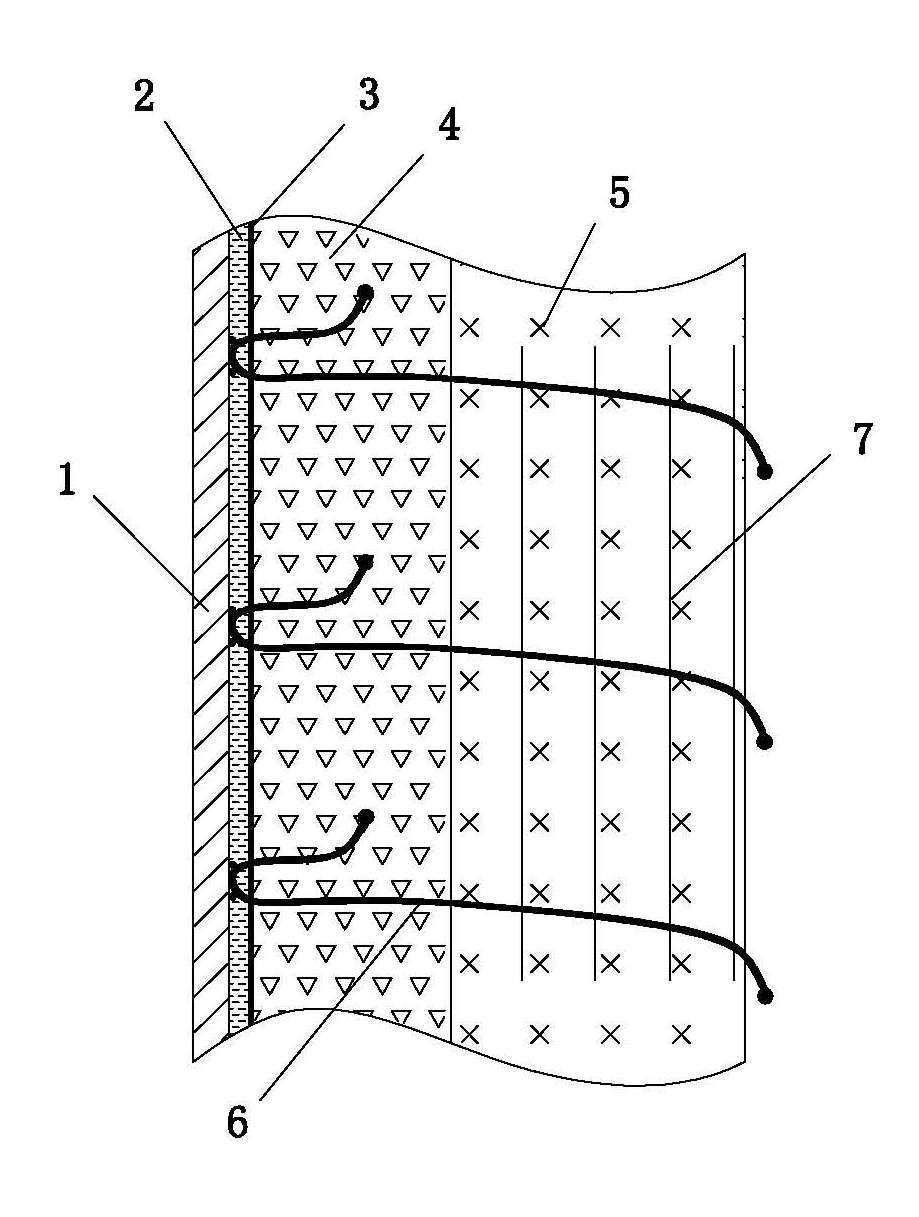

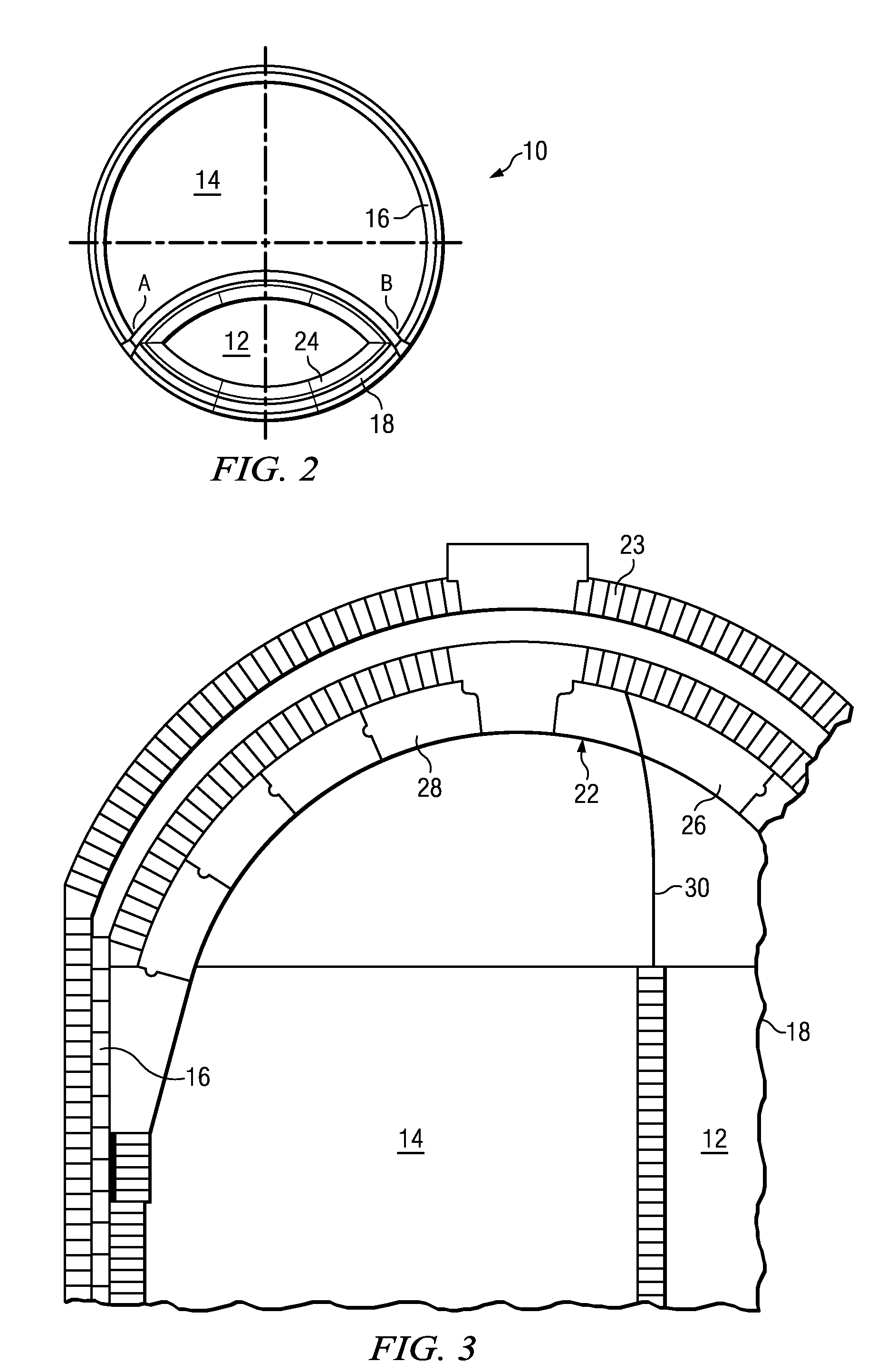

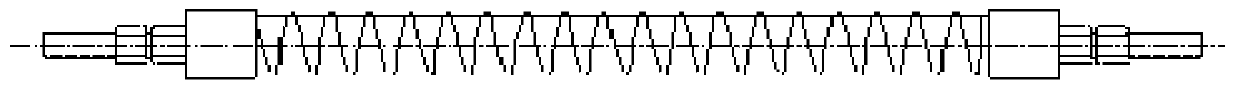

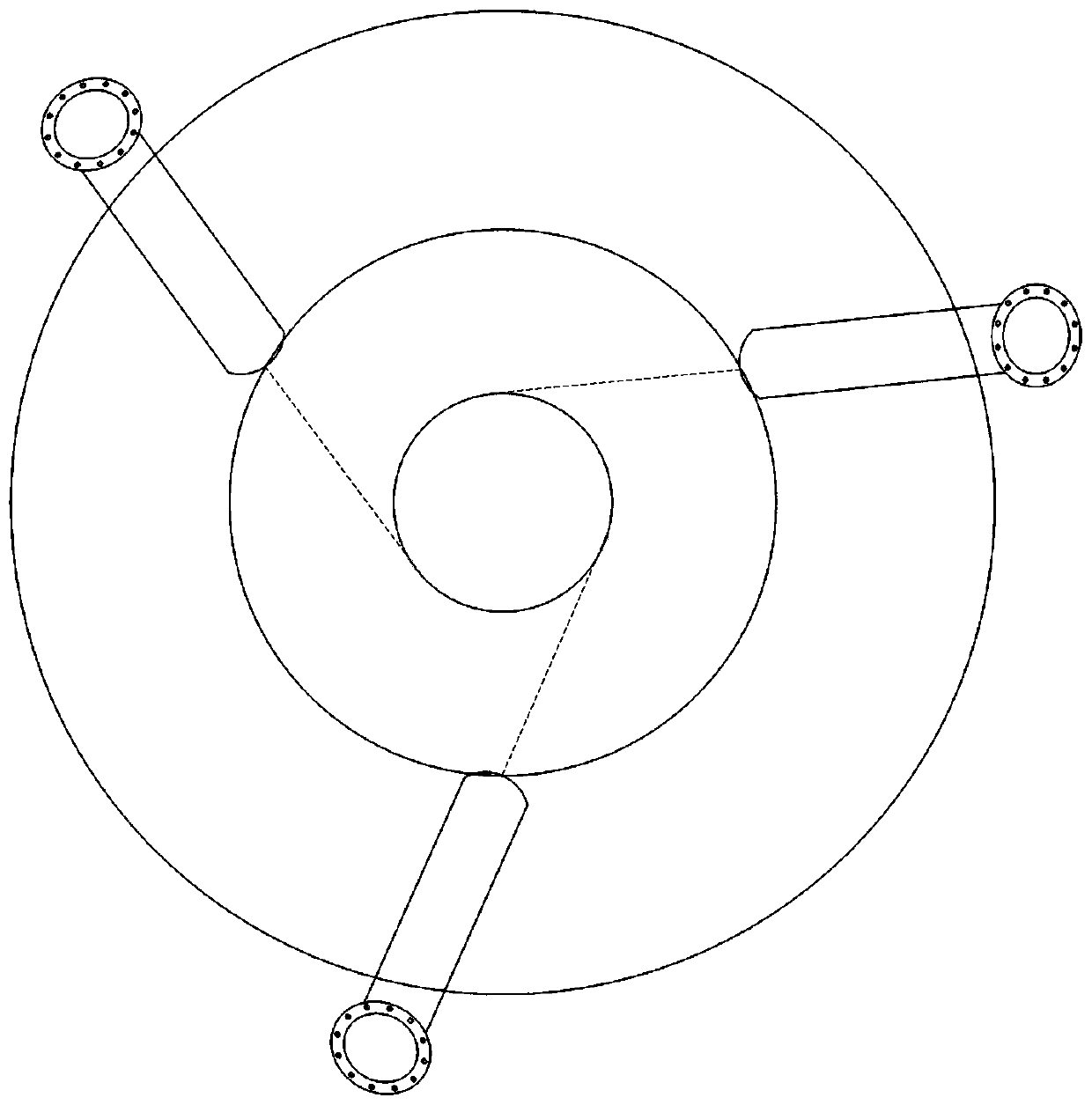

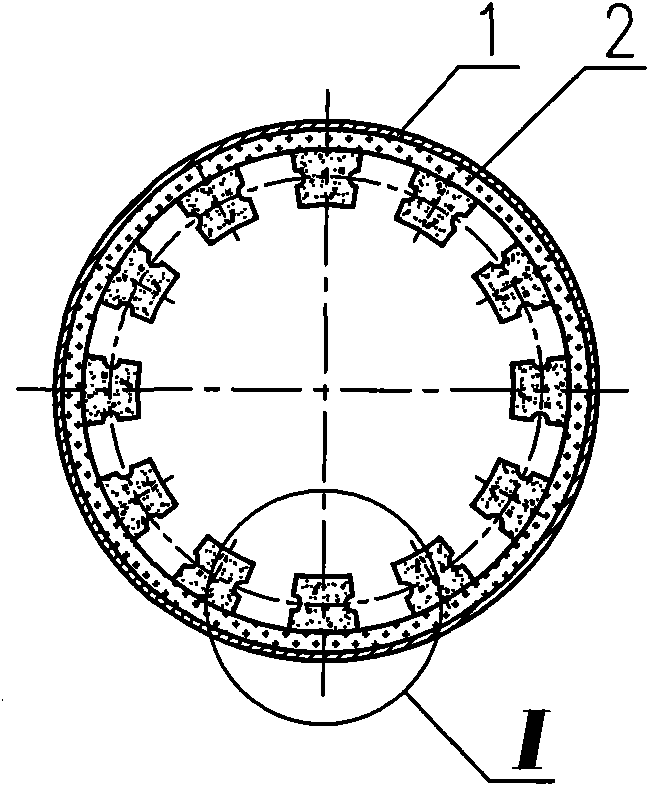

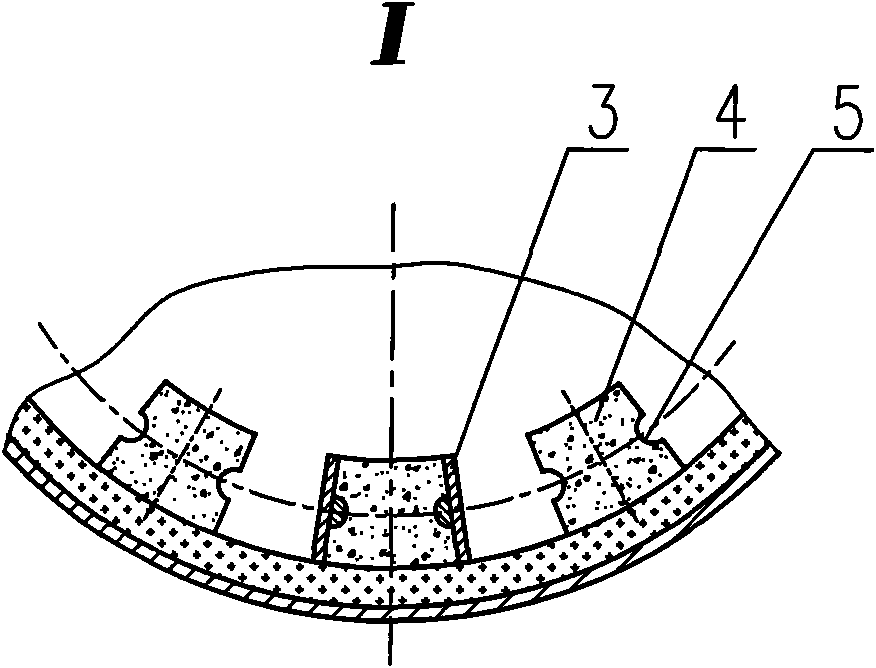

Gas preheater and process for controlling distribution of preheated reactive gas in a CVI furnace for densification of porous annular substrates

InactiveUS6572371B1Efficient heatingEfficiency of gasCharge manipulationChemical vapor deposition coatingPorous substrateSusceptor

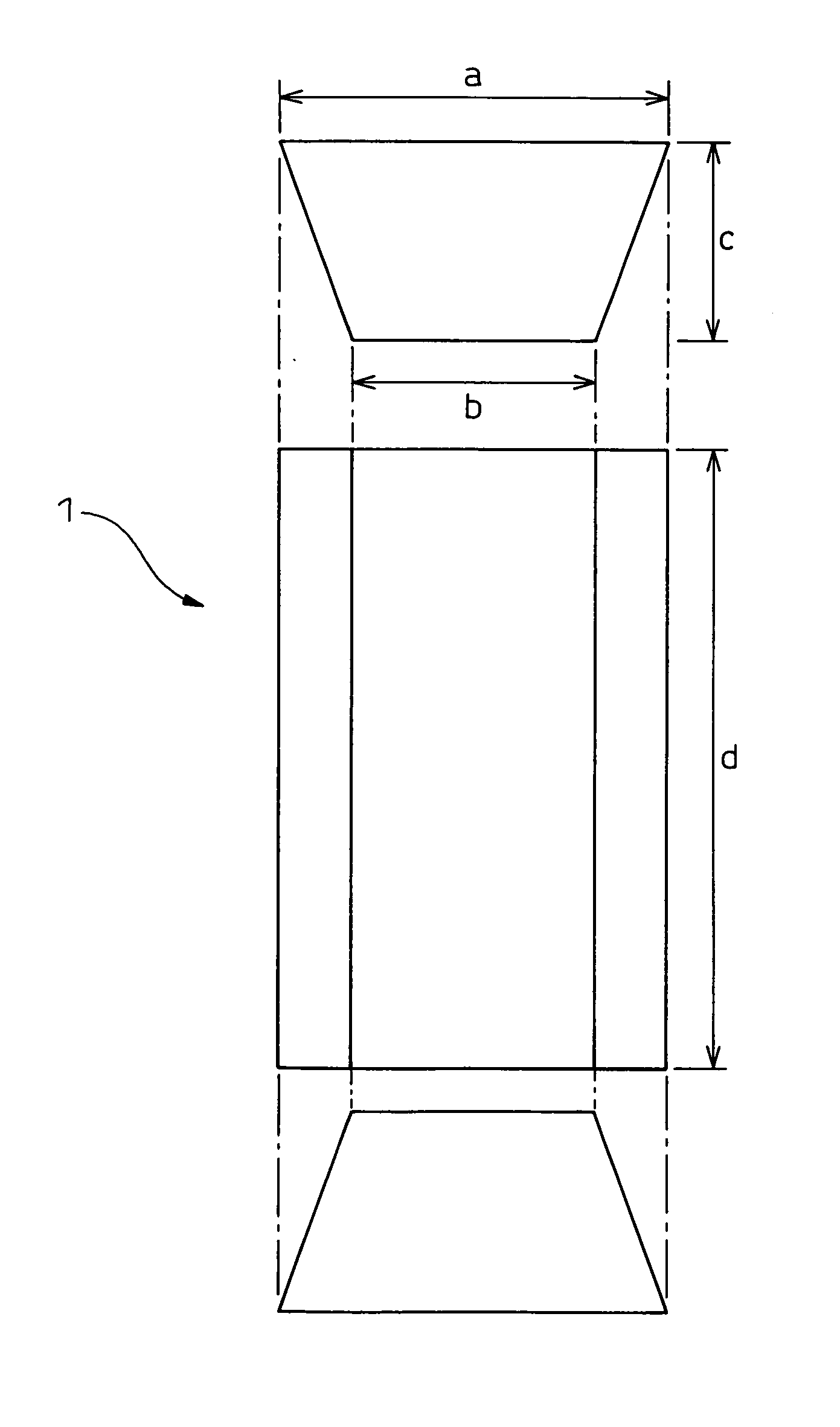

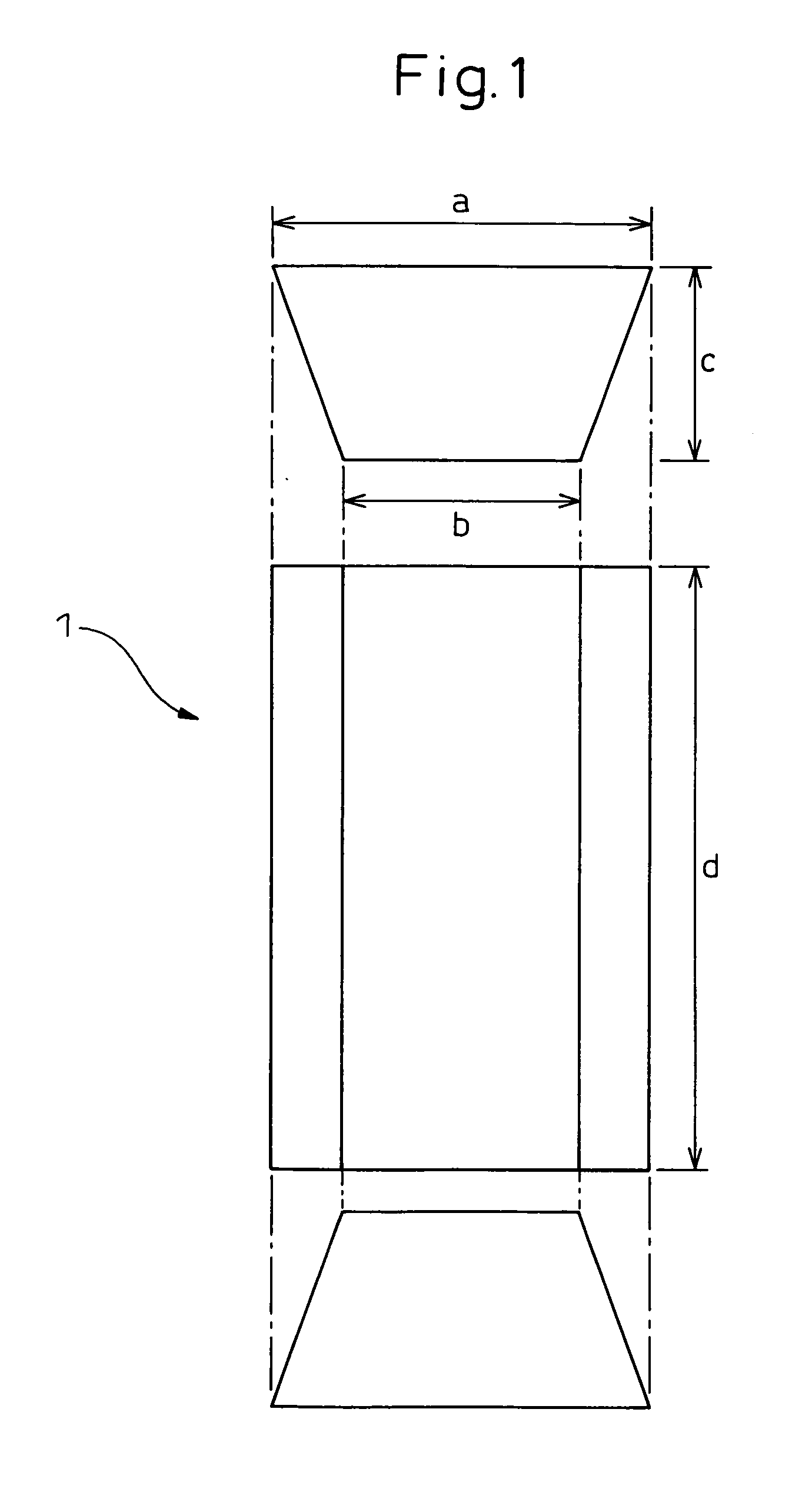

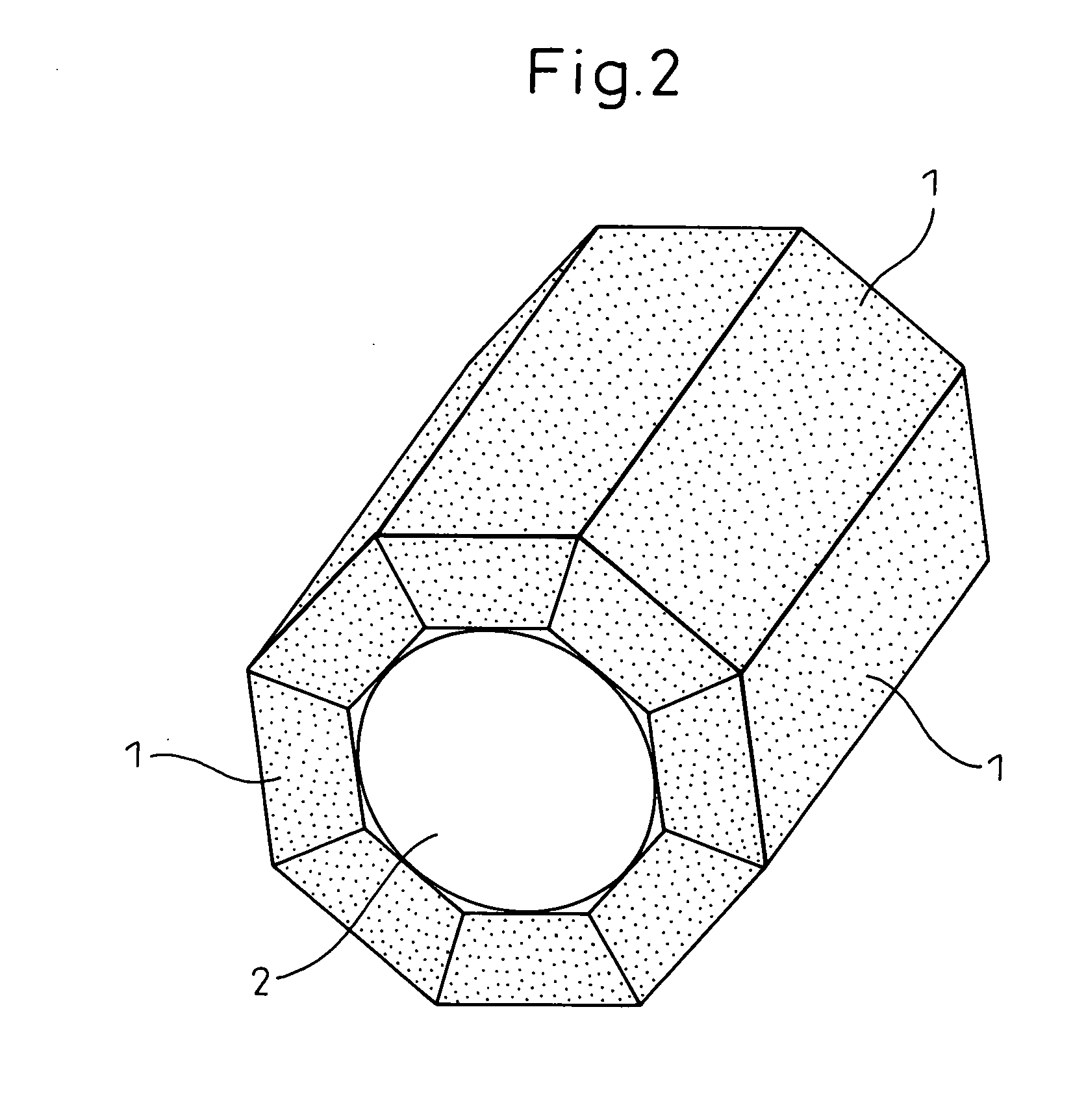

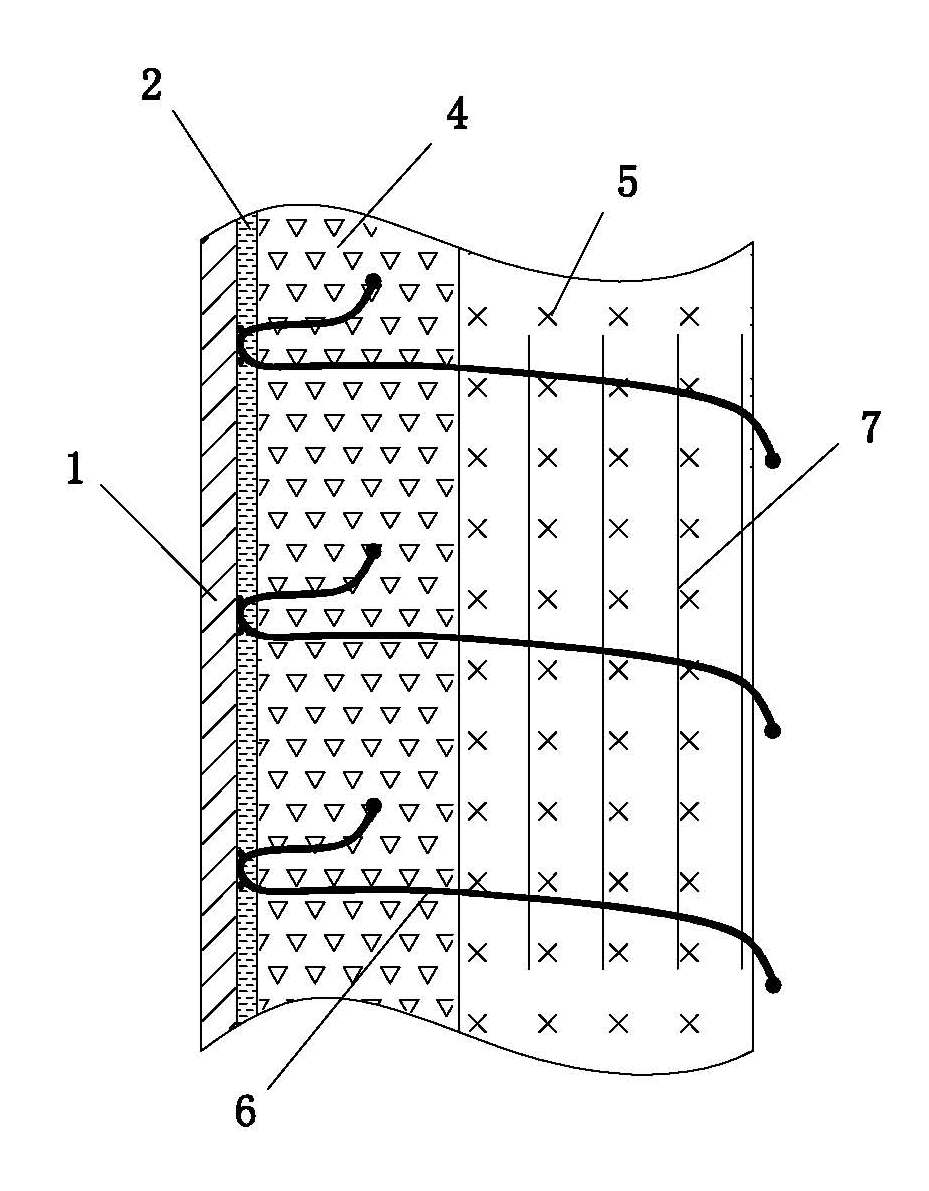

A gas preheater for a CVI furnace designed for the densification of annular porous substrates arranged in a plurality of vertical annular stacks of substrates, comprising: a sleeve made of heat conductive material resting upon the bottom wall of a susceptor and delimiting a gas preheating chamber, with a gas inlet opening in the gas preheating chamber; a heat exchange assembly located in the gas preheating chamber; a gas distribution plate resting upon the sleeve, covering the gas preheating chamber and provided with a plurality of passages for preheated gas; a load supporting plate for supporting stacks of annular substrates and provided with a plurality of passages in communication with respective passages of the gas distribution plate and registration with internal volumes of respective stacks of annular substrates; and nozzles inserted in passages communicating the gas preheating zone with the internal volumes of respective stacks of annular substrates for adjusting the flows of preheated gas respectively admitted in said internal volumes.

Owner:SAFRAN LANDING SYSTEMS

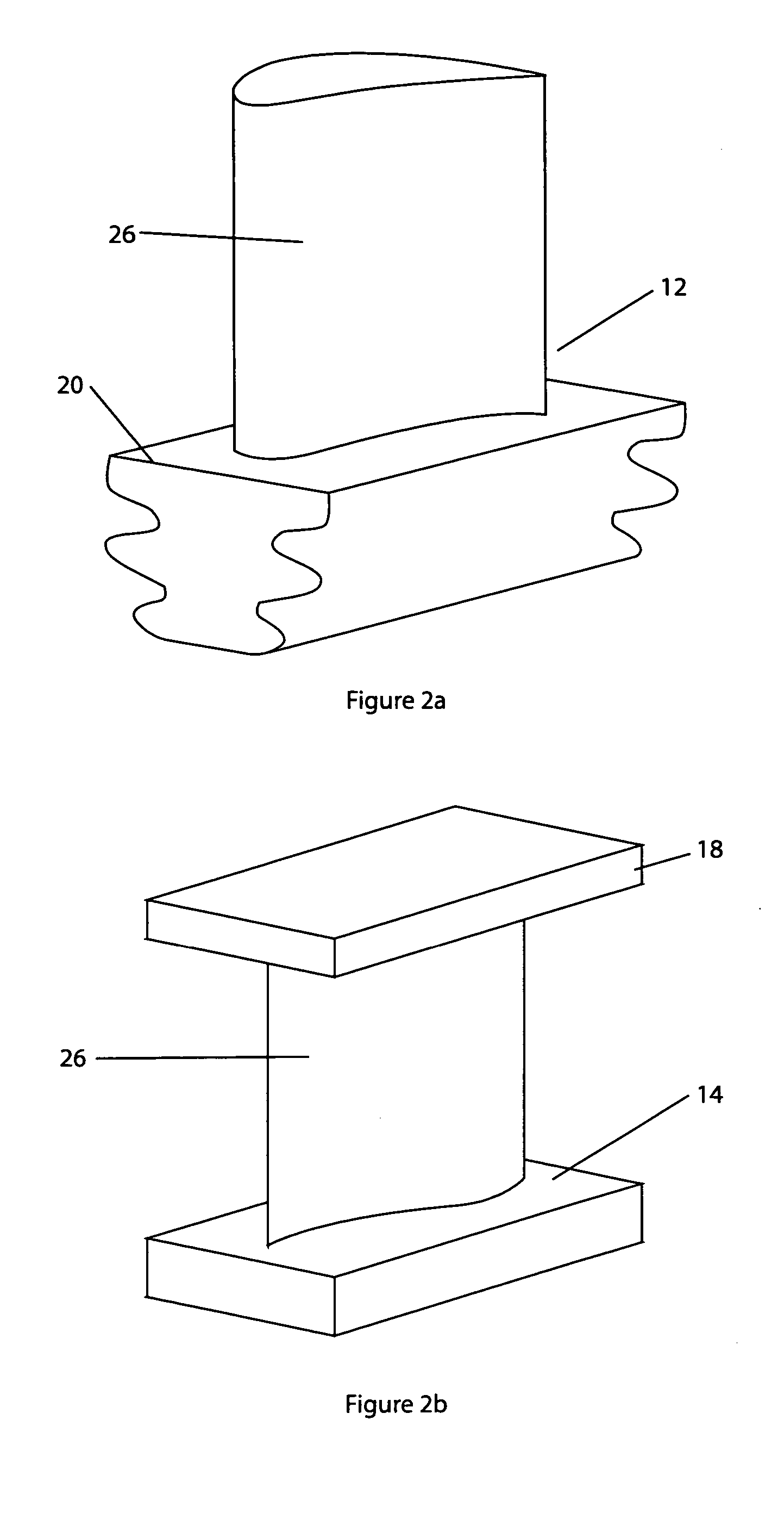

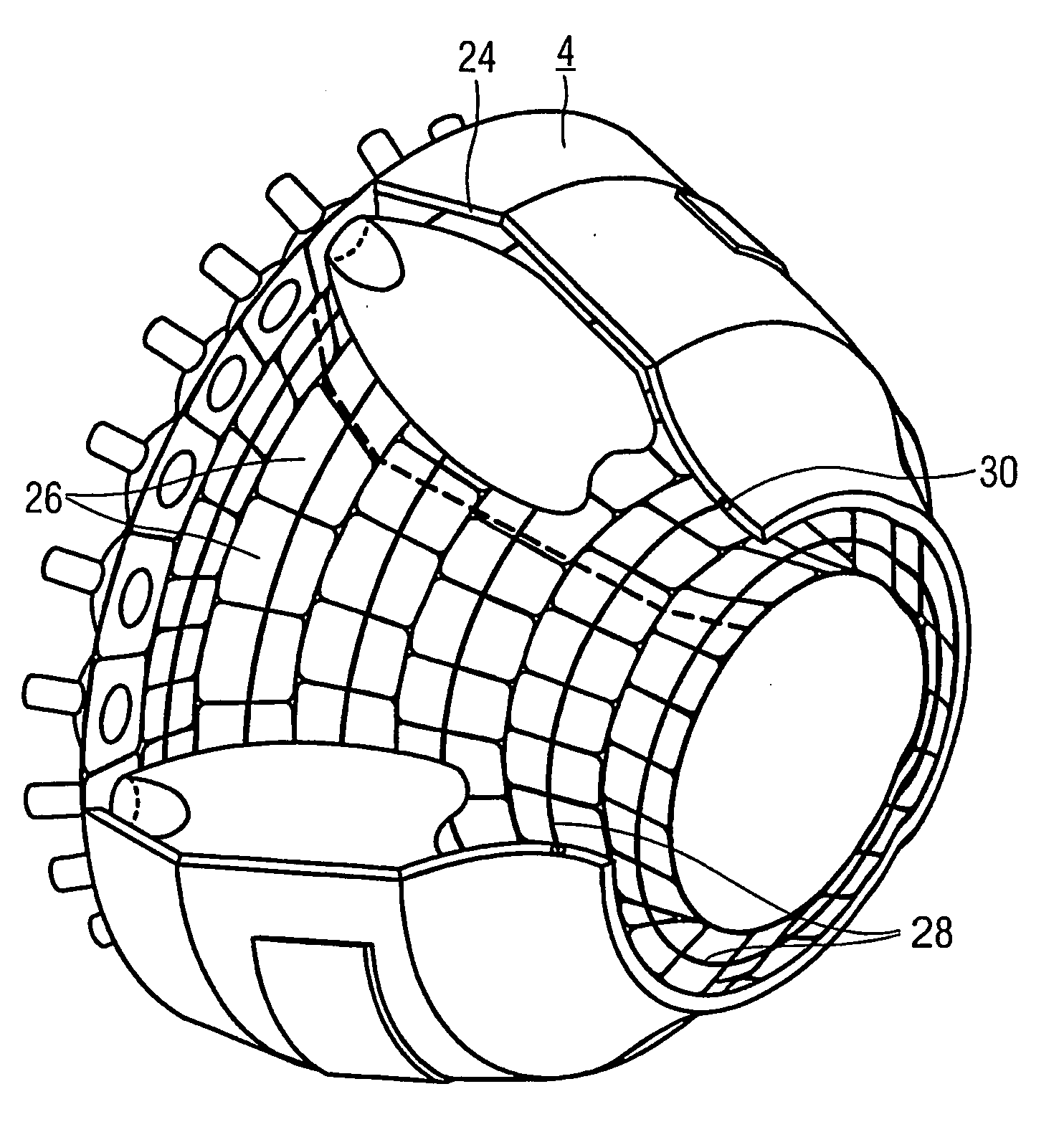

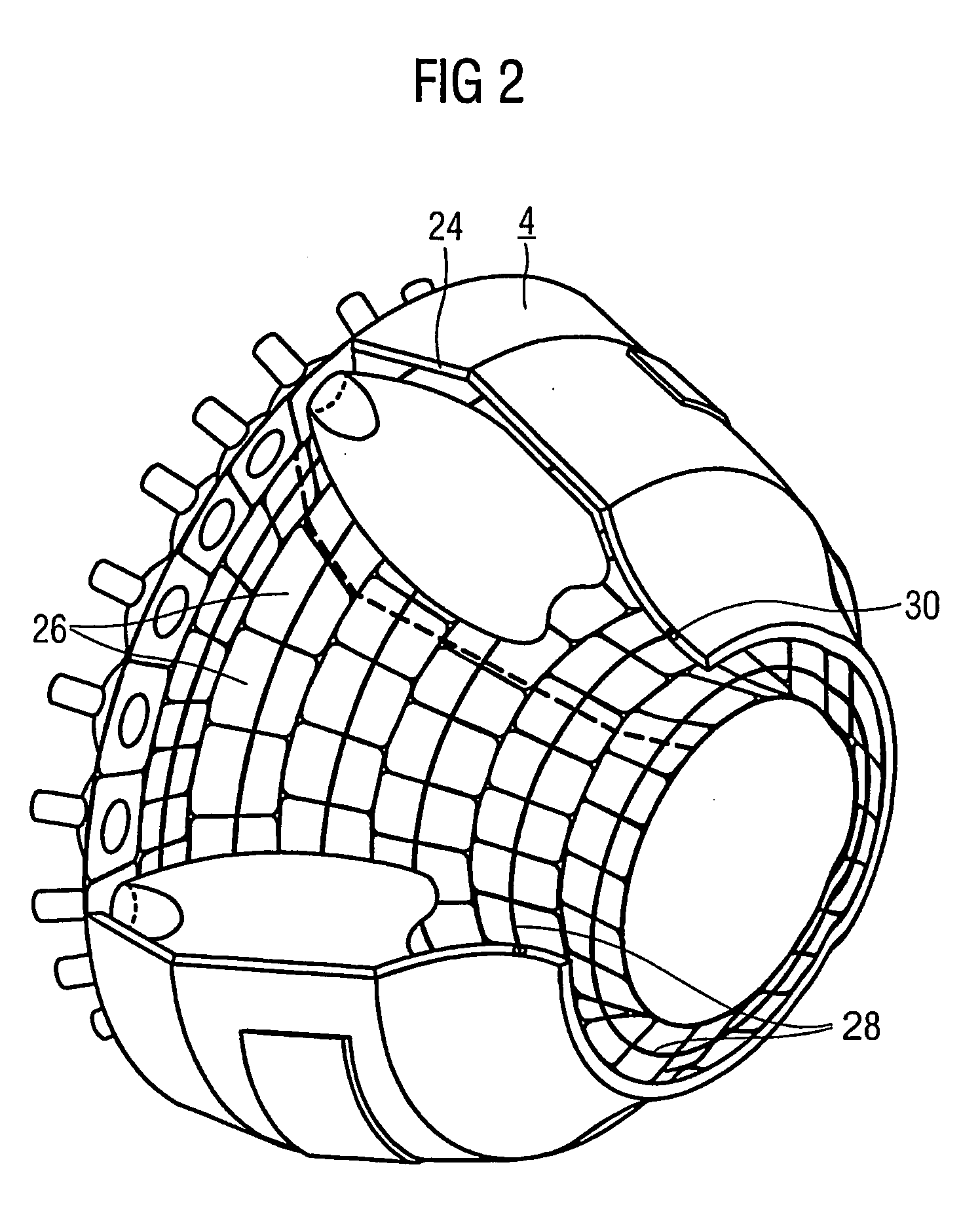

Turbine blade for use in a gas turbine

InactiveUS7540710B2Improve cohesionIncrease the number ofPropellersReaction enginesTurbine bladeGas turbines

Owner:SIEMENS AG

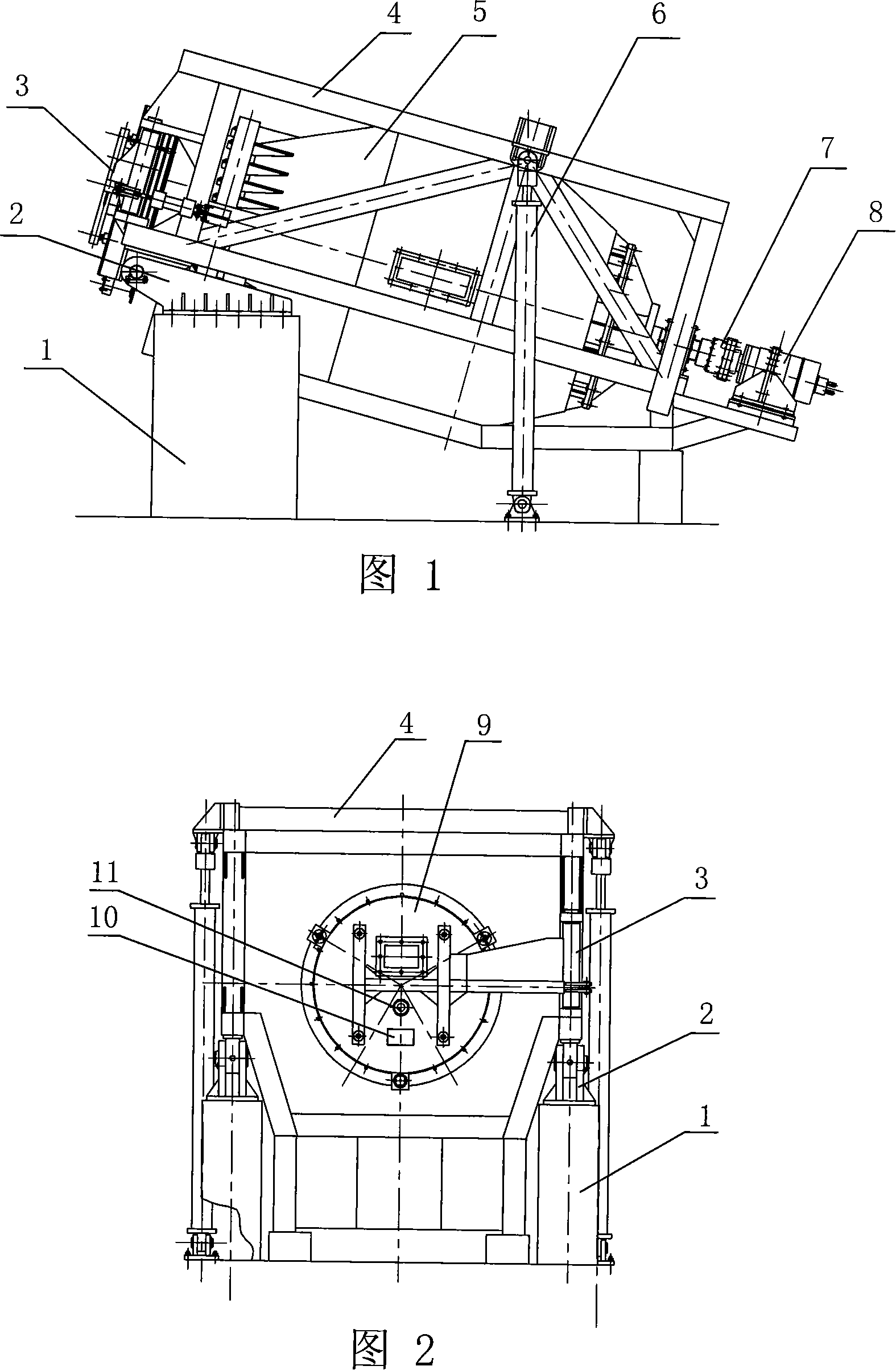

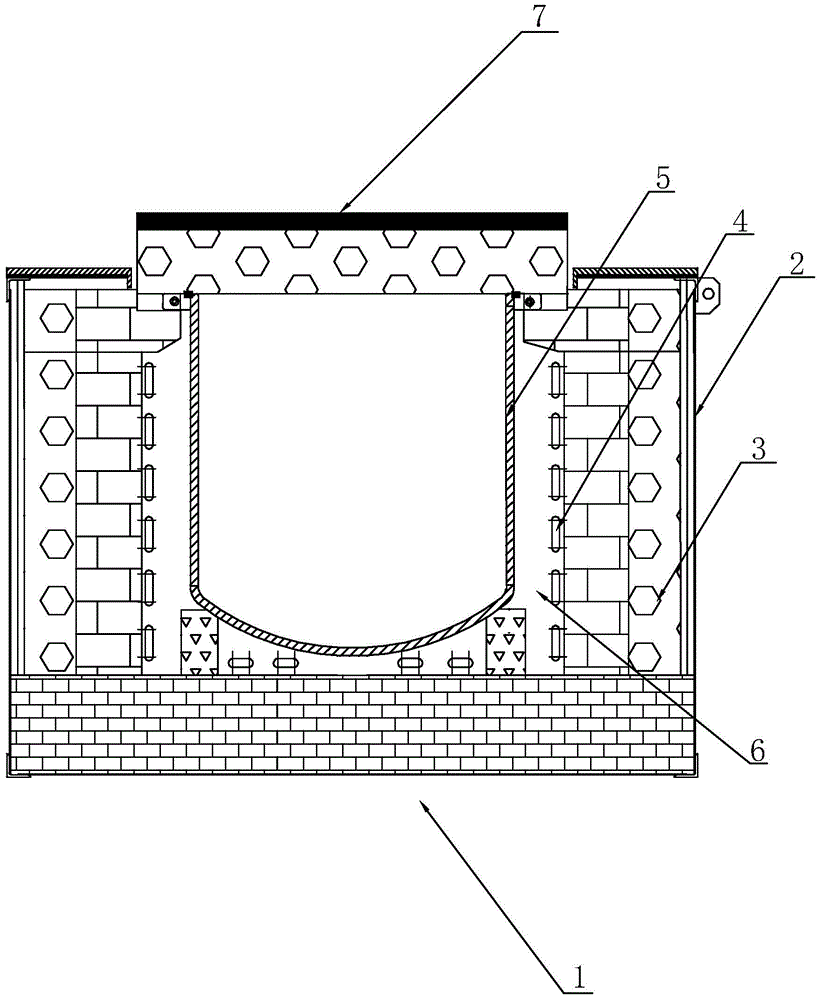

Tiltable rotary secondary aluminum smelting furnace

InactiveCN101131304AImprove performanceIncrease production capacityRotary drum furnacesClinker productionCombustorRotary furnace

This invention relates to a tilting rotary secondary aluminum smelting furnace. It includes roller type rotary furnace body, which is supported on the steel support. The anterior end of rotary furnace is arranged in the sleeve. The anterior end face of the rotary furnace has round furnace opening. The posterior end of rotary furnace connects to power device. The steel support corresponding to the rotary furnace posterior end parts connects to lifting cylinder. The steel support corresponding to the rotary furnace anterior end part connects to supporting shaft. There is round furnace door corresponding to the round furnace opening. There is sealing ring between the round furnace opening and door. The round furnace door is arranged on the roll-over shaft and connects to controlling oil cylinder. The round furnace door has fuel gas combustor and waste air discharging opening. The structure is simple. This invention is convenient. It has low energy dissipation and high producing efficiency.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

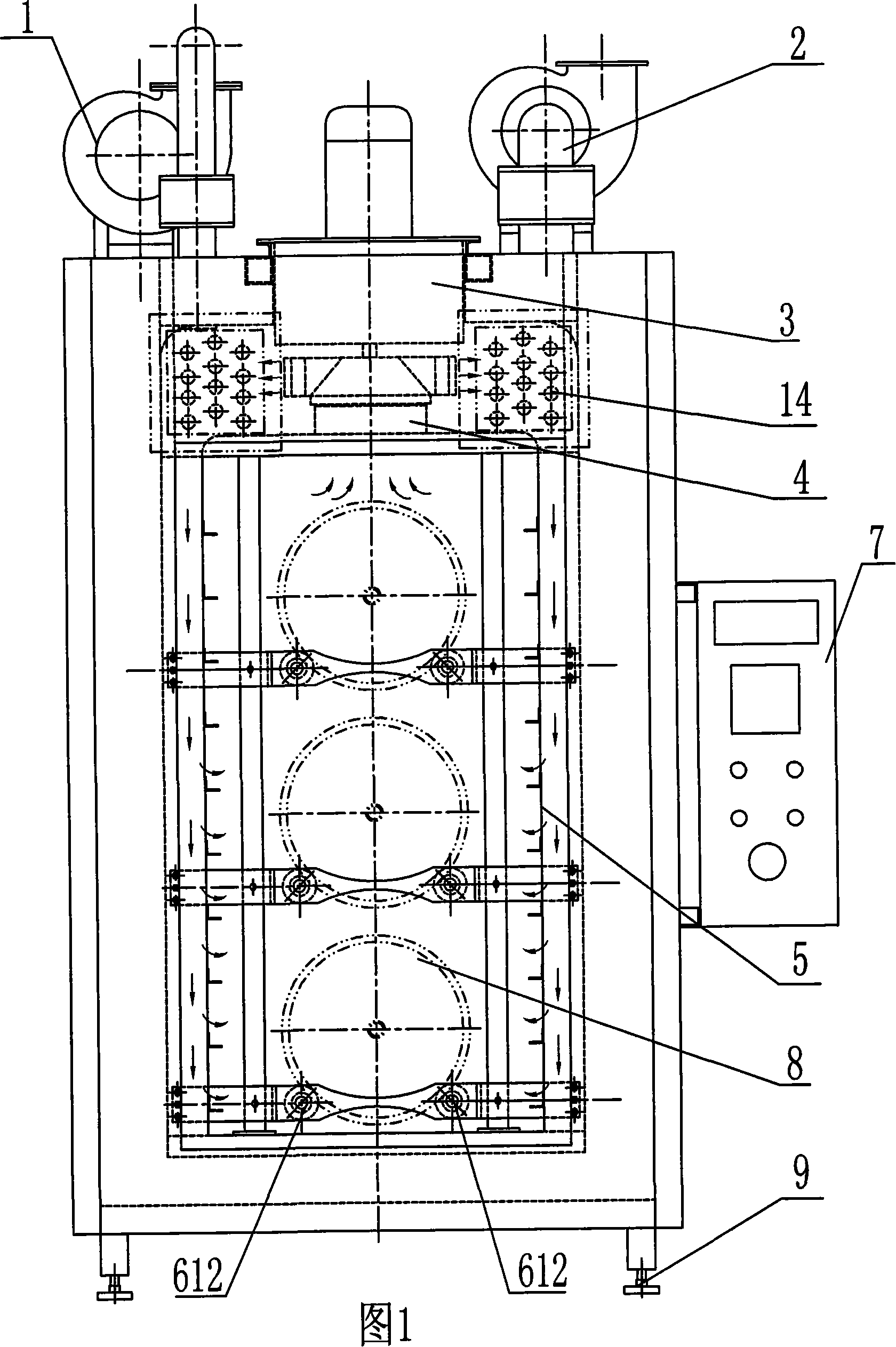

Heated air circulation bake oven

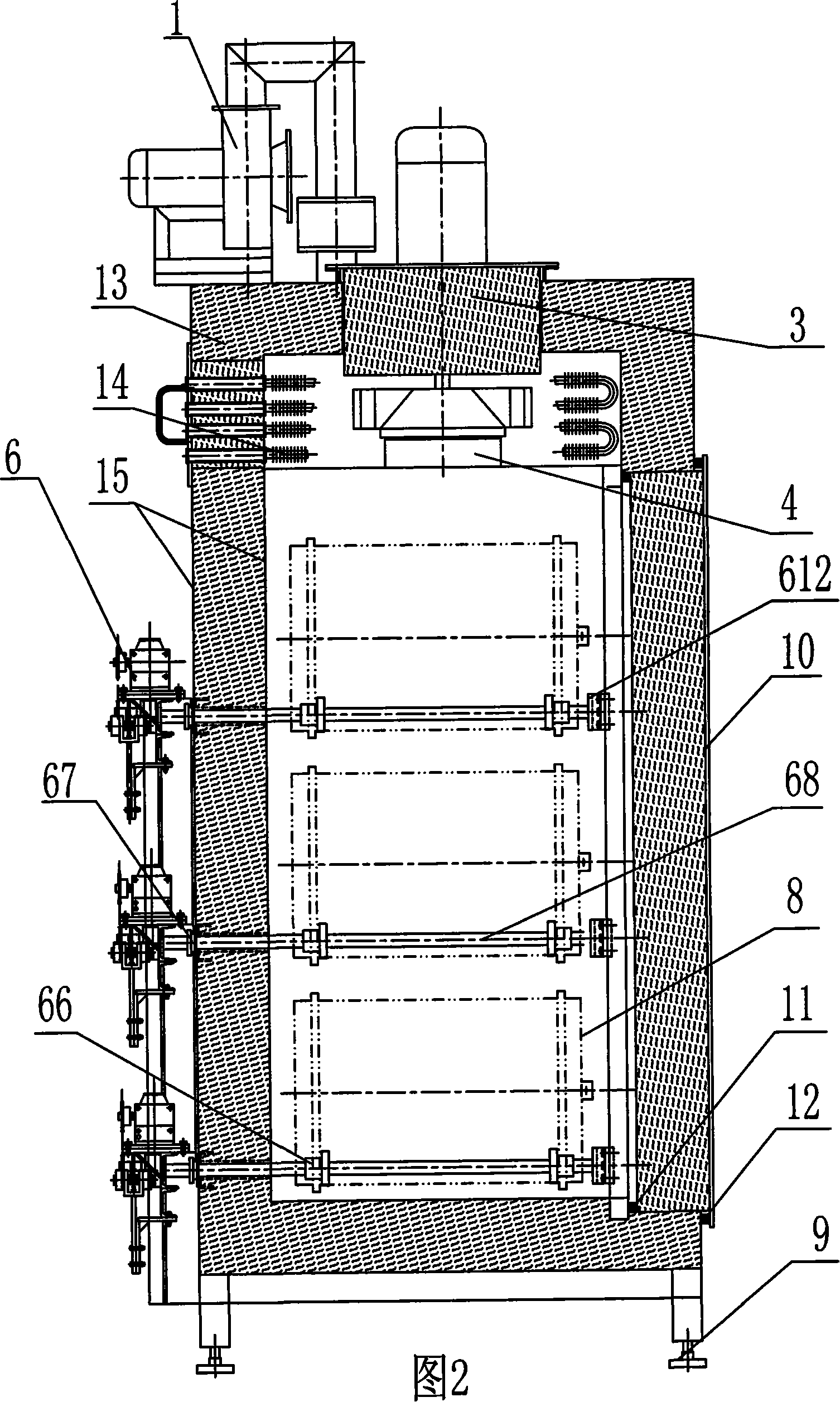

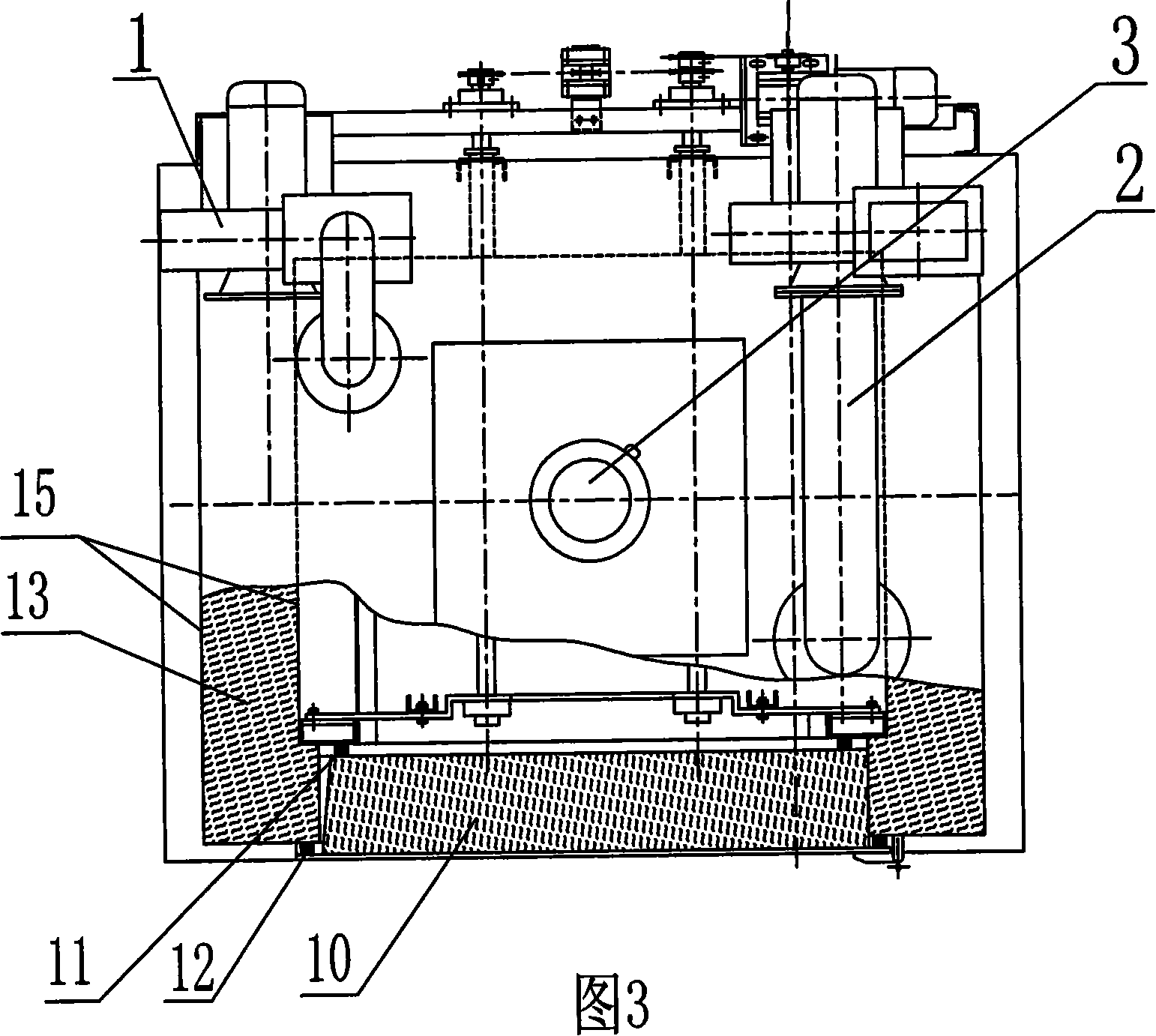

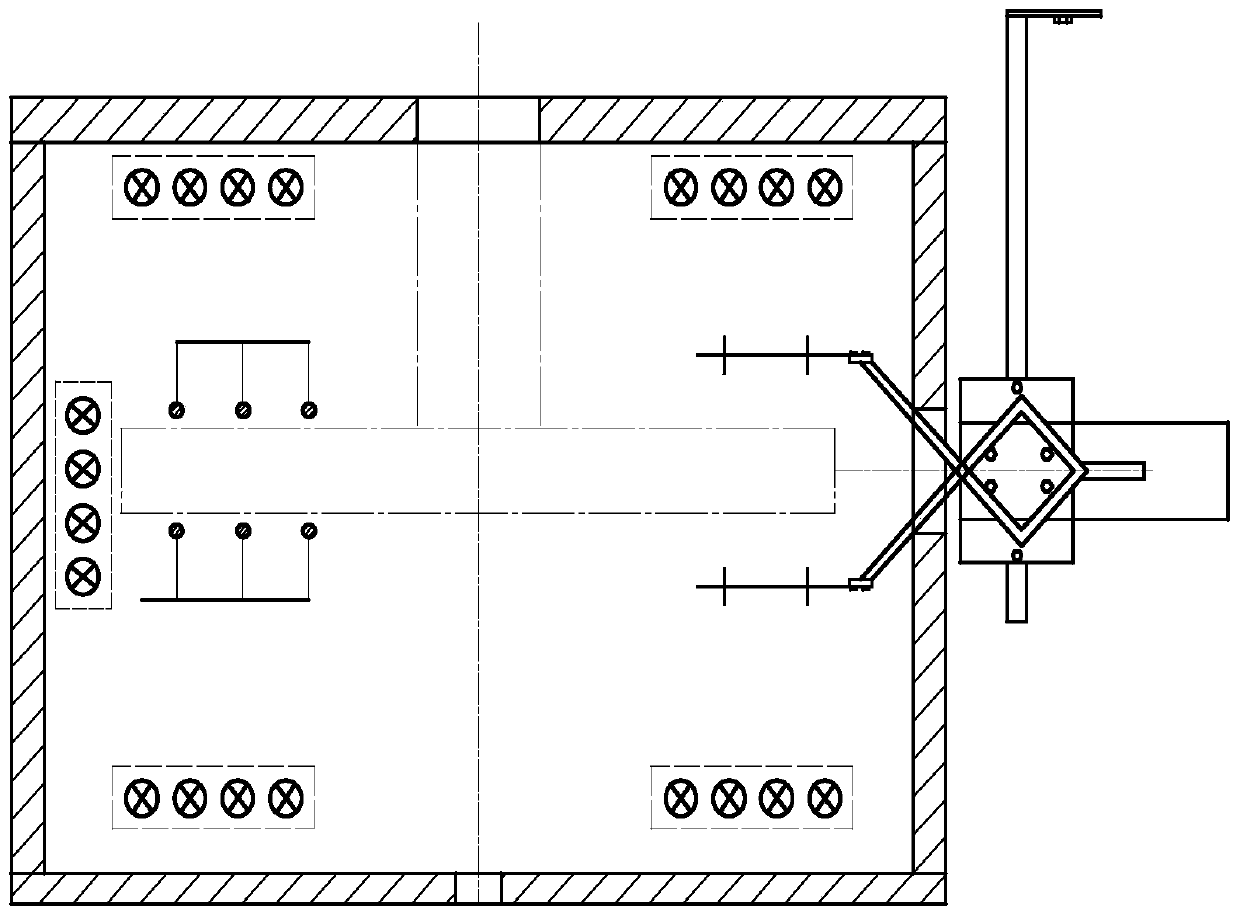

InactiveCN101118113AImprove temperature uniformityAchieving Furnace Temperature UniformityRotary drum furnacesMonolithic liningsFurnace temperatureInsulation layer

The present invention relates to a hot air circulating dry oven, which belongs to a periodical electric cooker and comprises a stainless square pipe and an electric cooker main body welded by steel plates. The furnace casing is divided into an inner layer and an outer layer, and an insulation layer is arranged between the two layers; a hot air circulating system, a charging basket rotating system and a fast cooling system are arranged on the electric cooker main body. The hot air circulating system comprises a hot air circulating blower arranged at the top part of the electric cooker main body, a fan connected with the hot air circulating blower, two heaters arranged at both sides of the fan and an air guiding system composed of air deflectors at the top and both sides of each heater. The charging basket rotating system comprises at least one group of traversing slewing machine which can perform separate slewing heating for at least one charging basket; the fast cooling system comprises an air blower and a draught fan connected with the air guiding system. The present invention aims at resolving the problems of the uneven material changing and the great local temperature variation during the material clotting, tempering and annealing process, improves the production efficiency, reduces the production and operation cost, and resolves the problem of evenness of the furnace temperature for the structure.

Owner:SHANGHAI ZHONGJIA ELECTRIC FURNACE

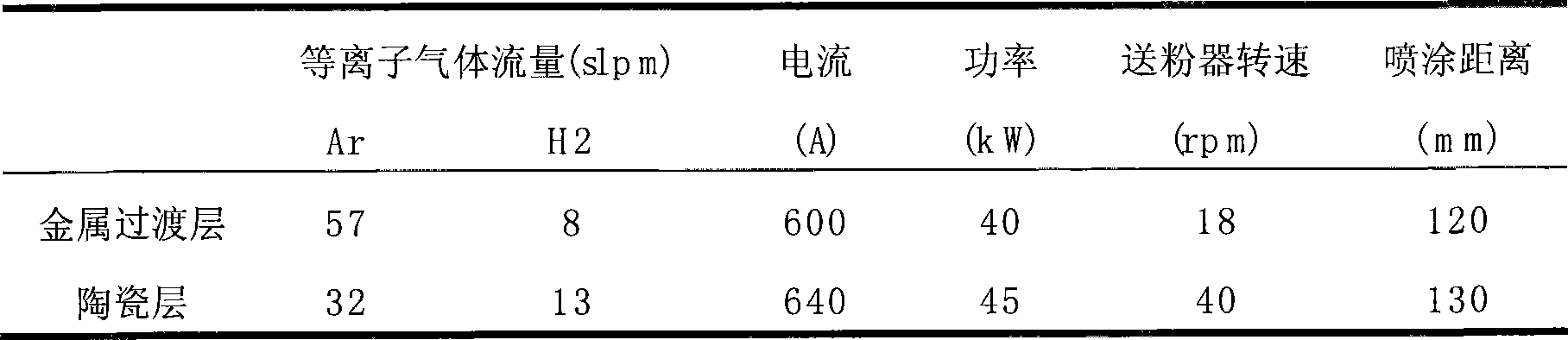

Composite coating for high-temperature container for metal melting and method for making same

The invention relates to a composite coating use for a smelting metal high-temperature vessel and a preparation method thereof, belonging to the technical field of smelting and preparing noble metal or rare metal. The method comprises the following steps: the surface of the smelting metal high-temperature vessel is provided with one or more metal tungsten, metal molybdenum, metal tantalum or metal niobium transition layers; the transition layer is provided with one or more yttrium oxide, calcium zirconate or magnesium zirconate coatings; or more than three layers of ladder coatings consisting of the metal tungsten, the metal molybdenum, the metal tantalum or the metal niobium and a ceramic surface material are formed on the surface of the smelting metal high-temperature vessel, with the compositions from more to less or from less to more. The composite coating solves the problem that smelting metal at high temperature reacts with the high-temperature vessel, and can be applied to the field of high-temperature smelting.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

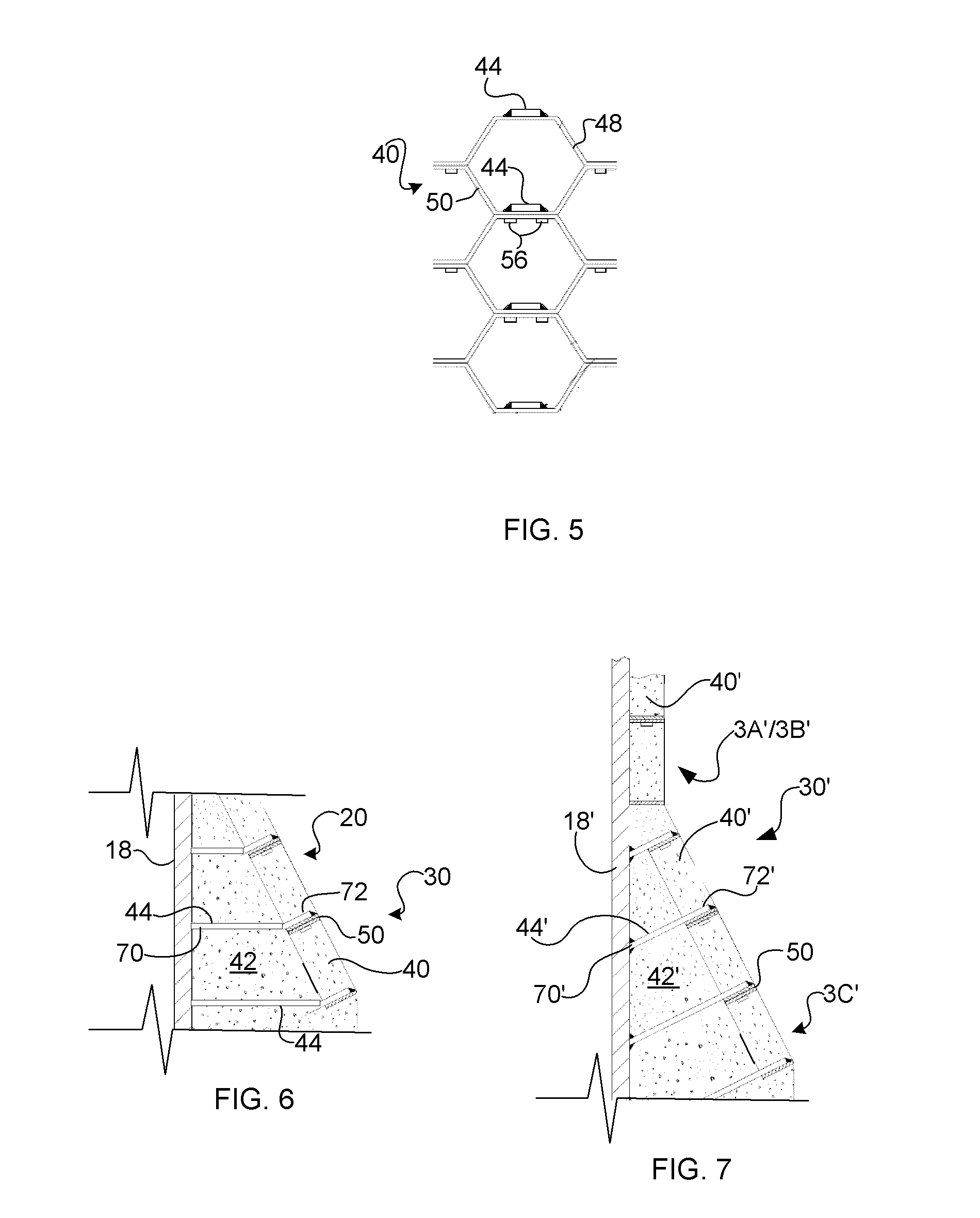

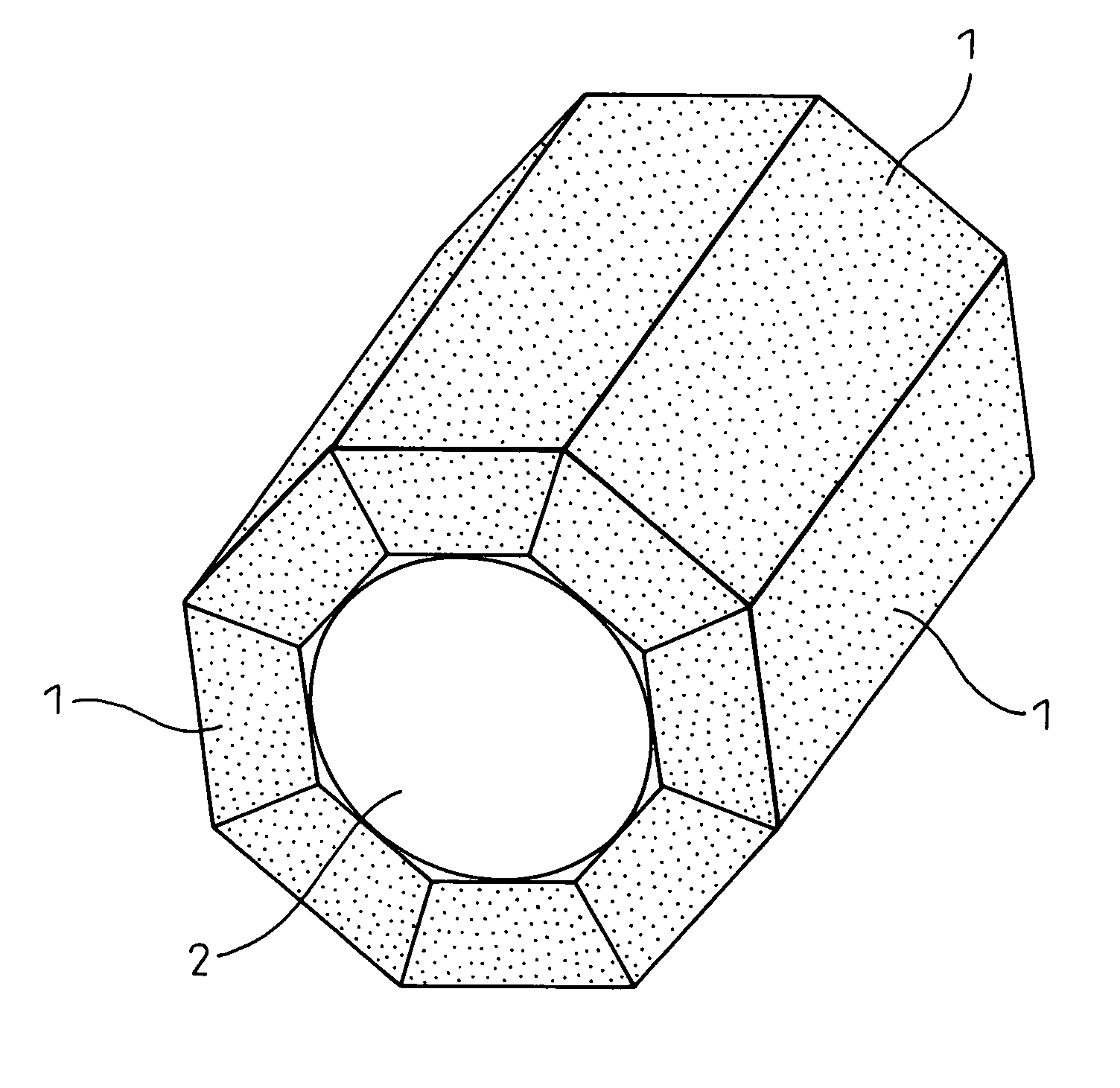

High yield ladle bottoms

ActiveUS20120126467A1Quantity minimizationLower the volumeMelt-holding vesselsBlast furnace componentsHigh elevationMaterials science

A refractory bottom lining for lining the bottom of a metallurgical vessel. The refractory bottom includes a stepped portion and an impact portion. The impact portion is formed of a first refractory material. The stepped portion is formed of a second refractory material and is disposed around the impact portion. The stepped portion includes an upper surface that has a plurality of discrete surface sections. The plurality of discrete surface sections includes an uppermost surface section, at least two intermediate surface sections and a lowermost surface section. Each surface section has a different elevation such that the uppermost surface section has a highest elevation and the lowermost surface section has a lowest elevation. The uppermost surface section, the at least two intermediate surface sections and the lowermost surface section define a continuously downward stepped path from the uppermost surface section to the lowermost surface section.

Owner:HARBISONWALKER INT INC

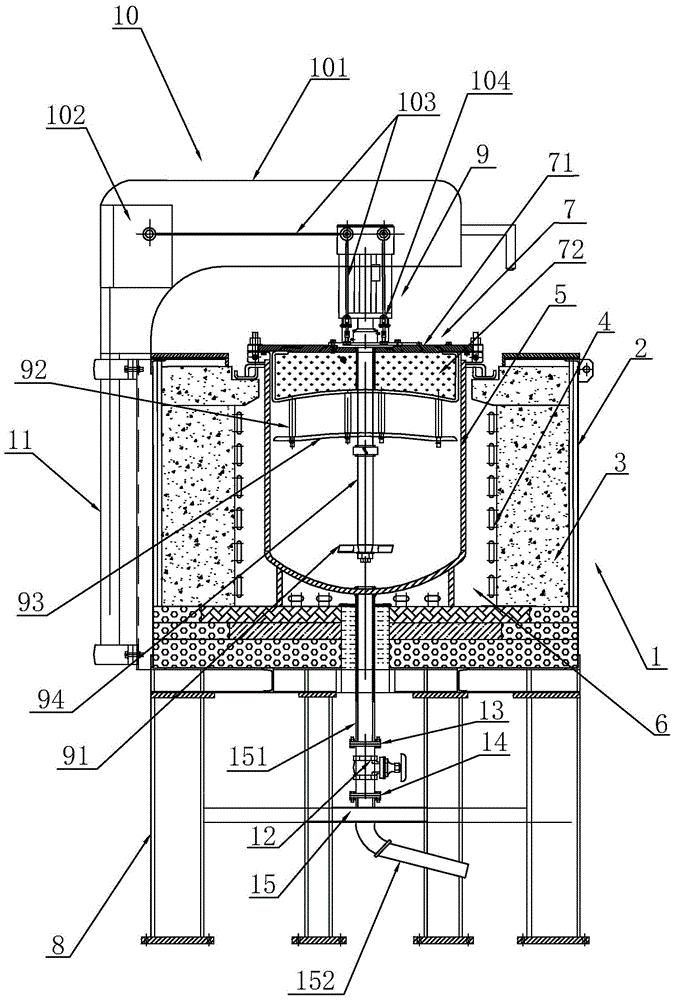

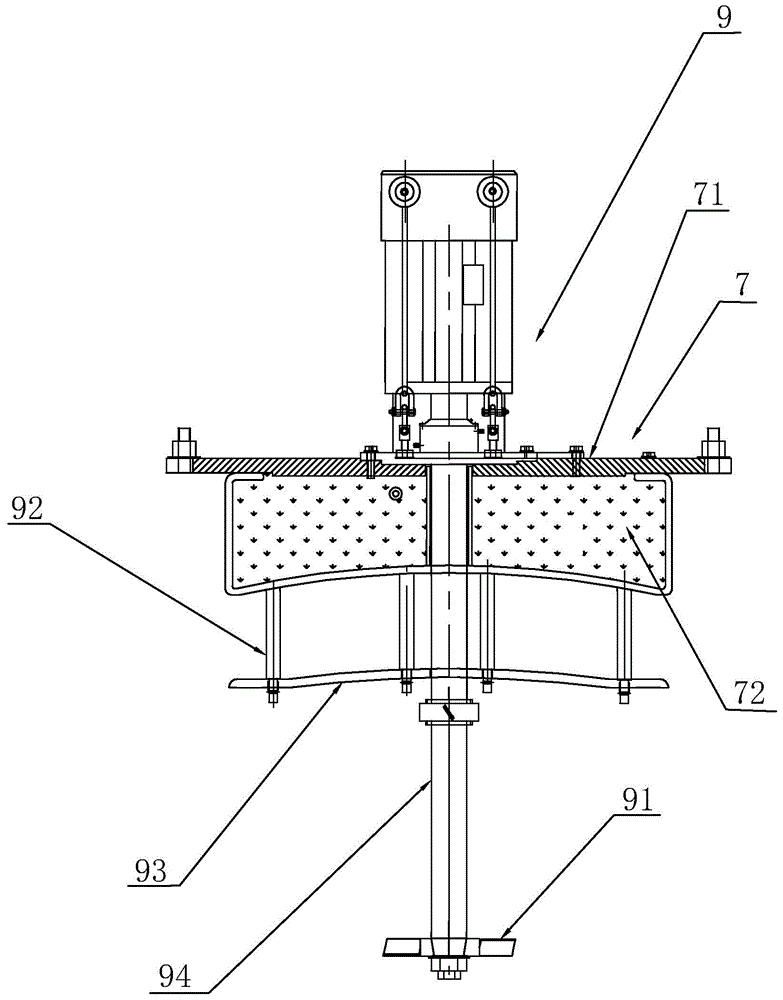

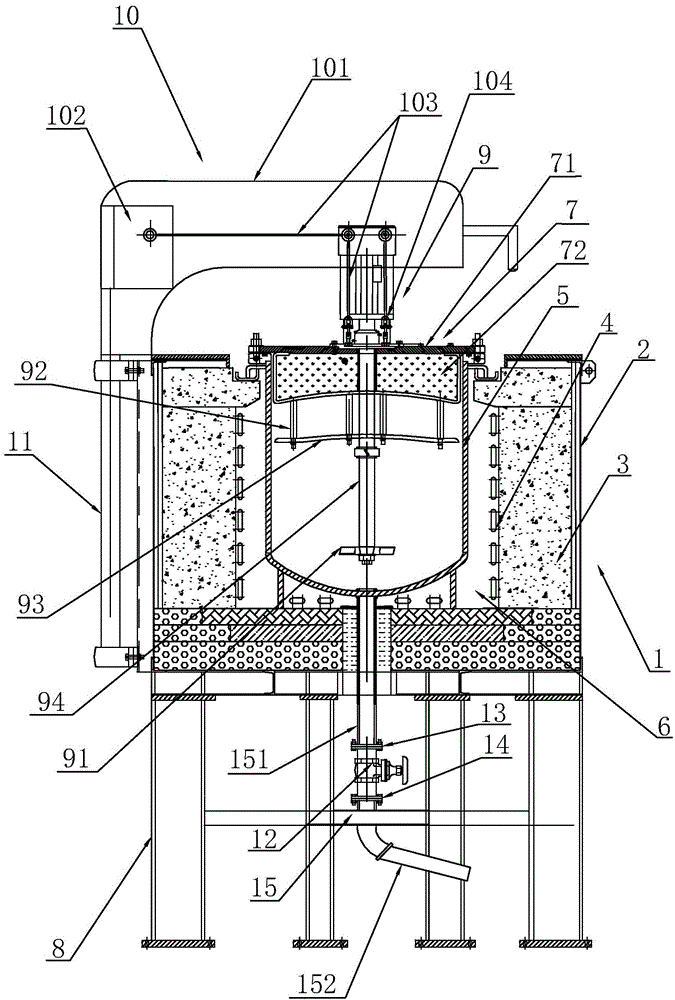

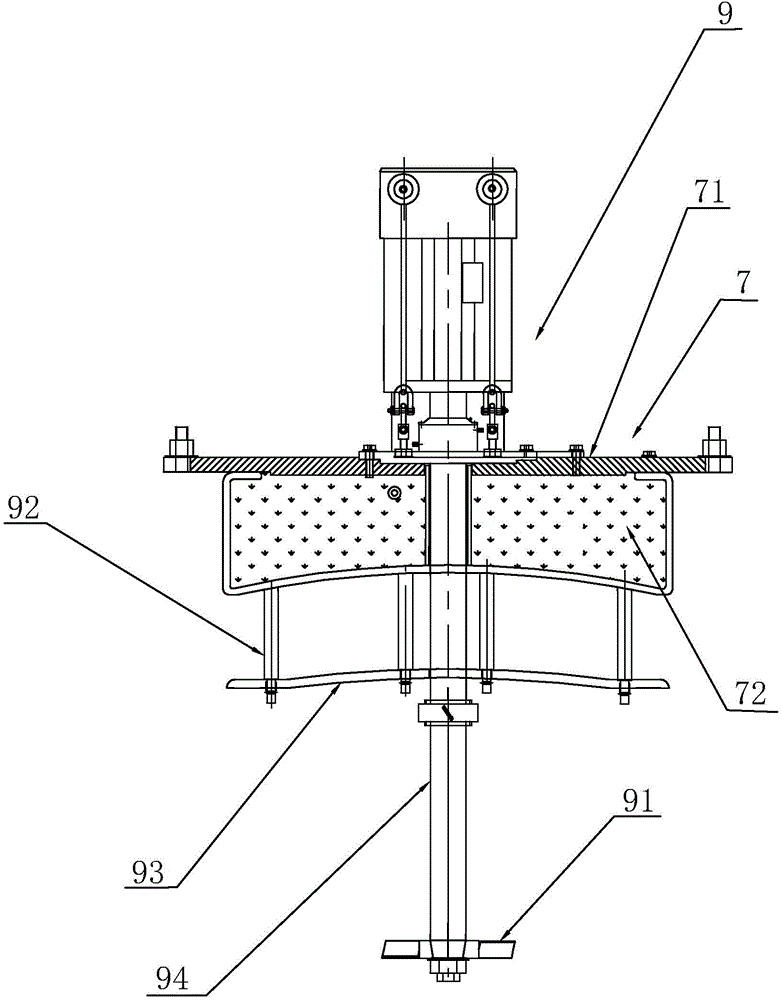

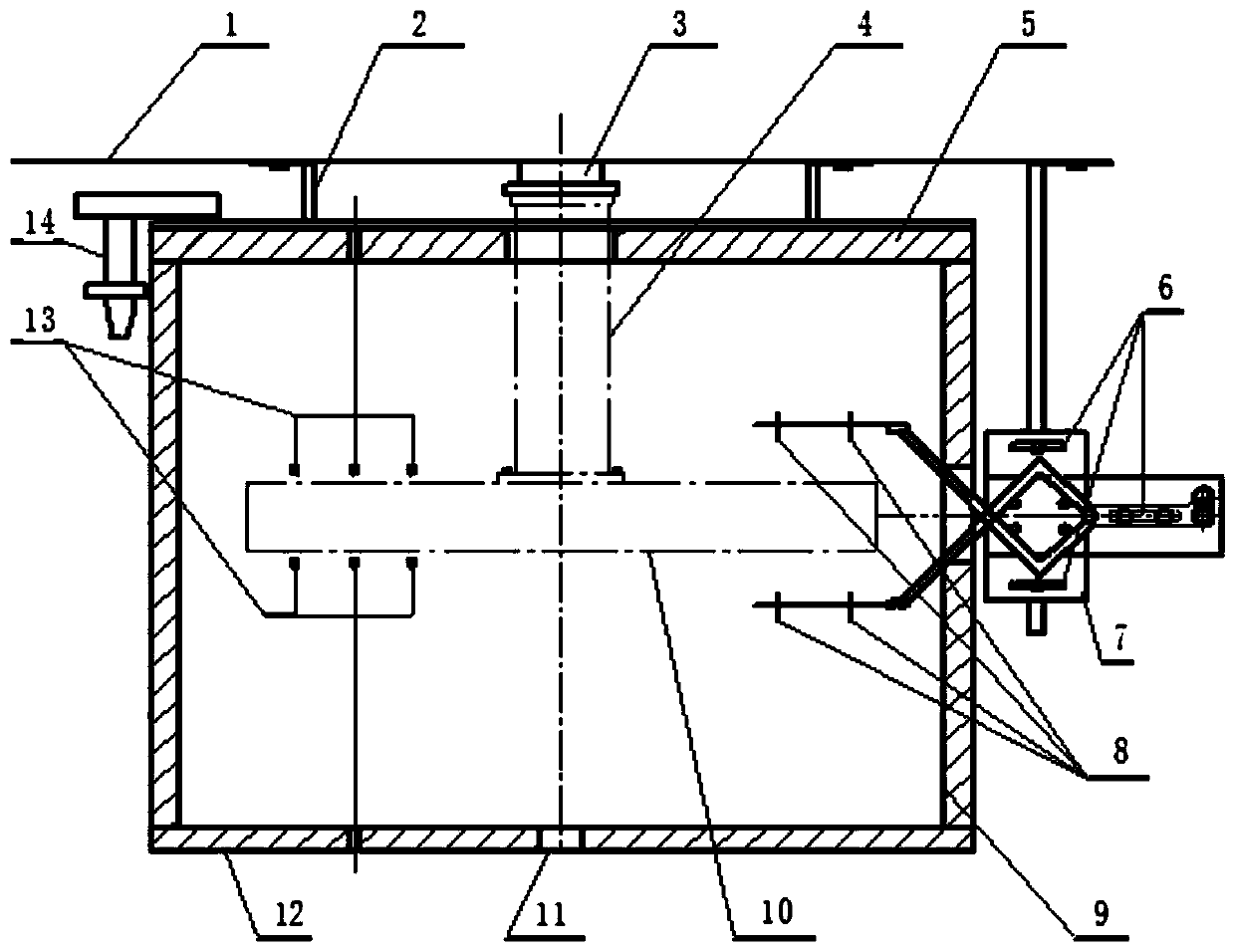

Metal homogenizing melting furnace

InactiveCN104390457AWith lossOxidation resistantStirring devicesCrucible furnacesCrucibleMolten metal

The invention relates to a metal homogenizing melting furnace. The metal homogenizing melting furnace comprises a furnace body and a support used to fix the furnace body, wherein the furnace body comprises a furnace shell, a furnace lining, a heating element and a crucible, which are sequentially arranged from outside to inside, the heating element is arranged around the outer surface of the crucible, the crucible is provided with a furnace cover, a stirrer is arranged on the furnace cover, and a stirring shaft of the stirrer is stretched into the crucible, and stirs molten liquid in the crucible through stirring impellers arranged at the bottom of the stirring shaft. The metal homogenizing melting furnace stirs molten metal through the stirrer, uniforms constituents of the molten metal obtained after melting metal, and greatly improves product quality.

Owner:贵州鑫凯达金属电源有限责任公司

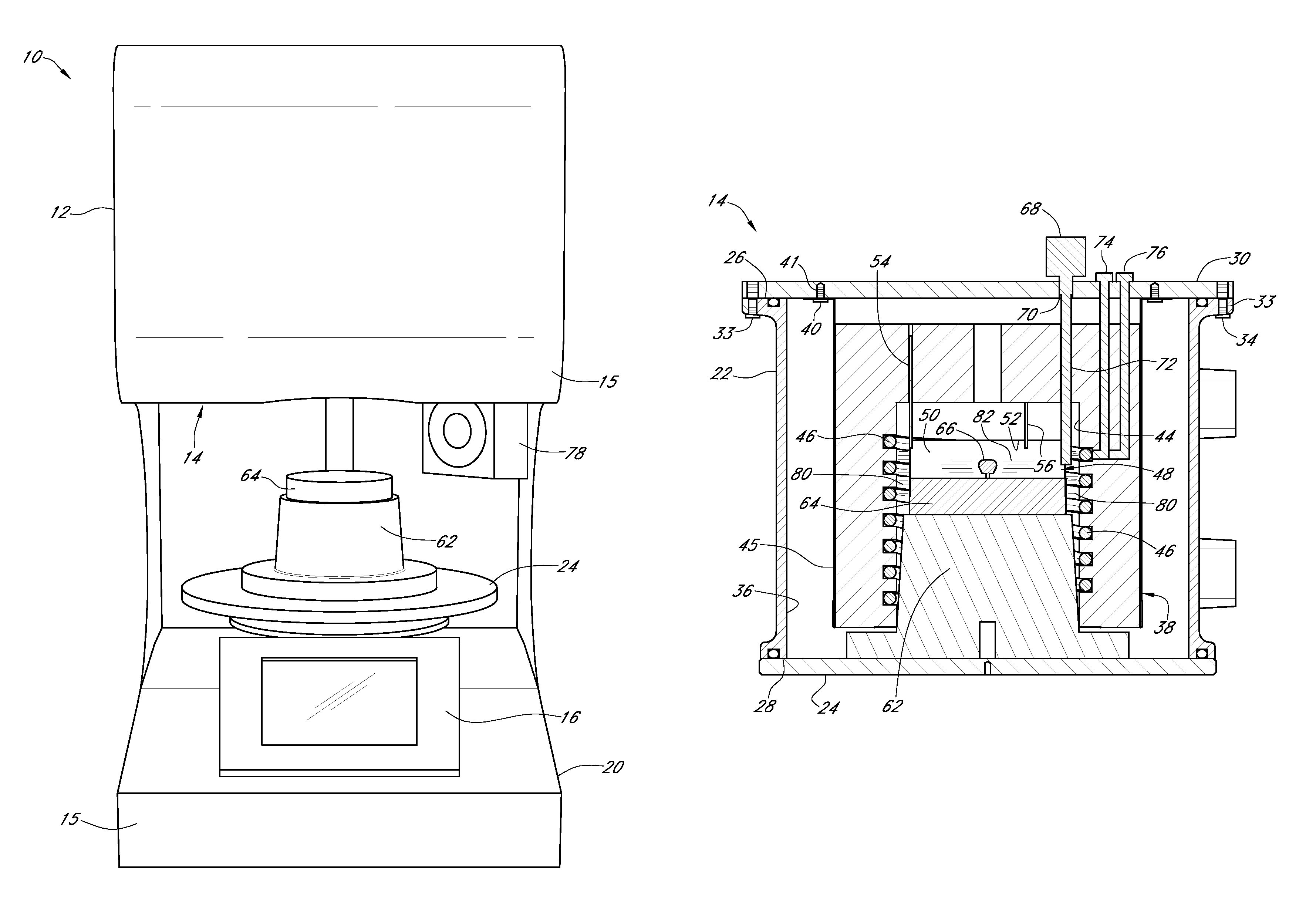

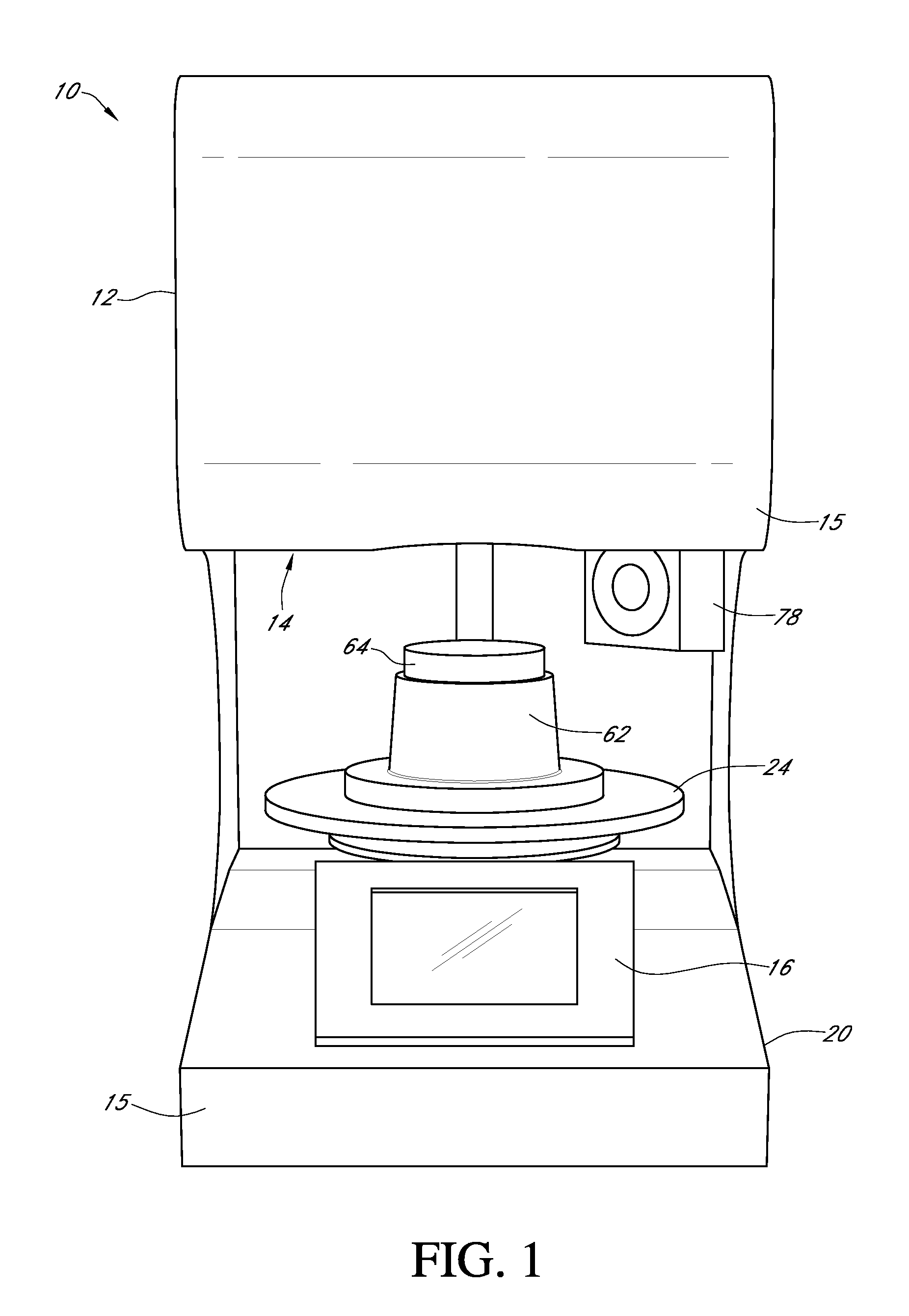

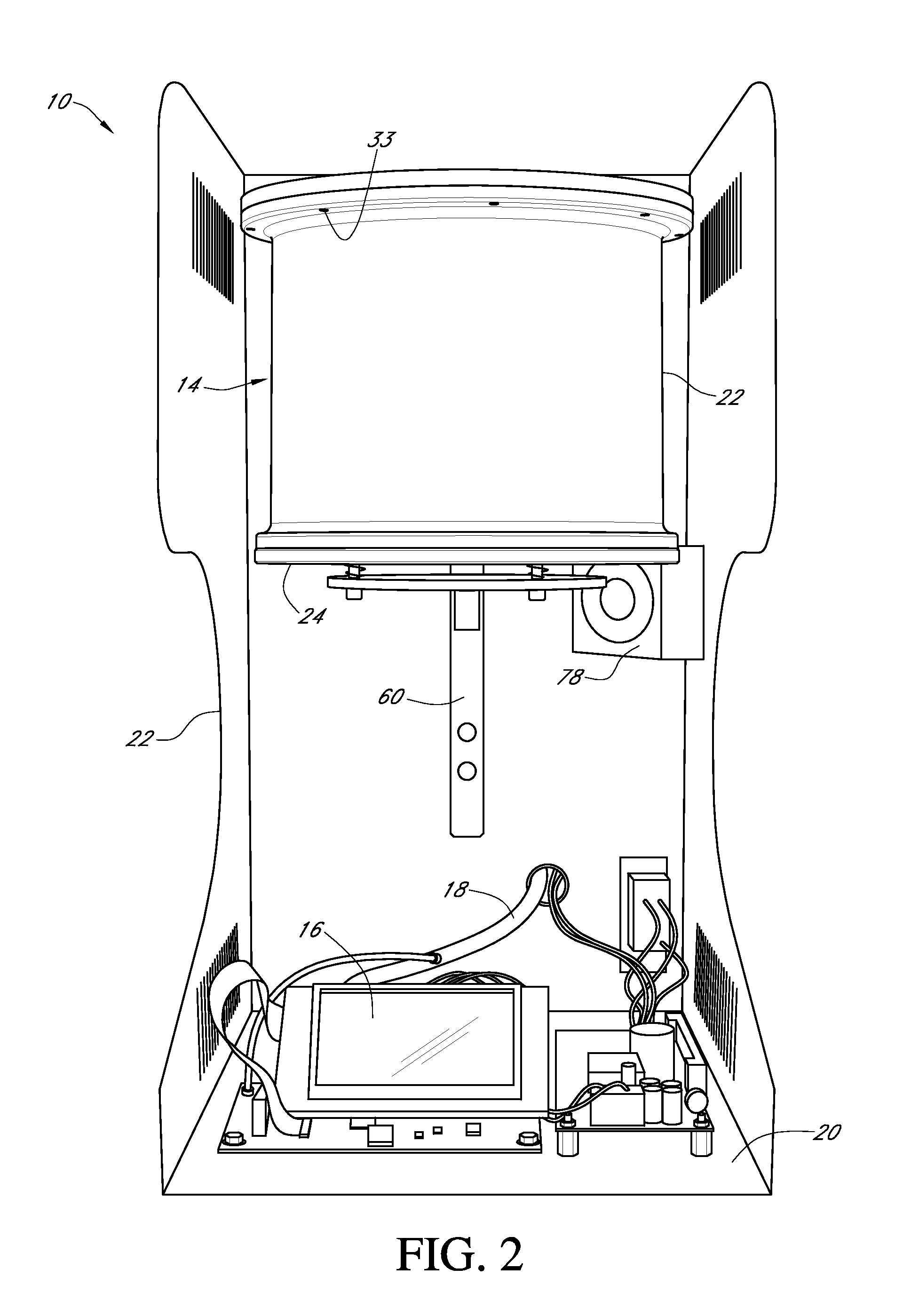

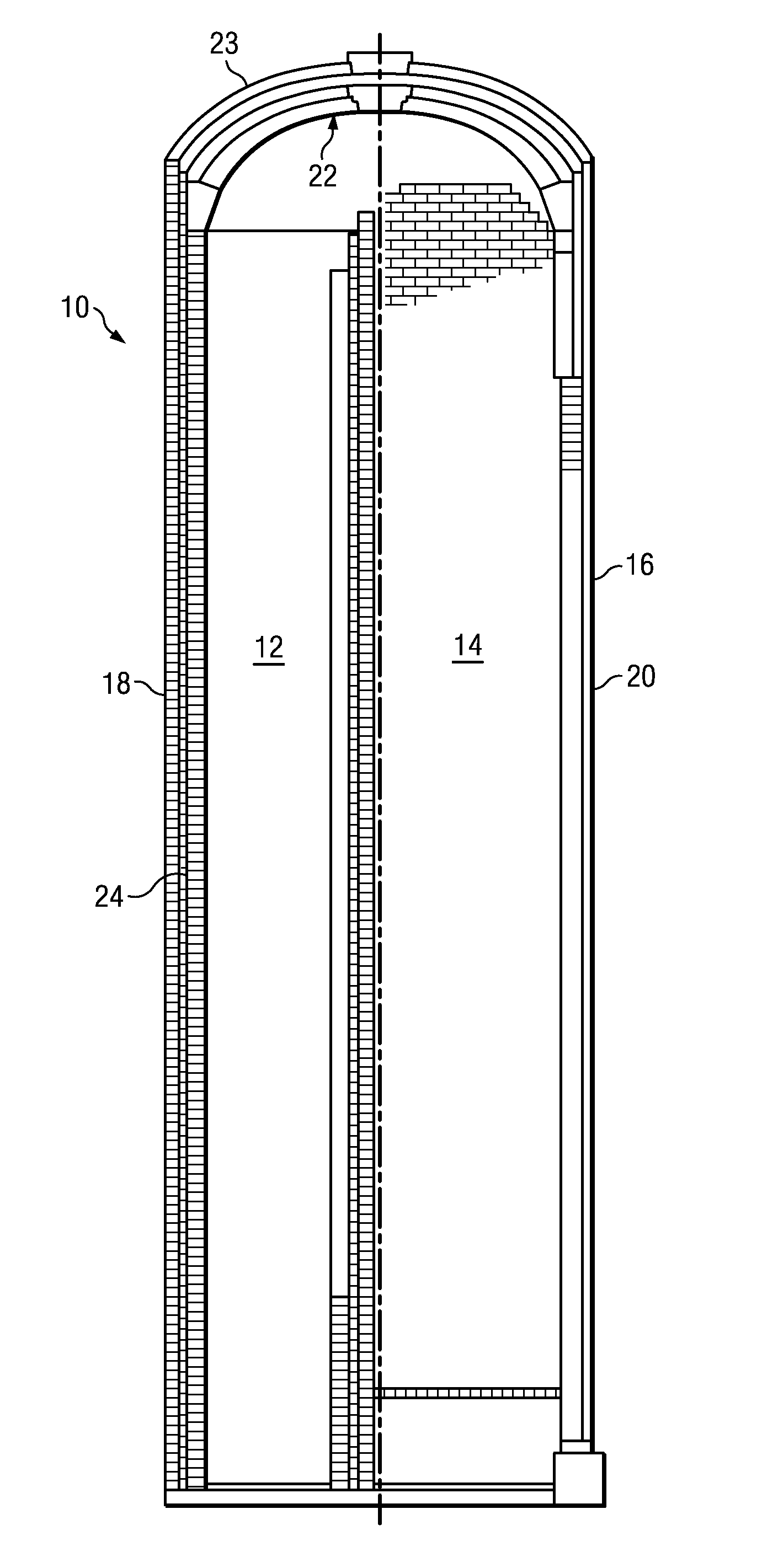

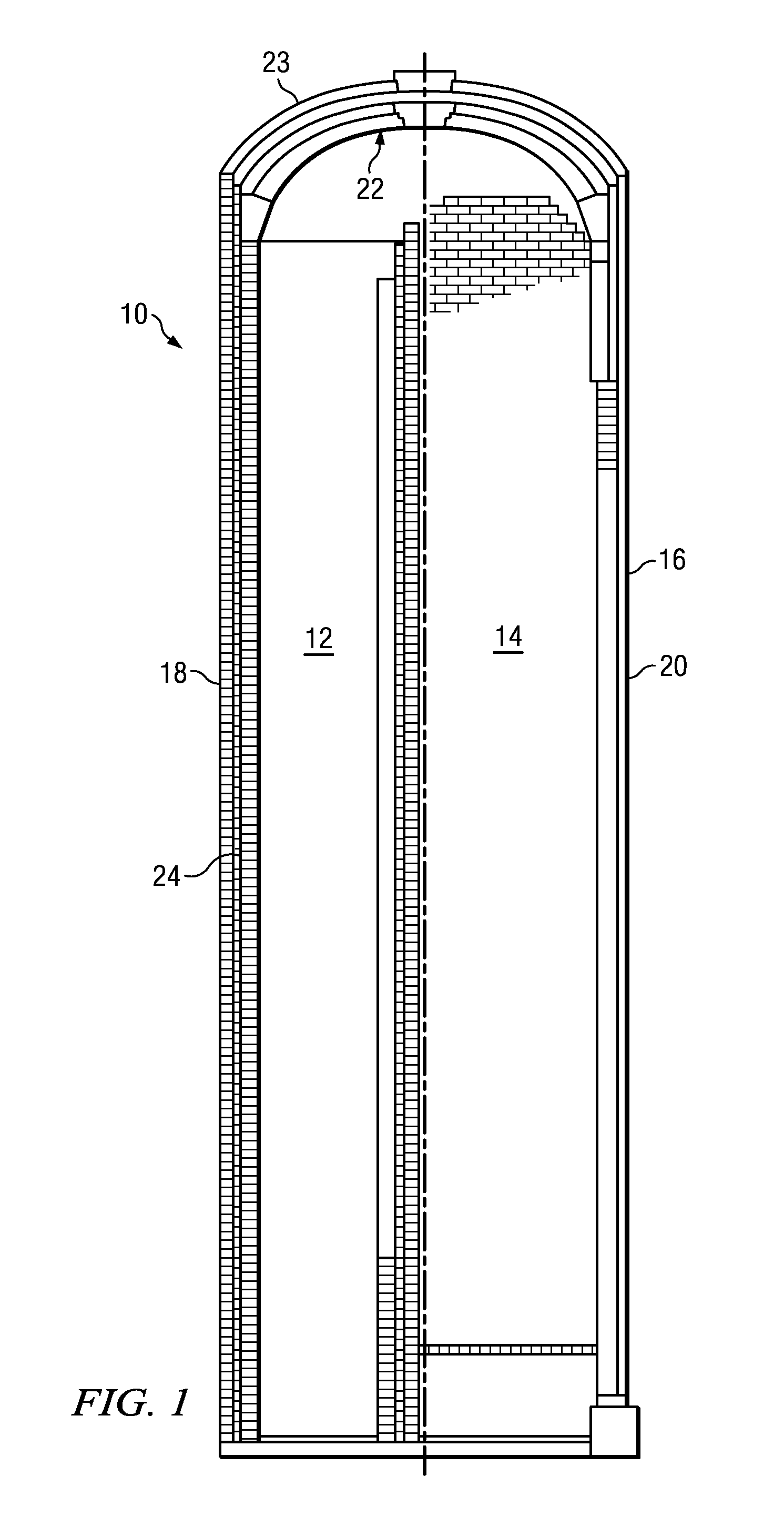

Vacuum oven

A vacuum oven or vacuum furnace is disclosed having a heat distribution sleeve that conforms to the shape of an interior heating chamber. The heat distribution sleeve may be of generally annular shape, like a ring, and located in a substantially regularly spaced and offset relationship from a heating element located within walls adjacent the interior heating chamber. The heat distribution sleeve includes a thermal conductive material which absorbs and re-radiates heat emitted from the heating element, thereby providing more consistent and regular radiation fields for heating treating a work piece that is loaded on a work holding tray and, upon the vacuum oven being in an operational position, the work piece is located within the furnace chamber.

Owner:IBEX DENTAL TECH

Crack-resistant insulating dry refractory

Owner:ALLIED MINERAL PROD

HTEE series special infrared radiation coating for high temperature kiln

InactiveCN101481551APerformance impactReduce the temperatureChemical industryCoatingsChromium trioxideSodium phosphates

The invention relates to an HTEE series nocturnal radiation paint which is a special energy-saving material for a high temperature furnace and is applicable to petrochemical engineering furnaces and furnaces in the metallurgic, electric power, ceramic, architectural and aviatic industries and other industries, as well as civil furnaces. The invention utilizes a Y2O3 rare-earth nanophase material for enhancing the strength and the aging resistance performance of nocturnal radiation paint and provides a high temperature nocturnal radiation paint which is directly coated on the lining of a metal heating device or on a heater or a fire-resistant ceramic material of the high temperature furnace. The high temperature radiation paint has the advantages of high thermal efficiency, high temperature resistance, stable adhesive property, capability of effectively saving energy, furnace-body service life prolonging, and the like. The invention adopts the hydro-thermal method to synthesize the Y2O3 rare-earth nanophase material, the solid material of the high temperature paint is selected to comprise 50% of zirconia, 20% of monox, 8-15% of aluminum oxide, 3-6% of ferric oxide, 10-14% of chromium trioxide, 3-9% of sodium sodium phosphate and 1-3% of calcium carbonate. A corresponding liquid material (adhesive agent) is a special high temperature adhesive agent and mainly comprises 0.5-3% of Y2O3, 2-6% of aluminum oxide, 1-3% of ferric oxide, 0.4-2% of manganese oxide, 1-3% of calcium carbonate, and the balance of tap water. The ratio of the solid material and the liquid material is maintained to be 3:2. The solid material and the liquid material are proportionally mixed and then evenly stirred at the normal temperature, and then the special nocturnal radiation paint for the high temperature furnace can be obtained. The use temperature of the nocturnal radiation paint ranges from 1,200 DEG C to 1,800 DEG C.

Owner:曾宏图 +1

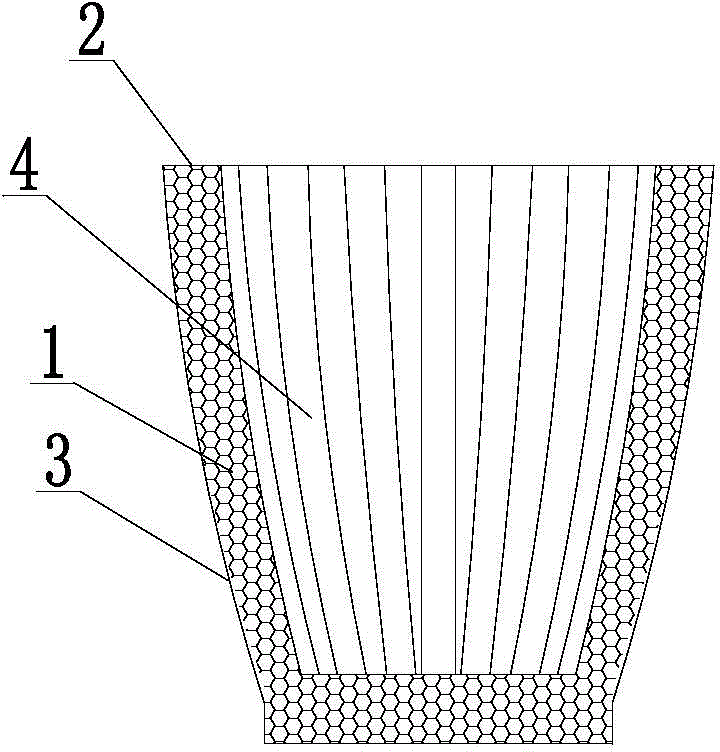

Large area air outlet fluidized calcining furnace refractory lining

ActiveCN101261079AGuaranteed reliabilityExtend your lifeLining supportsFluidised-bed furnacesCamber angleRefractory

The invention provides a large-area tuyere zone fluidizaton roasting furnace refractory lining. A steel fibrous reinforced castable or a high intensity low cement castable refractory is adopted to be cast with the furnace steel housing into a whole. The inside of the refractory lining is provided with a plurality of heat-proof stainless steel clips. The end surface of one end of each heat-proof stainless steel clip is welded with the furnace steel housing; the other end of each heat-proof stainless steel clip is lied inside the furnace refractory lining in a separated way or a ring-shaped link way. The heat-proof stainless steel clip is also applied by more than two layers of asphalt lac. A camber angle ring beam is arranged between the inner layer of the spherical vault and the combined furnace wall of the furnace body. The lower part of the furnace lining weight adopts the way of combing the bearing of an anchor ear beam and a furnace wall rivet clamping element. Under the condition that the roasting technology is not changed, the furnace body thins the furnace wall, and the furnace lining mass is reduced by 20 to 25 percent, thereby greatly lowering the cost, improving the leak tightness of the furnace body, preventing an isolated layer from being damaged, solving the problem that the insulating layer leaks SO2 to erode the furnace housing, improving the intensity, the air tightness and the stability of the furnace top and enhancing the whole structure of the furnace body.

Owner:洛阳市洛华粉体工程特种耐火材料有限公司

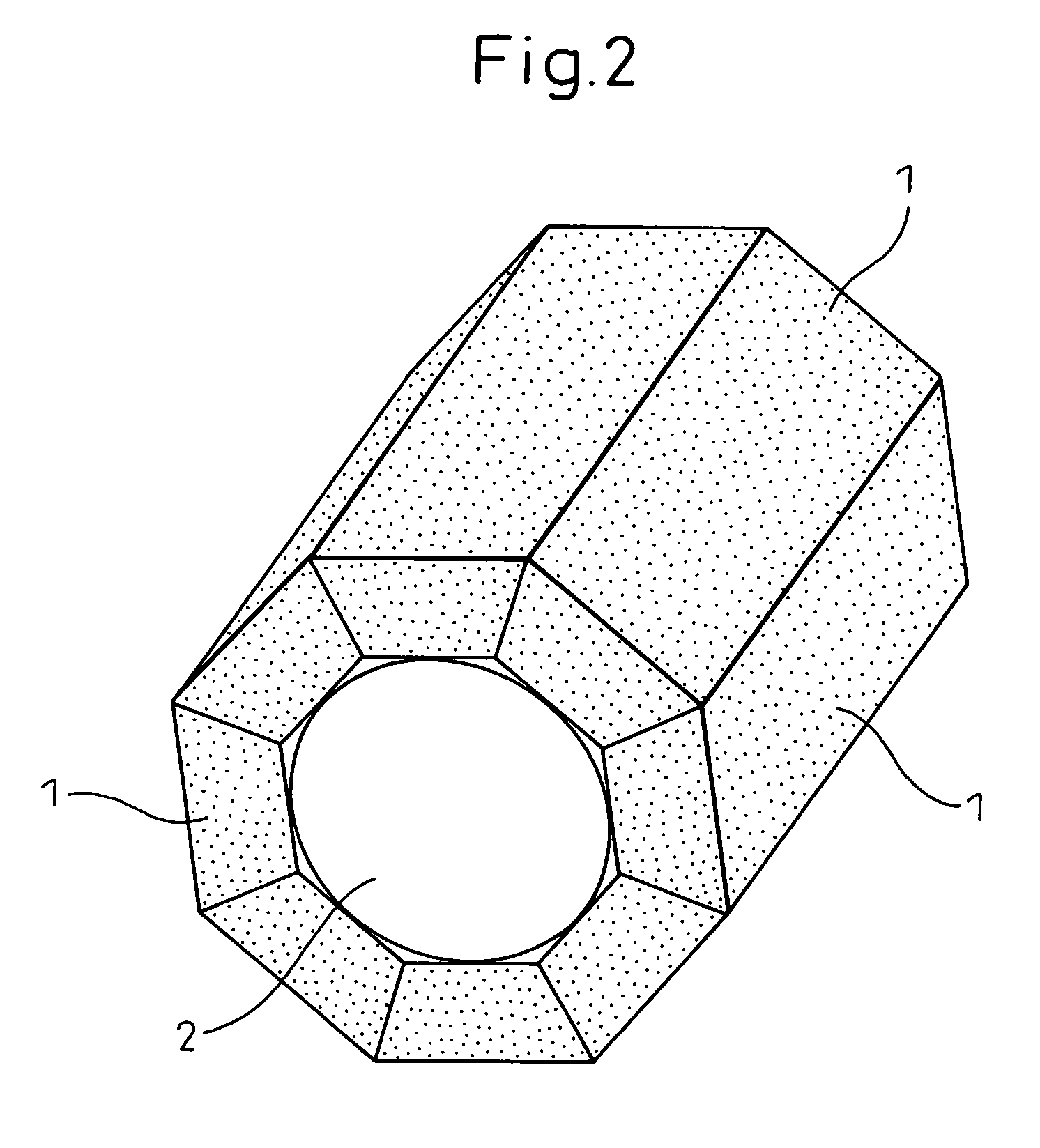

Thermal shield, especially for lining the wall of a combustion chamber

InactiveUS20070028592A1Improve cohesionIncrease the number ofContinuous combustion chamberBlast furnace componentsCombustion chamberMetallurgy

The aim of the invention is to provide a highly durable, high-strength thermal shield element for the interior lining of the combustion chamber of a gas turbine. For this purpose, the thermal shield element comprises a base produced from a solidified cast ceramic material into which a plurality of reinforcing elements are integrated.

Owner:SIEMENS AG

Manganese-rich slag electric furnace mounted with condensation lining

The invention belongs to a manganese-rich slag electric furnace and in particular relates to a manganese-rich slag electric furnace with a condensation furnace liner, which solves the problems that a furnace liner of the prior manganese-rich slag electric furnace is easy to erode seriously, has short service life, causes frequent maintenance of the electric furnace, and seriously influences production. In the manganese-rich slag electric furnace with the condensation furnace liner, the condensation furnace liner comprises a hearth bricking layer and a furnace wall bricking layer; the hearth bricking layer consists of a bottom primary layer insulation material, a bottom secondary layer insulation material, an insulation material for a fusion region of the electric furnace and a hearth protection layer from bottom to top; and the furnace wall bricking layer consists of an outer layer corhart clinging to a steel plate ring of the furnace wall, an inner layer corhart and a furnace wall protection layer from outside to inside. The manganese-rich slag electric furnace has the advantage that the service cycle of the furnace liner reaches over 5 years, thereby reducing the maintenance probability and maintenance cost of the electric furnace.

Owner:JIAOCHENG YIWANG FERROALLOY

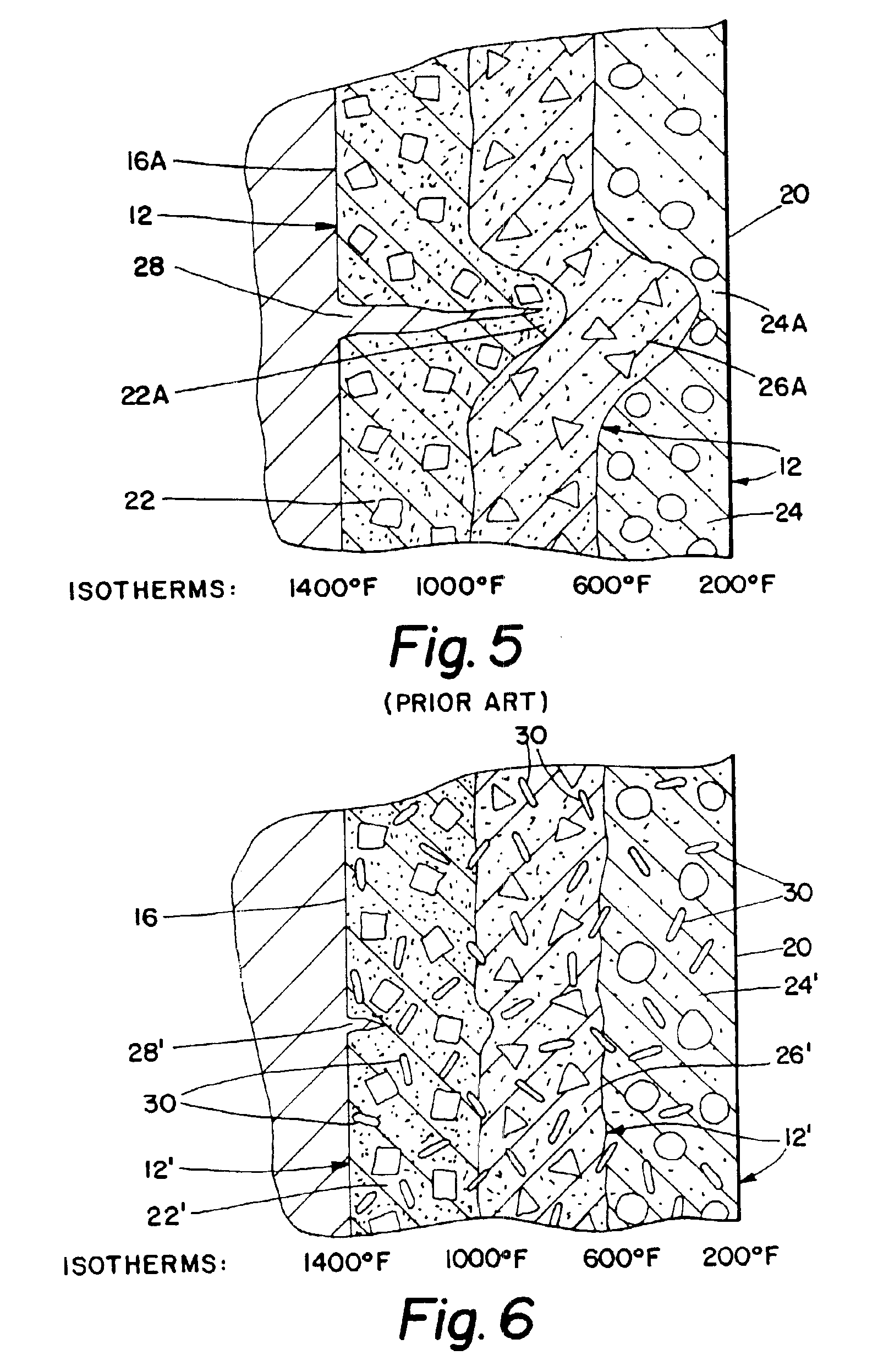

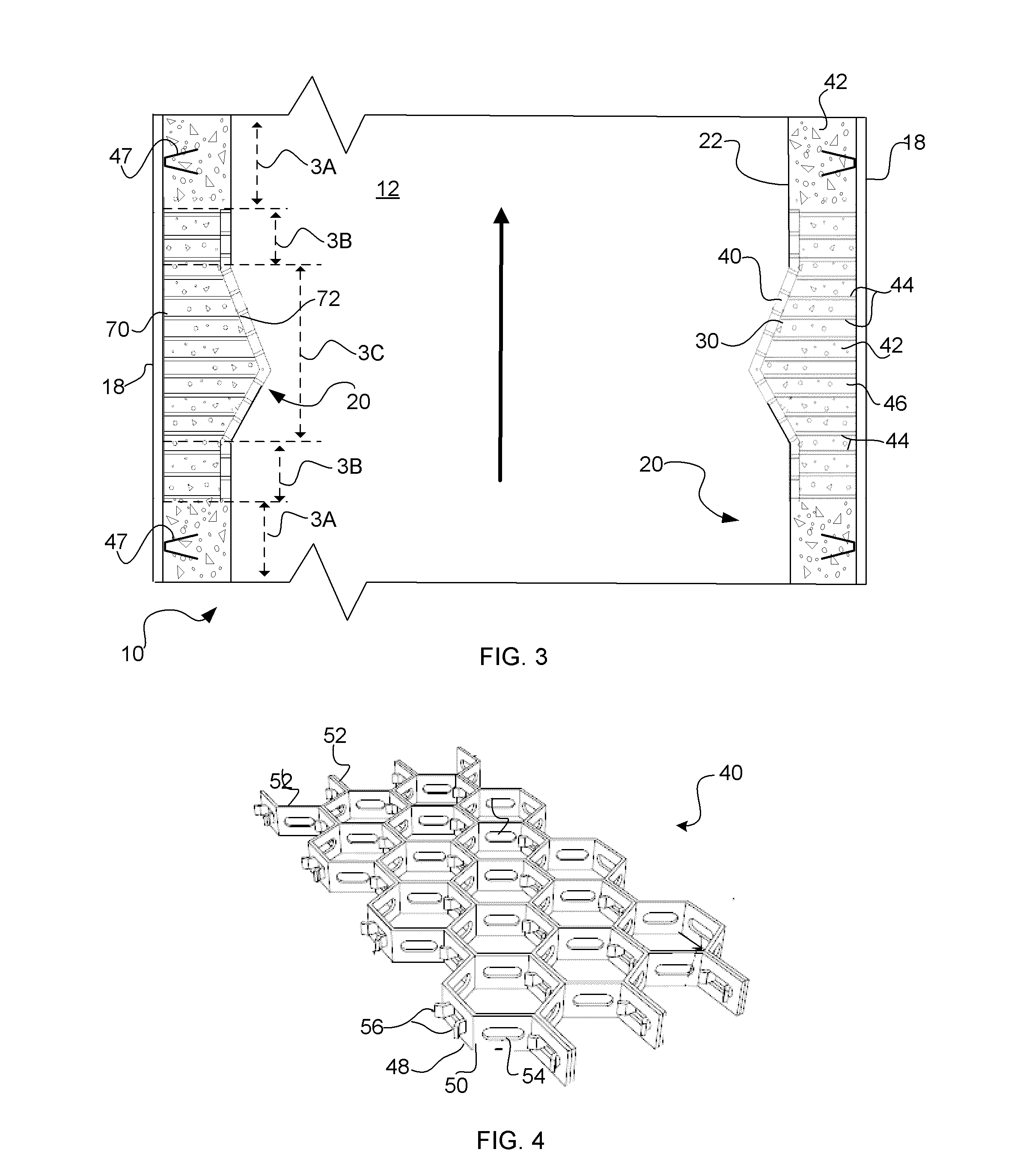

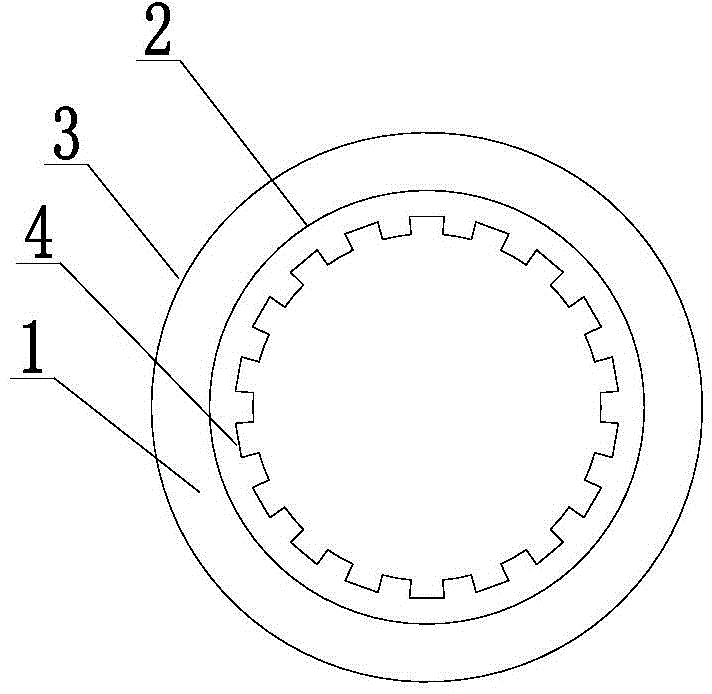

Riser reactor with flow disruptors

ActiveUS20130108519A1Reduce the risk of failureGaseous chemical processesCatalytic crackingRefractoryProcess engineering

An embodiment of the invention includes a riser reactor for reacting a feedstock and catalyst. The riser reactor wall defines an interior. A continuous refractory lining is attached to the reactor wall and defines a plurality of flow disruptors that extend inward from the wall into the reactor interior and disrupt flow patterns of the feedstock and catalyst.

Owner:UOP LLC

High yield ladle bottoms

ActiveUS20090206528A1Quantity minimizationLower the volumeMelt-holding vesselsMolten metal pouring equipmentsHigh elevationMaterials science

A refractory bottom for a metallurgical vessel comprised of a bottom lining having a bottom surface that is dimensioned to overlay a bottom of a metallurgical vessel and an upper surface. The upper surface is comprised of a plurality of discrete sections that include an uppermost section, an intermediate section and a lowermost section. Each section has an upper surface at a discrete elevation such that the upper surface of the uppermost section has a highest elevation and the upper surface of the lowermost section has a lowest elevation. The upper surface of the uppermost section, the intermediate section and the lowermost section comprise a series of successive stepped sections that define a stepped path from the uppermost section downward to the lowermost section. Each successive section of the upper surface is lower than a preceding section.

Owner:HARBISONWALKER INT INC

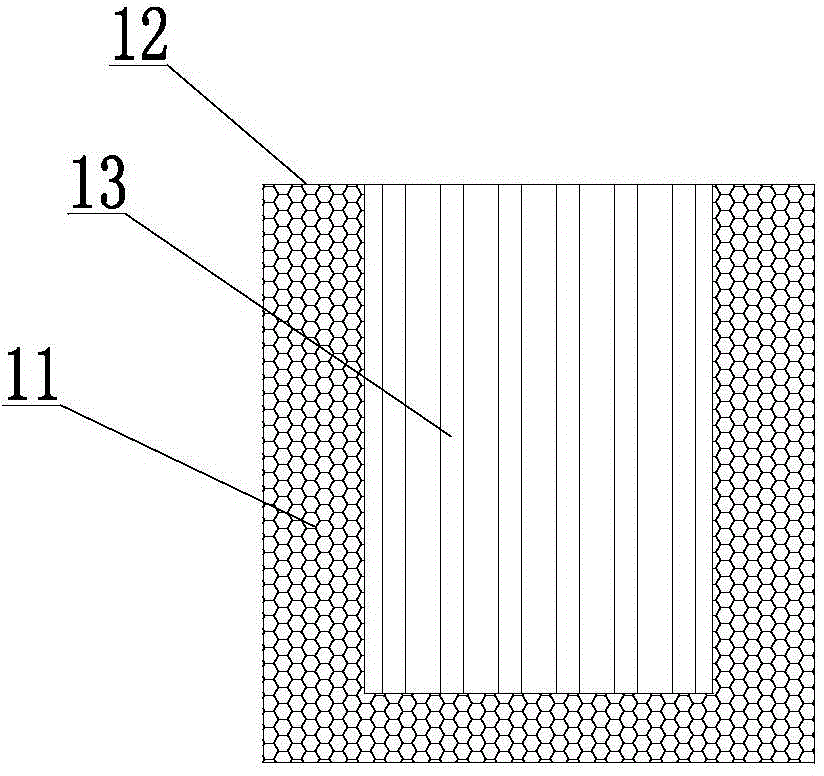

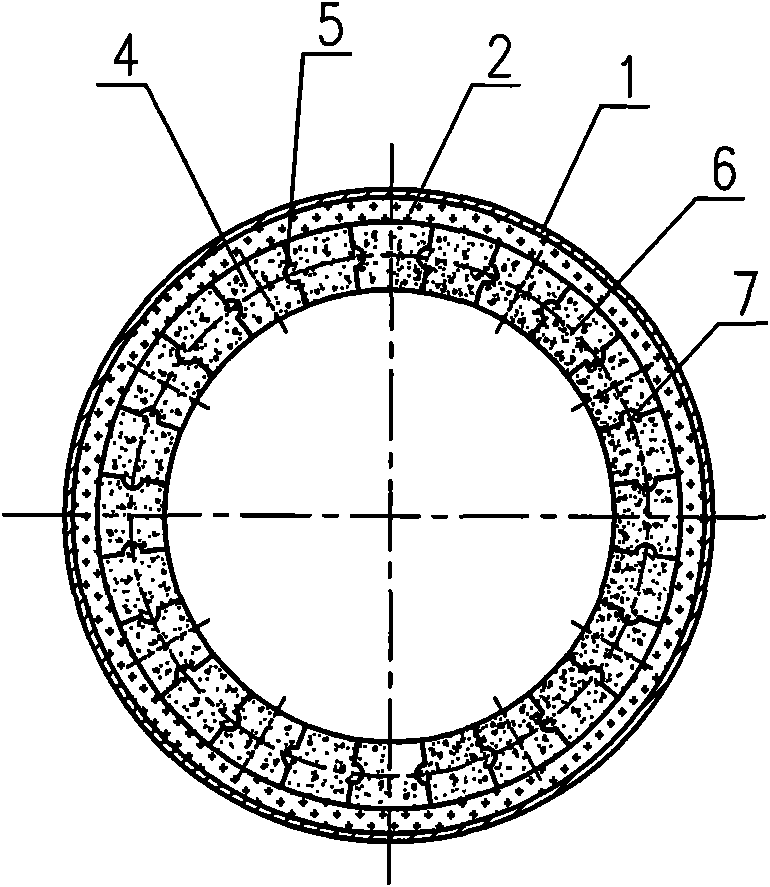

Trihydrate alumina gas phase fluidization calcining furnace lining

ActiveCN101261086AImprove impact resistanceExtended service lifeFluidised-bed furnacesMonolithic liningsFiberBrick

The invention provides a hydrafil dilute phase fluidizaton roasting furnace brick lining, comprising a furnace body top, an ascending tube wagon top, a furnace body side wall, a conic cylinder, a separator, a gas duct, a central cylinder and a furnace brick lining on a steering cylinder body, wherein, the furnace brick lining mainly consists of a fiber mat layer, a light castable refractory layer and a heavy castable refractory layer, the inside of the furnace brick lining is provided with at least one flexible suspension or points-shaped heat resisting metal clip respectively connecting the furnace body top, the ascending tube wagon top, the furnace body side wall, the conic cylinder, the separator, the gas duct, the central cylinder, the fiber mat layer on the steering cylinder body, the light castable refractory layer, the heavy castable refractory layer and the outside wall into a whole. The hydrafil dilute phase fluidizaton roasting furnace brick lining is provided with various refractory materials comprehensively, solves the problems of the system loss, the common crackle, the shedding of the material at the expanding position and the unreasonable structure caused by the high temperature of the furnace brick lining and realizes the obvious economic benefits of reaching production targets, exceeding the production goal, saving energy, decreasing the energy consumption and prolonging the service life.

Owner:李朝侠

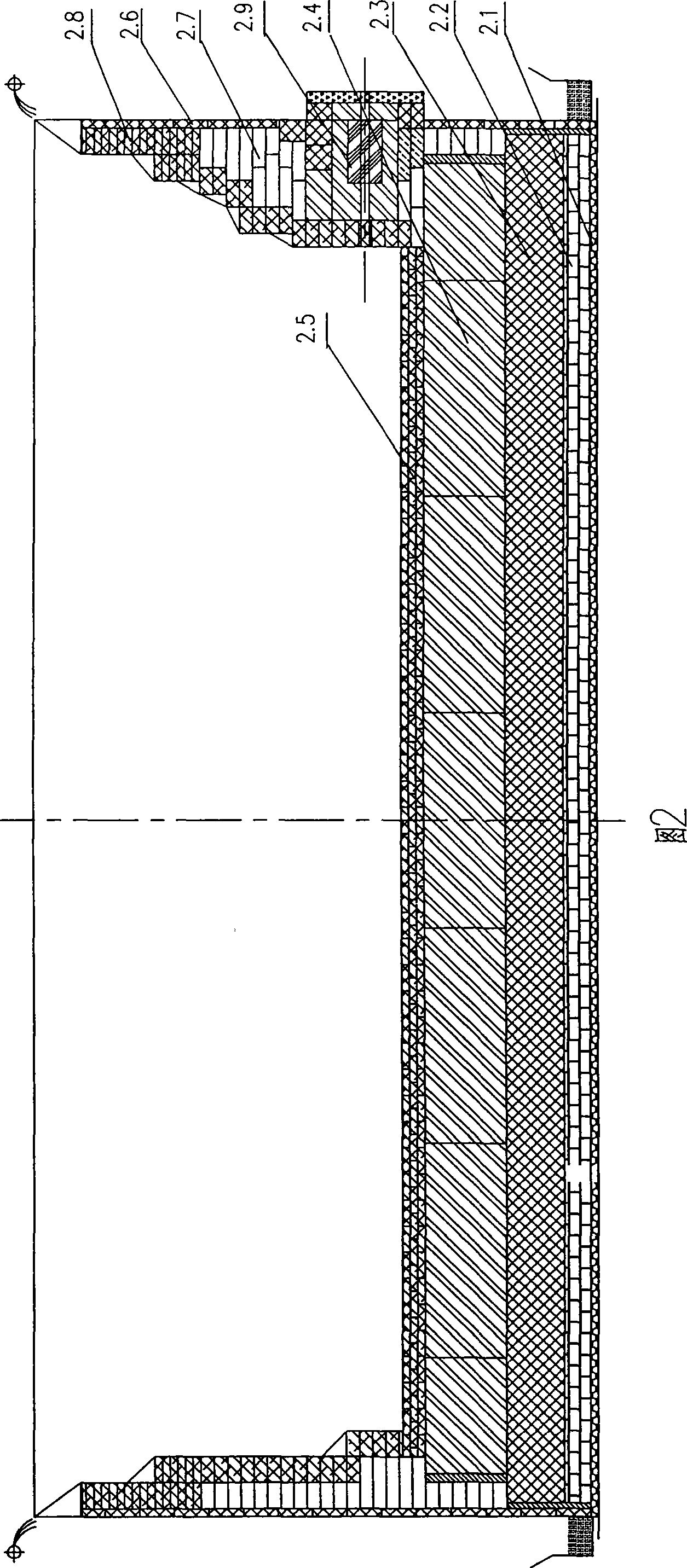

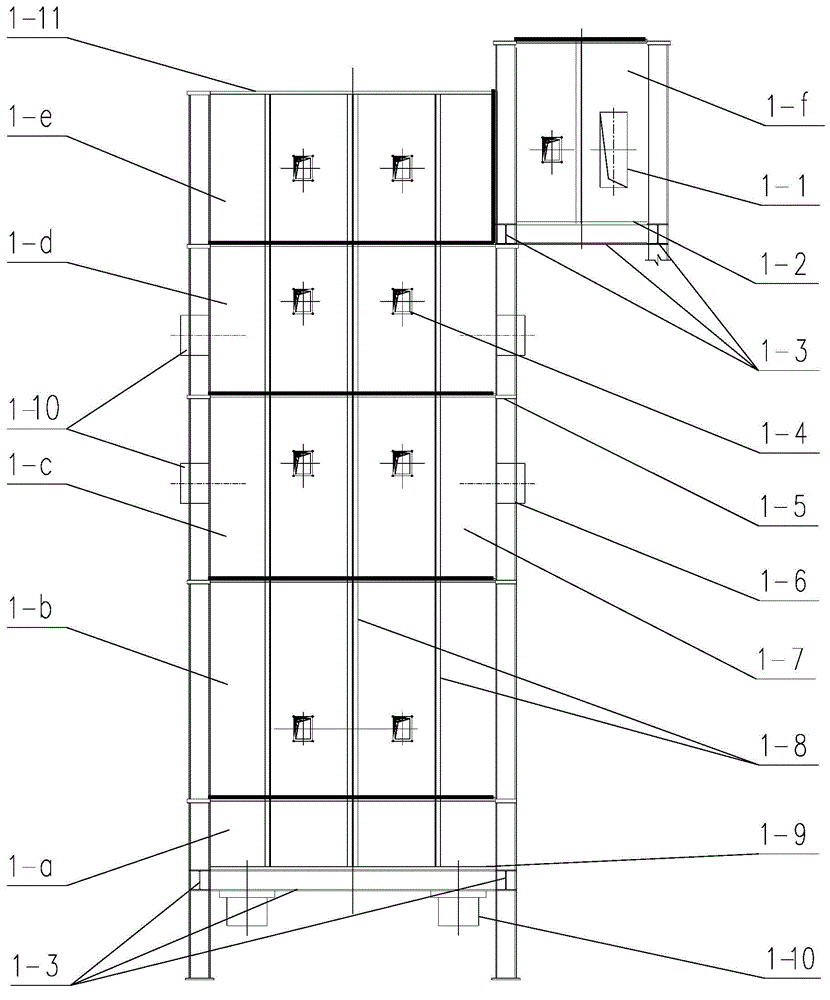

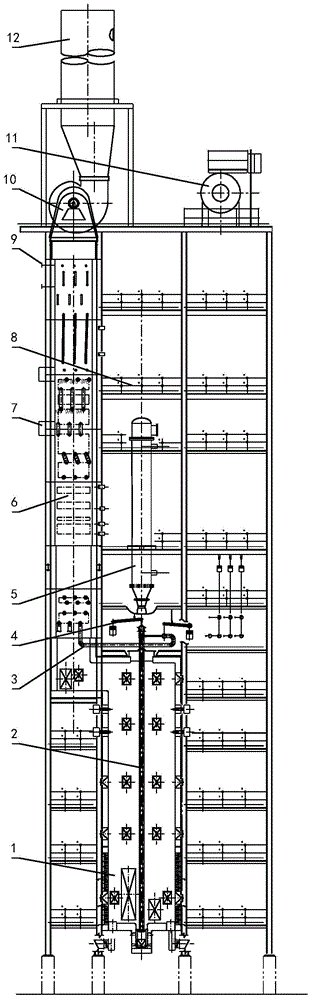

Integral modular structure of industrial furnace and construction method

ActiveCN104976894AShorten the construction periodGuaranteed Build QualityMonolithic liningsModular designModular structure

The invention discloses an integral modular structure of an industrial furnace and a construction method. The integral modular structure comprises a main body part and accessory equipment and accessories. The main body part of the integral modular structure of the industrial furnace comprises a radiation section modular structure, a convection segment, a radiation furnace pipe, a crossing pipe for connecting a convection furnace pipe with the radiation furnace pipe and a supporting hanging system for the radiation furnace pipe and the crossing pipe. The accessory equipment and accessories comprise a chimney, a waste heat boiler, a steam pocket, a draught fan, an ash ejector, parts of platform and ladder, an instrument and a cable of the instrument. The method comprises the steps that the main body part of an integral module of the industrial furnace and the accessory equipment and accessories of the integral module of the industrial furnace are manufactured and assembled in a workshop, integrally transported and integrally mounted to be in place. Integral modular design, workshop modular manufacturing, integral assembly, integral transportation and field integral mounting to be in place are adopted in the industrial furnace; the construction difficulty is reduced, the manufacturing precision and the construction schedule are ensured, the labor cost of site operation is low, the construction period is short, and construction is safe.

Owner:SINOPEC ENG +1

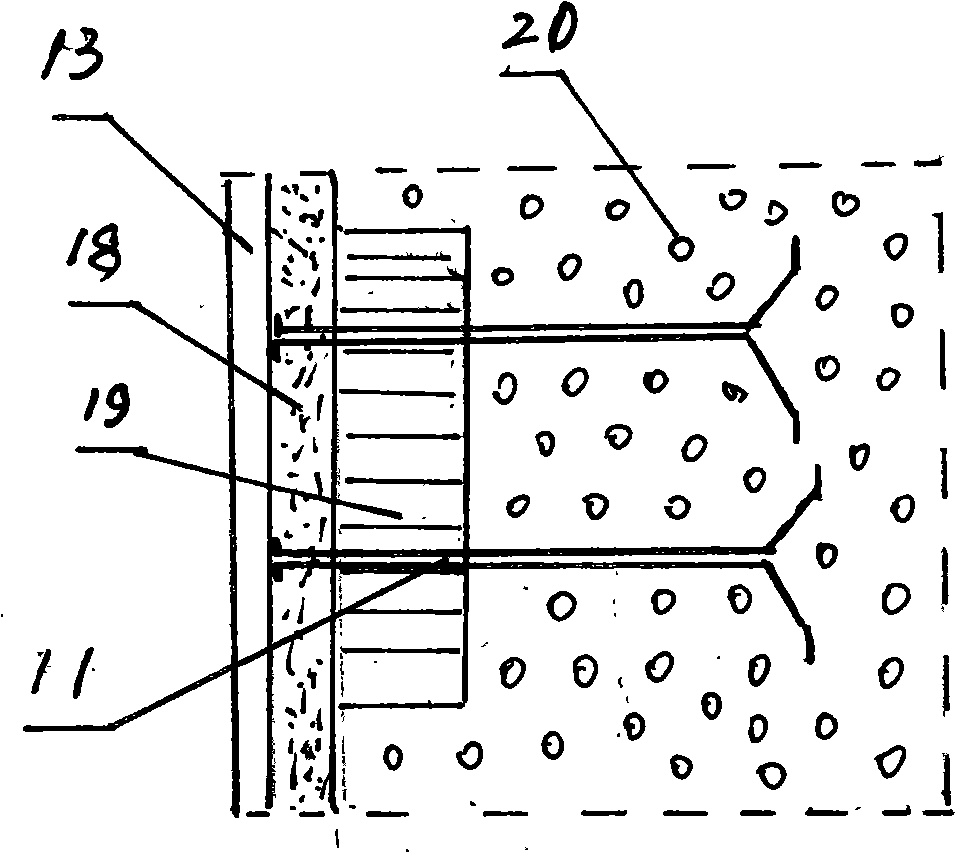

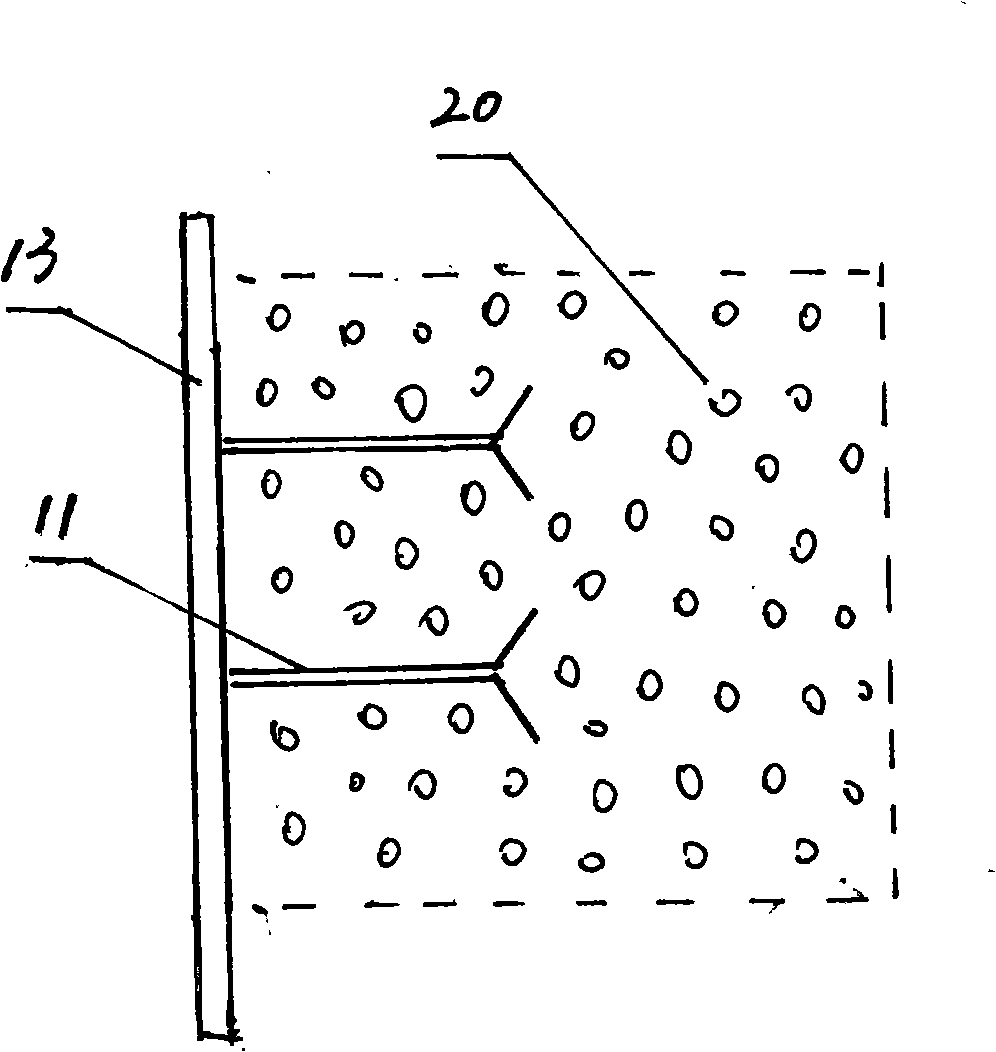

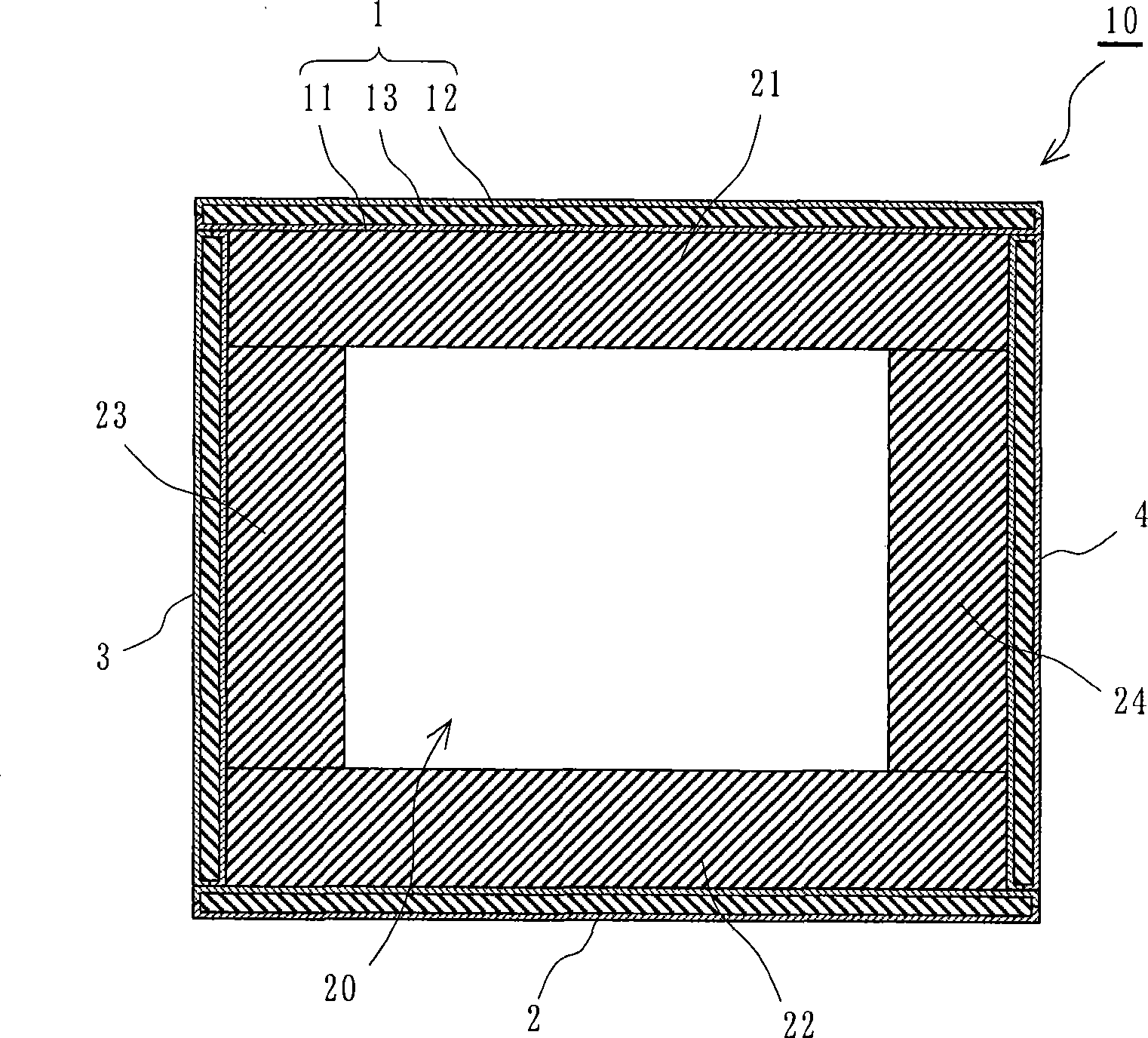

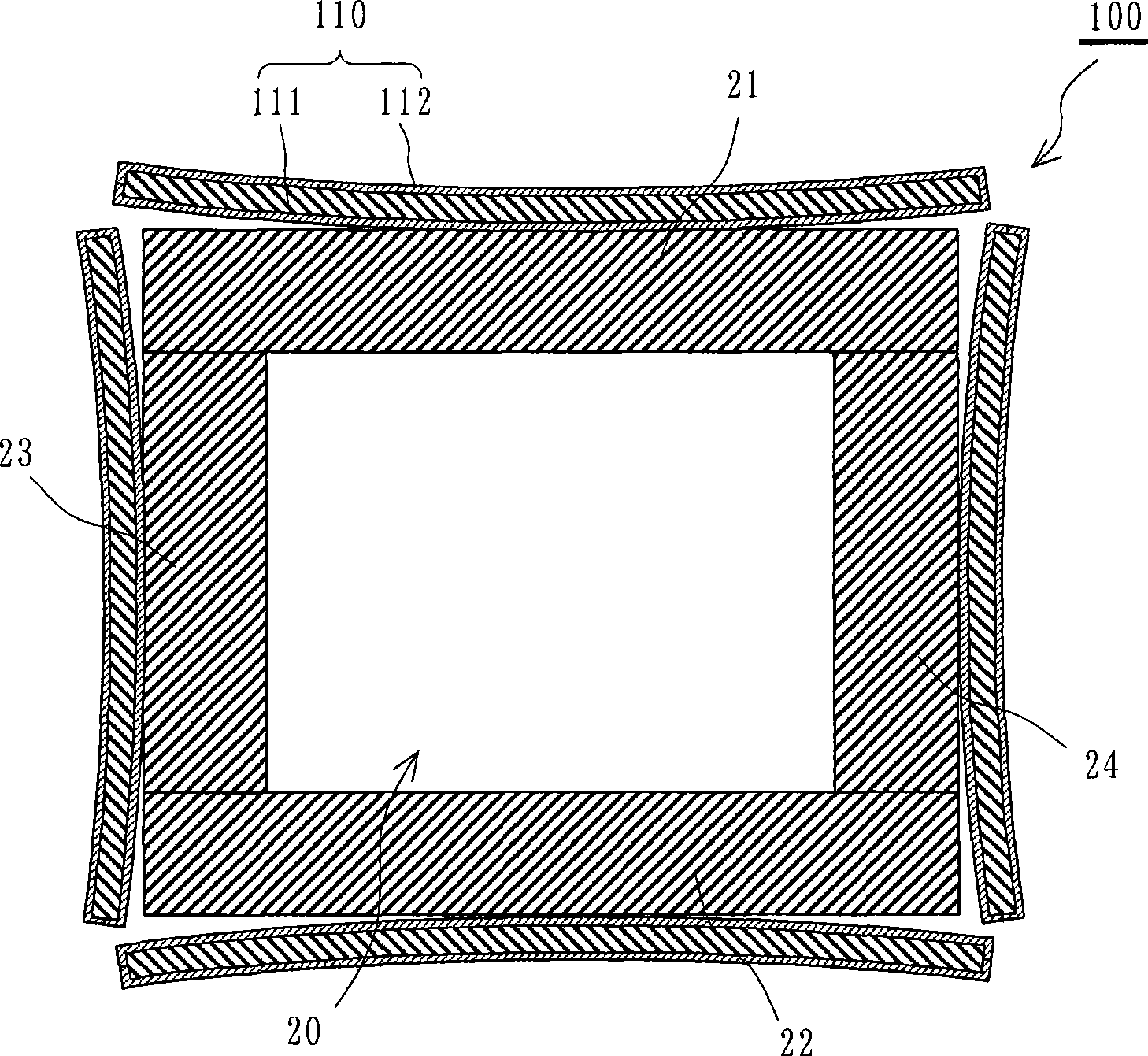

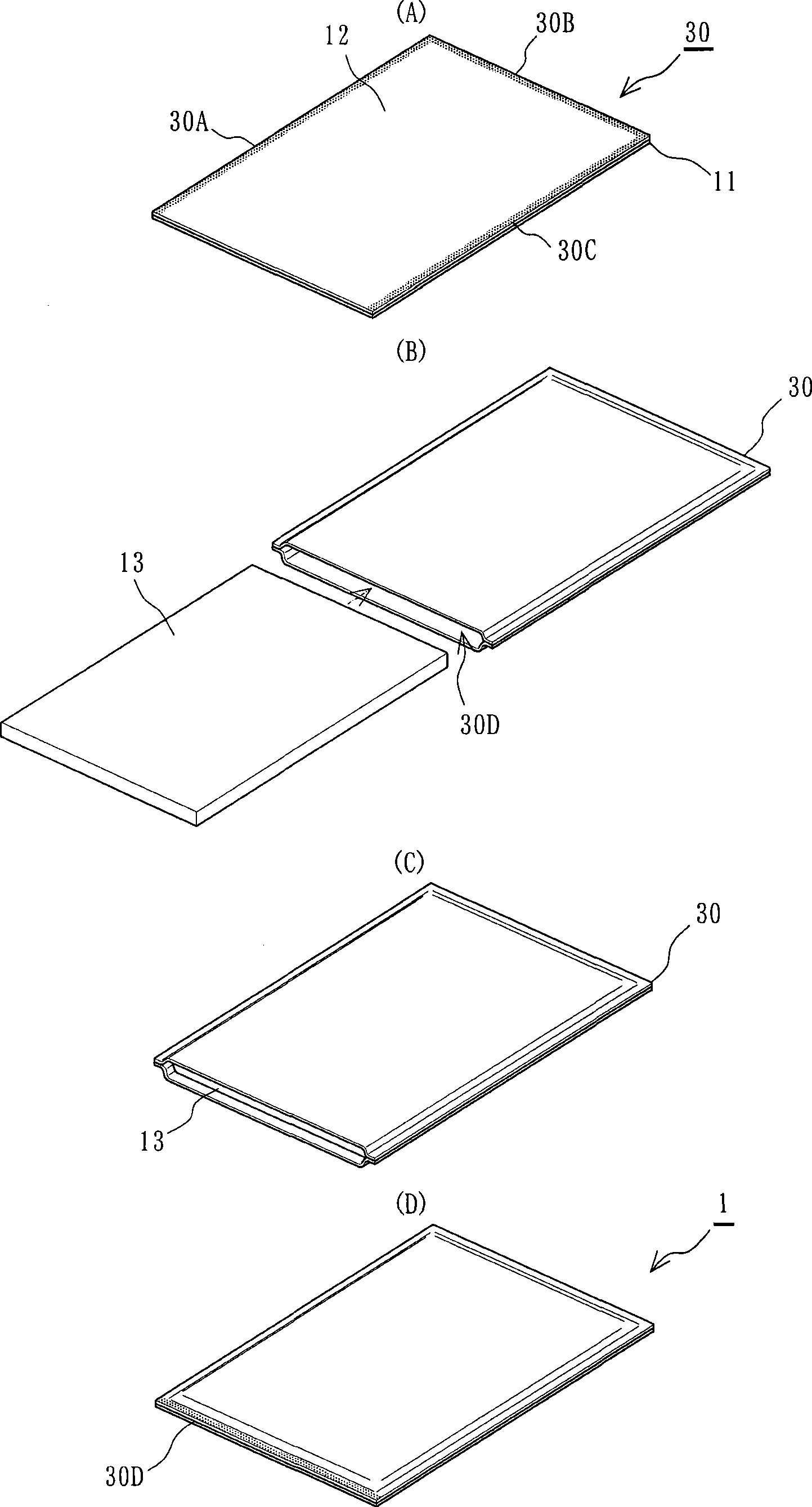

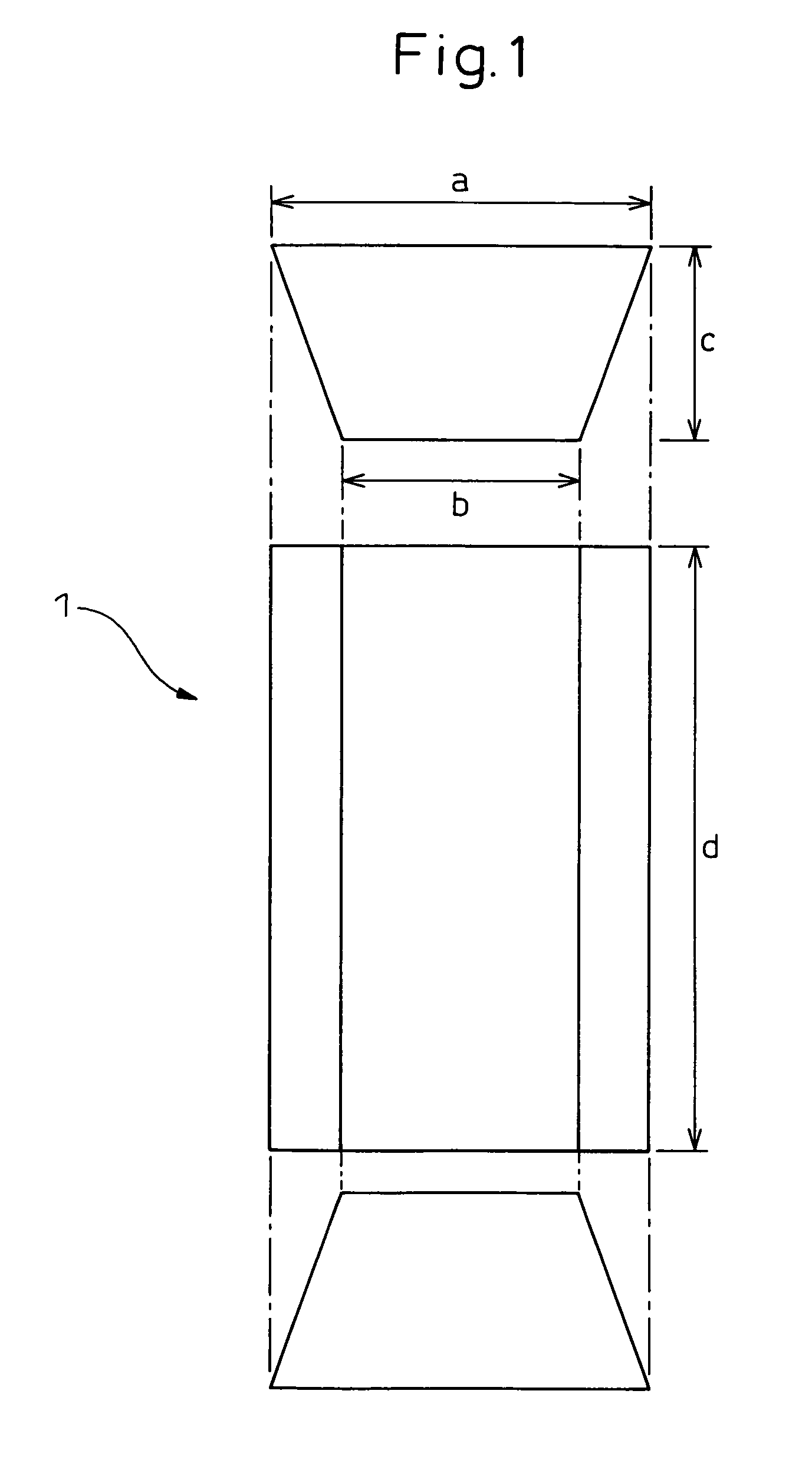

Heat resisting vacuum heat insulating material

InactiveCN101441038APrevent thermal deformationGood insulation performanceThermal insulationPipe protection by thermal insulationThermal expansionEngineering

The present invention provides a heat-proof vacuum insulation material, having an outer housing body composed of an internal surface material with smaller coefficient of linear thermal expansion than that of an outer surface material, such that opening interstice may not form between the outer surface of the wall surface and the internal surface of the heat-proof vacuum insulation material, which holds adiathermancy of a heating chamber. A first component (11) configured on a high temperature side is composed of material with smaller coefficient of linear thermal expansion than that of material of a second component (12) configured on a low-temperature side, after a core is accommodated between the first component (11) and the second component (12), the inside become vacuum state, such that large difference may not generate between the heat distortion of the first component (11) and that of the second component (12), thereby preventing reduction of adiathermancy of the heating chamber (20) caused by separation of the heat-proof vacuum insulation material (1) from the heat-proof insulation material (21) after deformation in thickness direction.

Owner:KOYO THERMO SYST CO LTD

Binder for monolithic refractories and monolithic refractory

ActiveUS20110039683A1High purityLow physical propertyRotary drum furnacesMonolithic liningsSlagRefractory

A binder for monolithic refractories characterized by containing ingredients comprised of a chemical composition of at least one of CaxSr1-xAl2O4, and CaySr1-yAl4O7 or these plus 12(CaO)z(SrO)1-z.7Al2O3 (where, 0<x<1, 0<y<1, and 0<z<1) and a binder for monolithic refractories and monolithic refractories superior in erosion resistance to slag or molten iron by monolithic refractories comprised of this binder and refractory aggregates are provided.

Owner:NIPPON STEEL CORP +1

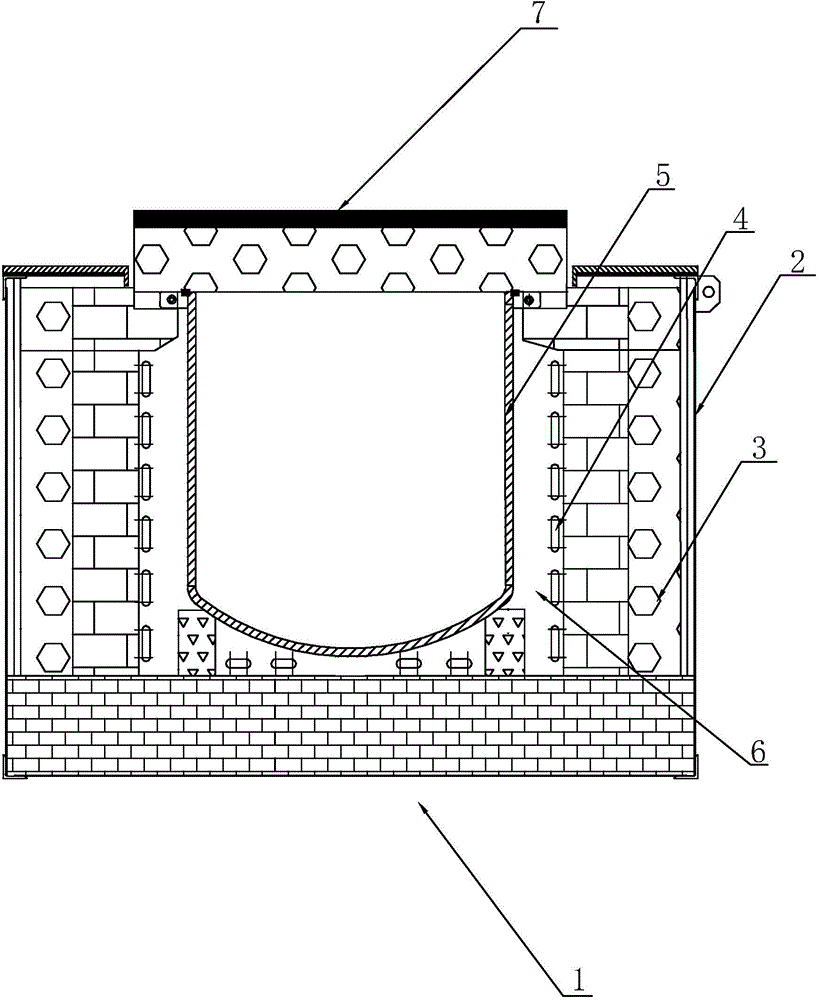

High-temperature-resisting anti-corrosive thermal-insulation composite lining structural member and manufacturing method thereof

The invention discloses a high-temperature-resisting anti-corrosive thermal-insulation composite lining structural member and a manufacturing method thereof. The high-temperature-resisting anti-corrosive thermal-insulation composite lining structural member comprises a metal shell, a light thermal-insulation lining material layer, a cellucotton layer and an anchor nail, further comprises a dew-point corrosion preventing coating layer, and can also comprise high-temperature-resisting alloy-steel wires and a high-temperature-resisting fiber paper layer. The manufacturing method comprises the following steps of welding and fixing the head of the anchor nail on the inner wall of the metal shell body, blade-coating the dew-point corrosion preventing coating layer, applying the light thermal-insulation lining material layer, and spray-coating the cellucotton layer. According to the invention, a composite lining layer is formed by the dew-point corrosion preventing coating layer, the light thermal-insulation lining material layer and the cellucotton layer through a special structure, which play the roles of resisting high-temperature, preventing dew-point corrosion and insulating heat simultaneously, and ensures that the composite lining layer can be combined with a shell body of a thermal facility into a firm integer; meanwhile, the composite lining structural member has better strain property on expansion on heating and contraction on cooling, and makes petrochemical thermal power equipment be used for a long time in the reliable and economical premise.

Owner:陈海渊

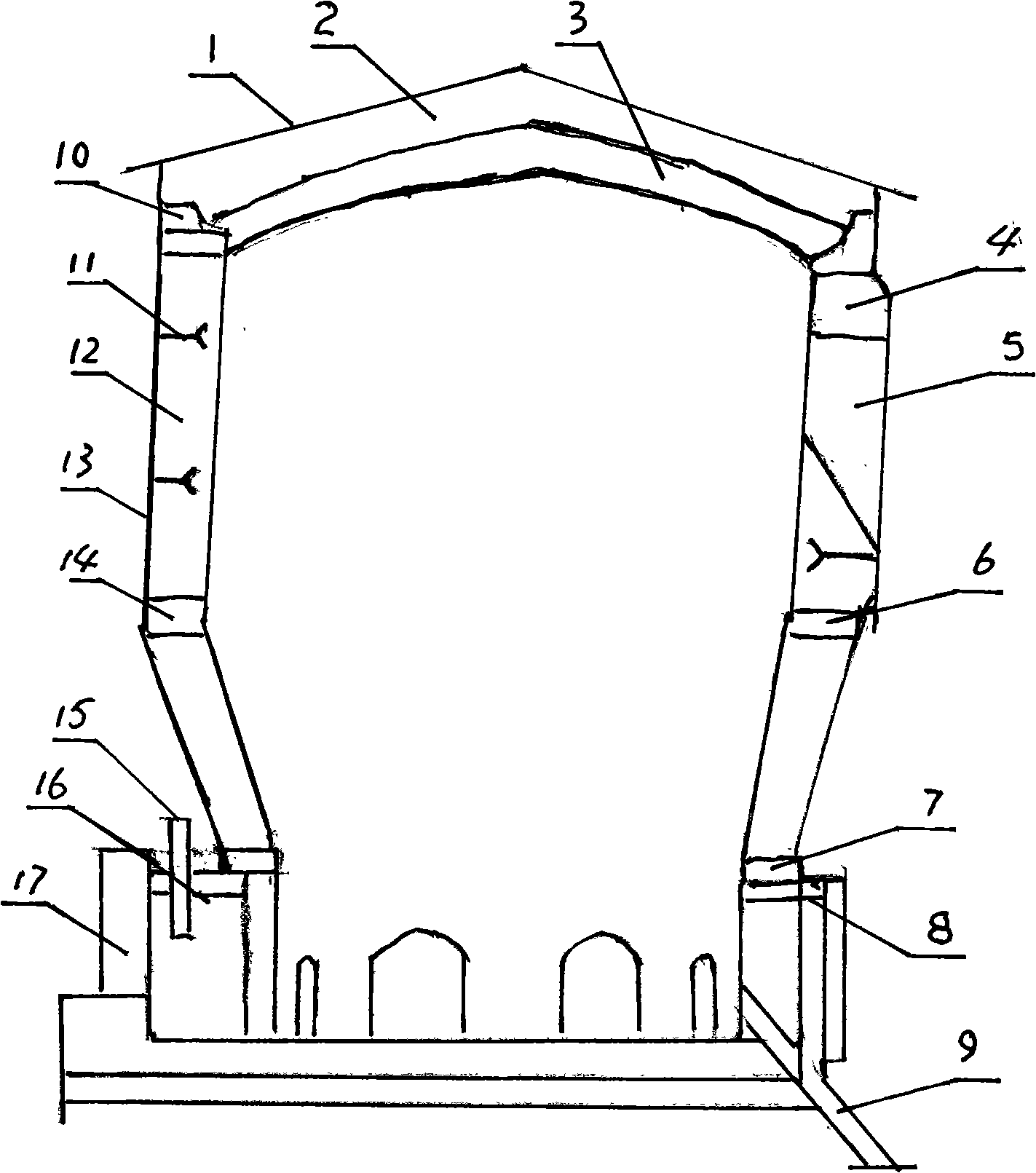

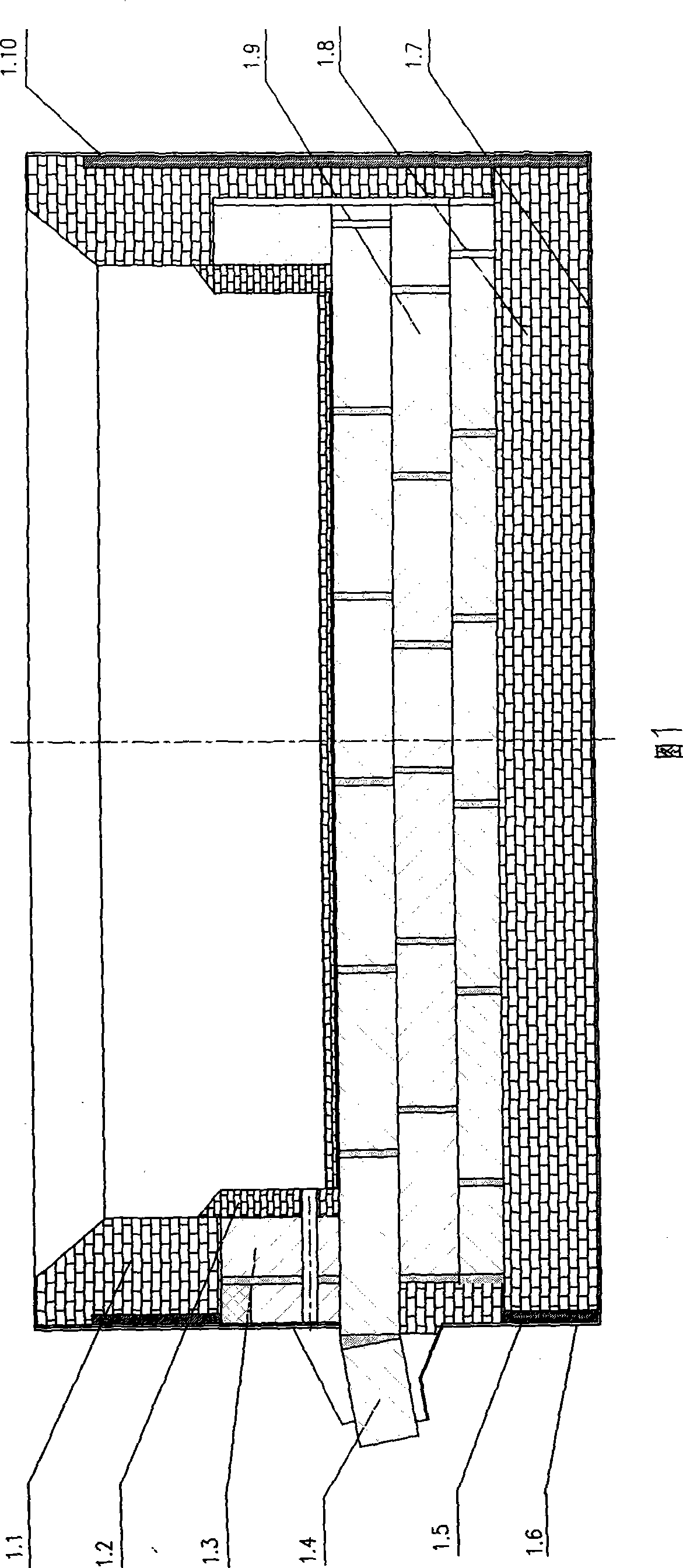

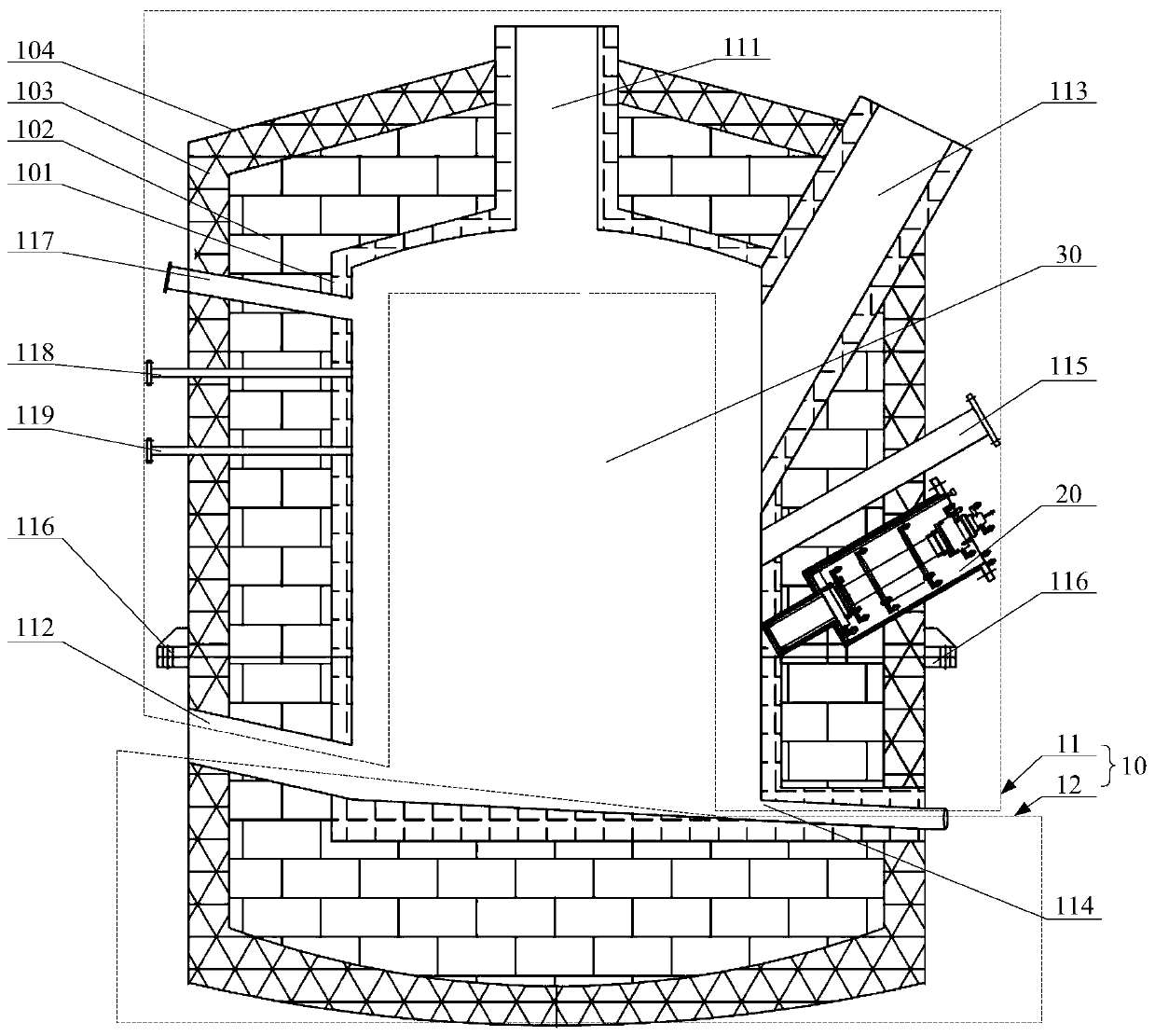

Hot Blast Stove Dome and Hot Blast Stove

ActiveUS20110200958A1Significant engineeringSignificant materialBrick-hot blast stovesLining supportsCombustion chamberEngineering

A hot blast stove dome comprises a first dome portion adapted for support on a combustion chamber wall of a hot blast stove, and a second dome portion adapted for support on a checker chamber wall of a hot blast stove, wherein a vertical expansion joint is provided between the first dome portion and the second dome portion and is adapted to allow the first dome portion and the second dome portion to independently accommodate vertical expansion of their respective supporting walls. The dome is suitably provided in a hot blast stove which comprises a combustion chamber, a checker chamber, a cylindrical housing comprising a combustion chamber wall and a checker chamber wall.

Owner:ALLIED MINERAL PROD LLC

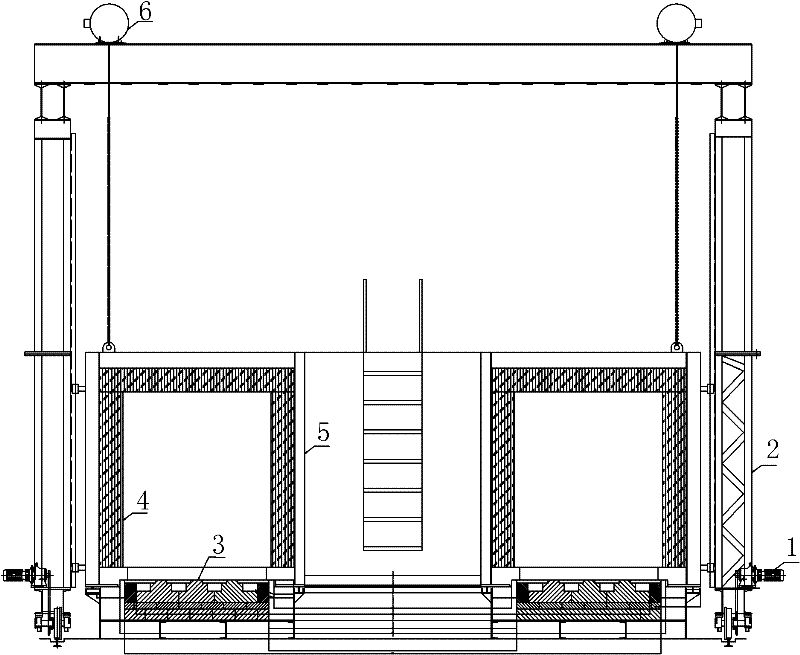

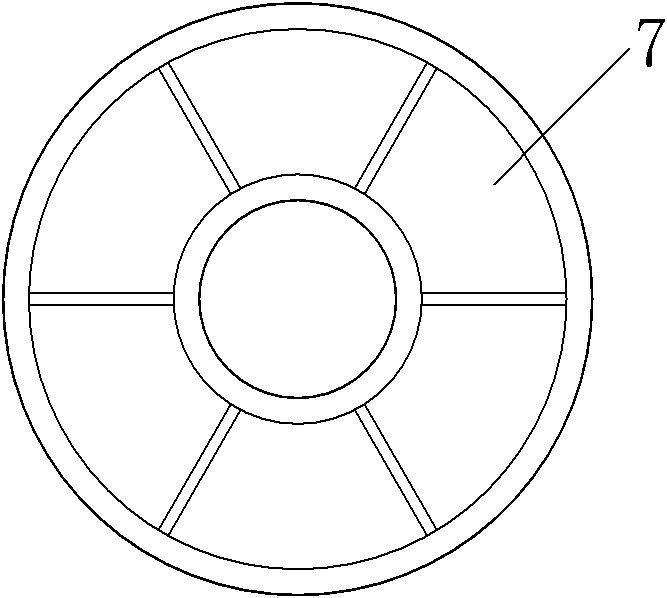

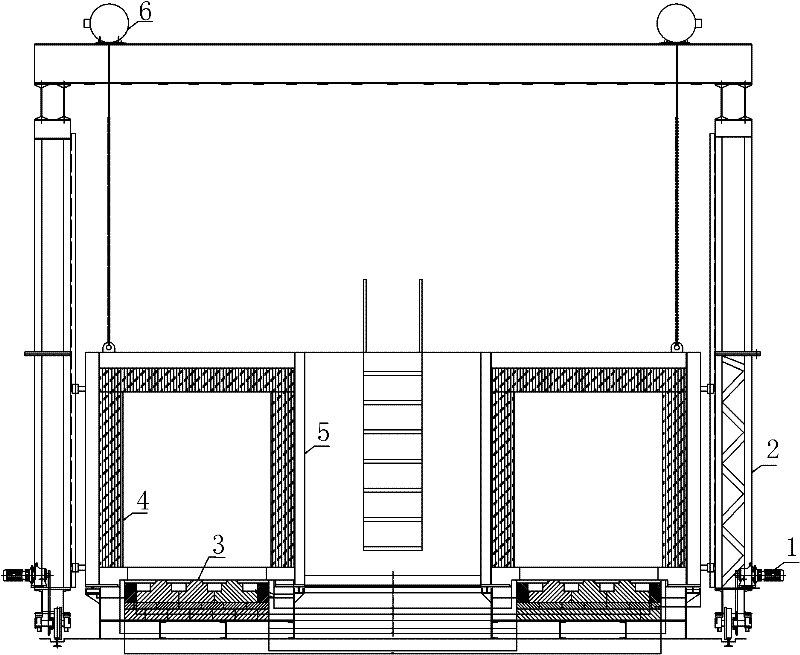

Bell-type movable full fiber resistance furnace

InactiveCN102243018ALayout improvementImprove uniformityFurnace typesElectric heating for furnacesFurnace temperatureProduction rate

The invention discloses a bell-type movable full fiber resistance furnace, which comprises a furnace cover, a lift mechanism for moving the furnace cover, a furnace base for supporting the furnace cover, a furnace frame for installing the lift mechanism and a transmission mechanism connected with the furnace frame; the furnace cover comprises an internal furnace cover and an external furnace cover; the internal furnace cover is in a hollow structure; heating elements are arranged between the internal furnace cover and the external furnace cover; and heating bricks are arranged on the furnace base and spliced to form a plurality of spaced concentric rings. By adopting a furnace body with a particular structure, the heating area can be increased, the heating space can be reduced, the uniformity of the furnace temperature is improved, the speed of temperature rise is increased, and the electric energy is saved; by adopting the arc heating bricks, the bearing can be ensured, the number of the heating elements on the furnace bottom can be increased, and the comprehensive uniformity of a heated workpiece is improved; and by adopting the lift mechanism to move the furnace cover, the working intensity of operators can be reduced, the production rate is greatly improved, and the personnel safety is simultaneously ensured.

Owner:JIANGSU HUADONG FURNACE IND

Inner liner material for industrial kiln furnace

The invention discloses an inner liner material for an industrial kiln furnace. The inner liner material comprises a base body and a high-emissivity coating, wherein the base body is a prefabricated element with a semi-sealed cavity and is formed through adding 10 percent of explosion-proof fiber into high-temperature fire-resistance materials, carrying out sufficient stirring and carrying out sintering or casting. The explosion-proof fiber starts to soften, contract and melt after reaching a certain temperature in the sintering process along with the prefabricated element, finally, a plurality of irregular micro holes are formed, antioxidant and sintering agents are brushed and coated on the inner wall of the semi-sealed cavity of the prefabricated element, then, bonding agents are coated, next, the high-emissivity coating with the thickness being 0.2 to 2mm is sprayed and coated, natural drying in the shade is carried out at room temperature, finally, high-temperature heating solidification is carried out, the heating speed is 10 DEG C / min, the sintering is completed after heat insulation for 5 hours at 1300 DEG C, and black body sources are formed. The inner liner material has the advantages that the heat storage function is strong, the radiance is high, the heat transfer area of a furnace hearth can be greatly increased, the furnace liner inner wall blackness and the irradiance can also be improved, the temperature uniformity of the furnace hearth is improved, and the service life of the furnace is prolonged.

Owner:四川科达节能技术有限公司

Metal homogenizing and melting furnace

ActiveCN104390456AWith lossOxidation resistantStirring devicesCrucible furnacesCrucibleUltimate tensile strength

Owner:如东县东广物流有限公司

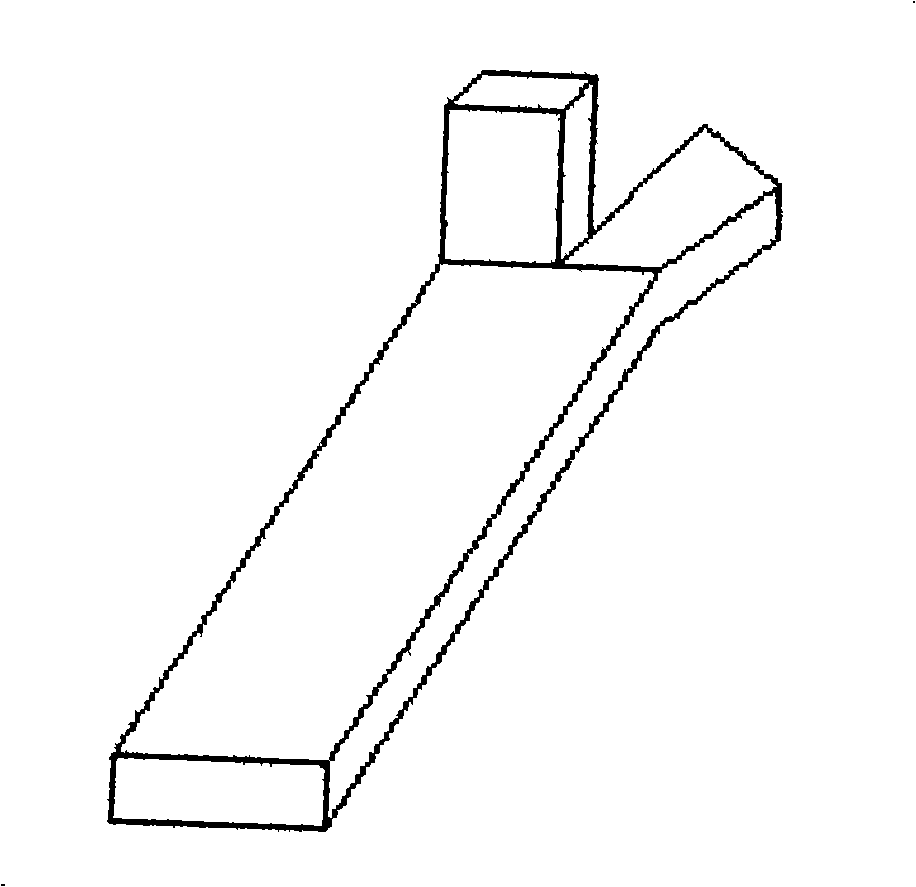

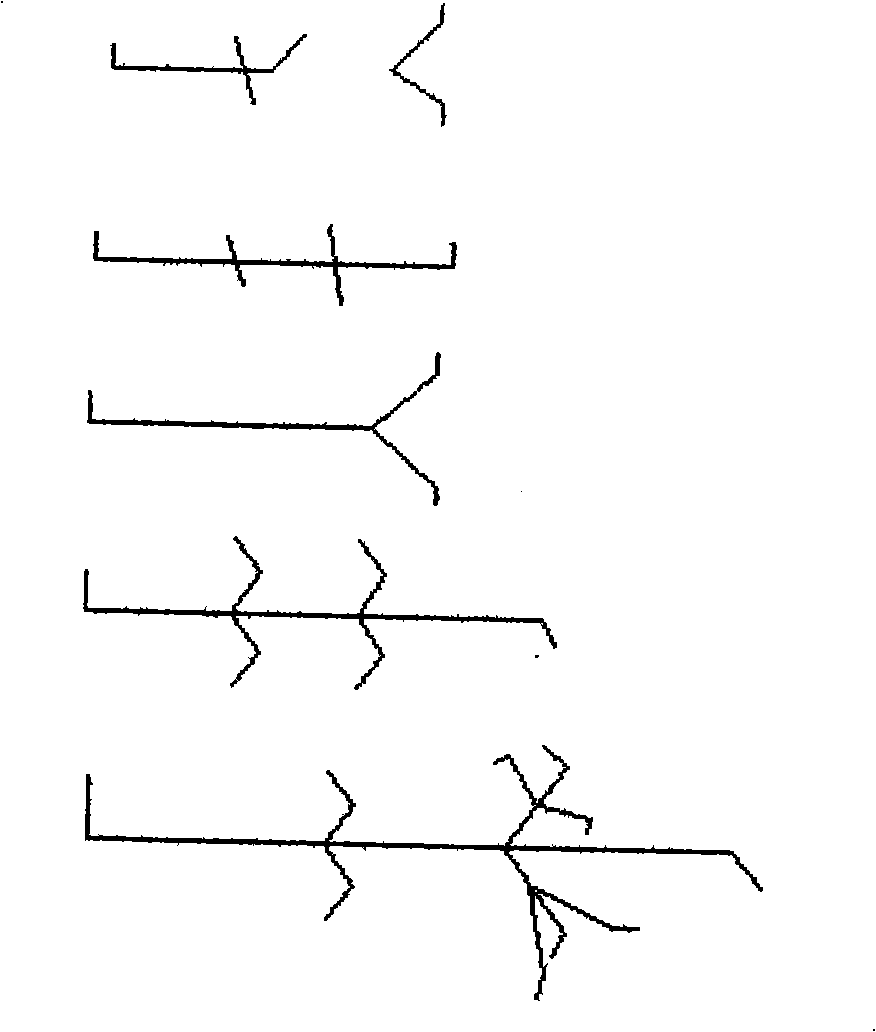

Large-sized industrial kiln lining anchoring piece and method of use thereof

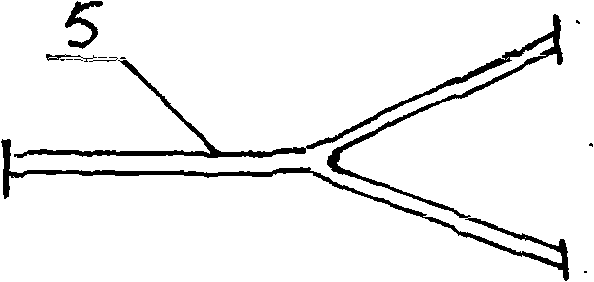

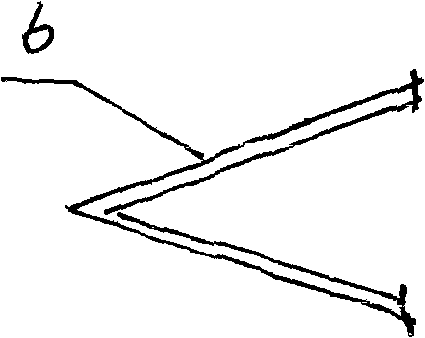

InactiveCN101261083AStrong toughnessImprove performanceFluidised-bed furnacesMonolithic liningsShaped beamBrick

The invention provides a clip for a large-sized industry furnace brick lining. At least one end of the clip is provided with a V-shaped component, the included angle between V-shaped beam anchoring walls is more than 60 degrees, the V-shaped component is connected by a connecting reinforcing steel bar with the two ends provided with pothooks which are sleeved and hung inside the V-shaped component and are connected into a whole by the method of tack welding. The use method is as follows: (1) one end of the clip is welded on the furnace wall; (2) the clips are distributed inside the furnace brick lining in a cross way; (3) the clips are arranged transversely and horizontally and arranged vertically in a cross way; (4) the transverse distance between clips is more than or equal to 300 centimeters and the vertical distance between clips is more than or equal to 400 centimeters. The clip has great toughness reinforcing property and traction force, is easy to realize the industrialized and standard production, saves the raw steel material, lowers the cost, replaces the rigid anti-thrust fixing anchor brick of the furnace body, changes the fix force of the lateral wall into the traction force and adapts to the heat expansion force change direction of the furnace wall.

Owner:李朝侠

Heating device for low cycle fatigue life test of aeroengine turbine disc

InactiveCN109798771AImprove securityEvenly heatedFurnace typesElectric heating for furnacesEngineeringThermal radiation

The invention provides a heating device for a low cycle fatigue life test of an aeroengine turbine disc. Heating elements are separately arranged in interlayers of a furnace bottom, a furnace hood anda furnace roof, a turbine disk test assembly is heated by means of heat radiation, the heat radiation enables the turbine disk test assembly to be more evenly heated, and energy is more saved. Meanwhile, the heating elements are prevented from occupying a space of a furnace body, an internal working space of the furnace body is indirectly increased, the furnace body is enabled to be applicable toa hot test of any type of turbine disk test assembly, and the safety performance of the test is improved.

Owner:AECC AVIATION POWER CO LTD

Monolithic graphitic castable refractory

ActiveUS20120052196A1Reduce deliveryImprove thermal conductivityLayered productsPretreated surfacesWater dispersibleRefractory

A monolithic refractory castable material comprises from about 25 to about 80 weight percent of graphite, from about 1 to about 15 weight percent of a water dispersible, curable phenolic novolac resin, and from about 70 to about 15 weight percent of one or more refractory aggregates, based on the weight of the monolithic refractory castable material. The monolithic refractory castable material is water dispersible and may be delivered to a structure surface by casting, pumping, shotcreting or gunning processes. In one embodiment, the monolithic refractory castable material may be employed to install or replace a blast furnace lining.

Owner:ALLIED MINERAL PROD LLC

Melting furnace

InactiveCN111396882AEvenly heatedImprove heat utilizationIncinerator apparatusMonolithic liningsSlagHearth

The invention provides a melting furnace which comprises a furnace body and a plurality of heaters. The furnace body comprises a furnace wall and a furnace bottom. A hearth is formed with the furnacewall and the furnace bottom in an enclosure mode. The furnace wall is provided with a feed port, a discharge port, a smoke discharge port, a slag discharge port and an air duct port. The feed port, the discharge port, the smoke discharge port, the slag discharge port and the air duct port all communicate with the hearth. The melting furnace is characterized in that the plurality of heaters surround the furnace wall at intervals, each heater is fixedly connected with the furnace body through a heater connector, the ends, close to the hearth, of the plurality of heaters face the furnace bottom,and the vertical projection of the extension cords of the ends, close to the hearth, of the plurality of heaters on the furnace body are all tangential to the same circle. By means of the melting furnace, a heated material in the health is evenly heated by the plurality of heaters, and the heat utilization rate of the heaters is increased.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG

Binder for monolithic refractories and monolithic refractory

ActiveUS8309483B2High purityLow physical propertyRotary drum furnacesMonolithic liningsAdditive ingredientRefractory

A binder for monolithic refractories characterized by containing ingredients comprised of a chemical composition of at least one of CaxSr1-xAl2O4, and CaySr1-yAl4O7 or these plus 12(CaO)z(SrO)1-z.7Al2O3 (where, 0<x<1, 0<y<1, and 0<z<1) and a binder for monolithic refractories and monolithic refractories superior in erosion resistance to slag or molten iron by monolithic refractories comprised of this binder and refractory aggregates are provided.

Owner:NIPPON STEEL CORP +1

Carbon-calcining rotary kiln lining and second tuyere structure thereof

InactiveCN101608864AAlleviate the degree of crackingHigh strengthRotary drum furnacesMaintainance of heating chambersInsulation layerEngineering

The invention relates to carbon-calcining rotary kilns in the field of carbon production, in particular to a carbon-calcining rotary kiln lining and a second tuyere structure thereof. The lining comprises a metal kiln body and the second tuyere structure, wherein the inner side of the metal kiln body is provided with a light castable heat-insulation layer, and a lining equal-dividing strip with grooves and a lining equal-dividing strip with bosses are arranged on the light castable heat-insulation layer. The invention has the following advantages that cracking degree of construction joints can be effectively eased; the grooves on two sides of the lining equal-dividing strip formed by a special template can increase the integral strength of the kiln lining through the tight bite with the post-cast lining equal-dividing strip; high-temperature materials during the operation of rotary kilns can be effectively blocked to ensure that the materials cannot directly enter the heat-insulation layer so as to help protect the integrity of the heat-insulation layer and simultaneously protect the metal kiln body against the damage of the high-temperature materials; and the effect of prolonging the lifespan of the rotary kiln lining can be directly achieved so as to obviously reduce the cost for maintaining the rotary kiln lining and effectively reduce the cost of carbon-calcining production.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com