Large area air outlet fluidized calcining furnace refractory lining

A technology of refractory lining and tuyere area, applied in fluidized bed furnaces, furnaces, integral linings, etc., can solve the problems of unstable operating conditions, high cost, and wear and tear of the lining, reducing the weight of the lining and providing heat resistance. The effect of improving the seismic force and overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

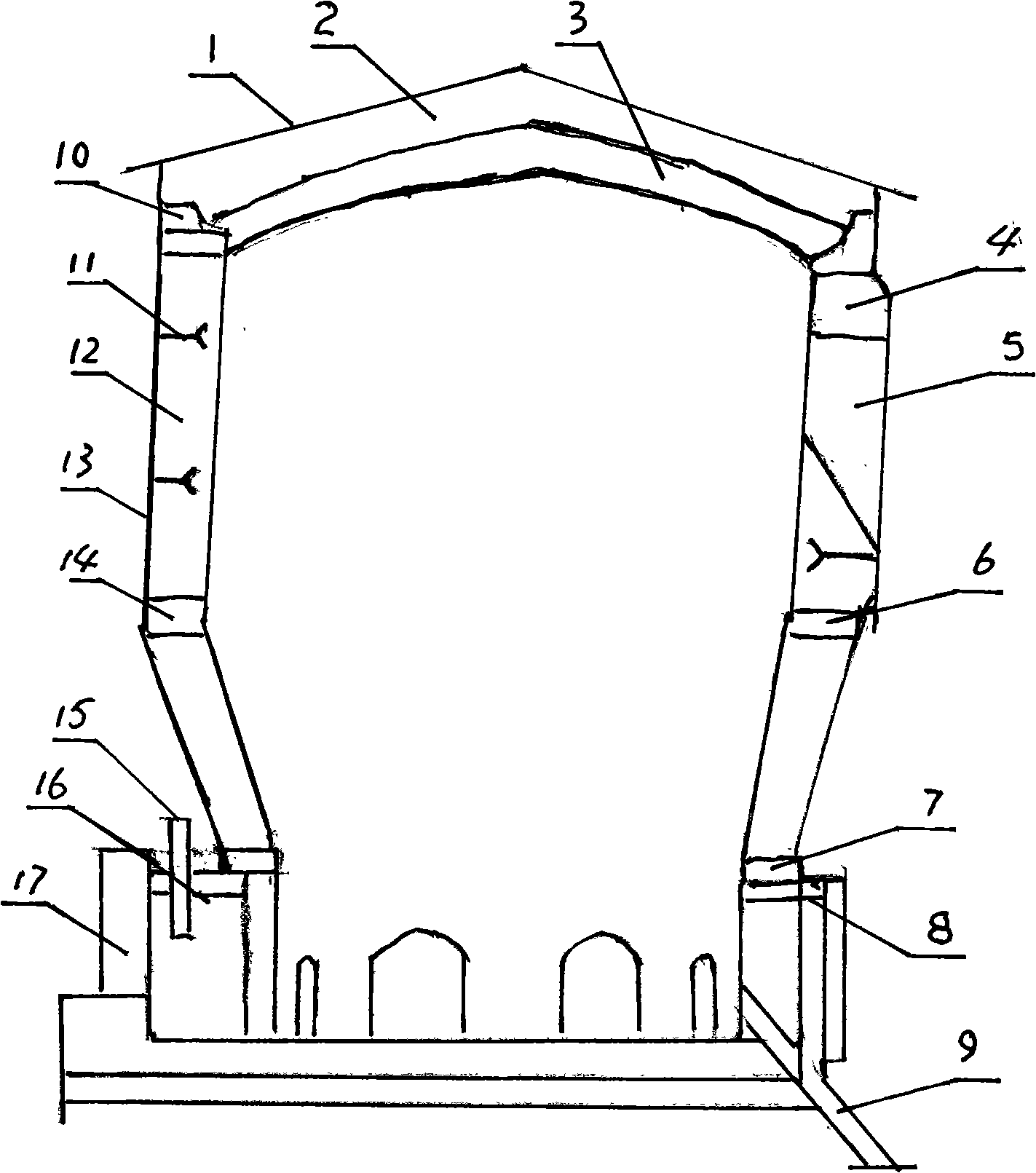

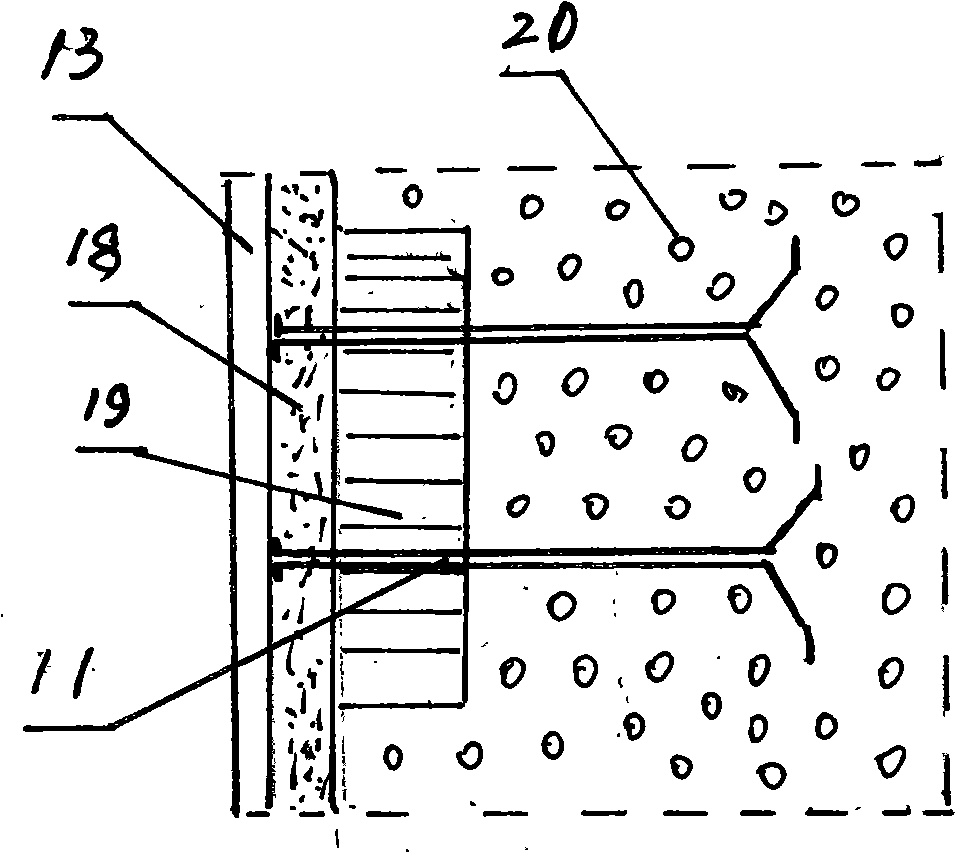

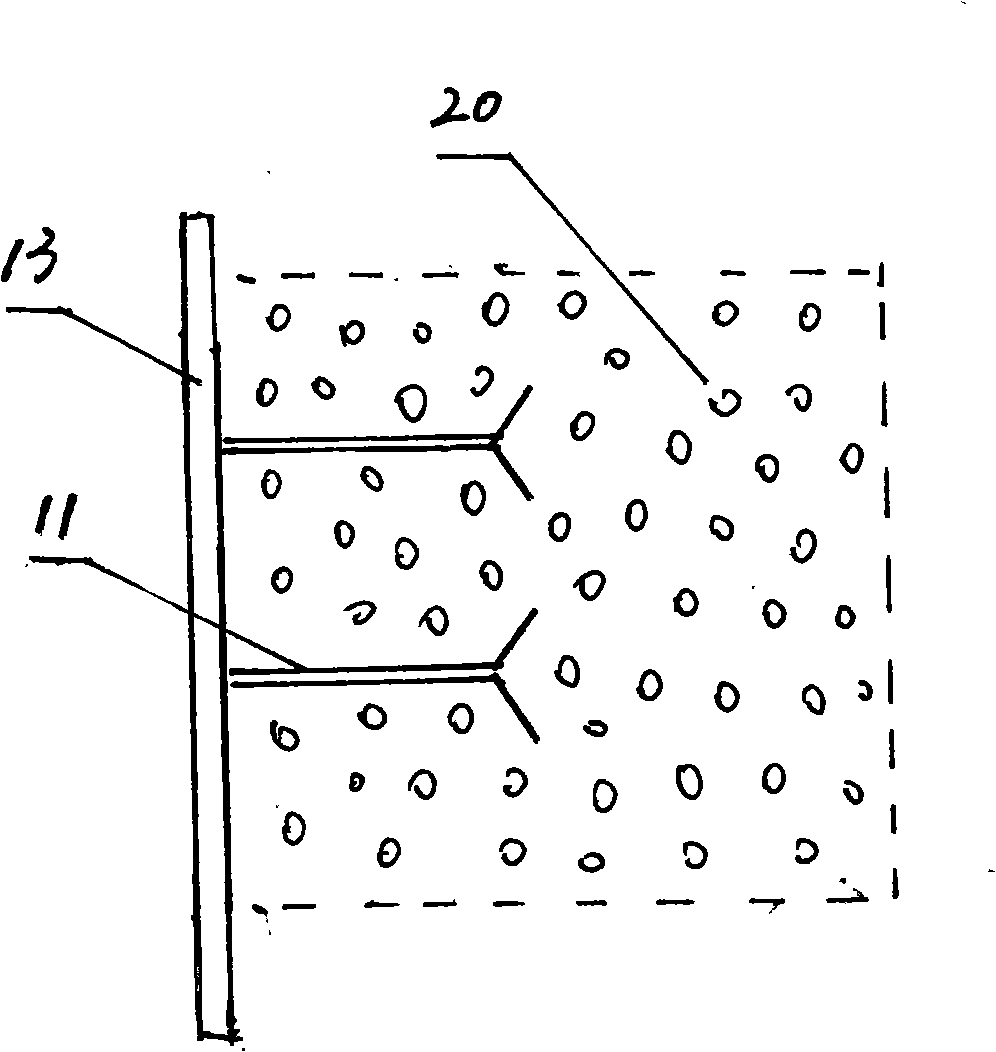

[0031] Depend on figure 1It can be seen that the refractory lining of the present invention is determined by the structural characteristics of the furnace body itself. The refractory lining is implemented with different firmware and reinforcement structures according to the shape changes of different parts, mainly including the furnace top castable layer 3 and the composite furnace wall of the furnace body. 12. Smoke exhaust port 5, front chamber roof 16, rear chamber roof 8, side wall 17, arch angle ring beam 10, hoop ring beam 14 and 6, and the refractory furnace lining is made of steel fiber reinforced wear-resistant refractory castable or high-strength and low-cement The refractory castable is integrated with the furnace steel shell 13, and a plurality of heat-resistant stainless steel anchors 11 are arranged in the refractory furnace lining. One end face of each heat-resistant stainless steel anchor 11 is welded to the furnace steel shell 13, and the other end is independe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com