Patents

Literature

1325 results about "Industrial furnace" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The purpose of an industrial furnace is to attain a higher processing temperature in comparison to open-air systems, as well as the efficiency gains of a closed system. Industrial furnaces typically deal with temperatures higher than 400 degrees Celsius.

Method and System for Optimizing Industrial Furnaces (Boilers) through the Application of Recursive Partitioning (Decision Tree) and Similar Algorithms Applied to Historical Operational and Performance Data

InactiveUS20090125155A1Improve efficiencyMechanical power/torque controlLevel controlPrediction algorithmsNaive Bayes classifier

A method is provided for deriving optimized operating parameter settings for industrial furnaces of different designs as commonly used in power generation that will achieve robust and desirable operations (for example, low NOx and low CO emissions while maintaining specific furnace exit gas temperatures). The method includes the application of recursive partitioning algorithms to historical process data to identify critical combinations of ranges of operational parameter (combinations of settings) that will result in robust (low-variability) desirable (optimized) boiler performance, based on empirical evidence in the historical data. The method may include the application of various algorithms for recursive partitioning of data, as well as the consecutive application of recursive partitioning methods to prediction residuals of previous models (a methodology also known as boosting), as well as the application of other prediction algorithms that rely on the partitioning of data (support vector machines, naive Bayes classifiers, k-nearest neighbor methods).

Owner:HILL THOMAS +1

High-temperature-resisting heat-insulation coating as well as preparation method and application thereof

ActiveCN103725074AEasy to use in constructionPlay the role of saving energy and reducing consumptionReflecting/signal paintsPetroleumEnergy consumption

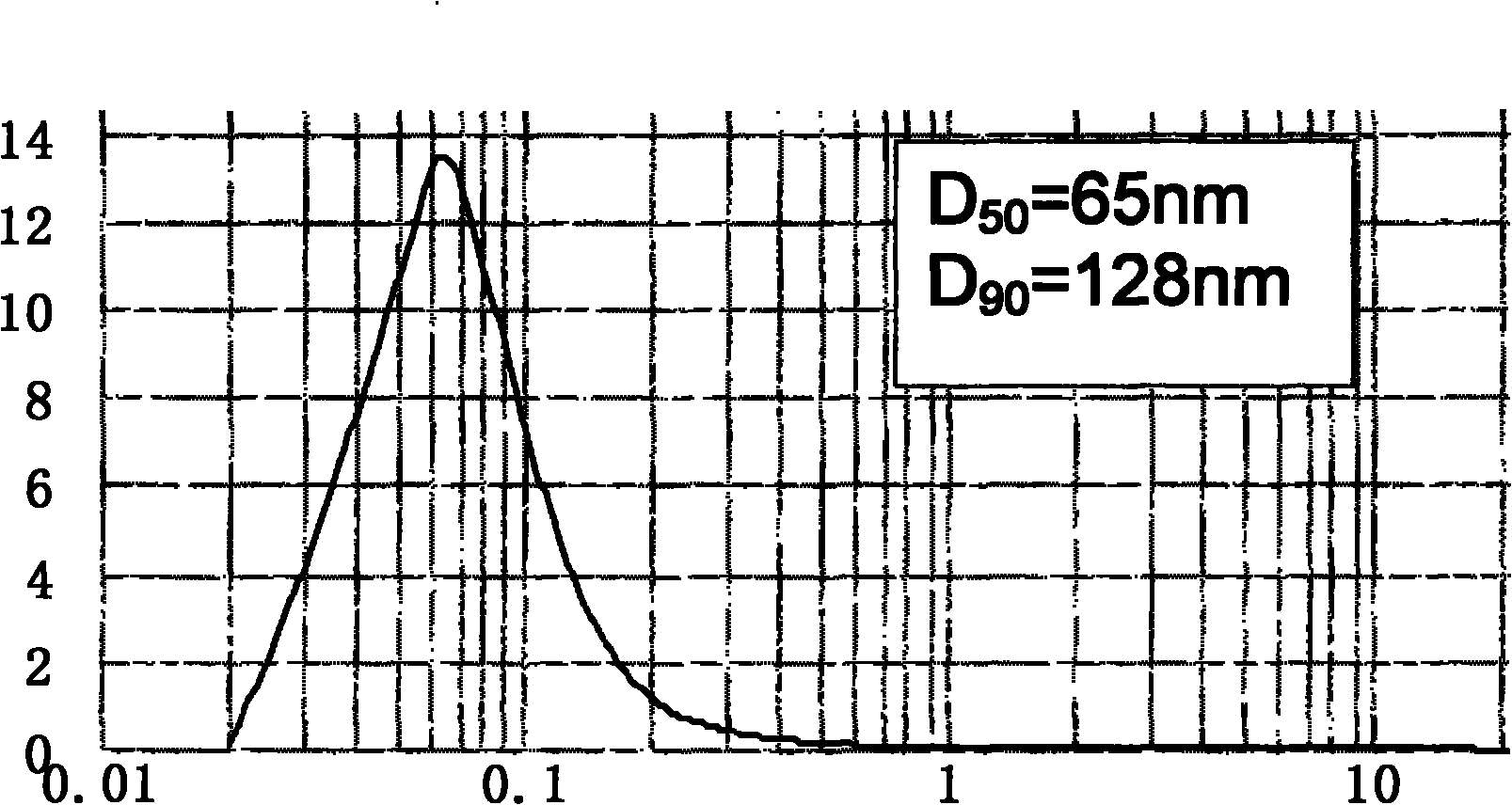

The invention relates to the field of functional coatings and particularly relates to a high-temperature-resisting heat-insulation coating and a preparation method thereof. The high-temperature-resisting heat-insulation coating is composed of the following raw materials in percentage by mass: 10%-40% of high-reflection paint with a shell-core structure, 10%-40% of heat-insulation powder with the shell-core structure, 1%-5% of a toughening agent, 10%-50% of a high-temperature bonding agent, 1%-10% of a coating auxiliary agent, and the balance of water. The preparation method comprises the following steps: mixing, dispersing and grinding raw materials; carrying out homogenization to enable an average grain diameter to be 325-400 meshes; and filtering and packaging to obtain a finished product. The high-temperature-resisting heat-insulation coating can be applied to high-temperature fields of industrial furnaces, industrial boilers, high-temperature steam pipelines, petroleum cracking equipment, engine parts, high-temperature smelting, sintering furnaces and the like, and can be used under a higher temperature for long time; the energy consumption can be saved and the service life of the furnaces is prolonged.

Owner:武汉双虎涂料股份有限公司

Method for preparing low-temperature SCR (selective catalytic reduction) denitration catalyst

InactiveCN102716752AGood activity at low temperatureHigh activityDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsNitric oxideAmmonium metavanadate

The invention relates to a method for preparing a low-temperature SCR (selective catalytic reduction) denitration catalyst, and belongs to the technical field of catalysis. The denitration catalyst has a good nitric oxide removal rate, water resistance and sulfur resistance when the temperature of flue gas ranges from 150 DEG C to 250 DEG C. The method includes dissolving ammonium metavanadate, transition metal salts and titanium and tungsten powder in water; and drying and calcining the mixed liquor to prepare the low-temperature SCR denitration catalyst. The prepared catalyst is good in low-temperature activity, and can keep the good nitric oxide removal rate, the water resistance and the sulfur resistance at the temperature ranging from 150 DEG C to 250 DEG C. In addition, owing to the high activity and poison resistance at the temperature ranging from 150 DEG C to 250 DEG C, the catalyst can be applied to the field of flue gas after the flue gas flows via dust catchers of thermal power plants and flue gas, with the temperature ranging from 150 DEG C to 250 DEG C, of industrial furnaces and the like, and denitration catalyst technology and application breakthrough is realized.

Owner:JIANGSU LONGYUAN CATALYST CO LTD

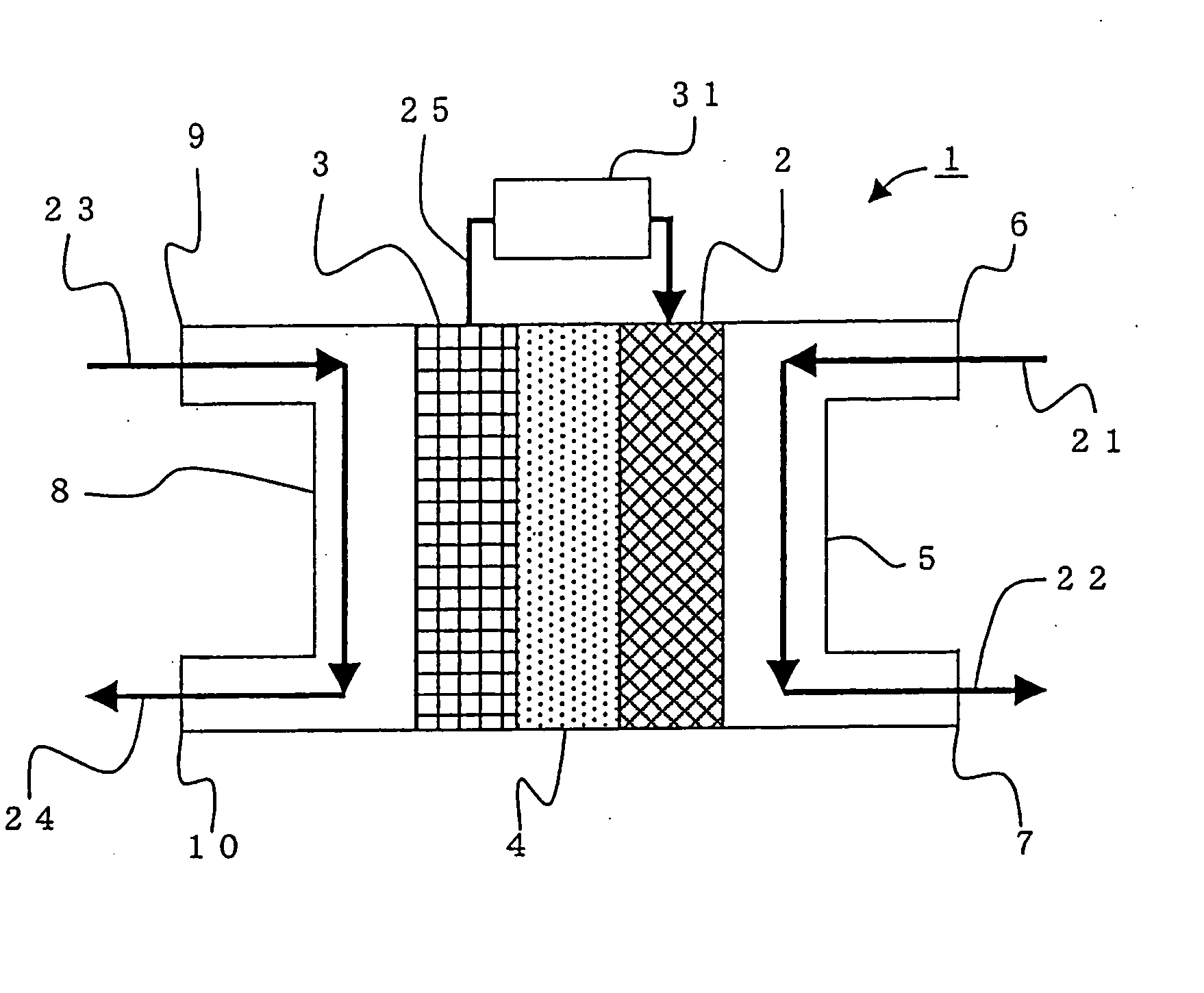

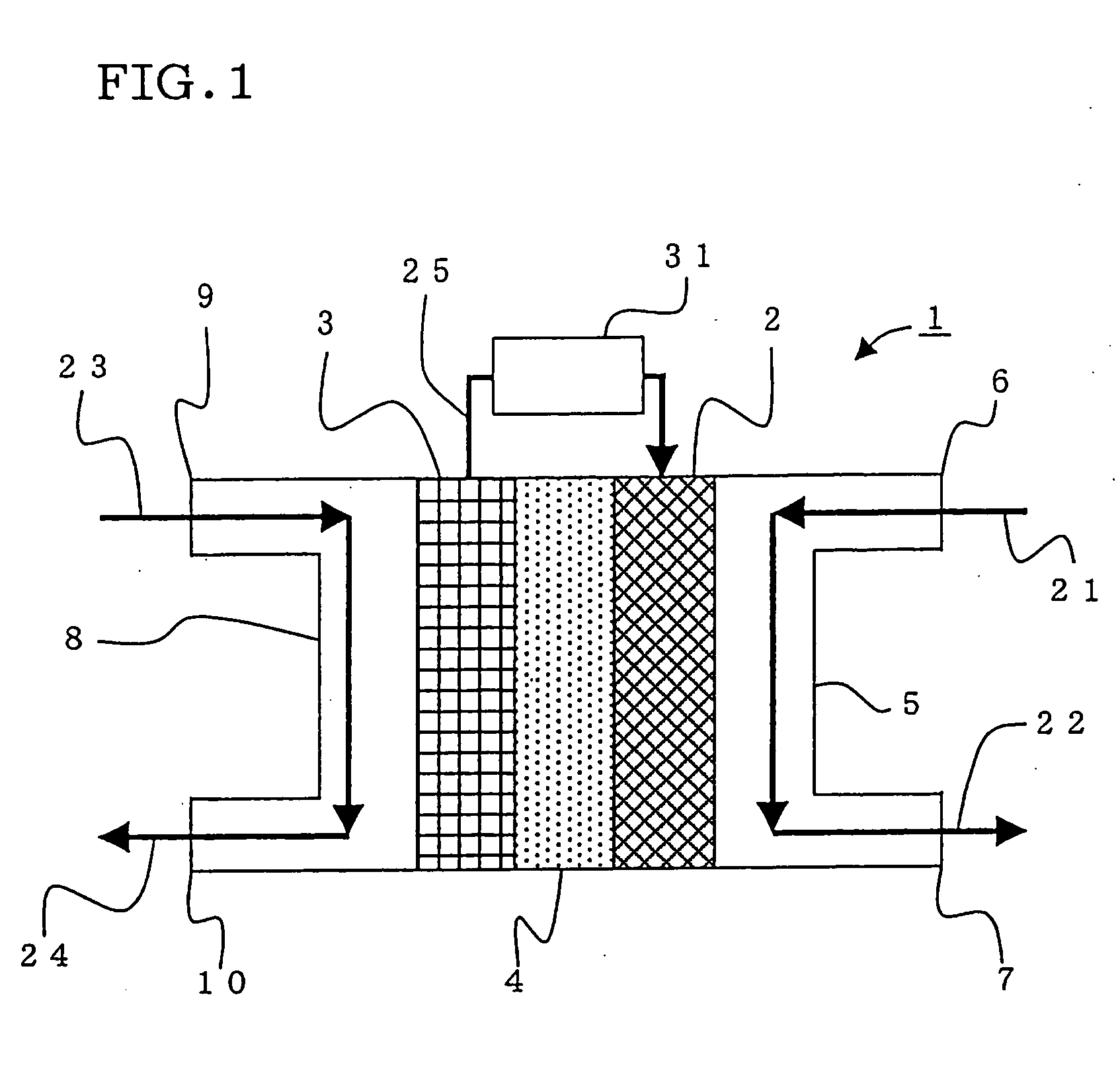

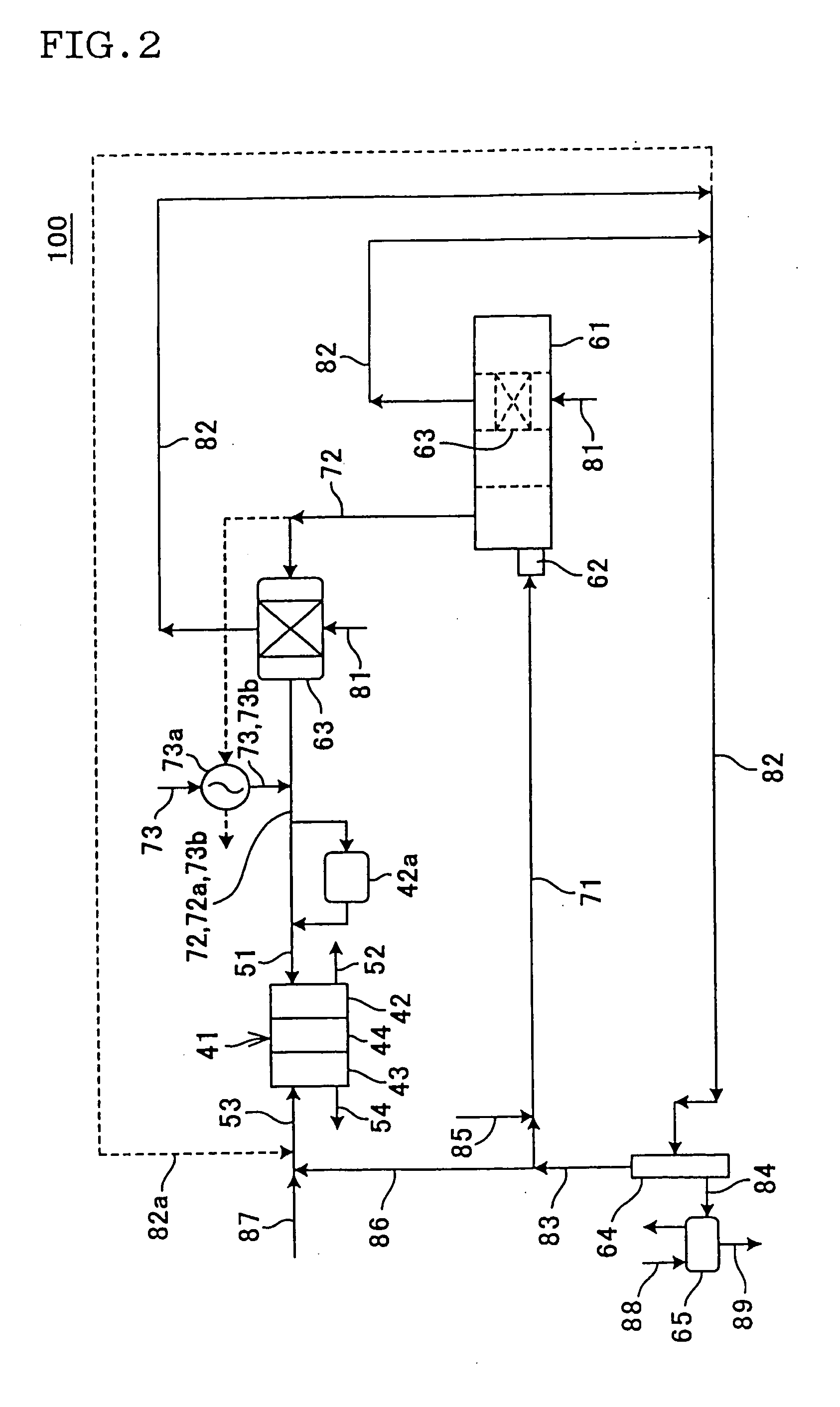

Fuel cell, operating method thereof, sintering furnace, and power generator

InactiveUS20060127718A1Increase carbon dioxide concentrationEfficient heatingHydrogen separationChemical industryFuel cellsMetallurgy

A molten carbonate fuel cell, operating method of the fuel cell, sintering furnace equipped with the fuel cell, and power generator, wherein a cathode gas with a high carbon dioxide concentration can be obtained without a process of increasing the carbon dioxide concentration, and the heat of furnace exhaust gas can be effectively reclaimed and the fuel consumption can be reduced. The cathode gas is a gas containing a furnace exhaust gas discharged from an industrial furnace for heating materials, a mixed gas of the furnace exhaust gas and a gas for cathode use or a preheated gas for cathode use, which is a gas for cathode use preheated using the furnace exhaust gas as a heating source, or the preheated gas for cathode use, and the carbon dioxide concentration of the cathode gas is 0.1-50 vol %.

Owner:NGK INSULATORS LTD

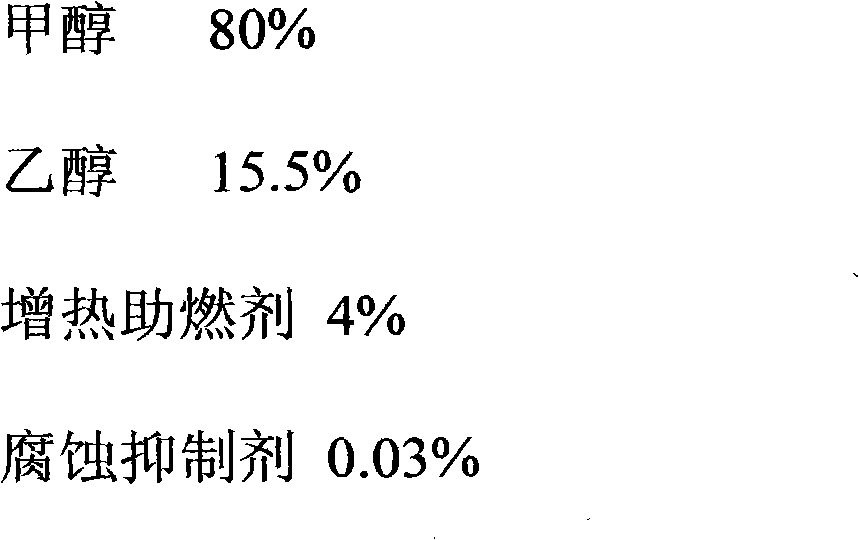

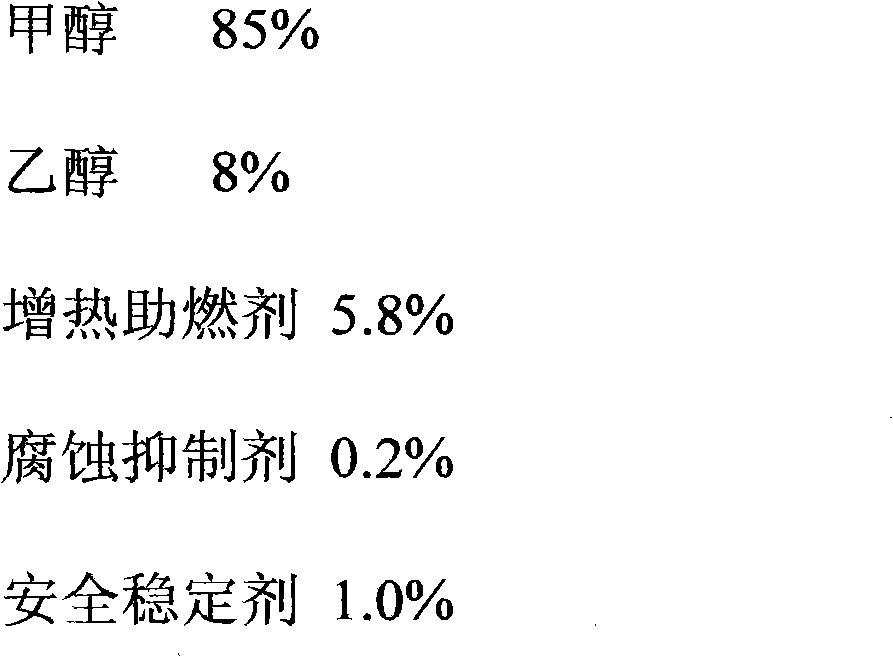

Novel high-heat anticorrosive biomass alcohol-based fuel

The invention relates to a novel high-heat anticorrosive biomass alcohol-based fuel, and relates to the field of environment protection. The alcohol-based fuel is prepared with main combustion agents of methanol and ethanol and auxiliary materials of alcohol-based fuel additives. The fuel is prepared from 60-90% of methanol, 10-30% of ethanol, 2-8% of a combustion-enhancing heat-gain agent, 0.01-0.2% of a corrosion inhibitor, and 0.1-1% of a safe stabilizer. The fuel provided by the invention has the advantages of high heat value, easy ignition, stable combustion, corrosion resistance, no air resistance, explosion-proof safety, clean property and no odor, low emission, low cost, energy saving, and environment friendliness. The heat value can be increased to 6500-7000 kcal / kg, and a central flame temperature can reach 1200-1300 DEG C. The fuel provided by the invention can be used in fields such as stoves, boilers, industrial furnaces, and the like.

Owner:QIQIHAR NORTH KUN SYNTHETIC POLYMER MATERIALS

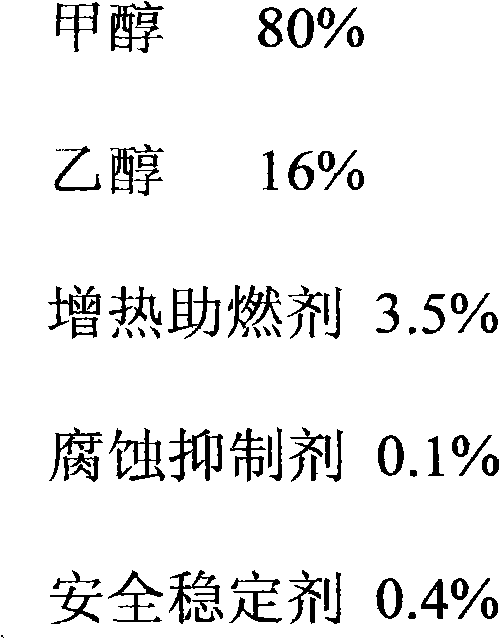

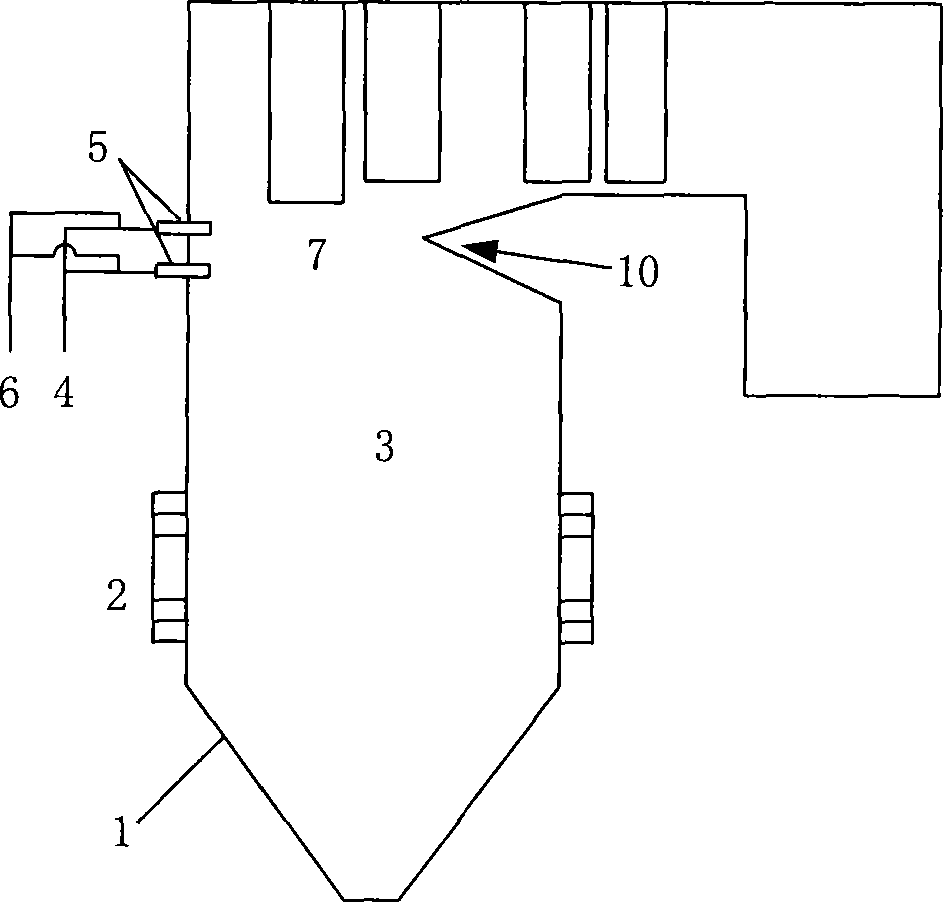

Method for accelerating selective non-catalytic reduction of nitrogen oxides

InactiveCN101244361AWiden the temperature rangeIncrease reaction rateDispersed particle separationRetention timeReaction rate

The invention relates to a promoting method for selective non-catalytic reduction (SNCR) of nitrogen-oxide, which is a technological method of adding addition agent to promote the denitrification process in the SNCR denitrification process for the power plant boiler and industrial furnace and other members, belonging to the nitrogen-oxide control technical field. The invention discloses a SNCR nitrogen-oxide method with the coal dust, natural gas or syngas as addition agent, in allusion to the problem of narrow suitable temperature range and lacking retention time existing in general SNCR denitrification technical application, which is characterized in that: the denitrification reaction rate is increased; the temperature range suitable for SNCR reaction is widen; the denitrification rate is increased and the leakage of ammonia is decreased. The promoting SNCR nitrogen-oxide method has advantages that: the reform is simple; the implementing is easy; the adoptive addition agent is cheap and available; the dosage is a little, so the combust process in the furnace is not influenced and no obvious secondary pollution is brought.

Owner:TSINGHUA UNIV

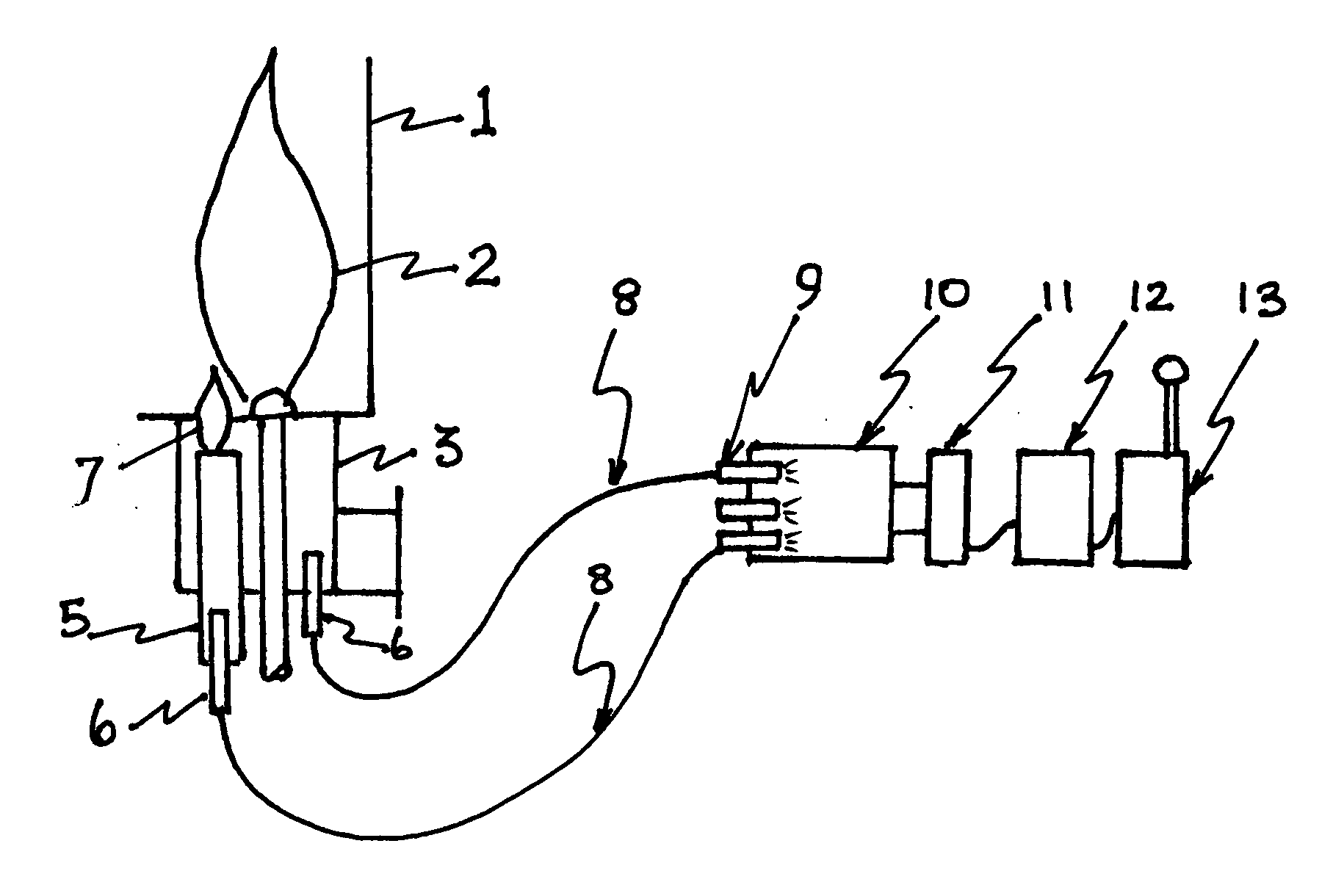

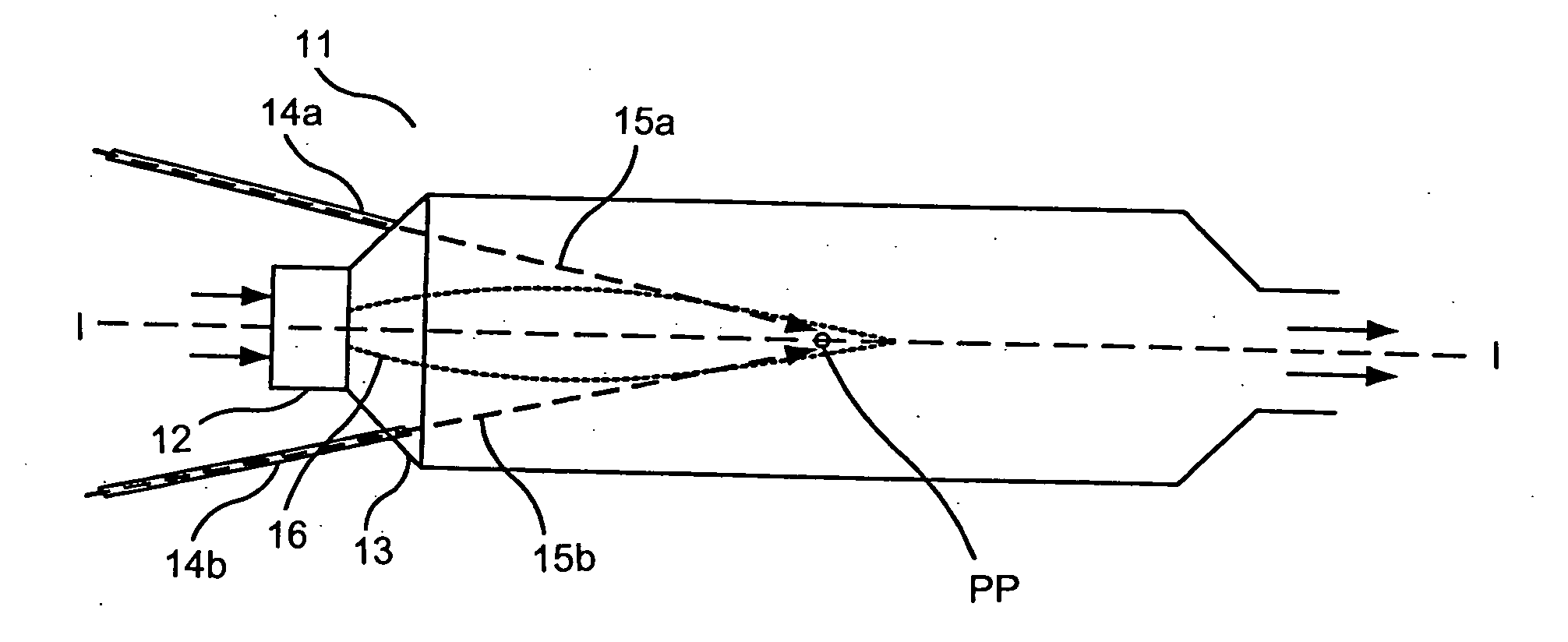

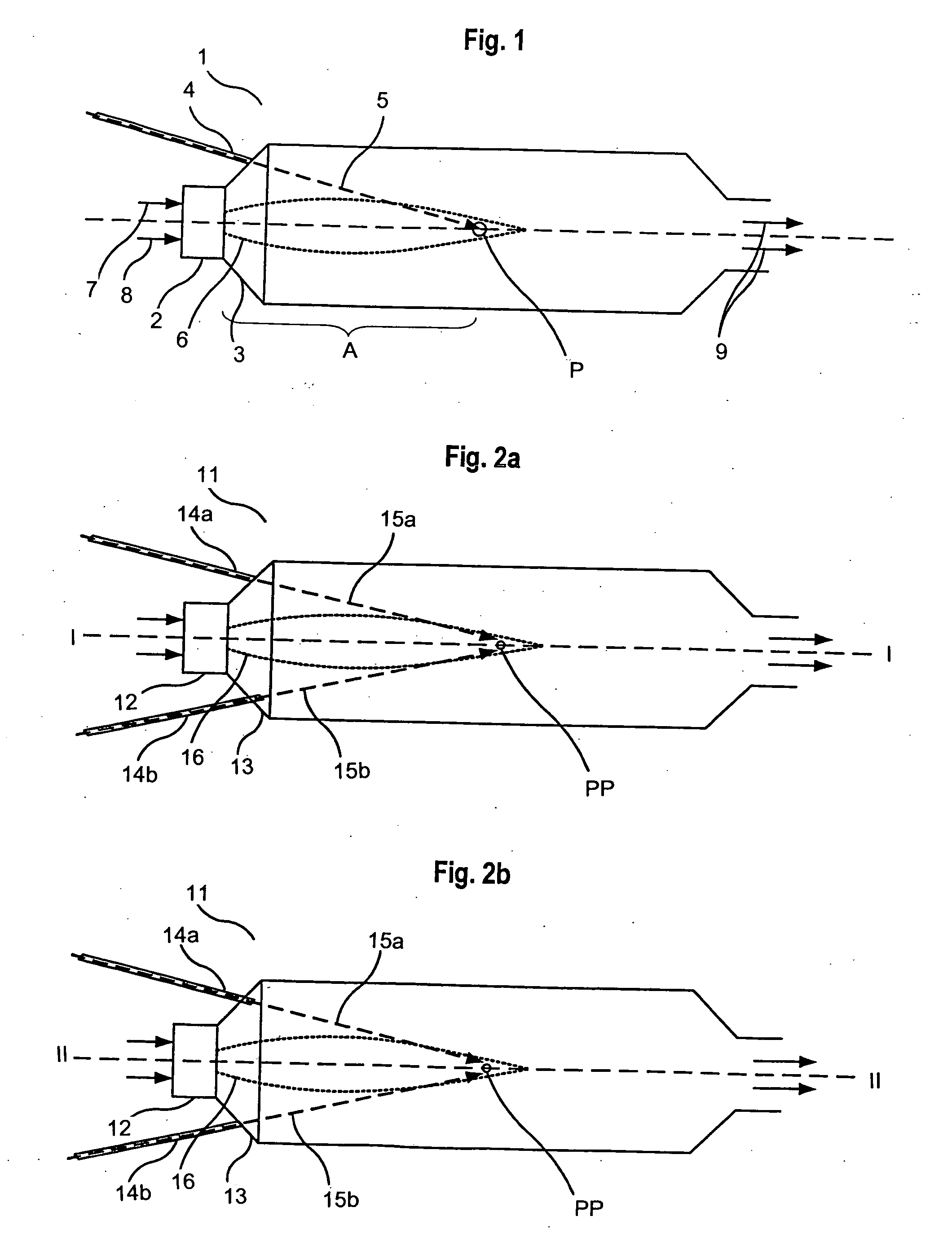

Monitoring of flames using optical fibers and video camera vision system

InactiveUS20050266363A1Increased safety marginLow costFuel supply regulationFlame sensorsFlareVisual perception

This invention relates to a flame detection method and apparatus. More specifically, this invention relates to a flame d on method and apparatus designed for simultaneously monitoring several flames of different types such as pilot flames and main flames of differing sizes and intensity. These detected flames can be in one combustion unit or in several combustion units such as industrial furnaces or ground flares. The underlying principle of the invention is to collect and transmit light from each of the flames by use of optical fibers and to insect the collected light by a video camera vision system at the other end of the optical fibers and to transmit the “live” images of the glows as well as the “on / off” status of the burners to the control room, through modern electronic communication techniques such as Ethernet and / or wireless radio units.

Owner:GANESHAN RAM

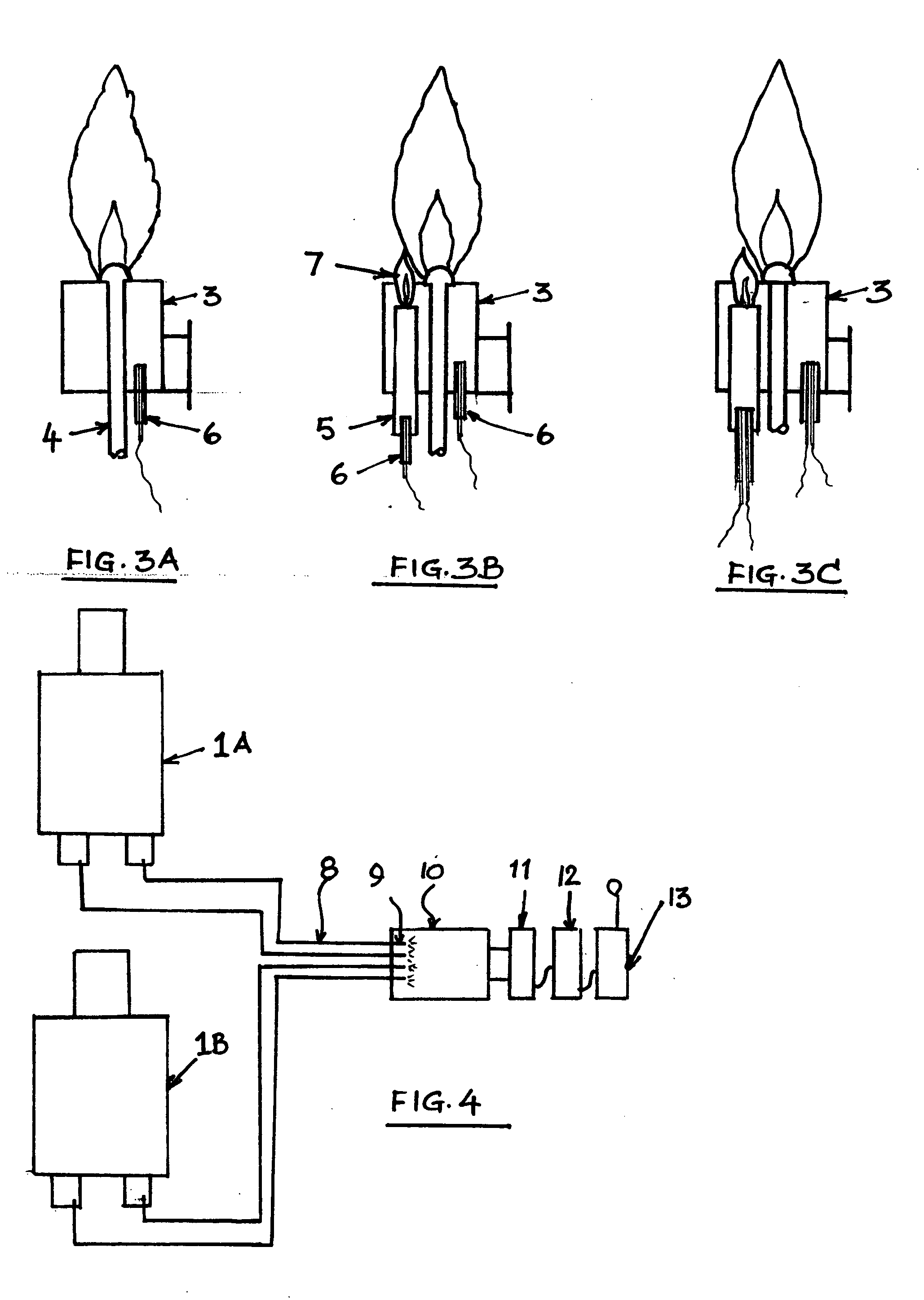

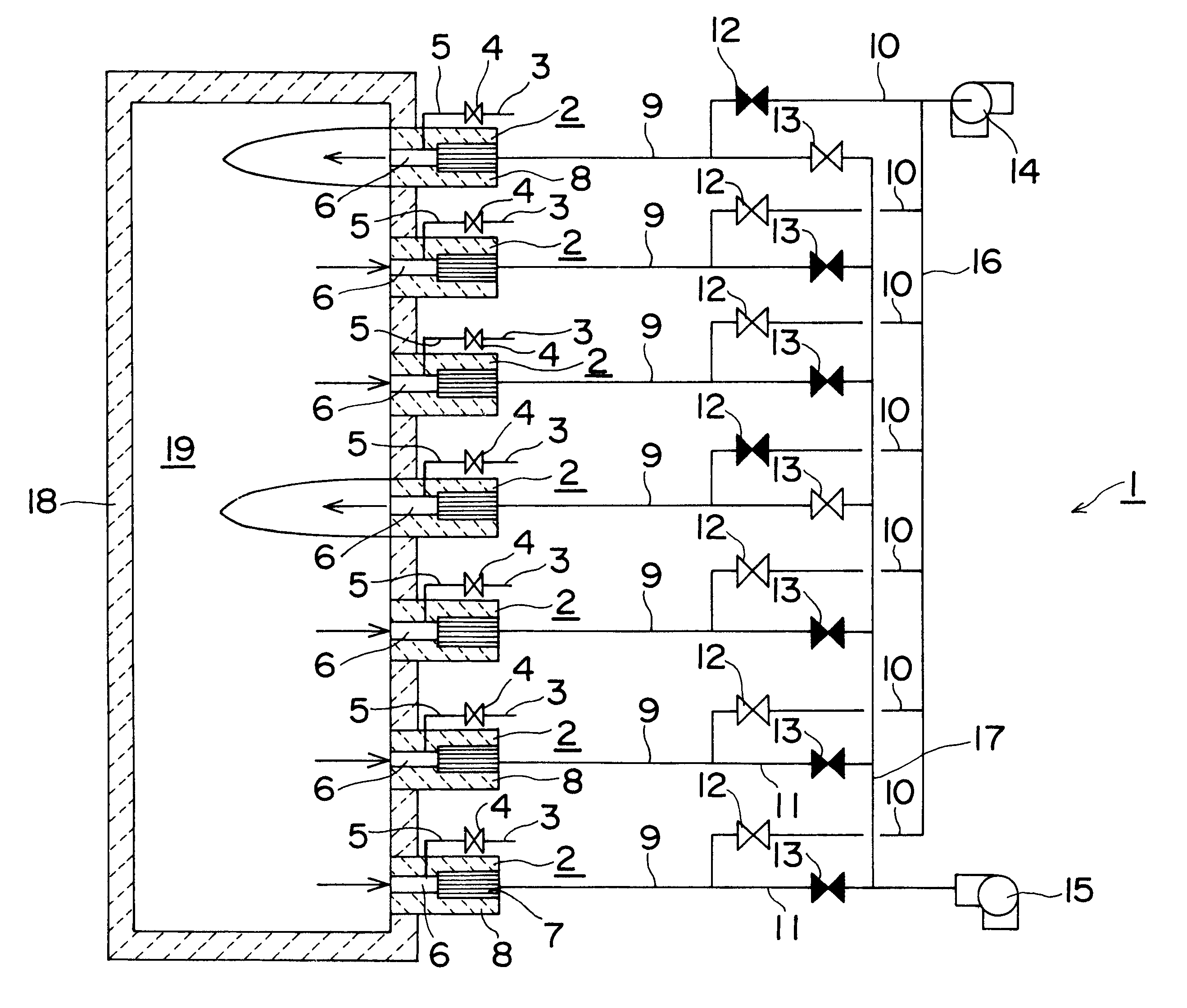

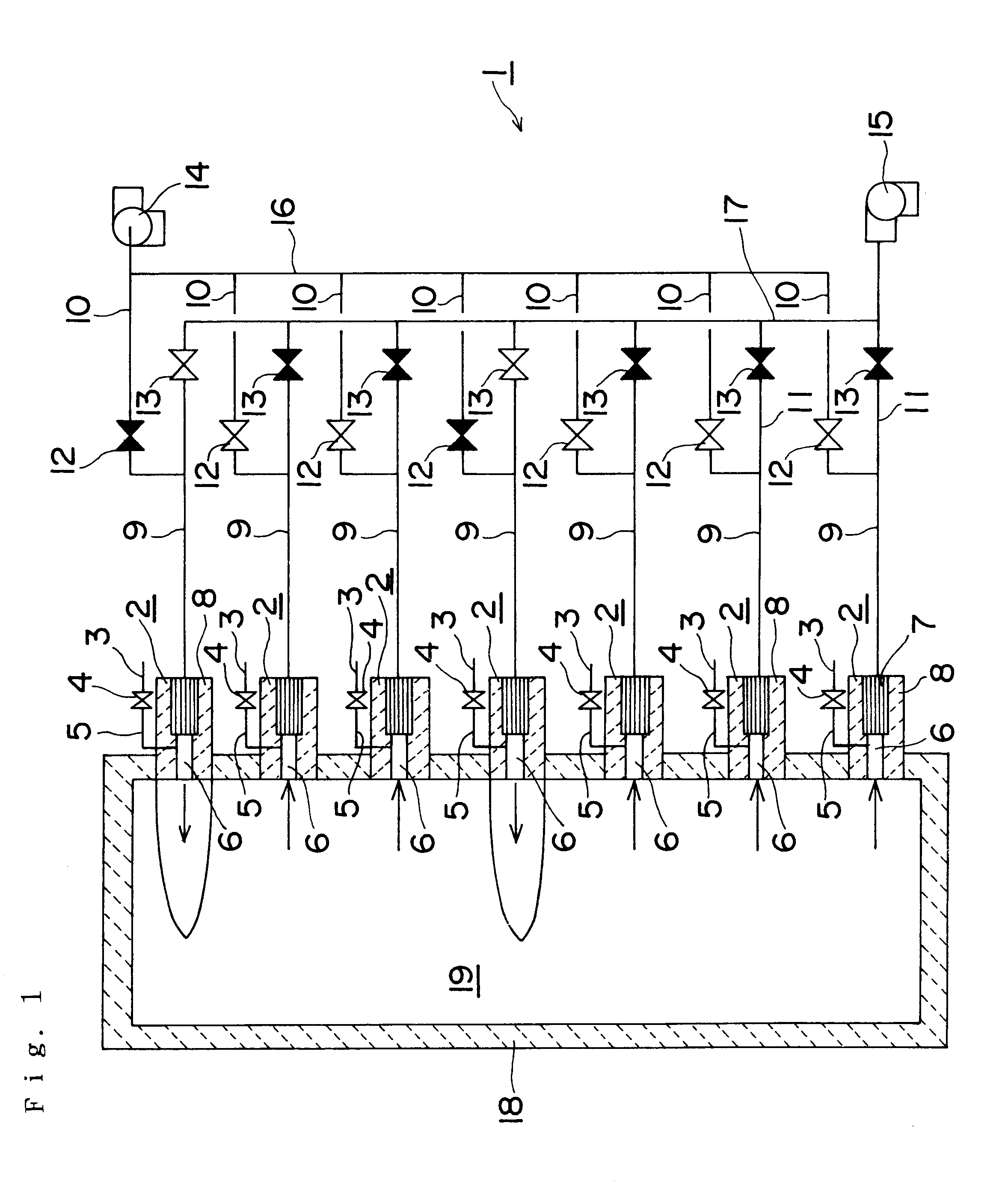

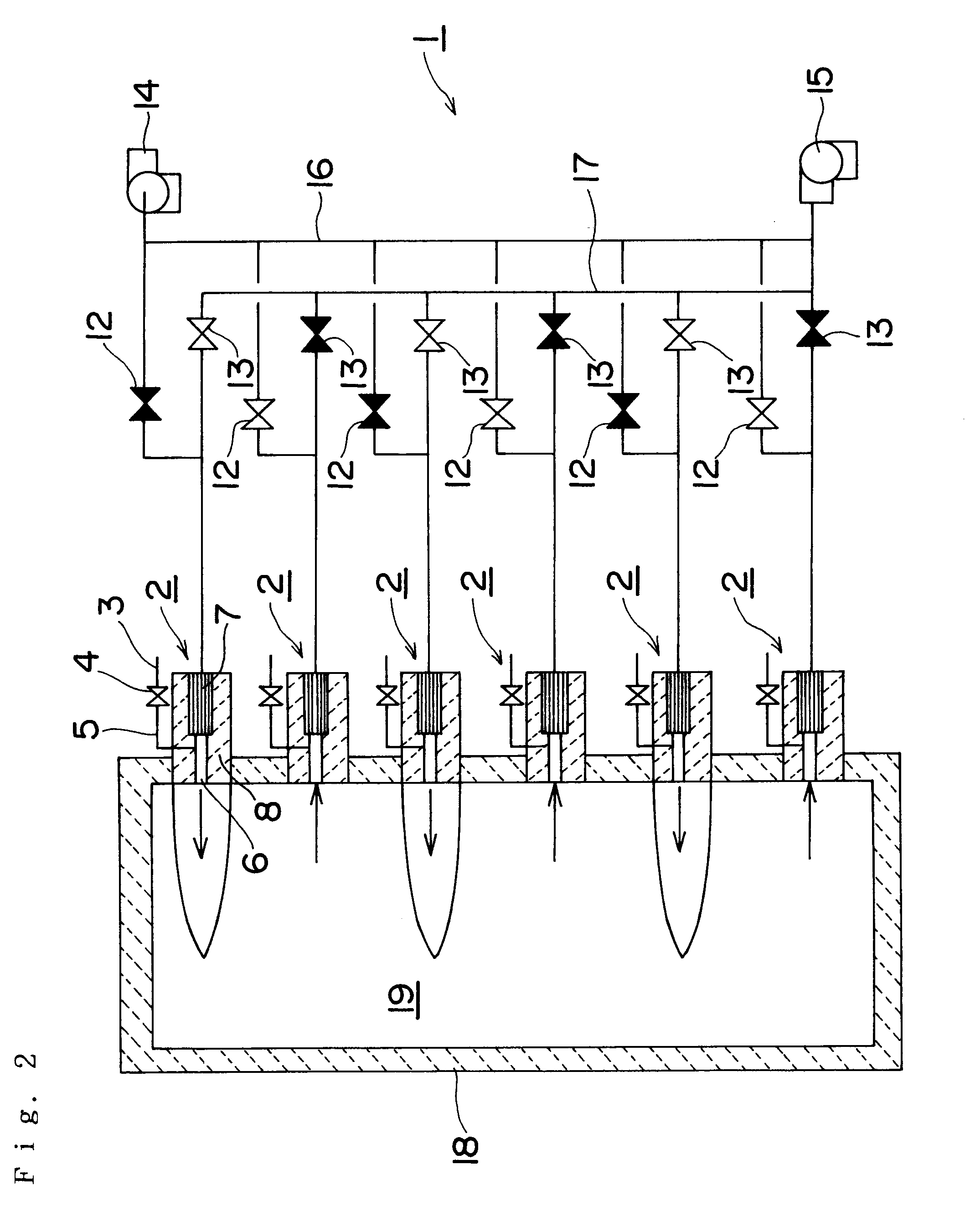

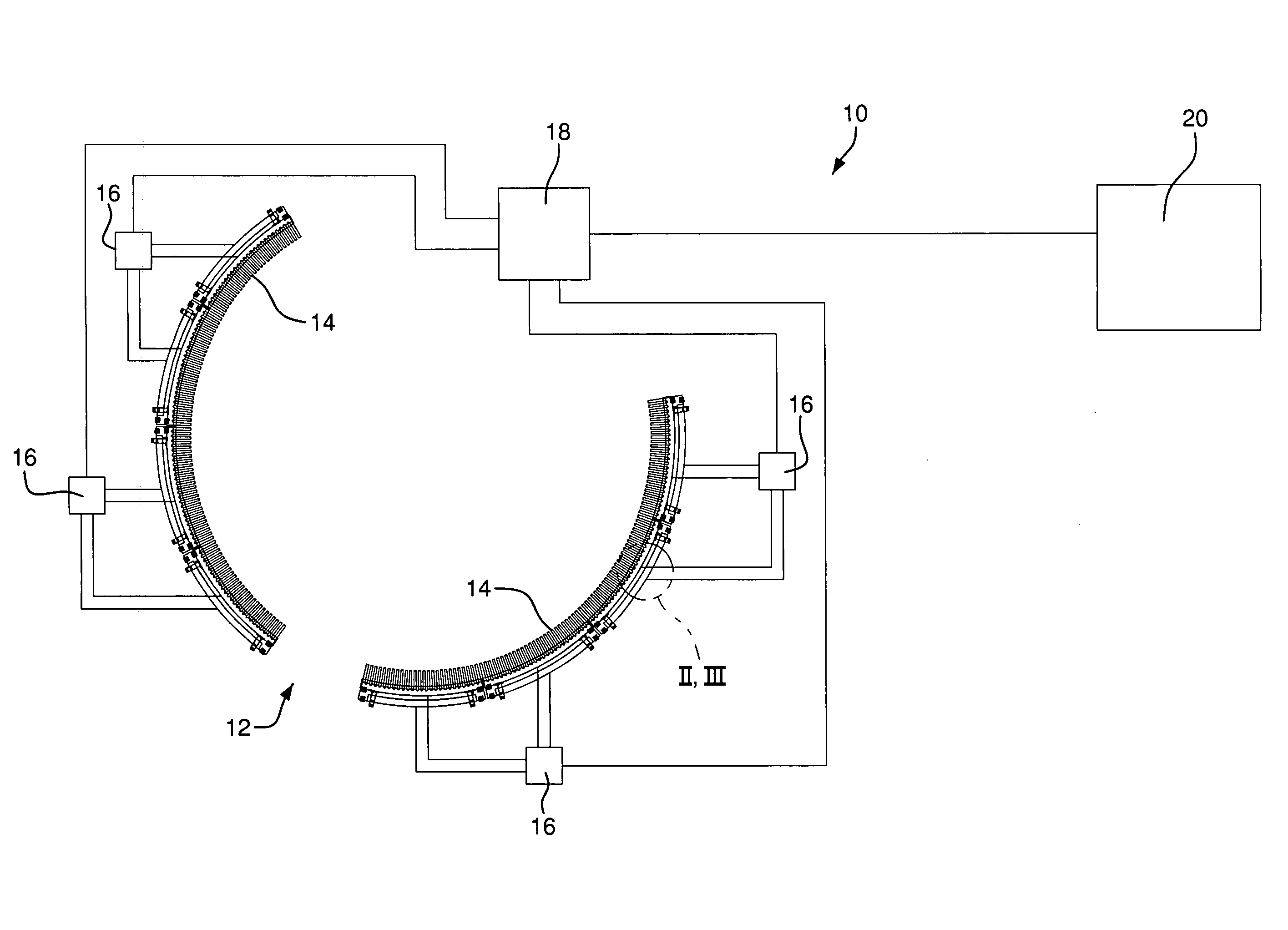

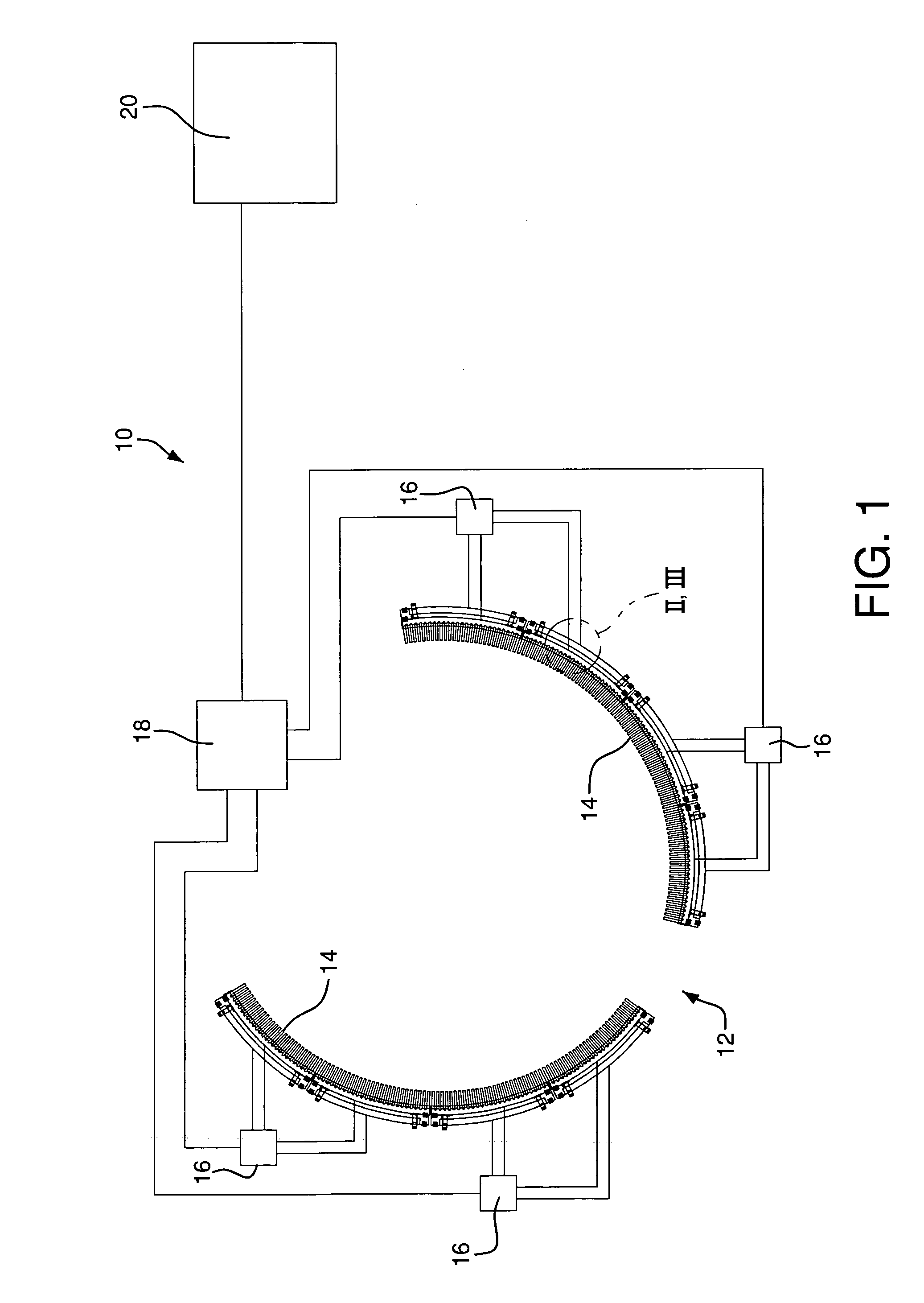

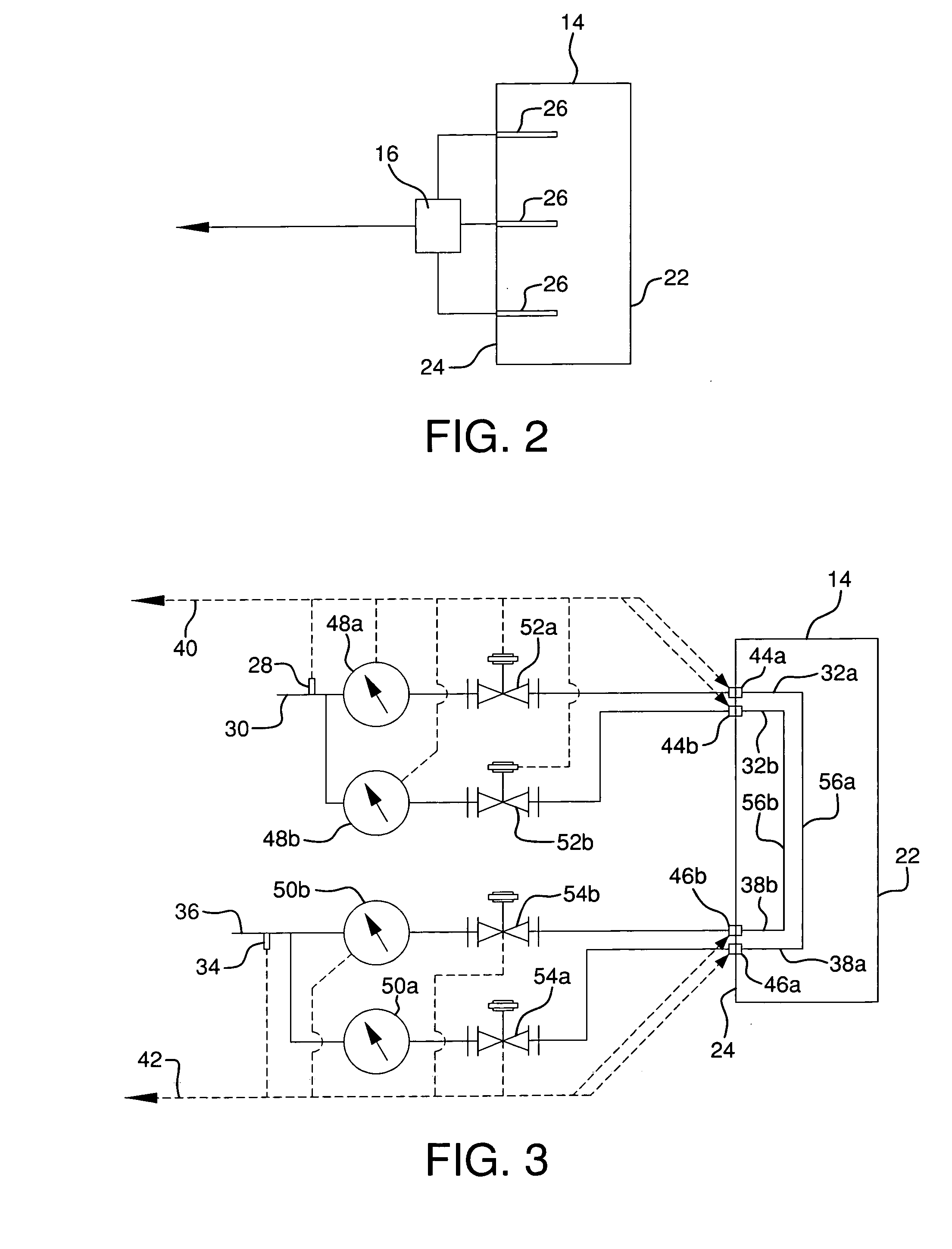

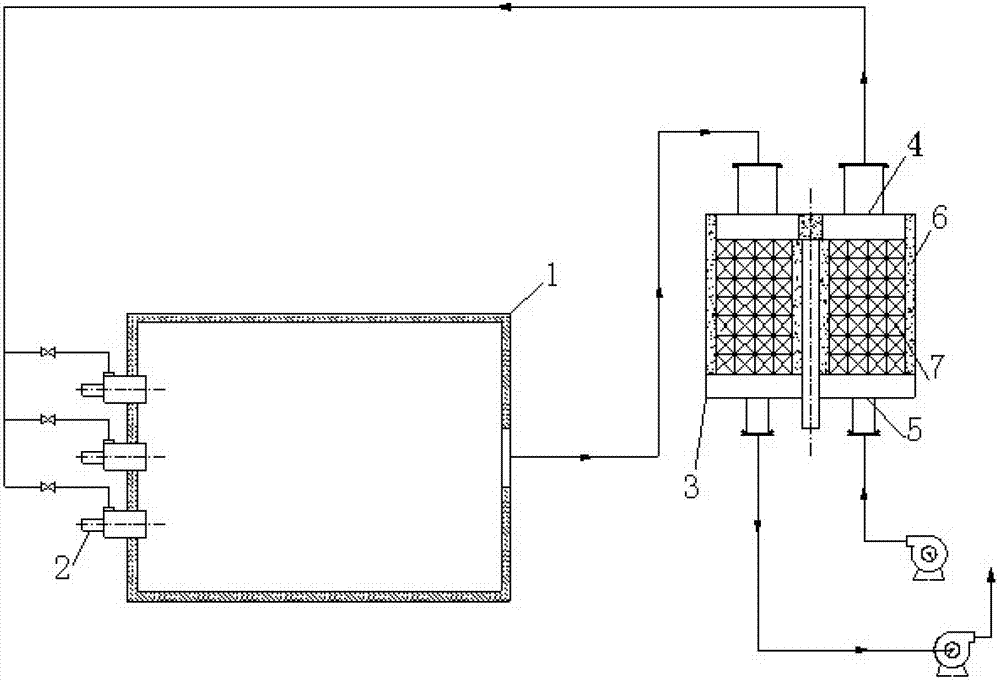

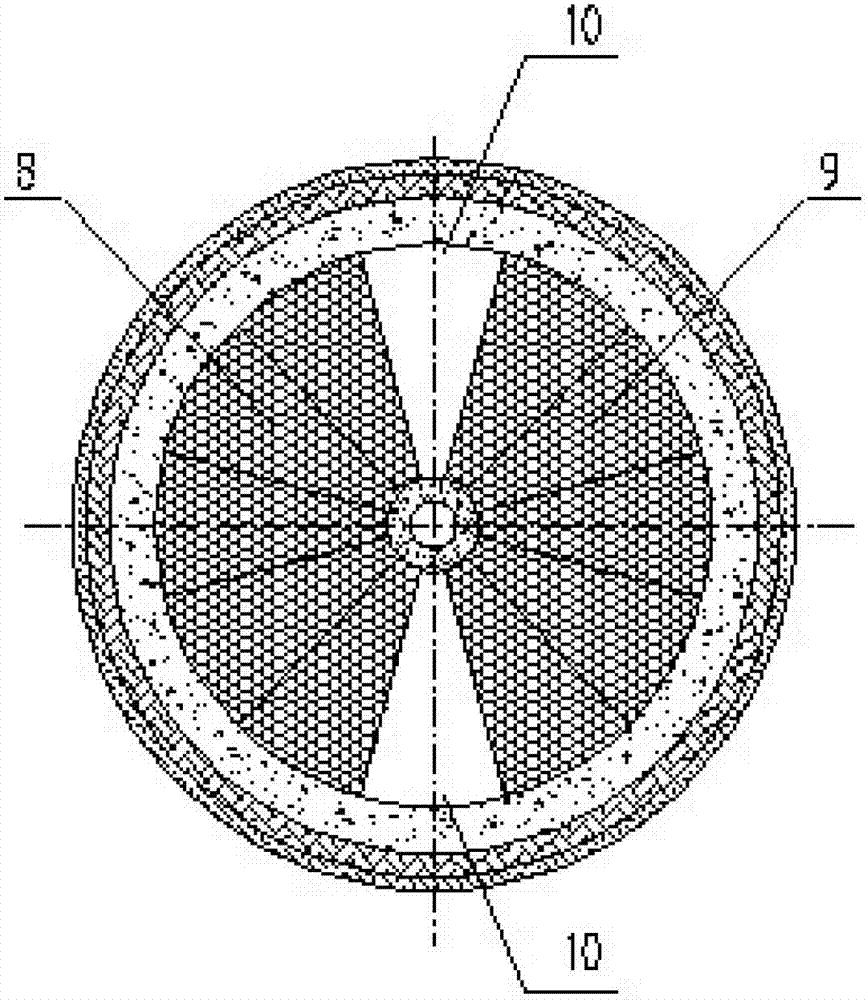

Inter-switching heat accumulating regenerative burner system

InactiveUS6234789B1Reduce rateImprove heat transfer performanceBurnersDomestic stoves or rangesCombustion systemProcess engineering

The present invention provides an alternate changeover regenerative burner system suitable for use as a heat source for an industrial furnace and the like where re-increase in temperature is relatively-often carried out; an alternate changeover regenerative burner constituted by a burner 2 having a regenerator 7 and air supply / exhaust switching mechanisms 12 and 13 for switching connection with an air supply system 17 and an exhaust system 16 of the burner 2 is regarded as a module unit; and three or more units of the alternate changeover regenerative burner constitute a combustion system 1; a ratio of the number of the burners 2 performing combustion and the number of the burners 2 being stopped is variable; and combustion is controlled in such a manner that all the units sequentially repeat alternate regenerative combustion with the units forming no fixed pairs. According to the present invention, a flow velocity of air injected from a burner throat can be variable irrespective of a quantity of combustion; the flow velocity of air emitted from the burner throat can be maintained high even if the operation is carried out with a quantity of combustion lower than the burner capacity; and a non-stationary flame can be formed in a wider range.

Owner:NIPPON FURNACE KOGYO KAISHA LTD

Calcium hexaluminate and corundum composite porous light heat insulation refractory material and preparation method thereof

The invention relates to a calcium hexaluminate and corundum composite porous light heat insulation refractory material, in particular to a high-quality refractory material for high temperature kiln liners, which has the advantages of low heat conductivity, high strength, high stability in high-temperature reducing atmosphere, high alkali and scouring corrosion resistance and long service life, and belongs to the technical field of refractory materials. The main phases of the refractory material are a calcium hexaluminate phase and a corundum phase; and the main chemical compositions of the refractory material are Al2O3 and CaO which account for over 95 weight percent. CaCO3, Ca(OH)2, CaO and the like are taken as calcium sources, and Al2O3, Al(OH)3 and the like are taken as aluminium sources; and a preparation method comprises the following steps of: uniformly mixing Al2O3 and CaO according to a molar ratio of more than 6, grinding, adding a certain amount of pore-forming material, uniformly stirring, and performing a series of technological processes such as forming, drying, sintering, cutting and the like to prepare the calcium hexaluminate and corundum composite porous light heat insulation refractory material. The heat insulation refractory material is a light refractory brick for the high temperature kiln liners, which has the advantages of low heat conductivity, high strength and long service life, and can provide high-efficiency and energy-saving guarantee for industrial furnace equipment.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

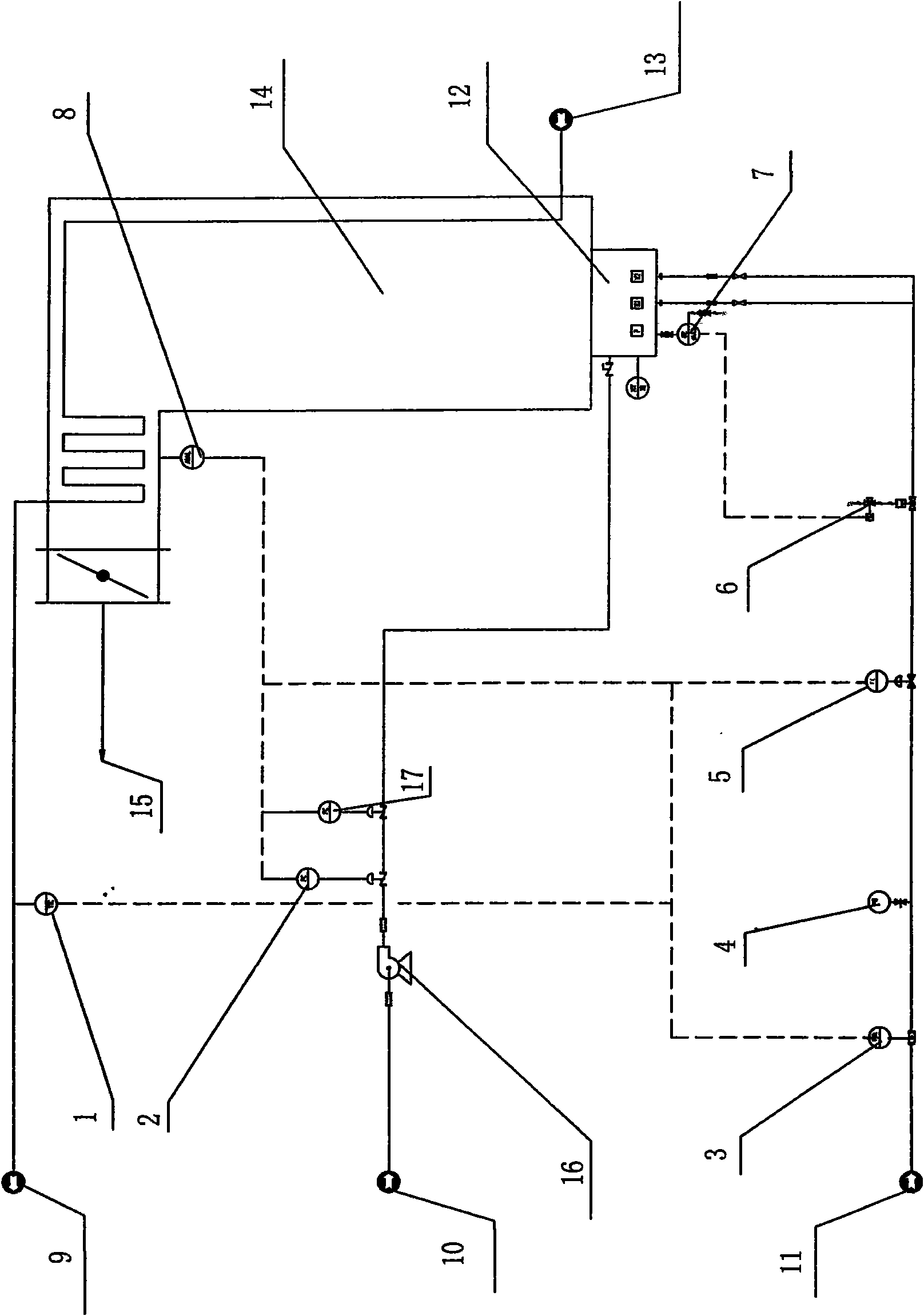

Multiparameter automatic control method of industrial furnace burner

ActiveCN101655245AAvoid structureAvoid unrealizable problemsCombustion regulationAutomatic controlLimit value

The invention relates to a multiparameter automatic control method of an industrial furnace burner. A temperature parameter measured by a furnace tube or a hearth outlet temperature display control meter is utilized to control a fuel flow control valve of fuel supply volume; a fuel pressure gauge of the fuel supply volume judges whether the fuel pressure satisfies the combustion demand or not; a parameter of a fuel flow display control meter on a supplied fuel feed pipeline provides a control parameter for a combustion-supporting gas flow control regulator valve; combustion-supporting air amount is regulated proportionally; then an oxygen content parameter measured by an on-line analysis sensor of a fume detector of a furnace fume outlet serves as the control parameter of the combustion-supporting gas flow control regulator valve so as to regulate an upper limit value control parameter of the combustion-supporting air amount or the oxygen content; and a carbon monoxide or fuel composition content parameter measured by the on-line analysis sensor of the furnace outlet fume detector serves as the control parameter of the combustion-supporting gas flow control regulator valve so as toregulate a lower limit value control parameter of the combustion-supporting air amount or the oxygen content. The method can meet the accurate control demand of the fuel on the combustion-supportingair amount in the combustion process.

Owner:江苏焱鑫科技股份有限公司

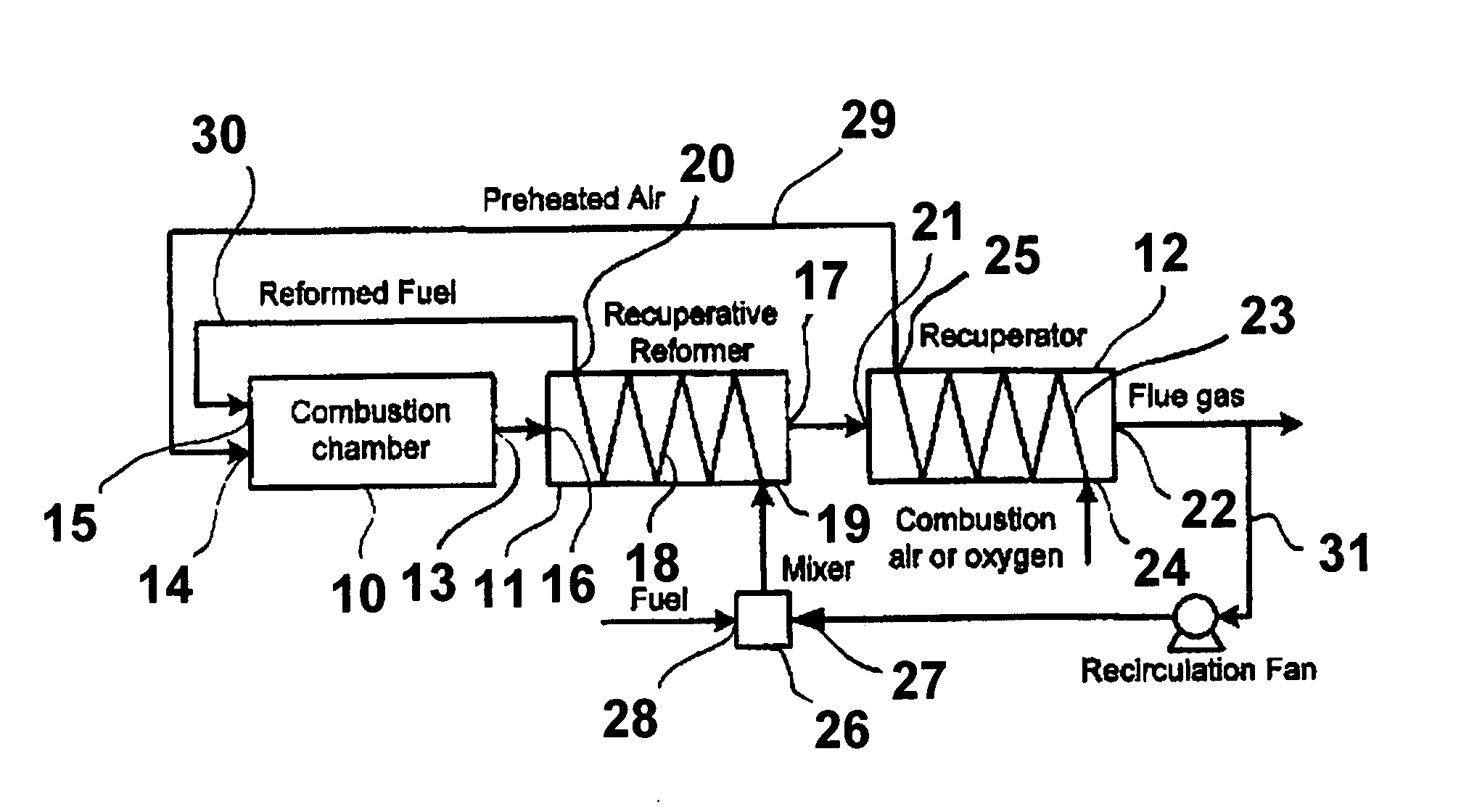

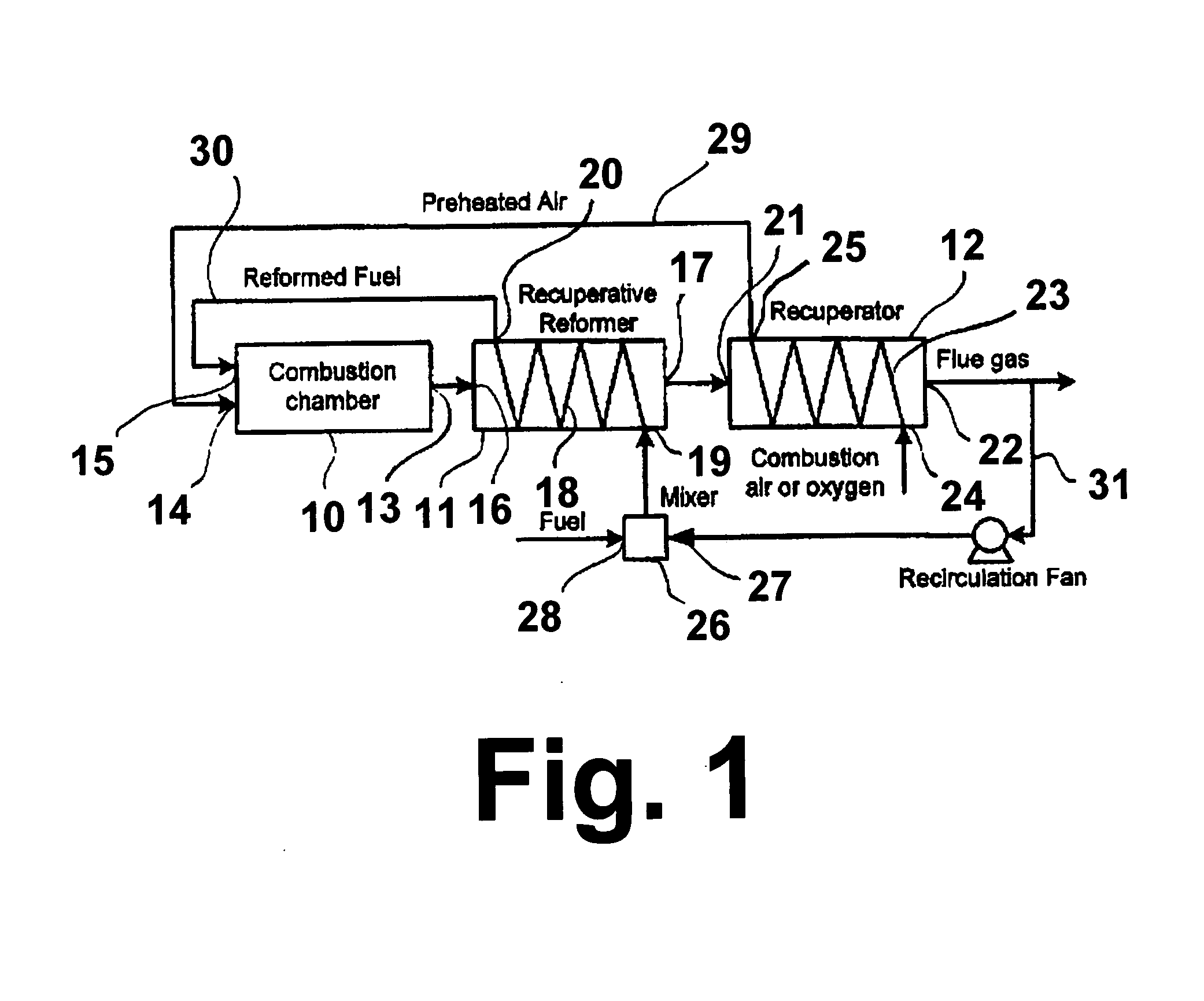

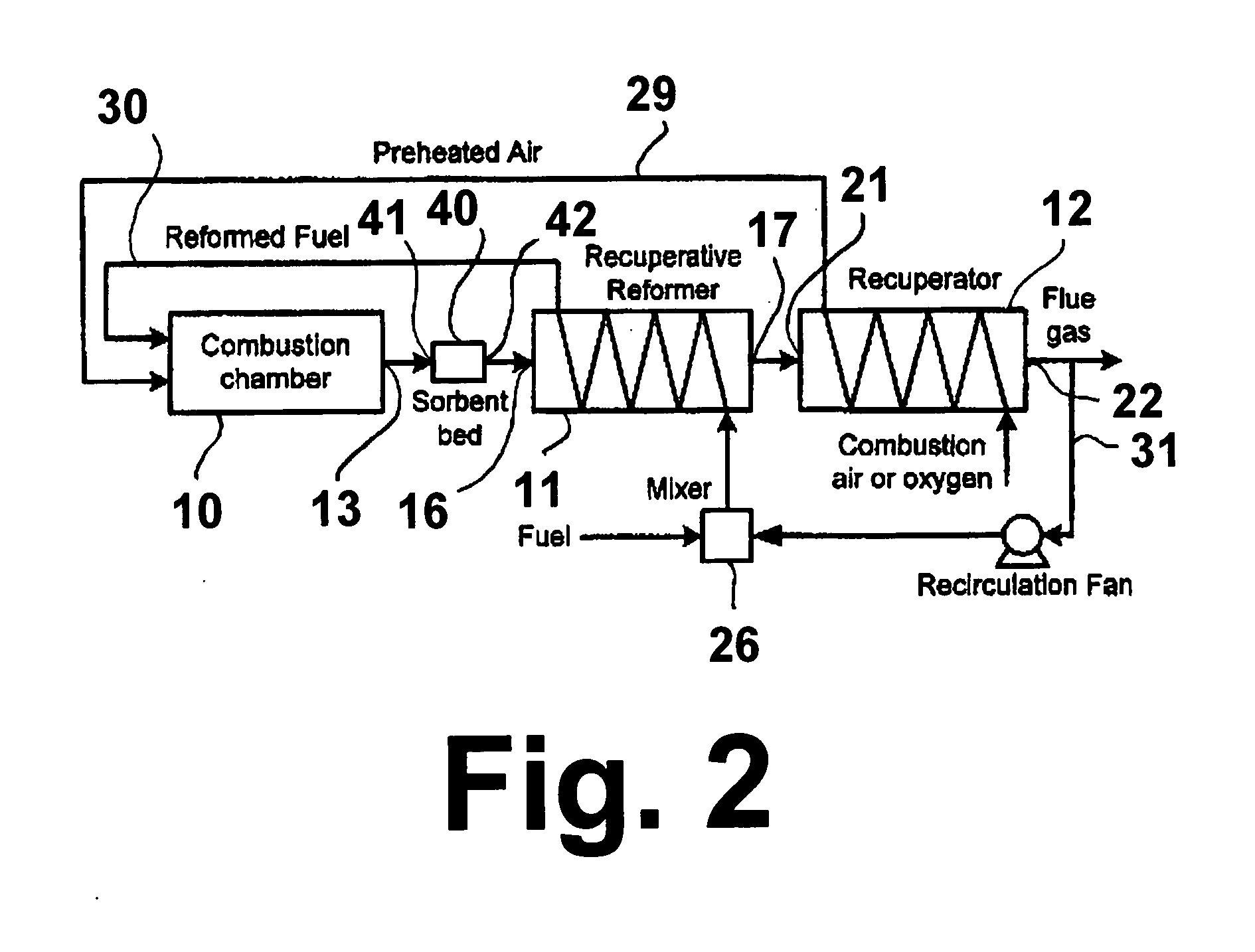

Method and apparatus for thermochemical recuperation with partial heat recovery of the sensible heat present in products of combustion

InactiveUS20090011290A1Increase enthalpyIncrease heat inputHydrogenProductsEngineeringCombustion process

A system and method for fuel reforming in which at least a portion of the exhaust gases from a combustion process, such as an industrial furnace, is mixed with a fuel, such as natural gas, and the mixture is introduced into a first stage heat exchange vessel in which the fuel is reformed. The reformed fuel is then returned to the combustion process for burning. In accordance with one embodiment, primary combustion oxidant is introduced into a second stage heat exchange vessel in which it is heated by a portion of the exhaust gas exiting the first stage heat exchange vessel. The heated oxidant is then introduced into the combustion process for burning of the fuel(s) therein.

Owner:GAS TECH INST

Calcium hexaluminate lightweight refractory brick and preparation method thereof

The invention relates to a calcium hexaluminate lightweight refractory brick, in particular to a high-quality refractory material with low heat conduction coefficient, good stability under high-temperature reducing atmosphere, good alkali resistance and slag erosion resistance and long service life for a high-temperature kiln lining, and belongs to the technical field of refractory materials. Calcium hexaluminate is used as a main crystal phase, and the sum of the main chemical components Al2O3 and CaO of the calcium hexaluminate is more than 90 weight percent. Calcium carbonate, calcium hydroxide, calcium oxide, limestone or lime or the like is used as a calcium source; and aluminum oxide, aluminum hydroxide or the like is used as an aluminum source. The calcium hexaluminate lightweight refractory brick is prepared by a series processes of mixing the materials uniformly according to the theory of the calcium hexaluminate, grinding the mixture, adding a certain amount of pore forming agent into the mixture and stirring the mixture uniformly, then performing half dry vibration casting, wet adjusting controllable drying, high-temperature air introducing pore formation, one-step reductive reaction sintering, cutting and processing and the like. The lightweight refractory brick for the high-temperature kiln lining has low heat conduction coefficient and long service life, and can provide efficient and energy-saving guarantee for industrial furnace equipment.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

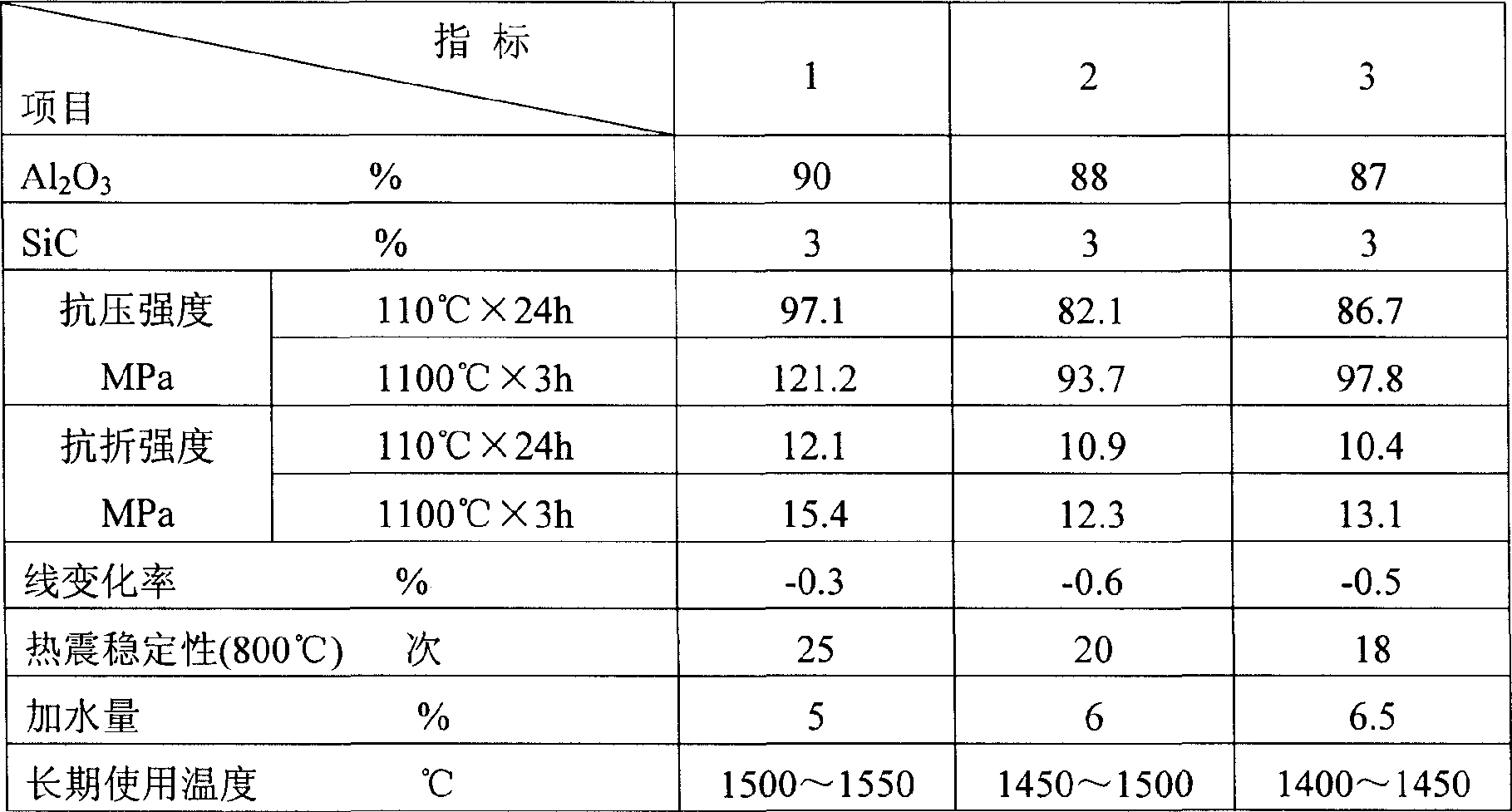

Silicon carbide corundum pouring material

The silicon carbide corundum pouring material as a kind of refractory material consists of first grade white corundum, fine corundum powder, alumina powder silica powder, fine silicon carbide powder, cement, sodium tripolyphosphate, steel fiber and RE water reducing agent in certain proportion. The poured refractory material has high strength, high fire resistance and high wear strength, and is suitable for laying various kinds of high temperature industrial furnaces and kilns.

Owner:宜兴市泰科耐火材料有限公司

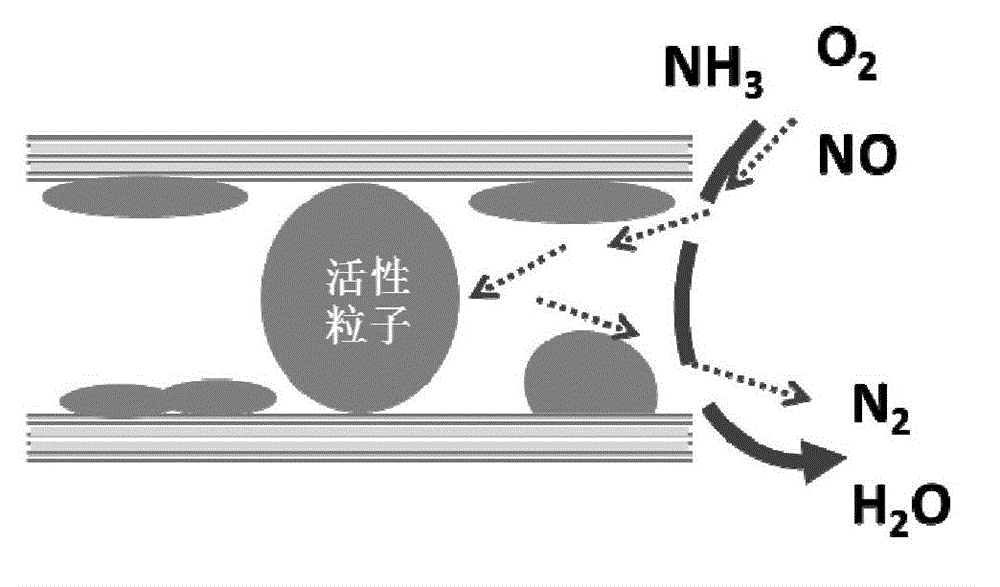

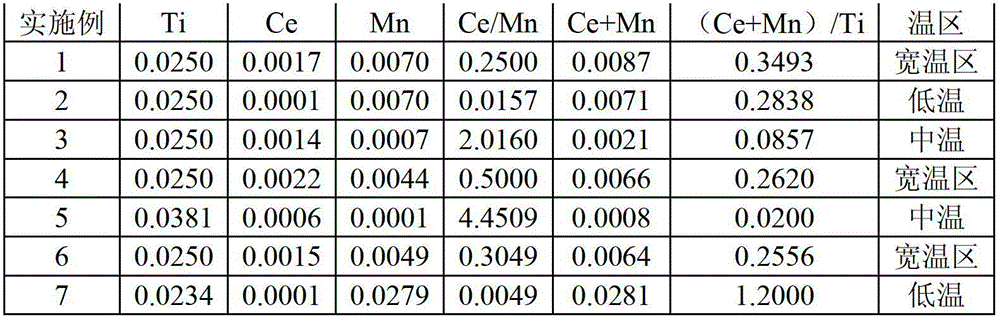

Medium/low-temperature core-shell denitration catalyst and preparation method and application thereof

ActiveCN102941083AStrong resistanceStrong anti-poisoningDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsManganeseCerium

The invention discloses a medium / low-temperature core-shell denitration catalyst and a preparation method and application thereof, belonging to the technical field of air pollution control. Main raw materials consist of a titanium-based nano tube, soluble salt of cerium and soluble salt of manganese, wherein a carrier shell of the catalyst is formed by the titanium-based nano tube, and an active nanoparticle core is formed by oxides of cerium and manganese. The molar ratio of the total amount of cerium and manganese to the amount of titanium is (0.02-0.12):1, the molar ratio of cerium to manganese is more than 0.5 or less than 0.25, and when the molar ratio of cerium to manganese is between 0.25 and 0.5, the catalyst has good activity in a medium-temperature zone, a low-temperature zone and a medium / low-temperature zone. The preparation method comprises the steps of soaking the titanium-based nano tube in an organic solvent, adding the soluble salt of cerium and the soluble salt of manganese, impregnating, drying and roasting, thereby obtaining the medium / low-temperature core-shell denitration catalyst. The catalyst has broad application prospects in treatment of waste gases with high contents of solid toxic components, such as exhaust gas of industrial furnaces, flue gas of power plants using biomass fuels and the like.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

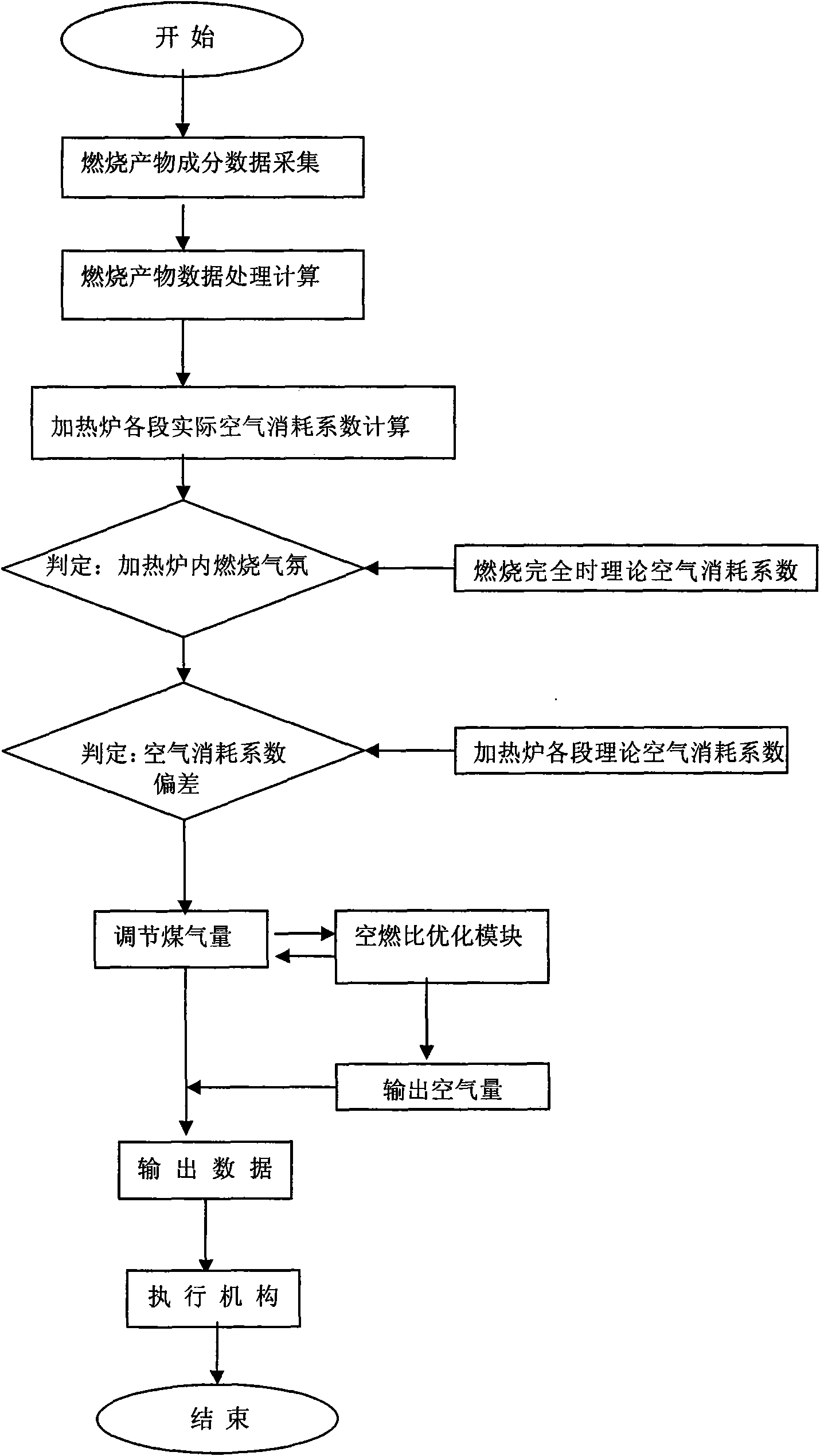

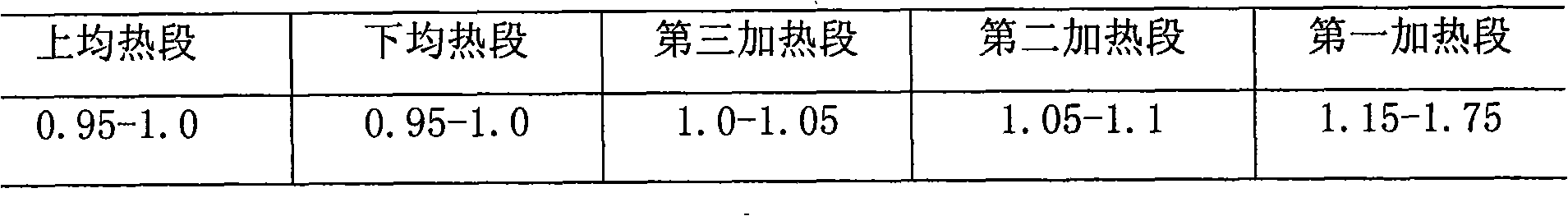

Method for controlling combustion atmosphere in large-scale walking beam type plate blank heating furnace

ActiveCN101561224AReduce burning rateReduce heat lossMaintainance of heating chambersFurnace typesFurnace temperatureComputer control system

The invention relates to a method for controlling combustion atmosphere in a large-scale walking beam type plate blank heating furnace, which belongs to the technical field of fuel combustion of industrial furnaces. A plate blank is heated through a preheating section, each heating section and a soaking section to finish the process of heating and temperature equilibrium; and in the process, a first-level computer control system and a second-level computer control system automatically generate a heating process and automatically set and control the furnace temperature in each section according to original data of the plate blank called from a database; and on the basis of an output control value of a residual oxygen analyzer, the computer control systems calculate the air consumption coefficient of each combustion area, perform dynamic track on the combustion atmosphere in the whole furnace along with the changes of thermal loads, correct the combustion atmosphere according to the actual air-fuel ratio of six combustion areas, adjust the proportion of combustion air and gas, and determine the reasonable air and gas flow to achieve the furnace temperature required by the heating process. The method has the advantages that the condition of furnace gas component changes in the furnace is quantificationally provided for a heating furnace operator in time, so that the combustion in the heating furnace reaches good state; and simultaneously, the energy-saving and environmental protection effects are remarkable.

Owner:SHOUGANG CORPORATION

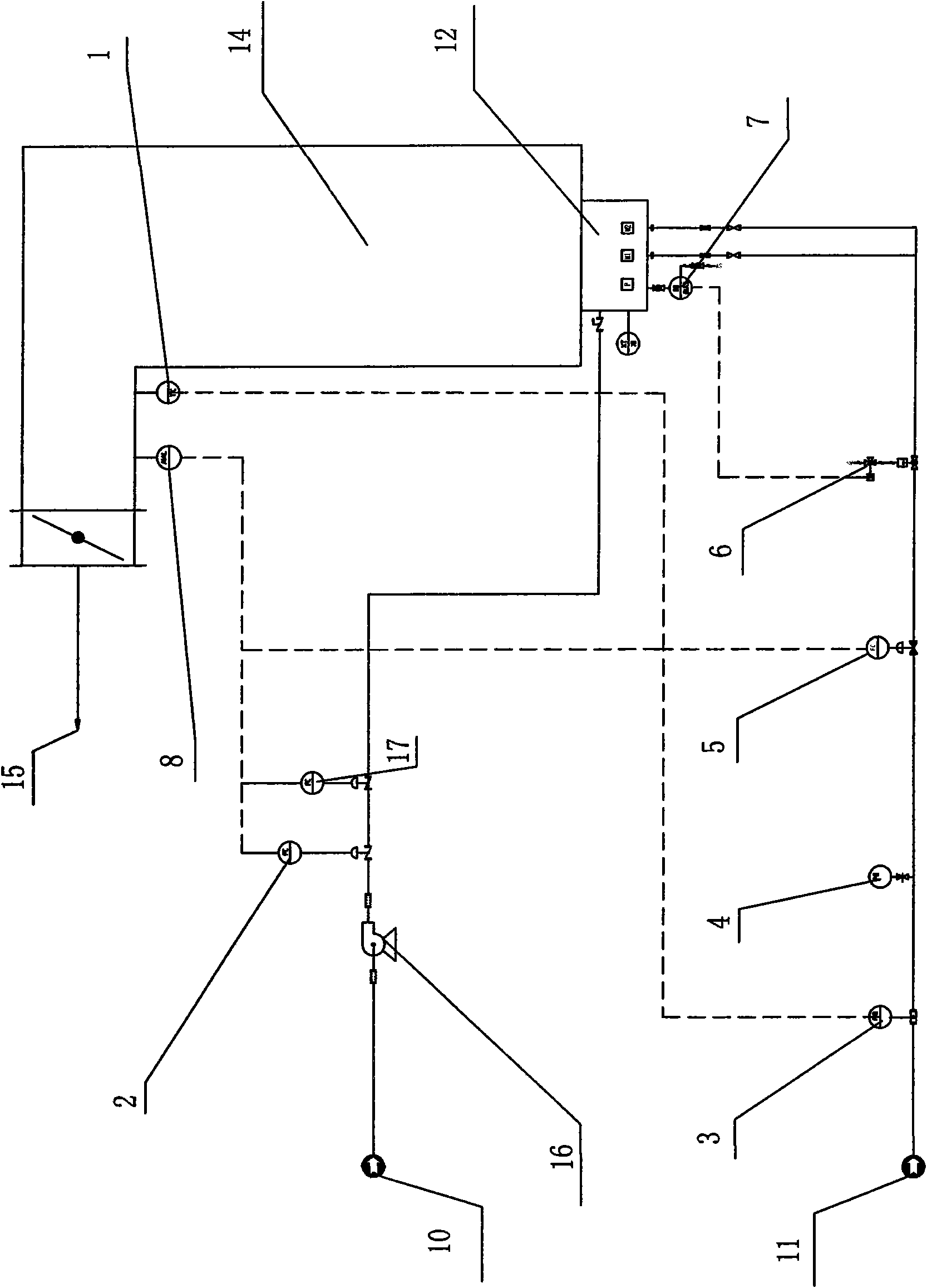

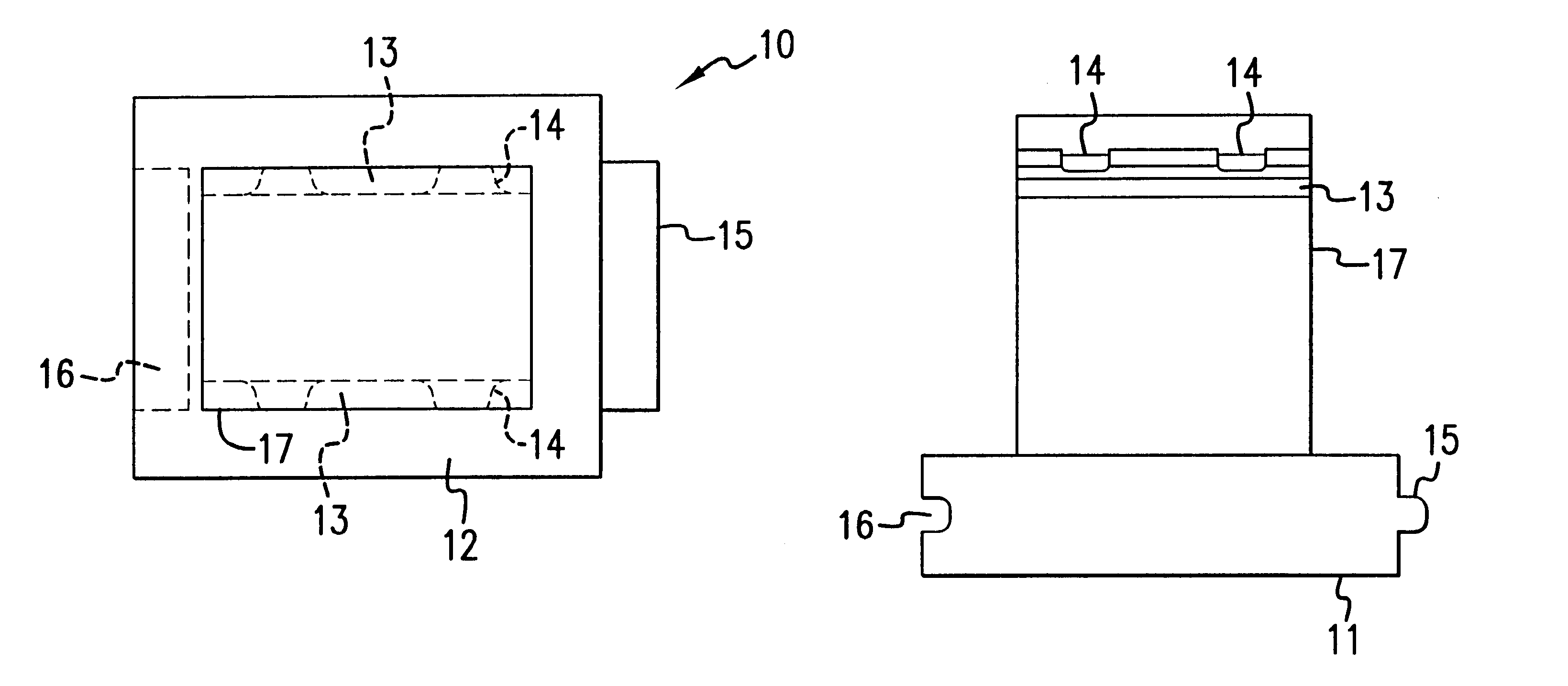

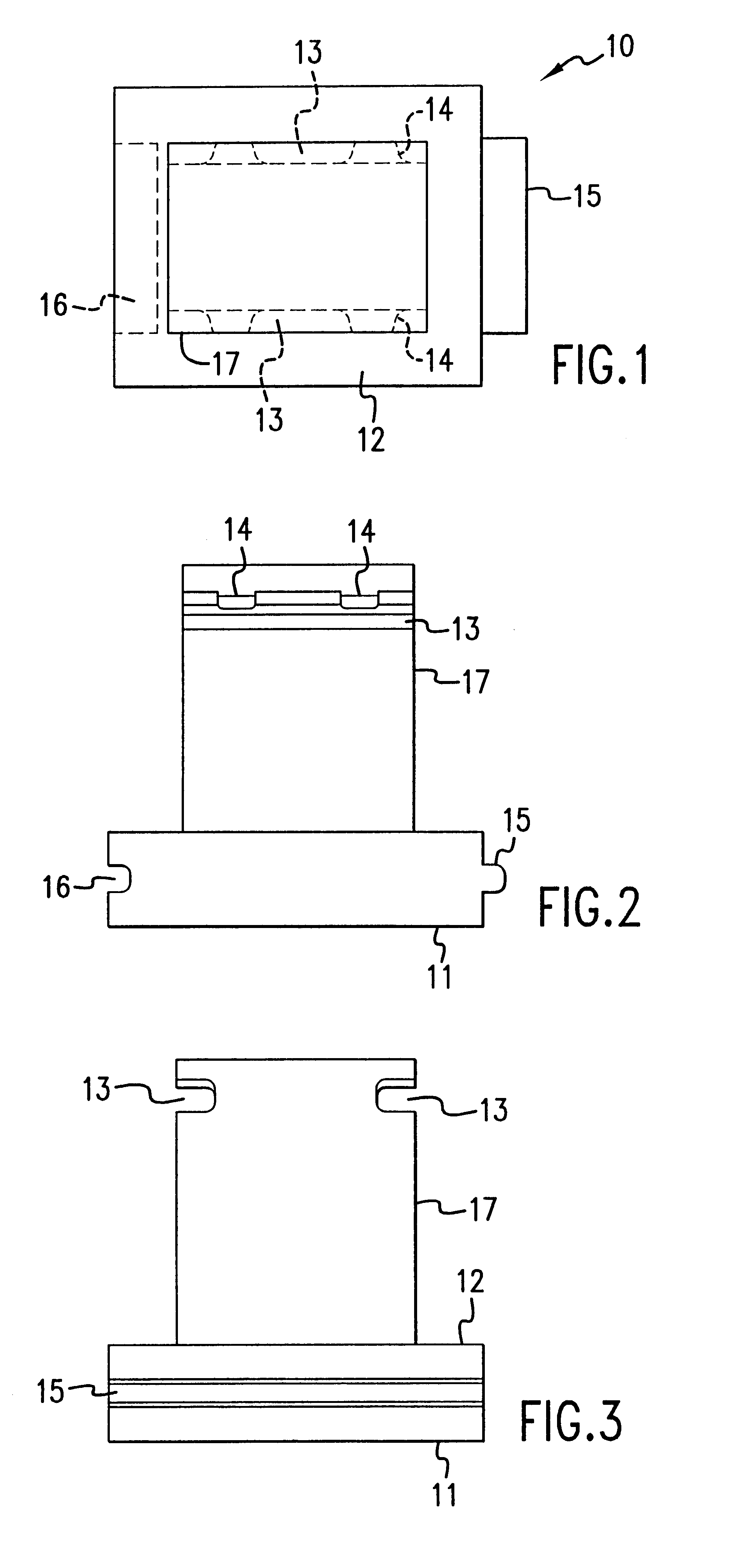

Furnace panel leak detection system

ActiveUS20090148800A1Detection of fluid at leakage pointFurnace cooling arrangementsElectric arc furnaceCoolant flow

A furnace panel leak monitoring and control system for fluid-cooled panels in high temperature industrial furnaces such as, for example, smelting furnaces, blast furnaces and electric arc furnaces. The system performs at least two and up four functions simultaneously. At minimum, the system includes one or more temperature sensors received within the body of the panel to monitor temperature within the metal of the panel itself, and pressure sensors installed proximate the inlet and outlet of each panel coolant fluid circuit, which circuits are preferably periodically automatically tested, to check for leaks in the coolant circuits. In addition, the system preferably includes temperature and flow sensors for monitoring the furnace panel coolant circuit(s) for temperature and flow fluctuations, respectively, which may be indicative of leaking cooling circuits. The system triggers visual and / or audible alarm means to alert a human operator of an apparent coolant fluid leak situation.

Owner:BERRY METAL

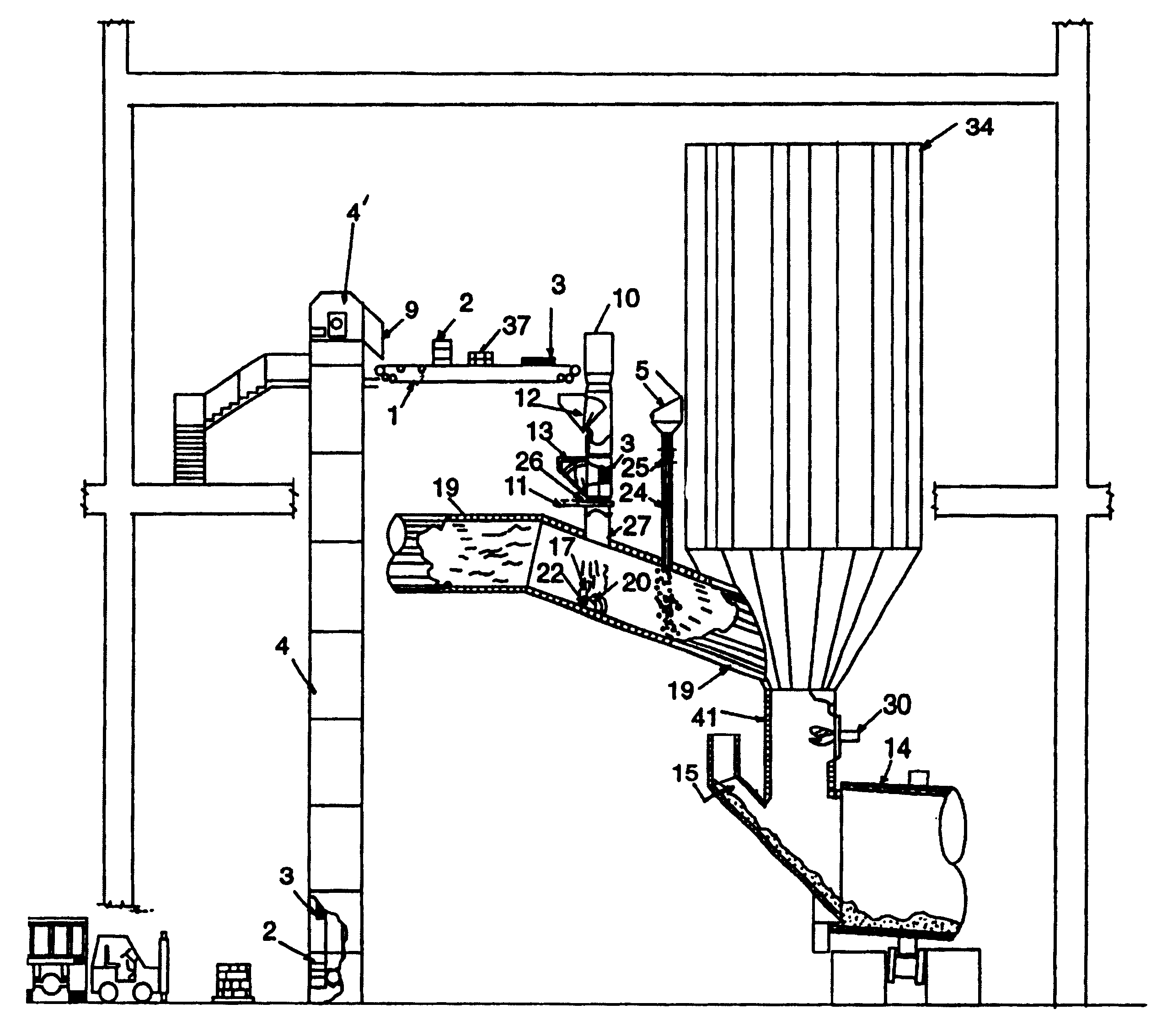

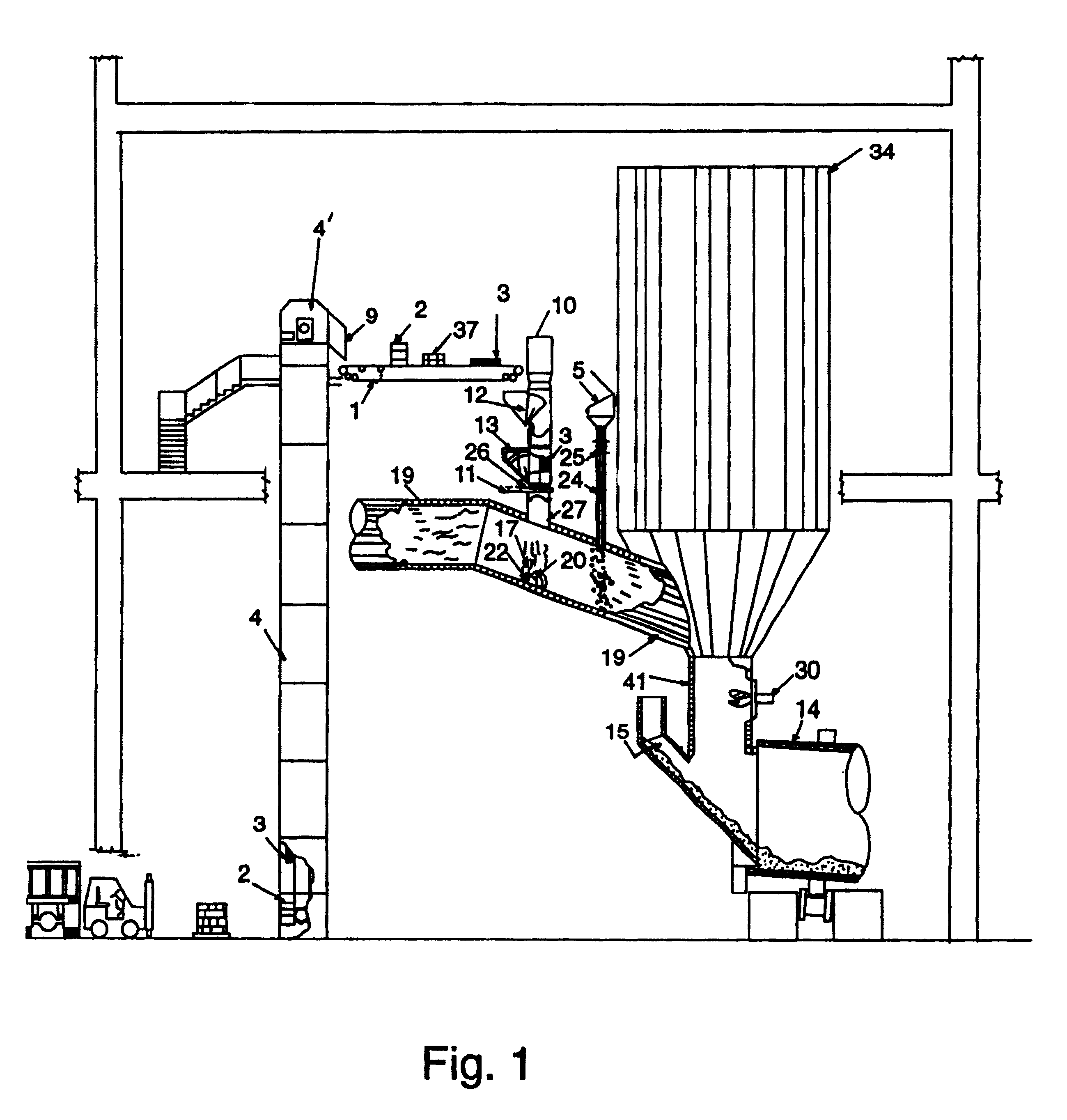

Method and apparatus for recovering energy from wastes by combustion in industrial furnaces

InactiveUS6470812B1Efficient energy recoveryEffective recoveryBranding equipmentMechanical apparatusWastewaterAtmospheric pollution

Method and apparatus to recover energy from waste by means of combustion of such waste in industrial furnaces, particularly of the rotary type, that has an external calciner, feeding such waste into the tertiary air duct of the calciner and burning the waste inside the duct itself, to efficiently make use of the energy produced by such combustion, as a contribution of the total cost of fuel necessary to operate the industrial furnace. The method and apparatus permit the elimination of hazardous wastes that are efficiently disassociated when burned sufficiently to produce effluents that are typically non-toxic, producing greatly reduced or even no atmospheric pollution nor environmental damage.

Owner:CEMEX DE C V

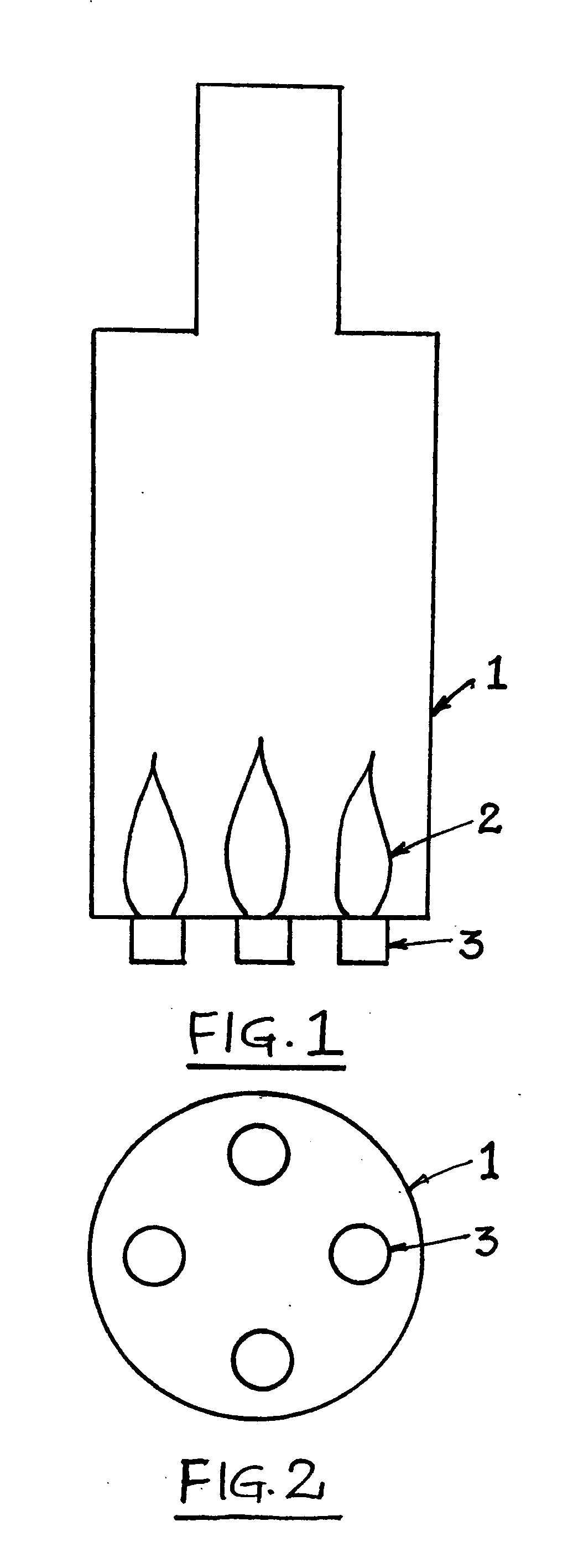

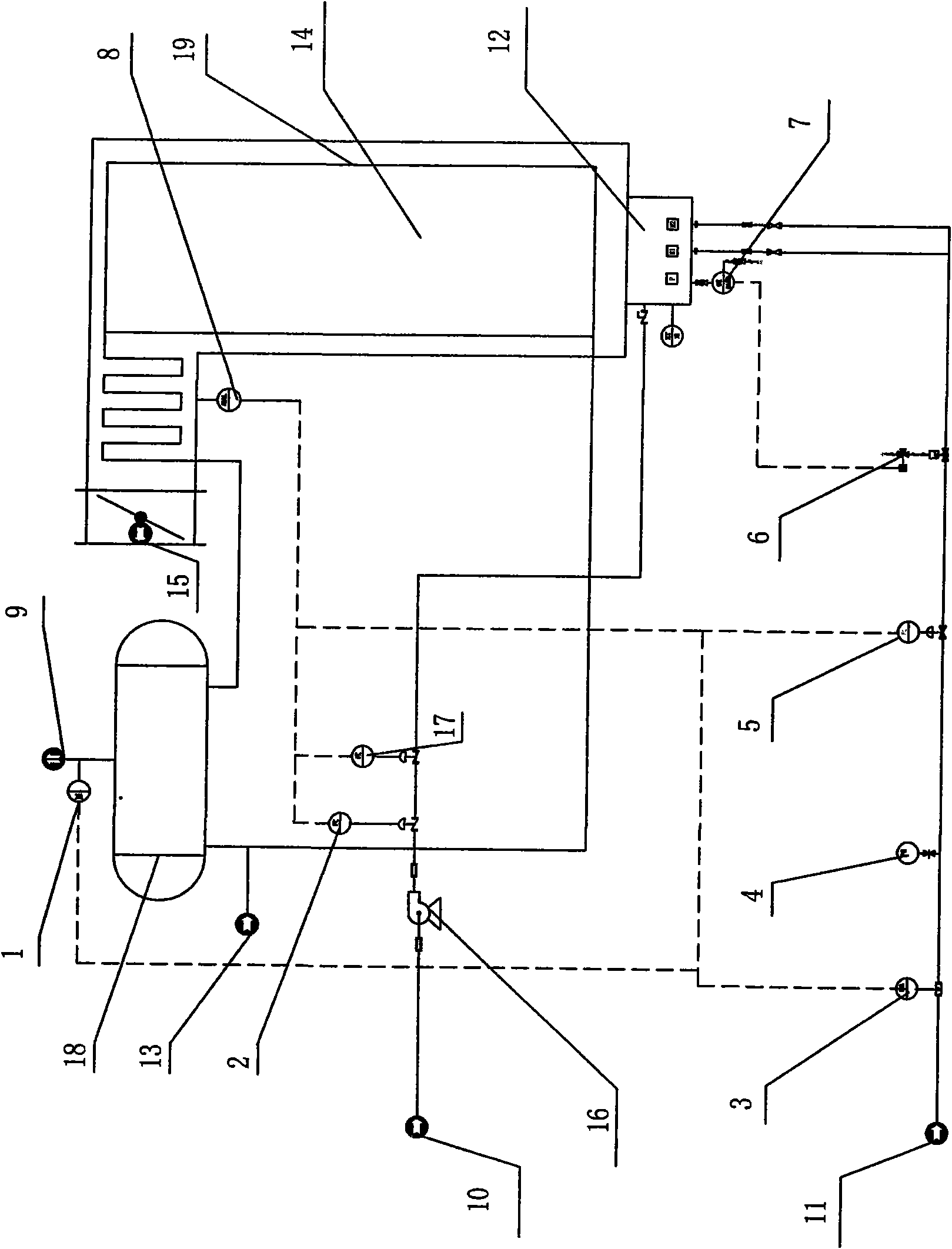

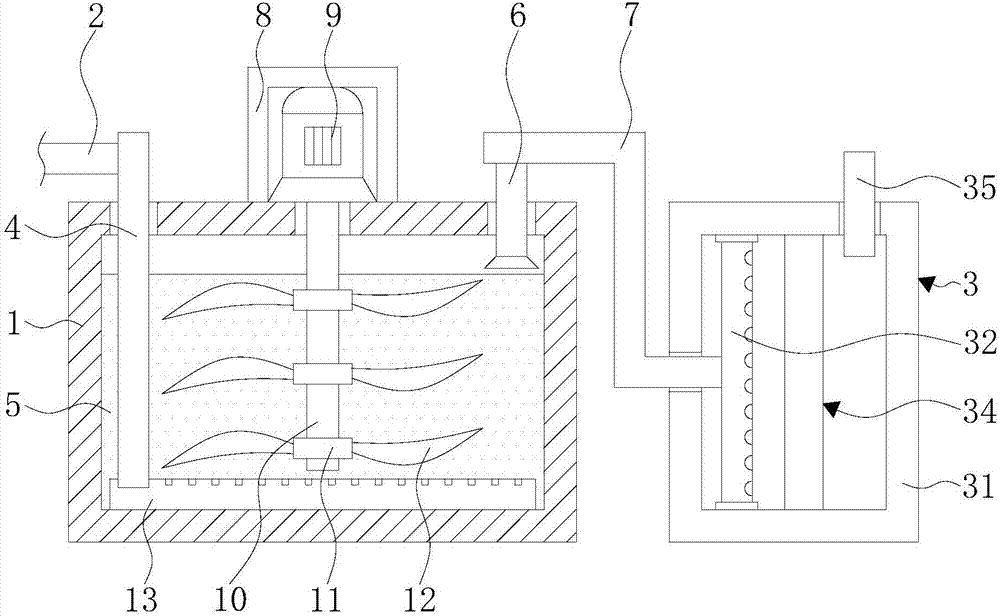

Continuous combusting regenerative industrial furnace

InactiveCN102878817AOptimize layoutStable combustionCombustion processIndirect carbon-dioxide mitigationCombustorProcess engineering

The invention discloses a continuous combusting regenerative industrial furnace, which includes a rotary regenerative heat exchanger, wherein the rotary regenerative heat exchanger includes a rotary cylinder, an upper cover and a lower cover, and the rotary cylinder is internally provided with a regenerator; the high-temperature smoke outlet on the furnace body is connected with an induced draft fan through the high-temperature smoke inlet and the low-temperature smoke outlet of the rotary regenerative heat exchanger in sequence; an air blower is connected with an combustor on the furnace body through the normal temperature air inlet and the preheated air outlet of the rotary regenerative heat exchanger in sequence; and the rotary cylinder is connected with a rotary driving device. The regenerator in the rotary regenerative heat exchanger rotates to continuously preheat the air, the preheated air can be continuously fed into the furnace, the whole combusting process needs no reversing, the pipeline arrangement is simple, the continuous regenerative heat exchange between the high-temperature smoke and the normal temperature air can be realized, and the whole combusting process needs no reversing and is stable.

Owner:SHENWU TECH GRP CO LTD

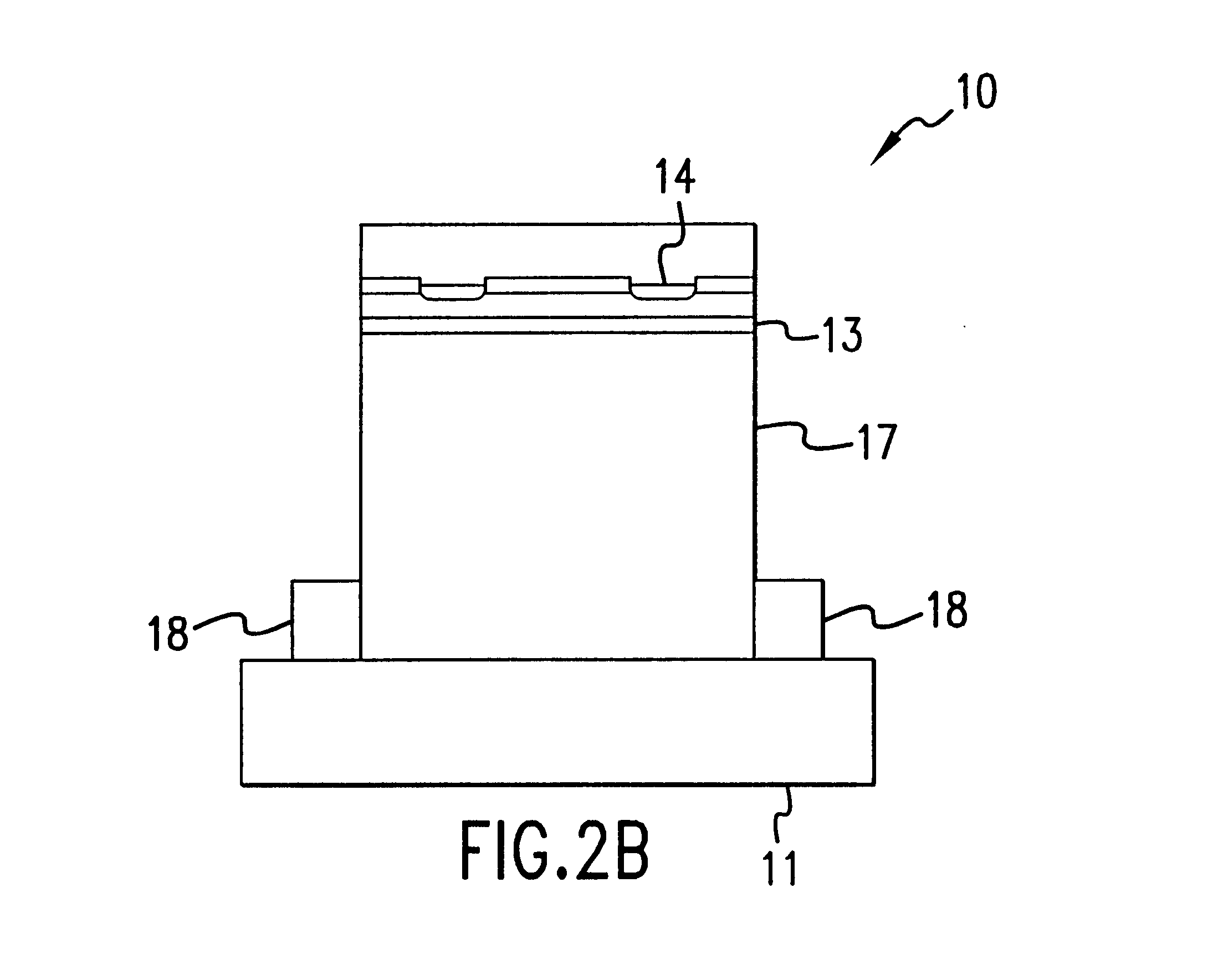

High temperature industrial furnace roof structure

InactiveUS6427610B1Reduces joint lengthImprove accessibilityLining supportsGlass furnace apparatusBrickEngineering

Owner:MERKLE ENGINEERS

Flame-resistant corrosion-resistant coating

The invention discloses a flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating is an amorphous flame-resistant corrosion-resistant coating for protecting the surface of a liner of an industrial furnace. The flame-resistant corrosion-resistant coating is characterized in that fine powder of tabular corundum and magnesium aluminate spinel, calcined alpha-Al2O3 micro-powder, pure calcium aluminate cement as a curing agent, sodium hexametaphosphate as a sintering assistant, and a phosphoric acid or aluminum dihydrogen phosphate solution as a binder are blended into the flame-resistant corrosion-resistant coating. The flame-resistant corrosion-resistant coating can resist corrosion produced by a high-concentration fluoride and a high-concentration hydrogen fluoride atmosphere, and has the advantages of high purity, good heat stability, application convenience, smooth and compact surface and relatively low cost. The flame-resistant corrosion-resistantcoating is suitable for the surface of a liner of a furnace with fluorides and a hydrogen fluoride atmosphere and also is suitable for the surface of a liner of a high-temperature and low-oxygen content furnace with a strong reduction atmosphere.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

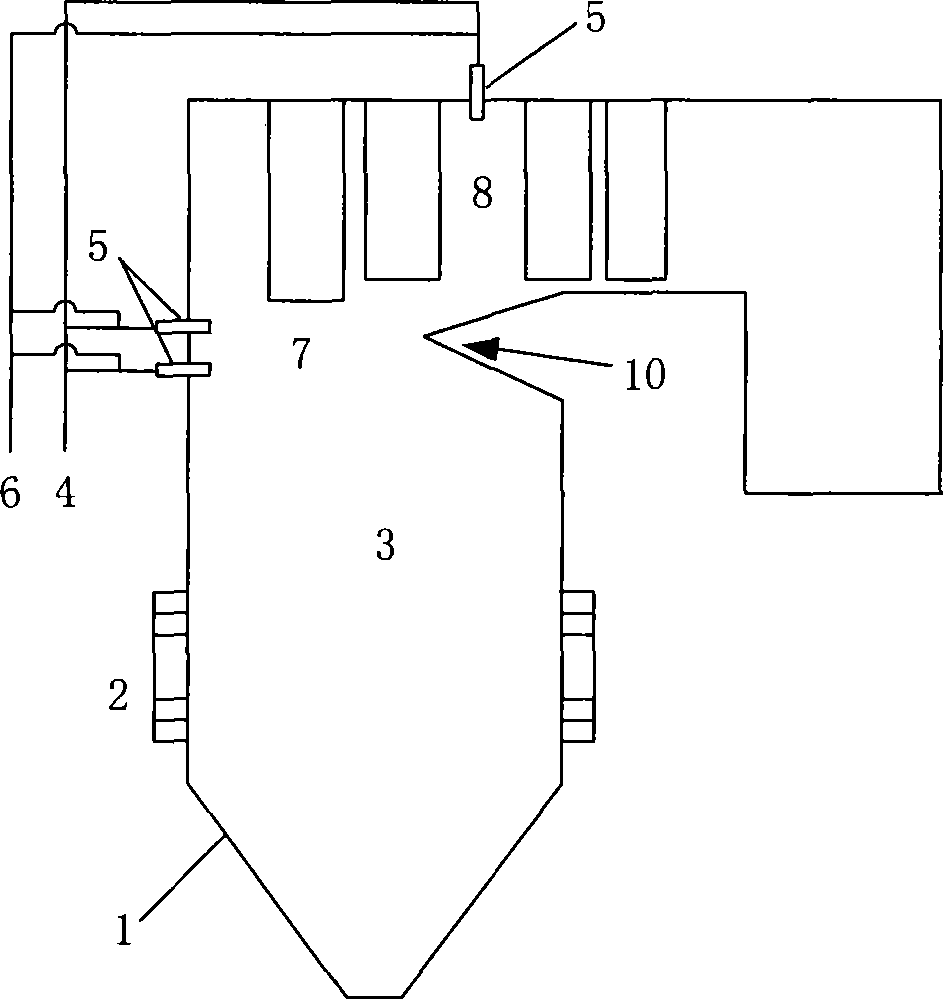

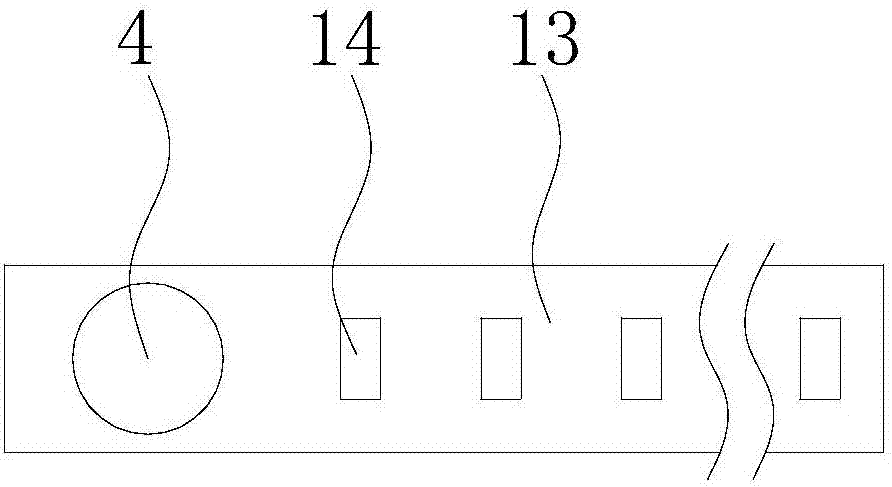

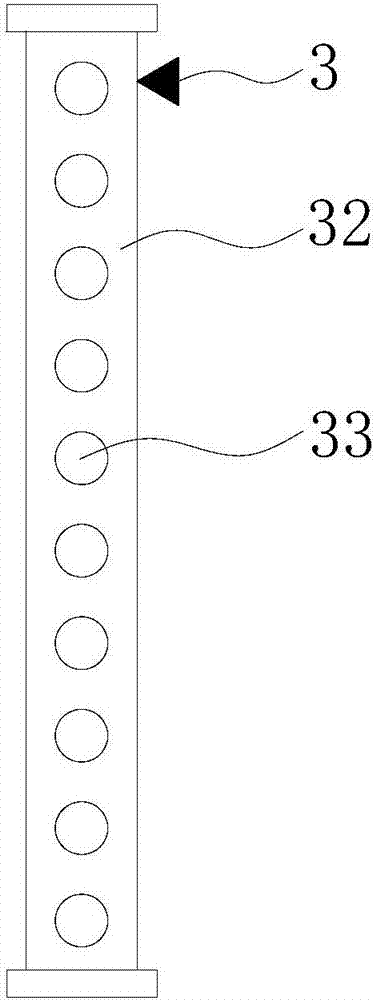

Waste gas treatment device for industrial furnace

InactiveCN106925070AAchieving processing powerEliminate effectiveCombination devicesUsing liquid separation agentDust controlEnvironmental engineering

Owner:长兴鼎诺机电有限公司

Aluminum-silicon light heat insulation brick and preparation method thereof

ActiveCN102167622ARaw materials are cheap and easy to getSimple production processCeramicwareInsulation layerBrick

The invention relates to an aluminum-silicon light heat insulation brick and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing 40-55 percent by weight of light alumina aggregate, 25-40 percent by weight of bauxite chamotte, 5-12 percent by weight of calcium aluminate cement, 8-13 percent by weight of organic polymer, 2-5 percent by weight of silicon powder, 0.05-0.15 percent by weight of water reducing agent and 15-25 percent by weight of water, calendering and molding by casting; curing under the condition of room temperature for 24-48 hours, demolding and drying at the temperature of 100-120 DEG C for 20-36 hours; and preserving heat at the temperature of 1,400-1,550 DEG C for 3-5 hours to obtain the aluminum-silicon light heat insulation brick. The preparation method has the advantages of wide raw materials, simple process and low production cost; the prepared aluminum-silicon light heat insulation brick has the advantages of high compressive strength, low volume density, low heat conductivity, high using temperature, low re-burning linear change rate, high thermal shock stability and the like; the product is applied to various industrial furnace heat insulation layers, has a wide application range and remarkably-reduced energy consumption and temperature outside a furnace, and can be safely and effectively produced.

Owner:WUHAN UNIV OF SCI & TECH

Lancing of oxygen

A method for providing uniform heat distribution within a furnace as well as decreasing the amount of NOx in the combustion products, when operating an industrial furnace having at least one conventional burner using air as the oxidant. At least one lance is connected with the furnace, and an oxidant including oxygen gas is flowed into the furnace through the lance to impinge against a flame issuing from the burner at a certain impingement point. The amount of oxygen supplied by the air supply to the burner together with the amount of oxidant issuing from the lance corresponds with the stoichiometric amount for a fuel supplied to the burner. At least 50% of the supplied oxygen for combustion is supplied through the lancing of oxidant, and the oxidant is flowed into the furnace through the lance at a velocity of at least 200 m / s.

Owner:MESSER IND USA INC

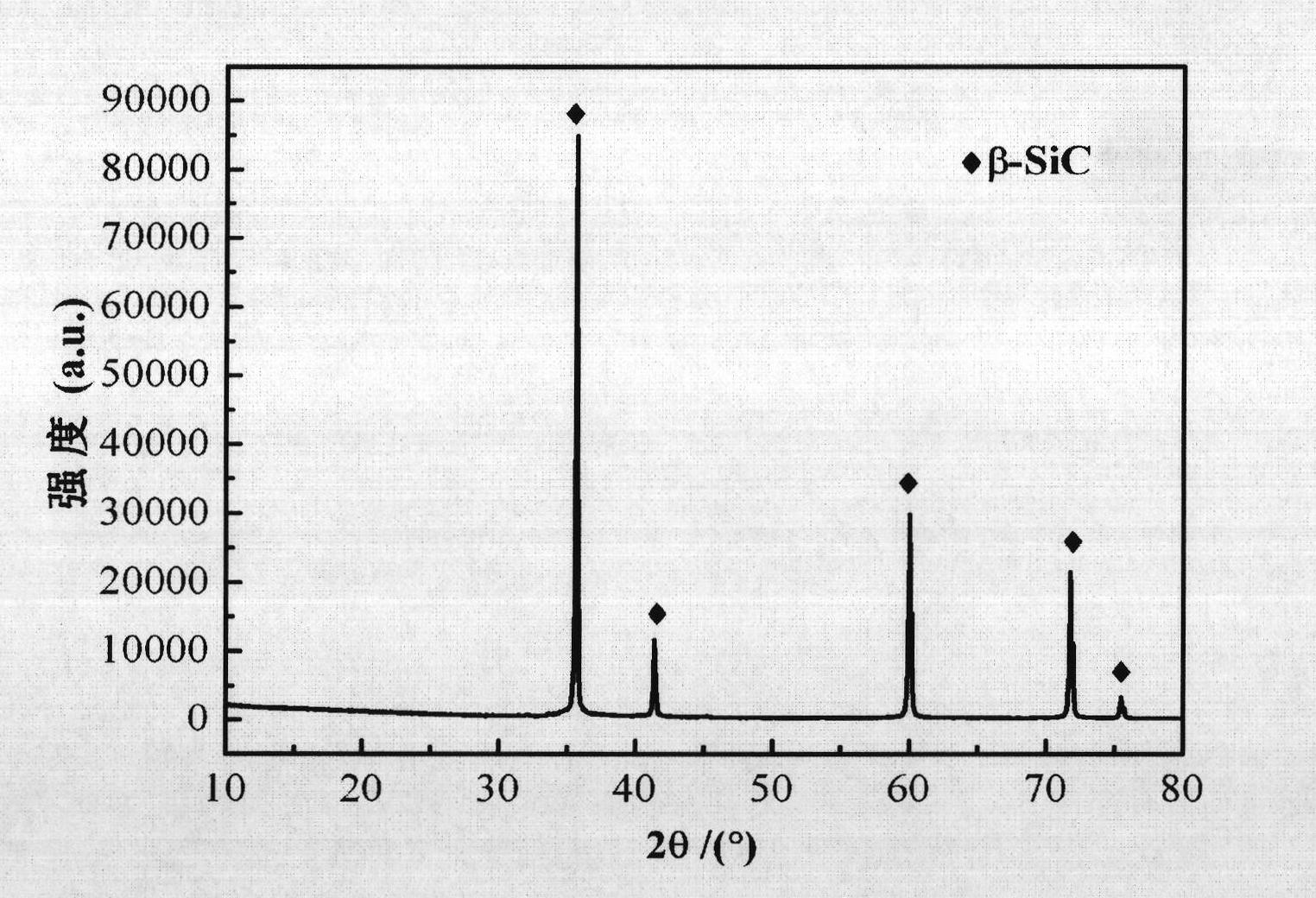

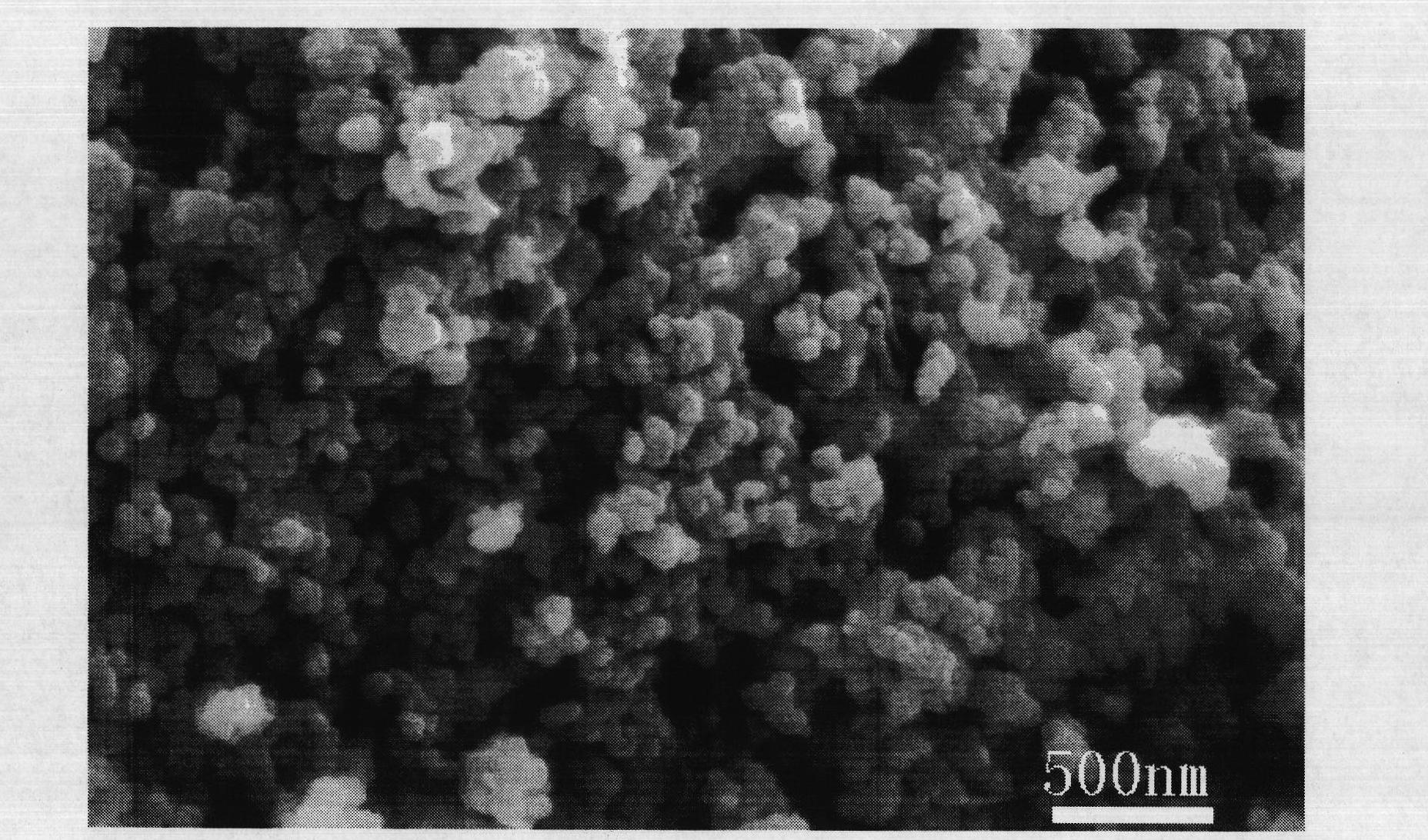

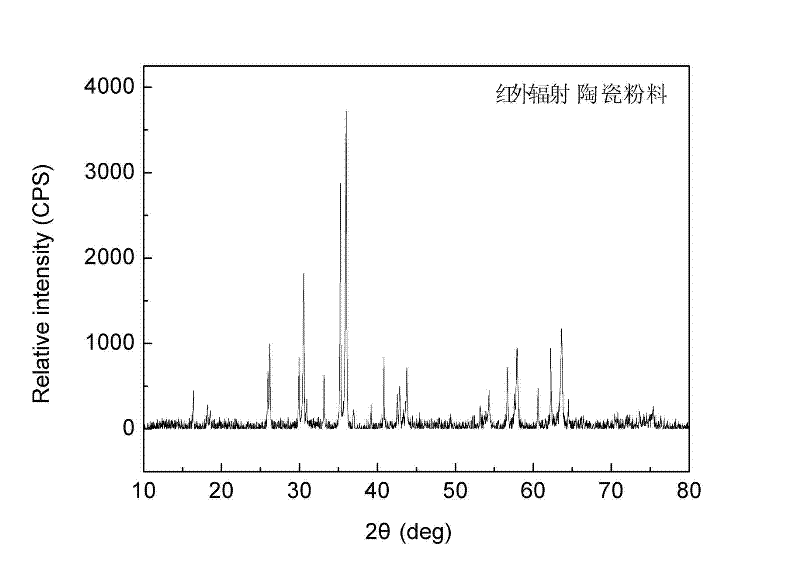

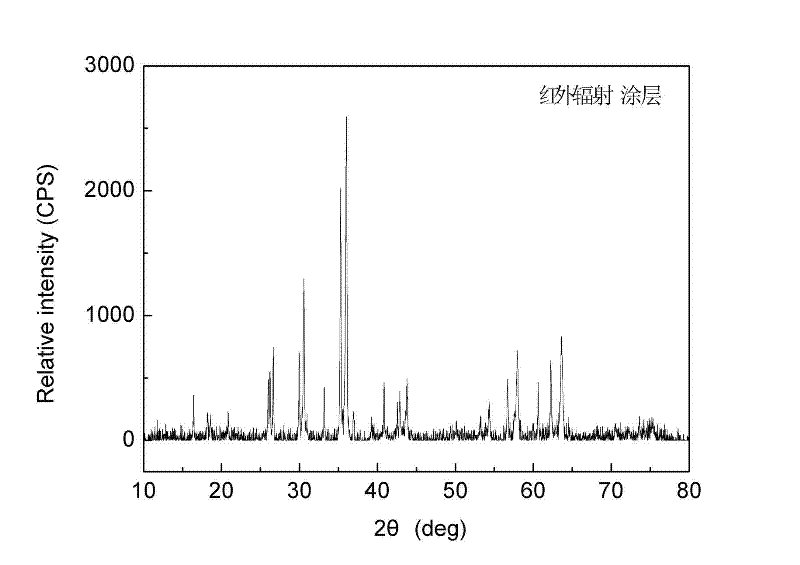

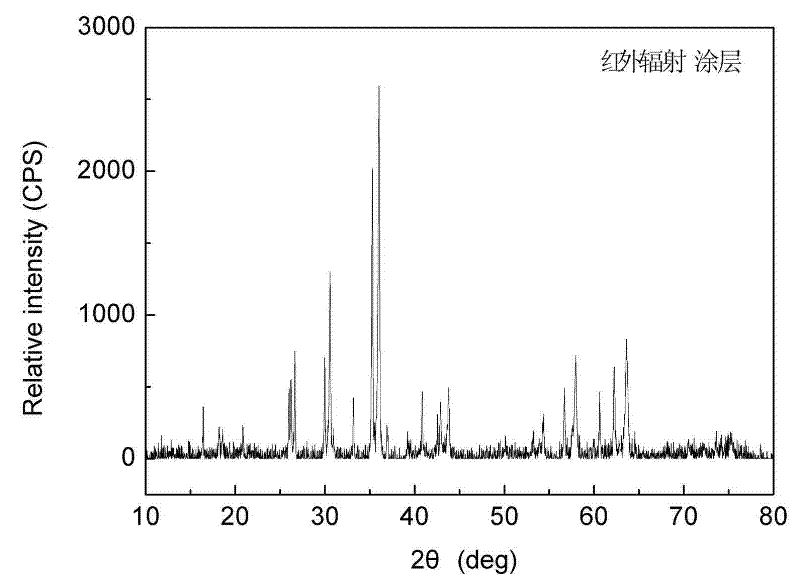

Nanometer silicon carbide-series infrared radiation coating and preparation method thereof

The invention belongs to the field of far infrared energy-saving coating used for a high-temperature industrial furnace, which particularly relates to a nanometer silicon carbide-series infrared radiation coating and a preparation method thereof. The coating is composed of a powder radiation material, a binding material, a slurry accessory ingredient and water, wherein the mass ratio of the waterto the powder radiation material is (0.5-2):1; the binding material is 10-30% of the total mass of powder radiation material; the slurry accessory ingredient is 0.1-3% of the total mass of powder radiation material; and the powder radiation material is composed of nanometer silicon carbide powder, zirconia powder, chromium hemitrioxide powder, ferric oxide powder, nickel oxide powder, bentonite powder and siliceous dust powder. The infrared energy-saving radiation coating disclosed by the invention has the advantages of high radiation coefficient and excellent thermal shock resistance. After high-temperature sintering, a sintering layer is formed on a refractory brick or cellucotton, the sintering layer can be firmly adhered on the surface of the lining of a kiln to perform the energy-saving effect on increasing radiant heat utilization and reducing heat loss.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

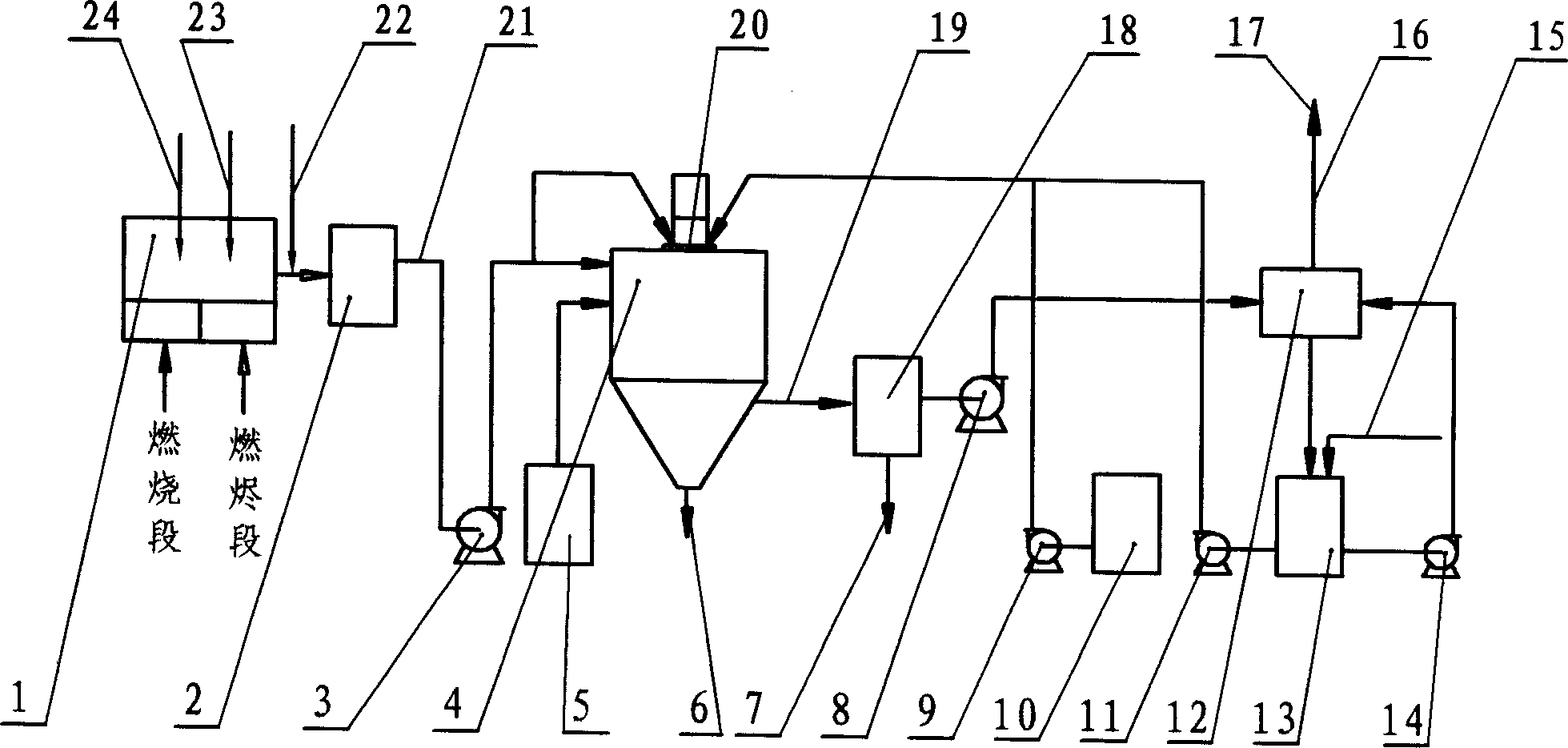

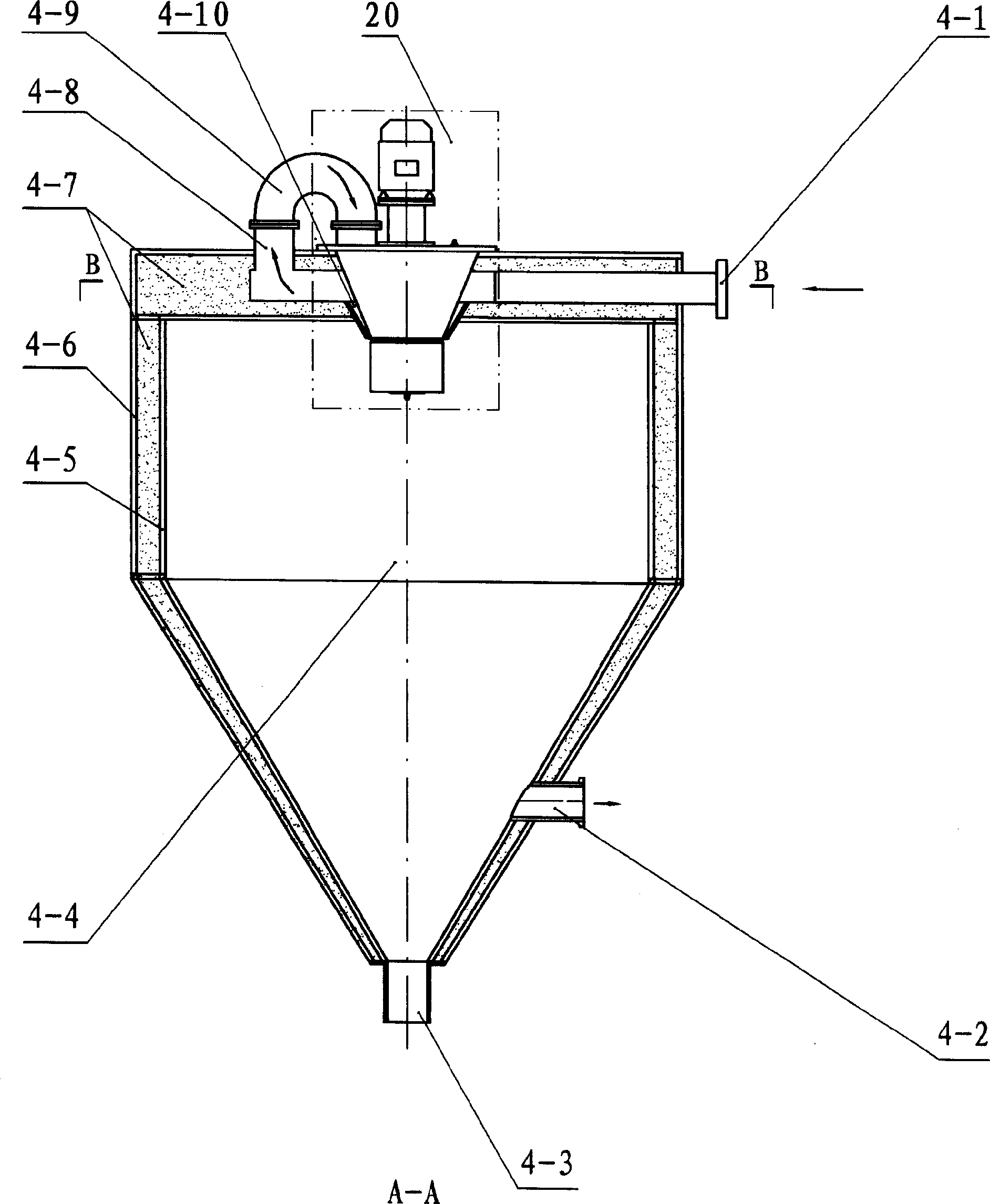

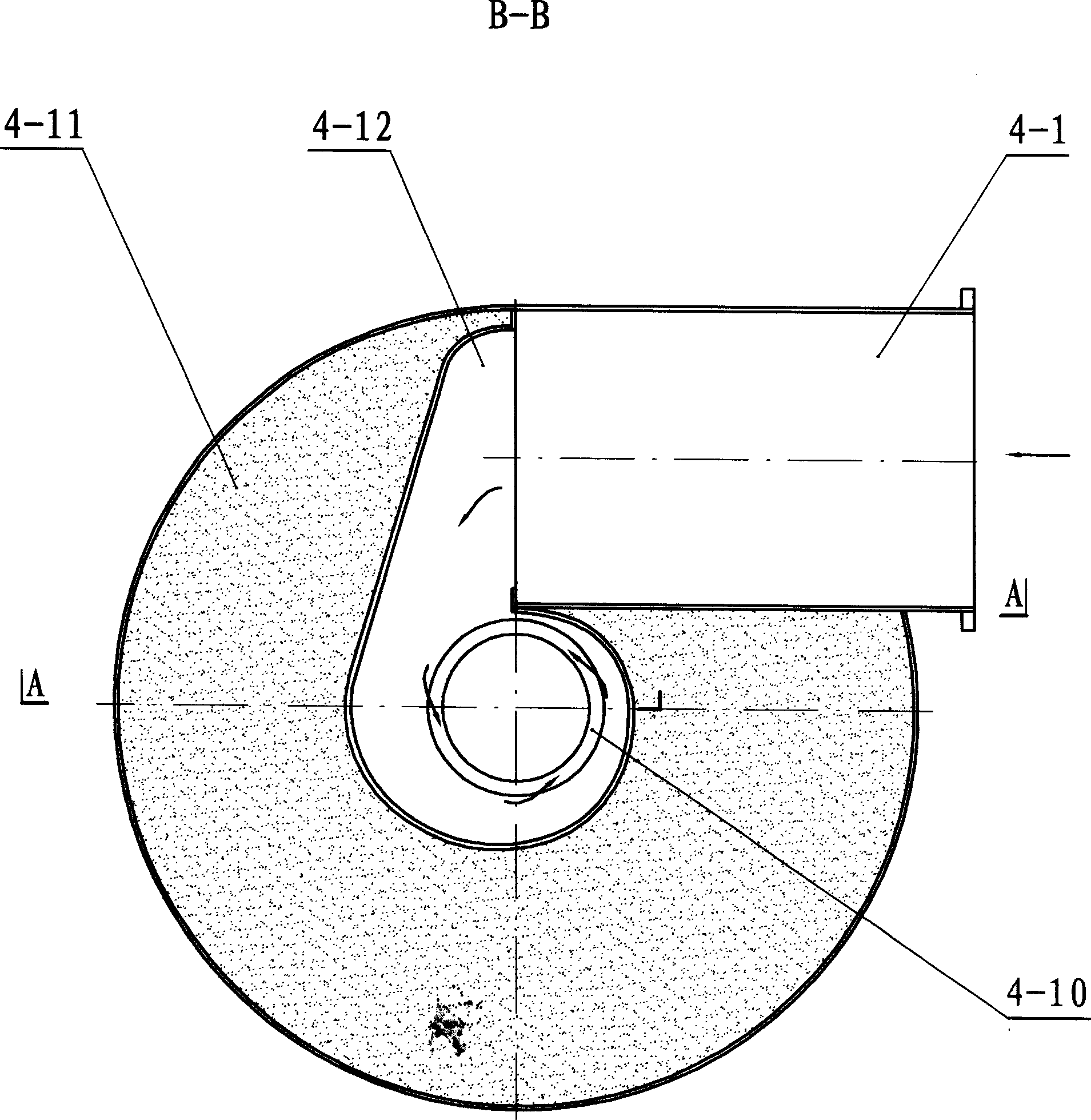

Smoke desucfuration denitrification dedust process and device

A process for desulfurizing, denitrifying and dusting the fume includes such steps as regulating the air supply of industrial furnace to decrease the generation of NOx, reversely spraying ammonia into combustion box, introducing oxygen to back smoke chamber, removing dust, reaction in centrifugally spraying drying tower to generate ammonium sulfate, separating, and washing in supergravitational washer. Its apparatus is composed of cyclone duster, draught fan, centrifugal spraying drying tower, oxygen generator, supergravitational washer and cyclone separator. Its advantages are high effect, low cost and no secondary pollution.

Owner:重庆正和生物能源有限公司

One-stage mineral wool technology high-effectly utilizing industrial furnace smelting slag heat

InactiveCN1418834AObvious fluctuationsSolve the problem of continuous temperature measurementGlass making apparatusQuality levelManganese

The one-step method for producing mineral wool by using industrial furnace molten slag sensible heat includes the following steps: according to the requirement for chemical composition of mineral wool adding proper auxiliary raw material, at the same time, in homogenizing furnace making concurrent heating and regulating its chemical composition temp. and viscosity to make them reach to the requirements of mineral wool molten body, making molten body acidity coefficient be up to 1.1-1.8 (acidity coefficient=SiO2+Al2O3 / CaO+MgO), and the molten body temp. is 1300-1340 deg.C, homogenizing its chemical components, feeding the thermally-refined molten body into high-speed centrifuge and feeding it into fibre-forming procedure of mineral wool so as to obtain the invented product.

Owner:杨铧

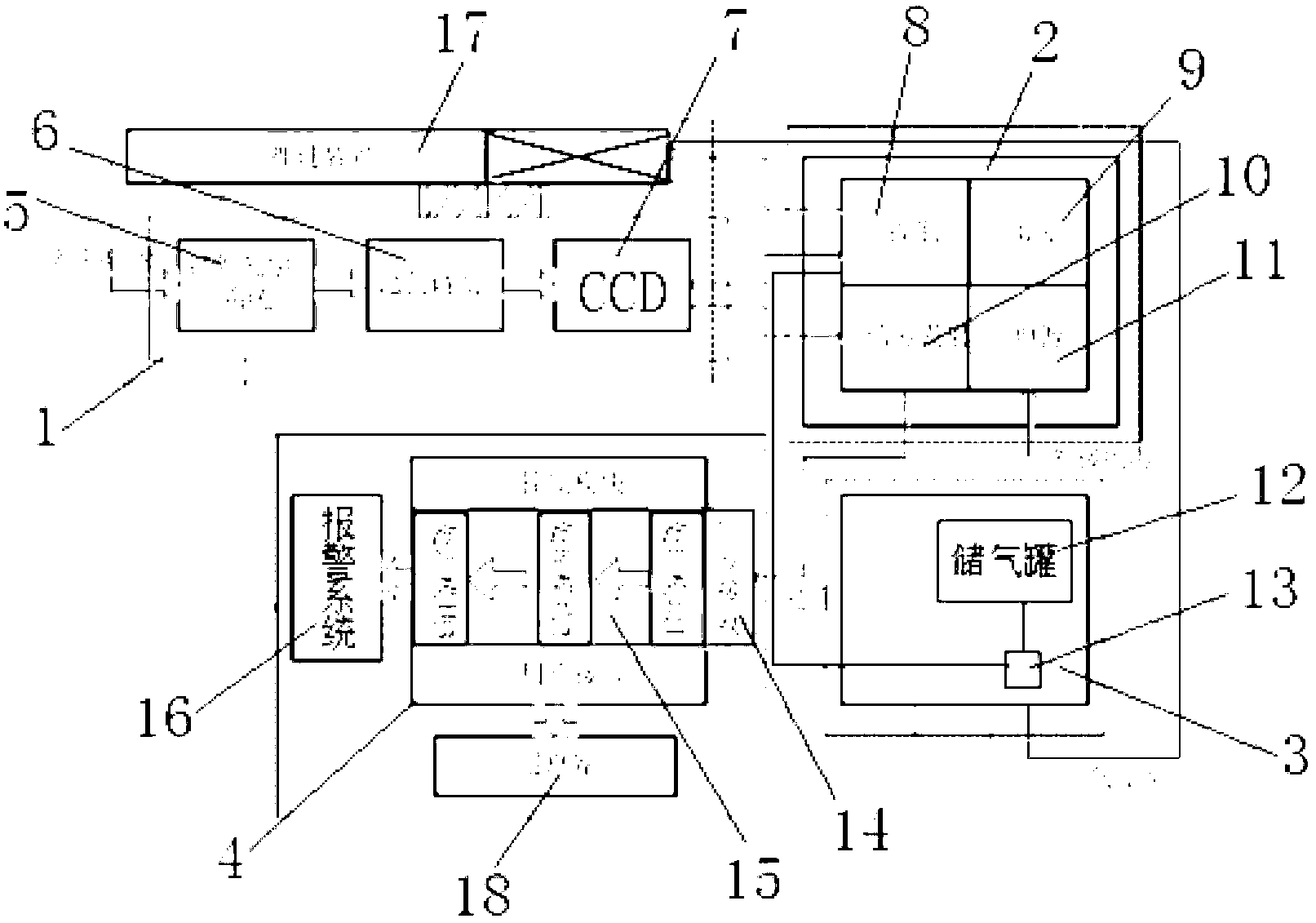

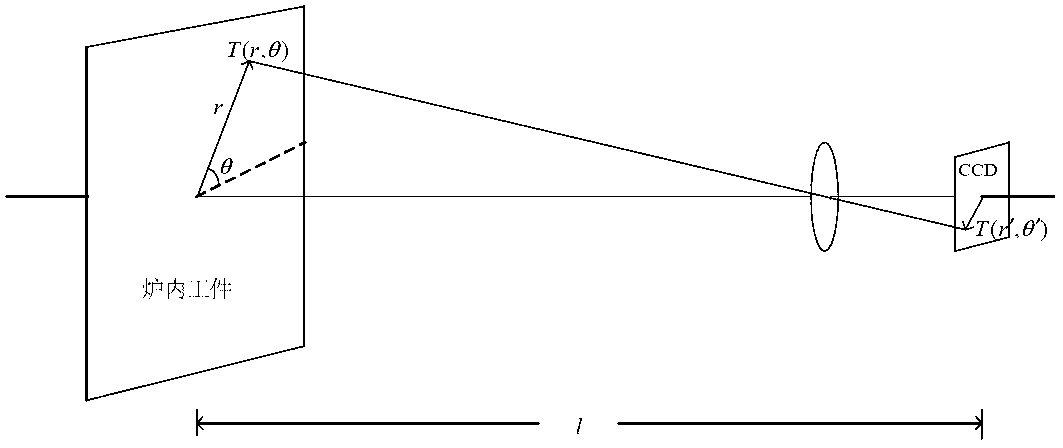

Real-time monitoring and safety warning device for temperature of furnace tube of tubular industrial furnace

ActiveCN102798294ARealize real-time monitoringRealize overrun alarmFurnace componentsVisual perceptionDigital image processing

The invention discloses a real-time monitoring and safety warning device for the temperature of a furnace tube of a tubular industrial furnace. The real-time monitoring and safety warning device comprises four parts, namely a detecting device, an electrical control device, an air source control cabinet and a computer process and control part. According to the characteristics of infrared radiation of the furnace tube, an infrared radiation image of the furnace tube is obtained by an optical imaging system suitable for colorimetric temperature measurement, the infrared radiation image is analyzed by adopting technologies of digital image processing, pattern recognition, computer vision measurement and the like, the distribution state of the temperature on the surface of the furnace tube is obtained in real time by virtue of the colorimetric temperature measurement technology so as to give an overtemperature alarm, and the change trend of the distribution of a temperature field of the furnace tube is obtained by utilizing a database to analyze history data in the whole operation cycle of the furnace tube so as to provide intuitive and effective basis for the evaluation of the efficiency of a heating furnace and the residual service life of the furnace tube. The real-time monitoring and safety warning device provides key parameters for the optimization of burning of the industrial furnace, and has great significance on ensuring safety production and improving productive efficiency.

Owner:HEFEI RUISHI MEASUREMENT & CONTROL ENG TECH

Lightweight aluminum-magnesium castable and preparation method of lightweight aluminum-magnesium castable

The invention relates to a lightweight aluminum-magnesium castable and a preparation method of the lightweight aluminum-magnesium castable. The technical scheme is as follows: using 60-85wt% of microporous corundum granules as an aggregate, and using 5-30wt% of fine corundum powder, 2-10wt% of magnesium oxide micropowder and 4-9wt% of alpha-aluminum micropowder as matrix materials; premixing a polycarboxylate-type water reducer and the matrix materials firstly, wherein the polycarboxylate-type water reducer is 0.05-0.3wt% of the sum of the aggregate and the matrix materials; adding the premixed matrix materials into the aggregate; and then additionally adding a binding agent which is 3-10wt% of the sum of the aggregate and the matrix materials, and stirring uniformly to obtain the lightweight aluminum-magnesium castable. The lightweight aluminum-magnesium castable prepared by the method has the characteristics of small volume density, low apparent porosity, large high-temperature strength, good volume stability, low thermal conductivity and strong capability of resisting the corrosion of media such as steel slag; and the prepared lightweight aluminum-magnesium castable is applied to a working lining of a high-temperature industrial furnace, the energy consumption can be reduced, and the service life is long.

Owner:WUHAN UNIV OF SCI & TECH

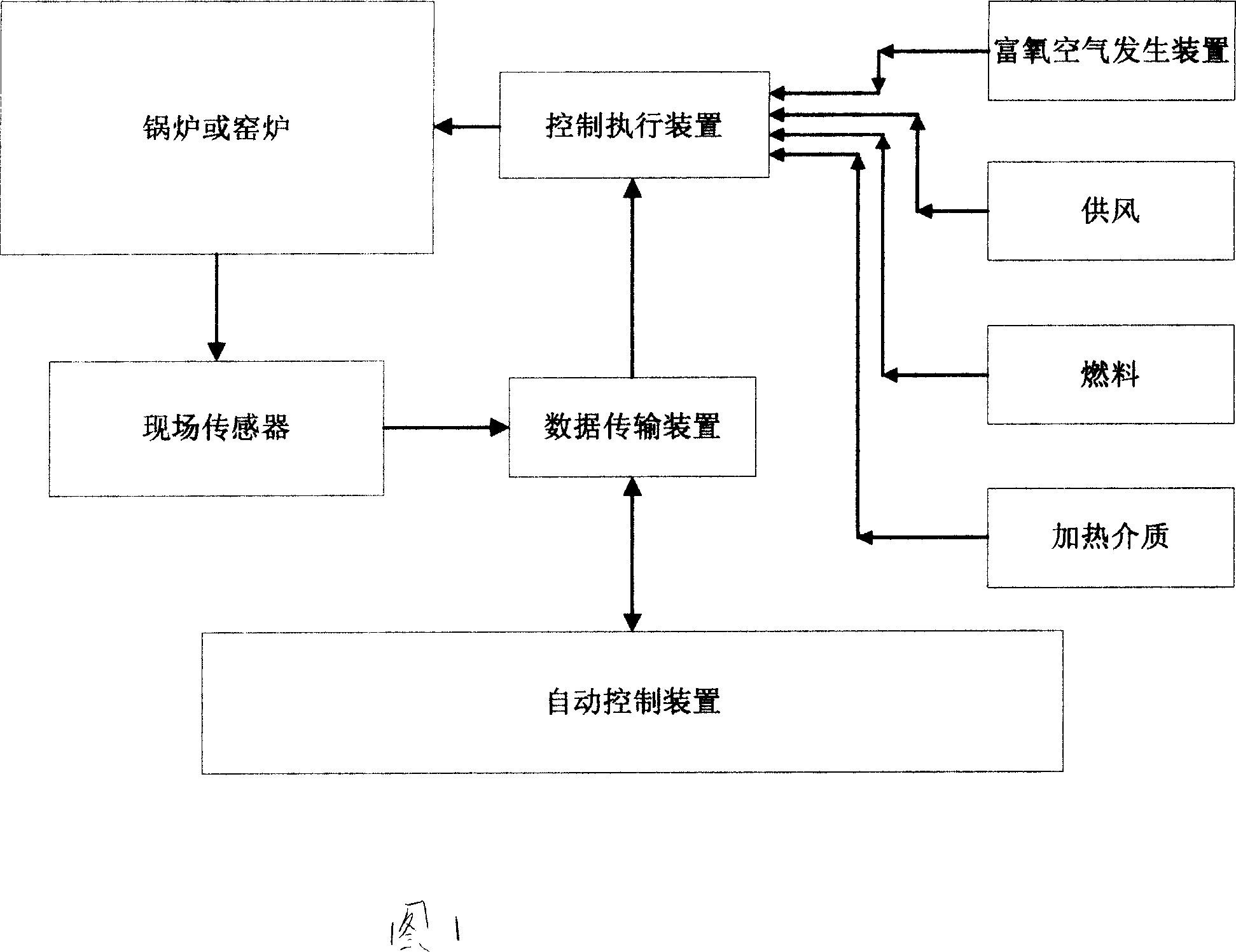

Comprehensive energy-saving method for boiler or industrial furnace and kiln

InactiveCN101046296AGood energy saving effectImprove energy savingFuel supply regulationIndirect carbon-dioxide mitigationAutomatic controlAir volume

The present invention is comprehensive energy-saving method for boiler and industrial furnace and kiln. The present invention adopts one system comprising an oxygen-rich air supply device, an in-site sensor, a data transmission device, an automatic intelligent controller and an executor in regulating air quantity, fuel quantity, heated medium, etc for boiler and industrial furnace and kiln, so as to reach comprehensive energy-saving effect. In condition of changing heat load, the system can regulate air quantity, fuel quantity, heated medium, etc to follow the heat load change for reaching excellent oxygen-rich air combustion supporting effect. The present invention has been applied practically.

Owner:吴仲贤 +1

Infrared radiation coating and use method thereof

The invention discloses an infrared radiation coating for a lining surface of an industrial furnace, which is prepared by the following raw materials in percentage by mass: 30-60% of spinel and silicate multi-phase composite system infrared radiation powder, 1-10% of inorganic combination addition agent, 25-60% of bonder, 0-2% of anti-settlement agent, 0-1% of dispersing agent, 0-1% of defoaming agent, and 0-1% of flatting agent. The invention further discloses a method for using the infrared radiation coating. After the coating disclosed by the invention is dried and solidified, a formed coated surface is compact and has good infrared radiation performance and can be firmly combined with substrates, such as fire-proof material, metal and the like. After being used at high temperature fora long time, the coated surface cannot be split and fallen off, can resist corrosion and has good thermal shock resistance performance.

Owner:KING STRONG MATERIAL ENG LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com