Novel high-heat anticorrosive biomass alcohol-based fuel

An alcohol-based fuel and biomass technology, which is applied in fuels, liquid carbon-containing fuels, petroleum industry, etc., can solve the problems of difficult use of alcohol-based fuels in large-scale industrial fields, deterioration of low-temperature operation performance, and strong corrosiveness of alcohol-based fuels. Achieve the effects of easy ignition, corrosion inhibition and stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] The high-heat anti-corrosion alcohol-based fuel is composed of alcohol and additives, and the weight percentage of each component is:

[0015] Thereby slowing down the corrosion of the metal. The combined effect of several functions expands the scope of application of corrosion inhibitors and makes them have better comprehensive corrosion inhibition effects.

[0016] (3) Special ester compounds are added to the fuel to effectively increase the octane number and cetane number and make the combustion more stable. Moreover, the additive can increase explosive combustion at the initial stage of ignition, making ignition easier and solving the problem of low-temperature start-up. The problem of air resistance is overcome.

[0017] (4) The comprehensive effect of additives makes the new alcohol-based fuel safe, stable, flexible and convenient in the process of production, storage, transportation and use. Less oxygen is needed during combustion, the fuel burns fully, show...

specific Embodiment approach

[0020] The following are some implementation examples of the present invention, but not limited thereto.

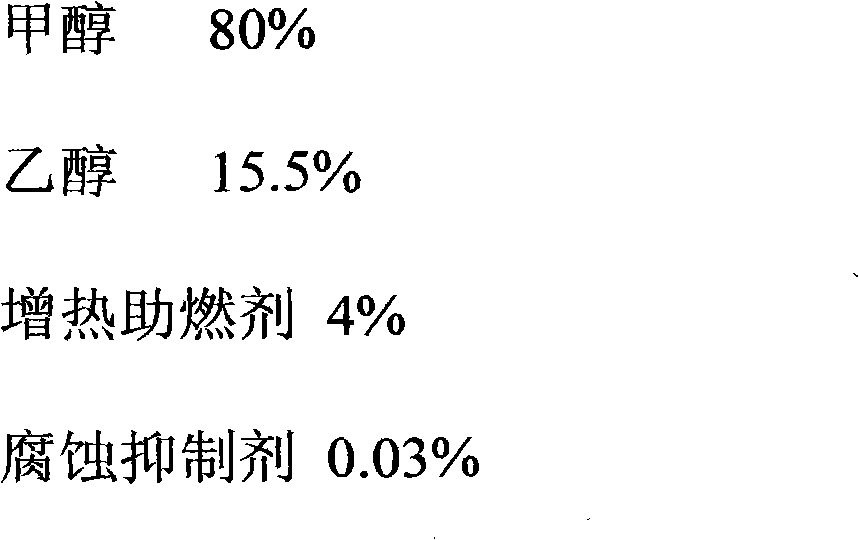

Specific implementation mode one:

[0021] The high-heat anti-corrosion alcohol-based fuel is composed of alcohol and additives, and the weight percentage of each component is:

[0022]

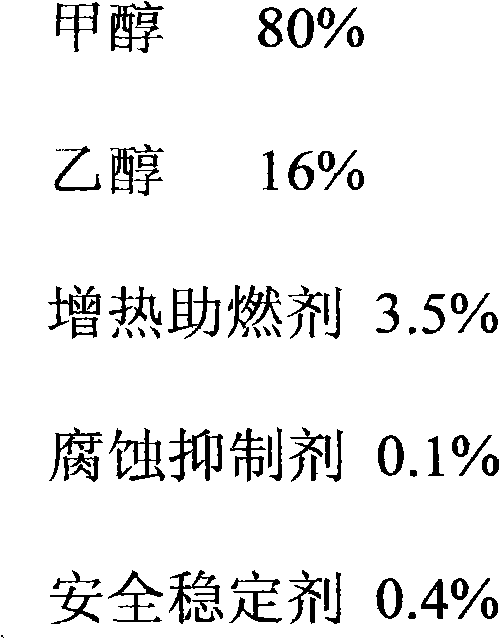

[0023]

[0024] The heat-increasing combustion aids include acetone, hexamethylenetetramine, xylene, nitroaniline KMnO 4 ; Corrosion inhibitors include imidazoline, benzodiazole and phytic acid; safety stabilizers are isoamyl nitrate, methyl tert-butyl ether and aliphatic ketones.

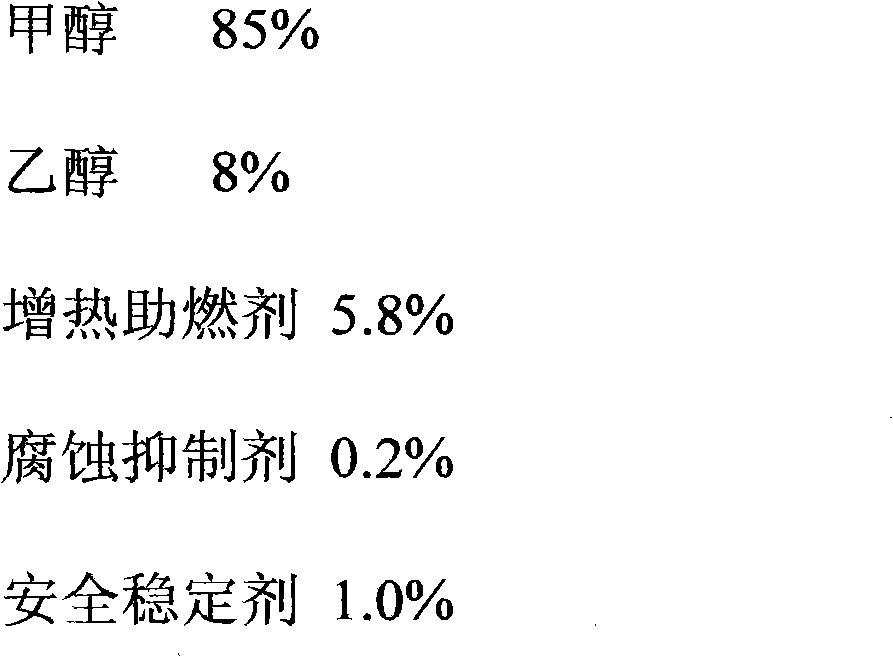

specific Embodiment approach 5

[0025]

[0026] The heat-increasing combustion aids include acetone, hexamethylenetetramine, petroleum ether, KMnO 4 and H 2 o 2 ; Corrosion inhibitors include N-methylmorpholine, benzodiazole, cerium chloride and phytic acid; safety stabilizers are isoamyl nitrate, tert-amylamine and camphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com